Patents

Literature

1025 results about "Azodicarbonamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Azodicarbonamide, ADCA, ADA, or azo(bis)formamide, is a chemical compound with the molecular formula C₂H₄O₂N₄. It is a yellow to orange-red, odorless, crystalline powder. It is sometimes called a 'yoga mat' chemical because of its widespread use in foamed plastics. It was first described by John Bryden in 1959.

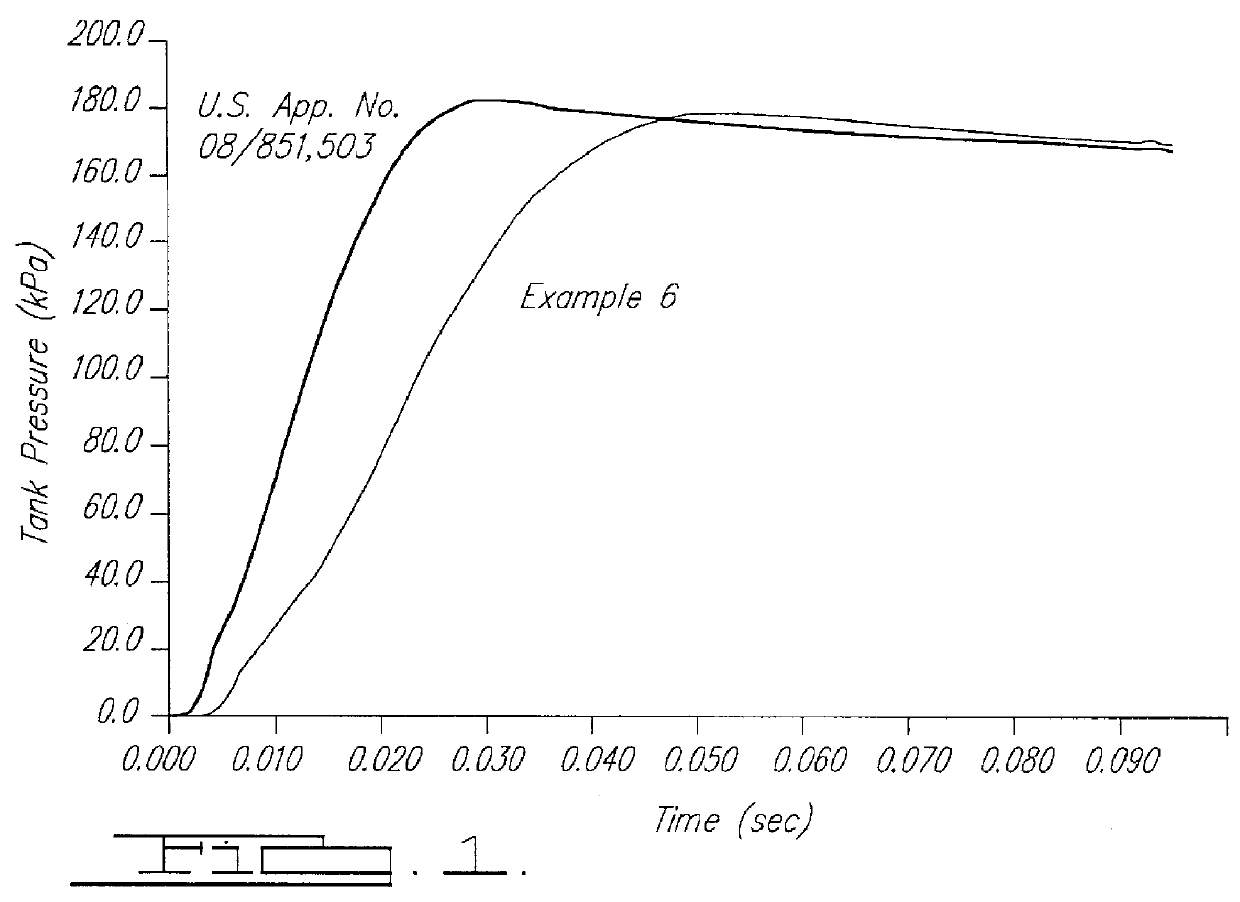

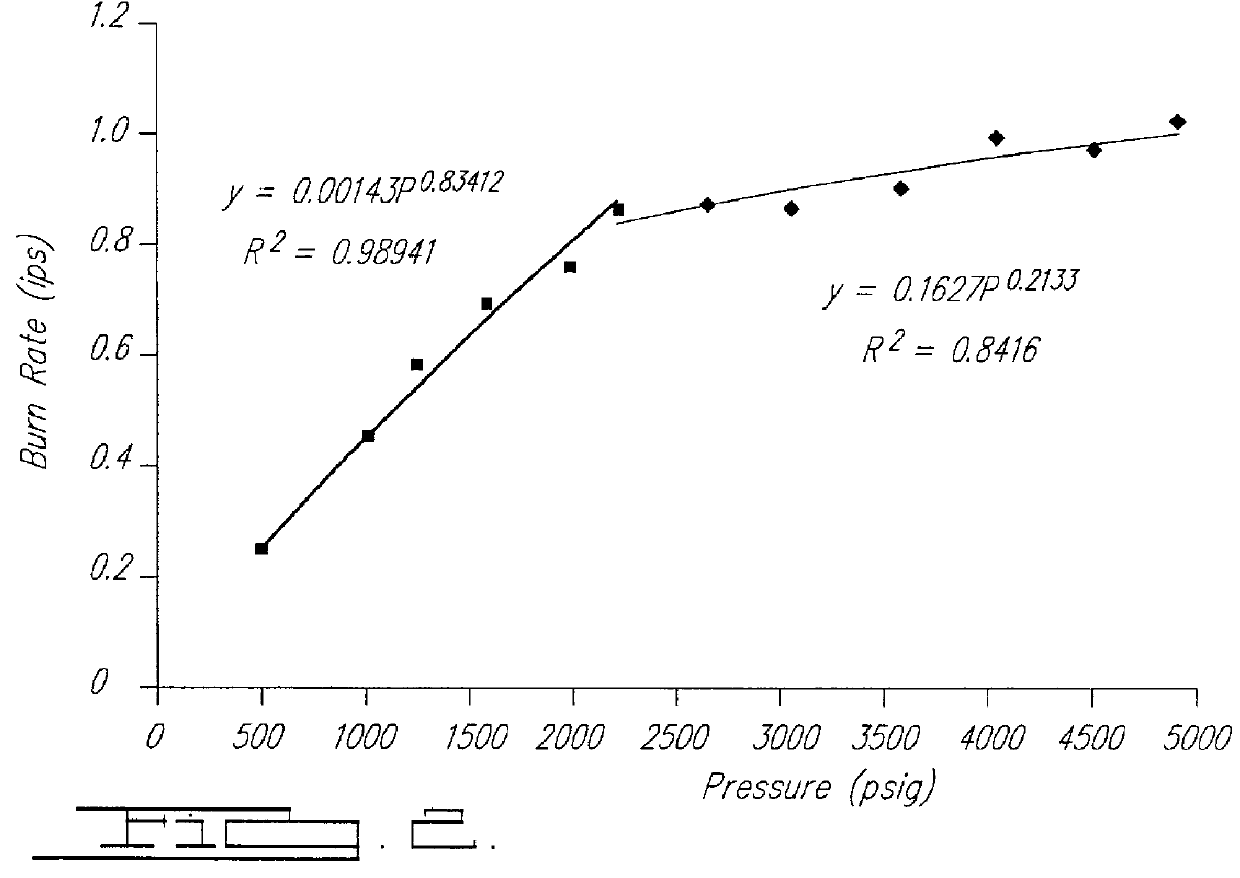

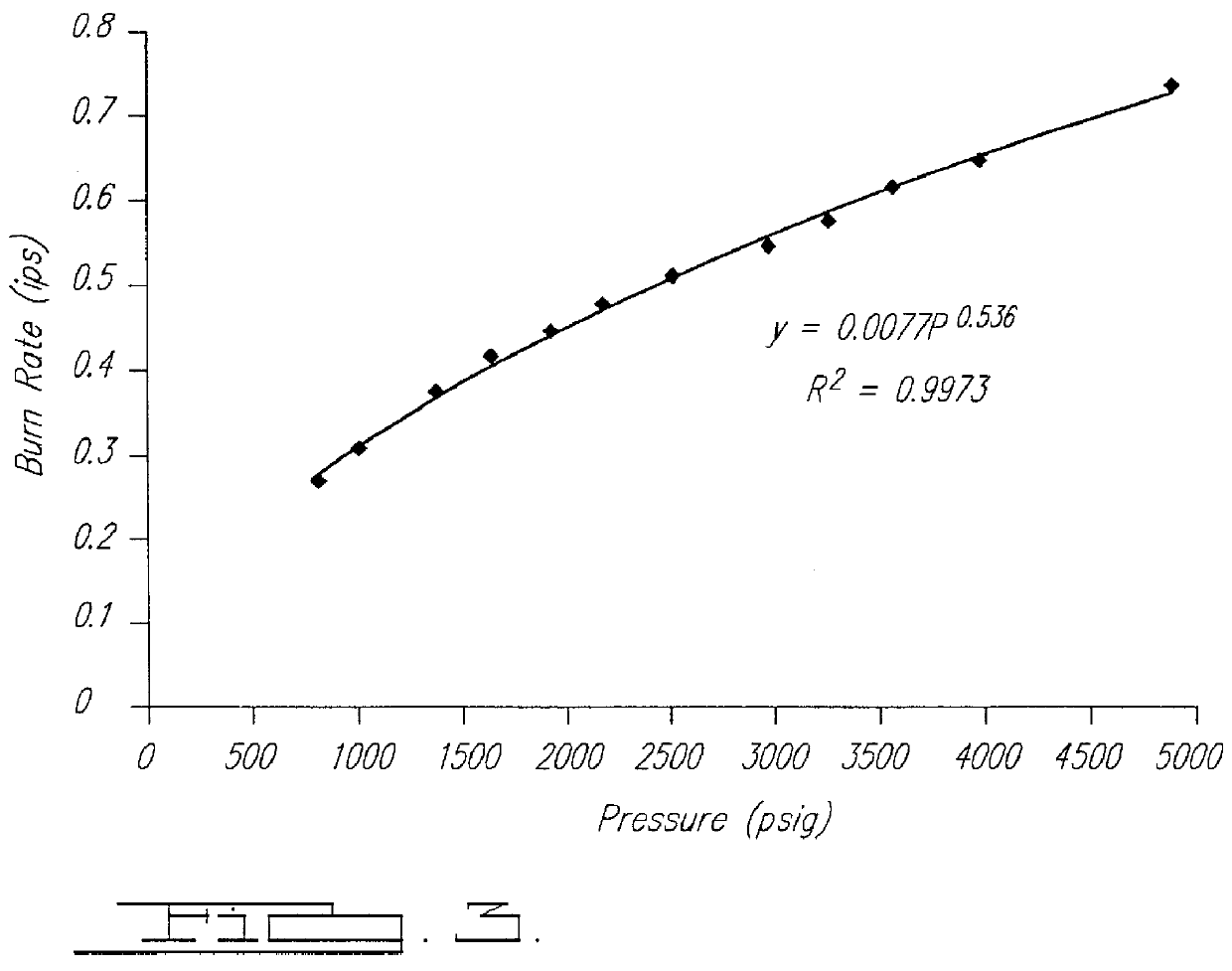

Smokeless gas generant compositions

Thermally stable gas generant compositions incorporate a combination of one or more primary nonazide high-nitrogen fuels selected from a group including tetrazoles, bitetrazoles, and triazoles, and salts thereof; and one or more secondary nonazide high nitrogen fuels selected from azodicarbonamide and hydrazodicarbonamide. The primary and secondary fuels are combined with phase-stabilized ammonium nitrate that when combusted, results in a greater yield of gaseous products per mass unit of gas generant, a reduced yield of solid combustion products, lower combustion temperatures, and acceptable burn rates, thermal stability, and ballistic properties. These compositions are especially suitable for inflating air bags in passenger-restraint devices.

