Patents

Literature

2523 results about "Aluminum composites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

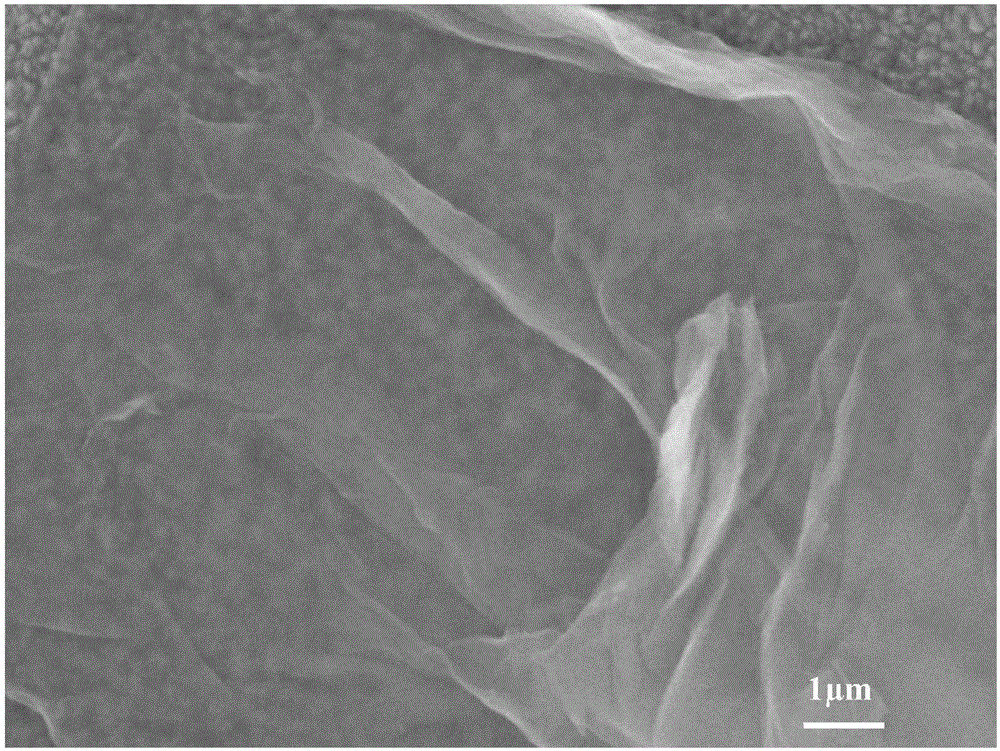

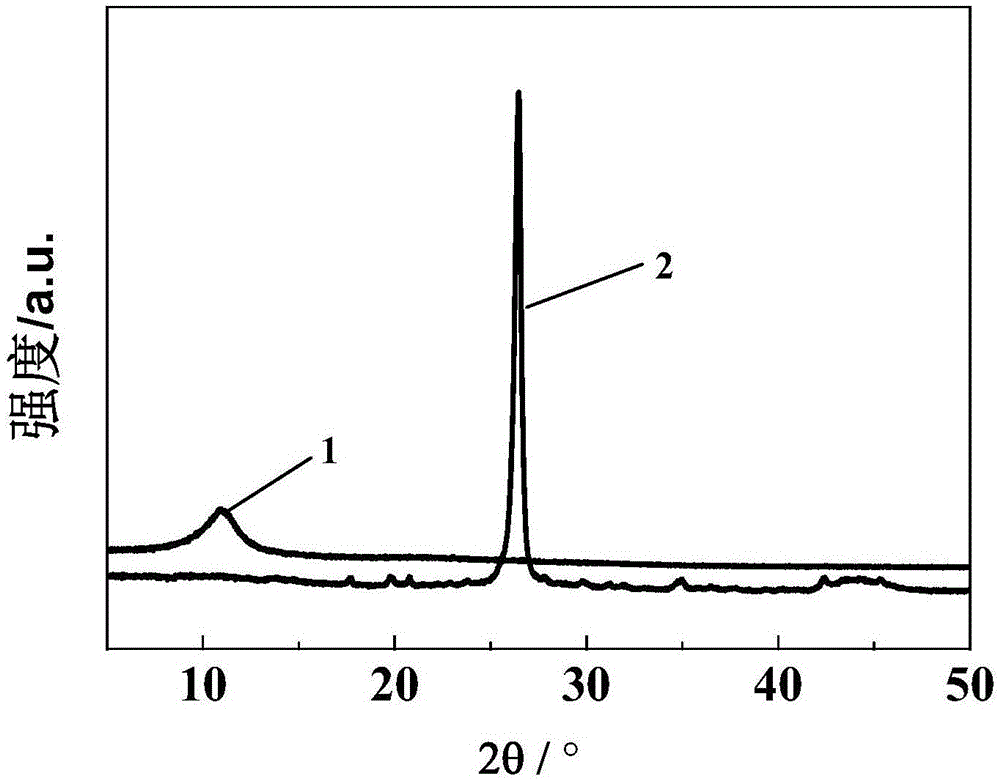

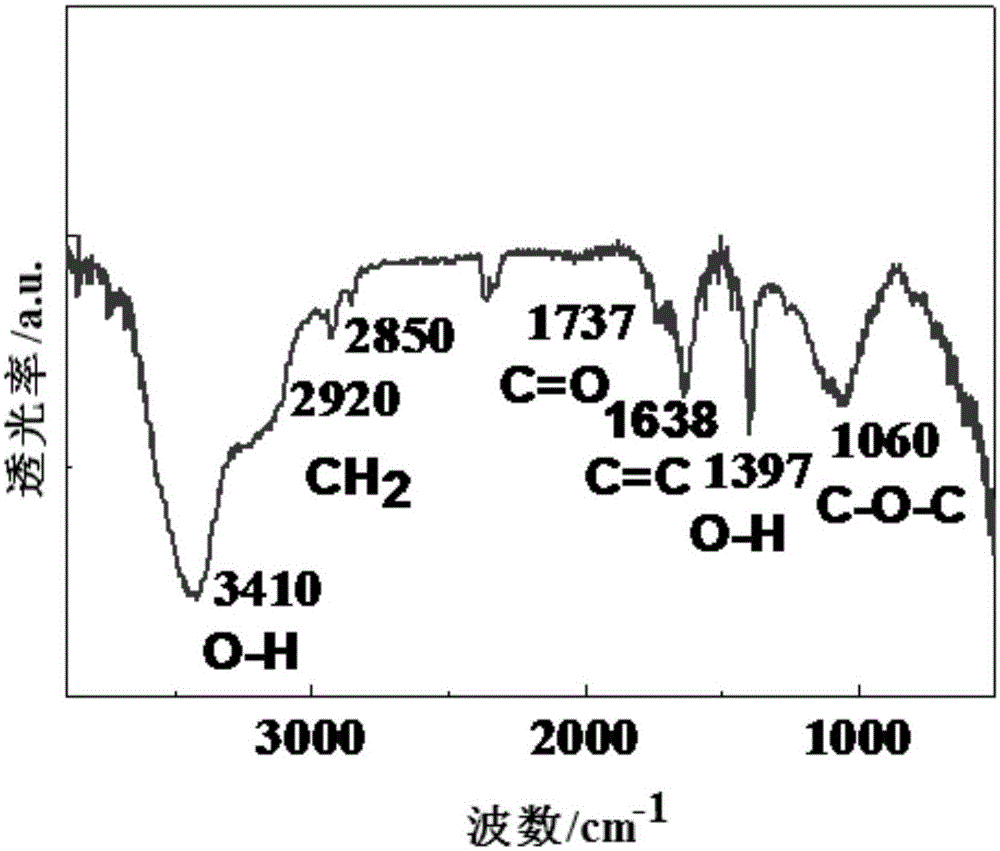

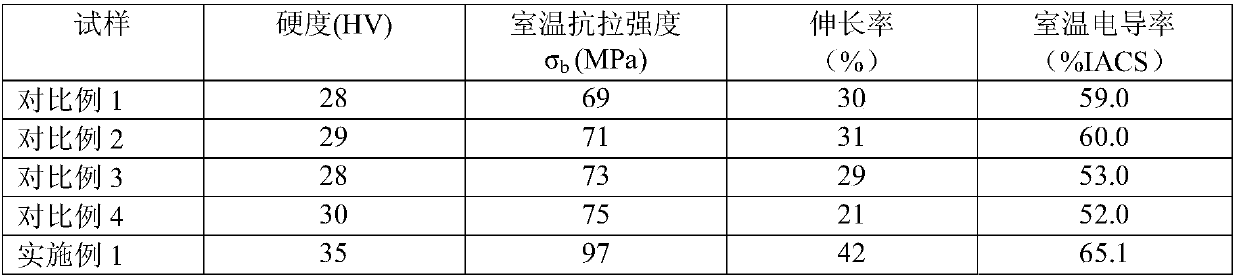

Method for preparing grapheme reinforced aluminum matrix composite material

The invention relates to a method for preparing a grapheme reinforced aluminum matrix composite material. The method aims at solving the technical problems that in an existing method for preparing the grapheme reinforced aluminum matrix composite material, the grapheme dispersibility is poor, and agglomeration is prone to happening. The method includes the steps that (1) oxidized grapheme is prepared; (2) surface modification on aluminum powder is carried out; (3) oxidized grapheme-aluminum composite powder is prepared; and (4) the grapheme reinforced aluminum matrix composite material is prepared. An electrostatic self-assembly method is adopted in the method, so that graphene is evenly dispersed in an aluminum matrix to enable the graphene to be more evenly dispersed, phenomena of damage to graphene size and work hardening generated on the aluminum matrix during ball-milling treatment are avoided, and graphene agglomeration is prevented; in addition, the mechanical property of the composite material is obviously improved; and compared with a pure aluminum material, the strength of extension is improved by 10%-20%, and the hardness is improved by 10%-30%.

Owner:HARBIN UNIV OF SCI & TECH

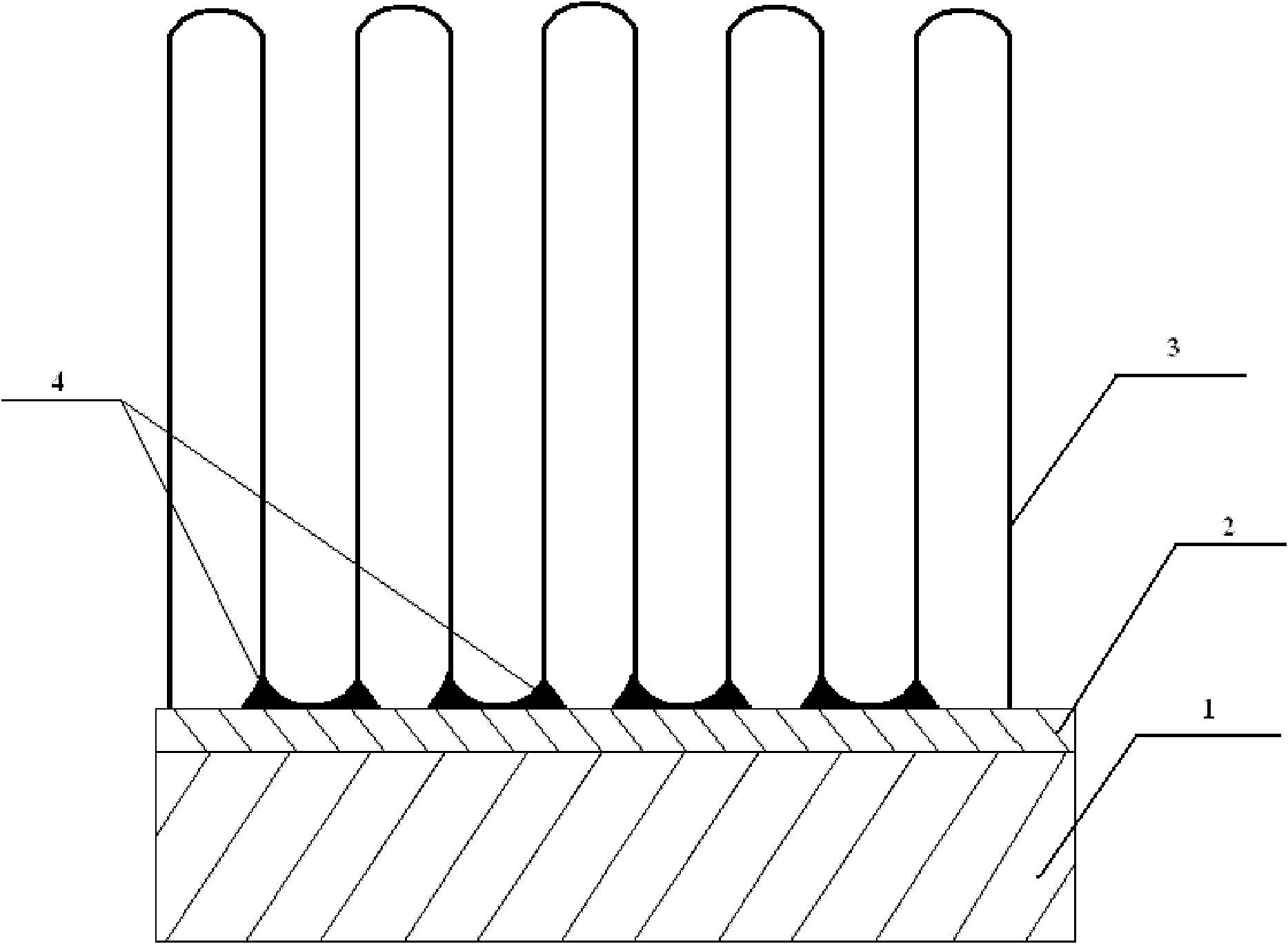

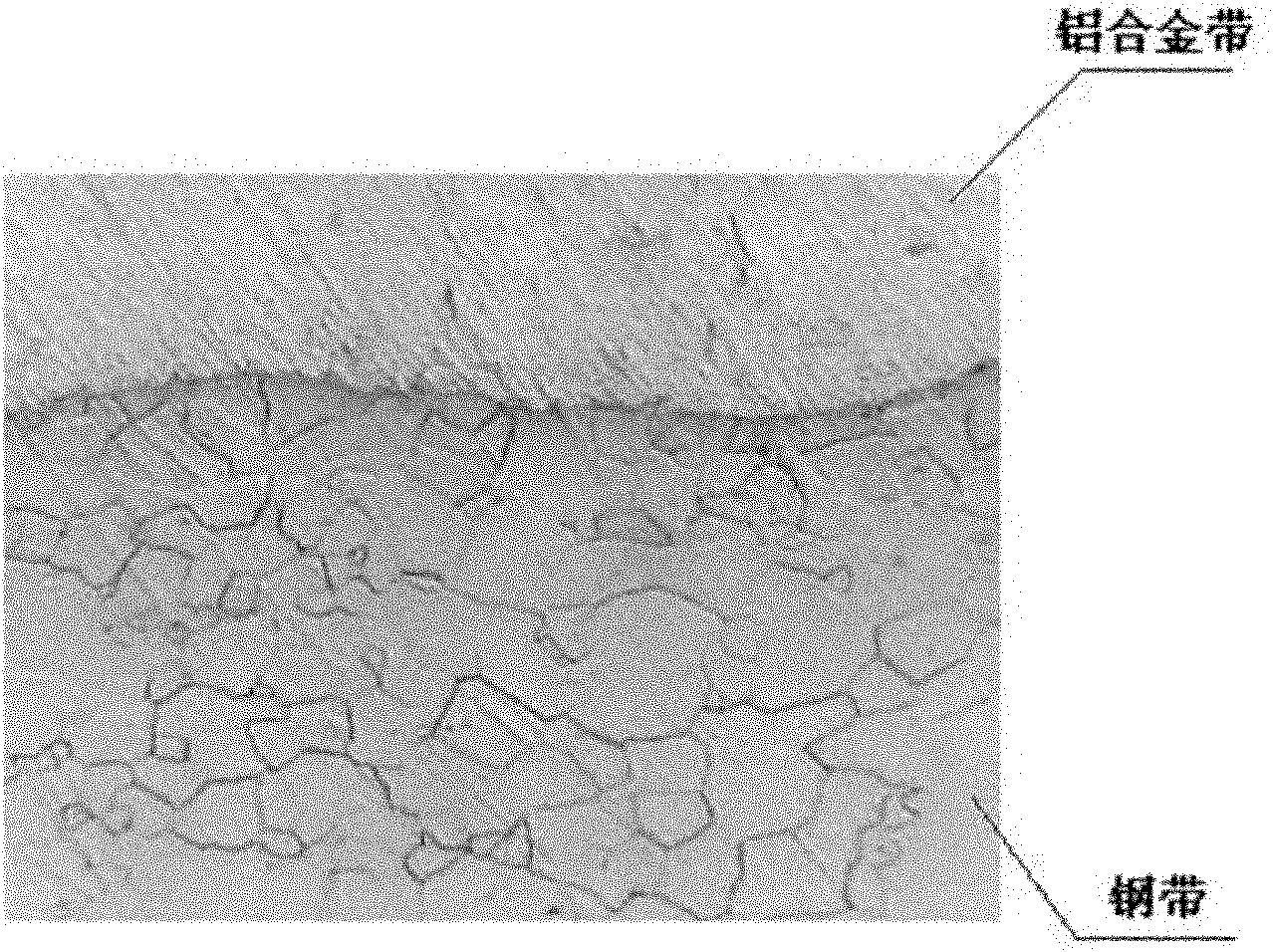

Aluminium-clad steel strip for coolers and preparation method thereof as well as steel strip and aluminium alloy strip used thereby

InactiveCN102019727AGuaranteed bonding strengthImprove mechanical propertiesLaminationLamination apparatusAluminum compositesSteel belt

The invention relates to an aluminium-clad steel strip and a preparation method thereof as well as a steel strip and an aluminium alloy strip used thereby, in particular to an aluminium-clad steel strip for coolers and a preparation method thereof as well as a steel strip and an aluminium alloy strip used thereby. The invention solves the problems of pinholes, composite layer inclusions, generation of brittle iron aluminium metallic compounds and failure to adapt to brazing technology in the industrially produced steel-aluminium composite material at present. The aluminium-clad steel strip for coolers is prepared by cladding a steel strip and an aluminium alloy strip. The preparation method comprises the following steps: 1. pretreating the surfaces of the steel strip and the aluminium alloy strip; 2. sandwich-rolling; and 3. recrystallization annealing. In the steel strip, the content of C is less than 0.01%, the content of Si is less than 0.01%, the content of Mn is 0.20-0.30%, and the content of Alt is less than 0.005%. In the aluminium alloy strip, the content of Si is 0.70-0.90%, and the content of Fe is 0.30-0.45%. The invention is applicable to the field of brazing coolers.

Owner:HARBIN SONGRUN METAL PRODS

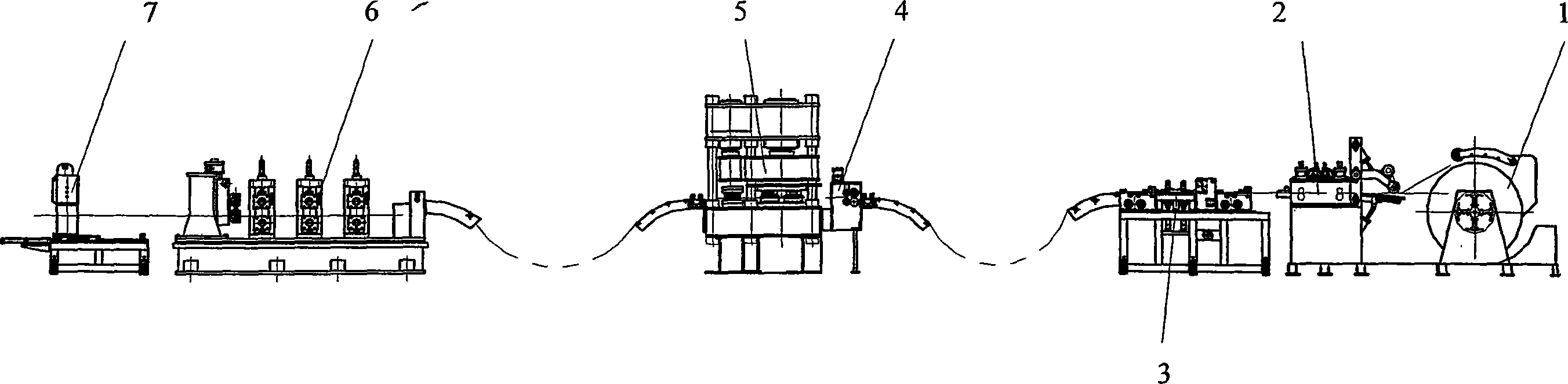

Stainless-steel band special apparatus for steel-aluminum composite contact rail

InactiveCN101028685AImprove performanceQuality improvementMetal-working feeding devicesOther manufacturing equipments/toolsButt weldingControl theory

