Patents

Literature

1257results about "Arch-type bridge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

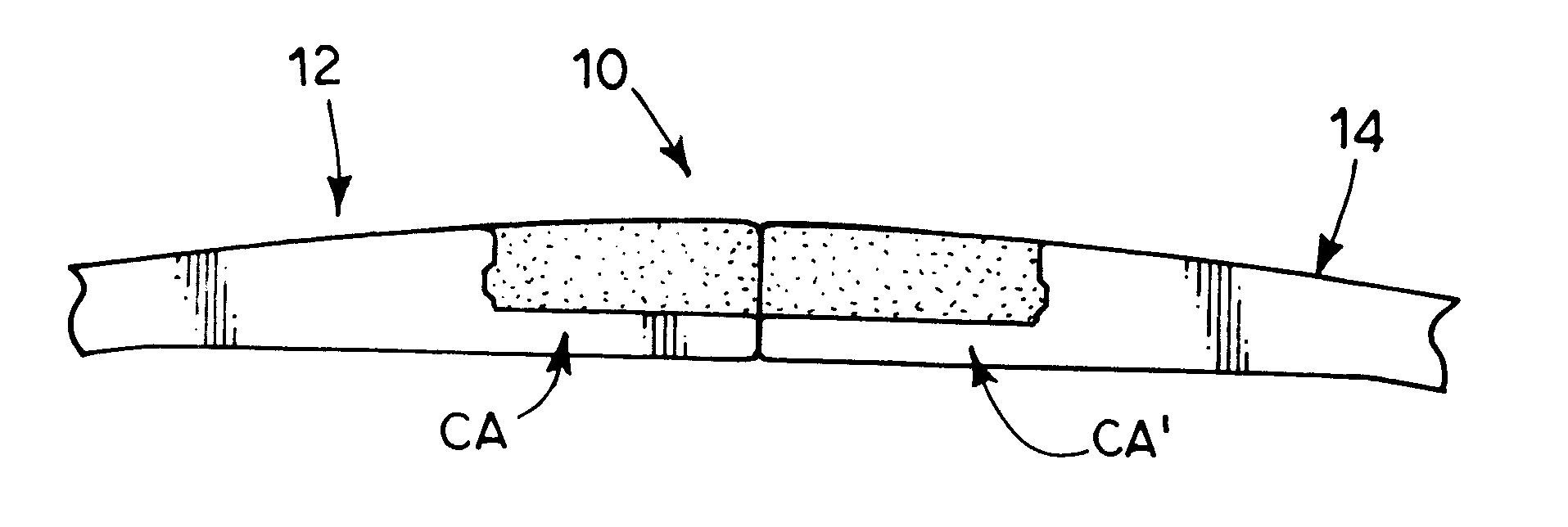

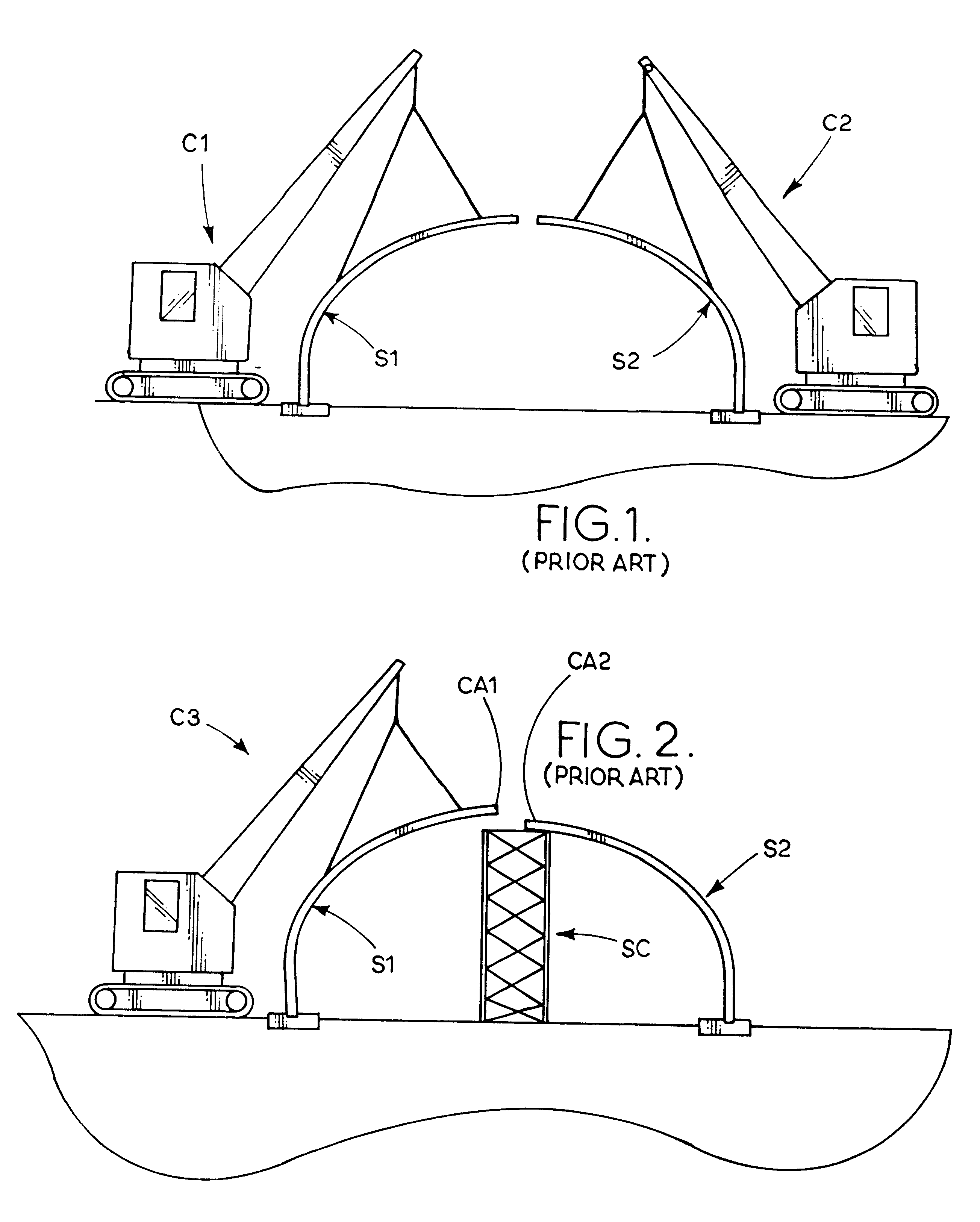

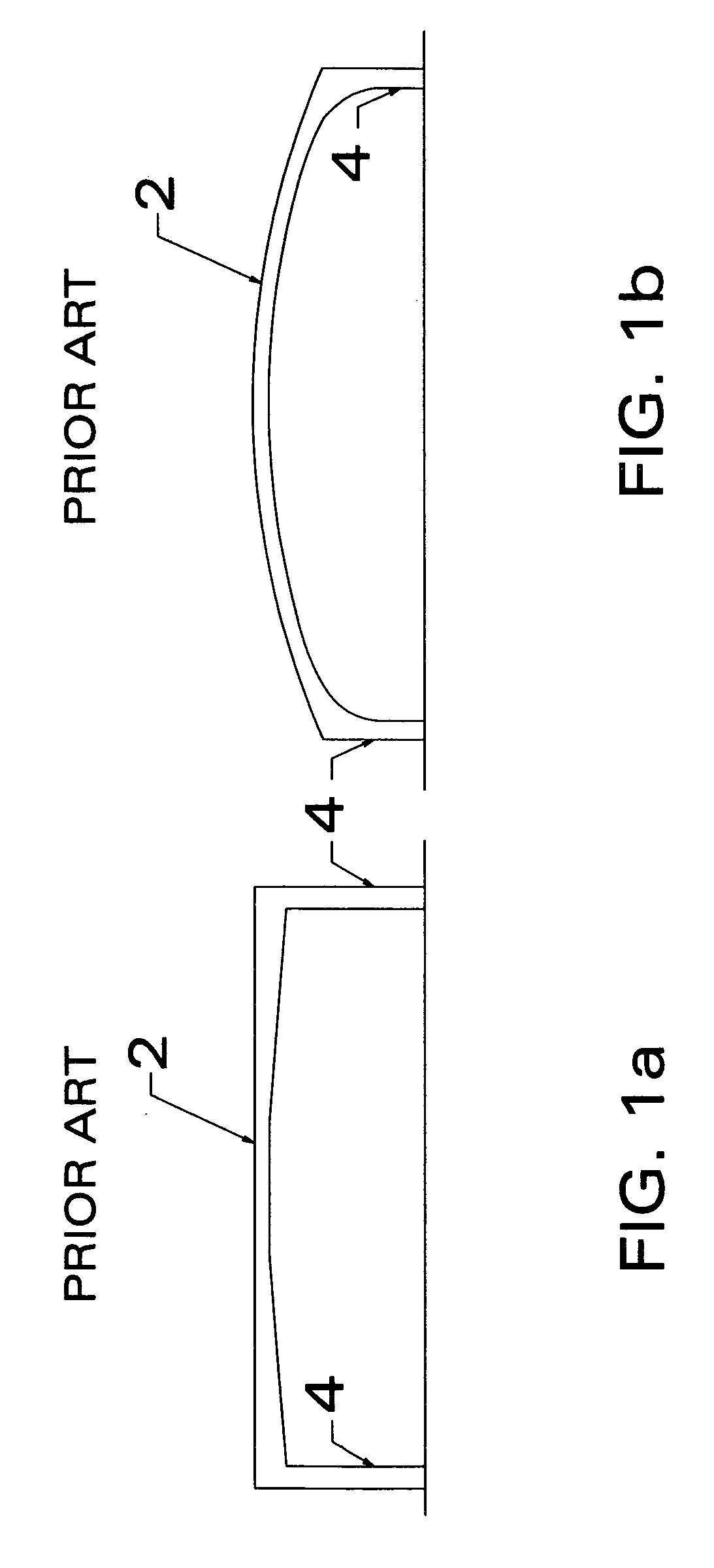

Joint for pre-cast concrete twin-leaf arch sections

InactiveUS6243994B1Efficiently and accurately formForming accuratelyUnderground chambersBuilding material handlingControl theoryPrecast concrete

A joint for pre-cast concrete twin-leaf arch sections is self-aligning when the two arch sections are initially brought into abutting contact with each other. The joint provides a rigid connection between the twin units and is achieved on site by means of re-inforced cast-in-place concrete. Reinforcement splices for the connection are lap splices, and the joint allows pouring the cast-in-place concrete without the need of formwork. For load distributing purposes, a continuous connection of individual arch rings in the longitudinal direction at the arch crown is possible. An initial abutting contact between the twin units is provided by the joint of the present invention. The contact provided by the joint of the present invention is self-aligning, locking, allows the controlled transmission of the abutting force and allows for a temporary connection. The joint includes mechanical elements for aligning and locking the two arch sections together. The mechanical elements include, in the preferred embodiment, a projection on one arch section and a depression on the other arch section. Cast-in-place concrete is placed in boxed-out, or step, sections located adjacent to the mechanical elements and completes the joint.

Owner:CONTECH ENGINEERED SOLUTIONS

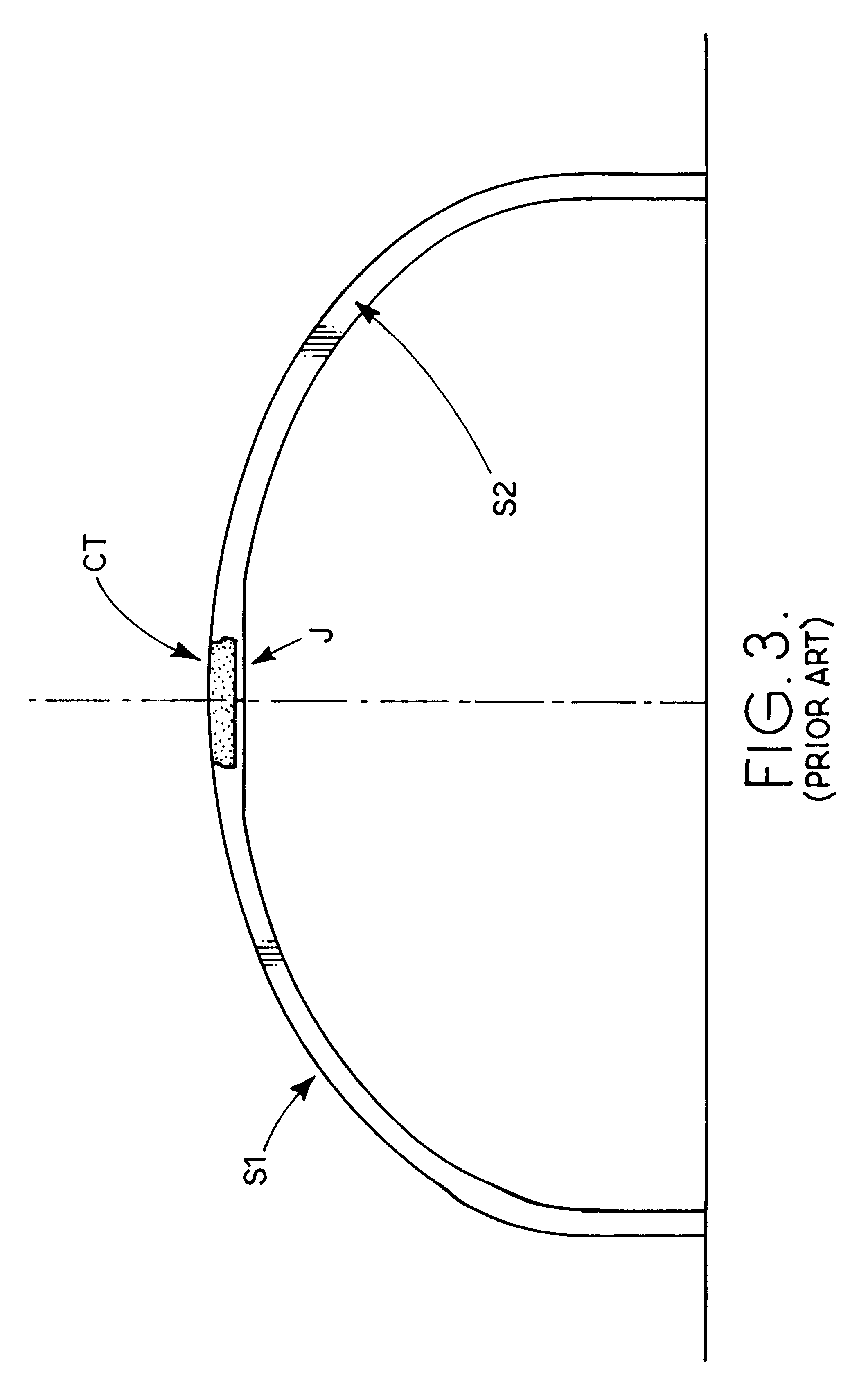

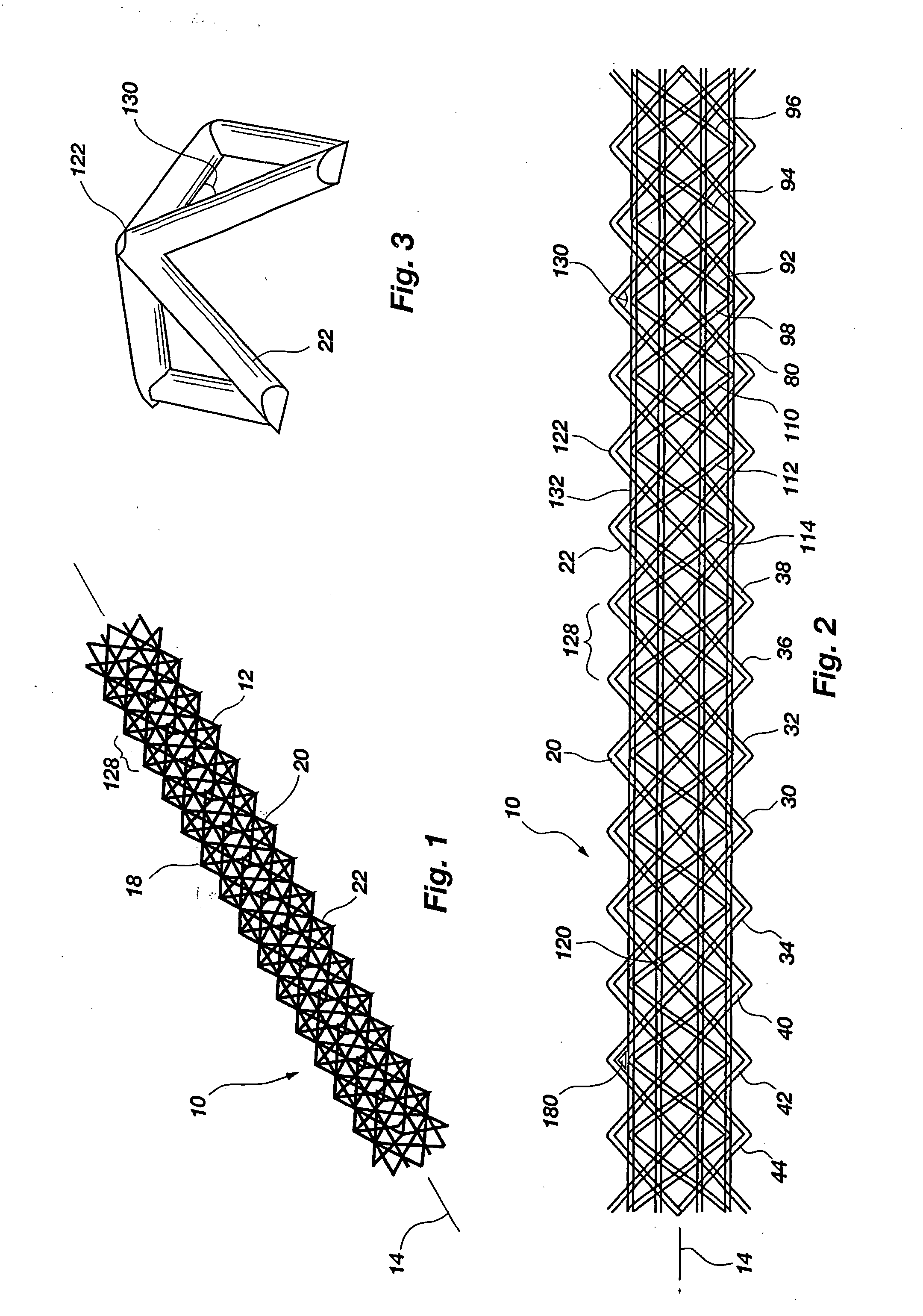

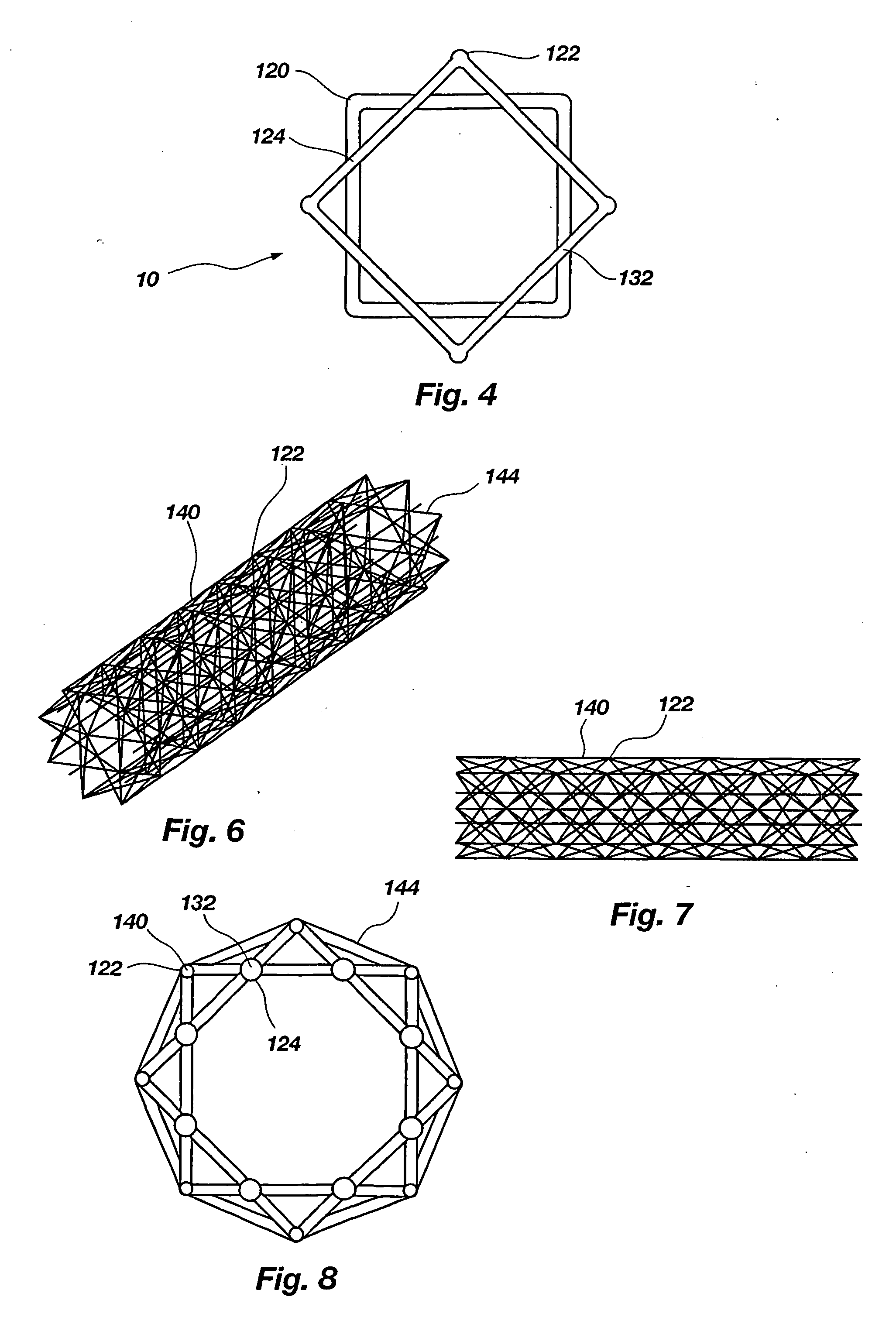

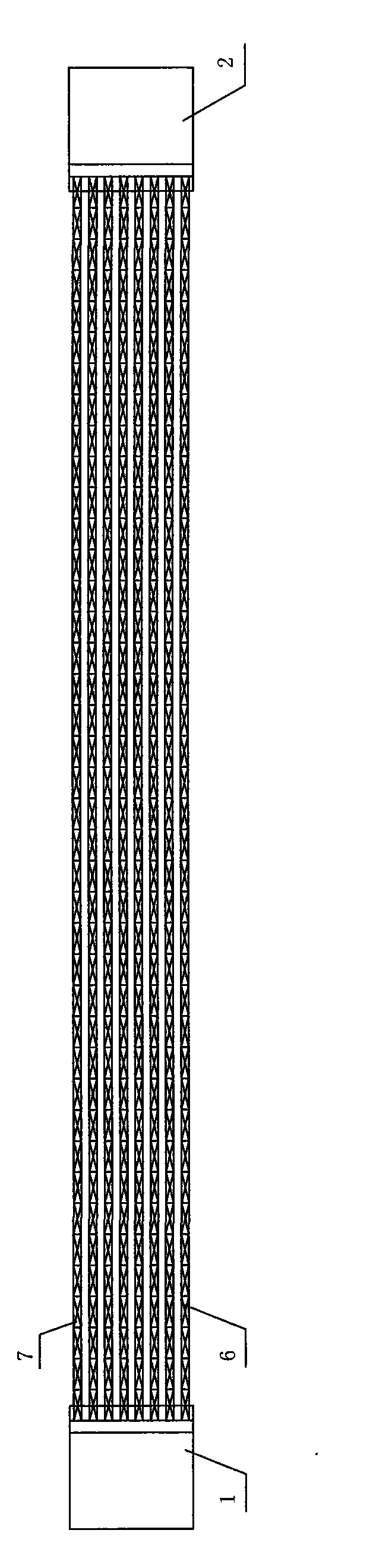

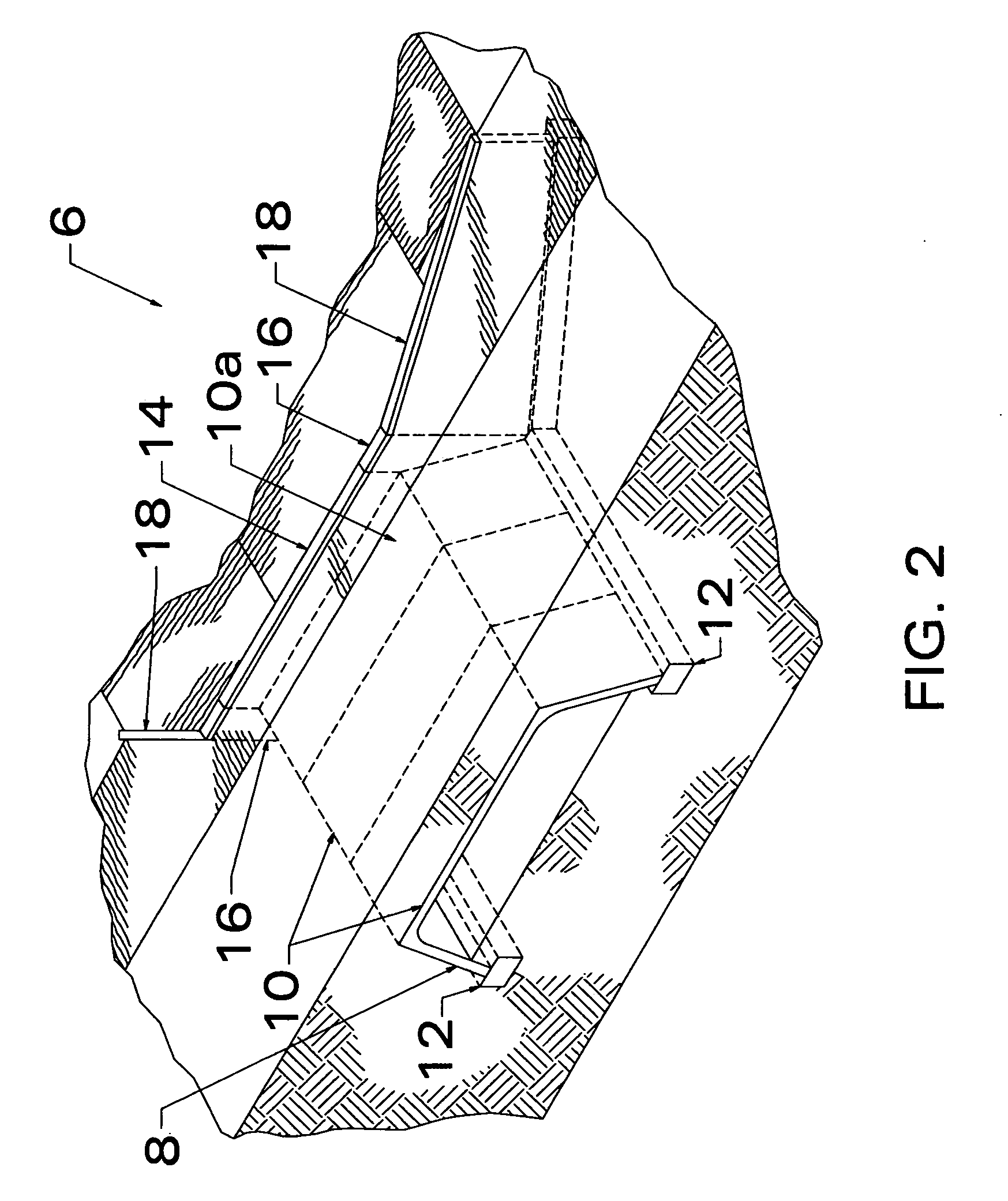

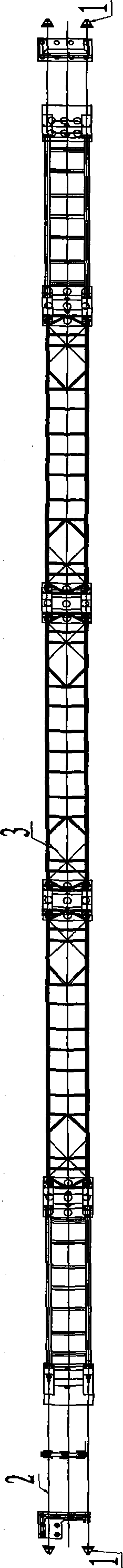

Iso-truss structure

InactiveUS20050115186A1Improved performance characteristicsReduced strengthTravelling sacksTruss-type bridgeSquare cross sectionAngular orientation

An iso-truss structure (10) includes at least two helical components (30, 32) and at least one reverse helical component (34) attached thereto with opposing angular orientations. Each helical and reverse helical component preferably includes at least four elongate, straight segments (22) rigidly connected end to end in a helical configuration forming a single, substantially complete rotation about a common axis (14) forming a first square cross section. The structure may further include at least two rotated helical components (80, 92) and at least one rotated reverse helical component (98) which are rotated with respect to the helical and reverse helical components forming a second square cross section, rotated with respect to the first. The structure may be straight, curved, flexible, or form angles.

