Patents

Literature

97results about How to "Meet the seismic requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technique for producing 500MPa level high-strength quake-proof reinforcing steel bar

The invention discloses a technique for producing 500MPa level high-strength quake-proof reinforcing steel bar. Nitrogen is blown into molten steel in a steel ladle by a microwave field in the process of steel taping, [N] in the molten steel ranges from 0.08% to 0.012%; reducible manganese oxide pellets are added in the metaphase of smelting; reducible vanadium oxide and niobium oxide pellets are added in the later stage of smelting; manganese family alloy, silicon family alloy and carburant are added in the process of steel taping, [Mn] in the molten steel ranges from 0.60% to 1.40%, [Si] in the molten steel ranges from 0.20% to 0.60%; ferrovanadium and ferroniobium are added in the process of steel taping to fine tunes vanadium and niobium in the steel, [V] in the steel ranges from 0.02% to 0.055%, [Nb] ranges from 0.02% to 0.055%; molten steel is cast into steel billets by a conticaster, the steel billets are heated by a heating furnace, heating temperature is between 1050 DEG C and 1250 DEG C, start rolling temperature is between 950 DEG C and 1150 DEG C, finishing temperature is between 950 DEG C and 1050 DEG C, and cooling speed after rolling is between 15 DEG C / s and 500 DEG C / s; Rel of the reinforcing steel bar produced by the method is between 530MPa and 560MPa, Rm is between 660MPa and 730MPa, A is between 18% and 25%, Rm / Rel is between 1.30 and 1.45, ageing lasts for three months, undulating quantity of Rel and Rm is less than 15MPa, welding performance is good, and popularization and application prospects are promising.

Owner:CENT SOUTH UNIV

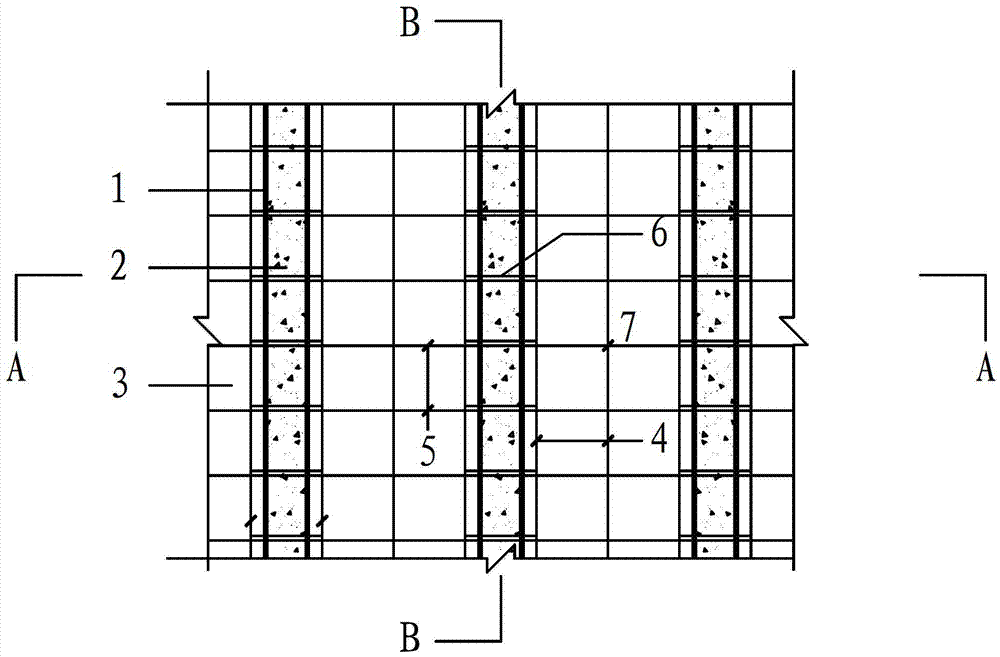

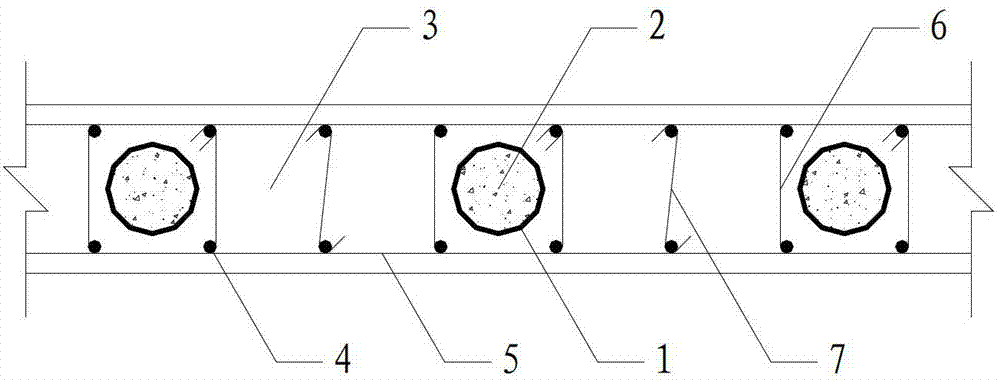

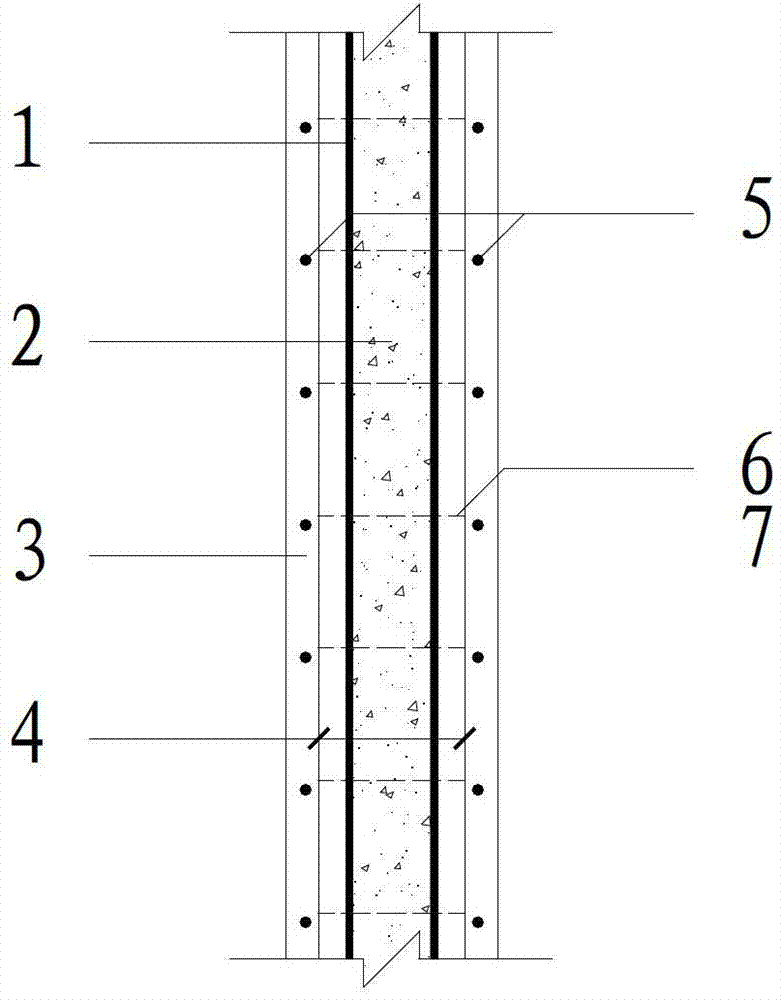

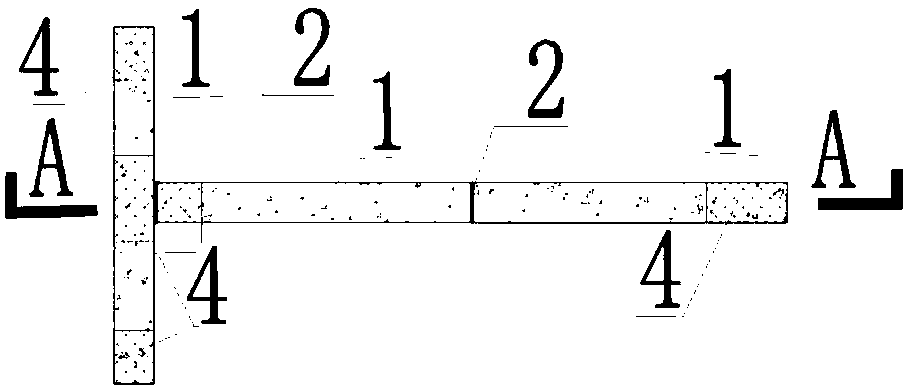

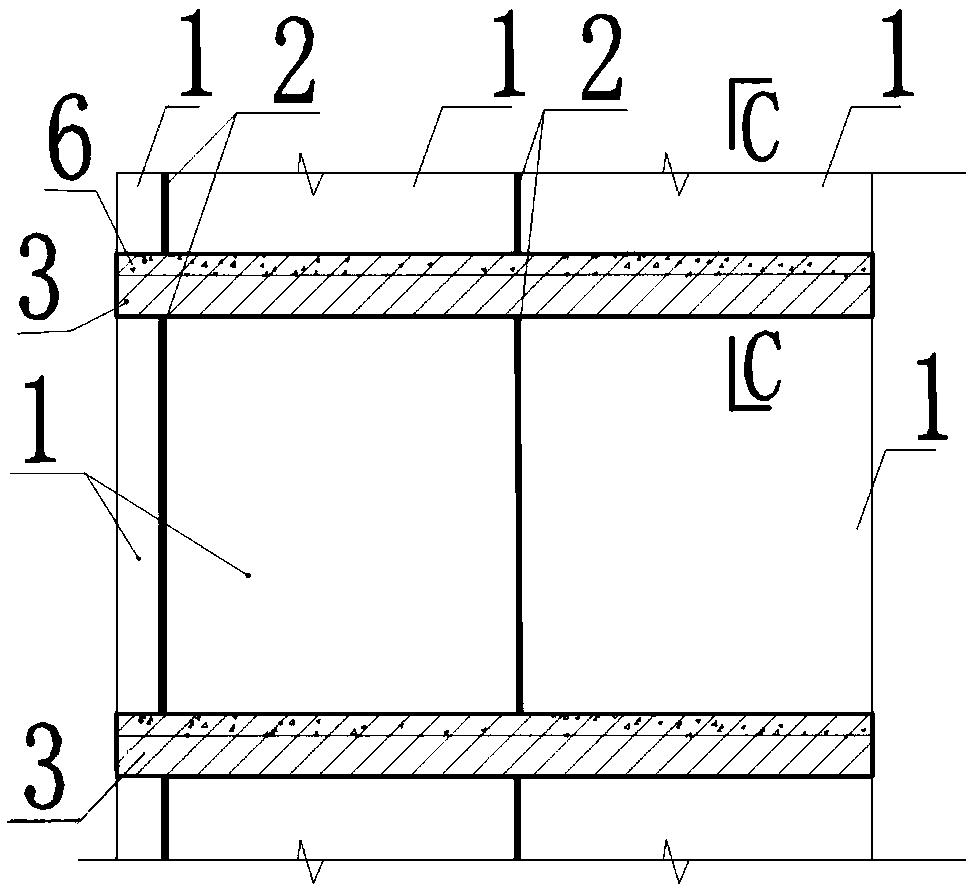

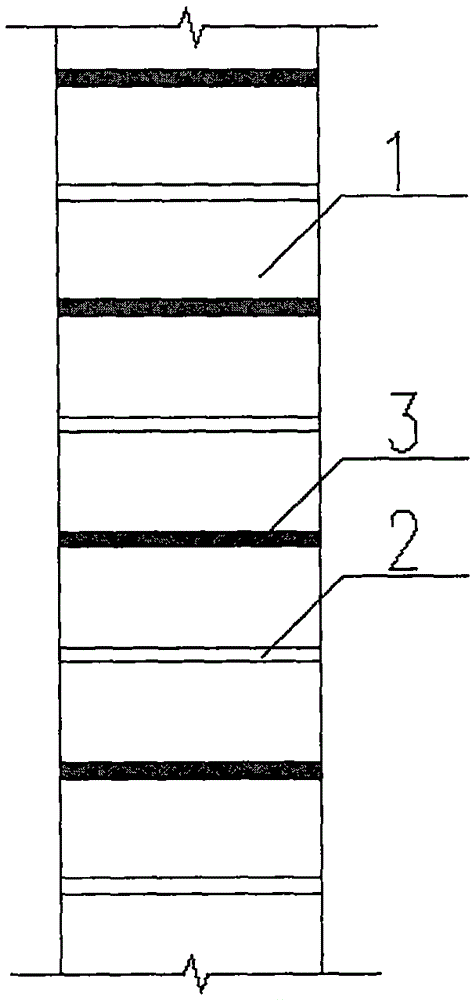

Concrete-filled steel tube combined shear wall and construction process thereof

InactiveCN102900169AHigh strengthImprove ductilityWallsBuilding material handlingReinforced concreteShear capacity

The invention relates to a concrete-filled steel tube combined shear wall and a construction process thereof. The shear wall comprises steel tubes which are distributed uniformly along the section of the shear wall, concrete filled into the steel tubes, concrete poured outside the steel tubes, square stirrups arranged outside the steel tubes, and vertically-distributed steel bars and horizontally-distributed steel bars which are arranged on front and rear sides of the steel tubes, tie steel bars which are tied between the steel tubes and the vertically-distributed steel bars and between the steel tubes and the horizontally-distributed steel bars, and longitudinal steel bars which are arranged at the positions of restraint members on edges of two sides of the steel bars. According to the concrete-filled steel tube combined shear wall, the steel tubes are embedded into the ordinary reinforced concrete shear wall, and the bearing capacity of the concrete is improved under the restraint action of the steel tubes, so that the sectional dimensions of the members are reduced, the dead weight of a structure is reduced, a seismic effect is reduced, and more usable areas are provided for buildings under the condition of the same design axial force; and anti-seismic properties of the flexural capacity, shear capacity, damage ductility and the like of the shear force are improved effectively by utilizing the high bearing capacity and high ductility of the concrete-filled steel tubes.

Owner:TSINGHUA UNIV

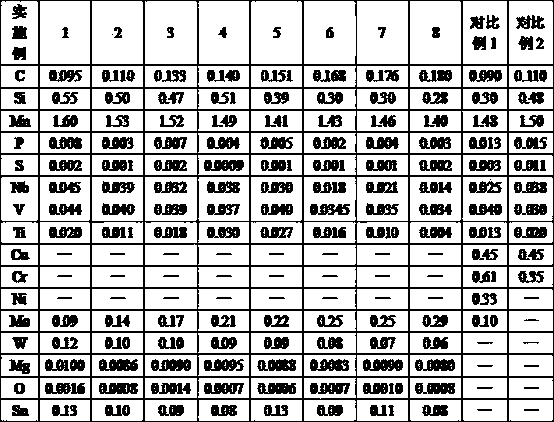

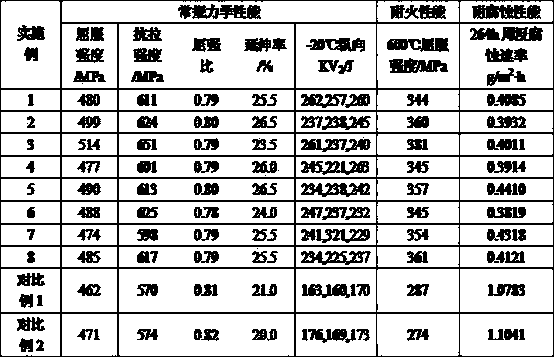

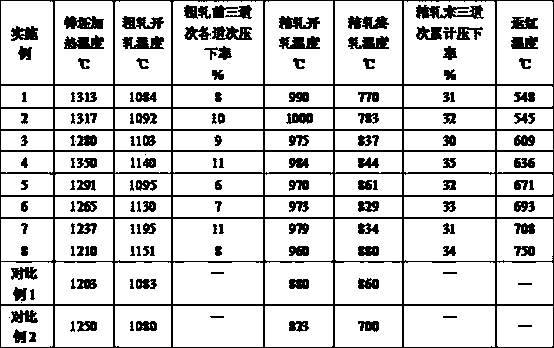

Fire-resistant corrosion-resistant anti-seismic construction steel with yield strength of 460MPa and production method

The invention discloses fire-resistant corrosion-resistant anti-seismic construction steel with yield strength of 460MPa. The steel comprises the following components in percentage by weight: 0.095-0.180% of C, 0.28-0.55% of Si, 1.40-1.60% of Mn, less than or equal to 0.008% of P, less than or equal to 0.002% of S, 0.014-0.045% of Nb, 0.004-0.030% of Ti, 0.034-0.044% of V, 0.09-0.29% of Mo, 0.06-0.12% of W, 0.0080-0.0100% of Mg, 0.08-0.13% of Sn and less than or equal to 0.0016% of O. The steel is prepared through processes, including molten iron desulphurization, smelting in a converter, vacuum treatment, casting blank heating, sectional rolling, cooling and stand-by. On premise that the use properties of the steel meet the requirements of GB / T19879 Steel Plates for Building Structure, the yield strength is no less than 460MPa, the yield ratio is less than or equal to 0.80, the fire resistance is that the yield strength is no less than 2 / 3 at the room temperature, the corrosion resistance complete immersion corrosion rate is not greater than 0.45g / m<2>.h, meanwhile the requirements on fire resistance, corrosion resistance and seismic resistance are met, and the properties are excellent.

