Polypropylene foaming masterbatch and production method thereof

A technology of foaming masterbatch and polypropylene, which is applied in the field of polypropylene foaming masterbatch and its preparation, can solve problems such as failure to consider cell dispersion and cell structure, difficulty in industrial production, high production cost, etc., and achieve The subsidence is not obvious, the effect of overcoming the high production cost and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Raw material formula:

[0033] 45 parts of polyethylene, 20 parts of foaming agent azodicarbonamide, 30 parts of nano-montmorillonite, 3 parts of glyceryl monostearate, 1.5 parts of zinc stearate, and 0.5 parts of polydimethylsiloxane.

[0034] preparation:

[0035] 1. Mix the foaming agent azodicarbonamide, glyceryl monostearate, zinc stearate and polydimethylsiloxane in a high-speed mixer for 10-15 minutes at a material temperature of 60-80°C to obtain Activated blowing agent;

[0036] 2. Mix polyethylene, nano-montmorillonite and activated foaming agent in a high-speed mixer for 5-8 minutes, and then extrude and granulate through an extruder to obtain a foaming masterbatch. The parameters of the extruder during extrusion and granulation are temperature 100-200°C, screw speed 200-400r / min, and feeding speed 30-60r / min.

[0037] The homopolypropylene and the foaming masterbatch prepared in this example were mixed in a high-speed mixer at a mass ratio of 97:3 for 3-5...

Embodiment 2

[0040] The preparation method of this example is the same as that of Example 1, except that the copolymerized polypropylene and the foaming masterbatch prepared in this example are mixed in a high-speed mixer at a mass ratio of 97:3 when preparing the polypropylene microfoaming material for 3 -5 minutes, then injection molding to obtain polypropylene micro-foaming material.

