Patents

Literature

1451 results about "Polyoxymethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyoxymethylene (POM), also known as acetal, polyacetal, and polyformaldehyde, is an engineering thermoplastic used in precision parts requiring high stiffness, low friction, and excellent dimensional stability. As with many other synthetic polymers, it is produced by different chemical firms with slightly different formulas and sold variously by such names as Delrin, Ultraform, Celcon, Ramtal, Duracon, Kepital, Polypenco, and Hostaform.

Toughened polyoxymethylene-poly(lactic acid) compositions

Toughened polyoxymethylene-poly(lactic acid) resin compositions comprising polyoxymethylene, poly(lactic acid), and an impact modifier comprising an ethylene copolymer impact modifier made from monomers (a) ethylene; (b) one or more olefins of the formula CH2═C(R1)CO2R2, where R1 is hydrogen or an alkyl group with 2-8 carbon atoms and R2 is an alkyl group with 1-8 carbon atoms, such as methyl, ethyl, or butyl; and (c) one or more olefins of the formula CH2═C(R3)CO2R4, where R3 is hydrogen or an alkyl group with 1-6 carbon atoms, such as methyl, and R4 is glycidyl. The ethylene copolymer impact modifier may further be made from carbon monoxide monomers. The compositions may further comprise one or more ethylene / acrylate and / or ethylene / vinyl ester polymers, ionomers, and cationic grafting agents.

Owner:DUPONT POLYMERS INC

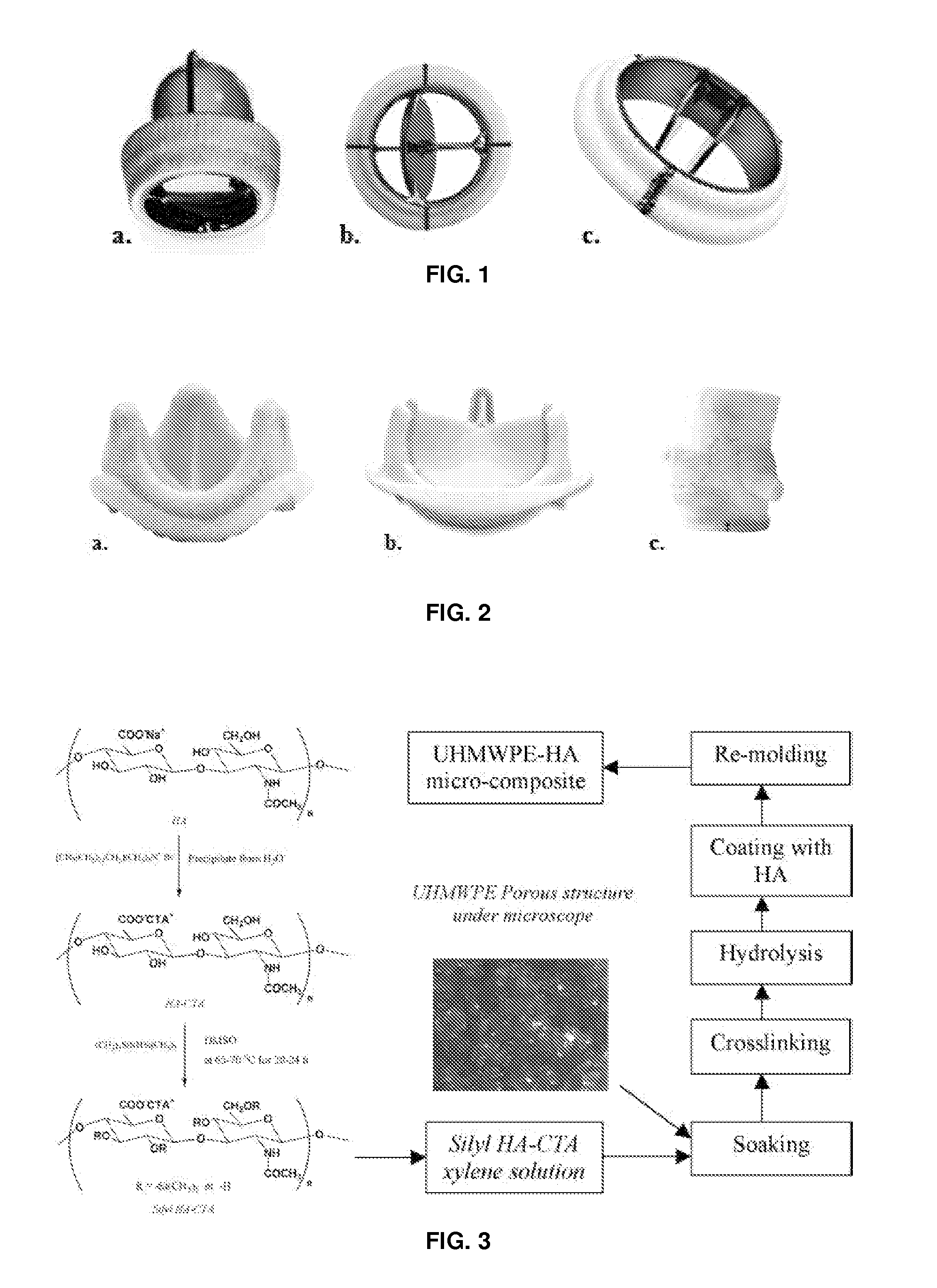

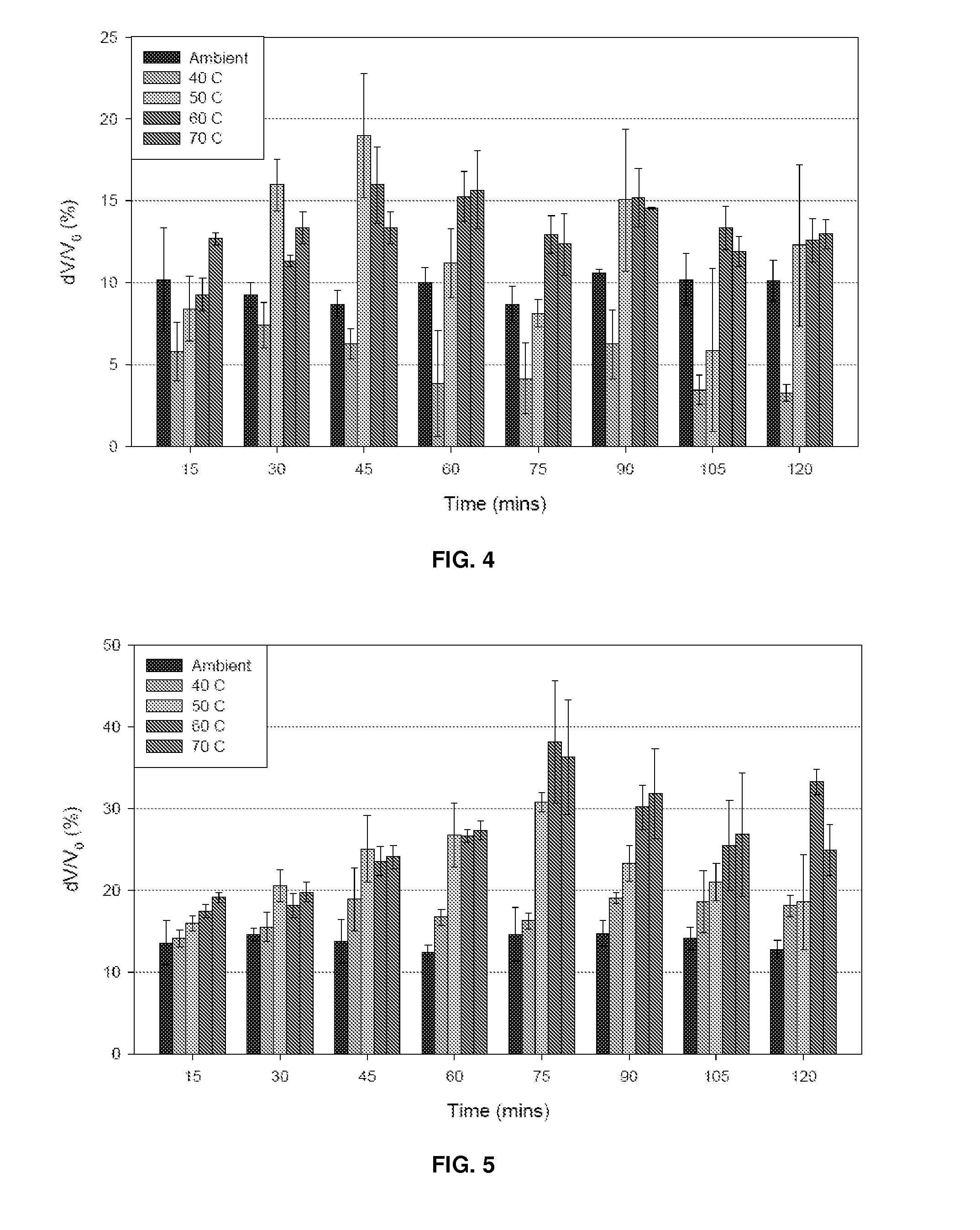

Glycosaminoglycan and Synthetic Polymer Material for Blood-Contacting Applications

ActiveUS20150196688A1Improve surface chemistryFeasible at commercial productionSuture equipmentsOrganic active ingredientsLow-density polyethyleneLinear low-density polyethylene

Provided herein is a composite, comprising: a polymer host selected from the group consisting of low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), polyethylene terephthalate (PET), polytetrafluoroethylene (PTFE), and polypropylene (PP), polyurethane, polycaprolactone (PCL), polydimethylsiloxane (PDMS), polymethylmethacrylate (PMMA), and polyoxymethylene (POM); and a guest molecule comprising hyaluronic acid; wherein the guest molecule is disposed within the polymer host, and wherein the guest molecule is covalently bonded to at least one other guest molecule. Also provided herein are methods for forming the composite, and blood-contracting devices made from the composite, such as heart valves and vascular grafts.

Owner:COLORADO STATE UNIVERSITY

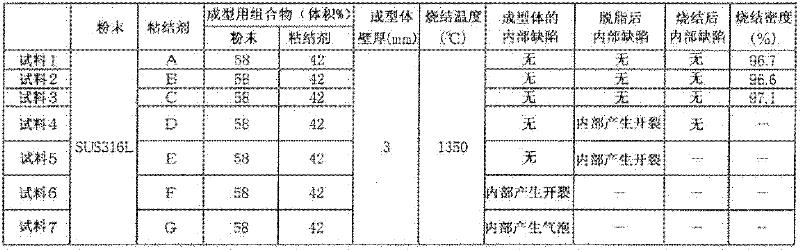

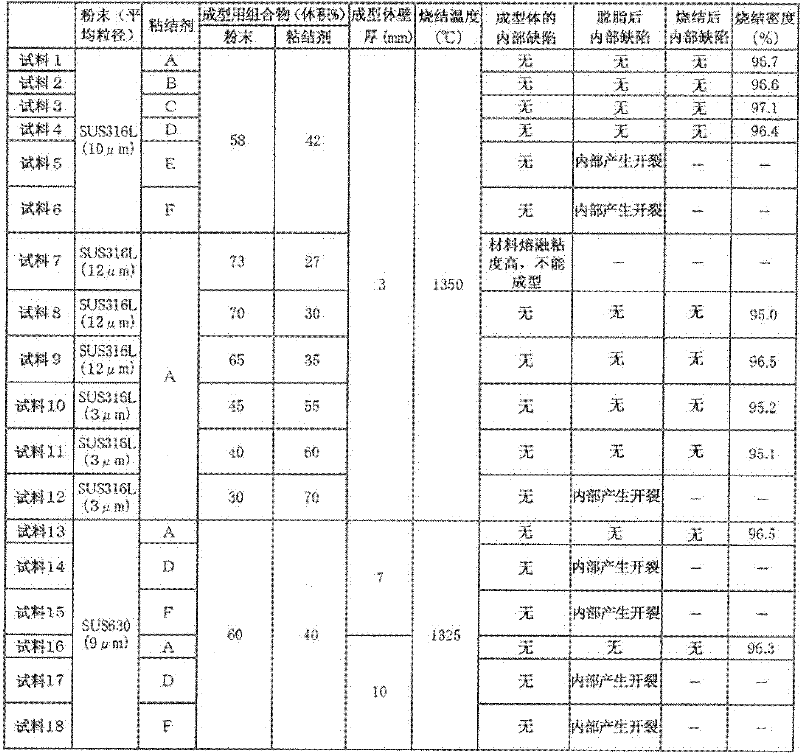

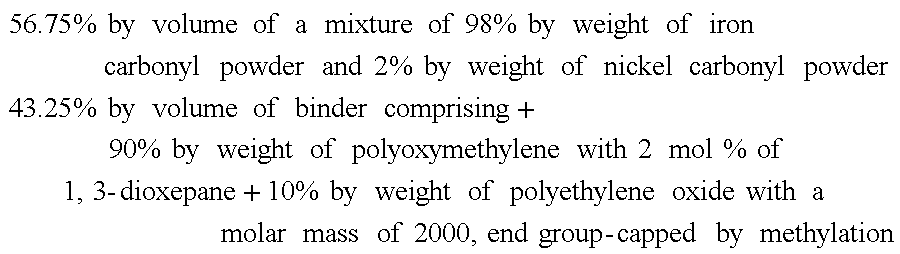

Metal powder injection moldable composition, and injection molding and sintering method using such composition

InactiveUS6051184AHigh strengthAvoid deformationTransportation and packagingMetal-working apparatusPolyoxymethyleneInjection molding machine

A metal powder injection moldable composition which hardly causes debinding deformation is obtained. This composition consists of a metal powder and an organic binder. The components which constitute the organic binder are: a. polyoxymethylene having a Vicat softening temperature A> / =150 DEG C., b. polypropylene having a Vicat softening temperature B> / =130 DEG C., c. an organic compound whose viscosity at said Vicat softening temperature A ( DEG C.) is not more than 200 mPaxs, and d. a thermoplastic resin whose Vicat softening temperature is not higher than said B ( DEG C.).

Owner:IHI CORP

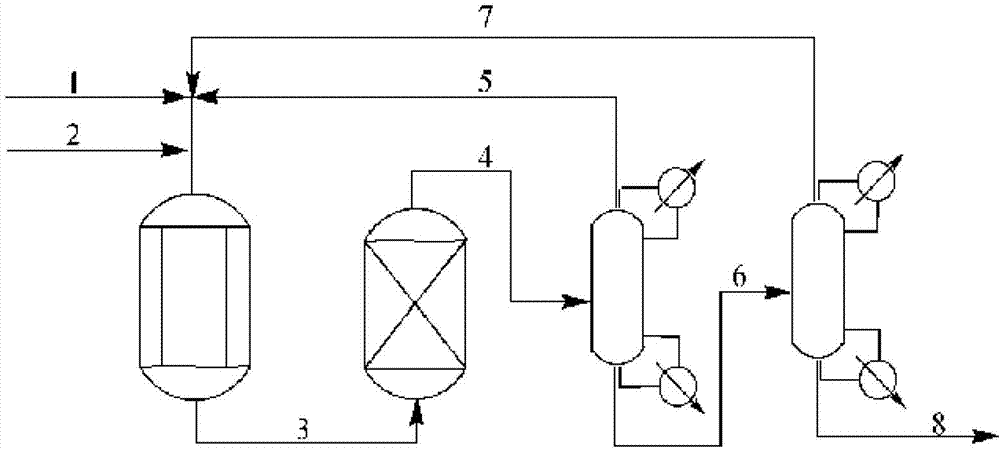

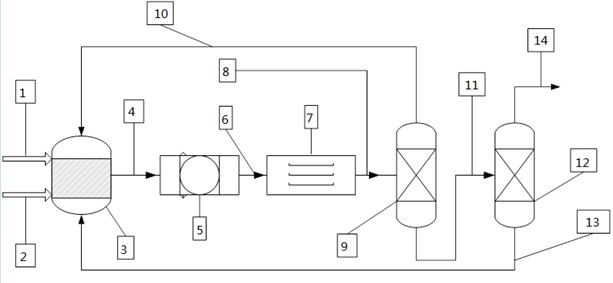

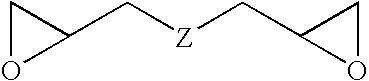

Method for continuous production of polyformaldehyde dimethyl ether

InactiveCN102786397ARealize industrial productionImprove stabilityOrganic chemistryOrganic compound preparationPtru catalystDistillation

The invention provides a method for continuous production of polyformaldehyde dimethyl ether. The method is characterized by comprising the following steps: a) feeding dimethoxymethane and hot-melted paraformaldehyde into a fixed bed reactor and adopting an acidic resin catalyst, so as to prepare polyformaldehyde dimethyl ether (DMM3-8), wherein the reaction temperature is 120-180 DEG C and the pressure is 0.1-10 MPa; b) cooling the reaction product, and then performing adsorptive separation through a dehydrating tower, so as to obtain polyformaldehyde dimethyl ether of which most water, cytidine glycol and hemiacetal are desorbed; c) feeding the polyformaldehyde dimethyl ether subjected to desorption into a distillation tower for separation, wherein most of a low-boiling component (dimethoxymethane (DMM)), poly-di-formaldehyde dimethyl ether (DMM2), a by-product (methanol) and triformol are extracted first, and then the materials in a tower kettle are fed into a rectifying tower in the next step, so as to extract the rest of the DMM2 and the triformol; and d) returning the low-boiling component (dimethoxymethane (DMM)), the methanol, the DMM2 and the triformol, which are evaporated out by the distillation tower and the rectifying tower in the last step, into the fixed bed reactor to continue to react to prepare polyformaldehyde dimethyl ether.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Polymer/foamed aluminium composite material and production method thereof