Owner:武汉钢铁有限公司

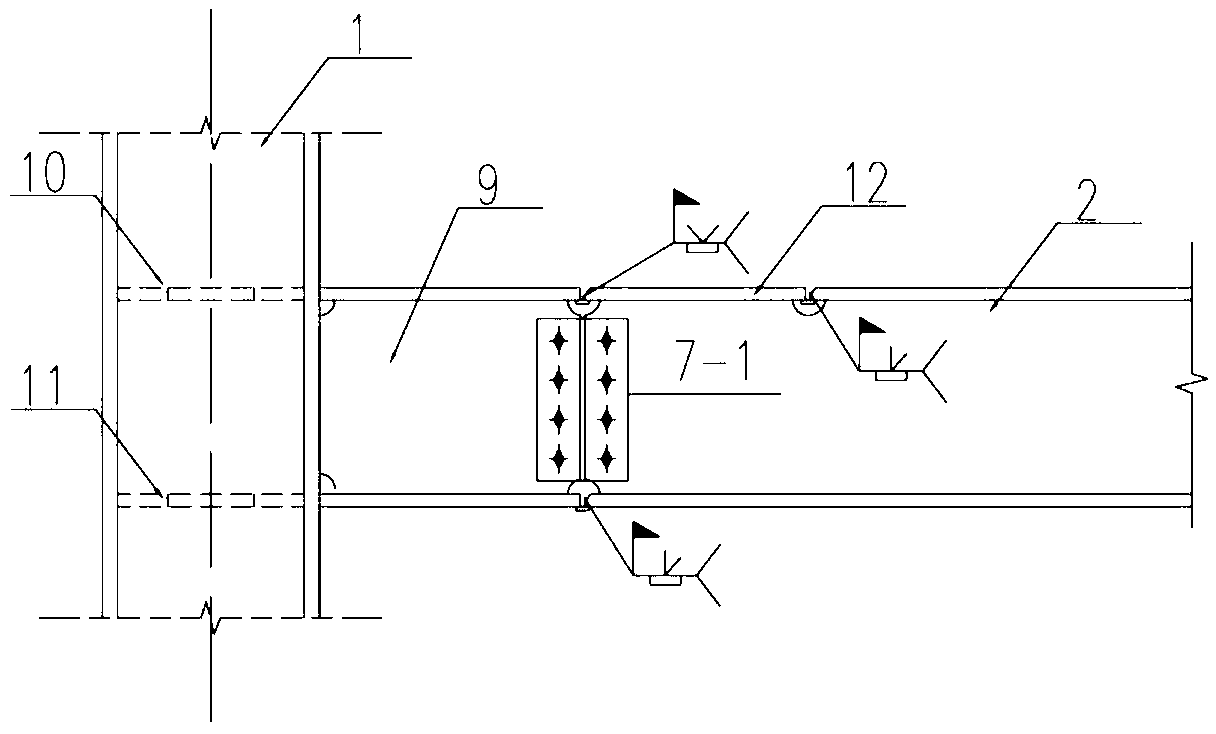

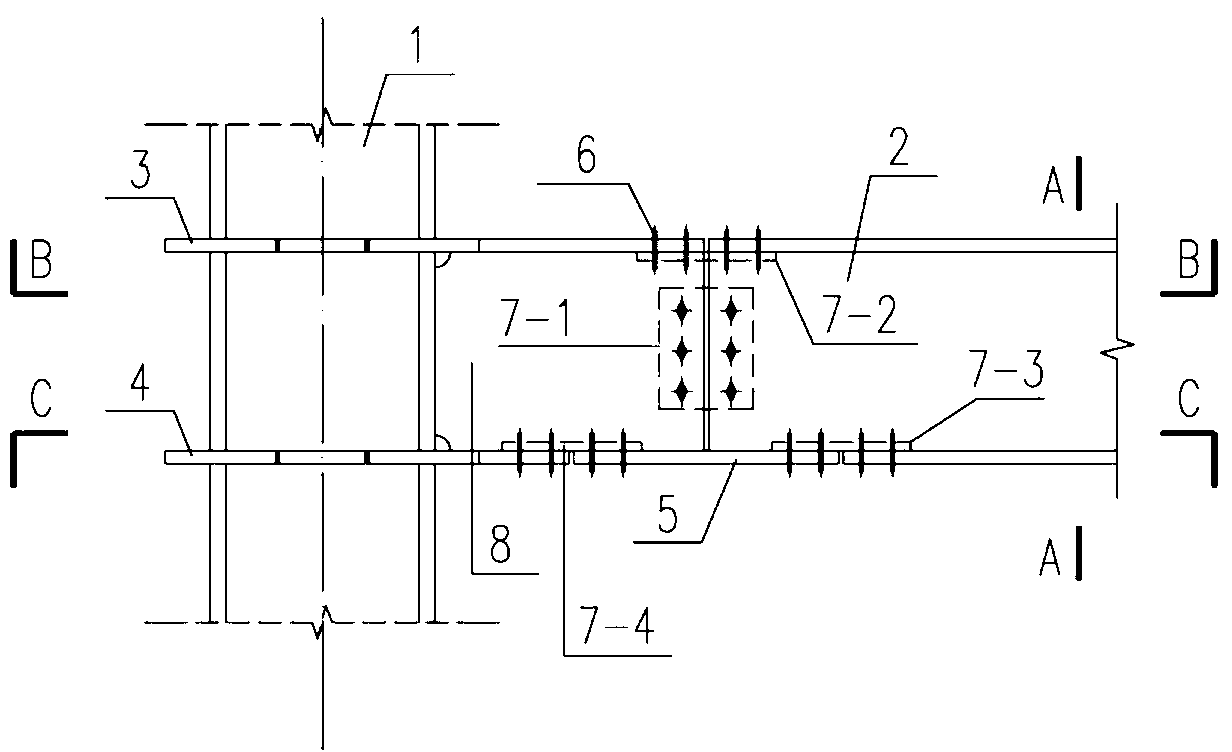

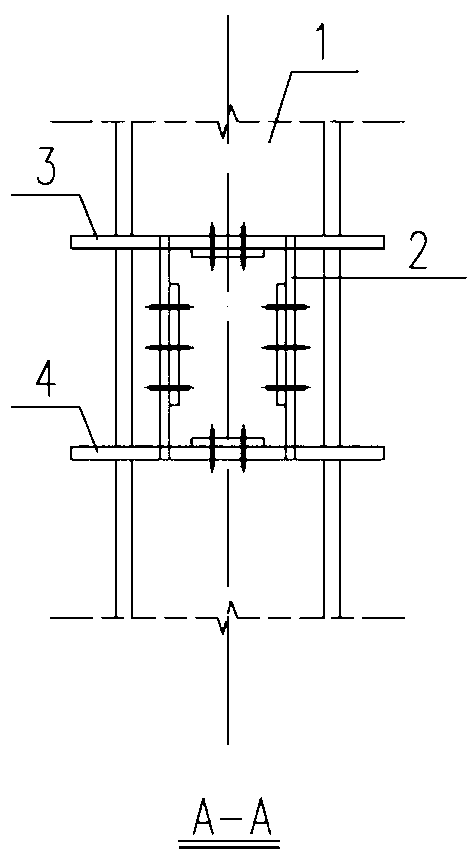

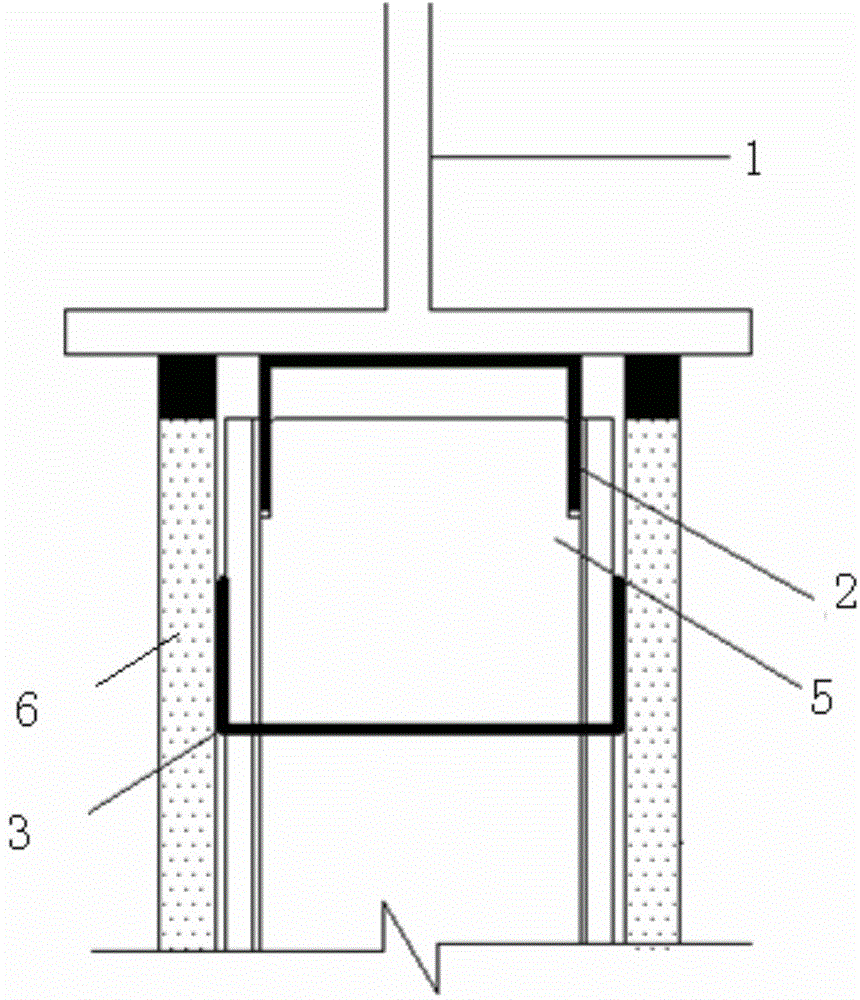

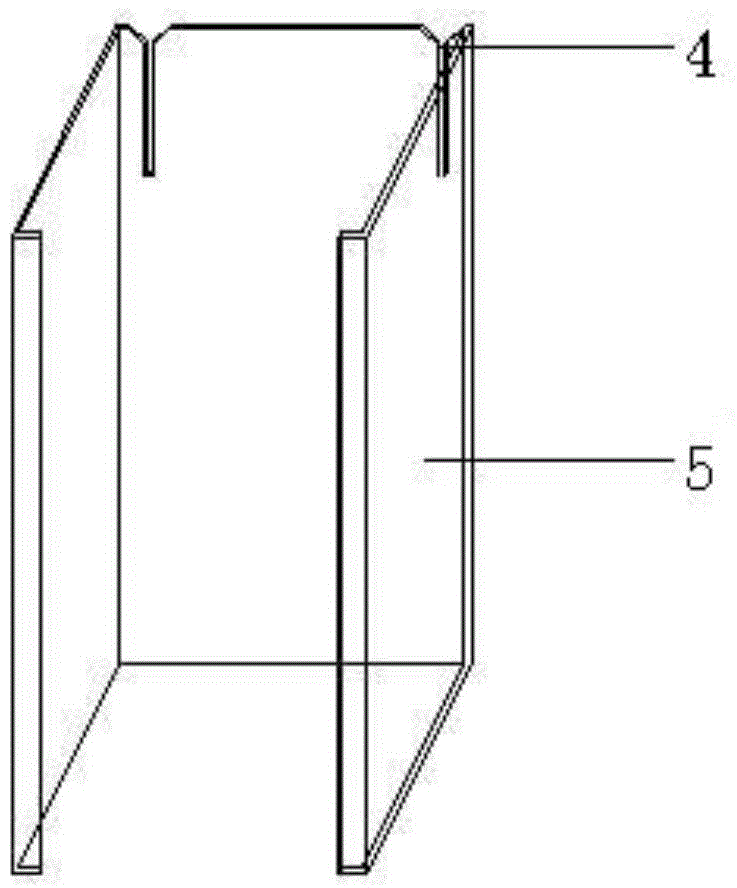

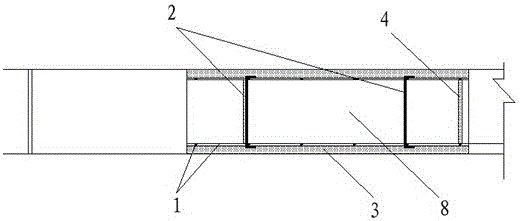

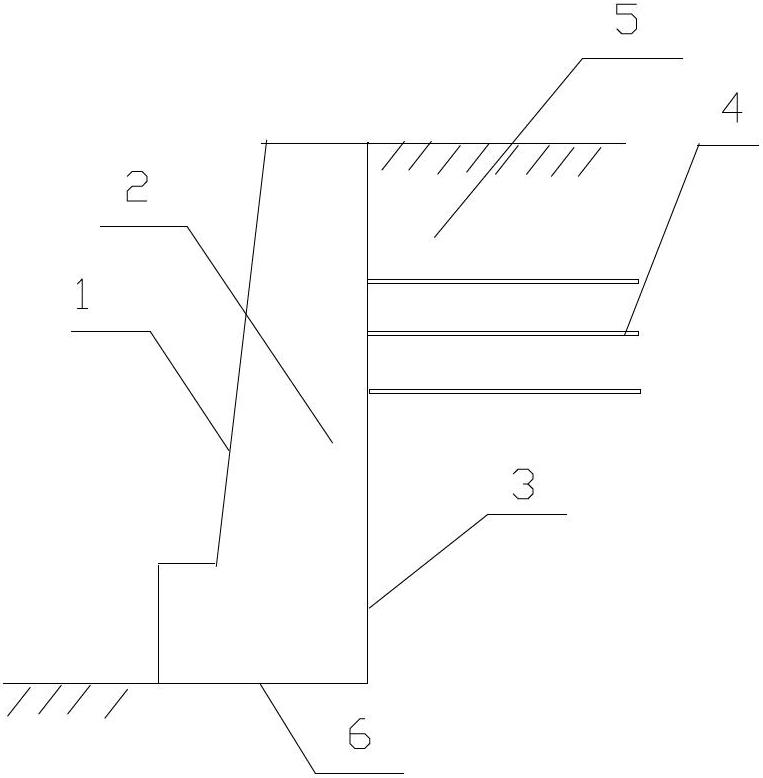

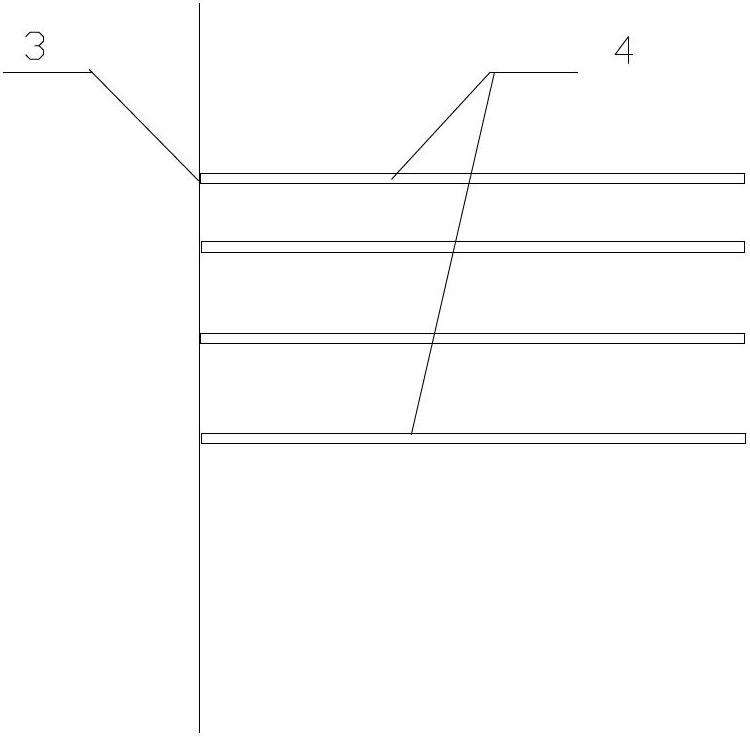

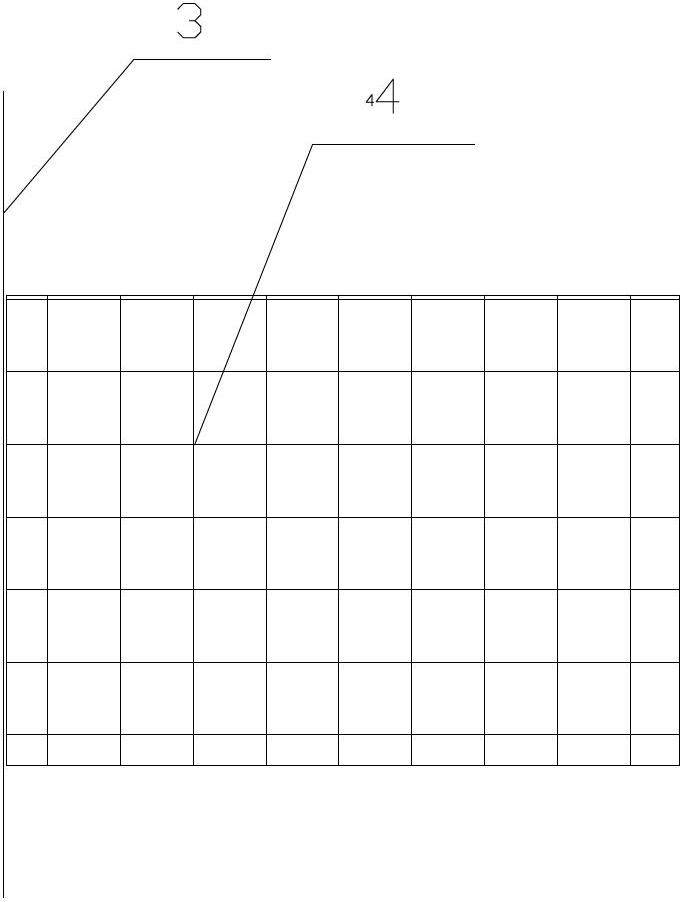

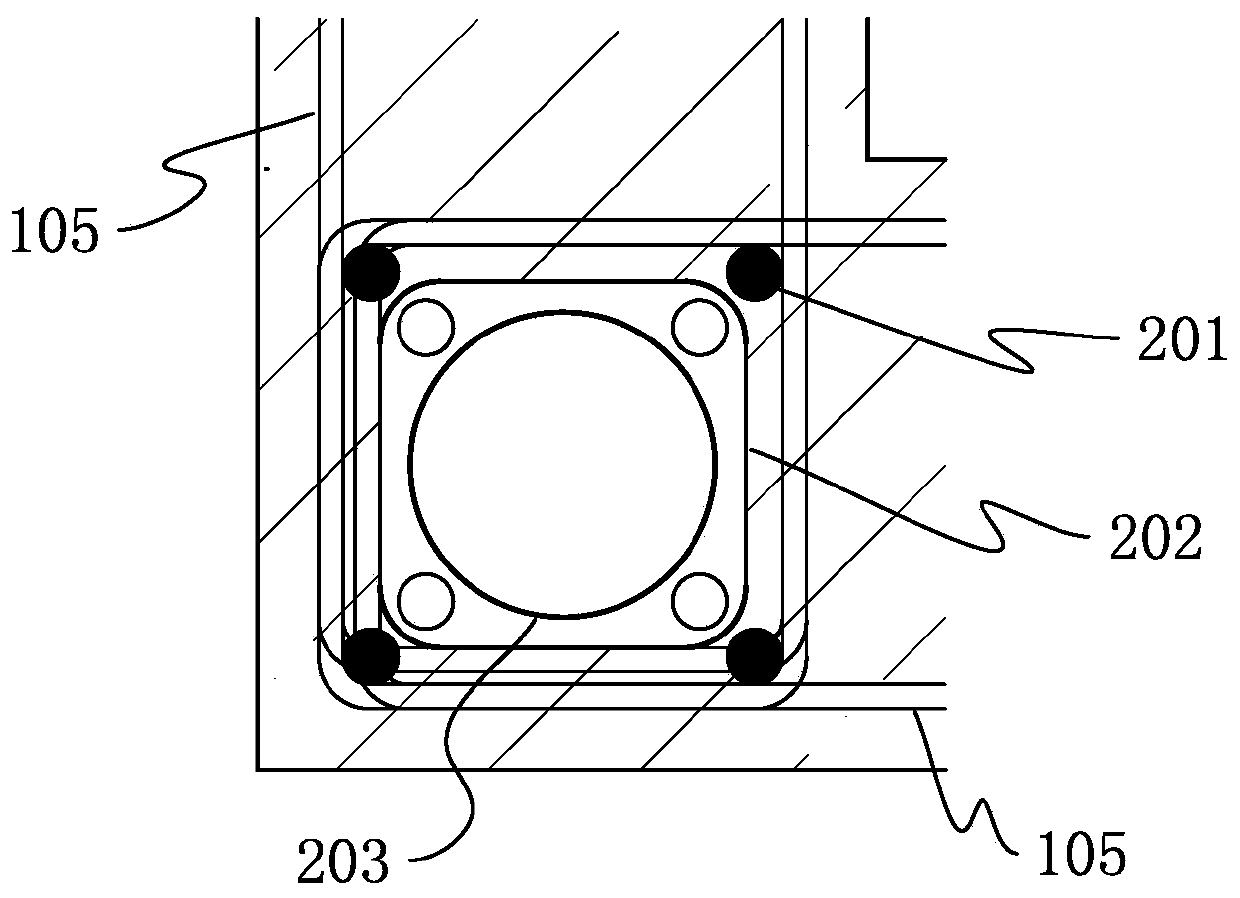

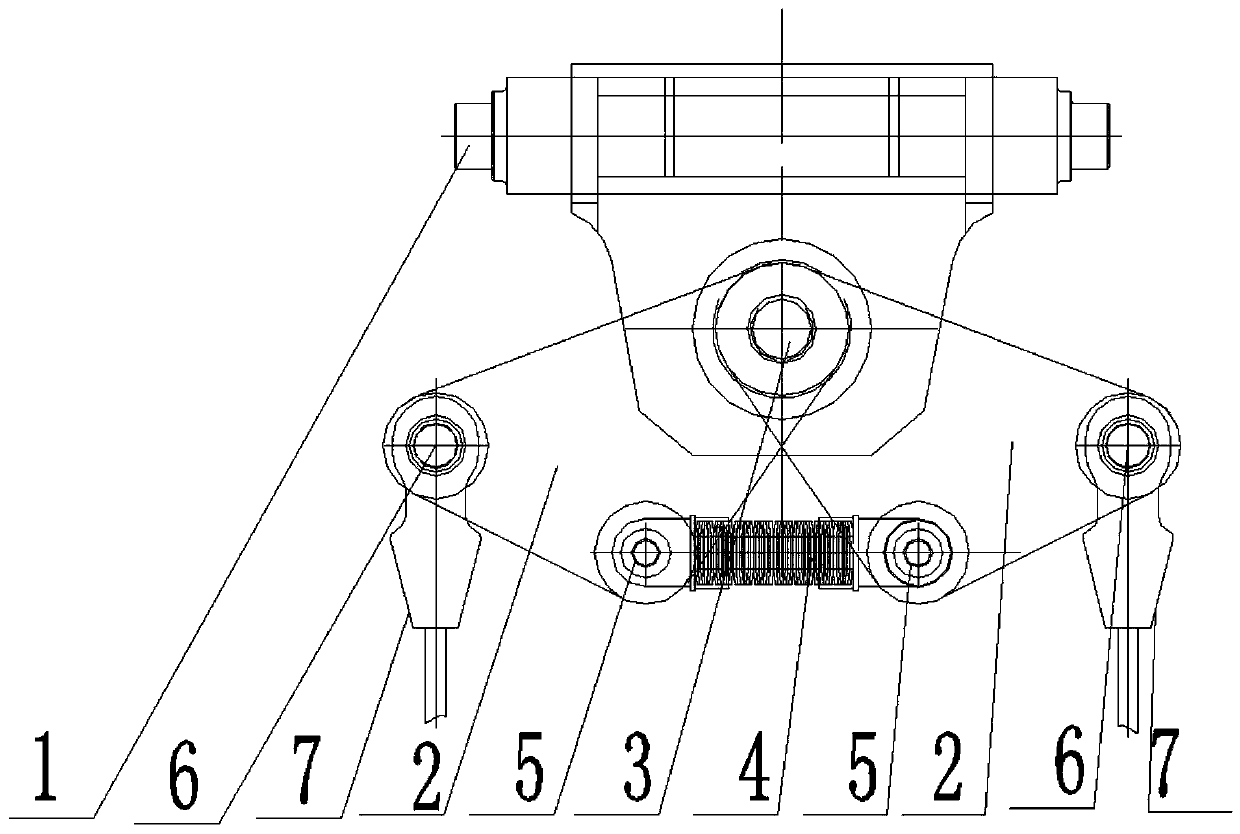

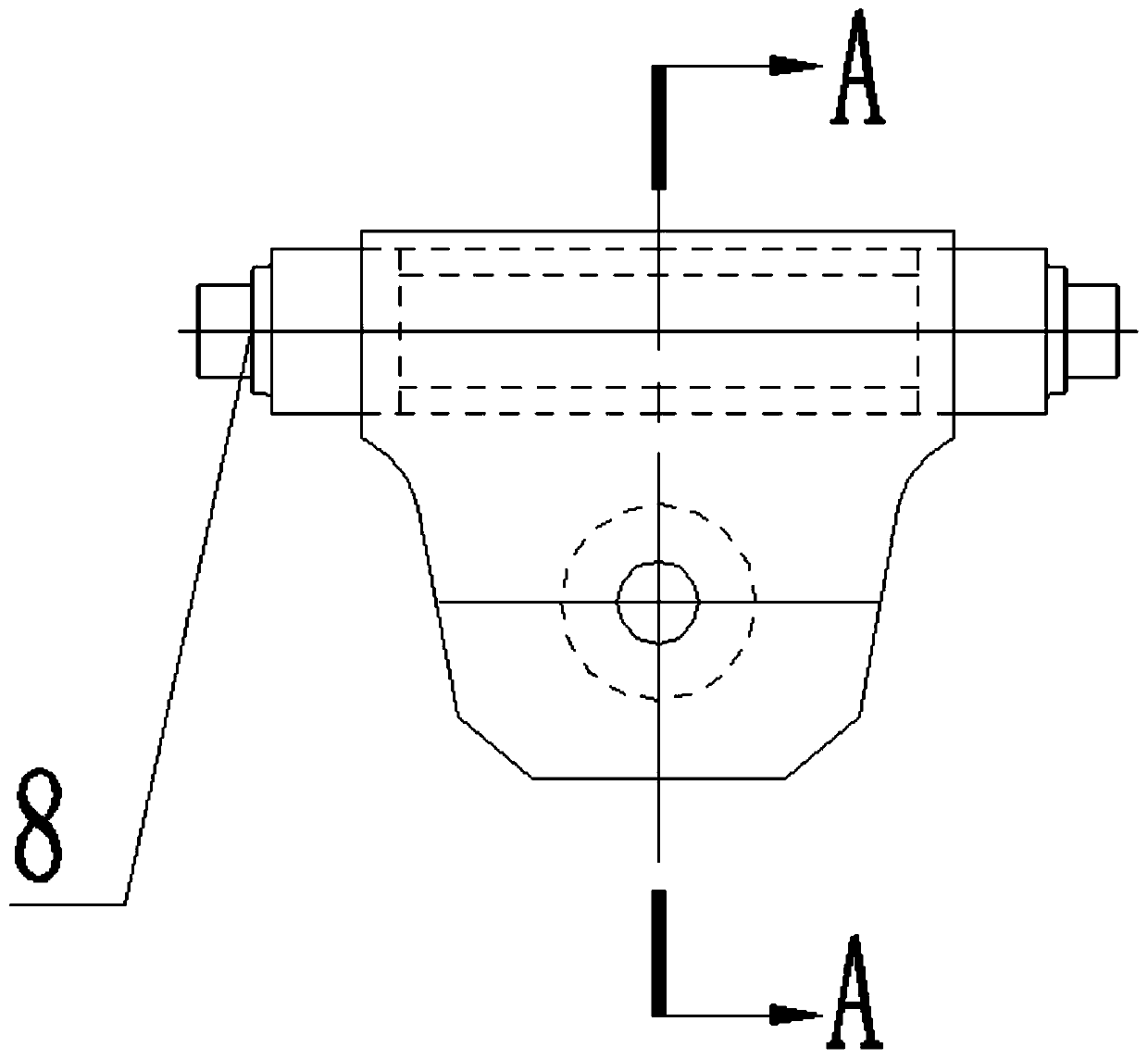

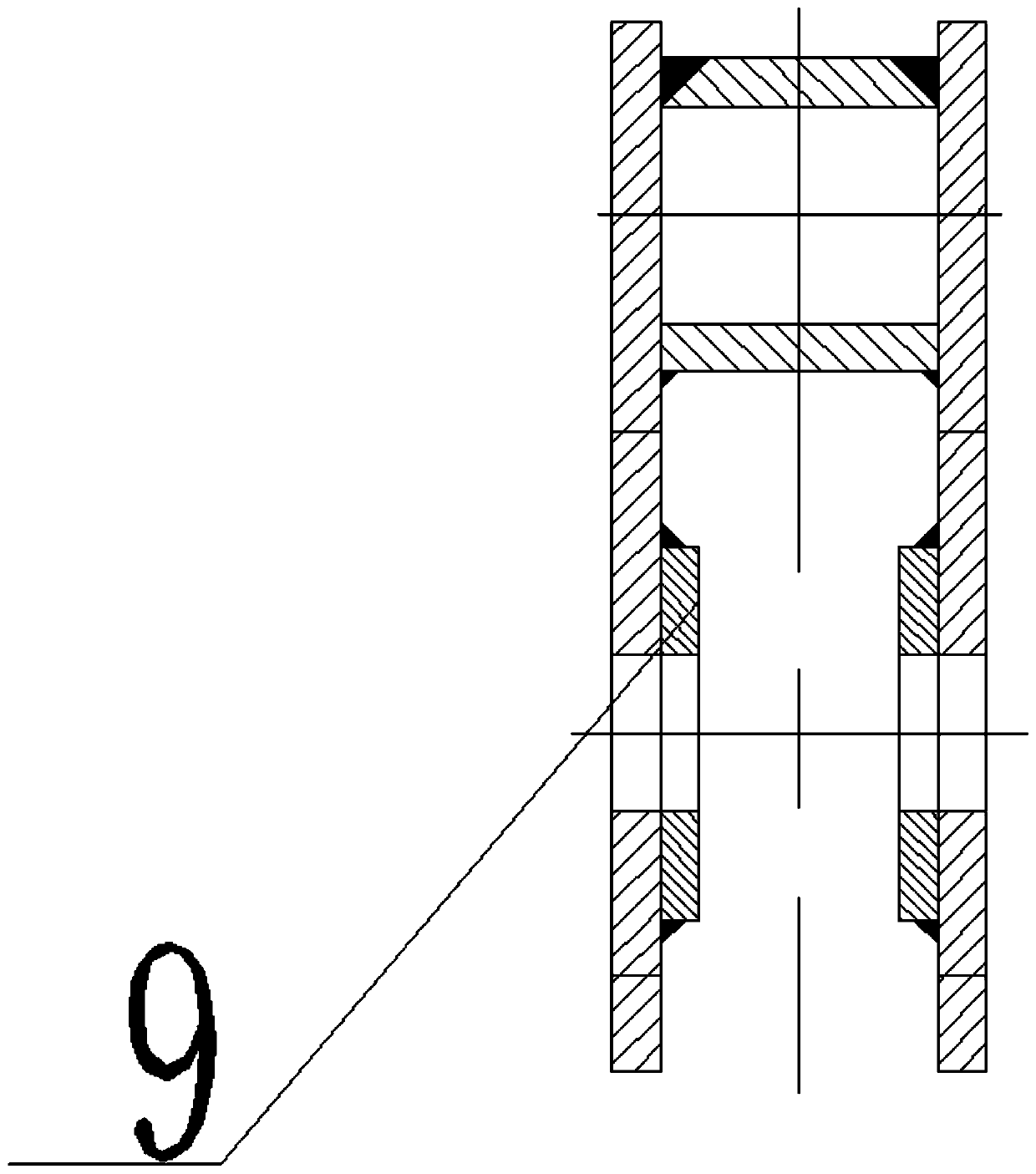

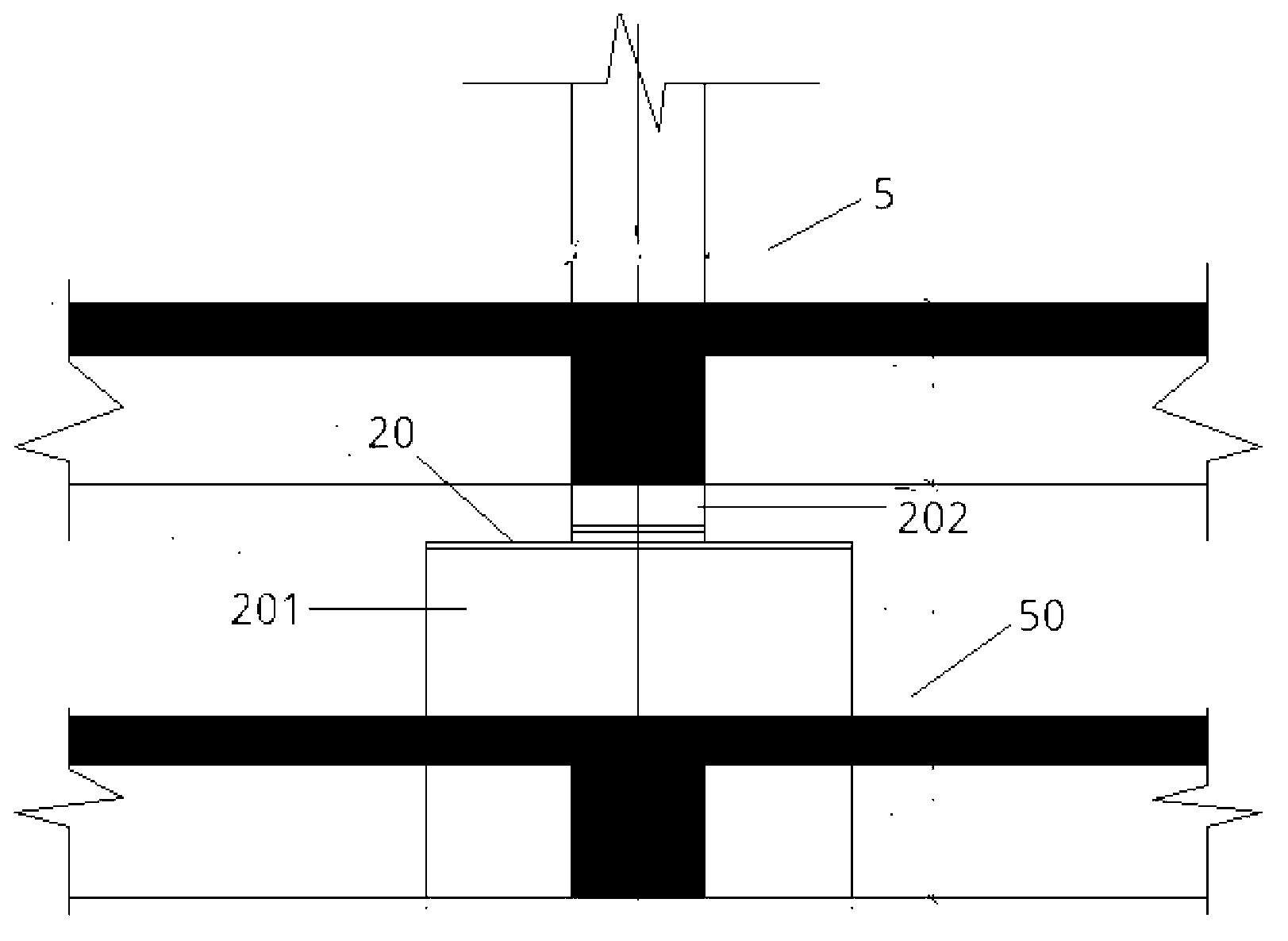

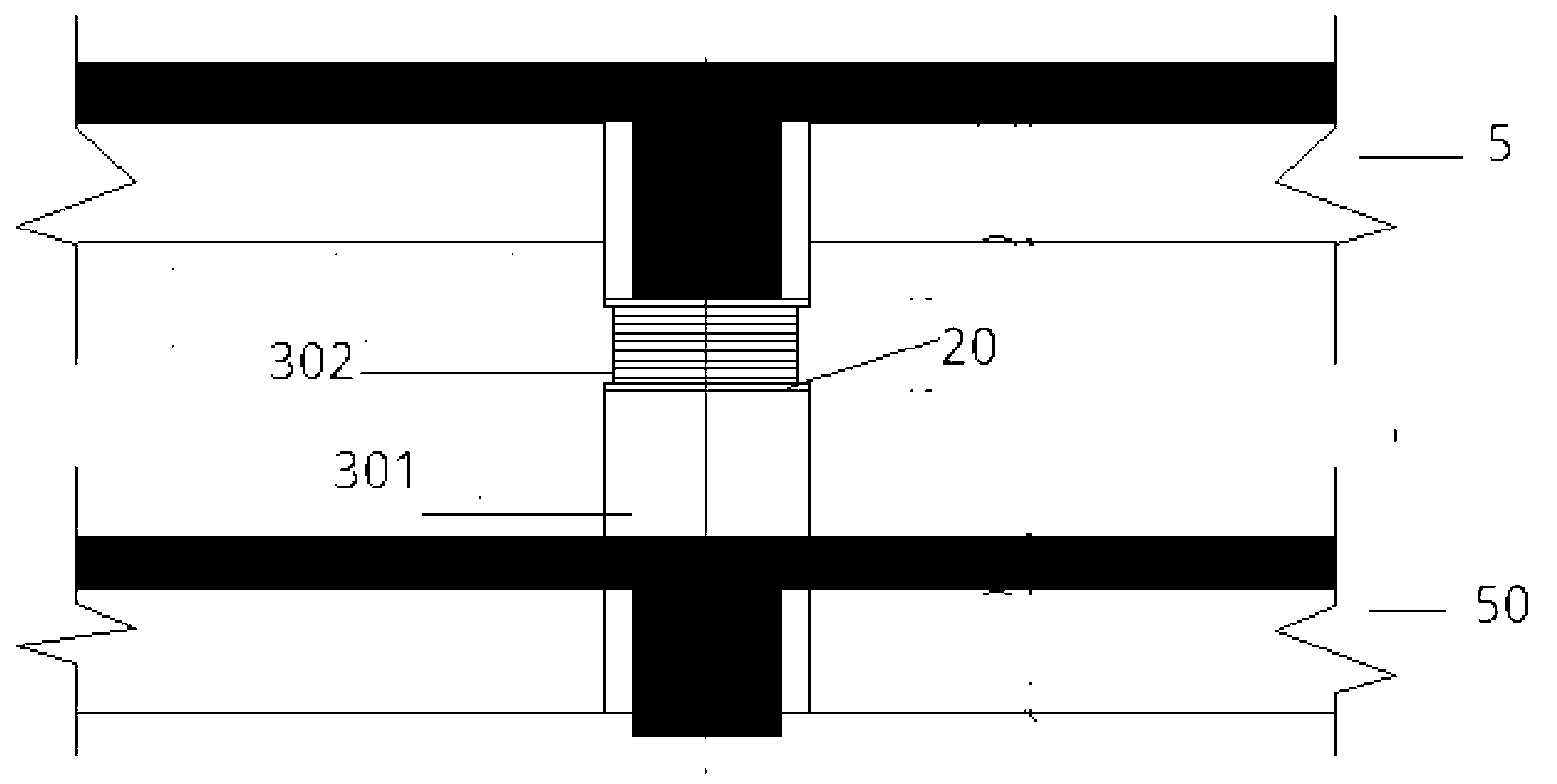

Concrete-filled rectangular steel tube column-box girder full-bolt connection node and construction method

ActiveCN102995756AAvoid weakeningMeet the seismic requirementsBuilding constructionsBox girderSteel tube

The invention belongs to the technical field of building structure engineering, and relates to a concrete-filled rectangular steel tube column-box girder full-bolt connection node. The concrete-filled rectangular steel tube column-box girder full-bolt connection node comprises a concrete-filled rectangular steel tube column, a box girder, an upper run-through clapboard, a lower run-through clapboard, a lower cover plate, a plurality of high-strength bolts, a plurality of connection plates and two shear plates. The upper run-through clapboard and the lower run-through clapboard penetrate through a concrete-filled rectangular steel tube column wall and are welded with the surrounding of the steel tube column wall of the concrete-filled rectangular steel tube column; the two webs of the box girder are welded together with the groove of the concrete-filled rectangular steel tube column via one shear plate respectively; the upper flange of the box girder is connected with the upper run-through clapboard by the high-strength bolts via the connection plates arranged in the box girder; the two webs of the box girder and the two shear plates are connected by the high-strength bolts via the connection plates arranged in the box girder respectively; and one end of the lower cover plate is connected with the lower flange of the box girder via the connection plate, and the other end of the lower cover plate is connected with the lower flange of the lower run-through clapboard via the connection plate. The invention provides a construction method for the node aforementioned simultaneously. The node and the construction method disclosed by the invention have the advantages of being convenient, fast, and easy to realize.

Owner:TIANJIN UNIV

Construction method for non-prestressed centrifugal high-strength concrete pile planted pile

InactiveCN105421445AIncrease resistanceImprove pullout resistanceBulkheads/pilesHigh strength concreteSocial benefits

The invention provides a non-prestressed centrifugal high-strength concrete pile planted pile structure and a construction method thereof. The method comprises the construction steps that a pile planting machine is in place, the hole guiding operation is conducted, a bearing stratum is determined, base expansion is carried out, pile end cement paste is injected, pile periphery cement paste is injected and drill stems are pulled out, pile connection of pre-drilled holes is conducted, and non-prestressed centrifugal high-strength concrete piles are planted into pile holes. The pile planting construction method has the effects that damage to pile bodies is effectively reduced; the ductility of the pile bodies is improved more than 30%; the pile body cracking phenomenon is avoided; the whole performances of the pipe piles are improved more than 20%; the technique is simple, the cost is low and the cost performance is high; the centrifugal concrete piles which are high in vertical bearing capacity and horizontal pile foundation bearing capacity and capable of meeting the anti-seismic requirement can penetrate through a hard middle layer and a thick solidified layer and can be widely applied to foundation construction of various soil textures; it is ensured that the requirement of housing industrialization for quality is met; the pile planting construction method has good social benefits and popularization value.

Owner:TIANJIN JIANCHENGJIYE GRP

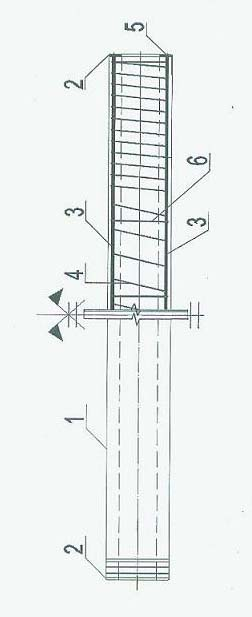

Connecting structure for light steel keel internal parting wall and steel beam

The invention relates to a connecting structure for a light steel keel internal parting wall and a steel beam. The connecting structure comprises a wall plate, a steel beam, horizontal keels and vertical keels, and is characterized in that a U-shaped steel clamp is welded under the steel beam corresponding to each vertical keel; slots matched with the two lateral edges of the U-shaped steel clamp are formed in the back at the upper end of each vertical keel; the two lateral edges of the U-shaped steel clamp are vertically inserted into the slots, so that the U-shaped steel clamp is in sliding connection with the vertical keel; the vertical keels are connected with each other through the horizontal keels located under the U-shaped steel clamp; the wall plate is fixed on the vertical keels. The connecting structure has the advantages that the vertical keels and the wall plate fixed on the vertical keels are in sliding connection with the steel beam, the connecting structure can adapt to the deformation of a structural main body and the construction design and the seismic requirement are met; the component processing and welding can be finished in a factory; on-site operation is reduced; the assembling is convenient and simple; the construction efficiency is high; the industrial production is easily realized; the connecting structure is fit for on-site assembling type light steel keel internal parting wall as well as a prefabricated type light steel keel internal parting wall and is wide in application scope.

Owner:SHENYANG JIANZHU UNIVERSITY

Masonry filler wall reinforcement and plastering constructional column and construction method thereof

