Patents

Literature

1469results about How to "Fair price" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

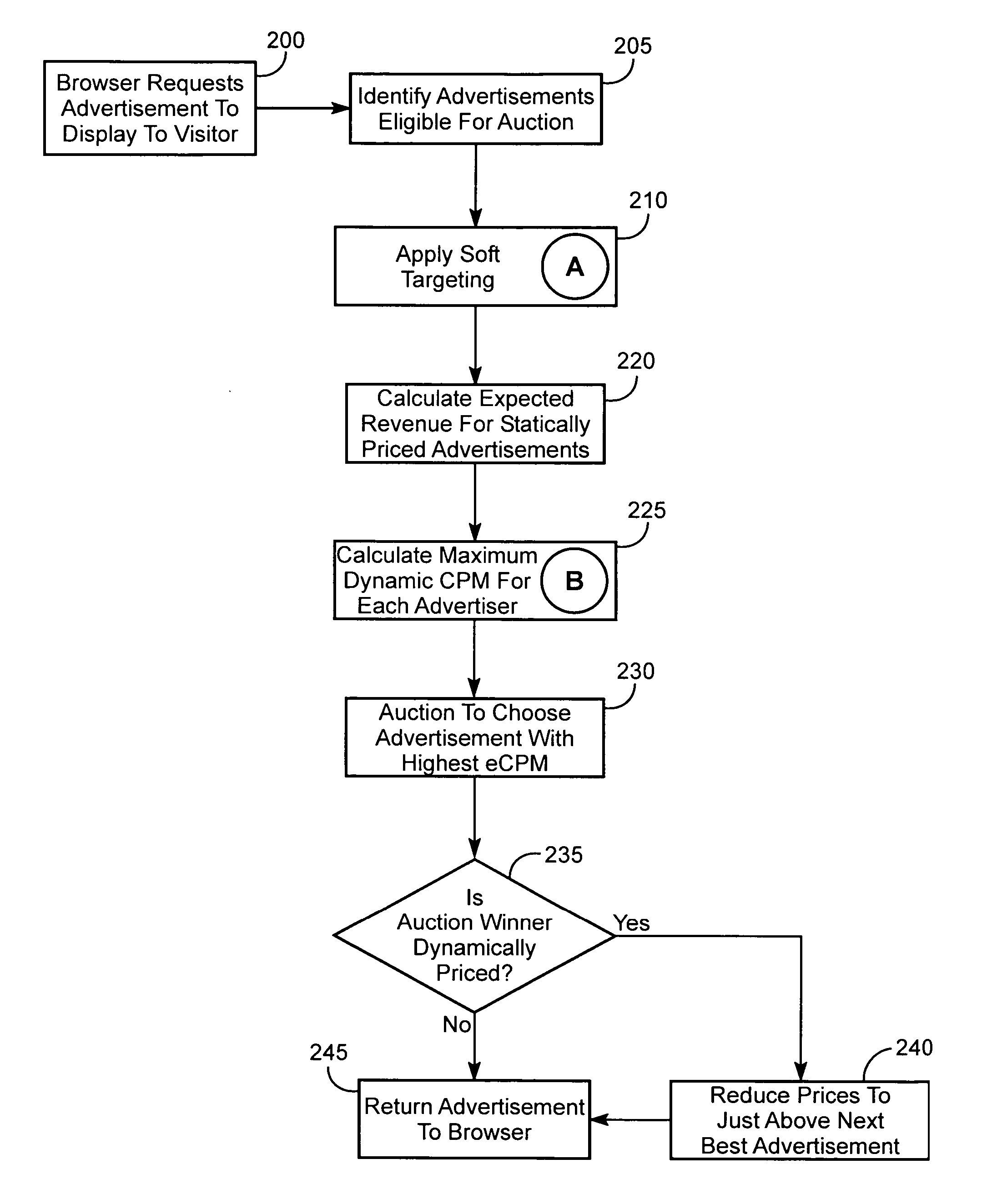

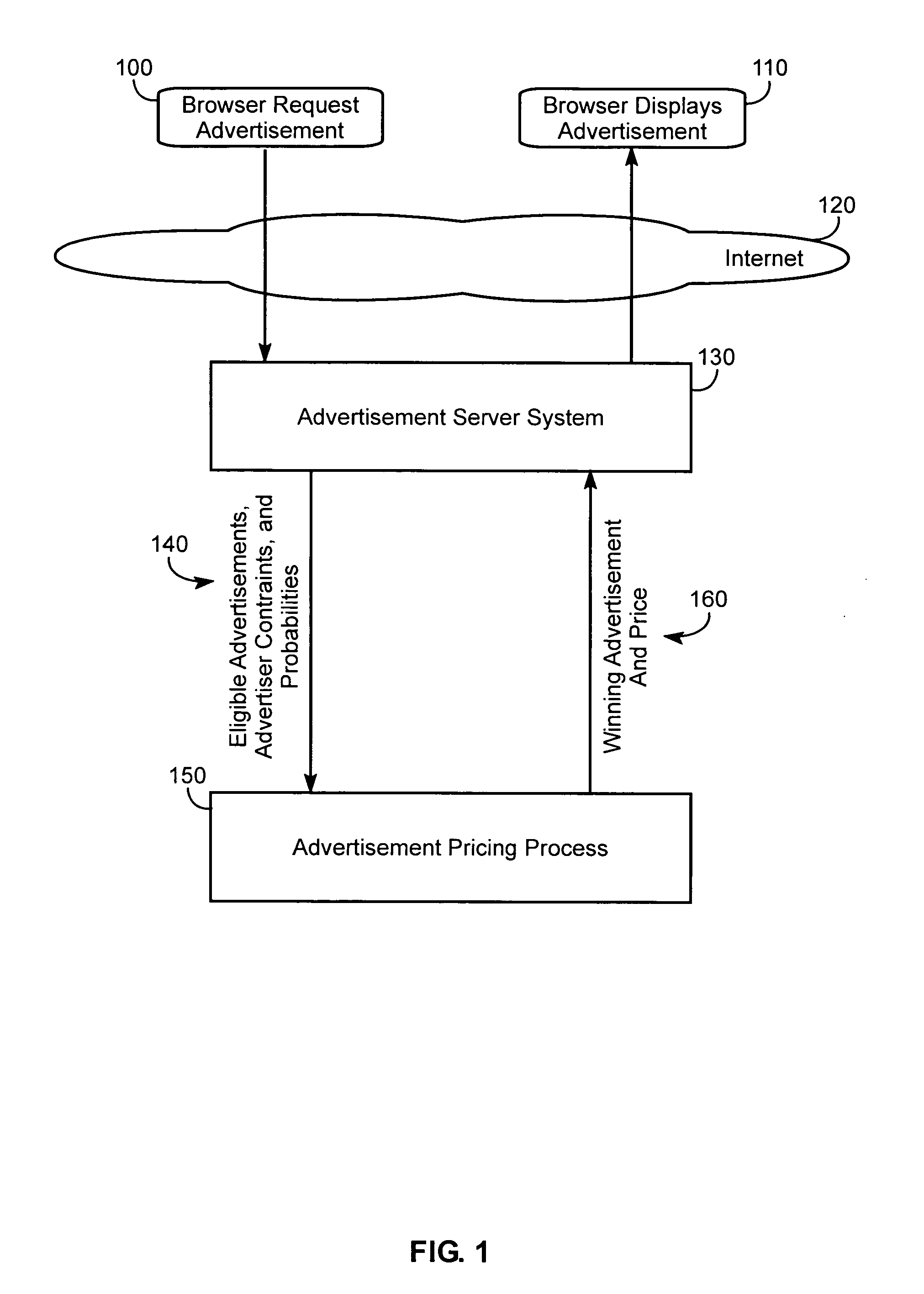

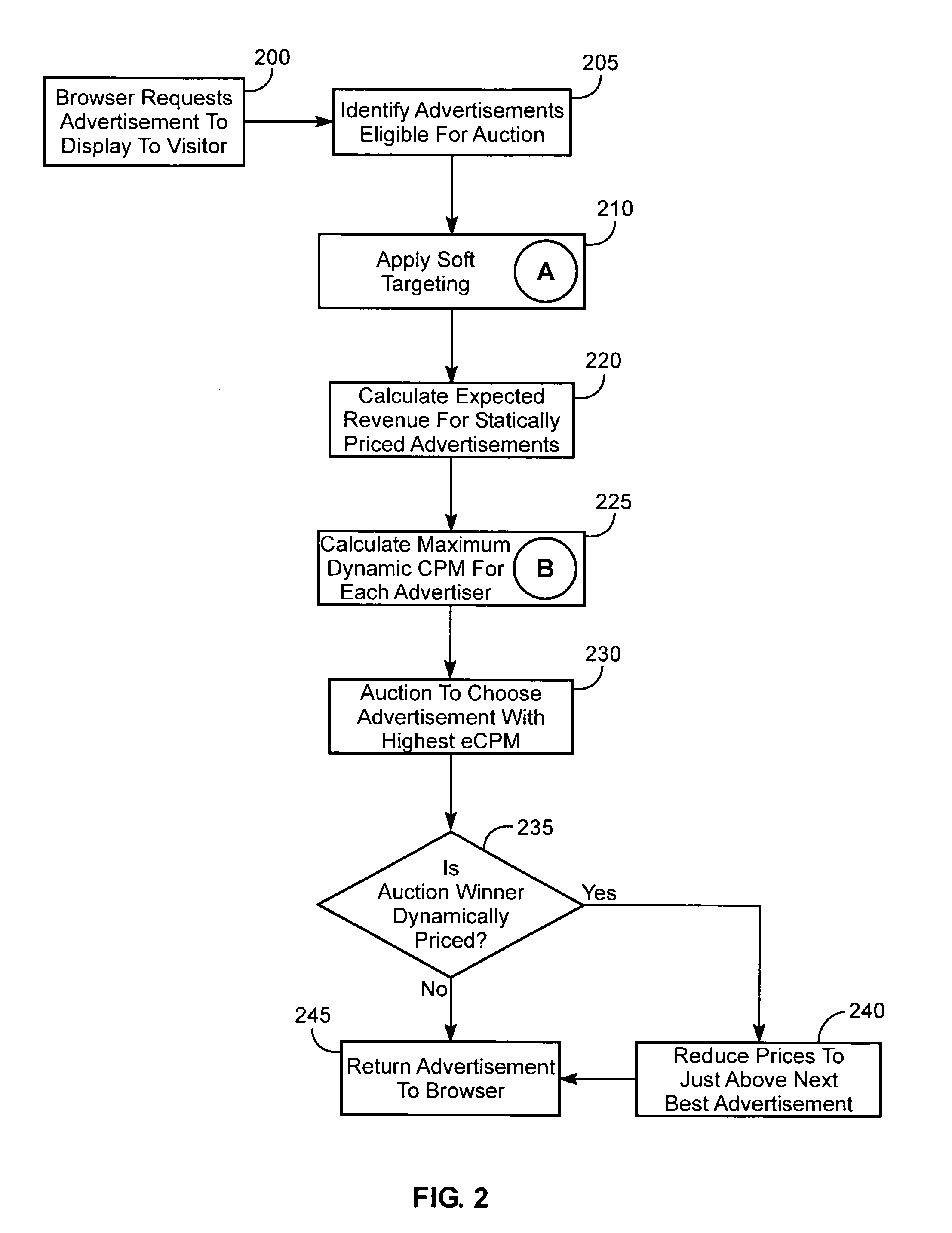

Method and system for pricing electronic advertisements

InactiveUS20060122879A1Maximizes publisher revenueEfficient priceAdvertisementsElectric/magnetic computingWorld Wide Web

A system and method of pricing an electronic advertisement that includes receiving a request for an electronic advertisement to be presented to a visitor, setting a price of the electronic advertisement, and presenting the electronic advertisement to the visitor.

Owner:YAHOO HLDG INC

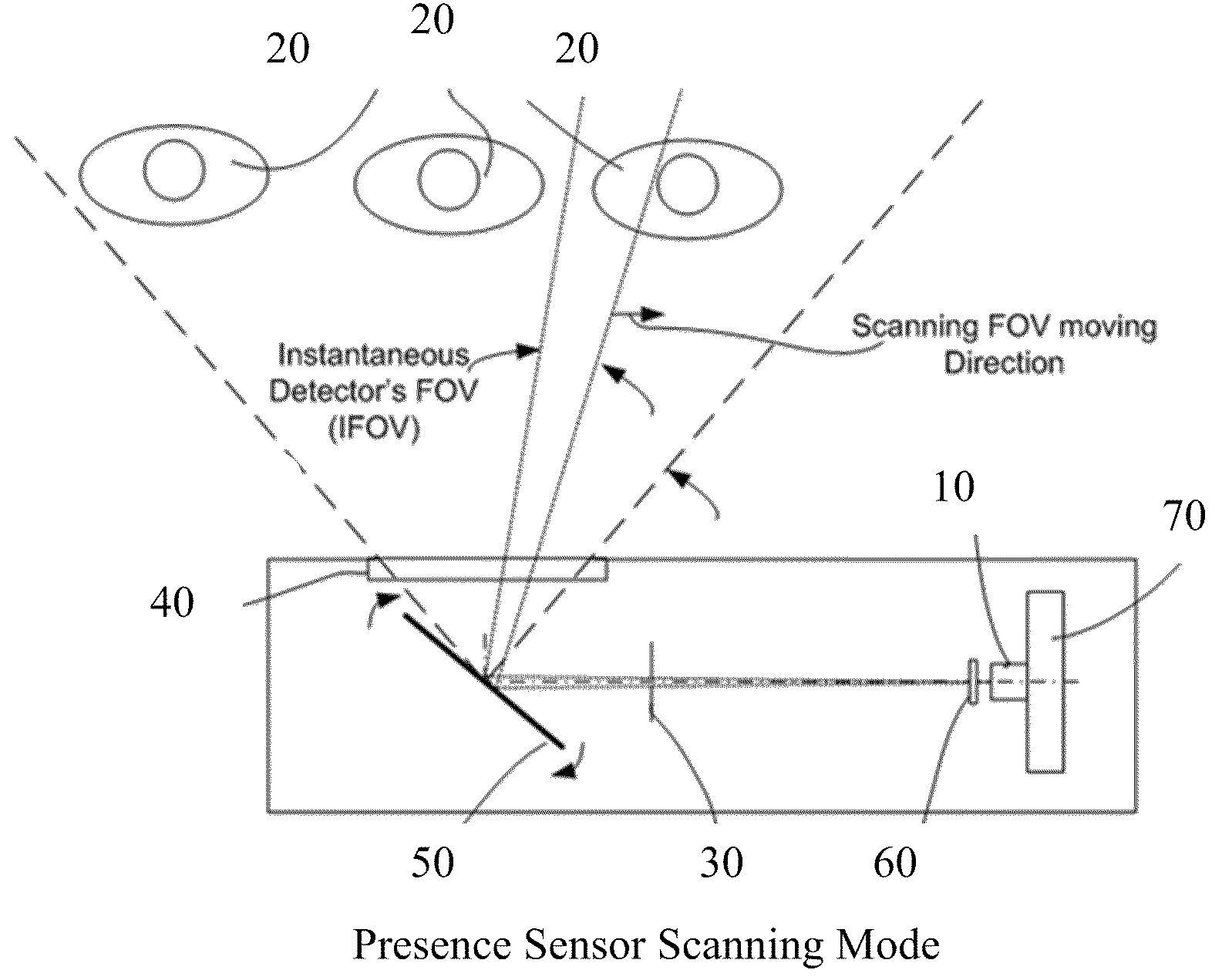

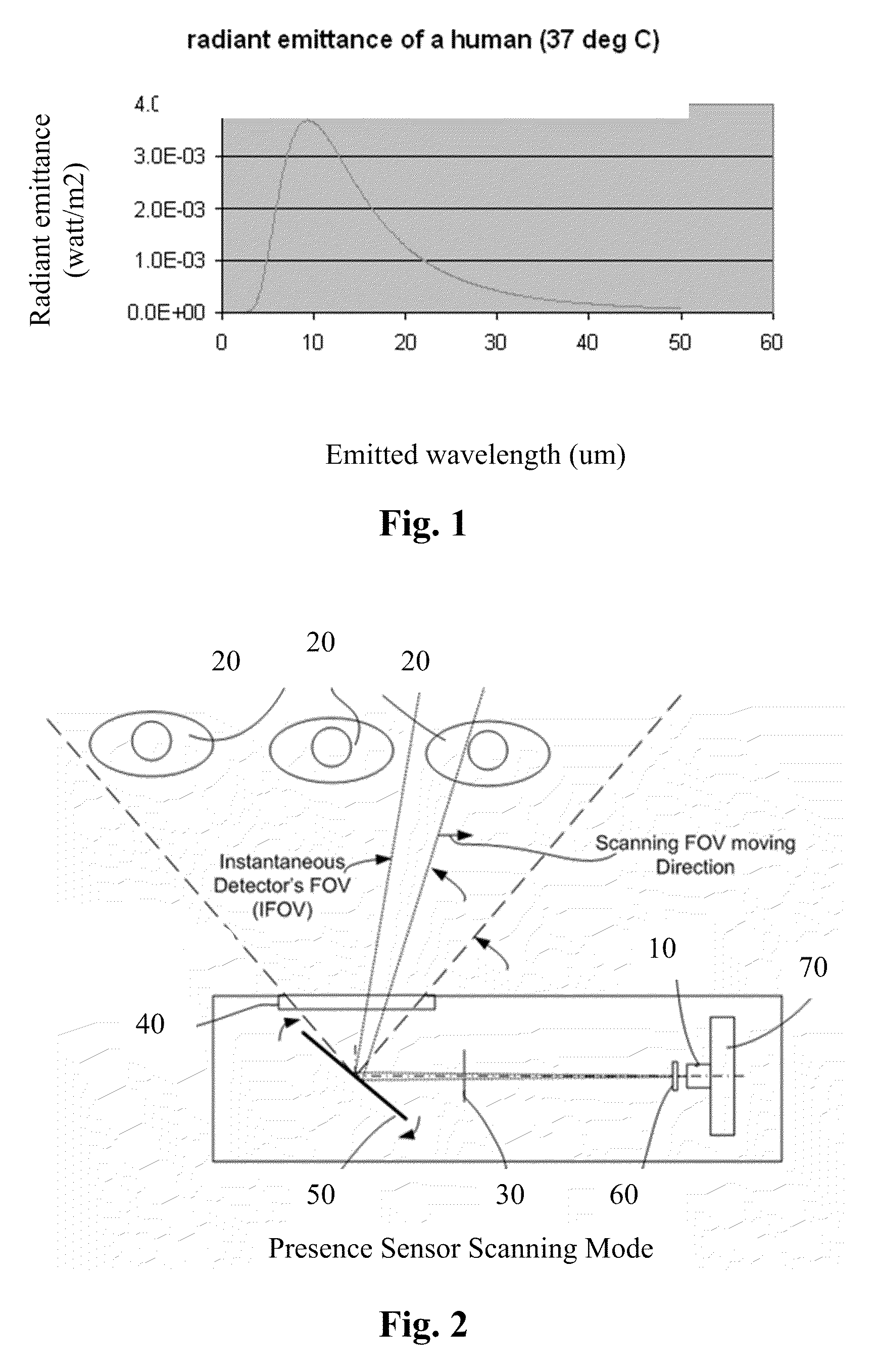

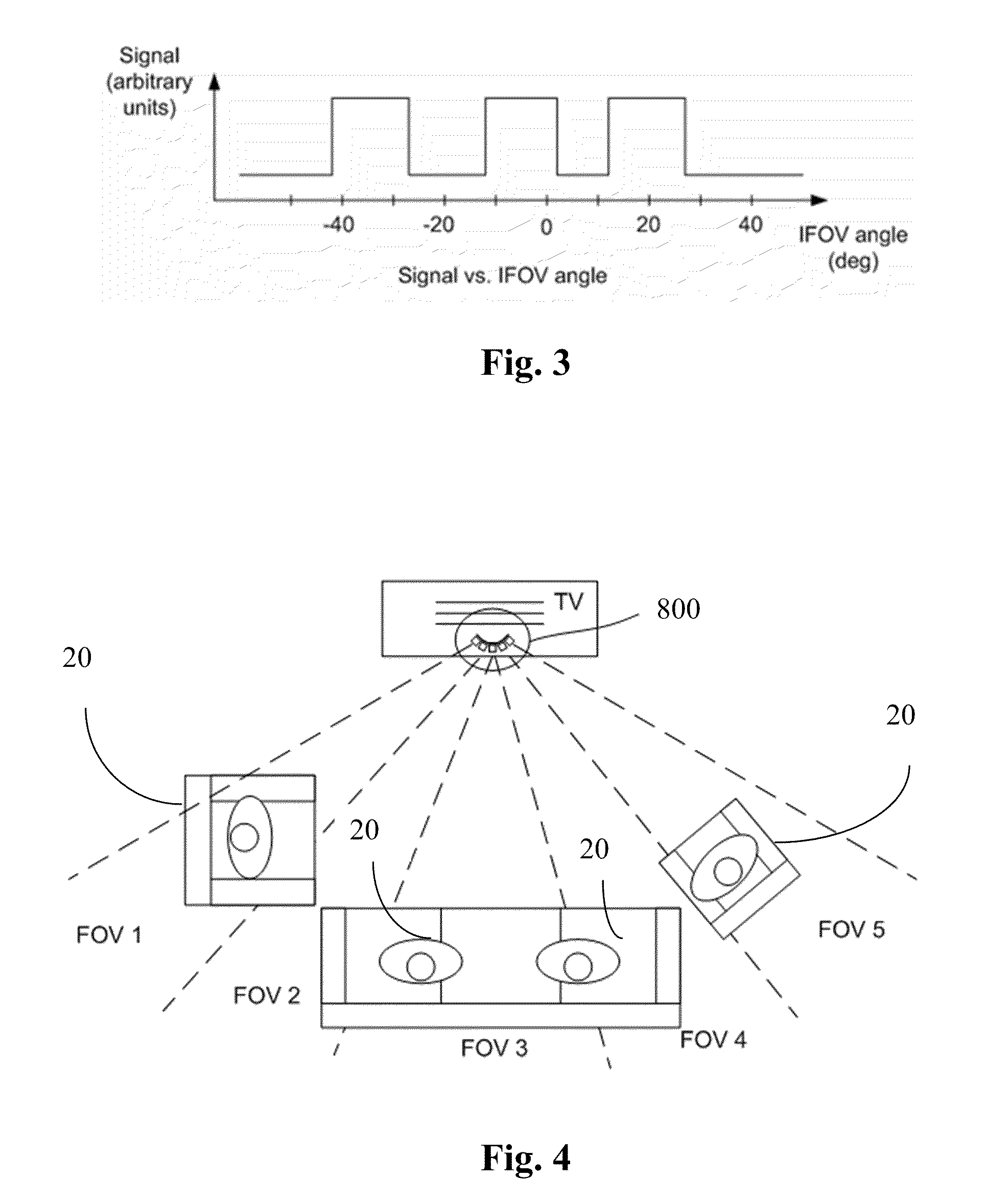

Presence Detector and Method for Estimating an Audience

InactiveUS20100162285A1Fair priceAnalogue secracy/subscription systemsBroadcast components for monitoring/identification/recognitionData signalInformation capture

A presence detector for detecting and estimating an audience watching television comprising: one or more presence sensors adapted to capturing signals emitted by or reflected from the audience; and a translator connected to the one or more presence sensors adapted to translating output signals created by the one or more presence sensors to data signals representing the estimated number of people in the audience. Presence information captured is converted to television rating data and is very useful for pricing advertisements accurately.

Owner:WAVEBREAK TECH

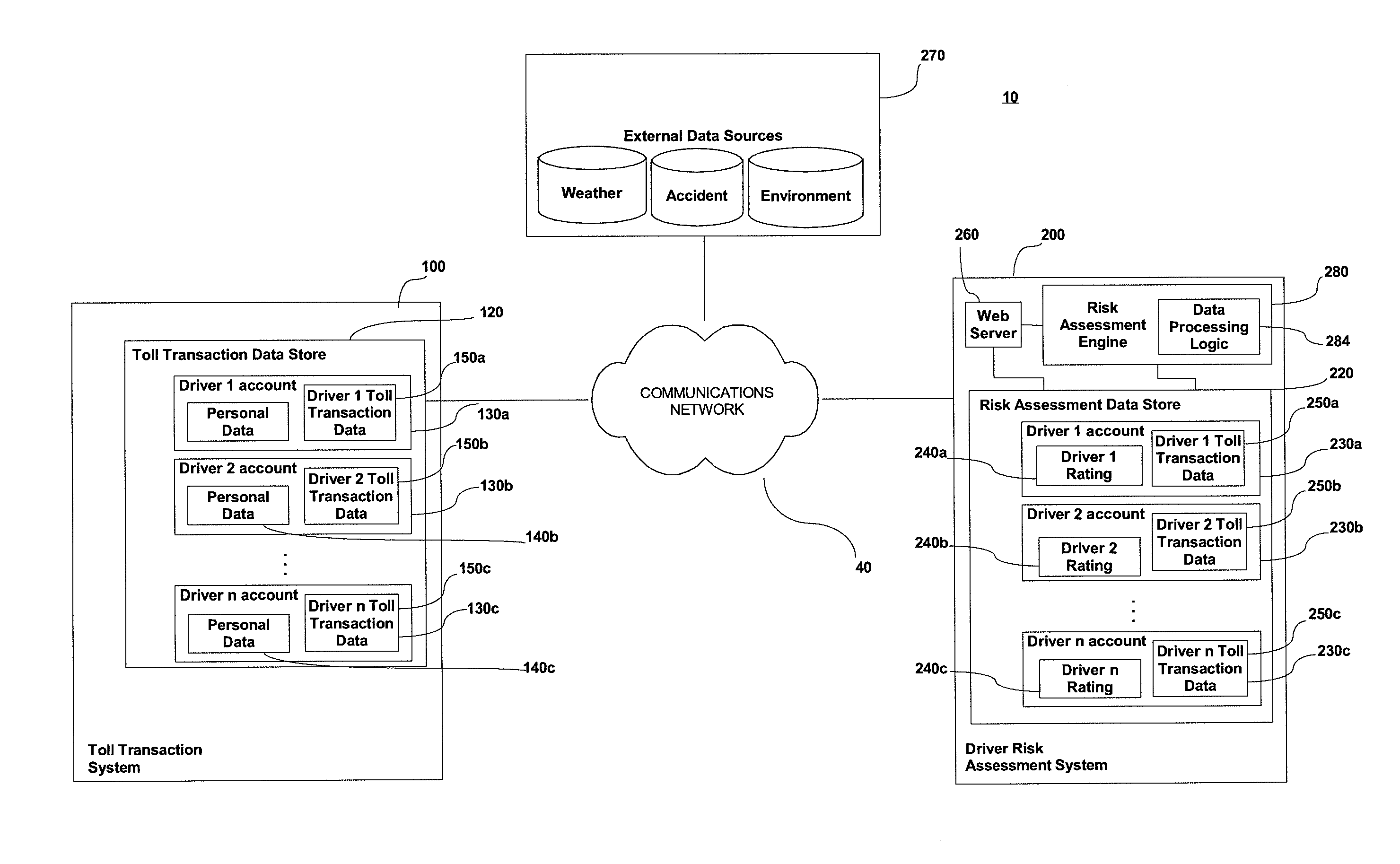

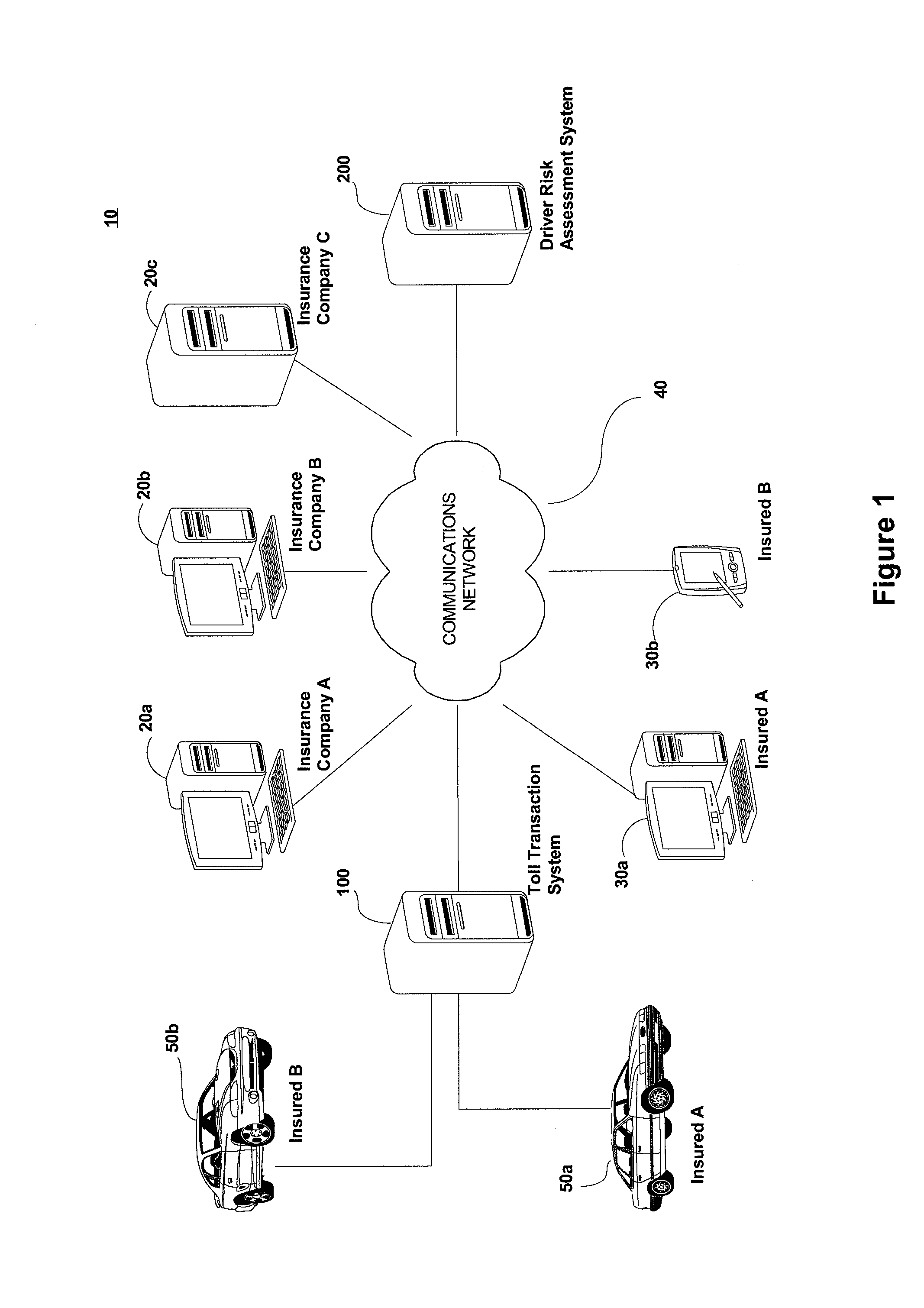

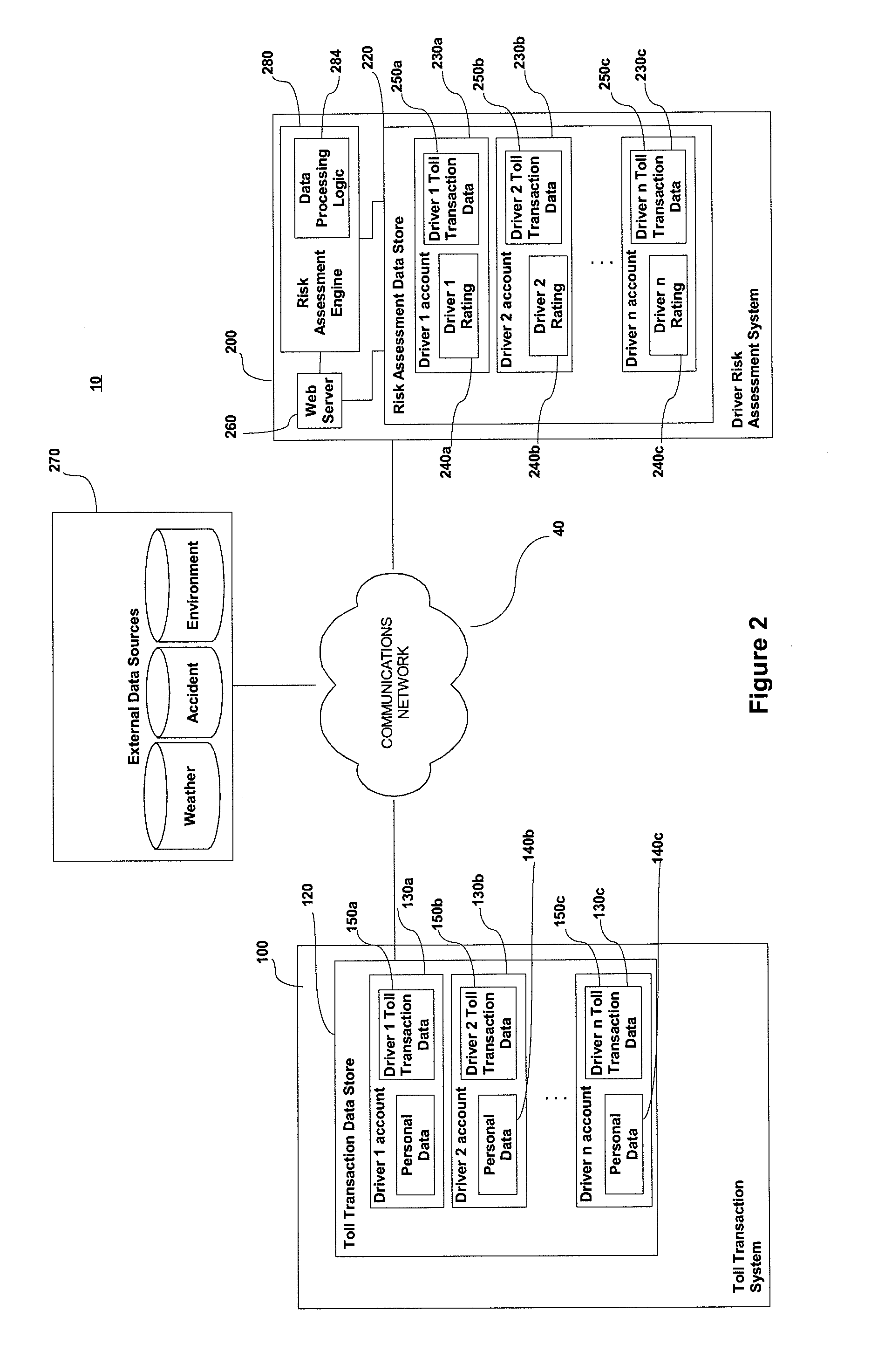

System and method for developing a driver safety rating

Driver performance is assessed using existing datasets derived from conventional highway travel, such as a datasets from wireless highway toll payment systems. Existing datasets are processed to develop a driver safety rating and / or otherwise assess driver performance to determine a level of driver performance and / or risk, and to determine suitability for insurance discounts, etc. An exemplary system and method for providing a driver risk rating representative of driver performance involves: receiving from a toll transaction system toll trip data, the toll trip data reflecting data recorded as a result of operation of an automobile associated with at least one driver; processing the toll trip data to determine toll trip metrics as a function of the toll trip data; and processing the toll trip metrics in accordance with predefined data processing logic to develop a driver risk rating for each driver as a function of the toll trip data.