ActiveCN102501357AGood mechanical propertiesImprove thermal conductivityCoatingsPolyoxymethyleneCooking & baking

A polymer / foamed aluminium composite material and a production method thereof; polymer melt is injected into voids of foamed aluminium to form a composite material composed of foamed aluminium and polymer; the polymer is a mixture of one or more than one of polypropylene, polyethylene, polystyrene, and polyoxymethylene. The production method of the polymer / foamed aluminium composite material comprises the following steps: embedding foamed aluminium in a mold; preparing the polymer / foamed aluminium composite material by a injection molding method of the polymer or the mixture; performing heat preservation of the obtained polymer / foamed aluminium composite material in a baking oven at a temperature of 50-80 DEG C for 1-3 hours.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

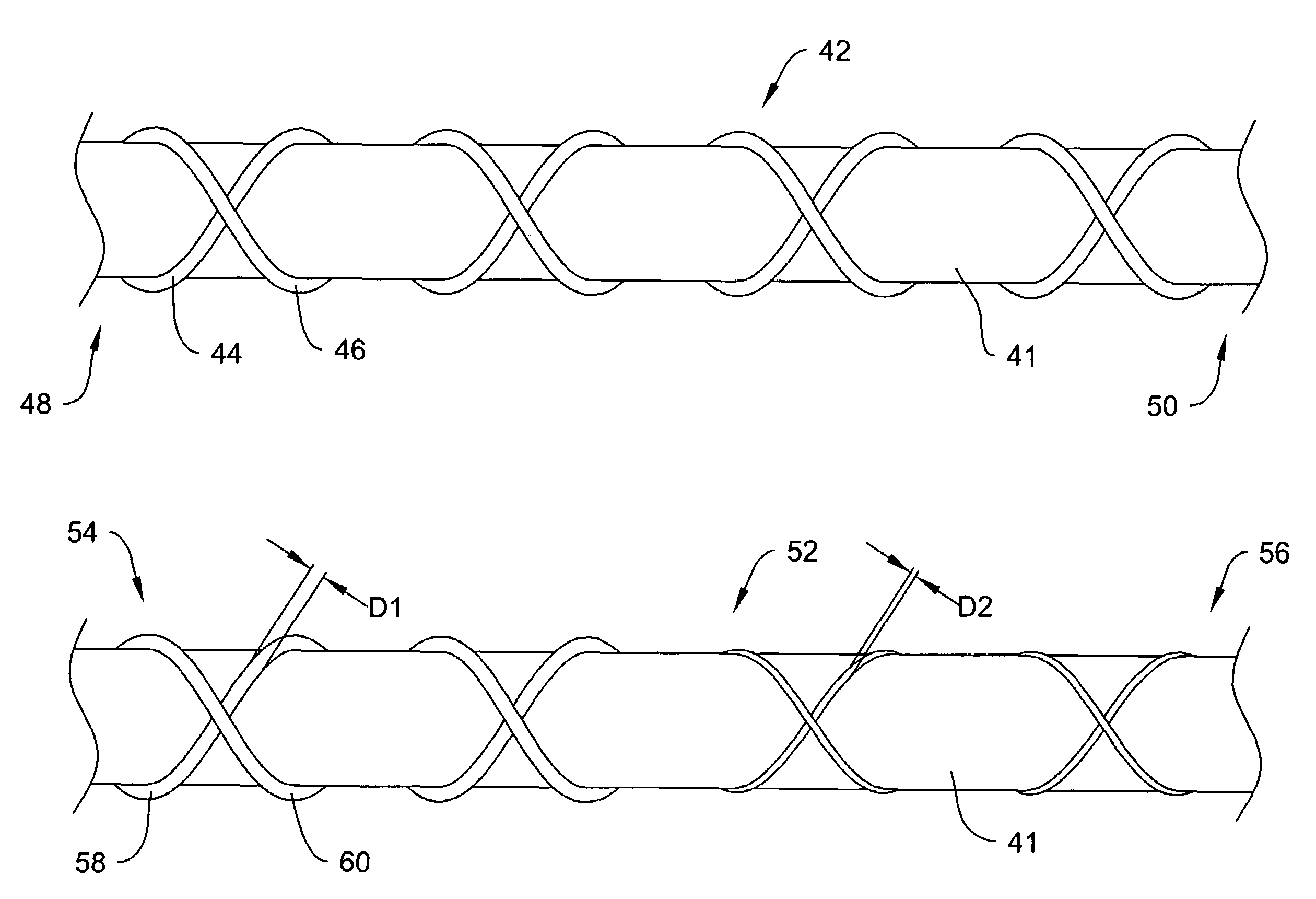

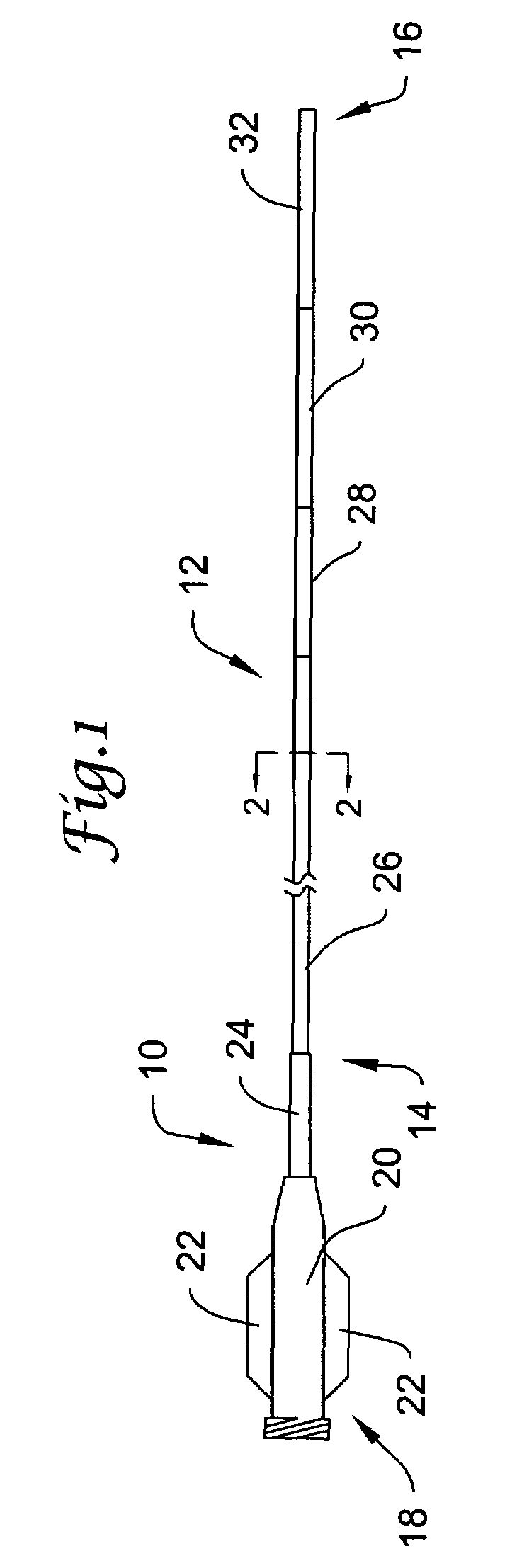

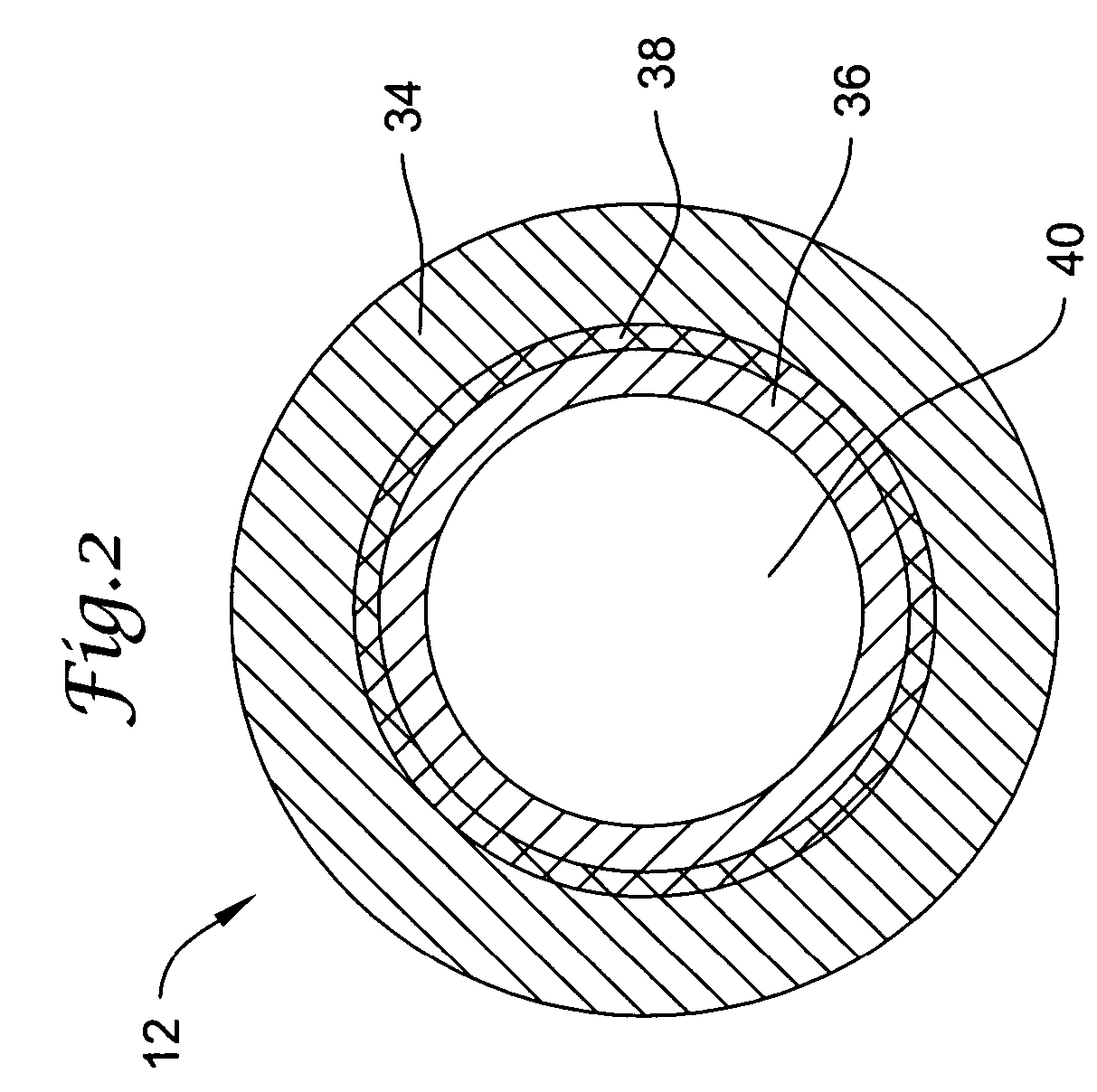

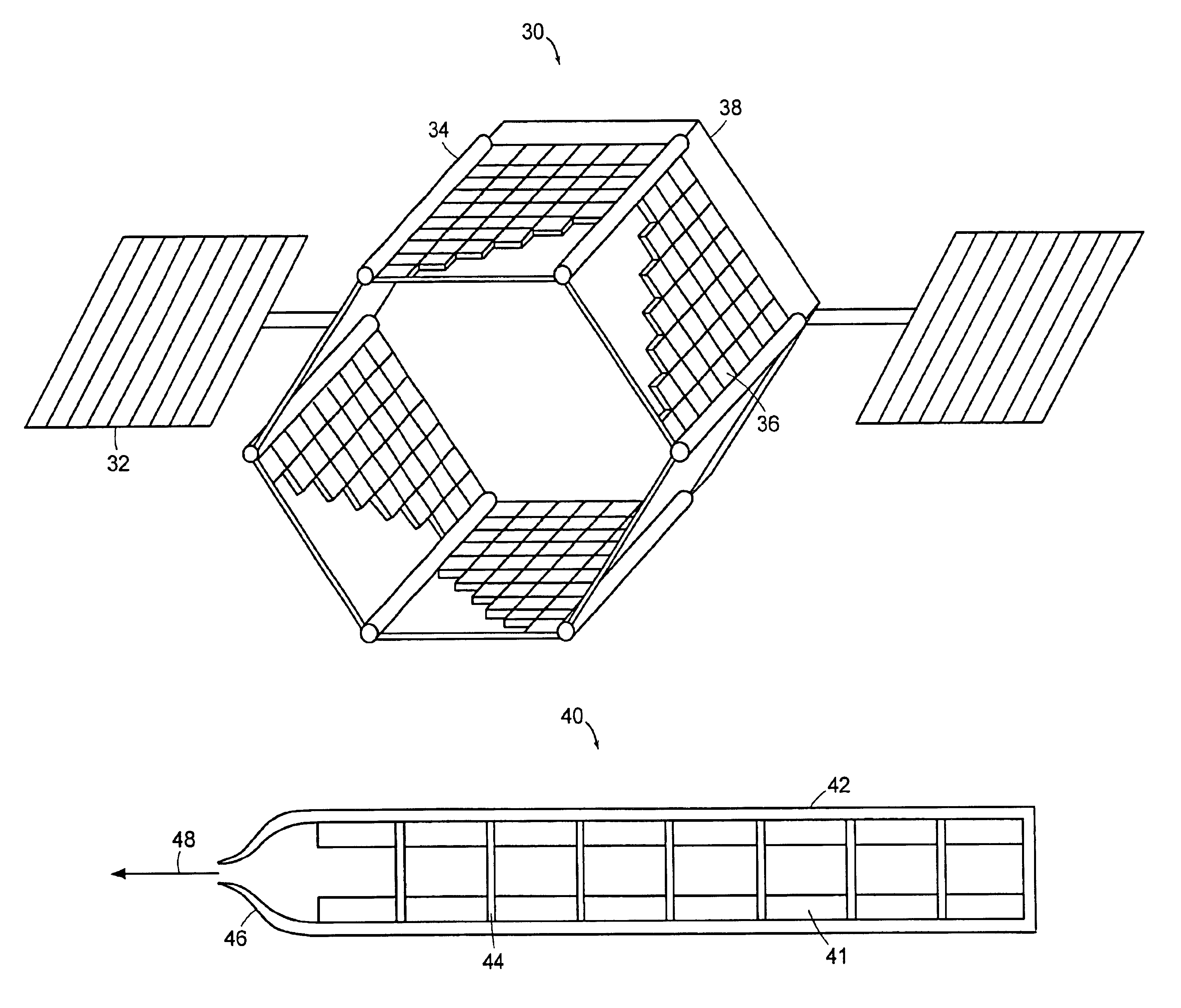

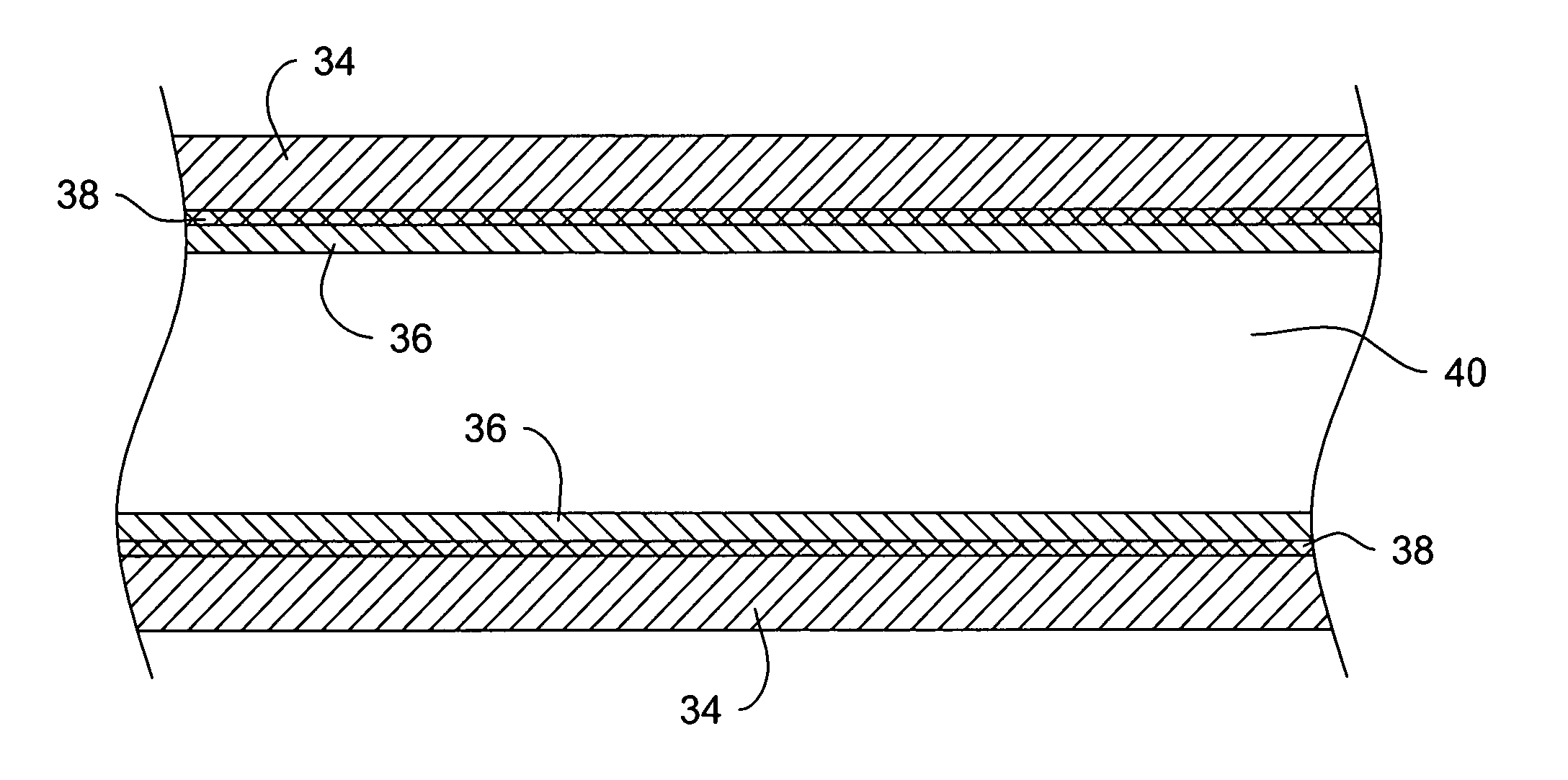

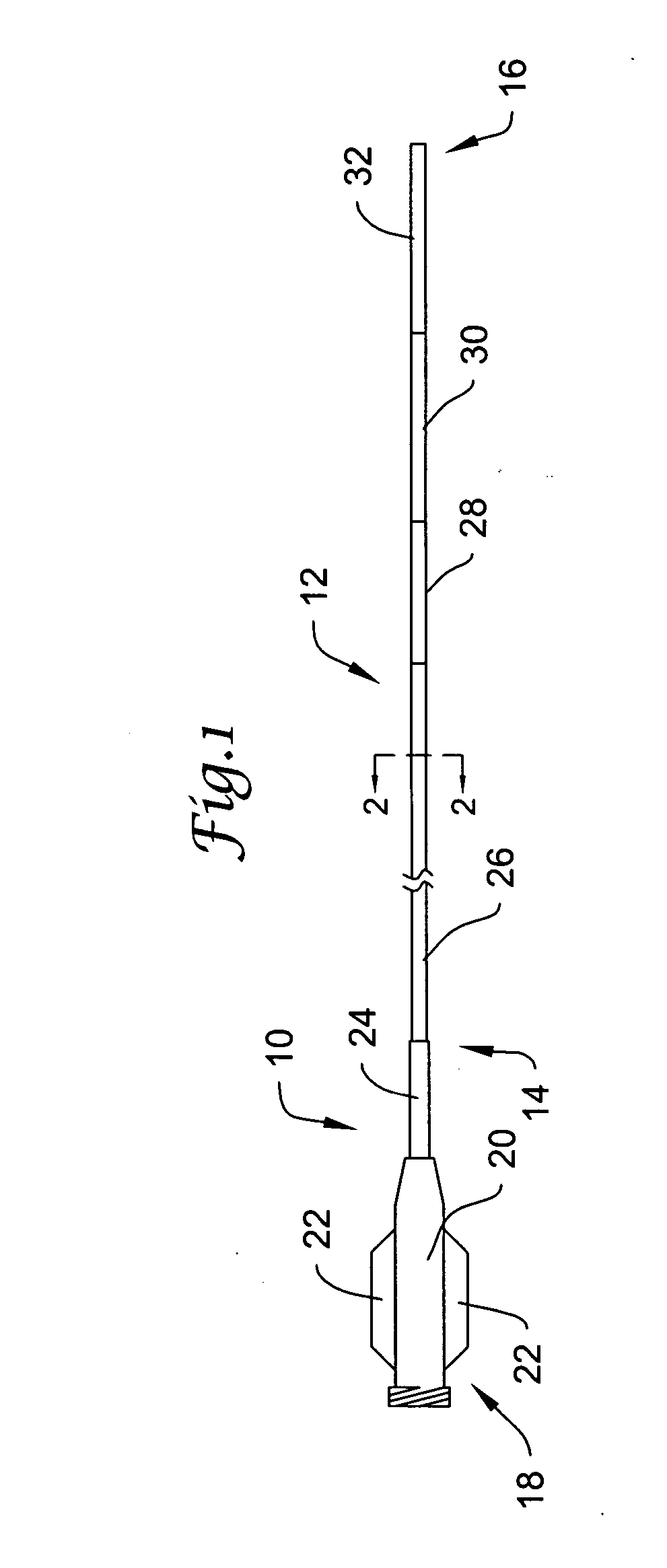

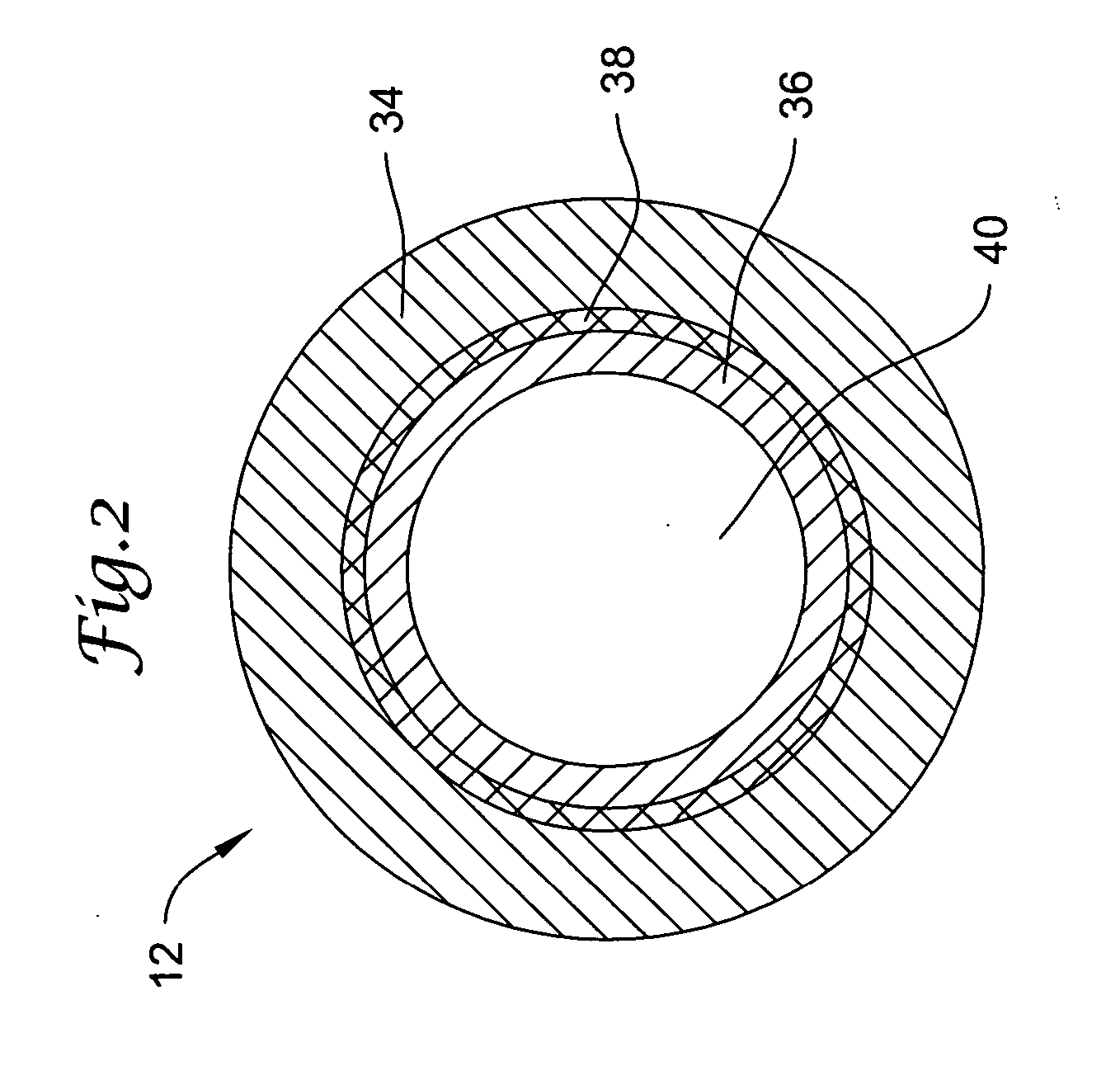

Medical device incorporating a polymer blend

A catheter including a catheter shaft formed from a polymer blend and / or a braid. The polymer blend may include polyoxymethylene added in the dispersion phase to a polymer blend. The catheter braid can be formed from at least two continuous wires that are woven together. The catheter braid can include a proximal braid section and a distal braid section. Each of the continuous wires has a proximal diameter corresponding to the proximal braid section and a distal diameter corresponding to the distal braid section. The distal diameter of each wire can be less than the proximal diameter of that wire. A catheter braid so formed can be included in a catheter.