Owner:ISOTRUSS IND LLC

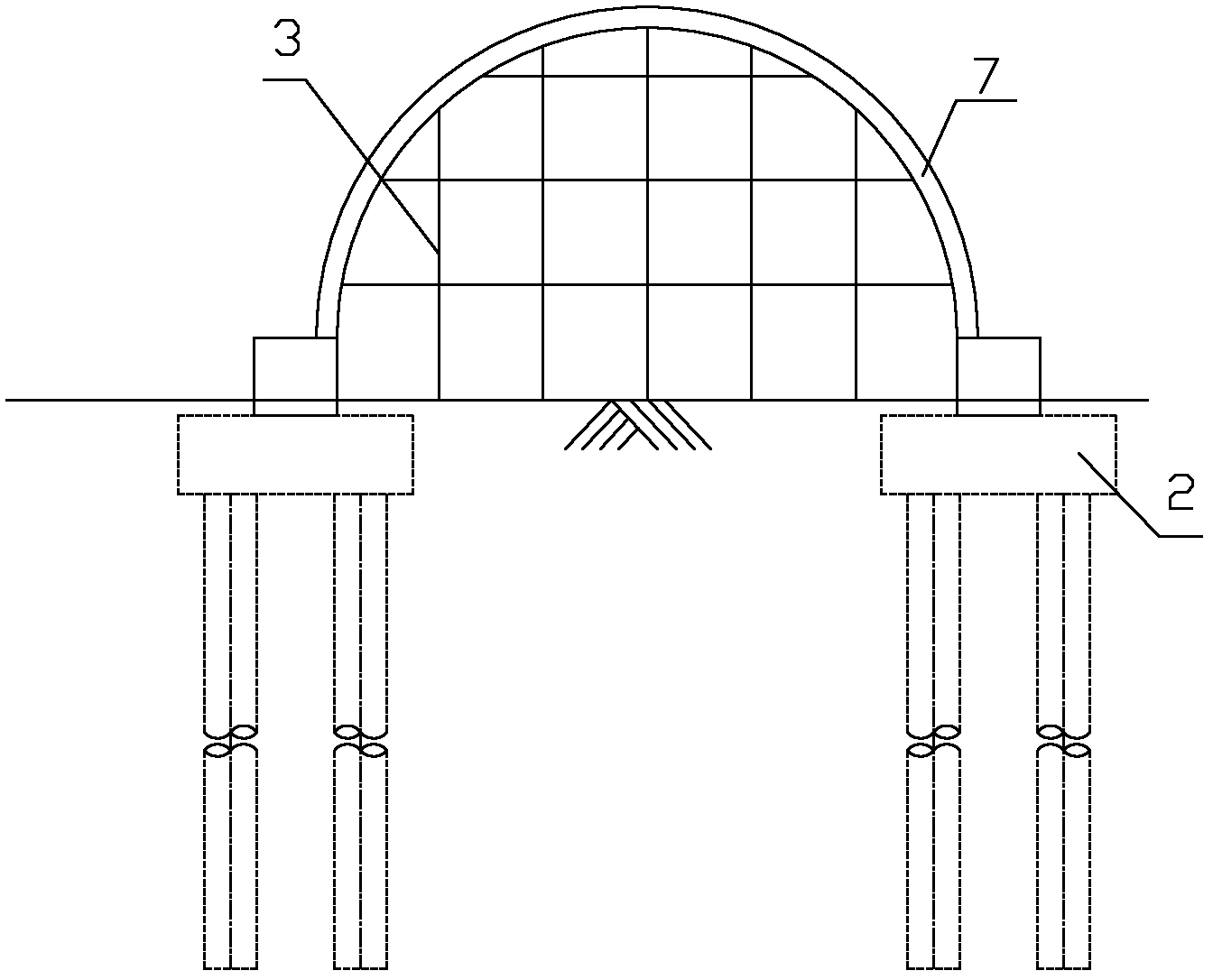

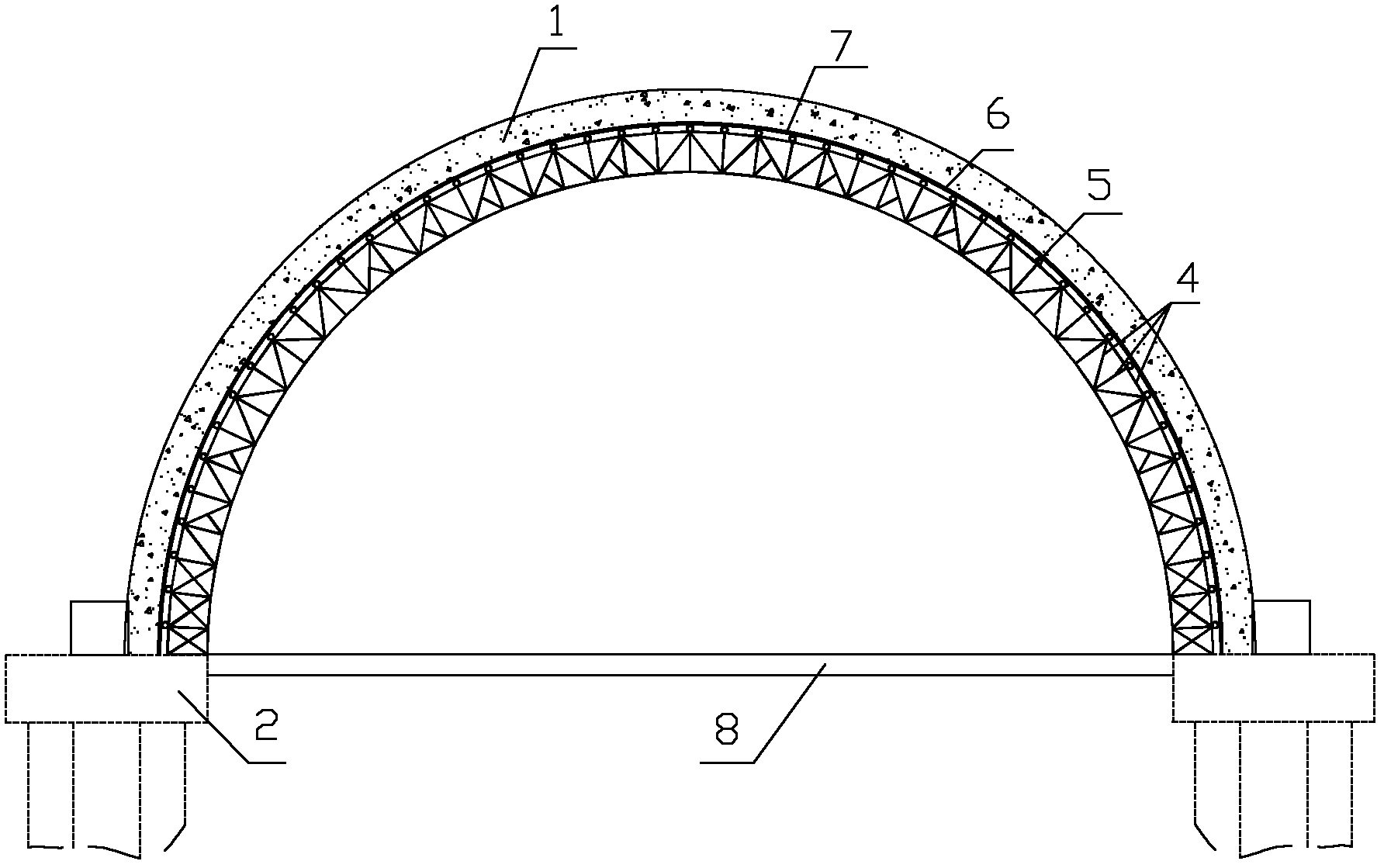

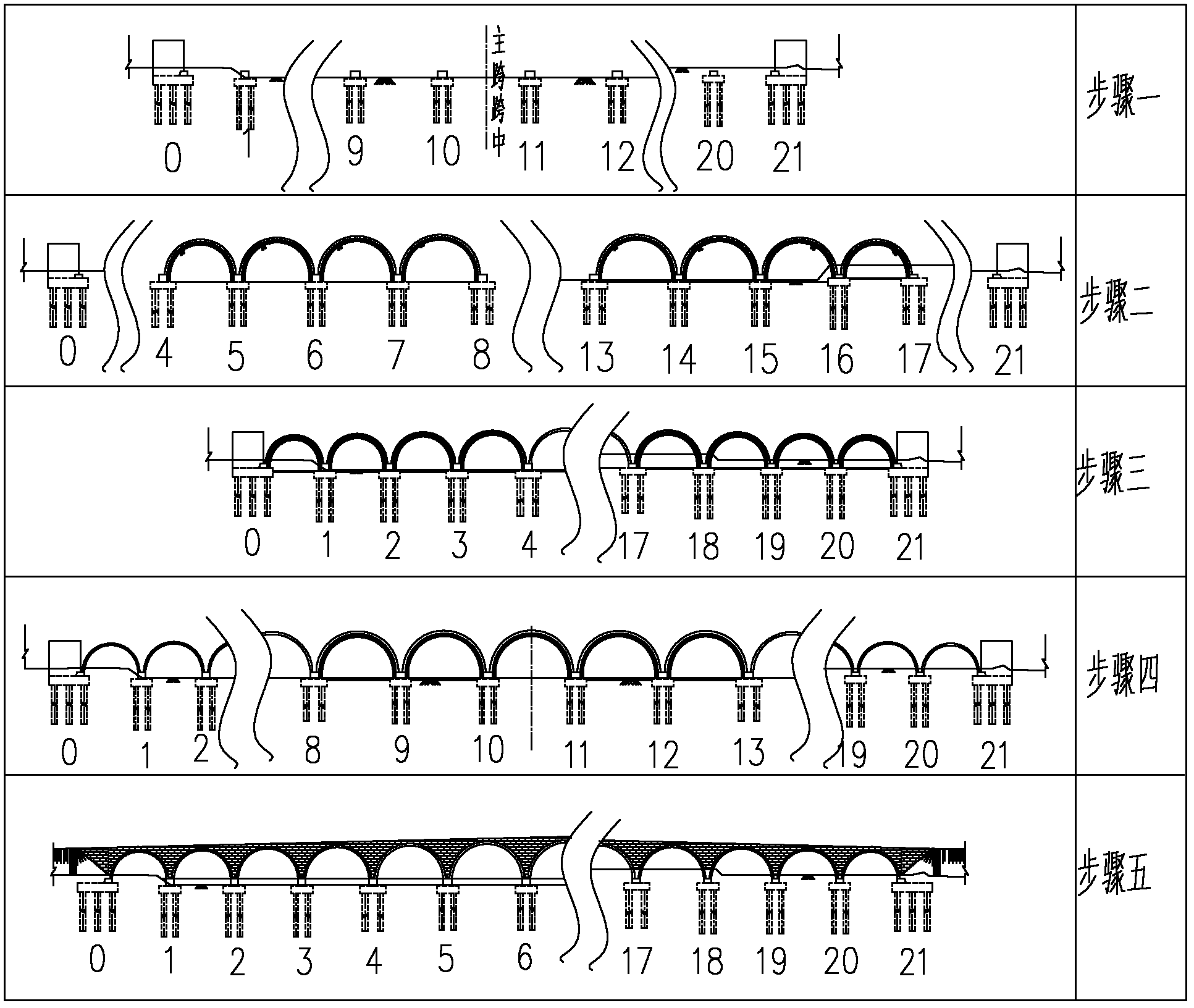

Reinforced concrete arch bridge construction method

ActiveCN102493360AAvoid deformationStable structureBridge erection/assemblyArch-type bridgeReinforced concreteAbutment

The invention discloses a reinforced concrete arch bridge construction method, which comprises the following steps of: 1, constructing a pile foundation, a pile cap, a bridge abutment body side wall and a bridge pier body; 2, erecting arch ring supports from the fourth hole to the eighth hole and from the thirteenth hole to the seventeenth hole on two sides of an arch bridge, arranging a locking system, and finally pouring concrete to arch rings of the eight holes; 3, detaching the arch ring supports in the step 2, erecting arch ring supports from the zero hole to the fourth hole and from theseventeenth hole to the twenty-first hole on the bridge abutment side, arranging a locking system and finally pouring concrete to arch rings of the eight holes; and 4, detaching the arch ring supports erected in the step 3, erecting arch ring supports from the eighth hole to the thirteenth hole in the span, arranging a locking system, pouring concrete to arch rings of the five holes, and folding the whole bridge. Main bodies of the arch ring supports have arch truss structures, a characteristic that steel bars are tensioned is utilized, the structures are firm, the middles of the structures are not required to be supported, materials are saved, the arch ring supports are convenient to detach, and constriction time is saved.

