Patents

Literature

31results about How to "Avoid tying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

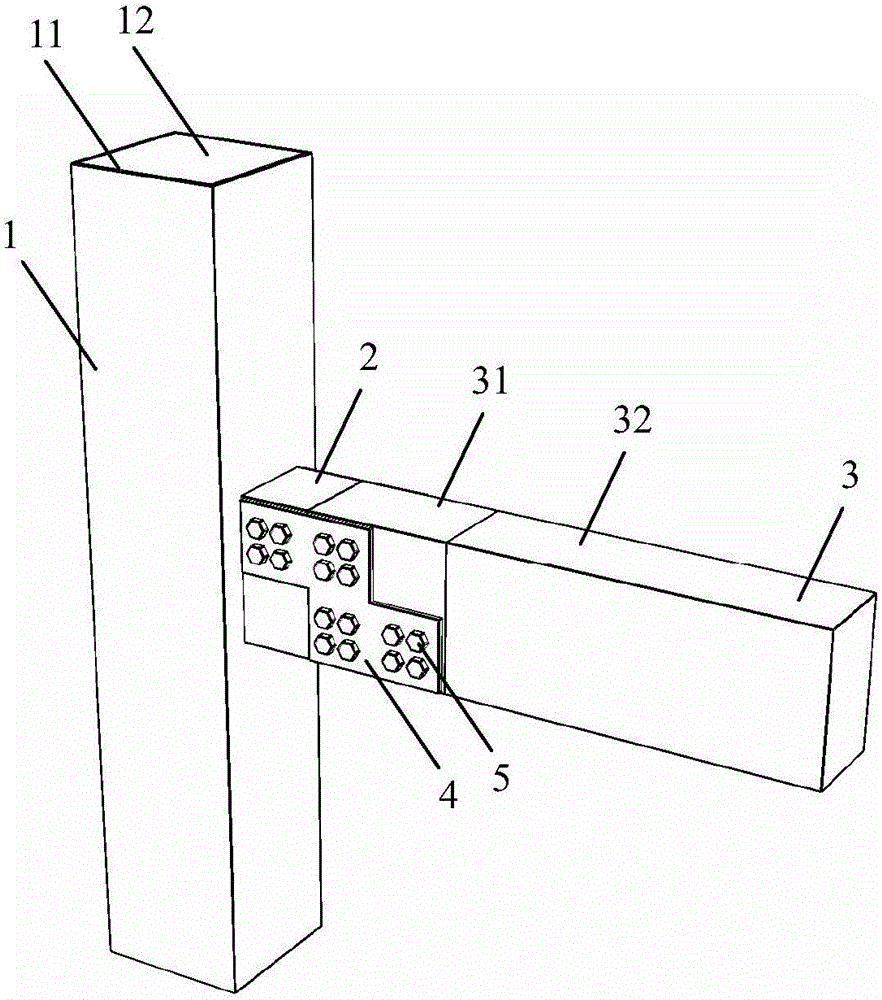

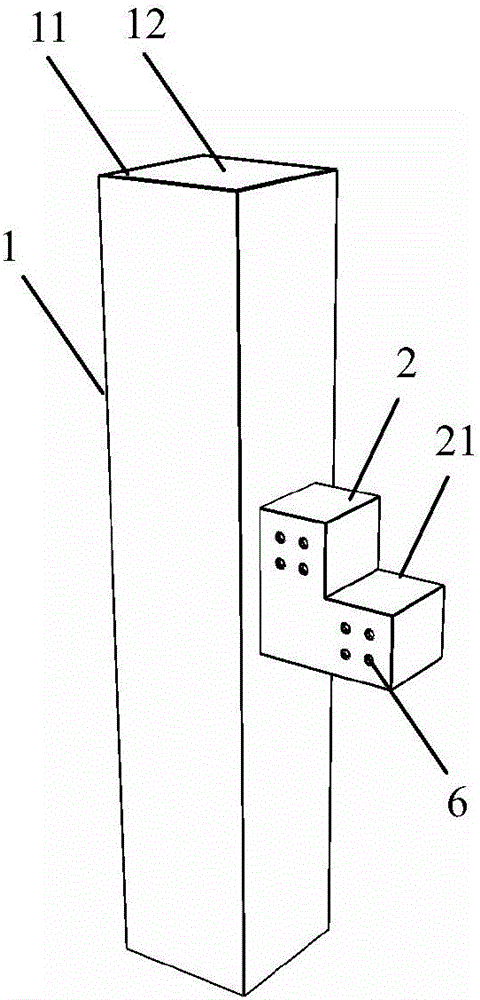

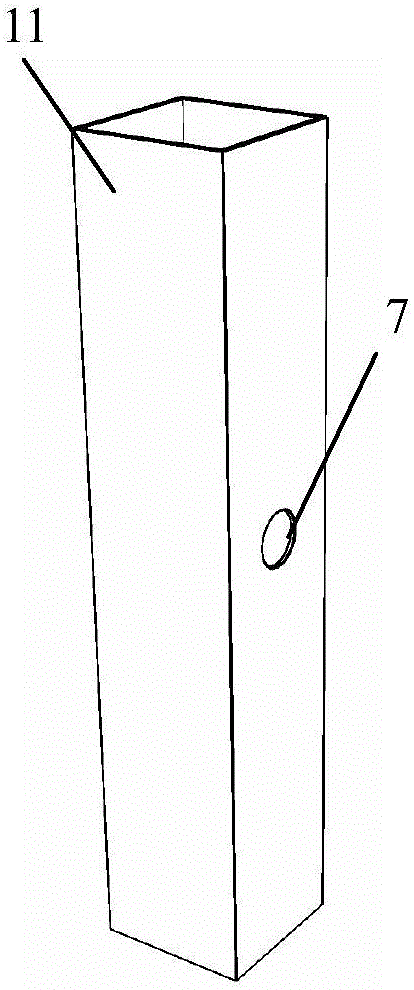

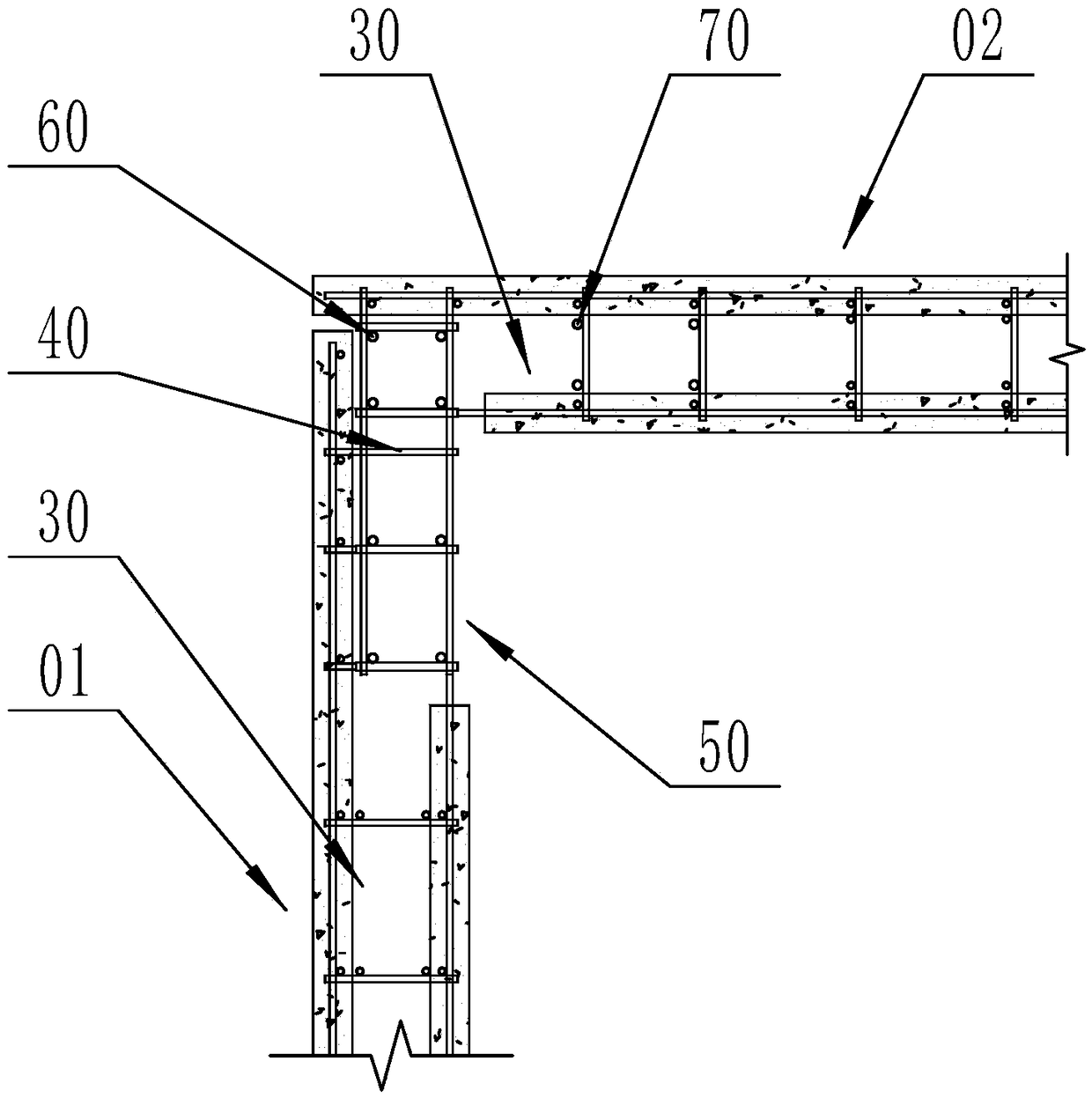

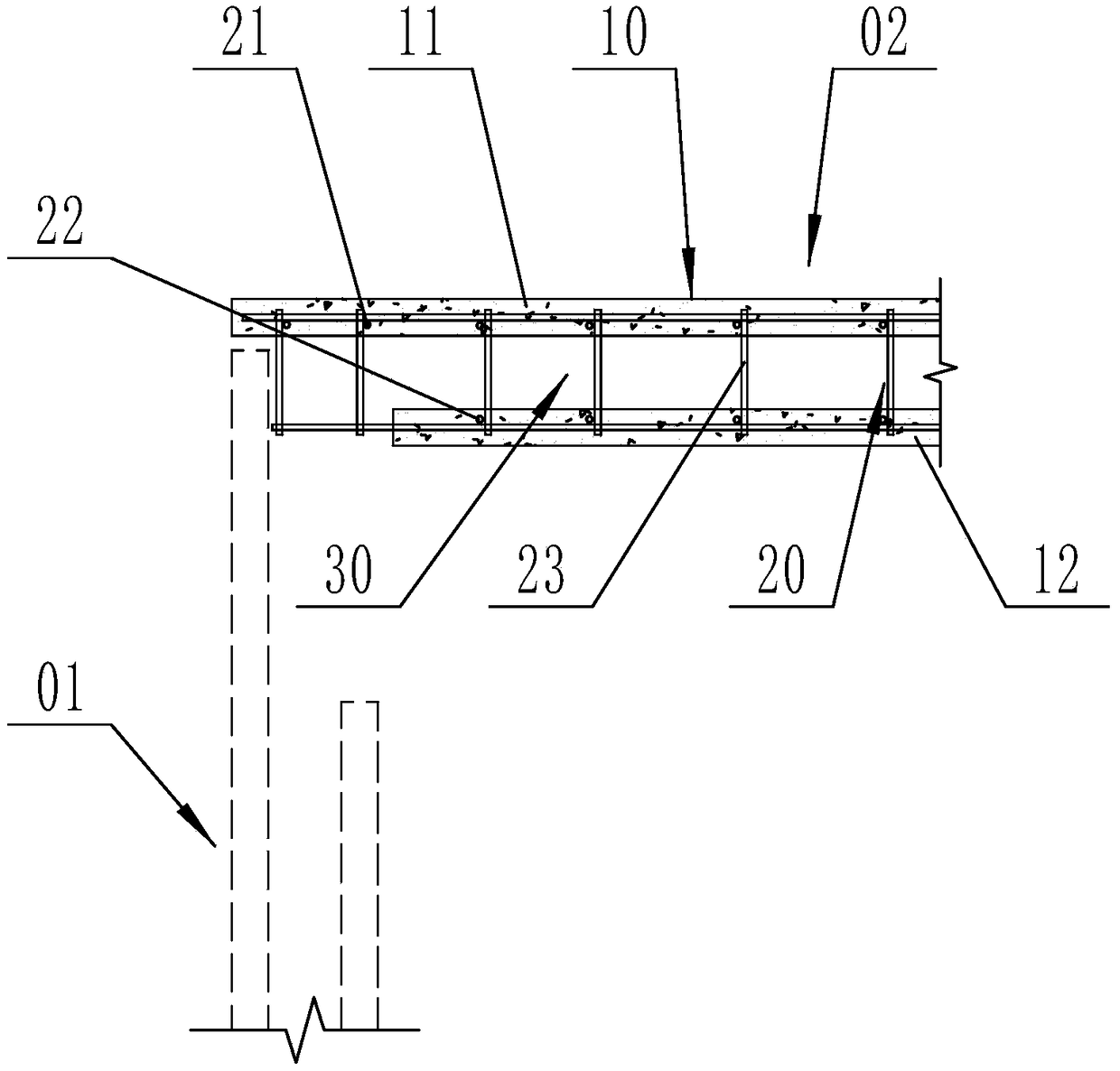

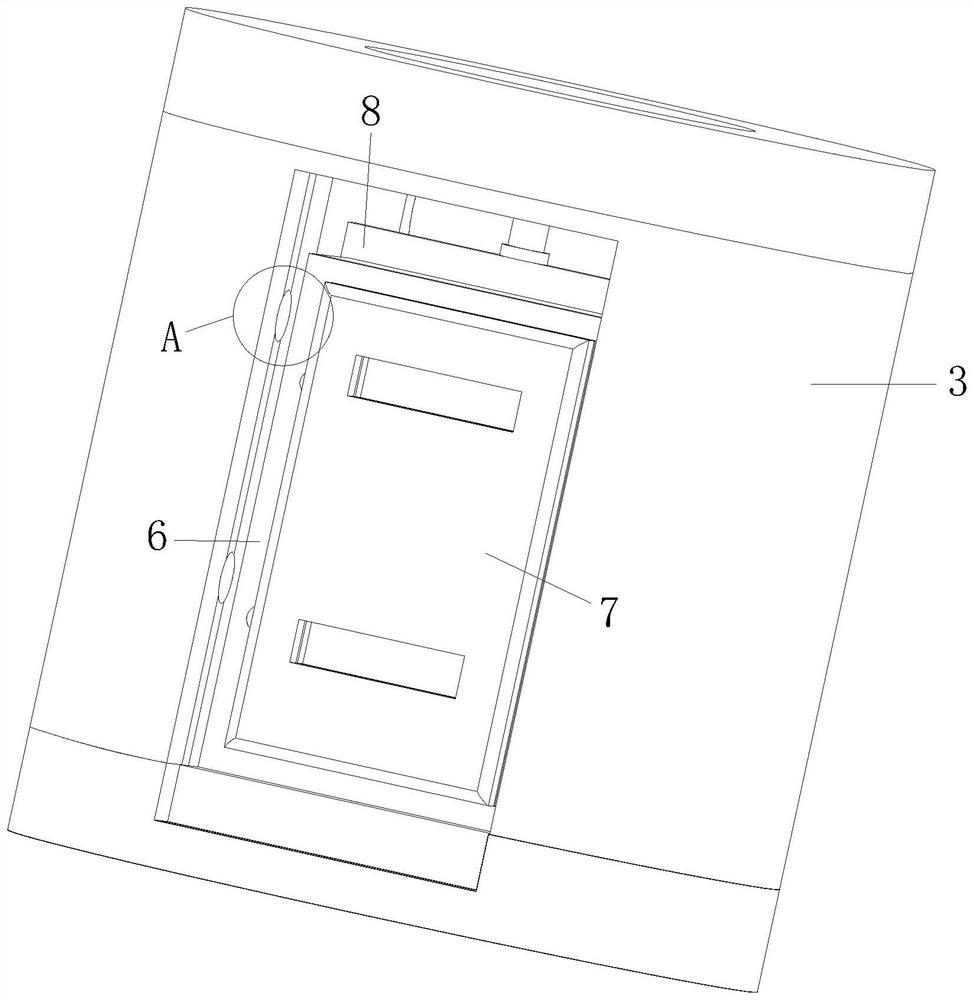

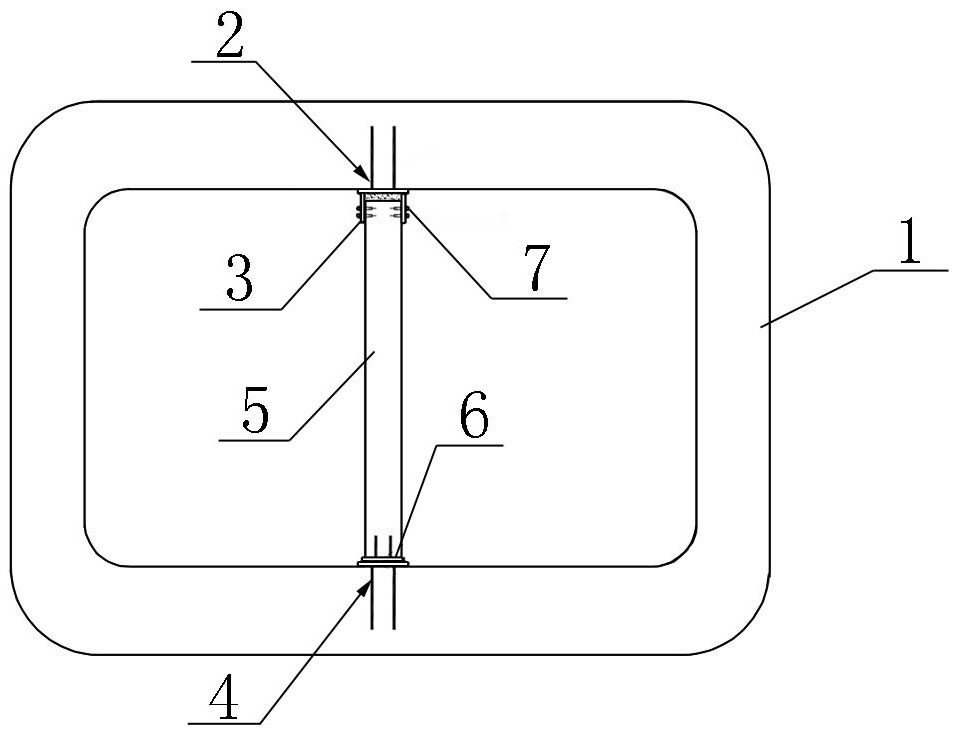

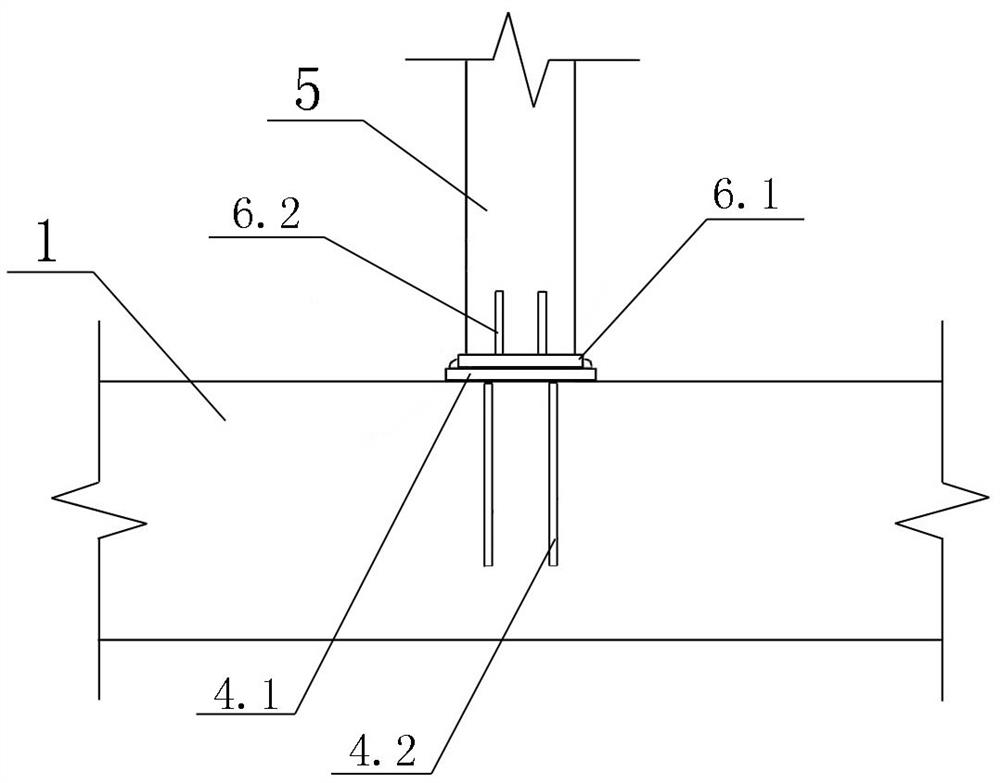

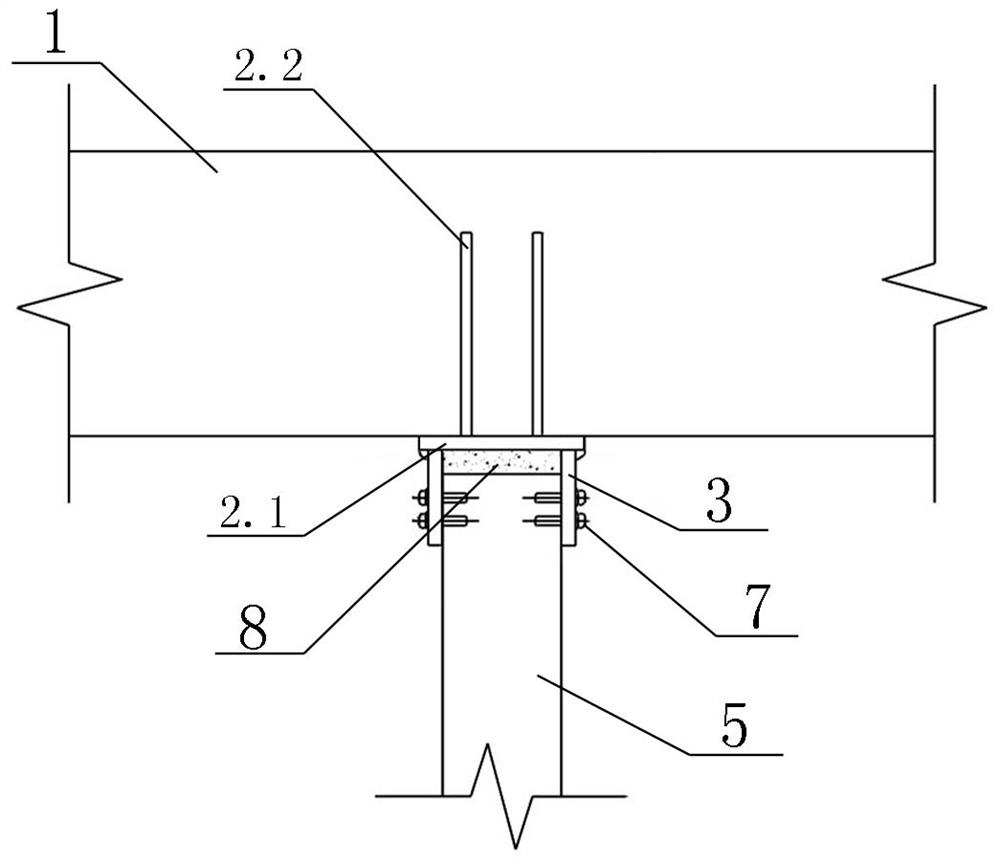

Assembly structure of prefabricated concrete beam and concrete-filled steel tube column

InactiveCN105780923AImproved dissipation capacityAvoid punchingBuilding constructionsConcrete beamsRebar

