Patents

Literature

48results about How to "Low steel content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

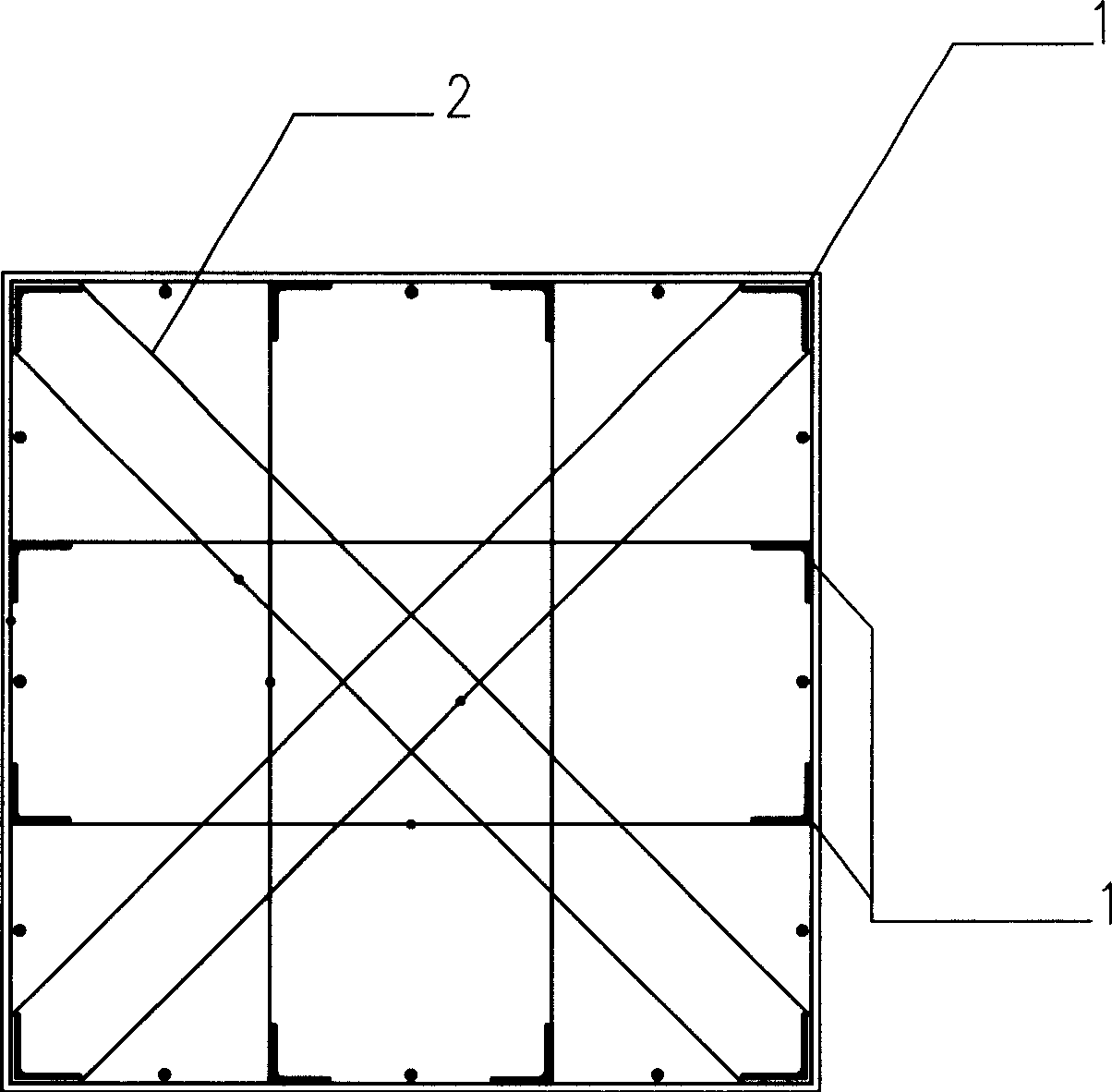

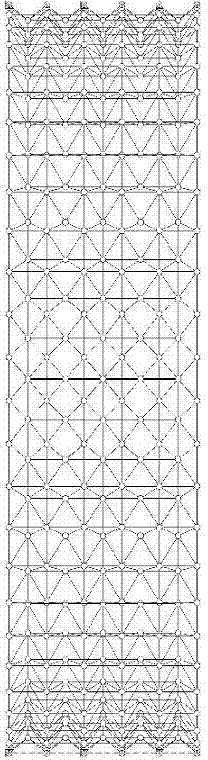

Super large span double-layer network frame dome construction technique

ActiveCN101440644AShorten the timeLow costGeometric CADBuilding roofsArchitectural engineeringConstruction management

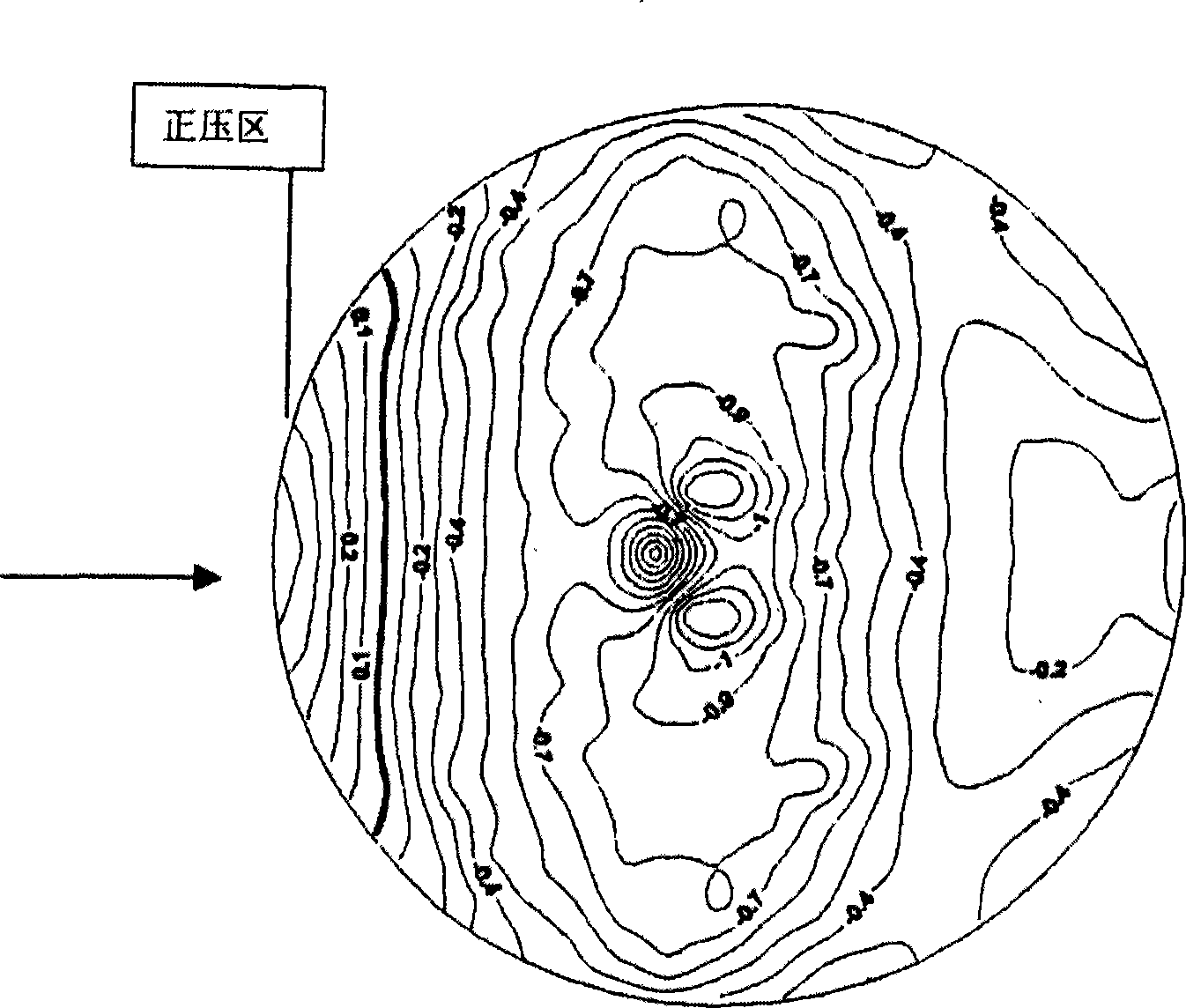

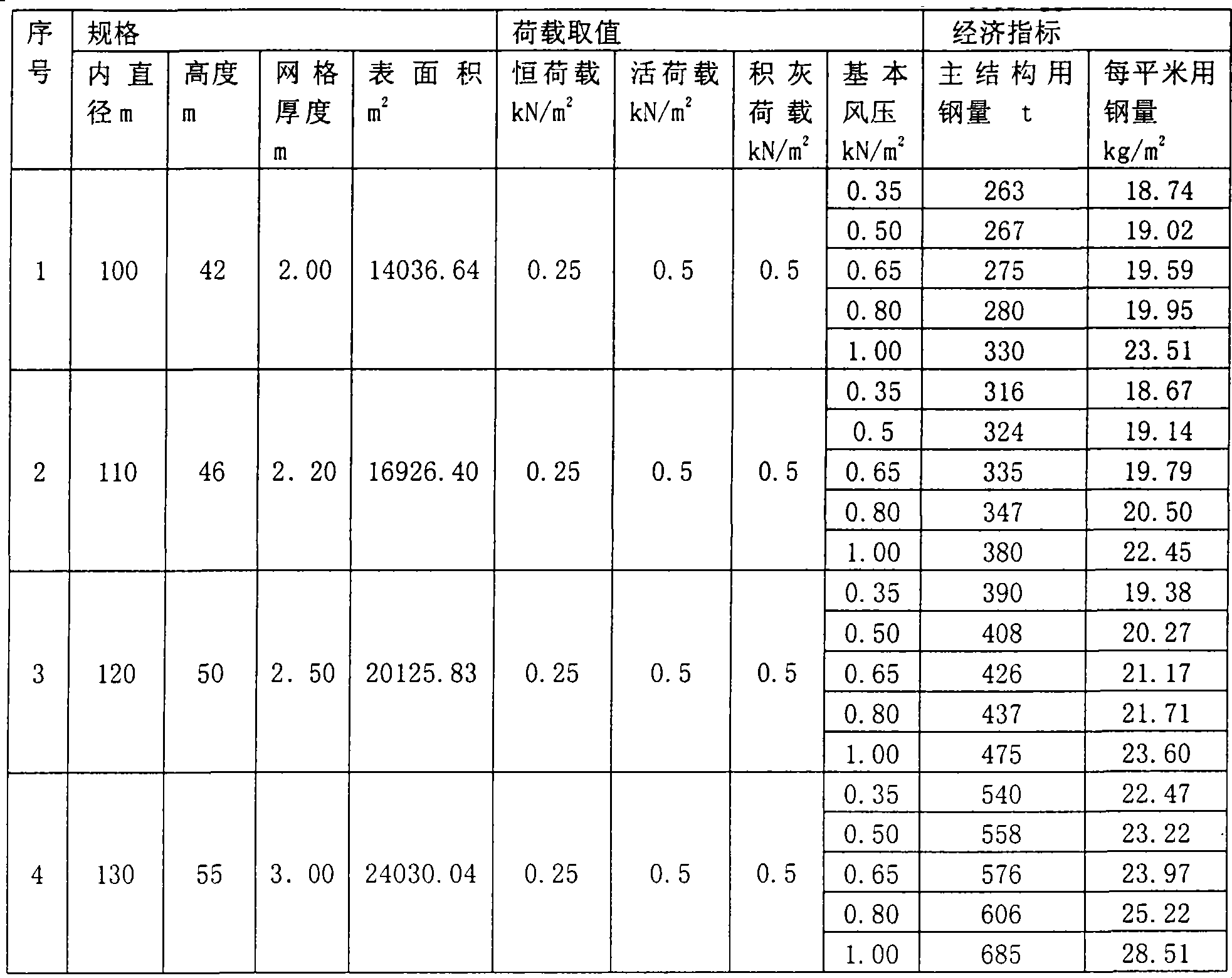

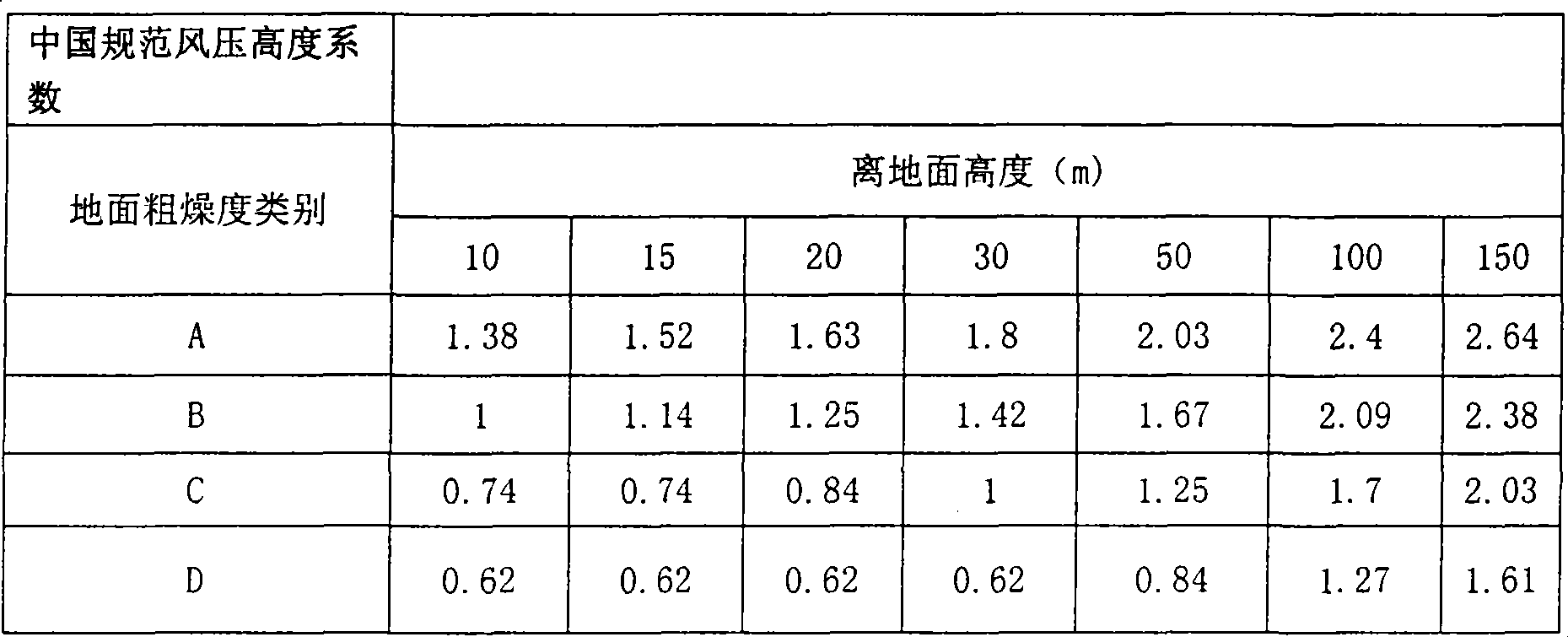

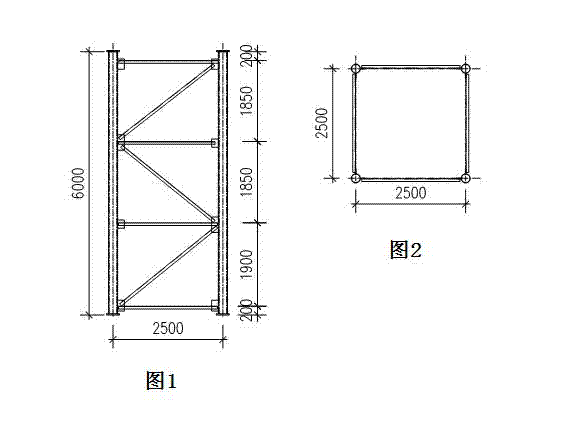

The invention provides a super-large span double-layer net rack dome construction process. The process is characterized in that computer wind tunnel simulated software is used to compute wind load of grid to replace wind tunnel test of the whole spherical shell, so that the accurate steel consumption can be worked out; according to the steel consumption in each square meter, the sizes and nodes of members are worked out; in construction, by ring-by-ring construction closing and a small standing derrick sling, small splicing units are lifted, thereby solving the problems of difficult construction and overcoming the defects of difficult construction management and high cost due to full framing construction. The process has the advantages of greatly reducing steel consumption, shortening construction period by more than 50 percent, and substantially lowering construction cost.

Owner:XUZHOU ZM BESTA HEAVY STEEL STRUCTURE

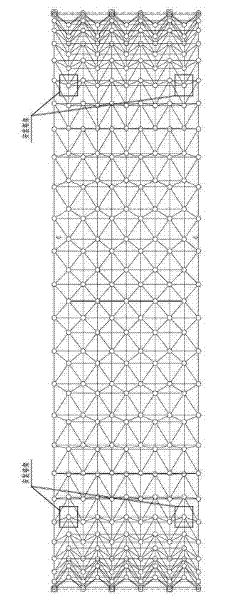

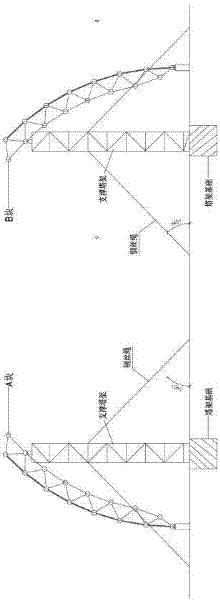

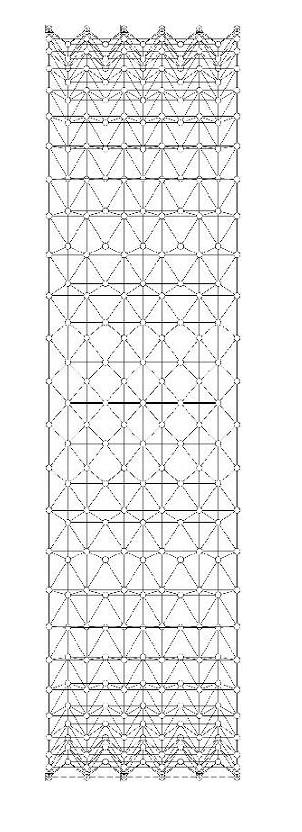

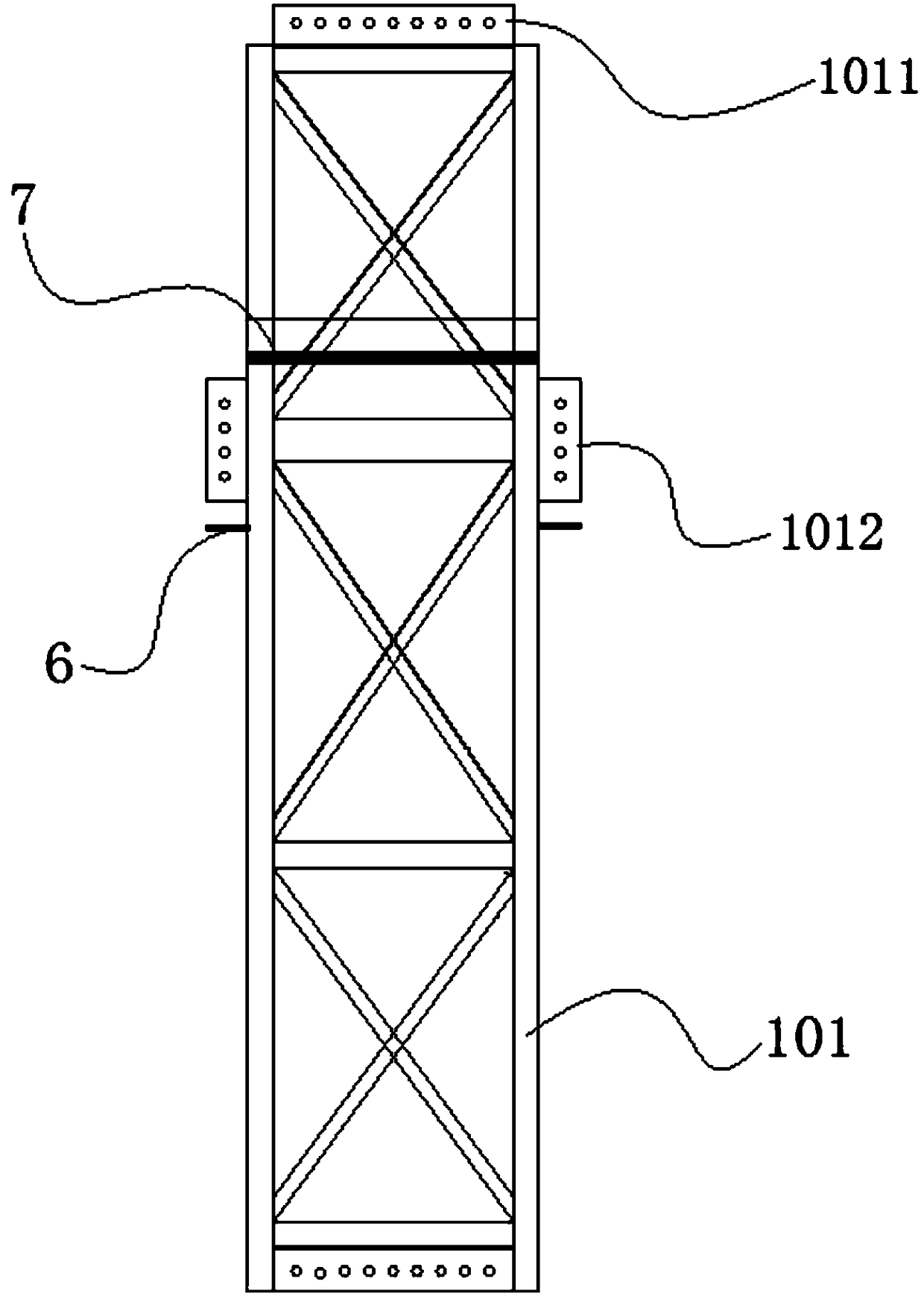

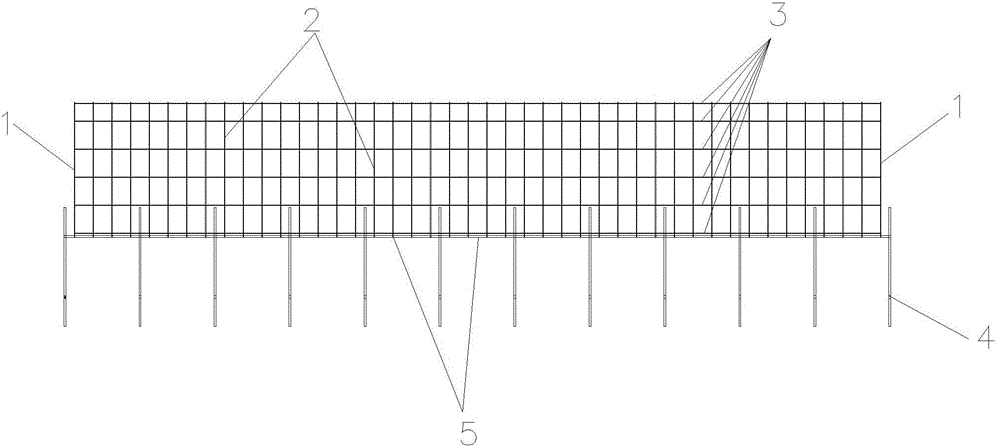

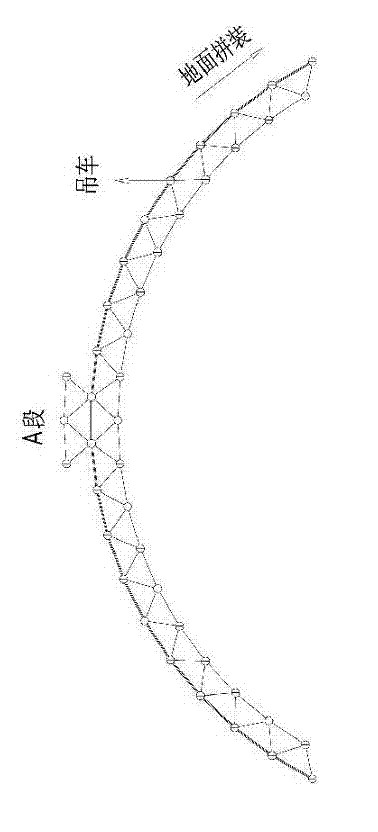

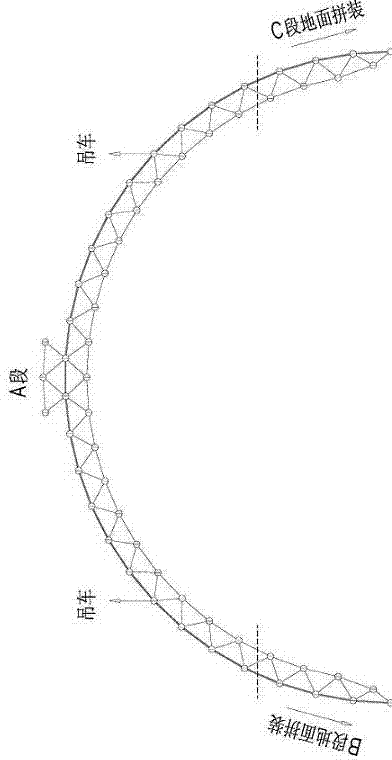

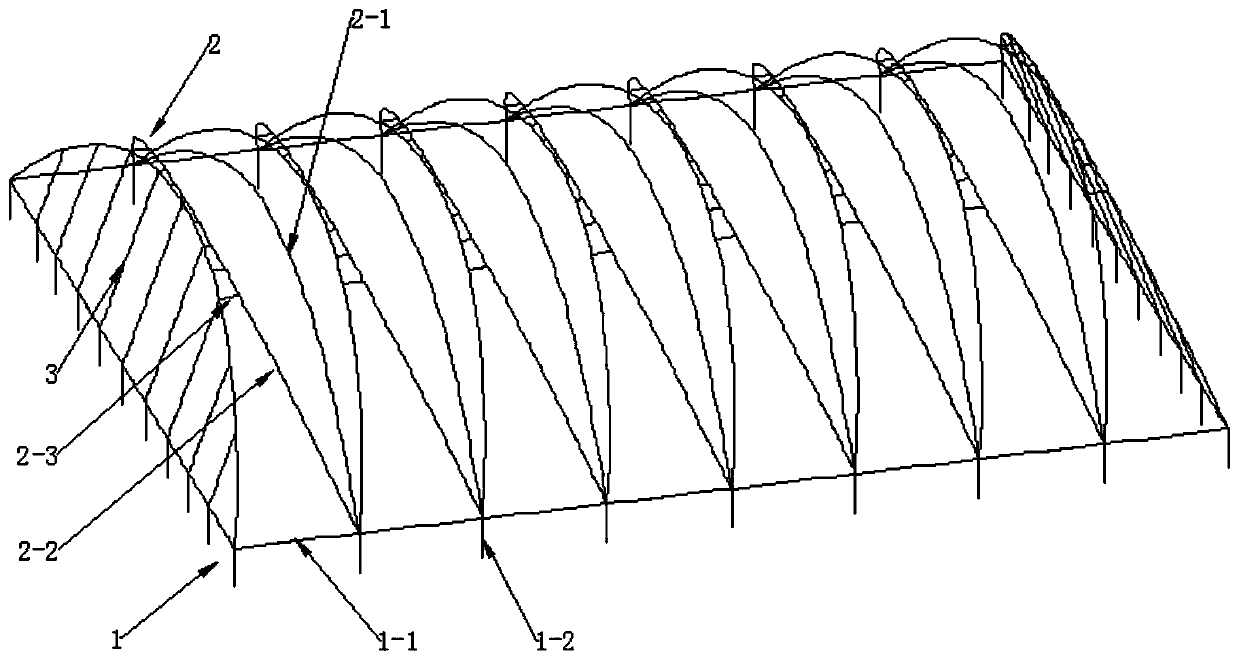

Construction process of ultra-large-span net-frame arch-shaped shed type storage silo

ActiveCN102337785AImprove accuracyShorten the timeLoad-supporting elementsBuilding material handlingFinite element algorithmEngineering

The invention relates to a construction process of an ultra-large-span net-frame arch-shaped shed type storage silo, which is characterized by comprising: obtaining dimensions of node rods of a net frame via a CFD (computational fluid dynamic) numerical wind tunnel computing technology and a finite element algorithm at first according to local weather conditions, the most adverse weather conditions and physical parameters of an arch-shaped shed, i.e. the ball head diameter of each node and geometric parameters of the rods on each node, and preparing a construction drawing, wherein the construction drawing at least comprises the serial number of each node and the number of rods on each node; and dividing construction steps into installation of basic units and installation of overhead cantilever units. Scaffolds are not needed to be erected in a whole house. The invention has the advantages that the time and materials can be saved, and the process is safe and reliable.