Owner:BOSTON SCI SCIMED INC

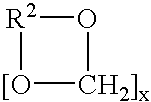

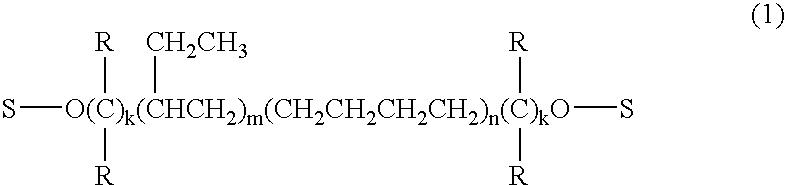

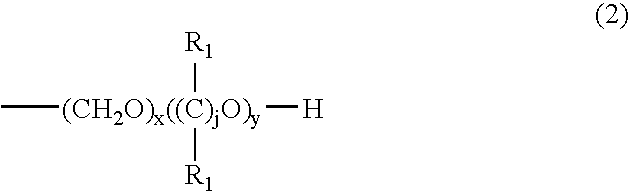

Method for preparing low-polymerization-degree polyformaldehyde dialkyl ether from mixture of lower alcohols and application thereof

InactiveCN102180778AHigh CN valueEasy to makeOrganic chemistryOrganic compound preparationAlcoholEconomic benefits

The invention belongs to the technical fields of clean utilization of coal and clean diesel fuel and particularly relates to a preparation method of a low-polymerization-degree polyformaldehyde dialkyl ether capable of serving as a fossil diesel fuel additive. The structural general formula of the low-polymerization-degree polyformaldehyde dialkyl ether is shown as CnH2n+10(CH2O)mCnH2n+1, wherein m is an integer of 1-5, and n is an integer of 1-5. The prepared low-polymerization-degree polyformaldehyde dialkyl ether has a high CN value, can be widely and effectively applied to a diesel fuel without high polymerization degree, and has a relatively simple preparation process; and fusel serving as a byproduct in the industrial process of alcohol brewing or the mixture of lower alcohols produced in a Fischer-Tropsch synthesis reaction is taken as a raw material which can be used without purification treatment, so that the production cost is greatly saved, a good process technical route is provided for the comprehensive utilization of a large quantity of mixtures of lower alcohols produced in industry, and a remarkable economic benefit is achieved.