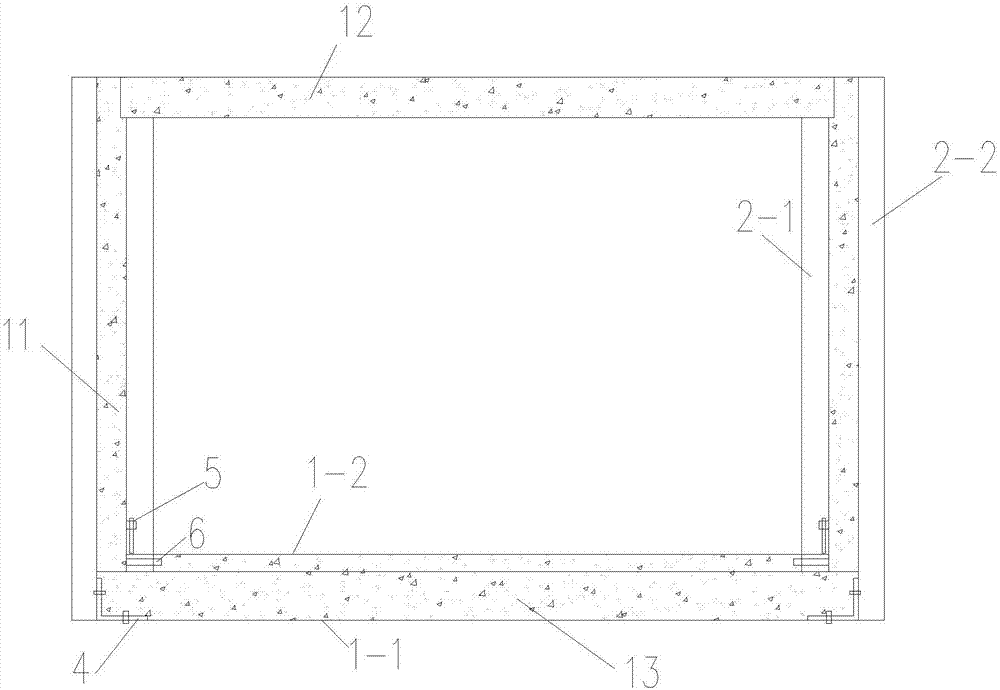

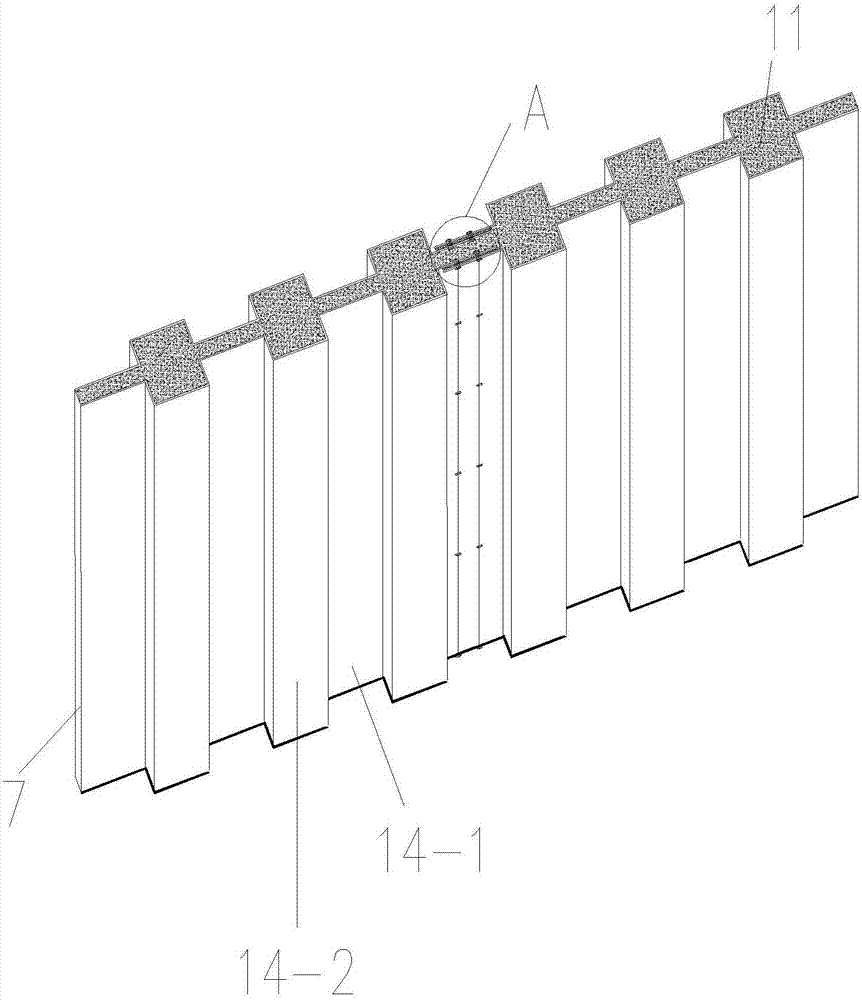

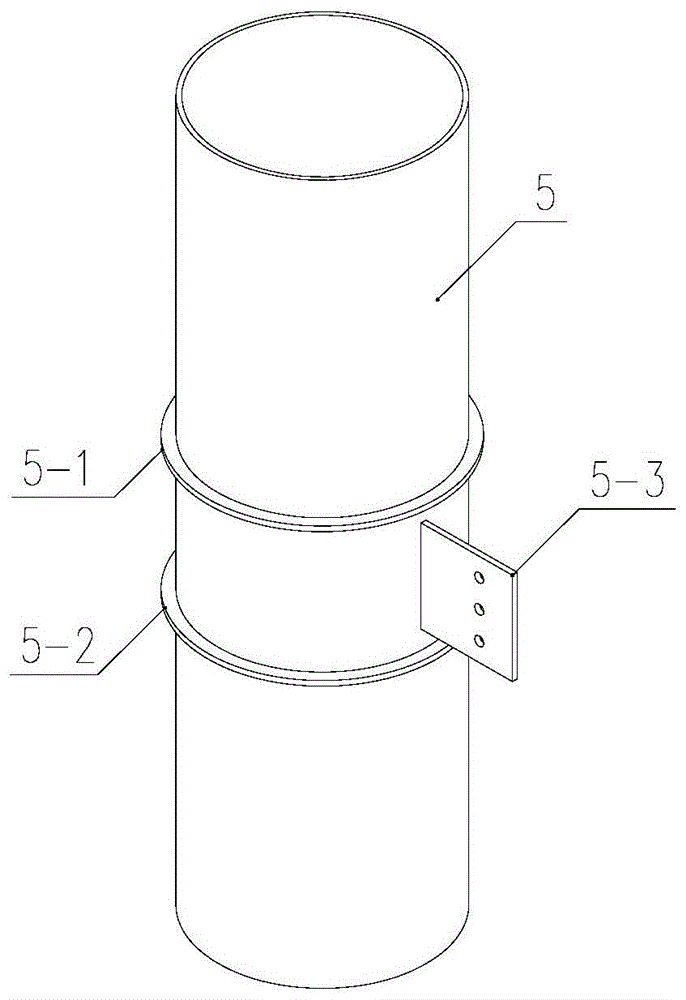

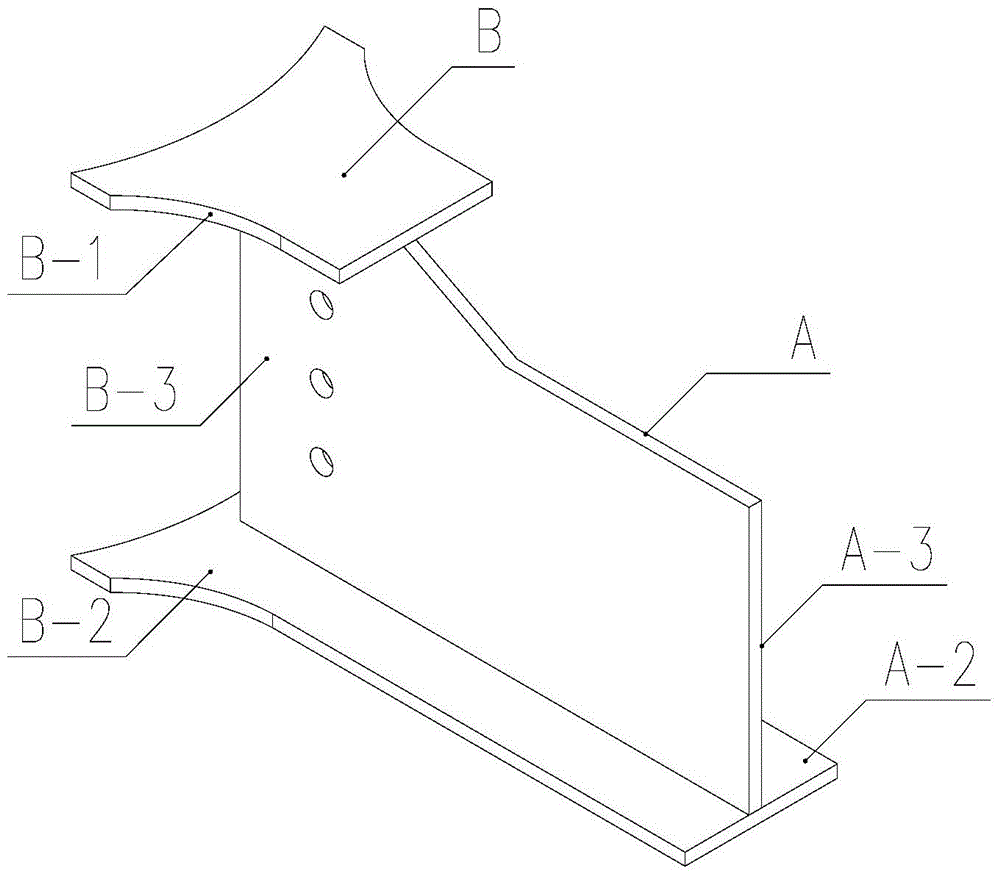

The invention discloses an assembly structure of a prefabricated concrete beam and a concrete-filled steel tube column. The assembly structure comprises the concrete-filled steel tube column, a concrete-filled steel tube bracket, the prefabricated concrete beam, beam end pre-buried steel and a connection plate, wherein the concrete-filled steel tube bracket is welded with a side part of the concrete-filled steel tube column; the concrete-filled steel tube bracket is step-shaped; the concrete-filled steel tube bracket comprises bracket-shaped steel and bracket concrete filled in the bracket-shaped steel; a plurality of opposite-pull bolt holes are formed in the side surface of the bracket-shaped steel; the prefabricated concrete beam comprises the beam end pre-buried steel and prefabricated reinforced concrete; the beam end pre-buried steel is step-shaped and is matched with the shape of the concrete-filled steel tube bracket; a plurality of opposite-pull bolt holes are also formed in the side surface of the beam end pre-buried steel; the connection plate is arranged on the side surface of the bracket-shaped steel and the beam end pre-buried steel and is locked and fastened by a plurality of opposite-pull bolts. The assembly structure of the prefabricated concrete beam and the concrete-filled steel tube column is high in bearing capacity, high in earthquake-resistant ductility, high in node energy dissipation capacity, convenient to construct and high in construction quality, and can provide effective restraint on the concrete.

Owner:FUJIAN UNIV OF TECH

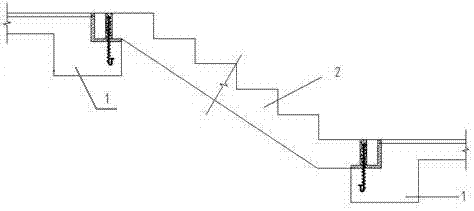

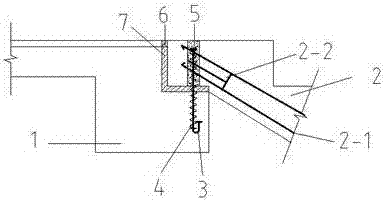

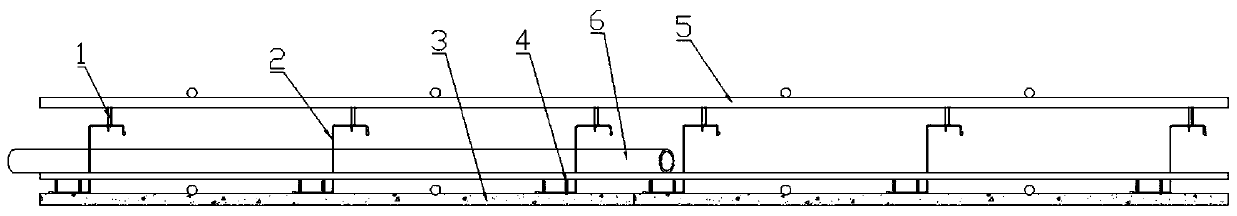

Prefabricated staircase connection method

The invention relates to a prefabricated stair connection method, comprising a floor platform and a stair. The upper end of the stair is placed on the upper floor; polystyrene is used to fill the space between the stair and the upper floor, and cement mortar is used for leveling; the lower end of the stair is placed on the lower floor, and the stair is connected to the upper floor. The lower floors are separated by linoleum and leveled with cement mortar; during installation, the prefabricated components to be connected are transported to the site, and after adjusting their positions properly, the corresponding steel bars are corrected, and then connected to the reserved steel bars at the connection site, and Concrete grouting is poured at the joints to achieve reliable force transmission; spiral bars arranged along the length of the hole are embedded around the pre-embedded steel bars to strengthen the integrity of the connection between components; the connection structure is relatively simple to operate and low in cost. It avoids a large number of steel bar lapping, binding, and cast-in-place work at the junction, which greatly improves work efficiency. It is more suitable for the connection between components of prefabricated stairs in the construction of industrialized houses.

Owner:SHENYANG JIANZHU UNIVERSITY

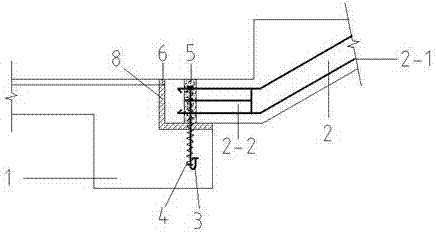

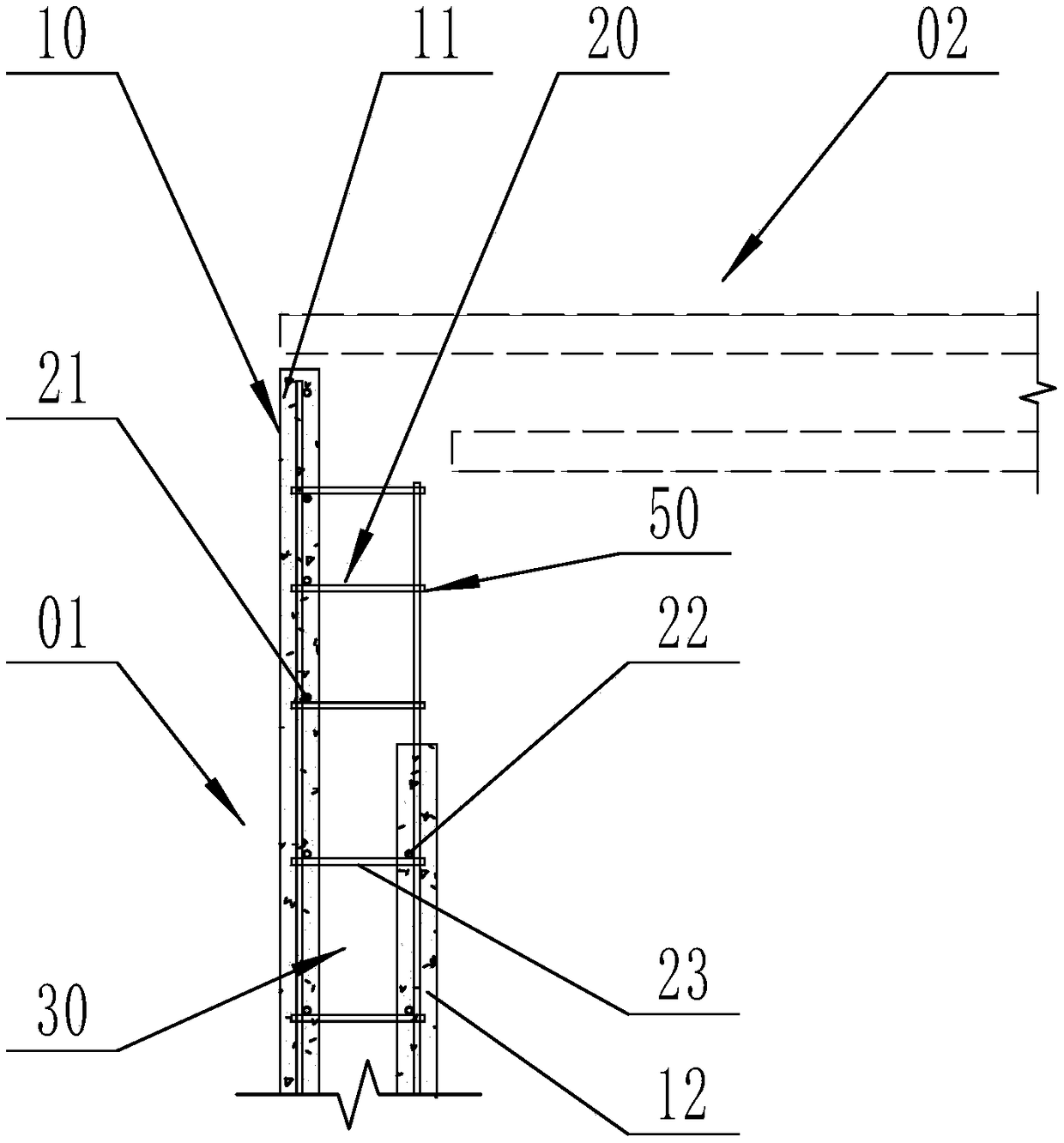

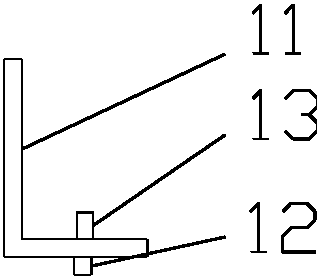

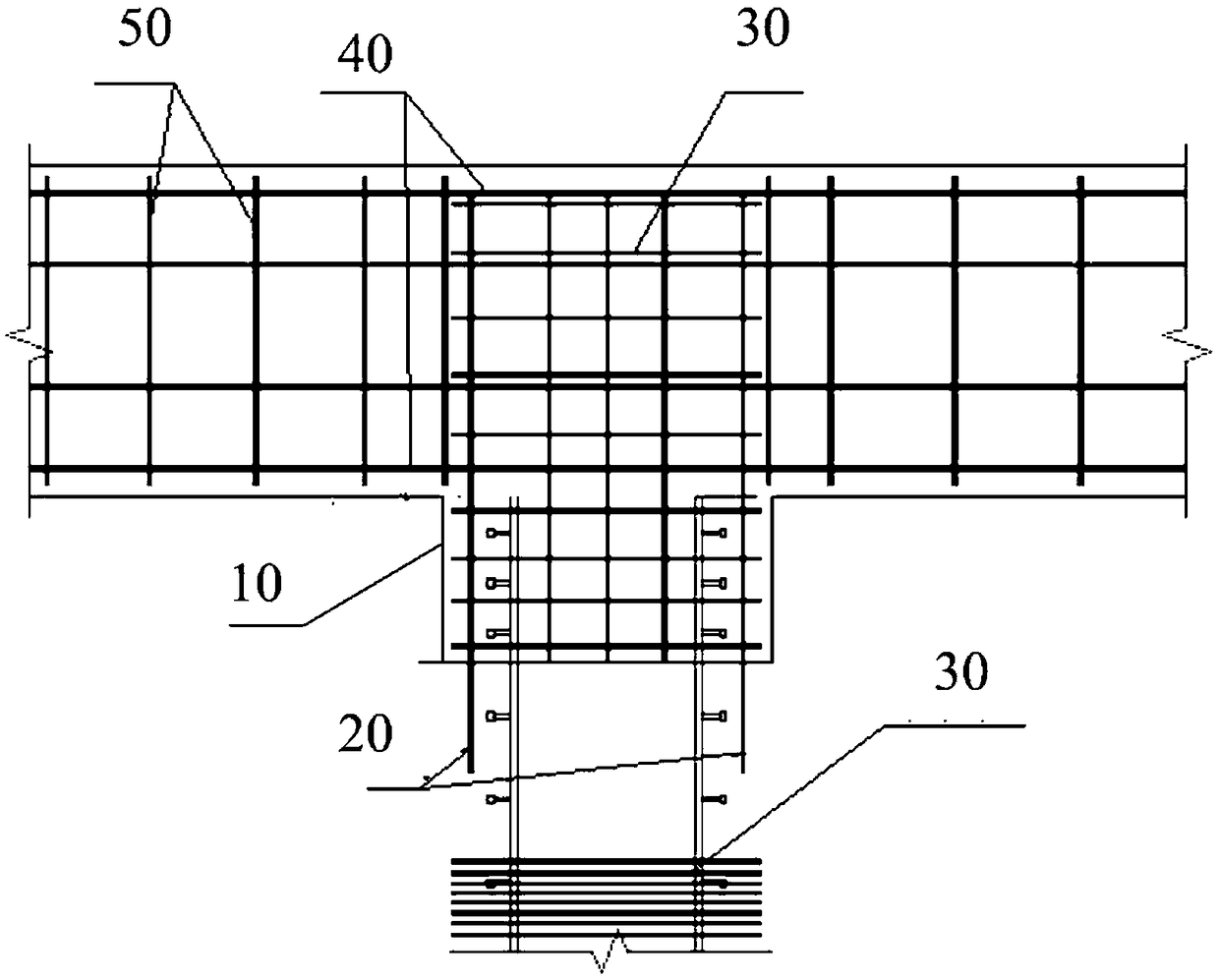

L-shaped wall connecting structure and assembly type building structure system

The invention relates to the technical field of assembly type buildings and particularly relates to an L-shaped wall connecting structure and an assembly type building structure system. The L-shaped wall connecting structure comprises prefabricated walls; each prefabricated wall comprises a wall shell and a moulding reinforcement cage; two prefabricated walls are provided, a first prefabricated wall and a second prefabricated wall; one side of the first prefabricated wall is vertical to one side of the second prefabricated wall to form an L shape; the L-shaped wall connecting structure comprises a connection reinforcing mesh; one end of the connection reinforcing mesh is connected with the moulding reinforcement cage of the first prefabricated wall, and the other end of the connection reinforcing mesh is connected with the moulding reinforcement cage of the second prefabricated wall. The L-shaped wall connecting structure provided by the invention has the advantages of simple structure and convenience in construction; the formwork quantity is greatly reduced, and the construction efficiency is improved. Moreover, through in-place casting of concrete for the prefabricated wall on the construction site, comprehensive performance of the wall is equivalent to that of common cast-in-place concrete structure.

Owner:SANY CONSTR TECH CO LTD

Green concrete prefabricated pile for strengthening soft foundation and construction method

The invention belongs to the technical field of soft soil foundation reinforcement construction, and in particular relates to a green concrete prefabricated pile for strengthening a soft foundation and a construction method. According to the green concrete prefabricated pile, a base material is internally provided with a tensile reinforcing material; and the base material is prepared from coal ash, quick lime, blast furnace slag micro powder, sulfate aluminum cement and the like. The green concrete prefabricated pile is manufactured by taking full advantages of conventional equipment and materials, the material structure and the construction procedures are changed, and the green concrete prefabricated pile has the advantages of good piling quality, high pile foundation bearing force and low manufacturing cost; and as the green concrete prefabricated pile is prepared from industrial waste slag such as coal ash and steel slag as mineral admixtures, and clay aggregate or construction waste recycled aggregate, industrial waste slag and construction wastes are effectively utilized, the environment pollution is reduced, and the foundation treatment cost can be lowered.

