A reinforced concrete composite beam and steel pipe column seismic connection structure

A technology for reinforced concrete and connecting structures, which is applied in earthquake resistance, building components, building structures, etc., can solve problems such as cumbersome construction, and achieve the effect of reducing the amount of on-site work, avoiding the binding of steel bars, and shortening the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

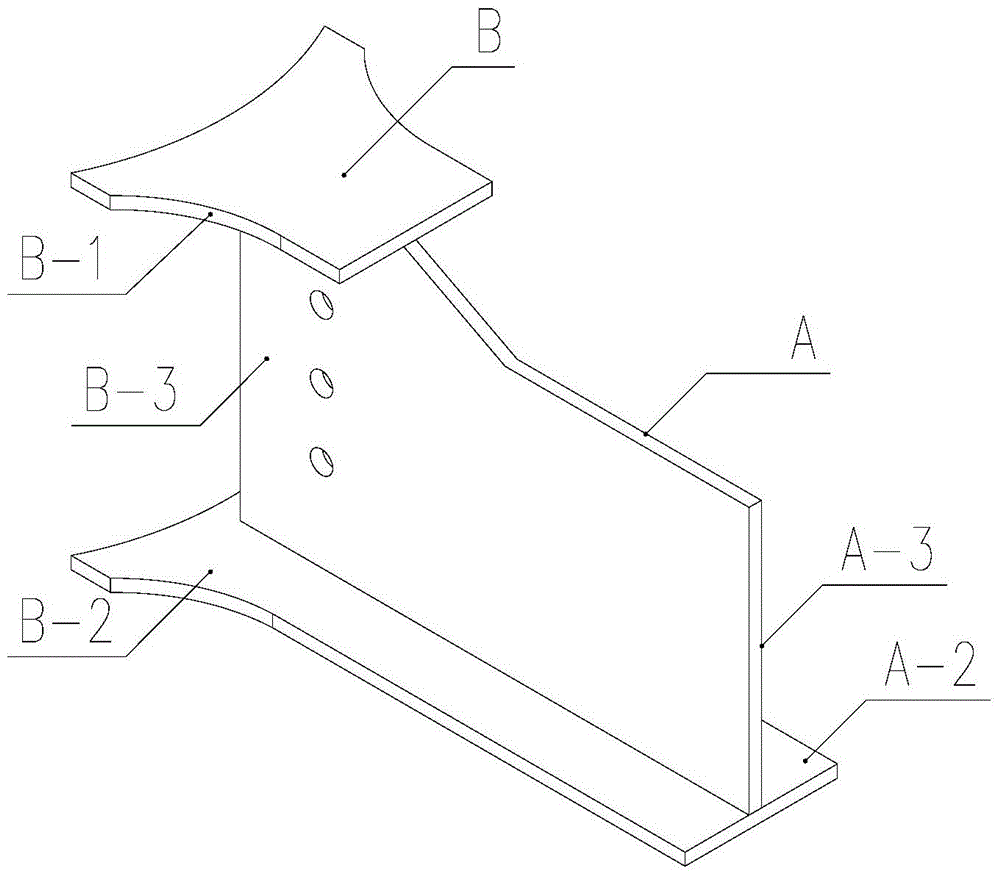

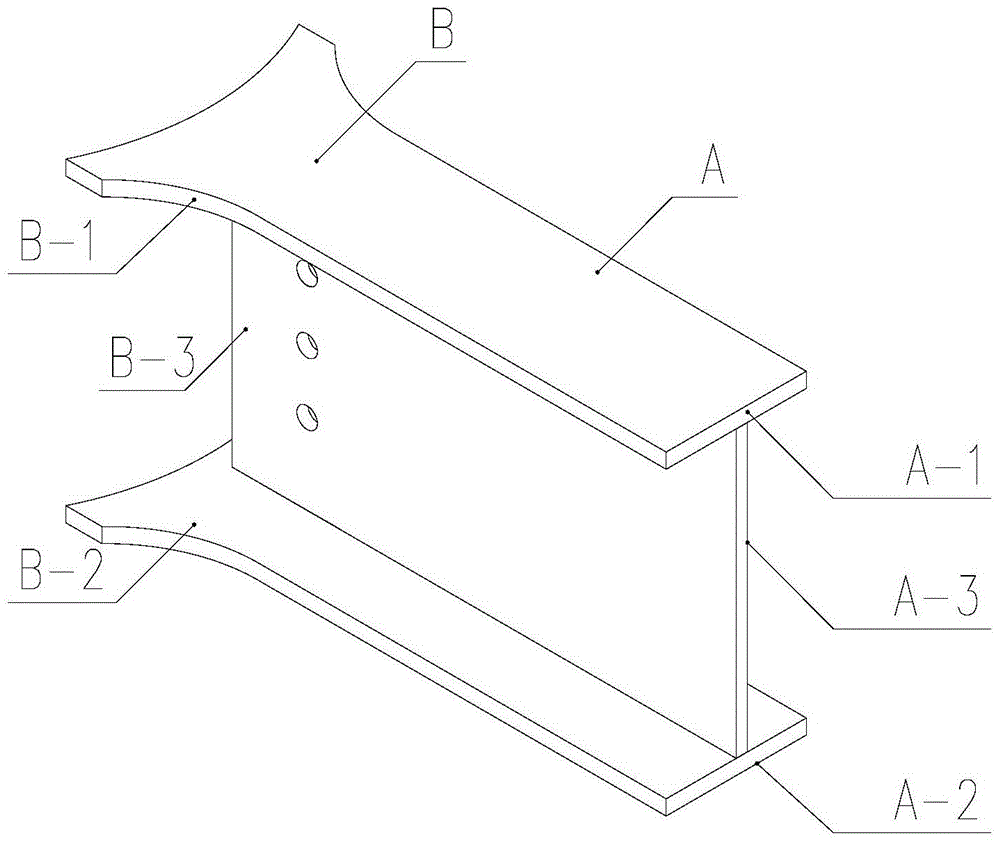

[0030] According to the above-mentioned embodiment, the beam-end section steel connector A of the beam-column transition member correspondingly welded on the upper and lower longitudinal steel bars 4-1 and 4-2 of the prefabricated reinforced concrete lower beam 2 reinforcement cage 4 is an inverted T Sectional steel connector, the upper longitudinal reinforcement 4-1 of the steel cage 4 of the prefabricated reinforced concrete lower beam 2 is welded to the upper flange plate B-1 of the H-shaped steel connector B at the column end, and the lower longitudinal reinforcement 4-2 is connected to the inverted T-shaped steel The bottom surface A-2 of the head is corresponding to welding, and the rest are as described in the detailed description.

Embodiment 2

[0032] According to the above-mentioned embodiment, the beam-end section steel connector A of the beam-column transfer member correspondingly welded between the upper and lower longitudinal reinforcement bars 4-1 and 4-2 of the prefabricated reinforced concrete lower beam 2 reinforcement cage 4 is an H-section steel Connectors, the upper and lower longitudinal steel bars 4-1, 4-2 of the reinforcement cage 4 of the prefabricated reinforced concrete lower beam 2 are respectively connected to the top and bottom surfaces A-1, A-2 corresponds to welding, and the rest are as described in the detailed description.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com