A cadmium-stibium-based p type thermal electrical material and its making method

A thermoelectric material, antimony-based technology, applied in the direction of thermoelectric device junction lead-out materials, etc., can solve the problems of thermoelectric properties that have not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

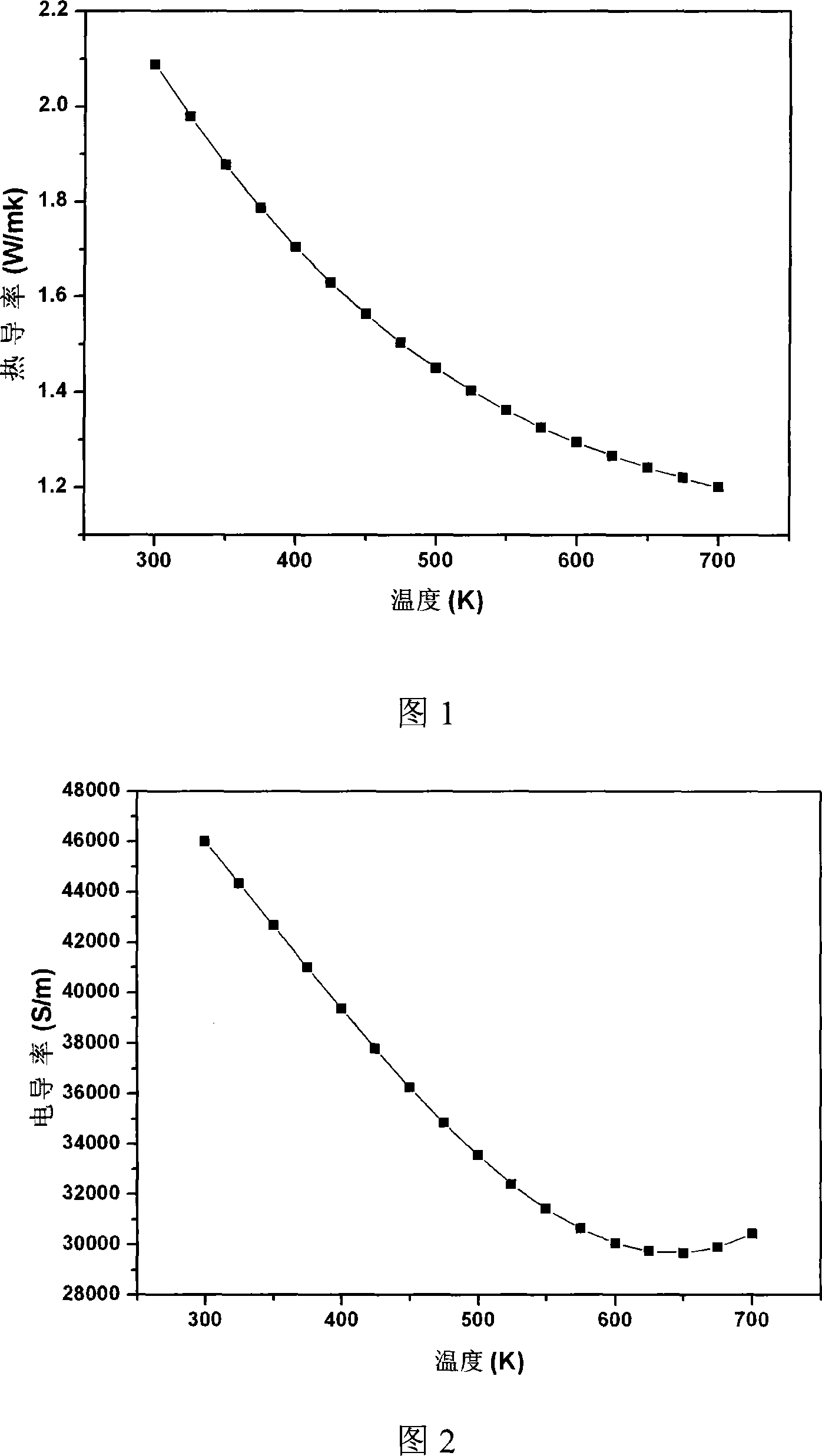

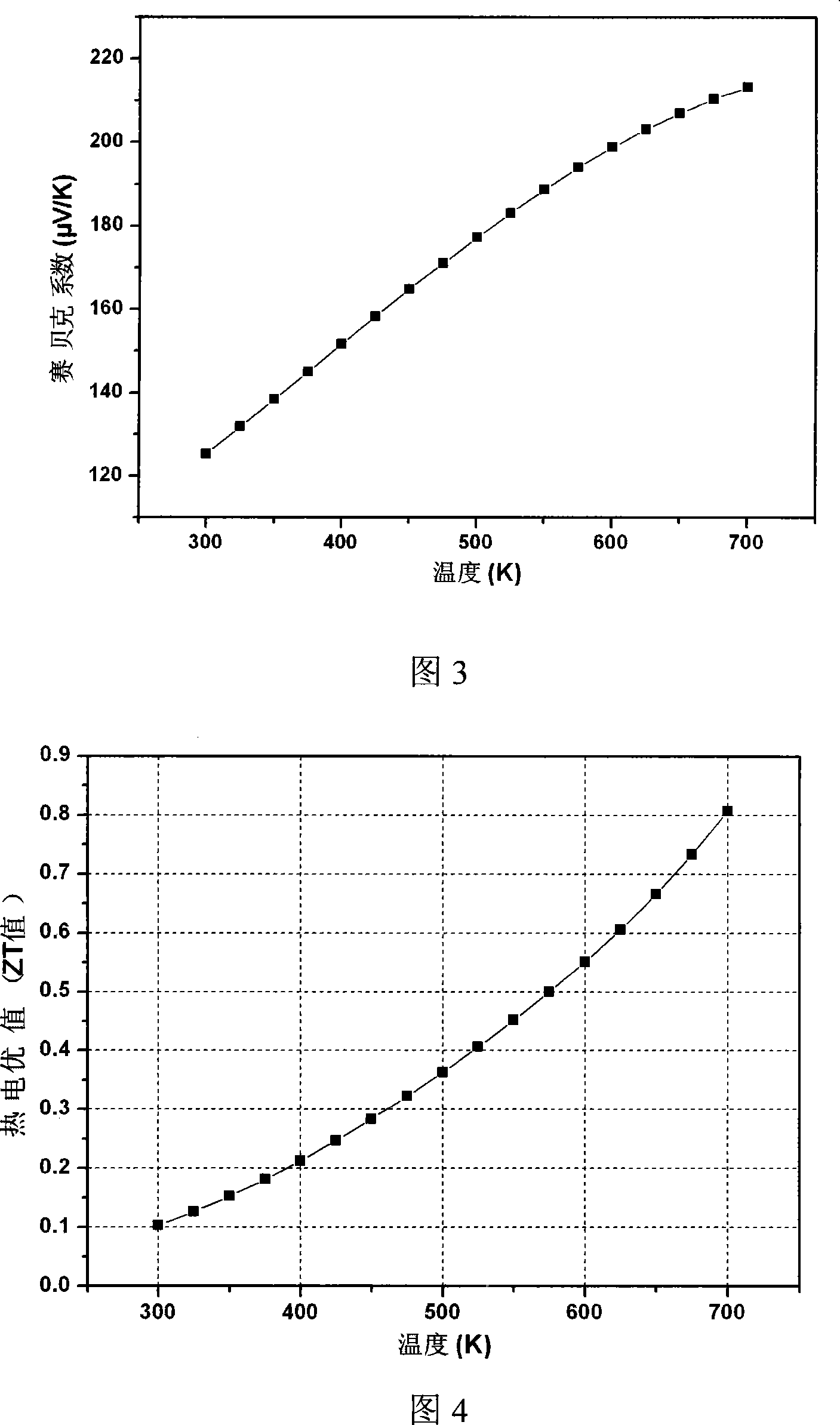

[0014] In the glove box, weigh 0.674g of Cd particles (99.999%), 0.525g of Yb metal (99.9%), and 0.731g of antimony particles (99.999%), and put the raw materials into a 25mm× Put the crucible in a graphite crucible with a diameter of Φ10mm, and then put the crucible into a quartz tube with an inner diameter of Φ11mm, plug it with a rubber stopper and take it out from the glove box. Then quickly evacuate it with a vacuum pump until the vacuum degree reaches 1×10 -6 When torr, it is sealed with a hydrogen-oxygen flame. Then put it into a heating furnace, raise the temperature to 900°C at a rate of 1°C / min, keep it warm for 72 hours, and take it out with the furnace cooling. The product was confirmed as YbCd by powder XRD 2 Sb 2 pure phase. The obtained sample is ground into powder, and then sintered at 450° C., 50 MPa, and vacuum atmosphere for about 15 minutes by using rapid plasma sintering (SPS). The density of the obtained ceramic sample is about 98%. Then the thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com