Patents

Literature

3732results about How to "Guarantee welding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

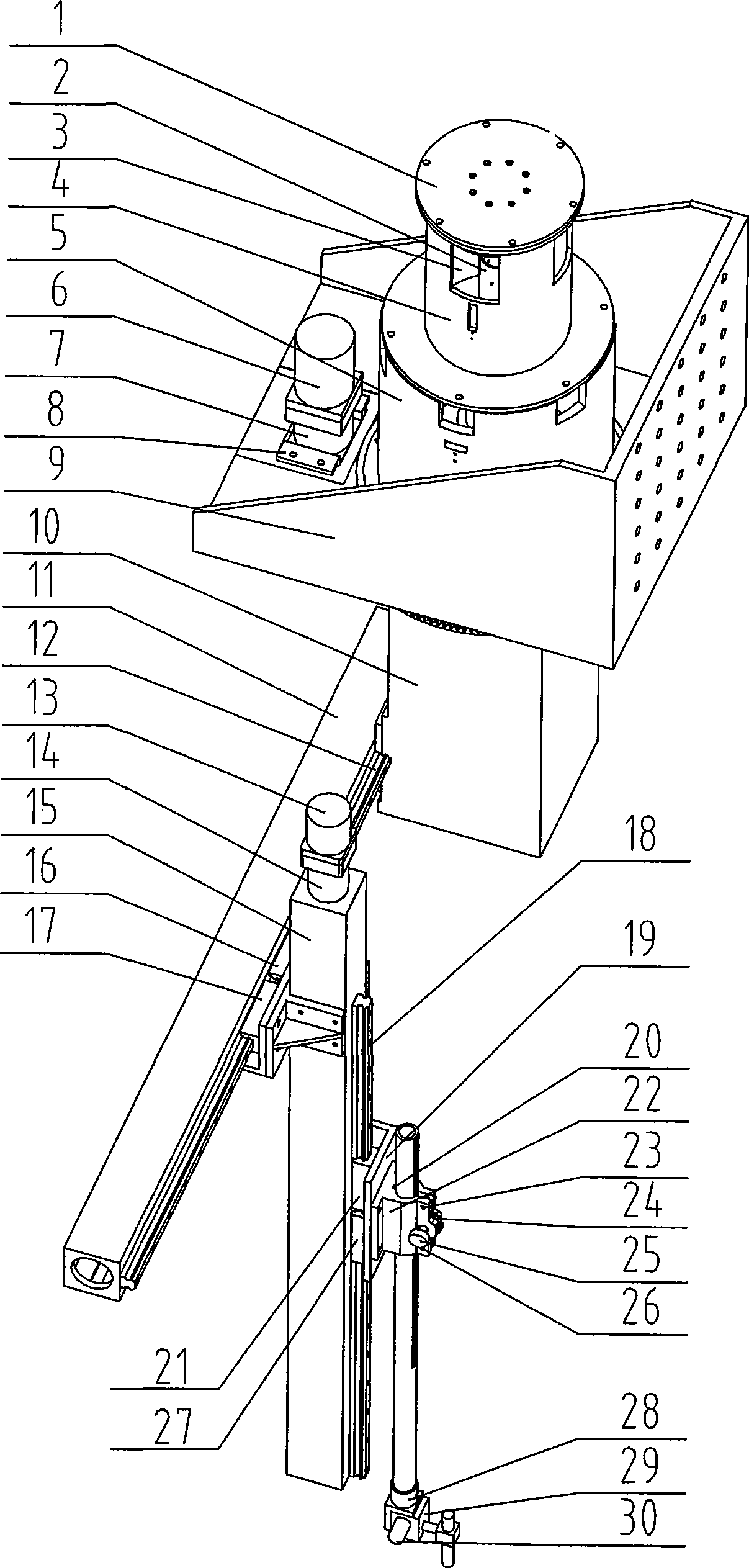

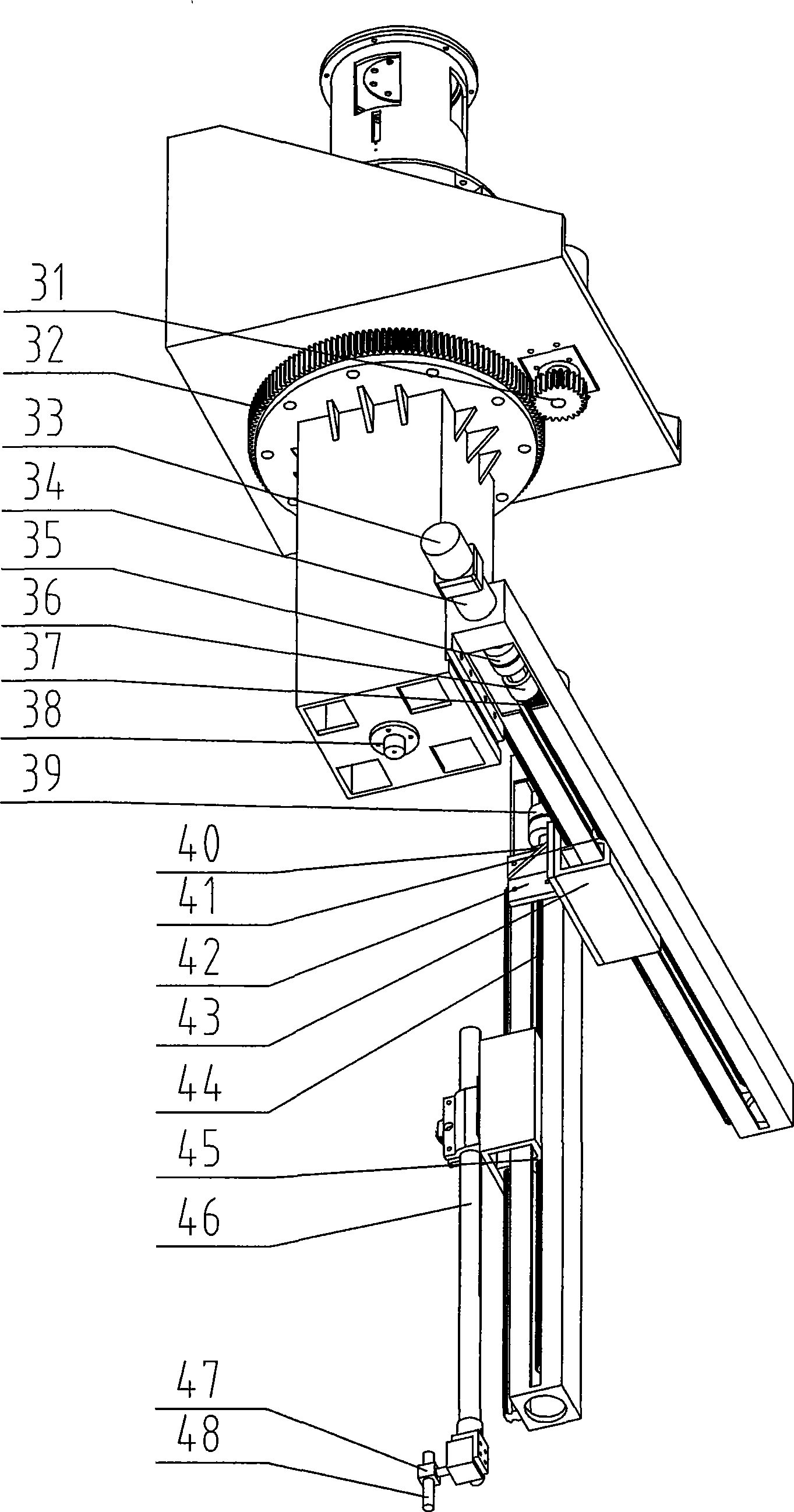

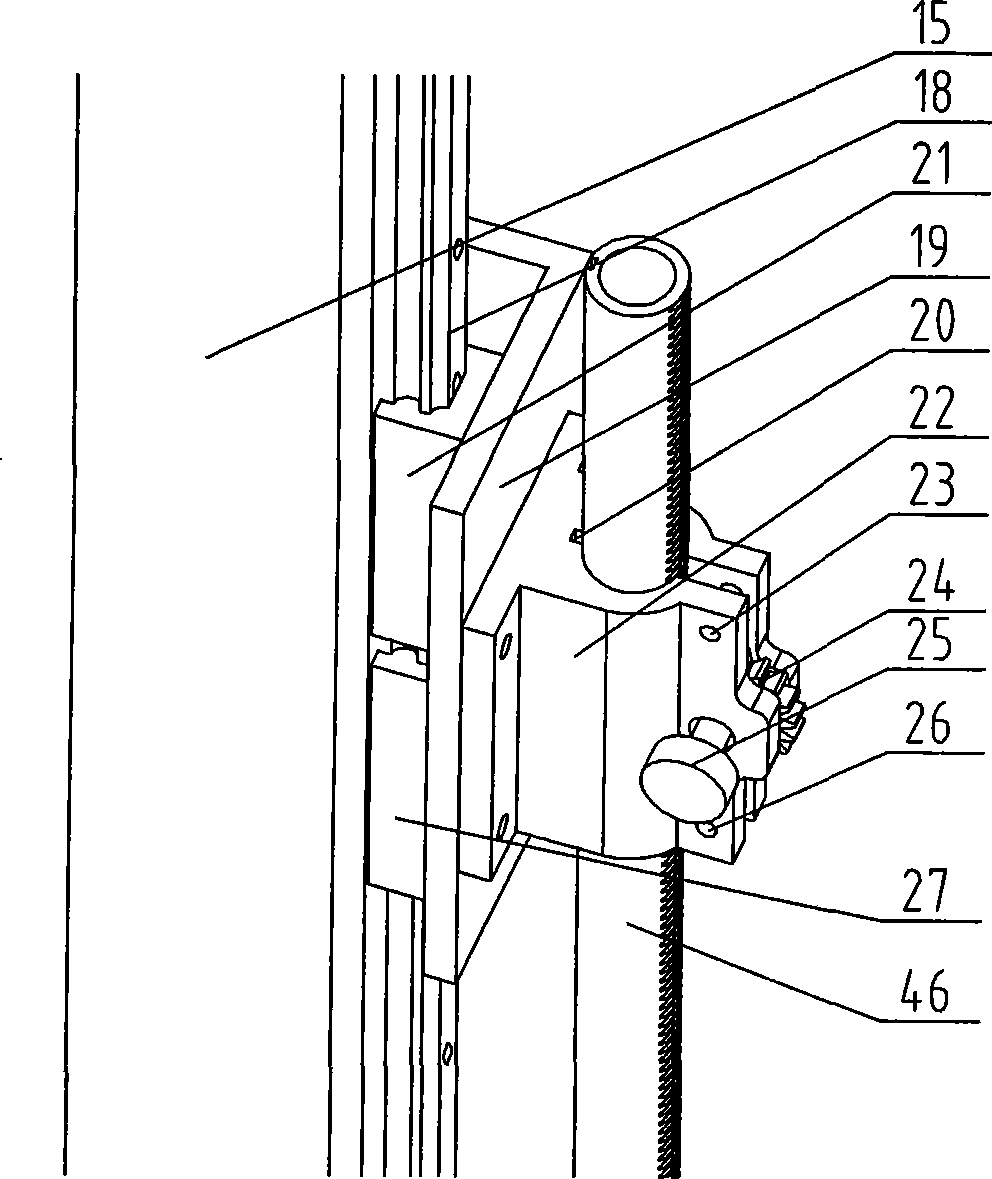

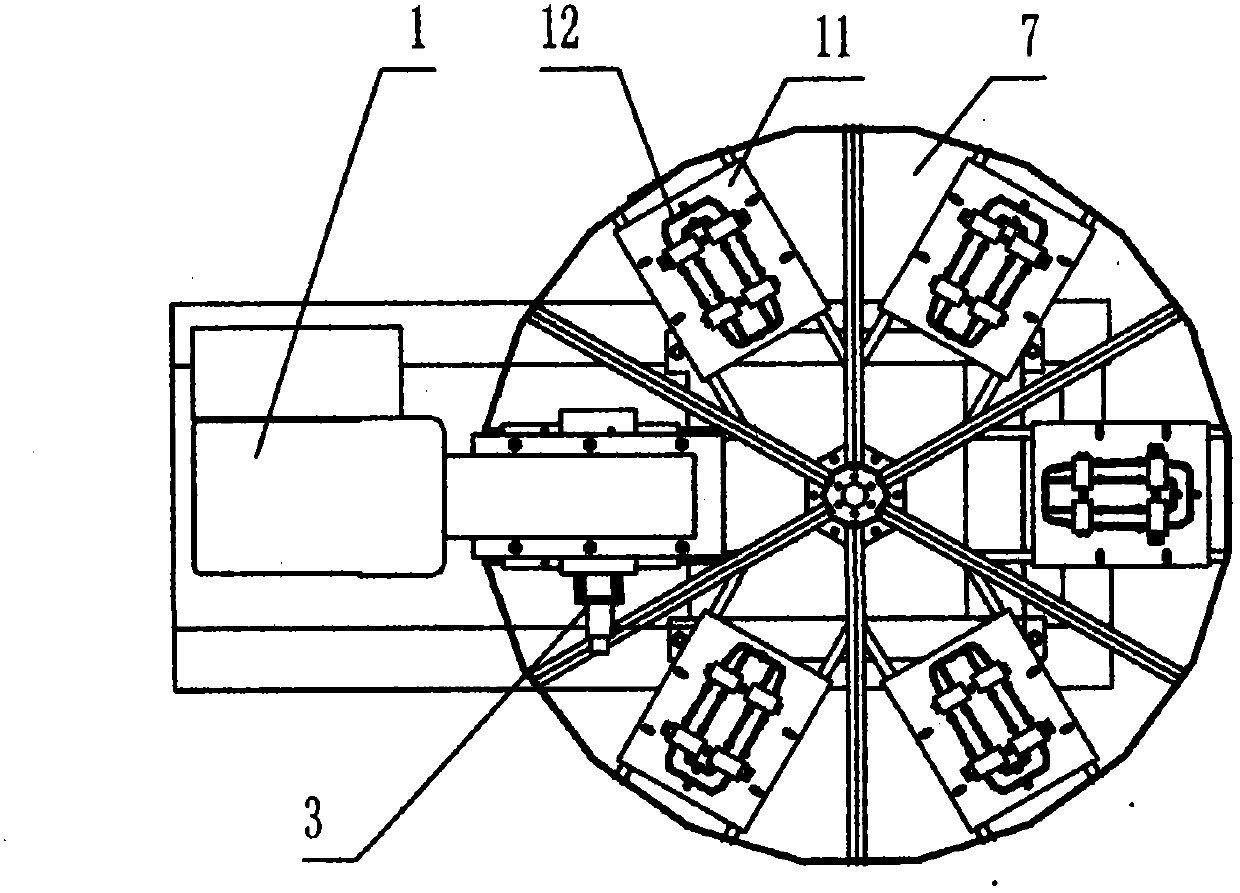

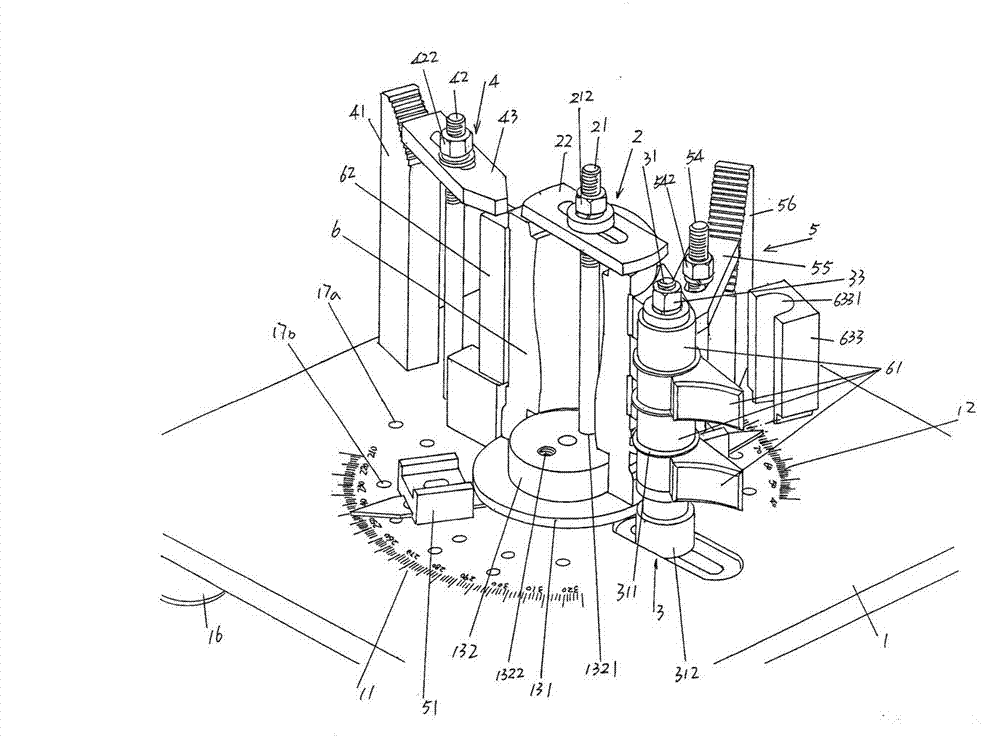

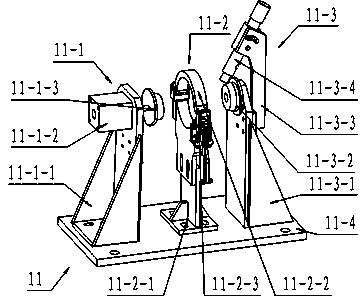

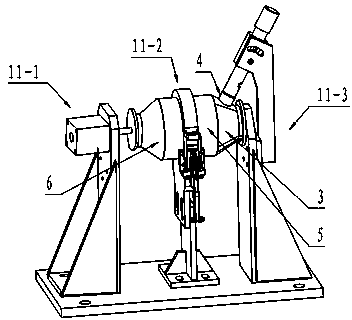

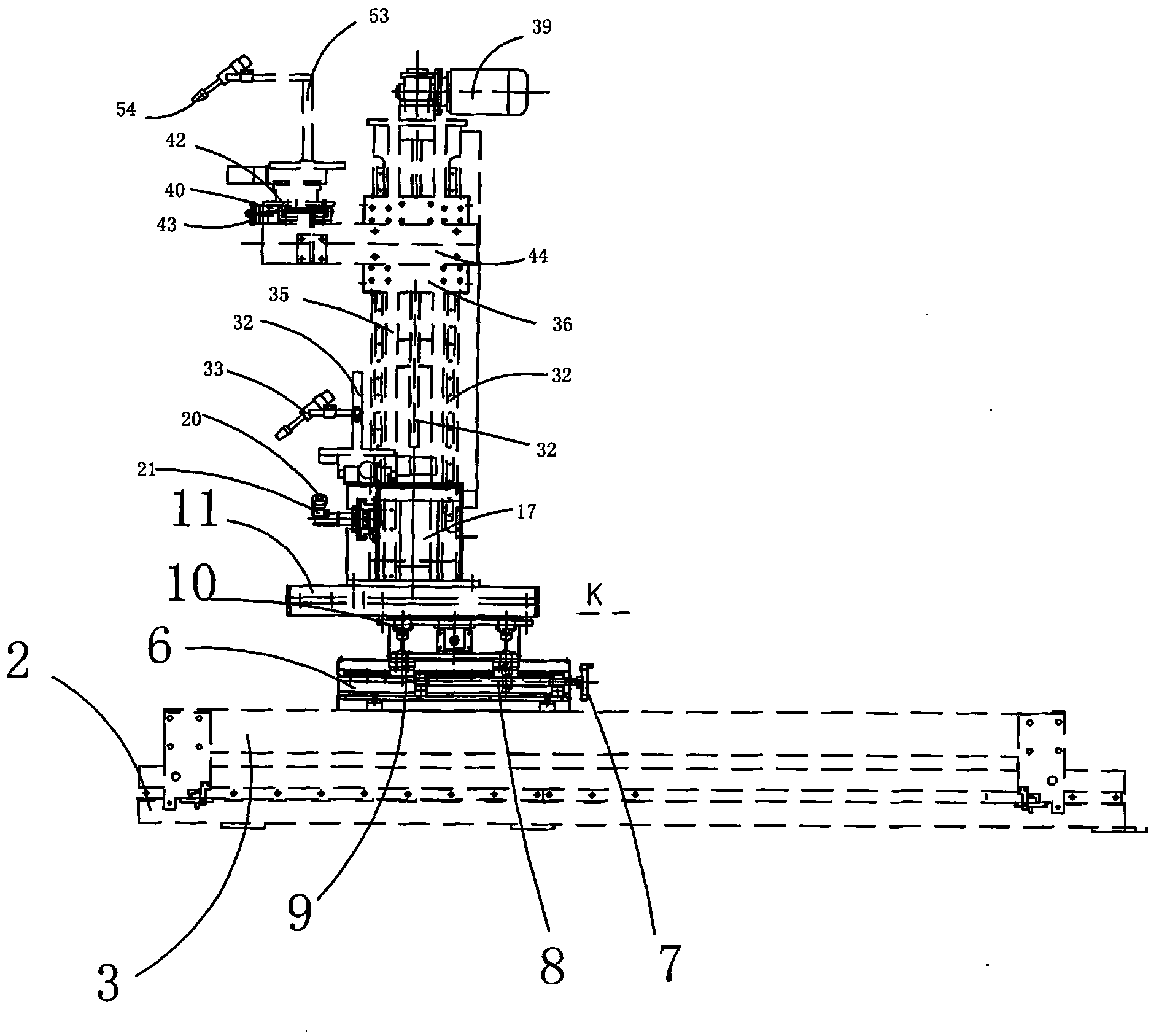

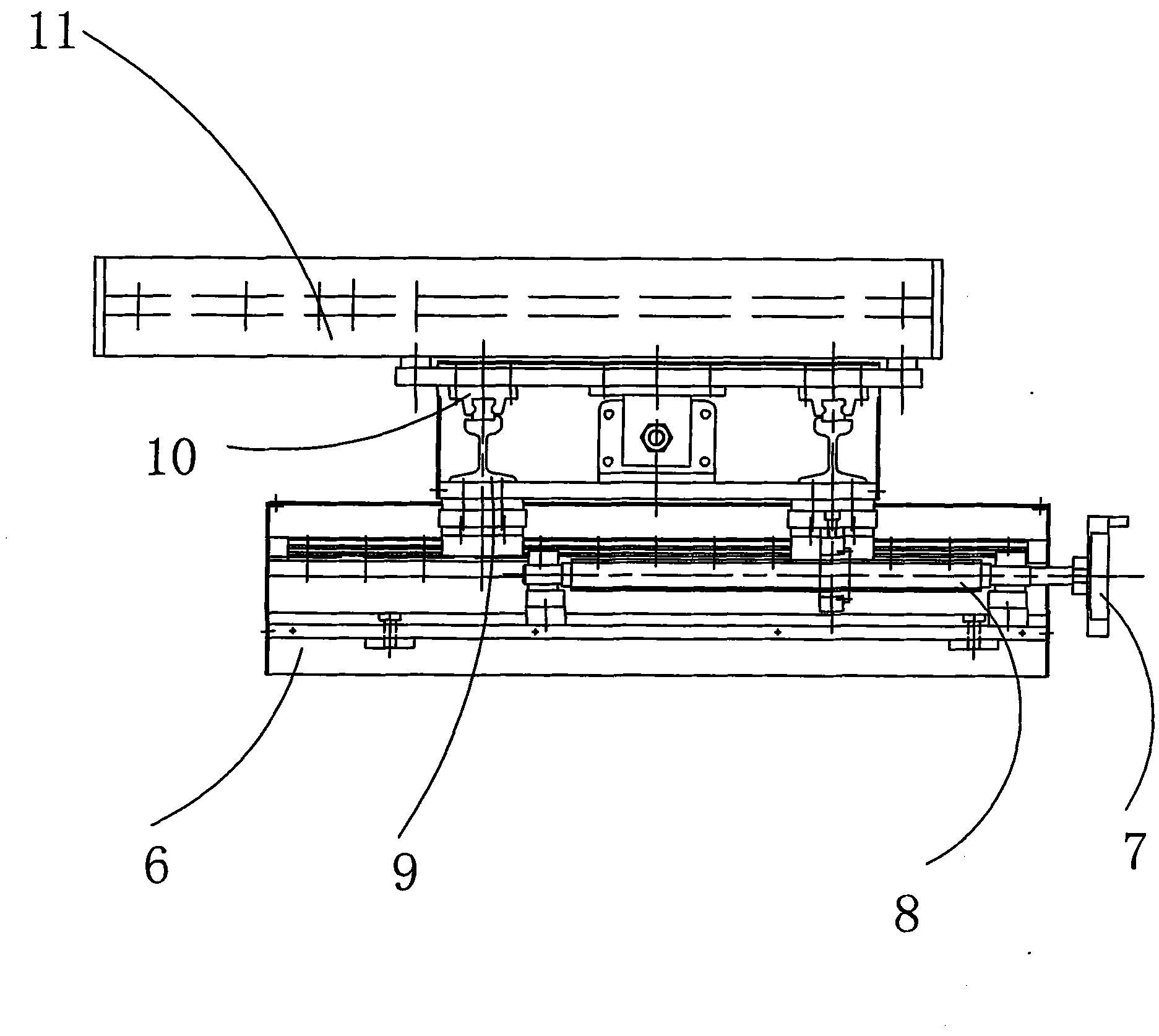

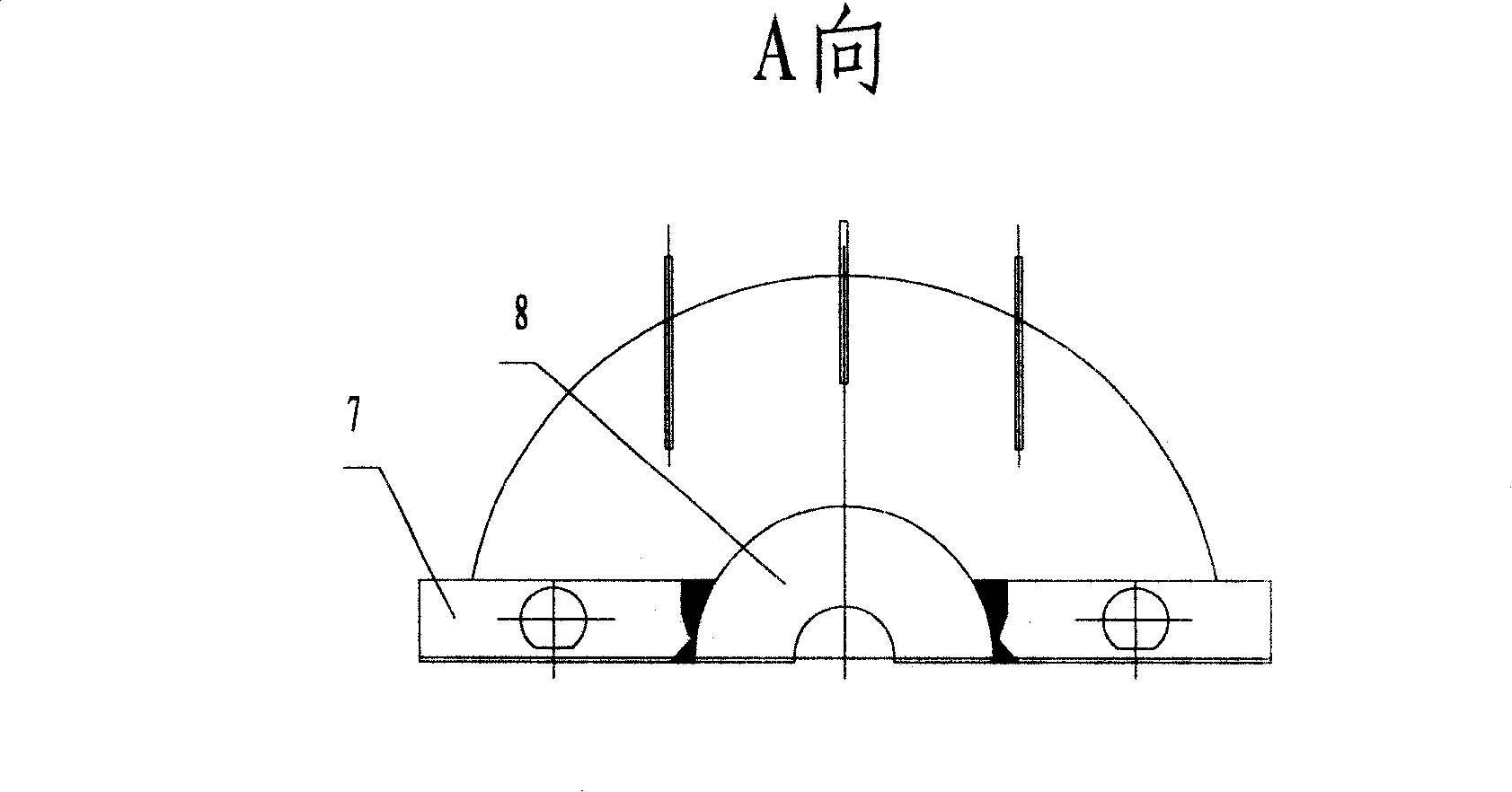

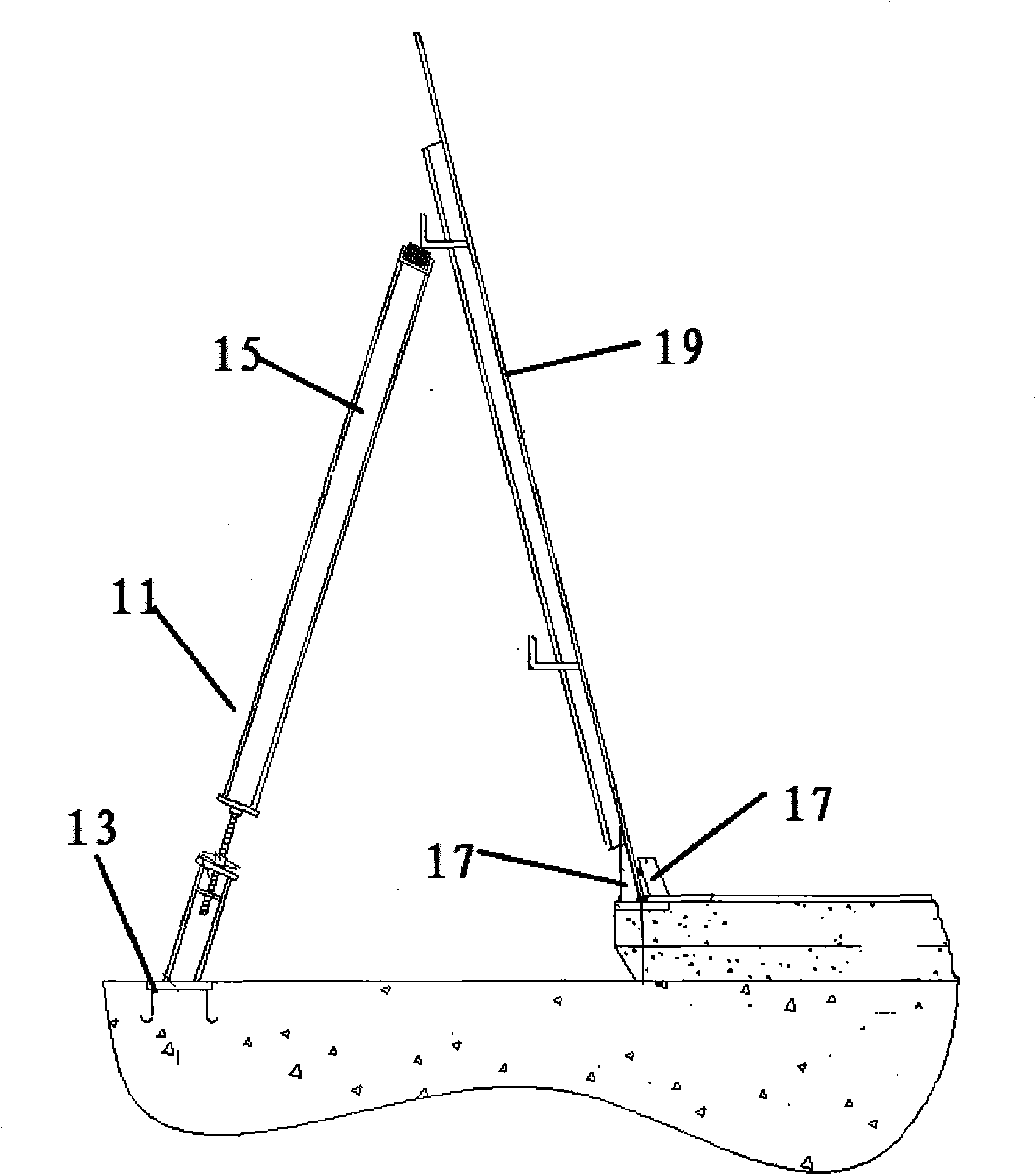

Suspended type pipe-jointing welding robot

ActiveCN101391354AReduce labor intensityImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesDegrees of freedomEngineering

The invention provides a hanging-style pipe connecting welding robot composed of an electrical sliding loop part, a rotary mechanism, a stretching mechanism, a lifting mechanism, a sewing mechanism and a manually lifting adjusting mechanism. The rotary mechanism consists of a fixed part and a rotary part. The fixed part of the rotary mechanism is fixed on the end of the horizontal arm of the cross arm as a seat of the hanging-style robot, and the stretching mechanism is arranged on the rotary part of the rotary mechanism. The lifting mechanism is arranged on the stretching mechanism, and the lifting adjusting mechanism is arranged on the lifting mechanism, the sewing mechanism is arranged on the manually lifting adjusting mechanism. The electrical sliding loop part is arranged on the rotary mechanism. By adjusting the relative position between the welding robot and the connecting pipe and adjusting the manually lifting adjusting mechanism to proper welding position, the hanging-style pipe connecting welding robot can realize linkage at four degrees of freedom, and can perform automatic welding for different shape of pipes with the advantages of good welding quality, high efficiency and reduced labor intensity of workers.