Owner:XUZHOU ZM BESTA HEAVY STEEL STRUCTURE

Profiled angle steel reinforced concrete structure, structure and member combination

InactiveCN1837527AFew structural partsLose weightStrutsBulkheads/pilesReinforced concreteMaterial consumption

The invention relates to a special angle iron steel bar concrete structure, which uses the special angle iron steel bar concrete into construction. The invention can reduce the size of element, reduce the weight, reduce the material consumption, reduce the pollution, and simplify the operation.

Owner:黄昱元

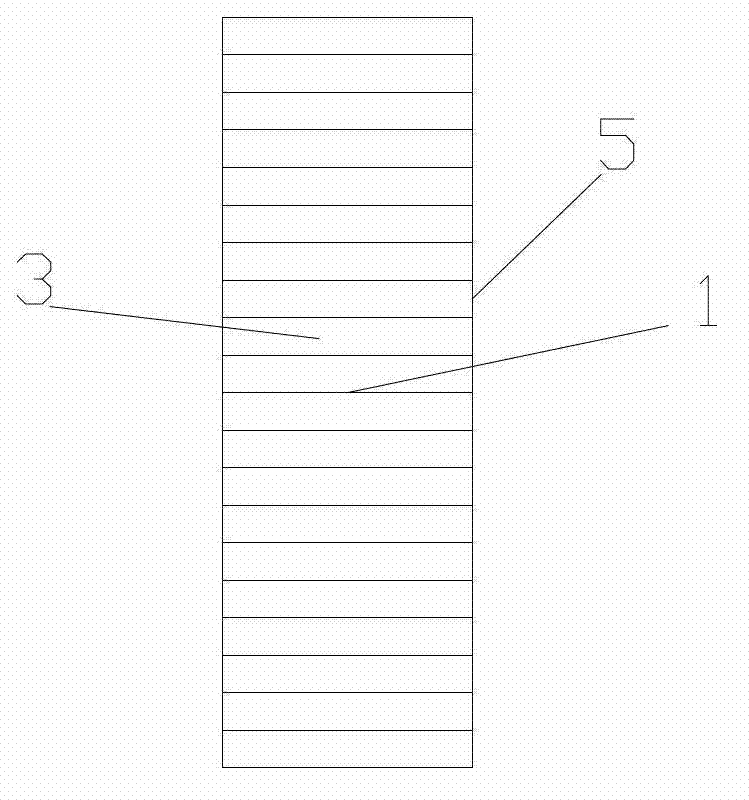

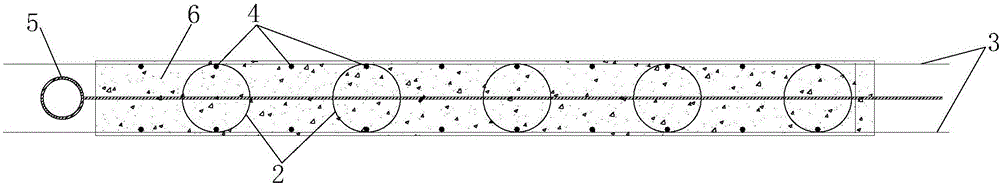

Installation construction process of bolt net rack cylindrical shell storage bin

ActiveCN102425326AImprove accuracyShorten the timeBuilding roofsBuilding material handlingFinite element algorithmStructural engineering

The invention discloses an installation construction process of a bolt net rack cylindrical shell storage bin, which is characterized by comprising the steps of: firstly, according to local meteorological conditions, obtaining sizes of net rack node rod members by adopting a CFD (Computational Fluid Dynamics) numerical value wind tunnel calculation technology and a finite element algorithm according to most disadvantageous conditions and tunnel physical parameters, namely, drawing a construction drawing by using a bulb diameter of each node and a geometric parameter of the rod members arranged on each node, wherein the construction drawing at least comprises a number of each node and the quantity of rod members of each node; and then dividing the construction step into a starting unit installation and an air overhanging unit installation. Due to no need of erecting an accomplished scaffold, the installation construction process has the characteristics of time and material saving, safety and reliability.

Owner:XUZHOU ZM BESTA HEAVY STEEL STRUCTURE

Frame-supporting column with high strength steel bars and super high strength concrete

InactiveCN103046692AReduce section sizeIncrease ultimate strainStrutsPillarsHigh strength concreteReinforced concrete

The invention relates to a reinforced concrete frame-supporting column, in particular to a frame-supporting column with high strength steel bars and super high strength concrete. The frame-supporting column overcomes defects that axial compression ratio limits of ordinary reinforced concrete frame-supporting columns and steel reinforced concrete frame-supporting columns are low, protective covers fall easily under earthquake force, longitudinal bars and steel flanges are easy to bend, the columns are difficult to repair after an earthquake, and high strength steel bars and super high strength concrete cannot be applied, and defects that node constructions of steel reinforced concrete and steel pipe concrete frame-supporting columns are complex, the steel pipe concrete frame-supporting columns do not constrain concrete fully, and steel pipes are easy to bend. The frame-supporting column comprises longitudinal high strength steel bars, high strength closed stirrups and self-compaction super high strength concrete; and constraints include that stirrup spacing of concrete protective covers in whole concrete ranges from 30mm to 35mm, outer surfaces are aligned to outer surfaces of concrete frame-supporting columns, and the stirrup spacing of longitudinal high strength steel bars is constrained to range from 60 mm to 120 mm. By aid of constraining of closely-matched high strength welding closed stirrups on the whole concrete, mechanical properties of super high strength concrete are improved, anti-seismic properties of the column are improved, and the frame-supporting column has a wide application prospect in high-rise or super high-rise structures.

