Flip ball grid array packaging base plate and making technique thereof

A technology of ball grid array and packaging substrate, which is applied in multilayer circuit manufacturing, semiconductor/solid-state device manufacturing, and printed circuits connected with non-printed electrical components. Low performance and other problems, to achieve the effect of improving electrical performance and reliability, a wide range of options, and affordable prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

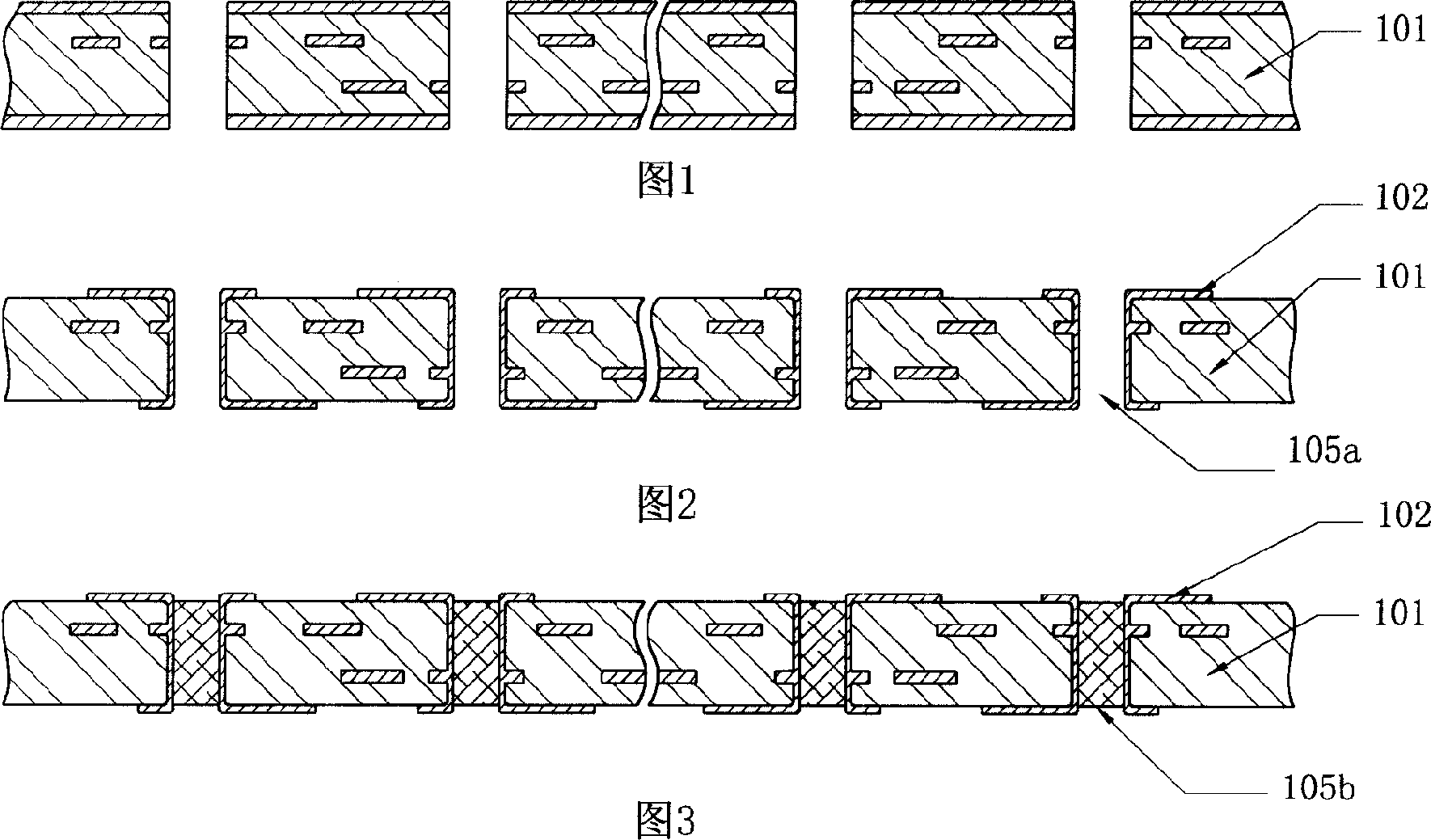

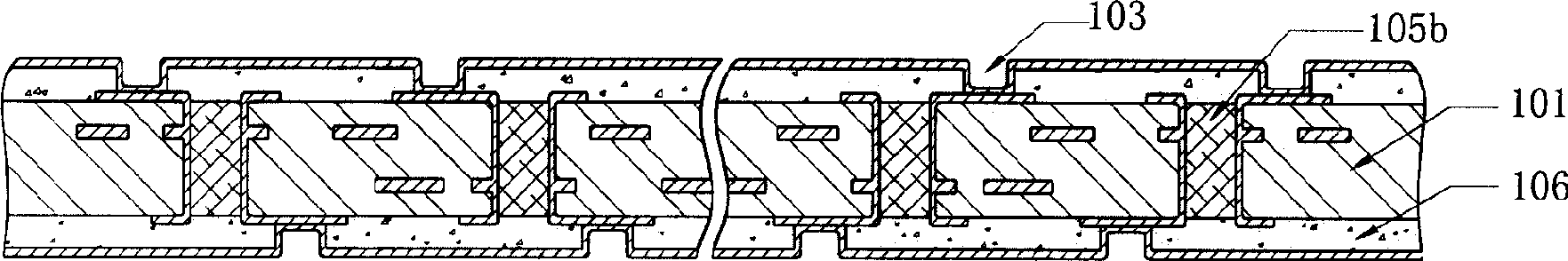

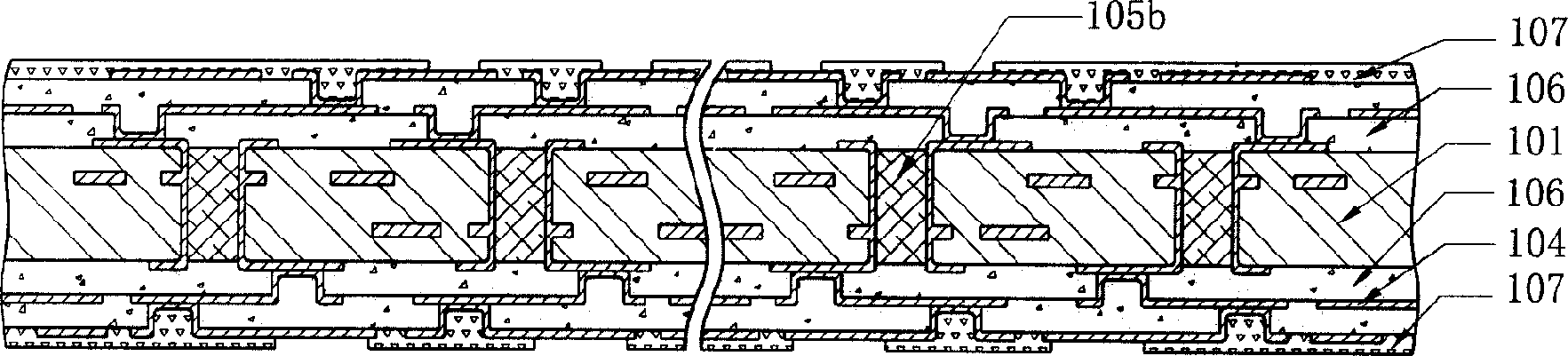

[0028] The manufacturing process of the obtained integrated circuit (IC) FC-BGA package substrate is as follows: 1. Electroplating on the copper plate the metal conductive pillar for the interconnection of the composite multi-metal layer structure

[0029] Such as Figure 7 , 8 As shown, after surface treatment is performed on the reinforced metal copper sheet 201, a photosensitive and anti-electroplating dry film 203 is pasted on the surface of the reinforced metal copper sheet 201. Such as Figure 9-12 As shown, the metal conductive pillars 206 for the interconnection of the composite multi-metal layer structure are formed by the methods of exposure, development, sequential pattern electroplating of Ni204, Au202, Cu205, and film removal.

[0030] 2. After electroplating the metal conductive pillars 206 for the interconnection of the composite multi-metal layer structure on the copper plate, the first application of the insulating dielectric layer and the formation of the circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com