Patents

Literature

113results about How to "High physical and mechanical strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

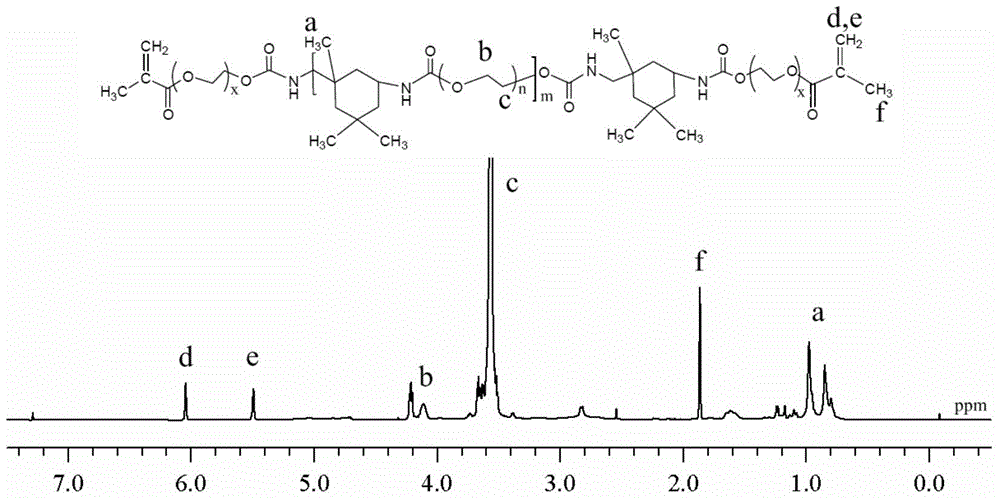

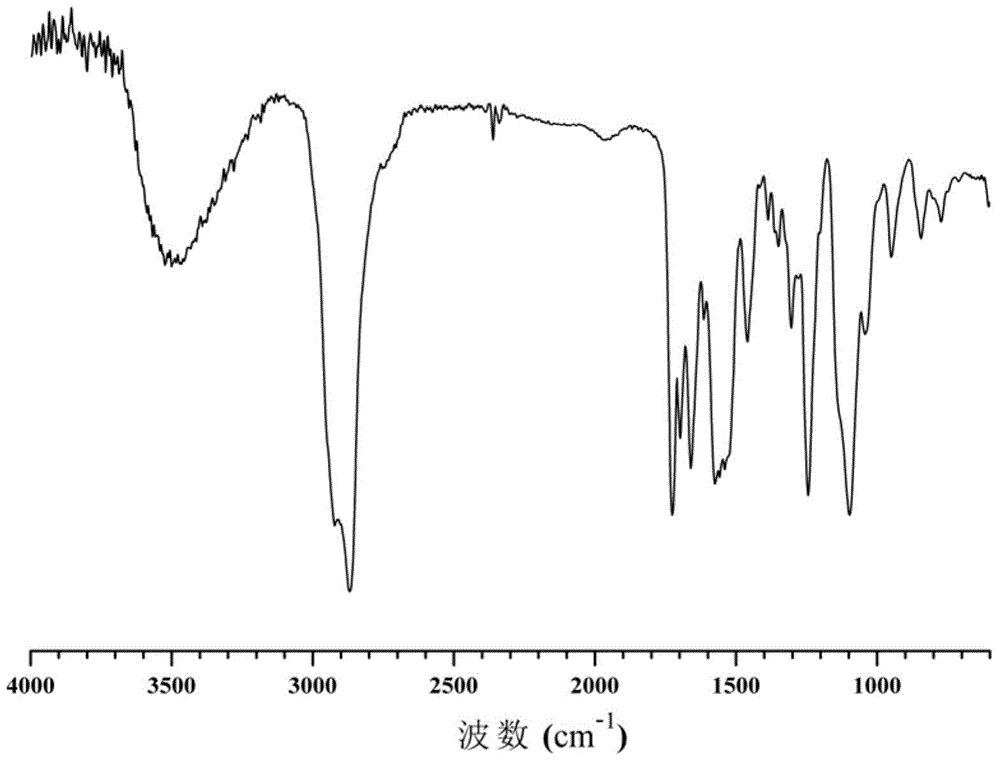

Self-repairing polyurethane hydrogel and preparation method thereof

The invention relates to a self-repairing polyurethane hydrogel and a preparation method thereof. The polyurethane hydrogel comprises the following components in parts by mass: 10-30 parts of polyisocyanate, 30-50 parts of hydrophilic polyester polyol or hydrophilic polyether polyol, 10-50 parts of acrylamide monomer, 0.5-3 parts of chain extender, 3-10 parts of methacrylic acid functional monomer containing an UPy unit, 0.5-2 parts of catalyst and 0.5-3 parts of photoinitiator. The preparation method comprises the following steps of firstly preparing a hydrophilic polyurethane macromonomer terminated with an acrylic acid monomer and carrying out radical polymerization with the methacrylic acid functional monomer containing the UPy unit under the action of photo-initiation. According to the self-repairing polyurethane hydrogel, the self-repairing of the damage of the polyurethane hydrogel can be completed without need of any repairing agent or specific environmental requirements, the polyurethane hydrogel has the advantages of high repairing efficiency, high mechanical strength and low cost and the repeatedly repairing function can be achieved on the same site.

Owner:SOUTH CHINA UNIV OF TECH

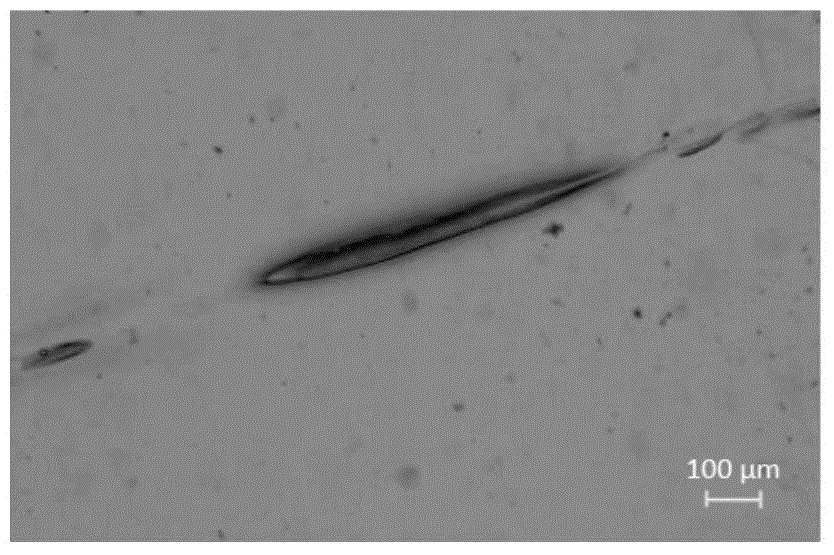

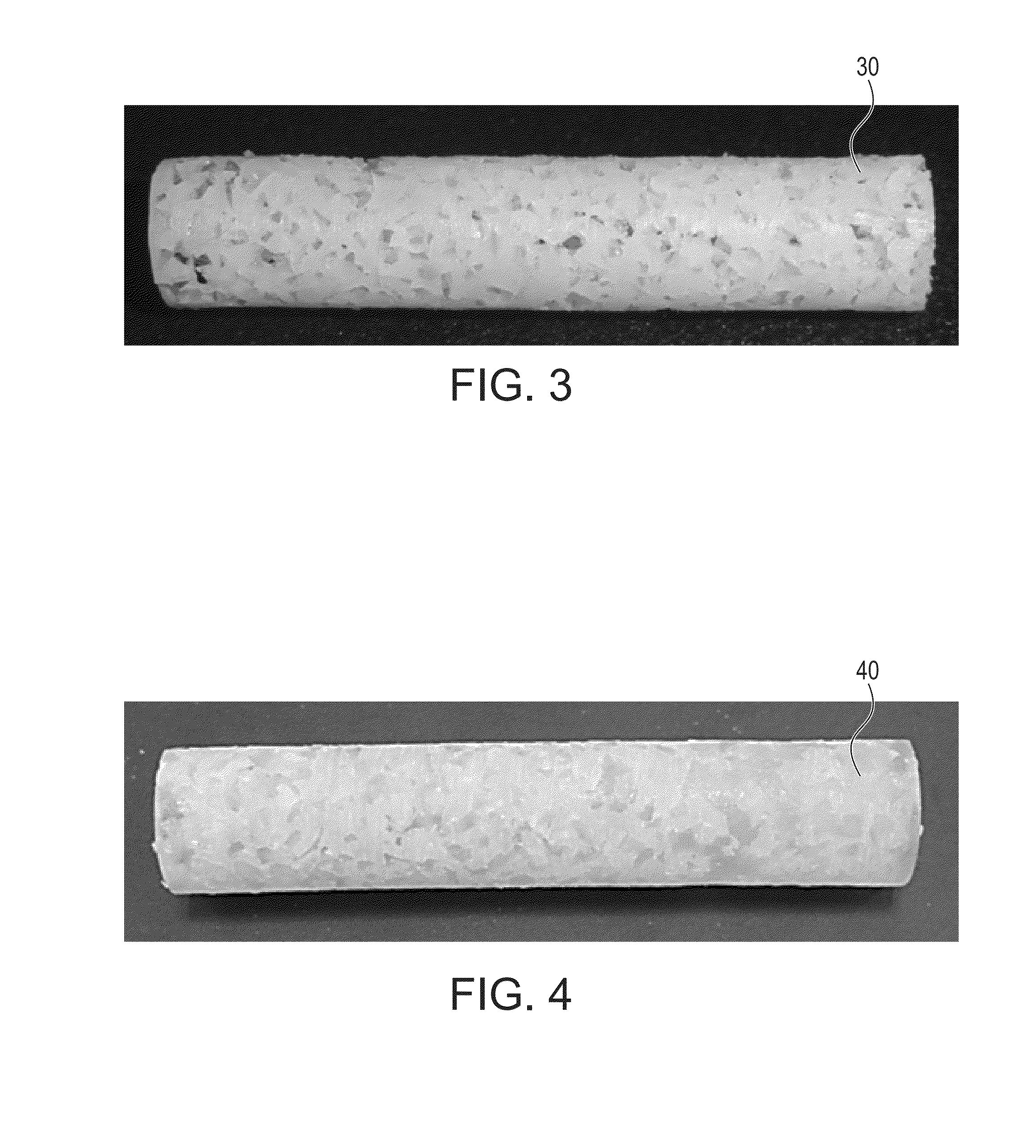

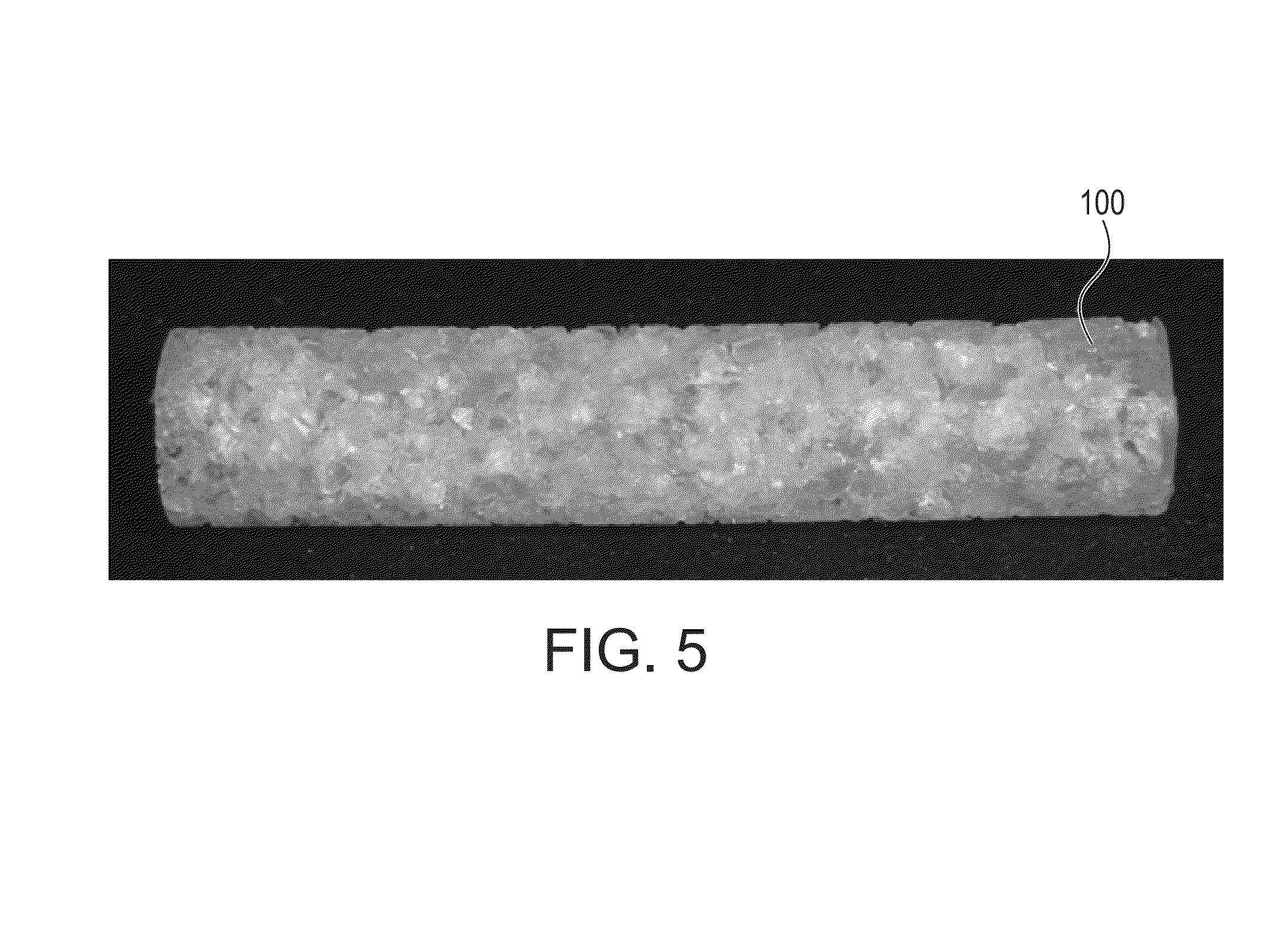

Modified porous materials and methods of creating interconnected porosity in materials

ActiveUS20140243439A1Solve Porosity InsufficiencyHigh mechanical strengthSurgeryAbsorbent padsSuture anchorsInterference screws

Techniques, mixtures and improved porous materials (interconnected porous constructs) that are capable of maintaining a sufficient porosity while conferring improved mechanical and physical strength to the final construct. A sacrificial construct (for example, a sacrificial material such as polymethyl methacrylate (PMMA)) is used to obtain an inverse porosity of the construct it was molded into. The process provides a less porous end material that may be used as an arthroplasty device or surgical implant (for example, an interference screw of suture anchor) among many other applications. The process employs a sacrificial material to reduce the porosity of the final construct to about 35%.

