Patents

Literature

88results about How to "Small resilience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

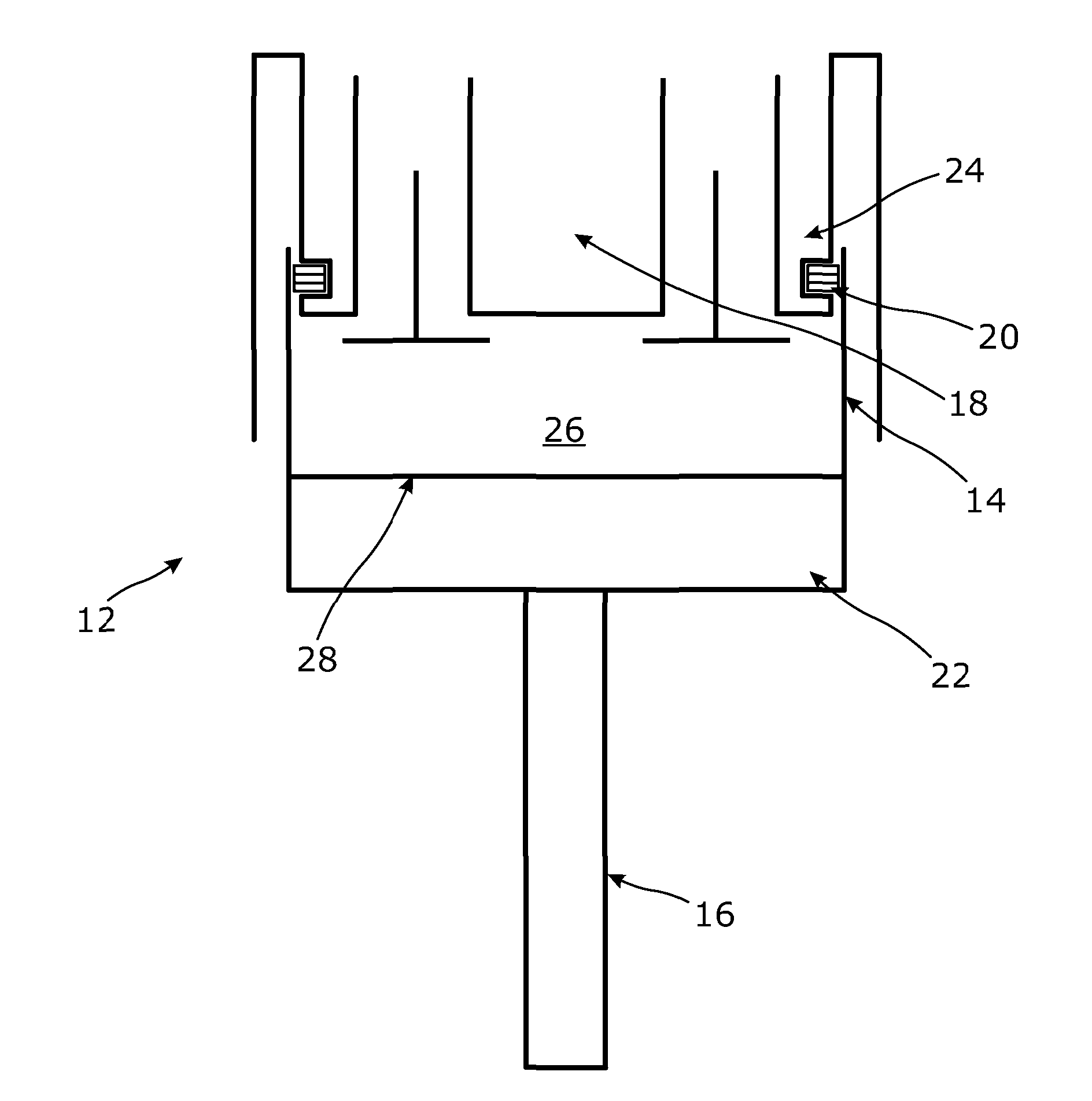

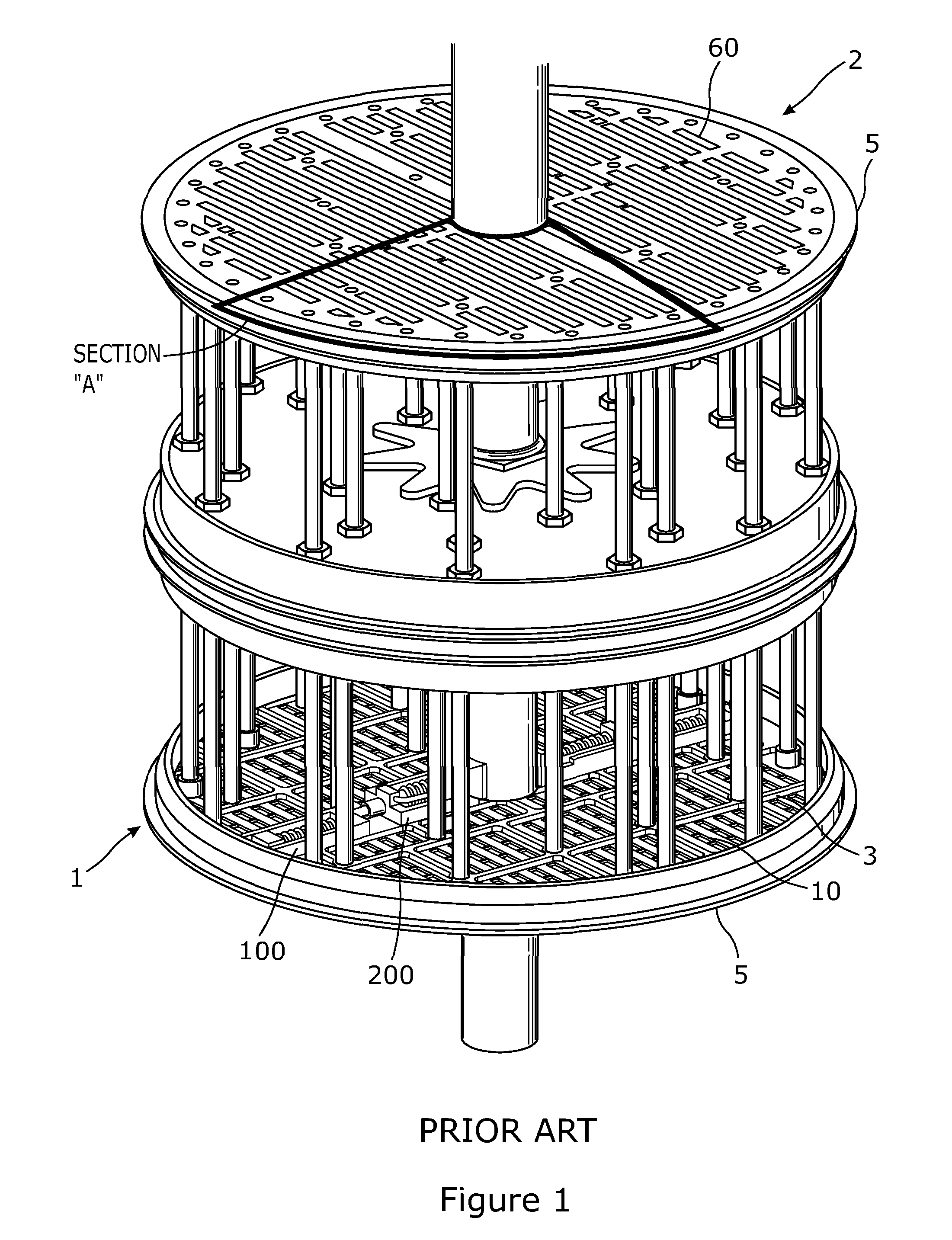

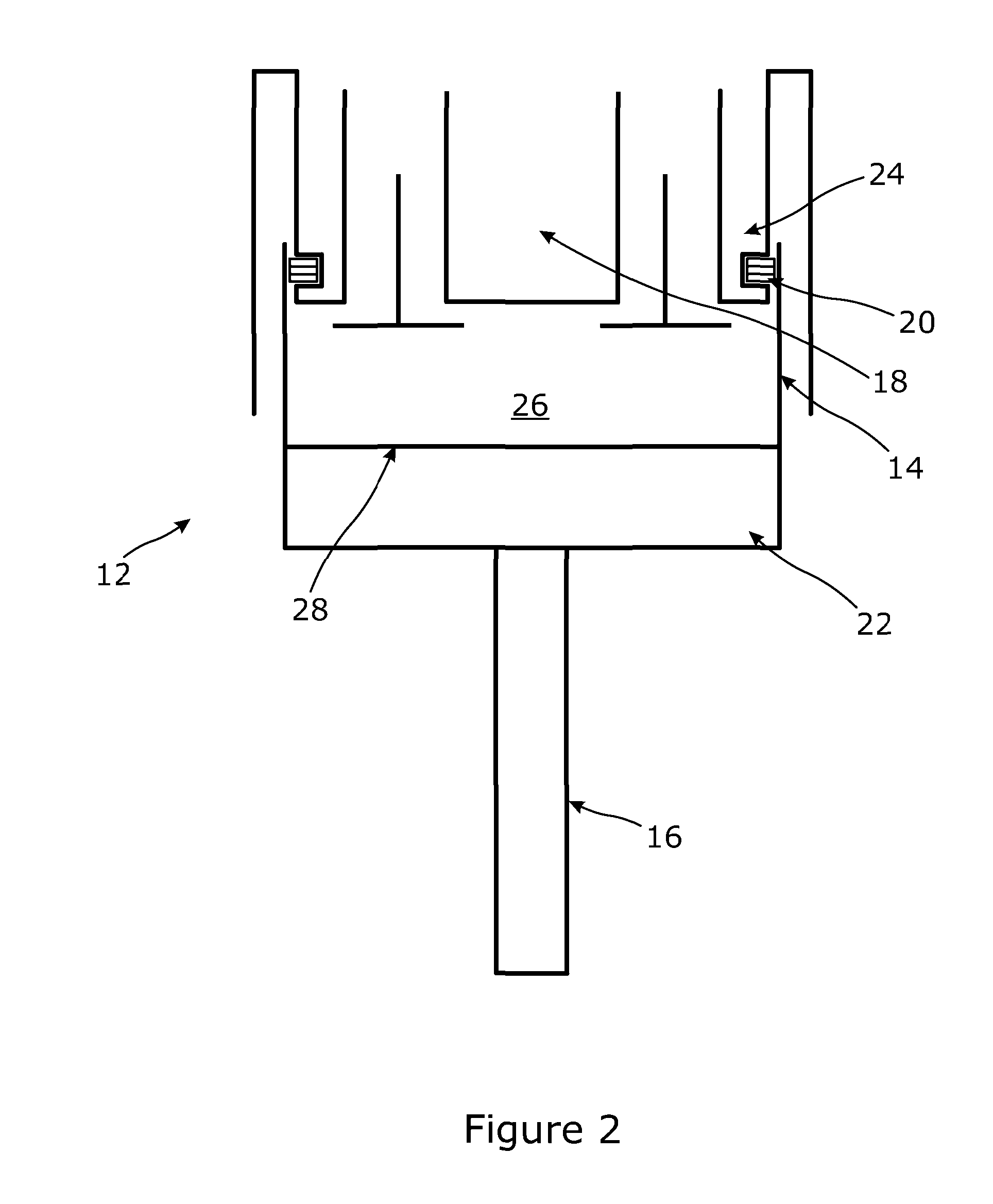

Piston Assembly

InactiveUS20150114217A1Reduce inertia forceReduce quality problemsEngine sealsPositive displacement pump componentsCylinder headGraphite

A piston assembly (12) comprising a reciprocating sleeve (14) incorporating an integral internal piston surface (28), which sleeve is slidably mounted upon a cylinder head (18) so as to define a piston chamber (26) therewith, the piston chamber being sealed in the vicinity of the cylinder head (18) by a circumferential static seal (20) that acts to seal against the reciprocating sleeve (14). The static seal (20) may occupy a horizontal plane and may include sacrificial wear zones and be formed from a graphite-based material. The piston assembly may be an oversquare assembly for use in an oil-free environment for processing high temperature gases, for example, a hot gas engine or heat pump or heat engine such as may be used in an energy storage system.

Owner:ENERGY TECH INST

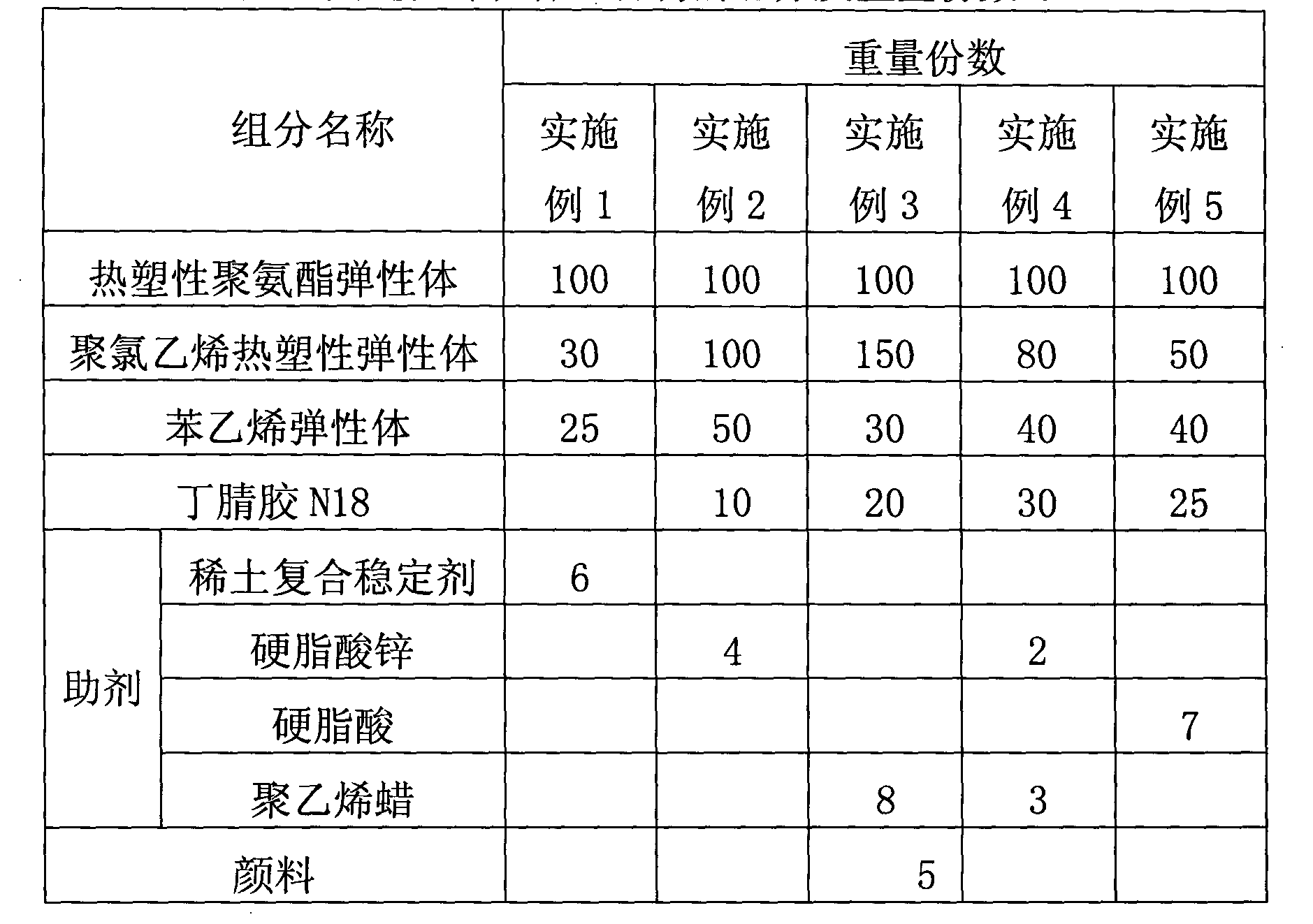

Thermoplastic elastomer composition

The invention discloses a thermoplastic elastomer composition which is plasticated by the following main components by weight: 100 parts of polyurethane thermoplastic elastomers, 30-150 parts of polyvinyl chloride thermoplastic elastomers, 25-50 parts of styrene elastomers, 0-30 parts of blend and 4-8 parts of auxiliaries, wherein the auxiliary is any one or more of a composite rare-earth stabilizer, zinc stearate, calcium stearate, stearic acid or polyethylene wax; and the blend is butyronitrile N18. The invention selects the thermoplastic elastomers with similar polarity and complementary properties to be synthesized and used and selects compatilizers to organically combine several best molecules with different structures, so that the generated novel thermoplastic elastomer has superior performance and appropriate price, can meet the requirements of market products and has wide application range because the product has the technical advantages of excellent oil resistance, resistance to low temperature of minus 35 DEG C, acid-alkali resistance, aging resistance and lower proportion than the vulcanized products with the same price.

Owner:营口巨成教学科技开发有限公司 +1

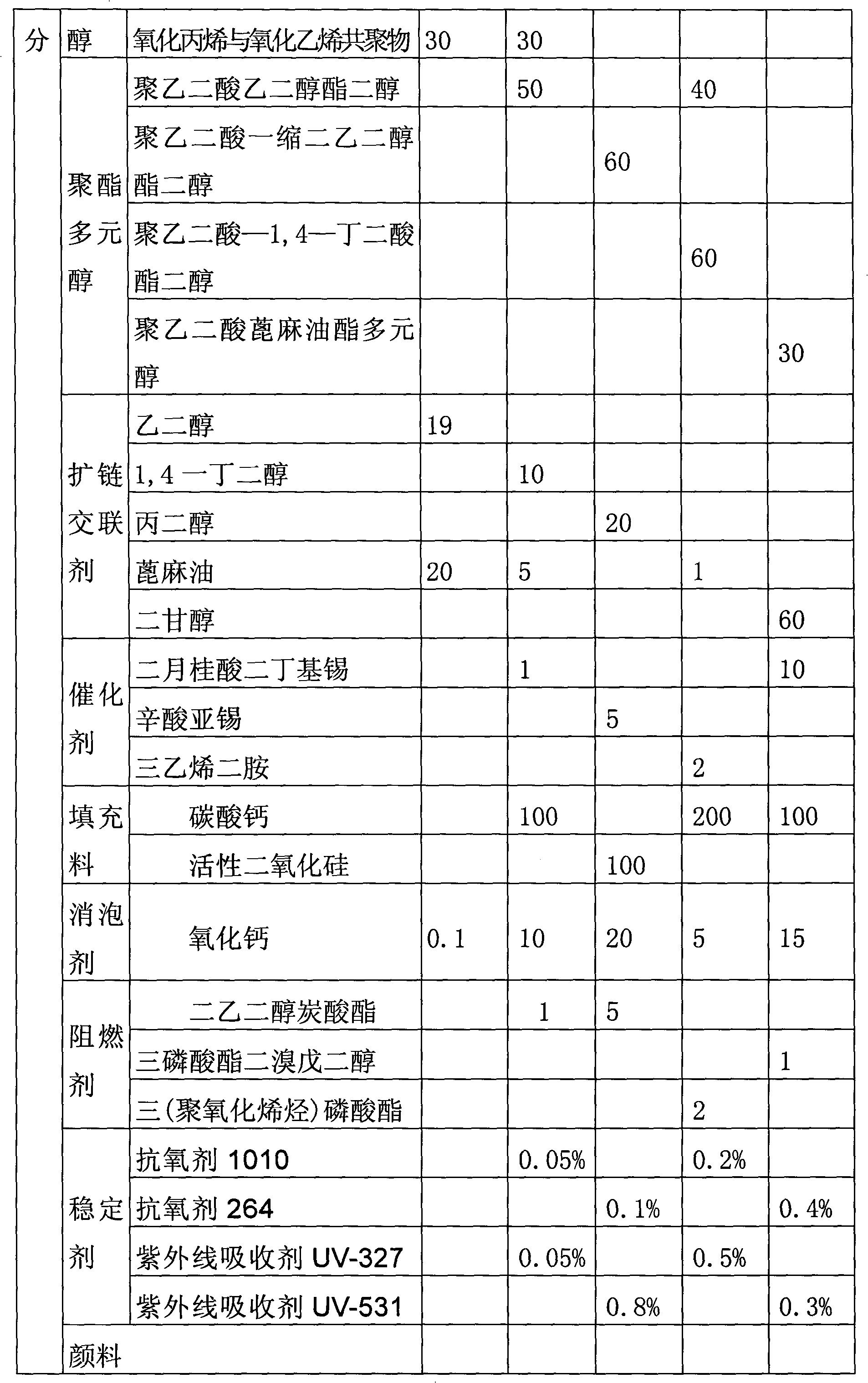

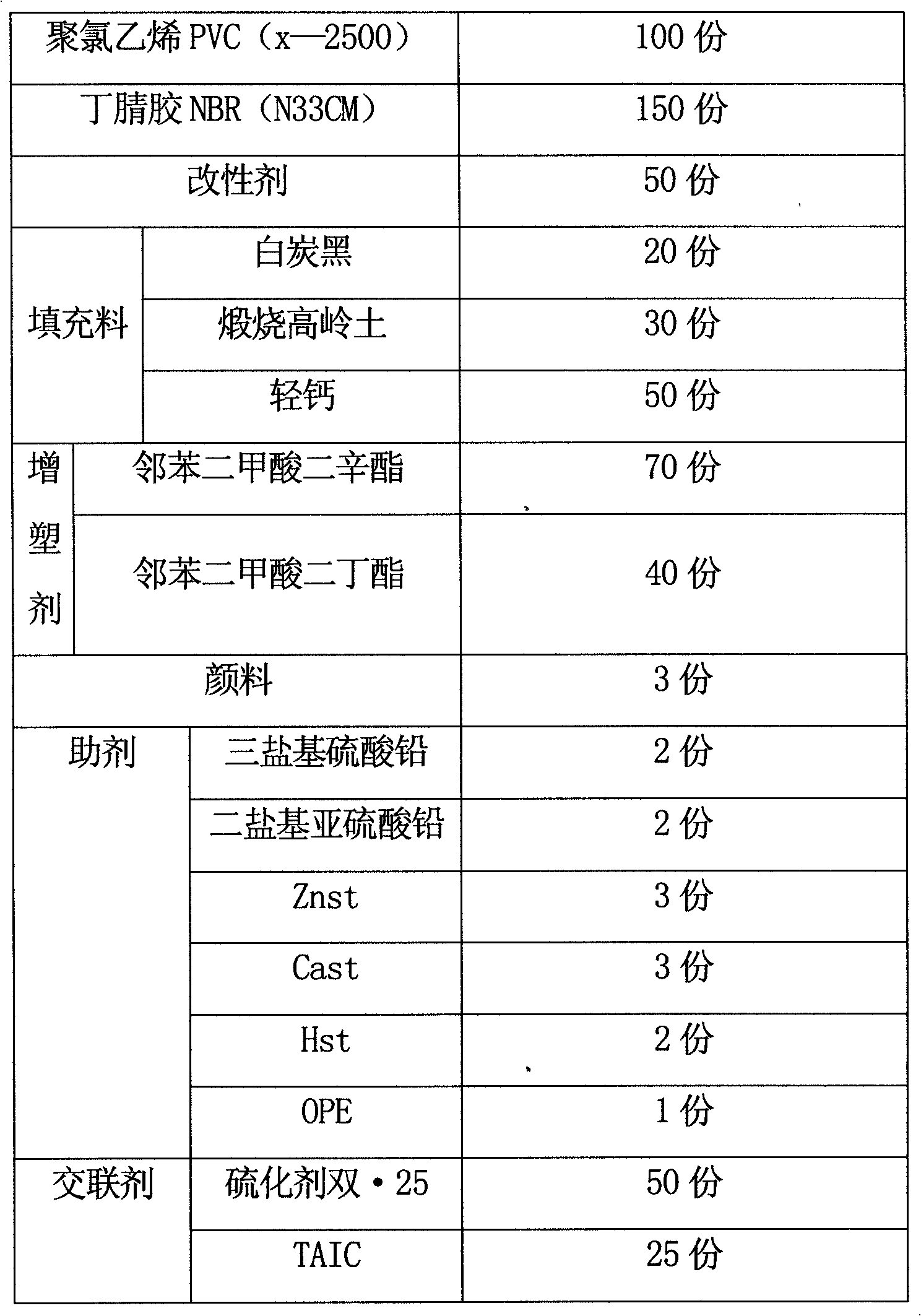

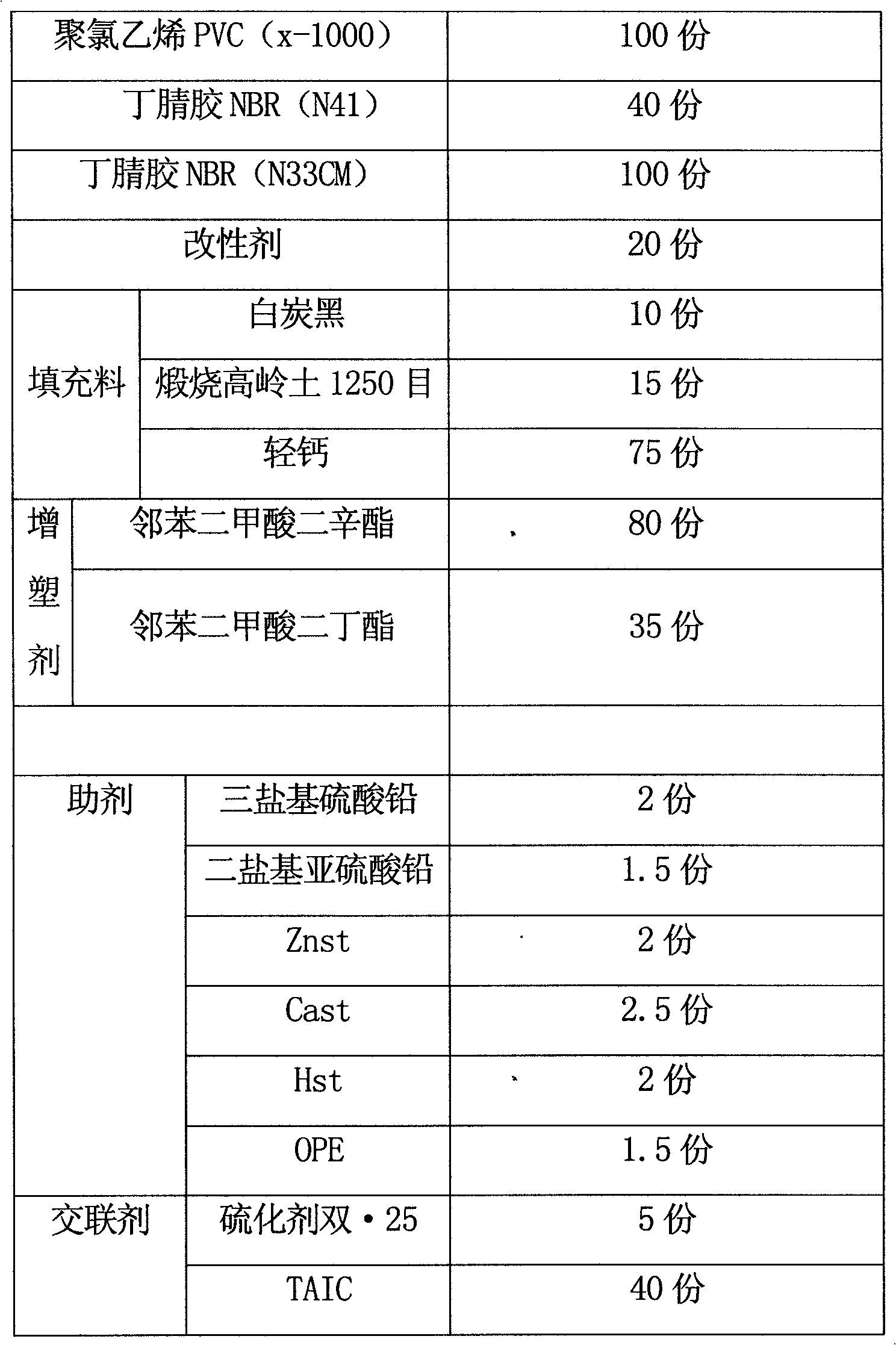

Oil-resistant and low temperature-resistant thermoplastic elastomer and production method

