Patents

Literature

187results about How to "Simple productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Martensite series wear-resistant steel and preparation method thereof

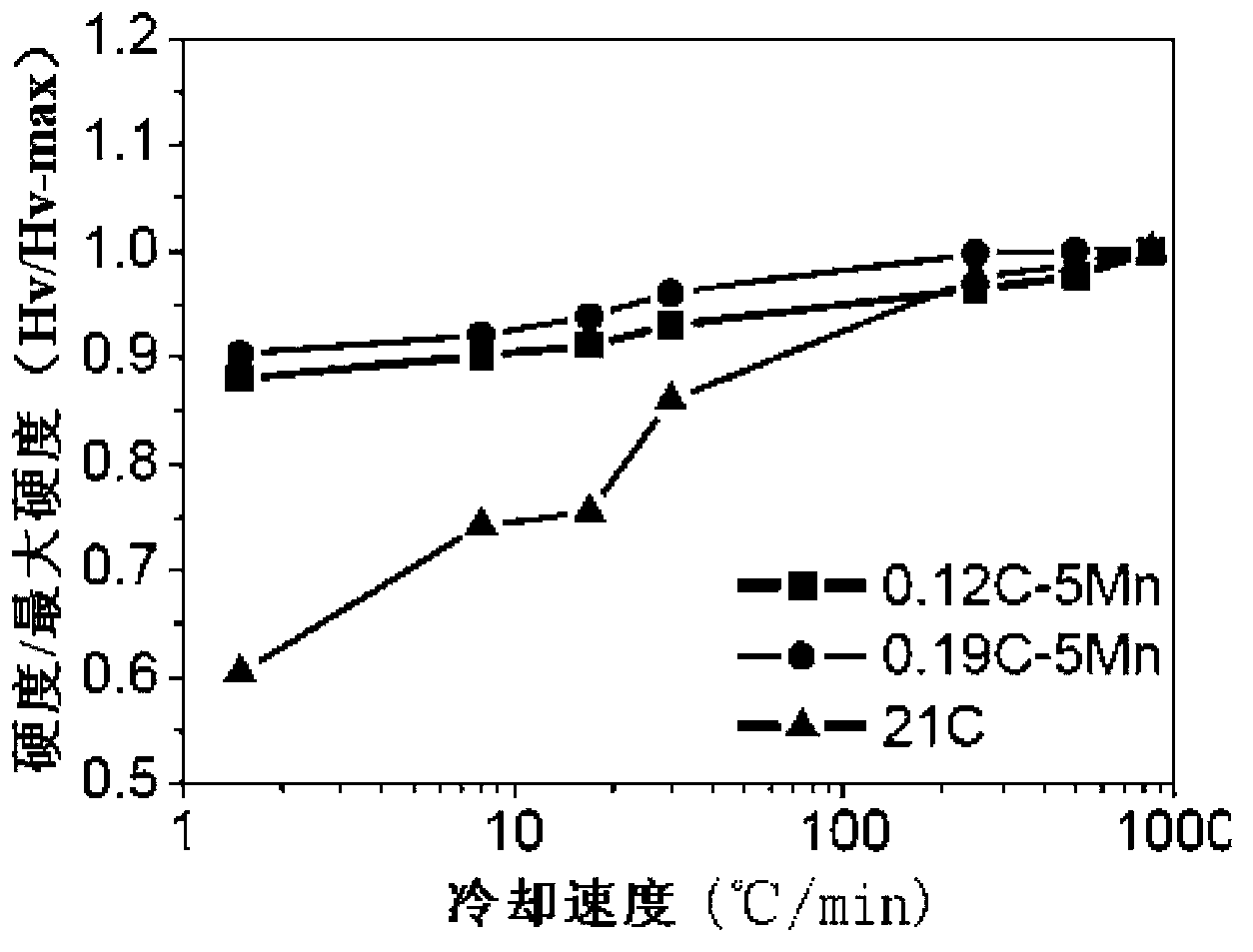

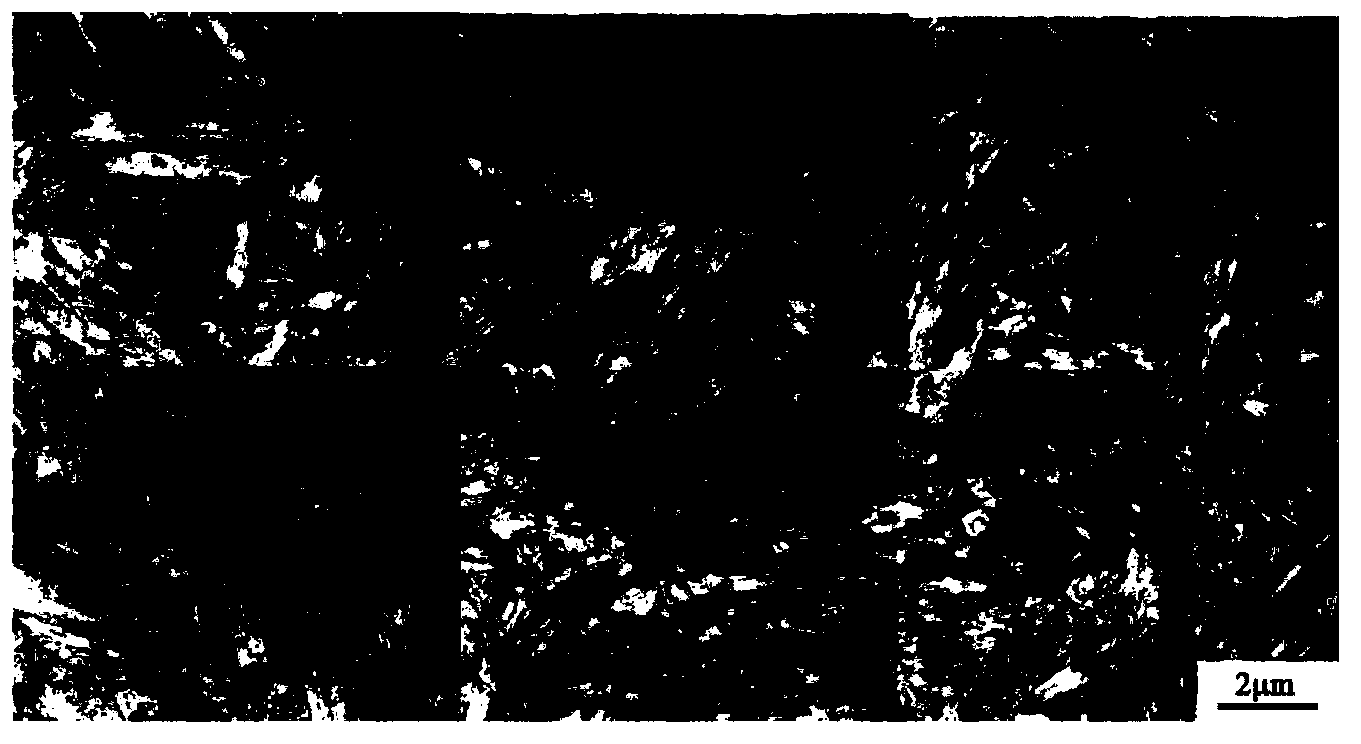

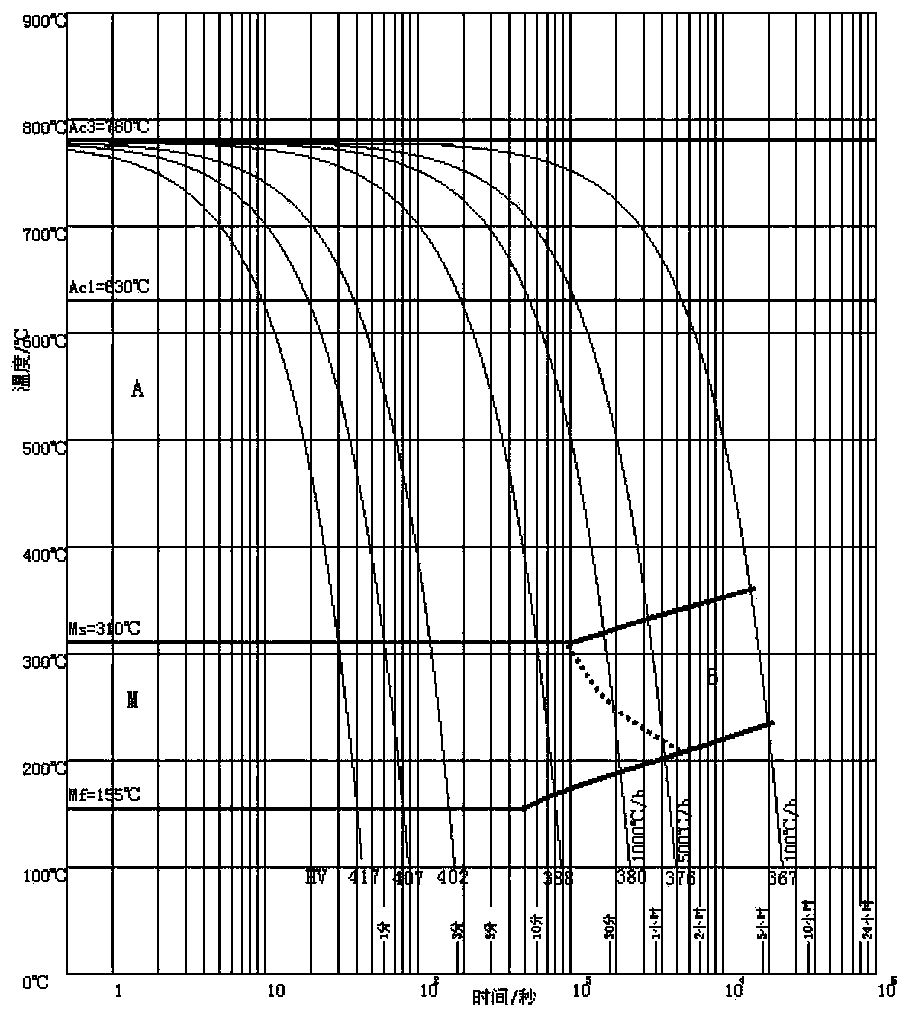

The invention relates to martensite series wear-resistant steel and a preparation method thereof, belonging to the technical field of wear-resistant steel. The steel comprises the following chemical components: 0.05-0.51wt% of C, 2.0-10wt% of Mn, 0-1.5wt% of Al, 0-1.5wt% of Si, 0-1.5wt% of Cr, 0-1.5wt% of Cu, 0-1.5wt% of Ni and the balance of Fe and inevitable impurities, wherein the Mn / C ratio is not less than 9. Based on this, the following one or more composite elements can be optionally added: 0.02-0.50wt% of Mo, 0.02-0.50wt% of V, 0.02-0.50wt% of Nb, 0.01-0.5wt% of Ti, 0.02-0.50wt% of B and 0.02-0.50wt% of RE. The wear-resistant steel provided by the invention is easy to produce, low in cost and high in performance. The invention is applicable to the technical field of wear-resistant materials for mines, energy, transportation, agricultural machinery, engineering machinery and other industries.

Owner:CENT IRON & STEEL RES INST

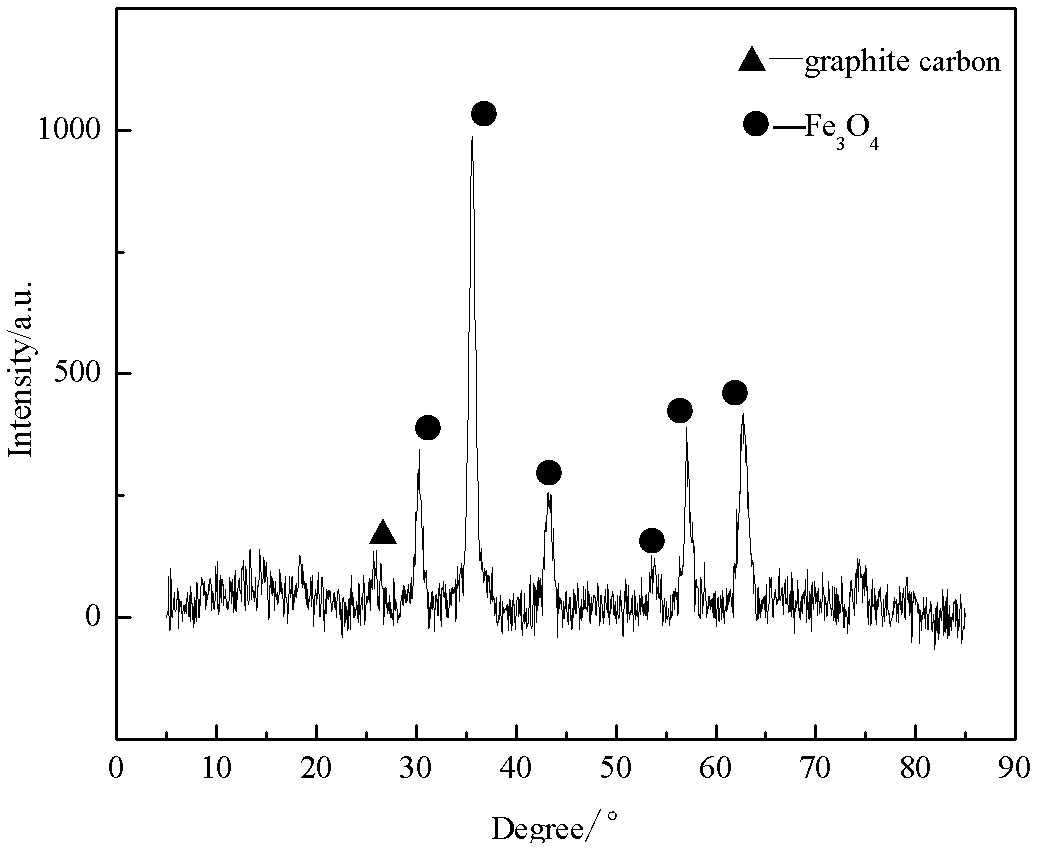

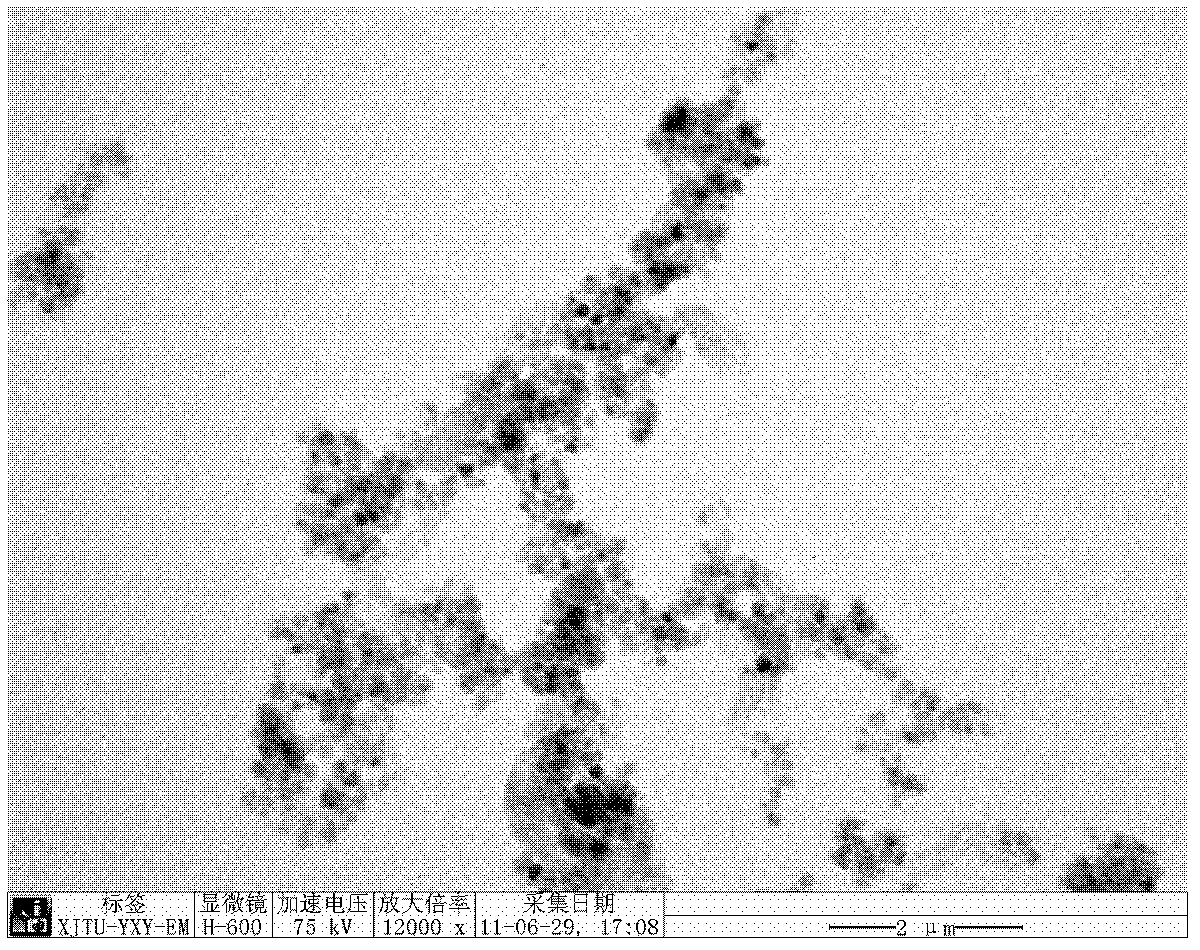

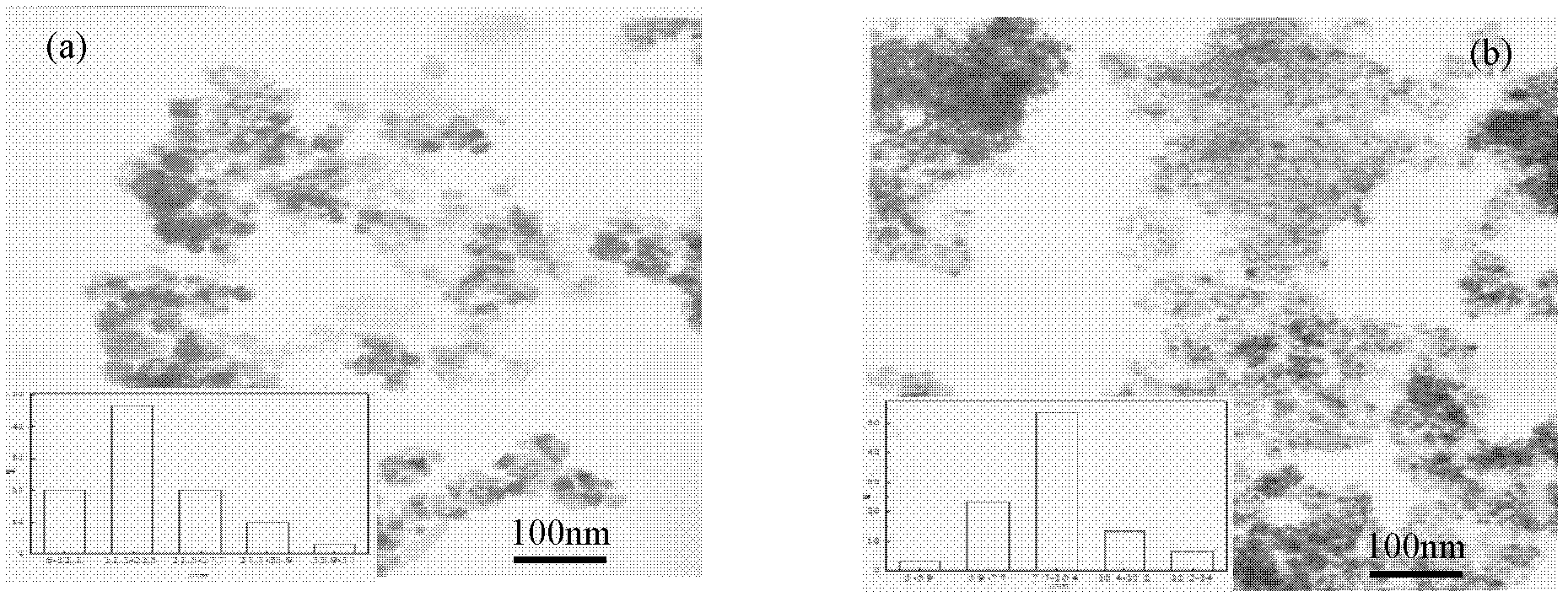

Method for preparing ferroferric oxide/ carbon nano tube composite material

InactiveCN102583315AUniform particle sizeThe synthesis process is simpleMaterial nanotechnologyCarbon compoundsAmmonium ferrous sulfatePolyvinyl alcohol

The invention discloses a method for preparing a ferroferric oxide / carbon nano tube composite material, which is used for solving the technical problem that the nano Fe3O4 particle diameter of the coating prepared by the conventional method for preparing the ferroferric oxide / carbon nano tube composite material is not uniform. According to the technical scheme, multi-wall carbon nano tubes, ammonium ferrous sulfate, ferric chloride and sodium hydroxide are used as raw materials, polyvinyl alcohol is used as a surfactant, the ferroferric oxide / carbon nano tube magnetic nano composite material is obtained by adopting a reverse co-precipitation method, and nano Fe3O4 coatings with different particle diameters are obtained by changing the reaction temperature and the concentration of the reaction solution. The nano Fe3O4 particle diameter of the coating of the ferroferric oxide / carbon nano tube composite material prepared by the method is uniform, the average nano particle diameter is less than 10 nanometers, and the synthesis process and the production equipment are simple.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