Owner:ARTHREX

Preparation method of inner decoration material for automobile

ActiveCN1966265AOvercome the shortcoming that some functions are easily weakenedSoft touchLamination ancillary operationsFibre treatmentMetallurgySlurry

The invention relates to a method for producing decorates material of vehicle, wherein it comprises that: (1), pretreating base cloth, while the base cloth is immerged with disinfection and flameproof, dried, cooled and coiled; (2), wet solidifying coat that rolling the base cloth, scraping on coating machine, while the slurry amount is 100-300g / m2, drying, solidifying in solidifying groove, washing, drying and shaping, cooling and coiling; (3), dry transfer surface shaping that special paper transfer adhering; (4), rolling and drying the semi-product, coiling and packing. The inventive product has water resistance, etc.

Owner:HAININ JINDA COATING

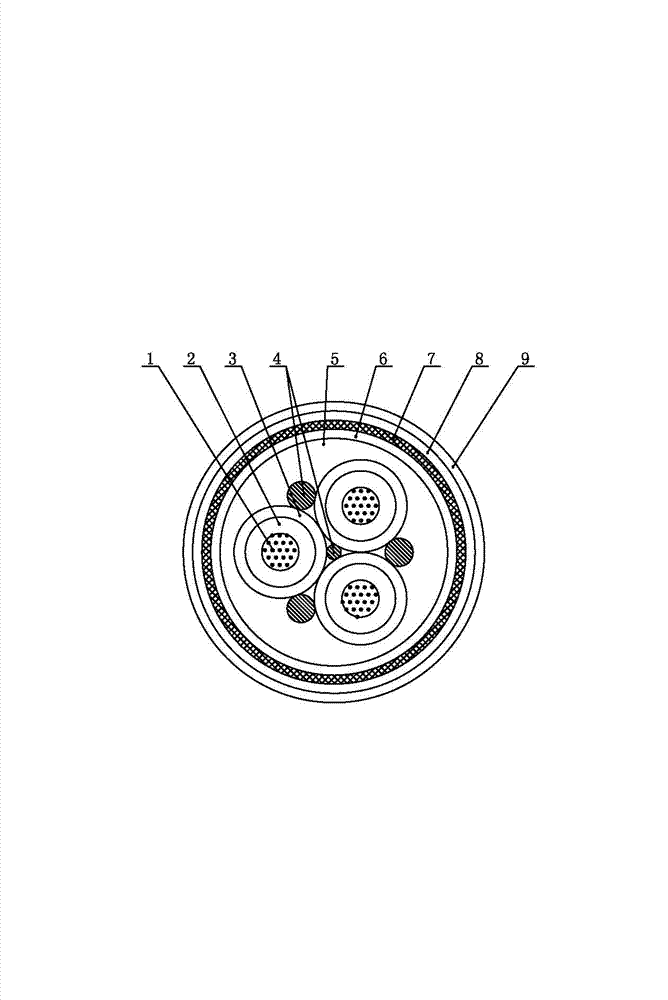

Shielding longitudinal watertight degaussing cable and production method thereof for ships

ActiveCN102855982AEnsure watertight effectImprove sealingInsulated cablesCable/conductor manufactureCopper conductorVulcanization

The invention discloses a shielding longitudinal watertight degaussing cable and a production method thereof for ships. A tinned copper wire is impregnated with a sealant and then twisted into a twisted copper conductor which is impregnated with a conductor sealant layer on the periphery, an electro-insulating rubber layer is extruded on the periphery of the conductor sealant layer to form insulation core wires, chloroprene rubber filling bars are filled into gaps between the insulation core wires, and a plurality of insulation core wires are twisted wholly into a cable core. A cable core inner sealant layer, an inner jacket rubber layer, an armor shielding layer and an outer jacket rubber layer are sequentially arranged on the periphery of the cable core. A single wire of the cable conductor is impregnated with the sealant, the twisted copper conductor is impregnated with the conductor sealant layer on the periphery, the cable core inner sealant layer is extruded on the periphery of the cable core to form multiple sealing, the chloroprene rubber filling bars swell during follow-up vulcanization and can fill in the gaps inside the cable core completely, and tangency between the insulation core wires can be avoided, so that the sealant can permeate to the inside of the cable core to guarantee the watertight effect when the cable core inner sealant layer is extruded.

Owner:嘉兴顾翔制冷设备有限公司

Method for preparing nano polytetrafluoroethylene microporous membrane

InactiveCN102151493AHigh nanofiber contentHigh physical and mechanical strengthSemi-permeable membranesPorosityFiber

The invention discloses a method for preparing a nano polytetrafluoroethylene microporous membrane, which comprises: mixing high-molecular-weight polytetrafluoroethylene dispersion resin and lubricating oil according to a weight ratio of (4-6):1, extruding a pasty material in an extruder at 20 to 120 DEG C, calendering the pasty material into a belt in a calender, and transversely stretching the belt by 0 to 8 times; removing oil in an oven at 50 to 300 DEG C to obtain a dry membrane, and stretching at 335 to 390 DEG C; and finally, performing thermosetting to obtain the polytetrafluoroethylene microporous membrane with an average thickness of 1 to 300 micrometers, an average aperture smaller than or equal to 180 nanometers, a porosity more than or equal to 78 percent, a water pressure resistance more than or equal to 3kg / cm<2>, and a moisture permeability more than or equal to 10,000 grams of water per square meter per day. The obtained microporous membrane has high nano fiber content and high mechanical strength such as tensile strength. The super-small nano micropores can meet the application requirements for higher water pressure resistance or better filtering effect.

Owner:上腾新材料科技(苏州)有限公司

Modified porous materials and methods of creating interconnected porosity in materials

ActiveUS9345817B2Solve Porosity InsufficiencyHigh physical and mechanical strengthSurgeryProsthesisSuture anchorsInterference screws

Owner:ARTHREX

Functional fiber and the multifunctional fiber thereof

InactiveCN1811021AEasy to prepareLow costMonocomponent synthetic polymer artificial filamentAlkali metal oxides/hydroxidesFiberPolymer science

The present invention relates to one kind of functional fiber and the multifunctional fibers thereof. The functional fiber includes basic fiber polymer and functional additive in the weight ratio of 60-96 to 4-40, the basic fiber polymer may be wet spun and the functional additive is superfine adsorbent of average diameter of 0.01-20 microns. The multifunctional fibers are produced with the functional fiber of the present invention and through further ionizing treatment, and include strong acid ion exchange multifunctional fiber, weak acid cation exchange multifunctional fiber, multiple-functional group ion exchange multifunctional fiber and alkali anion exchange multifunctional fiber. The functional fiber has excellent physical adsorption property; and the multifunctional fibers have both physical adsorption effect and chemical adsorption effect, and may be used in treating electroplating effluent, treating food industry waste water, purifying automatic tail gas, etc.

Owner:TIANJIN POLYTECHNIC UNIV

Linear low-density polyethylene composition

ActiveCN102477180AUniform viscosityEliminate cracksLow-density polyethyleneLinear low-density polyethylene

The invention relates to a linear low-density polyethylene composition comprising components of, by weight: 50-98 parts of linear low-density polyethylene with a density of 0.918-0.922g / cm<3> and a melt flow index of 0.1-10g / 10min, 0.5-45 parts of low-density polyethylene with a density of 0.910-0.925g / cm<3> and a melt flow index of 0.1-30g / 10min, 0.5-45 parts of high-density polyethylene with a density of 0.941-0.970g / cm<3> and a melt flow index of 0.5-10g / 10min, 0.5-45 parts of polypropylene with a density of 0.830-0.910g / cm<3> and a melt flow index of 0.5-50g / 10min, 0.1-20 parts of an ethylene-vinyl acetate copolymer with a density of 0.926-0.939g / cm<3>, 0.01-1 part of a rheology modifying agent, and 0.5-20 parts of a compatibilizing agent with a melt flow index of 0.5-50g / 10min. With the composition, extrusion processing performance can be effectively improved, a melt fracture phenomenon can be eliminated, and the compatibility can be improved. With the composition, the strength, flexibility and aging resistance of a product can be improved. The composition can be used for producing films, drip irrigation tapes, and pipes with various specifications.

