Patents

Literature

5686 results about "Zinc stearate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc stearate is a "zinc soap" that is widely used industrially. In this context, soap is used in its formal sense, a metal "salt" of a fatty acid. It is a white solid that repels water. It is insoluble in polar solvents such as alcohol and ether but soluble in aromatic hydrocarbons (e.g., benzene) and chlorinated hydrocarbons when heated. It is the most powerful mold release agent among all metal soaps. It contains no electrolyte and has a hydrophobic effect. Its main application areas are the plastics and rubber industry, where it is used as a releasing agent and lubricant which can be easily incorporated.

Antioxidant and ultravioresistant polypropylene woven bag raw material

InactiveCN102766918AImprove antioxidant capacityImproves UV resistanceMonocomponent polyolefin artificial filamentArtifical filament manufactureUv absorberStearic acid

The invention discloses an antioxidant and ultravioresistant polypropylene woven bag raw material. The polypropylene woven bag raw material is added with anti-oxidant B215, anti-oxidant 1010, auxiliary anti-oxidant DLTP (dilauryl thiodipropionate) or DSTP (distearyl thiodipropionate), ultraviolet absorber UV531, light stabilizer GW-480, stearic acid, calcium stearate, calcium carbonate, mono-alkoxy titanate coupling agent YDH-101, and zinc stearate in powdered polypropylene, and then subjected to wiredrawing treatment in a drawing machine. Compared with the prior art, the raw material provided by the invention has advantages of good antioxidant and ultravioresistant properties, the raw material is particularly suitable for being used as woven bag raw materials, especially for being used as the raw material for manufacturing container bags.

Owner:尚勇

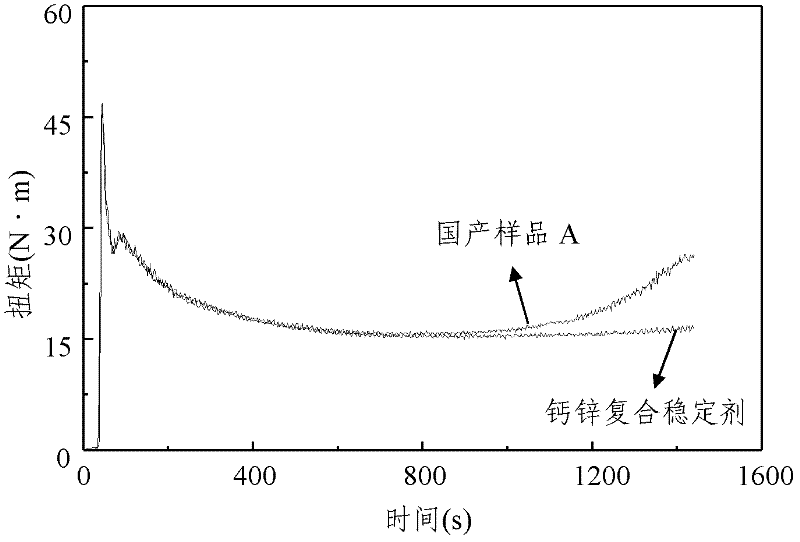

Powdery calcium-zinc complex heat stabilizer and preparation method and application thereof

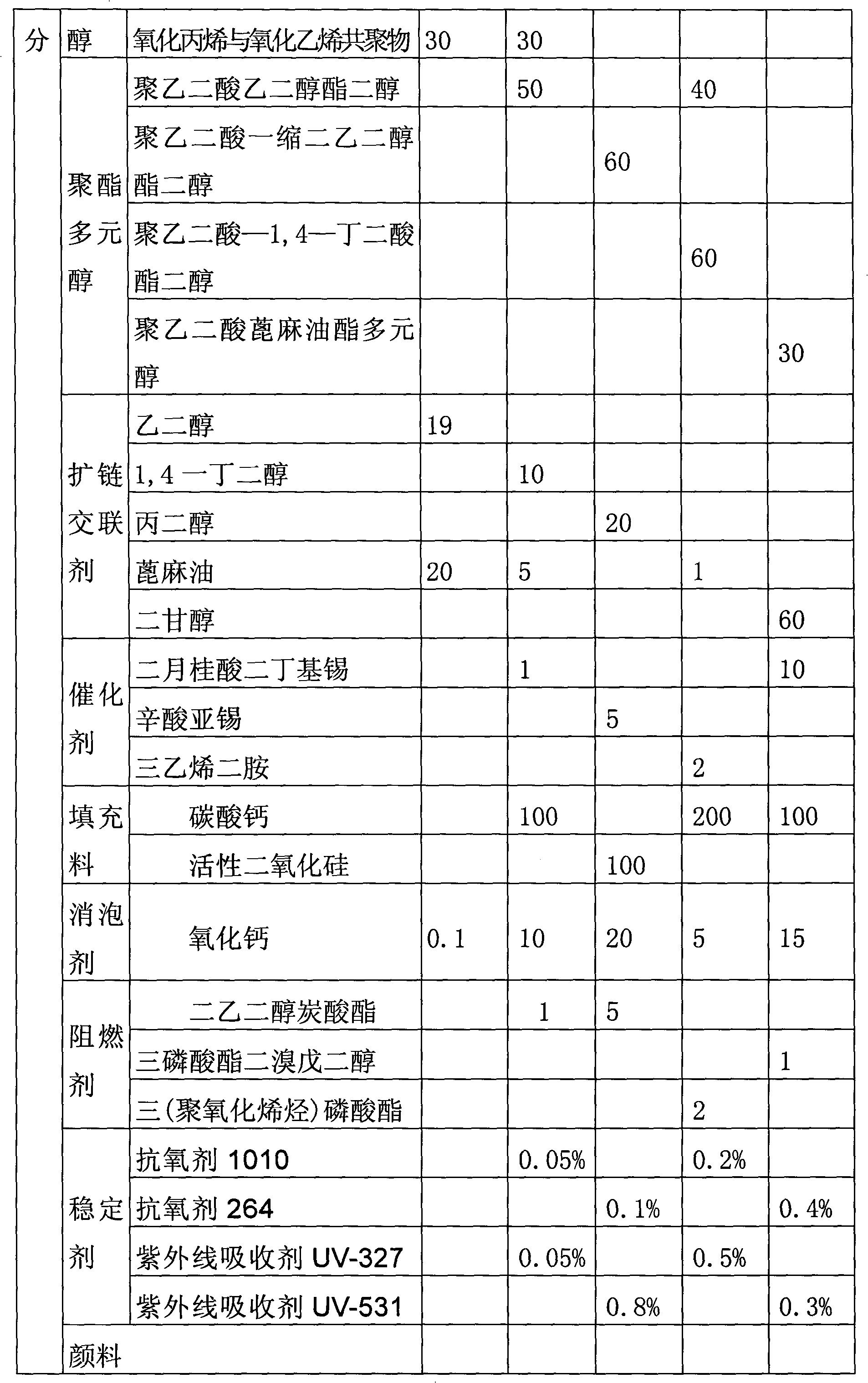

The invention discloses a powdery calcium-zinc complex heat stabilizer, which comprises the following components in weight ratio: 20-30 parts of zinc stearate, 15-25 parts of calcium stearate, 4-8 parts of epoxy compound, 15-25 parts of beta-diketone, 2-6 parts of antioxidant, 10-15 parts of polyatomic alcohol, 12-16 parts of inorganic assistant and 10-15 parts of lubricant. The powdery calcium-zinc complex heat stabilizer disclosed by the invention is capable of effectively delaying the generation of zinc-burning phenomenon of a system and improving the initial-stage and long-term heat stability of polyvinyl chloride (PVC), and moreover, the system has a good lubrication component, thus, the dispersion property and the processing property of the system in resin can be improved, thereby being beneficial to reducing energy consumption.