Owner:安徽行健智能制造装备股份有限公司

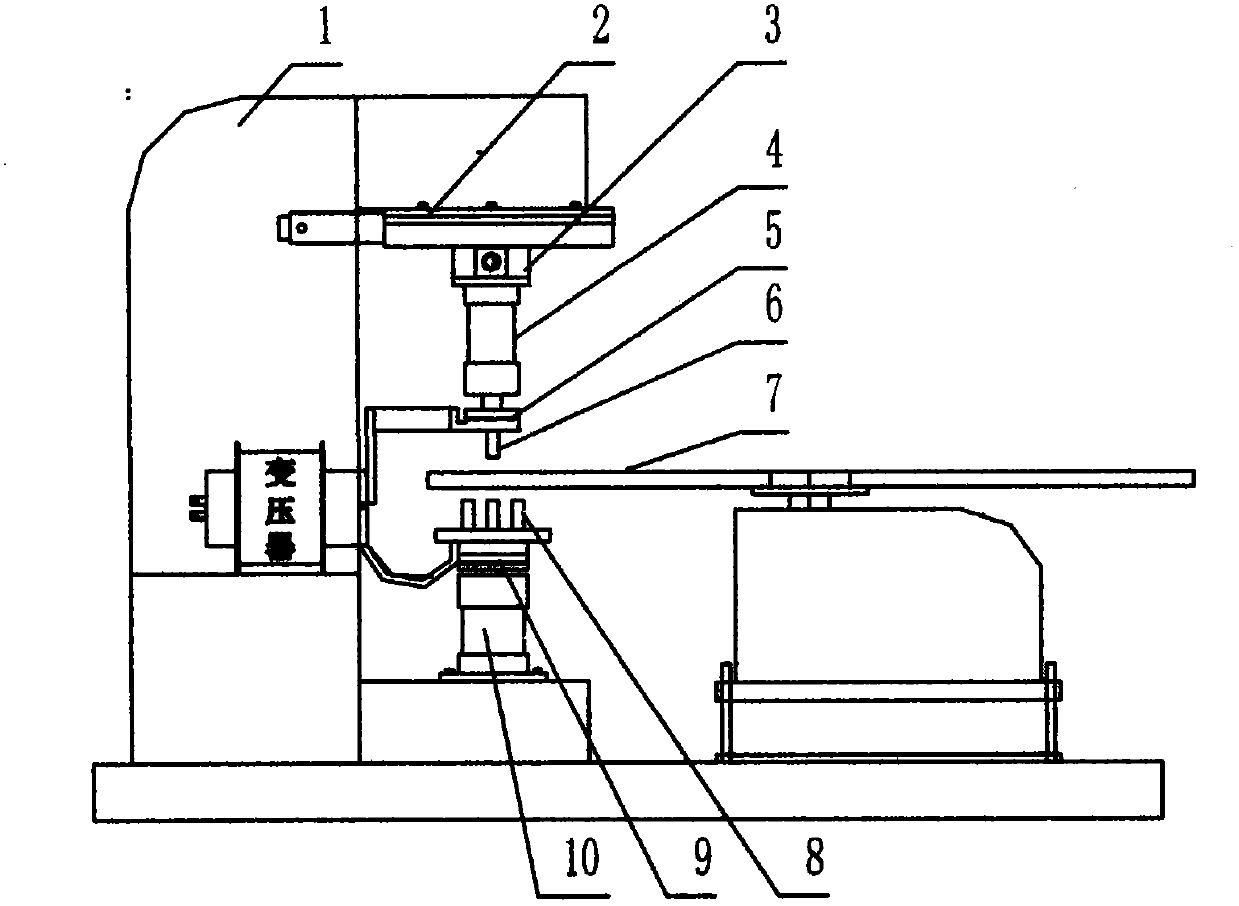

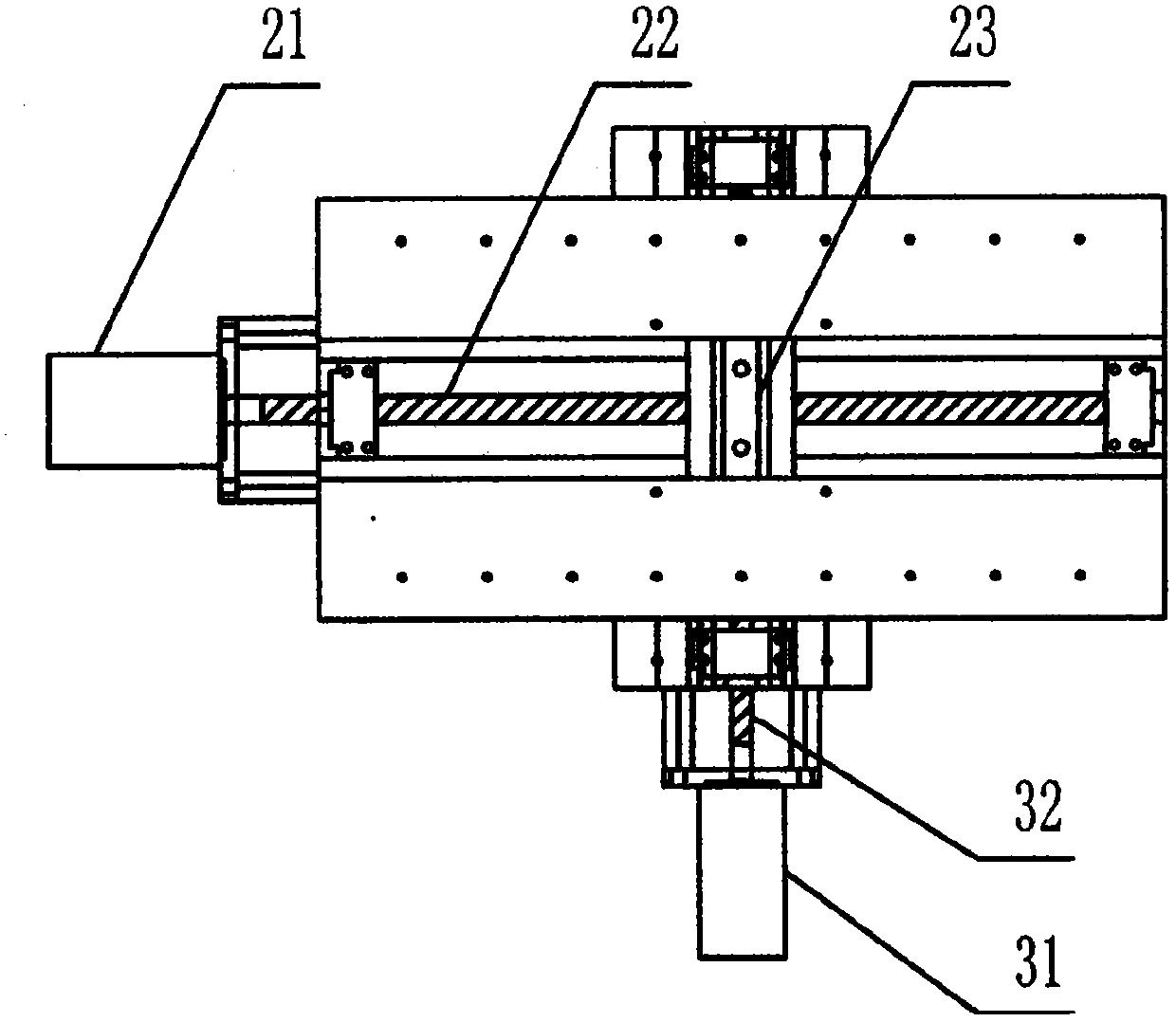

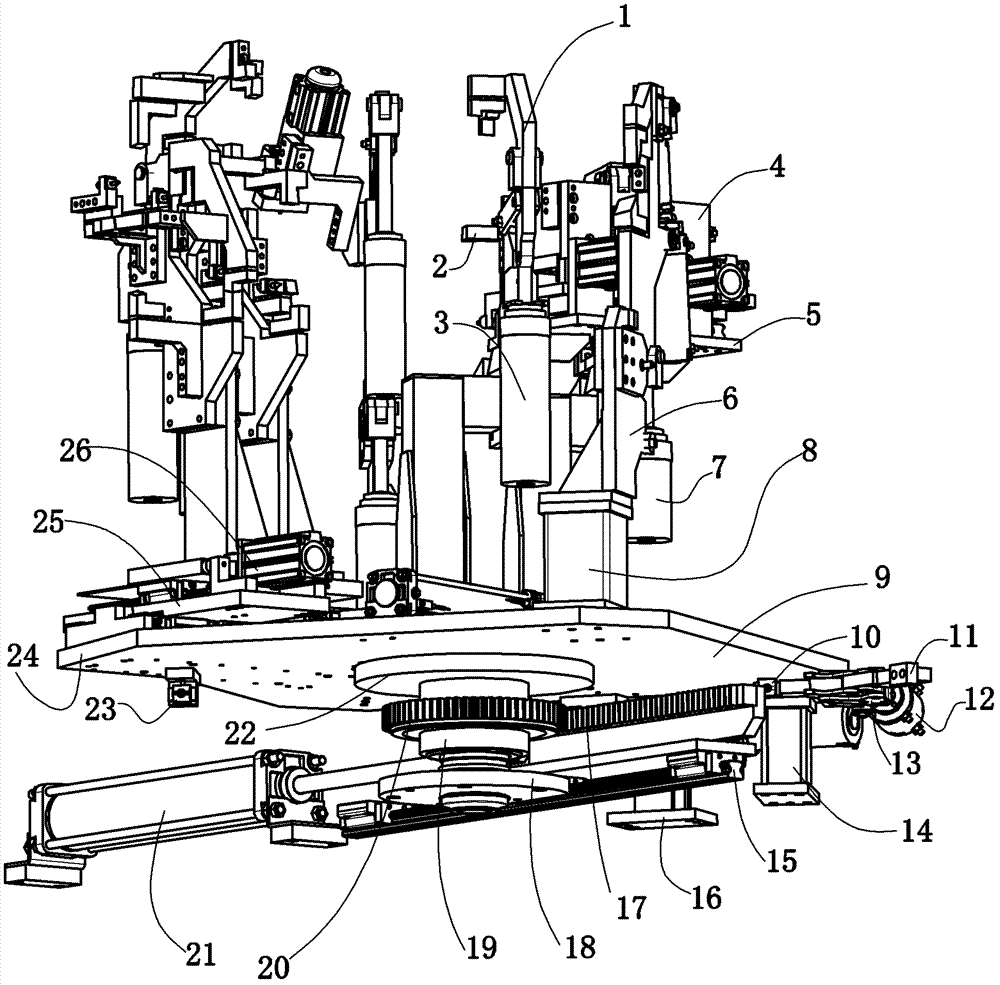

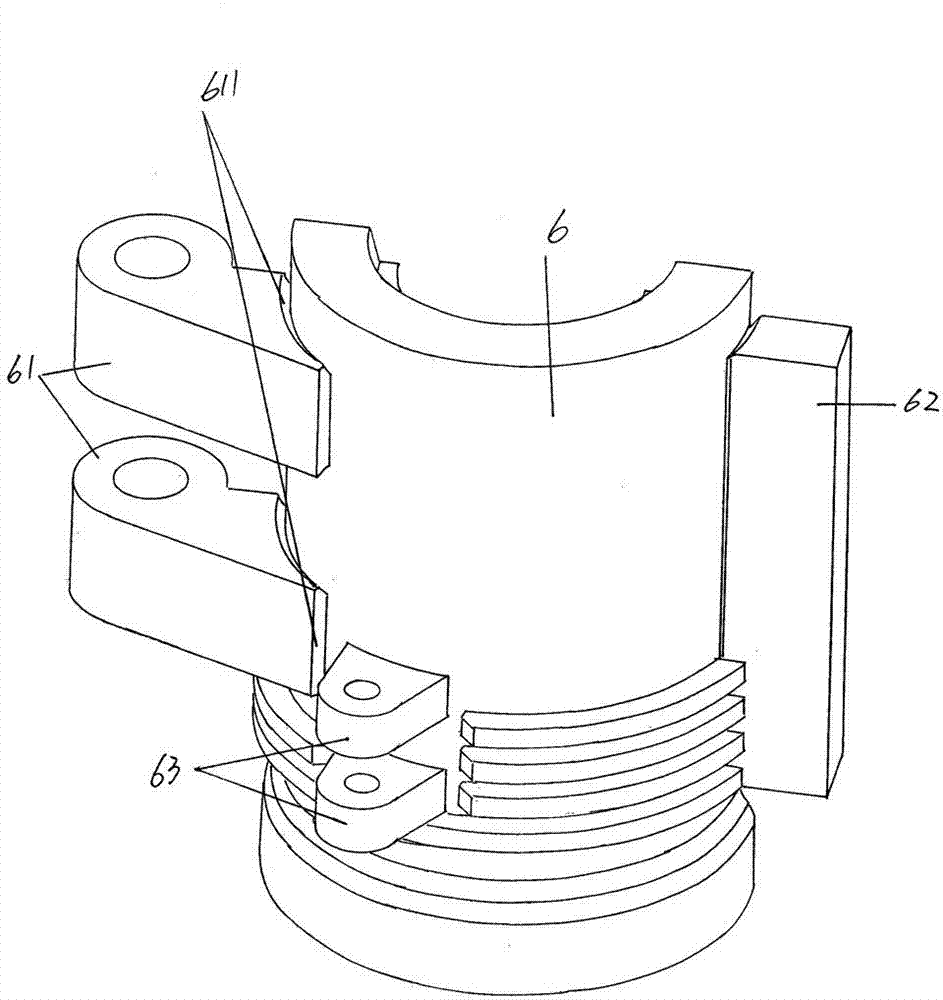

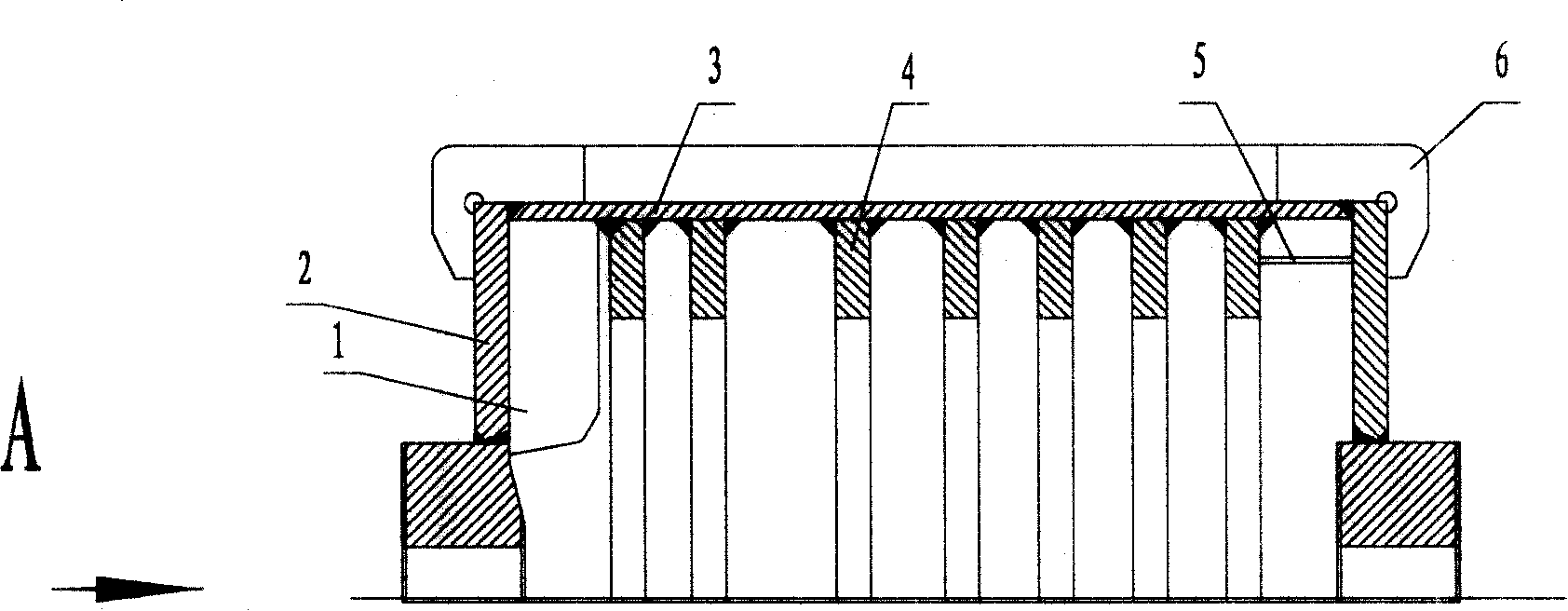

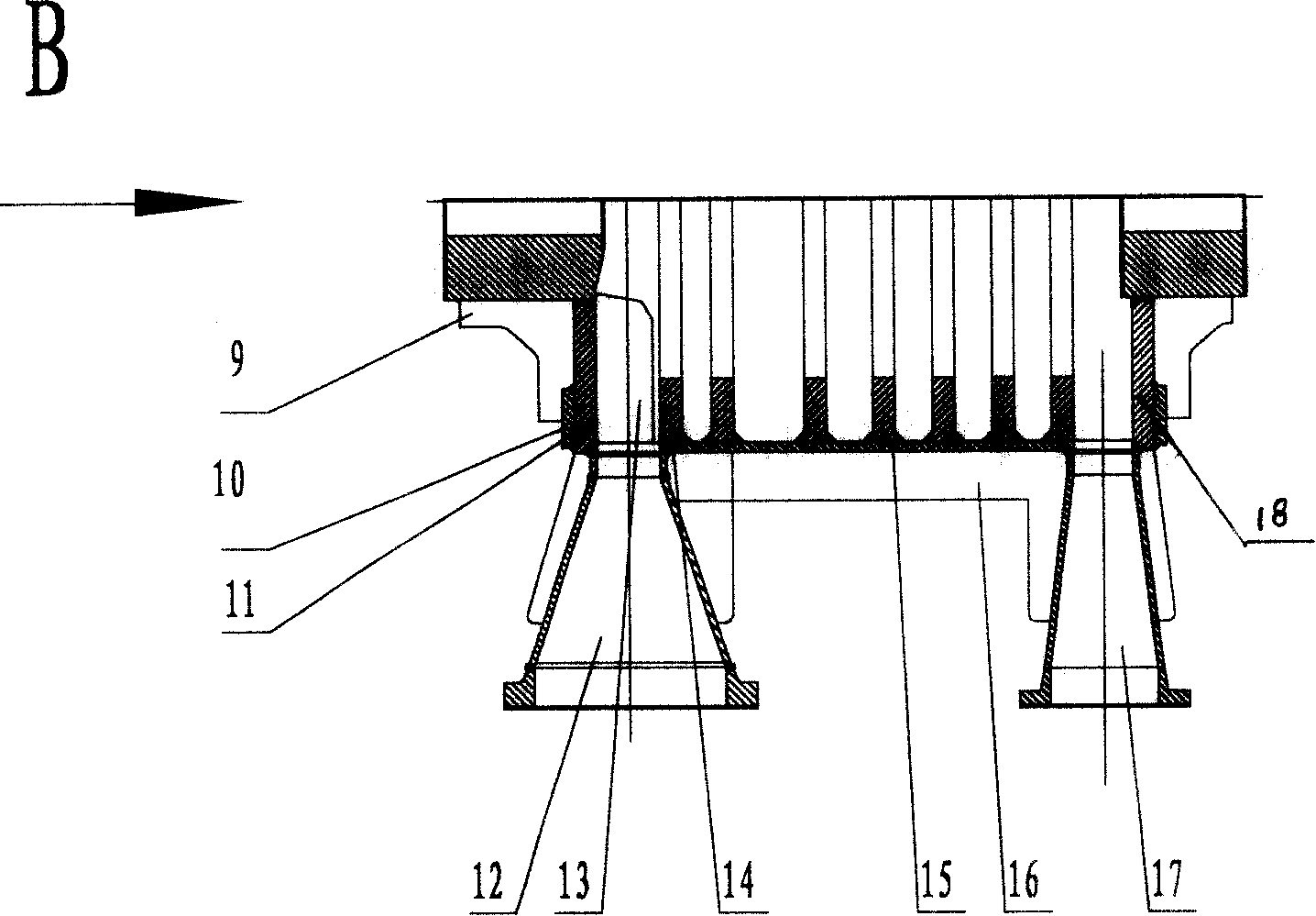

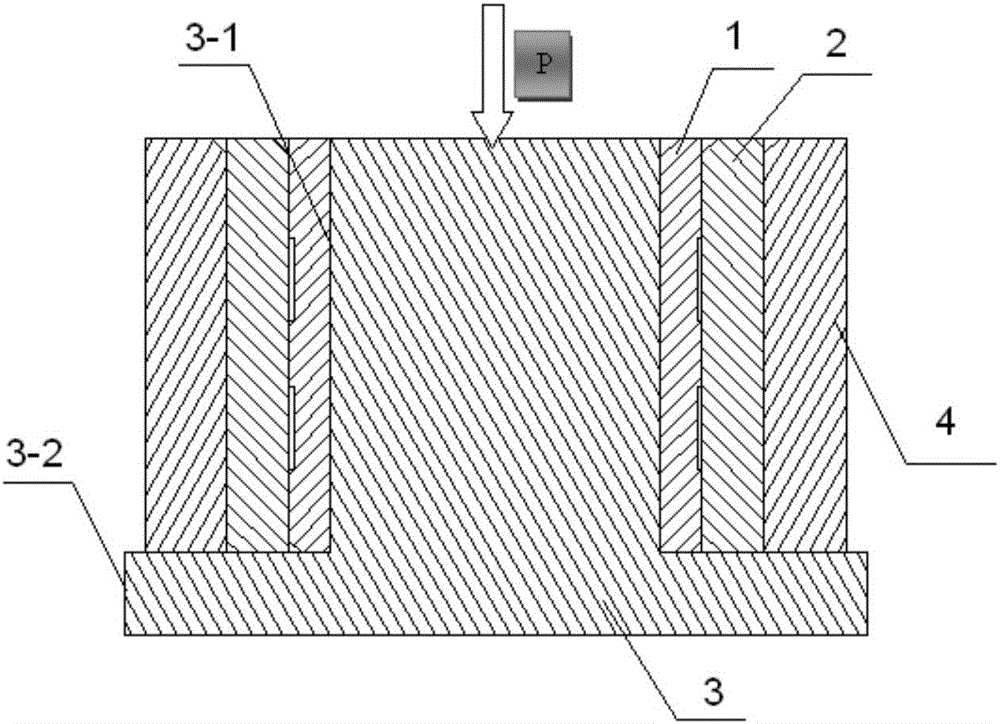

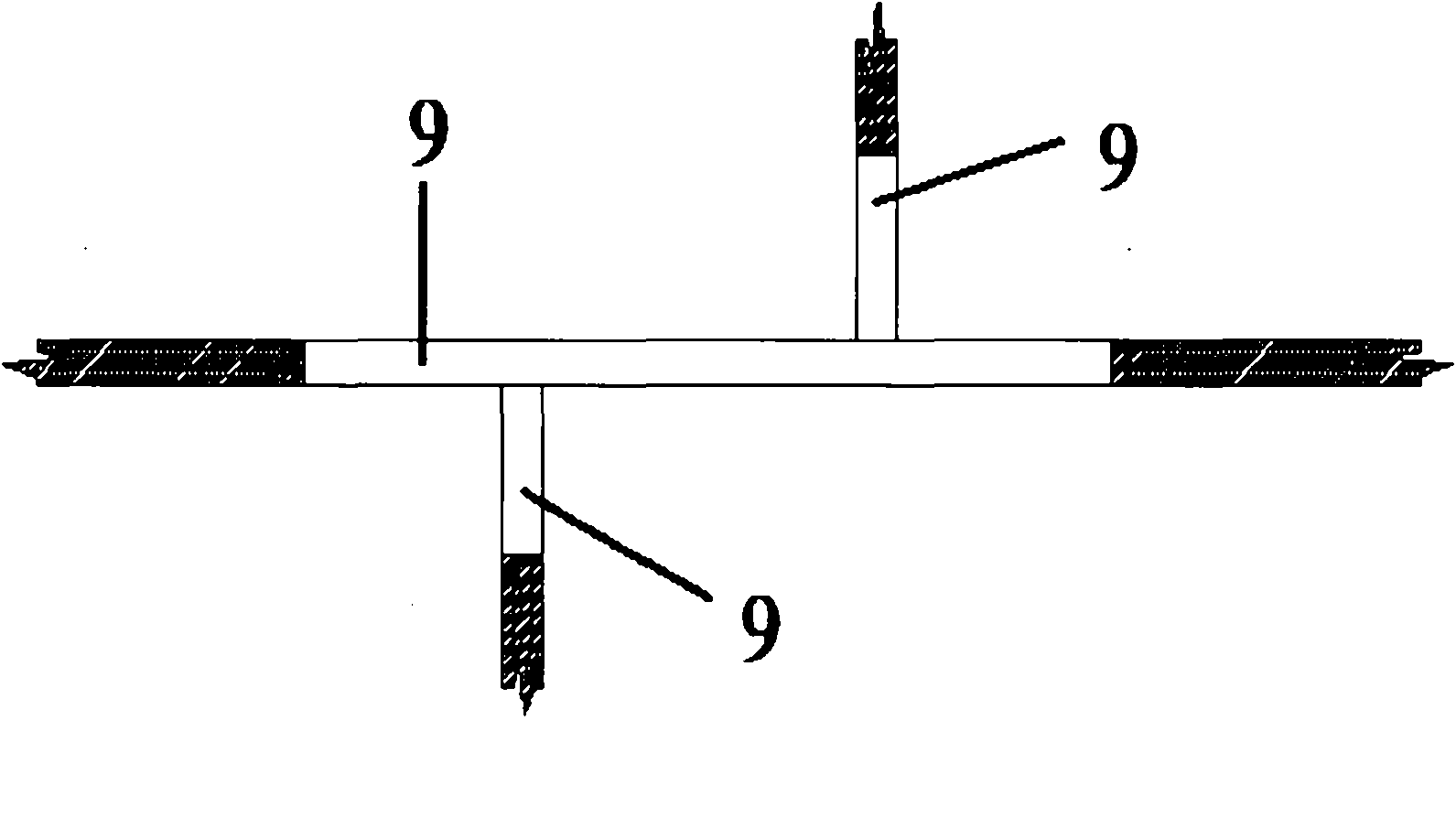

Two-axis multipoint automatic spot welding device and using method

InactiveCN103273181AImprove welding process efficiencyGuarantee welding qualityElectrode featuresDrive motorControl mode

The invention discloses a two-axis multipoint automatic spot welding device and a using method. The two-axis multipoint automatic spot welding device comprises a spot welding machine, a rotary working platform, workpiece forming dies, a machine base and a transformer. The spot welding machine is a two-axis spot welding machine, an X-axis linear module and a Y-axis linear module are arranged on the upper portion of an upper spot welding arm, the upper spot welding arm is installed on a transverse sliding block of the Y-axis linear module, the Y-axis linear module and a longitudinal sliding block of the X-axis linear module are fixed together through a two-axis connecting plate, a plurality of lower electrodes are arranged on a lower electrode holder of a lower spot welding arm, and a programmable controller is further arranged, and is connected with a driving motor in a control mode. The using method includes the steps of (1) manufacturing the workpiece forming dies, (2) manufacturing an upper electrode, (3) manufacturing the lower electrodes, (4) producing welding point coordinate information, inputting the welding point coordinate information to a numerical control system in the digital programmable controller, (5) setting the control state of the digital programmable controller to the rotary working platform, and (6) carrying out machine starting and operation. The two-axis multipoint automatic spot welding device is applicable to multipoint welding operation, complete in structure and high in degree of automation, work and labor are saved, energy is saved, and efficiency is high.