Owner:浙江大东吴集团建设有限公司

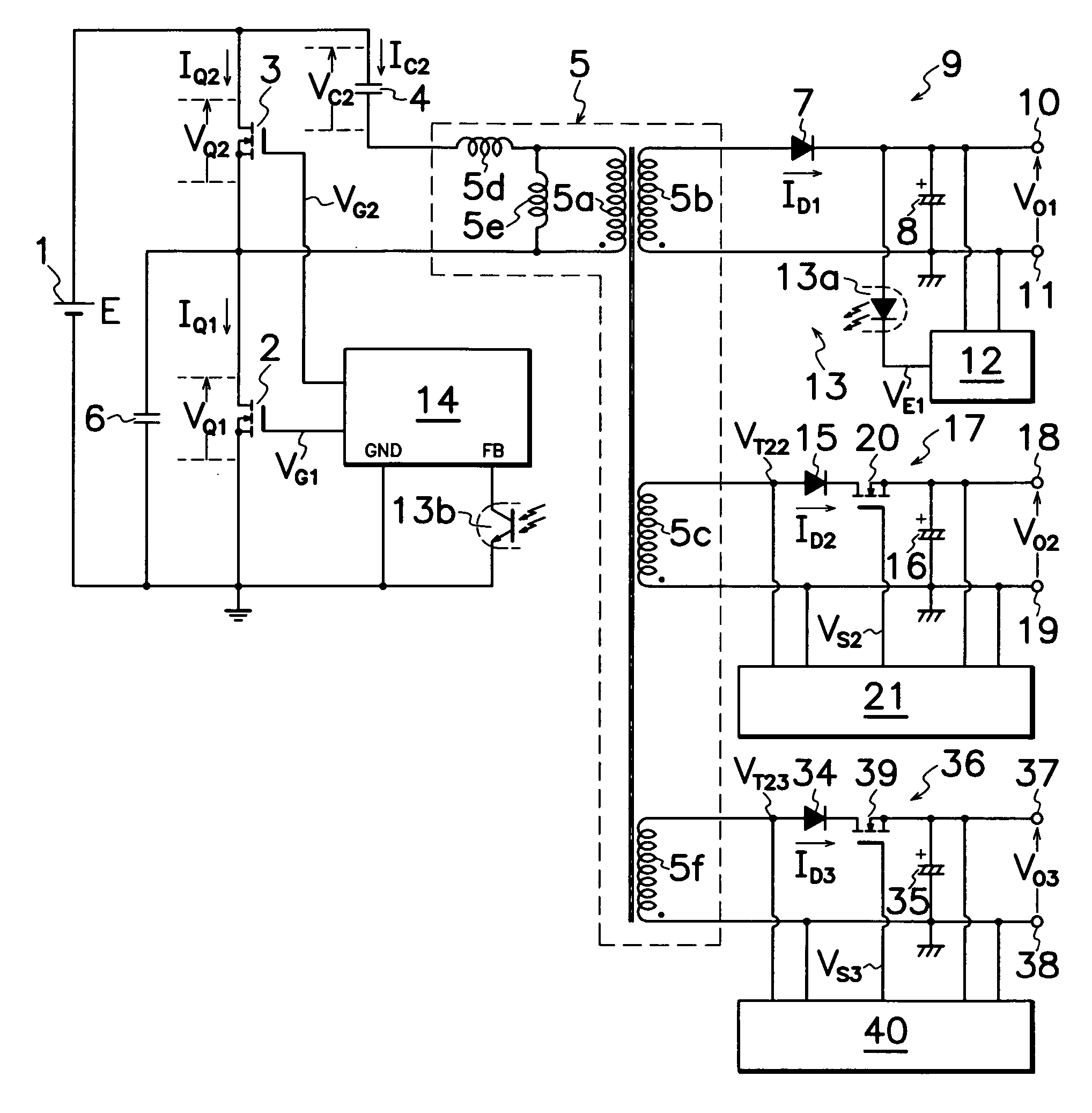

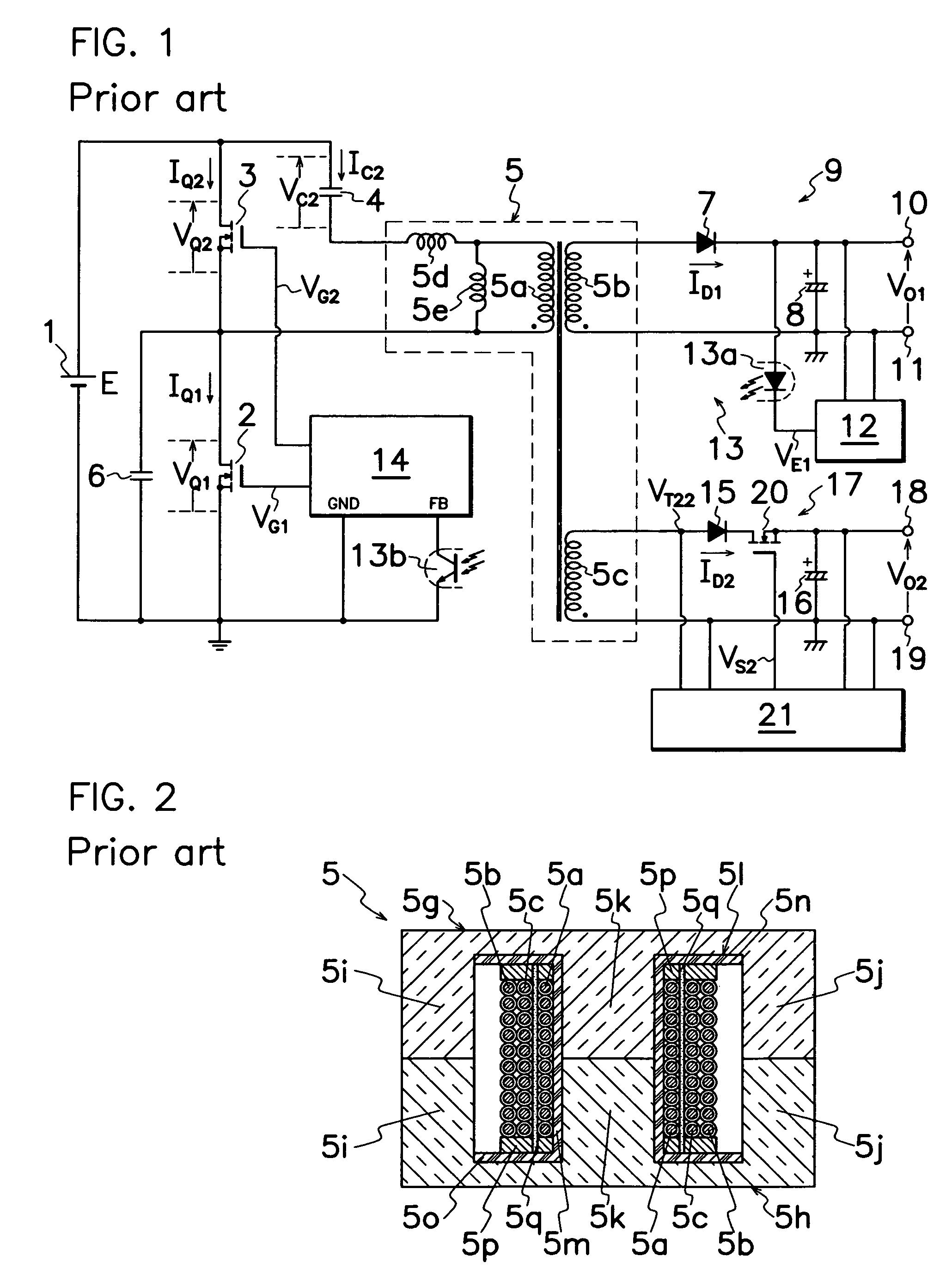

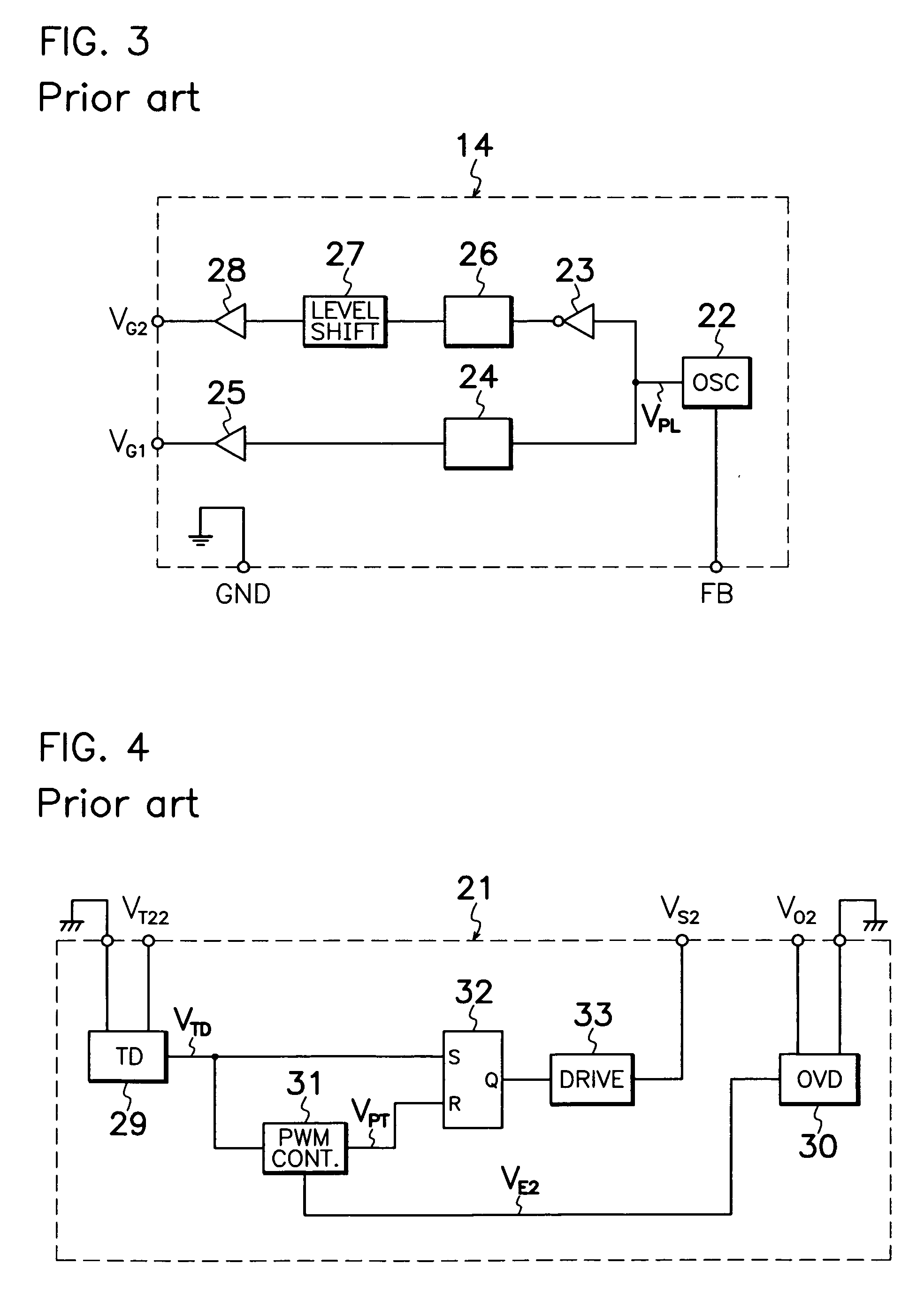

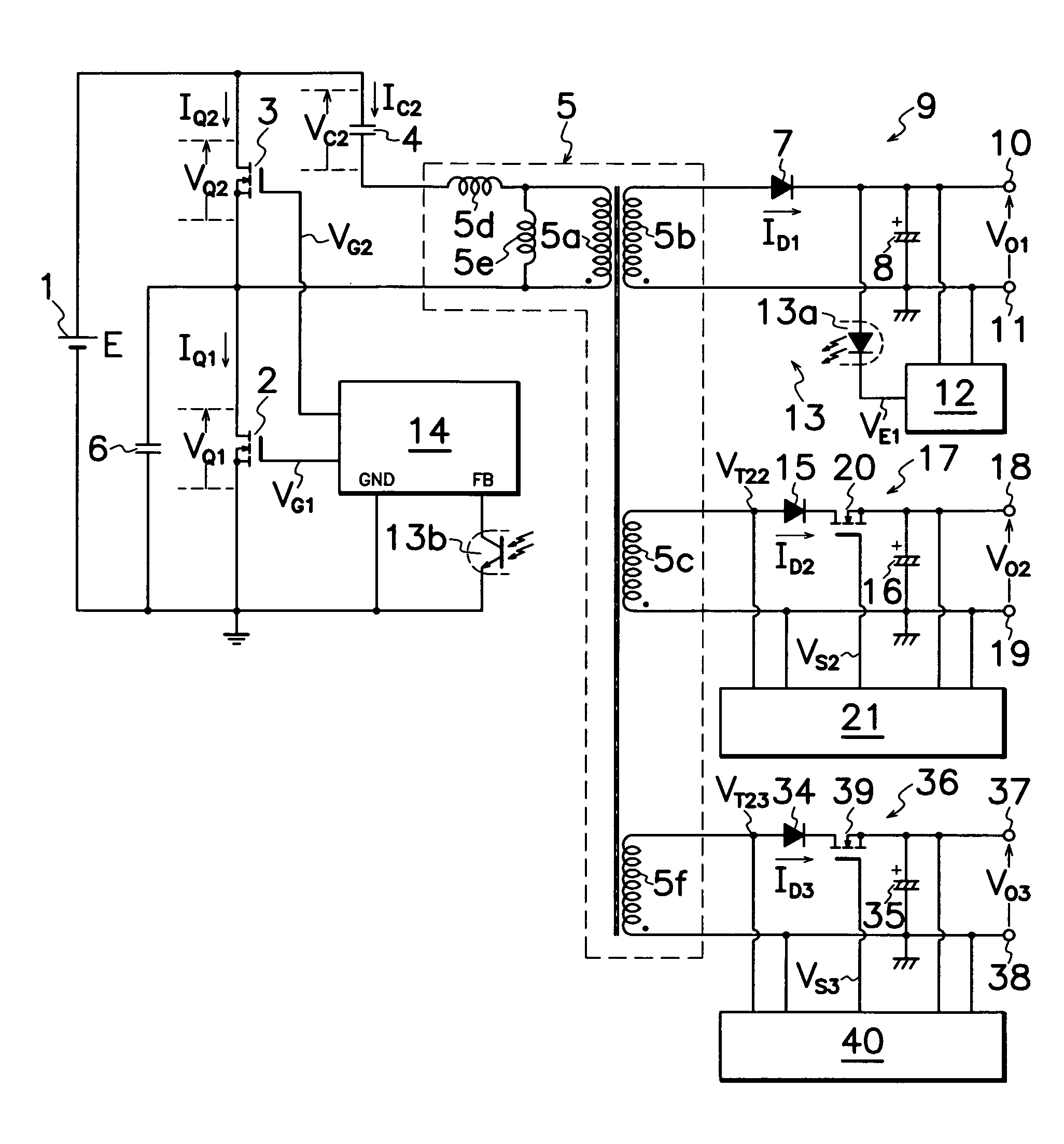

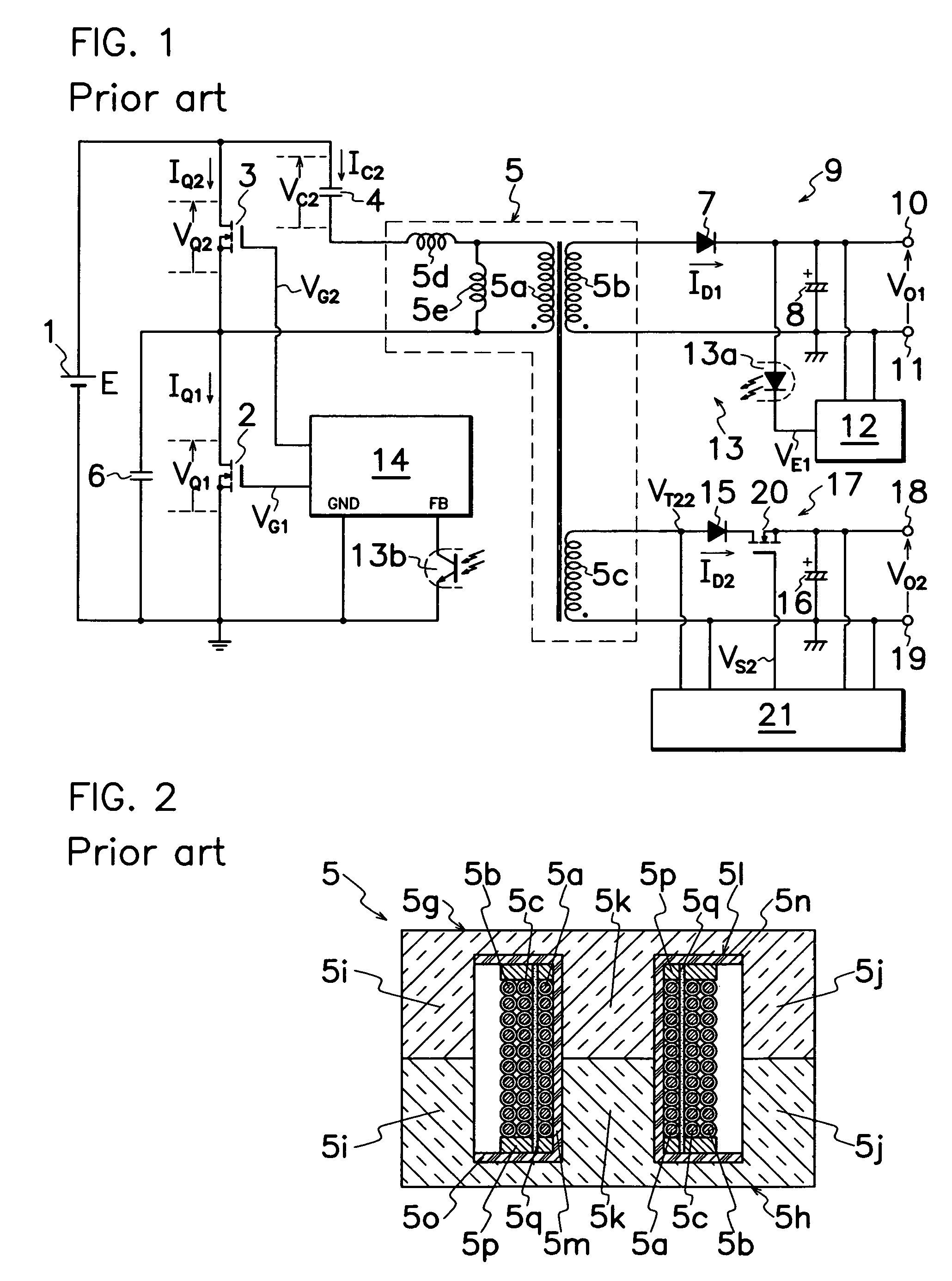

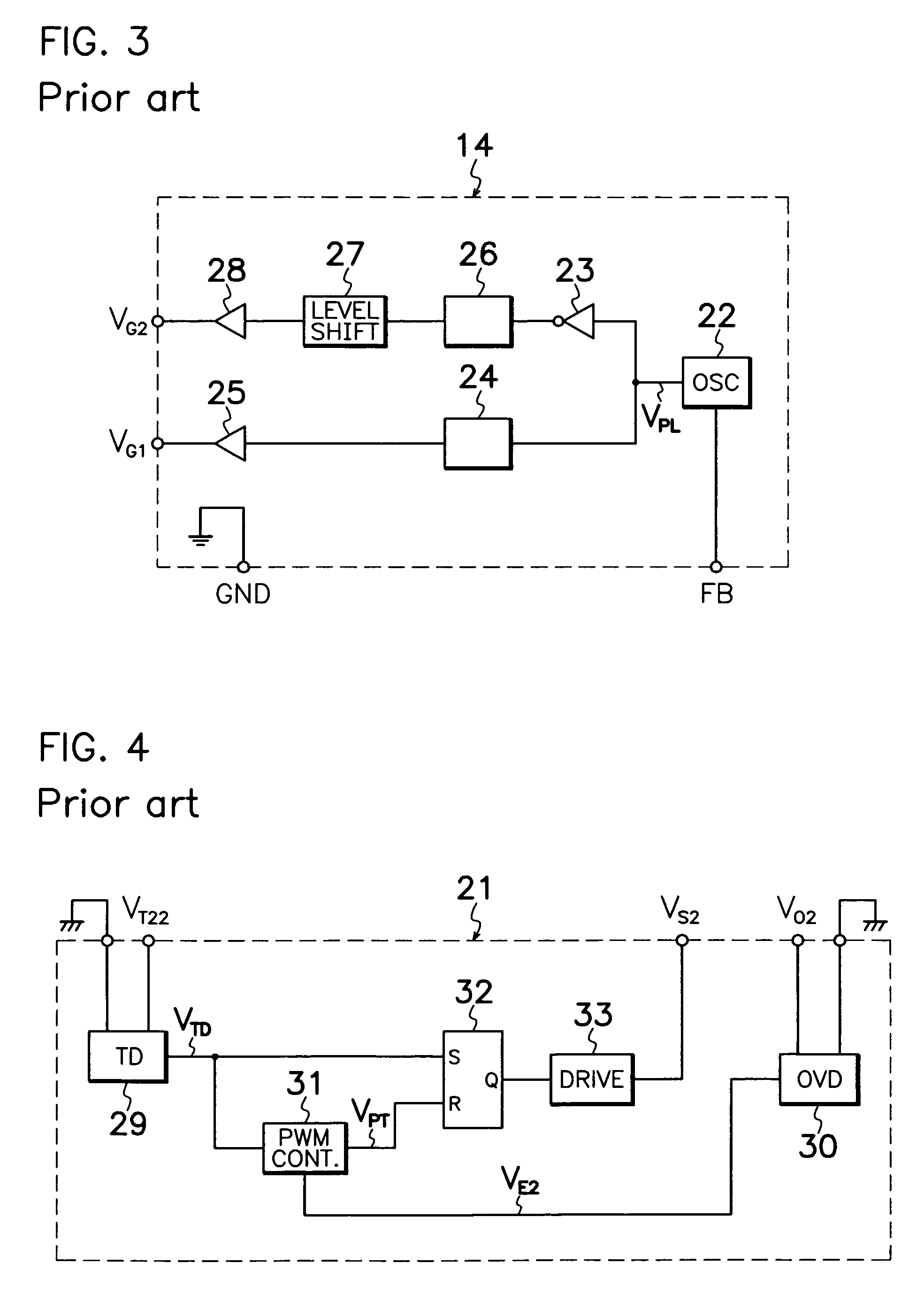

DC-DC converter of multi-output type

InactiveUS20060158908A1Reduce, attenuate or relax serge voltageDc network circuit arrangementsAc-dc conversion without reversalElectric forceDc dc converter

A DC-DC converter of multi-output type is provided wherein a primary winding 5a is wound around core halves 5g, 5h of a transformer 5 between first and second secondary windings 5b, 5c of transformer 5 also concentrically wound around core halves 5g, 5h to form an electromagnetic sparse coupling between first and second secondary windings 5b, 5c. When on-off operation of first and second primary MOS-FETs 2, 3 generates first and second DC outputs VO1, VO2, the electromagnetic sparse coupling can reduce, attenuate or relax serge voltage induced on first secondary winding 5b. This restrains or controls potential increase in first output voltage VO1 resulted from serge voltage through first rectifying smoother 9 under the light- or no-load condition to control fluctuation in second output voltage VO2 through second rectifying smoother 17 without restricting transmission of electric power from the primary to the secondary side making use of feedback control to primary control circuit 14 in order to generate stable first and second DC output voltages VO1 and VO2 throughout the entire loaded and unloaded range.

Owner:SANKEN ELECTRIC CO LTD

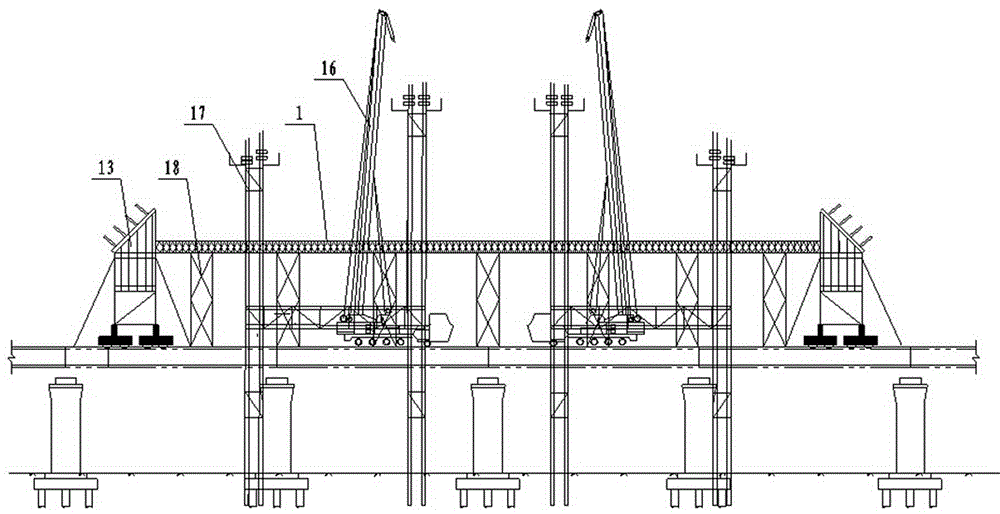

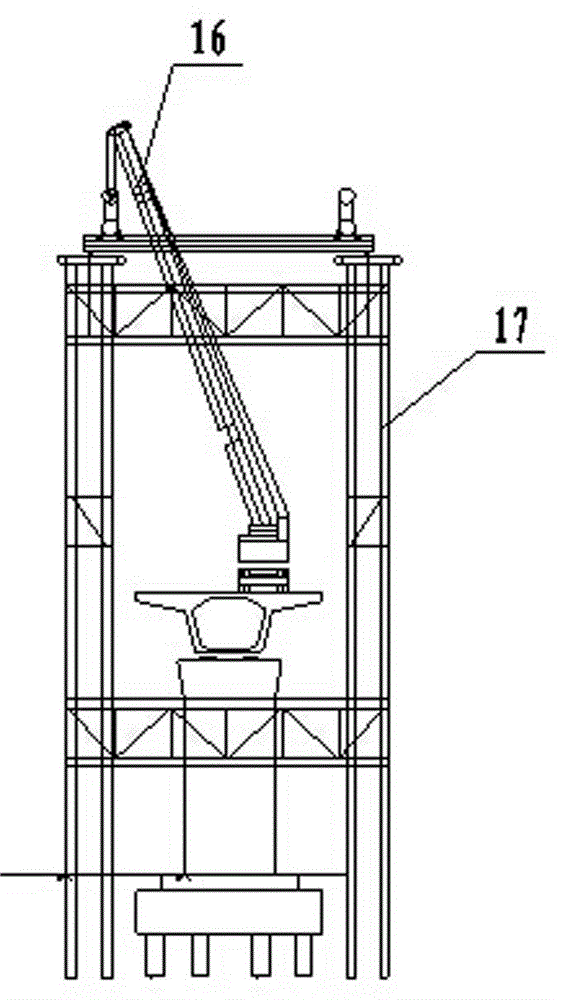

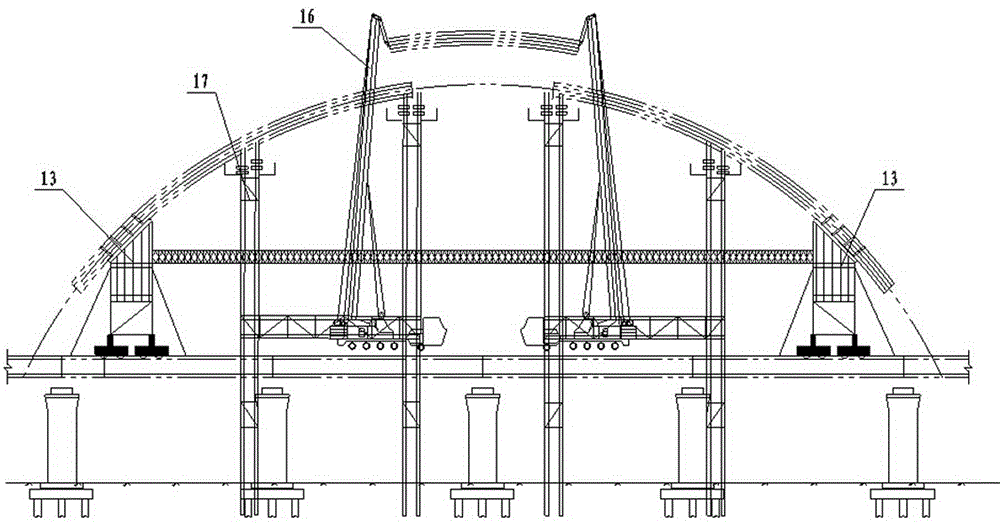

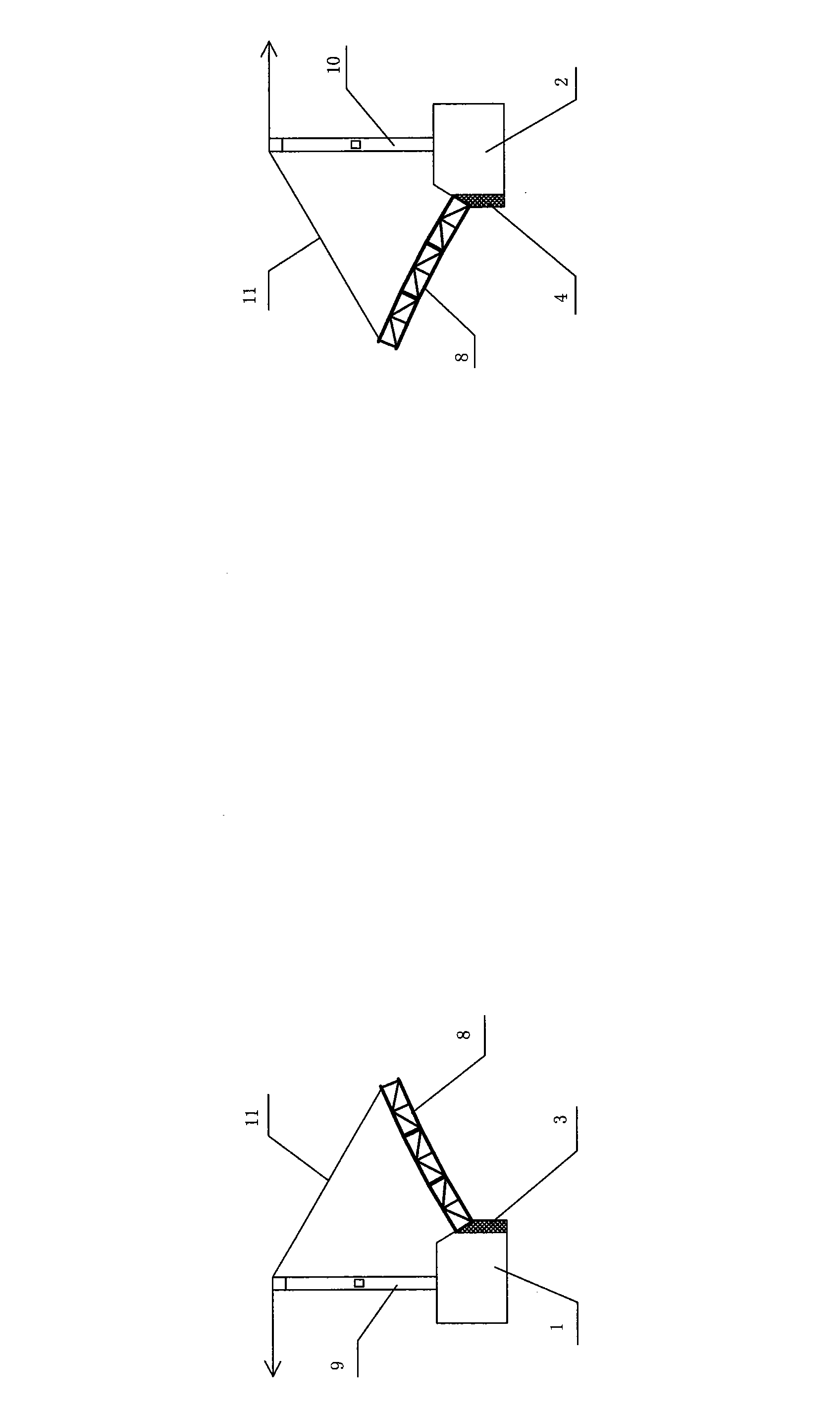

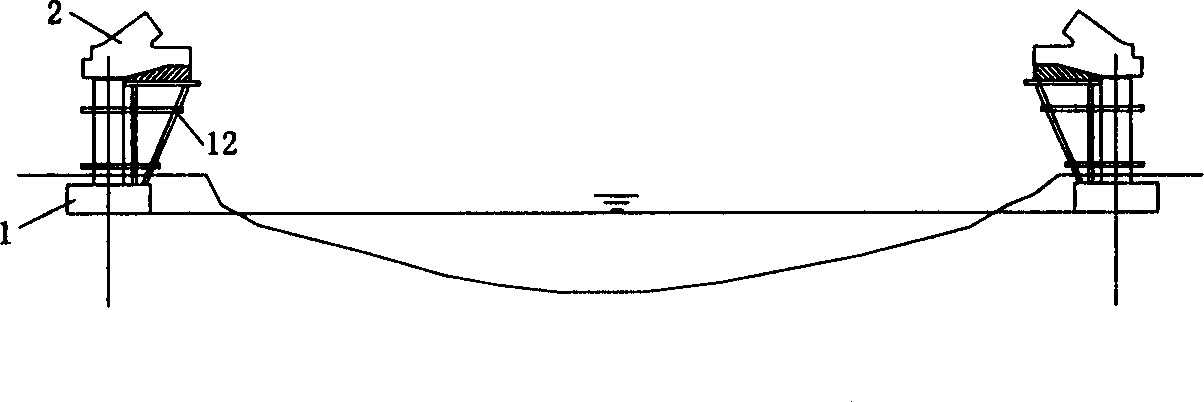

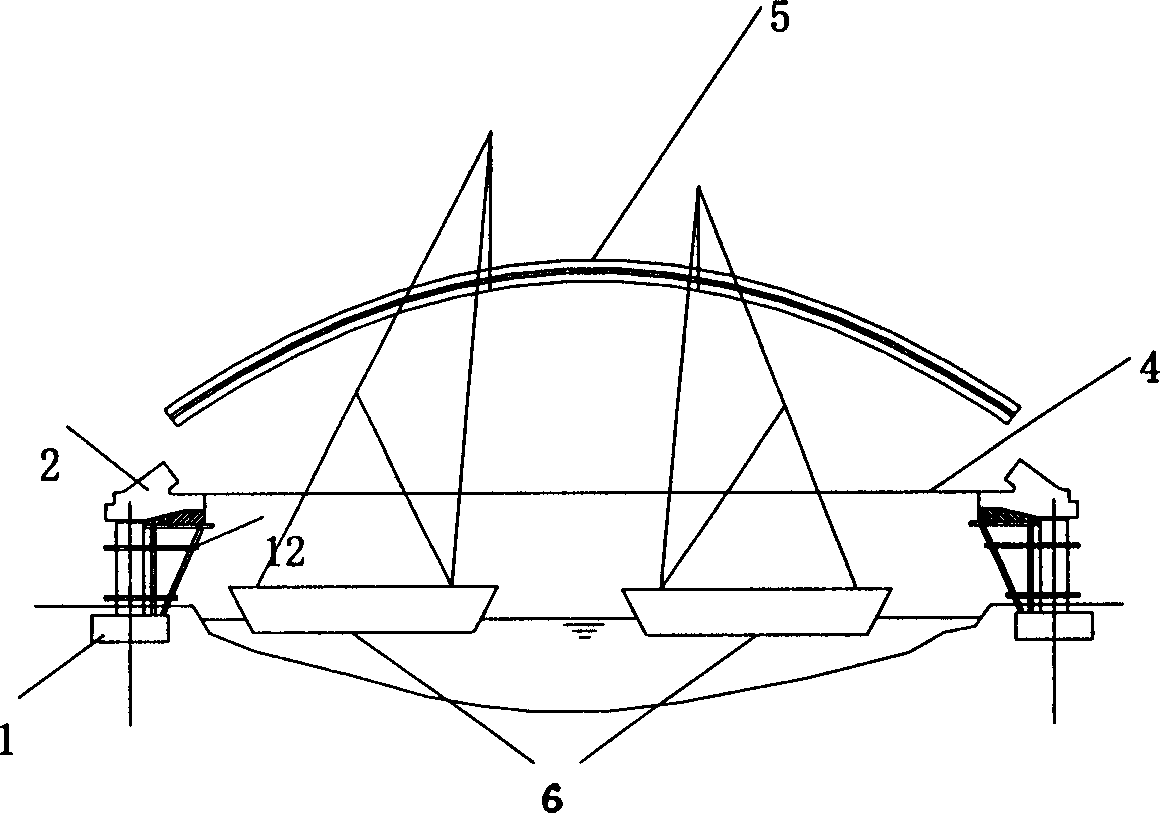

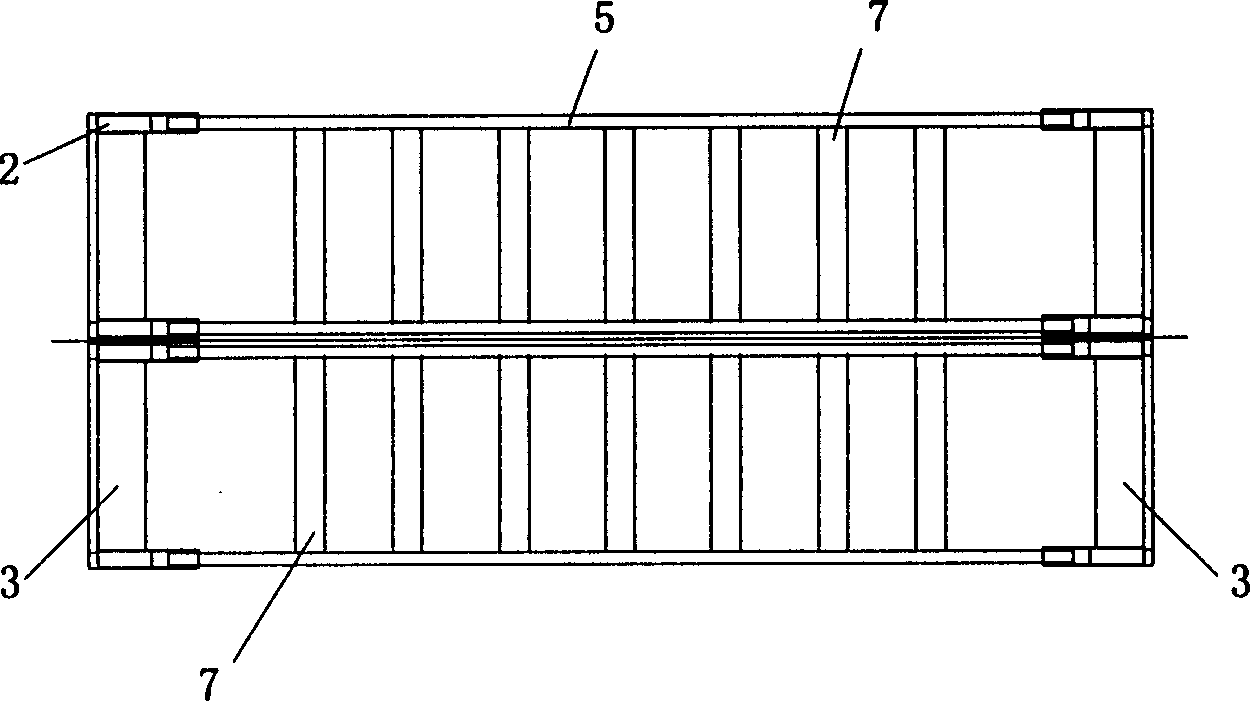

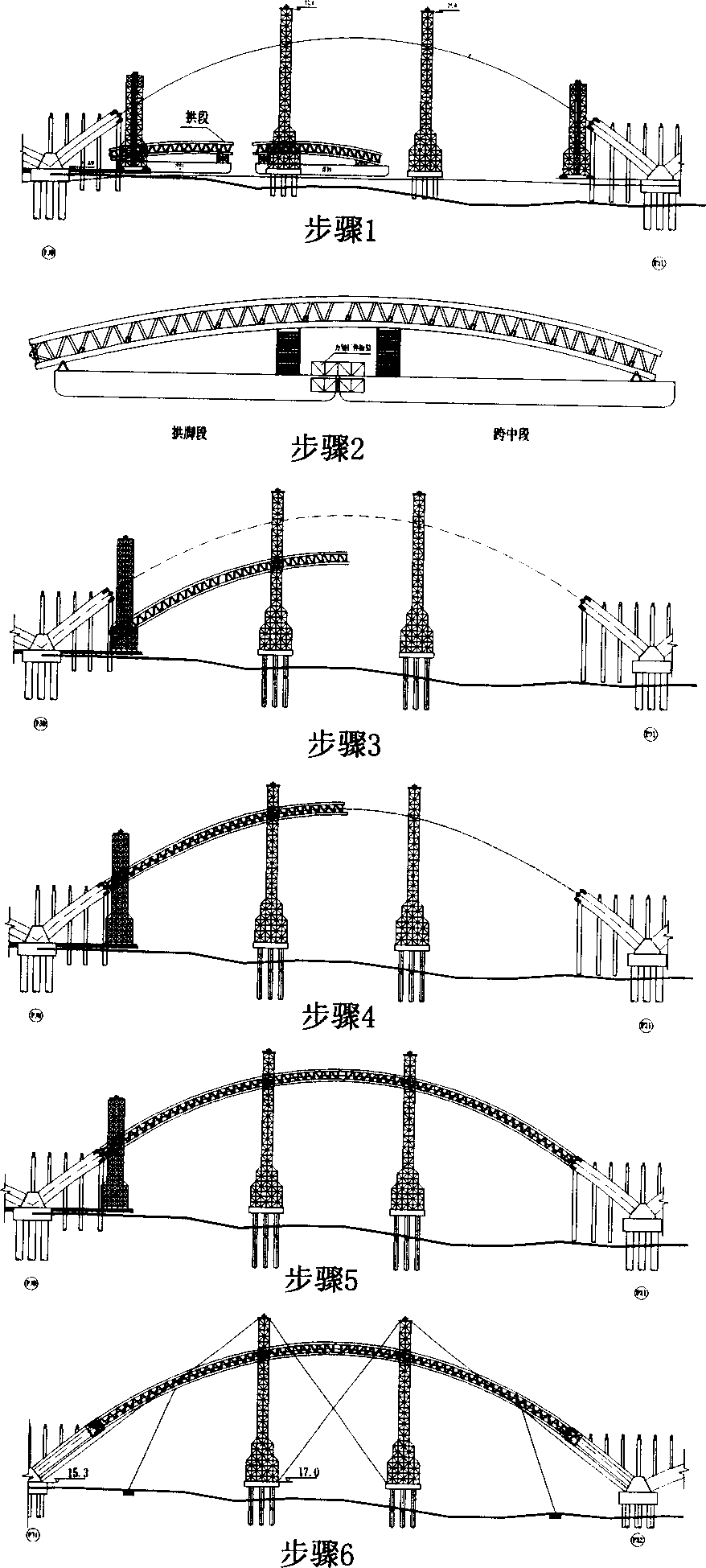

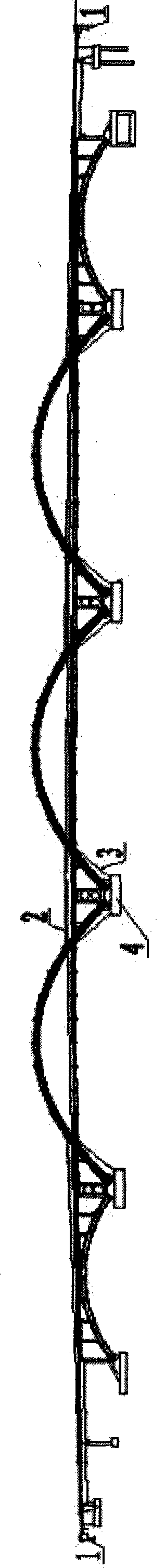

Construction method for continuous tie bar steel tube arch bridge

ActiveCN104562936AStress state is the sameSolving the Linear Control ChallengeBridge erection/assemblyArch-type bridgeEngineeringAbutment

The invention relates to a bridge construction method, in particular to a construction method for a continuous tie bar steel tube arch bridge; the construction method aims at solving the problems that the construction cycle is long, the potential safety hazard is big, the construction difficulty is big, and the like by adopting the existing support method. The construction method comprises the following steps of performing construction on assembling supports for a steel tube arch; processing the steel tube arch by stages, and hoisting the steel tube arch onto the assembling supports; installing temporary abutment supports and opposite-pull steel stranded wires to enable the steel tube arch to form a bowstring whole bearing structure; supporting the steel tube arch by the temporary abutment supports instead of the assembling supports, and removing the whole assembling supports; installing a longitudinal movement pushing system for the steel tube arch to enable the steel tube arch to move forward; welding the steel tube arch after the steel tube arch are pushed in place. Firstly, The difficult problem that the safety risk is big due to the fact that the pushing distance is far and the steel tube arch needs to cross the existing railways and highways after the steel tube arch is assembled is solved; secondly, the problem that arch feet are low in installation accuracy is solved, so that the linearity and design linearity of the whole steel tube arch are enabled to be consistent, and the stress state and the design state of the steel tube arch are finally enabled to be consistent; thirdly, the stress state and the design state of a beam body are consistent, so the construction quality is finally guaranteed.

Owner:CHINA RAILWAY SIXTH GRP CO LTD

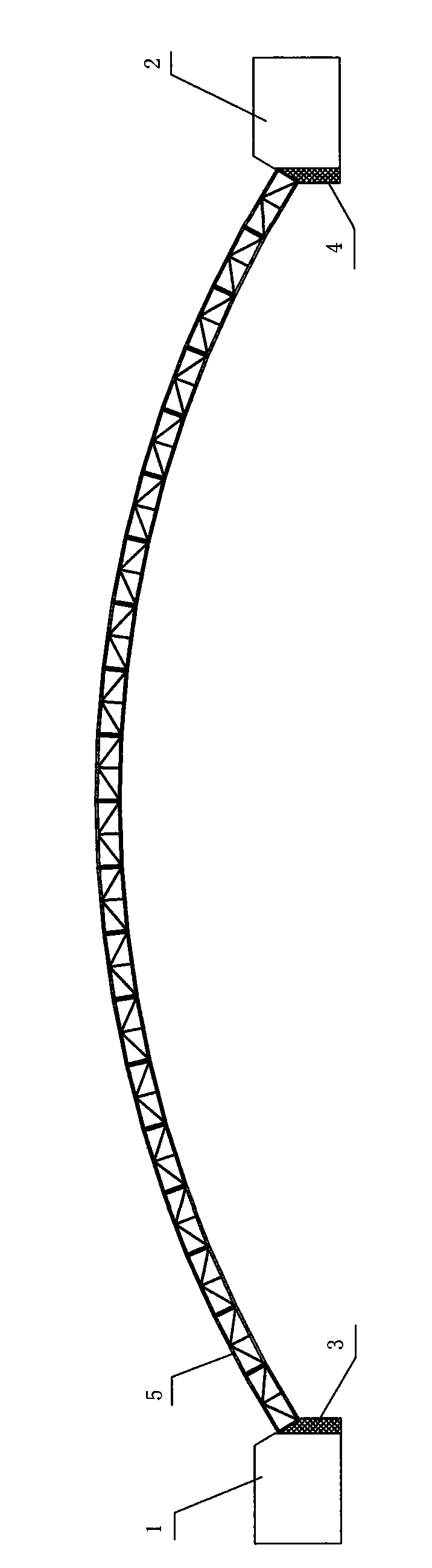

Large-span steel truss arch construction method

InactiveCN101581074AGood effectImprove structural stabilityBridge erection/assemblyArch-type bridgeTerrainReinforced concrete

The invention relates to a large-span steel truss arch construction method. The invention is characterized in that the method comprises the following steps: 1) based on the alignment design of an main arch ring of a reinforced concrete arch bridge, if a main arch span of the reinforced concrete arch bridge is not more than 100m, an arc line is adopted as the line shape of a arch axis line of the steel truss arch; if the main arch span of the reinforced concrete arch bridge is more than 100m, a catenary line or a parabola curve is adopted as the line shape of the arch axis line of the steel truss arch; big samples of a first unit truss segment and a second unit truss segment are produced for steel truss arch ribs on a sample platform according to the scale of 1:1; 2) the inner side of a first main arch support is widened to form a first base of the steel truss arch, the inner side of a second main arch support is widened to form a second base of the steel truss arch; 3) the erection sequence of the unit truss segments is that: first arranging steel truss arch ribs on the upper course of a river, then arranging steel truss arch ribs in sequence to the lower course of the river; 4) the back arch elevation of the steel truss arch is adjusted to the level of the arch soffit elevation of the main arc ring. The construction method is not limited by the terrain condition and site condition of bridge location and is simple and easy to install and remove.

