Patents

Literature

355results about How to "Reduce traction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

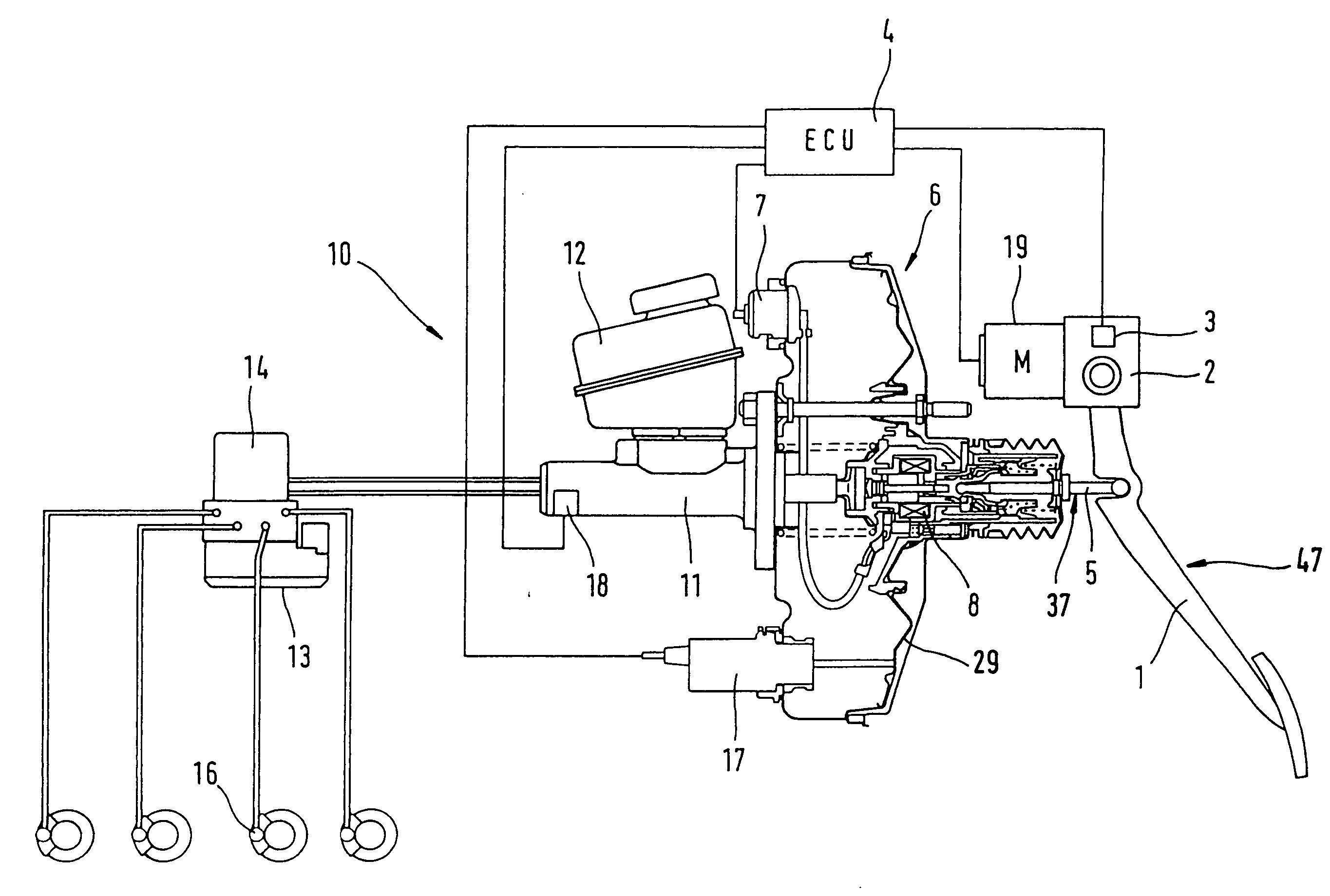

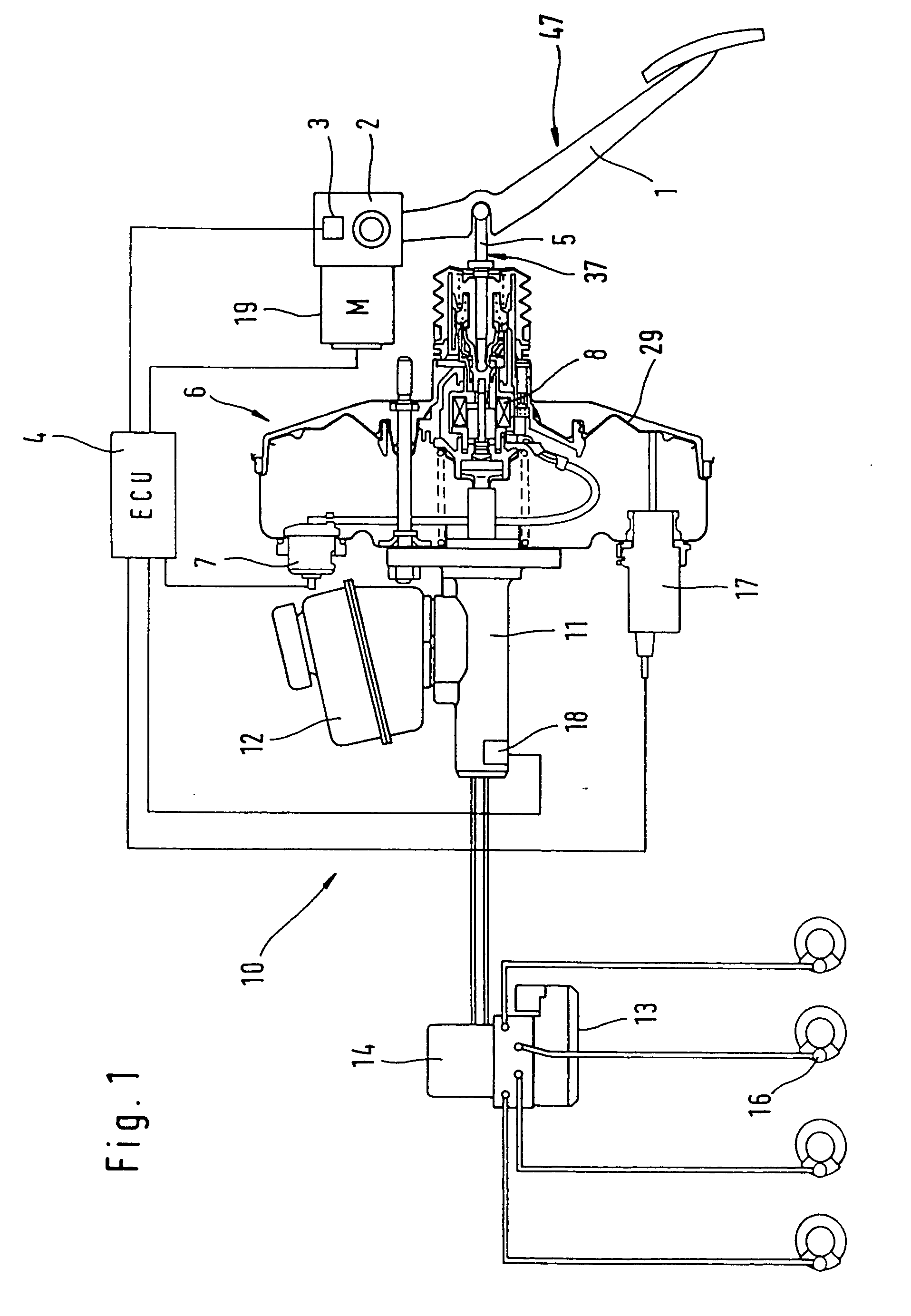

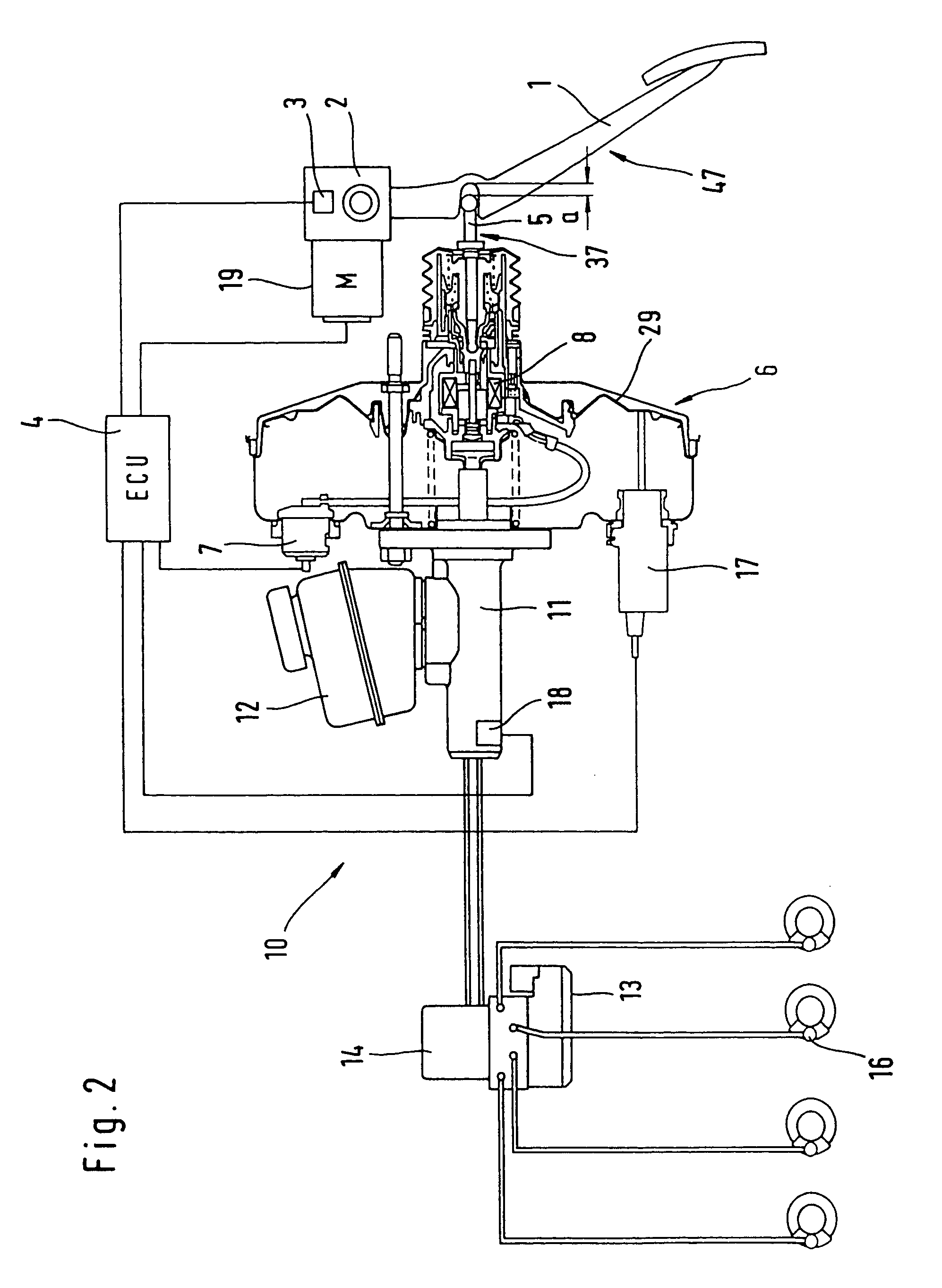

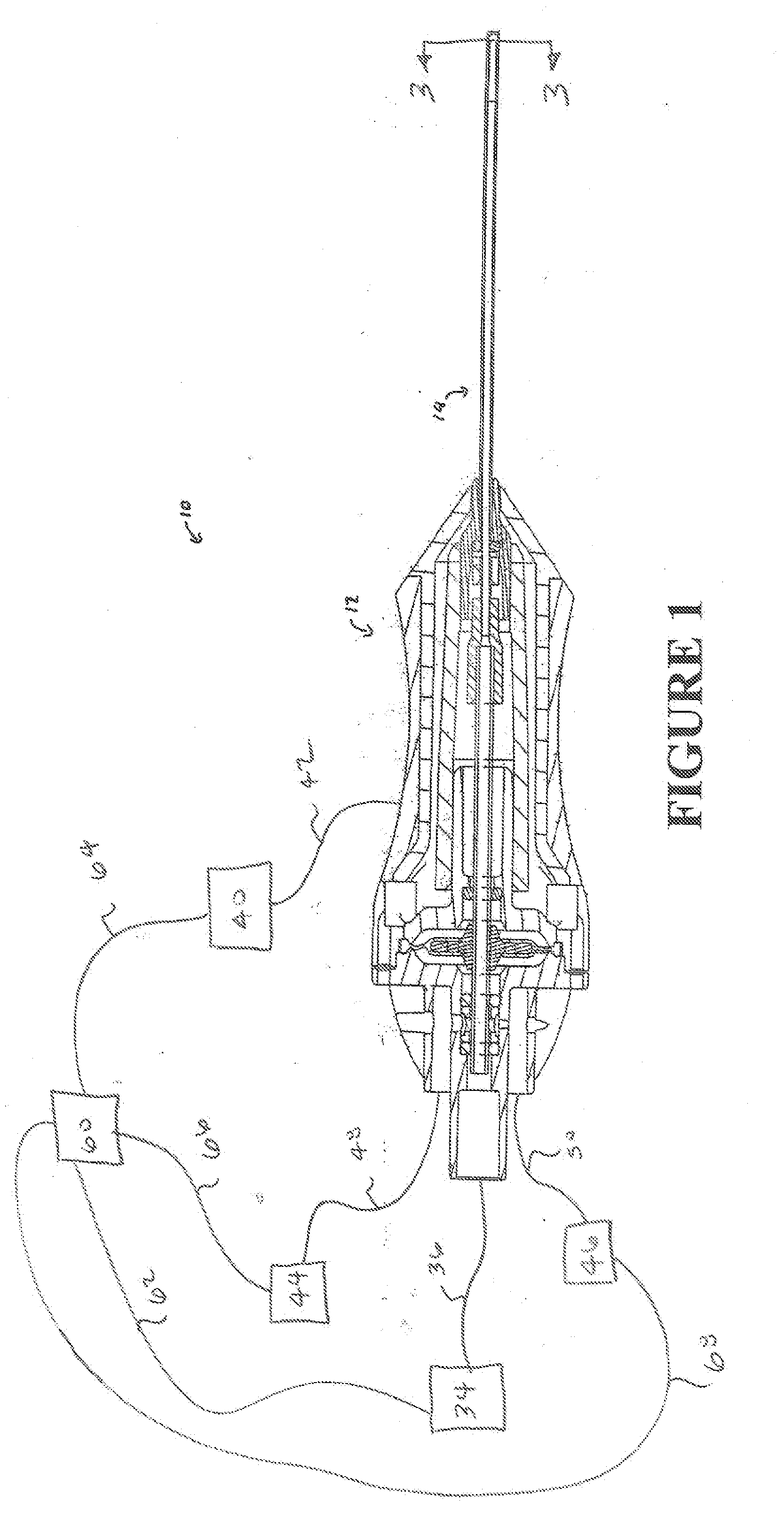

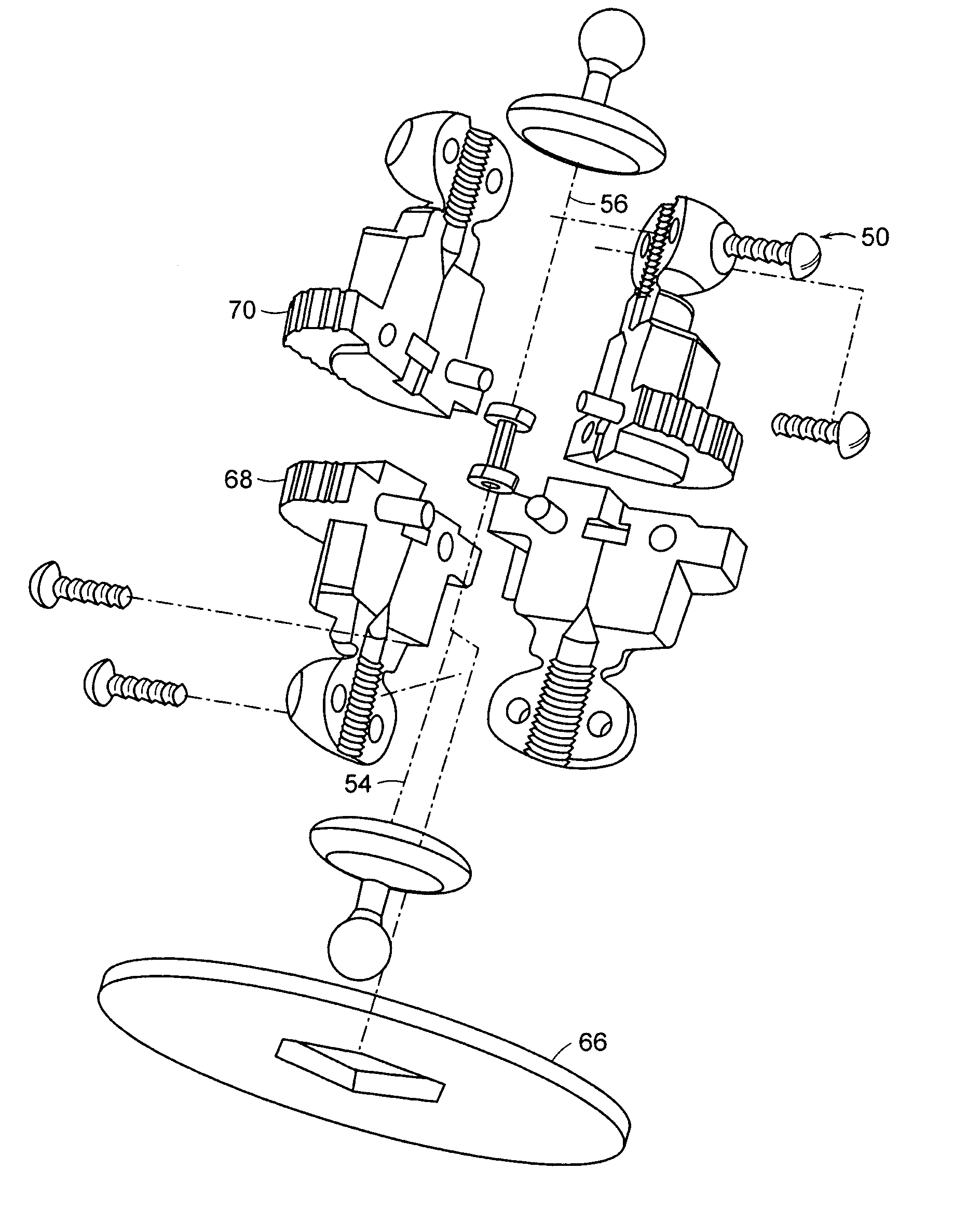

Brake by-wire actuator

InactiveUS20060163941A1High brake pressureReduce tractionBraking action transmissionFoot actuated initiationsMobile vehicleDistributor

The present invention relates to a brake-by-wire actuator for actuating the brake system of a motor vehicle, comprising a simulator which can be acted upon by a brake pedal, with a signal of an actuation sensor being sent to an electronic control unit which controls a pressure source in response to the signal of the actuation sensor, and wherein an output of the pressure source is connected to a distributor device for the brake force and actuates individual wheel brakes of the vehicle, also comprising means for enabling actuation of the brakes by muscular power within a fallback mode. In order to provide an improved fallback mode in a brake-by-wire actuator, according to the invention, a lost travel is provided between a first actuation component such as a brake pedal in particular or a component articulated at the brake pedal and an actuation component that is connected downstream in the flux of force, in particular an input member, in order to uncouple the first actuation component mechanically from the reactions of force of the motor vehicle brake system in the by-wire mode.

Owner:CONTINENTAL TEVES AG & CO OHG

Reduced traction vitrectomy probe

A vitrectomy probe that minimizes retinal traction by balancing infusion inflow and aspiration outflow near its cutting port.

Owner:ALCON INC

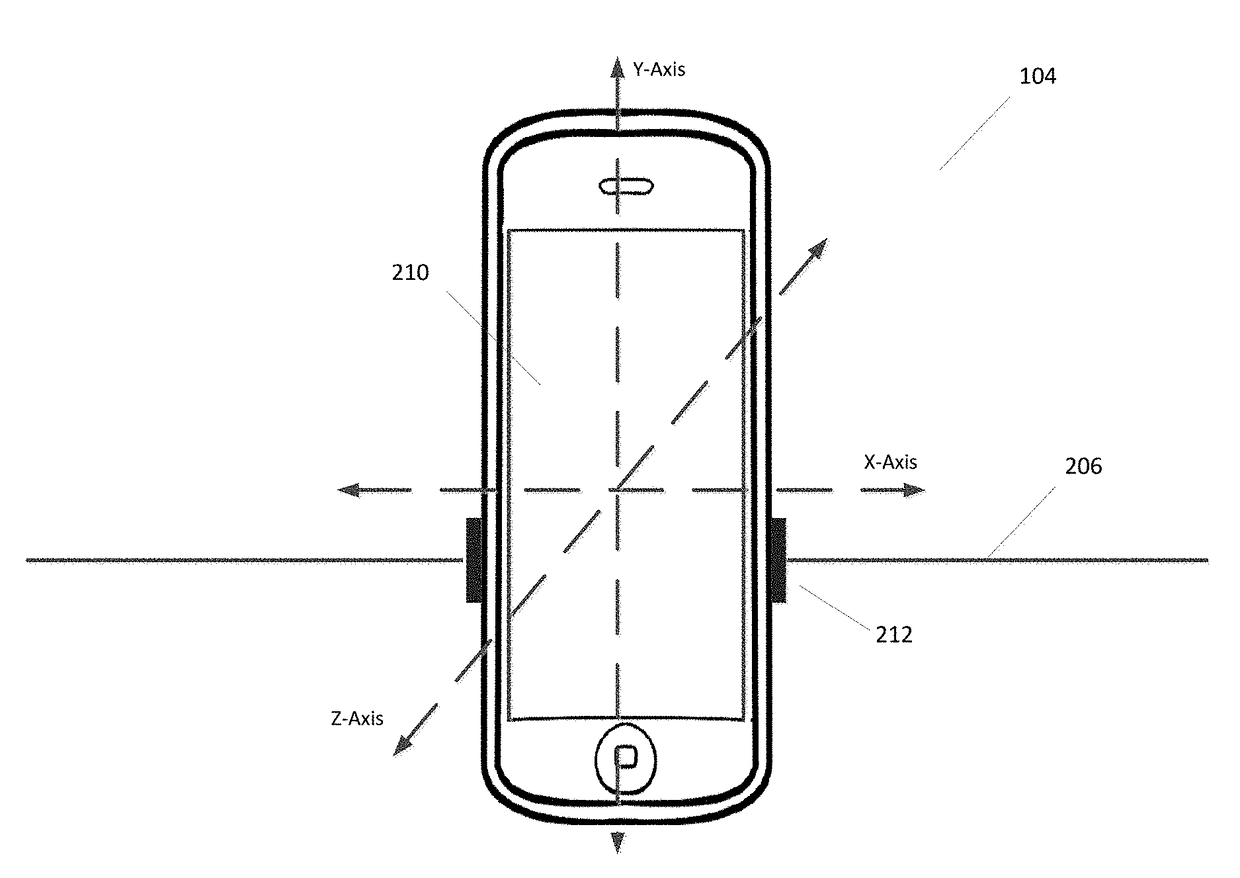

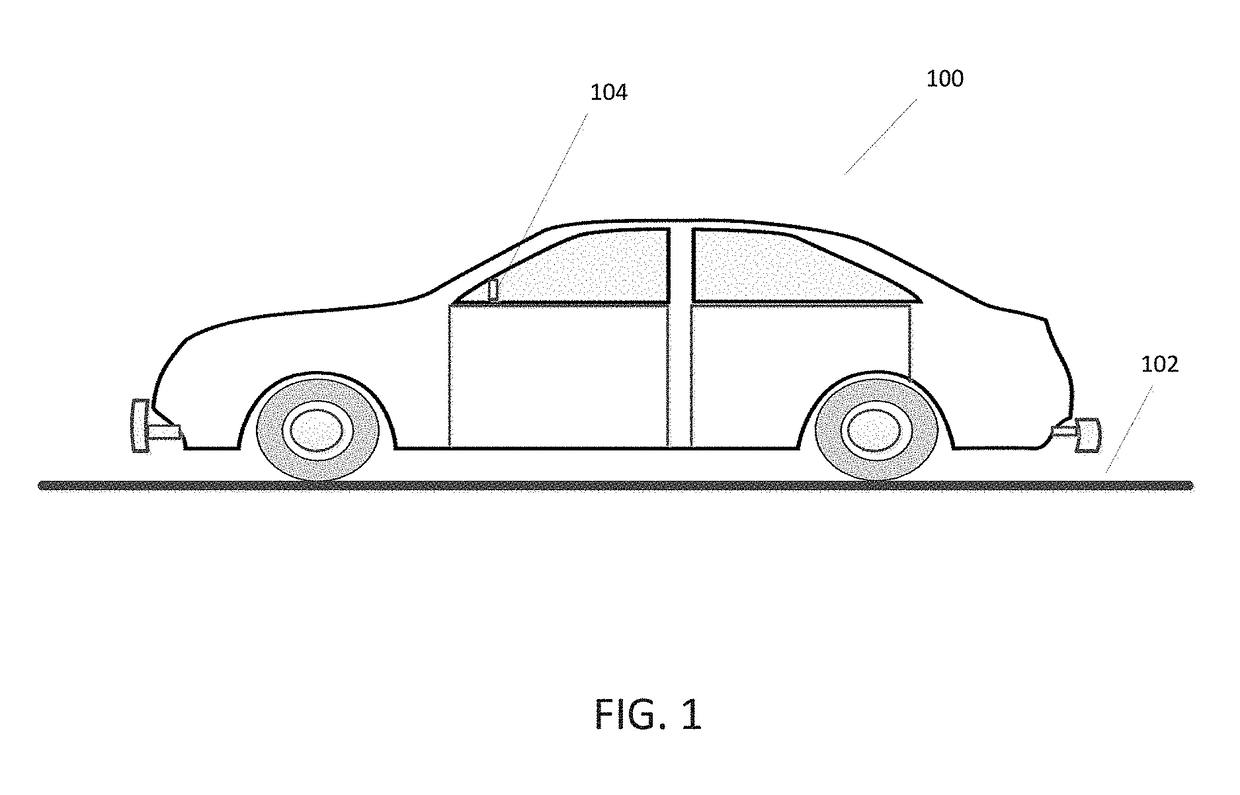

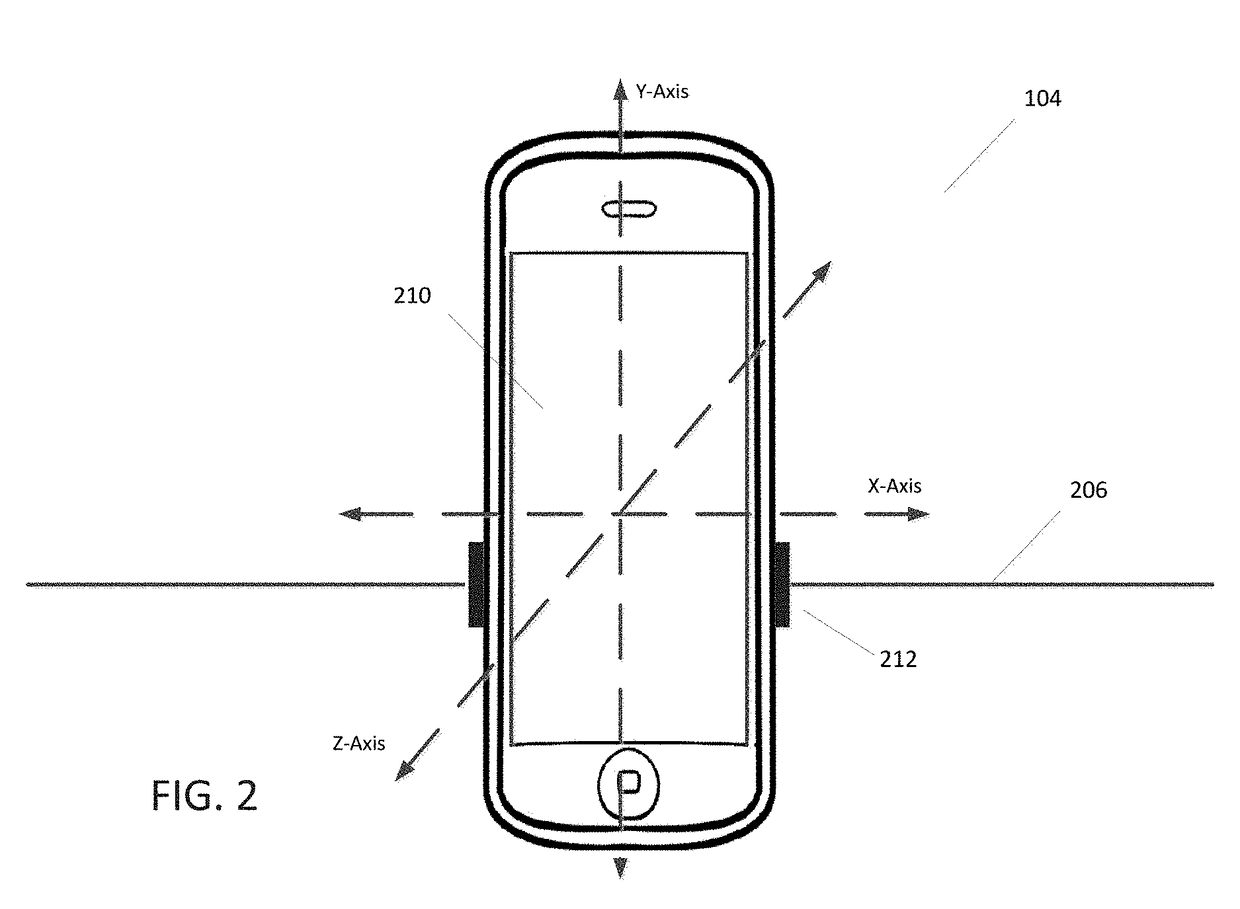

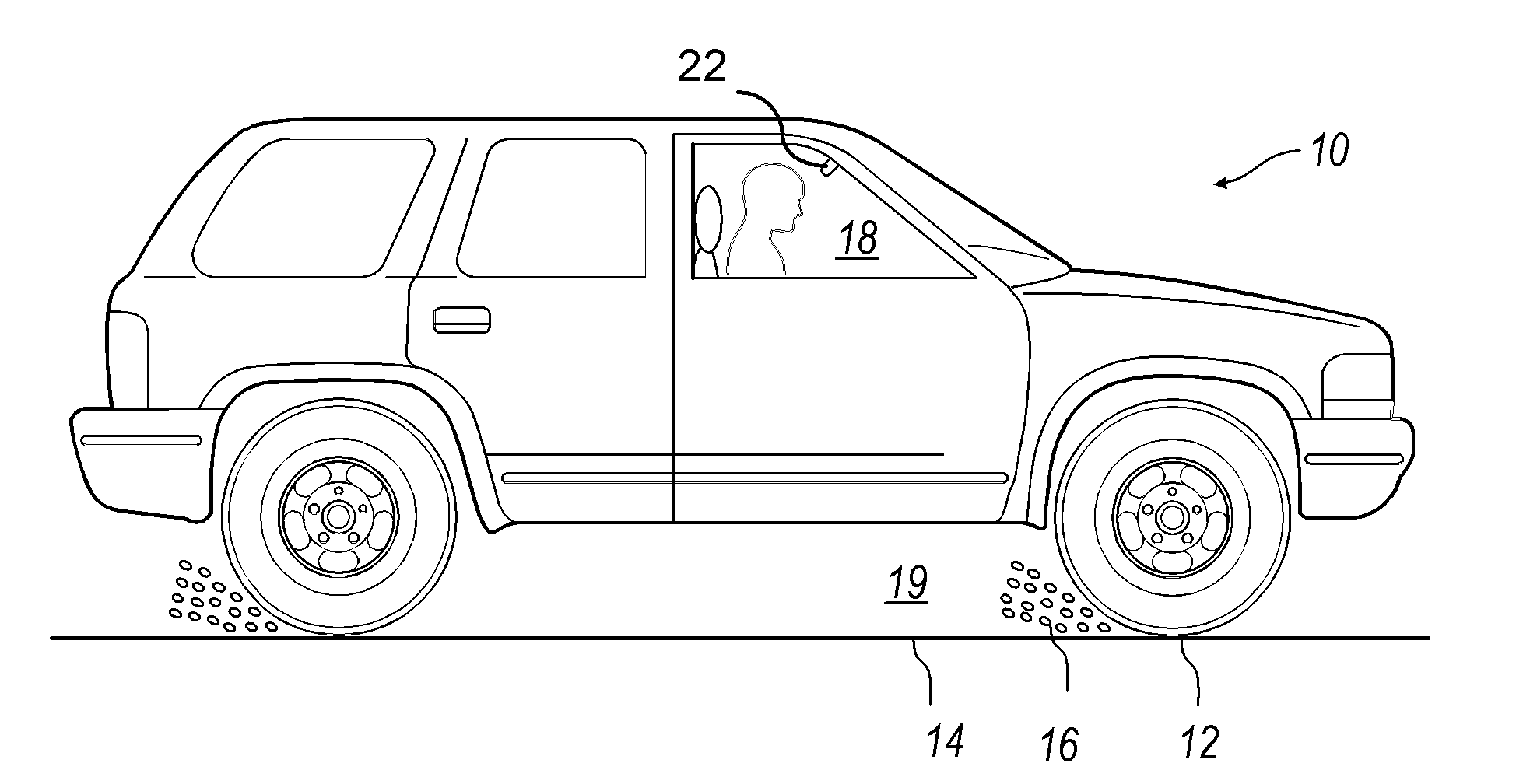

Applying motion sensor data to wheel imbalance detection, tire pressure monitoring, and/or tread depth measurement

ActiveUS20180003593A1Improve securityReduce fuel consumptionVibration measurement in solidsSubsonic/sonic/ultrasonic wave measurementMobile vehicleAccelerometer

A computer-based method to facilitate detecting wheel imbalance, a tire pressure problem, or excessive tread wear on tires of a moving vehicle is disclosed. The method includes collecting (e.g., from an accelerometer of a mobile personal computing device) data that represents vibration that results, at least in part, from the vehicle's motion, and determining, with a computer-based processor, whether the moving vehicle has wheel imbalance, a tire pressure problem, and / or excessive tire tread wear based at least in part on the vibration data produced by the accelerometer (and, possibly other data), where the mobile personal computing device and the accelerometer are moving with the vehicle when the data is being collected.