Owner:ZHEJIANG HIMPTON NEW MATERIAL

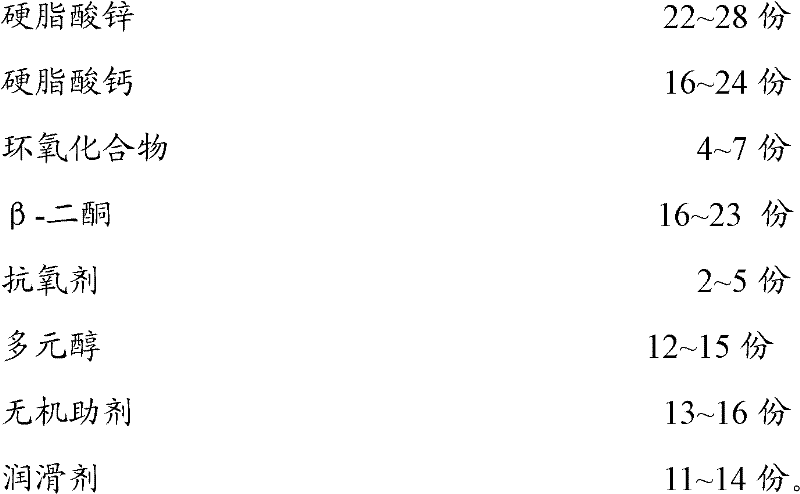

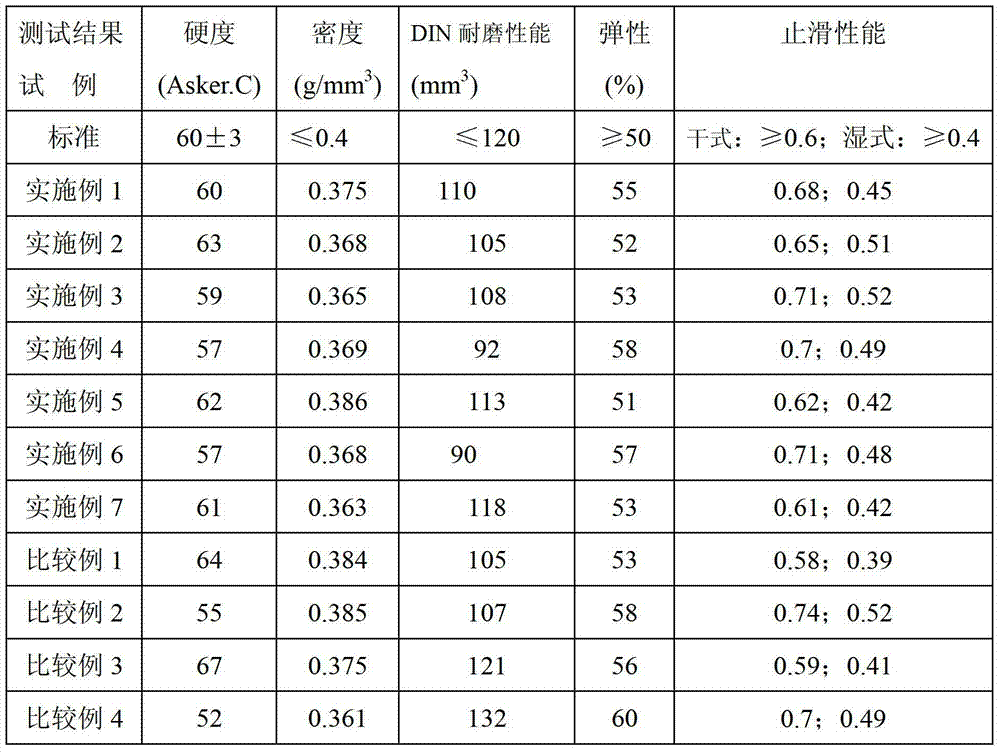

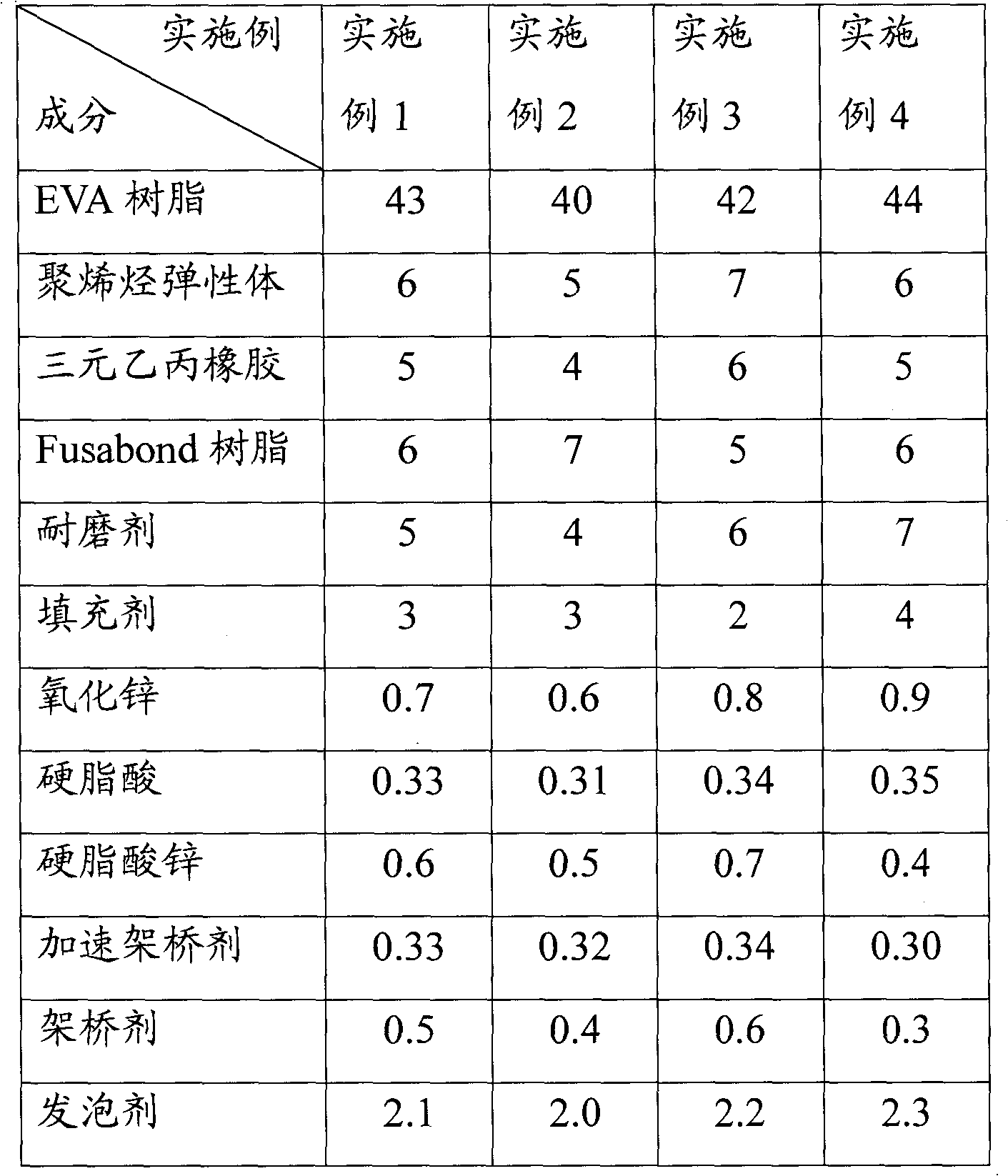

High-elasticity sneaker air cushion sole and production method thereof

The invention provides a high-elasticity sneaker air cushion sole and a production method thereof and researches a sneaker sole with high elasticity, high wear resistance and low hardness. The high-elasticity sneaker air cushion sole comprises a phylon (MD) midsole, an air cushion and a large sole which are sequentially and fixedly connected with one another from top to bottom, wherein an ethylene-vinyl acetate copolymer (EVA) cushion piece is assembled on a heel part of the air cushion; and the material formula of the MD midsole comprises the following components in parts by weight: 40-60 parts of EVA, 0-20 parts of ethylene propylene ternary gel, 0-30 parts of polyolefin elastomer (POE), 0-10 parts of talcum powder, 2.0-4.0 parts of a foaming agent, 0.6-1.0 part of a bridging agent, 1.0-2.0 part of a zinc oxide desulfurizing agent, 0.6-1.2 parts of stearic acid, 0.5-1.0 part of zinc stearate, 0.8-1.5 parts of a flow promotor and 0.3-0.8 part of a bridging addition agent.

Owner:新侨伟(福建)鞋服有限公司

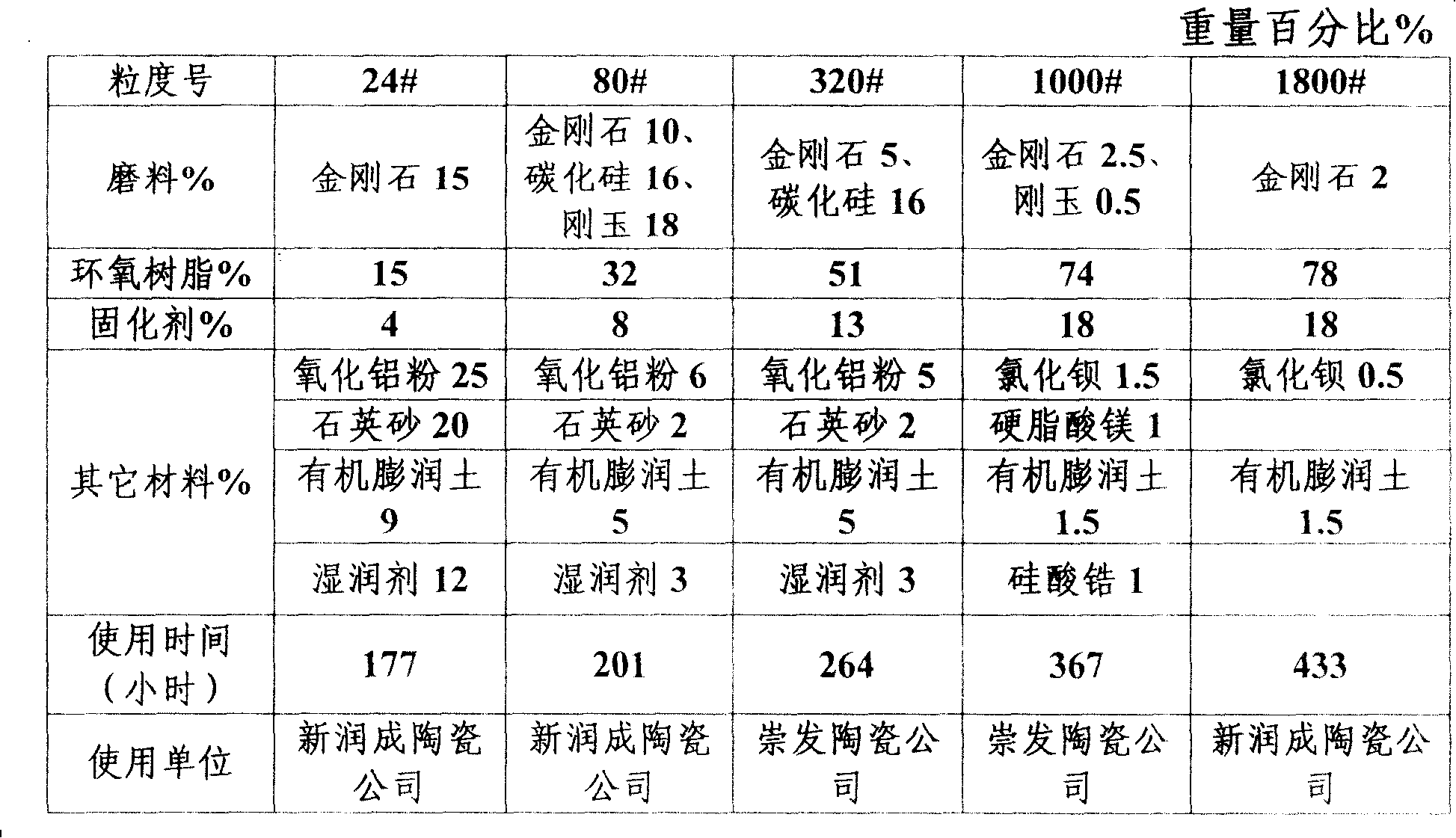

Abrasive tool of epoxy resin combined with compounded abrasive

Disclosed is an abrasive tool made of epoxy resin-bonded compound abrasive material, which comprises epoxy resin, abrasive material and curing agent. The weight percentages are as follow: the epoxy resin is 15 to 78 percent, the abrasive material is 2 to 44 percent and the curing agent is 4 to 18 percent. Wherein, the abrasive material comprises one of diamond, silicon carbide or corundum or the combination of more than one material. The curing agent comprises one of 4.4`-methylenedianil, solid diaminodiphenyl methane or liquid modified diaminodiphenyl methane or the combination of more than one material. The component of the abrasive tool also comprises the other auxiliary material, which comprises one of alumina, barium chloride, sodium chloride, quartz sand, organobentonite, wetting agent, zirconium silicate, calcium carbonate, graphite powder, garnet, magnesium sulfate, phenolic resin, zinc stearate and magnesium stearate, or the combination of more than one material. The product can be made into any shape the same with the present product, which can be applied in various grinding and polishing equipment with wide application scope.

Owner:广东奔朗新材料股份有限公司

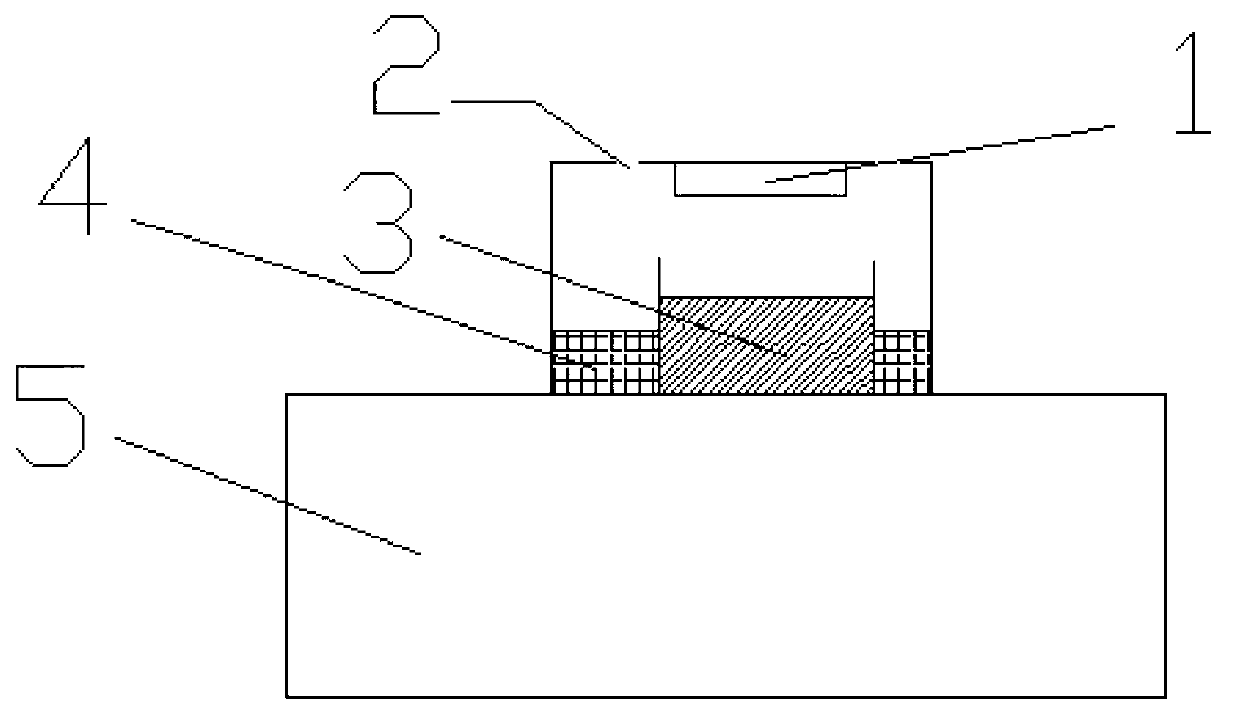

Steel-based copper alloy dual-metal sliding bearing and preparation method thereof

ActiveCN101649858ALow costImprove carrying capacityBearing componentsReflex reflectorsStearic acidLubrication

The invention discloses a dual-metal sliding bearing and a preparation method thereof. Carbon steel or stainless steel is taken as an outer layer material, and a powder metallurgy material taking a copper alloy as a basal body is taken as an inner layer material; the inner surface of the outer layer material is electroplated to form an electroplated copper layer with the thickness of 4-8 micrometres; the inner layer material comprises the following components by weight percent: 1%-20% of aluminum, 1%-8% of titanium, 1%-15% of stannum, 0.1%-5% of ferrum, 0.1%-2% of phosphorus, 0.1%-5% of nickel, at least one of 0.1%-2% of graphite and 0.1%-2% of molybdenum disulfide or 0.1%-2% of zinc stearate, and the balance of copper; and the bearing is impregnated with lubricating oil. The dual-metal sliding bearing has the advantages of low cost, high carrying capability, self-lubrication, excellent abrasion resisting capability, and the like, and can be widely applied to reciprocating swing positions of a swing arm, a bucket rod, a bucket, and the like of a large-tonnage and high-power excavator.