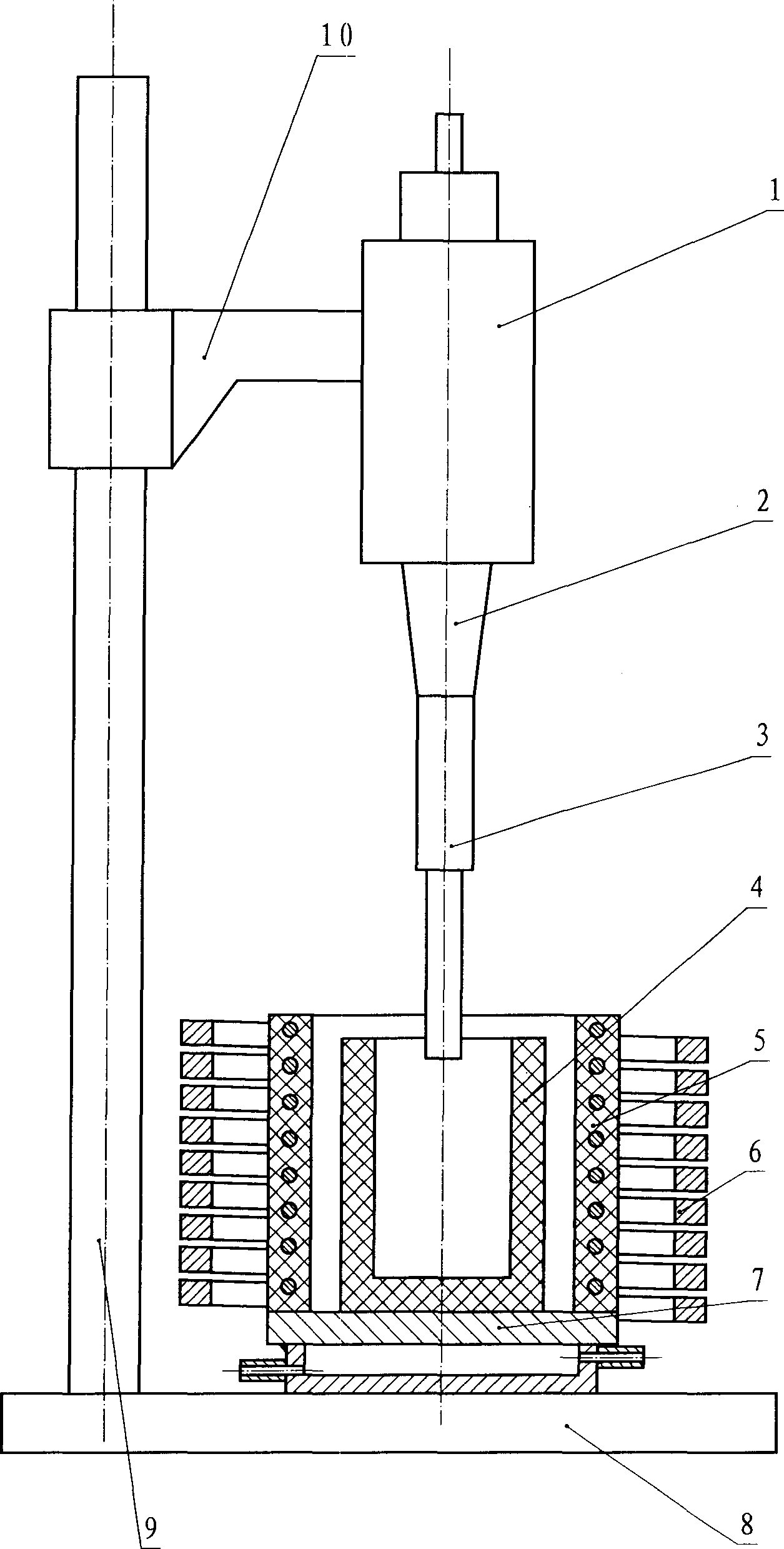

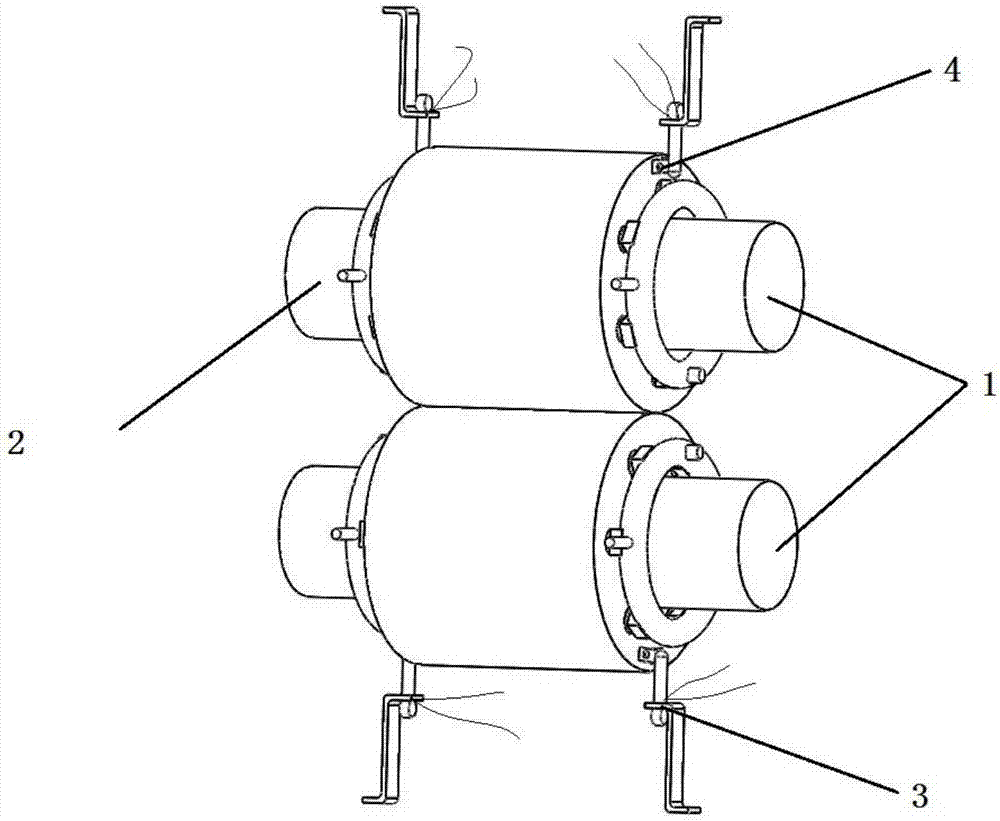

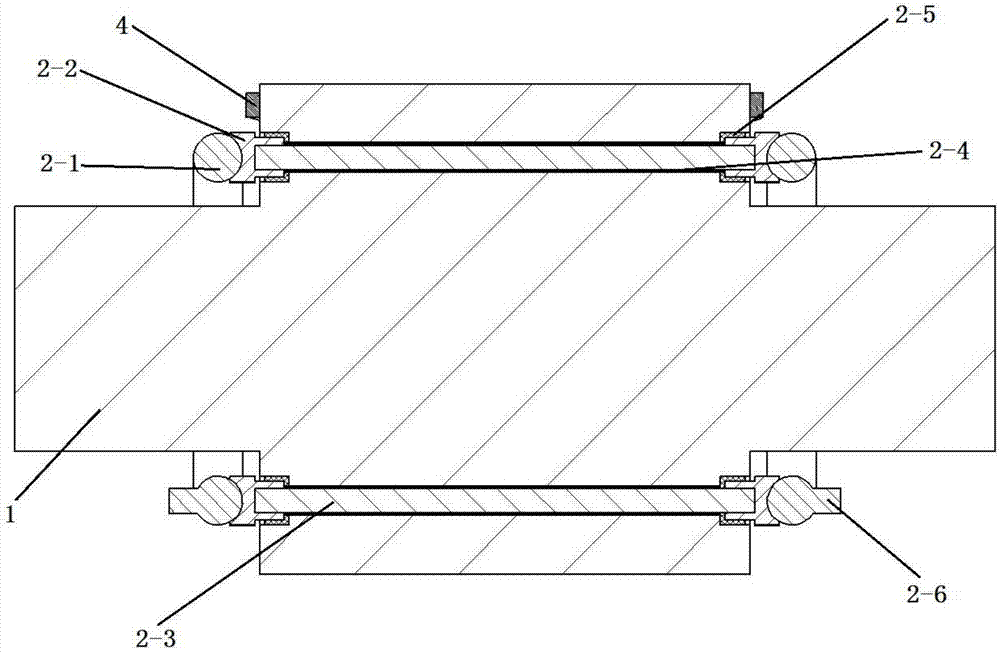

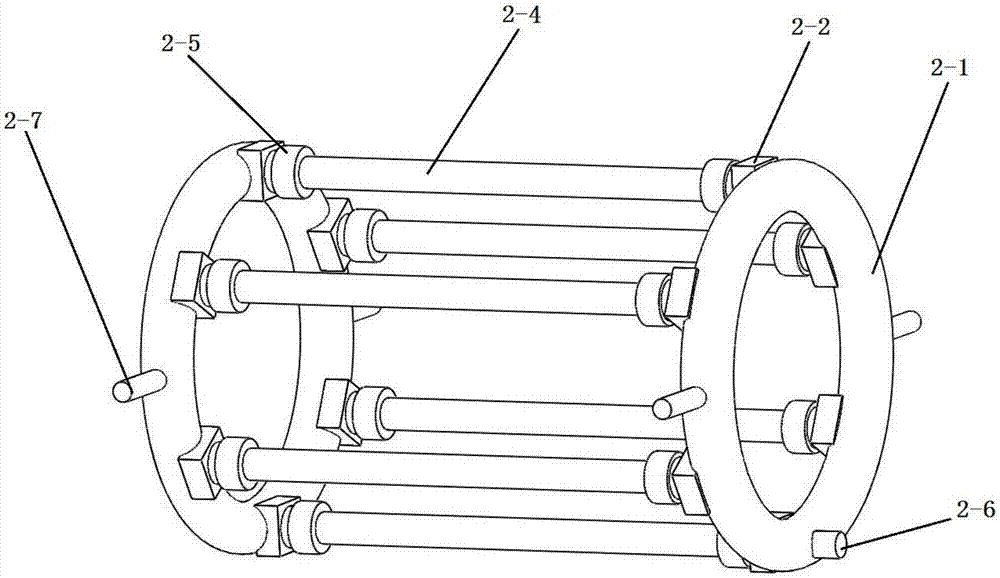

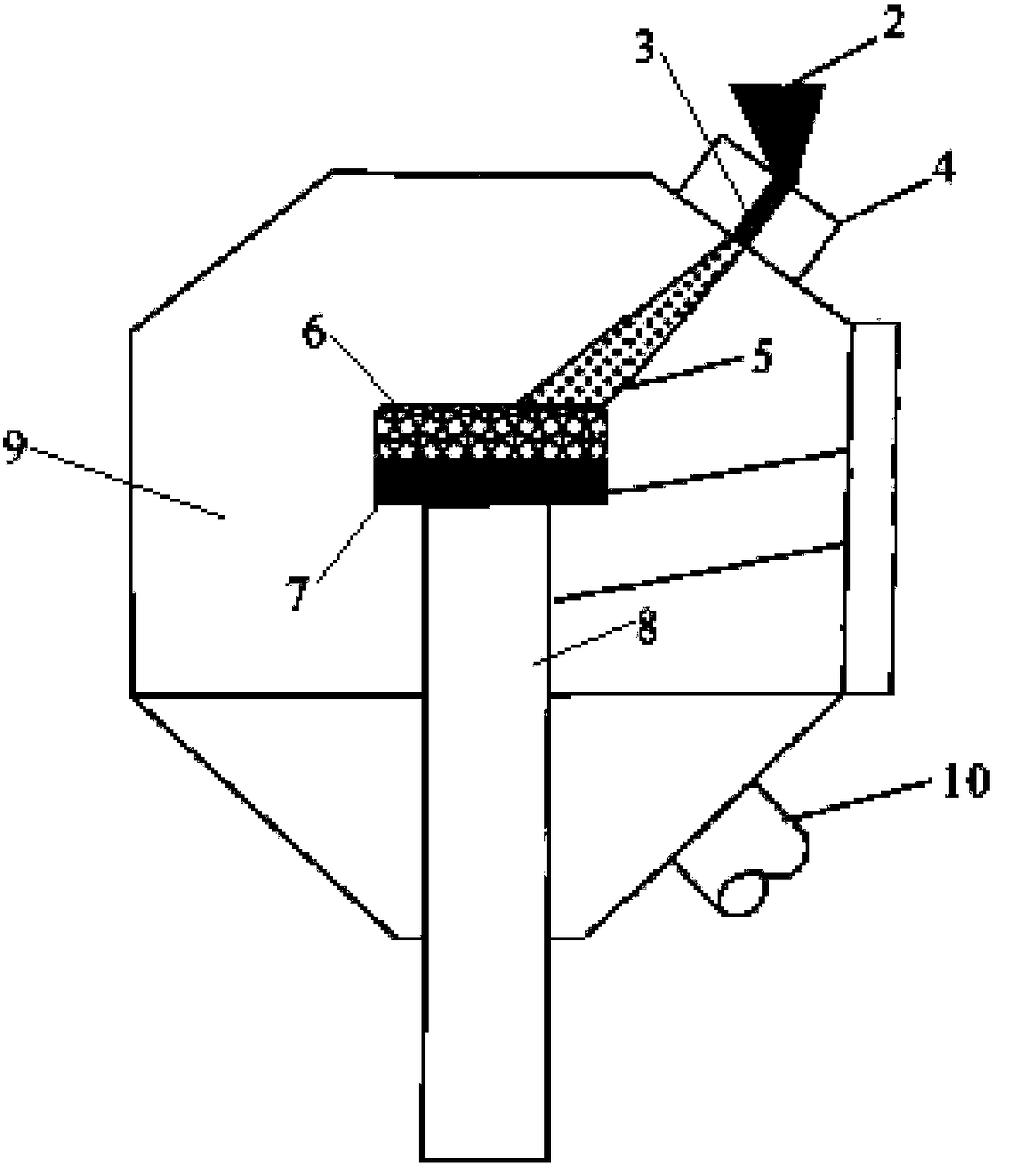

Method for preparing nanocystalline ingot casting by magnetic field and ultrasonic combined treatment of metal melt and dedicated apparatus therefor

It is a method for preparation and the special device of nanocrystalline ingotting from metallic fondant treated jointly by magnetic field and supersonic wave, solving the present technique problem of complex device, high cost, and difficulty to prepare large-scale nanometer material and so on. The invented method is as the following steps: melting and heating the matched raw material, deairing the metallic fuse-elements, pouring rapidly the deaired metallic fuse-elements into preheated crucible, heating upwards the liquidus curve, applying electromagnetic mixing and ultrasonic vibration, chilling until it freezes totally, then the block-shaped nanocrystalline ingotting being prepared; the special device that applied joint treatment of electromagnetic mixing and ultrasonic vibration having a holding furnace, which is equipped with a crucible, the special being characterized in that outboard of the holding furnace is equipped with magnetic field generator, over the crucible there is a ultrasonic transducer, and bottom of the crucible is equipped with a chiller.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

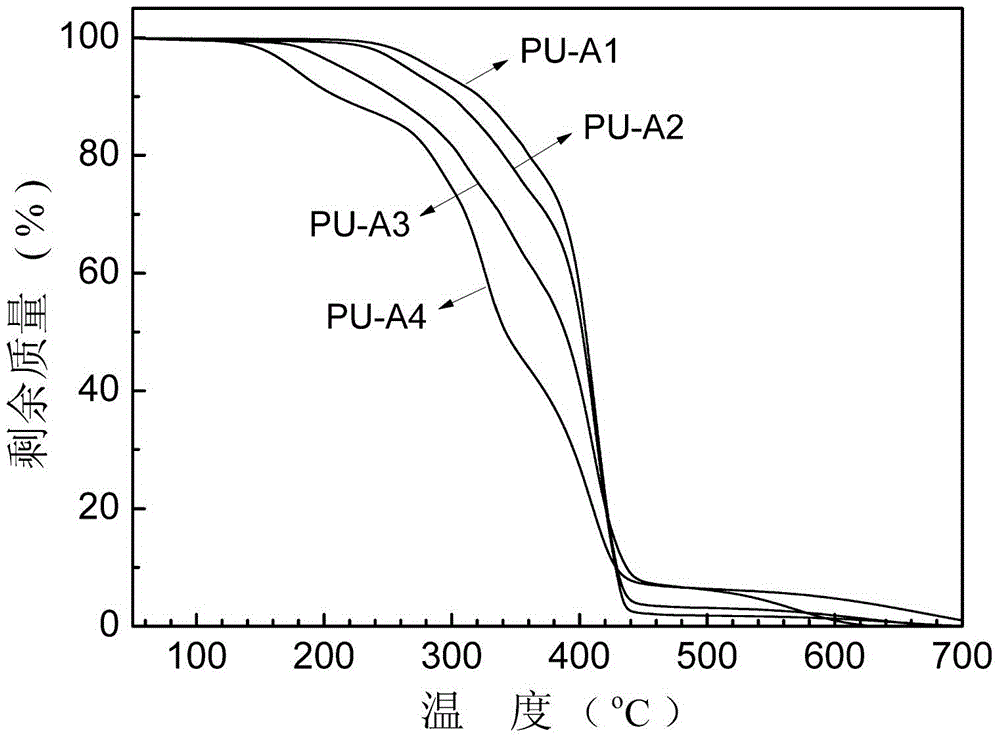

Solvent type polyurethane structure adhesive and preparation method thereof

InactiveCN104893644ADouble curing effectPlay the effect of curing cross-linkingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCross-linkPolyurethane adhesive

The invention discloses a method for preparing a solvent type polyurethane structure adhesive. The method is characterized in that an isocyanate solidifying agent sealed by a sealing agent and a polyurethane prepolymer at the sealed end of hydroxyl group are mixed to obtain a polyurethane adhesive, or the polyurethane prepolymer sealed by the sealing agent and a trihydroxy compound are mixed, or the polyurethane prepolymer sealed by the sealing agent and the isocyanate solidifying agent sealed by the sealing agent are mixed to be added into an adsorbing filling material to obtain the polyurethane adhesive. When in use, the adhesive is heated and unsealed to obtain the isocyanate solidifying agent or polyurethane prepolymer containing NCO, and reacts with polyurethane prepolymer or the trihydroxy compound to obtain cross-linked and cured polyurethane. The adhesive can be stably stored at the room temperature, can be heated to obtain reaction type bi-component when in construction, and is different from the conventional bi-component solvent type polyurethane which wastes time in the processes of metering, mixing and the like, the construction process is simple, the performance adjustment of the single component polyurethane system is realized, and the unsealed unsealing agent cannot overflow.

