Patents

Literature

93results about How to "The synthesis process is simple and controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

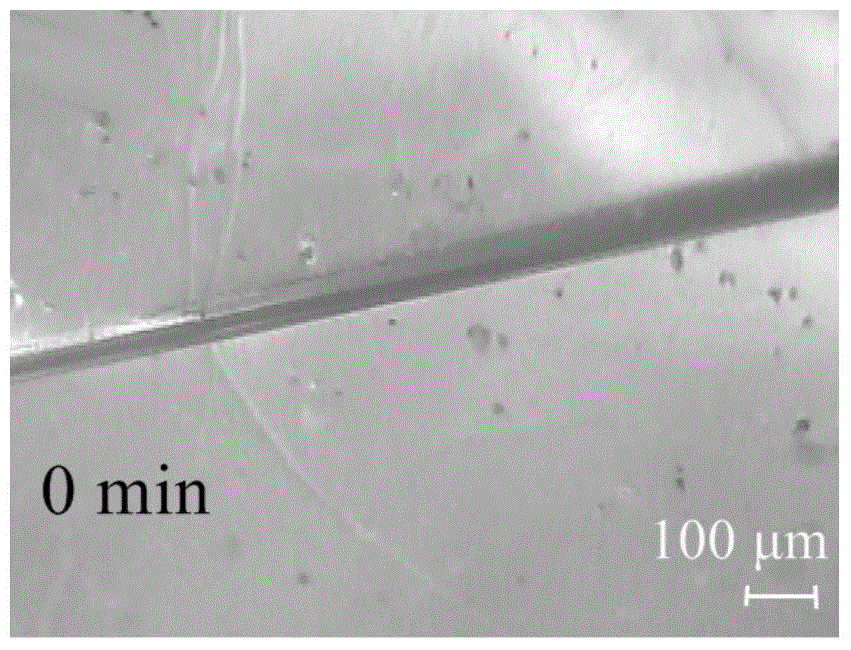

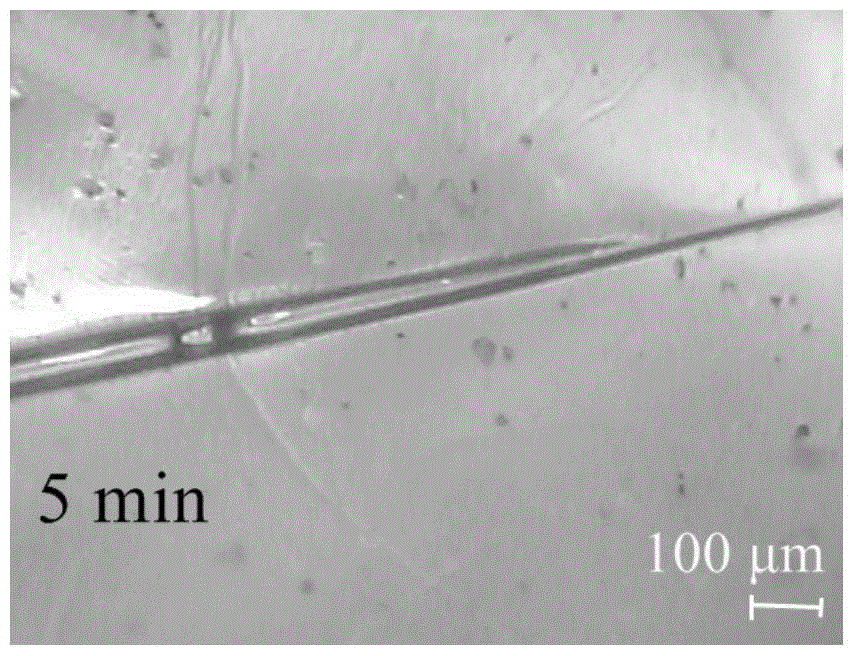

Self-healing polyurethane resin containing disulfide bond and preparation method thereof

The invention relates to self-healing polyurethane resin containing disulfide bond and a preparation method thereof. The polyurethane resin comprises, by weight parts, 10-30 parts of polyether or polyester polyol, 3-20 parts of polyisocyanates, 1-10 parts of chain extender containing the disulfide bond, 0.001-1 part of organic tin or tertiary amine catalyst and 50-80 parts of organic solvent. The method for preparing the self-healing polyurethane resin containing the disulfide bond comprises the steps of weighing raw materials, stirring, heating and performing dehydration for the polyether or polyester polyol under vacuum conditions, lowering the temperature to 85 DEG C or below, adding the polyisocyanates and the organic tin or tertiary amine catalyst, reacting, lowering the temperature to 50 DEG C or below, adding the organic solvent and the chain extender containing the disulfide bond, reacting and performing vacuum defoamation to obtain the self-healing polyurethane resin. The self-healing polyurethane resin heals by itself under the heating or ultraviolet (UV) light conditions, the required conditions are mild, the healing speed is high, the effect is good, the preparation method is simple and easy to control, and raw materials are goods of commercialized production and are cheap and easy to obtain.

Owner:DONGHUA UNIV

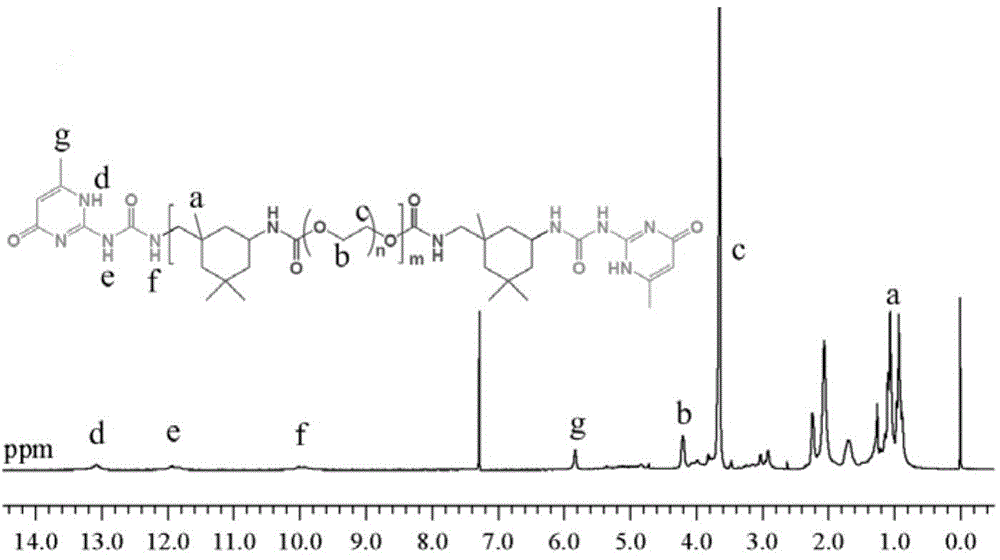

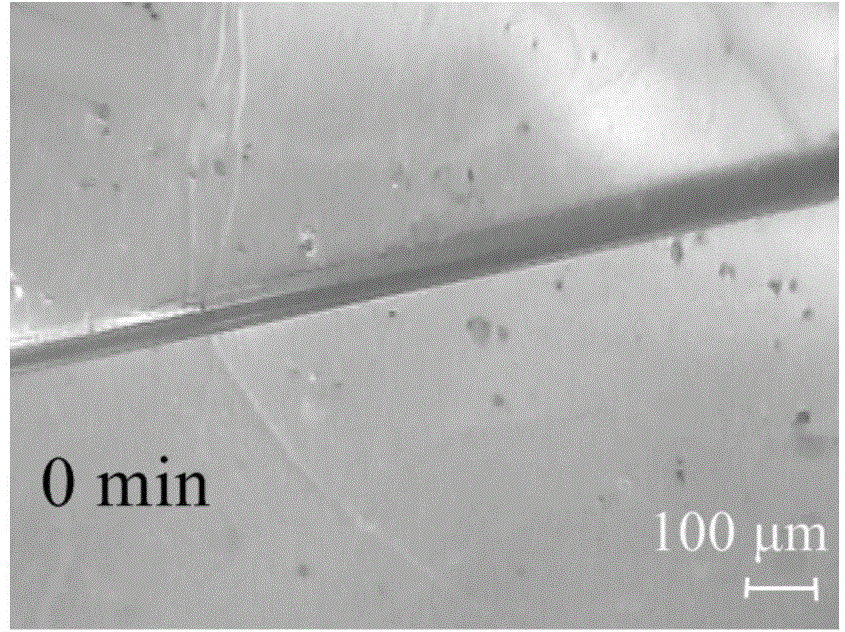

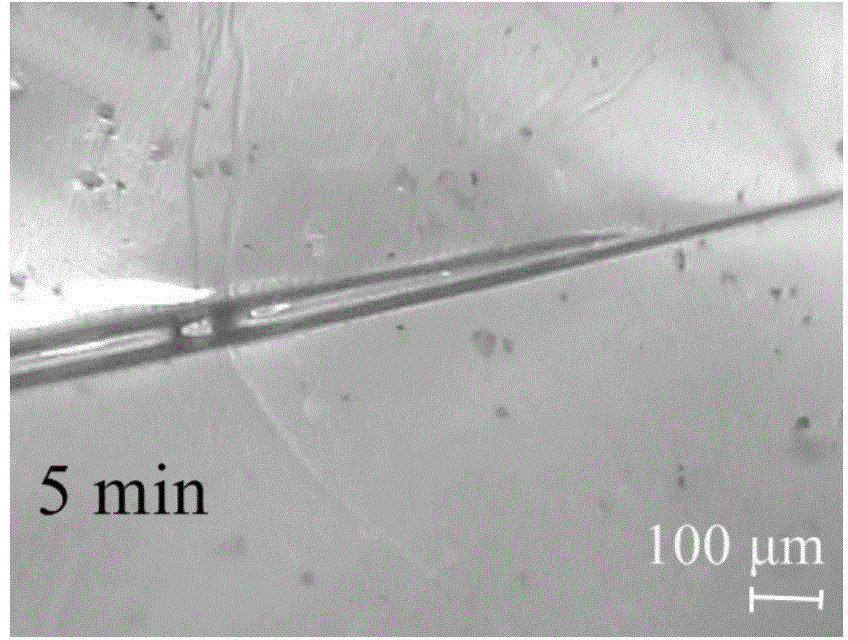

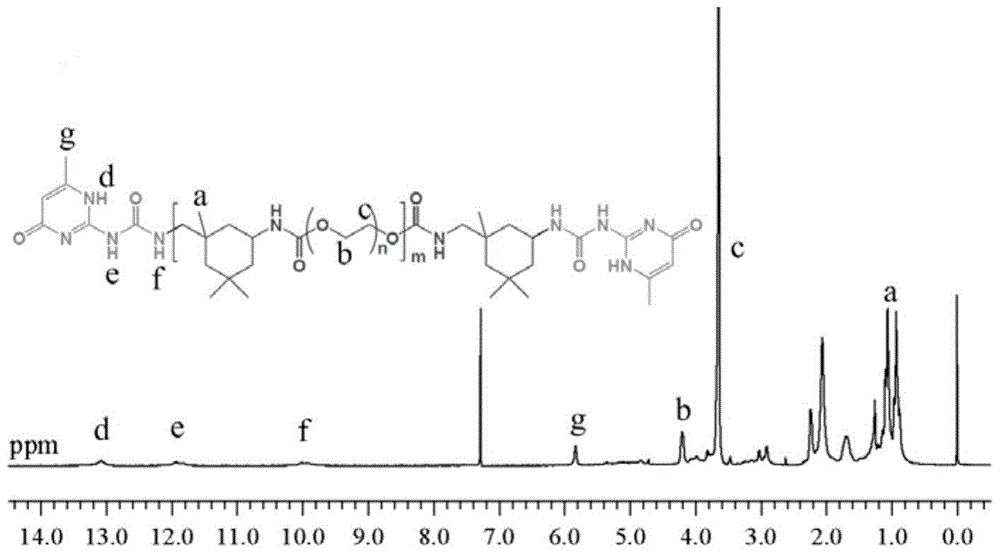

Self-repairing polyurethane hydrogel and preparation method thereof

The invention relates to a self-repairing polyurethane hydrogel and a preparation method thereof. The polyurethane hydrogel comprises the following components in parts by mass: 10-30 parts of polyisocyanate, 30-50 parts of hydrophilic polyester polyol or hydrophilic polyether polyol, 10-50 parts of acrylamide monomer, 0.5-3 parts of chain extender, 3-10 parts of methacrylic acid functional monomer containing an UPy unit, 0.5-2 parts of catalyst and 0.5-3 parts of photoinitiator. The preparation method comprises the following steps of firstly preparing a hydrophilic polyurethane macromonomer terminated with an acrylic acid monomer and carrying out radical polymerization with the methacrylic acid functional monomer containing the UPy unit under the action of photo-initiation. According to the self-repairing polyurethane hydrogel, the self-repairing of the damage of the polyurethane hydrogel can be completed without need of any repairing agent or specific environmental requirements, the polyurethane hydrogel has the advantages of high repairing efficiency, high mechanical strength and low cost and the repeatedly repairing function can be achieved on the same site.

Owner:SOUTH CHINA UNIV OF TECH

Self-repairing polyurethane coating and preparation method thereof

ActiveCN104356338ARepair damageGood physical and mechanical propertiesPolyurea/polyurethane coatingsPolyesterPolyol

The invention discloses a self-repairing polyurethane coating and a preparation method thereof. The polyurethane coating comprises the following raw materials in parts by mass: 15-20 parts of polyisocyanates, 40-60 parts of hydrophilic polyester polyol or polyether polyol, 2-3 parts of a chain extender and 7-15 parts of methylcystein. The preparation method comprises the following steps: preparing a hydrophilic polyurethane prepolymer from hydrophilic polyester polyol or polyether polyol and the chain extender, and reacting the isocyanate group in the hydrophilic polyurethane prepolymer with methylcystein, so as to obtain a polyurethane material of which the tail end or the main chain contains 2-urea-4-pyrimidone units; spraying or coating the polyurethane material on the surface of a substrate, thereby obtaining the self-repairing polyurethane coating. The self-repairing of the self-repairing polyurethane coating disclosed by the invention can be completed without external repairing agent or requirements of special environment, the coating is good in transparency, high in strength, good in filming property, simple in process and low in cost, and the function of repeated repairing in same positions can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

High-resilience self-repair high-polymer aquagel and preparation method thereof

The invention discloses a high-resilience self-repair high-polymer aquagel and a preparation method thereof. The high-resilience self-repair high-polymer aquagel is prepared from the following raw materials in parts by mass: 15-20 parts of polyisocyanate, 40-75 parts of hydrophilic polyester polyol or hydrophilic polyether glycol, 1-5 parts of acrylate monomer, 10-15 parts of acrylamide monomer, 0.5-2 parts of chain extender, 1-3 parts of surfactant, 0.1-1 part of alkyl acrylate monomer and 0.5-2 parts of catalyst. The preparation method comprises the following steps: preparing an acrylate-monomer-terminated hydrophilic polyurethane high-polymer monomer self-assembly and an alkyl acrylate micelle; and carrying out radical copolymerization with acrylamide monomer under the photoinitiation action. The obtained self-repair high-polymer aquagel can complete self repair on self damage without any repair agent or specific environment, and has excellent resilience and physical and mechanical properties.

Owner:SOUTH CHINA UNIV OF TECH

Self-repaired graphene oxide/polyurethane composite material and preparation method thereof

The invention discloses a self-repaired graphene oxide / polyurethane composite material and a preparation method thereof. The preparation method comprises the following steps: performing a reaction on 2-amino-4-carbonyl-6-methylpyrimidine with an amino, polyisocyanate, polyester polyol or polyether polyol and a chain extender to synthesize polyurethane with quadruple hydrogen bonding units; adding 2-amino-4-carbonyl-6-methylpyrimidine into polyisocyanate to react to synthesize isocyanate with quadruple hydrogen bonding units, and then performing a reaction on the isocyanate and graphene oxide to obtain graphene oxide with quadruple hydrogen bonding units; and finally, compounding the polyurethane with quadruple hydrogen bonding units and the graphene oxide with the quadruple hydrogen bonding units to obtain the self-repaired graphene oxide / polyurethane composite material. The self-repaired graphene oxide / polyurethane composite material prepared by the invention can realize self-repair of the material without any additional repair agents and requirements on special environments. The material is simple in synthetic process and the repair rate reaches up to 85%.

Owner:SOUTH CHINA UNIV OF TECH

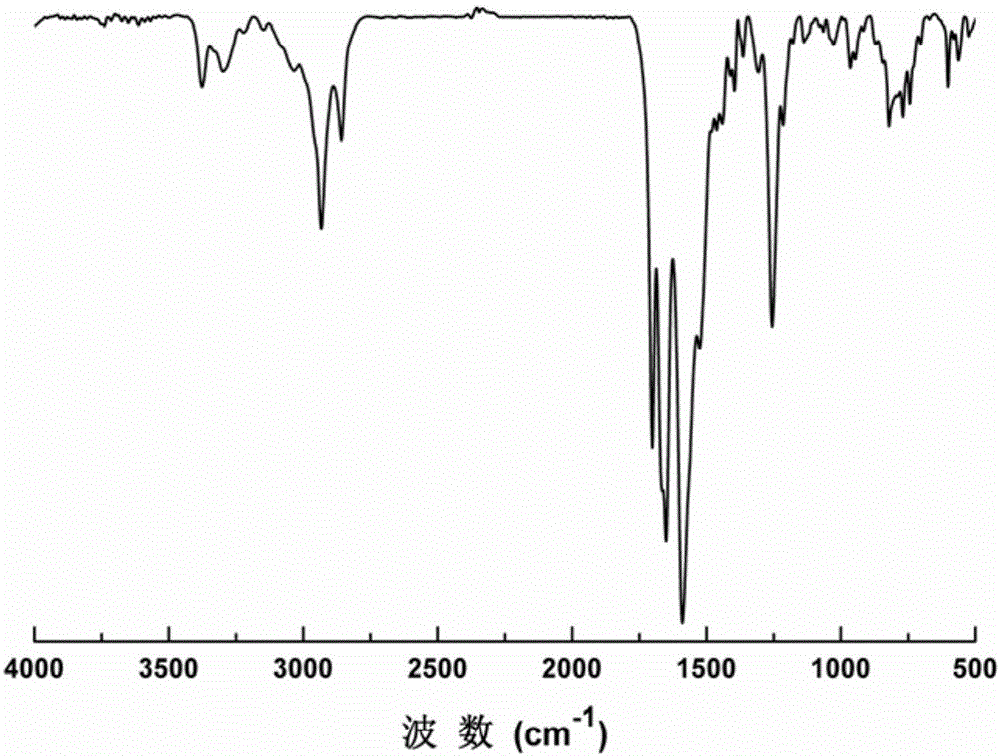

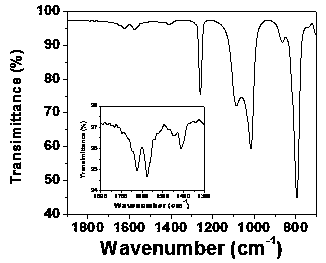

Polysiloxane-carbamate elastomer containing Diels-Alder bond and preparation method of polysiloxane-carbamate elastomer

InactiveCN105949422AHigh tensile strengthHigh elongation at breakOrganic chemistryElastomerPolyester

The invention relates to the field of materials, in particular to a polysiloxane-carbamate elastomer containing a Diels-Alder bond and a preparation method of the polysiloxane-carbamate elastomer. The polysiloxane-carbamate elastomer is prepared from a cross-linking agent, isocyanato-terminated polydimethylsiloxane, isocyanato-terminated polyester or polyether, diol containing the Diels-Alder bond as well as a catalyst dibutyltin dilaurate through curing after a reaction in anhydrous 1,4-dioxane under the protection of nitrogen. The elastomer has a microphase separation structure, multiple plastic micro-areas are formed in the elastomer, and on one hand, the micro-areas are taken as physical crossing points to improve tensile strength; on the other hand, the plastic micro-areas generate plastic deformation in a stretching process to increase elongation at break. The method adopts easily available raw materials, a synthesis process requires no special conditions or equipment, a synthesis technology is simple and easy to control, and the yield is high.

