Thermoplastic elastomer composition

A thermoplastic elastomer and composition technology, applied in the field of plastic or rubber materials, can solve the problems of poor weather resistance, low permanent deformation, and high price, and achieve the effects of weather resistance, low compression deformation, and reasonable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

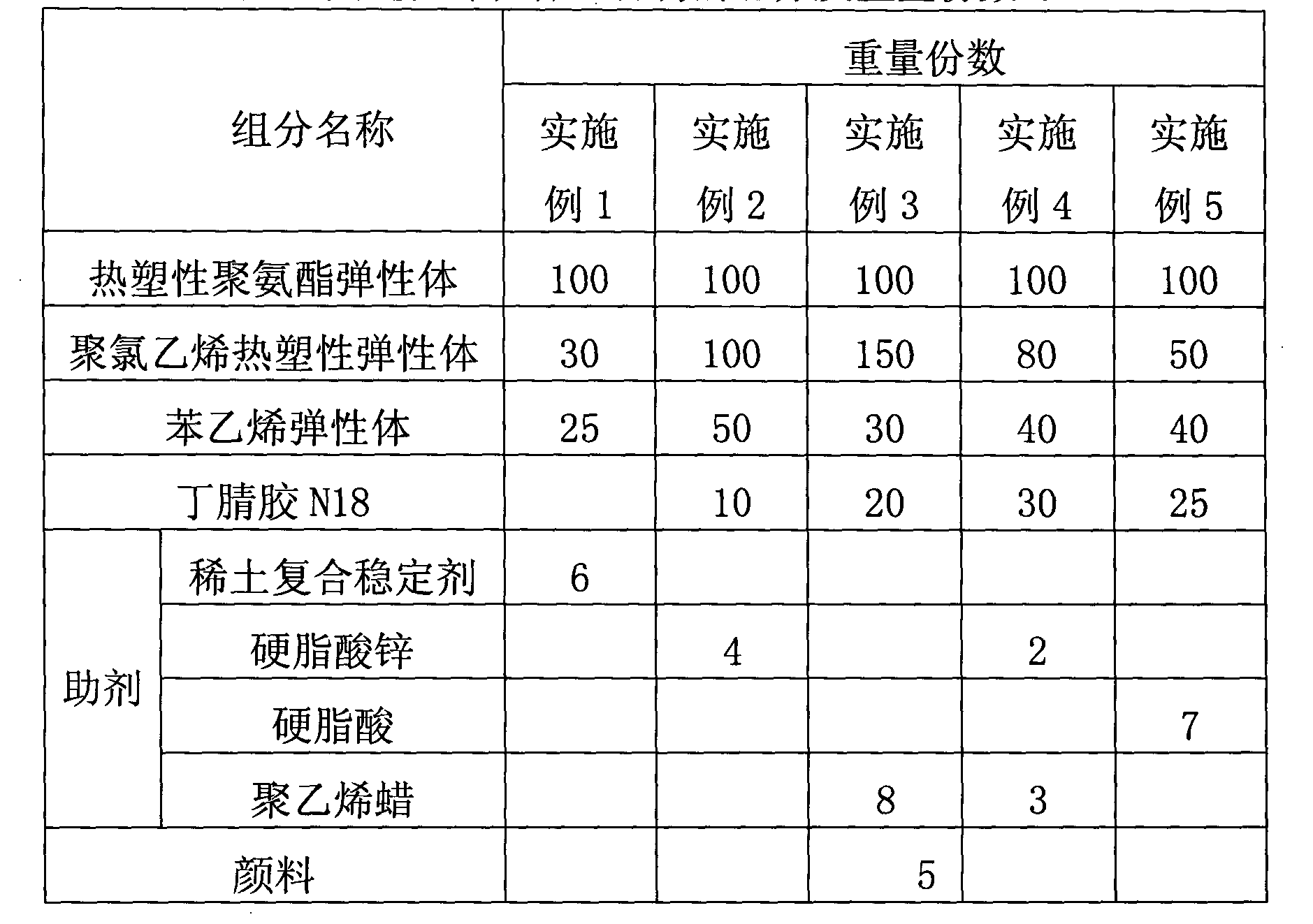

[0017] (1) Refer to Table 1 for the components and weight ratios of the thermoplastic elastic composition.