Owner:UNIV OF SCI & TECH OF CHINA

Preparation method for polymer microcapsule modified emulsified bitumen

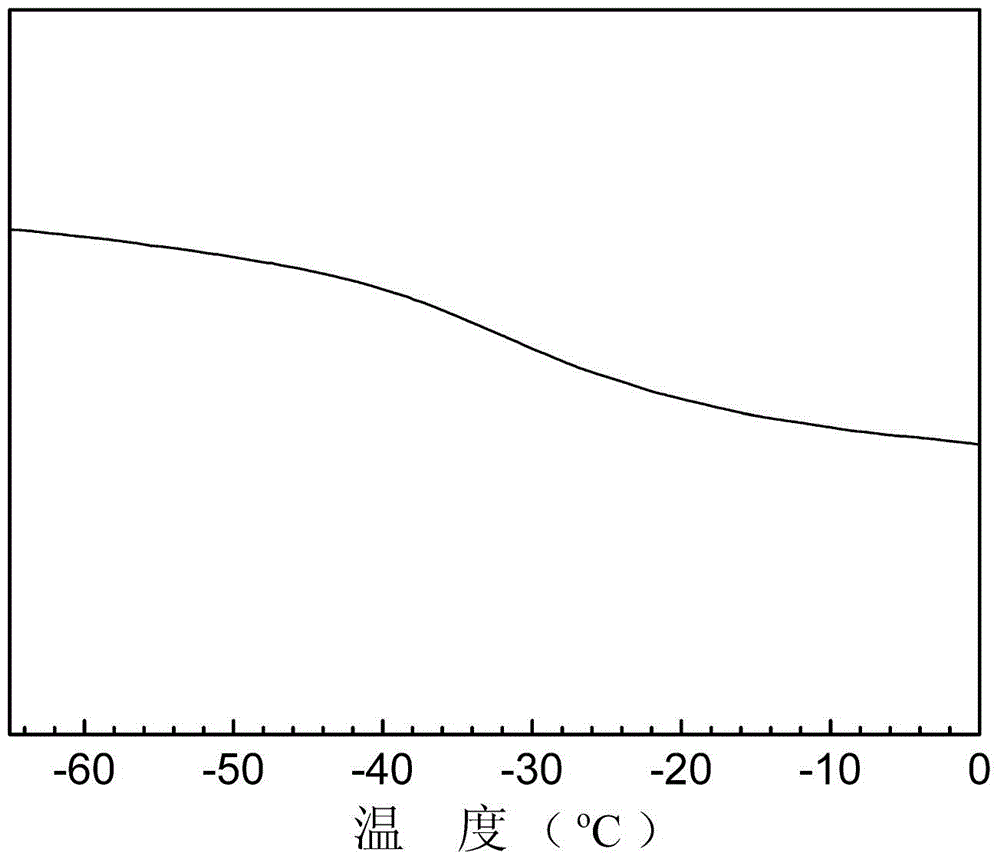

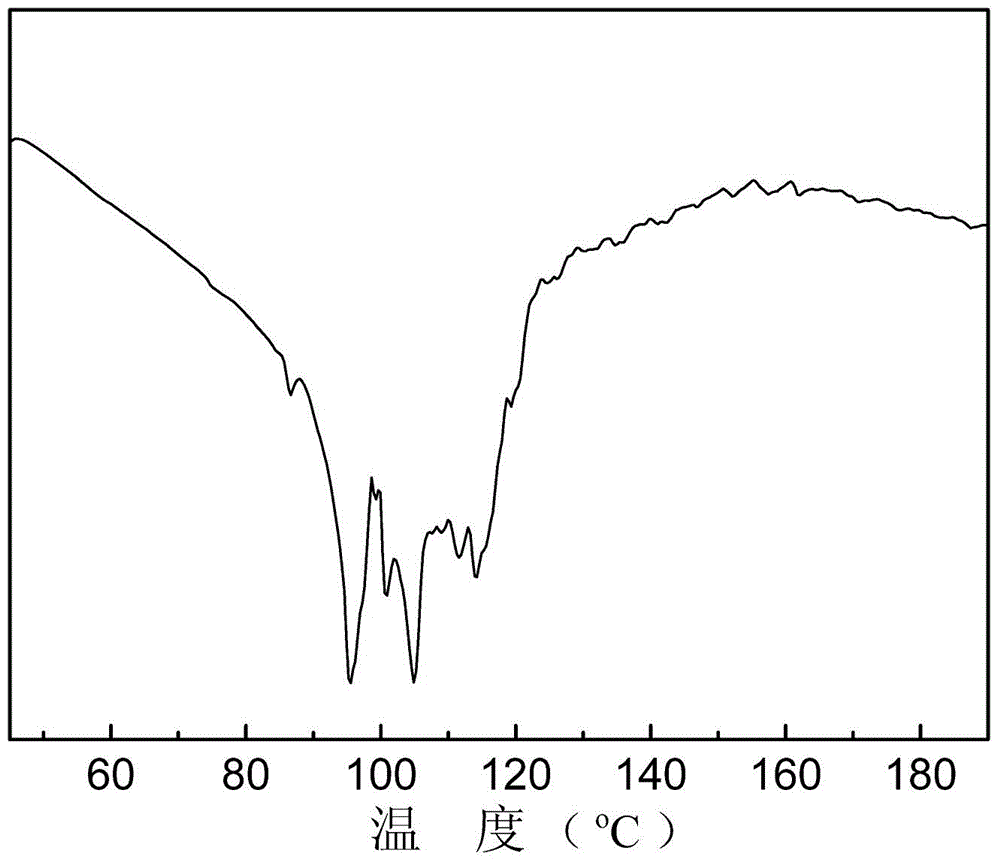

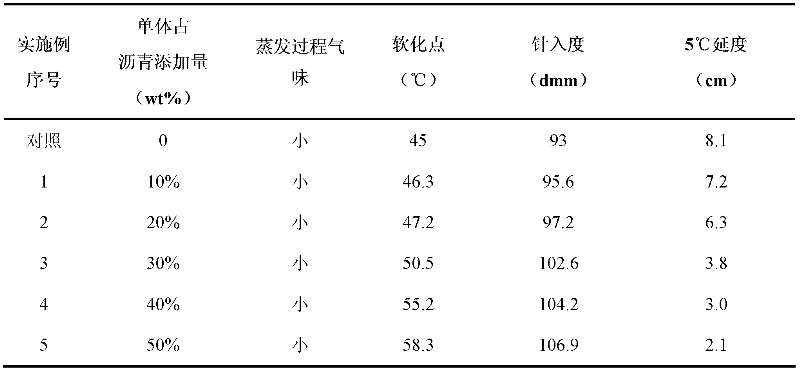

ActiveCN102352113AImprove stabilityImprove performanceBuilding insulationsPolymer modifiedCrack resistance

The invention discloses a preparation method for polymer microcapsule modified emulsified bitumen, which belongs to the technical field of modification of bitumen. A polymer shell layer is formed through microcapsule in-situ cladding and crosslinking on the surface of bitumen microballoons by using the method of miniemulsion polymerization, and an organic / inorganic composite core-shell structure is formed. After the polymer microcapsule modified emulsified bitumen becomes a film, an interpenetrating polymer network of a polymer and bitumen is formed; the polymer microcapsule modified emulsified bitumen has the characteristics of an organic / inorganic composite, better heat resistance and a high softening point; a mixture fabricated with the polymer microcapsule modified emulsified bitumen has good resistance to permanent deformation, can prevent harmful damage like formation of ruts on a pavement in high temperature seasons and better adapts to needs for pavement construction and maintenance in hot areas. Since the polymer microcapsule modified emulsified bitumen has the characteristic of modification by the polymer, the emulsified bitumen has improved toughness and good crack resistance, and can be extensively used in the fields like emulsified bitumen cement mortar for plate type ballastless tracks of high-speed railways or urban light rails.

Owner:TSINGHUA UNIV

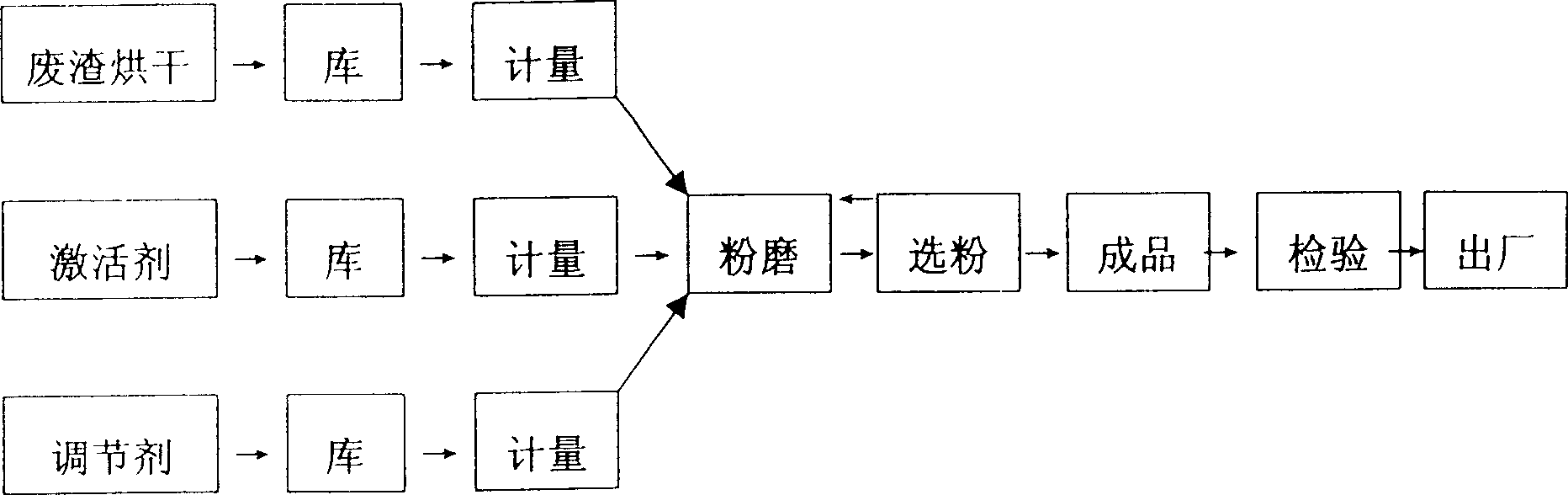

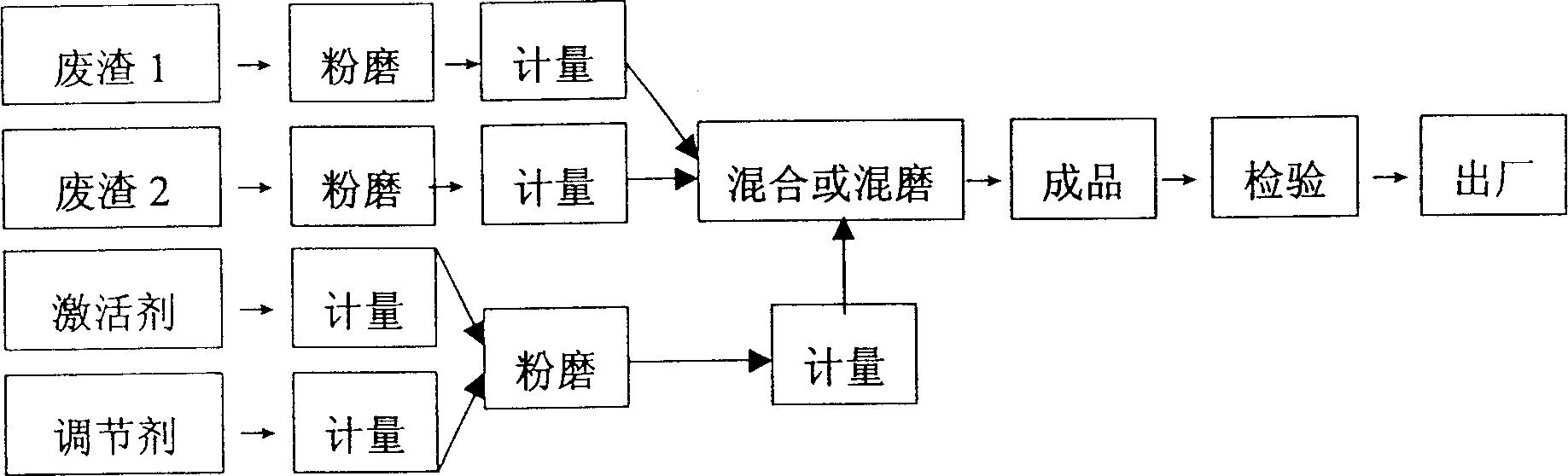

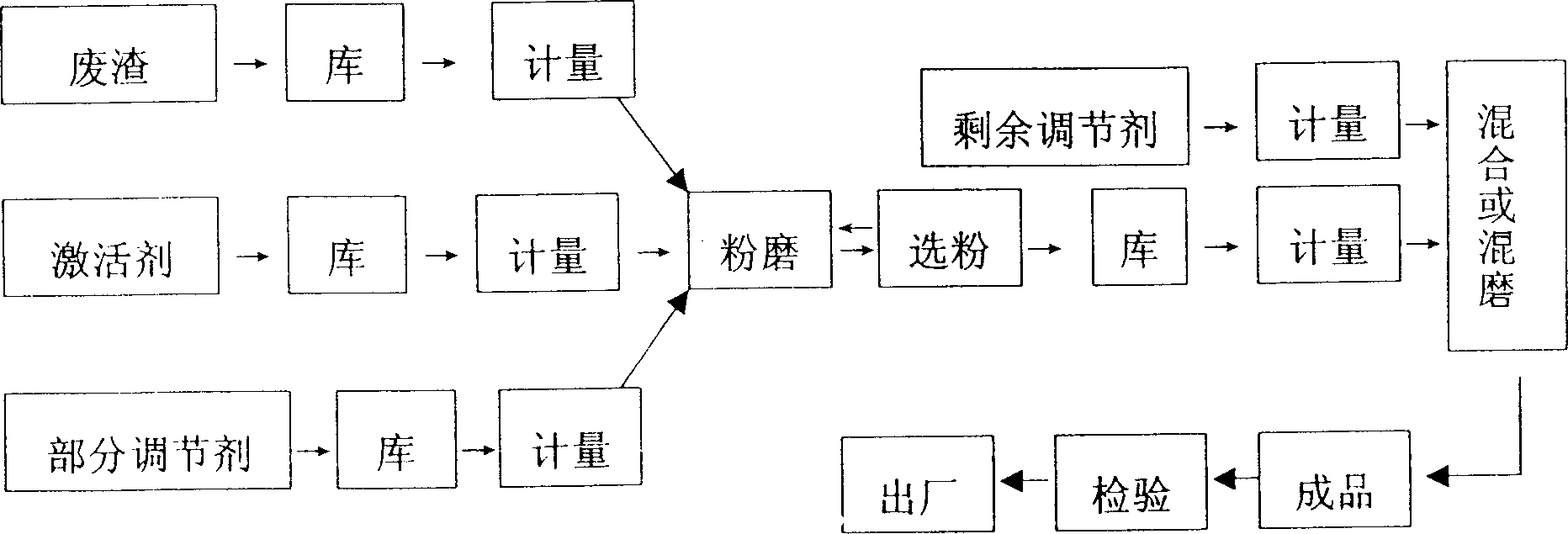

High-performance cement and concrete and their production

InactiveCN1896024AImprove compactnessImprove liquidityCement productionMaterials scienceHeating energy

High-performance cement, concrete and its production are disclosed. The cement consists of industrial fag end, activator, functional regulator and performance regulator, and Bosi specific surface is 300-550m2 / kg. Its advantages include excellent fluidity and endurance, less loss and hydrated heat energy, better density and strength.

Owner:张卫党

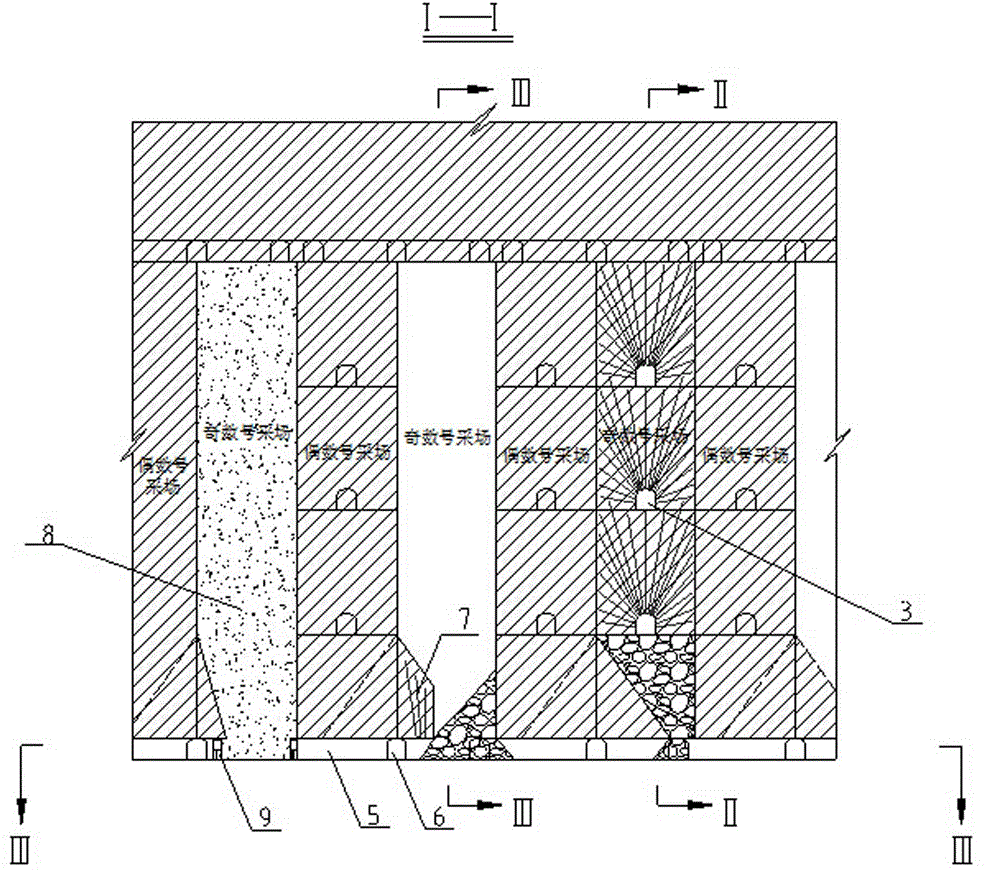

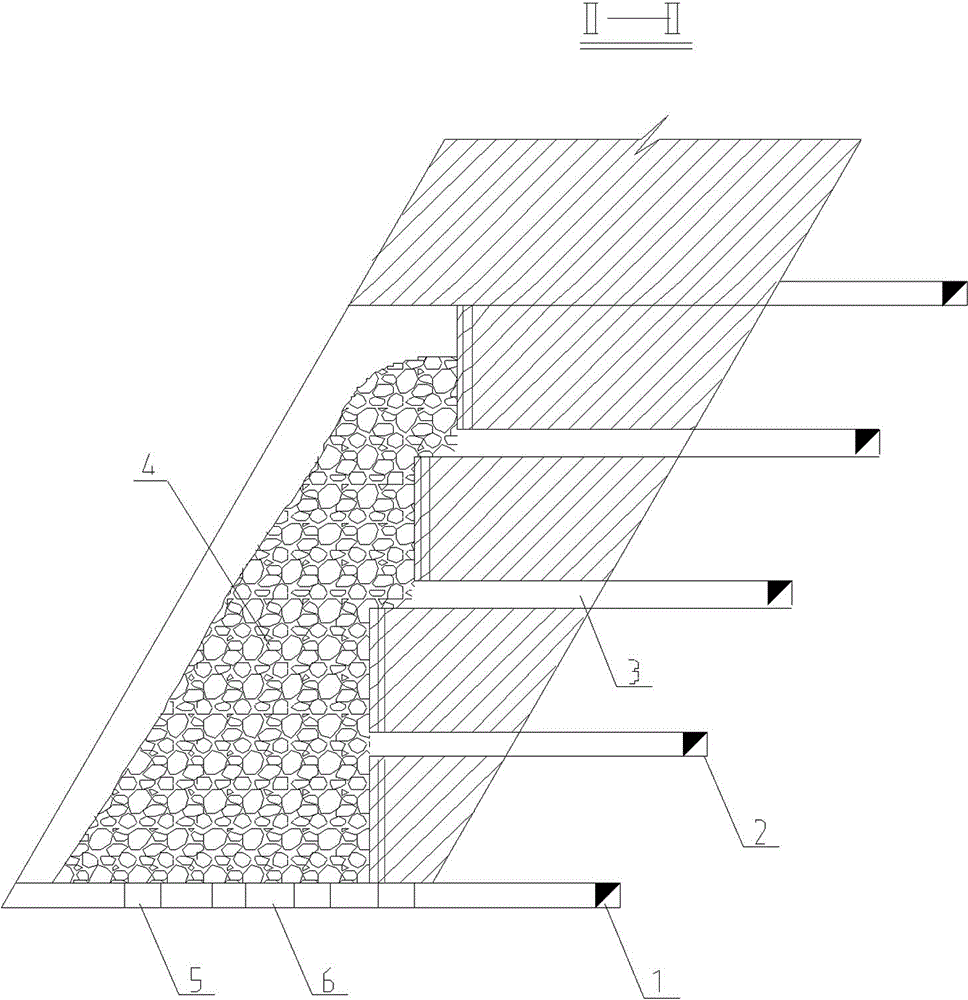

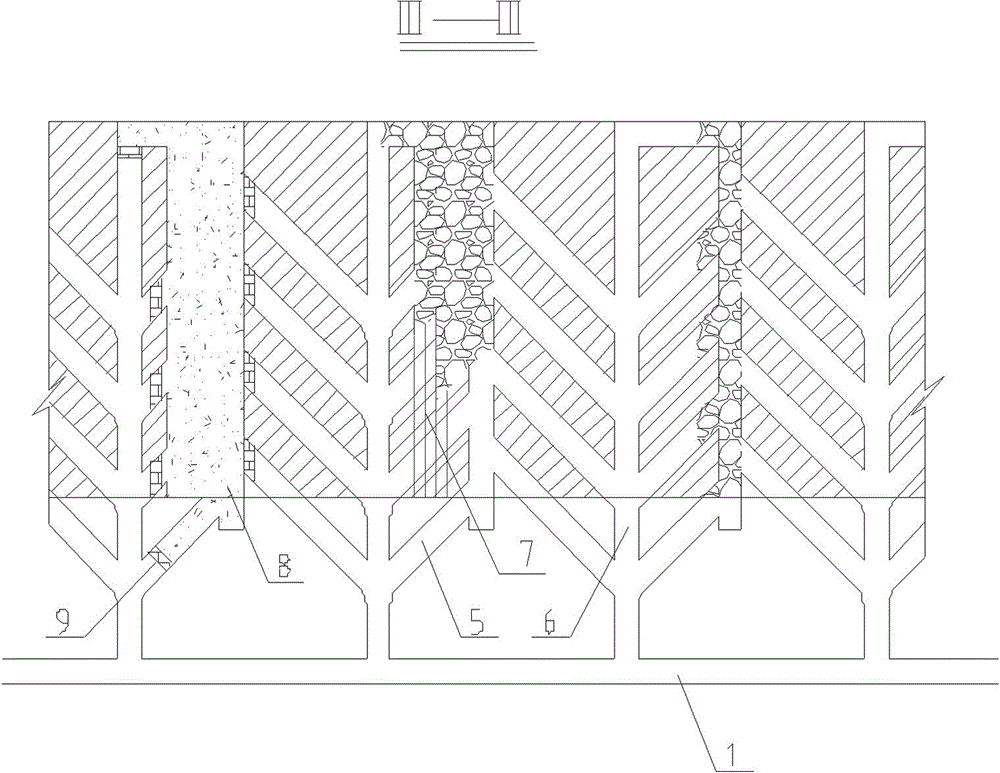

Large-structure sublevel drilling stage ore removal mining method with delayed filling