Owner:SICHUAN UNIV

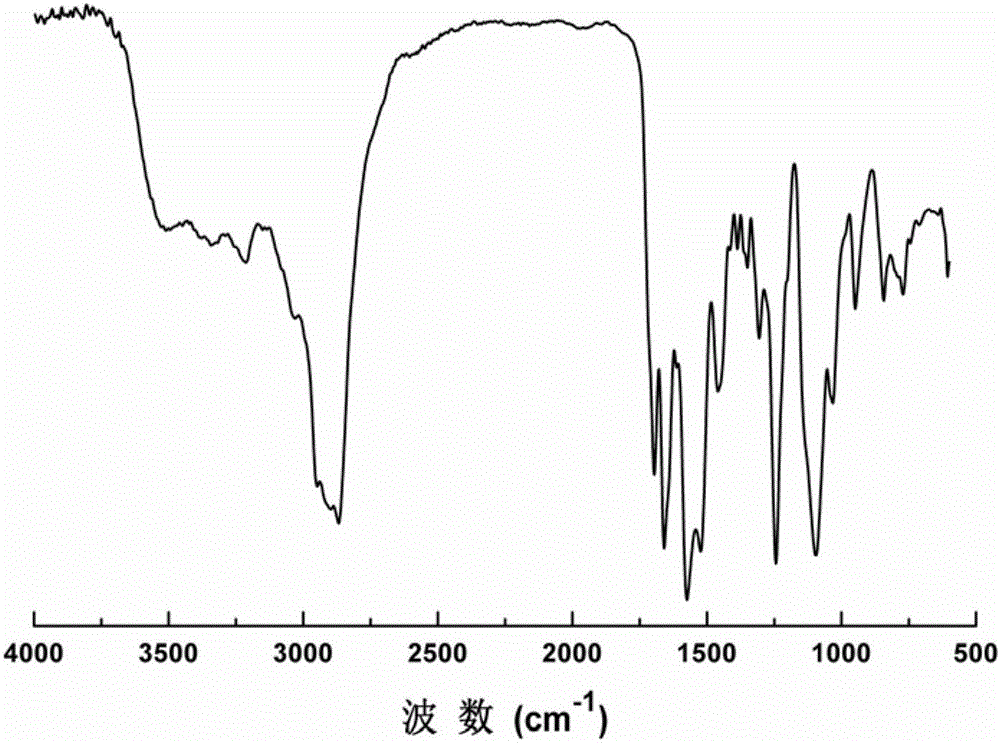

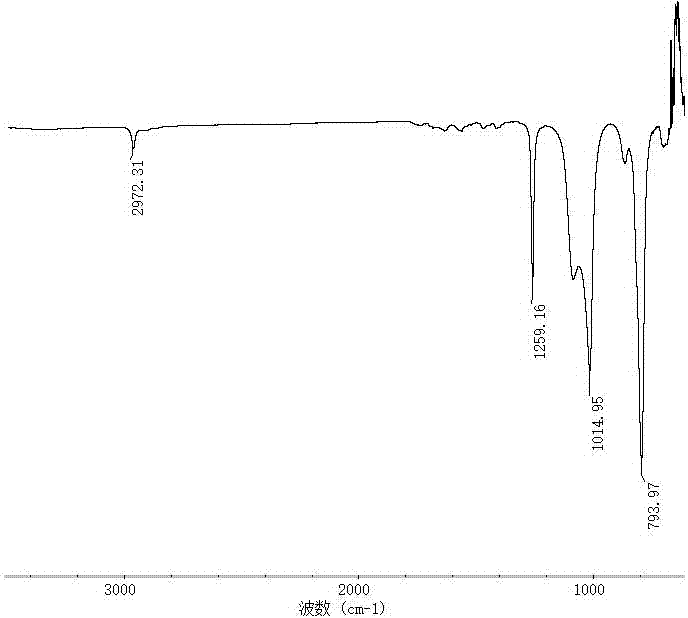

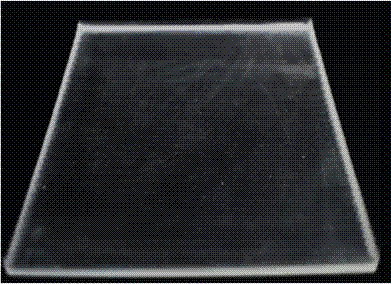

Polysiloxane elastomer and preparation method and application thereof

InactiveCN108003317AHigh mechanical strengthCapable of heavy processingAdditive manufacturing apparatusElastomerSolvent

The invention relates to the technical field of new materials, in particular to a polysiloxane elastomer and a preparation method and application thereof. Amino or hydroxyl end capped polydimethylsiloxane, diisocyanate, phenol compounds and a cross-linking agent are dissolved into an organic solvent, a proper amount of catalyst is added, after the reaction is finished, a prepolymer is poured intoa polytetrafluoroethylene mold, heating and solidification are performed, and after the solvent is removed, the novel polysiloxane elastomer is obtained. The polysiloxane elastomer is good in mechanical strength, has the good thermoplasticity, can be reprocessed, has the self-repairing function, and is applied to the fields of flexible electronics, 3D printing, biomedicine and the like.

Owner:SICHUAN UNIV

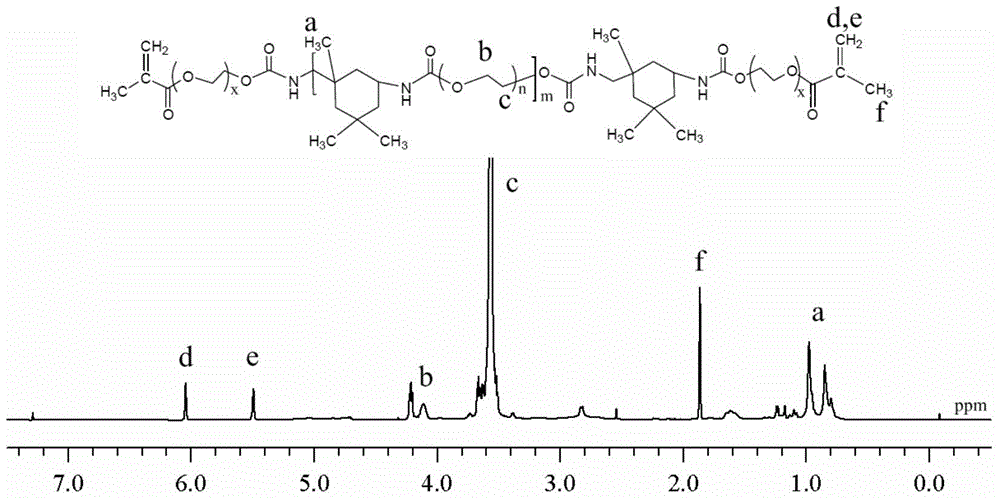

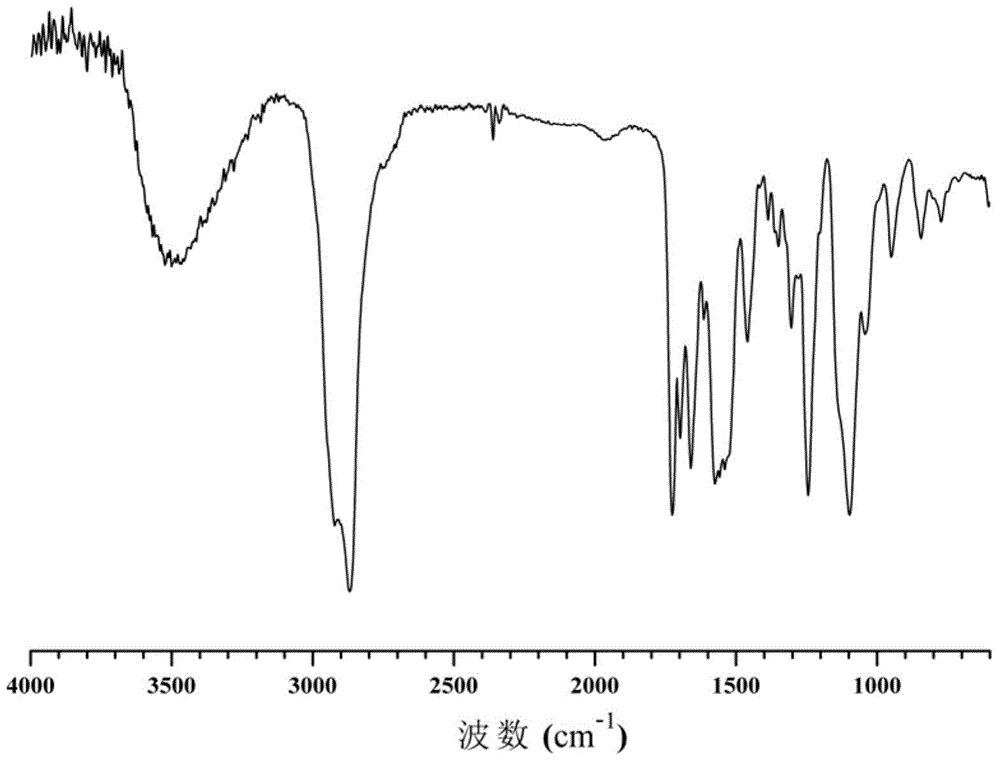

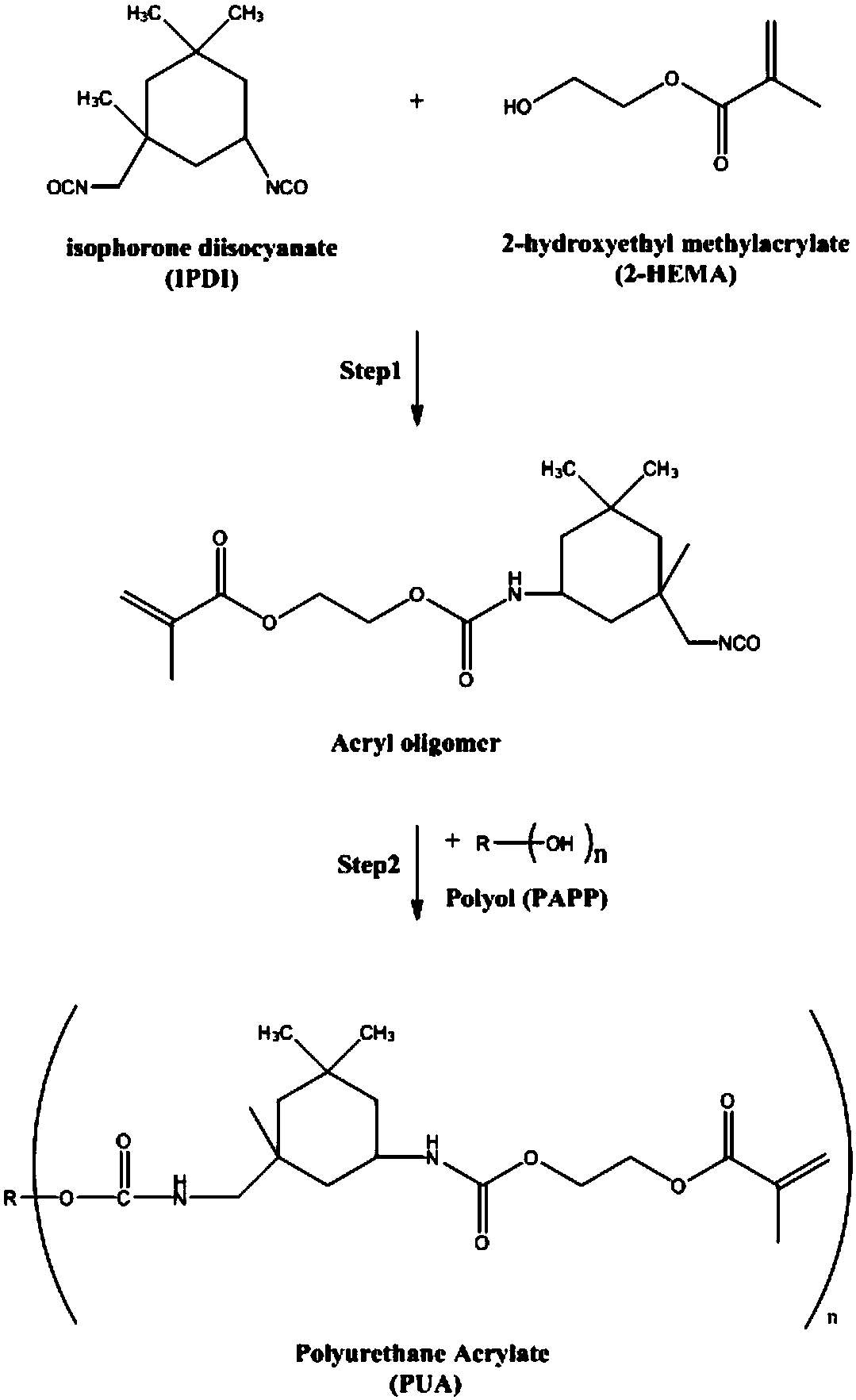

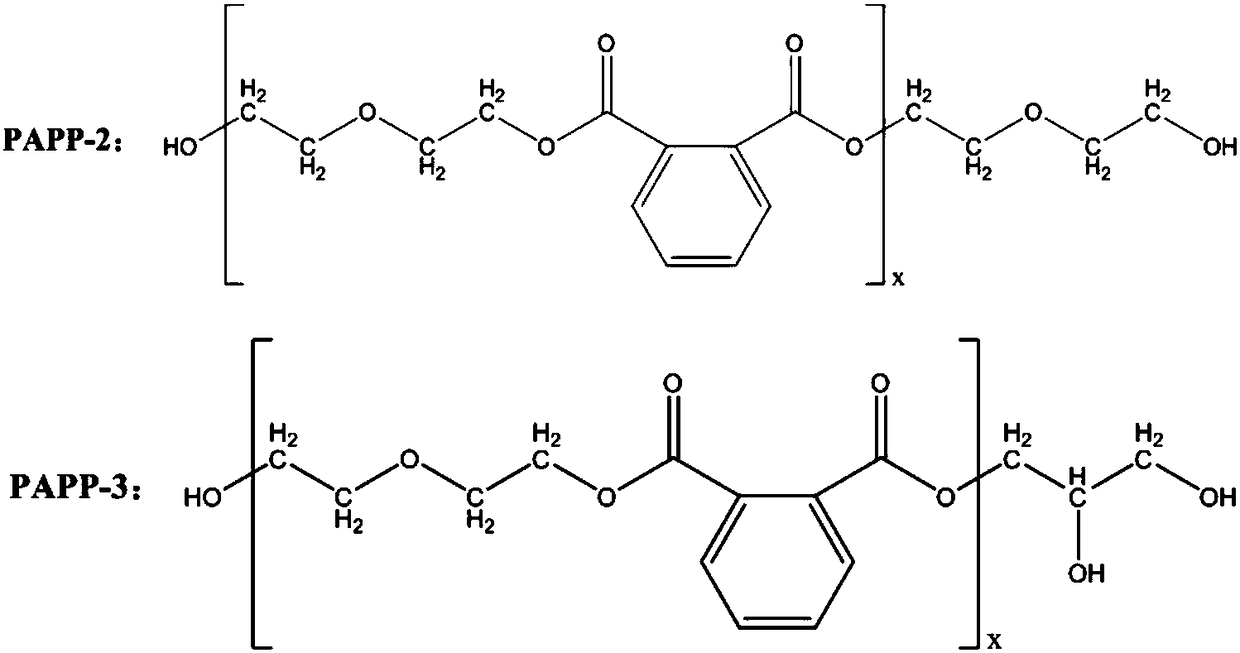

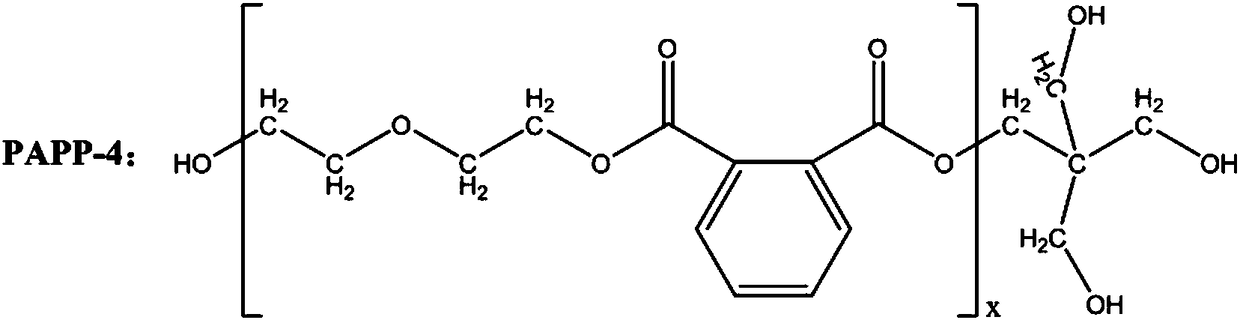

Ultraviolet light curable high-strength polyurethane acrylate resin and preparation method thereof

InactiveCN108383974AOptimize the synthetic routeThe synthesis process is simple and controllablePolyesterAdhesive

The invention relates to ultraviolet light curable high-strength polyurethane acrylate resin and a preparation method thereof. The resin is composed of the following components: 50-80 wt% of polyurethane acrylate and 20-50 wt% of a reactive diluent, wherein the polyurethane acrylate is composed of the following materials: 32-50 wt% of diisocyanate, 19-29 wt% of hydroxyacrylate, 22-49 wt% of a polyester polyol, 0.05-0.3 wt% of a catalyst, and 0.02-0.05 wt% of a polymerization inhibitor; and the method comprises the following steps: 1, mixing the diisocyanate (-NCO: 2 mol), the catalyst, the polymerization inhibitor and the hydroxyacrylate (-OH: 1 mol), and performing a reaction for 2-5 h at the temperature of 45-65 DEG C to obtain a first step product; 2, adding the polyester polyol (-OH: 1mol), and performing a reaction for 1-4 h at the temperature of 65-85 DEG C to obtain polyurethane acrylate (PUA); and 3, adding the reactive diluent to obtain the PUA resin. The method provided by the invention adopts the aromatic polyester polyol to improve the number of double bonds and structural rigidity of the PUA resin, so that the PUA resin can be rapidly cured and has high strength and high modulus; and the resin can be cured by ultraviolet light and heat, and has broad application prospects in the fields of composite material resin matrix, coatings, adhesives and structural adhesives.

