Soft high-temperature-resistant polypropylene foam material and preparation method thereof

A technology of foaming material and polypropylene, which is applied in the field of soft high-temperature-resistant polypropylene foaming material and its preparation, and can solve problems such as poor mechanical strength, few nucleation sites, and poor microporous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

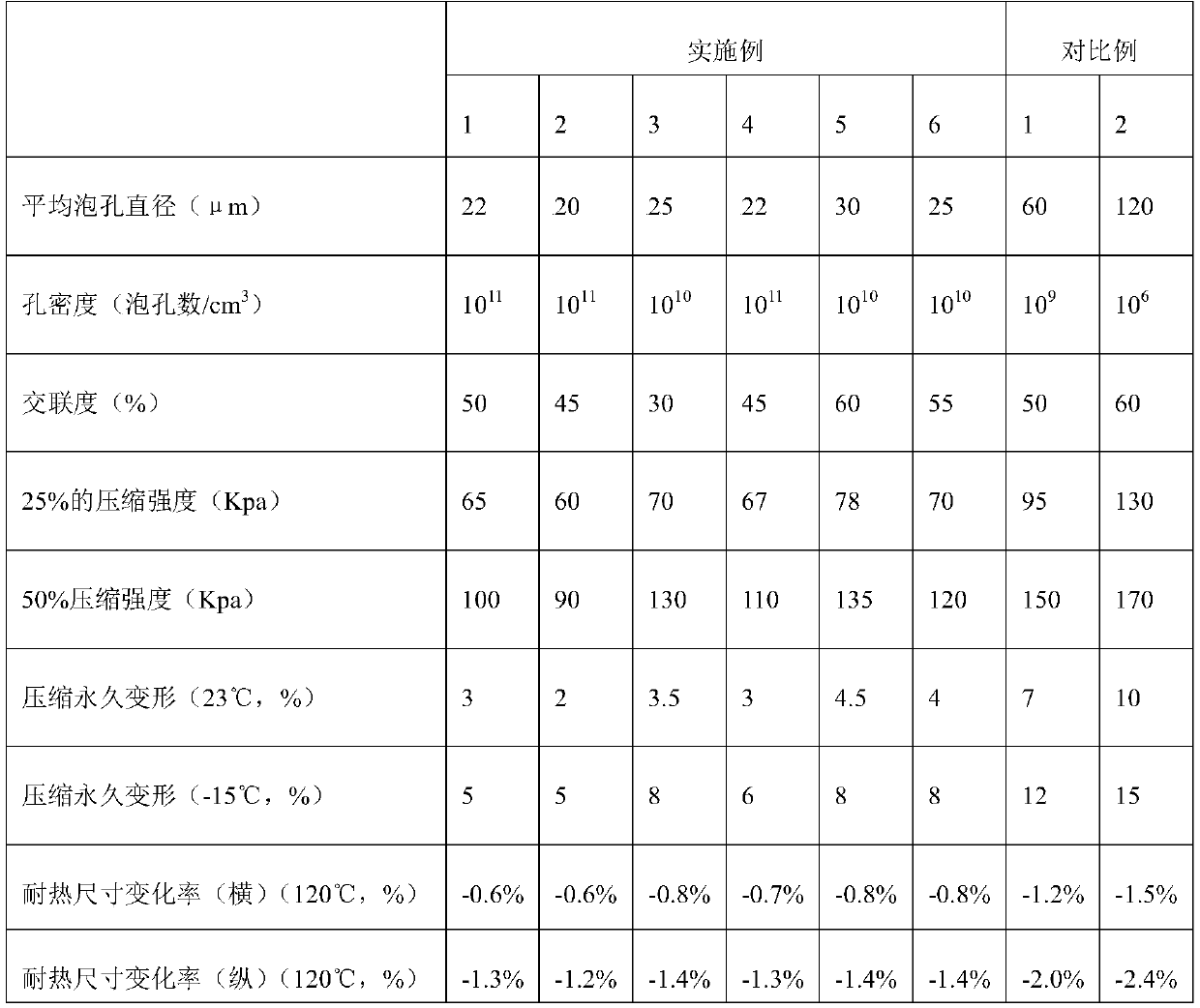

Examples

Embodiment 1

[0030] Polypropylene foam sheet 1 component and weight ratio:

[0031] Copolymer polypropylene 100 copies Polyolefin Block Copolymer Resin 15 copies High-density polyethylene 10 copies Foaming agent 2 copies low molecular weight polytetrafluoroethylene 2 copies

[0032] The melt index MI of the copolymerized polypropylene resin is 5g / 10min, the test condition (190°C / 2.16KG), the softening temperature is 180°C, the melt index MI of the polyolefin block copolymer resin is 1g / 10min, and the soft segment content is 30%. The blowing agent is azodicarbonamide (AC), the particle size is 15nm, the gas generation capacity of the blowing agent is 280ml / g, the low molecular weight polytetrafluoroethylene is 2 parts, and the particle size is 2μm.

[0033] The preparation method of polypropylene foam sheet 1:

[0034] 1) take by weighing polypropylene resin, polyolefin block copolymer resin, high-density polyethylene resin, blowing agent and low ...

Embodiment 2

[0039] Polypropylene foam sheet 2 components and weight ratio:

[0040] Copolymer polypropylene 100 copies Polyolefin Block Copolymer Resin 14 copies High-density polyethylene 9 servings Foaming agent 2 copies low molecular weight polytetrafluoroethylene 1.5 servings

[0041] The melt index MI of the copolymerized polypropylene resin is 1.5g / 10min, the test condition (190°C / 2.16KG), the softening temperature is 140°C, the melt index MI of the polyolefin block copolymer resin is 1.2g / 10min, and the soft segment content is 22 %, the blowing agent is azodicarbonamide (AC), the particle size is 10nm, the gas generation amount of the blowing agent is 240ml / g, and the particle size of low molecular weight polytetrafluoroethylene particles is 3 μm.

[0042] The preparation method of polypropylene foam sheet 2:

[0043]1) take by weighing polypropylene resin, polyolefin block copolymer resin, high-density polyethylene resin, blowing agent an...

Embodiment 3

[0048] 3 components and weight ratio of polypropylene foam sheet:

[0049] Copolymer polypropylene 100 copies Polyolefin Block Copolymer Resin 12 copies High-density polyethylene 8 servings Foaming agent 1 copy low molecular weight polytetrafluoroethylene 3 copies

[0050] Copolymer polypropylene resin melt index MI is 3g / 10min, test conditions (190°C / 2.16KG), softening temperature is 130°C, polyolefin block copolymer resin melt index MI is 1.5g / 10min, soft segment content is 10% , the blowing agent is azodicarbonamide (AC), the particle size is 4nm, the gas generation capacity of the blowing agent is 220ml / g, and the particle size of low molecular weight polytetrafluoroethylene particles is 4μm.

[0051] The preparation method of polypropylene foam sheet 3:

[0052] 1) take by weighing polypropylene resin, polyolefin block copolymer resin, high-density polyethylene resin, blowing agent and low molecular weight polytetrafluoroethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com