Owner:南京赛彤铁路电气化有限公司

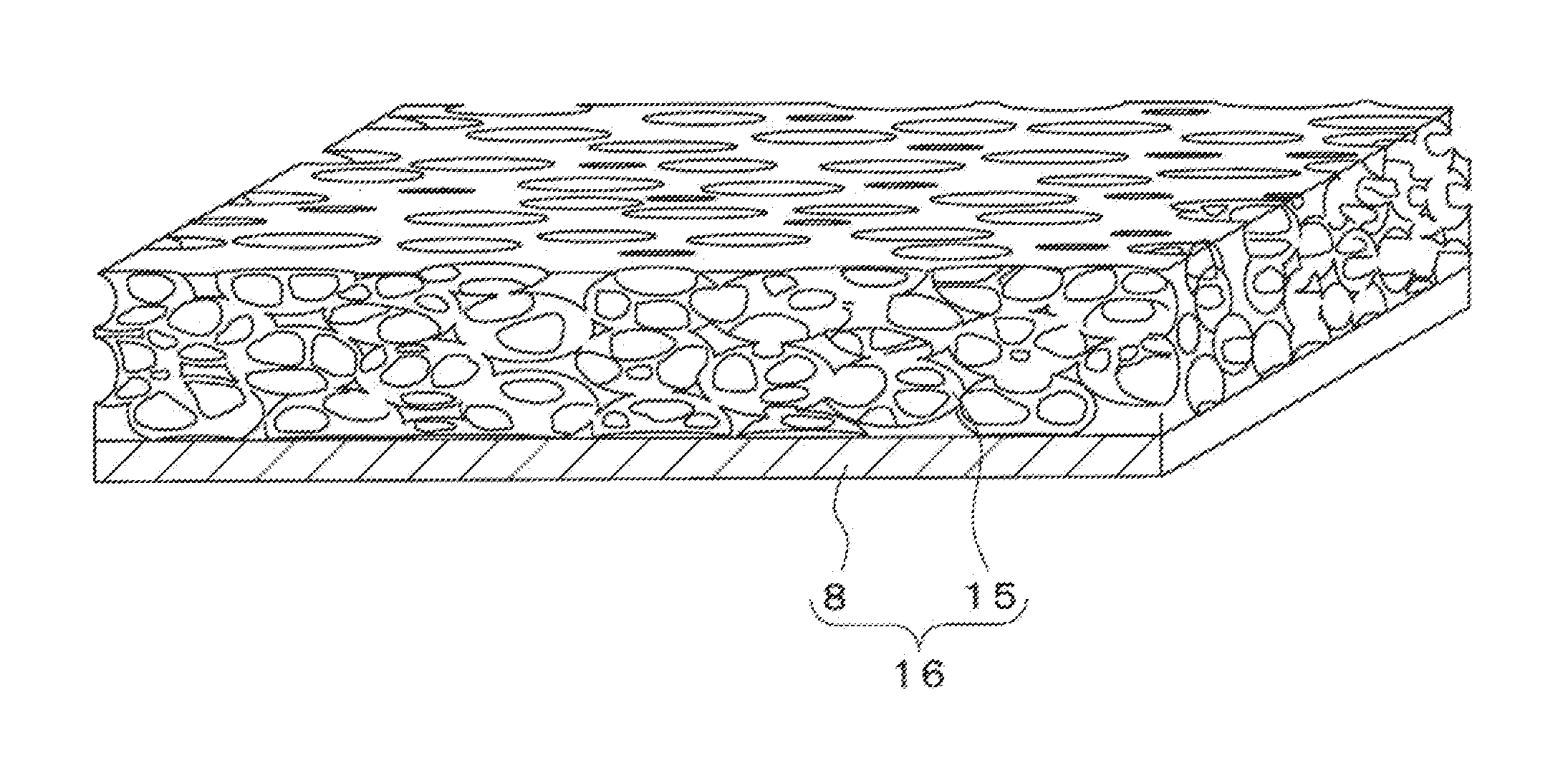

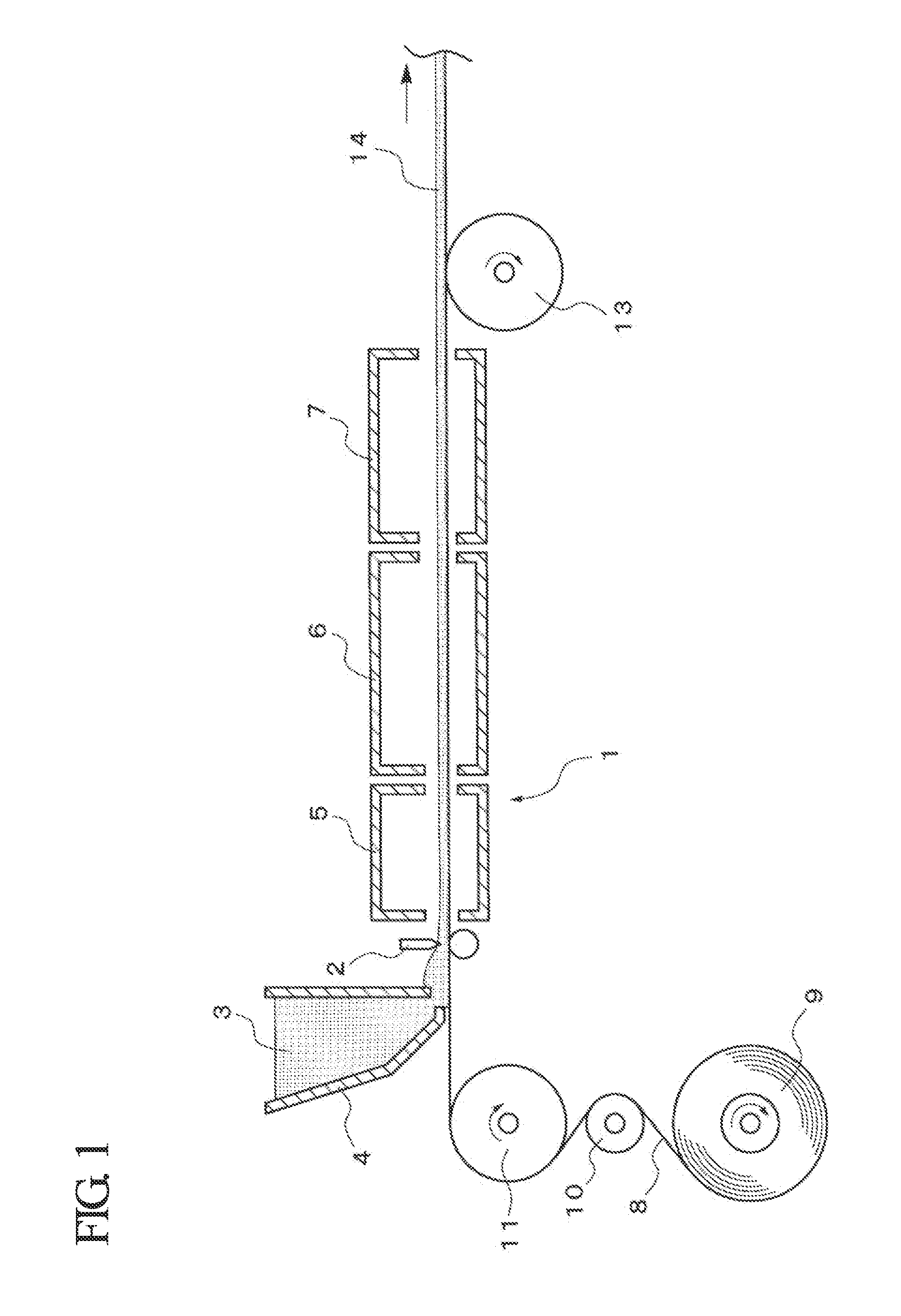

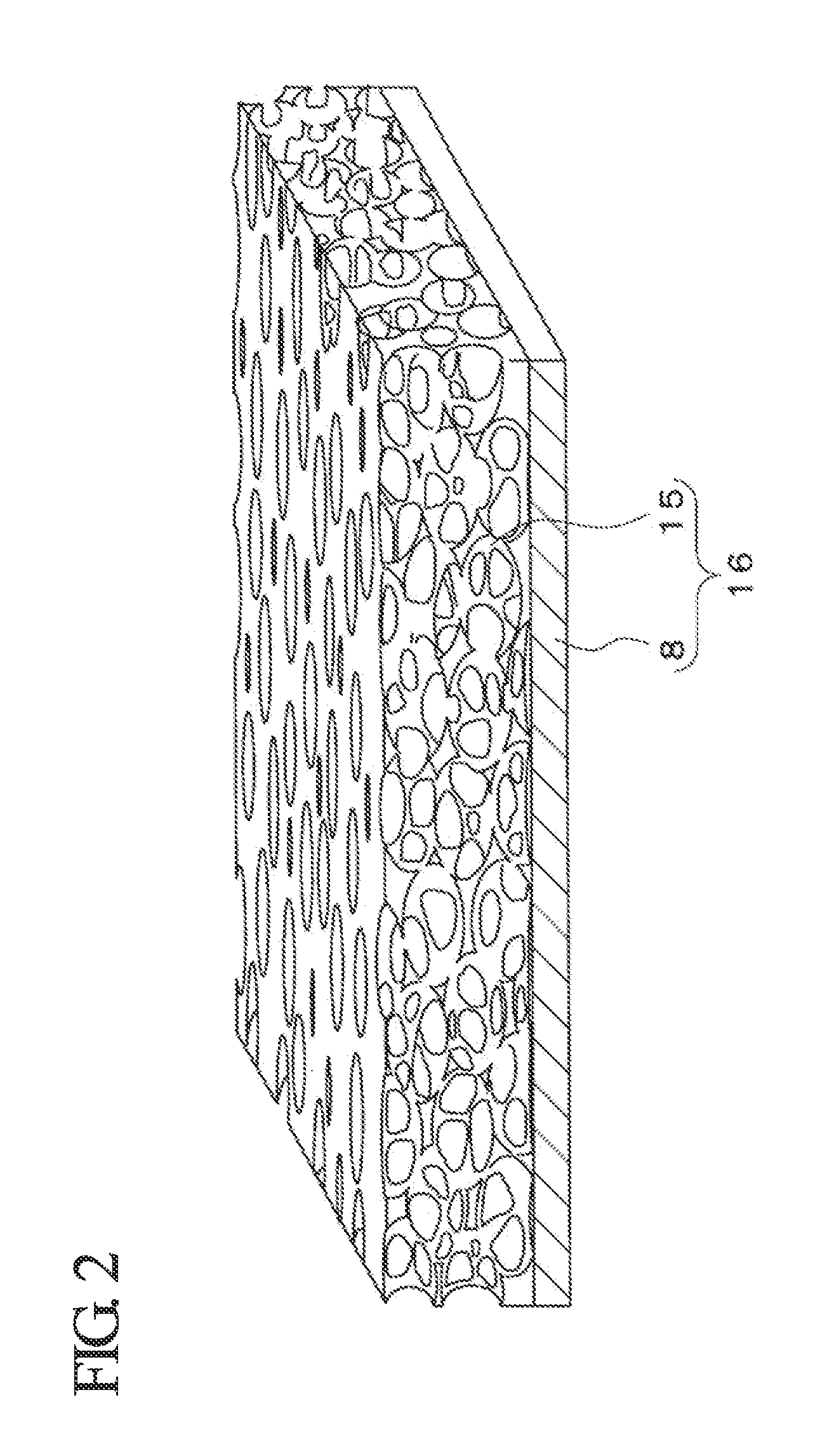

Process for production of aluminum complex comprising sintered porous aluminium body

ActiveUS20120135142A1Reduced strengthAvoid inhibitionTransportation and packagingElectrode carriers/collectorsWater insolubleCoordination complex

This method for producing an aluminum composite including porous sintered aluminum, includes: mixing aluminum powder with a sintering aid powder containing either one or both of titanium and titanium hydride to obtain a raw aluminum mixed powder; adding and mixing a water-soluble resin binder, water, a plasticizer containing at least one selected from polyhydric alcohols, ethers, and esters, and a water-insoluble hydrocarbon-based organic solvent containing five to eight carbon atoms into the raw aluminum mixed powder to obtain a viscous composition; shape-forming the viscous composition on an aluminum foil or an aluminum plate and causing the viscous composition to foam to obtain a formed object prior to sintering; and heating the formed object prior to sintering in a non-oxidizing atmosphere to obtain an aluminum composite which includes porous sintered aluminum integrally joined onto the aluminum foil or the aluminum plate, wherein when a temperature at which the raw aluminum mixed powder starts to melt is expressed as Tm (° C.), then a temperature T (° C.) of the heating fulfills Tm-10 (° C.)≦T≦685 (° C.).

Owner:MITSUBISHI MATERIALS CORP

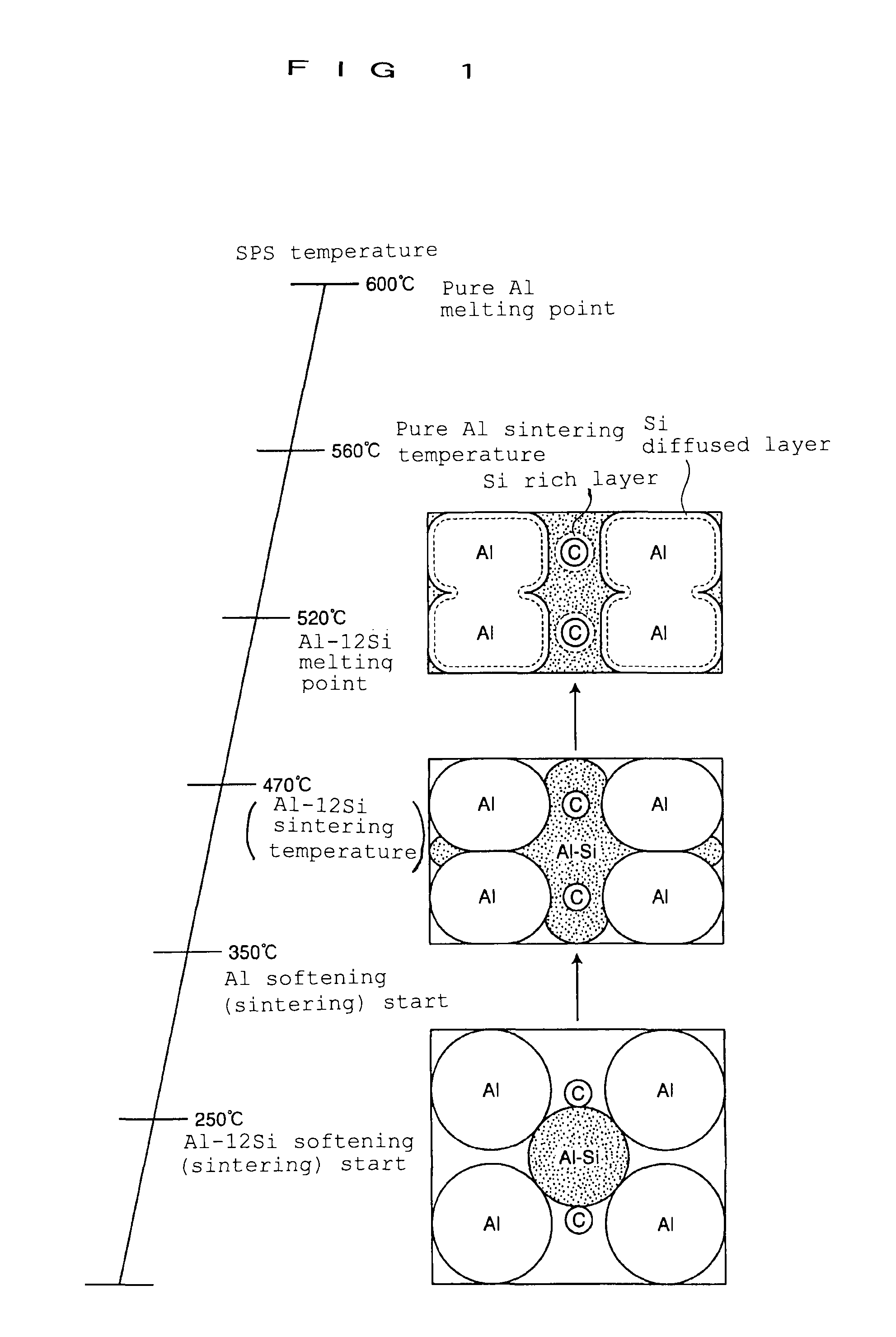

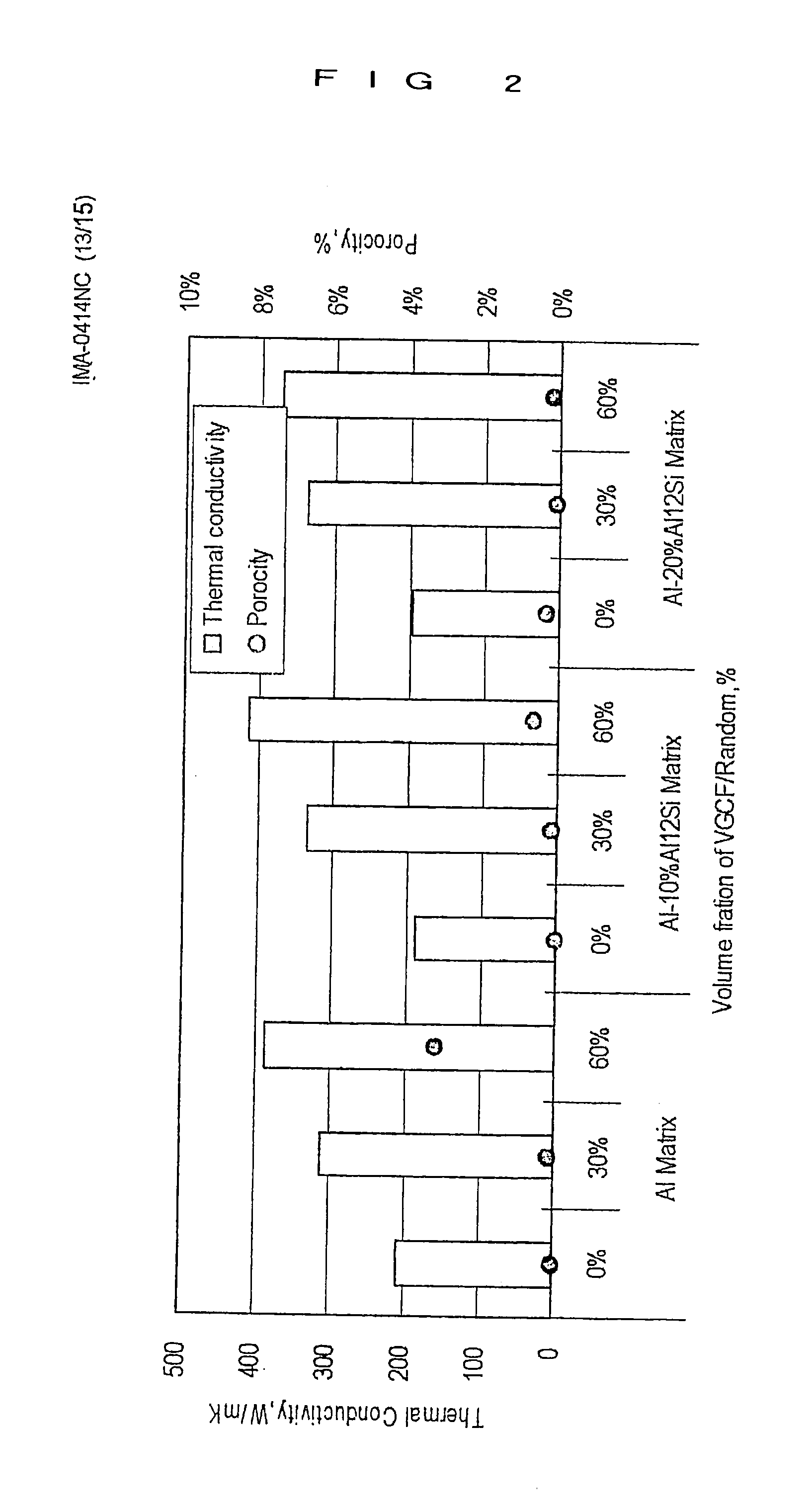

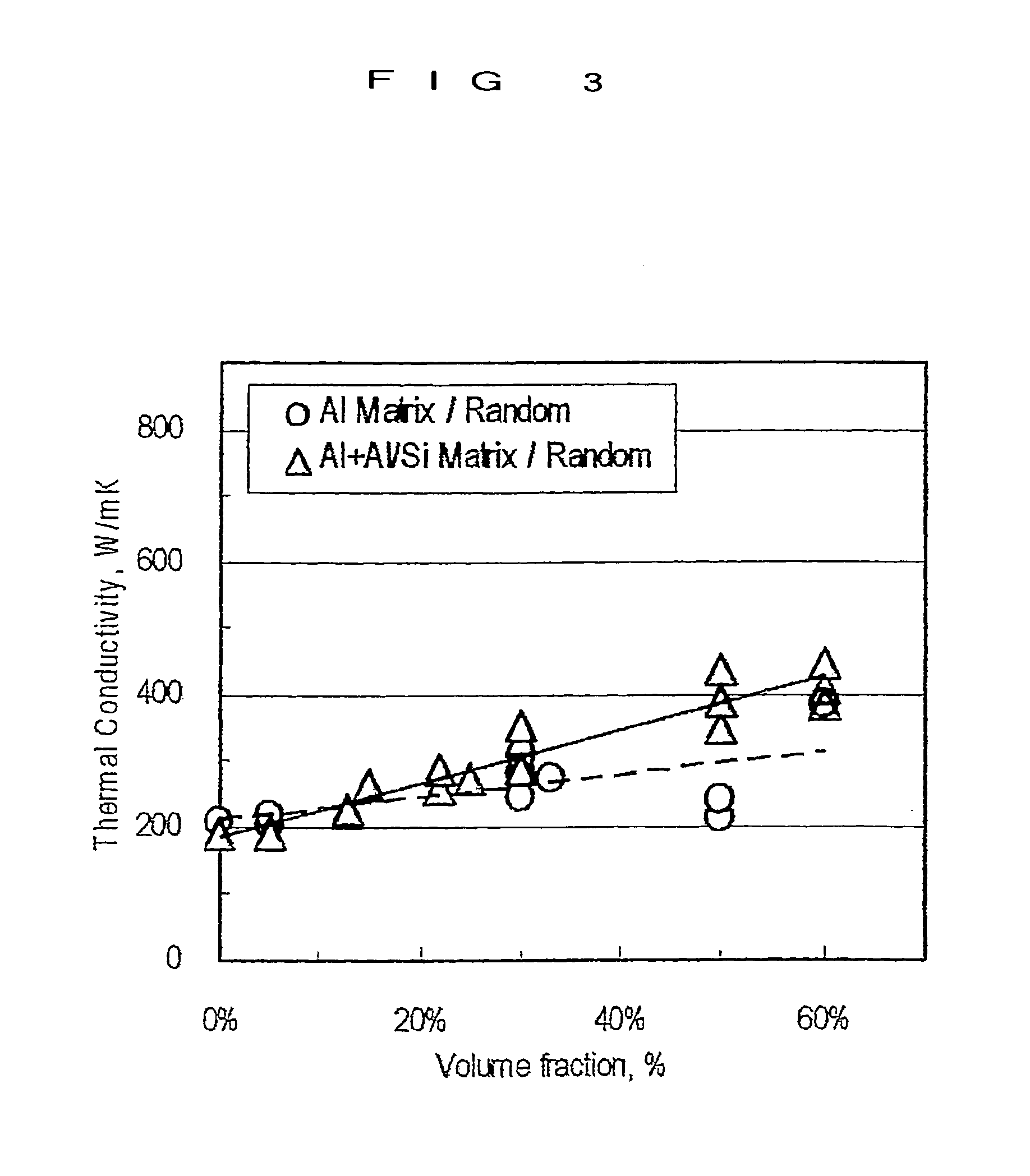

Highly heat-conductive composite material

InactiveUS8163060B2Improve the heating effectIncrease resistanceSingle layer grapheneAluminium powderAlloy

The heat conductivity of an aluminum composite material containing a fibrous carbon material is enhanced. In order to realize this, a spark plasma sintered body having a fibrous carbon material compounded in a metal matrix powder of aluminum or the like is fabricated. At the time of fabrication, an aluminum powder serving as a matrix mother material is compounded with an Al alloy powder such as an Al-12Si powder having a melting point lower than the sintering temperature of the mother material. During the process of sintering the aluminum powder, the Al alloy powder is melted, whereby the heat conductivity between the aluminum powder particles and between the aluminum powder particle and the fibrous carbon material is improved.