Owner:窦川忠

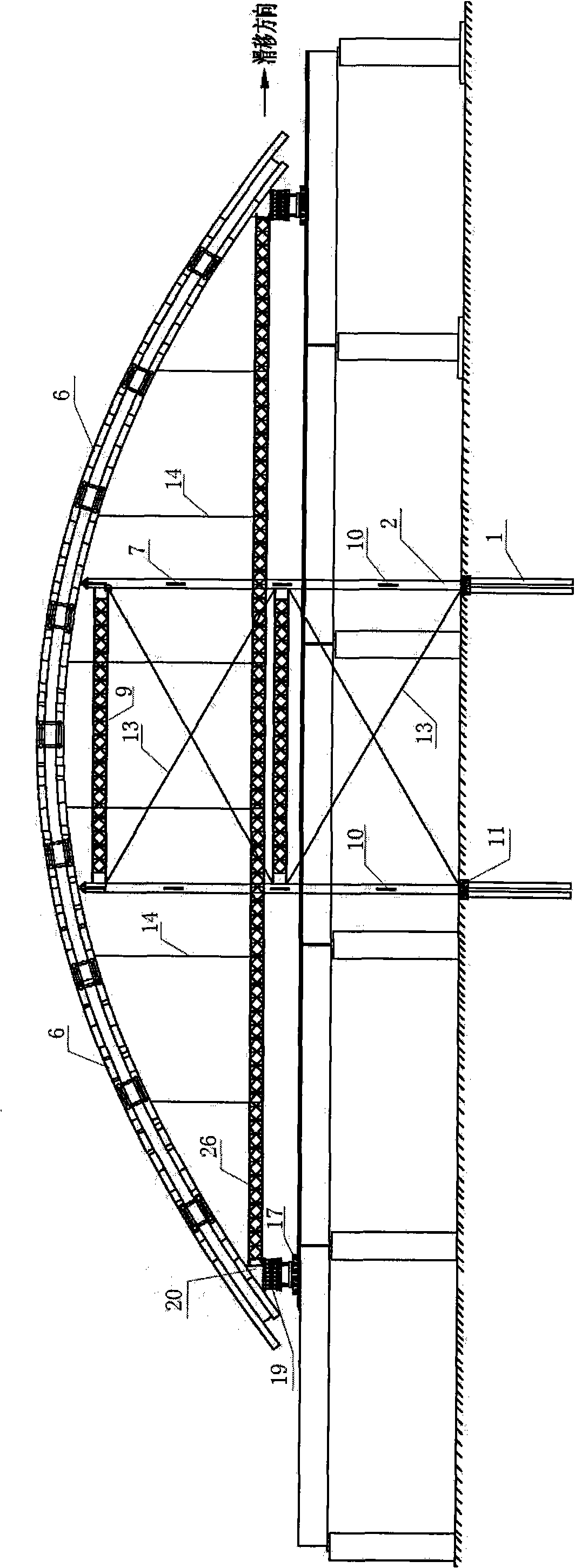

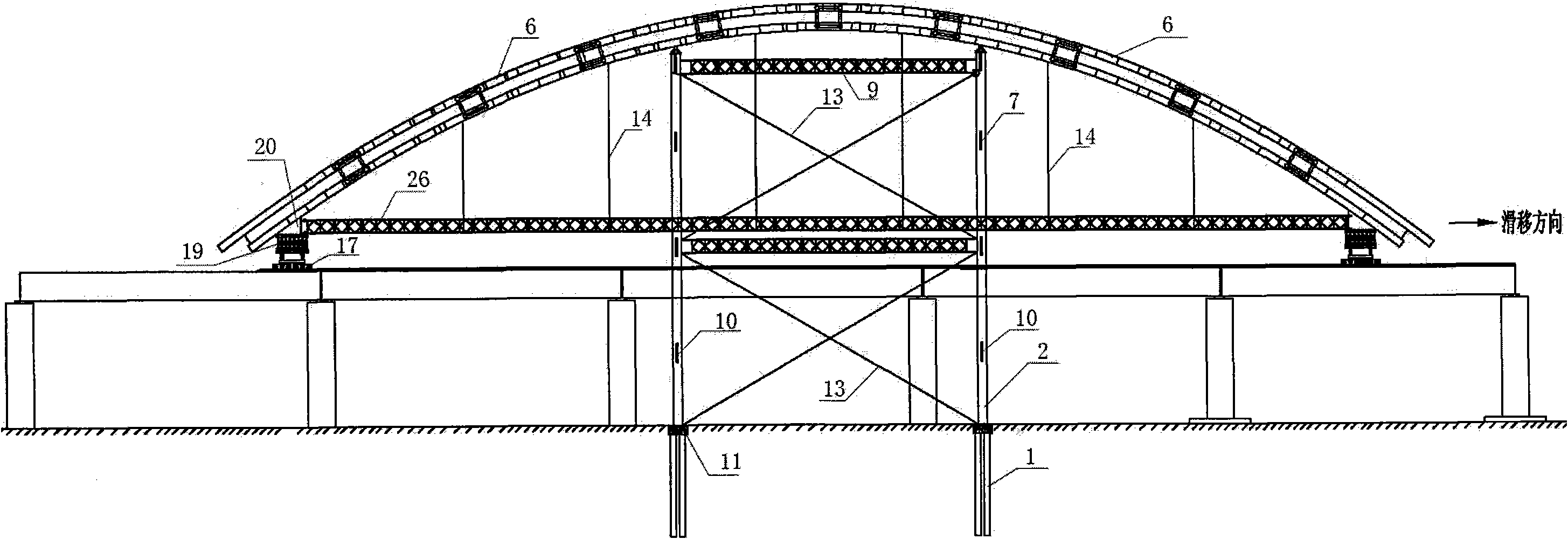

Construction method for integrally sliding large-span steel pipe arch of curved bridge

ActiveCN101935987AReduce occupancyReduce in quantityBridge erection/assemblyBridge engineeringConcrete beams

The invention relates to a construction method for integrally sliding a large-span steel pipe arch of a curved bridge, belonging to the field of bridge engineering construction. The method comprises the following steps: firstly, carrying out on-site splicing and welding on the manufacturing and installing sections of a steel pipe arch to form a large hoisting section; then installing a temporary arch-splicing support on a bridge-site longitudinal splicing site position, arranging arch ribs on the temporary arch-splicing support, and adopting an arch springing restraint device to preload arch springings after finishing splicing the steel pipe arch, thus enabling the steel pipe arch to form a stressed entirety; and finally, dismantling the temporary arch-splicing support, and adopting a pushing power system to realize integrally sliding the whole steel pipe arch into a proper position. The construction method of the invention has the advantages of small site occupation, integral hoisting of large sections, less hoisting subsection and less arch-splicing support amount, thus the construction cost is economical, the high-altitude welding quantity is less, the welding quality is ensured, the arch axis linetype control is easy, the steel pipe arch splicing and a concrete beam can be simultaneously constructed, arch splicing is carried out on an ectopic bridge site, the underbridge navigation is not influenced, the construction is safe and the construction progress can be quickened.

Owner:CHINA FIRST HIGHWAY ENG +1

Welding and heat treatment processes of large-diameter and thick-wall nuclear process pipes

ActiveCN102554402AReduce labor intensityEnsure continuous weldingArc welding apparatusFurnace typesNuclear technologyNuclear engineering

The invention discloses welding and heat treatment processes of large-diameter and thick-wall nuclear process pipes, which are suitable for welding and heat treatment of large-diameter and thick-wall pipes. The pipes welded by the welding and heat treatment processes are steady and reliable in the quality of welding lines, and can completely meet the quality requirement of nuclear technology.

Owner:江苏利柏特股份有限公司

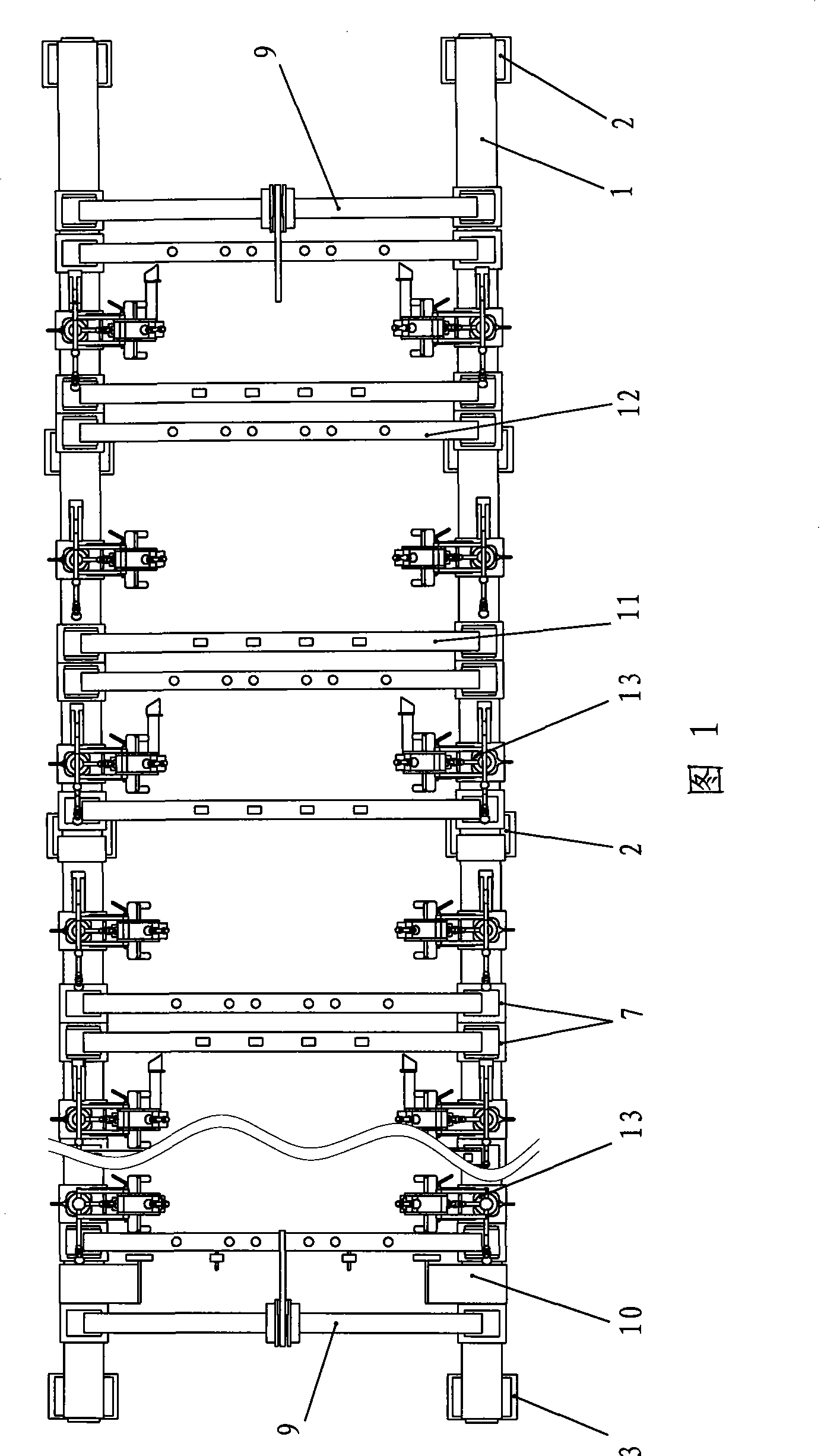

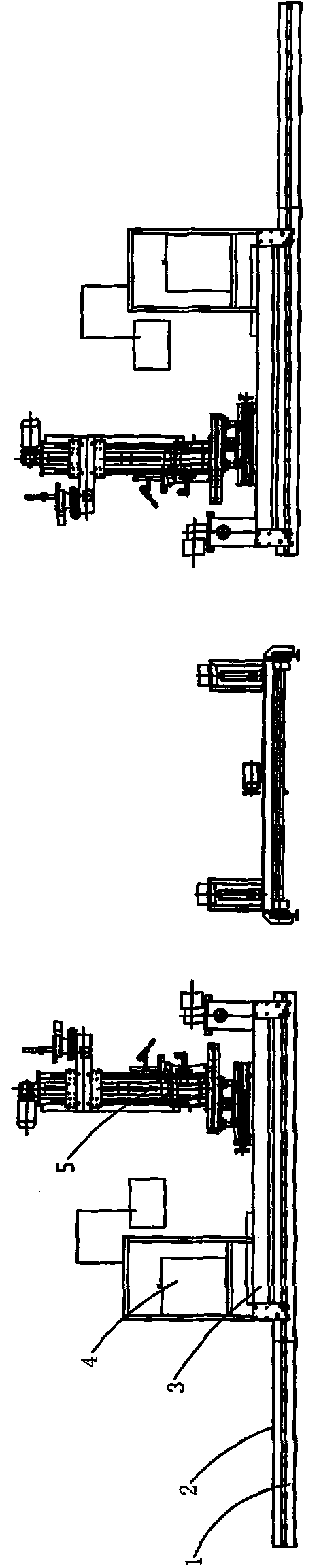

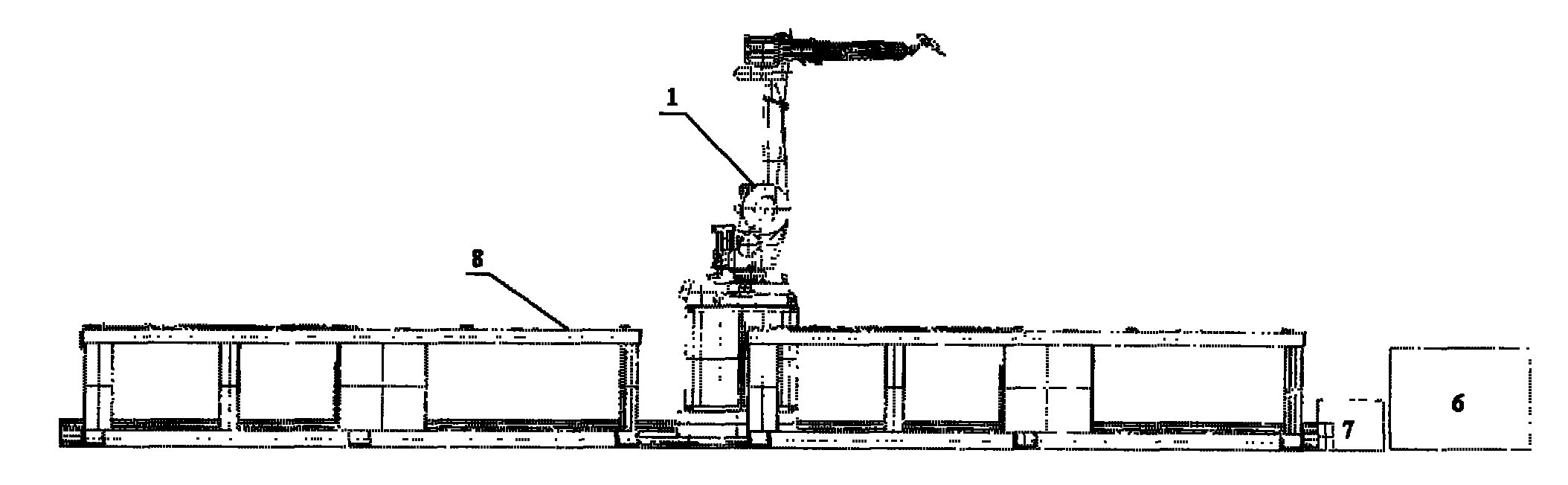

High speed motor train unit roof assembly-welding device

ActiveCN101456108AImprove space utilizationReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesManufacturing technologyEngineering

The invention discloses an assembly welding device for high-speed bullet train tops and belongs to the technical field of railway vehicle body manufacturing. The assembly welding device comprises two foundational beams which are arranged parallelly and a plurality of fixed plates arranged on the foundational beams, wherein the foundational beams are formed by a plurality of sections which have horizontal H-shaped cross sections and are connected by connecting pieces at two ends serially into a whole, and the bottom surfaces of the foundational beams are fixedly connected with two connecting plates pre-buried in a foundation; the fixed plates are provided with central positioning racks, top positioning racks, a plurality of flat-top supporting racks, round-top supporting racks and a plurality of pairs of clamping racks. Through full investigation and research and absorption of advantages of rail passenger train manufacturing technology at home and abroad, the welding device makes a structural break through and innovation in the prior mode, realizes the manufacturing of all of the five kinds of train tops of high-speed bullet trains, uses the cooperation of one set of tool and a welding mechanical arm and realizes the welding of the insides and the outsides of the train tops. In addition, the device reduces the area for welding operation, improves the utilization rate of plant space, saves capital, ensures welding quality, greatly improves working efficiency and reduces the labor intensity of operators.

Owner:CRRC TANGSHAN CO LTD

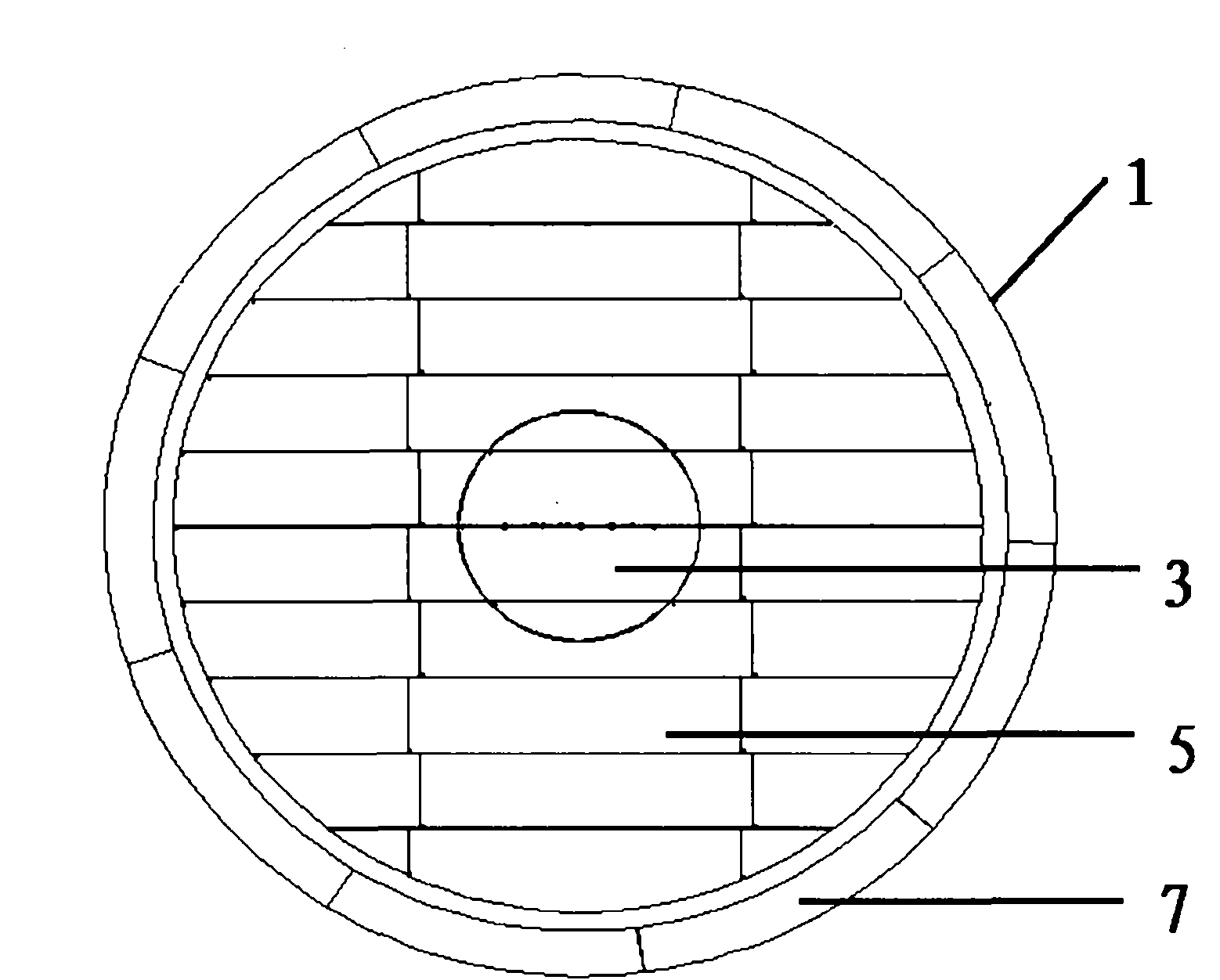

Method for assembling and welding cased crane-beam in circular rail of nuclear-power station

ActiveCN101074085ASmall amount of welding deformationGuarantee welding qualityArc welding apparatusRunwaysPower stationNuclear power

The invention is concerned with an assembled and seal method of box crane beam with ring type orbit using for nuclear power plant, belonging to the establishment construction technology field of nuclear power plant. It relates to rectification of stuff, sealing inner and outside webs and clapboard, sealing upper and down wing edge and the inner and outside webs, sealing stiffened panel, sealing end plate and the rectify after seal. Assemble and seal the web and inner muscle plate to a type of H to reduce the distortion and keep the seal quality, while the temporary backboard controls the final seal distortion when sealing the end plate. It will control the distortion effectively to reach the demand of the first level of nuclear quality and nuclear safety through easy adjustment of circle crane beam after sealed with steady quality.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

