Construction method, mounting structure and combined structure for coupling beam between shear wall limbs

A technology for installing structures and construction methods, applied to walls, building components, building structures, etc., can solve the problems of calculating additional internal forces, reducing the cross-sectional size of coupling beams, reducing the steel content of coupling beams, etc., to reduce the difficulty of design calculations, The effect of reducing the design and construction period and reducing the steel content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

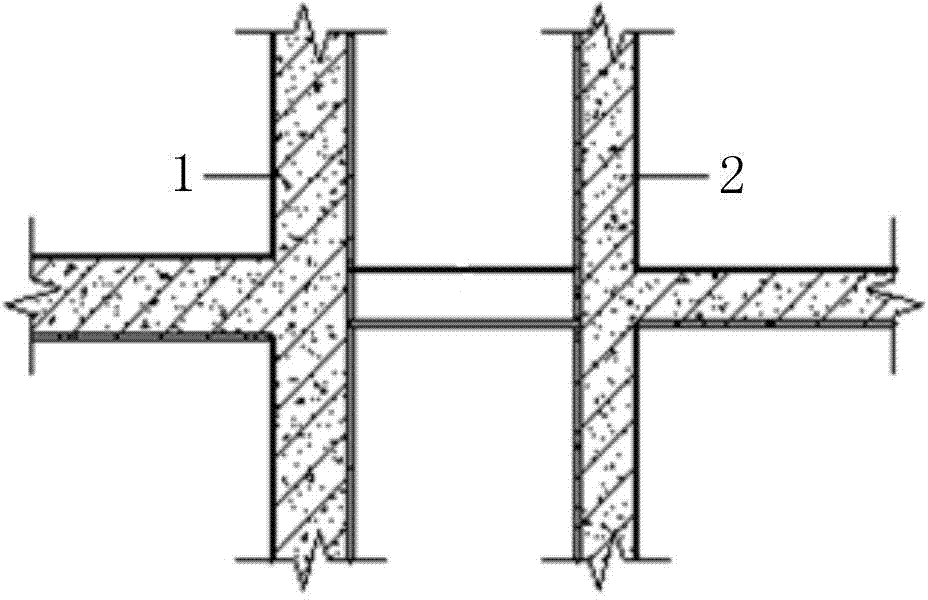

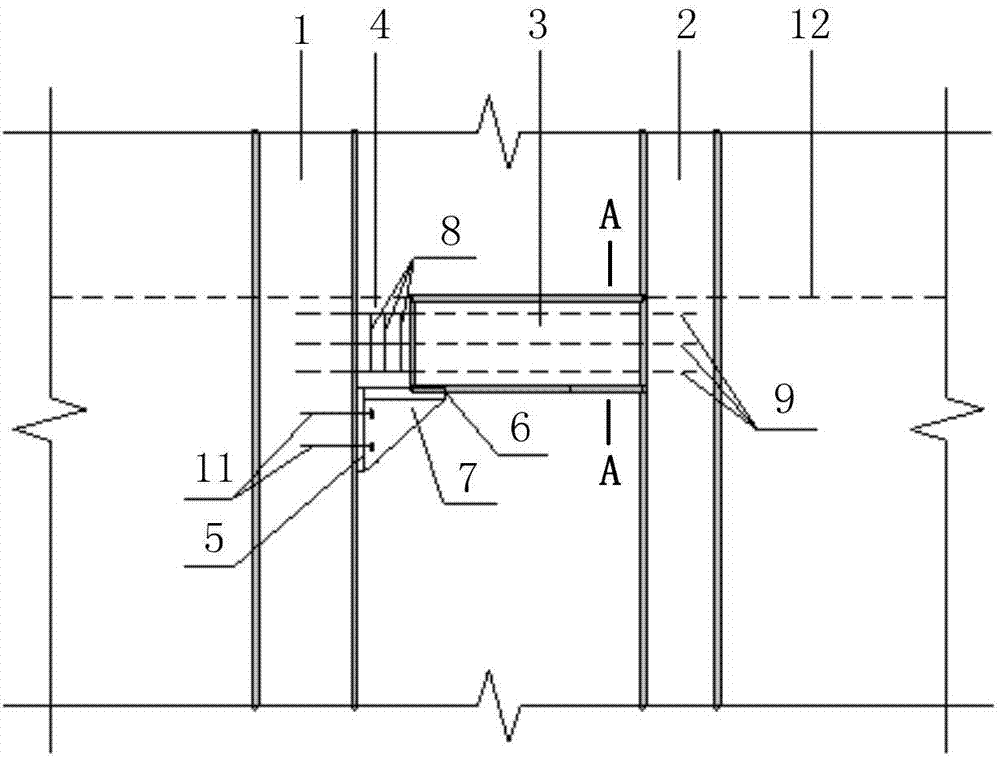

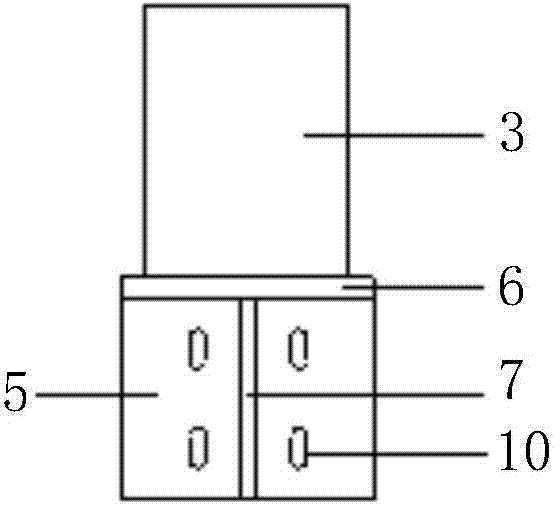

[0034] figure 1 It is a schematic diagram of the connection between the coupling beam and the shear wall pier. figure 2 It is a schematic diagram of the installation structure of the connecting beam between the shear wall piers. image 3 for along figure 2 A side sectional view in the direction of A-A. Such as figure 1 , 2 As shown in and 3, the present embodiment provides a mounting structure for connecting beams between shear wall limbs, including:

[0035] The connecting beam pouring section 3 and the steel support frame; the steel support frame includes a vertical plate 5, a horizontal steel plate 6 and a triangular rib plate 7, and the two right-angled sides of the triangular rib plate 7 are respectively fixedly connected with the vertical plate 5 and the horizontal steel plate 6, and the horizontal steel plate 6 Above the triangular rib 7, the riser 5 is used for fixed connection with the shear wall; one end of the connecting beam pouring section 3 is installed on...

Embodiment 2

[0040]This embodiment provides a combined structure of connecting beams between shear wall limbs, including a connecting beam and a steel support frame; the connecting beam is fixedly arranged between two shear wall limbs, and the steel supporting frame is arranged under the bottom surface of the connecting beam It is used to support the connecting beam, and the connecting beam is provided with stirrups and longitudinal steel bars; the steel support frame includes vertical plates, horizontal steel plates and triangular ribs, and the two right-angled sides of the triangular ribs are fixedly connected with the vertical plates and horizontal steel plates respectively, and the horizontal The steel plates are above the triangular ribs, and the vertical plates are used for fixed connection with the shear wall pier.

[0041] Wherein, the width of the horizontal steel plate is greater than the width of the coupling beam. Both sides of the horizontal steel plate are 50mm wider than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com