Owner:COB PRECISION PARTS

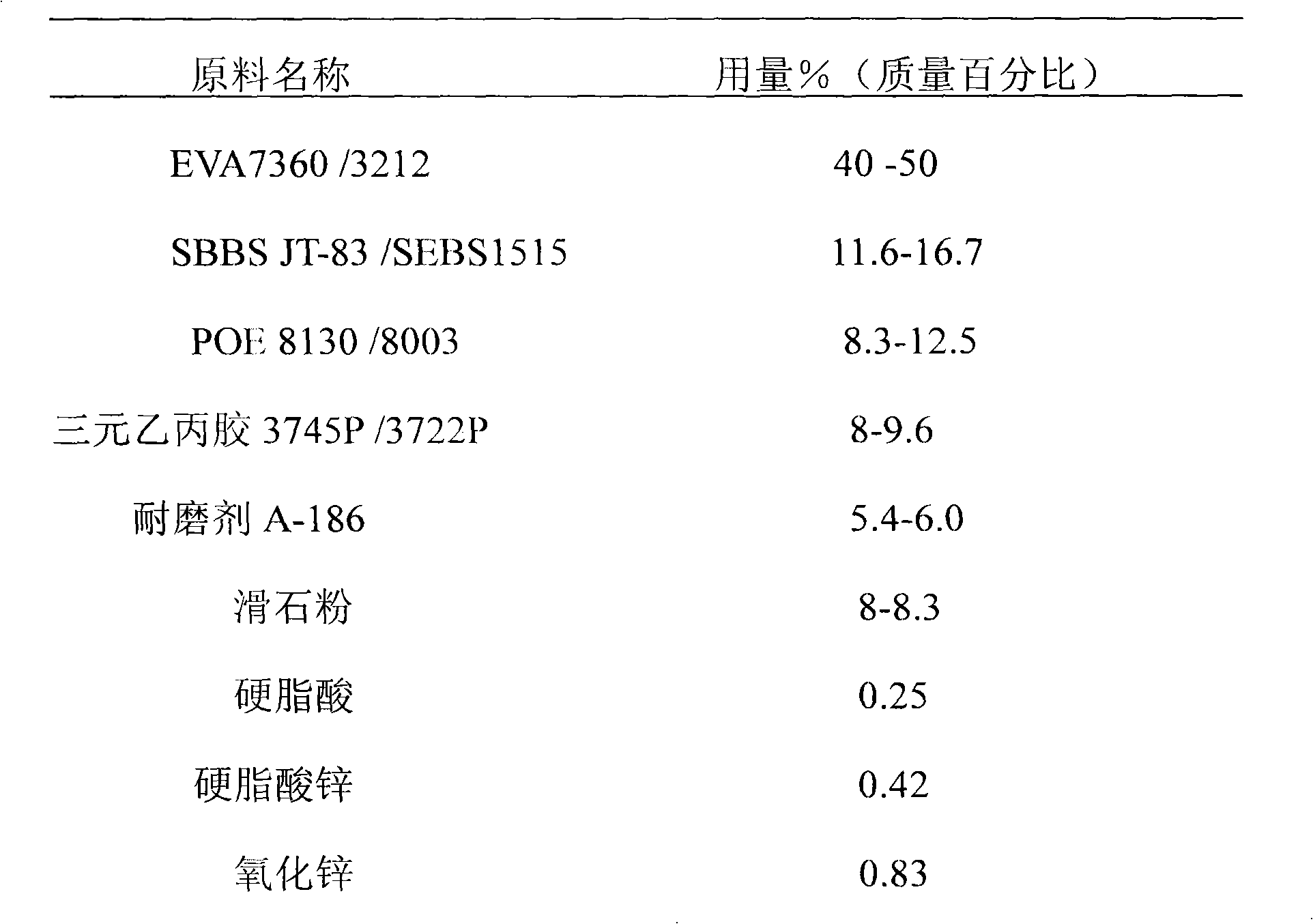

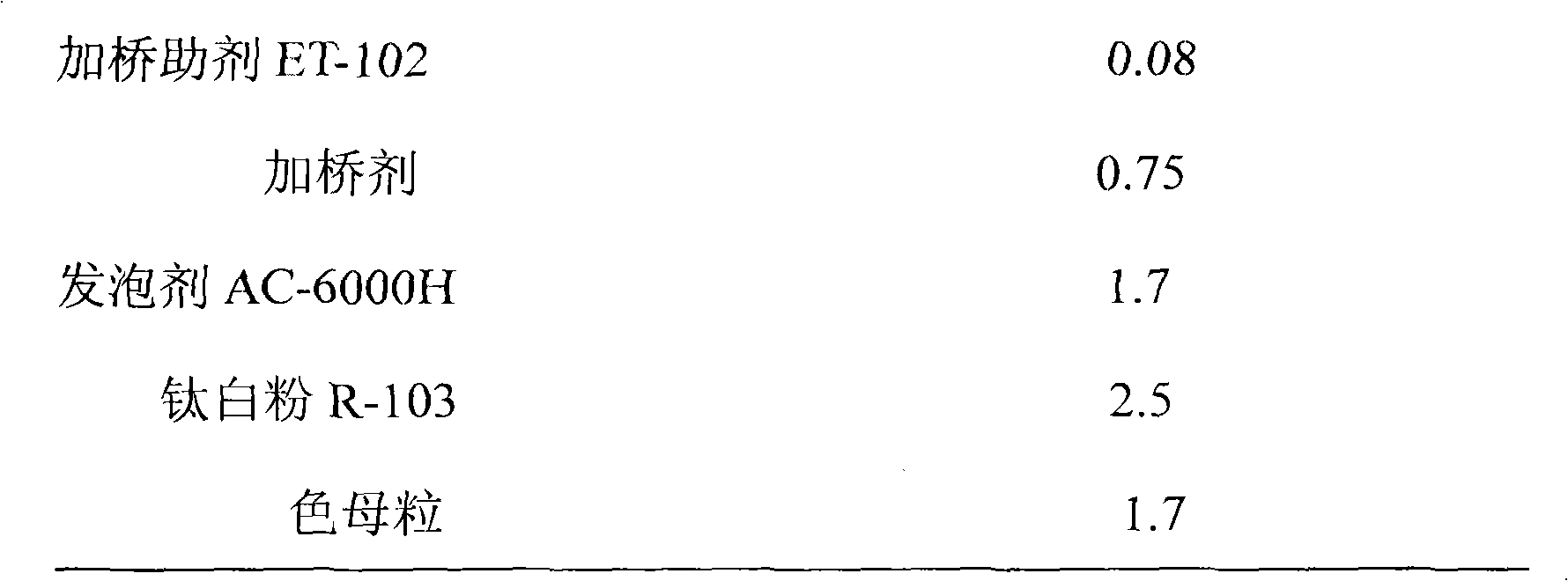

Formula of soles of PU-simulated foaming sneakers through injection and manufacturing method

The invention relates to a formula of soles of PU-simulated foaming sneakers through injection, which comprises the following raw materials in percentage by mass: 40 percent of 21 percent ethylene-vinyl acetate copolymer (EVA 7360), 16.7 percent of styrene butadiene copolymer SBBSJT-83, 12.5 percent of ethylene octylene copolymer POE8130, 8.3 percent of ethylene-propylene-diene copolymer 3745P, 65.9 percent of wear-resisting agent A-18, 8.3 percent of talcpowder, 0.25 percent of stearic acid, 0.42 percent of zinc stearate, 0.9 percent of zinc oxide, 0.08 percent of bridging auxiliary agent ET-102, 0.75 percent of bridging agent DCP, 1.7 percent of high-temperature foaming agent AC-6000H, 2.5 percent of titanium white powder R-103 and 1.7 percent of master batch. The preparation method comprises the steps of banburying, mixing, granulation, injection molding, physical property tests and the like. Thus, in the research and development and application, the PU-simulated foaming soles not only have the physical and chemical properties of no crease marks, high elasticity, low compression and wear resistance of PU soles, and but also have the advantages of low production cost, light specific gravity, good limited-slip properties, no hydrolysis and long service life.

Owner:泰亚投资集团有限公司

Expanding fire retardant composition without halide for polyolefine

The fire retardant composition consists of pentaerythritol phosphate 18-54 wt%, melamine polyphosphate 40-80 wt%, stearic acid or zinc stearate 0.1-5 wt%, coupling agent 0.1-5 wt% and stuffing 0.1-5 wt%. It is used as fire retardant for polypropylene powder or grains, and when the addition amount is 28 wt% fireproof level of UL94V-0 is reached; and is also used as fire retardant for polyethylene,and when the addition amount is 30 wt% fireproof level of UL94V-0 is reached.

Owner:BALING PETRO CHEM CO LTD SINOPEC

Powder metallurgy prescription and technique

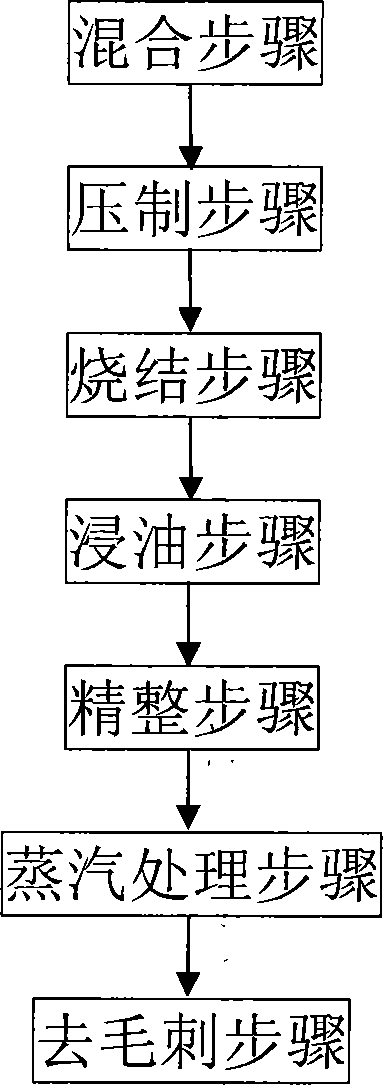

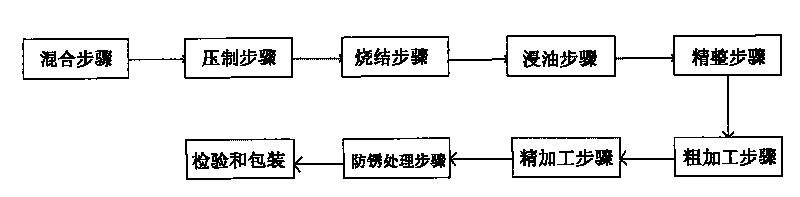

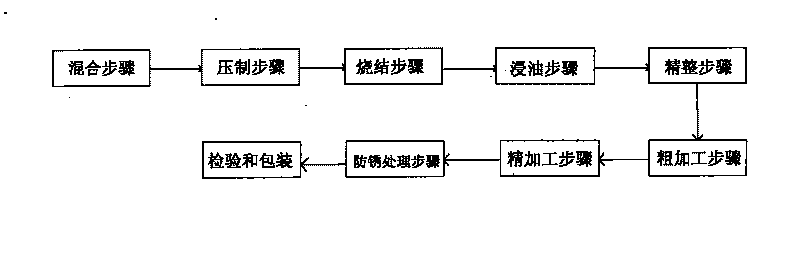

The invention discloses a metallurgic powder formulation and a process thereof. The metallurgic powder comprises graphite powder 0.05% to 5%, zinc stearate 0.08% to 7%, copper powder 0.1% to 10%, and iron powder in balance. The process comprises the following steps of: mixing, pressing, sintering, soaking in oil, finishing, treating by steaming, and deburring. Compared with prior art, the metallurgic powder has low cost and reliable product performance by adopting the formulation: graphite powder 0.05% to 5%, zinc stearate 0.08% to 7%, copper powder 0.1% to 10%, and iron powder in balance. Moreover, the process is properly optimized and simplified, and the steam treatment step can form a dense protection film on the product surface to improve the rustproof performance.

Owner:ZHEJIANG ZHONGPING POWDER METALLURGY

Clopidogrel bisulfate tablet formulation

Pharmaceutical tablets comprising clopidogrel bisulfate and a lubricant selected from zinc stearate, stearic acid, and sodium stearyl fumarate.

