Double-water-way copper-aluminum composite radiator

A technology of copper-aluminum composite and radiator, which is applied in the direction of indirect heat exchanger, heat exchanger type, household heating, etc. It can solve the problems of low heat dissipation efficiency and large indoor space occupation, and achieve the effect of increasing the heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

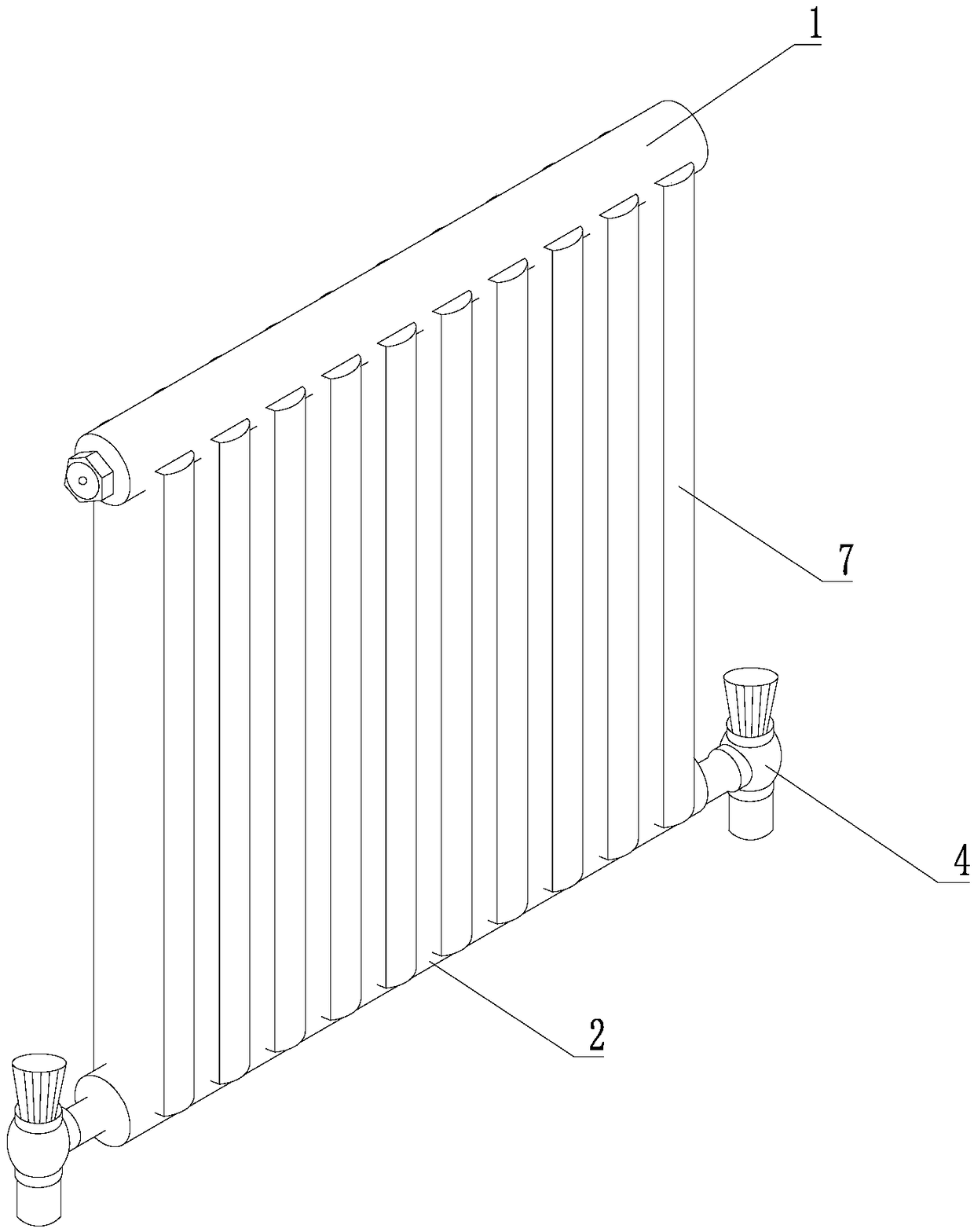

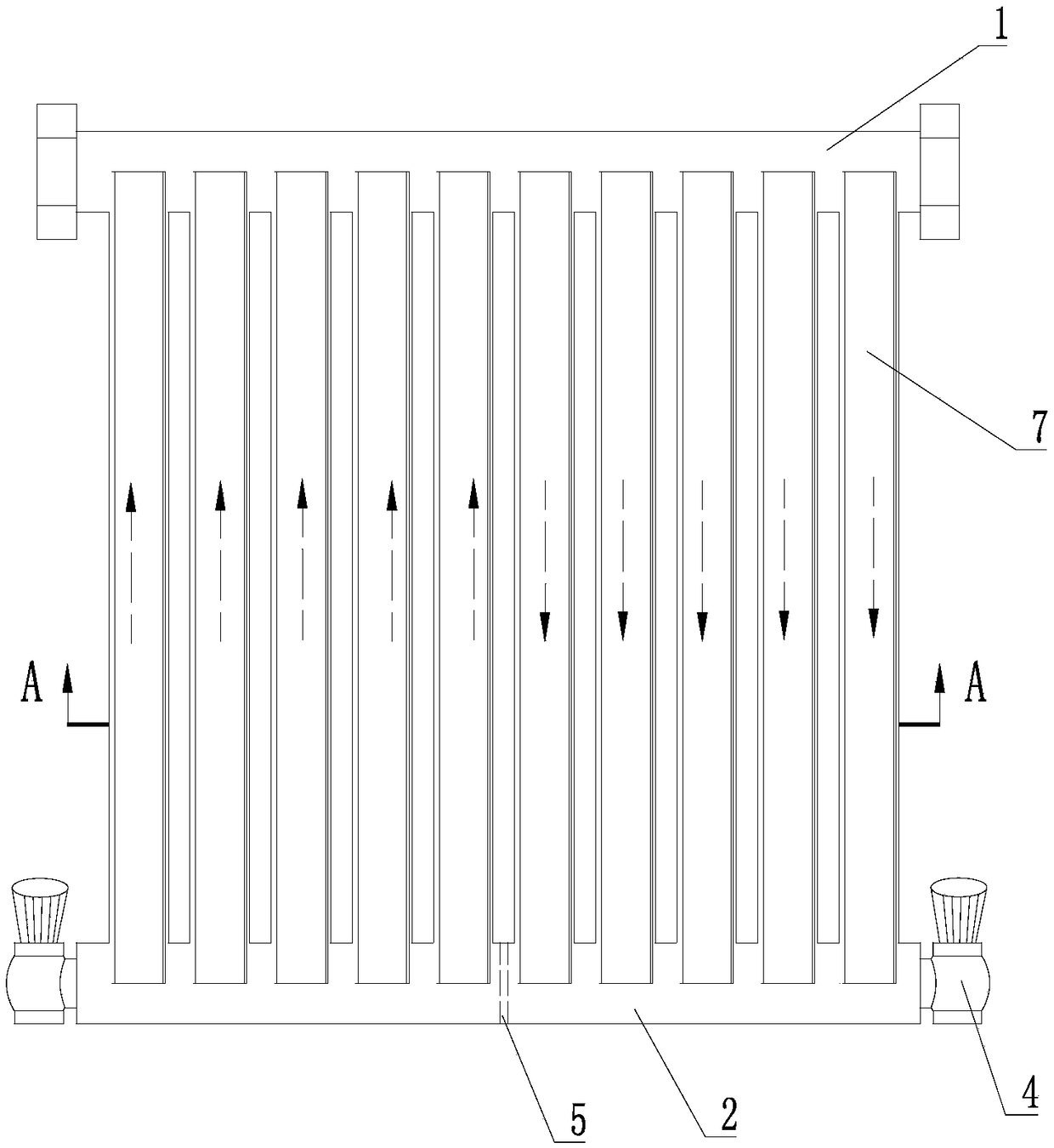

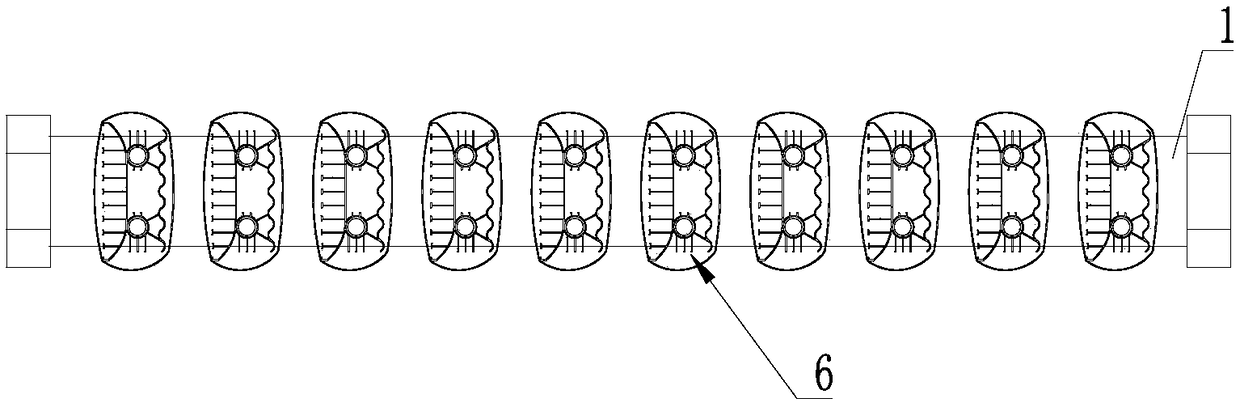

[0019] Such as Figure 1 to Figure 4 As shown, the dual-channel copper-aluminum composite radiator includes an upper water pipe 1 and a lower water pipe 2 arranged at intervals up and down. There are several branch pipes 3 connected between the upper water pipe 1 and the lower water pipe 2. One end of the lower water pipe 2 The water inlet end of the water supply system is connected through the regulating valve 4, and the other end of the downwater pipe 2 is connected with the backwater end of the water supply system through the regulating valve 4. The middle part of the downwater pipe 2 is fixedly provided with a barrier piece 5, and the The branch pipes 3 include several pairs symmetrically arranged front and back, each pair of the branch pipes 3 has a heat dissipation profile 6 respectively expanded on the outside, and the outside of the heat dissipation profile 6 is covered with a heat dissipation shell 7, and the heat dissipation profile 6 includes a A pair of circular tu...

Embodiment 2

[0024] Such as Figure 5As shown, the structural principle of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The only difference is that the structure of the heat dissipation profile 6 is different. In this embodiment, the circular tube 8 on the front side extends three long fins 18 forward and two short fins 19 backward respectively, and the circular tube 8 on the rear side extends backward respectively. Three long fins 18 and two short fins 19 extending forward; also include a left-curved curved fin 17 on the left side, the right side of the curved fin 17 is connected to a pair of The circular tube 8 is tangent, and the left side of the curved fin 17 is evenly distributed with a number of left sub-fins 15 arranged in parallel; it also includes a wave fin 14 on the right side, and the wave fins 14 are respectively It is connected with the two circular tubes 8 through two right sub-fins 16 . In this embodiment, the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com