Owner:MASSACHUSETTS INST OF TECH

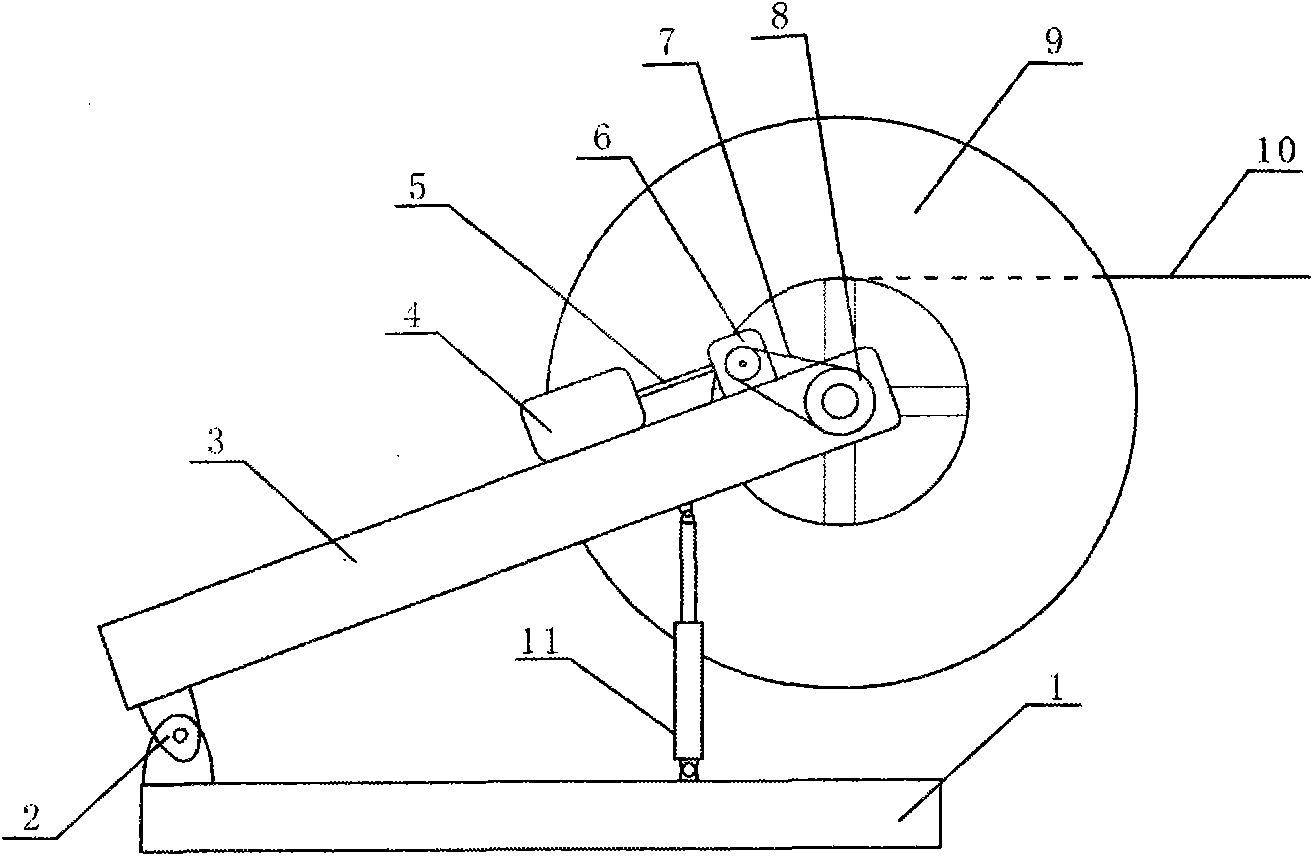

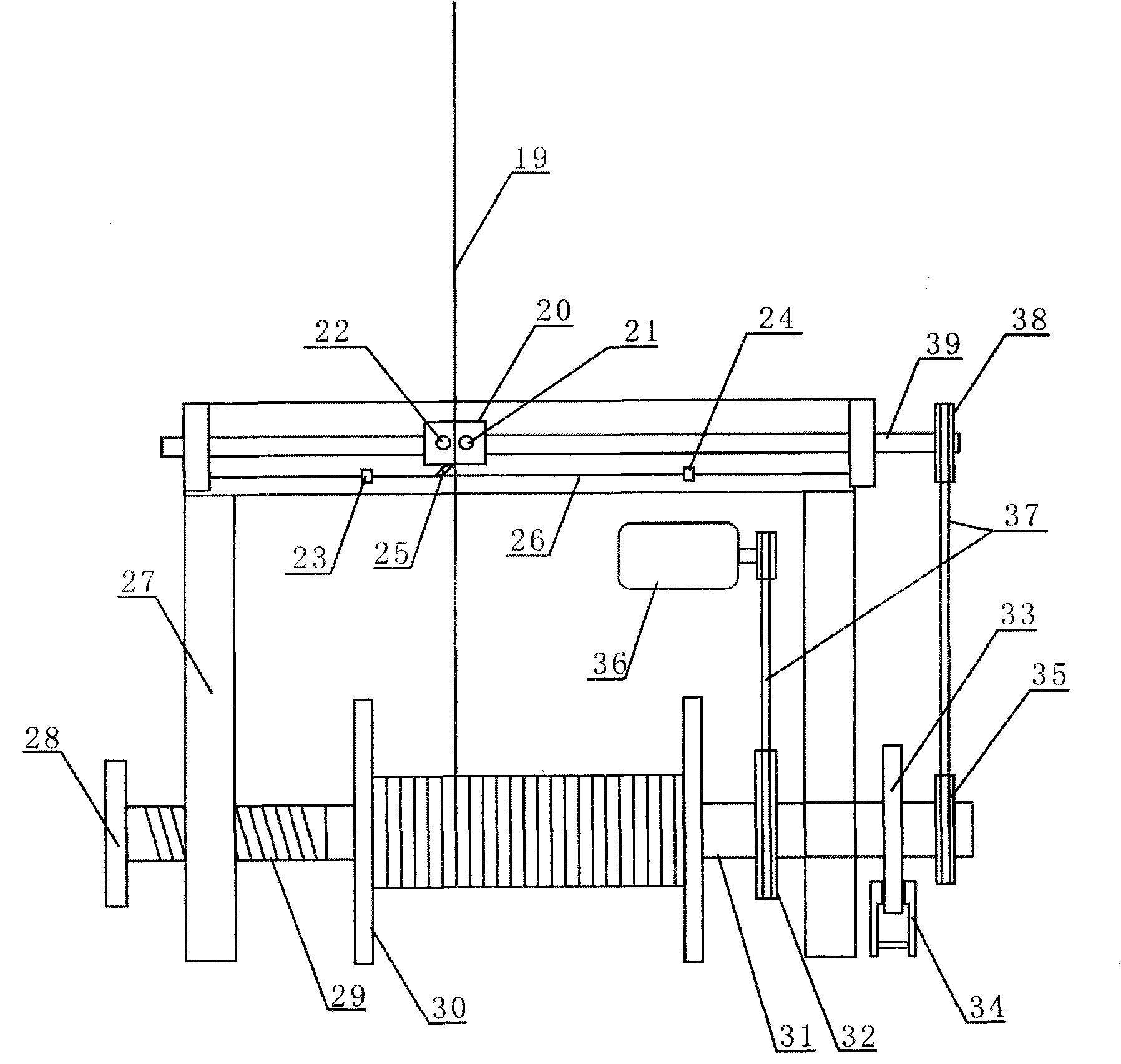

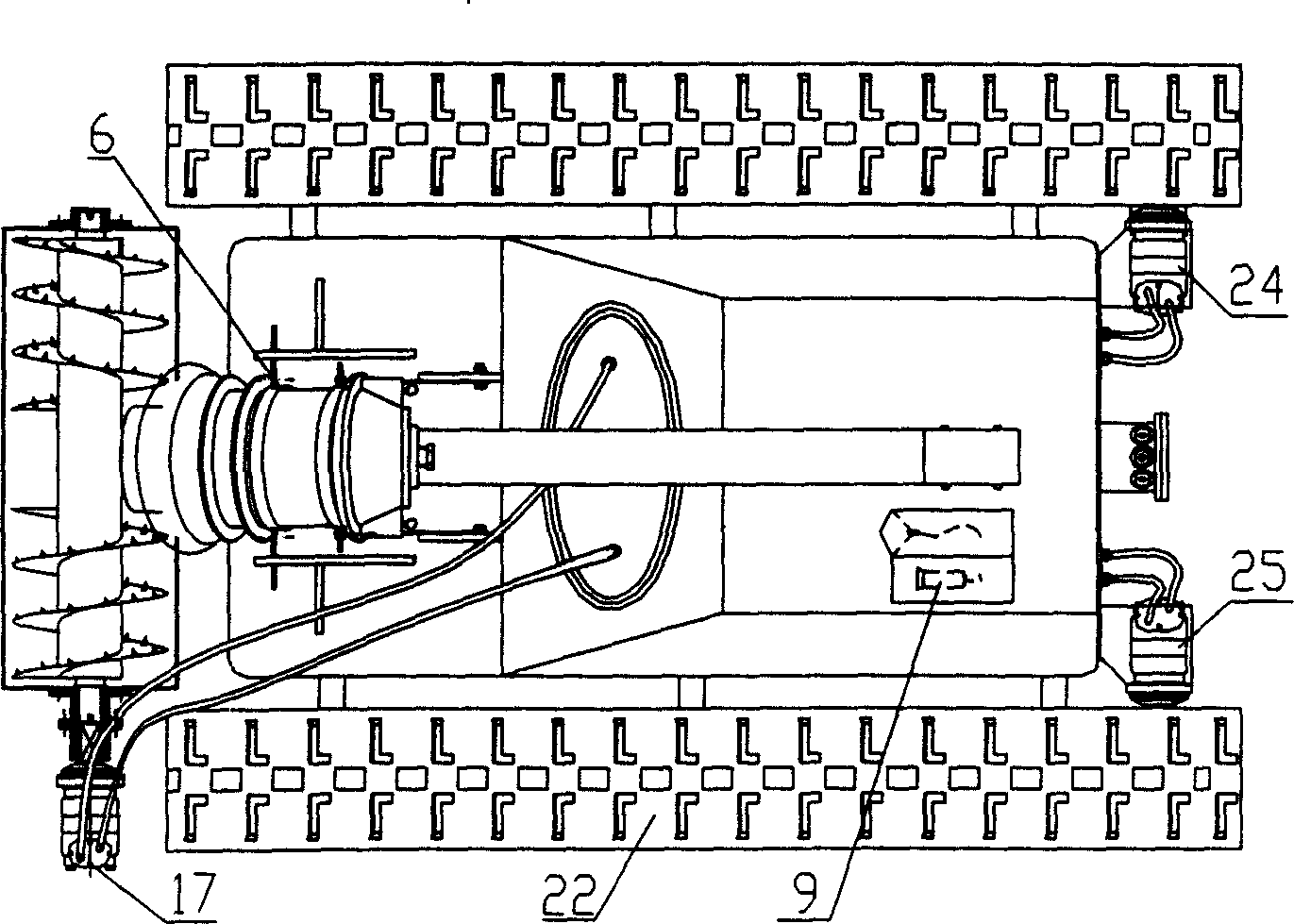

Active wire paying-off rewinder of aluminum clad steel wires

The invention discloses an active paying-off rewinder of aluminum clad steel wires. The rewinder is characterized by comprising an active paying-off mechanism, a tension mechanism and an automatic wire arranging and taking-up mechanism, wherein the aluminum clad steel wire grail tool of the active paying-off mechanism of the rewinder is driven by a motor to realize uniform wire paying-off; an upper tension pulley of the tension mechanism is fixed on a rack, and a lower tension pulley of the tension mechanism is jointly supported by a pneumatic cylinder and a lower tension pulley support; under the action of the pneumatic cylinder and aluminum clad steel wire tension, the tension pulley is used for adjusting the aluminum clad steel wire tension by vertical movement; and the automatic wire arranging and taking-up mechanism is characterized in that a wire arranging seat rotating shaft, a wire arranging seat guide rail, a movable mandril and a fixed mandril are arranged between two fixed supports; the wire arranging seat rotating shaft is provided with a wire arranging seat and a wire arranging seat driving wheel; the wire arranging seat guide rail is provided with two stop pins for playing a limit role; the movable mandril and the fixed mandril are respectively connected with the grail tool in a splicing mode; the fixed mandril is provided with a grail tool driving wheel, a brake pad and a driven wheel; and the driven wheel is connected with the wire arranging driving wheel which is arranged on the wire arranging seat rotating shaft by a driving belt. Therefore, the product quality is ensured, the production efficiency is improved and the labor intensity is reduced.

Owner:HENAN TONG CABLE

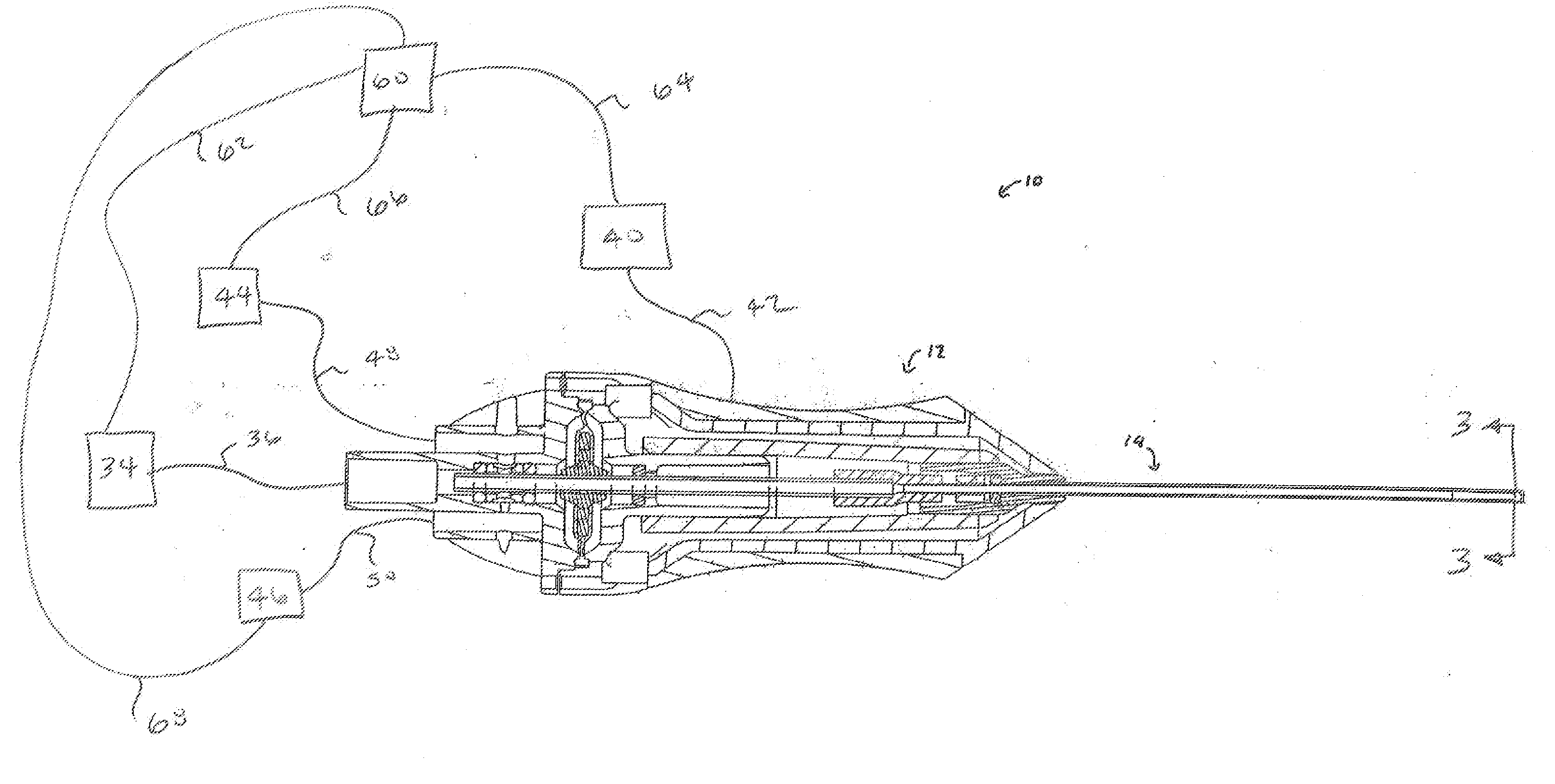

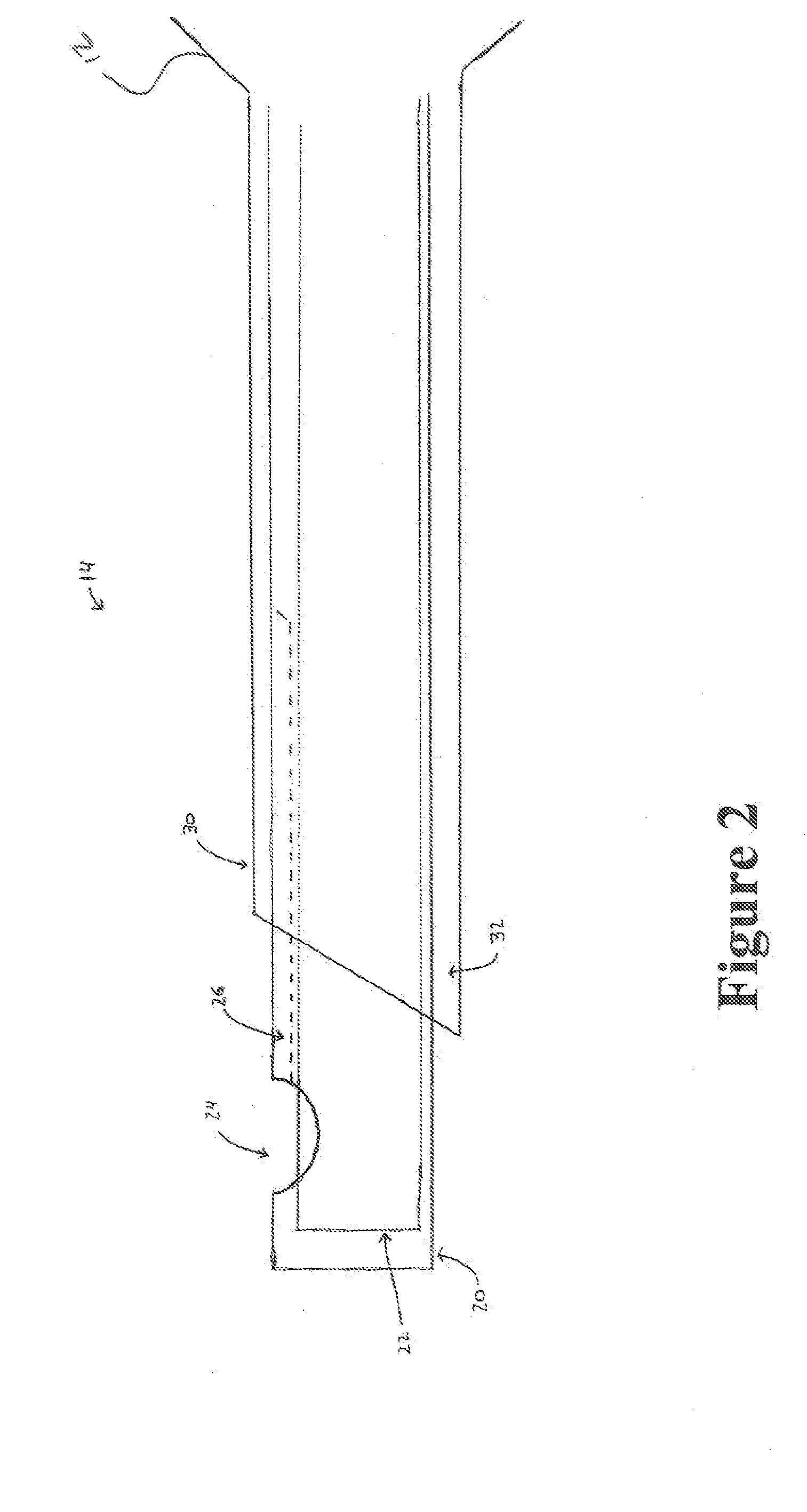

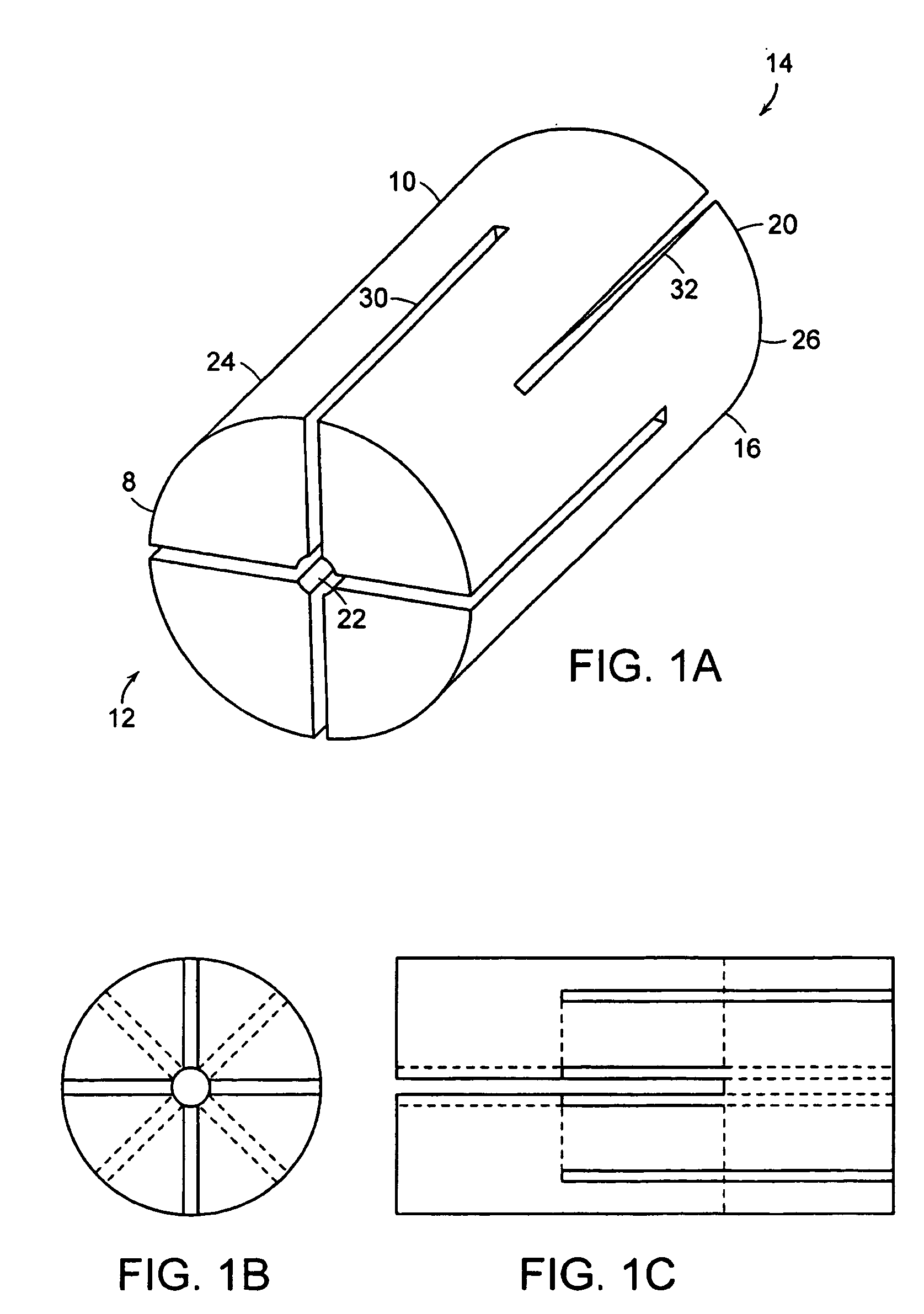

Optical fiber connector assembly

The present invention is directed to an optical fiber (12,14) connector (10) comprising a longitudinally extending body (16), said body (16) comprising a first end (18) and a second end (20), and said body having a conduit (22) extending from said first end (18) to said second end (20), and said body (16) comprising a plurality of finger projections (24,26) that extend longitudinally at each end of said first (18) and second ends (20), the connector assembly (10) including a first collar circumferentially coupled to said first end (18) of said connector (10) and a second collar (36) circumferentially coupled to said second end (20) of said connector (10), the connector assembly (10) comprises a connector housing of four portions (38), which, when assembled, define a connector chamber for receiving and retaining a connector (10) as aforesaid.

Owner:LE SAVOIR DU GARDIEN

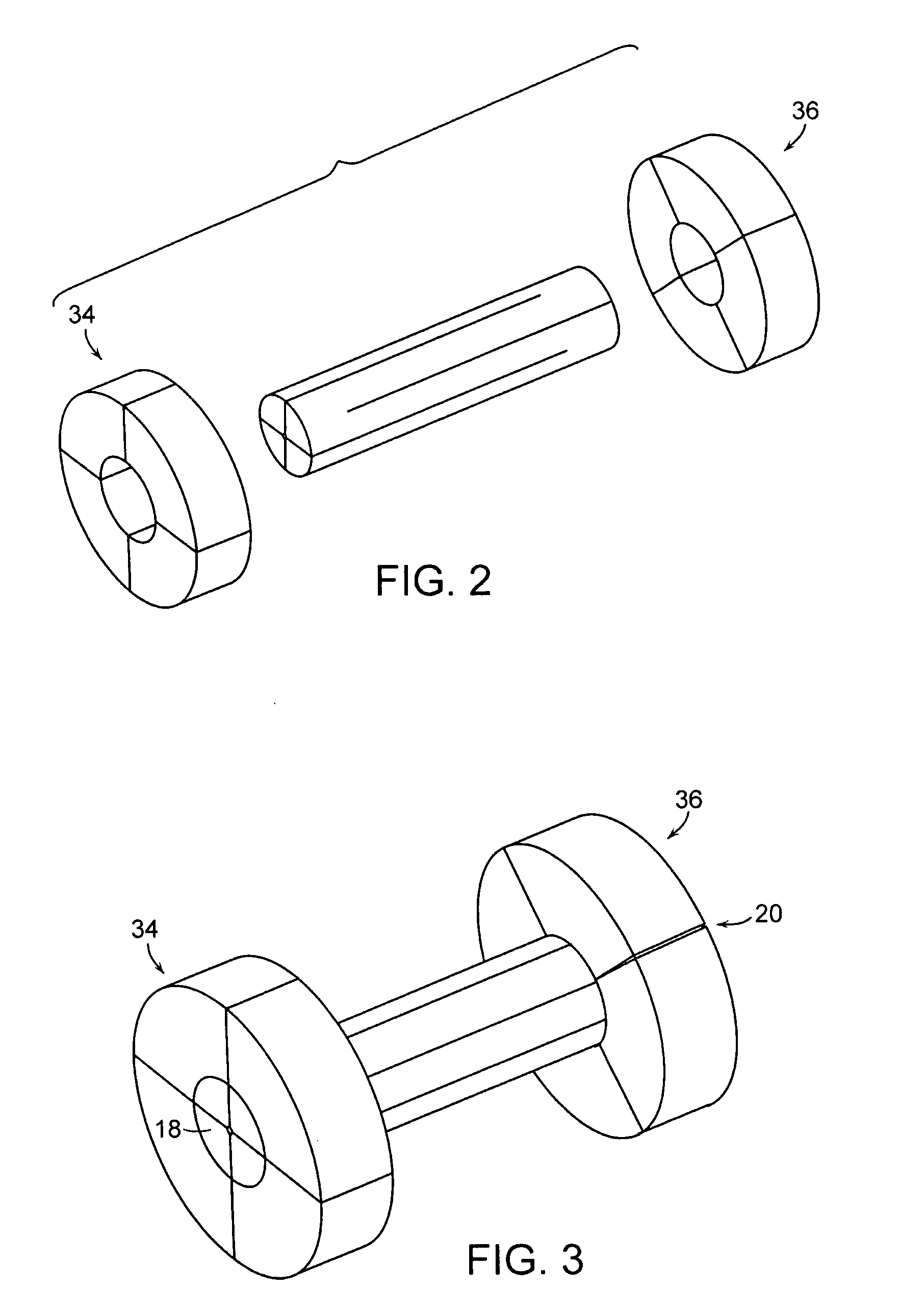

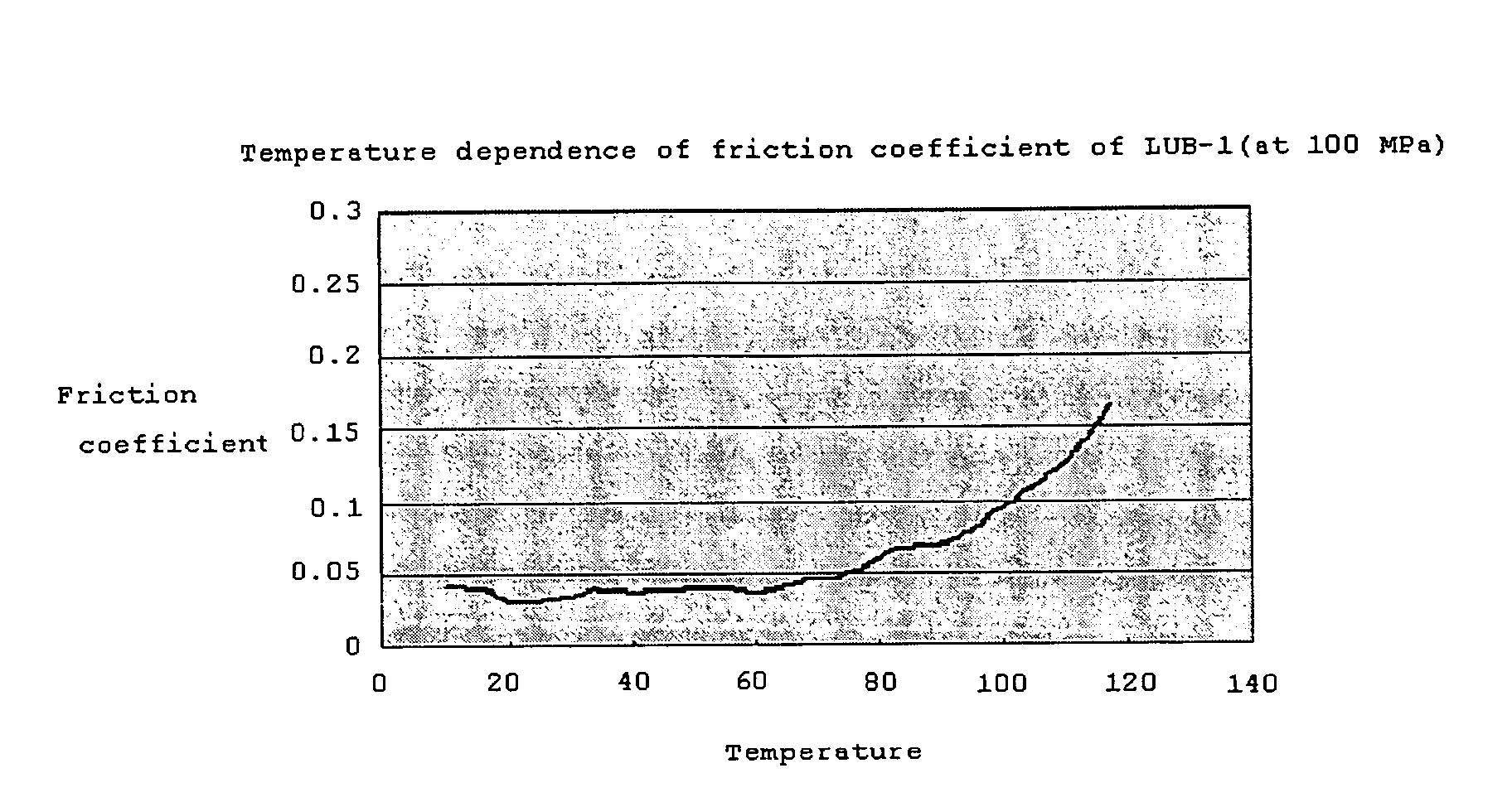

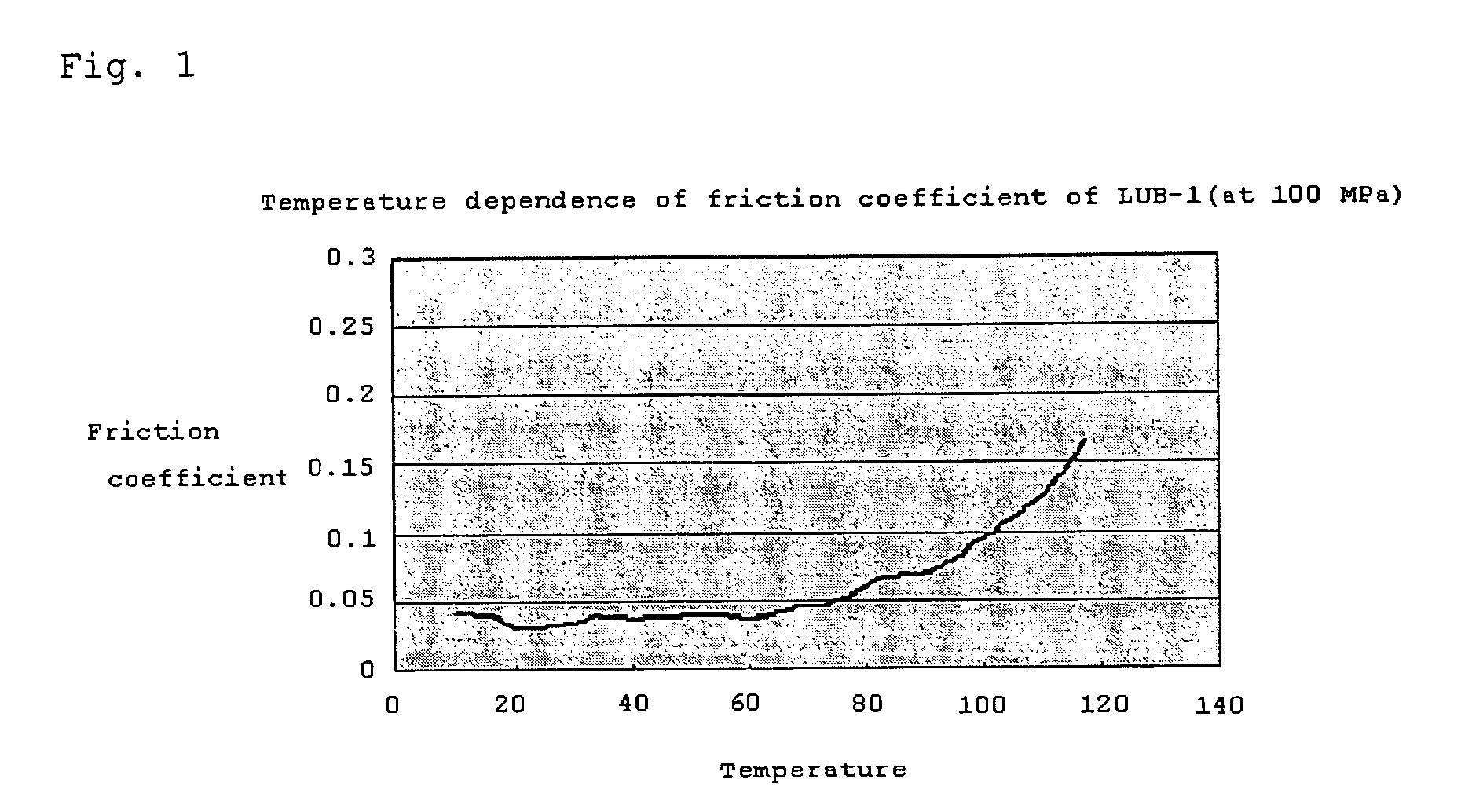

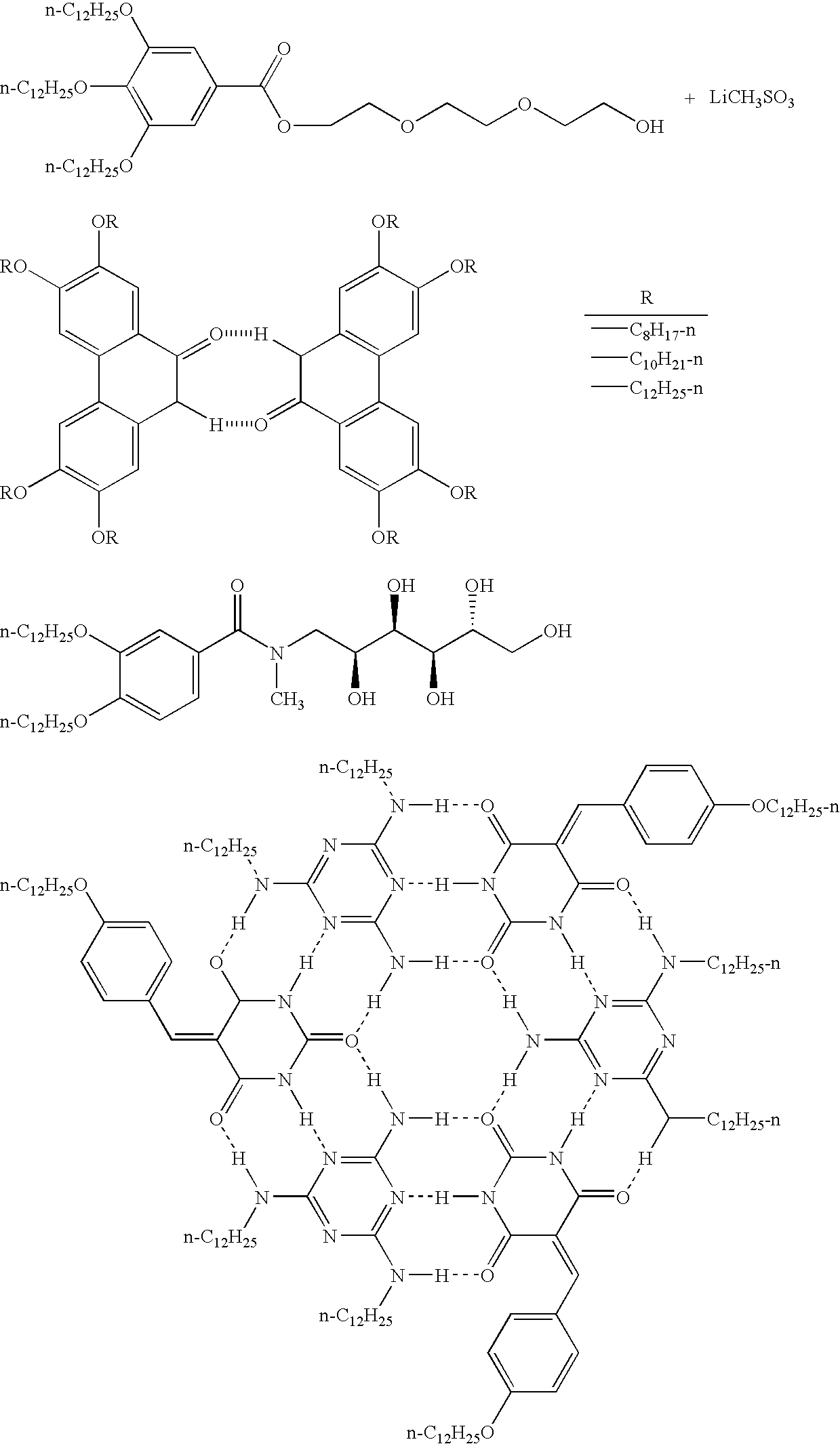

Lubricant composition and mechanical element

InactiveUS20060270568A1Low viscosityImprove friction resistanceLiquid carbonaceous fuelsAdditivesOrganic compoundLamellar phase

A novel lubricant composition is disclosed. The lubricant composition comprises at least one organic compound, and, when disposed between two surfaces moving at peripheral speeds differing from each other, is capable of exhibiting a discotic columnar phase or a discotic lamellar phase in which a plurality of molecules of said organic compound is assembled.