Owner:CHINA FIRST METALLURGICAL GROUP

DC-DC converter of multi-output type

InactiveUS7304867B2Reduce, attenuate or relax serge voltageDc network circuit arrangementsAc-dc conversion without reversalDc dc converterCoupling

A DC-DC converter of multi-output type is provided wherein a primary winding 5a is wound around core halves 5g, 5h of a transformer 5 between first and second secondary windings 5b, 5c of transformer 5 also concentrically wound around core halves 5g, 5h to form an electromagnetic sparse coupling between first and second secondary windings 5b, 5c. When on-off operation of first and second primary MOS-FETs 2, 3 generates first and second DC outputs VO1, VO2, the electromagnetic sparse coupling can reduce, attenuate or relax serge voltage induced on first secondary winding 5b. This restrains or controls potential increase in first output voltage VO1 resulted from serge voltage through first rectifying smoother 9 under the light- or no-load condition to control fluctuation in second output voltage VO2 through second rectifying smoother 17 without restricting transmission of electric power from the primary to the secondary side making use of feedback control to primary control circuit 14 in order to generate stable first and second DC output voltages VO1 and VO2 throughout the entire loaded and unloaded range.

Owner:SANKEN ELECTRIC CO LTD

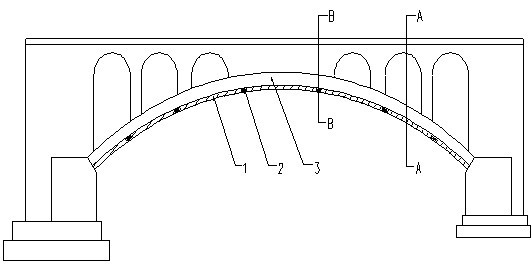

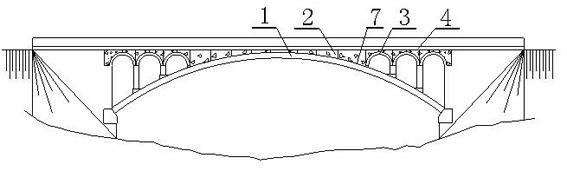

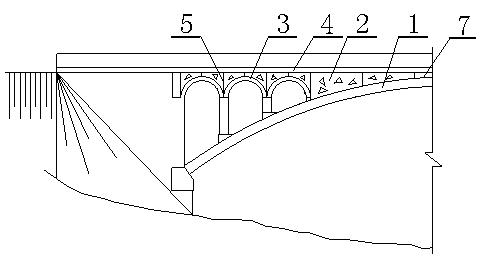

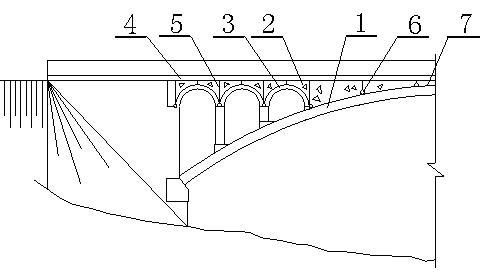

Reinforcing method of masonry arch bridge

InactiveCN102322026AReduce dosageImprove bearing capacityBridge erection/assemblyBridge strengtheningReinforced concreteEngineering

The invention discloses a reinforcing method of a masonry arch bridge, which comprises the following steps of: a, planting ribs on an arch ring of the arch bridge along the cambered surface direction of the arch bridge; b, planting ribs at the position close to the two sides, on the circular arc surface of the arch ring along the cambered surface direction of the arch bridge; and c, forming symmetrically distributed reinforced concrete ribs along the distribution direction of the planted ribs in the step a and the step b in a way of casting molding, wherein the cross section of the reinforcedconcrete ribs is L-shaped. The reinforced concrete ribs which are of integral structures are formed along the two sides of the arch ring in the way of planting the ribs and casting concrete, then load can be directly transferred to an arch base through the symmetrically distributed reinforced concrete ribs of which the cross section is L-shaped, and the stress to the reinforced concrete ribs is equal to that to a ribbed arch bridge. When the method is compared with the method of singly increasing the area of the arch ring, the dependence on the primary arch ring is smaller, even the primary arch ring can be supported, the damage to the primary arch ring is small, the requirement of increasing the loading capacity of the masonry arch bridge is met, and the damage to the primary old arch ring is avoided to the maximal degree.

Owner:CHONGQING JIAOTONG UNIVERSITY

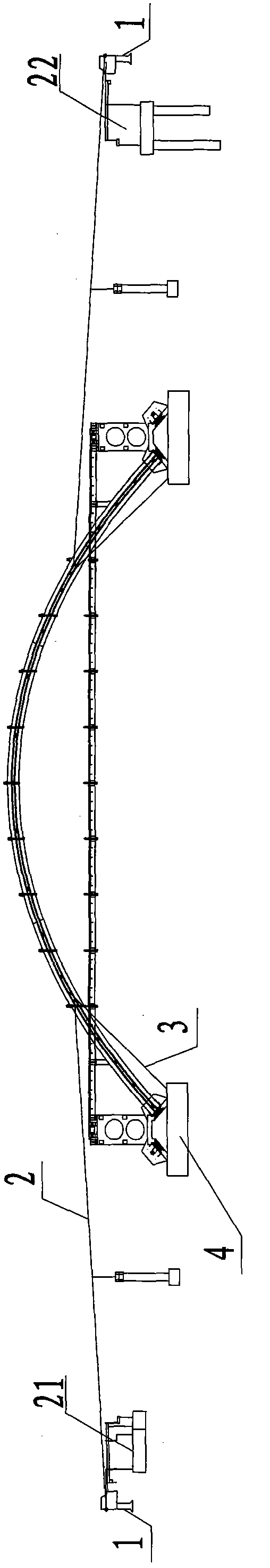

First-arch-then-beam concrete steel skeleton constructing process for through arch bridge with mooring post of steel pipe concrete

InactiveCN1811070AFast constructionLow costBridge erection/assemblyArch-type bridgePre stressPre stressing

The first-arch-then-beam concrete steel skeleton constructing process for through arch bridge with mooring post of steel pipe concrete includes the following steps: A. tensing permanent horizontal pre-stressed steel cable at the end cross beam; B. assembling steel pipe arch rib, floating and conveying the steel pipe arch rib and hoisting with floating crane to the site; C. controlling the displacement of abutment by using the permanent pre-stressed steel cable temporarily as the constructing pulling cable and regulating the tensing stress of the horizontal pre-stressed steel cable to bear the horizontal pushing force of the steel pipe concrete arch bridge; and D. hoisting bridge surface pre-stressed beam to site with the steel pipe concrete arch rib and suspender. Compared with conventional construction process, the present invention has fast construction speed, low cost, reduced overhead welding work load and high construction quality.

Owner:SHANGHAI NO 7 CONSTR

Method for mounting box arch bridge

ActiveCN101519864ASimplified installation procedureReduce engineering costsBridge erection/assemblyArch-type bridgeT-beamAbutment

The invention discloses a method for mounting a box arch bridge. The method comprises the following steps: (1) excavating earth and stone work of a main arch abutment, and mounting a cable system; (2) pouring concrete of the main arch abutment and haunch; (3) hoisting the haunch; (4) mounting a bent on the arch; (5) mounting a T beam; and (6) constructing a bridge floor system. In haunch hoisting, after a first arch rib is mounted, a knotted rope used for stabilizing the haunch is detached, and the knotted rope is used for mounting a second haunch, and the like, so that all haunches can be mounted by the first knotted rope. The method simplifies mounting program of the box arch bridge, and greatly saves construction cost.

Owner:CHINA RAILWAY 23RD BUREAU GRP THIRD ENG CO LTD

Steel tube arch rib vertical lifting method

ActiveCN101672011AReduce construction investmentThe structural force is clearBridge erection/assemblyArch-type bridgeButt jointTower

The invention discloses a steel tube arch rib vertical lifting method, which comprises the following steps: separating the steel tube arch rib into two side sections and middle-section closure sections, taking an arch hinge of a side section arch springing as a rotating point and vertically lifting the two side sections of the steel tube arch rib, adopting a temporary support for respectively stabilizing the two side sections on two lifting towers after reaching a set position; lifting the middle-section closure sections of the steel tube arch rib which is butt-jointed and closed with the twoside sections; the side sections and the middle-section closure sections can be split into two to four pieces of processing sections; the maximum weight of all sections is less than 20 tons; and all the sections can be assembled and welded on the spot before lifting. The steel tube arch rib vertical lifting method has the beneficial effects that the method has little constructional investment, clear structural force, shortcut and convenient construction process, and effectively solves the technical problem that the steel-tube arch is transferred and assembled into in a hoisting section in theconstruction process of a little span, low height and first-beam and post-arch arch bridge and the section of the steel-tube arch is arranged in place.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