Owner:XINJIANG TIANYE WATER SAVING IRRIGATION SYST

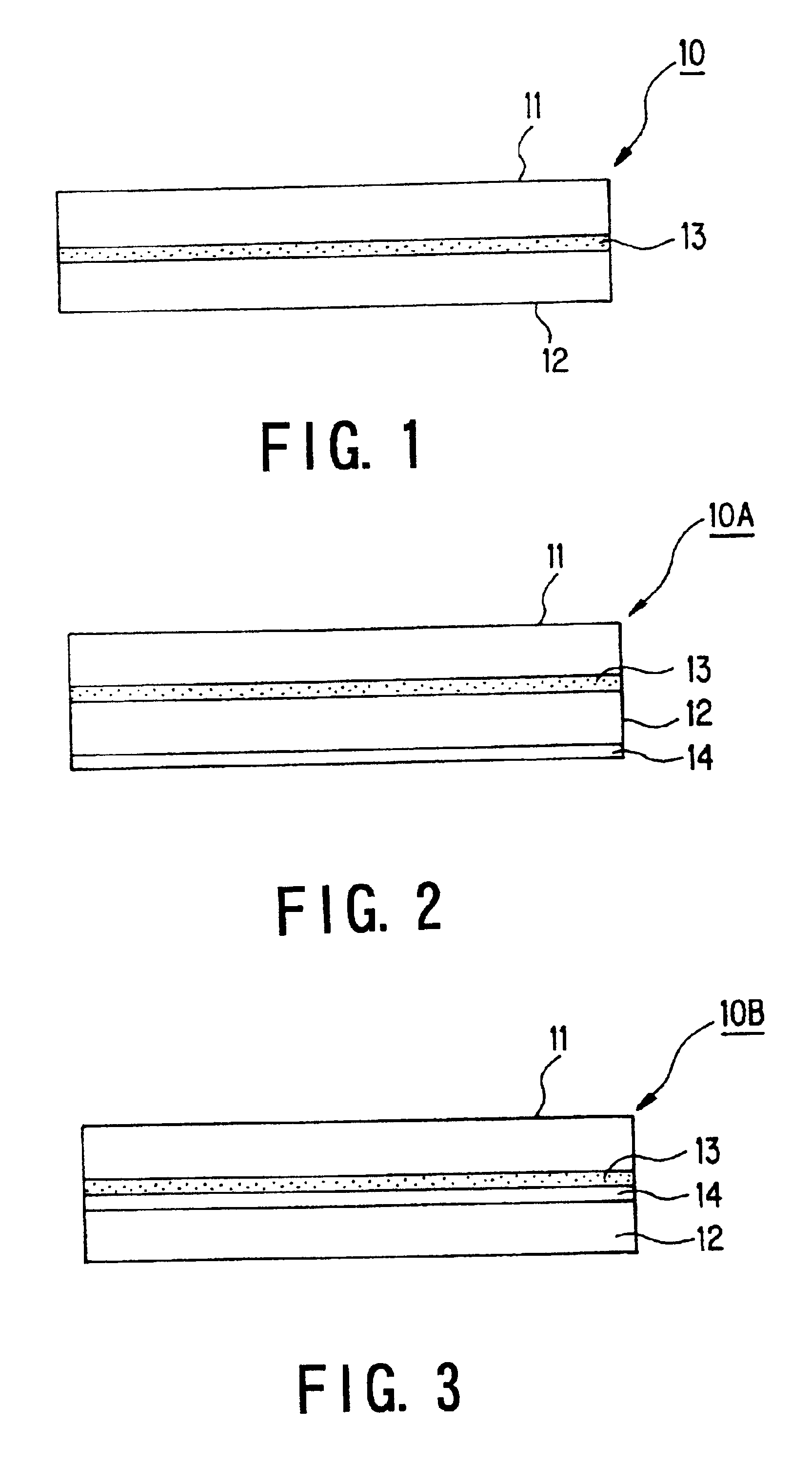

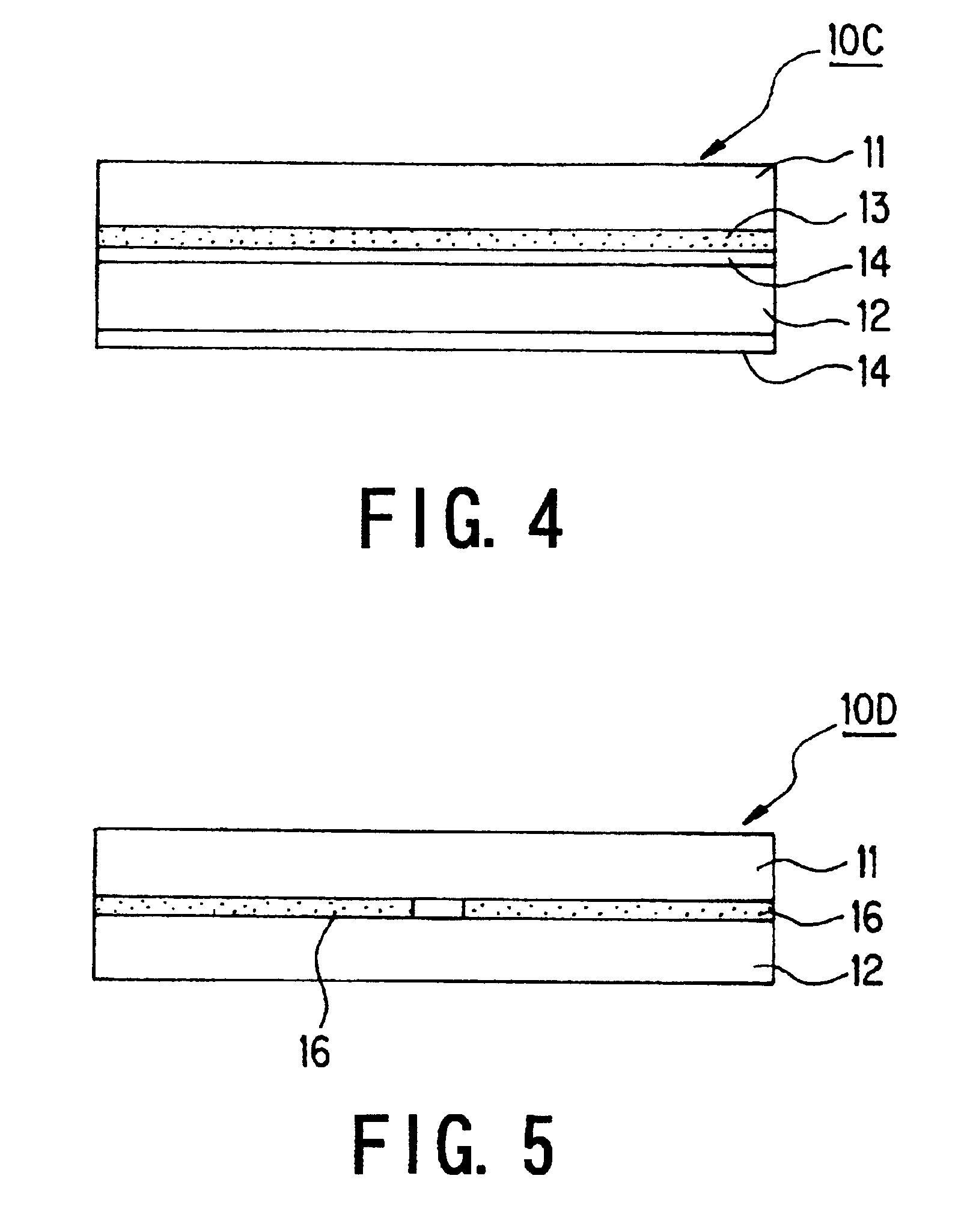

Display unit and mobile apparatus using the unit

InactiveUS6859365B2Small sizeReduce weightStatic indicating devicesFinal product manufactureElectrical batteryDisplay device

The display unit comprises a display device such as liquid crystal cell or the like; and a secondary battery disposed to a rear side of the display device. A heat shielding layer having a thermal conductivity of at most 5 W / mK, preferably at most 1 W / mK is formed as a heat shielding plate between the display device and the secondary battery, and the display device and the secondary battery are integrally assembled to form a module structure. According to the above structure of the present invention, since the display device such as liquid crystal cell or the like and the secondary battery are integrally assembled to form a module structure, the display unit can be made compact and thin to attain a light weight.

Owner:KK TOSHIBA

Double-surface filling composite film containing fluorine and chlorine conductive macromolecules and preparation method thereof

ActiveCN106968110AHigh physical and mechanical strengthImprove antifouling performanceStain/soil resistant fibresCarbon fibresComposite filmMoisture

The invention discloses a double-surface filling composite film containing fluorine and chlorine conductive macromolecules and a preparation method thereof. The double-surface filling composite film containing the fluorine and chlorine conductive macromolecules comprises a micropore film framework and fluorine and chlorine containing conductive macromolecules, more than 60% of double surfaces of the micropore film framework are filled with fluorine and chlorine containing conductive macromolecule resin, the mechanical strength is high, the waterproofness, the oil resistance and the pollution resistance are relatively high, and the film can meet the requirements of higher water resistance and poisonous and harmful chemical invasion resistance and higher moisture-penetrability; the film has convenience and high water and poisonous and harmful chemical resistance, is comfortable, keeps warm and can improve the fighting capacity of soldiers greatly when applied to biochemical protective clothing; when the film is applied to fuel cells, the electric conductivity is high so that better electrical performance is obtained, and the fuels such as hydrogen or ethyl alcohol can be burnt and utilized relatively thoroughly.