Owner:FUJIFILM CORP

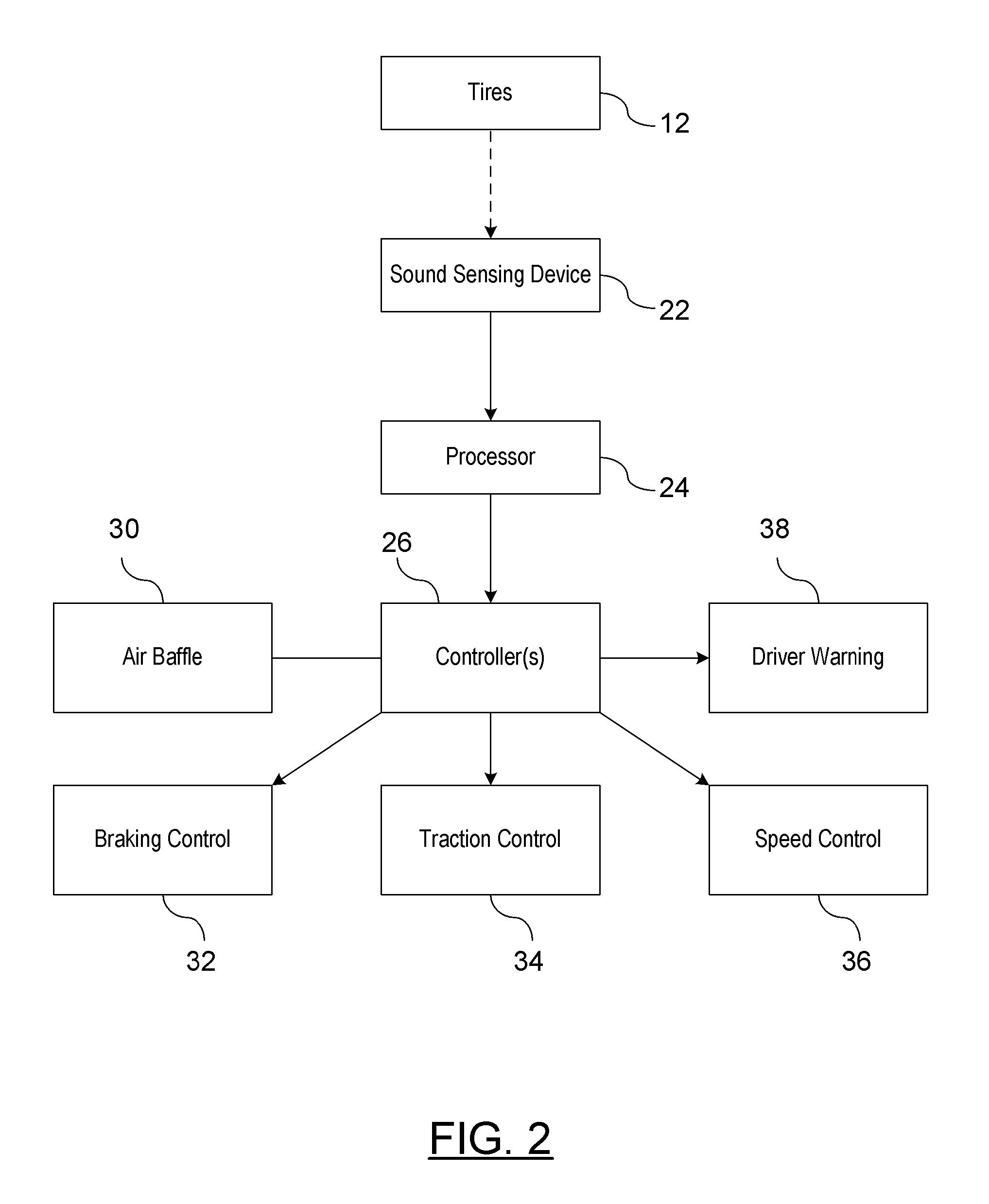

Method and System for Identifying Wet Pavement Using Tire Noise

ActiveUS20110109448A1Avoid intakeReduce tractionRoad vehicles traffic controlOptical signallingEngineeringRoad surface

A wet road surface detection system is provided for a vehicle driving on a road. The wet road surface detection system includes a sound sensing device coupled to the vehicle for capturing noise of the vehicle tires as the vehicle drives on a road surface. A processor processes sounds captured by the audible sensing device. The processor quantifies a variable sound level of the captured noise between a first frequency and a second frequency. The processor determines whether each quantified sound level between the first frequency and the second frequency is above a predetermined sound level threshold below the sound level at the first frequency. The processor determines that the vehicle is driving on a wet road surface in response to each quantified sound level between the first frequency and the second frequency being above a predetermined sound level threshold below the sound level at the first frequency.

Owner:GM GLOBAL TECH OPERATIONS LLC

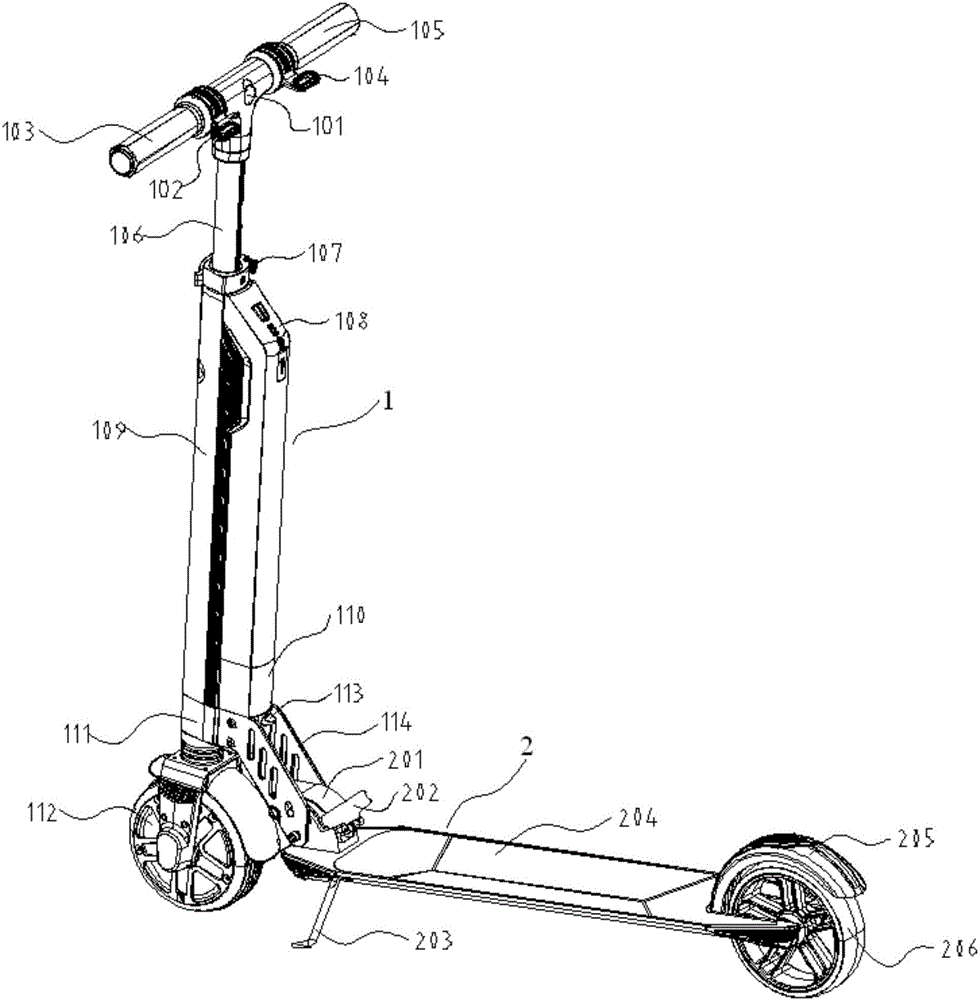

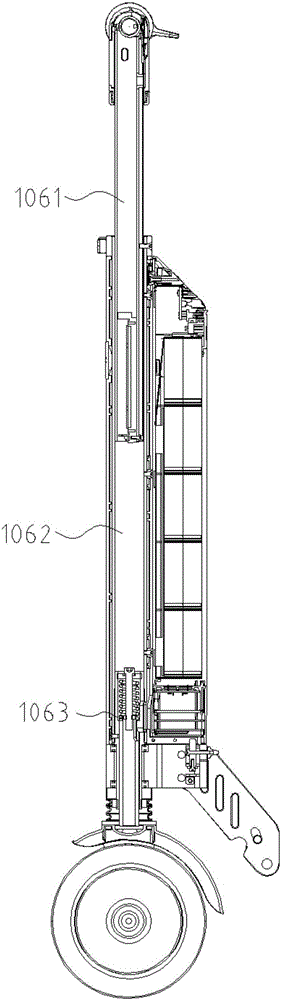

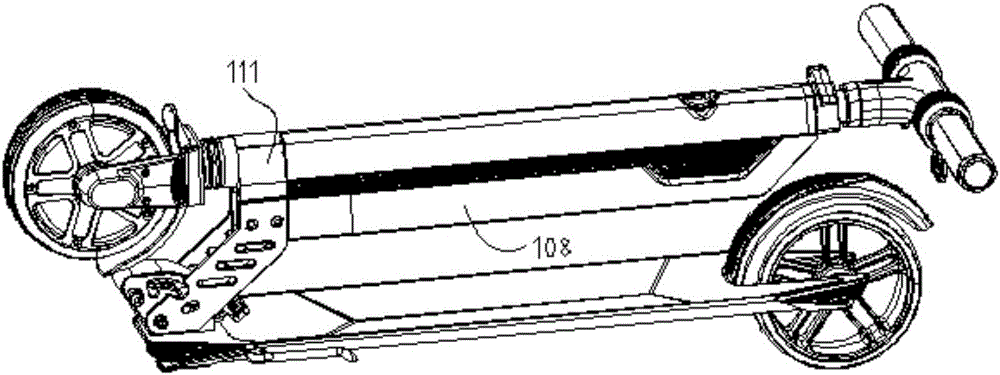

Intelligent folding scooter

ActiveCN105818912AIngenious structural designSimple and stylish structureSteering deviceFoldable cyclesDrive wheelHuman–computer interaction

The invention relates to an intelligent folding scooter which comprises a front scooter body and a rear scooter body. The front scooter body and the rear scooter body are connected in a foldable mode through a front scooter body and rear scooter body connecting piece. The front scooter body comprises handlebars, a handlebar lifting rod and a driving wheel, wherein the handlebars are connected to the two sides of the top end of the handlebar lifting rod through threads, a front wheel fork piece is fixedly arranged at the bottom of the handlebar lifting rod, and the driving wheel is rotationally installed on the front wheel fork piece. The rear scooter body comprises a pedal, a folding device and a rear wheel, wherein the folding device is fixedly installed at the front end of the pedal and provided with a folding footstep, the front scooter body and rear scooter body connecting piece is movably connected to the folding device, a rear wheel installation base is arranged at the rear end of the pedal, the rear wheel is rotationally installed on the rear wheel installation base, a battery locking device and a controller are arranged on the handlebar lifting rod, a detachable and replaceable battery pack is installed on the battery locking device, and the controller is electrically connected with the detachable and replaceable battery pack. The intelligent folding scooter is light and flexible, easy to fold and store, complete in function and good in man-machine interaction performance.

Owner:NANJING KUAILUN INTELLIGENT TECH CO LTD

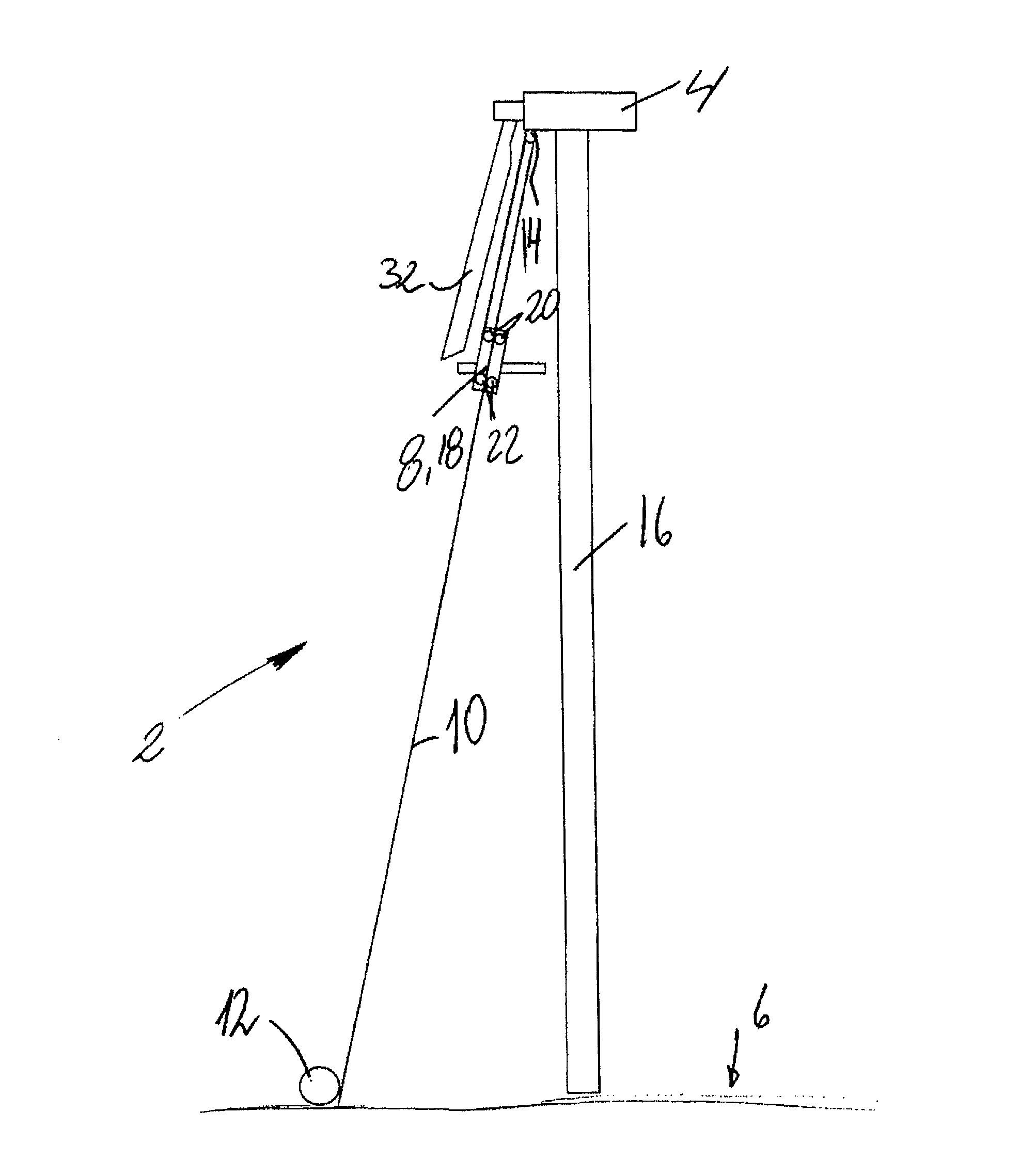

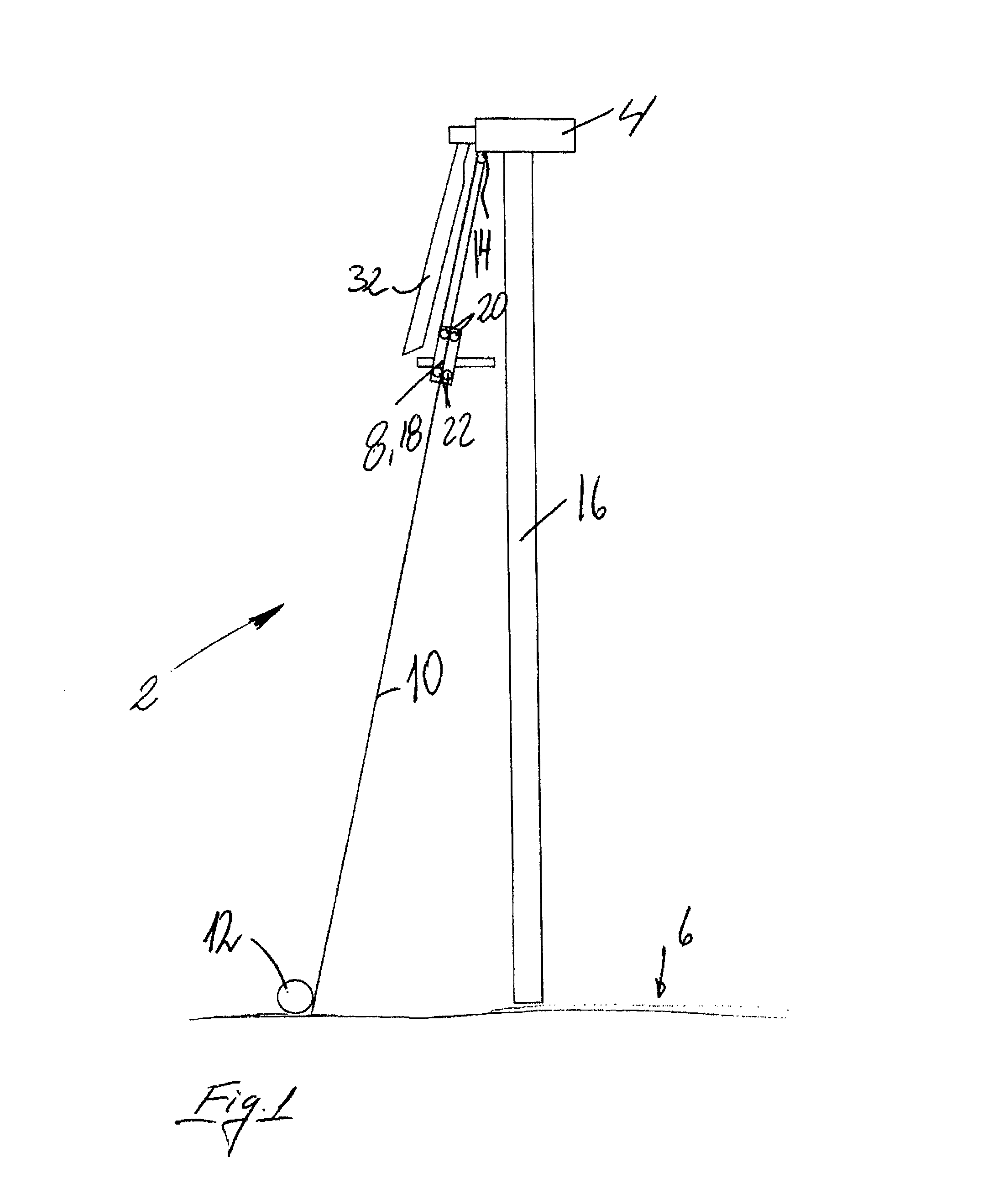

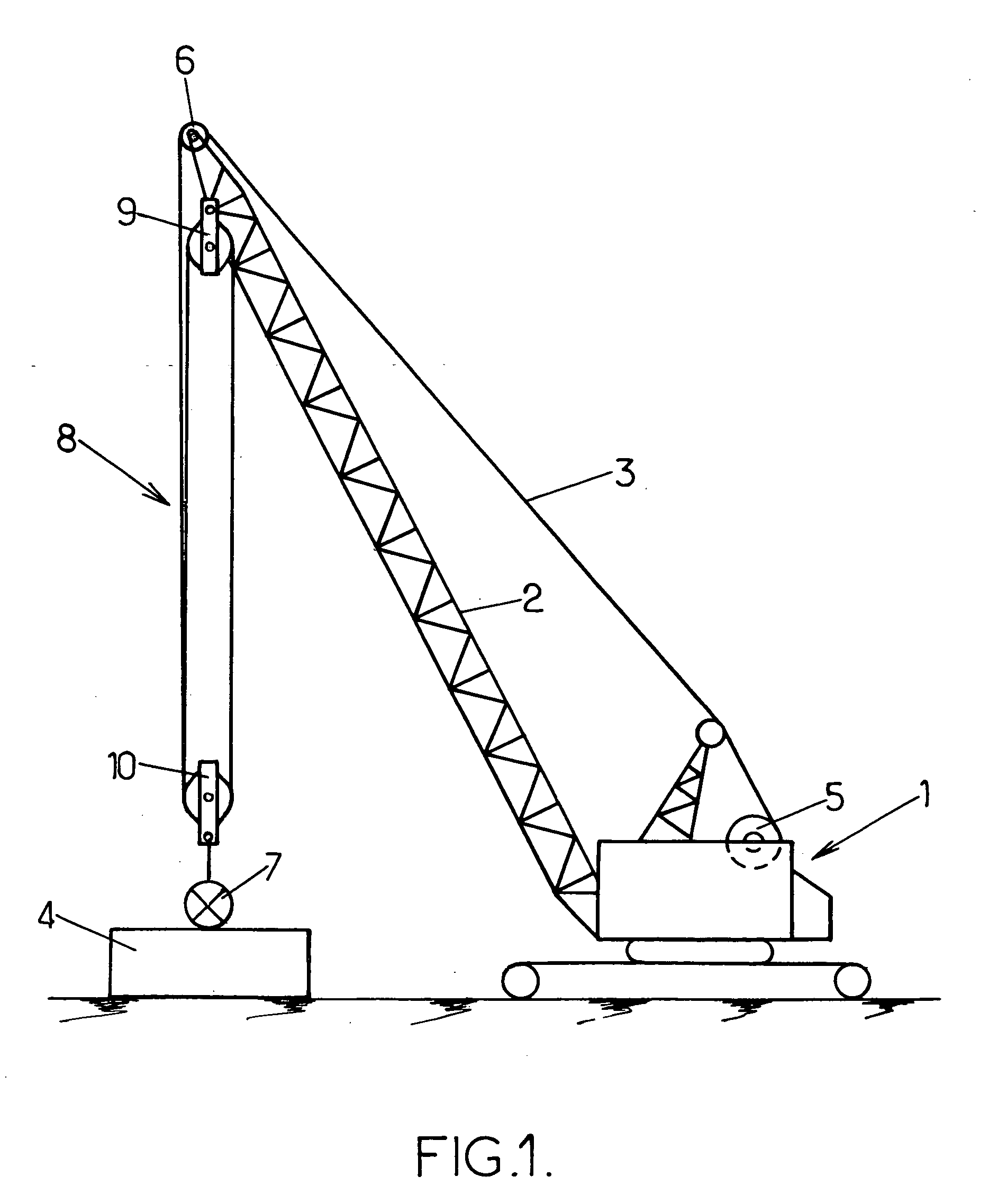

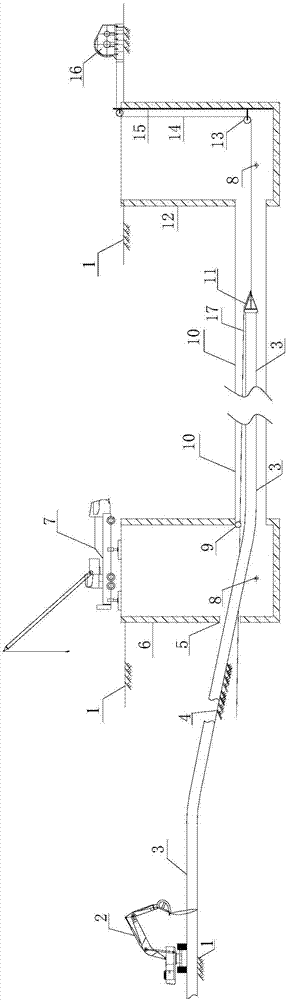

Device for establishing admittance and transport of cargo to and from a wind turbine construction above ground level

ActiveUS20120217089A1Improve securityAvoid liftingMachines/enginesEngine componentsAbove groundTurbine

A device for establishing admittance and transport of cargo to and from a wind turbine construction above ground level and having a part which can be raised and / or lowered by wires and winches located at ground level and connected with snatch blocks attached to a part so that it can be raised and / or lowered in relation to the construction. The part has a number of travelling crabs according to the numbers of winches and the travelling crabs are guided of the wires between the winches and the snatch blocks, and that the part with the travelling crabs is displaced upwards or downwards by the wires. Advantageously, the wires are used for both hoisting the part and as guide for the travelling crabs.