Owner:DONGFANG HONGSHENG NEW ENERGY APPL TECH RES INST +1

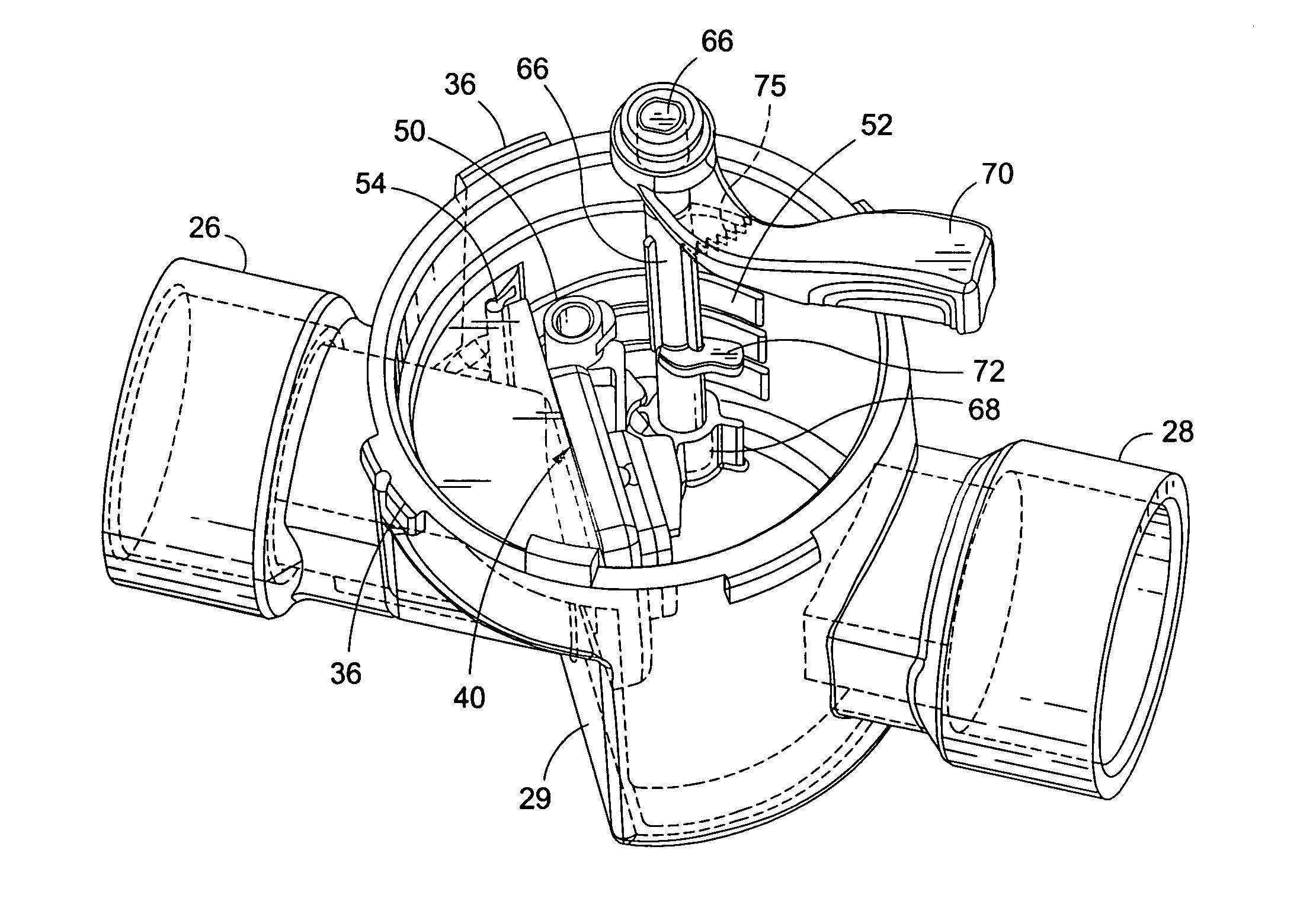

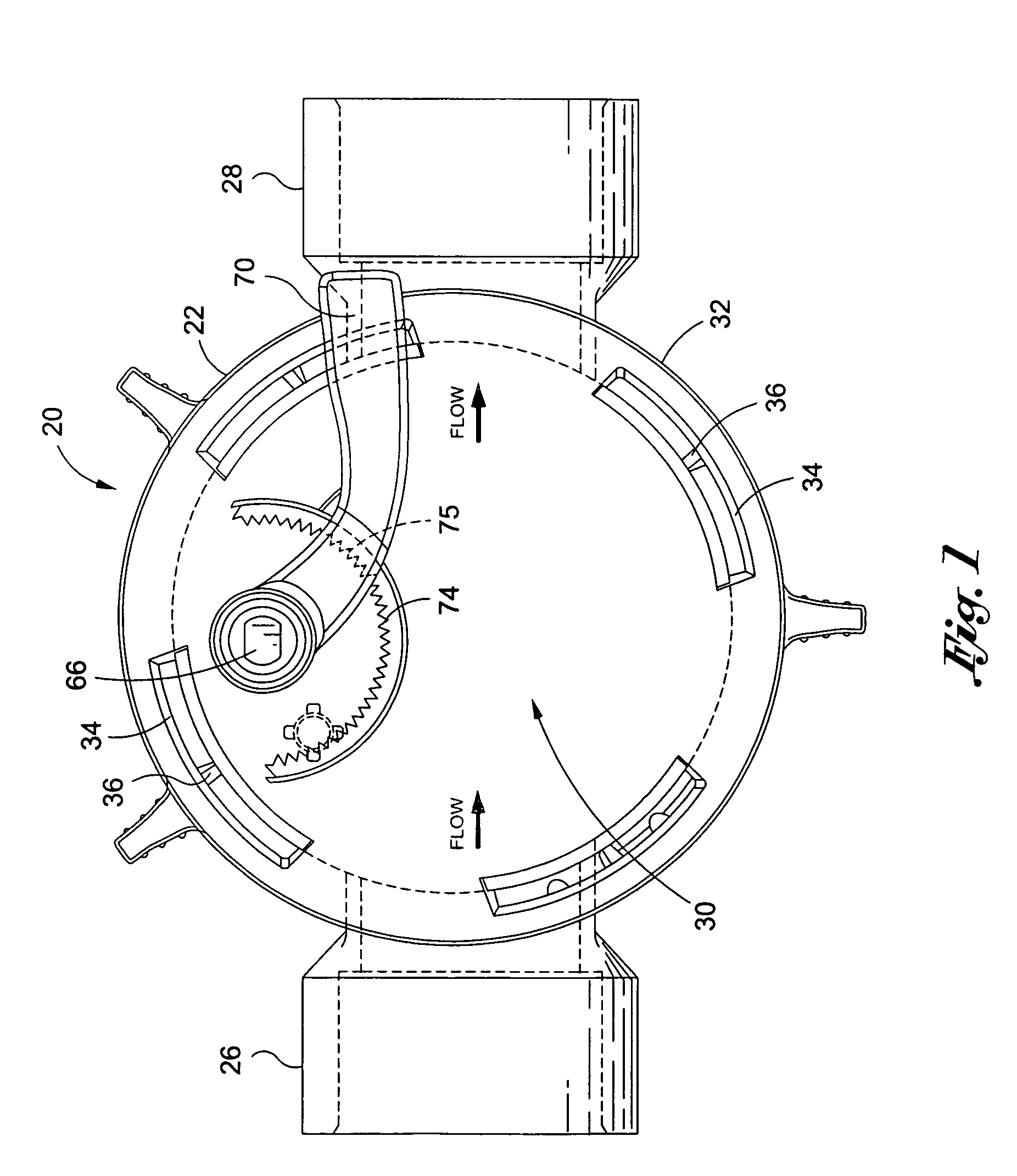

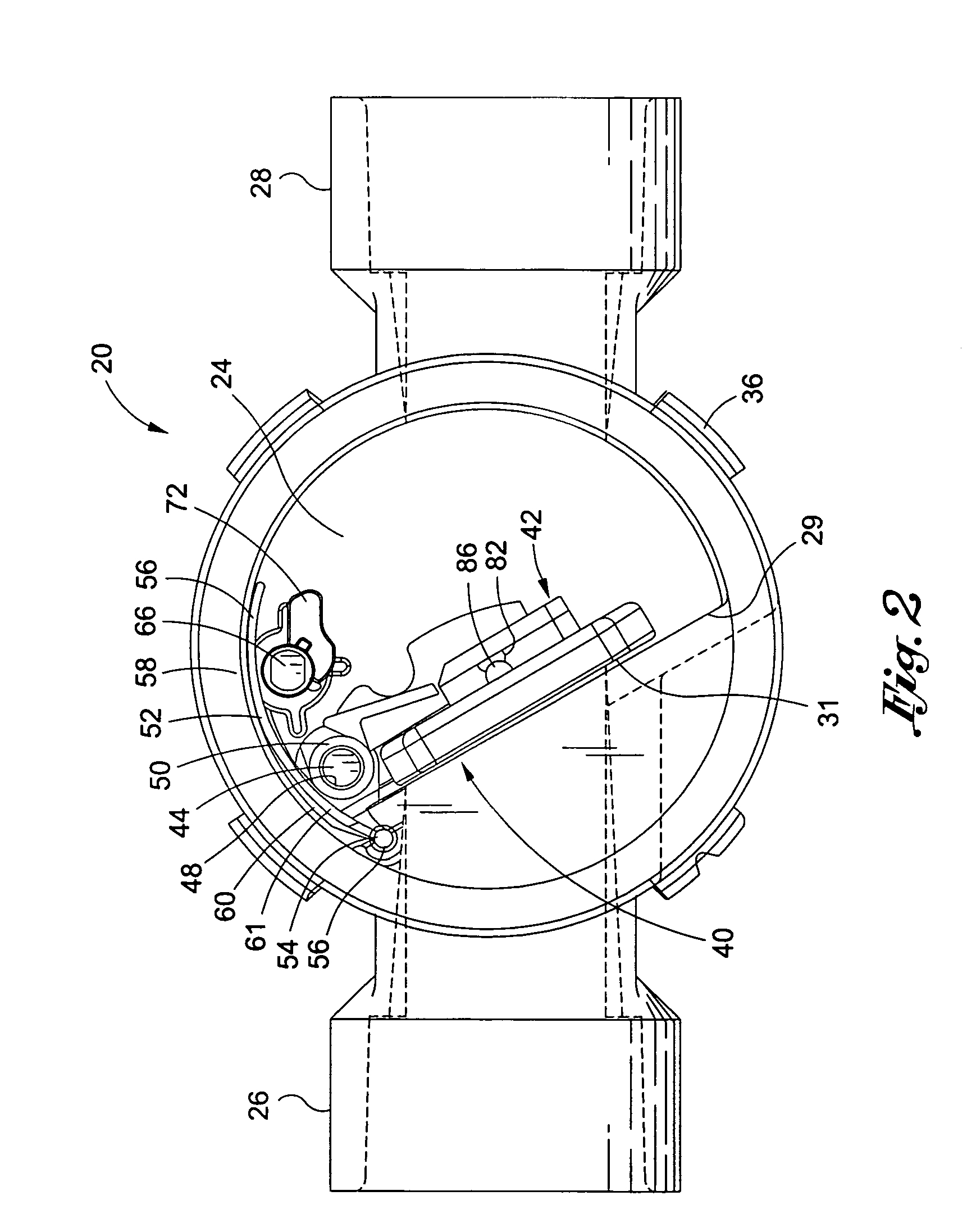

Flow control device

ActiveUS8128058B2Low costReduce spacingOperating means/releasing devices for valvesLift valvePolyoxymethyleneEngineering

Owner:NAT DIVERSIFIED SALES

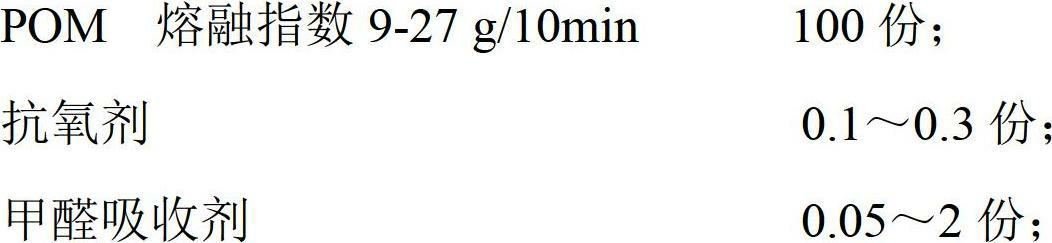

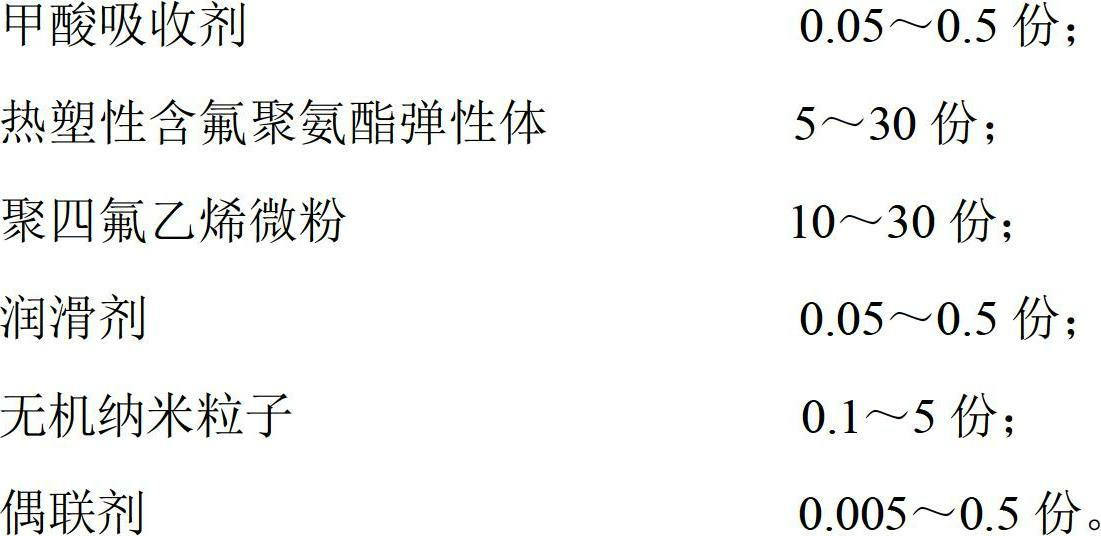

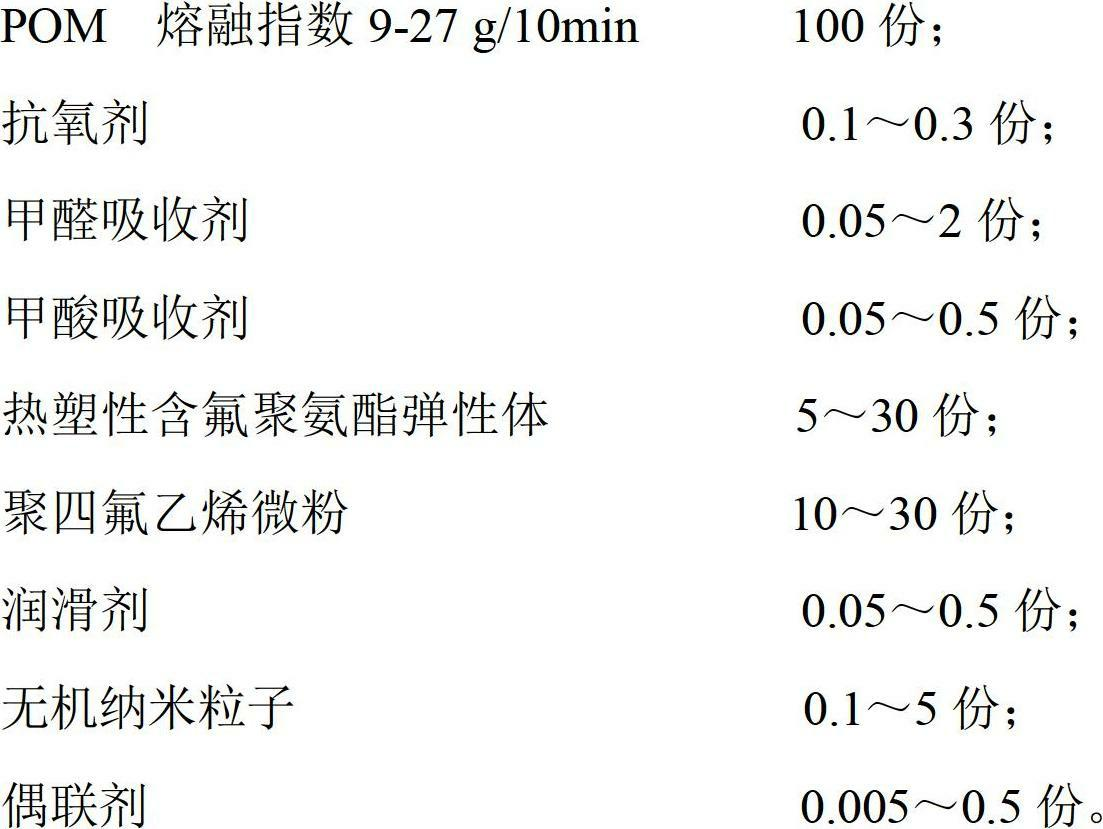

Wear resistant self-lubricating polyformaldehyde and preparation method thereof

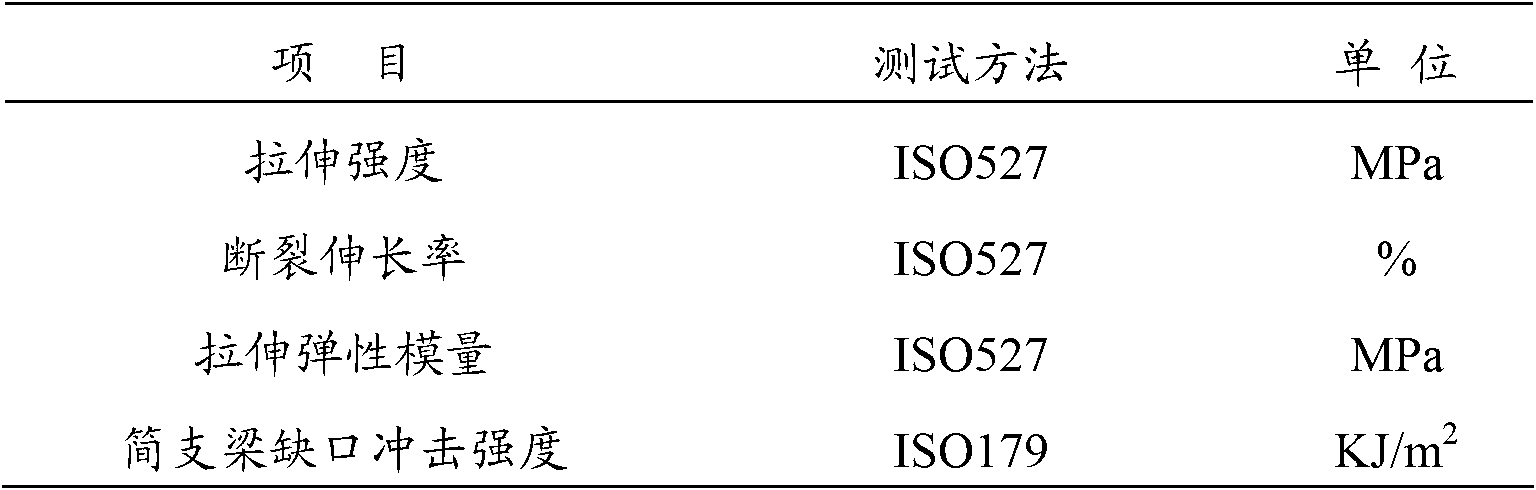

The invention discloses wear resistant self-lubricating polyformaldehyde, which is prepared by the following components through a preparation method comprising the following steps: adding 100 parts of POM (polyoxymethylene) resin, 0.1-0.3 part of antioxidant, 0.05-2 parts of formaldehyde absorber, 0.05-0.5 part of formic acid absorber, 15-30 parts of thermoplastic fluorine-containing polyester elastomer, 10-30 parts of polytetrafluoroethylene micro-powder, 0.1-5 parts of inorganic nano-particles subjected to surface treatment and 0.05-0.5 part of lubricant into a high-speed mixer and mixing, melting and mixing by an exhaust type double-screw extruder, extruding and pelleting to obtain the polyformaldehyde, wherein a rotating speed of screws is 50-200 revolutions per minute, and the temperature of a charging barrel is 140-220 DEG C. According to the invention, the thermoplastic fluorine-containing polyester elastomer with excellent strength and toughness and better compatibility with POM and PTFE (polytetrafluoroethylene) and the inorganic nano-particles are composited with POM and PTFE, so that a tensile strength of the polyformaldehyde reaches 45 MPa, and a notch impact strength reaches about 20 KJ / m<2>.