Owner:WUHAN UNIV OF TECH

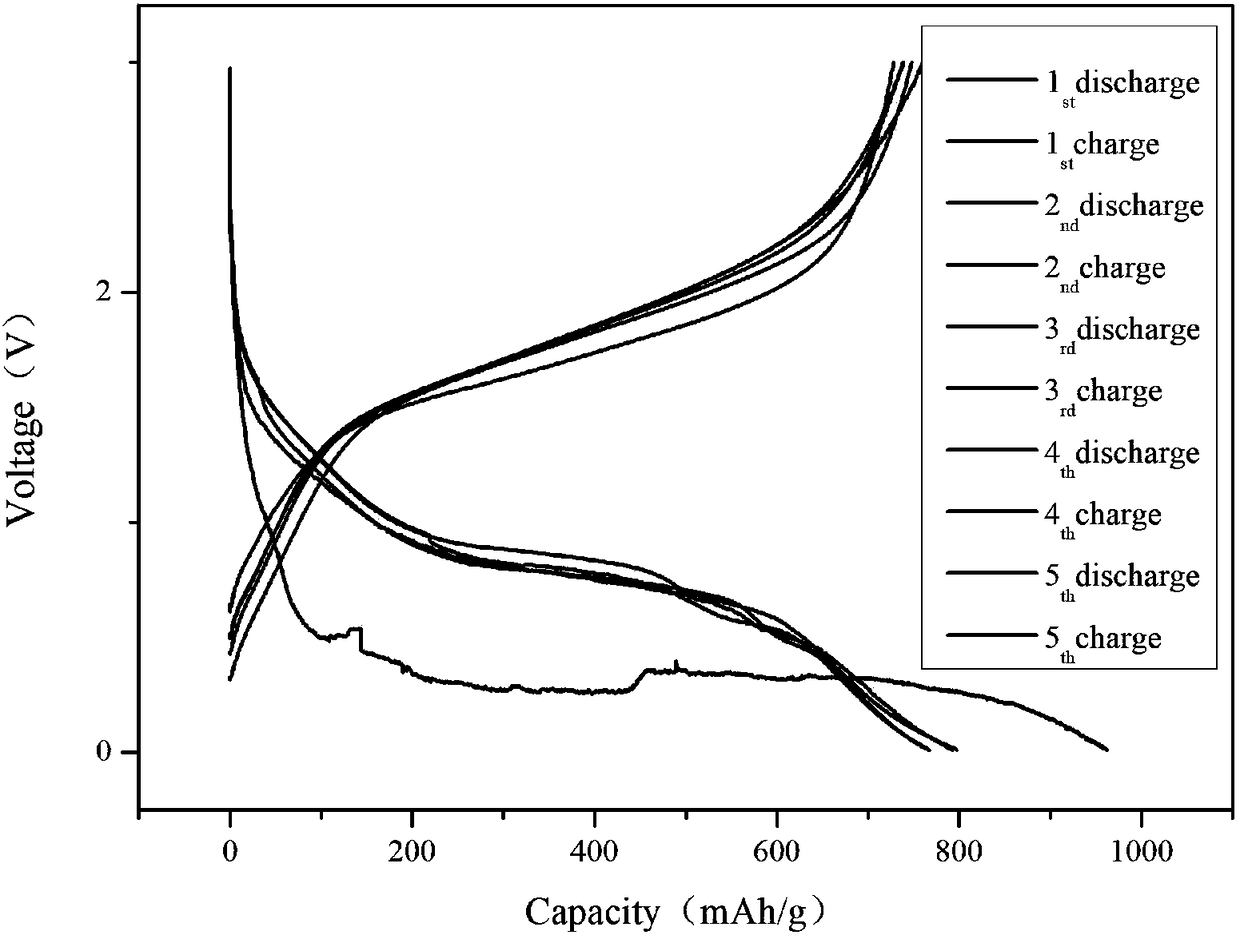

MoS2/nitrogen-doped carbon tube composite material and preparation method and application thereof

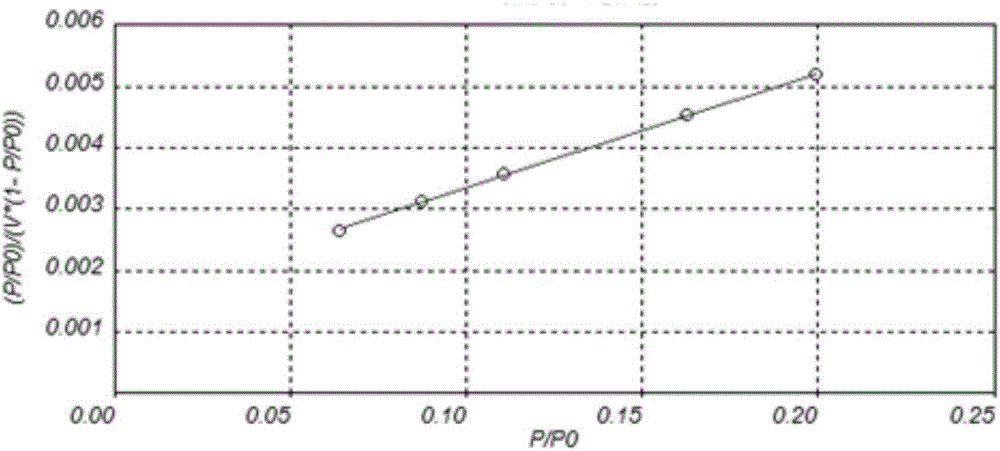

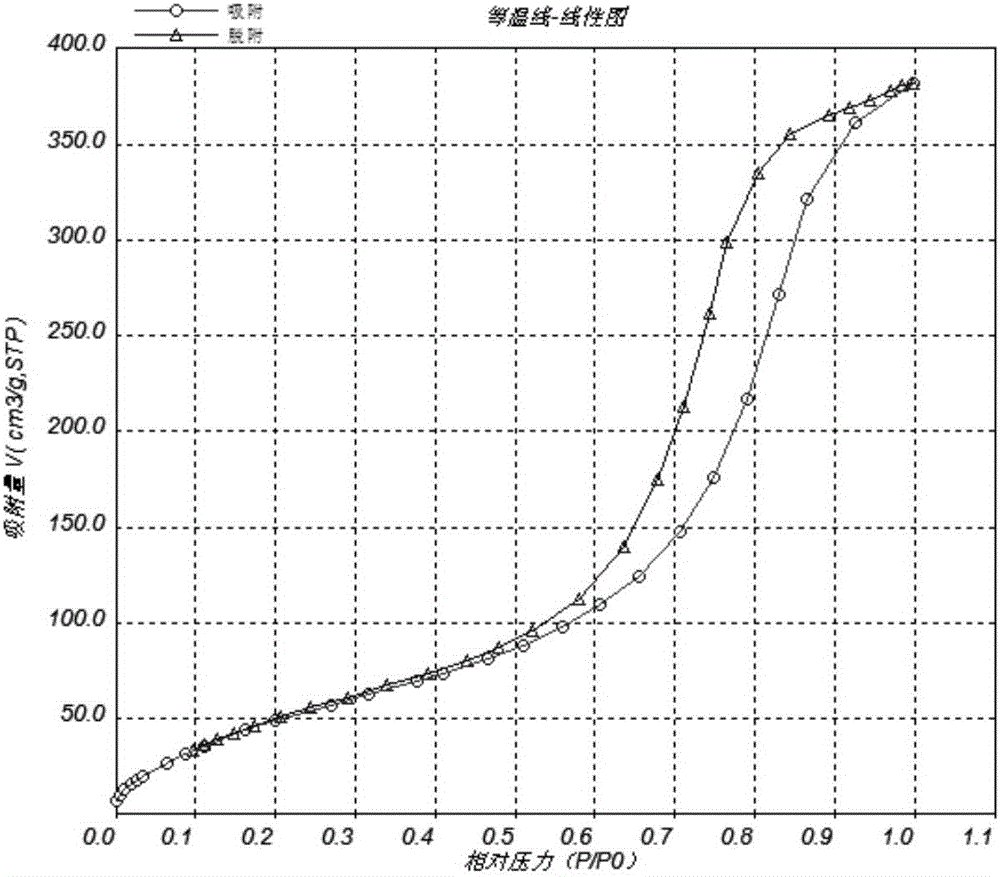

ActiveCN107799757AUniform shapeAvoid uneven loadMaterial nanotechnologyCell electrodesFiberSodium-ion battery

The invention relates to the technical field of a sodium ion battery, in particular to a MoS2 / nitrogen-doped carbon tube composite material and preparation method and application thereof. Low-cost melamine sponge is used as a template material, a layer of MoS2 is grown on a surface of sponge fiber, high-temperature calcination is performed under argon protection, the sponge fiber contracts and iscollapsed from inside to outside, a unique three-dimensional hollow structure is grown, a layer of MoS2 nanosheet is uniformly grown at an outer layer, a nitrogen-doped carbon tube structure is arranged at an inner layer, electrolyte moving is facilitated, rapid electron transfer is also facilitated; and a nitrogen-doped carbon tube is arranged at an inner wall, many active sites are increased bya large amount of nitrogen, and the material obtains very excellent cycle property and rate performance when used as a sodium ion battery negative electrode material.

Owner:QINGDAO UNIV

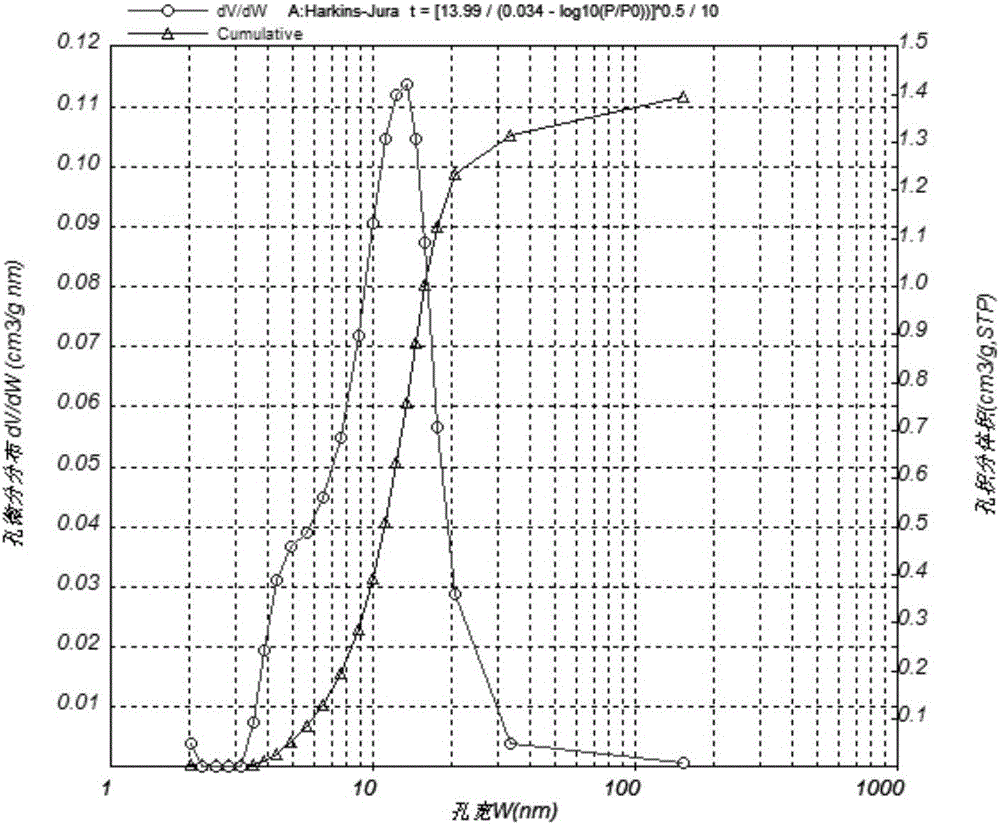

Catalyst for epoxidation of olefin and preparation method thereof

ActiveCN106582809ARaw materials are easy to getLow costMolecular sieve catalystsFiltrationThermal insulation

The present invention relates to a catalyst for epoxidation of an olefin. The catalyst is a modified titanium silica molecular sieve, the pore size is 10-30 nm, the content of TiO is 0.5-10 wt%, the pore volume is 1.0-1.5 mL / g, the aperture distribution rate is >=93.5%, and the specific surface area is 150-500 m<2> / g. A preparation method comprises the following steps: a template agent, a template modifier, water and a solvent are added into a reactor, heating under stirring is conducted, then a silicon source is added, and thermal insulation, suction filtration and drying are conducted to obtain a molecular sieve raw powder; the molecular sieve raw powder, an extrusion aid, an adhesive agent and a glue mixing agent are mixed evenly, an obtained mixture is subjected to extrusion molding, and then drying and roasting are conducted to obtain a molded molecular sieve; a titanium source is added into the molded molecular sieve to prepare the titanium silica molecular sieve, and finally a surface modifier is added for modificationto obtain the catalyst. The catalyst provided by the present invention is suitable for catalyzing the oxidation of propylene with cumyl hydroperoxide. The conversion rate of cumyl hydroperoxide is high, the selectivity of propylene oxide is high and the content of a byproduct, namely phenol is relatively little.

Owner:HONGBAOLI GRP CO LTD +1

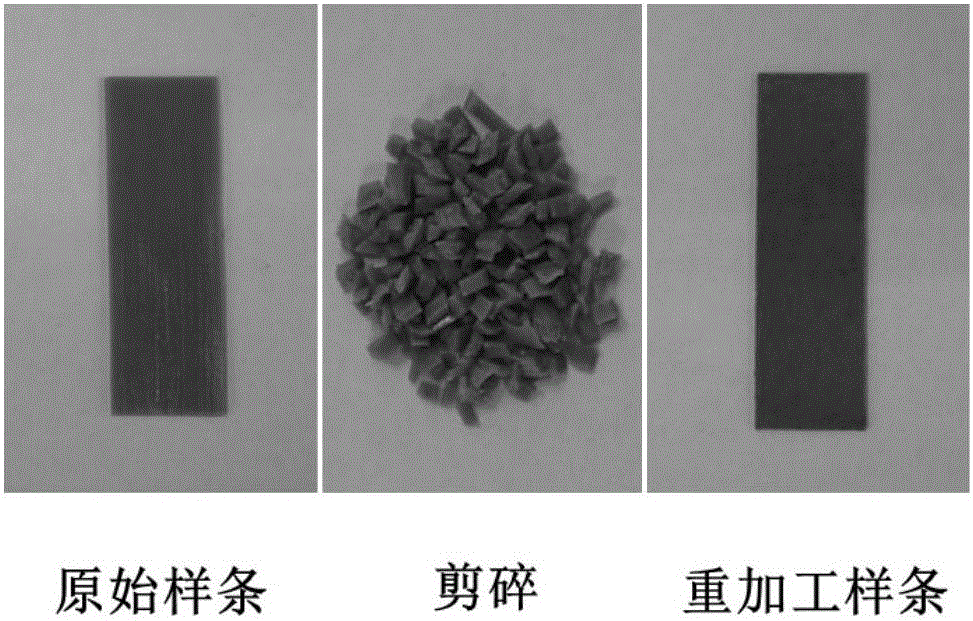

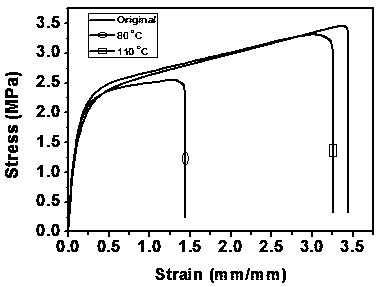

Self-repairing repeatable-processed polysiloxane elastomer, preparation method and application

The invention relates to the technical field of novel materials and specifically relates to self-repairing repeatable-processed polysiloxane elastomer, a preparation method and application. The self-repairing repeatable-processed polysiloxane elastomer has a following structural formula shown in a following image, wherein the R and the R1 in the structural formula are long chains prepared from carbon, hydrogen, oxygen and nitrogen. The prepared self-repairing repeatable-processed polysiloxane elastomer disclosed by the invention has the following advantages: a molecular main chain has urea bonds, and hydrogen bonds formed between the urea bonds can improve mechanical strength of materials; under catalytic action of metal ions, the urea bonds have thermal reversibility, and the material notonly has a self-repairing effect, but also can be recycled and processed again; the material can be applied to the fields of 3D printing, flexible electrode base materials and the like; a preparationtechnology is simple, and cost is relatively lower.

Owner:SICHUAN UNIV

Strong-acid type polystyrene cation exchange resin as well as preparation method and application thereof

ActiveCN102626661AImprove hydrophilicityImprove expansion and contraction stabilityCation exchanger materialsOther chemical processesIce waterMeth-

The invention relates to a strong-acid type polystyrene cation exchange resin as well as a preparation method and application thereof. The strong-acid type polystyrene cation exchange resin is characterized in that styrene is used as a monomer, methylene diacrylyl is used as a cross-linking agent, and the mass ratio of the monomer styrene to the cross-linking agent methylene diacrylyl is 1:(0.01-0.5). The preparation method comprises the steps of: performing balling, sizing and ageing on the styrene and the methylene diacrylyl under the action of a porogen and an initiator to obtain microspheres, then ultrasonically washing in an alcohol solvent to remove the porogen, performing sulfonation treatment to obtain a sulfonation product, then, directly pouring the solfonation product into ice water, and washing and filtering to obtain the strong-acid type polystyrene cation exchange resin. The strong-acid type polystyrene cation exchange resin has the advantages of high qualification rate, uniform cross-linking structure, high moisture content, large ion exchange capacity, low raw material cost, simple, convenient and controllable synthesis process, and environment friendliness, is applied to adsorption of rare earth metal ions without pretreatment or addition of other reagents, is pollution-free without generation of any wastes and is good in adsorption effect.