Owner:贵州中建伟业建设(集团)有限责任公司

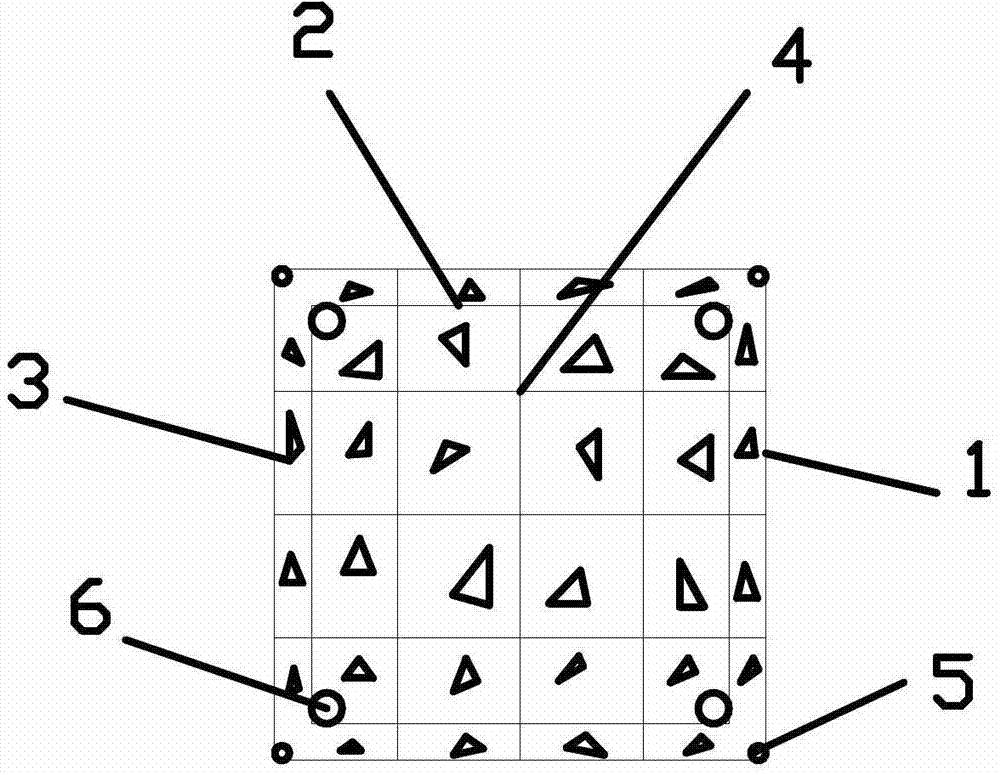

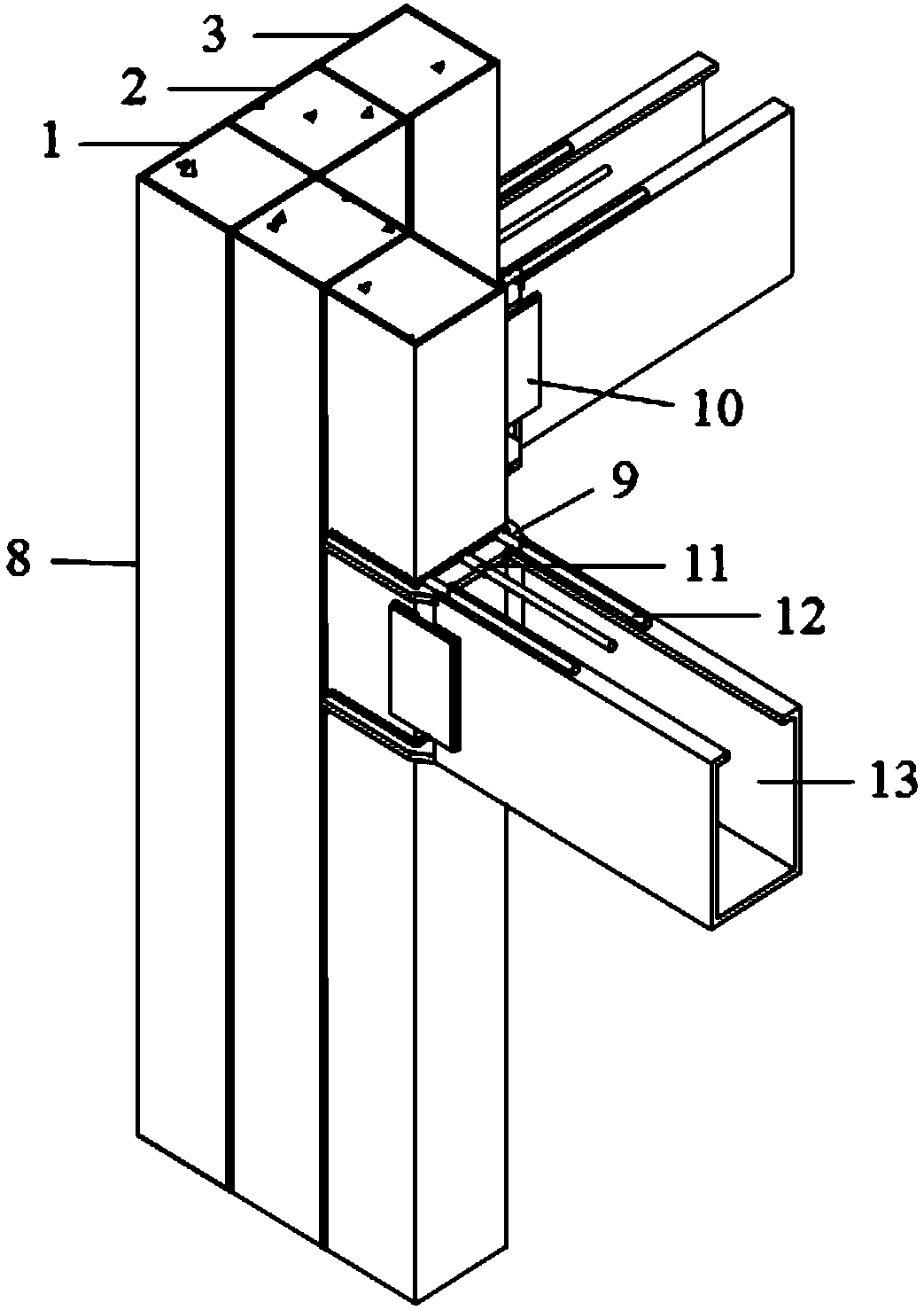

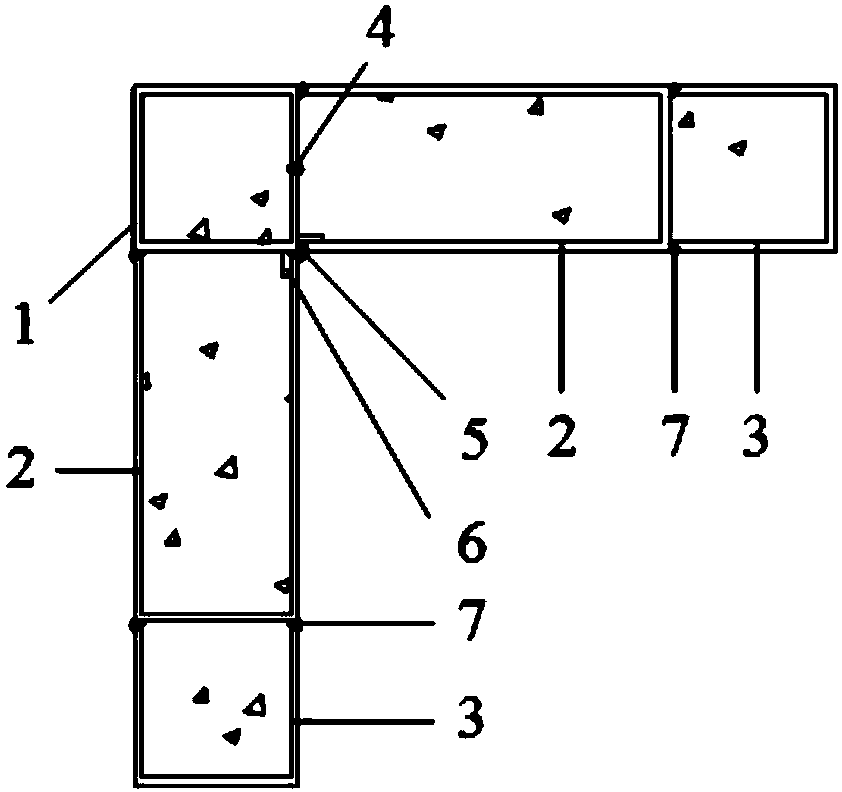

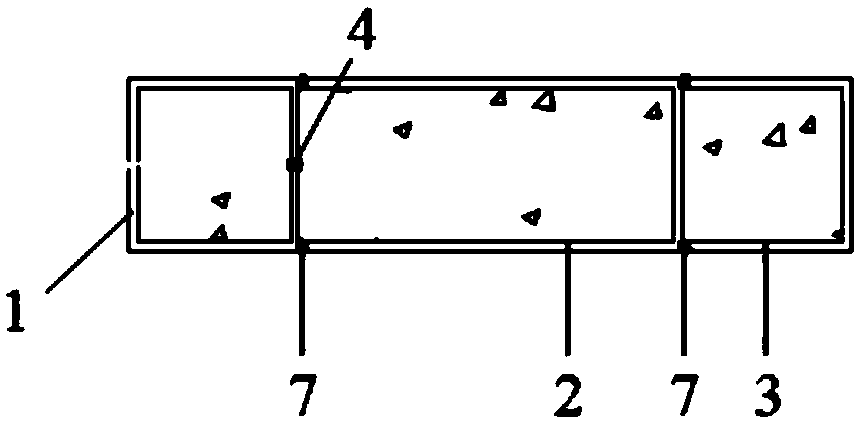

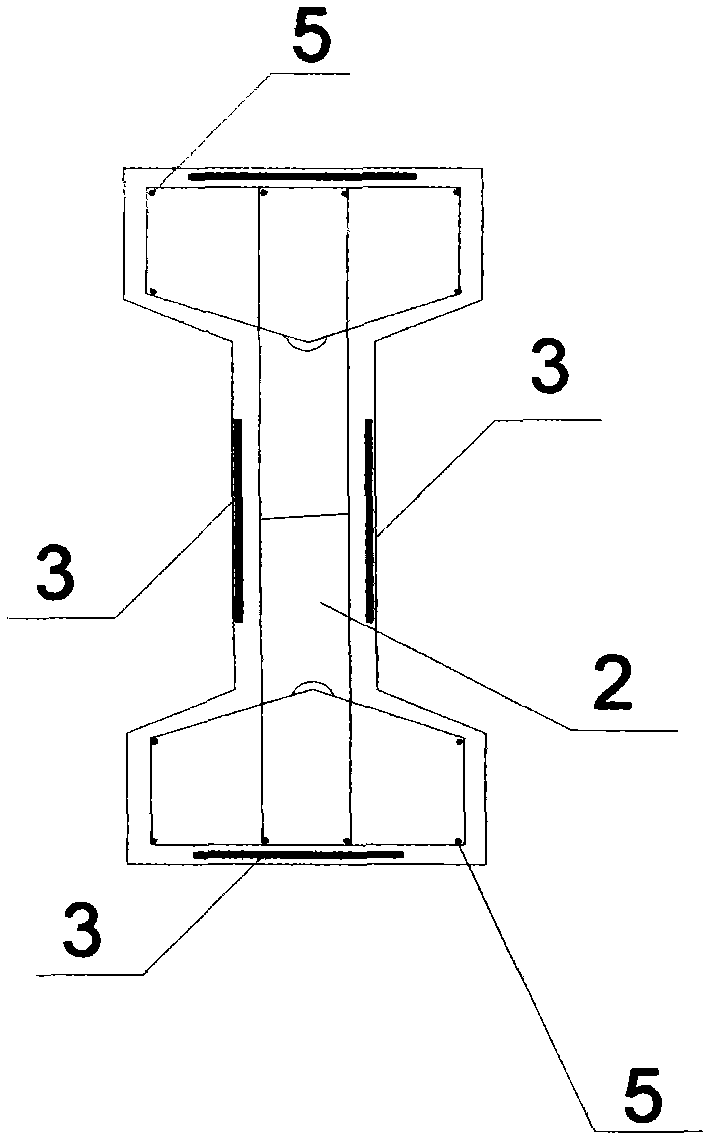

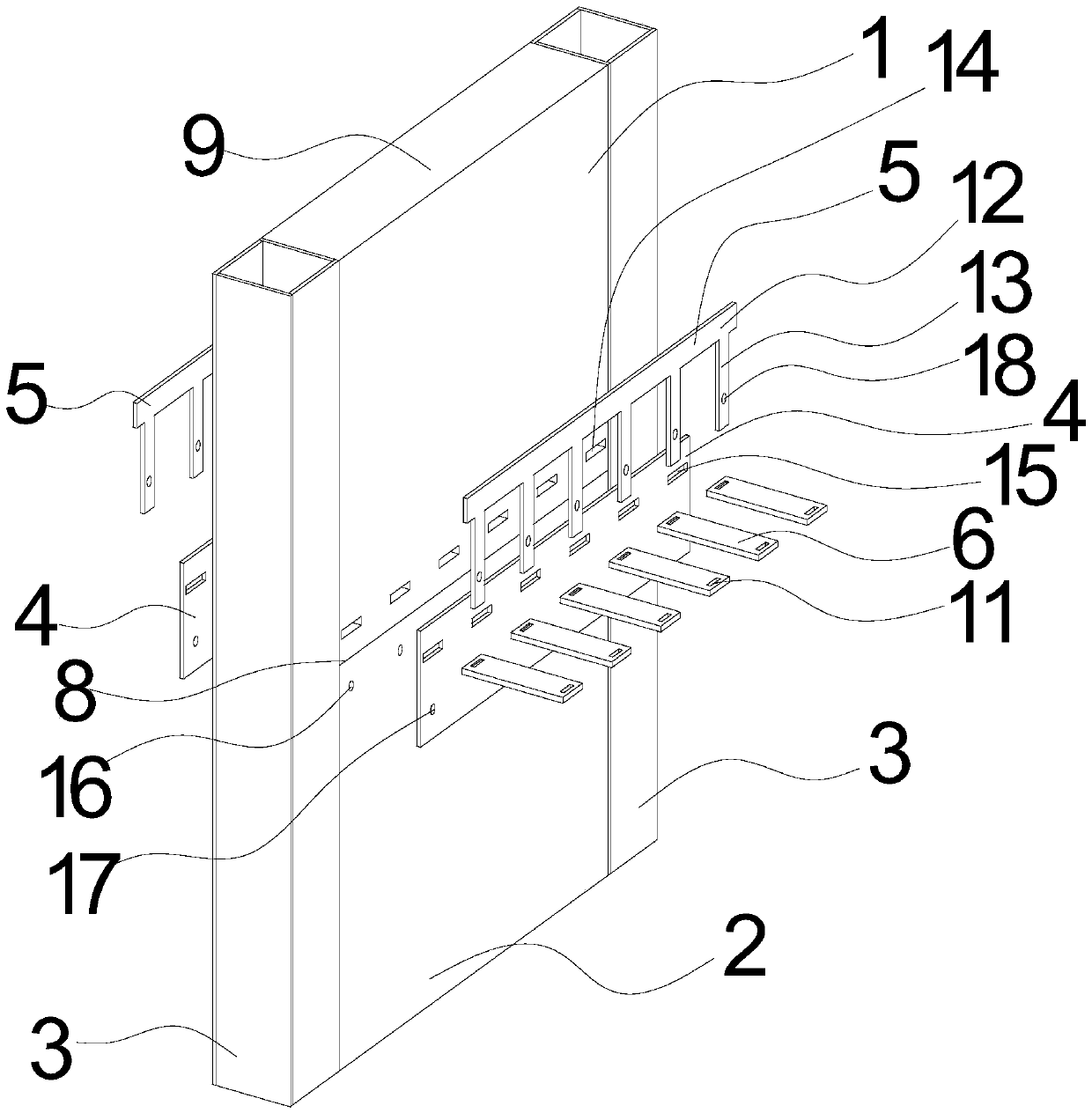

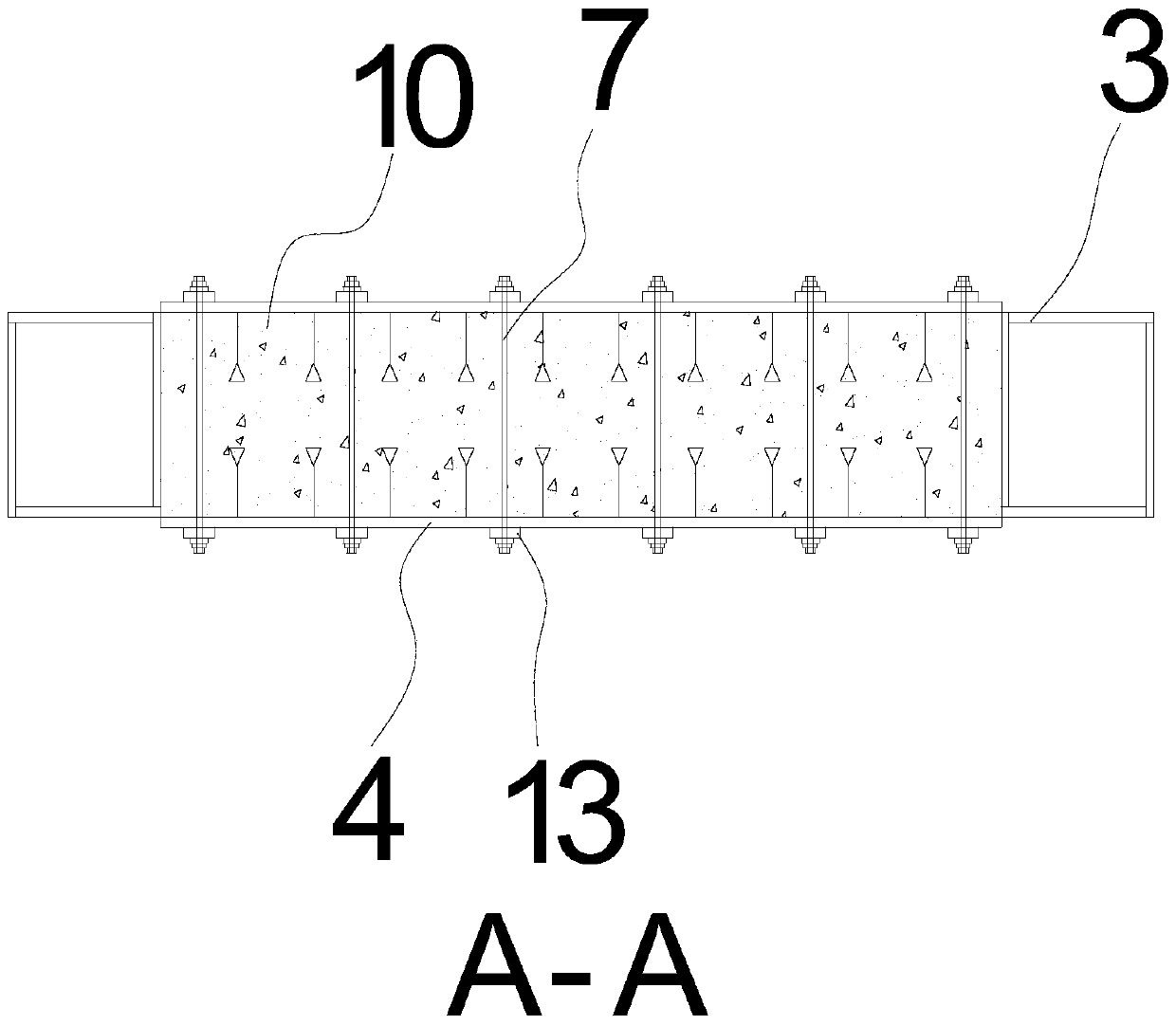

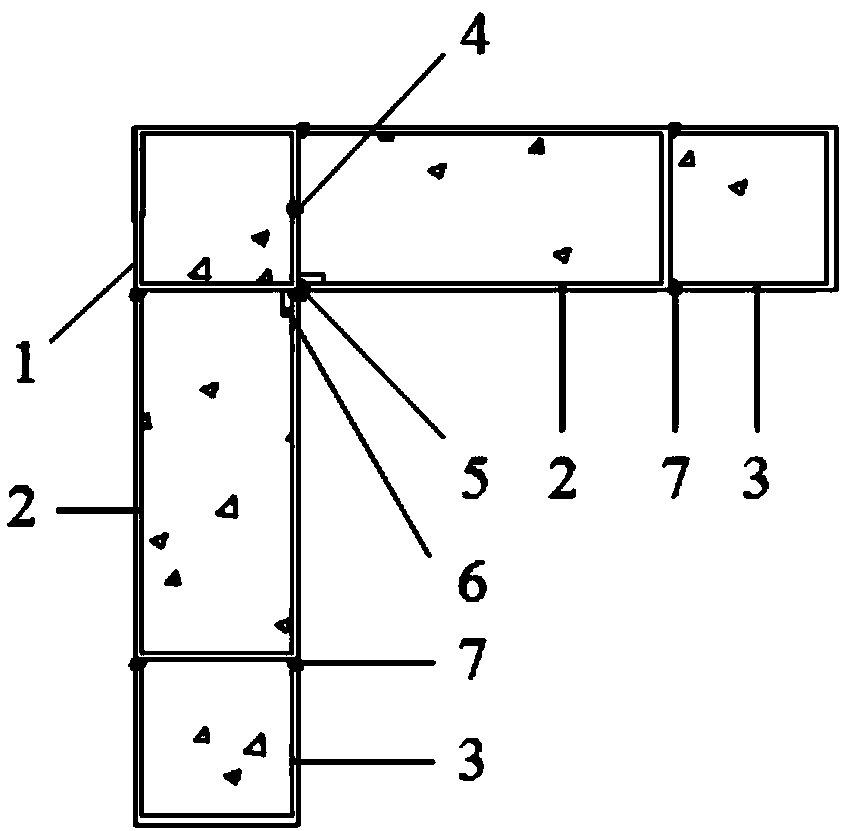

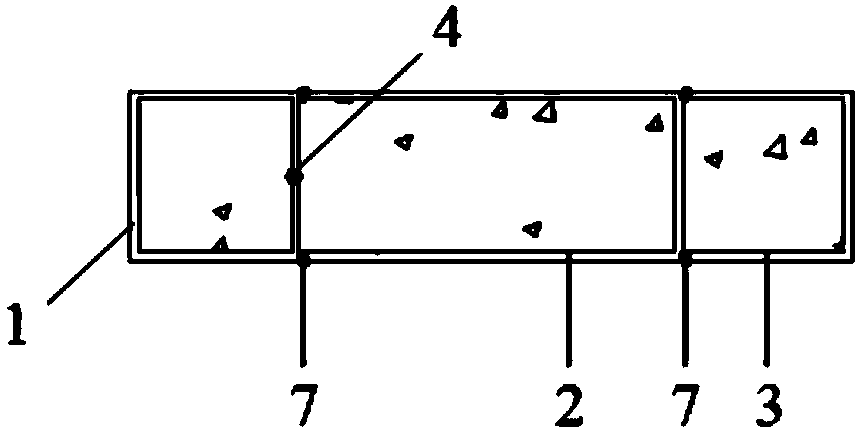

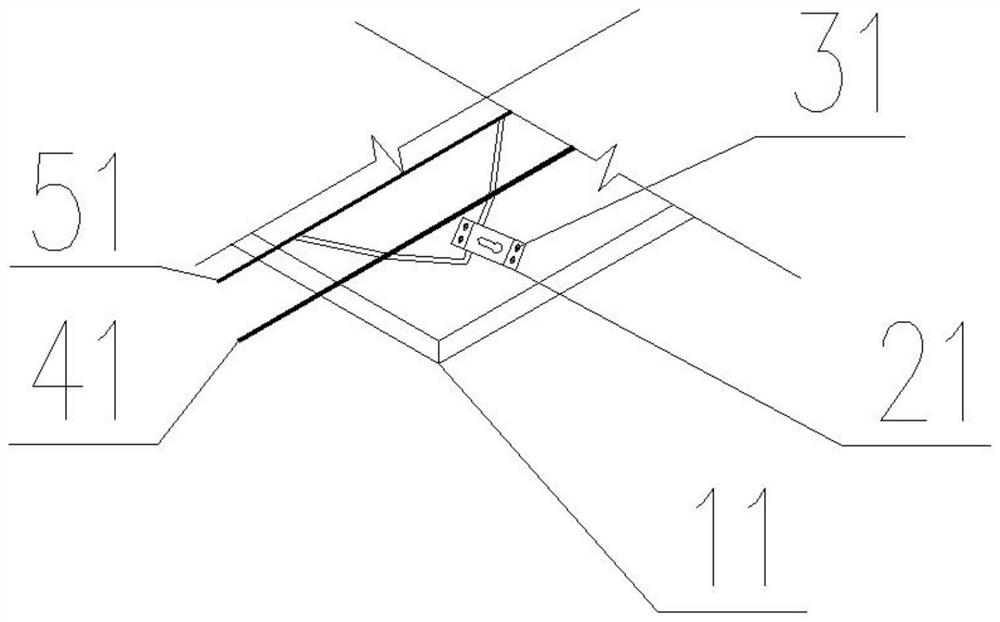

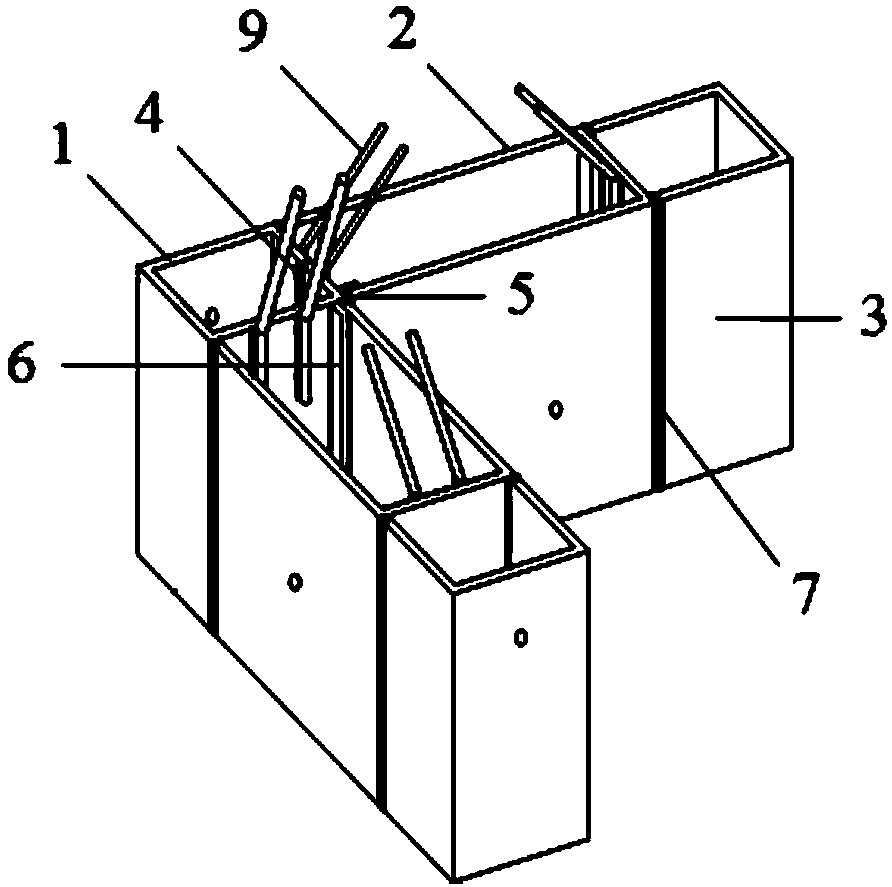

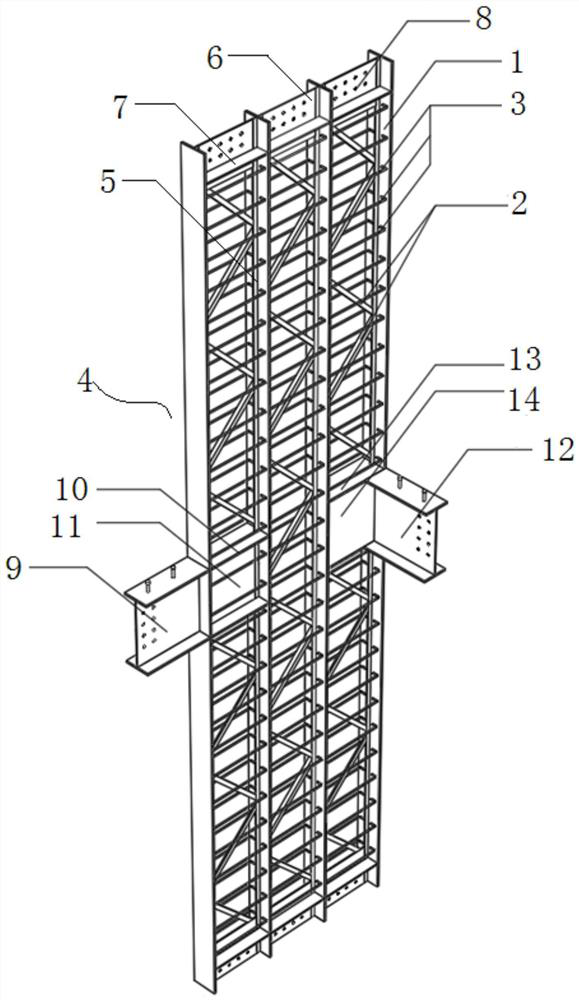

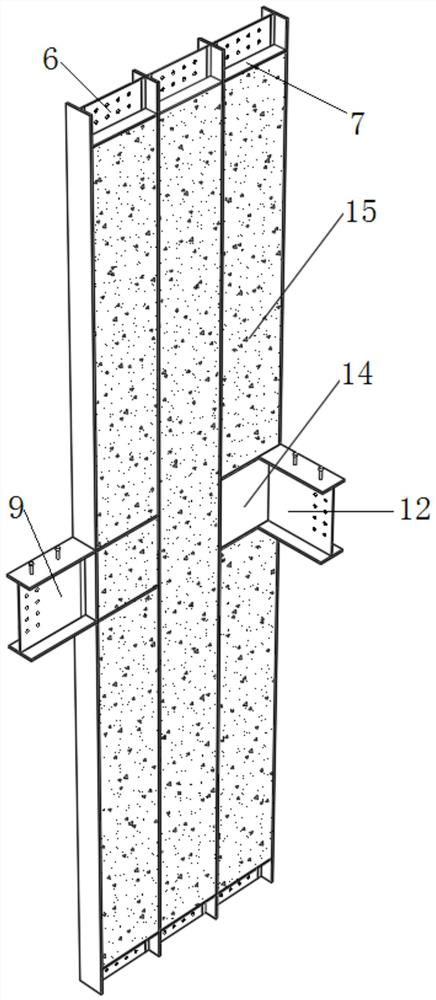

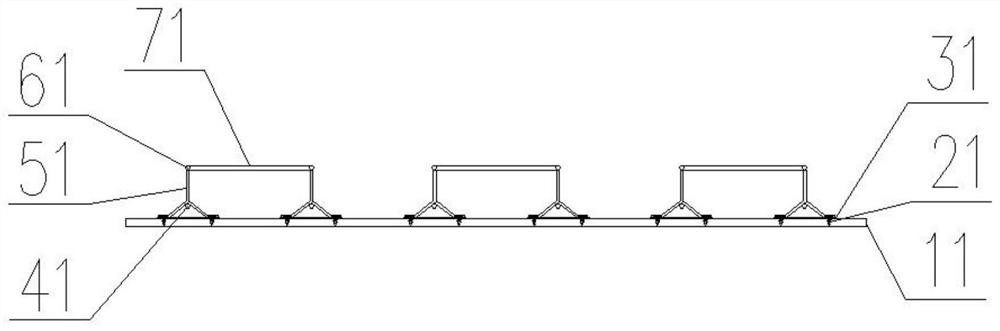

Rigid connection joint of cold-bending multi-cavity steel tube concrete special-shaped column and U-shaped combination beam

PendingCN108104271AImprove utilization efficiencyImprove exposed defectsBuilding constructionsSheet steelEngineering

The invention provides a rigid connection joint of a cold-bending multi-cavity steel tube concrete special-shaped column and a U-shaped combination beam. The machining method is described in that a thin-walled steel plate is machined to be a core column steel tube in cold-bending and welding methods; then, the side surfaces of the core column steel tube is taken as column-rib connection surfaces with the core column steel tube as the center; U-shaped members formed by cold bending are welded; end-column steel tubes are welded with flange connection boards and multiple sleeves; above-mentionedprefabricated members are finished, delivered to the site and welded with negative-bending longitudinal bars; then, the prefabricated members are connected with cold-bending U-shaped steel beams together; next, cavities of steel tubes are filled with concrete in order to manufacture the rigid connection joint of an in-line, L-shaped, T-shaped, or cross-shaped cold-bending multi-cavity steel tube concrete special-shaped column and a U-shaped steel beam. The U-shaped steel beam serves as a template. There is no need to install any template for concrete pouring. The factory prefabrication processcan help reduce construction time. Additionally, the joint is good in mechanical property, convenient in construction and cost-effective and reasonable. The joint has a joint form with a combinationstructure which enjoys a promising application prospect.

Owner:重庆市中科大业建筑科技有限公司

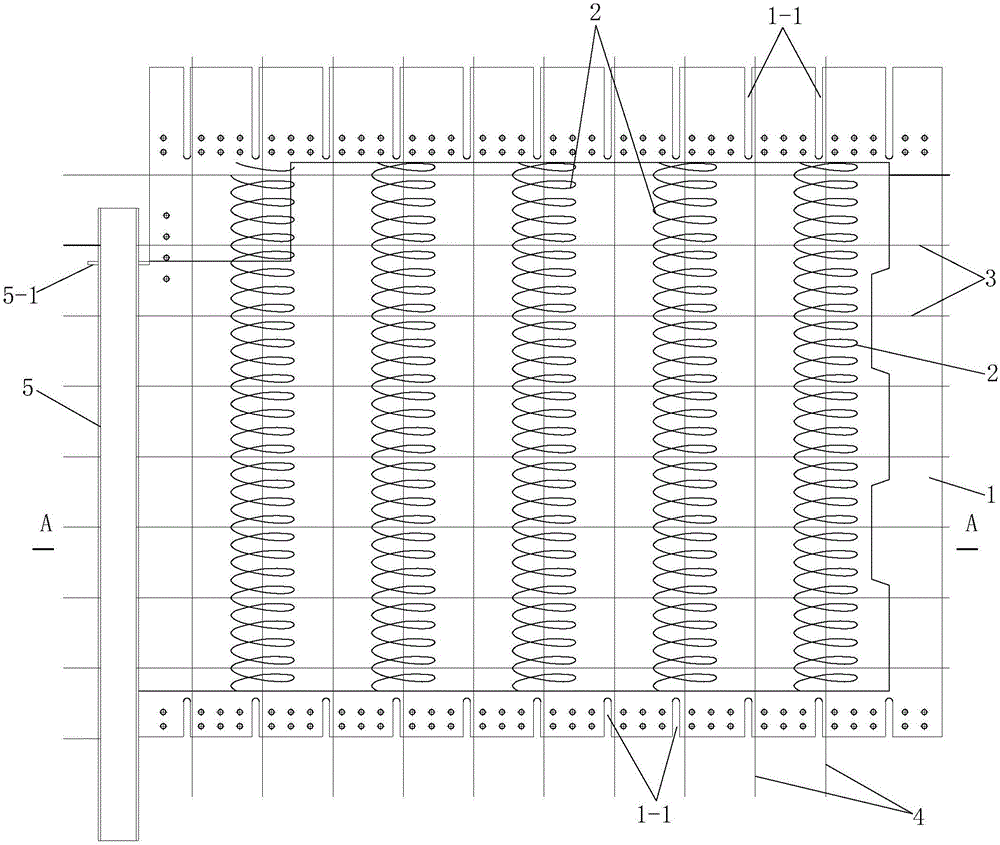

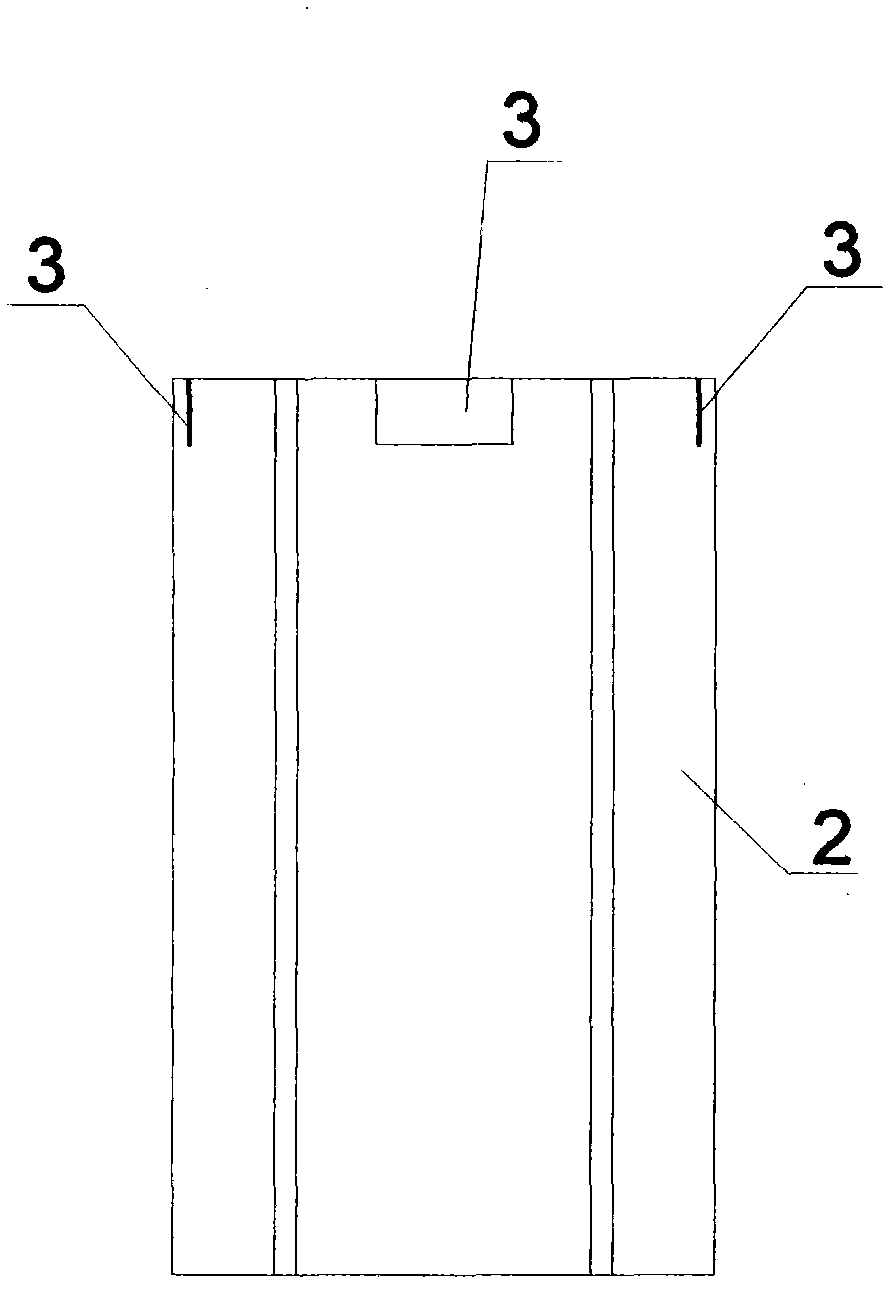

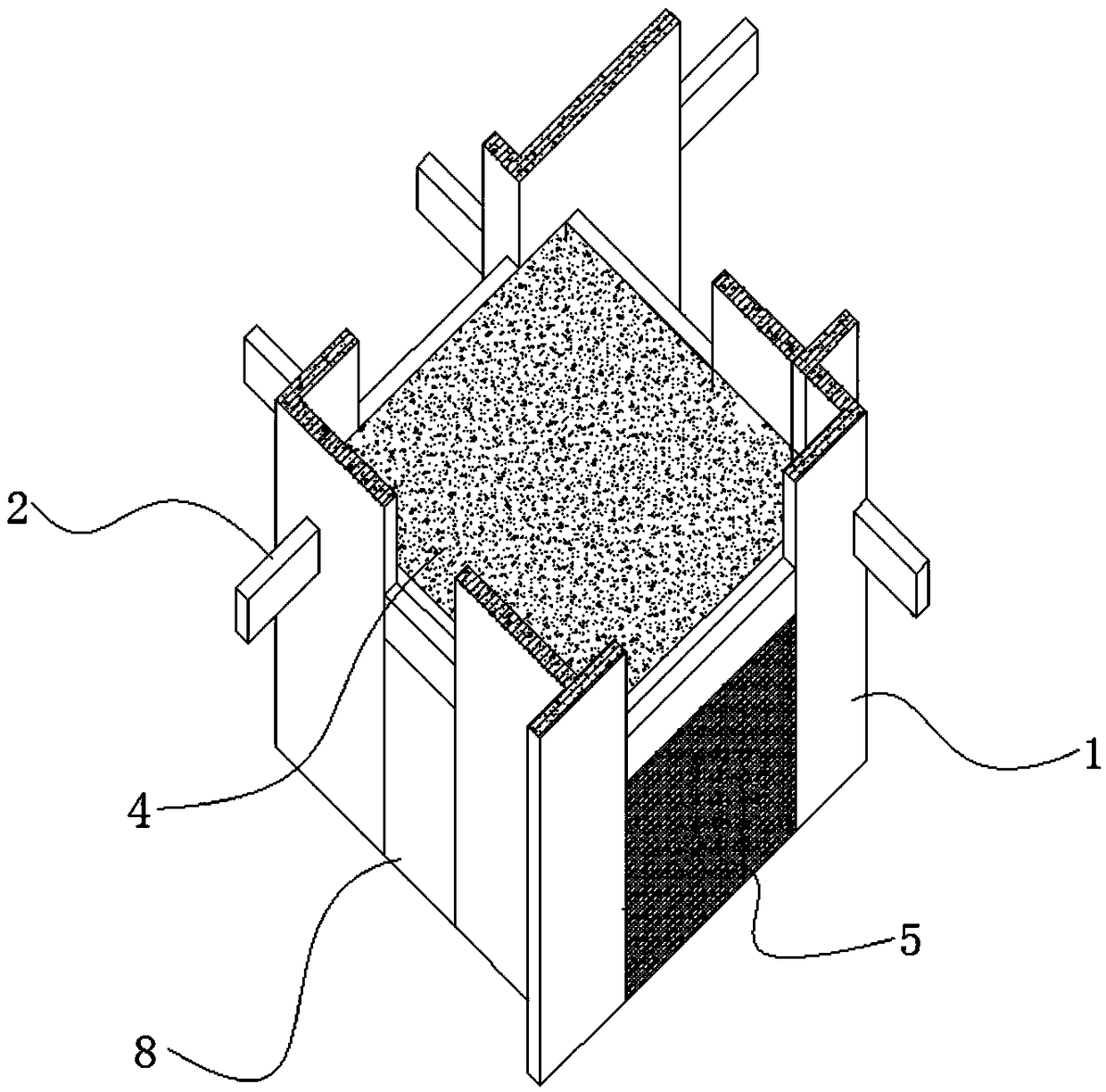

Fabricated structural system of steel plate reinforced concrete shear walls and construction method of fabricated structural system

ActiveCN106639052AReduce section loss rateOvercome the technical difficulty of being unable to fix on the vertical steel plateWallsLoad-supporting elementsFloor slabSheet steel

The invention discloses a fabricated structural system of steel plate reinforced concrete shear walls. The fabricated structural system comprises a beam member, the steel plate reinforced concrete shear walls, a floor and a sleeve connecting piece. Each steel plate reinforced concrete shear wall comprises vertical steel plates and continuous spiral stirrups. The structural system is high in assembling rate. The invention further discloses a construction method of the fabricated structural system of the steel plate reinforced concrete shear walls. The construction method comprises the steps that firstly, one prefabricated steel plate reinforced concrete shear wall is manufactured; secondly, the steel plate reinforced concrete shear wall on the lower layer is assembled; thirdly, the sleeve connecting piece is assembled on the steel plate reinforced concrete shear wall on the lower layer; fourthly, the beam member is assembled, and the floor is installed; fifthly, the floor and the beam member as well as the floor and the steel plate reinforced concrete shear wall on the lower layer are connected by pouring concrete, and concrete is poured to the junction of the beam member and the steel plate reinforced concrete shear wall on the lower layer; and sixthly, the steel plate reinforced concrete shear wall on the upper layer is hoisted, and finally concrete is poured to the junction of the steel plate reinforced concrete shear walls on the upper layer and the lower layer in situ. By adoption of the fabricated structural system of steel plate reinforced concrete shear walls and the construction method of the fabricated structural system, construction can be completed with the high assembling rate.