Owner:SUMITOMO PRECISION PROD CO LTD +1

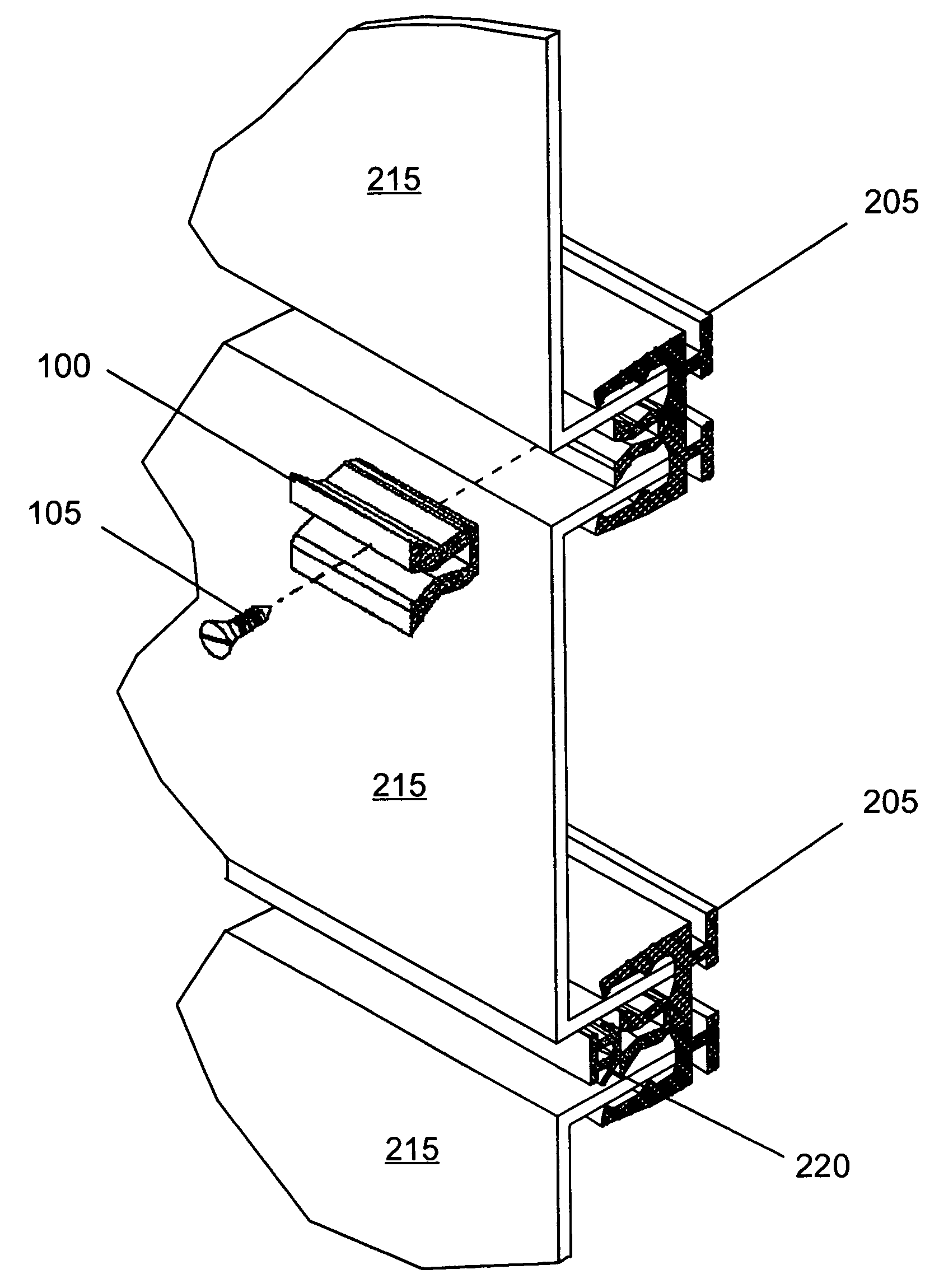

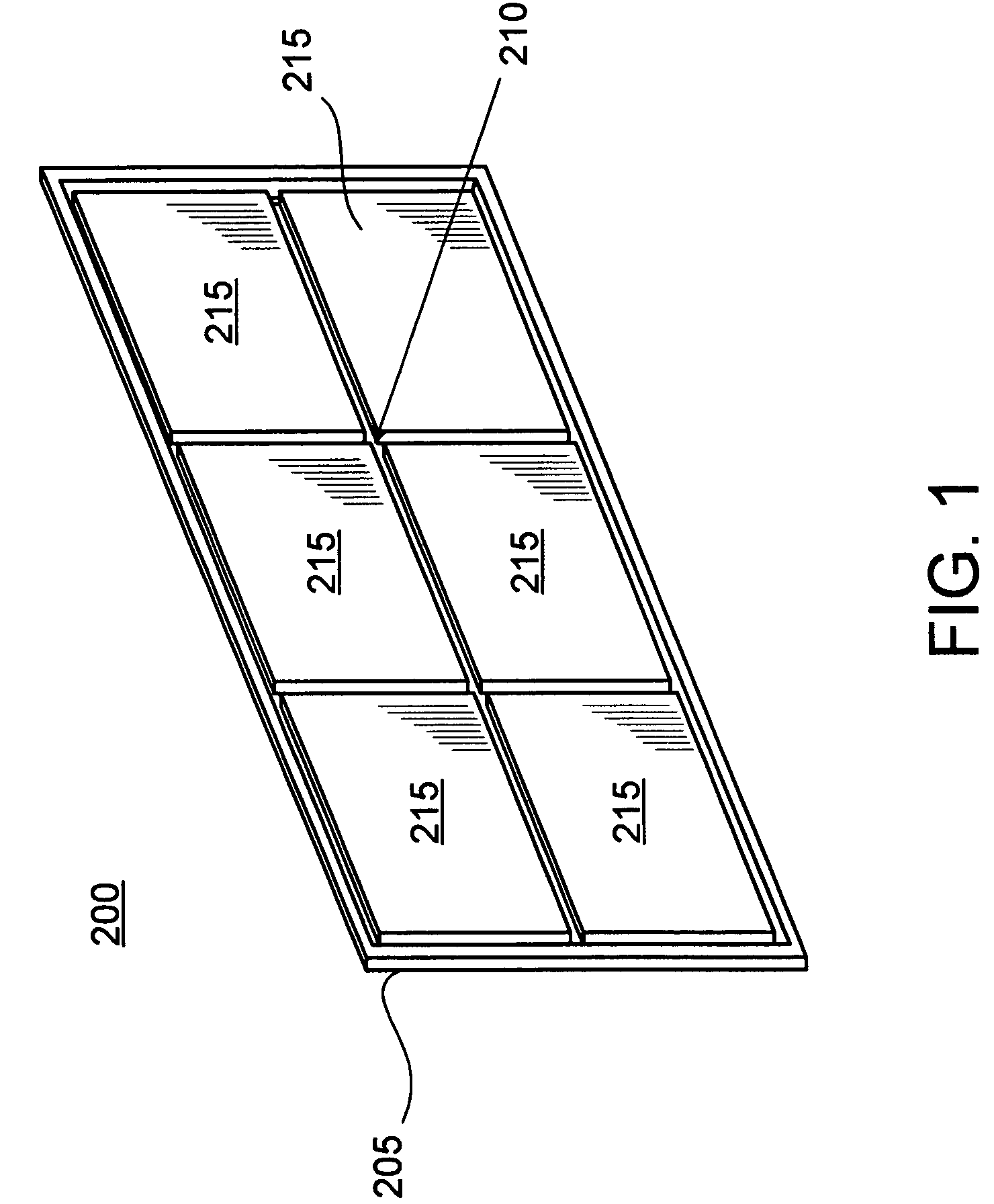

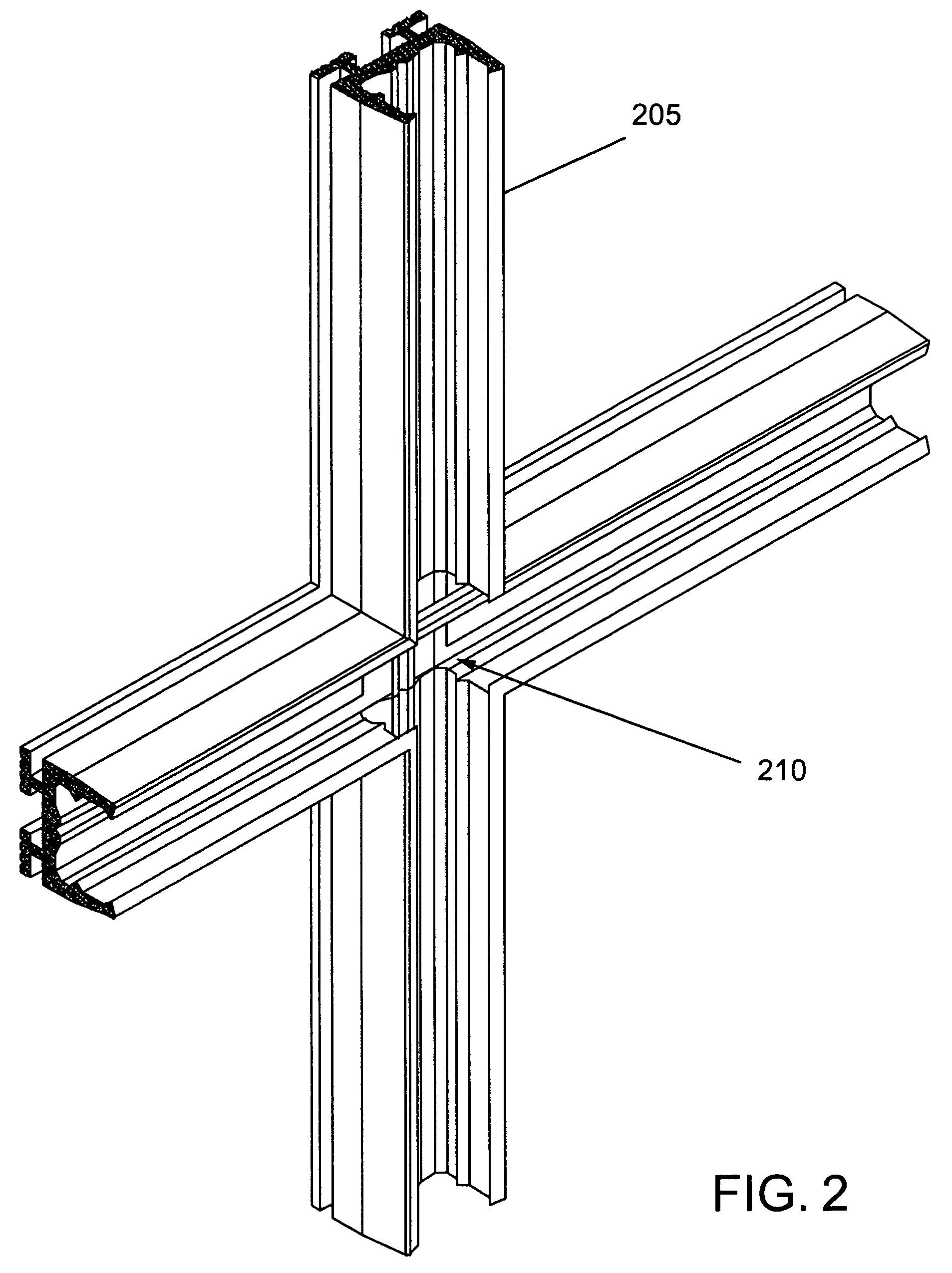

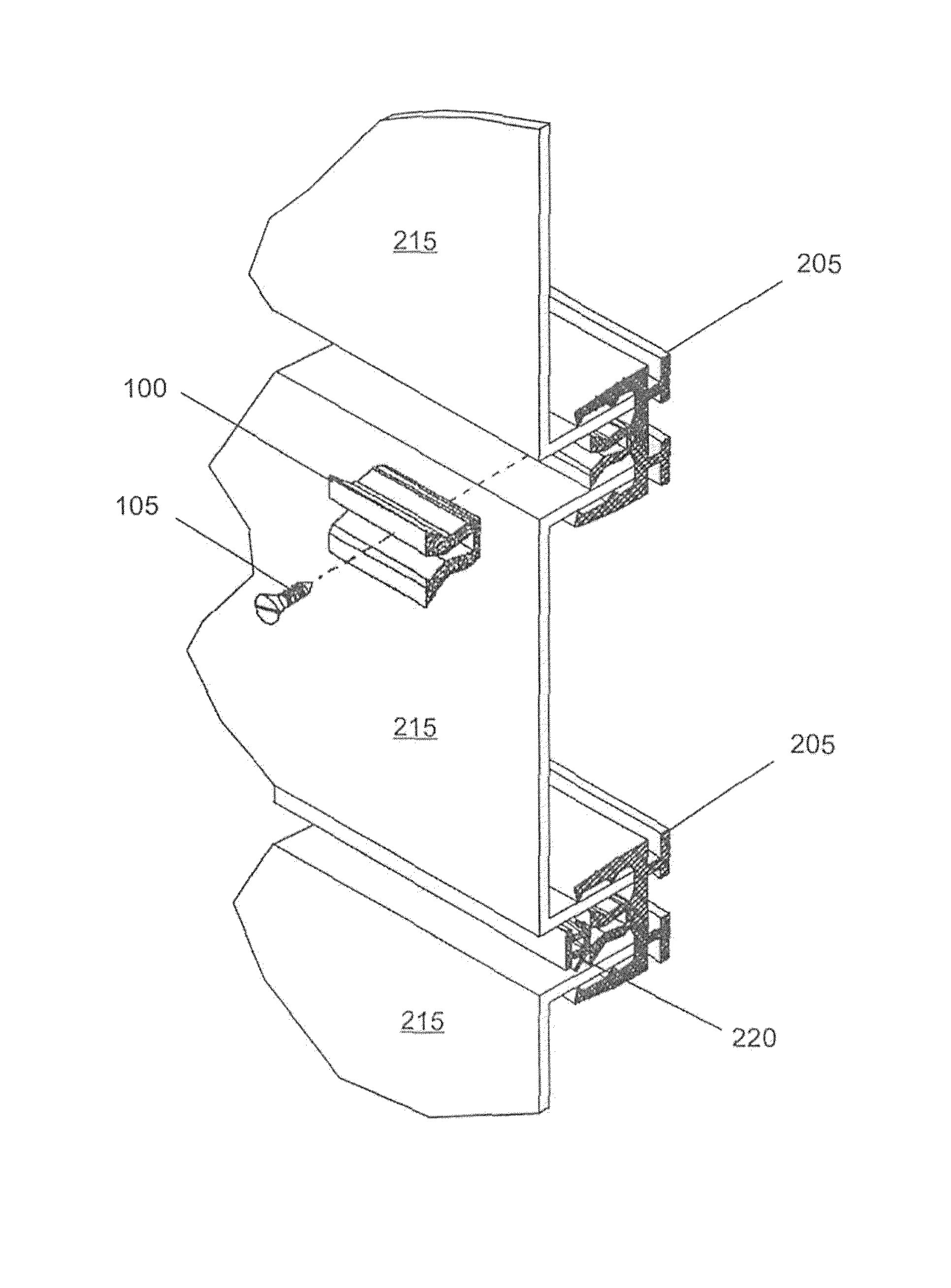

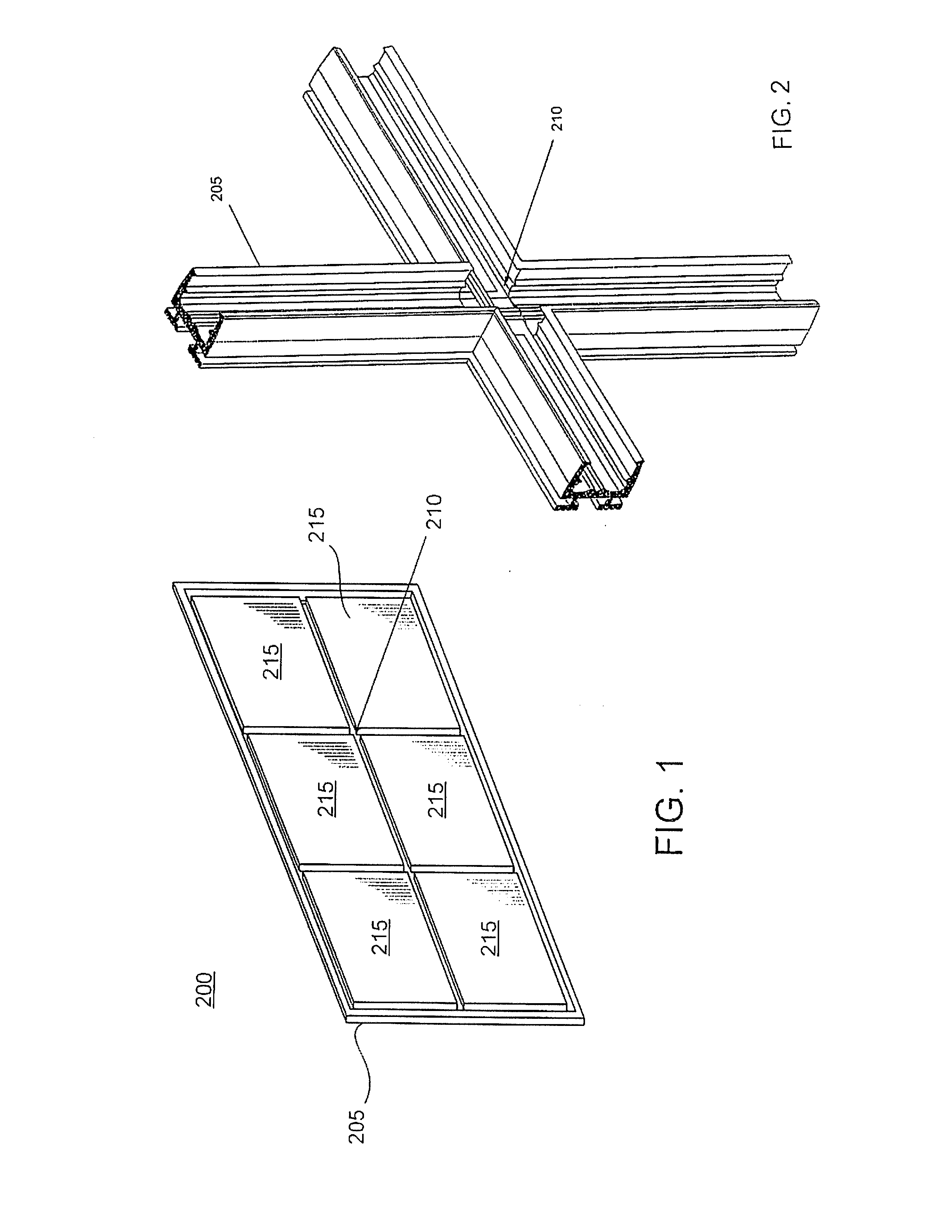

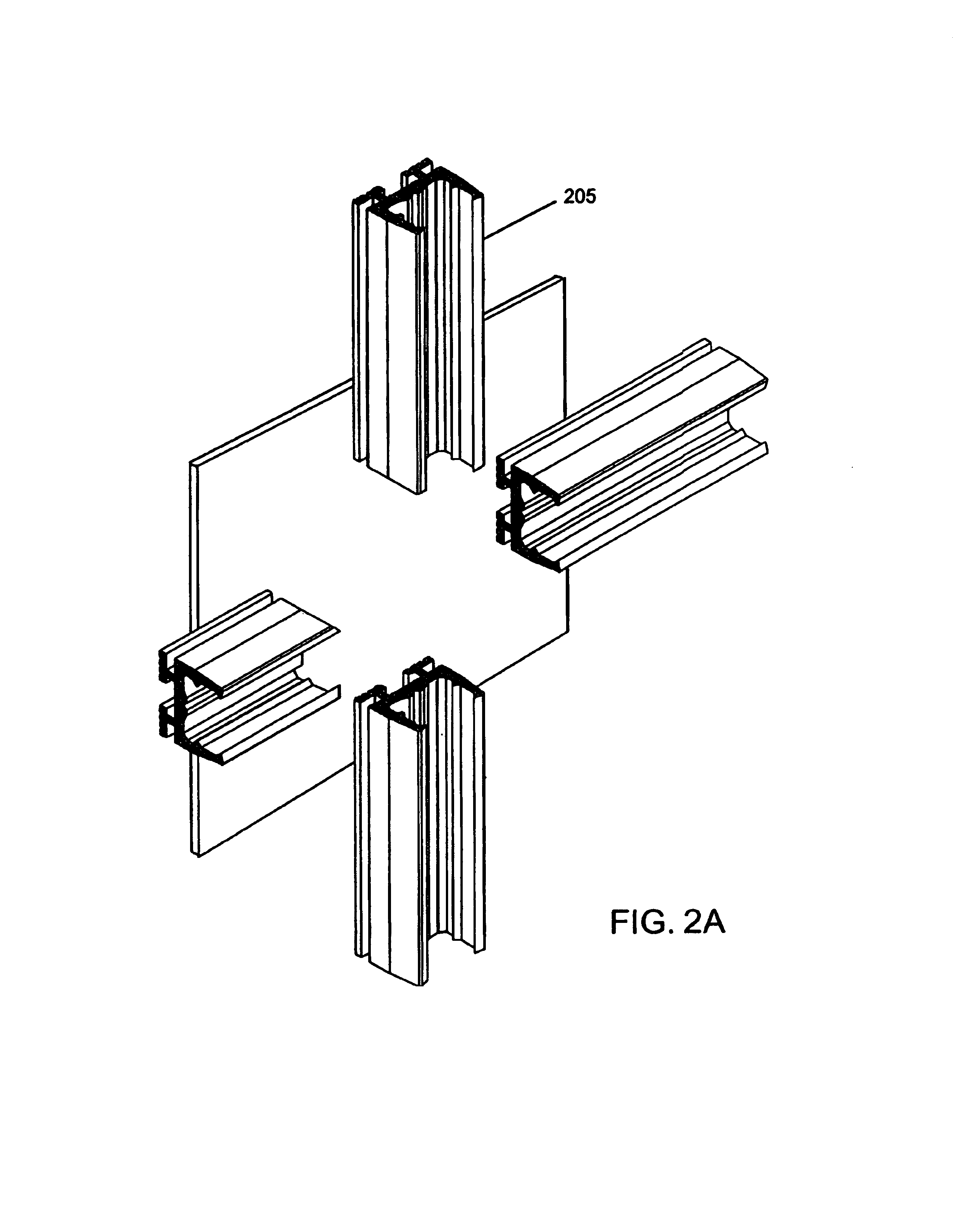

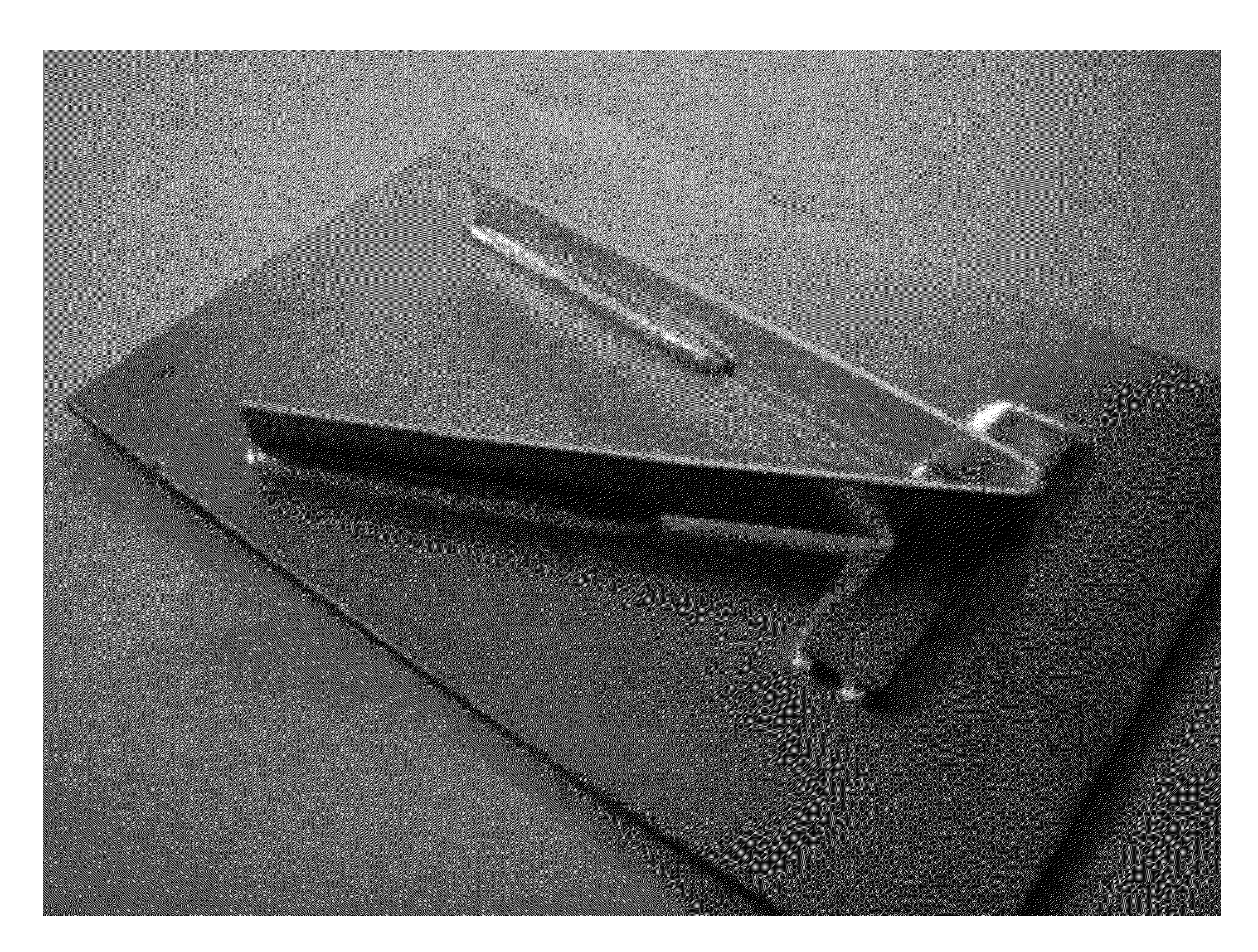

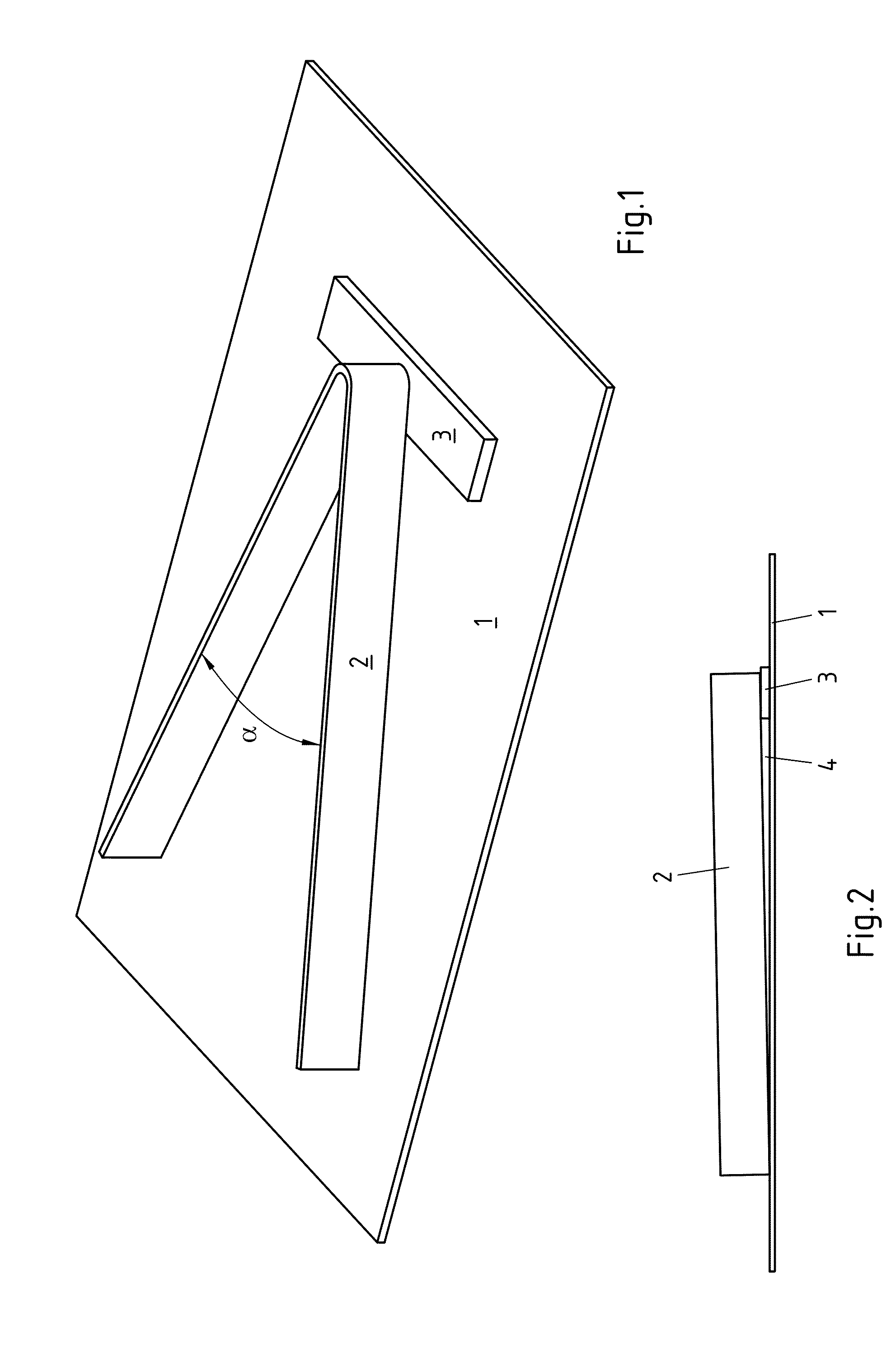

ACM panel retaining clip and self-adjusting coplanar panel mounting system

The present invention provides for a self-leveling structural element in a non-progressive attachment system, a U-shaped retentive clip having a base and two upwardly extending arms that are forced apart by the installation of a self-drilling screw, the novel retentive clip with screw coacting with an extruded frame to mount and retain a plurality of aluminum composite material (ACM) panels in a coplanar manner, to form an Aluminum Composite Cladding System; thereby comprising a non-progressive system that enables removal of individual panels for replacement or repair.

Owner:ROEGGE STEPHEN +2

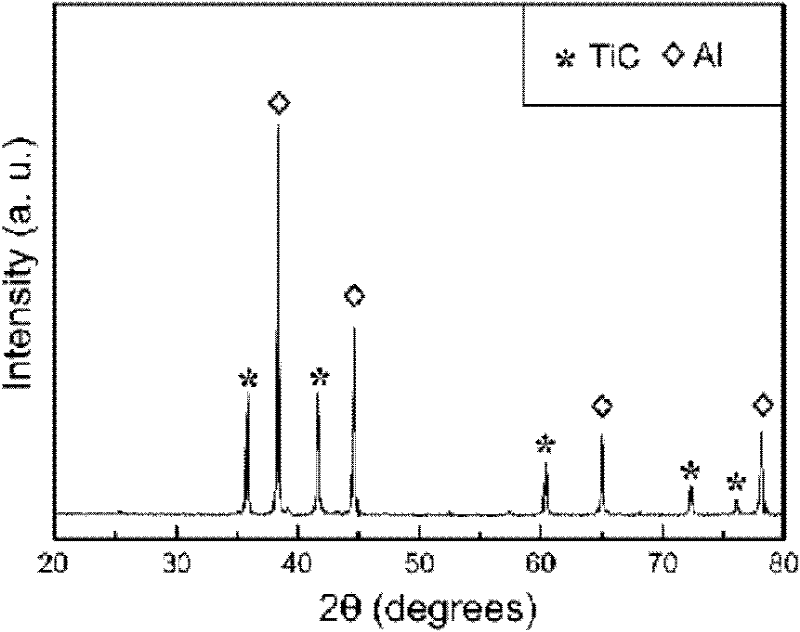

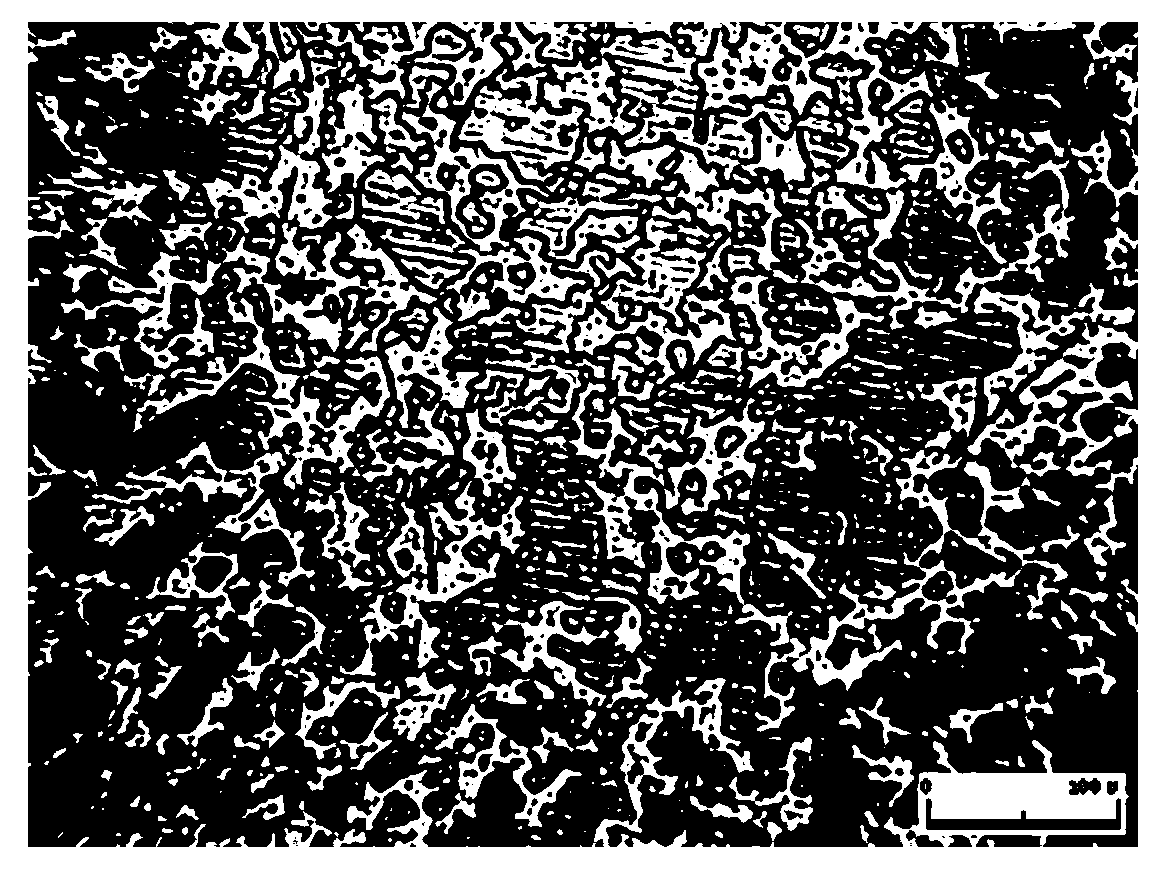

A kind of in-situ nano-tic ceramic particle reinforced aluminum matrix composite material and preparation method thereof

ActiveCN102260814APure surfaceImprove the bonding strength of the interfaceChemical reactionGraphite

The invention relates to an in situ nano TiC ceramic particle reinforced aluminum based composite material and a preparation method thereof. According to the invention, an in situ nano TiC ceramic particle reinforced aluminum or aluminum alloy based composite material is prepared by using a combustion synthesis chemical reaction method and a hot-press technology; and the size of the TiC ceramic particle synthesized by an in situ reaction is below 100 nm, and the weight percentage content of the TiC ceramic particle is 3-30. The preparation method comprises the following steps: 1) mixing reactant powder materials in a certain proportion and then making blanks; 2) evenly mixing in a drum-type ball mill and a triturator in turn; 3) pressing at the room temperature so as to form reaction prefabricated blocks; and 4) putting a graphite mould with the prefabricated blocks in a vacuum / atmosphere protected combustion reaction furnace with a hydraulic device and then initiating a combustion reaction, immediately applying an axial pressure of 40+ / -5 MPa to the prefabricated blocks once the combustion reaction occurs, and cooling the prefabricated blocks to room temperature along with the furnace after keeping the pressure for 30-40 seconds, so as to synthesize the nano TiC ceramic particle reinforced pure aluminum or aluminum alloy based composite material.

Owner:JILIN UNIV

Polymer/foamed aluminium composite material and production method thereof

ActiveCN102501357AGood mechanical propertiesImprove thermal conductivityCoatingsPolyoxymethyleneCooking & baking

A polymer / foamed aluminium composite material and a production method thereof; polymer melt is injected into voids of foamed aluminium to form a composite material composed of foamed aluminium and polymer; the polymer is a mixture of one or more than one of polypropylene, polyethylene, polystyrene, and polyoxymethylene. The production method of the polymer / foamed aluminium composite material comprises the following steps: embedding foamed aluminium in a mold; preparing the polymer / foamed aluminium composite material by a injection molding method of the polymer or the mixture; performing heat preservation of the obtained polymer / foamed aluminium composite material in a baking oven at a temperature of 50-80 DEG C for 1-3 hours.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

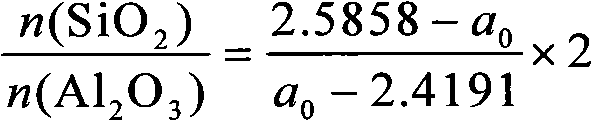

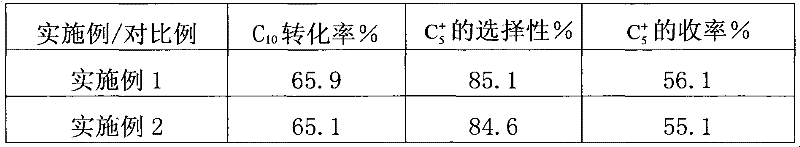

Preparation method for nano-Y-shaped molecular sieve/amorphous silicon-aluminum composite material

ActiveCN102451740AHigh yieldEasy to operateMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveAmorphous silicon

The invention relates to a preparation method for a nano-Y-shaped molecular sieve / amorphous silicon-aluminum composite material. According to the method, a guiding agent is synthesized, and a surfactant is added during the guiding agent synthesizing process; a surfactant is added during a preparation and synthesis process of gel of the Y-shaped molecular sieve, and a hydrothermal crystallization method is adopted to synthesize the nano-Y-shaped molecular sieve; an aqueous solution of a mixture is added to the slurry containing the nano-Y-shaped molecular sieve, wherein the mixture comprises water glass and an aluminum source; an acid is added to adjust the pH value to 7-9.5 to form the gel; the gel is washed, dried and baked to obtain the composite material. According to the present invention, the grain of the Y-shaped molecular sieve in the composite material prepared by the method of the present invention is maintained to less than 100 nm, and the composite material of the present invention is suitable for catalytic cracking reactions and hydrocracking reactions of heavy oil macromolecules.

Owner:PETROCHINA CO LTD +1

Cold rolling manufacture method of copper and aluminum composite plate strips

InactiveCN102615102ADiffuse fullyFull responseAuxillary arrangementsMetal rolling arrangementsChemical reactionCopper