Owner:ELEVATORRA IP APS

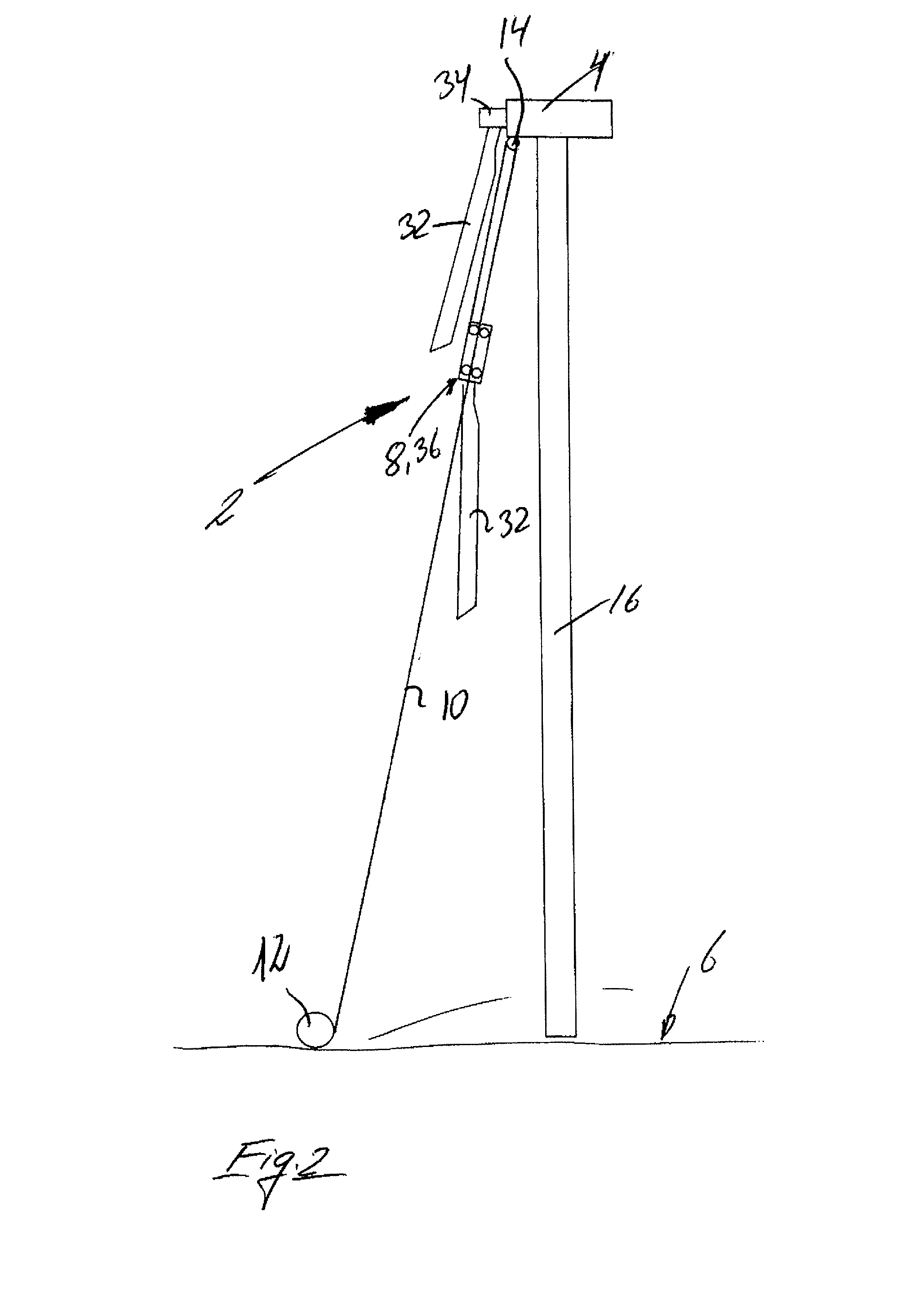

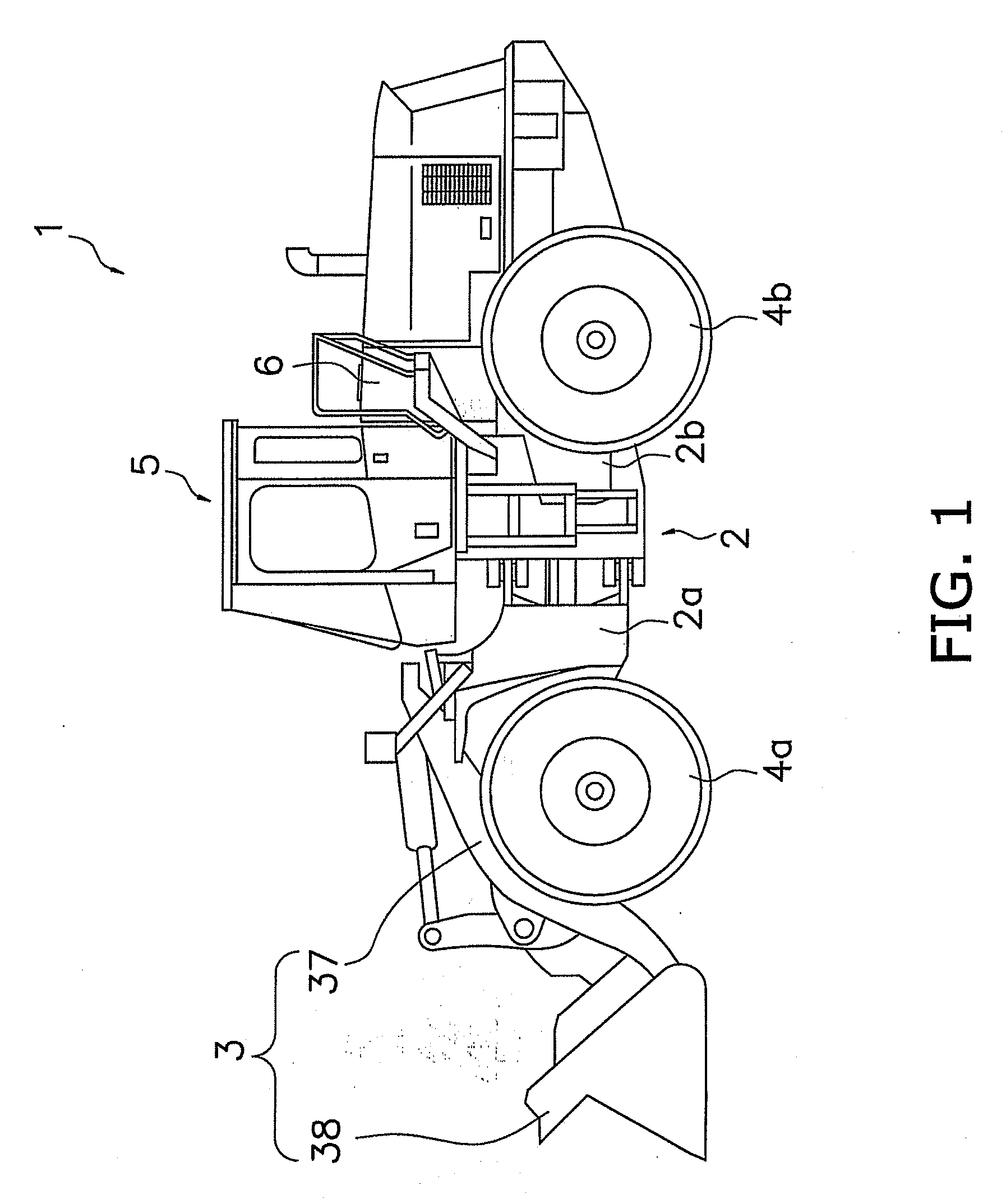

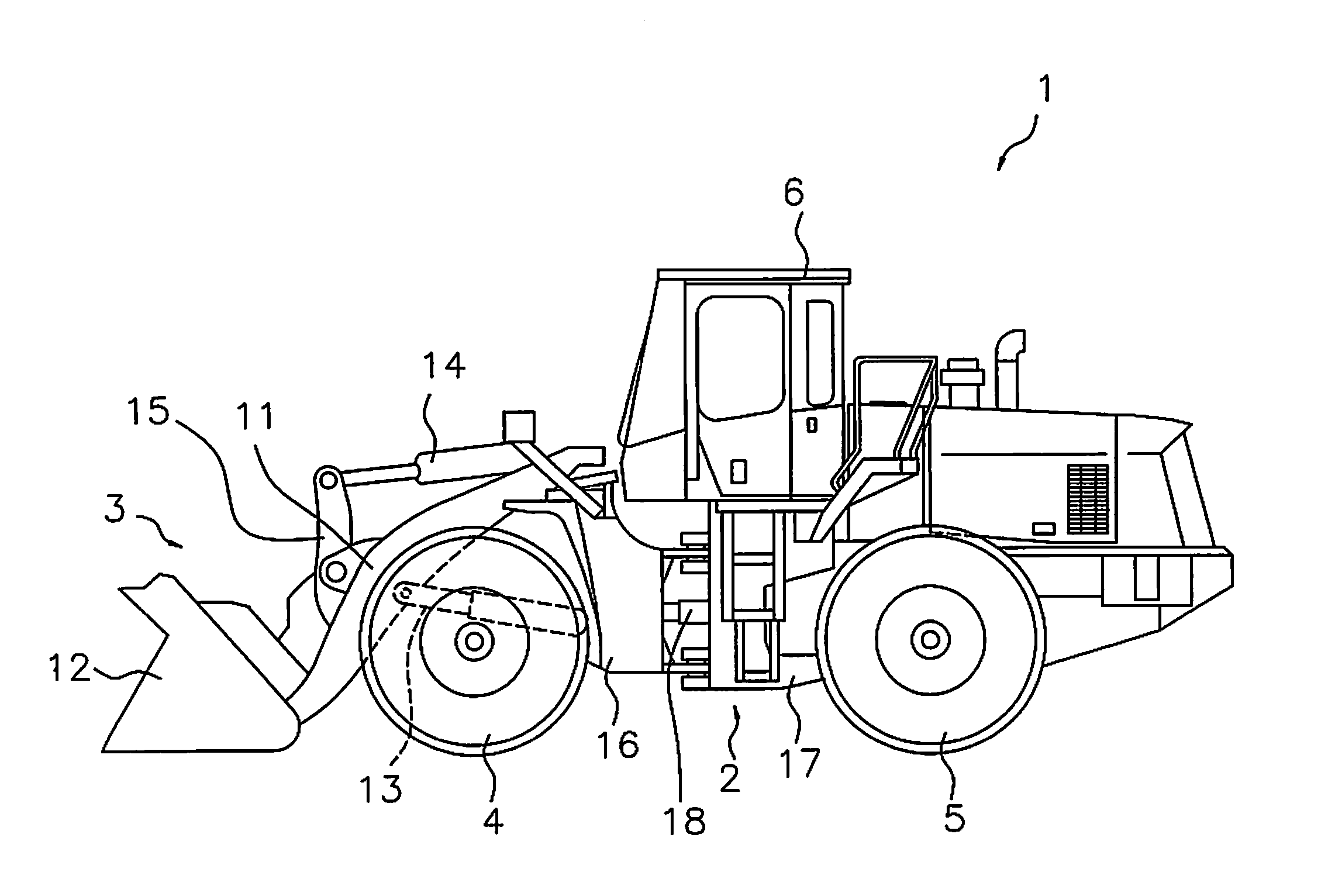

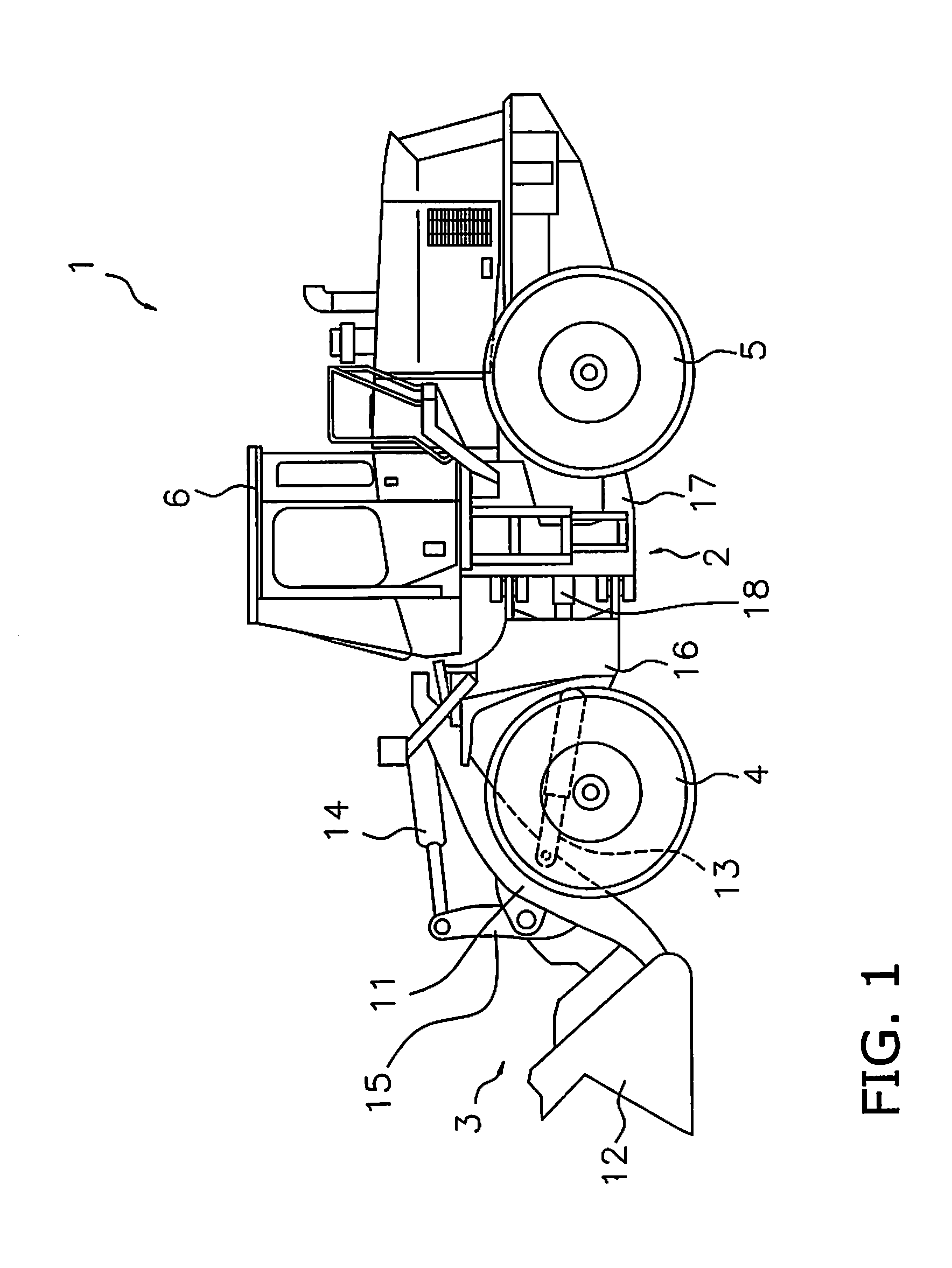

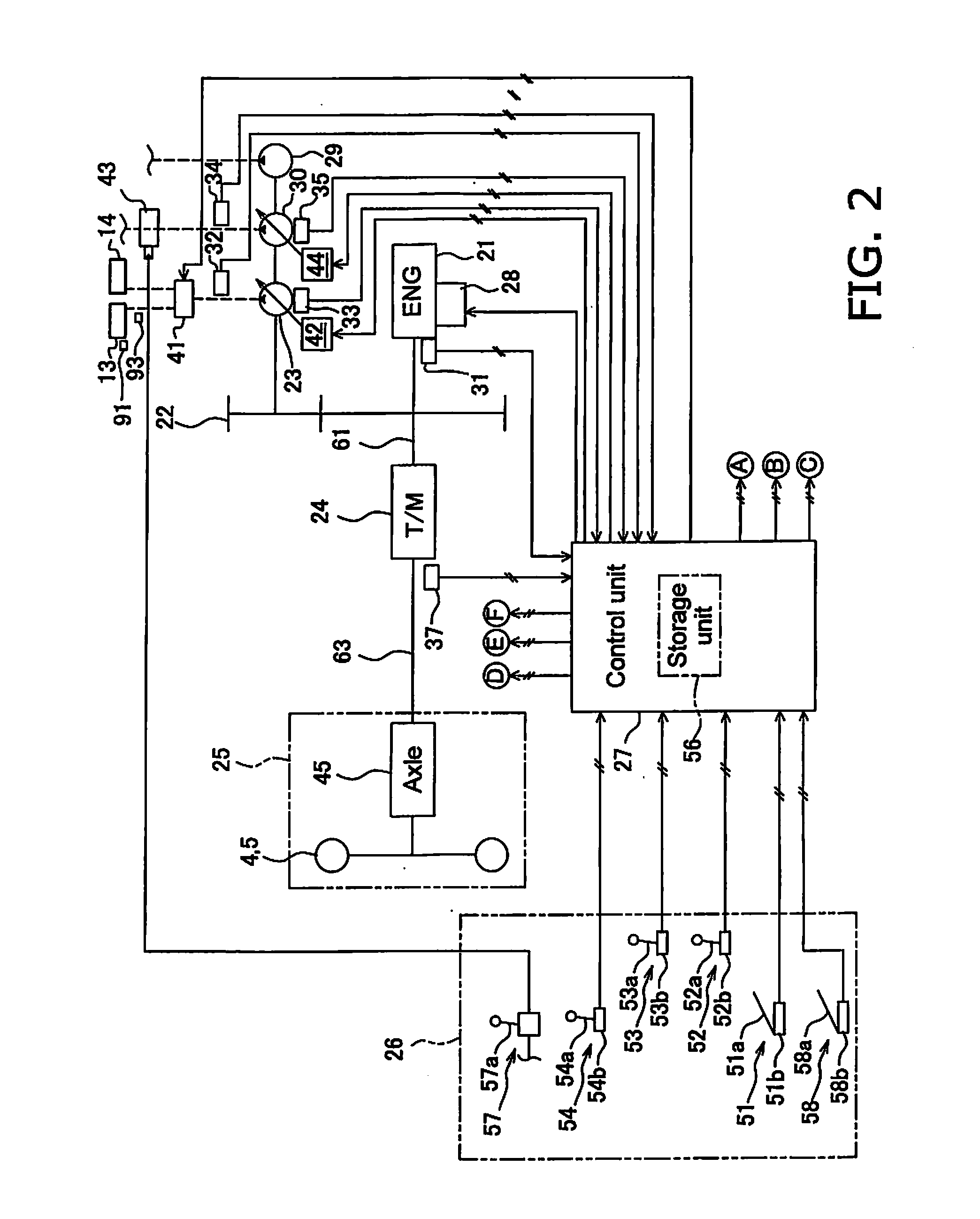

Construction vehicle

ActiveUS20100009806A1Prevent slippingSuppress reduction in traction forceGearing controlEngine controllersHydraulic motorLow speed

A construction vehicle includes an engine, a hydraulic pump driven by the engine, a travel hydraulic motor driven by pressure oil discharged from the hydraulic pump, travel wheels driven by the drive force of the travel hydraulic motor, and a controller. The controller is configured to control an engine speed, displacement of the hydraulic pump, and displacement of the travel hydraulic motor in order to control a vehicle speed and the traction force. The controller is further configured to increase a maximum displacement of the travel hydraulic motor as the vehicle speed decreases within a low speed range in which the vehicle speed is equal to or less than a predetermined threshold.

Owner:KOMATSU LTD

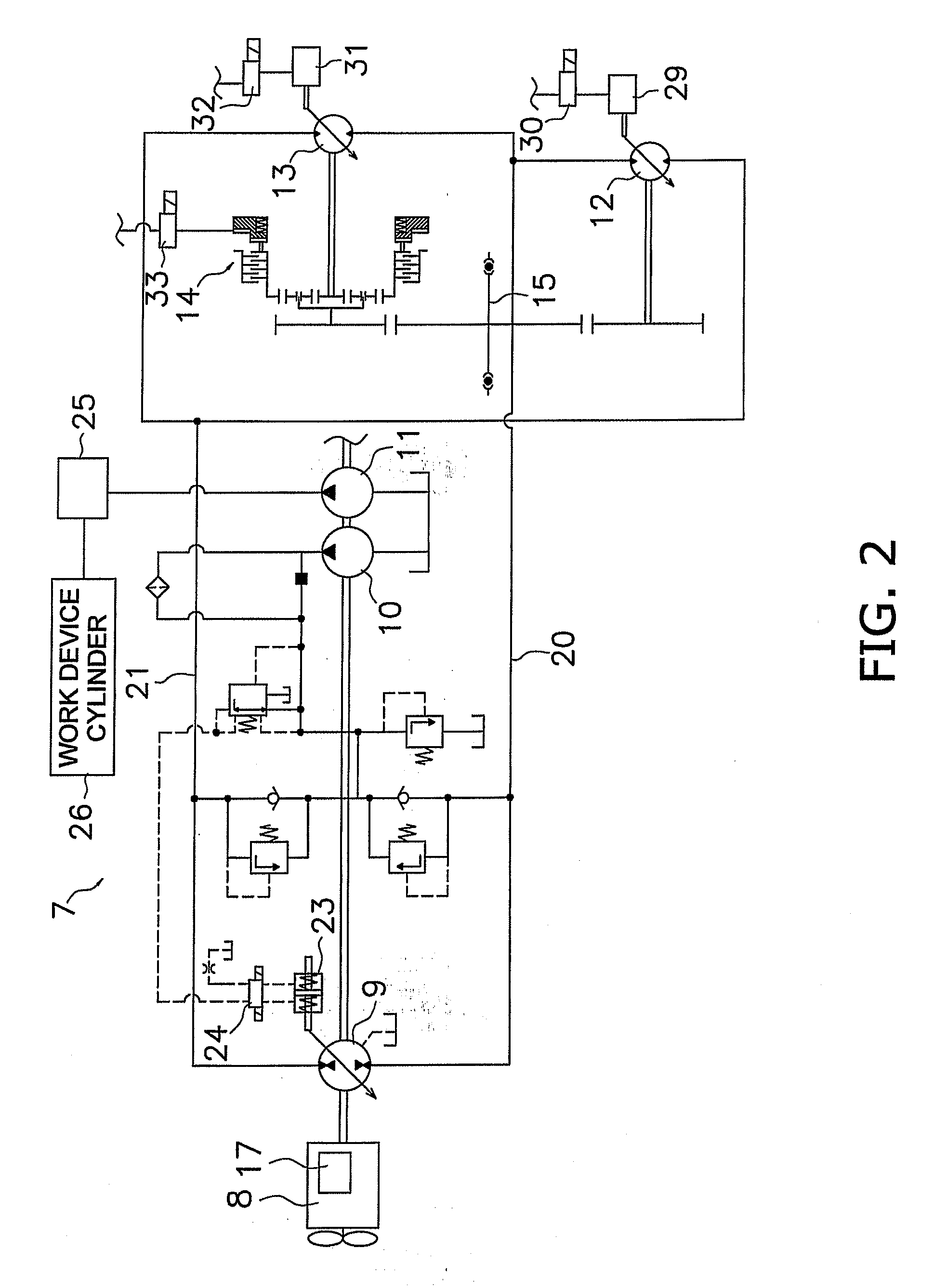

Intelligent shoveling bus controlling system of loader

ActiveCN103590436AReduce energy lossImprove stability and comfortMechanical machines/dredgersEnergy lossPilot valve

The invention discloses an intelligent shoveling bus controlling system of a loader. According to the intelligent shoveling bus controlling system of the loader, a collecting bucket oil port, a movable arm lifting oil port, an overturning bucket oil port, a movable arm descending oil port and a floating oil port of an electric-hydraulic proportional pilot valve are connected with a collecting bucket oil port, a movable arm lifting oil port, an overturning bucket oil port, a movable arm descending oil port and a floating oil port of an electric-hydraulic proportional distribution valve respectively, a second oil inlet of the electric-hydraulic proportional pilot valve is connected with a large cavity of a movable arm oil cylinder, and an overturning bucket cylinder displacement sensor, a movable arm displacement sensor, a shoveling bucket horizontal displacement sensor, a main controller, a descending height setting button, a lifting height setting button, an electric control pilot handle and an engine controller are respectively connected with a bus. The intelligent shoveling bus controlling system of the loader is efficient, saves energy, is small in energy loss, improves the stability and comfort of work of the whole loader, is long in service life, is good in leveling function, avoids accidents, guarantees operation safety, improves operation efficiency, is favorable for upgrading and modification of products, and is used for controlling the shoveling process of the loader.

Owner:XCMG CONSTR MACHINERY

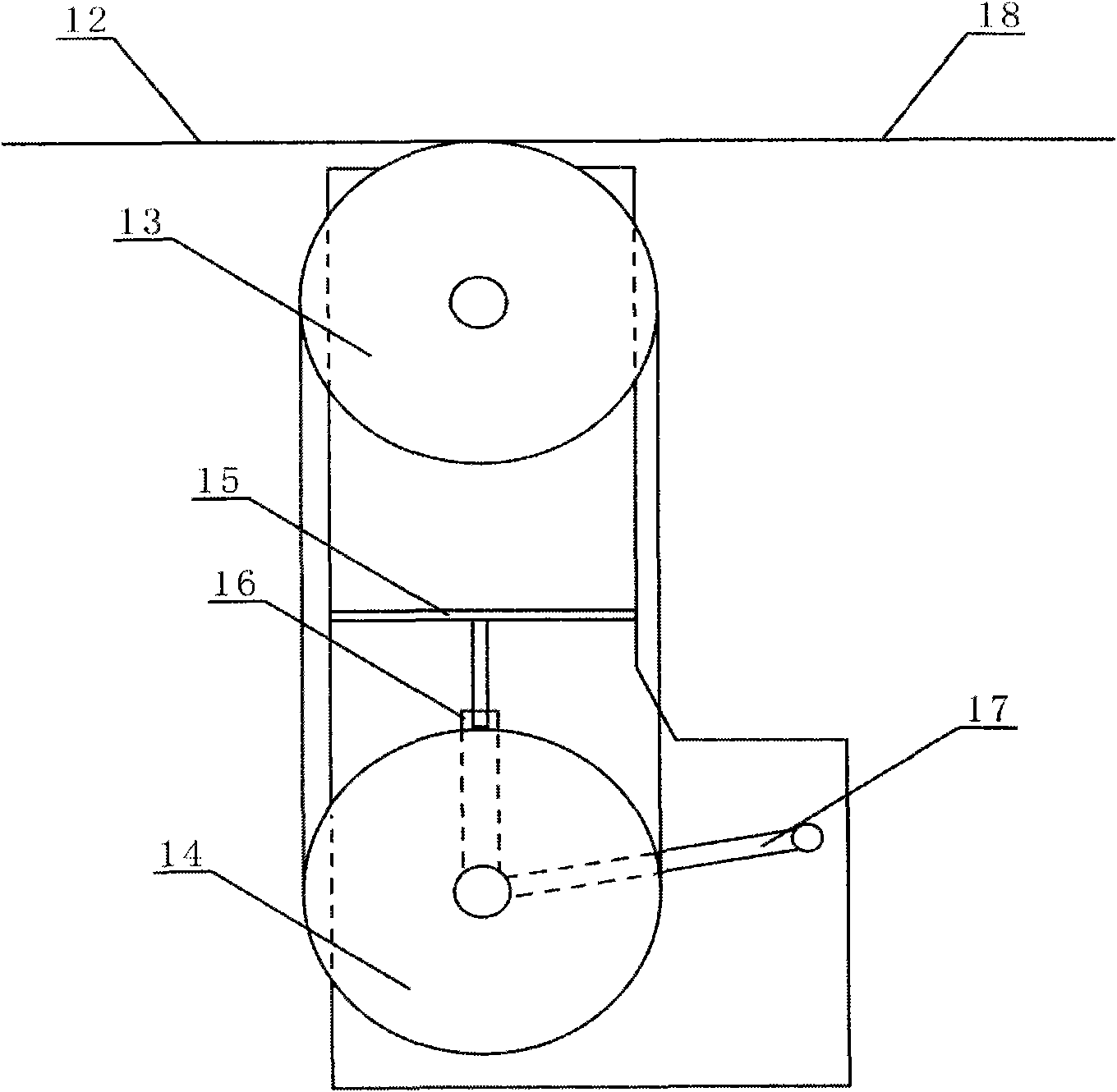

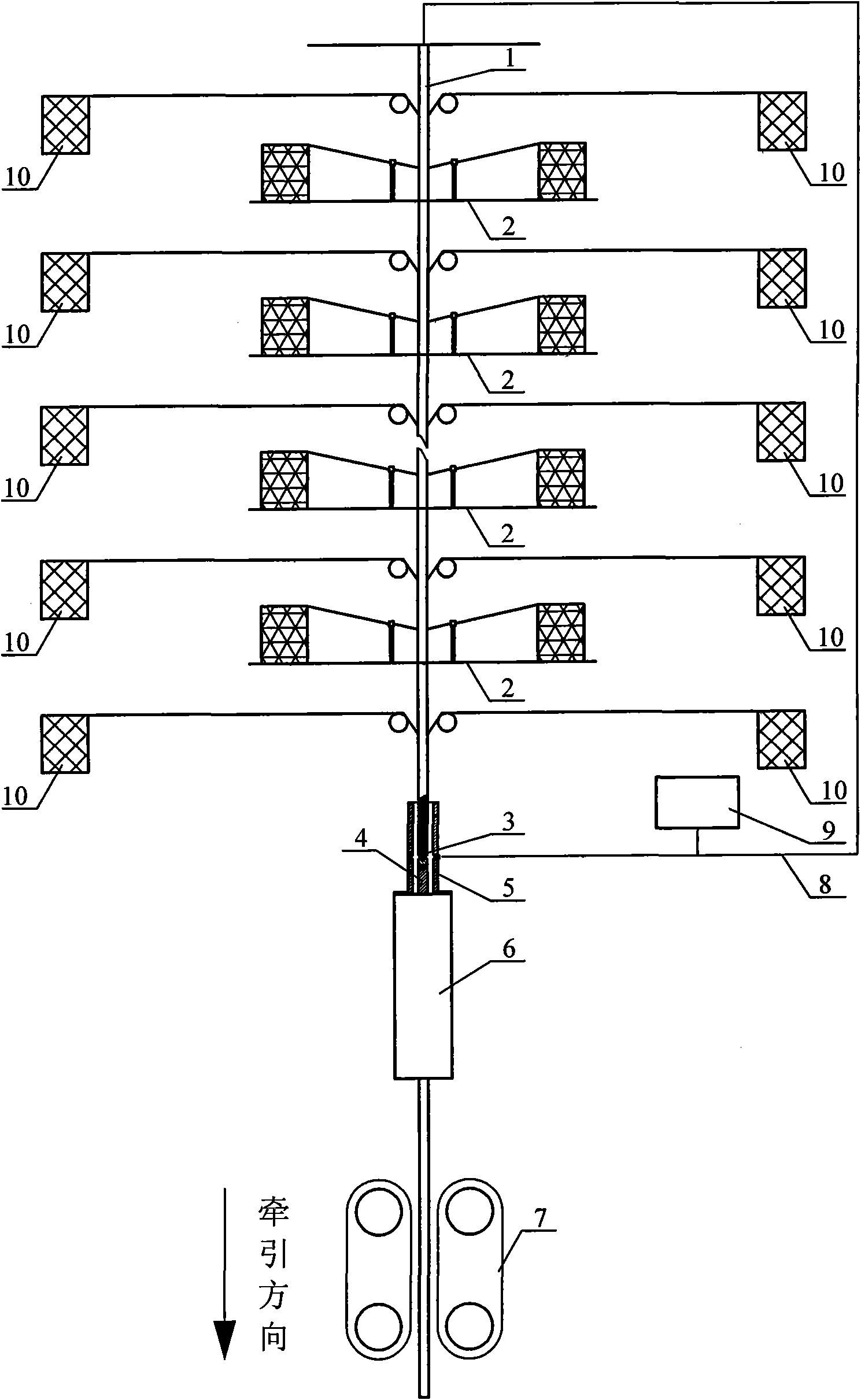

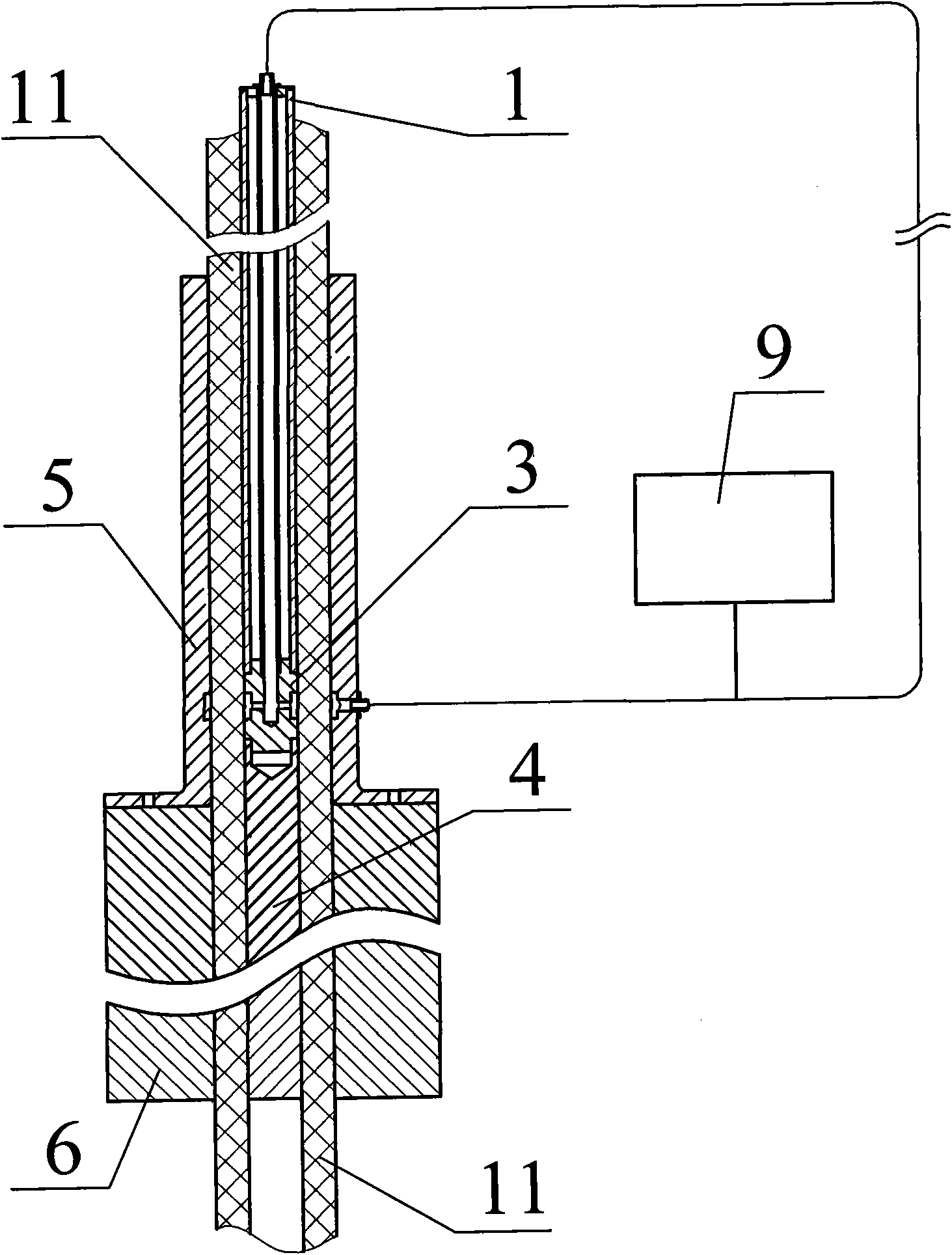

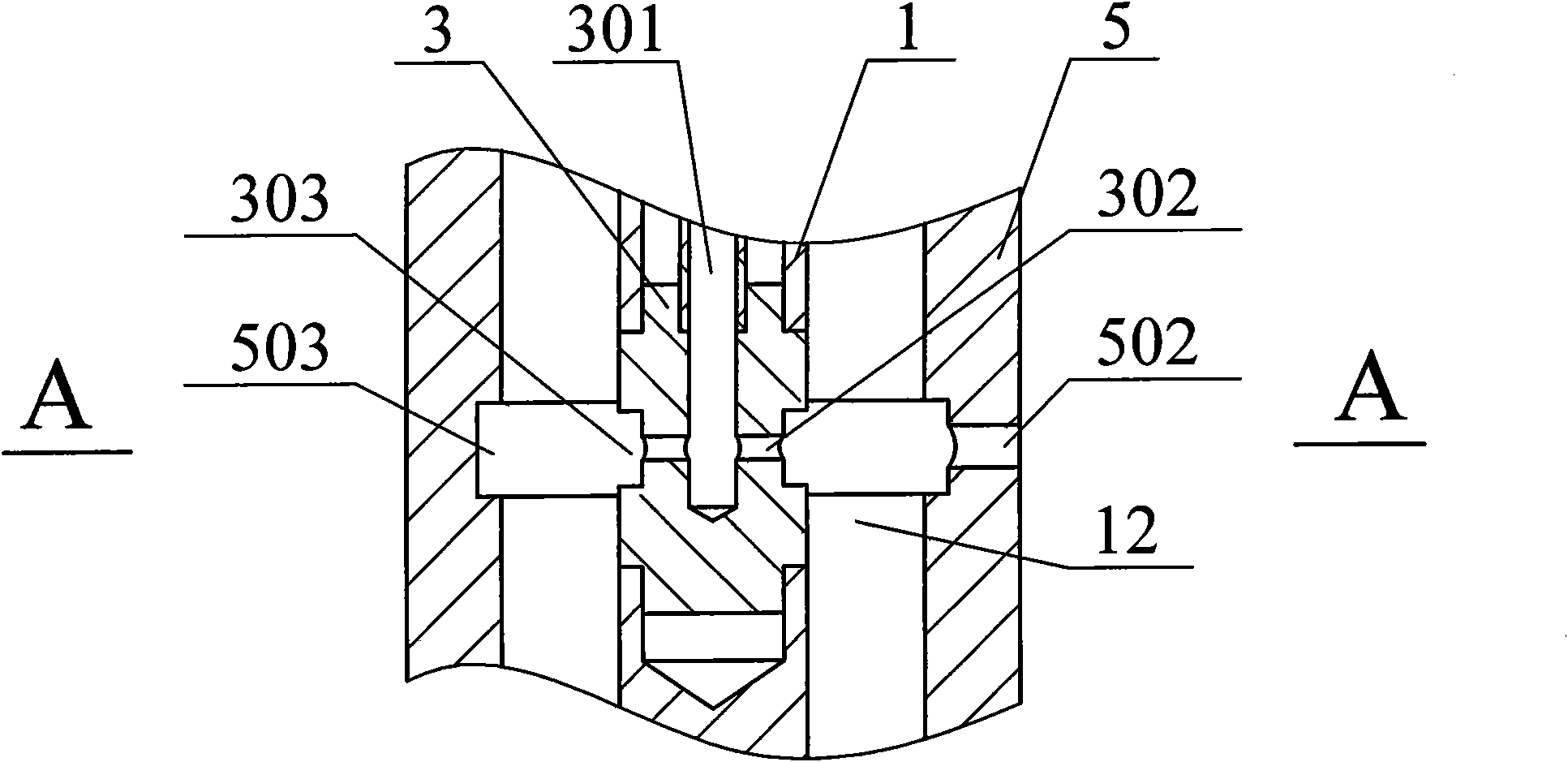

Vertical pultrusion process and device of multilayer fiber composite laminated section bar

InactiveCN101913254AImprove performanceOvercome shortcomings such as oxidationOther domestic articlesYarnFiber bundle

The invention relates to a vertical pultrusion process of a multilayer fiber composite laminated section bar, which comprises the steps of: arranging longitudinal and circular fibers on a tubular core die to form a fiber bundle laminated fiber composite laminate and tracting to move; introducing one part of glue into the fiber composite laminate and injecting, injecting the other part of glue from the outer part of the fiber composite laminate to ensure that the glue dips the fiber composite laminate; and finally, heating for forming and cooling. A pultrusion device comprises a tracting machine used for tracting the fiber composite laminate and a heating forming die, wherein the heating forming die is provided with an internal and external injection device, a tubular core die is arranged on the internal and external injection device, an internal injection hole of the internal and external injection device is connected with one pipe mouth of the tubular core die, the other pipe mouth of the tubular core die and an external injection hole of the internal and external injection device are connected to an injection pump, at least one group of yarn distributors are sleeved on the tubular core die and comprise a longitudinal yarn coil and a circular yarn winder, and the longitudinal yarn coil is positioned in front of the circular yarn winder along the traction direction.

Owner:高宝安

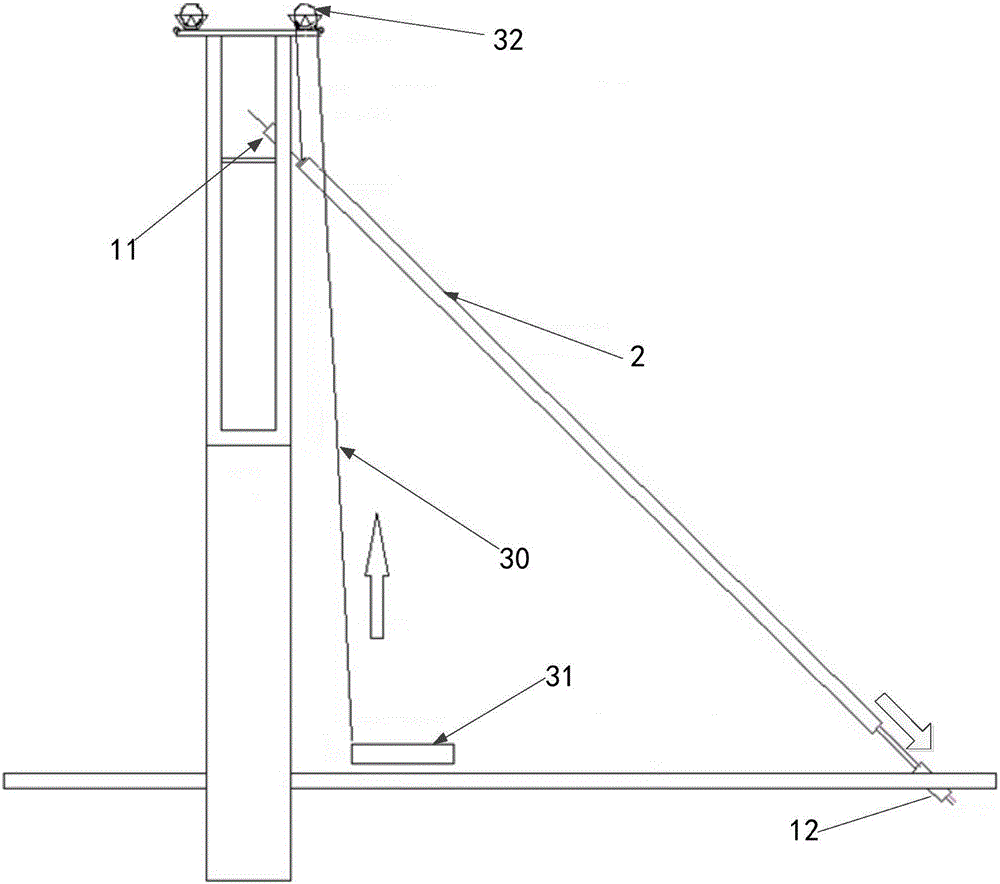

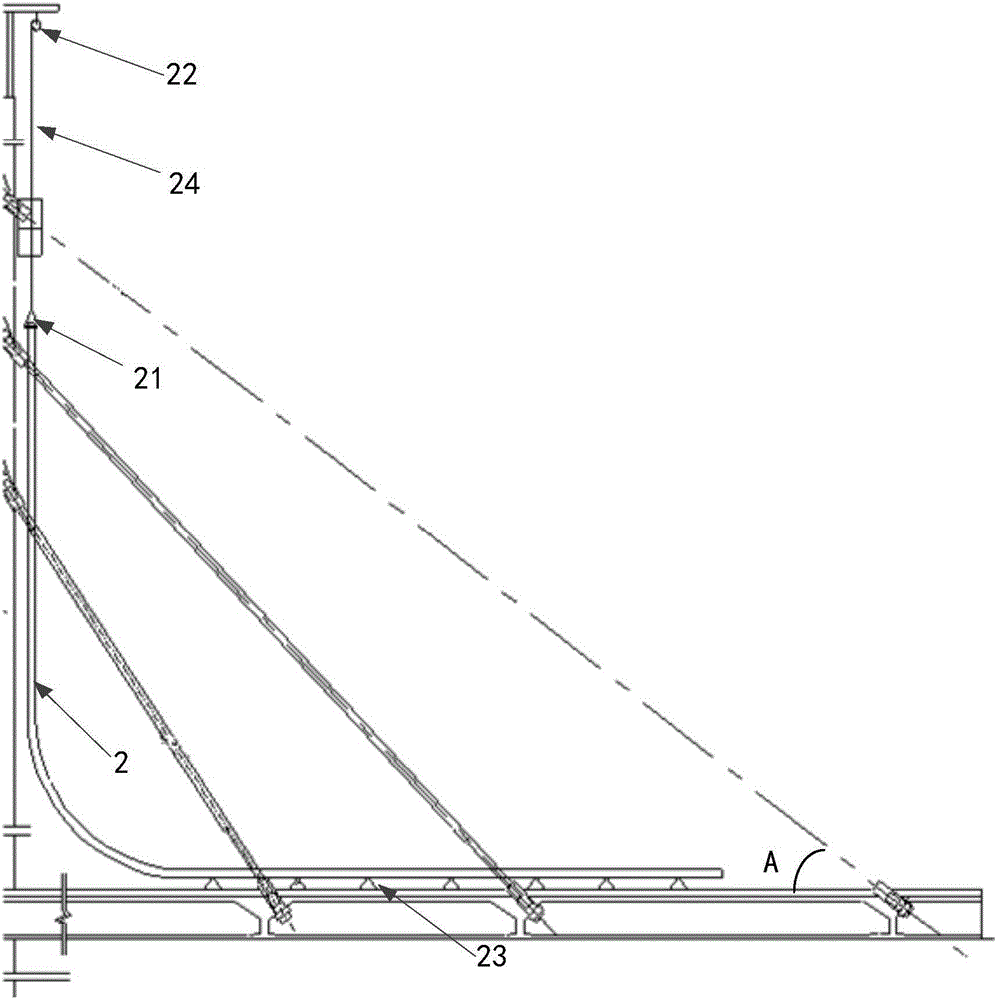

Mounting method of stayed cable of cable-stayed bridge

InactiveCN106592441AReduce loadReduce tractionCable-stayed bridgeBridge structural detailsCable stayedTower

The invention discloses a mounting method of a stayed cable of a cable-stayed bridge. The mounting method comprises the following steps that an under-girder anchoring device is mounted on a main girder section; a tower-end anchoring device is mounted on a cable bent tower; a stayed cable outer protection sleeve is hoisted and lifted and laid with a preset angle, and the stayed cable outer protection sleeve is collinearly arranged with the under-girder anchoring device and the tower end anchoring device which are relative to the stayed cable anchor; steel stranded wires penetrate through the outer protection sleeve one by one from the tower end to the beam end, and the two ends of each steel stranded wire are anchored on the under-girder anchoring device and the tower end anchoring device correspondingly; and the stayed cable is integrally tensioned. According to the explosive-removing unmanned aerial vehicle, the steel stranded wires penetrate through the outer protection sleeve from top to bottom, so that in the hoisting process of the steel stranded wires, the needed tractive force is reduced, construction procedures are reduced, construction time is saved, and meanwhile, abrasion to the outer protection sleeve is reduced.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