Owner:陕西省建筑设计研究院(集团)有限公司

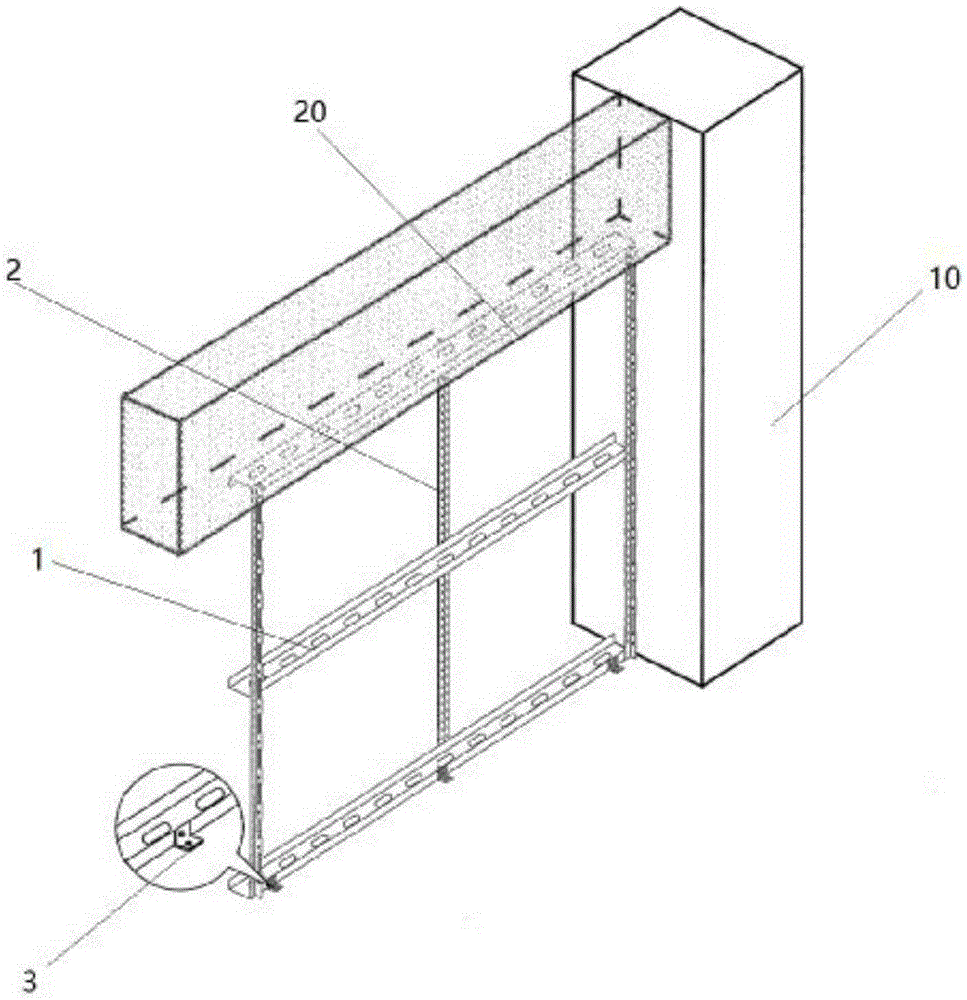

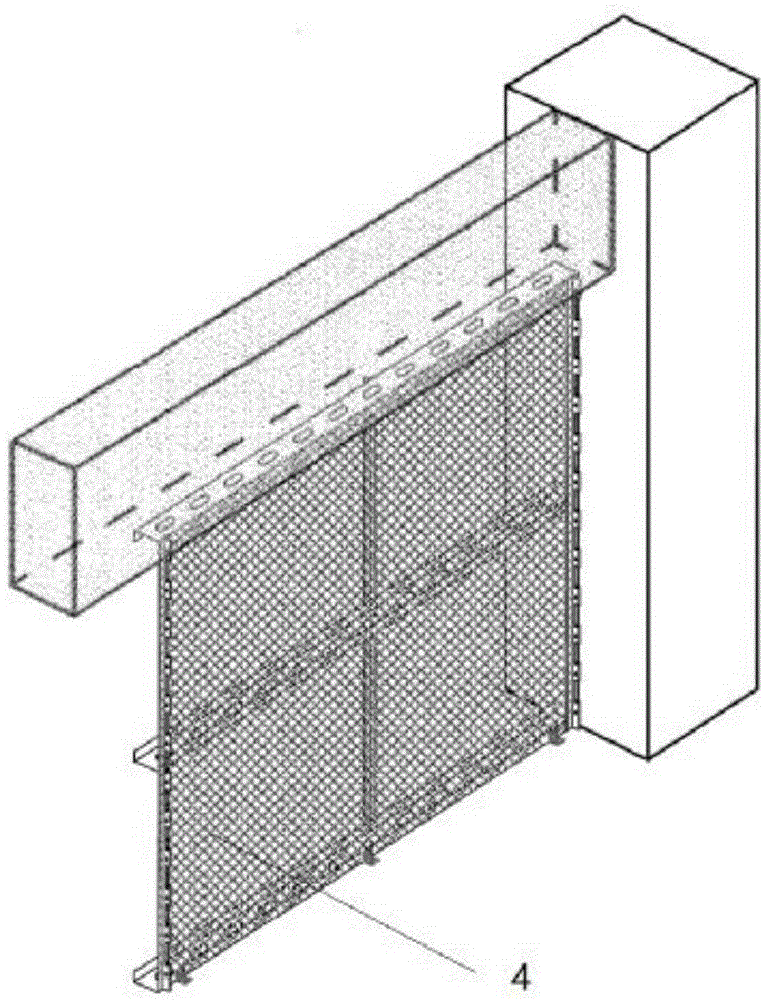

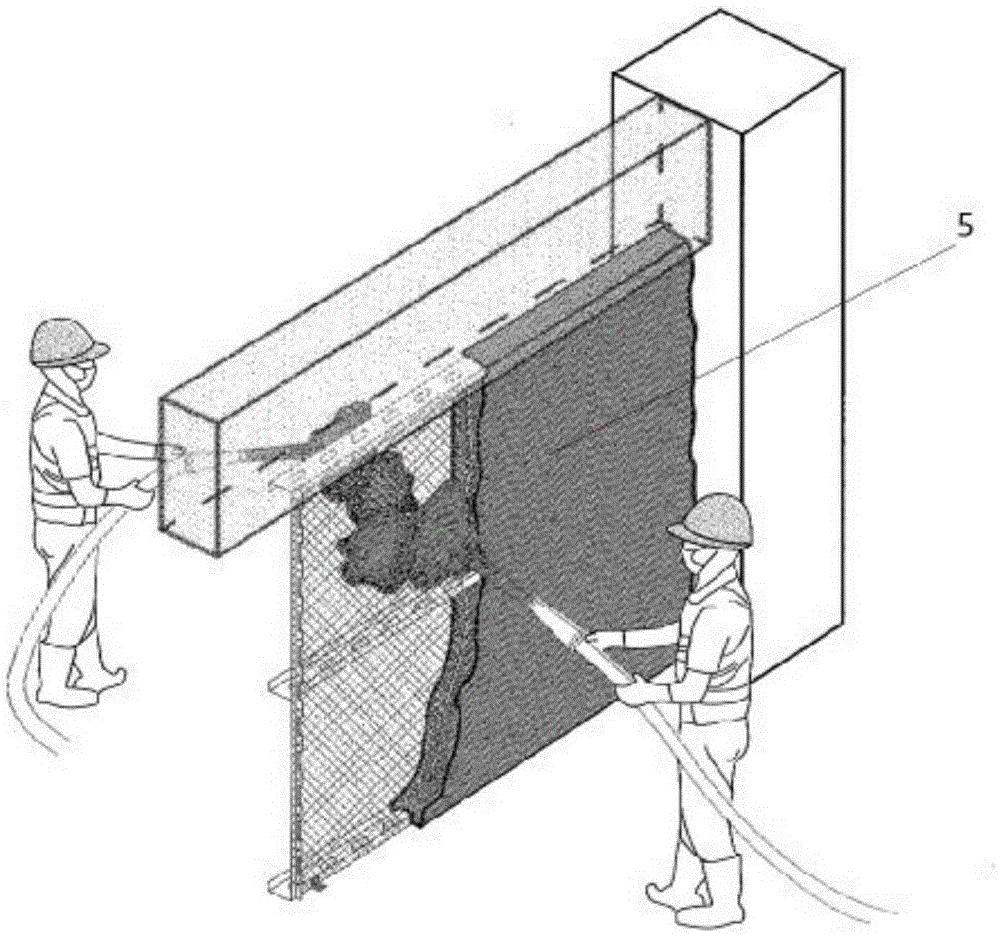

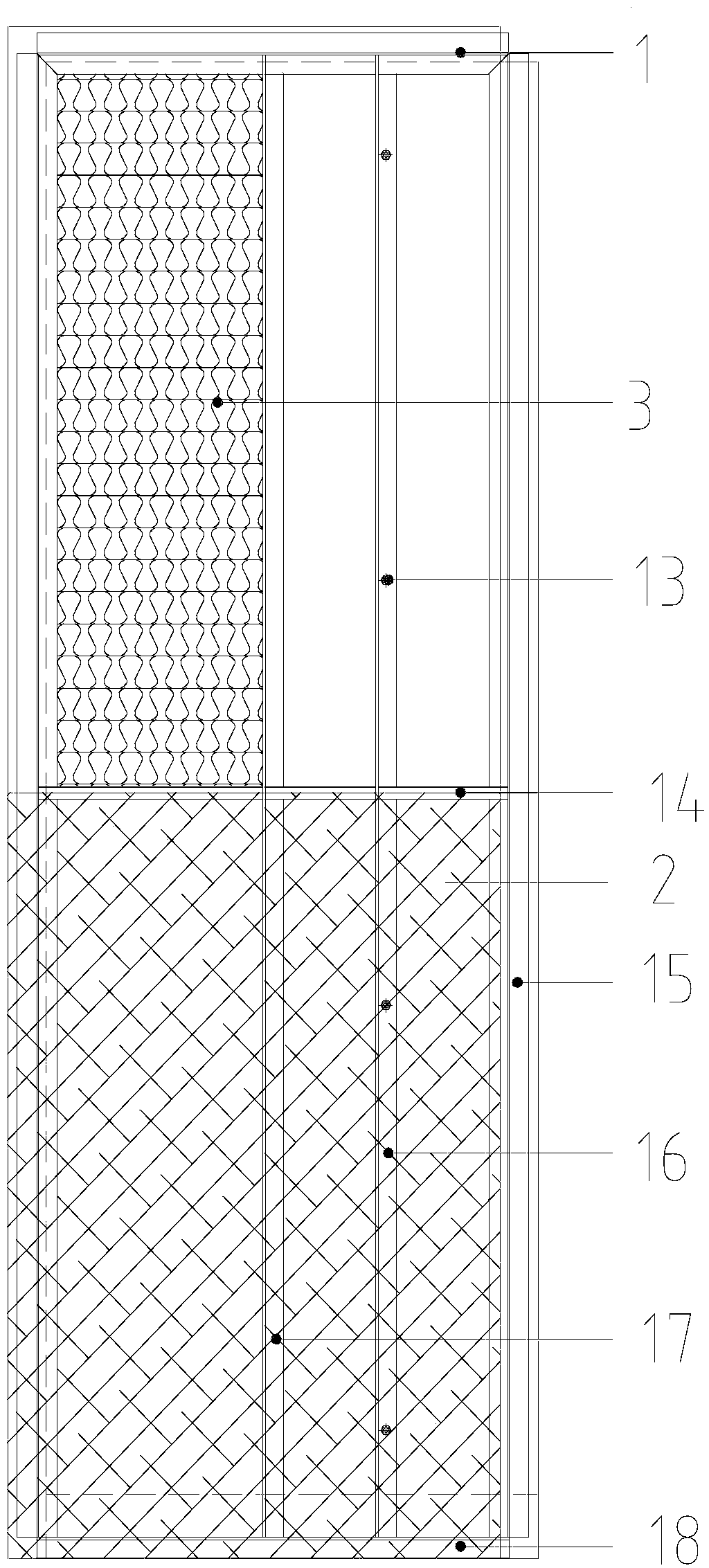

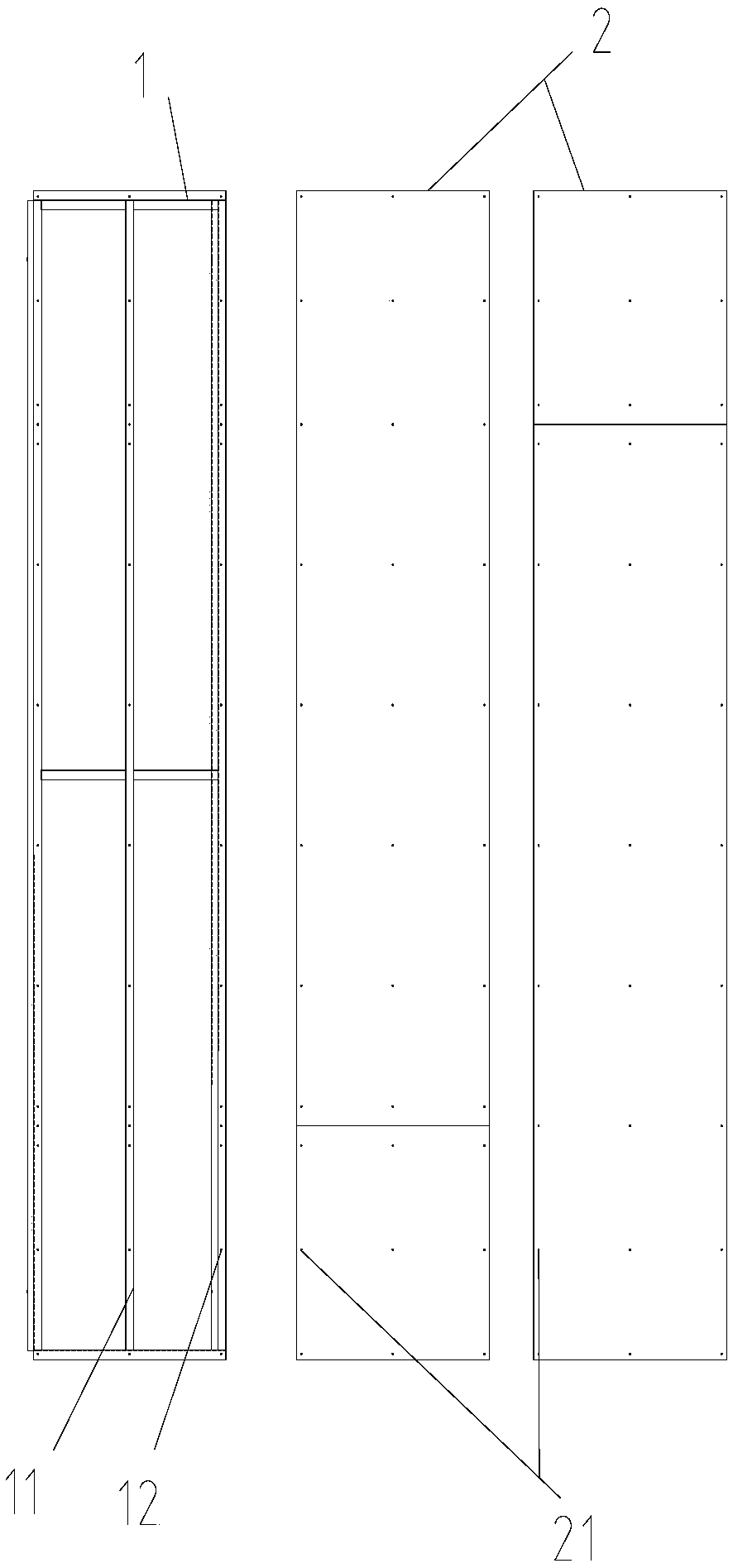

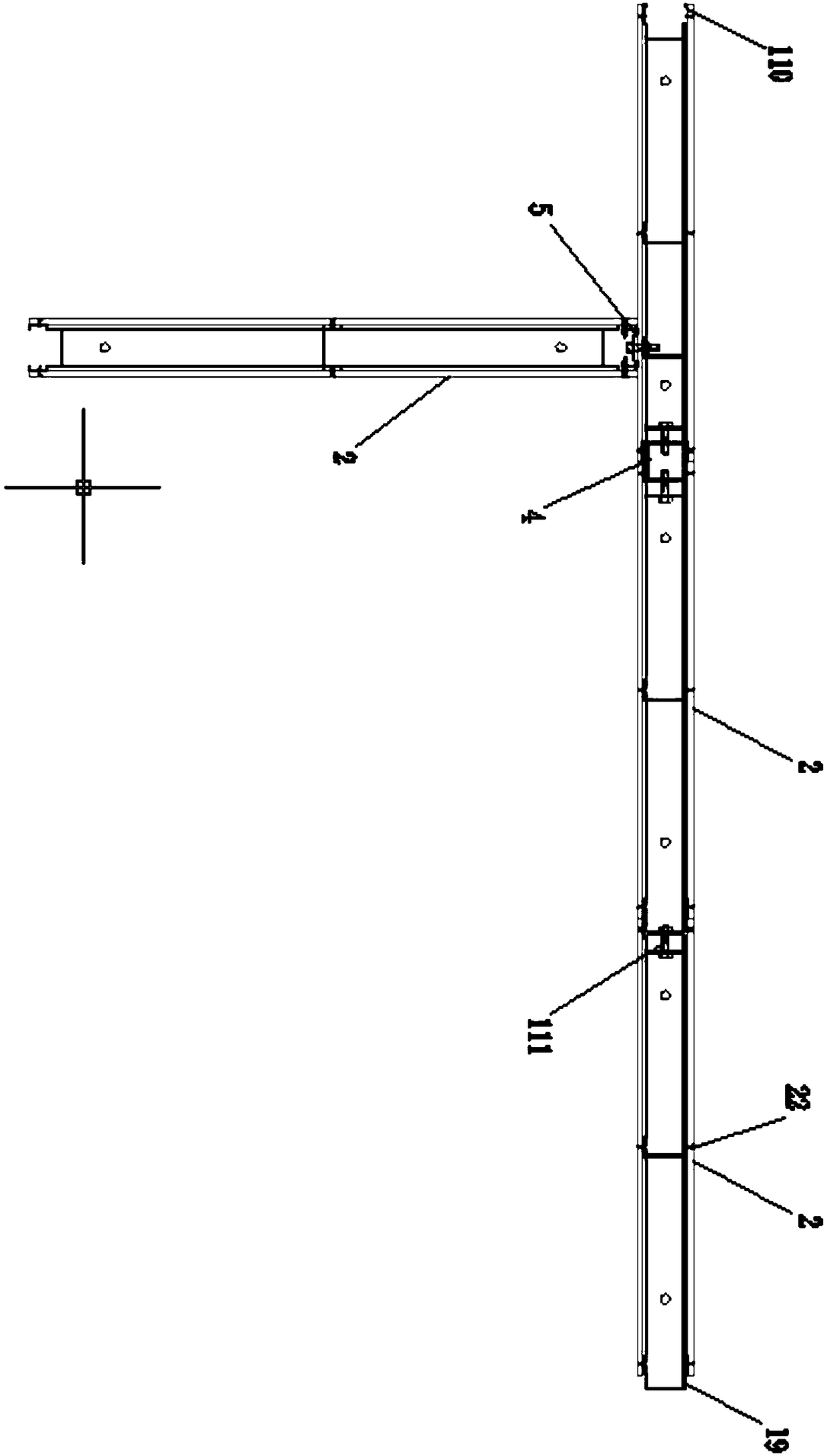

Structured injection wall and construction process thereof

InactiveCN105401671AReduce weightLow steel contentWallsStructured systems analysis and design methodJoist

The invention discloses a structured injection wall and a construction process thereof. The structured injection wall comprises a transverse light steel joist frame and a vertical light steel joist frame, wherein the end parts of the transverse light steel joist frame are fixed on a column; the end parts of the vertical light steel joist frame are respectively fixed on a floor and a beam bottom; a steel wire plate net is fixed on a bracket structure formed by the transverse light steel joist frame and the vertical light steel joist frame; and slurry is coated on the steel wire plate net. The injection wall realizes structural design, is convenient for construction, realizes the wall lightweight, and facilitates to improve the building earthquake resistance.

Owner:翁荣森 +2

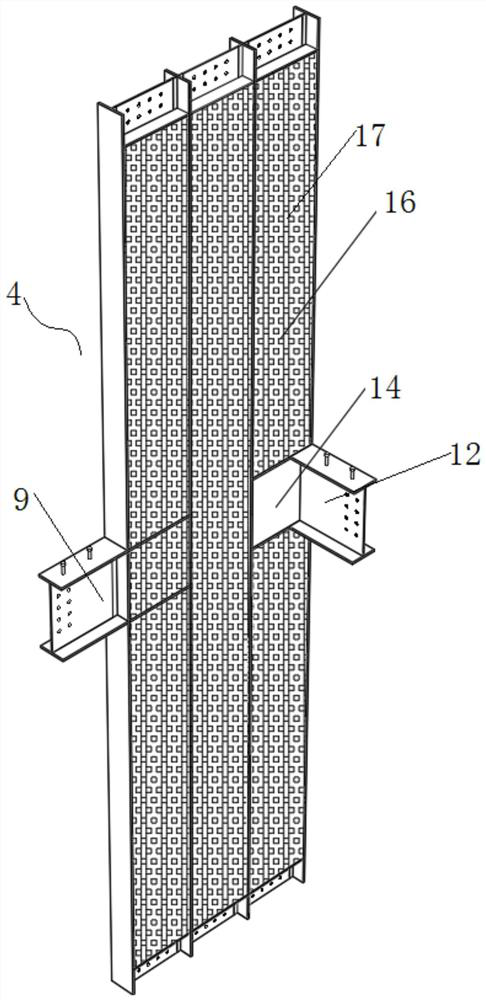

Prefabricated fabricated profiled steel sheet concrete shear wall and construction method thereof

The invention discloses a prefabricated fabricated profiled steel sheet concrete shear wall structure and a construction method. A thinner profiled steel sheet is adopted as an encased steel sheet ofa shear wall so as to reduce the whole steel ratio of the shear wall. In order to ensure the structural strength of the shear wall, a binder coating is additionally arranged between a steel material and concrete. The binder coating can effectively bind the steel material and the concrete, and outward local buckling of the profiled steel sheet can also be prevented. According to the prefabricated fabricated profiled steel sheet concrete shear wall structure and the construction method, the technical effects that on the basis that the structural strength is ensured, the steel ratio of a wall body of the prefabricated fabricated shear wall is reduced, the structure is simplified, and the construction difficulty is reduced are achieved.

Owner:HUAQIAO UNIVERSITY

Enclosure method for inserting H-shaped reinforced concrete slab piles in three-axis (two-axis) cement mixing pile

InactiveCN102383432AOptimize the force structureImprove bending resistanceExcavationsBulkheads/pilesRebarPollution

The invention discloses an enclosure method for inserting H-shaped reinforced concrete slab piles in a three-axis (two-axis) cement mixing pile. The method comprises the following three processes of: making the H-shaped reinforced concrete slab piles; digging to obtain the three-axis (two-axis) cement mixing pile; and inserting the H-shaped reinforced concrete slab piles into the three-axis (two-axis) cement mixing pile, wherein multiple reinforcing steel bars are arranged in each H-shaped reinforced concrete slab pile; a plurality of embedded iron are arranged around one end of each H-shaped reinforced concrete slab pile; the three-axis (two-axis) cement mixing pile is formed through digging; multiple sections of the H-shaped reinforced concrete slab piles are welded with each other through welding the embedded iron and lifted by using a crawler crane; the welded H-shaped reinforced concrete slab piles are inserted into the three-axis (two-axis) cement mixing pile; the equipment is moved to a second position, to be dug, of the second three-axis (two-axis) cement mixing pile so as to carry out the same operations; and after a plurality of movements, the enclosure method for inserting the H-shaped reinforced concrete slab piles in the three-axis (two-axis) cement mixing pile can be completed. The enclosure method for inserting the H-shaped reinforced concrete slab piles in the three-axis (two-axis) cement mixing pile, disclosed by the invention, has the advantages of good bending resistance, low cost, high benefit, no noise, no pollution, environment friendliness and the like.

Owner:SHANGHAI CHENGDI CONSTR

Prefabricated hybrid structure frame-shear wall building system and construction method

InactiveCN108612315AHigh strengthHigh degree of industrializationBuilding material handlingFloor slabConcrete beams

The invention provides a prefabricated hybrid structure frame-shear wall building system and a construction method thereof. The prefabricated hybrid structure frame-shear wall building system includesprecast steel concrete shear walls and precast steel concrete superposed beams which are hoisted and spliced on a foundation. The precast steel concrete shear walls are connected with the precast steel concrete superposed beams to form a frame structure. A building system is formed by fixing a reinforced truss concrete floor, a prefabricated reinforced concrete staircase and a light masonry partition wall on a frame structure. The construction method of the prefabricated hybrid structure frame-shear wall building system includes the steps of constructing base of the foundation, installing theprefabricated steel concrete shear walls on the first floor, installing the prefabricated steel concrete beams, installing the reinforced truss concrete floor, installing the prefabricated reinforcedconcrete stair and the light masonry partition wall, and installing buildings on the next floor. The prefabricated hybrid structure frame-shear wall building system has the characteristics of high strength, light weight, fast construction speed, high degree of industrialization, recyclability and removability, and the steel structure is a reusable environmental protection material.

Owner:重庆宜府住工科技有限公司

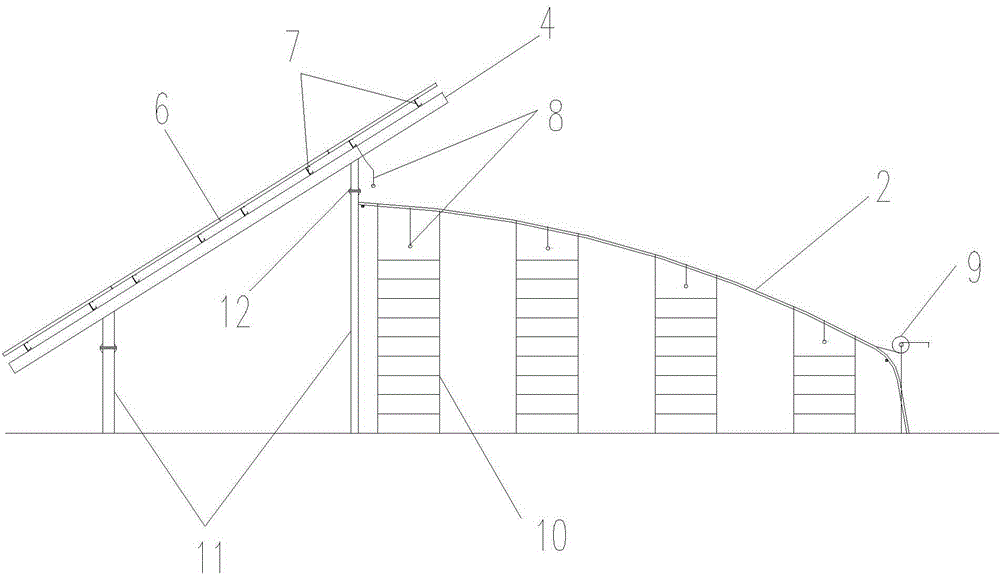

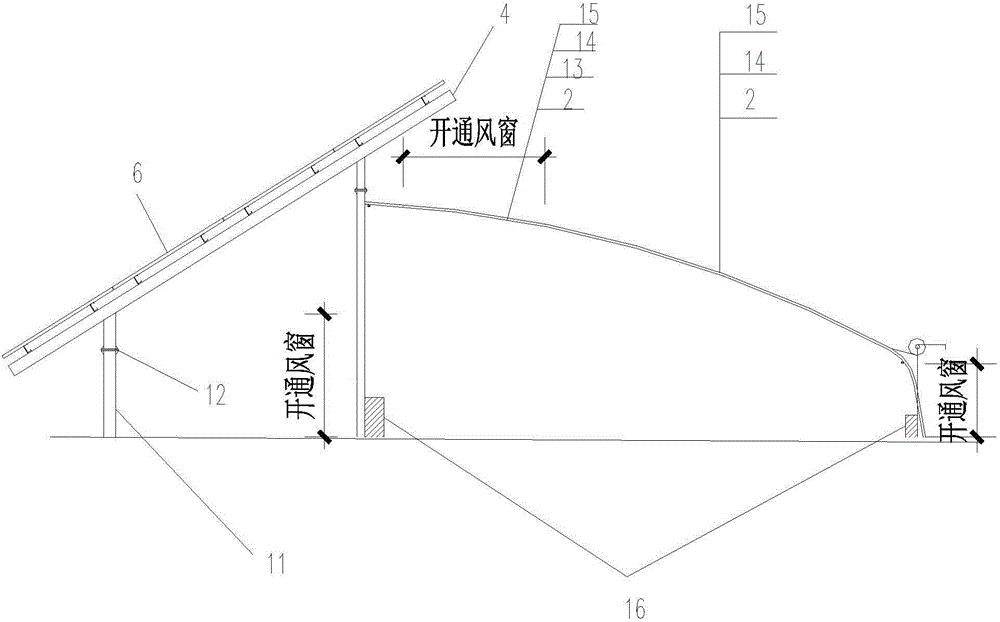

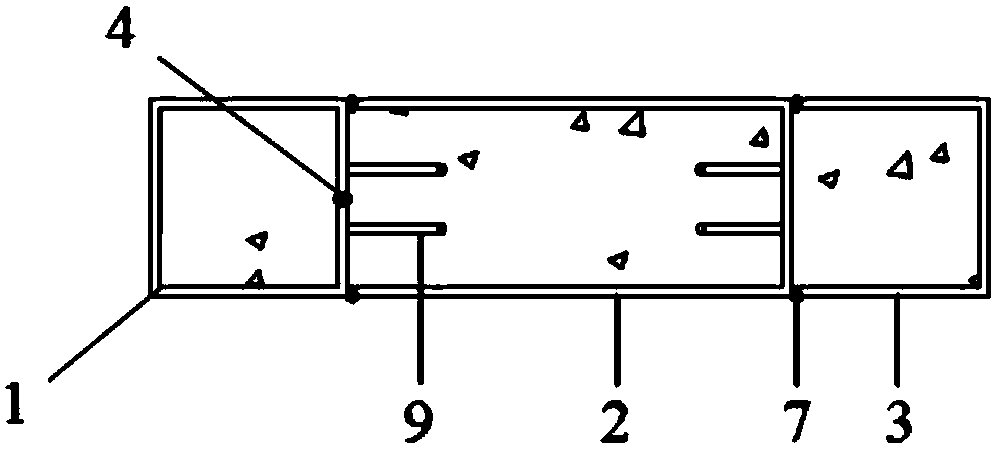

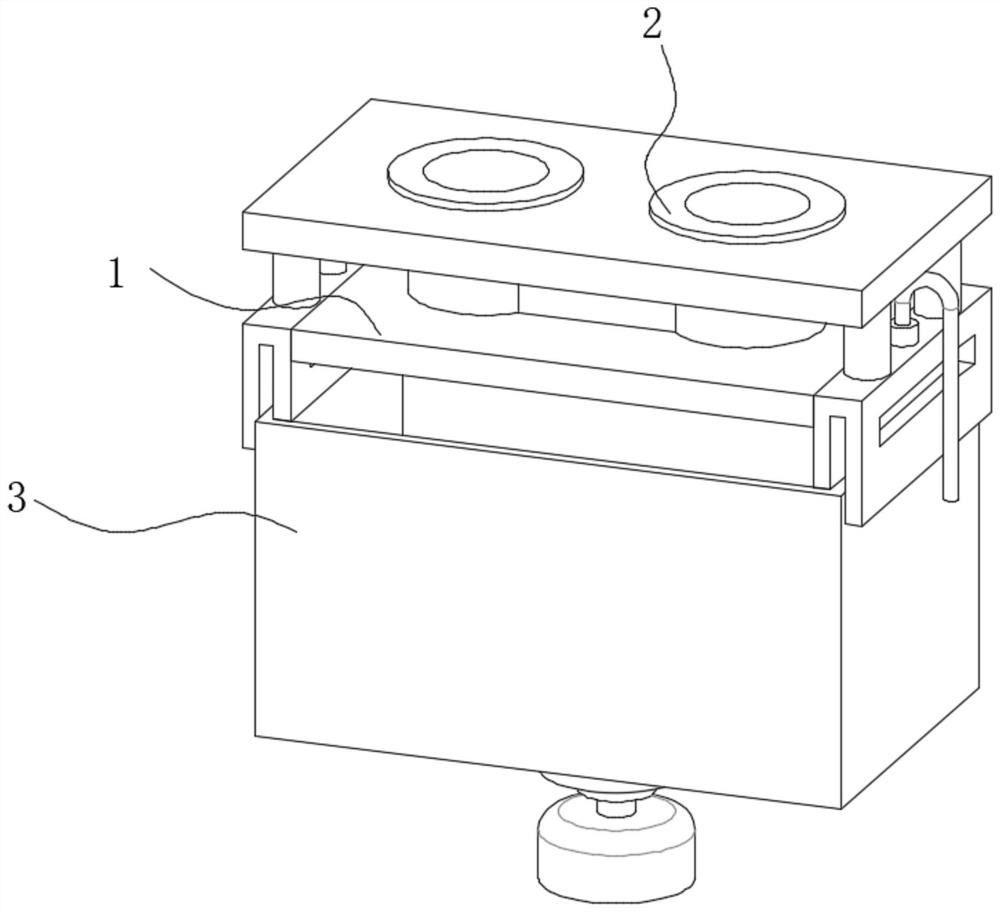

Photovoltaic greenhouse used for edible mushrooms

InactiveCN104350977ARealize power generationImprove stabilityPhotovoltaic supportsClimate change adaptationPurlinResource utilization

The invention discloses a photovoltaic greenhouse used for edible mushrooms. The photovoltaic greenhouse comprises a photovoltaic power generation device and an edible mushroom greenhouse, wherein the edible mushroom greenhouse comprises gable lagging jacks and middle lagging jacks, the gable lagging jacks are connected to the middle lagging jacks through transverse lagging jack supports which are vertical to the gable lagging jacks and the middle lagging jacks, the photovoltaic power generation device comprises multiple groups of photovoltaic uprights positioned at the south side of the edible mushroom greenhouse and photovoltaic crossbeams which are positioned at the tops of the photovoltaic uprights and are connected to the photovoltaic uprights, the photovoltaic uprights, which are close to the edible mushroom greenhouse, are higher than the photovoltaic uprights, which are far away from the edible mushroom greenhouse in each group of photovoltaic uprights, the photovoltaic crossbeams are connected to a purlin support plate through supporting purlins, a photovoltaic component is arranged on the purlin support plate, the photovoltaic component is connected to the photovoltaic power generation device, tie bars are arranged between the photovoltaic uprights corresponding to the ends of the gable lagging jack and the middle lagging jack, and the tie bars are connected to the ends of the gable lagging jacks and the middle lagging jacks through connecting pieces. The photovoltaic greenhouse used for the edible mushrooms has the advantages of high resource utilization rate, safe and firm structure, long service life and capabilities of guaranteeing the quality of the edible mushrooms and greatly improving the input-output ratio.

Owner:QINGDAO HUASHENG GREEN ENERGY AGRI TECH

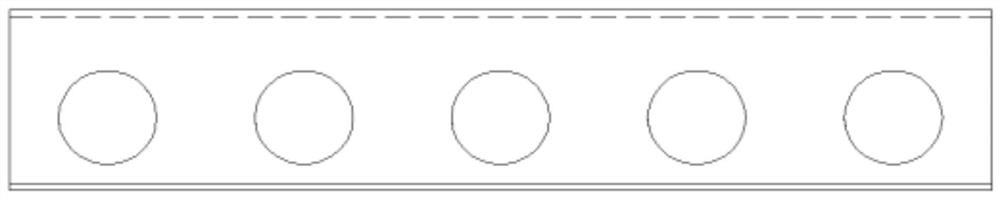

Reinforced concrete hollow beam and fabricating method thereof

The invention relates to a reinforced concrete hollow beam which is 7-8m long, 0.2m wide and 0.55m high, four holes with phi 100mm are arranged in the beam in parallel, the interval between the centers of each two holes is 125mm, the distance from the lower edge of the bottom hole to the lower side of the beam is 40mm, the distance from the upper edge of the top hole to the upper side of the beam is 35mm, and the distances from the left edge and the right edge of the four holes to the left side and the right side of the beam are 50mm respectively; and two deformed steel bars with phi 12 are vertically arranged in the positions on the lower surface of the beam of 15mm to the lower side and 10mm to the left side and the right side like two rows, two groups of four deformed steel bars with phi 12 are transversely arranged between the two deformed steel bars in parallel, one deformed steel bar with phi 10 is vertically arranged in the positions of 15mm to the upper side of the beam and 10mm to the left side and the right side respectively, the ten steel bars are longitudinally hooped by steel wires of phi 5, and concrete is used for casting and molding. The fabricated reinforced concrete hollow beam has concrete strength grade of C30 grade, steel bar content of 169.5kg / m3, uniformly distributed load of 13.7KN / m, standard bending moment of 109.6KN / m, small solid volume, light self-weight, a small number of a variety of used materials, low cost, standard production technology, high force-bearing strength and high success rate.