Owner:YANKUANG GRP CO LTD

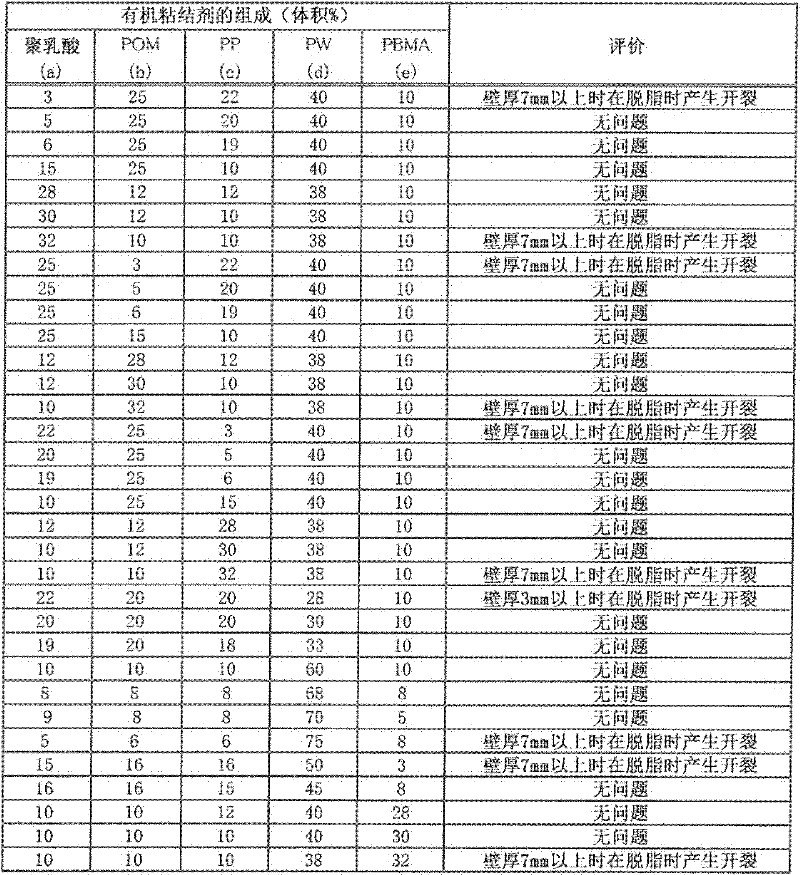

Injection molding composition

InactiveCN102355967ANo bloatingNo crackTransportation and packagingMetal-working apparatusPolyoxymethyleneMetal powder

Disclosed is an injection molding composition which has high thermal decomposability and rarely suffers from degreasing deformation when heated. The injection molding composition is capable of providing a good degreased body in a short time even in cases where a molded body has a large thickness. Specifically disclosed is an injection molding composition which is composed of a sinterable metal powder and an organic binder. The injection molding composition is characterized in that the organic binder is composed of (a) a polylactic acid, (b) a polyoxymethylene, (c) a polypropylene, (d) an organic compound having a viscosity at 150 DEG C of not more than 200 mPas, and (e) a thermoplastic resin having a Vicat softening point of not more than 130 DEG C.

Owner:IHI CORP

Nano composite polyformaldehyde material and its prepn

The present invention discloses one kind of nano composite polyformaldehyde material, and the composite contains polyformaldehyde 55-90 wt% and elastomer 2.5-30 wt% as well as characterized inorganicnano stuffing 0.1-10 wt% and compatibilizing agent 0.1-10 wt%. During the preparation, inorganic nano stuffing, compatibilizing agent and elastomer in certain proportion are smelted and mixed to obtain agglomerate; and the agglomerate is then diluted and dispersed in polyformaldehyde or polyformaldehyde / elastomer to obtain the product through further smelting and mixing. The present invention canstrengthen and toughen polyformaldehyde while reducing cost.

Owner:SICHUAN UNIV

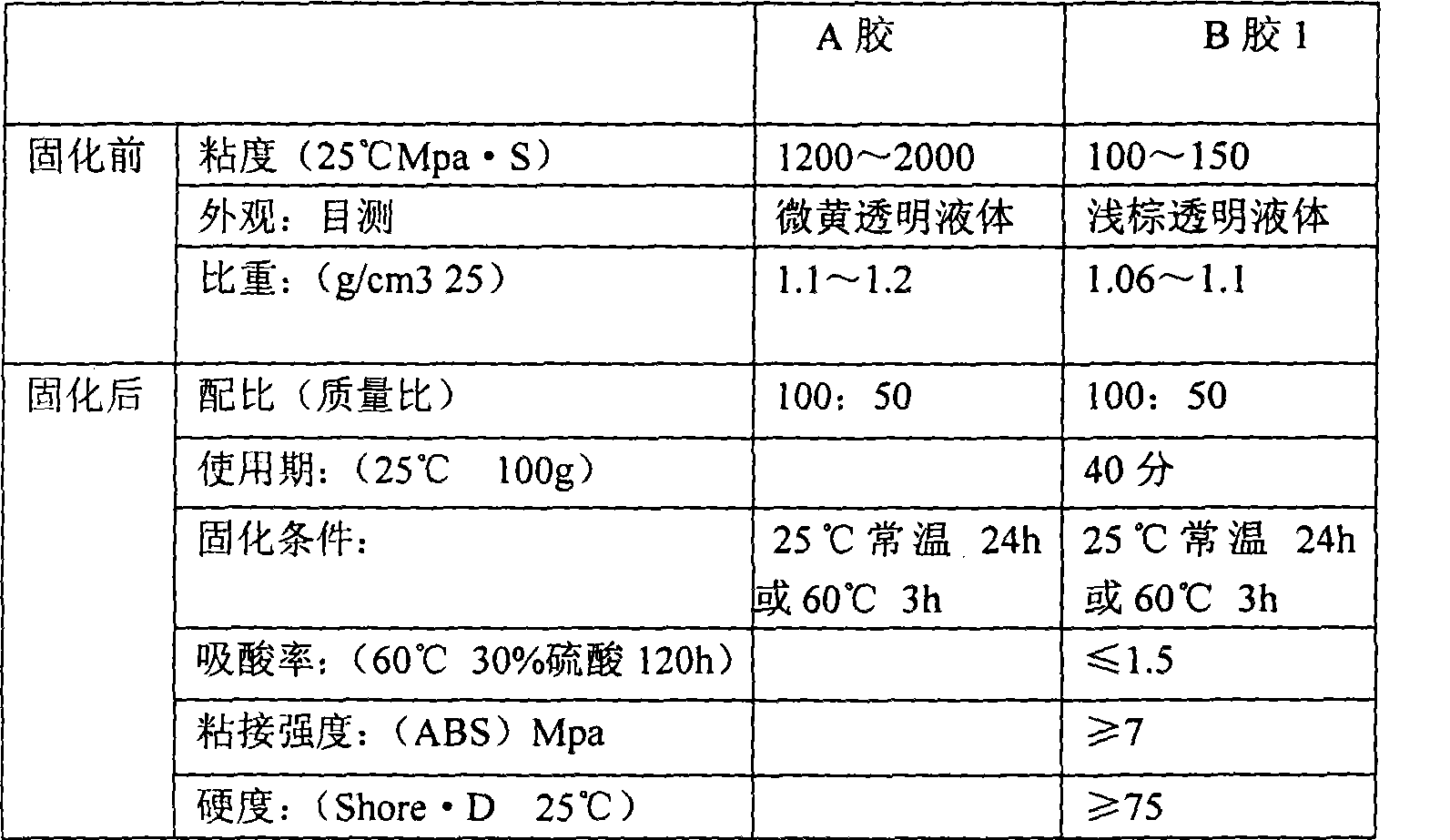

Lead accumulator epoxy resin sealant and preparation method thereof

ActiveCN101457133AEfficient responseReduce manufacturing costAldehyde/ketone condensation polymer adhesivesCell component detailsAnilineSealant

The present invention relates to a lead accumulator epoxy resins sealant and preparation method thereof, particularly a cementing compound used on lead acid batteries sealing and adhesive bonding. The lead accumulator epoxy resins sealant includes A component and B component, the mass portion proportioning between A component and B component is as following: A:B = 2:1, wherein the raw material mass proportioning of A component is as following: bisphenol A epoxy resins 70-80, bisphenol F epoxy resins 10-15, butyl glycidyl ether 3-5, 2-methylphenol glycidyl ether 8-12, polyurethane 5-8, resin acceptor 0.1; and the raw material mass portion proportioning of B component is as following: aniline 400, polyoxymethylene 70-76, aminic acid 30, water 100-300, benzenemethanol 300-500, anti-oxidant 2, cure accelerator 20-35, and nonyl phenol 60.

Owner:宜兴市普利泰电子材料有限公司

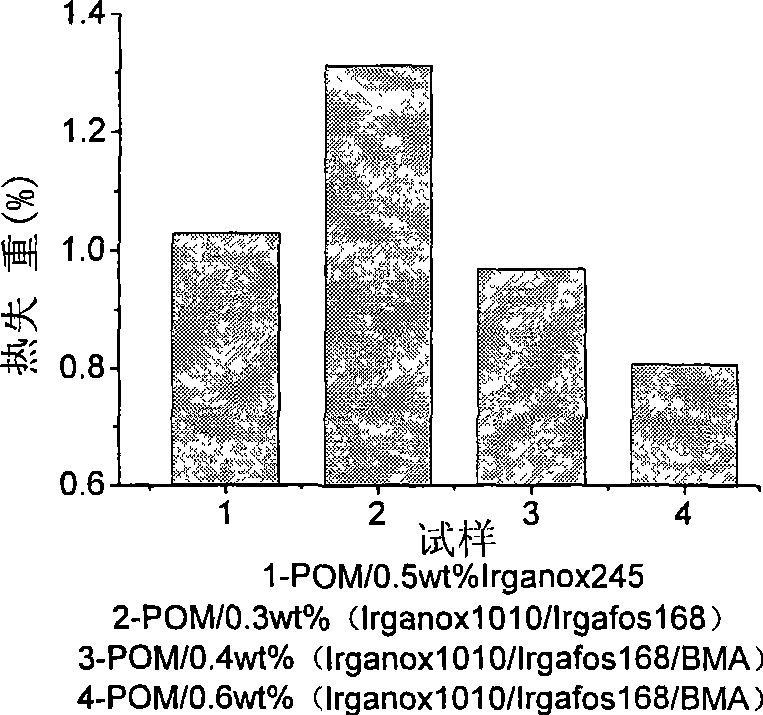

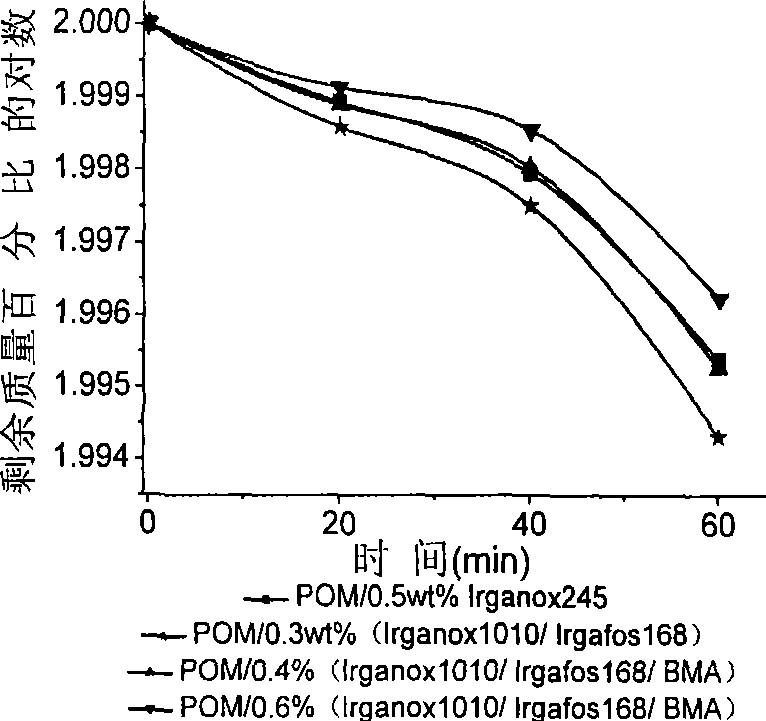

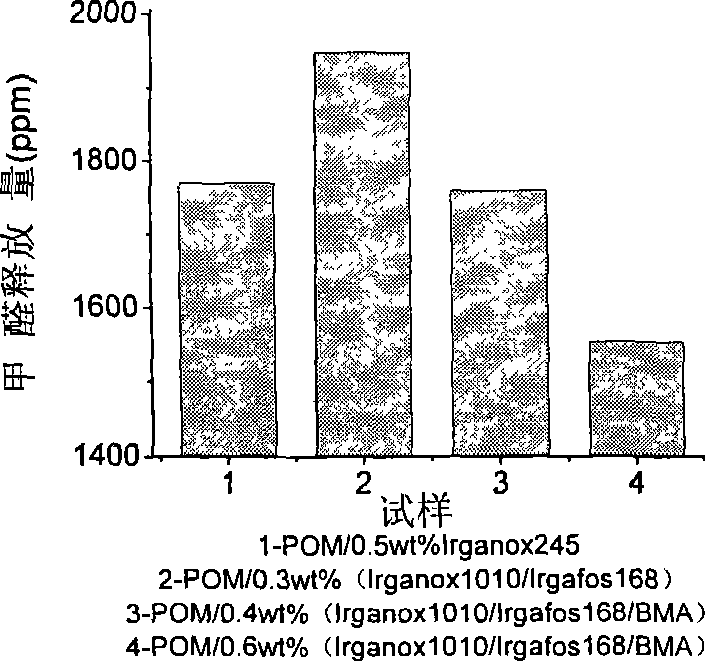

Thermal stable polyoxymethylene containing high-efficiency anti-oxidant and method for producing the same

InactiveCN101508819AImprove thermal stabilityExcellent thermal stabilityPolyoxymethyleneThermal stability

The invention discloses a thermally stable polyformaldehyde containing high-efficacy antioxidant and a preparation method thereof. The invention is characterized in that 100 parts of polyformaldehyde resin, 0.1 to 0.3 part of primary antioxidant, 0.1 to 0.3 part of complemental antioxidant 1, 0.05 to 0.5 part of complemental antioxidant 2, 0.05 to 2 parts of formaldehyde absorbent, 0.05 to 0.5 part of methanoic acid absorbent and 0.05 to 0.5 part of lubricant by part by weight are put into a high-speed mixer to be mixed and then are melted and mixed by an exhaust double-screw extruder to be extruded and granulated; the rotating speed of a screw is 30-150 revolution / minute, the temperature of a barrel is 140-230 DEG C; and the thermally stable polyformaldehyde is obtained.

Owner:SICHUAN UNIV

High density polyoxymethylene compositions

A high-density polyoxymethylene resin composition that comprises polyoxymethylene; at least one coated mineral selected from zinc oxide, barium sulfate, and titanium dioxide; and at least one thermal stabilizer.

Owner:EI DU PONT DE NEMOURS & CO

Modified coal tar, and producing method

InactiveCN1760331AIncrease electrode contentHigh strengthWorking-up pitch/asphalt/bitumen by chemical meansSmall footprintPhenol

A modified coal asphalt with linear resin molecule structure and adjustable softening point is prepared from one or more of coal tar, antracene oil, phenol oil, naphthelene oil and the coal asphalt with softening point lower than 130 deg.C through using acid to regulate pH value, and polymerizing reaction on formaldehyde or tripolyformaldehyde or polyformaldehyde which controlling temp, pressure and time.

Owner:任利华

Process for producing metallic or ceramic shaped bodies

ActiveUS20120235330A1Speed up the processCeramic shaping apparatusClaywaresPolyoxymethylenePolymer dissolution

A process for producing a metallic or ceramic shaped body from a thermoplastic material comprisingA) 40 to 65% inorganic sinterable powder AB) 35 to 60% binderB1) 50 to 95% polyoxymethylene homo- or copolymers;B2) 5 to 50% of a polymer dissolved or dispersed in B1) with a particle size of less than 1 μm,andC) 0 to 5% by volume of a dispersing aid,by injection molding or extrusion to give a green body, removing the binder and sintering, which comprises removing the binder bya) treating the molding with a solvent which extracts the binder component B2) from the molding and in which the binder component B1) is insoluble,b) removing the solvent from the molding by drying, andc) treating the molding in an acid-containing atmosphereis described.

Owner:BASF AG

High wear-resistant self-lubricating polyoxymethylene and process for preparing same

The invention relates to organic polymer composite material, in particular to high wear-resistant self-lubricating polyoxymethylene and a process for preparing the same. The high wear-resistant self-lubricating polyoxymethylene comprises the following components by weight percent: 85.5-96 percent of polyoxymethylene, 2-5 percent of silicon lubricant, 1-5 percent of toughening agent, 0.1-1.7 percent of polyoxymethylene absorbing agent, 0.1-0.4 percent of coupling agent, 0.3-2.0 percent of antioxidant and 0.1-2.5 percent of other auxiliary. The high wear-resistant self-lubricating polyoxymethylene has the characteristics of wear resistance and self-lubrication in addition to the original good comprehensive mechanical properties and is convenient to produce and purchase, thereby greatly improving the competitiveness of polyoxymethylene products and being more suitable for producing the workpieces needing to improve the wear resistance and reducing the material cost.

Owner:KECHUANG POLYMER SUZHOU

Preparation of high-ductility polyformaldehyde material with excellent comprehensive properties

The invention relates to a high-tenacity polyoxymethylene material with extremely outstanding comprehensive performance, which is characterized in that the material is made of the following raw materials according to the weight percentage as follows: 50 percent-70 percent of kematal, 15 percent-30 percent of polyurethane elastomer, 3 percent-10 percent of compatibilizer, 0.1 percent-0.5 percent of antioxidant, 0.1 percent-0.5 percent of lubricant. The preparation method comprises the following steps: the raw materials are scaled and taken according to weight proportion; all the materials are put into a high mixing machine to be mixed for 2-5 minutes; the materials are taken out; the mixed materials are put into a screw compressor for extruding prilling. The rotating speed of the screw compressor is 180-600 rotation per minute and temperature is 150-170 DEG C. The invention has the advantages that the prepared poformaldehyde material has excellent shock resistance, and the intensity of shock can be reached. The invention can be used instead of the non-ferrous metals and alloy, and which is widely used in the fields of automobile, electrical appliance industry, common and precise mechanism, building and construction materials, etc.

