Preparation and application methods of carbon fiber mat surface antioxidation coating

A technology of carbon fiber felt and anti-oxidation coating, which is applied in fiber processing, textiles and papermaking, etc., can solve the problems of poor use effect, rare research reports on the surface coating of thermal insulation layer, and high price, reaching the optional range wide, reduce man-made damage, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] An anti-oxidation coating for the surface of carbon fiber felt insulation materials, containing 90 parts by weight of phenolic resin, 4 parts by weight of boric acid, 5 parts by weight of silicon carbide, 15 parts by weight of benzenesulfonyl chloride and 80 parts by weight of graphite.

[0041] The preparation method of the anti-oxidation coating on the surface of the carbon fiber felt is as follows: 4 parts by weight of boric acid, 80 parts by weight of graphite, 5 parts by weight of silicon carbide and 10 parts by weight of p-toluenesulfonic acid are diluted with 30 parts by weight of industrial ethanol with a concentration of 95%. Finally, 90 parts by weight of phenolic resin was added after mechanical stirring for 20 minutes. Continue to stir for 30-40 minutes until the mixture is homogeneous to obtain an anti-oxidation coating.

[0042] The treatment method of coating the above-mentioned anti-oxidation coating on the surface of carbon fiber felt insulation, the sp...

experiment example 1

[0051] Application examples of carbon fiber felt insulation heat field for monocrystalline silicon furnace:

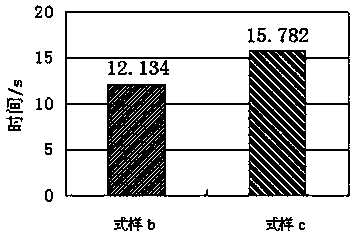

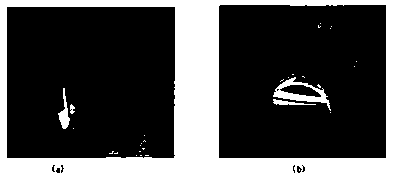

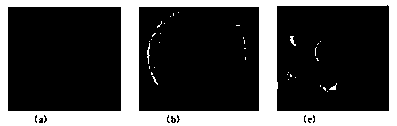

[0052] figure 1 The thermal field of ordinary graphite coating and the thermal field of the coating of the present invention are used to compare the macroscopic appearance of the exhaust hole after using 48 furnaces for the carbon fiber felt insulation of the single crystal silicon furnace. from figure 1 It can be seen that (a) uses 48 furnaces for the thermal field coated with ordinary graphite, that is, it is scrapped; figure 1 (b) is the quality status of the thermal field coated with the present invention after the same use of furnaces. The thermal erosion of the thermal field exhaust hole of the ordinary coating is serious and leads to scrapping; when the thermal field of the coating of the present invention is used for the same number of times, the damage to the exhaust hole is very small, indicating that the coating seals the opening on the surface of the ther...

Embodiment 2

[0054] An anti-oxidation coating for the surface of carbon fiber felt insulation materials, containing 90 parts by weight of furan resin, 5 parts by weight of boric acid, 2 parts by weight of borate ester, 3 parts by weight of zinc borate, 4 parts by weight of hexamethylenetetramine, 6 parts by weight Parts by weight of p-toluenesulfonic acid, 30 parts by weight of boron carbide, 20 parts by weight of silicon carbide, 15 parts by weight of silicon dioxide and 45 parts by weight of titanium carbide.

[0055] The preparation method of the anti-oxidation coating on the surface of the carbon fiber felt is as follows: use 30 parts by weight and a concentration of 95% acetone solvent as a diluent, first mix 5 parts by weight of boric acid, 2 parts by weight of boric acid ester, and 3 parts by weight of zinc borate under mechanical stirring. Blend for 20 minutes, then blend the mixed solution with 90 parts by weight of furan resin, add 4 parts of hexamethylenetetramine, 6 parts by wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com