Concrete-filled rectangular steel tube column-box girder full-bolt connection node and construction method

A technology of rectangular steel pipe and concrete column, applied in the direction of building, building structure, etc., can solve the problems of tearing damage at the connection between the inner clapboard and the column wall, large welding residual stress of the column wall, weak parts at the welding seam connection, etc. To achieve the effect of convenient and fast construction technology, to meet the structural bearing capacity and normal use, and to have a clear force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

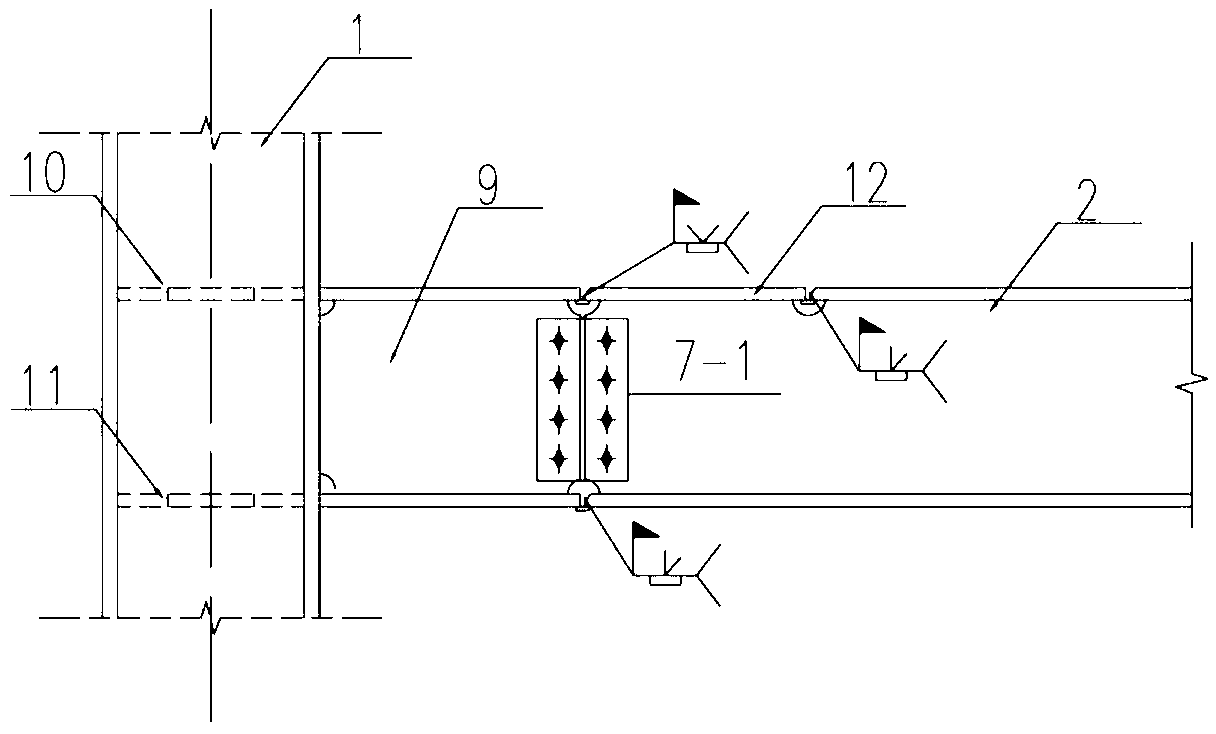

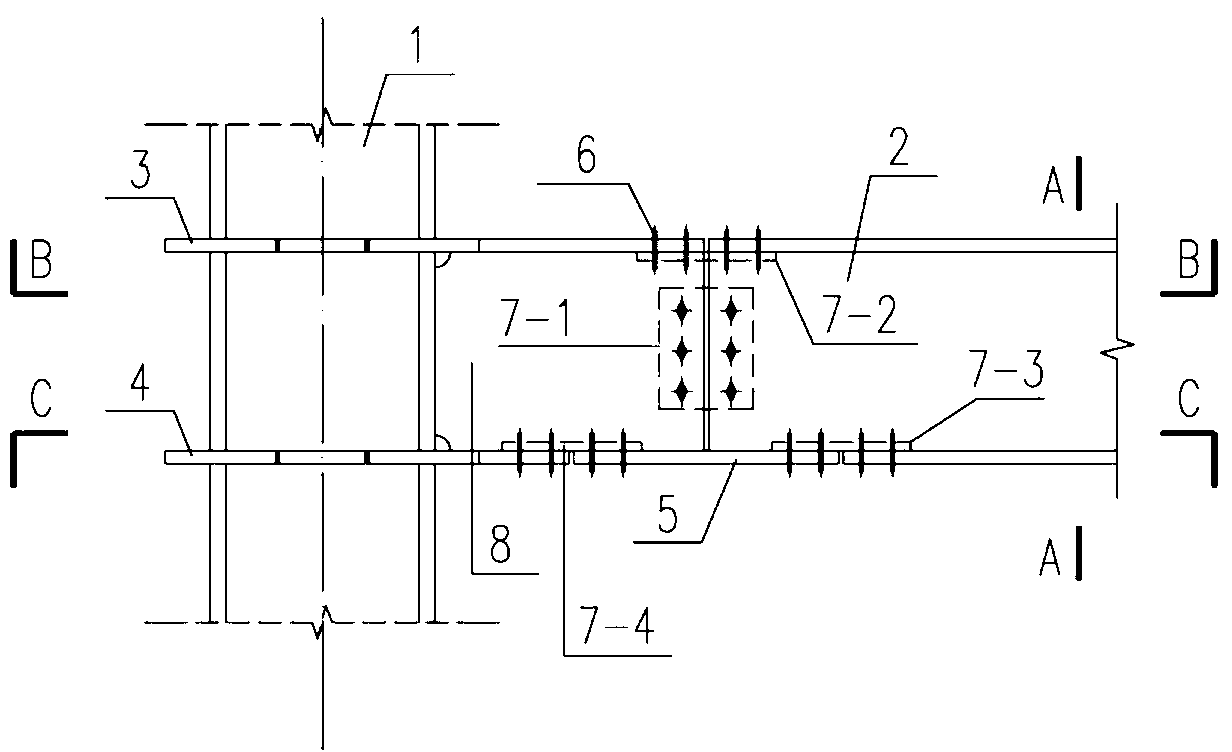

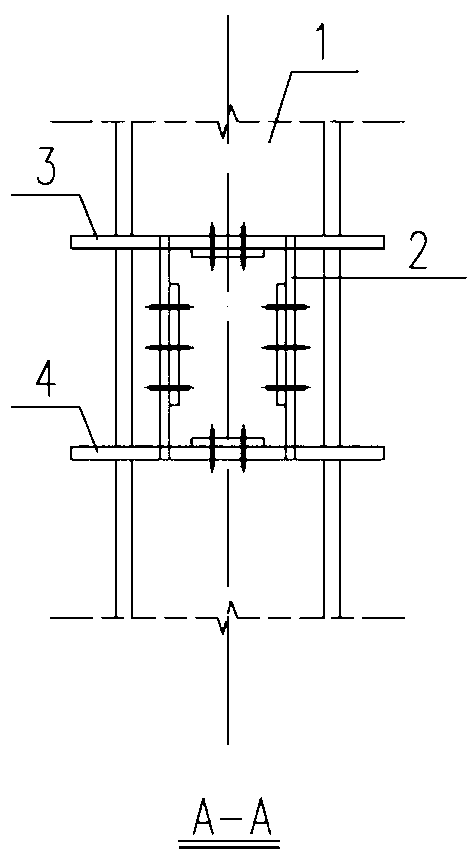

[0038] The present invention proposes a rectangular steel tube concrete column box girder full-bolt connection node, which is characterized in that it includes a rectangular steel tube concrete column 1, a box girder 2, an upper through partition 3, a lower through partition 4, a lower cover 5, and a high-strength Bolts 6, connecting plates 7, and shear plates 8 are composed of the following methods:

[0039] The upper through partition 3 and the lower through partition 4 run through the column wall of the rectangular steel tube concrete column 1, and are connected with the steel tube column wall of the rectangular steel tube concrete column 1 by cut welds. At the position corresponding to the rectangular steel tube concrete column 1 and the web plate of the box girder 2, two shear plates 8 are connected by a cut-out weld. The upper flange of the box girder 2 and the upper through partition 3 are connected by a connecting plate 72 arranged inside the box girder 2 with high-str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com