The invention provides an oil-resistant and low temperature-resistant thermoplastic elastomer and a production method according to the mechanism that the characters of a plurality of molecular materials are similar and compatible, mutually complementary and capable of mutually modifying. The oil-resistant and low temperature-resistant thermoplastic elastomer comprises the following components by weight parts: 100 parts of one or a plurality of polyvinyl chloride X-2000, X-2500, X1300 and X-1000, 40-150 parts of one or a plurality of nitrile butadiene rubber (NBR) N41, N33CM, N33M, N26 and N18,20-50 parts of modifier, 20-160 parts of filling agent, 70-150 parts of plasticizer, 15-75 parts of dynamic cross-linking agent, 0-5 parts of pigments and 8-20 parts of additives. The invention develops the modifier, selects the cross-linking agent and technological conditions of temperature, rotational speed and the like, thereby leading the product to achieve the technical requirements of oil resistance, low temperature resistance, acid-base resistance, aging resistance and smaller specific gravity than a vulcanized product with the same price. The elastomer can not only produce various oil-resistant pipes, ropes, wires and cables as well as sealing strips of aluminum-plastic doors and windows of vehicles, motor vehicles and buildings, but also manufacture various parts and products with different mechanical performance requirements on hardness, elasticity and the like through the different technologies of blow molding, extrusion molding, injection molding and the like.

Owner:NINGBO SUNLIGHT MOTOR PARTS

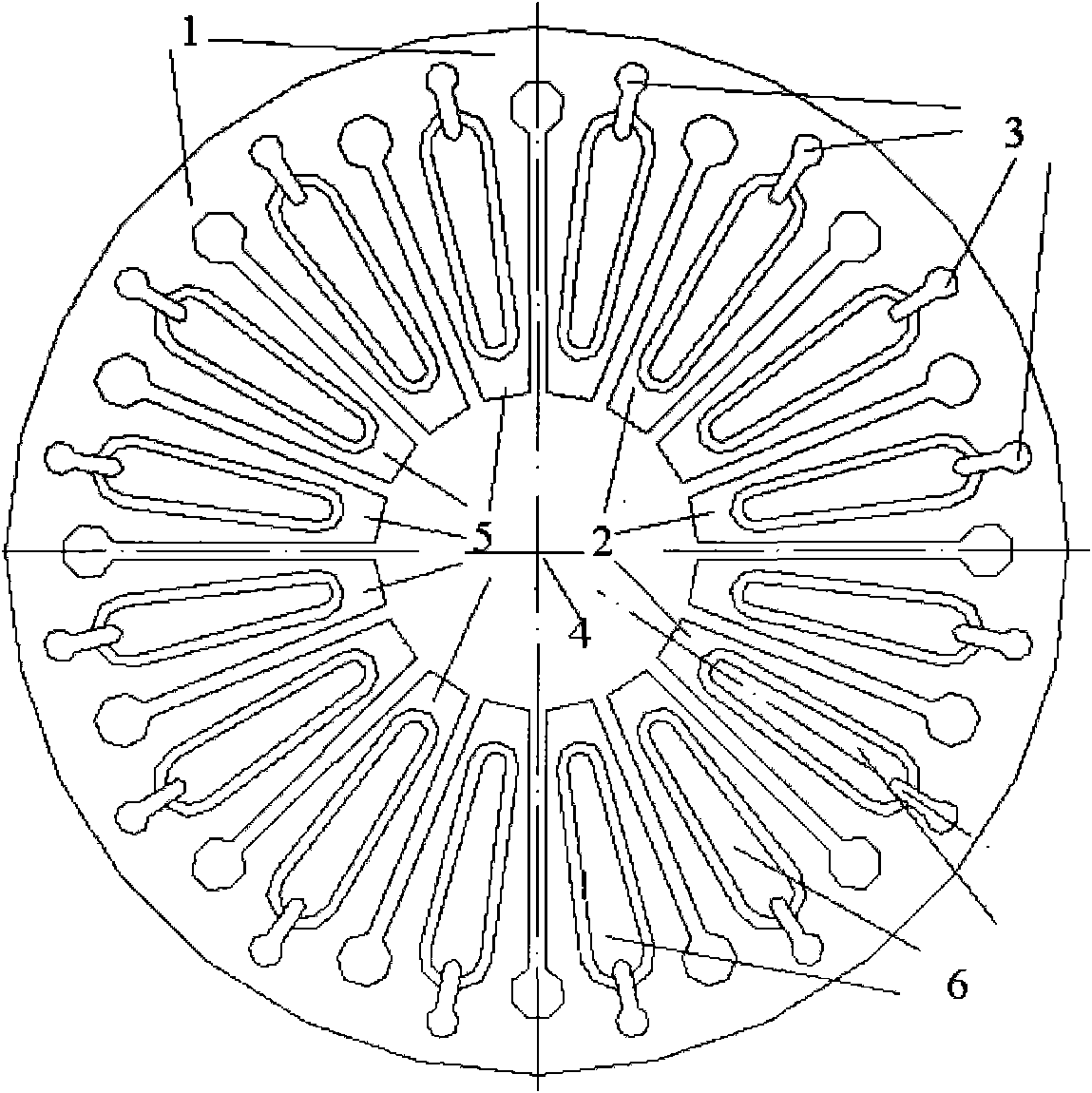

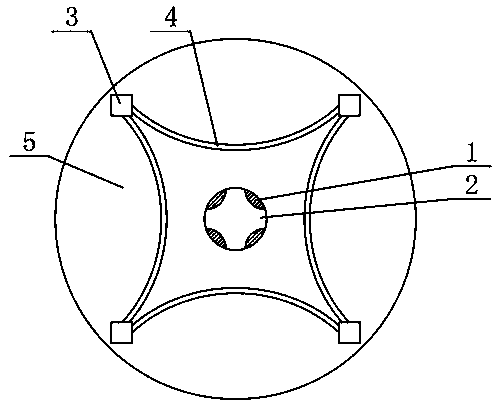

Diaphragm spring for normally open type clutch

The invention relates to a diaphragm spring for a normally open type clutch, belonging to the technical field of the automatic clutch of the automobile. The diaphragm spring is of disc-shaped structure and comprises a disc-spring part, a plurality of jointing finger parts and a plurality of stress releasing holes, wherein the plurality of jointing finger parts with the same structure are centrally symmetrical by the center of a circle of the diaphragm spring; and the outer ends of the jointing finger parts are fixedly connected with the disc-spring part which is provided with the plurality of stress releasing holes along the peripheral direction. The diaphragm spring not only reserves the advantages of being capable of reducing resilience force and having zero rigidity in a wearing route of a frictional plate, but also overcomes the problem of overlarge pressure, thus leading the elastic deformation of a thrust plate and a housing to decrease, leading the starting operation of an executive device to become easy and leading the load borne in the process of the executive device to obviously decrease.

Owner:SHANGHAI JIAO TONG UNIV

Open-cell foam of ethylene-propylene-diene rubber

Open-cell foam of ethylene-propylene-diene rubber that can convert to open-cell foams at the foaming of EPDM, rather than after the foaming of the same, and can produce low impact resiliency and improved filling capability. After 0.1·40 parts by weight of organic foaming agent, 2-40 parts by weight of inorganic foaming agent, and 2-40 parts by weight of foam auxiliary agent per 100 parts by weight of ethylene-propylene-diene rubber are mixed, the mixture is vulcanized and foamed to thereby produce open-cell foam of ethylene-propylene-diene rubber. This open-cell foam of ethylene-propylene-diene rubber has low impact resilience and good sealing performance so that it can be used as sealing materials of a variety of industrial products.

Owner:NITTO DENKO CORP

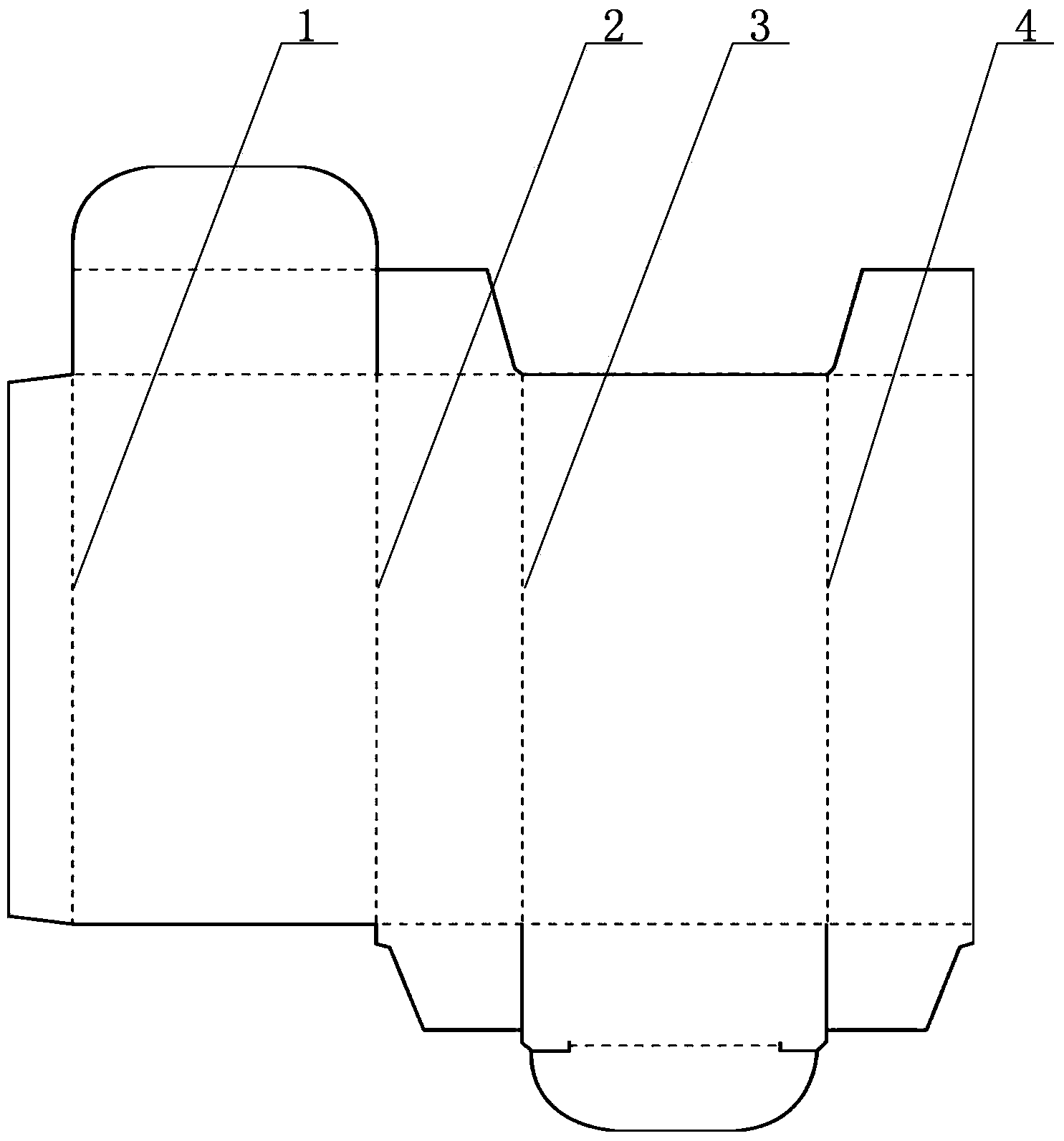

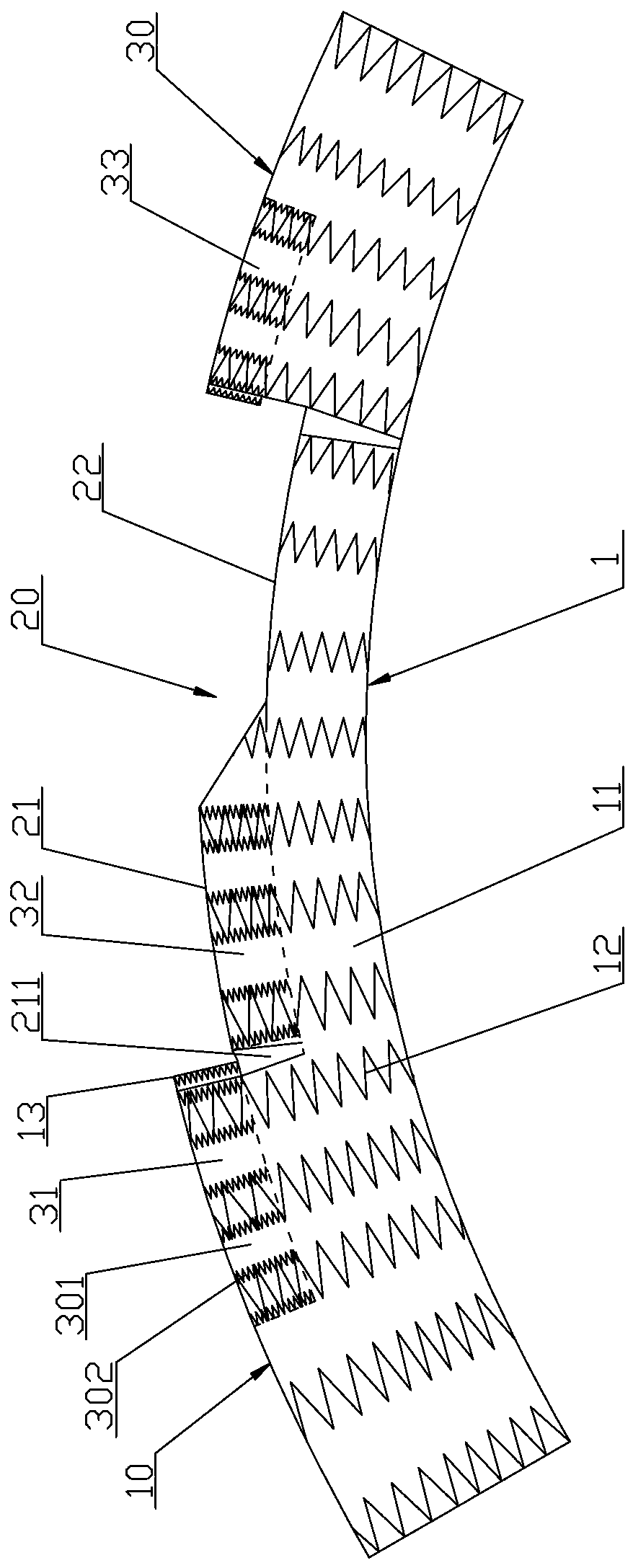

Post-printing processing process for high-speed mechanical packaging medicine packaging box

InactiveCN104139555ASmall resilienceImprove box-shaped circumferencePaper-makingBox making operationsCardboardEngineering

The invention belongs to the field of medicine packaging box processing, and particularly relates to a post-printing processing process for a high-speed mechanical packaging medicine packaging box. The post-printing processing process comprises a die cutting mark pressing process and a box pasting processing process, wherein the die cutting mark pressing process comprises the steps of cutter ranging, proper mark pressing width and die cutting steel wire height determining, plate mounting, pressure regulating, rule determining, rubber mark pressing strip pasting, test pressing die cutting, formal die cutting, waste cleaning and checking, then, the box pasting processing work is carried out, the temperature of the box pasting operation environment is controlled to be 20 to 25 DEG C, the relative humidity is controlled to be 60 percent to 70 percent, paper feeding is carried out, a third folding line of a paper board is enabled to be positioned in the center position of a box pasting machine, the deflection of the pasting opening of a paper box is prevented, pre-folding, gluing, folding, pressuring and compacting are carried out so that the paper box is firmly pasted, the paper box degluing is prevented, and the processed medicine packaging box is collected. The processing process provided by the invention has the advantages that the box type after the box forming is regular, the box pasting is firm, the quality of the medicine packaging box is improved, the machine halt rate in a high-speed mechanical packaging line can be greatly reduced, and the satisfaction degree of customers is improved.