Owner:GANZHOU RARE EARTH MINERAL IND

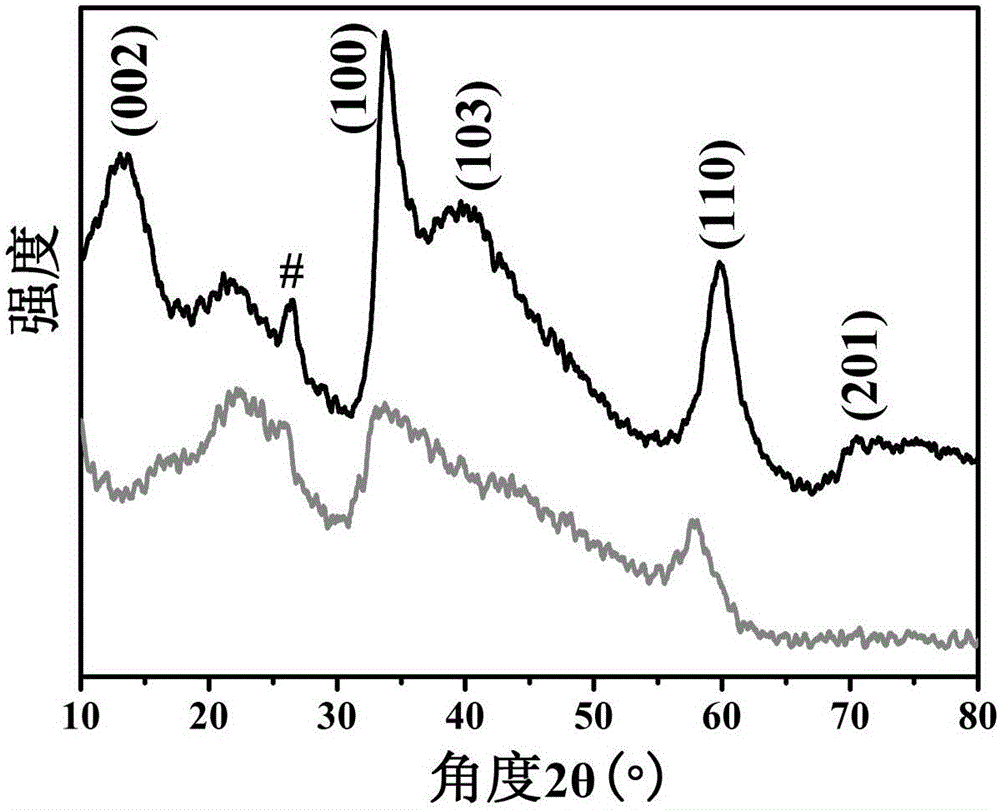

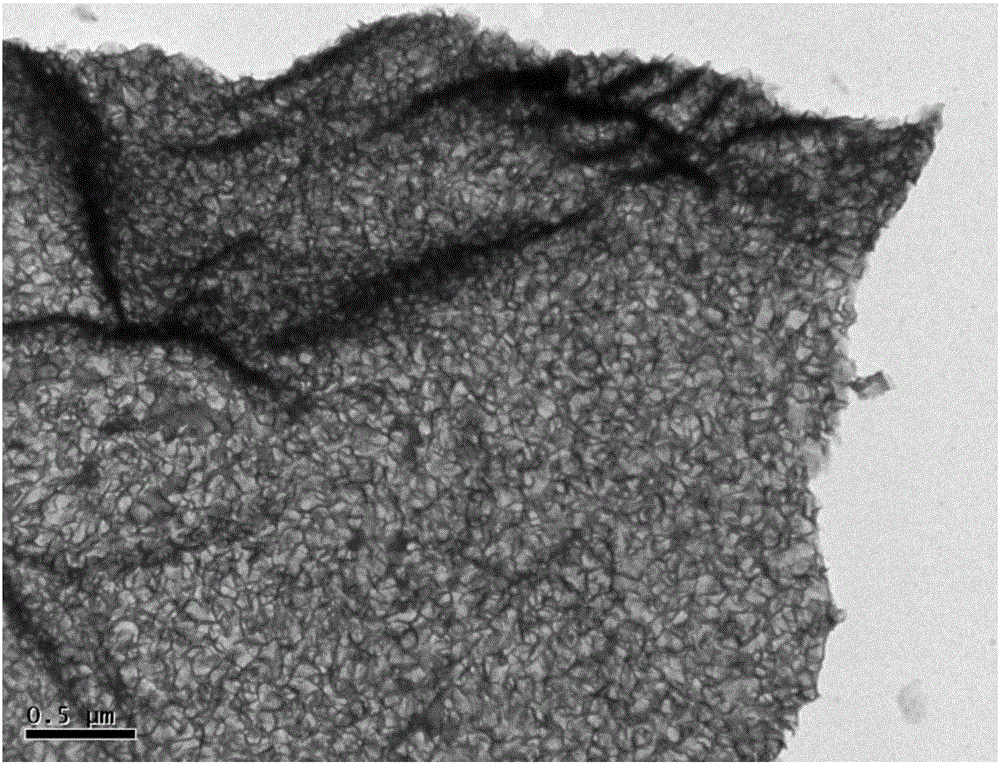

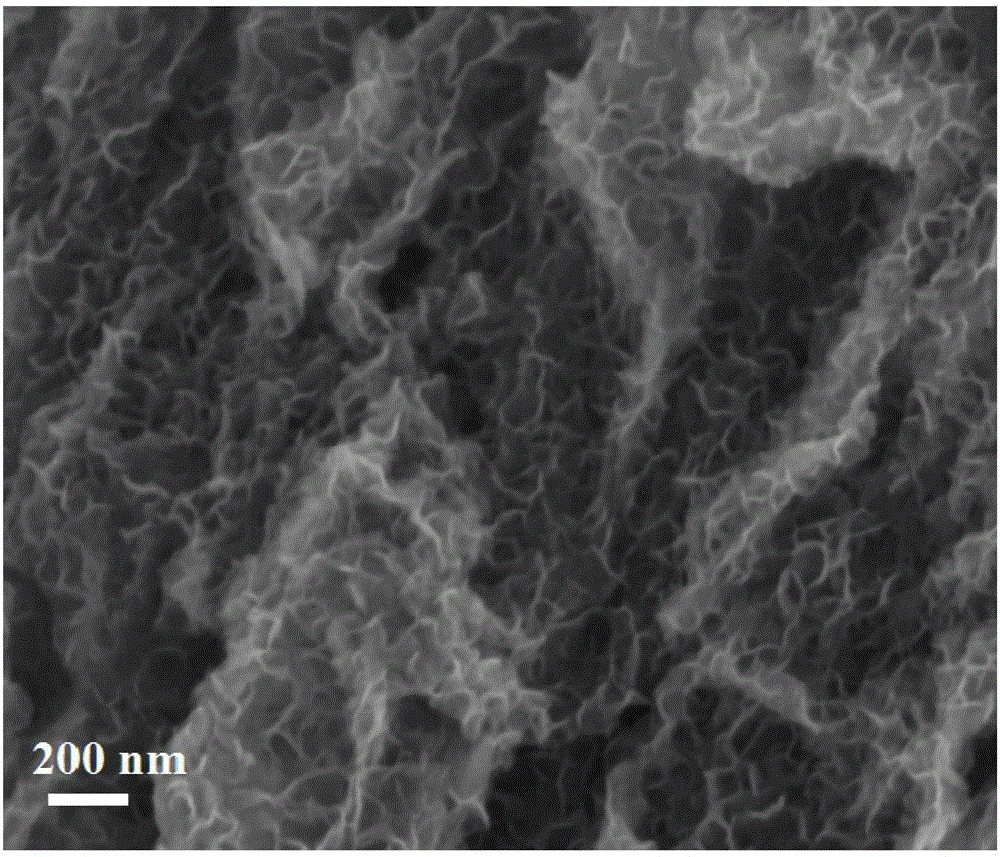

Two-dimensional sheet MoS<2>@ graphene composite nano-material and preparation method thereof

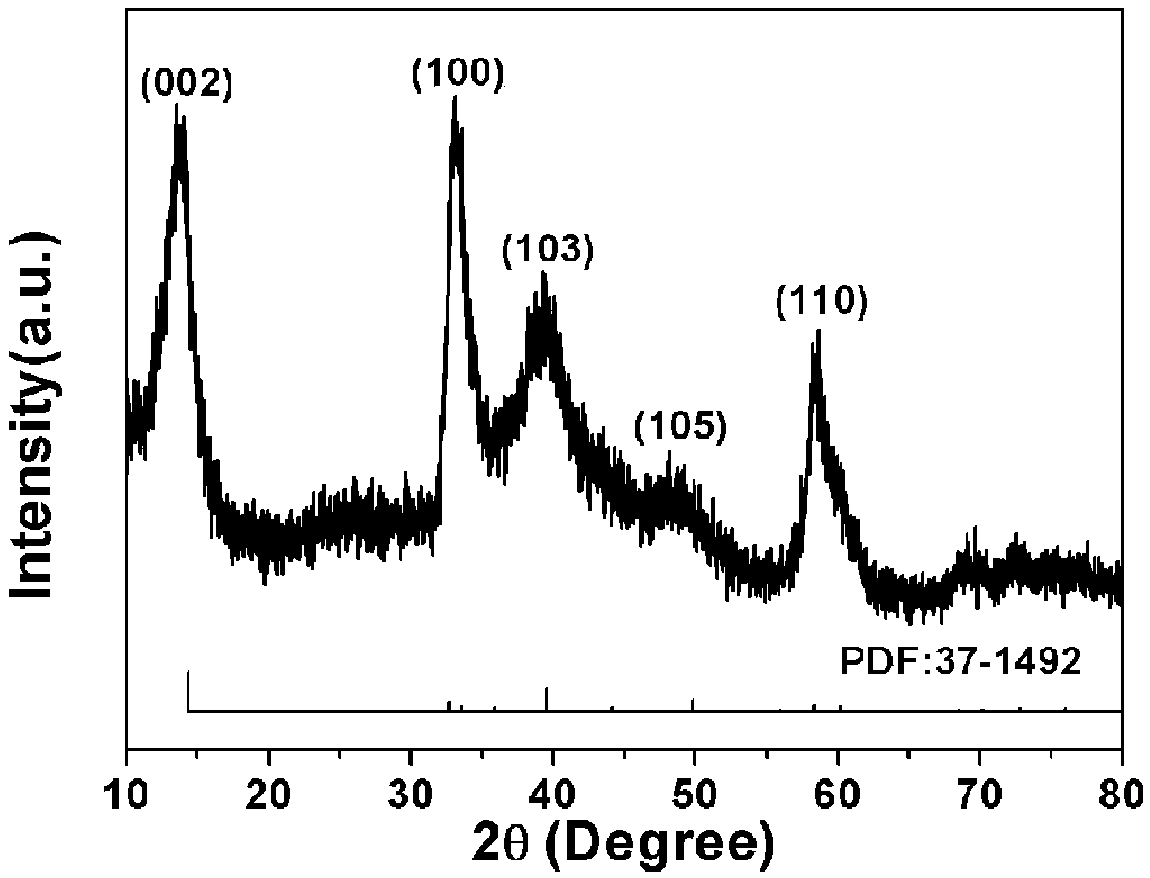

ActiveCN106410132AUnique shapeAvoid uneven loadMaterial nanotechnologyCell electrodesDispersityHexagonal crystal system

The invention relates to a two-dimensional sheet MoS<2>@ graphene composite nano-material and a preparation method thereof. Pyrolysis reduced graphene oxide, polymine, sodium molybdate and thiourea are used as raw materials; water is used as a solvent; and thus, by means of a simple hydrothermal synthesis method, the sheet MoS<2>@ graphene composite nano-material having uniform morphologies and structures can be prepared under the auxiliary action of polymine. An electron microscope result shows that an ultra-thin MoS<2> nano-sheet is loaded on high-quality graphene vertically and uniformly and the dispersity is good. An XRD spectrogram shows that: compared with an unheated precursor, the crystallinity of a roasted MoS<2> material is obviously increased; and the roasted MoS<2> material belongs to a typical 2H-MoS<2> crystalline phase of a hexagonal crystal system. According to the two-dimensional sheet MoS<2>@ graphene composite nano-material and the preparation method thereof disclosed by the invention, a synthesis process is simple and controllable; the morphology homogeneous degree and the load rate of the material are high; the repeatability is good; and thus, the two-dimensional sheet MoS<2>@ graphene composite nano-material and the preparation method thereof disclosed by the invention have a certain application prospect in new energy fields, such as lithium ion batteries.

Owner:SHANGHAI UNIV

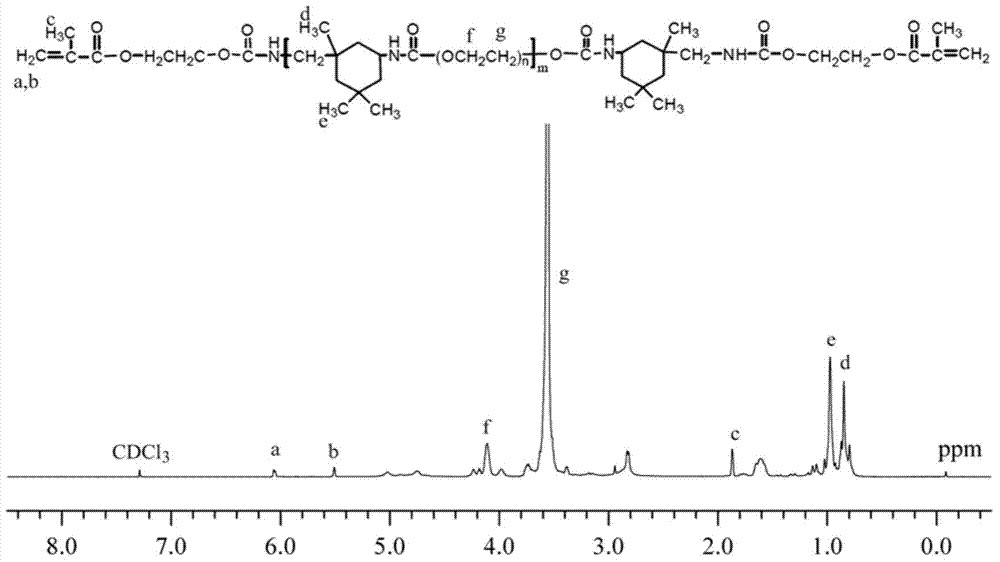

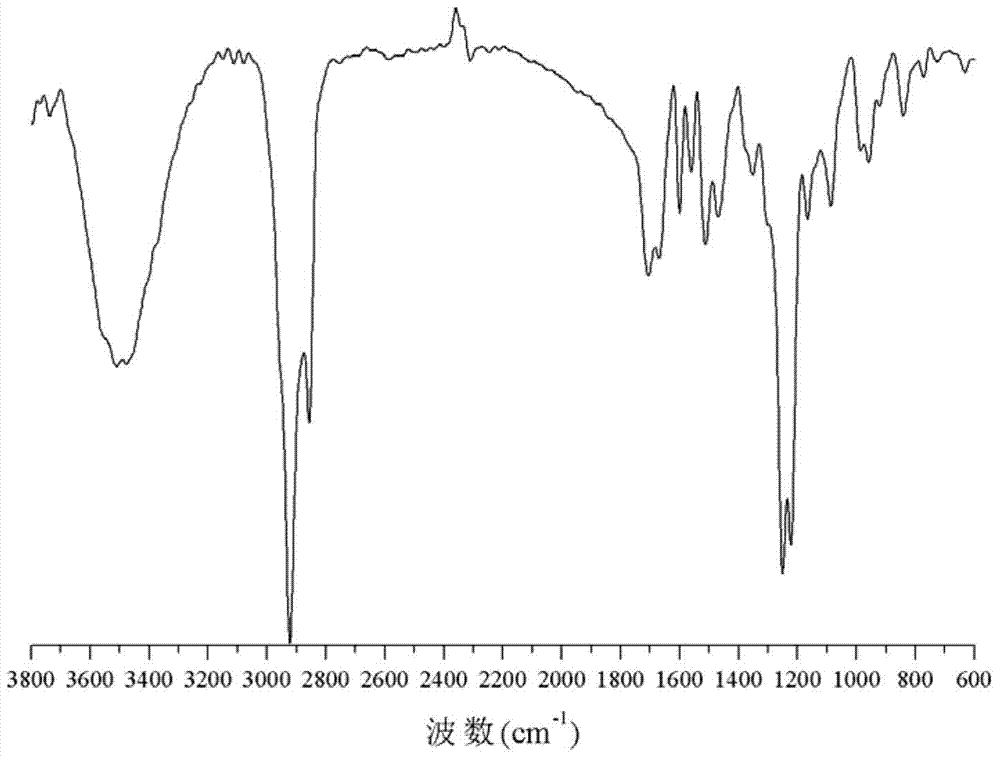

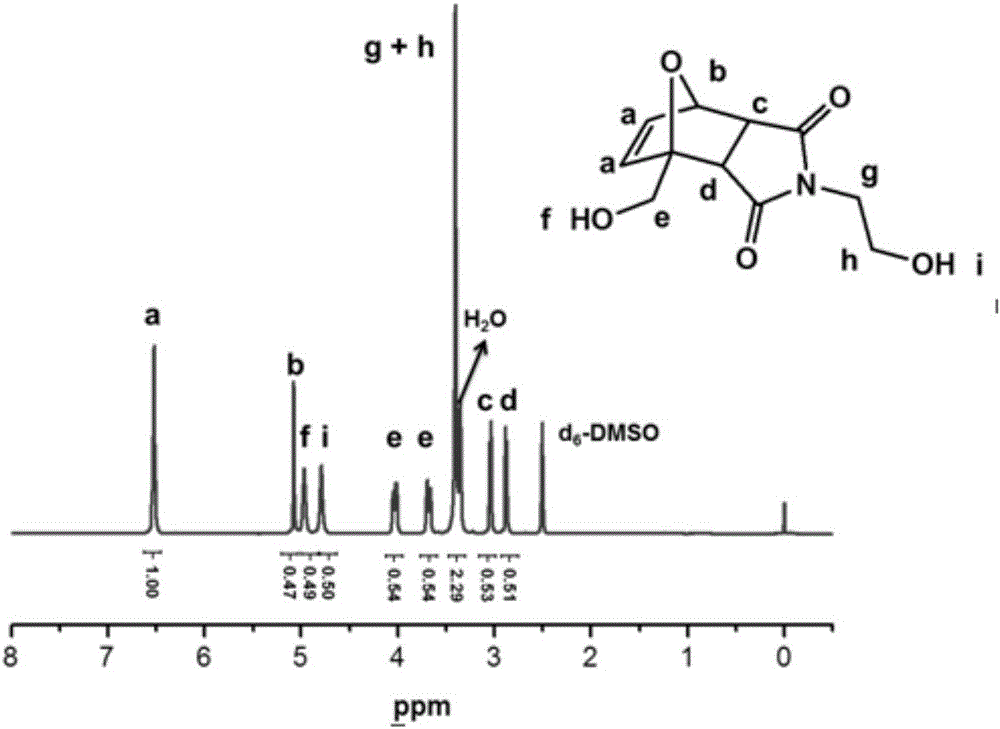

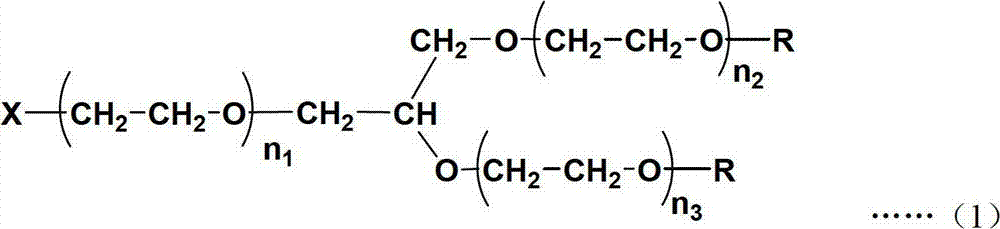

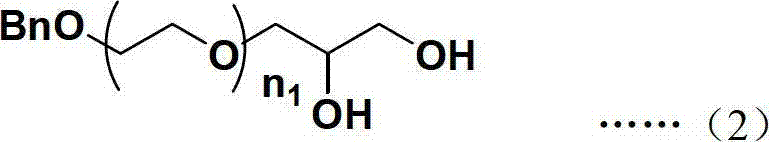

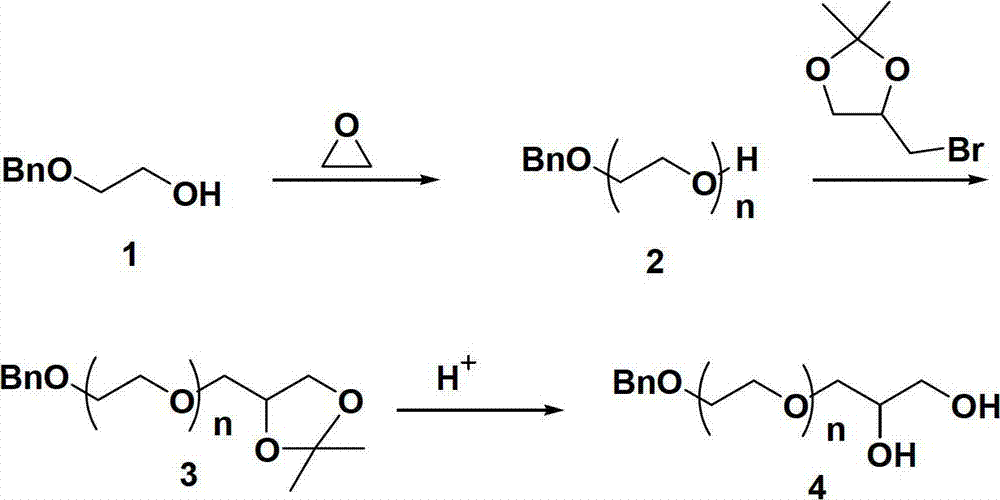

Single active functional group-containing Y-type polyethylene glycol and preparation method thereof

InactiveCN102898641AThe synthesis process is simple and controllableFew reaction stepsHeavy metal active ingredientsPharmaceutical non-active ingredientsAlcoholPolyethylene glycol

The invention relates to a single active functional group-containing Y-type polyethylene glycol and a preparation method thereof. The single active functional group-containing Y-type polyethylene glycol is shown in a general chemical structural formula (1), wherein in the general chemical structural formula (1), n1, n2 and n3 respectively represent polymerization degrees of branch chains; number-average molecular weight of polyethylene glycol chain segments is in a range of 5000 to 100000; X represents a terminal active functional group of polyethylene glycol; R represents the same or different the same or different alkyl groups from alcohol compounds; and polyethylene glycol molecular weight distribution is in a range of 1.01 to 1.1. The invention also relates to a use of the single active functional group-containing Y-type polyethylene glycol in preparation of carriers for a biological medicinal preparation.

