Polyformaldehyde composition and preparation method thereof

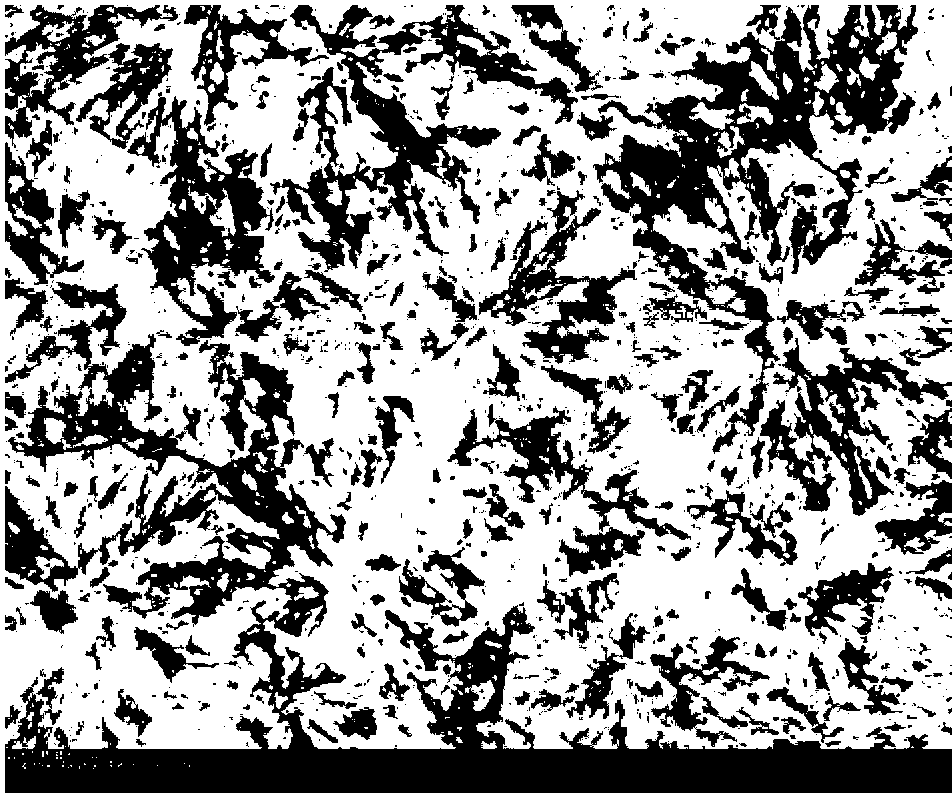

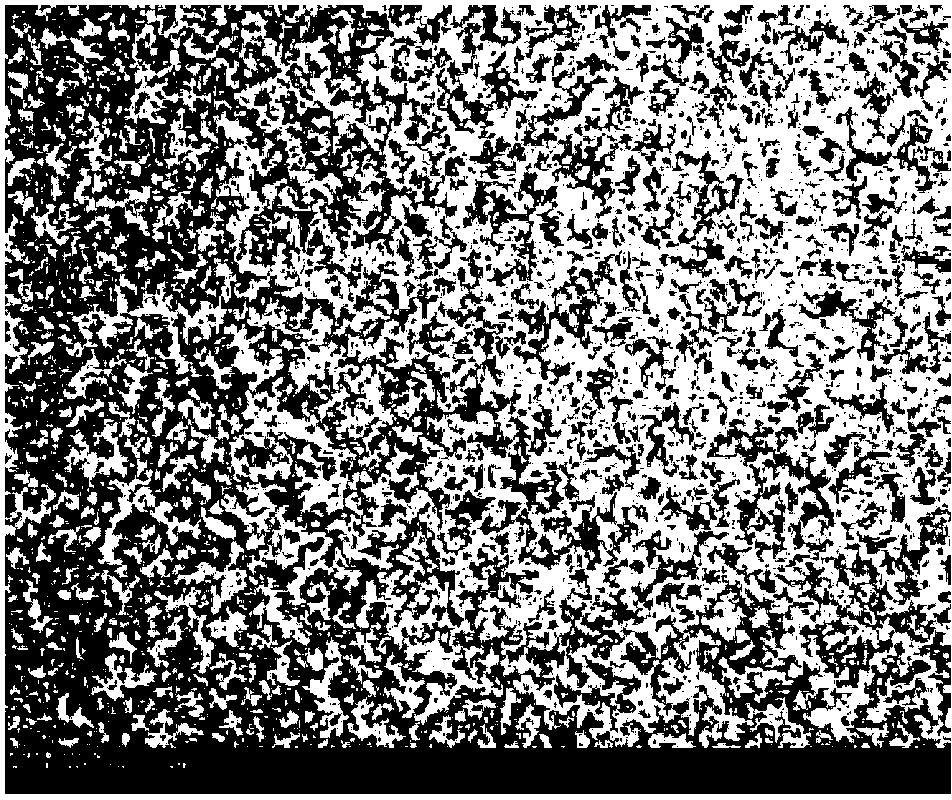

The technology of a polyoxymethylene composition and a polyoxymethylene resin is applied in the field of polyoxymethylene composition and its preparation, which can solve the problems of poor toughness, brittle material, and difficulty in demolding of polyoxymethylene materials, so as to improve crystal structure and reduce spherulites. Size, nucleation effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Correspondingly, the present invention also provides a preparation method of a polyoxymethylene composition, comprising the following steps: mixing 100 parts by weight of a polyoxymethylene resin, 0.01 to 2 parts by weight of an antioxidant, 0.01 to 2 parts by weight of a formaldehyde scavenger, 0.01-2 parts by weight of formic acid scavenger and 0.01-5 parts by weight of cross-linked polyoxymethylene resin are melted in a twin-screw extruder at 160-250° C., and the polyoxymethylene composition is obtained after extrusion.