Owner:ZHEJIANG HYPROOF TECH CO LTD +1

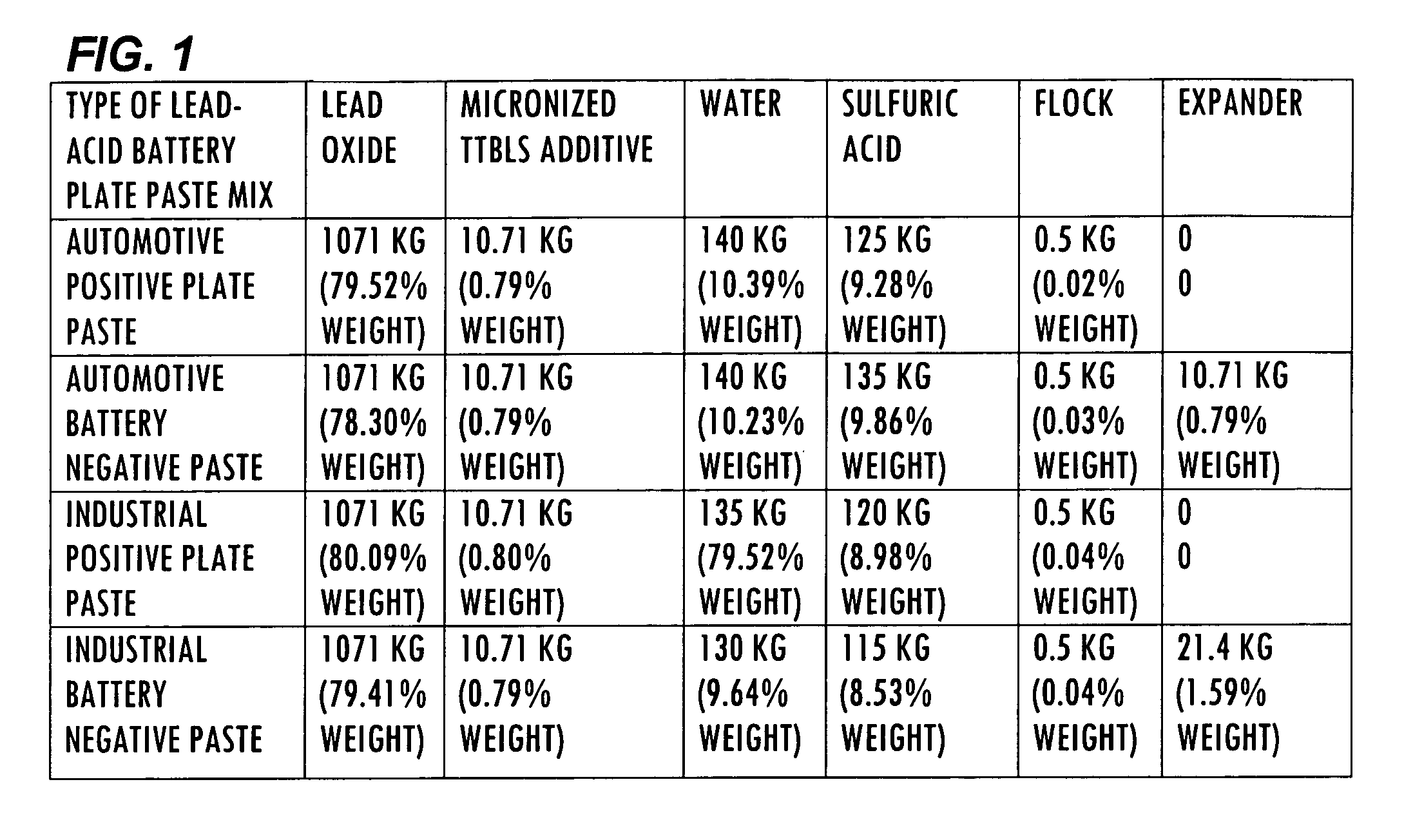

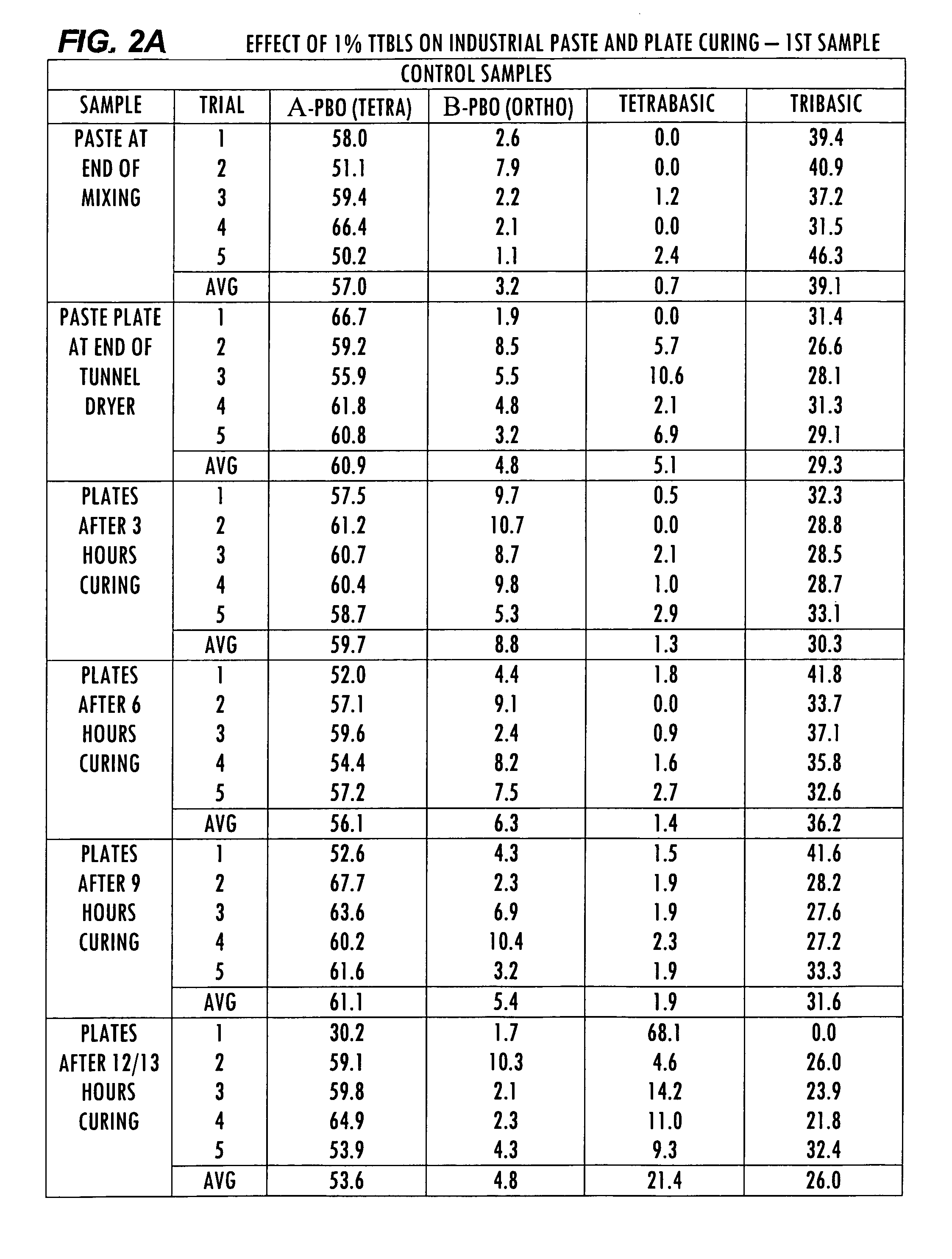

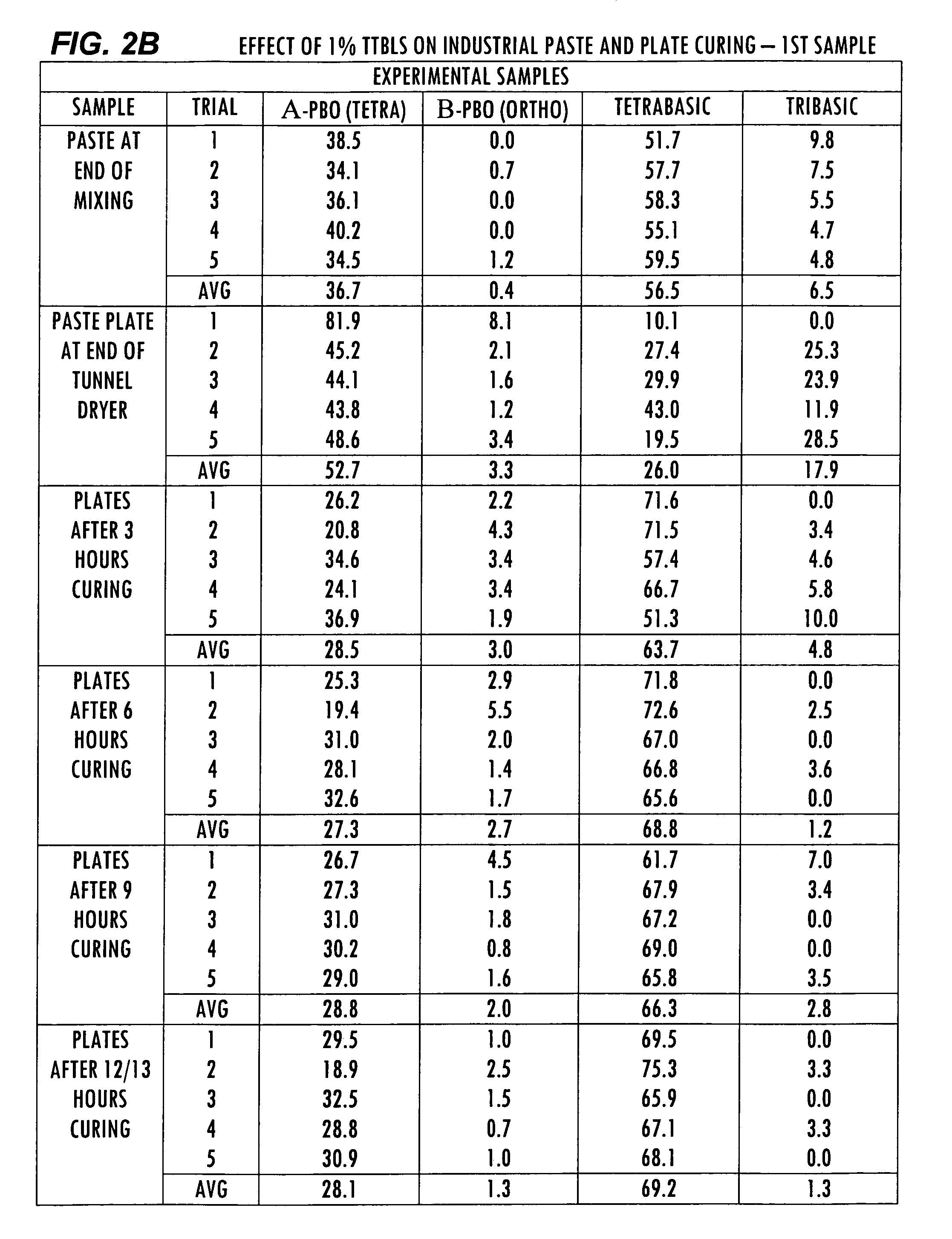

Battery paste additive and method for producing battery plates

ActiveUS7118830B1Increase productionShorten treatment timeLead-acid accumulatorsElectrode carriers/collectorsSeed crystalElectrical battery

A battery paste additive, and process for making the same comprising micronized seed crystals of tetra basic lead sulfate, is added to battery paste and results in accelerated curing time and other improvements in battery performance. The battery paste additive may be used to produce positive or negative battery plates and may be use with conventional mixing, pasting and curing processes and equipment.

Owner:HAMMOND GRP INC

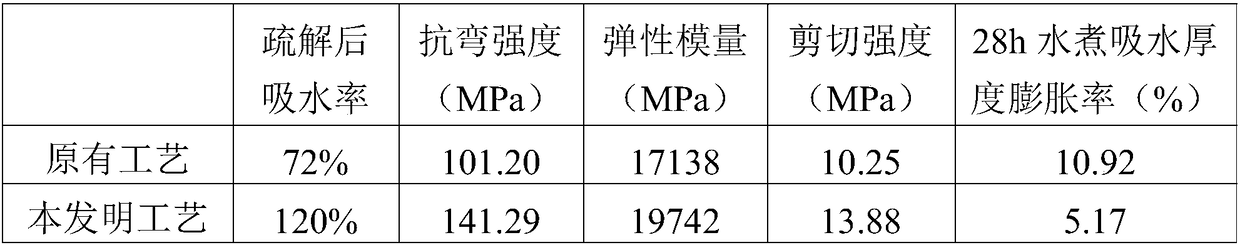

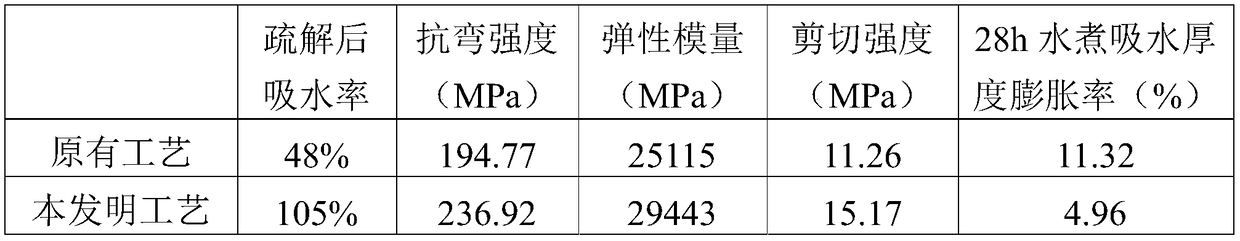

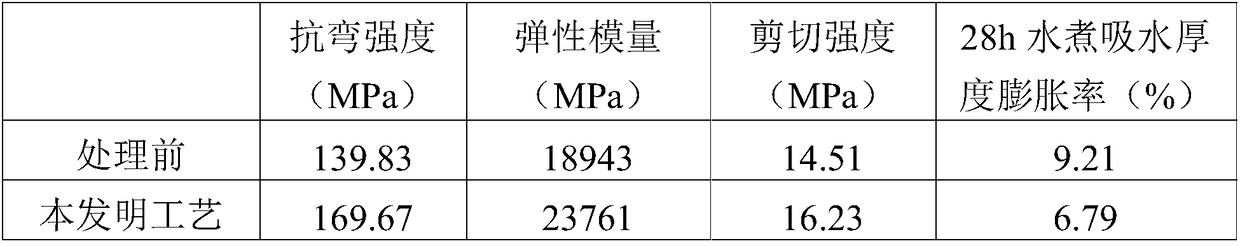

Method for using thin-wall bamboo materials to prepare bamboo scrimbers

PendingCN108127753AEnhance the ability to defuseEffective chemical attackWood compressionReed/straw treatmentWaxLiquid waste

The invention discloses a method for using thin-wall bamboo materials to prepare bamboo scrimbers. The method includes the steps that alkali is adopted for stewing thin-wall bamboo sheets, and then defibering, gum dipping, laying and hot pressing are carried out in sequence; NaOH is used for stewing the bamboo sheets, and the bamboo sheets are processed by lipase and then subjected to defibering,wherein by means of the procedures above, the defibering effect of bamboo bundles is obviously improved by 35% or above, bamboo green and tabasheer on the surfaces of the bamboo materials are effectively subjected to chemical erosion, the purpose of breaking wax layers and silicon layers is achieved, and the effect of improving gluing is achieved. A waste liquid generated after stewing is used fordiluting a glum liquid, and the problem of discharging the waste liquid is solved; by adopting a vacuum pressurizing dipping mode, even permeation of an adhesive in the bamboo materials is achieved,consumption of the adhesive is reduced, the production cost is reduced, efficient utilization of the thin-wall bamboo materials is achieved, and the environment is protected. The physical and chemicalstrength of the scrimbers are obviously improved, the horizontal shearing strength is improved by 25% or above, the thickness swelling rate of water absorption is reduced by 100% or above, the bending strength is improved by 20% or above, and the elasticity modulus is increased by 15% or above.

Owner:GUANGDONG ACAD OF FORESTRY

Degumming method of silk

InactiveCN103451746AReduced loss of breaking strengthReduced elongation loss at breakDe-gumming silkChemistryPolyester

The invention discloses a degumming method of silk, which belongs to the technical field of silk. The degumming method comprises the following steps of preparing the silk, tying the silk with polyester threads, putting the silk in a Na2CO3 solution with certain concentration, heating, boiling, adjusting the pH value of the solution to 9-11, and applying ultrasonic waves to the solution; and washing with deionized water, removing sericin, and drying the degummed silk. The degumming method disclosed by the invention has the advantages that by changing the degumming condition and applying the ultrasonic waves, the breaking strength loss and the breaking elongation of the degummed silk are reduced, and the physical and mechanical strength of the degummed silk is effectively improved; the time is short, the cost is low and the degumming efficiency is high.

Owner:SUZHOU SANHE KAITAI COLORED THREAD WEAVING CO LTD

Ethylene propylene diene monomer rubber composite material and preparation method thereof

The invention discloses an ethylene propylene diene monomer rubber composite material and a preparation method thereof. The preparation method is characterized by comprising the following steps: pretreating fabric-type carbon fibers by using a solubilizer, compounding ethylene propylene diene monomer rubber and a radiation sensitizer, putting in a mold, calendering into sheets, sandwiching the pretreated fabric-type carbon fibers between the two ethylene propylene diene monomer rubber sheets, putting in the mold, and calendering into a sheet; after the sheet is cooled to room temperature, carrying out plastic packaging, putting in a gamma-ray radiation field or electron-beam accelerator, and carrying out radiation crosslinking while keeping the total absorbed dose at 50-200 kGy; and after finishing radiation, removing the plastic package, and cutting off the edge, thereby obtaining the semitransparent ethylene propylene diene monomer rubber composite material. The composite material has excellent mechanical properties. By using the fabric-type carbon fibers as the reinforcing agent, the prepared ethylene propylene diene monomer rubber composite material is semitransparent. Meanwhile, the preparation method has the advantages of simple preparation process control and favorable repetitiveness.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Anti-wrinkle crease-free non-woven fabric polyurethane synthetic leather used for shoes and preparation method thereof

ActiveCN105002748AReduce creasesIncrease softnessLamination ancillary operationsSynthetic resin layered productsFiberWrinkle skin

The invention discloses anti-wrinkle crease-free non-woven fabric polyurethane synthetic leather used for shoes and a preparation method thereof. The preparation method comprises the steps that fiber screen laying and needling are carried out on a spunlaced non-woven fabric surface, and a anti-wrinkle non-woven base is formed; after dipping carried out in a polyurethane dipping sizing agent is finished, condensing and ironing are carried out in a DMF aqueous solution; after coating is carried out by a polyurethane coating, the condensing, washing and drying are sequentially carried out; a post-processing grinding machine is used for carrying out orientated grinding on the surface of a semi-finished product; one layer of a thermoplastic polyurethane resin dry coating sizing agent is coated on release paper, after drying is conducted, one layer of a thermoplastic polyurethane dry bonding layer sizing agent is coated on the release paper, then drying is carried out in a drying oven until the release paper is half-dried, and a dry synthetic leather semi-finished product is obtained; the dry synthetic leather semi-finished product is attached to the wet synthetic leather semi-finished product, and after drying and ripening are conducted, the non-woven fabric polyurethane synthetic leather is obtained. The non-woven fabric polyurethane synthetic leather has the advantages that wrinkles cannot be generated, the physical mechanical strength is high, meanwhile sizing of shoemaking is good, and the durability is good; processing and performance requirements for children shoes, sport leisure shoes and the like are completely met.