Owner:XIAMEN SINOPEG BIOTECH

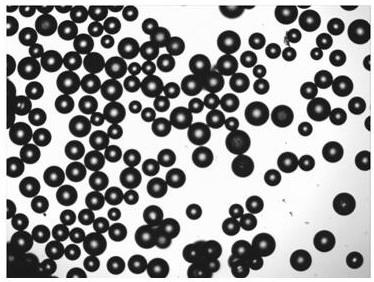

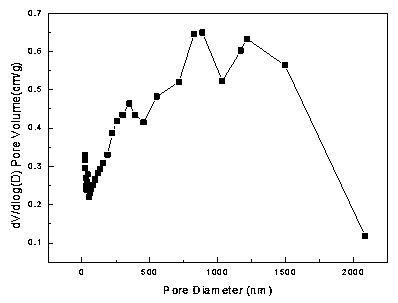

Preparation method of uniform-porous crosslinked polystyrene adsorption resin

The invention relates to a preparation method of uniform-porous crosslinked polystyrene adsorption resin, particularly comprising: (1) preparation of an oil phase: weighing proper amounts of a monomerM1, a monomer M2, a crosslinker, an initiator, and a pore forming agent, uniformly stirring the components for later use, thus preparing the oil phase; (2) preparation of a water phase: weighing a stabilizer, adding deionized water, heating the liquid to 50-90 DEG C, stirring the liquid for 2-3 h until the stabilizer is completely dissolved, and cooling the mixture to 30-50 DEG C to prepare the water phase; (3) polymerization: adding the oil phase to the water phase with stirring, heating the mixture to 60-75 DEG C to carry out a reaction for 1-5 h, adding auxiliary materials, heating the mixture to 80-95 DEG C to continuously carry out the reaction for 6-12 h, after the reaction is finished, cooling a product to room temperature, thus obtaining polymer microspheres; (4) cleaning: performing suction drying on the polymer microspheres, cleaning the microspheres with a solvent, and drying the microspheres to obtain the uniform-porous crosslinked polystyrene adsorption resin, which is low in raw material cost and simple in synthesis process, and has convenience in industrial production.

Owner:南京亘闪生物科技有限公司

Preparation method for single-component POSS/addition type silicon resin nanocomposite

The invention provides a preparation method for a single-component POSS / addition type silicon resin nanocomposite. The method comprises the following steps: double-bond-contained polyhedral oligomeric silsesquioxane (POSS) is synthesized, a silanol mixed solution containing different functional groups is prepared, and the double-bond-contained polyhedral oligomeric silsesquioxane (POSS) reacts with the silanol mixed solution to generate the target product namely single-component POSS / addition type silicon resin nanocomposite. The method comprises the following steps: (1), synthesizing the double-bond-contained polyhedral oligomeric silsesquioxane (POSS); (2) synthesizing silanol; (3), adding the double-bond-contained polyhedral oligomeric silsesquioxane (POSS) with different content, which is obtained through the step (1), into the silanol mixed solution obtained through the step (2), and reacting continuously for a period of time, so that a POSS / silicon resin nanocomposite prepolymer is obtained, then adding an end-capping agent, reducing pressure for removing low-molecular-weight by-products and absolute ethyl alcohol, and adding a cross-linking agent, a catalyst and an inhibitor auxiliary, so that the single-component POSS / addition type silicon resin nanocomposite is obtained.

Owner:JIANGXI PROVINCE HANGYU NEW MATERIAL CO LTD

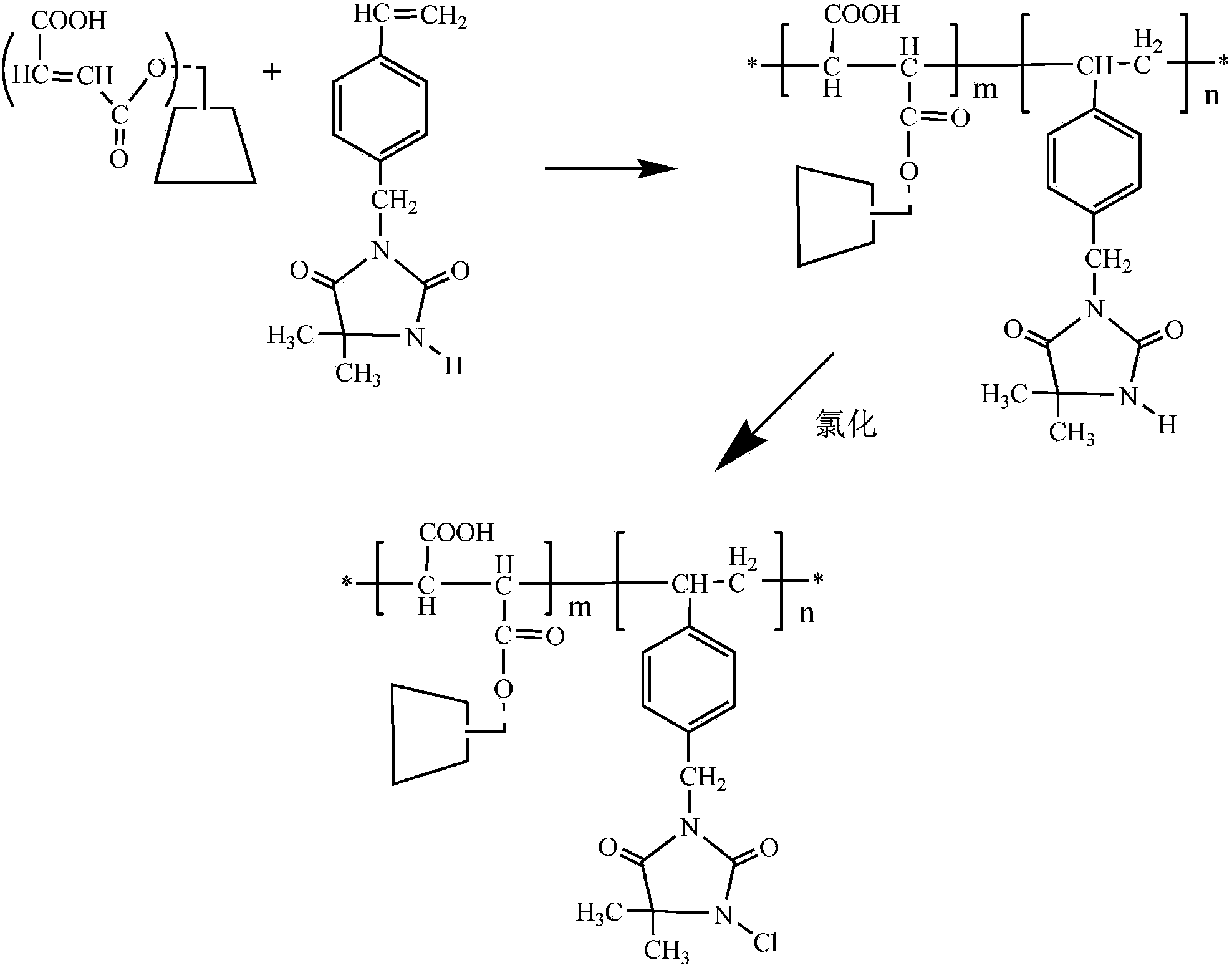

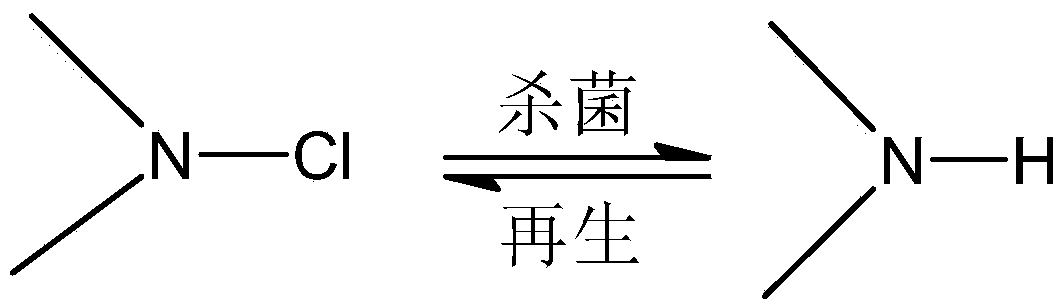

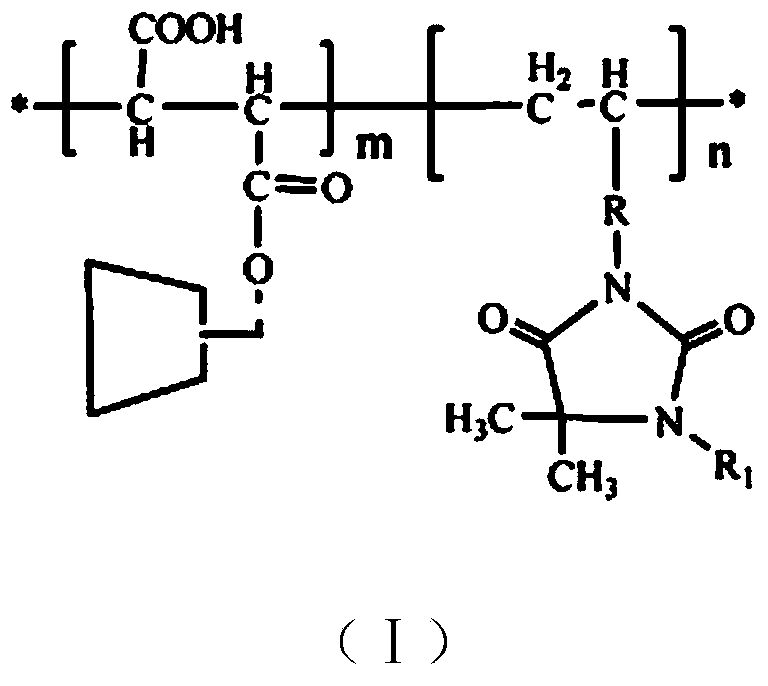

Beta-cyclodextrin containing halogen amine antimicrobial agent copolymer as well as preparation method and application of copolymer

ActiveCN103554367AGood water solubilityEnvironmentally friendlyBiocideArtificial filaments from cellulose derivativesFiberDouble bond

The invention discloses a beta-cyclodextrin containing halogen amine antimicrobial agent copolymer as well as a preparation method and an application of the copolymer. The antimicrobial agent copolymer is a compound shown as a formula (I). The preparation method comprises the steps: dissolving double-bond maleic anhydride modified beta-cyclodextrin and a double-bond halogen amine compound into a mixed solution of ethanol and water, adding a redox initiator, reacting at a temperature of 35-70 DEG C under the protection of nitrogen for 3-10 hours to acquire a beta-cyclodextrin containing halogen amine antimicrobial agent copolymer precursor, and halogenating the precursor to acquire a finished product of the beta-cyclodextrin containing halogen amine antimicrobial agent copolymer. In the application of the beta-cyclodextrin containing halogen amine antimicrobial agent copolymer in preparing antibacterial nano fiber materials, the precursor is mixed with easily spun high polymer materials in proportion in a proper solvent, then nano fiber materials are acquired through electrostatic spinning, and then antibacterial nano fiber materials are acquired after halogenation. The antimicrobial agent copolymer disclosed by the invention has excellent antibacterial performance, the synthetic process is easy and controllable, the reaction time is short, the condition is mild, and the acquired nano fiber materials have good antibacterial performance and high antibacterial efficiency.

Owner:JIANGNAN UNIV

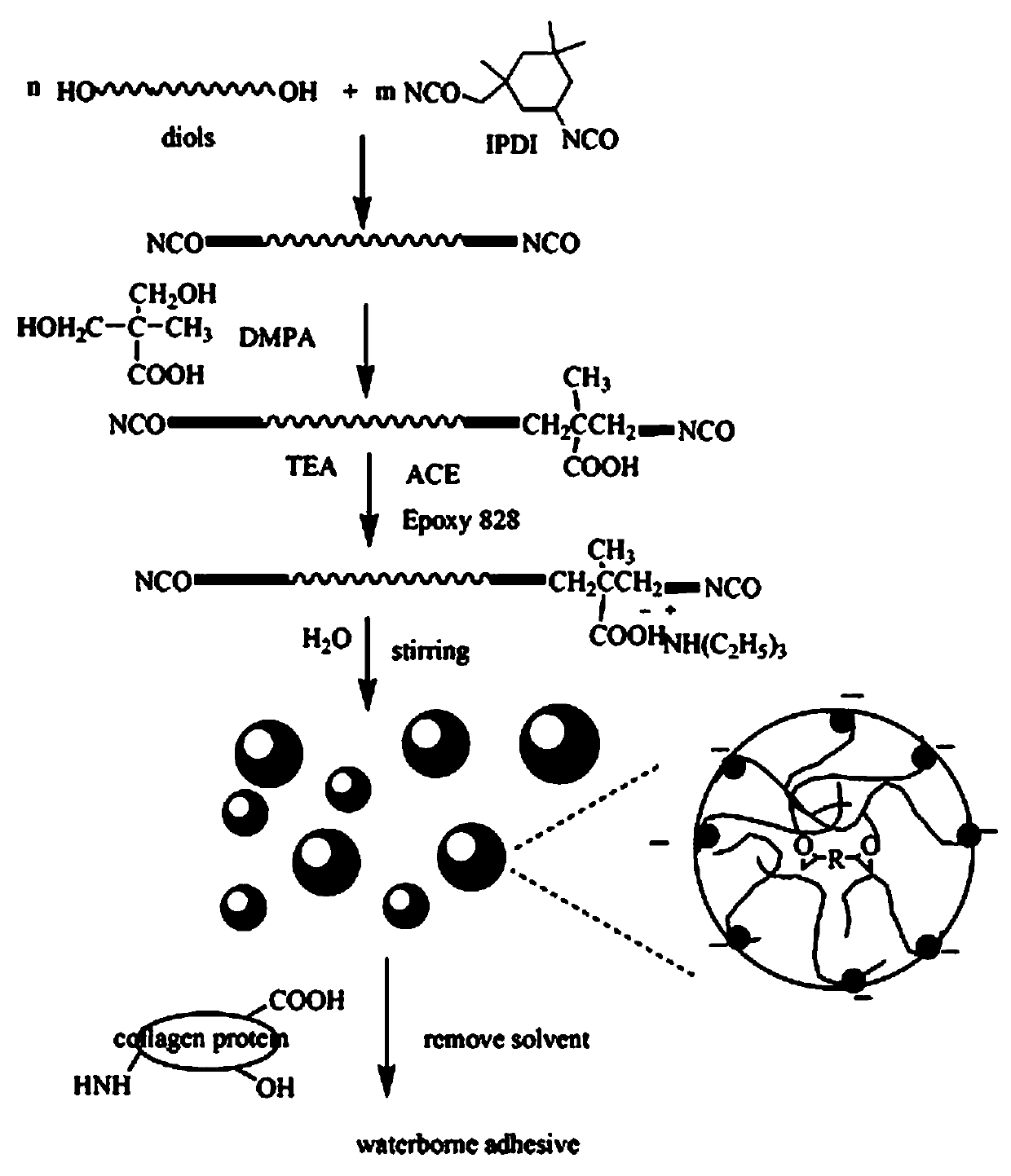

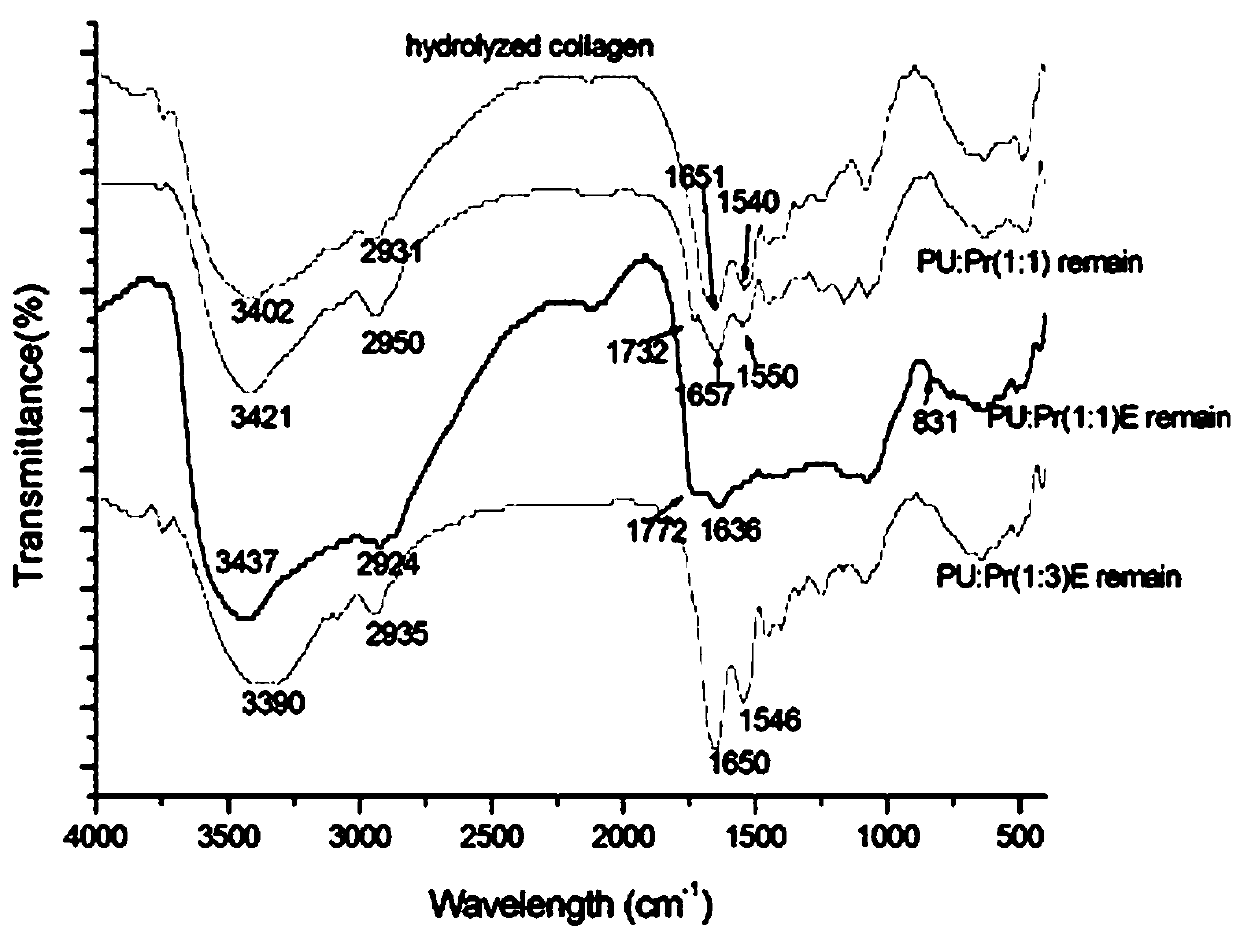

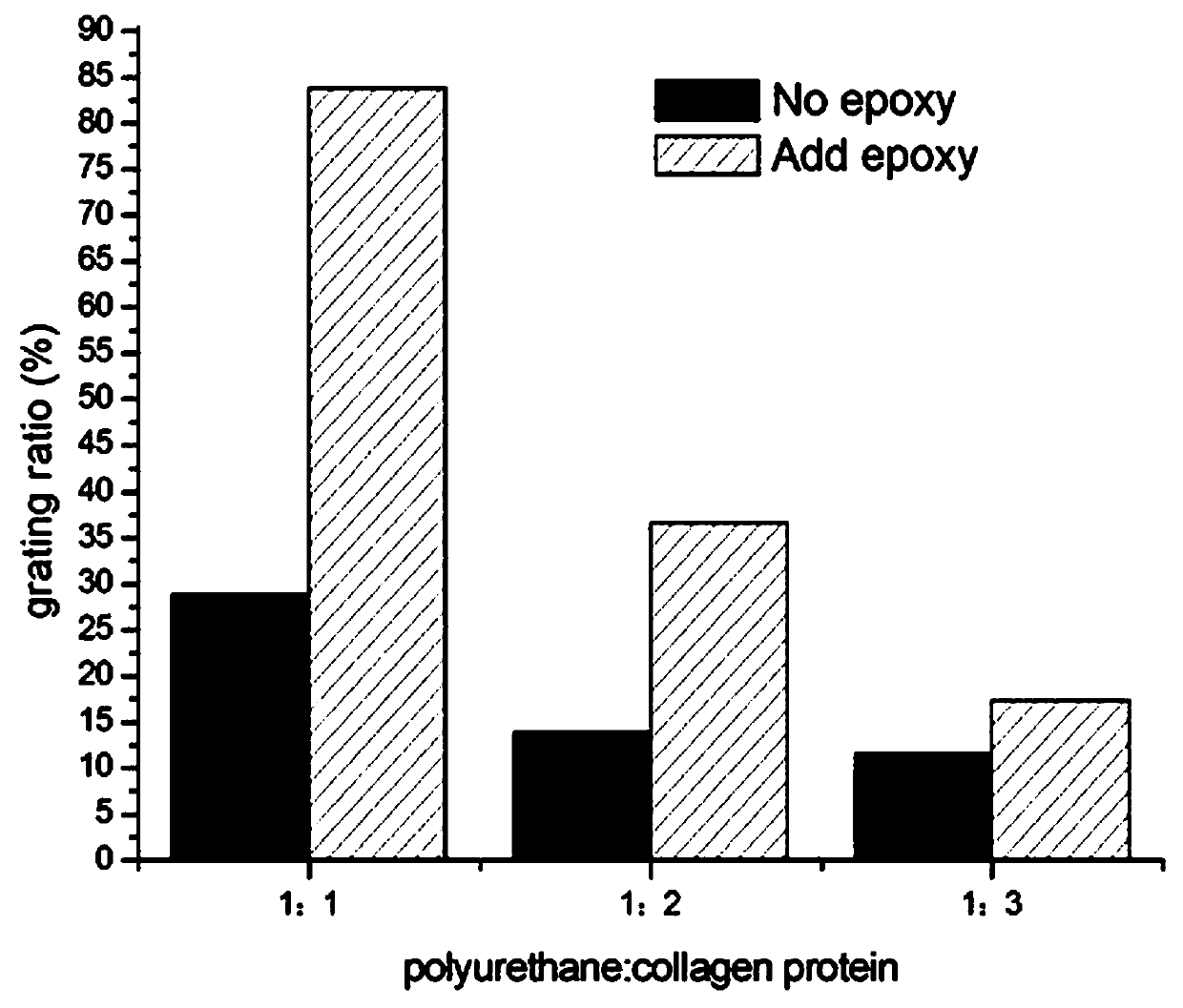

Preparation method and application of collagen-based adhesive

InactiveCN109554153AHigh bonding strengthOvercome the disadvantage of high costProtein adhesivesPolyureas/polyurethane adhesivesEpoxyEmulsion