Owner:HENAN UNIVERSITY +1

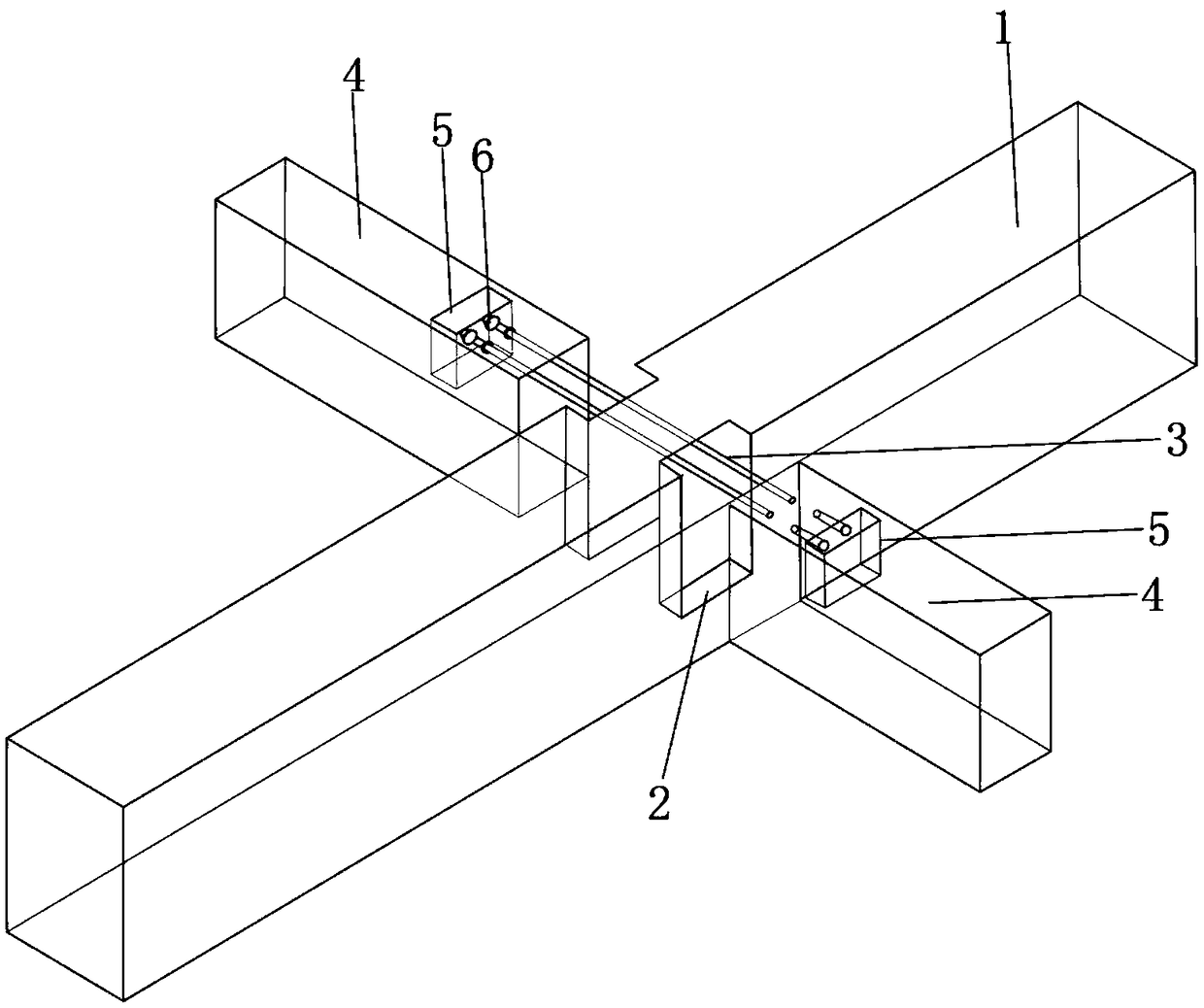

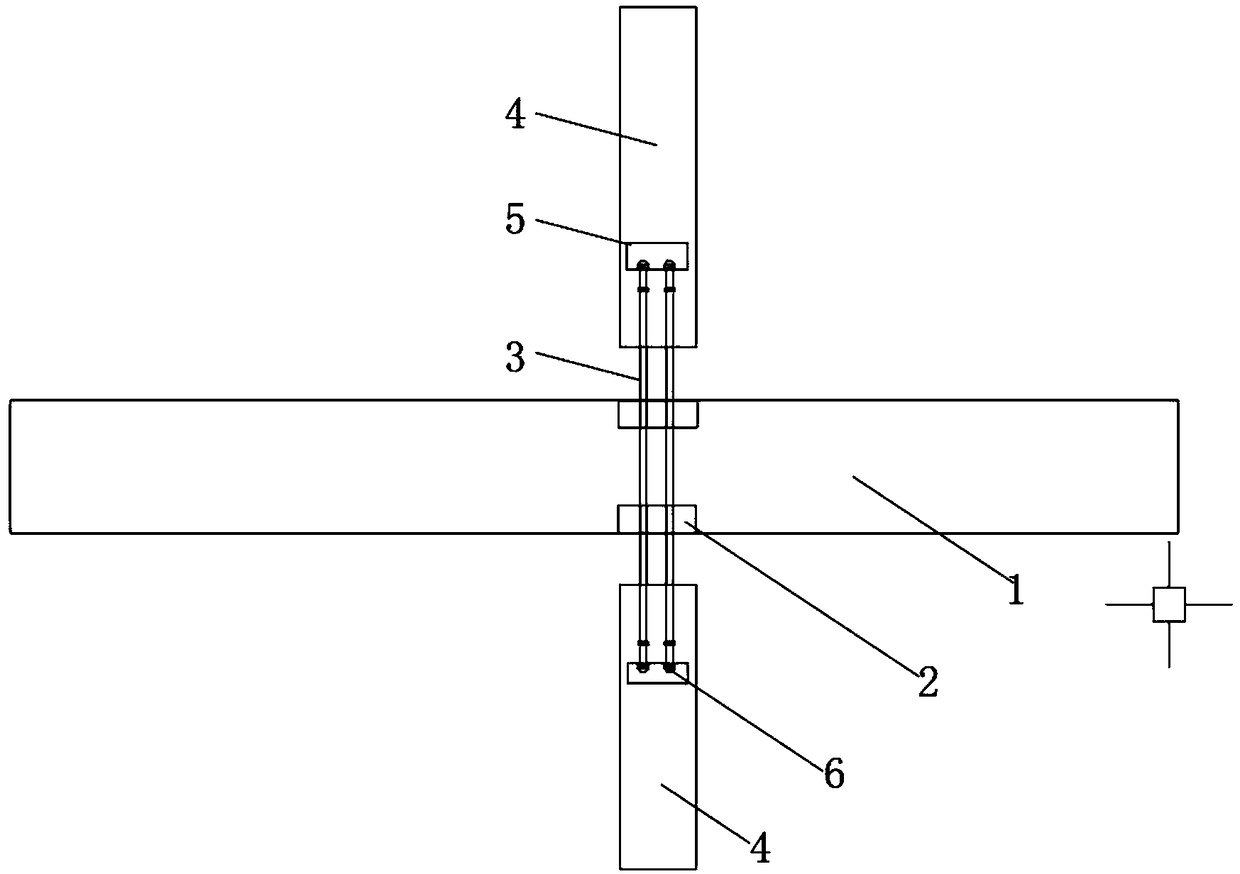

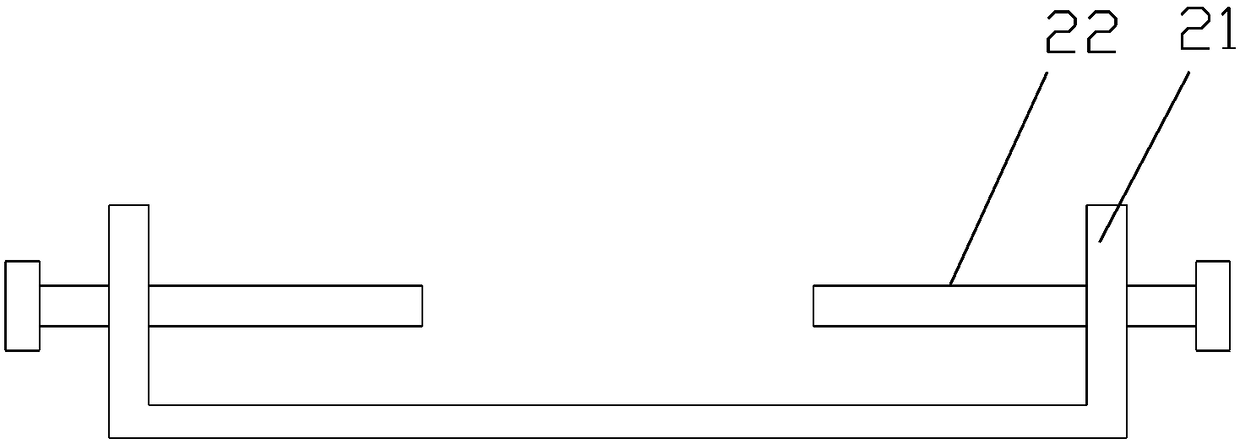

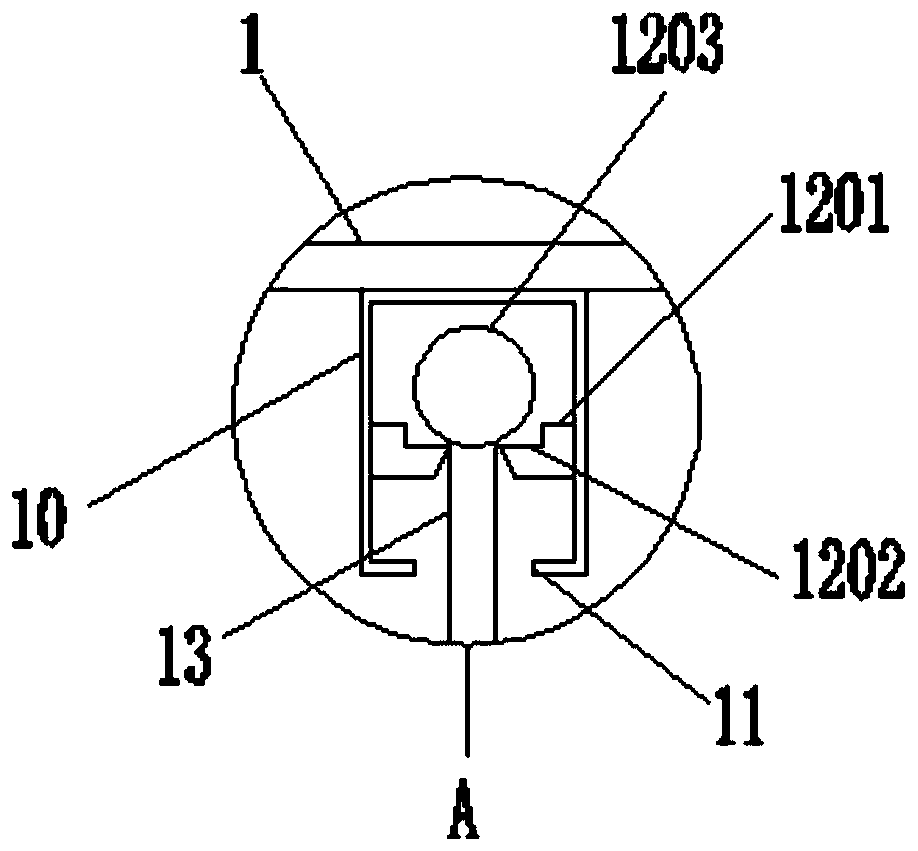

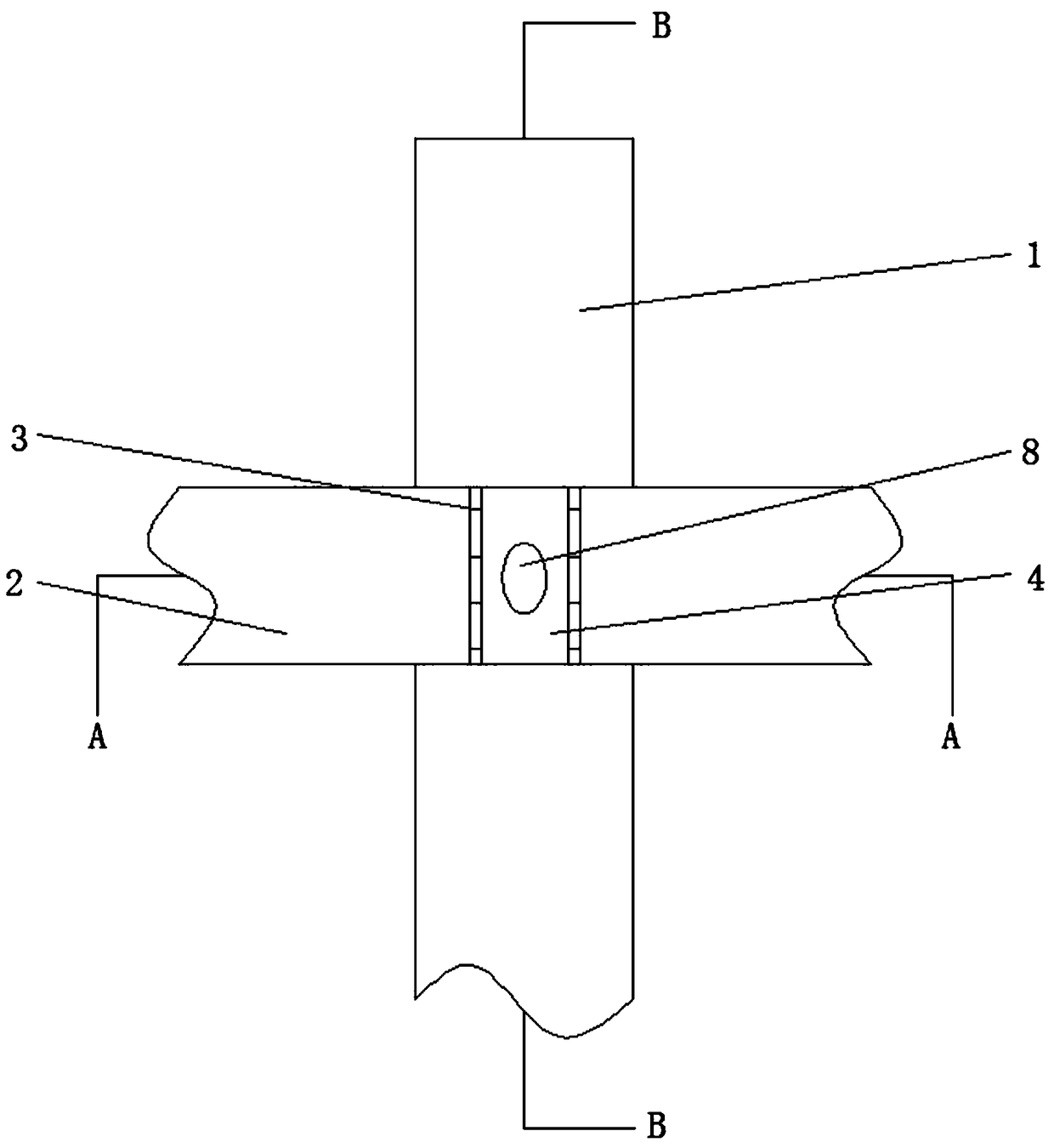

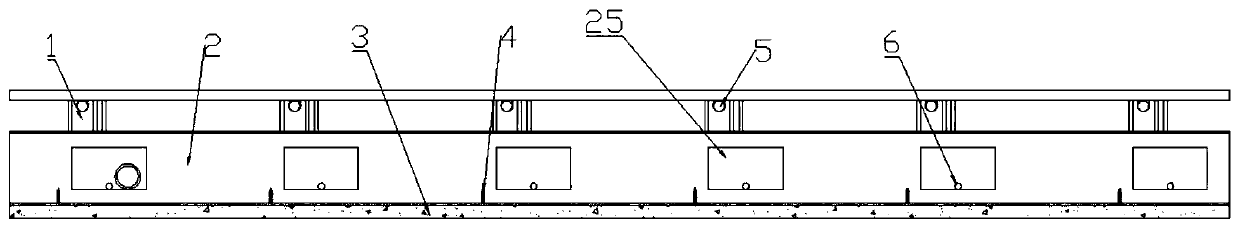

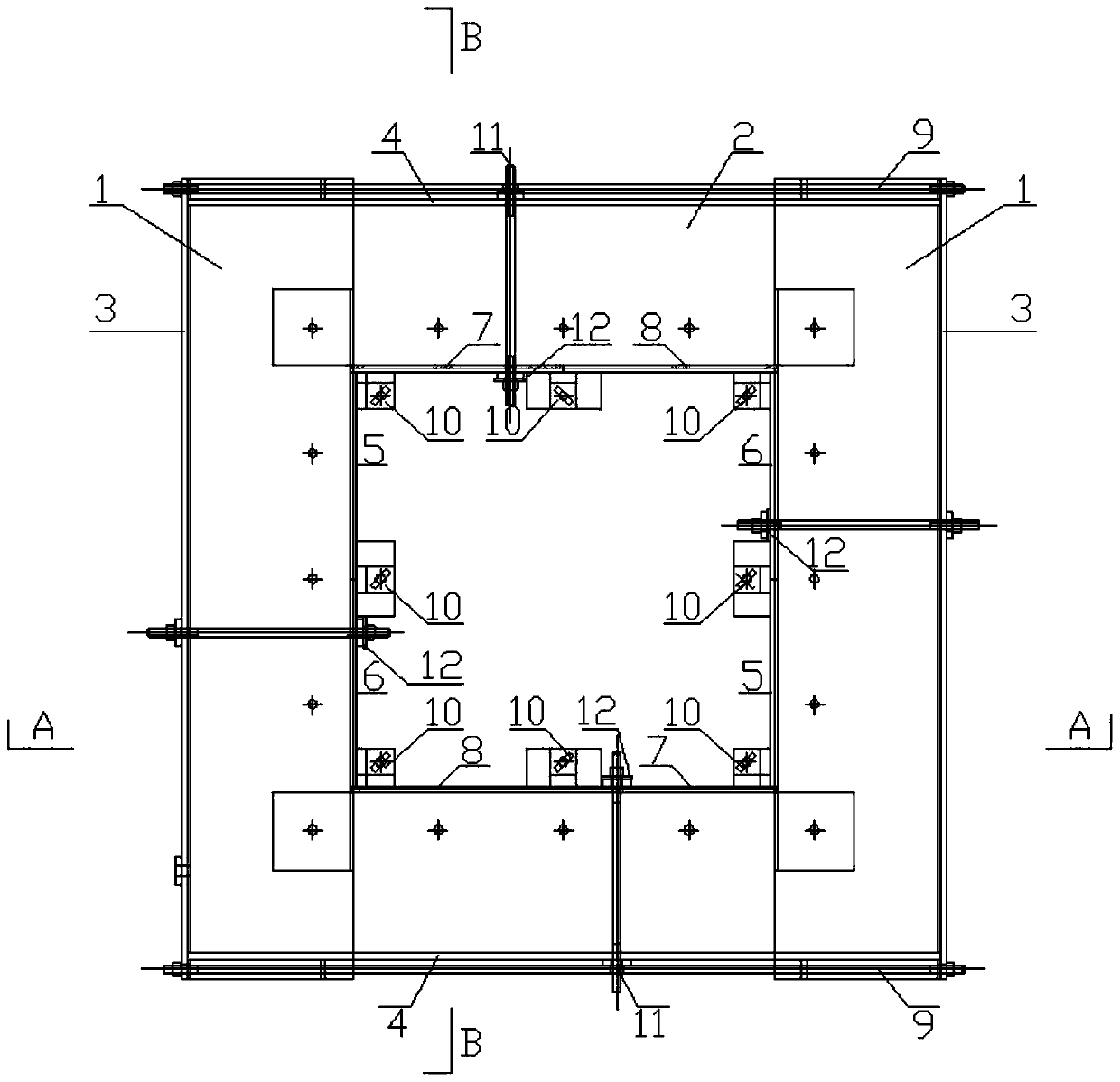

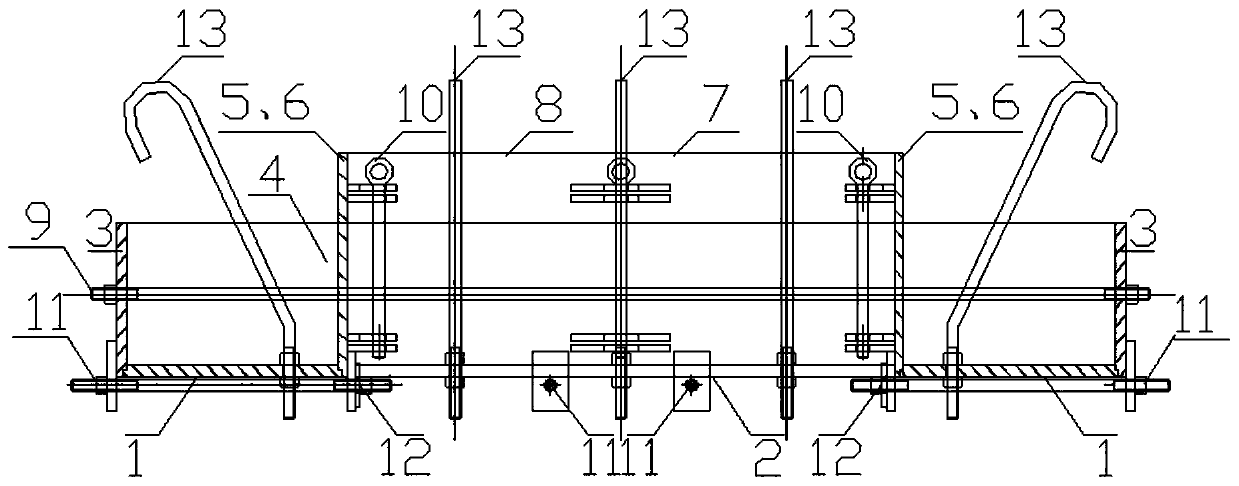

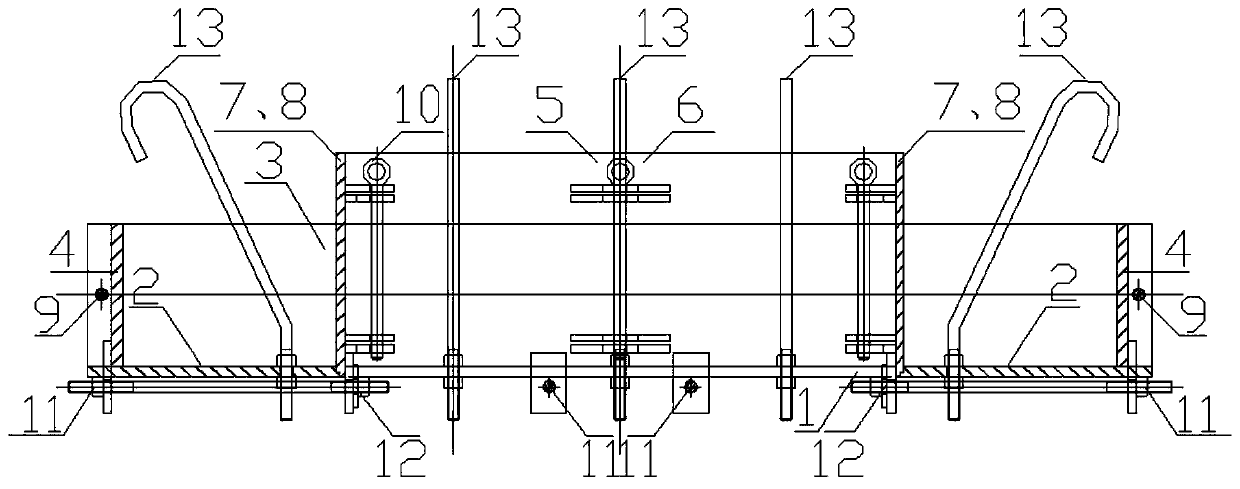

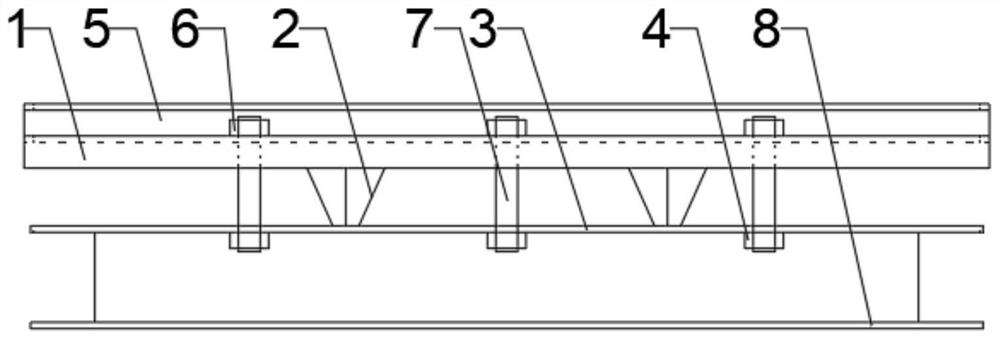

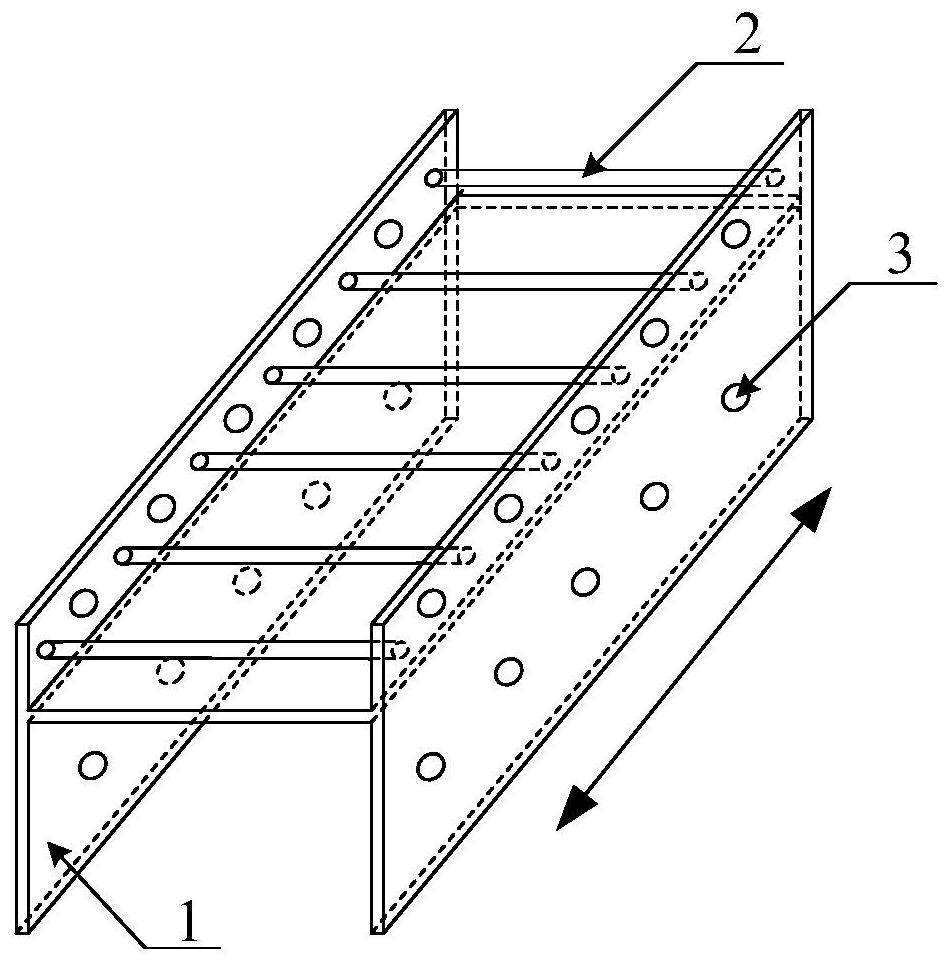

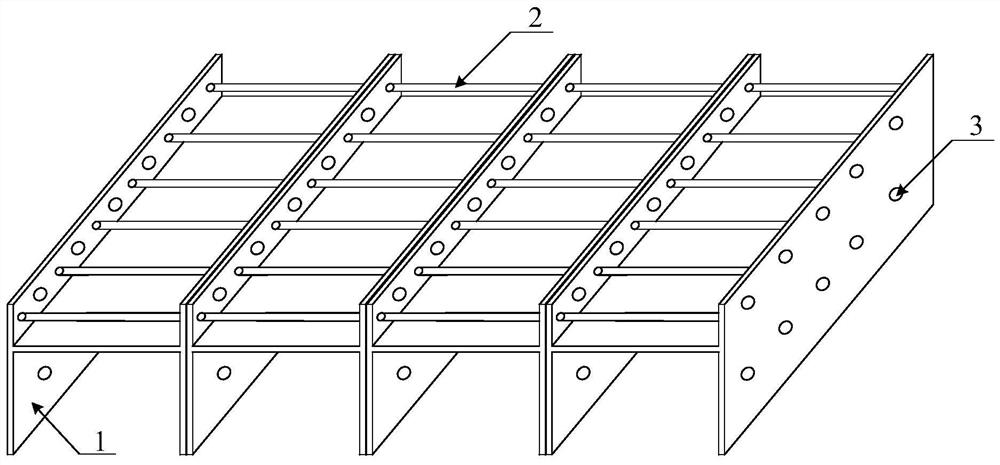

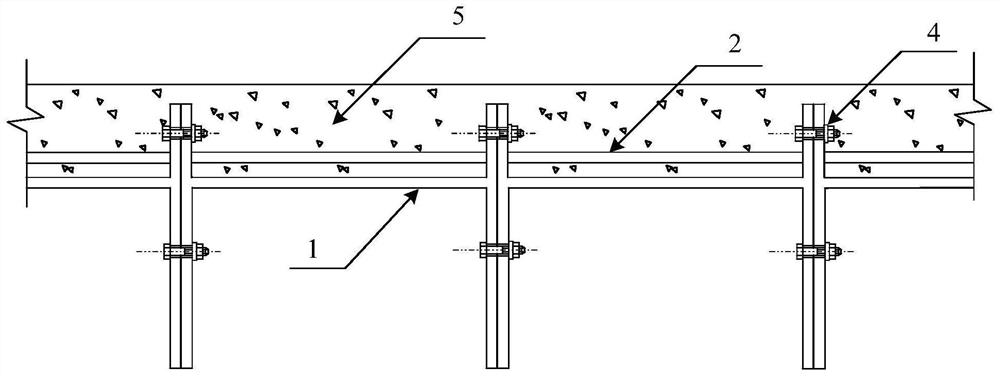

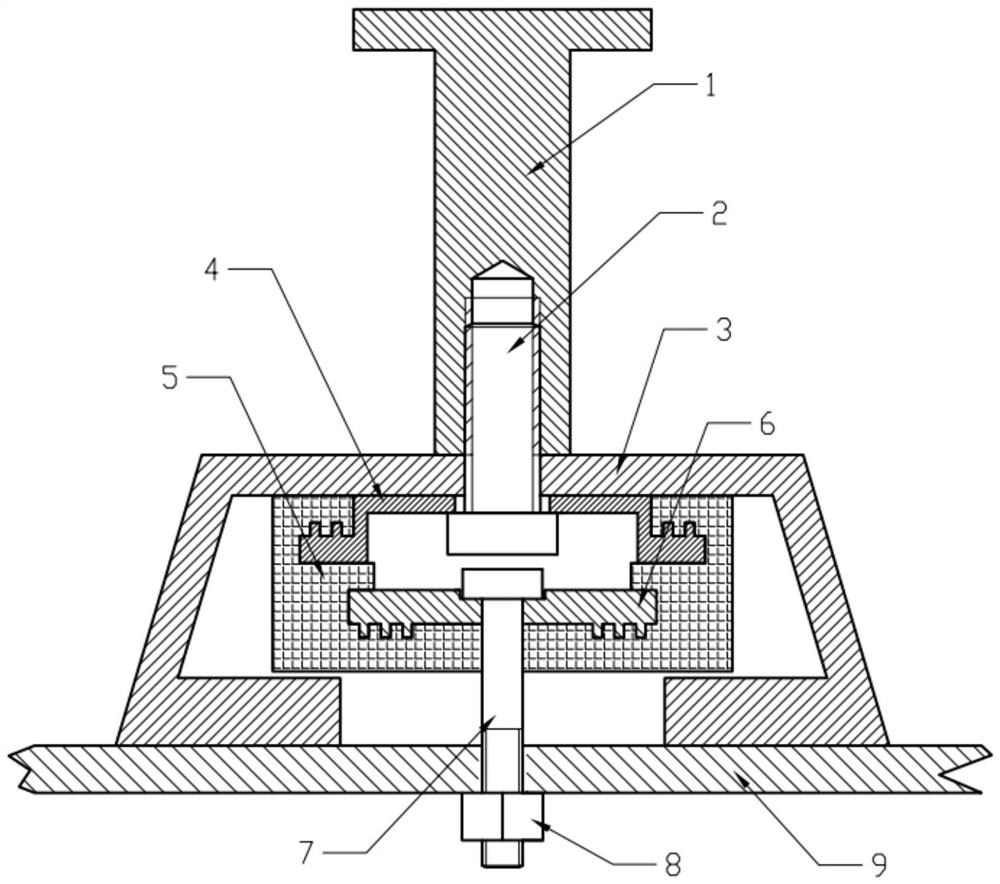

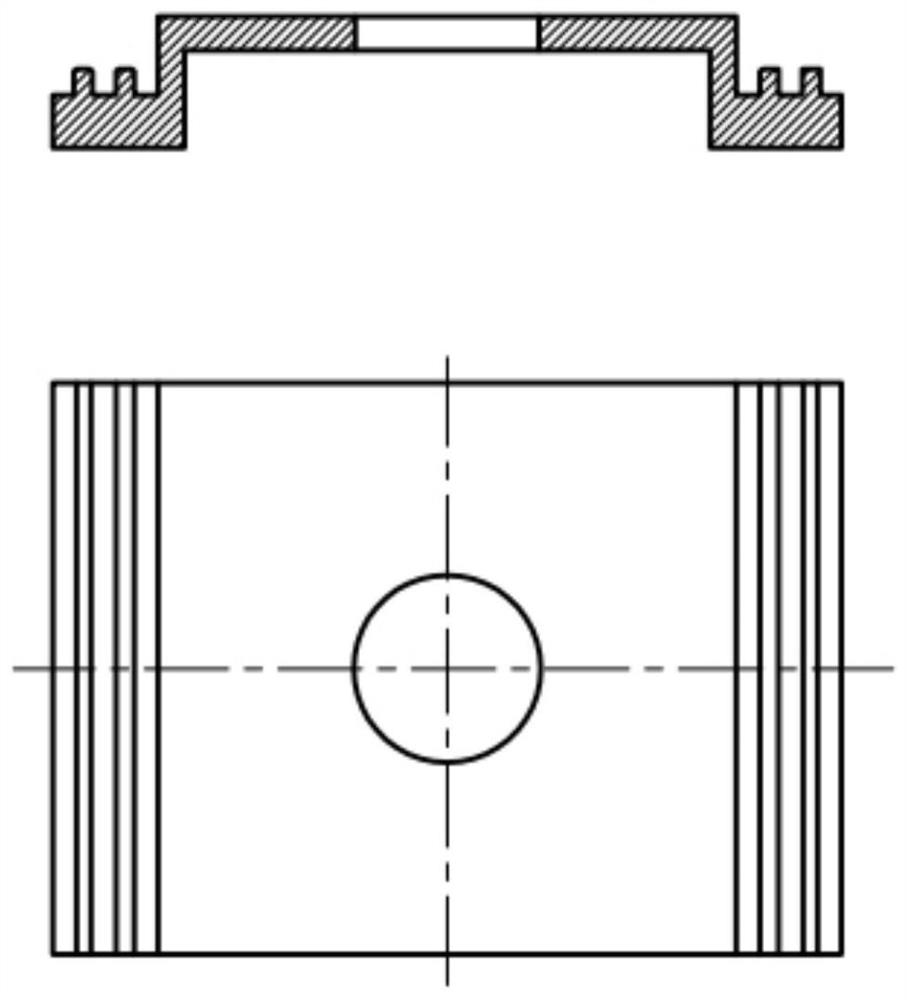

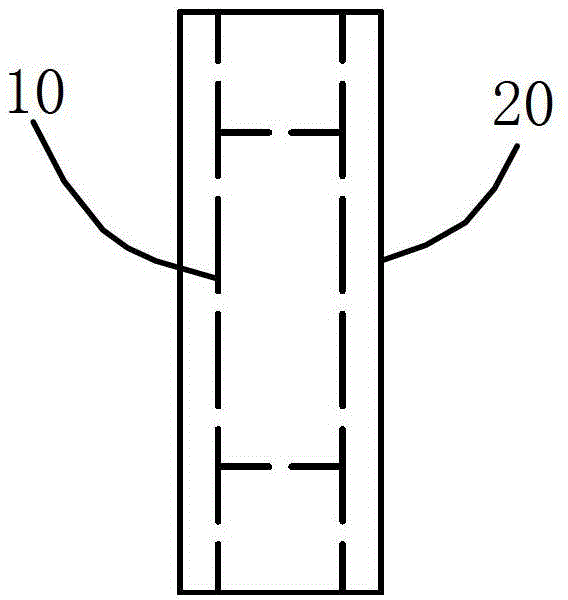

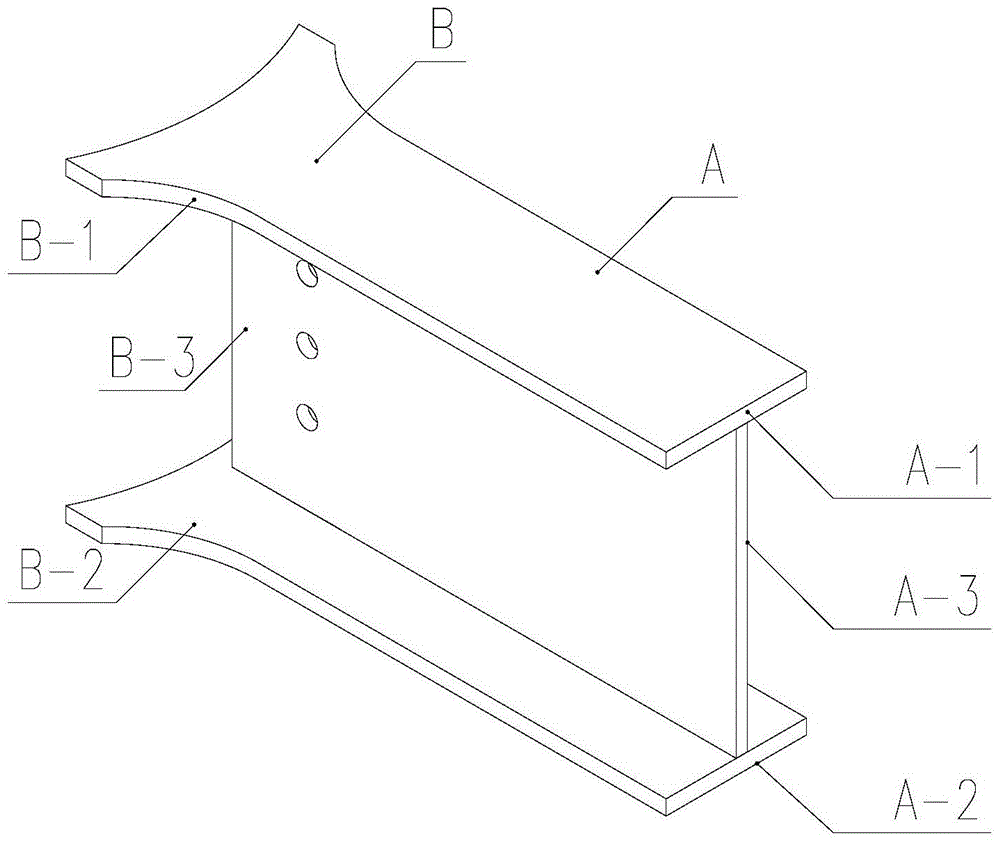

Novel assembly type primary and secondary beam connecting node and connection method thereof

PendingCN108978888ARaise the level of structureIncrease productivityBuilding material handlingRebarPre embedding

The invention discloses a novel assembly type primary and secondary beam connecting node and a connection method thereof. The node comprises a primary beam and secondary beams. Two sides of the primary beam are both equipped with secondary beam support tables. The positions where the primary beam is located in the middle positions of the secondary beam support tables are equipped with pre-embeddedbolts. Interiors of the secondary beams are equipped with reserved bolt holes. Positions of the reserved bolt holes match those of the pre-embedded bolts. Back sides of the reserved bolt holes are equipped with fastening nuts. Tops of the secondary beams are equipped with fixed openings. Heights and widths of the secondary beam support tables are the same as the secondary beams. The secondary beam support tables and the pre-embedded bolts are symmetrically arranged. The invention relates to the technical field of assembly type construction. With the novel assembly type primary and secondary beam connecting node and the connection method thereof, production efficiency of an assembly type industry is effectively increased, thereby avoiding bonding of steel bars during connection of the primary beam and the secondary beams and cast-in-situ of concrete during assembly type construction in the current stage. Assembly rate is increased and the assembly type structure is strengthened. Accordingly, the novel assembly type primary and secondary beam connecting node and the connection method thereof drives building industrialization forward.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

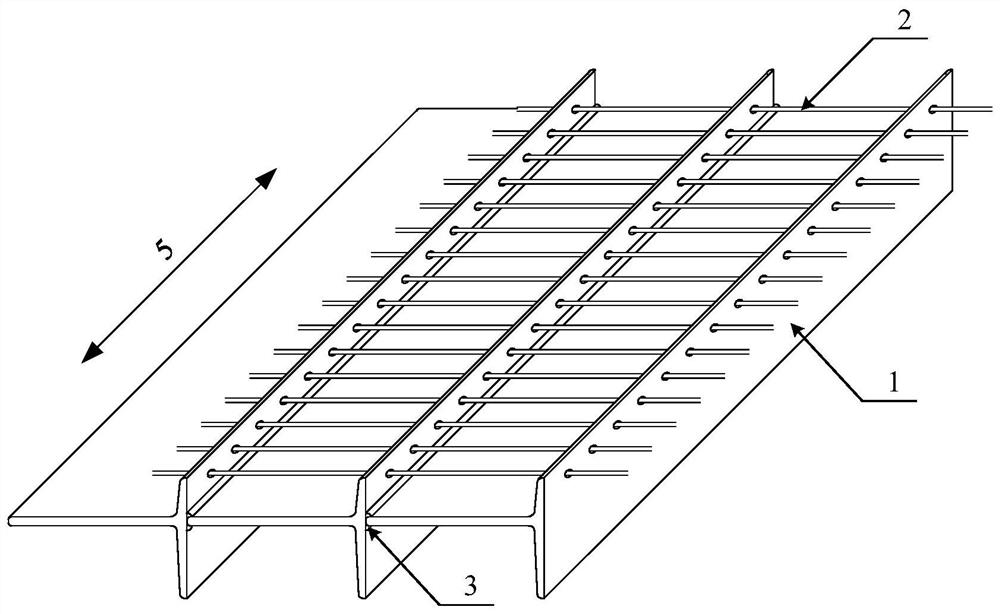

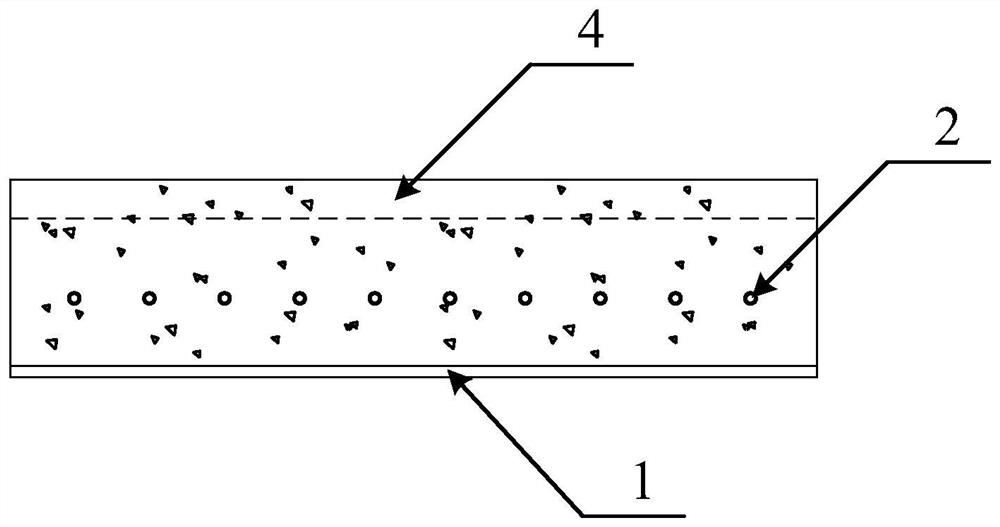

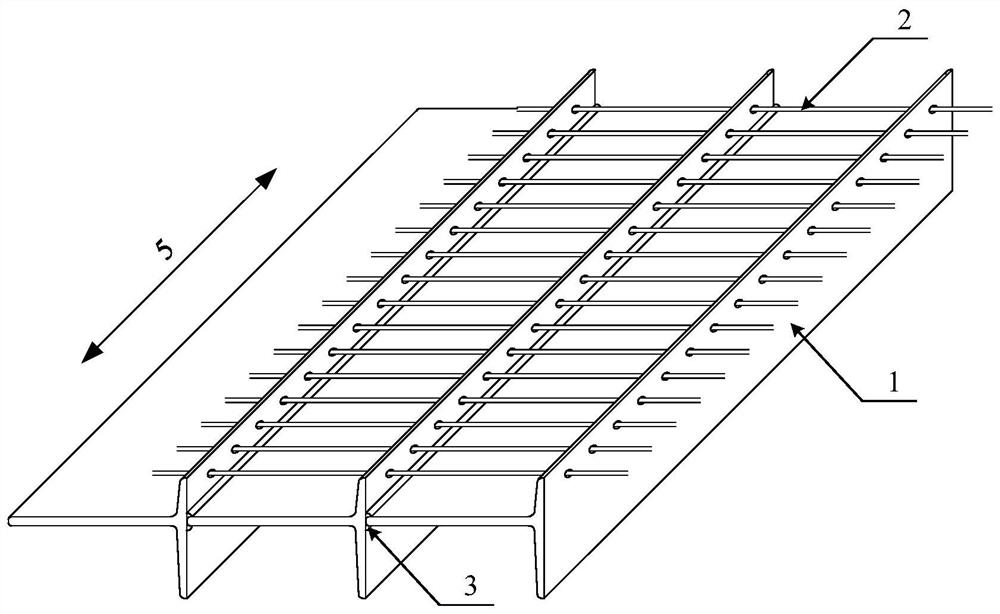

Tough combined bridge deck slab composed of T-shaped steel

ActiveCN112195778APrevent rustImprove toughnessSolid waste managementBridge structural detailsFillet weldBridge deck

The invention discloses a tough combined bridge deck slab system composed of T-shaped steel. The tough combined bridge deck slab system comprises hot-rolled T-shaped steel, transverse steel bars and ultrahigh-toughness concrete. The T-shaped steel is transversely and continuously placed side by side along a bridge deck, and adjacent steel is welded through two fillet welds to form a bridge deck steel framework. The lower side flange of the T-shaped steel is long and plays a role in reinforcing the outer side of the slab surface; the upper side flange of the hot-rolled T-shaped steel is short and is provided with a row of circular holes, and the transverse steel bars penetrate through the flanges of the T-shaped steel through the circular holes. The ultrahigh-toughness concrete is poured onthe bridge deck steel framework to play a role in protecting the bridge deck steel framework. In the combined bridge deck slab system provided by the invention, the ultra-high toughness concrete canensure that tiny cracks of 100 microns or below are not generated or only tiny cracks of 100 microns or below are generated, and the toughness and durability of the structure are improved; the T-shaped steel and the transverse steel bars are combined to replace the anti-shearing and anti-pulling effects of studs, so that the out-of-plane stability of the bridge deck slab is improved, the materialcost and the construction complexity are remarkably reduced, and the fatigue performance is excellent.

Owner:ZHEJIANG UNIV

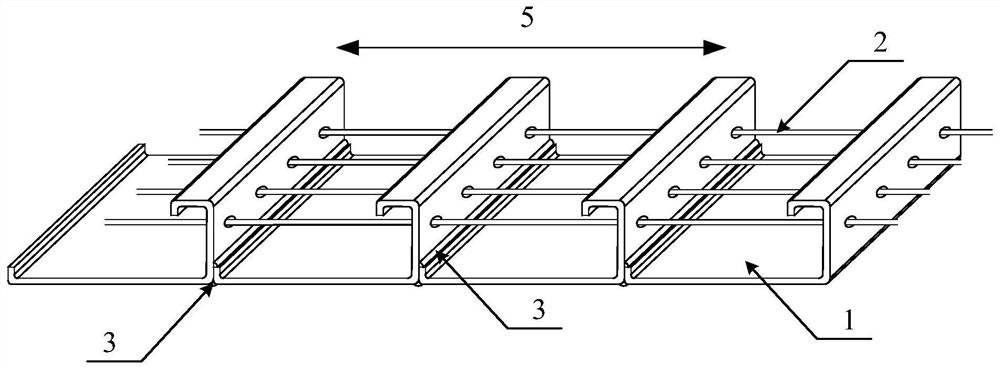

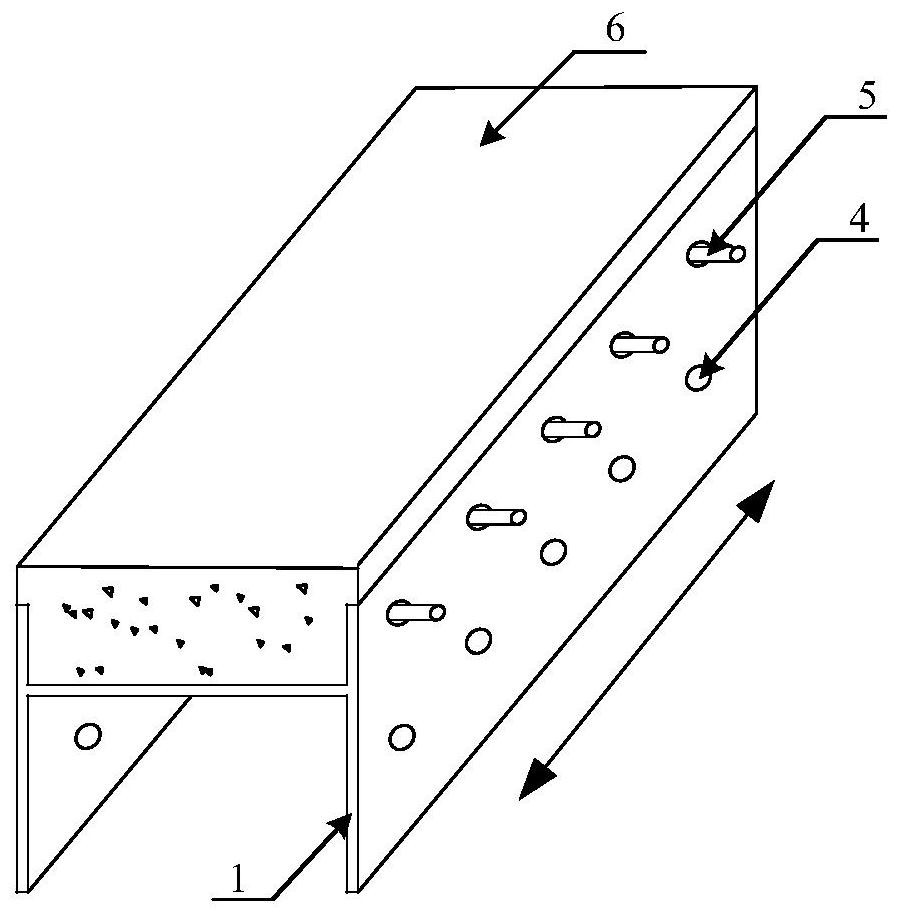

Stud-free tough combined bridge deck slab system

ActiveCN112227200APrevent rustImprove toughnessBridge structural detailsBridge materialsFillet weldArchitectural engineering