Owner:苑玉山

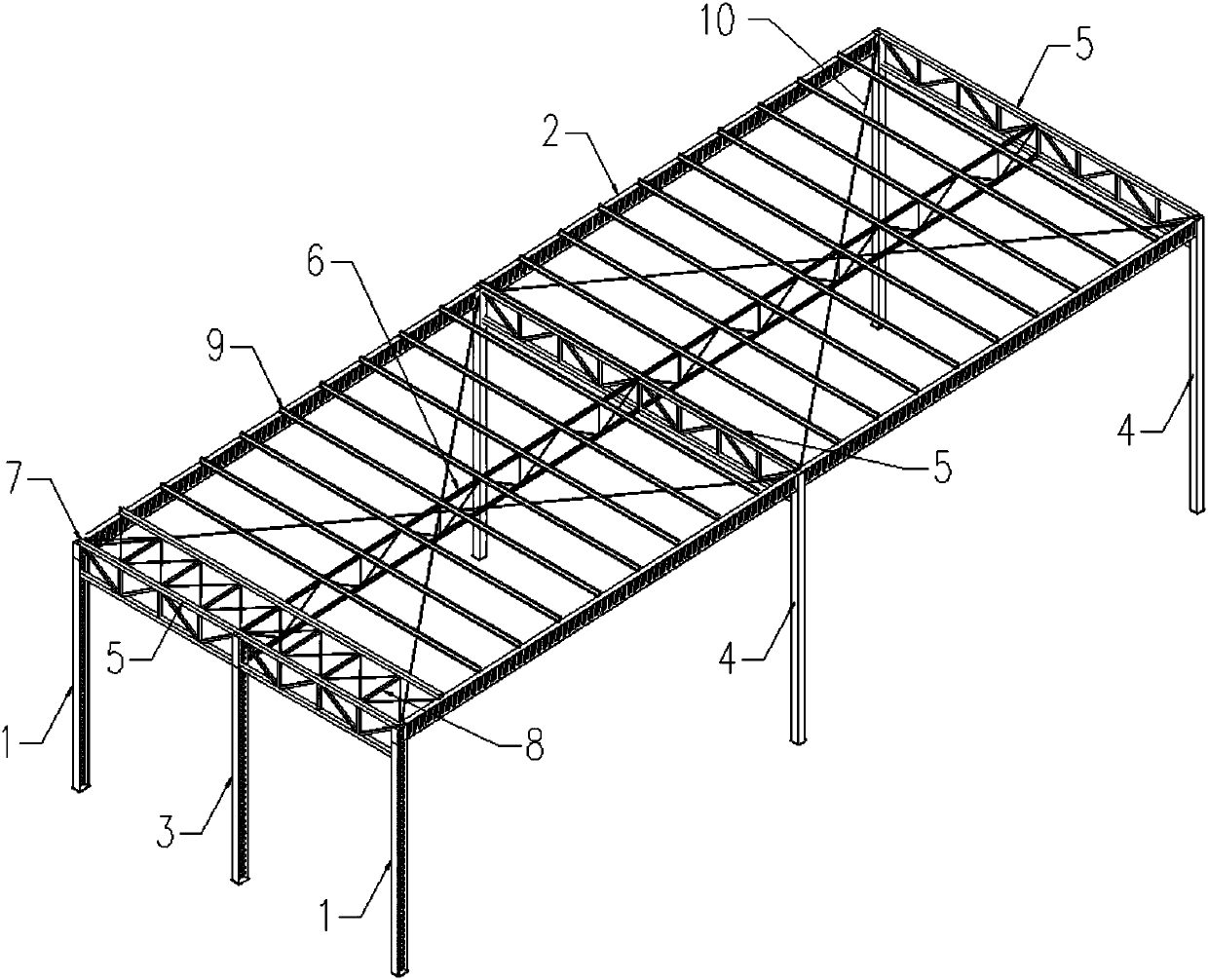

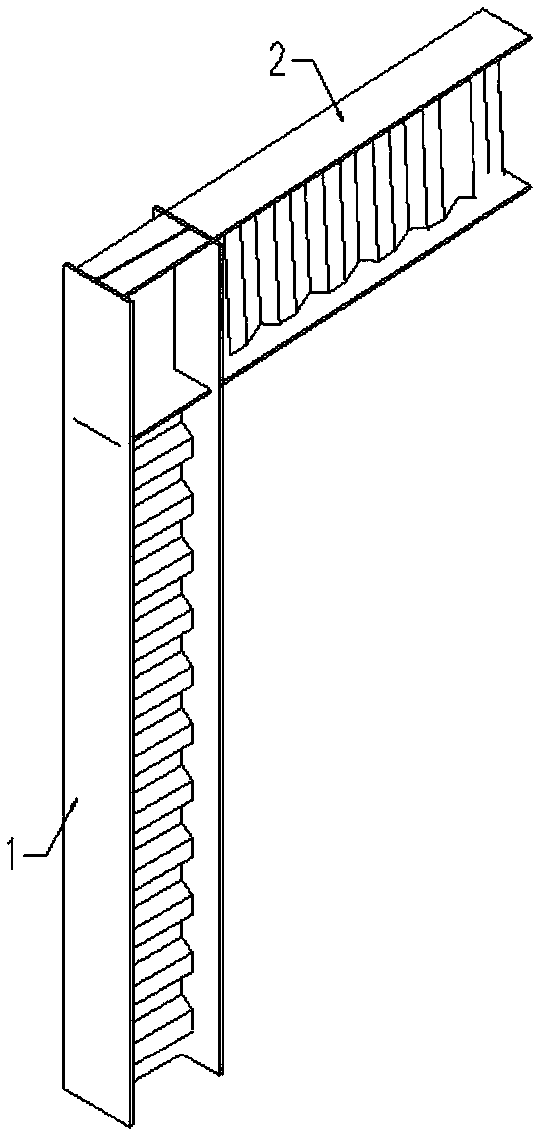

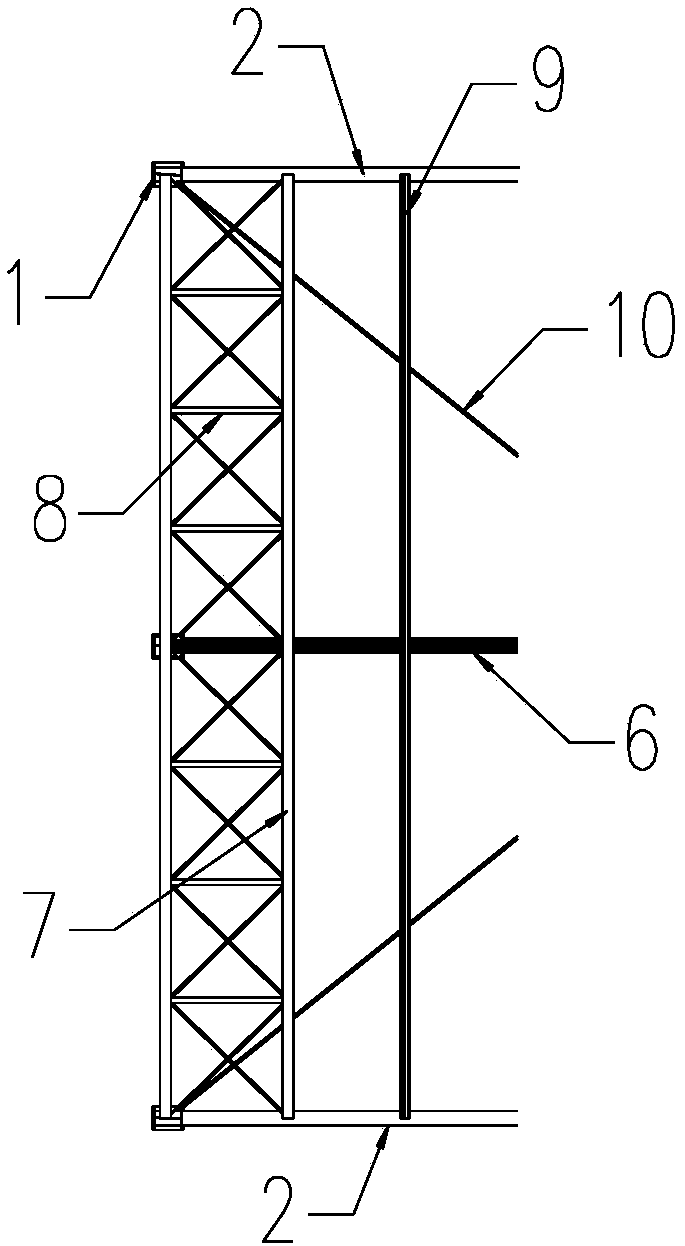

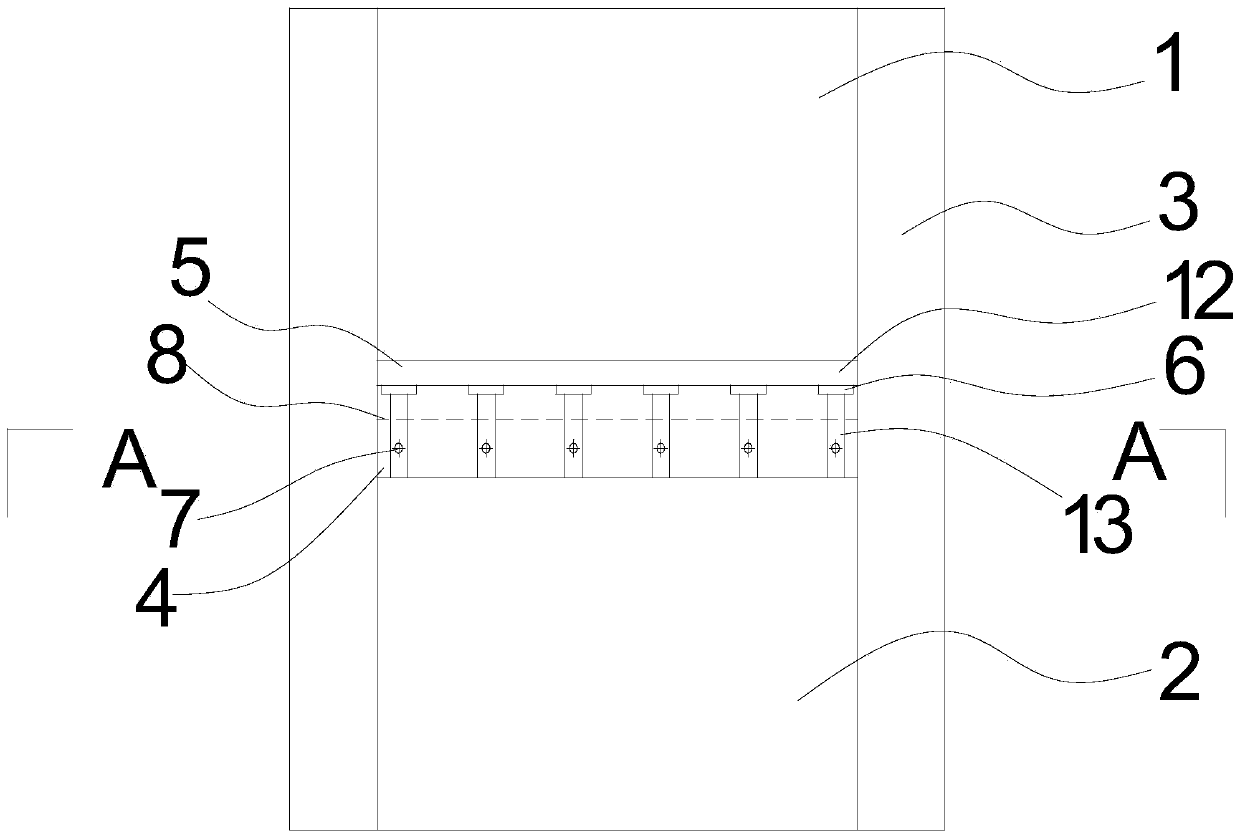

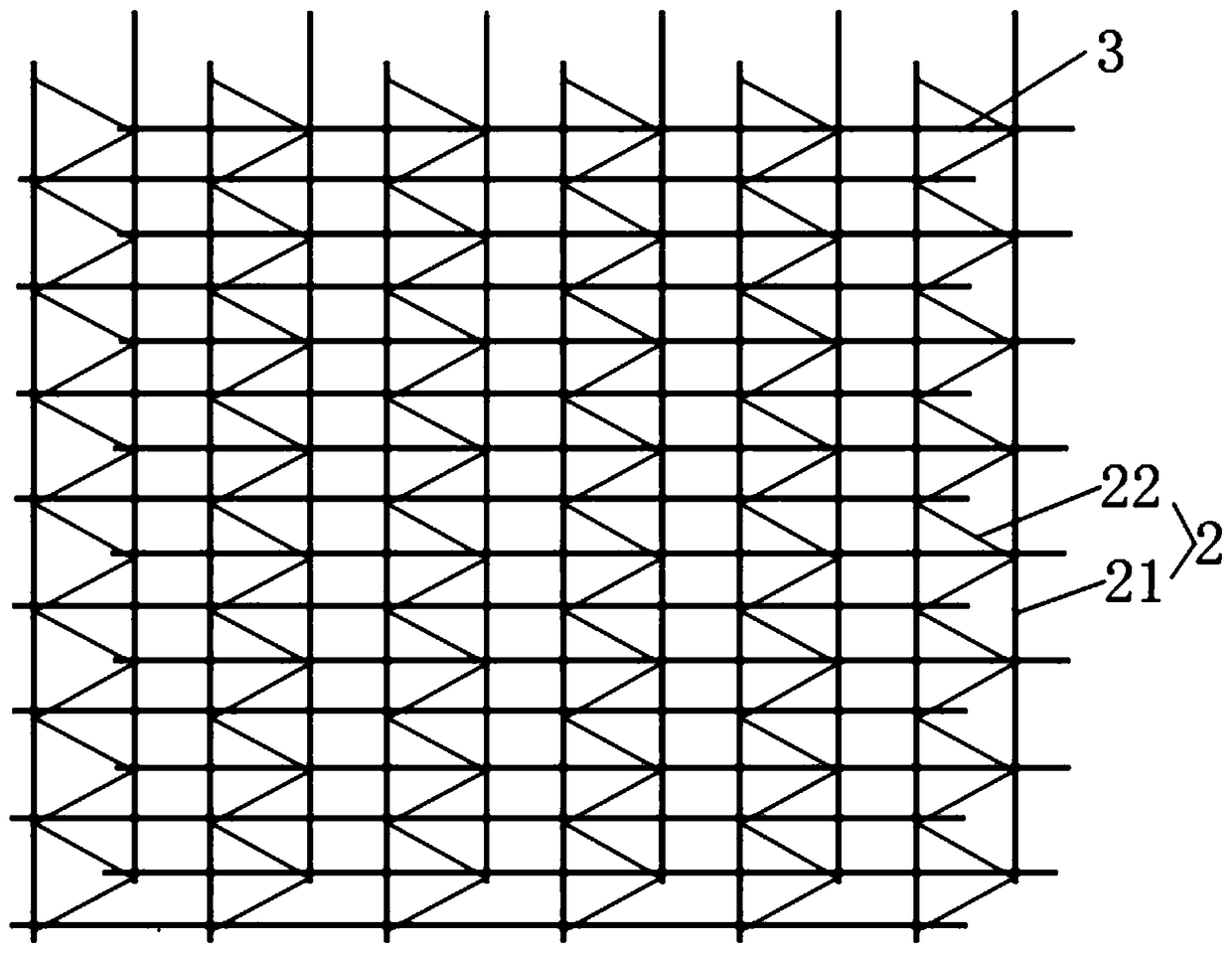

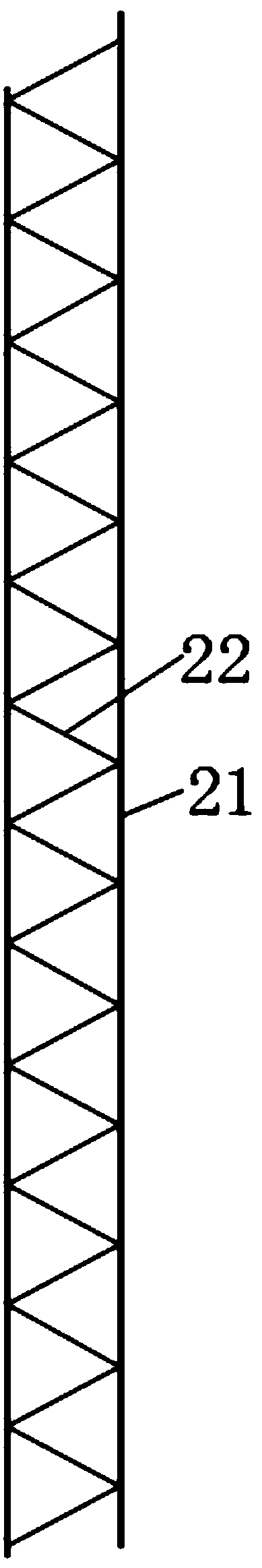

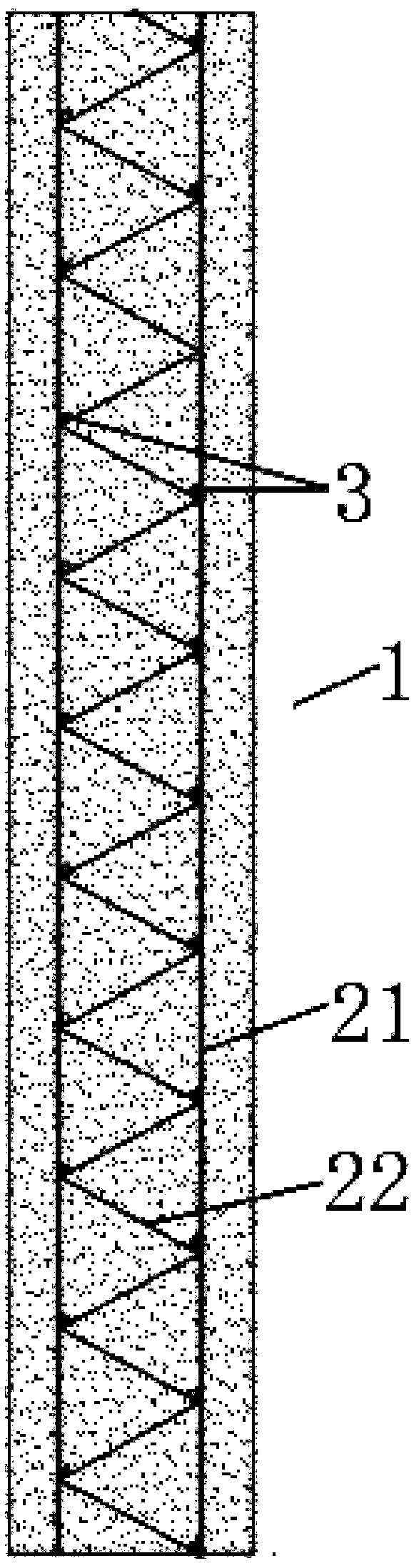

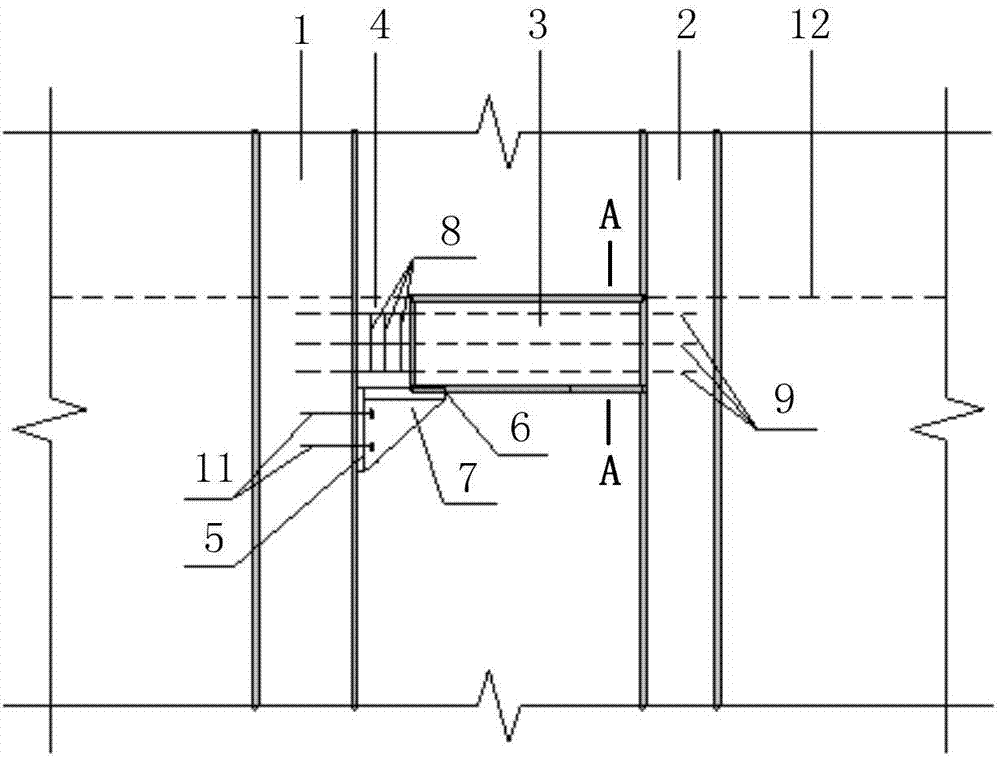

Building system combined truss with steel shaped like Chinese character 'zhi'

PendingCN107761956AReduce dosageLow costBuilding constructionsChinese charactersArchitectural engineering

The invention provides a building system combined a truss with steel shaped like a Chinese character 'zhi'. The building system is used for constructing a warehouse or a plant and comprises rigid frame column beams, middle columns, purlines, cornice supporting units, wall frame columns, truss type secondary beams and truss type joists. The rigid frame column beams are connected with the cornice supporting units and provided with the middle columns; the purlines are arranged between rigid frame beams and comprise cornice purlines and roof purlines; the cornice supporting units are arranged between the cornice purlines and connected with one ends of the rigid frame beams; the wall frame columns are parallelly arranged between the rigid frame columns; the truss type secondary beams are parallelly arranged between the rigid frame beams and located below the purlines; and the two ends of the truss type secondary beams are connected with the truss type joists correspondingly. According to the building system combined the truss with the steel shaped like the Chinese character 'zhi', all kinds of components with the cost performance ratio are economically combined, characteristics of the components are fully exerted, so that a plant or warehouse building within a certain specification and load range has small deflection and the low comprehensive construction cost, the steel content isgreatly reduced, and construction is convenient and fast.