ActiveCN104863592AReduce labor intensityImprove stope production capacityUnderground miningSurface miningResource recoveryStructure of the Earth

The invention relates to a large-structure sublevel drilling stage ore removal mining method with delayed filling. The mining method comprises stoping in stopes and bottom structure recovery which are carried out synchronously in a crossed manner, and comprises the following steps: step 1, stoping in odd-numbered stopes, wherein the stoping manner is sublevel drilling stage ore removal, and mined out space I is not filled immediately; step 2, stoping in 1 / 2 bottom structures I corresponding to the odd-numbered stopes, and filling ore rooms and the mined out space I, corresponding to the 1 / 2 bottom structures I, of the ore rooms after stoping is finished; step 3, stoping in even-numbered stopes, wherein mined out space II is not filled immediately; step 4, stoping in 1 / 2 bottom structures II corresponding to ore pillars, and filling the ore pillars and the mined out space II, corresponding to the 1 / 2 bottom structures II, of the ore pillars after stoping is finished. The mining method has the advantages that the mining-cutting work amount is reduced greatly; the production capacity of a single stope is high; the efficiency is high; workers' labor intensity is low; production, dispatching and management are simple. Moreover, stoping of the main ore in a stope and recovery of ore in the bottom structure of the stope are realized synchronously in a crossed manner, and the stoping operation is safe, so that the resource recovery rate is high.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST +1

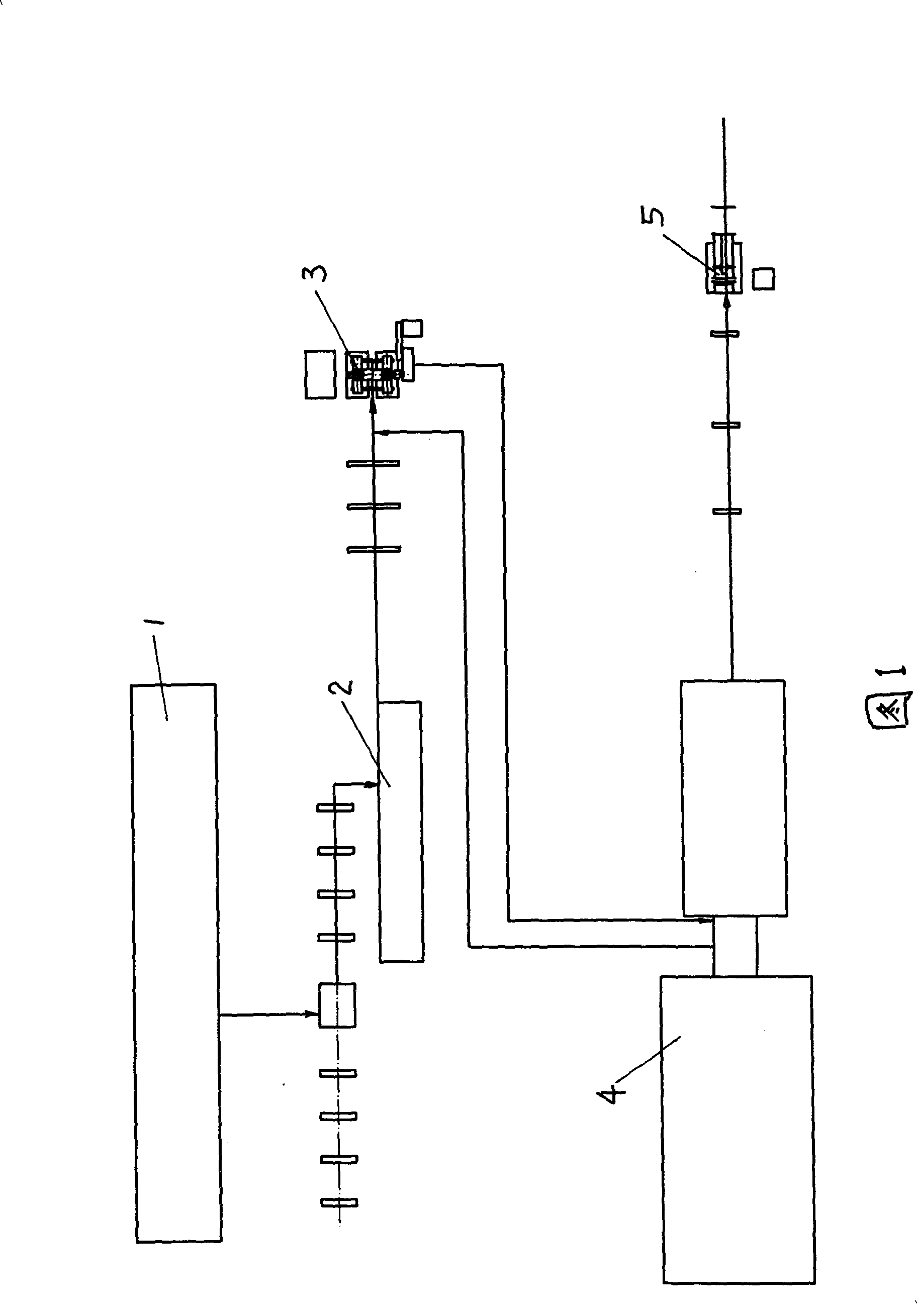

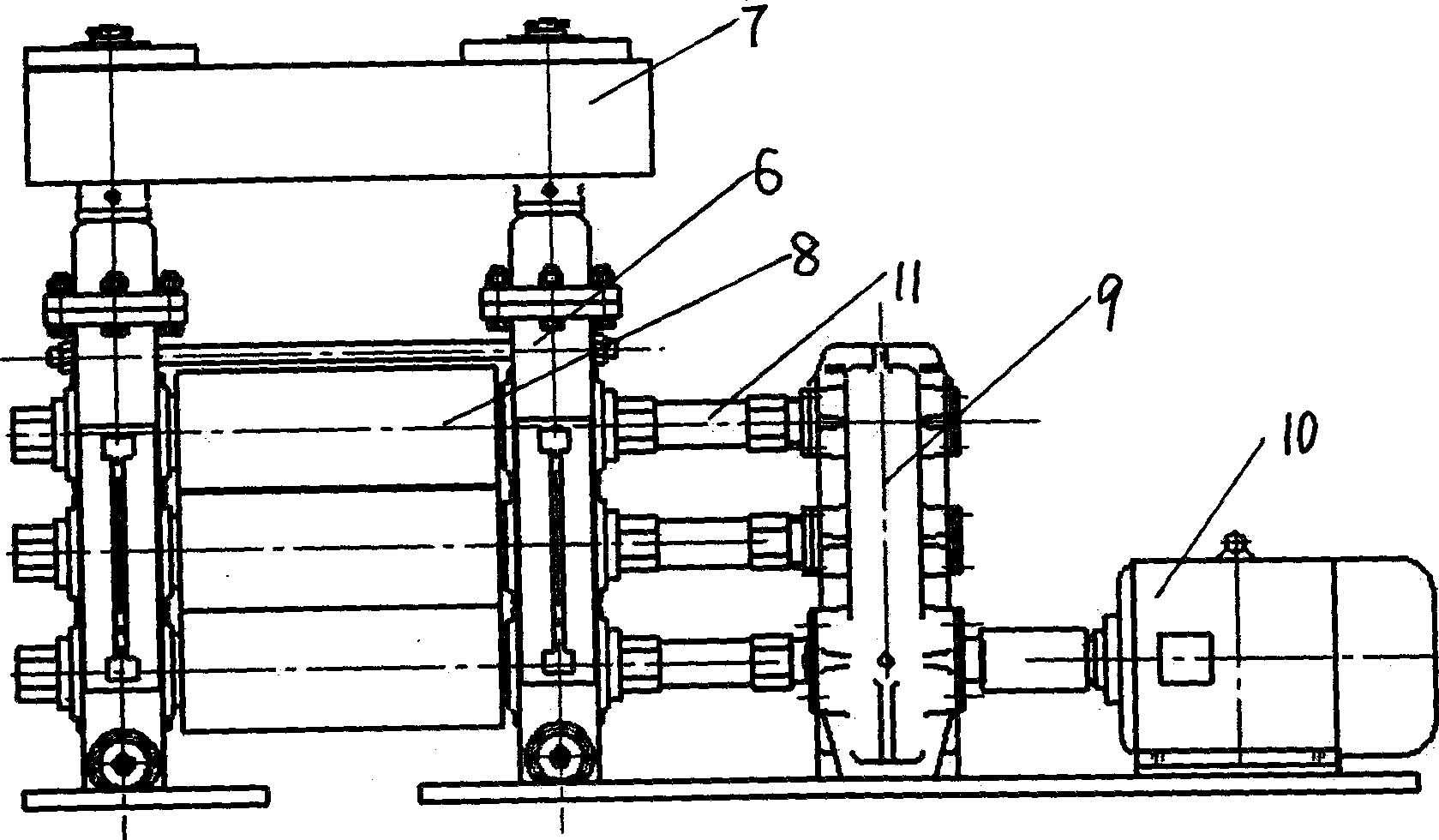

Copper coated aluminum bus bank production method and apparatus

InactiveCN101364459AReduce consumptionThe process steps are simpleSingle bars/rods/wires/strips conductorsCable/conductor manufactureAcid washingOxidation resistant

The invention belongs to a production method of a compound metal bus bar, particularly to a production method of a copper-clad aluminum bus bar, which comprises the following steps: (1) pretreatment of raw materials: acid washing a copper tube as a raw material, polishing, and placing an aluminum rod into the copper tube; (2) heat treatment before deformation: placing the raw material which is subjected to drawing into a vacuum annealing furnace for annealing; and (3) rolling the copper and the aluminum with fresh metal surface together under high pressure by using different lanes irreversible constant rolling speed hot rolling technique. The production method has the advantages of simple process, wide process conditions and easy operation. The obtained copper-clad aluminum bus bar has the same electrical conduction performance, oxidation resistance and other performances as those of a pure copper bus bar, while having remarkably reduced cost and copper consumption, which achieves resources saving purpose for countries being short of copper resources.

Owner:大连松辽玻璃钢船艇有限公司

Cored welding strip applied in resurfacing welding and preparation method thereof

InactiveCN101596653AImprove wear resistanceImprove stabilityWelding/cutting media/materialsSoldering mediaSteel beltDrug powder

The invention discloses a novel resurfacing welding cored welding strip which consists of a steel tube circled by steel strips and drug powder wrapped in the steel tube, the steel strips comprises an upper steel strip and a lower steel strip which can be purchased in the market. The shape of the steel tube circled by steel strips is that the longitudinal cross section is long flat form or rectangle-like shape, the longitudinal length is determined at will, and the steel tube can be cut out at will or winded into a tray according to requirements. The transverse edges of the upper steel strip and the lower steel strip are connected at the upper steel strip side in a related joint form, and the drug powder is filled in the steel tube circled by the steel strips evenly with the filling rate being 20-80%. According to the different types of resurfacing metals, the content of alloy element in the resurfacing welding cored welding strip is different. The cored welding strip has simple production equipment and technique, and low production cost, thus overcoming the defect that alloy welding filament used for filament resurfacing welding is difficult to produce and the problems of large investment on production equipment, high production cost and expensive price in cored welding filament production.

Owner:SHANDONG UNIV

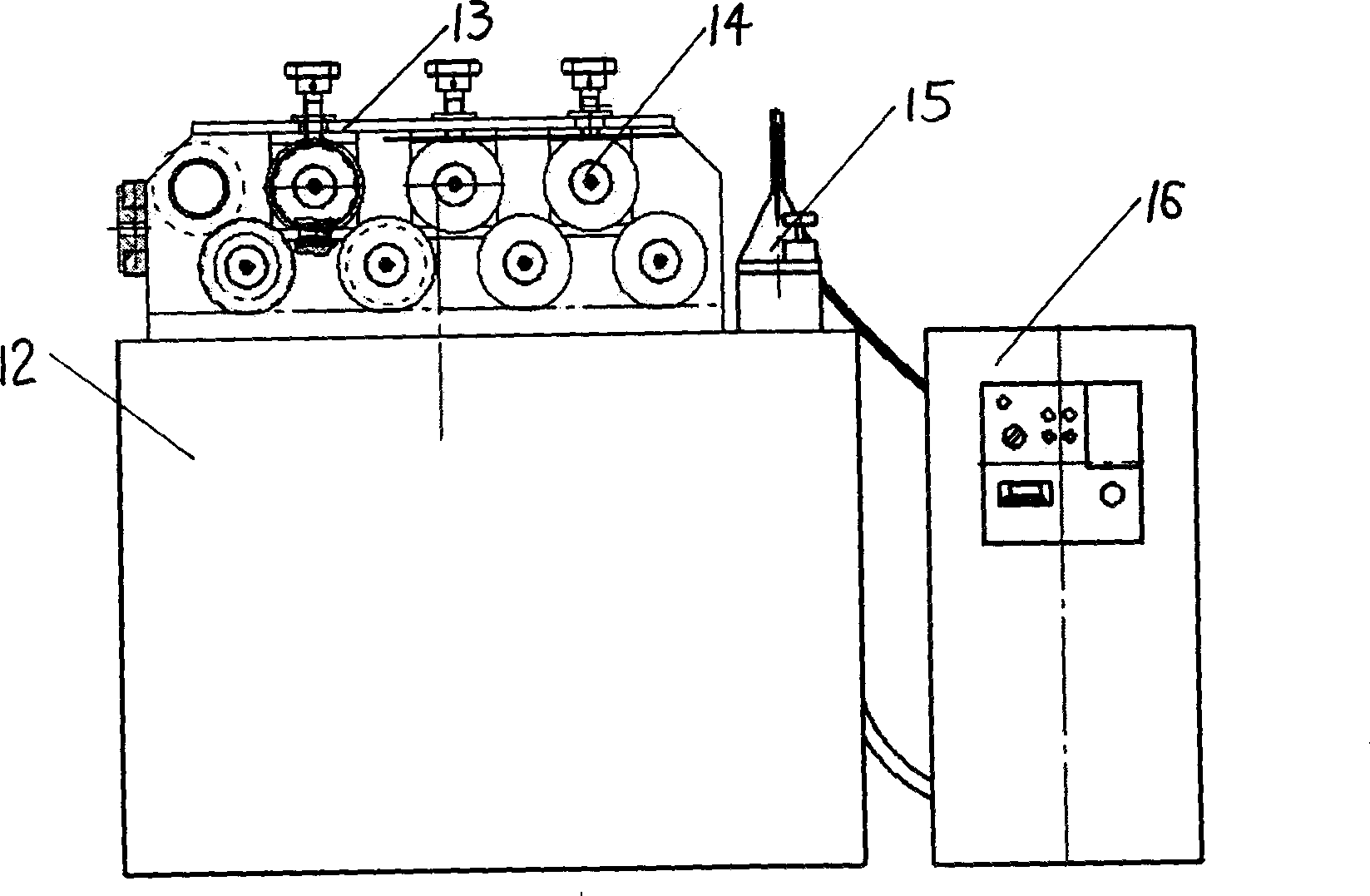

Device capable of improving online heating adaptability of roller

InactiveCN107282639AUniform temperature distributionImprove surface qualityMeasuring devicesRollsControl systemAsbestos

A device that can improve the adaptability of rolling on-line heating, which mainly includes: an axial through hole is arranged on an ordinary roll, and a heating rod wrapped with an asbestos layer is arranged in each axial through hole, and two heating rods of each heating rod The ends are respectively placed in the conductive block, and all the conductive blocks arranged at one end of the roll are in contact with a power-connecting coil, and a binding post and a fixed bracket are arranged on the power-connecting coil. In addition, a contact block with a certain height is arranged on the two end faces of the two rolls. The contact surface of the contact block and the thermocouple is an arc surface with a high middle and low sides, and one end of the thermocouple is set on the end face of the roll. Nearby, the other end of the thermocouple is connected to one end of the elastic piece, and the lead wire on the thermocouple is connected to the control system. The invention not only has a simple structure, but also can continuously heat the rolls on-line during the rolling process, has high production efficiency, low processing cost and convenient operation, and the temperature of the rolls is always in a reasonable temperature range, ensuring better, stable and uniform product quality.