Owner:AUTOMOTIVE SYST LAB

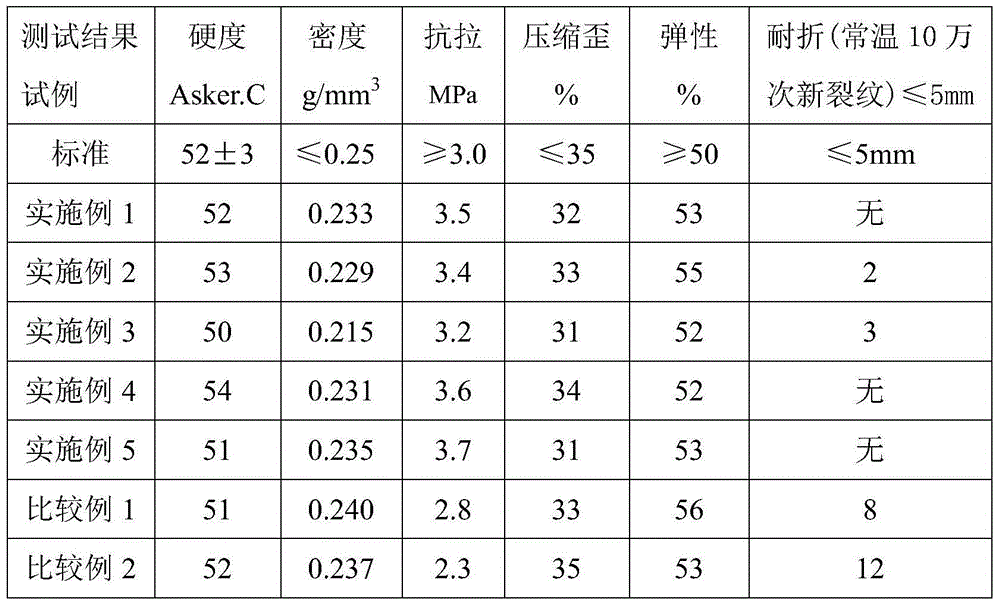

Wear-resisting anti-slip mountaineering sole material and preparation method thereof

The invention discloses a wear-resisting anti-slip mountaineering sole material which is characterized by being prepared from the following components in percentage by mass: 25-30% of natural rubber, 10-20% of butadiene rubber, 20-25% of butadiene styrene rubber, 5-10% of an ethylene-vinyl acetate copolymer, 5-10% of a modified starch polymer, 1-3% of short fibers, 5-10% of carbon black, 5-10% of white carbon black (SiO2), 2-3% of stearic acid (SA), 3-5% of zinc oxide, 2-3% of tert-thio disilane (Si-69), 2-5% of sulfur (S), 1-3% of a filling agent, 0.5-0.8% of zinc stearate, 0.5-0.8% of diisopropylbenzene peroxide, 0.3-0.5% of azodicarbonamide, 2-3% of an active agent, 0.5-2.5% of a coupling agent, 0.8-1.0% of an accelerant and 1-2% of an anti-aging agent. The wear-resisting anti-slip mountaineering sole material is outstanding in water absorption property and moisture releasability; the prepared sole is low in hardness, good in flexibility and bending resistance, low in consumption, high in wear resistance and anti-tear property and good in elasticity and puncturing resistance; and the comfort and the security of mountaineering fitness exercise are improved; therefore, the wear-resisting anti-slip mountaineering sole material is wide in market application prospect.

Owner:朱伟萍

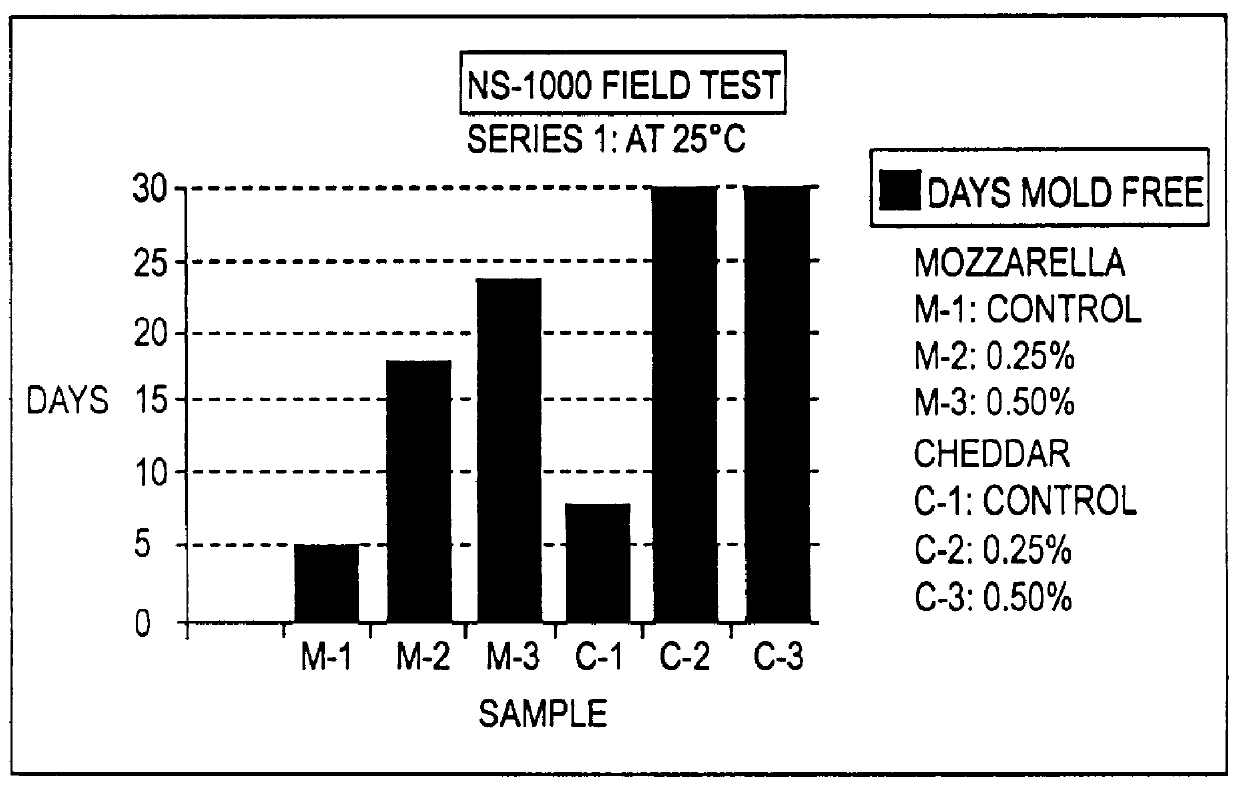

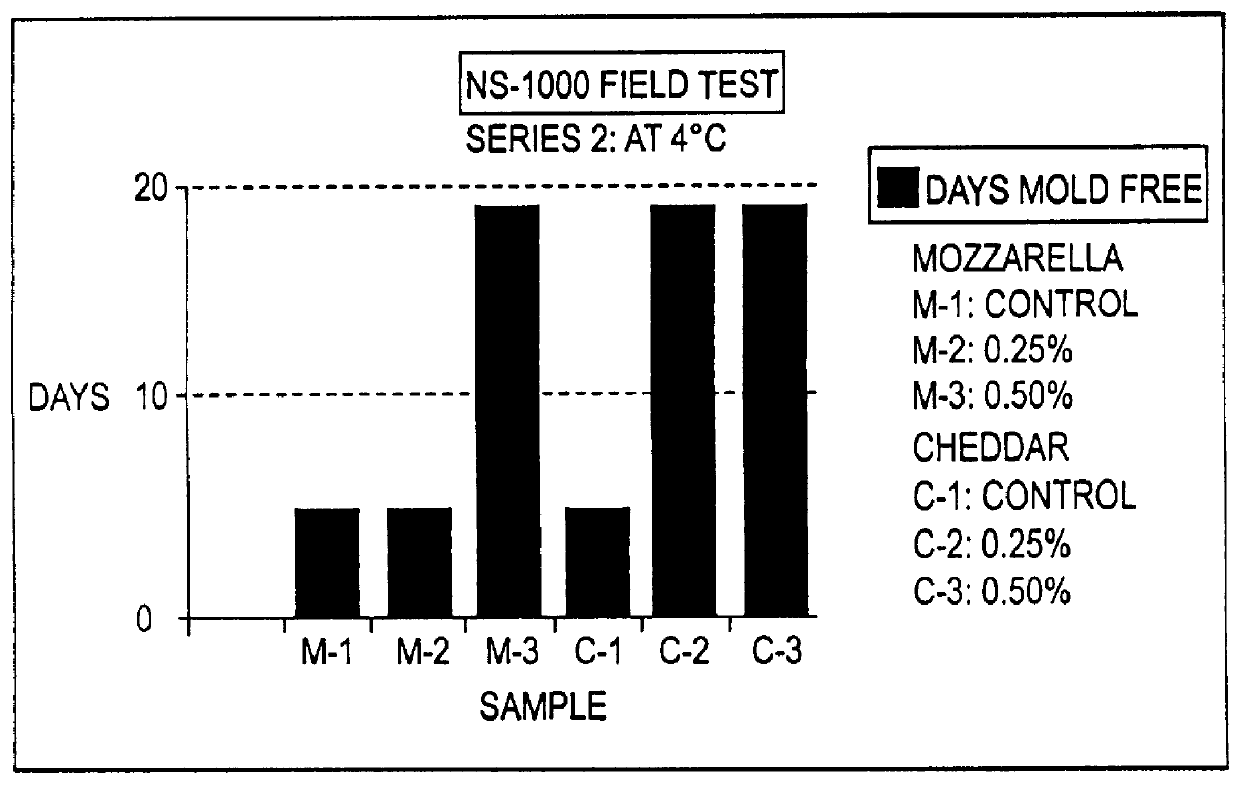

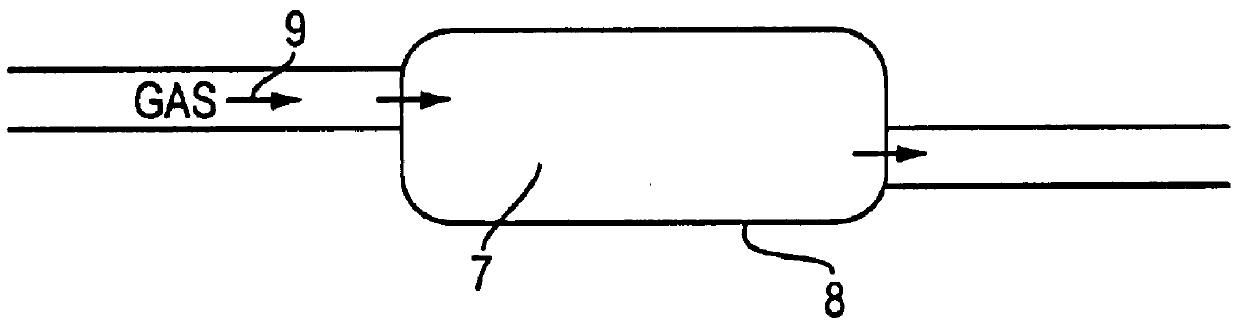

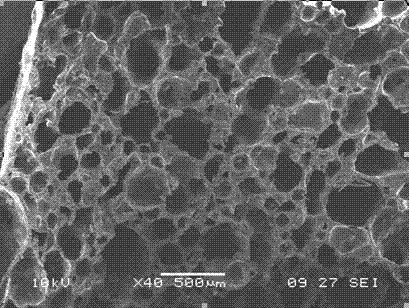

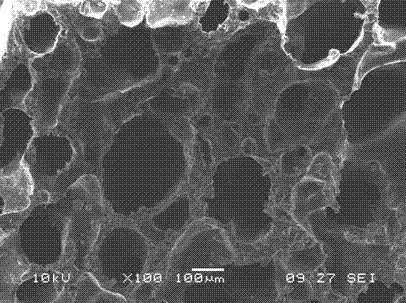

Methods of preparation and using antimicrobial products

InactiveUS6123973AEliminate bad tasteLower decomposition temperatureBiocideDough treatmentPropanoic acidSodium sorbate

Novel antimicrobial products and methods of making and using the same are shown, whereby the products can be used in the same or greater percentages as conventional microbial growth inhibitors without imparting an off-flavor, taste, color or odor to the products in which they are used. The antimicrobial products are formed by reacting azodicarbonamide or an ammonia gas with a compound selected from the group consisting of benzoic acid, sodium benzoate, calcium benzoate, potassium benzoate, acetic acid, sodium diacetate, paraben, niacin, calcium acetate, calcium diacetate, citric acid, lactic acid, fumaric acid, sorbic acid, sodium sorbate, calcium sorbate, potassium sorbate, propionic acid, sodium propionate, calcium propionate, potassium propionate and mixtures thereof. In one embodiment, the product is prepared by placing a layer of azodicarbonamide on a substrate and covering the layer with a gas permeable separator. The antimicrobial compound is then added on top of the separator, and the combination is heated to form the final product. In another embodiment, the product is prepared by exposing the antimicrobial compound to an ammonia gas. The ammonia gas reacts with free acids in the antimicrobial compound to convert the free acids into ammonium salts, thereby eliminating off-flavor and off-odor of the resulting antimicrobial product. The antimicrobial products prepared according to the present invention are suitable for use in foodstuffs, sanitation products, cosmetics, pharmaceuticals, and so forth.