Owner:SHANGHAI SUNNY

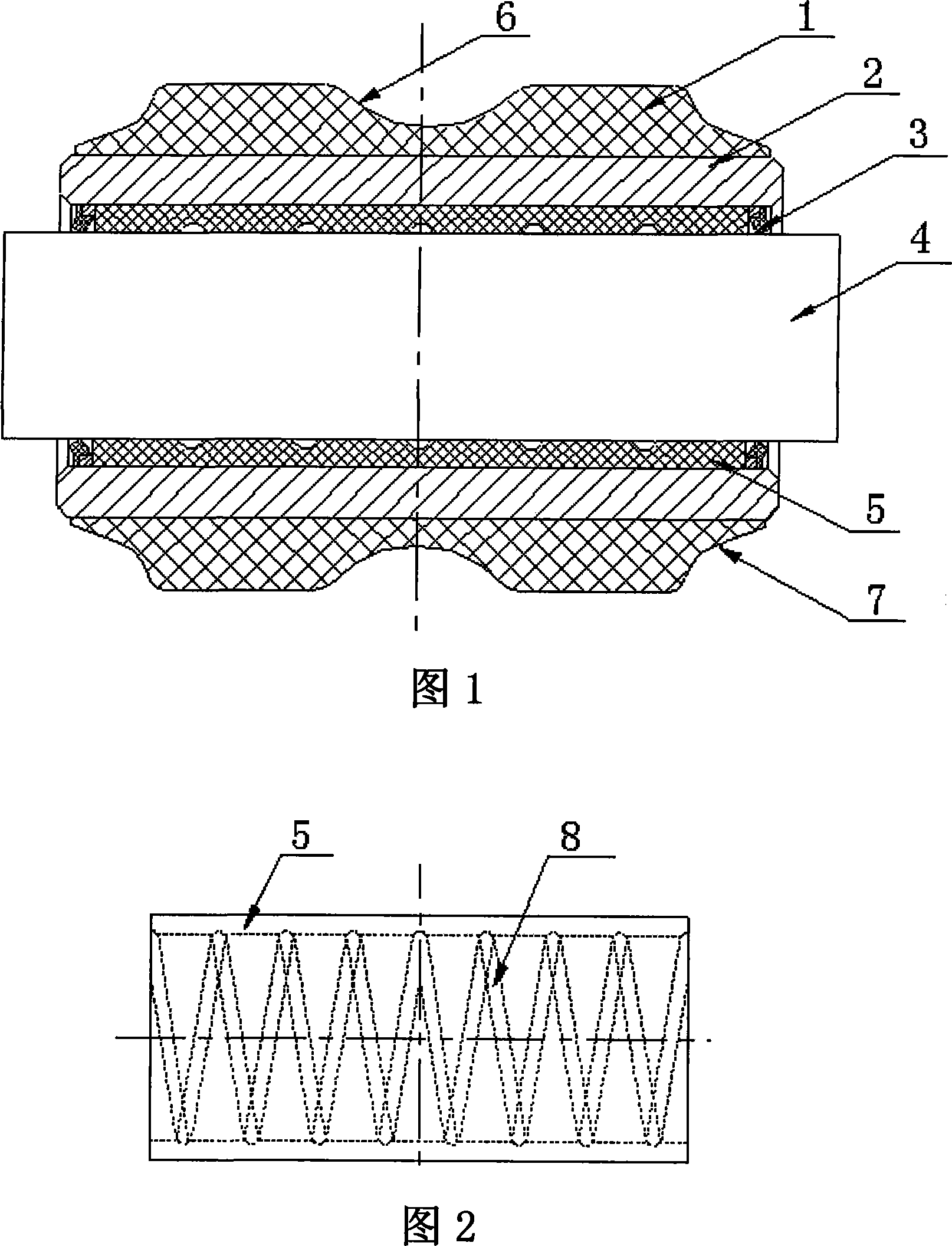

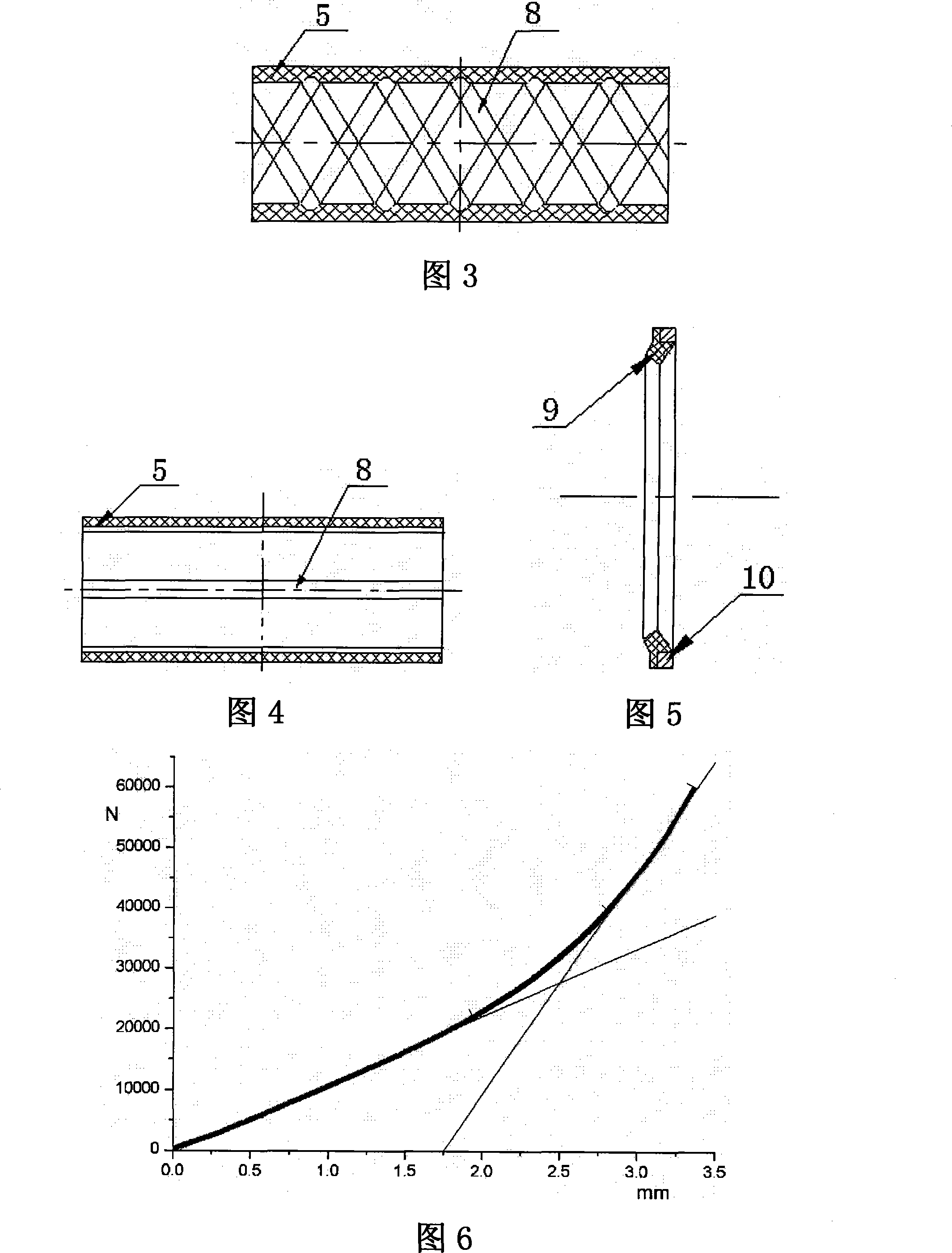

Rubber-plastic composite bush

ActiveCN101178106AOvercoming "stackingOvercome "stacking"Bearing componentsRubber-like material springsPolyoxymethyleneHeavy load

The invention provides a rubber plastic composite liner, belonging to a damping part or a sliding bearing used for connecting automobile parts. A rubber sleeve 1 is fixed on the an external cylindrical surface of the steel sleeve 2; an internal hole of the steel sleeve 2 is fixed with a plastic liner 5; the external cylindrical surface at the middle part of the rubber sleeve 1 is provided with at least a cirque concave trough 6; two ends of the rubber sleeve 1 are provided with conical chamfers 7. The invention is beneficial for fitting interference and variable rigidity design, overcomes the piling of the rubber layers of the liner, the axial contraction and press mounting not in place, misalignment, obliquity and abrasion offset of the liner, etc. The plastic liner 5 adopts the material of oil contained nylon or polyoxymethylene, can be suitable for heavy load working condition, and has the advantages of small abrasion, light weight, corrosion resistance, simple manufacture, small friction coefficient, stable performance, good sealing performance, and implementing the maintenance-free performance.

Owner:DONGFENG MOTOR CORP HUBEI

Polyoxymethylene as structural support member and propellant

InactiveUS6904749B2Improve featuresChange pressureCosmonautic vehiclesCosmonautic propulsion system apparatusCombustionSatellite

A vehicle includes at least one polyoxymethylene structural support member. The polyoxymethylene structural support member includes a polyoxymethylene component that is a propellant that provides thrust to the vehicle upon pyrolysis or combustion of the polyoxymethylene component of the product of pyrolysis of the polyoxymethylene component. The vehicle can be a satellite or other type of spacecraft.