Owner:BARBER ERNEST W

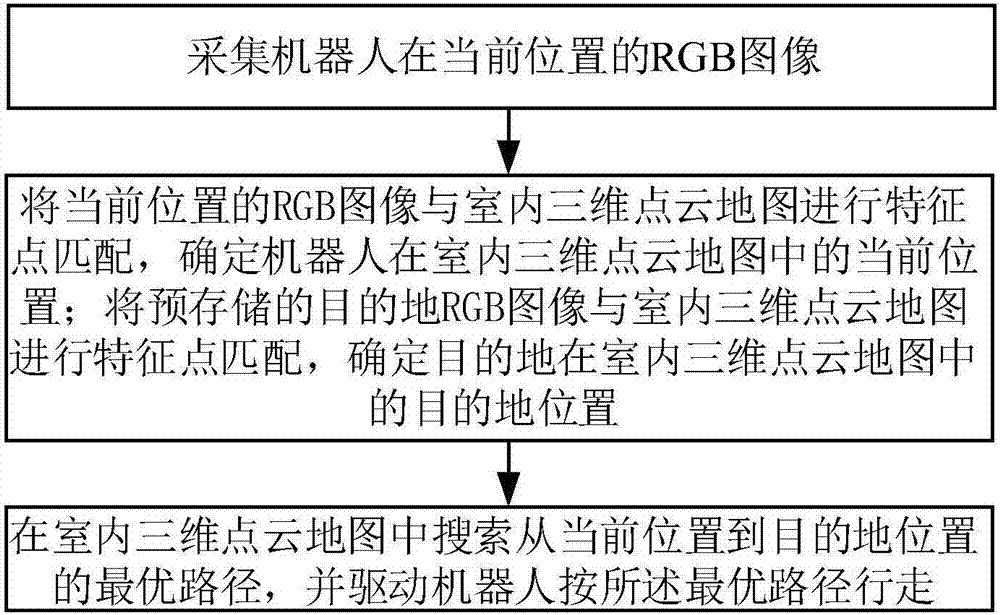

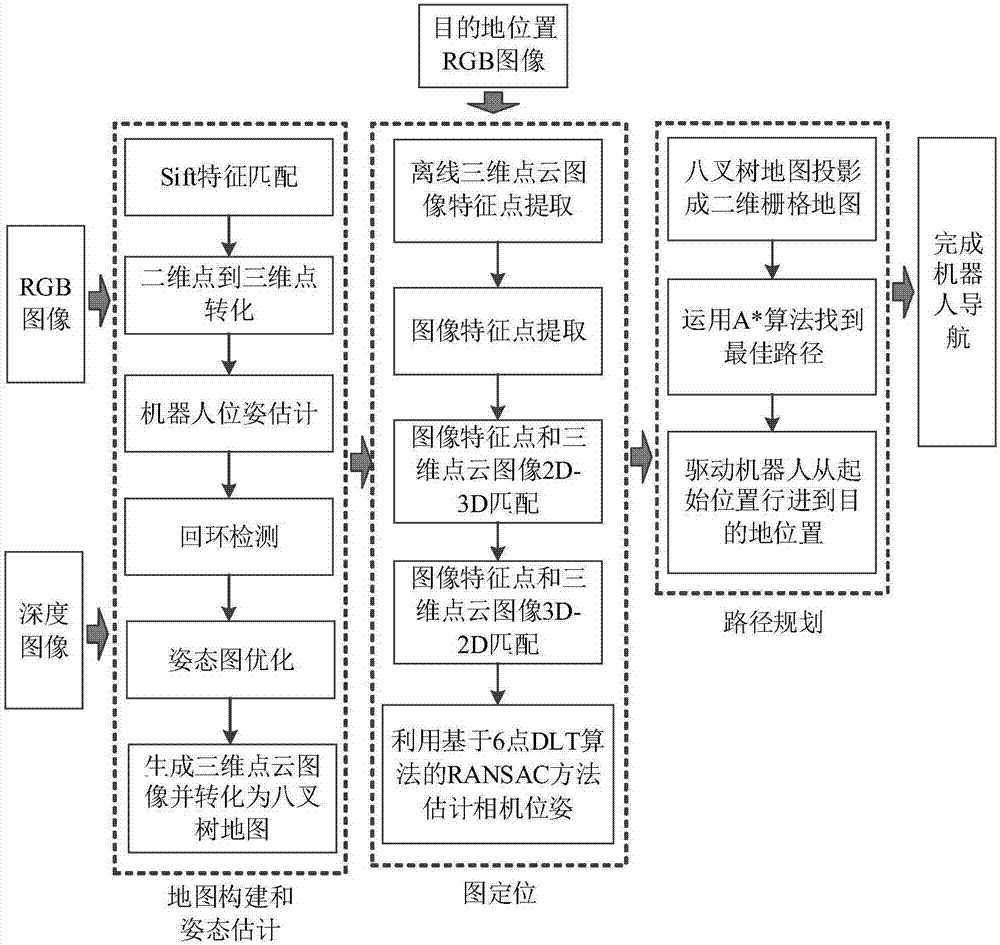

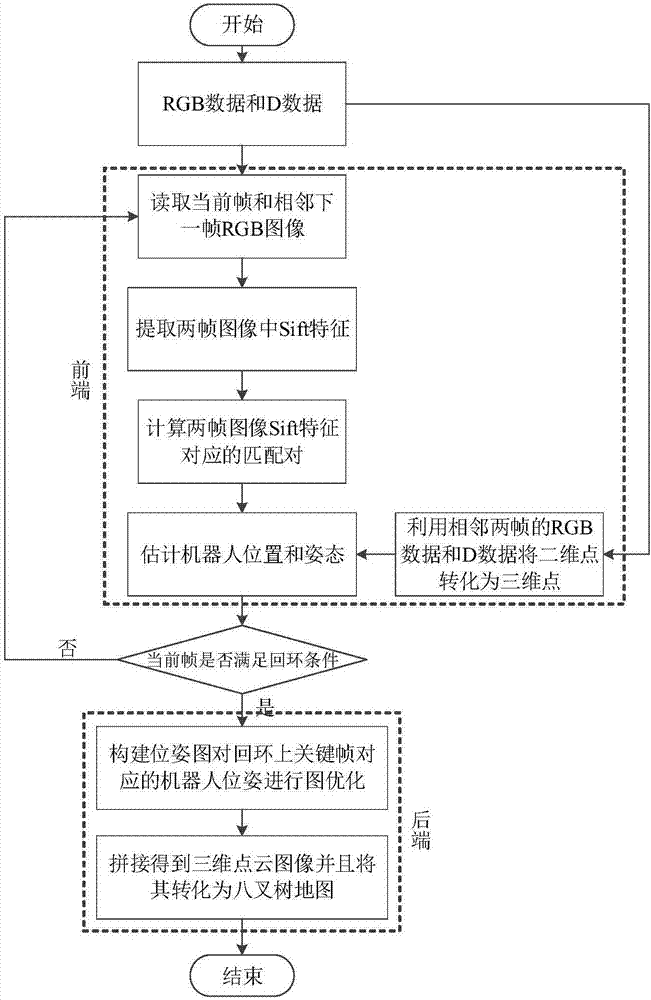

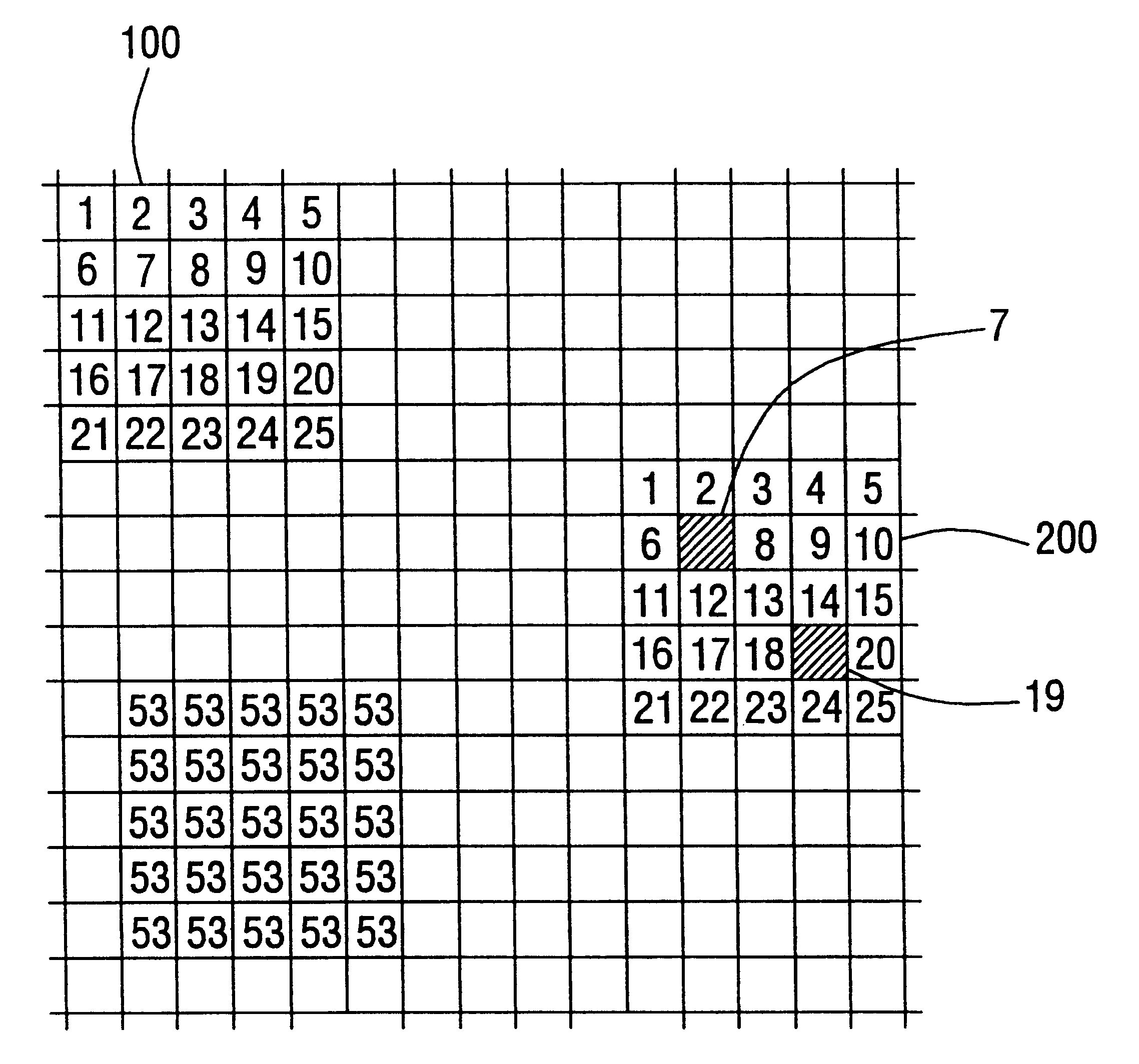

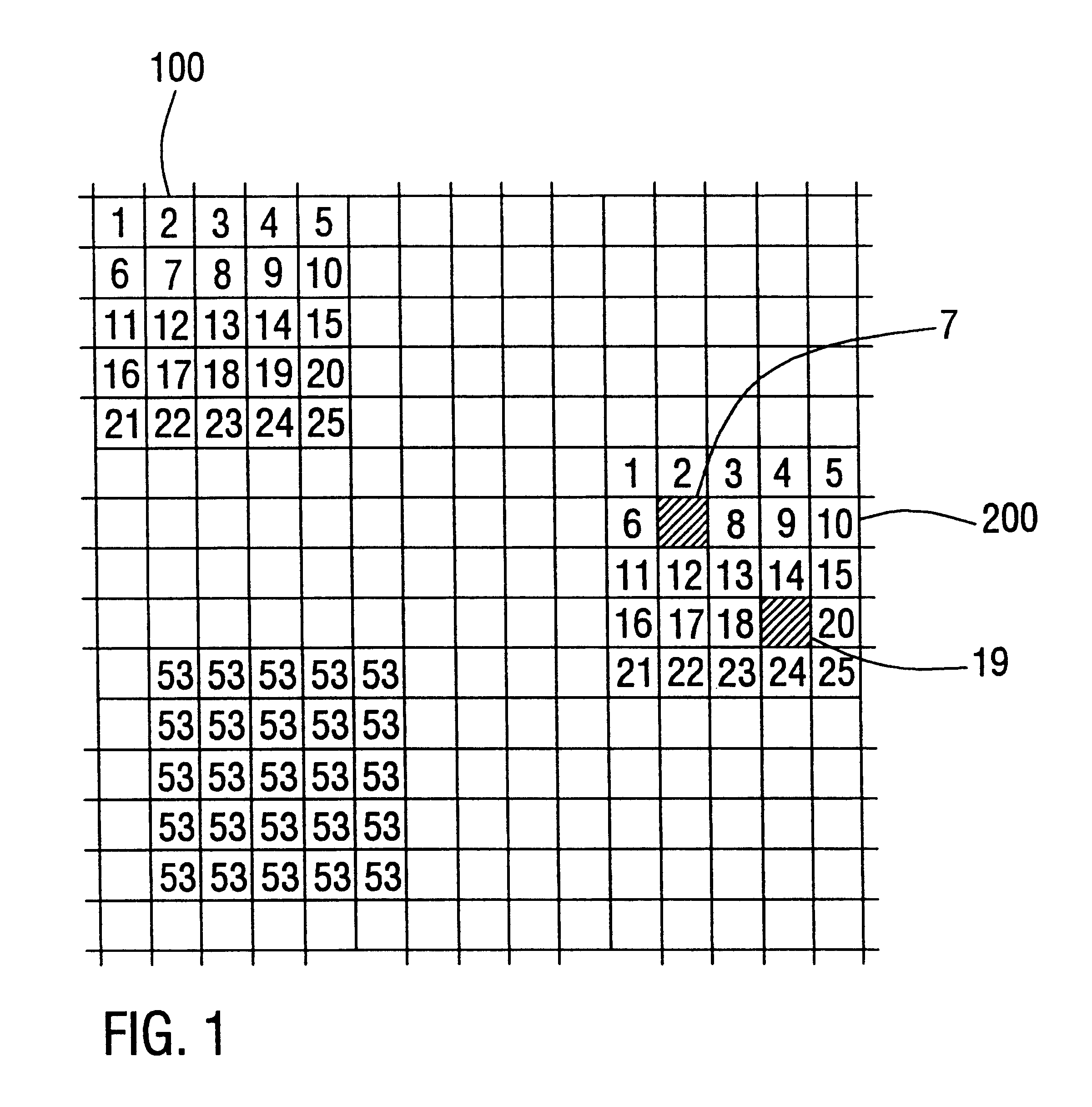

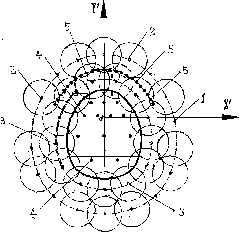

Autonomous location and navigation method and autonomous location and navigation system of robot

ActiveCN106940186AAutomate processingFair priceNavigational calculation instrumentsPoint cloudRgb image

The invention discloses an autonomous location and navigation method and an autonomous location and navigation system of a robot. The method comprises the following steps: acquiring the RGB image of the robot in the current position; carrying out characteristic point matching on the RGB image of the current position and an indoor three-dimensional point cloud map, and determining the current position of the robot in the indoor 3D point cloud map; carrying out characteristic point matching on a pre-stored RGB image of a destination and the indoor three-dimensional point cloud map, and determining the position of the destination in the indoor 3D point cloud map; and searching an optimal path from the current position to the destination position in the indoor 3D point cloud map, and driving the robot to run according to the optimal path. The method and the system have the advantages of completion of autonomous location and navigation through using a visual sensor, simple device structure, low cost, simplicity in operation, and high path planning real-time property, and can be used in the fields of unmanned driving and indoor location and navigation.

Owner:HUAZHONG UNIV OF SCI & TECH

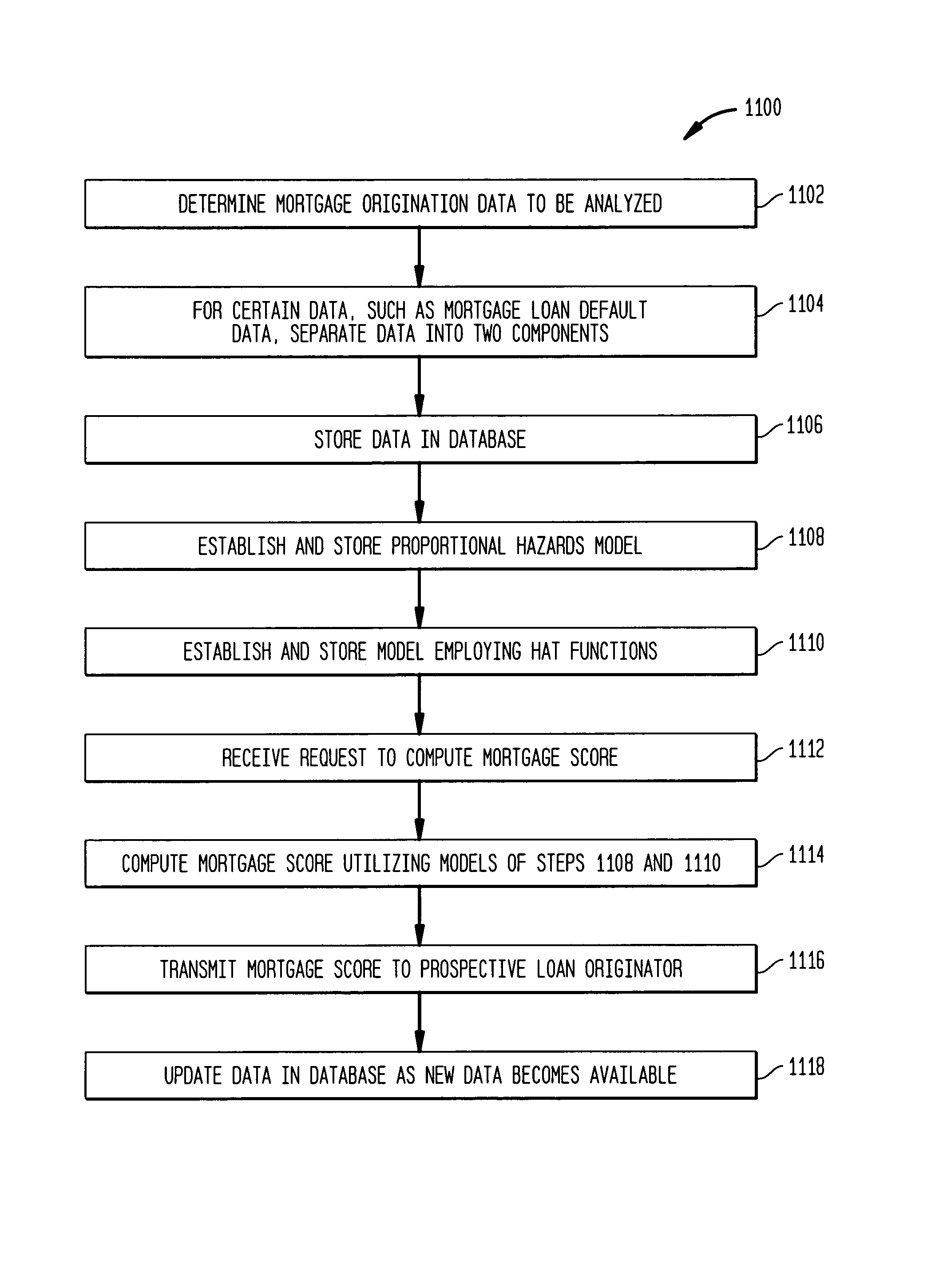

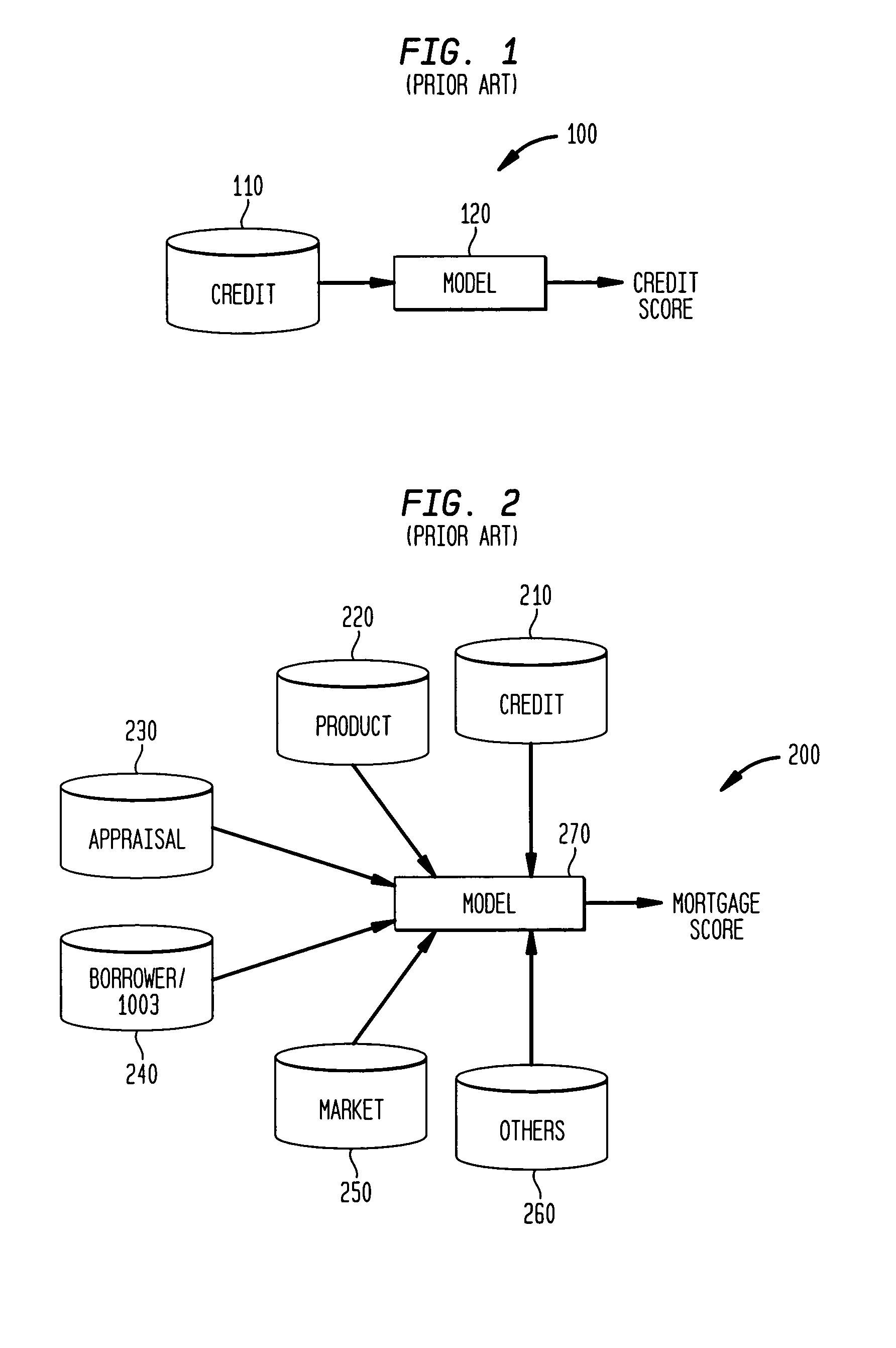

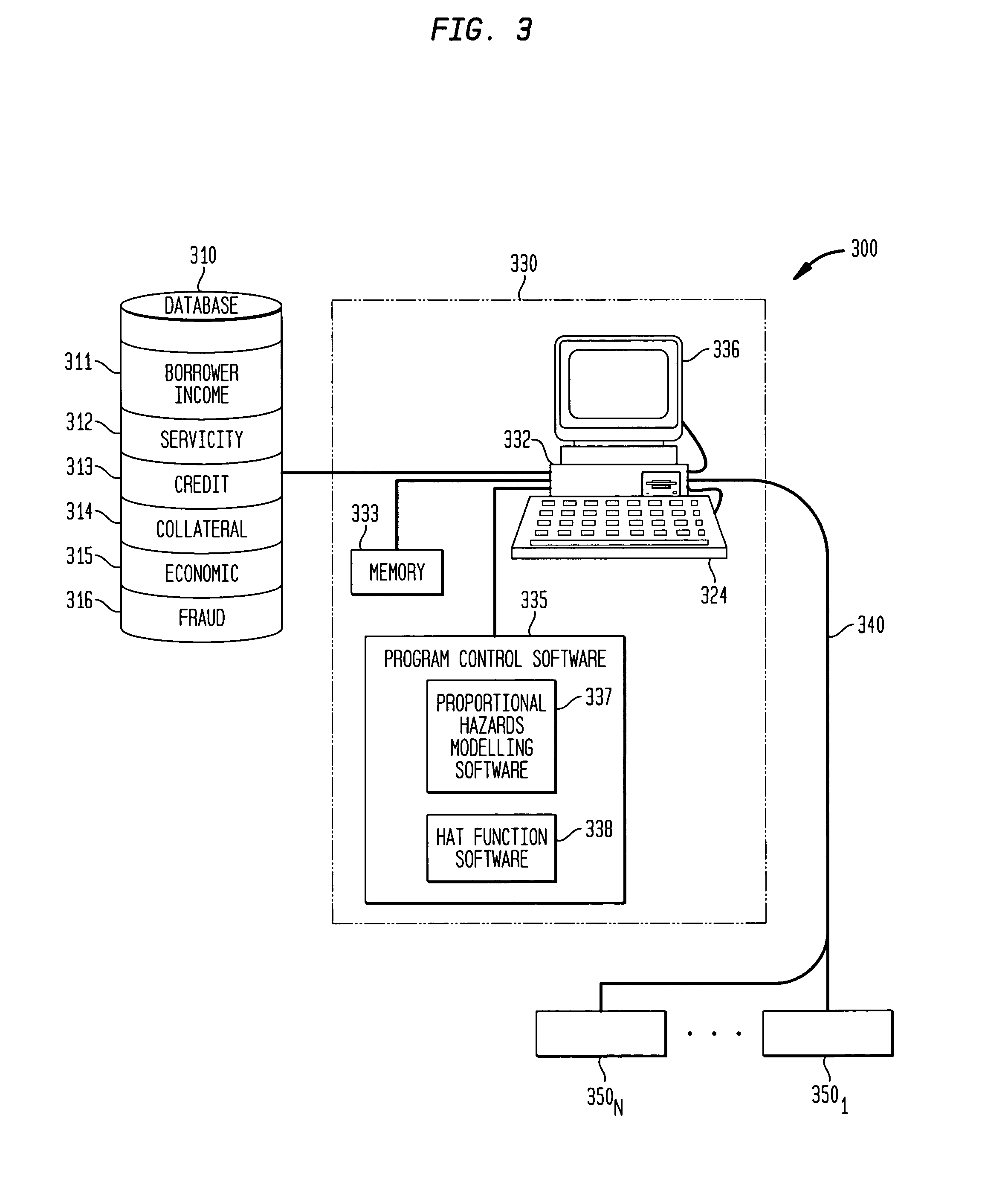

Methods and apparatus for utilizing a proportional hazards model to evaluate loan risk

InactiveUS7392216B1Increase valueAccurate identificationFinanceProportional hazards modelErrors and residuals

Systems and processes for more accurate mortgage scoring are described. A proportional hazards model is employed in which not only the occurrence of an event, but also the time to an event such as default of a loan, is considered. In this approach, a hazard rate can be viewed as the chance that an observation will experience an event in the next instant. There are two components to the response, and a binary variable is utilized to indicate whether the event was observed or not, and a time variable. As a result, the number of loans used for modeling is greatly increased, and the time it takes to observe the event, a valuable piece of information in itself, is included in the process. In addition, nonlinear effects are advantageously modeled in a continuous fashion using hat functions to map a series of independent variables. This approach typically yields smaller prediction errors near boundary points.