Owner:TILLIN

Ethylene propylene diene terpolymer sponge rubber and preparation method thereof

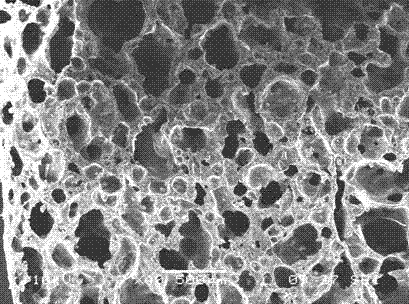

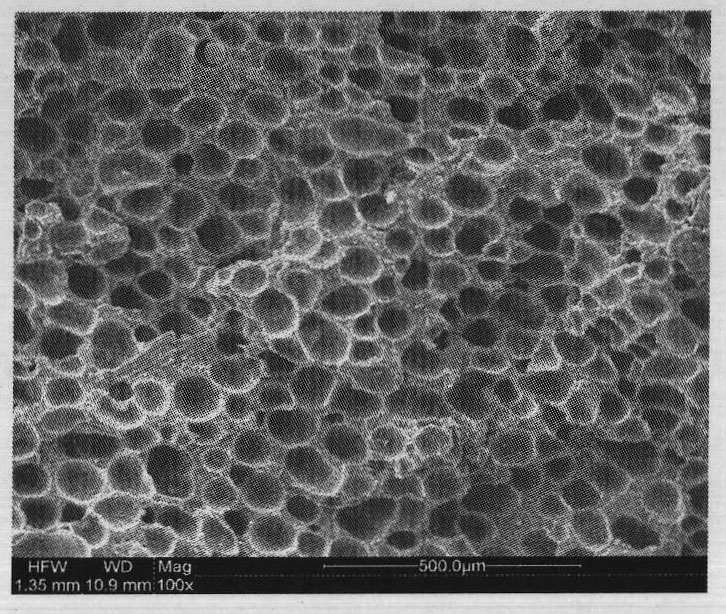

The invention provides an ethylene propylene diene terpolymer sponge rubber and a preparation method thereof, relating to a rubber and a preparation method thereof. The ethylene propylene diene terpolymer sponge rubber is prepared from ethylene propylene diene terpolymer, a foaming agent, a filling enhancer, a plasticizer, molecular sieve powder with a hygroscopic effect, a vulcanizing agent and a vulcanizing aid. The ethylene propylene diene terpolymer sponge rubber is characterized in that the molecular sieve powder is used for replacing traditional talc powder or calcium carbonate to be used as a filling agent, a foaming agent azobisformamide (AC) and a foaming agent 4,4'-oxy bis(benzenesulfonyl hydrazide) (OBSH) are combined and matched with an accelerant, and the decomposing rate of the foaming agent and the vulcanizing rate of the ethylene propylene diene terpolymer are matched, thus a microporous sponge rubber sealing product with a hygroscopic function is prepared under die pressing vulcanization conditions. The tensile strength, elongation percentage, stress at definite elongation, compression set and other indexes of the ethylene propylene diene terpolymer sponge rubber can meet the use performance requirements of sponge sealing strips; and at the same time, the sponge rubber has uniform foam pores, small density and hygroscopic function.

Owner:JINGDONG RUBBER

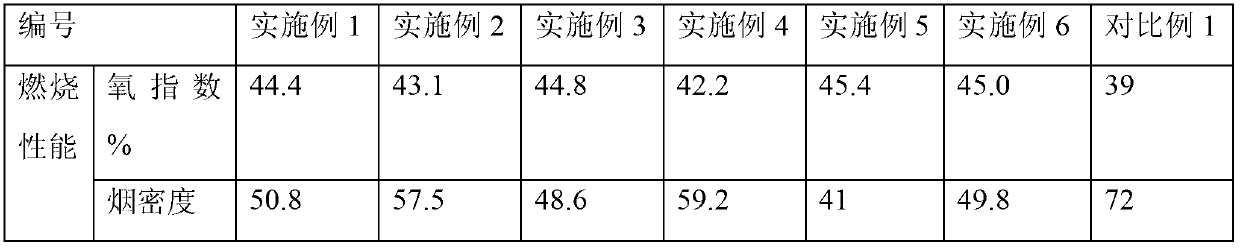

High flame retardancy type soft foam plastic insulation product and preparation method thereof

ActiveCN103102533AHigh oxygen indexImprove flame retardant performancePolyvinyl chloridePolyethylene glycol

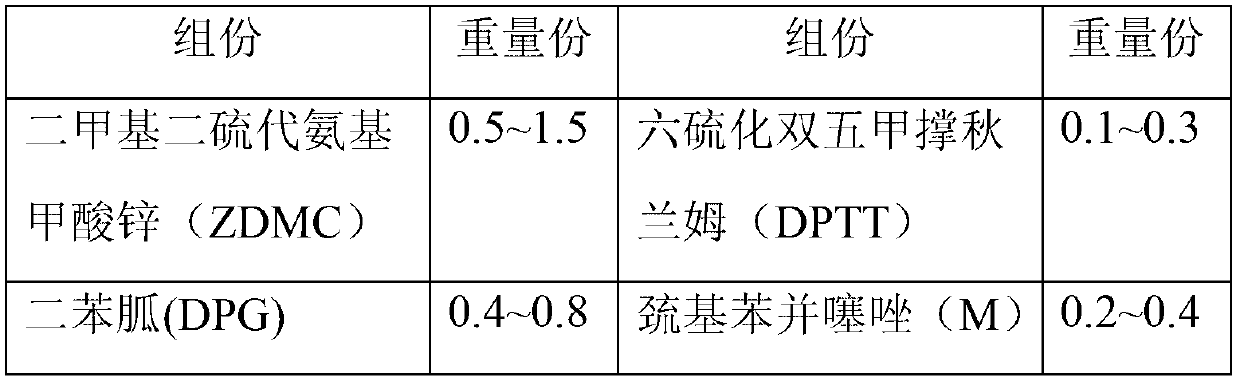

The invention provides a high flame retardancy type soft foam plastic insulation product and a preparation method thereof. The product comprises the following components in parts by weight: 12 to 15 parts of nitrile rubber, 8 to 10 parts of talcum powder, 0.5 to 0.8 parts of polyethylene glycol, 0.2 to 0.4 parts of antiager 4020, 15 to 20 parts of chlorinated paraffin, 0.6 to 0.9 parts of paraffin, 1 to 2 parts of epoxidized soybean oil, 0.1 to 0.3 parts of antiager RD, 0.4 to 0.7 parts of carbon black, 7 to 10 parts of polrvinyl chloride, 26 to 36 parts of fire retardant based on the total amount, 2 to 5 parts of dioctyl ester, 8 to 12 parts of azodicarbonamide, 0.2 to 0.5 parts of stearic acid, 0.4 to 0.7 parts of zinc oxide, 0.4 to 0.7 parts of sulphur, and 1.3 to 1.8 parts of accelerant based on the total amount. By adopting the high flame retardancy type soft foam plastic insulation product, the technical problem that the oxygen index and the smoke density are mutually conflicted in the technological manufacture is solved, and the bottleneck due to mutual limitation is broken through.

Owner:HEBEI HUAMEI CHEM & BUILDING MATERIALS GRP

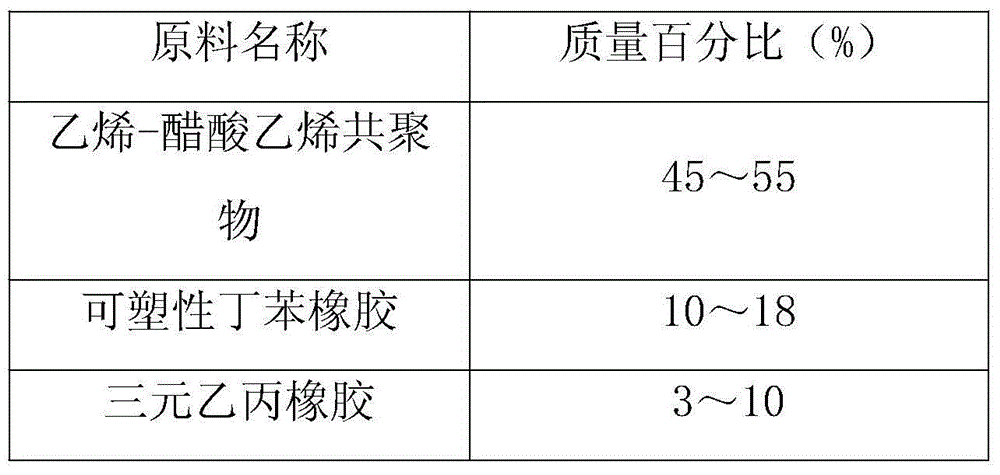

Super wear-resistant rubber foamed sport shoe material and preparation method thereof

InactiveCN104910507AImprove slip resistanceStrong slip resistanceSolesDomestic footwearPolymer scienceWear resistant

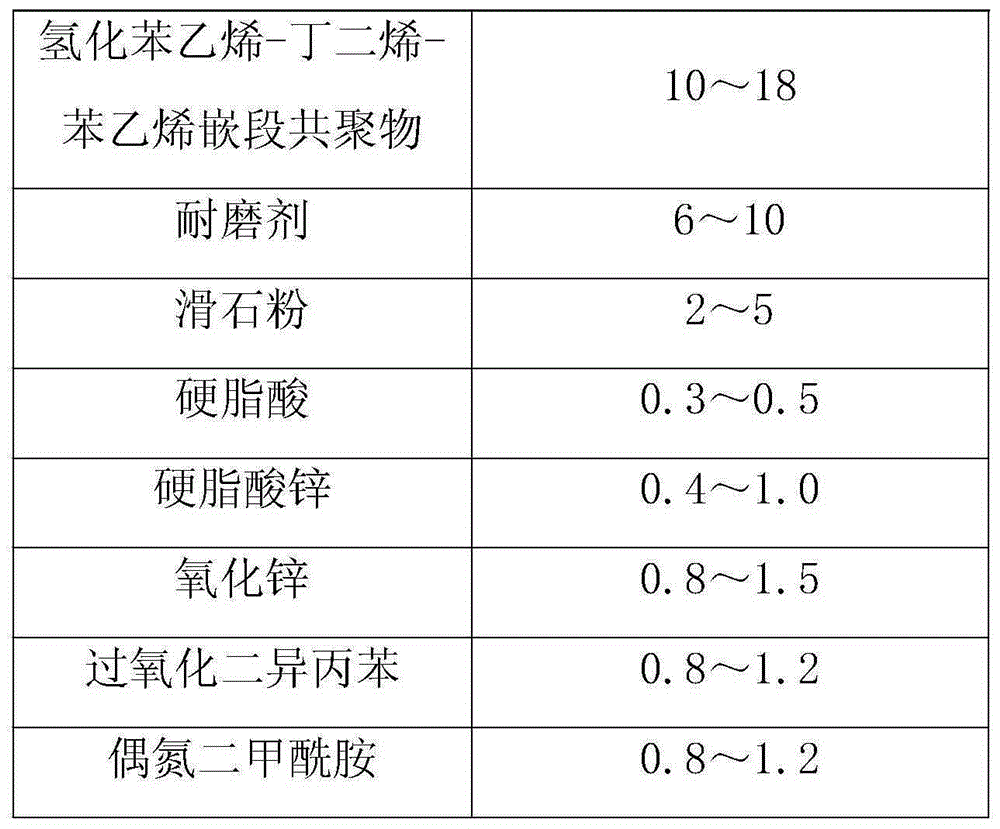

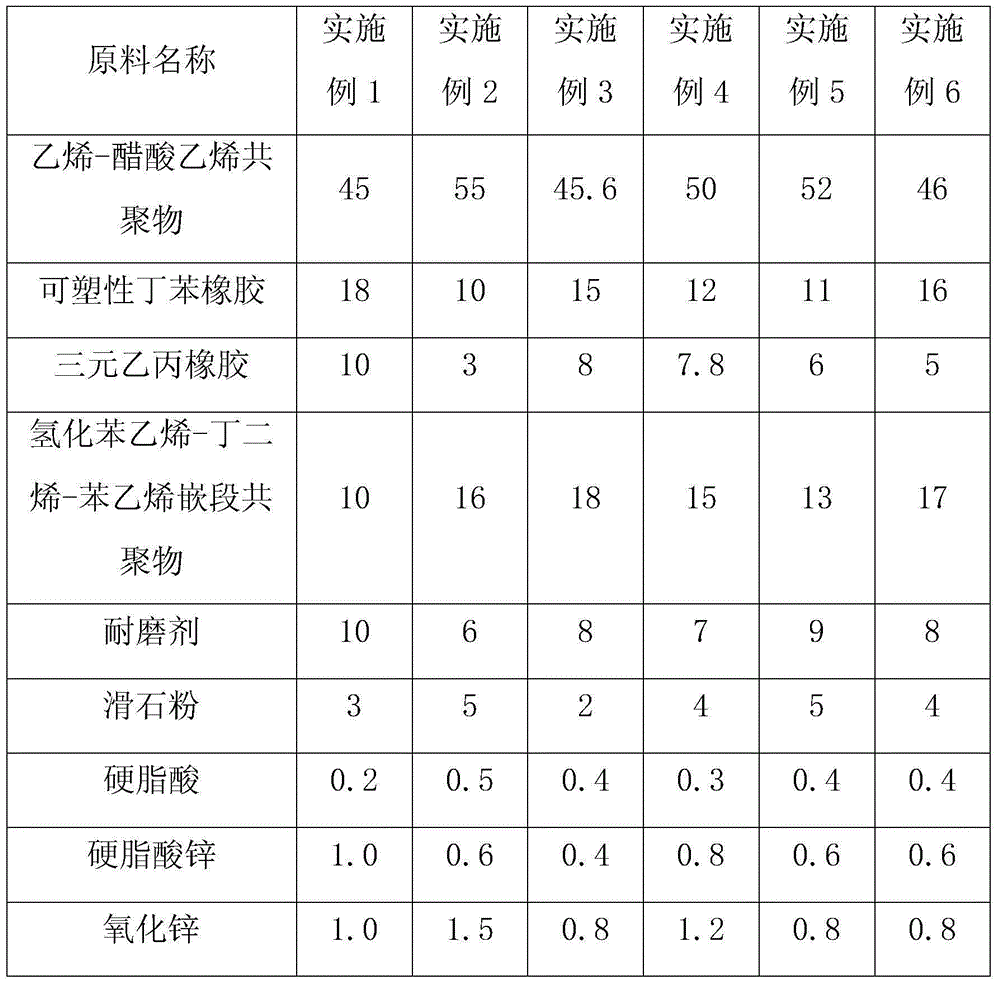

The invention discloses a super wear-resistant rubber foamed sport shoe material comprising the components of ethylene-vinyl acetate copolymer, plastic styrene-butadiene rubber (TVA), ethylene propylene diene monomer (EPDM), hydrogenated styrene-butadiene-styrene block copolymer (SEBS), a wear-resistant agent, talc powder, stearic acid, zinc stearate, zinc oxide, dicumyl peroxide (DCP) and azodicarbonamide. The invention also discloses a preparation method of the super wear-resistant rubber foamed sport shoe material. The super wear-resistant rubber foamed sport shoe material disclosed by the invention is good in slip resistance, the wear resistance of the sport shoe material is superior to that of common hard rubber, and the sport shoe material can be directly molded by ejecting. The invention also discloses a preparation method of the super wear-resistant rubber foamed sport shoe material, wherein physical parameters are strictly controlled during preparation to ensure that the prepared super wear-resistant rubber foamed sport shoe material has more excellent wear resistance and slip resistance.

