Fabricated anti-seismic strengthening structure of brick-concrete structure wall body

A brick-concrete structure and reinforced structure technology, which is applied in building construction, building maintenance, construction, etc., can solve unrealistic problems and achieve the effects of increasing safety, great social benefits, and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

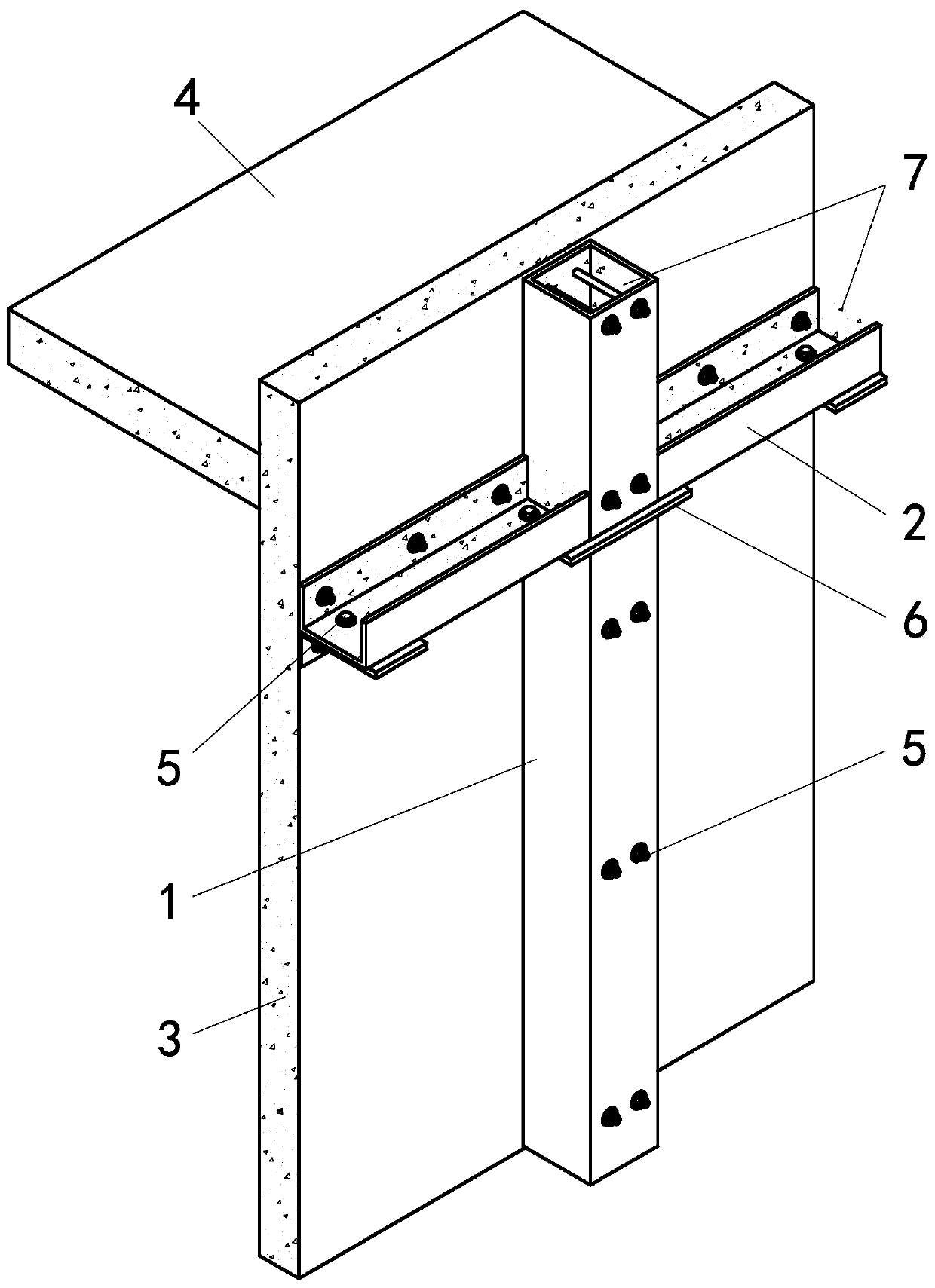

[0021] In specific implementation, such as figure 1 As shown, the reinforced column 1, reinforced beam 2 and backing plate 6 in the figure are all made in a specialized chemical factory. The bolt holes on the reinforcing column 1 and the reinforcing beam 2 can be directly drilled in the factory. The bolt holes on the backing plate 6 can be completed by on-site drilling. But the backing plate 6 that needs to be connected with the reinforcing column 1 is directly welded in the factory. After transporting the manufactured reinforcing column 1 and reinforcing beam 2 with backing plate 6 to the site, the reinforcement of the brick-concrete structure wall 3 is completed on site.

[0022] During specific reinforcement, the reinforcing column 1 should be arranged at the intersection of the outer longitudinal wall and the gable outer side of the brick-concrete structure house, where the longitudinal and transverse walls intersect. The spacing of the reinforcement columns 1 is genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com