Owner:ZIBO TAIBAO FP PROD CO LTD

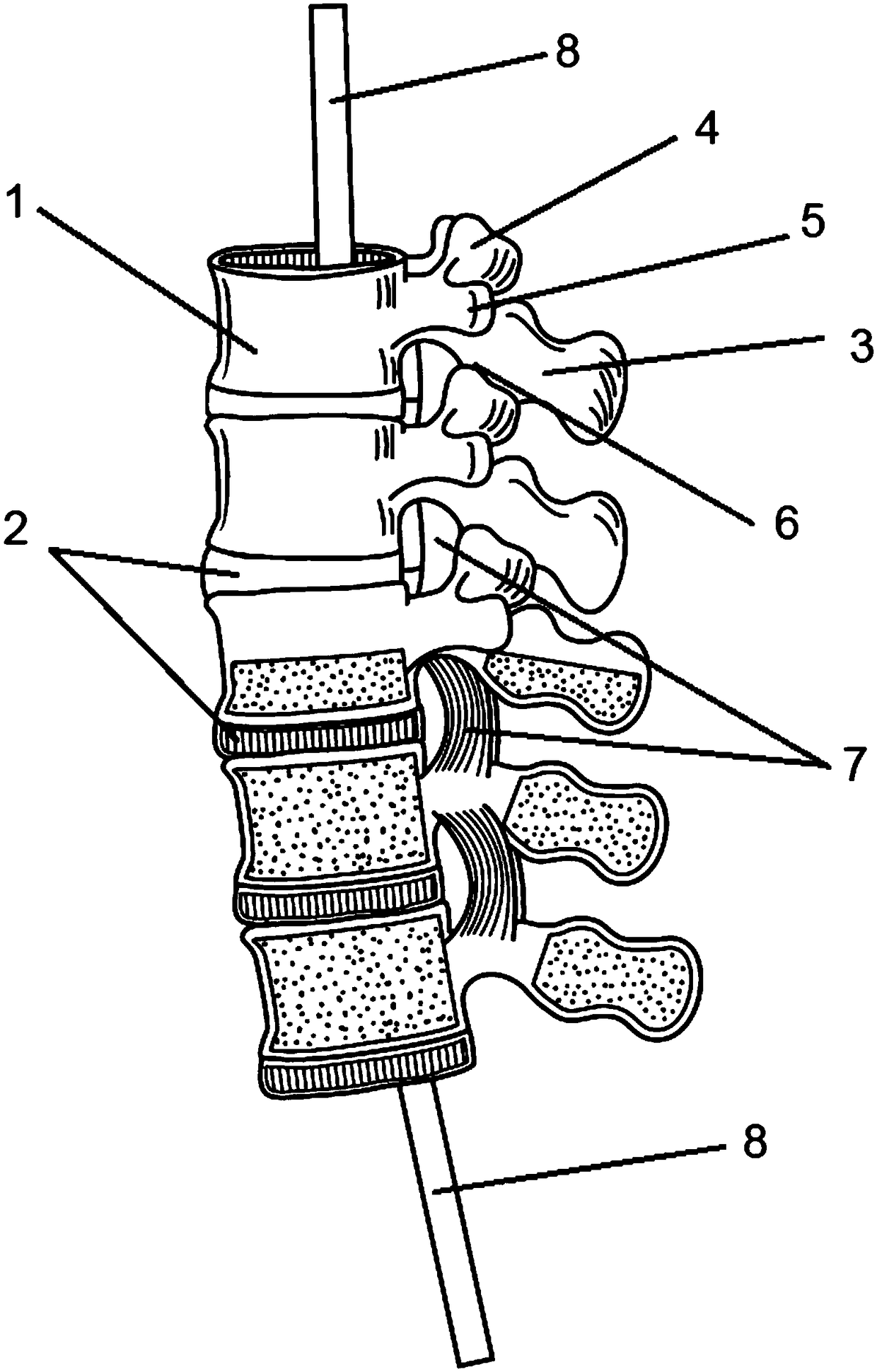

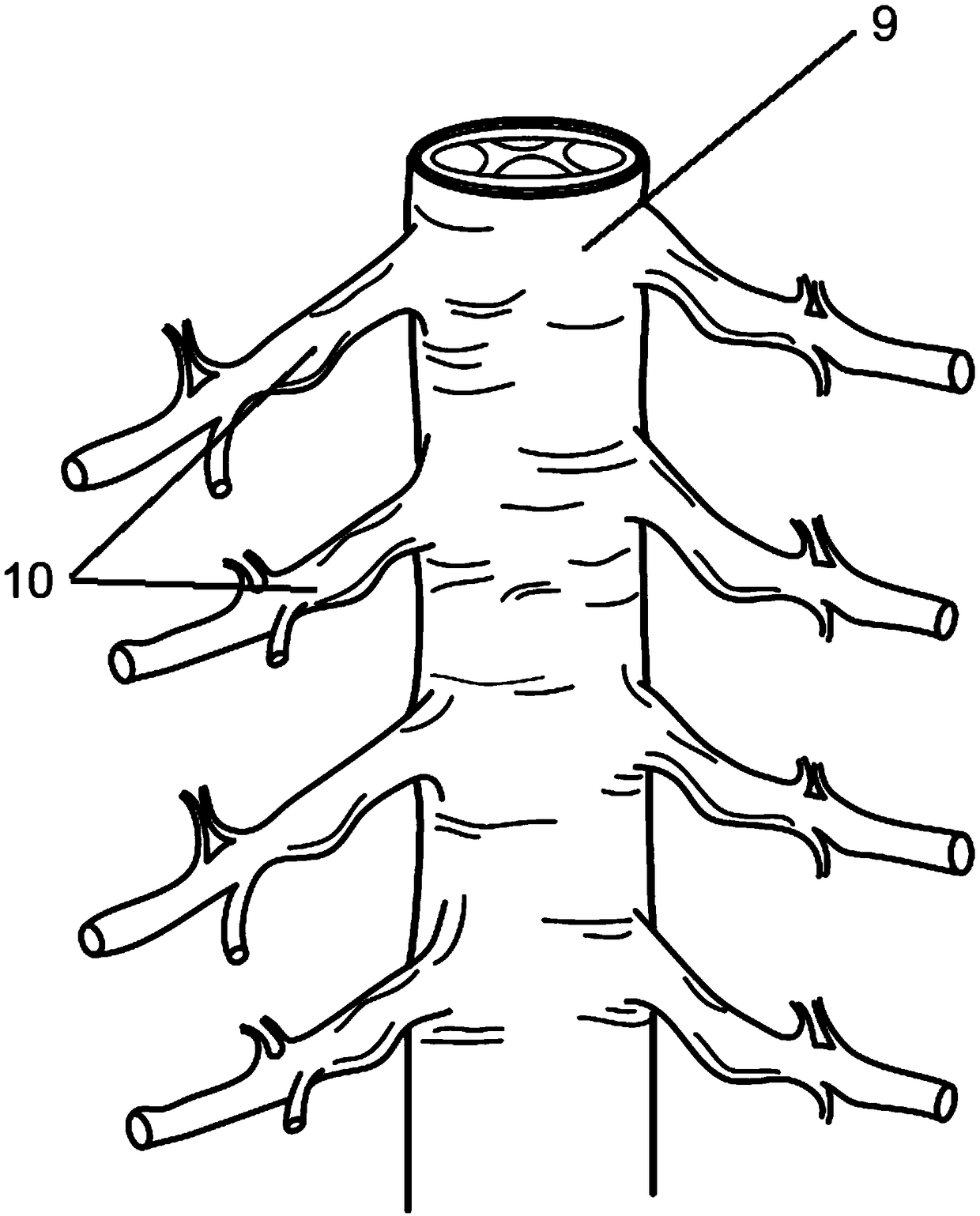

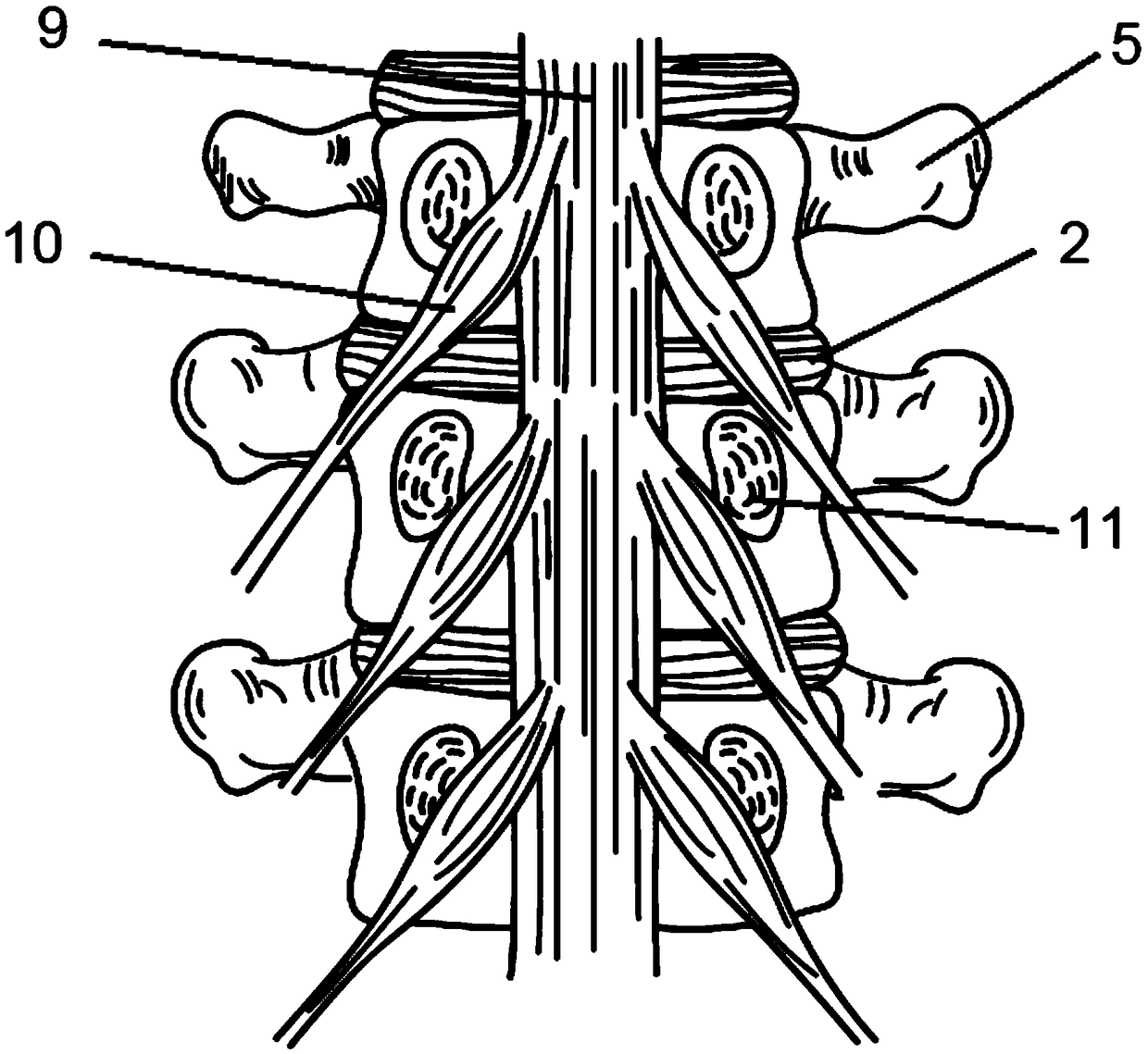

Spinal intervertebral foramen surgery model and manufacturing method thereof

InactiveCN108648593AConform to the real stateHave memoryEducational modelsSpinal columnTraining period

The invention discloses a spinal intervertebral foramen surgery model. The model comprises an artificial spine composed of multiple segments of artificial vertebral bones,an artificial intervertebraldisc located between every two adjacent artificial vertebral bones,an intervertebral disc protrusion simulated object bonded to each artificial intervertebral disc and artificial tissue wrapped on theexterior of the artificial spine; the intervertebral disc protrusion simulated objects are made of viscose fibers and bonded to arbitrary positions of the corresponding artificial intervertebral discs. The intervertebral disc protrusion simulated objects made of the viscose fibers can be glued to appropriate positions outside the corresponding intervertebral discs to simulate different types of intervertebral disc protrusions,and the shape and size of the intervertebral disc protrusion simulated objects can be adjusted according to needs to be better in line with the real state of the human body. Compared with a traditional mode of using corpses or non-dedicated models for training,the model has the advantages that the cost of training doctors can be greatly reduced,the repeatability is excellent,surgical modes are diversified,and the training period can be shortened.

Owner:JIANGSU PROVINCE HOSPITAL THE FIRST AFFILIATED HOSPITAL WITH NANJING MEDICAL UNIV

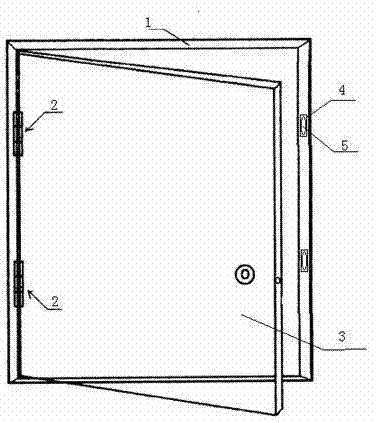

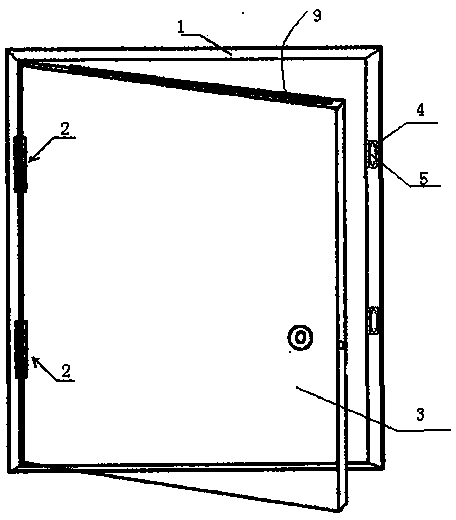

Door structure capable of preventing hands from being pinched

ActiveCN104234568ASimple structureAvoid tight closureBuilding braking devicesWindow/door framesStructural engineeringMechanical engineering

Owner:苏州盛泽科技创业园发展有限公司

High-speed digital signal transmission cabinet

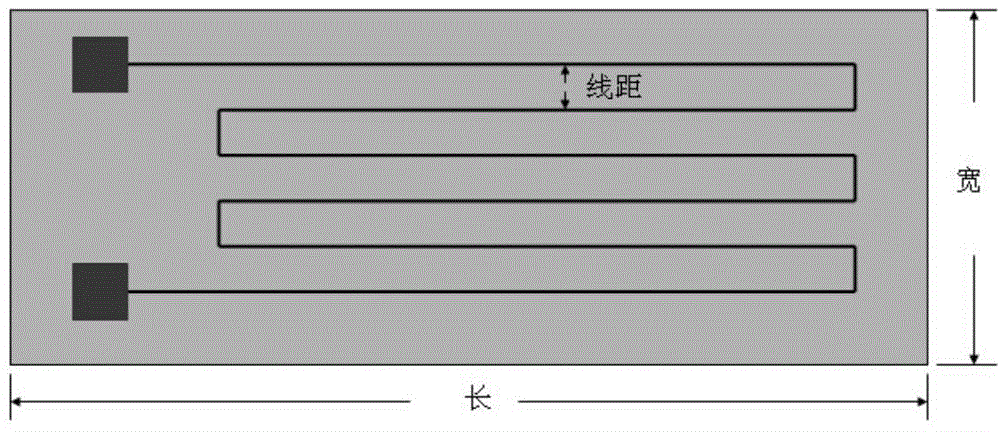

PendingCN108320840AReduce intensityRelieve stressCoaxial cables/analogue cablesFlat/ribbon cablesElectrical conductorDifferential signaling

A high-speed digital signal transmission cabinet comprises more than one differential signal cable, wherein each differential signal cable comprises an insulation core line, a shielding layer, a firststable layer or a sheath layer and a selectable drainage wire, the insulation core line comprises a pair of dual conductors, first insulation dielectric belts and an insulation stable layer, the pairof dual conductors are arranged in parallel, the first insulation dielectric belts respectively wrap the dual conductors, the insulation stable layer jointly wraps the first insulation dielectric belts, the material of each first insulation dielectric belt is a belt-shaped material having low density, low dielectric constant and low dielectric loss, and the first insulation dielectric belts are integrally and closely wrapped by the insulation stable layer. The high-speed digital signal transmission cabinet has the characteristics of small external diameter, light weight, small bending radius,more flexibility, low resilience, excellent temperature / mechanical stability, low loss and high cutoff frequency.

Owner:郑成

Anti-pinch airtight door structure

InactiveCN104295211ASimple structureAvoid tight closureWindow/door framesSealing arrangementsStructural engineeringMechanical engineering

Owner:SUZHOU COMFORT TEXTILE NEW MATERIALS TECH CO LTD

Double-door structure with hand clamping prevention function

ActiveCN104265130AAvoid tight closureImprove airtightnessFinger guardsDoor leavesEngineeringStructural engineering

