Heat tube cooling system and power equipment

A heat dissipation system and power equipment technology, applied in lighting and heating equipment, indirect heat exchangers, cooling/ventilation/heating transformation, etc., can solve the problems of inconvenient maintenance of heat pipe radiators, achieve space saving and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

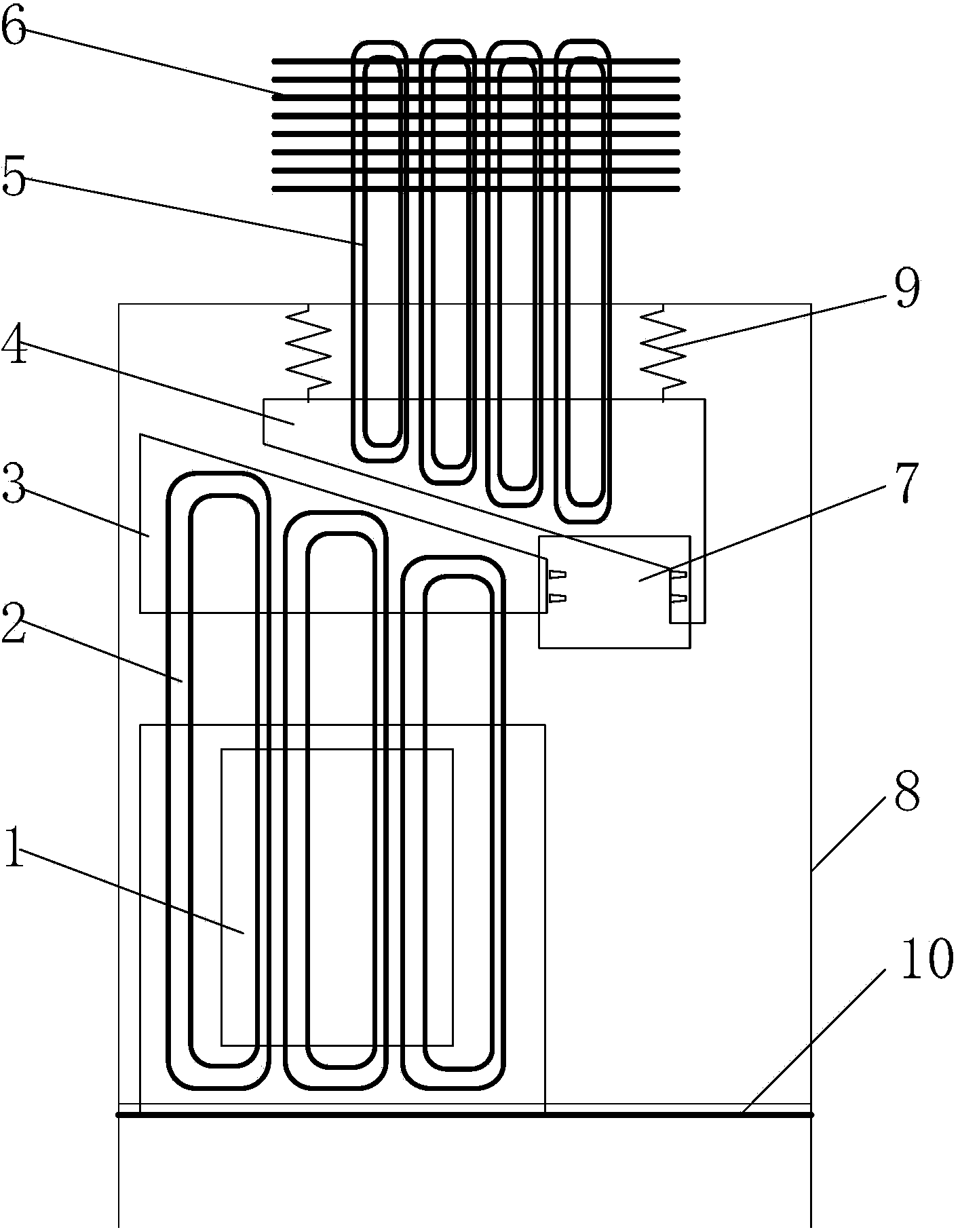

[0032] Such as figure 1 As shown, in the first aspect, the embodiment of the present invention provides a heat pipe heat dissipation system for dissipating heat from a heat generating device 1. The heat pipe heat dissipation system includes: a first heat exchange tube 2, a first heat exchange plate 3, a first The second heat exchange plate 4, the second heat exchange tube 5 and the condensing device 6, the first heat exchange tube 2 and the second heat exchange tube 5 both include an evaporation end and a condensation end, the evaporation end of the first heat exchange tube 2 is connected to the The heating device 1 contacts, the condensation end of the first heat exchange tube 2 contacts the first heat exchange plate 3, the evaporation end of the second heat exchange tube 5 contacts the second heat exchange plate 4, and the condensation end of the second heat exchange tube 5 Contact with the condensation device 6;

[0033] Such as figure 2As shown, when the heat pipe cooli...