The invention discloses a cold rolling manufacture method of copper and aluminum composite plate strips. The cold rolling manufacture method comprises the following steps that: 1, a copper plate and an aluminum plate are subjected to homogenization annealing treatment; 2, surface treatment is carried out: firstly, the copper plate and the aluminum plate subjected to the homogenization annealing treatment are subjected to soaking degreasing, then, the copper plate and the aluminum plate subjected to the soaking degreasing are taken out for drying, and next, the composite surfaces to be rolled of the copper plate and the aluminum plate are ground by a stainless steel wire brush; 3, the copper plate and the aluminum plate are subjected to cold rolling compounding by a cold rolling mill, so copper and aluminum composite plate blanks are obtained; and 4, the copper and aluminum composite plate blanks subjected to the cold rolling are subjected to the diffusion annealing treatment. The cold rolling manufacture method has the advantages that through improving the cold rolling process operation and the process parameters, the copper plate and the aluminum plate are subjected to full diffusion and chemical reaction on the composite surfaces in the manufacture process, so the transition structure with excellent performance is obtained at the composite surfaces, and the bonding intensity of finished products is effectively improved.

Owner:HONGGUANG ELECTRIC GROUP CO LTD

Modified aluminum oxide aerogel composite material and preparation method thereof

ActiveCN101955350AAvoid negative effectsLow thermal conductivityCeramicwareSupercritical dryingFiber

The invention provides a silicon-aluminum aerogel composite material which comprises silicon-aluminum composite aerogel (1) and an inorganic fiber material (2), wherein the silicon-aluminum composite aerogel is prepared from a silicasol aqueous solution. The invention also provides a method for preparing the silicon-aluminum aerogel composite material, which comprises the steps of preparing the silicon-aluminum composite aerogel, dipping sol, gelatinizing, ageing, overcritically drying and the like. With excellent high-temperature resistance, good mechanical property and low thermal conductivity at high temperature, the silicon-aluminum aerogel composite material can meet the high requirement of thermal protection in the fields of aviation, aerospace and military affairs and can also be applied to the field of civil heat insulation.

Owner:海鹰空天材料研究院(苏州)有限责任公司

Stainless steel/aluminum composite material and preparation method thereof

ActiveCN101992567AImprove bindingHigh mechanical strengthTemperature control deviceCleaning using liquidsSurface layerAluminum composites

The invention relates to a metal composite material and a preparation method thereof, in particular to a stainless steel / aluminum composite material and a preparation method thereof. The material comprises a three-layer structure formed by hot rolling, wherein the bottom layer is a stainless steel layer, the middle layer is an aluminum alloy layer, and the surface layer is a pure aluminum layer; and the aluminum ally contains elements of Cu, Mg and Mn. The preparation method of the material comprises the following steps of: cleaning the surface of a raw material plate; performing lamination, hot rolling and heat treatment on a stainless steel plate and an aluminum alloy plate to form a once hot rolled plate; and laminating a pure aluminum plate on the aluminum alloy layer of the once hot rolled plate to perform hot rolling and heat treatment. The stainless steel / aluminum composite material has high bonding force, and cannot deform, crinkle and delaminate in the subsequent stamping process and the like.

Owner:BYD CO LTD

Production method of aluminum and copper composite metal band

ActiveCN101758071ASolve Oxidation ProblemsUniform thicknessTension/compression control deviceMetal rolling arrangementsCopperUltimate tensile strength

The invention discloses a production method of an aluminum and copper composite metal band. In the method, the aluminum and copper composite metal band is manufactured by anaerobic continuous casting and rolling of semisolid aluminum or aluminum alloy and a solid copper band. In the production method of the invention, the anaerobic metallurgical combination of the solid copper band and molten aluminum is realized, the aluminum oxidization problem is solved, the combined strength is high, and the aluminum and copper bonding strength is more than or equal to 100MPa; the continuous casting and rolling of the copper band and the molten aluminum are adopted to produce the aluminum and copper composite metal band, so the production efficiency is greatly improved by scores of times and the product quality is stable; the produced aluminum and copper composite metal band retains the original surface quality of the copper band, has a uniformly-thick copper layer and can be deeply processed by cold rolling; and the copper band and the molten aluminum, which comprise different components, can be used, and products are diversified and widely applicable. The method has the advantages that: the production process of the copper and aluminum composite band is advanced and comprises a few working procedures; and the energy-saving, material-saving and economic effects are obvious.