The invention provides a production method for synthesizing an aqueous adhesive by using collagen modified by polyurethane and epoxy resin. The method includes: firstly, extracting a collagen hydrolysate from raw materials, such as leftover material of leather manufacturing, bones and the like, which contain the collagen, number-average molecular weight being 10,000 to 30,000; then at 50-80 DEG C,synthesizing an isocyanate-terminated polyurethane prepolymer containing a hydrophilic group and mixing the prepolymer with a certain amount of epoxy resin, and adding a salt-forming agent so as to form salts with carboxylic group; finally, adding deionized water, so that during dispersion and emulsion, the collagen hydrolysate can be subjected to grafting reaction with the polyurethane and epoxyresin, thereby synthesizing the aqueous adhesive based on the collagen modified by polyurethane and epoxy resin. In application, a curing agent and filler are not added, or are added to a certain amount, for adhesion of plywoods. With the leftover material of leather manufacturing being a main production raw material, which is reproducible, the product is free of formaldehyde, has excellent waterresistance and adhesion strength, is low in production cost, and can satisfy the use requirement of II-type plywoods. The production method is simple and is easy to control.

Owner:晋江全杰生物科技有限公司

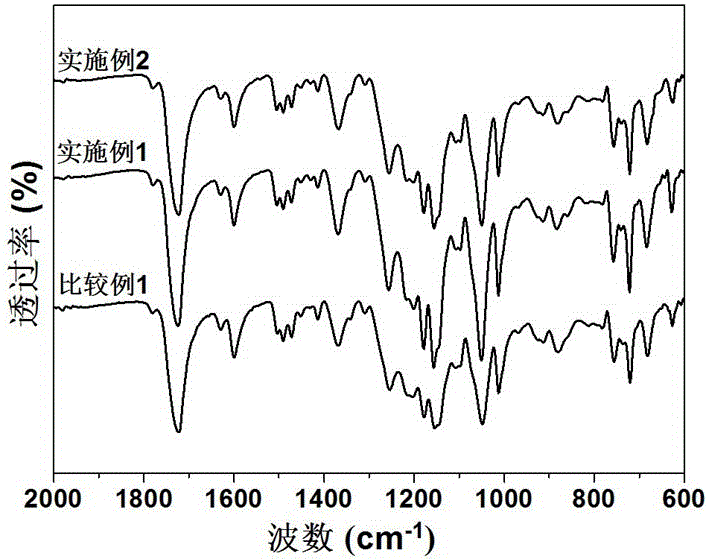

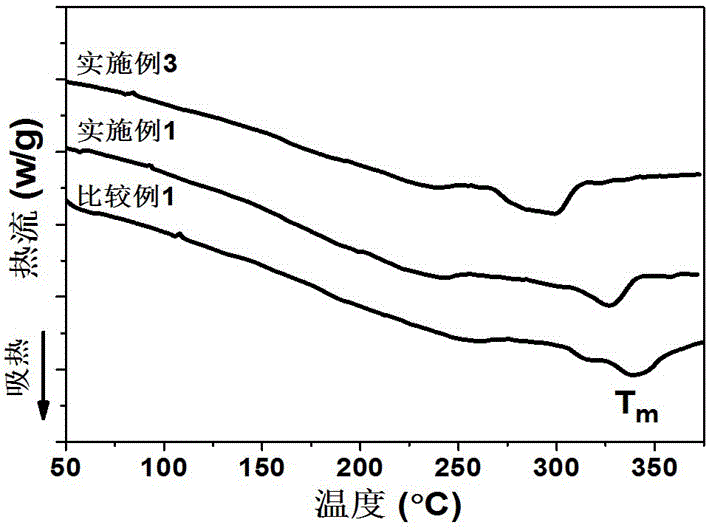

Aromatic polyesterimide and preparation method thereof

The invention discloses aromatic polyesterimide and a preparation method thereof. The preparation method includes adding aromatic diacid anhydride monomers, amino meta-substituted aromatic phenol monomers and acetic acid into a reactor to obtain aromatic diphenol monomers containing imide linkages, subjecting the aromatic diphenol monomers containing the imide linkages, meta-position aromatic diacid monomers, AB-type wholly-aromatic monomers containing terminal carboxyl groups A and terminal hydroxyl groups B, a catalyst and acetic anhydride to acetylation reaction prior to transesterification, grinding an obtained product into fine powder and subjecting the fine powder to condensation polymerization so as to obtain the aromatic polyesterimide. The preparation method has the advantages that self-enhancement of tensile strength and Tg is achieved in a polymerization process of the aromatic polyesterimide, low melt viscosity is obtained through structural symmetry decrease of the aromatic polyesterimide, and the preparation method is simple and controllable in preparation technology.

Owner:SUZHOU UNIV

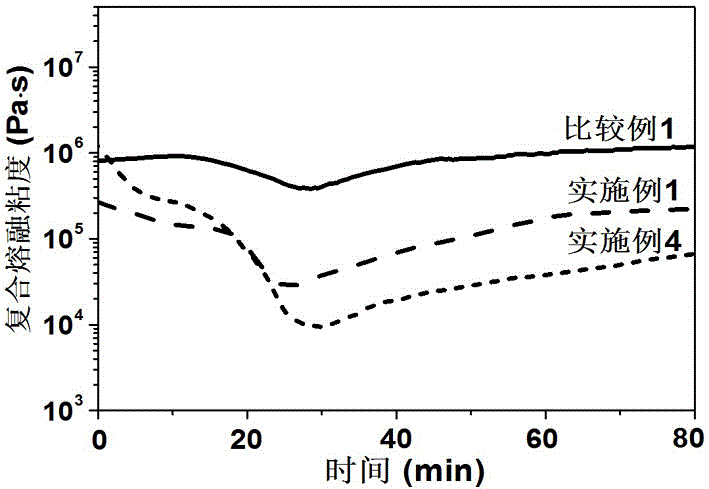

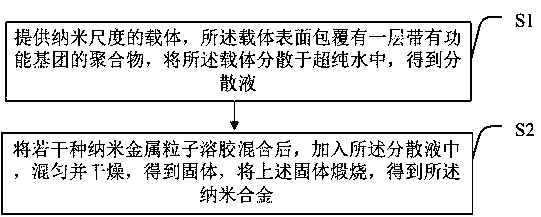

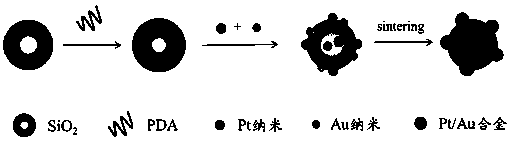

Nano-alloy and preparation method thereof

ActiveCN108940269AIncrease profitImprove catalytic stabilityMaterial nanotechnologyTransportation and packagingMetal particleAlloy

The invention provides a nano-alloy and a preparation method thereof, wherein the preparation method comprises the steps: a nano-scale carrier is provided, the surface of the carrier is cladded with alayer of polymer with functional groups, and the carrier is dispersed in ultrapure water to obtain a dispersion solution; after multiple kinds of nano-metal particle sols are mixed, the dispersion solution is added, mixing and drying are carried out, and a solid is obtained; and the nano-alloy is obtained by calcining the solid. The problems of insufficient durability of catalytic activity and complex preparation process of conventional nano-alloys are solved.