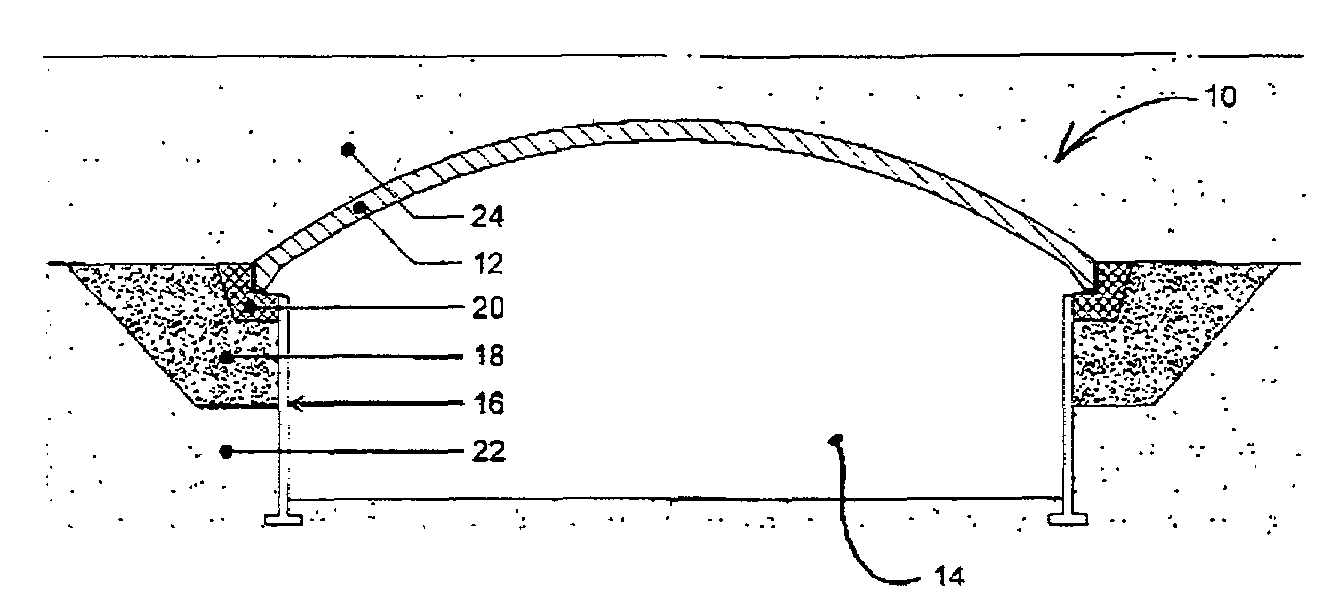

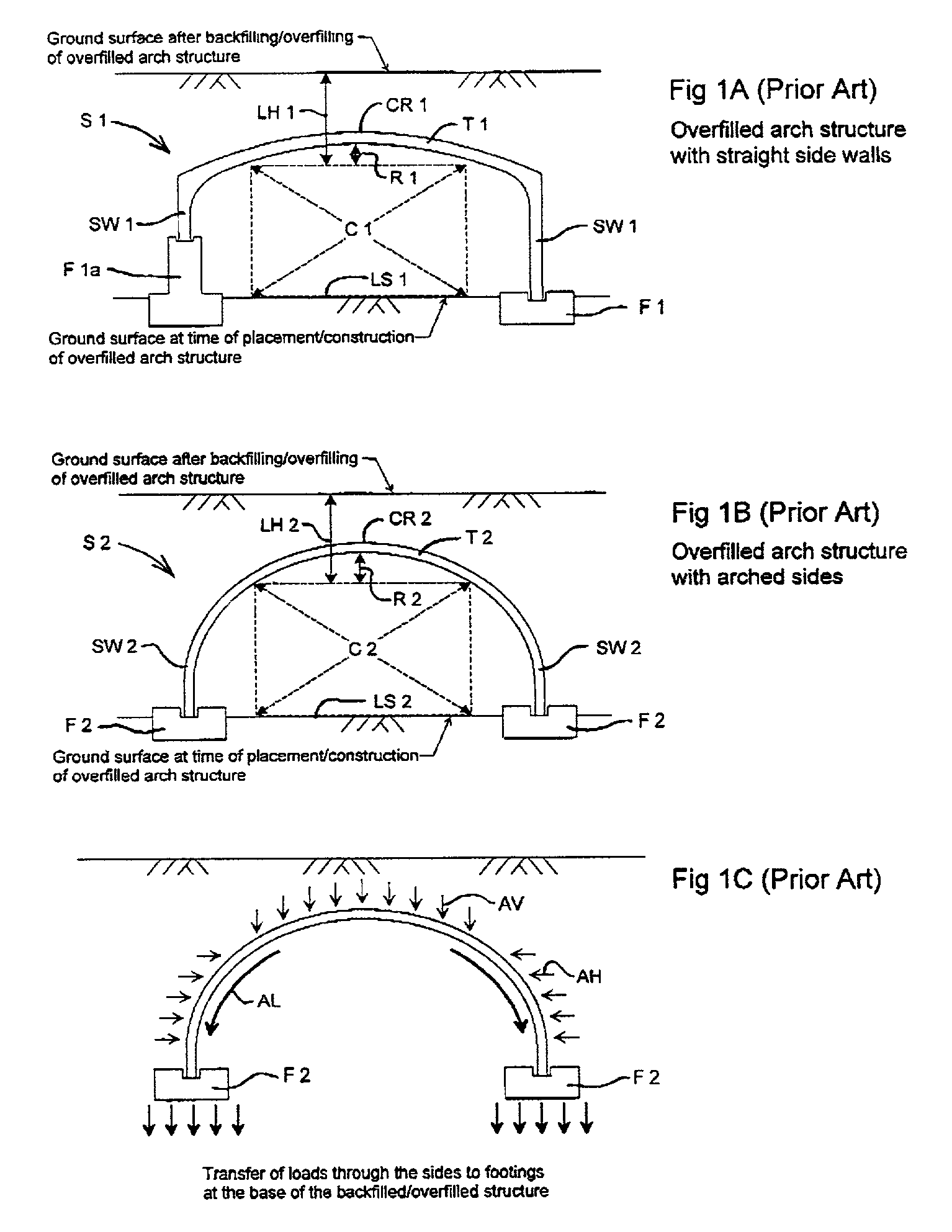

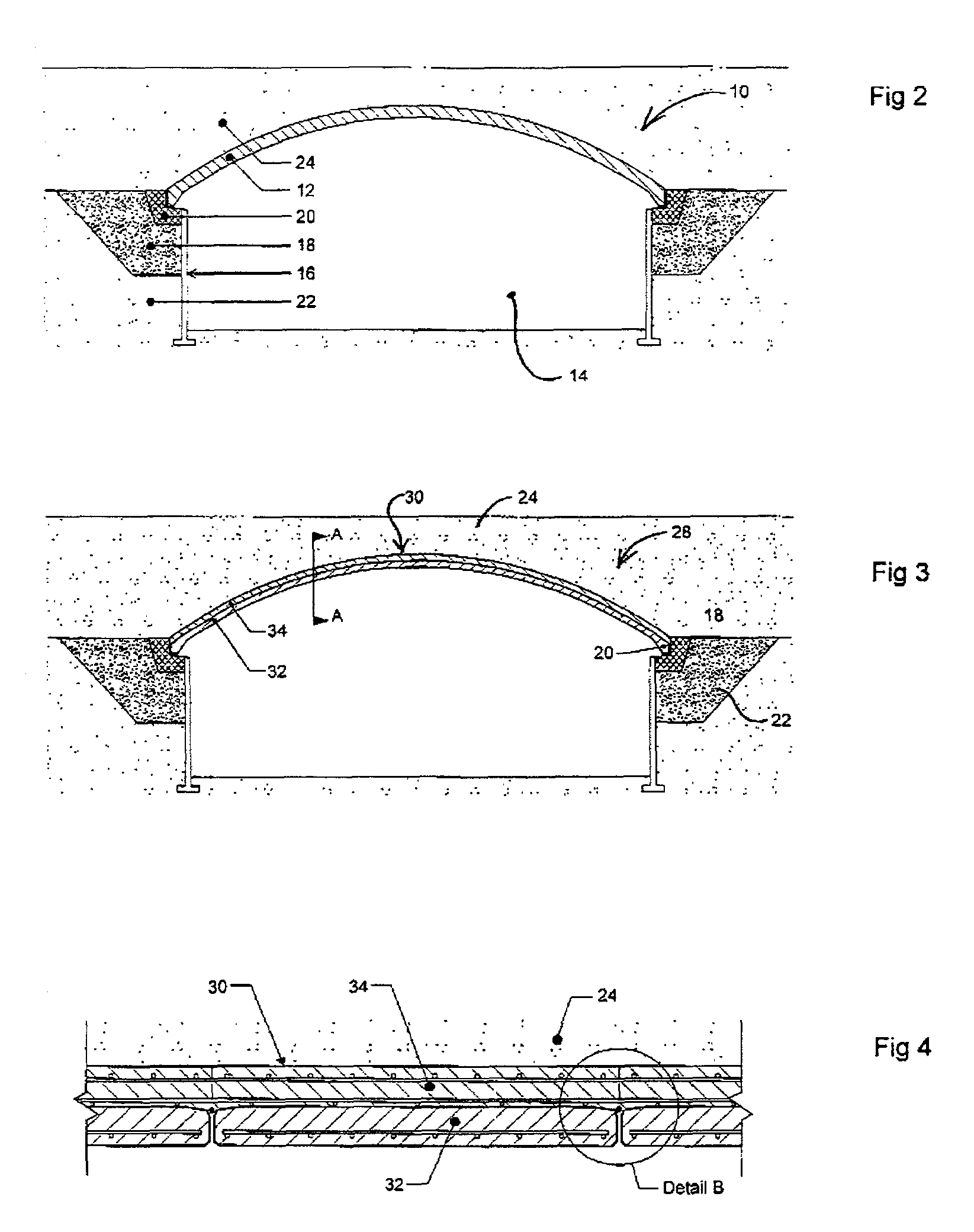

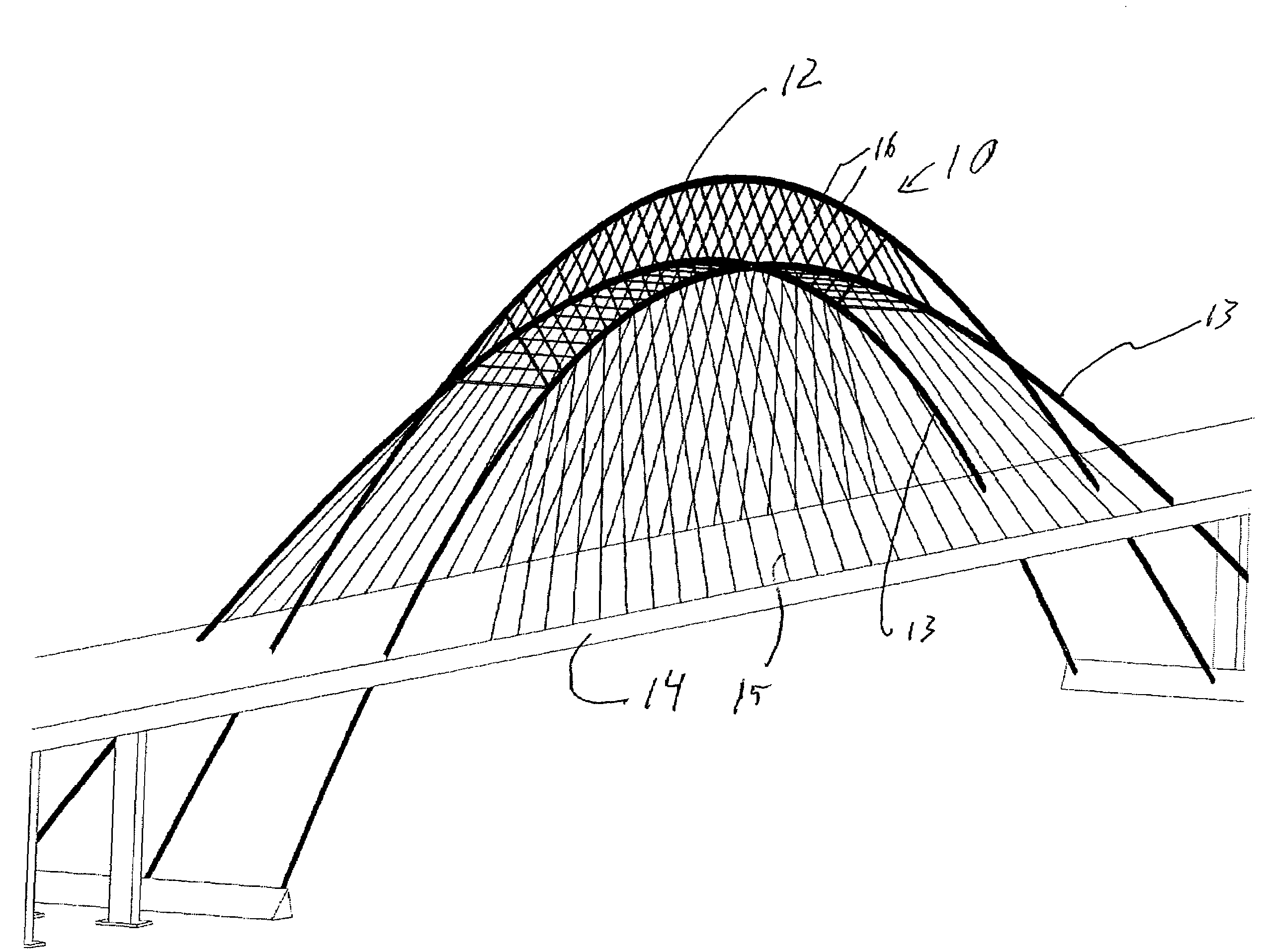

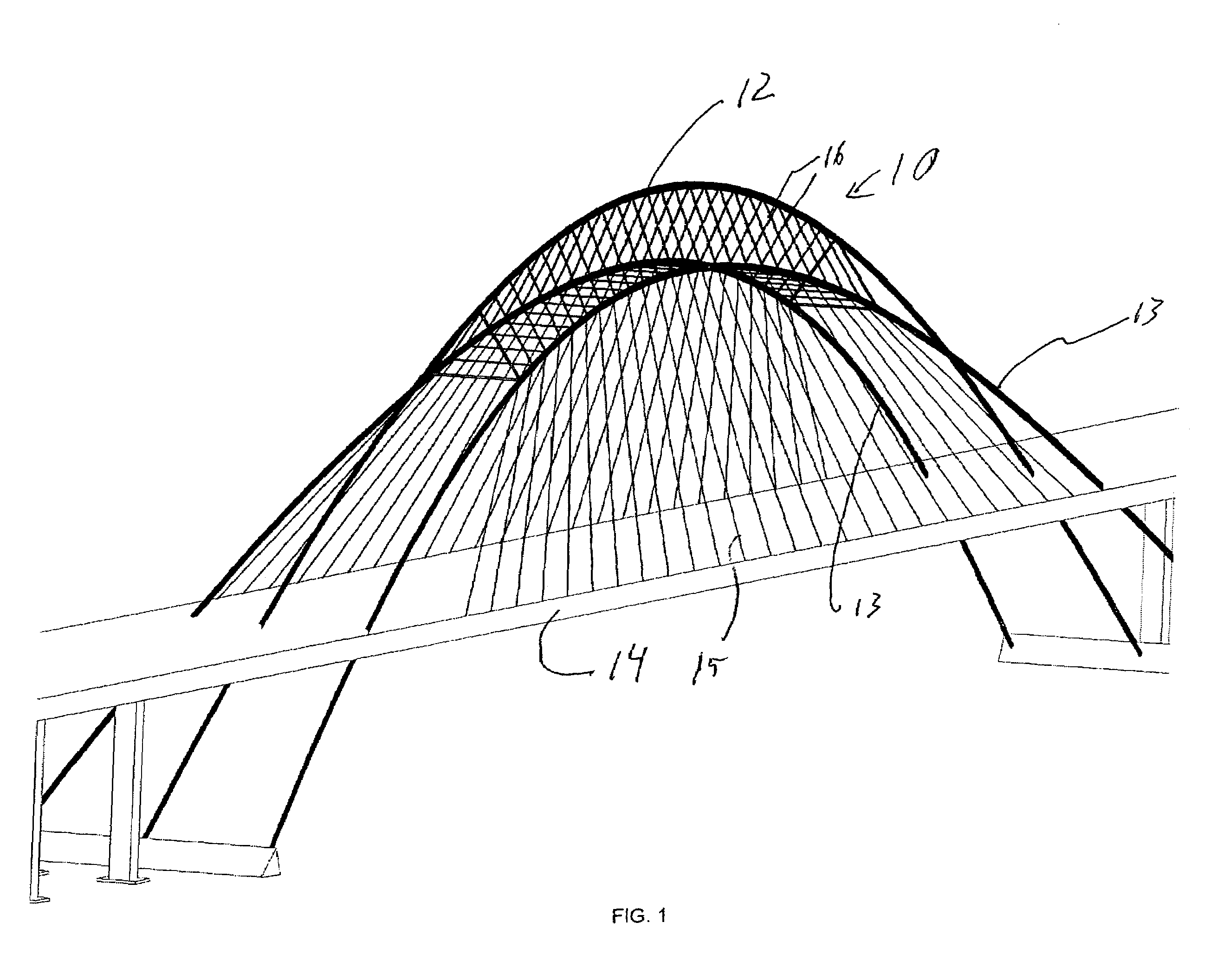

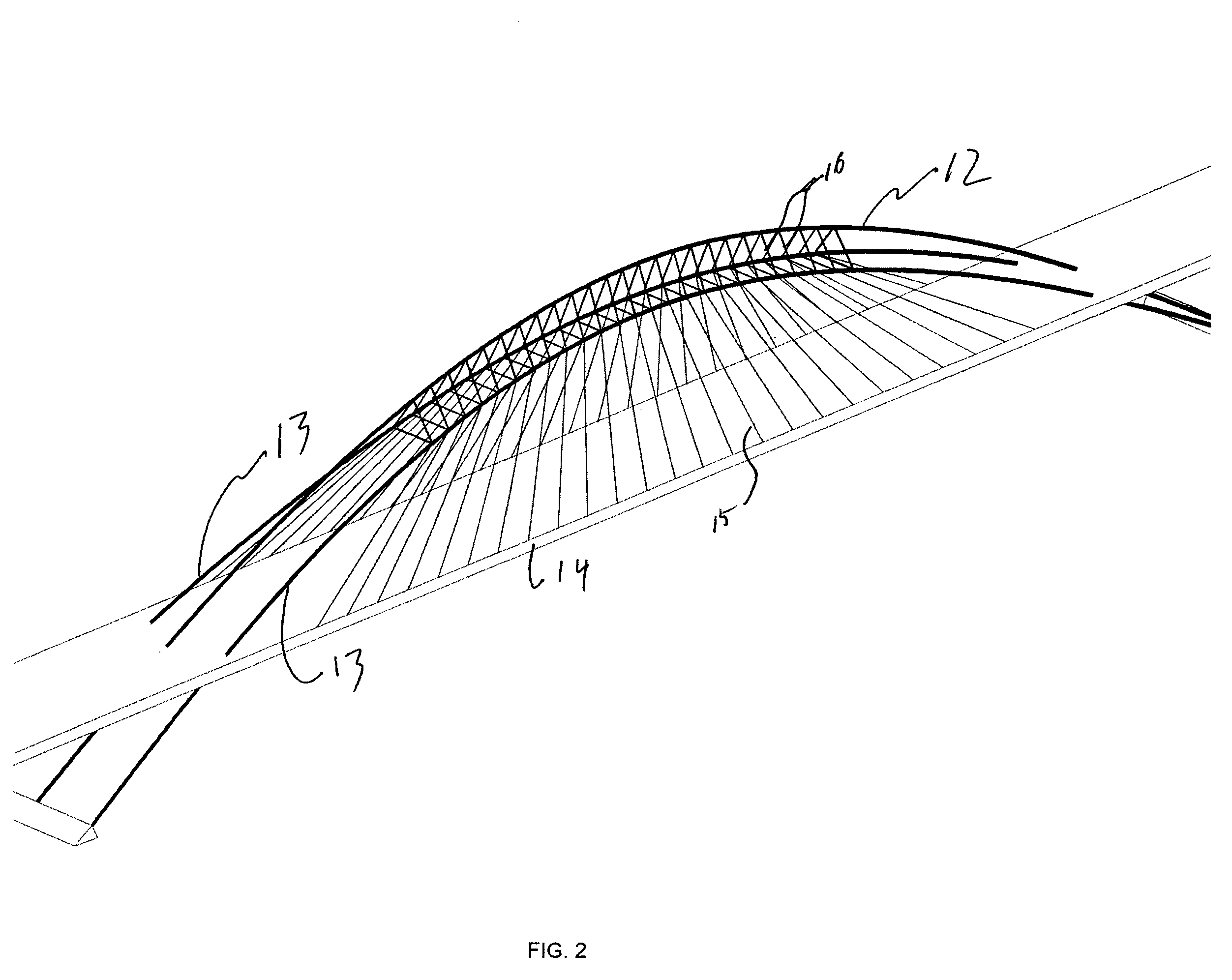

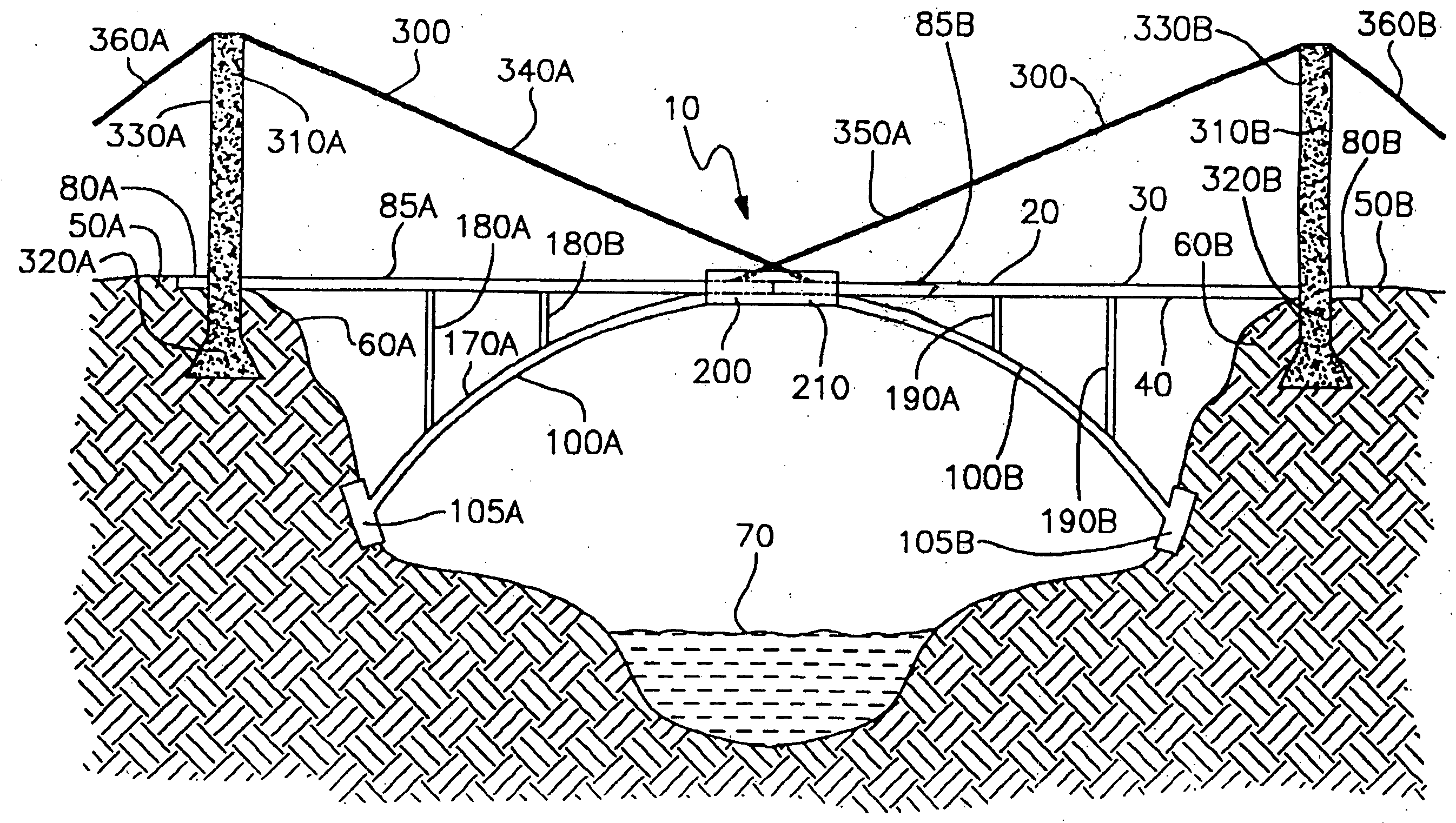

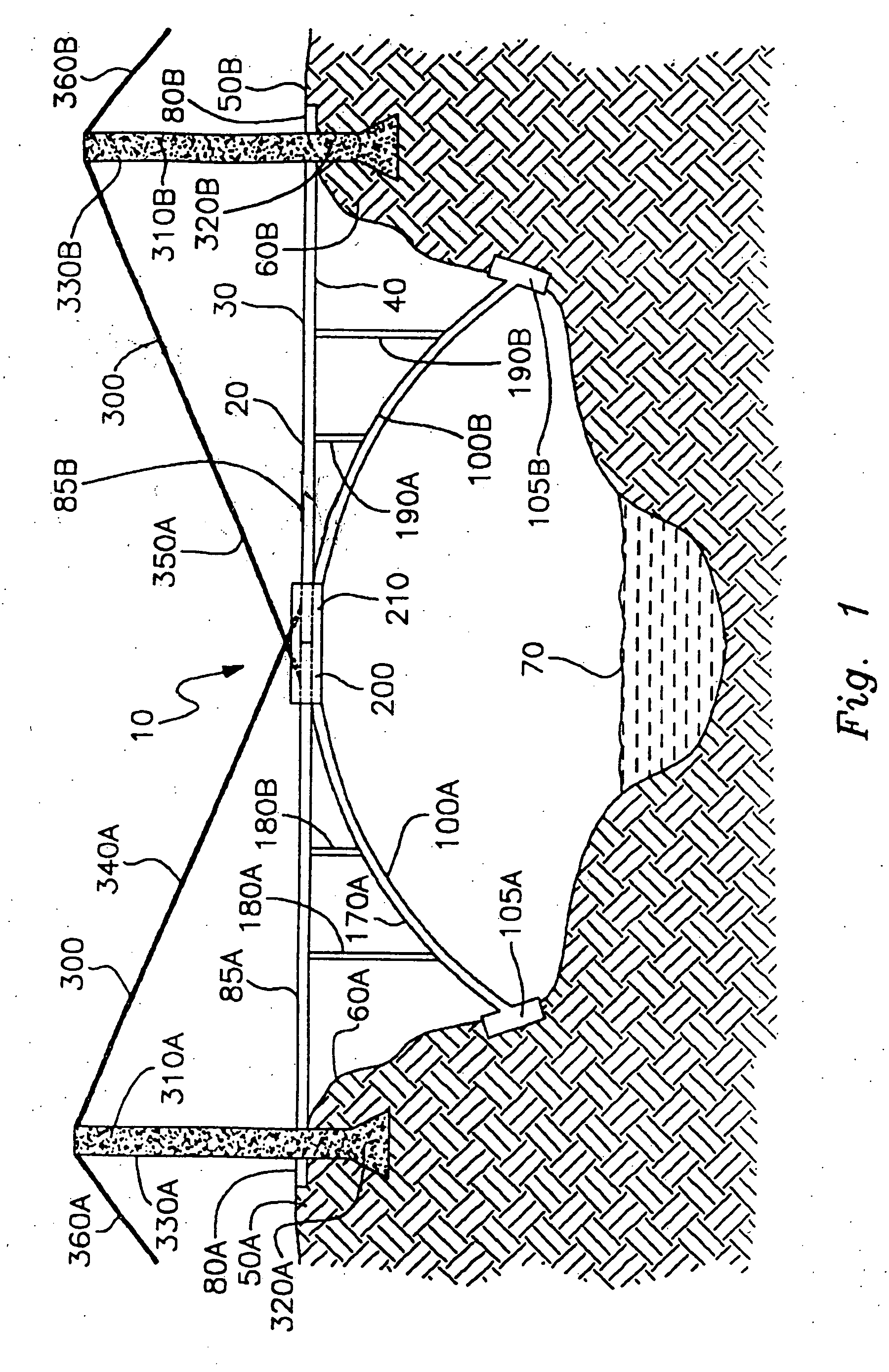

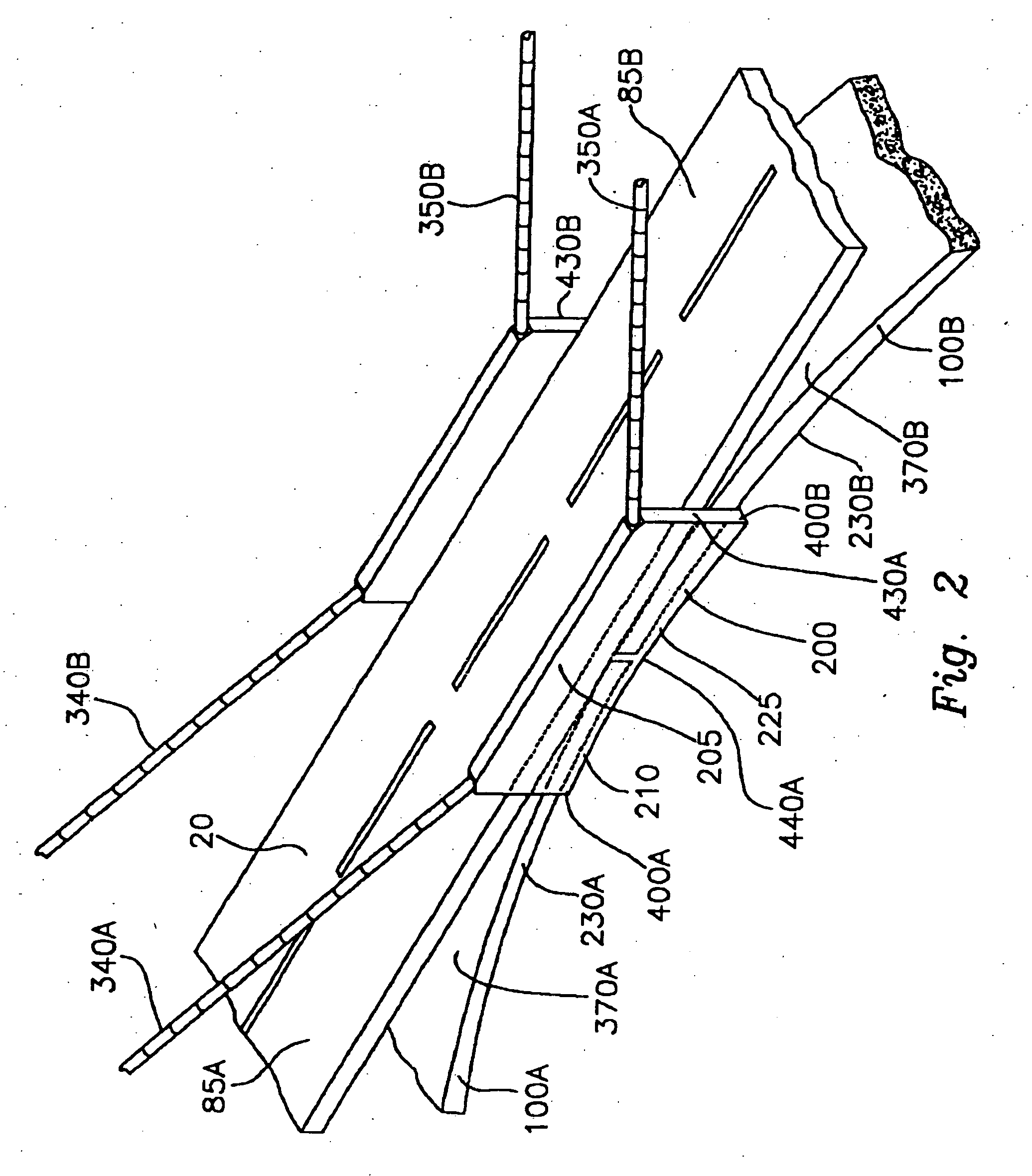

Composite overfilled arch system

InactiveUS7305798B1Enhanced advantageEfficiently and effectively accommodatedGround-workArched structuresPre stressArch bridge

An overfilled arch bridge system includes a composite arch which has a precast layer and a cast-in-place layer. The system further includes means for reducing bending moments within the overfilled arch. The means include customizing the arch end geometry and prestressing the arch prior to or during loading. The system can be used in connection with the overfilled arch system disclosed in co-pending patent application titled “Top Arch Overfilled System” filed by the same inventor on Mar. 22, 2002.

Owner:CONTECH ENGINEERED SOLUTIONS

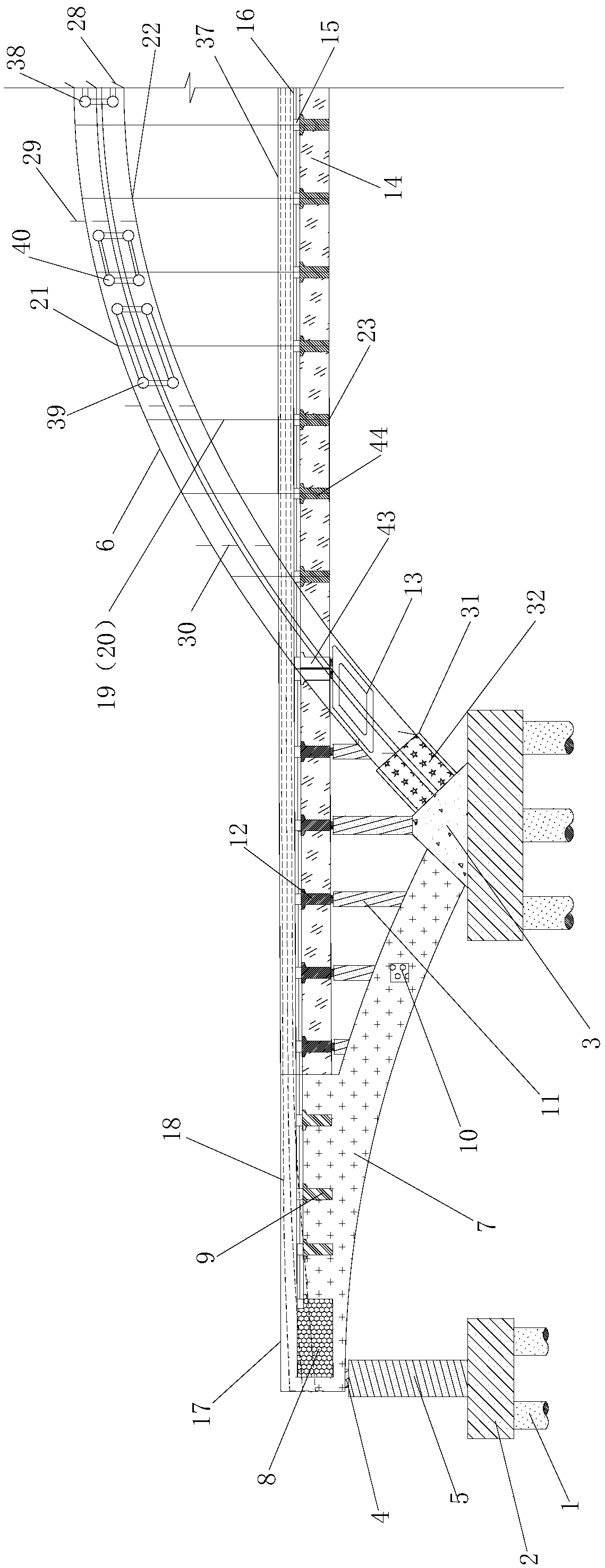

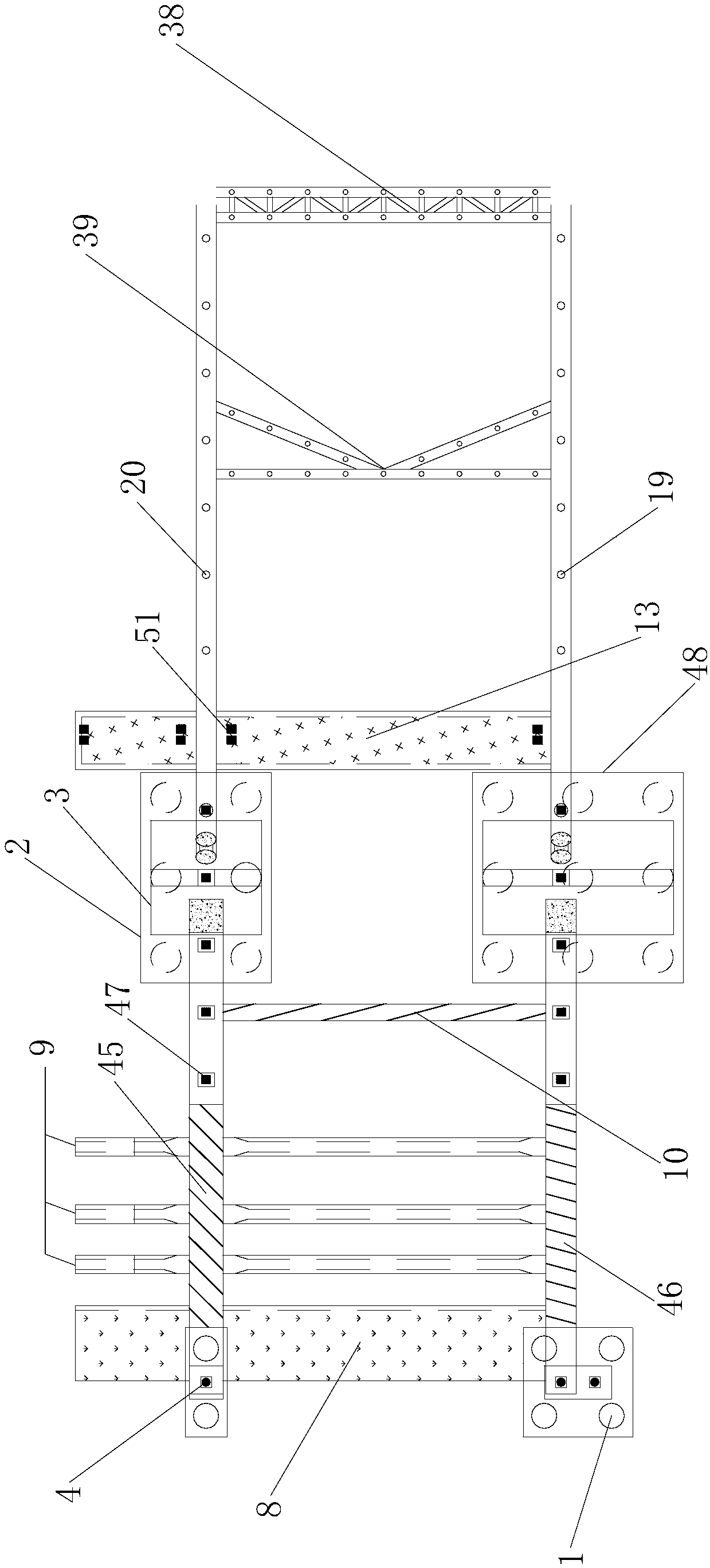

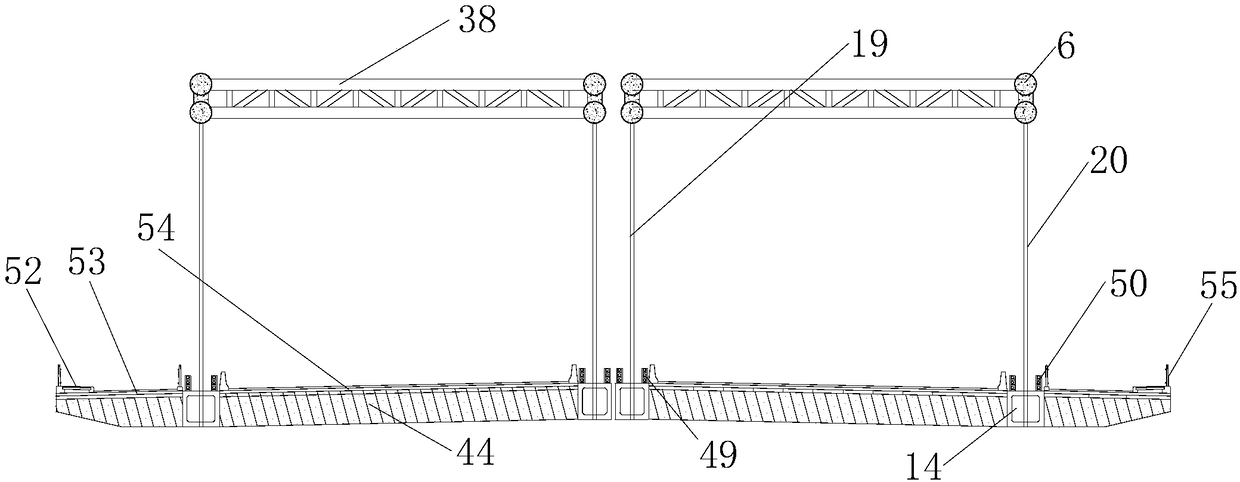

Concrete-filled steel tube arch bridge and construction method

PendingCN108660903AImprove stabilityGuaranteed docking accuracyBridge erection/assemblyArch-type bridgeReinforced concreteButt joint

The invention relates to a concrete-filled steel tube arch bridge. The concrete-filled steel tube arch bridge includes side arch ribs, main arch ribs, suspension bars, tie bars and a bridge pier and abutment structure. Side span structures include side arch supports, side span cast-in-place reinforced concrete arch ribs, cast-in-place side arch end cross beams, side span cast-in-place cross beamsbetween ribs, cast-in-place side arch rib tie beams, cast-in-place side upright posts, flexible prestressed tie bars and cast-in-place bridge deck slabs. Mid-span structures include abutments, mid-span concreted-filled steel tube arch ribs, main arch hollow cross beams between ribs, precast hollow longitudinal beams, flexible prestressed tie beams, tie-bar steel plate boxes, truss-type permanent upper wind braces, K-shaped permanent intermediate wind braces, temporary wind braces, arch foot pre-embedded sections, inner steel strand whole-bundle-squeezed inhaul cable suspension bars and outer steel strand whole-bundle-squeezed inhaul cable suspension bars. The concrete-filled steel tube arch bridge has the beneficial effects that steel tube arch rib fixation brackets involved in the concrete-filled steel tube arch bridge can improve the stability during installation and construction of steel tube arch ribs, and the accuracy of butt joint can be guaranteed effectively.

Owner:ANHUI HIGHWAY ENG CORP

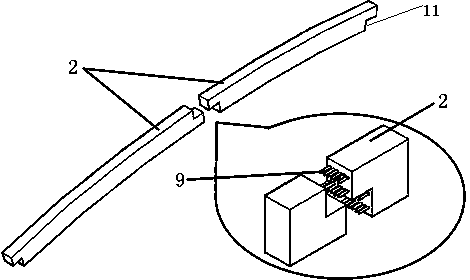

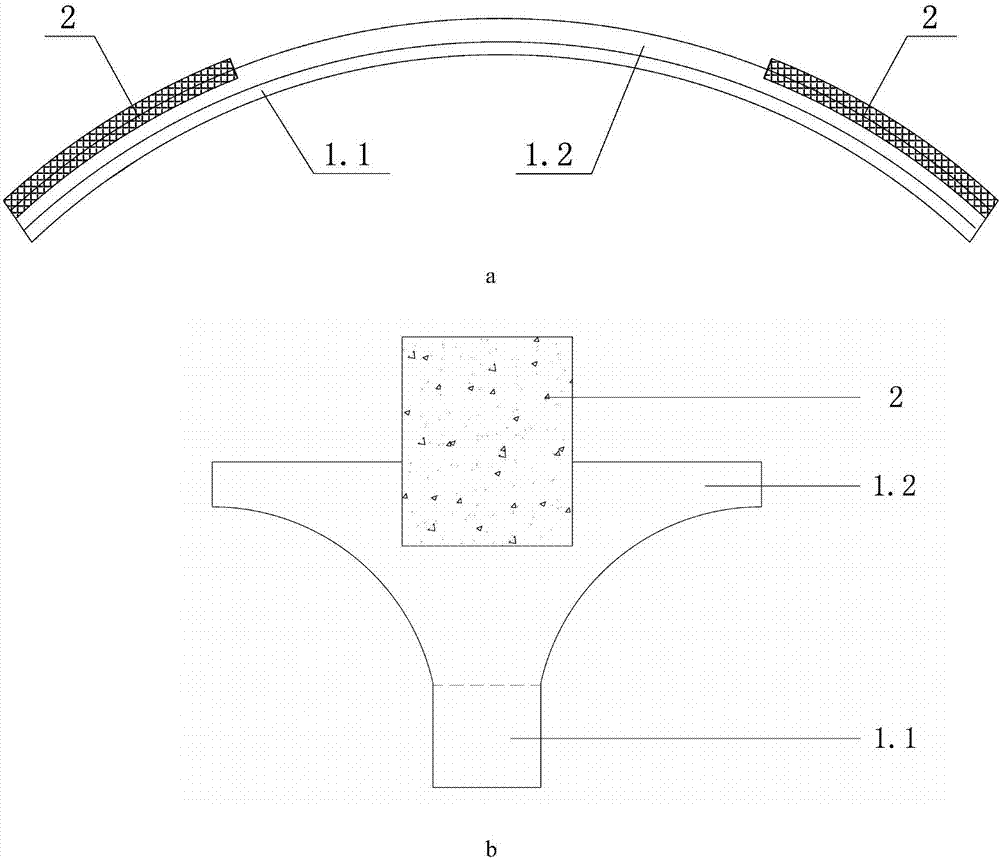

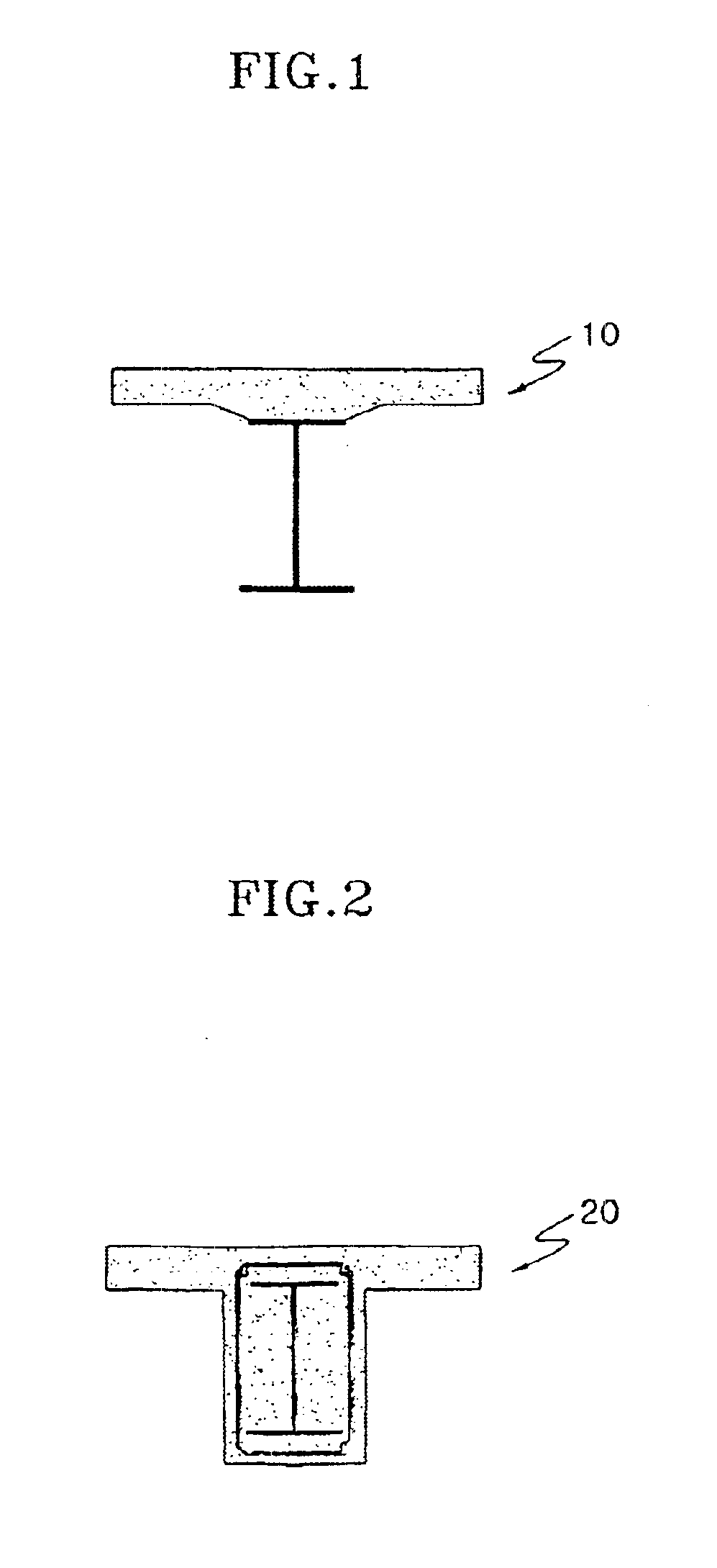

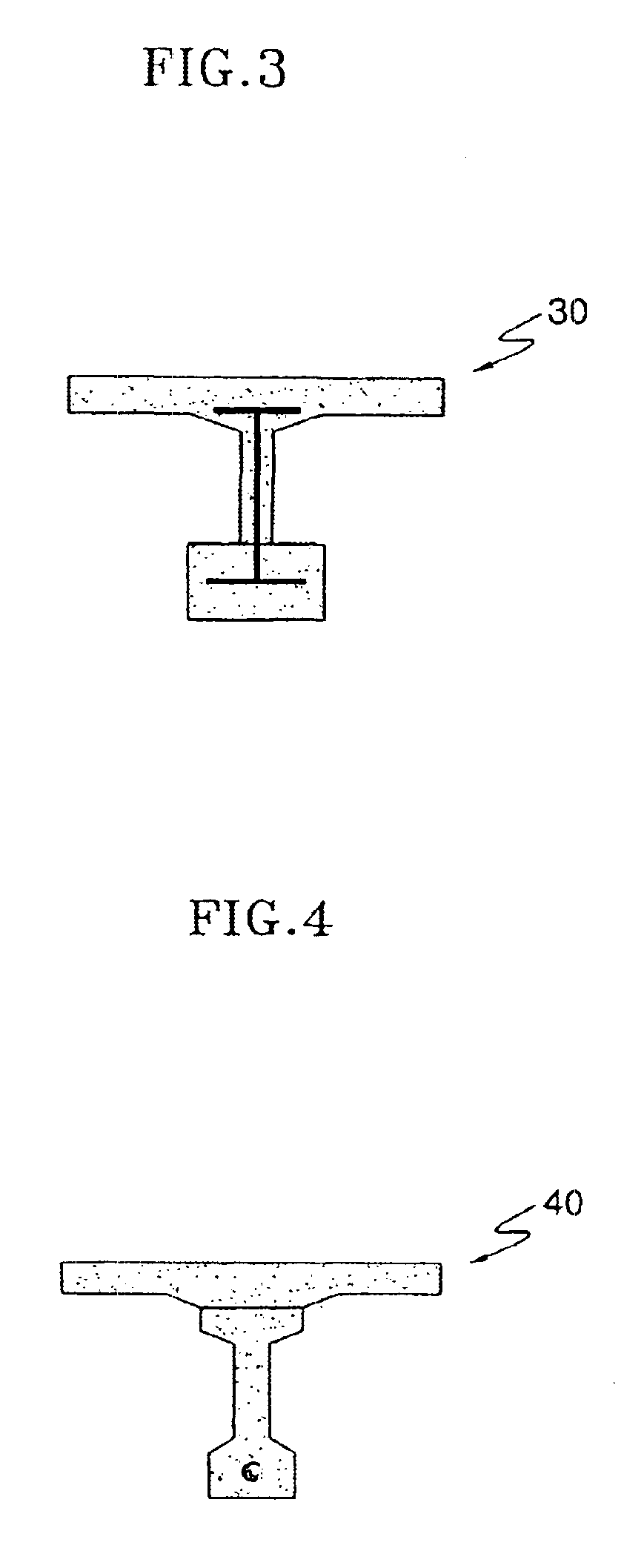

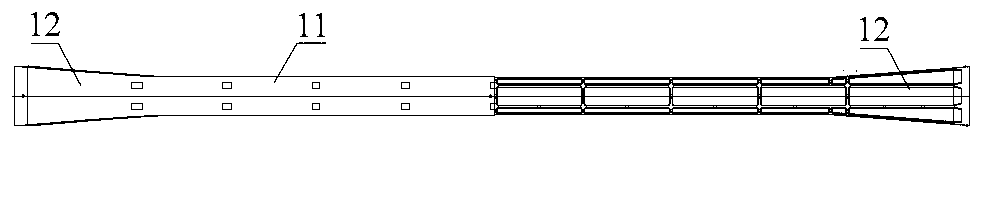

Ultrahigh-performance-concrete prefabricated assembled-type arch rib and manufacturing and mounting method thereof