Owner:SHERMAN BERNARD CHARLES

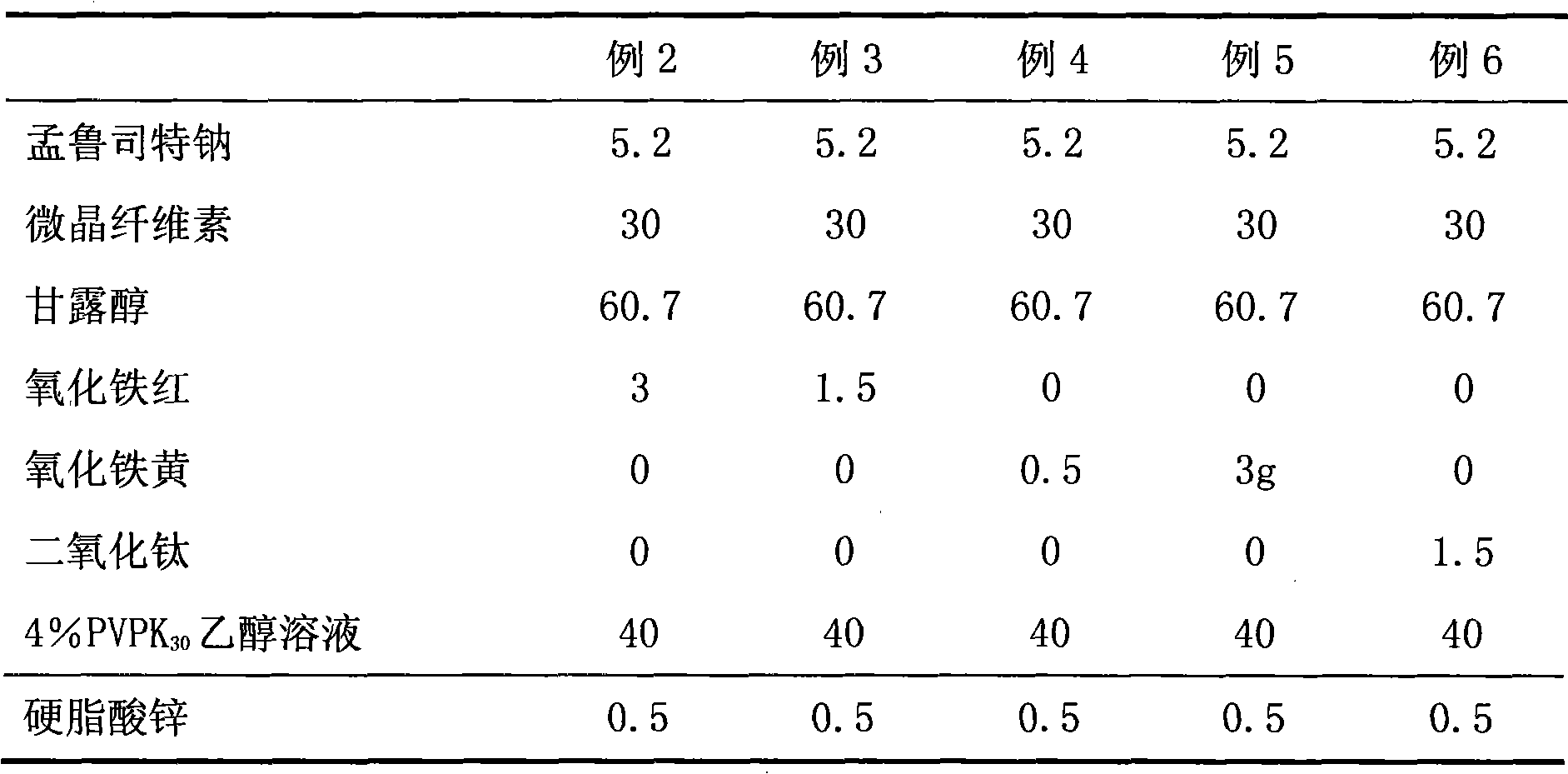

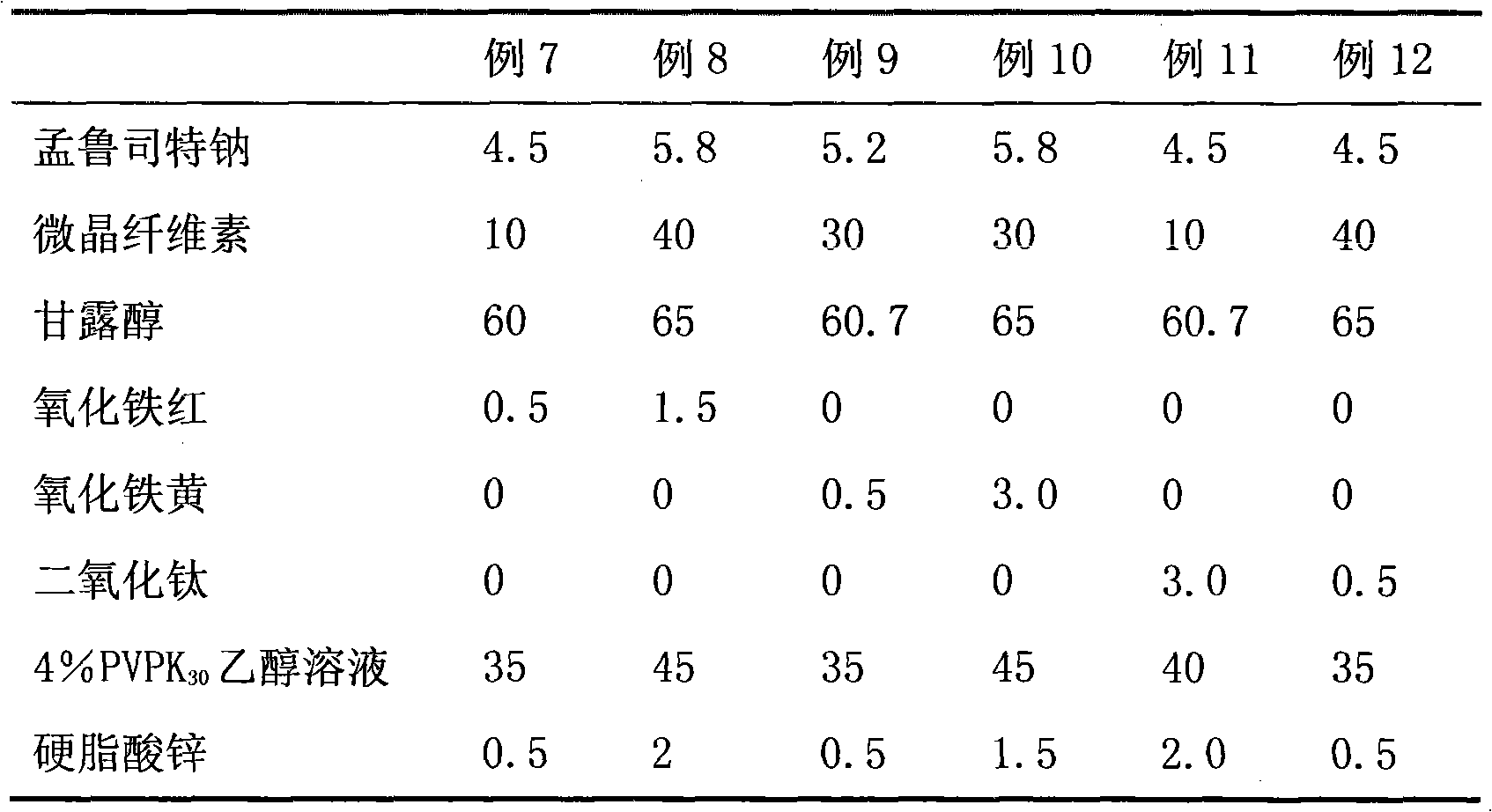

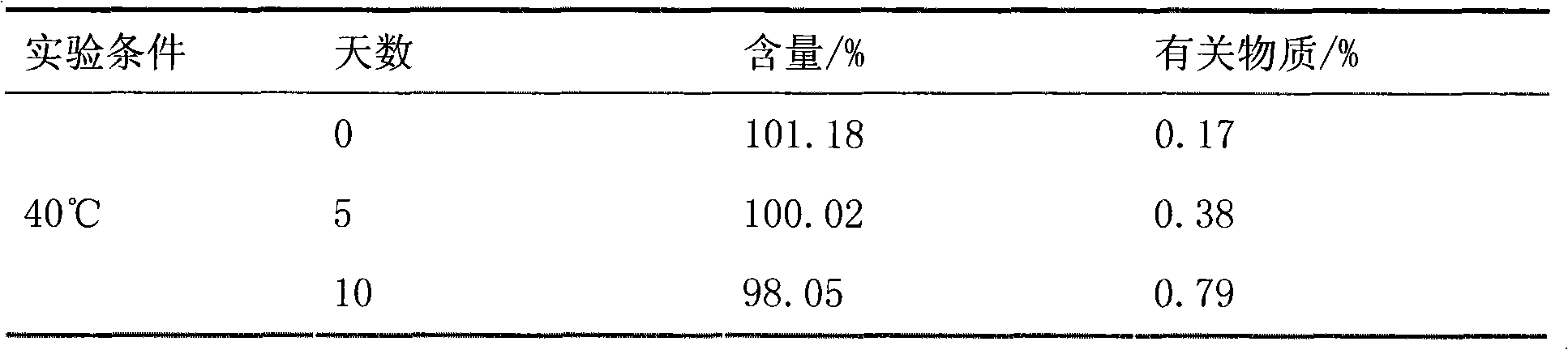

Chewable tablet containing montelukast sodium

ActiveCN101773481AImprove stabilityAvoid photolysisInorganic non-active ingredientsPill deliveryMedicineMontelukast Sodium

The invention belongs to the field of medicine preparations, which particularly relates to a chewable tablet of montelukast sodium. Because the production process of the chewable tablet of the montelukast sodium needs the light shielding operation at present, the mass production is inconvenient, and the chewable tablet of the montelukast sodium has the defect of poorer stability. In the invention, zinc stearate and an opacifier of iron oxide red, iron oxide yellow and titanium dioxide are added into the auxiliary materials of a chewable tablet of montelukast, so that the content of relevant substances can be lowered, and the stability of the chewable tablet is enhanced.

Owner:LUNAN PHARMA GROUP CORPORATION

Cementitious capillary crystalline waterproofing agent

InactiveCN101759414AImprove impermeabilityPromotes self-healingSolid waste managementSelf-healingSodium Bentonite

The invention discloses a cementitious capillary crystalline waterproofing agent, which contains the following raw materials in parts by weight: 50 parts of Portland cement; 25 parts of quartz sand; 9 parts of siliceous dust; 3 parts of calcium hydroxide; 2 parts of sodium bentonite; 1 part of kieselguhr; 3.9 parts of instant sodium silicate; 2.5 parts of aluminum potassium sulfate; 0.3 parts of zinc fluosilicate; 0.20 parts of sodium polyacrylate; 0.2 parts of hydroxypropyl methyl cellulose; 2 parts of zinc stearate; 0.5 parts of naphthalene water reducer; 0.2 parts of sugar lime; 0.1 parts of citric acid; and 0.1 parts of antifoaming agent. After the raw materials are weighed according to the proportions, the raw materials are ground into particles with grain size more than or equal to 200-mesh sieve in a ball mill to obtain the finished product. The invention has the advantages that the cost is low, the anti-permeability is good, the self-healing performance is good, the bonding power is strong, the steel bar corrosion is prevented, no toxicity and no harmfulness are caused and the construction is easy.

Owner:河南奥思达新材料有限公司

Magnetic toner and conductive developer compositions

Magnetic toner compositions, conductive developer compositions, and methods for producing images in a hybrid jumping development system, more specifically, in a magnetic ink character recognition system, are disclosed. The developer compositions contain coated magnetic toner particles and coated carrier particles. The toner compositions include a resin, colorant, wax, magnetic component, and surface additives of coated silica, titania, and zinc stearate.

Owner:XEROX CORP

Soles of ejection foamed rubber-plastic sports shoes and manufacturing method of soles

The invention relates to a pair of soles and particularly relates to a pair of soles of ejection foamed rubber-plastic sports shoes and a manufacturing method of the soles. The pair of soles of the ejection foamed rubber-plastic sports shoes consists of the following raw materials: an ethylene-vinyl acetate copolymer, an ethylene-octene copolymer, a hydrogenated styrene-butadiene-styrene block copolymer, an ethylene propylene diene monomer, polysiloxane resin, talcum powder, stearic acid, zinc stearate, zinc oxide, dicumyl peroxide, azobisformamide and masterbatch. The manufacturing method comprises the steps of: mixing the dicumyl peroxide and an azo foaming agent for later use, mixing other raw materials and then pouring into an internal mixer for first-stage internal mixing, then adding a mixture of the dicumyl peroxide and the azo foaming agent for second-stage internal mixing to obtain an internally mixed mixture, thinning the mixture on a roller machine, conveying the material which is evenly mixed by the roller machine into a granulator for granulation, proportioning aggregates after granulation according to set ratios, injecting the aggregates into a shoe mould by using an injection molding machine for molding, and sizing the molded soles into foamed profile products by using an incubator.

Owner:泉州泰亚鞋业有限公司

Photoconductor member with bound silicone oil

ActiveUS20060183041A1Improve the lubrication effectImprove wear resistanceElectrographic process apparatusCorona dischargeElectrical conductorMicrosphere

A charge transfer layer system that encapsulates or surrounds high viscosity silicone oils (polysiloxanes) using silicone microspheres, fluoropolymers such as polytetrafluoroethylene or inorganic particles such as silica, or metal soaps (zinc stearate). The encapsulation of the silicone oil results in aggregation or agglomeration of the silicone microspheres, fluoropolymers, or inorganic particles. The silicone oils have viscosity greater than 10,000 centistokes (cs) and the particles are about 6 μm or less.

Owner:LEXMARK INT INC

Plastic foam for sport shoe sole

The invention discloses a plastic foam for a sport shoe sole, which comprises the following components in part by weight: 70-74 parts of ethylene-vinyl acetate copolymer, 8-12 parts of ethylene-octylene copolymer, 6-10 parts of ethylene propylene ethylene-propylene-diene monomer, 8-12 parts of ethylene-acrylic acid copolymer, 8-9 parts of wear-resisting agent, 4-6 parts of filler, 1.0 -1.2 parts of zinc oxide, 0.5-0.6 part of stearic acid, 0.8-1.0 part of zinc stearate, 0.5-0.7 part of accelerate bridging agent, 0.8-0.9 part of bridging agent and 3.2-3.8 parts of foaming agent, wherein the ethylene propylene ethylene-propylene-diene monomeris a terpolymer of ethylene-propylene and non-conjugate diolefin. The plastic shoe sole of the sport shoe has the light weight performance, wear resistant performance and comfortable performance which are superior to those of a foam plastic formula injected by common IP, greatly reduces the physical consumption of athletes and has a plurality of performances such as durable comfort, durable buffer resistant performance and the like.