Owner:SHANGHAI OPEN STEEL JOIST

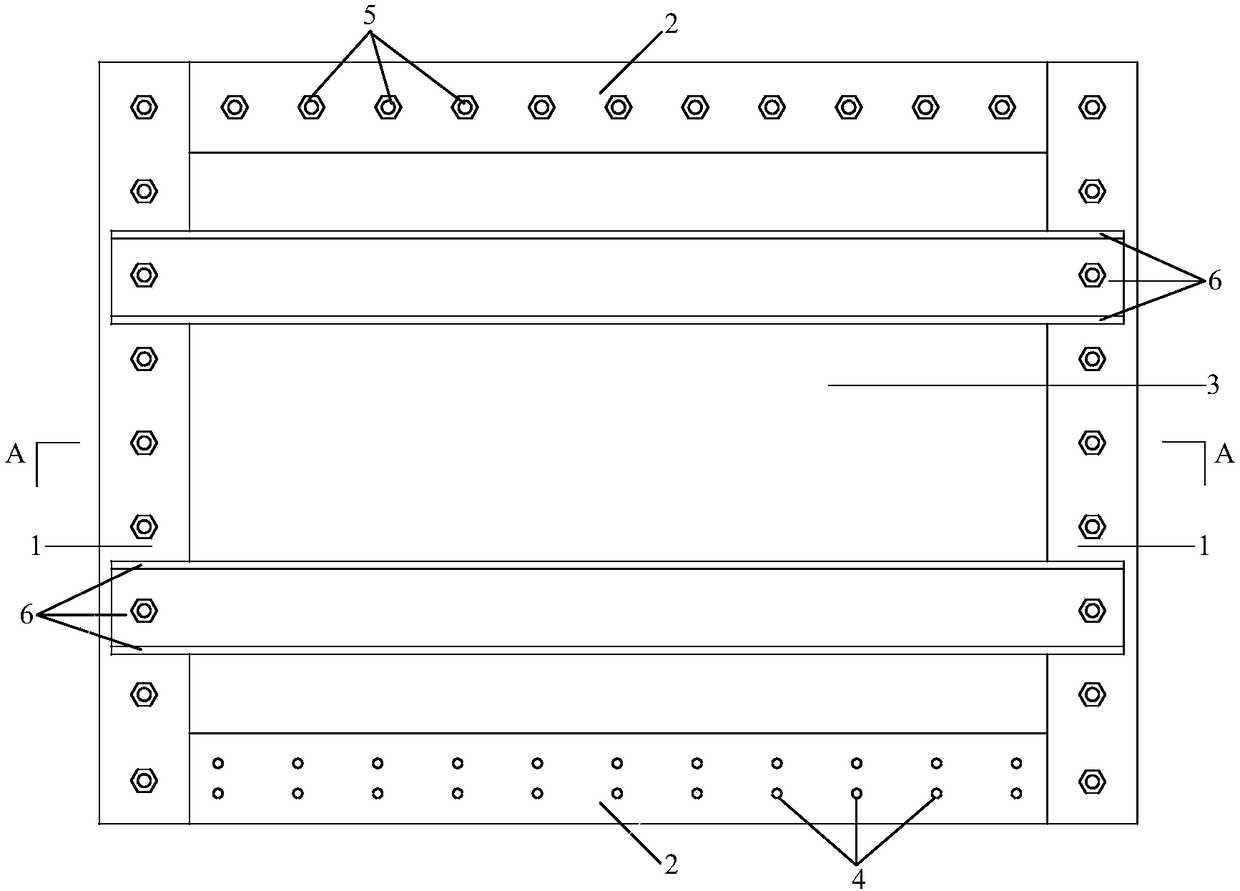

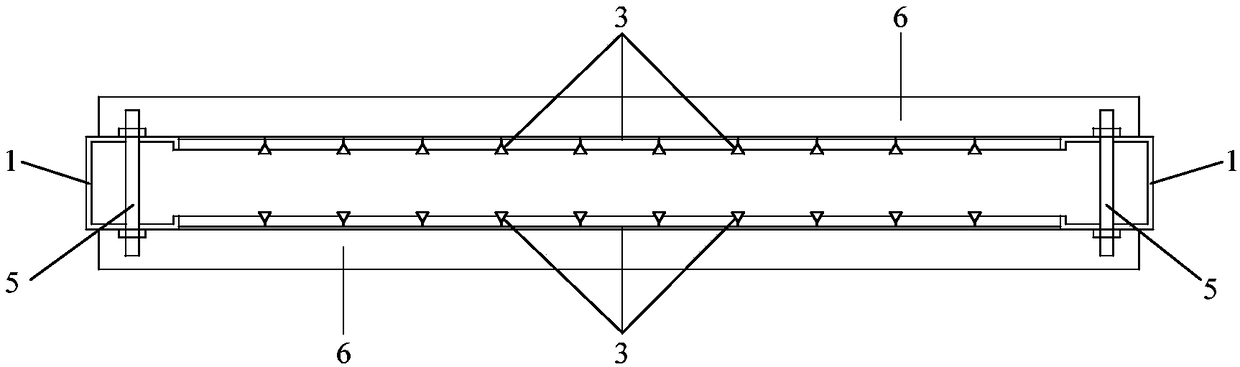

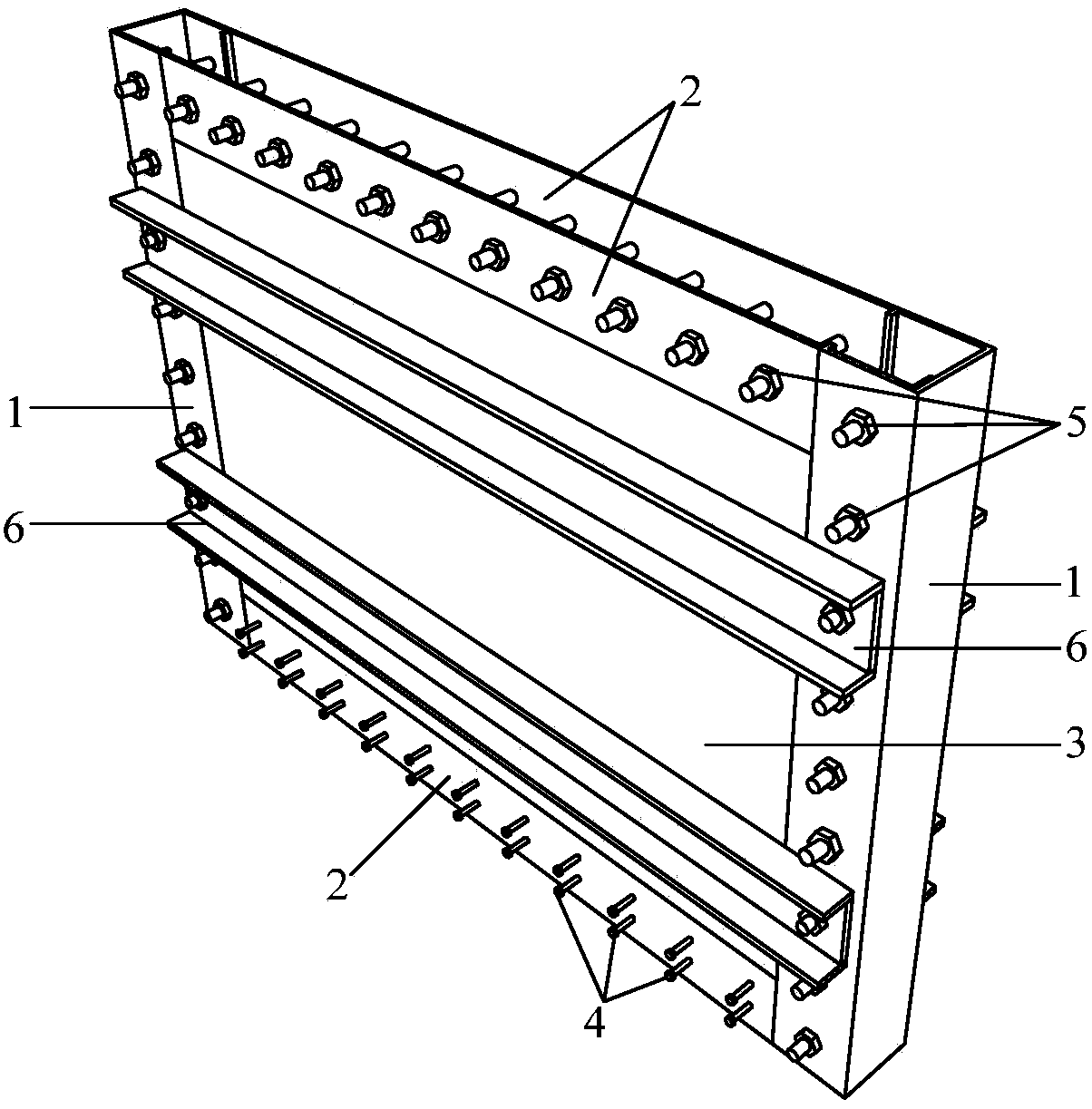

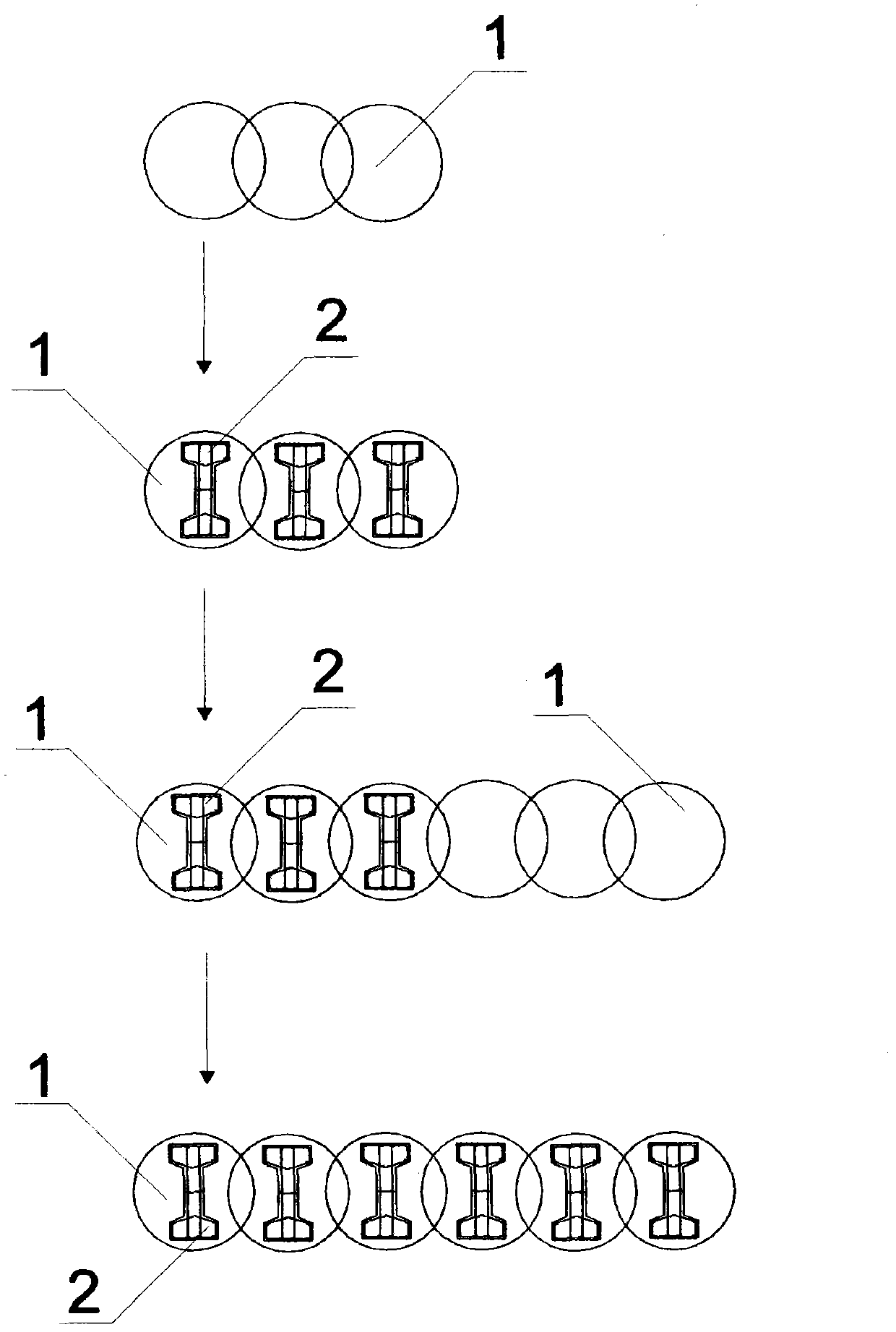

Prefabricated profiled steel sheet combined shear wall and construction method thereof

PendingCN110939218AOverall goodEfficient deliveryWallsBuilding material handlingSteel columnsShear wall

The invention discloses a prefabricated profiled steel sheet combined shear wall and a construction method thereof. The prefabricated profiled steel sheet combined shear wall comprises a first profiled steel sheet, a second profiled steel sheet, edge steel columns, a connecting steel plate, a plurality of vertical inserting plates, a plurality of transverse inserting plates and a plurality of split bolts; the first profiled steel sheet and the second profiled steel sheet are stacked in the vertical direction, and a joint seam is arranged at the stacked part; the edge steel columns are positioned on the two sides of the first profiled steel sheet and the second profiled steel sheet; the connecting steel plate covers the joint seam; first inserting holes are formed in the two ends of each ofthe transverse inserting plates; the transverse inserting plates sequentially penetrate through the connecting steel plate and the first profiled steel sheet to connect the connecting steel plate andthe first profiled steel sheet; the first inserting holes in the two ends of the transverse inserting plates are exposed to the external world; the vertical inserting plates are inserted in the firstinserting holes; the split bolts sequentially penetrate through the vertical inserting plates, the connecting steel plate and the second profiled steel sheet to connect the vertical inserting plates,the connecting steel plate and the second profiled steel sheet; the first profiled steel sheet and the second profiled steel sheet adopt closed type profiled steel sheets; a concrete cavity is formedin each of the first profiled steel sheet and the second profiled steel sheet; and concrete is filled in the concrete cavities.

Owner:SOUTH CHINA UNIV OF TECH

Installation construction process of bolt net rack cylindrical shell storage bin

ActiveCN102425326BImprove accuracyShorten the timeBuilding roofsBuilding material handlingFinite element algorithmStructural engineering

The invention discloses an installation construction process of a bolt net rack cylindrical shell storage bin, which is characterized by comprising the steps of: firstly, according to local meteorological conditions, obtaining sizes of net rack node rod members by adopting a CFD (Computational Fluid Dynamics) numerical value wind tunnel calculation technology and a finite element algorithm according to most disadvantageous conditions and tunnel physical parameters, namely, drawing a construction drawing by using a bulb diameter of each node and a geometric parameter of the rod members arranged on each node, wherein the construction drawing at least comprises a number of each node and the quantity of rod members of each node; and then dividing the construction step into a starting unit installation and an air overhanging unit installation. Due to no need of erecting an accomplished scaffold, the installation construction process has the characteristics of time and material saving, safety and reliability.

Owner:XUZHOU ZM BESTA HEAVY STEEL STRUCTURE

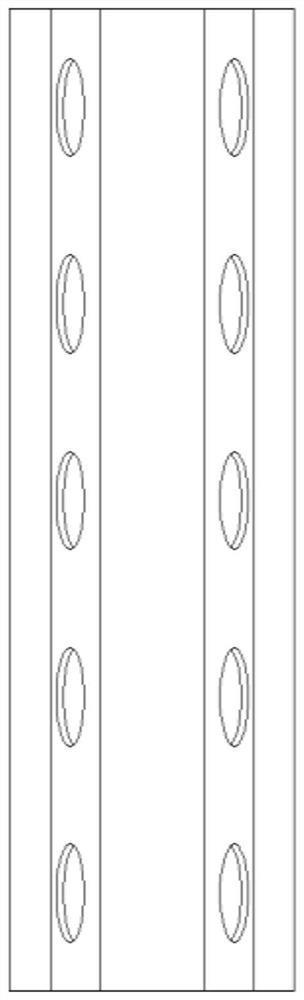

Web perforated box-type combined steel beam

The invention provides a web perforated box-type combined steel beam. The web perforated box-type combined steel beam comprises an upper flange, webs on the two sides and a bottom plate, wherein the webs are obliquely arranged, the two ends of the bottom plate extend out of the joints of the webs on the cross section, the section of a cavity formed among the upper flange, the webs and the bottom plate is trapezoidal or rectangular, a plurality of holes are formed in the web plates in the longitudinal direction at certain intervals, floor slab bottom steel bars and / or floor slab top steel bars can be inserted into the holes of the webs of the combined steel beams, and pipelines can be laid in the hollow cavity of the combined steel beam, and on-site trepanning reinforcement is not needed.

Owner:ZHONGQINGDA TECH HLDG CO LTD

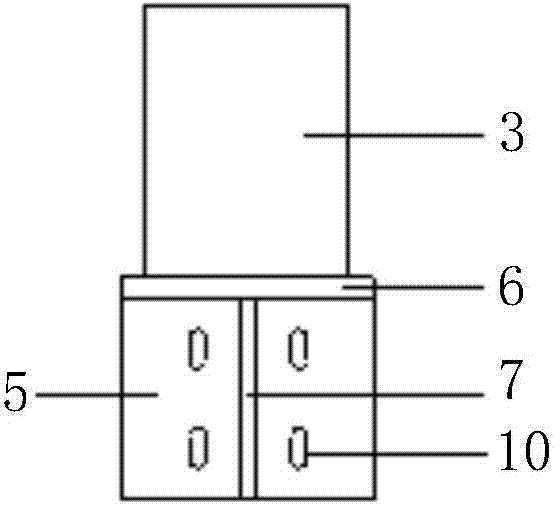

Light partition wall

The invention discloses a light partition wall, which comprises standard formworks. Each standard formwork comprises a light steel keel and two face plates, wherein the light steel keel is located between the two face plates; the face plates and the light steel keels are connected through bolts; the two opposite edges of the light steel keels are provided with overlaid parts which can be mutuallymatched; and the face plates do not cover the small ends of the overlaid parts. The light partition wall achieves the purposes that the light partition wall can replace a bricked partition wall and atraditional light steel keel partition wall manufactured on a field, assembling is convenient and quick, labor force is saved, and the construction and production efficiency is improved; and meanwhilethe house space is saved.

Owner:王工一

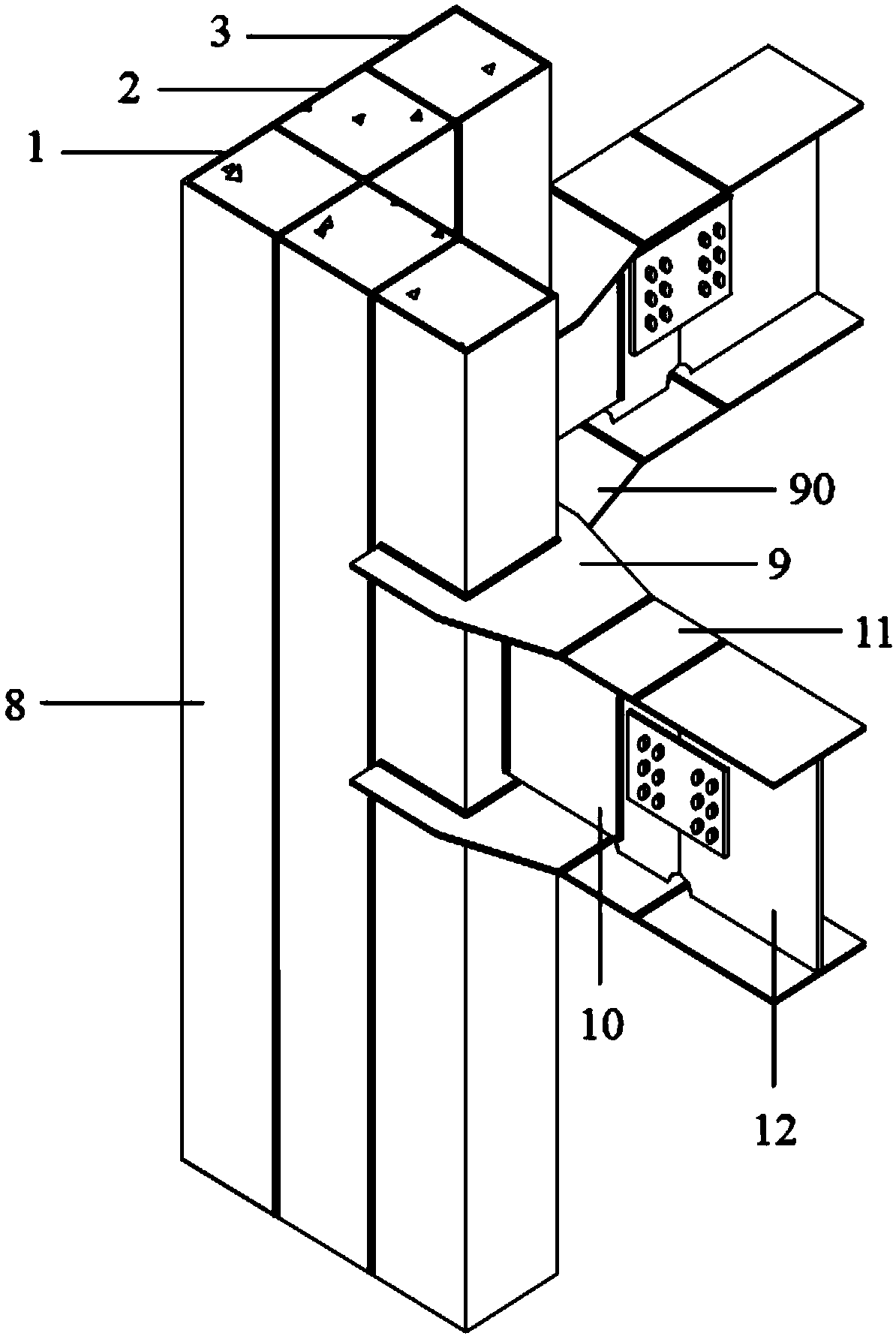

Rigid joint of cold-bending multi-cavity steel tube concrete special-shaped column and H-shaped steel beam

PendingCN108104270AImprove utilization efficiencyImprove exposed defectsBuilding constructionsCost effectivenessSteel tube

The invention provides a rigid joint of a cold-bending multi-cavity steel tube concrete special-shaped column and an H-shaped steel beam. According to a machining method thereof, a thin-wall steel plate is machined to be a core-column steel tube in cold-bending and welding manners. Moreover, the core-column steel tube is taken as the center. The side surfaces of the core-column steel tube are taken as column-limb connecting surfaces and orderly welded with U-shaped members formed by cold bending. Then, the end part of the column steel tube is welded with flange connection boards and short steel beams. Pre-fabricated members are finished and conveyed to the field. Splicing and assembly between the pre-fabricated members and framework beams are finished. Then, cavities of pipe bodies are filled with concrete in order to prepare a ridge joint of an in-line, L-shaped, T-shaped or cross-shaped cold-bending multi-cavity steel tube concrete special-shaped column and the H-shaped steel beam. From perspectives of machining efficiency and increase in cost-effectiveness, the joint is good in mechanical performance, convenient in construction, and is cost-effective and reasonable and has a joint form with a combined structure having a promising application prospect.

Owner:重庆市中科大业建筑科技有限公司

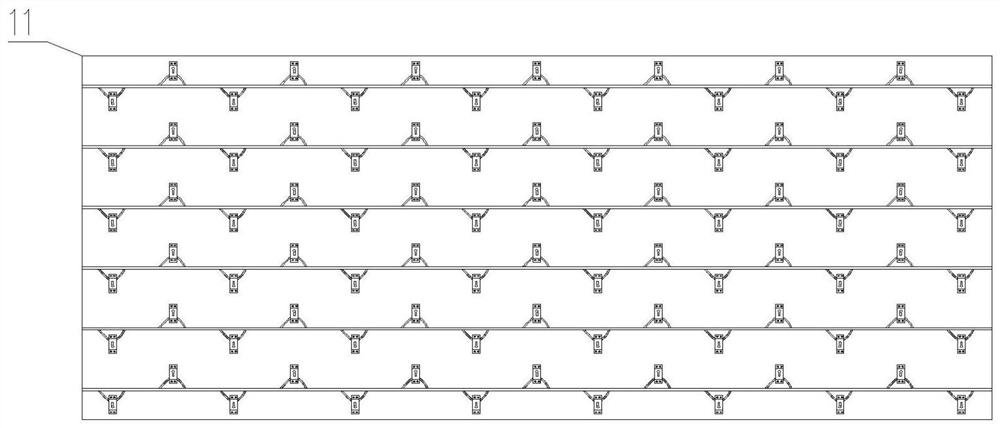

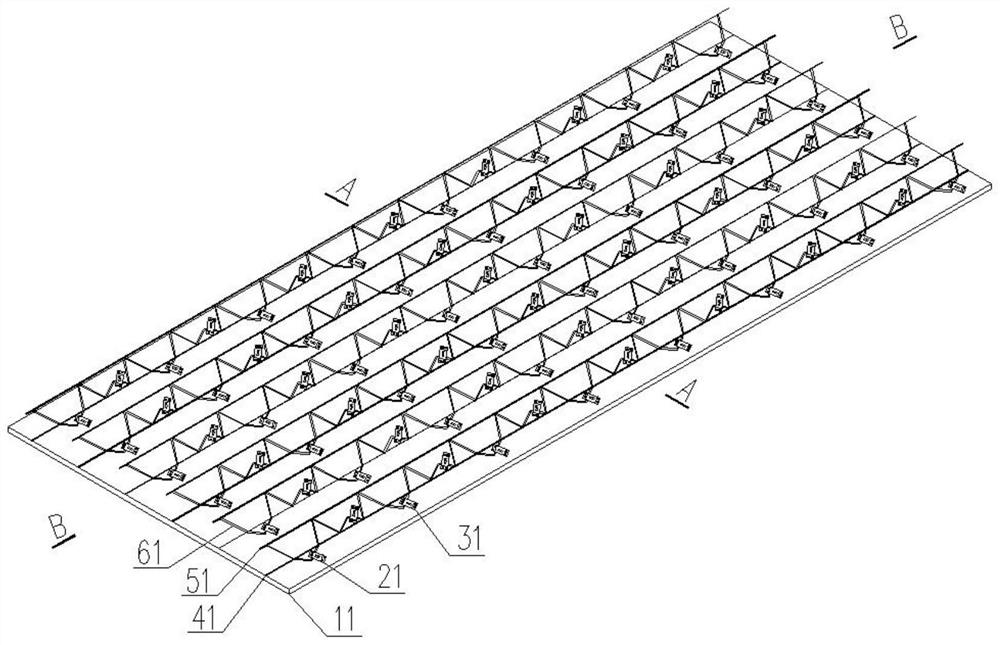

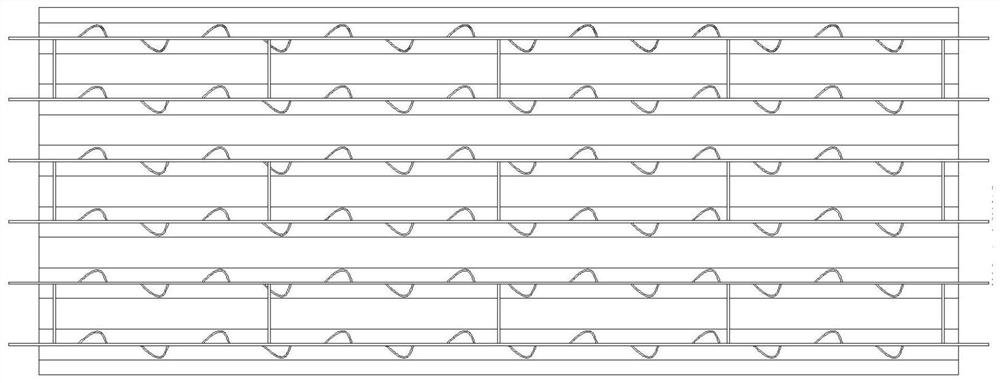

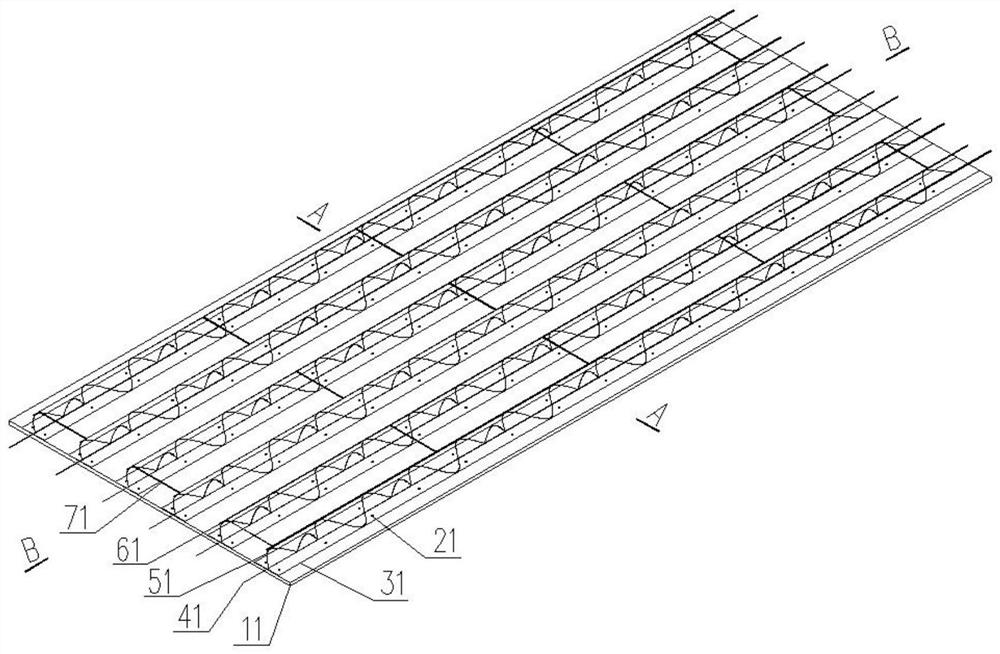

One-truss steel bar floor support plate with disassembly-free bottom form

PendingCN113374141ALow steel contentReduce the workload of demolitionFloorsRebarMechanical engineering

The invention discloses a one-truss steel bar floor support plate with a disassembly-free bottom form. The one-truss steel bar floor support plate is characterized by being formed by combining the disassembly-free bottom form, capital-omega-shaped material connecting pieces, self-tapping screws, lower chord longitudinal steel bars in a one-truss steel bar structure, upper chord longitudinal steel bars and web member wave-shaped steel bars with bent feet. According to the one-truss steel bar floor support plate with the disassembly-free bottom form, the longitudinally-arranged steel bars are single steel bar trusses, compared with triangular steel bar trusses in a steel bar truss floor support plate with a metal bottom form, due to the fact that the number of the lower chord longitudinal steel bars and the number of the web member steel bars used in each truss are both one smaller than the number of the steel bars used in the steel bar truss floor support plate with the metal bottom form, the steel content is greatly reduced, the steel content is closest to that of a traditional cast-in-place slab system, and the bottom of the disassembly-free bottom form can be directly subjected to puttying decoration; and according to the one-truss steel bar floor support plate with the disassembly-free bottom form, the cost is saved for a construction side, the fast turnover target is achieved, the workload of deepening design is saved for a design side, the construction progress is accelerated for the construction side, the construction quality is better controlled, and the productivity is completely released for a component producer, so that all project participants obtain respective benefits.

Owner:广西装配式建筑科技有限公司

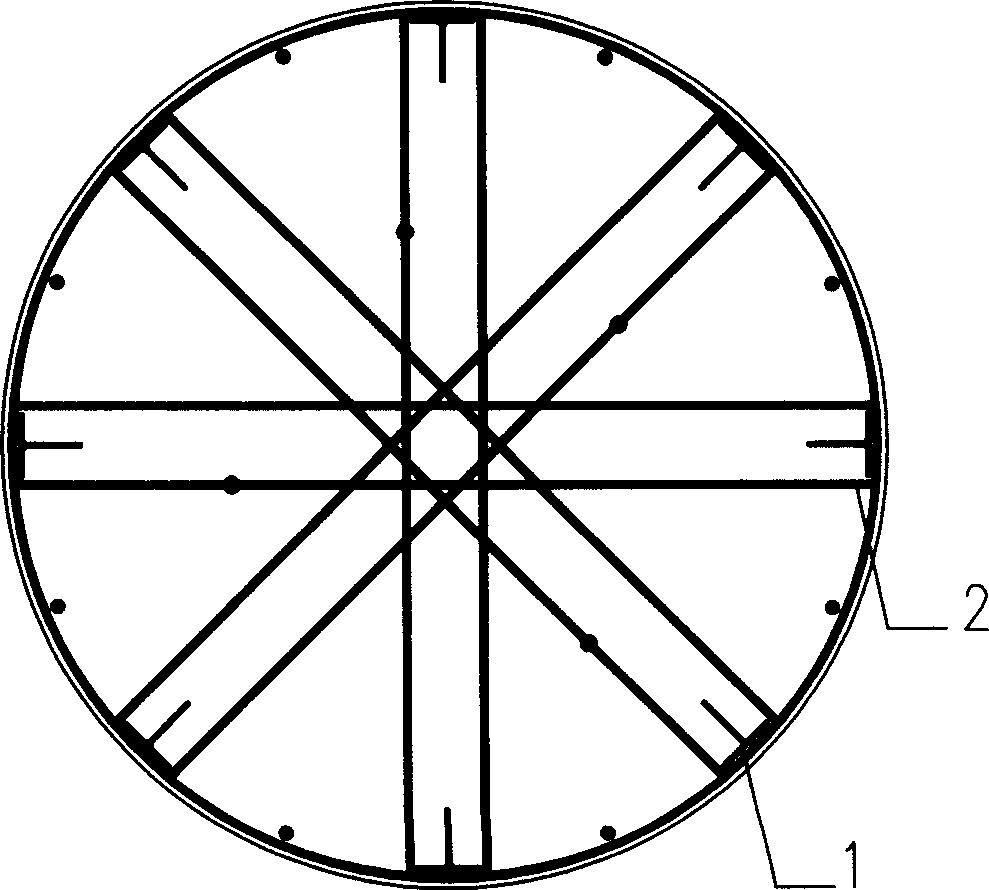

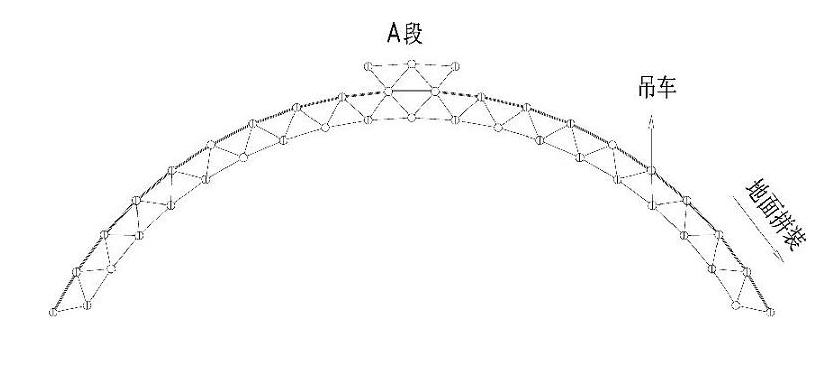

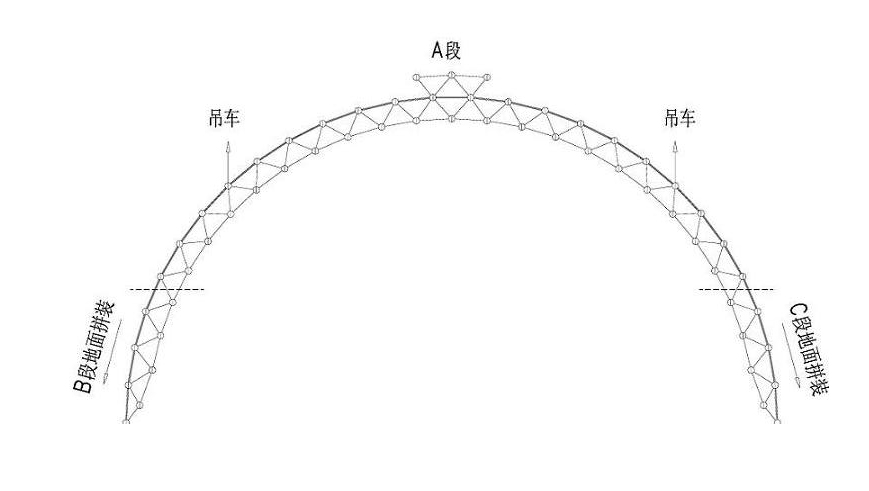

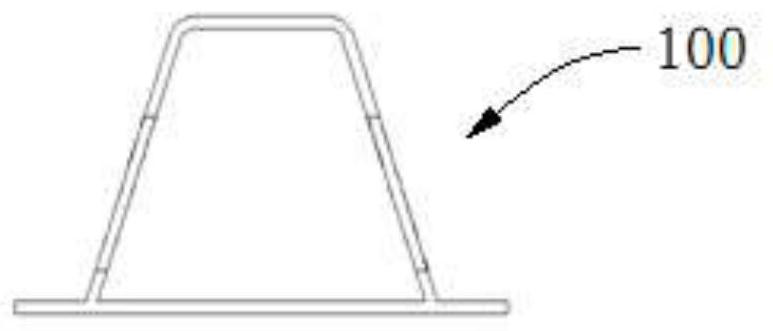

Leaning type arch center film structure

PendingCN111255076ALow steel contentSimple construction processExtraordinary structuresFilm materialFilm structure

The invention relates to a leaning type arch center film structure, belongs to the technical field of structural frames and mainly aims to solve the technical problems that the existing steel structure is high in antiseptic cost, large in quantity of working high above the ground, high in risk factor, difficult in supervising, common in space utilization ratio, high in dismantling cost and not suitable for mounting a film material. According to the technical scheme, the leaning type arch center film structure comprises a bottom steel structural bracket and a plurality of groups of upper framestructures, wherein the bottom steel structural bracket comprises a plurality of stand columns in rectangular arrangement; a horizontal steel pulling cable is arranged between the tops of every two adjacent stand columns; each of the upper frame structures comprises two leaning arch ribs symmetrically arranged and a plurality of connecting transverse beams between the two leaning arch ribs; building film materials are paved on the top surfaces of the upper frame structures; and a top surface steel pulling cable is arranged between every two adjacent upper frame structures above a tensile film.The leaning type arch center film structure has the advantages of being low in steel content, simple in construction technology, short in construction period, low in cost and suitable for adopting film material for sealing.