Owner:GE MORTGAGE HLDG

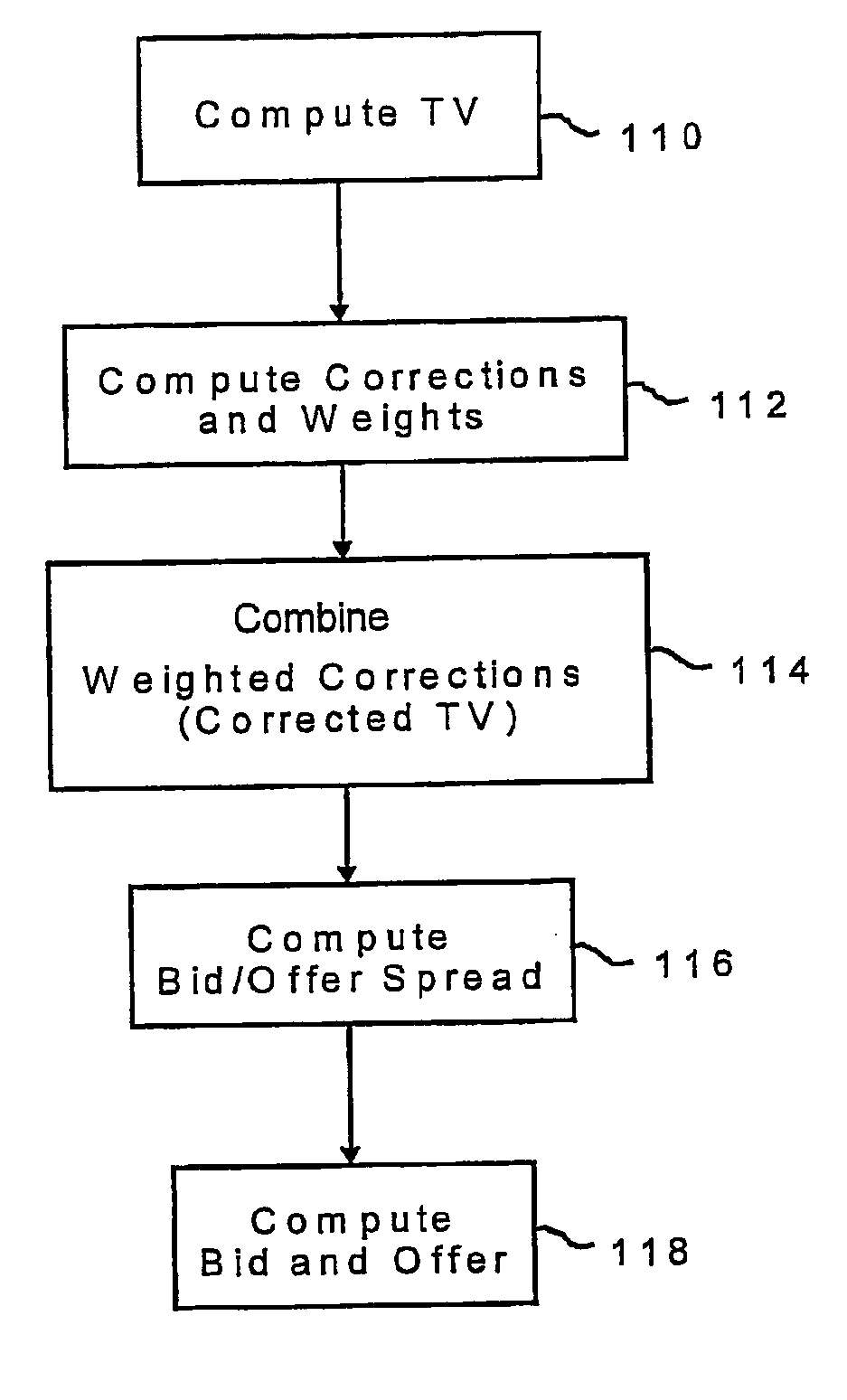

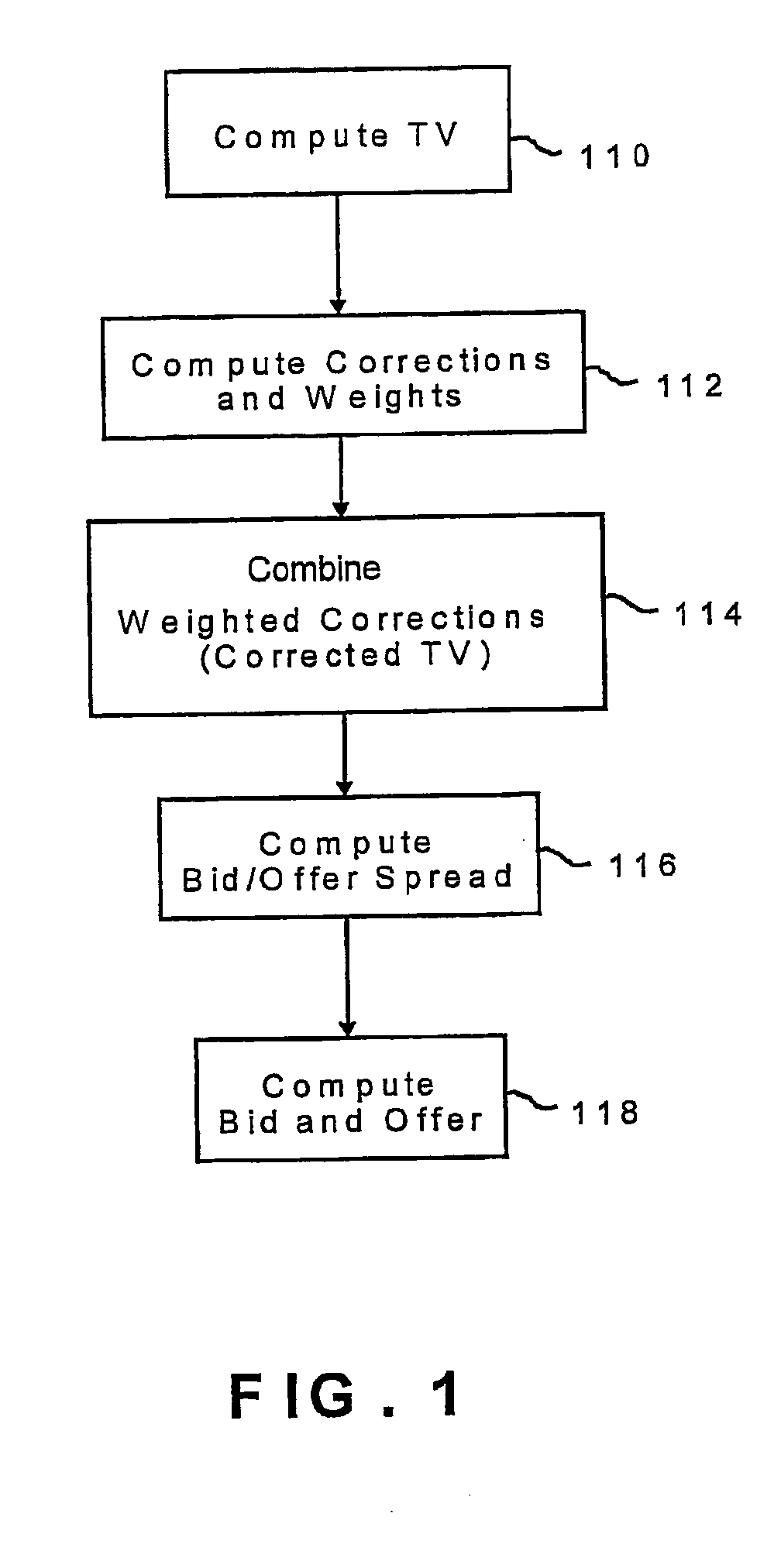

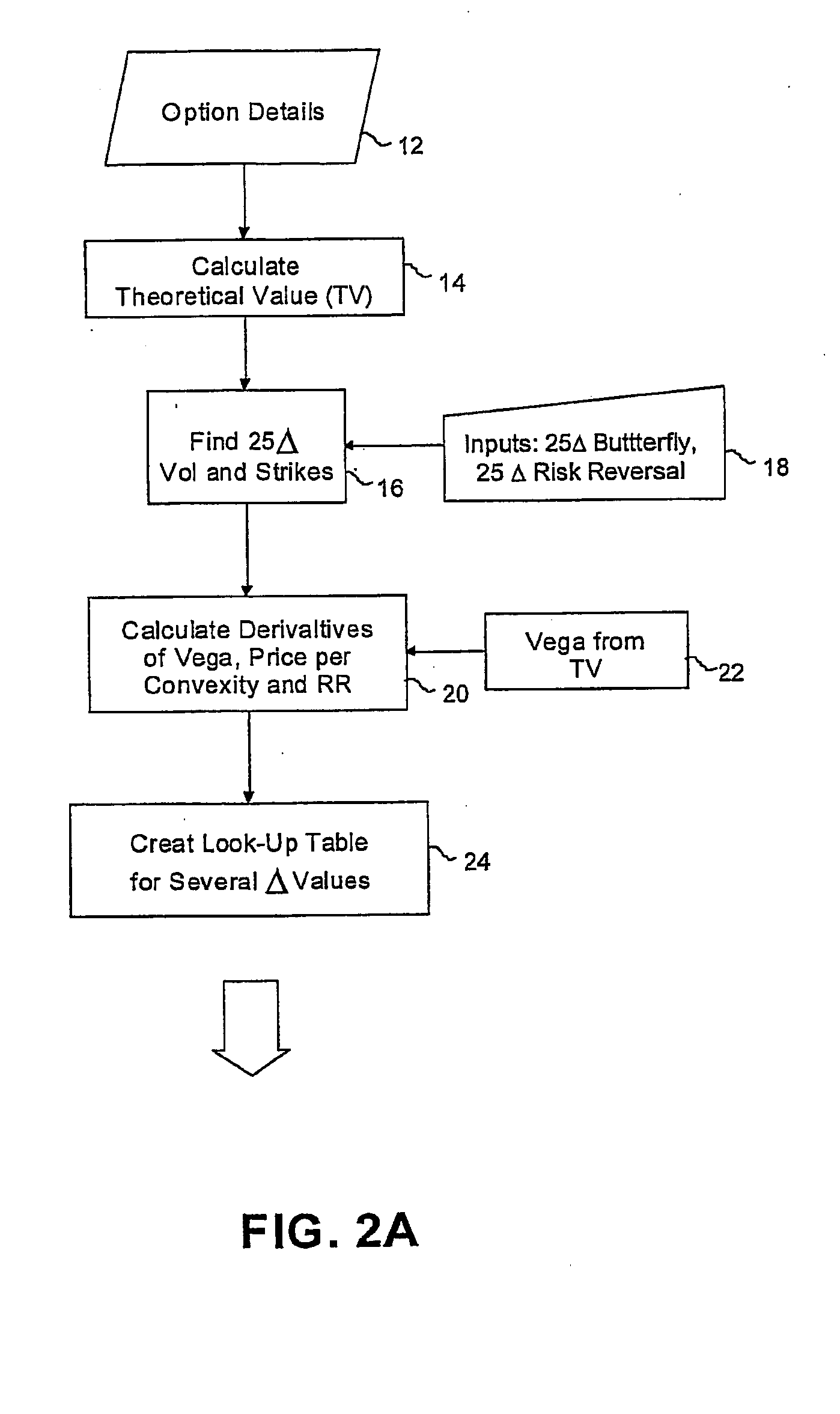

Method and system for pricing financial derivatives

ActiveUS20050027634A1Accurately determineFair priceFinanceSpecial data processing applicationsPrice differenceComputer science

A method for providing a bid price and / or an offer price of an option relating to an underlying asset, the method including the steps of receiving first input data corresponding to a plurality of parameters defining the option, receiving second input data corresponding to a plurality of current market conditions relating to the underlying value, computing a corrected theoretical value (CTV) of the option based on the first and second input data, computing a bid / offer spread of the option based on the first and input data, computing a bid price and / or an offer price of the option based on the corrected TV and the bid / offer spread, and providing an output corresponding to the bid price and / or the offer price of said option.

Owner:SUPERDERIVATIVES INC

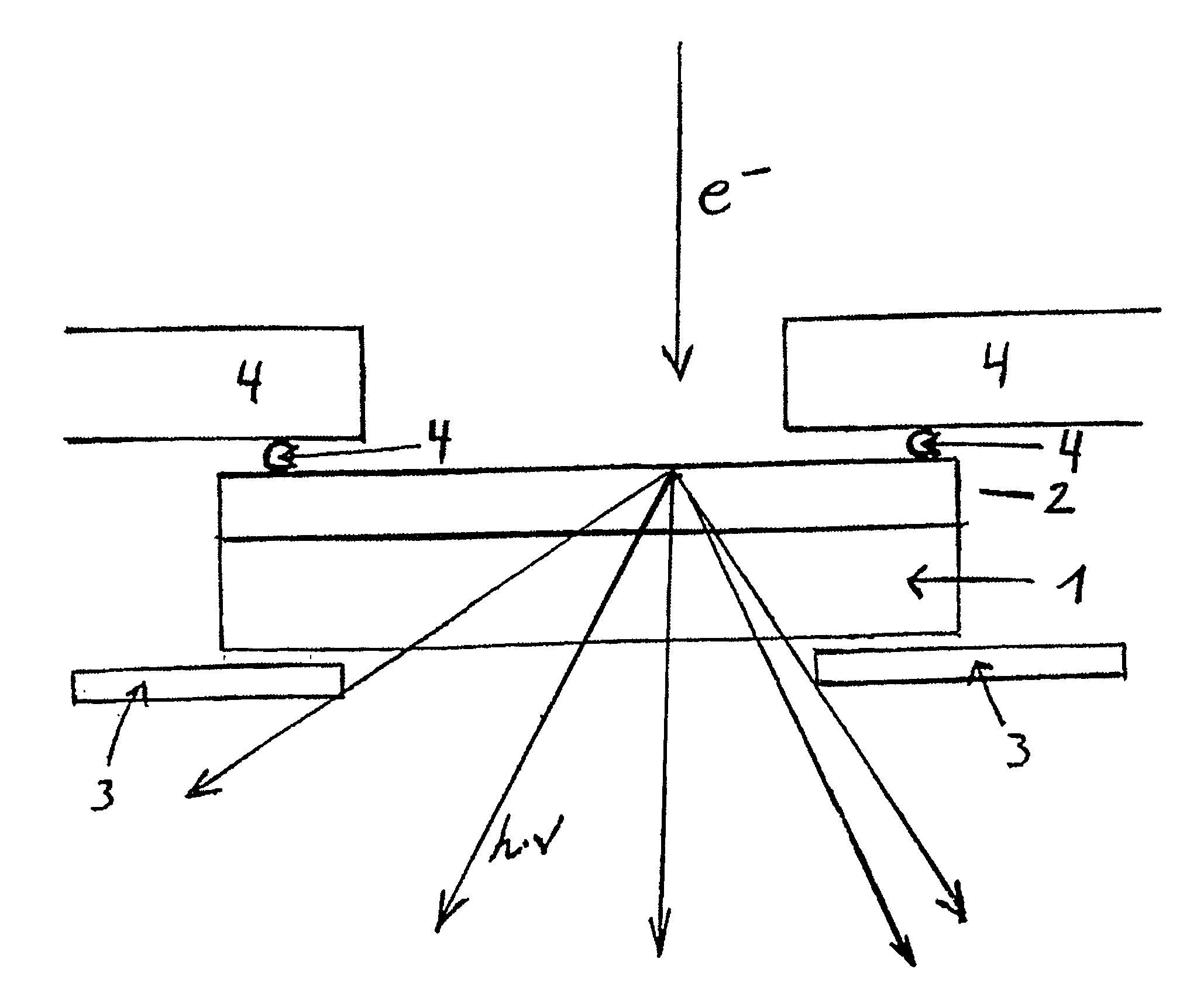

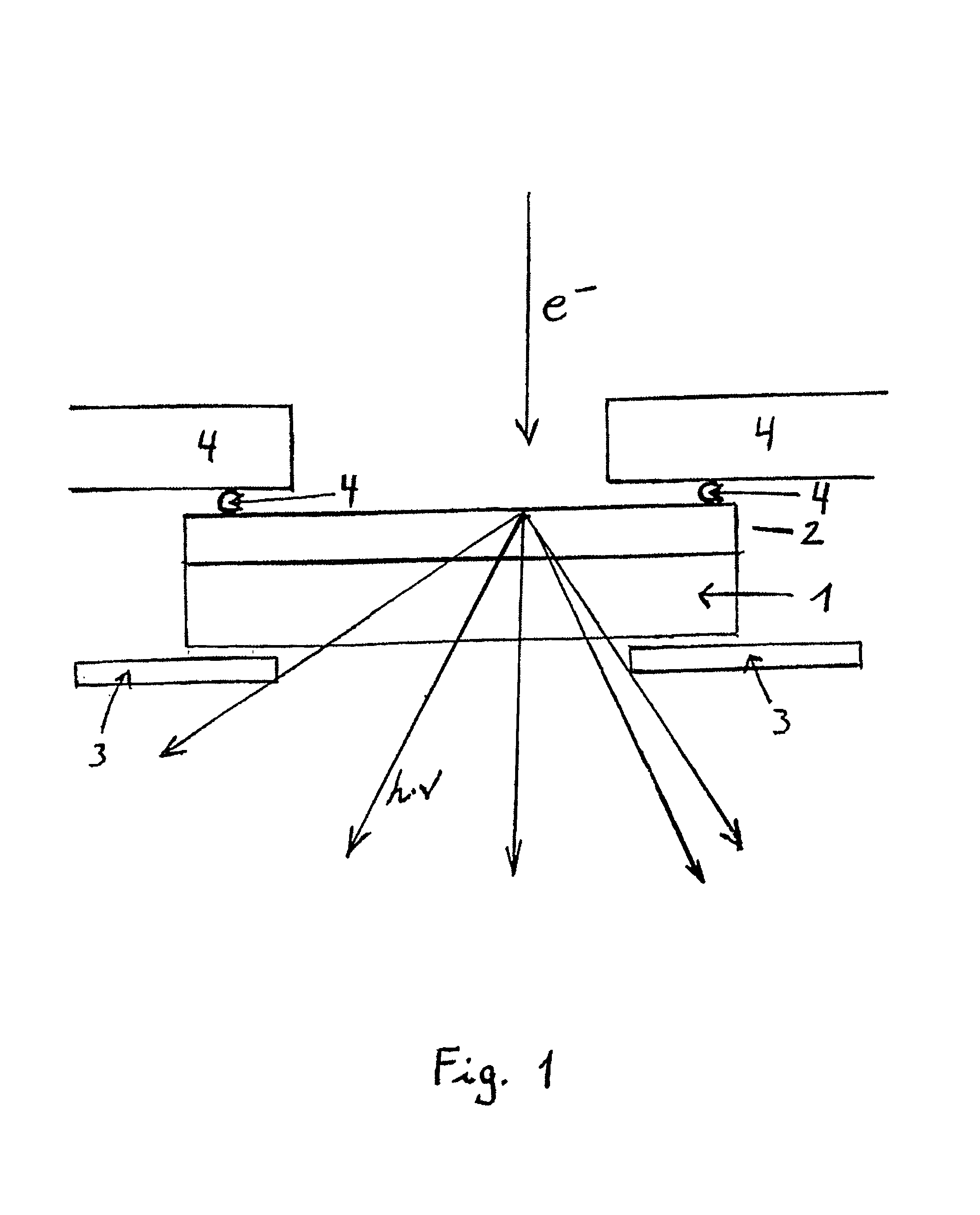

X-ray anode and process for its manufacture

InactiveUS6850598B1Improve the heating effectReduce absorptionRadiation/particle handlingX-ray tube electrodesSoft x rayImage resolution

The invention relates to an x-ray anode and a process for its manufacture. The x-ray anode is characterized in that the anode material is embodied as a layer on a diamond window. The x-ray anode is preferably used with x-ray units which require as selective as possible x-radiation production to achieve as high as possible radiation intensity. Use in x-ray microscopes in which a high radiation intensity guarantees the highest resolutions is particularly preferred.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

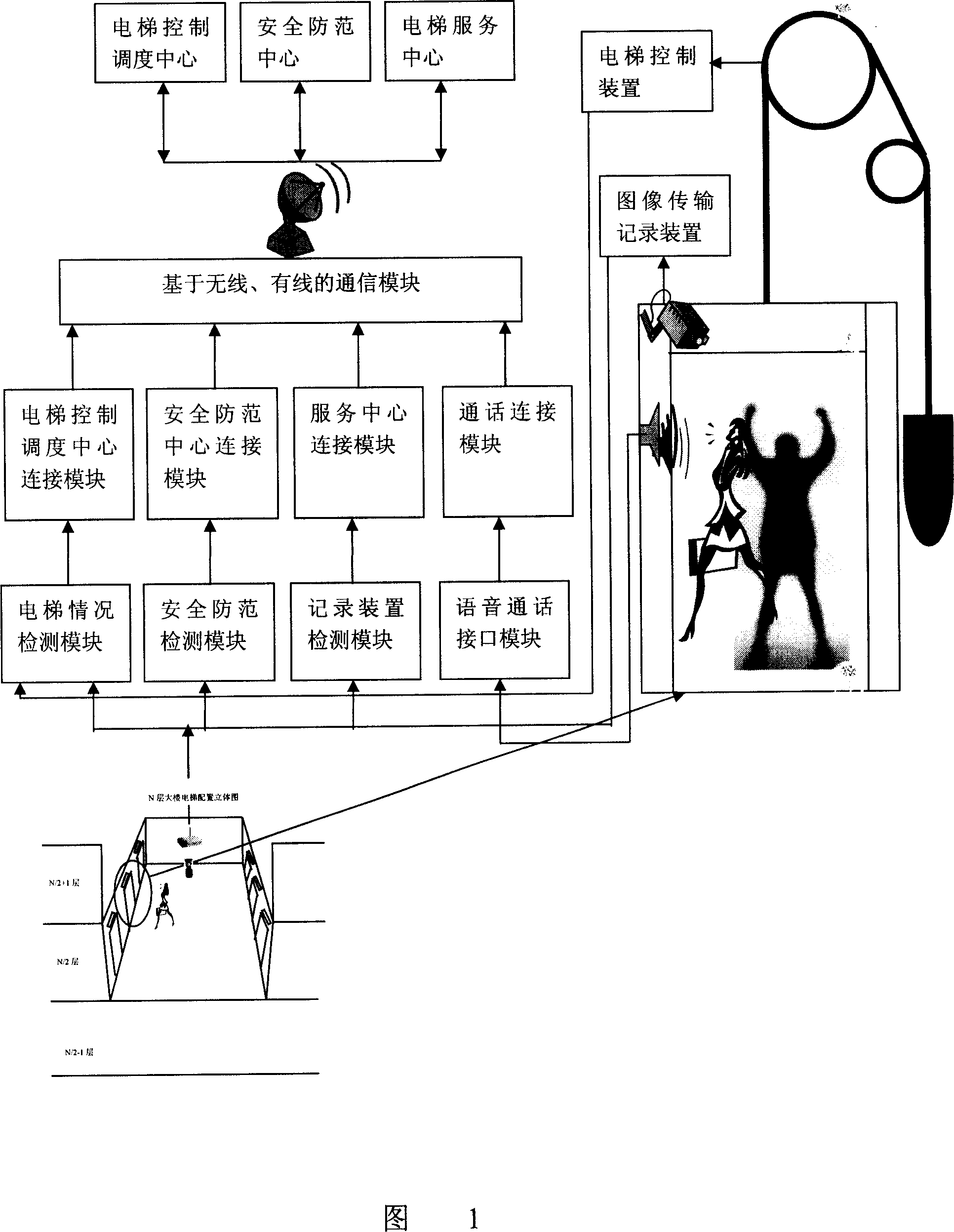

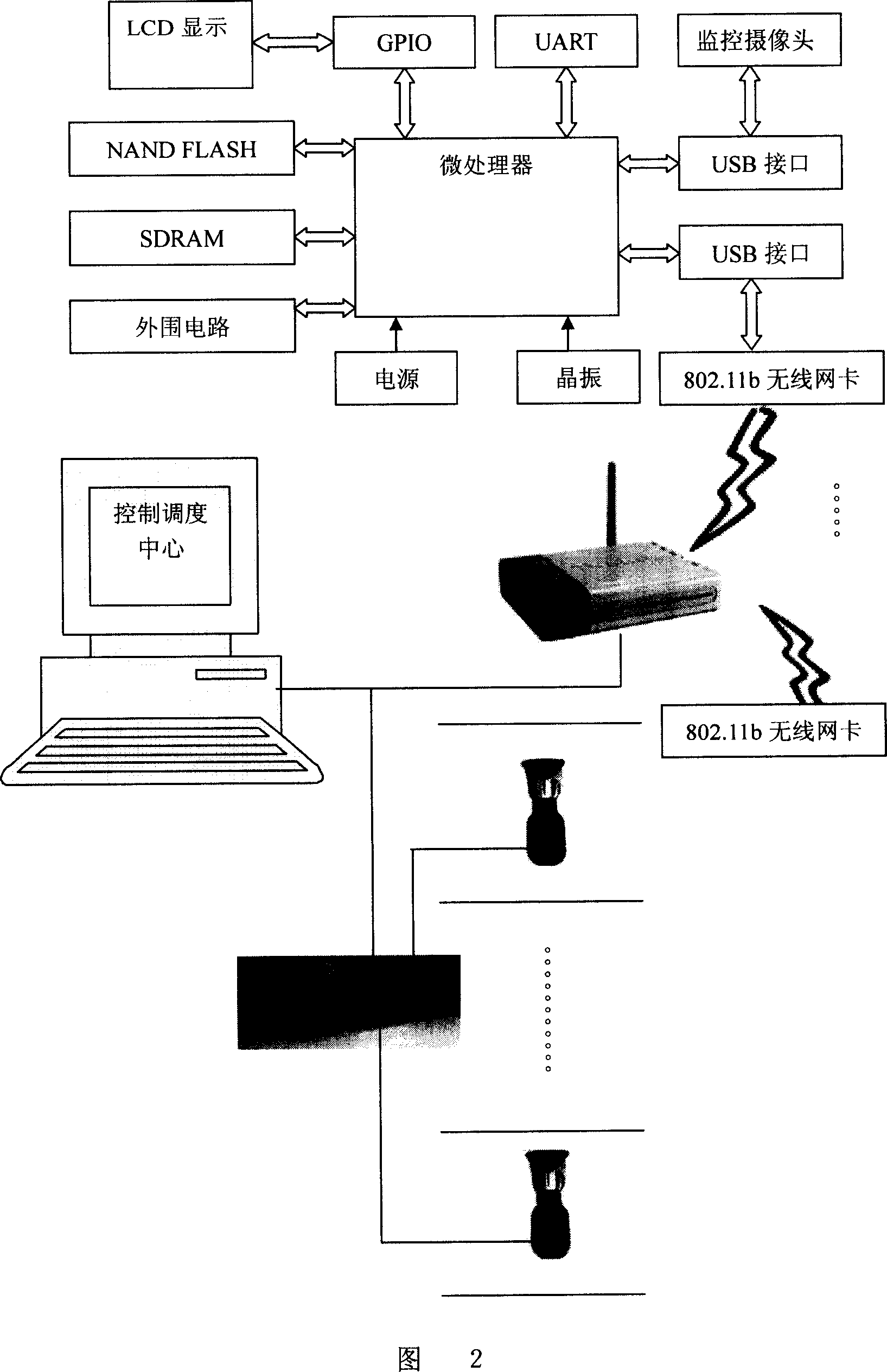

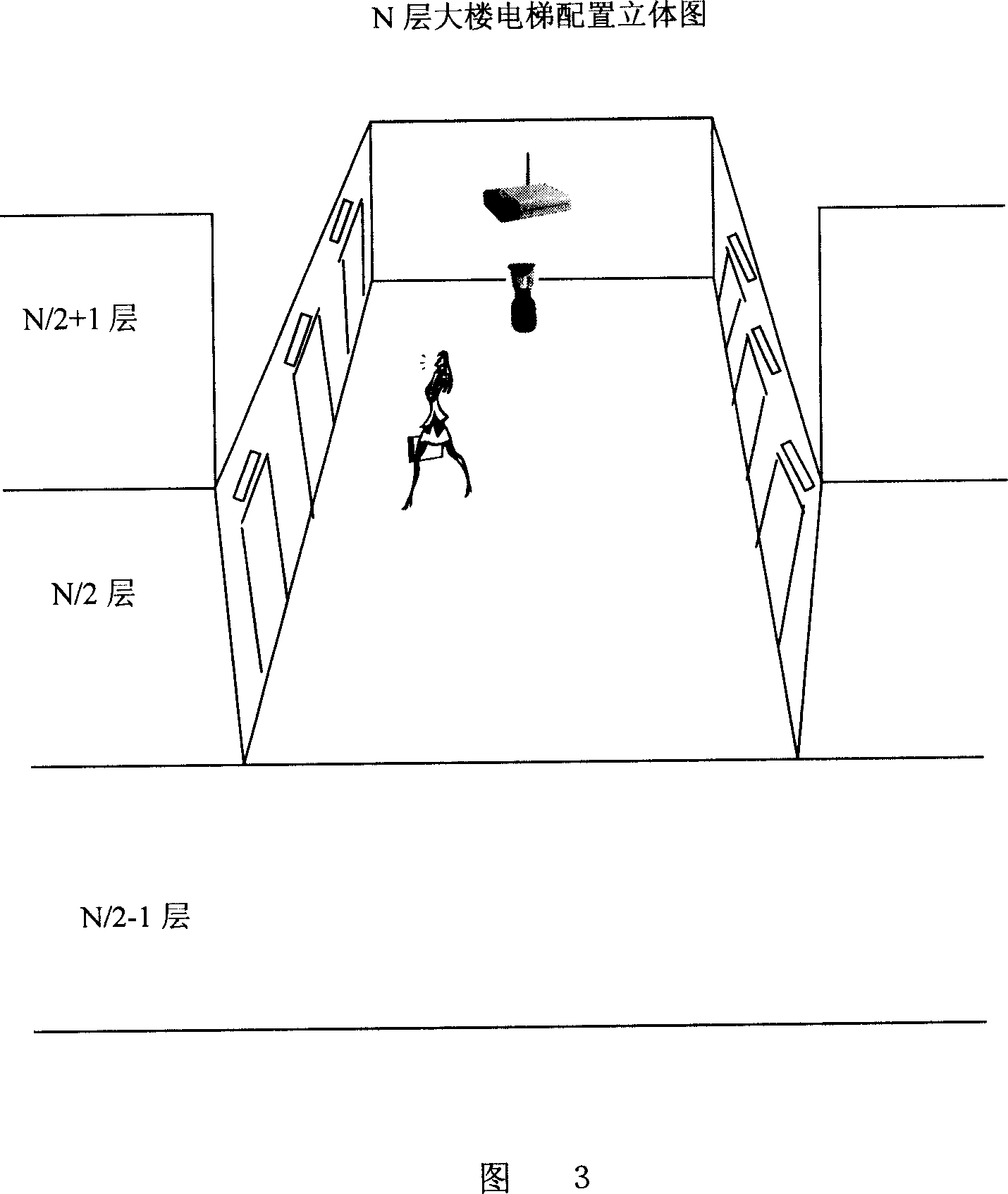

Intelligent dispatcher for group controlled lifts based on image recognizing technology

The intelligent dispatcher for group controlled lifts based on image recognizing technology includes one central dispatching computer for group controlled lifts and with one dispatching control strategy module for the optimized control of the lifts in the building, visual car sensors for acquiring the passenger flow information, and omnibearing visual sensors for acquiring the waiting passenger information, with the visual car sensors and the omnibearing visual sensors being connected to the central dispatching computer. The central computer includes also a lift passenger flow calculating module, and a running mode recognizing module to divide different lift group running modes, except its dispatching control strategy module for selecting dispatching control strategy fitting different running modes. The present invention can detect real-time passenger flow information and has precise group control dispatching.