ActiveCN105019579AGuaranteed integrationSave materialWallsBuilding material handlingFiberUpper joint

The invention discloses a masonry filler wall reinforcement and plastering constructional column and a construction method thereof, and belongs to the field of buildings. According to the technical scheme, the masonry filler wall reinforcement and plastering constructional column comprises a masonry body, steel mesh pieces are arranged on the two sides of the masonry body, masonry embedded bars penetrating through the masonry body are connected between the steel mesh pieces, the upper ends and the lower ends of the steel mesh pieces are fixedly connected with upper flat steel and lower flat steel respectively, upper joint bars are fixedly connected with the upper flat steel, lower joint bars are fixedly connected with the lower flat steel, and the inner sides of the steel mesh pieces are smeared with mortar. The masonry filler wall reinforcement and plastering constructional column has the advantages that the steel bar manufacturing and binding link, the constructional column concrete link and the framework erecting and disassembling link for a traditional constructional column are omitted, materials are saved, and labor and time limit for a project are saved; the masonry filler wall reinforcement and plastering constructional column is connected with a structural frame system, and therefore a building stress system is more reasonable; the steel mesh pieces, the flat steel, masonry blocks, review fiber anti-crack mortar and the like are finished products, so that the quality is better guaranteed, and the working period is only 10% that of a traditional method; working procedures are simple, operation is easy and convenient, and universality is high.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

Reinforced gravity type retaining wall antiknock construction

InactiveCN102691308AImprove anti-overturn performanceIncreased anti-overturning (seismic) capabilityArtificial islandsUnderwater structuresWhole bodyRetaining wall

The invention discloses a reinforced gravity type retaining wall antiknock construction, comprising a wall surface, a wall body, a wall back and a substrate. The construction of the invention has the characteristics that the wall back is equipped with a connecting structure and a bracing apparatus, one end of the bracing apparatus is connected with the wall back through the connecting structure, other parts stretch into a supported soil body and are connected with the supported soil body as a whole body. By adopting the gravity type retaining wall antiknock construction of the invention, after the bracing apparatus stretches into the wall, the construction work is allowed to work together with the filling soil after the wall, which enhances the anti-overturning (antiknock) capability of the gravity type retaining wall without increasing a retaining wall cross section,, substantially reduces the cost of the gravity type retaining wall, and provides economy and practicability.

Owner:SOUTHWEST JIAOTONG UNIV

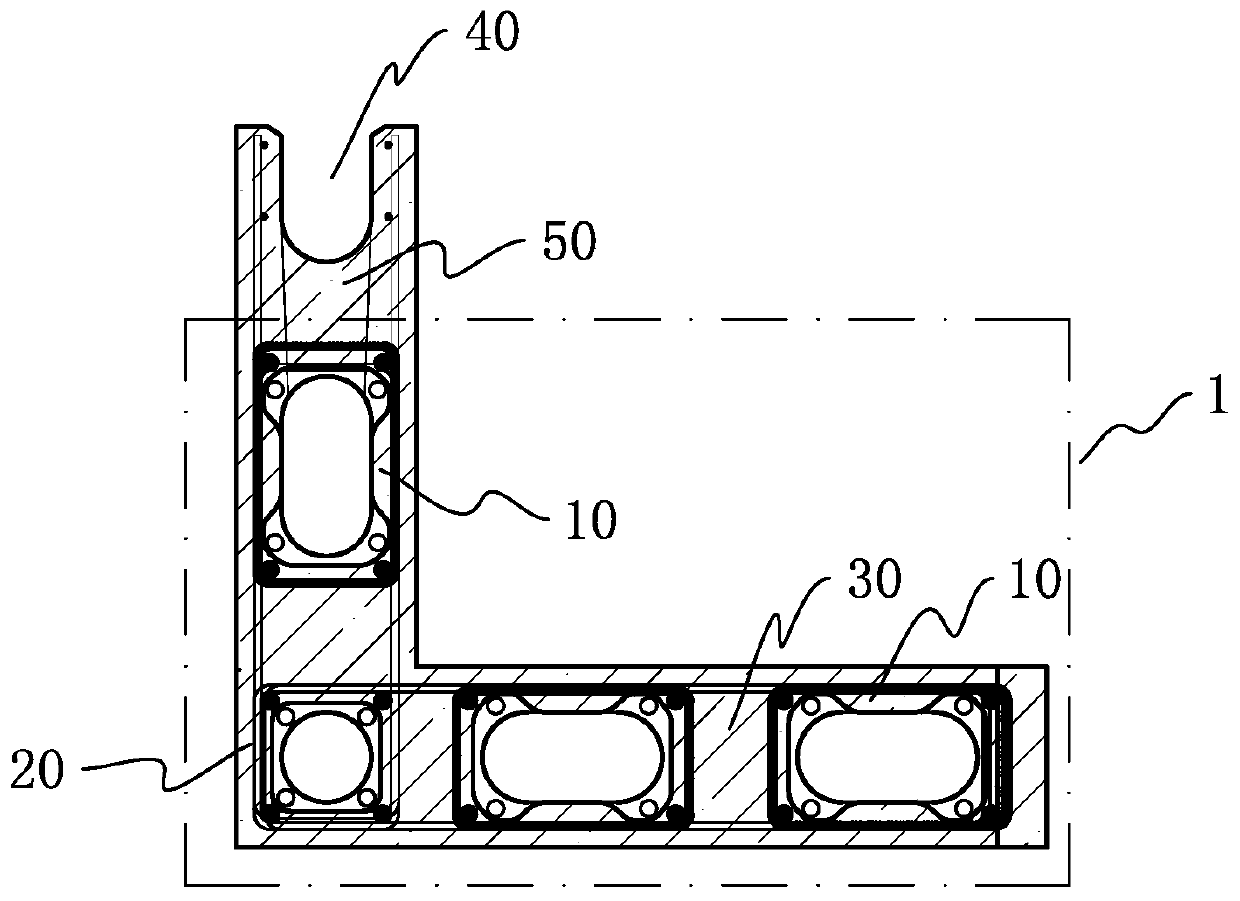

Non-prestressed centrifugal concrete pile

InactiveCN102071701AImprove horizontal bearing capacityMeet the seismic requirementsBuilding reinforcementsBulkheads/pilesPre stressArchitectural engineering

The invention discloses a non-prestressed centrifugal concrete pile, which is characterized by comprising a centrifugal concrete pile body, a non-prestressed main bar, a spiral stirrup and two end plates, wherein the non-prestressed main bar is longitudinally distributed and is welded or bound on the spiral stirrup; and the two ends of the non-prestressed main bar are welded respectively or anchored on the two end plates through anchor holes. Based on the conventional non-prestressed centrifugal concrete pile, a prestressed main bar which is positioned on a reinforcement framework and can longitudinally pass through the entire framework is replaced by the non-prestressed main bar, a centrifugal molding process is used in a production process and a part of residual water is brought out centrifugally, so that concrete is more compact. The advantages of a centrifugal pile and a solid square pile are brought into full play, and the centrifugal concrete pile which has high vertical bearing capacity and high horizontal bearing capacity of a pile foundation and can meet a seismic resistance requirement is provided. Simultaneously, a prestress application process is eliminated, so that the non-prestressed centrifugal concrete pile is produced by a production method which is simpler than the conventional production method of a prestressed centrifugal concrete pile, and production efficiency is higher.

Owner:宿迁市固丰管桩有限公司

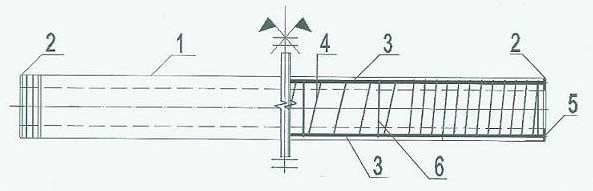

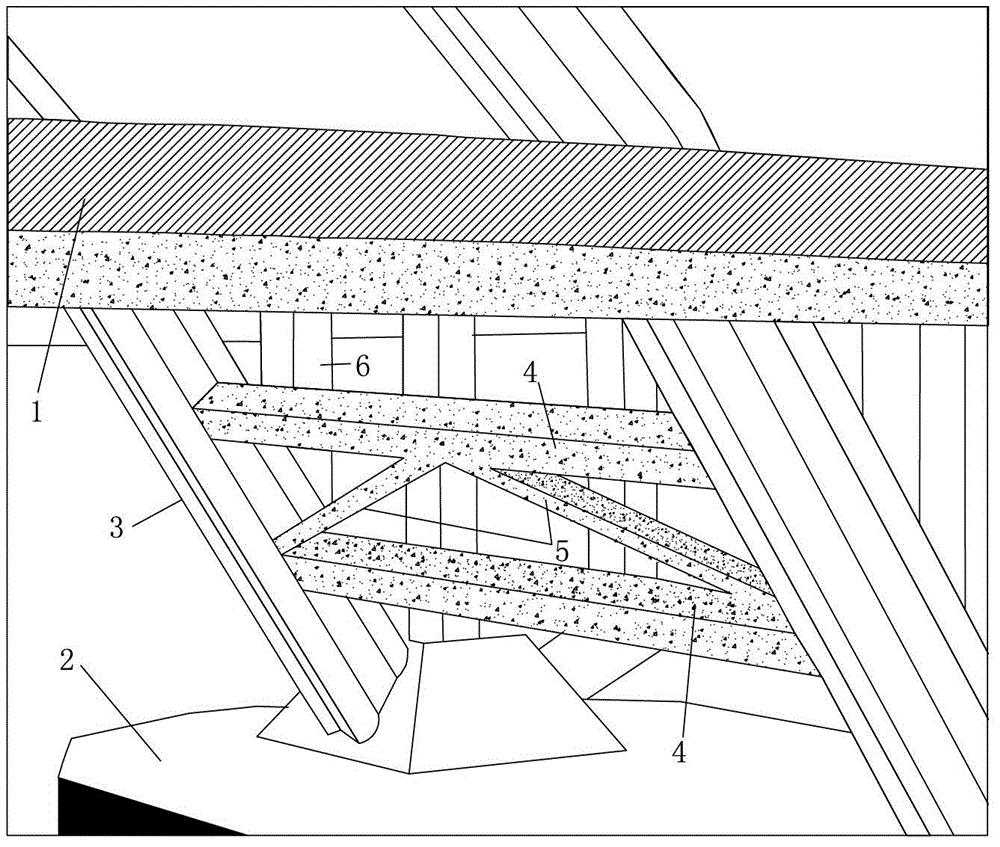

L-shaped and T-shaped concrete shear wall structure combined type prefabricated edge component

PendingCN109736478ASatisfy the requirement of steel lapMeet the seismic requirementsWallsCeramic shaping plantsRebarShear wall

The invention discloses an L-shaped and T-shaped concrete shear wall structure combined type prefabricated edge component which comprises an edge component area with an L-shaped or T-shaped cross section, and the edge component area is composed of at least two extending edge component units and a corner edge component unit. Through holes extending in the height direction are formed in the extending edge component units and the corner edge component units. The section shapes and the sectional areas of the upper parts and the lower parts of the through holes are not equal. Edge member steel barsextending in the height direction are arranged at four corners of each through hole. The edge component steel bars on the periphery of each through hole are connected together through edge componentstirrups. All the edge component stirrups of all the extending edge component units on any side of the edge component area and all the edge component stirrups of the corner edge component units are connected together through unit connecting ribs.

