Fuel cell oxygen-reduction catalyst taking protein as raw material and preparation method of fuel cell oxygen-reduction catalyst

A fuel cell and protein technology, which is applied in the preparation/purification of carbon, battery electrodes, circuits, etc., can solve the problems of insufficient durability, high cost of oxygen reduction reaction catalysts, and low activity, and is environmentally friendly and conducive to popularization and application , The synthetic process is simple and controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing a fuel cell oxygen reduction catalyst using protein as a raw material provided by the present invention, comprising:

[0030] Step A, adding protein into deionized water, stirring for 30-60 minutes to obtain a uniform protein solution;

[0031] Step B. Add conductive carbon black and transition metal salt solution to the above protein solution, stir evenly, and heat in multiple stages until the solvent is evaporated to dryness at 120-240° C. to obtain a solid mixture; wherein, the mass of conductive carbon black and protein The ratio is 0.5~1, and the mass ratio of the metal ion in the transition metal salt to the protein is 0.05~0.2.

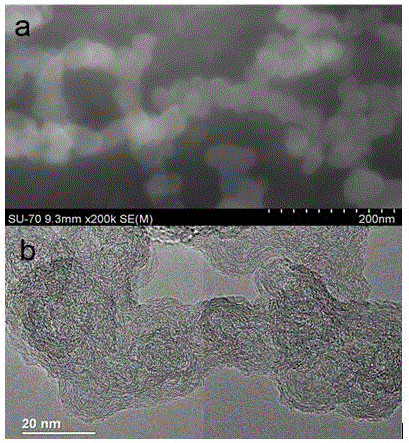

[0032] Step C, under the protection of an inert atmosphere, carbonize the above solid mixture at 700-1100°C for 1-3 hours to obtain a carbonized product;

[0033] Step D, grinding and sieving the above carbonized product to obtain an oxygen reduction catalyst.

[0034] In step A, the protein is first added to dei...

Embodiment 1

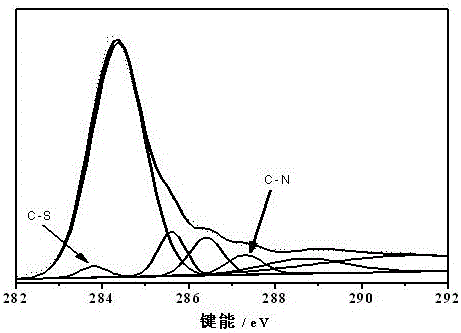

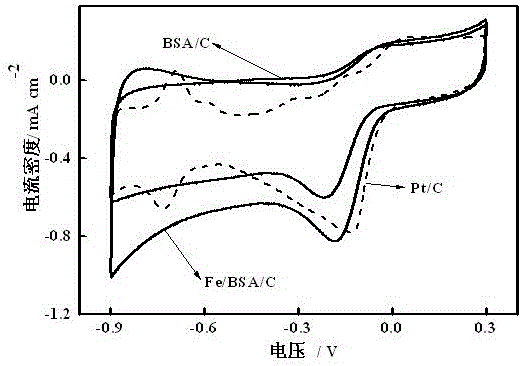

[0042] First, weigh 1g bovine serum albumin (BSA) powder and place it in a beaker, add 100mL deionized water to fully dissolve it. After that, weigh 483mg FeCl 3 ·6H 2 O in a beaker, add 20mL of deionized water, dissolve fully and add to the protein solution. Next, weigh 1 g of EC-300J commercial carbon black, add it into the above mixed solution, and stir it magnetically for 8 hours to make it evenly mixed. Then the beaker was transferred to a forced air drying oven, respectively, at 120 o C. 180 o C and 240 o Heating at constant temperature in an air atmosphere under C condition for 24h, 24h and 9h to achieve the effect of removing solvent and stabilizing solute mixture. Finally, the black solid was transferred to a porcelain boat, and the above magnetic boat was placed in a tube furnace at 900 o C under argon atmosphere at high temperature for 1h. After grinding and passing through a 200-mesh sieve to remove impurities with larger particles, the Fe / BSA / C catalyst is ...

Embodiment 2

[0048] First, weigh 1g bovine serum albumin (BSA) powder and place it in a beaker, add 100mL deionized water to fully dissolve it. Next, weigh 267mg CuCl 2 2H 2 In the beaker, add 20mL deionized water, fully dissolve and add to the protein solution. Next, weigh 1 g of EC-300J commercial carbon black, add it into the above mixed solution, and stir it magnetically for 8 hours to make it evenly mixed. Then the beaker was transferred to a forced air drying oven, respectively, at 120 o C. 180 o C and 240 o Heating at constant temperature in an air atmosphere under C condition for 24h, 24h and 9h to achieve the effect of removing solvent and stabilizing solute mixture. Finally, the black solid is transferred to a porcelain boat, and the above-mentioned magnetic boat is placed in a tube furnace at 900 o C under argon atmosphere at high temperature for 1h. After grinding and passing through a 200-mesh sieve to remove impurities with larger particles, the Cu / BSA / C catalyst is ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com