Owner:ZHEJIANG UNIV OF TECH

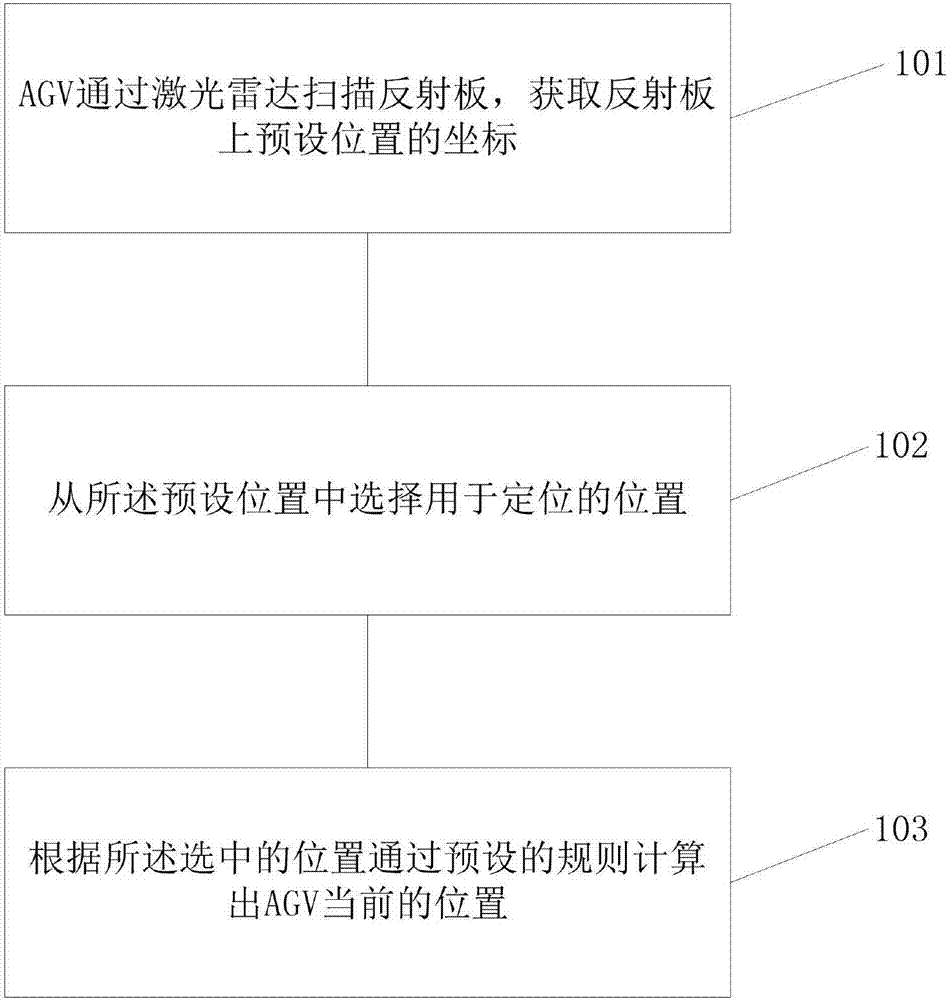

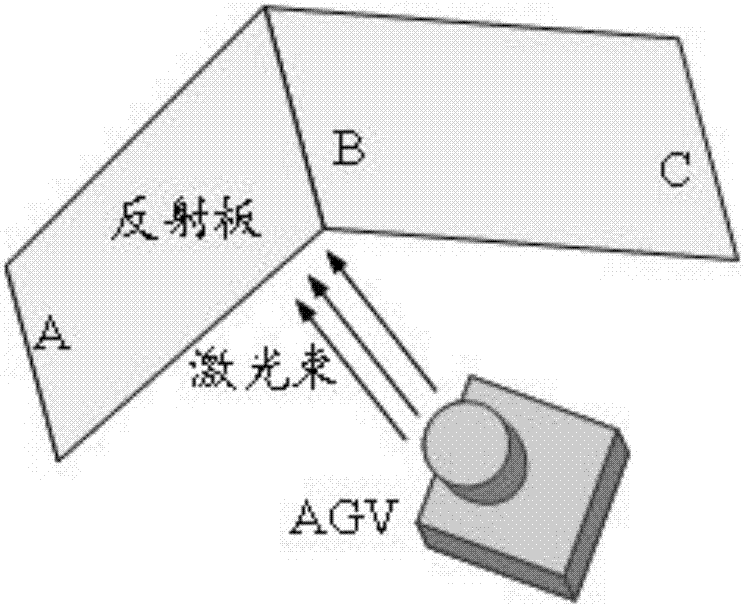

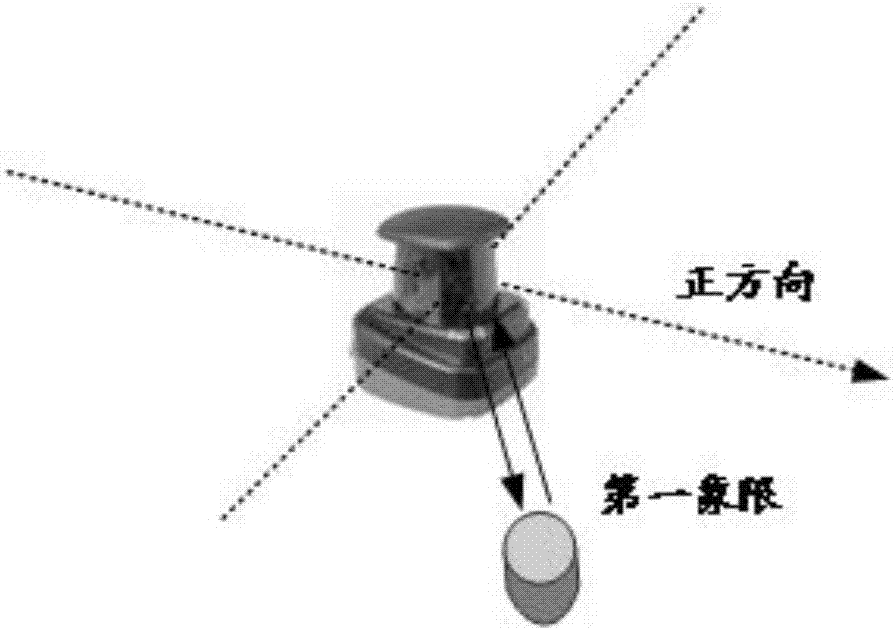

Accurate positioning and parking method of trackless navigation AGV

ActiveCN106969768AImprove reliabilityHigh precisionNavigational calculation instrumentsPosition fixationRadarGlobal coordinate system

The embodiment of the invention provides an accurate positioning and parking method of a trackless navigation AGV. The accurate positioning and parking method comprises the steps that the AGV scans a reflection plate through laser radar to obtain coordinates of preset positions on the reflection plate; a position for positioning is selected from the preset positions; the current position of the AGV is calculated according to preset rules and the selected position. According to the method, three special reflection points are extracted to achieve three-point positioning, the coordinate orientation of the AGV under a global coordinate system is determined mainly through a least square method, and then the direction angle of the AGV is calculated through multiple quadrants. The relative position and the direction angle of the AGV with respect to the reflection plate can be also calculated through outline detection so that the AGV can be accurately parked at the designated of the reflection plate. By adopting the method, the defect of poor positioning accuracy of an SLAM technology is overcome to the most degree, and a reliable solution is also provided for automatic charging of the trackless navigation AGV.

Owner:SHENZHEN ZHUMANG TECH CORP

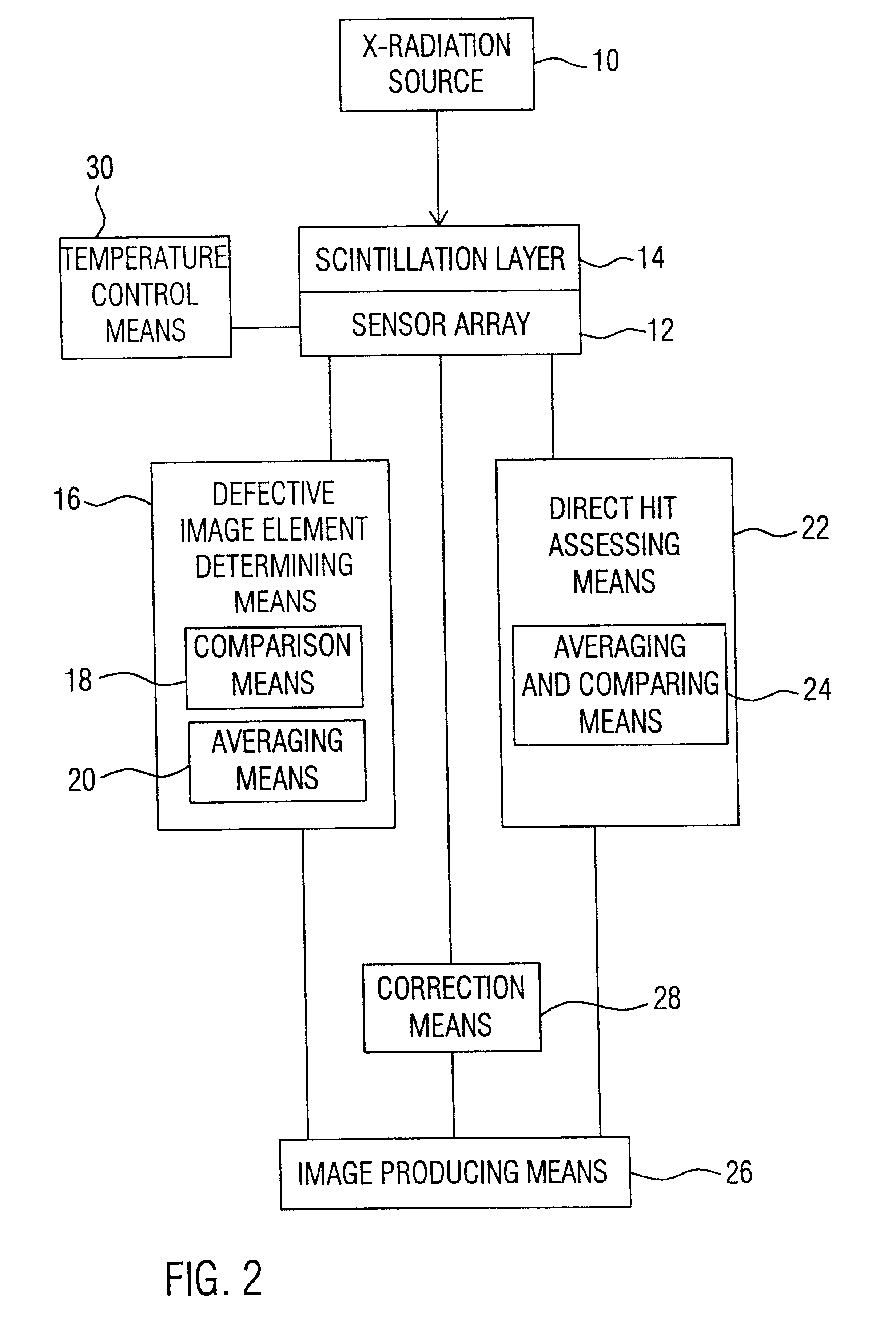

Method and device for imaging in digital dental radioscopy

InactiveUS6497511B1Substantial of quality of imageReduce image noiseTelevision system detailsX-ray/infra-red processesSensor arraySoft x ray

In a method for imaging in digital dental radioscopy making use of a sensor array, the individual image elements of which are smaller than a desired local resolution so that a plurality of image elements forms a respective effective image element, first reference signals, which are generated by the image elements of the sensor array when said sensor array is not exposed to X-radiation, are initially detected. In addition, second reference signals, which are generated by the image elements of the sensor array when said sensor array is exposed to X-radiation, are detected. Subsequently, defective image elements are determined on the basis of the detected first and second reference signals, whereupon an image of an object is produced using exclusively the image elements that have been determined as being non-defective. Furthermore, during production of the image of an object, it can be determined for the object signals detected for the respective image elements whether said image elements have been hit directly by an X-ray quantum. Image elements that have been hit directly by an X-ray quantum are not used for producing the image of the object.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Roof greening long-acting light type matrix formula

InactiveCN1460408AReduce loadReduce weightRoof improvementClimate change adaptationCountermeasureGreening

The present invention relates to a roof-greenting material with light matrix, said material is different from existent roof-greening material which mainly uses natural plant sedium lineare. Said invention mainly uses the waste and discarded material to form its roof-greening material matrix formula.

Owner:SOUTH CHINA PLANT INST CHINESE ACAD OF SCI

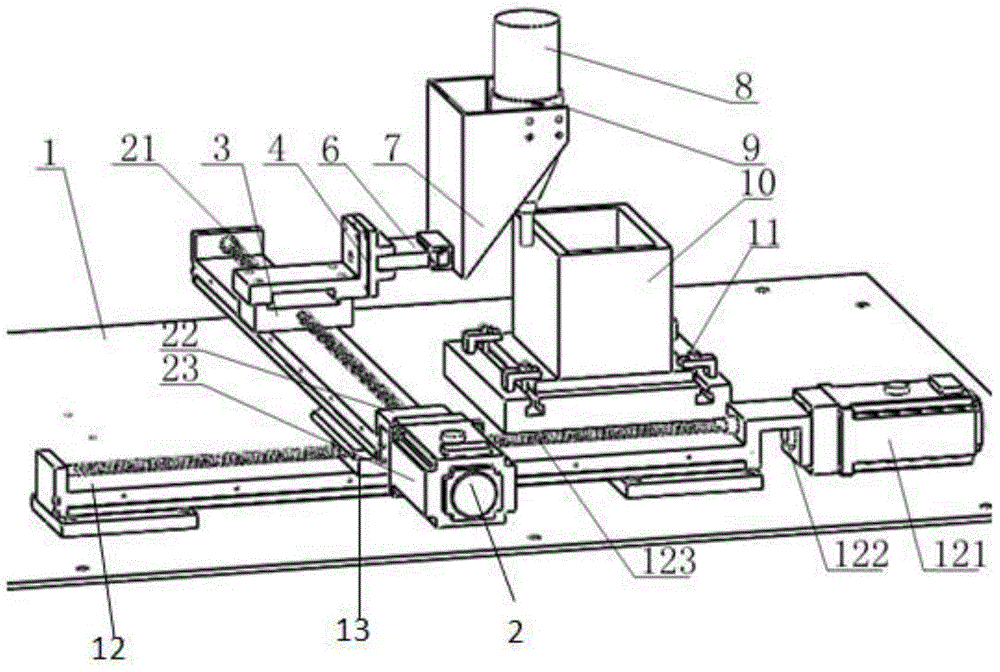

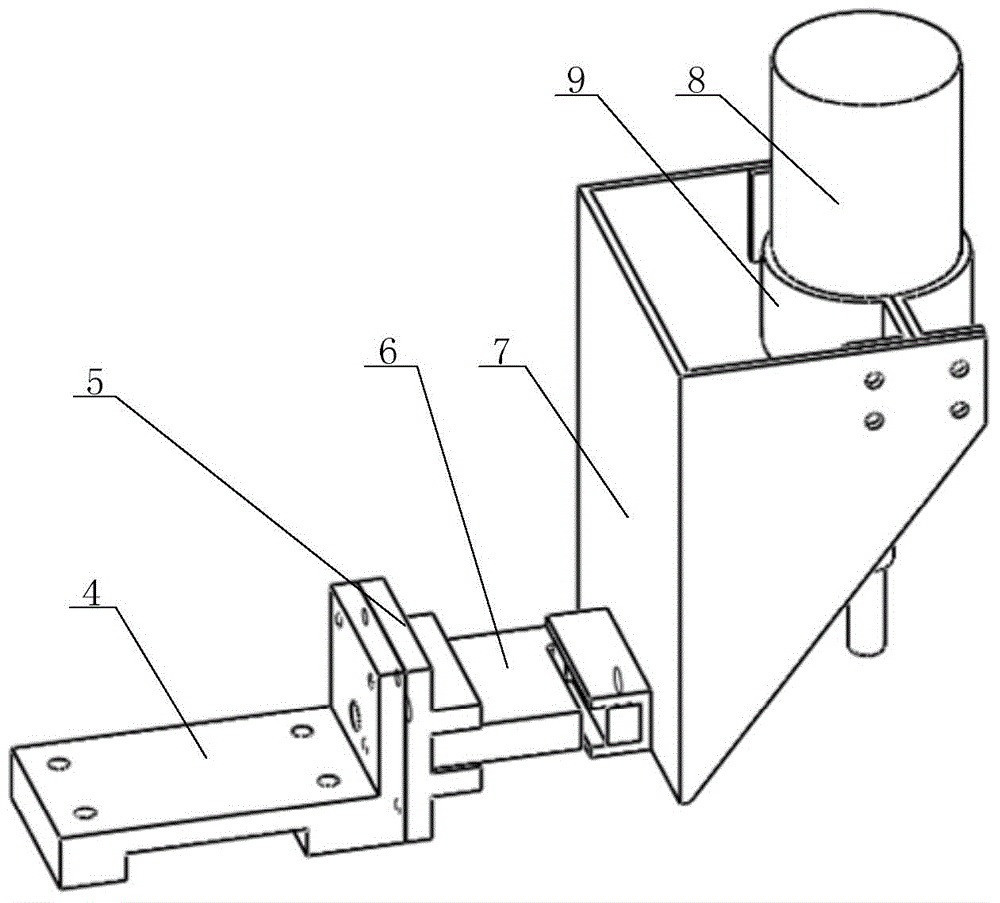

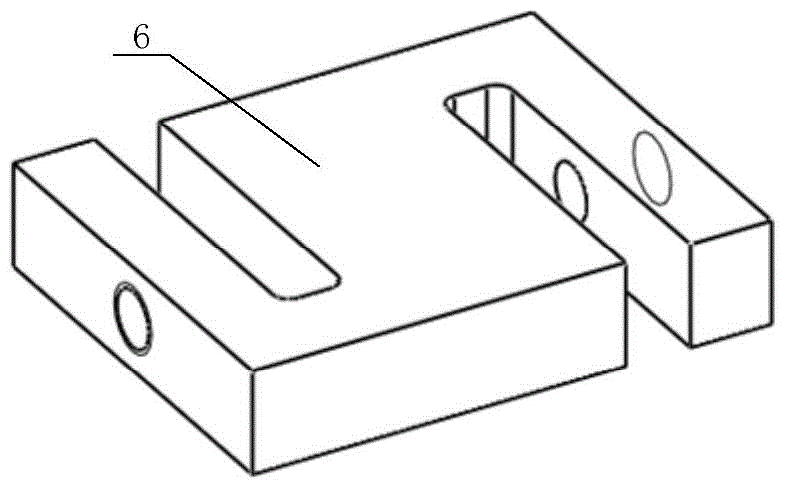

Constant pressure automatic grinding device and method based on fuzzy adaptive force control

InactiveCN104858782AReal-time control of grinding normal forceImprove versatilityGrinding feed controlSpeed/accelaration controlContact forceEngineering

The invention discloses a constant pressure automatic grinding method based on fuzzy adaptive force control. The grinding method comprises the following steps: detecting the contact force of a grinding head and a workpiece in a real-time manner to feed back force signals; changing an analog voltage value output by a controller according to a preset control algorithm, thereby controlling the output torque of an x-axis servomotor to control the contact force. The invention further provides a grinding device for realizing the grinding method. The grinding device comprises an industrial control main engine, a workbench, motion mechanisms, one-dimensional sensing equipment, a position sensor for acquiring the position coordinate of the workpiece, grinding equipment and workpiece clamping equipment. The grinding device can be used for detecting the normal grinding force in a grinding process based on an intelligent force control technology, and feeding back detection results; through the processing of the controller, driving signals are generated for continuous adjustment of the output torque of a driver, so that the normal grinding force can be controlled in a real-time manner and the constant pressure grinding can be realized.

Owner:SOUTH CHINA UNIV OF TECH

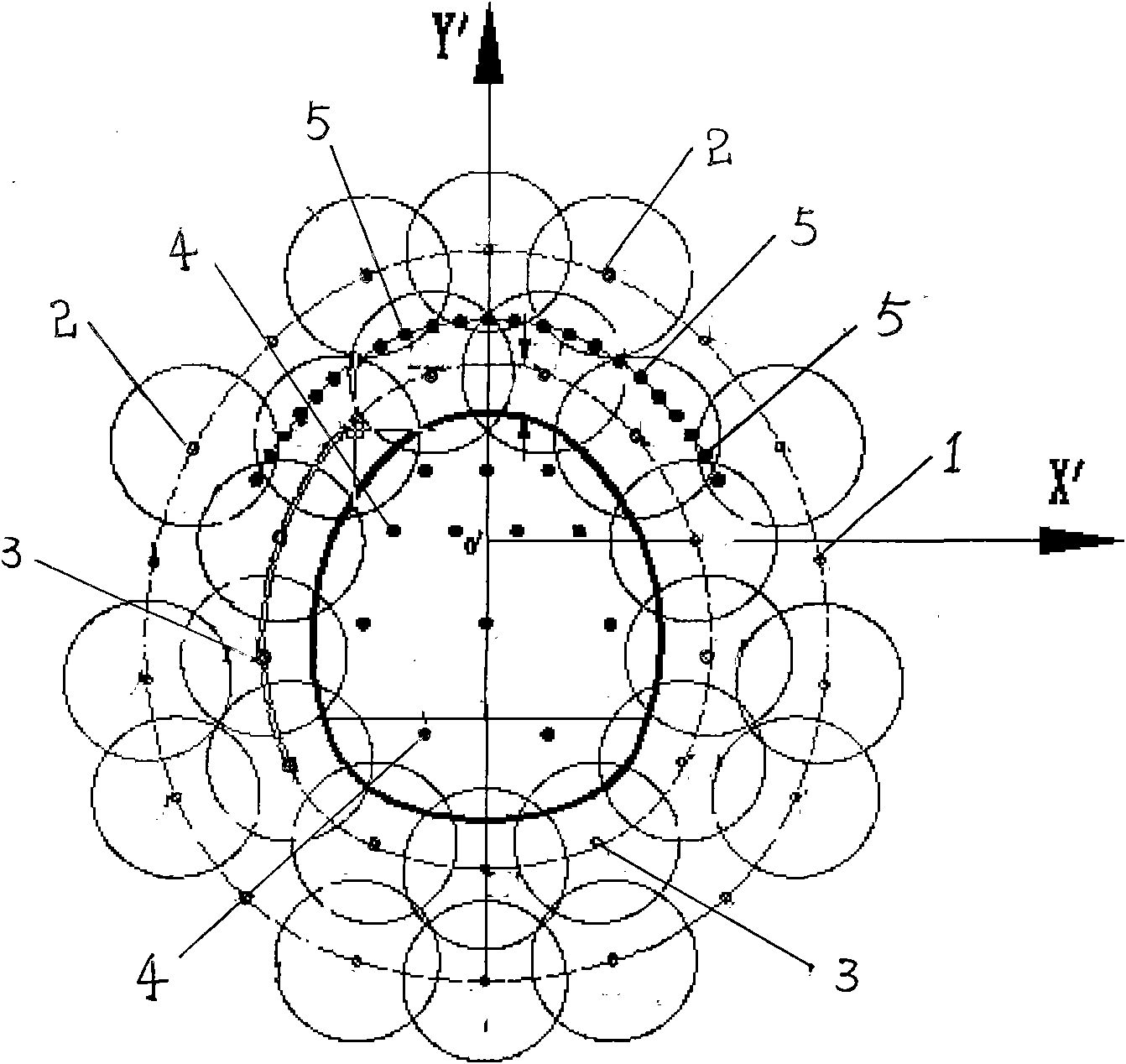

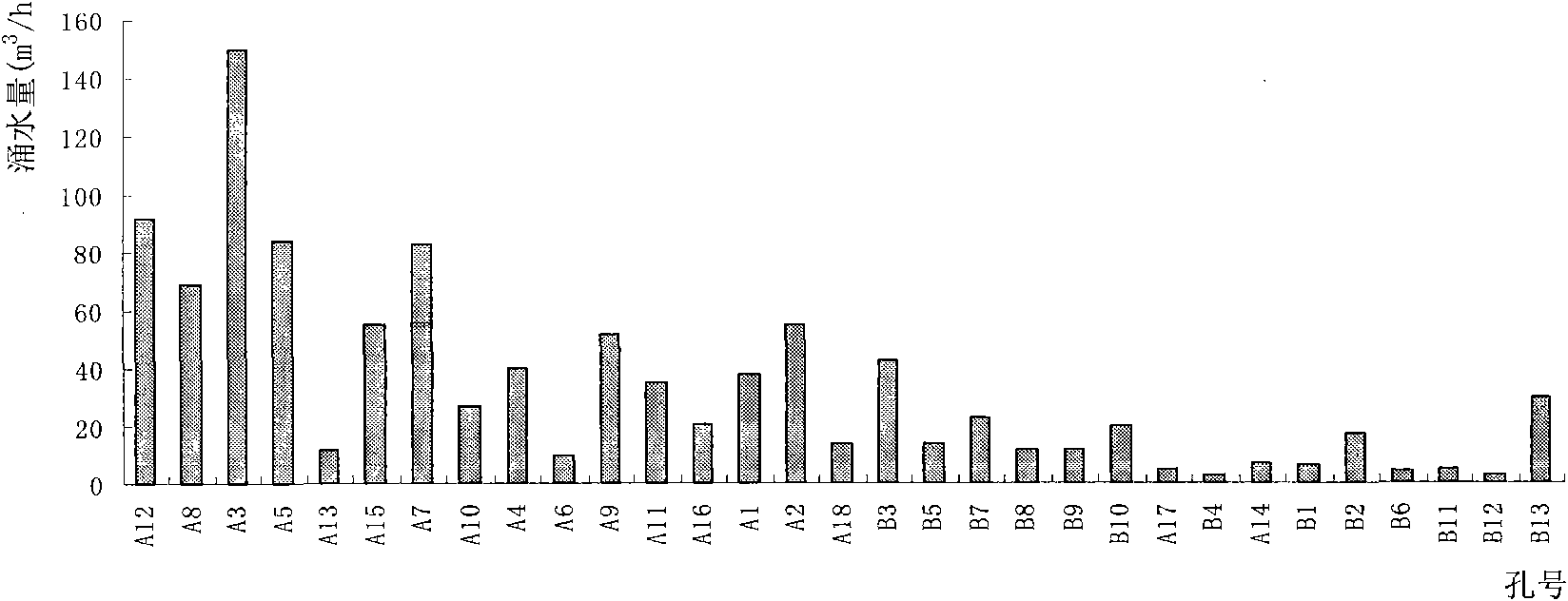

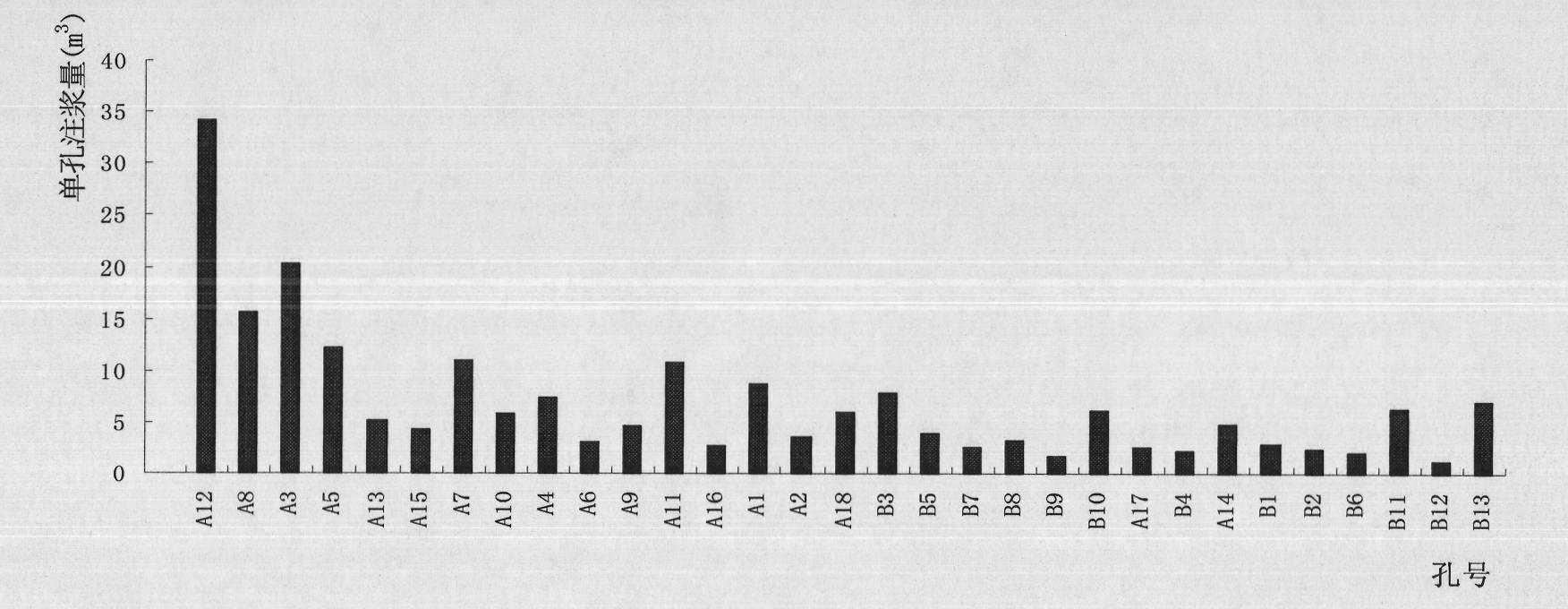

Tunnel information tracing accurate grouting method

ActiveCN101832142AOptimizing the Number of Grouting HolesReduce the amount of waterUnderground chambersTunnel liningGlass fiberGeomorphology

The invention relates to the field of tunnel grouting, in particular to a tunnel information tracing accurate grouting method, which solves the problems of thick reinforcing ring, large number of drilled holes, long construction period and the like of the traditional curtain grouting method adopted in current tunnel grouting. The method comprises the processes of grout stopping wall building, arrangement of orifice tubes and grouting tubes, measurement of the water burst of a drill hole, packer test, hole arrangement, drilling operation and grouting, wherein the hole arrangement and the grouting are performed according to the sequence from an advance geological drill hole to other outer ring holes to an inner ring hole to a working surface stabilizing hole to an access hole to a pipe-shed hole; and steps such as advance big pipe-shed construction of a working chamber and working surface stabilization by using a glass fiber anchor rod are saved. In the invention, a break through is made in the conventional construction philosophy, grouting design and geological change are tightly combined together, a grouting mechanism of 'crack blocking, water reduction, surrounding rock fixation and stratum stabilization' is adopted, the grouting holes are reduced by 30 to 40 percent, grouting quality is improved, the safe and quick construction is guaranteed, major water burst and mud burst accidents are eliminated, and the environment is protected maximally.