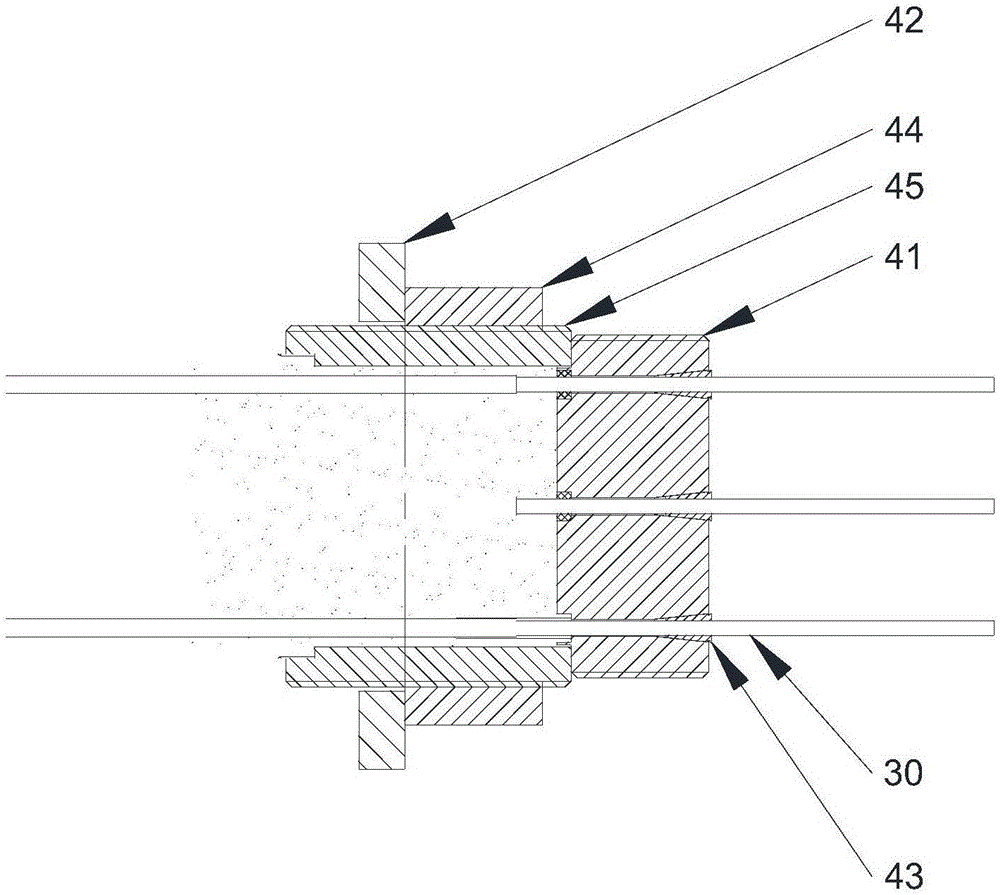

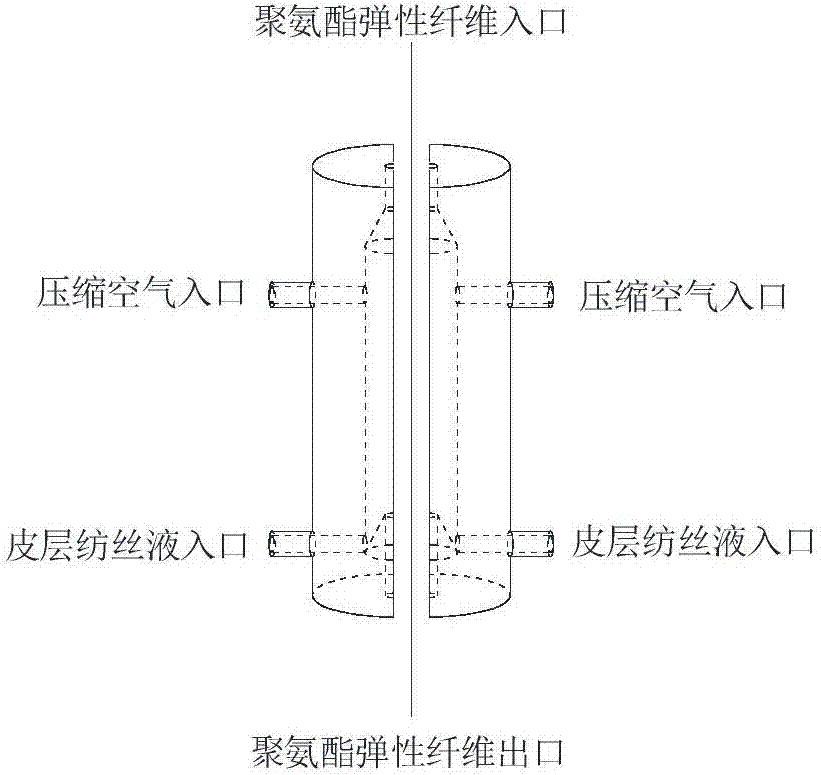

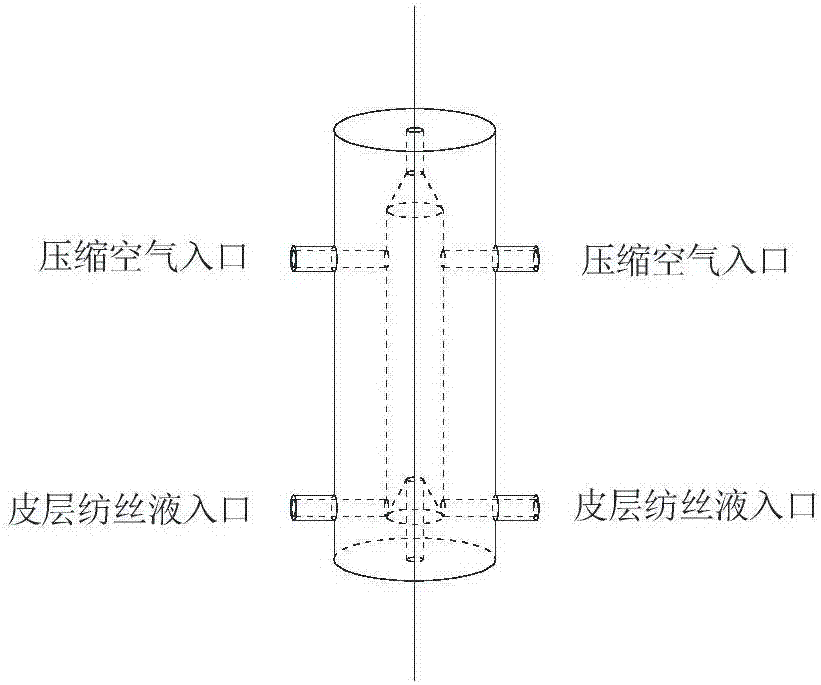

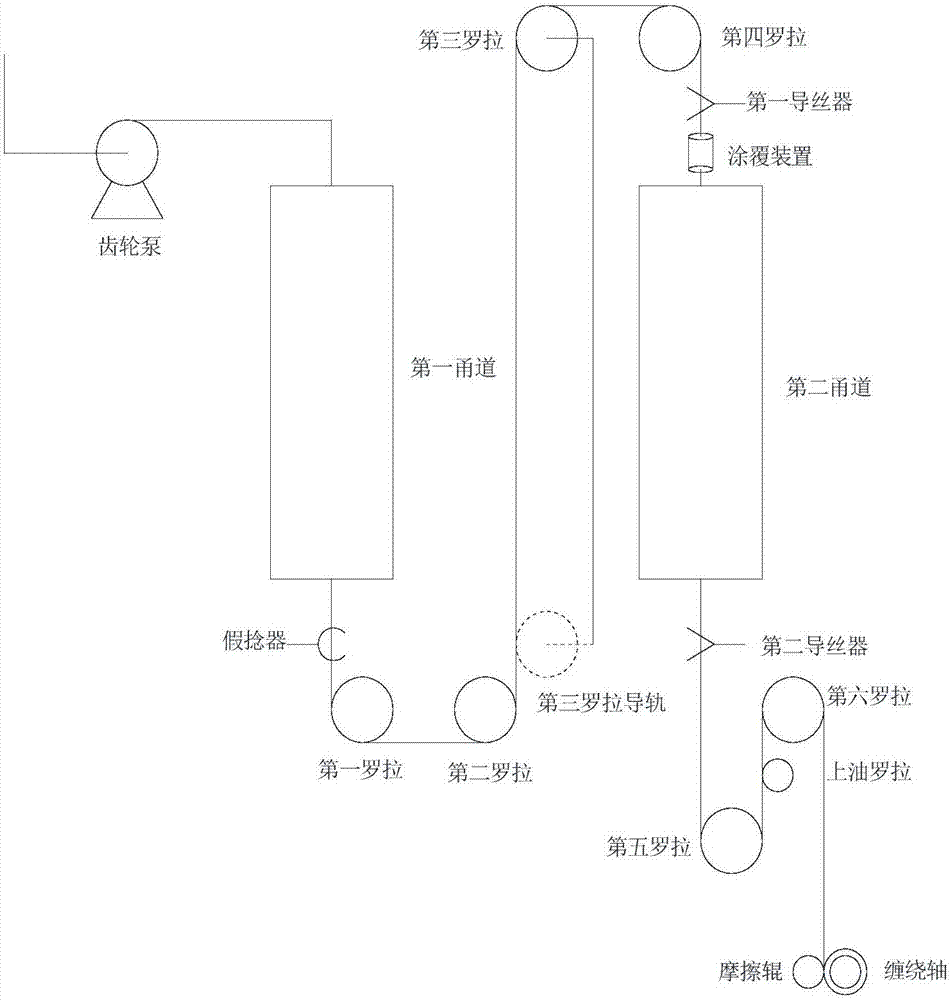

Skin-core structured polyurethane elastic fiber preparation method

ActiveCN107956127AIncrease productivityGuaranteed to pass throughFibre typesMonocomponent synthetic polymer artificial filamentElastic fiberPolyurea

The invention discloses a skin-core structured polyurethane elastic fiber preparation method. By adjustment of types and contents of skin and core layer spinning solution auxiliary agents, the auxiliary agents are enriched on a skin layer, and improvement of fiber environmental tolerance, changing of fiber surface properties and reduction of auxiliary agent utilization cost are realized. Skin-corestructured polyurethane elastic fiber preparation is characterized by including steps: 1) preparing N,N-dimethylacetamide solution of polyurethane-polyurea, aging to obtain core layer spinning solution, adopting a spinneret plate for spin stretching, and performing high-temperature drying through a first passage to obtain core layer polyurethane elastic fibers; 2) taking part of polyurethane-polyurea solution, and adding auxiliary agents for improvement of fiber environmental tolerance or changing of fiber surface properties to obtain skin layer spinning solution, coating the core layer fibersurface with the skin layer spinning solution through a special-structure coating device, performing high-temperature drying through a second passage, and carrying out oiling and winding forming to obtain skin-core structured polyurethane elastic fibers.

Owner:ZHEJIANG HUAFENG SPANDEX

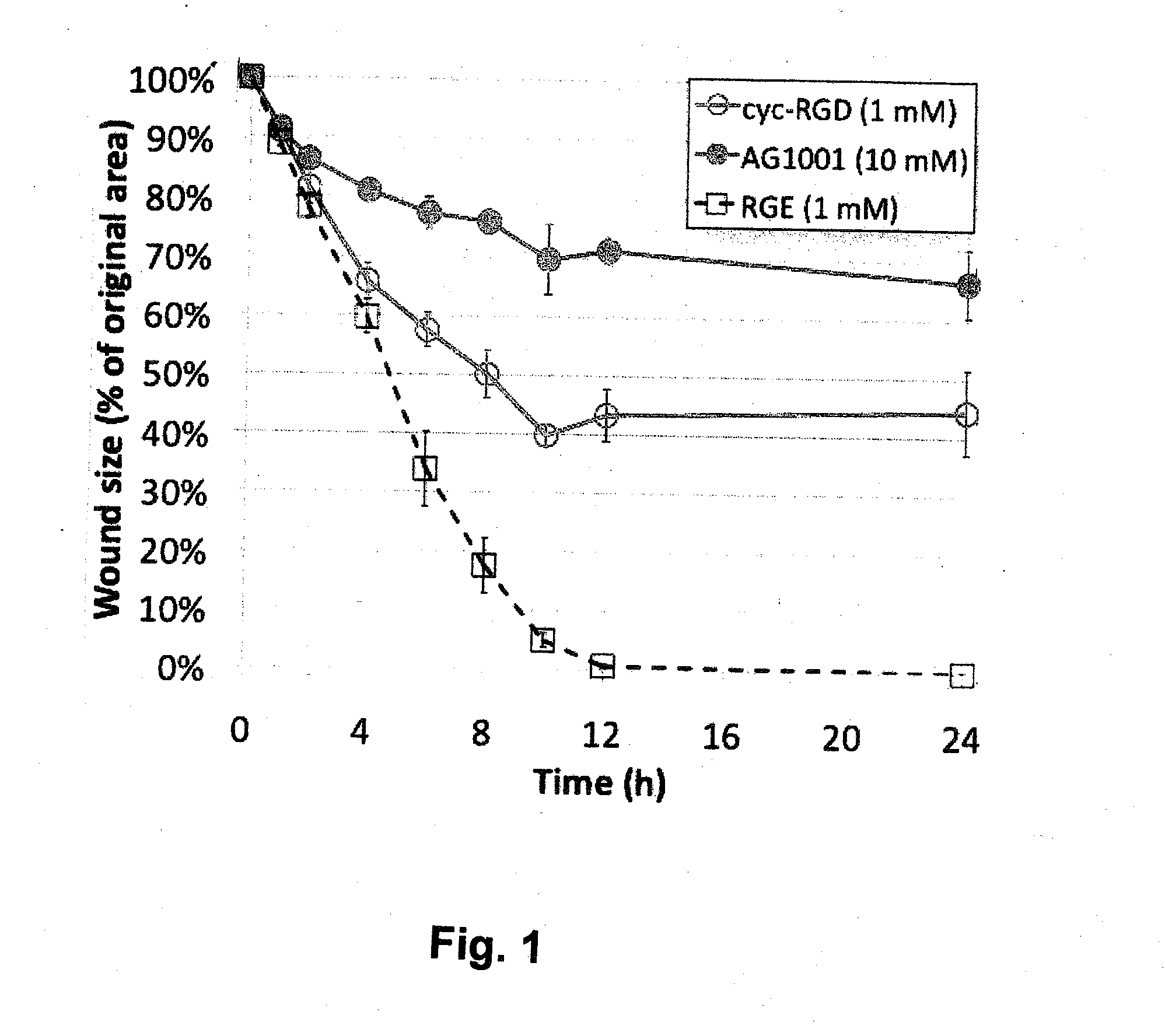

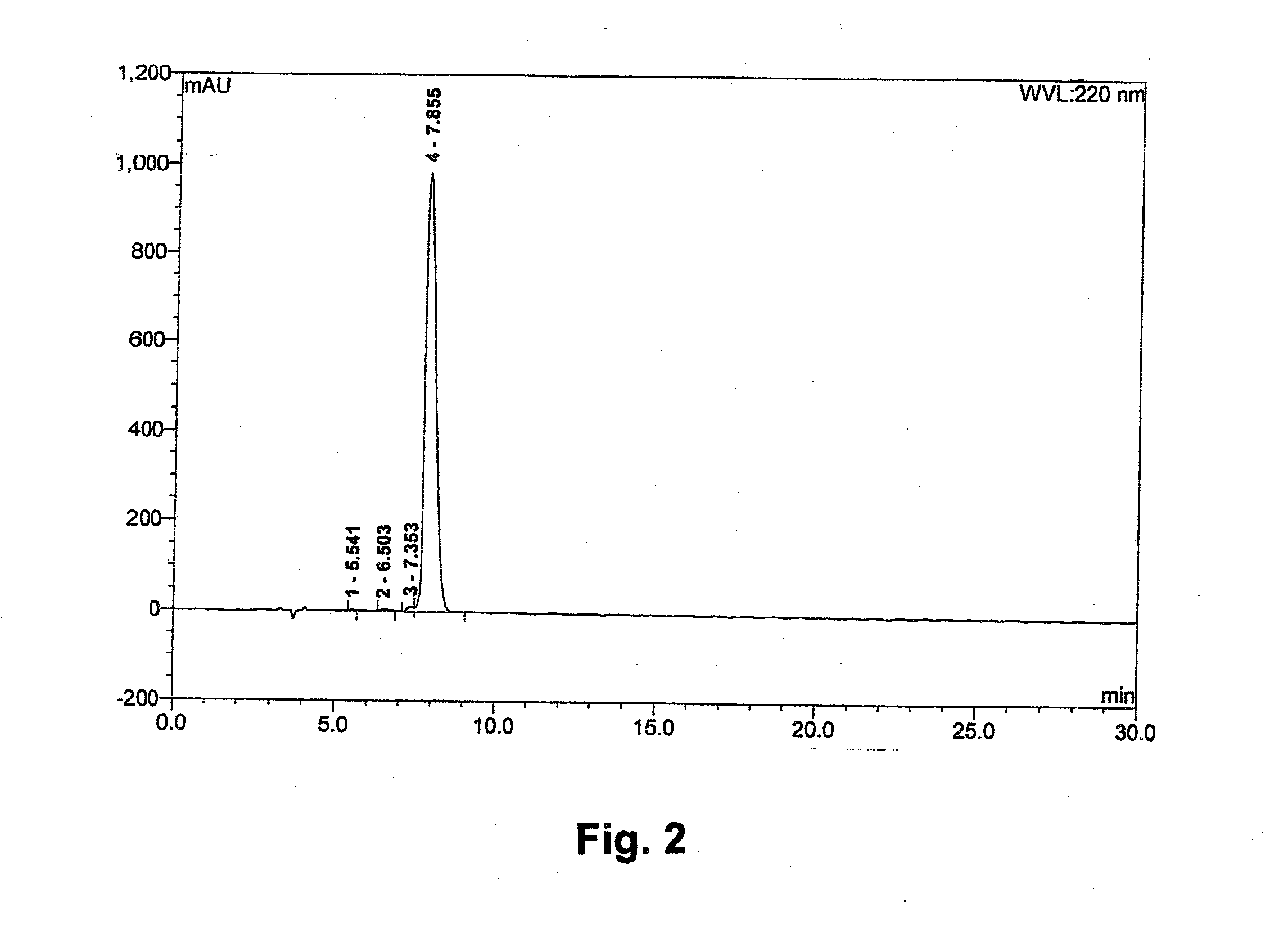

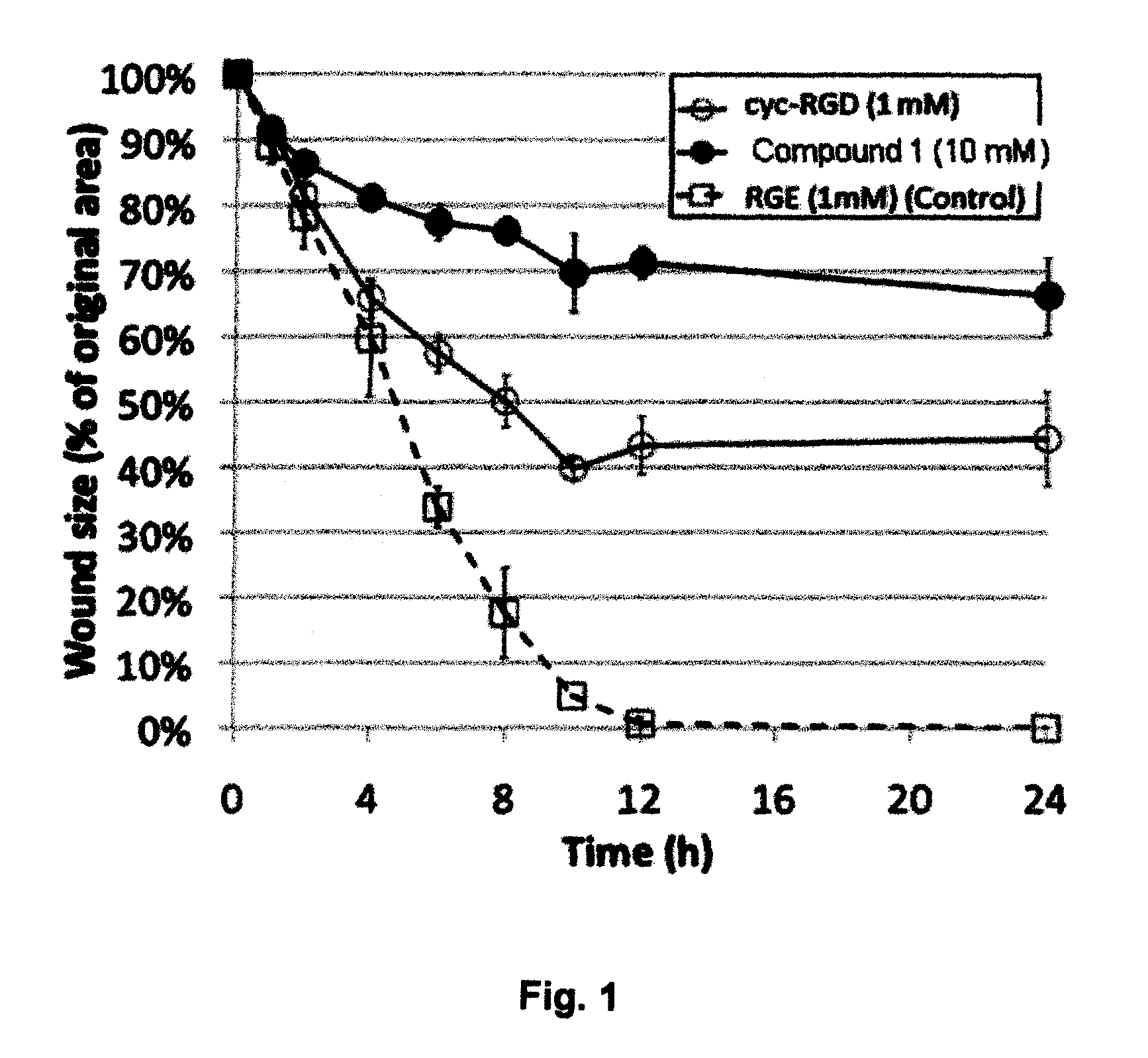

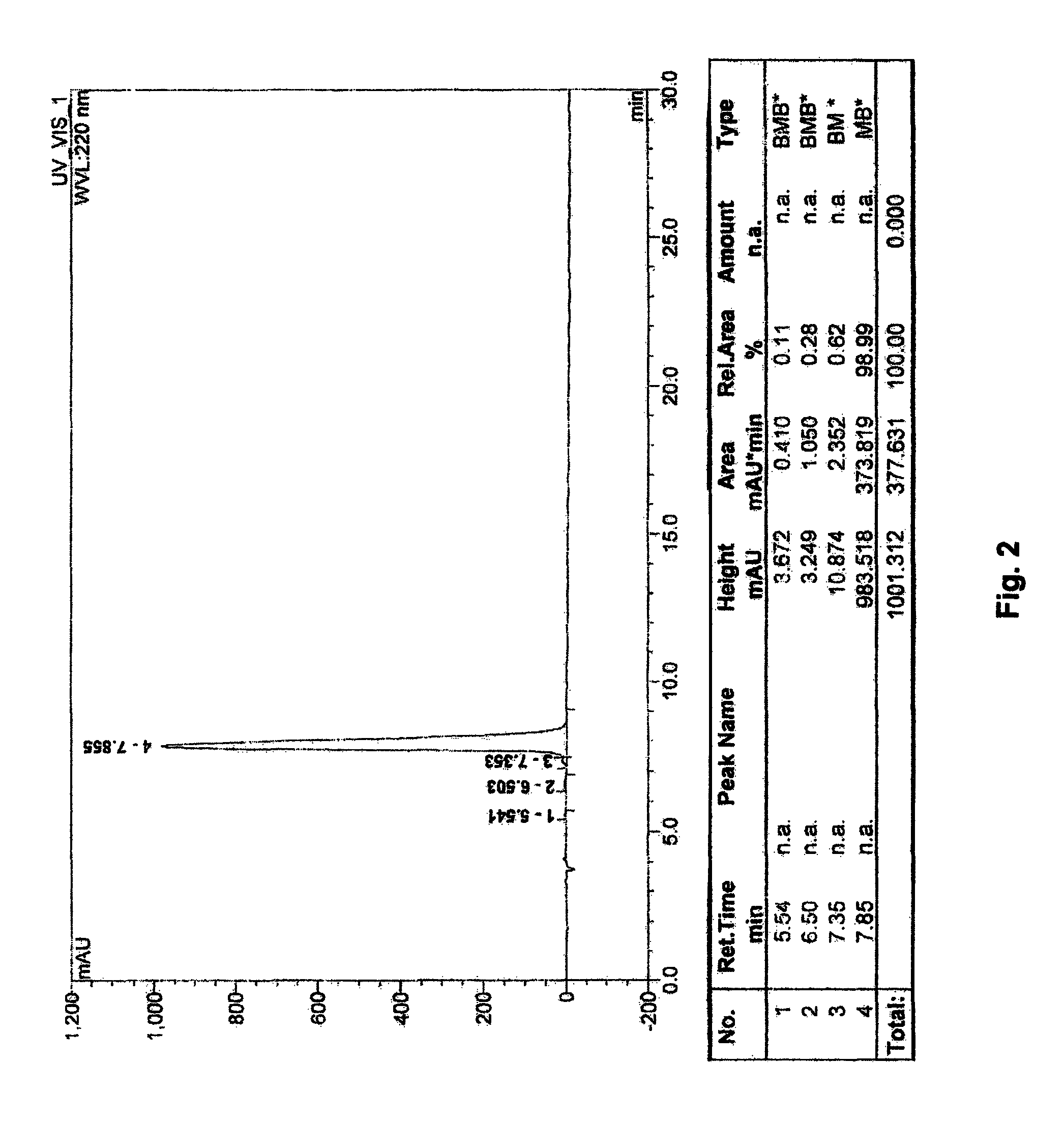

Integrin Receptor Antagonists and Their Methods of Use

ActiveUS20130129621A1Avoid blindnessAlleviate macular tractionAntibacterial agentsSenses disorderBinding siteAngiogenesis growth factor

Compounds comprising R-G-Cysteic Acid (i.e., R-G-NH—CH(CH2—SO3H)COOH or Arg-Gly-NH—CH(CH2—SO3H)COOH) and derivatives thereof, including pharmaceutically acceptable salts, hydrates, stereoisomers, multimers, cyclic forms, linear forms, drug-conjugates, pro-drugs and their derivatives. Also disclosed are methods for making and using such compounds including methods for inhibiting integrins including but not necessarily limited to α5β1-Integrin, αvβ3-Integrin and αvβ5-Integrin, inhibiting cellular adhesion to RGD binding sites, preventing or treating viral or other microbial infections, inhibiting angiogenesis in tumors, retinal tissue or other tissues or delivering other diagnostic or therapeutic agents to RGD binding sites in human or animal subjects.

Owner:ALLEGRO PHARMA

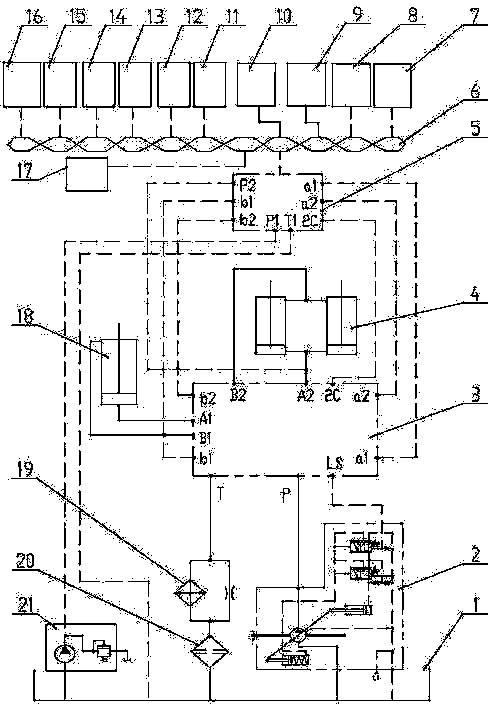

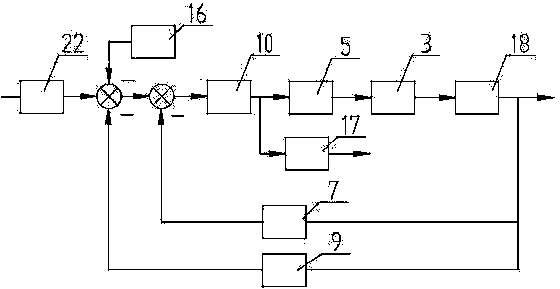

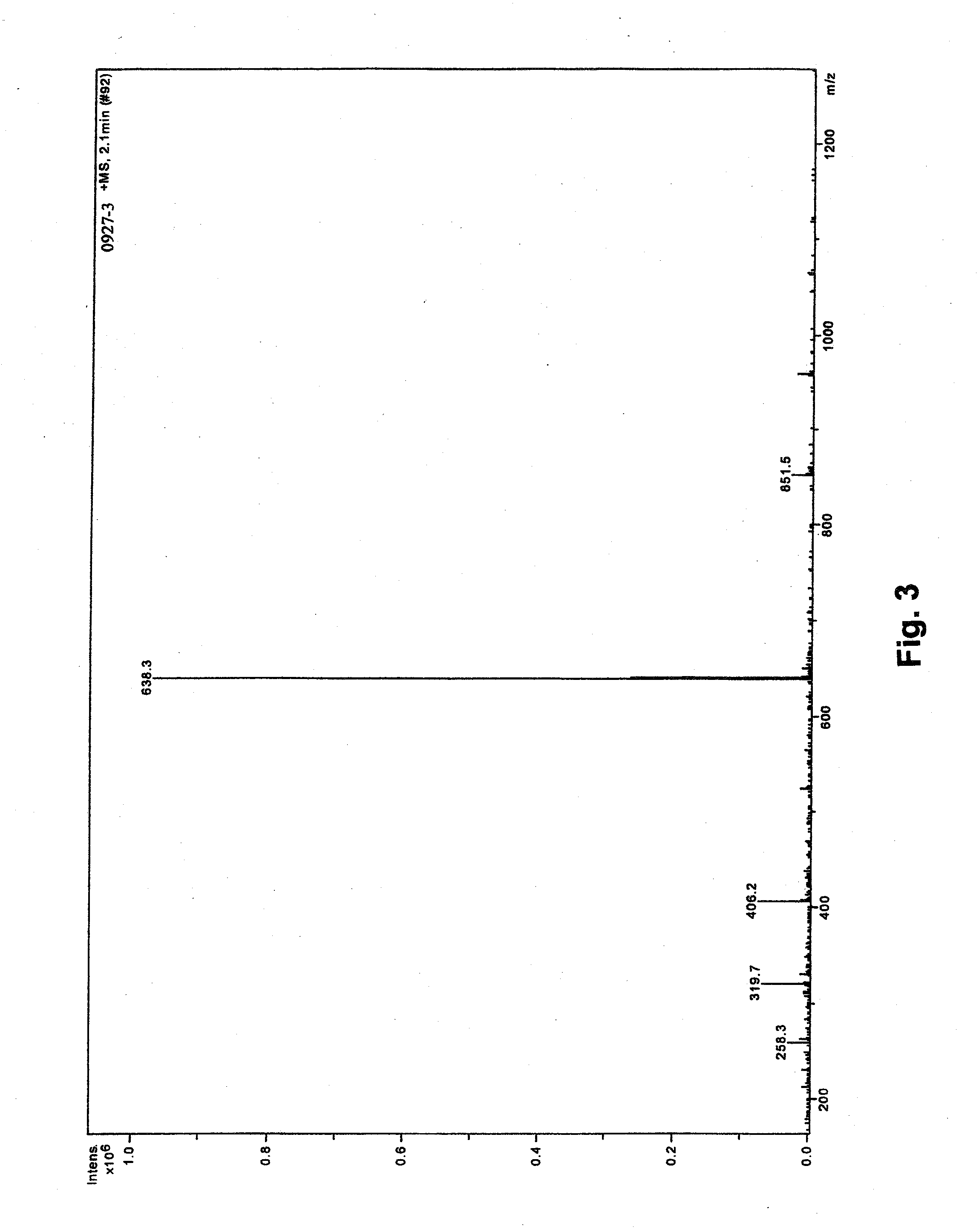

Work vehicle and control method for same

ActiveUS20150361636A1Easy to operateReduce tractionHybrid vehiclesAnalogue computers for trafficEngineeringRequirements determination

A control unit of a work vehicle has a transmission requirement determination unit, a command-torque determination unit, and a tractive force limiting unit. The transmission requirement determination unit determines a required tractive force on the basis of an operating amount of an accelerator operating member. The required tractive force is a target tractive force of a travel device. The command-torque determination unit determines an output torque of the electric motor so that the tractive force of the vehicle reaches the required tractive force. The tractive force limiting unit reduces the required tractive force to a value less than a value corresponding to the operating amount of the accelerator operating member when the vehicle is excavating.

Owner:KOMATSU LTD

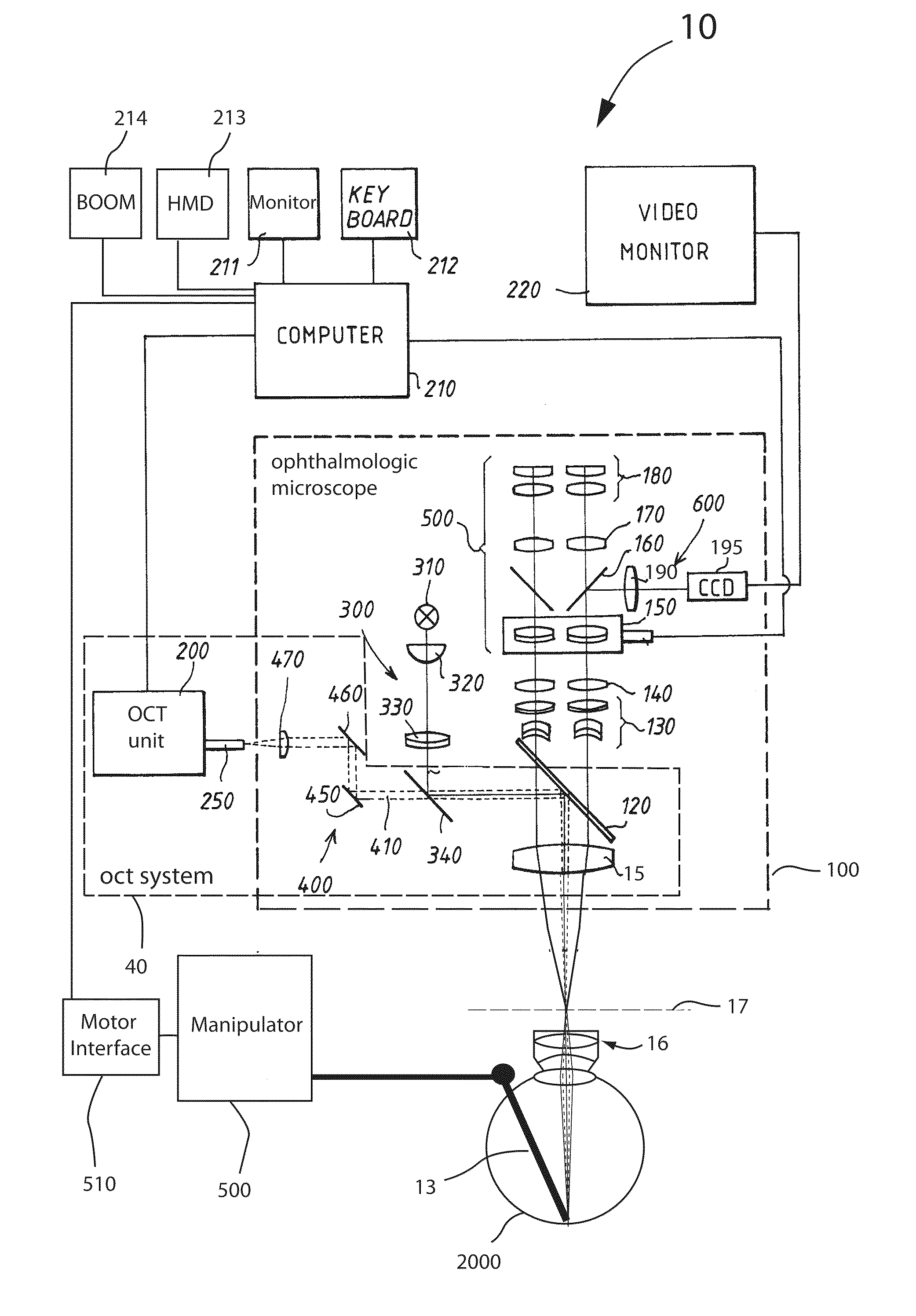

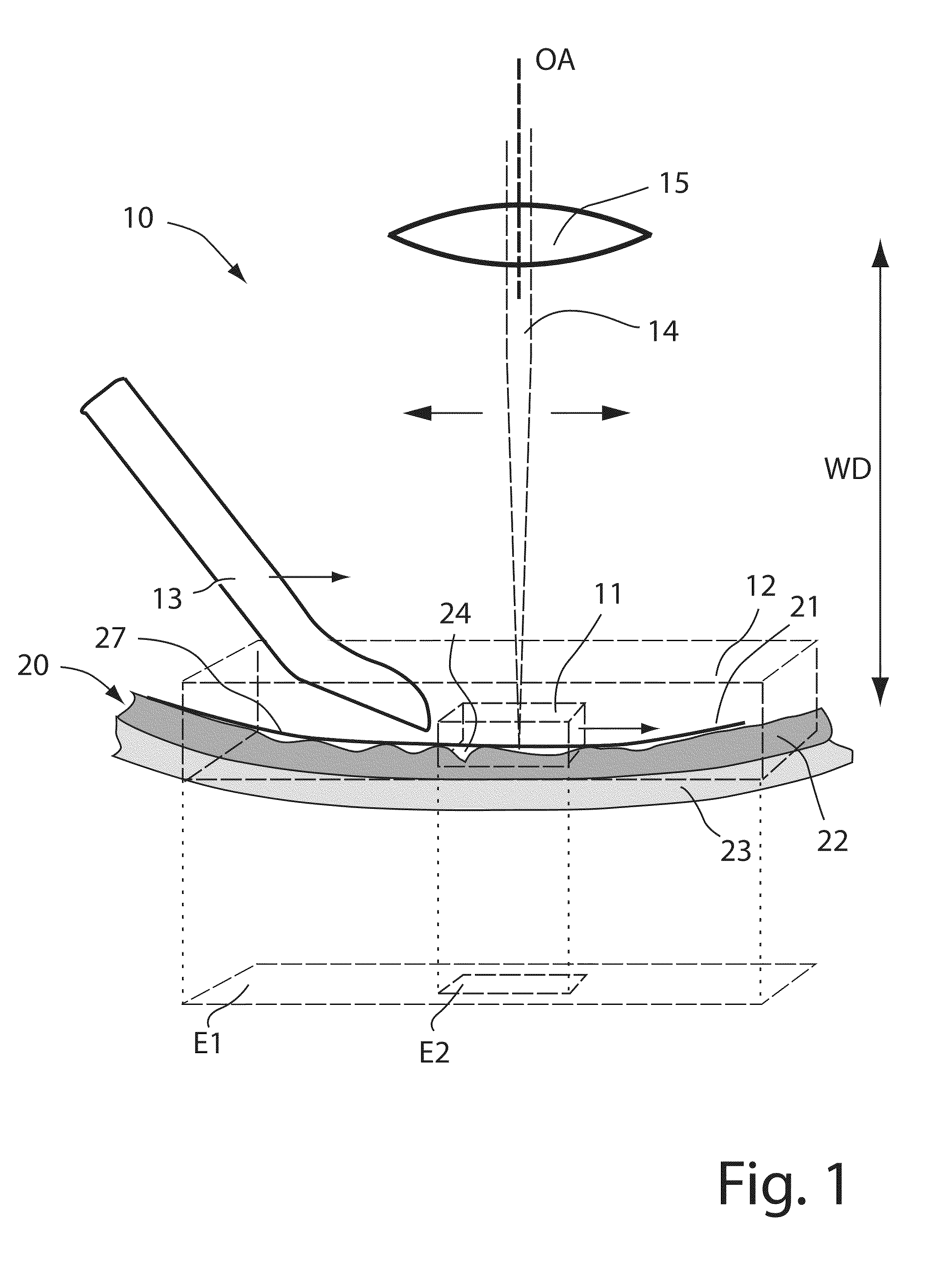

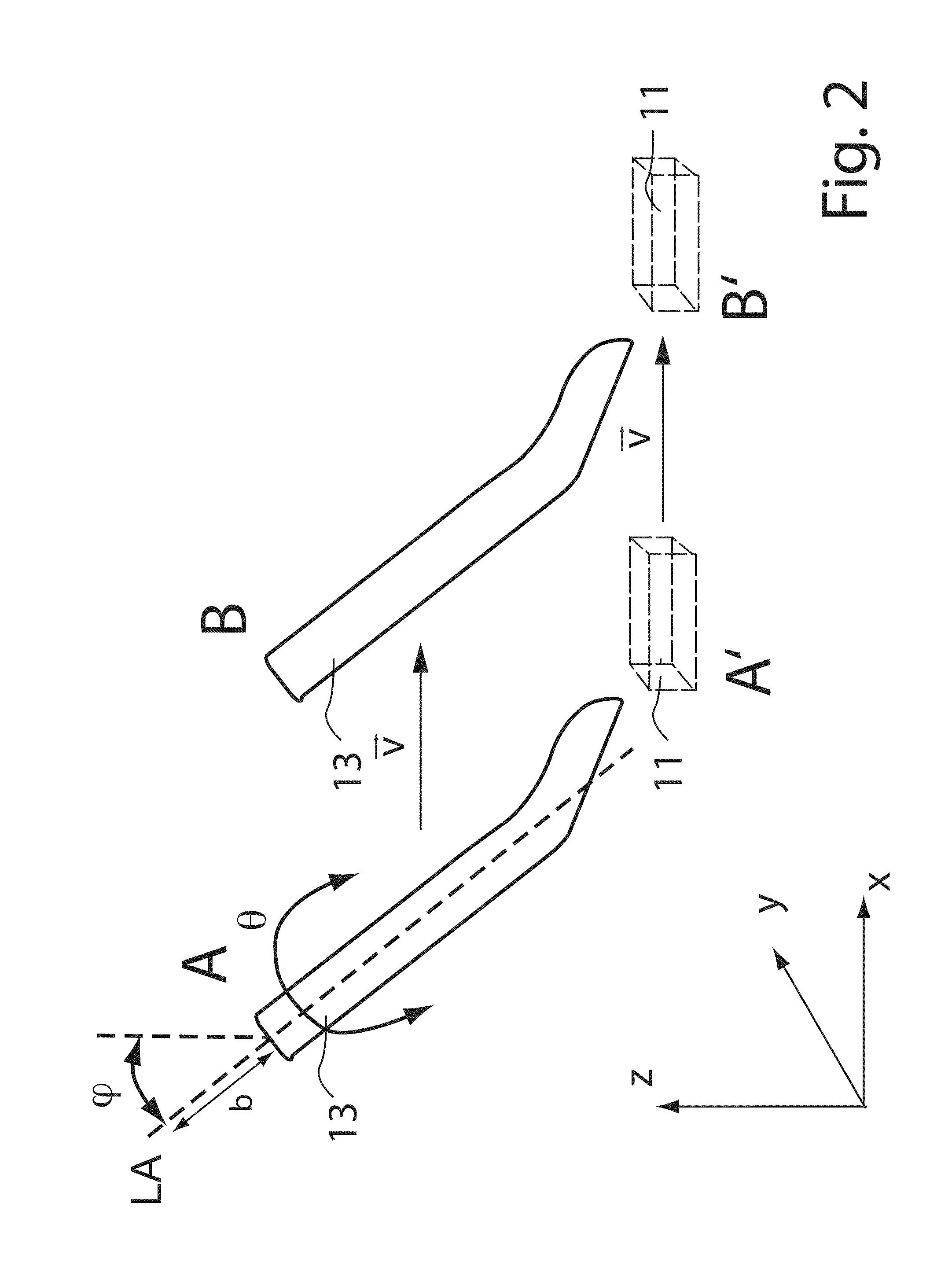

System and Method for Visualizing Objects

A method of visualizing objects using an optical system including an OCT system configured to obtain OCT data from voxels within a first volume having a first lateral extent includes obtaining position data indicative of a position of a predetermined portion of a movable instrument relative to the optical system and determining a first set of voxels from the voxels of the first volume based on the determined position such that at least 80% of the first set of voxels is located within a second volume having a second lateral extent with a size at least half the size of the first lateral extent. The method also includes obtaining OCT data of the first set of voxels, visualizing a representation of the OCT data of the first set of voxels, and repeating the steps of the method at a first repetition rate higher than 5 times per second.