Owner:YANSHAN UNIV

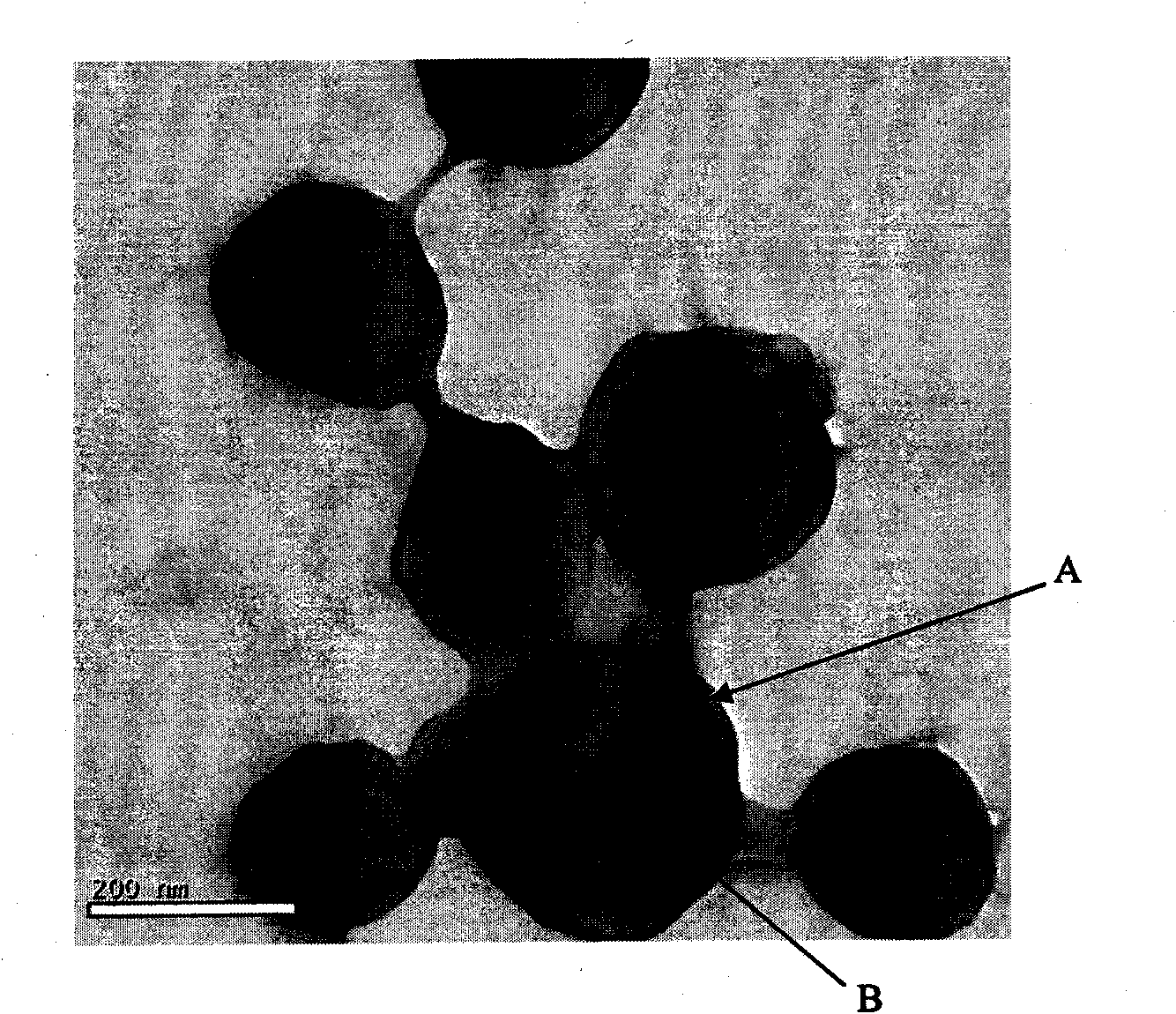

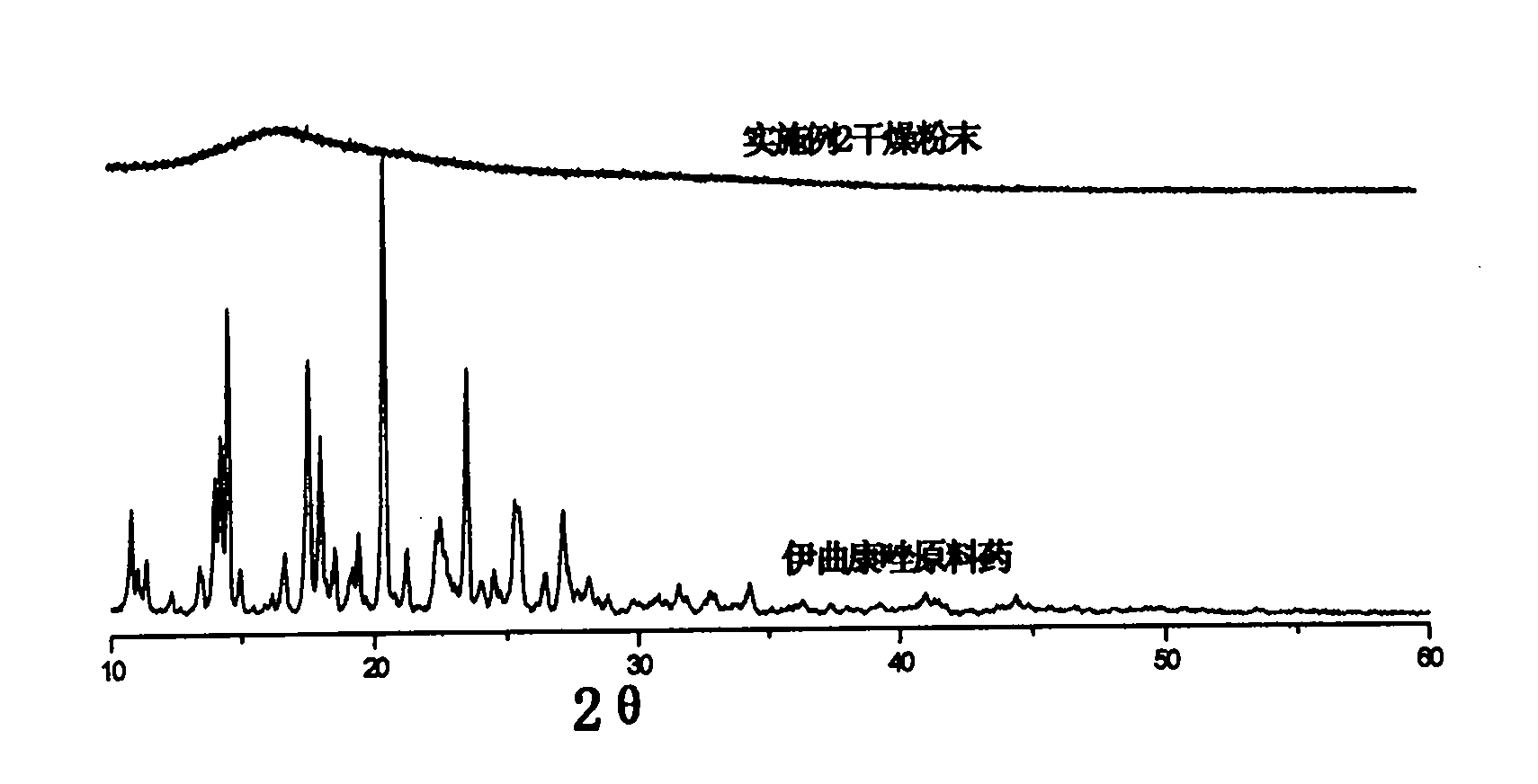

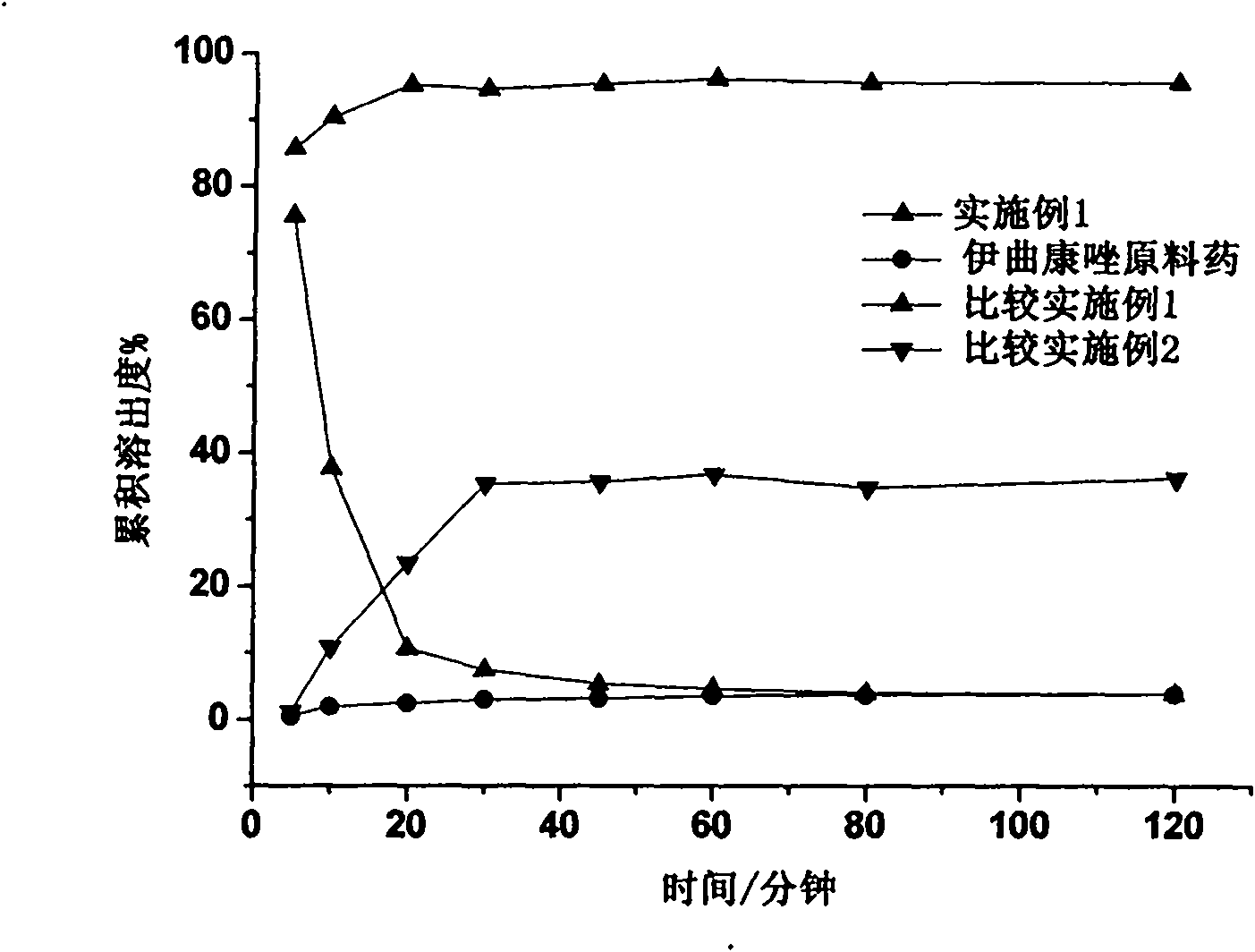

Itraconazole nanocrystals and preparation method and application thereof

ActiveCN101961313AImprove bioavailabilitySmall particle sizePowder deliveryOrganic active ingredientsSolubilityNanoparticle

The invention provides itraconazole nanocrystals and a preparation method and application thereof. Acid phase in which itraconazole is dissolved is dropwise added into alkaline phase to over-saturate the itraconazole; the itraconazole molecules are aggregated into amorphous nanocrystalline particles in the presence of a high molecular stabilizer to form a stable structure with itraconazole nanocrystals as a core and the high molecular stabilizer as a shell; and both the solubility and the dissolution rate of the itraconazole nanocrystals are greatly improved compared with those of normal itraconazole nanoparticle suspension. A hydrophilic fragment of the high molecular stabilizer, which is extended into the water, improves the hydrophobicity of the surfaces of the itraconazole nanoparticles, so that the high molecular stabilizer is more easily moistened and dissolved; and the high molecular stabilizer serving as the shell enhances the adhesion between the medicament particles and gastrointestinal mucous membrane, is favorable for improving the bioavailability and reduces the influence of a diet state on the bioavailability. The method of the invention has the advantages of no use of toxic solvent, simple preparation process, low cost and easy industrialization.

Owner:HUAZHONG UNIV OF SCI & TECH

Aluminum lithium alloy for spaceflight and method for preparing proximate matter through aluminum lithium alloy

The invention relates to an aluminum lithium alloy for spaceflight and an aluminum lithium alloy proximate matter preparing method, and relates to the aluminum lithium alloy and the aluminum lithium alloy proximate matter preparing method. The aim is to solve the problems that the production difficulty of the aluminum lithium alloy is large, and the aluminum lithium alloy strength is low. The aluminum lithium alloy is composed of Mg, Li, Ti, Zr and Al, the Mg accounts for 5.5%-6.5%, the Li accounts for 2.2%-2.5%, the Ti accounts for 0.03%-0.12%, the Zr accounts for 0.15%-0.20%, the Zr+Ti is smaller than or equal to 0.25%, and the balance is the Al. The method includes the steps of raw material weighing, aluminum alloy molten liquid preparing, refining, spray forming, short bar cutting, blind die extrusion, heat extrusion, quenching, tension leveling and aging treatment. According to the aluminum lithium alloy and the aluminum lithium alloy proximate matter preparing method, through spray forming, the problems that the aluminum lithium alloy production difficulty is large, and the quality is poor are solved, the strength of extension reaches 485 Mpa, the ruled non-proportional extending strength reaches 345 Mpa, the percentage elongation after fracture reaches 10.0%, and blind die extrusion enables a casting ingot to be more compact.

Owner:NORTHEAST LIGHT ALLOY CO LTD

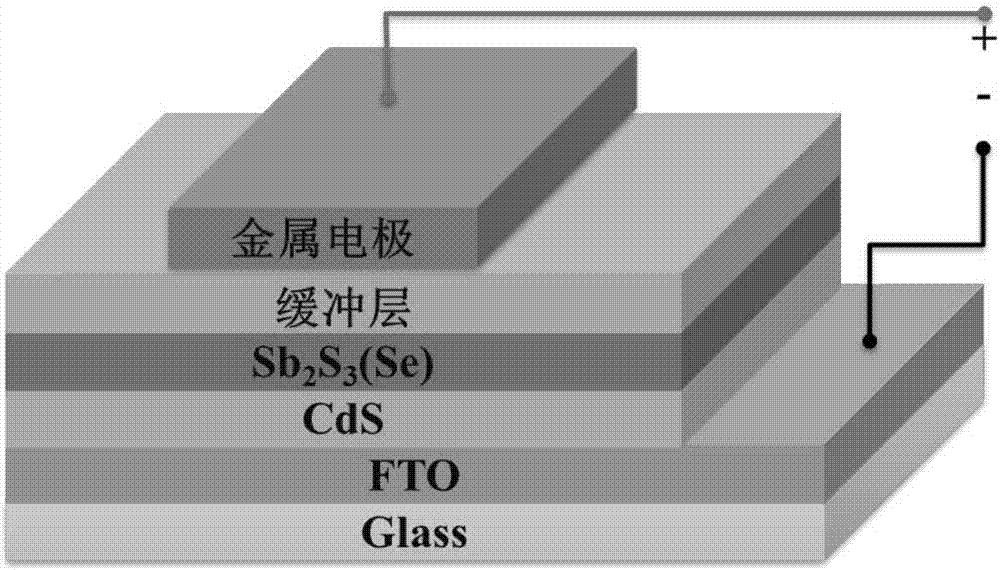

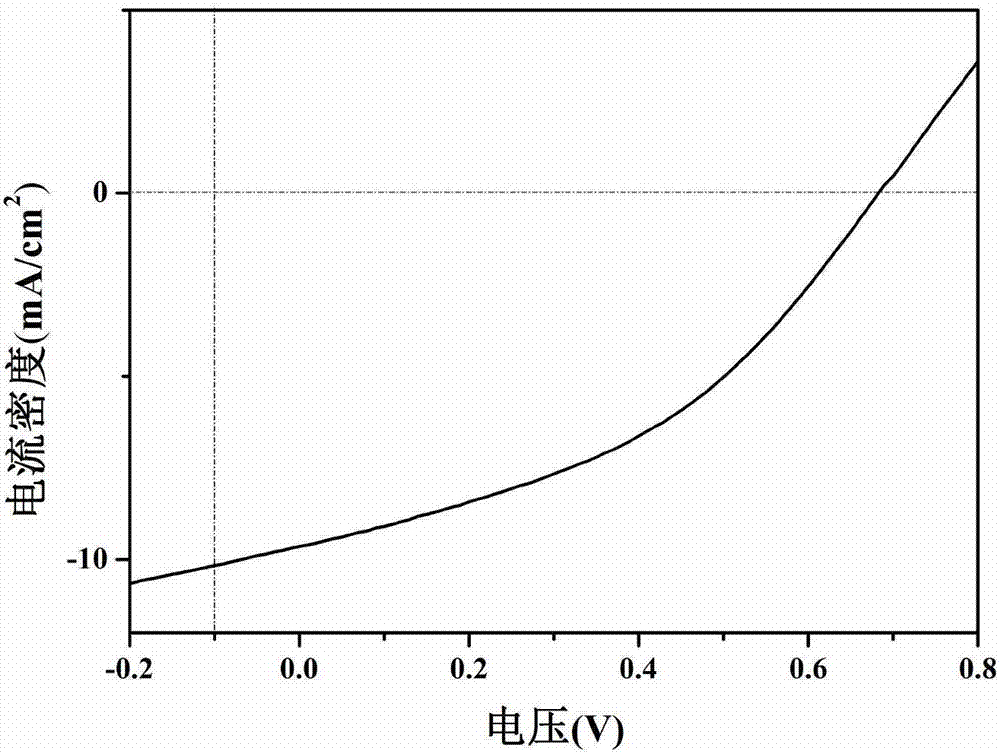

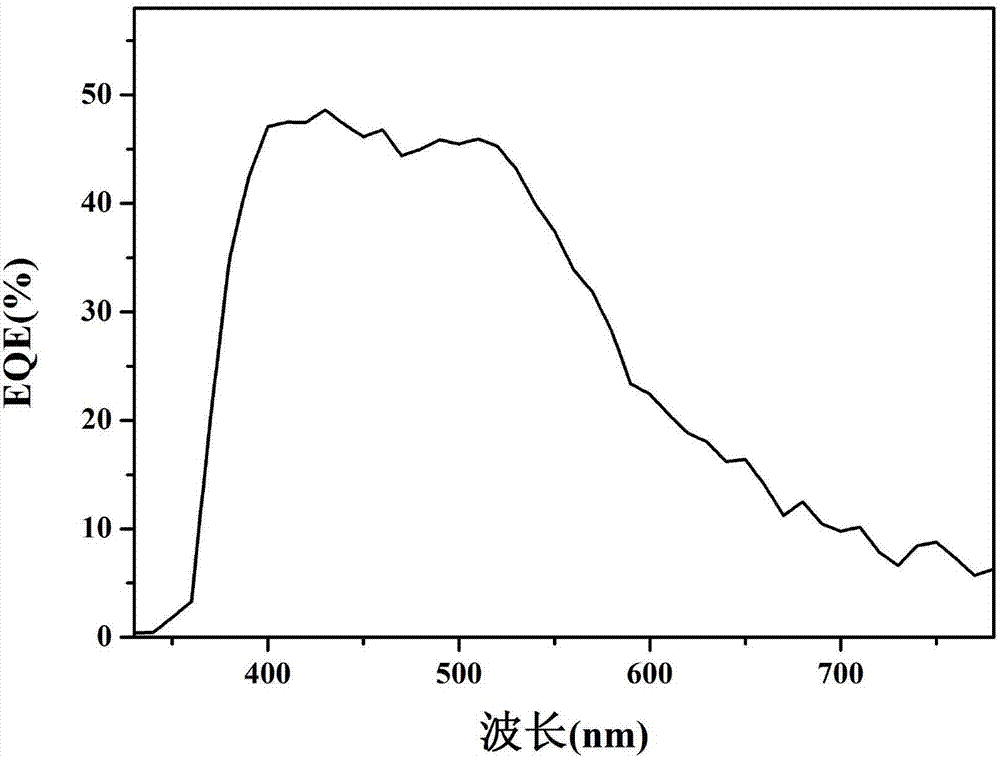

Thin film solar cell and preparation method thereof

InactiveCN107068797ALow costAvoid damageFinal product manufacturePhotovoltaic energy generationMetallic materialsWork function

The present invention belongs to the inorganic nonmetallic material science and photoelectric film and device manufacturing field, and especially discloses to a thin film solar cell and a preparation method thereof. The structure of a thin film solar cell is FTO / CdS / Sb2S3 (Se) / a buffer layer / a metal electrode, wherein the buffer layer is p-type transition metallic oxide and includes but not limited to WO3, MoO3, NiO, CoO and the like, and the metal electrode is a high-work-function metal and includes but not limited to Ag, Au, Pt and the like. The preparation steps comprises: (1) cleaning of the substrate; (2) deposition of the CdS film; (3) preparation of the Sb2S3 (Se) film; and (4) deposition of the buffer layer and the metal electrode. The objective of the invention is to provide Sb2S3(Se) thin film solar cell based on new materials and a new structure, and a technology with low cost and capable of preparing the large-area Sb2S3(Se) thin film and the solar cell.

Owner:CHONGQING UNIV OF ARTS & SCI

Self-emulsifying defoaming composition

ActiveCN101780386AIncrease productivitySimple productivityTransportation and packagingMixingPaper manufacturingSelf emulsifying

The invention discloses a self-emulsifying defoaming composition, which comprises the following components in percentage by weight: 46-91.8% of modified polysiloxane, 3-25% of silicon dioxide granule, 5-25% of dispersing agent and 0.2-4.0% of emulsifier. Each component of the composition can be uniformly mixed without undergoing a high temperature impregnation stage, and the composition still has the exchange anti-foaming performance in a high temperature alkaline environment, and is applicable to the processes of pulping, pigment dispersing, coating, film forming and the like during paper manufacturing.

Owner:JIANGSU SAIOUXINYUE DEFOAMER

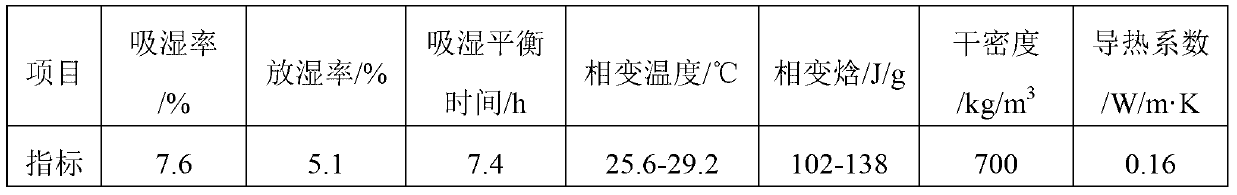

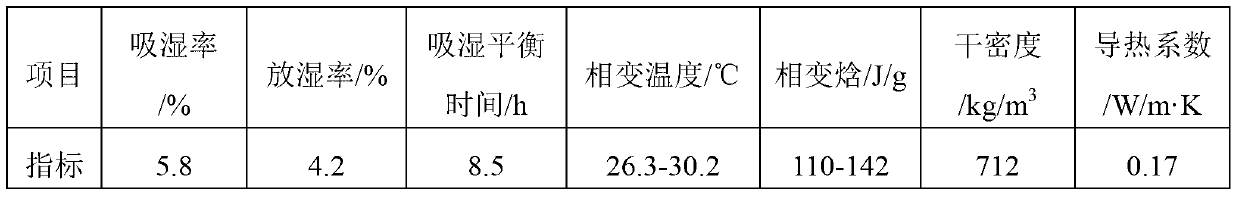

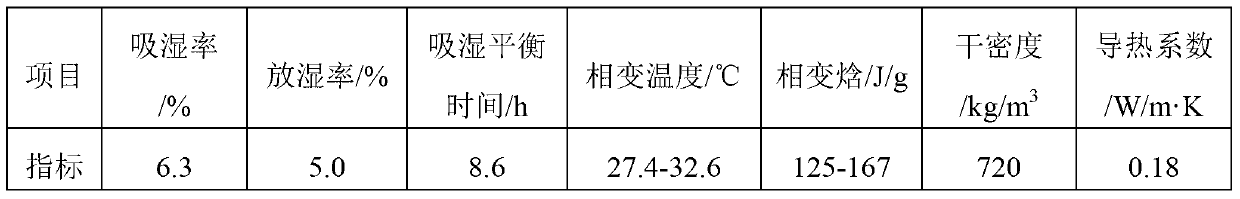

Temperature-sensitive humidity-sensitive functional building material and preparation method thereof

The invention relates to a temperature-sensitive humidity-sensitive functional building material and a preparation method thereof. The functional building material is a plate made from the following ingredients in parts by weight: 40-60 parts of cementing material, 6-12 parts of composite temperature control material, 15-30 parts of semi-carbonized plant fiber, 10-25 parts of filling, 0.5-2 parts of foaming agent, and 0.05-0.2 parts of foam stabilizer. The preparation method comprises the following steps of: uniformly mixing all the ingredients, adjusting the ratio of water to materials to 0.30-0.45 to prepare the plate, curing the plate in an environment at the temperature of 25 DEG C and relative humidity not less than 80% for 7 days and then drying the plate to obtain the temperature-sensitive humidity-sensitive functional building material. Therefore, the temperature-sensitive humidity-sensitive functional building material provided by the invention can be used for effectively improving the comfort of an indoor environment, is simple in production and construction process, can be widely applied to the inner walls of an existing building and a new building, and is of a great significance in energy conservation, emission reduction and circular economy development.