Owner:ANHUI ANLI MATERIAL TECH

Wood plastic composite and preparation process thereof

The invention discloses a wood plastic composite and a preparation process thereof. The wood plastic composite is prepared by mixing wood powder and high-density polyethylene resin, which serve as a base stock, with an additive, an aluminum-titanium composite coupling agent, an antioxidant 1010 and zinc stearate serving as a lubricant, wherein the content of the wood powder in the base stock is 50 to 90 weight percent; the content of the high-density polyethylene resin in the base stock is 10 to 50 weight percent; the used amount of the aluminum-titanium composite coupling agent is 1 to 6 weight percent based on the wood powder content; the used amount of the antioxidant 1010 is 0.2 to 2 weight percent based on the total weight of the base stock including the wood powder and the high-density polyethylene resin; and the used amount of the zinc stearate serving as the lubricant is 1 to 5 percent based on the total weight of the base stock including the wood powder and the high-density polyethylene resin. The wood plastic composite has high wood powder content, low manufacturing cost, high physical mechanical strength and high surface finishment, is water resistant, chemical corrosion resistant and easy to degrade and is a green, environmentally-friendly novel wood and plastic substitute.

Owner:DONGGUAN MINGFENG PACKAGING CO LTD

Environment-friendly plant fiber wood-plastic composite material and preparation method thereof

The invention provides an environment-friendly plant fiber wood-plastic composite material and a preparation method thereof. The environment-friendly plant fiber wood-plastic composite material is prepared from the following components serving as base stock by weight percent: 50-90% of plant fibers, 5-40% of waste polystyrene plastic recovery particles and 5-10% of styrene butadiene styrene (SBS), as well as a proper amount of an assistant-silane coupling agent and stearic acid, wherein the use amount of the silane coupling agent accounts for 1-10wt% of the plant fibers while the use amount of the stearic acid accounts for 2-5wt% of the plant fibers. The environment-friendly plant fiber wood-plastic composite material has the advantages of insect prevention, moth resistance, chemical corrosion resistance, large additive amount of cellulose, high physical and mechanical strength, low cost, easy decomposition and wide application, and is environment-friendly.

Owner:广东普科特粉末涂料有限公司

Fluorine-containing and chlorine-containing conductive macromolecule single-side-filled composite film and preparation method thereof

ActiveCN106977640AHigh physical and mechanical strengthImprove antifouling performanceElectro-spinningWet spinning methodsElectricityComposite film

The invention discloses a fluorine-containing and chlorine-containing conductive macromolecule single-side-filled composite film and a preparation method thereof. The fluorine-containing and chlorine-containing conductive macromolecule single-side-filled composite film material comprises a micropore film framework and fluorine-containing and chlorine-containing conductive macromolecules, wherein more than 85 percent of pores of a single side of the micropore film framework are filled with fluorine-containing and chlorine-containing conductive macromolecule resin; the physical mechanical strength is high; the waterproof, oil-proof and anti-pollution performance is high; the film can meet the requirements of resisting water and preventing toxic and hazardous chemicals from invading; the performance is high; the moisture permeability is higher; when the composite film is applied to biochemistry protection clothing, the effects of light weight, portability, high protection performance on the water and the toxic and hazardous chemicals, comfort and heat insulation are achieved, and the fighting capacity of soldiers can be greatly improved; when the composite film is applied to fuel cells, the electric conductivity is high, so that the obtained electric performance is good, and fuels such as hydrogen gas or alcohols can be completely burnt and utilized.

Owner:ZHEJIANG HYPROOF TECH CO LTD +1

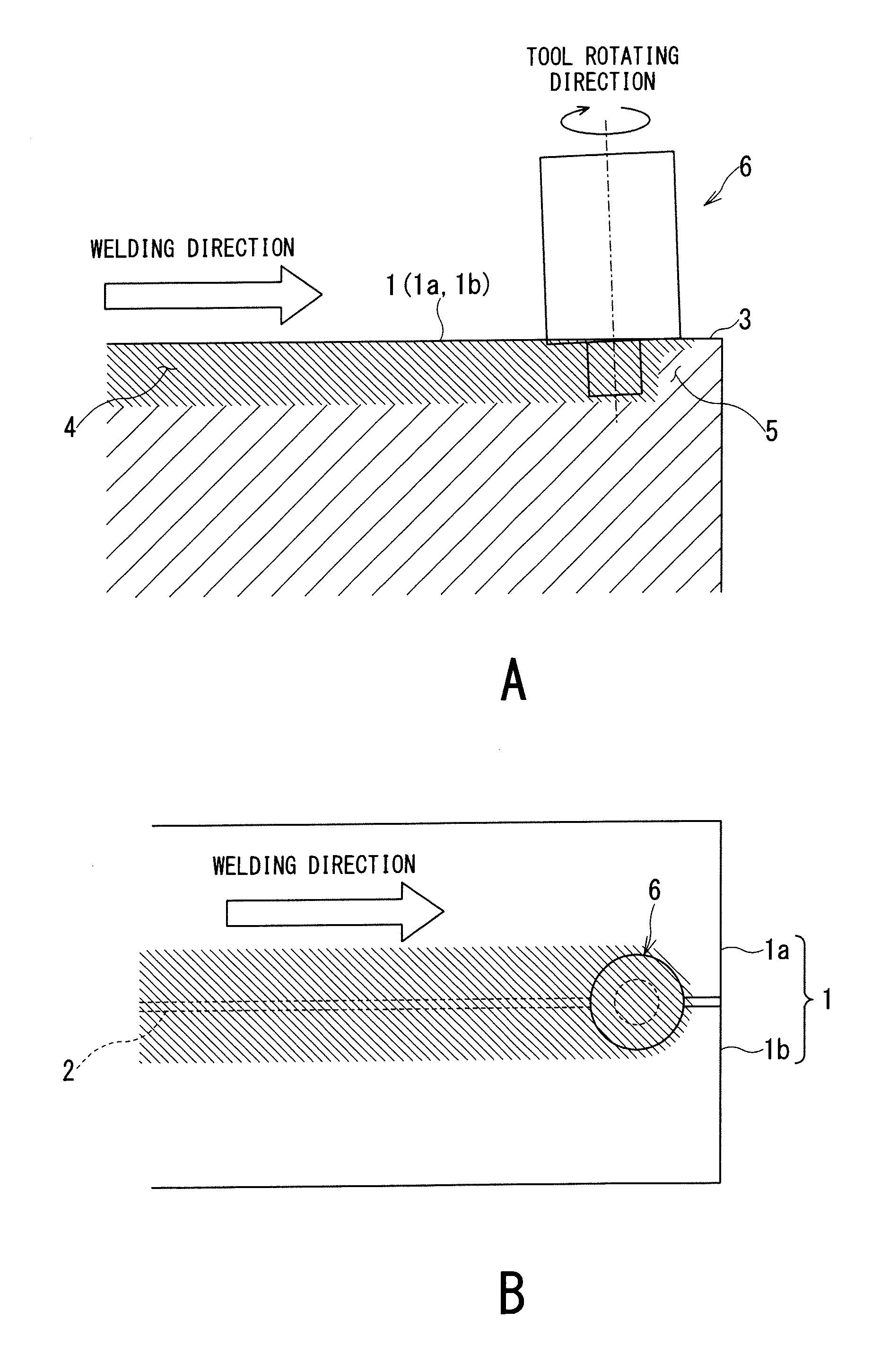

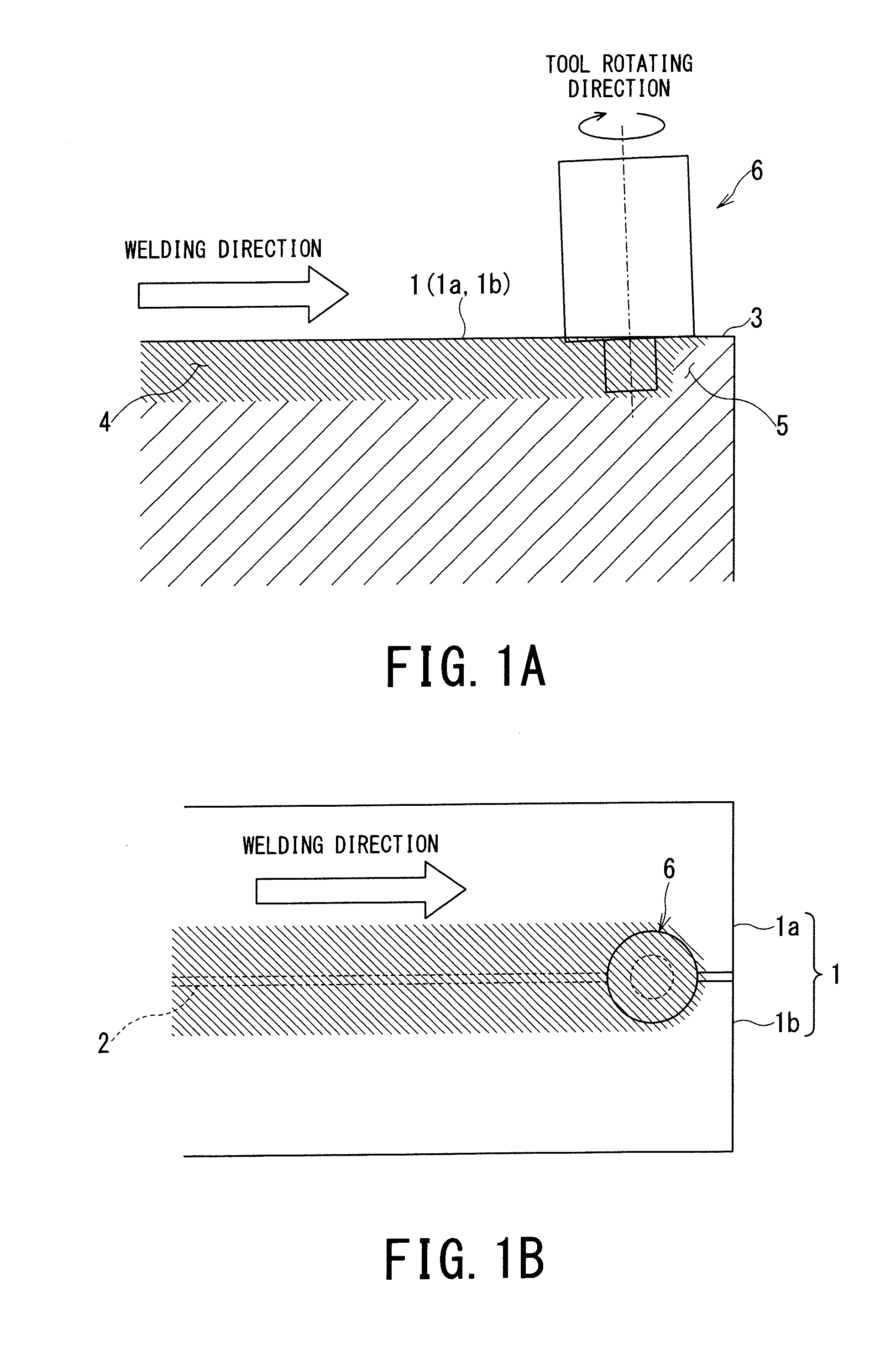

Friction stir welding method for metal material and metal material welded body obtained thereby

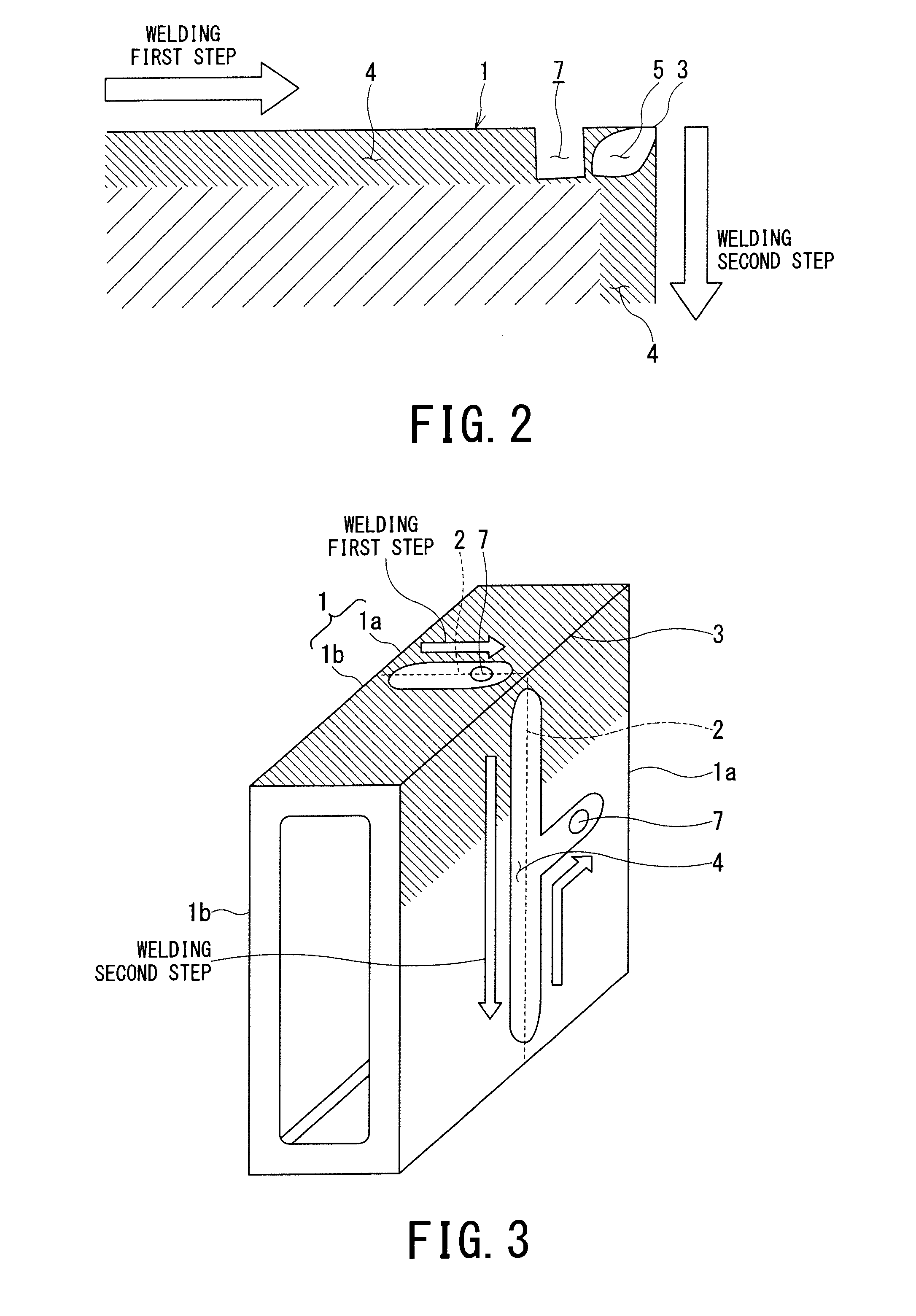

ActiveUS20140004375A1Easy to makeImprove appearance qualityThin material handlingMetal layered productsButt weldingMetallic materials