Owner:厦门联合信诺新材料有限公司

Bamboo-plastic composite section bar

A bamboo plastic composite sectional material consists of PVC 100 proportion, bamboo-sand optical powder 100-200 proportion, barium stearate 0.6-1.0 proportion, CPE 4-6 proportion, lead stearate 0.6-1.0 proportion, industrial stearic acid 1-1.5 proportion, n-octyl ester phthalate 2-3.5 proportion, light calcium carbonate 15-45 proportion, stabilizer 3-6 proportion, ACR 2-6 proportion, foaming regulator 5-10 proportion, ADC foaming agent 1-2 proportion and polyvinyl wax 0.2-1.0 proportion. It costs low and is simple. It has better quality, strength and toughness and various uses. It can be used for door, window, decorative line and floor.

Owner:重庆星星套装门(集团)有限责任公司

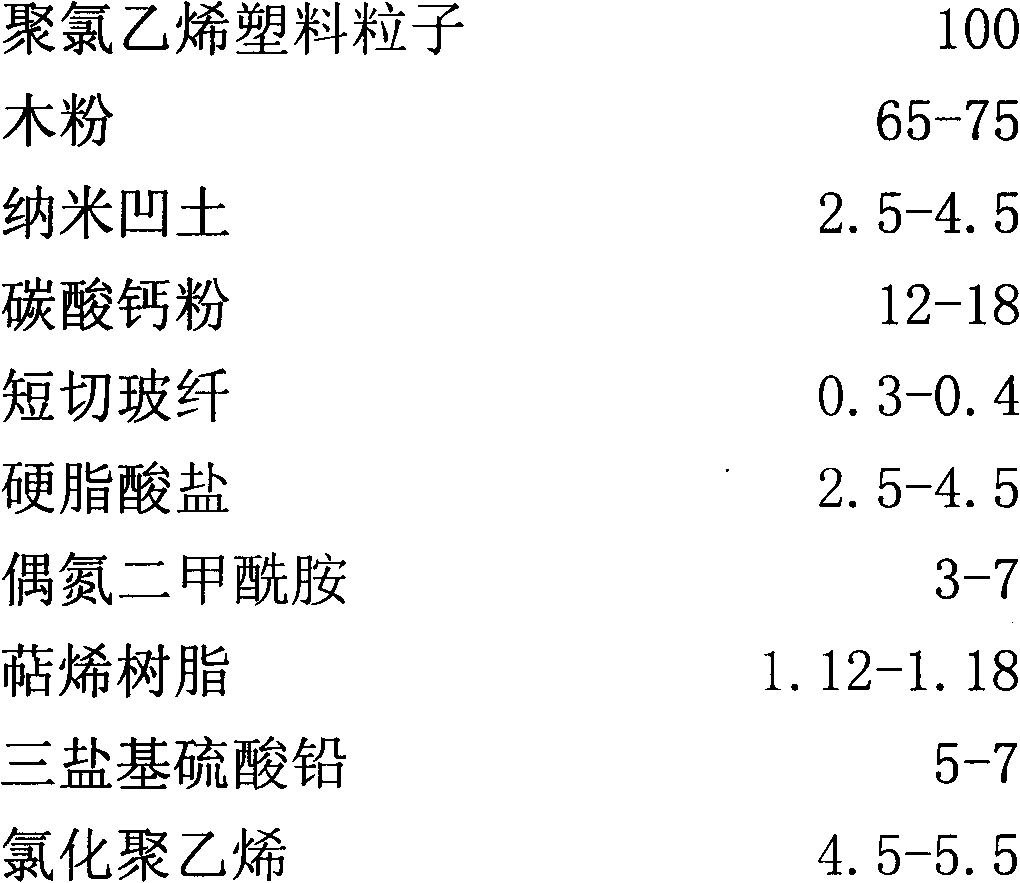

Wood plastic composite dalle and preparation method thereof

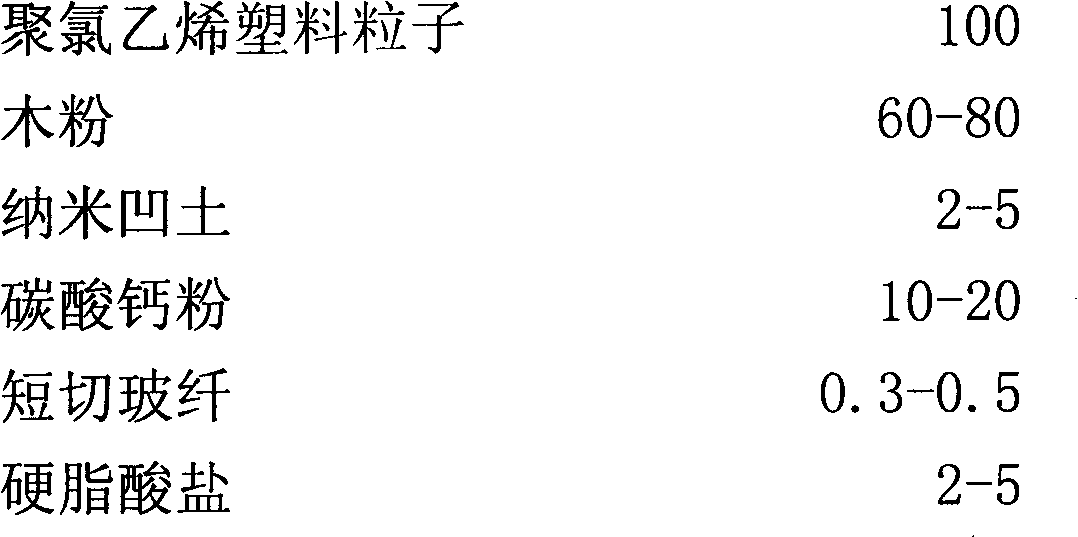

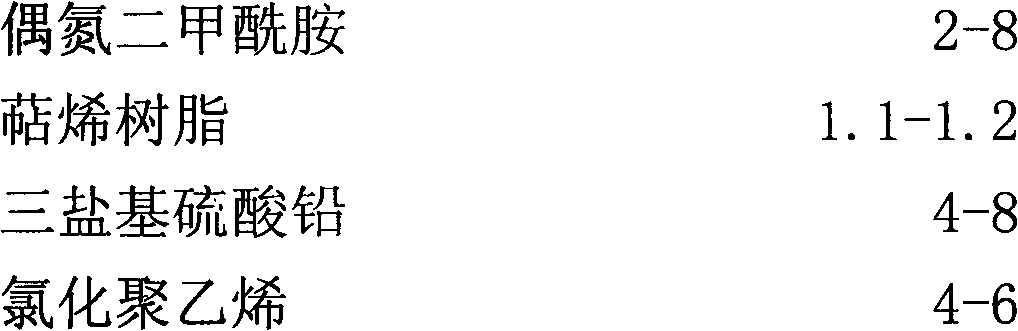

The invention relates to a wood plastic composite, in particular relating to a wood plastic composite dalle and a preparation method thereof. The preparation method comprises the following steps: mixing polrvinyl chloride particles, nano attapulgite, calcium carbonate powder, short glass fibers, terpene resin, chlorinated polyethylene, tribasic lead sulfate and stearate, extruding and pelleting, so as to obtain a modified plastic particle; evenly mixing the modified plastic particle with wood poader and azodicarbonamide and pelleting so as to obtain a wood plastic particle; and finally, extruding the wood plastic particle, foaming and forming so as to obtain the wood plastic composite dalle. The wood plastic composite dalle can be manufactured conveniently, and has the advantages of high production mechanization degree and less required labor. Compared with the common plastic dalle, the wood plastic composite dalle provided by the invention has the following advantages: the plastic dosage of the wood plastic composite dalle is reduced, and wood plastic composite dalle is environment-friendly, and has the characteristics of high modulus, low density, creepage resistance and low product cost. Compared with the gypsum boards, aluminum plates and the like, the wood plastic composite dalle provided by the invention has the following advantages: the cost is lower, the density is smaller, the installation and maintenance are more convenient, and the wood plastic composite dalle has an air purification function. The wood plastic composite dalle can be widely applied to various scenes such as buildings and houses, home offices and the like.