Owner:北京博创绿色建筑科技有限公司

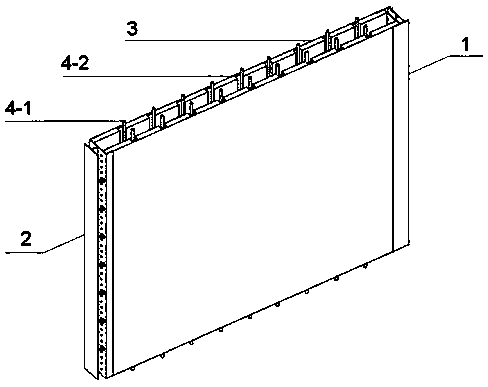

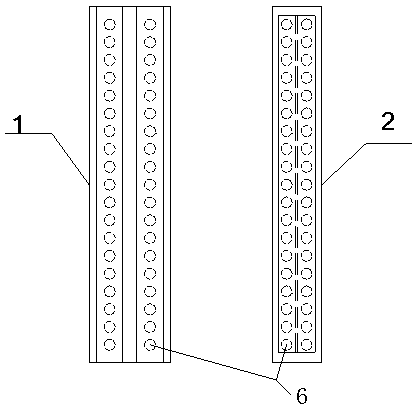

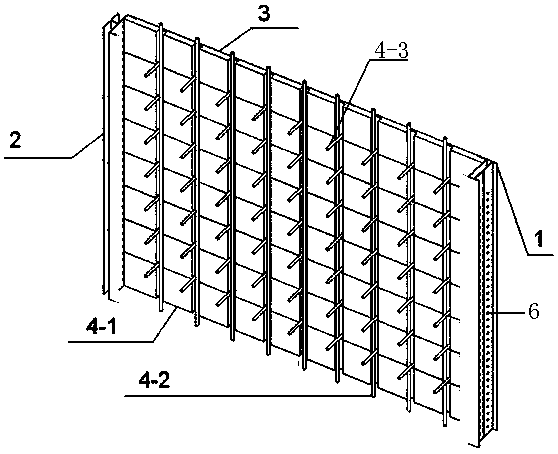

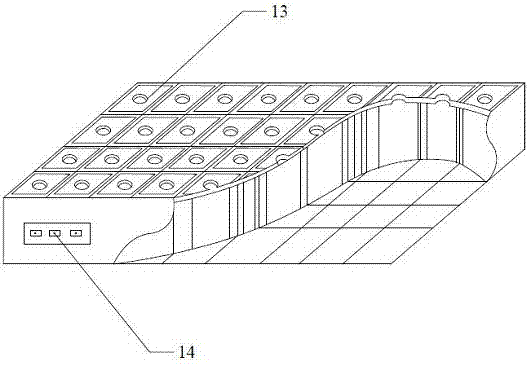

Prefabricated steel structural superposed shear wall and construction method thereof

The invention provides a prefabricated steel structural superposed shear wall and a construction method thereof. According to a prefabricated steel structural superposed shear wall plate, each shear wall comprises two double-faced heat preservation light wall plates; a deep longitudinal groove and a plurality of rows of transverse holes penetrating through the groove are formed in each wall plate;and self-locking components formed by welding a plurality of steel plates are arranged on the left and the right of a wall body, and the wall body can select different chaining lock catches and tailend lock catches according to different joints. The upper, lower, left and right portions of the wall body are all of symmetrical structures, a plurality of rows of transverse penetrating reinforcingsteel bars are arranged in the wall body, longitudinal reinforcing steel bars are connected with the transverse reinforcing steel bars in a lap joint or welded mode, and short bars are welded to the joint points of the transverse reinforcing steel bars and the longitudinal reinforcing steel bars. The construction method of the prefabricated steel structural superposed shear wall comprises the following steps that in-situ wire paying off is conducted, and temporary fixing frames are mounted; the shear wall is assembled and spliced in place, and connected and fixed to the temporary fixing frames; a prefabricated upper layer floor slab is placed in place; hidden beam steel plates and various additional reinforcing steel bars are arranged, and pipelines are arranged; high-fluidity free of vibration concrete is poured; and mounting construction of a next layer is entered in.

Owner:SHENYANG JIANZHU UNIVERSITY

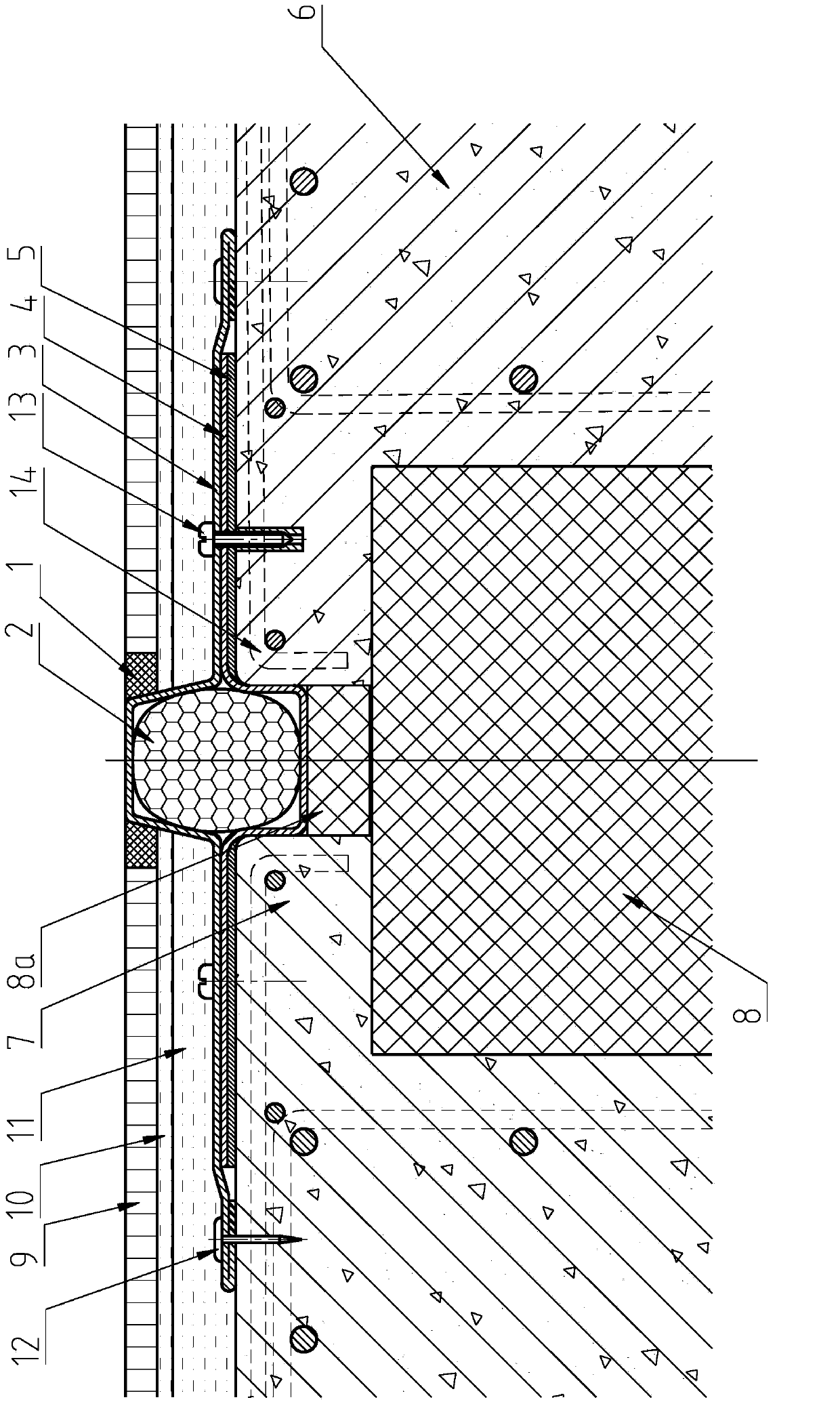

Quakeproof bed joint water-proof structure for outside hall of high-rise building and construction method

ActiveCN103628574AImprove waterproof performanceEasy to walkBuilding insulationsStructure of the EarthEngineering

The invention discloses a quakeproof bed joint water-proof structure for an outside hall of a high-rise building and a construction method. The quakeproof bed joint water-proof structure for the outside hall of the high-rise building comprises two sections of edge beams, water-proof belts and protective steel plates, a quakeproof bed joint is reserved between the edge beams, the upper ends of the edge beams extend in the opposite directions to form weak cornices, and a narrow seam smaller than 50mm is formed between the weak cornices. The water-proof belts are arranged above the narrow seam, and the bottom faces of the water-proof belts are adhered to the top faces of the edge beams. The protective steel plates are arranged on the water-proof belts, and the protective steel plates are fixed to the edge beams through shooting nails and / or expansion bolts. The weak cornices are adopted in the quakeproof bed joint water-proof structure, so that the narrow seam is formed in the upper end of the quakeproof bed joint, water is conveniently resisted, walking is convenient, and meanwhile the requirement for daily normal temperature deformation can be met. Encountering a strong shock, the quakeproof bed joint water-proof structure is easily damaged, but people cannot be hurt by dropped objects, the seismic requirement is met, and post-earthquake repair is also facilitated.

Owner:深圳市清华苑建筑与规划设计研究有限公司

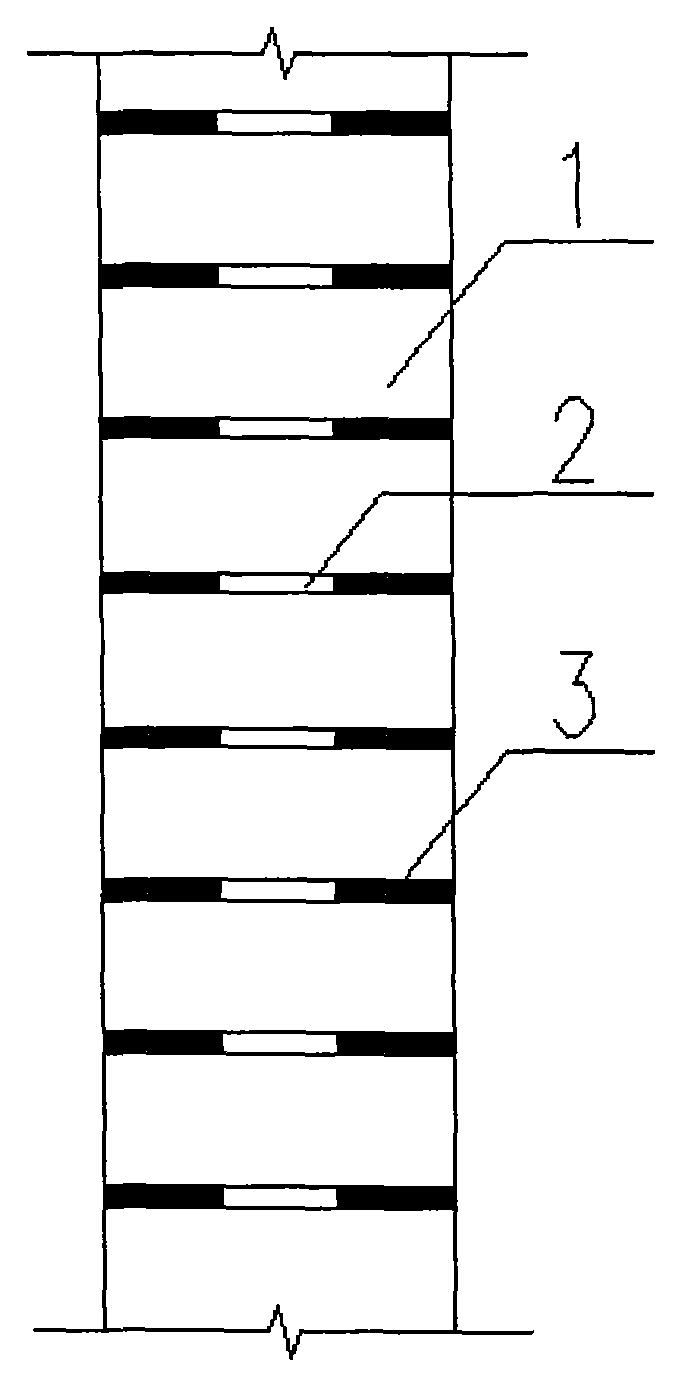

Method of replacing mortar in mortar joint for masonry structure reinforcement

ActiveCN103924792ASimple construction operationReduce construction costsWallsBuilding repairsMortar jointLow graded

The invention relates to a method of replacing mortar in a mortar joint for masonry structure reinforcement and belongs to the technical field of seismic hardening of houses. The method relates to an original masonry structure wall, the original low-grade mortar in the original mortar joint and newly backfilled high-grade mortar. The method is a method for replacing mortar in pass-length type mortar joints in the two sides of the wall and comprises the steps of tunneling through the two ends, in the transverse thickness direction of the wall, of the original mortar joint horizontally in the longitudinal direction of the original masonry structure wall, removing the original low-grade mortar, backfilling the high-grade mortar to improve the compression resistance and shearing resistance of a masonry structure, and reserving the middle part, in the transverse thickness direction of the wall, of the original low-grade mortar. According to the method, the compression resistance and shearing resistance of the masonry structure are improved by replacing the low-grade mortar in the wall with the high-grade mortar, the safety of the houses is guaranteed, construction cost is low, and original space is not occupied after wall reinforcement. The method can be widely applied to house reinforcement.

Owner:中智建设集团有限公司

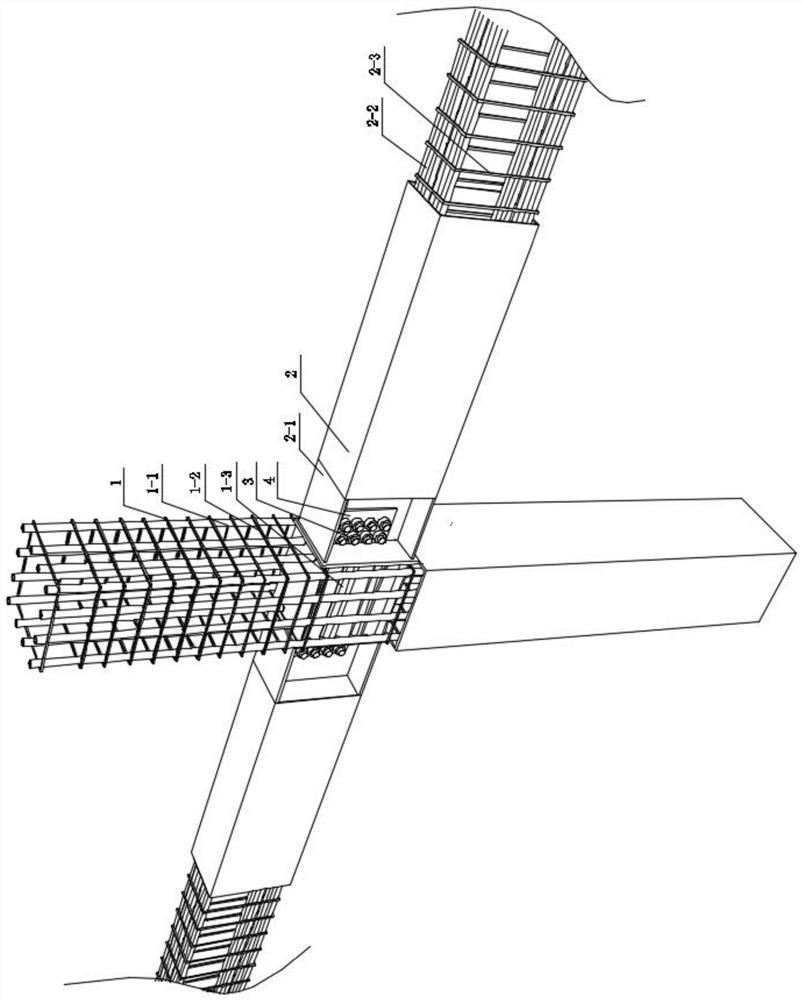

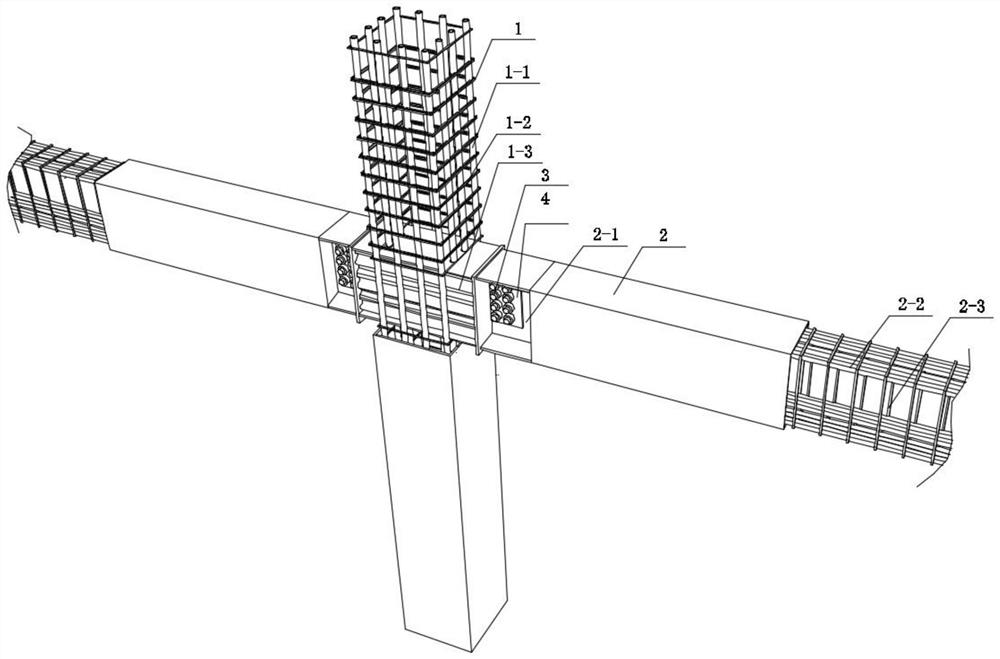

Assembly type prefabricated beam and column connecting joint and construction method

InactiveCN111997193AImprove integritySimple structureBuilding constructionsArchitectural engineeringStirrup

The invention relates to an assembly type prefabricated beam and column connecting joint. The joint comprises a prefabricated column and prefabricated beams; the prefabricated column comprises in-column longitudinal bars, in-column stirrups and in-column embedded parts; the prefabricated beams comprise in-beam longitudinal bars, in-beam stirrups and embedded H-shaped steel; and during on-site construction, beam and column connecting steel sheets are welded to the end faces of the in-column embedded parts of the prefabricated column, and the prefabricated beams are externally connected with theend faces of the in-column embedded parts of the prefabricated column through the end of the embedded H-shaped steel and are in bolted connection with the beam and column connecting steel sheets. Theinvention further provides a construction method of the assembly type prefabricated beam and column connecting joint. According to the joint and the method, the construction is easy, the stress performance of the connecting position is excellent, the rigidity is high, and the technical problem of difficult connection of a beam and column joint in an assembly type concrete frame structure is solved.

Owner:HEBEI UNIV OF TECH

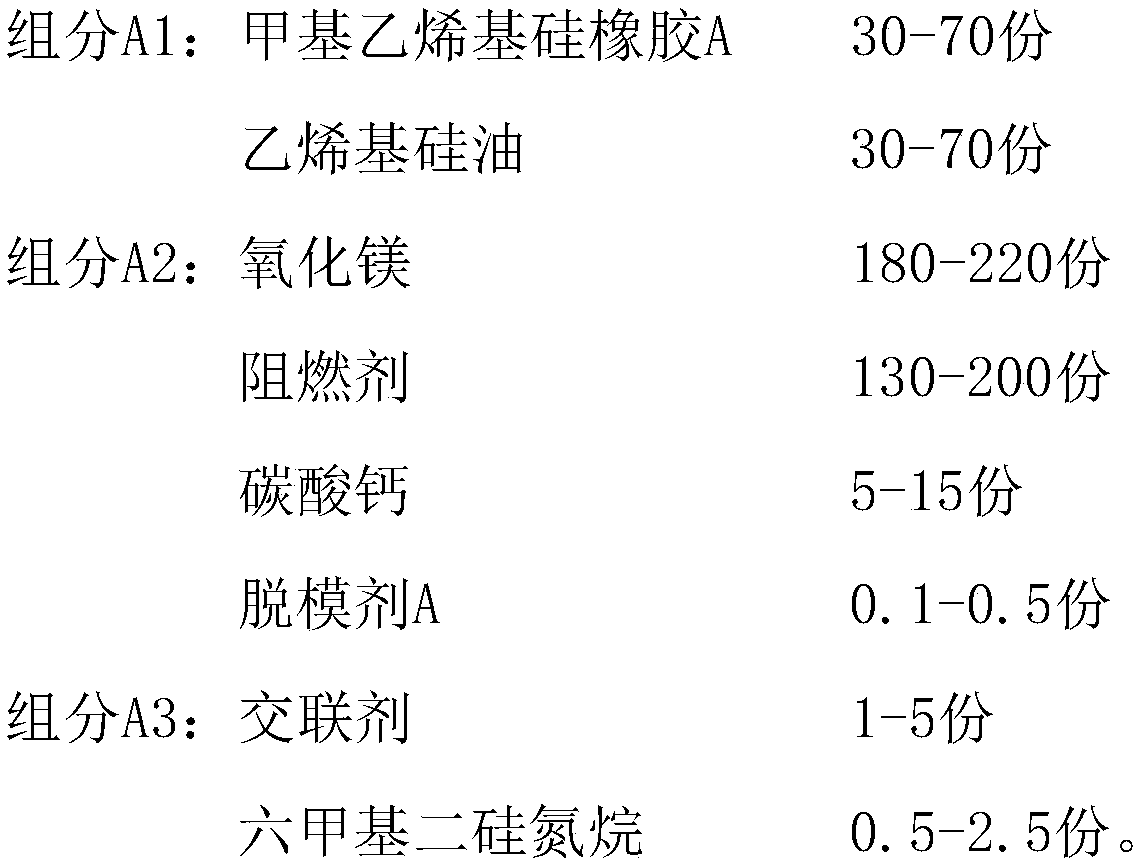

Flexible fire-resistant branch cable with anti-vibration and anti-spraying performances

InactiveCN108022673AImprove stabilityImprove seismic performanceInsulated cablesInsulated conductorsEngineeringOxygen barrier

The invention relates to the technical field of cables, in particular to a flexible fire-resistant branch cable with anti-vibration and anti-spraying performances. The flexible fire-resistant branch cable comprises a main cable body and a branch cable connected to the middle of the main cable body. A branch connection body sleeves the outer walls of the main cable body and the branch cable and consists of an inner layer, a middle layer, and an outer layer that are connected successively from inside to outside; the inner layer is a ceramic oxygen-barrier mud layer, the middle layer is a stainless steel armor layer, and the outer layer is a ceramic silicone rubber layer; and the space among the main cable body, the branch cable, and the middle layer is filled with ceramic oxygen-barrier mud.The flexible fire-resistant branch cable has the good incrustation effect to avoid the melted dripping effect; the cable having the excellent high-temperature resistant, fire-resistant, and seismic-resistant performances is not easy to crack; and because of the good anti-spraying performance, the service life of the cable is prolonged.