Owner:SHENZHEN UNIV

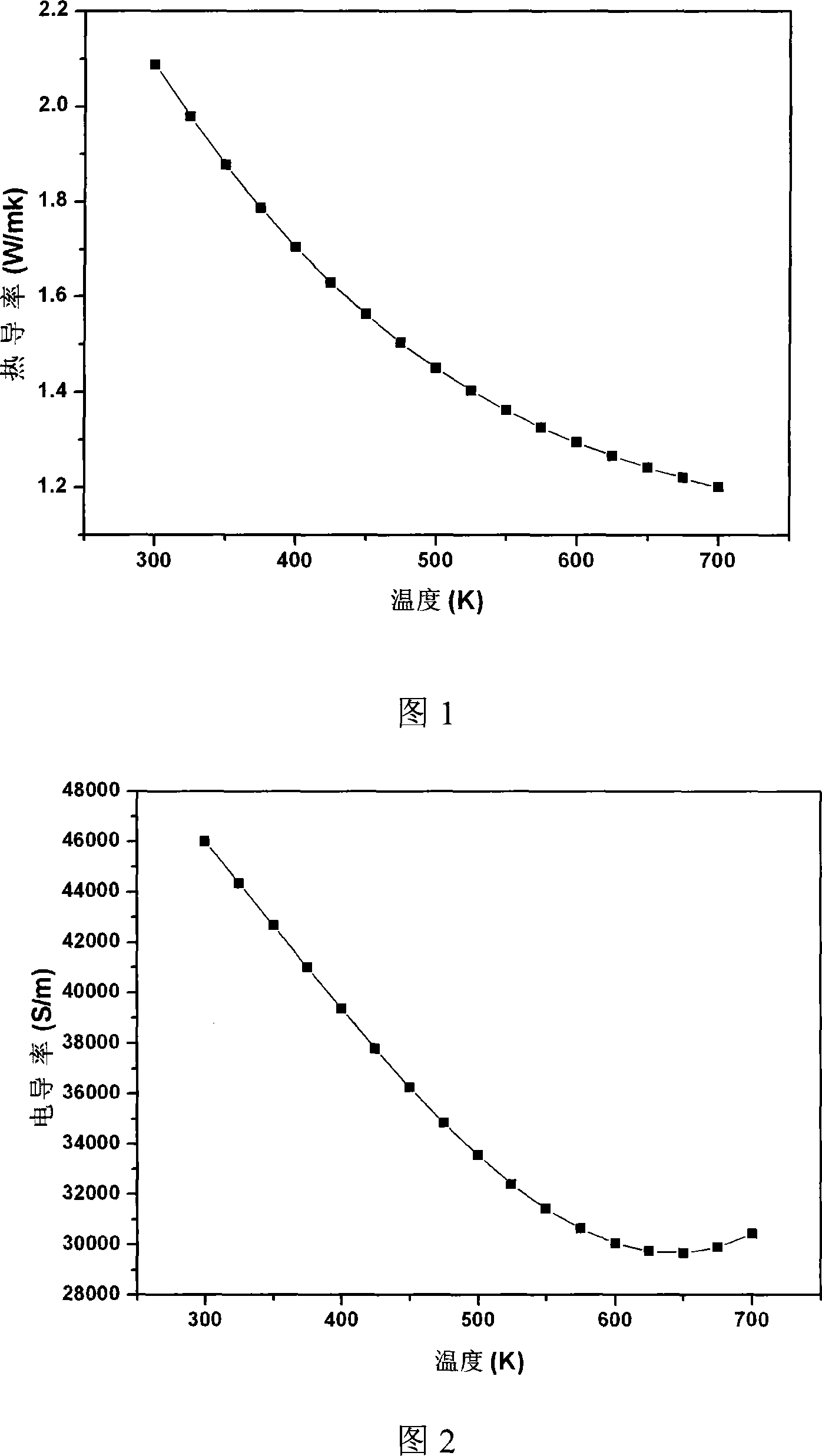

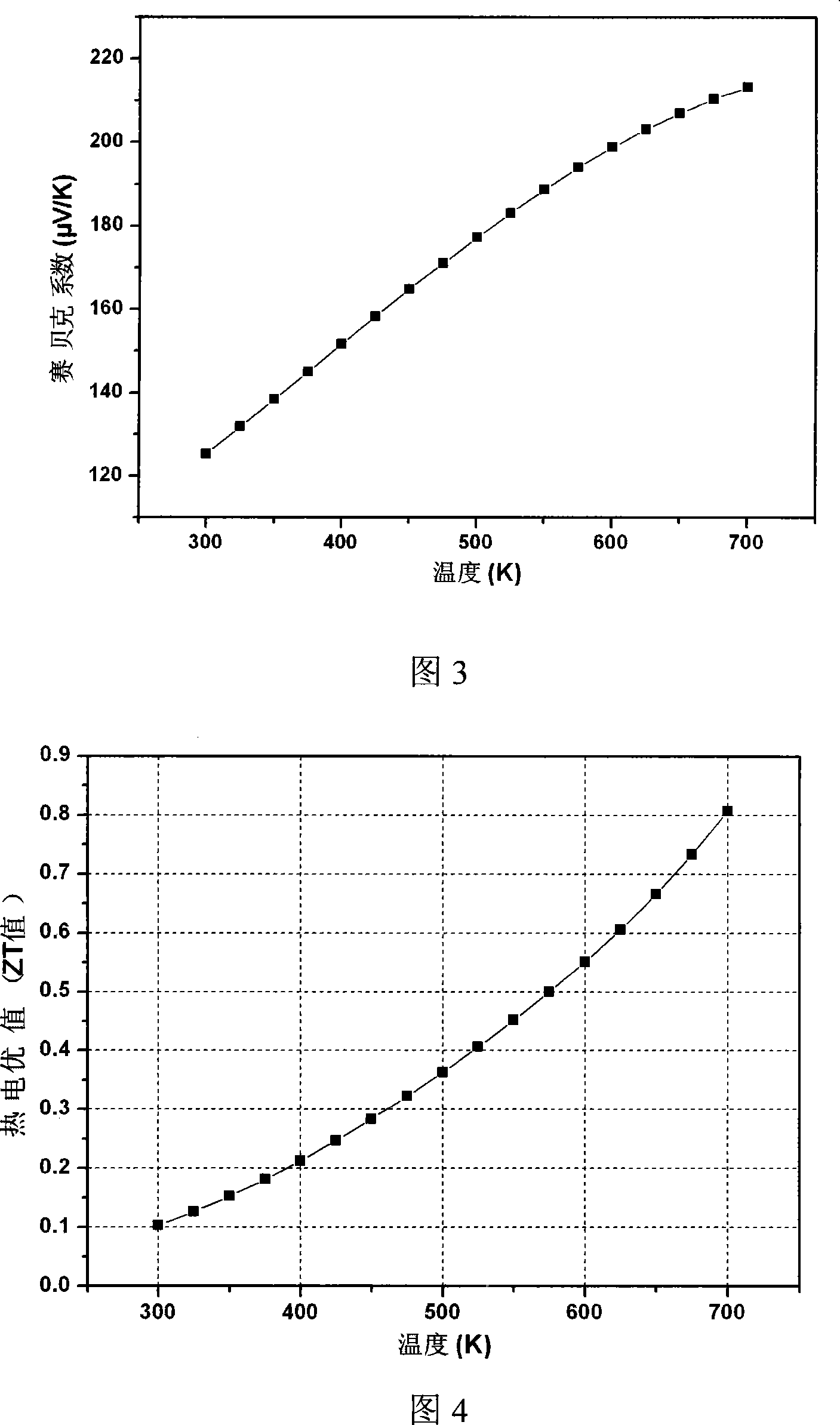

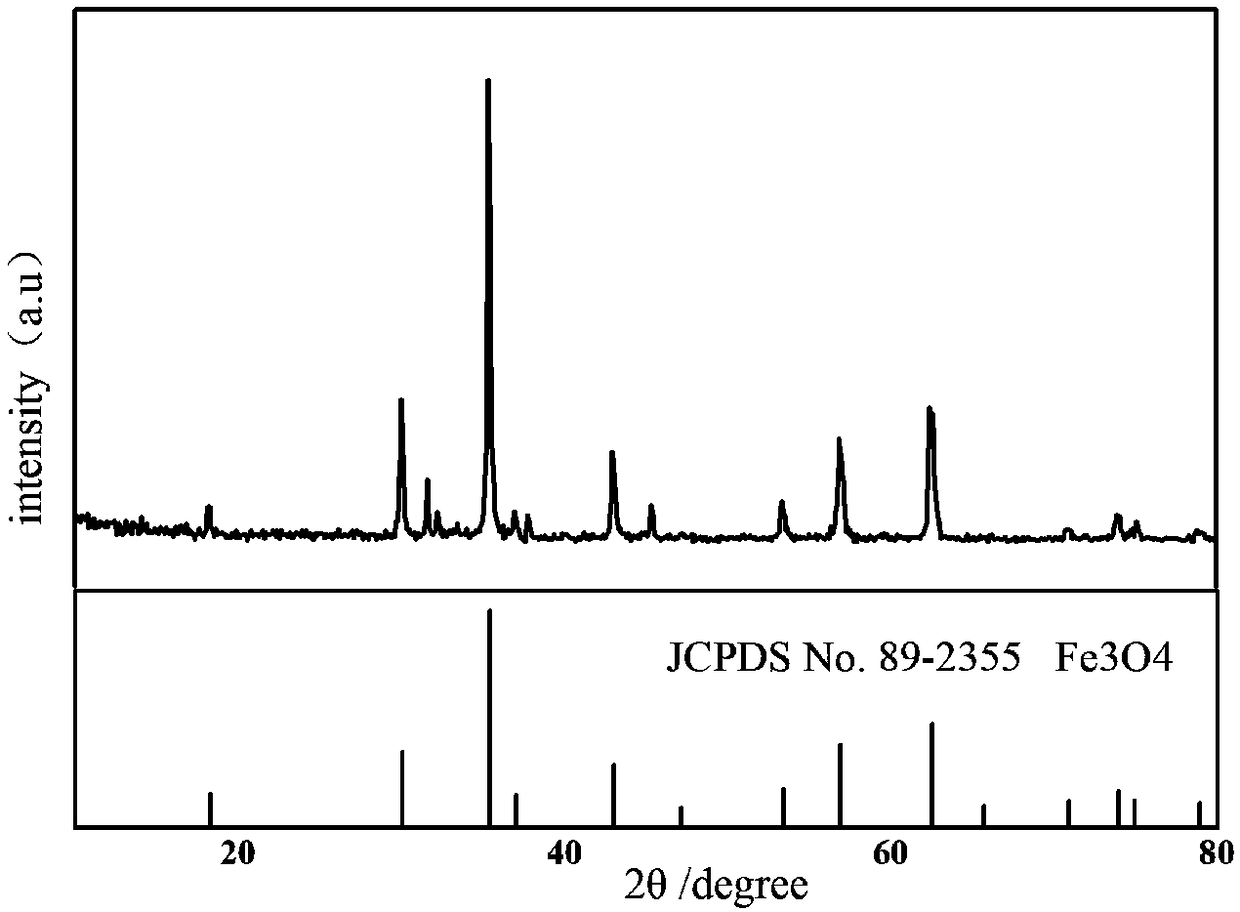

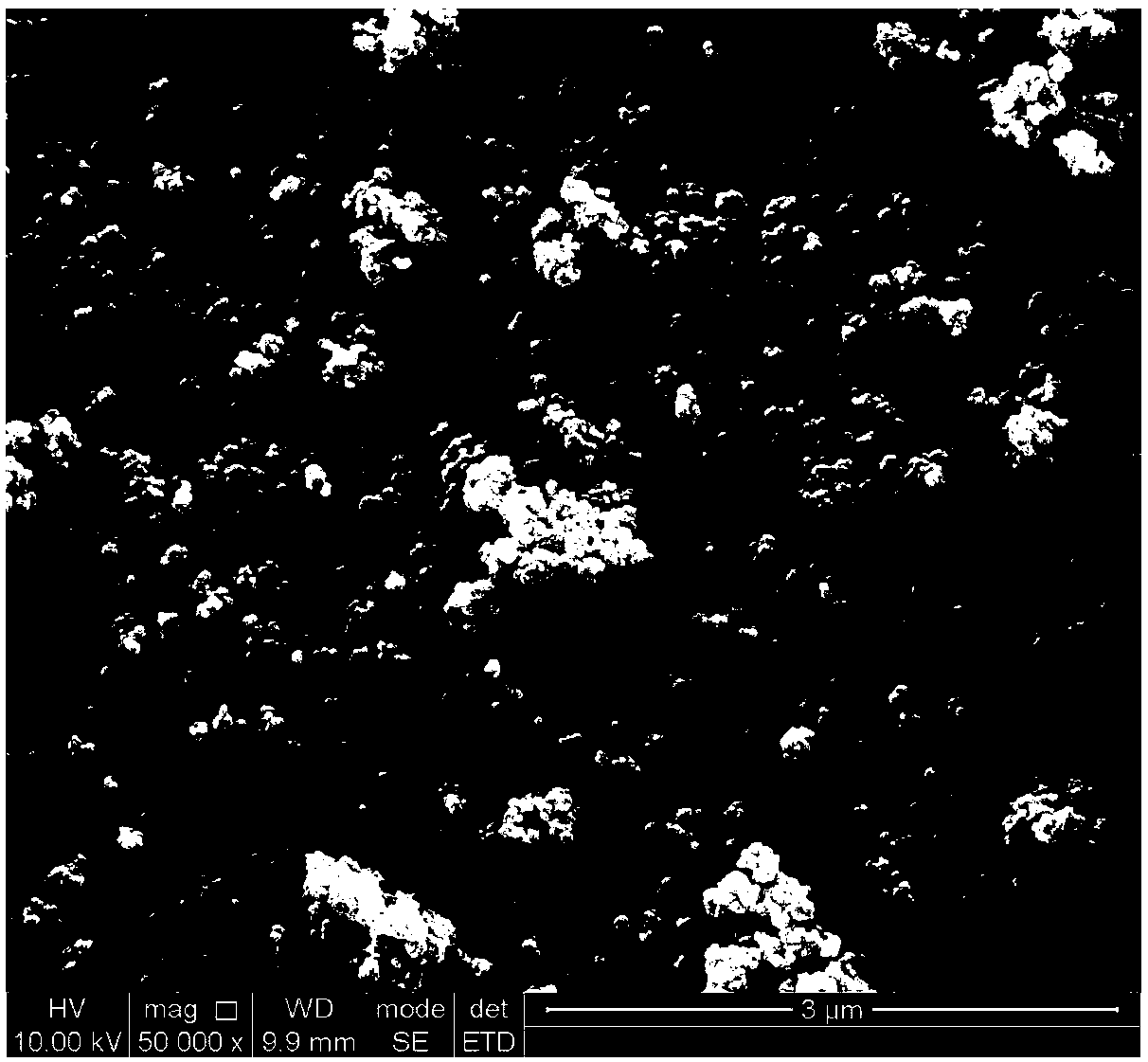

A cadmium-stibium-based p type thermal electrical material and its making method

InactiveCN101101954AThe synthesis process is simple and controllableImprove thermoelectric performanceThermoelectric device junction materialsThermoelectric materialsS doping

The present invention relates to a cadmium-stibium base p type thermoelectric material and its preparation method, belonging to the field of thermoelectric converting material. The present invention thermoelectric material composition formula is: RCd2-xZnxSb2-ySy, wherein R is one or two solid solution with arbitrary proportion of Yb, Eu, Ca, Sr and Ba; x is Zn solid solution component, range is more than or equal to 0 and less than 2; S is one of Ge, Sn, Se and Te; y is S doped real component, range is more than or equal to 0 and less than or equal to 0.2. Method for using vacuum or inert gas solid-phase to synthesis, speed plasma sintering (SPS) or thermal pressing sintering to prepare compact ceramic sample. The sample YbCd2Sb2 ZT value reaches to 0.8 at 430 DEG C, corresponding with the current used for middle temperature section (200 DEG C to 500 DEG C) mature thermoelectric material PbTe alloy (ZT 430 DEG C equals to 0.8), the present invention also increases its thermoelectric converting efficient through solid-phase and doped, the model thermoelectric material preparation method is simple and stable in air, can be used for thermoelectric converting apparatus.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of strong-acidity polystyrene cationic exchange resin

InactiveCN107652406AImprove stabilityImprove adsorption capacityCation exchanger materialsOther chemical processesIce waterMicrosphere

The invention discloses a preparation method of strong-acidity polystyrene cationic exchange resin, comprising the steps of mixing well methyl styrene, methylene bisacrylamide, and methylbenzene, adding pre-processed rice hull and gelatin solution, mixing well, adding tert-butyl peroxy-2-ethylhexanoate, heating and stirring, heating, holding the temperature, aging, and filtering to obtain polystyrene microspheres; feeding the polystyrene microspheres into n-heptane for swelling, dropwise adding sulfuric acid solution while stirring, adjusting the temperature after dropwise adding, stirring, washing with ice water, and filtering to obtain the strong-acidity polystyrene cationic exchange resin. The pre-processed rice hull is prepared by: stirring rice hull and kaolin, feeding into an anaerobic muffle furnace, heating for calcining, cooling, grinding, adding nitric acid solution, stirring, washing until neutrality, drying, adding hyperbranched polysiloxane and acetone, ultrasonically treating, treating with microwave, and drying by spraying.

Owner:ANHUI WANDONG CHEM

In-situ nano Fe3O4@C composite porous lithium ion battery anode material and preparation method thereof

InactiveCN108428877AImprove lithium storage performanceIncrease contactMaterial nanotechnologyCell electrodesPorous carbonDecomposition

The invention discloses an in-situ nano Fe3O4@C composite porous lithium ion battery anode material and a preparation method thereof and belongs to the technical field of production of lithium ion battery electrode materials. On the basis of polyhydroxy structure features of citrate, the in-situ Fe3O4@C composite porous lithium ion battery anode material with Fe3O4 obtained through carbonization dispersed and distributed in a porous carbon framework is designed on the molecular scale with ferric citrate chelate as a precursor. The ferric citrate precursor is prepared with a complexing precipitation method and carbonized in the inert atmosphere, Fe<3+> produces Fe3O4 at in-situ sites, C6H5O7<3-> decomposes to form the carbon framework, the porous structure benefits from overflow of other decomposition products, the preparation condition is mild, the synthesis process is simple and controllable, and the cost is low. The synthesized electrode material can realize in-situ nano crystallization and dispersion distribution of Fe3O4, external carbon sources are not required, meanwhile, by the aid of the porous structure of carbon, the electron migration rate is increased, contact of an electrolyte and the electrode material is enhanced, the lithium storage performance of the electrode material is improved, the synergistic effect of Fe3O4 and the porous carbon structure is realized, andthe problems of significant capacity fading, poor cycle stability and the like caused by the Fe3O4 volume effect are solved effectively, so that the Fe3O4@C composite material has good electrochemical performance.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

A kind of self-healing polyurethane coating and preparation method thereof

ActiveCN104356338BAchieve self-healingImplement multiple repeat repairsPolyurea/polyurethane coatingsPolyesterPolyol

Owner:SOUTH CHINA UNIV OF TECH

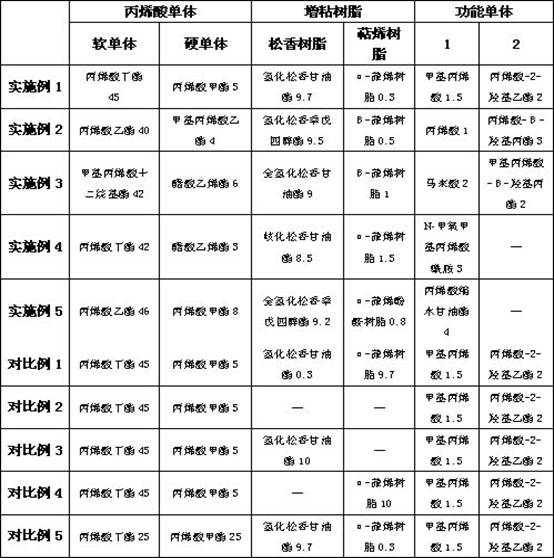

Thin-coating high-viscosity water-based polyacrylate pressure-sensitive adhesive as well as preparation method and application thereof

ActiveCN113372854AImprove performanceStrongMacromolecular adhesive additivesAmide/imide polymer adhesivesAdhesive cementPolymer science

The invention provides a thin-coating high-viscosity water-based polyacrylate pressure-sensitive adhesive and a preparation method thereof. The thin-coating high-viscosity water-based polyacrylate pressure-sensitive adhesive is prepared from the following components: 40 to 55 parts of an acrylate monomer, 35 to 60 parts of deionized water, 0.5 to 4 parts of a functional monomer, 6 to 15 parts of mixed tackifying resin, 0.5 to 2 parts of a reactive emulsifier, 0.5 to 2 parts of an anionic emulsifier, 0.1 to 0.5 part of an initiator, 0.5 to 1.5 parts of a pH regulator and 0.01 to 0.2 part of a pH buffering agent. According to the pressure-sensitive adhesive disclosed by the invention, mixed tackifying resin of rosin resin and terpene resin is dissolved in the acrylate monomer, the double-type emulsifier is introduced, and the functional monomer is introduced by adopting a cross-linking modification technology to participate in polymerization, so that the prepared adhesive has the advantages of high viscosity, large tensile strength, strong cohesion, high stripping force and the like, is environment-friendly and low in cost, and is simple and controllable and is suitable for large-scale production.

Owner:XIANGYANG SUNVALOR AEROSPACE FILMS CO LTD

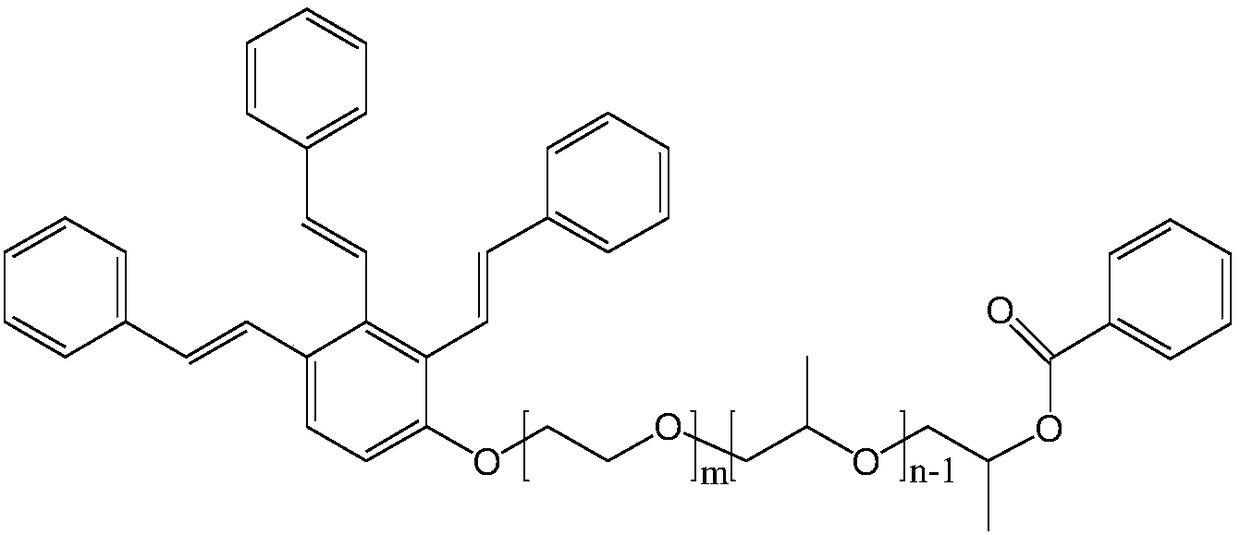

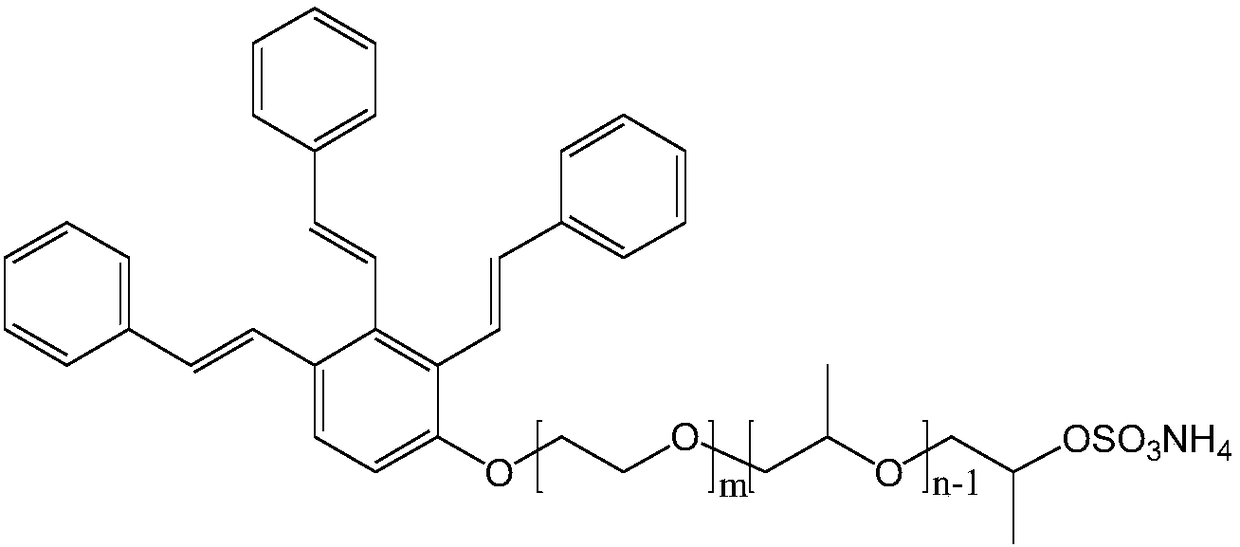

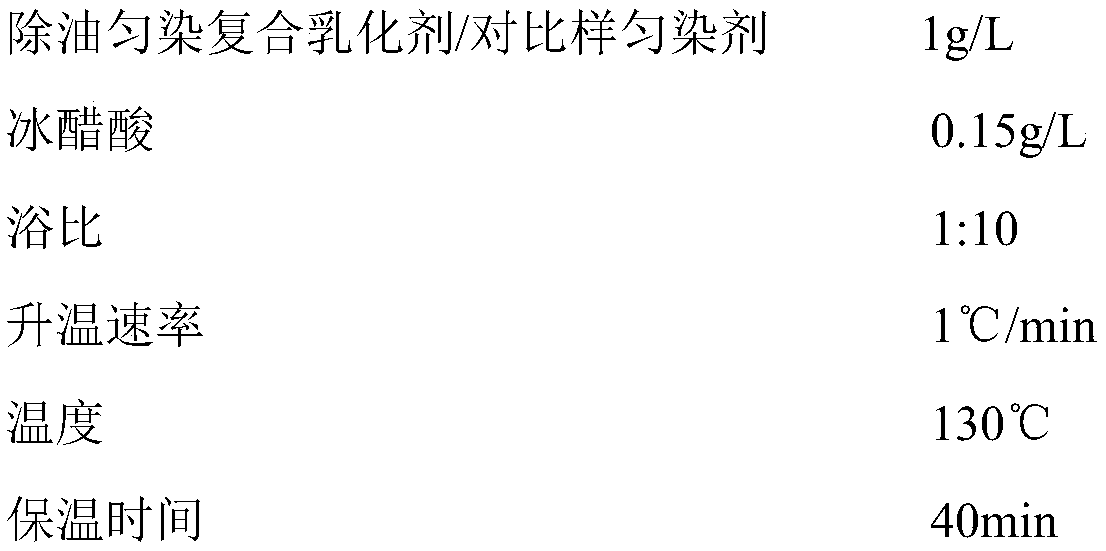

Preparation method of a degreasing and level dyeing composite emulsifier for polyester fabrics

The invention relates to a preparation method of a degreasing and level dyeing composite emulsifier for polyester fabrics, and belongs to the field of textile aids. In the traditional process, degreasing and level dyeing are performed in two steps, such that the production process is long, and the consumption of water and electricity is more. According to the present invention, the composite emulsifier is formed by mixing the following components by mass: 18-22% of tristyrylphenol polyoxyethylene polyoxypropylene ether benzoate, 8-12% of tristyrylphenol polyoxyethylene polyoxypropylene ether ammonium sulfate, 8-12% of isotridecanol polyoxyethylene polyoxypropylene ether sodium sulfate, 3-7% of isotridecanol polyoxyethylene ether, and the balance of water; the composite emulsifier does notcontain phosphorus, has good degreasing property, good dyeing retarding property and good transferability, and has little influence on the dye uptake rate of dyes; and the degreasing and the dyeing are integrated so as to shorten the dyeing and finishing process, improve the production efficiency, reduce the production cost, and achieve the purposes of energy saving and emission reduction.