Owner:PHYSICAL SCI

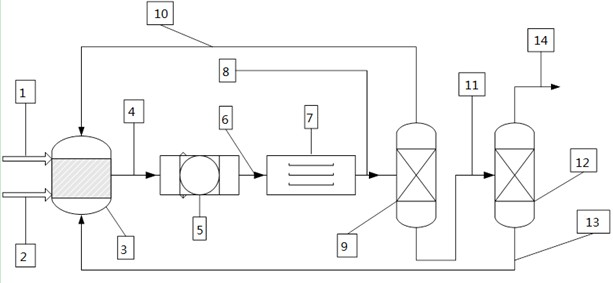

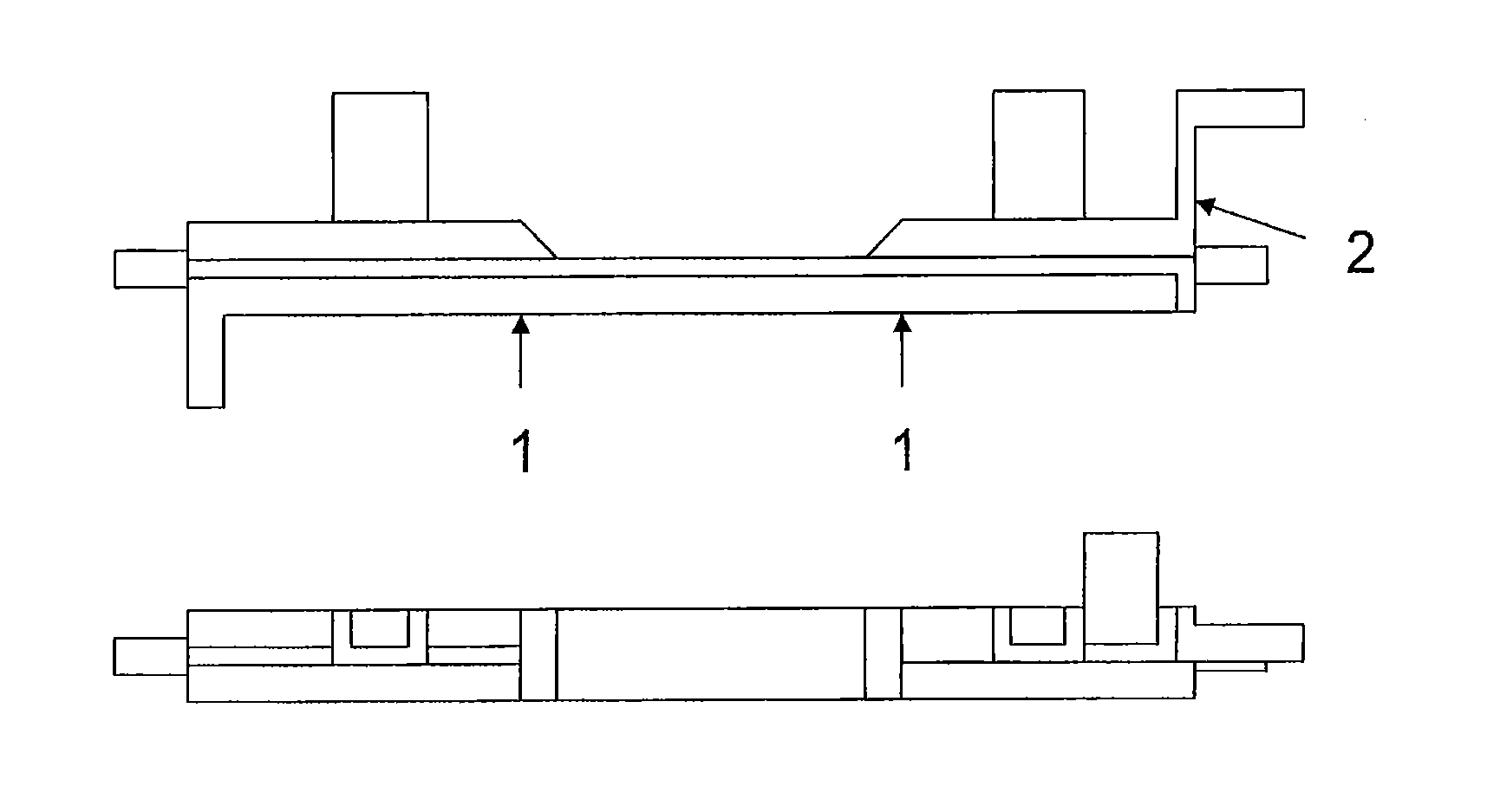

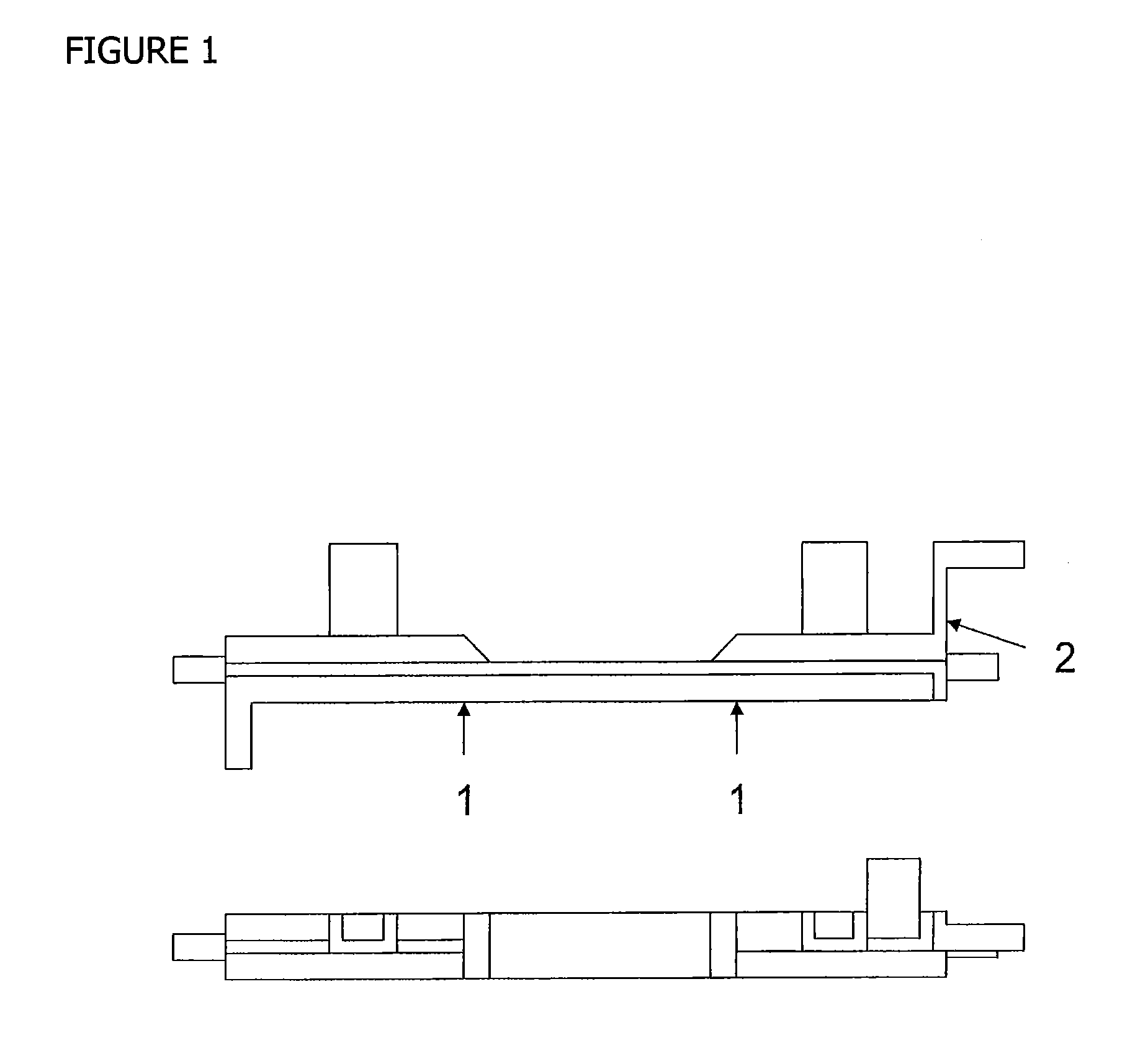

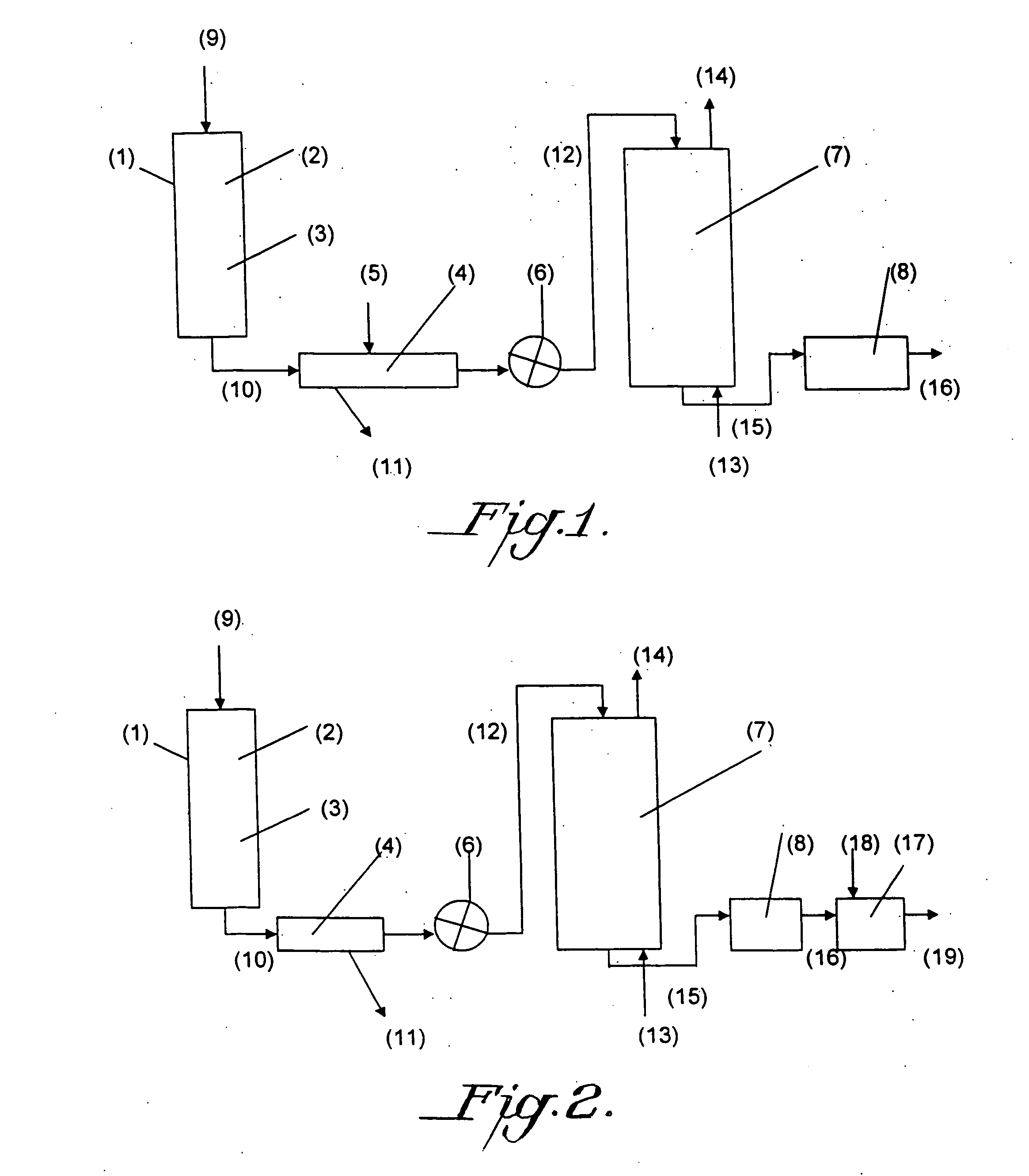

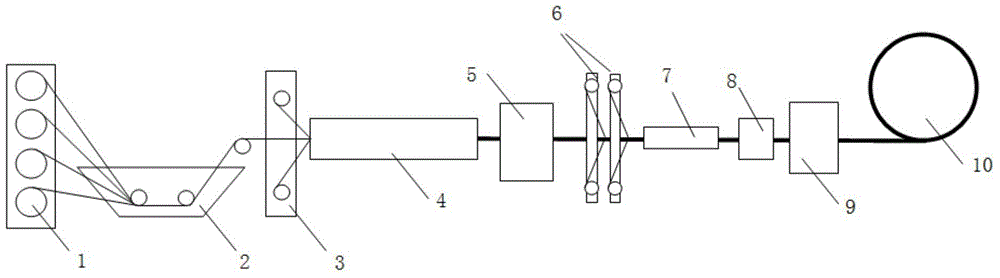

Process for preparing polyoxymethylene homo- and copolymers and apparatus suitable for this purpose

Process for preparing polyoxymethylene homo- and copolymers and apparatus suitable for this purpose An apparatus is described for preparing polyoxymethylene homo- and copolymers. This has the following elements: A) reactor (1) encompassing a polymerization zone (2) and a deactivation zone (3) directly downstream thereof for polymerizing and deactivating polyoxymethylene homo- and copolymers in a homogeneous phase in a manner known per se, B) depressurizing assembly (4), which, if appropriate, has a metering apparatus (5) for additives for the polymer, C) pelletizer (6), D) extraction apparatus (7), and E) if appropriate, a drying apparatus (8). Use of the apparatus and of the polymerization process carried out therein can achieve particularly low residual monomer contents in a simple manner which saves energy.

Owner:TICONA GMBH

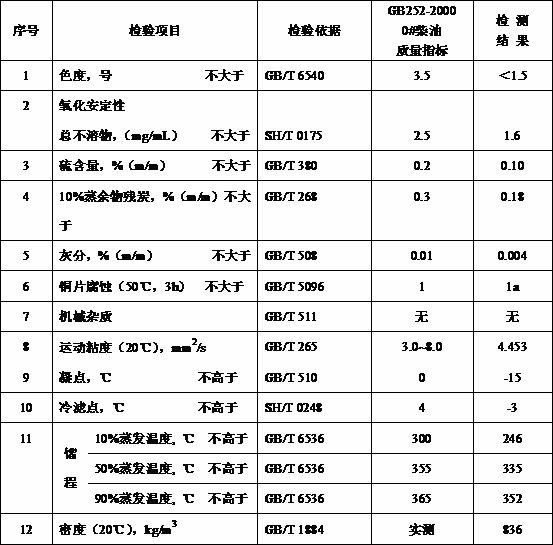

Method for preparing novel clean synthetic diesel oil

The invention relates to a method for preparing novel clean synthetic diesel oil and mainly solves the problems that the conventional diesel oil is low in cetane number and is combusted insufficiently in an engine, and a large amount of solid pollutant, COx and NOx are discharged. The method mainly comprises the following steps of: uniformly mixing 5 to 30 mass percent of diesel oil substitute component, 5 to 30 mass percent of additive and 40 to 90 mass percent of diesel oil at normal temperature, standing for 8 to 10 hours, and after liquid is clarified, canning to obtain the novel clean synthetic diesel. The diesel oil substitute component is polyformaldehyde dimethyl ether, methylal or mixture of polyformaldehyde dimethyl ether and methylal in any ratio. By the method, the combustion efficiency of the synthetic diesel oil is improved, the discharge of free carbon and harmful gas is reduced, the quality of the synthetic diesel oil is improved, cost is reduced, a novel way from coal to oils is developed, and the method has good social and economic benefit. The novel clean synthetic diesel oil can be used independently and can also be mixed with petroleum diesel oil to be used, and the engine is not needed to be changed.

Owner:HENAN COAL CHEM IND GROUP INST

Polyoxymethylene resin composition and moldings thereof

InactiveUS20070129484A1Increase flexibilityExcellent vibration-dampingFilm/foil adhesivesPolyolefinPolymer chemistry

A polyoxymethylene resin composition which comprises (A) a polyoxymethylene resin, (B) a polymer having at least one block made of a hydrogenated aromatic vinyl / conjugated diene random copolymer having the main dispersion peak of tan δ at 60° C. or below in the viscoelastic spectrum, and, if necessary, (C) a polyolefin resin with the provisos that the amount of (A) is 10 to 99.5 parts by weight and the total amount of (B) and (C) is 0.5 to 90 parts by weight, each per 100 parts by weight of the sum of (A), (B) and (C) and that the (B) / (C) weight ratio is 100 / 0 to 20 / 80.

Owner:ASAHI KASEI CHEM CORP

Reinforced and toughened polyformaldehyde and preparation method thereof

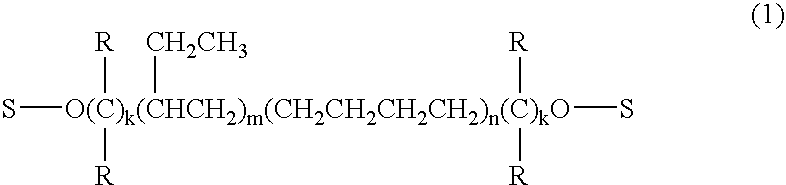

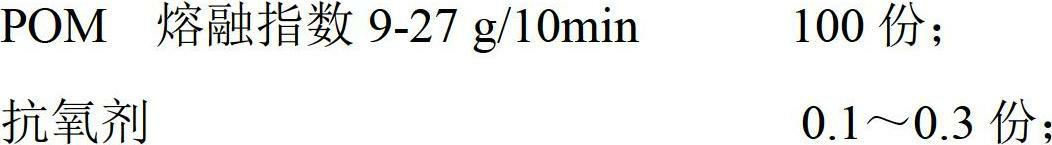

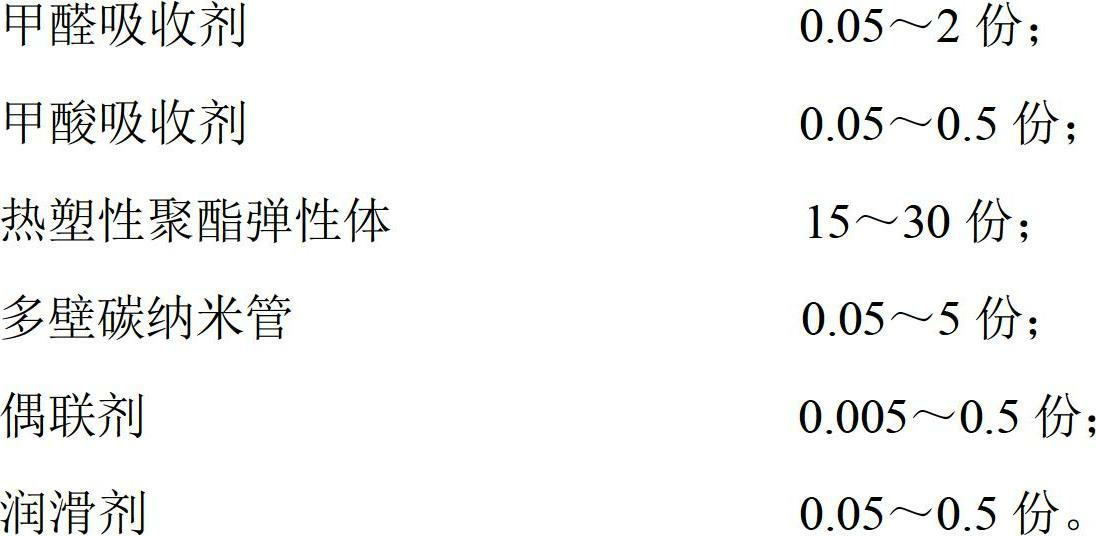

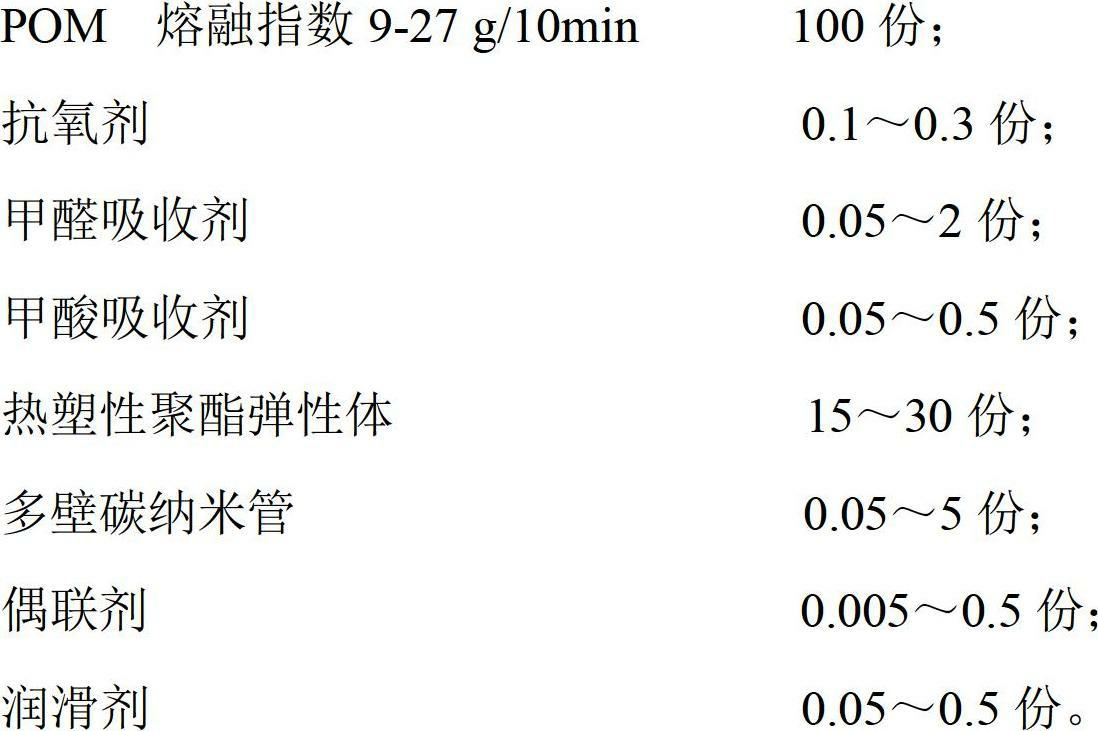

The invention discloses reinforced and toughened polyformaldehyde, which is prepared from the following components through a preparation method comprising the following steps: adding 10 parts of POM (polyoxymethylene) resin, 0.1-0.3 part of antioxidant, 0.05-2 parts of formaldehyde absorber, 0.05-0.5 part of formic acid absorber, 15-30 parts of thermoplastic polyester elastomer, 0.05-5 parts of functionalized multi-wall carbon nano tube subjected to surface treatment and 0.05-0.5 part of lubricant into a high-speed mixer and mixing, melting and mixing by an exhaust type double-screw extruder, extruding and pelleting to obtain the reinforced and toughened polyformaldehyde, wherein a rotating speed of screws is 50-200 revolutions per minute, and temperature of a charging barrel is 140-220 DEG C. The thermoplastic polyester elastomer with higher heat stability and excellent strength and toughness is adopted, and the functionalized multi-wall carbon nano tube with higher length-diameter ratio and better compatibility with a POM matrix, is composited with the POM so as to realizing reinforcing and toughening for the POM, so that a notch impact strength of the polyformaldehyde reaches about 25 KJ / m<2>, and a higher tensile strength is kept and reaches 41-45 MPa.

Owner:YANKUANG GRP CO LTD

Abrasion-resisting reinforced polyformaldehyde alloy material and preparation method thereof

The invention relates to an abrasion-resisting reinforced polyformaldehyde alloy material and a preparation method thereof. According to the material, both the abrasive resistance and other rigidity indexes such as strength of extension and flexural strength of polyformaldehyde are improved, and furthermore, the thermal defomation temperature of the polyformaldehyde is improved greatly. A formulaof the material comprises the following compositions: 100 parts of polyformaldehyde, 5-35 parts of chopped glass fiber, 0-5 parts of surface treating agent, 3-20 parts of polytetrafluoroethylene, 0-1part of antioxygen, 0-1 part of methanal absorbent and 0-1 part of lubricating agent. The preparation method comprises the following steps of mixing by a high-speed mixer and extruding and granulating by twin screws. The alloy material has an excellent mechanical property and an abrasion resistance, and furthermore has a higher thermal deformation temperature, so that the material can be used in a high temperature environment; and the material can be used for producing bars, plates, gears, bearings and the like which have demands on high abrasion resistance, high strength and high heat resistance.