Owner:ANTA CHINA

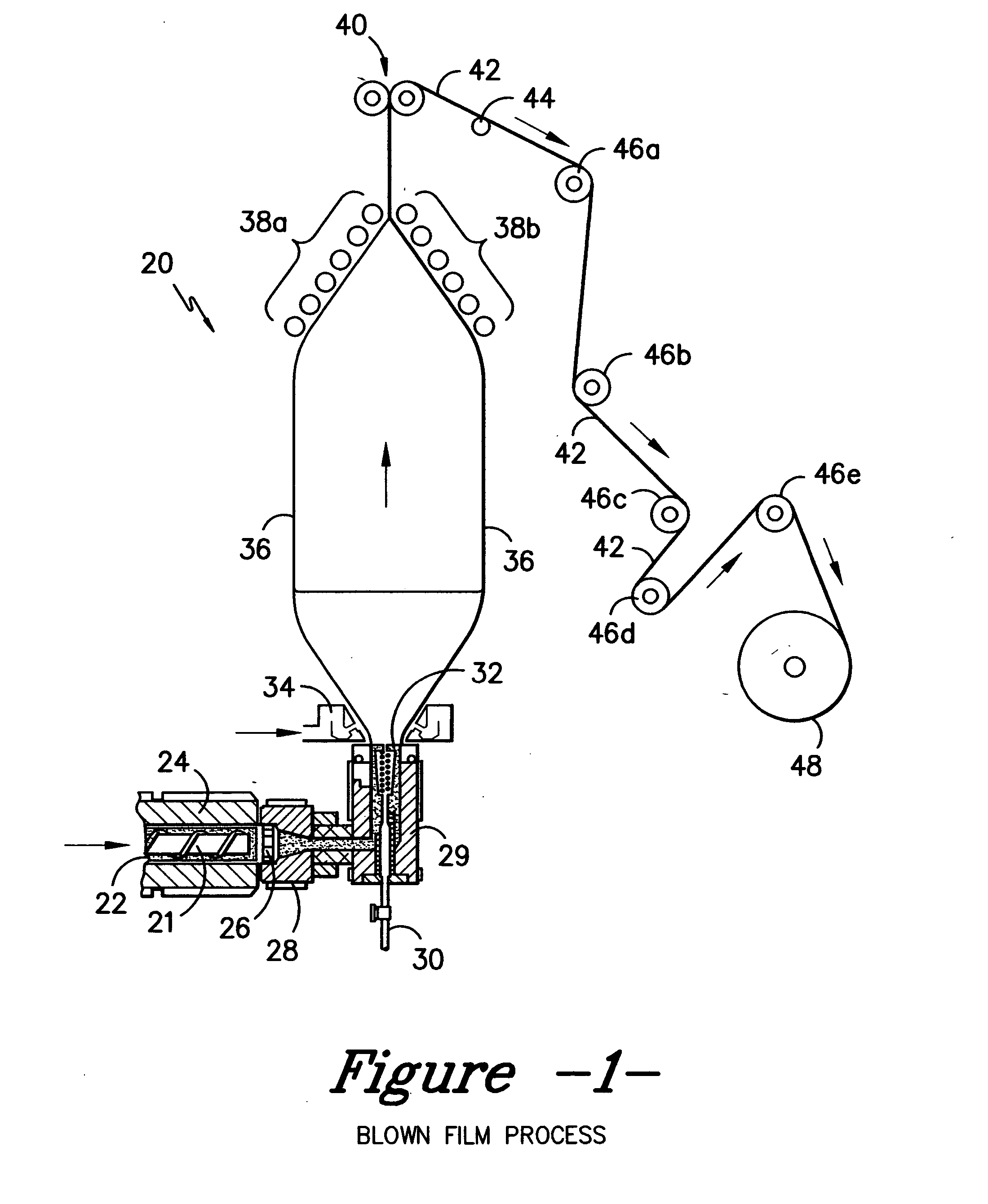

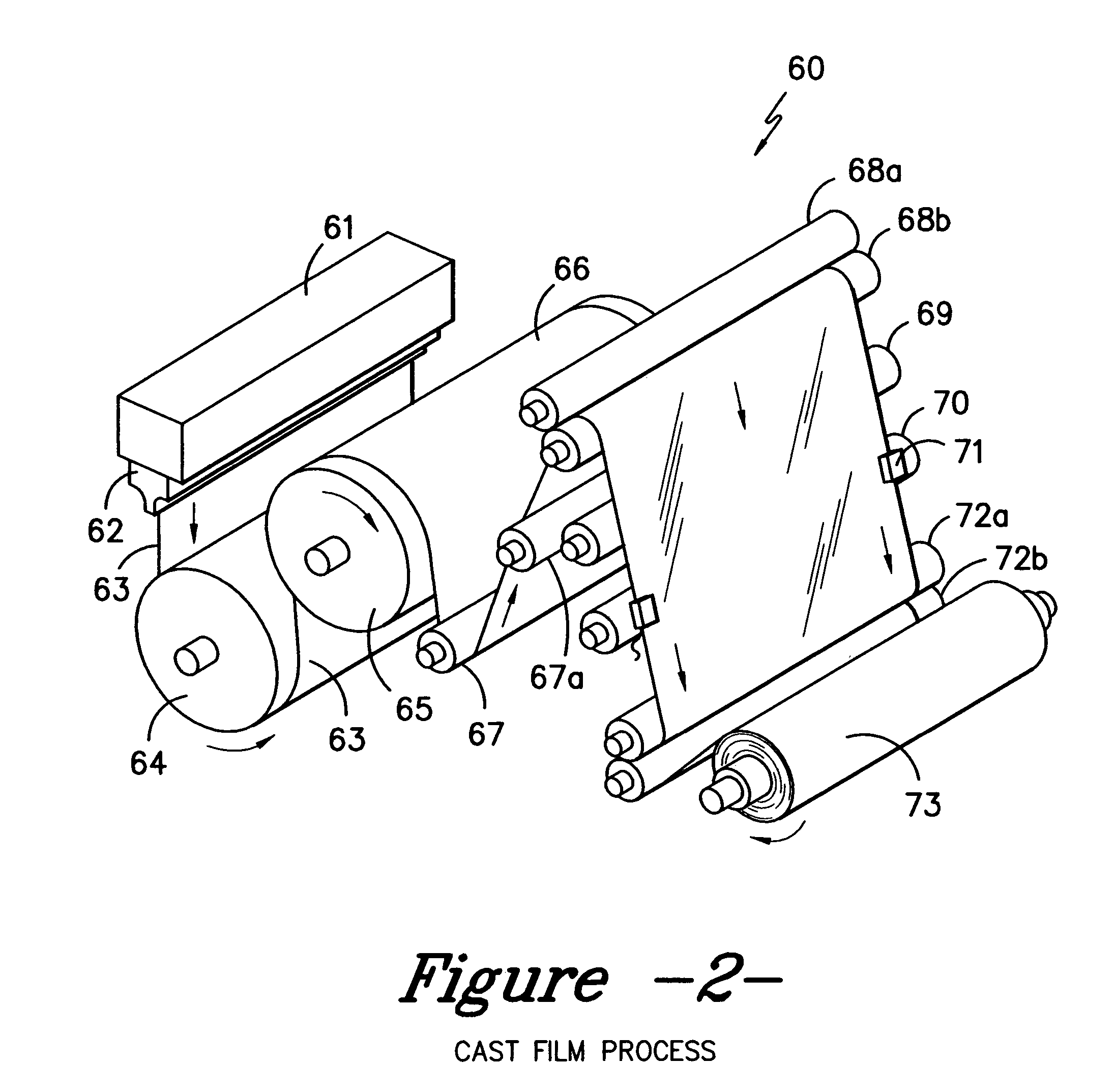

Film and methods of making film

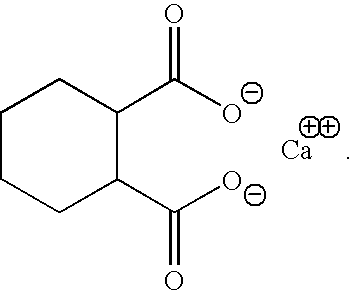

A film article comprising a polyethylene polymer or copolymer and a cycloaliphatic metal salt is disclosed. A method of making a blown and a cast polyethylene film is shown. The film may also include various additives that are employed to improve the properties of the film, including stearate-containing compounds. Additives employed in one embodiment of the invention may reduce the percent haze of film formed in the process, thereby providing desirably low levels of haze. Zinc stearate is one additive that can be employed in making a low haze polyethylene film.

Owner:MILLIKEN & CO

Modified nano mineral powder-containing aerated brick

The invention discloses a modified nano mineral powder-containing aerated brick. The aerated brick is prepared from the following raw materials by the conventional process for preparing the aerated brick: 25 to 30 weight parts of carbide slag, 5 to 10 weight pars of cement, 10 to 15 weight parts of quick lime, 5 to 10 weight parts of modified nano mineral powder, 5 to 10 weight parts of shell powder, 3 to 5 weight parts of gypsum, 0.05 to 0.1 weight part of aluminum powder, 0.002 to 0.008 weight part of lauryl sodium sulfate, 0.03 to 0.08 weight part of tea seed cake powder, 0.3 to 0.5 weight part of soda ash, 0.5 to 0.8 weight part of expanded vermiculite powder, 0.3 to 0.5 weight part of zinc stearate, 0.01 to 0.03 weight part of aluminum hydroxide, 0.05 to 0.1 weight part of sodium diacetate and an appropriate amount of water. By adding the nano mineral powder, the volume weight of the brick, and the energy consumption are reduced; the brick is high in thermal insulation performance and sound insulation performance; compared with the conventional aerated brick, the aerated brick has the advantages that the thermal insulation performance and the sound insulation performance are improved obviously; the raw materials are mixed according to an optimized formula; and the intensity and the freezing resistance of the brick are improved obviously.

Owner:广东合盛建筑工程有限公司

Polyvinyl chloride heat stabilizer and preparation method thereof

ActiveCN102898741ASimple preparation processApplication productivity is reliablePolyvinyl chlorideStearic acid

The invention discloses a novel environment-friendly type PVC heat stabilizer comprising 1,3-dimethyl-6-Aminouracil as a main stabilizing agent. The novel environment-friendly type PVC heat stabilizer comprises the following ingredients: 1-5weight parts of 1,3-dimethyl-6-Aminouracil, 10-100 weight parts of epoxy soybean oil, 3-10 weight parts of calcium stearate, 3-10 weight parts of zine stearate, and 2-15 weight parts of organic auxiliary agent. According to the invention, the heat stabilizer disclosed herein significantly raises the stability of PVC materials in the processing process; and compared with traditional stabilizing agents, the heat stabilizer disclosed herein contains no heavy metal, and is an environment-friendly efficient novel heat stabilizer.

Owner:太原市塑料研究所

Starch-polyvinyl alcohol dual-degradationplastic film

The invention discloses a starch-polyvinyl alcohol dual-degradationplastic film, and relates to the technical field of film production. The starch-polyvinyl alcohol dual-degradation plastic film is made by using the following raw materials, by mass, 50-65 parts of starch, 15-30 parts of polyvinyl alcohol, 5-10 parts of Sa-son seed gum, 2-8 parts of hydroxy propyl cellulose, 5-10 parts of pulullan polysaccharide, 3-6 parts of nanometer silica, 5-10 parts of zinc stearate, 4-8 parts of oxidized polyethlene wax, 2-4 parts of ethyl silicon oil, 3-5 parts of calcium carbonate, 4-10 parts of glutaraldehyde and 3-5 parts of octodecyl alcohol. The plastic film made in the invention has biological and optical degradation effects, can effectively solve the white pollution problem caused by difficult degradation of common plastic films, and has the advantages of simple production technology, low cost and industrial production benefiting.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

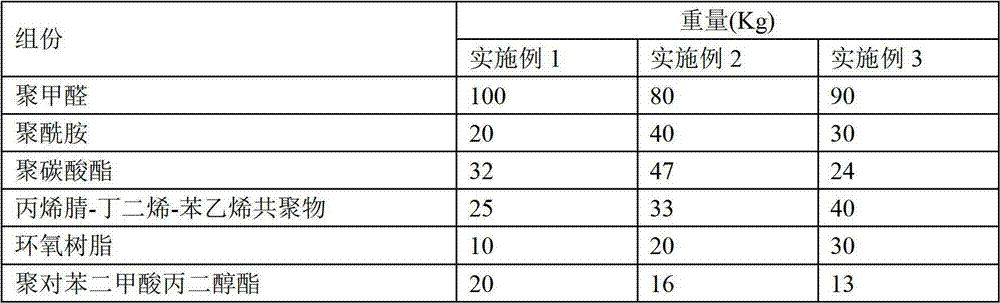

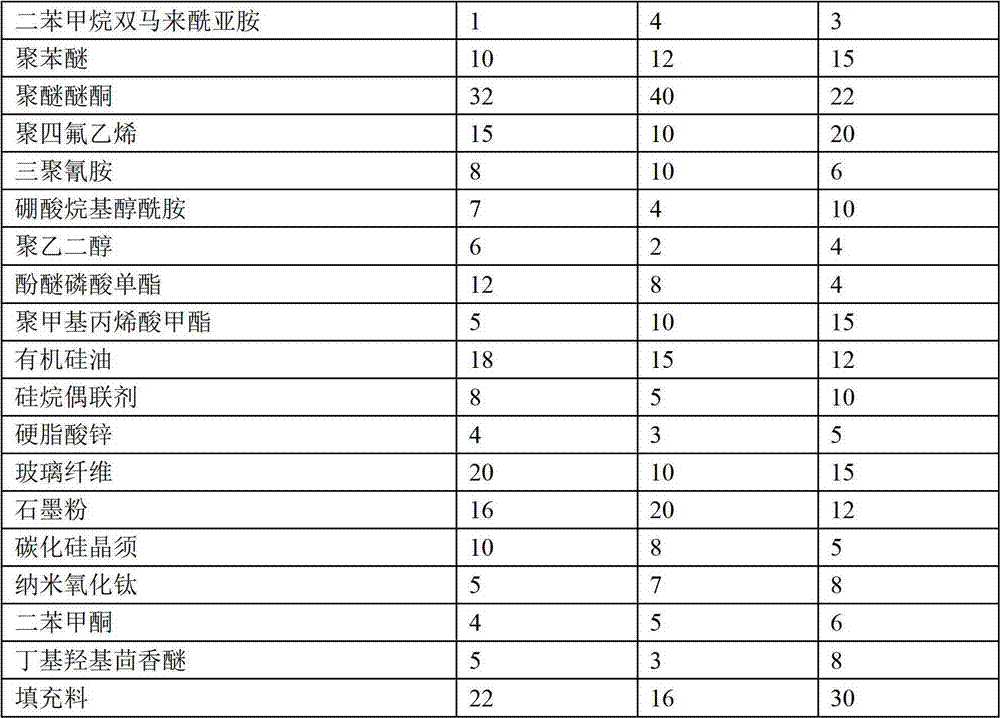

Engineering plastic with high wearing resistance

InactiveCN102875956AGood mechanical propertiesReduce wear ratePolyethylene glycolPolymethyl methacrylate

The invention provides an engineering plastic with high wearing resistance. The engineering plastic is made from the following raw materials by weight: 80-100 parts of polyformaldehyde, 20-40 parts of polyamide, 20-50 parts of polycarbonate, 25-40 parts of acrylonitrile-butadiene-styrene copolymer, 10-30 parts of epoxy resin, 12-20 parts of polytrimethylene terephthalate, 1-5 parts of diphenylmethane bismaleimide, 10-15 parts of polyphenyl ether, 20-40 parts of polyether-ether-ketone, 10-20 parts of polytetrafluoroethylene, 5-10 parts of melamine, 4-12 parts of boric acid alkanolamide, 2-6 parts of polyethylene glycol, 4-12 parts of phenolic ether phosphomonoester, 5-15 parts of polymethyl methacrylate, 10-20 parts of organic silicone oil, 5-10 parts of silane coupling agent, 3-5 parts of zinc stearate, 10-20 parts of glass fibre, 12-20 parts of graphite, 5-10 parts of silicon carbide whisker, 5-8 parts of nanometre titanium oxide, 4-6 parts of diphenyl ketone, 3-8 parts of butylated hydroxyanisole and 15-30 parts of filler. The engineering plastic provided by the invention has a good wear-resisting property.