Embodiment 2

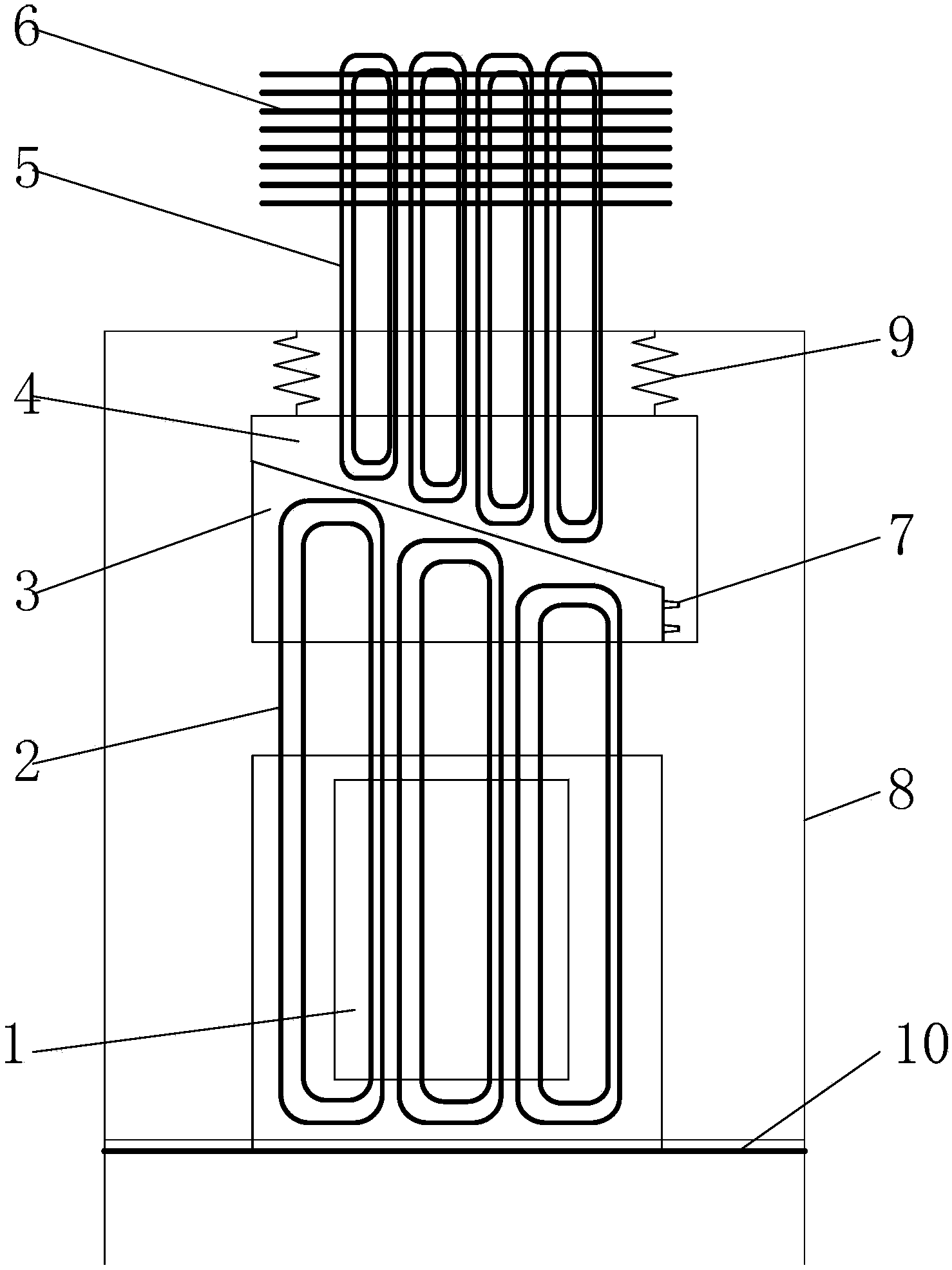

[0043] Such as figure 2 As shown, in the second aspect, the embodiment of the present invention provides a kind of power equipment, the power equipment includes: a heat pipe cooling system, a cabinet 8 and electronic components, the electronic components are arranged inside the cabinet 8, the The heat pipe cooling system is in contact with the electronic components, and the heat pipe cooling system is used for cooling the electronic components.

[0044] The structure and function of the heat pipe cooling system of the present invention is the same as that of the heat pipe cooling system in the above embodiments, and will not be repeated here. Meanwhile, the electronic components in the embodiments of the present invention are the heating device 1 in the above embodiments. When the heat dissipation system is applied in different fields, the heat generating device 1 can be different. The power equipment provided by the present invention can install the electronic components in...