[0039] The present invention takes polyoxymethylene resin, antioxidant, formaldehyde scavenger, formic acid scavenger and cross-linked polyoxymethylene resin as preparation raw materials, wherein, the polyoxymethylene resin is -[CH 2 O]-homopolyoxymethylene as the main repeating unit or -[CH 2 O]-and-[CH 2 -CH 2 O]-copolyoxymethylene as the main repeating unit. The melt index of the polyoxymethylene resin under standard conditions is preferably 1...

Embodiment 1

[0054] 100 parts by weight of polyoxymethylene, 2450.3 parts by weight of antioxidant, 0.05 parts by weight of melamine, 0.1 part by weight of calcium stearate, 0.1 part by weight of cross-linked polyoxymethylene, and 0.05 parts by weight of nano-calcium carbonate are prepared in proportion, and placed in a high-mixer Stir in medium for 3 minutes and use twin-screw extruder to extrude and granulate to obtain polyoxymethylene composition. The specific processing technology is: temperature: 175°C in zone 1, 180°C in zone 2, 185°C in zone 3, 190°C in zone 4, 190°C in zone 5 Zone 190°C, Zone 6 190°C, Zone 7 190°C, Zone 8 190°C, Zone 9 190°C, Machine Head 190°C; Feeding speed 15; Screw speed 200.

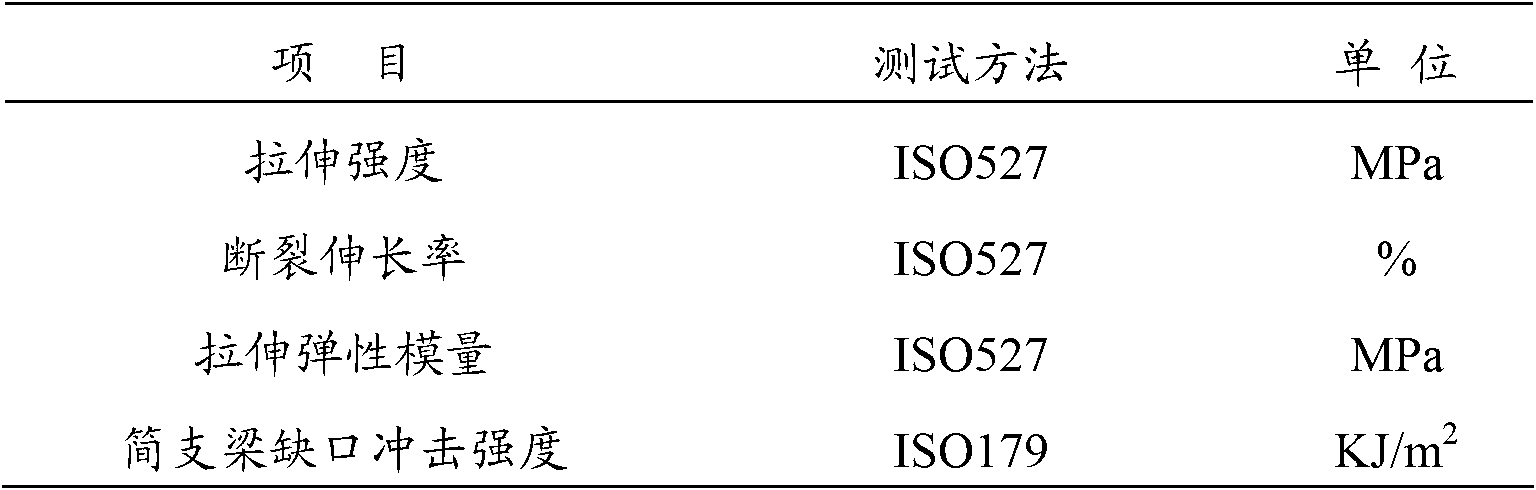

[0055] The properties of the polyoxymethylene composition prepared in this example were tested for tensile strength, tensile modulus, elongation at break, notched impact and 5% weight loss time, and the results are shown in Table 2.

[0056] The polyoxymethylene composition prepared in t...

Embodiment 2

[0058] 100 parts by weight of polyoxymethylene, 2450.3 parts by weight of antioxidant, 0.05 parts by weight of melamine, 0.1 part by weight of calcium stearate, 0.1 part by weight of cross-linked polyoxymethylene, and 0.05 parts by weight of nano-calcium carbonate are prepared in proportion, and placed in a high-mixer Stir in medium for 3 minutes and use twin-screw extruder to extrude and granulate to obtain polyoxymethylene composition. The specific processing technology is: 1 zone 195°C, 2 zone 200°C, 3 zone 205°C, 4 zone 210°C, 5 zone 210 ℃, the sixth zone is 210°C, the seventh zone is 210°C, the eighth zone is 210°C, the ninth zone is 210°C, the head is 210°C; the feeding speed is 15; the screw speed is 200.

[0059] The properties of the polyoxymethylene composition prepared in this example were tested for tensile strength, tensile modulus, elongation at break, notched impact and 5% weight loss time, and the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com