Owner:LUOYANG TONGYI METAL MATERIAL DEV +2

Method for preparing lead-aluminum composite anode plate

The invention relates to a lead and aluminum compound anode plate material and the preparing method, which belongs to the field of electrolysis technology. The invention adopts purified aluminum plate or aluminum alloy plate, purified lead or lead and silver alloy and copper electric conducting beam as raw materials. The invention later adopts acid corrosion operation to the purified aluminum plate or the aluminum alloy plate so as to remove an oxide film. And then the surface of the aluminum plate is plated with a layer of other metals such as Ag, Mg, Sr, Zn or Sn, and the processed purified aluminum plate or aluminum alloy is placed into a mould so as to be evenly poured with a purified lead or lead and silver alloy fluid to make out the lead and aluminum compound cathode plate blank. Finally, the lead and aluminum compound cathode plate blank is milled into the lead and aluminum compound cathode plate. The lead and aluminum compound anode plate has the advantages of fine electric conduction, possible groove voltage reduction, electric energy conservation and high intensity of the compound anode plate as well as impossible deformation.

Owner:YUNNAN METALLURGICAL GROUP

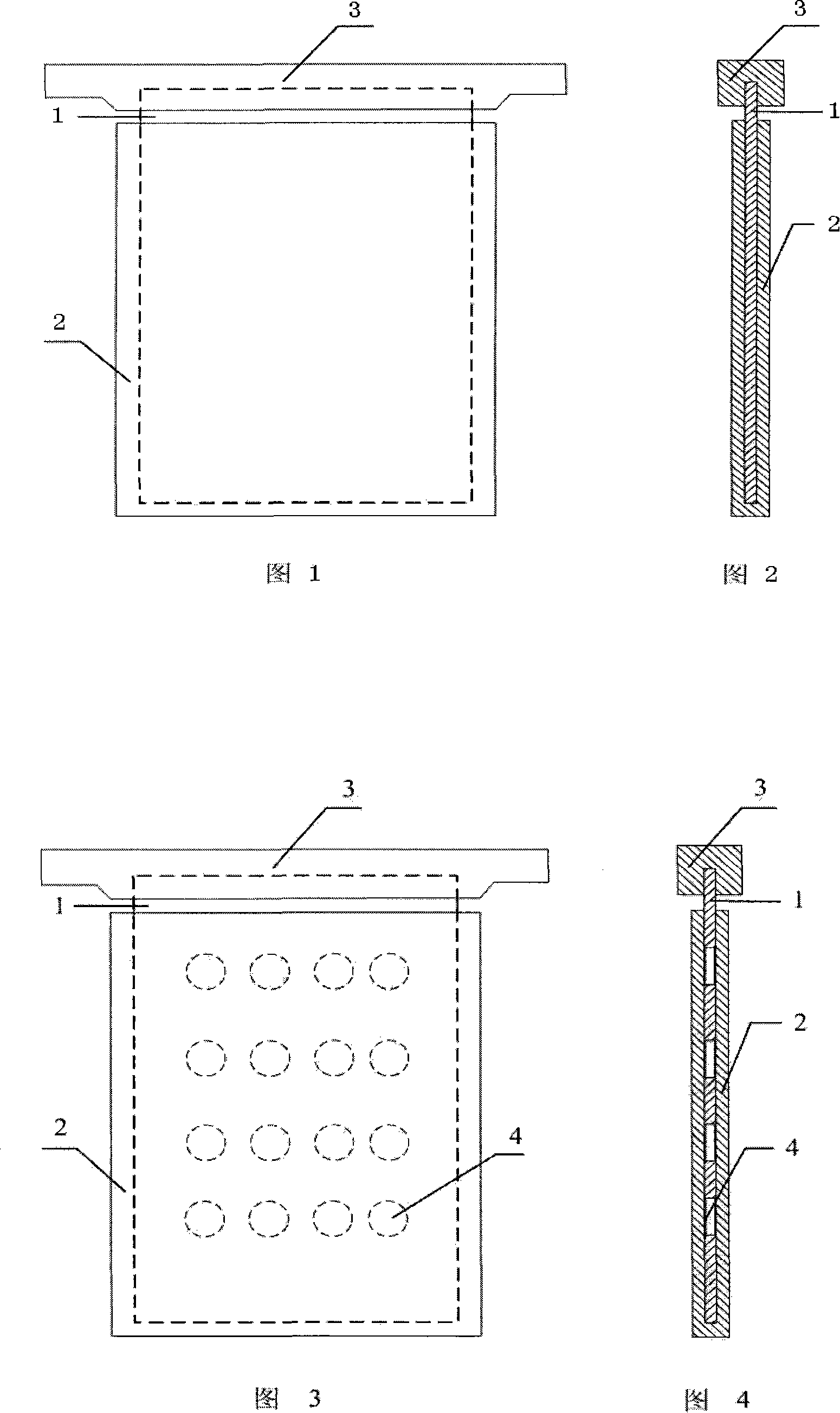

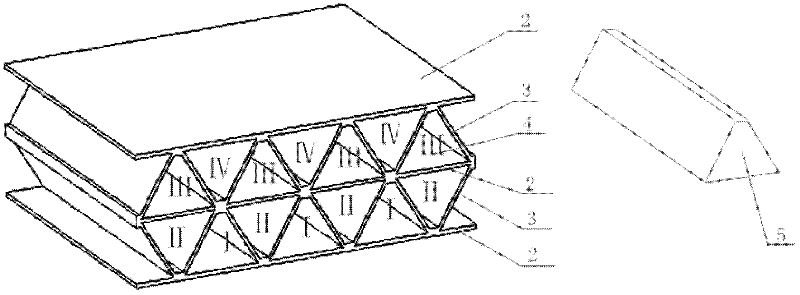

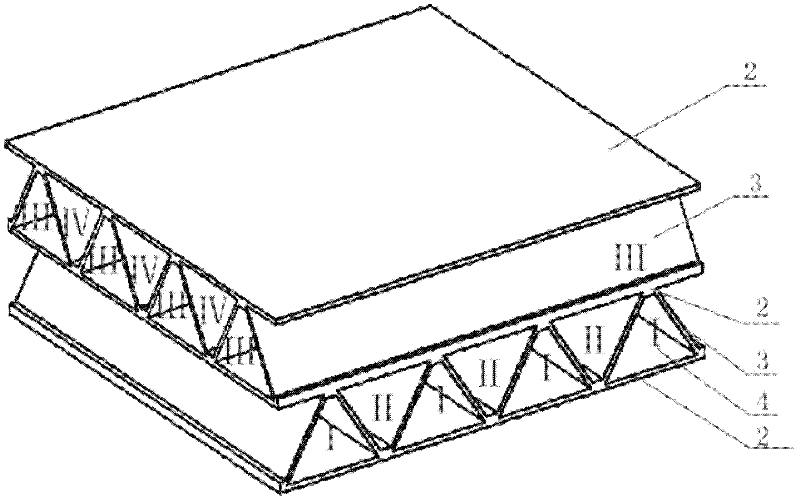

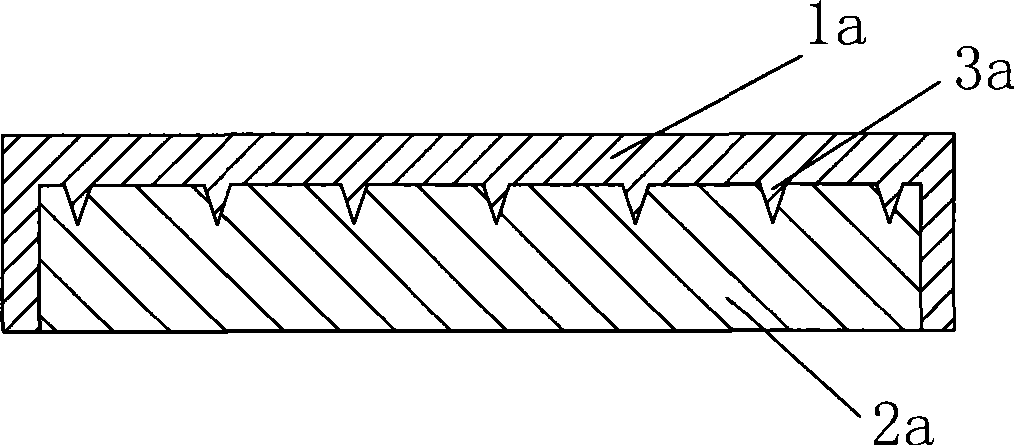

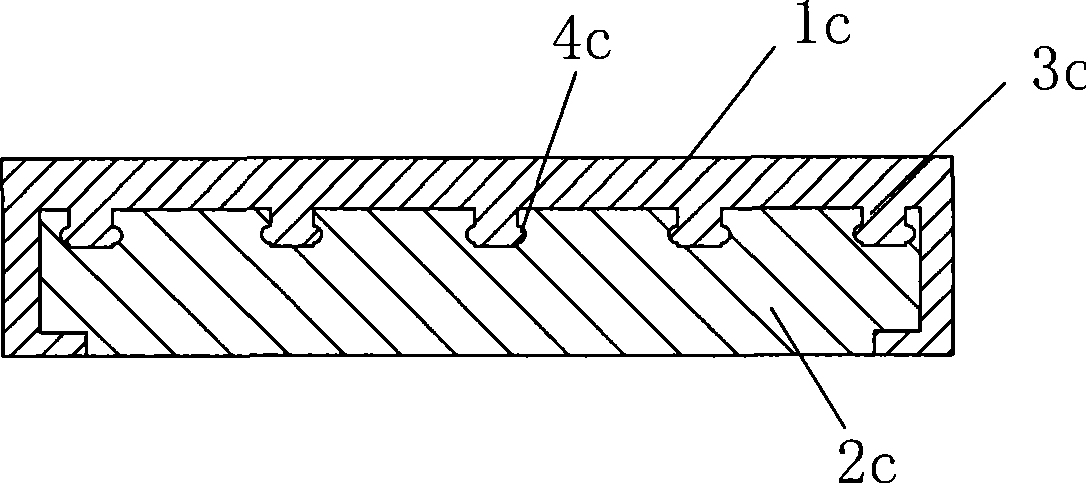

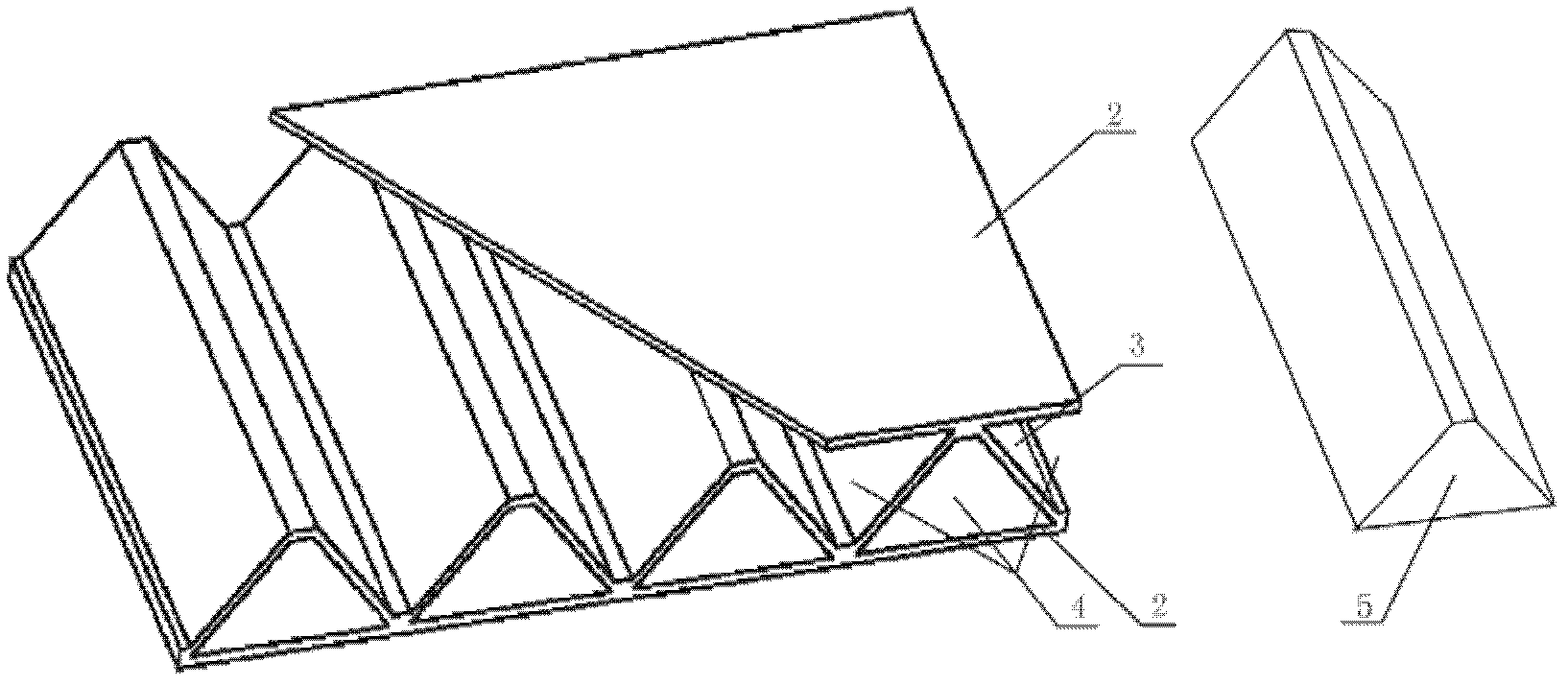

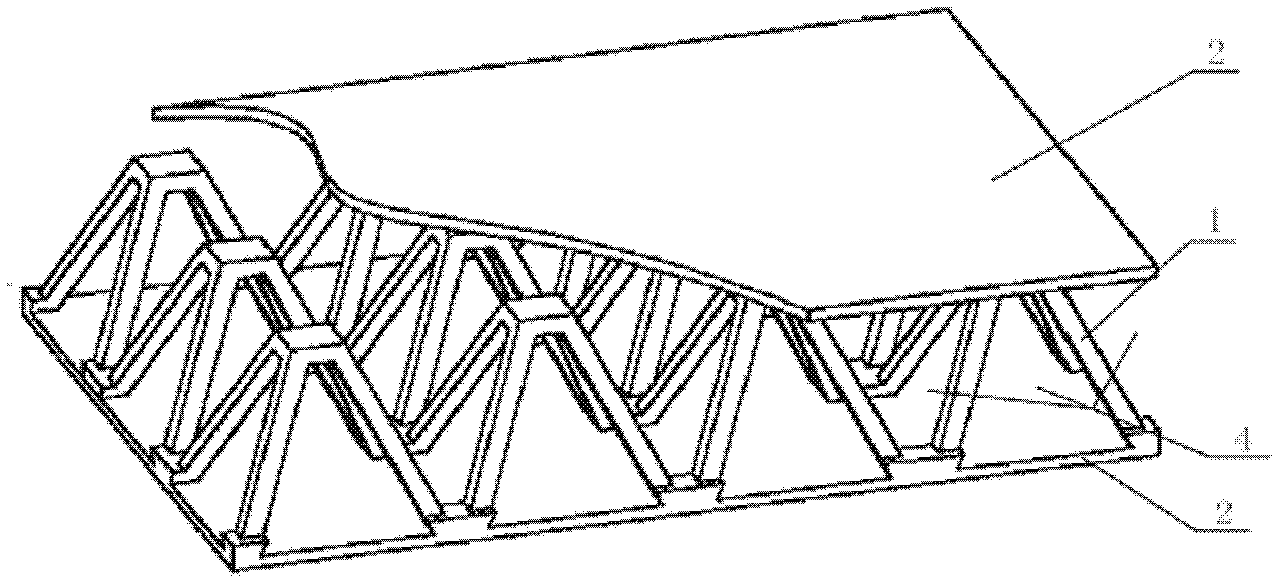

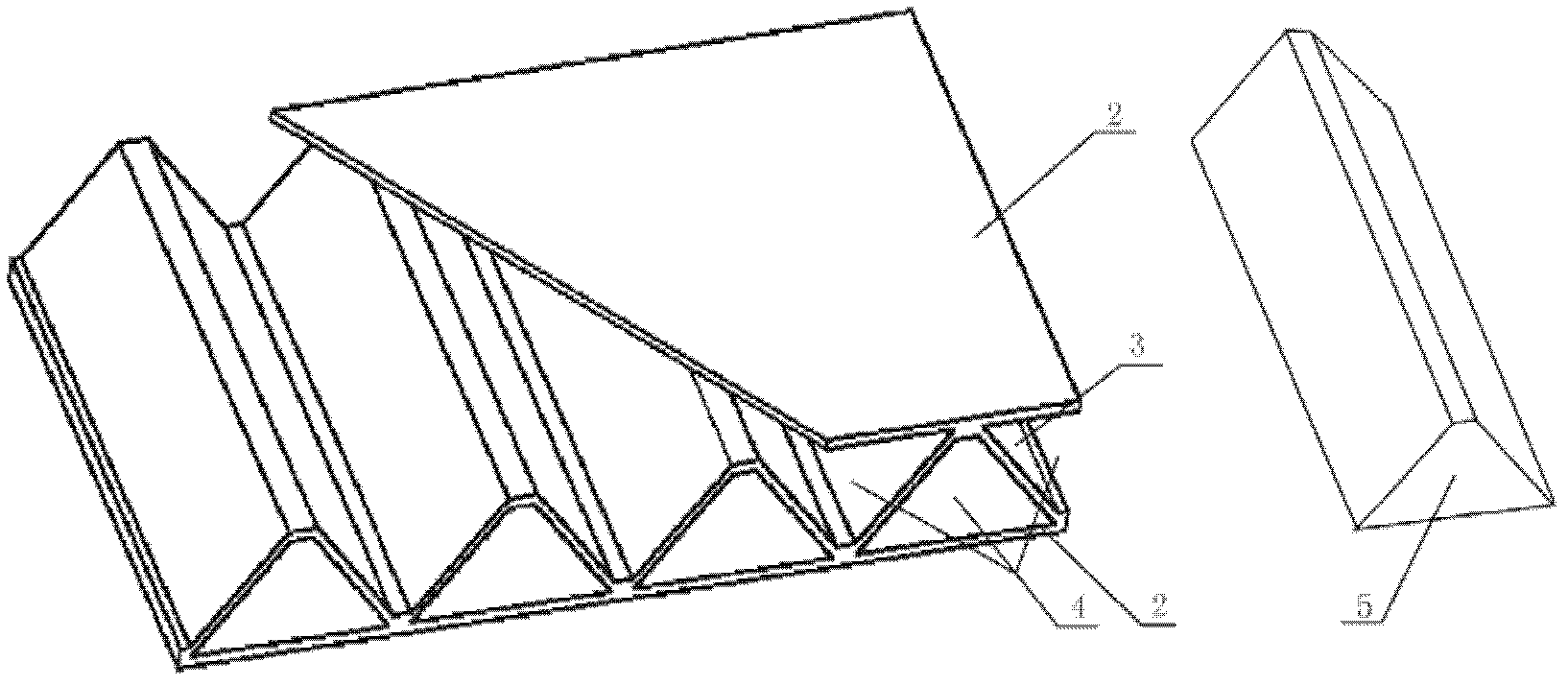

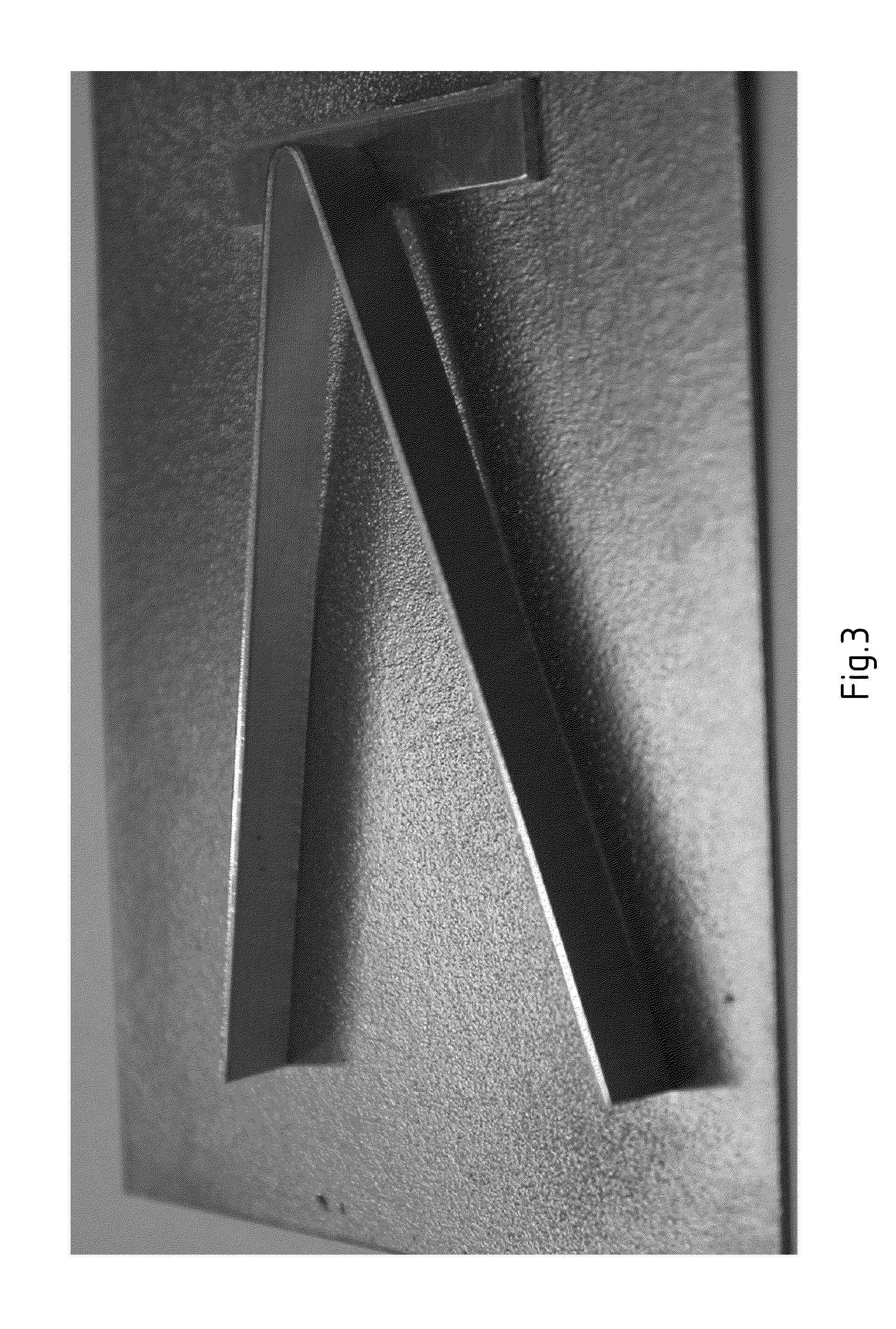

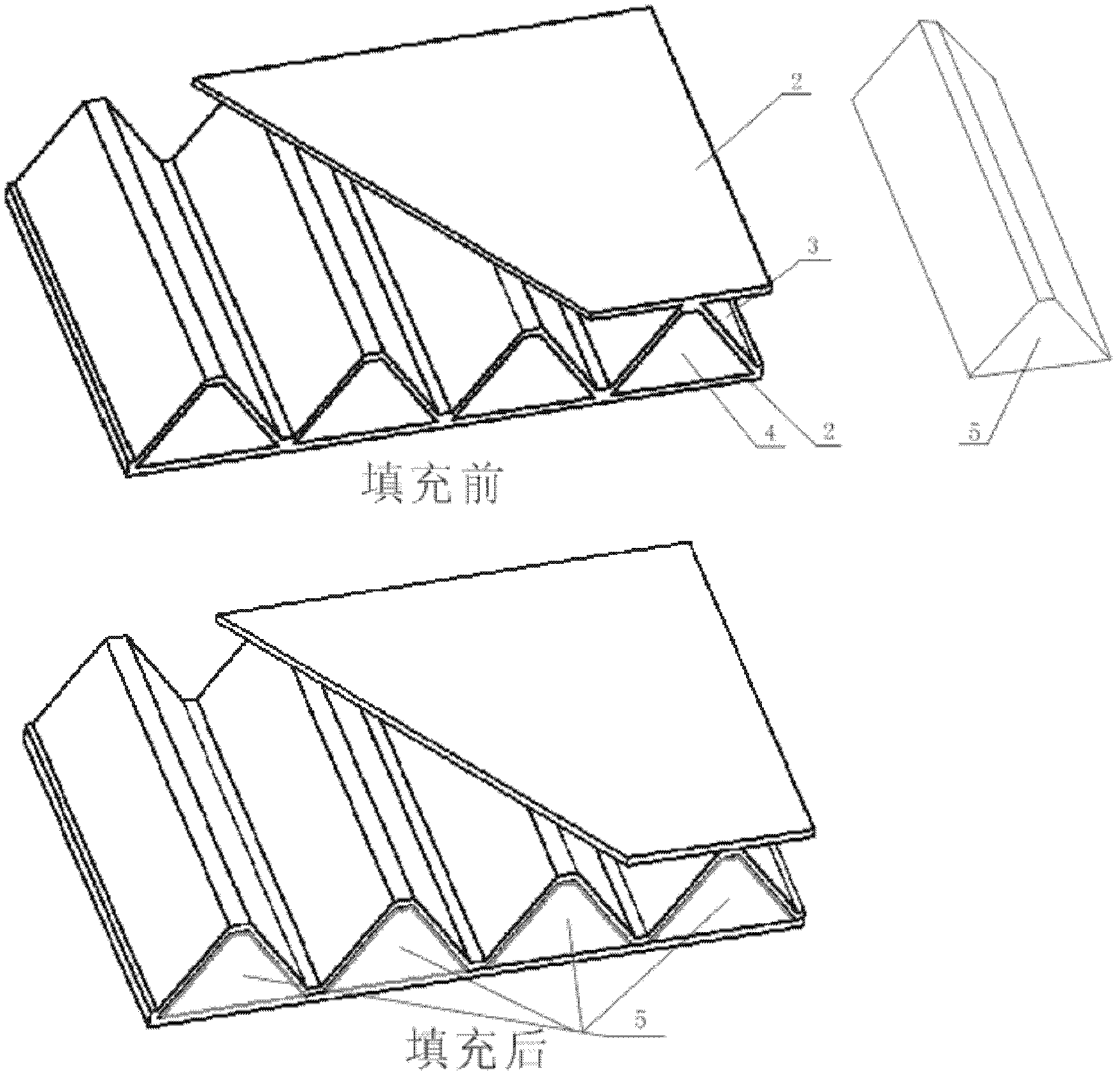

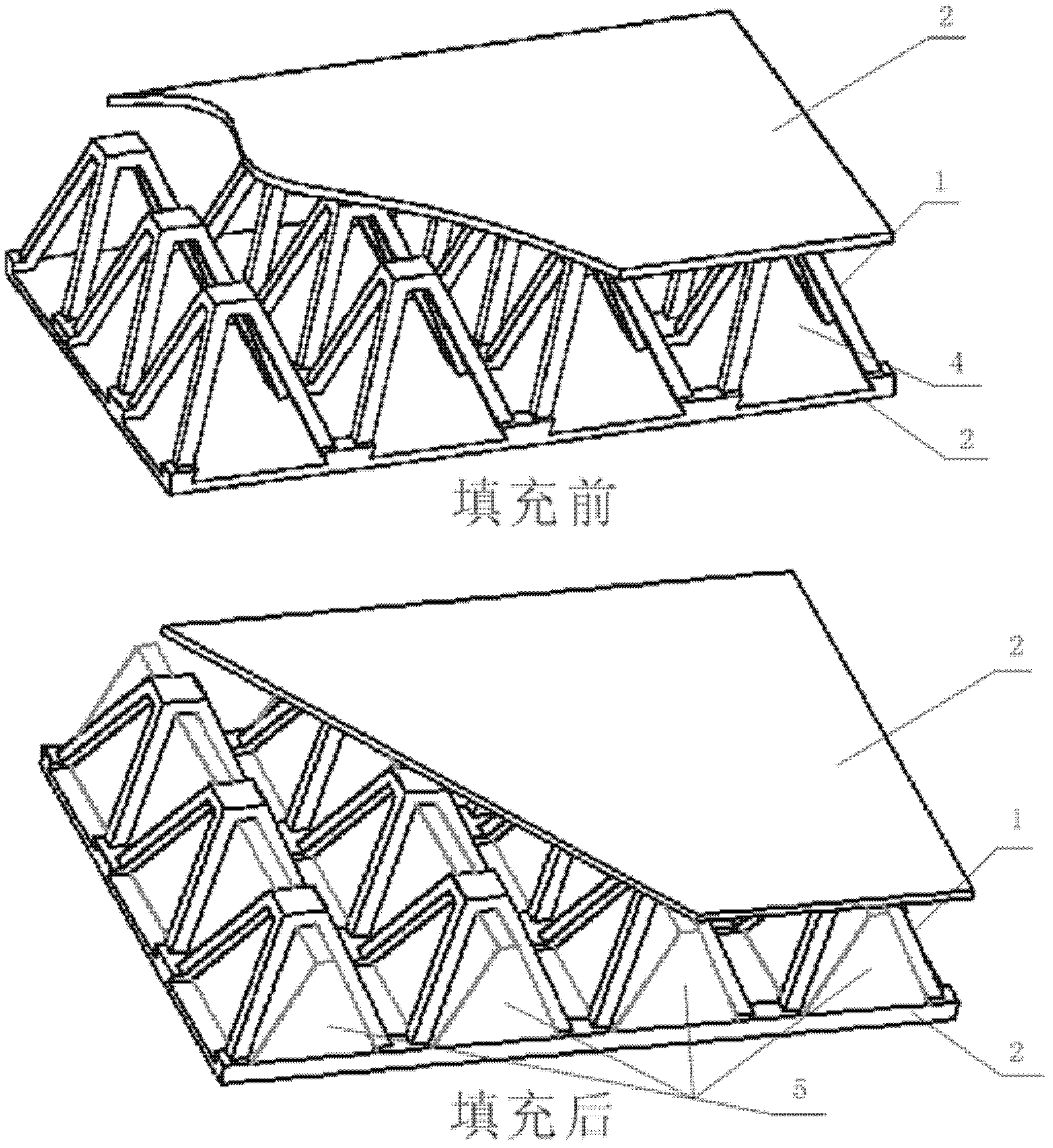

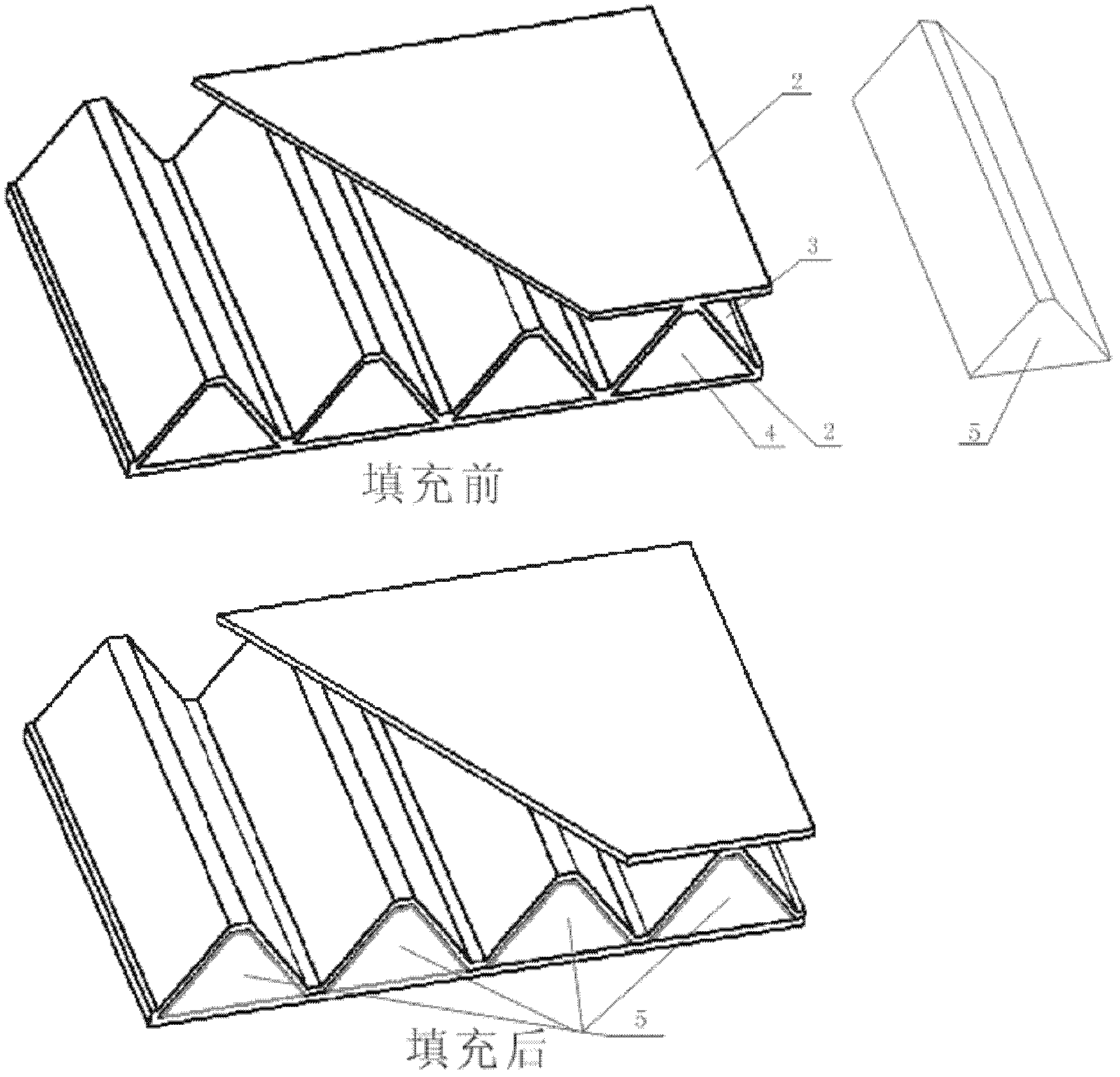

Method for preparing multilayered lattice metal and foamed aluminium composite material

InactiveCN102390136AGood mechanical propertiesImprove performanceMetal layered productsAluminum compositesLayer wise

