Fire-resistant corrosion-resistant anti-seismic construction steel with yield strength of 460MPa and production method

A yield strength, construction steel technology, applied in the field of seismic construction steel, can solve the problems of high Cu content and non-compliance, and achieve the effects of excellent performance, low cost and excellent seismic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further described below:

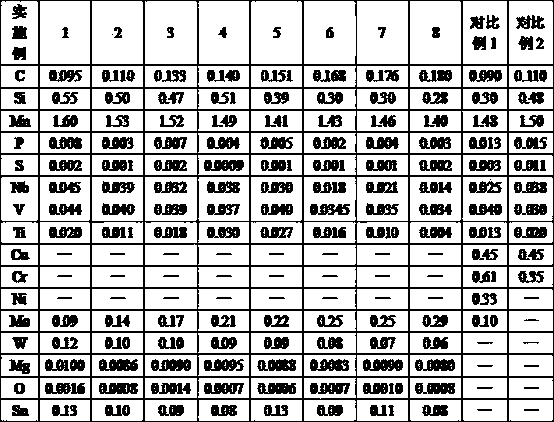

[0033] Table 1 is a list of chemical components and weight percentages of each embodiment of the present invention and comparative examples;

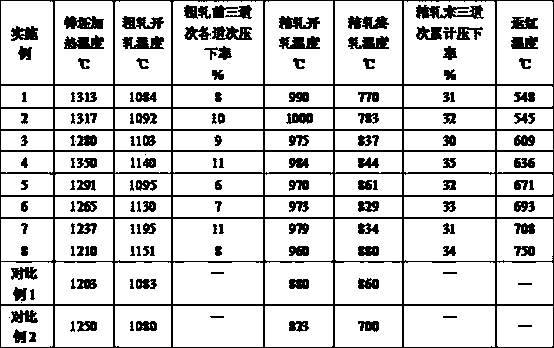

[0034] Table 2 is the value list of the main process parameters of each embodiment of the present invention and comparative examples;

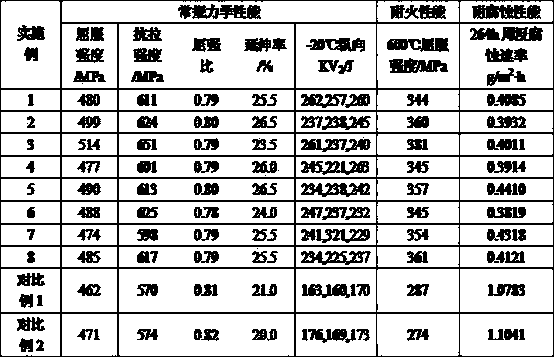

[0035] Table 3 is a list of test results of mechanics, fire resistance and corrosion resistance of each embodiment of the present invention and comparative examples.

[0036] Each embodiment of the present invention is produced according to the following process steps:

[0037] 1) Carry out desulfurization of molten iron, and control S in molten iron to ≤0.001%;

[0038] 2) Carry out converter smelting, and control the C in molten steel: 0.095~0.180%, P≤0.008%;

[0039] 3) Vacuum treatment in the RH furnace: the total time of vacuum treatment is not less than 16 minutes; when the vacuum treatment reaches 6 minutes, Sn is added at one time, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com