A friction stir welding method for a metal material for longitudinally welding members to be butted and then welded with complicated shape portions in section at end portions. The friction stir welding method includes preparing members to be welded and formed with excess thickness portions and a welding tool provided with a probe; performing a first welding to the members to be welded; inserting the welding tool from the excess thickness portion to cause plastic flow of the metal material subsequent to the butt-welding; and performing a second welding.

Owner:SUZUKI MOTOR CORP

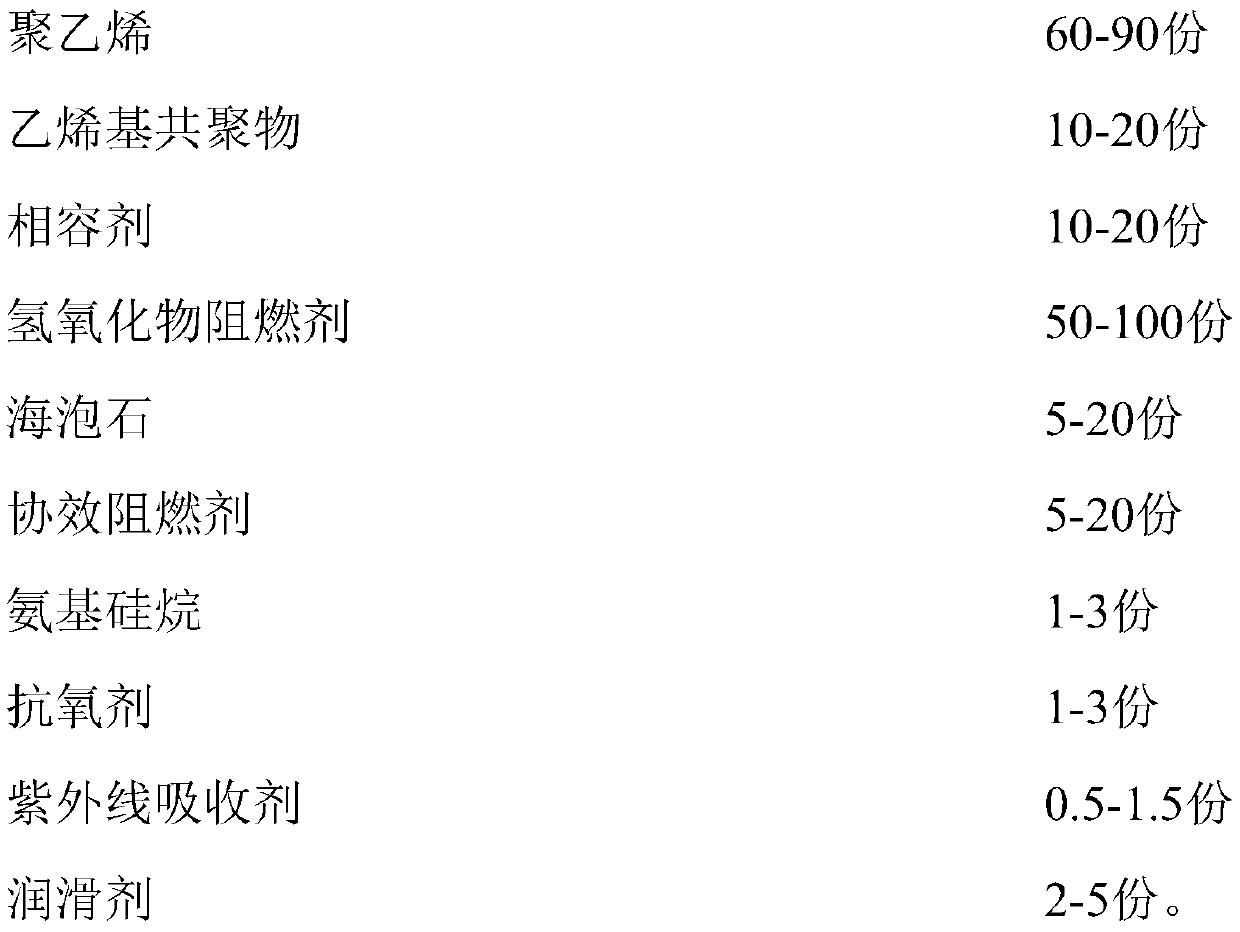

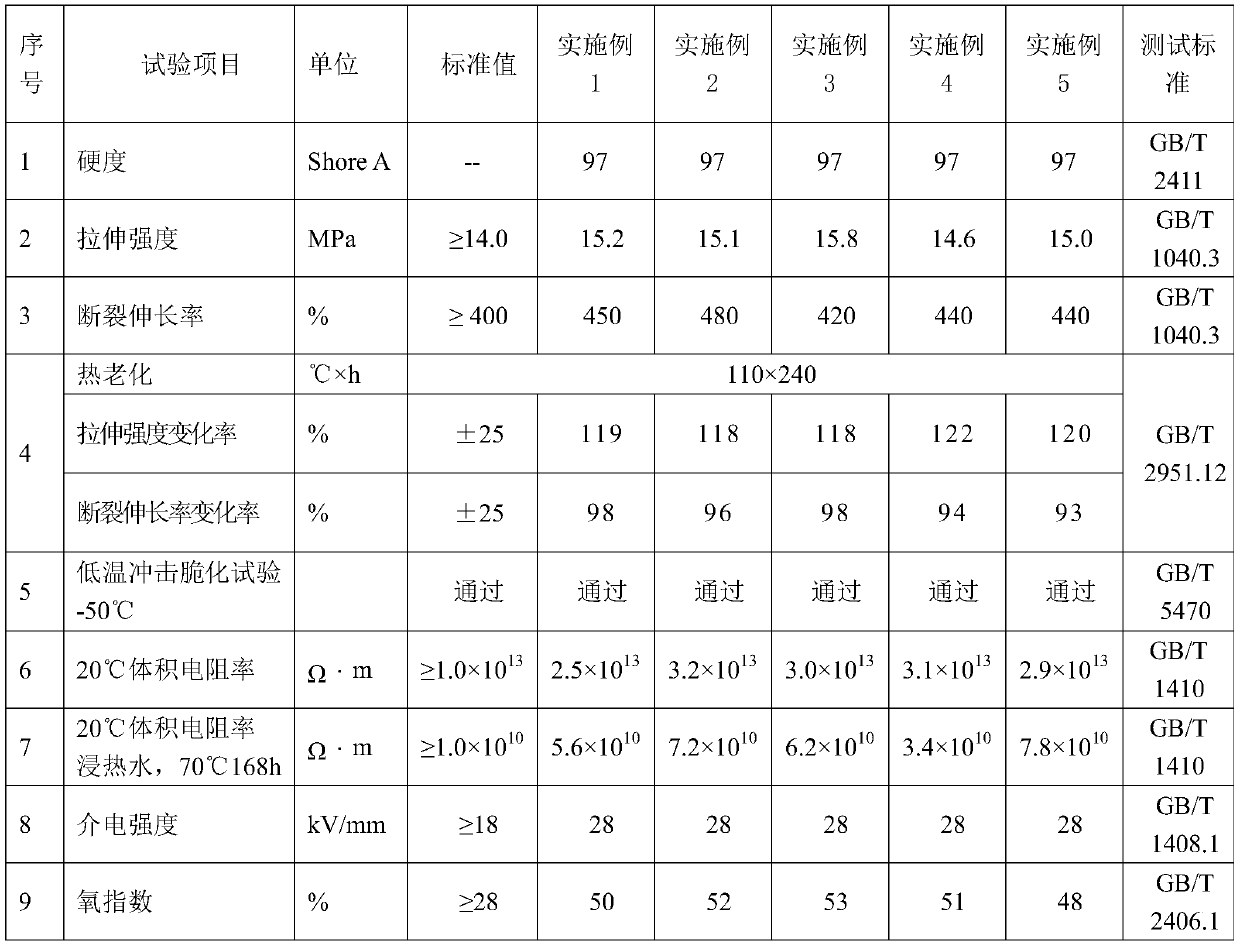

90DEG C cracking-resistant moisture-proof and flame-retardant polyethylene cable material and preparation method thereof

PendingCN110903538AGood crack resistanceGood flame retardant performancePlastic/resin/waxes insulatorsChemistryUv absorber

The invention discloses a 90DEG C cracking-resistant moisture-resistant and flame-retardant polyethylene cable material and a preparation scheme thereof. The cable material is composed of the following components by weight: 60-90 parts of polyethylene, 10-20 parts of a vinyl copolymer, 10-20 parts of a compatilizer, 50-100 parts of a hydroxide flame retardant, 5-20 parts of sepiolite, 5-20 parts of a synergistic flame retardant, 1-3 parts of aminosilane, 1-3 parts of an antioxidant, 0.5-1.5 parts of an ultraviolet light absorber and 2-5 parts of a lubricant. The 90-DEG C cracking-resistant moisture-resistant and flame-retardant polyethylene cable material disclosed by the invention has the characteristics of resistance to a low temperature of -50DEG C, outstanding cracking resistance, insulativity and moisture resistance (volume resistivity of 70DEG C*168h after immersion), good flame retardance, low smoke, no toxicity and the like, also has the advantages of fast extrusion processingspeed, difficult generation of air holes, etc., and can be widely applied to an outer sheath layer of a 1kV-220kV cable.

Owner:中广核三角洲(江苏)塑化有限公司

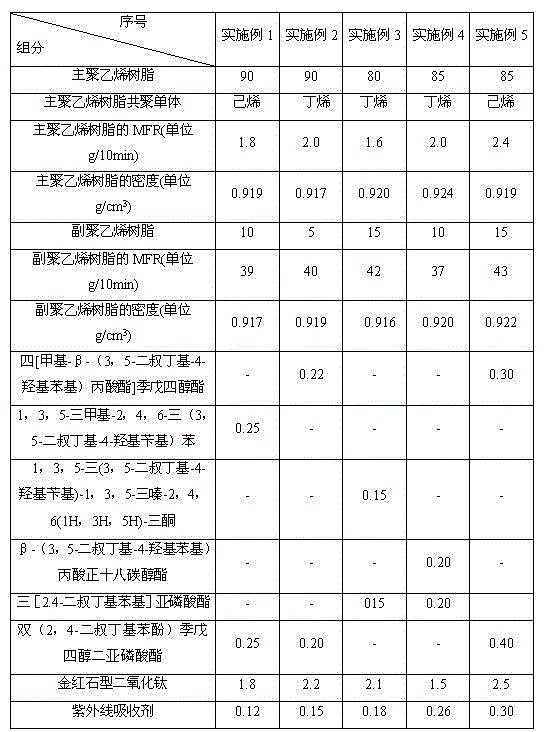

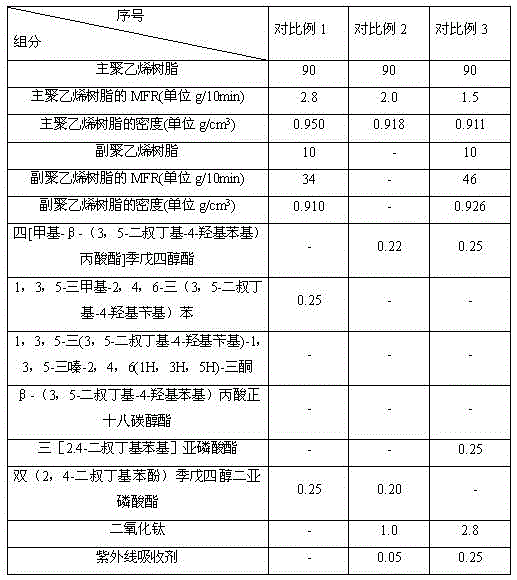

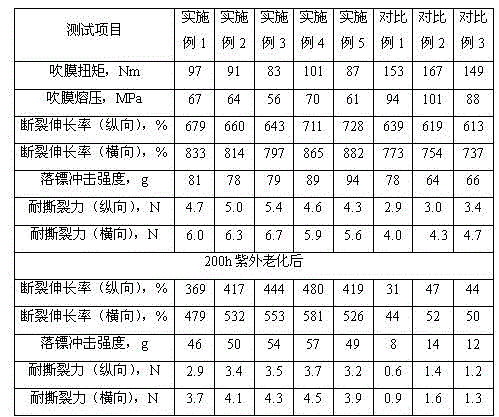

Polyethylene composite with excellent puncture resistance and weather resistance

ActiveCN104558788AStrong puncture resistanceStrong anti-ultraviolet aging abilityAntioxidantUltraviolet