Owner:CHINA RAILWAY 12TH BUREAU GRP

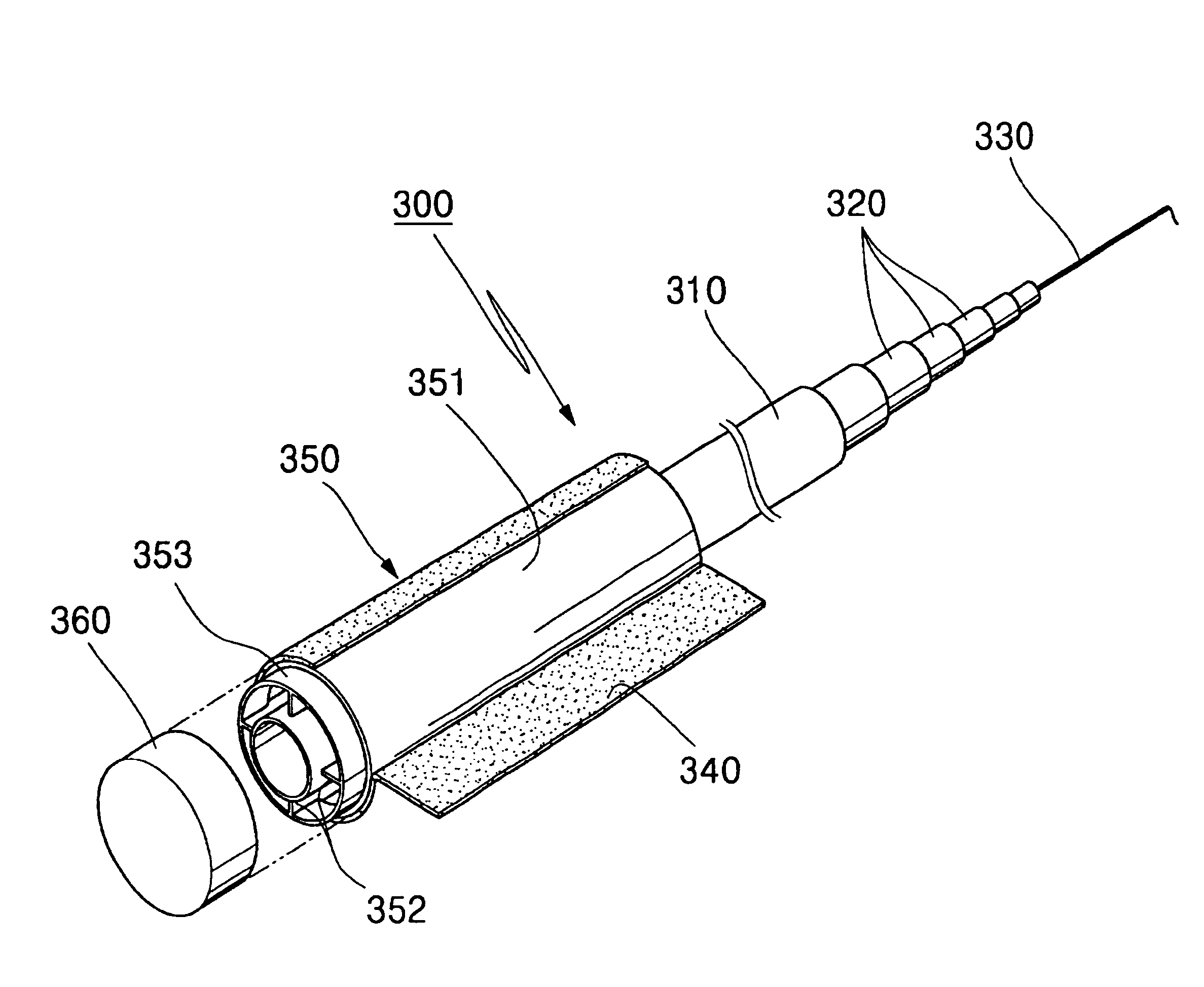

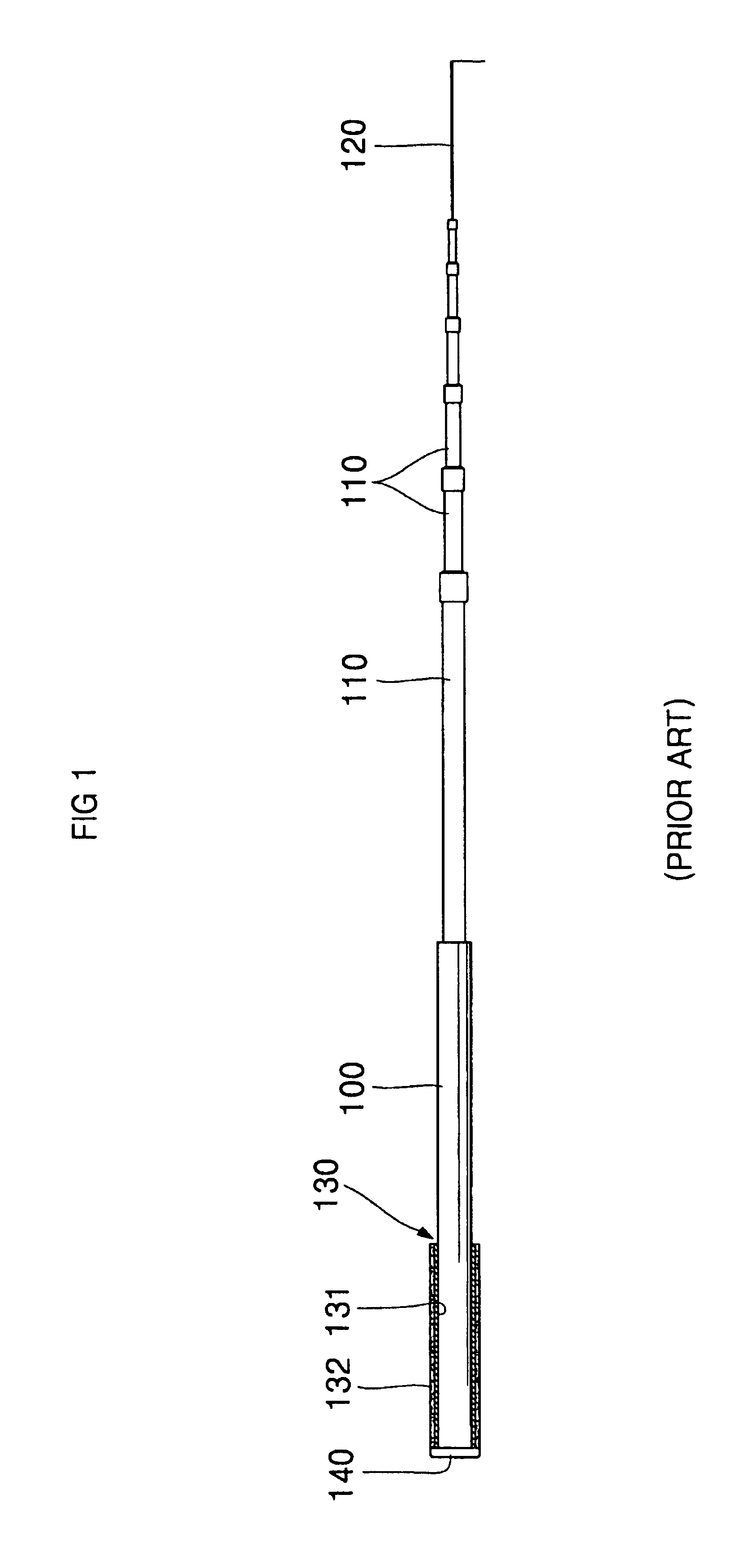

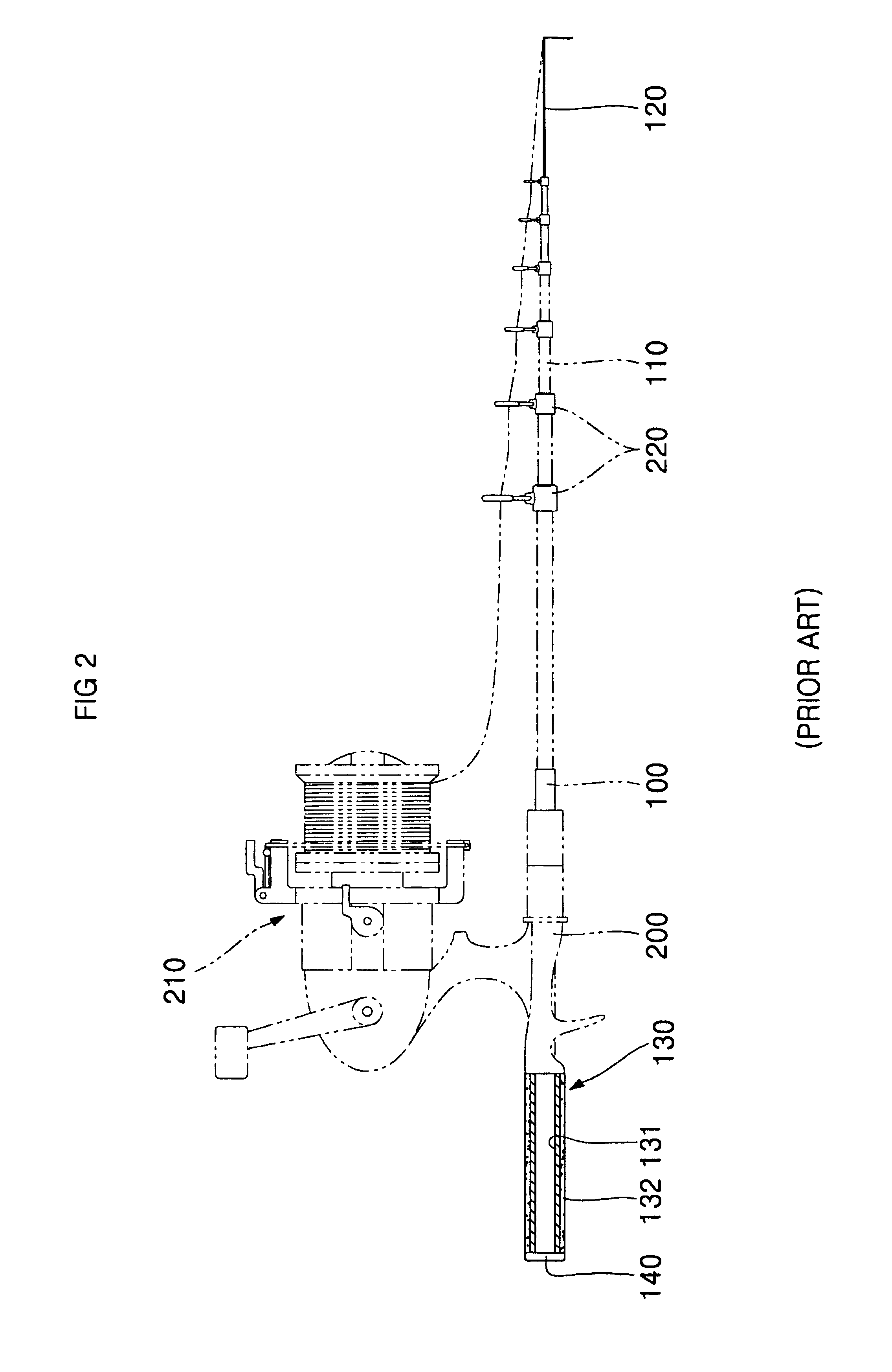

Fishing rod and butt grip for such rods

InactiveUS6973750B1Thrilling and agreeable feelingDoubling a user's interest in fishingRodsPleasant FeelingEngineering

The fishing rod of this invention includes a hollow cylindrical butt pipe, and a plurality of hollow cylindrical sections sequentially jointed together to form a telescopically retractable structure jointed to the butt pipe such that the sections are sequentially retracted into the butt pipe. A tip rod is mounted to the end of the outermost one of the sections remote from the butt pipe. A butt grip is fitted over the butt pipe, and consists of a hollow cylindrical tube opened at both ends thereof. A plurality of radial support ribs are formed on the inner surface of the tube while being directed in radial directions and spaced apart from each other at regular intervals. When the butt grip is fitted over the butt pipe, the external surface of the butt pipe is brought into close contact with the inside edges of the radial support ribs. The butt grip directly transmits vital vibrations of a fish taking a bait or caught by the hook to the hand of a user holding it, thus allowing the user to have a thrilling and agreeable feeling while fishing, and doubling a user's interest in fishing.

Owner:KIM MYUNG KWON

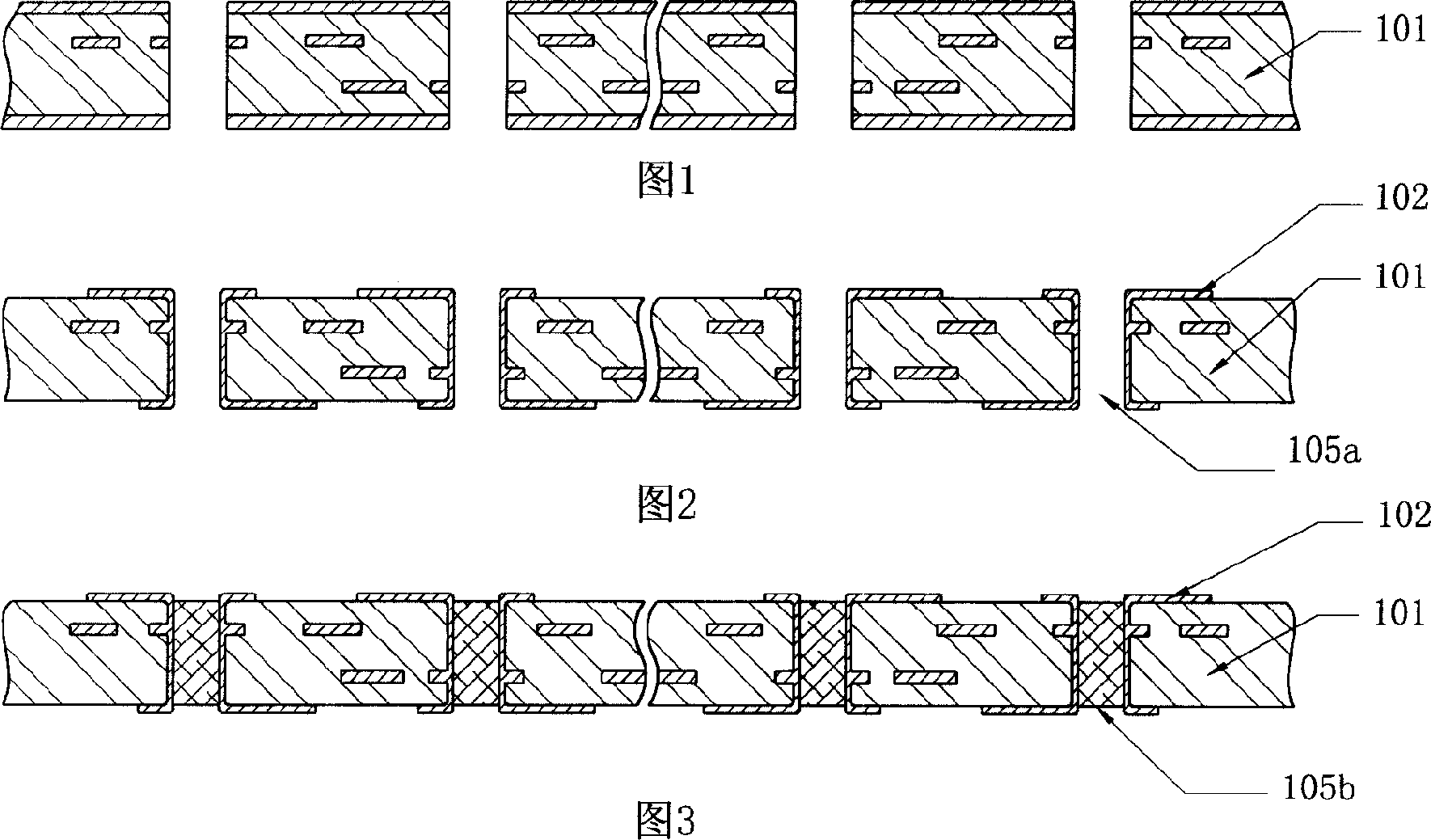

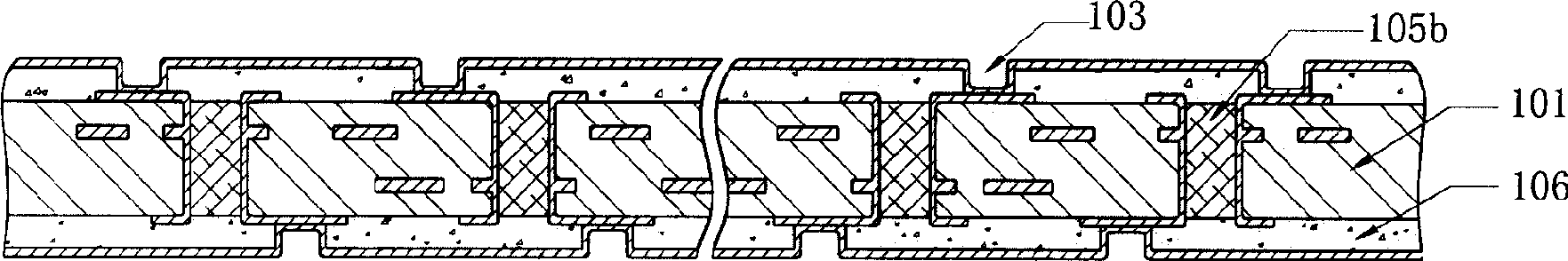

Flip ball grid array packaging base plate and making technique thereof

InactiveCN1691314AWide range of optionsFair priceSemiconductor/solid-state device detailsSolid-state devicesSolder ballEngineering

The invention discloses a packaging base plate of flip chip ball grid array integrated circuit and the making process. The base plate comprises enhanced metal core layer, insulating medium layer, conductive layer of the ball grid array base plate solder ball connection pattern and the lead pattern anti soldering layer and the back enhancing metal copper plate. Form a hollow in the back enhancing metal copper plate of the base plate and set chips. Coating insulating medium on the enhancing metal copper plate and forming the circuit, getting the final required structure by the special line connection structure and the special process of one-way gradually add layers.