Owner:扬州润友复合材料有限公司

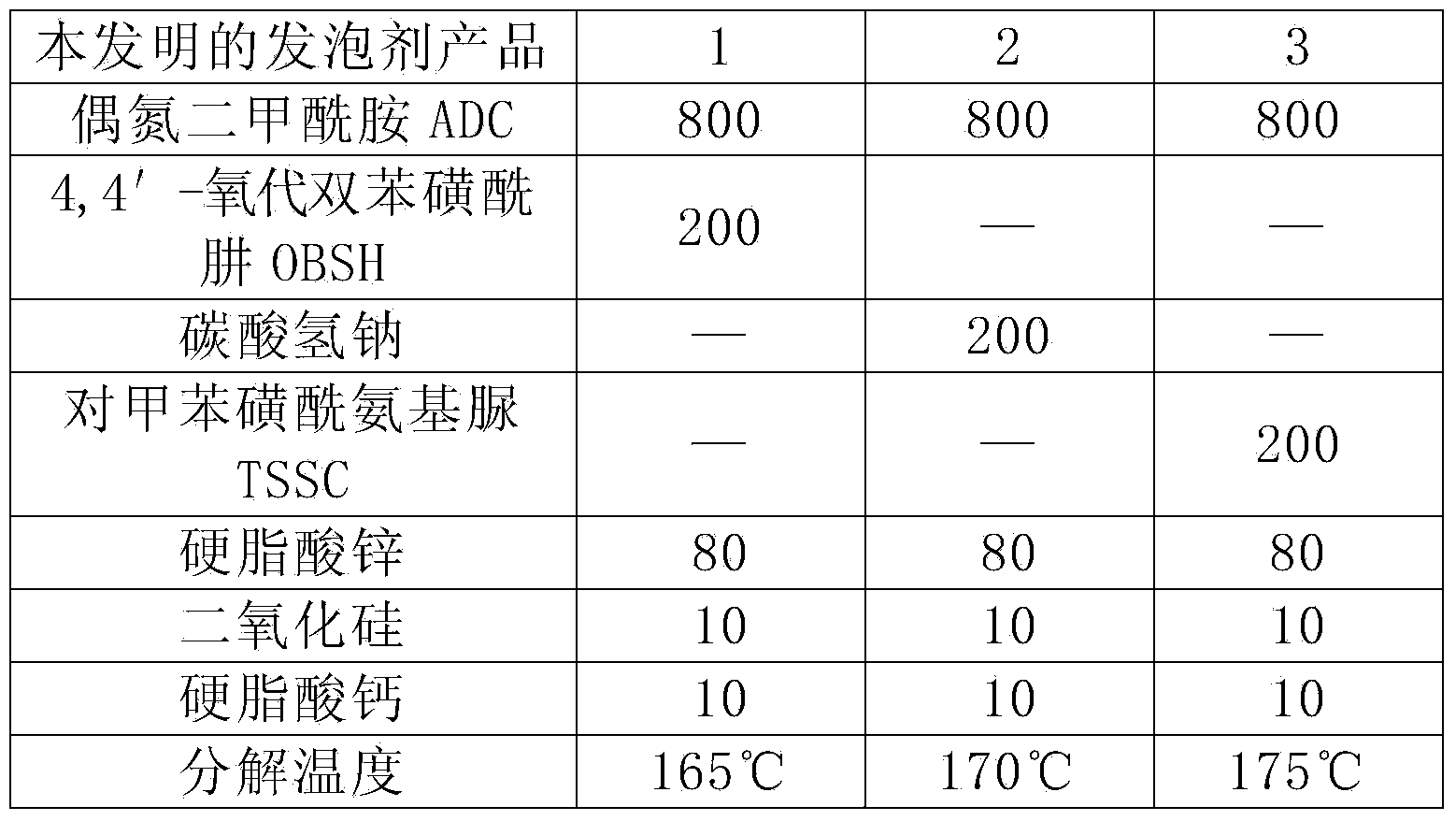

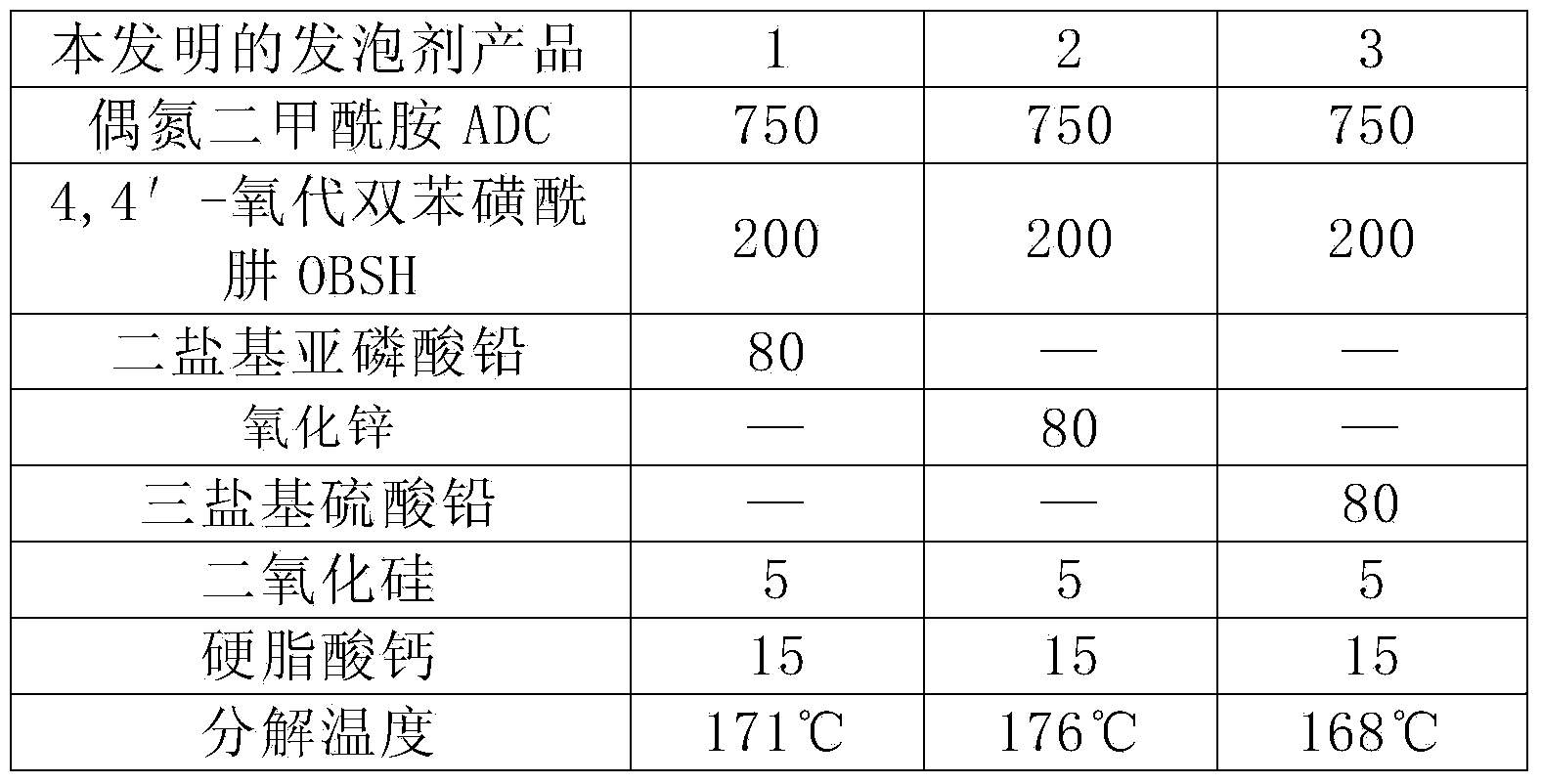

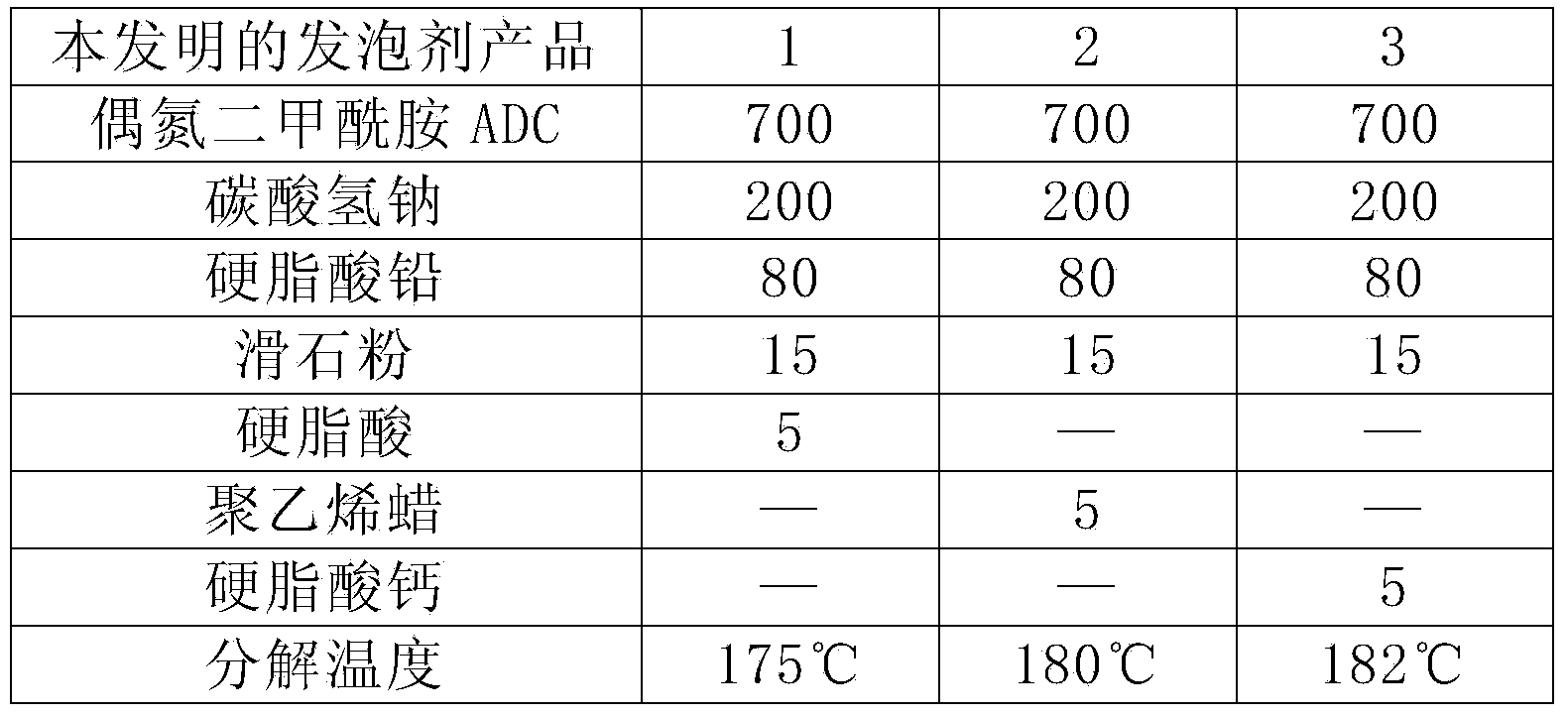

Special foaming agent for hard PVC (polyvinyl chloride) low-foaming material and preparation method thereof

The invention discloses a special foaming agent for a hard PVC (polyvinyl chloride) low-foaming material and a preparation method thereof. The special foaming agent comprises the following materials in parts by weight: 20-80 parts of azodicarbonamide (ADC), 20-80 parts of auxiliary foaming agent, 1-20 parts of activating agent, 0.2-10 parts of dispersing agent and 0.2-5 parts of processing agent. The preparation method comprises the steps: adding the dispersing agent and the processing agent in a mixer, mixing for 3-7 minutes, and sequentially uniformly mixing the ADC, the auxiliary foaming agent and the activating agent in the mixer to prepare the special foaming agent. The special foaming agent is suitable for hard PVC low-foam materials such as PVC crushing and low-foaming sectional bars, tubular products and sheets, a wood-plastics low-foaming material and the like. The special foaming agent has the positive effects that 1, the decomposition temperature is 160-190 DEG C, and is within a processing temperature range of the hard PVC low-foaming material; 2, the foaming process is short in induction period, the decomposition is performed without mutation, and the foaming process is easily controlled; 3, the hard PVC low-foaming material is used on a hard PVC low-foaming product, and has a smooth surface and has no discoloring and ageing phenomena; and 4, the special foaming agent is low in cost and good in comprehensive performance, and accords with the use requirement.

Owner:WEIFANG YAXING GRP CO LTD

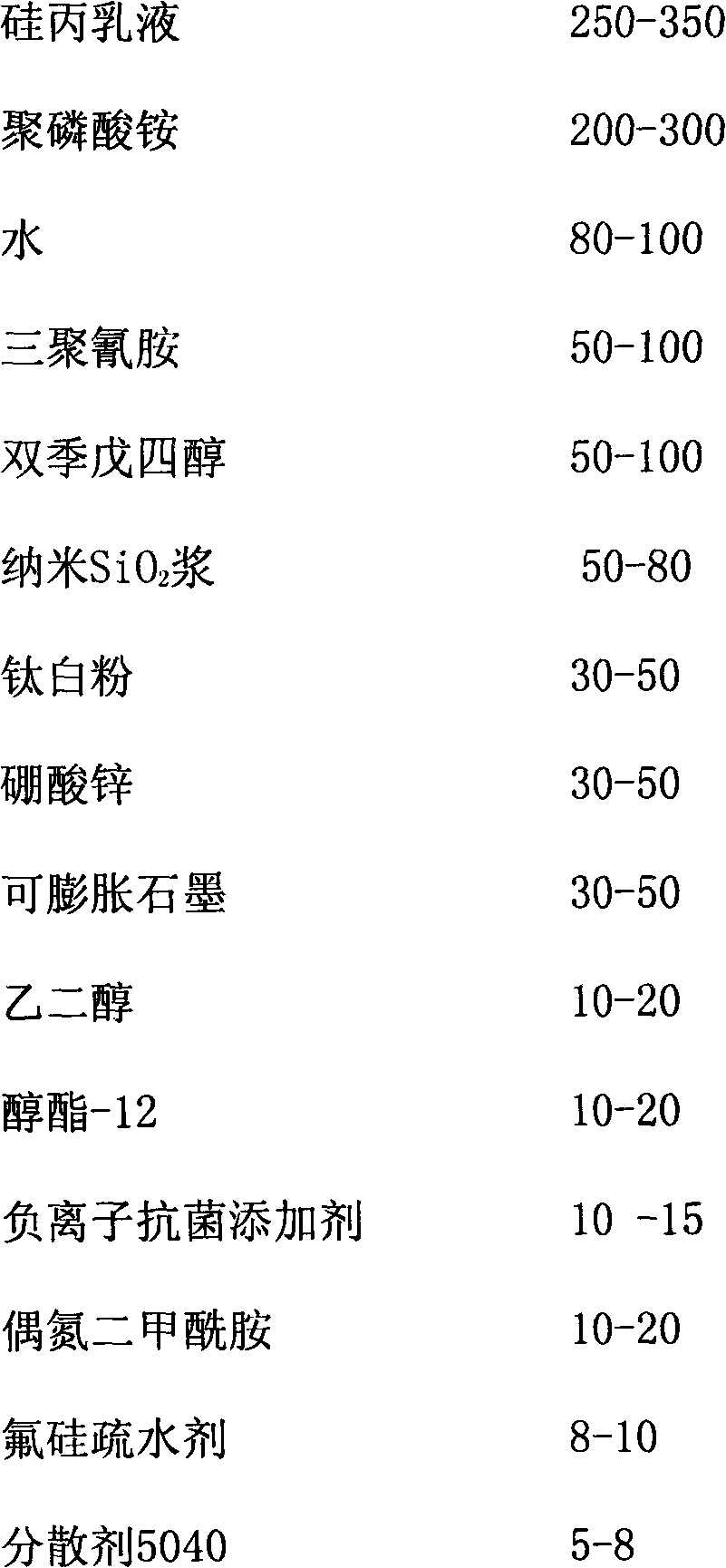

Water expansion type fire-proof mildew-proof coating for tunnels

InactiveCN102634256AWaterproof and anti-seepageLong fire resistanceFireproof paintsAntifouling/underwater paintsTunnel wallAzodicarbonamide

The invention discloses a water expansion type fire-proof mildew-proof coating for tunnels, which are prepared through conventional preparation processes with the cooperation of auxiliary agents, wherein silicone acrylic emulsion serves as a film forming matter, modified ammonium polyphosphate, melamine, dipentaerythritol and azodicarbonamide serve as fire retardants; titanium dioxide, zinc borate and expansible graphite serve as fillers; nanometer SiO2 serves as a modified material and an anion antibacterial additive serves as a mildew-proof bactericide. The mildew-proof fire-proof protective coating disclosed by the invention has the advantages of long fire-proof time limit, good adhesion property, water resistance and permeability resistance, mildew resistance and antibacterial property, environmental protection and no toxicity, good decorative effect, thinness in coating and convenience for construction and is suitable for various tunnel walls.

