Multifunctional digitized welding machine

A multifunctional welding machine technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of lack of multifunctional digital welding machine design, unsatisfactory dynamic and static characteristics, and poor welding machine performance, etc., to achieve Fast software upgrade and update speed, flexible and diverse control methods, high-quality welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

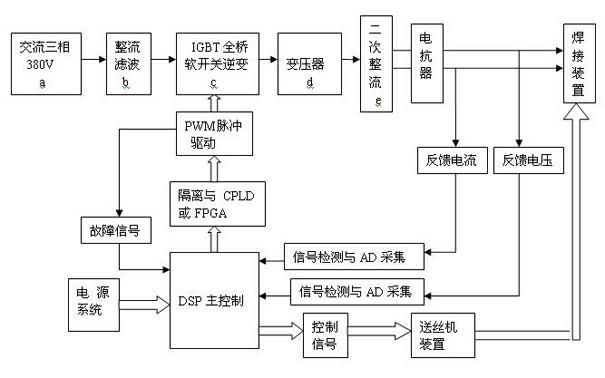

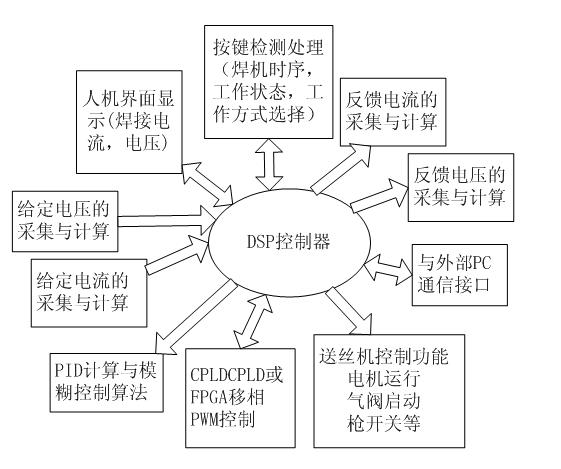

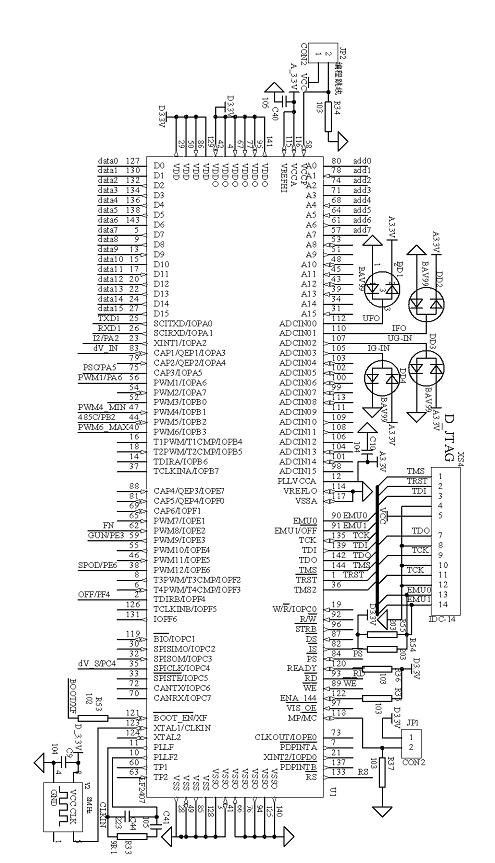

[0028] The multifunctional digital welding machine of the present invention is a soft-switching inverter digital welding machine based on a digital signal processor DSP and a programmable logic controller CPLD or FPGA. Its working circuit includes a full-bridge inverter main circuit composed of IGBTs, a DSP control circuit, and a soft-switching PWM drive circuit based on CPLD or FPGA symmetrical carrier.

[0029] The main circuit is mainly composed of figure 1 The shown rectification and filtering module b, IGBT full-bridge inverter module c, main transformer d, and secondary rectification and filtering module e are composed.

[0030] The control circuit mainly includes: a DSP control processor; a control board power supply circuit; a manual no-load reduction circuit containing a rectification part; a feedback current output by the welding machine, a voltage signal conditioning detection and sampling circuit; Acquisition and setting circuit of constant voltage; interface with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com