Owner:美龙翔微电子科技(深圳)有限公司

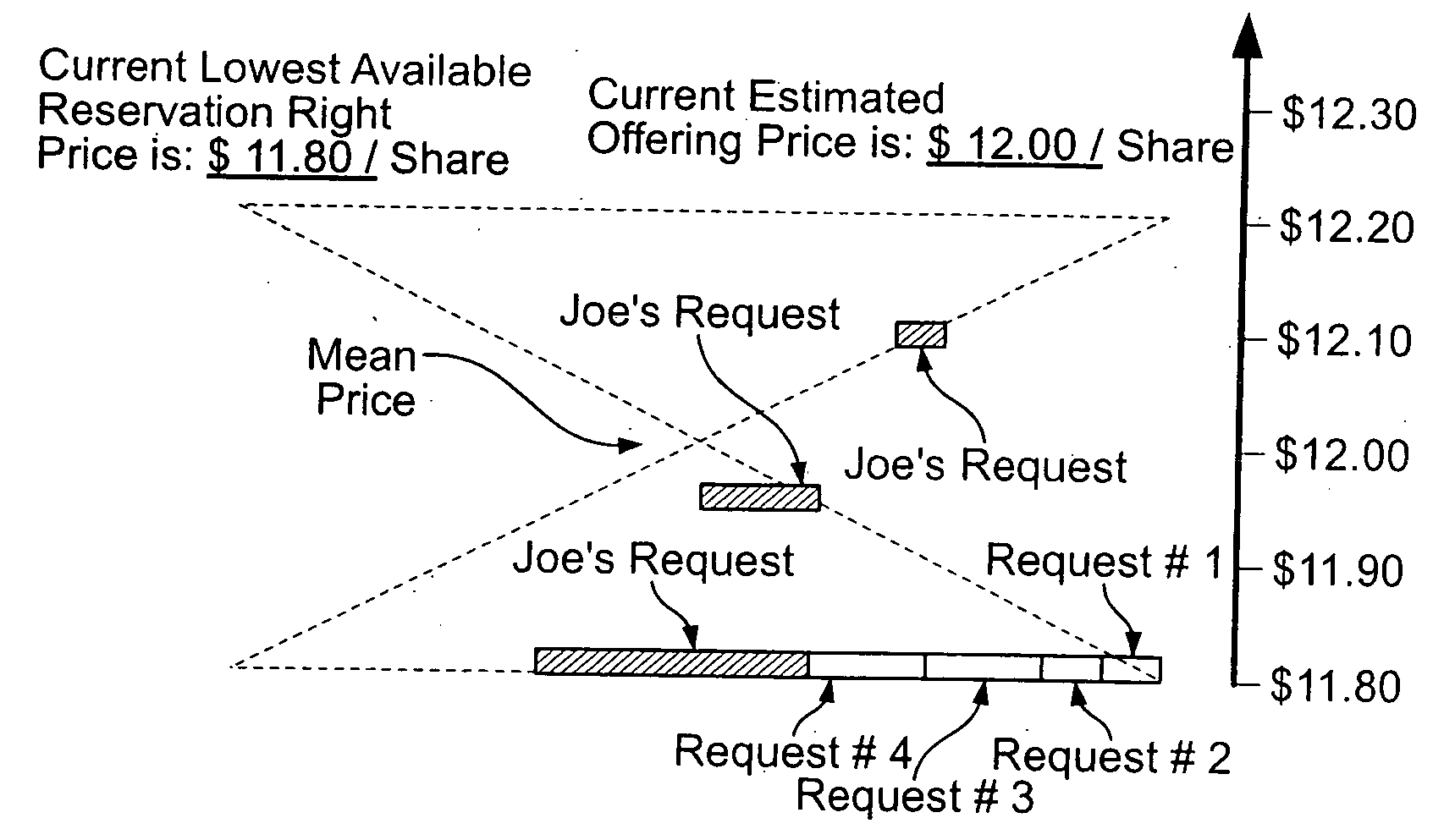

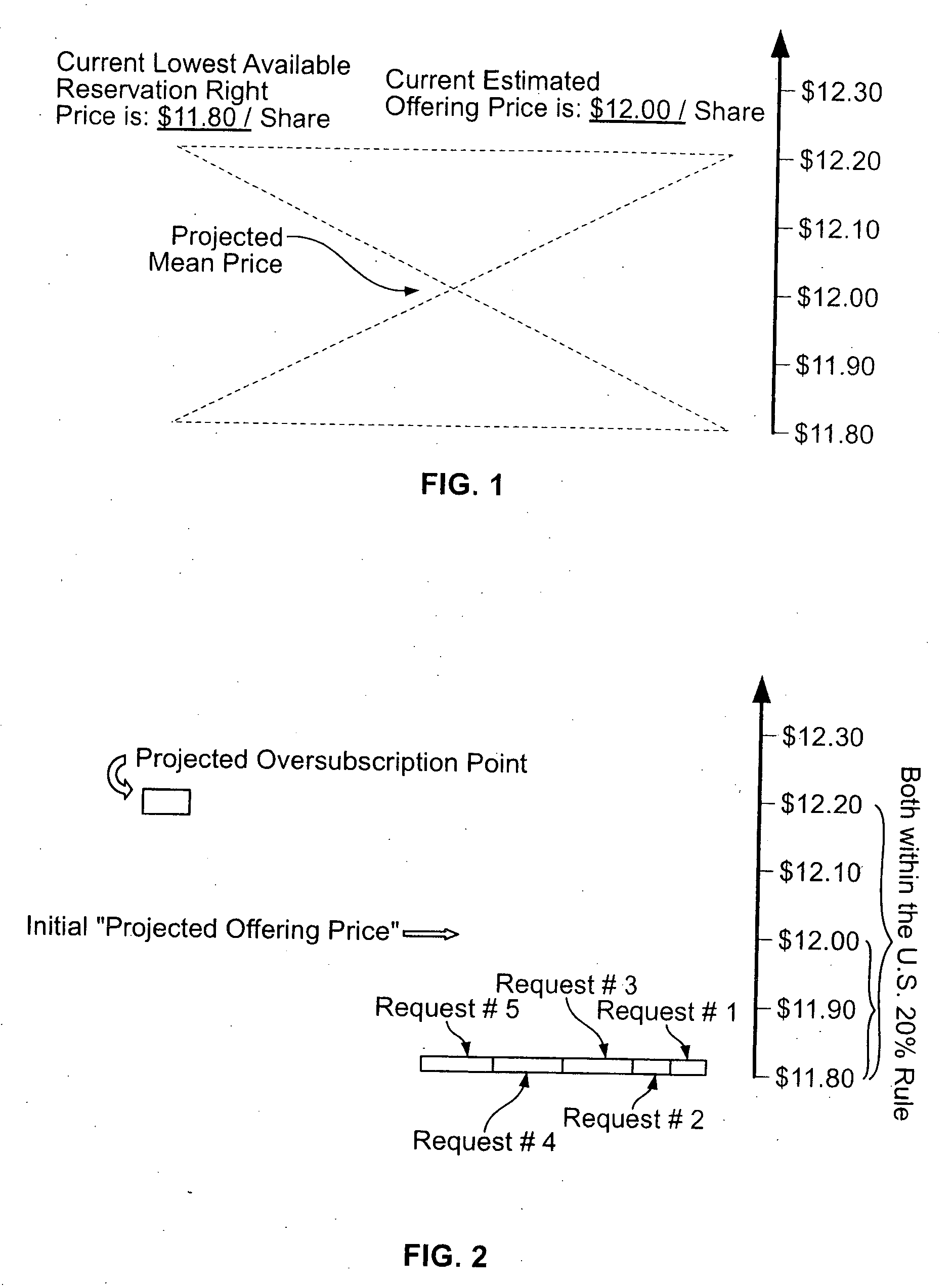

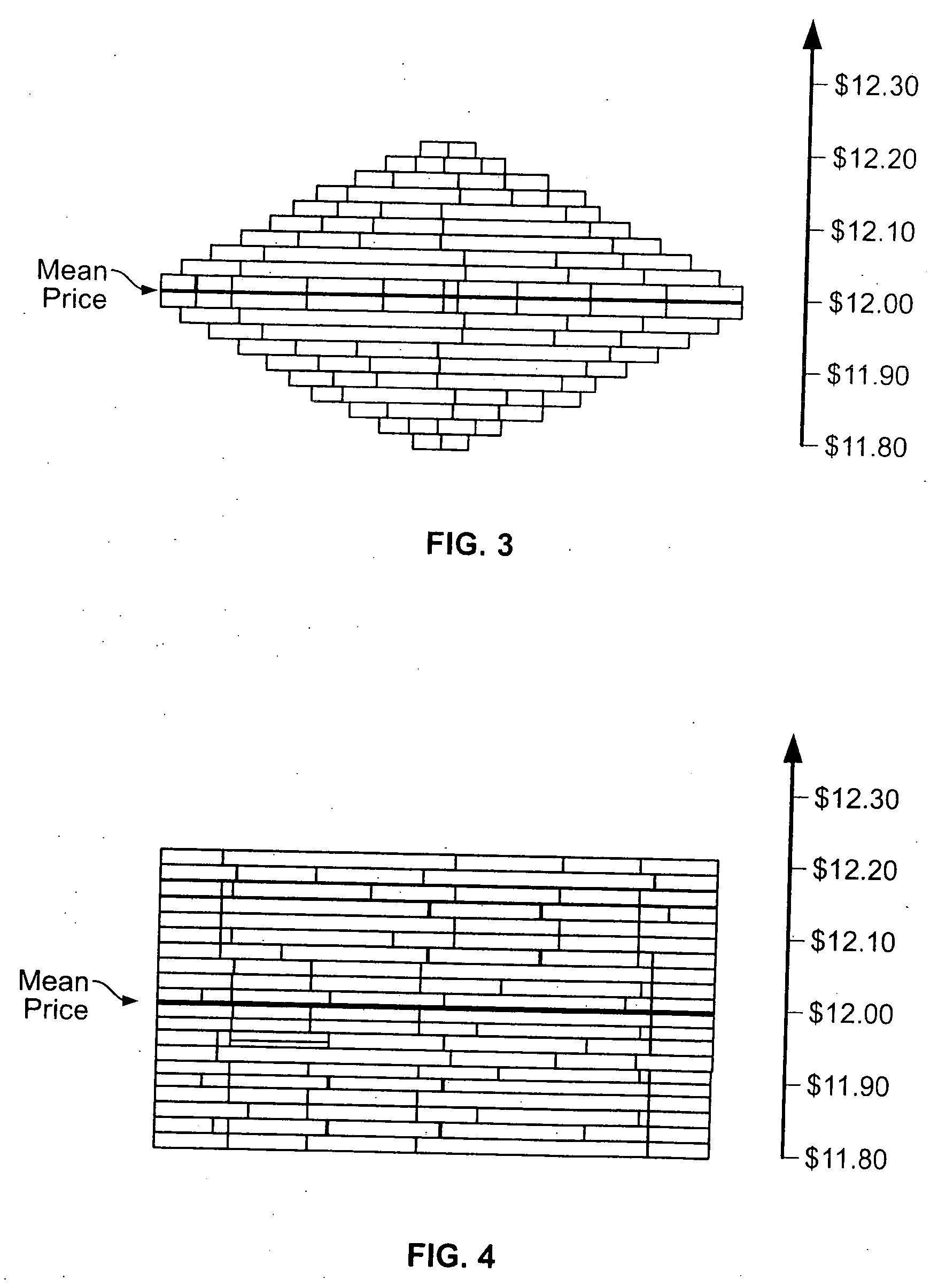

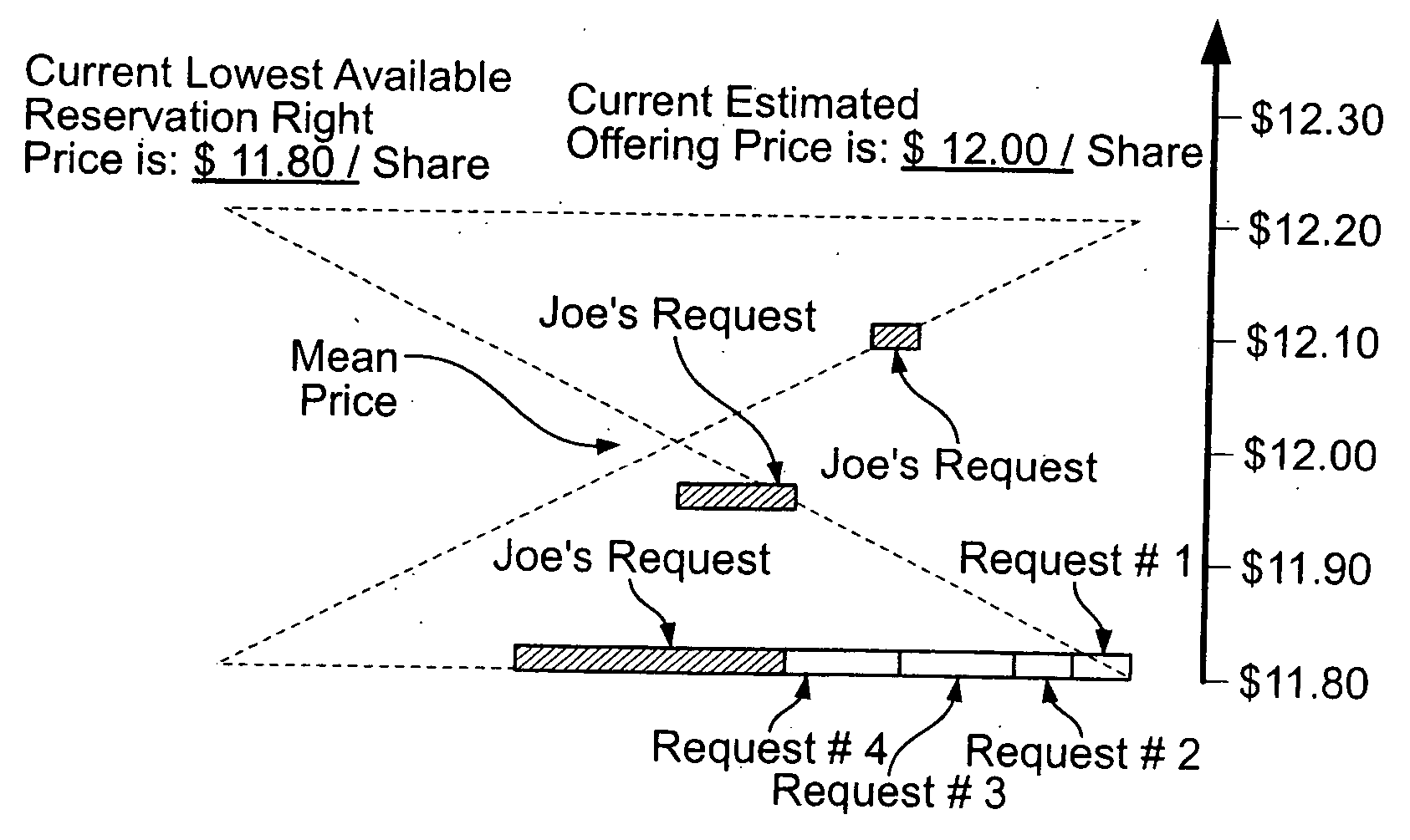

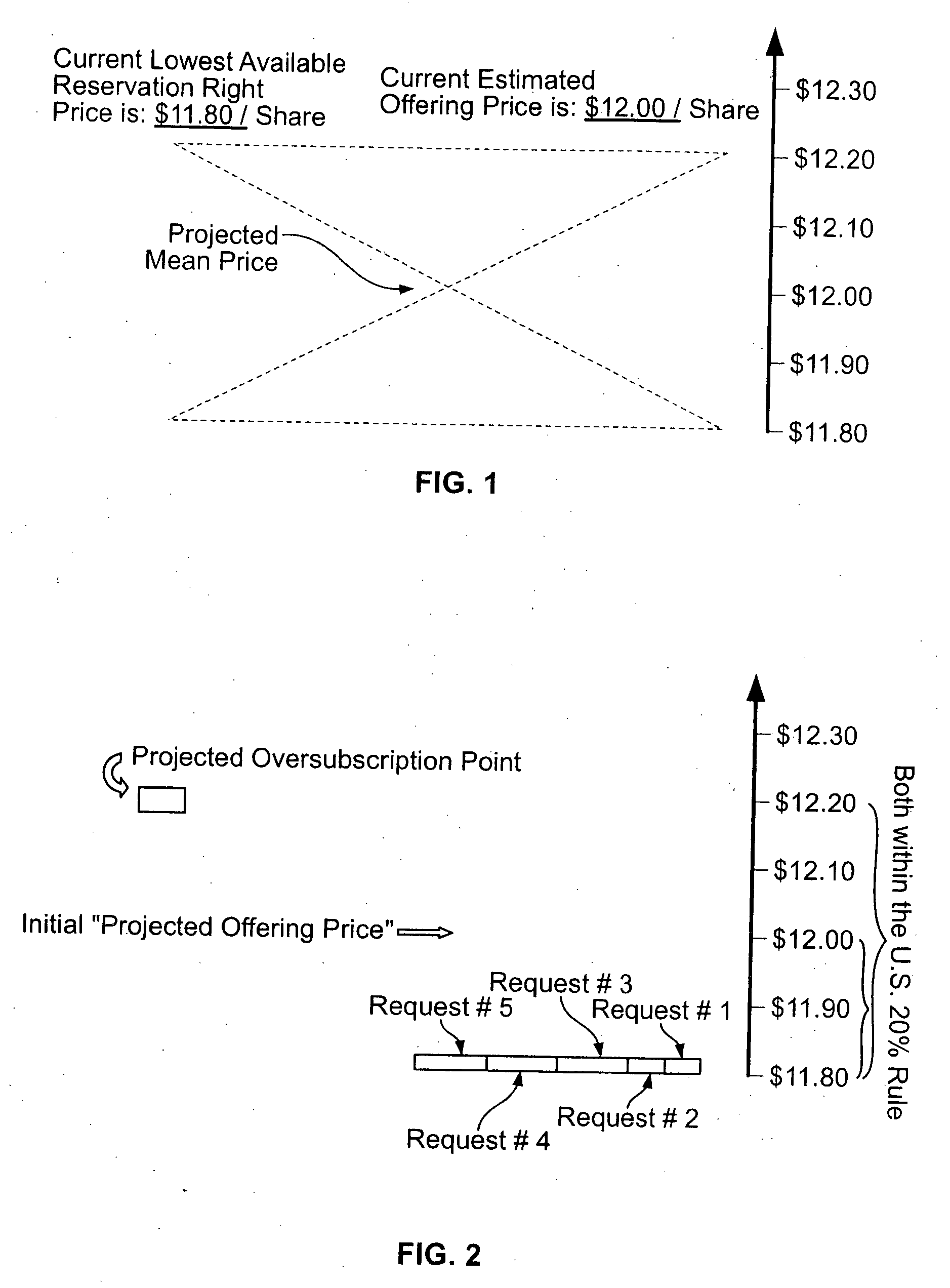

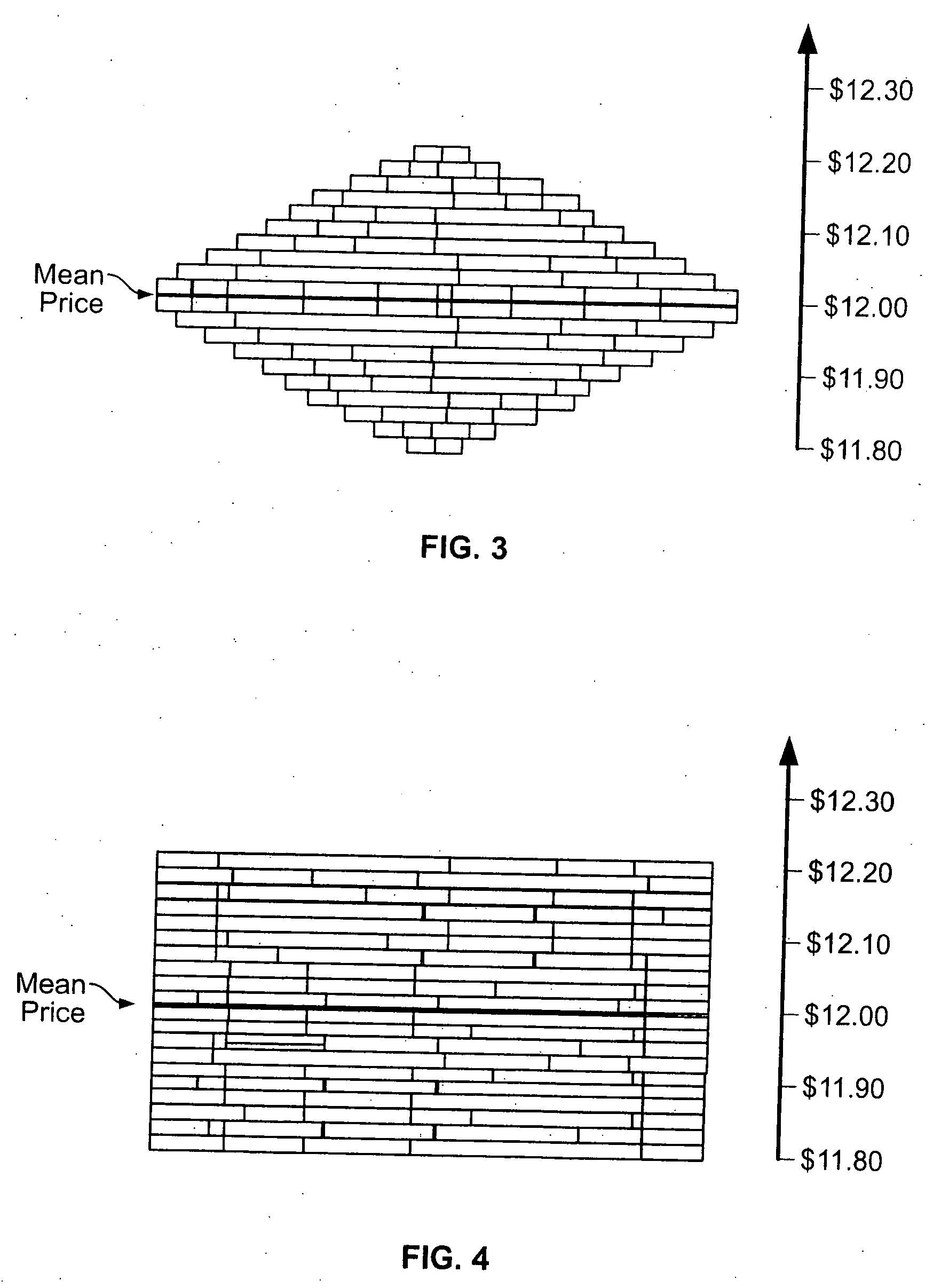

Method and system for optimal pricing and allocation with additional units allocated

ActiveUS20070118464A1Increase awarenessImprove visibilityFinanceMarketingGraphicsIntellectual property

A method and system for the determination of optimal pricing and allocation of securities in an open, competitive environment. The method and system may also be used in developing pre-markets of other items that are difficult to price and allocate in a competitive manner, such as the underwriting / securitization of contracts for property; future revenue / earning streams from an asset and / or group of assets; underwritten insurance portfolios, intellectual property and other goods and services. The system of price optimization and allocation is accomplished by interactive feedback of information using a display and including competitive participation of individual members of the public (and / or their agents) or institutional buyers over a data network e.g., the Internet, uncovering the nature and identification of demand in a self-organizing fashion. Demand emerges through participants' interaction with the system and with each other, via a graphically-supported, interactive reservation process. Also, there is provided an interactive reservation process whereby additional units may be allocated.

Owner:FORMAN BARRY

Rapid construction method of high-pressure water-rich fault zone of tunnel

ActiveCN101798930AReduce water pressure in tunnelReduce water and mud inrushUnderground chambersTunnel liningWorld classTunnel construction

The invention relates to the field of tunnel construction, in particular to a rapid construction method of a high-pressure water-rich fault zone of a tunnel, which solves a plurality of problems in the construction method of high-pressure water-rich fault zone tunnels under the guide of the traditional knowledge. A draining branch tunnel is additionally arranged between a main tunnel and a parallel heading, the water flow pressure of the hanging wall of a fault interface is reduced progressively, and a large amount of water is discharged from the main tunnel by adopting a guiding and non-clogging mode; when the water pressure of the main tunnel is reduced to 0.3-0.5MPa, an informationized tracking and accurate grouting method is used for grouting and reinforcing the main tunnel; and rapidly excavating and sealing technology is used for excavating the main tunnel and the parallel heading. The invention adopts the technology combining the water distribution and pressure reduction mode, the informationized tracking and accurate grouting method and the rapidly excavating and sealing technology for high-pressure water-rich shattered fault zones for the first time, breaks through the traditional concept that the water distribution and pressure reduction mode is opposite to the grouting and reinforcing construction method, solves the world-class problem of construction of the high-pressure water-rich fault zone of the tunnel, improves the construction progress and the construction efficiency, and ensures safe and rapid perforation of the tunnel.

Owner:CHINA RAILWAY 12TH BUREAU GRP

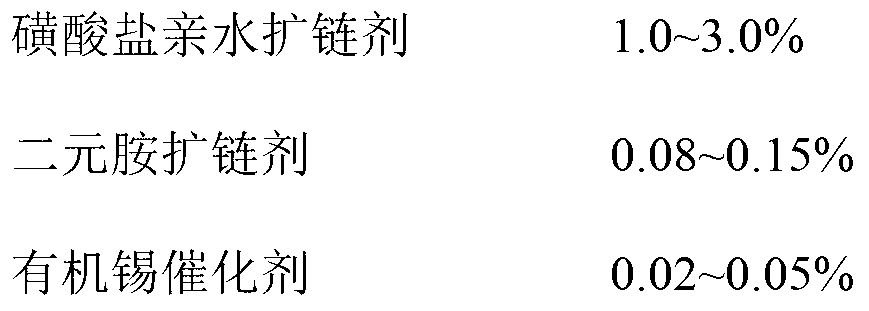

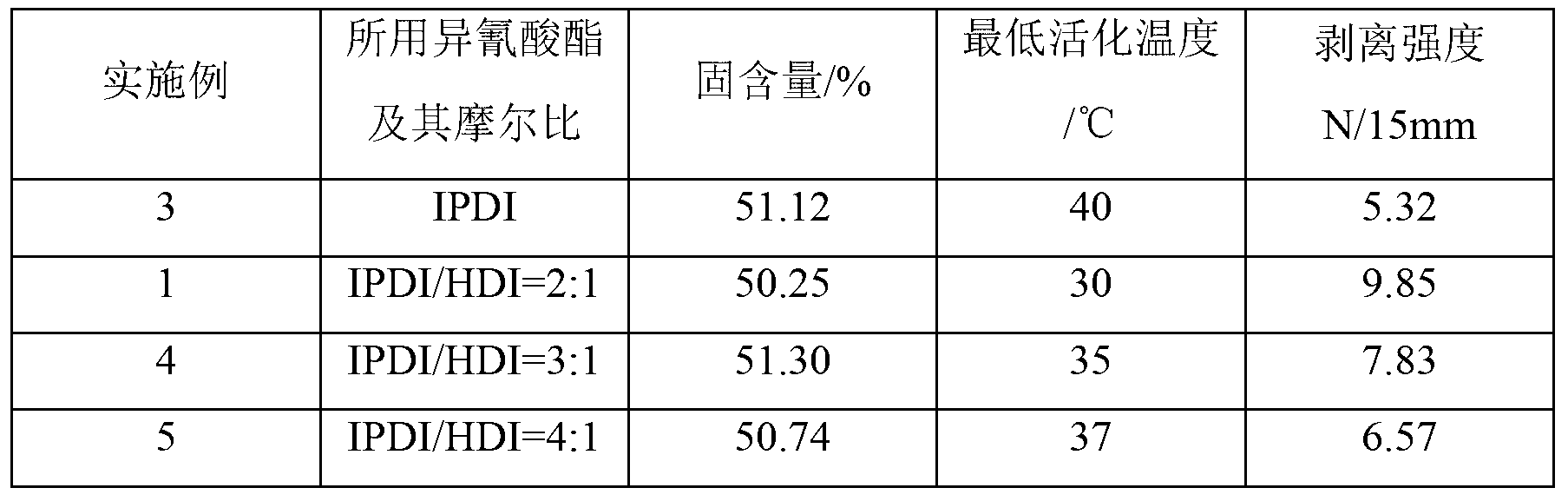

Preparation method of sulfonic acid type waterborne polyurethane adhesive

InactiveCN103254867AHigh solid contentLow activation temperaturePolyureas/polyurethane adhesivesPolyesterEthylenediamine

The invention discloses a preparation method of a sulfonic acid type waterborne polyurethane adhesive. The preparation materials of the sulfonic acid type waterborne polyurethane adhesive comprise the following components in percentage by weight: 75%-89% of polyalcohol, 8.5%-22% of diisocyanate, 0.06%-0.10% of cross-linking agent, 1.0%-3.0% of sulfonate hydrophilic chain extender, 0.08%-0.15% of diamine chain extender, and 0.02%-0.05% of organic tin catalyst, wherein the polyalcohol is polyester polyalcohol or polyether polyalcohol or a mixture of the polyester polyalcohol and the polyether polyalcohol; and the sulfonate hydrophilic chain extender is ethylenediamine-based sodium ethyl sulfonate or 1,2-dyhydroxyl-3-sodium propyl sulfonate. The sulfonic acid type waterborne polyurethane adhesive prepared by the preparation method disclosed by the invention has the characteristics of being high in solid content, low in lowest activation temperature and large in peel strength.

Owner:JUSHI GRP CO

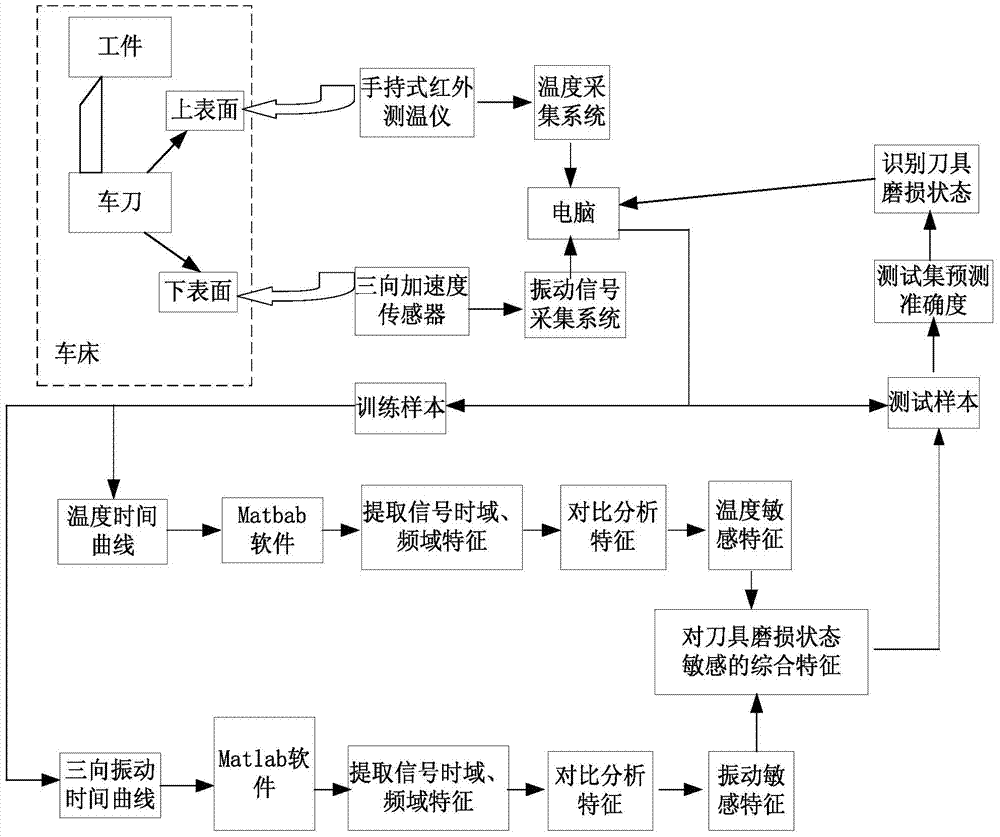

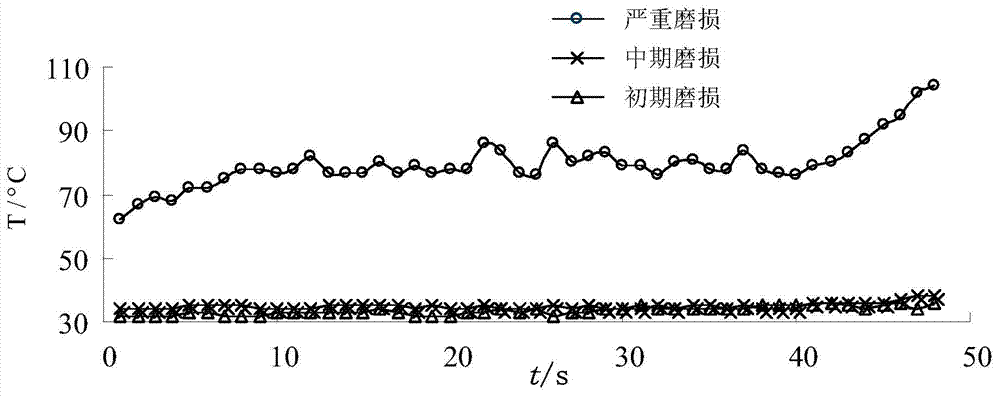

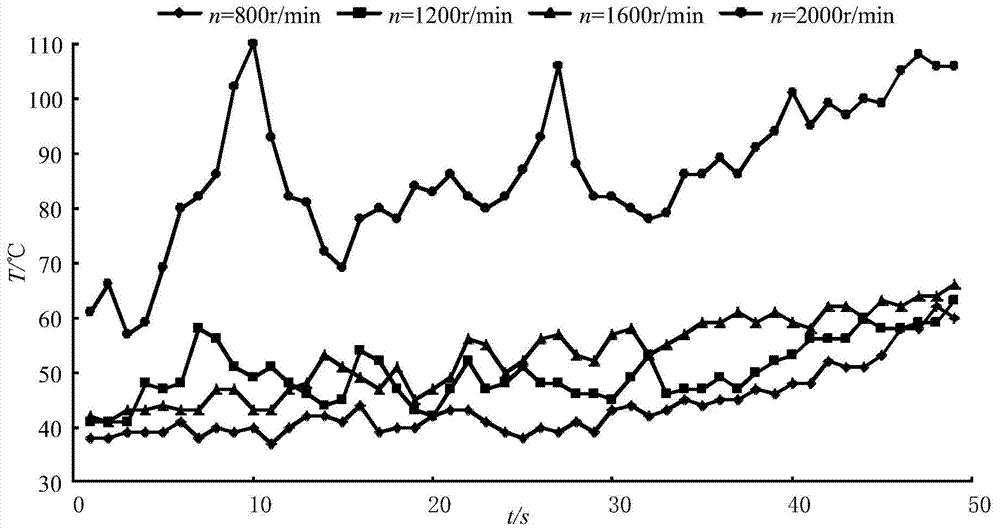

Turning cutter wear state monitoring system

InactiveCN104741638AEffective identification of wear statusEasy to set upAuxillary equipmentMeasurement/indication equipmentsPilot systemMonitoring system

The invention discloses a turning cutter wear state monitoring system. The turning cutter wear state monitoring system comprises a signal collecting system and a cutter wear state identifying system; the signal collecting system comprises a temperature collecting system and a vibration signal collecting system, wherein the temperature collecting system collects temperature of a cutter point of a rake face of the cutter, and the vibration signal collecting system collects a three-dimensional vibrating signal at the lower surface of a cutter handle corresponding to the utter point of the rake face of the cutter; after pretreating the signal collected by the signal collecting system, the sensitive characteristic of the cutter wear state is obtained and transmitted to the well-trained cutter wear state identifying system; thus the wear state of the cutter is judged through the cutter wear state identifying system. The turning cutter wear state monitoring system is simple and applicable, and is convenient to operate; moreover, the sensor in use is relatively universal in use, moderate in cost, and easy to build up a testing system; the turning cutter wear state monitoring system can largely reduce the monitoring cost, effectively identify the wear state of the cutter and reduce the cutter waste.

Owner:XUZHOU NORMAL UNIVERSITY

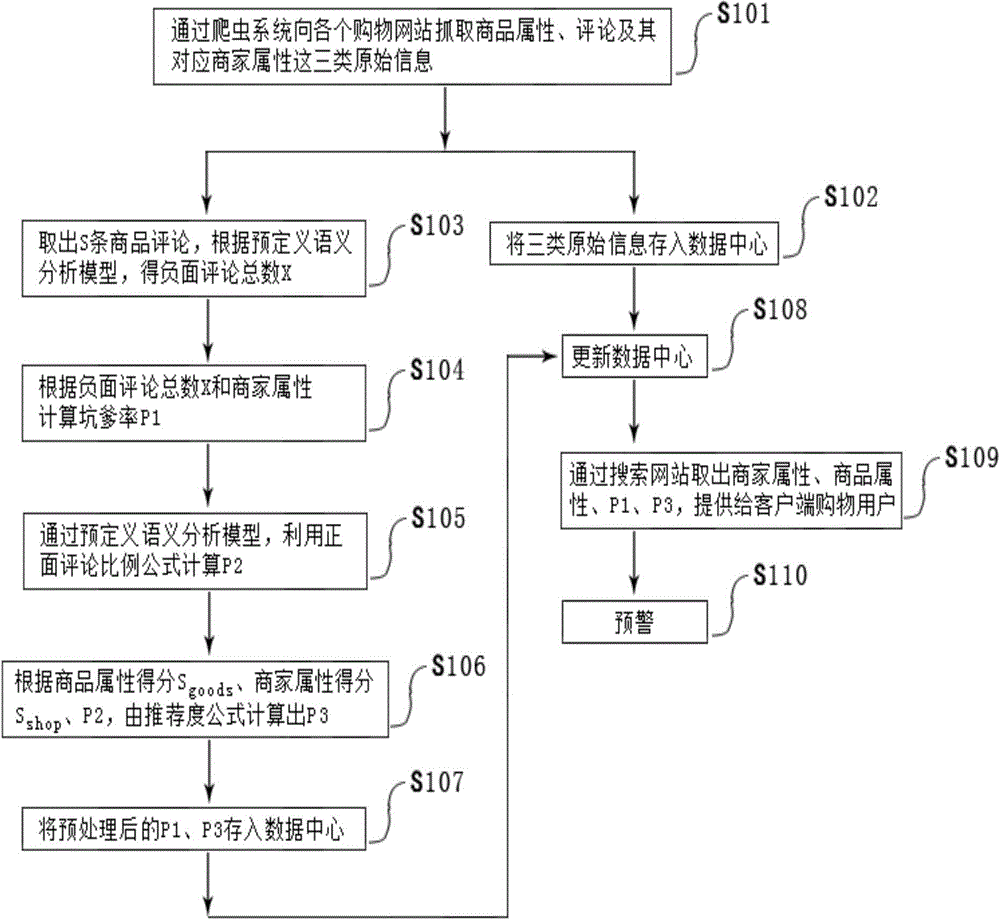

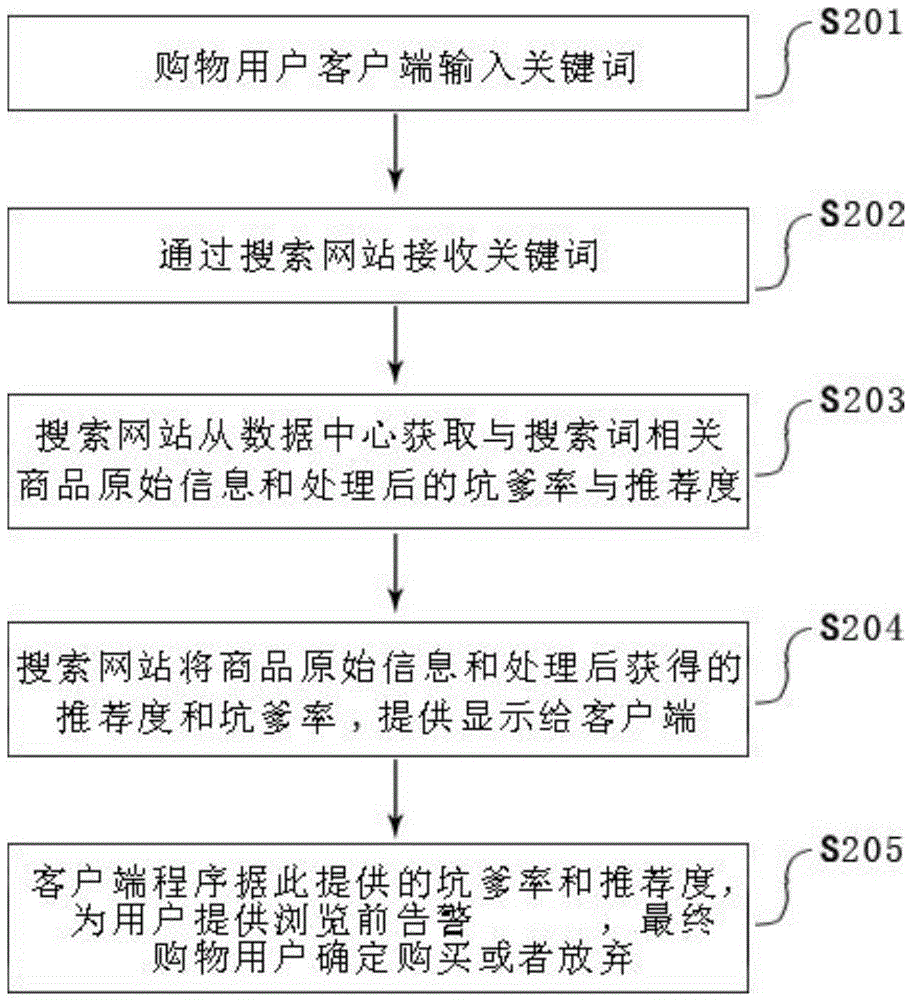

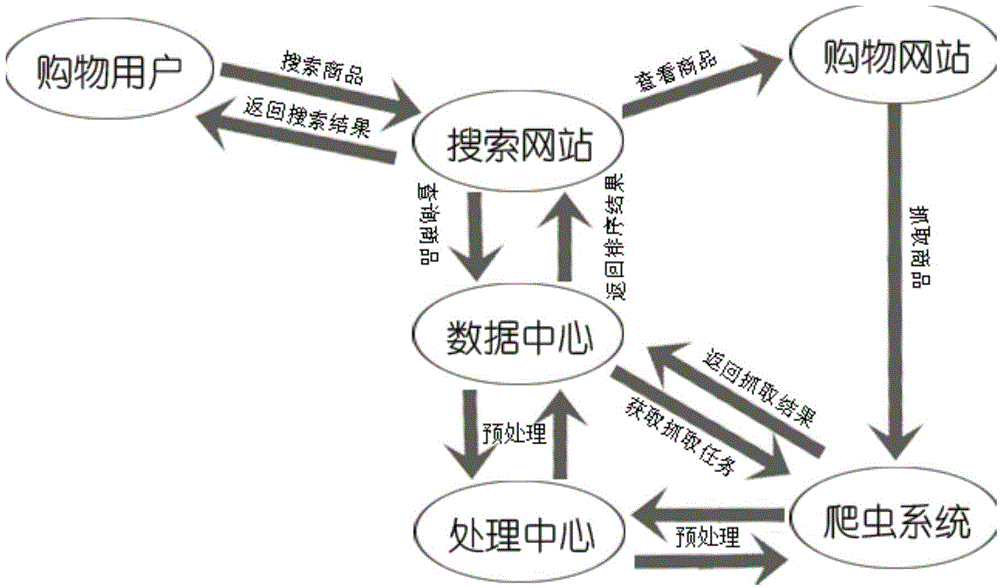

Shopping search recommending and alarming method and system

ActiveCN104462333AReduce the risk of fraudulent shoppingFair priceBuying/selling/leasing transactionsSpecial data processing applicationsPre treatmentAnalysis models

The invention relates to a shopping search recommending and alarming method and system and relates to the technical field of Internet. The method comprises the following steps: in a background pre-treatment stage, S101, capturing raw information from shopping websites by virtue of a crawler system; S102, directly storing the raw information so as to update a database center; S103, obtaining the sum X of negative comments according to a predefined semantic analysis model; S104, calculating the cheating rate P1; S105, calculating to obtain the sum Z of positive comments according to the predefined semantic analysis model; S106 calculating to obtain a recommendation level P3; storing the cheating rate P1 and the recommendation level P3 in the data center so as to update the data center; S109, providing information to the client by virtue of the search websites after the data center is updated in real time; S110, providing browsing for users by the client according to the cheating rate P1 and the recommendation level P3 provided. The interactive shopping search recommending system comprises a crawler system, a pre-treatment center, a data center and search and result display websites; the risk that the user is cheated in shopping is reduced.