The invention discloses a stud-free tough combined bridge deck slab system. The stud-free tough combined bridge deck slab system comprises L-shaped hemming profile steel, longitudinal reinforcing steel bars and ultrahigh-toughness concrete. The L-shaped hemming section steel is continuously arranged side by side in the longitudinal direction of a bridge deck, and adjacent section steel is welded through two fillet welds to form a bridge deck steel framework. A row of circular holes are formed in each L-shaped hemming section steel flange plate, and the longitudinal reinforcing steel bars penetrate through the L-shaped hemming section steel flange plates through the circular holes. And the ultrahigh-toughness concrete is poured on the bridge deck steel skeleton to play a role in protectingthe bridge deck steel skeleton. In the combined bridge deck slab system provided by the invention, the ultra-high toughness concrete can ensure that tiny cracks of below 100 microns are not generatedor only generated under the action of various loads, and the toughness and durability of the structure are improved; the structural mode of combining the L-shaped hemming profile steel and the longitudinal reinforcing steel bars achieves the effective anti-shearing and anti-pulling effects, the effects of studs and transverse reinforcing steel bars are replaced, so that the material cost and the construction complexity are greatly reduced, and the fatigue performance is excellent.

Owner:ZHEJIANG UNIV

Tough combined bridge deck composed of cold-bent Z-shaped steel

ActiveCN112227199AImprove toughnessIncreased durabilityBridge structural detailsBridge materialsFillet weldBridge deck

The invention discloses a tough combined bridge deck composed of cold-bent Z-shaped steel. The tough combined bridge deck comprises cold-bent curled Z-shaped steel, transverse reinforcing steel bars and ultrahigh-toughness concrete. And the cold-bent Z-shaped steel is transversely and continuously placed along the bridge deck and forms bridge deck steel framework through fillet weld welding. The lower side flange of the cold-bent Z-shaped steel is long and plays a role in reinforcing the outer side of the plate surface; the upper side flange is short and is provided with a row of circular holes, and the transverse reinforcing steel bars penetrate through the cold-bent Z-shaped steel flanges through the circular holes. And the ultrahigh-toughness concrete is poured on the bridge deck steelskeleton to play a role in protecting the bridge deck steel skeleton. In the combined bridge deck slab system provided by the invention, the ultra-high toughness concrete can ensure that tiny cracks of below 100 microns are not generated or only generated, and the toughness and durability of the structure are improved; the construction mode of combining the cold-bent Z-shaped steel and the transverse reinforcing steel bars replaces the anti-shearing and anti-pulling effects of studs, meanwhile, the out-of-plane stability of the bridge deck slab is improved, the material cost and the construction complexity are remarkably reduced, and the fatigue performance is excellent.

Owner:ZHEJIANG UNIV

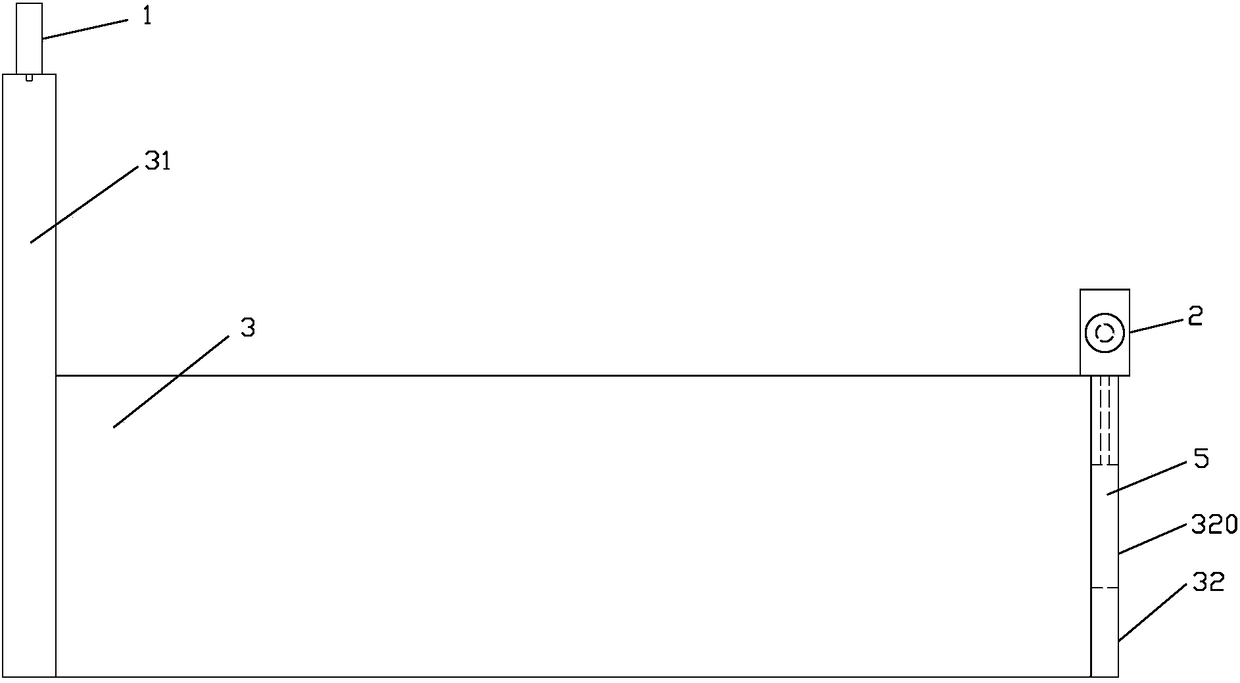

Bamboo ladder vehicle-mounted device

InactiveCN108859929AAvoid tyingAvoid shakingSupplementary fittingsLoad securingIn vehicleEngineering

The invention discloses a bamboo ladder vehicle-mounted device, and relates to the field of power supply, in particular to a bamboo ladder vehicle-mounted device for repairing a vehicle. The bamboo ladder vehicle-mounted device is convenient to install and carry and saves time, and comprises an upper positioning assembly and a lower positioning assembly, the upper positioning assembly is arrangedon a front supporting plate of a compartment, the lower positioning assembly is arranged on a rear supporting plate of the compartment, and the upper positioning assembly and the lower positioning assembly are used for supporting a bamboo ladder; the upper positioning assembly comprises a pair of opposite L-shaped plates, the bottoms of transverse plates of the L-shaped plates are provided with positioning pillars, multiple positioning holes are formed in the front supporting plates, and the positioning pillars are adaptively arranged in the positioning holes; multiple first positioning grooves are symmetrically formed in each of the two sides of the bamboo ladder, and bolts can extend into the first positioning grooves. The bamboo ladder vehicle-mounted device improves working efficiencyand is reliable in vehicle mounting.