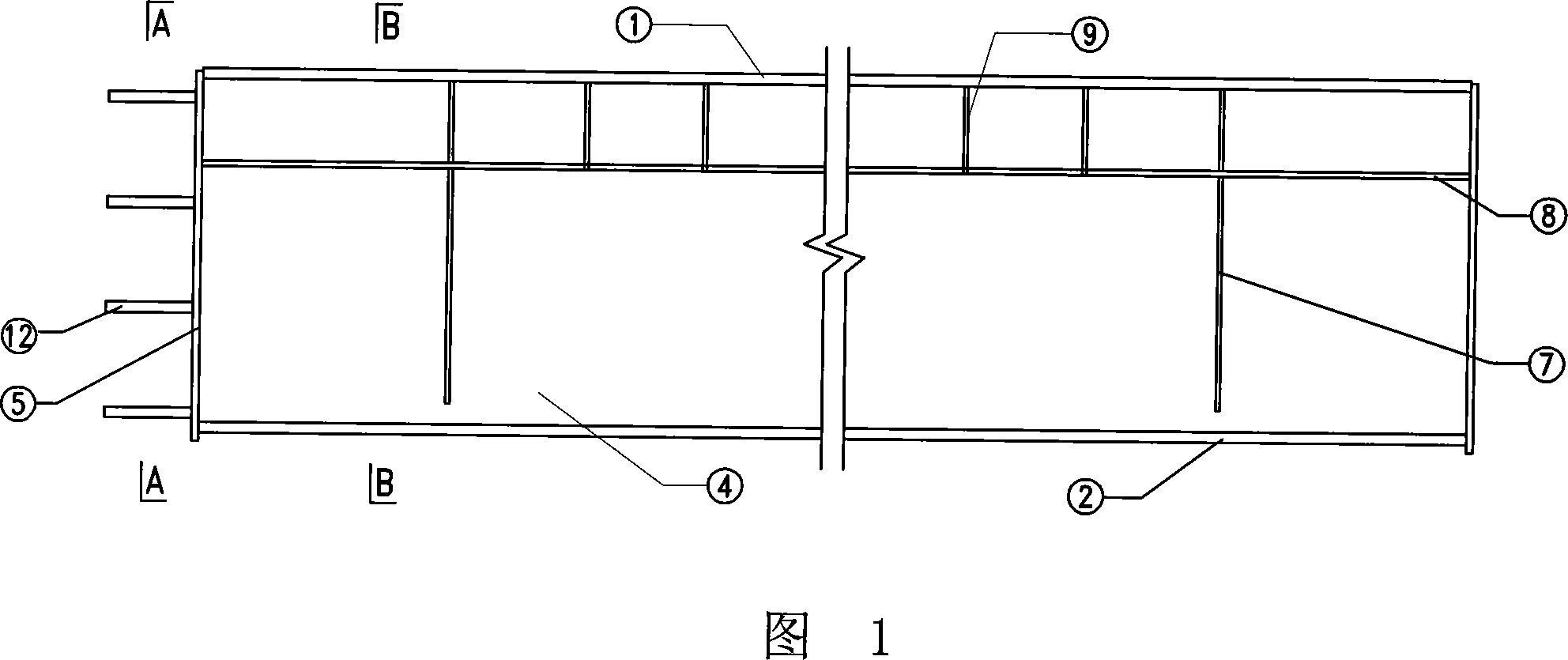

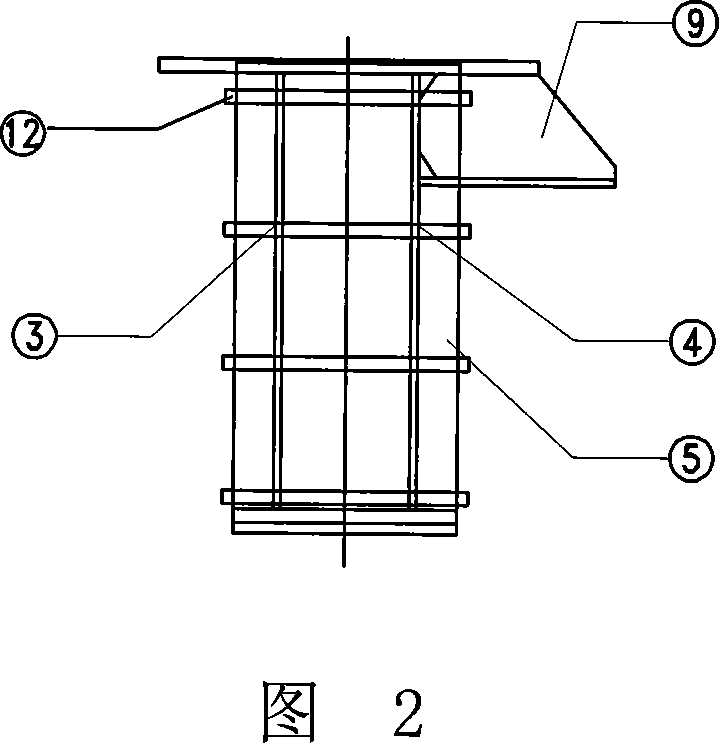

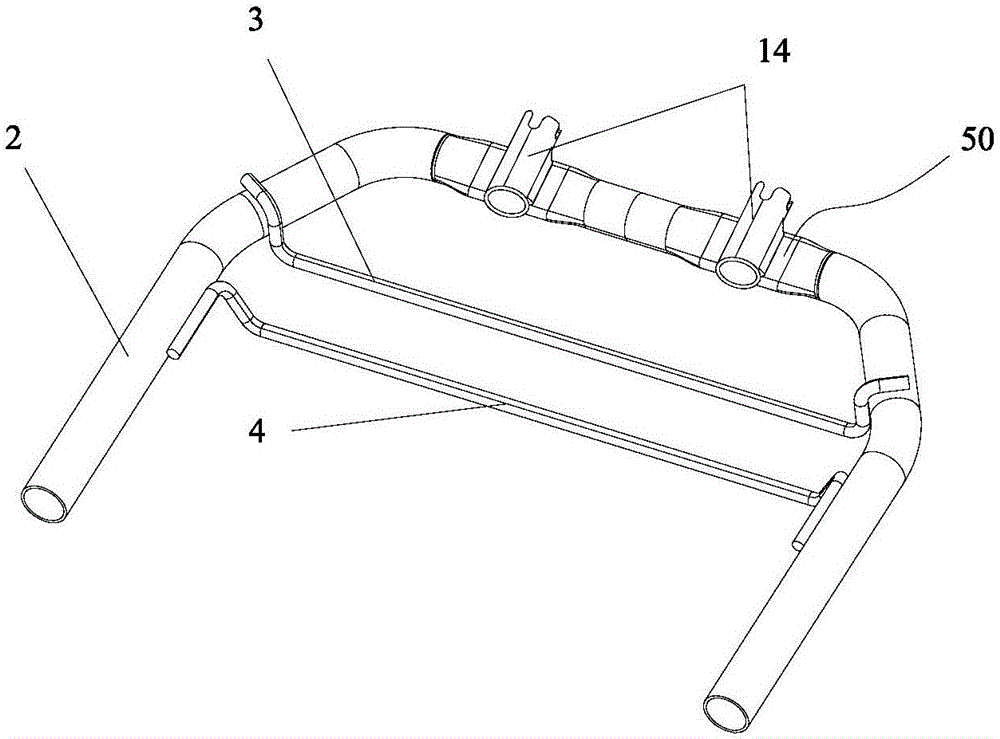

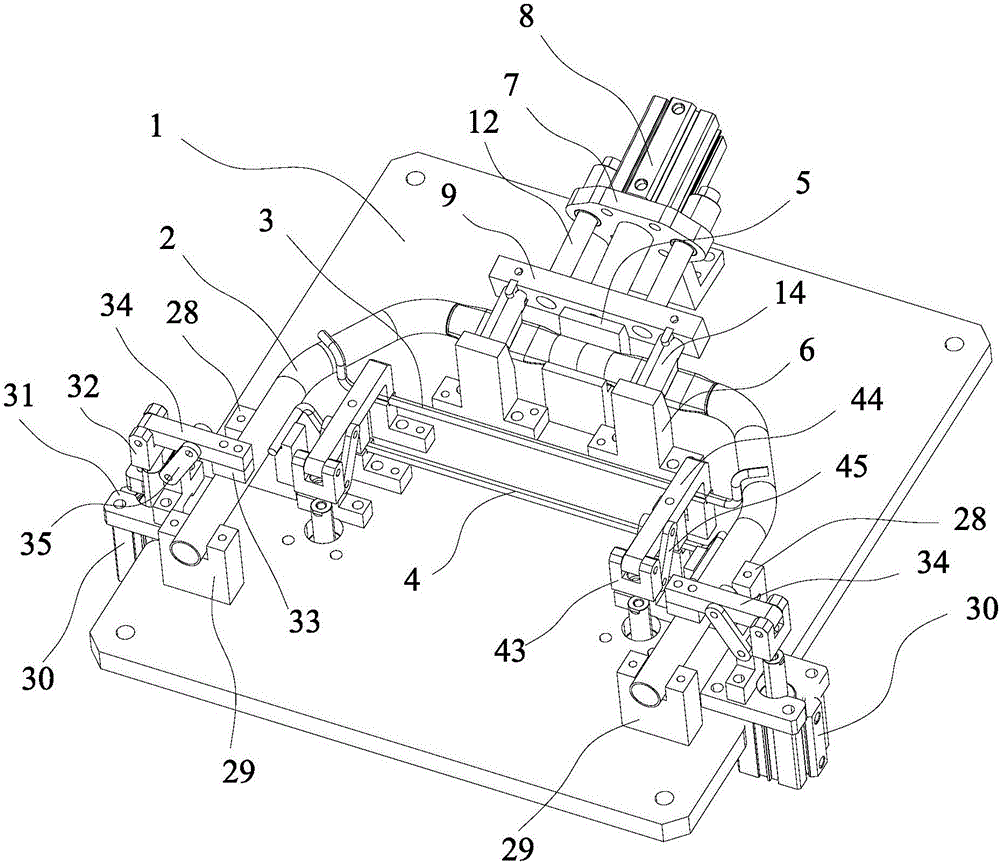

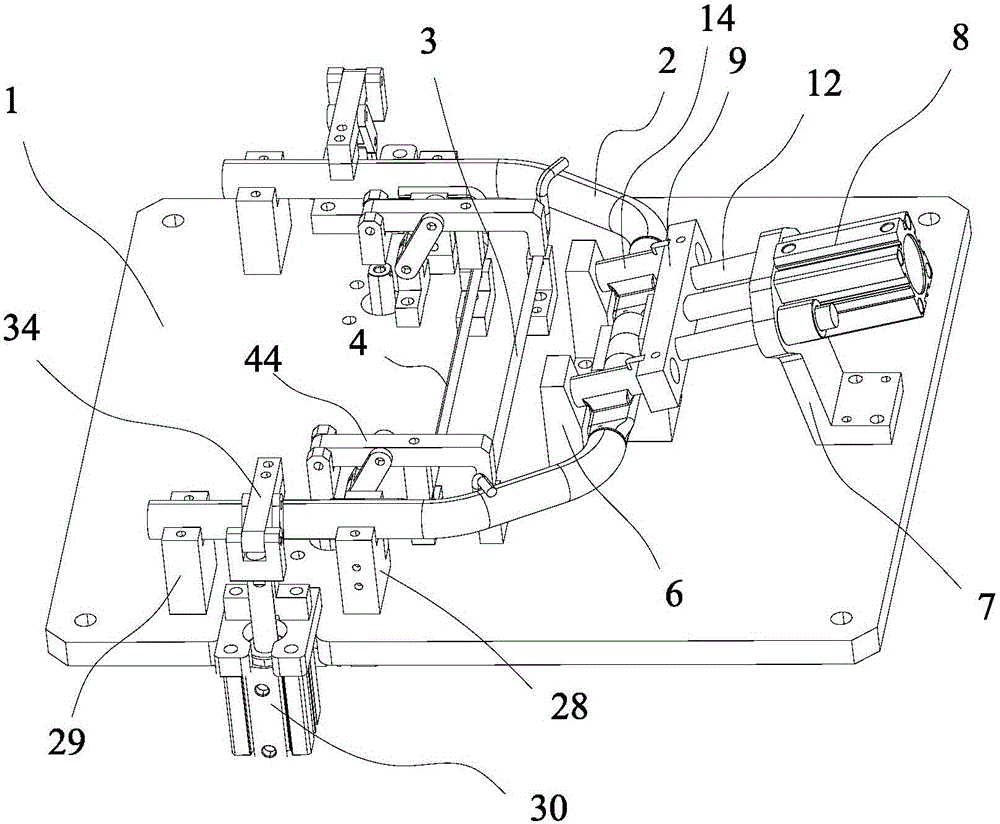

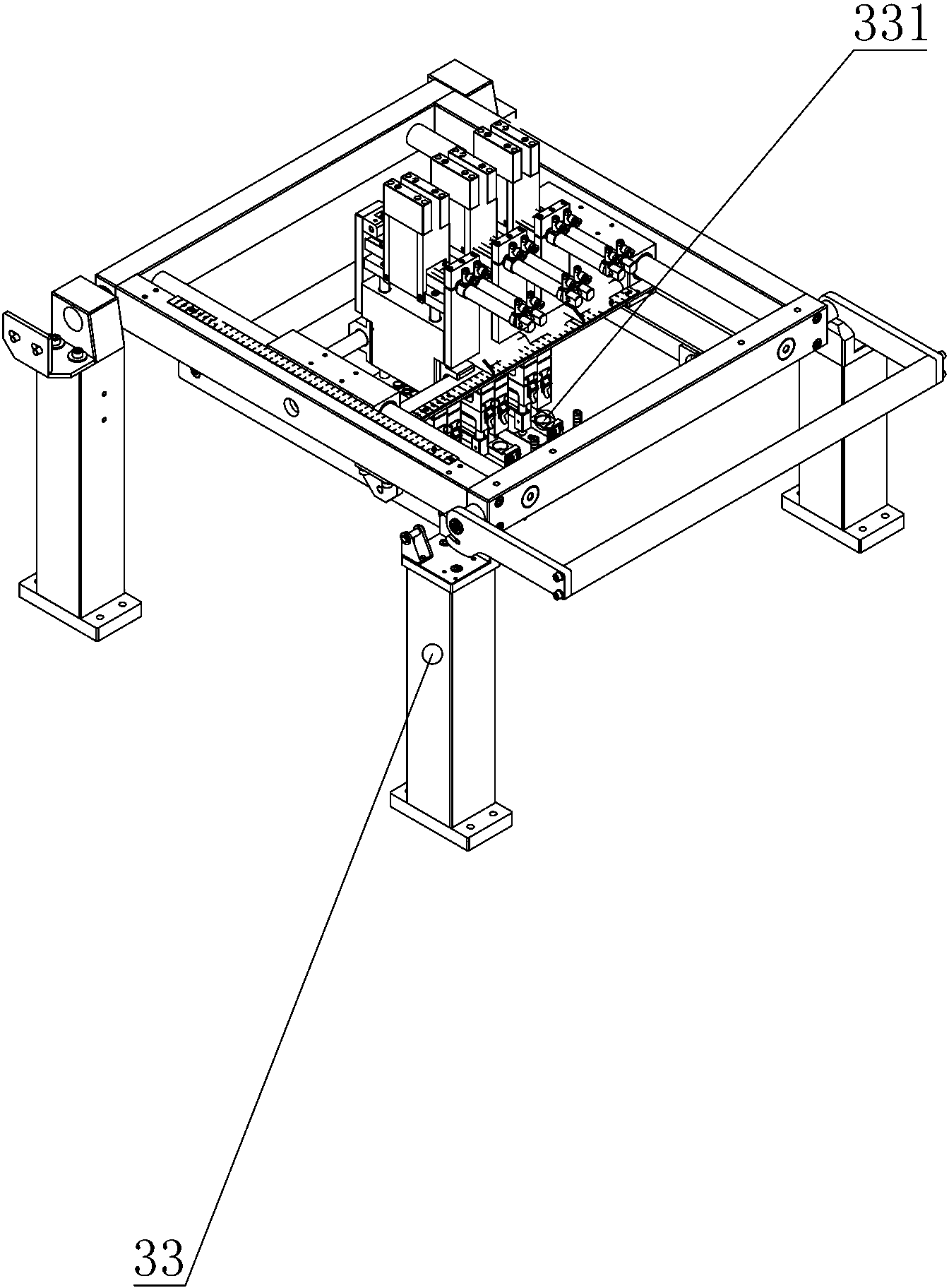

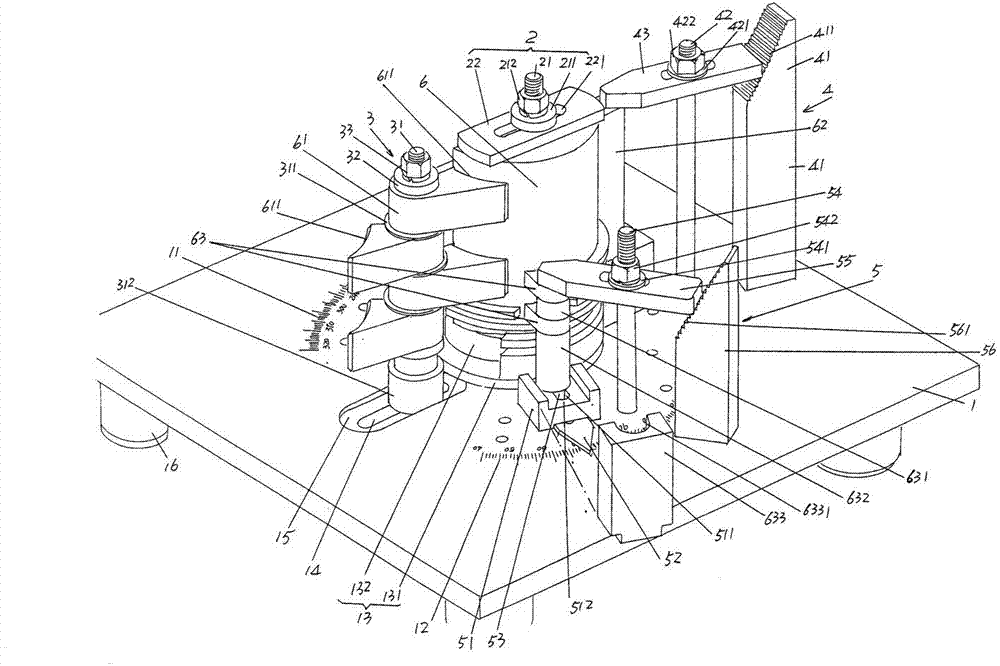

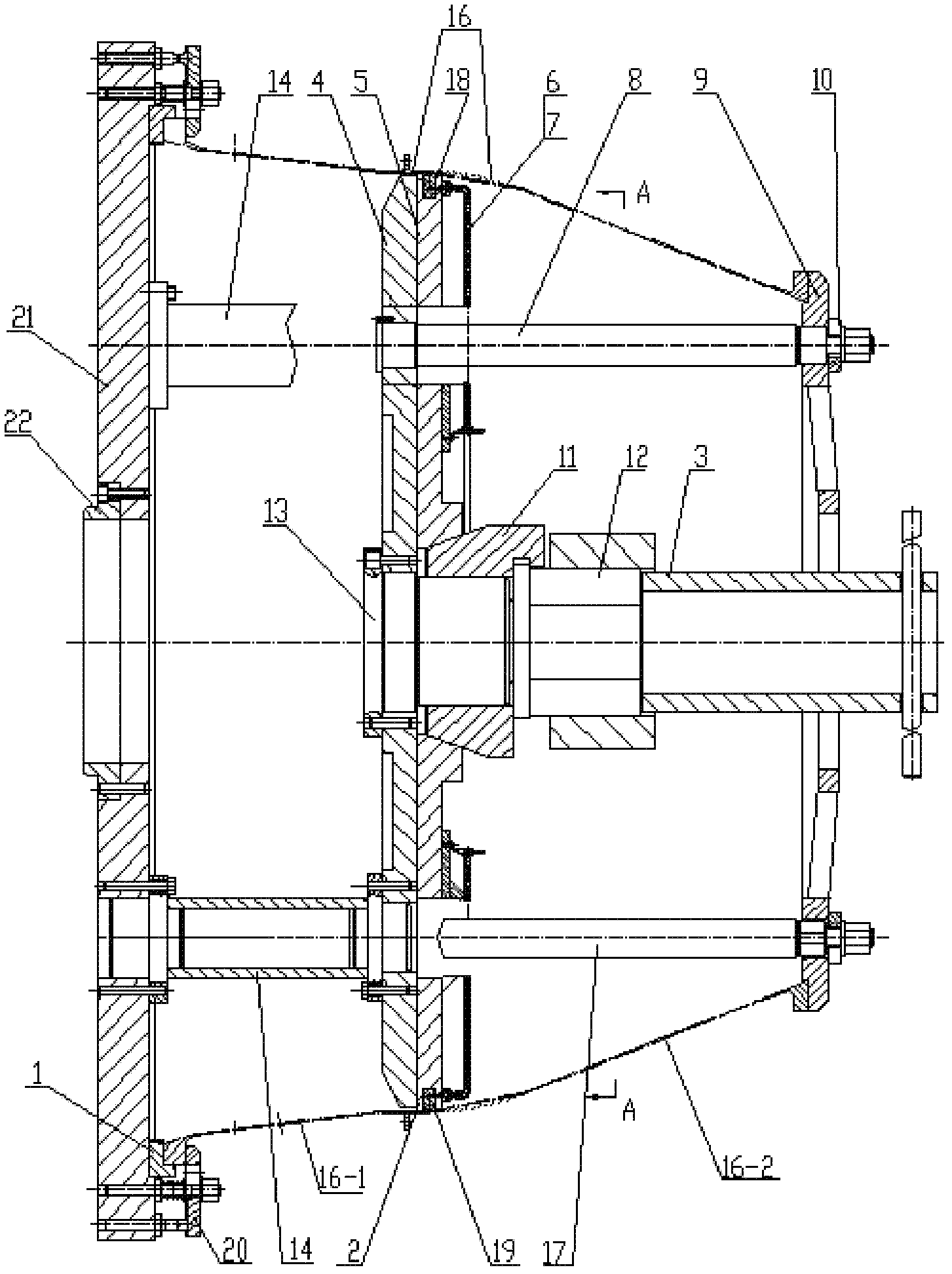

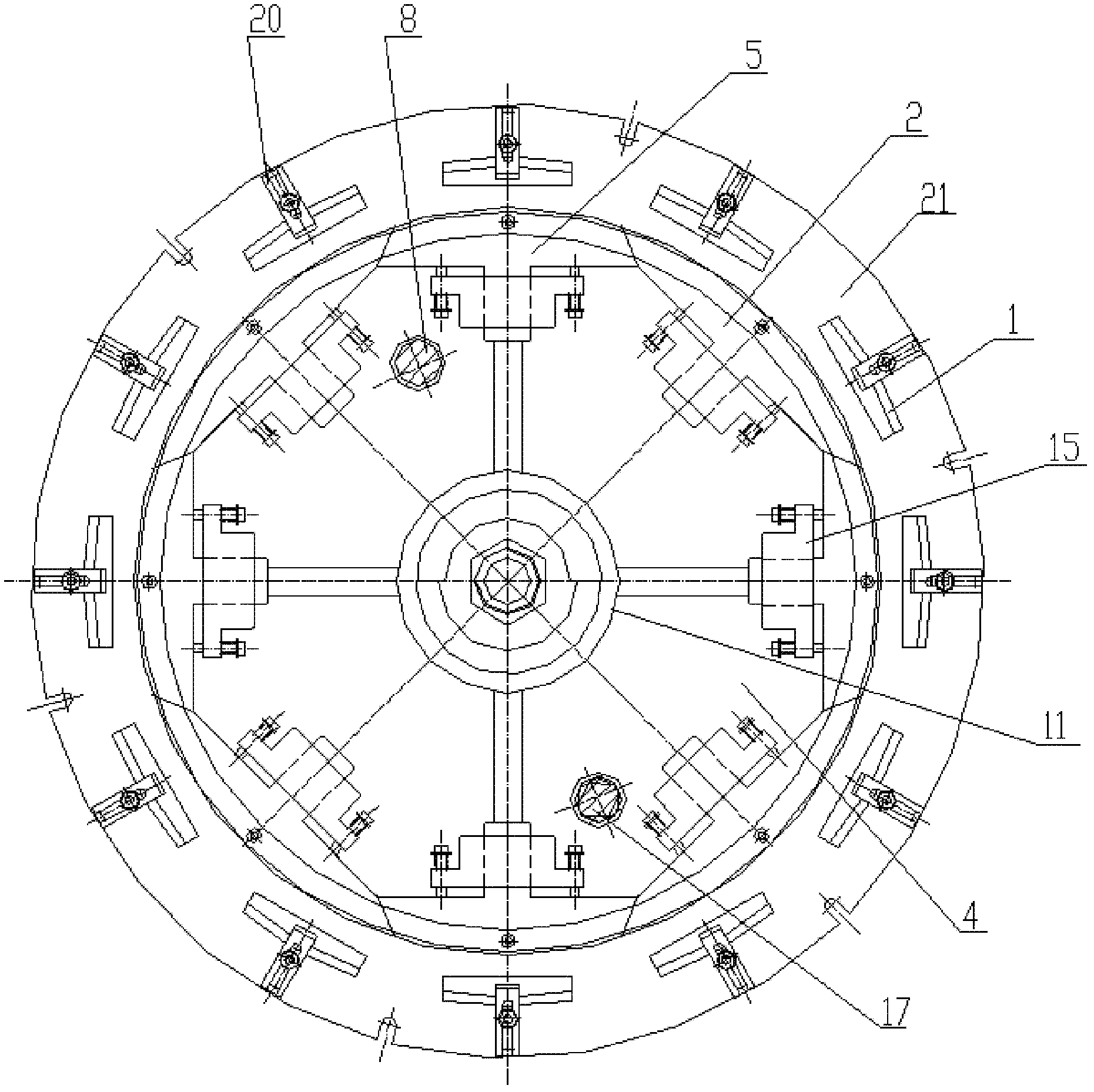

Welding tool for production of automobile seat framework

ActiveCN106112371AEnsure consistencyGuaranteed accuracyWelding/cutting auxillary devicesAuxillary welding devicesLap jointEngineering

The invention discloses a welding tool for production of an automobile seat framework. The welding tool for production of the automobile seat framework comprises a base (1), a feed clamping device, two side section clamping devices and a supporting bar clamping device, wherein the feed clamping device is provided with a sleeve (14) in advance and pushes the sleeve to the position above a slope (50) of the bottom section of a U-shaped bent pipe (2) in the automobile seat framework, the two side section clamping devices are used for fixedly clamping two side sections of the U-shaped bent pipe (2), and the supporting bar clamping device is used for fixedly clamping a first supporting bar (3) and a second supporting bar (4) so that the two ends of the first supporting bar (3) and the two ends of the second supporting bar (4) can be in fixed lap joint to the two side sections of the U-shaped bent pipe (2) correspondingly. By the adoption of the structure, the U-shaped bent pipe, the first supporting bar and the second supporting bar can be fixedly clamped, and therefore the welding tool for production of the automobile seat framework can guarantee fixed clamping of the U-shaped bent pipe and the welding precision and the product consistency of the first supporting bar and the second supporting bar during automatic welding.

Owner:宁波明望汽车饰件有限公司

Method of welding dissimilar steel 10Cr9Mo1VNb and 1Cr18Ni9

InactiveCN101011774AGuaranteed performanceGuaranteed to meltArc welding apparatusWelding/cutting media/materialsTemperature controlEngineering

The invention provides a method for the welding of steels like 10Cr9Mo1VNb and 1Cr18Ni9, which controls the temperature between 150-200deg.C before welding at the layer. With the back welding current being 115A / 85A(peak / base), welding speed 2-3cm / min, thickness no less than 3mm, filling welding current 150A / 20A (peak / base), welding speed 2-3cm / min, width of the welding channel being 2-3 times of the solder wire. It has smaller welding depth, reasonable control of the fuse ratio and chemical effusion.

Owner:WORKER WELDING & CUTTING TECHN ASSOC OF HEBEI

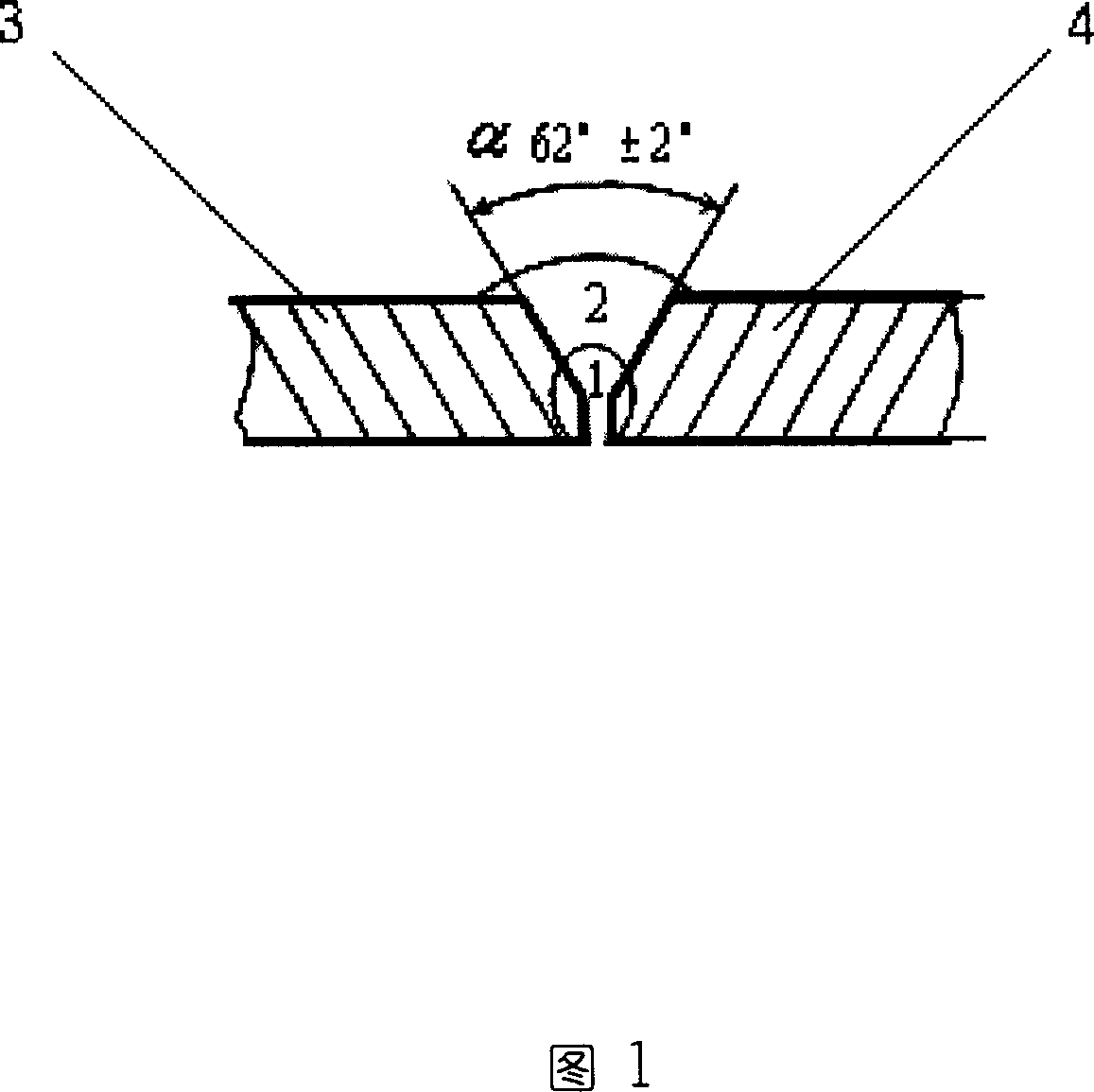

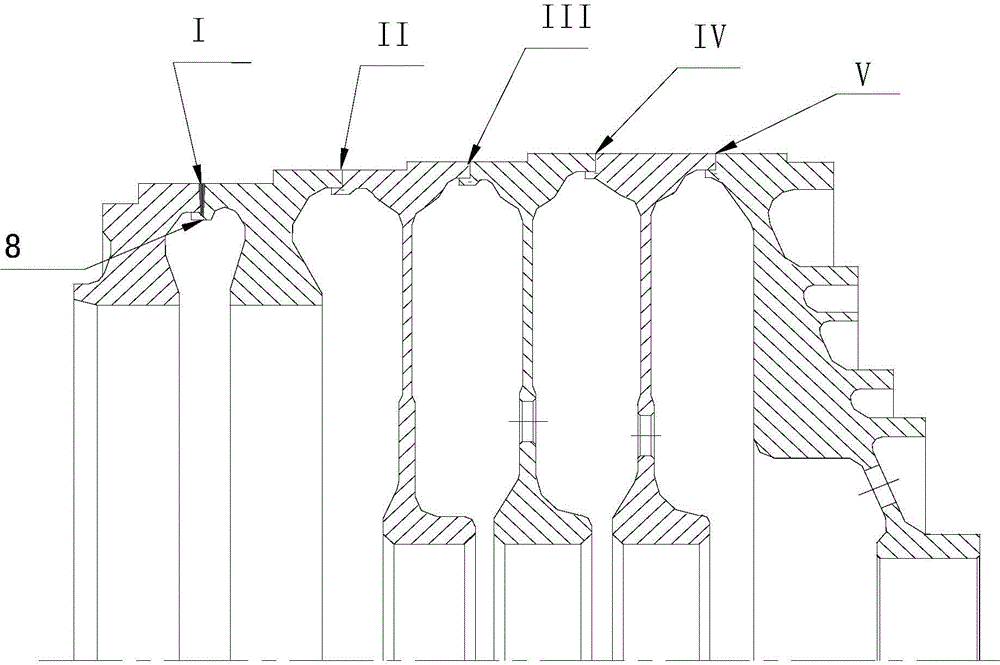

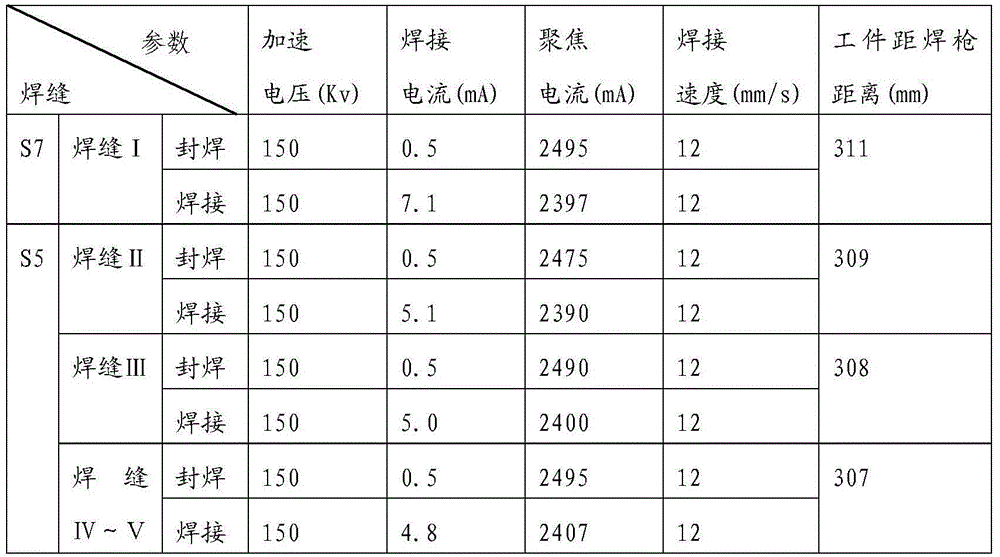

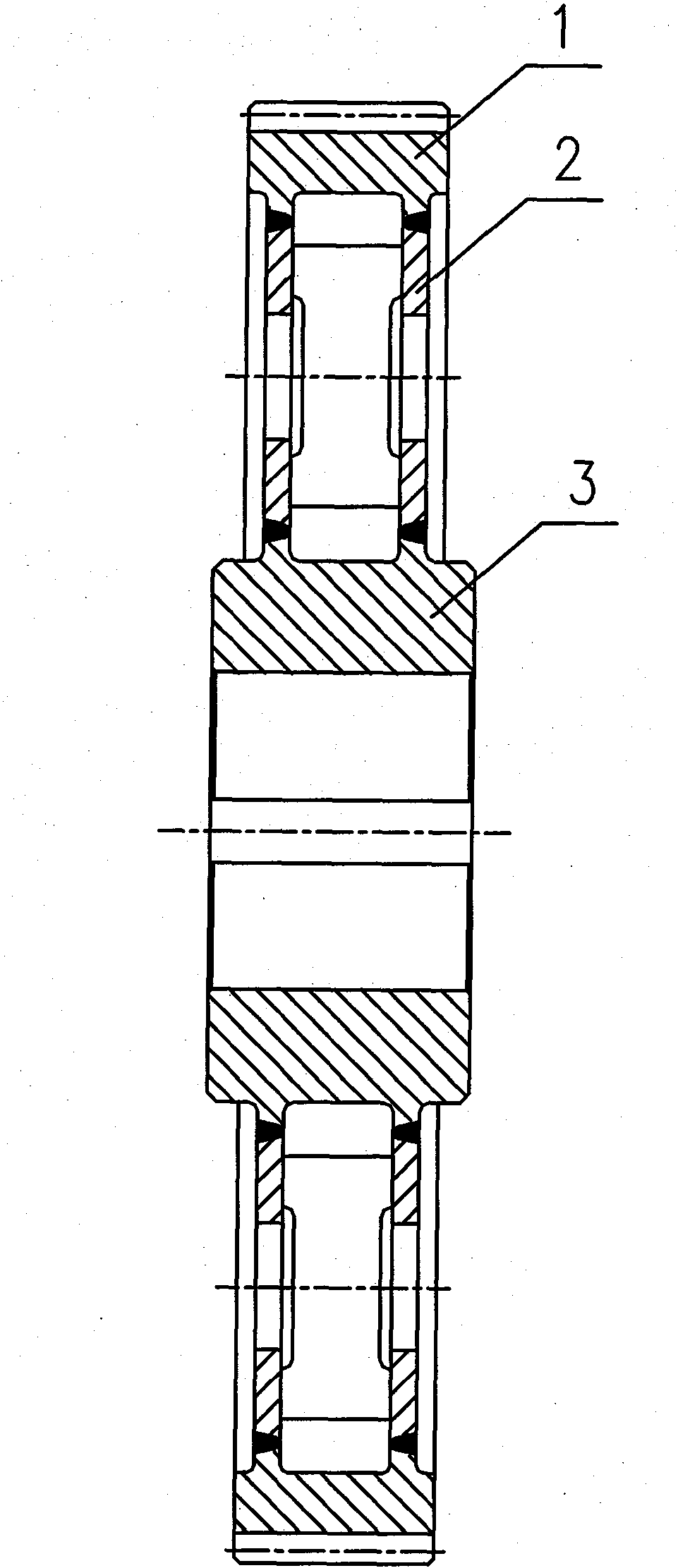

Vacuum electronic beam welding method for titanium-alloy rotor component

ActiveCN104057198AGuarantee welding qualityMeet the design requirementsElectron beam welding apparatusWelding/soldering/cutting articlesGas compressorWeld seam

The invention relates to a vacuum electronic beam welding method for a titanium-alloy rotor component. Five welding seams of a rotor of a gas compressor are welded by an electronic beam welding process. The vacuum electronic beam welding method has the advantages that reasonable welding sequence and welding parameters are adopted for controlling the welding deformation and the quality of the welding seams, the technical difficulties of poor whole rigidity, larger welding amount and difficult control for welding deformation and the like of a product are overcome, the quality of the welding seams is ensured, and the design requirement is met.