Owner:北京国泰瑞华精藻硅特种材料有限公司

Expandable resin composition

An expandable resin composition comprising (A) HDPE (high density polyethylene); (B) a high pressure, low density homopolymer of ethylene (HP-LDPE); (C) polypropylene; (D) a polysiloxane-polyether block copolymer; and (E) a nucleating agent of azodicarbonamide and / or talc.

Owner:NIPPON YUNIKAA

Low energy consumption ecological leatheroid preparation method

ActiveCN103669021ALow VOC residual rateLow atomization valueSynthetic resin layered productsTextiles and paperOrganic solventPlasticizer

The invention discloses a low energy consumption ecological leatheroid preparation method. The preparation method adopts an environmental-friendly plasticizer to replace a phthalate noxious plasticizer to prepare a PVC surface layer and a foam layer, utilizes a low temperature foaming agent with a foaming temperature ranging from 160 DEG C to 190 DEG C to replace the conventional azodicarbonamide (AC) high temperature foaming agent to foam on the foaming layer, and finally uses an environmental-friendly aqueous resin as a base cloth glue and a PVC surface treating agent, as a result, the low energy consumption ecological leatheroid preparation method is obtained. The discharging and residue of the noxious plasticizer and an organic solvent are avoided by using the environmental-friendly plasticizer, as a result, the ecological grade of the finished leatheroid is improved; the application of the low temperature foaming agent can remarkably lower the energy consumption caused by the leatheroid preparation, the production cost is saved, meanwhile, the foam holes are fine and uniform, destructive air holes are avoided, and the color is fleet and weak. By adopting the process, the prepared leatheroid has the characteristics that the cost is low and the content of the volatile organic substance is lower than 5 mg / kg, satisfies quality requirement of EU ecological leatheroid, and remarkably improves the international market competitiveness and the environmental protection grade of the leatheroid.

Owner:SICHUAN UNIV

Foaming material for sports shoe sole and preparation method thereof

InactiveCN102030941AIdeal raw material function combinationHigh elastic performanceSolesLow-density polyethyleneAlpha-olefin

The invention discloses a foaming material for sports shoe sole, which is prepared by following components by weight part: 40 to 80 parts of ethylene-vinyl acetate copolymer, 10 to 30 parts of ethylene-alpha olefin copolymer, 5 to 20 parts of ethylene vinyl acetate copolymer resin, 5 to 20 parts of metallocene low-density polyethylene, 5 to 30 parts of filler, 0.5 to 2.0 parts of zinc stearate, 0.5 to 2 parts of stearic acid, 0.5 to 3.0 parts of zinc oxide, 0.4 to 1.2 parts of diisopropyl benzene peroxide, and 2 to 5 parts of azodicarbonamide. The invention also discloses a preparation method for the foaming material. The foaming material of the invention has unmatched super elasticity and touching feel and has various excellent anti-impact properties such as front and back damping of the fatigued sole, rebounding property, and the like.

Owner:ANTA CHINA

Flexible, highly-elastic and wear-resistant EVA foamed shoe and manufaturing method thereof

The invention discloses a flexible, highly-elastic and wear-resistant EVA foamed shoe and a manufacturing method thereof, and relates to a shoe. Raw materials of the foamed shoe comprise 40-54% of an ethylene-vinyl acetate copolymer, 10-16% of a hydrogenated styrene-butadiene-styrene block copolymer, 10-16% of an ethylene-butylene copolymer, 8-12% of an olefin block copolymer, 5-8% of a wear resisting agent, 3-5% of talcum powder, 0.3-0.5% of stearic acid, 0.5-0.8% of zinc stearate, 0.6-1.0% of zinc oxide, 0.5-0.6% of di(tert-butylperoxyisopropyl)benzene, 1.6-2.0% of azodicarbonamide and 2-3% of color master batch. The manufacturing method comprises the following steps: mixing di(tert-butylperoxyisopropyl)benzene with azodicarbonamide to obtain a mixture A, mixing remaining raw materials, internally mixing the remaining raw materials, heating the remaining raw materials, adding the mixture A, internally mixing the remaining raw materials and the mixture A, and thinning the obtained mixture; granulating the thinned mixture; standing the granulated mixture, injecting the obtained mixture to a shoe die, and molding the injected mixture; and carrying out sole fixing to form the foamed shoe.

Owner:厦门联合信诺新材料有限公司

Expandable resin composition

An expandable resin composition comprising: (A) 100 parts by weight of HDPE (high density polyethylene) having a DSC melting point of about 127 to about 136 degrees C.; a density of 0.945 to 0.967 gram per cubic centimeter; and a melt flow rate of about 0.1 to about 10 grams per 10 minutes, and for each 100 parts by weight of component (A), (B) about 2 to about 50 parts by weight of polypropylene having a DSC melting point of at least about 130 degrees C.; (C) about 50 to about 200 parts by weight of an ethylene / alpha-olefin copolymer, prepared with a metallocene catalyst, having a DSC melting point of about 98 to about 121 degrees C.; a density of 0.900 to 0.935 gram per cubic centimeter; and a melt flow rate of about 0.5 to about 3 grams per 10 minutes; (D) about 0.1 to about 5 parts by weight of a polysiloxane-polyether block copolymer having the following formula:R3-Si-O-R2(SiO)m-RX(SiO)n-SiR3 wherein each R is independently a monovalent alkyl, alkoxy, hydroxy, aryl, or aralkyl group; X has the formula: -(CH2)p-(O)q-(CtH2tO)s-R'; R' is the same as R above and (CtH2tO)s is a radical group of ethylene oxide or propylene oxide polymer; and m is 5 to 300; n is 2 to 20; p is 0 or 2; q is 0 or 1; t is 2 or 3; and s is 5 to 100; and (E) about 0.02 to about 5 parts by weight of a nucleating agent selected from the group consisting of azodicarbonamide, talc, and mixtures thereof.

Owner:NIPPON YUNIKAA

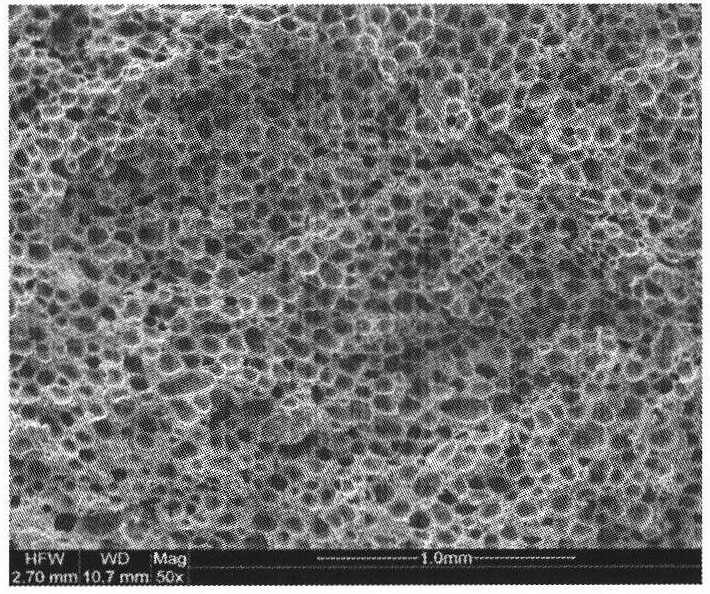

Injection microcellular foamed wood-plastic composite material and preparation method thereof

The invention discloses an injection microcellular foamed wood-plastic composite material and a preparation method thereof. The composite material comprises wood-plastic pellets and foaming master batches, wherein the wood-plastic pellets contain the following components: wood powder with the granularity of 100-200 meshes, regenerated polypropylene (PP), stearic acid or salt thereof, maleic anhydride grafted PP with the molecular weight of 5,000-30,000, titanate coupling gent, nano absorbent, nano assistant foaming agent and super-micro nucleating agent; and the foaming master batches containthe following components: low-density polyethylene (LDPE), vinylacetate copolymer, azodicarbonamide, and stearic acid or salt thereof. The preparation method comprises the following steps of: preparing the wood-plastic pellets and the foaming master batches, mixing in a ratio of 15:4-17:4, injecting and foaming to prepare the injection microcellular foamed wood-plastic composite material. The composite material has the characteristics of light weight, high strength and toughness, low cost and the like, can widely replace the plastics, and is used for the production of the products with complicated shapes.

Owner:JIANGSU HENGFAMU PLASTIC SCI & TECH +1

Mullite lightweight refractory material and preparation method thereof

The invention relates to a mullite lightweight refractory material and a preparation method of the mullite lightweight refractory material. The invention adopts the technical scheme that the method comprises the steps of preparing materials under a 40-55 DEG C water bath condition according to a mass ratio of an AC (azodicarbonamide) foaming agent to polyethylene glycol 400 to ammonium bicarbonate to water of 1:(2-5):(1-4):(80-120), stirring, preparing foaming liquid, preparing materials at a mass ratio of the foaming liquid to rho-Al2O3 to gangue powder of (50-60):(1-3):100, stirring, forming to prepare a formed mixture, putting the formed mixture in a vacuum freeze drier for freeze drying for 72-84h, preparing a dried formed mixture, putting the dried formed mixture in a resistance furnace, holding temperature at 1280-1400DEG C for 45-50min, naturally cooling with the furnace, and obtaining the mullite lightweight refractory material. The method has the characteristics of low cost, simple technology and high finished product rate, and the prepared mullite lightweight refractory material is low in volume density, high in cold crushing strength and low in heat conductivity coefficient.

Owner:SUZHOU ZIGUANG WEIYE LASER TECH CO LTD

EVA-TPU dual hardness foaming sole material and preparation method thereof

The invention discloses a sole material capable of realizing dual hardness foaming. The sole material is prepared from the following raw materials in parts by weight: 100 parts of TPU and EVA in total, 20-30 parts of a compatibilizer, 5-8 parts of a foaming agent, 0.7-1 part of a crosslinking agent, 3-5 parts of an activator and 19-20 parts of a nucleating agent, wherein TPU accounts for 30-70 parts, EVA accounts for 30-70 parts, the compatibilizer is a high polymer of ethylene and octylene, the foaming agent is azodicarbonamide, the crosslinking agent is dicumyl peroxide, the activator is one of zinc oxide / stearic acid or zinc stearate, and the nucleating agent is calcium carbonate. The sole material disclosed by the invention has the advantages that wear resistance of a TPU foaming material and the flexibility and processability of an EVA foaming material are comprehensively utilized, so that the problem that an EVA-TPU composite is poor in compatibility is solved, the sole material which realizes synchronous crosslinking and uniform foaming, 'outsole-insole' integrated moulding and dual hardness foaming is prepared, and the sole material has excellent wear resistance, high elasticity and comfort.

Owner:LIMING VOCATIONAL UNIV

Polyvinylchloride (PVC) plastic wood plank and preparation method thereof

The invention provides a polyvinylchloride (PVC) plastic wood plank and a preparation method thereof. The PVC plastic wood plank consists of the following ingredients: PVC, calcium carbonate, wood flour, azodicarbonamide (AC) foaming agents, stabilizing agents, coupling agents, acrylicester (ACR), paraffin wax, stearic acid and fire retardants. By means of the PVC plastic wood plank, appending proportion of the calcium carbonate is enhanced by reducing the amount of the wood flour, and at the same time, by adjusting the amount of the PVC, and the type and amount of other additives, not only can hardness of the plank be greatly enhanced, but also appropriate toughness can be possessed. Therefore, the plank is guaranteed to be not only possess enough hardness when used as wood floors in public places so that damage and sinking of the surface of the plank are not prone to occurring, but also meet requirements of the wood floors due to the toughness of the plank so that the plank can be ensured to be not easy to crack.