ActiveCN103898831AQuick assemblyGuarantee the construction qualityBridge structural detailsBridge erection/assemblyEngineeringSingle step

The invention discloses an ultrahigh-performance-concrete arch rib and a prefabricated component manufacturing method thereof. Ultrahigh-performance concrete is adopted to manufacture arch rib prefabricated components, and the arch rib prefabricated components are spliced to be the arch rib. An arch ring is composed of two separated arch ribs, the arch rib prefabricated components are connected by adopting single-step-type glued joints, multiple reserved holes are formed at one end of each arch rib prefabricated component, and multiple connecting rods matched with the reserved holes in size are fixed at the other end of each arch rib prefabricated component. Before hoisting, sufficient epoxy resin is smeared on arch rib prefabricated component ports, the reserved holes and the connecting rods; during hoisting, the connecting rods at one end of one of each two arch rib prefabricated components are inserted into the reserved holes at one end of the other arch rib prefabricated component. By the method, quick assembling of the arch ribs within short time can be guaranteed, and construction quality of the arch ribs and durability of a whole bridge are ensured.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

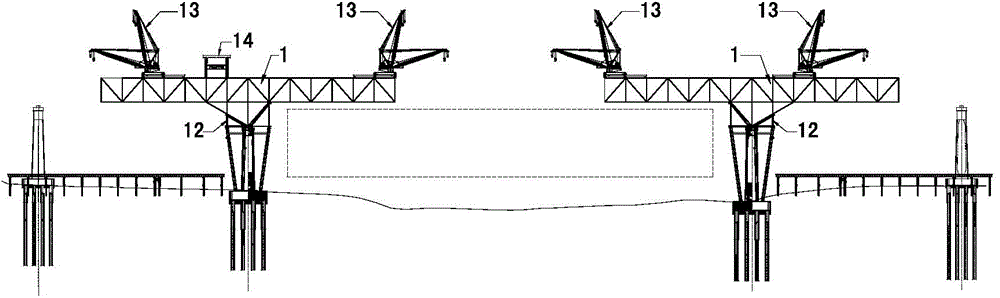

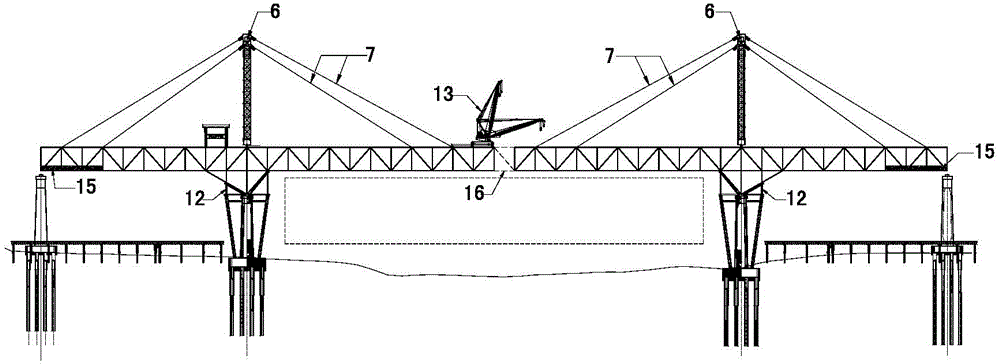

Gate-type crane semiarch integral-hoisting steel-pipe arch process

InactiveCN1851137AQuick investmentImprove securityBridge erection/assemblyArch-type bridgeSpandrelSteel tube

The invention relates to erecting construction of a steel pipe concrete arch bridge, especially a door crane-used half-arch integral steel pipe arch hoisting process, dividing each arch rib into two hoisted units, where each 1 / 2 arch is hoisted by two door cranes, where a fixed door crane serves as an arch span hoister and an active door crane serves as an arch foot hoister. And the invention is applied to bottom, middle and top bearing arch bridges constructed by bracket-free process. And the span of the steel pipe arch installed by the invention can reach above 300 meters, and the weight of the installed steel pipe can reach above 2000 tons. And it does not influence navigation, able to applied to single- or multiple- span construction; the hoisting safety is higher; and the shape of the arch axis is good; it needs no huge anchoring system and applied to various arch bridges.

Owner:CHINA RAILWAY FIRST GRP CO LTD

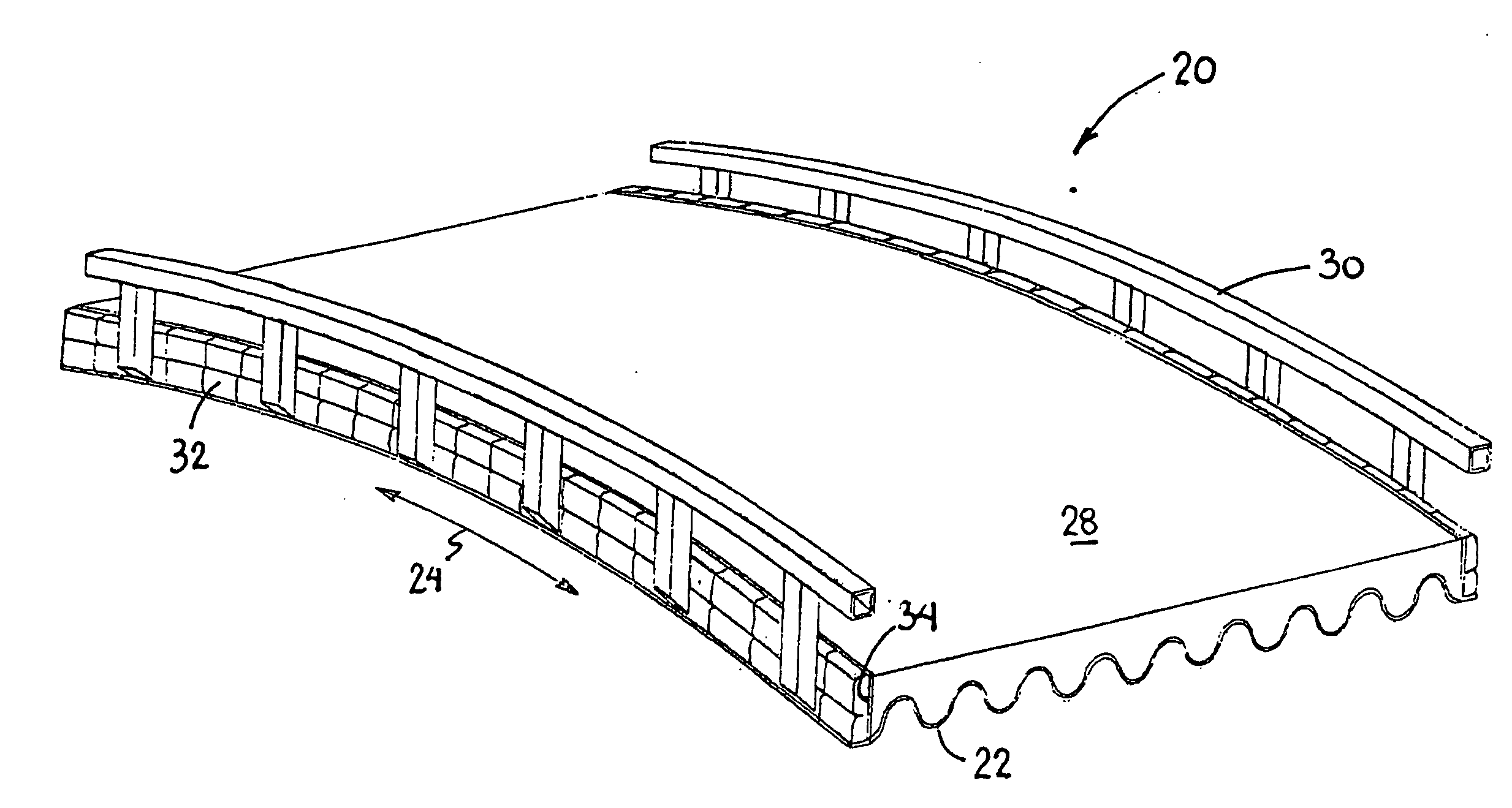

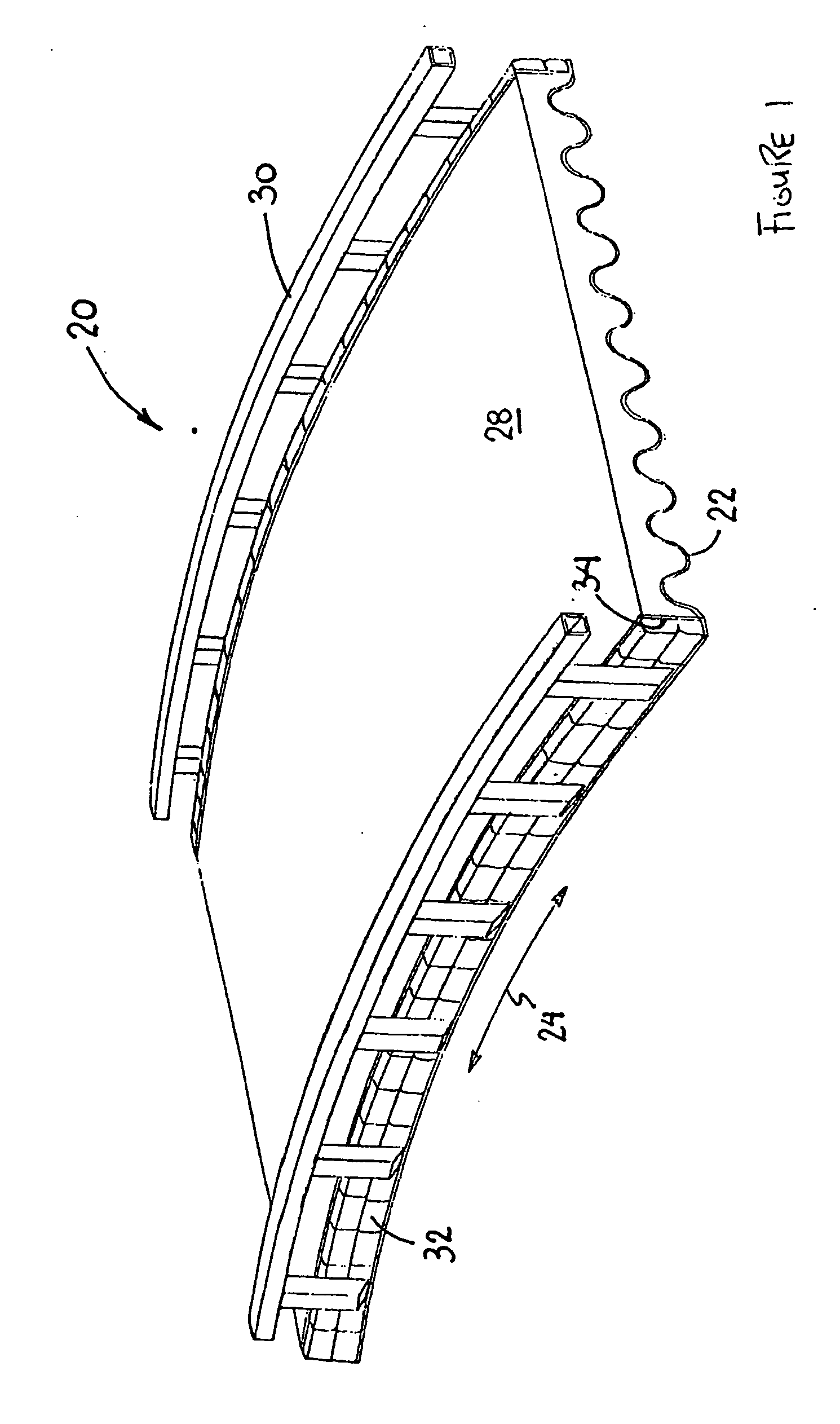

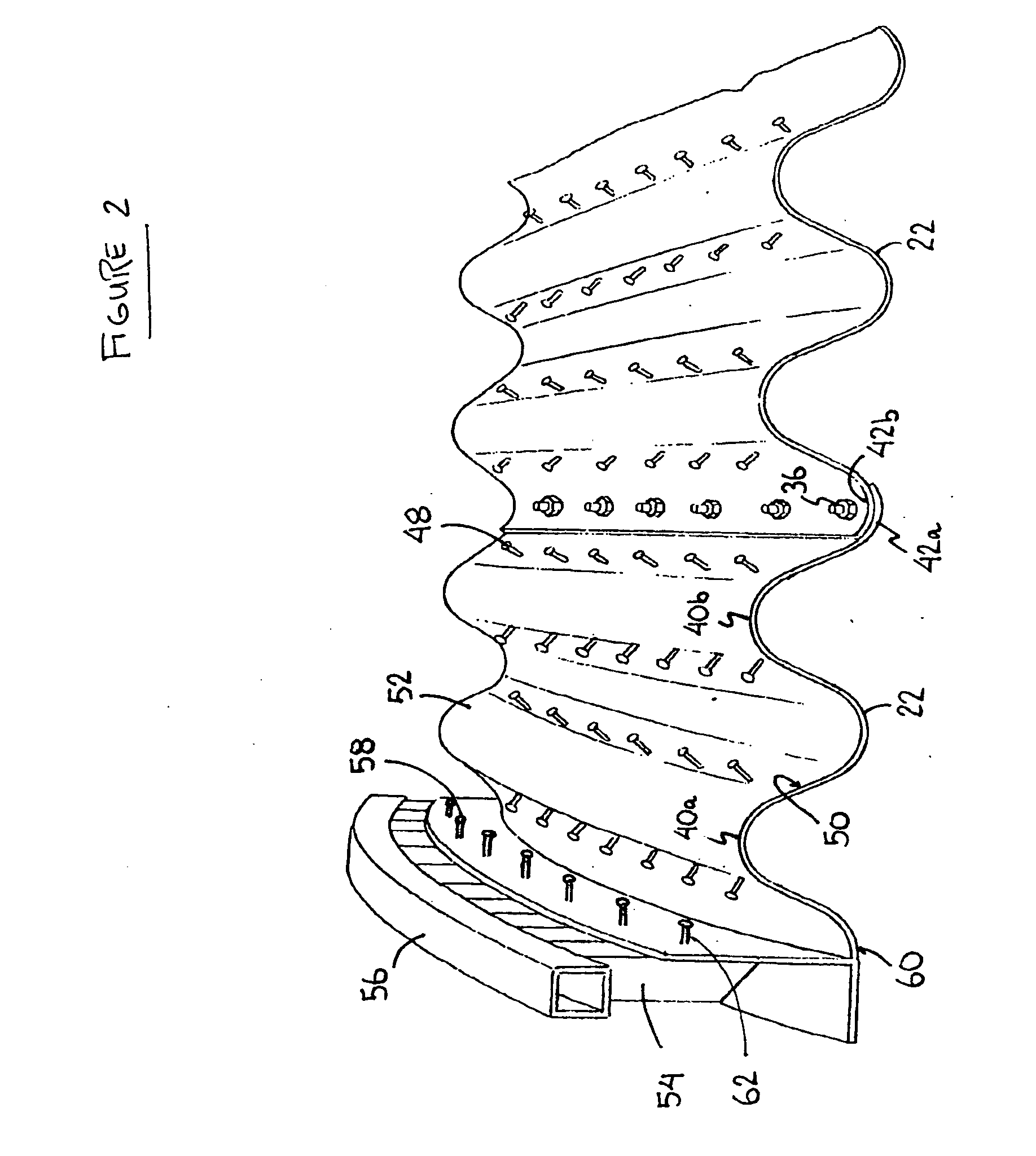

Corrugated metal plate bridge with composite concrete structure

A light to medium-duty bridge structure suitable for use in golf-courses, parks and similar settings. The bridge structure comprises at least one corrugated metal plate having corrugations oriented parallel to the longitudinal axis of the bridge structure. Applied to the upper surface of this corrugated metal plate is a layer of concrete or like material to provide a support / running surface. The corrugated metal plate is provided with a plurality of devices adapted to engage the concrete or like material so as to provide a composite corrugated metal plate-concrete structure capable of supporting light to medium-duty loads.

Owner:AIL INT

Arch bridge

A bridge, comprising a set of arches, each extending longitudinally along the bridge, including at least one central arch and at least two side arches, symmetrically disposed about the central arch. The side arches are slanted transversely inwardly so that they are closest at the longitudinal center of the bridge and are generally disposed either above or below the central arch. In addition, transverse members connect the arches together and a deck is suspended from the set of arches.

Owner:MORRIS DAVID C

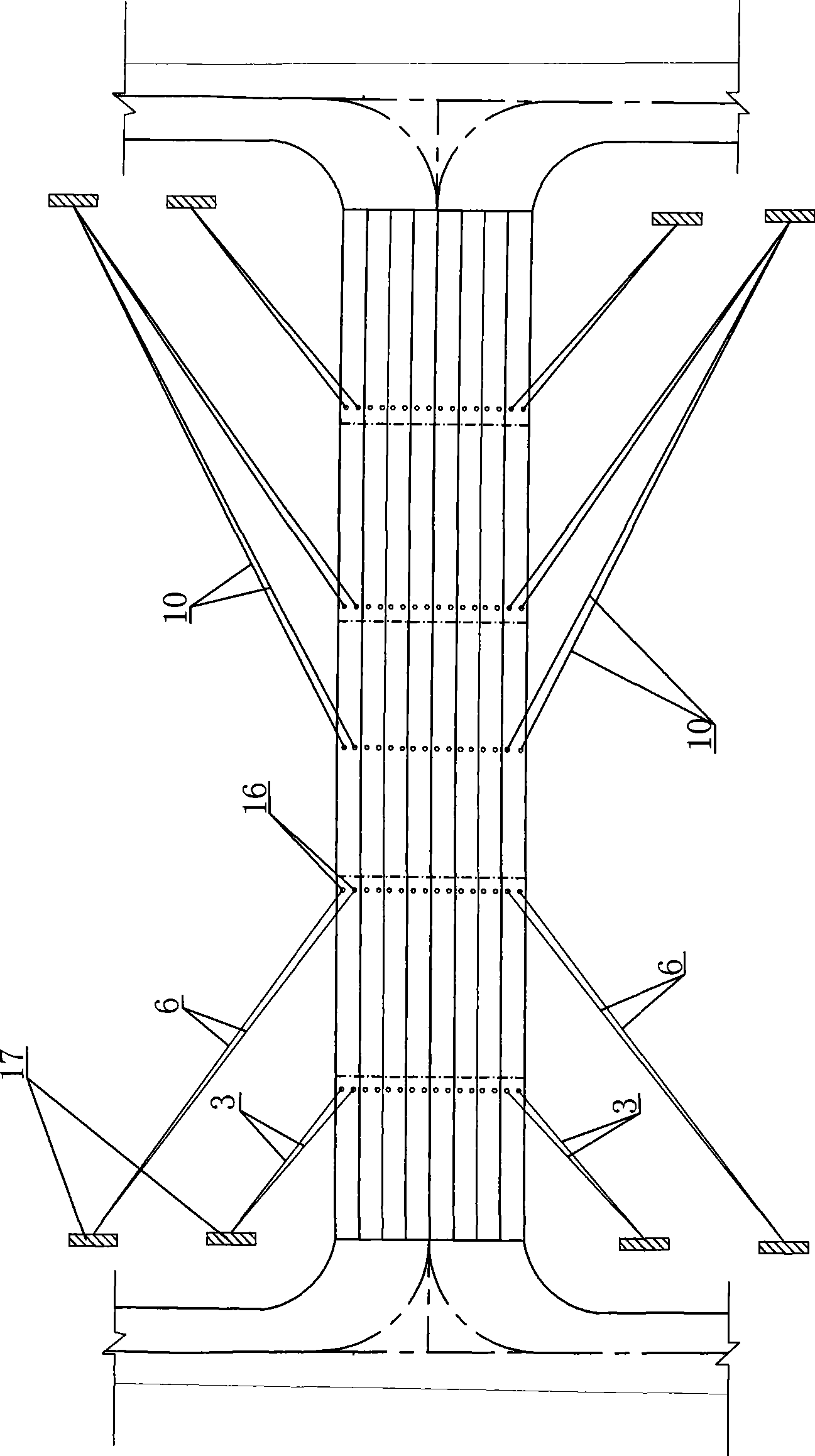

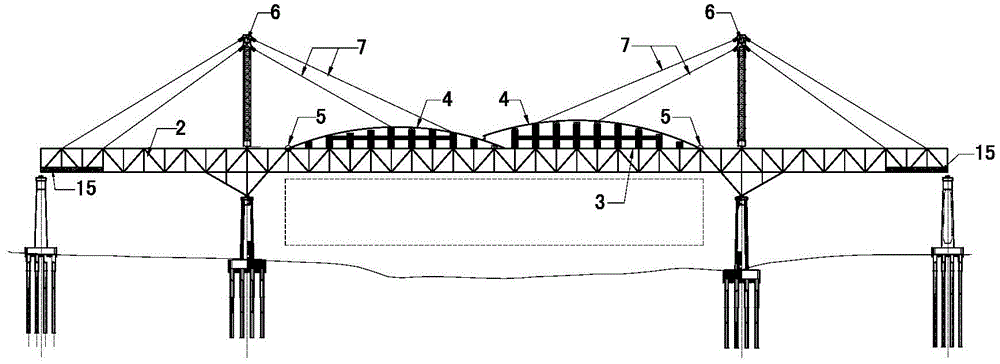

Integral Pushing Construction Method of Network Tied Arch Bridge

InactiveCN102261039AFast constructionReduce coefficient of frictionBridge erection/assemblyArch-type bridgeEngineeringPiston

The invention relates to a guiding-beam-free integral thrusting construction method of a network tied arch bridge. The method is characterized in that the following structure and method are adopted for thrusting the network tied arch bridge: a vertical jack is arranged at the front end in the thrusting direction of a steel box tie beam; a sliding mechanism which can ensure a piston of the jack toslide on the top surfaces of temporary piers is arranged on the top surfaces of the temporary piers; during thrusting, when the front end of the arch bridge is close to the temporary piers, the piston of the jack moves downwards to push against the sliding mechanism and the height of the front end of the arch bridge relative to the top surfaces of the temporary piers is adjusted by controlling the extension elongation of the piston to ensure chutes at the bottom of the steel box tie beam to fall on pulleys; and the chutes are supported by the pulleys and slide relative to the pulleys along with thrusting movement of the arch bridge. The method has the following beneficial effects: in the thrusting process, a main arch ring, inclined hangers, the steel box tie beam, the temporary supports and the like are integrally thrust, thus giving play to the function of partial inclined hangers to enhance the structural rigidity in the thrusting process, simultaneously avoiding installation inconvenience and construction difficulty after the members are thrust in place and improving the thrusting construction efficiency.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Flared leg precast concrete bridge system

InactiveUS20090183321A1Simple structureRealized benefitsGround-workTruss-type bridgeEngineeringSpandrel

A concrete building system includes a set of parallel spaced apart strip footers and one or more precast concrete sections supported by the footers in a predetermined alignment. Each precast concrete section has a top slab integrally connected to a pair of equally flared legs. Each leg depends from an end of the top slab at an effective flare angle to form a corner. The precast section includes haunch sections formed between the top slab and each leg resulting in a corner thickness greater than the uniform thickness of the angled leg to which it is integrally formed and the top member. The length of the effective span of each section varies between 60 and 90 percent of the distance between the bottom-of-leg span. The sections can be used to construct bridges, culverts, underground storage units, fluid detention units and dam structures.

Owner:COUNTY MATERIALS CORP +1

Novel reinforcement method for two-way curved arch bridge

InactiveCN106958208AIncrease weightLess weight gainBridge erection/assemblyBridge strengtheningBridge deckOperability

The invention discloses a novel reinforcement method for a two-way curved arch bridge comprising the following steps: (1) closing to traffic on a bridge deck, dismantling the bridge deck and auxiliary facilities of the bridge deck and removing fillings on arches; (2) cutting rectangular grooves along the two-way curved arch bridge on the top of an extrados corresponding to an original arch rib; (3) chipping the bottom of the rectangular grooves, planting anti-shear reinforcement bars, erecting a formwork on the extrados on the top of the rectangular grooves, assembling the anti-shear reinforcement bars and pouring concrete to form new arch ribs, of which the height is same relative to the extrados, protruding from the extrados; (4) repairing transverse walls, chipping the sections, which are at the outer side of the transverse walls along the two-way curved arch bridge, of the extrados and the new arch ribs, planting reinforcement bars on the extrados and the new arch ribs which are chipped, erecting the formwork and pouring the concrete; (5) chipping the top of the transverse walls, planting vertical reinforcement bars and erecting new columns for supporting the bridge deck; (6) newly building the bridge deck. The novel reinforcement method for the two-way curved arch bridge has the advantages of being small in dead weight of a bridge structure, good in unity of an old structure and a new structure, low in reinforcement cost, good in adaptability, not restricted by surroundings under the two-way curved arch bridge, unchanged about the original appearance of the two-way curved arch bridge, good in operability and good in application prospect.