Owner:吴学究

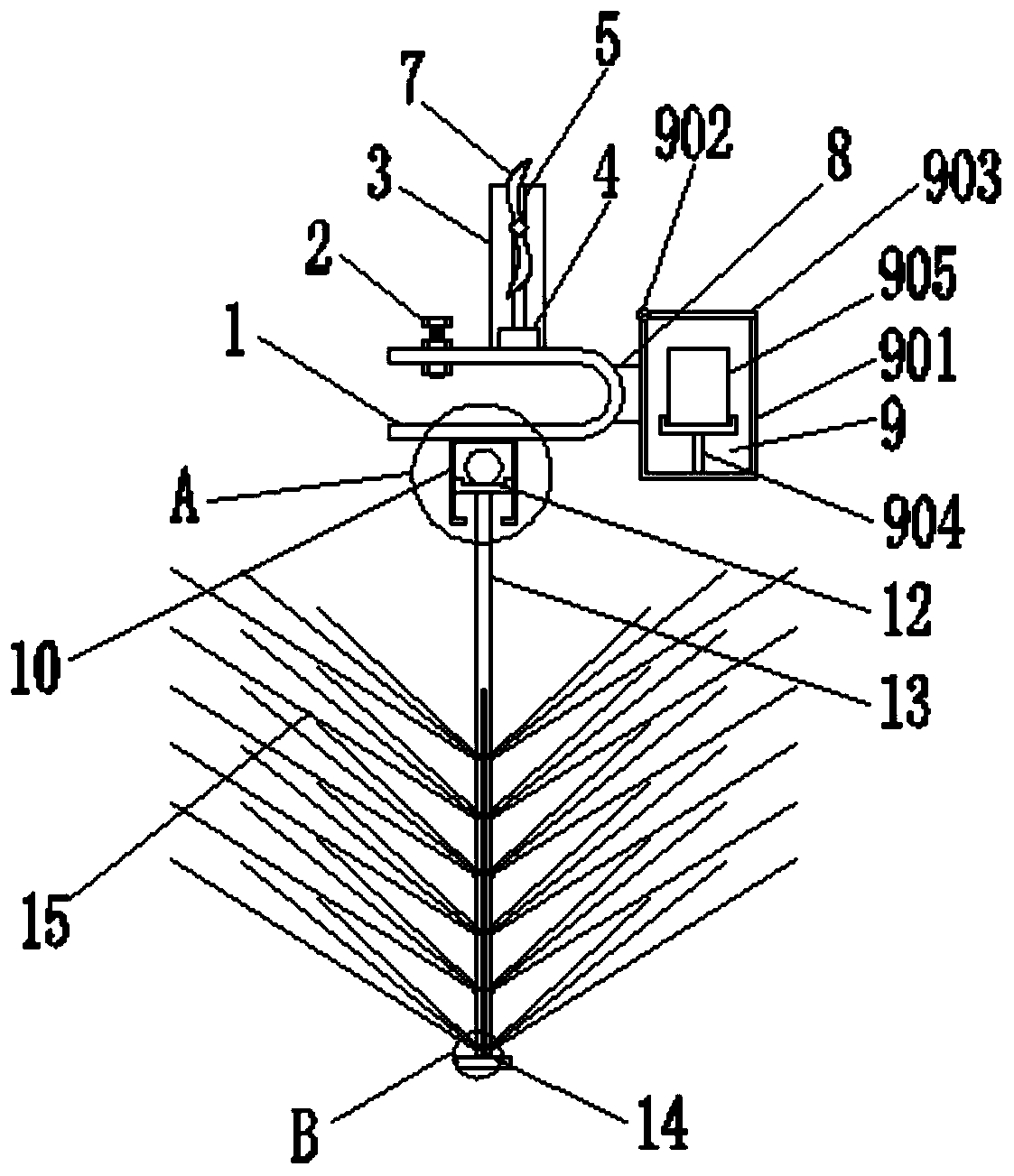

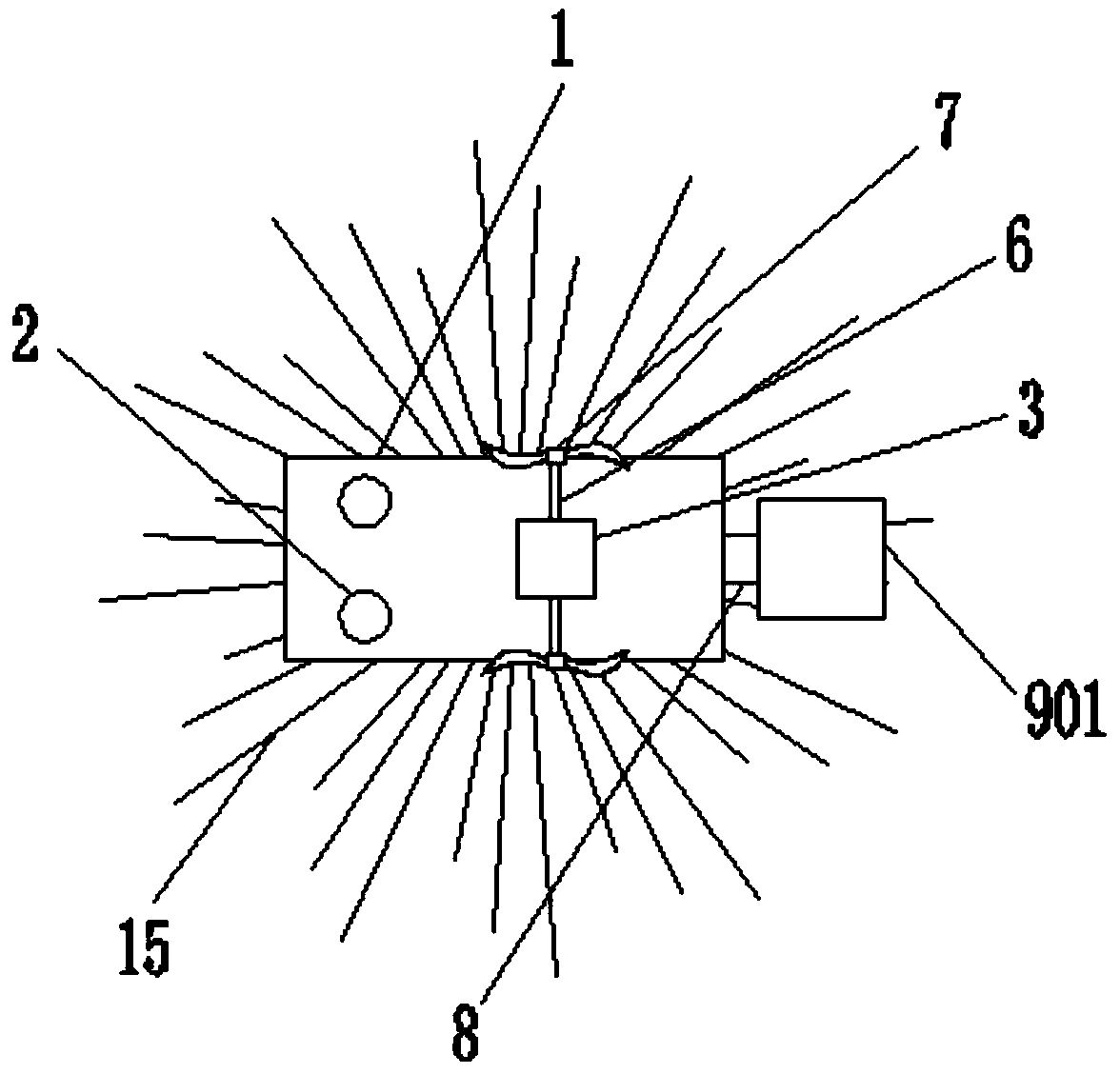

Anti-bird thorn

PendingCN110710524AAll-round bird repellent operationExpand the scope of workOverhead installationAnimal repellantsAnimal scienceElectric power equipment

The invention discloses an anti-bird thorn, and belongs to the technical field of electric power equipment. The anti-bird thorn comprises a U-shaped fixed seat, a fixed bolt is mounted on one side ofthe top end of the U-shaped fixed seat, an upper supporting sleeve is fixed into the middle of the top end of the U-shaped fixed seat, a storage battery is mounted at the bottom end of the inner wallof the upper supporting sleeve, a connecting rod is connected at the output end of the storage battery, a supporting rod is fixed at the top end of the connecting rod, fan blades are mounted at the tail end of the supporting rod, a supporting frame is fixed onto one side of the U-shaped fixed seat, and a drug releasing mechanism is connected at the tail end of the supporting frame. According to the anti-bird thorn, the fan blades can rotate under the action of the storage battery to generate air flow, an electric transmission line cross rod is blown, so that birds stay at the cross rod are expelled, the drug releasing mechanism is arranged, the birds stay at the cross rod can be expelled by drugs under blowing of natural wind, and the birds can be comprehensively expelled as compared witha traditional anti-bird thorn.

Owner:TIELING POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER COMPANY +1

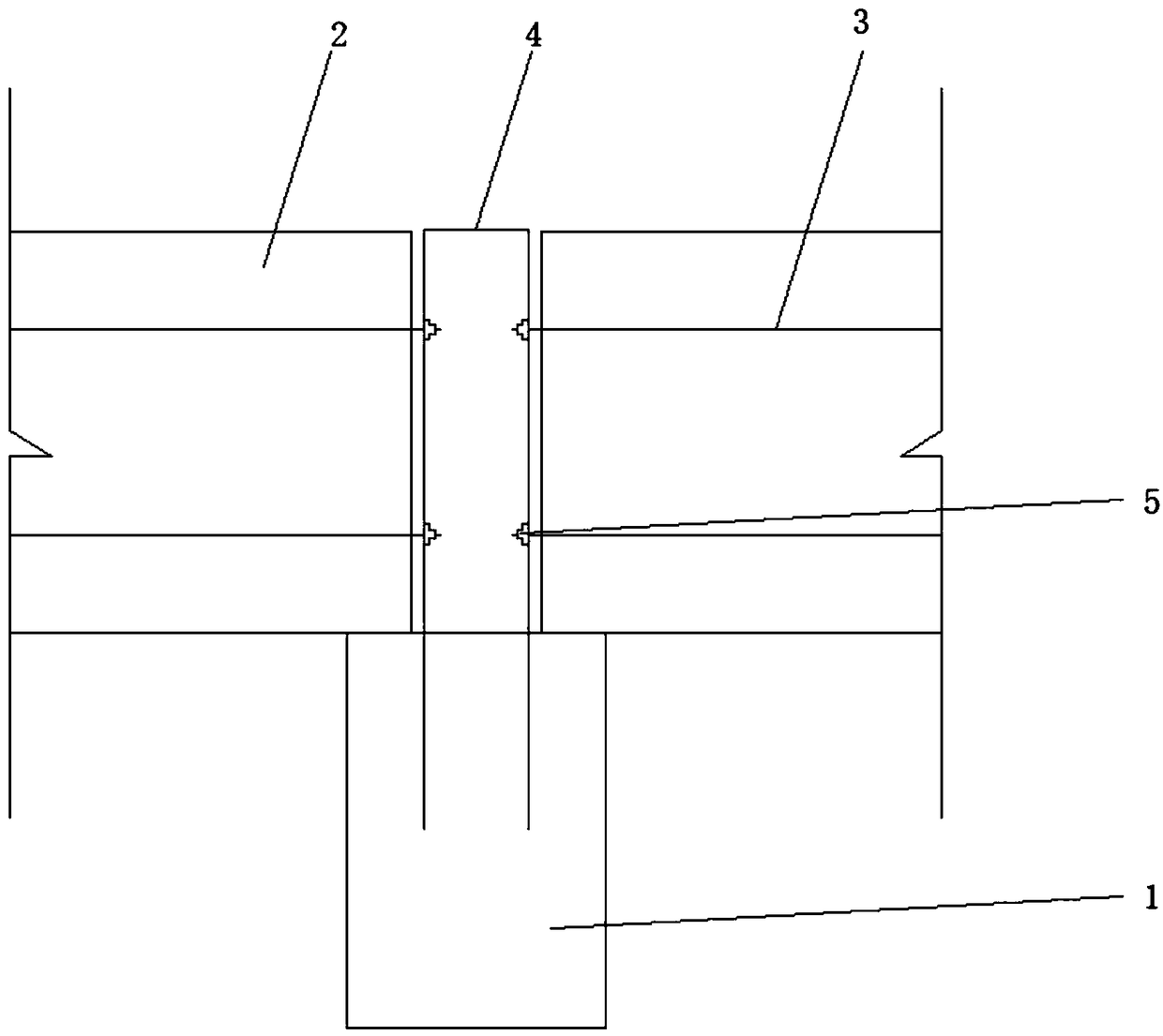

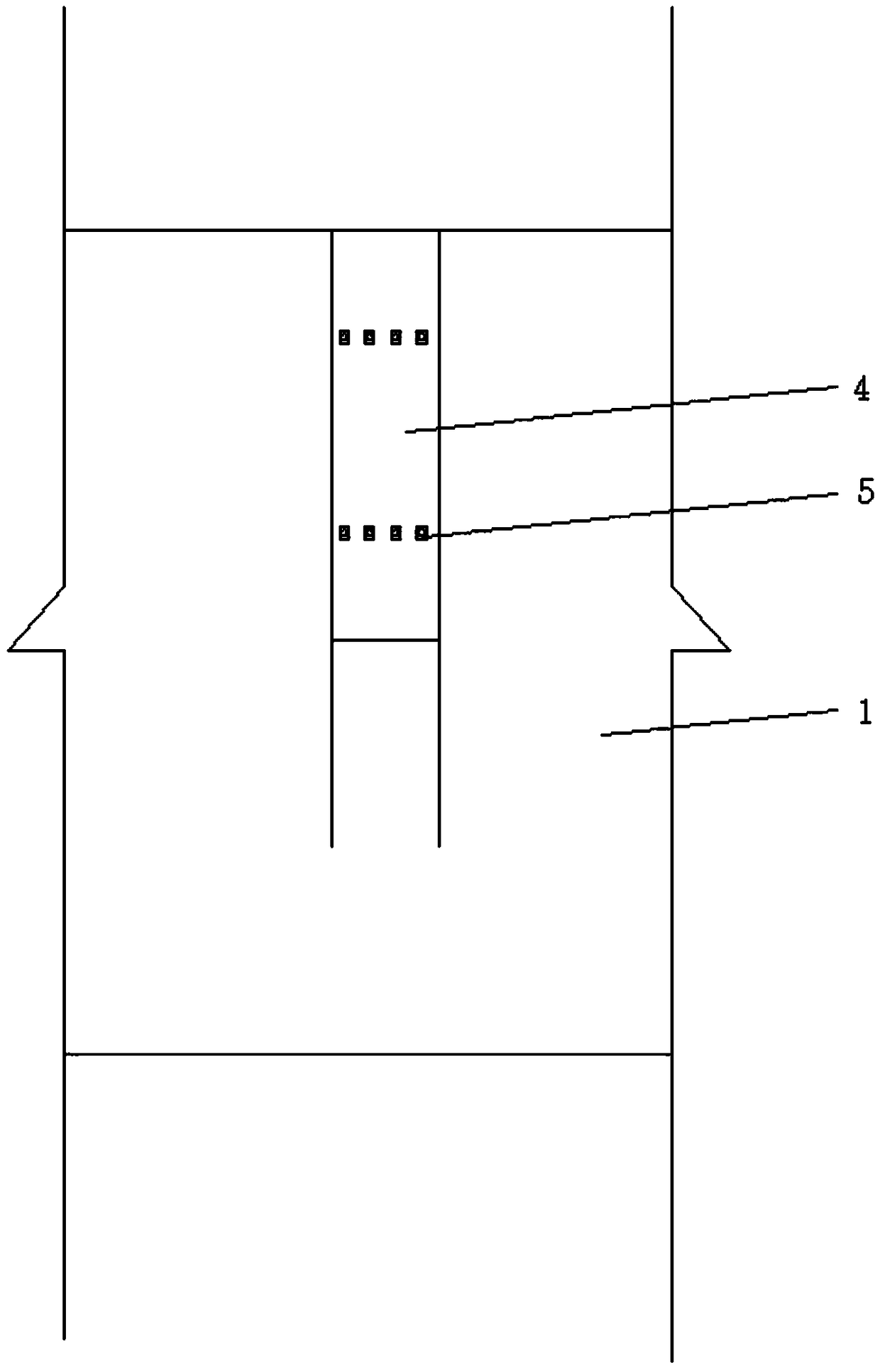

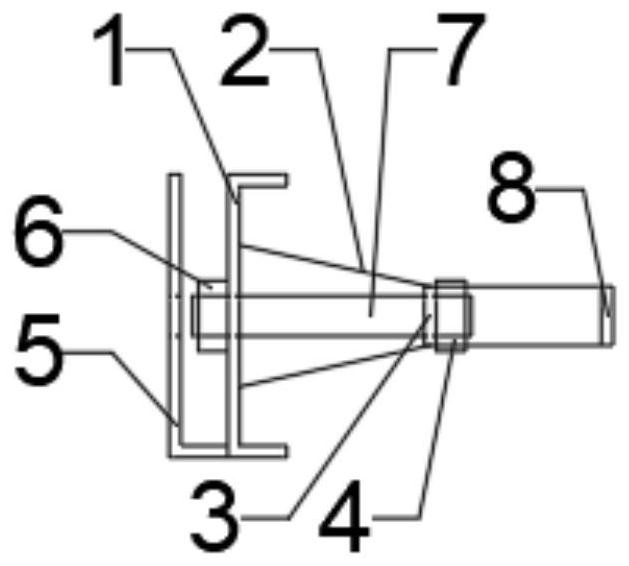

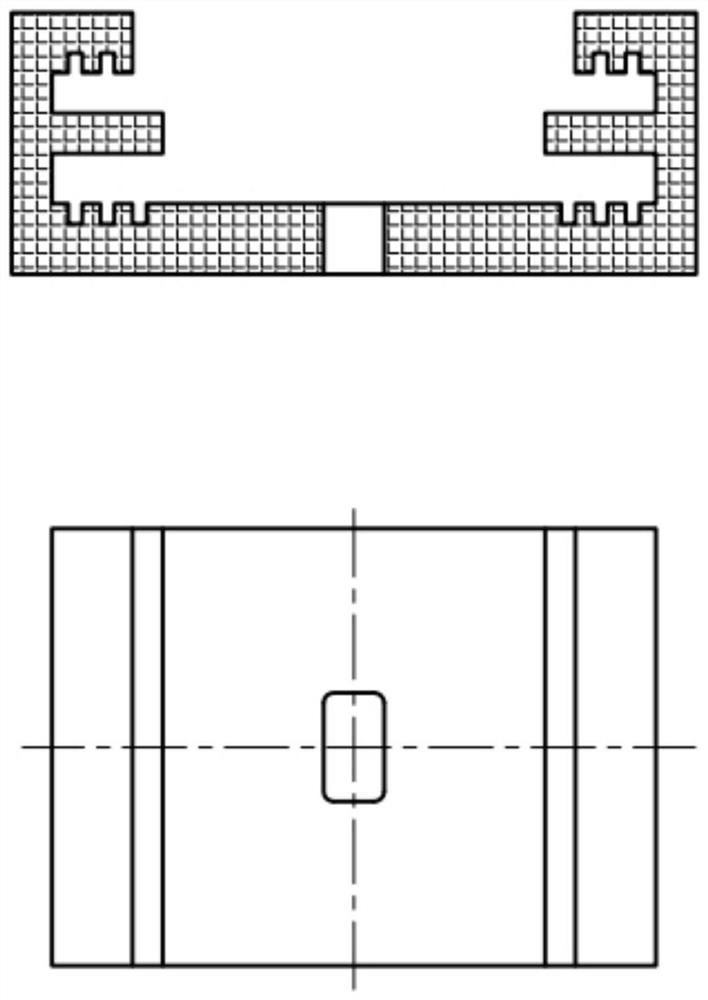

Novel prefabricated primary and secondary beam composite connecting node and connecting method thereof

ActiveCN108978890AImprove connection efficiencyFirmly connectedBuilding material handlingProduction rateArchitectural engineering

The invention discloses a novel prefabricated primary and secondary beam composite connecting node. The node comprises a primary beam. A trench is arranged in the middle position of the right side ofthe primary beam. The middle position in the interior of the trench is fixed with channel steel. Positions, located on left and right sides of the channel steel, in the interior of the trench are bothfixedly connected with secondary beams. Interiors of the secondary beams are fixedly connected with steel bars. One ends, approaching the middle of the trench, of the steel bars penetrate through outsides of the secondary beams. Surfaces on two sides of the channel steel are equipped with steel bar holes. One ends, located in the interior of the channel steel, of the steel bars are in threaded connection with nuts. The middle position outside the channel steel is equipped with a grouting circular hole. The node relates to the technical field of building beams. With the novel prefabricated primary and secondary beam composite connecting node and the connecting method thereof, improvements are made on assembly type primary and secondary beam connection. The connection efficiency of the primary beam and the secondary beams is increased. The wet construction amount is reduced. Assembly efficiency and productivity are improved. Safety and quality are enhanced. The purpose of driving modernization of the building industry is fulfilled.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

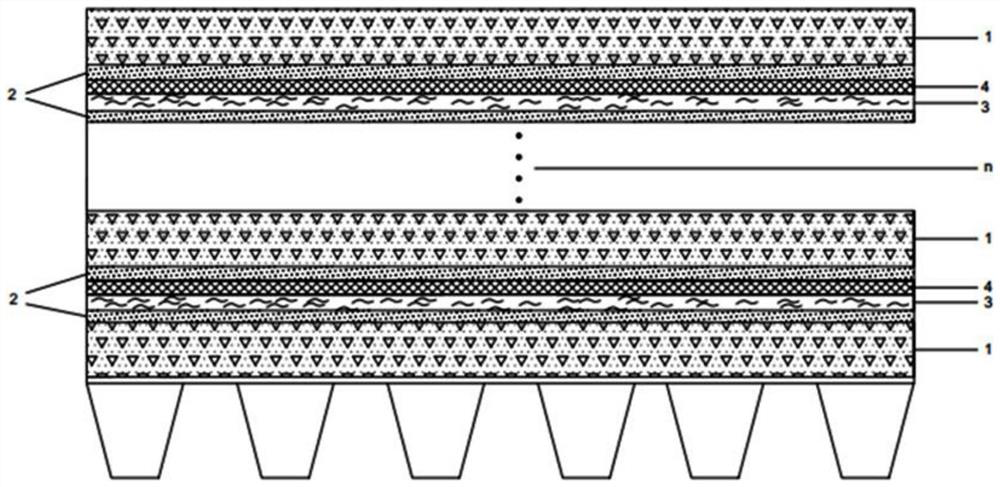

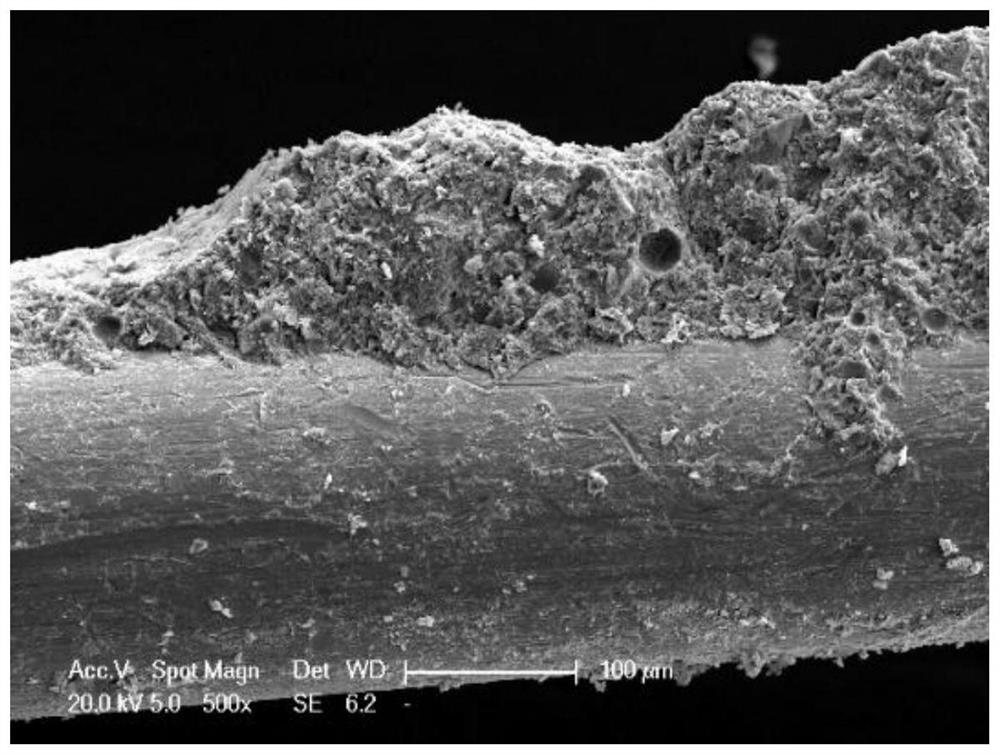

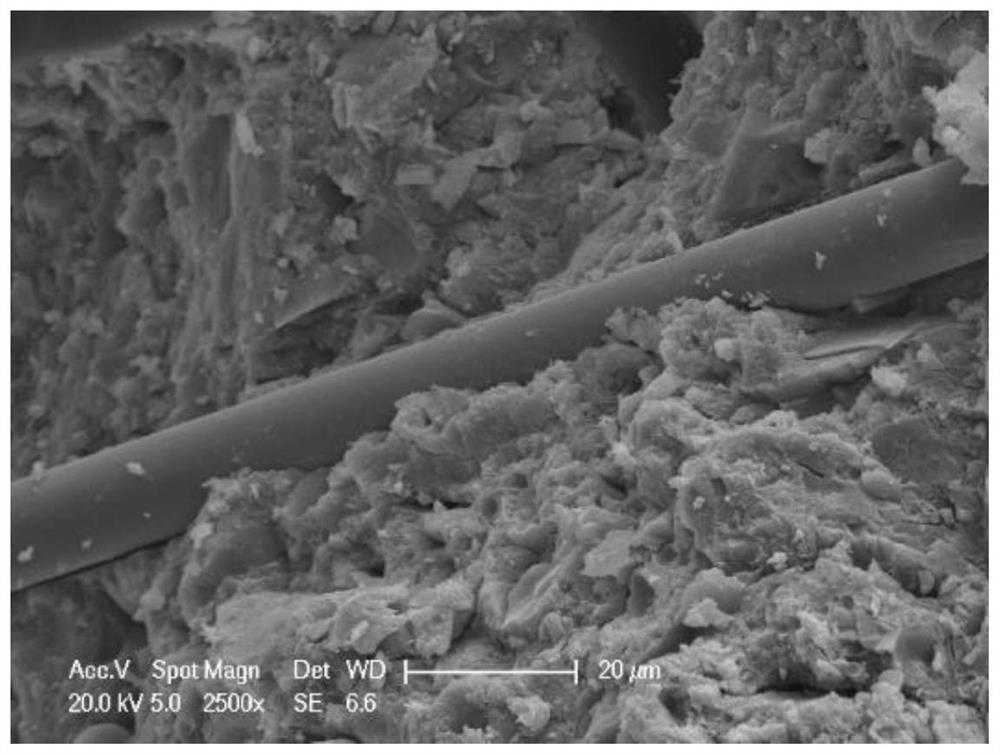

UHPC bridge deck pavement structure and preparation method thereof

ActiveCN114134809AImprove effective utilizationMeet the demand for anti-crackingBridge structural detailsSolid waste managementFiberRoad engineering

The invention relates to the technical field of road engineering, in particular to a UHPC bridge deck pavement structure and a preparation method thereof. The paving structure comprises a paving unit, the paving unit comprises a UHPC layer, an interlayer binder layer, a long fiber layer, a gridding cloth layer and an interlayer binder layer which are sequentially arranged, the paving unit is circulated for multiple times, and finally, the UHPC layer is used for sealing. According to the invention, the use mode that the fibers and the mortar are mixed, conveyed and paved together in the traditional UHPC is abandoned, the short fibers and the long fibers are introduced into the UHPC, the adding opportunity and mode of the fibers with two sizes are adjusted, and the short fibers and the UHPC mortar are mixed in advance, so that the toughness of the UHPC is improved at one time on the premise that the construction difficulty is not increased.