Owner:上海同刚网络科技有限公司

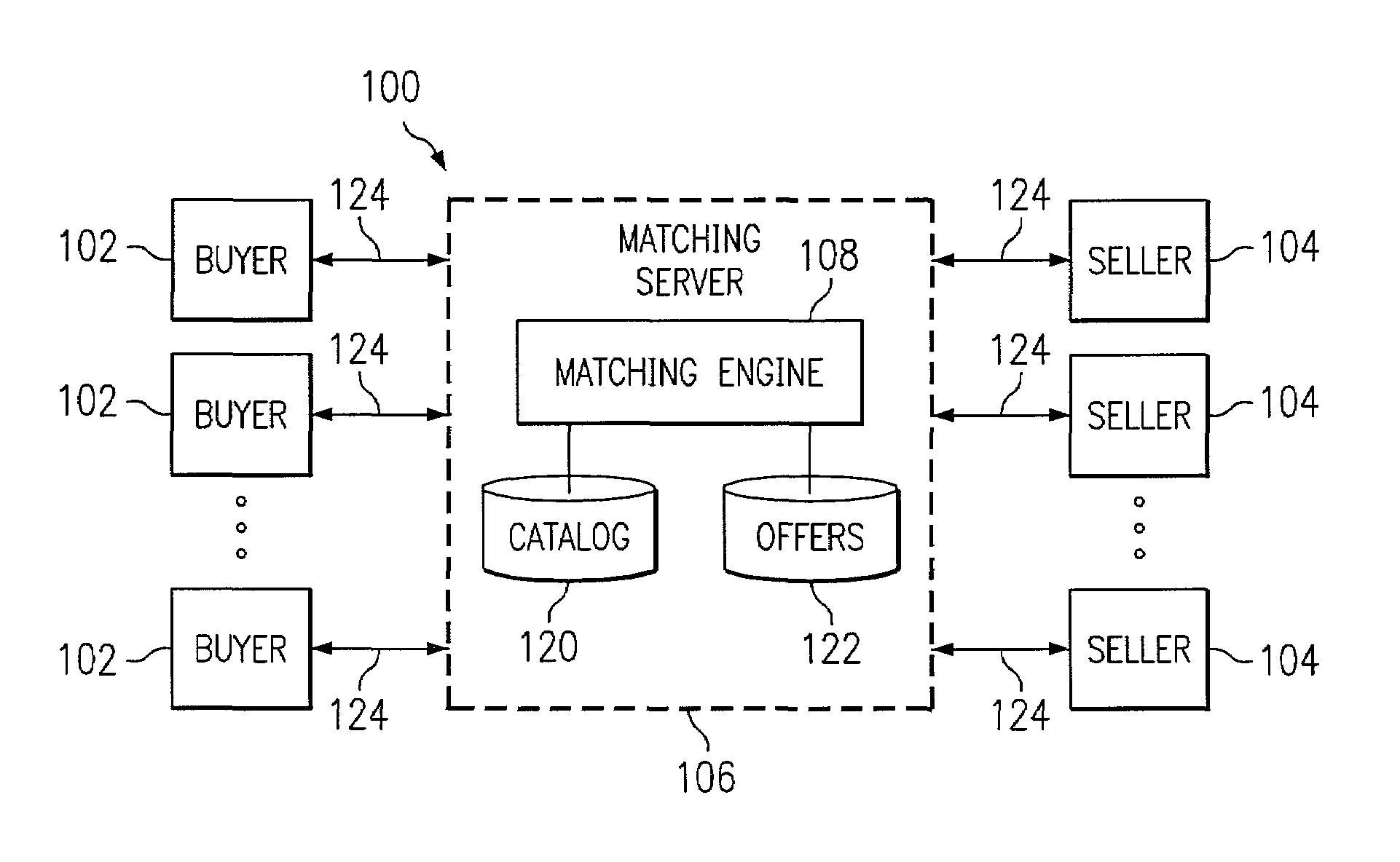

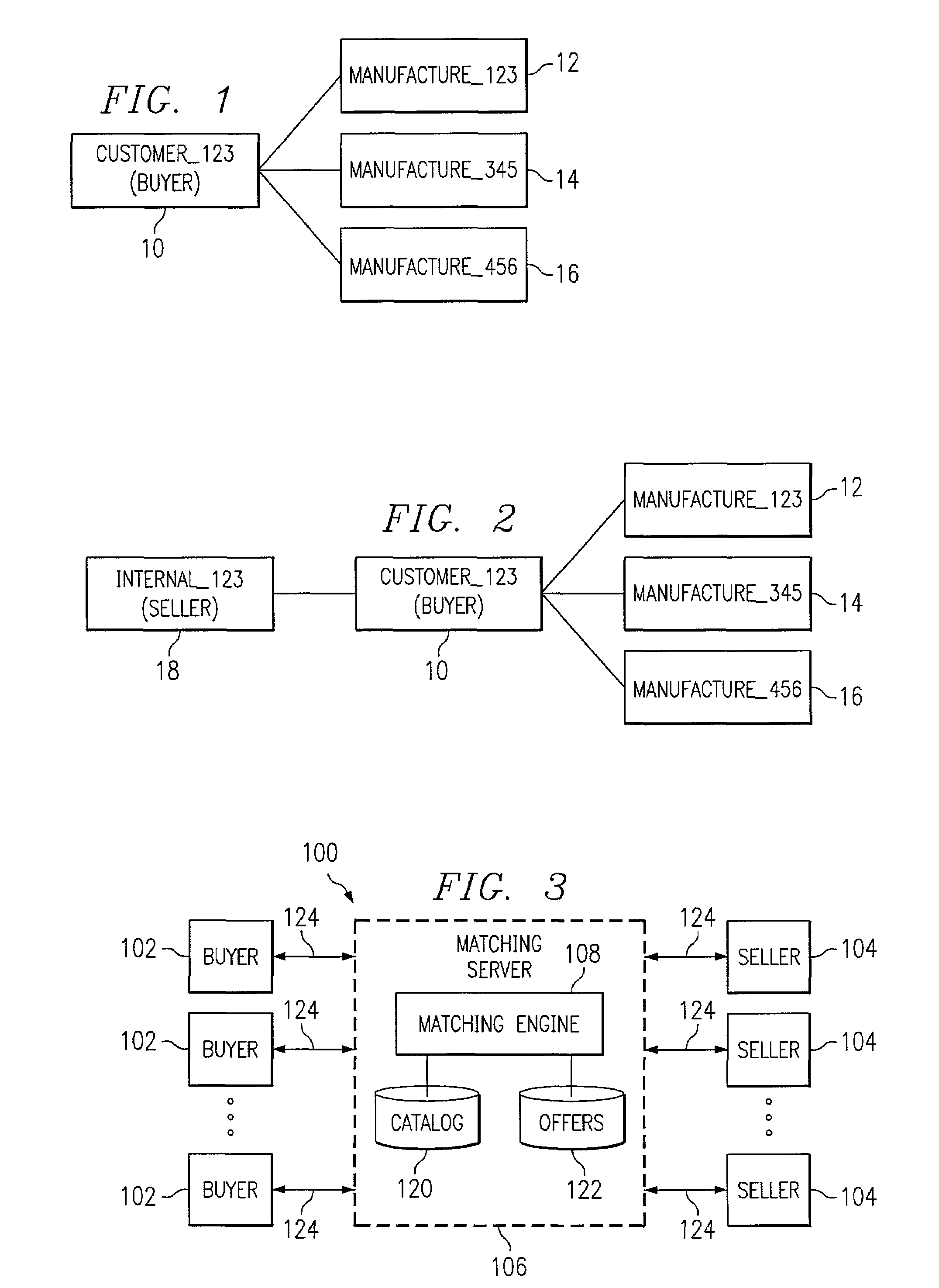

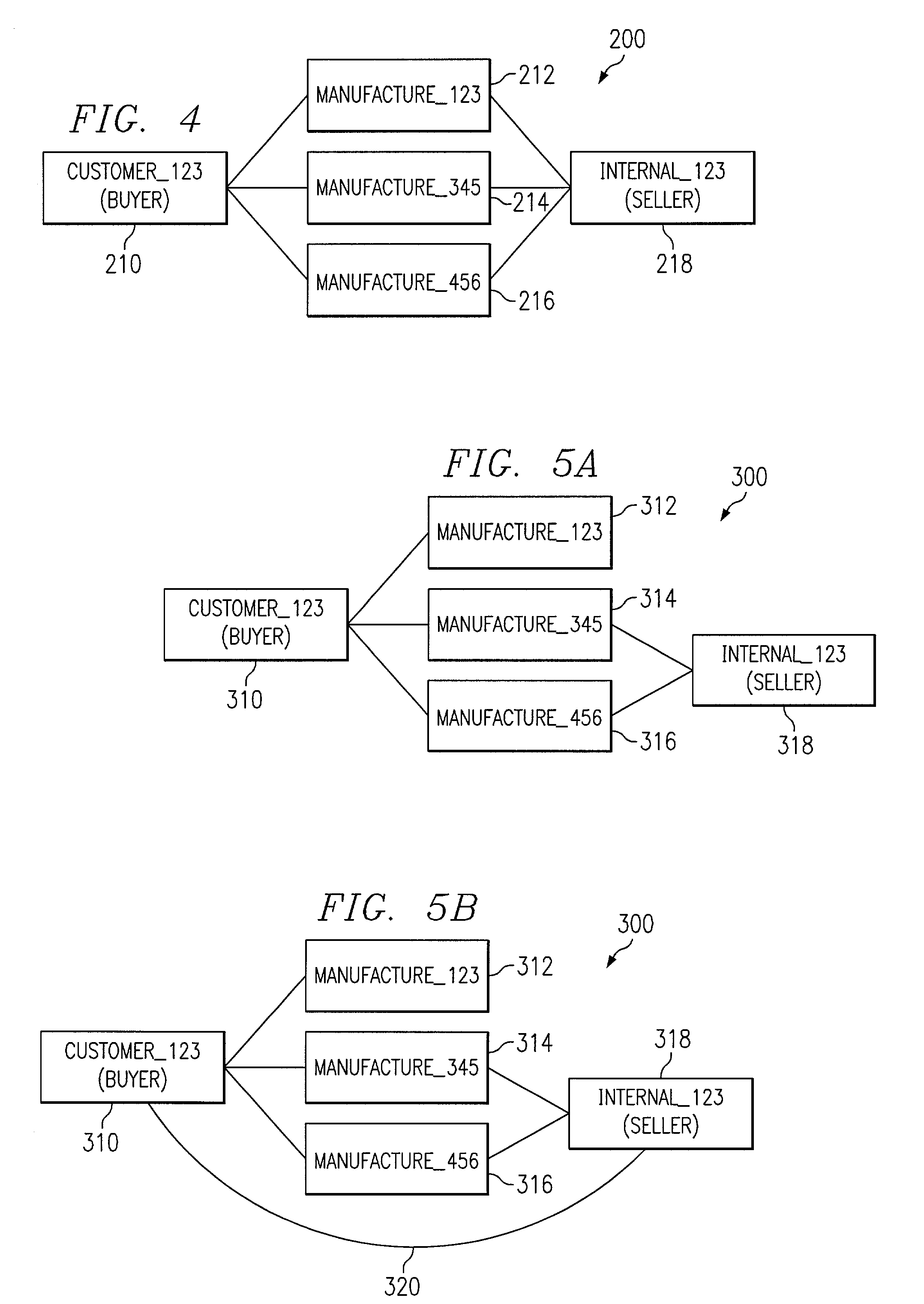

Mapping between part numbers that are based on different part numbering schemes

InactiveUS6988111B2Accurate item priceReduce complexityComputer security arrangementsBuying/selling/leasing transactionsComputer scienceNumbering scheme

A computer-implemented method for mapping between part numbers that are based on different part numbering schemes includes receiving a first part number associated with an item, the first part number associated with the item being defined according to a first part numbering scheme. A database is searched for one or more second part numbers that are associated with the item and also cross-referenced to the first part number associated with the item, the one or more second part numbers associated with the item being defined according to one or more corresponding second part numbering schemes. In response to identifying the one or more second part numbers associated with the item, a database is searched for a third part number that is associated with the item and also cross-referenced to at least one second part number associated with the item, the third part number associated with the item being defined according to a third part numbering scheme, the first part number associated with the item being mapped to the third part number associated with the item through the at least one second part number associated with the item.

Owner:BLUE YONDER GRP INC

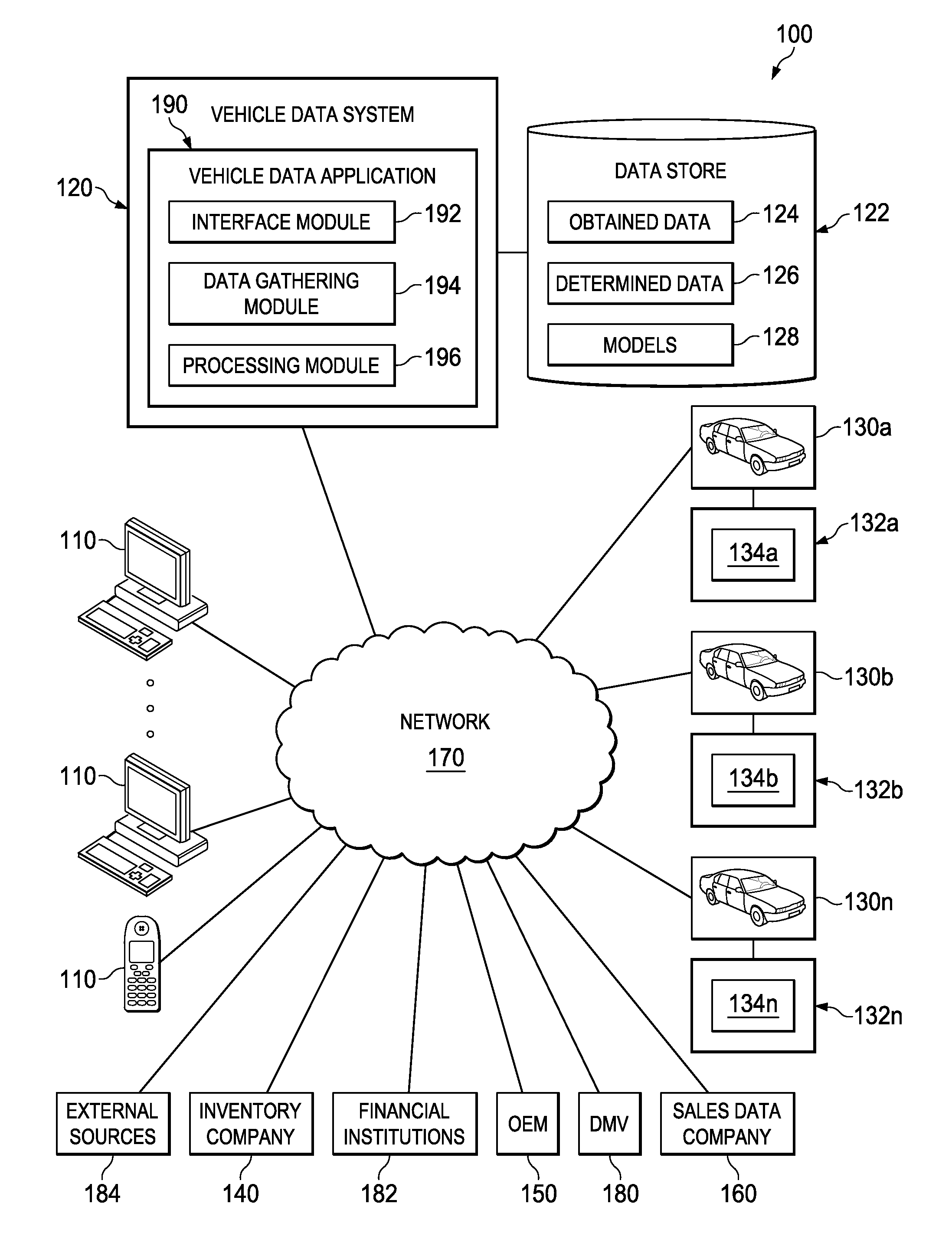

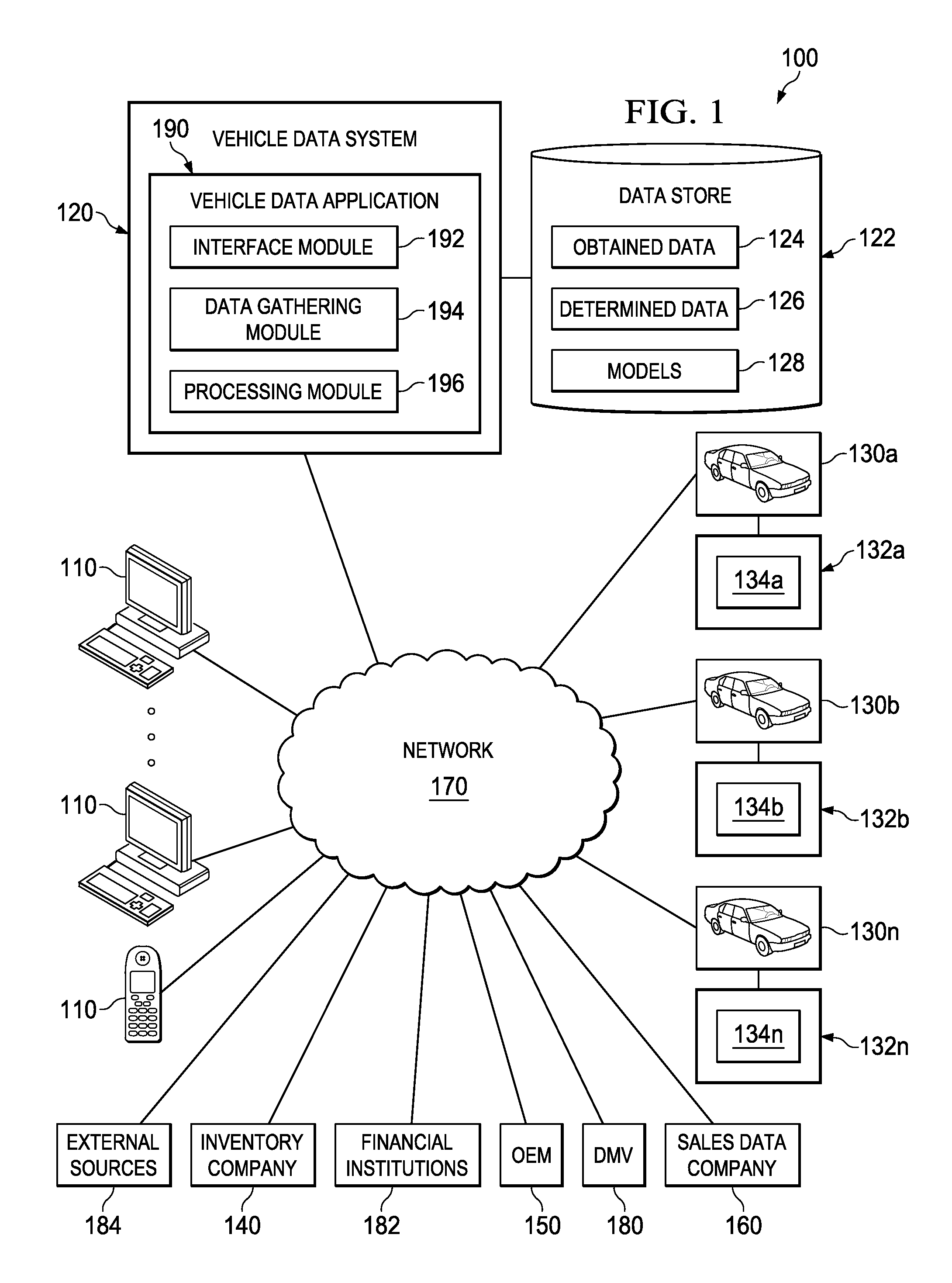

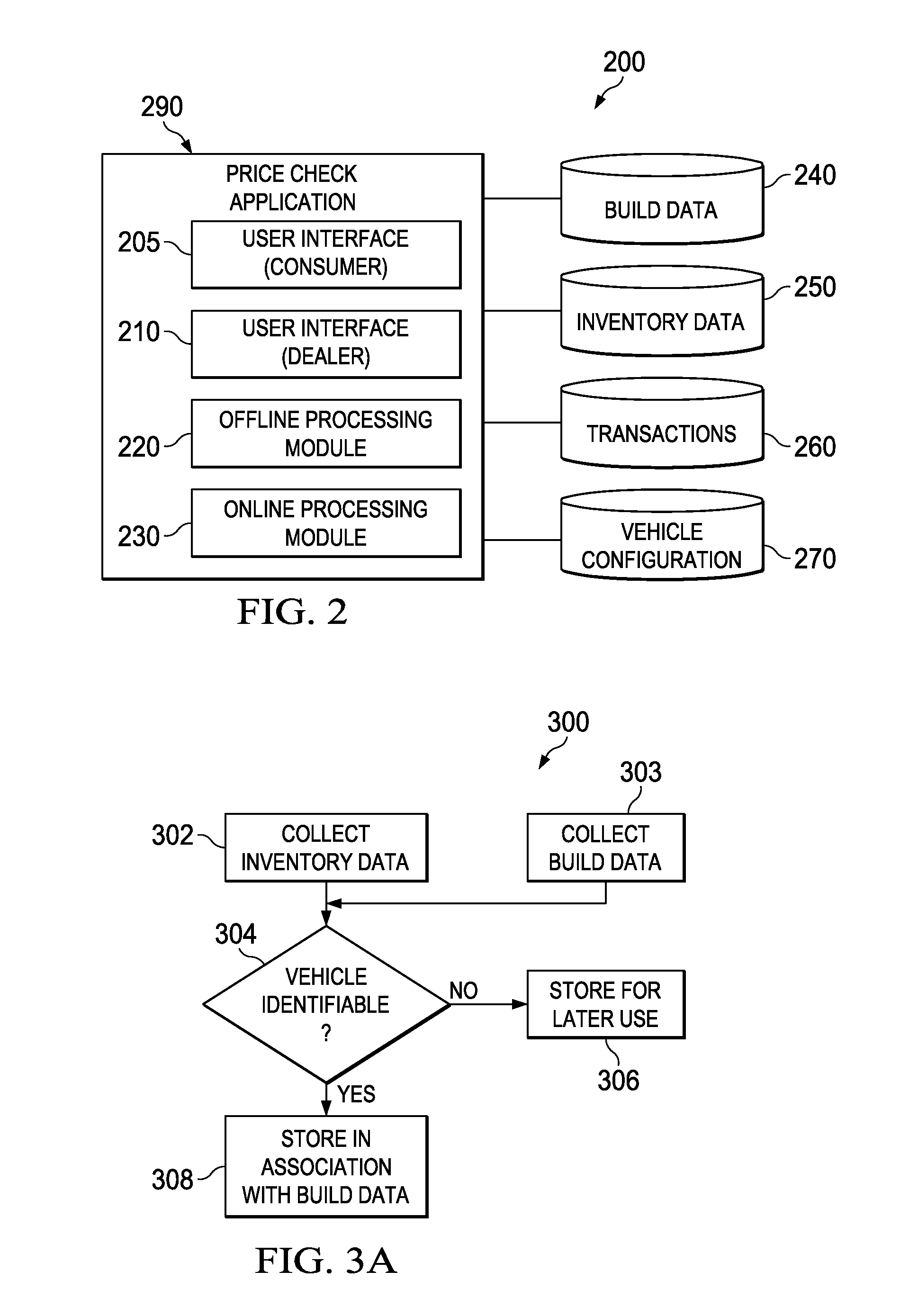

Mobile price check systems, methods and computer program products

ActiveUS20150242926A1Improve close rateFair priceCharacter and pattern recognitionBuying/selling/leasing transactionsComputer programReal-time computing

A price check system may receive a vehicle identification number (VIN) or determine the VIN via an image from a mobile price check application. The price check system may determine if build data is available for a vehicle associated with the VIN and, if build data is available for the vehicle, determine one or more prices for the vehicle based on the build data and provide same to the mobile price check application. If build data is not available for the vehicle, the price check system may prepare and send a request to the mobile price check application to obtain configuration information on the vehicle from a user of the mobile price check application. The price check system may then determine one or more prices for the vehicle based on the configuration information and provide same to the mobile price check application in real time or substantially real time.

Owner:TRUECAR

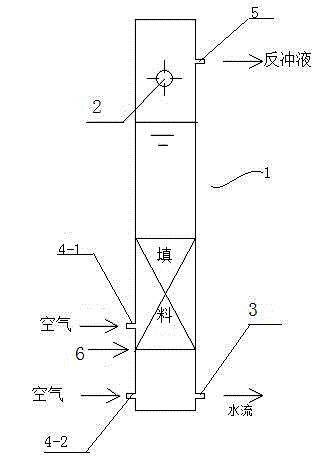

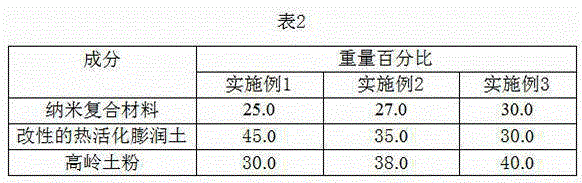

Nano biological filler for purifying aquaculture wastewater in biological filter tank and preparation method of nano biological filler

InactiveCN104085979AGood biocompatibilityLarge specific surface areaSustainable biological treatmentOn/in inorganic carrierBiological filterKaolin clay

The invention discloses nano biological filler for purifying aquaculture wastewater in a biological filter tank and a preparation method of the nano biological filler. The biological filler comprises an EM rejuvenation solution and an adsorption carrier of the EM rejuvenation solution, wherein the EM rejuvenation solution is a product obtained by performing mixed fermentation on an EM stock solution, molasses and deionized water; the adsorption carrier is obtained by performing mixed pressing on composite nano powder, kaolin powder and modified bentonite; the composite nano powder is a product obtained by performing mixing and high-temperature sintering on nano-level aluminum oxide, titanium dioxide and silicon dioxide; modified bentonite is prepared from sodium diethyldithiocarbamate modified original soil. The preparation method comprises the following steps: pressing adsorption carrier particles; fermenting to obtain the EM rejuvenation solution; dipping the EM rejuvenation solution by using the adsorption carrier to obtain the nano biological filler. The obtained nano biological filler is high in pore volume, high in cell adsorption capacity, large in specific surface area and strong in stability, has a good treatment effect on aquaculture sewage, and can be used for rapidly removing ammonia nitrogen, phosphorus and heavy metal ions in an aquaculture water body.

Owner:江苏三新山水生物科技有限公司

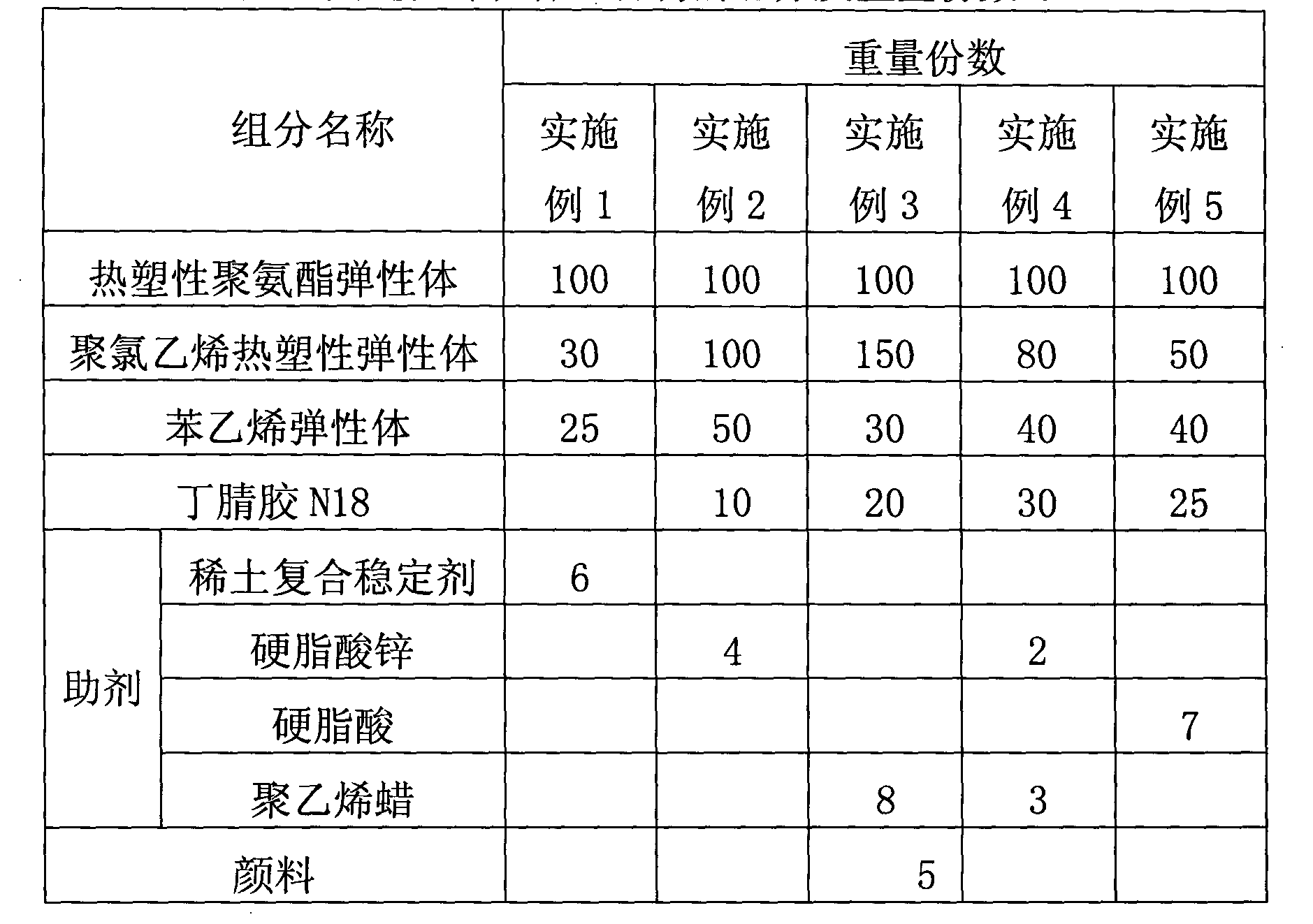

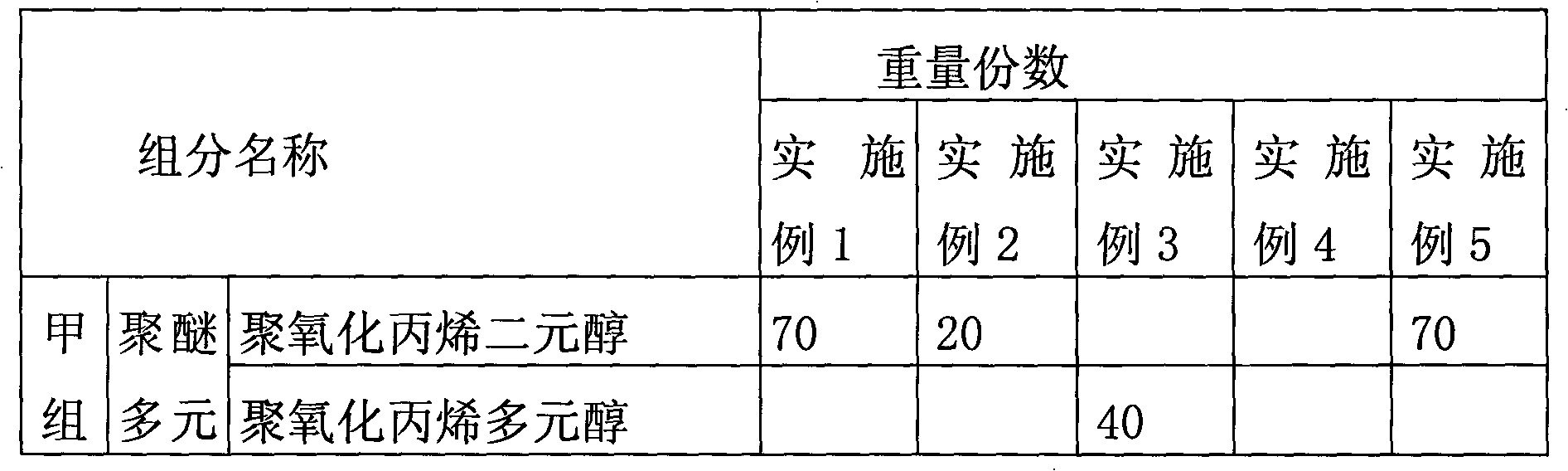

Thermoplastic elastomer composition

The invention discloses a thermoplastic elastomer composition which is plasticated by the following main components by weight: 100 parts of polyurethane thermoplastic elastomers, 30-150 parts of polyvinyl chloride thermoplastic elastomers, 25-50 parts of styrene elastomers, 0-30 parts of blend and 4-8 parts of auxiliaries, wherein the auxiliary is any one or more of a composite rare-earth stabilizer, zinc stearate, calcium stearate, stearic acid or polyethylene wax; and the blend is butyronitrile N18. The invention selects the thermoplastic elastomers with similar polarity and complementary properties to be synthesized and used and selects compatilizers to organically combine several best molecules with different structures, so that the generated novel thermoplastic elastomer has superior performance and appropriate price, can meet the requirements of market products and has wide application range because the product has the technical advantages of excellent oil resistance, resistance to low temperature of minus 35 DEG C, acid-alkali resistance, aging resistance and lower proportion than the vulcanized products with the same price.