A method for preparing multilayered lattice metal and foamed aluminium composite material comprises the steps of welding a lattice metal core body (comprising corrugated structures and pyramid structures) and a steel plates one layer after another to get the multilayered lattice metal interlayered plate, and getting the multilayered lattice metal and foamed aluminium composite material after compounding with cut foamed aluminium in a gluing manner. The invention realizes the preparation of the multilayered lattice metal material and the compounding of the multilayered lattice metal and the foamed aluminium, and can get the multilayered lattice metal and foamed aluminium composite material interlayered plate. The multilayered lattice metal and foamed aluminium composite material interlayered plate has a broad application prospect in security safeguard, military, and other fields, can effectively reduce construction weight, improves impact deformability, has excellent buffering energy-absorber effect and low intensity when being used in personnel and equipment security safeguard particularly, has obvious edges compared with solid material on specific strength and specific stiffness, and has a lower manufacturing cost.

Owner:XI AN JIAOTONG UNIV

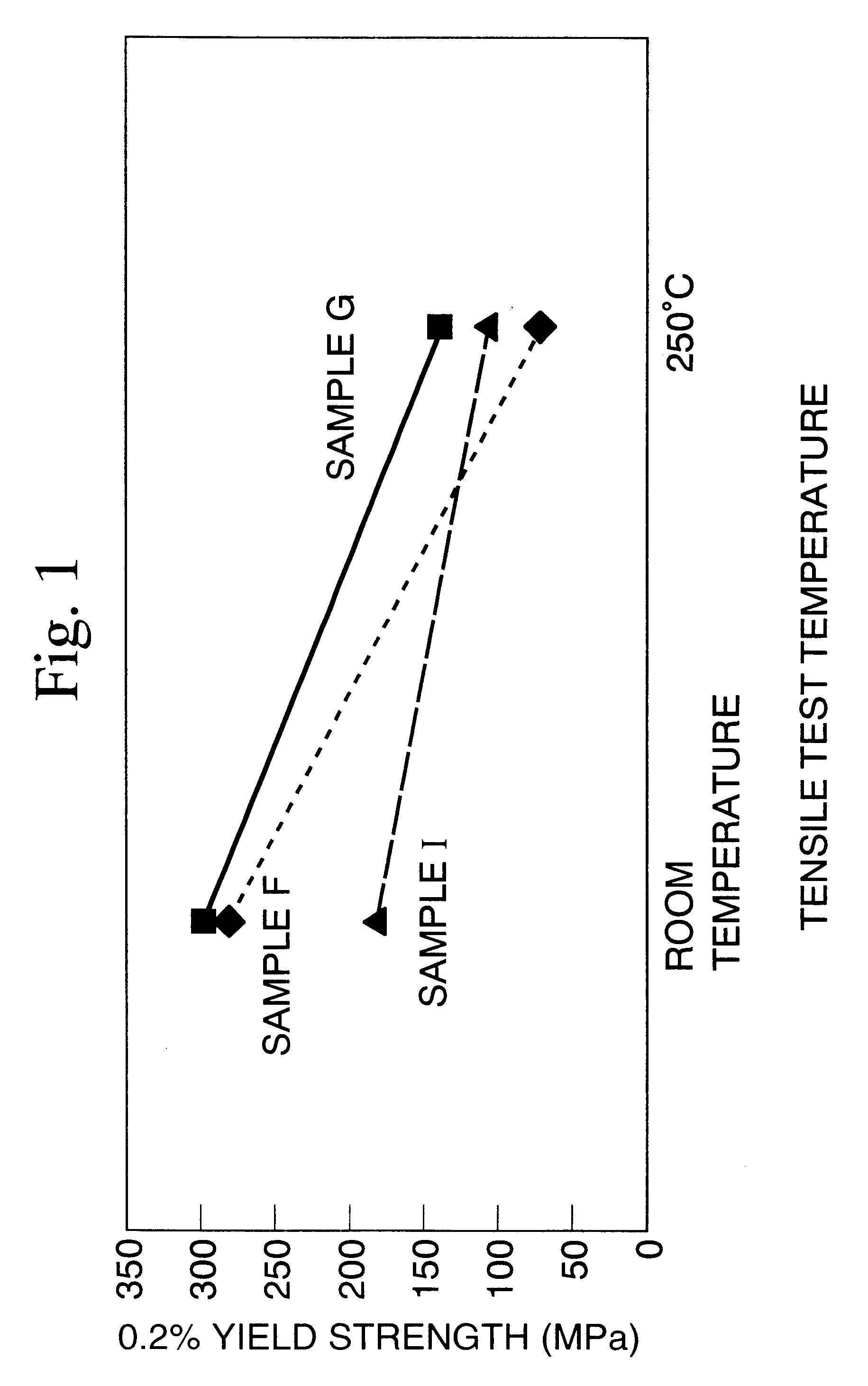

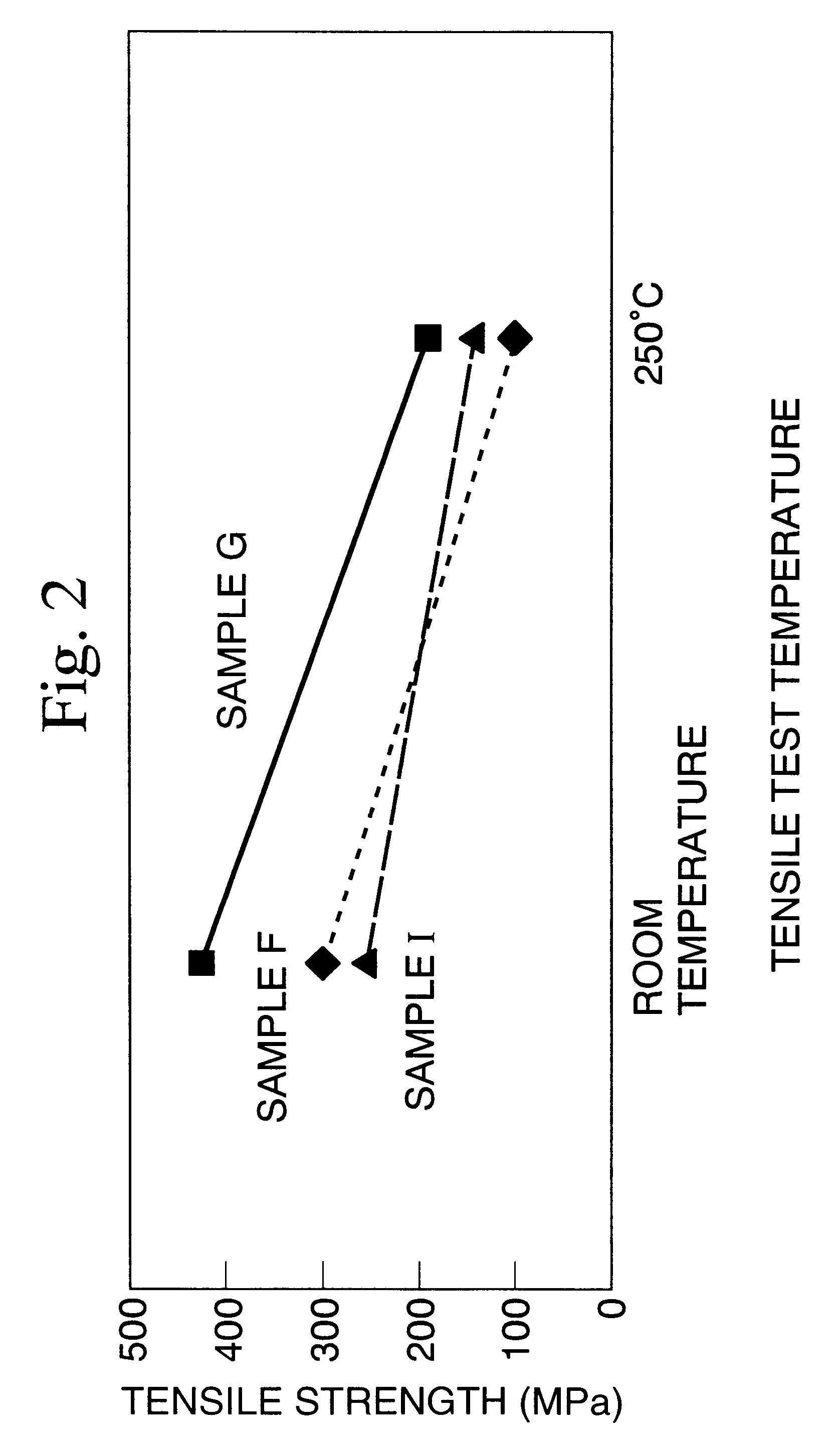

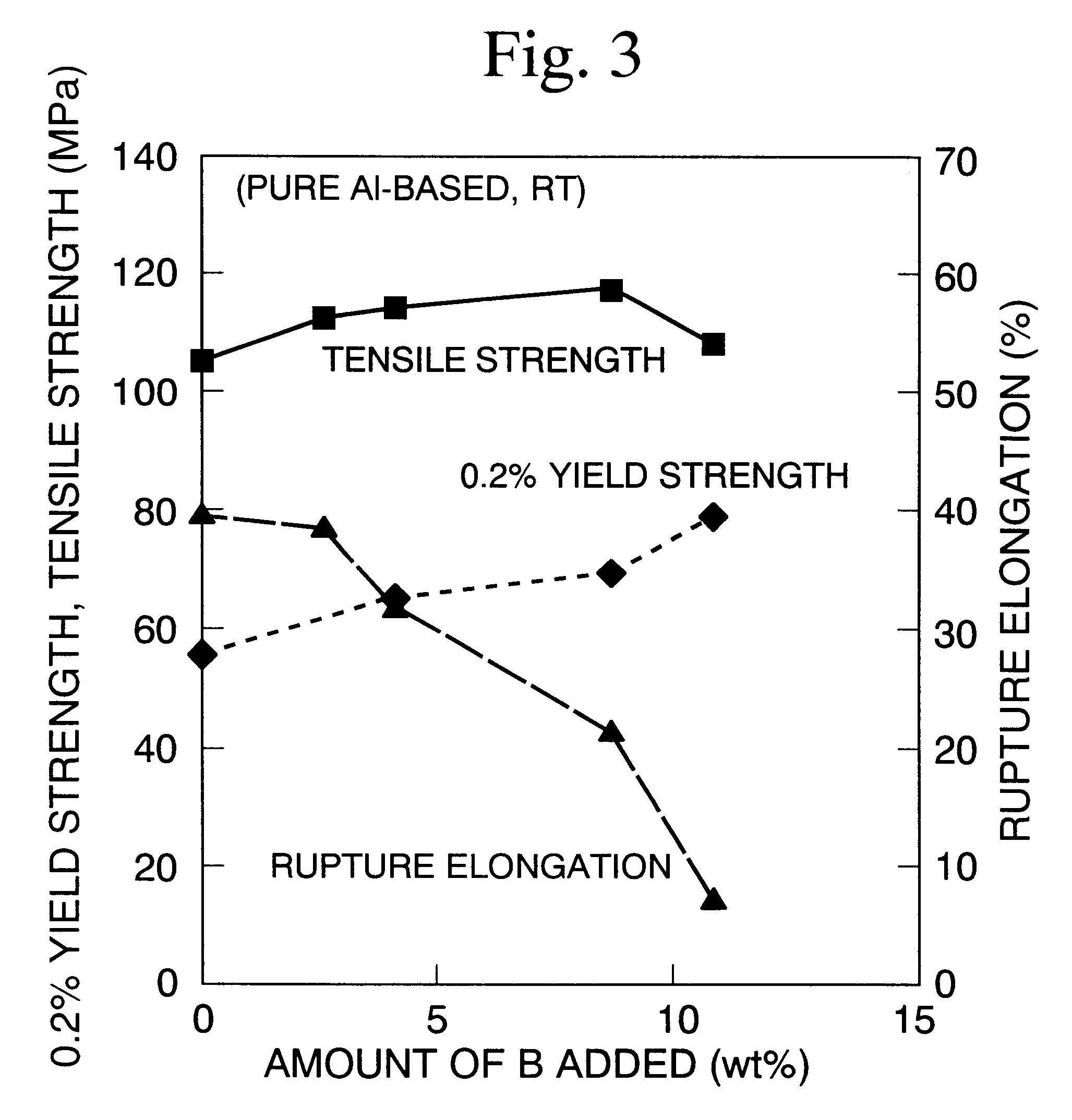

Aluminum composite material having neutron-absorbing ability

InactiveUS6602314B1Improve mechanical propertiesImprove workabilityNuclear engineering problemsNuclear engineering solutionsAlloyAbsorbed power

The present invention provides an aluminum composite material having neutron absorbing power that improves the ability to absorb neutrons by increasing the content of B, while also being superior to materials of the prior art in terms of mechanical properties and workability. The aluminum composite material having neutron absorbing power contains in Al or an Al alloy matrix phase B or a B compound having neutron absorbing power in an amount such that the proportion of B is 1.5% by weight or more to 9% by weight or less, and the aluminum composite material has been pressure sintered.