Owner:HARBIN DONGAN ENGINE GRP

Manufacturing method of large-size welding type carburizing and quenching gear

The invention discloses a manufacturing method of a large-size welding type carburizing and quenching gear, comprising the following steps of: selecting gear material; determining the basic process routes when processing a gear ring, a subplate and a hub, and processing sperately; and integrally processing the gear. The manufacturing method has the advantages of reducing welding lobar intensity, improving production efficiency and ensuring the stability of welding quality.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

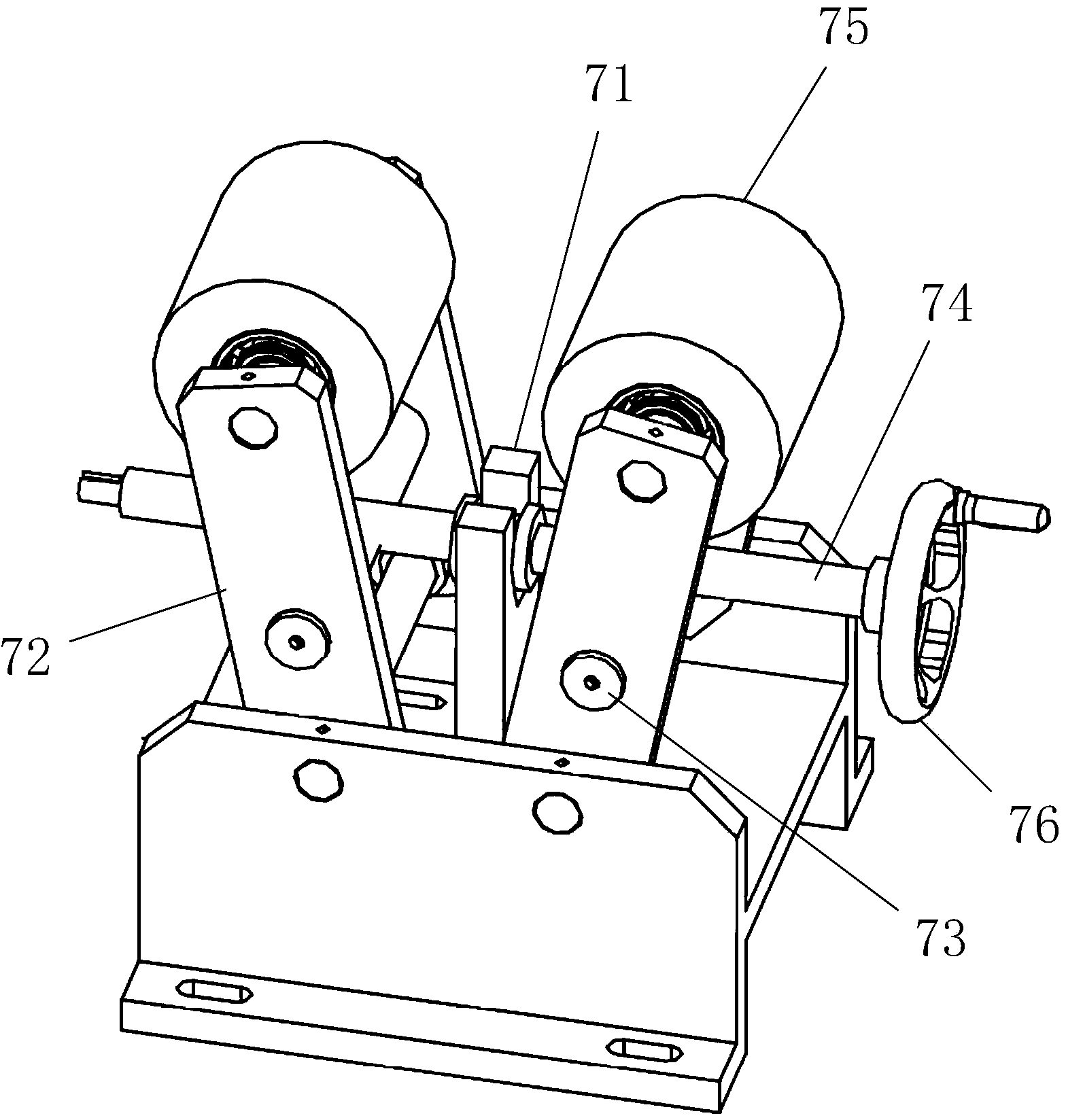

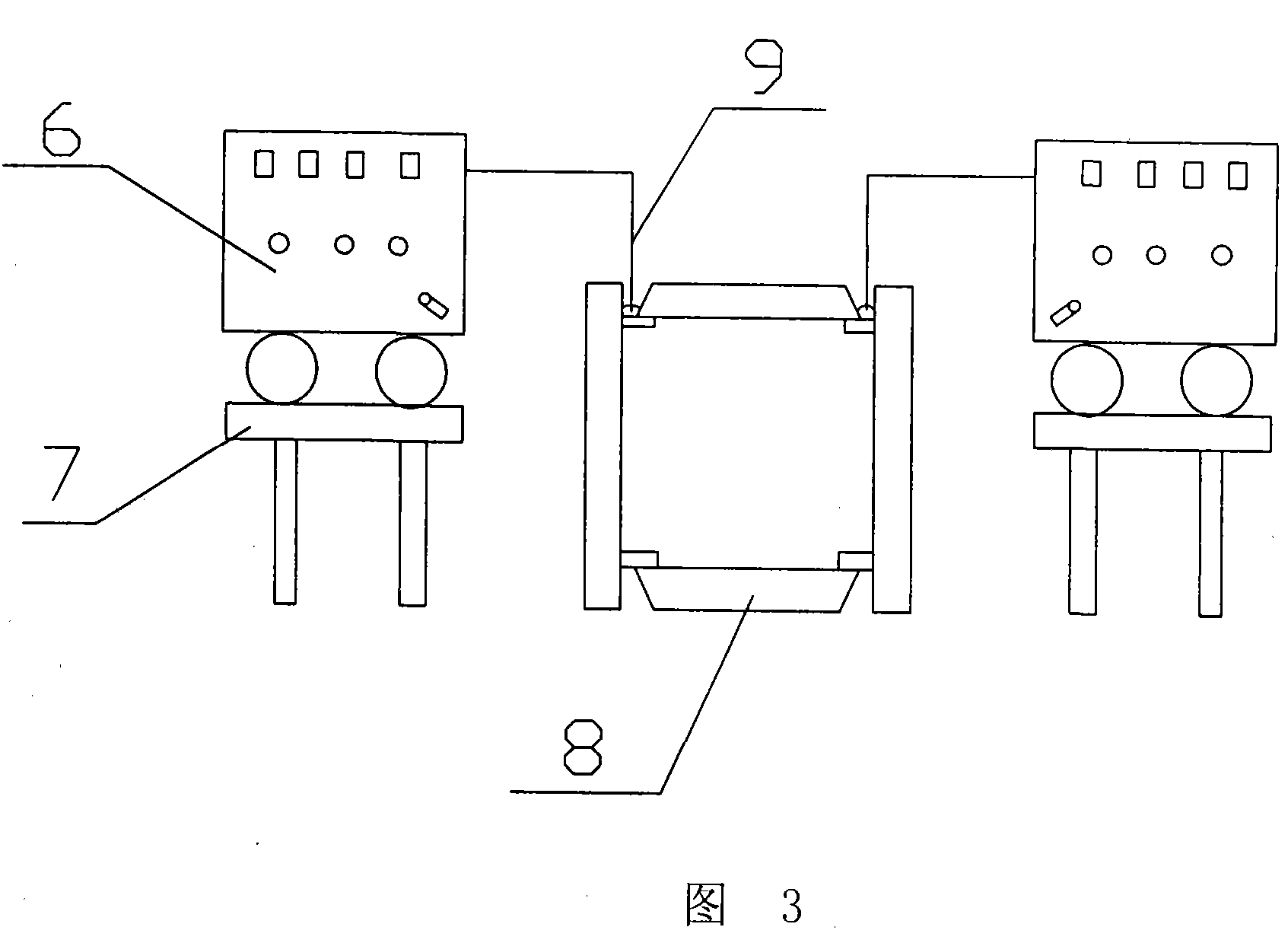

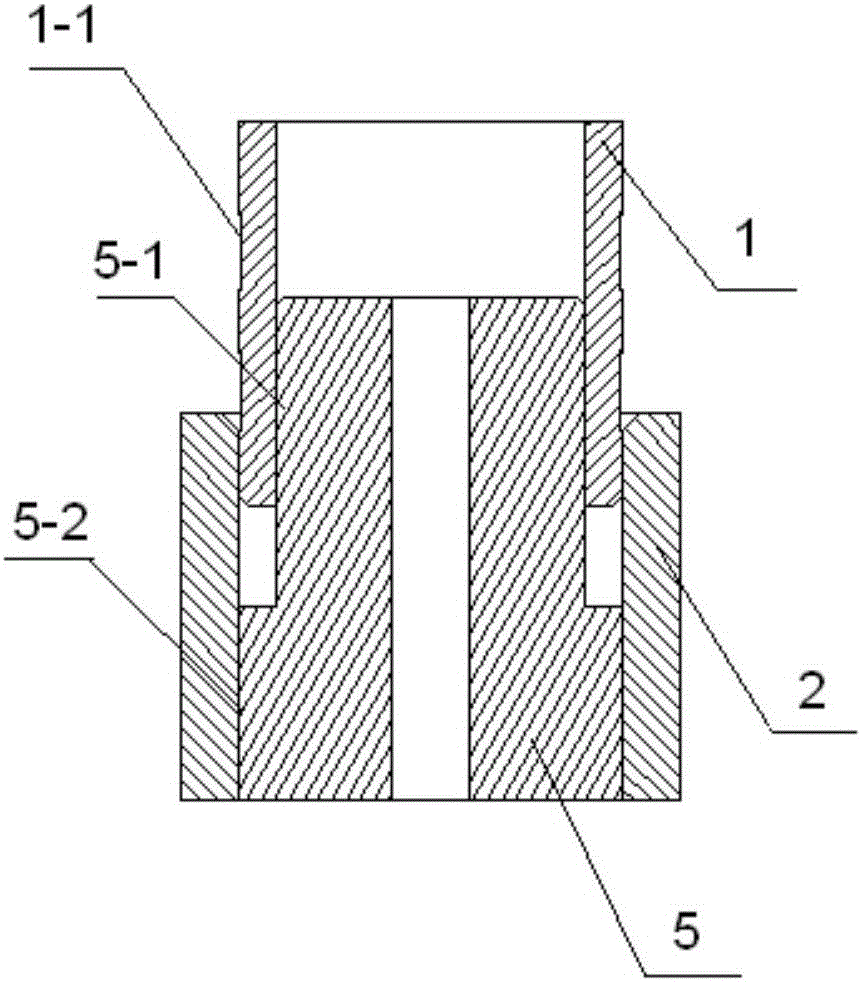

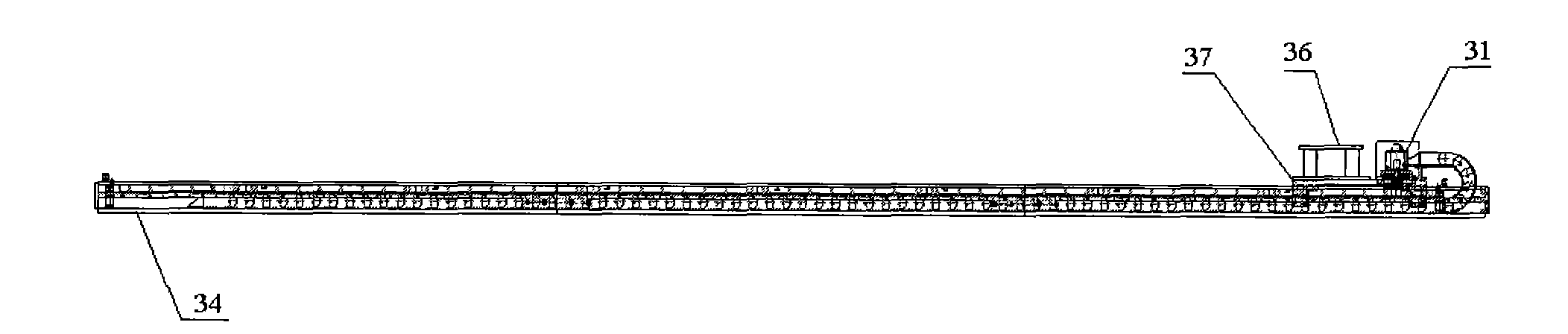

Flange welding method and welding device

ActiveCN102000921AAvoid deformationNot easy to shakeWelding/cutting auxillary devicesAuxillary welding devicesConical tubeEngineering

The invention discloses a flange welding method. The method comprises the following steps of: arranging chunk seats at the two ends of rails; arranging flanges on the chunk seats; placing steel tubes on automatic adjusting brackets; adjusting the positions of the steel tubes so as to butt the steel tubes with the flanges; after finishing butting, performing spot-welding on the flanges; removing the automatic adjusting brackets; driving the chunk seats to rotate by using driving devices; and simultaneously driving the flanges to rotate and welding by using welding equipment. A flange welding device comprises two rails; automatic adjusting brackets are arranged on the rails; a fixed chunk seat and a moveable chunk seat are respectively arranged at the two ends of the rails; and rotary supports, the driving devices and flexible welding equipment are arranged on the two chunk seats. The method and the device have the advantages that: the flanges can be prevented from being deforming when welding so as to ensure welding quality; and the steel tubes cannot jitter when welding seam circular tubes, polygonal tubes and conical tubes with the flanges. The horizontal movement of the steel tubes can be realized by using the automatic adjusting brackets so as to realize the accurate butt of the steel tubes and the flanges.

Owner:辽宁锦兴电力金具科技股份有限公司

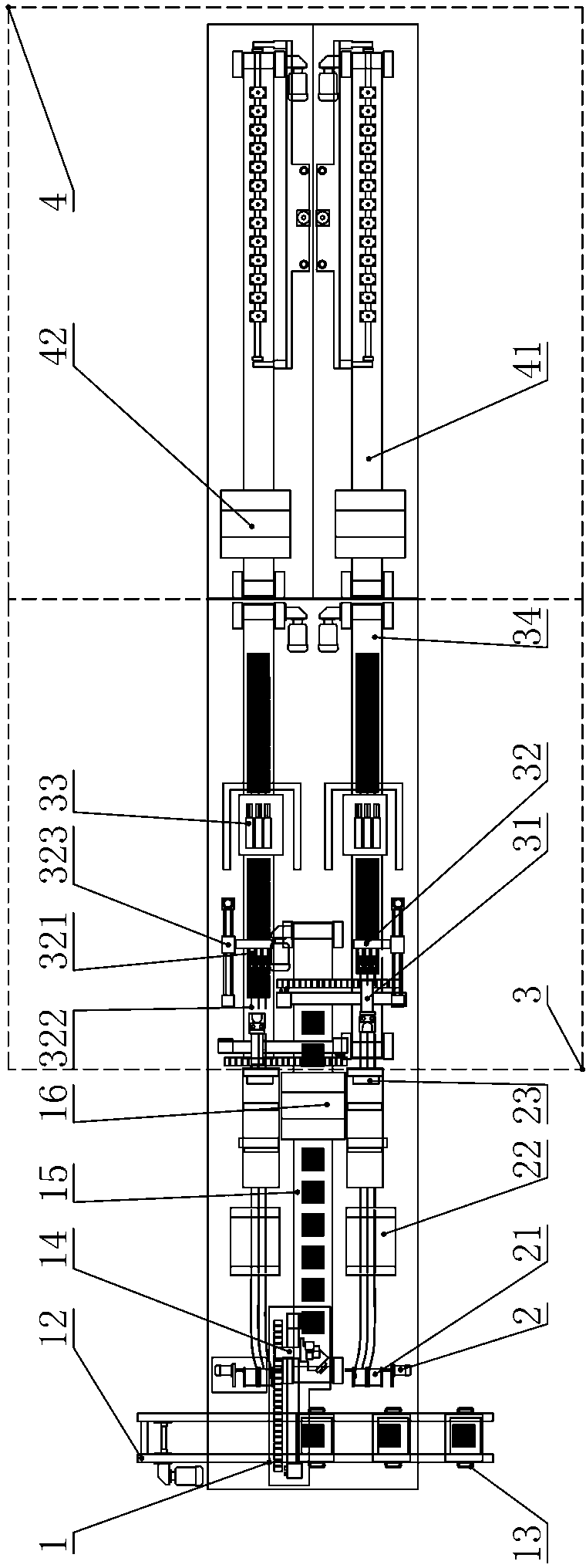

Solar cell crystal silicon wafer series welding machine

InactiveCN103182579AImprove work efficiencyAchieve integrationFinal product manufactureHeating appliancesEngineeringSolar cell

The invention discloses a solar cell crystal silicon wafer series welding machine, which comprises a welding mechanism and a welding assisting mechanism which is directly or indirectly connected with the welding mechanism, wherein the welding assisting is an automatic feeding mechanism, a welding strip feeding mechanism or an automatic discharging mechanism. The automatic feeding mechanism, the welding strip feeding mechanism, the welding mechanism and the automatic discharging mechanism are sequentially connected. All mechanisms work cooperatively and can realize the continuous, rapid and stable welding of cells.

Owner:深圳市晶拓光伏自动化设备有限公司

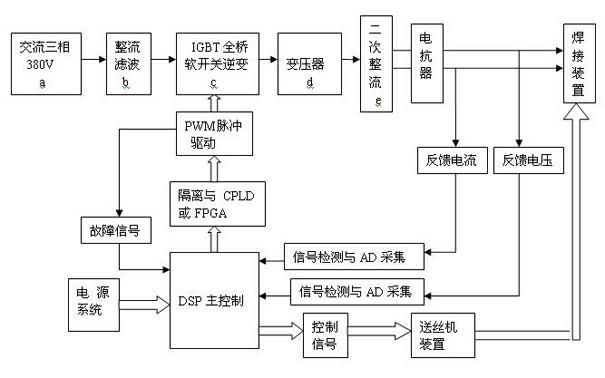

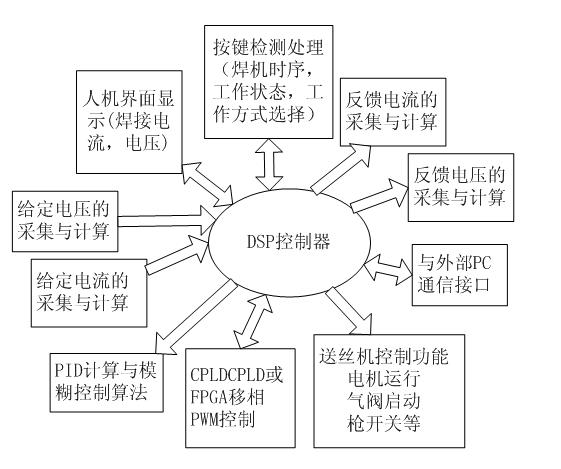

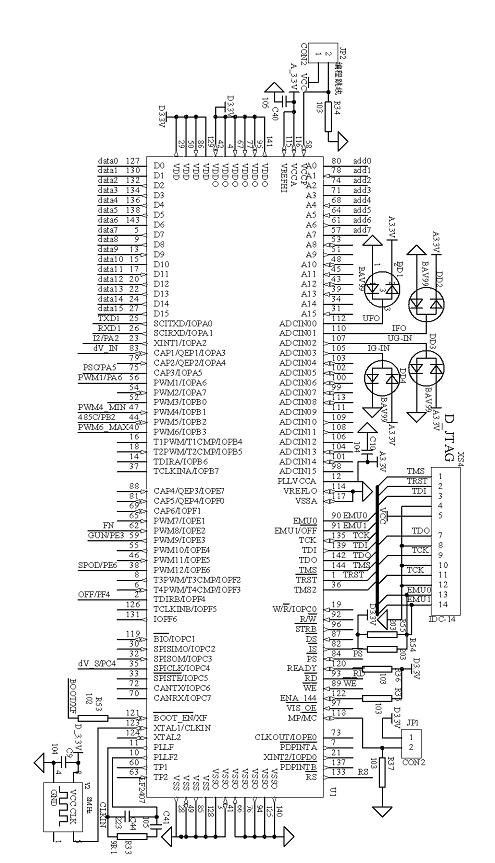

Multifunctional digitized welding machine

InactiveCN102350569ABeautiful shapeImprove dynamic response performanceArc welding apparatusFull bridgeTransformer

The invention relates to a multifunctional digitized welding machine, which comprises a full-bridge type inversion main circuit, a control circuit and a soft switch PWM (Pulse-Width Modulation) driving circuit, wherein the full-bridge type inversion main circuit is composed of an IGBT (Insulated Gate Bipolar Translator); the soft switch PWM driving circuit of a symmetric carrier is based on a CPLD (Complex Programmable Logic Device) or FPGA (Field Programmable Gate Array); the inversion main circuit comprises a rectifying filtering module, an IGBT full-bridge inversion module, a main transformer and a secondary rectifying filtering module; the control circuit comprises a DSP (Digital Signal Processor) control processor, a manual idle-dropping circuit, a regulating, detecting and sampling circuit for a feedback current and voltage signal outputted by the welding machine, a collecting and setting circuit for a feeding speed and given voltage of the welding machine, a display circuit for an interface and parameter of an external keyboard and a communication circuit connected to a PC (Personal Computer); the regulating, detecting and sampling circuit for the feedback current and voltage signal outputted by the welding machine comprises a Hall voltage sensor for detecting a feedback arc voltage outputted by the welding machine and a Hall current sensor for detecting an output current of the welding machine; and the collecting and setting circuit for the feeding speed and given voltage of the welding machine comprises a collecting circuit for a given voltage and given current, namely the feeding speed, on a panel of a feeder.

Owner:PANDA ELECTRONICS GROUP +2

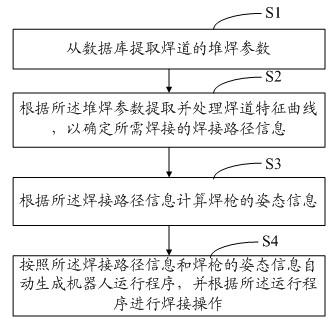

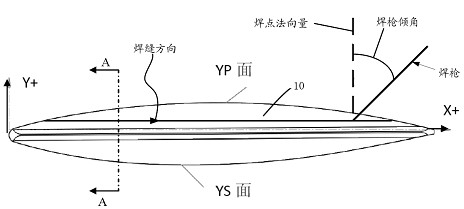

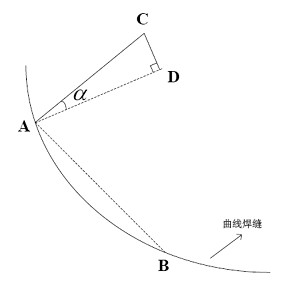

Method and system for automatic robot welding based on multilayer and multi-pass welding of curved surfaces

InactiveCN102672306AGuarantee welding qualityImprove work efficiencyArc welding apparatusRobot weldingRobot controller

The invention discloses a method and system for automatic robot welding based on multilayer and multi-pass welding of curved surfaces. The method comprises the following steps of: S1, extracting a surfacing parameter of a welding pass from a database; S2, extracting and processing a welding-pass characteristic curve according to the surfacing parameter so as to determine welding path information needed in welding; S3, calculating posture information of a welding gun according to the welding path information; and S4, automatically generating a robot operating program according to the welding path information and the posture information of the welding gun, and carrying out welding operation according to the operating program. According to the invention, a specific computation model and an arrangement strategy are established according to the relevant parameters of the current welding pass needing to carry out multilayer and multi-pass welding so as to calculate the whole movement locus and the welding-gun posture needed by welding accurately, and the operating program of a robot controller is automatically generated for carrying out corresponding welding action, so that the welding quality is guaranteed and the working efficiency of welding of a robot is greatly increased.

Owner:昆山华恒机器人有限公司

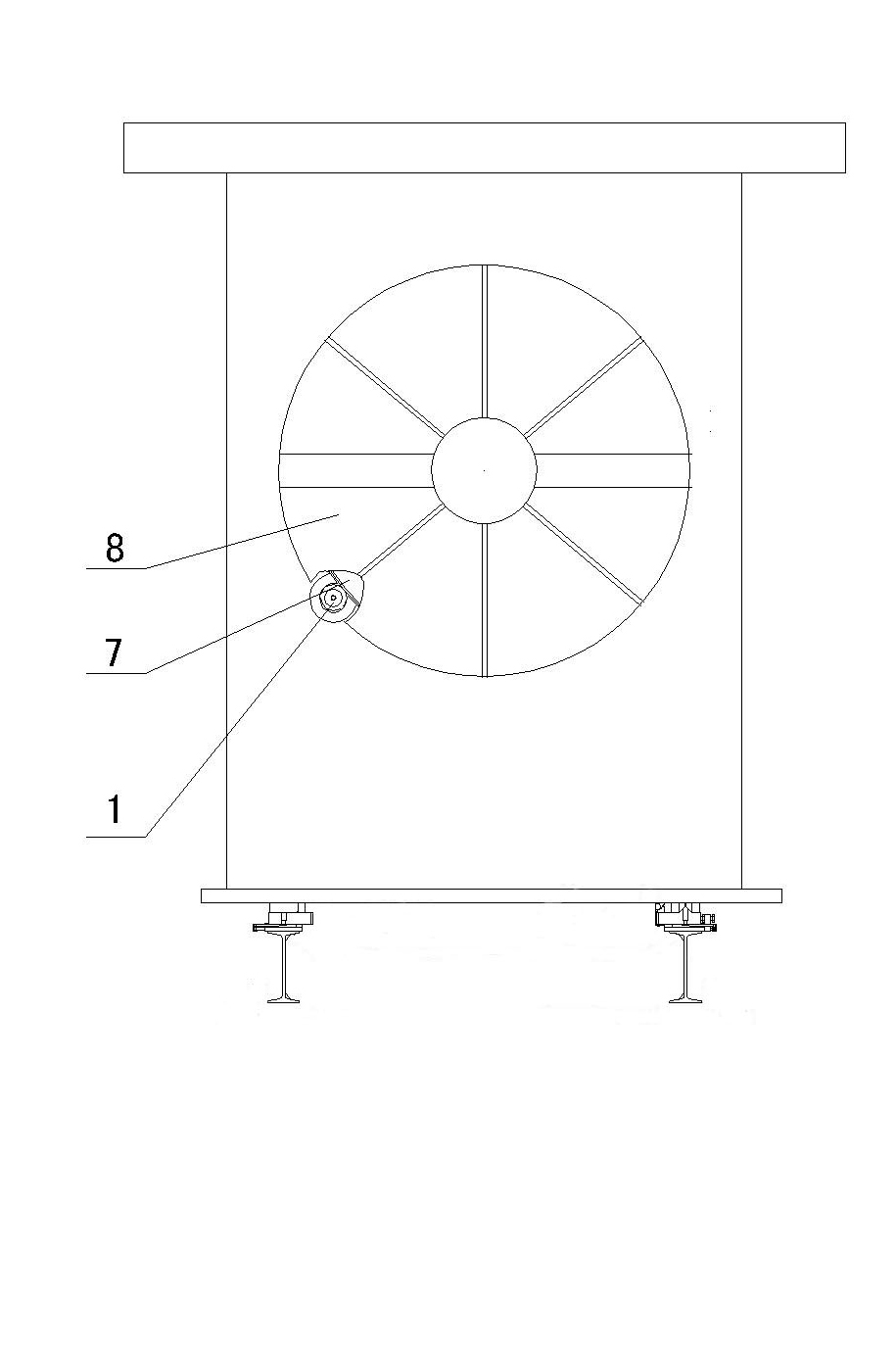

Automobile model switching mechanism of automobile production line

ActiveCN102873477ARealize automatic clampingQuick conversionWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention relates to an automobile model switching mechanism of an automobile production line, and solves the defect that in the prior art, one welding clamp only can correspond to one automobile model, so that the automobile model switching is inconvenient, the switching operation is troublesome and disordered, and the work efficiency is low. The automobile model switching mechanism comprises a rotating platform, at least two sets of clamping and positioning mechanisms on the rotating platform, and a rotary driving mechanism fixed under the rotating platform, wherein the clamping and positioning mechanisms comprise frame bodies, clamping arms, positioning arms and driving units; the clamping arms and the positioning arms are hinged to the frame bodies; the driving units correspond to the clamping arms and the positioning arms respectively; and the rotary driving mechanism comprises a rotating shaft and a driving gear meshed with outer teeth of the rotating shaft. As the clamping and positioning mechanisms are arranged on the rotating platform, and the lower part of the rotating platform is arranged on the production line, one set of rails is shared, and the rotary driving mechanism drives the rotating platform to rotate, the fast switching between two or three sets of the clamping and positioning mechanisms on the rotating platform is realized, the efficiency is high, the structure is simple, no transfer rail is required to be arranged additionally, and the cost is reduced.

Owner:ZHEJIANG JINGANG AUTOMOBILE +1

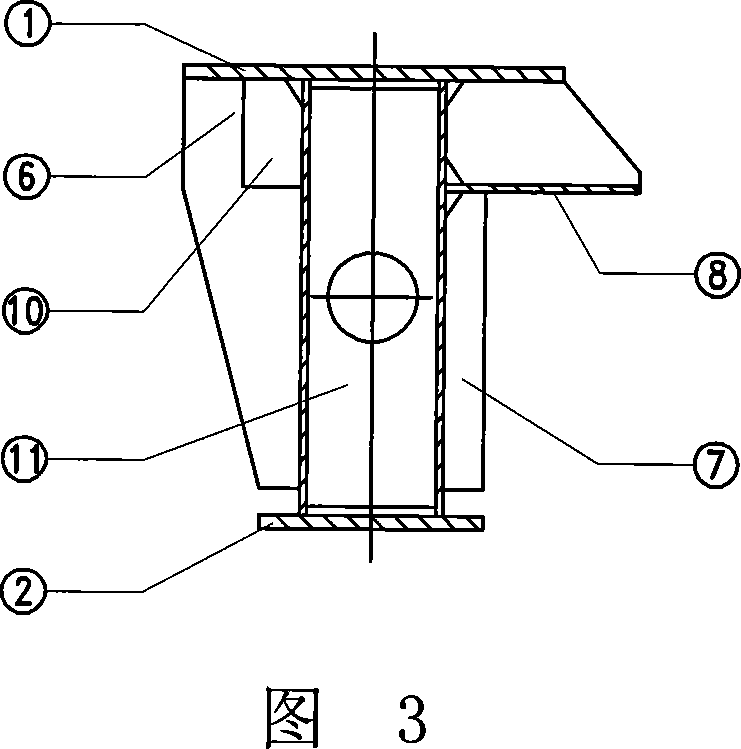

Open-close type frock clamp structure for forming die hinge welding

ActiveCN103084771AShorten production timeReduce work intensityWelding/cutting auxillary devicesAuxillary welding devicesLeft halfBody positions

The invention discloses an open-close type frock clamp structure for forming die hinge welding and belongs to the technical field of frock clamps. The open-close type frock clamp structure for forming die hinge welding comprises a base board and a die body positioning device. A left half die angle ruler and a right half die angle ruler are arranged on the base board, and a die body centering mechanism is further fixed on the base board, wherein the die body centering mechanism is positioned between the left half die angle ruler and the right half die angle ruler. The die body positioning mechanism is arranged on the die body centering mechanism, a hinge positioning clamping mechanism is arranged on the base board, and a lock module positioning and clamping mechanism is arranged on the base board. A die opening and positioning device is arranged on the base board and positioned between the hinge positioning clamping mechanism and the lock module positioning and clamping mechanism. The open-close type frock clamp structure for forming die hinge welding has the advantages that a hinge, a lock module and a die opening mechanism can be welded on a die body, the requirement for precise positioning of two half dies of a glass die body can be met, and welding quality is ensured. The condition needed by a welding craft is ensured, manufacture time is effectively reduced, and working intensity for an operator can be relieved.