Owner:苏州盛泽科技创业园发展有限公司

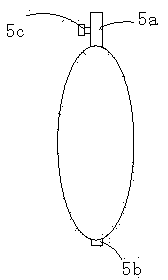

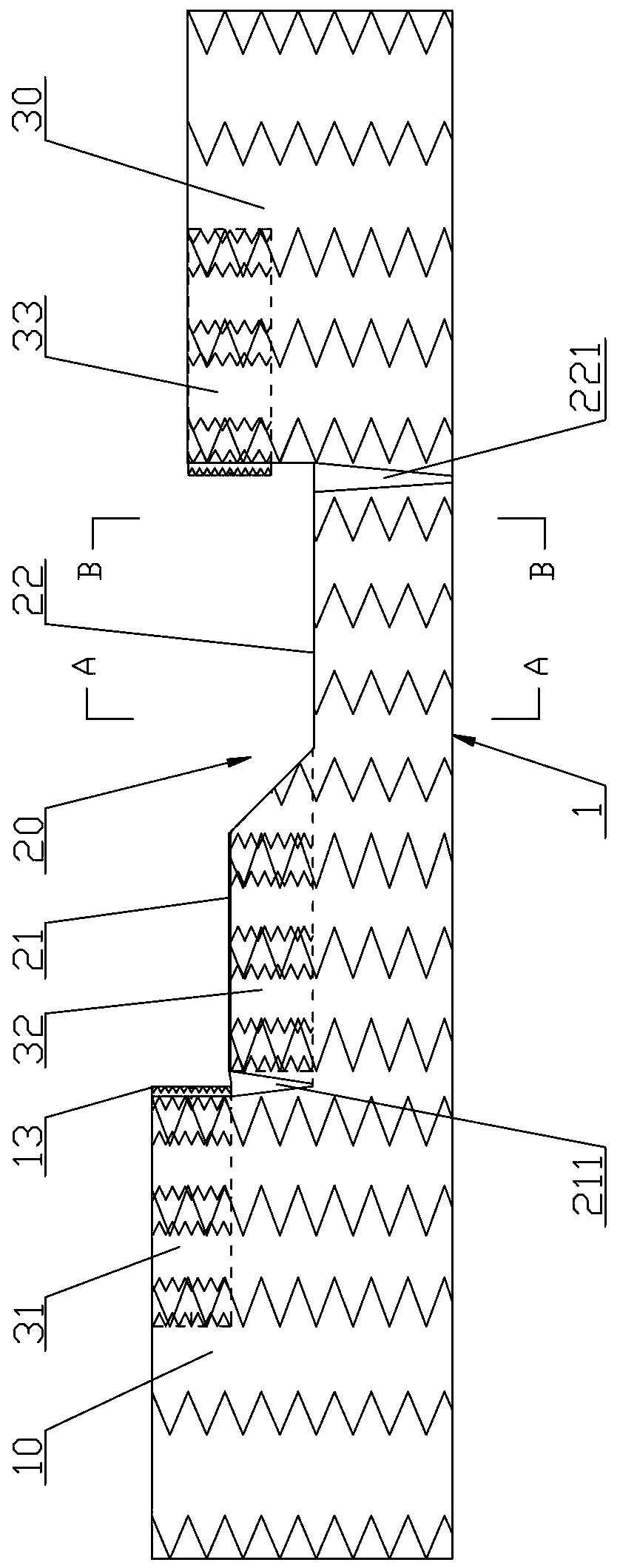

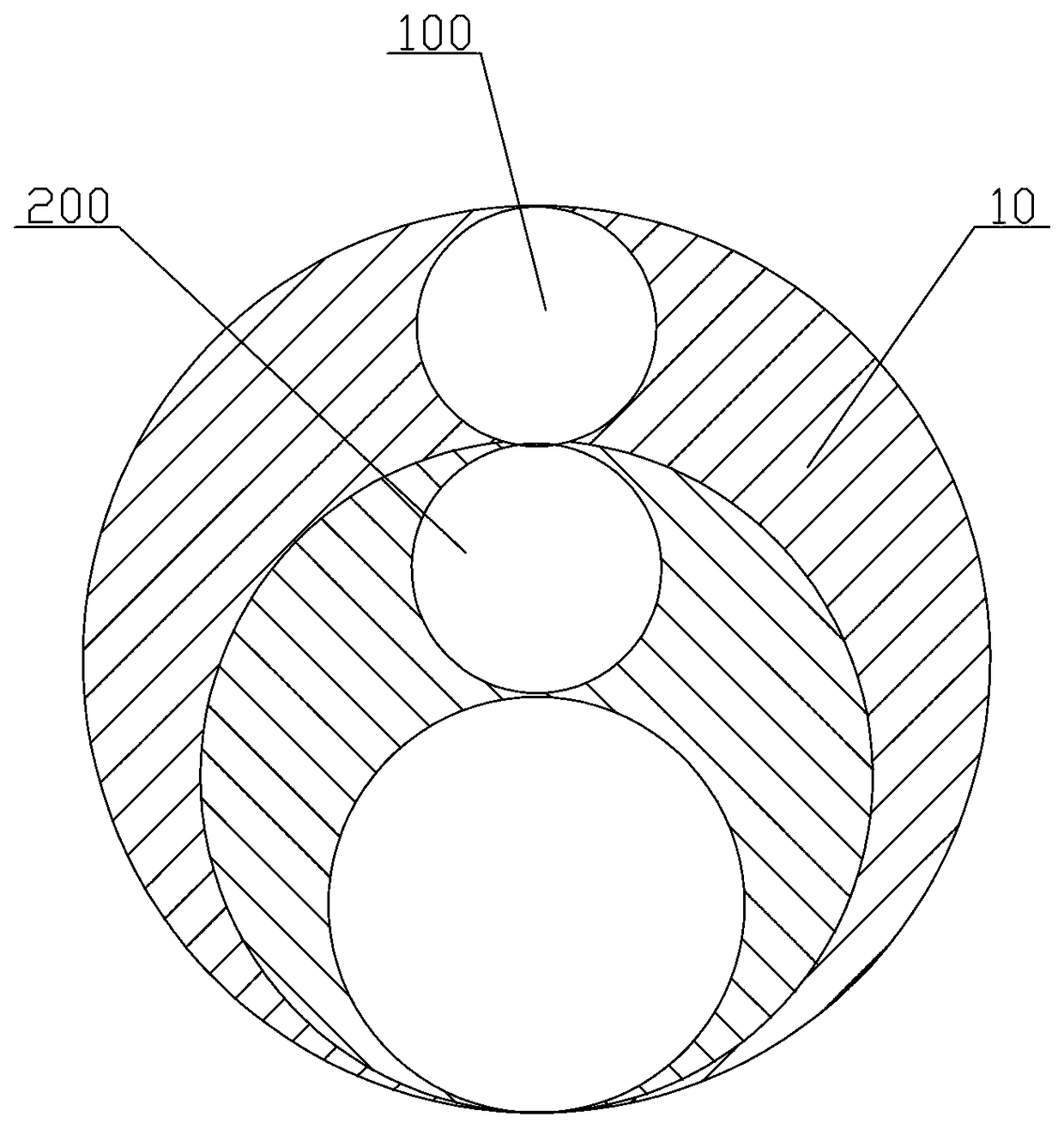

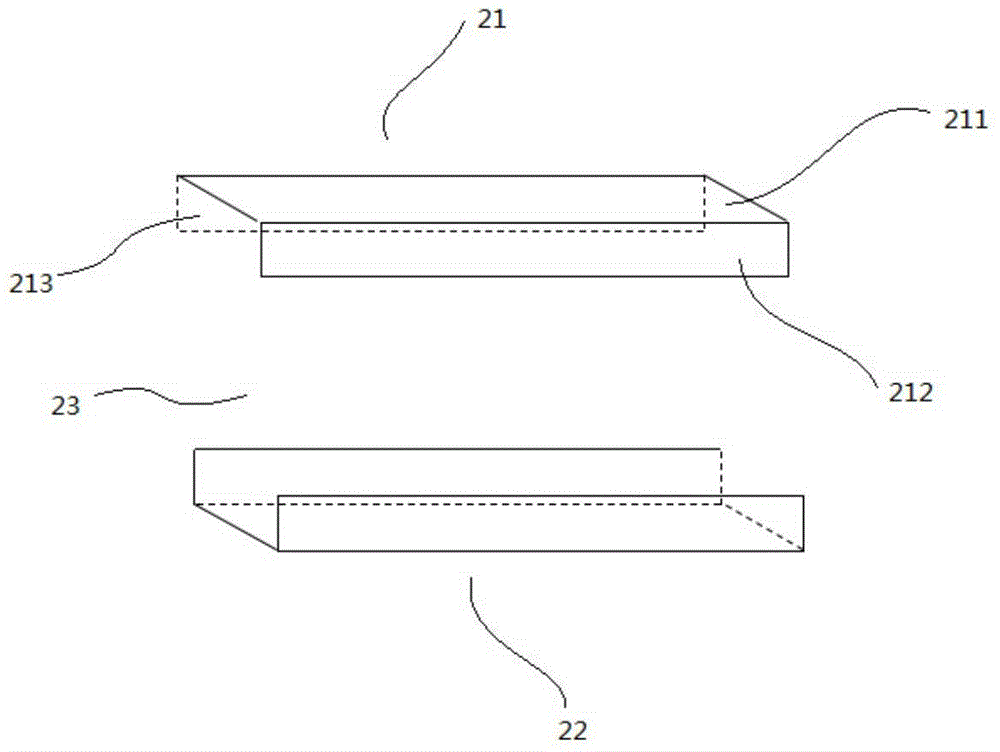

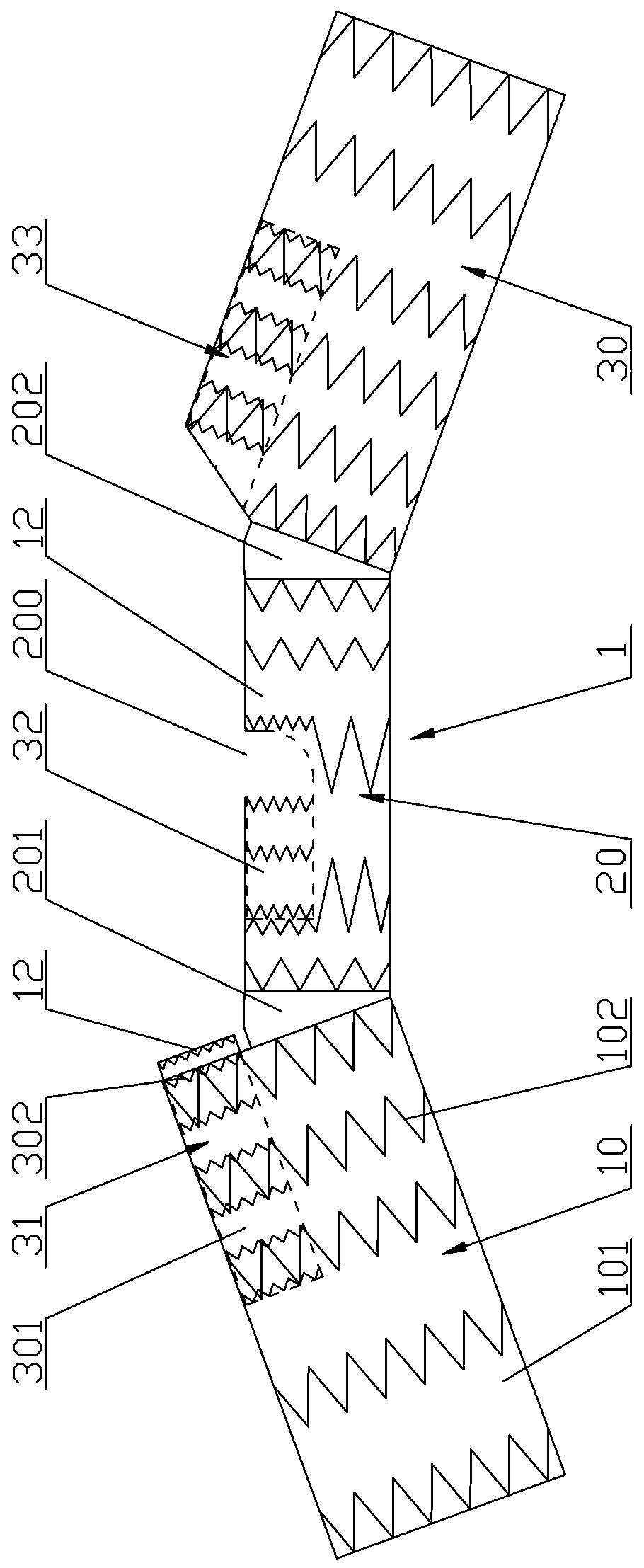

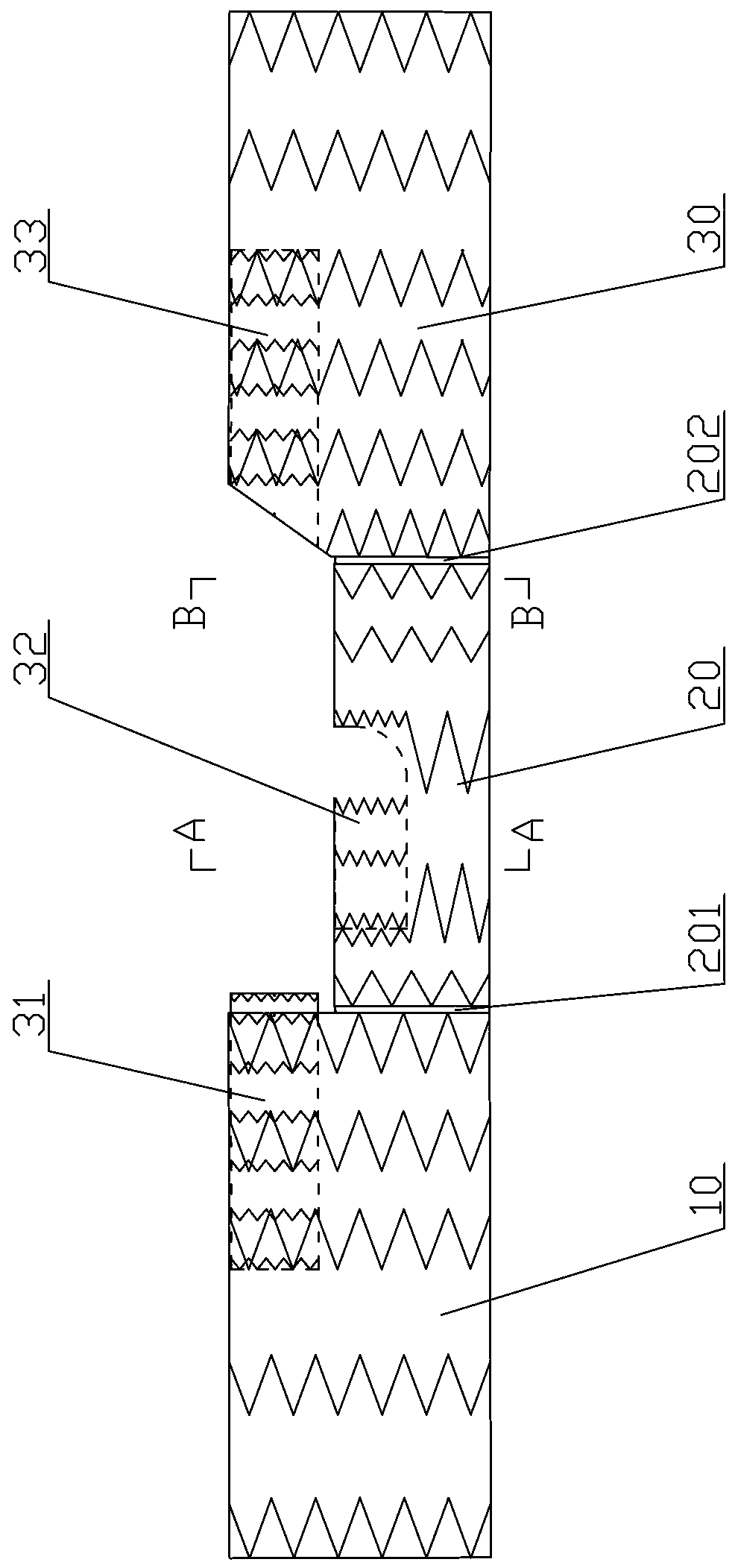

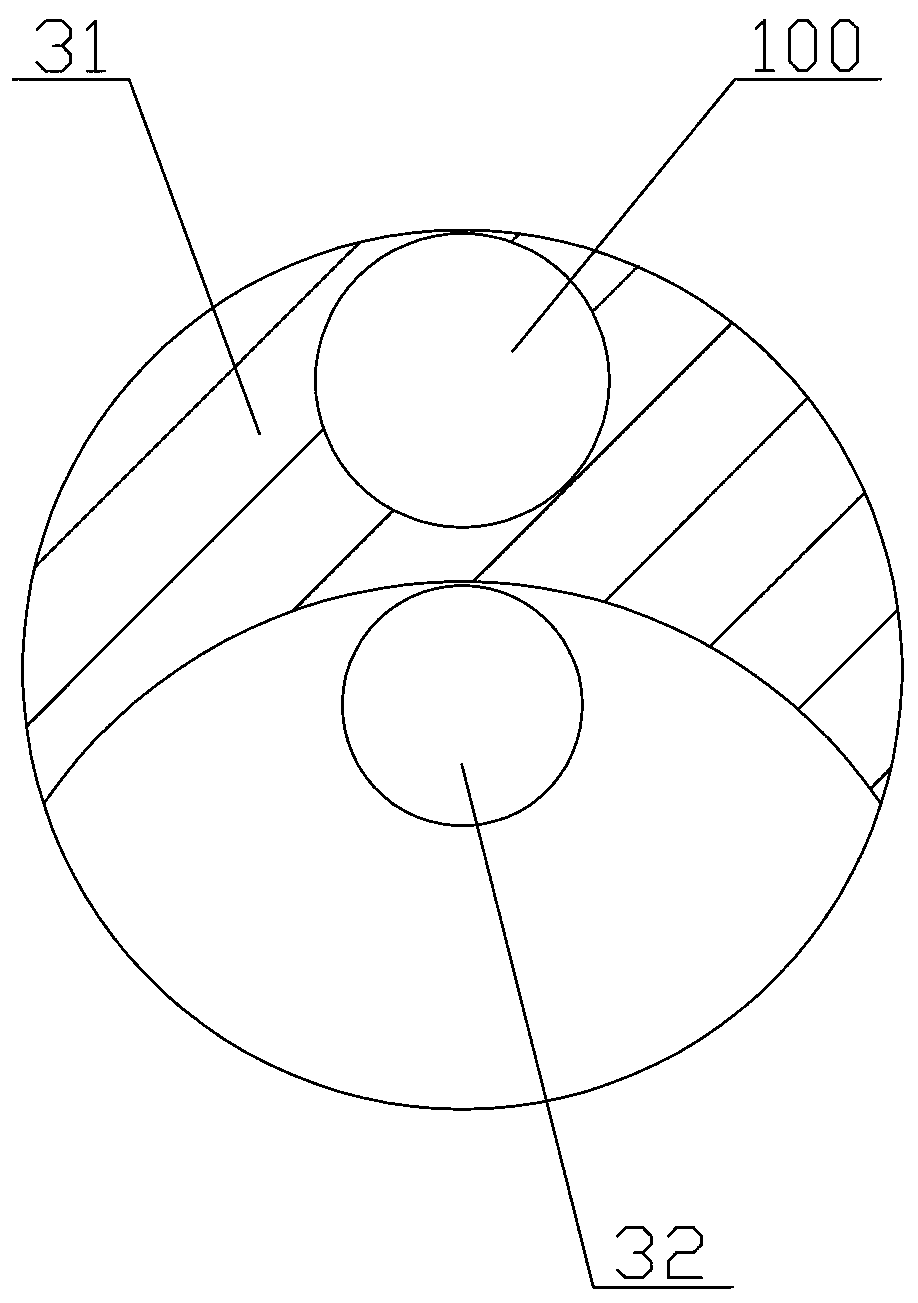

Improved aortic arch stent graft blood vessel

An improved aortic arch stent graft blood vessel includes an aortic stent blood vessel and three branch arterial stent blood vessels, wherein the aortic stent blood vessel is in a pre-curved shape andcomprises a heart-proximal-end segment, a recessed portion and a heart-distal-end segment. The recessed portion comprises a first step and a second step. The heart-proximal-end segment has an opening1 on the upper middle portion of its right sidewall. An opening 2 is disposed on the right side of the first step. An opening 3 is disposed on the upper middle portion of the left sidewall of the heart-distal-end segment. Inner chimney brackets 1, 2, and 3 are fixed to the openings 1, 2 and 3 respectively. The three branch arterial stent blood vessels are disposed in the three inner chimney brackets respectively. The improved aortic arch stent graft blood vessel can prevent the mutual interference between the two inner chimney brackets at the heart-proximal end when compressed, so that the aortic stent blood vessel is easy to be compressed and placed into a small-diameter delivery system, and a guide wire and a catheter are likely to select respective inner chimney brackets.

Owner:ZHONGSHAN HOSPITAL FUDAN UNIV

Flexibility testing method for flexible panels

InactiveCN104483195AEasy to test softnessAvoid operations such as installation and fixingMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesSample fixationMaterials testing

The invention discloses a flexibility testing method for a flexible panel. The flexibility testing method comprises the following steps: producing a to-be-tested sample, namely cutting the flexible panel, and bonding the two opposite sides of the cut flexible panels, so as to obtain the to-be-tested sample; producing an auxiliary testing device, wherein the auxiliary testing device comprises a first auxiliary testing piece and a second auxiliary testing piece which are oppositely arranged, and a height-variable testing channel is formed between the first auxiliary testing piece and the second auxiliary testing piece and is used for accommodating the to-be-tested sample; assembling the auxiliary testing device with a universal material testing machine, namely mounting the center of the auxiliary testing device in a sensing region of a sensor of the universal material testing machine; and testing, namely pushing the to-be-tested sample into the sensing region along the testing channel, so as to test the flexibility of the flexible panel. According to the flexibility testing method for the flexible panel, the auxiliary testing piece and the universal material testing machine are combined for use by virtue of simple operation, so that the testing efficiency is greatly improved; meanwhile, the operation errors such as sample fixation are avoided, and acquired data are stable and accurate.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

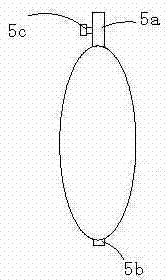

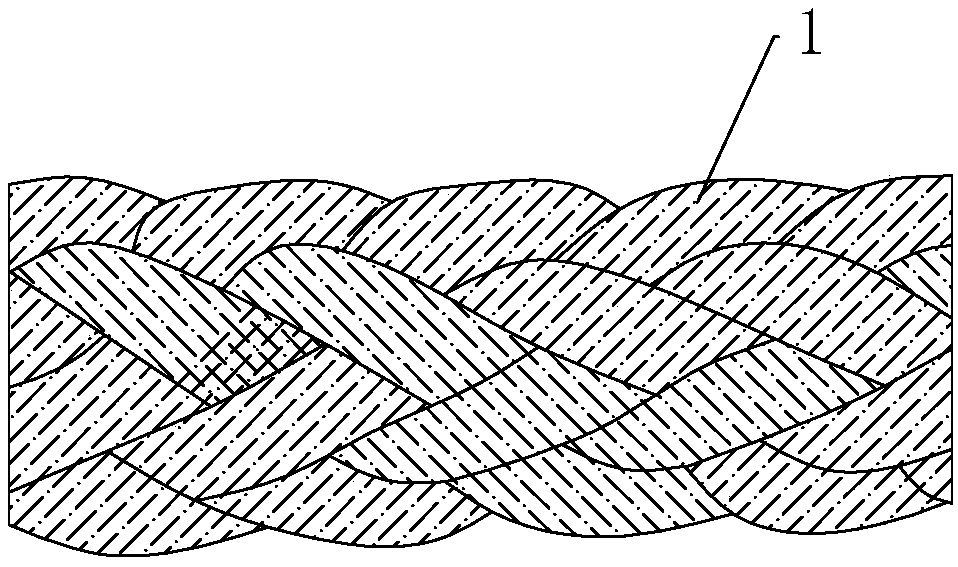

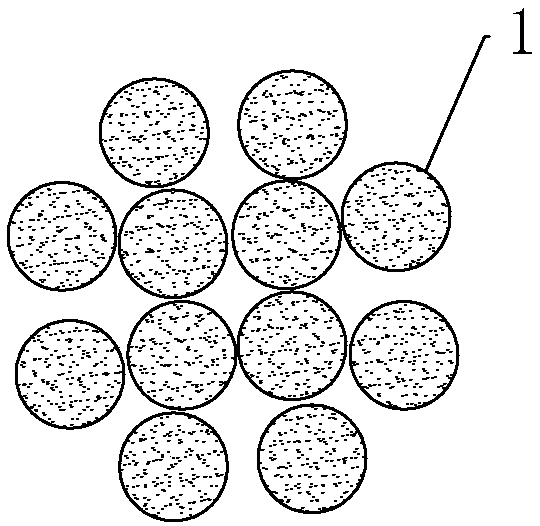

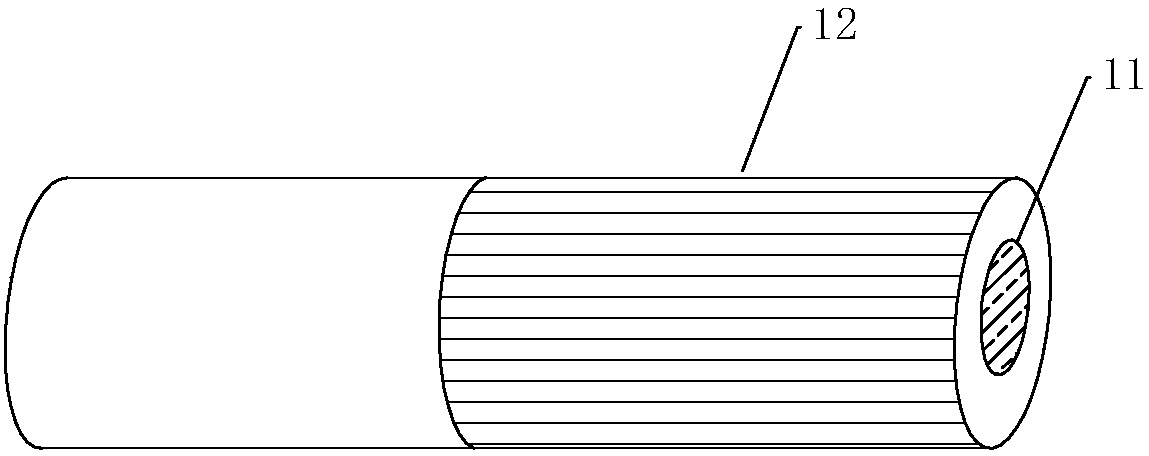

Anti-rebound rope

PendingCN107558273ASafe to useSmall resilienceBraidTextile cablesFiber elongationStructural engineering

The invention discloses an anti-rebound rope. The anti-rebound rope comprises multiple strands, each strand comprises inner core fibers and outer packing fibers located on the outer layer of the corresponding inner core fibers, wherein the fiber elongation rate of the inner core fibers is larger than that of the outer packing fibers. The anti-rebound rope has the advantages that in the strands ofthe anti-rebound rope, the fiber elongation rate of the inner core fibers is larger than that of the outer packing fibers, so that when the anti-rebound rope is broken due to overload, the outer packing fibers are broken at first, and the inner core fibers are not broken immediately due to the larger fiber elongation rate; rebound force is released gradually during breaking of the outer packing fibers, so that the rebound force is reduced after the anti-rebound rope is broken, and then the effects of rebound prevention and safe use are achieved.

Owner:浙江四兄绳业有限公司

Improved aortic arch stent graft blood vessel

An improved aortic arch stent graft blood vessel includes an aortic stent blood vessel and three branch arterial stent blood vessels, wherein the aortic stent blood vessel is an approximately arc multi-segment structure formed by splicing a heart-proximal-end segment, a recessed segment and a heart-distal-end segment. The heart-proximal-end segment has an opening 1. An opening 2 is formed in the top wall of the recessed segment. An opening 3 is disposed in the heart-distal-end segment. Inner chimney brackets 1, 2, and 3 are fixed to the openings 1, 2 and 3 respectively. The three inner chimneybrackets are staggered in the axial direction. The three branch arterial stent blood vessels are disposed in the three inner chimney brackets respectively. The improved aortic arch stent graft bloodvessel can prevent the mutual interference between the two inner chimney brackets at the heart-proximal end when compressed, so that the aortic stent blood vessel is easy to be compressed and placed into a small-diameter delivery system, and a guide wire and a catheter are likely to select respective inner chimney brackets, so as to facilitate the delivery and the release of the branch arterial stent blood vessels.

Owner:泉州市第一医院

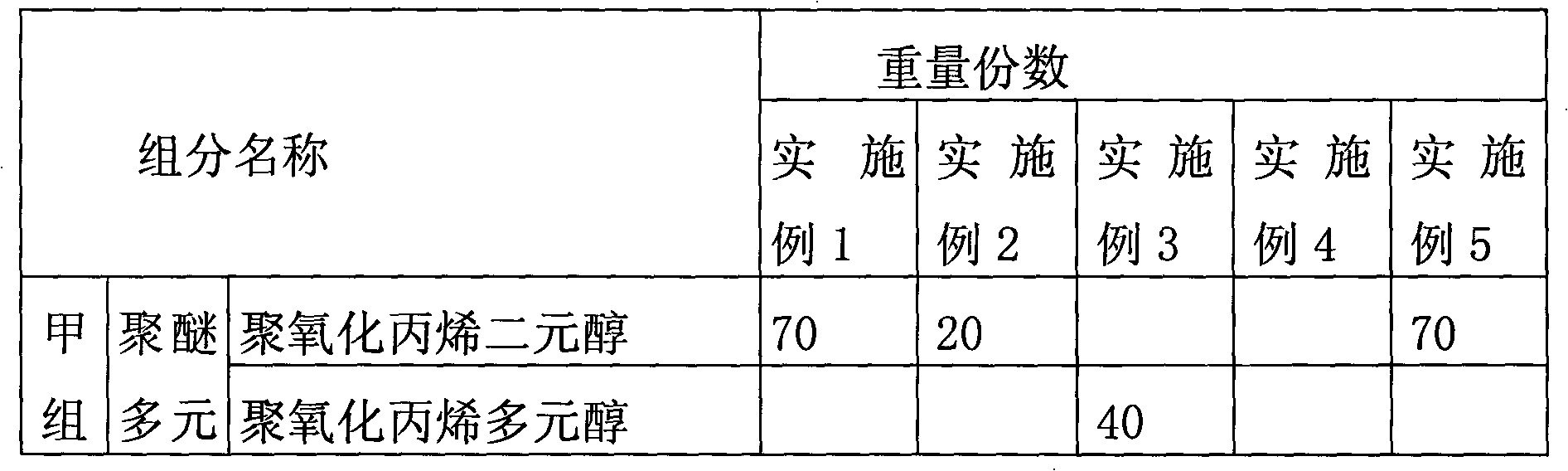

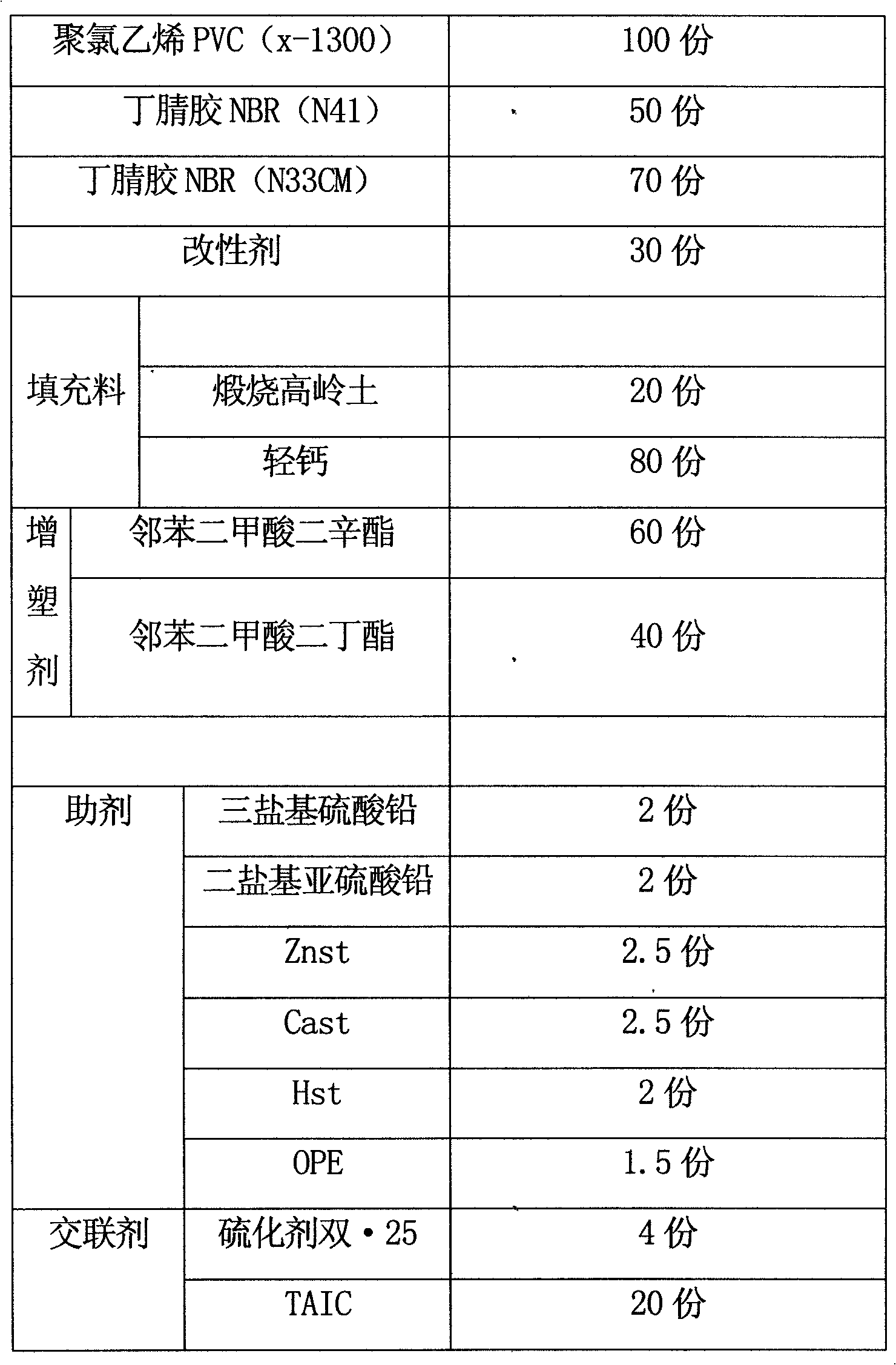

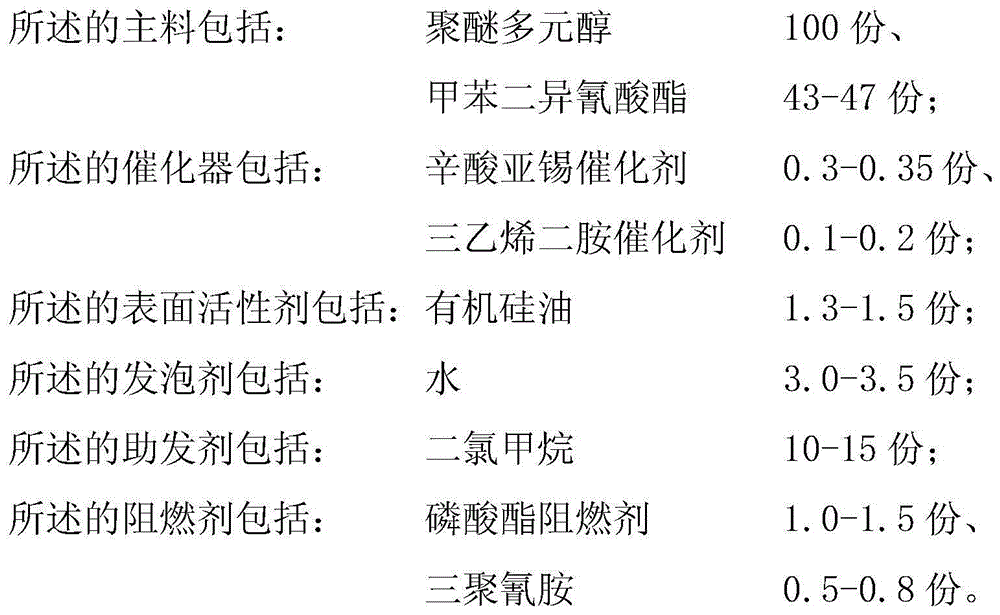

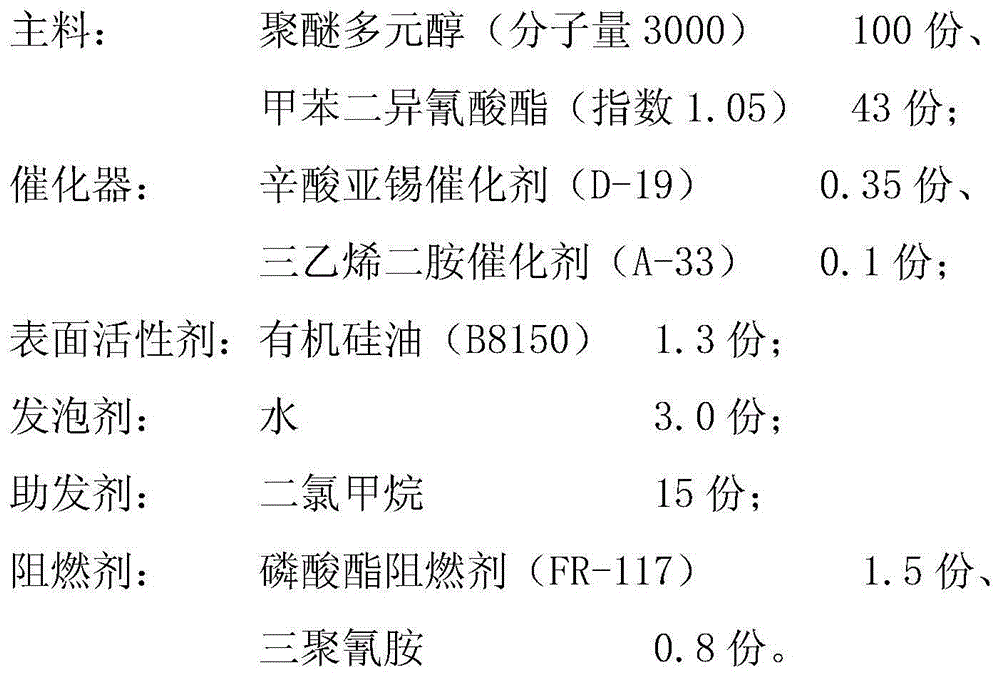

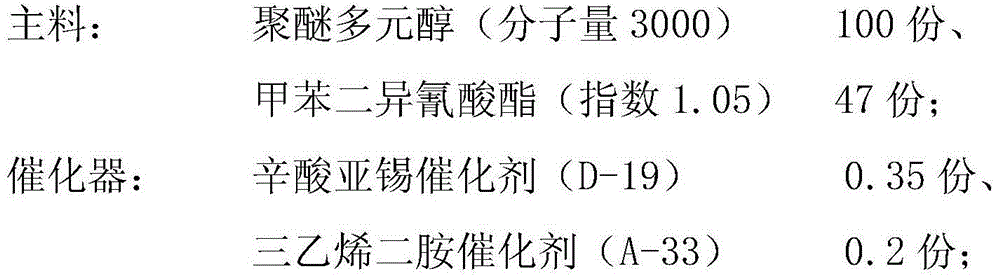

Formula of soft polyurethane composite waterproof sound-absorbing film

The invention discloses a formula of a soft polyurethane composite waterproof sound-absorbing film. The formula comprises polyether polyol, toluene diisocynate, a stannous octoate catalyst, a triethylenediamine catalyst, organic silicone oil, dichloromethane, a phosphate flame retardant and melamine. Use amount of each raw material is limited. According to the invention, formability is excellent, generation of foam structured pinholes during the foaming process is minimized, and foams of a product are fine and uniform. By addition of a reactive flame retardant phosphate (preferably FR-117) and the additive flame retardant melamine, a molecular structure of a cavernous body contains high content of fire retardant elements, and physical property of the product burning core is prevented from being poor. Meanwhile, use amount of water is controlled, and foams coarsening and resilience force descending due to too much water and too many urea-containing chains generated by a reaction are prevented.