Owner:CARL ZEISS MEDITEC AG

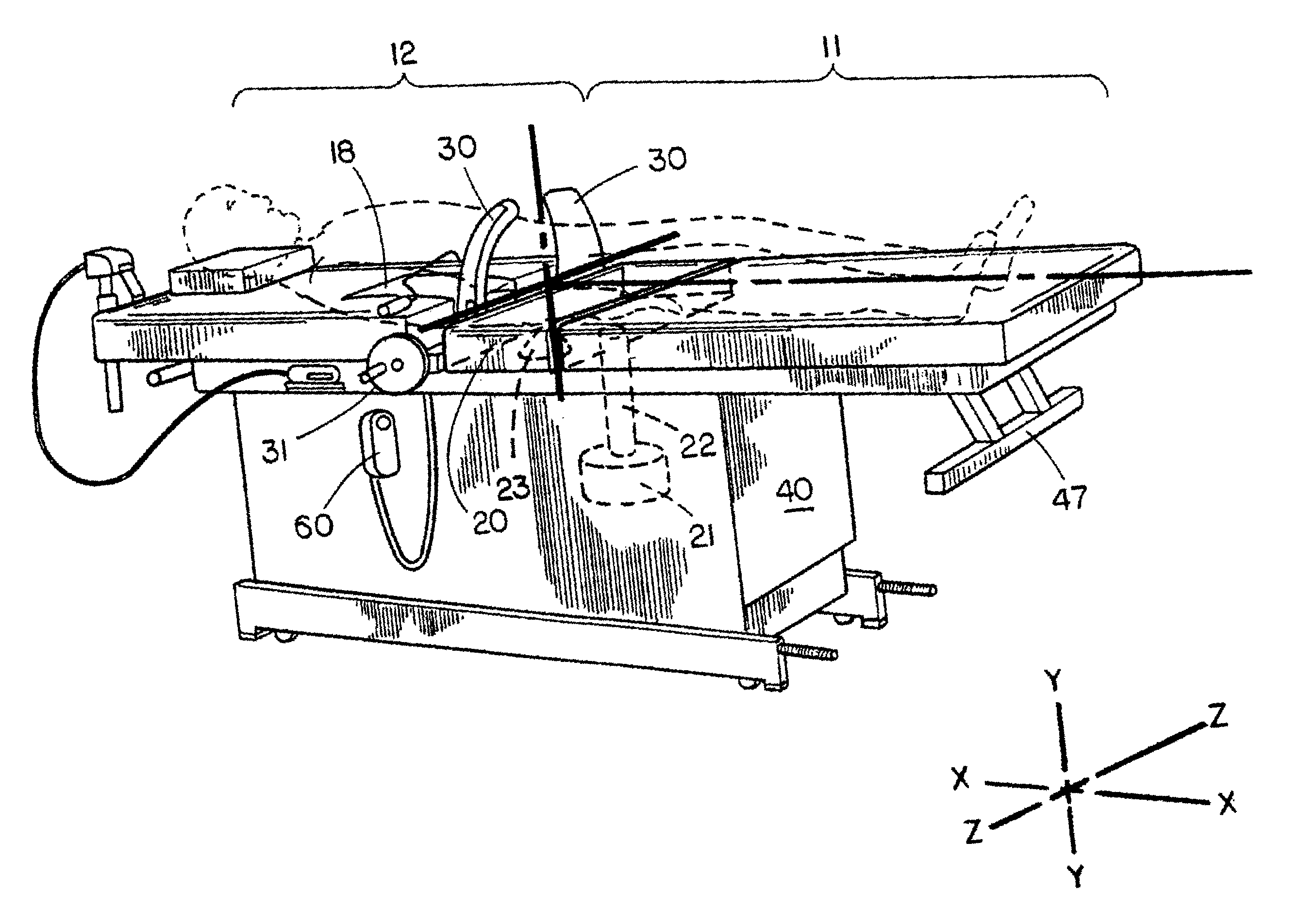

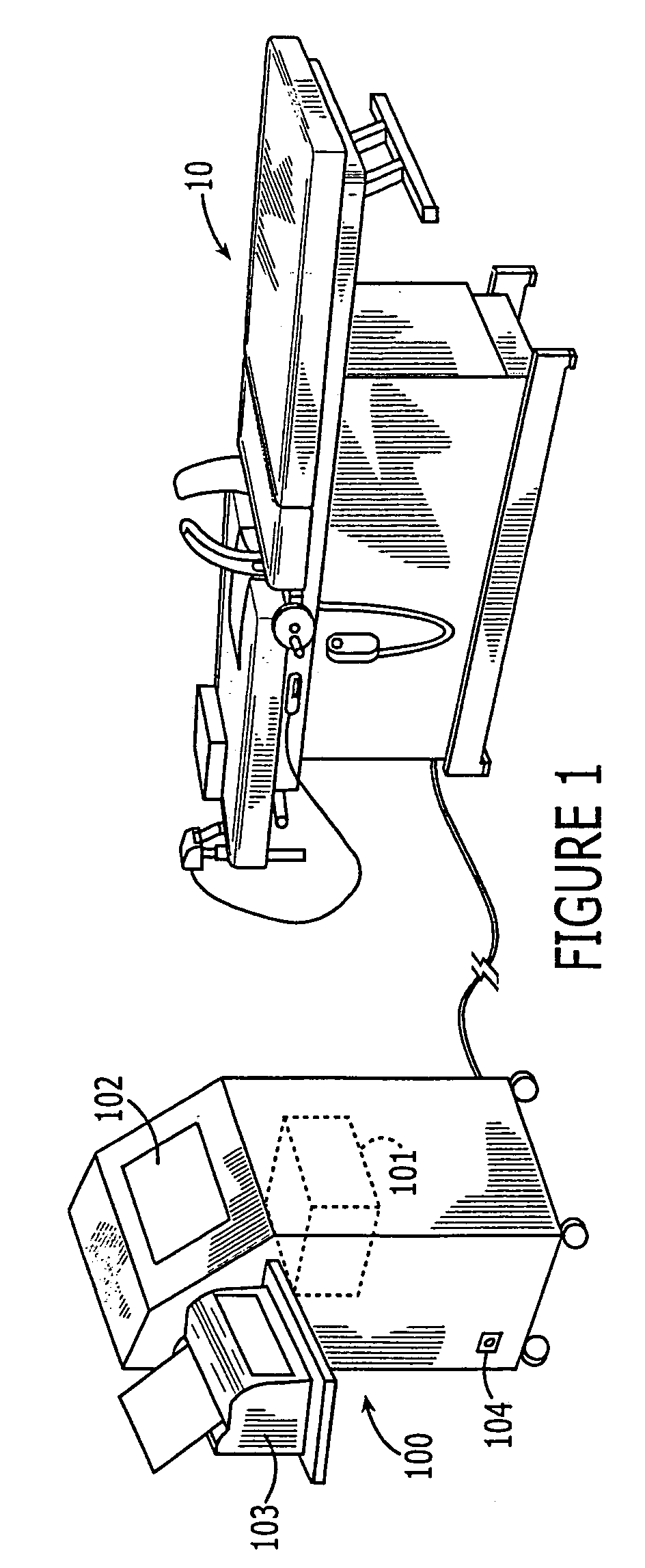

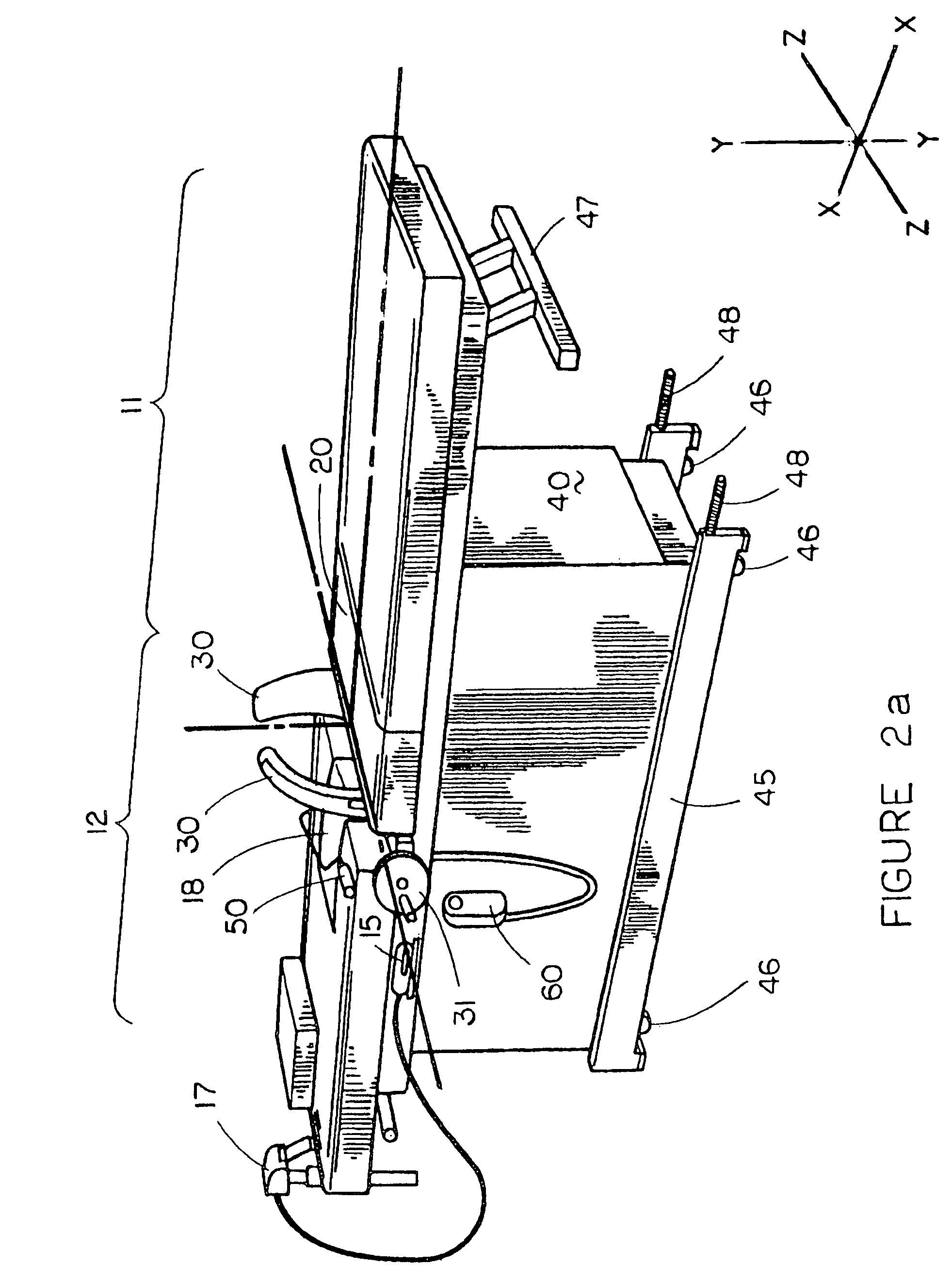

Method and apparatus for therapeutic treatment of back pain

ActiveUS7201729B2Precision therapyEliminate side effectsOperating chairsOperating tablesDistractionMedicine

A therapeutic table construction which isolates a first portion of the patient's body to a fixed table portion and a second portion of the patient's body to a moveable table portion, and applies a distraction force to the moveable portion of the patient's body while positioning the portion of the patient's spine that is to be treated at an angle so as to isolate the portion of the patient's spine which receives the distraction force.

Owner:SPINEMED SALES INT

Peptide compositions and therapeutic uses thereof

ActiveUS9018352B2Promotes proliferationEasy SurvivalSenses disorderAntipyreticBinding siteAnimal subject

Compounds comprising R-G-Cysteic Acid (i.e., R-G-NH—CH(CH2—SO3H)COOH or Arg-Gly-NH—CH(CH2—SO3H)COOH) and derivatives thereof, including pharmaceutically acceptable salts, hydrates, stereoisomers, multimers, cyclic forms, linear forms, drug-conjugates, pro-drugs and their derivatives. Also disclosed are methods for making and using such compounds including methods for inhibiting cellular adhesion to RGD binding sites or delivering other diagnostic or therapeutic agents to RGD binding sites in human or animal subjects.

Owner:ALLEGRO PHARMA

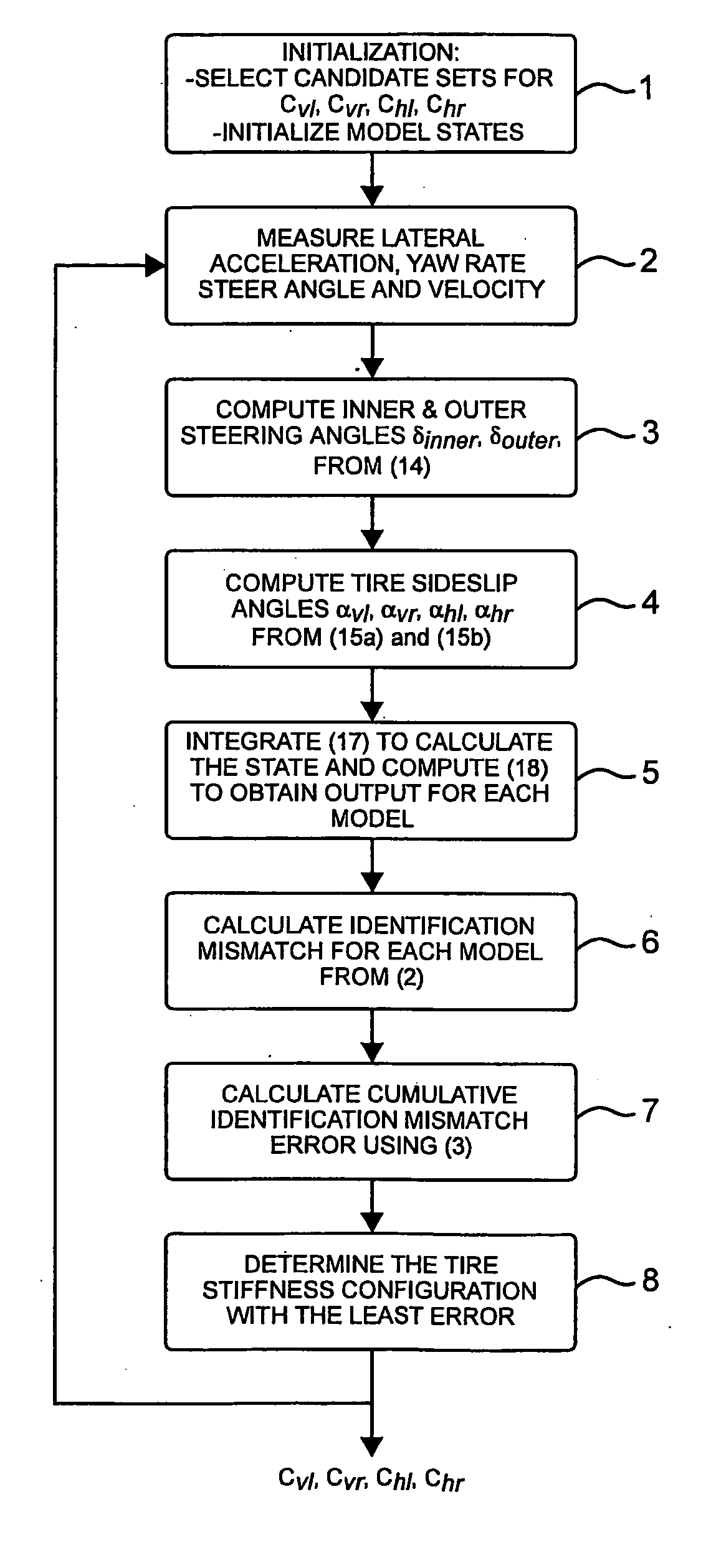

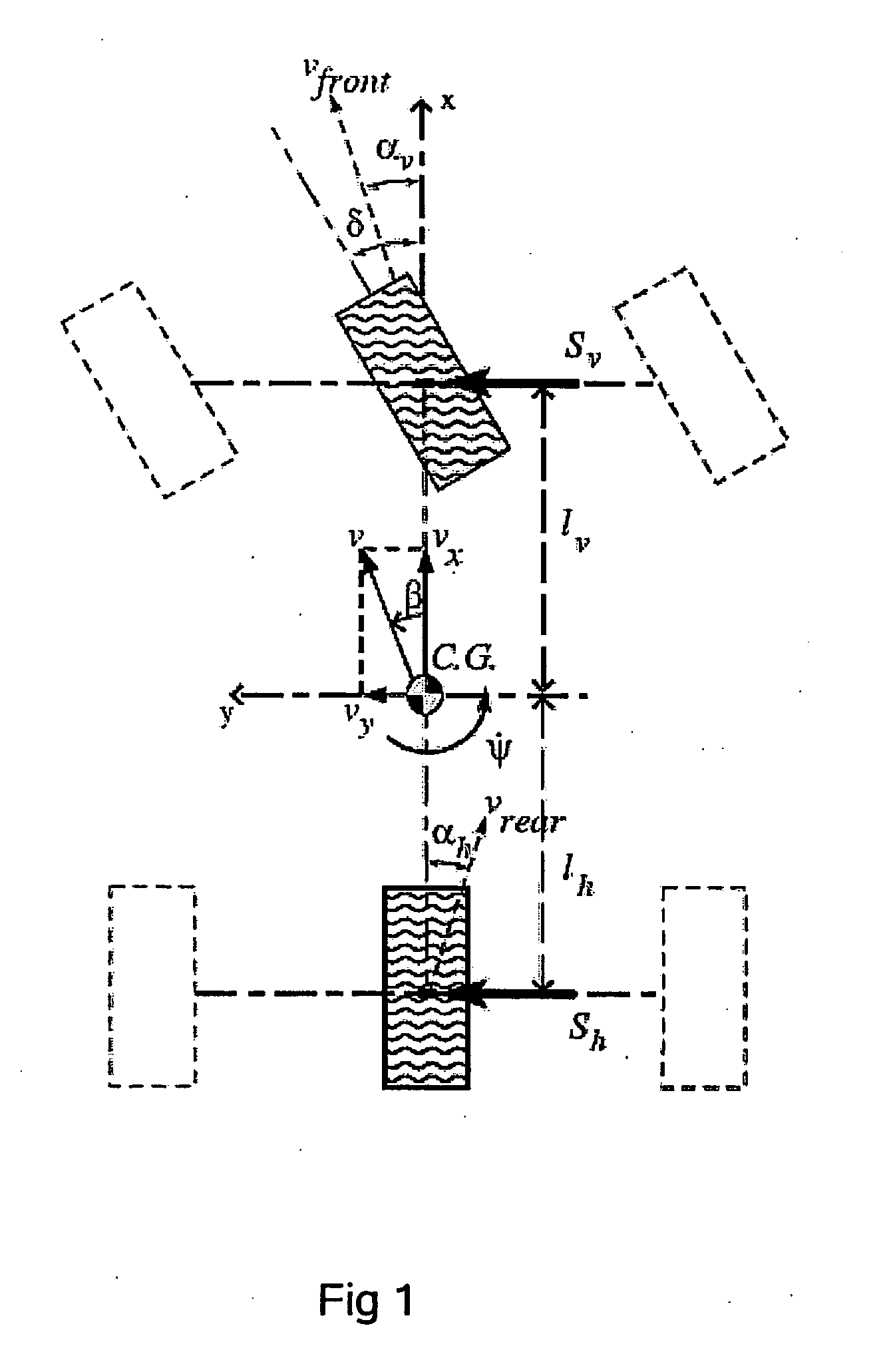

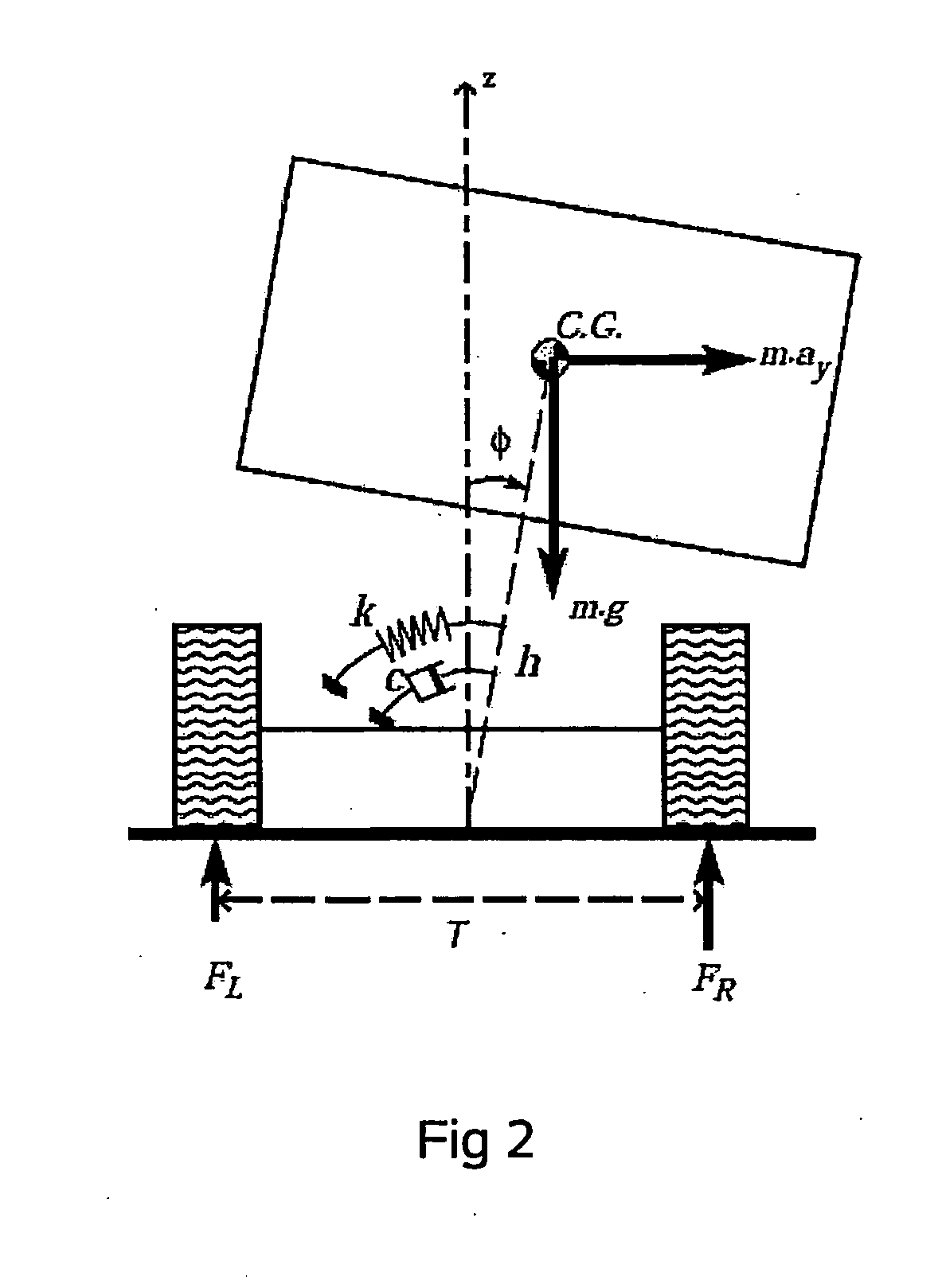

Method for determining the centre of gravity for an automotive vehicle

InactiveUS20090024269A1Accurately reflectQuick identificationVehicle testingRegistering/indicating working of vehiclesVehicle behaviorGravity center

Methods for determining the height, horizontal position, and lateral position of the centre of gravity of a vehicle are disclosed. The methods comprise constructing a plurality of models of vehicle behaviour, each model including a plurality of parameters that determine vehicle behaviour including parameters that define the position of the centre of gravity. The method then measures actual vehicle behaviour during operation of the vehicle. The actual behaviour and the behaviour predicted by the models are then compared to determine which of the models most effectively predicts behaviour of the vehicle. The model that is most effective in predicting the actual behaviour of the vehicle is then assumed to include amongst its parameters an estimate of the position of the centre of gravity of the vehicle.

Owner:NAT UNIV OF IRELAND MAYNOOTH

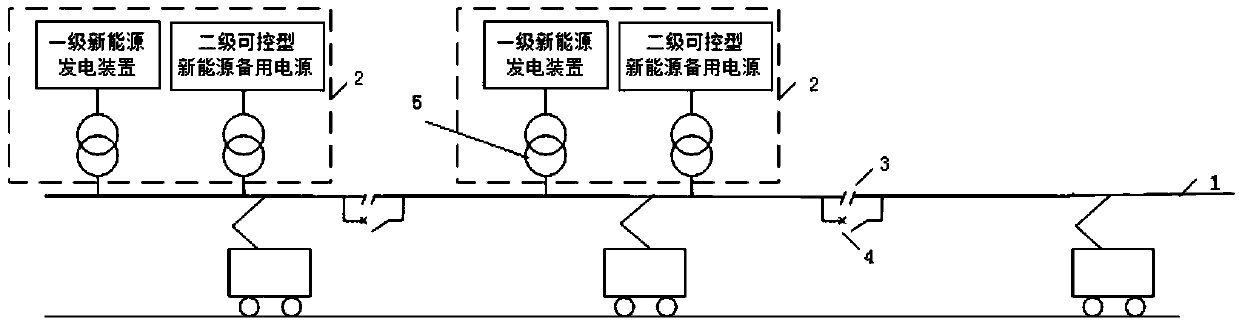

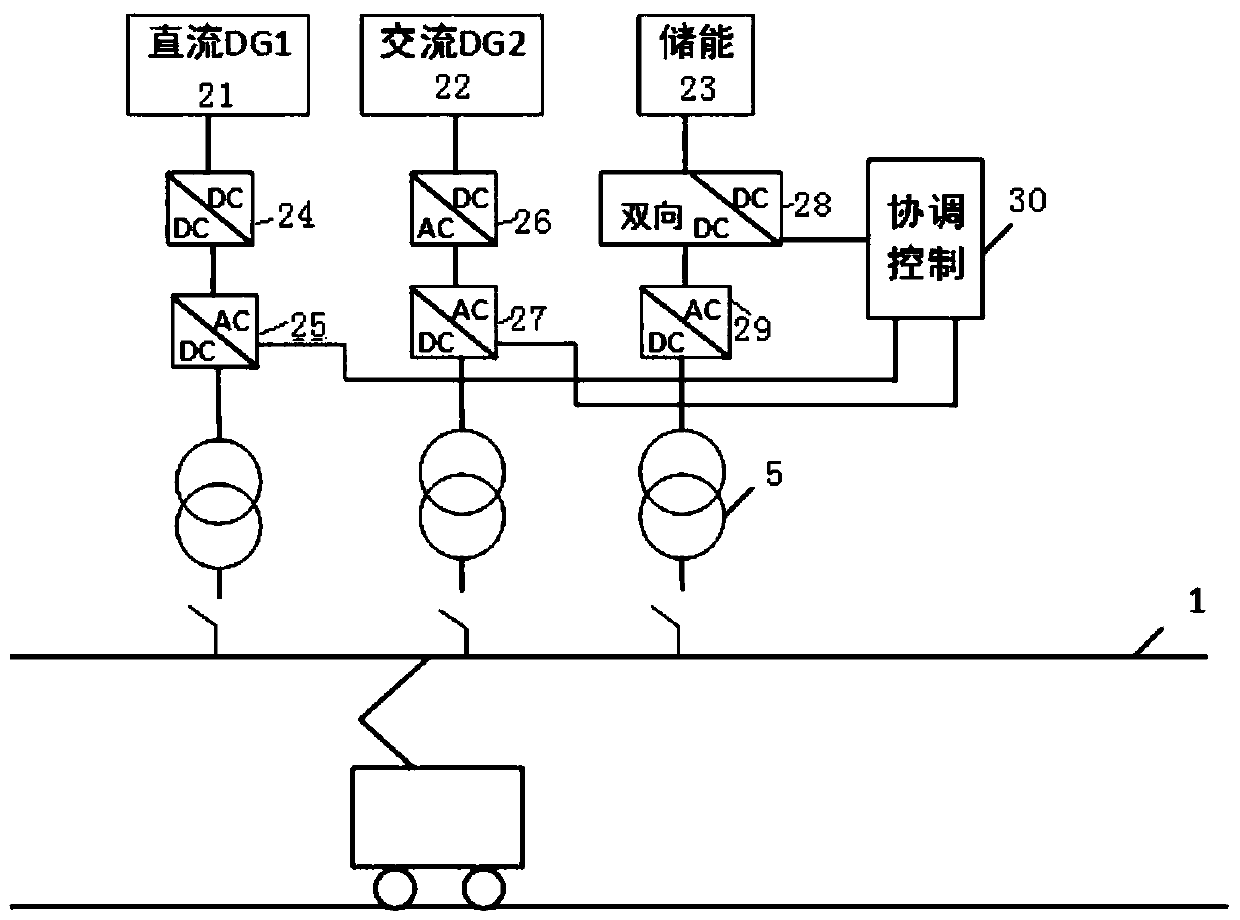

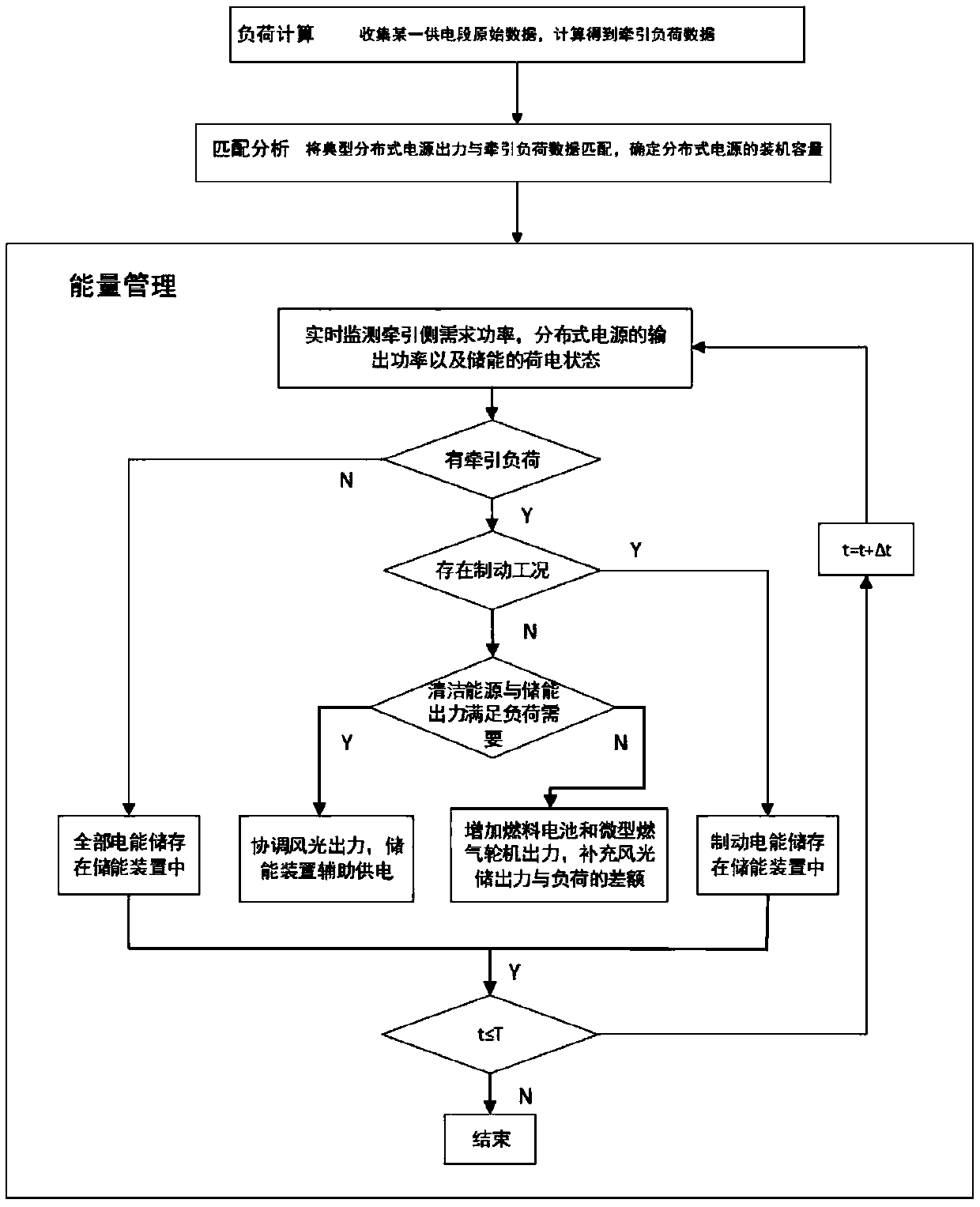

Off-grid railway traction power supply system and regulation and control method

The invention discloses an off-grid railway traction power supply system and a regulation and control method. The off-grid railway traction power supply system comprises a catenary, a distributed power substation, an electrical split phase and an electrical split phase switch, wherein the output end of the distributed power substation is connected to the catenary; the electrical split phase is arranged on the catenary between the adjacent distributed power substations; the electrical split phase switch is arranged on the electrical split phase in parallel; the distributed power substation comprises a primary new-energy power generation device, a secondary controllable new-energy backup power supply and single-phase boosting transformers; the primary new-energy power generation device and the secondary controllable new-energy backup power supply are independent of each other, and are connected to the catenary through the respective single-phase boosting transformers. The off-grid railway traction power supply system achieves off-grid operation of a train and improves the stability and the reliability of traction power supply of a microgrid railway; the off-grid railway traction power supply system is applicable to a grid-free area, consumes clean energy on a spot, and achieves energy conservation and emission reduction and green sustainable development of rail transit; the off-grid railway traction power supply system conforms to electric transmission locomotives widely used in China railways and has strong applicability.