The invention discloses a polyethylene composite with excellent puncture resistance and weather resistance, and belongs to the field of high polymer materials. The composite is characterized by being prepared from the following components in parts by weight: 80-90 parts of polyethylene resin A, 5-15 parts of polyethylene resin B, 0.3-0.7 parts of antioxidant, 1.5-2.5 parts of nano titanium oxide and 0.1-0.3 parts of ultraviolet absorber, wherein the polyethylene resin A is a copolymer of ethylene and 1-butylene or / and 1-hexylene; the density is 0.917-0.924g / cm<3>; a melt flow rate (MFR) is 1.6-2.4g / 10min; the polyethylene resin B is metallocene polyethylene; the density is 0.916-0.922g / cm<3>; and an MFR is 37-43g / 10min. The composite has good ultraviolet ageing resistance, good puncture resistance and higher physical and mechanical strength; and the strength of a film material after long-term use under an ultraviolet condition can be improved.

Owner:CHINA PETROLEUM & CHEM CORP

Wood plastic starch composite material and preparation method thereof

The invention relates to a wood plastic starch composite material and a preparation method thereof. The wood plastic starch composite material is prepared by mixing base materials, an additive aluminium titanium composite coupling agent, glycerol, an antioxidant 1,010 and a lubricant zinc stearate, wherein the base materials comprise 40 to 65 weight percent of recycled corrugated paper fiber, 10 to 40 weight percent of low-density polyvinyl resin and 10 to 30 weight percent of starch; the using amount of the additive aluminium titanium composite coupling agent is 1 to 6 weight percent of the recycled corrugated paper fiber content; the glycerol content is 5 to 15 weight percent of the starch content; the antioxidant 1,010 content is 0.5 to 2 percent of the total weight of the base materials; and the weight of the lubricant zinc stearate is 1 to 4 percent of the total weight of the base materials. The wood plastic starch composite material has high recycled corrugated paper fiber content, low cost, high physical and mechanical strength, high surface finishment, water resistance and chemical corrosion resistance, is susceptible to degradation, and is a new environmentally-friendly wood-plastic product.

Owner:HUNAN UNIV OF TECH

Method for preparing polyacrylate/nano ZnO composite leather finishing agent by Pickering emulsion polymerization

InactiveCN104892828AHigh physical and mechanical strengthImprove wet and dry rub resistanceCoatingsLeather surface finishingLithium hydroxideActive agent

The invention relates to a method for preparing a polyacrylate / nano ZnO composite leather finishing agent by Pickering emulsion polymerization. When the polyacrylate finishing agent prepared by conventional emulsion polymerization uses a surfactant, the dry / wet rubbing resistance of the finished leather can be lowered. The method comprises the following steps: mixing and heating zinc acetate dihydrate and ethanol to obtain a zinc acetate dihydrate-ethanol solution; adding lithium hydroxide, and carrying out ultrasonic treatment to obtain a nano ZnO alcosol; adding distilled water, stirring, centrifuging, separating, washing with water, and dispersing in distilled water to obtain a nano ZnO water dispersion; and dropwisely adding butyl acrylate-methyl methacrylate mixed monomers, dropwisely adding an ammonium persulfate water solution, keeping the temperature, and cooling to obtain the finishing agent. By using the nano ZnO sol prepared by the sol-gel process instead of the traditional surfactant, the polyacrylate / nano ZnO composite leather finishing agent prepared by Pickering emulsion polymerization has the advantages of favorable physical and mechanical strength and higher dry / wet rubbing resistance.

Owner:SHAANXI UNIV OF SCI & TECH

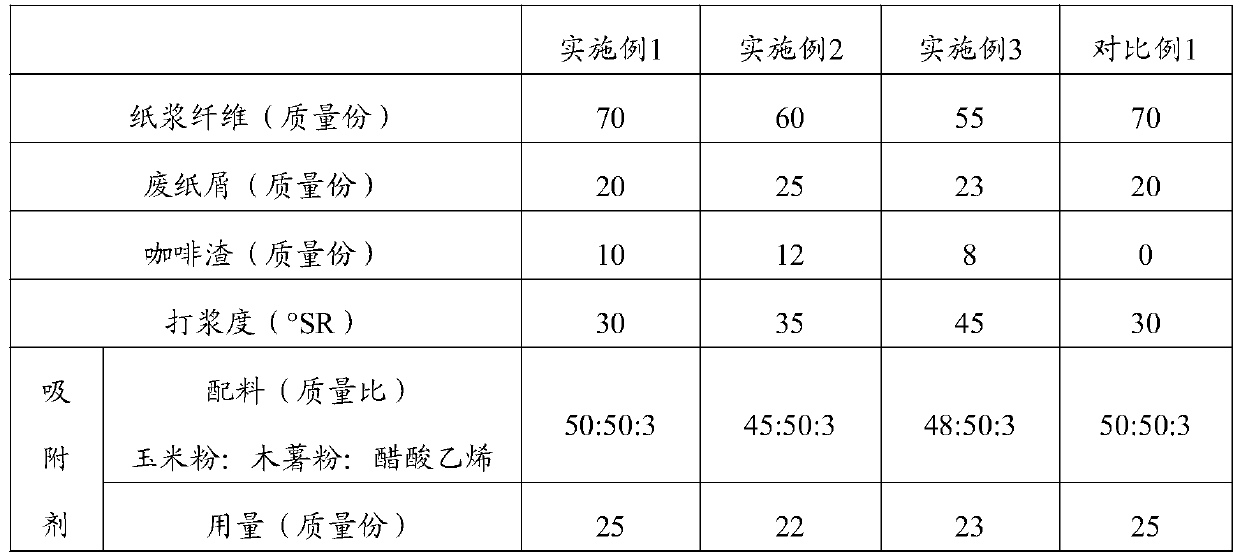

Paper with coffee flavor and preparation method and application thereof

ActiveCN110284361AHigh physical and mechanical strengthReduce usageVegetable material additionPaper/cardboardFiberSorbent

The invention belongs to the technical field of recycling and reusing of coffee grounds, and specifically relates to paper with coffee flavor and a preparation method and application thereof. The paper with the coffee flavor provided by the invention is prepared from the following raw materials in parts by mass: 50-70 parts of pulp fibers, 15-25 parts of waste paper scraps, 6-13 parts of the coffee grounds, 4-5 parts of an adsorbent and 5-15 parts of a charge balancing agent. According to the paper with the coffee flavor and the preparation method and application thereof, the coffee grounds are used as one of the raw materials of papermaking, so that the paper has the coffee flavor and has the function of removing odor; meanwhile, the use of the coffee grounds also improves the physical and mechanical strength of the paper; the use of the coffee grounds and the waste paper scraps reduces the use amount of pulp raw materials and reduces papermaking cost.

Owner:东莞市绿保纸塑制品有限公司 +1

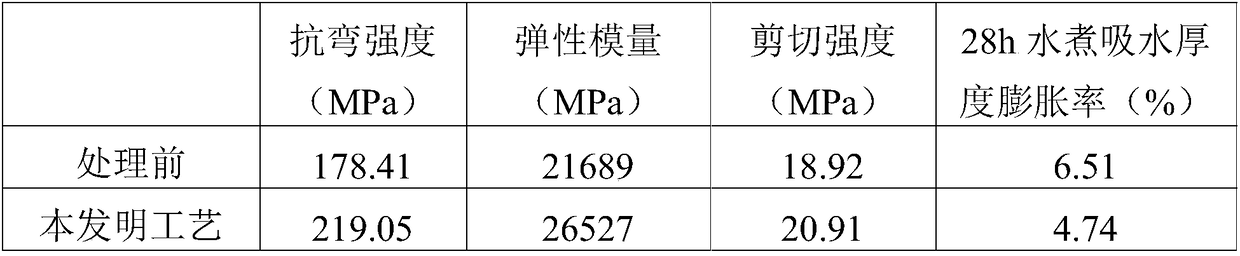

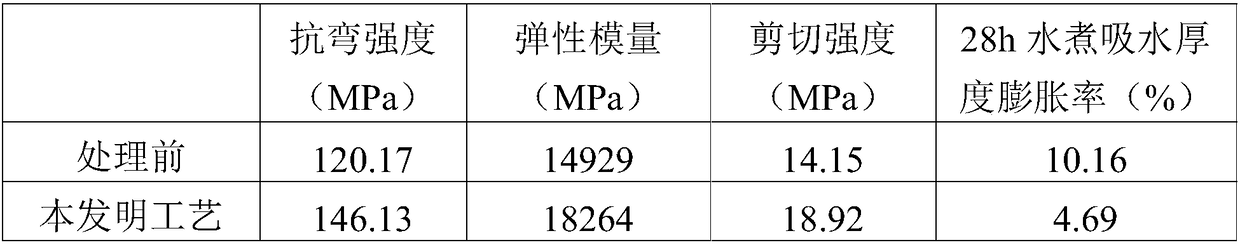

Method for improving bonding performance of reconstituted bamboo

ActiveCN108162105AGood gluing propertiesEasy to operateWood treatment detailsCane mechanical workingWaxCarbonization

The invention discloses a method for improving bonding performance of reconstituted bamboo. The method includes the steps of bamboo defibering, bonding improvement treatment, drying, gum dipping, secondary drying of bamboo, reconstituting forming and the like. According to the method, the bamboo is subjected to mechanical defibering, then the bamboo is subjected to spraying treatment and high-temperature carbonization treatment with NaOH, and thus a silicon layer and a wax layer on the surface of the bamboo are effectively removed and damaged; and on the basis, gum dipping and secondary dryingare carried out, and finally reconstituting forming is carried out. According to the reconstituted bamboo prepared by the method, the bonding performance of the bamboo is improved, and in the processing progress, operation is simple, poison, harm and waste are avoided, and the physical mechanical strength is remarkably improved, wherein the horizontal shearing strength is improved by 10% or above, the water-absorbing thickness swelling rate is lowered by 26% or above, the bending strength is improved by 16% or above, and the elastic modulus is improved by 20% or above.

Owner:GUANGDONG ACAD OF FORESTRY

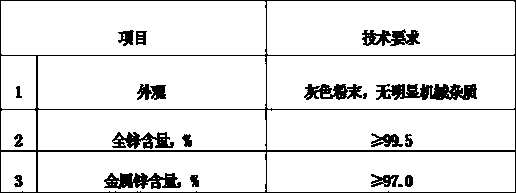

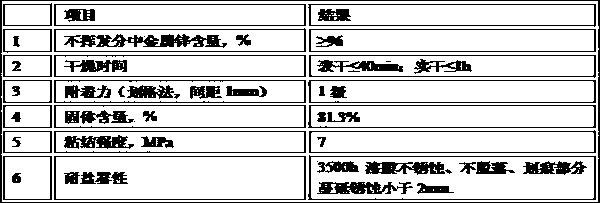

Cold-zinc-spray long-acting anti-corrosive coating

InactiveCN103965786AImprove water resistanceImprove aging resistanceAnti-corrosive paintsZincBonding strength

The invention discloses a cold-zinc-spray long-acting anti-corrosive coating. The coating comprises the components in a weight ratio: 11%-14% of silicone-grafted polymer, 78%-83% of ultrafine zinc powder and 6%-8% solvent gasoline. Compared with existing similar products, the product, of which the content of metallic zinc in dry paint film is greater than 96%, has the same antirust effect as hot galvanizing and a steel structure is protected from being corroding for 20-25 years in a severe marine-atmosphere environment; the anti-corrosive coating has the advantages of high bonding strength, salt-spray corrosion resistance, single component and convenience in construction and operation and the service life of the steel structure is significantly prolonged.