Owner:ANHUI ZHICHENG ELECTROMECHANICAL SPARE PARTS

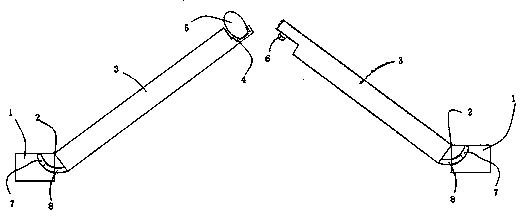

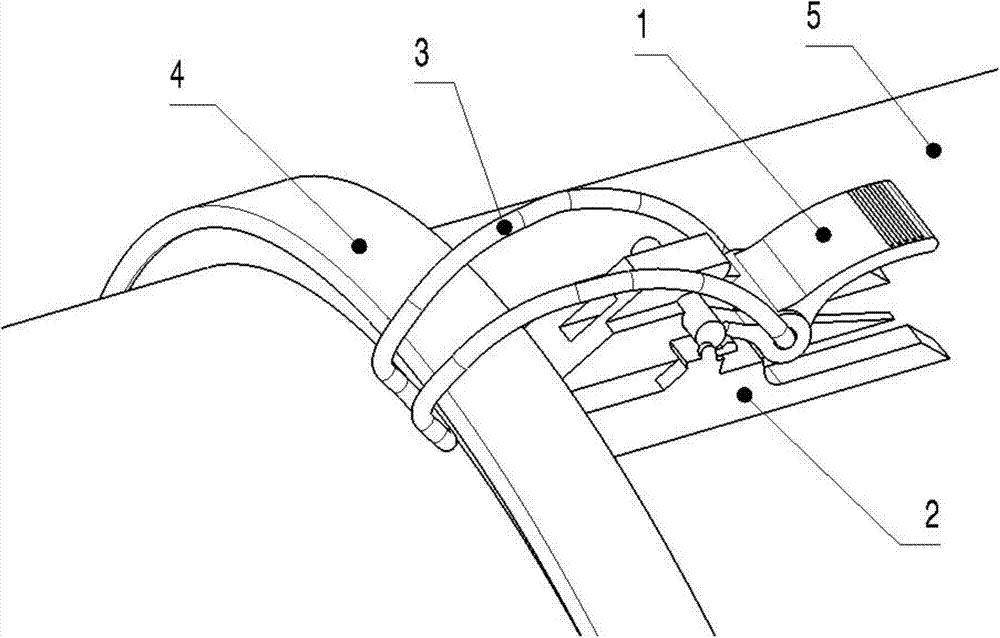

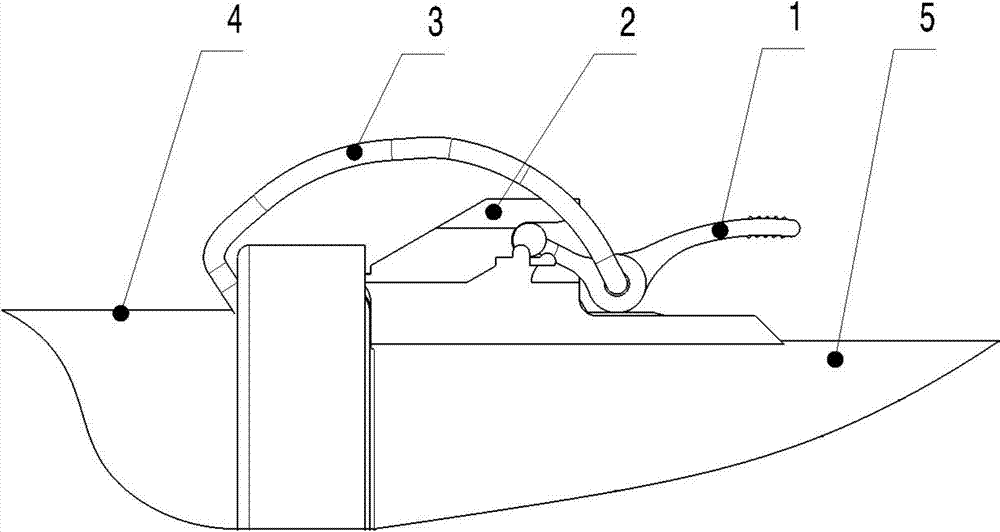

Locking and buckling mechanism for air filter

The invention relates to a locking and buckling mechanism for an air filter. The locking and buckling mechanism is used for connecting a bottom cover and a shell of the air filter; the buckling mechanism comprises a wrench, an installation support and a buckle, wherein the installation support is fixed on the bottom cover, the wrench is installed on the installation support, one end of the buckle is connected with the wrench, and the other end of the buckle is connected with the shell; when the wrench is pressed, the buckle is driven to enable the bottom cover and the shell to be locked. Compared with the prior art, the locking and buckling mechanism for the air filter has the advantages of being high in safety, convenient to install and easy to operate and the like.

Owner:MANNHUMMEL FILTER SHANGHAI

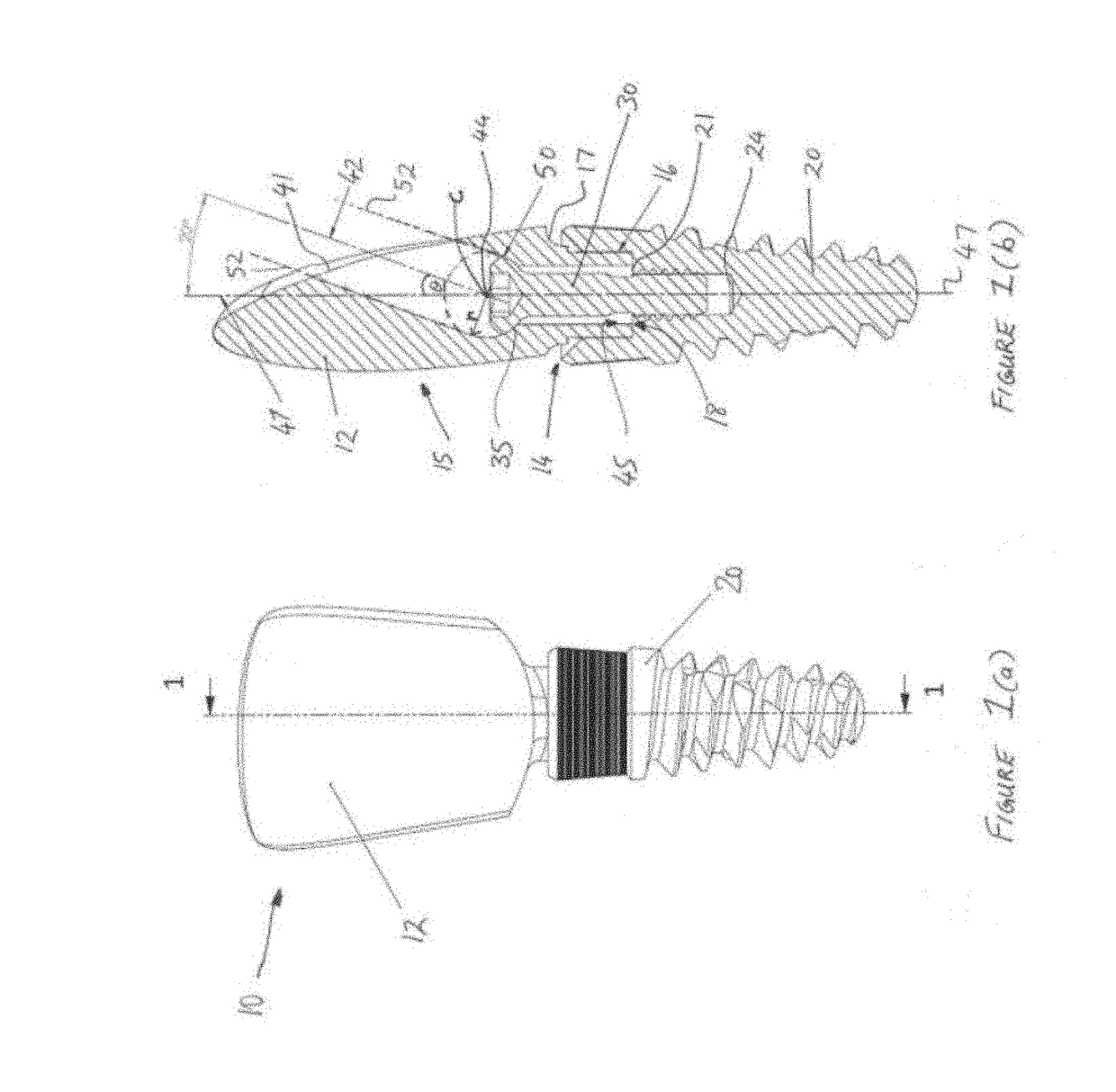

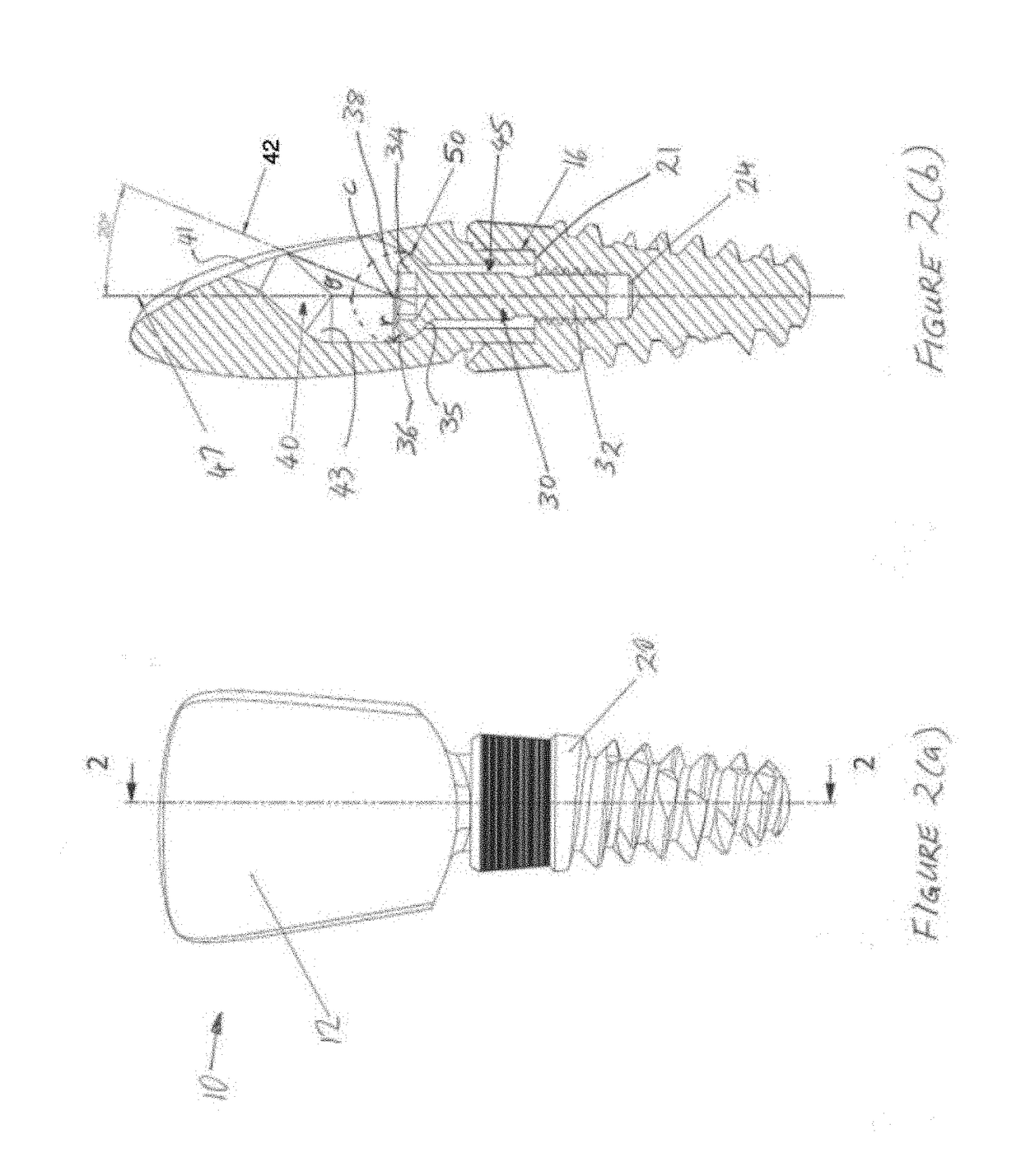

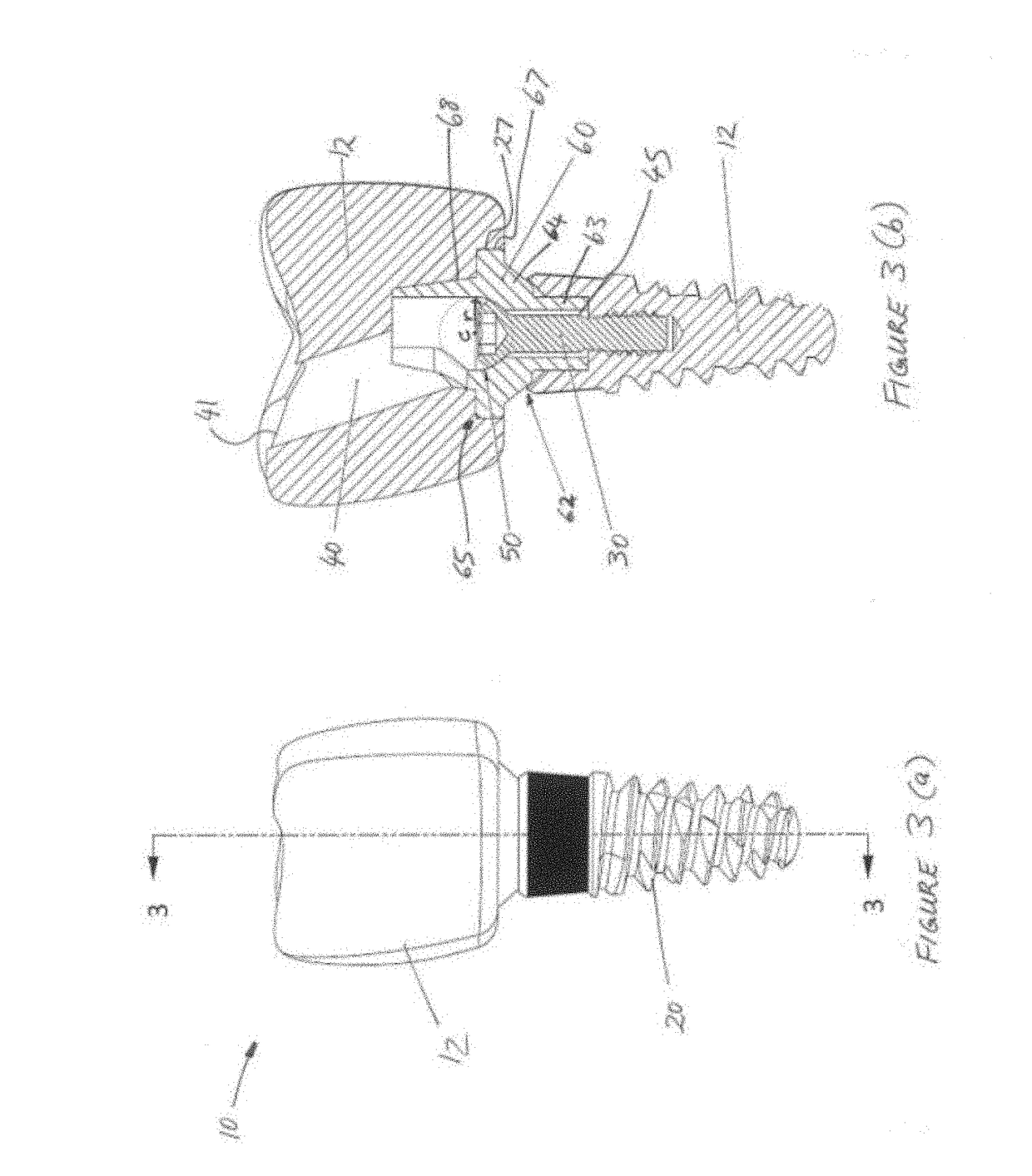

Fastening System

InactiveUS20190038418A1Reduce material usageHigh parts strengthDental implantsFastening prosthesisBone anchorBiomedical engineering

A system for fixing a prosthetic component to an anchor implanted in the bone of a patient. The prosthetic component includes a fixing channel and an installation channel. The fixing channel opens to an engagement collar configured to engage with a bone anchor. The installation channel opens from an outer surface of the prosthetic and communicates with the fixing channel. The installation channel permits placement of a fastener therethrough into the fixing channel to secure the prosthetic to the bone anchor. The axes of the fixing channel and the installation channel intersect at a point which lies within the radius of a fastener seat which is configured to engage a head of the fastener when the fastener is placed into the fixing channel.