Owner:武汉威尔博科技发展有限公司

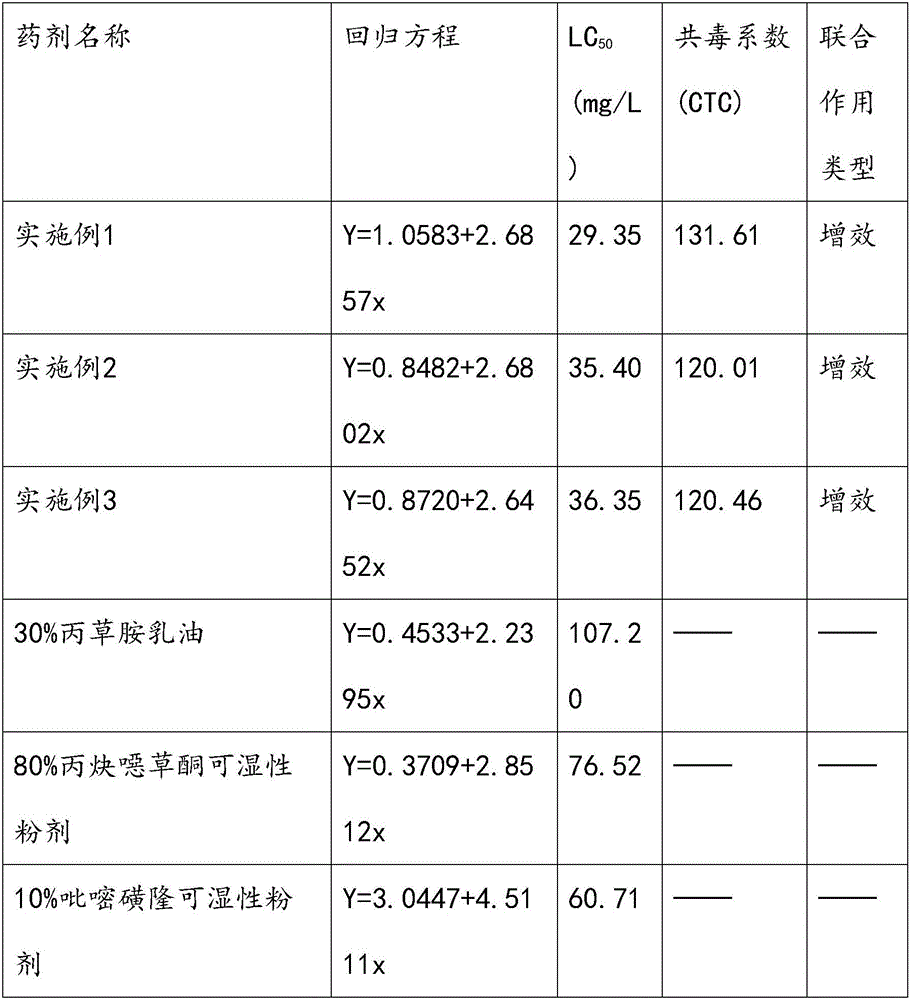

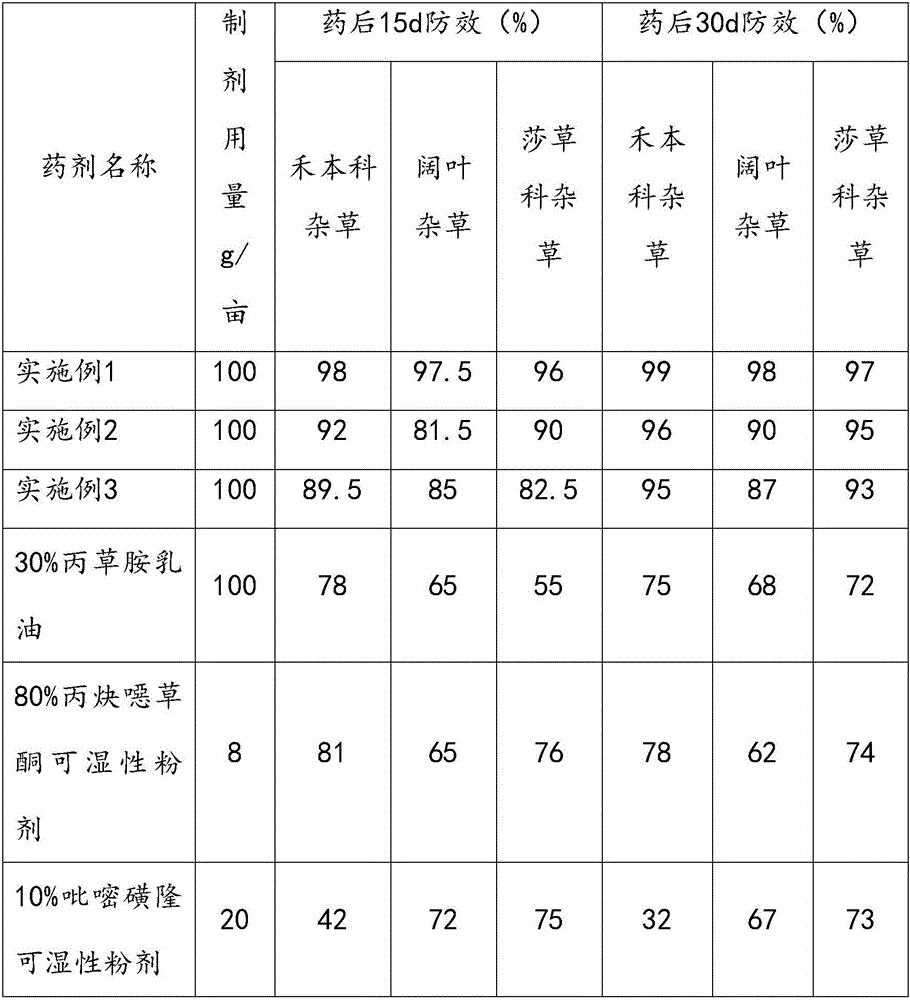

Dispersible oil suspending agent and preparation method thereof

InactiveCN106489923AEnsure safetyAvoid pollutionBiocideDead animal preservationPhytotoxicityPyrazosulfuron-ethyl

The invention discloses a dispersible oil suspending agent. The dispersible oil suspending agent comprises, by mass, 15-30% of pretilachlor, 3-6% of allylene oxadiazon, 1-3% of pyrazosulfuron-ethyl, 1-8% of dispersing agents, 5-15% of emulsifiers, 0.5-5% of wetting agents, 0.5-5% of thickeners, 0.5-8% of stabilizers, 0.2-2% of defoamers, 0.1-2% of pH regulators and the balance oil-base solvent. The dispersible oil suspending agent has the advantages that the dispersible oil suspending agent has low toxin on human, livestock and beneficial organisms, toxicity of effective components to chemical application persons can be reduced effectively, phytotoxicity of chemicals to target crops can be lowered, prevention effect of herbicide products on weeds and safety of the herbicide products on the crops are improved, and the dispersible oil suspending agent is a low-carbon, environment friendly and safe dosage form.

Owner:ZHEJIANG TIANFENG BIOLOGICAL SCI

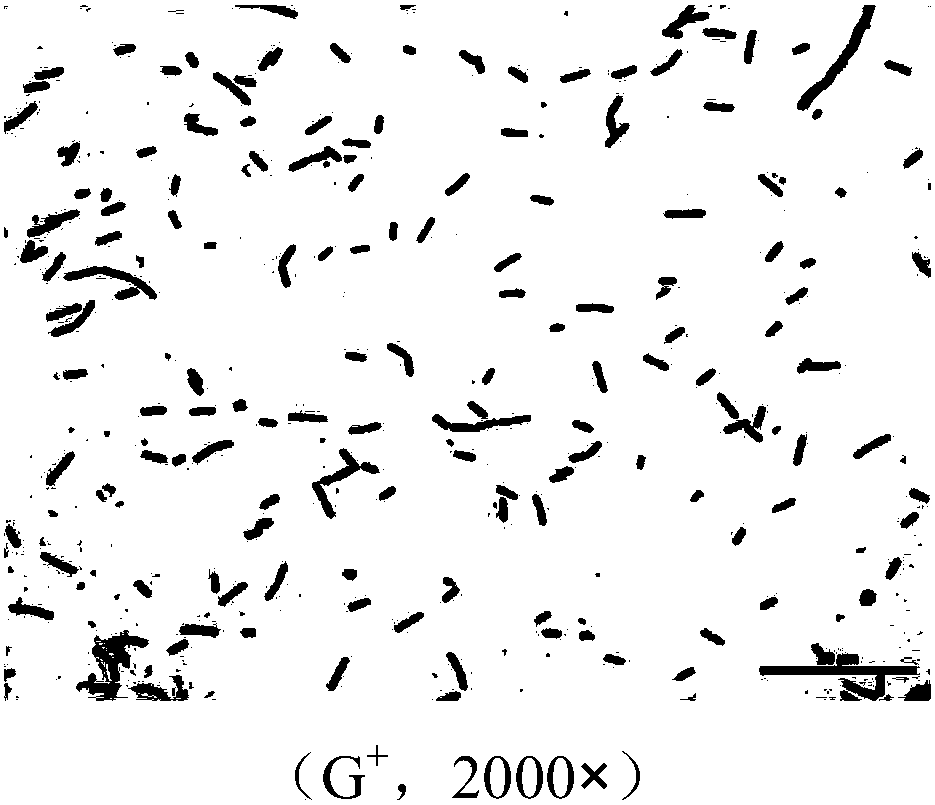

Screening and application of probiotic bacillus licheniformis of high-yield compound enzyme

ActiveCN108587957AThe number of viable bacteria did not decreaseHigh antibacterial activityBacteriaMicroorganism based processesBacillus licheniformisEscherichia coli

The invention belongs to the technical field of agricultural microorganism application, in particular to the screening and application of a probiotic bacillus licheniformis of a high-yield compound enzyme. The bacillus licheniformis has obvious bacteriostatic effect on common livestock intestinal pathogenic bacteria such as escherichia coli, staphylococcus aureus and clostridium welchii. The screening and application of the probiotic bacillus licheniformis of the high-yield compound enzyme comprises the isolation and identification of bacillus licheniformis strains, the study of biological characteristics and the application as livestock feed additives. According to the screening and application of the probiotic bacillus licheniformis of high-yield compound enzyme, the strain of the invention produces cellulase, amylase and proteinase, is resistant to low pH value of gastric acid and high osmotic pressure of intestinal bile salt, has the characteristics of fast growth, high stress resistance, high bacteriostasis and high enzyme production ability, and can be used for preparing livestock feed microbial additives.