Owner:科顿环境科学股份有限公司

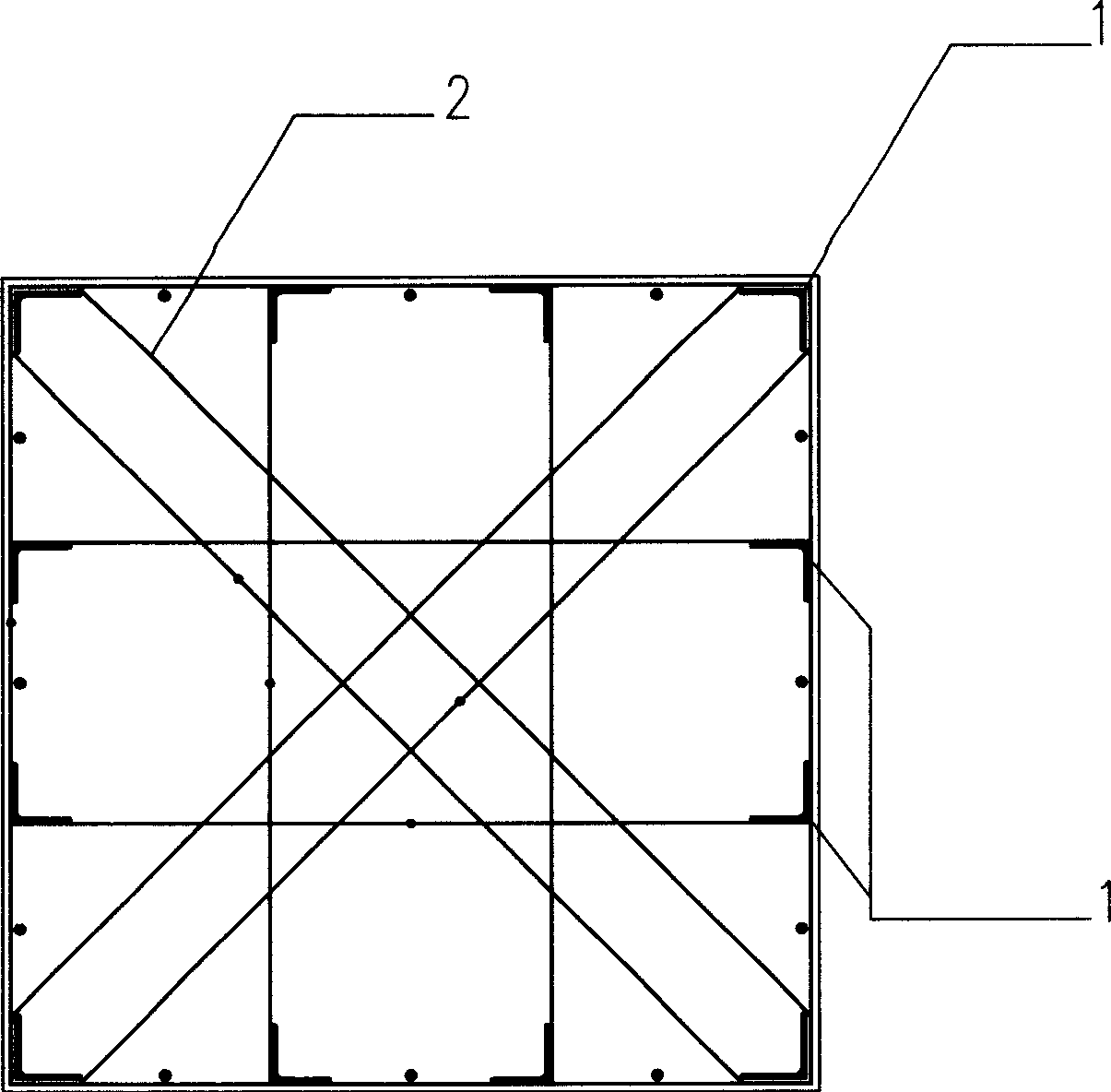

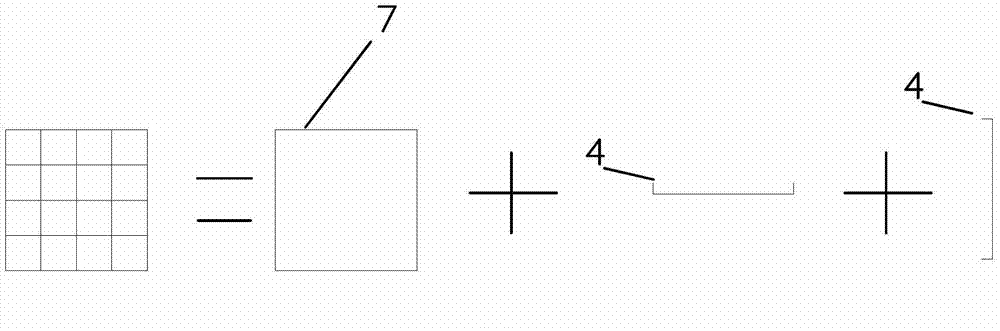

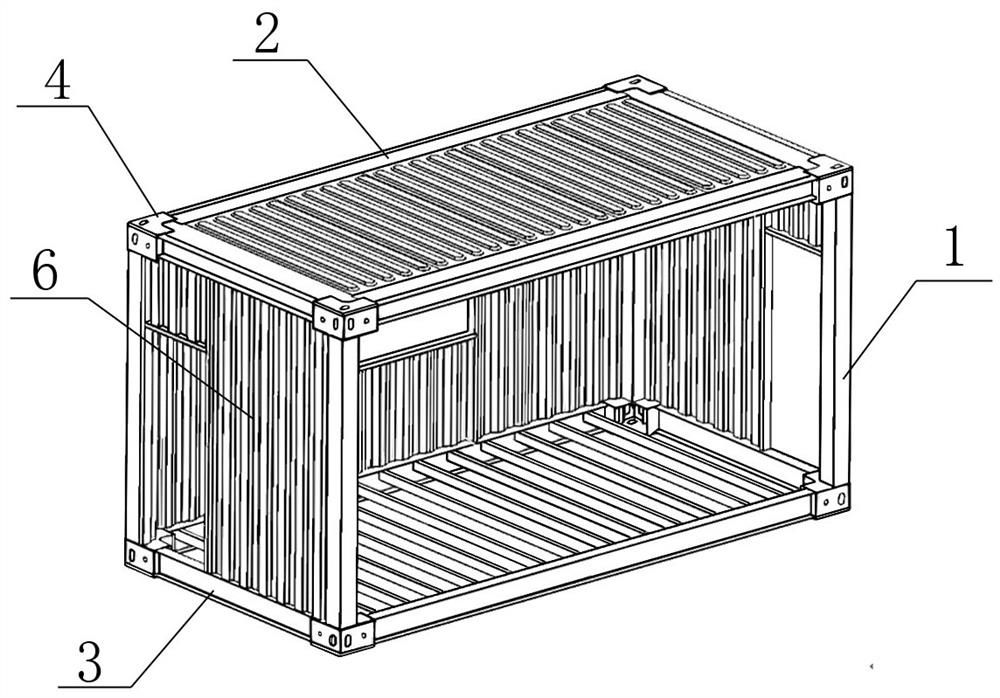

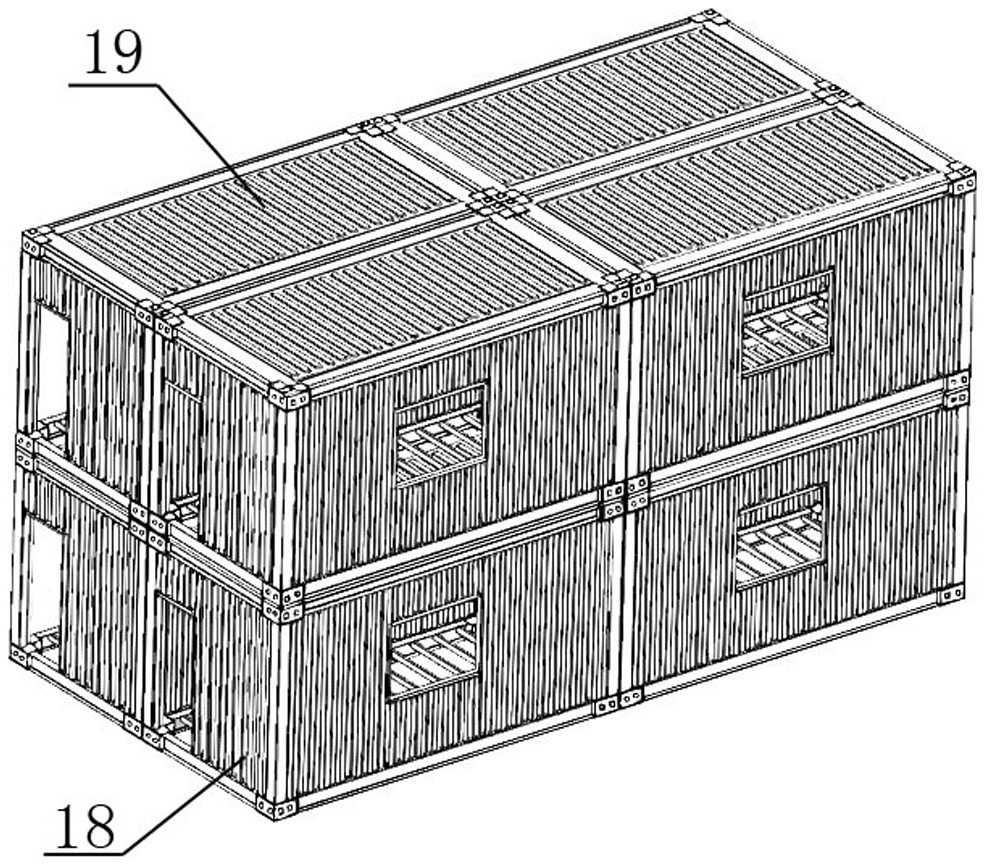

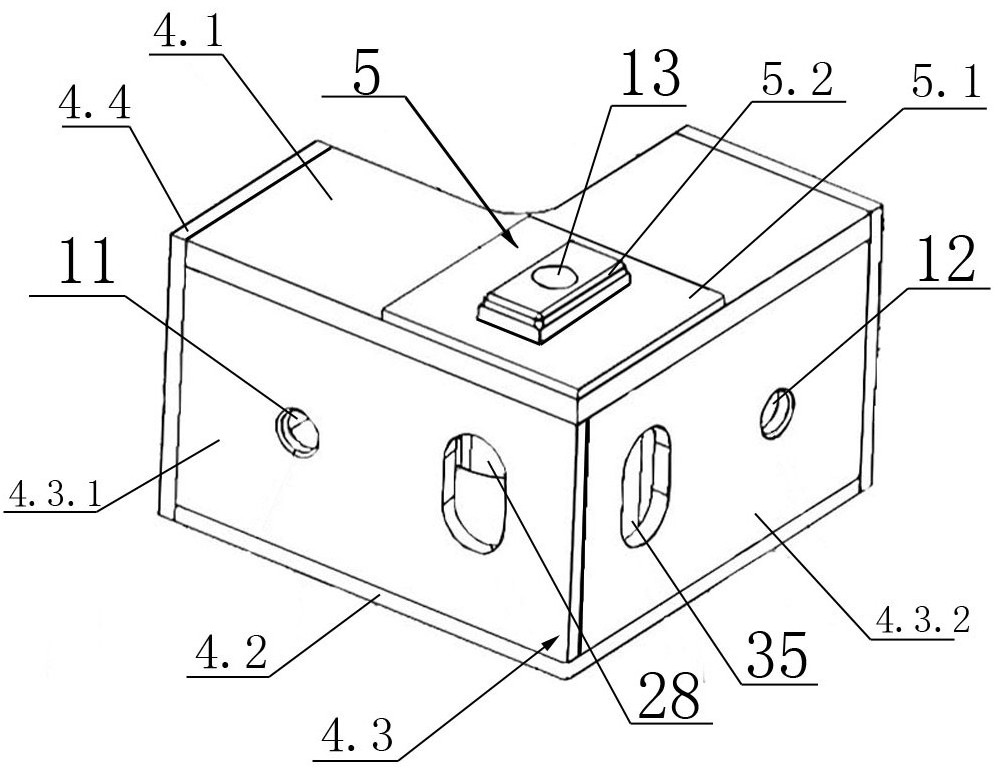

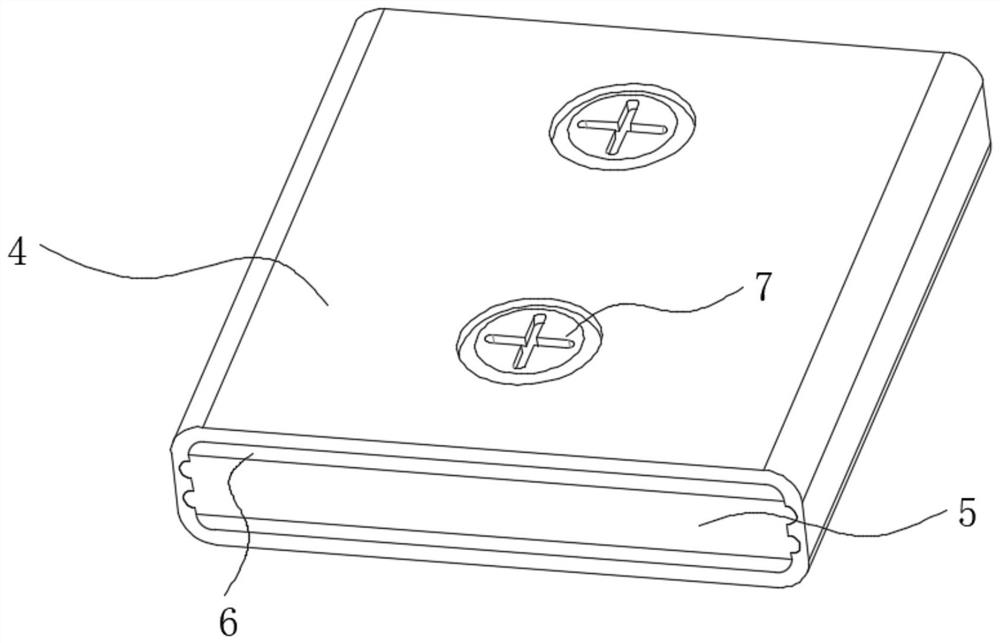

Module structure and system and construction method

InactiveCN111827488AIncrease stiffnessDoes not affect installationBuilding constructionsStringerBlock structure

The invention discloses a module structure and system and a construction method. The module structure comprises stand columns, transverse beams, longitudinal beams, corner pieces, first shear-resistant components and a module panel. Each corner piece comprises a top plate, a bottom plate, a vertical side plate and end plates, wherein the top plate is in an L shape, and the shape of the bottom plate is adapted to the shape of the top plate; the horizontal section of each vertical side plate is in an L shape, and each vertical side plate is connected between the outer side edge of the corresponding top plate and the outer side edge of the corresponding bottom plate; the two end plates are connected between the two ends of each top plate and the two ends of each bottom plate respectively; andthe edges of the sides, corresponding to the vertical side plates, of the end plates are fixedly connected. The first shear-resistant components are distributed on the sides, close to the stand columns, of the tops or bottoms of the corner pieces. Each first shear-resistant component comprises a first shear-resistant plate, first shear-resistant blocks and a first connection bolt, wherein the twofirst shear-resistant blocks are connected to the top and the bottom of the first shear-resistant plate respectively; and the first connection bolts make the corresponding corner pieces connected with the corresponding stand columns. The technical problems of poor connection strength, low industrial manufacturing degree, complicated construction and poor overall performance of a traditional module structure joint are solved.