Owner:东莞市朗晟材料科技有限公司

Special-shaped combined block and method for constructing wall body by adopting same

InactiveCN102650151ASolving Cold Bridge ProblemsReduce usageConstruction materialWallsComputer scienceCasting

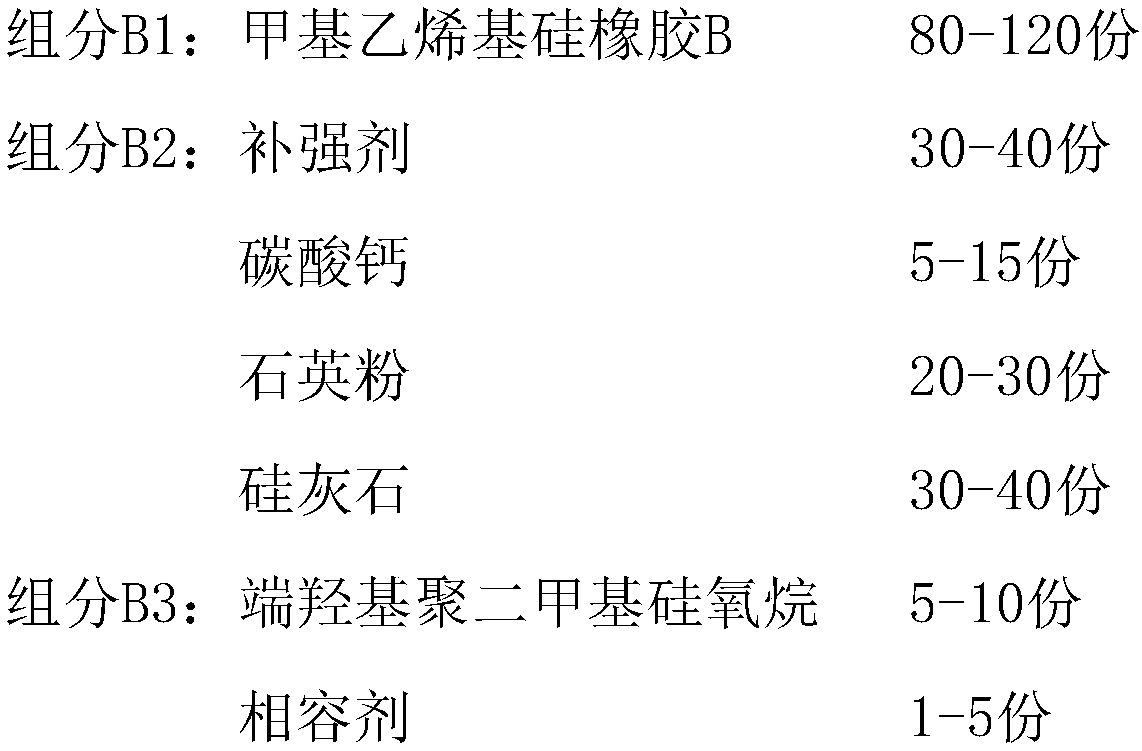

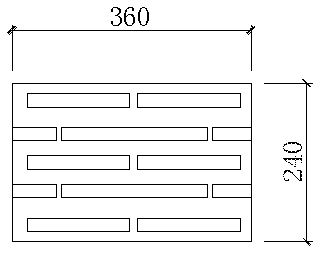

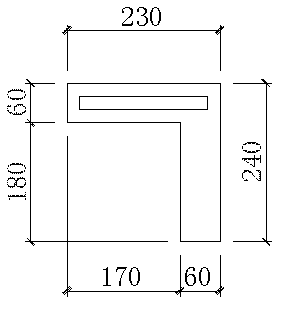

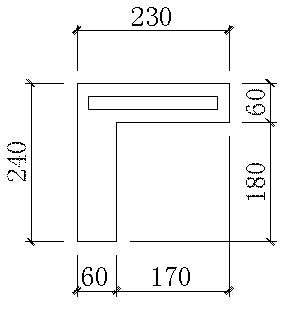

The invention discloses a special-shaped combined block and a method for constructing a wall body by adopting the same. The special-shaped combined block comprises a No. 0 block with a rectangle cross section and 6 blocks with L-shaped cross sections, wherein the 6 blocks are numbered from 1 to 6; the No. 0 block is a rectangular block with the length, width and the thickness of 360 mm, 240 mm and 60 mm; the No. 1 and the No. 2 blocks are L-shaped blocks with the length, width, thickness and the arm width of 230 mm, 240 mm, 60 mm and 60 mm; the No. 3 and the No. 4 blocks are L-shaped blocks with the length, width, thickness, narrow arm width and the wide arm width of 350 mm, 240 mm, 60 mm, 60 mm and 180 mm; and the No. 5 and the No. 6 blocks are L-shaped blocks with the length, width, thickness and the arm width of 240 mm, 300 mm, 60 mm and 60 mm. With the adoption of the special-shaped combined block and the method, the cold bridge problem of a ring beam and a constructional column in a self heat-preservation masonry structure is effectively solved, and the number of templates used in the casting of concrete at the ring beam and the constructional column is greatly reduced, and the construction is also facilitated.

Owner:SOUTHEAST UNIV +1

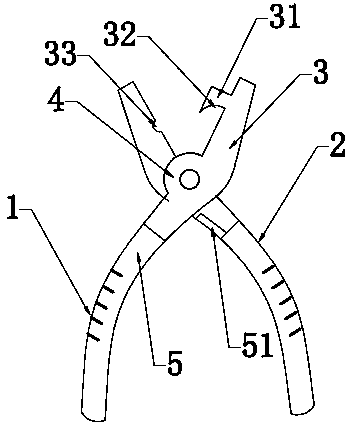

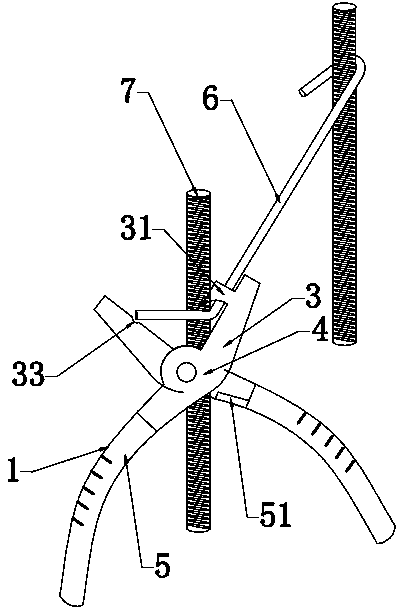

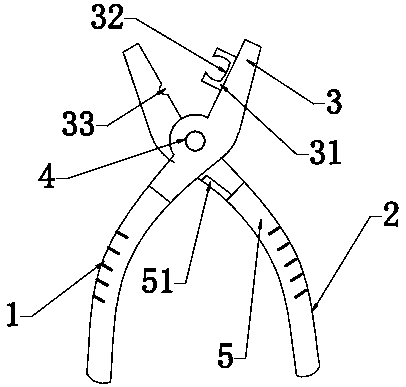

Pliers facilitating bending of rebars

The invention discloses a pliers facilitating bending of rebars. The pliers comprise a main plier part and a plier part arranged in mutual intersection and rotatably fixed together, and each of the main plier part and the auxiliary plier part is composed of a plier head, a connection portion and a handle. The pliers are characterized in that the inner side of the plier head of the main plier part is provided with a fastening portion used for holding a longitudinal bar, the upper end of the handle of the auxiliary plier part is provided with a limiter protrusion that is higher than the upper end of the handle of the main plier part and the connection portion, a gap is formed between the end of the limiter protrusion close to the connection portion and the connection portion when the corresponding handle is not moved, and the limiter protrusion abuts to the adjacent handle and stops rotate after the handle is turned by a certain angle. The pliers obtained by the invention have the advantages of simple structure, bending effectiveness and high bending precision.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Novel ribbed arch bridge transverse earthquake resistant structure system with buckling restrained brace

InactiveCN103334373AIncrease stiffnessExcellent hysteresis energy consumption performanceBridge structural detailsArch-type bridgeEarthquake resistanceBuckling-restrained brace

The invention discloses a novel ribbed arch bridge transverse earthquake resistant structure system with buckling restrained brace, which comprises a main beam, a pier, arch ribs used for connecting the main beam and the pier and a conventional cross arm and buckling restrained brace used for connecting the adjacent arch ribs, wherein the main beam is fixed above the pier through the arch ribs; the main beam is connected with the arch ribs through a hanger rod, no fewer than 2 arch ribs are transversely distributed corresponding to the bridge surface of the main beam; the buckling restrained brace is fixed between every two adjacent arch ribs, and is transversely fixed corresponding to the bridge surface; the system adopting the technical scheme has the advantages that the characteristics of high strength, large stiffness and excellent hysteretic energy performance are utilized through the transverse earthquake resistant structure novel system for the ribbed arch bridge with the buckling restrained brace, the problem that a conventional system is easy to buckle and is unstable, so that strength is wasted is solved, and therefore the earthquake resistance specification requirement is satisfied.

Owner:DALIAN MARITIME UNIVERSITY

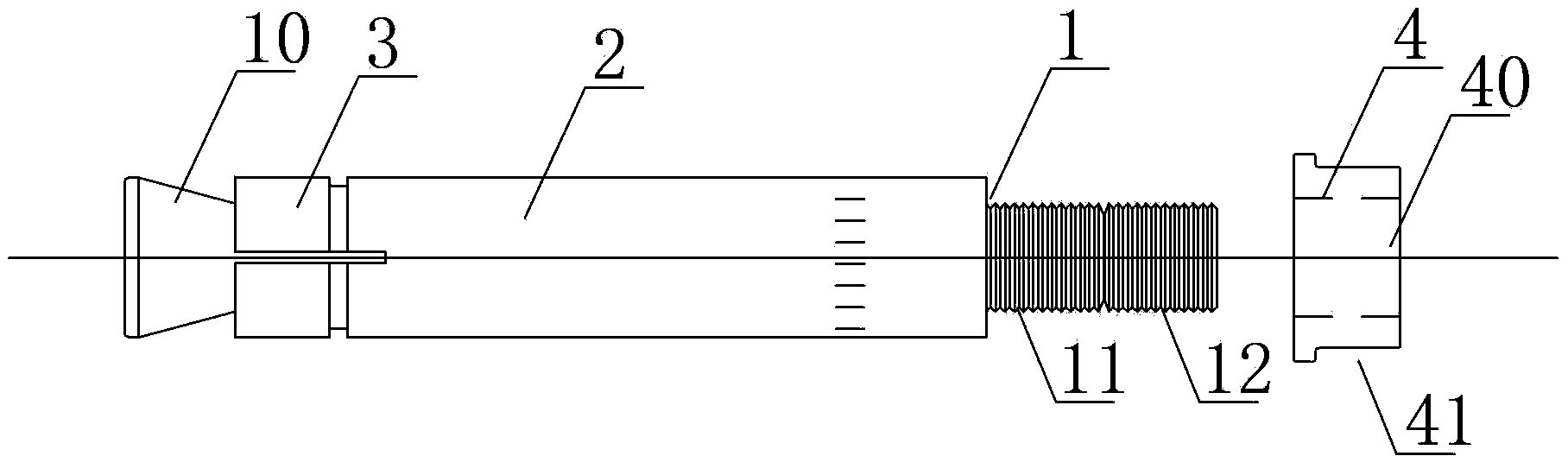

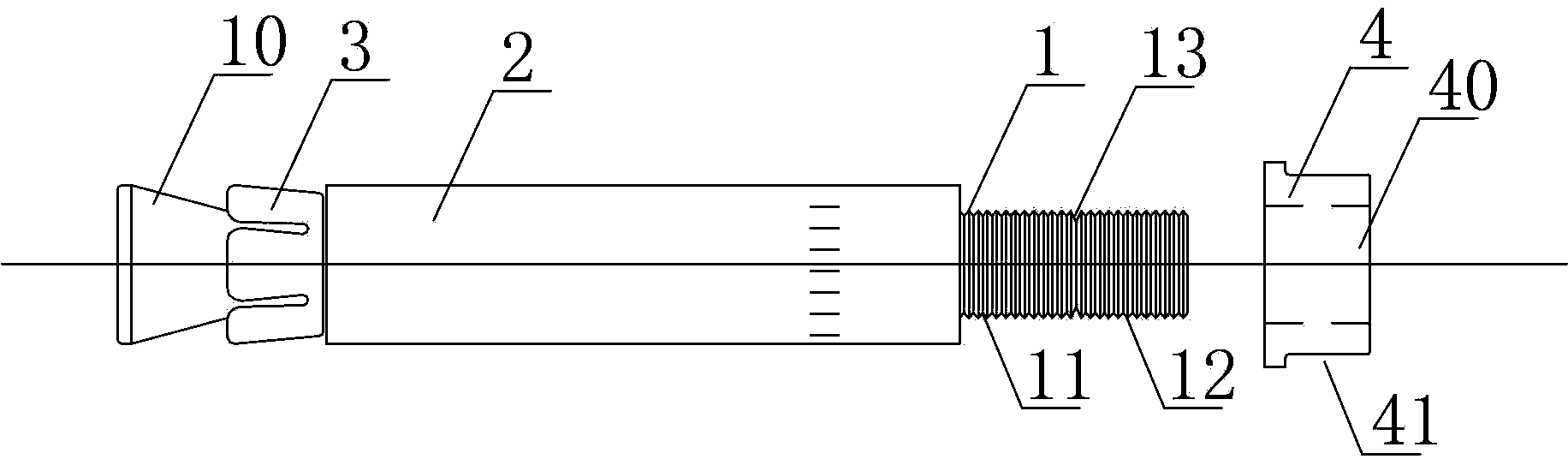

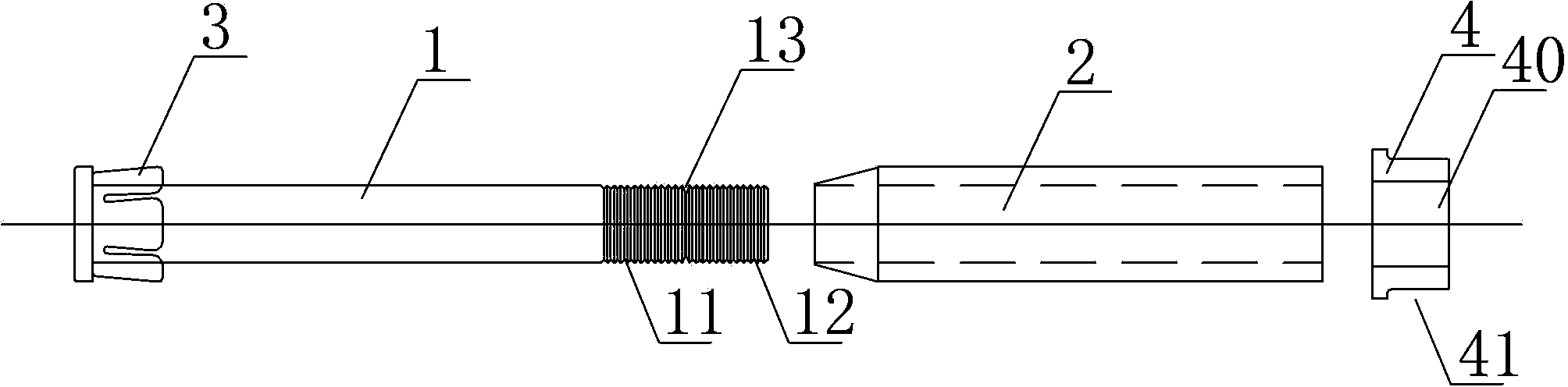

Fire-proofing shock-resisting loss-preventing undercut anchor and connecting structure thereof

InactiveCN103410256AImprove connection strengthMeet the seismic requirementsWallsFire proofingInterference fitEngineering

The invention provides a fire-proofing shock-resisting loss-preventing undercut anchor and a connecting structure thereof. A metal anchor rod of the undercut anchor comprises a loss-preventing anchoring segment. The undercut anchor further comprises a fixing sleeve; by the affection of a tool, the fixing sleeve is pressed against a connecting part, an inner hole of the fixing sleeve is tightened and wrapped outside the loss-preventing anchoring segment, and a bumpy inner-hole surface matching with loss-preventing lines on the surface of the loss-preventing anchoring segment is formed simultaneously; permanent connection is formed and welding is emitted. The front end of the fixing sleeve is provided with a convex ring or a projection which is extruded into a clearance between the wall of a hole, for the metal anchor rod penetrating, of a building appendant between the metal anchor rod so as to form tight extrusion or interference fit. Permanent and firm connection and loss prevention of the undercut anchor can be realized and the welding is omitted, connecting strength is increased greatly, and labor force and cost can be saved. Drifting-preventing and positioning relationship between the anchoring sleeve and the building appendant is brought in, structure is simple, and using effect is good. The invention further provides a solution for fire proofing and heating resisting of the undercut anchor, and the undercut anchor is adaptable to various fire resisting areas.

