A prefabricated load-bearing intermediate partition wall structure and construction method of a rectangular pipe jacking gallery

A rectangular pipe jacking and pipe jacking technology is applied in earthwork drilling, shaft equipment, wellbore lining and other directions, which can solve the problems of difficult connection of main bars in construction space, poor construction environment, and difficulty in supporting formwork, etc. Fast installation and good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

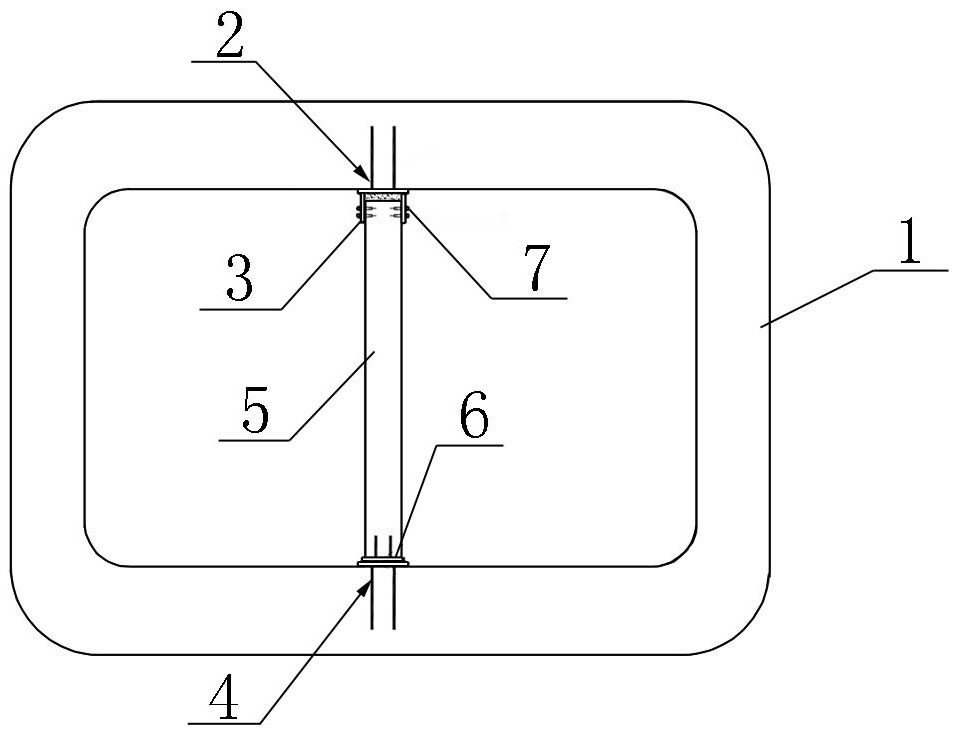

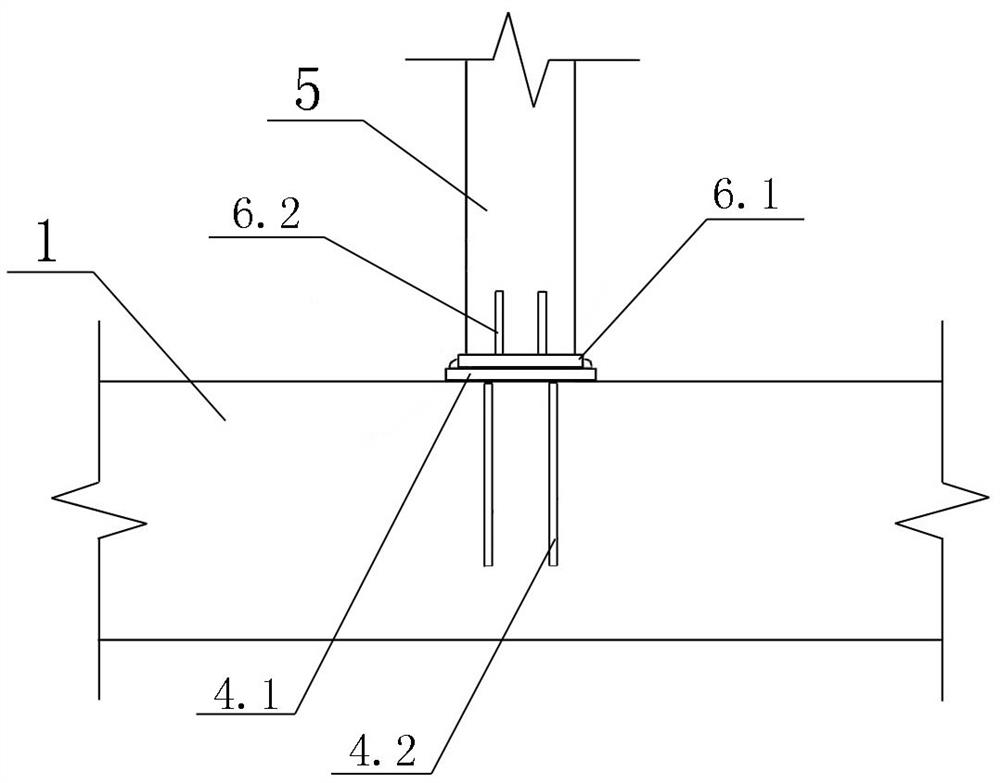

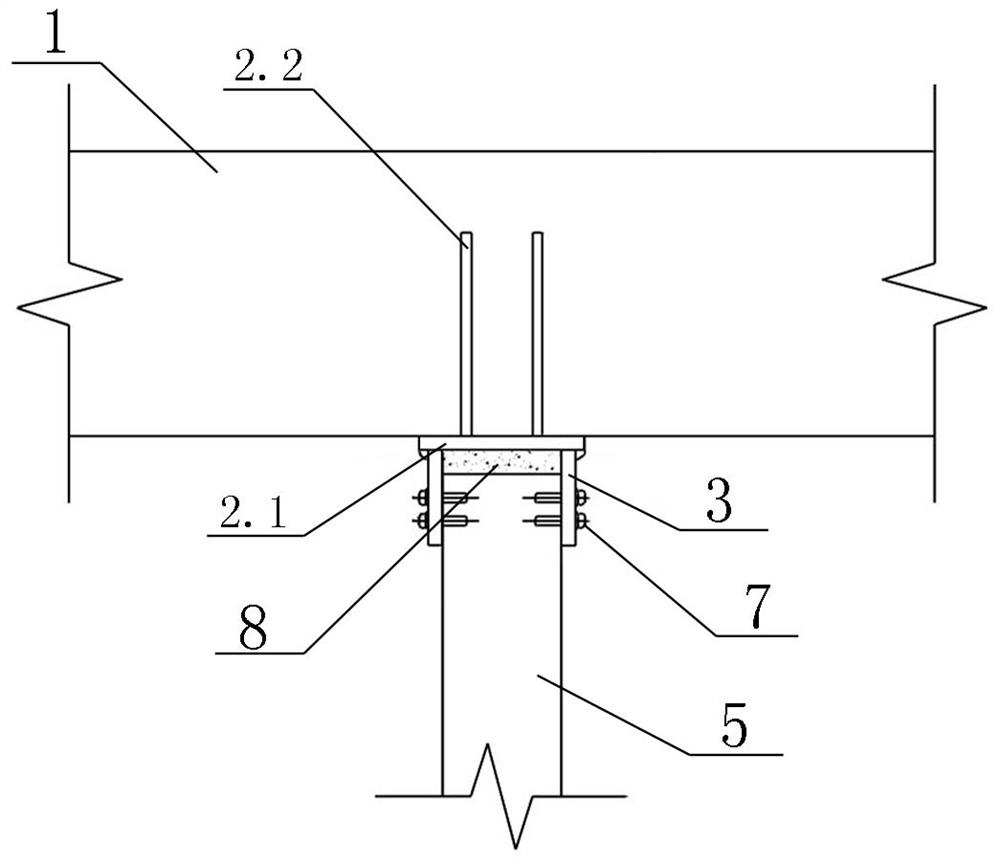

[0037] Such as Figure 1-5 As shown, the prefabricated load-bearing partition wall structure of this rectangular pipe jacking gallery is installed in the pipe jacking gallery; The cross section is rectangular; the prefabricated load-bearing partition wall structure includes pipe top embedded parts 2, vertical force transmission steel plates 3, pipe bottom embedded parts 4 and wall body 5; the pipe top embedded parts 2 include pre-buried The top anchor bar 2.2 on the top of the pipe jacking 1 and the pipe top embedded plate 2.1 horizontally connected to the lower end of the top anchor bar 2.2; On the upper pipe 1, and the left and right ends of the pipe top buried plate 2.1 respectively exceed the left and right sides of the wall 5; the vertical force transmission steel plate 3 has two pieces, which are connected to the bottom surface of the pipe top buried plate 2.1 along the horizontal parallel interval Above; each vertical force transmission steel plate 3 is set along the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com