Owner:中建集成科技有限公司

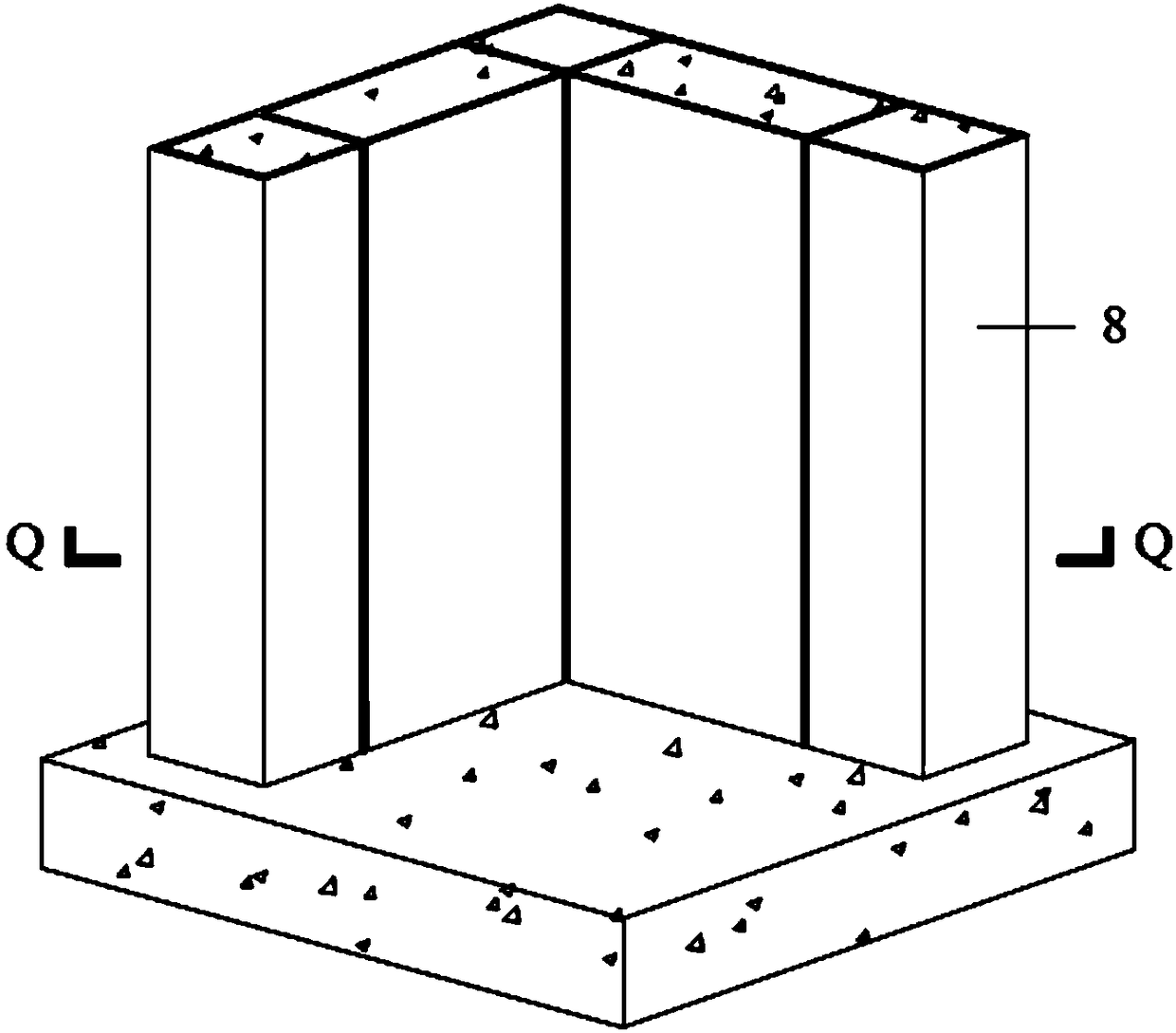

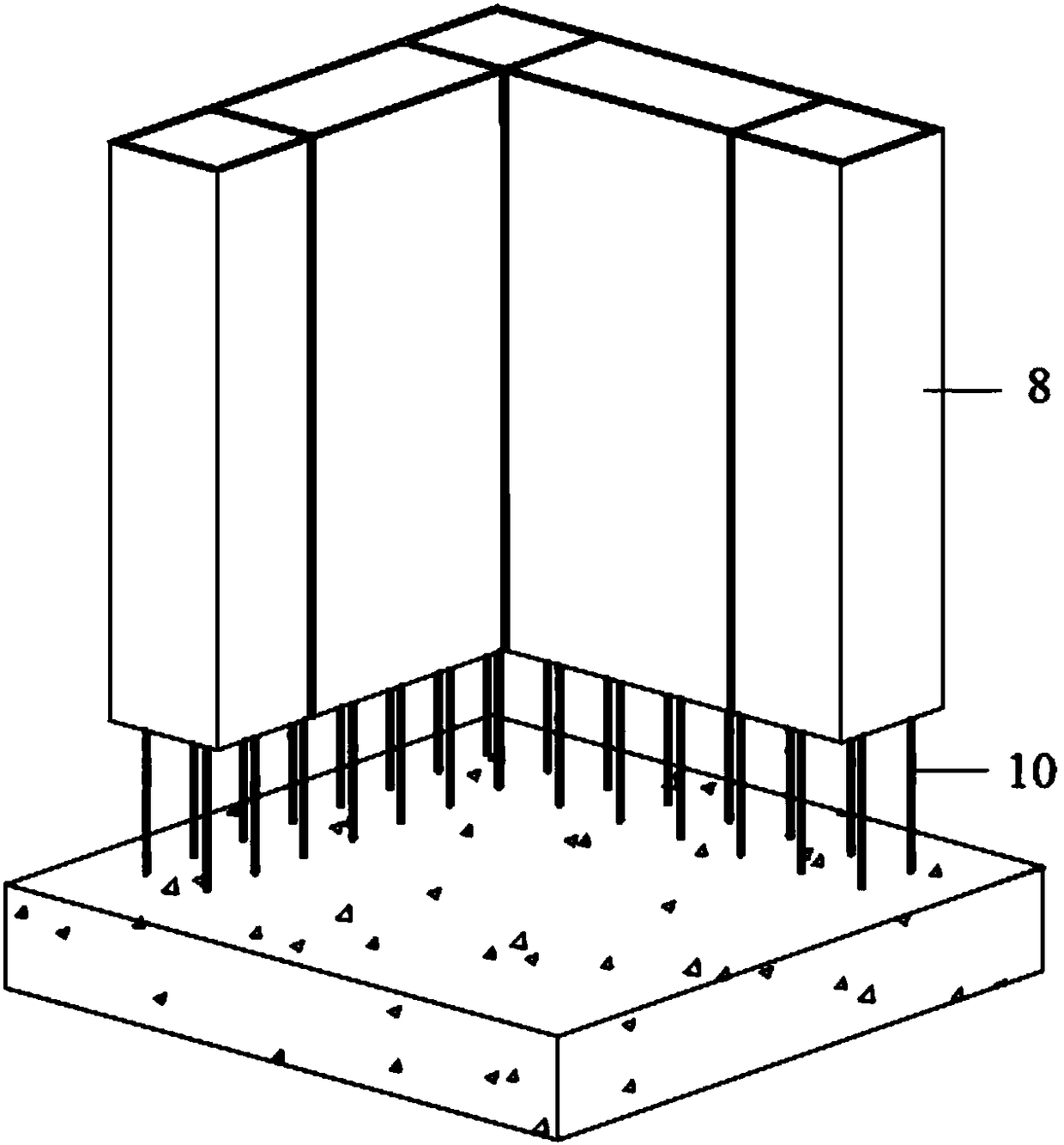

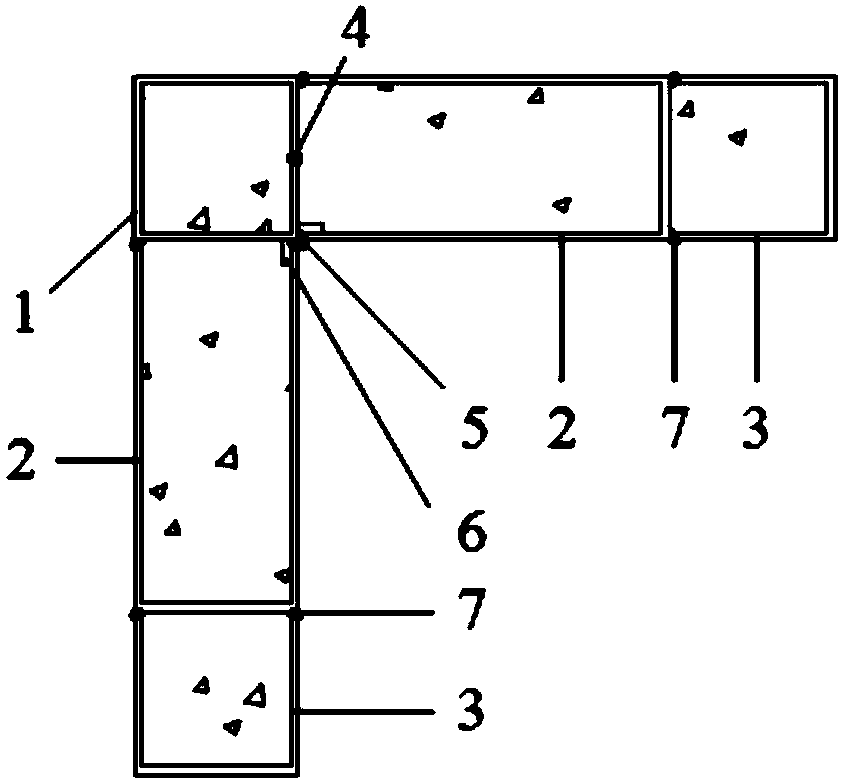

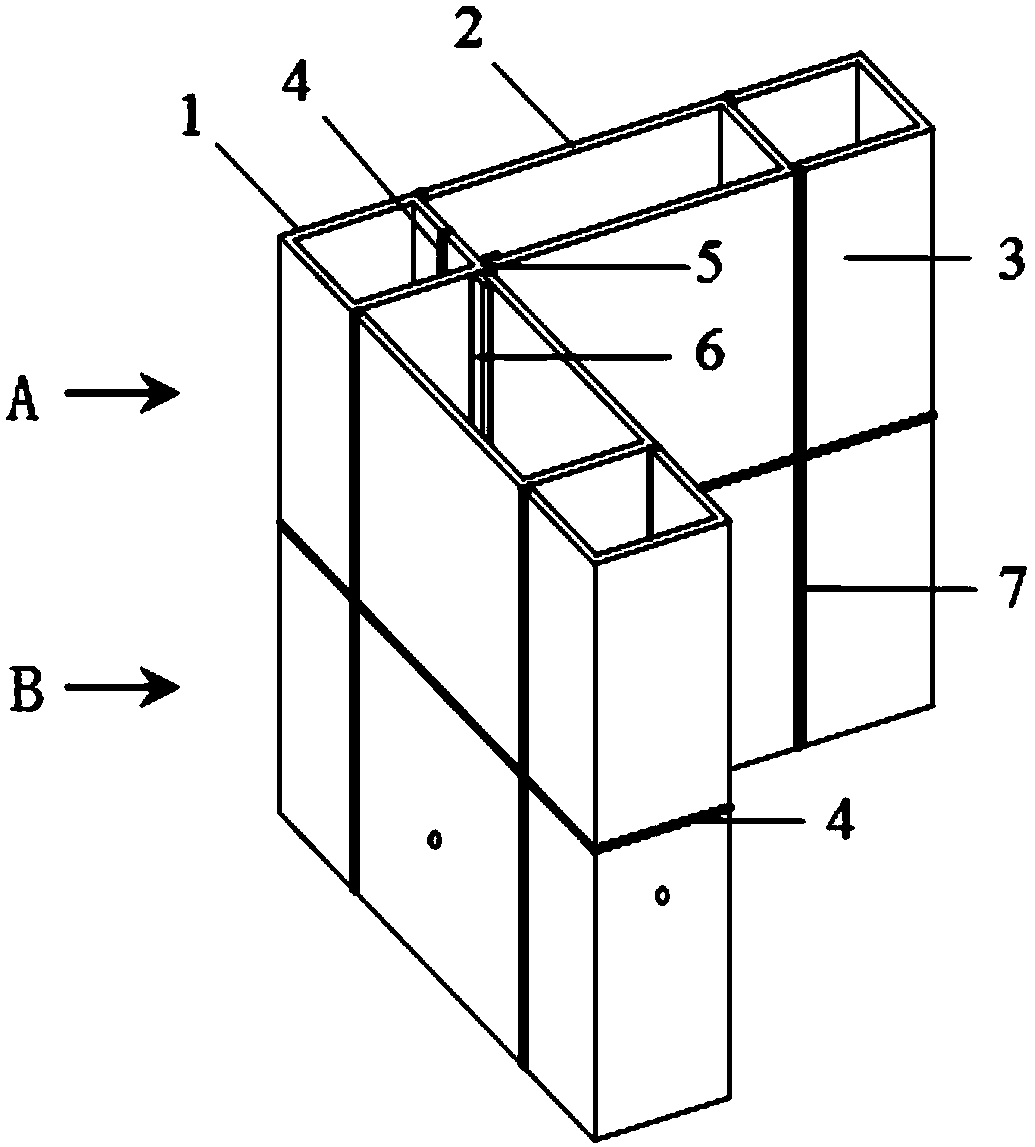

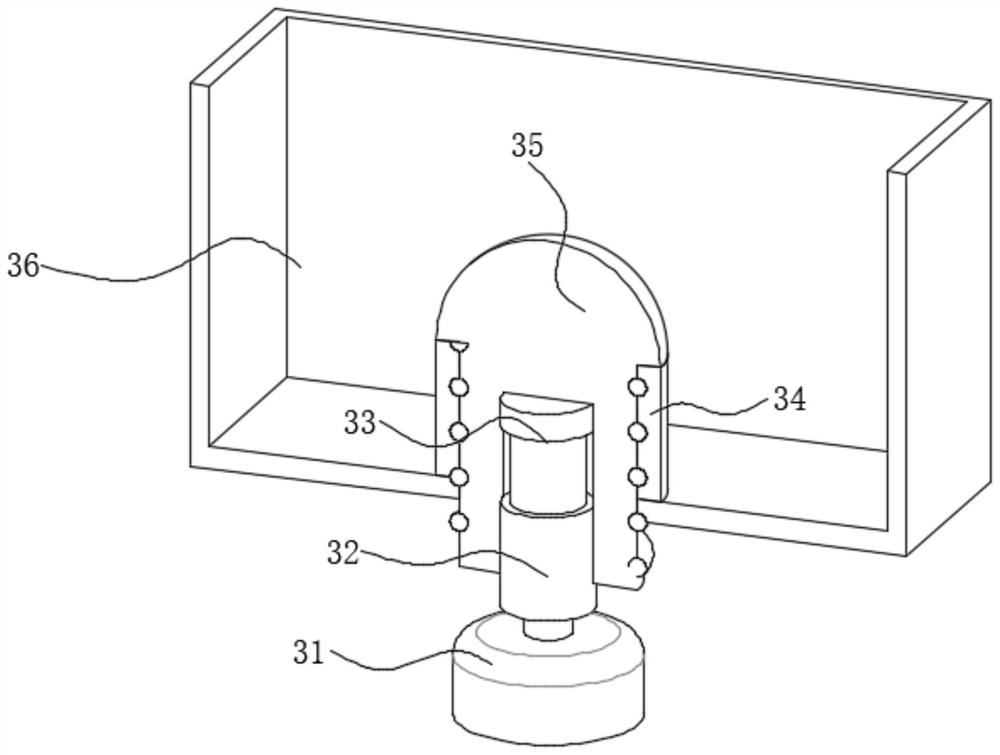

Rigid connection column base of cold-bent multi-cavity steel tube special-shaped concrete column

PendingCN108104368AImprove utilization efficiencyImprove exposed defectsStrutsPillarsSheet steelSteel bar

The invention provides a rigid connection column base of a cold-bent multi-cavity steel tube special-shaped concrete column. A processing method of the rigid connection column base comprises steps asfollows: a core column steel tube of the special-shaped column is processed from a thin-wall steel plate through cold bending and welding, cold-bent formed U-shaped components are sequentially weldedby utilizing the core column steel tube as a center and side surfaces of the core column steel tube as column limb connecting surfaces, steel plates are welded on inner walls of cavities of the tube bodies, and the multi-cavity steel tube is fixed on a concrete foundation with reinforcing steel bars inserted. Bending moment borne by the multi-cavity steel tube can be effectively transmitted to concrete in the column by the welded steel plates and then is transmitted to the concrete foundation through basic steel dowels; meanwhile, column shear force can be transmitted to the foundation throughthe concrete in the column. The whole member is good in mechanical performance, stress is simple, the force transmission path is clear and reasonable, the problem about connection of the cold-bent multi-cavity steel tube special-shaped concrete column and the foundation is solved, meanwhile, industrialized production of main components can be realized, construction is convenient, and time is saved.

Owner:重庆市中科大业建筑科技有限公司

Butt-joint mode of cold-bending multi-cavity steel tube concrete special-shaped column

PendingCN108104262AImprove utilization efficiencyImprove exposed defectsStrutsPillarsSheet steelReinforced concrete

The invention provides a butt-joint mode of a cold-bending multi-cavity steel tube concrete special-shaped column. According to a machining method thereof, a thin-wall steel plate is machined to be acore-column steel tube in cold-bending and welding manners. Additionally, the side surface of the core-column steel tube is welded with a U-shaped member in order to form a multi-cavity steel tube. Apartition board in the interior of the multi-cavity steel tube is welded with butt-joint anchor bars. Anchor effect between the butt-joint anchor bars and concrete is utilized for connecting reinforced concrete in upper and lower column bodies as a whole. The butt-joint mode helps resolve the problem that stress of a butt-joint connection node of a traditional steel tube concrete special-shaped column is weak. Meanwhile, a butt-joint connection node of the cold-bending multi-cavity steel tube concrete special-shaped column is simple in structure and clear-cut in force-transmission principle and can be prefabricated and produced within a factory. Therefore, construction is convenient and quick.

Owner:重庆市中科大业建筑科技有限公司

High-strength anti-seismic wall, integral cast-in-situ building and construction method thereof

PendingCN109235636AImprove seismic performanceLow steel contentBuilding reinforcementsBuilding material handlingSteel barHigh intensity

The invention relates to a high-strength anti-seismic wall, an integral cast-in-situ building and a construction method thereof. The high-strength anti-seismic wall includes a concrete wall, a plurality of truss stand columns and a plurality of transverse reinforcing bars, wherein the truss stand columns and the transverse reinforcing bars are embedded in the concrete wall in advance; the truss stand columns have the same specifications and are parallel to each other and arranged in a row at equal intervals; each truss stand column includes two vertical reinforcing bars and a first connectionbar, the two truss stand columns are vertically arranged at intervals, and the first connection bar is arranged between the two vertical reinforcing bars and fixed with the two vertical reinforcing bars through welding. The transverse reinforcing bars horizontally run through all the truss stand columns. The advantages are as follows: the construction period is short, the working procedure is simple, the cost is low, energy conservation and environment protection are achieved, the overall structural strength is high and the anti-seismic performance is good.

Owner:刘家宇

Novel lattice type combined shear wall

PendingCN111809773APrevent bucklingImprove performanceWallsProtective buildings/sheltersEarthquake resistanceRebar

The invention discloses a novel lattice type combined shear wall. The novel lattice type combined shear wall comprises T-shaped flanges, truss web members and tie bars. Every two T-shaped flanges forma set and are oppositely arranged, and the T-shaped flanges are connected together through the truss web members. Every two tie bars form a set and are horizontally welded between the two corresponding opposite T-shaped flanges. The two tie bars in each set are symmetrically welded into cavities on two sides of the corresponding T-shaped flange, two ends of each tie bar are bent and welded on thecorresponding T-shaped flange, and the plurality of sets of T-shaped flanges are welded together to form a shear wall body of a multi-grid cavity structure. The shear wall has a brand-new shear wallstructure, does not need fire prevention measures, has good seismic performance, is low in steel content, greatly saves cost, is very convenient to construct, and can be prefabricated in a factory andpoured on site.

Owner:上海结奕建筑咨询事务所

Modular steel bar truss floor support plate

PendingCN112814243ALow steel contentReduce the workload of demolitionFloorsHeat proofingSheet steelArchitectural engineering

The invention discloses a modular steel bar truss floor support plate. The modular steel bar truss floor support plate is characterized by comprising a prefabricated bottom plate, self-tapping screws or rivets, a galvanized steel sheet, lower chord longitudinal steel bars, upper chord longitudinal steel bars, web member wave-shaped steel bars and upper chord transverse short bars. Steel bars matched with the modular steel bar truss floor support plate are in-line single-truss steel bar trusses, the steel content is less, the bottom is flat, and putty can be directly scraped for decoration. According to the modular steel bar truss floor support plate, the cost is saved for a construction party, the purpose of fast turnover is achieved, the workload of deepening design is saved for a design party, the construction progress is accelerated for the construction party, the construction quality is better controlled, the capacity is completely released for a component production party, and therefore all parties involved in a project can obtain respective benefits.

Owner:广西装配式建筑科技有限公司

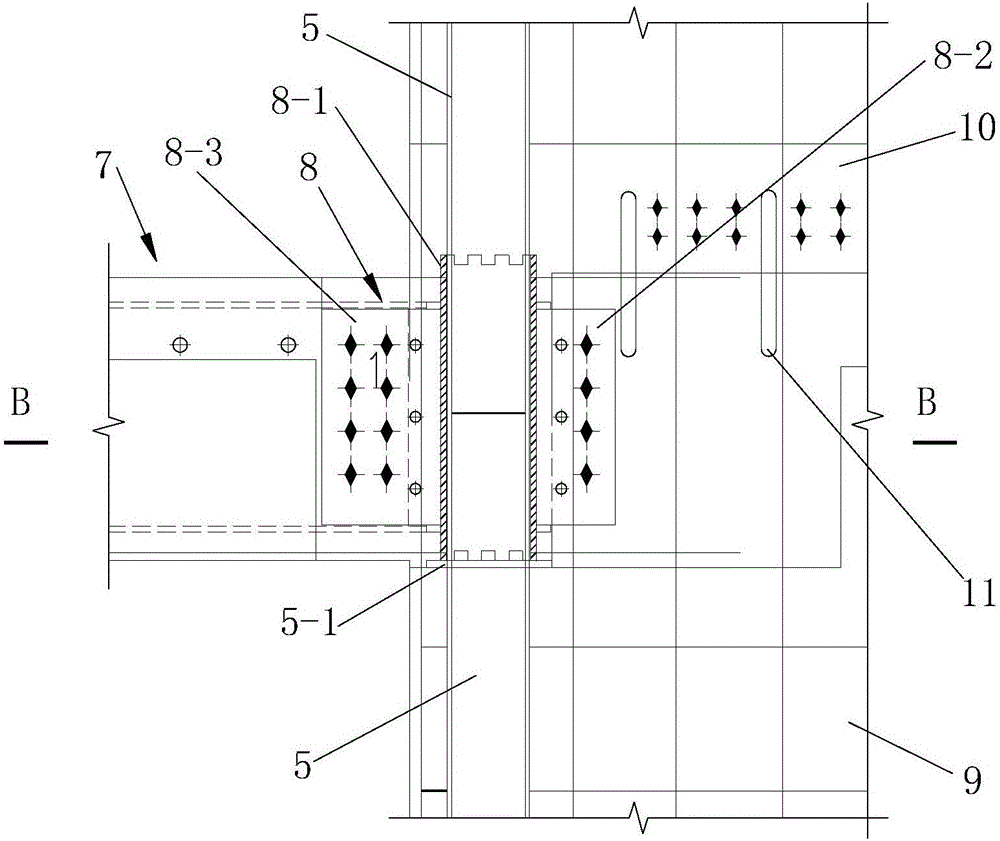

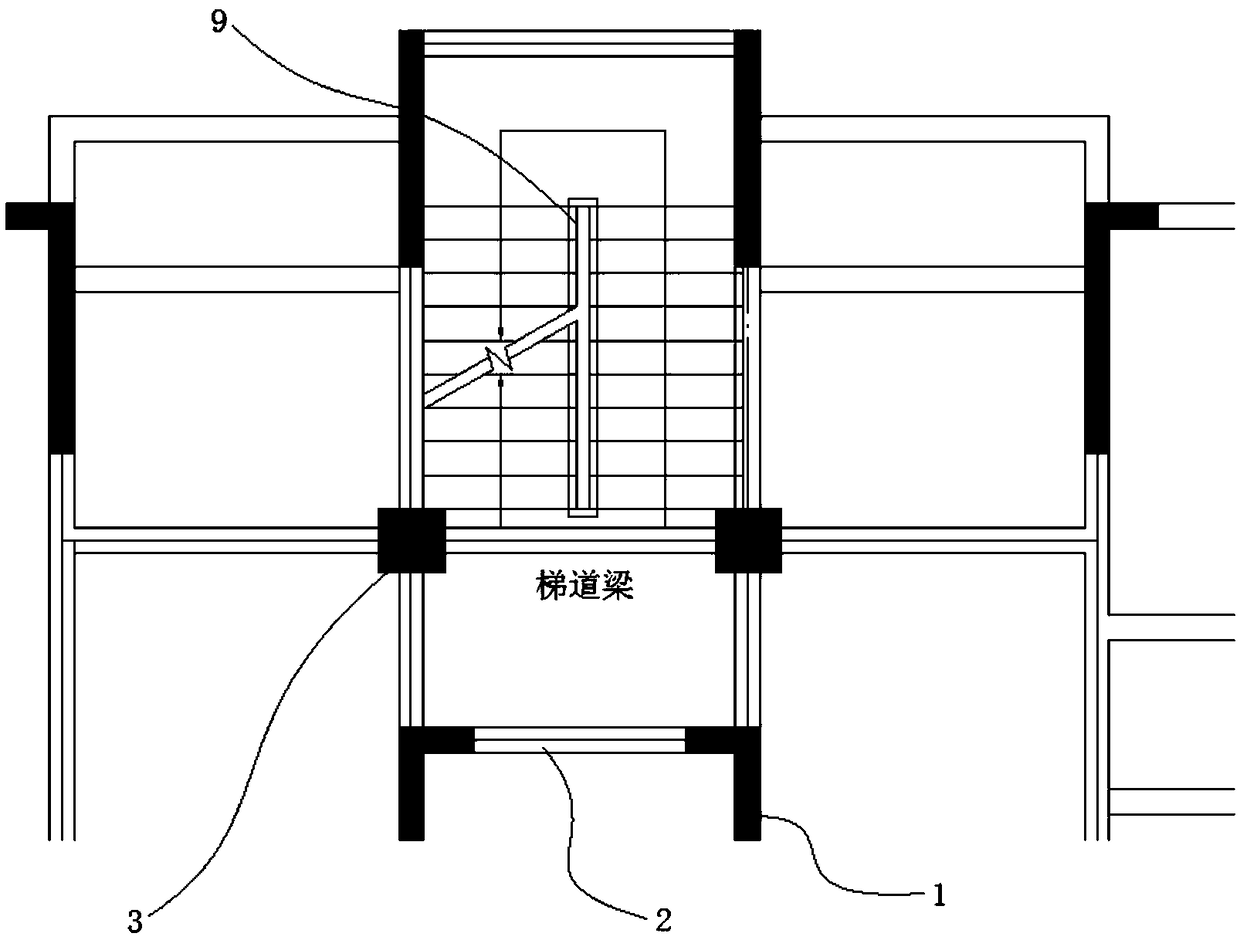

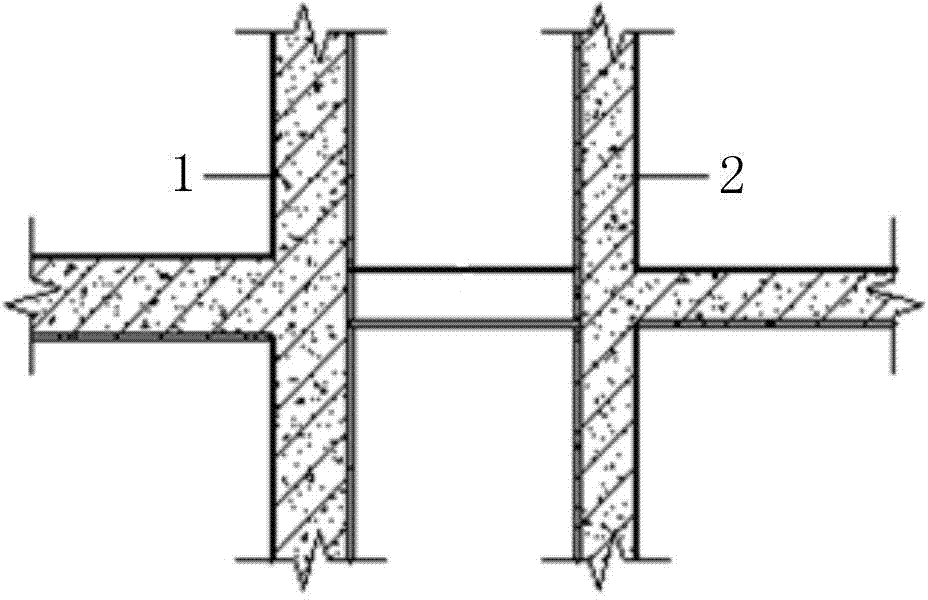

Construction method, mounting structure and combined structure for coupling beam between shear wall limbs

ActiveCN104847111AReduce section sizeLow steel contentWallsBuilding material handlingRebarCoupling beam

The invention relates to the field of constructional engineering and provides a construction method, a mounting structure and a combined structure for a coupling beam between shear wall limbs. The construction method includes: burying anchor bolts in a shear wall limb on one side; fixing a steel support frame on the shear wall limb with the anchor bolt via anchor bolts and nuts; above the steel support frame, constructing stirrups and longitudinal reinforcement steel bars of the coupling beam; pouring concrete of the coupling beam to enable one end of the poured section of the coupling beam to be mounted on the shear wall limb without the steel support frame, enable the other end of the poured section of the coupling beam to overlap on the steel support frame and reverse a vertical seam between the poured section of the coupling beam and the shear wall limb with the steel support frame; after vertical differential settlement between each of two ends of the poured section of the coupling beam and the corresponding shear wall limb is smaller than 2-4mm, pouring concrete to the vertical seam to form an integral coupling beam. The construction method, the mounting structure and the combined structure have the advantages that additional internal force generated from vertical deformation difference between two ends of the coupling beam can be released, section size of the coupling beam can be decreased, and steel content of the coupling beam is decreased.

Owner:中国建筑东北设计研究院有限公司

Manufacturing method of high-strength galvanized steel sheet

The invention belongs to the technical field of iron-based alloys, and particularly relates to a high-strength galvanized steel sheet manufacturing method.The high-strength galvanized steel sheet manufacturing method comprises a galvanizing device, adjusting devices are slidably connected to the left side and the right side of the upper portion of the outer surface of the galvanizing device, pressure devices are arranged on the lower portions of the inner walls of the adjusting devices, and the galvanizing device comprises an electrolytic tank; a penetrating rotating opening is formed in the middle of the lower portion of the inner wall of the electrolytic tank, the lower portion of the inner wall of the electrolytic tank is fixedly connected with a vertical guide shell through the penetrating rotating opening, and a threaded rotating groove is formed in the inner wall of the vertical guide shell. Compared with a common steel plate, the anti-pressure capacity and toughness of the device are improved through the rock wool sandwich layer in the galvanized steel plate sleeve, when the galvanized steel plate sleeve on the outer layer is impacted, the rock wool sandwich layer on the inner layer can effectively absorb the impact force, the impact force borne by the other side of the galvanized steel plate sleeve is greatly reduced, and the service life of the device is prolonged. And therefore, the impact resistance of the galvanized steel sheet is relatively high.

Owner:韩倩倩

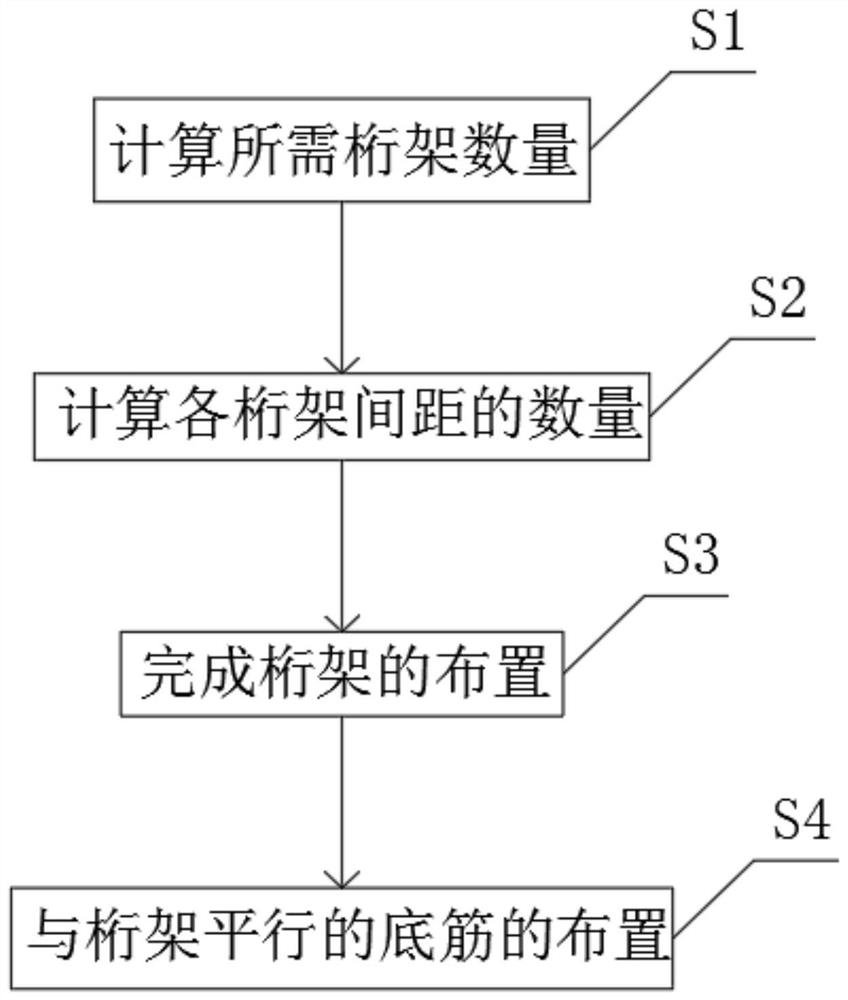

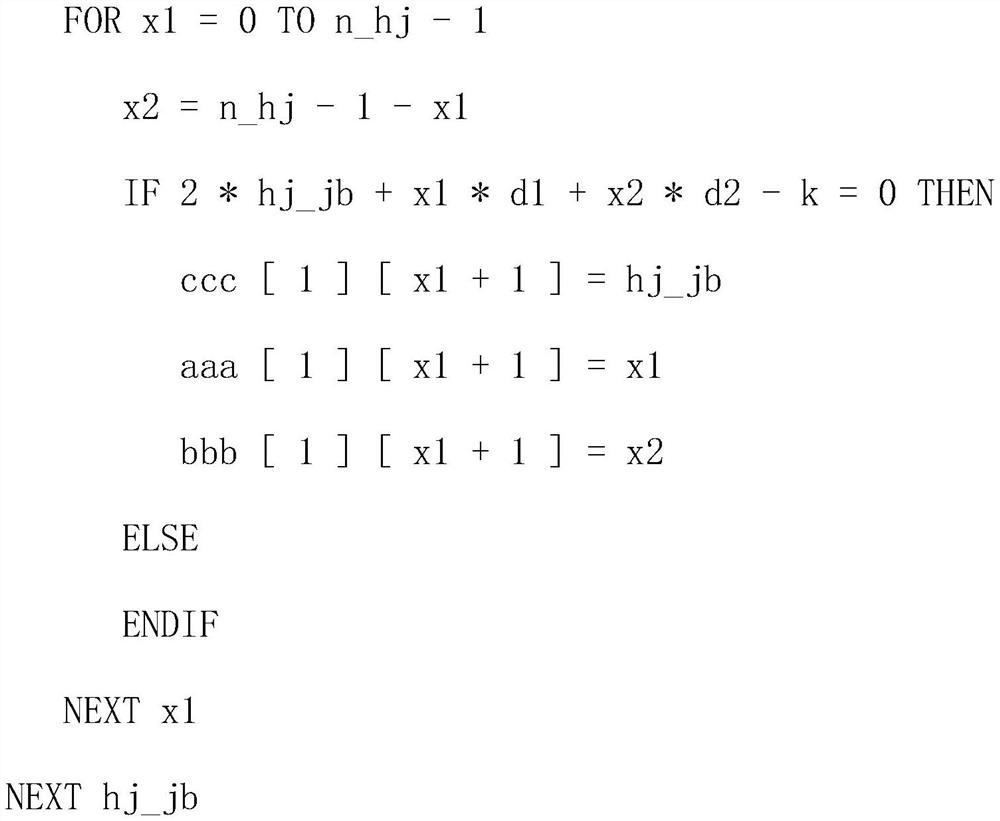

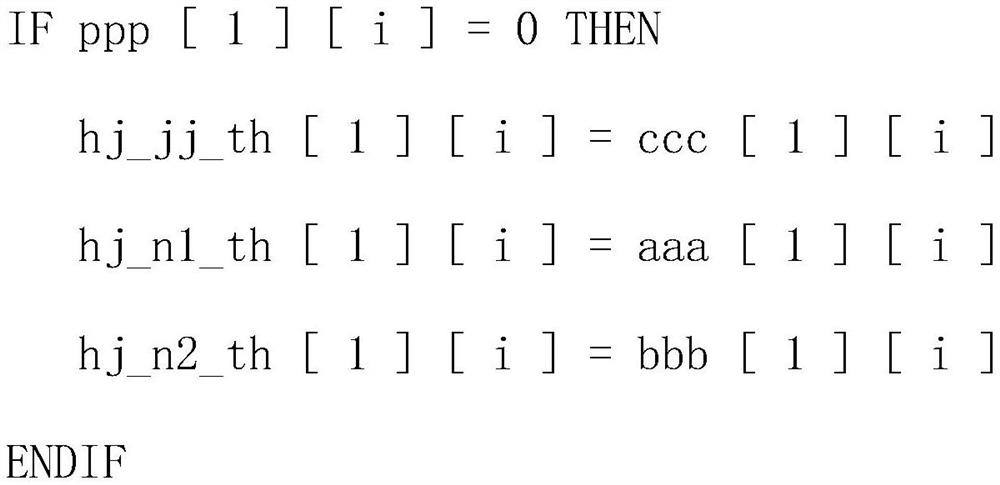

A method for arranging laminated floor trusses and bottom bars

ActiveCN112459329BReduce manufacturing costSymmetrical arrangementGeometric CADFloorsFloor slabArchitectural engineering

The invention discloses a method for arranging laminated floor trusses and bottom bars, wherein the method for arranging laminated floor trusses includes step S2: calculating the number of distances between each truss, which is obtained specifically by establishing a loop algorithm and a screening function. The invention can automatically arrange the bottom bars and trusses according to the rules through the size of the prefabricated components and the spacing of the steel bars, and make the trusses and bottom bars symmetrically arranged, uniform and beautiful; it can effectively reduce the steel content of the concrete prefabricated components and save components The production cost is greatly improved, and the design efficiency of laminated floor trusses and bottom bars is greatly improved.

Owner:CHONGQING ZHONGKE CONSTR GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com