Owner:SMARTSCREW PTY LTD

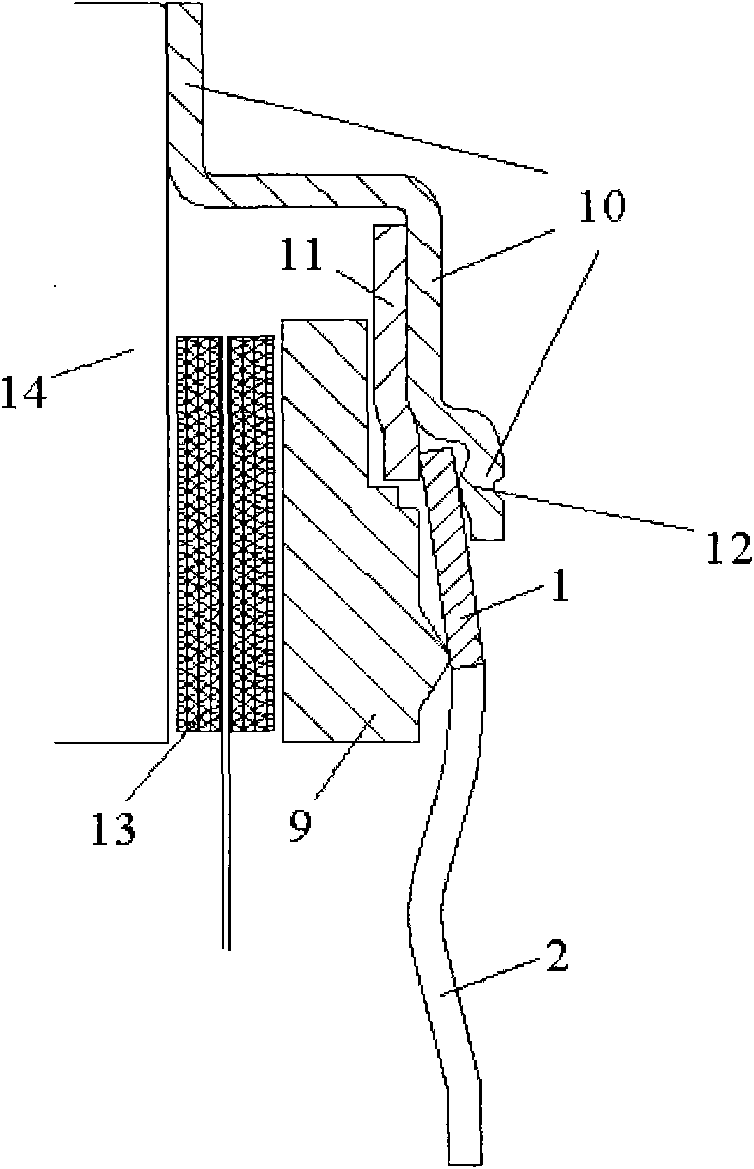

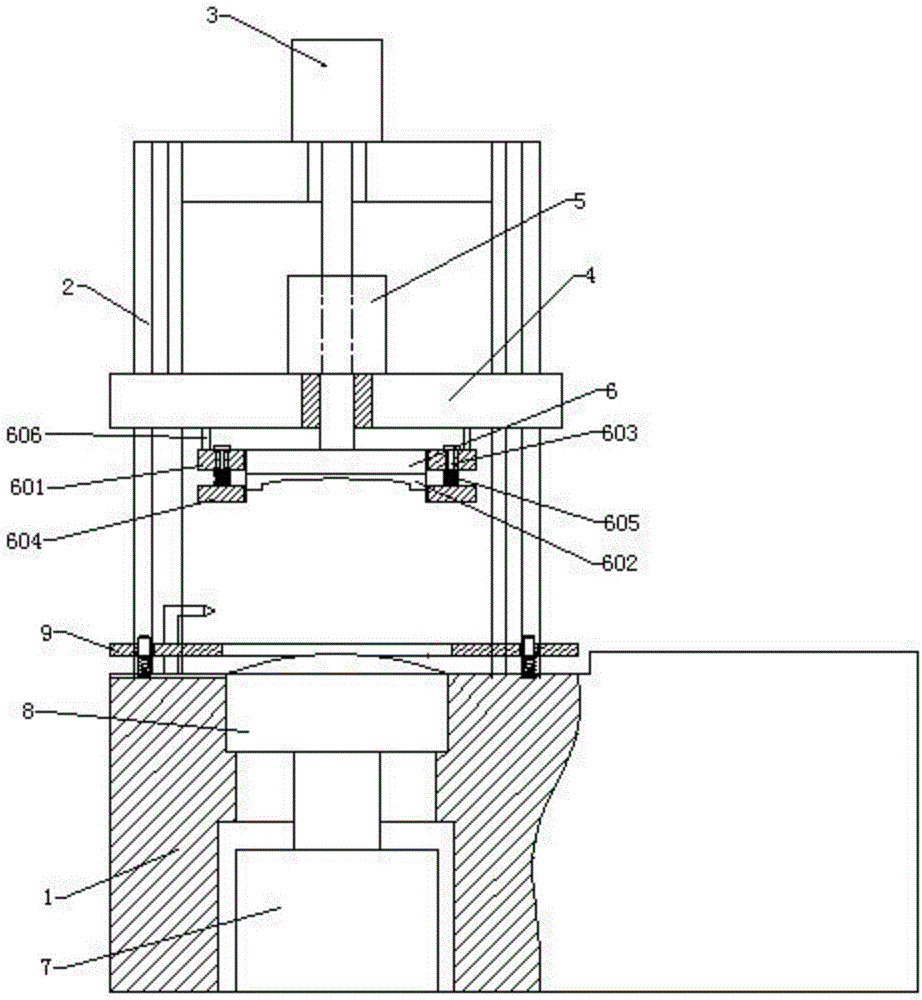

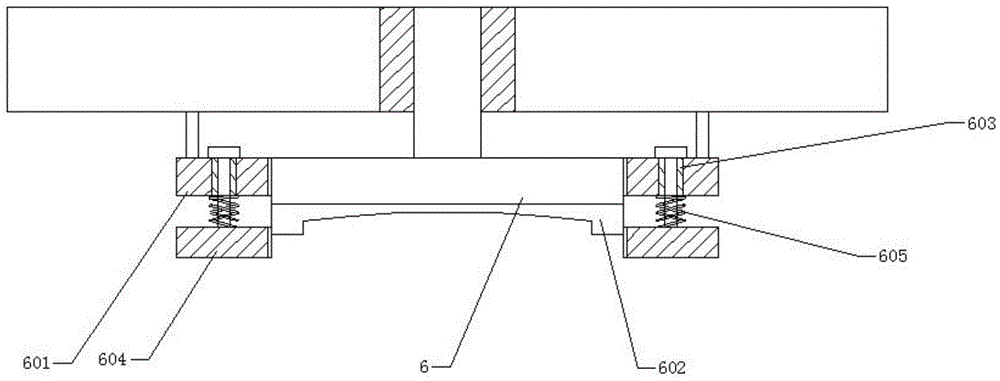

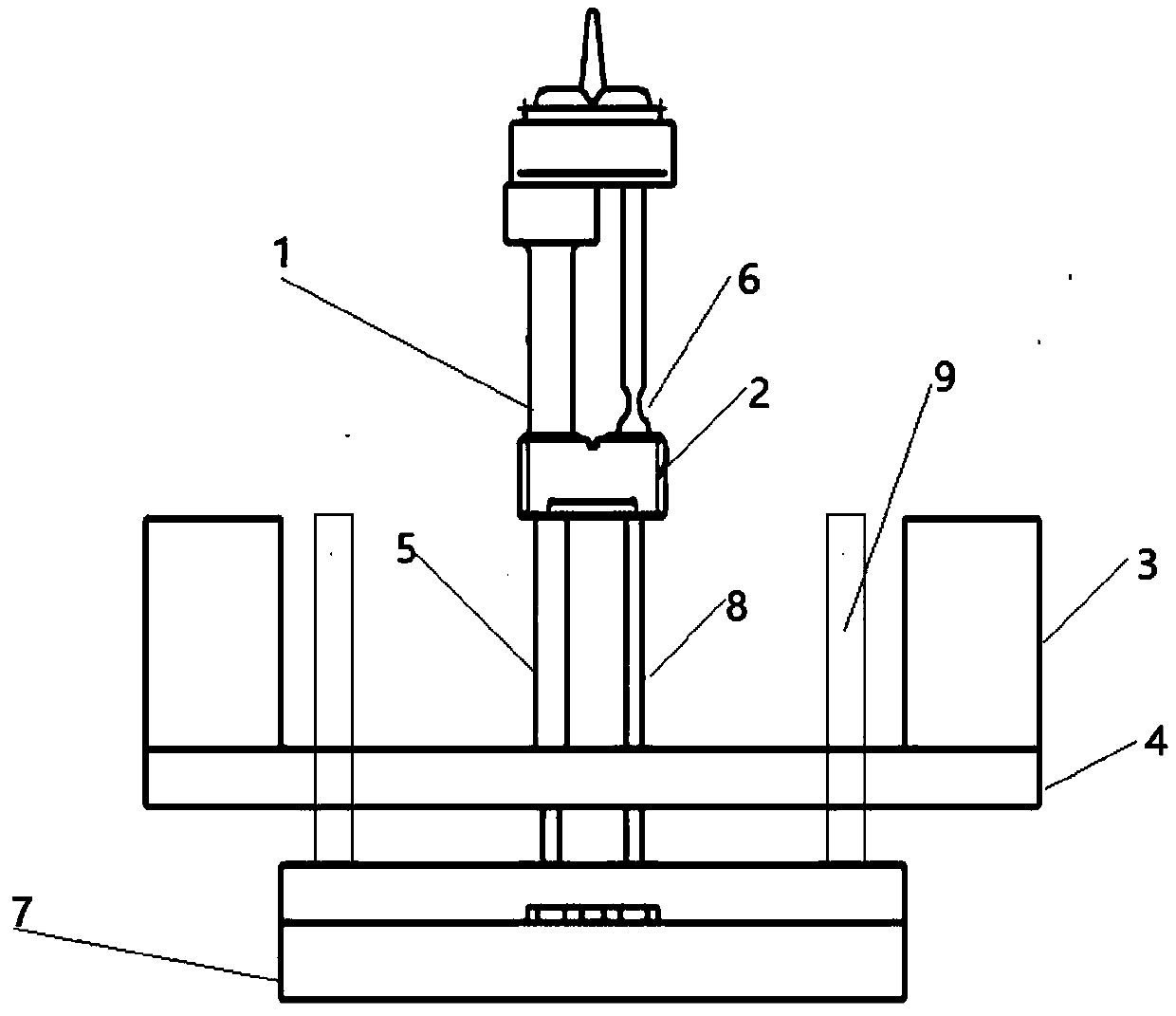

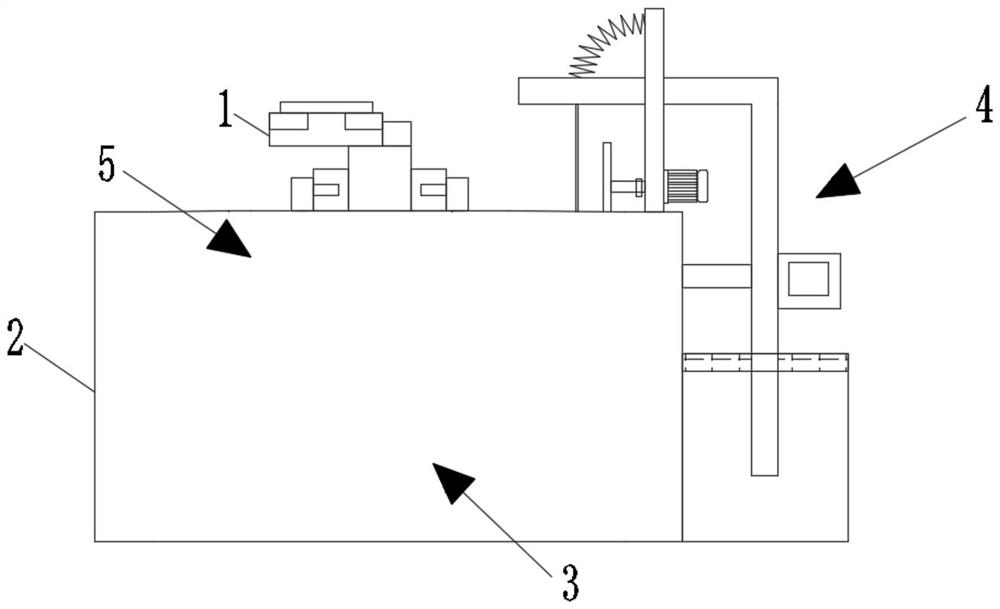

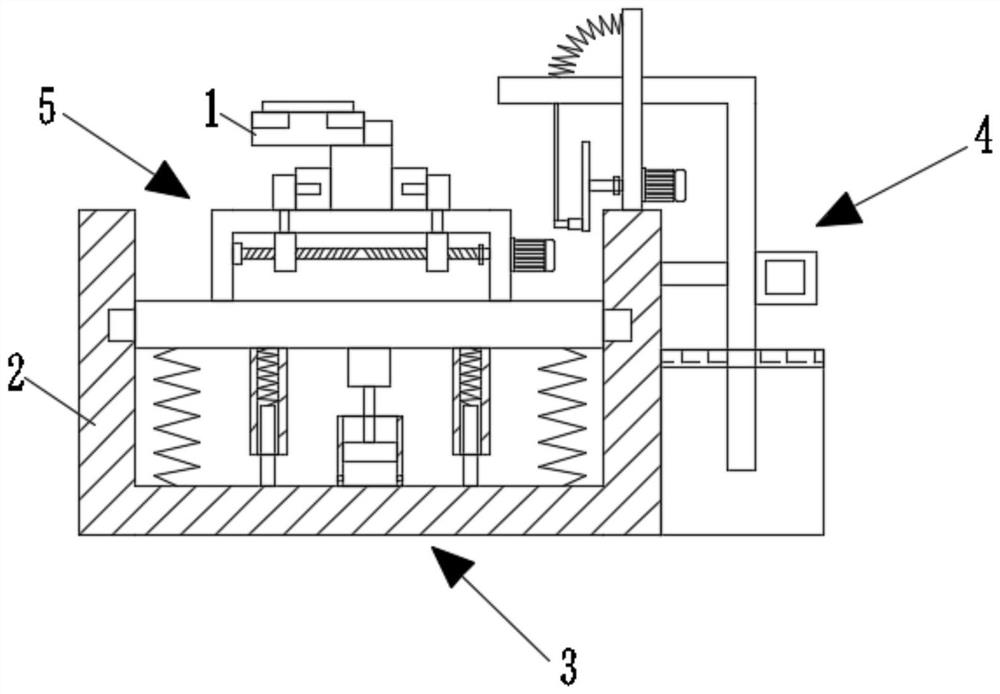

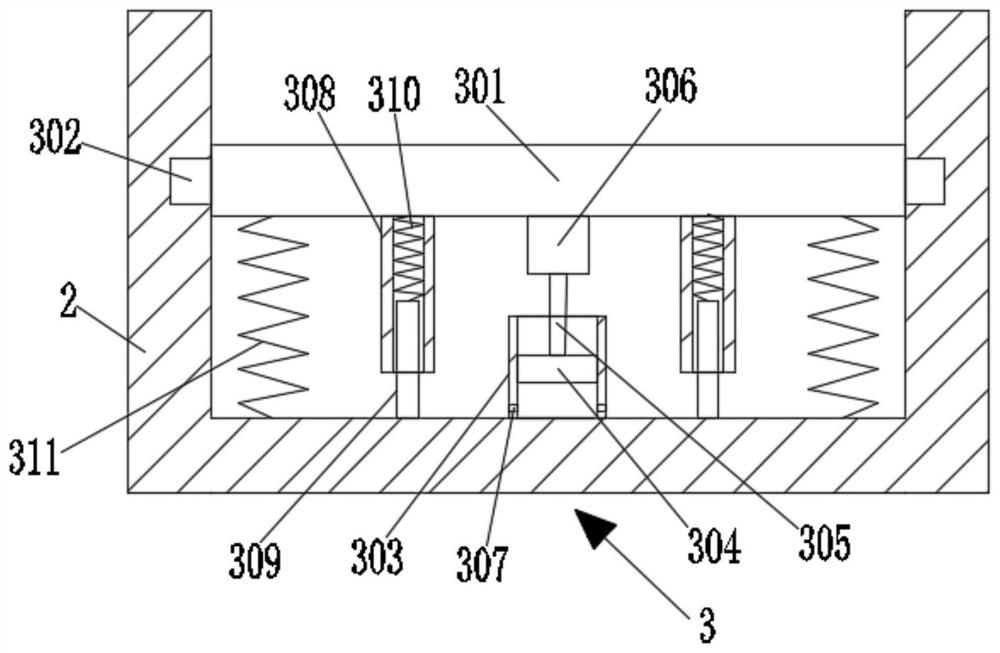

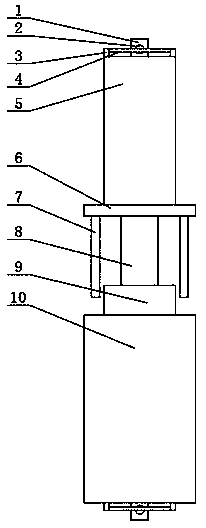

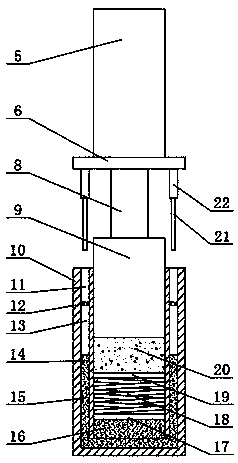

Floating extruding device for end cover of water tank of solar water heater

The invention discloses a floating extruding device for an end cover of a water tank of a solar water heater. The floating extruding device comprises a rack, a supporting base, a hydraulic cylinder, a movable plate, a motor, an upper floating mould, an ejector hydraulic cylinder, a lower mould and a lower floating plate. Compared with the prior art, a to-be-processed plate is placed on the top of the lower mould, the hydraulic cylinder pushes the movable plate to downwards move, the motor drives the upper floating mould to rotate, the plate is pressed by a floating pressure plate and the lower floating plate, and the lower mould is upwards ejected through the ejector hydraulic cylinder, so that a rolling mould and the lower mould extrude with each other, and the friction and rolling molding are performed on the plate; the friction rolling belongs to plastic deformation processing, so that the resilience force is extremely small, the deformation after molding is avoided, and the product quality is guaranteed.

Owner:池州海琳服装有限公司

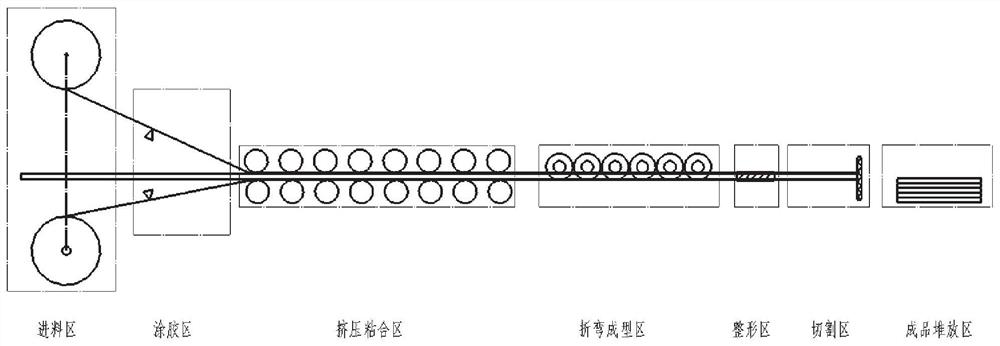

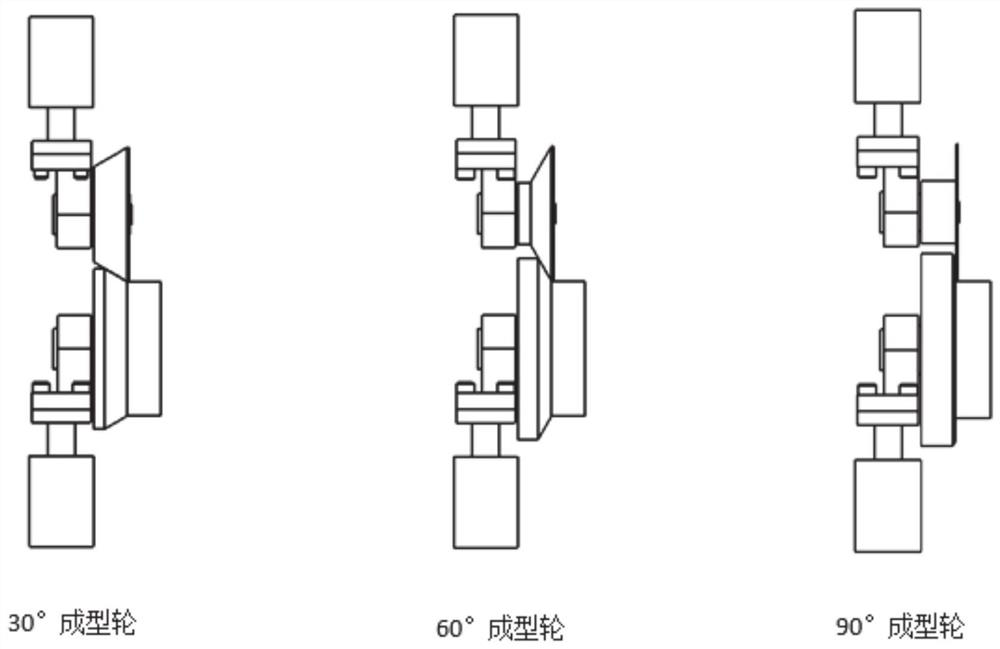

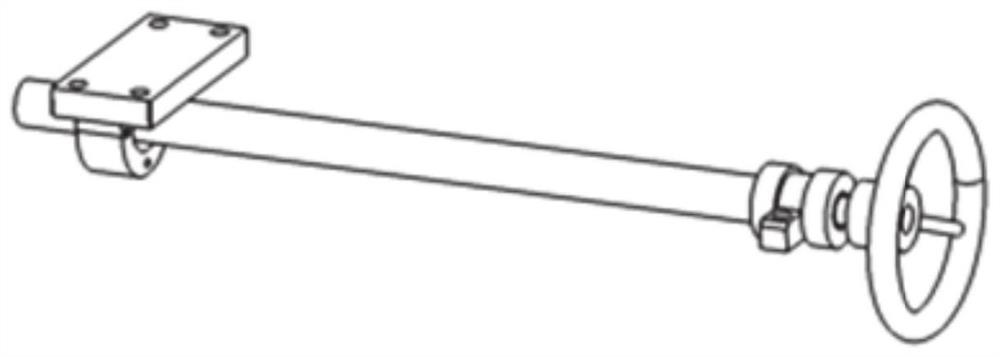

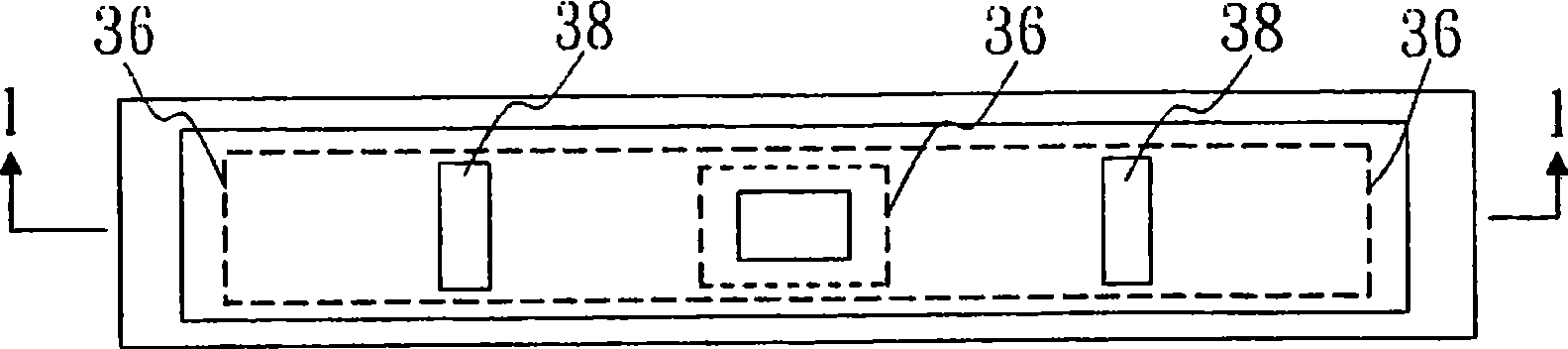

Teaching board self-wrapping automatic assembly line and method

PendingCN111659804ALabor savingImprove consistencyLaminationLamination apparatusStructural engineeringAssembly line

The invention provides a teaching board self-wrapping automatic assembly line and method, and belongs to the technical field of teaching boards. The teaching board at least comprises a panel, a back board and an interlayer. The assembly line at least comprises a bending mechanism. The two sides of the bending mechanism are symmetrically provided with forming wheels. The forming wheels are configured to bend the surplus portions on the two sides of the panel at least twice to wrap the side portions of the interlayer and the back board. The product consistency and yield are improved under the premise of reducing a large amount of labor. Simple and easy operation can be carried out. Twenty-four-hour non-stop operation is supported.

Owner:SHANDONG LANBEISITE EDUCATIONAL EQUIP GRP

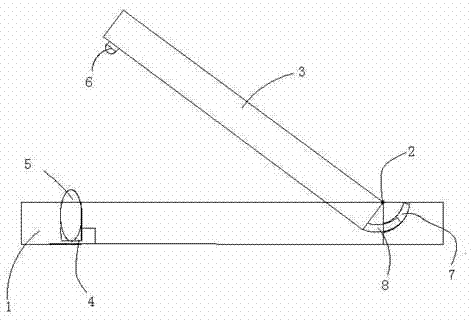

Novel door holder

Owner:江汇装饰用品(鹤山)有限公司

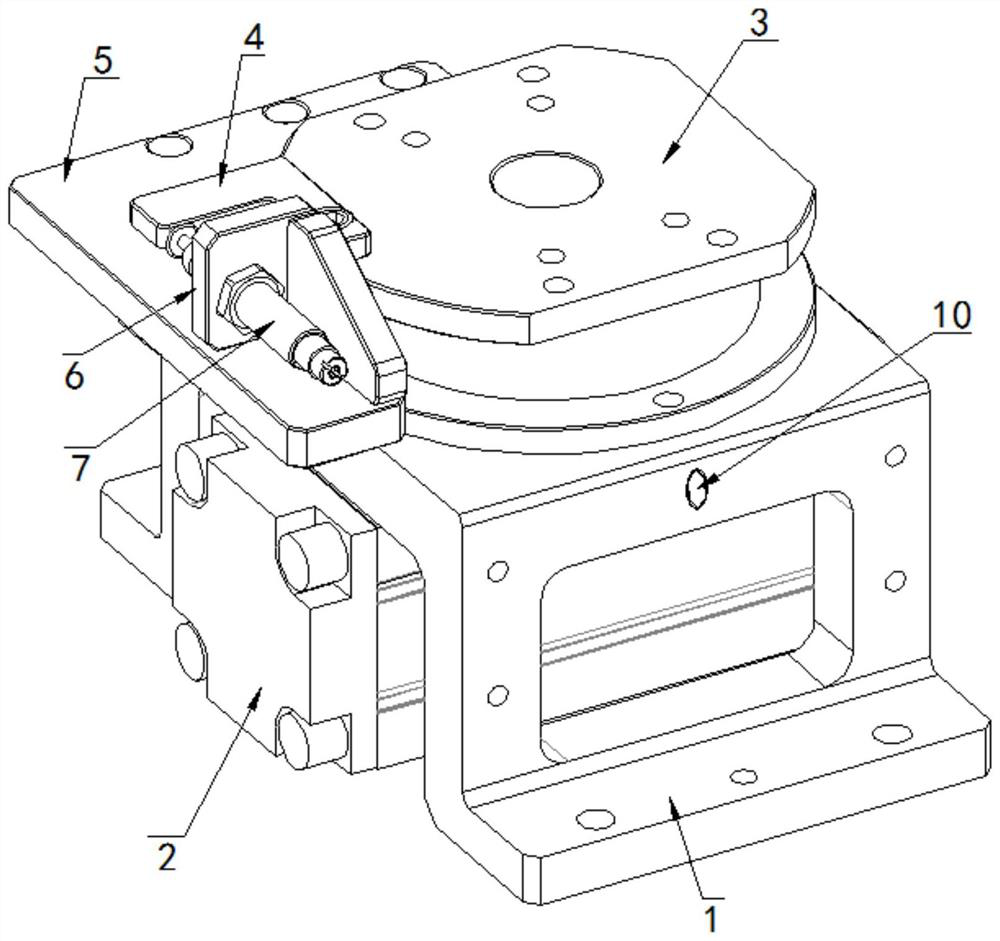

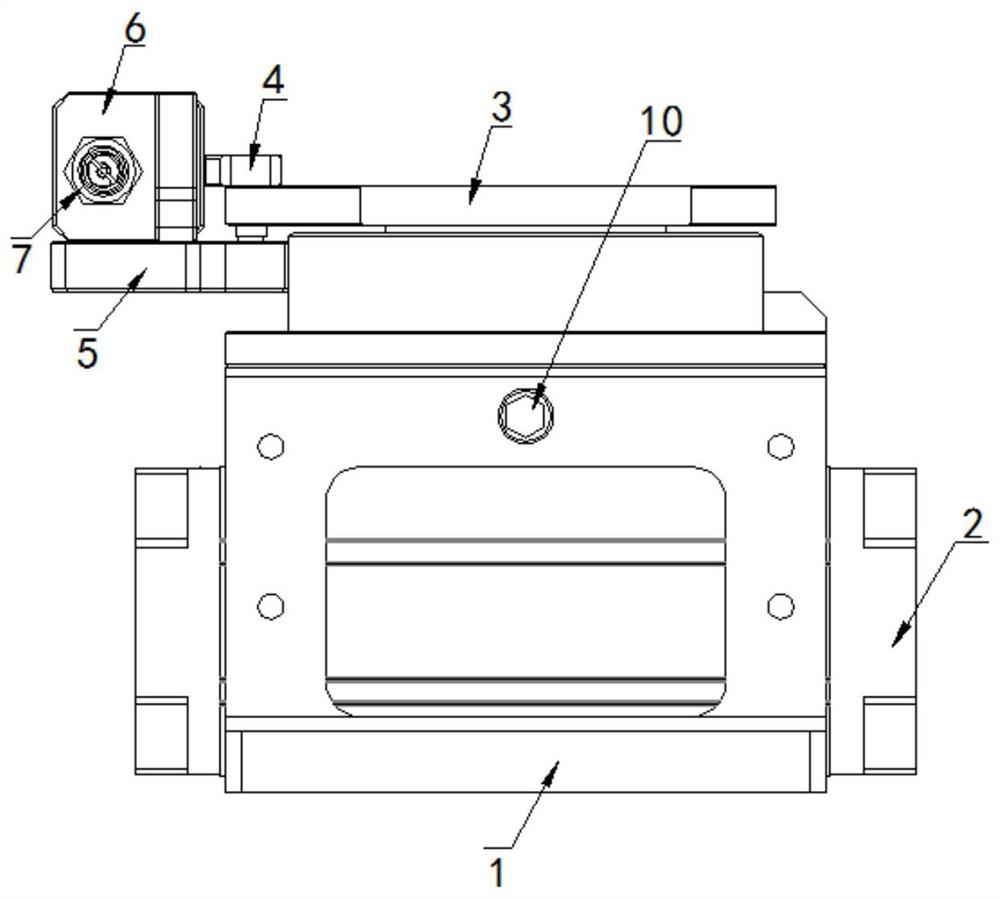

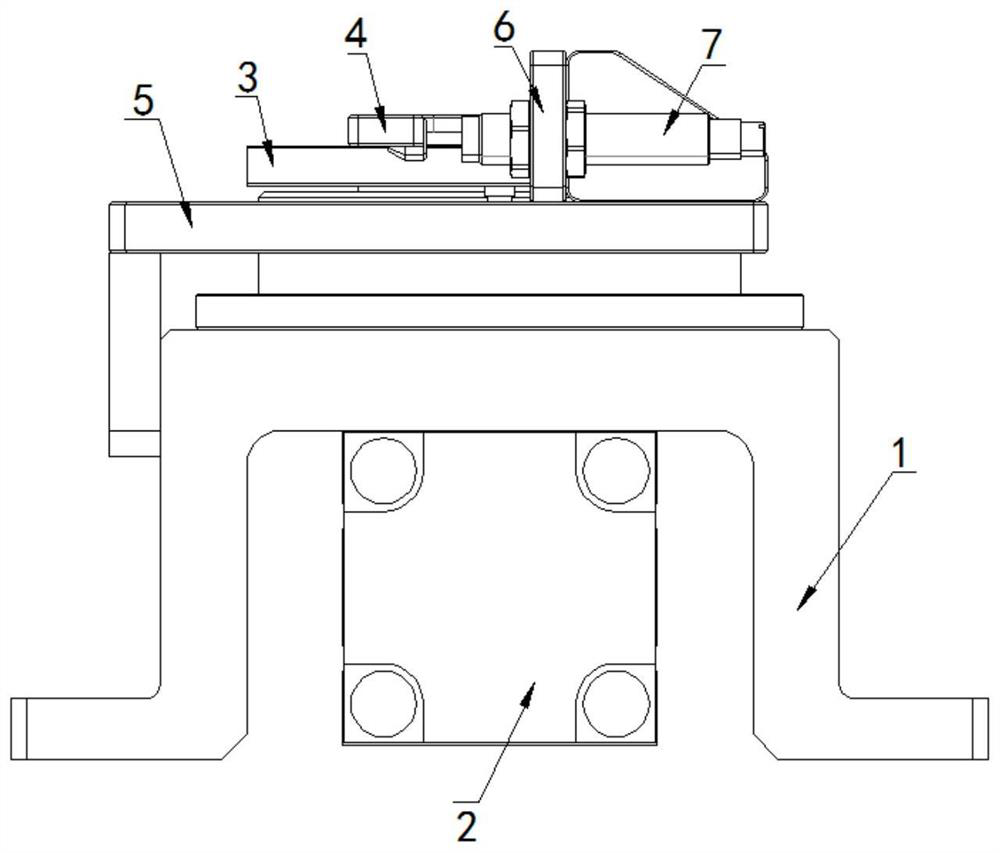

External limiting and buffering device suitable for rotating air cylinder

PendingCN113323940AThe equipment runs stablyIncrease productivityFluid-pressure actuator componentsPhysicsPlastic bag

The invention discloses an external limiting and buffering device suitable for rotating air cylinder. The external limiting and buffering device comprises a mounting seat fixedly mounted in a working area; the rotating air cylinder is arranged at the inner end of the mounting seat, and a connecting piece is arranged at the top end of the mounting seat; a side key is fixedly connected to the outer side of an output end of the air cylinder, and the side key is connected with the inner side of a shaft end of the connecting piece through an inner groove; moreover, a limiting block is fixedly installed at the top end of the connecting piece; a fixing seat is fixedly installed at the upper end of the mounting seat; amounting plate is fixedly installed at the upper end of the fixing seat; and an oil buffer playing a buffering and limiting role is arranged at the inner end of the mounting plate. The external limiting and buffering device suitable for the rotating air cylinder consists of a rotating assembly, a limiting assembly and a buffering mechanism assembly. According to the device, a resilience force of rotation in place can be reduced through the oil buffer, so that the device runs more stably, the production efficiency of the device is improved, the service life of the device is prolonged, and the production efficiency and the qualification rate of plastic bag products are also improved.