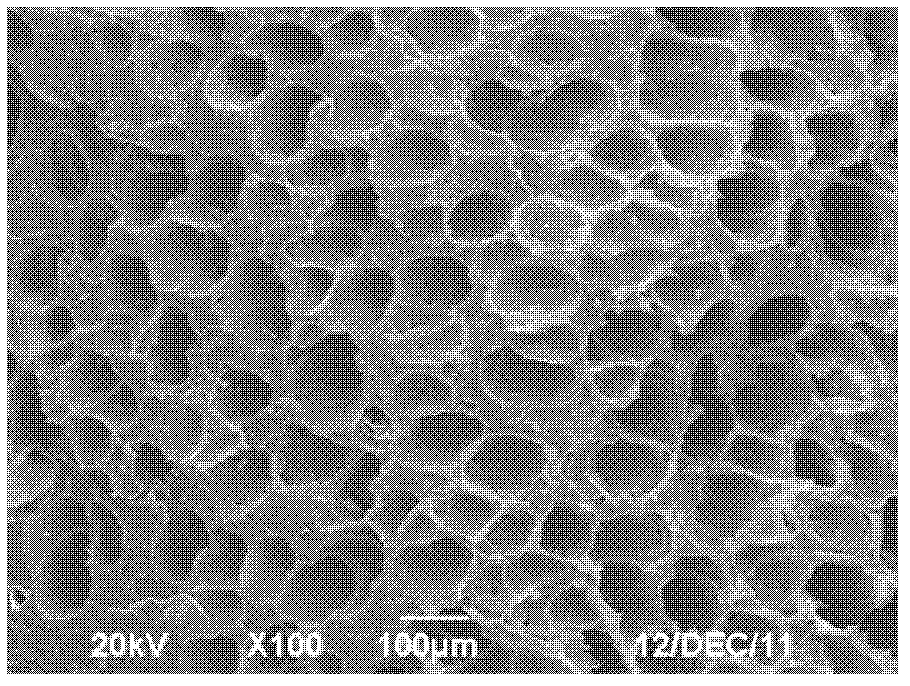

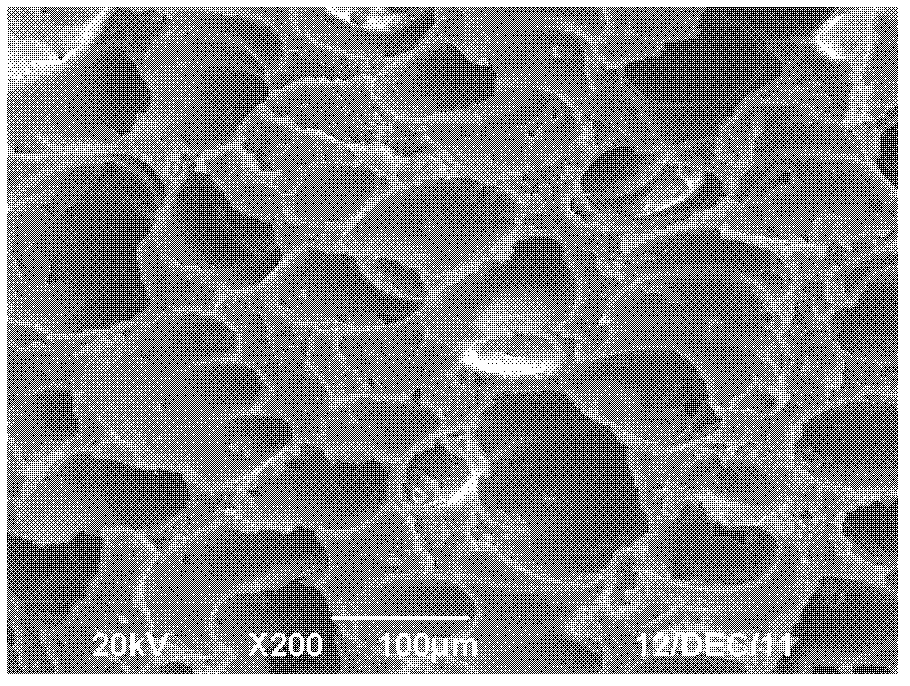

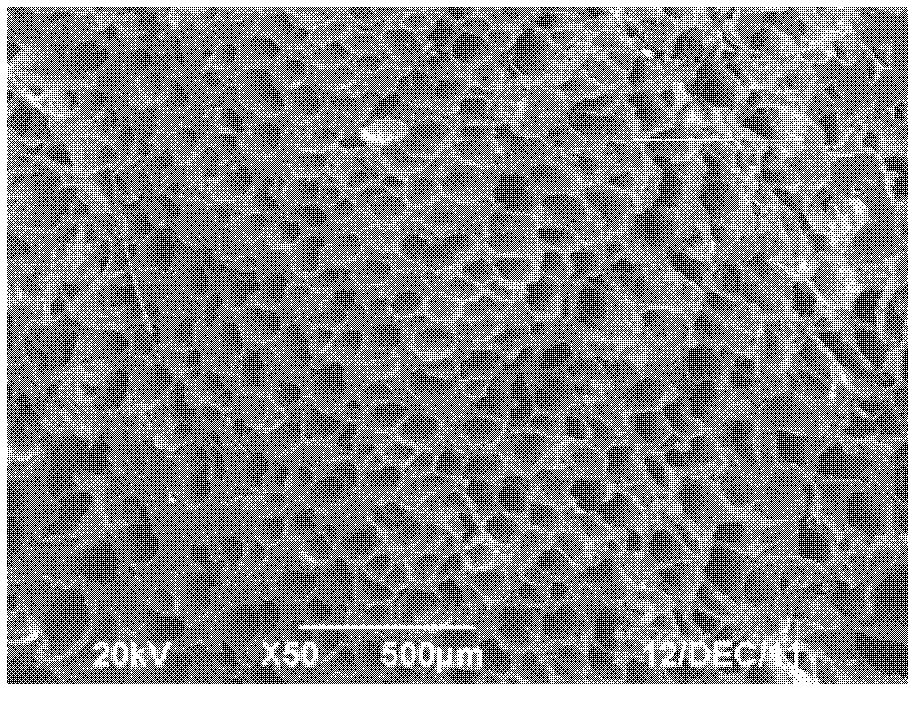

[0041] The photo of the cross-sectional cell structure of the polypropylene microfoam material prepared in this embodiment is shown in figure 2 . The tensile strength is 28.1MPa, the bending strength is 34.4MPa, and the impact strength is 48.5kJ / m 2 , the cell diameter is small and evenly distributed, and the density of the micro-foamed polypropylene composite material is 0.80g / cm 3 .

Embodiment 3

[0043] Raw material formula:

[0044] 40 parts of polyethylene, 25 parts of foaming agent azodicarbonamide, 30 parts of nano-montmorillonite, 2 parts of glyceryl monostearate, 1.5 parts of zinc stearate, 0.5 parts of polydimethylsiloxane, uniform Foam agent 1 part.

[0045] preparation:

[0046] 1. Mix the foaming agent azodicarbonamide, glyceryl monostearate, zinc stearate, polydimethylsiloxane and foam stabilizer in a high-speed mixer for 10-15 minutes, and the material temperature is 60- 80°C to get activated foaming agent;

[0047] 2. Mix polyethylene, nano-montmorillonite and activated foaming agent in a high-speed mixer for 5-8 minutes, and then extrude and granulate through an extruder to obtain a foaming masterbatch. The parameters of the extruder during extrusion and granulation are temperature 100-200°C, screw speed 200-400r / min, and feeding speed 30-60r / min.

[0048] The homopolypropylene and the foaming masterbatch prepared in this example were mixed in a high-sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com