Owner:SUZHOU YUNYUAN NETWORK TECH

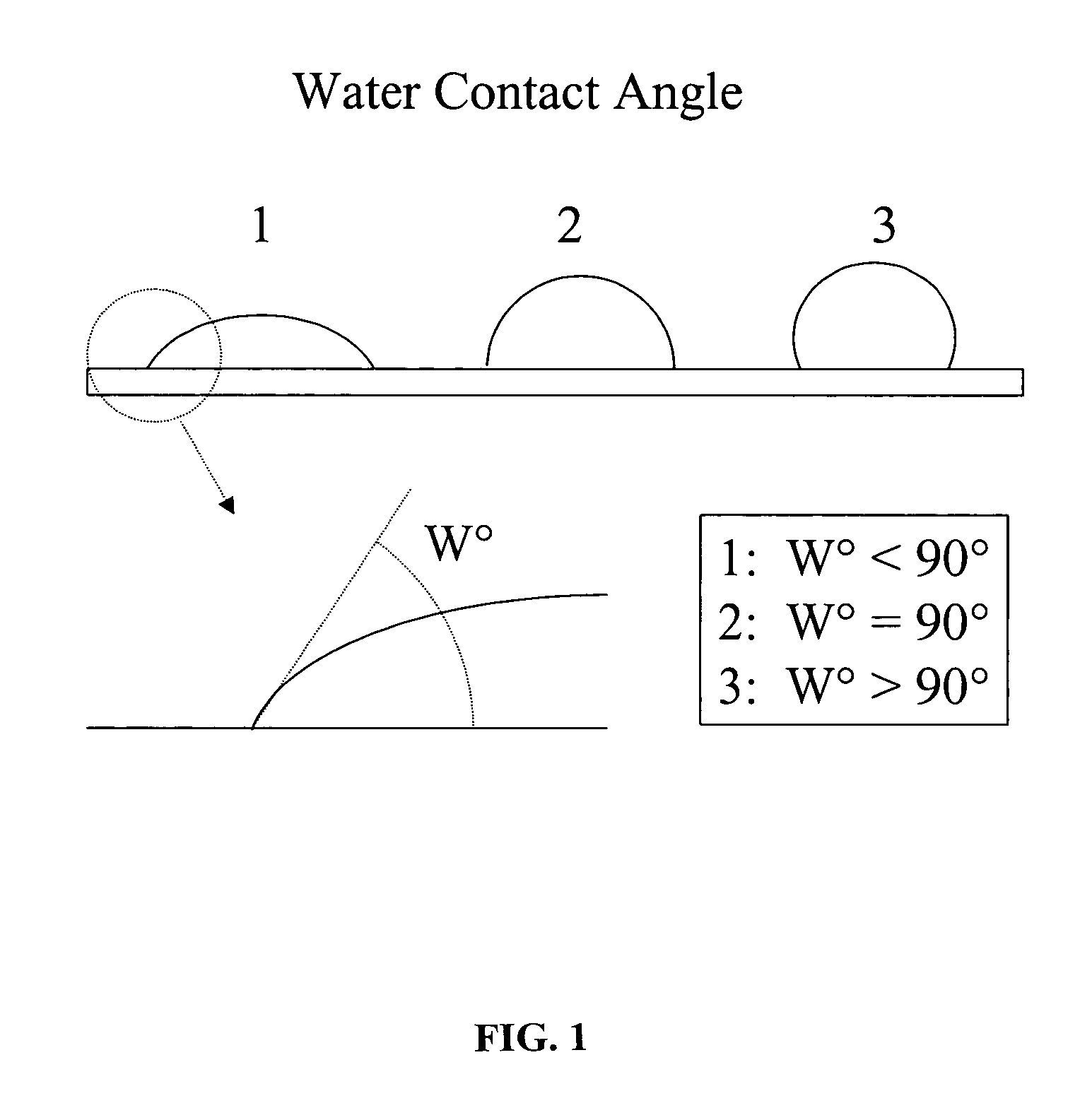

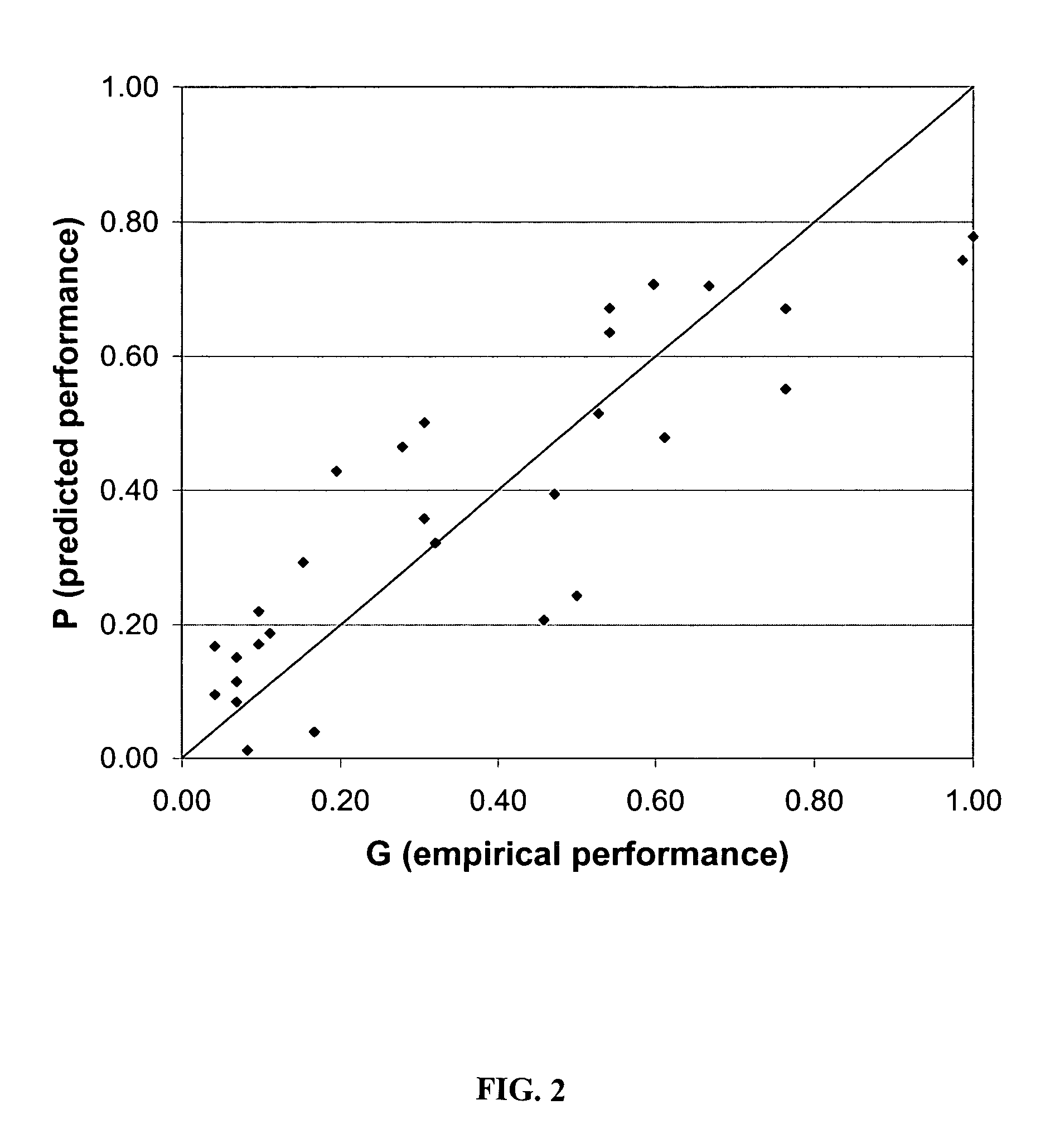

Antiloading compositions and methods of selecting same

ActiveUS20050085167A1Low costQuality improvementPigmenting treatmentOther chemical processesSimple Organic CompoundsZinc stearate

An antiloading composition includes a first organic compound. The compound has a water contact angle criterion that is less than a water contact angle for zinc stearate. The first compound also satisfies at least one condition selected from the group consisting of a melting point Tmelt greater than about 40° C, a coefficient of friction F less than about 0.3, and an antiloading criterion P greater than about 0.3. Another embodiment includes a second organic compound, having a different water contact angle from that of the first organic compound. The composition has a particular water contact angle W°p that is determined, at least in part, by the independent W°g of each compound and the proportion of each compound in the composition. Also, an abrasive product includes the antiloading composition. A method of grinding a substrate is disclosed that includes employing effective amount of an antiloading composition. Further disclosed is a method of selecting an antiloading compound.

Owner:SAINT GOBAIN ABRASIVES INC

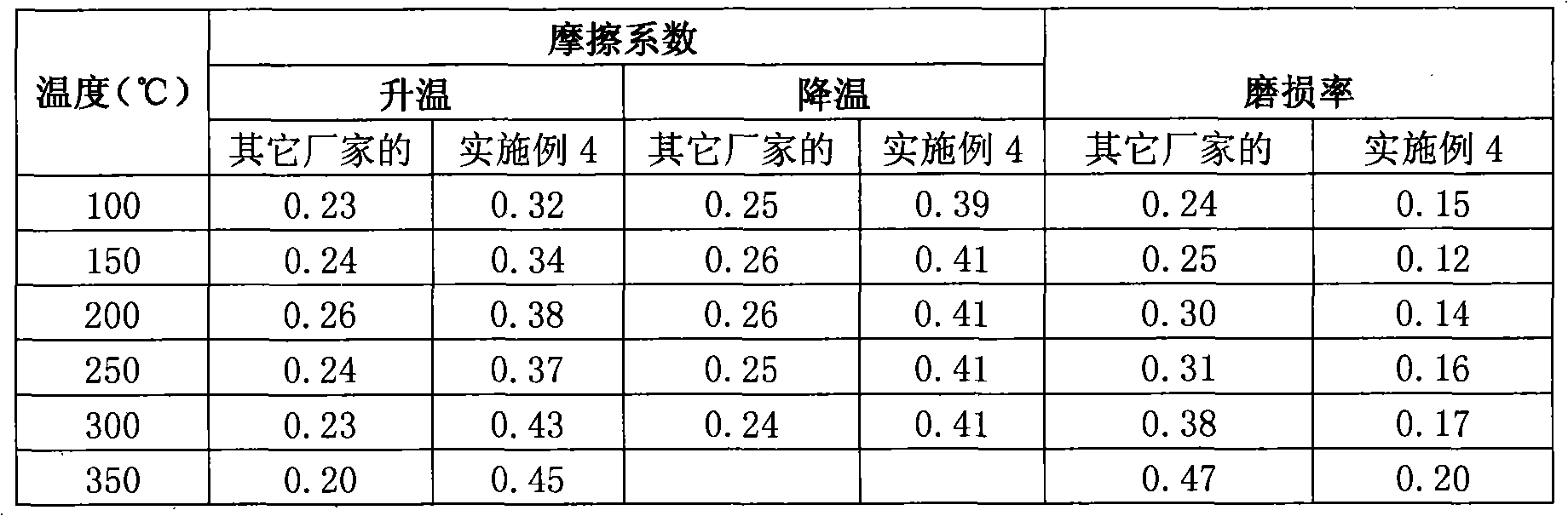

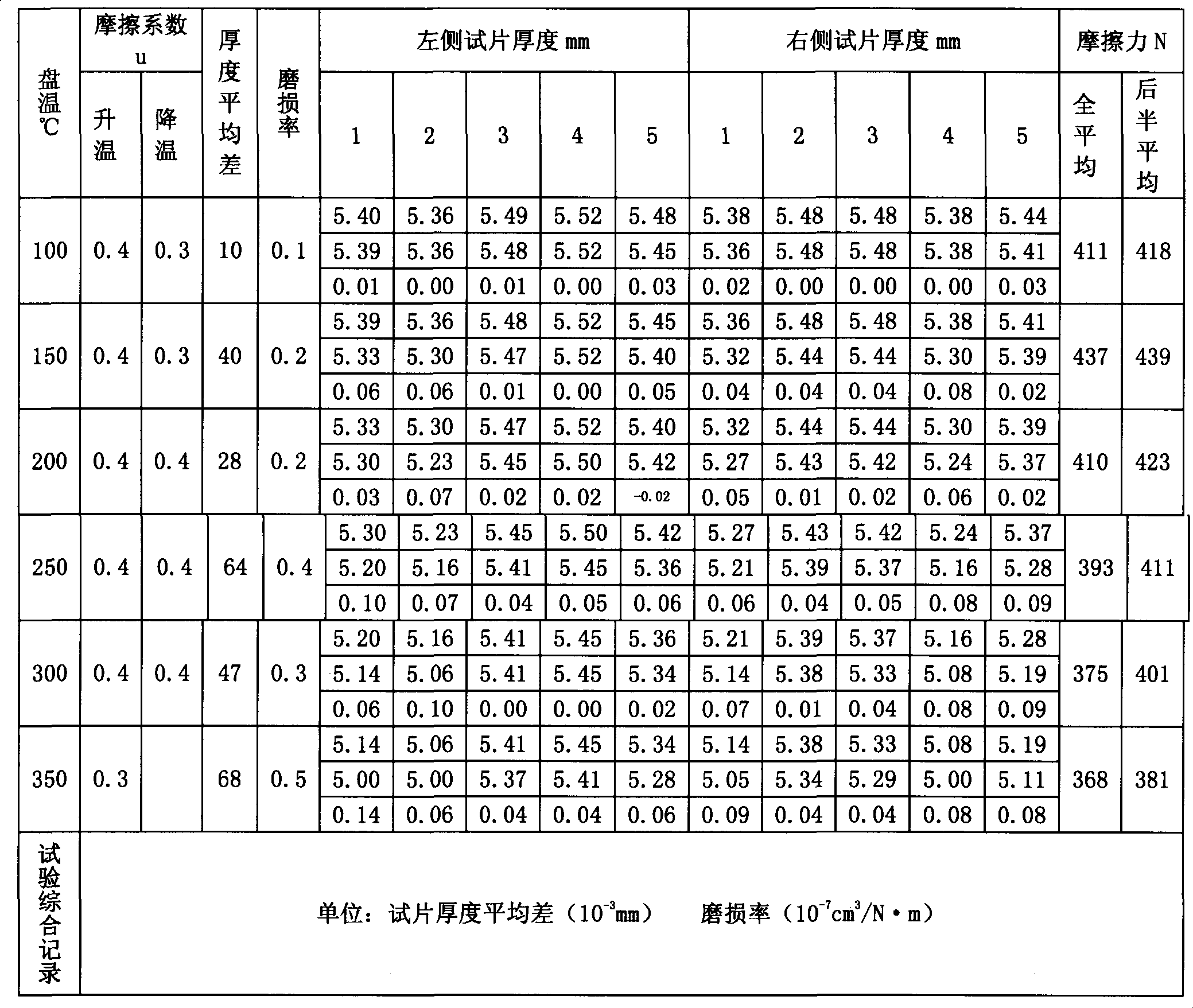

High-performance semi-metallic brake pad

ActiveCN101555915ASensitive brakesReduce brake noiseFriction liningGraphite particleAluminium silicate

A high-performance semi-metallic brake pad comprises the following components according to weight percentages: 4-6% of nitrile rubber powder, 2-4% of tyre powder, 3-5% of crystalline flake graphite, 6-9% of foam iron powder, 9-13% of boron containing phenolic resin, 8-12% of chopped steel fibre, 2-4% of alumina fibre, 8-11% of red copper fibre, 2-5% of cashew nut oil friction powder, 2-3% of graphite particle, 2-3% of calcined petroleum coke, 7-13% of barite, 3-4% of chromite, 2-3% of magnetite, 2-4% of diatomite, 7-10% of glued aluminium silicate fibre, 3-5% of flake aluminium powder, 2-4% of molybdenum disulfide, 0.2-0.5% of zinc stearate, 0.7-1% of antimony sulphide, 0.5-1% of copper sulphide, and 0.3-0.5% of tungsten carbide. After the brake pad is used, the car brake is sensitive, brake noise is low and comfort performance is good. The brake drum or brake disc has no damage in long-term use.

