Cored welding strip applied in resurfacing welding and preparation method thereof

A technology of welding strips and medicines, which is applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems that the performance of the welding process needs to be improved, the powder of the core strip electrode is easy to move, and the application range is limited, so as to increase the variety and application range, avoid powder migration, and improve the effect of process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Preparation of surfacing flux-cored welding strip

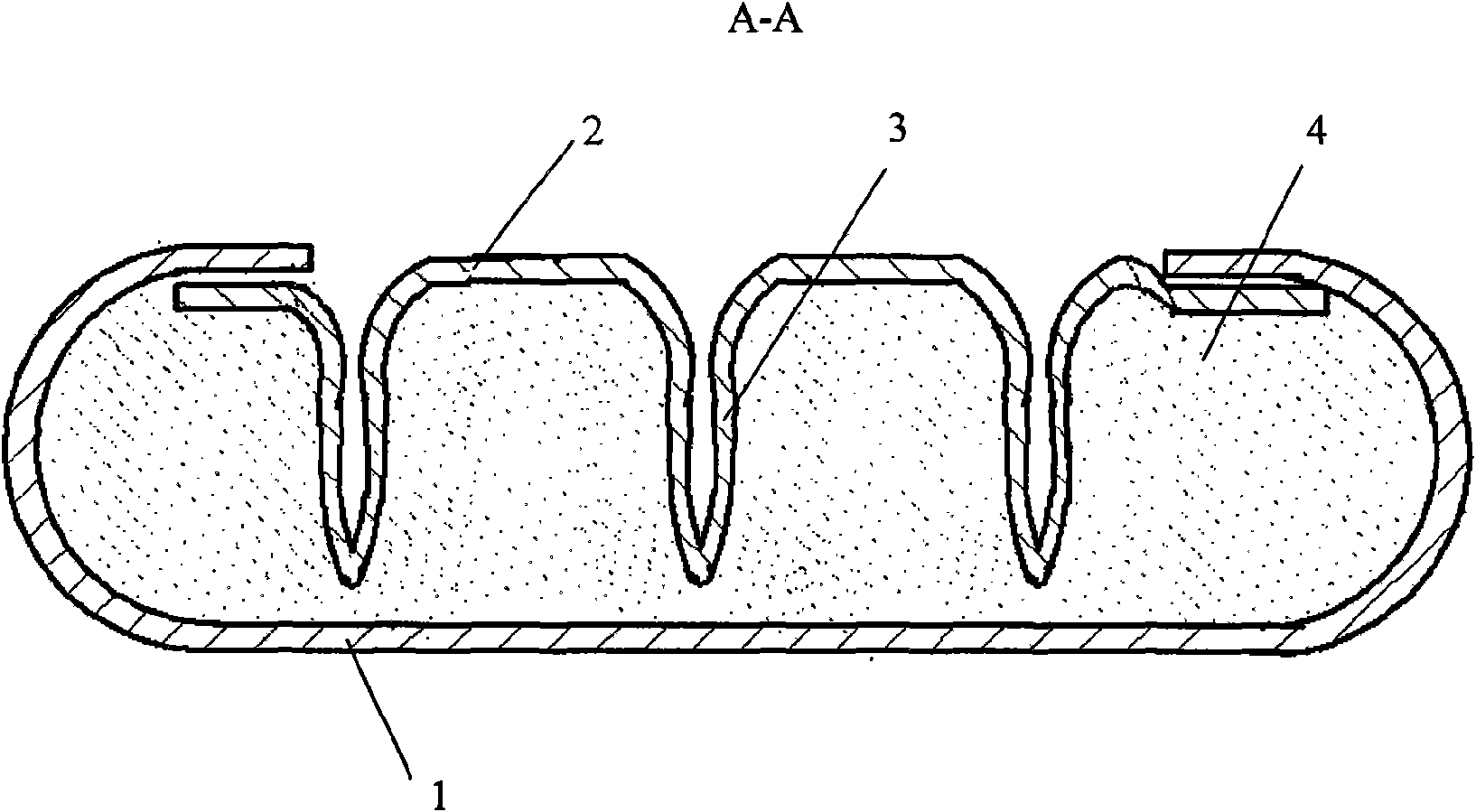

[0050] (1) A commercially available SPCC low-carbon steel strip with a thickness of 0.4mm was selected, and a lower steel strip 1 with a width of 78mm and an upper steel strip 2 with a width of 72mm were slit by using conventional strip slitting equipment.

[0051] (2) The surfacing metal is low-alloy steel. The content of alloy elements in the welding strip is calculated by mass percentage, 0.4%C, 0.8%Mn, 0.5%Si, 3.2%Cr, 0.035%S, 0.03%P, and the rest is Fe. Use powdered metal and alloy compounding powder, add aluminum powder with 1% of the mass of the welding ribbon to the powder, and use conventional powder mixing equipment to mix the powder for 20 minutes to obtain the drug powder 4 of the flux-cored welding ribbon.

