Punching device and method for automotive aluminum plate

A technology for aluminum plates and vehicles, applied in the field of aluminum forming, can solve the problems of not having hot stamping experiments for aluminum plates, unsuitable for the exploration of aluminum plate stamping for vehicles, and precise control of blank-holding force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is specifically illustrated by the following examples, but the scope of the present invention is not limited to the following examples.

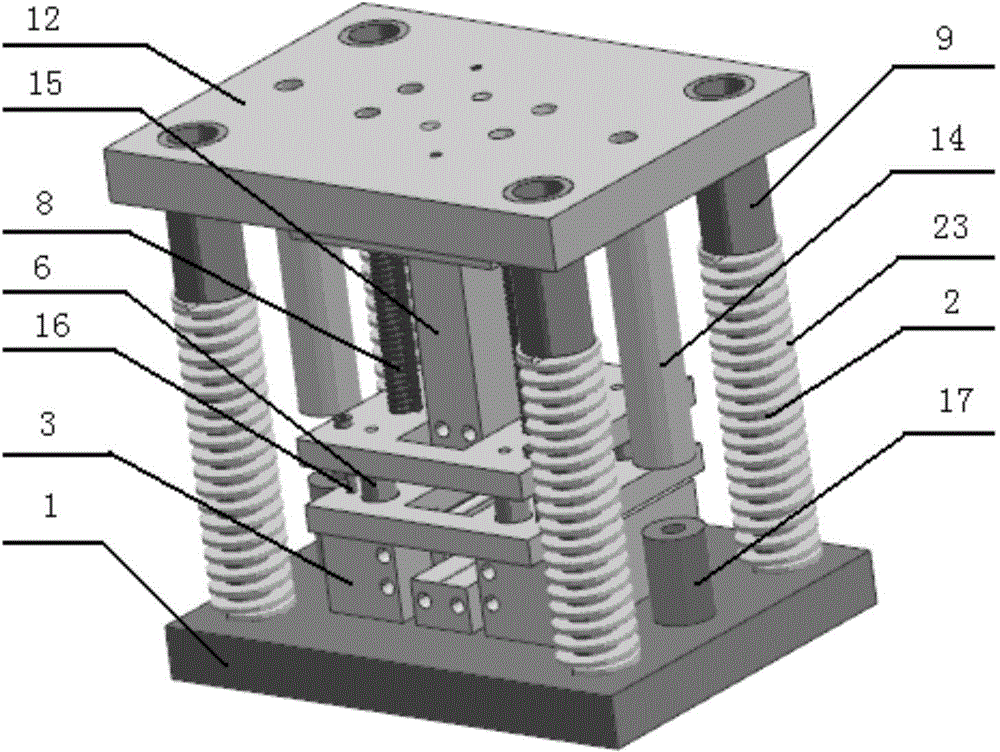

[0030] In the device designed by the present invention, at least the guide post 2 and the discharge rod 8 can move relative to the upper mold base 12 in the vertical direction, but the components including the guide post 2 and the discharge rod 8 cannot be extended. Out of the upper mold base 12.

[0031] In the experimental device structure of the present invention, as Figure 5-6 As shown, there are through holes on the punch 15, the bottom plate 19 of the die and the die plate 3, and its function is, for example, to insert a thermal resistor to heat the device, so that it can realize the functions of heating the blank and warm stamping.

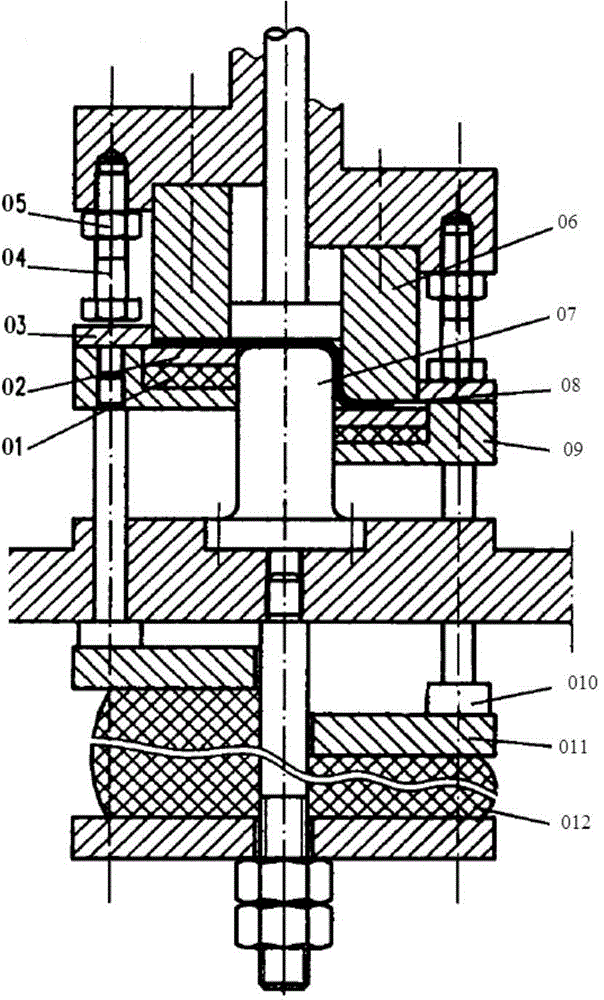

[0032] Depend on Figure 3-6 It can be seen from the middle structure that the device provided by the present invention can keep the blank holder force constant during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com