Owner:摩擦一号制动科技(仙桃)有限公司

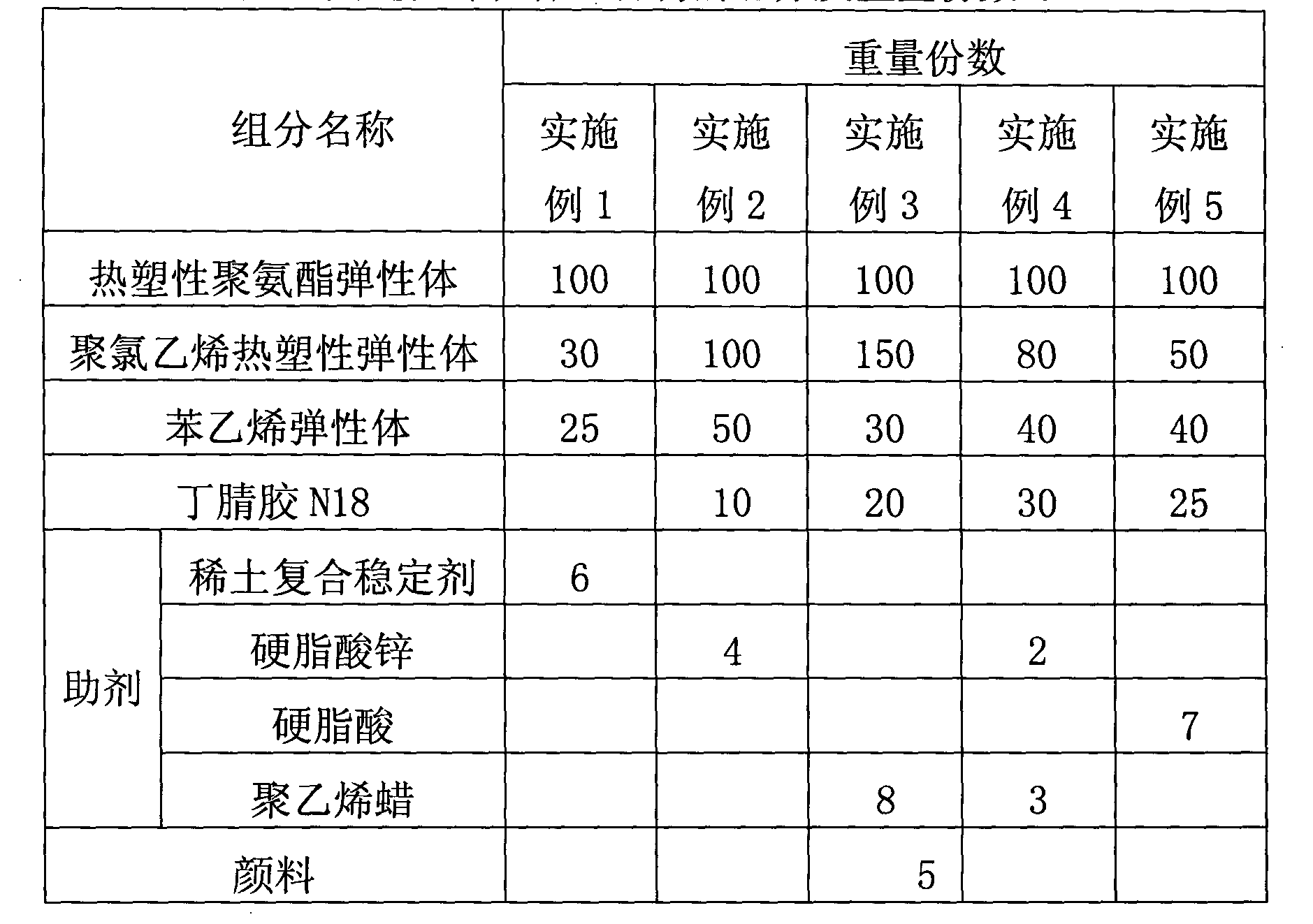

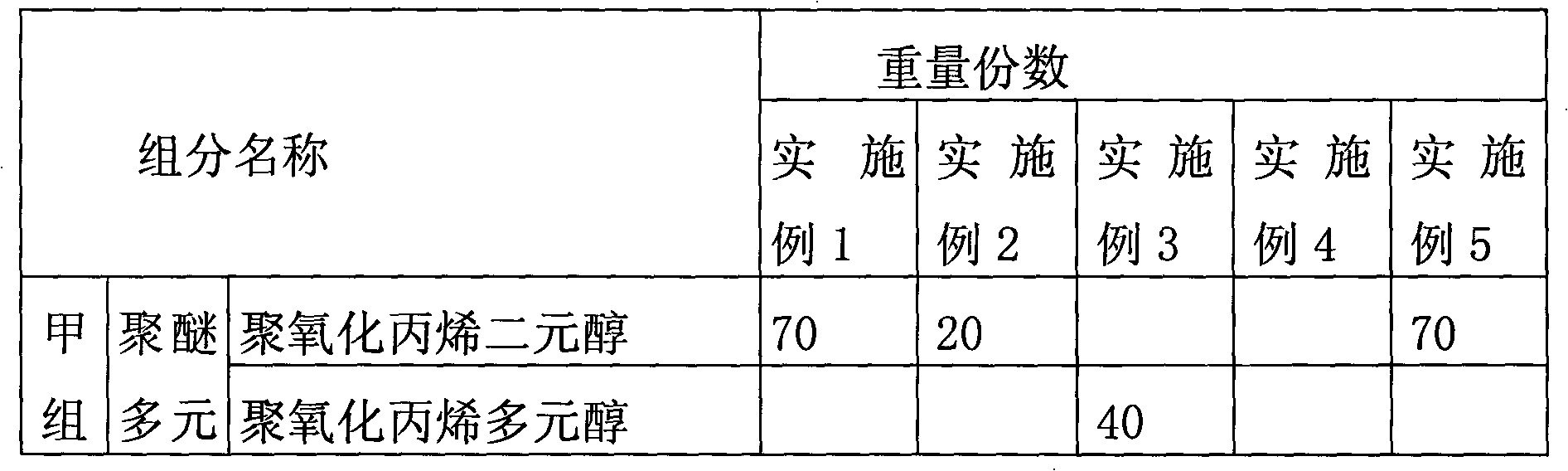

Thermoplastic elastomer composition

The invention discloses a thermoplastic elastomer composition which is plasticated by the following main components by weight: 100 parts of polyurethane thermoplastic elastomers, 30-150 parts of polyvinyl chloride thermoplastic elastomers, 25-50 parts of styrene elastomers, 0-30 parts of blend and 4-8 parts of auxiliaries, wherein the auxiliary is any one or more of a composite rare-earth stabilizer, zinc stearate, calcium stearate, stearic acid or polyethylene wax; and the blend is butyronitrile N18. The invention selects the thermoplastic elastomers with similar polarity and complementary properties to be synthesized and used and selects compatilizers to organically combine several best molecules with different structures, so that the generated novel thermoplastic elastomer has superior performance and appropriate price, can meet the requirements of market products and has wide application range because the product has the technical advantages of excellent oil resistance, resistance to low temperature of minus 35 DEG C, acid-alkali resistance, aging resistance and lower proportion than the vulcanized products with the same price.

Owner:营口巨成教学科技开发有限公司 +1

Polyethylene wood plastic and preparation method thereof

The invention relates to a polyethylene wood plastic and a preparation method thereof and belongs to the technical field of plastic compound modifying processing. The invention provides a formula of the polyethylene wood plastic and a preparation method for a section bar; extruding temperature and extruding speed are increased; a polyethylene wood plastic section bar produced according to the preparation method has excellent high-temperature resistance; and according to the technical scheme, the polyethylene wood plastic comprises the following raw materials in parts by weight: 30-40 parts of polyethylene, 50-70 parts of wood flour, 0.5-2 parts of maleic anhydride grafted polyethylene, 0.8-1.5 parts of polyethylene wax, 1-3 parts of zinc stearate, 2-6 parts of toner, 0.5-1 part of antioxidant, 0.4-0.9 part of anti-ultraviolet light absorber UV-531 and 0.5-1.2 parts of stearic acids. The preparation method provided by the invention is suitable for the extruding molding of the polyethylene wood plastic section bar.

Owner:山西峰岩新型建材股份有限公司

Zn-Ca compound stabilizer

The invention discloses a Zn-Ca compound stabilizer, comprising the following components in parts by weight: 28-35 parts of zinc stearate, 8-11 parts of calcium stearate, 18-32 parts of hydrotalcite, 14-22 parts of polyalcohol, 4.5-10.5 parts of Stearoylbenzoylmethane, 3.6-12 parts of external lubricant, 3.8-9.8 parts of internal lubricant and 1.0-5 parts of antioxidant. Compared with the prior art, the invention has the following characteristics of long continuous production period and good production stability; realization of toxicity and environmental protection without containing heavy metals, such as Ba, Cd, Pb and the like in the components; and avoidance of discoloration at the time of switching mercaptan organic tin without containing heavy metals, such as Ba, Cd, Pb and the like.

Owner:WUHU CONCH NEW MATERIAL

Powder metallurgy technical formula and technical process thereof

The invention discloses a powder metallurgy technical formula and a technical process thereof. The formula is iron-base powder formed by uniformly mixing graphite powder, copper powder, zinc stearate and iron powder. The forumula is characterized in that ferrophosphorus alloy and manganese sulfate are added to the iron-base powder; and the iron-base powder comprises the following components in percentage by weight: 0.4-1.5% of graphite powder, 1-3% of copper powder, 1-2.5% of manganese sulfide, 1-2.5% ferrophosphorus alloy, 0.5-1% of zinc stearate and 70-98% of iron powder. The technical process comprises the following steps: (1) mixing; (2) compacting; (3) sintering; (4) oil immersing; (5) finishing; (6) rough processing; (7) fine processing; and (8) rust-proofing treatment. The invention replaces electrolytic copper with ferrophosphorus alloy, thereby enhancing the performance and the strength of the product, reducing the manufacturing cost, enhancing the production efficiency and having the advantages of strong wear resistance, short sintering time and stable quality.

Owner:安徽省芜湖市信达粉末冶金零部件有限公司

Method for preparing brake pad friction material by using rice and wheat straws

InactiveCN103820078AAbundant resourcesReduce recycling costsOther chemical processesFriction liningFiberAtmospheric pollution

The invention discloses a method for preparing a brake pad friction material by using rice and wheat straws and relates to the technical field of composite materials. The brake pad friction material has the following formula: 15 percent of toughened fibers, 16 percent of modified resin, 14 percent of a friction increase agent, 9 percent of sulfur and tin powder, 1.6 percent of carbon black, 2.5 percent of zinc oxide, 8.9 percent of barium sulfate, 10 percent of rice and wheat straw carbon powder, 6 percent of aluminum hydroxide, 14 percent of modified li beads and 3 percent of zinc stearate. The materials are uniformly mixed and stirred, pressed in a mold and subjected to machining such as grinding and chamfering according to a technical requirement to obtain a braking pad. According to the method, the rice and wheat straws are used as raw materials to prepare carbon powder which replaces graphite in a friction material formula, so that the atmospheric pollution caused by severe combustion of straws in each year is alleviated, the production cost of the brake pad is reduced, and the brake performance and the braking effect are enhanced; the friction coefficient is stable; the brake pad is simple in structure, low in brake noise, environment-friendly and pollution-free.