Owner:江西铁木真装饰材料有限公司

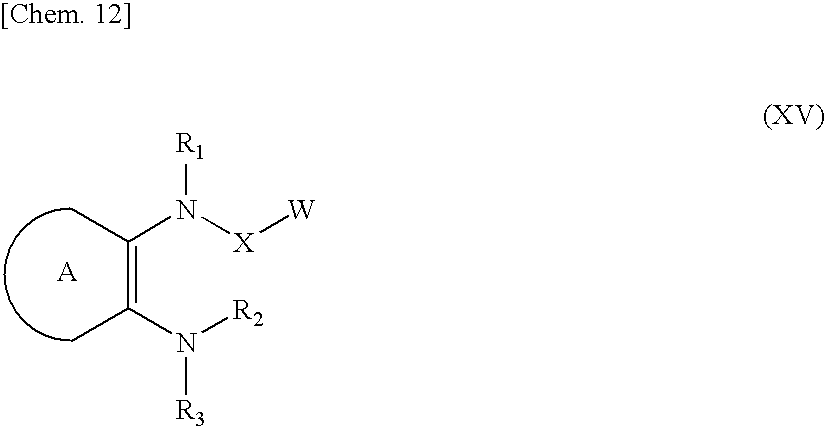

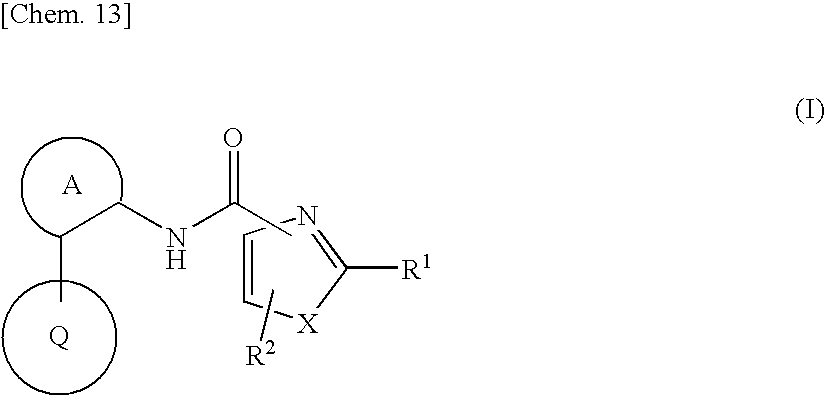

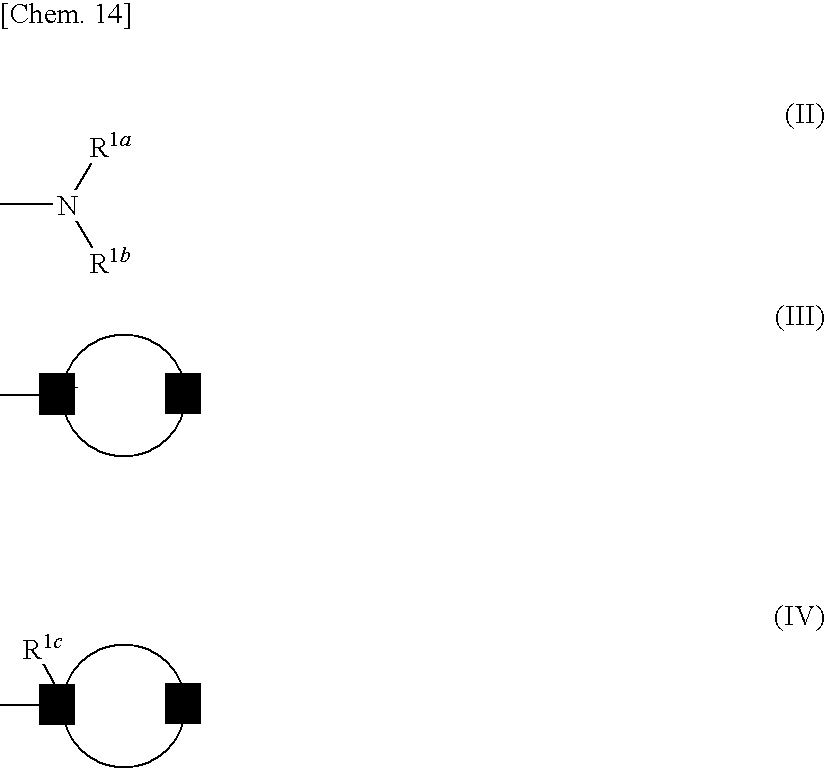

Azolecarboxamide derivative

InactiveUS20090286766A1Potent activityImprove actionBiocideNervous disorderDiseaseInterstitial cystitis

Provided is an agent for treating or preventing urinary frequency, urinary urgency and urinary, incontinence which are associated with overactive bladder, a lower urinary tract disease such as interstitial cystitis and chronic prostatitis accompanied by lower urinary tract pain, and various diseases accompanied by pain. A novel azolecarboxamide derivative in which an azole ring such as thioazole or oxazole is bonded to a benzene ring, pyridine ring or pyrimidine ring through carboxamide was confirmed to have a potent trkA receptor-inhibitory activity and found to be an agent for treating or preventing lower urinary tract disease and various diseases accompanied by pain, which is excellent in efficacy and safety, and thus the present invention was accomplished.

Owner:ASTELLAS PHARMA INC

Rubber and plastic sole material with high wear resistance and high elastic resilience and preparation method thereof

InactiveCN105419069AThe material formula is scientific and reasonableLow costSolesElastomerHigh resistance

The invention discloses a rubber and plastic sole material with high wear resistance and high elastic resilience and a preparation method thereof, belonging to the technical field of rubber and plastic sole materials. The rubber and plastic sole material is prepared from the following raw materials in percentage by weight: 25%-35% of EVA with VA content of 26%, 10%-20% of EVA with VA content of 40%, 5%-15% of ethylene propylene terpolymer, 2%-8% of isoprene rubber, 5%-15% of polyolefin elastomer POE, 5%-10% of thermoplastic rubber SEBS, 2%-6% of talcum powder, 5%-15% of a wear resisting agent, 1%-3% of high-activity zinc oxide, 0.5%-1.5% of zinc stearate, 0.5%-1.5% of stearic acid, 0.5%-1.5% of a bridging agent DCP and 1%-3% of azodicarbonamide. The preparation method comprises the steps of banburying, open-milling, granulating and the like. The preparation process is reasonable and simple. By improving the raw material formula content and reasonable process design, the rubber and plastic sole material has high wear resistance and high elastic resilience, and can be recycled.

Owner:FUJIAN JINJIANG DONGFENG SHOES & PLASTIC CO LTD

Magnetic foamed plastic

The invention relates to the foaming plastic technical field, in particular to magnetic foaming plastic, which comprises 25-65% plastic rubber composition, 20-60% magnetic powder, 5-15% foamable agent, 5-30% talcum powder filling agent and 2-10% resin acids lubricating agent according to parts by weight, wherein plastic rubber composition is one of EVA, PVC, PE, POE and TPE, magnetic powder is rare earth magnet neodymium iron boron magnetic powder, foamable agent is azobisformamide, adhesive agent is dicumyl peroxide, resin acids lubricating agent is one of monoglyceryl stearate and calcium stearate. Plastic after shaped can be randomly bended according to demanded shapes, and has elasticity, and can joint with other materials, the surface can be randomly polished, and the magnetism is much stronger after polished, recovery and usage space is large, the plastic can be shaped secondly, which is reshaped into shapes which is required through coining heating, and is easy to process since hardness is small.

Owner:林彬

Foamed polypropylene composite board and preparation method thereof

InactiveCN102504426ALight in massAvoid deformationSynthetic resin layered productsPolymer scienceThermal deformation

The invention discloses a foamed polypropylene composite board, which comprises a foamed polypropylene board and non-woven fabric or polyvinyl chloride of which single face or both faces are compounded onto the foamed polypropylene board, wherein the foamed polypropylene board comprises the following raw materials in parts by weight: 40-60 parts of modified polypropylene, 30-50 parts of co-polypropylene, 5-20 parts of glass fiber, 0-6 parts of ethylene-vinyl acetate copolymer, 0-10 parts of polyethylene, 1-4 parts of foaming agent azodicarbonamide (AC)or OT (o-Toluidine), 0.5-2 parts of foaming initiator, 0.3-1 part of cross-linking agent, 0.2-0.4 part of fire retardant and 0.2-0.5 part of mineral oil. The invention also provides a preparation method for the foamed polypropylene composite board. The foamed polypropylene composite board disclosed by the invention has the performances of light weight, high thermal deformation load temperature, hardness in deformation, high bending modulus, high tensile strength, high notch impact strength, low contractibility rate, good rebound resilience, good toughness, noise reduction, good sound insulation effect, easiness in processing, no water is not water absorbability and recyclability.

Owner:CHONGQING JUWENG PLASTIC MFG

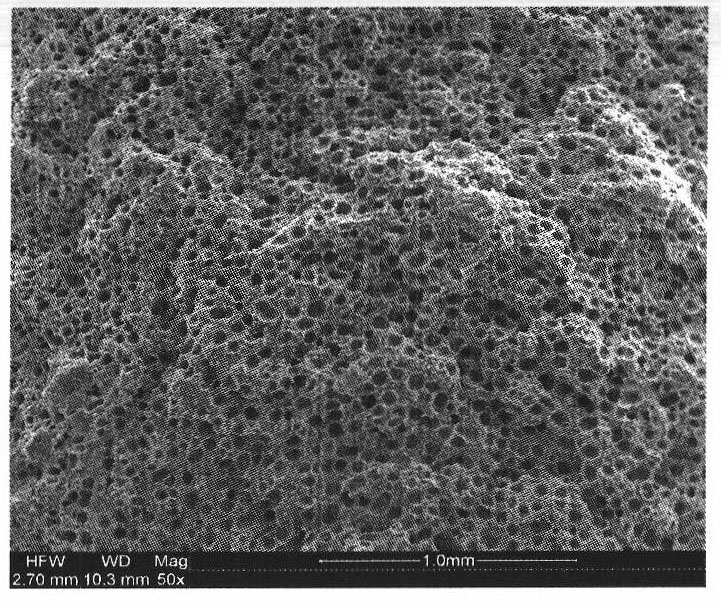

Foamed aluminum composite porous material and preparation method thereof

The invention discloses a foamed aluminum composite porous material and a preparation method thereof. The foamed aluminum composite porous material comprises open-cell foamed aluminum and a porous filler filled in the pores of the foamed aluminum and formed by chemical foaming, wherein the filler at least comprises 40-60 weight parts of recycled foaming polyurethane, 50-60 weight parts of low-density polyethylene, 0.6-0.7 weight part of dicumyl peroxide, 2-4 weight parts of azodicarbonamide, 0.7-0.9 weight part of zinc oxide and 1-2 parts of zinc stearate, and is formed by foaming in the pores of the foamed aluminum. The preparation method comprises the steps of blending the mixture at 130-140 DEG C; plasticizing and cutting into particles; mixing at 130-140 DEG C, and tabletting to obtain an un-foamed material; feeding the un-foamed material into the pores of the foamed metal, and maintaining pressure at 4-5MPa at 180-195 DEG C for 8-10 minutes for a chemical foaming reaction; releasing the pressure so that the filler is sufficiently foamed; cooling to obtain the composite porous material.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Soft and flexible EVA (ethylene-vinyl acetate copolymer) foam sports shoe material and method for manufacturing same

InactiveCN104817763AEasy to bendImprove toughnessSolesDomestic footwearCarvacryl acetateStearic acid

The invention discloses a soft and flexible EVA (ethylene-vinyl acetate copolymer) foam sports shoe material and a method for manufacturing the same, and relates to an EVA foam shoe material. The soft and flexible EVA foam sports shoe material comprises ethylene-vinyl acetate copolymers, ethylene-octene copolymers, ethylene-acrylic acid copolymers, talc powder, stearic acid, zinc stearate, zinc oxide, dicumyl peroxide, azodicarbonamide and color master batches. The method includes mixing the dicumyl peroxide and the azodicarbonamide with each other for standby application, mixing remaining raw materials with one another to obtain mixtures, pouring the remaining materials into a banbury mixer, carrying out first-stage banburying on the mixtures to uniformly mix the materials, adding mixtures of the dicumyl peroxide and the azodicarbonamide into the materials when the temperatures of the materials reach 100-105 DEG C, starting the banbury mixer again to carry out second-stage banburying on the materials and the mixtures of the dicumyl peroxide and the azodicarbonamide until the temperatures of the materials and the mixtures rise and reach 105-110 DEG C, uniformly mixing all raw materials to obtain mixtures which are subjected to effective banburying, thinning the mixtures twice and granulating the mixtures; allowing grains to stand for 24h, then pouring the grains into shoe molds, vulcanizing the grains, molding the grains and setting the grains to obtain the soft and flexible EVA foam sports shoe material.

Owner:泰亚投资集团有限公司

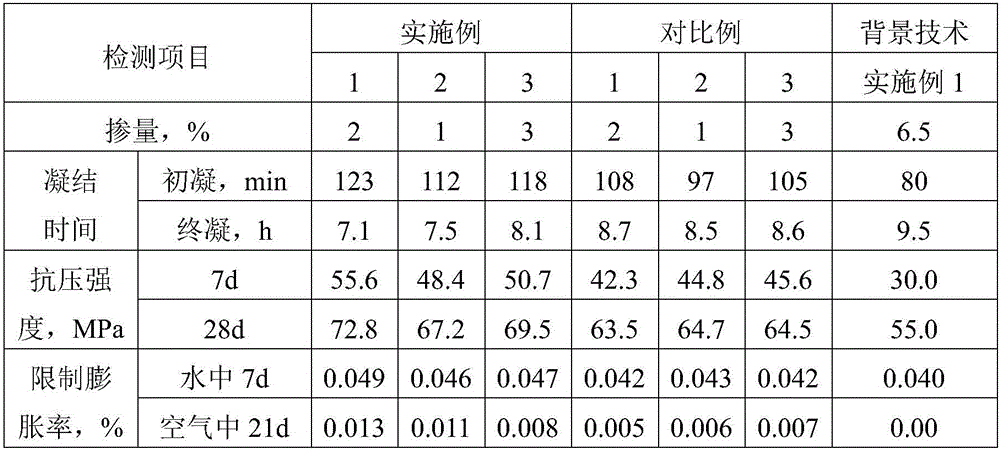

Modified concrete expansive agent

The invention discloses a modified concrete expansive agent, made from, by weight, 10-20 parts of calcium silicoaluminate, 25-30 parts of calcium sulfoaluminate, 20-25 parts of sulfur fixing waste residue, 10-20 parts of modified red clay, 1-5 parts of tourmaline powder, 6-8 parts of iron slag, 4-6 parts of modified calcium oxide, 4-6 parts of magnesium oxide, 3-5 parts of sodium methyl silicate, 2-4 parts of calcium formate, 0.1-0.3 part of azodicarbonamide, 0.4-0.7 part of maltodextrin, 1-4 parts of sodium lignin sulfonate, 0.3-0.6 part of polyglycol ether, 1-3 parts of a polycarboxylate superplasticizer, 2-5 parts of modified diatomite powder, and 0.5-0.8 part of nano calcium carbonate. The modified concrete expansive agent has the advantages of high strength, good compensating capacity and the ability to control calcium oxide reaction and is a promising concrete admixture.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