Owner:MITSUBISHI HEAVY IND LTD

Magnalium composite board and method for producing the same

The invention discloses a magnesium-aluminum composite board and a method for manufacturing the same. The magnesium-aluminum composite board comprises at least one layer of magnesium or magnesium alloy plate and at least one layer of aluminum or aluminum alloy plate which are cast together by vacuum die-casting, and at least one two-layer joint surface which is provided with a mutually occlusive zigzag structure, namely the magnesium-aluminum composite board consists of a magnesium plate and an aluminum plate, or the magnesium alloy plate and the aluminum plate, or the magnesium plate and the aluminum alloy plate, or the magnesium alloy plate and the aluminum alloy plate by vacuum die-casting, and can be a structure with two layers, three layers or more than three layers. The method for manufacturing the composite board comprises the following steps: preheating a manufactured aluminum or aluminum alloy plate finished product as an insert of a die to certain temperature, and then putting the insert into a magnesium or magnesium alloy vacuumized die; matching the die in a vacuum pressure casting machine; pouring the molten magnesium or magnesium alloy molten; performing vacuumizing injection; and finally forming the magnesium-aluminum composite board. The joint surface of the composite board is provided with the mutually occlusive zigzag structure so that the layers are closely connected with each other sequentially and the combined strength is higher.

Owner:青岛地恩地材料科技有限公司

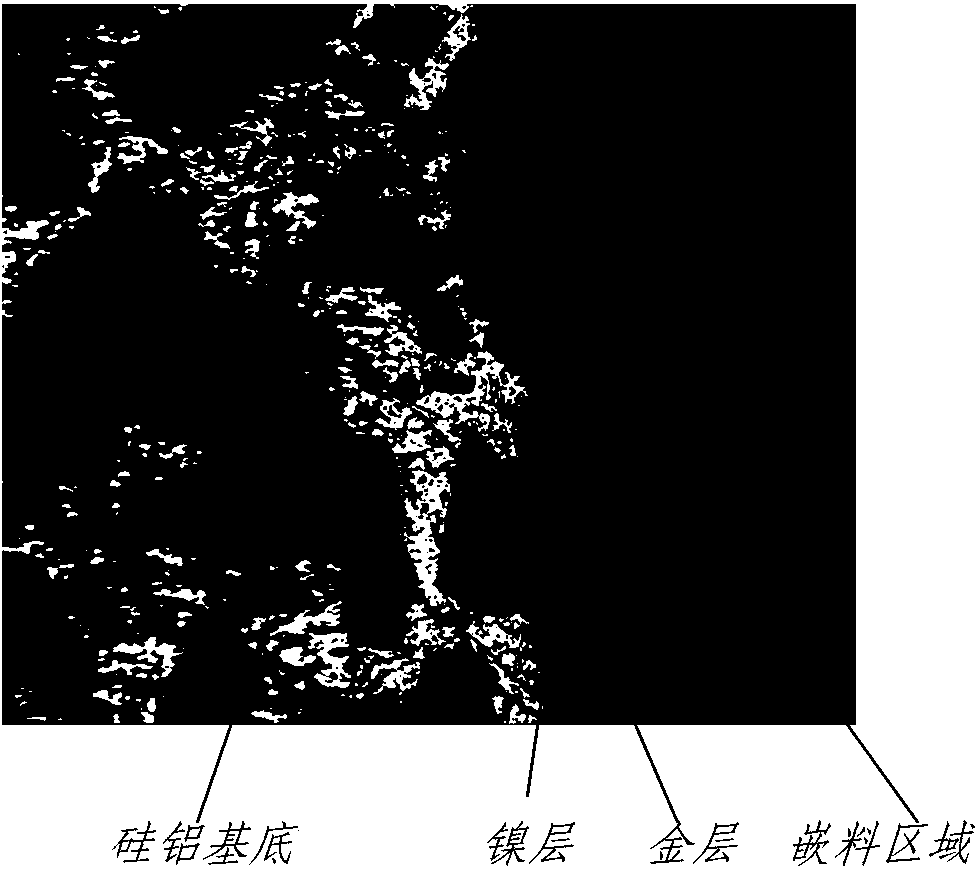

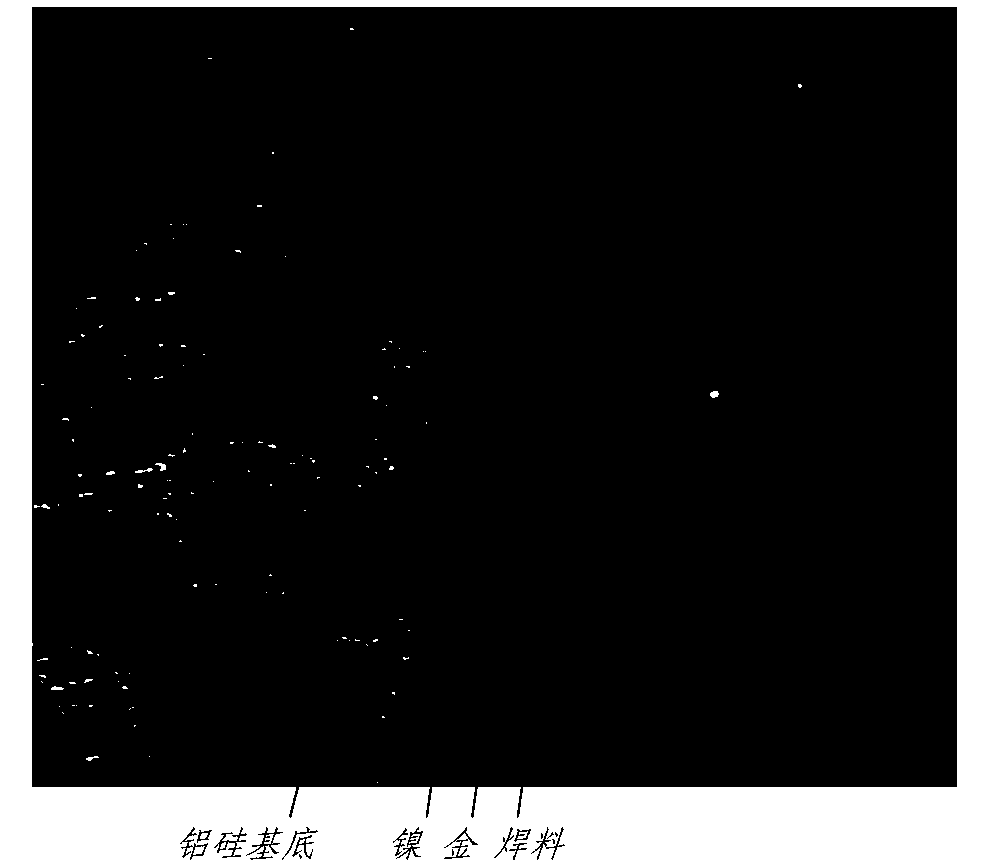

Gold-plating method of high silicon-aluminum composite material

ActiveCN103540935AImprove bindingNo foamingSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingBinding forceAlkaline etching

The invention relates to a gold-plating method of a high silicon-aluminum composite material. According to a second zinc immersion treatment method of conventional aluminum alloy electroplating, pre-treatment of the method comprises the following six steps: cleaning and oil removing; alkaline etching; bright dipping; primary zinc immersion; zinc annealing; secondary zinc immersion. The gold-plating method subsequently comprises the following steps: I, preplating chemical nickel in a chemical nickel-plating liquid; II, plating nickel for the first time according to a conventional nickel-plating method, wherein the nickel layer is 2-3 microns thick; III, performing aging treatment; IV, performing activating treatment; V, plating nickel for the second time according to a conventional nickel-plating method, wherein the nickel layer is 2-3 microns thick; VI, taking a pure gold plate or a platinum titanium mesh as an anode and the high silicon-aluminum composite material as a cathode according to a conventional pure gold-plating method, wherein the gold layer is 2-3 microns thick; VII, detecting the binding force of the plating layer. The plating layer observed under tenfold amplifying glass is free from peeling and bubbling phenomena and good in binding force. The binding force of the gold-plating plating layer and a high silicon-aluminum base material adopted by the method provided by the invention is firm and reaches the standard of appendix A of GJB1420 General Specification of Semiconductor Integrated Circuit Shell.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

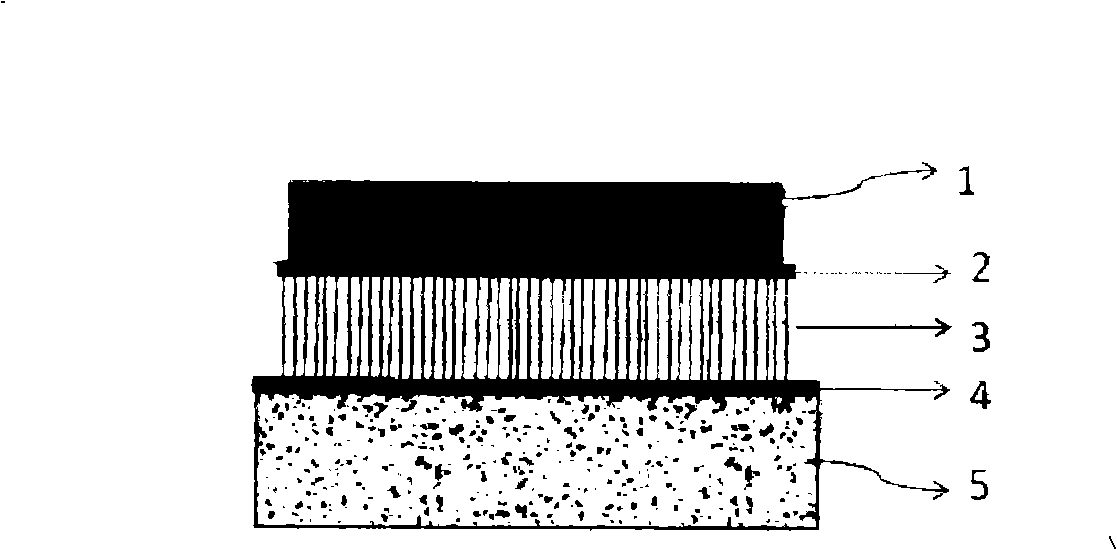

Light packaging member of power machine with high heat transfer efficiency

InactiveCN101315913AReduce thermal stressImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesCarbon compositesBond interface

The invention relates to the technical field of packaging structures of power devices, in particular to a packaging part of a power device with light weight and high efficiency of thermal conductivity, which is characterized in that: an upper high thermal conductivity bonding interface layer, a heat sink thin film, a lower high thermal conductivity bonding interface layer and a radiating substrate are sequentially bonded on the back surface of a chip from top to bottom to form the packaging part; and the radiating substrate adopts high thermal conductivity graphite flake or high thermal conductivity nano-carbon tube / fiber composite material or high thermal conductivity pitch-based carbon-carbon composite material or carbon-copper or carbon-aluminum composite material, or aluminum-based or copper-based silicon carbide or boron nitride or aluminum nitride or silicon nitride ceramic composite material. Compared with the prior art, the back surface of the chip of the invention is directly bonded with the bonding film, the heat sink layer and the radiating substrate, when in work, the heat on the chip is directly guided out of a working region by the three-layer radiating structure, thus enhancing the radiation performance of the product, effectively reducing the heat stress between the chip and the radiating substrate and improving the reliability and the service life of the device.

Owner:上海芯光科技有限公司 +1

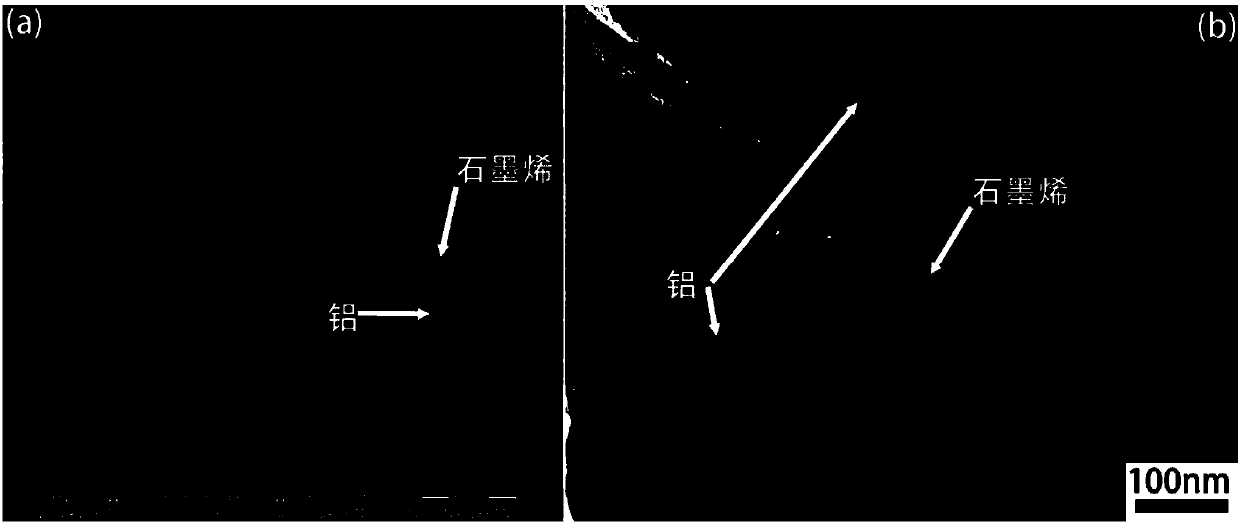

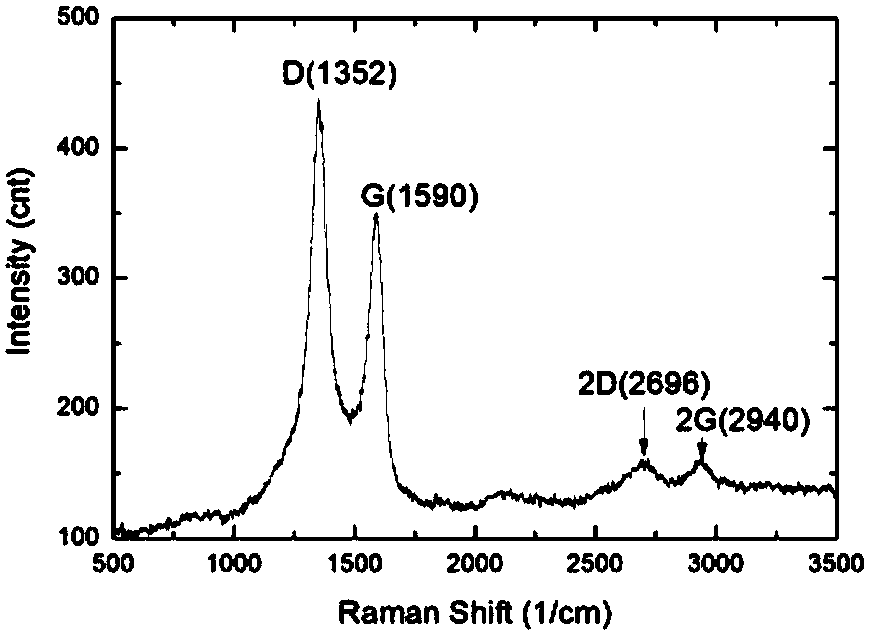

Single-layer graphene/aluminum composite material and preparation method thereof

InactiveCN107675028AHigh strengthImprove conductivityConductive materialMetal/alloy conductorsIngotSingle layer graphene

The invention relates to a single-layer graphene / aluminum composite material and a preparation method thereof. The preparation method comprises the following specific steps: (1) single-layer graphenepowder is added in anhydrous ethanol for ultrasonic dispersion to obtain single-layer graphene dispersion liquid; (2) aluminum powder is added in the single-layer graphene dispersion liquid for mixingball mill under argon protection, and is dried in vacuum to obtain single-layer graphene / aluminum composite powder; (3) the single-layer graphene / aluminum composite powder is prepared through a discharge plasma sintering method to obtain a single-layer graphene / aluminum prefabricated body; and (4) a pure aluminum block body or an aluminum alloy block body is smelted to obtain molten aluminum; then, heating is performed; and under the stirring condition, the single-layer graphene / aluminum prefabricated body is dispersed in the molten aluminum, is cast as a round ingot, and is thermally extruded to mold the single-layer graphene / aluminum composite material. The single-layer graphene / aluminum composite material is uniform in component, high in strength and electric conductivity, simple in production process and capable of realizing industrial production.

Owner:广州埃米石墨烯科技有限公司

A copper adulterated aluminum complex flat line and its making method

ActiveCN101236798AImprove performanceEliminate processabilitySingle bars/rods/wires/strips conductorsCable/conductor manufactureCopperAluminum composites

The invention relates to a copper-clad aluminum composite flat wire and a preparation method thereof, relating to bimetal layered composite materials. The copper-clad aluminum composite flat wire is formed by composition of sandwich layer aluminum and clad copper, and the area ratio of the copper clad is 15 percent to 40 percent. The preparation steps are as follows: copper-clad aluminum composite blanks are directly compounded and formed by adoption of horizontal continuous casting; multi-pass groove rolling and / or multi-pass drawing is performed on the copper-clad aluminum blanks as required; the rolling speed of 3 to 60 meters per minute is adopted, and the single-pass relative percent reduction is 20 percent to 40 percent; or the drawing speed of 2 to 30 meters per minute is adopted, and the single-pass section scalage is 10 percent to 25 percent; under the condition of multi-pass processing and that the overall section scalage of the copper-clad aluminum composite materials reaches 75 percent to 95 percent, low-temperature intermediate annealing is performed on the copper-clad aluminum composite materials; the annealing temperature is 200 to 450 DEG C; the annealing time is 0.5 to 2 hours; the blanks after annealing are rolled or drawn further, and the copper-clad aluminum composite flat wire with required section shape and size is prepared. The invention not only can prepare the high performance copper-clad aluminum composite flat wire but also has high production efficiency.

Owner:UNIV OF SCI & TECH BEIJING

Regeneration method for waste composite paper film

A regeneration method for waste composite paper film material includes a separation step (1) and a separation step (2), wherein the separation step (1) mainly separates mostly paper fiber, and the separation step (2) further separates plastic film or / and plastic-aluminum composite film. The method including two steps can increase quality and quantity of regenerating paper, and reduce content of the plastic film and aluminum foil in the regenerating paper. The waste composite paper film material can be separated and regenerated without pollution, and can be used as raw material or auxiliary material for paper industry, rubber and plastic product industry and aluminum industry, wherein all kinds of recovery components are utilized.