Owner:湖北华大瑞尔科技有限公司

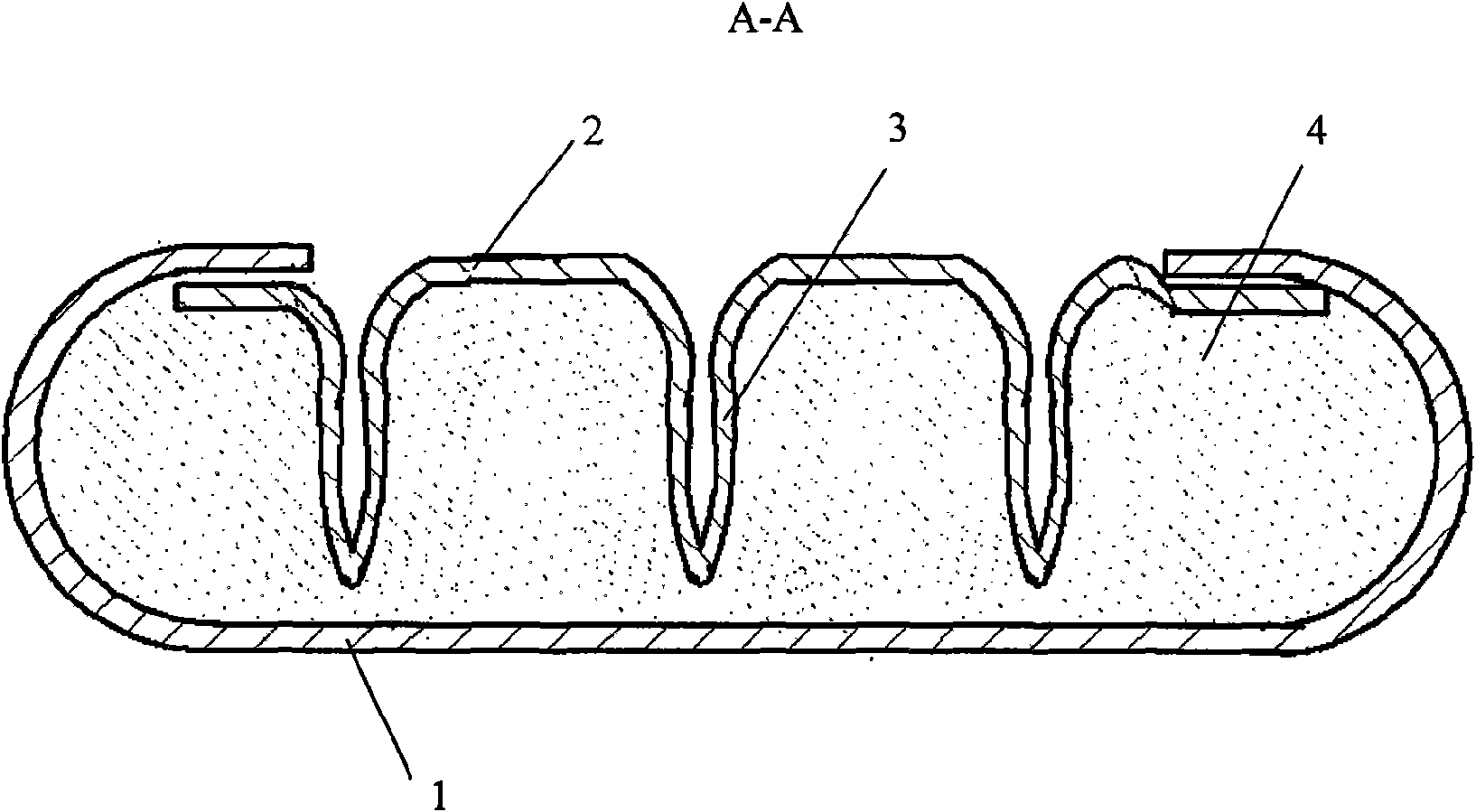

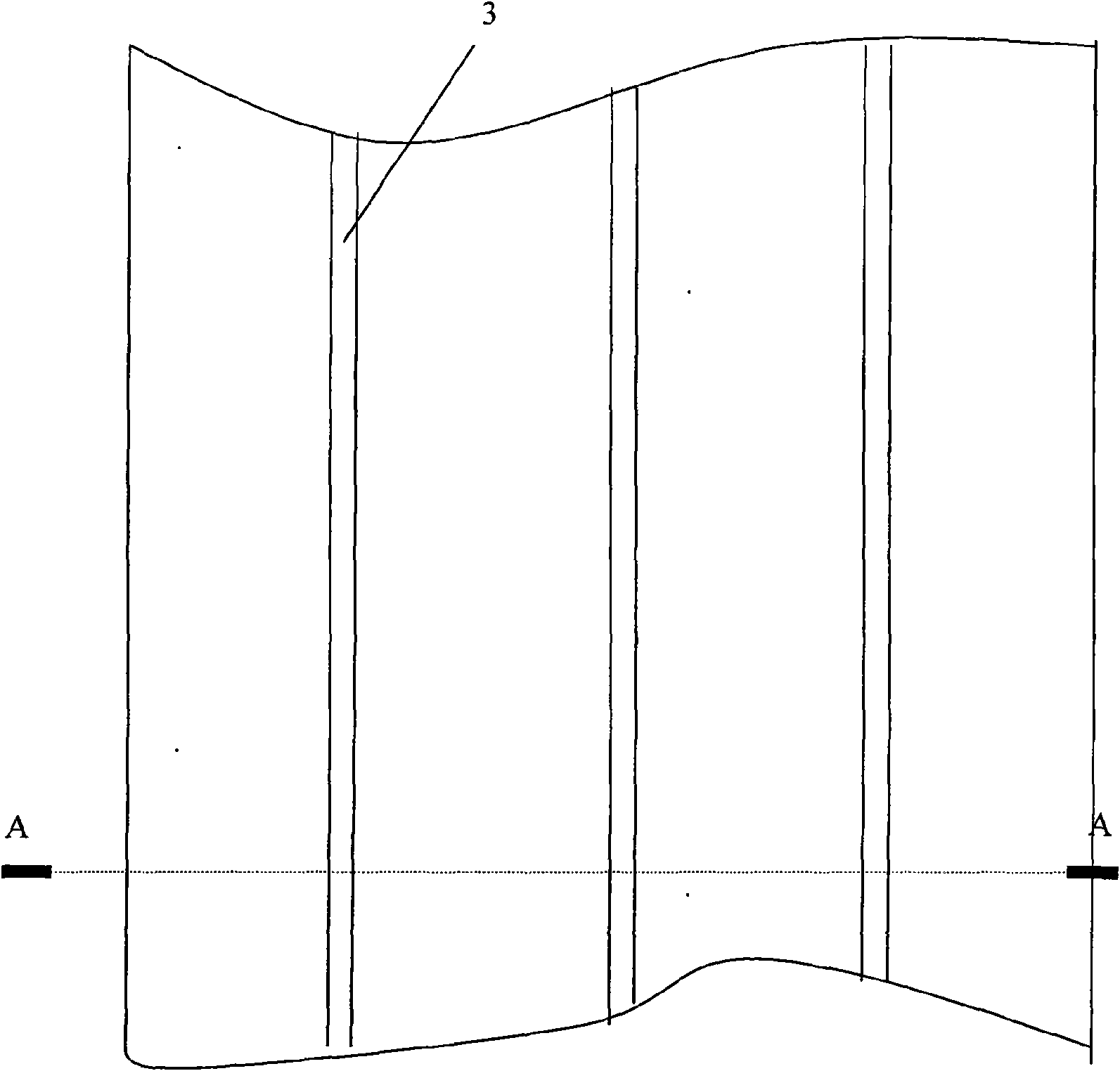

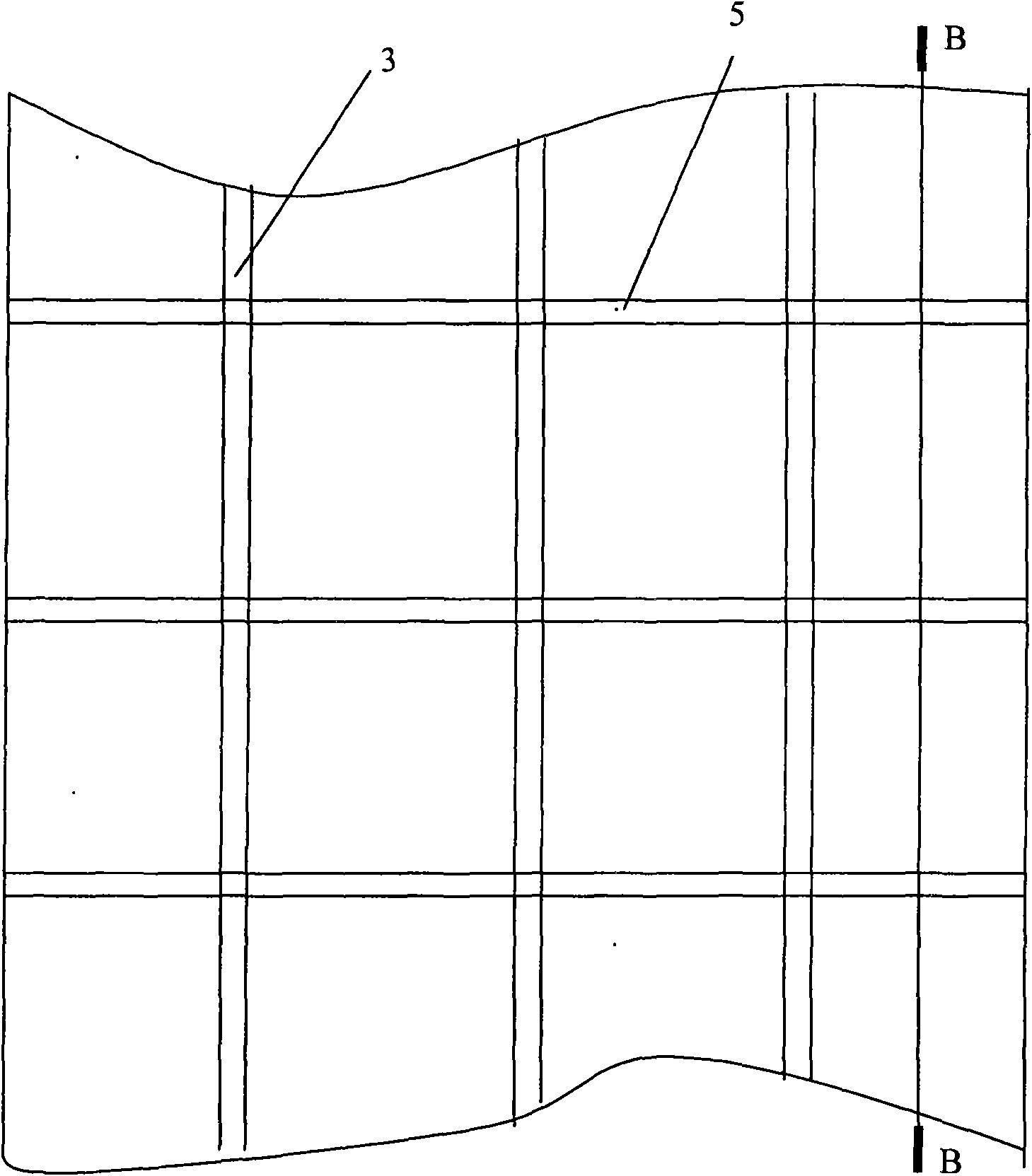

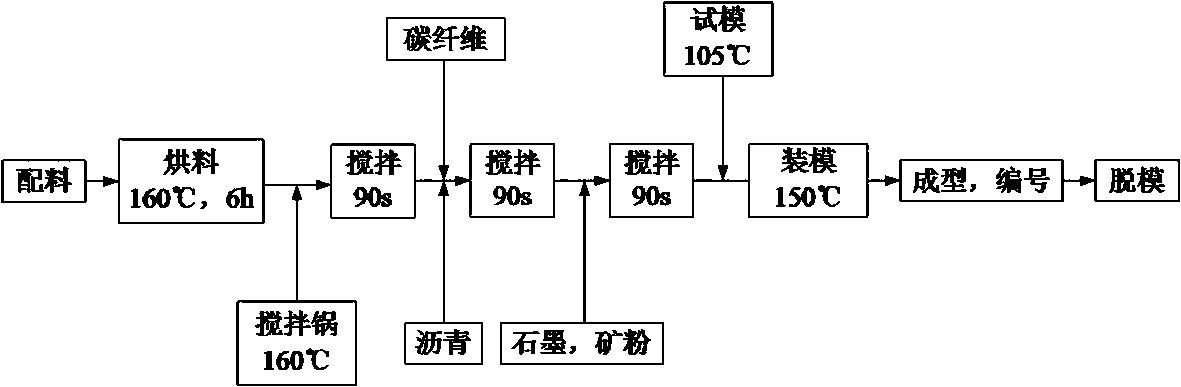

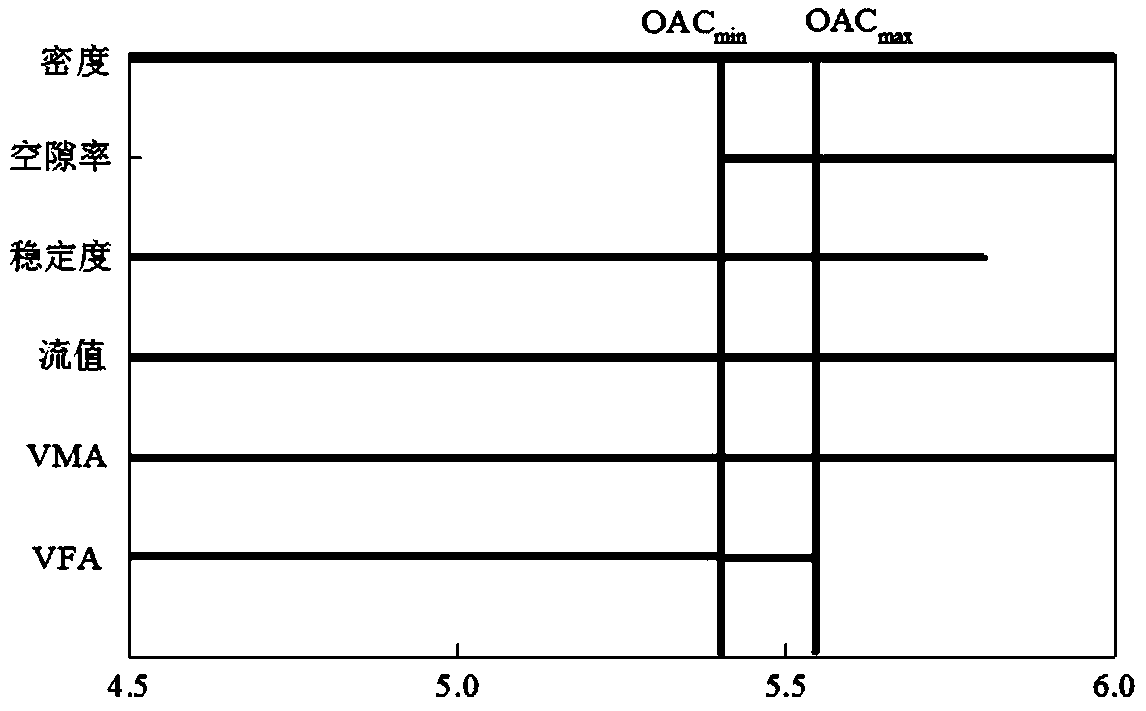

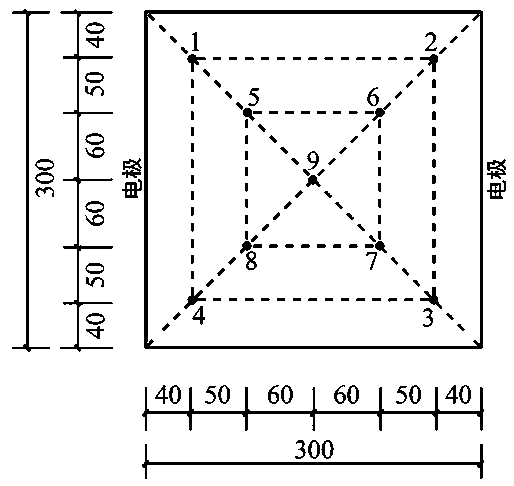

Electrothermal asphalt concrete doped with graphite and carbon fibers

The invention belongs to the technical field of bituminous pavements in road construction, and particularly relates to patent application of electrothermal asphalt concrete. The electrothermal asphaltconcrete is doped with a conductive phase material, and is electrified and heated so as to achieve the purposes of melting snow and deicing. Preparation raw materials of the electrothermal asphalt concrete consist of asphalt, aggregates, mineral powder and a conductive phase material, and the asphalt-aggregate ratio is 4.5%-6.0%; the conductive phase material consists of graphite and carbon fibers; in percentages by volume, in the electrothermal asphalt concrete, the mixing amount of the graphite is 0-30%; and in percentages by mass, the mixing amount of the carbon fibers is 0-0.3%. The graphite and the carbon fibers are compounded and blended into the asphalt concrete, and jointly act to improve the conductivity of the asphalt concrete; and by addition of composite conductive fillers, the anti-rutting performance of the electrothermal asphalt concrete is improved, the thermal cracking performance is reduced, therefore, requirements for pavement performance are met well, and the practical value is high.

Owner:HENAN UNIVERSITY

Anisodine hydrobromide drop pill and preparing method thereof

InactiveCN1528304ADisintegration and dissolution fastQuality improvementNervous disorderAntipyreticHydrobromideReduced dose

The present invention utilizes ultramicropulverization and dripping pill preparation production process to make aniosidine hydrobromide dripping pills, and can attain the goal of raising disintegration and dissolution speed, quickly obtaining therapeutic effect, raising stability of medicine, reducing dose of auxiliary material, reducing production cost and convenient administration. Said pill not noly can be sucket, but also can be swallowed, and its compliance is good.

Owner:HONGYI SCI & TECH CO LTD NANCHANG

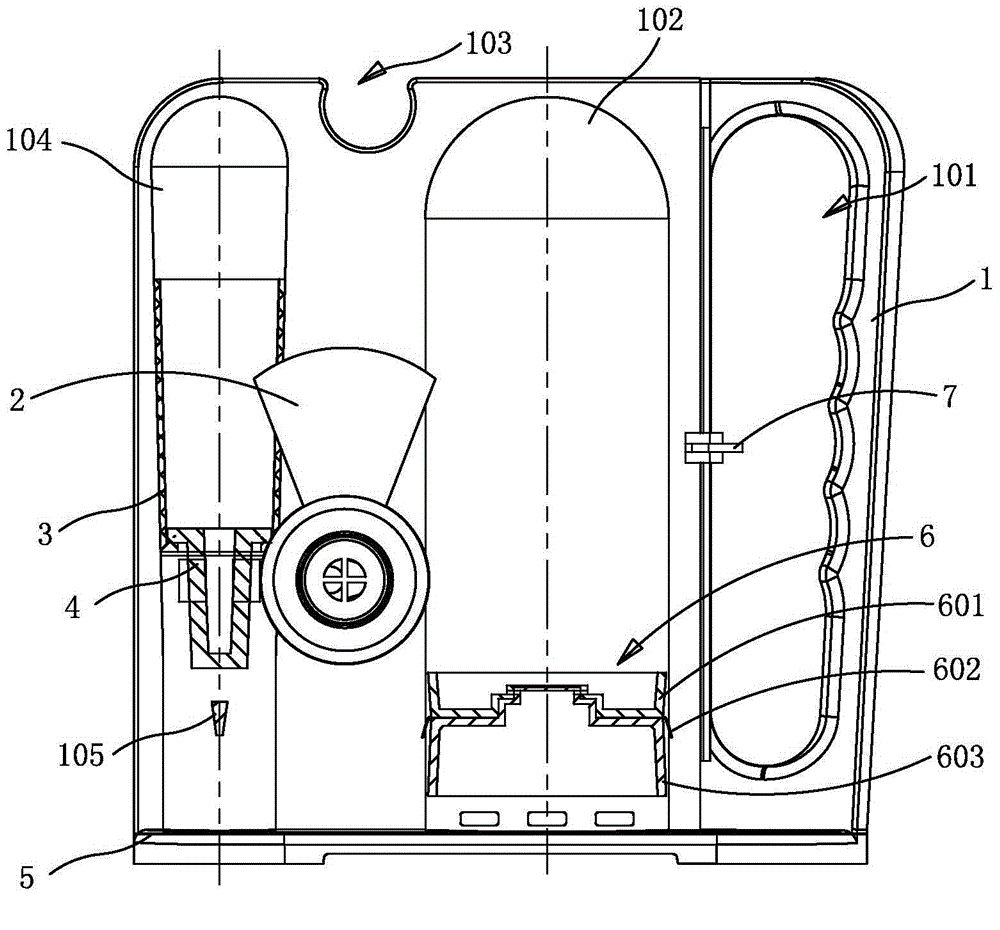

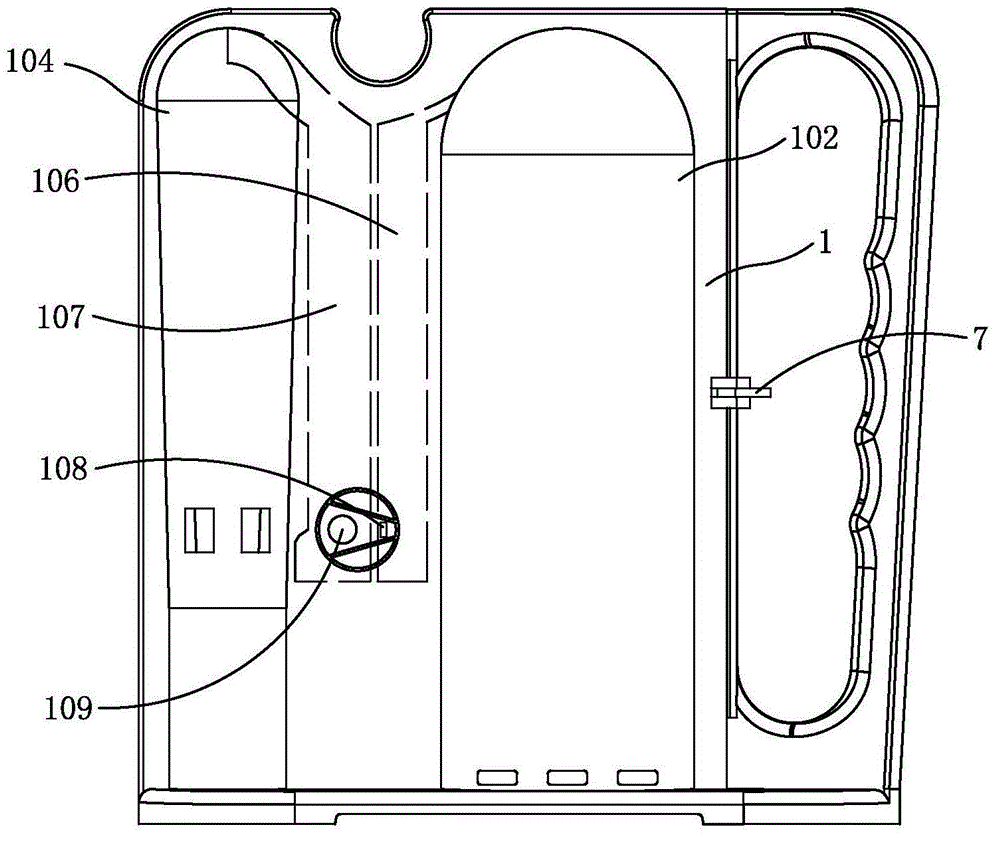

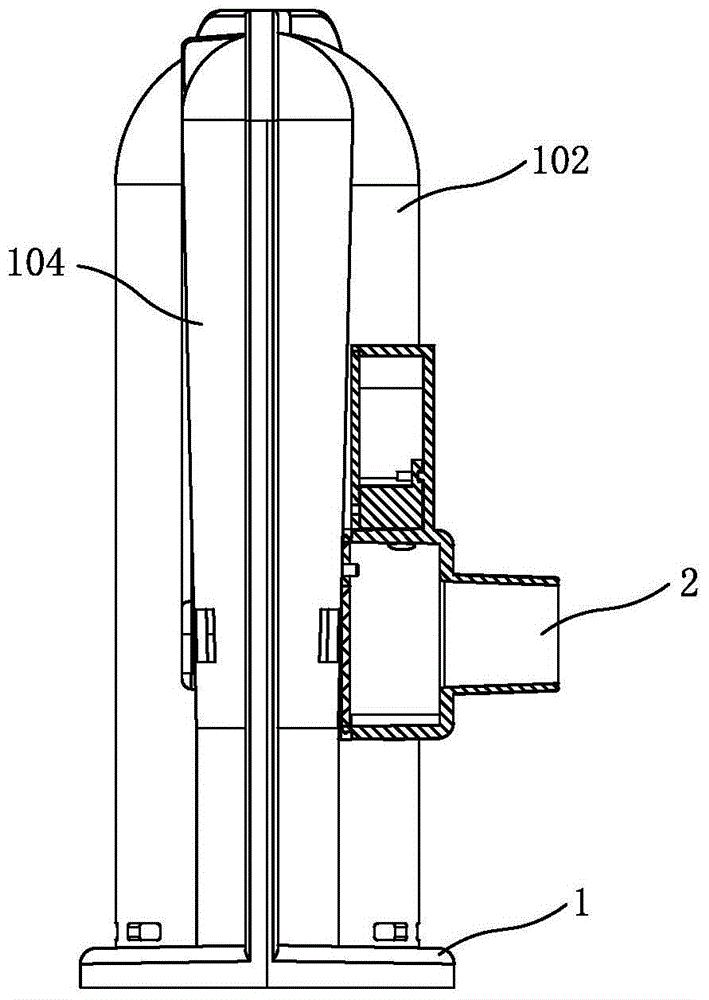

Breath training device

ActiveCN104958872AReasonable structural designEasy to useGymnastic exercisingMain channelEngineering

The invention relates to a breath training device which is designed for solving the technical problem that an existing similar product is not good enough in exhaling and inhaling structure design. The breath training device comprises a bottle body, a corrugated hose and an air nozzle; a cavity is formed in the bottle body by connecting bottle body shells on the two sides and a film at the bottom, an air hole of the bottle body is provided with an exhaling assembly, and an inhaling assembly is arranged in the bottle body. According to the technical scheme, the exhaling assembly comprises a cover shell, a pointer, a cover plate, a one-way membrane and a seat shell; the one-way membrane is arranged in the seat shell located at the air hole of the bottle body, the pointer is arranged in a fan-shaped air cavity window of the cover shell, an air inlet is formed at the communication position of the air cavity window and the cover shell, and a swaying block is arranged under a positioning hole of the pointer; a main air cavity and a side air cavity are formed in the bottle body, a main channel of the main air cavity is communicated with the main air cavity and a main air hole located in the air hole of the bottle body, and a piston valve is arranged in the main air cavity; a side channel of the side air cavity is communicated with the side air cavity and a side air hole located in the air hole of the bottle body, and a seal cone is arranged in the side air cavity. The breath training device is suitable for being used for rehabilitation training.

Owner:王伟

Ginseng stem leaf total saponin drip pill and its preparation method

InactiveCN1493298ADisintegration and dissolution fastHigh dissolution rateOrganic active ingredientsMetabolism disorderMedicineGinseng

Owner:HONGYI SCI & TECH CO LTD NANCHANG

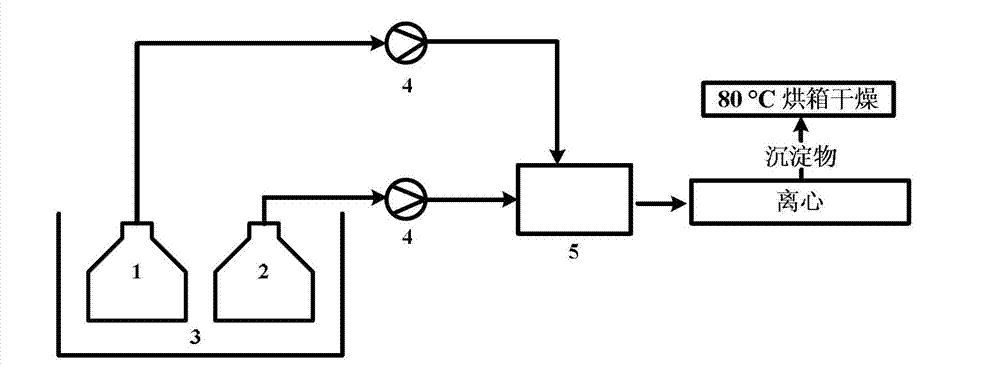

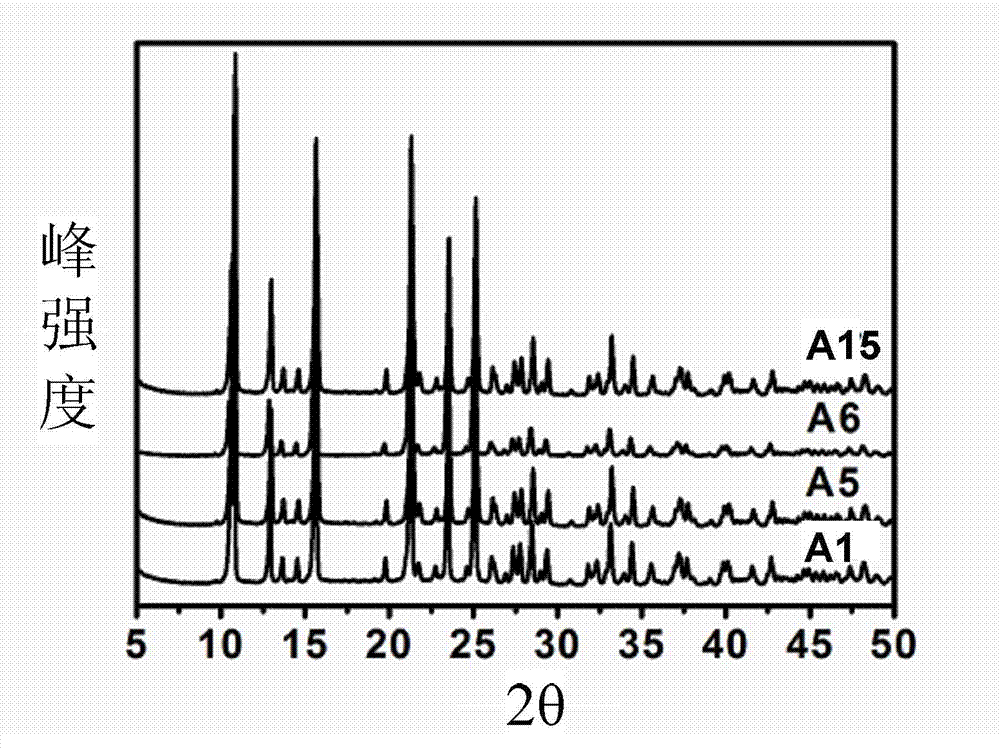

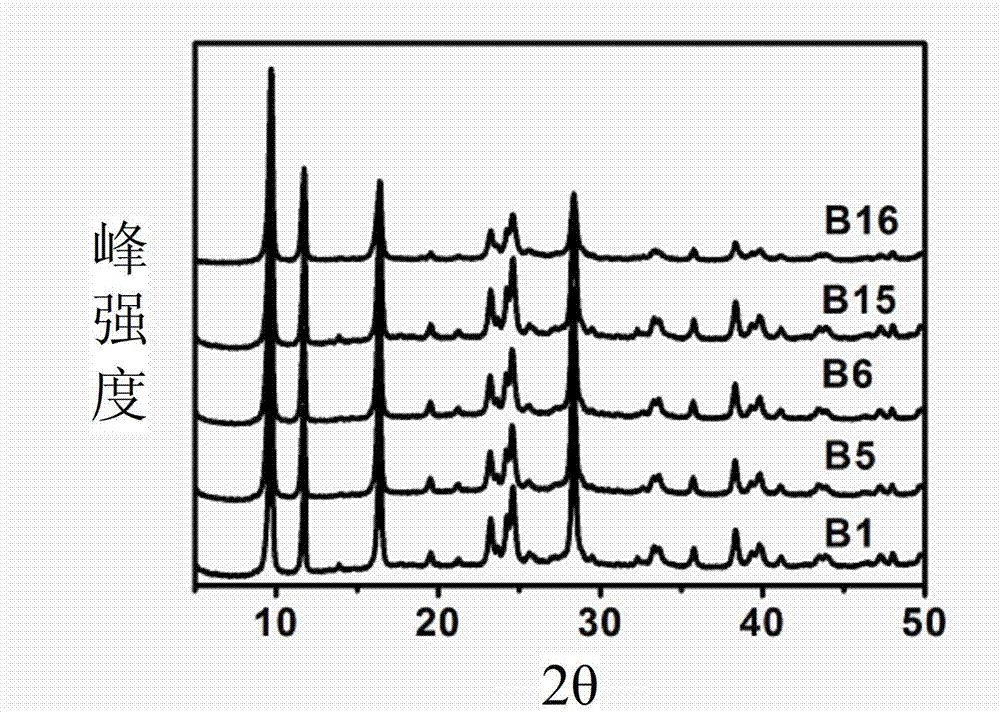

Method for continuously and controllably preparing small-size pyrithione granules

InactiveCN103242228AUniform particle sizeSmall particle sizeOrganic chemistryChemical/physical/physico-chemical processesSodium PyrithioneMicroreactor

The invention relates to a method for continuously and controllably preparing small-size pyrithione granules. According to the method, pyrithione or a water soluble salt of pyrithione and a polyvalent metal salt solution are respectively fed by respective feeding pumps into a microreactor connected with the pumps and the molar ratio of pyrithione or the water soluble salt of pyrithione to the polyvalent metal salt solution in the microreactor is (0.1-10):1; pyrithione or a water soluble salt of pyrithione and the polyvalent metal salt solution are mixed to carry out chemical precipitation reaction in a mixing channel of the micoreactor at the reaction temperature of 0-100 DEG C, so as to obtain a polyvalent metal salt mixed solution of pyrithione; the mixed solution is separated, washed and dried to finally obtain the polyvalent metal salt granules of pyrithione of which the granule size is controllable and granule size distribution is narrow. The method has the advantages of operation continuity, simple and convenient process and freely changed reaction conditions and the like.