Embodiment 3

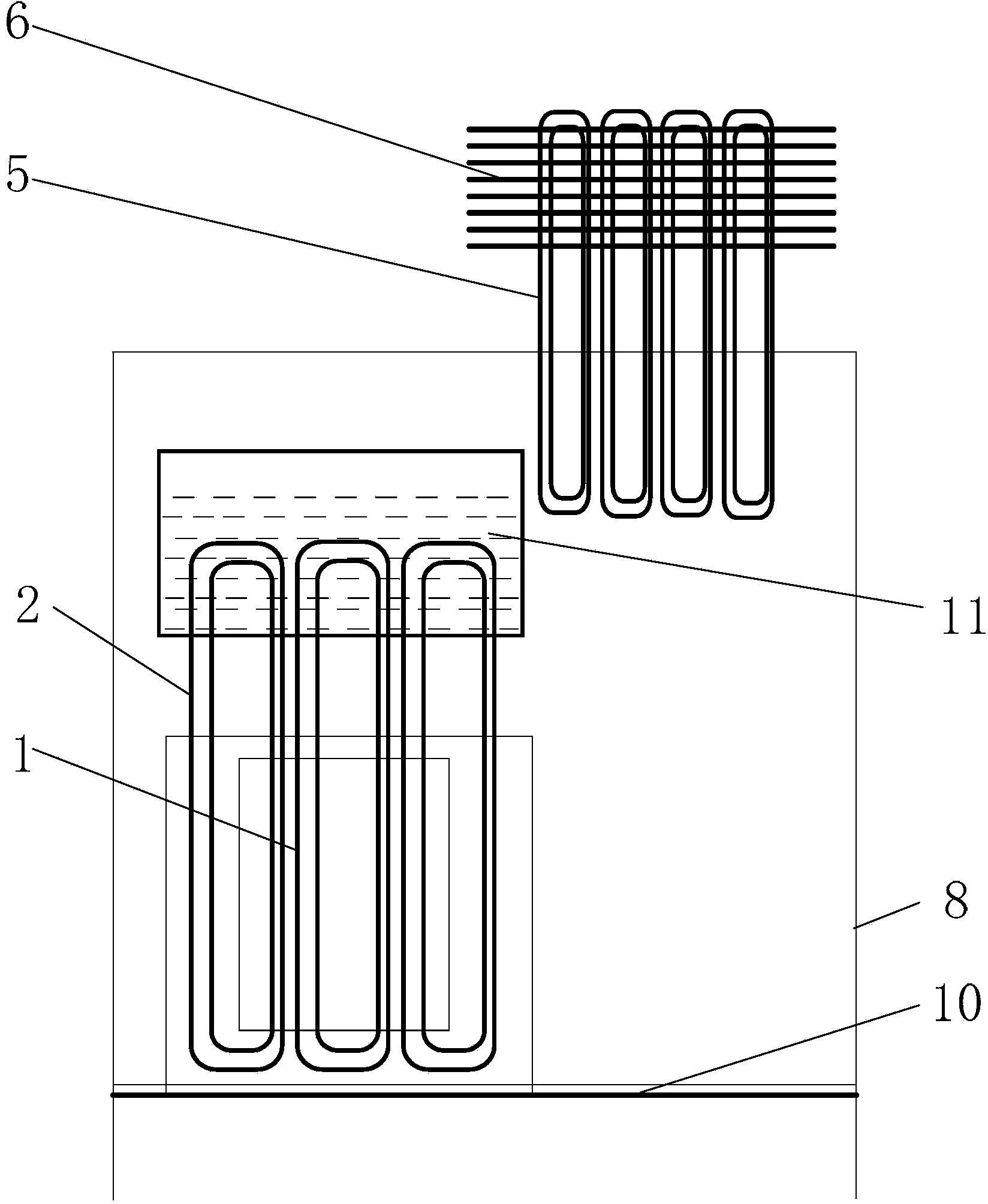

[0052] Such as image 3 As shown, in the third aspect, the embodiment of the present invention provides a heat pipe heat dissipation system for dissipating heat from the heat generating device 1, the heat pipe heat dissipation system includes: a first heat exchange tube 2, a heat exchange device with a cavity 11 the second heat exchange tube 5 and the condensation device 6, and the heat exchange medium is stored in the cavity of the heat exchange device 11, the first heat exchange tube 2 and the second heat exchange tube 5 both include an evaporation end and a condensation end, The evaporation end of the first heat exchange tube 2 is in contact with the heating device 1 , the condensation end of the first heat exchange tube 2 extends into the heat exchange medium, and the condensation end of the second heat exchange tube 5 is in contact with the condensation device 6 ;

[0053] Such as Figure 4As shown, when the heat pipe cooling system is working, the evaporation end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com