Owner:JIANGSU SINOROAD TRANSPORTATION SCI & TECH CO LTD

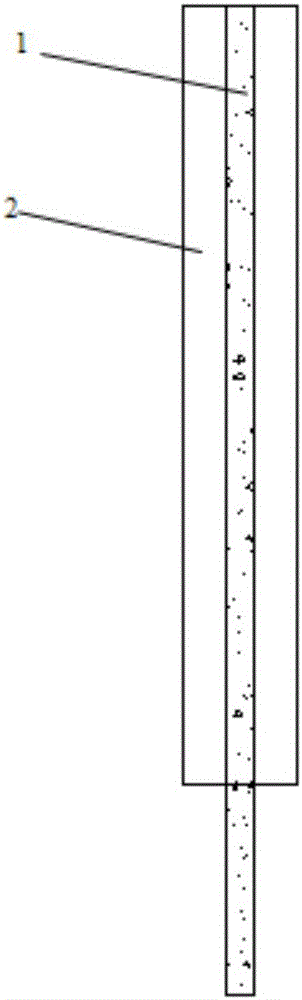

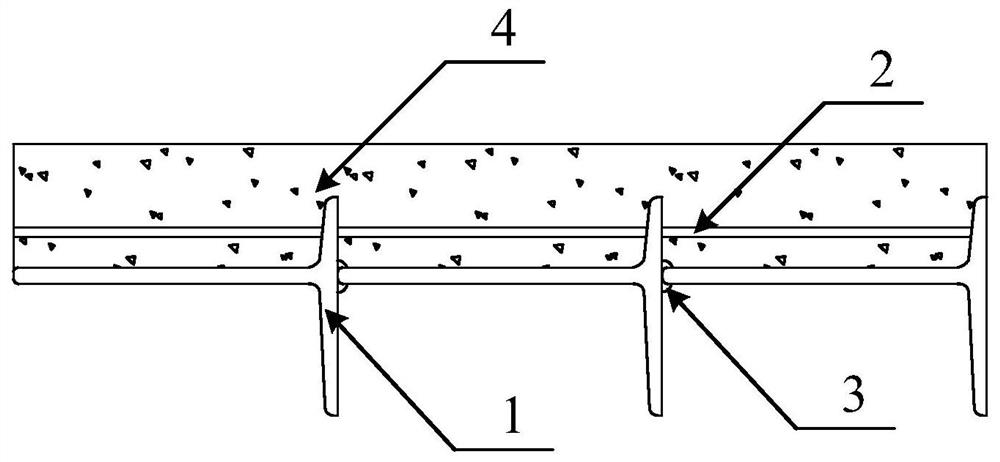

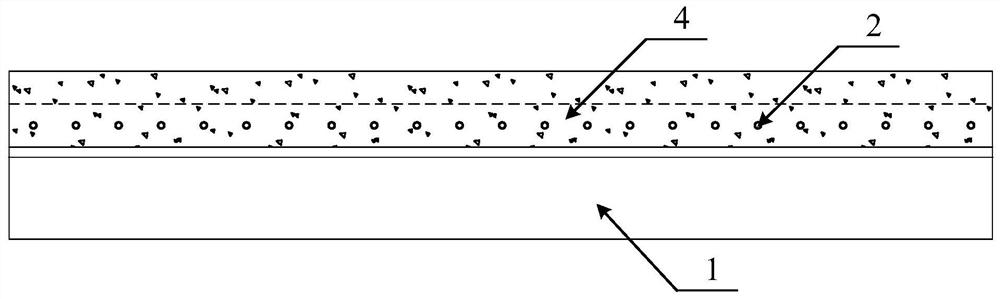

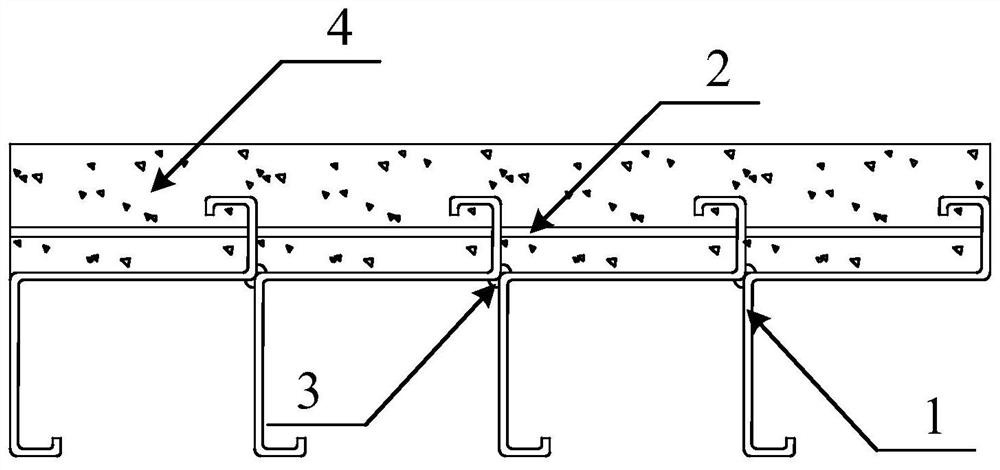

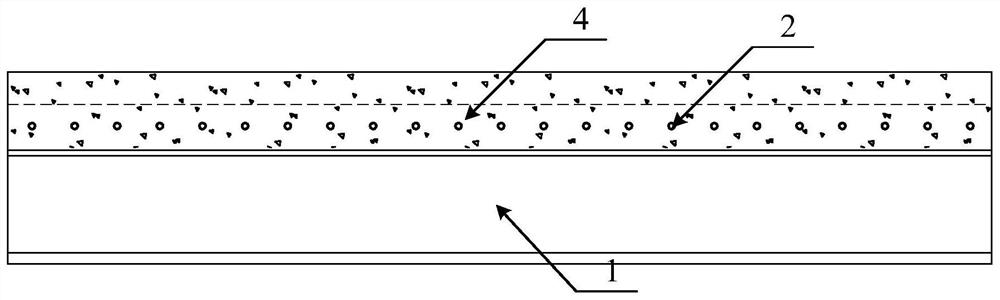

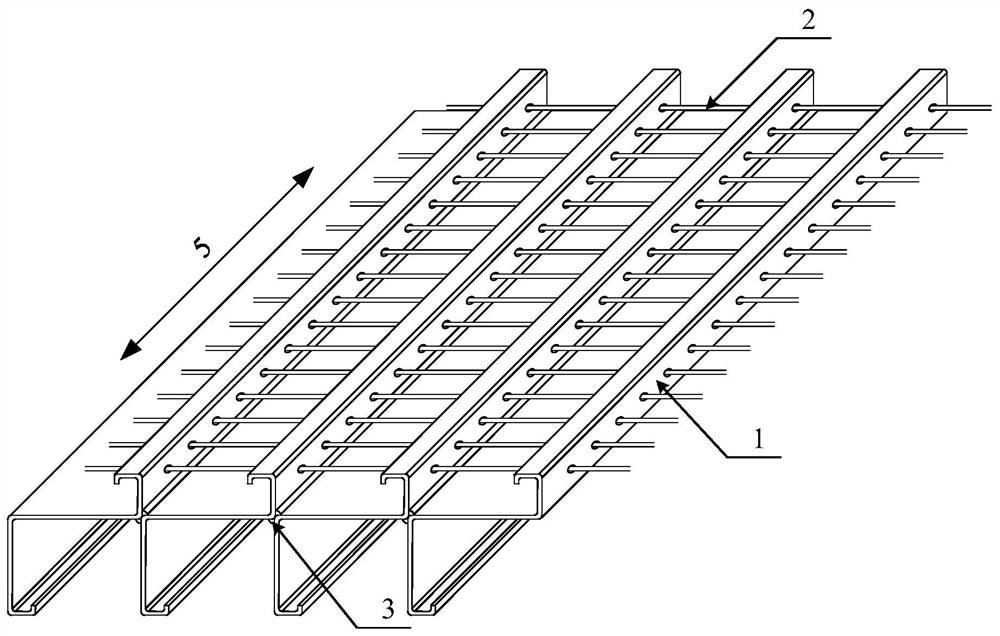

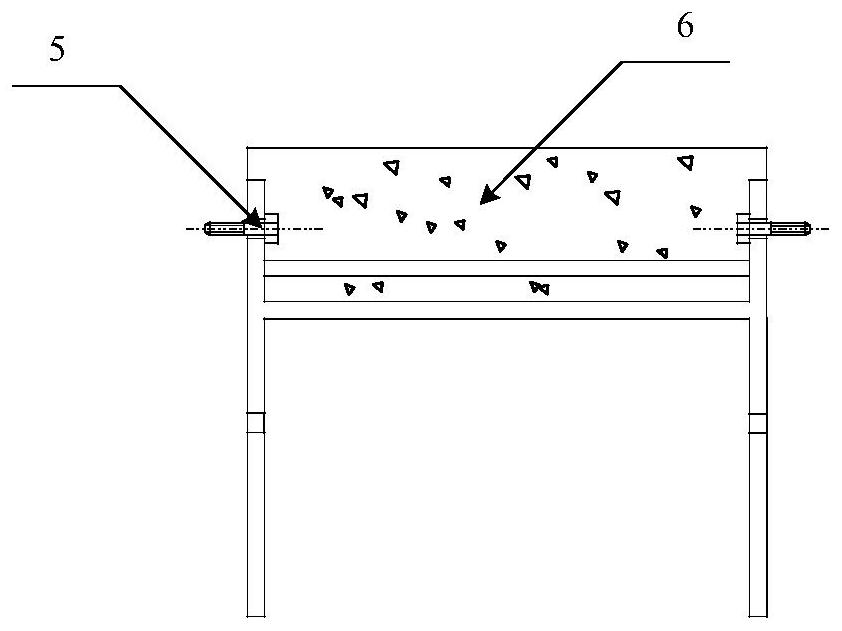

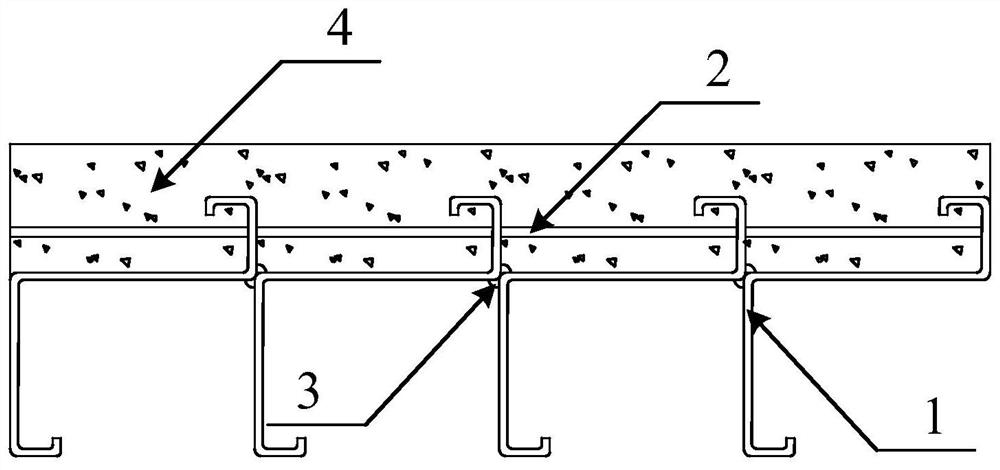

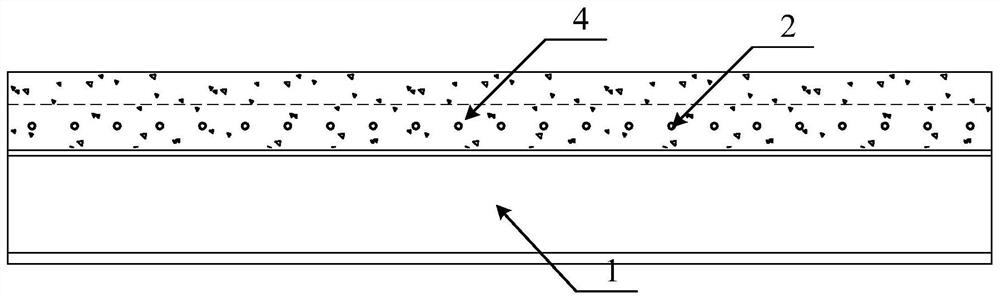

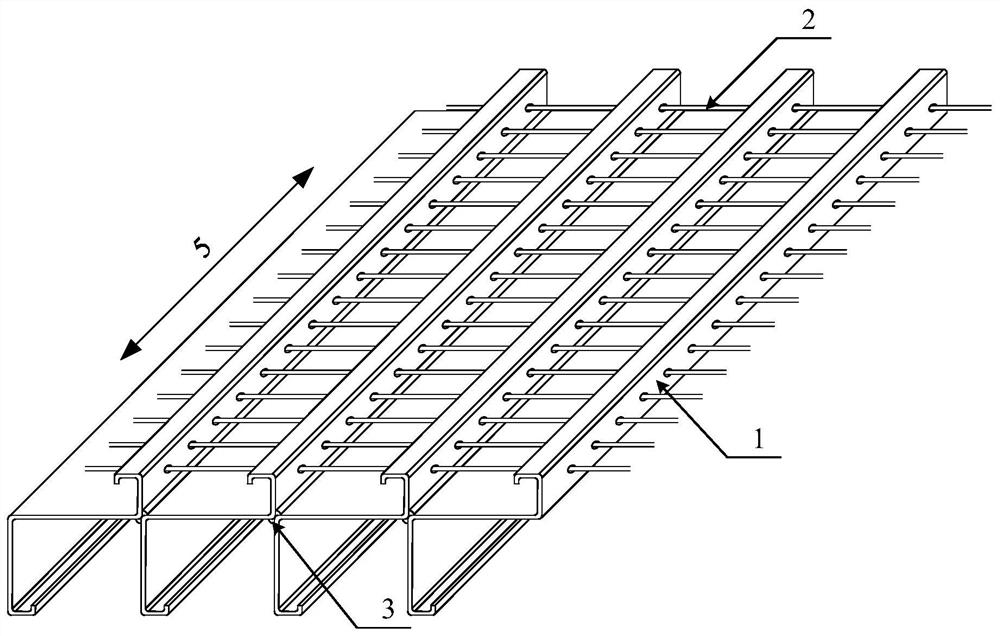

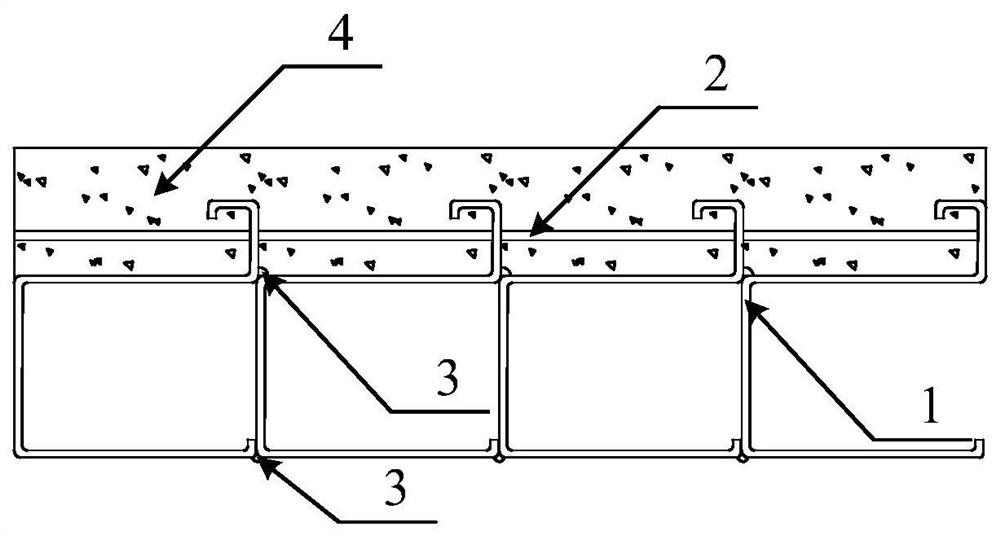

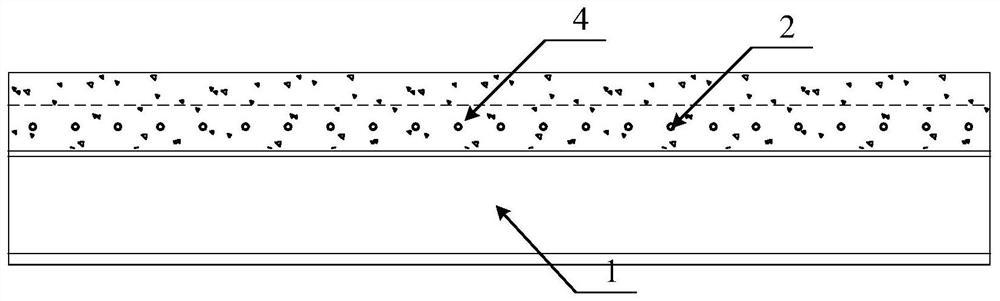

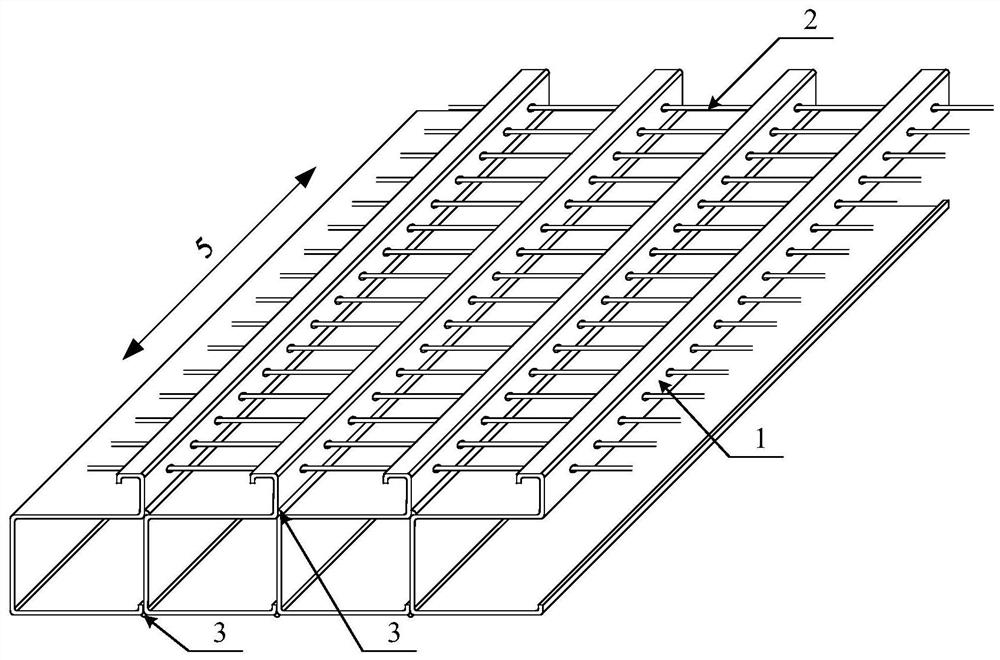

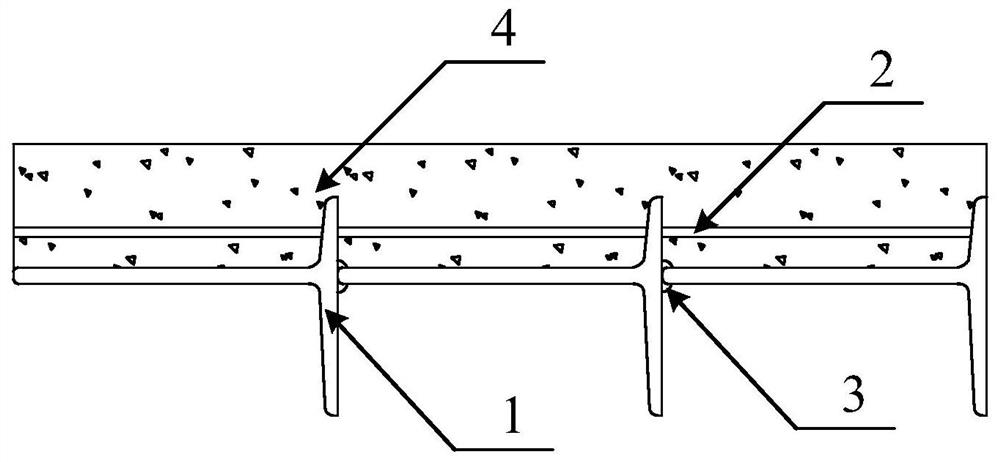

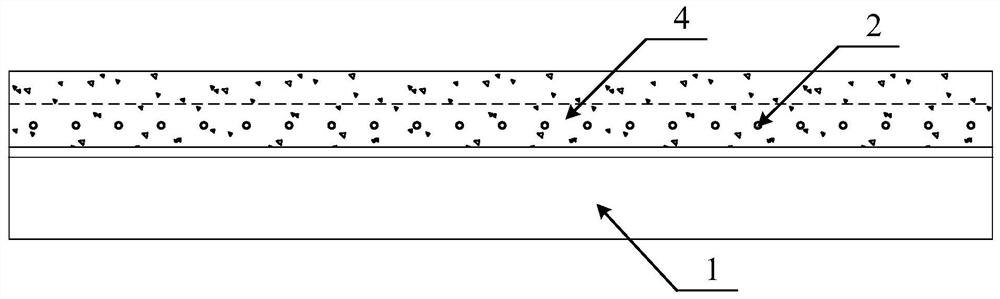

Novel building disassembly-free laminated slab with buckle type split heads

PendingCN111456332AQuality assuranceAdapt to various engineering needsFloorsBuilding reinforcementsPunchingArchitectural engineering

The invention provides a novel building disassembly-free laminated slab with buckle type split heads. The novel building disassembly-free laminated slab comprises a bottom supporting plate and the multiple buckle type split heads; the top ends of the buckle type split head are supporting parts, and the bottom ends opposite to the top ends are fixing parts; the end parts of the supporting parts arestamped to form at least one punching groove; and the fixing parts are detachably connected and fixed with the surface of the bottom supporting plate. By means of the detachable split type design structure of the bottom supporting plate and the buckle type split heads, and therefore, the novel building disassembly-free laminated slab is low in cost, high in installation efficiency, high in production efficiency and wider in application range is provided.