Owner:ORI MOLD TECH SUZHOU

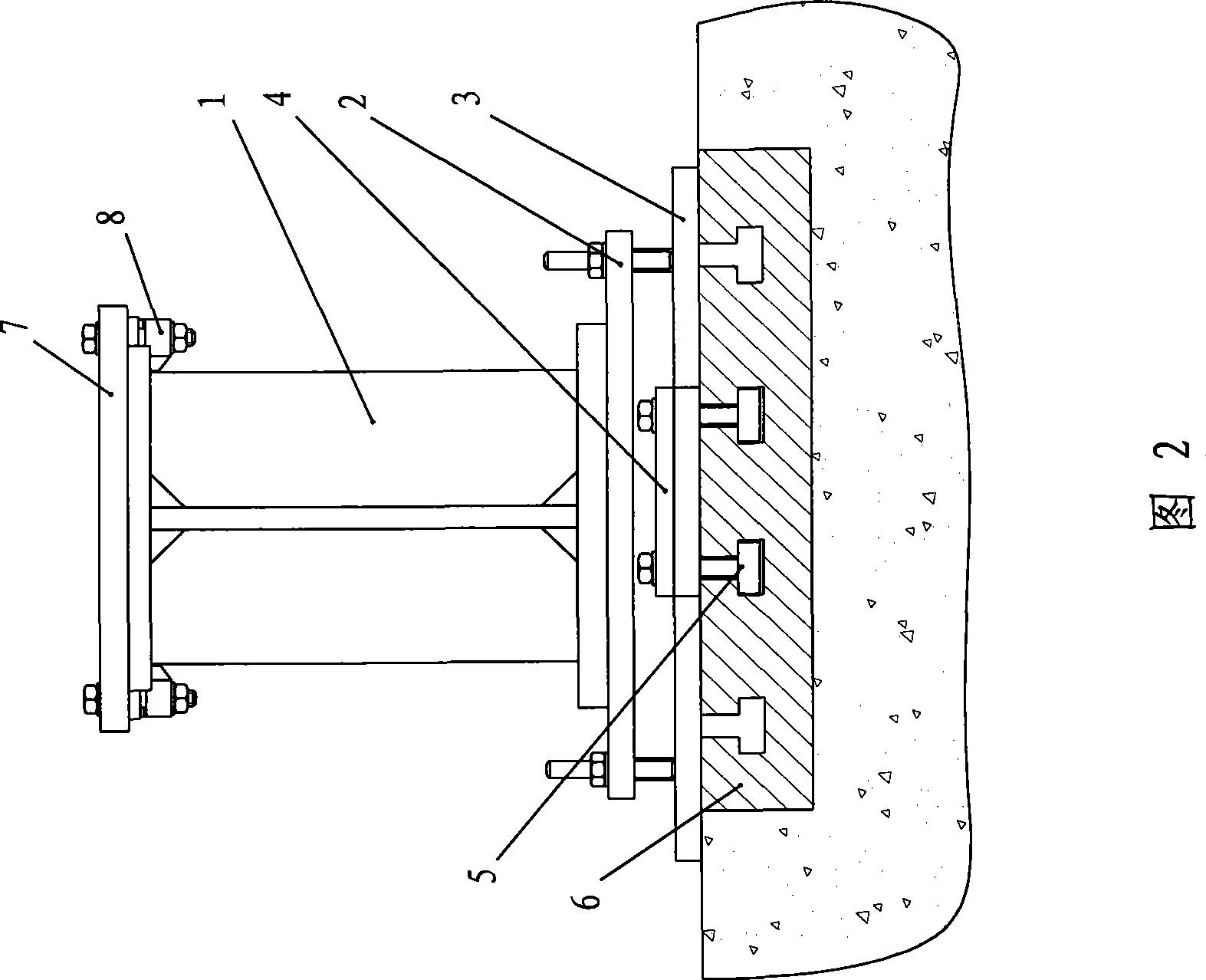

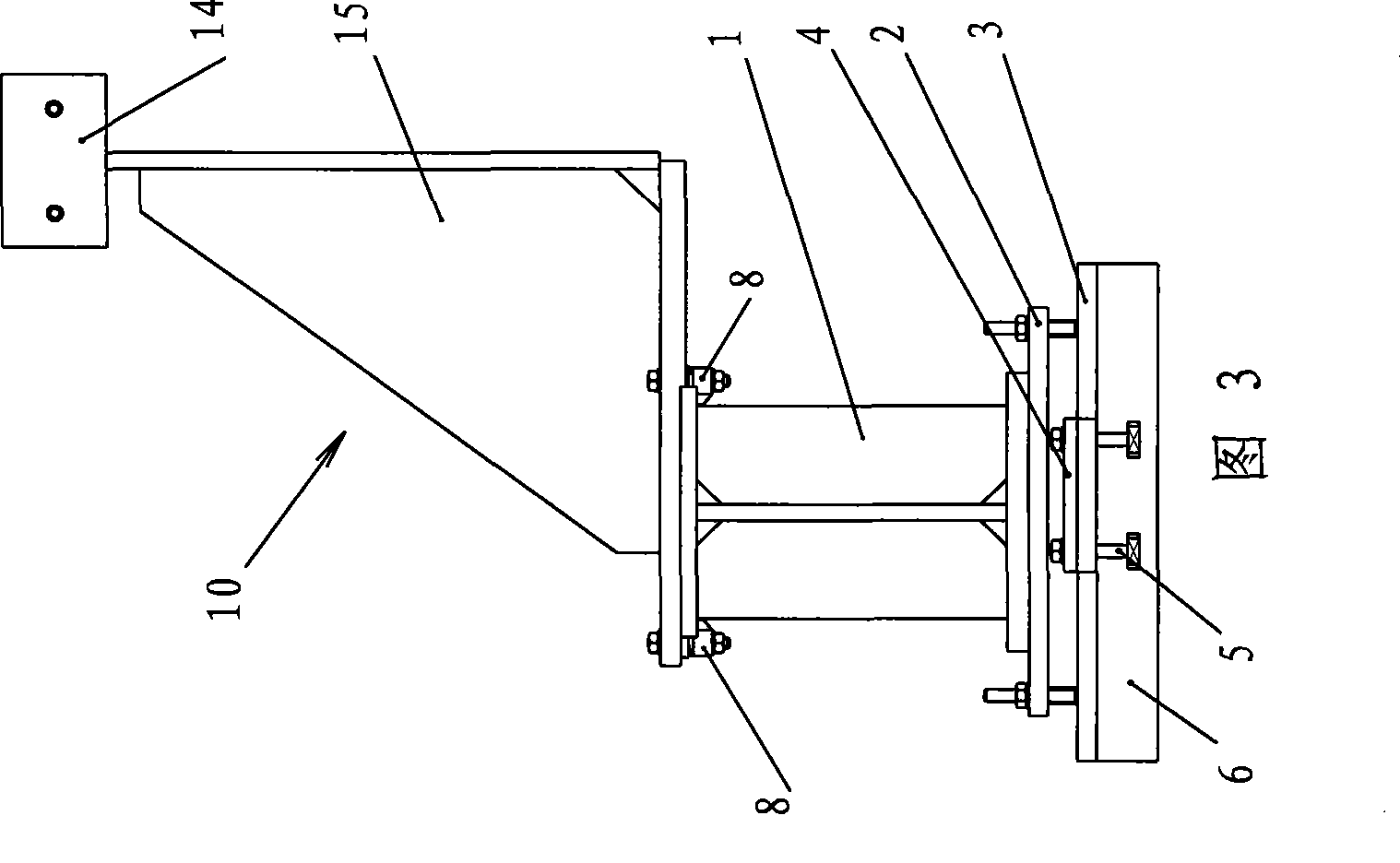

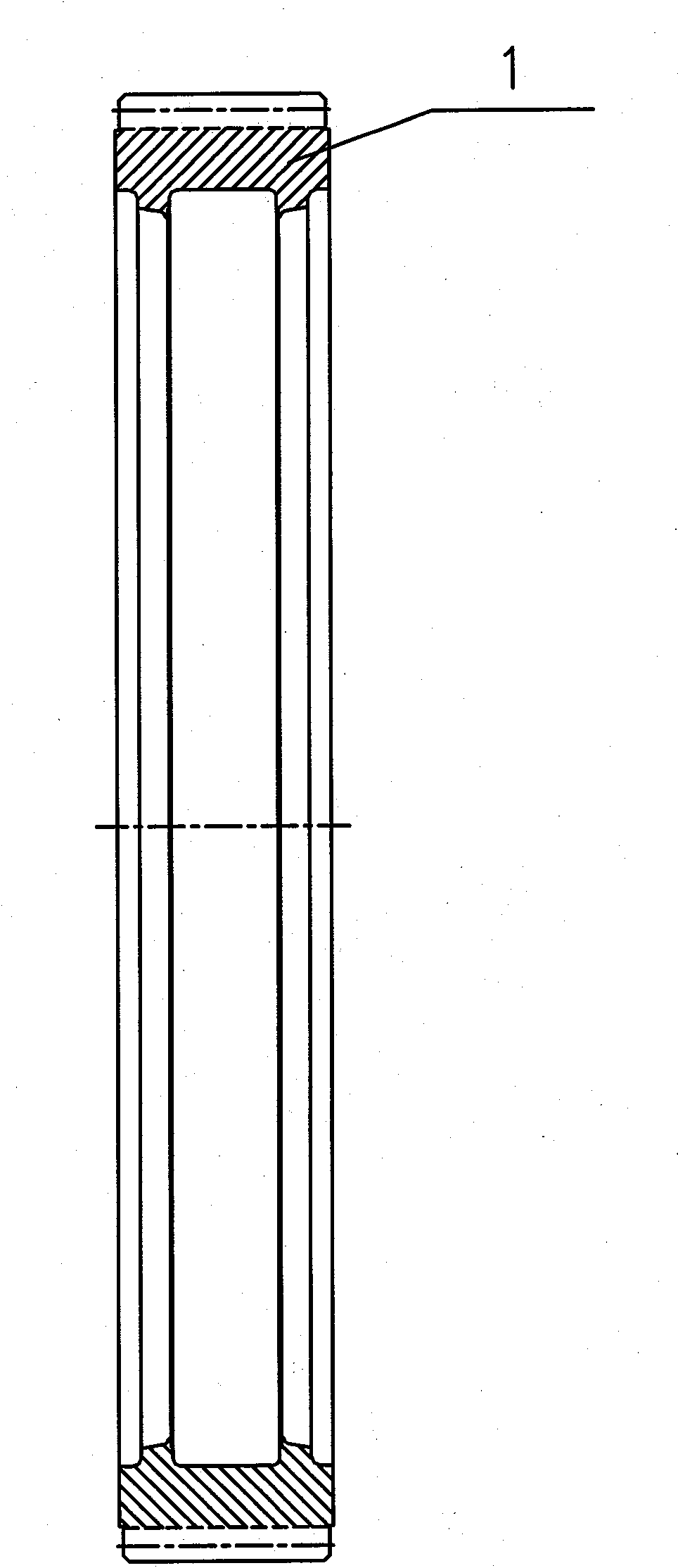

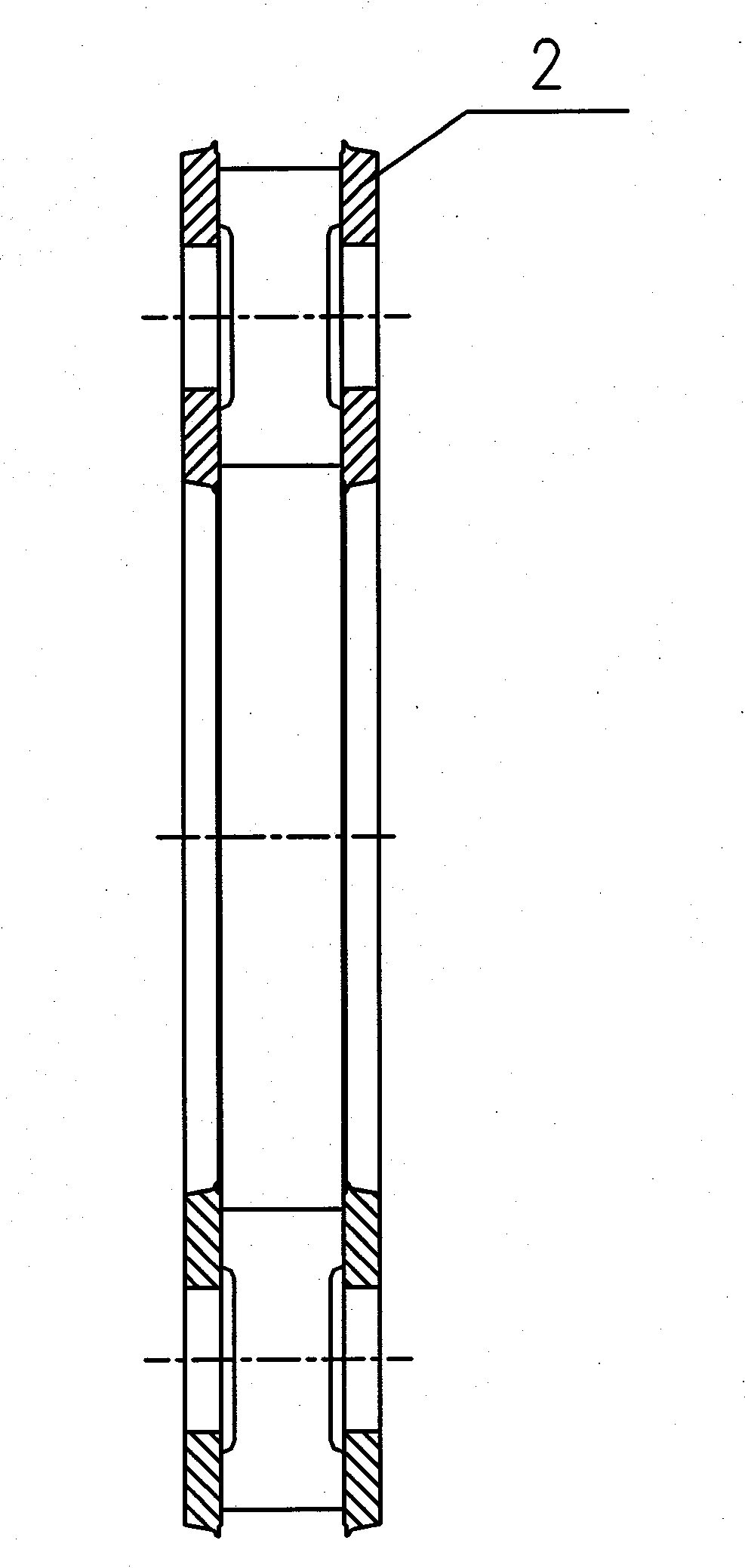

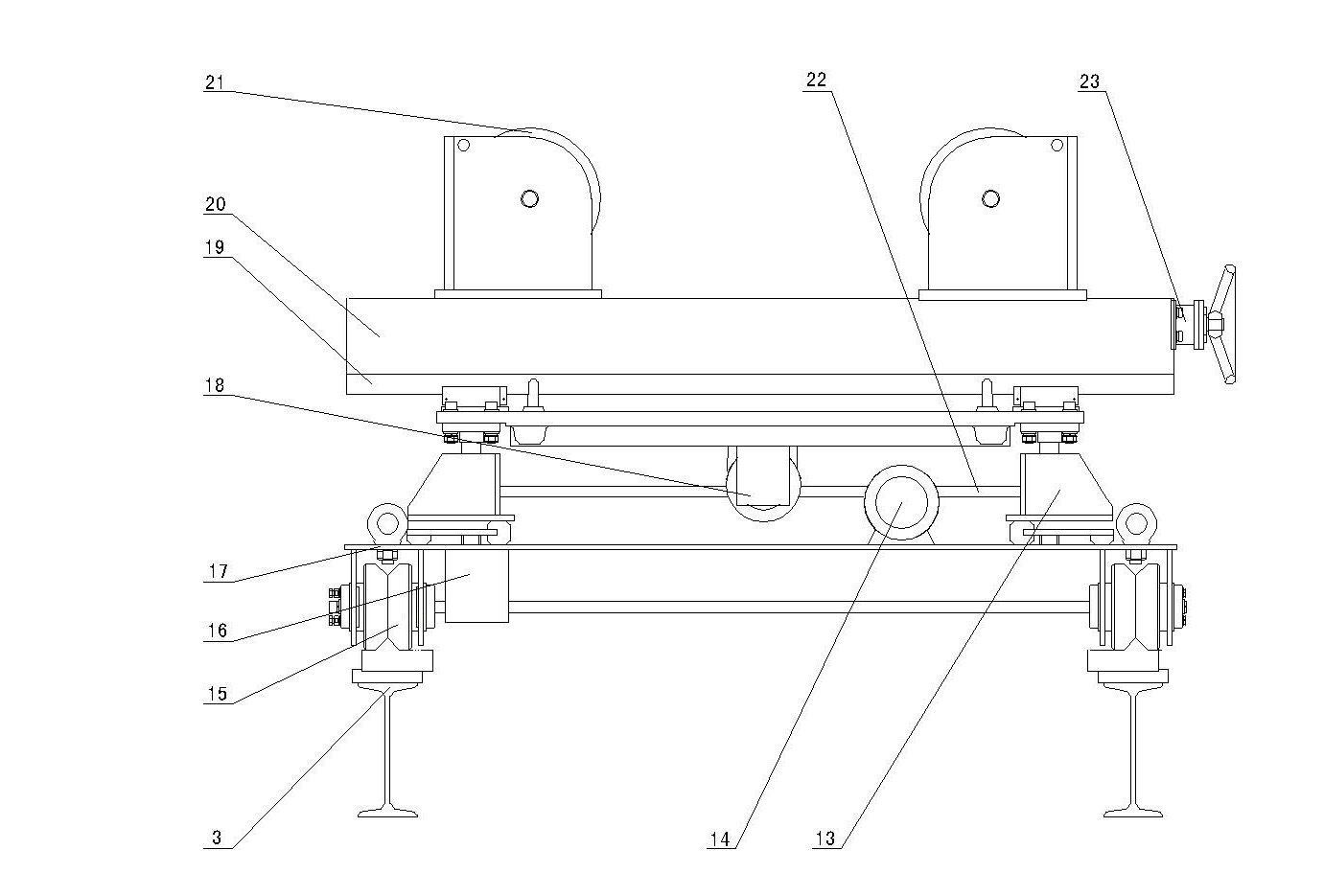

Steel pipe flange welding and positioning device

ActiveCN104014954ARealize dockingStable and easy to controlWelding/cutting auxillary devicesPipeline systemsSteel tubeFlange

The invention relates to the technical field of welding, and provides a steel pipe flange welding and positioning device. The steel pipe flange welding and positioning device comprises a first sliding rail, a first platform and a second platform, wherein the first platform and the second platform are arranged on the first sliding rail in a sliding mode. Limiting devices are arranged between the first platform and the first sliding rail and between the second platform and the first sliding rail. A first fixing jaw and a second fixing jaw which are used for positioning flanges are connected to the first platform and the second platform in a relatively rotating mode, and at least one of the first fixing jaw and the second fixing jaw is driven by a power device to rotate. Roller carriers used for holding steel pipes are arranged at the positions, between the first fixing jaw and the second fixing jaw, of the first platform and the second platform, and the height of the roller carriers is adjustable. The device is ingenious in structural design, is particularly suitable for positioning of steel pipes of various diameters and flanges of various diameters, and can achieve stable welding and guarantee the welding quantity; the steel pipes and the flanges can be positioned conveniently. In addition, the device is simple in structure, low in cost and easy to popularize.

Owner:HEBEI FLEXTRONICS ELECTRICAL TECH

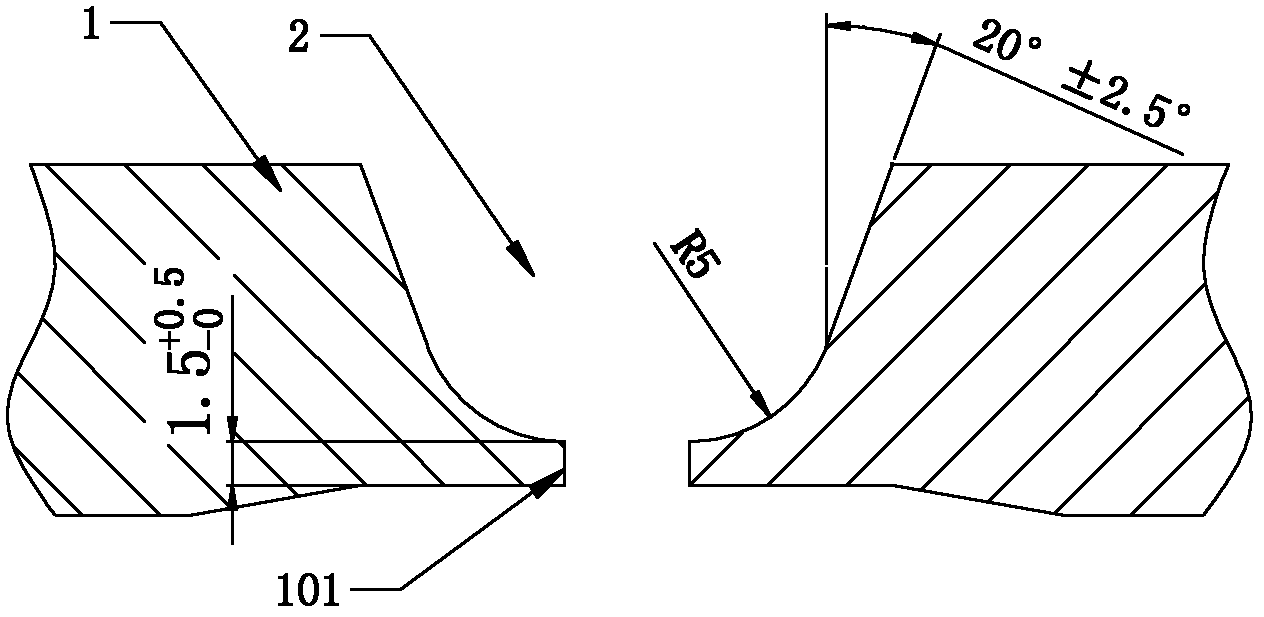

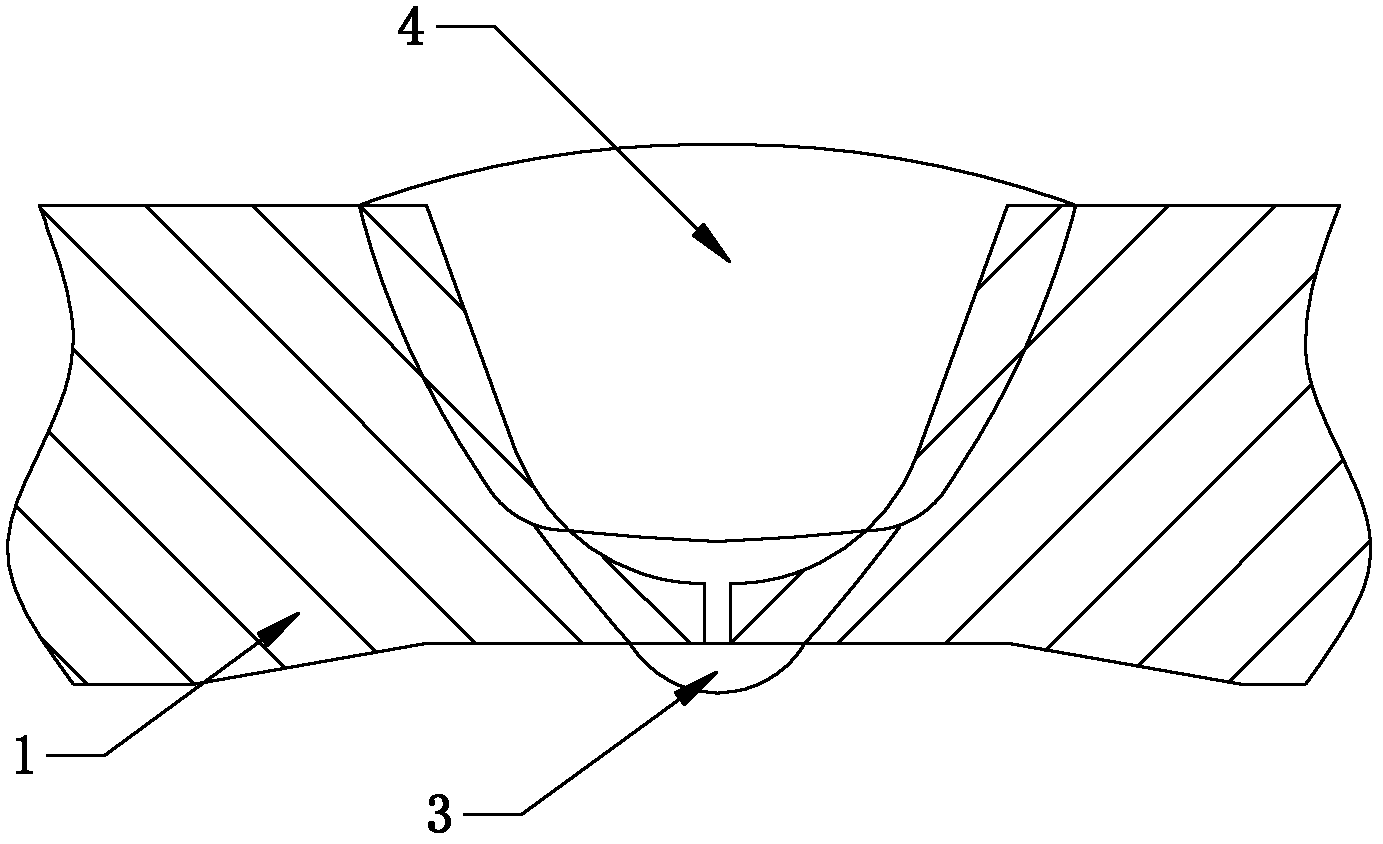

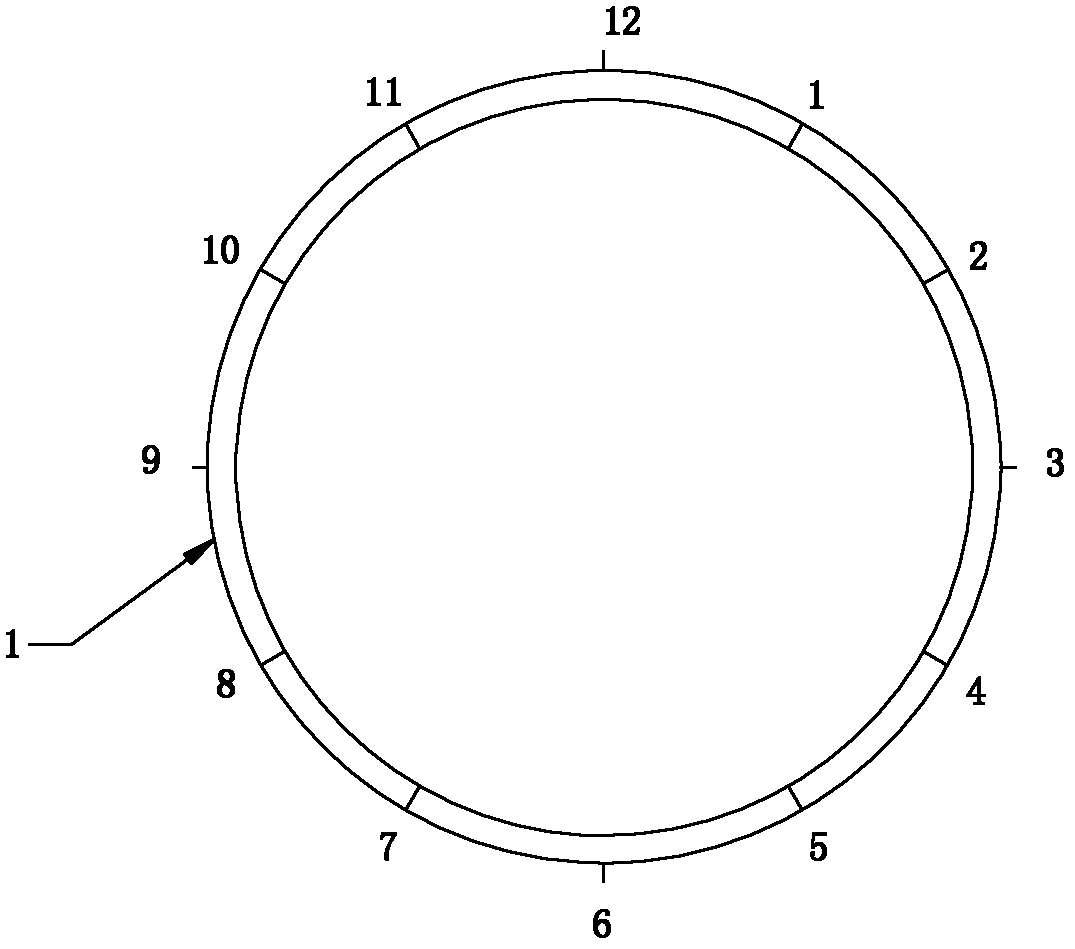

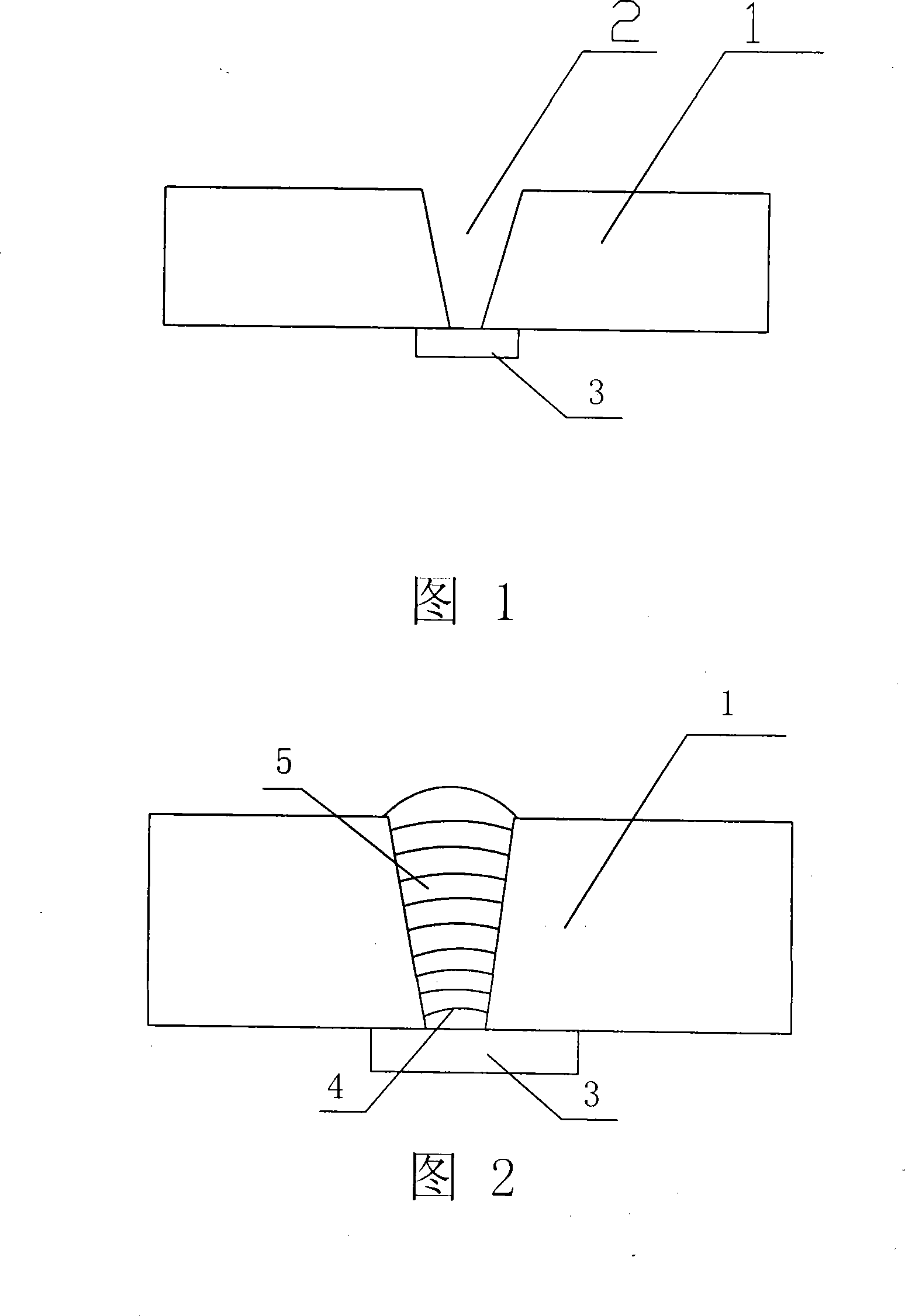

Small bevel angle full-automatic CO2 gas shielded welding and automatic submerged arc welding combined welding technique

The invention relates to a welding technique, especially a combined welding process combining small bevel angle full-automatic CO2 gas shielded protection welding with unionmelt welding, comprising following steps: (1) opening a corresponding small angle bevel on the weldment with a bevel angle of 25+50DEG; (2) paring, ensuring welding space of 8+20mm; (3) grounding welding by using full-automatic CO2 gas shielded protection welding; (4) performing filling in and capping welding by using unionmelt welding. The advantages of the invention are: (1) small bevel angle welding, saving material and improving productivity; (2) grounding welding by using unionmelt welding, the electrical arc heat quantity is centralized, the heated area is small, the welding speed is quick, head affection range is contracted, and welding deformation is small; (3) crackle generation tendency is decreased; (4) bottom slag cleaning is avoided to prepare for narrow gap welding and welding efficiency is increased; (5) filling in and capping are performed by using unionmelt welding, so that welding speed and external appearance forming quality are assured.