Owner:江苏山力漆业有限公司

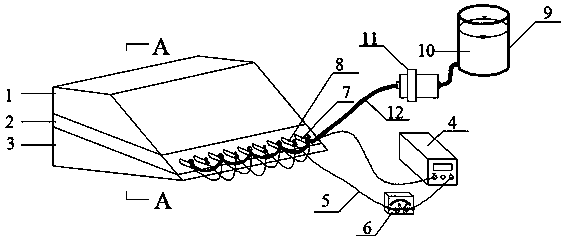

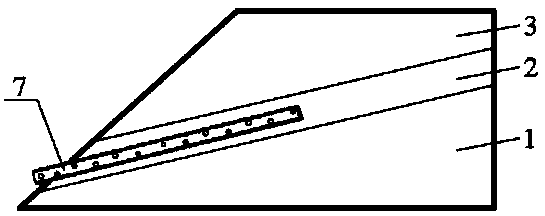

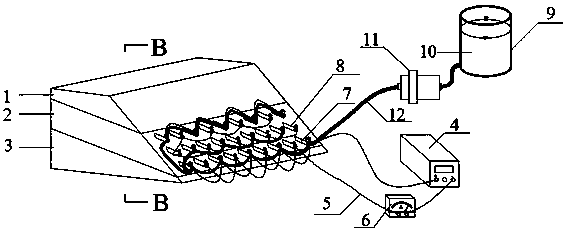

Method for electrochemical reinforcement of down dip weak interlayer of strip mine slope

InactiveCN111364485AHigh strengthHigh physical and mechanical strengthExcavationsSoil preservationPotential differenceWater flow

The invention discloses a method for electrochemical reinforcement of a down dip weak interlayer of a strip mine slope. The method comprises the steps that anodes and cathodes are alternately arrangedin the weak interlayer at intervals; all the anodes and cathodes are correspondingly and sequentially connected in series through wires and then connected with a direct current power supply, and theouter end parts of the anodes communicate with a solution bin containing an electrolyte solution through a solution delivery pipe; and the electrolyte solution in the solution bin is delivered into ananode metal pipe through the solution delivery pipe, and overflows into the weak interlayer from drilled holes in the surfaces of the anodes, and after the anodes are powered by the direct current power supply, the anodes and the electrolyte solution can react chemically to form metal compounds and hydrated cations. The metal compounds play a role in cementing and solidifying soil of the weak interlayer, the potential difference between the anodes and the cathodes drives the water inside the weak interlayer to move to the cathodes and enter into a cathode metal pipe through the drilled holes,the water flows by gravity to flow out freely from the lower end of the cathode metal pipe and be discharged to the outside of the weak interlayer, and the reinforcement effect of the weak interlayeris good.

Owner:CHINA UNIV OF MINING & TECH

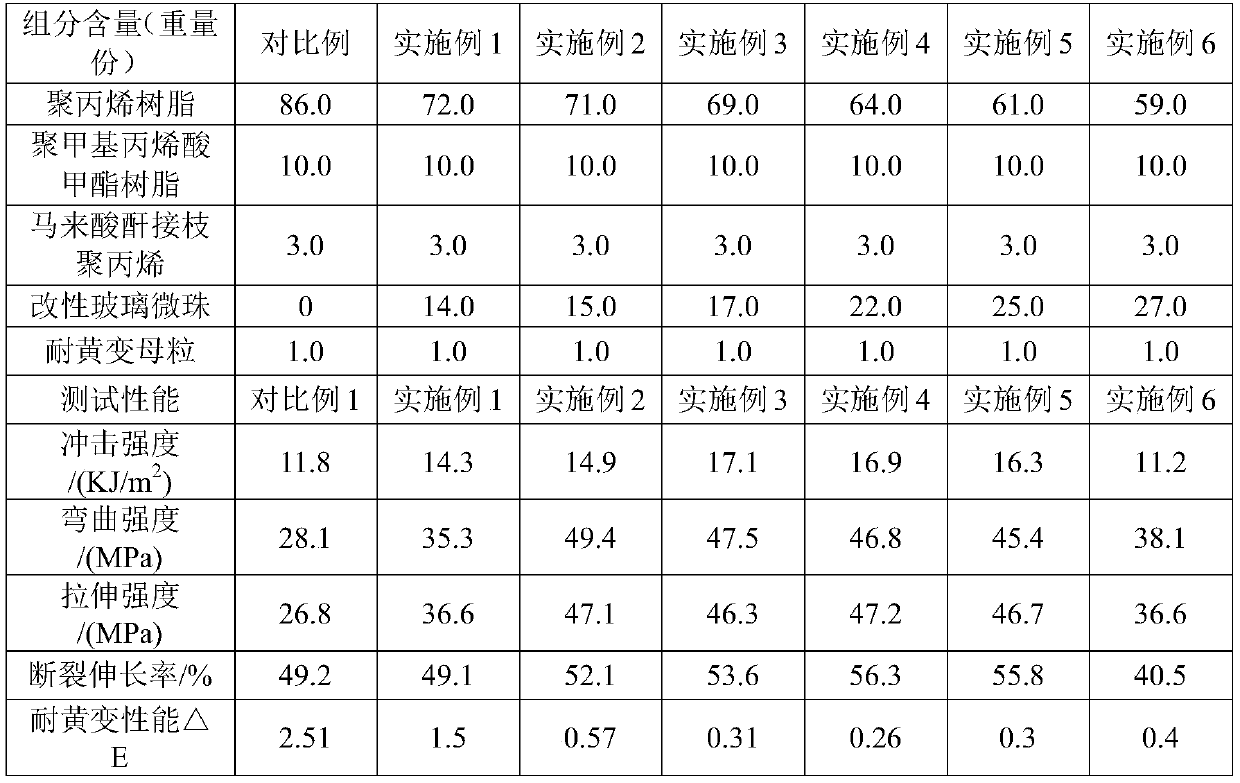

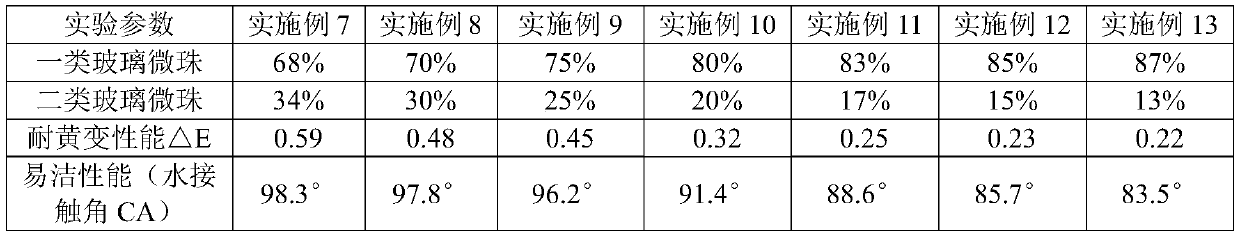

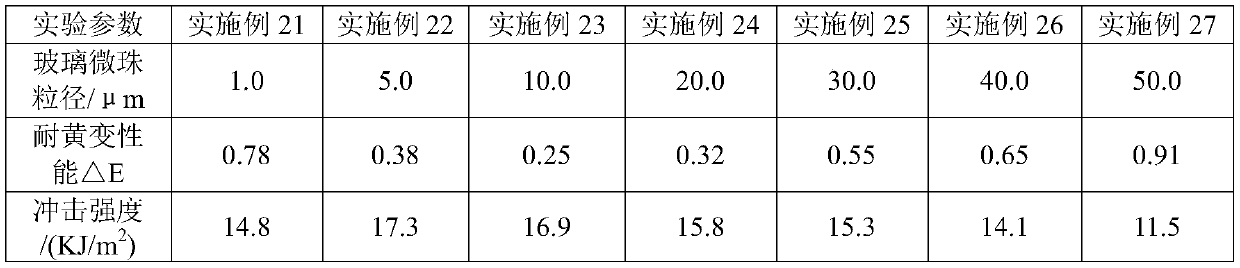

Modified glass microsphere and preparation method thereof and method for preparing composite resin product by using modified glass microsphere

The invention discloses a modified glass microsphere and a preparation method thereof and a method for preparing a composite resin product by using the modified glass microsphere. The modified glass microsphere includes a first class glass microsphere and a second class glass microsphere, a discontinuous metal layer and an ultraviolet absorbent wrap the surface of the first class glass microsphere, a hydrophobic material wraps the surface of the second class glass microphere, the coverage rate of the metal layer on the surface of the first glass microsphere is 45.0%-85.0%, and the modified glass microbead is added into the component of a common anti-yellowing product to improve the anti-yellowing property and the mechanical property of the product.

Owner:JOMOO KITCHEN & BATHROOM

Environment-friendly and durable sisal bag and preparation method thereof

InactiveCN107383432AHigh physical and mechanical strengthStrong water resistanceEnvironmental resistanceCarbon fibers

The invention discloses an environment-friendly and durable sisal bag and a preparation method thereof. The environment-friendly and durable sisal bag comprises raw materials in parts by weight as follows: sisal fibers, shengma fibers, ramie fibers, bamboo fibers, carbon fibers, banana fibers, konjac starch, polyvinyl alcohol, polyvinyl chloride, aromatic particles, negative ion mineral particles, thermoplastic polyurethane, titanium dioxide, laccase, agar, a plasticizer, a surfactant, a plant extract solution and an antibacterial agent. The natural degradable fibers including the sisal fibers, the shengma fibers, the ramie fibers, the bamboo fibers, the carbon fibers and the banana fibers are selected as the main raw materials, the plastic bag can be degraded rapidly in a natural state by means of combined use of titanium dioxide and the laccase, and by means of cooperation with other additives such as the plasticizer, the surfactant and the like, the environment-friendly and durable sisal bag is easy to degrade and has higher environmental resistance, water resistance, durability and antibacterial property.

Owner:GUANGXI TEACHERS EDUCATION UNIV

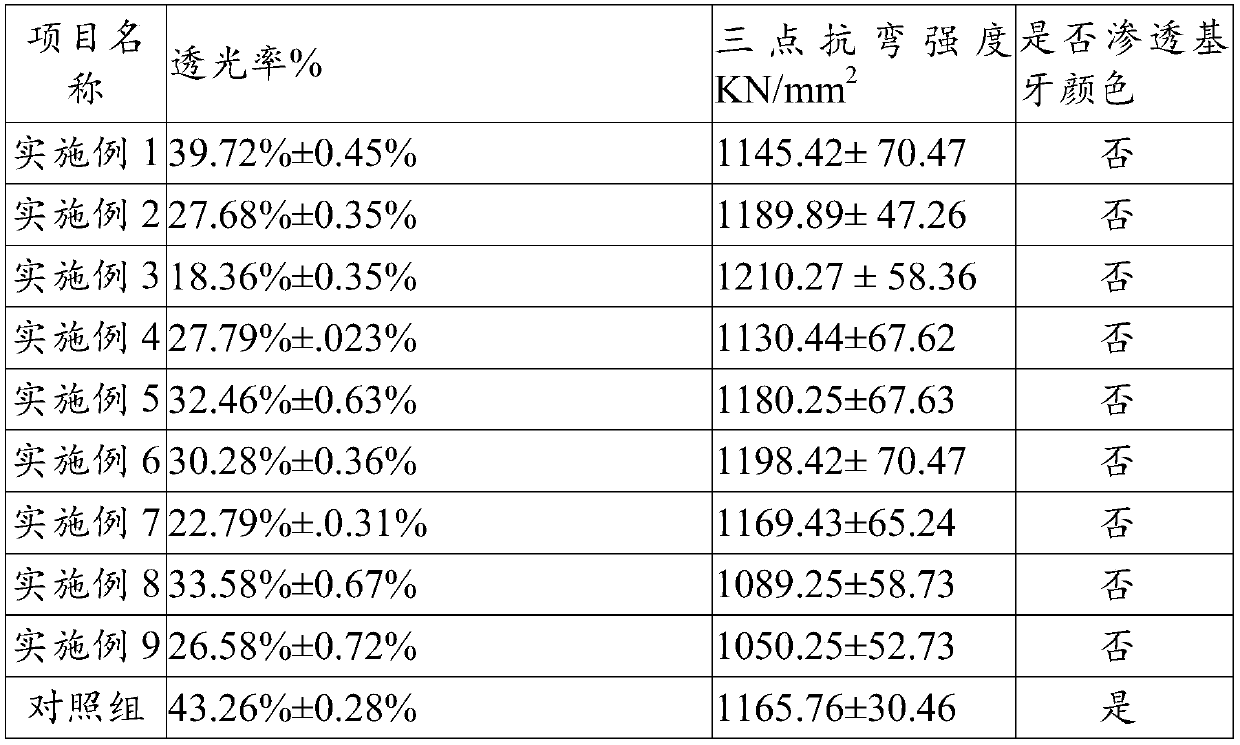

Masking liquid for dental zirconium oxide ceramic as well as preparation method and application thereof

The invention discloses a masking liquid for a dental zirconium oxide ceramic. The masking liquid comprises a masking agent, a color indicating agent, an additive and deionized water. The masking liquid can reduce the transparency in a tooth restoration without affecting the color effect out of the restoration. Meanwhile, the invention also discloses a preparation method of the masking liquid forthe dental zirconium oxide ceramic. The preparation method has the obvious advantages of simple process, low manufacturing cost and good repeatability. Moreover, the invention also discloses application and an application method of the masking liquid for the dental zirconium oxide ceramic. The problem that the transparency in the dental zirconium oxide ceramic is too high can be improved obviously, so that the finally obtained tooth restoration can obtain a natural emulational effect.

Owner:AIDITE (QINHUANGDAO) TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com