Owner:SHANGHAI OPEN STEEL JOIST

Reverse construction type one-column one-pile construction method and structure for reserving column joint stirrup

PendingCN109339107AImprove the shortcomings of difficult constructionShorten construction timeArtificial islandsUnderwater structuresBuilding construction

The invention relates to a reverse construction type one-column one-pile construction method and structure for reserving a column joint stirrup, and belongs to the technical field of building engineering. The construction method is characterized in that all the column stirrups, required by a structural column, at all layers sleeve the four sides of the structural column in an overlapping manner during constructing the column stirrups in an one-column one-pile project; then reserved stirrups at a current excavating layer are fixed to joints of beams and slabs; the stirrups are reserved for thecurrent excavating layer while downwards excavating each layer; the rest stirrups are arranged to the bottom part of the structural column, namely, the quantity of the stirrups overlapped on the structural column decreases as the construction downwards goes on; the abovementioned operations are repeated until all column stirrups are constructed. According to the structure, the column stirrups of the current excavating layer are fixedly bound to the beam and slab joints in the current excavating layer; the column stirrups of the rest layers sleeve the bottom part of the structural column undera construction area of the current excavating layer in an overlapping manner; and beam stirrups are arranged around the periphery of a main beam of a structural column at a beam and column joint.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

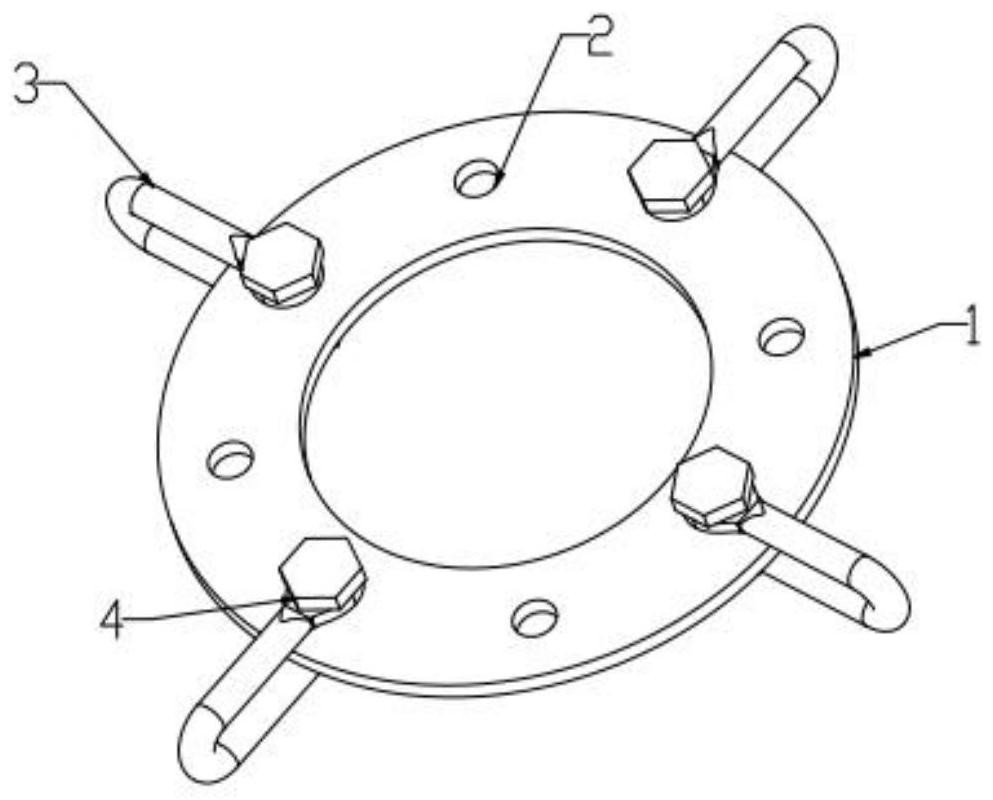

Lifting steering device for standardizing iron tower assembling and erection

PendingCN113602990AAvoid safety hazardsAvoid tyingTowersWinding mechanismsTowerIndustrial engineering

The invention belongs to the technical field of power transmission line engineering iron tower construction tools, and particularly relates to a lifting steering device for standardizing iron tower assembling and erection. The lifting steering device for standardizing iron tower assembling and erection comprises a pulling force steering flange plate, a tower foot plate and a fire bending pulling force steering plate, wherein connecting holes are formed in the two sides of the fire bending pulling force steering plate; one end of the fire bending pulling force steering plate is directly connected with a construction hole formed in the tower foot plate; an eye hole is formed in the pulling force steering flange plate; a first U-shaped ring is connected outside the eye hole through a bolt; and a bearing rope is hinged between the first U-shaped ring and the fire bending pulling force steering plate. The lifting steering device for standardizing iron tower assembling and erection is simple in shape, low in cost, easy to machine and operate, time-saving, labor-saving, and capable of guaranteeing quality, standardizing safe and civilized construction and eliminating potential safety hazards of tower assembling and erection; and safe and civilized construction is standardized, the civilized production requirement is met, and the assembling and erection time of each foundation of iron tower can be greatly shortened.

Owner:甘肃送变电工程有限公司 +2

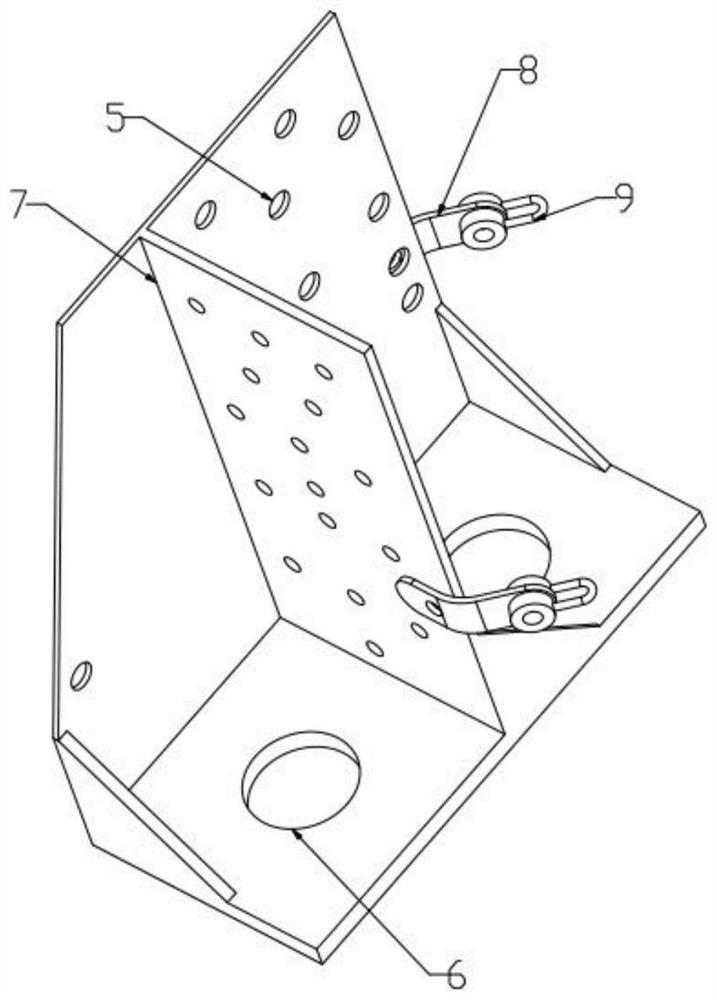

Construction mold for concrete structure stock bin assembly type funnel opening

PendingCN111452192ALow costAvoid tying rebarMouldsBulk storage containerFastenerArchitectural engineering

The invention discloses a construction mold for a concrete structure stock bin assembly type funnel opening. The construction mold comprises concentric-square-shaped structure type bottom plates, inner ring side plates and outer ring side plates, a pouring cavity is defined by the bottom plates, the inner ring side plates and outer ring side plates in a matched mode, side plate positioning structures for positioning the mounting positions of the inner ring side plates and the outer ring side plates are arranged at the edges of the bottom plates, the inner ring side plates and the outer ring side plates are fixed and installed through fasteners located on the outer side of the pouring cavity. The assembly type construction mold is adopted so that the funnel opening can be prefabricated firstly, the funnel opening is integrally installed after certain strength is achieved, then other parts are constructed, disassembly and assembly are convenient, the construction strength is low, operation is easy and convenient, the labor productivity can be improved, the construction progress can be accelerated, meanwhile the engineering cost can be reduced through repeated utilization, and the forming quality of the funnel opening and the mounting quality of embedded bolts are guaranteed through prefabrication in advance, thereby improving the engineering quality.

Owner:MCC TIANGONG GROUP

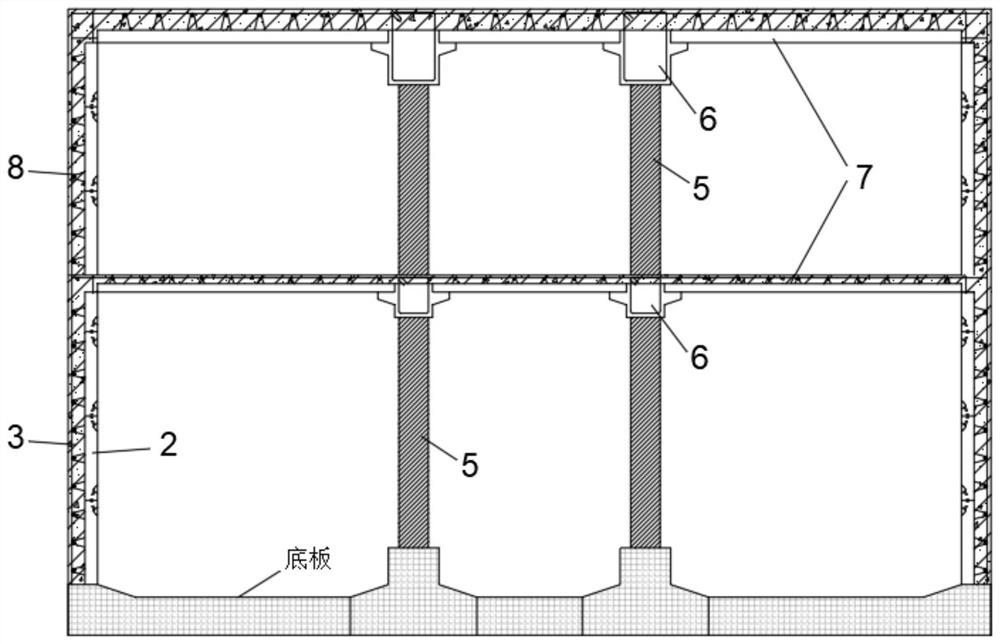

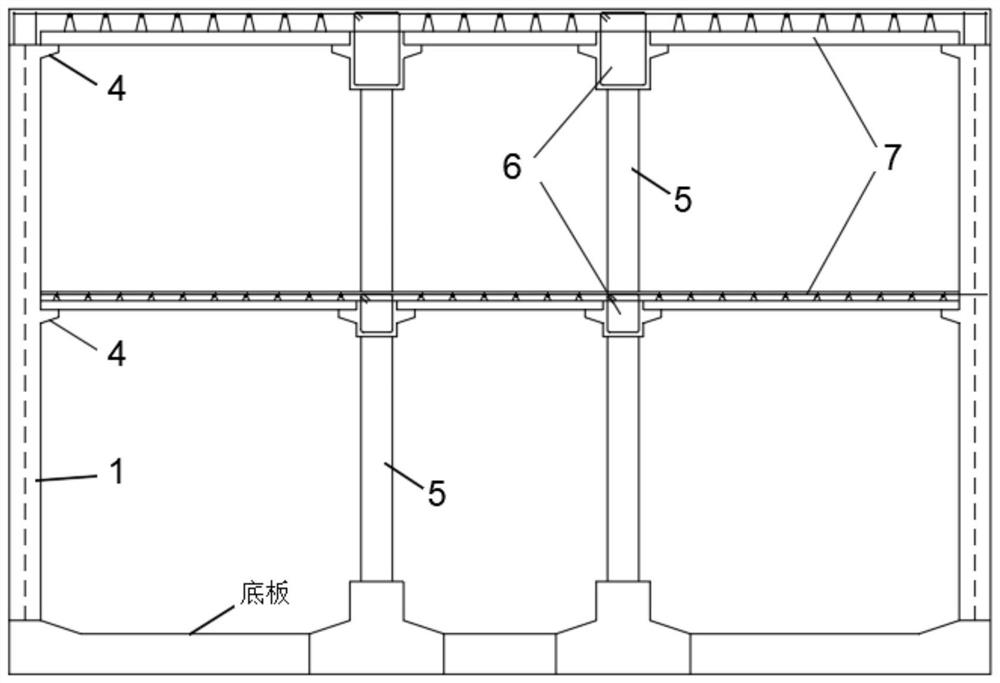

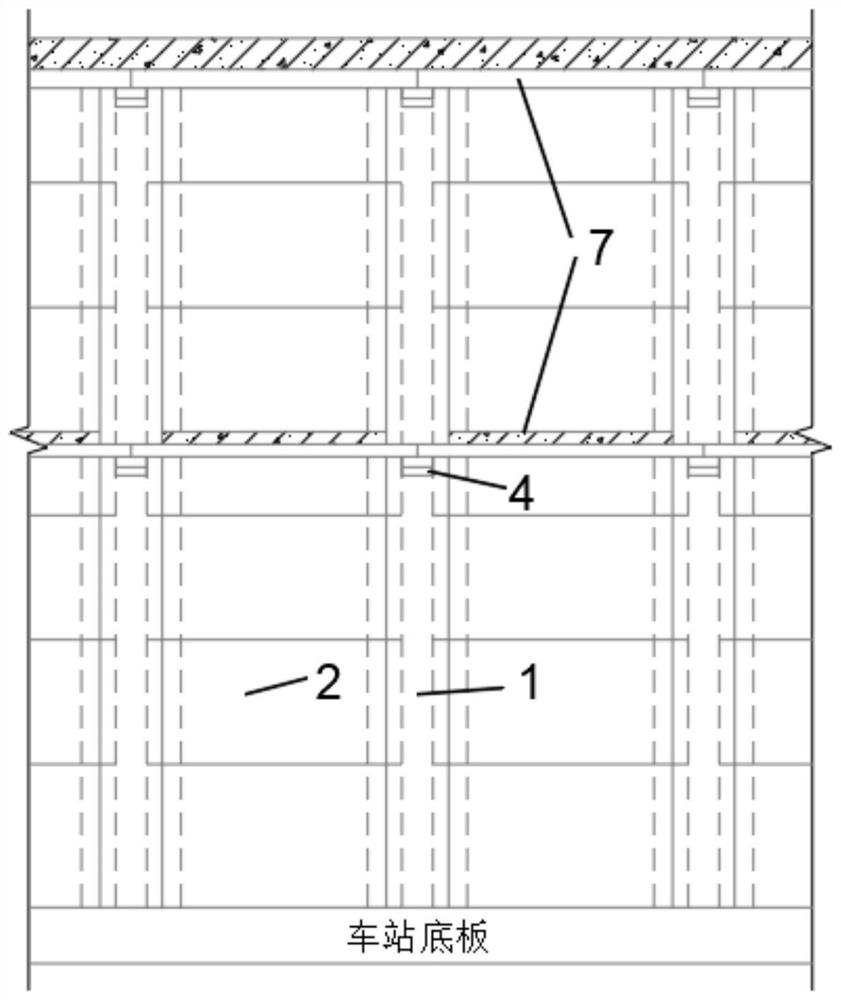

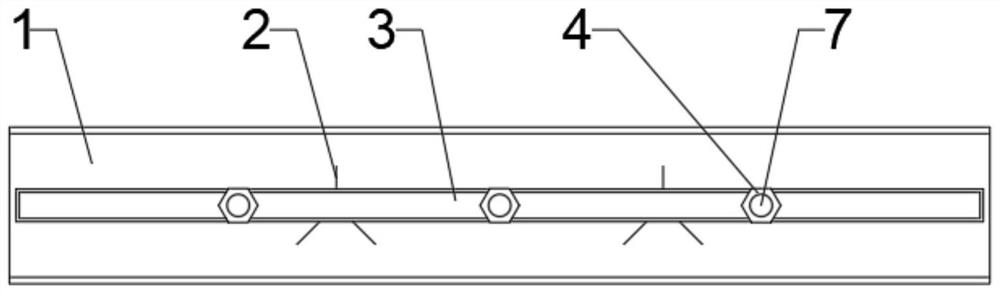

Structure of station side wall formed by combination of omega-shaped inserting plates and convex pilasters and construction method

ActiveCN114855868AAvoid tyingImprove the quality of structural constructionArtificial islandsClimate change adaptationFalseworkArchitectural engineering

The invention relates to the technical field of subway engineering, and discloses a structure of a station side wall formed by combining omega-shaped inserting plates with convex pilasters and a construction method, the structure comprises prefabricated pilasters, omega-shaped prefabricated inserting plates, a wall back pouring layer, pilaster brackets, prefabricated middle columns, prefabricated middle (top) longitudinal beams, laminated middle (top) plates and steel bar trusses, the omega-shaped prefabricated inserting plate is fixedly connected with the prefabricated pilaster through bolts, a steel bar truss is arranged on the omega-shaped prefabricated inserting plate, the wall back pouring layer is located between the foundation pit side wall and the omega-shaped prefabricated inserting plate, the omega-shaped prefabricated inserting plate is provided with the steel bar truss, on-site steel bar binding is directly and effectively avoided, and the construction efficiency is improved. The structure construction quality is improved, and the construction efficiency is improved; by means of the prefabricated pilaster, the pilaster bracket, the omega-shaped prefabricated inserting plate and other components, formwork-free and scaffold-free construction on a construction site can be achieved, the efficiency is improved, and meanwhile the problems that formwork erecting is difficult, and the risk is large are solved; the method is suitable for assembly type subway stations and similar projects, and the application range is wide.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

Precise positioning template device for concrete pull rod or dowel bar and using method

PendingCN114657850AAccurate locationAvoid tyingPaving detailsRoads maintainenceArchitectural engineeringDowel

A concrete pull rod or dowel bar accurate positioning formwork device comprises a formwork and a positioning perforated plate, the formwork comprises a first formwork body and a second formwork body, the second formwork body is fixedly connected to one side of the first formwork body, and the positioning perforated plate is fixedly connected to the other side of the first formwork body; the positioning perforated plate is provided with a long-strip-shaped through hole used for containing a pull rod or a dowel bar. Penetrating holes corresponding to the long-strip-shaped penetrating holes in the positioning perforated plate are formed in the first template and the second template; and the pull rod or the dowel bar sequentially penetrates through the positioning perforated plate, the first template and the second template. The accurate positioning template device for the concrete pull rod or the dowel bar disclosed by the invention is wider in application range, and can be suitable for the condition that the pull rod or the dowel bar has different distances; positioning can be rapidly and accurately carried out, installation is faster and more convenient, and the working efficiency is greatly improved; the device can be manufactured at a time and recycled, and the construction cost is effectively saved.

Owner:HEBEI CONSTR GRP CO LTD

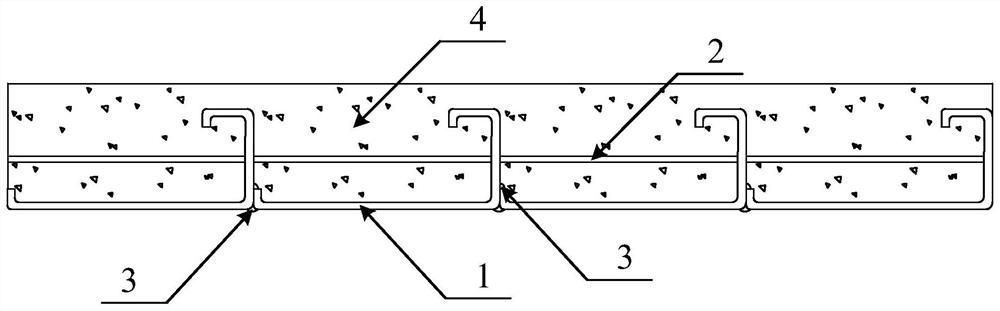

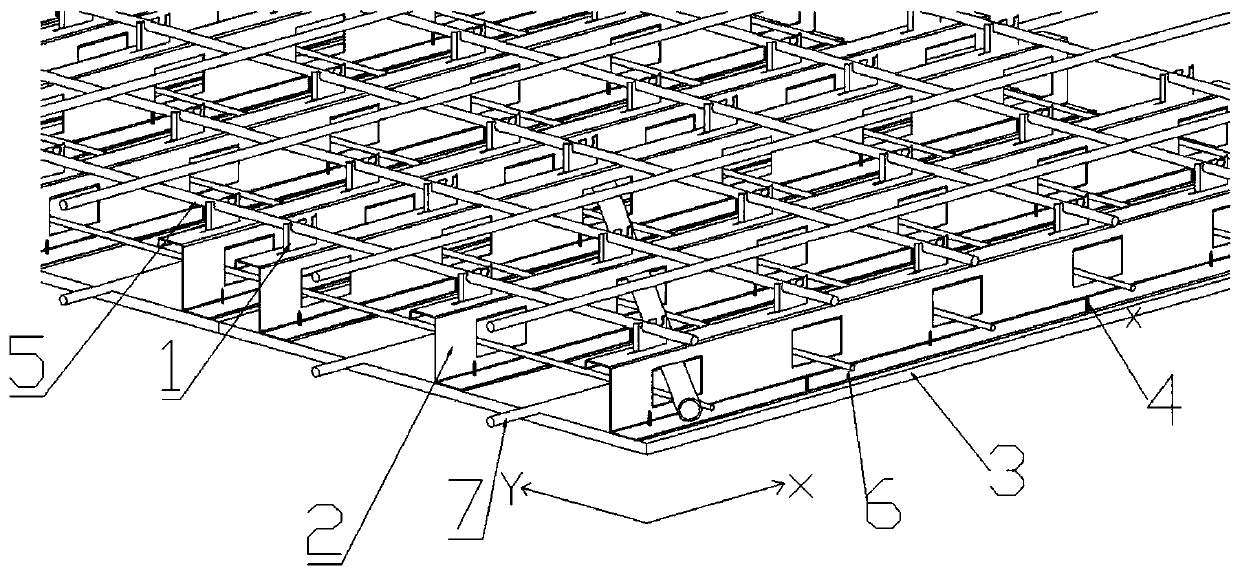

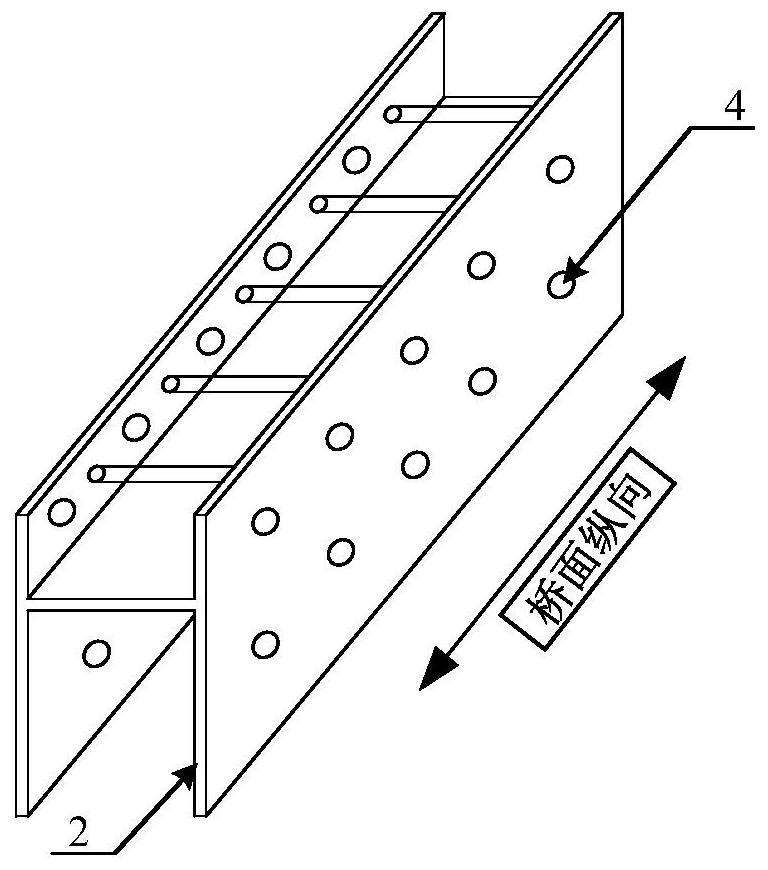

Prefabricated assembly type toughness combined bridge deck slab with cast-in-place wet joints and manufacturing method

ActiveCN113062216APrevent rustImprove toughnessBridge structural detailsBridge erection/assemblyStructural fatigueBridge deck

The invention discloses a prefabricated assembly type toughness combined bridge deck slab with cast-in-place wet joints and a manufacturing method. The combined bridge deck slab is composed of profile steel combined prefabricated parts, prefabricated connecting parts, high-strength bolts and cast-in-place ultrahigh toughness concrete. In the section steel combined prefabricated parts, a bolt hole is formed in a flange of wide hot-rolled H-shaped steel, a transverse round steel bar is welded to a flange plate on the wide hot-rolled H-shaped steel, and ultrahigh-toughness concrete is poured after the high-strength bolts and screws are pre-embedded. In the prefabricated connecting parts, a bolt hole is formed in a flange of narrow hot-rolled H-shaped steel, and a transverse round steel bar is welded on a flange plate on the upper side of the narrow hot-rolled H-shaped steel. In the construction process, the section steel combined prefabricated parts and the prefabricated connecting parts are arranged side by side at intervals, the prefabricated parts are connected into a whole through the high-strength bolts, and the ultrahigh-toughness concrete is cast in situ on the upper portions of the prefabricated connecting parts, so that the cast-in-situ wet joints are formed. The system provided by the invention has the advantages of high toughness, high prefabrication degree, no need of arrangement of studs, no need of field welding, low cast-in-place concrete proportion, convenience in construction and remarkable improvement of structural fatigue performance.

Owner:ZHEJIANG UNIV

A ductile composite bridge deck composed of cold-formed z-shaped steel

ActiveCN112227199BPrevent rustImprove toughnessBridge structural detailsBridge materialsFillet weldBridge deck

The invention discloses a ductile composite bridge deck composed of cold-formed Z-shaped steel, which comprises cold-formed and curled Z-shaped steel, transverse steel bars and ultra-high toughness concrete. The cold-formed Z-shaped steel is continuously placed laterally along the bridge deck and welded by fillet welds to form the steel skeleton of the bridge deck. The lower flange of the cold-formed Z-shaped steel is longer, which plays the role of external reinforcement of the plate surface; the upper flange is shorter and has a row of round holes on it, and the transverse steel bars pass through each cold-formed Z-shaped steel flange through the round holes. The ultra-high toughness concrete is poured on the steel skeleton of the bridge deck to protect the steel skeleton of the bridge deck. In the composite bridge deck system proposed by the present invention, the ultra-high toughness concrete can ensure that no or only tiny cracks below 100 microns will be generated, and the toughness and durability of the structure will be improved; The anti-shear and pull-out effects of the studs are improved, and the out-of-plane stability of the bridge deck is improved, the material cost and construction complexity are significantly reduced, and the fatigue performance is superior.

Owner:ZHEJIANG UNIV

Fabricated steel-ultrahigh toughness concrete combined bridge deck

PendingCN112878192APrevent rustImprove toughnessBridge structural detailsBridge materialsStructural fatigueArchitectural engineering

The invention discloses a fabricated steel-ultrahigh-toughness concrete combined bridge deck which comprises hot-rolled H-shaped steel, round steel bars, high-strength bolts and ultrahigh-toughness concrete. Bolt holes are formed in flanges of the hot-rolled H-shaped steel, and transverse round steel bars are welded to flange plates on the flanges, so that the section steel prefabricated part units are formed. The high-strength bolts penetrate through the bolt holes and are connected with the adjacent hot-rolled H-shaped steel to form a bridge deck steel framework. The ultrahigh-toughness concrete is poured on the bridge deck steel framework to play a role in protecting the bridge deck steel framework. In the combined bridge deck slab system, the ultra-high toughness concrete can ensure that micro cracks of 100 microns or below are not generated or only generated, and the toughness and durability of the structure are improved; the bridge deck steel framework is formed by connecting factory prefabricated parts through the high-strength bolts, the prefabrication and assembly degree is high, and the construction precision and quality are guaranteed; and no stud needs to be arranged, so that the construction complexity is reduced, and the structural fatigue performance is ensured.