Owner:SOUTHWEST JIAOTONG UNIV

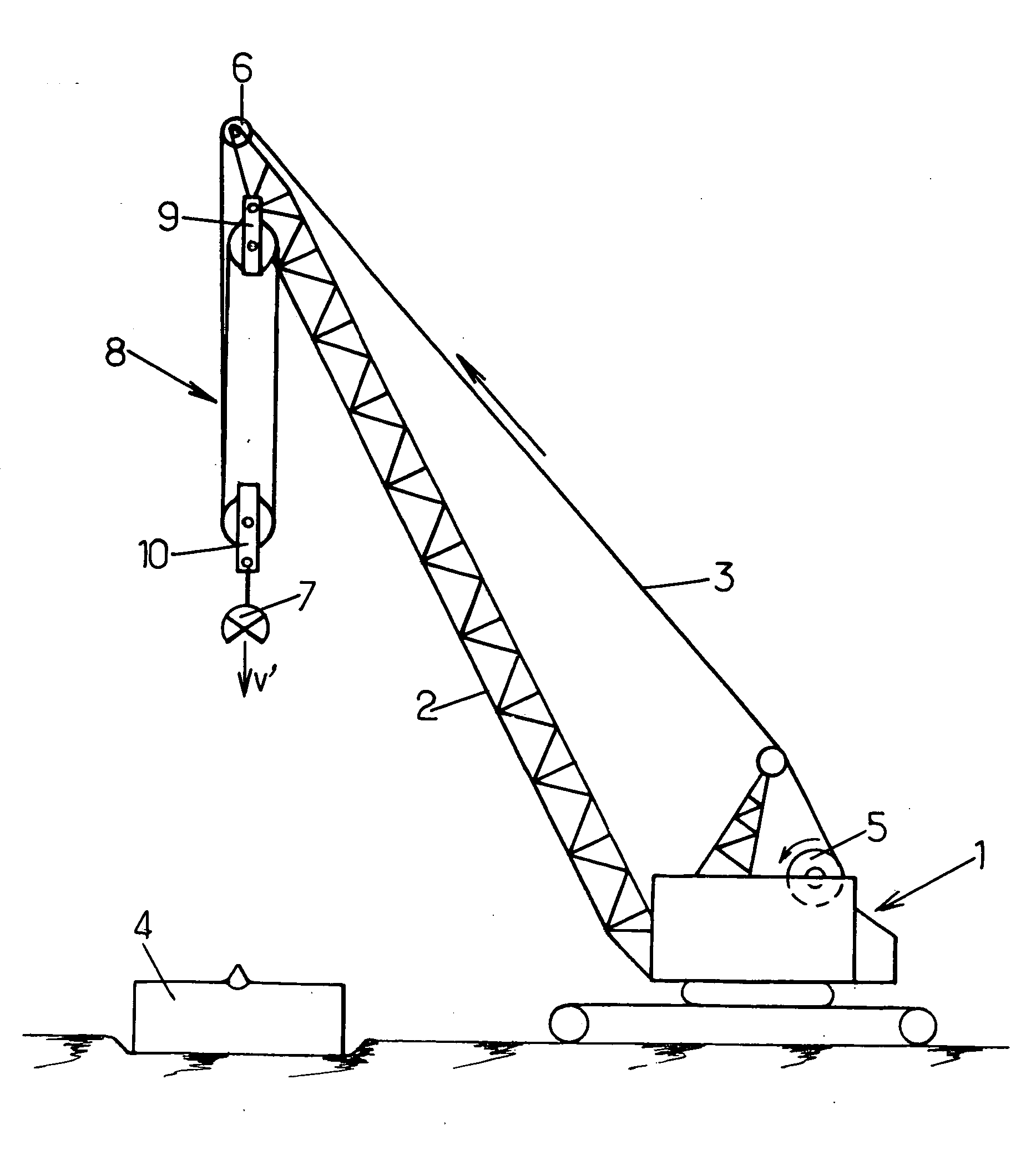

Method and machine for dynamic ground compaction

ActiveUS20050152750A1Avoid damage to the structureReduce the necessary timeWinding mechanismsSoil preservationEngineeringTractive force

At least one cable is attached to a load lying on the ground via releasable connection means. A traction force is applied to the cable to hoist the load up to a prescribed height. That traction force is then eliminated or reduced to initiate a downward movement of the load followed by the cable. The connection means are then released while the load is moving downwardly.

Owner:FREYSSINET INT STUP

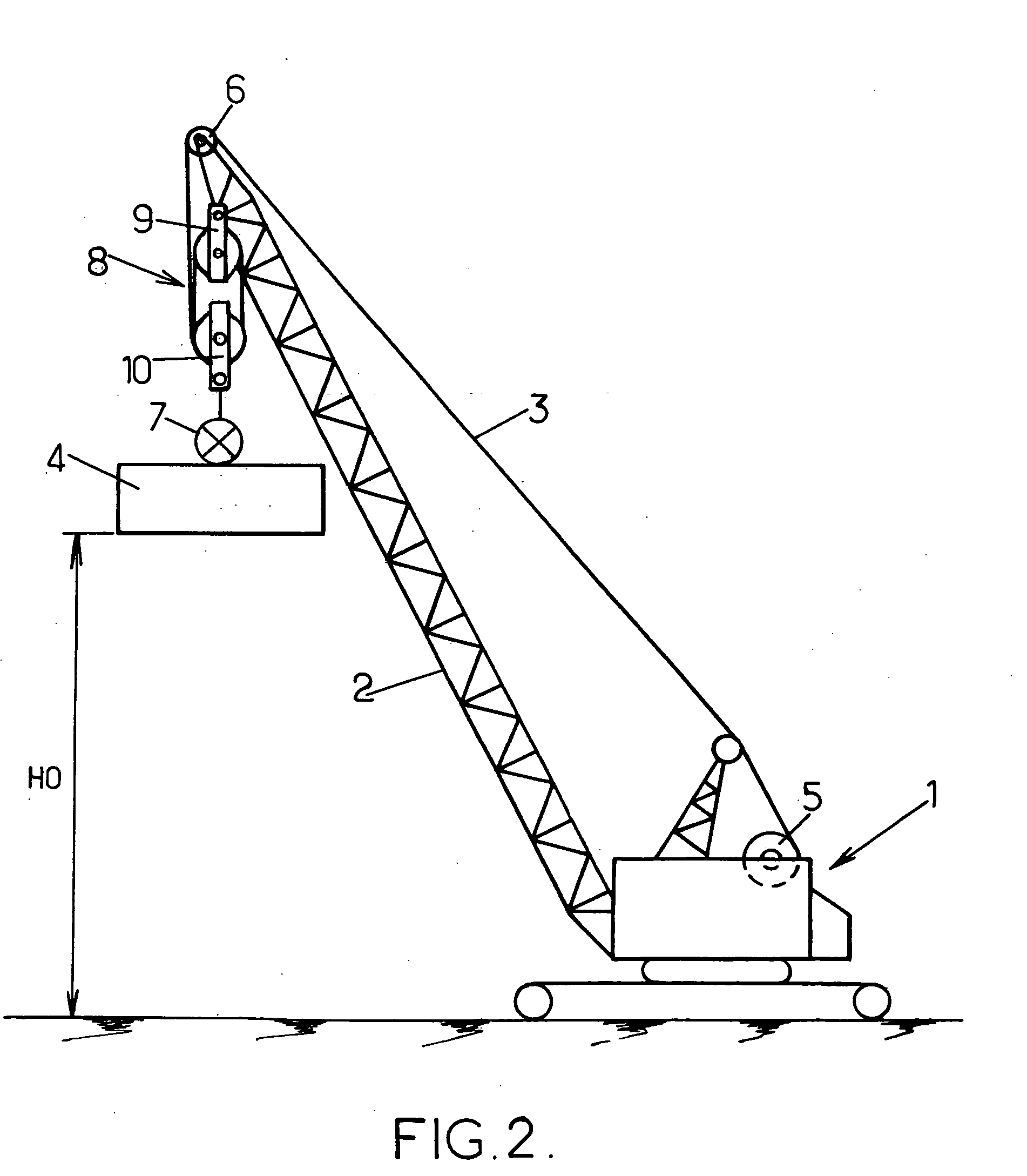

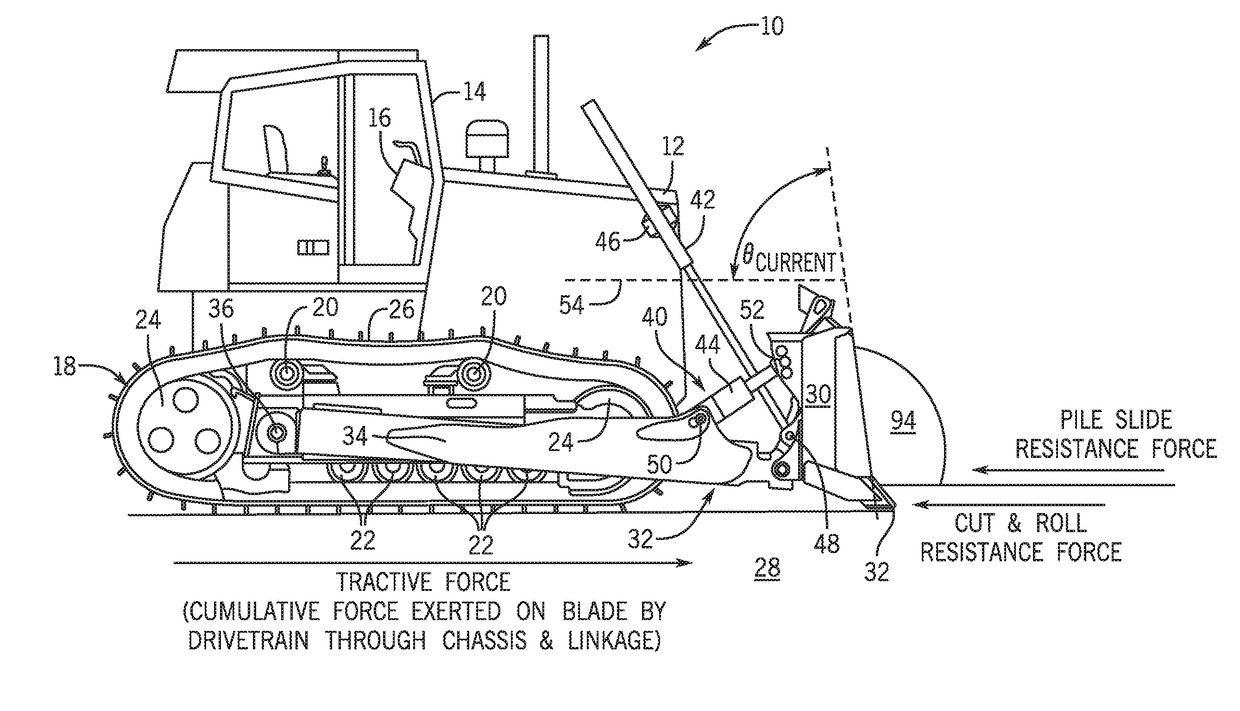

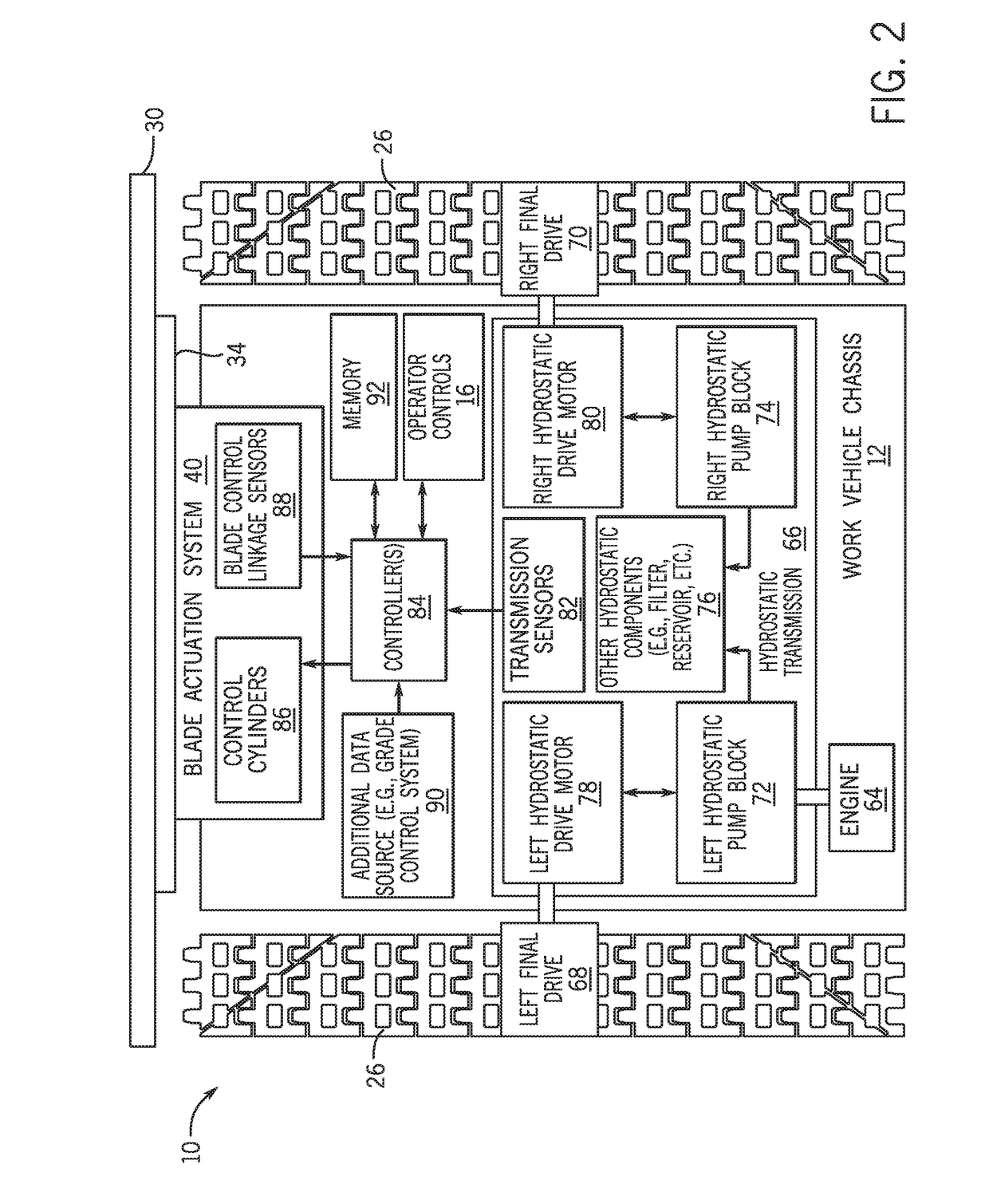

Force-based work vehicle blade pitch control

ActiveUS20170226717A1Total current dropReduce tractionMechanical machines/dredgersAutomotive engineeringBlade pitch

A system and method for automatically adjusting blade pitch in crawler dozers, motor graders, and other bladed work vehicles includes estimating a current tractive force of the work vehicle utilizing one or more controllers that establish whether the current tractive force of the work vehicle can be reduced by rotating the blade to an optimized pitch angle. A command is transmitted from the one or more controllers to a blade actuation system to rotate the blade to the optimized pitch angle. The method may be performed iteratively to repeatedly adjust the blade pitch to optimized angles as the work vehicle operates and conditions affecting the optimal blade pitch angle vary.

Owner:DEERE & CO

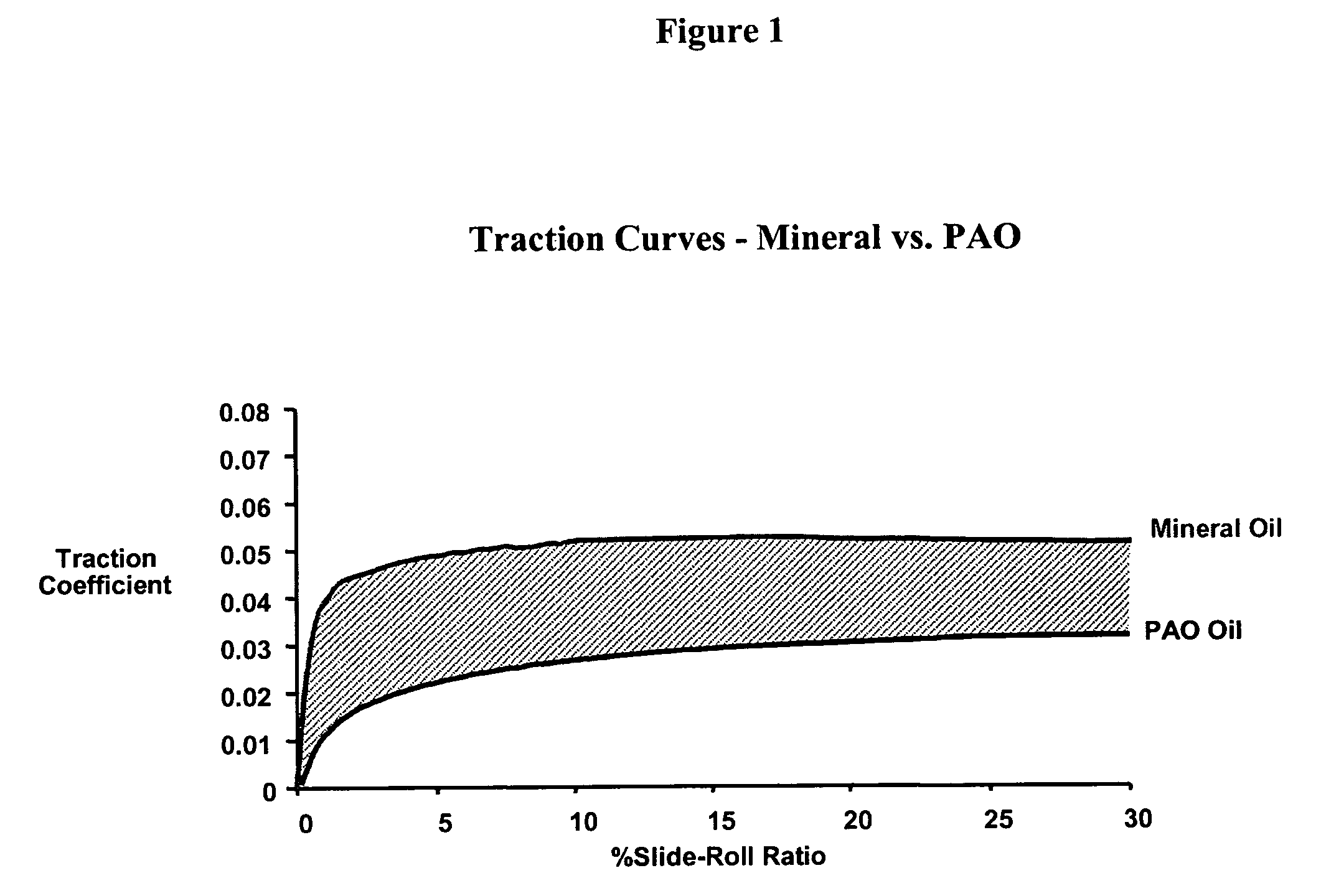

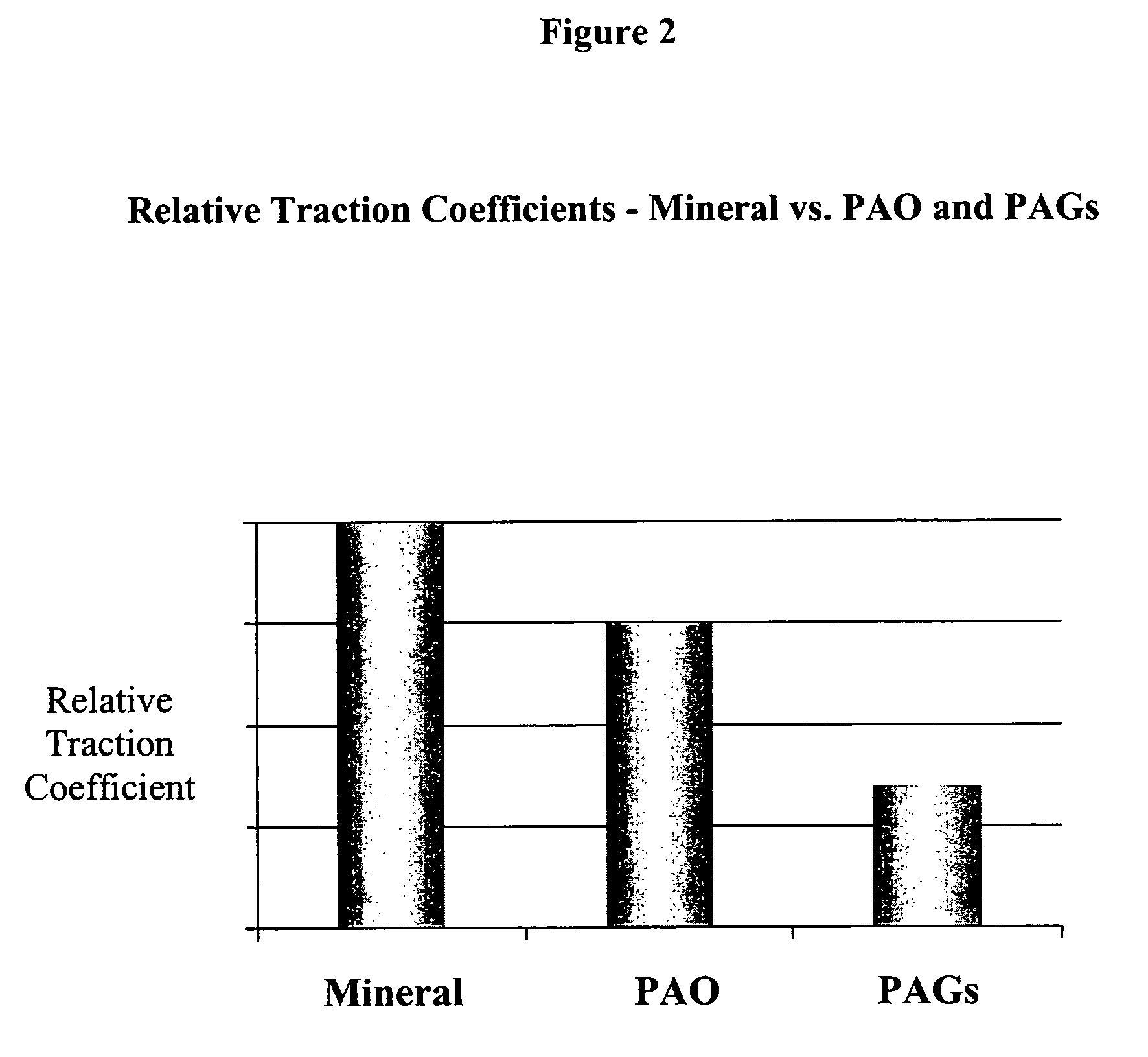

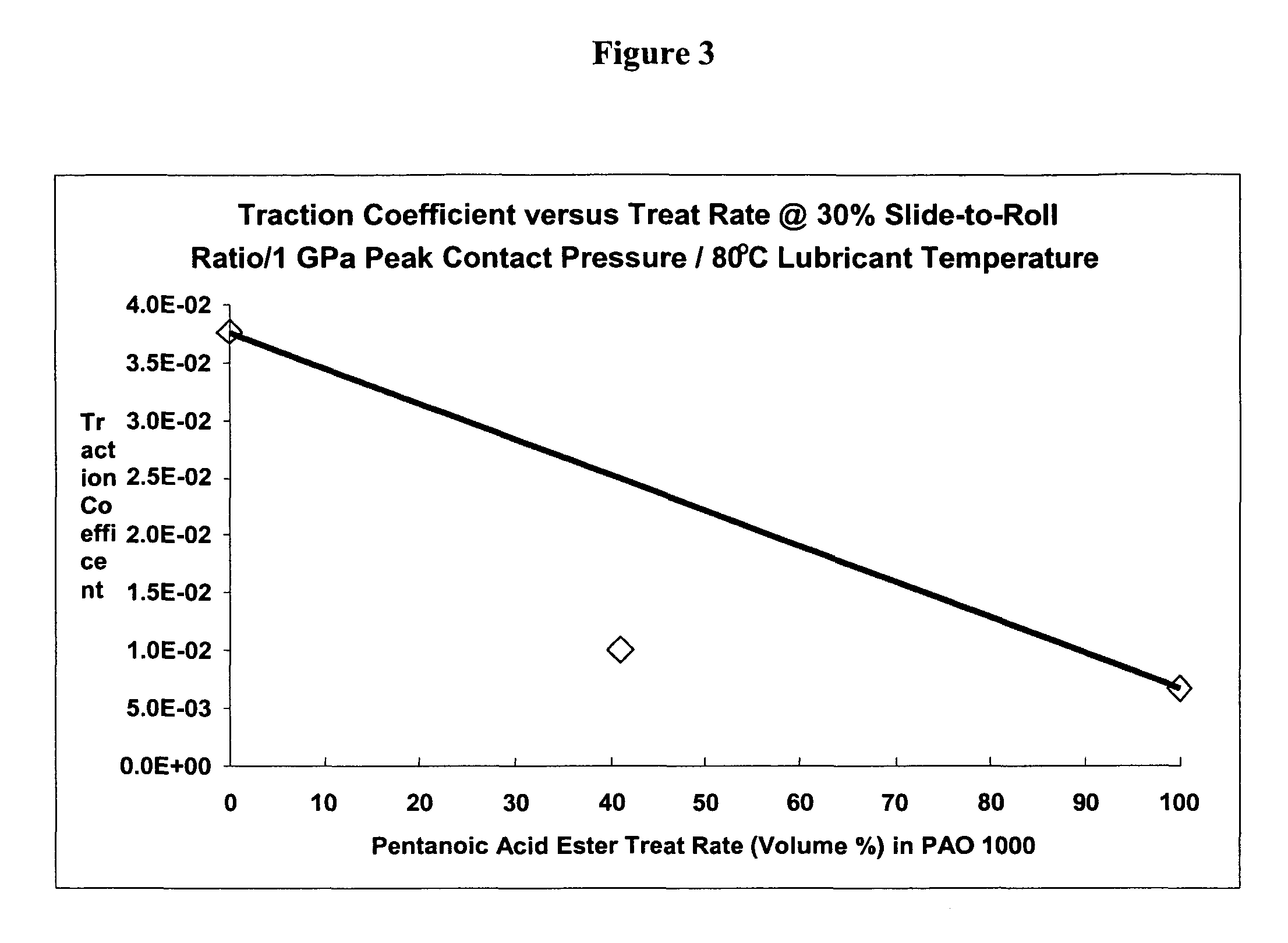

Lubricating fluids with low traction characteristics

InactiveUS7732389B2Reduce tractionImprove efficiencyBase-materialsOrganic chemistryPolymer chemistry

Owner:EXXONMOBIL CHEM PAT INC

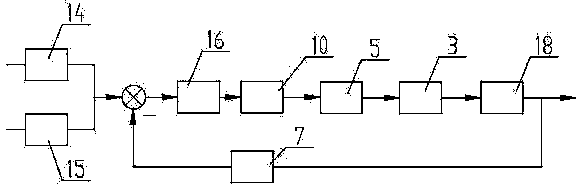

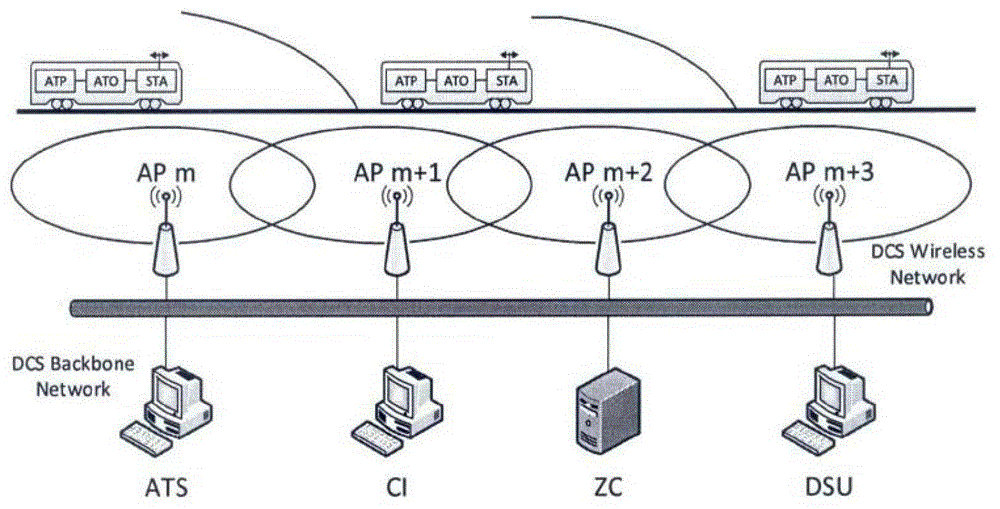

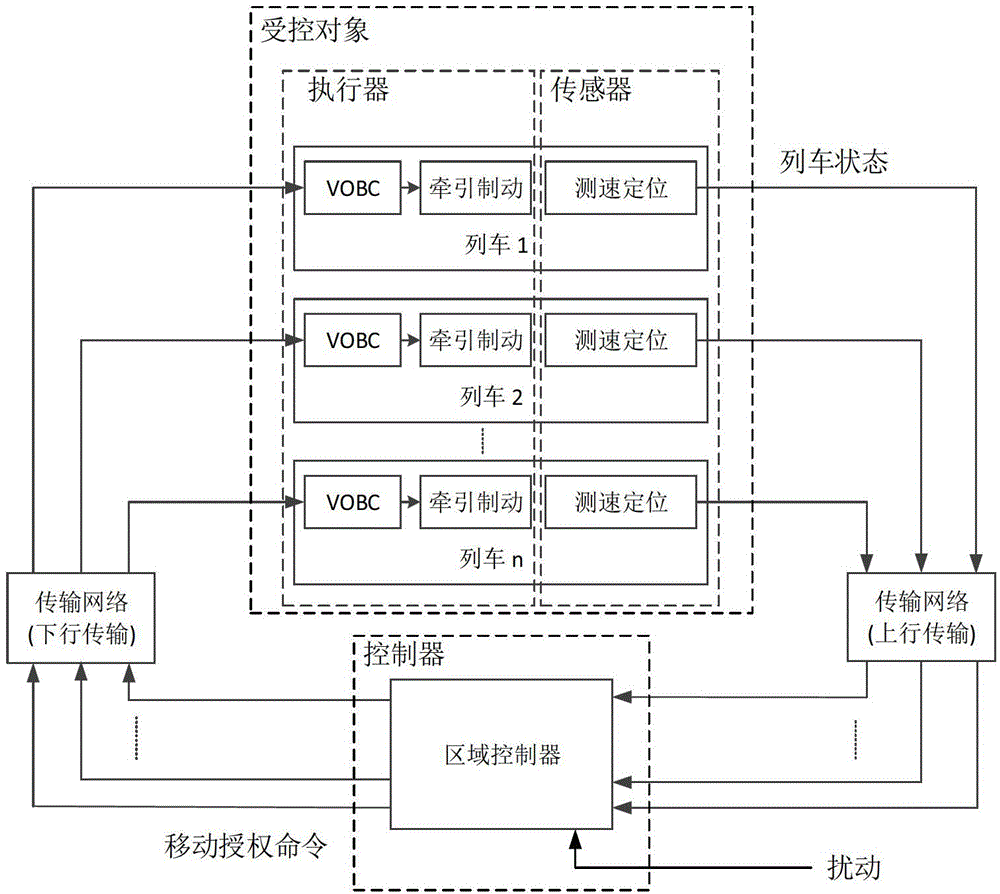

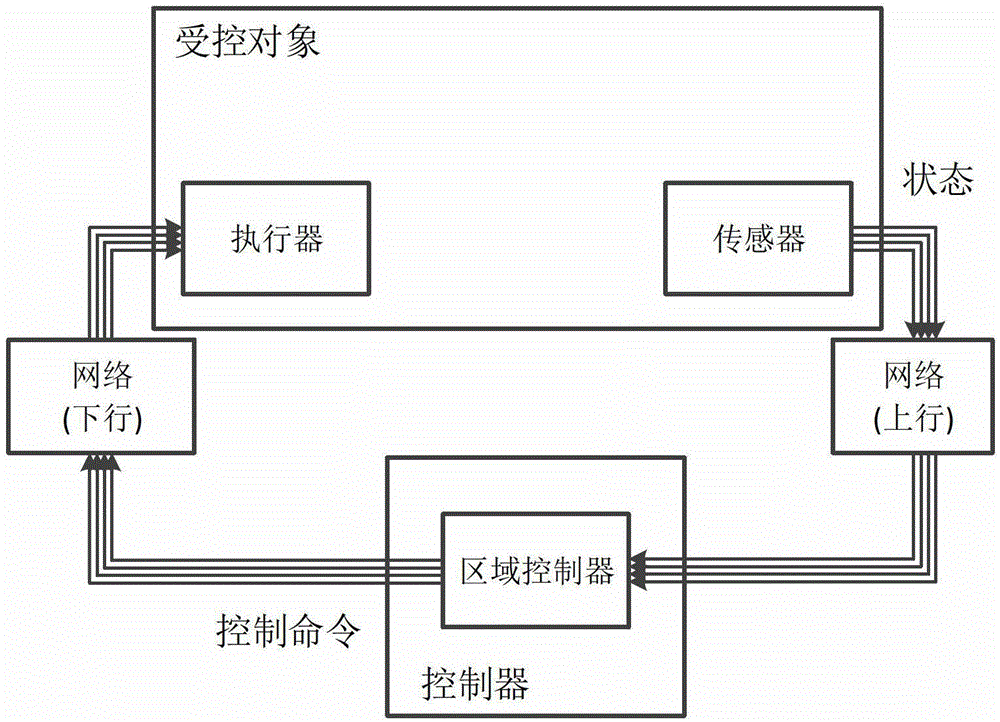

Improvement method of performance of train operation control system

InactiveCN103332211AEliminate the impact of operational control performanceReduce tractionRailway signalling and safetyControl systemTime delays

The invention discloses an improvement method of performance of a train operation control system in the technical field of train operation control. The method comprises the steps that a zone controller receives current status information of all trains at the beginning of the kth period; when the set maximum allowable waiting time is not exceeded, the zone controller computes the total time delay for generating and sending a moving authority command during the kth period; the zone controller forecasts the status information of all the trains, and generates the moving authority command according to the status information of each train and the status information of all the trains in front of the train; a timestamp is inserted into the moving authority command and sent to all the trains; after each train receives the moving authority command, the timestamp is extracted, and the execution time of the moving authority command is computed according to the specified waiting time; after each train reaches the execution time of the moving authority command, the moving authority command is executed; the next period is entered; and the steps are continued. The method eliminates an influence of train uplink and downlink transmission time delay on the train operation control performance.