Owner:斯泰科技(杭州)有限公司 +2

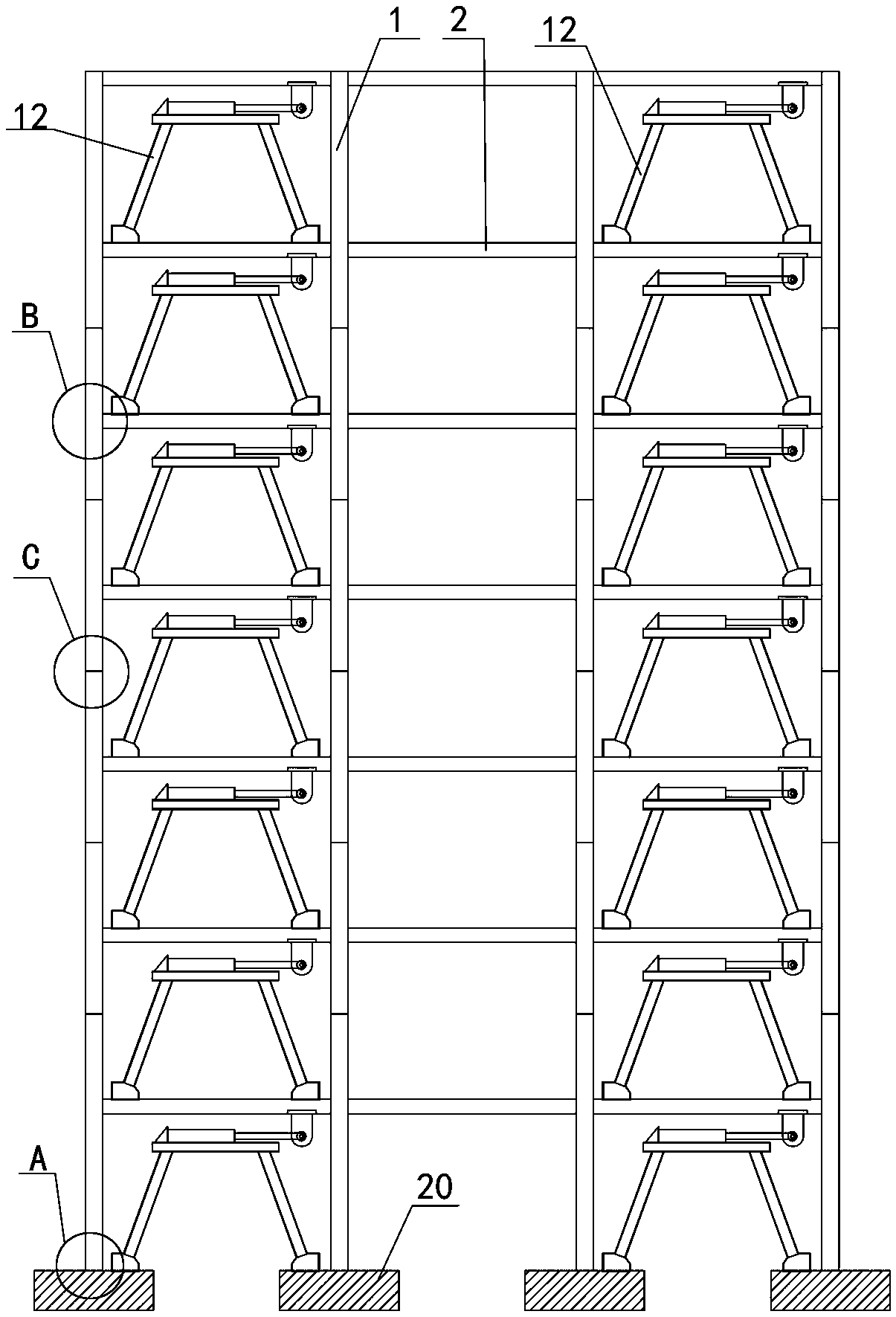

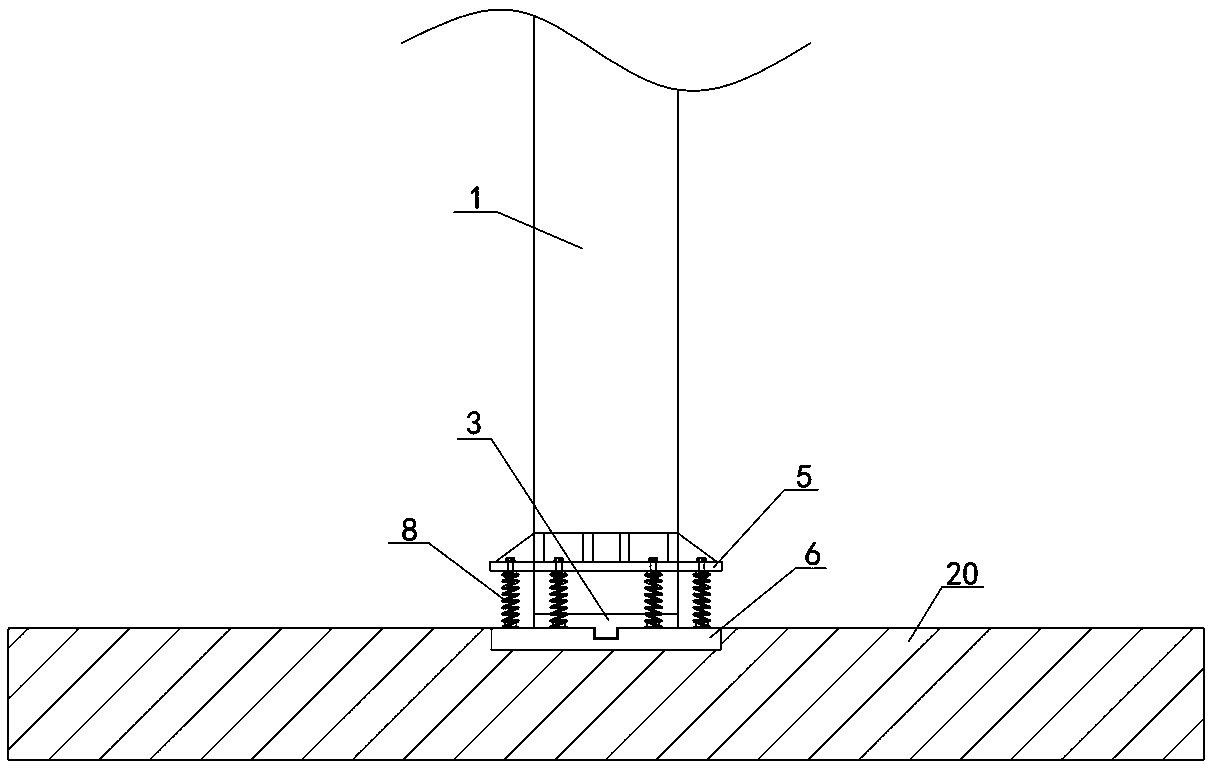

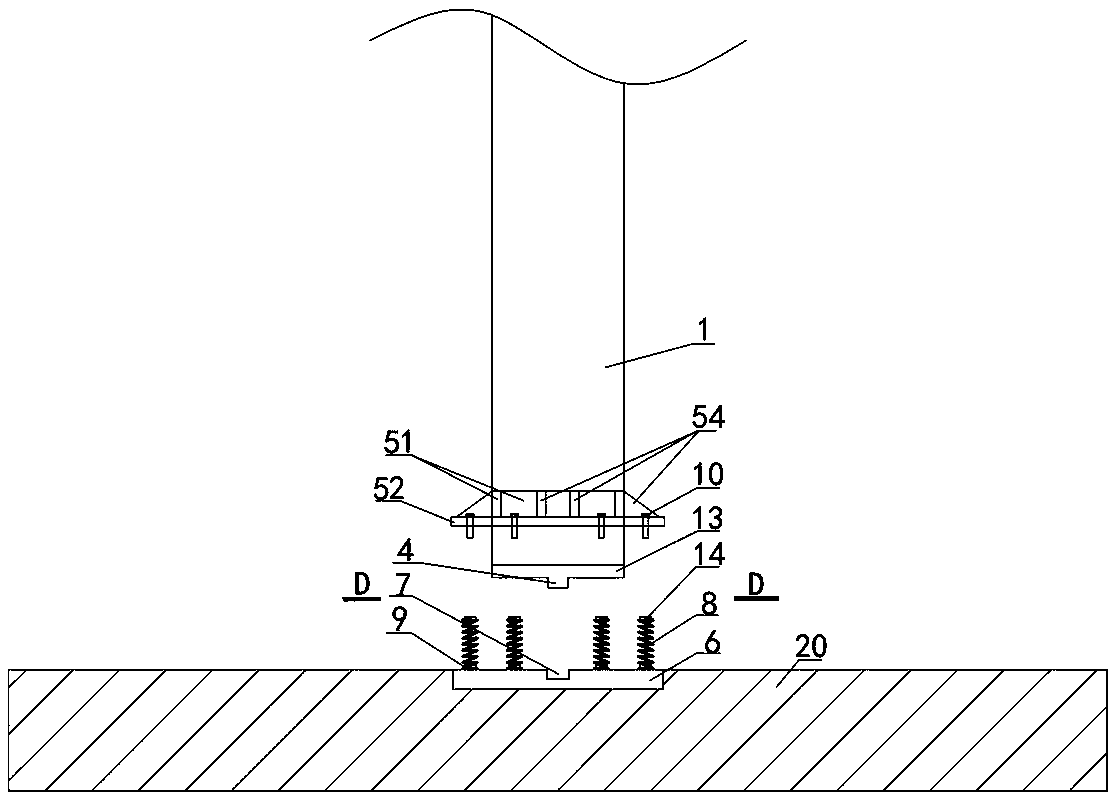

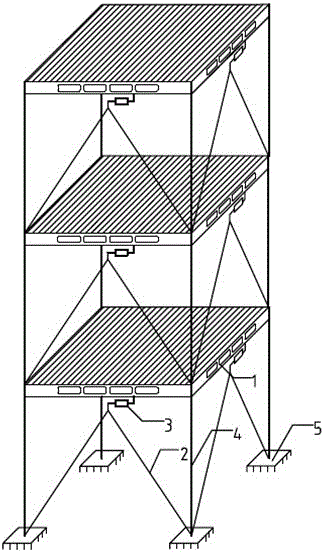

Non-damage energy dissipation prefabricated assembly-type frame structure system and construction method thereof

InactiveCN108487456AAchieve destructionClear mechanicsProtective buildings/sheltersShock proofingEngineeringDamping ratio

The invention discloses a non-damage energy dissipation prefabricated assembly-type frame structure system and a construction method thereof. The non-damage energy dissipation prefabricated assembly-type frame structure system comprises foundations, prefabricated frame columns connected with the foundations and prefabricated frame beams connected with the prefabricated frame columns, and further comprises energy dissipation dampers arranged between the interlayer prefabricated frame beams. The prefabricated frame columns and the foundations are connected through column foot connecting structures, the beams and the columns are connected through beam and column connecting structures, and the prefabricated frame columns are connected through column joint connecting structures. The shortcomings of an existing prefabricated assembly structure system are overcome, all joints adopt the ideas of bending and shearing separation, strong shearing and weak bending, and bending shearing elasticity,the anti-earthquake requirement is met, the structure is simple, processing is convenient, construction and mounting are convenient, and meanwhile the economically feasible performance cost ratio ishigh. The energy dissipation devices are further arranged, the viscous fluid dampers are arranged between the interlayer beams to conduct energy dissipation so as to increase the damping ratio of thestructure, the earthquake response of the structure is reduced, it is guaranteed that large earthquake members are not damaged, and thus repairing is avoided.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Seismic energy dissipation hollow floor structure system

InactiveCN106285142AMeet the seismic requirementsFully utilizeProtective buildings/sheltersShock proofingStructure of the EarthEngineering

The invention relates to a seismic energy dissipation hollow floor structure system for the technical field of engineering seismology and seismic energy dissipation. The structure system comprises hollow floors, column bracings and damping units, wherein the hollow floors are rigidly connected with or hinged to frame columns and the column bracings; the column bracings can be multiple types of structural components; the damping units are arranged at joints of the bracings and the hollow floors. According to the structure system, the hollow floors are cast-in-situ hollow floors, so that the free height of a room is increased, the story height is reduced, the problem of relatively lower lateral rigidity of an ordinary hollow floor system is solved, and relatively higher structural flexibility is achieved; the energy dissipation capability of damping elements under the seismic action can be fully used for dissipating seismic energy, so that damage of an earthquake to a main structure system is effectively reduced; in addition, the horizontal structural rigidity is not required to be improved, and the used structural space is enlarged; seismic energy dissipation units formed by the column bracings and the damping units are arranged unidirectionally and bidirectionally in the hollow floor structure system, so that the seismic requirements of the structure system can be met, meanwhile, the space of a building space can be fully utilized, and functions of the floor hollows and dampers are fully utilized.

Owner:TONGJI UNIV

Total precast lower structure of bridge and construction method

ActiveCN107165038ASatisfy the height limitFulfil requirementsBridge structural detailsBridge erection/assemblyPre stressHigh intensity

The invention discloses a total precast lower structure of a bridge and a construction method. The structure is mainly composed of single whole precast lower components, a precast base plate, a prestressed steel strand and aseismic ribbed bars; single precast components which are precast in a factory overall are composed of cover beams, pier columns and enlarged foundations; the cover beams of the whole single precast components are reserved with corrugated pipes, and the prestressed steel strand is connected with the components in series through the reserved corrugated pipes in site assembly; concrete cast-in-site segments are arranged between the enlarged foundations of the single precast components, and the enlarged foundations of the single precast components are integrally connected in site construction; the whole precast base plate is arranged on the bottom of a whole foundation; when main beams to be precast is reserved on the tops of the cover beams of the precast components, the tops of the cover beams extend into the aseismic ribbed bars of main beam reserved holes. According to the total precast lower structure of the bridge and the construction method, the mode is simple, and the structure is suitable for a high intensity seismic zone.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

Assembly type house with composite environment-friendly wall boards

The invention discloses an assembly type house with composite environment-friendly wall boards. The assembly type house comprises steel beams, stand columns, bases and the wall boards, the stand columns are fixedly connected with the bases, and the two ends of each steel beam are fixedly connected with the corresponding stand columns respectively so as to make the two adjacent stand columns connected; the upper surface of a U-shaped keel is arched to form a protruding part; the long bottom surface of each steel pipe is a connecting surface, and the short bottom surfaces of the two steel pipesare the upper and lower bottom surfaces of an inner joint or an outer joint respectively; the lower end of each first steel plate is provided with a first stop strip which is bent outwards, and mounting keels used for being connected with connecting mechanisms are arranged on the upper portions of the wall boards; each mounting keel is in an inverted U shape, and the center of the upper surface ofa protruding block of each mounting keel is sunken downwards to form a second filling groove; first filling grooves and the second filling grooves are filled with rubber pads. According to the house,reliable connection between unit systems is achieved through prefabricated parts, the working procedures of field construction are simplified, the construction period is shortened, and a lot of laborcost is reduced.

Owner:苏州阳地钢装配式建筑技术有限公司

Fabricatedshear wall structure connection system, design method and vertical seam connection structure of fabricated shear wall structure connection system

PendingCN109440970AImprove seismic performanceMeet the requirements of seismic codesGeometric CADWallsEngineeringStructure system

The invention discloses a fabricated shear wall structure connection system, a design method and vertical seam connection structure of the fabricated shear wall structure connection system. The fabricated shear wall structure connection system comprises precast shear wall units, horizontal seam connection joints and vertical seam connection structures, and the precast shear wall units are assembled into a complete shear wall structure system through the horizontal seam connection joints and the vertical seam connection structures; and a prefabricated concrete structure building of the fabricated shear wall structure connection system can achieve anti-seismic performance of prefabricated buildings or even surpass cast-in-place concrete structure buildings in the prior art. In addition, theinvention further discloses the design method for the fabricated shear wall structure connection system and the vertical seam connection structure for the fabricated shear wall structure connection system.

Owner:刘祥锦

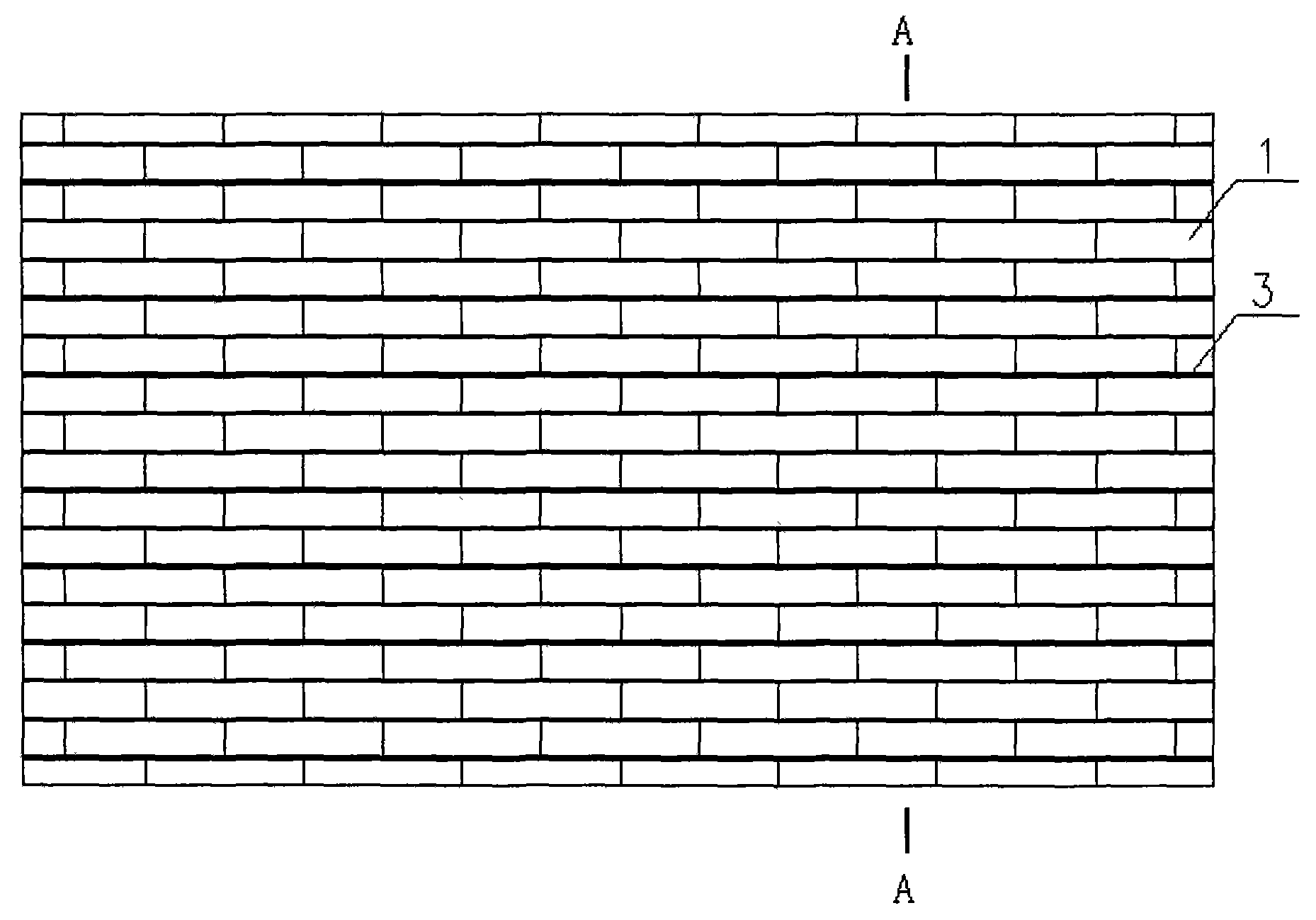

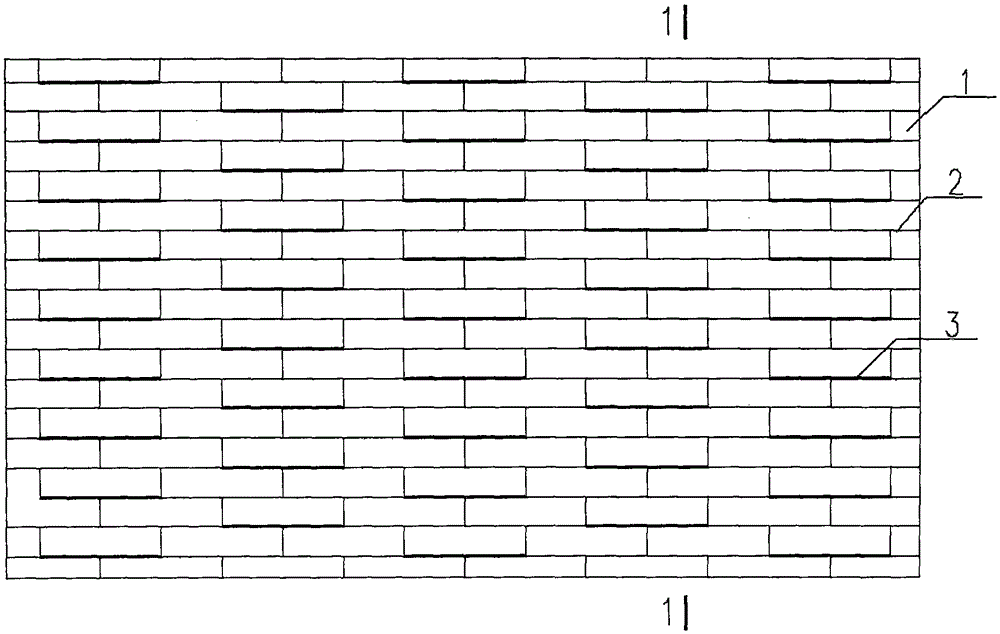

Quincuncial mortar joint mortar reinforced masonry structure and construction method thereof

PendingCN105421811ASimple construction operationReduce construction costsBuilding repairsMortar jointLow graded

The invention relates to a quincuncial mortar joint mortar reinforced masonry structure belonging to the technical field of old building reinforcement. The quincuncial mortar joint mortar reinforced masonry structure comprises an original masonry structure wall and also comprises original low-grade mortar and newly backfilled high-grade mortar. Mortar joint mortar is of the quincuncial mortar joint mortar reinforced masonry structure, namely the horizontal part of an original mortar joint wall is excavated in a quincuncial layout way and is backfilled with mortar. According to the quincuncial mortar joint mortar reinforced masonry structure, the low-grade mortar in the wall is replaced with the high-grade mortar, so that the compression resistance and shear resistance of a masonry are improved, and the safety performance of a house is ensured; and meanwhile the construction cost is relatively low, and the original space is not occupied after the wall is reinforced, so that the quincuncial mortar joint mortar reinforced masonry structure can be widely applied to house reinforcement.

Owner:BEIJING ZHUFU ARCHITECTURE AFFAIRS CO LTD

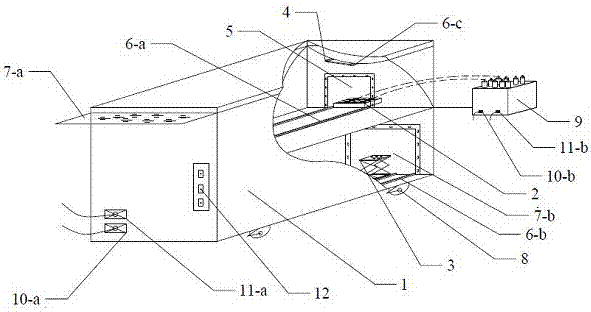

High-flux experimental platform for water/ salt transportation/ dissolution/ crystallization characterization

ActiveCN107328773AQuick collectionEfficient collectionRaman scatteringColor/spectral properties measurementsHigh fluxTest sample

The invention relates to a high-flux experimental platform for water / salt transportation / dissolution / crystallization characterization. The platform includes a casing frame, a test sample placer, a top cover, an automatic liquid supply system and a power supply unit. A two-dimensional slide rail A, carrying the test sample placer, of the casing frame, is divided into two independent chambers up and down. The upper top part of the casing frame is provided with a two-dimensional rail system B, and a lower bottom part of the casing frame is provided with a two-dimensional rail system C. A top elevating mechanism with a test instrument installed is arranged on the rail system B and is parallel to the rail A, and a bottom elevating mechanism with a test instrument installed is arranged on the rail system C and is parallel to the rail A. The provided high-flux experimental platform for water / salt transportation / dissolution / crystallization characterization can fast efficiently complete batch fine experimental data, can greatly shorten the period of laboratory study, and is saved in time and labor.