Owner:WUHAN UNIV OF TECH

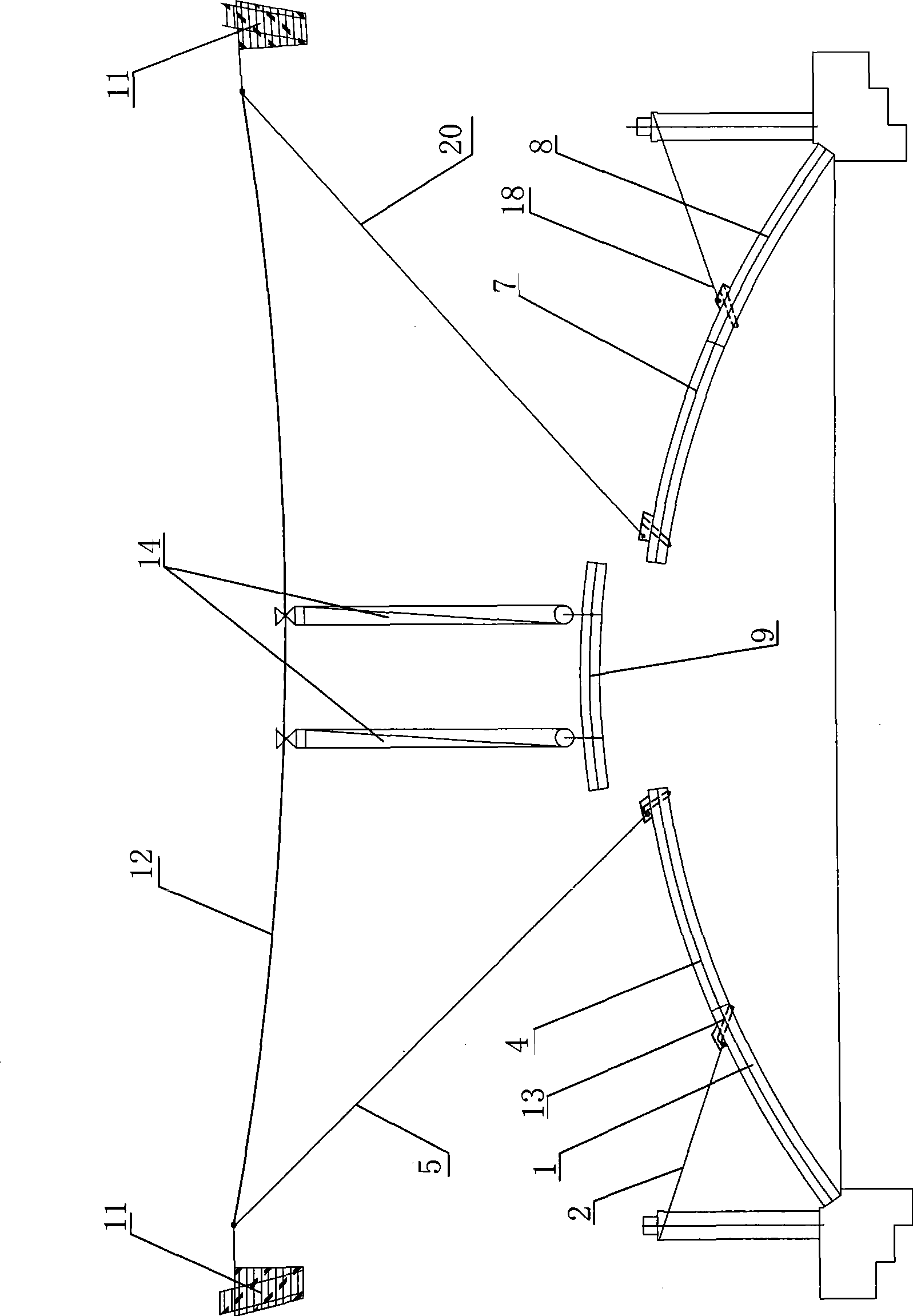

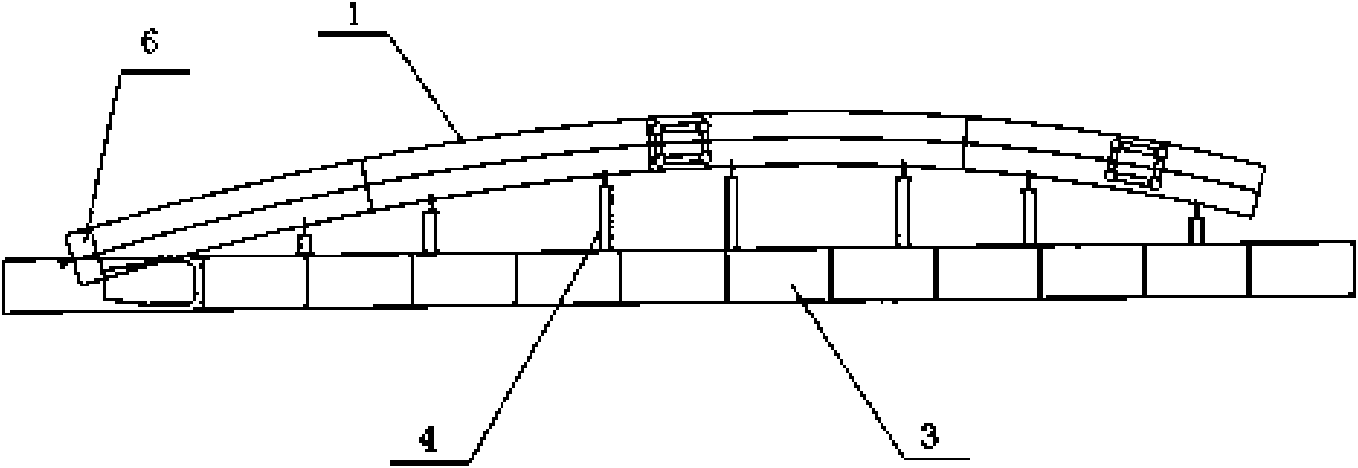

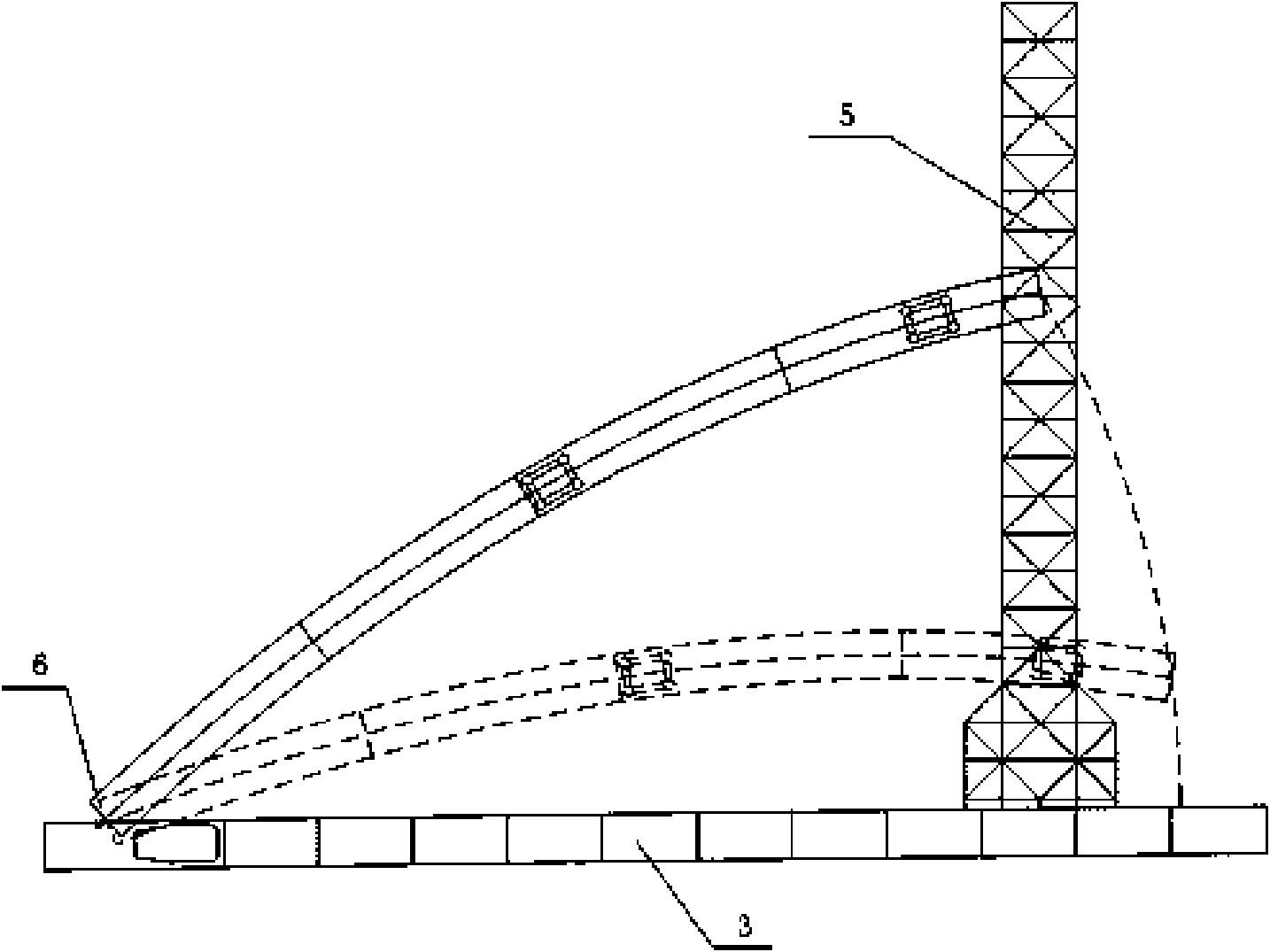

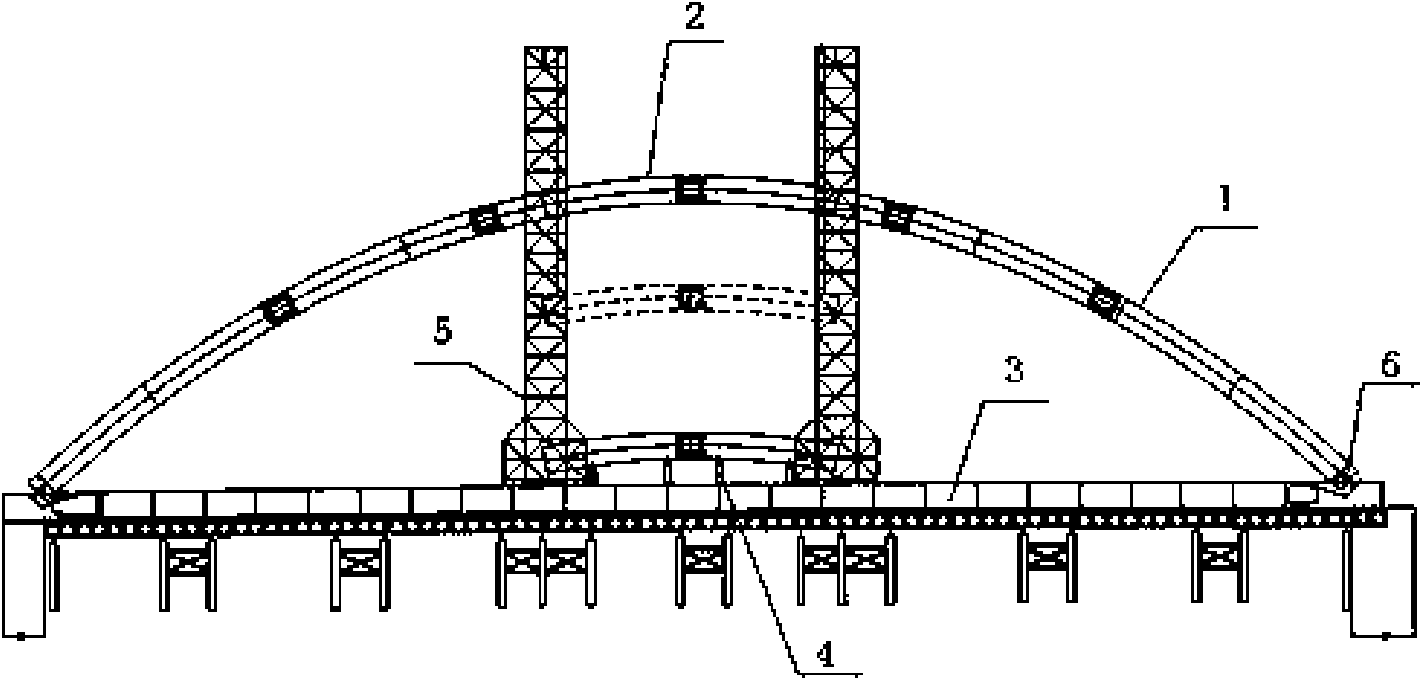

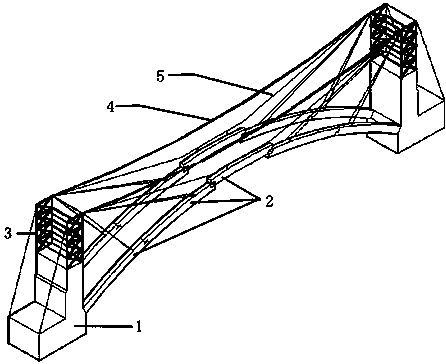

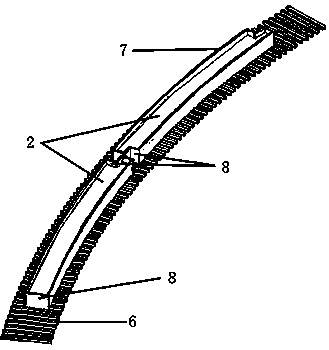

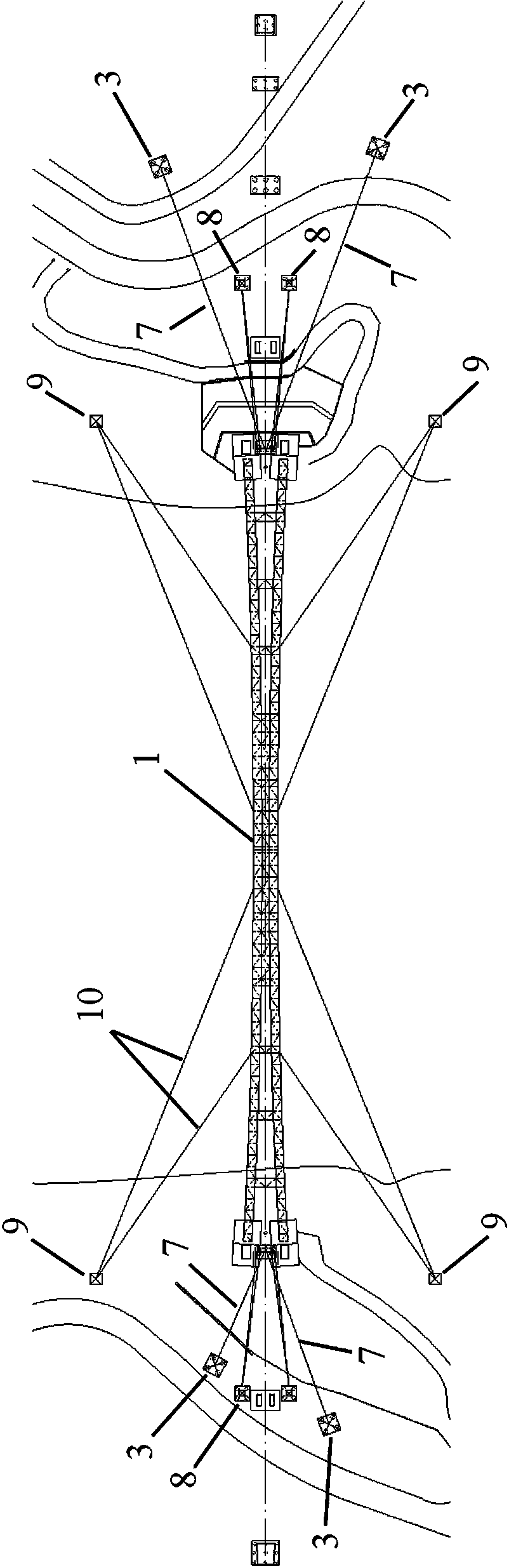

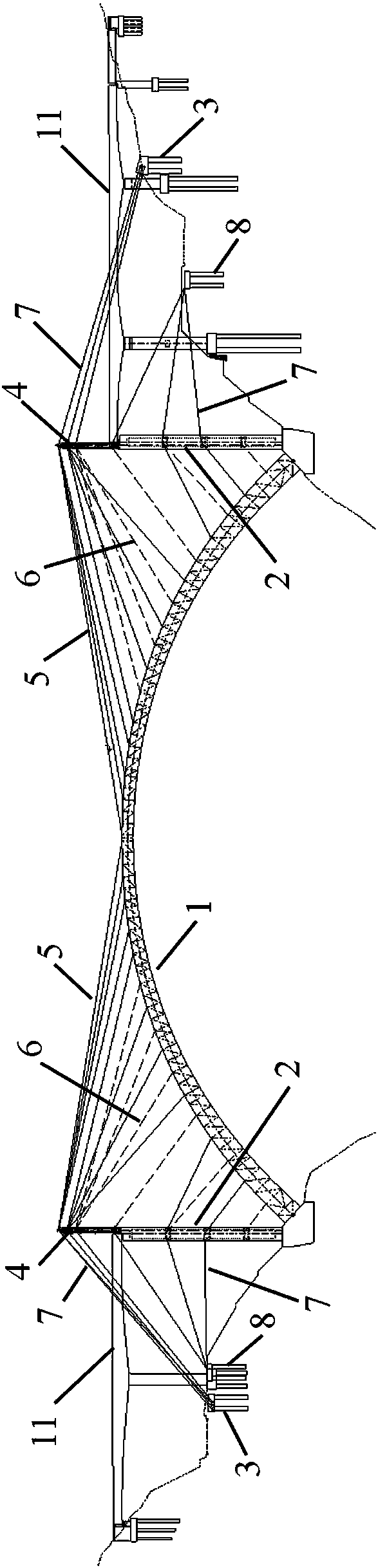

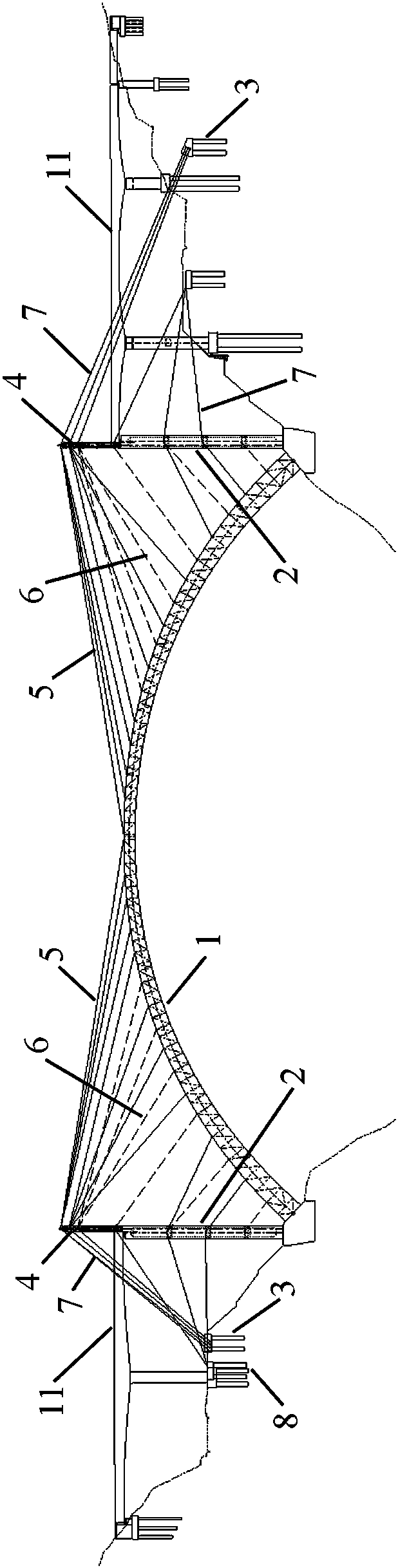

Construction method for long-span handle-basket arch bridge steel arch rib fastening and hanging system in high speed railway

InactiveCN108374347AReduce investmentLow terrain requirementsBridge structural detailsBridge erection/assemblyCable stayedOperability

The invention discloses a construction method for a long-span handle-basket arch bridge steel arch rib fastening and hanging system in a high speed railway. The construction method is used for assisting in mounting long-span steel arch ribs and linear adjustment, the fastening and hanging system mainly comprises a fastening anchorage cable, a cable tower, an anchor cable and anchorage, a side wind-cable and anchorage and a fastening and hanging anchoring structure. Long-span steel arch ribs are hoisted through a segmental mode, each segment adopts a fastening cable to be hung and fastened, theupper end of the cable tower is aslant anchored to an anchor eye of a tension platform on the top of the cable tower, the cable tower and the corresponding anchor cable are simultaneously and symmetrically stretched and drawn, and the anchor cable is anchored to the anchor cable and anchorage in advance. The steel arch rib is hoisted through the segmental mode, each segment is fastened and hung with one set of fastening cable. The construction method for the long-span basket handle arch bridge steel arch rib fastening and hanging system in the high speed railway has the advantages that the steel arch rib segments are installed by adopting the cable-stayed fastening and hanging system, the technical problem of the long-span arch bridge construction under complex topography conditions suchas mountain areas, river valleys and the like is overcome, it is achieved that an arch bridge can be built without supports in mid-span, the dependence of bridge construction on topography and landform is reduced, the adjustment of installation linearis is convenient, the operability is strong, the overall structure layout is reasonable, safe and reliable, and the construction method for the long-span basket handle arch bridge steel arch rib fastening and hanging system in the high speed railway has popularization and application value.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

Steel tube arch bridge towerless buckling three-section type double-rib folding hoisting construction method

InactiveCN103437296AImprove the tension effectHigh control precisionBridge erection/assemblyArch-type bridgeEdge segmentSteel tube

The invention relates to a steel tube concrete arch bridge hoisting construction method, belongs to the technical field of bridge construction, and discloses a steel tube arch bridge towerless buckling three-section type double-rib folding hoisting construction method. The method includes the following steps of 1, arch rib pre-assembly, 2, ground anchor arrangement, 3, single-floating-crane transportation, 4, single-edge segment adjustment to be close to design angles through a floating crane, 5, buckling system installation, 6, repetition of the steps 3, 4 and 5 and installation of the other section of a single-edge segment, 7, double-floating-crane transportation, and 8, folding and welding. The method improves production efficiency, accelerates construction, saves engineering cost, and guarantees arch rib installation quality.

Owner:中天交通建设投资集团有限公司

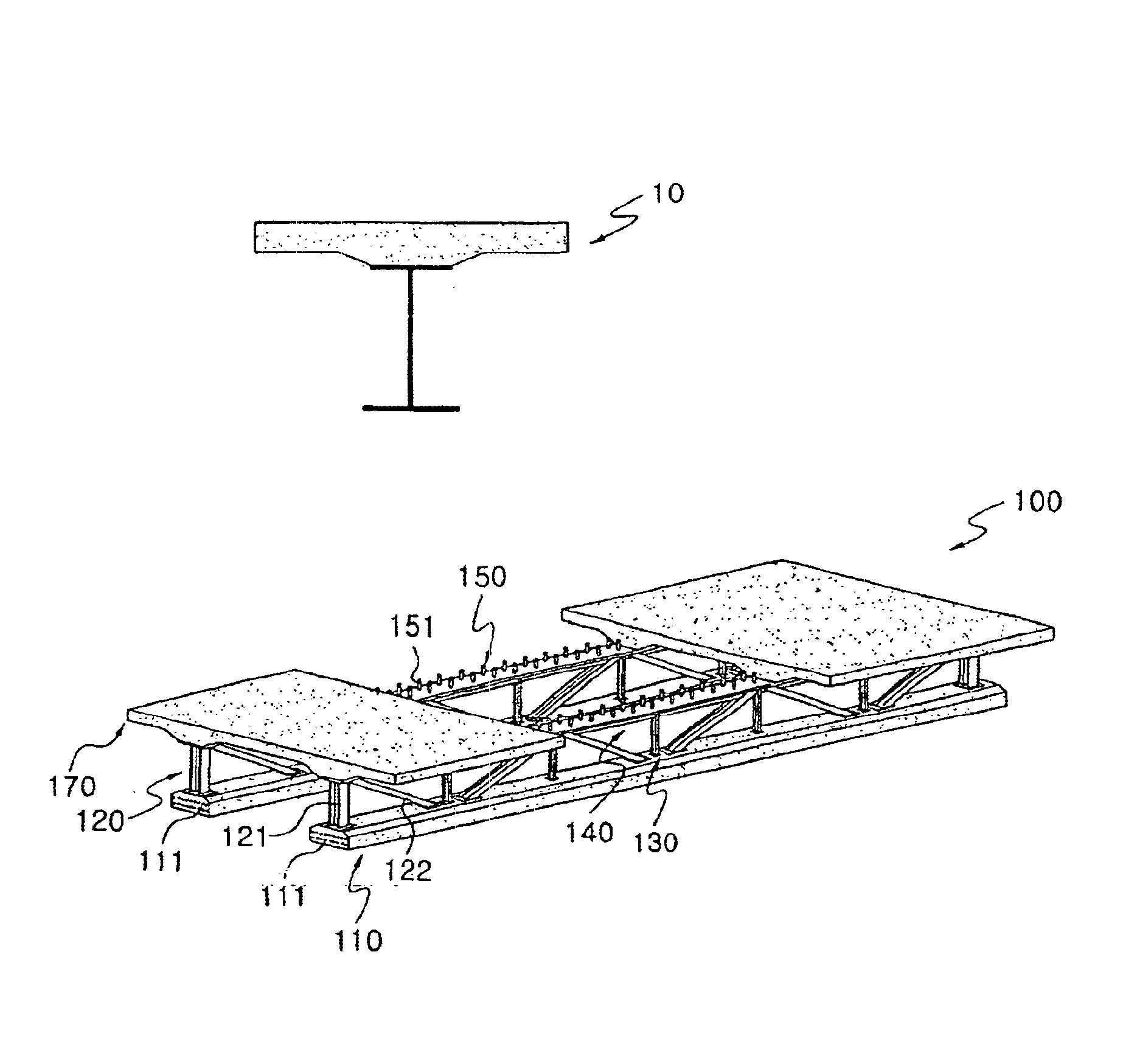

Prestressed composite truss girder and construction method of the same

InactiveUS6915615B2Maximizing material use efficiencyMaximize efficiencyTruss-type bridgeFloorsPre stressUltimate tensile strength

The present invention relates to prestressed composite truss girder and construction method of the same. The prestressed composite truss girder of the present invention comprises a concrete bottom plate having structure of composite truss; a lower-chord member being composed of prestressed concrete wherein prestress is induced to resist against the elongation strength generated when composing and not composing and to reduce the droop occurred at the state of composition and having perpendicular and horizontal cross-section of certain shape and certain length; web members wherein vertical chords and diagnal chords composed of rolled steel to upper plate of said lower-chord member; and upper-chord member combined with said web members along the longitudinal direction of said lower-chord member to resist against the compressive force generated before said concrete bottom plate being composed.

Owner:WON DAE YON

Construction method of flexible arch bridge with rigid beams

ActiveCN104612058AReduce construction difficultyLower the lifting heightBridge erection/assemblyArch-type bridgeEconomic benefitsBridge deck

The invention relates to a construction method of a flexible arch bridge with rigid beams. Steel truss beams, a steel box arch and flexible hanging rods are divided into single members in a factory and manufactured in a segmented mode; by the adoption of the symmetrical cantilever erection method, installation of the rigid steel truss main beam is completed firstly; then, an arch rib is installed, a crane travels on an upper bridge deck, the arch rib is divided into two half arches, welding forming is conducted on the two half arches on the upper bridge deck, the arch rib is vertically rotated in place through auxiliary facilities such as vertical rotating hinges, temporary sling towers and temporary inhaul cables between the arch rib and the steel truss beams, and middle span closing of the arch rib is achieved. After installation of the steel truss beams and the arch rib is completed, flexible slings are installed on the upper bridge deck and tensioned, and installation of the main structure is completed. By the adoption of the construction method that the steel truss beams are installed first and then the arch rib is installed, construction difficulty of the arch rib is reduced, the hoisting height of the crane is reduced, the construction period is greatly shortened, construction costs are lowered, economic benefits are increased, structural integrality and stability of the large-span arch bridge are enhanced in the construction process, and construction risk is reduced.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