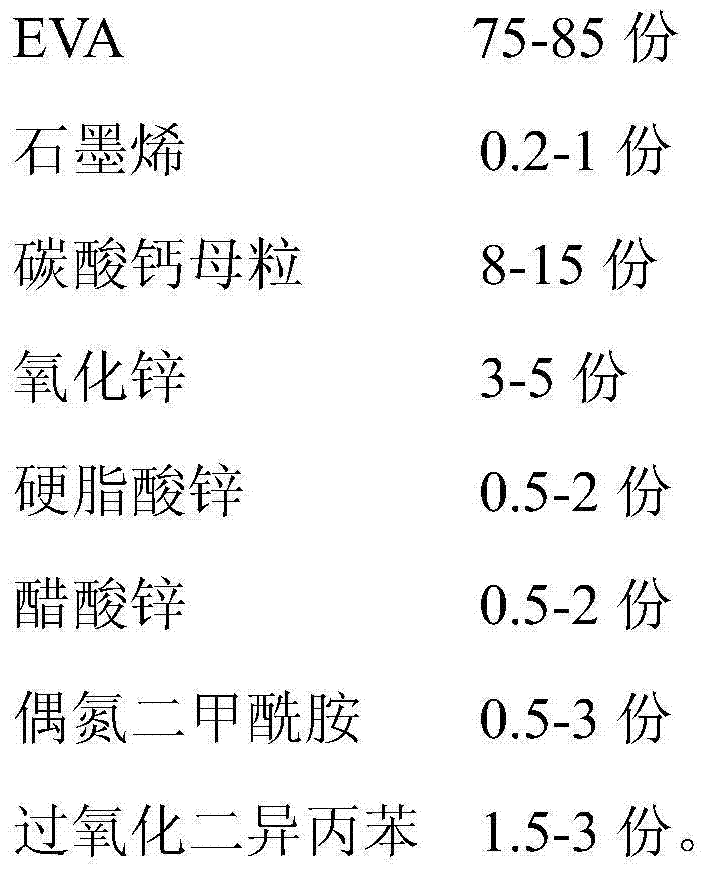

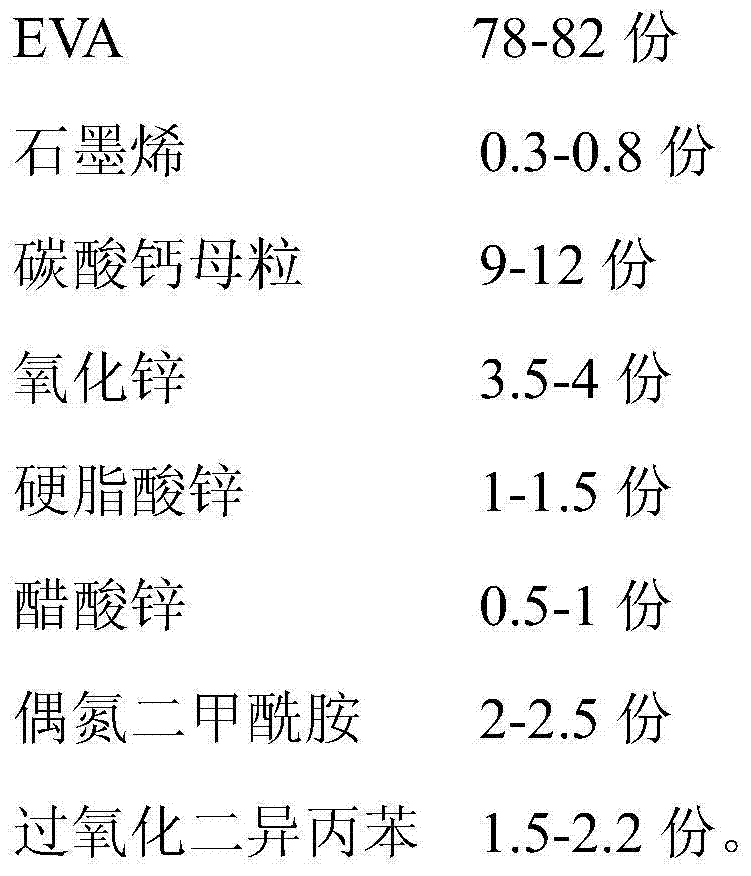

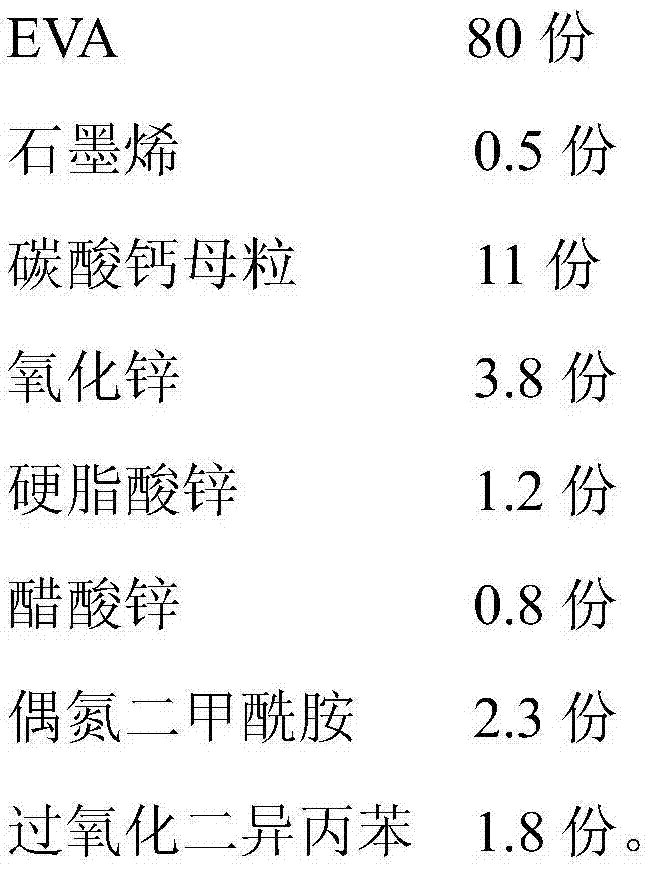

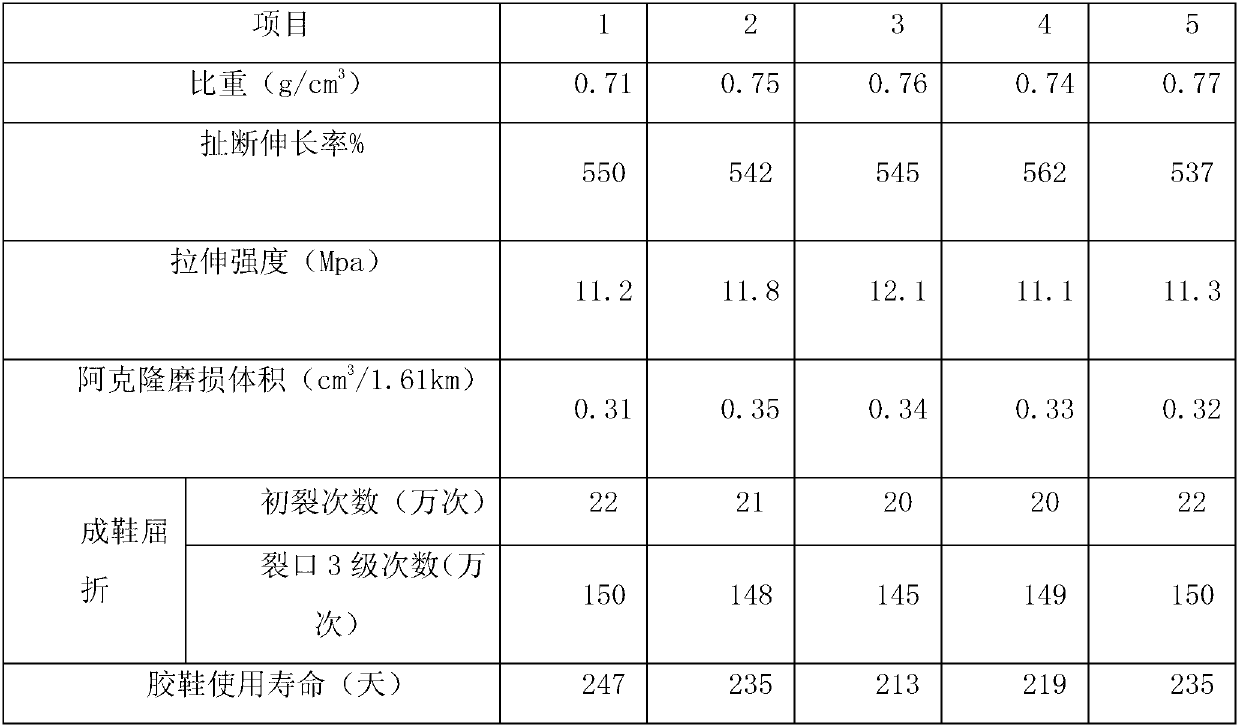

EVA (ethylene vinyl-acetate copolymer) sole material and preparation method thereof

InactiveCN104725713AImprove skid resistanceImprove tear resistanceSolesGrapheneZinc Acetate Dihydrate

The invention relates to an EVA (ethylene vinyl-acetate copolymer) sole material and a preparation method thereof. The EVA (ethylene vinyl-acetate copolymer) sole material consists of the following ingredients in part by weight: 75-85 parts of EVA, 0.2-1 part of graphene, 8-15 parts of calcium carbonate master batch, 3-5 parts of zinc oxide, 0.5-2 parts of zinc stearate, 0.5-2 parts of zinc acetate, 0.5-3 parts of azodicarbonamide and 1.5-3 parts of dicumyl peroxide. Compared with the prior art, the EVA sole material has the advantages that after the graphene is added in the EVA sole material, the sliding resistance of the EVA sole material is improved, and the EVA sole material has high tearing resistance, is not easy to damage and is durable. The wear resistance of the EVA sole material is high even if wear-resisting agents are not added in the EVA sole material, and the wear resistance is improved.

Owner:GUANGZHOU WEIZHEN CHEM TECH CO LTD

Light anti-slipping high-wear-resistance rubber material for sole and preparation method thereof

The invention relates to a rubber composite material and particularly relates to a light anti-slipping high-wear-resistance rubber material for a sole and a preparation method thereof. The light anti-slipping high-wear-resistance rubber material for the sole is prepared from the following raw materials in parts by weight: 55-75 parts of EVA (Ethylene Vinyl Acetate), 8-25 parts of NR (Natural Rubber), 8-25 parts of SBR (Styrene Butadiene Rubber), 2-6 parts of CaCO3, 2-6 parts of wear-resisting agent, 1-5 parts of ZnO, 1-5 parts of ZnST, 0.5-2.5 parts of ST, 0.5-1.5 parts of DCP (Dibasic Calcium Phosphate) and 1.2-2.5 parts of AC (Azodicarbonamide). Compared with the prior art, the components and the ratios of all raw materials are optimized and the light anti-slipping high-wear-resistance rubber material has the advantages of light weight, anti-slipping performance and wear resistance under the synergistic effect of the components with the ratios. The light anti-slipping high-wear-resistance rubber material is particularly suitable for manufacturing a light and anti-slipping sneaker sole.

Owner:MAOTAI FUJIAN SOLES CO LTD

Polypropylene foaming masterbatch and production method thereof

The invention discloses polypropylene foaming masterbatch and a production method thereof. The polypropylene foaming masterbatch is made by using polyethylene resin as substrate, adding azodicarbonamide, nano-montmorillonite, glycerin monostearate, zinc stearate, polydimethylsiloxane and foam stabilizer, mixing, extruding and granulating. The polypropylene foaming masterbatch is simple in production process and low in cost. When serving as polypropylene micro-foaming material in preparation, additive amount of the polypropylene foaming masterbatch in resin is little, so that the defect that producing the micro-foaming material by supercritical process is high in input cost, high in production equipment complexity and high in process requirement is overcome.

Owner:HEFEI UNIV OF TECH

Composite for manufacturing yoga ball and preparation method of composite

The invention relates to a composite for manufacturing a yoga ball and a preparation method of the composite. The composite is prepared from, by mass, 60-80 parts of TPE colloidal particles, 10-25 parts of aramid fibers, 15-30 parts of mica powder, 2-9 parts of azodicarbonamide, 1-5 parts of di-isopropyl peroxydicarbonate, 0.3-0.8 part of antimony oxide, 0.1-0.5 part of coumarone resin, 0.7-2 parts of titanium dioxide, 0.1-0.5 part of ethylene-vinyl acetate copolymer, 1-2.5 parts of color master batches, 10-20 parts of lavender and 10-20 parts of geranium. The composite has excellent toughness and elasticity, the yoga ball made of the composite is free of peculiar smell and wear resistant, the mosquito repelling and mothproof effects can be achieved in summer, the yoga ball is not prone to being stuck to the skin when a person sweats, and the service life is long.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com