Owner:SHANGHAI UNIV +1

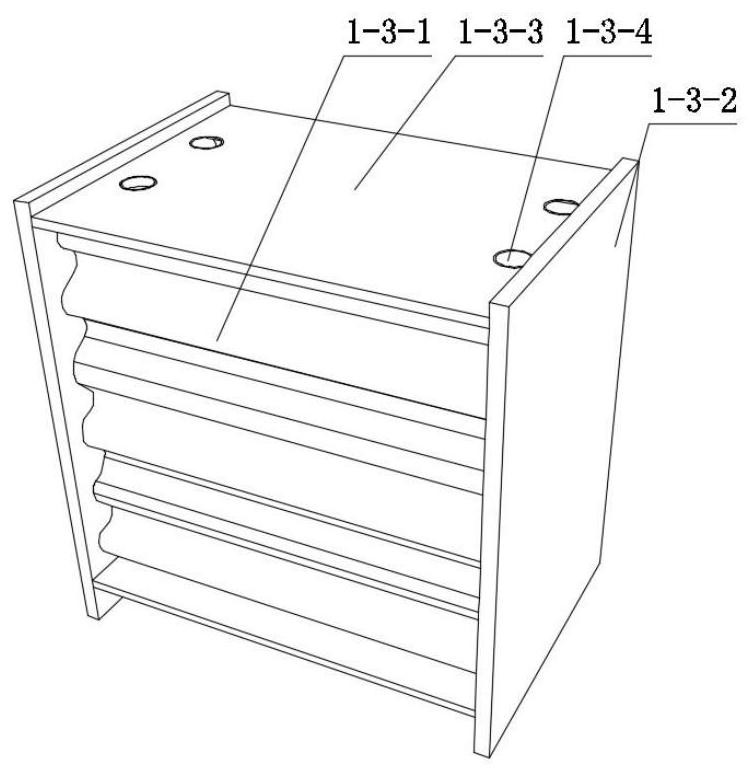

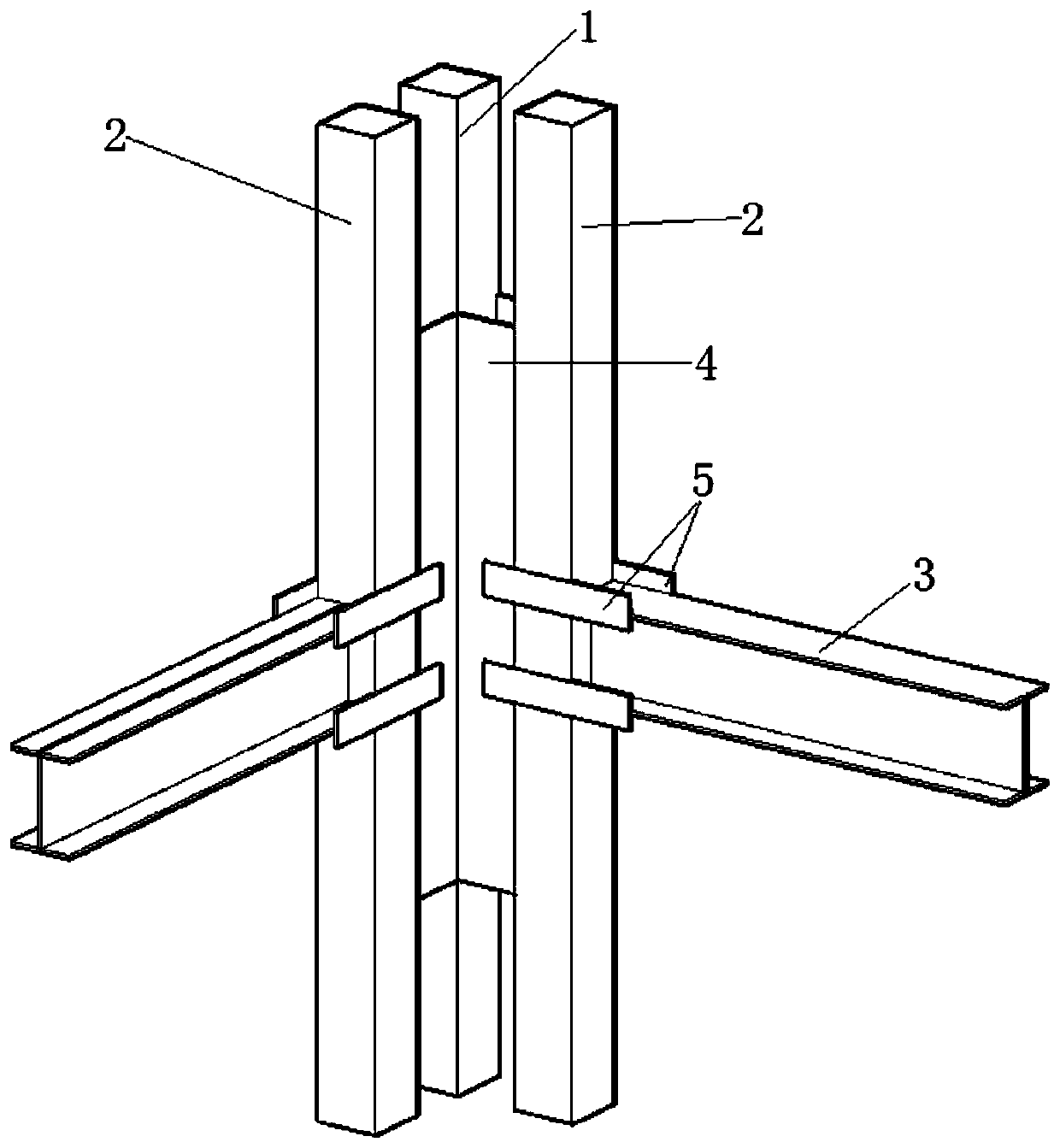

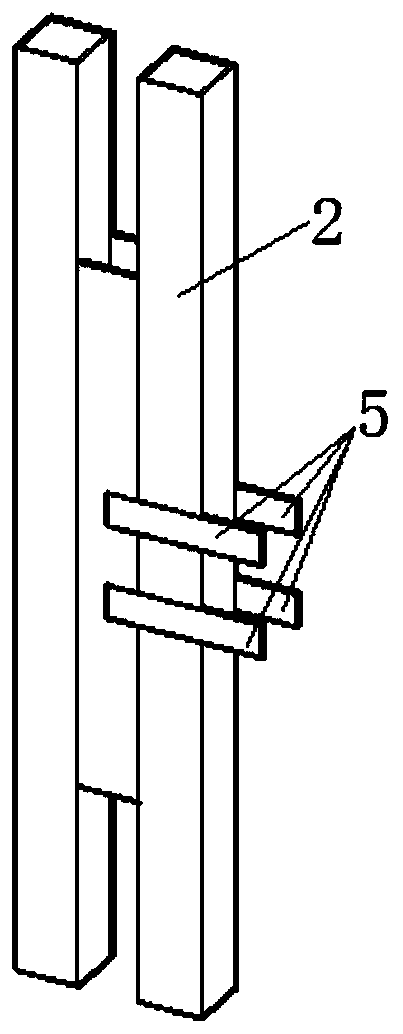

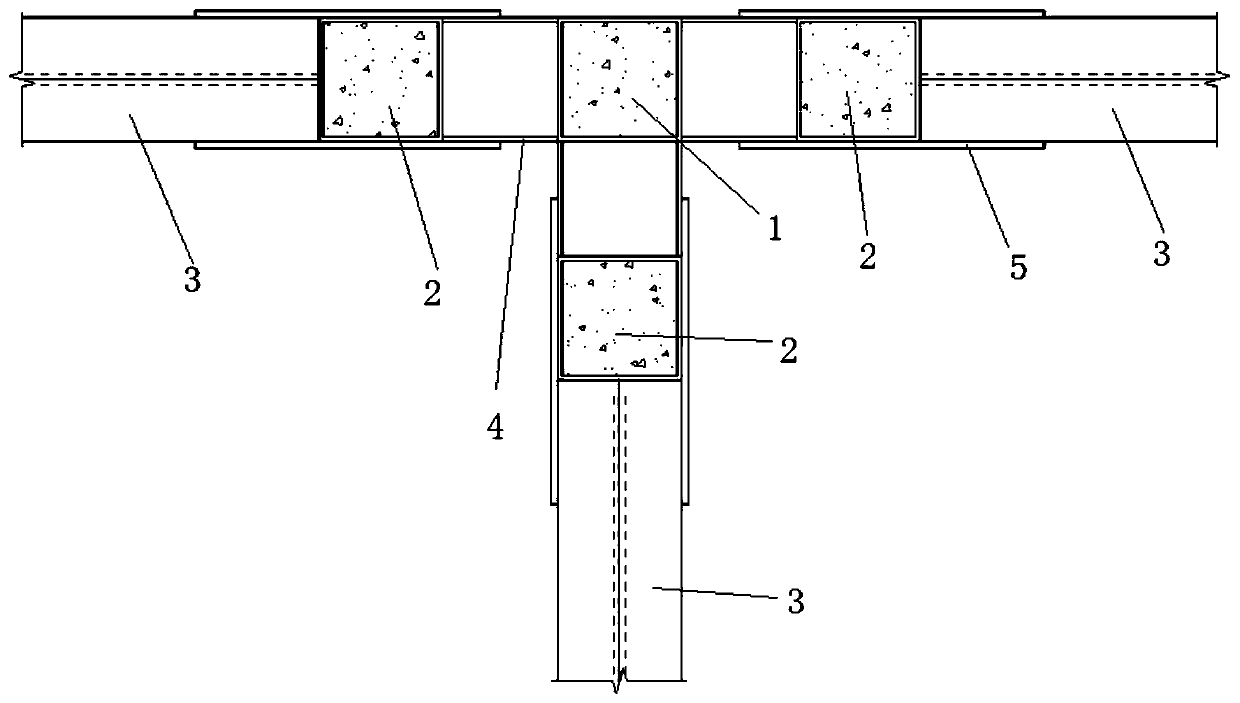

Assembling type concrete-filled steel pipe combined column node area connection structure

InactiveCN110284605AMeet the seismic requirementsMake sure to work togetherBuilding constructionsMachining processFlange

The invention relates to the field of architectural structure members and discloses an assembling type concrete-filled steel pipe combined column node area connection structure. The assembling type concrete-filled steel pipe combined column node area connection structure comprises a central square steel pipe, end square steel pipes, H-type steel beams, connecting plates and stiffening plates. The central square steel pipe and the end square steel pipes are connected through two parallel connecting plates. The H-type steel beams are perpendicularly fixed to the end square steel pipes. Two side edges of flange plates of the H-type steel beams and the inner and outer side faces of the end square steel pipes are in the same horizontal plane. The stiffening plates are fixedly arranged on the inner sides and the outer sides of the end square steel pipes. The two ends of the stiffening plates are fixedly connected with the connecting plates and the flange plates of the H-type steel beams respectively. According to the assembling type concrete-filled steel pipe combined column node area connection structure, anti-seismic requirements for strong columns and weak beams and strong nodes and weak members can be satisfied; structural integrity is good; structural rigidity is high; node stress is more reasonable; it is guaranteed each branch column can work cooperatively and bear the stress together; and the whole machining process is all completed in a factory, only installation is needed to be conducted on site, the construction period is shortened greatly, and the project cost is saved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