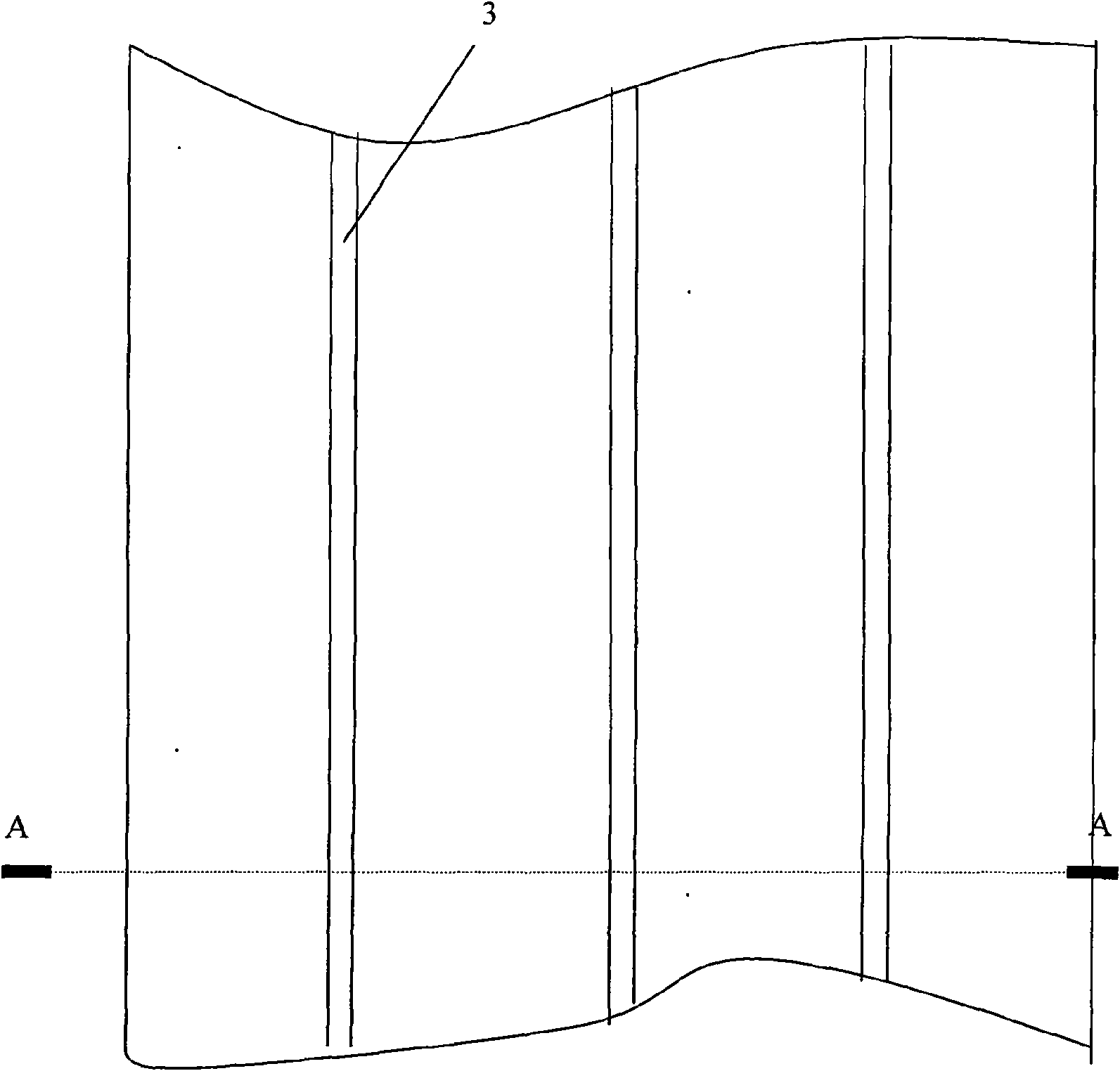

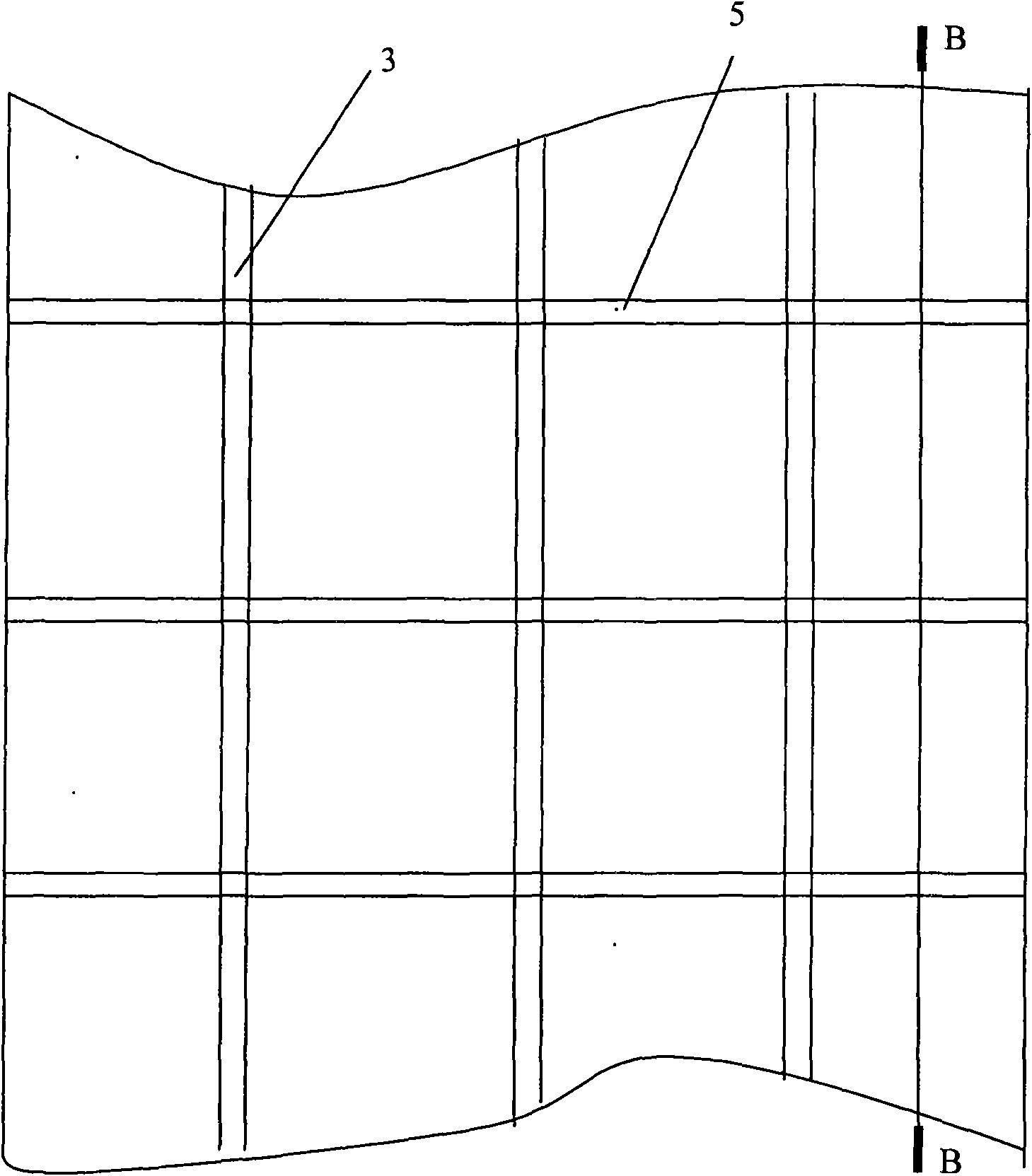

[0052] (3) Using the existing rolling technology and special equipment, roll it along the length direction (longitudinal direction) of the lower steel strip 1 into a cross-sectional width o...

Embodiment 2

[0059] Example 2: Preparation of surfacing flux-cored welding strip

[0060] (1) A commercially available SPCC low-carbon steel strip with a thickness of 0.5 mm is selected, and a lower steel strip 1 with a width of 56 mm and an upper steel strip 2 with a width of 46 mm are slit by using conventional strip slitting equipment.

[0061] (2) The surfacing metal is alloy cast iron, and the content of alloy elements in the welding strip is calculated as mass percentage, 5.8%C, 0.9%Mn, 0.6%Si, 26.5%Cr, 2.1%Mo, 1.2%B, 3.1%V , 0.035% S, 0.03% P, and the rest is Fe. The drug powder is powdered metal and alloy compounding powder, and the powder is mixed for 20 minutes by conventional powder mixing equipment to obtain the drug powder 4 of the flux-cored ribbon.

[0062] (3) Utilize the existing rolling technology and special equipment, along the length direction (longitudinal direction) of the lower steel strip 1, it is rolled into a "cross-sectional width" of 40mm. " shaped groove, a...

Embodiment 3

[0069] Example 3: Preparation of surfacing flux-cored ribbon

[0070] (1) A commercially available SPCC low-carbon steel strip with a thickness of 0.4 mm is selected, and a lower steel strip 1 with a width of 105 mm and an upper steel strip 2 with a width of 140 mm are slit by using conventional strip slitting equipment.

[0071] (2) The surfacing metal is high-chromium steel, and the content of alloy elements in the welding strip is calculated as mass percentage, 0.10%C, 0.8%Mn, 0.7%Si, 15.2%Cr, 0.5%Mo, 1.8%Ni, 1.2% W, 0.025% S, 0.03% P, the rest being Fe. The drug powder is made of powdered metal and alloy compounding powder, and the powder is mixed for 25 minutes by conventional powder mixing equipment to obtain the drug powder 4 of the flux-cored ribbon.

[0072] (3) Using existing rolling technology and special equipment, it is rolled along the length direction (longitudinal direction) of the lower steel strip 1 into "" with a cross-sectional width of 90 mm " shaped groo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com