Owner:MCC JINGTANG CONSTR

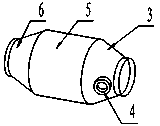

Catalytic converter assembly welding method for vehicle exhaust system

ActiveCN103464912ASimple structureImprove accessibilityWelding/cutting auxillary devicesAuxillary welding devicesWelding residual stressWelding deformation

A catalytic converter assembly welding method for a vehicle exhaust system uses incremental part welding and includes the following steps of welding a front cone, a carrier shell and a rear cone on carrier shell subassembly welding equipment to form carrier shell subassembly, welding a front flange, a front connection tube, a middle connection tube, and the welded carrier shell subassembly on a front subassembly welding equipment to form a front subassembly, and welding flexible connection, a rear connection tube, a rear flange and the front subassembly on assembly welding equipment so as to form a catalytic converter assembly. The catalytic converter assembly welding method for the vehicle exhaust system has the advantages of greatly reducing cumulative welding residual stress caused by integrated welding and forming, avoiding deformation of complex welding on junctions of various part, improving product quality, eliminating quality problems caused by welding residual stress and a large of unqualified products owing to the welding deformation, and improving production efficiency.

Owner:保定市屹马汽车配件制造有限公司

Welding fixture for thin-wall part

ActiveCN102248269AGuaranteed adjustabilityPrecise positioningWelding accessoriesEngineeringThin walled

The invention relates to a welding fixture for a thin-wall part. In the welding fixture for the thin-wall part, a pedestal is connected with a supporting plate through a connecting shaft; a pressing plate is used for fixing the welded part; a mandrel is fixed in a central hole of the pedestal; the number of positioning blocks is at least four; each positioning block is arranged on the same circumference of the pedestal; the number of pressing blocks is as same as that of the positioning blocks; the pressing blocks are used for fixing the welded part; one end of a positioning shaft is fixed inthe central hole of the supporting plate; a wedge block is arranged on the positioning shaft; a dowel nut is arranged at the thread section of the positioning shaft and is connected with the wedge block; the number of driving parts is at least three; the number of driven parts is as same as that of the driving parts; the number of guide parts is equal to the sum of the number of the driving partsand the driven parts; each driving part and each driven part are placed on the supporting plate along the circumference of the supporting plate at intervals; each guide part corresponding to one driving part or one driven part is fixed on the supporting plate; a first insert is arranged on one driving part; a second insert is arranged on one driven part; and an air tap jack and a vent hole communicated with the air tap jack are formed on each insert.

Owner:SICHUAN FST MACHINING MFG

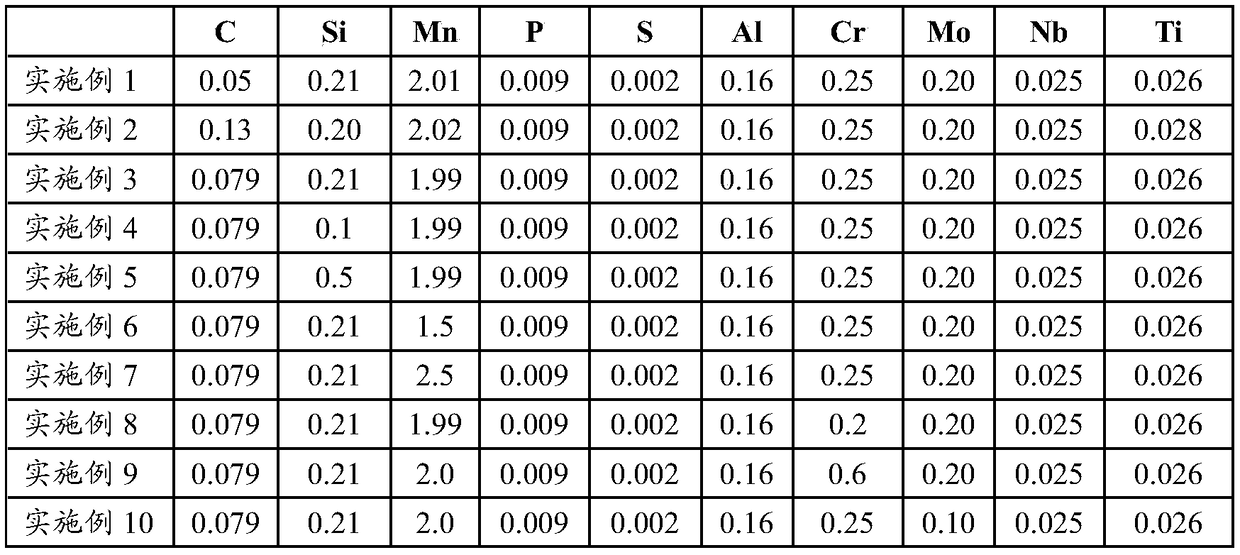

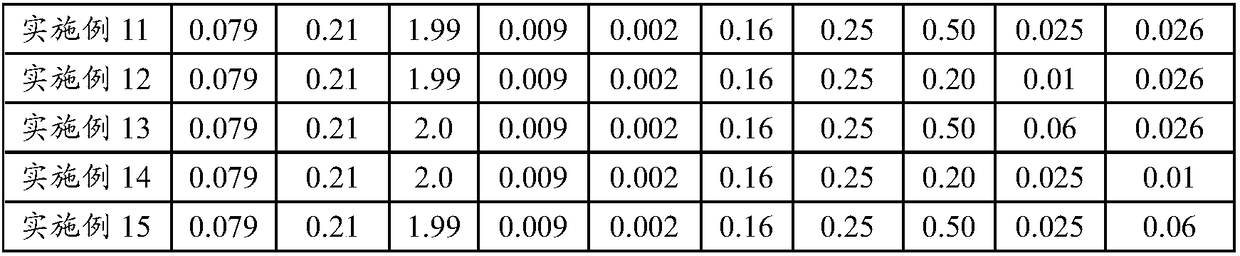

Cold-rolled hot-galvanized complex phase steel and preparation method thereof

The invention relates to a kind of cold-rolled hot-galvanized complex phase steel. Chemical components of the cold-rolled hot-galvanized complex phase steel comprise, by weight, 0.05-0.13% of C, 0.1-0.5% of Si, 1.5-2.5% of Mn, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 0.1-0.6% of Al, 0.2-0.6% of Cr, 0.1-0.5% of Mo, 0.01-0.06% of Nb, 0.01-0.06% of Ti, and the balance Feand inevitable impurities. The invention further relates to a preparation method of the cold-rolled hot-galvanized complex phase steel. The preparation method comprises the following steps of castingmolten steel into a steel billet; conducting hot rolling on the steel billet to obtain a hot-rolled plate and conducting cold rolling on the hot-rolled plate to obtain a cold-hardened steel strip; conducting continuous galvanizing and annealing process treatment on the cold-hardened steel strip to obtain a finished cold-rolled hot-galvanized complex phase steel product. The bending performance ofthe cold-rolled hot-galvanized complex phase steel is improved on the basis of meeting the requirement for strength.

Owner:SHOUGANG CORPORATION

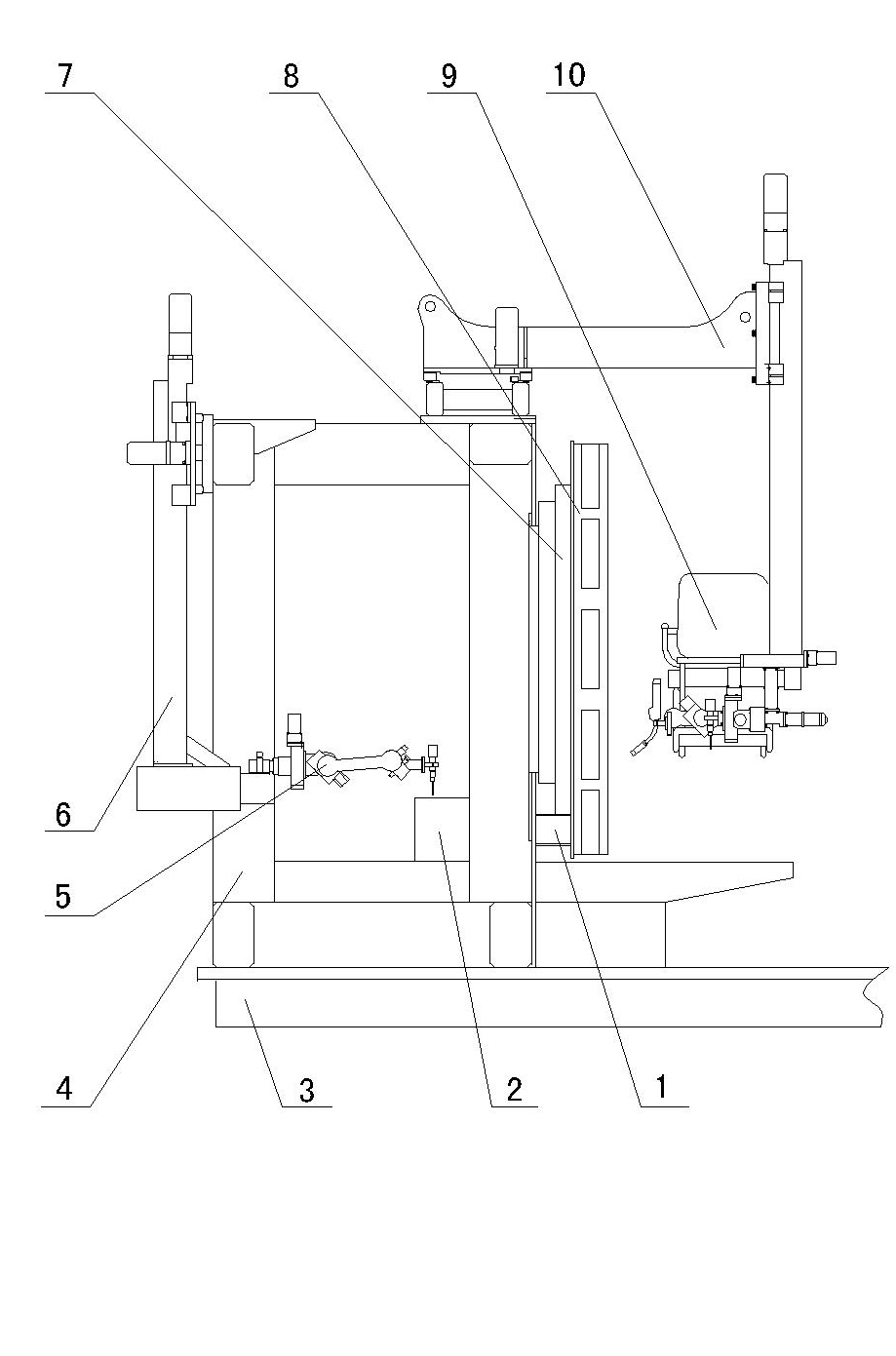

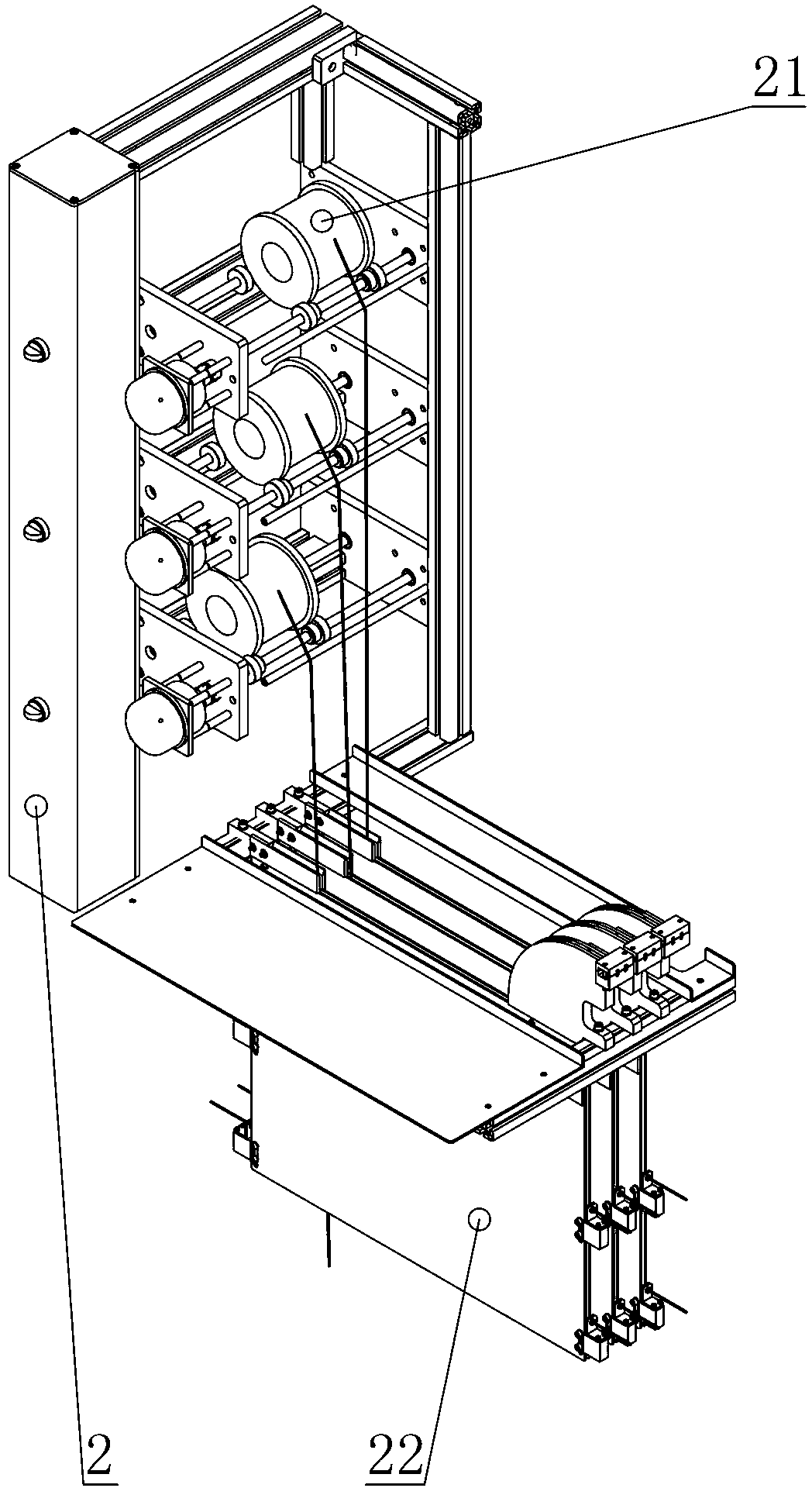

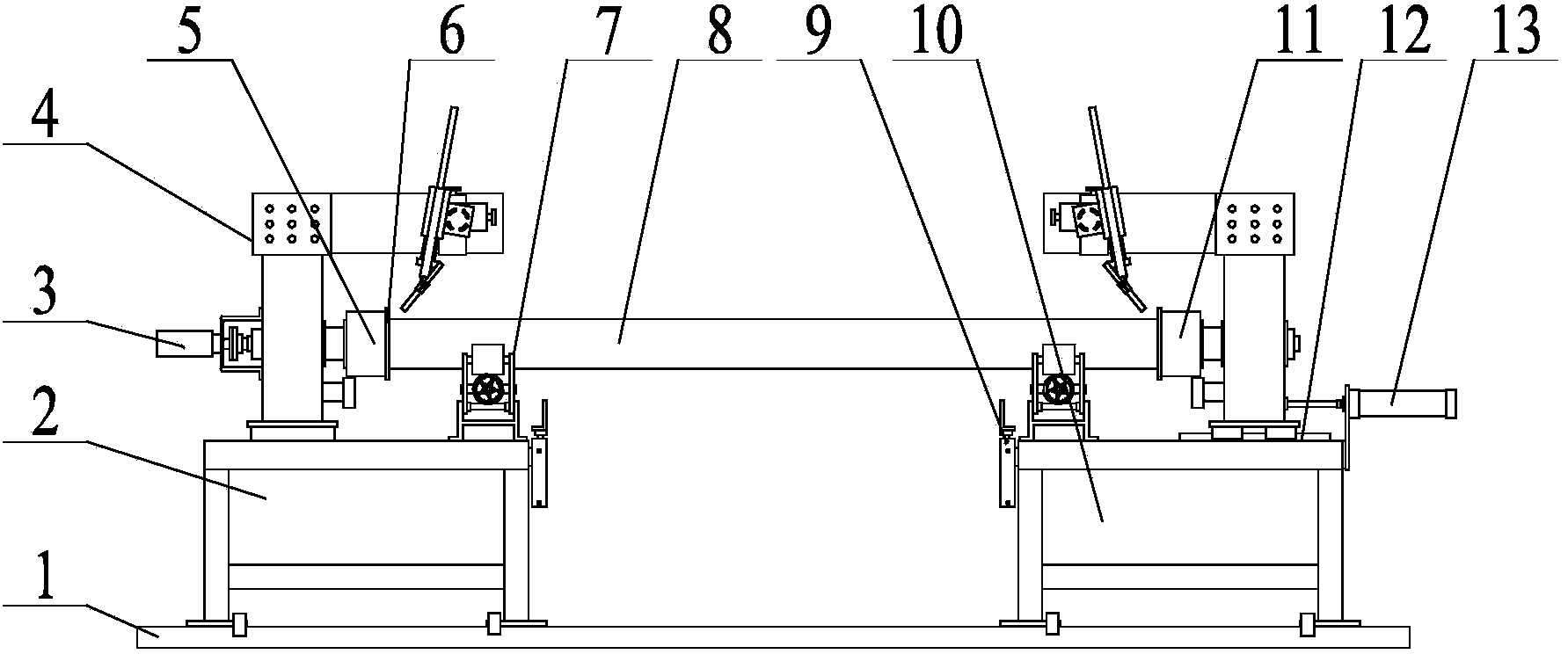

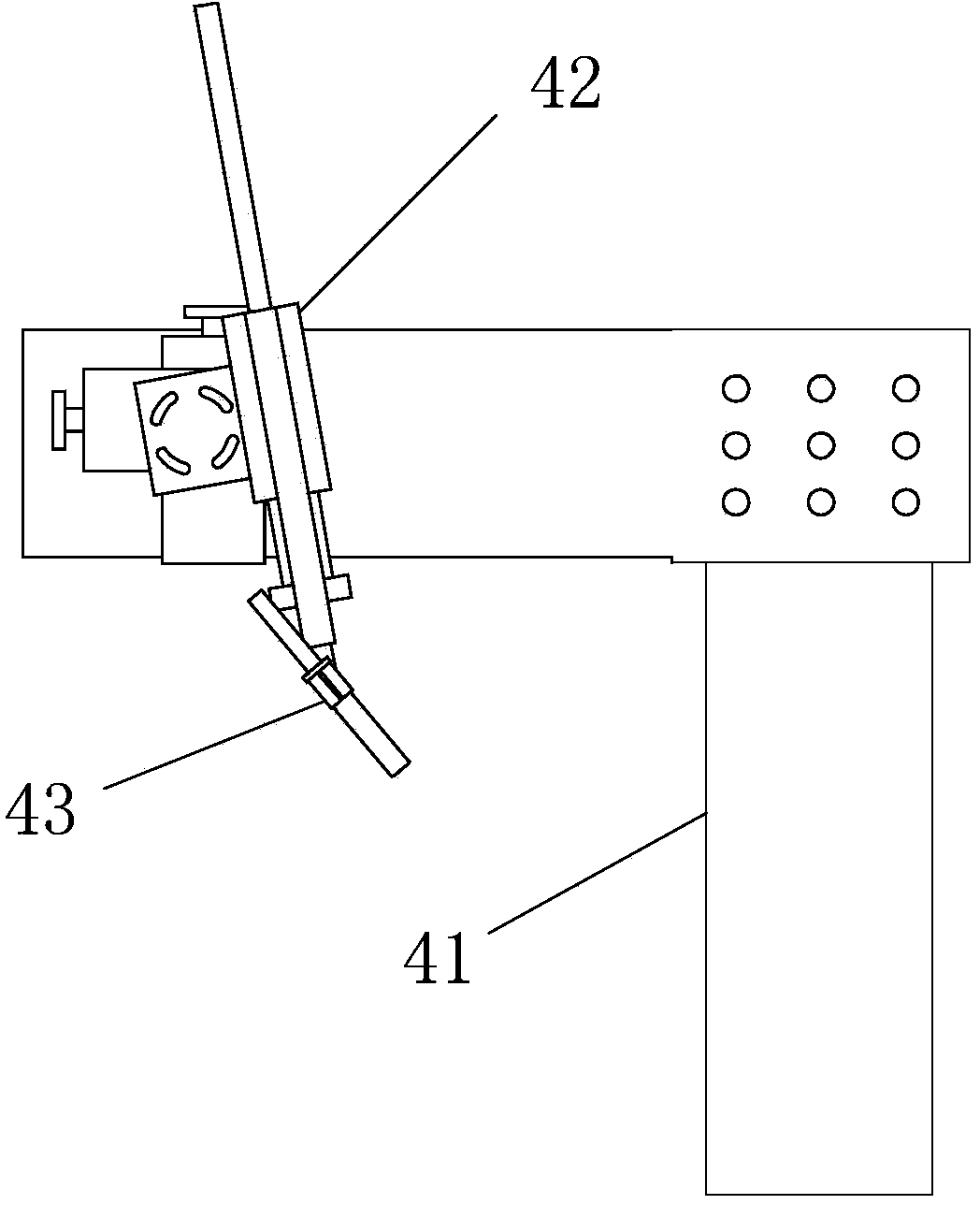

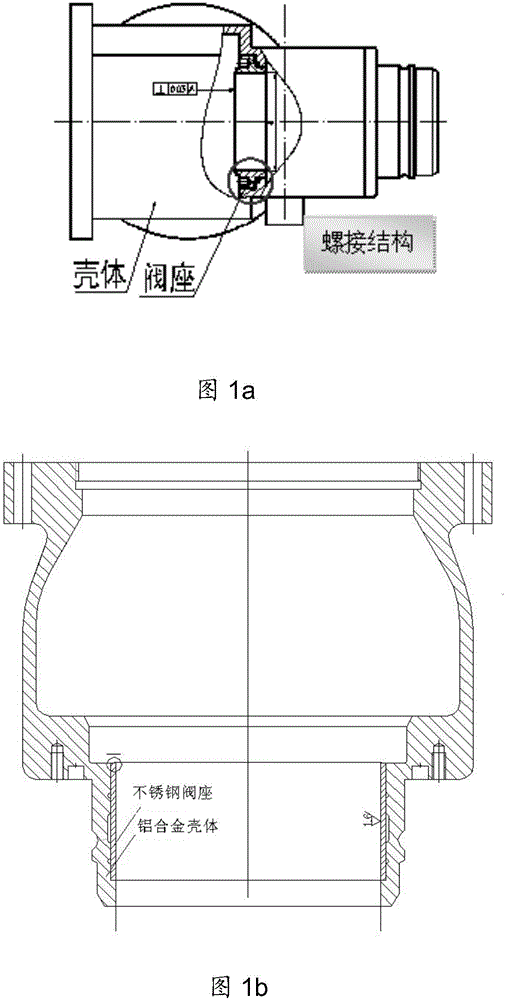

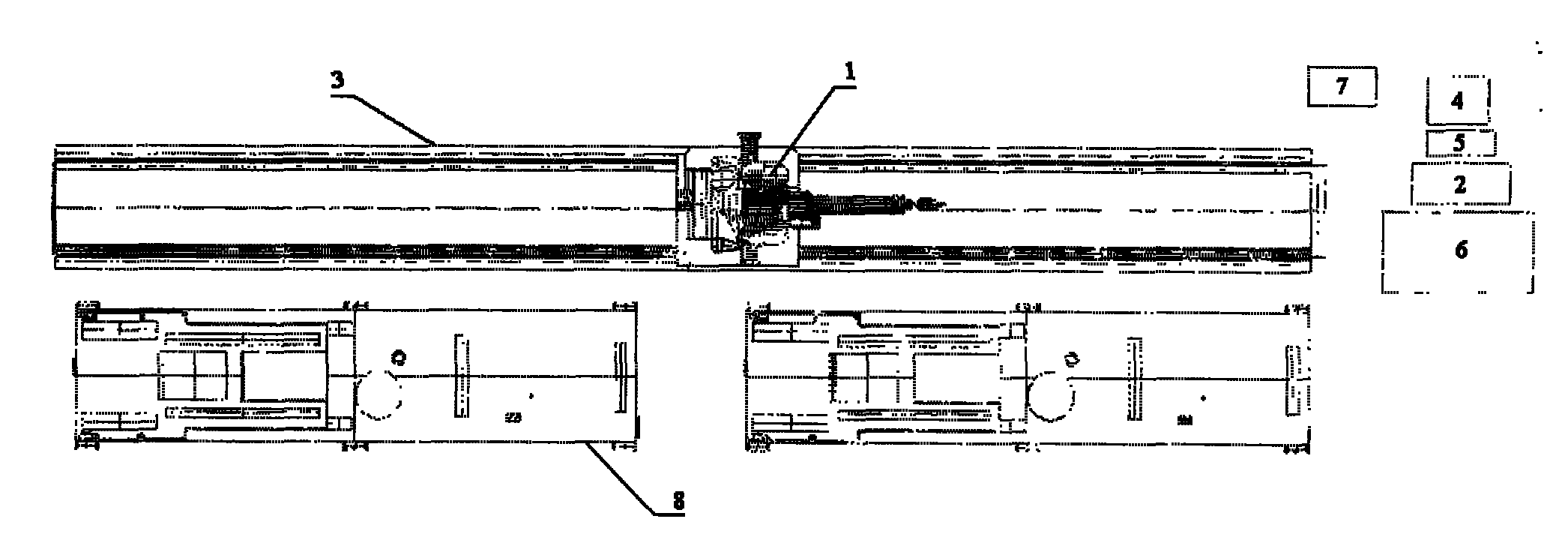

Automatic straight pipe flange welding machine

InactiveCN102009254AReduce playKeep the relative position unchangedElectrode supporting devicesWelding accessoriesWeld seamEngineering

The invention relates to a welding machine, particularly to an automatic straight pipe flange welding machine which is suitable for both plug-in type flange assembly type welding and butt-joint type flange assembly welding. The automatic straight pipe flange welding machine comprises a base, wherein base guide rails are arranged on the base, a trolley base is arranged on the base guide rails, a control system is arranged on one side of the trolley base, a welding torch machine is arranged on the trolley base and comprises a longitudinal adjusting mechanism, a lateral adjusting mechanism, an inner welding torch mechanism, an outer welding torch mechanism and a roller adjusting mechanism, wherein the inner welding torch mechanism consists of an inner welding torch upright post device and aninner welding torch device, and the outer welding torch mechanism includes an outer welding torch upright post device and an outer welding torch device. The automatic straight pipe flange welding machine has high automatic degree, improves welding efficiency, reduces grinding time and waste of welding materials, guarantees welding quality, and attractive formation of weld seams, is convenient to operate, saves labor, and lightens labor intensity.

Owner:HANGZHOU XINCHENGXIANG ELECTROMECHANICAL TECH

Welding process of low temperature steel welding body case

InactiveCN101209508AShorten welding cycleStable deliveryArc welding apparatusFurnace typesPower flowCurrent range

The invention relates to a welding technique in equipment manufacture industry, which is a welding speciality technique of a welding casing of an MCL-typed horizontal cutting centrifugal compressor, in particular to a welding process of the welding casing of the centrifugal compressor with low-temperature steel 09MnNiDR material at -70 DEG C. The gas protection welding is adopted; the welding wire grade is HS09MnNiDR and the diameter of the welding wire is Phi1.2mm; the polarity of the power supply is reversed DC power. The invention comprises a processing before welding, a welding process and a processing after welding; wherein, the process parameters in the welding process are that the welding current ranges from 150A to 200A, the welding voltage ranges from 24V to 28V, the protection gas is the mixed gas with 80% of Ar and 20% of CO2 according to the volume percentage, the welding speed ranges from 250mm / min to 280mm / min, the dry elongation ranges from 10mm to 15mm, and the gas flux ranges from 20L / min to 25L / min. The welding wire of the gas protection welding of the invention is not required to be dried, the welding wire is automatically fed in the welding process, and a welding rod is not required to be replaced; as the heat of the MAG melting polar gas protection welding is concentrated, the invention has the advantages of narrow thermal effect area, little deformation, beautiful forming, good quality, low cost, fast welding speed, high welding efficiency, etc.

Owner:SHENYANG BLOWER WORKS GROUP CORP

Diffusion welding method of dissimilar metal

ActiveCN106808078AGuarantee welding qualityGuaranteed coaxialityWelding/soldering/cutting articlesNon-electric welding apparatusAxial pressureConcentration gradient

The invention relates to a diffusion welding method of dissimilar metal. A specially designed outer side limiting tool and an inner support tool are adopted for thermal expansion constraint in the welding process of an assembled to-be-welded dissimilar metal part, thus, sufficient and even welding pressure on the radial welding face is obtained, and reliable welding guarantee is provided for diffusion welding of the dissimilar metal. The expansion constraint pressurizing idea is provided by the invention for dissimilar metal interface radial pressurizing, radial expansion of the to-be-welded part is constrained through an inner side limiting tool and the outer side limiting tool, and axial expansion of the to-be-welded part is constrained through axial pressure applied by a diffusion welding device or tool, so that expansion pressure is effectively applied to the welding interface of the dissimilar metal, and the dissimilar metal weld part with good joint performance and airtightness is obtained; and the seaming condition of the whole welding interface is good, obvious concentration gradient of the welding interface exists, and the diffusion characteristic is met.