Owner:吴宸 +1

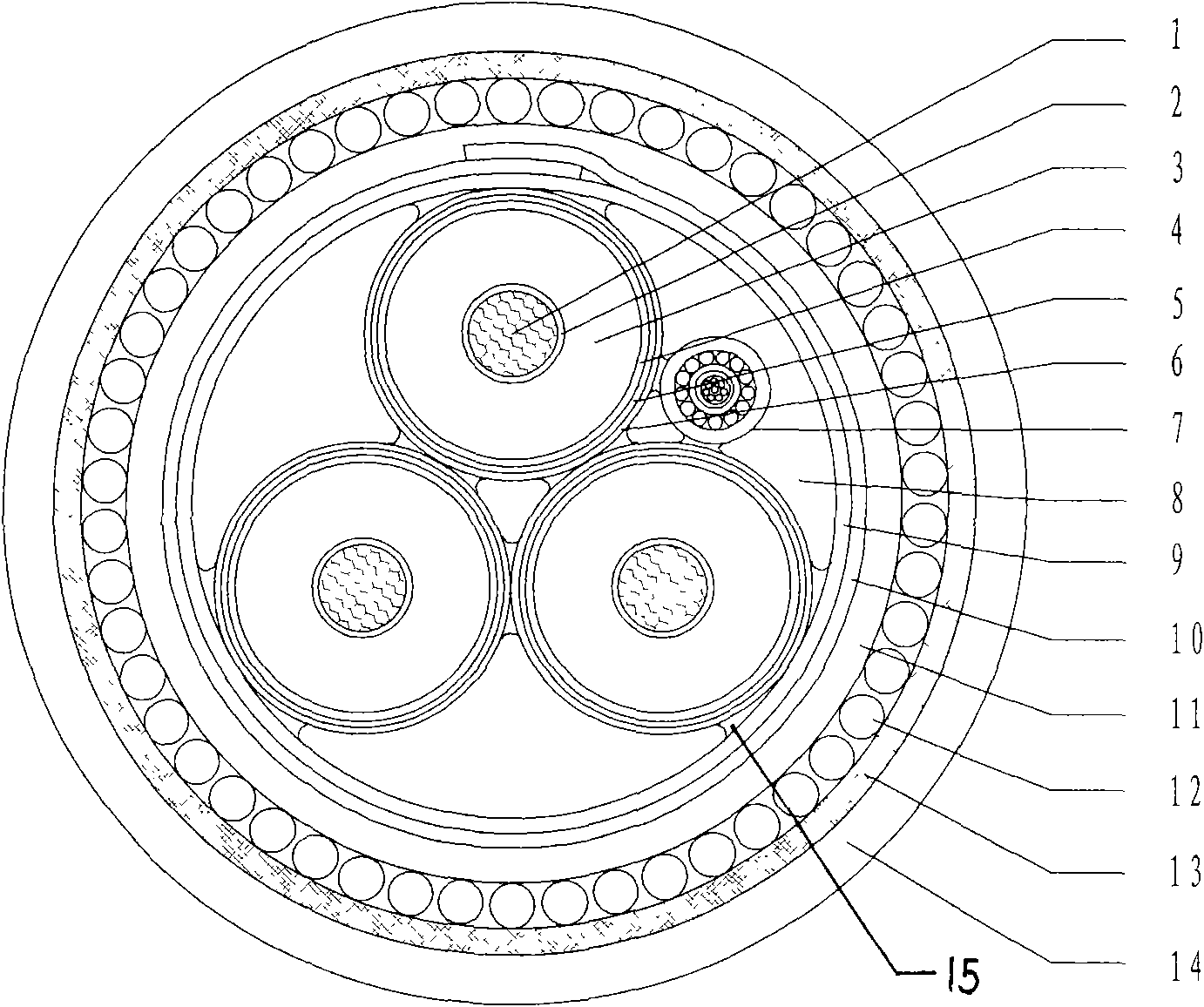

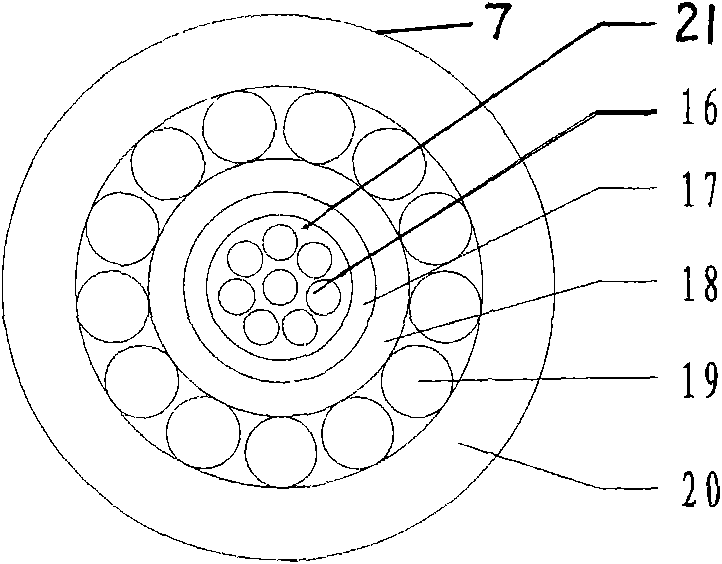

Rated voltage of 35kv or below shallow sea wind farm photoelectrical transmission composite cable

InactiveCN101562064ALow costEasy to layCommunication cablesSubmarine cablesFiberElectric power transmission

A rated voltage of 35kv or below shallow sea wind farm photoelectrical transmission composite cable comprises a cable core provided with a lead and a water-blocking filling piece, a water-blocking belting layer, a plastic-aluminum composite band layer, an internal sheath, a wire armoring layer and an external sheath, wherein the cable core are externally coated with the water-blocking belting layer, the plastic-aluminum composite band layer, the internal sheath, the wire armoring layer and the external sheath in turn, the cable core is internally provided with a fiber optic communication unit, a steel-tape armoring layer is arranged between the external sheath and the wire armoring layer. The structure of the fiber optic communication unit is as follows: a fiber loose tube is externally coated with an internal sheathing layer, an armoring layer and an external sheathing layer in turn. A conductor of the lead adopts two-tier structure: a central layer conductor is formed by twisting multiple stranded brass wires coated with water-blocking balm, and then coats a central layer semiconductive water-blocking band layer; an external layer conductor is coated outside the central layer semiconductive water-blocking band layer by multiple stranded brass wires coated with water-blocking balm, and then coats an external layer semiconductive water-blocking band layer. The invention has the complex function of optical communication and power transmission, one cable has two uses, thereby saving cost and facilitating laying; in addition, the cable has high strength, excellent wear resistance, corrosion resistance and waterproof function, and can adapt to the requirement for subsea use in long term.

Owner:JIANGSU HENGTONG POWER CABLE

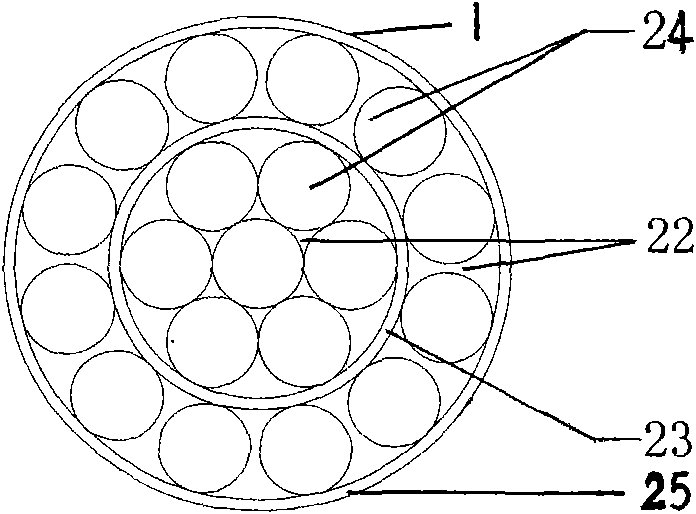

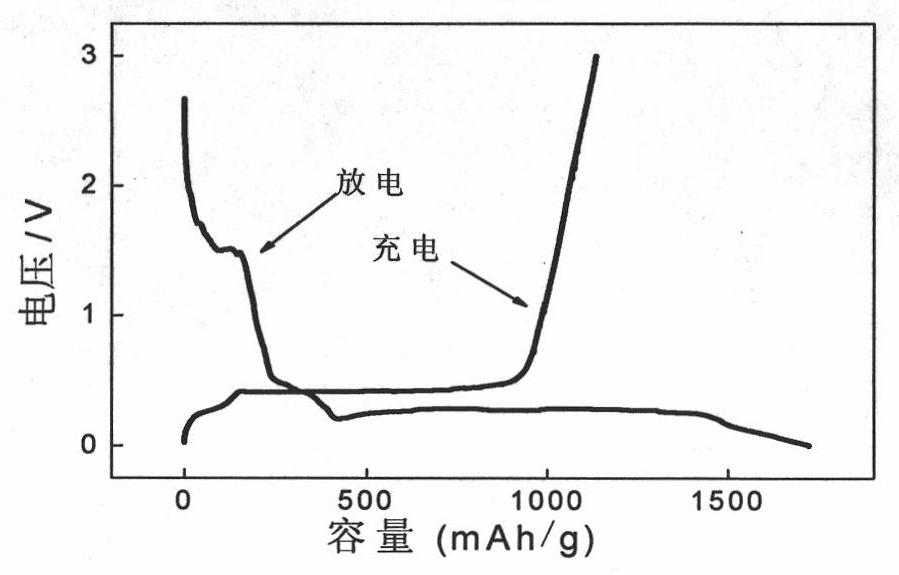

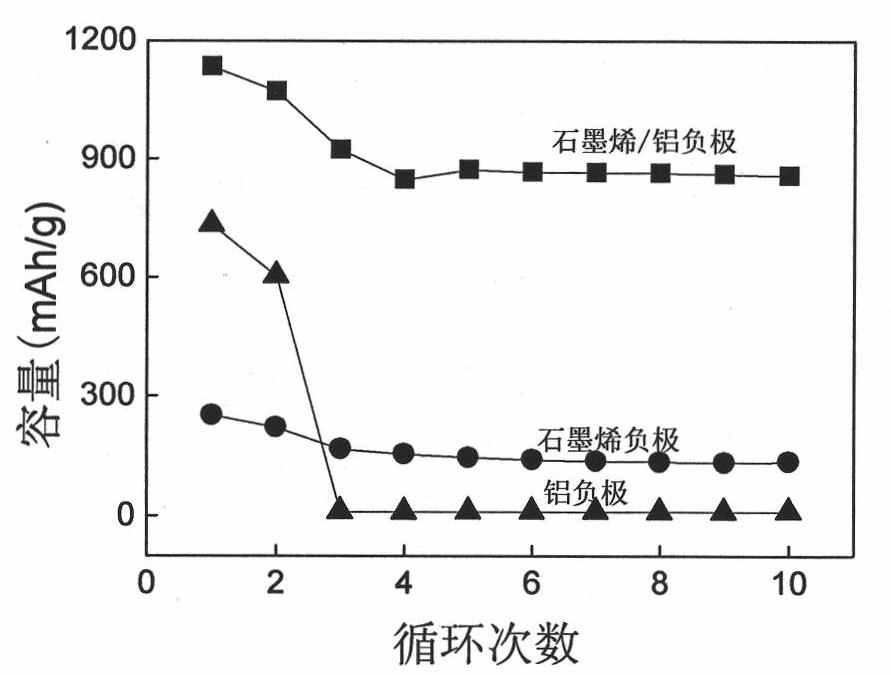

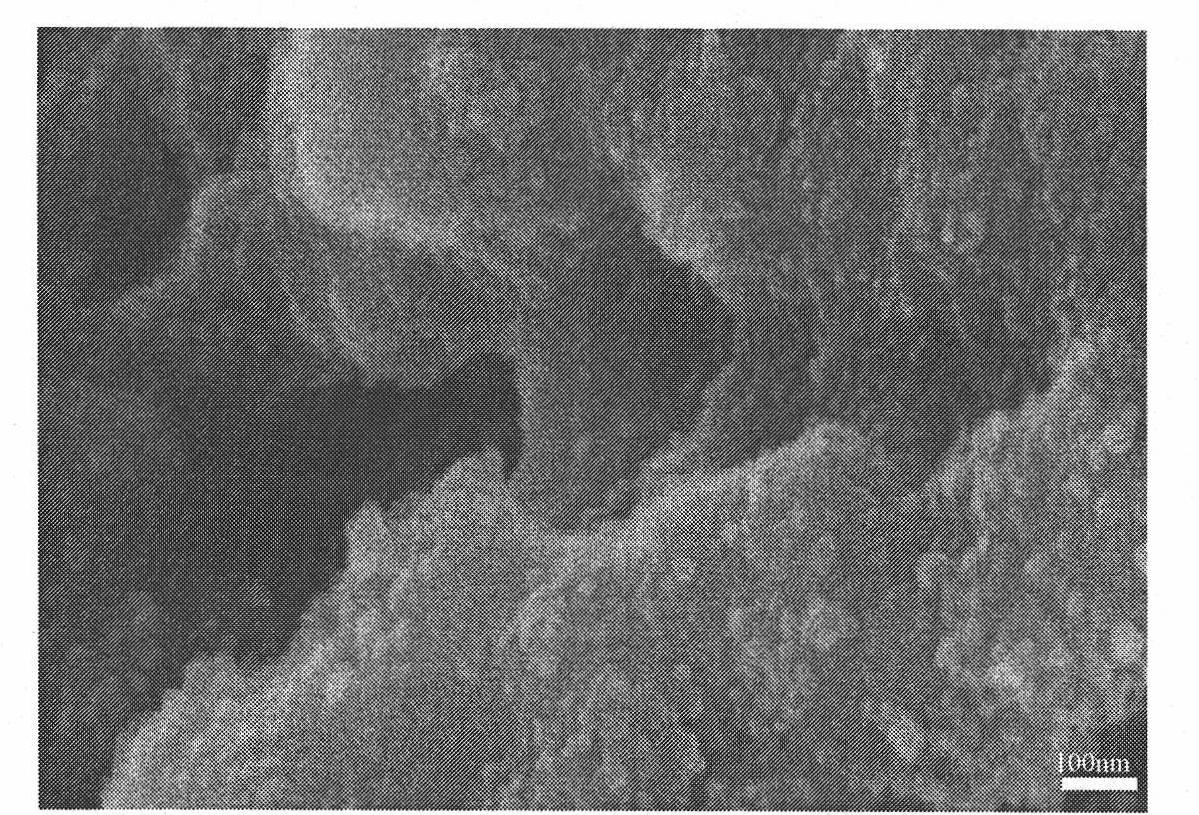

Graphene/aluminum composite cathode material of lithium ion battery and preparation method thereof

InactiveCN101937994AIncrease capacityImprove cycle performanceCell electrodesElectrical batterySodium-ion battery

The invention discloses a graphene / aluminum composite cathode material of lithium ion battery and a preparation method thereof and belongs to the cathode material technology of lithium ion battery technology. The cathode material comprises grapheme and aluminum in a mass ratio of 1:0.1-100, and the capacity is between 600 and 1,200 mAh / g. The preparation process of the cathode material comprises the following steps of: uniformly mixing the grapheme and the aluminum according to the mass ratio; pressing the mixed material on a copper foil current collector so as to obtain an electrode plate; assembling a battery by using the lithium plate; and performing the charge and discharge for 1 to 100 cycles for curing under a current density of 1 to 500 mA / mg so as to obtain the graphene / aluminum cathode material of the lithium ion battery. The graphene / aluminum cathode material of lithium ion battery and the preparation method have the advantages that: the preparation process is simple; the capacity and the circulation performance are much higher than those of a pure-aluminum and pure-graphene cathode material as well as the conventional commercial cathode material; and the graphene / aluminum cathode material is easy to realize and can widely promoted.

Owner:TIANJIN UNIV

Laminar titanium aluminum composite plate and preparation method thereof

ActiveCN101450542ALow densityImprove mechanical propertiesRoll mill control devicesExplosivesAlloy substrateVolumetric Mass Density

The invention relates to a laminated titanium aluminum clad plate and a preparation method thereof. The laminated titanium aluminum clad plate is characterized in that the titanium aluminum clad plate consists of an aluminum alloy substrate layer and a titanium-coated layer; and the total thickness is 1.5 mm. Compared with a TAI plate material with thickness of 1.5 mm, the laminated titanium aluminum clad plate can save a titanium material by 80 percent around so as to reduce the material cost and also reduce the whole density of the plate material by about 35 percent; and compared with a 2024 plate material with the thickness of 1.5 mm, the laminated titanium aluminum clad plate not only improves anticorrosive performance and thermal shock resistance of the material but also improves the whole mechanical performance of the plate material.

Owner:有研金属复材技术有限公司

Self-adjusting coplanar ACM panel mounting system secured by novel retaining clip

A self-leveling structural element in a non-progressive attachment system, a U-shaped retentive clip having a base and two upwardly extending arms that are forced apart by the installation of a self-drilling screw, the novel retentive clip with screw coacting with an extruded frame to mount and retain a plurality of aluminum composite material (ACM) panels in a coplanar manner, to form an Aluminum Composite Cladding System, for a non-progressive system that enables removal of individual panels for replacement or repair.

Owner:MCINTIRE J ANDREW +1

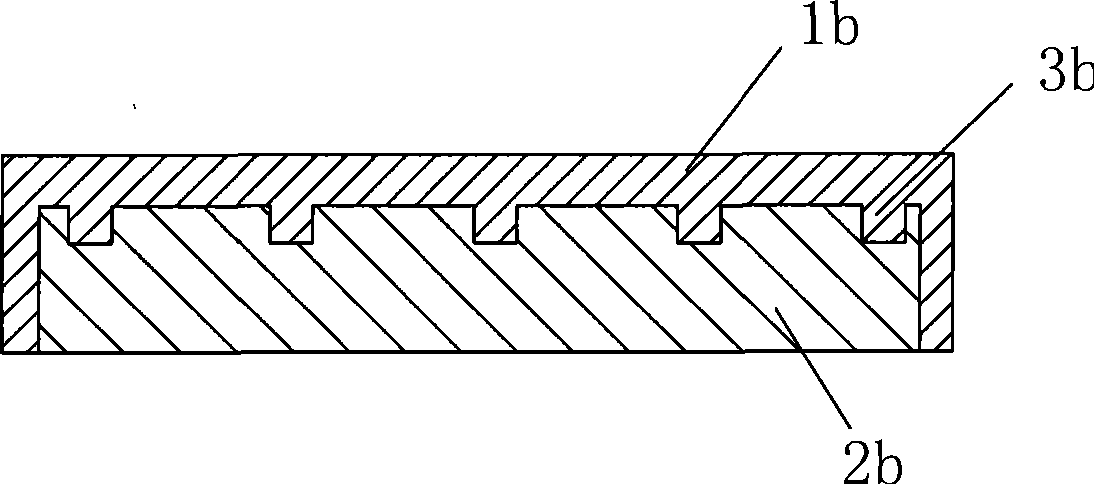

Lattice metal-foamed aluminium composite material and preparation method thereof

InactiveCN102416714AGood mechanical propertiesImprove performanceMetal layered productsMetallic materialsHigh intensity

The invention discloses a preparation method of a lattice metal-foamed aluminium composite material, characterized by cementing a lattice metal material (including ripple structure and pyramid structure) and cut foamed aluminium to obtain a multifunctional composite porous material. The lattice metal-foamed aluminium composite sandwich panel disclosed herein has a wide application prospect in the fields of transportation, mechanical manufacturing, and military, can effectively reduce the structure weight, improves the performances of impact deformation and magnetic shield, especially brings the performances of high intensity, high rigidity and excellent damping capacity into play in the field of mechanical manufacturing, and has the advantage of low production cost.

Owner:XI AN JIAOTONG UNIV

Aluminium Composite Material for Fluxless Brazing

InactiveUS20150053751A1Increased durabilityLow production costFoundry mouldsWelding/cutting media/materialsShielding gasProduct gas

Use of an aluminium composite material consisting of at least one aluminium core alloy and at least one outer brazing layer consisting of an aluminium brazing alloy provided on one or both sides of the aluminium core alloy. Based on this prior art the object of the present invention is to provide a thermal joining process for an aluminium composite material, so that the use of fluxes can be dispensed with, this object being achieved in that the aluminium brazing layer of the aluminium composite material has a pickled surface and the aluminium composite material is used in a fluxless thermal joining process and the joining process is carried out in the presence of a protective gas.

Owner:HYDRO ALUMINIUM ROLLED PROD GMBH

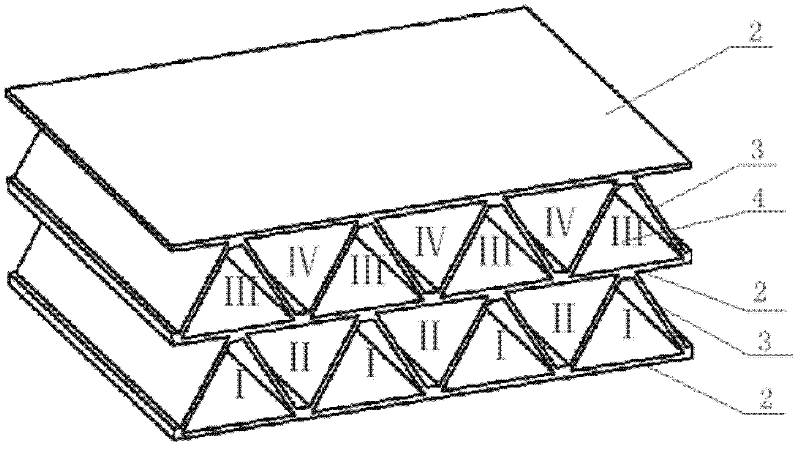

Lattice-gradient foamed aluminum composite material and preparation method thereof

InactiveCN102416713AImprove performanceGood mechanical propertiesMetal layered productsMetallic materialsHigh intensity

A preparation method of a lattice-gradient foamed aluminium composite material comprises the adhesive bonding and combination of a lattice metal material (including a ripple structure and a pyramid structure) and a cut foamed aluminium to obtain a multifunctional gradient composite porous material. The invention realizes the combination of a lattice metal material and foamed aluminium, and obtains a lattice-gradient foamed aluminium composite structural material sandwich plate with a geometric gradient. The lattice metal-gradient foamed aluminium composite material sandwich plate has wide application prospects in fields of safety protection, traffic transportation, mechanical manufacturing, and military affairs, has very effective performance with respect to structure weight reduction, impact deformation improvement, magnetic shielding and the like, can bring into play its high strength, high rigidity and excellent damping performance especially in mechanical manufacturing industry, and also has low manufacturing cost.

Owner:XI AN JIAOTONG UNIV

Preparation method of high-volume-fraction diamond/aluminum composite material with heat conduction function

The invention belongs to the technical field of preparation of composite materials, and relates to a preparation method of a high-volume-fraction diamond / aluminum composite material with heat conduction function. The diamond / aluminum alloy interface binding performance is improved by metallizing the diamond grain salt bath coated surface, using gel injection molding prefabricated body technique by adding high-temperature aluminum phosphate adhesive, improving the constituent of aluminum alloy and other means. The composite material is prepared by a non-pressure impregnation technique which has the advantages of low cost and is simple to operate and implement. The diamond / aluminum composite material has uniform and compact microstructure, and has favorable diamond / aluminum alloy interface binding performance; and the density is 3.17g / cm<3>, the heat conductivity is up to 518W / m.K, the thermal expansion coefficient is only 4.61*10<-6> / K, the bending strength is 306Mpa, and the Young's modulus is 280GPa. The invention completely satisfies the requirements of superhigh heat conductivity, low density and low thermal expansion coefficient for the high-density electronic packaging material.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com