Owner:YINGKOU XIAOJIAZU IND +1

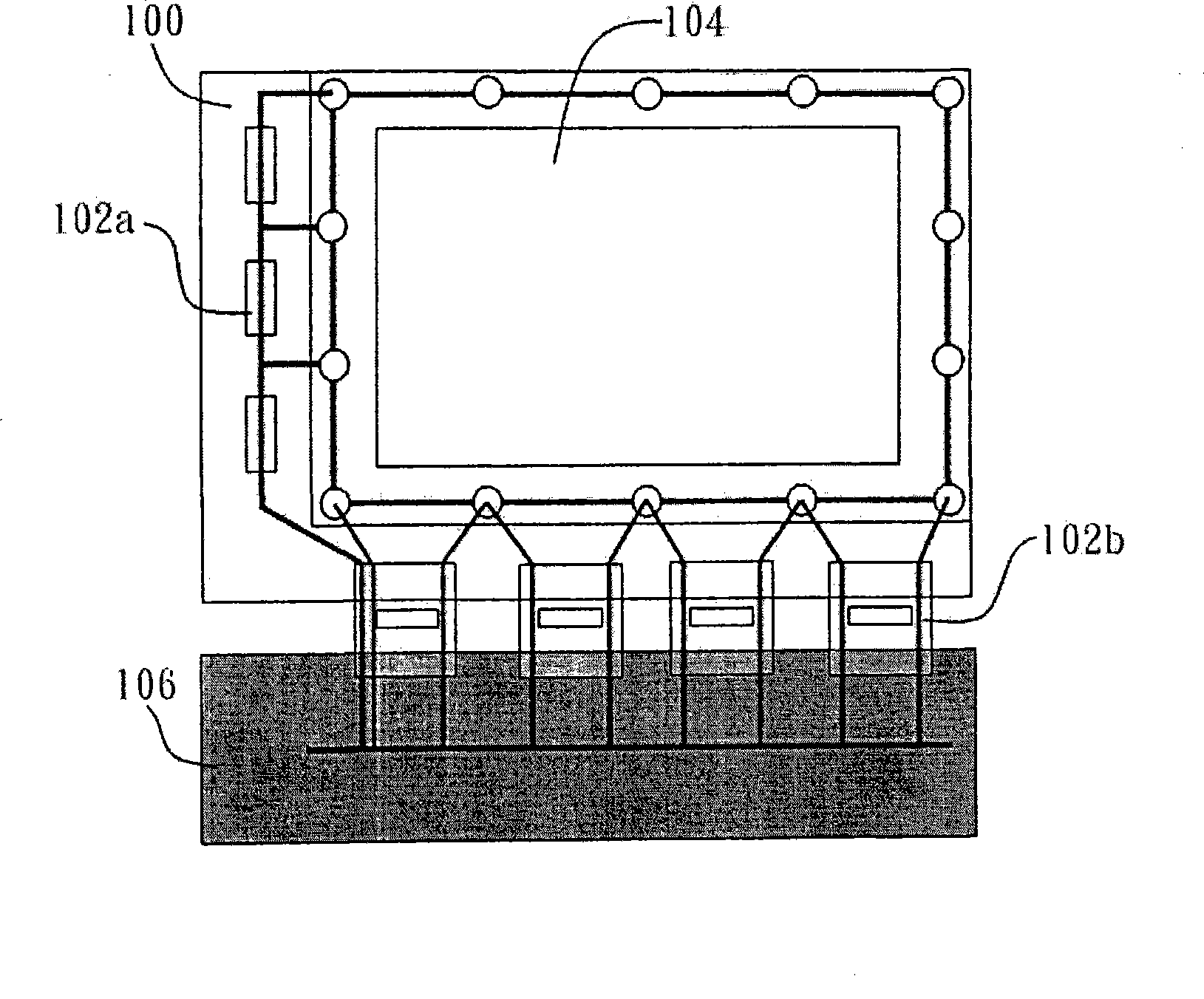

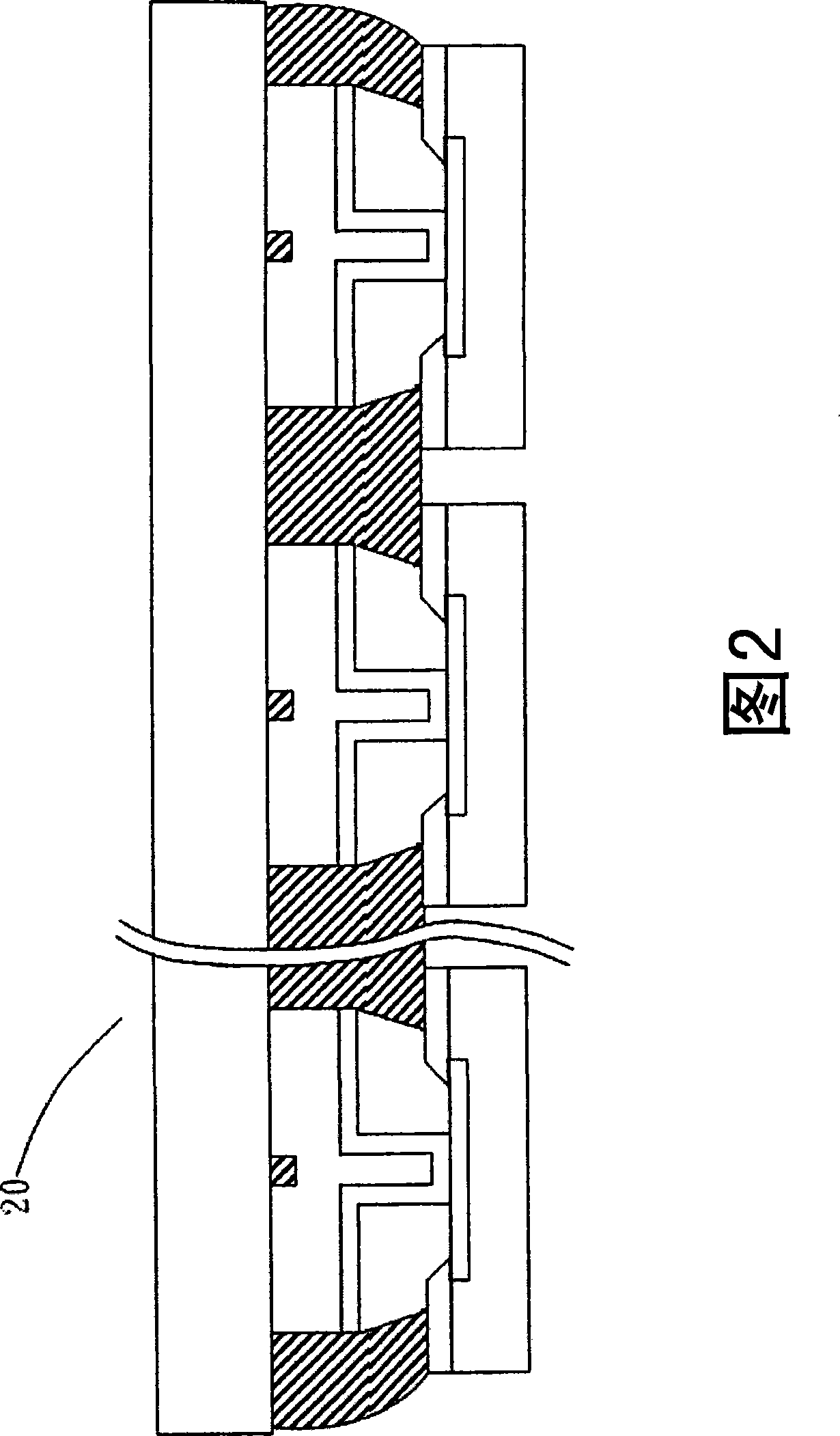

Semiconductor device

InactiveCN101378043ASmall resilienceMake up for bad jointsSemiconductor/solid-state device detailsSolid-state devicesAdhesion forceAdhesive

The invention provides an electronic component or semiconductor device provided with conduction projections, comprising an organic buffer layer provided with undercut structure. The buffer layer can lead to deformation in a joint process so as to make up for defective joint due to the height difference between projections; in addition, an adhesive is also provided between an integrated circuit chip and a basal plate and partially permeates into the undercut structure, thus not only increasing adhesion area to strengthen the adhesion force between the integrated circuit chip and the basal plate, but also dispersing part of pressure in junction to reduce the resiliency of the adhesive generated between the circuit chip and the basal plate.

Owner:HANNSTAR DISPLAY CORPORATION

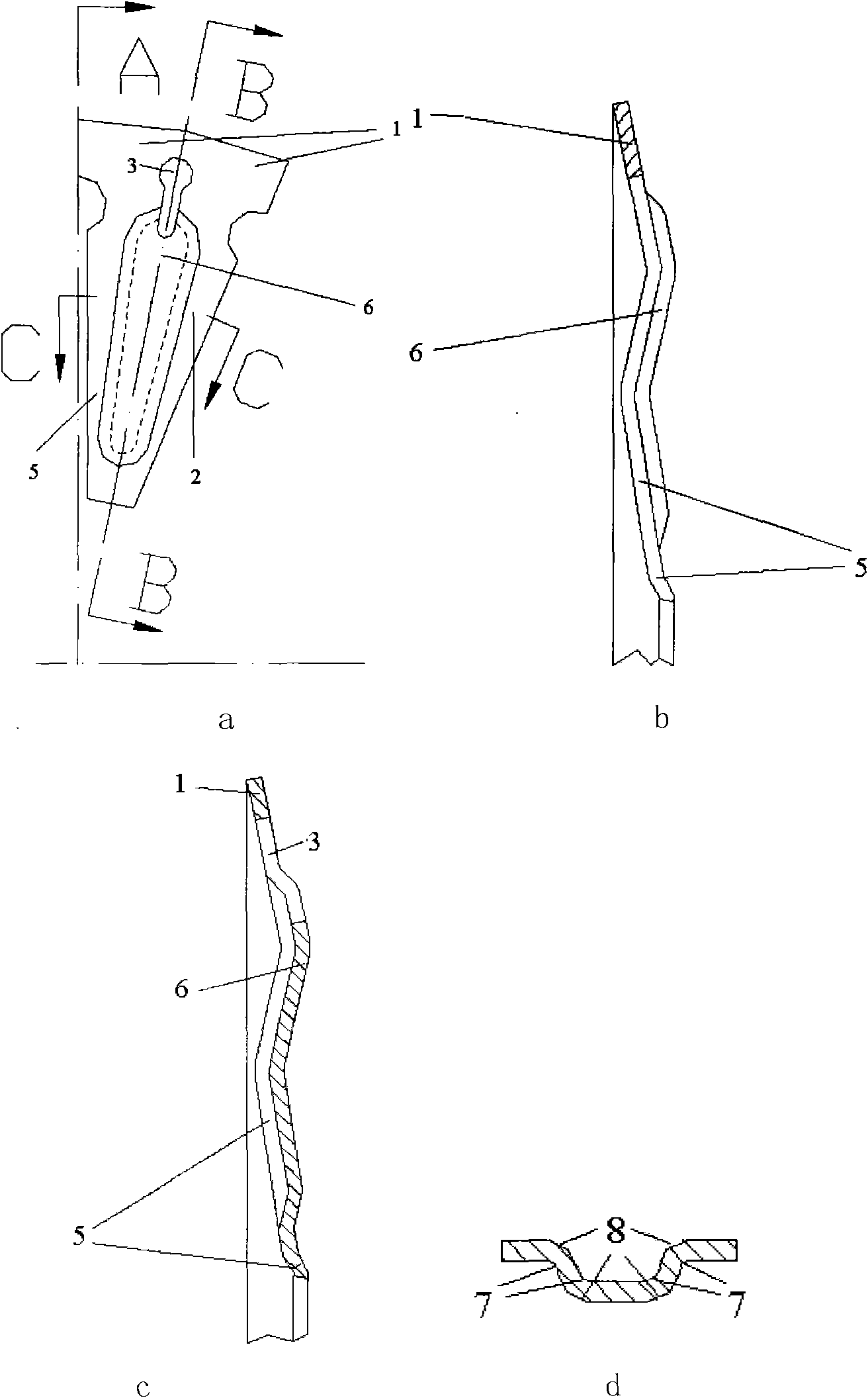

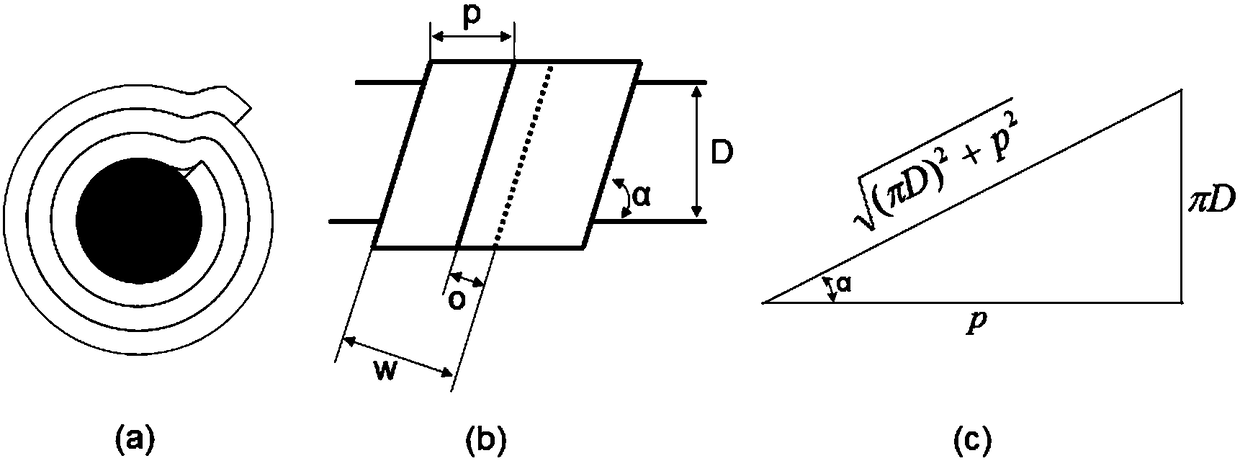

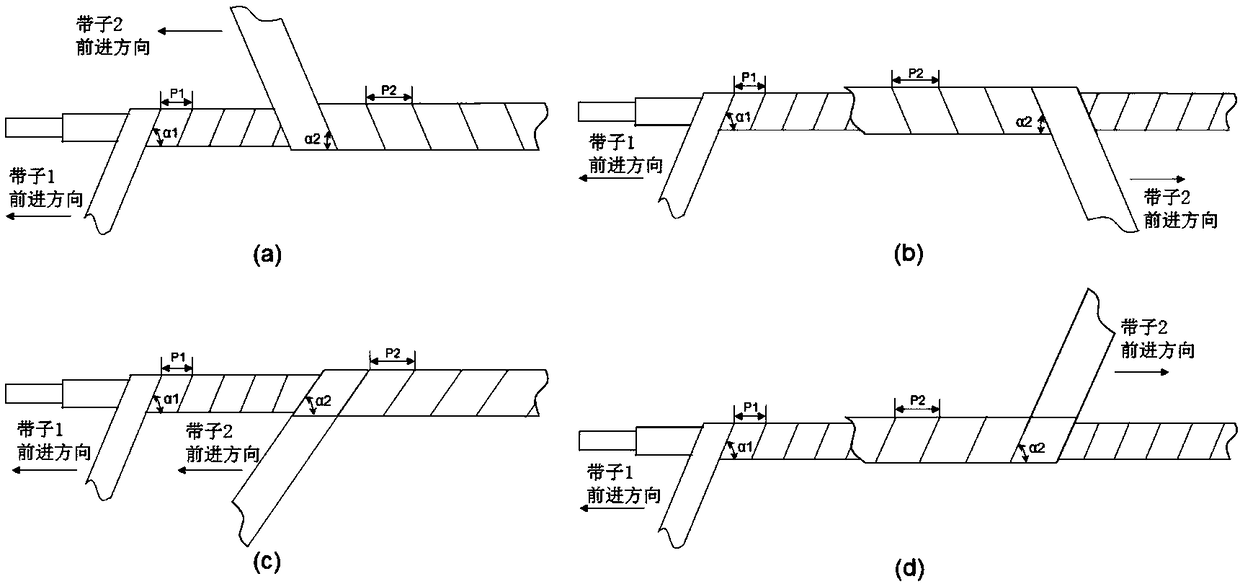

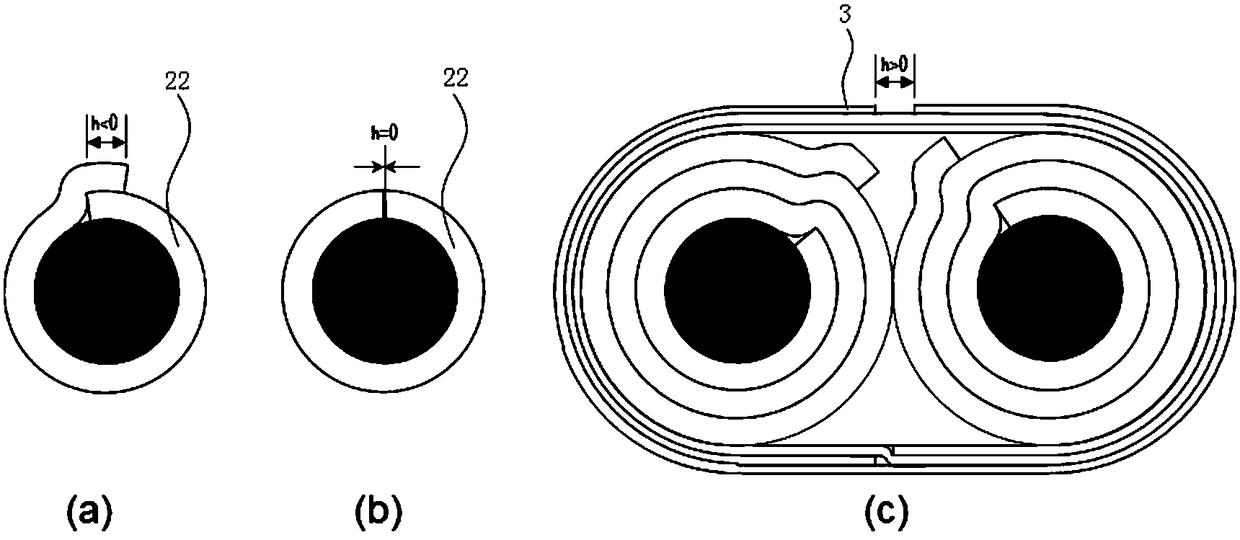

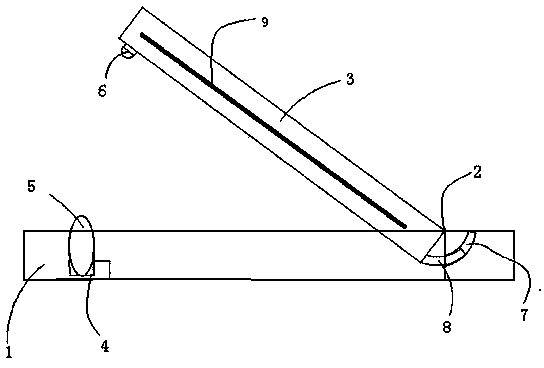

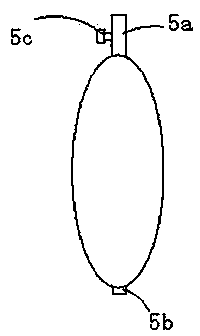

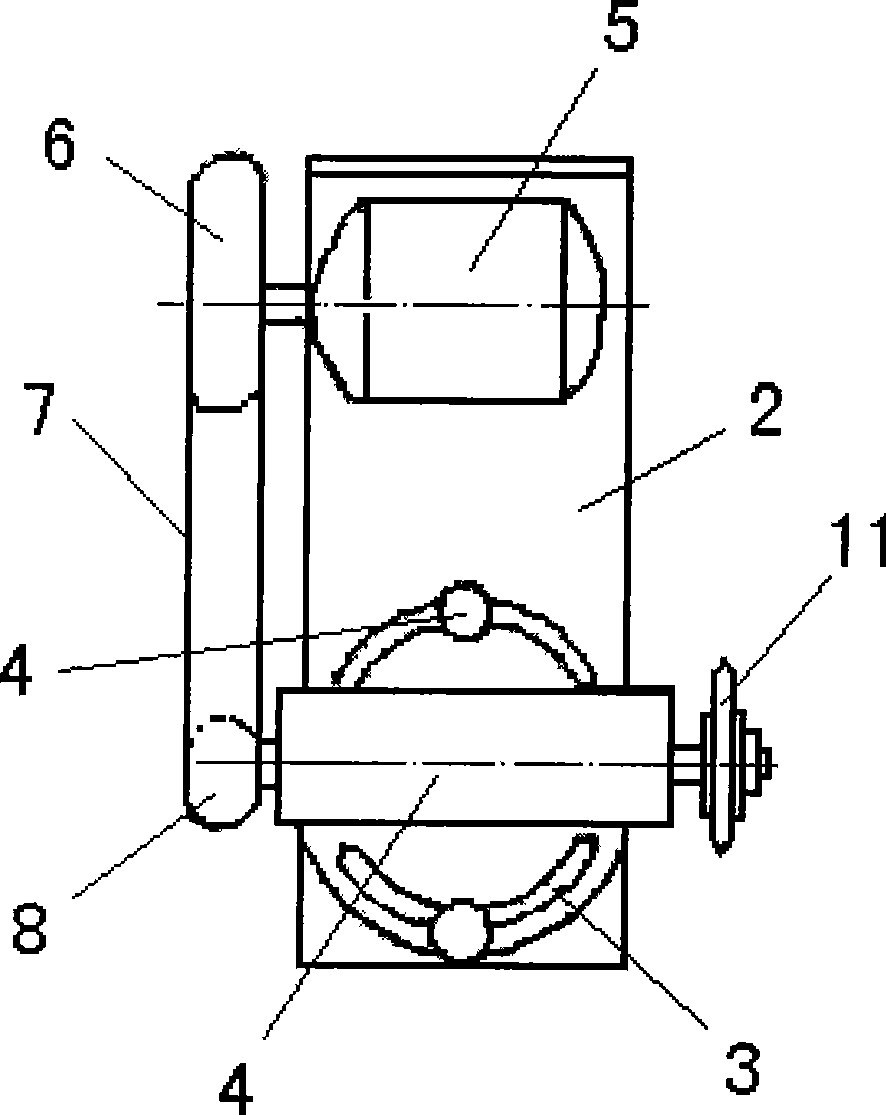

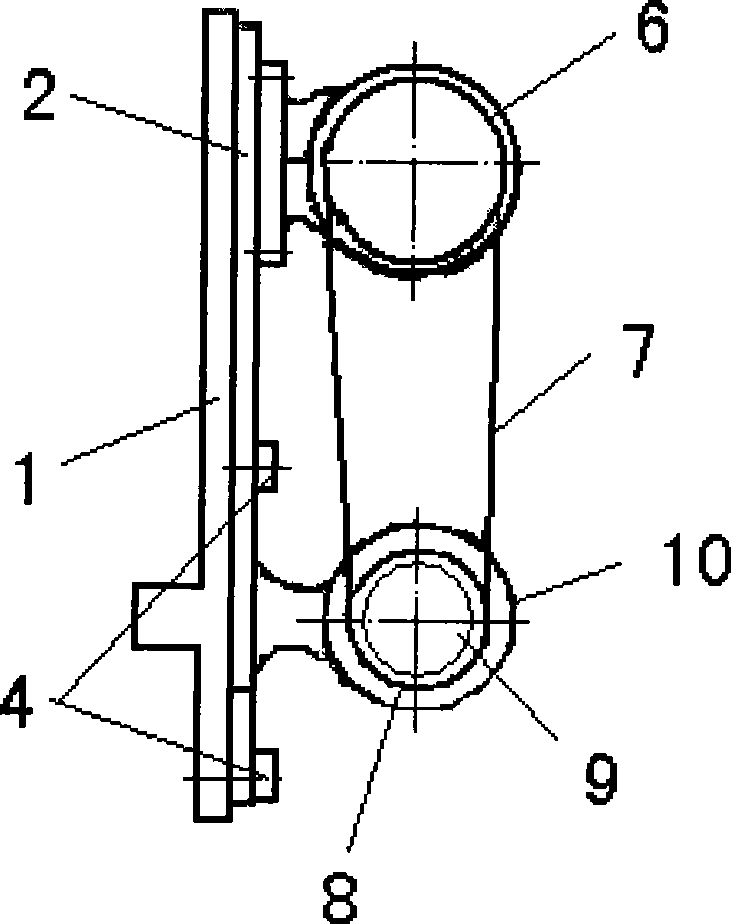

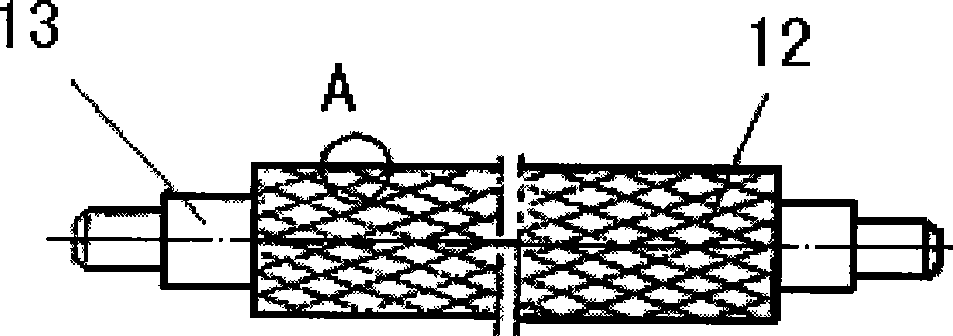

Method for grinding helical burr on soft rubber roller and processing device

InactiveCN101433985AReduce radial forceSmall resilienceThread cutting feeding devicesThread cutting machinesEngineeringScrew thread