Owner:ZHEJIANG SILK TECH

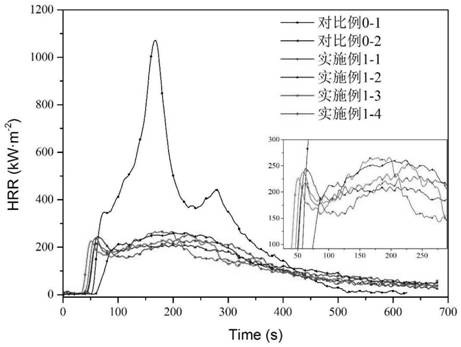

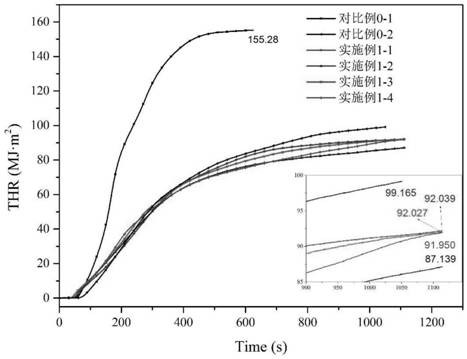

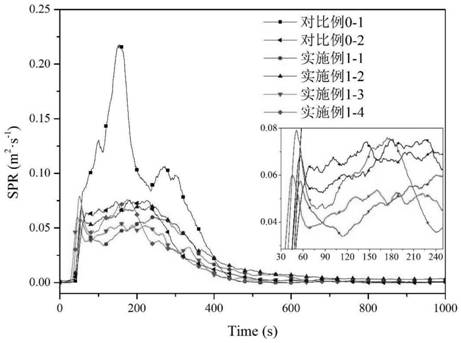

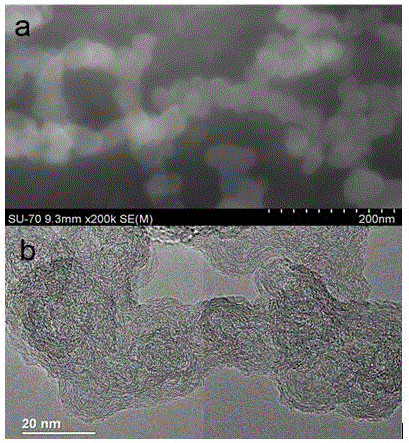

Carbon nitride-polyaniline nano composite material and preparation method thereof, and carbon nitride-polyaniline intumescent fire retardant coating and preparation method thereof

ActiveCN112812296AThe synthesis process is simple and controllableRaw materials are cheap and easy to getFireproof paintsMaterial nanotechnologyEpoxyCarbon layer

The invention provides a carbon nitride-polyaniline nano composite material and a preparation method thereof as well as a carbon nitride-polyaniline intumescent fire retardant coating and a preparation method thereof, relates to the field of fire retardant coatings, and aims to solve the problem that epoxy resin is easily modified and is combined with other materials to form a composite material with performances superior to that of the epoxy resin and the other materials, but due to the interaction of extremely strong Van der Waals force between carbon nitride layers, the carbon nitride is extremely easy to agglomerate and is difficult to disperse well in epoxy resin. The carbon nitride-polyaniline nano composite material is cheap, and the technological process is simple and easy to control. The carbon nitride-polyaniline intumescent fire retardant coating prepared from the obtained carbon nitride-polyaniline nano material has excellent flame retardant property and is environment-friendly.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method of epoxy-POSS/silicone modified epoxy resin composite

InactiveCN109988429AImprove mechanical propertiesImprove high temperature resistanceEpoxyWeather resistance

A preparation method of an epoxy-POSS / silicone modified epoxy resin composite comprises the following steps: synthesizing epoxy-polyhedral oligomeric silsesquioxane (epoxy-POSS for short); preparing asilicone modified epoxy resin prepolymer; and compounding the epoxy-POSS with the silicone modified epoxy resin prepolymer to generate the target product epoxy-POSS / silicone modified epoxy resin composite. The epoxy-POSS / silicone modified epoxy resin composite provided in the present invention is composed of the silicone modified epoxy resin, the epoxy-POSS, an active diluent and a latent curingagent with substantial improvements in mechanical properties and high temperature resistance in comparison to a previous cured polysiloxane product; the preparation method of the epoxy-POSS / silicone modified epoxy resin composite has the advantages that the preparation of the composite meets the requirements of going green and environmental protection with no three wastes discharged, and the composite is synthesized through a simple and controllable process and has excellent weather resistance and mechanical properties. The epoxy-POSS / silicone modified epoxy resin composite prepared by the preparation method disclosed by the invention can be widely used for high temperature resistant insulation protection of electrical, electronic and photoelectric materials.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

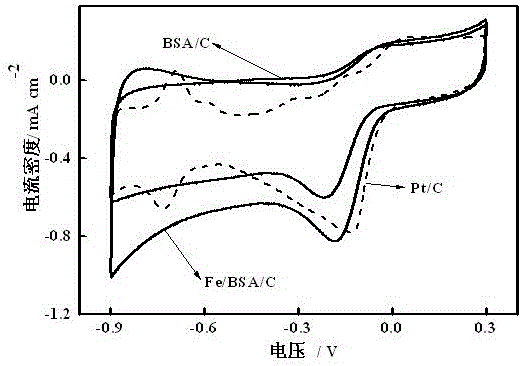

Fuel cell oxygen-reduction catalyst taking protein as raw material and preparation method of fuel cell oxygen-reduction catalyst

ActiveCN106848337AEasy to exploreLow costCell electrodesCarbon preparation/purificationProtein solutionFuel cells

The invention provides a fuel cell oxygen-reduction catalyst taking protein as a raw material and a preparation method of the fuel cell oxygen-reduction catalyst. The preparation method comprises the steps of firstly, adding the protein into deionized water, and performing stirring for 30-60 minutes to obtain an uniform protein solution; secondly, adding conductive carbon black and a transition metal salt into the protein solution, heating the mixture according to many segments in an environment of 120-240 DEG C after uniform stirring until the solvent is evaporated to obtain a solid mixture; thirdly, carbonizing the solid mixture for 1-3 hours at 700-1,100 DEG C under protection of an inert atmosphere to obtain a carbonization product; and finally, sieving the carbonization product after grinding to obtain the oxygen-reduction catalyst. According to the method, the protein is used as the raw material to prepare the oxygen-reduction catalyst, the oxygen-reduction catalyst is low in cost, is also environmental-friendly, is also relatively good in catalytic performance and is approximate to a limited current of a precious metal Pt catalyst, and promotion and application are convenient.

Owner:SHENZHEN UNIV

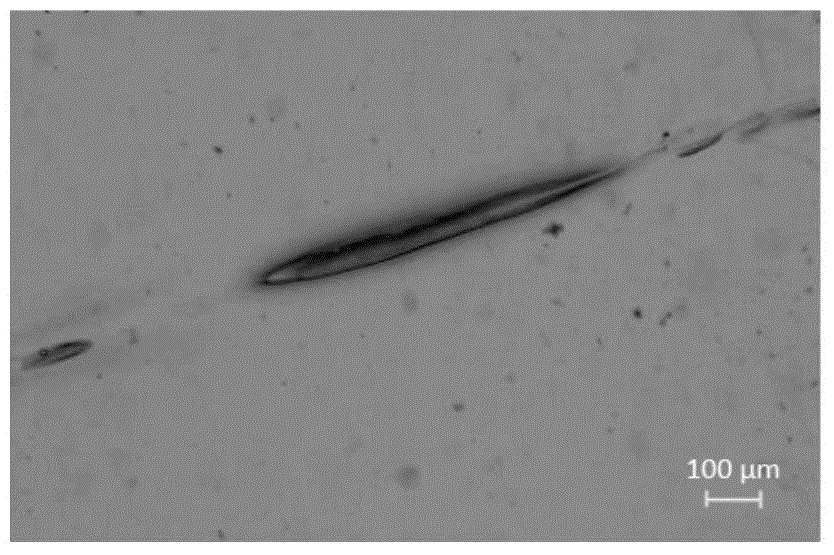

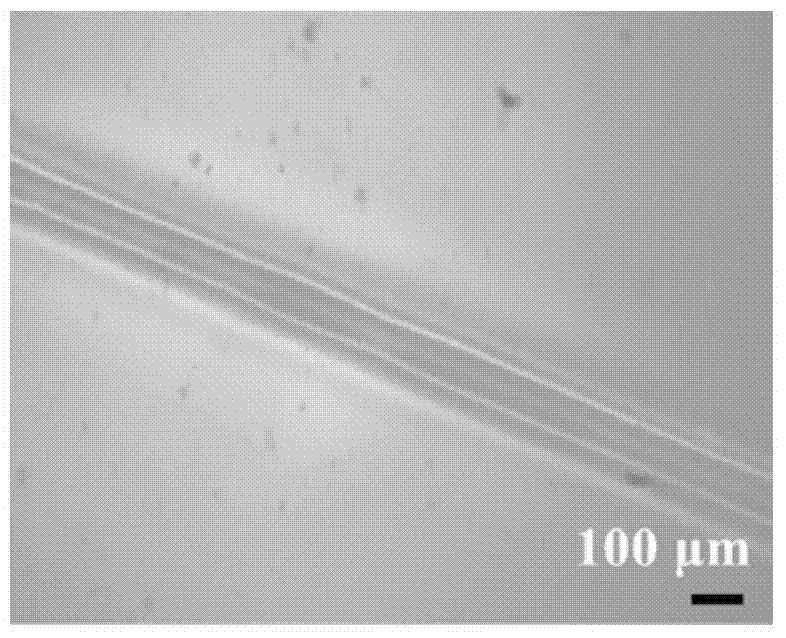

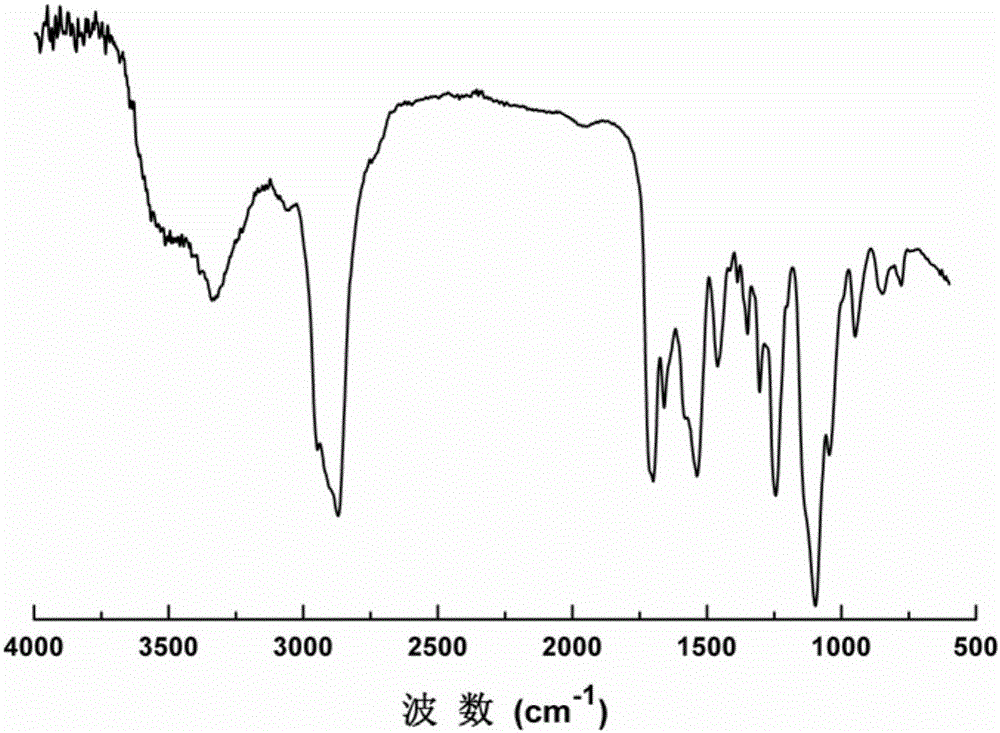

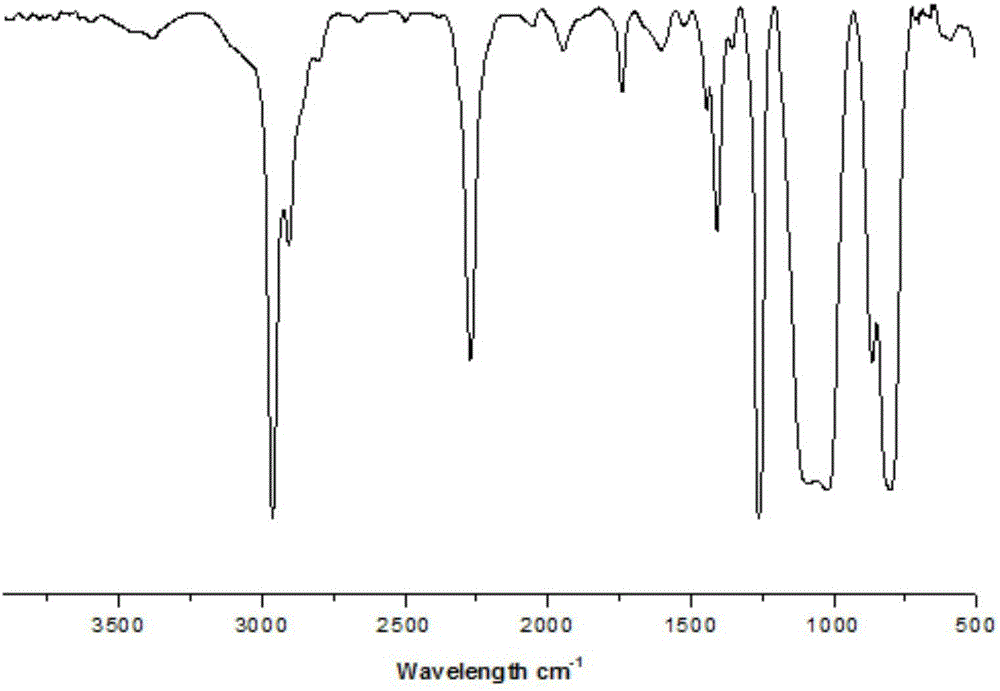

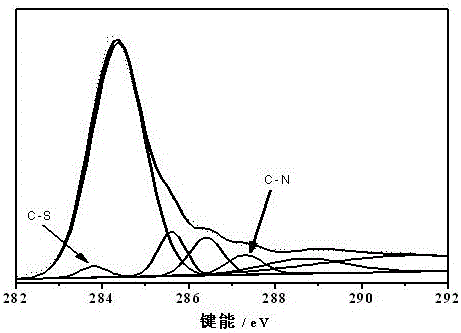

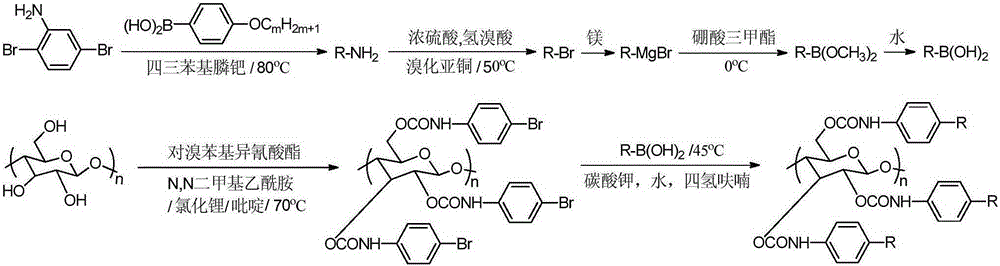

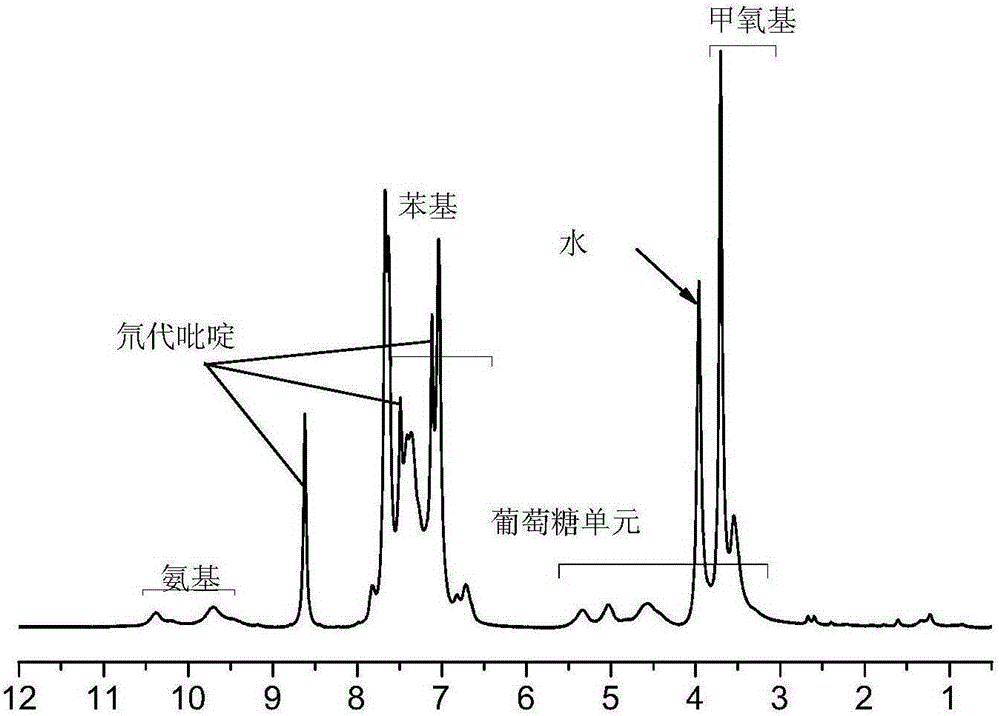

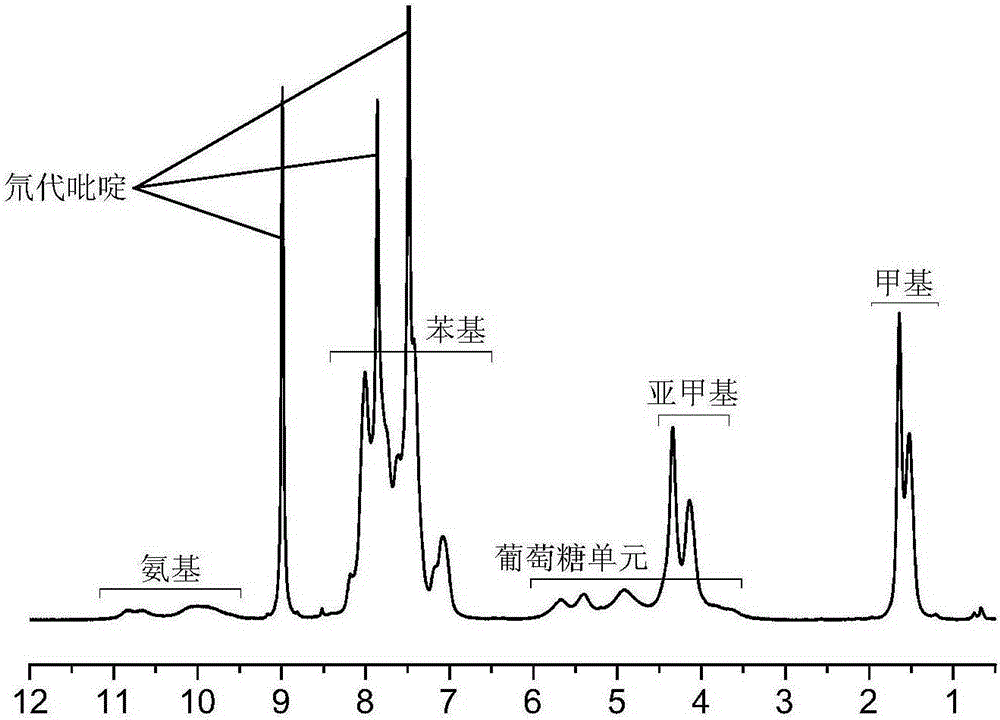

Synthetic method for cellulose derivative with large volume liquid crystal unit side group

The invention provides a synthetic method for cellulose derivative with a large volume liquid crystal unit side group. The synthetic method comprises: by taking 2,5-dibromoaniline and 4-alkoxyl phenylboronic acid as raw materials, synthesizing 2,5-bi(4'-alkoxyl phenyl) phenylboronic acid through Suzuki coupling reaction, Sandmeyer reaction, Grignard and the like; then by taking microcrystal cellulose as a reaction medium, synthesizing cellulose-tri(4-bromophenyl amino formate); and carrying out Suzuki coupling reaction on the synthesized 2,5-bi(4'-alkoxyl phenyl) phenylboronic acid and cellulose-tri(4-bromophenyl amino formate) to finally synthesize the novel cellulose phenyl amino formate derivative with large volume liquid crystal unit side group, wherein a benzene ring replaces p-terphenyl in a p-position. The molecular structure of a product is represented in detail and analyzed by applying Fourier transform infrared spectrometer, a nuclear magnetic resonance hydrogen spectrum and a nuclear magnetic resonance carbon spectrum, and the liquid crystal performance of the synthesized novel cellulose derivative is further inspected by applying a differential scanning calorimeter and a polarizing microscope.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com