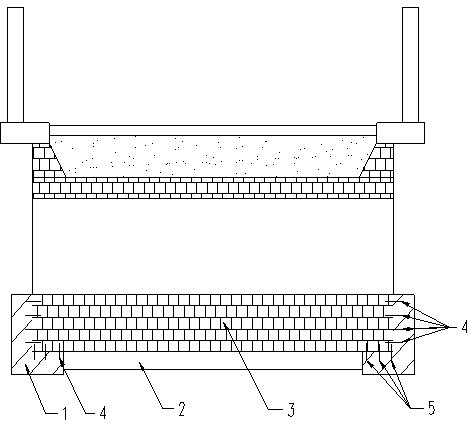

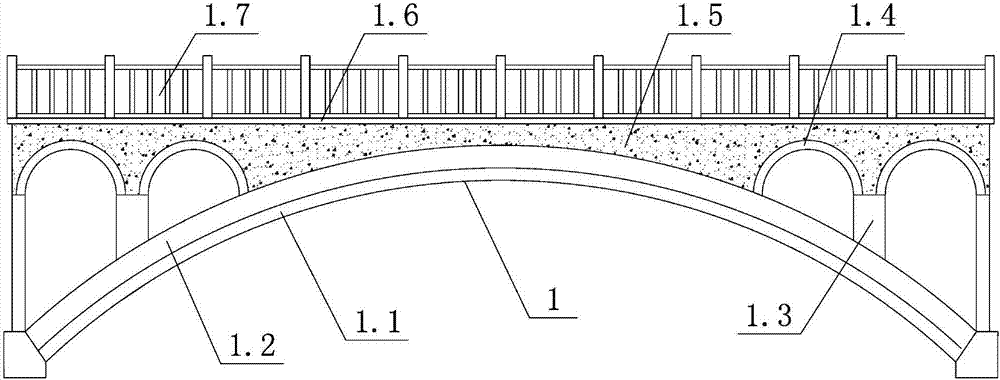

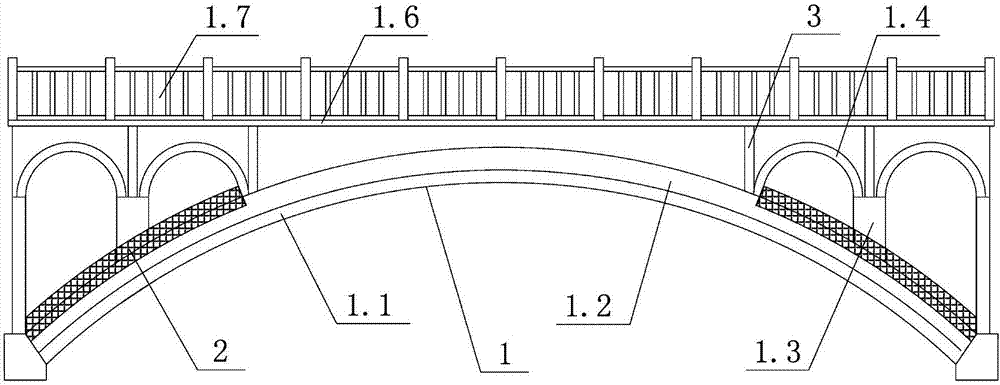

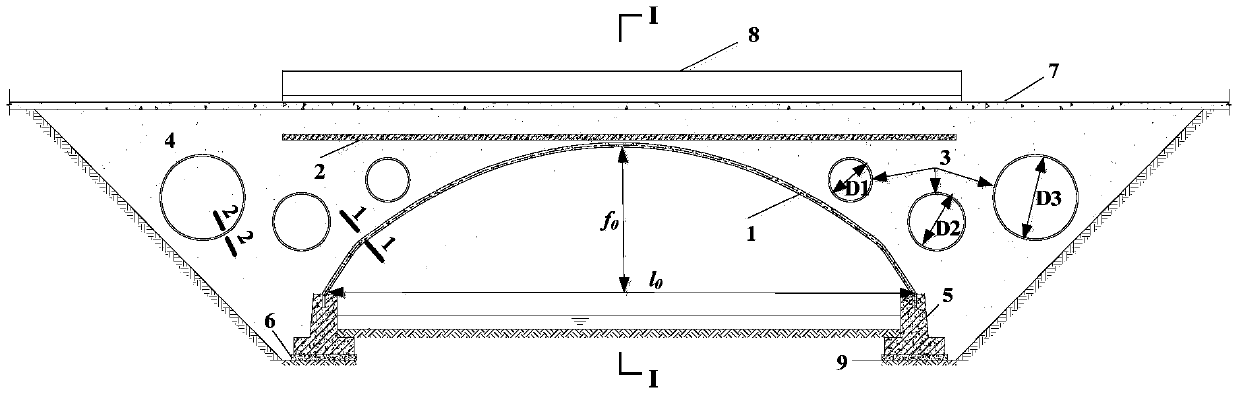

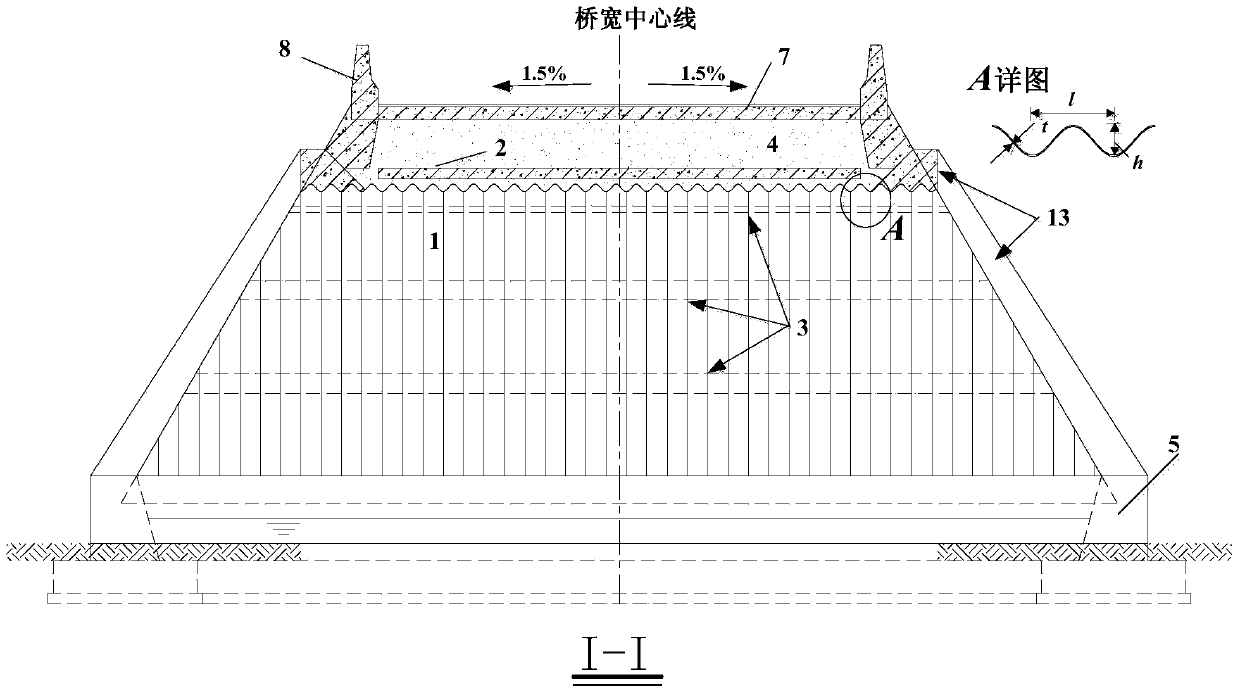

Masonry arch bridge using lightweight concrete as arch filler

ActiveCN102587268AImprove carrying capacityLose weightBridge structural detailsBridge erection/assemblyApparent densityCarrying capacity

The invention discloses a masonry arch bridge using lightweight concrete as arch filler. The masonry arch bridge comprises a main arch ring (1), a spandrel arch (3) and an arch filler layer (2) and is characterized in that the arch filler layer (2) is a lightweight concrete filler layer, and the apparent density of the lightweight concrete filler layer is 800kg / m<3>-1950kg / m<3>; a leveling layer (4) is arranged on the top surface of the arch filler layer (2); a waterproof layer (7) is arranged between the main arch ring (1) and the arch filler layer (2); and saw joints (5) are arranged along the transverse direction of the bridge; and water permeating pipes (6) are arranged in the lowest position of each filler formed by the pairwise saw joints (5) and at two sides of a side wall. The waterproof layer (7) is formed by laying a permanent condensate or asphalt. The masonry arch bridge has the advantages that the stress of the arch can be effectively improved, the internal force of a dead load is reduced, and the carrying capacity of a bearing live load of the masonry arch bridge is increased.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

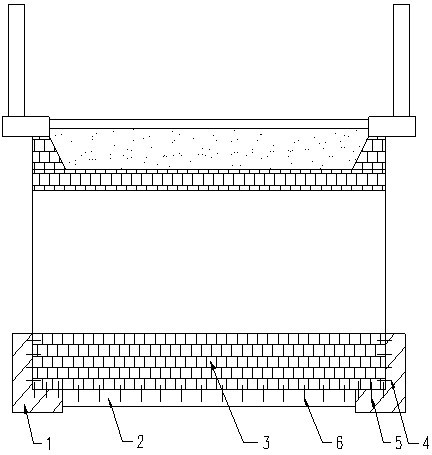

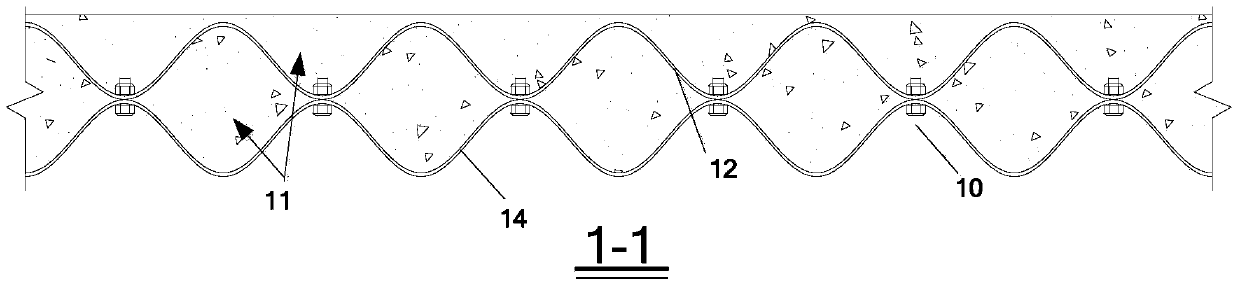

Reinforcement method of earthed corrugated steel plate-concrete combined arch bridge

ActiveCN104213514AImprove longitudinal and lateral stiffnessIncreased durabilityBridge erection/assemblyBridge strengtheningShock resistanceRebar

The invention discloses a reinforcement method of an earthed corrugated steel plate-concrete combined arch bridge. According to the method, an earthed corrugated steel plate-concrete combined arch ring has greatly enhanced strength and rigidity; concretes at the top of an upper steel plate can be used for improving the durability, shock resistance and flame resistance of the arch ring; a reinforced concrete ring beam can be used for protecting a road foundation protective slop and improving the whole transverse stiffness of a composite structure; a reinforced concrete unloading plate can be used for enlarging the stress region of the structure and reducing stress and deformation of the arch ring due to automobile mobile load; a galvanized corrugated steel tube can be used for alleviating the dead load of the combined arch ring, reducing the stress and deformation of the combined arch ring and improving the span and aesthetic feeling of the structure. The reinforcement method has the characteristics of low construction cost, high construction speed, good durability, low maintenance cost, environmental friendliness, and the like, and has favorable application prospect in middle-span or small-span bridges and culverts.

Owner:ZHEJIANG UNIV

Method for reinforcing double arch bridge

InactiveCN101881005ASolve the problem of poor combination structureImprove carrying capacityBridge erection/assemblyBridge strengtheningPre stressPre stressing

The invention discloses a method for reinforcing a double arch bridge, which belongs to the technical field of bridge reinforcement. The method comprises the following steps of: grinding and cleaning the inside of an arch tile and the surface of an adjacent arch rib, and spraying an epoxy interface agent; drilling a through hole from the arch back to the lower side of the arch tile; implanting a structural main reinforcing steel bar at an arch springing; implanting a constructional steel bar from the lower side of the arch tile to an arch plate; slightly jacking each control section of the arch rib and applying a pre-stress to the control section; binding the steel bars below the arch tile to form a steel bar framework; mounting a template below the steel bar framework between the arch ribs; casting micro-expansion concrete in a closed space formed among the arch rib, an arch support and the template below the arch tile from the through hole; unloading a jack after the micro-expansion concrete to be cast reaches the strength of a design requirement; and dismounting the template to finish the reinforcement of the double arch bridge. The method entirely solves the problem of poor composite structure of the double arch bridge, greatly improves the bearing capacity of the bridge and can be widely applied to the reinforcement and reconstruction of the existing double arch bridge.

Owner:王绍先 +1

Process for rebuilding double arch bridge by replacing arch style construction on arch with continuous slabs

InactiveCN101289835AImprove the state of stressReasonable forceBuilding repairsBridge erection/assemblyNatural resourceBridge deck

The invention relates to a reforming method of replacing double arch bridges in arched spandrel structure with continuous slabs. The method comprises the following steps that: a bridge floor system, a spandrel arch ring and a solid web section of a double arch bridge in arched spandrel structure are dismantled first; a plate girder pier is arranged on a ribbed main arch ring, and a former spandrel arch pier is heightened to form another plate girder pier, ensuring that the plate girder piers are identical in interval and horizontal height; bridge piers are heightened to ensure that the horizontal height of the bridge piers is equal to the plate girder piers; continuous slabs are cast on the plate girder piers and the bridge piers, and then the continuous slabs are paved with a bridge deck. The method improves the stress state of the ribbed main arch ring and ensures that the stress of the ribbed main arch ring tends to be more reasonable; as the arched spandrel structure is replaced with the continuous slabs, the dead load weight of an arch is reduced, and the bearing capacity of the bridge is improved correspondingly; the method saves the occupancy of natural resources and economic resources, which is caused by abandonment, old bridge demolishment and reconstruction, has the reinforcement cost which is 50 percent of new construction cost, and avoids the pollution on the natural environment caused by abandonment and old bridge demolishment.

Owner:江西中煤建设集团有限公司

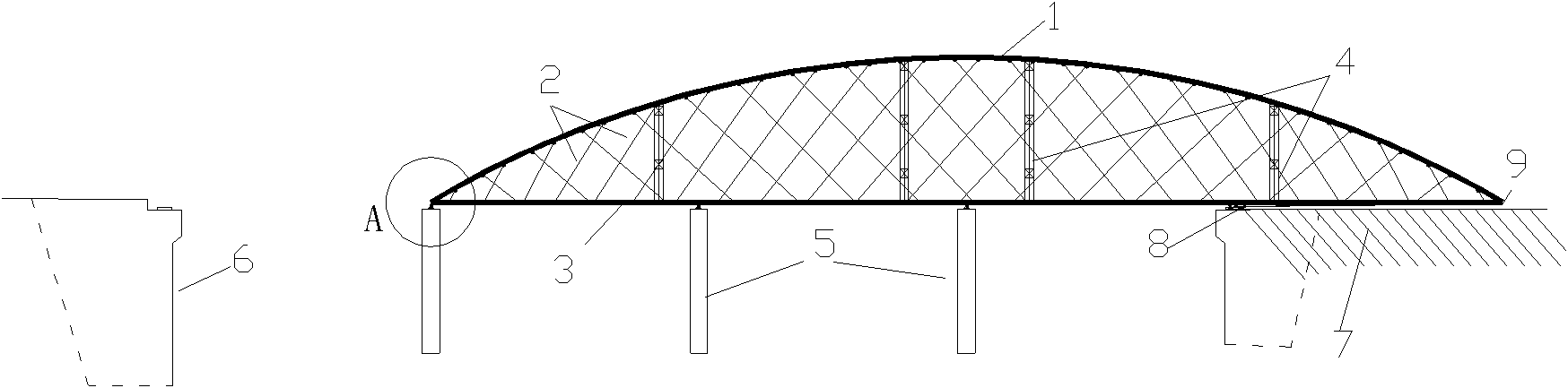

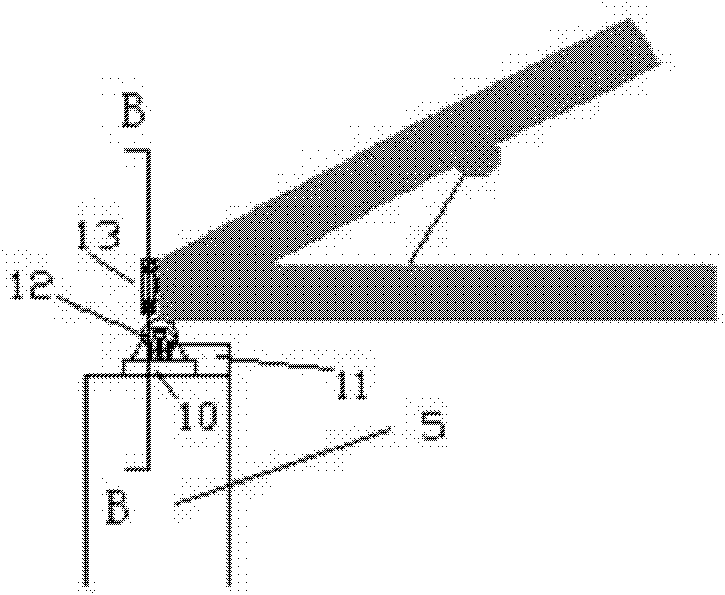

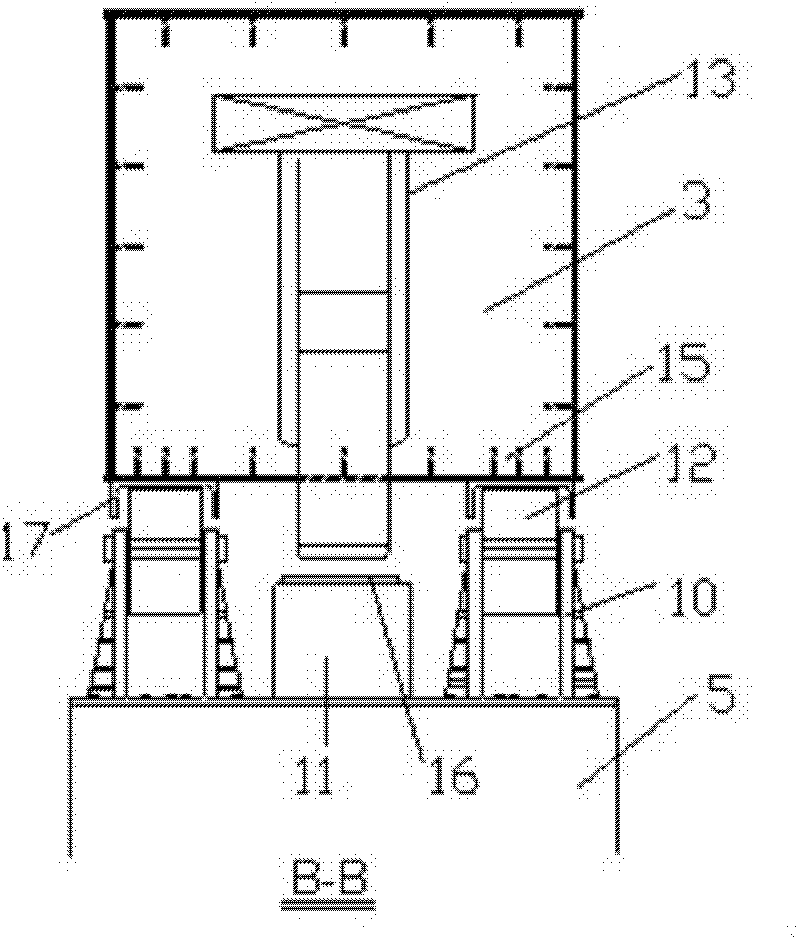

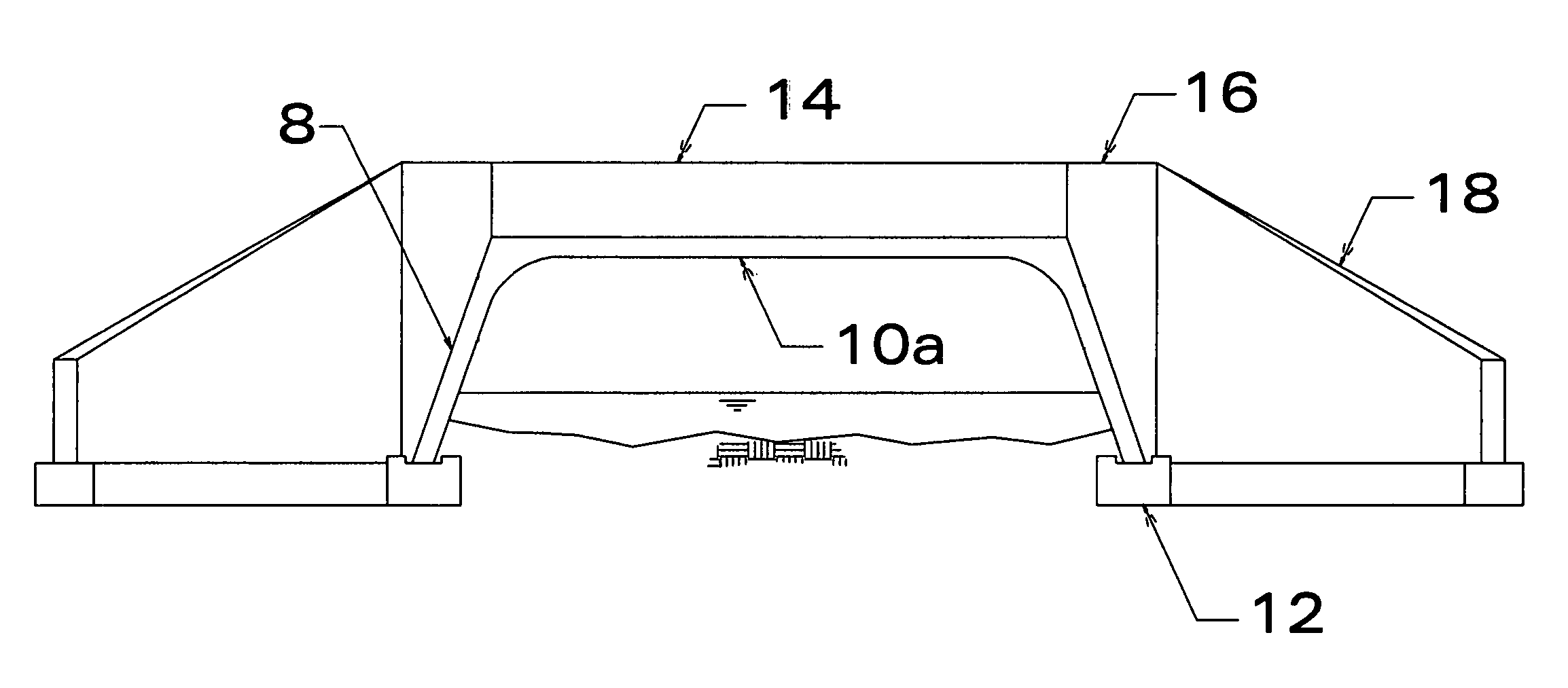

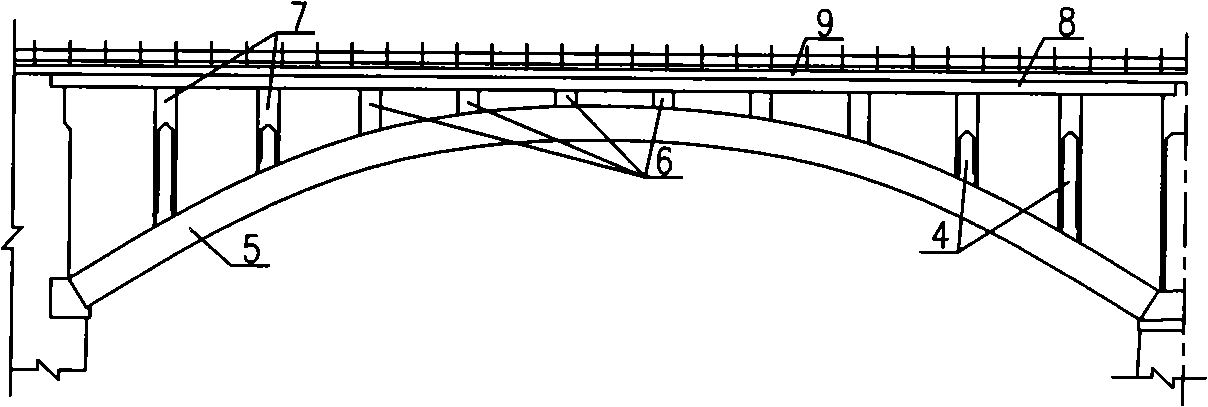

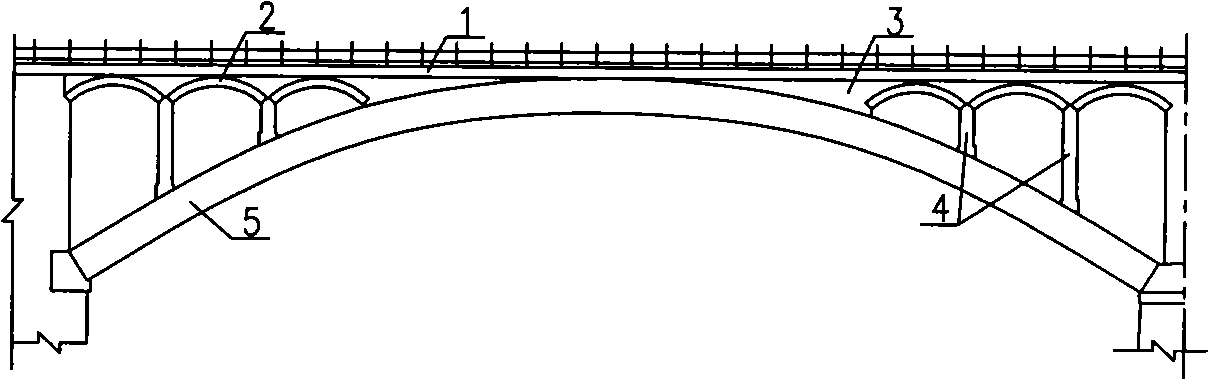

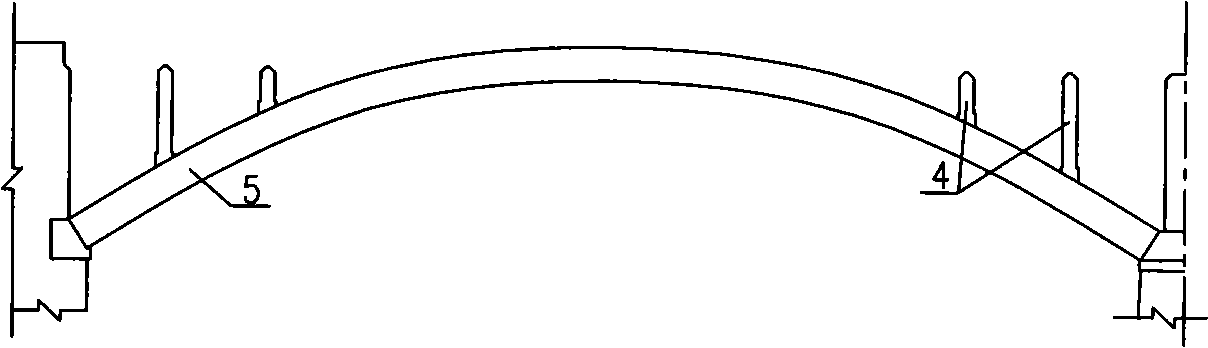

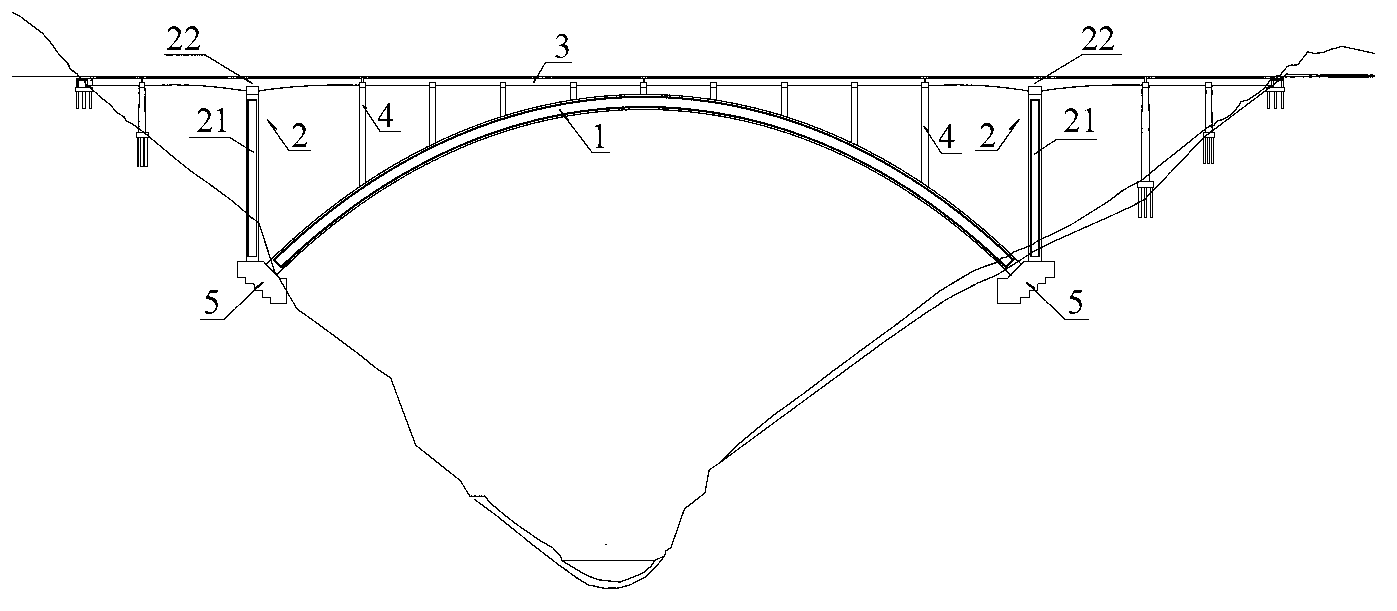

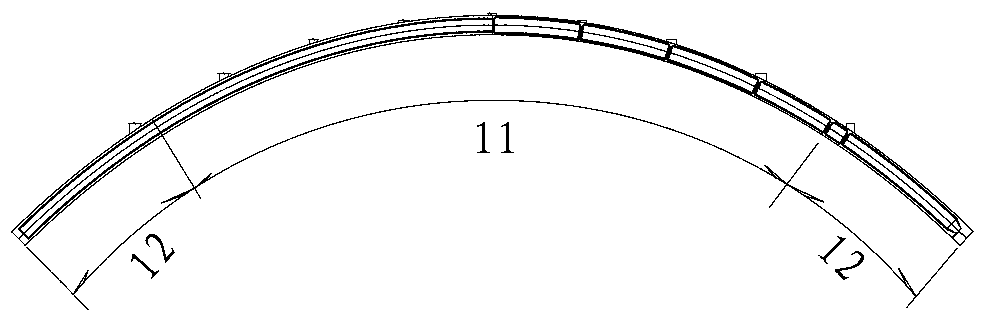

Large-span railway desk type concrete arch bridge structure

InactiveCN102797218AReasonable forceReduce construction difficultyArch-type bridgeContinuous beamSpandrel

The invention provides a large-span railway desk type concrete arch bridge structure. When transverse and longitudinal rigidities and stresses of the arch bridge structure are preferably satisfied, construction difficulties and construction risks of a main arch ring and an arch structure can be reduced, and engineering cost is greatly reduced. The large-span railway desk type concrete arch bridge structure comprises the main arch ring (1), a border pier (21), an arch beam (3), an arch column (4) and an arch support foundation (5), wherein arch feet on two sides of the border pier (21) and the main arch ring (1) are supported on the arch support foundation (5); the arch beam (3) is supported on the main arch ring (1) by the arch column (4). The main arch ring (1) is equal-height single-box and multi-chamber section box-like plate arch; the arch top of the main arch ring is an equal-width section (11); and arc foot parts close to two sides of the main arch ring are linear widened sections (12). The border pier (21) forms a border pier T structure (2) together with a T structure beam (22) fixedly connected with the top end of the border pier (21); and the arch beam (3) is a multi-span continuous beam.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Bridge structure

InactiveUS20050097686A1Simple structureHigh strengthCable-stayed bridgeArch-type bridgeSupporting systemBridge deck

The subject invention is an improved bridge structure comprising the use of both arch structural support systems along with suspension systems, combined together to support a multiple bridge support structure, with such multiple support systems being focused and combined through a unitary member in a center portion of the bridge, with the unitary member being an under support member in one embodiment, with such under support member supporting a portion of the bridge deck. More particularly, the subject invention is focused on utilizing multiple structural support systems for a bridge, with such multiple support systems being centered on a longitudinally extending secondary under support member, which is supported and held partially by the supplementary bridge support system, such secondary support member structurally having multiple and varied support systems and being adapted to provide an under support system as a supplementary support mechanism for the bridge structure. In summary, the subject invention comprises a secondary support system for a bridge to provide additional support to the primary support system for the bridge, such secondary support system having its forces focused on an undersupport system that is positioned beneath the bridge deck as an undersupport member that helps hold the bridge deck, along with the support provided by the primary support system.

Owner:ROYER GEORGE R

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com