The invention relates to a grinding and processing method for screw threads on a soft rubber roller and a processing device. The method is as follows: a main shaft of a machine tool drives the soft rubber roller to rotate, a grinding wheel for grinding the screw threads is arranged in the radial direction of the soft rubber roller at the same time, and the grinding wheel is fixed on a feeding device of the machine tool through a grinding head connected with the grinding wheel; and when the main shaft drives the soft rubber roller to rotate, the feeding device of the machine tool drives the grinding wheel to feed in the direction parallel to the direction of the main shaft, so as to grind and process the driven screw threads on the soft rubber roller. The device comprises a supporting plate on which a rotating plate is arranged, two semicircular arc grooves are arranged on the rotating plate, and a fastening bolt connected with the supporting plate is respectively arranged in the two semicircular arc grooves; and the rotating plate is provided with an electric motor, an output shaft of the electric motor is connected with a driving pulley which is connected with a driven pulley through a belt, the driven pulley coaxially drives a grinding head which is rotationally arranged in a grinding head sleeve fixedly supported on the rotating plate, and an extending end of the grinding head is connected with the grinding wheel. The method has the advantages of high processing efficiency and good processing quality, and can effectively solve problem of processing the screw threads of the soft rubber roller.

Owner:BEIJING NANKOU RAILWAY TRANSIT MACHINERY

Method for adjusting shape regularity of medicine packaging boxes

InactiveCN104097349AImprove box-shaped circumferenceSmall resilienceBox making operationsPaper-makingEngineeringPackaging Case

The invention relates to a method for adjusting shape regularity of medicine packaging boxes. The method includes: under the premise that paper is not exploded during the die cutting and creasing process of the medicine packaging boxes, (1), narrowing creasing, to be more specific, selecting a pointed-end steel wire 0.71mm in thickness as a die cutting steel wire, and allowing the creasing width B to be equal to 1.5c+d-N, wherein c is the thickness of paper, d is the thickness of the die cutting steel wire, and N is 0.05-0.06m; (2), deepening the creasing, to be more specific, customizing the die cutting steel wire matched with a die cutting cutter wire, and allowing the height Xh of the die cutting steel wire to be equal to Dh-c+0.05, wherein Dh is the height of the die cutting cutter wire. By the method convenient for large-scale popularization and application, the shape regularity of the medicine packaging boxes can be increased, the shutdown rate of a high-speed mechanical medicine packaging line is effectively controlled within 1 / 10000, and production efficiency of clients is guaranteed and client orders are increased evidently while cost of medicine packaging box manufacturers is lowered effectively.

Owner:ZIBO TAIBAO FP PROD CO LTD

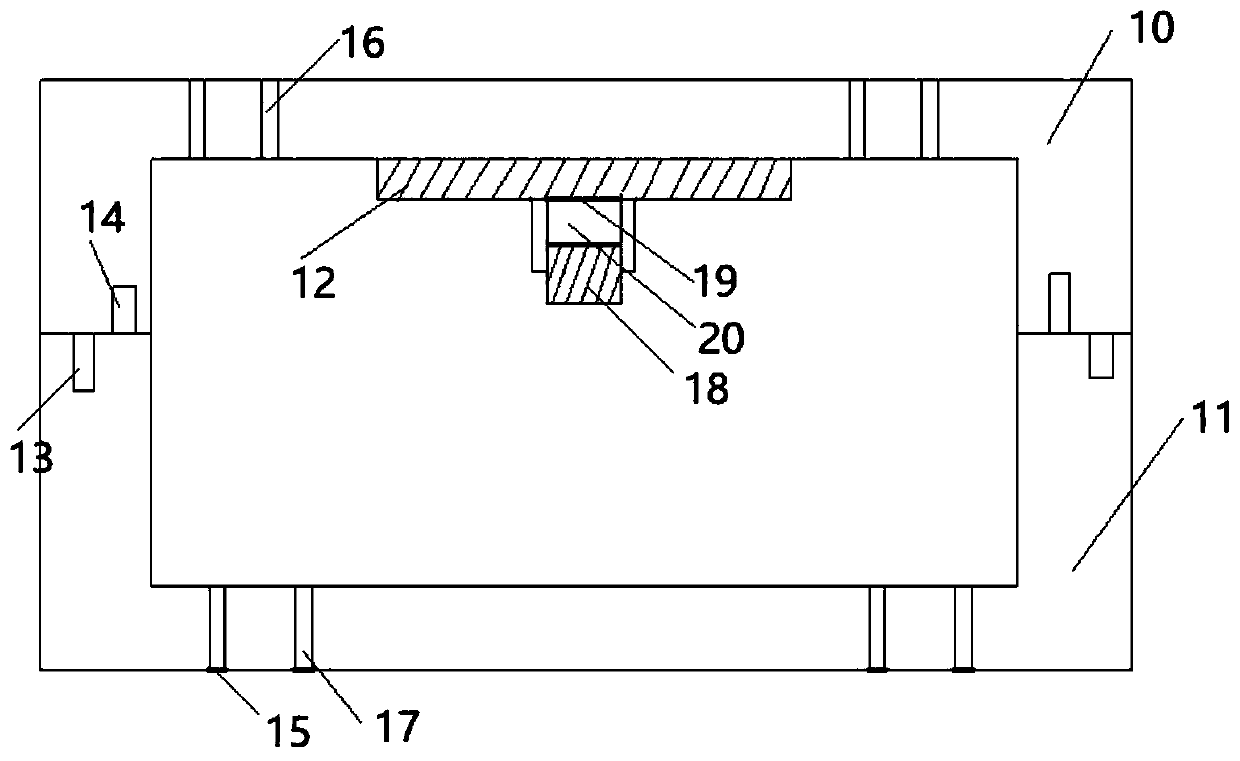

Injection mold structure suitable for forming power battery relay shell blank body

The invention discloses an injection mold structure suitable for forming a power battery relay shell blank body. The injection mold structure comprises a hot runner nozzle, a gate, an injection moldedpart, an action cylinder, an injection molding machine ejector rod, a material cutting push plate, a gate needle push plate, a material cutting needle and a gate needle, wherein the hot runner nozzleand the gate are fixedly arranged on the upper end of the injection molded part; the gate needle and the material cutting needle are fixedly arranged below the injection molded part; the material cutting needle is connected with the material cutting push plate; the gate needle is connected with the gate needle push plate; the action cylinder is fixedly arranged on the material cutting push plate;and the injection molding machine ejector rod is fixedly arranged on the gate needle push plate. According to the injection mold structure, automatic demolding of the injection molding part from a semi-circular arc gate is realized, the product performance and the yield are greatly improved, the phenomena of air holes in a sintered finished product and cracking are reduced, and fluid overflowingin a cavity of the injection molded part is prevented during injection molding.

Owner:LOUDI ANTAEUS ELECTRONICS CERAMICS

Motor cooling ventilation controlled valve and motor cooling ventilation automatic control method

ActiveCN105370963AImprove maintenance efficiencyRealize real-time monitoringOperating means/releasing devices for valvesMachines/enginesAutomatic controlElectric machine

The invention provides a motor cooling ventilation controlled valve. The motor cooling ventilation controlled valve is arranged in redundant space of a motor cooling ventilation pipeline and comprises a mounting plate and an electromagnetic valve, wherein the mounting plate is fixed in redundant space; the electromagnetic valve is arranged on the mounting plate; the top of the electromagnetic valve is pushed against a ventilation inlet of the redundant space; the electromagnetic valve comprises an electromagnet, a valve, an elastic compression member and a contact-type inductive switch; the elastic compression member is arranged between the electromagnet and the valve; the contact-type inductive switch is arranged on the upper surface of the electromagnet and is connected to a motor control system through monitoring circuits; the elastic compression member is arranged along a vertical direction so as to push the valve against the ventilation inlet of the redundant space; the electromagnet is provided with an armature column which can be pulled by the electromagnet to move downwards; the armature column extends out from the electromagnet; and the top of the armature column is fixedly connected to the valve. The motor cooling ventilation controlled valve has the beneficial effects that the motor cooling ventilation controlled valve realizes the automatic starting and stopping of the motor cooling ventilation pipeline and the real time monitoring of a valve operation state and improves the maintenance efficiency of motor ordinary operation. The invention also provides a motor cooling ventilation automatic control method.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

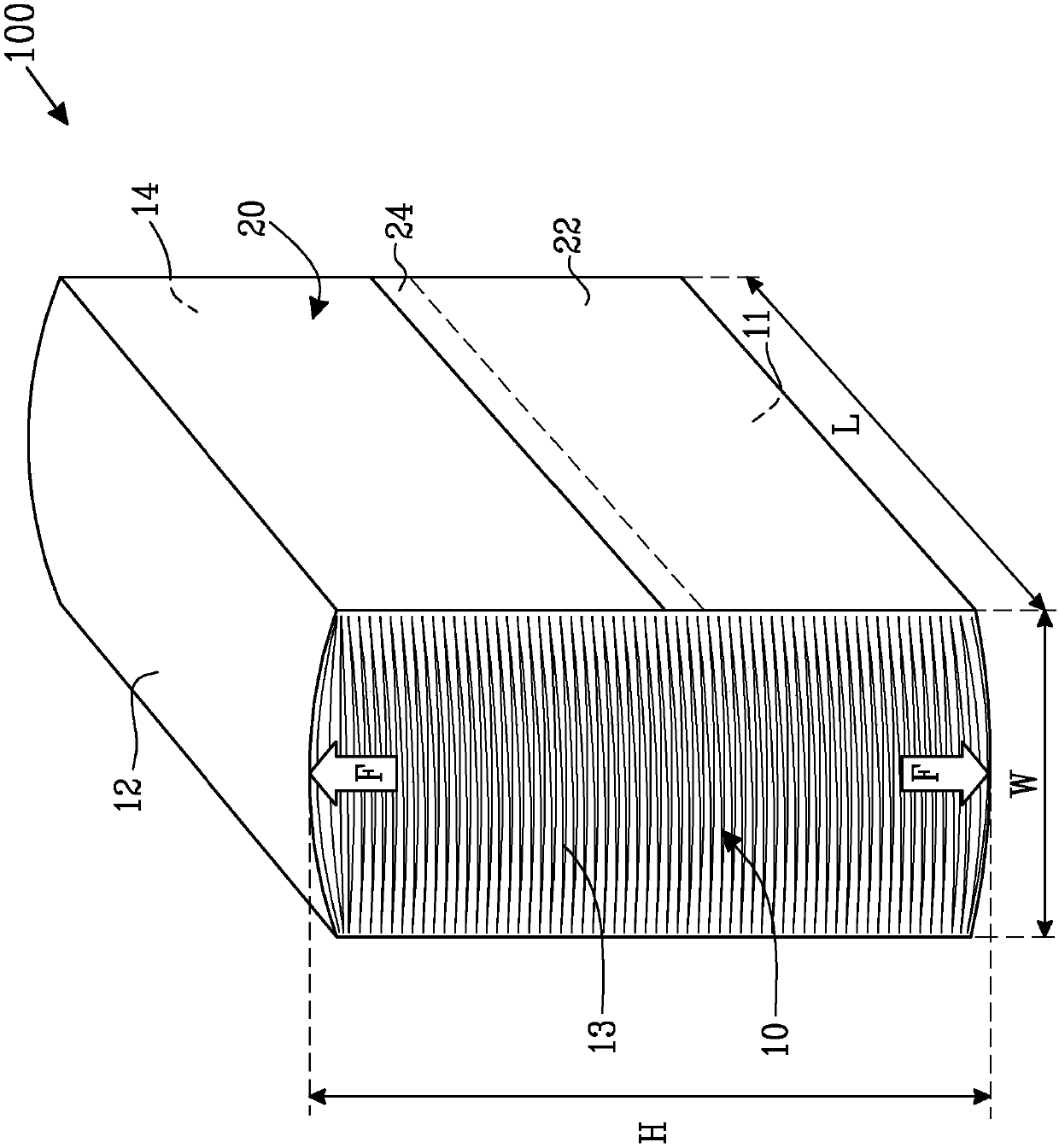

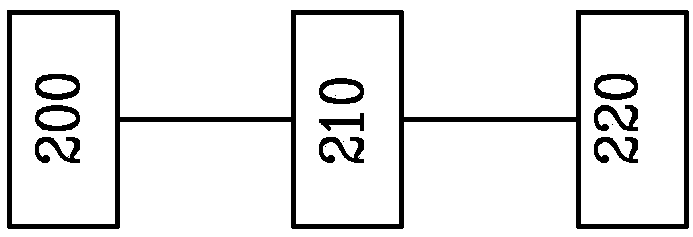

Method and apparatus for forming a package comprising a stack of absorbent tissue paper material and a packaging

ActiveCN107614385ASmall resilienceReduce bloatContainers for flexible articlesPaper article packagingTissue materialEngineering

The present disclosure relates to a method for forming a package (100) comprising a stack (10) of absorbent tissue paper material and a packaging (20), the tissue paper material in said stack formingpanels having a length (L), and a width (W) perpendicular to said length (L), said panels being piled on top of each other to form a height (H) extending between a first end surface and a second end surface of the stack, and the packaging encircling the stack so as to maintain the stack in a compressed condition in said package, with a selected packing density D0 of said stack (10), and a selectedpacking height H0; wherein said absorbent tissue paper material is a dry crepe material, and said selected packing density D0 is between 0.30 and 0.95 kg / dm3, or alternatively, said absorbent tissuepaper material is a structured tissue material, and said selected packing density D0 is between 0.20 and 0.75 kg / dm3, or alternatively said absorbent tissue paper material is a combination material, comprising at least a dry crepe material and at least a structured tissue material, and the selected packing density D0 is between 0.25 and 0.80 kg / dm3; the method comprising the following steps: forming (200) said stack (10) of absorbent tissue paper material; compressing (210) each portion of said stack (10) in a direction along said height (H) to assume a temporary height H1 being c1*H0, where c1 is between 0.30 and 0.95; and applying (220) said packaging (20) to the stack (10). The disclosure also relates to an apparatus for performing the method.

Owner:ESSITY HYGIENE & HEALTH AB

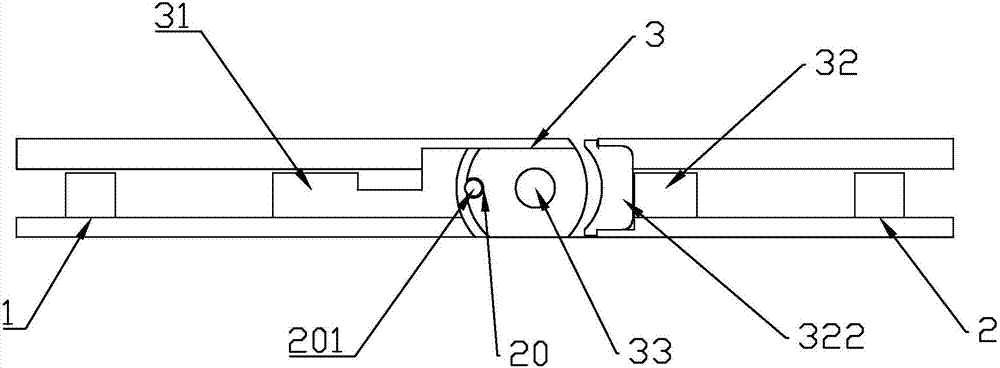

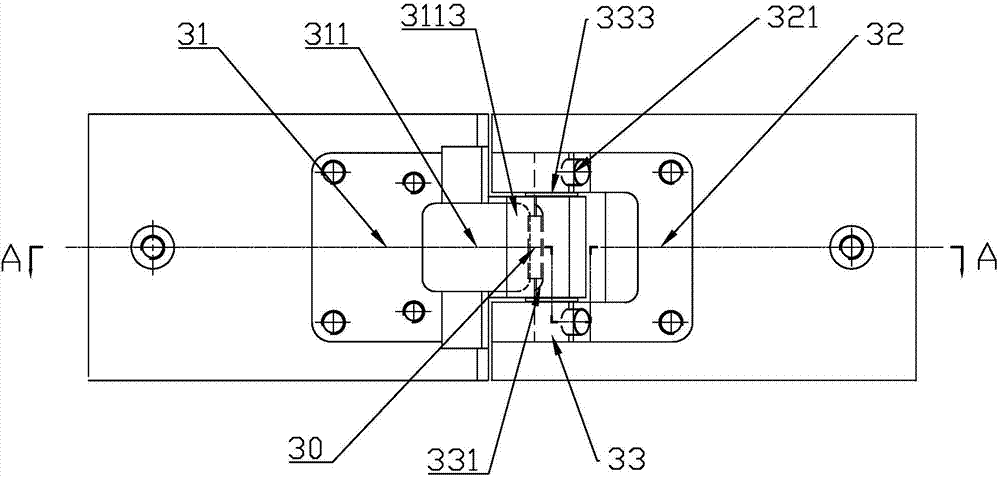

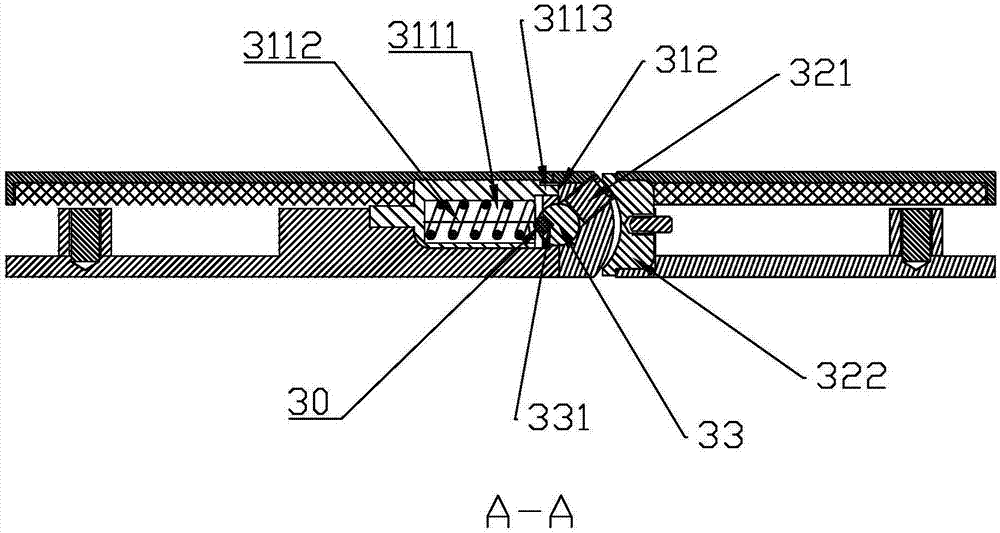

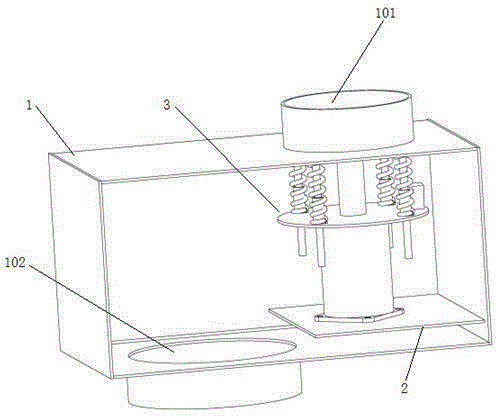

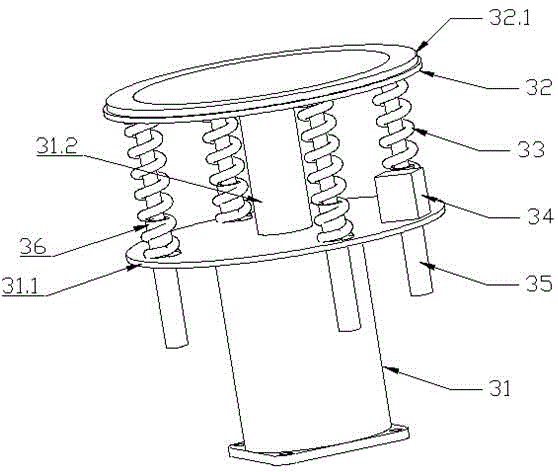

Large-torque hollow rotating platform

PendingCN114526309ASmall resilienceImprove stabilityStands/trestlesWind energy generationMechanical engineeringPiston

The invention relates to the technical field of rotating platforms, and discloses a large-torque hollow rotating platform which comprises a hollow rotating platform body and a box body, the top of the box body is provided with an opening, the hollow rotating platform body is arranged above the box body, and a damping device is arranged in the box body. The piston slides in the air pipe to extrude or expand air in the air pipe, so that air resistance is generated, the air slowly enters or is exhausted from the two exhaust holes, preliminary vibration reduction is achieved, vibration reduction is further achieved through the elastic force action of the two first springs in cooperation with the elastic force action of the two second springs, and the vibration reduction effect is improved. And meanwhile, resilience force of two first springs and two second springs is continuously weakened through air resistance generated by sliding of the piston, the stability of the damping device is enhanced, and the effect that the hollow rotating platform body is prevented from being damaged due to vibration caused by long-time operation of the hollow rotating platform body is achieved.

Owner:立川无锡半导体设备有限公司

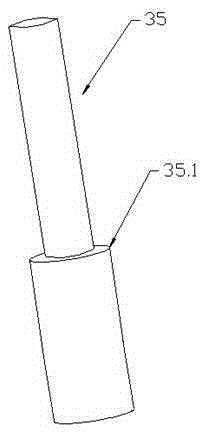

Hydraulic motorcycle shock absorber and shock absorption method thereof

The invention discloses a hydraulic motorcycle shock absorber and a shock absorption method of the hydraulic motorcycle shock absorber. The hydraulic motorcycle shock absorber comprises a movable rodand a sleeve which are arranged coaxially, one end of the sleeve is closed, the movable rod and the closed end of the sleeve are respectively fixedly connected with a connecting piece, the movable rodis fixedly connected with a connecting rod and a plurality of push rods, the connecting rod is fixedly connected with a first piston rod, and the first piston rod extends into the sleeve. A pluralityof channels which correspond to the push rods one by one and extend in the axial direction are formed in the wall of the sleeve, second piston rods are arranged in the channels in a sliding mode, thechannels communicate with a cavity, the cavity communicates with an inner cavity of the sleeve, and the cavity is filled with pressure-bearing liquid. According to the hydraulic motorcycle shock absorber and the shock absorption method of the hydraulic motorcycle shock absorber, the stroke of the first piston rod is effectively reduced by adopting a double-hydraulic mode, so that the driving comfort is improved.

Owner:BOHAN QUANZHOU MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com