Owner:BEIJING JIAOTONG UNIV

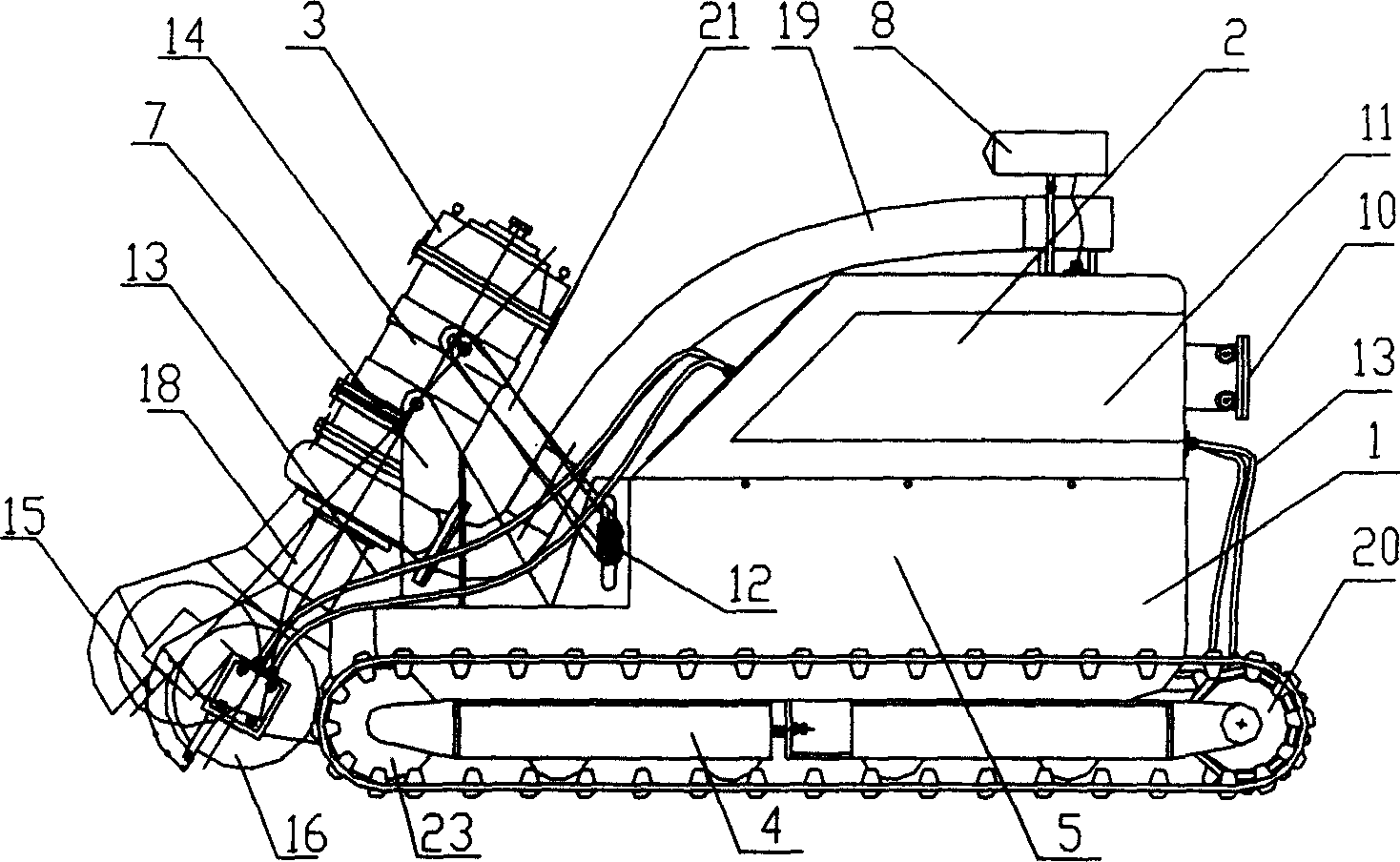

Crawler-type under water ecological precision thin layer slurry dredger

InactiveCN1554833A"Endogenous" Pollution ControlLarge footprintMechanical machines/dredgersSludgeControl system

The present invention belongs to the field of environment protecting technology. The crawler-type underwater ecological precise thin-layer sludge dredger consists of main system, hydraulic control system, sludge sucking system in front of the main system, and walking system below the main system. The main system includes box, support rods, frame, lighting unit and video monitor. The present invention has small size, light weight, simple structure and easy operation, and is suitable for dredging sludge in river, lake, reservoir, etc.

Owner:章永泰

Floating mounting construction method for multiple PE pipes in large jacking pipe

ActiveCN107339111AWelding quality is guaranteedReduce resistanceMining devicesTunnelsEngineeringWire rope

The invention discloses a floating mounting construction method for multiple PE pipes in a large jacking pipe. A working well and a receiving well are excavated at the two ends of the jacking pipe correspondingly, and a lower slope path is excavated to a reserved hole of the working well; welding of the PE pipes is completed outside the working well, and a pulling head is welded to the head end of the welded PE pipe; a winch is placed at one end of the receiving well, and a fixing bracket and a roller set are arranged in the receiving well; a steel wire rope wound on the winch manually winds across the roller set, is pulled into the receiving well, is pulled outside the working well through a pulling trolley sequentially along the jacking pipe and the working well, and is connected with the pulling head, and a thin steel wire rope body is tied at the head end of the steel wire rope; water is injected into the jacking pipe to reach a certain water level; and the PE pipe is pulled to a predetermined position through the steel wire rope, water is pumped out, and the PE pipe sinks to the preset position. According to the floating mounting construction method, the welding quality of the PE pipe is improved, the PE pipe is pulled by the steel wire rope to move forwards, the pulling resistance of the PE pipe is reduced through the buoyancy of the water, and the problem of difficult mounting in-place of the multiple PE pipes in the narrow space is solved.

Owner:中城投集团第六工程局有限公司

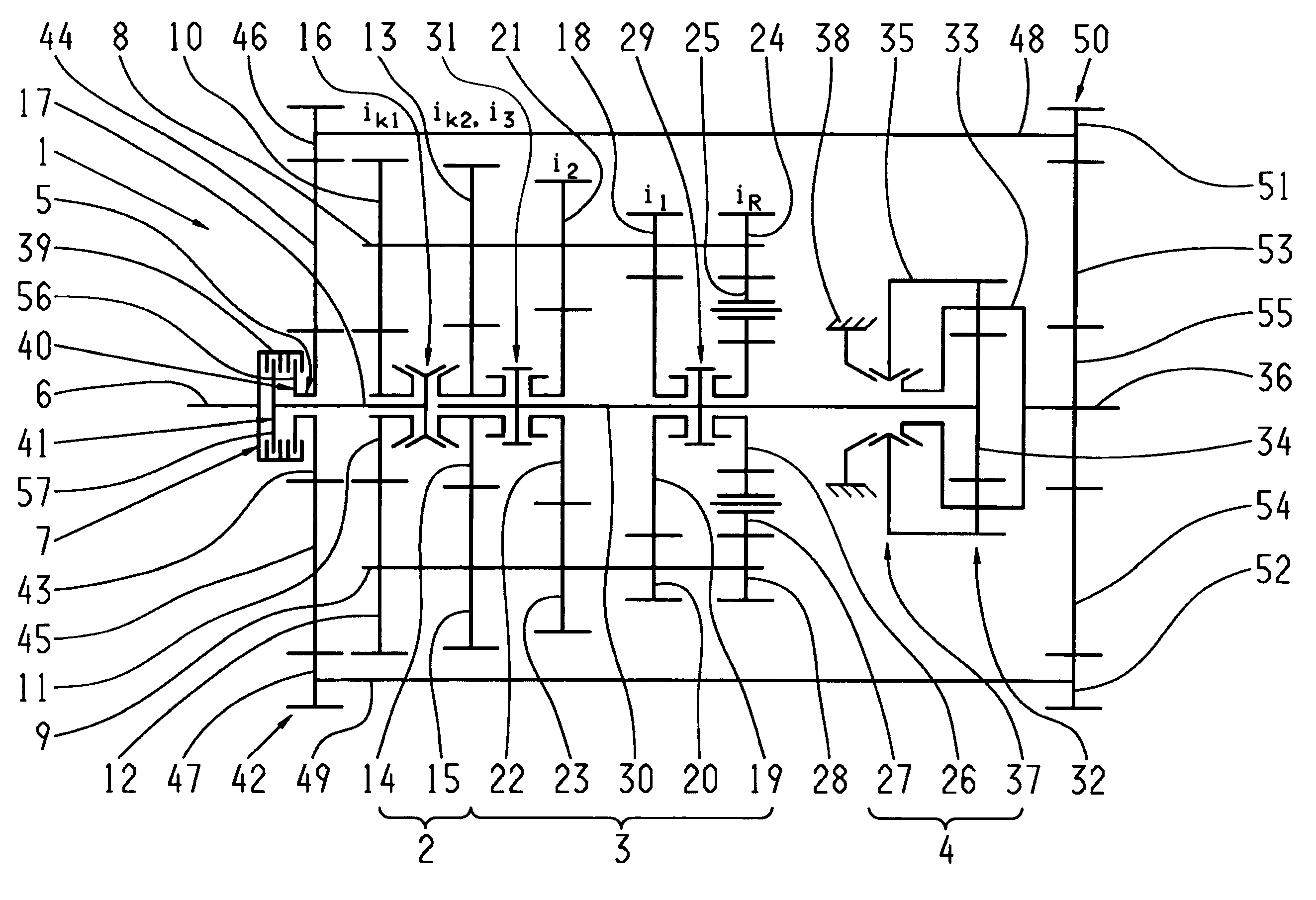

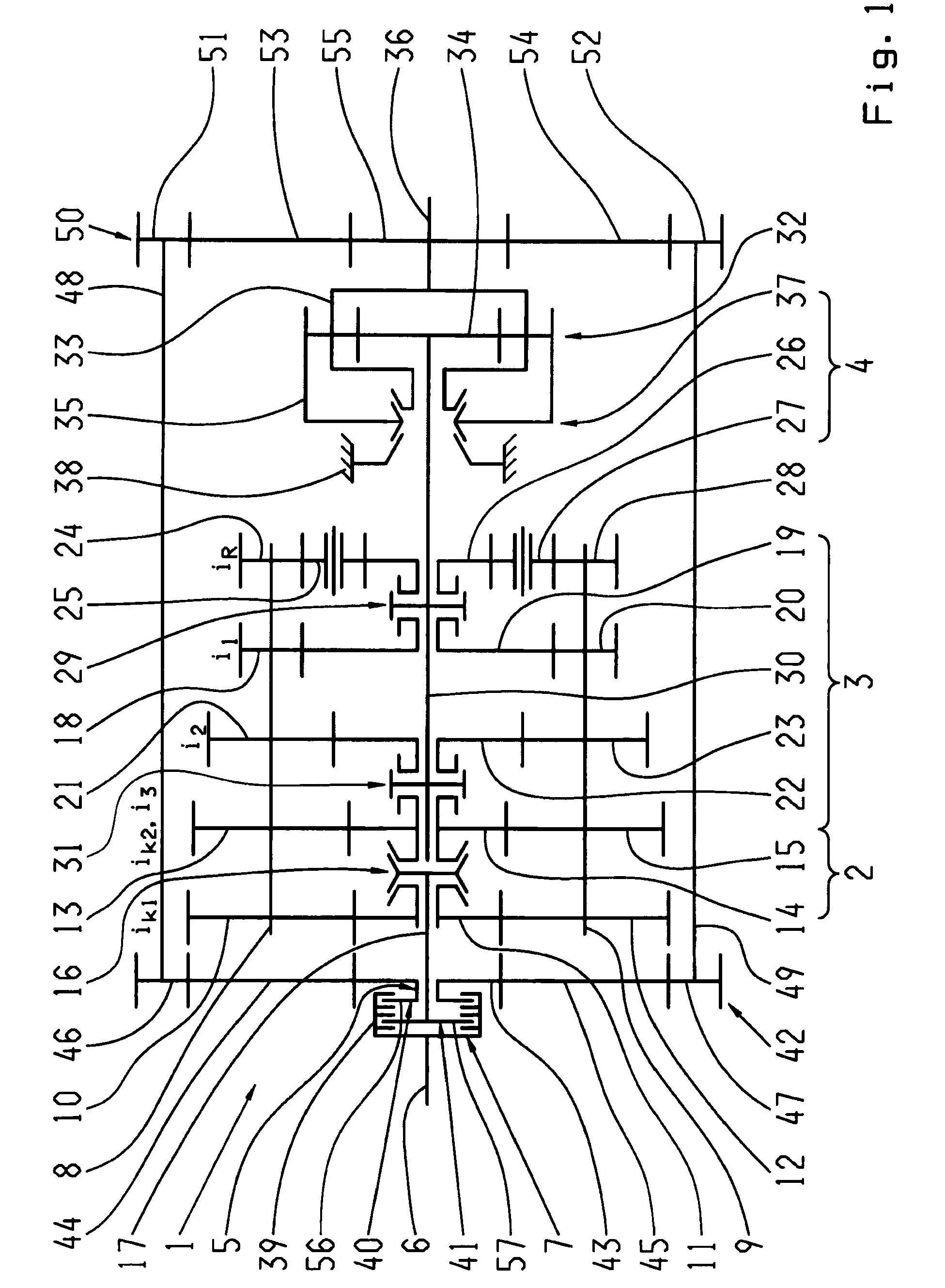

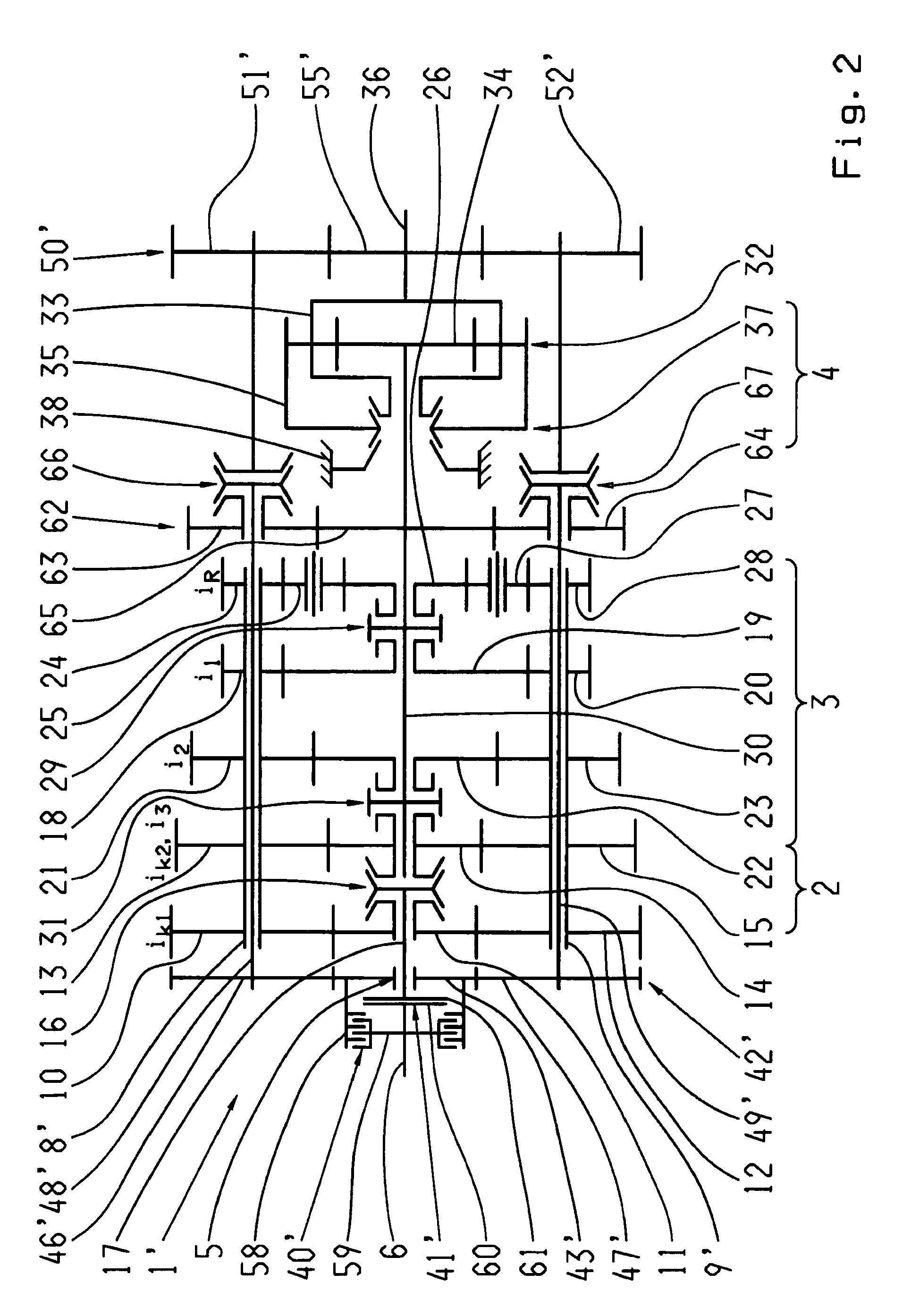

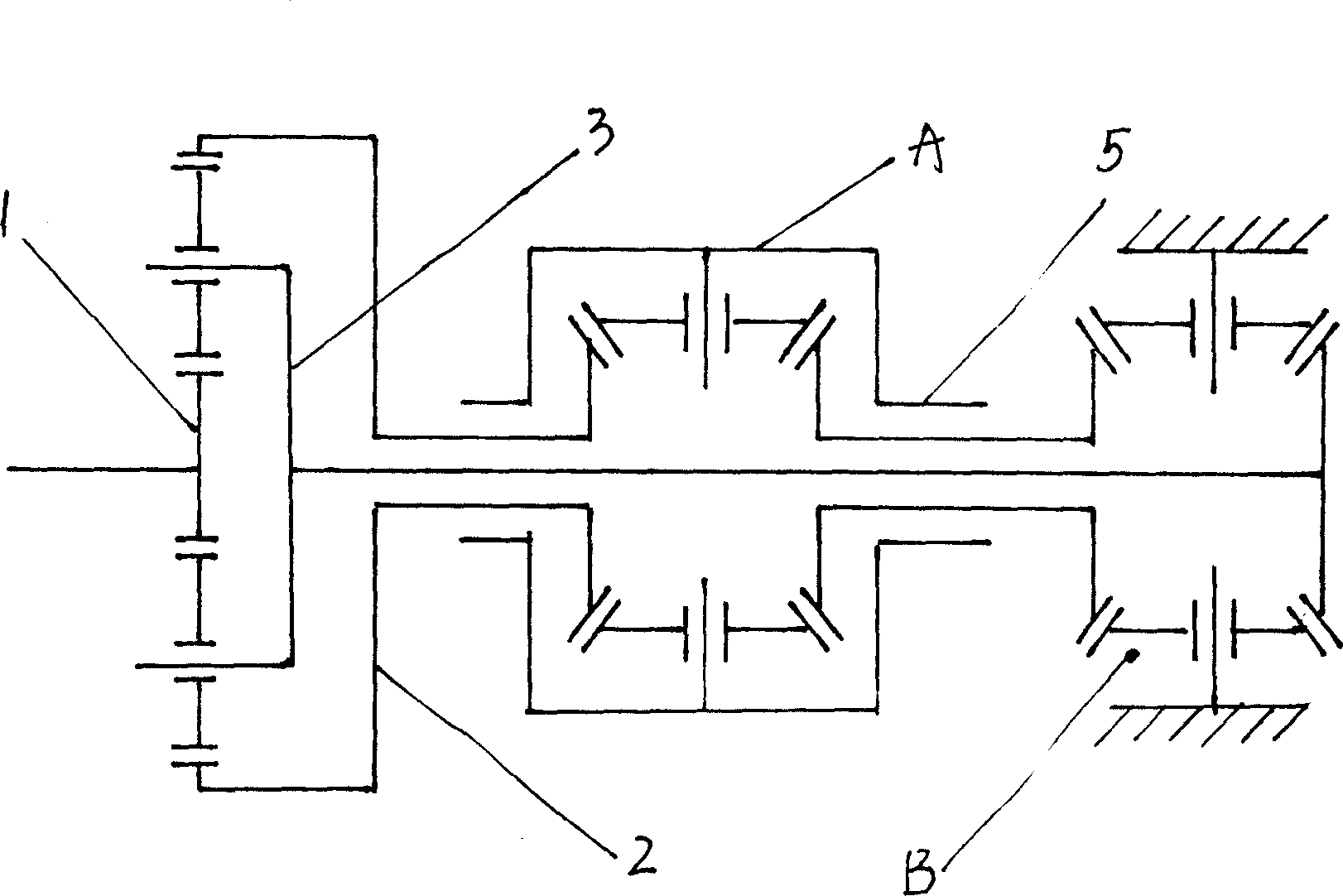

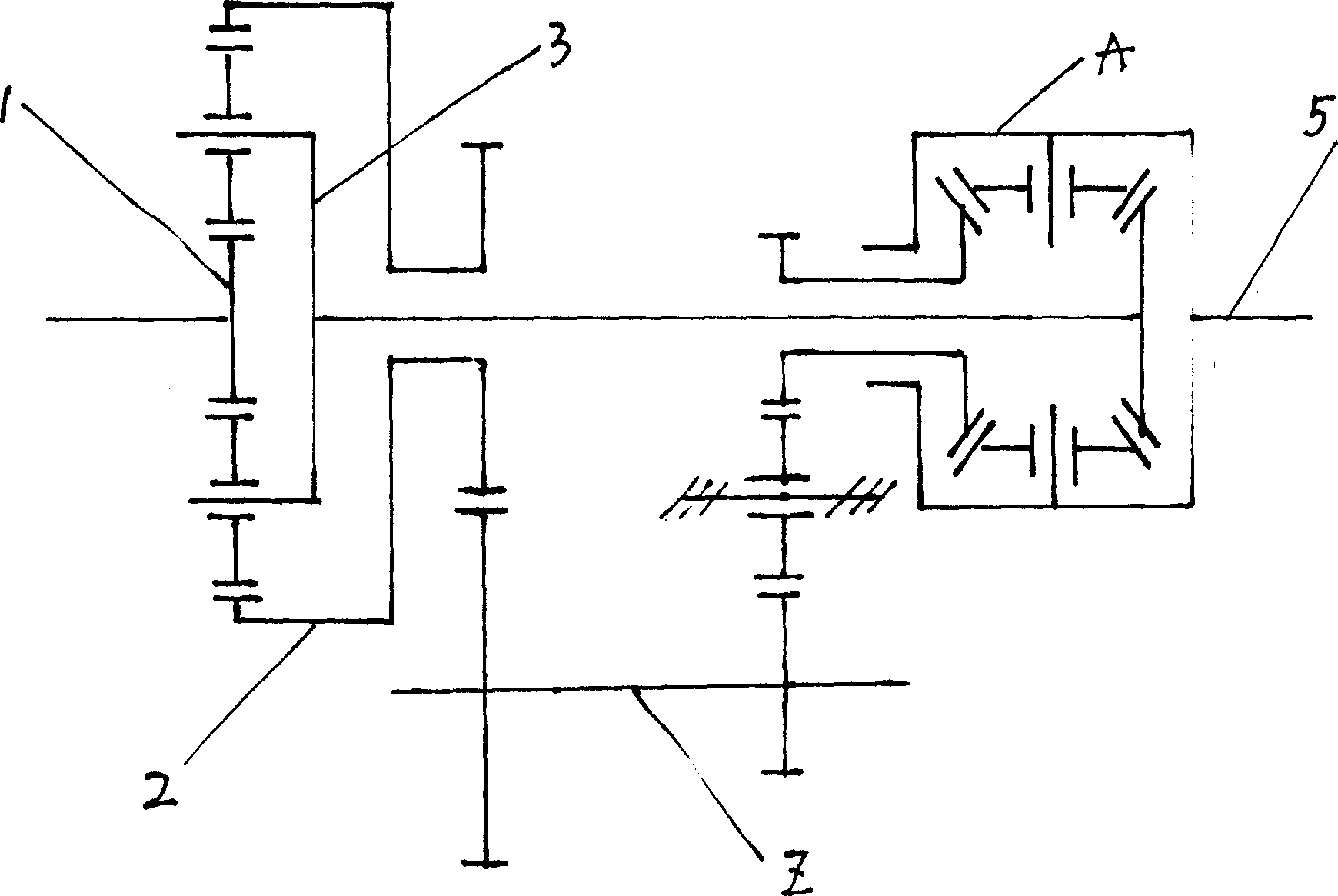

Multi-group transmission of a motor vehicle

A multi-group transmission of a motor vehicle and a method of operating the transmission. The transmission has at least two transmission groups in the drive train and a mechanism for engaging an intermediate gear to reduce drive force interruptions during gearshifts. To obtain comfortable, shift operations that are free from drive force interruptions by way of an intermediate gear, a starting element and a shift-under-load element are arranged between a drive shaft, that is actively connected to a motor, and a transmission input, such that by way of the shift-under-load element, an active connection is formed between the driveshaft and a transmission output shaft, via at least one auxiliary shaft made as an intermediate gear shaft, with a drive input gearset and at least one drive output gearset bypassing at least a main group and independent of the engagement or disengagement of the starting element.

Owner:ZF FRIEDRICHSHAFEN AG

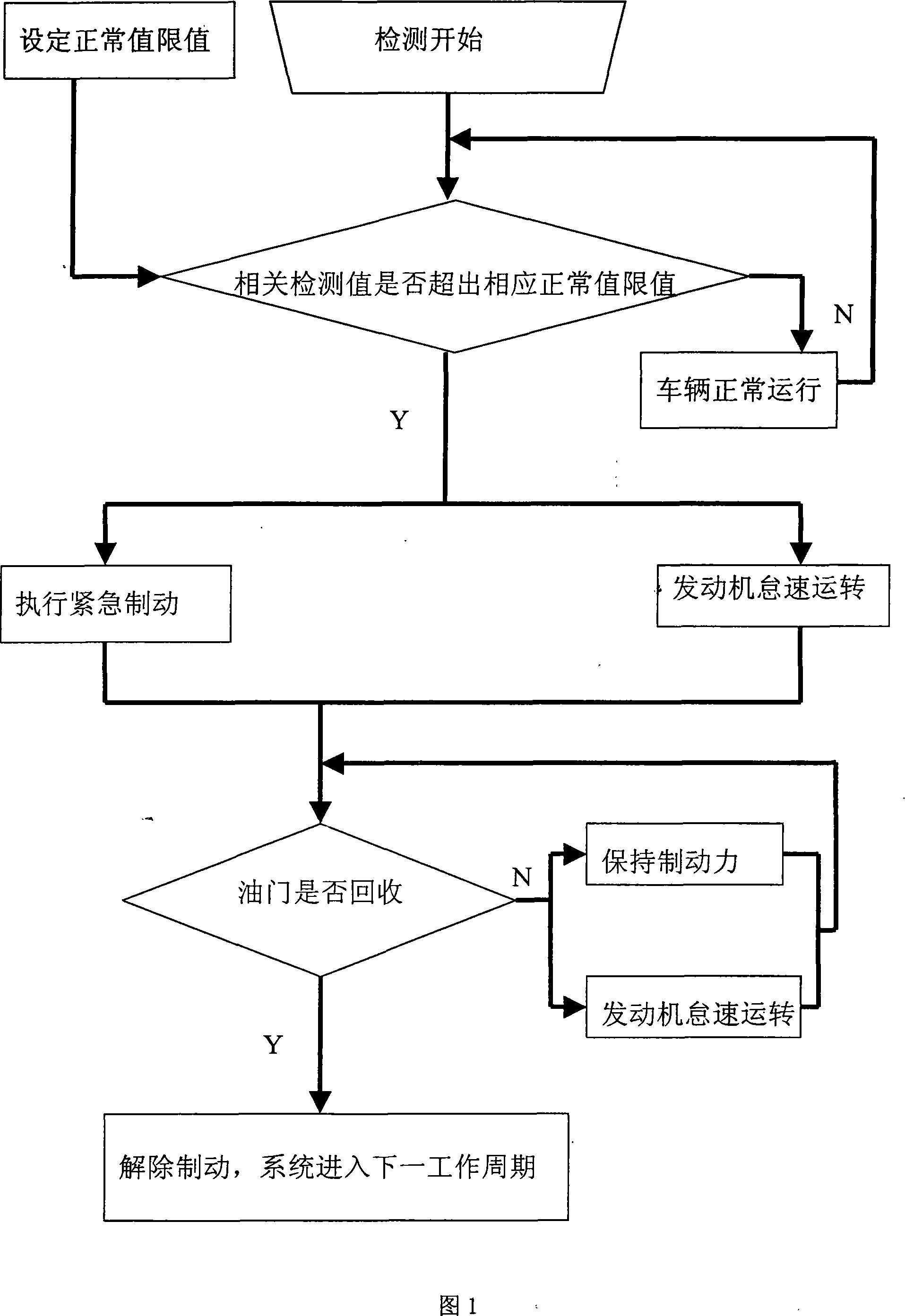

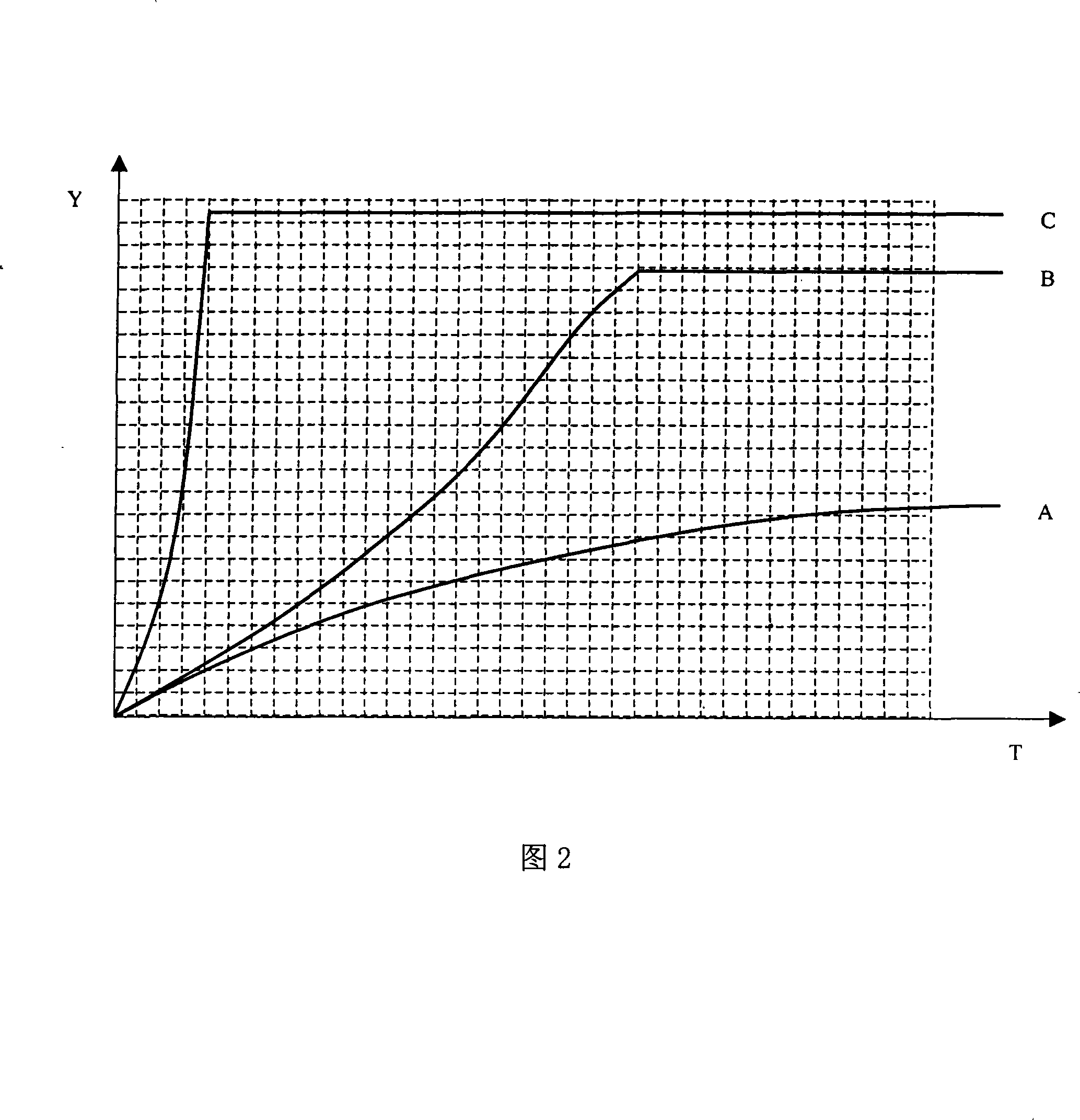

Emergency protective system for mistake floorboarding of vehicle

The invention discloses an automobile safety system for mistakenly treading a throttle in emergency, relating to an active safety field of automobile; the invention comprises a judging device of mistakenly treading the throttle and a brake device; an engine control unit (ECU) is used for detecting the displacement amount in a certain period according to senor signals; the action of treading the throttle at a time is judged as a mistake when the detected value exceeds a corresponding threshold value of normally treading the throttle; when the throttle is treaded by mistake, the ECU outputs a braking current to start the brake device and control an engine to operate in an idle speed state; when a throttle pedal is withdrawn, the automatic brake ends up and enters into the next work period.

Owner:张国法

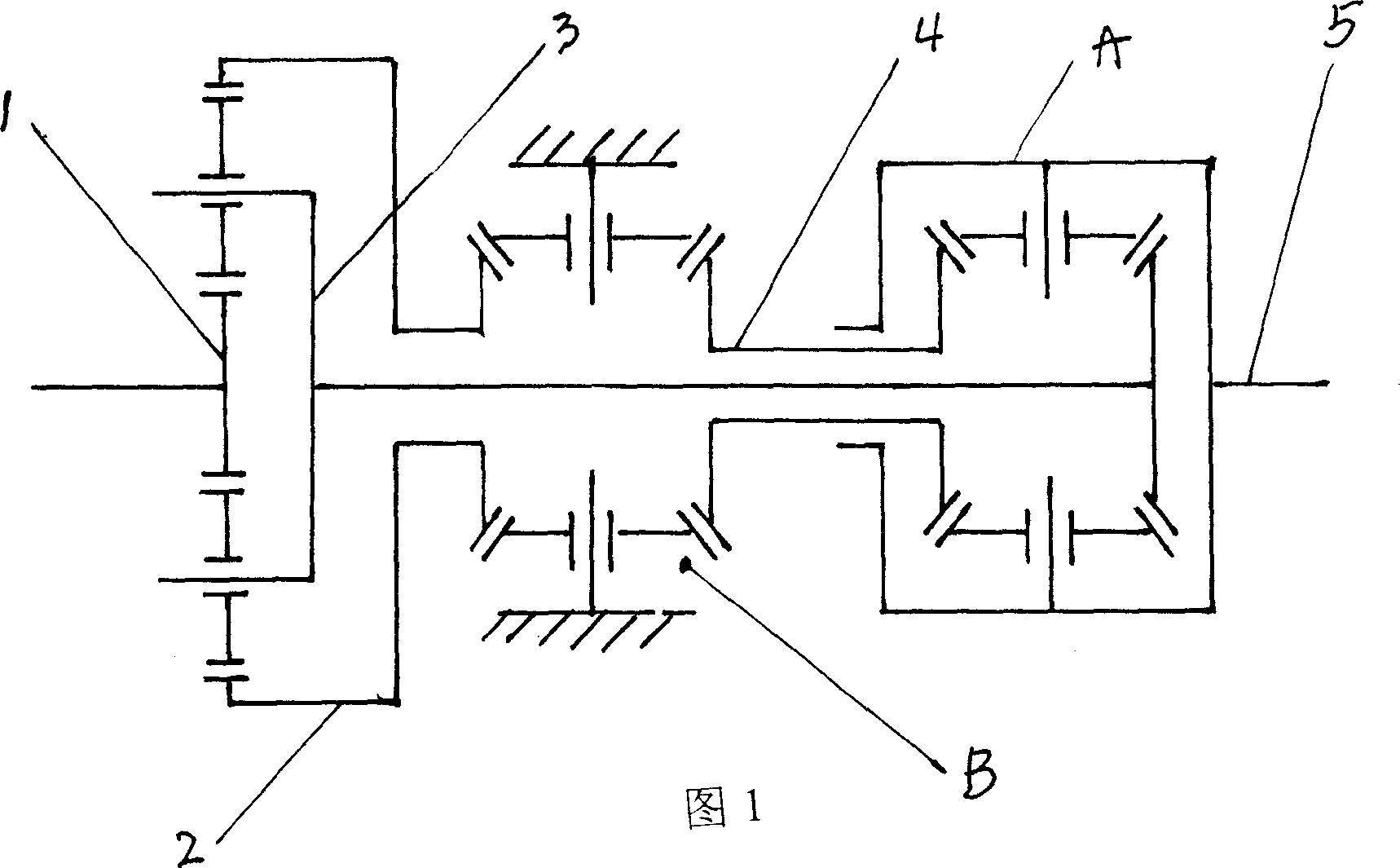

Mechanical stepless automatic transmission

InactiveCN1865732AGood powerGood fuel economyToothed gearingsDifferential gearingsAutomatic transmissionGear wheel

The invention discloses a mechanical stepless automatic speed changer, which is formed by planet device, speed-differential device and a frame. Wherein, it is characterized in that: the planet device and the speed-differential device both have two freedoms; the sun wheel of planet device is connected to the power output wheel of engine; the planet support is connected to the one semi-axle gear wheel of differential device; the cross axle of differential device is connected to the output axle; two semi-axle gear wheels of another differential device are connected to the tooth ring of planet device and another idle semi-axle gear wheel of the front differential device; the cross axle of differential device is connected to the frame. The invention has simple structure and standard equiaxed hyperbola power output character.

Owner:吴秋明

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com