Computer Aided Measurement Method of Steel Frame Beam-to-Column End-plate Joint Rotation Angle

A computer-aided measurement method technology, which is applied in the field of structural engineering steel structure, can solve the problem of inability to accurately measure the joint angle of beam-column end plate connection joints in steel frame structures, and achieve the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

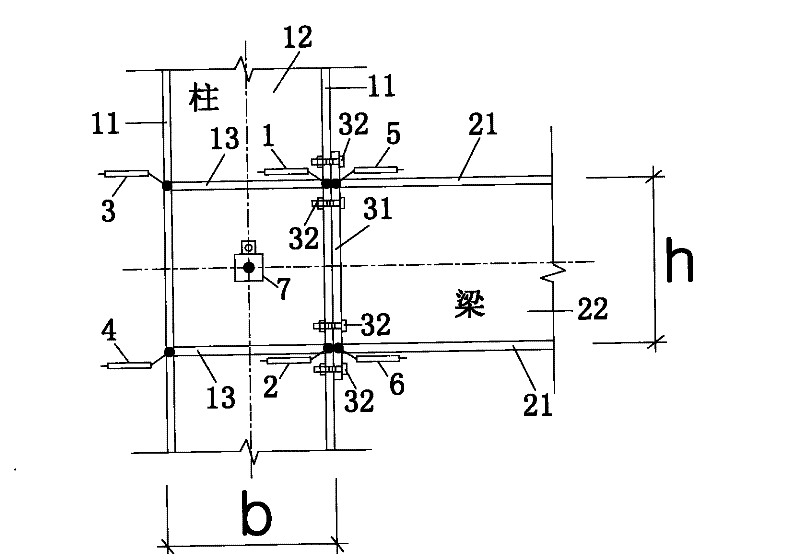

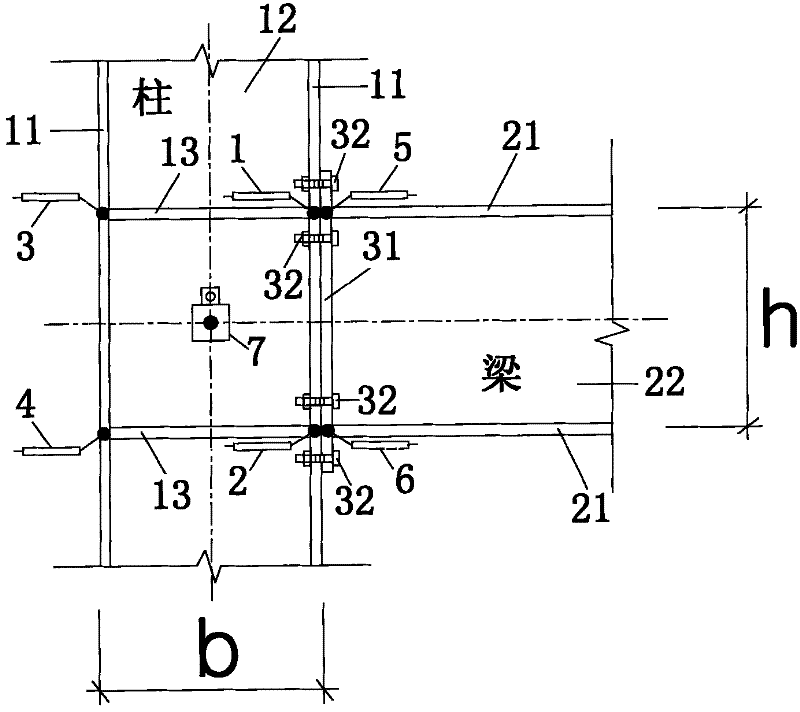

[0043] Embodiment 1 (see figure 1): This method is a method involving the measurement of the rotation angle of the end-plate joint in the experimental study of the mechanical performance of the steel frame joint, which is realized by 6 displacement meters and 1 inclinometer arranged at the end-plate joint. The column is composed of a column flange 11, a column web 12, and a horizontal stiffener 13 in the node domain. The beam is composed of a beam flange 21 and a beam web 22 . The end plate connection assembly consists of an end plate 32 and a high-strength friction bolt 32 . Displacement meter 1 measures the displacement of the corner point of the node domain adjacent to the tension flange of the beam along the axial direction of the beam, which is recorded as Δ 1 , the displacement meter 2 measures the displacement of the corner point of the node domain adjacent to the beam compression flange along the axial direction of the beam, which is recorded as Δ 2 , the displaceme...

Embodiment 2

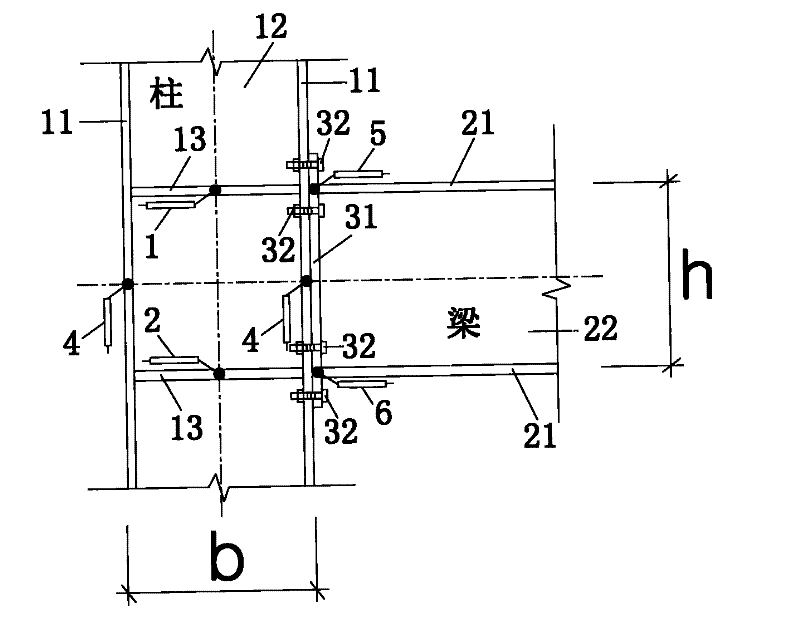

[0044] Embodiment 2 (see figure 2 ): This method is also a method involving the measurement of the rotation angle of the end-plate joints in the experimental study of the mechanical performance of the steel frame joints, which is realized by six displacement gauges arranged at the end-plate joints. The column is composed of a column flange 11, a column web 12, and a horizontal stiffener 13 in the node domain. The beam is composed of a beam flange 21 and a beam web 22 . The end plate connection assembly consists of an end plate 32 and a high-strength friction bolt 32 . Displacement meter 1 measures the displacement of the node domain along the axial direction of the beam at the intersection of the center line of the beam tension flange and the column axis, and the displacement is recorded as Δ 1 , the displacement meter 2 measures the displacement of the node domain along the beam axis at the intersection of the center line of the beam compression flange and the column axis,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com