Owner:CAPITAL AEROSPACE MACHINERY +1

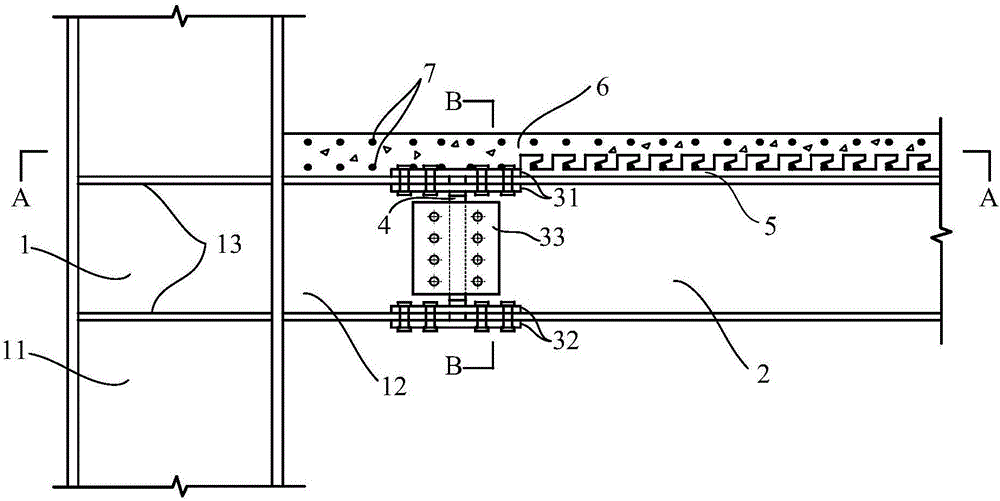

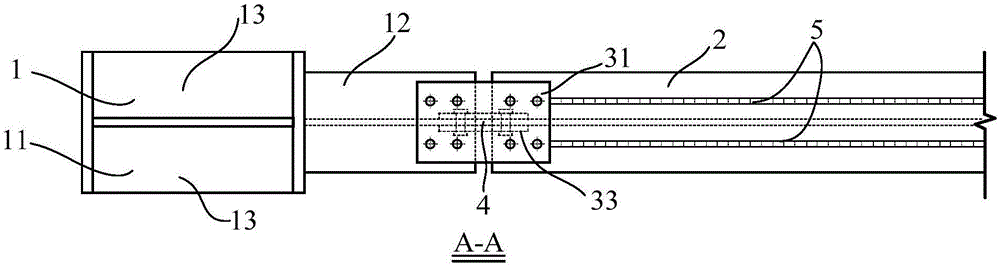

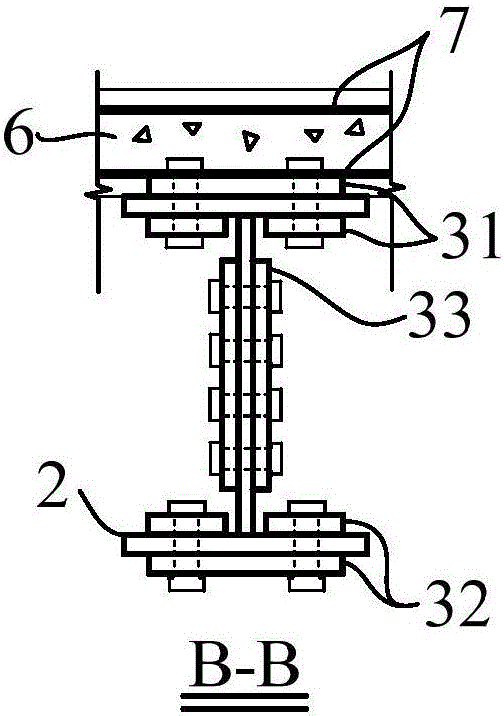

Assembly type steel frame connection node with post-seismic recoverable function

InactiveCN106638961AGuarantee the construction qualityReduce labor intensityProtective buildings/sheltersShock proofingSteel columnsFloor slab

The invention discloses an assembly type steel frame connection node with a post-seismic recoverable function. A frame steel column comprises a column body and an outward extending short beam which are vertically fixedly connected, a post-seismic replaceable energy consumption connecting plate comprises an upper flange cover plate, a lower flange cover plate and a web cover plate, an upper flange of the outward extending short beam is fixedly connected to an upper flange of a body steel beam through the upper flange cover plate, an lower flange of the outward extending short beam is fixedly connected to a lower flange of a body steel beam through the lower flange cover plate, and a web of the outward extending short beam is fixedly connected to a web of the body steel beam through the web cover plate; a gap reserved between the outward extending short beam and the body steel beam is filled with a rubber pad plate; the upper flange of the body steel beam is fixedly connected to a concrete floor slab through a lift-resistant tooth-and-slot plate connecting piece. Through the double effects of connection and energy consumption exerted by the post-seismic replaceable energy consumption connecting plate, the structural damage and failure mechanism are actively controlled, it is guaranteed that the body structure keeps elasticity, damage occurs on a specified position, as a replaceable component, the post-seismic replaceable energy consumption connecting plate facilitates post-seismic replacement and repair, and a shear force connecting piece guarantees structural integrity and full exertion of combined stressed performance.

Owner:BEIJING JIAOTONG UNIV

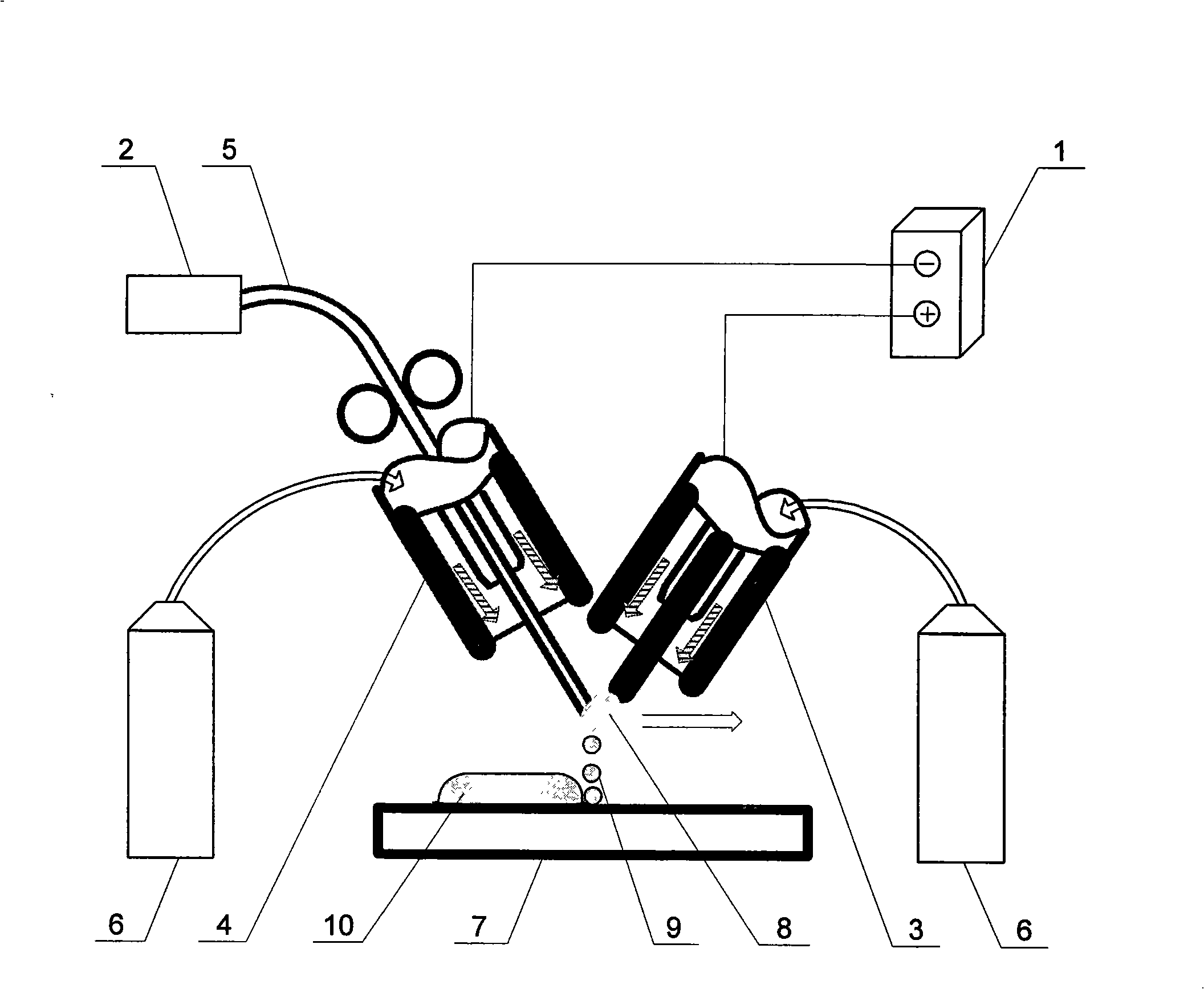

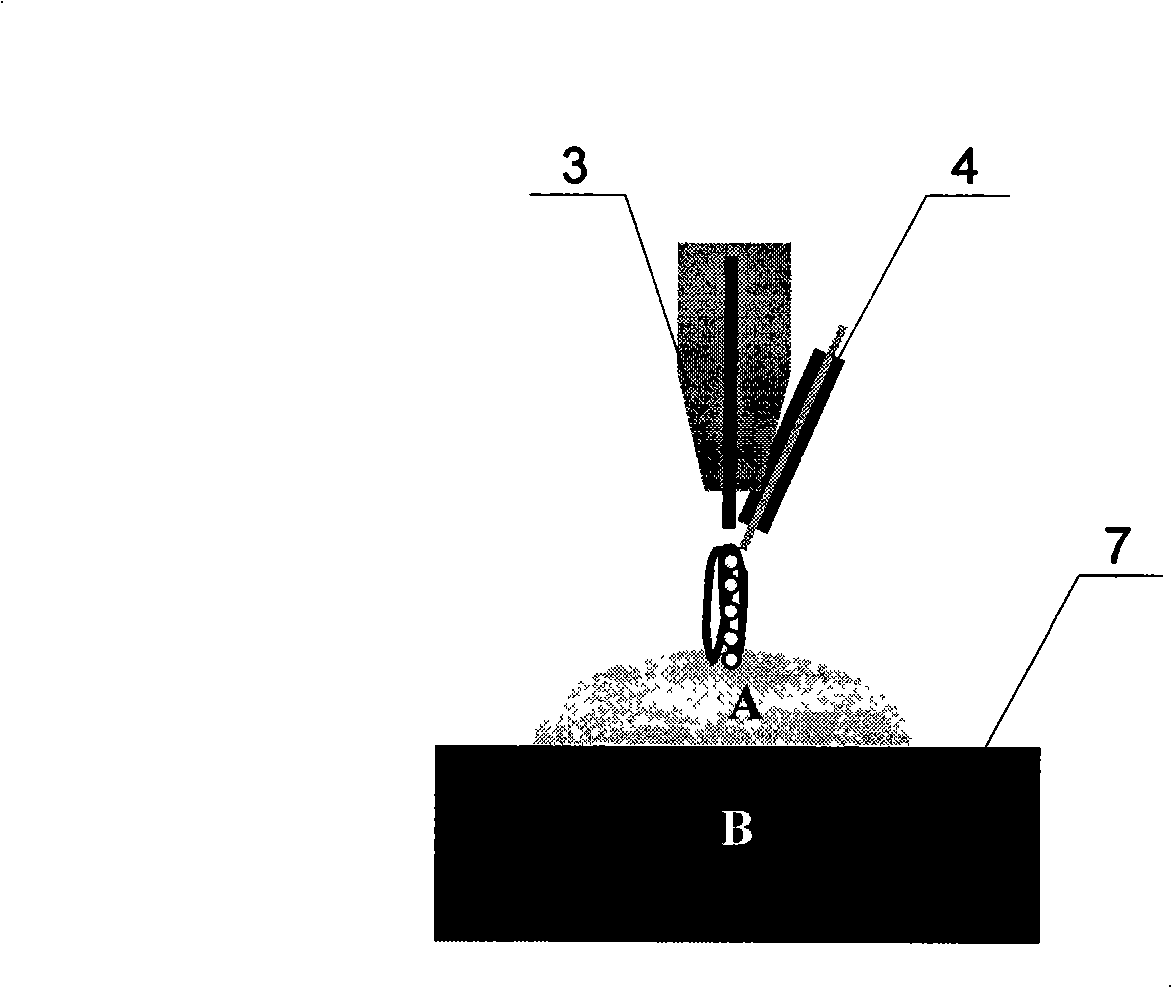

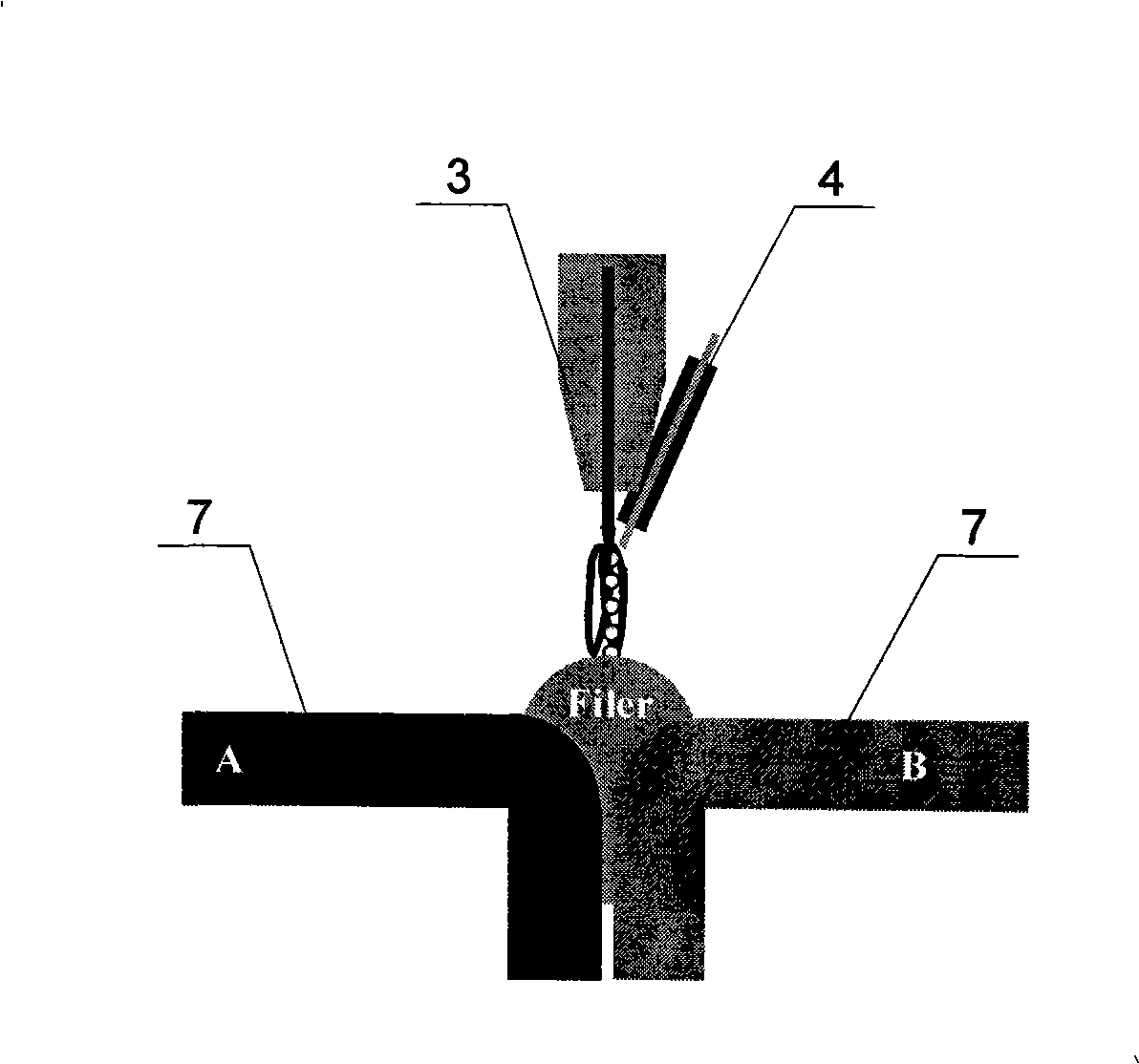

Tungsten electrode-consuming electrode indirect electric arc welding device and its welding method

The invention relates to an indirect arc welding device between tungsten electrode and melting electrode and a welding method thereof, belonging to the technical field of material welding device and welding method, which is used to solve the problems in the prior arc welding devices, such as high hot input, low weld joint deposited ratio and high dilution ratio. The two ends of the welding wire are respectively connected with a wire feeder and a melting electrode welding torch, and exposed outside of the conductive mouth of the melting electrode welding torch. The welding wire is connected with a power supply, and the tungsten electrode welding torch and the melting electrode welding torch are connected respectively with the positive and negative electrodes of GTAW, and the axial point of the two welding torches is on the top of the weldment to be welded, and two protection gas cylinders are connected respectively with the protection gas inlets. Based on the device to weld in a certain welding process, turning on the arc generating switch, and using arc only generated between the tungsten electrode and melting electrode to quickly heat to melt the welding wire, and the droplet of the melted welding wire with heat heats the device indirectly and welds. The welding method has the advantages that the weld joint deposited ratio is increased up to 50g / min and the dilution ratio is controlled within 5%.

Owner:HARBIN INST OF TECH

Method for mounting bottom plates and cylinder of steel lining of nuclear power plant

ActiveCN102061788AShort construction periodShorten the construction periodCovering/liningsArc welding apparatusSupporting systemArchitectural engineering

The invention provides a method for mounting bottom plates and a cylinder of a steel lining of a nuclear power plant. The bottom plates are basically circular, and are divided into circular center bosses, annular intermediate annular plates and annular edge plates which consist of a plurality of precast slabs from inside to outside; the cylinder comprises frustums and cylinder wall plates which are formed by splicing the plurality of precast slabs; and the cylinder wall plates are divided into a plurality of layers. The mounting method sequentially comprises the following steps of: mounting a bottom plate support system; putting the bottom plates on the bottom plate support system; putting the frustums; welding the bottom plates and the frustums in pairs; and mounting each layer of cylinder wall plates from bottom to top respectively. By rationally setting a welding process and a construction assembly process, a mounting construction period of the steel lining is effectively shortened, and the sealability of welding seams of the steel lining is ensured.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

Welding method of ultra-thick and high-strength water-power steel

ActiveCN101905365ATo achieve the welding effectReduce fillingArc welding apparatusWorkpiece edge portionsEngineeringWelding defect

The invention relates to a welding method of ultra-thick and high-strength water-power steel, belonging to the welding field. Welding is realized by adopting a mixed welding mode, i.e. hand welding is adopted as a basis for filling the bottom, and gas shielded welding is adopted for a middle layer and a cover part, multilayer and multi-pass welding are adopted, a carbon arc is cropped out after a single side is filled, and the input of welding heat is controlled within 65 kJ / cm. A welding bevel adopts an asymmetric U-shaped bevel, a thick steel plate of 145-155 mm is preheated to 100 DEG C before welding, the inter-layer temperature is kept between 100 DEG C to 160 DEG C, and heat treatment stress is not carried out after welding, and the problem of reheat embrittlement of a welding joint of the high-strength water-power steel is solved. The invention needs simple welding equipment, realizes welding through a combined welding process on the basis of the traditional equipment, reduces the filling amount of welding metal, and achieves the welding effect of a narrow gap. Compared with the hand arc welding, the invention greatly improves the welding efficiency of the thick steel plate and lowers the possibility of welding defects easily generated on the hand arc welding of an ultra-thick steel plate, such as cold cracks, incomplete fusion, crisp fusion, and the like.

Owner:SHOUGANG CORPORATION +1

Welding robot workstation system for injection molding machine frame

InactiveCN101780584AGuarantee welding qualityGuaranteed welding efficiencyWelding accessoriesWeld seamRobot control

The invention relates to a welding robot workstation system for an injection molding machine frame, which comprises a welding robot, a welding device, a robot mobile slip way, a welding torch cooling device, an intelligent searching and tracking device and a robot control box, and the welding robot is arranged on the robot mobile slip way; the welding device is respectively connected with the welding robot and the welding torch cooling device; and the robot control box is respectively connected with the welding robot, the robot mobile slip way, the welding device and the intelligent searching and tracking device, to control the movement and the welding of the welding robot. The welding robot workstation system for the injection molding machine frame can automatically carry out MAG welding to a plane on the injection molding frame and other reachable weld seams, thereby ensuring the welding quality and the efficiency of the product.

Owner:NINGBO KAITAI MACHINERY

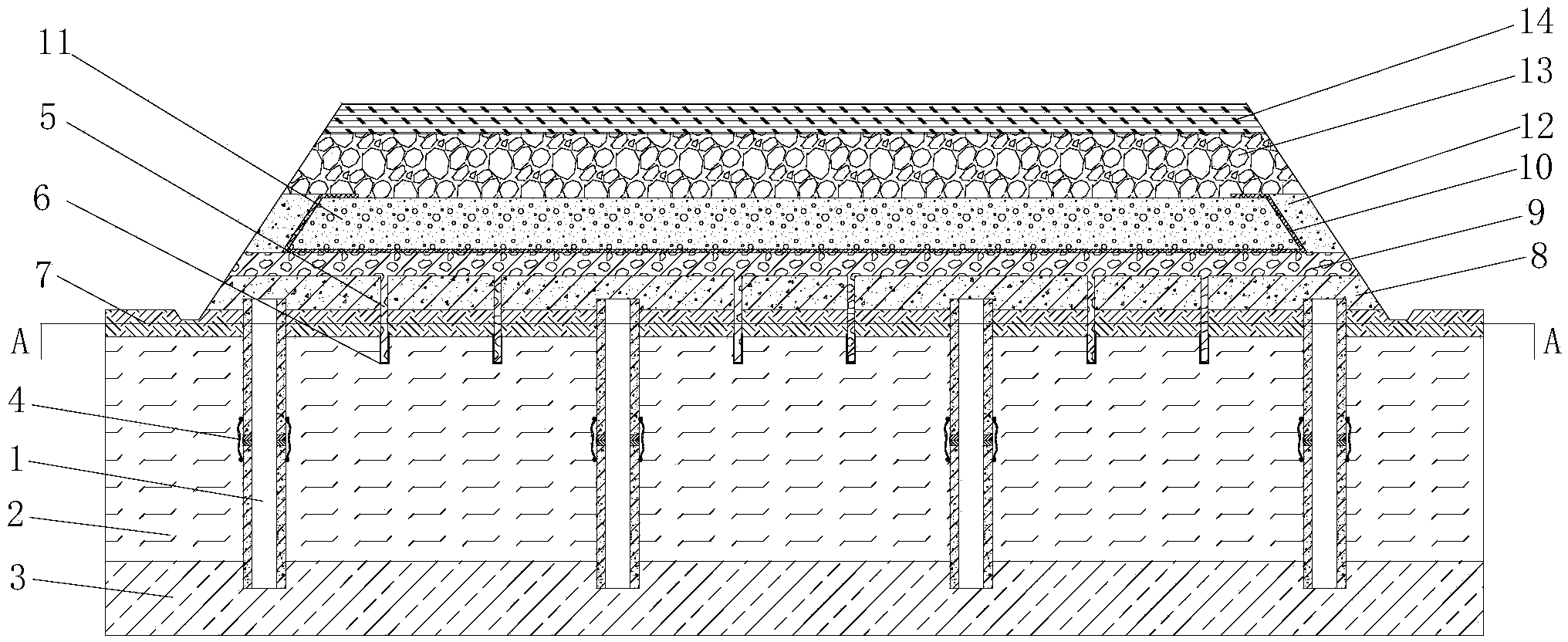

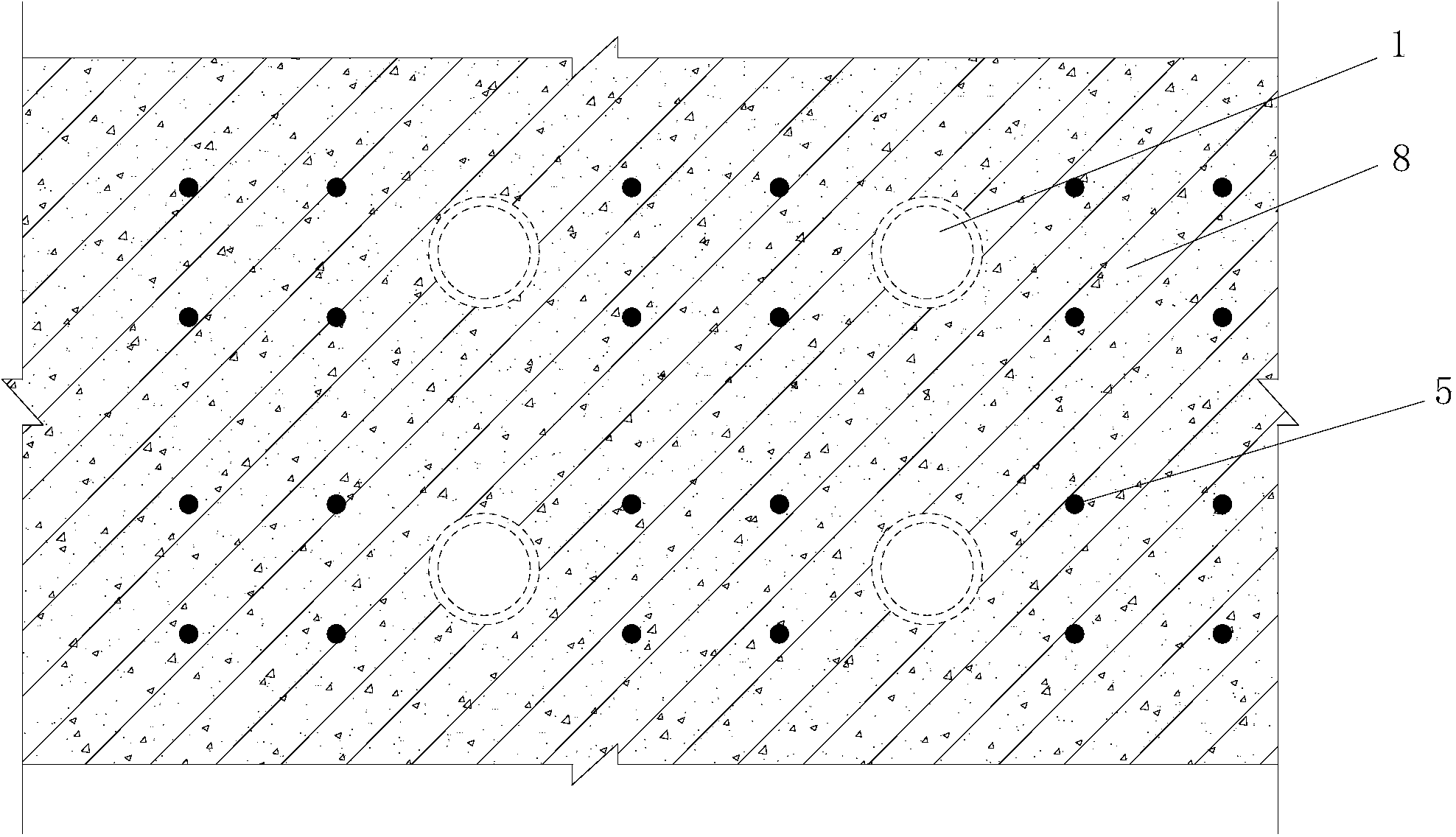

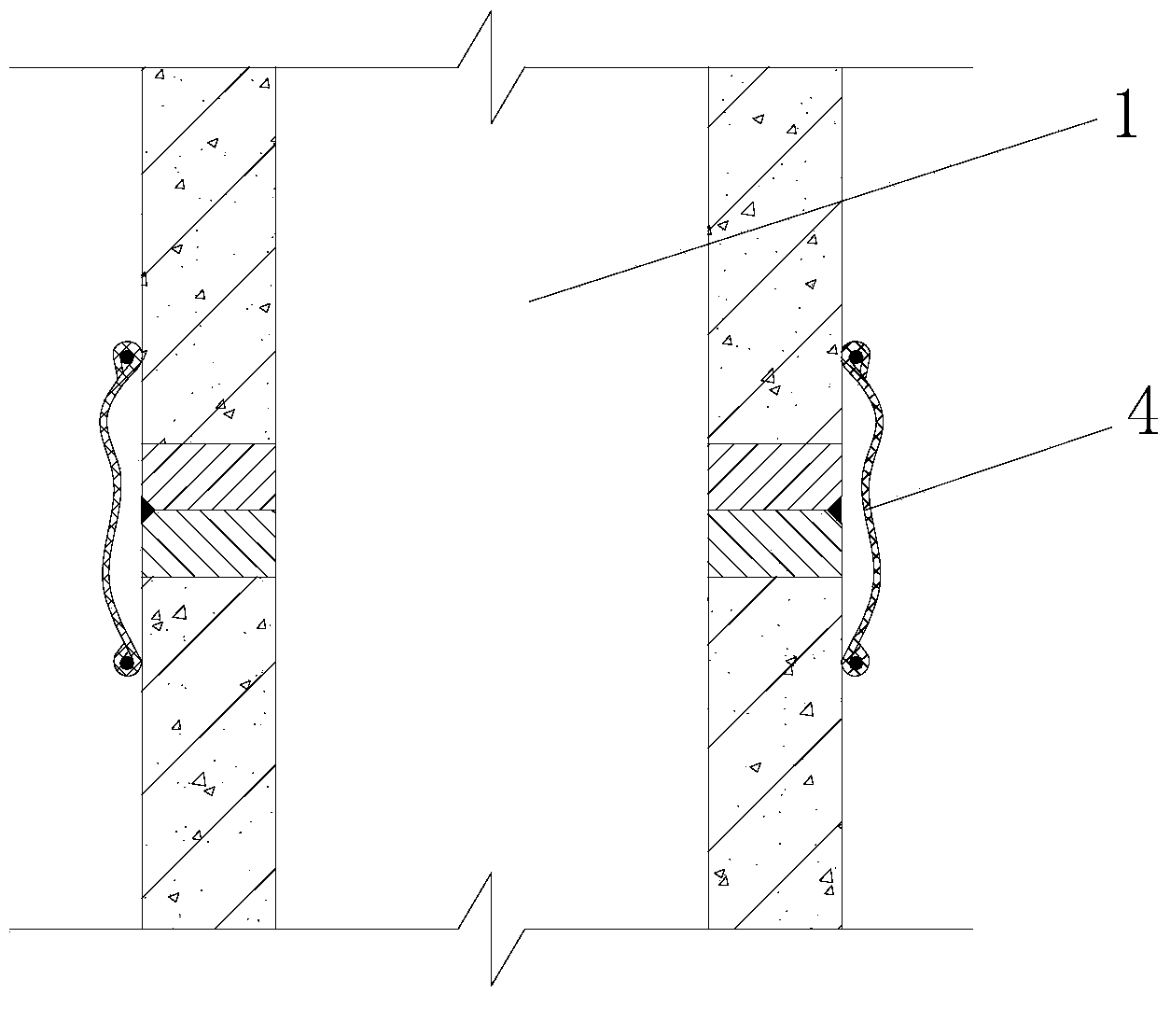

Prefabricated tube pile embankment structure and construction method thereof

InactiveCN103774514AReduce settlementEnsure stabilityRoadwaysProtective foundationReinforced concreteSlag

The invention relates to a prefabricated tube pile embankment structure, which mainly comprises a prefabricated tube pile, a vertical drain tube, a shallow curing plate, a thin reinforcement concrete continuous plate, a rubble layer, a bubble concrete rolling-resistant layer, a concrete protection layer, a slag layer and a pavement structure, wherein the prefabricated tube pile penetrates through a soft soil layer and extends a relative bearing stratum; a weld seam protection device is arranged outside a prefabricated tube pile welding end plate; the shallow curing plate is arranged at the periphery of the top of the prefabricated tube pile; the thin reinforcement concrete continuous plate is arranged on the shallow curing plate; the top of the prefabricated tube pile is embedded in the thin reinforcement concrete continuous plate; the vertical drain tubes are pre-buried in the thin reinforcement concrete continuous plate and the shallow curing plate, the lower ends of the vertical drain tubes are externally coated with a reverse filter geotextile which is communicated with the rubber layer on the thin reinforcement concrete continuous plate; the bubble concrete rolling-resistant layer, the slag layer and the pavement structure are sequentially arranged on the rubble layer. The prefabricated tube pile embankment structure is high in bearing capacity, less in differential settlement, high in overall structure stability, and convenient to construct.

Owner:JIANGSU ZHONGRUI ROAD & BRIDGE CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com