Owner:上海蓝星聚甲醛有限公司

Medical device incorporating a polymer blend

A catheter including a catheter shaft formed from a polymer blend and / or a braid. The polymer blend may include polyoxymethylene added in the dispersion phase to a polymer blend. The catheter braid can be formed from at least two continuous wires that are woven together. The catheter braid can include a proximal braid section and a distal braid section. Each of the continuous wires has a proximal diameter corresponding to the proximal braid section and a distal diameter corresponding to the distal braid section. The distal diameter of each wire can be less than the proximal diameter of that wire. A catheter braid so formed can be included in a catheter.

Owner:BOSTON SCI SCIMED INC

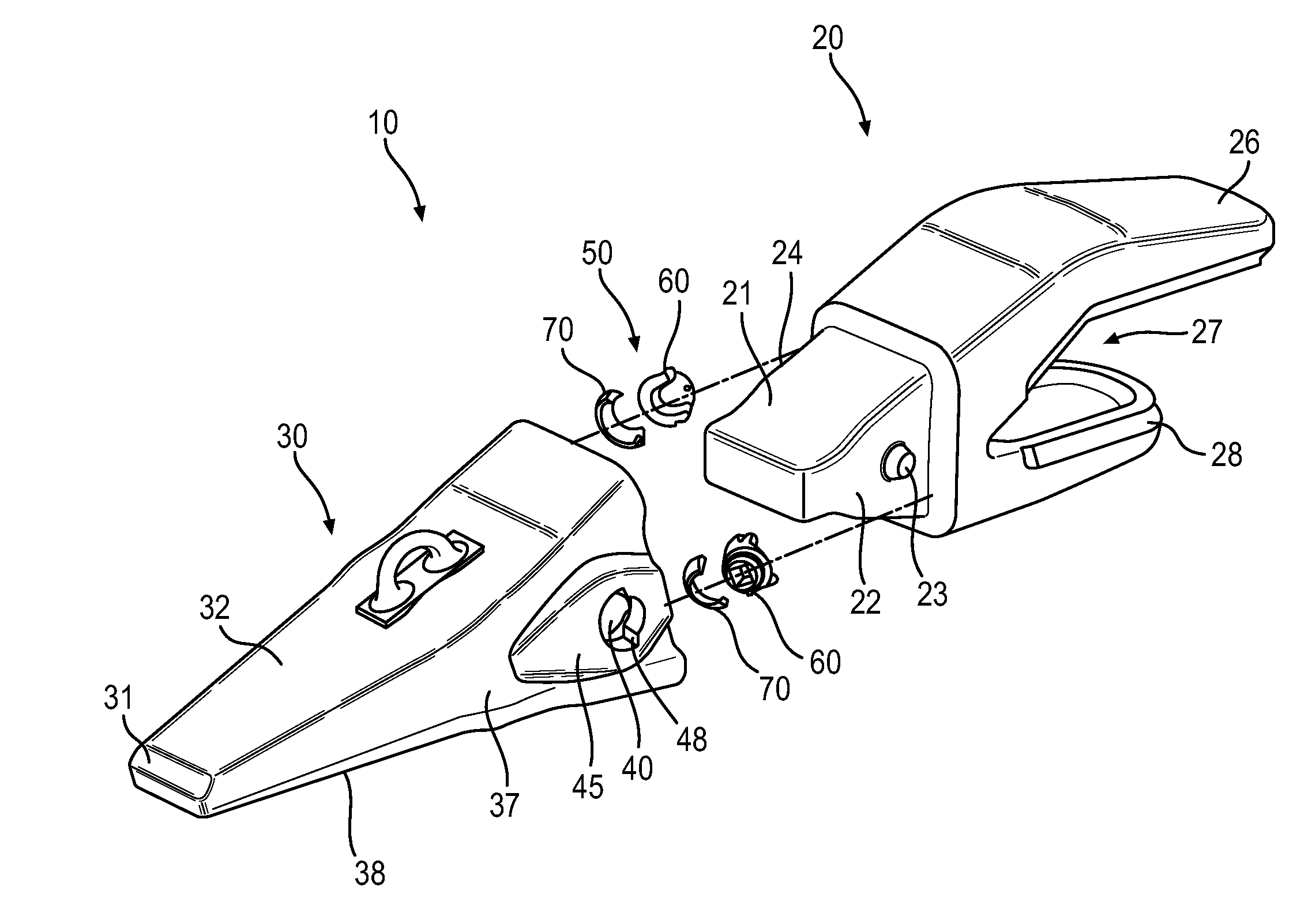

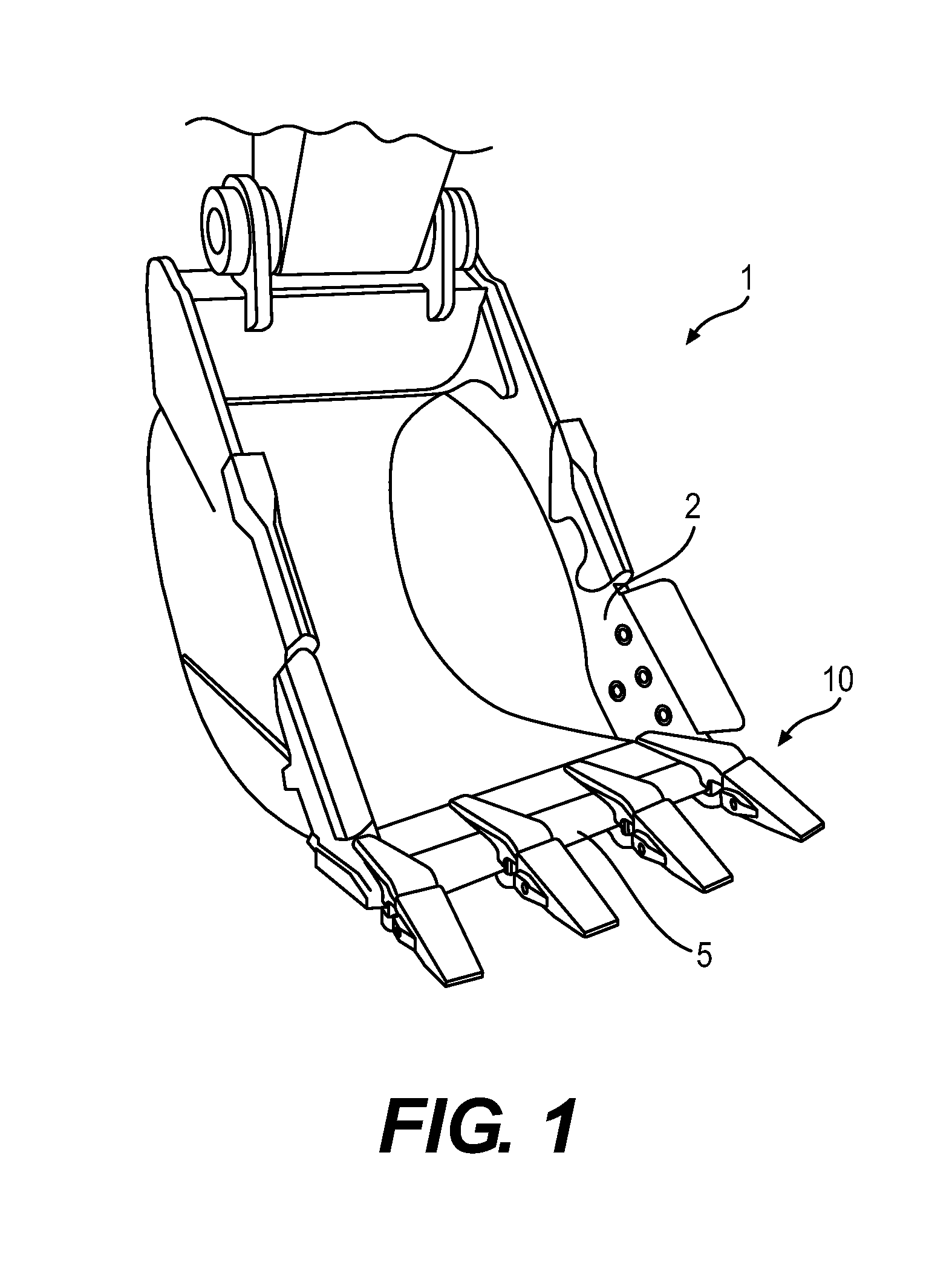

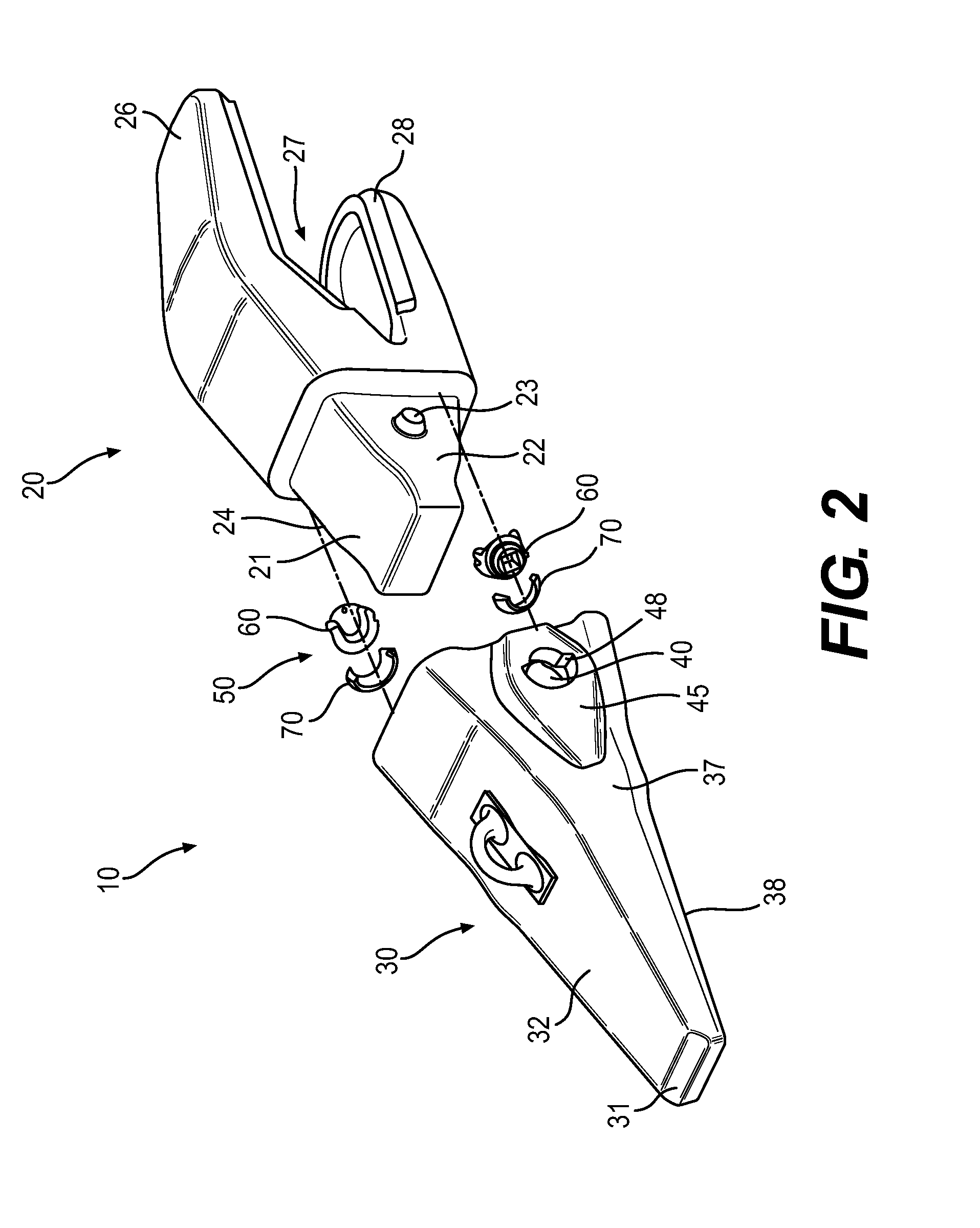

Retainer systems for ground engaging tools

Disclosed are various exemplary embodiments of a retainer bushing for use with a lock of a ground engaging tool. The retainer bushing may include a skirt extending around a retainer axis, where the skirt may include an outer surface configured to mate with a lock cavity of the ground engaging tool and an inner surface configured to rotatably receive an outer surface of the lock. The retainer bushing may also include a detent projection extending radially inward from the inner surface and configured to engage a detent recess of the lock to resist rotation of the lock. The skirt and the detent projection may be integrally constructed of a thermoplastic material comprising polyoxymethylene.

Owner:CATERPILLAR INC

Polyformaldehyde composition and preparation method thereof

The invention discloses a polyformaldehyde composition and a preparation method thereof. The polyformaldehyde composition contains by part of weight: 100 parts of acetal resins, 0.01-2 parts of oxidation inhibitors, 0.01-2 parts of formaldehyde catching agents, 0.01-2 parts of formic acid catching agents and 0.01-5 parts of crosslinking acetal resins. Compared with the prior art, the crosslinking acetal resins serve as nucleating agents and are obvious in nucleating effects, and a great number of crystal nucleuses are formed before crystallization of the acetal resins, so that crystallization of the acetal resin is induced, the number of the crystal nucleuses is improved, crystallization degree and temperature are improved, sphaerocrystal dimension is lowered, and accordingly crystallization structure of the acetal resin is improved. Further, due to the fact that the adding amount of the crosslinking acetal resins is small, and bad influence on mechanical property, thermal performance and surface morphology of the polyformaldehyde composition is avoided. Experiment results prove that the sphaerocrystal dimension of the polyformaldehyde composition is about 40 mu m, and the polyformaldehyde composition has good crystalline structure and good mechanical property.

Owner:YUNNAN YUNTIANHUA

Method for preparation of polyoxymethylene dimethyl ether from paraformaldehyde

InactiveCN102964227ARealize industrial productionImprove stabilityOrganic chemistryOrganic compound preparationPolyoxymethyleneMolecular sieve

The invention relates to a method for preparation of polyoxymethylene dimethyl ether from paraformaldehyde, in particular to a method for preparation of polyoxymethylene dimethyl ether in the presence of an acidic resin catalyst and separation of polyoxymethylene dimethyl ether. The method adopts methylal and paraformaldehyde as raw materials to prepare polyoxymethylene dimethyl ether under mild reaction conditions. The reaction product is first subjected to molecular sieve adsorption, then to a reaction with an alkaline substance, and further to atmospheric and vacuum distillation so as to separate low-boiling point by-products and polyoxymethylene dimethyl ether (DMM3-8) as well as higher polymerization degree polyoxymethylene dimethyl ether (DMMn, with n being larger than 8), wherein the low-boiling point part and the high-boiling point part further react to prepare polyoxymethylene dimethyl ether. The separated polyoxymethylene dimethyl ether (DMM3-8) product can be directly used as a component for co-combustion with diesel.

Owner:CHINA NAT OFFSHORE OIL CORP +1

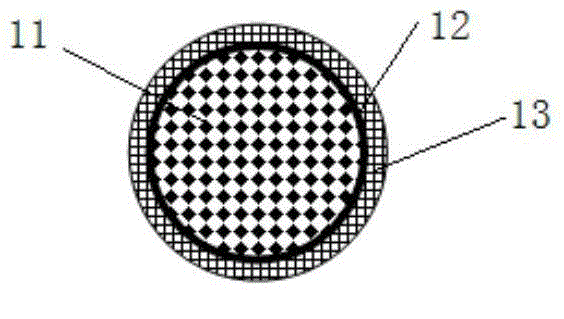

Sucker rod with composite spiral abrasion-resistant layer, manufacturing device and manufacturing method

ActiveCN105003209AImprove partial wear resistanceResilientDrilling rodsDrilling casingsResin matrixPolyamide

The invention discloses a sucker rod with a composite spiral abrasion-resistant layer, a manufacturing device and a manufacturing method. The abrasion-resistant layer made of fiber reinforced thermoplastic resin-matrix composite materials covers the surface of the sucker rod, reinforced fibers of the abrasion-resistant layer are aramid fibers or ultrahigh molecular weight polyethylene fibers, resin matrixes of the abrasion-resistant layer are made of one of polyethylene, polyamide, polyphenyl ether, polysulfone, polyphenylene sulfide, polytetrafluoroethylene, polyoxymethylene or polyether ether ketone; the reinforced fibers can be wound on the surface of the sucker rod in such a manner that narrow bands made of two-dimensional fabrics are wound on the surface of the sucker rod. The sucker rod, the manufacturing device and the manufacturing method have the advantages that the sucker rod with the structure is excellent in deflection abrasion resistance, the abrasion-resistant layer on the surface of the sucker rod has certain toughness and strength, the problem of crack in sucker rod winding procedures due to poor mechanical properties of pure thermoplastic resin can be solved, micro-pore meshed structures are subjected to strong interface bonding owing to the self-protection layer made of the thermoplastic composite materials and a sucker rod body, and the self-protection abrasion-resistant layer can be prevented from slipping and layering from the surface of the sucker rod.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com