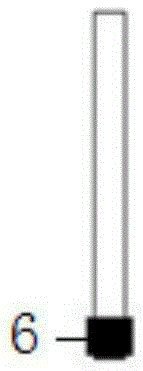

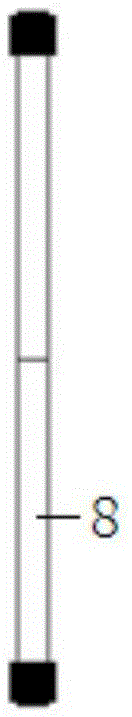

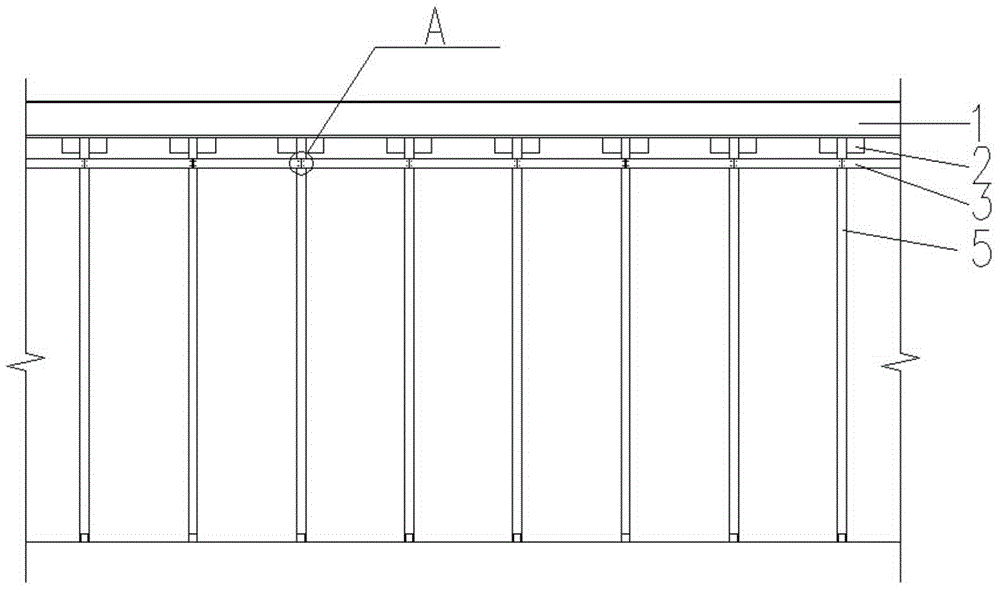

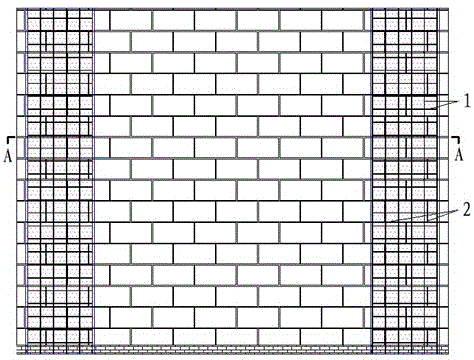

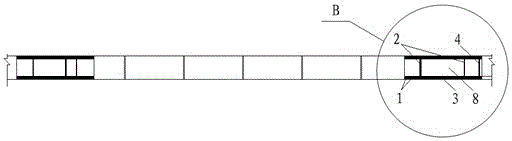

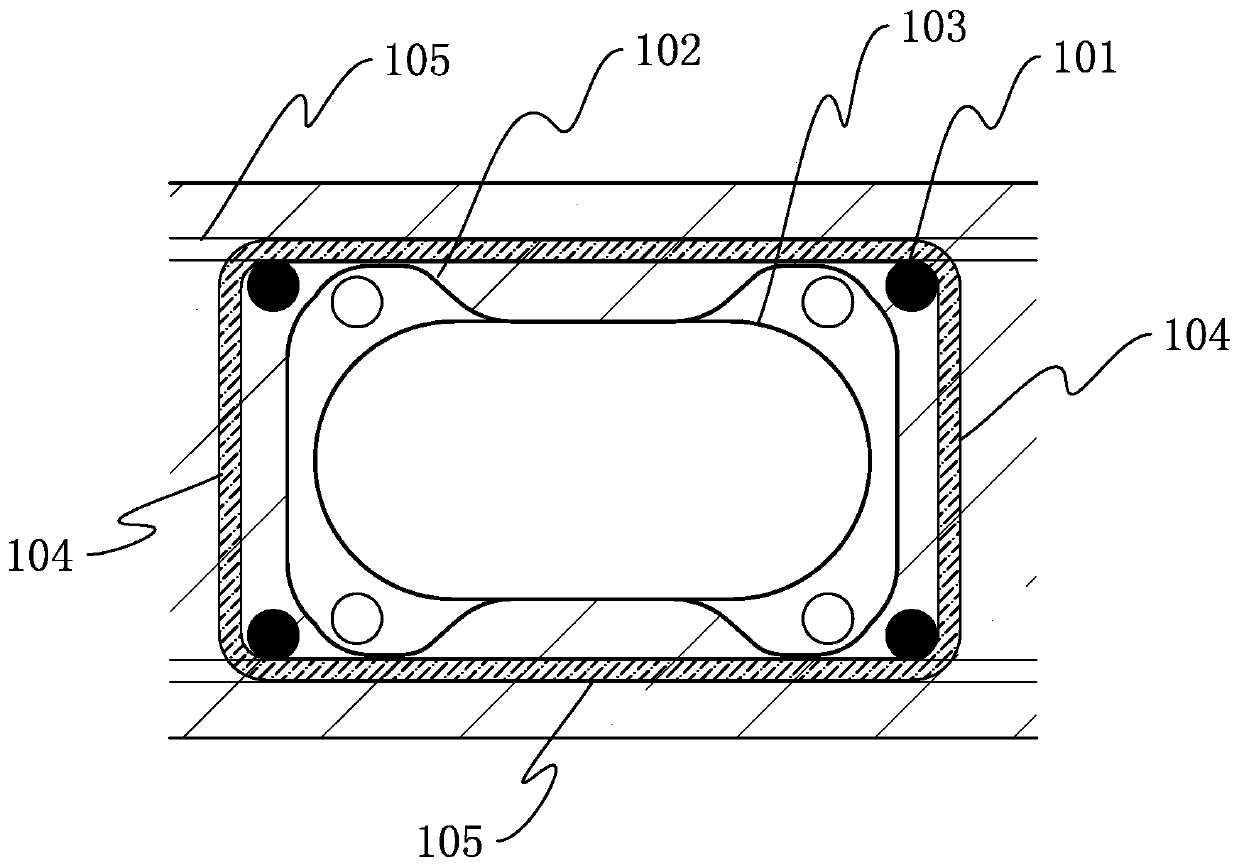

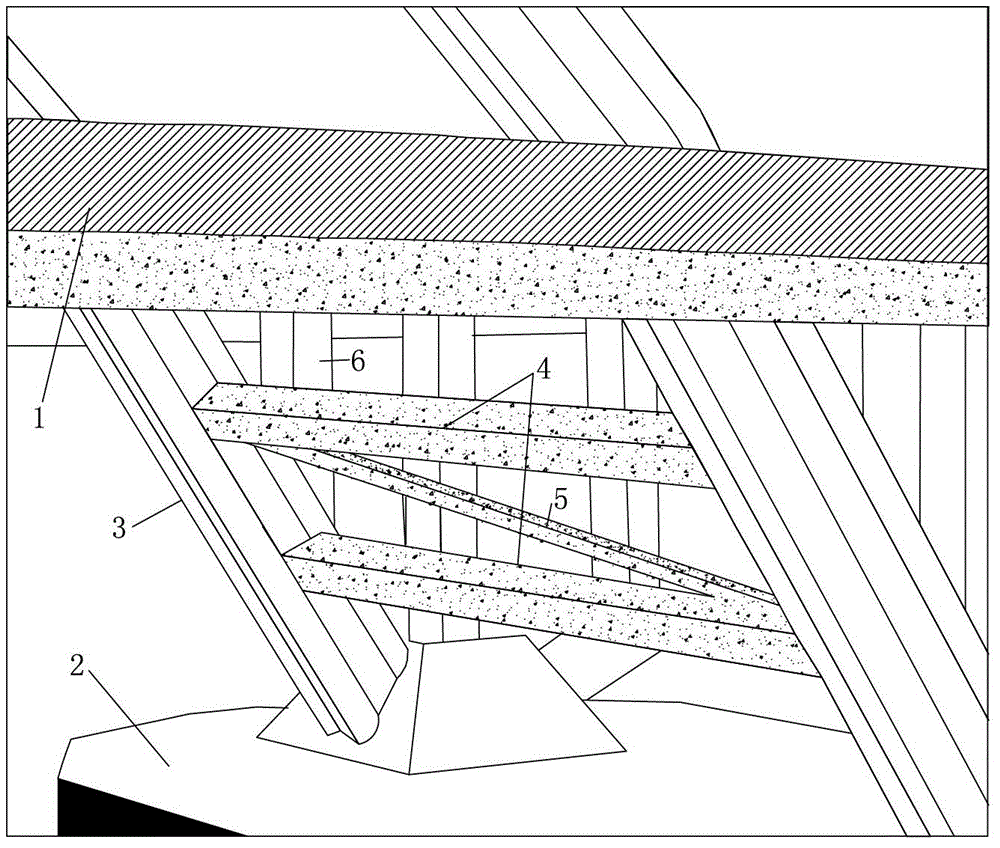

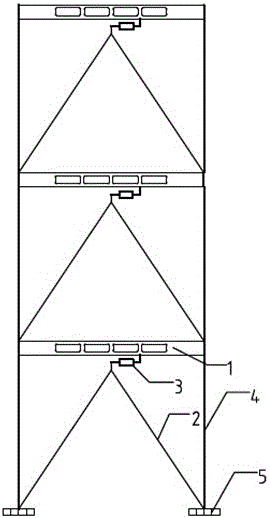

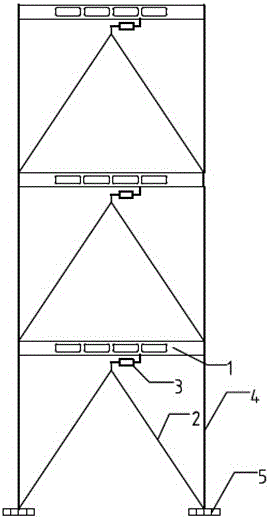

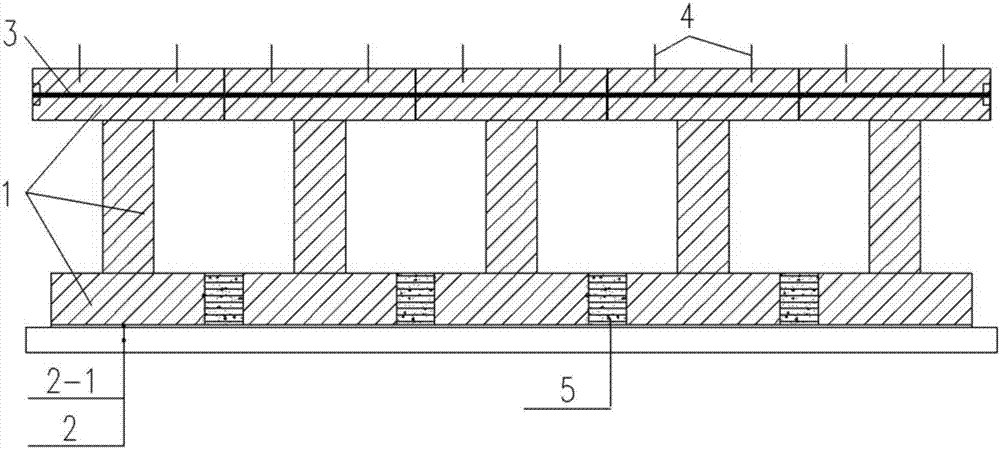

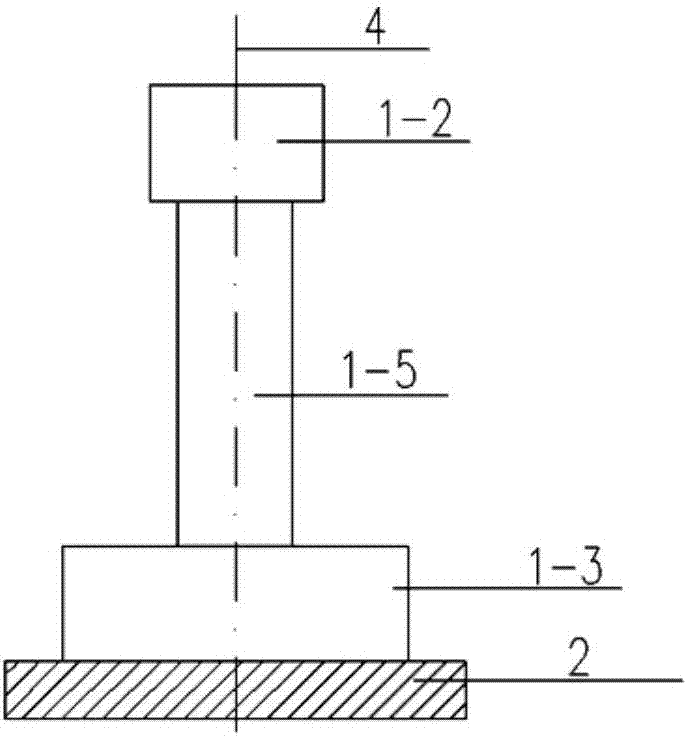

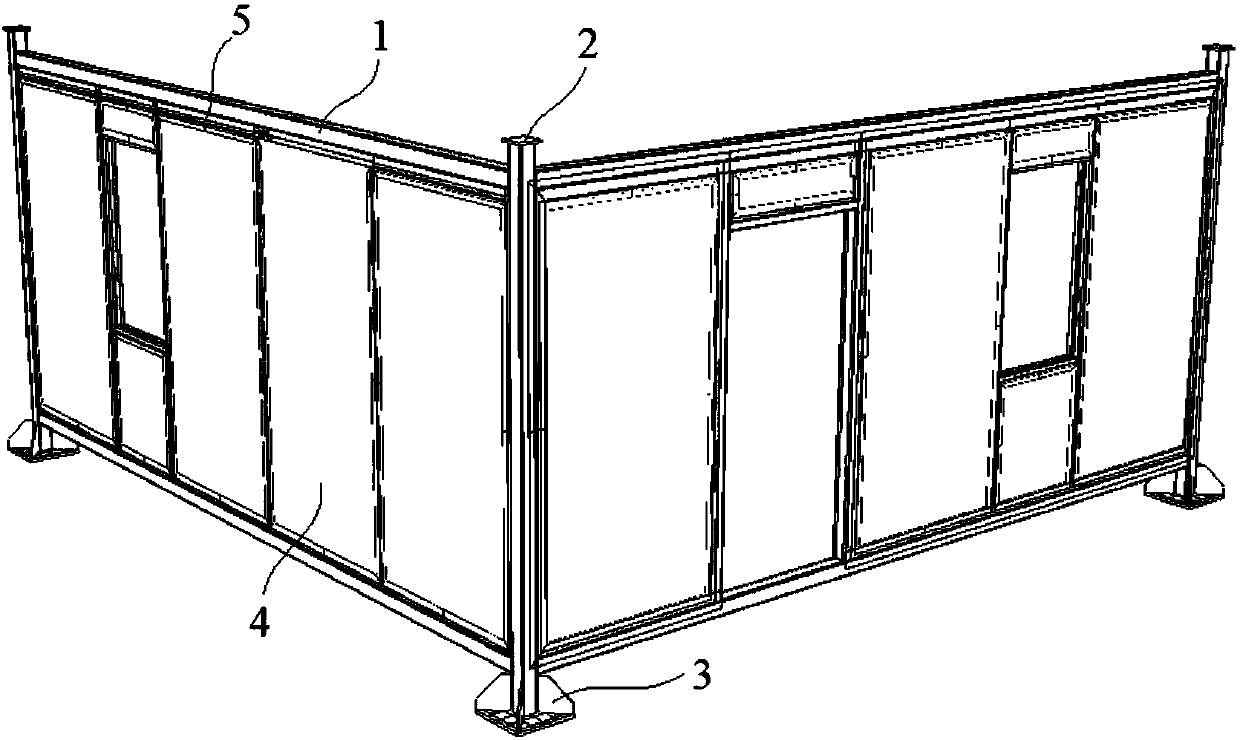

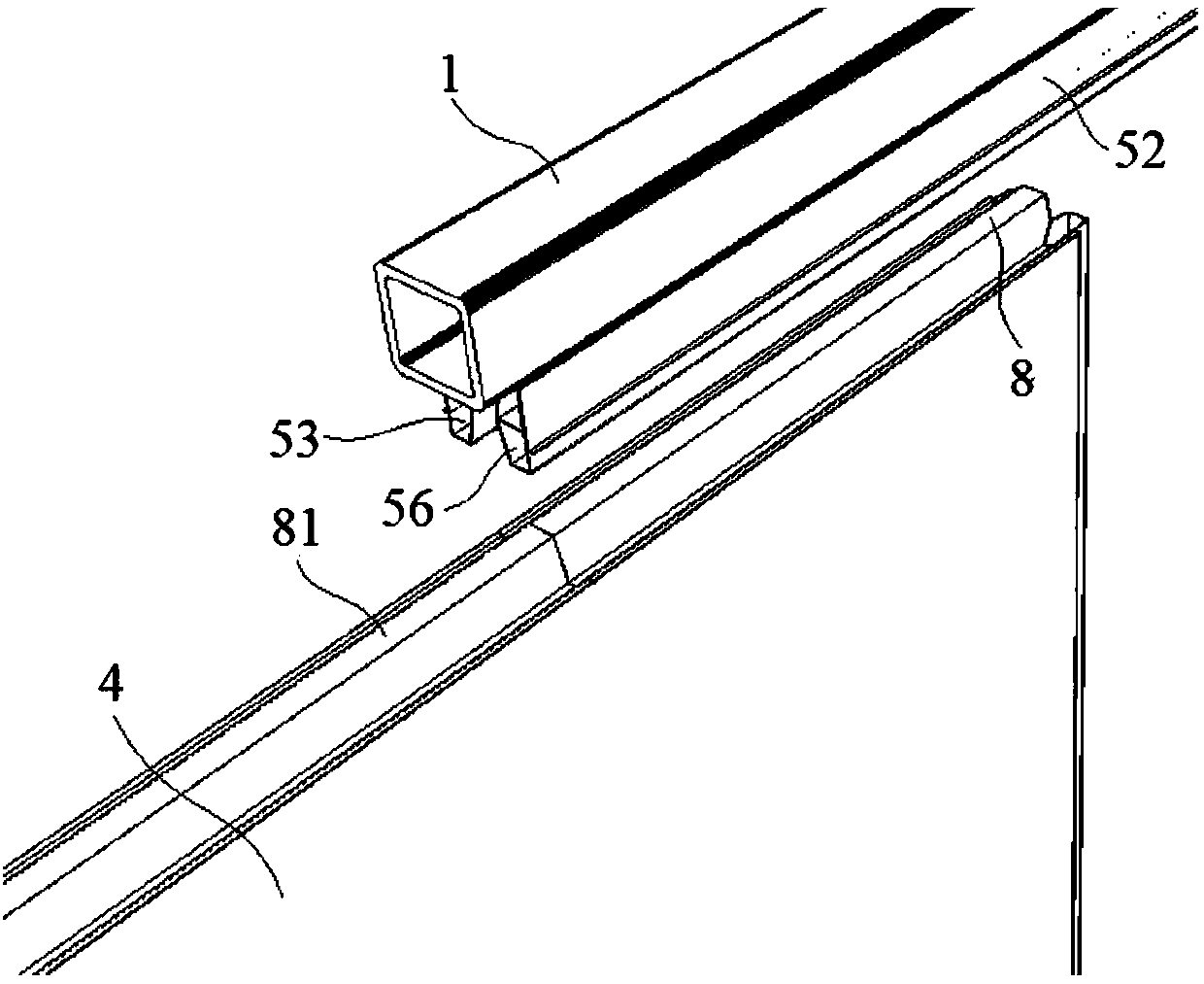

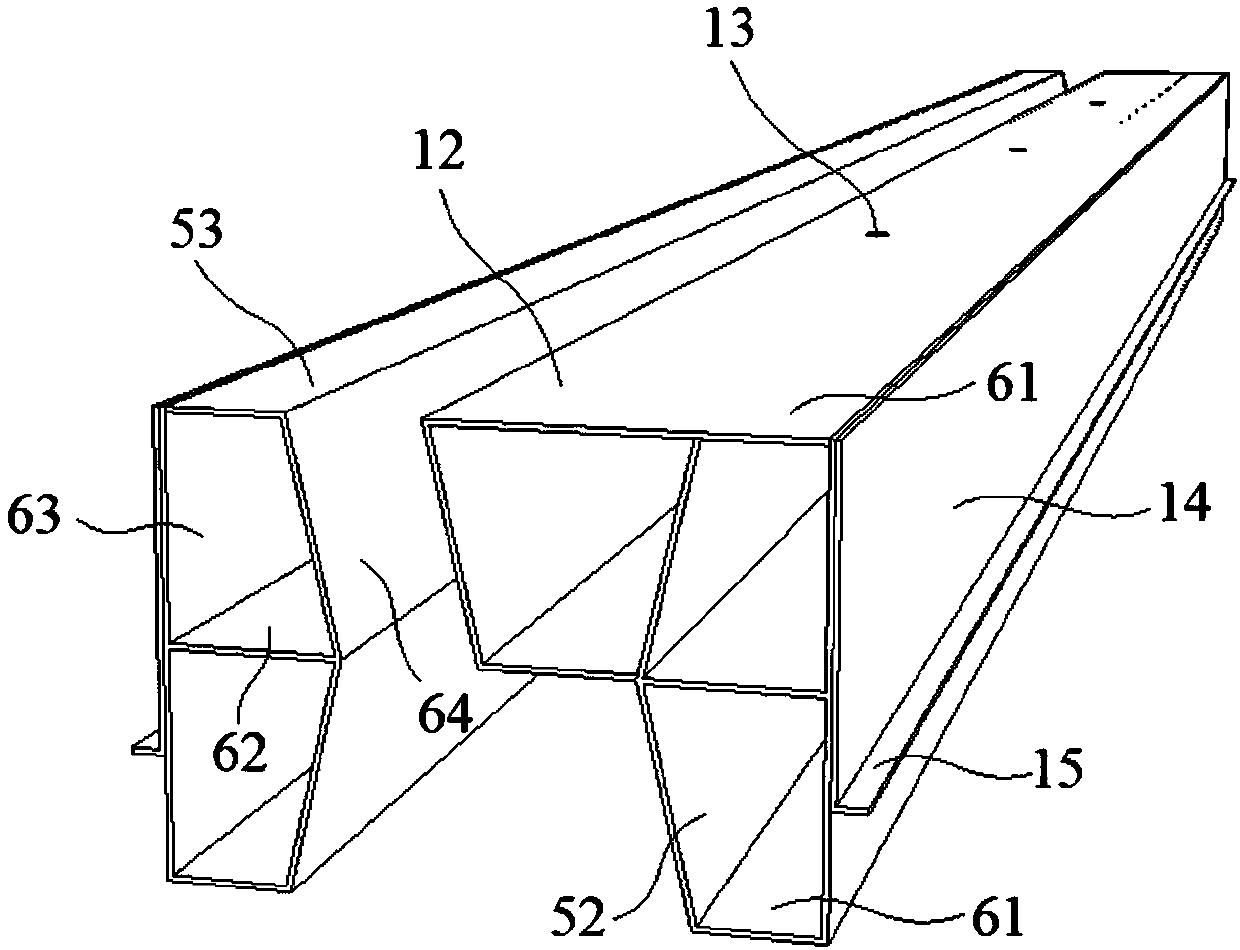

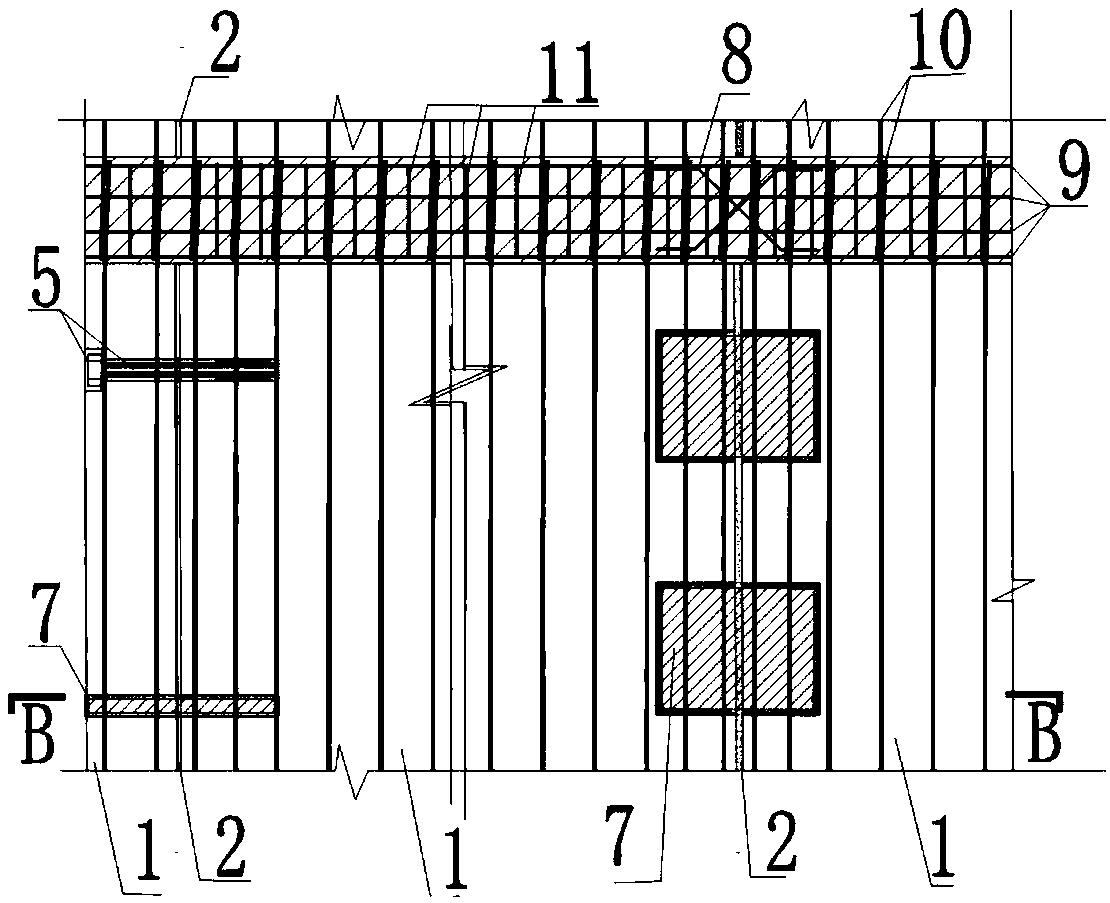

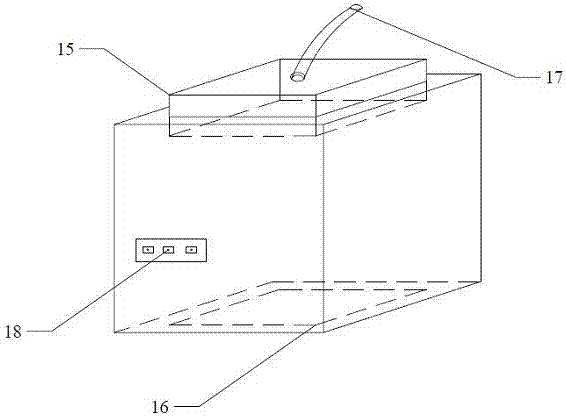

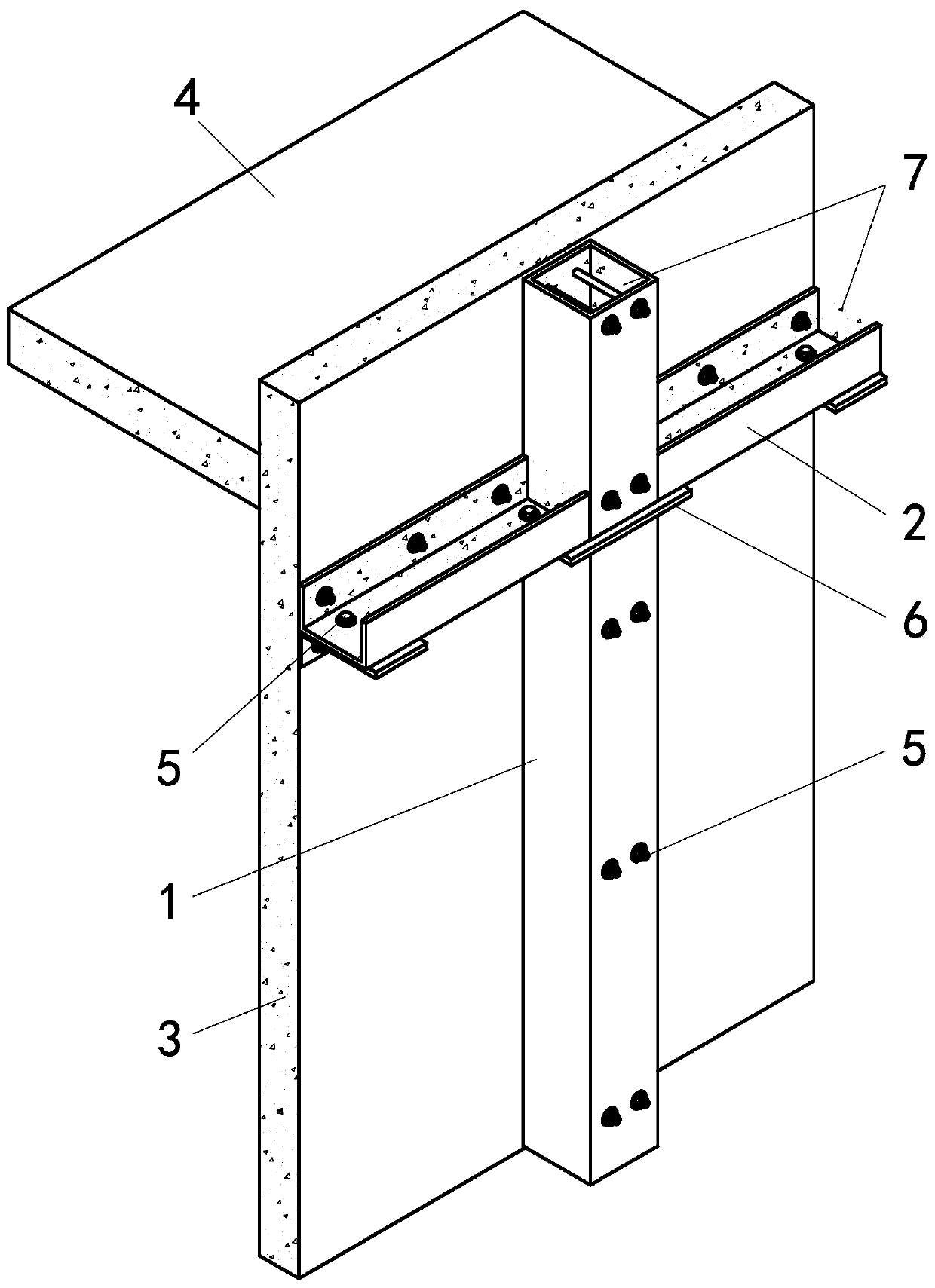

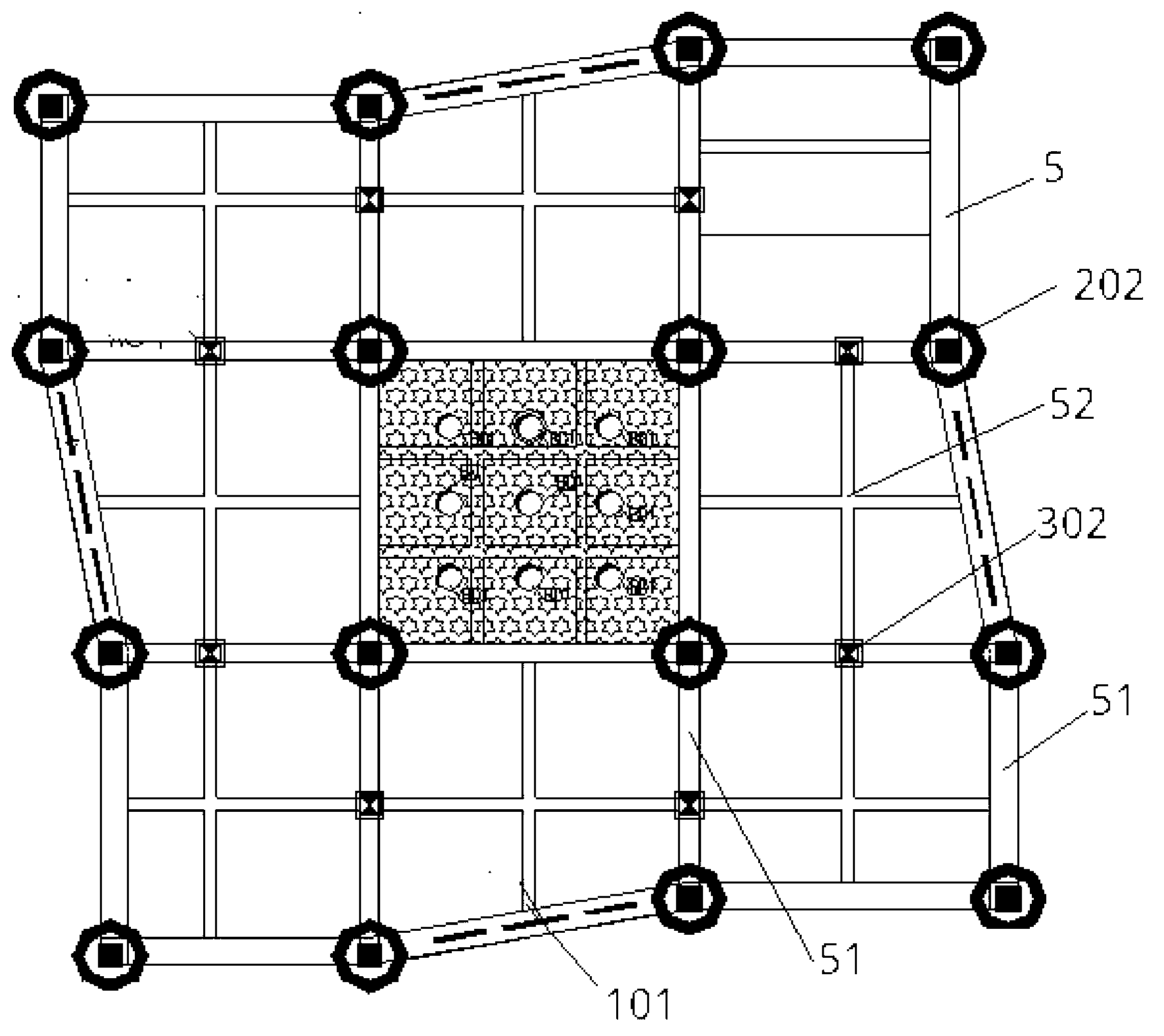

Fabricated anti-seismic strengthening structure of brick-concrete structure wall body

The invention discloses a fabricated anti-seismic strengthening structure of a brick-concrete structure wall body. The fabricated anti-seismic strengthening structure comprises the brick-concrete structure wall body (3); a floor slab (4) is arranged on the inner side of the brick-concrete structure wall body (3); a group of reinforcing columns (1) and reinforcing beams (2) are arranged on the outer wall surface of the brick-concrete structure wall body (3); and the reinforcing columns (1) and the reinforcing beams (2) are fixedly connected with the brick-concrete structure wall body (3) through tying bolts (5). According to the fabricated anti-seismic strengthening structure, a reinforced wall body of a house is connected with the reinforcing columns and the reinforcing beams in the fabricated anti-seismic strengthening structure to form a whole new wall body, so that the anti-seismic performance of the original brick-concrete structure house is greatly improved. According to the technical scheme, the fabricated anti-seismic strengthening structure is reliable, safe, fast and convenient, construction facilities does not need to be prepared on site too many, the construction speed is improved, social benefits for the earthquake-resistant comprehensive reconstruction of old residential buildings are obvious, the bearing capacity of the old residential buildings is increased, andmeanwhile the fabricated anti-seismic strengthening structure is beneficial to fire prevention and corrosion prevention.

Owner:CHINA CONSTR FOURTH ENG DIV +1

Balance arm device with shock absorption function and crane trolley provided with device

The invention provides a balance arm device with a shock absorption function and a crane trolley provided with the device. The balance arm device comprises a balance arm frame, wherein two balance beams are symmetrically arranged at the left side and right side of the lower portion of the balance arm frame, and upper ends of the two balance beams are connected with the lower portion of the balancearm frame through the same hinged shaft I; the ends, close to each other, of bottoms of the two balance beams are connected through a disc spring set, and two ends of the disc spring set are connected with the balance beams respectively through hinged shafts II; and the ends, away from each other, of the bottoms of the two balance beams are connected with steel wire rope connecting ends through pin shafts, and the pin shafts are higher than the hinged shafts II and lower than the hinged shaft I. The crane trolley is provided with the balance arm device and is connected with a lifting hook component through the balance arm device. According to the balance arm device and the crane trolley, the stress of a steel wire rope under an earthquake condition is reduced, and the safety coefficient of the steel wire rope is increased; and meanwhile, the stress of the crane trolley and a whole crane product is reduced, the anti-shock requirement is met, and product cost is lowered.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

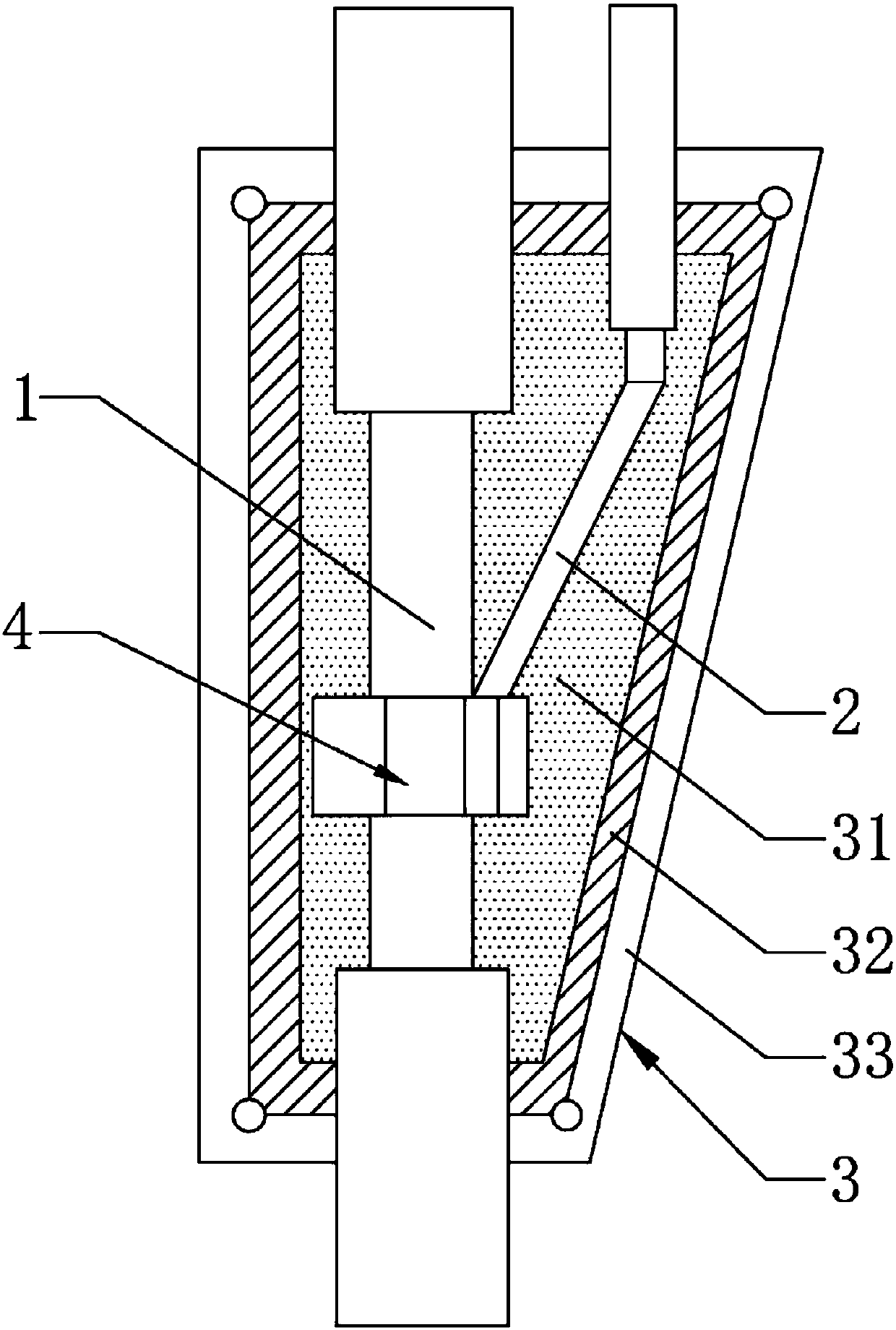

Construction method of construction damping device

InactiveCN103174234AReduce section sizeImprove shock absorptionBuilding material handlingShock proofingEngineeringAbutment

The invention discloses a construction method of a construction damping device. The construction damping device comprises a damping frame, a panel sliding bearing is arranged between the lower position of the frame upright which is located on a cross point of a vertical and horizontal main framed girder of an upper frame and a lower frame, and a laminate rubber bearing is arranged between the lower position of the frame upright which is located on a cross-shaped cross point of an auxiliary framed girder of the upper frame and the lower frame. The construction method of the construction damping device comprises the following steps: (1), arranging an abutment pattern plate on the lower frame in a supporting mode; (2), erecting steel embedded plates; (3) pouring the steel embedded plates and abutments in integration; (4) arranging the laminate rubber bearing and the panel sliding bearing; and (5), fixing the laminate rubber bearing and the panel sliding bearing with the upper frame. The construction method of the construction damping device integrally applies the laminate rubber bearing and the panel sliding bearing to form a hybrid control damping system. Advantages of the construction damping device are exerted, earthquake energy is consumed, and therefore ideal damping effect is achieved.

Owner:ZHEJIANG HAITIAN CONSTR GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com