Floating mounting construction method for multiple PE pipes in large jacking pipe

A construction method and pipe jacking technology, which is applied to mining equipment, earthwork drilling, mining equipment, etc., can solve the problems of difficulty in installing multiple PE pipes, achieve great promotion value, technical feasibility, and reduce resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

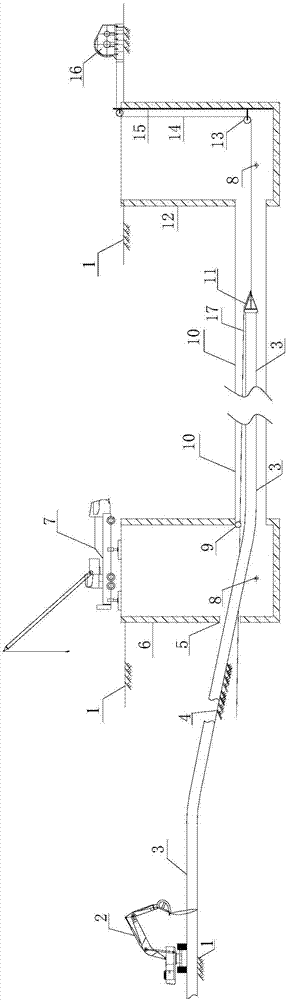

[0016] Embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

[0017] The construction method of floating installation of multiple PE pipes in large jacking pipes, such as figure 1 shown, including the following steps:

[0018] (1) excavate the working well 6 at the head end of the pipe jacking 10, excavate the receiving well 12 at the end of the pipe jacking 10, the pipe jacking 10 connects the working well 6 and the receiving well 12, and the side of the working well 6 far away from the pipe jacking 10 has a preliminary Leave hole 5, excavate a descending ramp 4 from natural ground 1 to reserved hole 5;

[0019] (2) Weld several sections of standard PE pipes into a PE pipe 3 of required length, and weld the pulling head 11 at the head end; manually set the fixed bracket 15 and the pulley block 13 in the receiving well 12, and set them at the outlet of the receiving well 12 Hoist 16;

[0020] (3) Manually lead the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com