[0018] Table 1 Components and parts by weight ratio of the thermoplastic elastomer composition

[0019]

[0020] Note: ①The pigment mentioned is any one or more of Lithor Red, Lithor Scarlet, Benzidine Yellow, Direct Fast Yellow, Phthalocyanine Blue, Titanium Green or Titanium Dioxide.

[0021] Preparation:

[0022] A. prepare materials according to the components listed in Table 1 and the parts by weight;

[0023] B. First, add the components provided in step A into the mixing mixer and stir evenly;

[0024] C. Mastication: heat up the temperature of each section of the plastic extrusion granulator to 100°C-160°C, feed the material, and control the temperature of each section at 100°C-160°C at a speed of 28-32 rpm. The raw materials are fully mixed, masticated, cooled, and automatically pelletized to obtain a thermoplastic elastomer composition.

[00...

Embodiment 2、 Embodiment 3

[0050] Embodiment 2, embodiment 3, embodiment 4 and embodiment 5

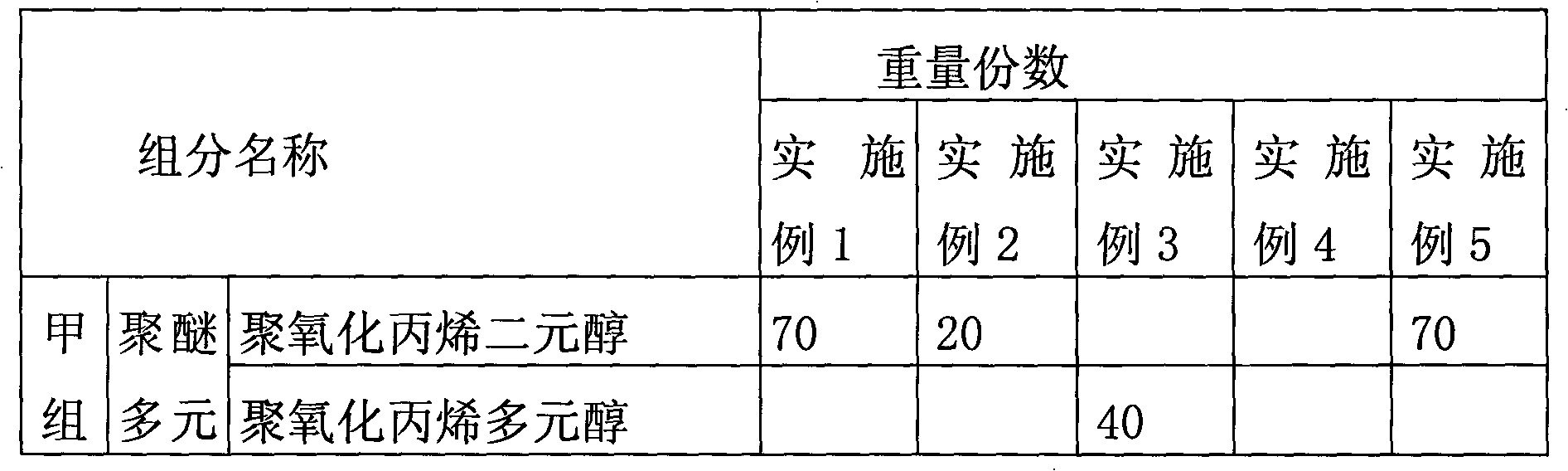

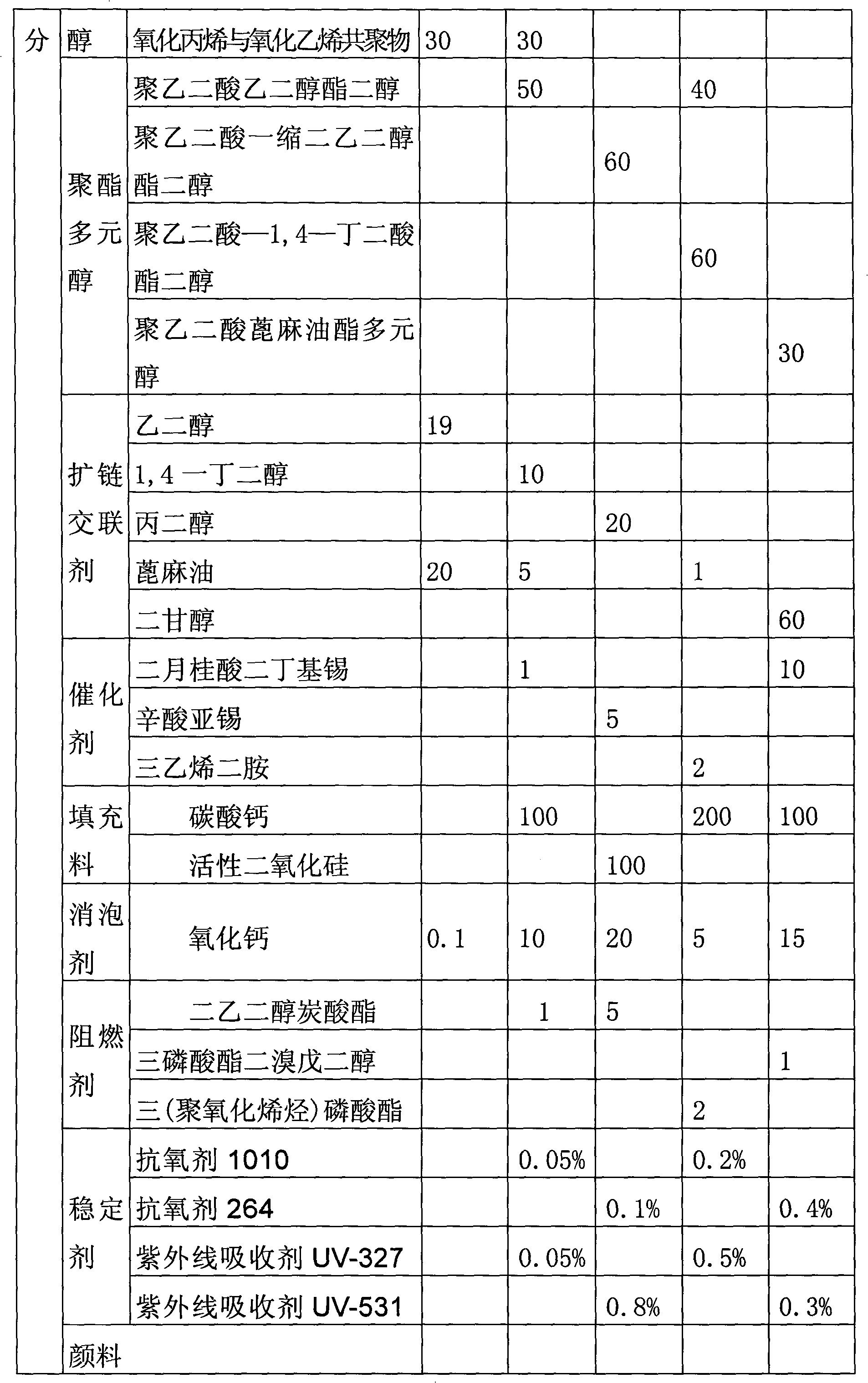

[0051] See Table 1, Table 2, Table 3 and Table 4 for the components and parts by weight ratio of the thermoplastic elastomer composition, thermoplastic polyurethane elastomer, polyvinyl chloride thermoplastic elastomer and styrene elastomer, and its preparation method and embodiment 1 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com