Owner:营口巨成教学科技开发有限公司 +1

Roof greening light host material made from industrial and agricultural wastes

ActiveCN101960980AReduce loadReduce weightSolid waste disposalCultivating equipmentsNatural resourceAdditive ingredient

The invention provides a roof greening light host material made from industrial and agricultural wastes and is characterized in that the industrial and agricultural wastes serve as the major ingredients to prepare a light roof greening planting substrate; the substrate is a compound with the following main materials: flyash, coal cinder, straw grains, garden wastes and yellow soil; the proportions of the materials are as follows: 11-20% of flyash, 10-22% of coal cinder, 20-25% of straw grain, 20-32% of garden waste and 18-20% of yellow soil. In the invention, the common industrial and agricultural wastes are applied to the light roof greening planting substrate, which facilitates reduction of the cost of roof greening materials, improves comprehensive utilization level of natural resources and promotes cyclic utilization of the industrial and agricultural wastes and protection of the natural environment. The material of the invention has the advantages of few component types, easily available materials, low cost, environmental protection and high efficiency and suitability for large-scale promotion throughout the country.

Owner:武汉市林业果树科学研究所 +1

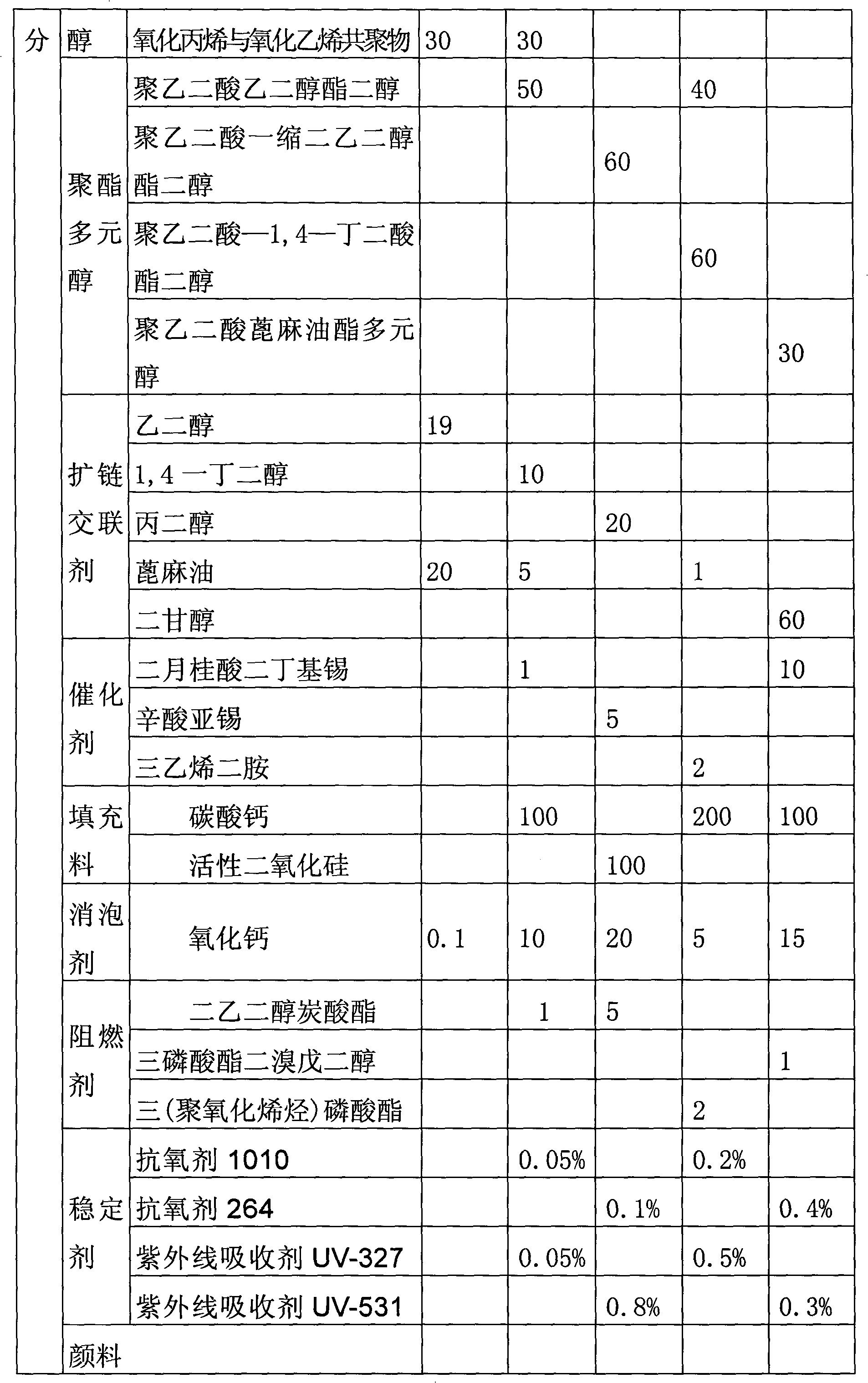

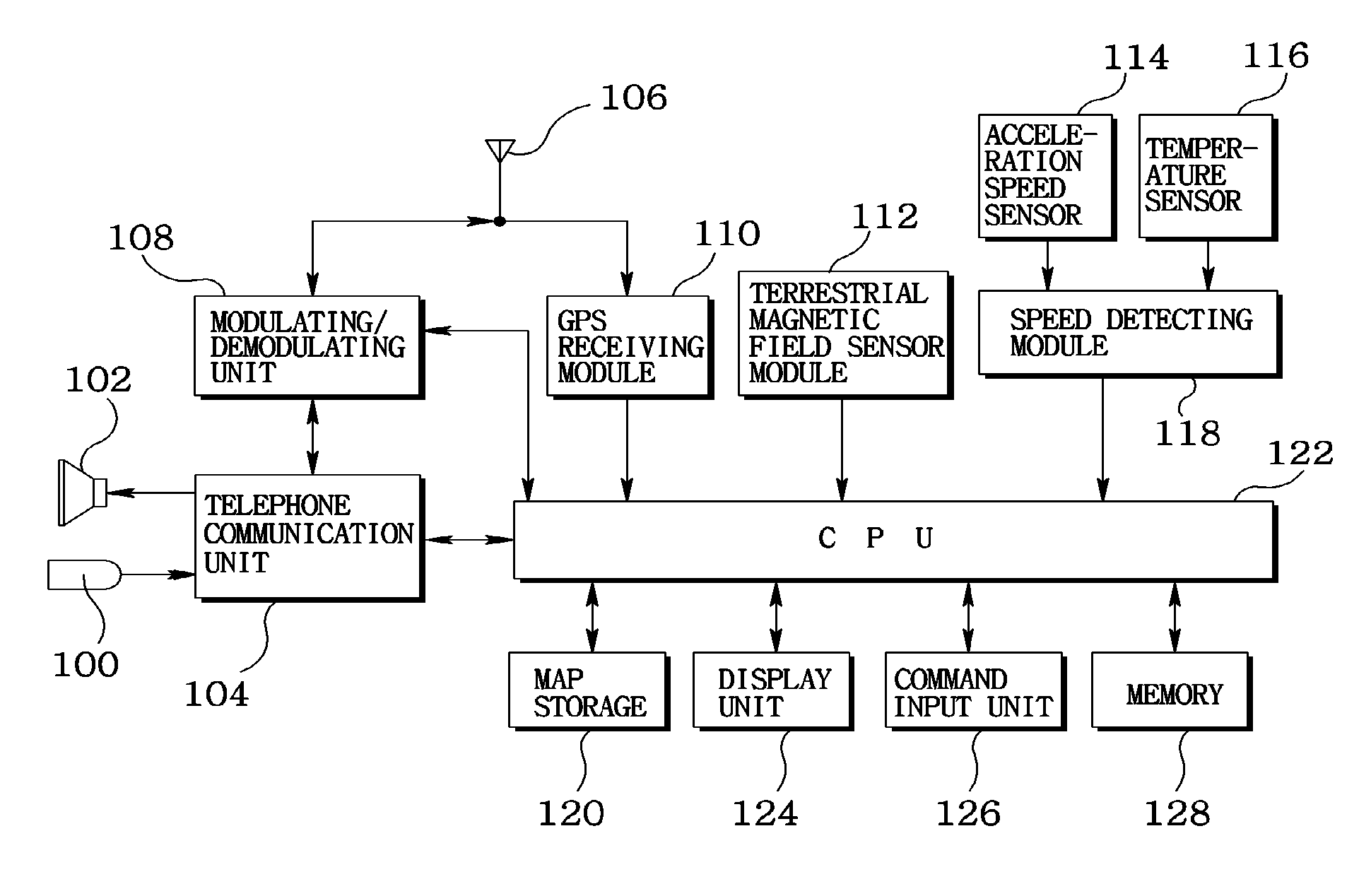

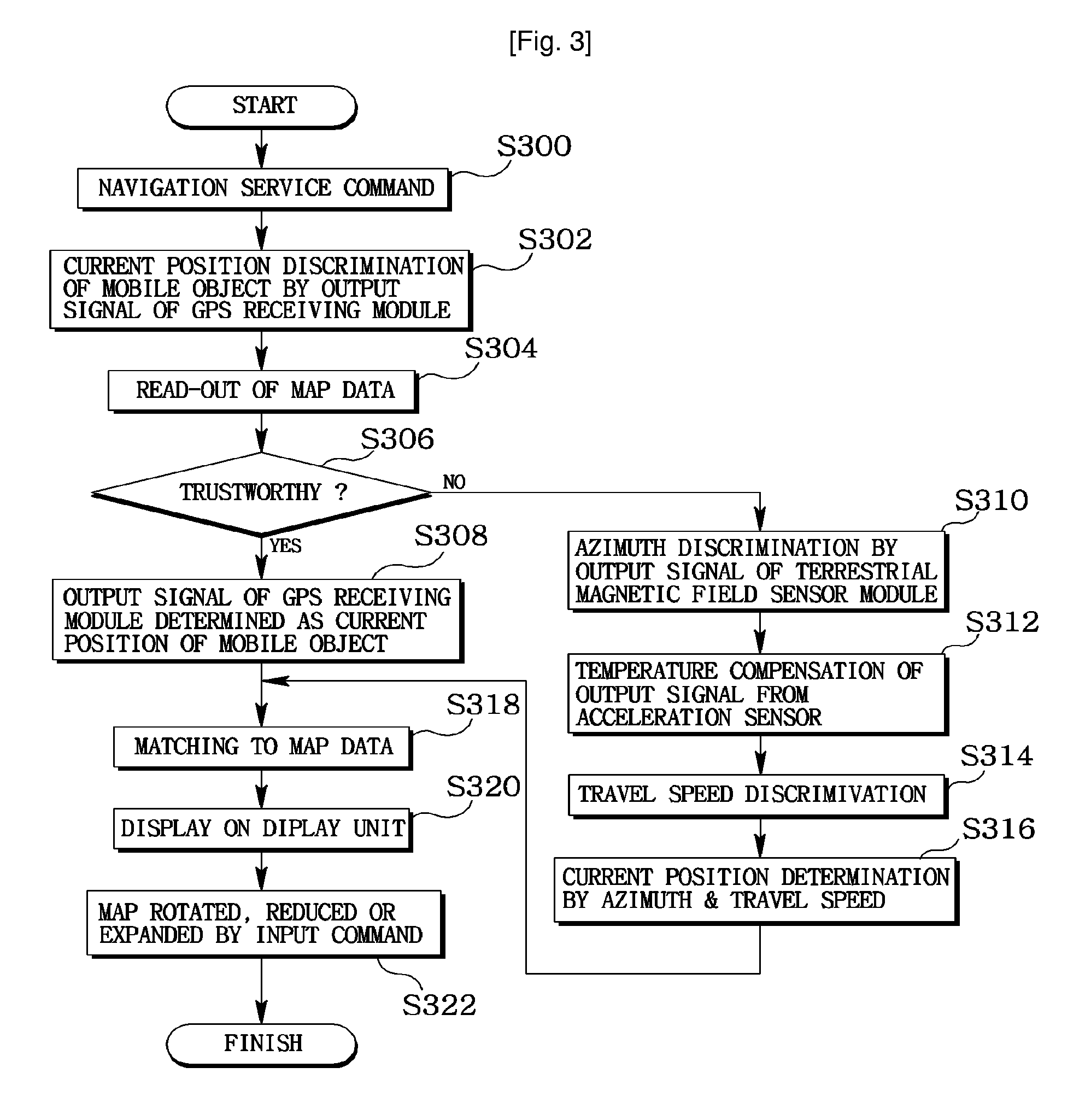

Navigation System and Method for Controlling the Same

InactiveUS20070244631A1Fair priceInstruments for road network navigationNavigational calculation instrumentsNavigation systemNavigation function

A navigation system and a method for controlling the same wherein navigation functions are integrally mounted in a mobile communication terminal to enable to guide the travel of a mobile object in real time. A GPS receiving module is integrally mounted in the mobile communication terminal to receive navigation messages transmitted by the GPS satellites and to detect the position of the mobile object, terrestrial magnetic field is detected by a terrestrial magnetic field sensor module to detect an azimuth of the mobile object, an acceleration speed is detected by an acceleration speed sensor, and the travel speed of the mobile object is calculated by a speed detecting module using the acceleration speed thus detected, a current position of the mobile object is determined by an output signal from the GPS receiving module, the terrestrial magnetic field sensor module, and the speed detecting module, and the current position of the mobile object thus determined is matched to a map data stored in a map storage for display in a display unit.

Owner:LG ELECTRONICS INC

Method and system for optimal pricing and allocation in an offering of a plurality of types

ActiveUS20070118463A1Increase awarenessImprove visibilityFinanceMarketingGraphicsIntellectual property

Owner:FORMAN BARRY

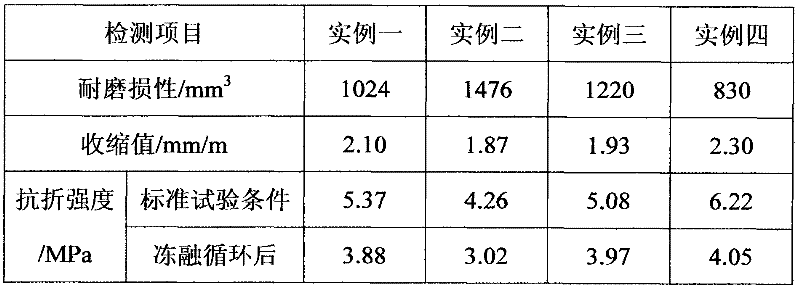

Non-base-return color ceramic tile joint mixture

The invention relates to a safe environment-friendly non-base-return color ceramic tile joint mixture. The safe environment-friendly non-base-return color ceramic tile joint mixture comprises the following components in percentage by weight: 30 to 50 percent of white cement, 40 to 75 percent of filler, 0.03 to 0.30 percent of cellulose ether, 0.50 to 5 percent of adhesive, 0.05 to 0.40 percent of cellulose fiber, 0 to 0.10 percent of chemical fiber, 0 to 0.40 percent of thixotropic agent, 0 to 0.70 percent of water reducing agent, 0 to 0.80 percent of retarder, 0 to 0.4 percent of mildew preventive, 0 to 0.25 percent of water repellent and 0 to 5 percent of ferric oxide series pigment. The safe environment-friendly non-base-return color ceramic tile joint mixture can solve the base return problem of the joint mixture radically and has the advantages of moderate price, safety, environmental friendliness, convenience of production, transportation and storage, wide usable range and the like.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

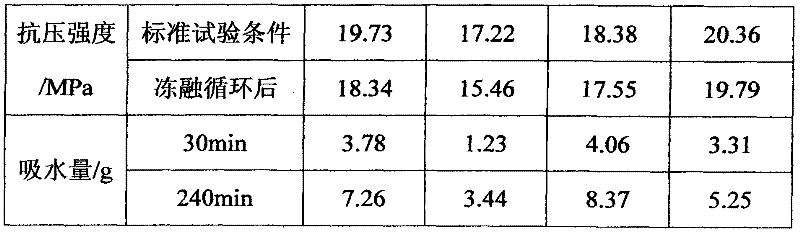

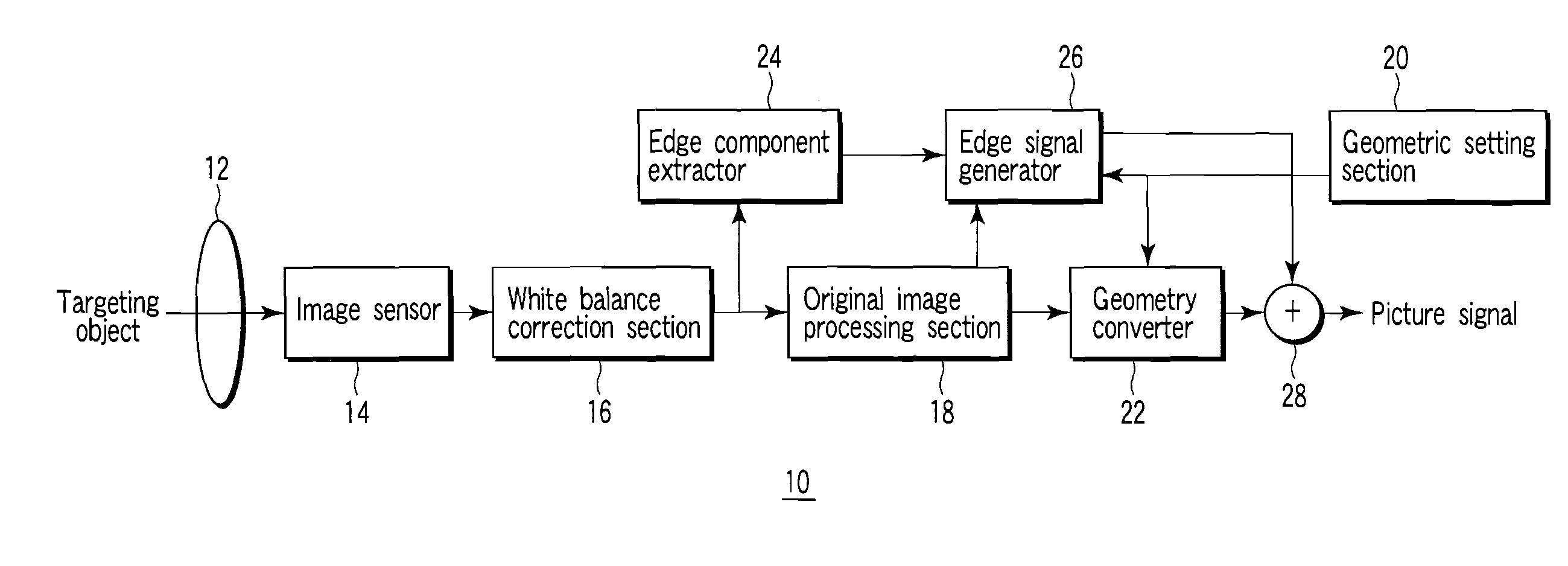

Camera

InactiveUS20080278602A1Improve resolutionImprove sharpnessImage enhancementTelevision system detailsImaging processingMagnification

A camera includes an optical system, an image sensor, a white balance correction section, an original image processing section, a geometric setting section which sets a desired geometric transformation for the original picture signal, a geometry converter which generates a geometrically converted picture signal based on the geometric setting made by the geometric setting section, an edge component extractor, an edge signal generator, and an image synthesizer which synthesizes the geometrically converted picture signal and signal at the edges to generate a picture signal. The edge signal generator performs geometrical transformation of the edges of the image based on the geometric setting and is parameter-controlled based on a geometry parameter computed from a coefficient to emphasize edges for controlling the enhancement at the edges amount for the edges of the image and magnification to zoom an image calculated based on the geometric setting.

Owner:OLYMPUS CORP

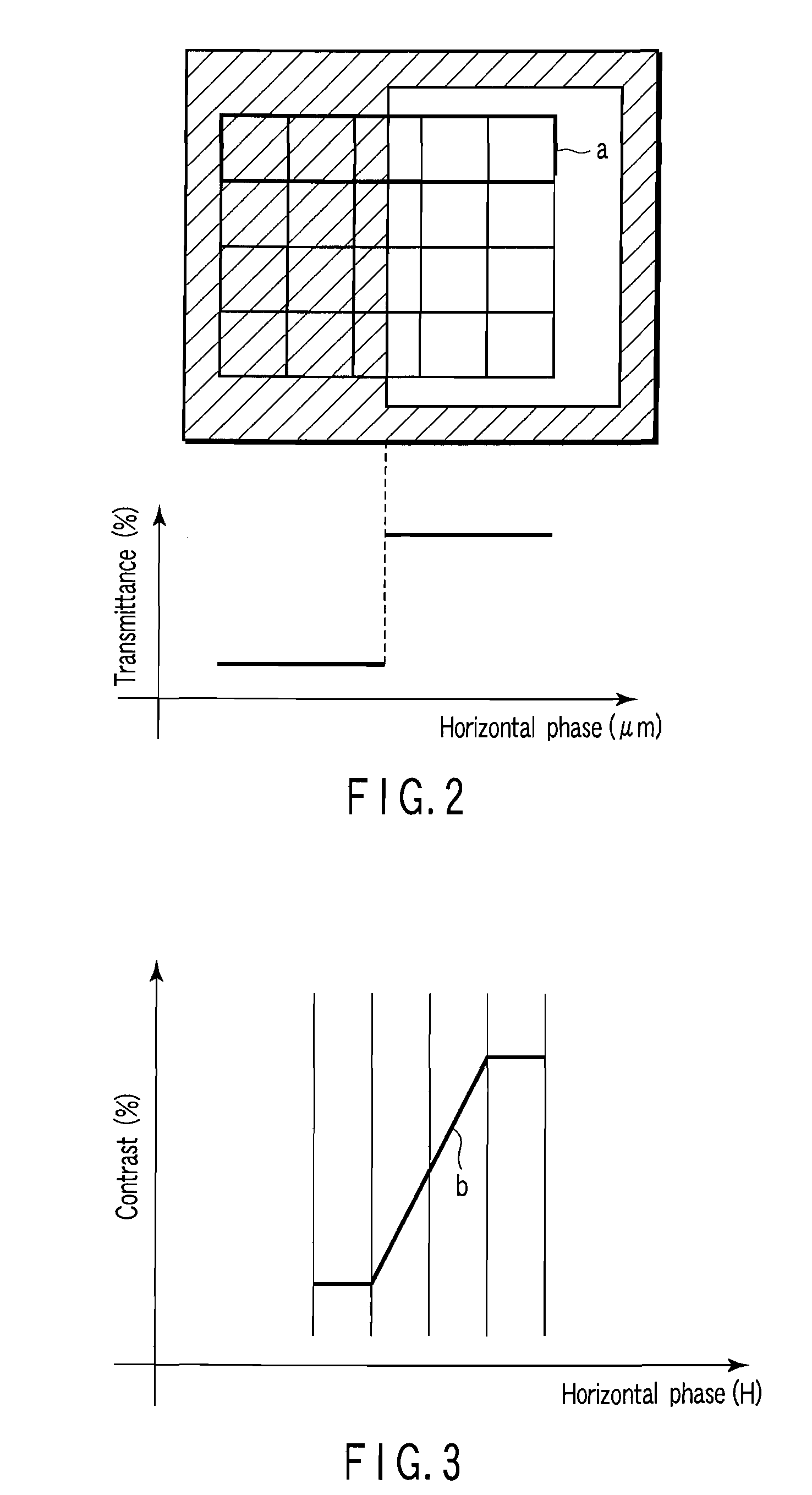

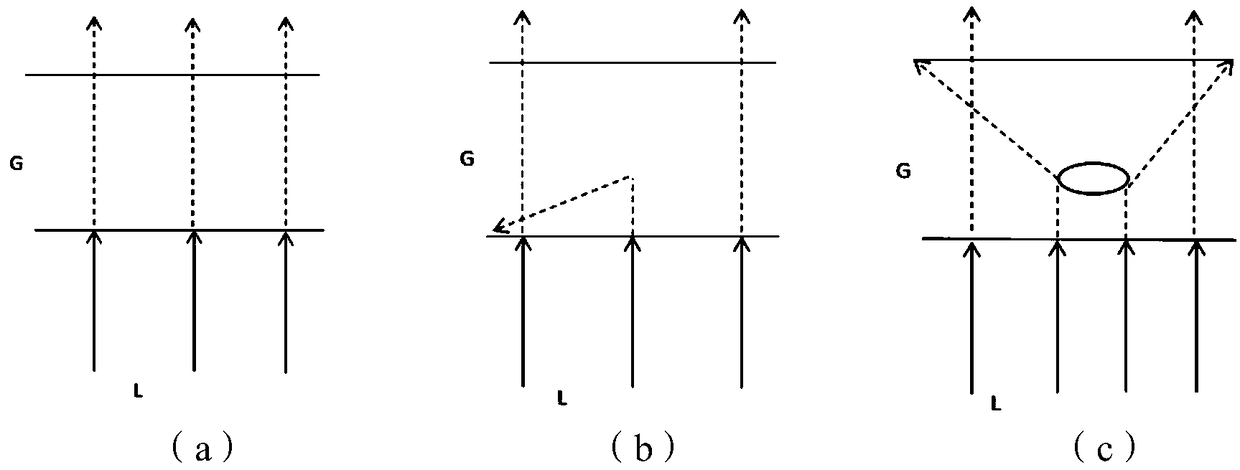

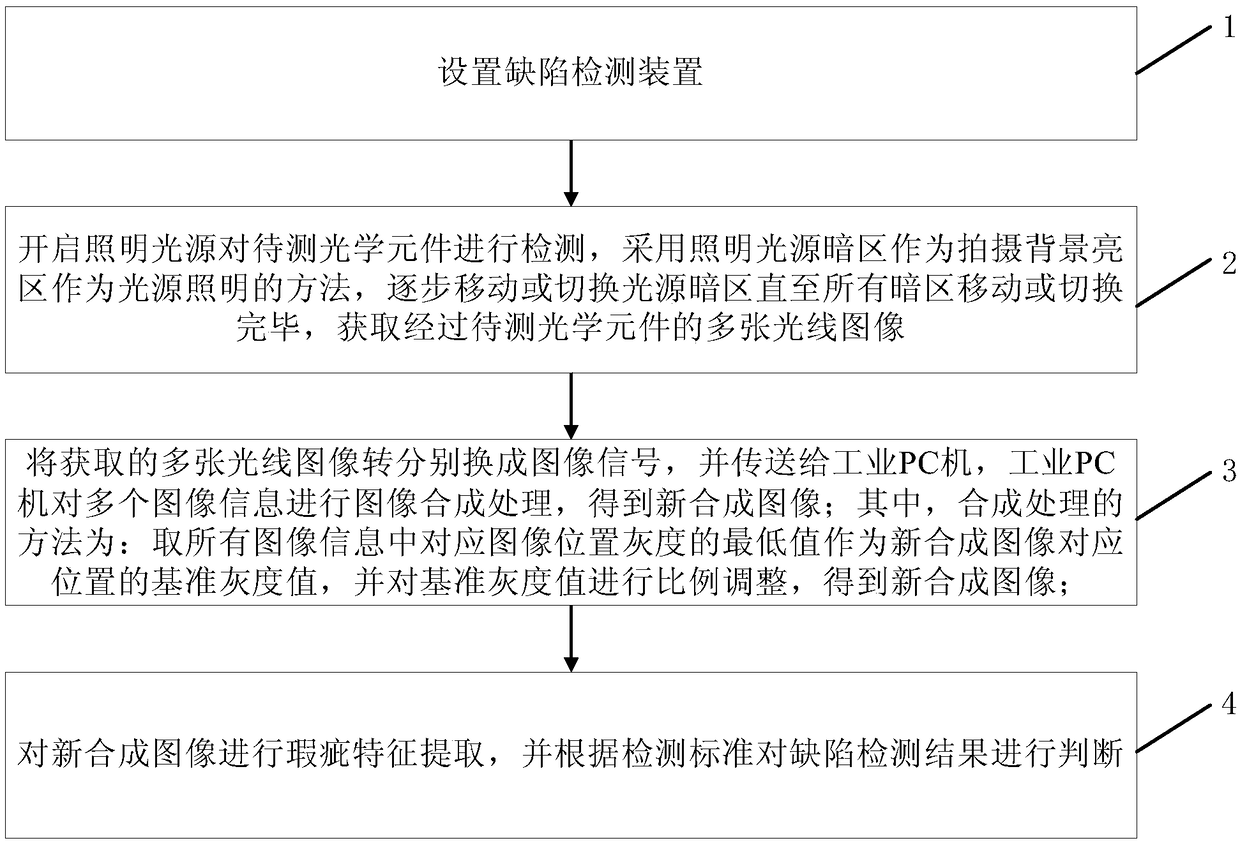

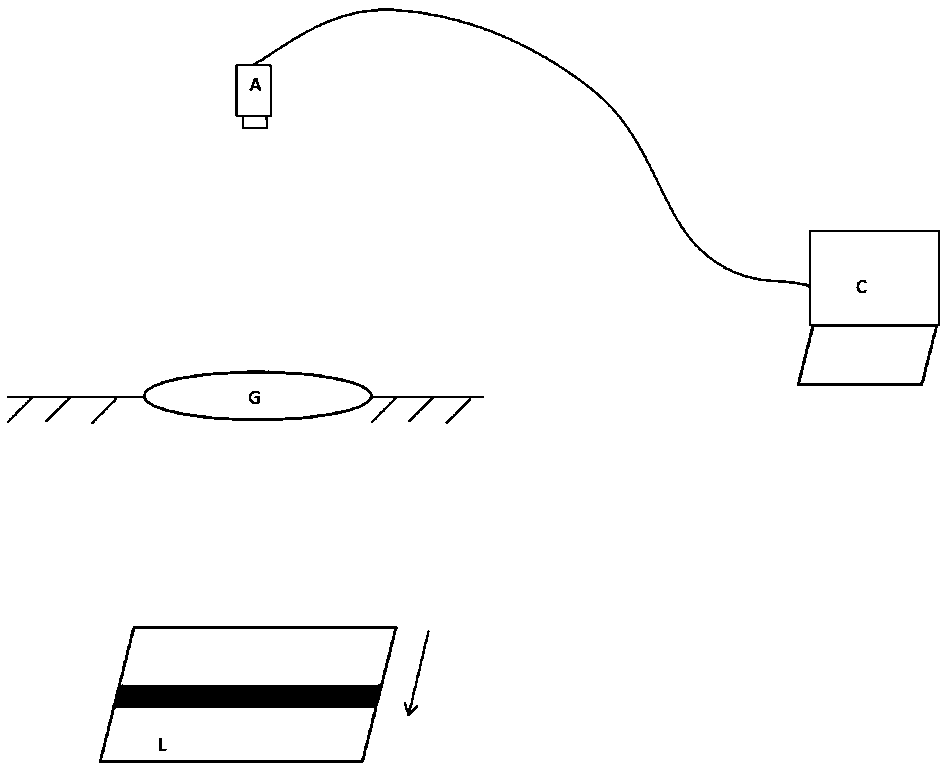

Optical element defect detection method based on machine vision technology

InactiveCN109030495AReduce false detection rateSimple structureOptically investigating flaws/contaminationLight sourcePhysics

The invention relates to the field of optical element detection, and provides an optical element defect detection method based on machine vision technology, comprising the following steps of: step 1,setting a defect detection device; step 2, turning on an illuminating light source to detect the optical element to be detected, and gradually moving or switching dark regions of the light source until all dark regions are completely moved or switched to acquire a plurality of light images passing through the optical element to be detected by adopting the dark regions of the illumination light source as a shooting background and the bright regions as a light source to illuminate; step 3, converting the plurality of acquired light images into image signals, and transmitting the image signals toan industrial PC, wherein the industrial PC performs image synthesis processing on the information of the plurality of images to acquire a new composite image; and step 4, performing defect feature extraction on the new composite image, and judging a defect detection result according to the detection standard. The optical element defect detection method based on machine vision technology realizesthe high-quality defect detection using alternating changes in gray values of the light source, and can stably detect slight defects and replace the manual detection.

Owner:大连鉴影光学科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com