Integral Pushing Construction Method of Network Tied Arch Bridge

A technology of tied arch bridge and jacking construction, applied in arch bridges, bridges, bridge forms, etc., can solve the problem of high construction cost, achieve the effect of short construction period, high construction stability and automation, and improve safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

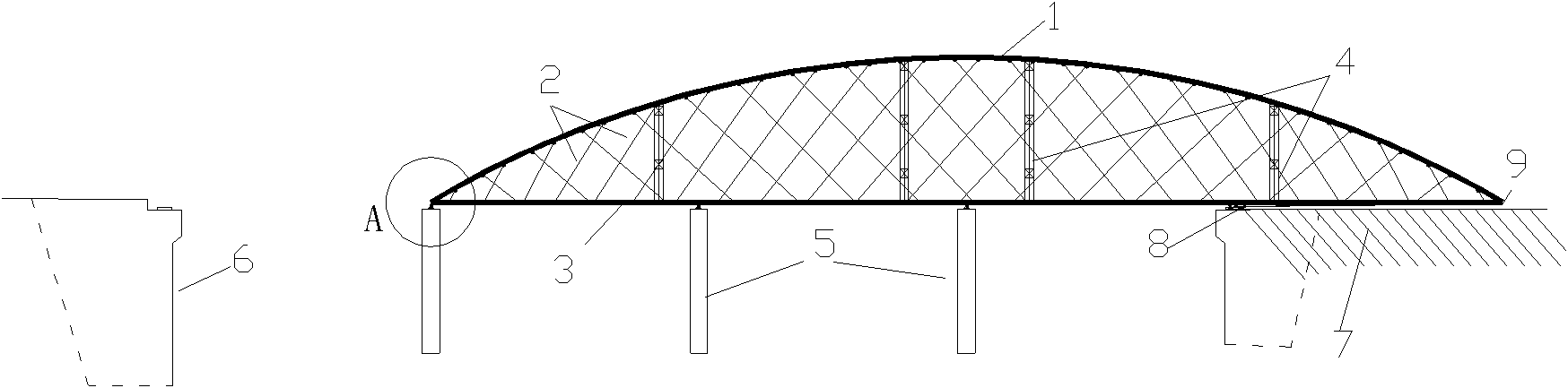

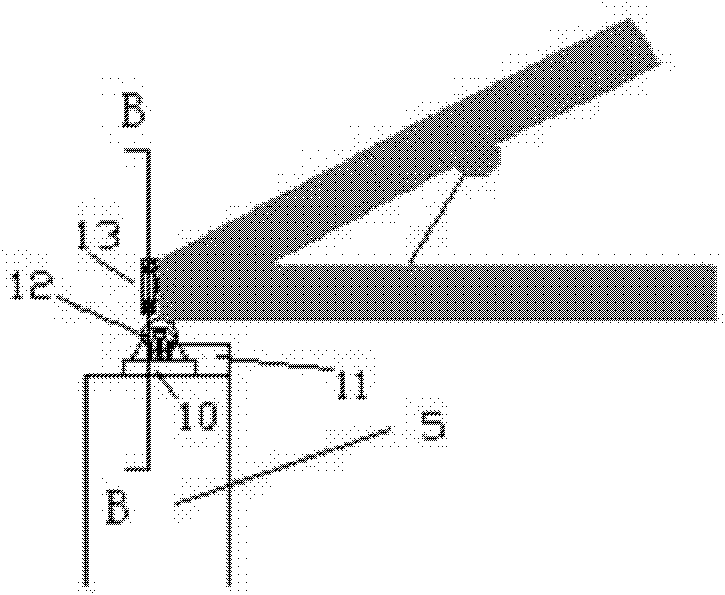

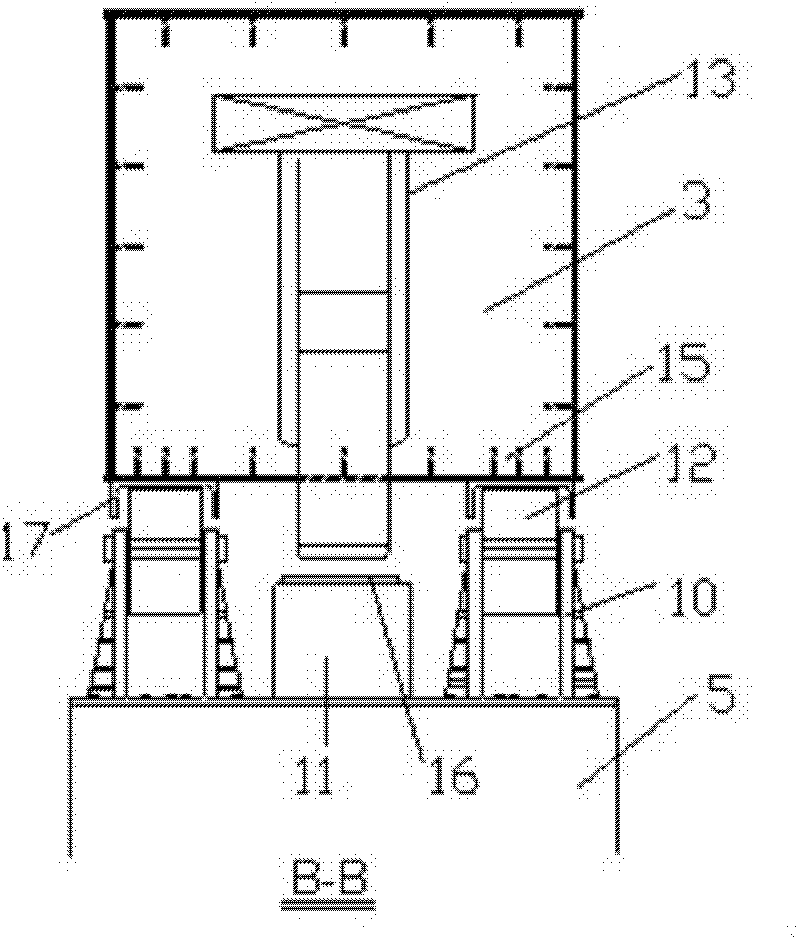

[0045] refer to Figure 1-Figure 10 , a kind of overall pushing construction method of network tie-bar arch bridge, at least one temporary pier 5 is arranged between two abutments 6, and this construction method comprises the following steps:

[0046] a. Assemble and weld the steel box tie beam 3 on the backfield assembly platform 7;

[0047] b. Install the first-stage beam 18;

[0048] Phase I crossbeam 18 is the first crossbeam at the front end of the arch bridge pushing direction and part of the crossbeam at the rear of the tie beam;

[0049] c. Install the main arch ring 1;

[0050] The installation steps of the main arch ring are as follows: symmetrically install the steel truss type temporary support 4 on the steel box tie beam 3, and then respectively install the first section of the main arch ring 21 at both ends of the steel box tie beam 3, and install one end on the steel box tie beam 3 The other end is installed on the steel truss type temporary support 20; then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com