Frame-supporting column with high strength steel bars and super high strength concrete

A technology of ultra-high-strength concrete and high-strength steel bars, which is applied in the direction of pillars, columns, pier columns, etc., can solve the problems of concrete protective layer falling off, less transverse restraint stirrups, etc., and achieves convenient node handling, reduced cross-sectional size, and good fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

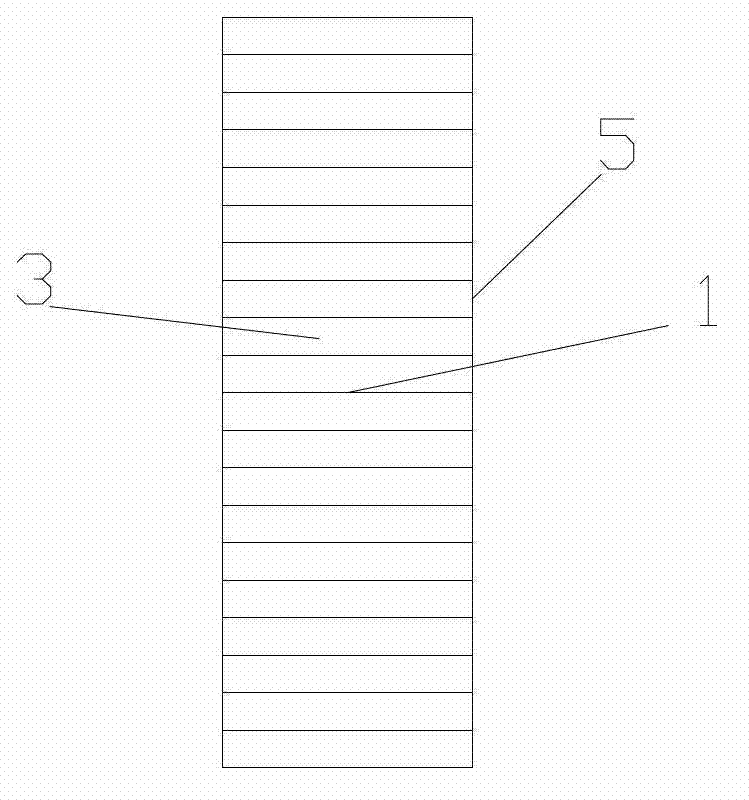

[0036] All longitudinal steel bars and stirrups are processed by professional steel bar processing companies through CNC steel bar processing machines. The size error of longitudinal steel bars is controlled within ±5mm, and the size error of stirrups is controlled within ±1mm.

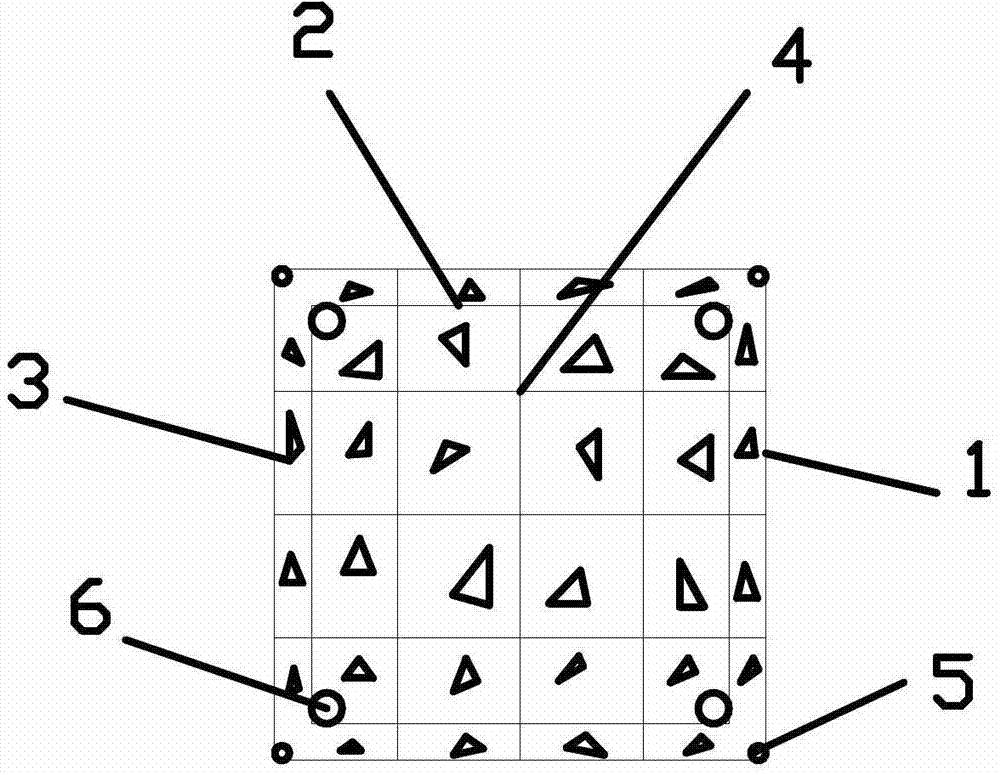

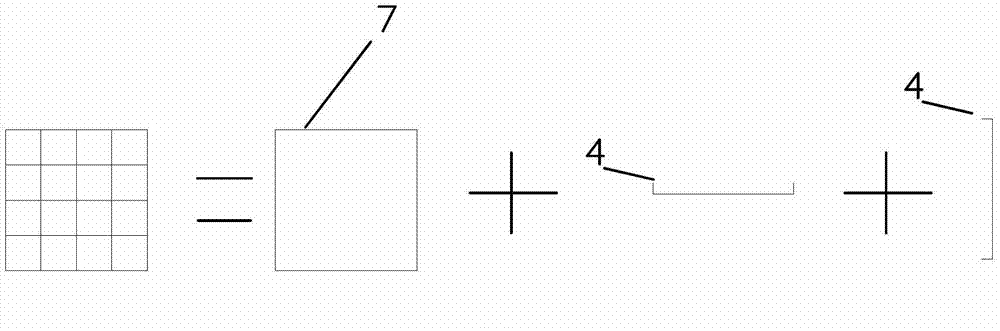

[0037] The closed stirrup 7 can be obtained by lap welding, double-sided welding, the lap length is not less than 5d, and single-sided welding, the lap length is not less than 10d, where d is the diameter of the steel bar.

[0038] Tie bar 4 should leave a 90-degree hook on both sides during processing. The length of the horizontal section of the hook is not less than 5d when double-sided welding, and the length is not less than 10d when single-sided welding, where d is the diameter of the steel bar.

[0039] Closed stirrups 1 and 2 are obtained by welding closed stirrups 7 and tie bars 4 .

[0040] Bind the stirrups and longitudinal steel bars according to the design drawings, support the formwork, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com