Owner:YANCHENG XINHAO MACHINERY

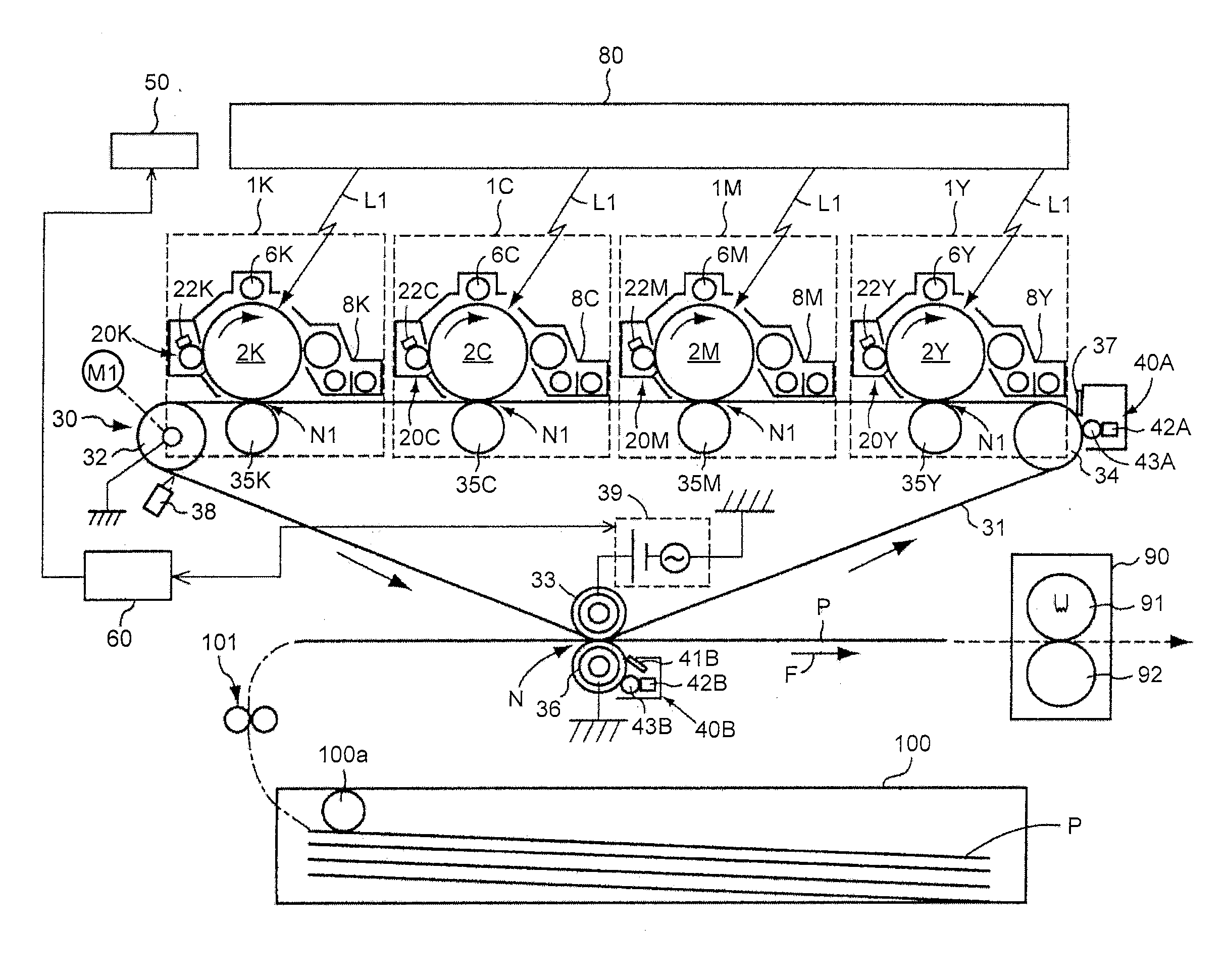

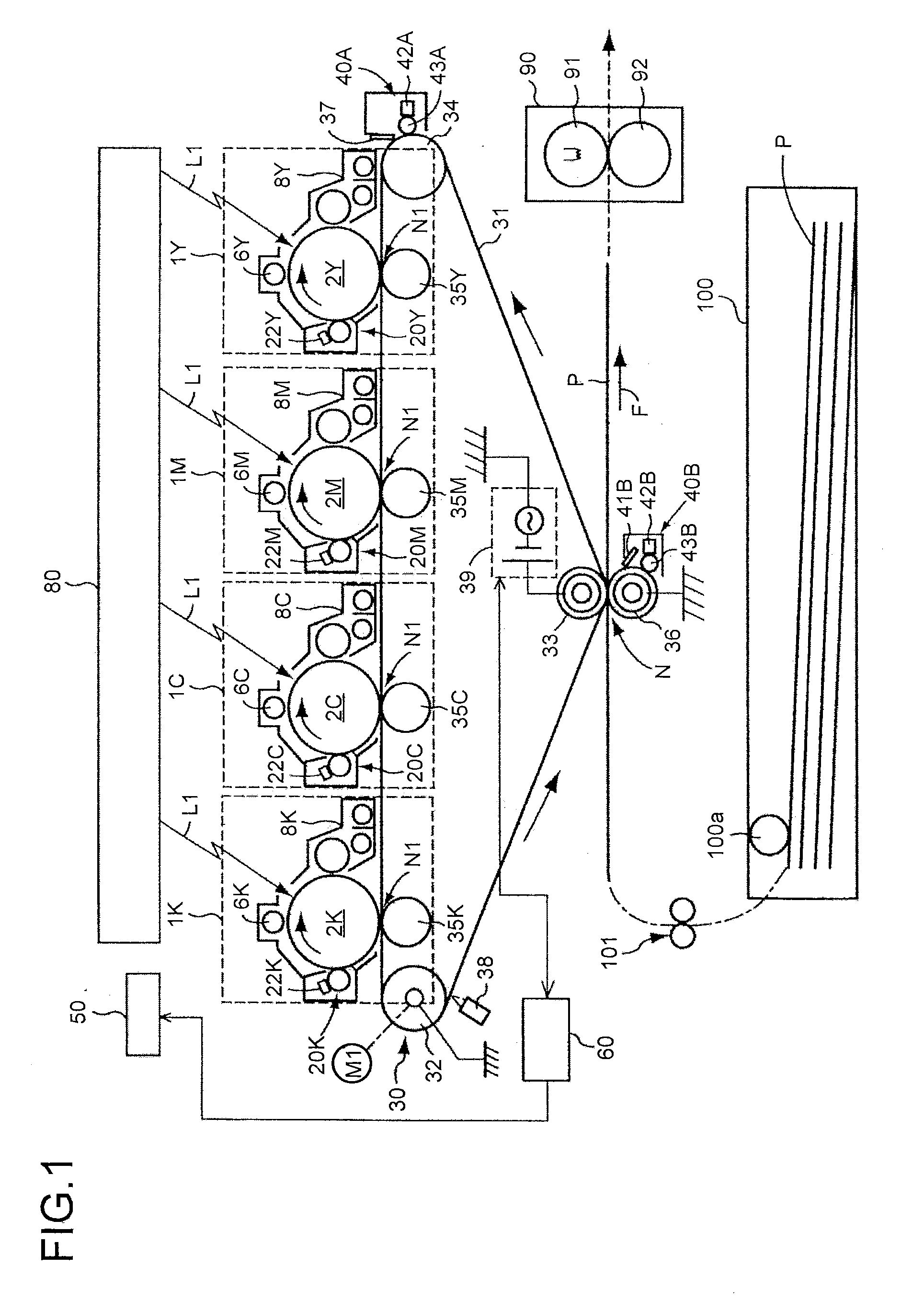

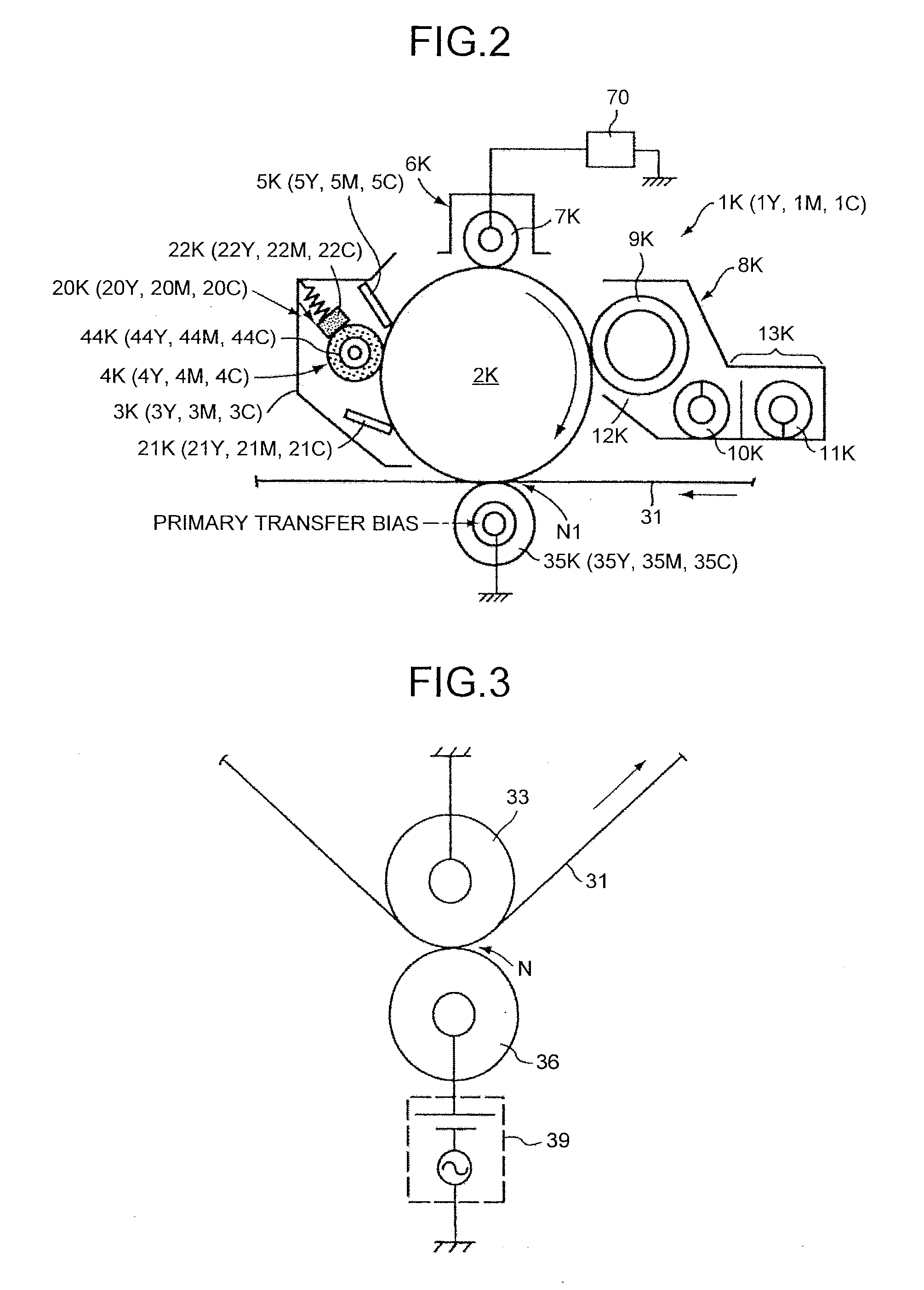

Image forming apparatus

An image forming apparatus includes an image carrier that carries an electrostatic latent image; a developing unit that develops the electrostatic latent image using a toner; an intermediate transfer body onto which toner image is transferred; a secondary transfer member that comes in contact with a surface of the intermediate transfer body; a power supply that outputs a voltage for transferring the toner image on the intermediate transfer body onto a recording member; and a protective agent supply unit that applies a protective agent including zinc stearate and boron nitride onto a surface of the image carrier. The voltage is alternatively switched in a transfer direction and an opposite direction. The voltage in the transfer direction enables transfer of the toner image from the intermediate transfer body to the recording member, and the voltage in the opposite direction has polarity opposite to polarity of the voltage in the transfer direction.

Owner:RICOH KK

Preparation method of powder-metallurgy refrigeration compressor valve sheet

ActiveCN102380613AHigh forming densityImprove production continuityTurbinesOther manufacturing equipments/toolsRefrigeration compressorAlloy

The invention relates to a preparation method of a powder-metallurgy refrigeration compressor valve sheet. The preparation method is characterized by comprising the following steps of: mixing iron powder, high-alloy main powder, graphite powder, manganese sulfide powder and zinc stearate powder according to certain proportion, leading the weight percentage of all elements in the total components to be as follows: 0.5-2.0% of carbon, 3.0-6.5% of cobalt, 2.5-4.5% of chromium, 2.5-4.5% of molybdenum, 0.5-2.0% of nickel, 0.2-1.0% of vanadium, less than 3% of impurities and the balance of iron; using a mold to press and form the mixture to obtain a powder-metallurgy green blank; putting the green blank in a sintering furnace to sinter for more than 5 minutes with the sintering temperature being 1150-1250 DEG C; carrying out repressing and finishing on the sintered blank; carrying out quenching and annealing under the protective atmosphere; and carrying out grinding on the valve sheet. In the preparation method, the problems of the adding mode and effective alloying of the powder-metallurgy high alloy are solved, and higher forming density needed by the powder-metallurgy valve sheet material under higher alloy content is realized, so that the powder-metallurgy refrigeration compressor valve sheet achieves the needed wear resistance. The prepared powder-metallurgy refrigeration compressor valve sheet has the advantages of low material cost, high material utilization ratio and suitability for large-batch production.

Owner:NBTM NEW MATERIALS GRP

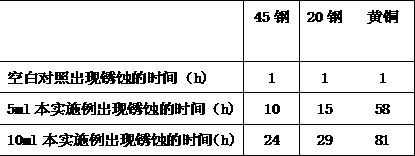

Metal rust-preventive oil comprising butyl acrylate

ActiveCN103214886AGood gas phase anti-rust effectExcellent contact rust resistanceAnti-corrosive paintsMeth-Composite film

The invention discloses metal rust-preventive oil comprising butyl acrylate. The oil is prepared from the raw materials of: No.120 solvent oil, paraffin, methyl diethanolamine, epoxy octyl stearate, magnesium naphthenate, a silane coupling agent KH560, a silane coupling agent A171, microcrystalline wax, aluminum stearate, magnesium lanolin soap, monoethanolamine, barium petroleum sulfonate, sodium lauryl sulfate, trioctyl trimellitate, benzotriazole, 2-aminoethyl heptadecenyl imidazoline, zinc stearate, an antioxidant BHT, an antioxidant 1010, dipropylene glycol, phytic acid, butyl acrylate, modified nano-grade dolomite powder, a composite film-forming material, and ferrocene. The rust-preventive oil provided by the invention has excellent contact rust resistance and good gas-phase rust resistance. The rust-preventive oil provided by the invention provides good gas-phase rust resistance and contact rust resistance for steel and brass.

Owner:SHANTOU HONGSHENG BOLT IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com