Owner:SHANDONG TRAFFIC PLANNING DESIGN INST +1

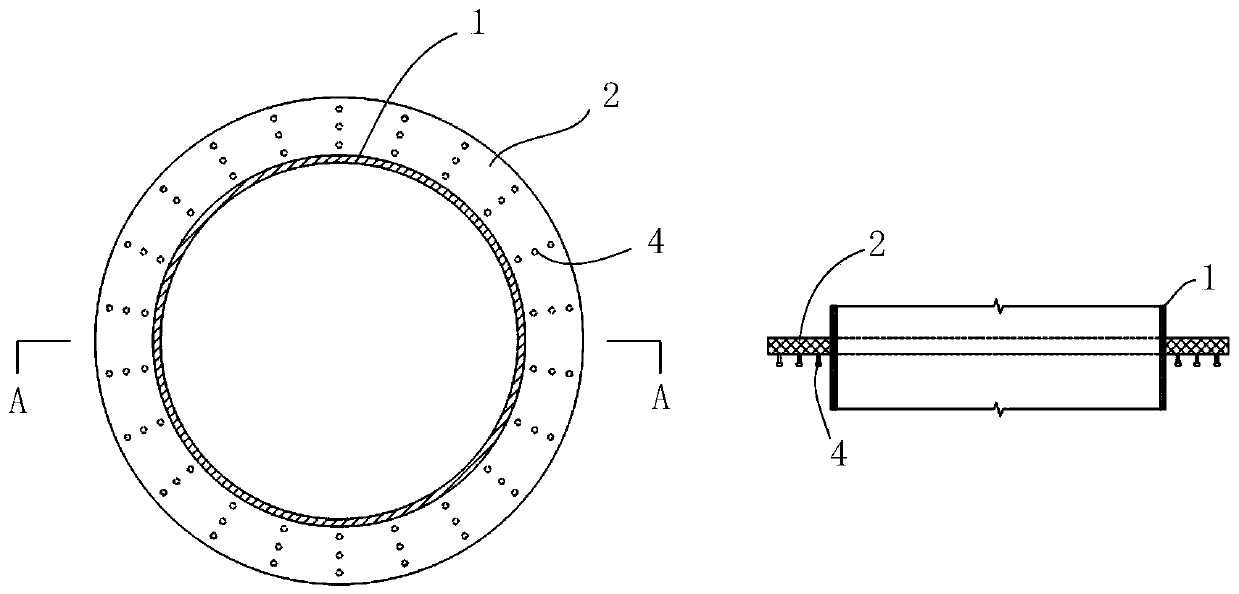

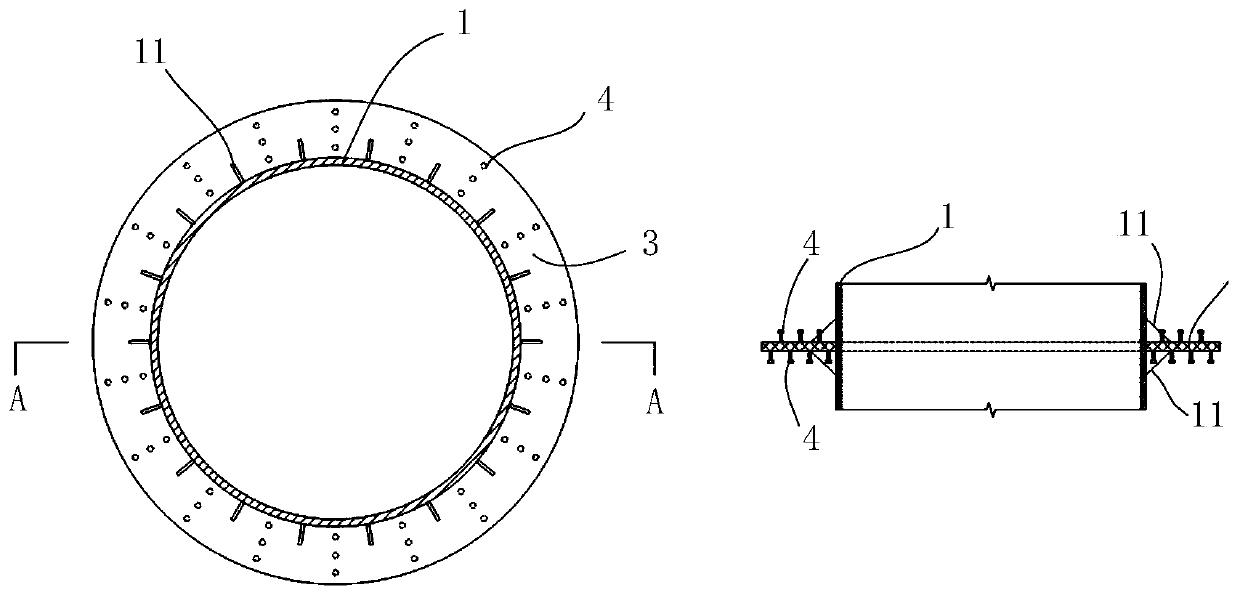

Simple duct piece mold positioning device for pre-buried channel

InactiveCN113047870APrecise positioningEasy to installUnderground chambersTunnel liningRebarRock bolt

The invention discloses a simple device for positioning a duct piece mold at a pre-buried channel. The simple device comprises a pre-buried anchor rod, a locking screw, a channel, an n-shaped anti-loose gasket, an E-shaped nylon connecting piece, a positioning support steel plate, a positioning connecting rod and a fastening nut. The defects that a traditional pre-buried channel is positioned by virtue of a ground anchor and a T-shaped bolt, the ground anchor easily makes contact with a steel bar, and a duct piece is difficult to demould are overcome. The E-shaped nylon connecting piece is arranged, so that the n-shaped anti-loose gasket and the positioning support steel plate are integrated, simple installation and accurate positioning of the channel are realized through the positioning connecting rod, the contact between the ground anchor and the main steel bar is avoided, and the demolding efficiency of the concrete duct piece is improved; a plastic component can be prevented from remaining in the concrete duct piece so as not to influence the stress performance of the duct piece; anti-skid ribs are arranged, so that the E-shaped nylon connecting piece, the n-shaped anti-loose gasket and the positioning support steel plate are difficult to fall off in the demolding process; and the n-shaped anti-loose gasket is arranged between the channel and the locking screw, so that the anti-loose performance of the pre-buried channel is improved.

Owner:HENAN JINGWEI ELECTRIC POWER TECH

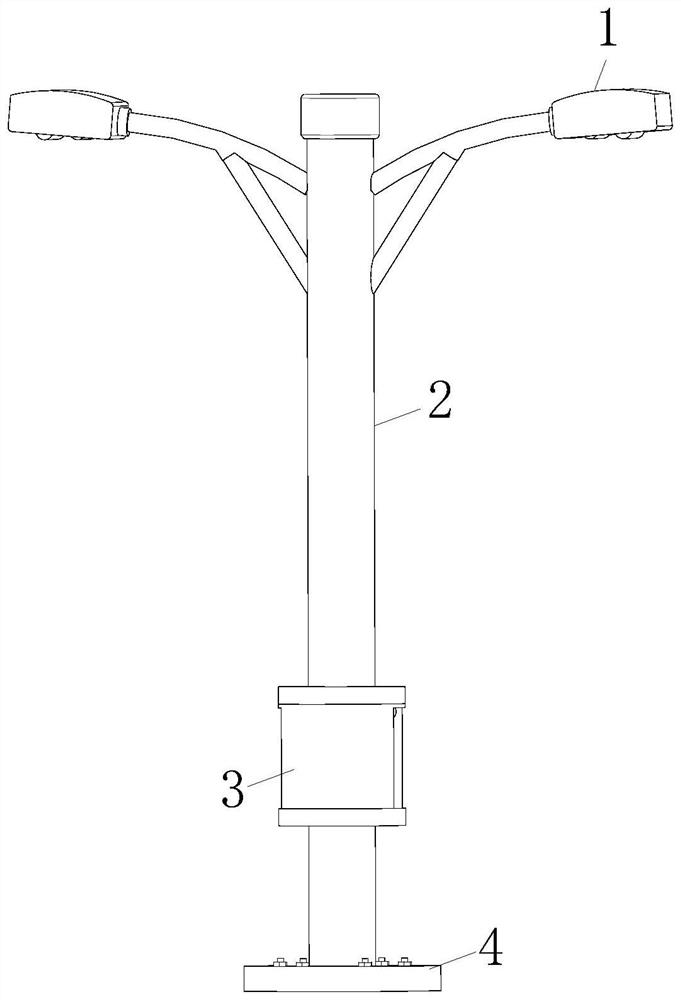

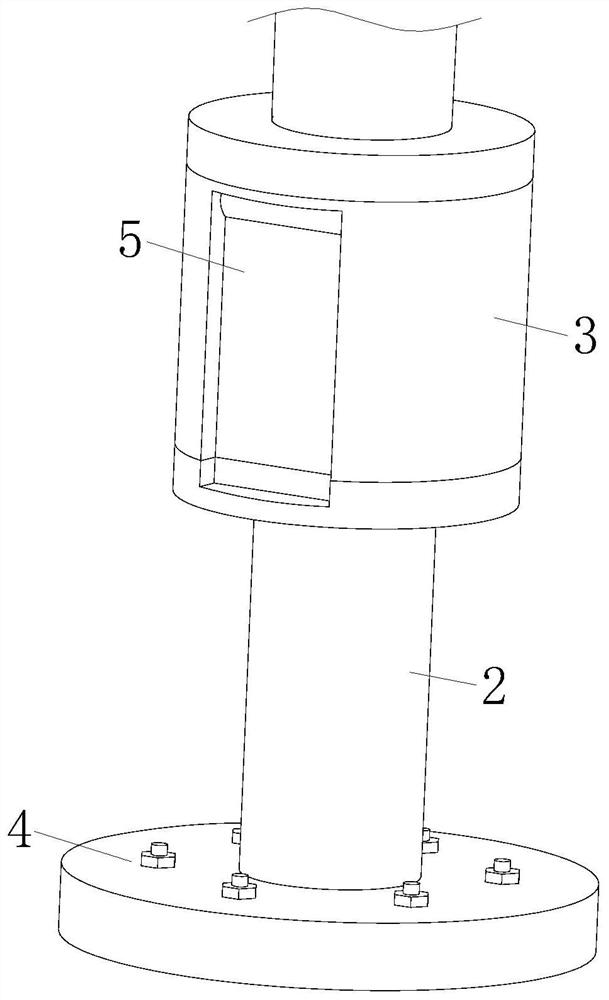

Single lamp controller applied to street lamp

PendingCN114321847AAvoid tyingSafe and reliable workElectric circuit arrangementsOutdoor lightingStructural engineeringElectric wire

The invention relates to the technical field of single lamp controllers, in particular to a single lamp controller applied to a street lamp, which comprises a lampshade, a lamp post, a mounting plate, a base, a protection plate, a mounting frame, a control box and a fixing plate, connecting rods are arranged on the outer walls of the two sides of the lamp post, the lampshade is arranged on the outer walls of the connecting rods, and the street lamp is arranged on the inner wall of the lampshade; the inner wall of the lamp post is of a tubular structure, a control line is arranged on the inner wall of the lamp post, a street lamp in the lampshade is electrically connected with the control line, the bottom end of the lamp post is fixedly connected with the base, a mounting plate is arranged on the outer wall of the lamp post, and the distance between the mounting plate and the base is small. And mounting grooves which are symmetrically distributed are formed in the outer wall of the mounting plate. According to the single lamp controller applied to the street lamp, due to the fact that the control box and the clamping opening are in clamping fit, the effect of rapid maintenance can be achieved only by replacing the control box, and binding of various electric wires at high-altitude operation is avoided.

Owner:岳西天时利电子科技有限公司

Manufacturing method of stator

InactiveCN102946171AIncrease productivityAvoid tyingManufacturing stator/rotor bodiesStatorScotch tape

The invention discloses a manufacturing method of a stator. The manufacturing method comprises the following steps: an enamelled wire is wound on a stator core, then a lead and / or a circuit board is arranged on a winding formed by the winding of the enamelled wire, and the lead and / or the circuit board is fixed by using an insulated rubber tape to obtain a stator module; a plastic film is wound on the peripheral region of the stator module, and the plastic film extends to the two outer ends of the stator module respectively, then the plastic film is heated by using a heating device to be subjected to plastic deformation so as to form an annular plastic groove wrapping the outer surface of the stator module; and the stator module the outer surface of which is provided with the annular plastic groove is put into a mould and is molded on the periphery of the stator module by injection molding and curing so as to form a main case. As the stator of a plastic package motor is manufactured by the method, the condition that scotch tapes and the stator module need to be bound by utilizing a wire binding machine can be avoided, the operation is simple, convenient and rapid, the production efficiency of the stator is improved, and the production cost is lowered.

Owner:合肥凯邦电机有限公司

Cold-formed steel tough combined bridge deck with box-shaped ribs

ActiveCN112227201AImprove stabilityImprove mechanical performanceBridge structural detailsBridge materialsFillet weldBridge deck

The invention discloses a cold-formed steel tough combined bridge deck slab with box-shaped ribs. The cold-formed steel tough combined bridge deck slab is composed of cold-bending hemming section steel, transverse reinforcing steel bars and ultrahigh-toughness concrete. The cold-formed steel is transversely and continuously placed along the bridge deck and forms bridge deck steel framework throughfillet weld welding. Box-shaped ribs are formed on the lower side flanges of the cold-formed steel, the upper side flanges are short and are provided with a row of round holes, and transverse steel bars penetrate through the cold-formed steel flanges through the round holes. And the ultrahigh-toughness concrete is poured on the bridge deck steel skeleton to play a role in protecting the bridge deck steel skeleton. According to the invention, the ultrahigh-toughness concrete can ensure that no or only tiny cracks below 100 microns are generated, so that the toughness and durability of the structure are improved; the structural mode of combining the cold-formed steel and the transverse reinforcing steel bars replaces the anti-shearing and anti-pulling effects of studs; meanwhile, the out-of-plane stability and the transverse torsion stress performance of the bridge deck slab are remarkably improved through the box type closed stiffening ribs, the material cost and the construction complexity are remarkably reduced, and the fatigue performance is excellent.

Owner:ZHEJIANG UNIV

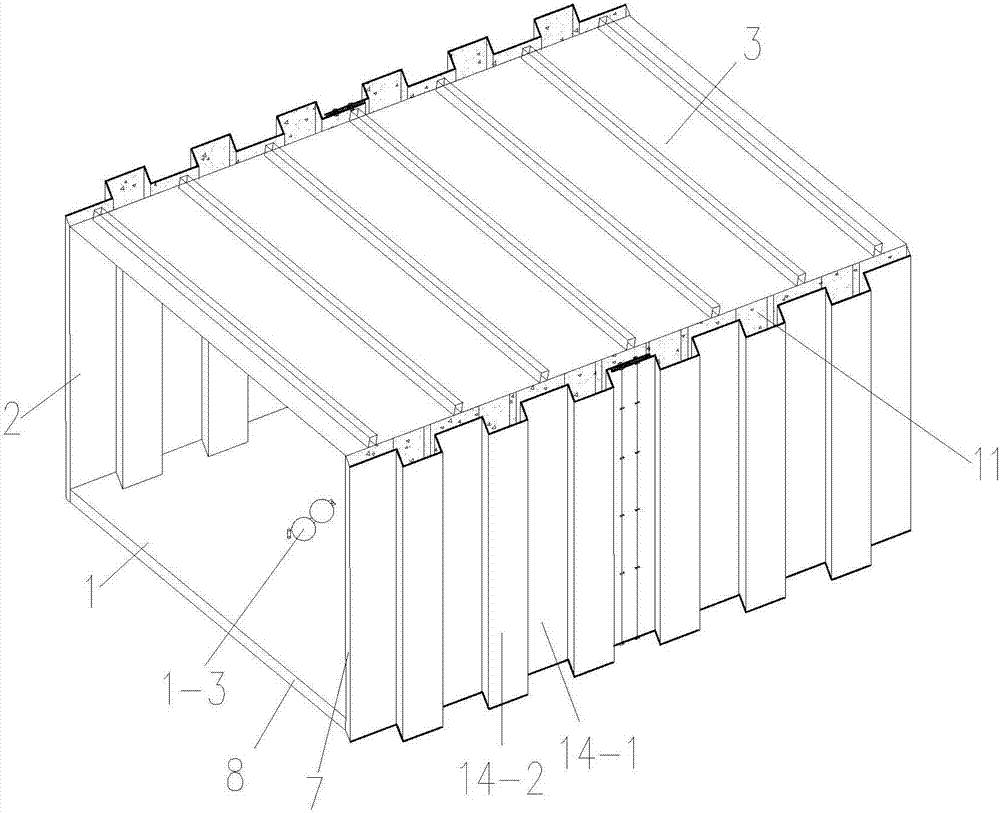

Utility tunnel and construction method thereof

PendingCN107354957AImprove stabilityLight in massArtificial islandsUnderwater structuresStructural engineeringArchitectural engineering

The invention discloses a utility tunnel and a construction method thereof. The utility tunnel comprises a horizontal arranged rectangular base plate, a rectangular top plate horizontally arranged above the rectangular base plate, and two corrugated compound walls vertically arranged between the rectangular base plate and the rectangular top plate, and the two corrugated compound walls are symmetrically arranged on the left side and the right side of the rectangular base plate respectively; the rectangular base plate, the rectangular top plate and the corrugated compound walls surrounds a tunnel channel. The construction method comprises the steps of digging a foundation pit where the construction tunnel locates, assembling boards, pouring concrete and back-filling the foundation pit. According to the utility tunnel, the corrugated compound walls are adopted for the side walls, and protruding portions of the corrugated compound walls have the effect of constructional columns. According to the construction method of the utility tunnel, concrete pouring is conducted on the scene, and joint cracks between tunnel segments are avoided.

Owner:陕西建筑产业投资集团有限公司

A reinforced concrete composite beam and steel pipe column seismic connection structure

InactiveCN104499575BIncrease widthMeet the seismic requirementsShock proofingReinforced concreteRebar

The invention discloses an anti-seismic connection structure between a reinforced concrete composite beam and a steel pipe column, which belongs to the field of industrialized assembled building structures. In this design, the joints of the steel pipe column are provided with circular positioning connectors, and the beam-to-column transfer member consists of a beam-end steel connector and a steel pipe column. The H-shaped steel connector at the column end is composed of the beam-end steel connector correspondingly connected between the upper and lower longitudinal steel bars of the prefabricated reinforced concrete lower beam reinforcement cage, and the poured concrete is connected with the lower beam; the integrally connected beam- The column-end section steel connector of the column transfer member is correspondingly connected with the steel pipe column node ring positioning connector, and the concrete is poured along the beam-column transfer member between the upper longitudinal reinforcement and the connection node with the steel pipe column to form a composite beam Integral connection with the steel column pipe, the invention converts the connection between the reinforced concrete structure and the steel structure into a mature steel structure bolt welding connection form through the beam-column adapter, which is safe and reliable, and meets the requirements of "strong columns and weak beams, strong nodes and weak beams". Components" seismic requirements.

Owner:HUBEI HONGSHUN STEEL STRUCTURE MFG

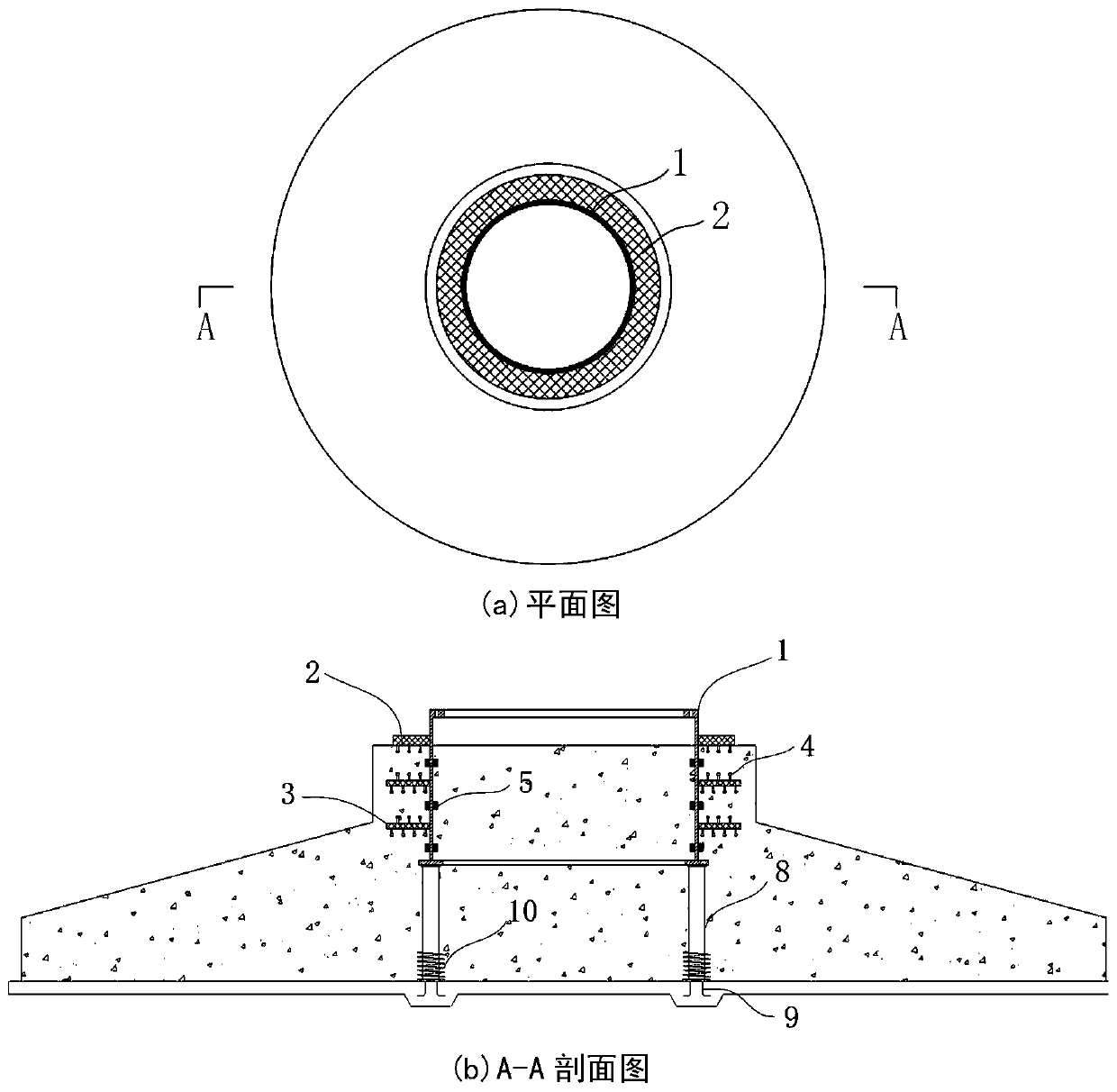

Basic performance improvement technique of basic ring type wind power tower

PendingCN109869283AReduce circumferential cracksLarge connecting surfaceWind motor supports/mountsWind energy generationElectricityEngineering

The invention discloses a basic performance improvement technique of a basic ring type wind power tower, and relates to the technical field of wind power generation. The system comprises a basic ring,an anti-cracking steel cover plate, an annular connecting steel plate, a stud, a rigid connecting piece, high-strength round steel pipe supports and a pre-embedded plate, wherein the basic ring is embedded into foundation concrete, and the upper part of the basic ring is connected with a wind power unit tower; the anti-cracking steel cover plate is arranged in the junction of the basic ring and the top surface of the concrete, and the stud is welded on one surface, which makes contact with the concrete, of the anti-cracking steel cover plate; the annular connecting steel plate and the rigid connecting piece are arranged at an interval according to a certain distance in the height direction of the basic ring; and four to six high-strength round steel pipe supports are annularly arranged atthe bottom of the basic ring, and the lower ends of the high-strength round steel pipe supports are welded with the pre-embedded plate. According to the technique, the common stress performance of the basic ring and the concrete is improved, the prominent problems of connection damage to the basic ring, concrete cracking, a large amount of perforated steel bars, complexity in construction and thelike in a traditional basic form are solved, and the technique has broad engineering application prospects.

Owner:CHONGQING UNIV

A prefabricated load-bearing intermediate partition wall structure and construction method of a rectangular pipe jacking gallery

ActiveCN111456740BLow costShorten the construction periodUnderground chambersTunnel liningArchitectural engineeringPipe

A prefabricated load-bearing partition wall structure of a rectangular pipe-jacking gallery and its construction method, including pipe top embedded parts, vertical force-transmitting steel plates, pipe bottom embedded parts and walls; pipe top embedded parts include top anchor bars and pipe top Buried plate; the pipe top buried plate is connected to the jacking pipe above the wall; there are two vertical force transmission steel plates, which are connected to the bottom surface of the pipe top buried plate; the distance between the two vertical force transmission steel plates is adapted to the thickness of the wall; The pipe bottom embedded parts include the bottom anchor bar and the pipe bottom buried plate; the pipe bottom buried plate is connected to the jacking pipe under the wall; the wall bottom is provided with the wall bottom embedded part; The upper end of the wall is inserted between two vertical force-transmitting steel plates, and the embedded part at the bottom of the wall is fixedly connected with the embedded part at the bottom of the pipe. The invention solves the technical problems of difficulty in connecting the main reinforcement of the cast-in-situ load-bearing intermediate partition wall in the traditional narrow construction space, difficulty in setting up formwork on site, difficulty in vibrating, slow construction speed, poor construction environment and the need for a large number of construction workers.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

A ductile composite bridge deck composed of T-section steel

ActiveCN112195778BPrevent rustImprove toughnessSolid waste managementBridge structural detailsFillet weldBridge deck

The invention discloses a toughness composite bridge deck system composed of T-shaped steel, including hot-rolled T-shaped steel, transverse steel bars and ultra-high toughness concrete. The T-section steels are continuously placed side by side along the bridge deck, and the adjacent section steels are welded by two fillet welds to form the bridge deck steel skeleton. The lower flange of the T-shaped steel is longer, which acts as an external stiffening effect on the plate surface; the upper flange of the hot-rolled T-shaped steel is shorter and has a row of circular holes, and the transverse steel bars pass through each T-shaped steel flange through the circular holes. The ultra-high toughness concrete is poured on the bridge deck steel frame to protect the bridge deck steel frame. In the composite bridge deck system proposed by the present invention, the ultra-high toughness concrete can ensure that no or only tiny cracks below 100 microns are generated, and the toughness and durability of the structure are improved; It also improves the out-of-plane stability of the bridge deck, significantly reduces material costs and construction complexity, and has superior fatigue performance.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com