Owner:NANJING UNIV OF TECH

Preparation method of slump retaining ether type polycarboxylic water reducing agent

The invention relates to a preparation method of a slump retaining ether type polycarboxylic water reducing agent. The method includes steps: (1) dissolving 80-100 parts of unsaturated polyether macromonomers into 60-85 parts of water, well stirring, and heating to 50-70 DEG C at a rate of 30-50 DEG C per hour to obtain a mixed solution; (2) keeping the temperature of the mixed solution at 50-70 DEG C, adding 0.5-1 part of an initiator, and well stirring to obtain a mixed solution; (3) keeping the temperature of the mixed solution at 50-70 DEG C while dropwise adding 15-30 parts of unsaturated carboxylic acid and unsaturated carboxylic acid derivative micromonomer solution and 20-30 parts of molecular weight regulator solution, keeping the temperature at 50-70 DEG C for 1-2h after adding is finished, and ageing to obtain a mixed solution; (4) adding 50-80 parts of water into the mixed solution, and dropwise adding sodium hydroxide solution to adjust a pH value to 6-7 to obtain the slump retaining ether type polycarboxylic water reducing agent.

Owner:厦门君科建材科技有限公司

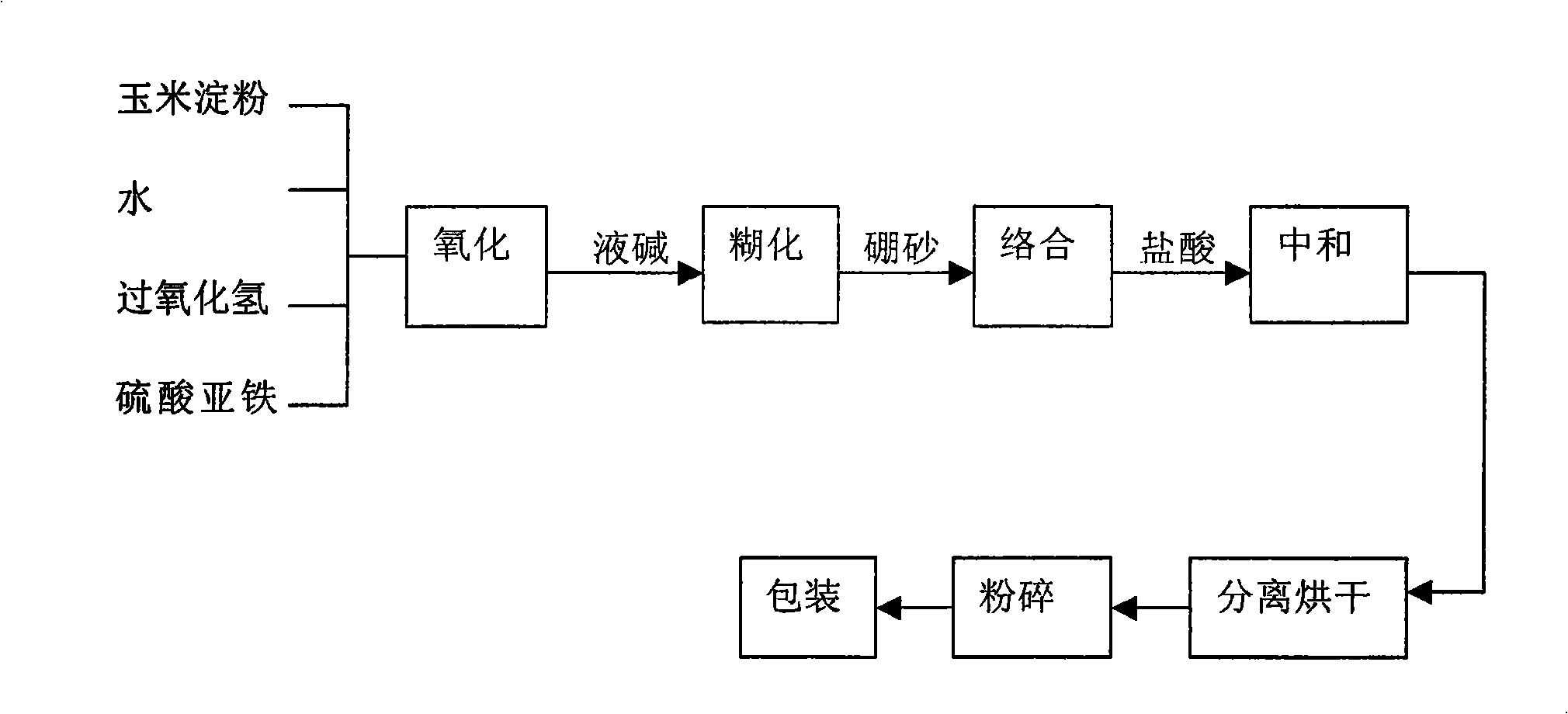

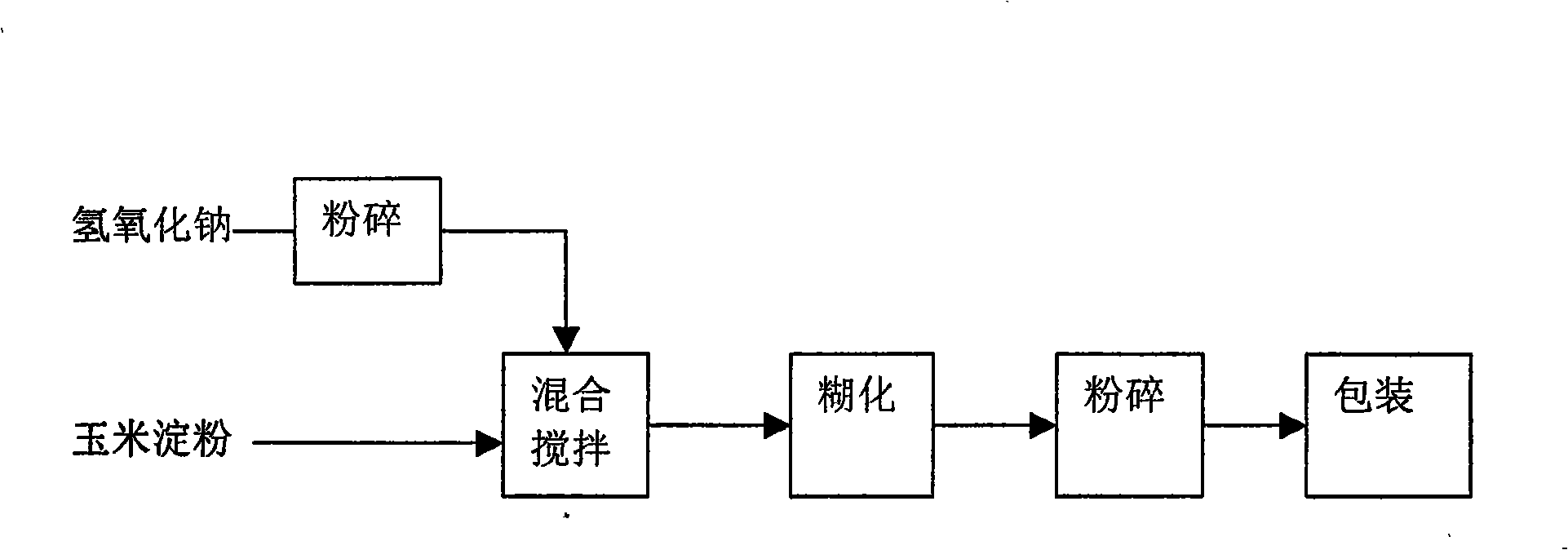

Adhesive for architectural materials and method for preparing same

The invention provides an adhesive used by building materials, the adhesive is powder manufactured by adopting corn starch and solid sodium hydroxide as raw materials, and the mixture ratio of the corn starch to sodium hydroxide is (5-15):1. The preparation method of the adhesive comprises the steps as follows: the solid sodium hydroxide is crushed, and mixed with the corn starch while stirring, so as to become loose granules which are then cooled and crushed to form the finished product. The adhesive has the advantages of simple manufacturing process, lower cost, high viscosity and no pollution.

Owner:BEIJING GREEN CHINA TECHNOLOGIC DEV

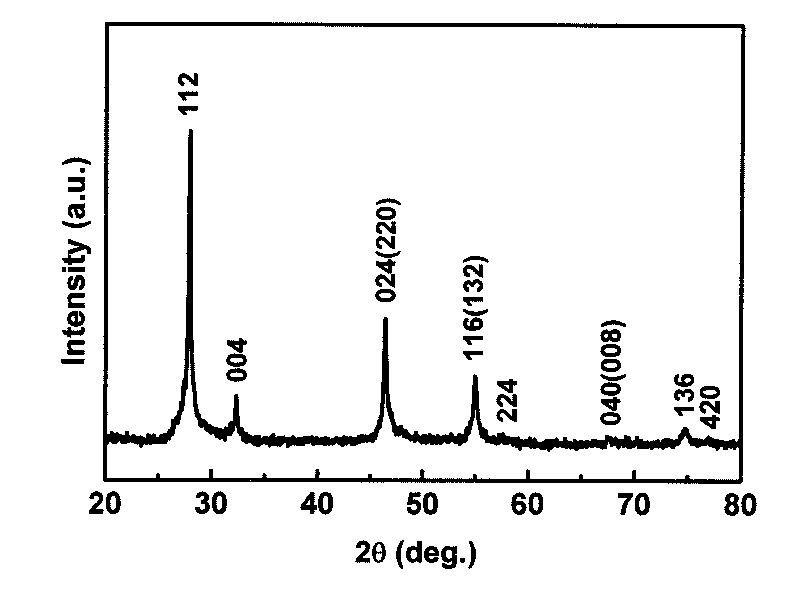

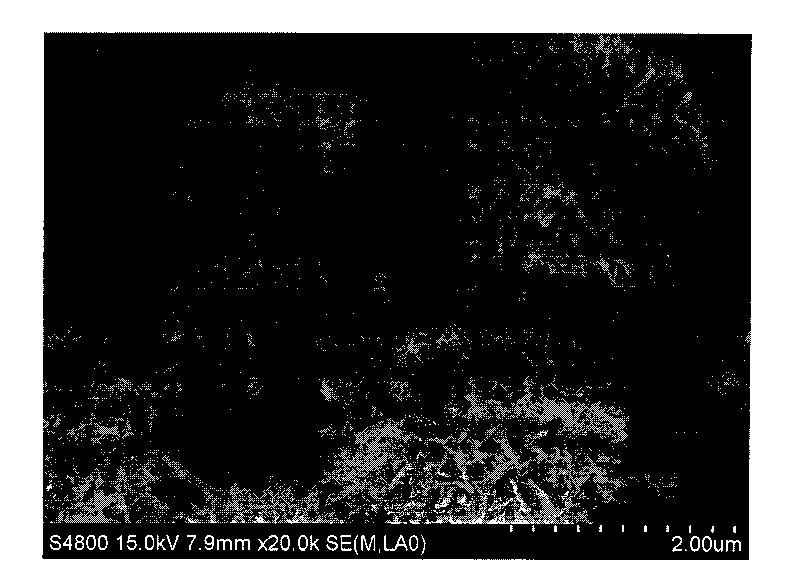

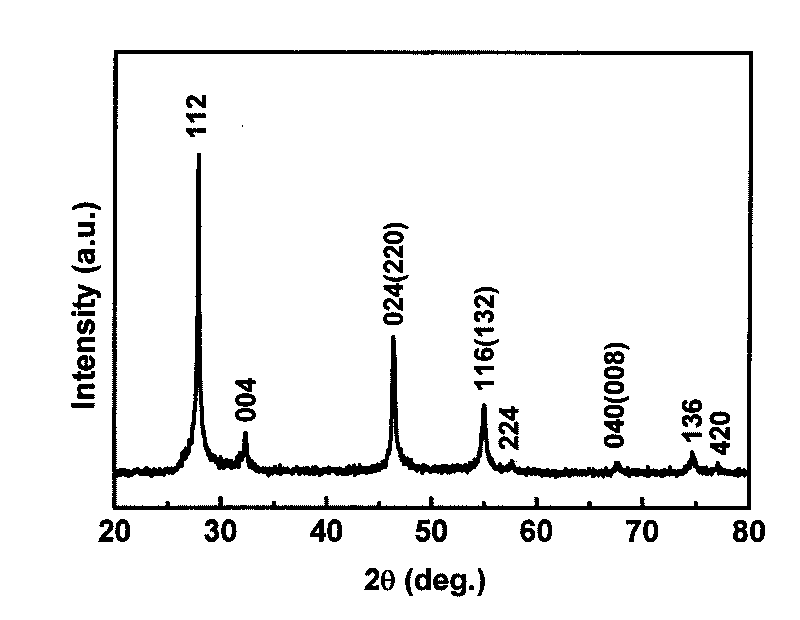

Method for preparing high-quality copper indium sulfide by employing single-source molecular precursor

InactiveCN101734712ASave raw materialsRaw materials are easy to getGallium/indium/thallium compoundsSolubilityGas phase

The invention relates to a method for preparing high-quality copper indium sulfide by employing a single-source molecular precursor. The method comprises the following steps: mixing copper chloride and indium chloride powder to prepare a solution, and preparing sodium diethyl dithiocarbamate powder into a solution; adding the former solution to the latter solution slowly in the way of stirring, filtering and drying precipitate, putting the obtained product into an autoclave and adding ethanol used as a solvent; sealing the autoclave and then placing the autoclave in an electric dry oven, heating and cooling naturally, washing with deionized water and absolute ethyl alcohol, and finally drying to obtain black copper indium sulfide powder. The invention solves the defaults of a gas phase method and a liquid phase method of expensive equipment, complex process operation, low yield, and the uniformity of the inner and outer composition of the product and the generation of a core-shell structure which are caused by the relatively larger solubility difference of the multi-source precursor in solvent. The invention has the advantages of cheap and easily obtained raw materials, no toxic H2S gas or vacuum environment, and simple process, and can obtain pure tetragonal phase copper indium sulfide with sea urchin-like morphology and high degree of crystallinity.

Owner:YANGZHOU UNIV

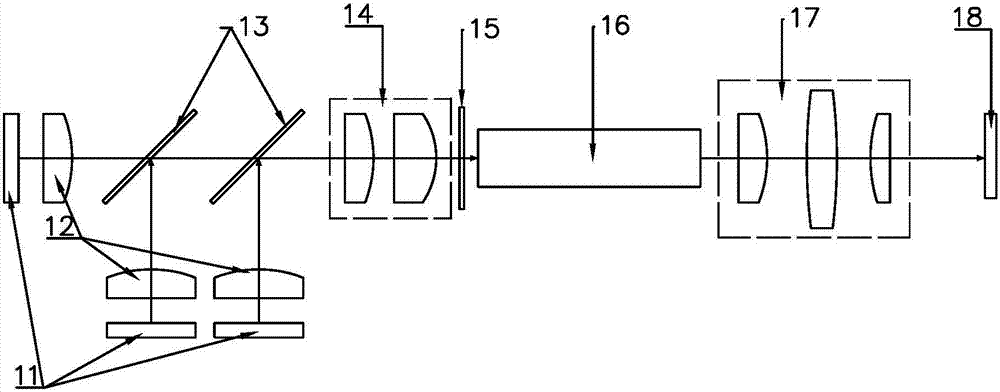

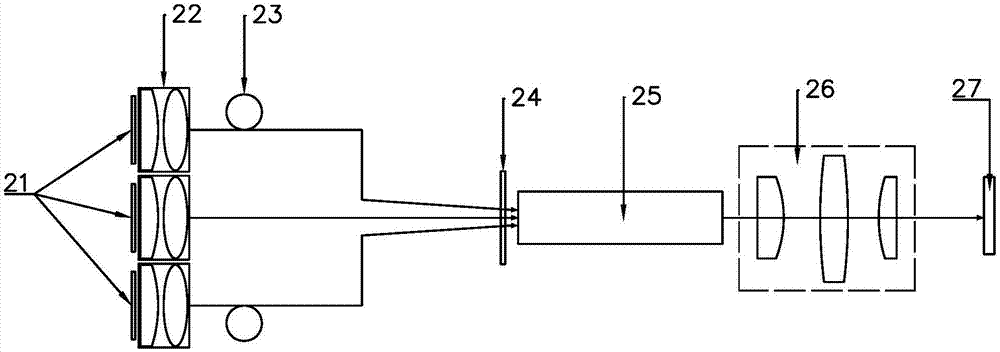

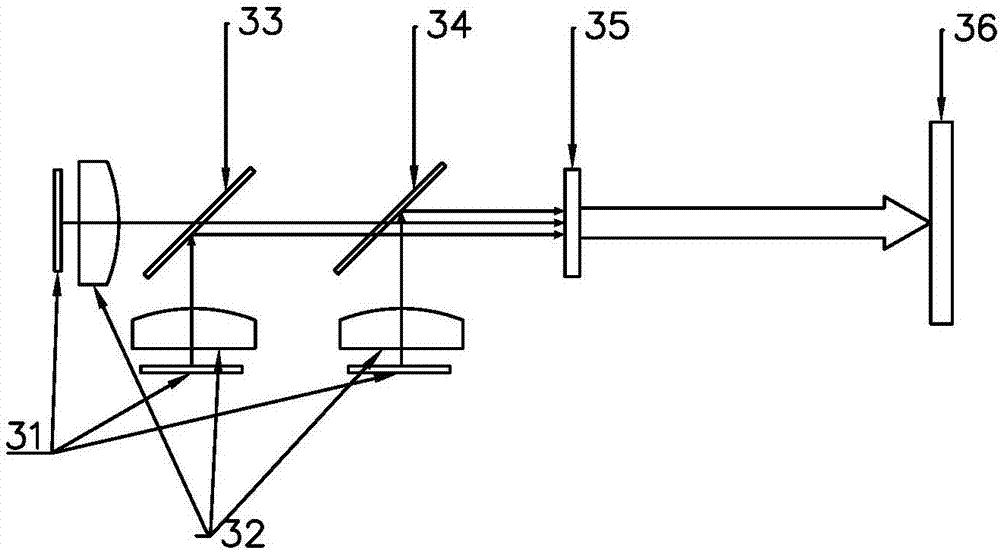

Novel laser projection illuminating system

The invention discloses a novel laser projection illuminating system, which comprises a laser light source, a collimation and compression system, a dichroic mirror, a binary optical element and a DMD chip, wherein the laser light source emits laser to be compressed by means of the collimation and compression system, the laser maintains parallel light emission and illuminates onto the dichroic mirror for beam splitting, and the laser is incident onto the binary optical element and reaches the DMD chip through the binary optical element; and the binary optical element is used for shaping the incident laser according to a proportion of an adopted display chip, and / or performing speckle-elimination processing on the incident laser. The novel laser projection illuminating system is simple and compact in structure, increases the optical efficiency by more than one time when compared with an illuminating system used at present, is simple in assembly and production, effectively improves the installation reliability and the production efficiency, is high in utilization rate, is suitable for scale production, and is worth popularizing in the industry.

Owner:成都九天光学技术有限公司

Rosa multiflora flower tea and production method thereof

Rosa multiflora flower tea is prepared from wild rosa multiflora serving as raw materials, the wild rosa multiflora grows in the mountain area of north China, and processes of picking, impurity eliminating, baking, drying and the like are carried out. Taking the wild rosa multiflora as the raw materials, the rosa multiflora flower tea has no pollution and belongs to a natural organic food. The rosa multiflora flower tea prepared by the method of the invention has a rose-like shape, pure and long aroma, and mellow mouthfeel and taste. With a simple production technology and a low-temperature and short preparation process, the rosa multiflora flower tea remains many kinds of nutrient components which are easy to oxidize and have health care functions in the raw materials. The raw materials of the rosa multiflora flower tea is widely distributed in north China, easy to pick and low in cost, besides, the picking of flowers does not affect the normal growth and development of plants. The rosa multiflora flower tea has simple production equipment and operation, and is easy to popularize and beneficial to the economy and society.

Owner:左权县馨源丰商贸有限公司

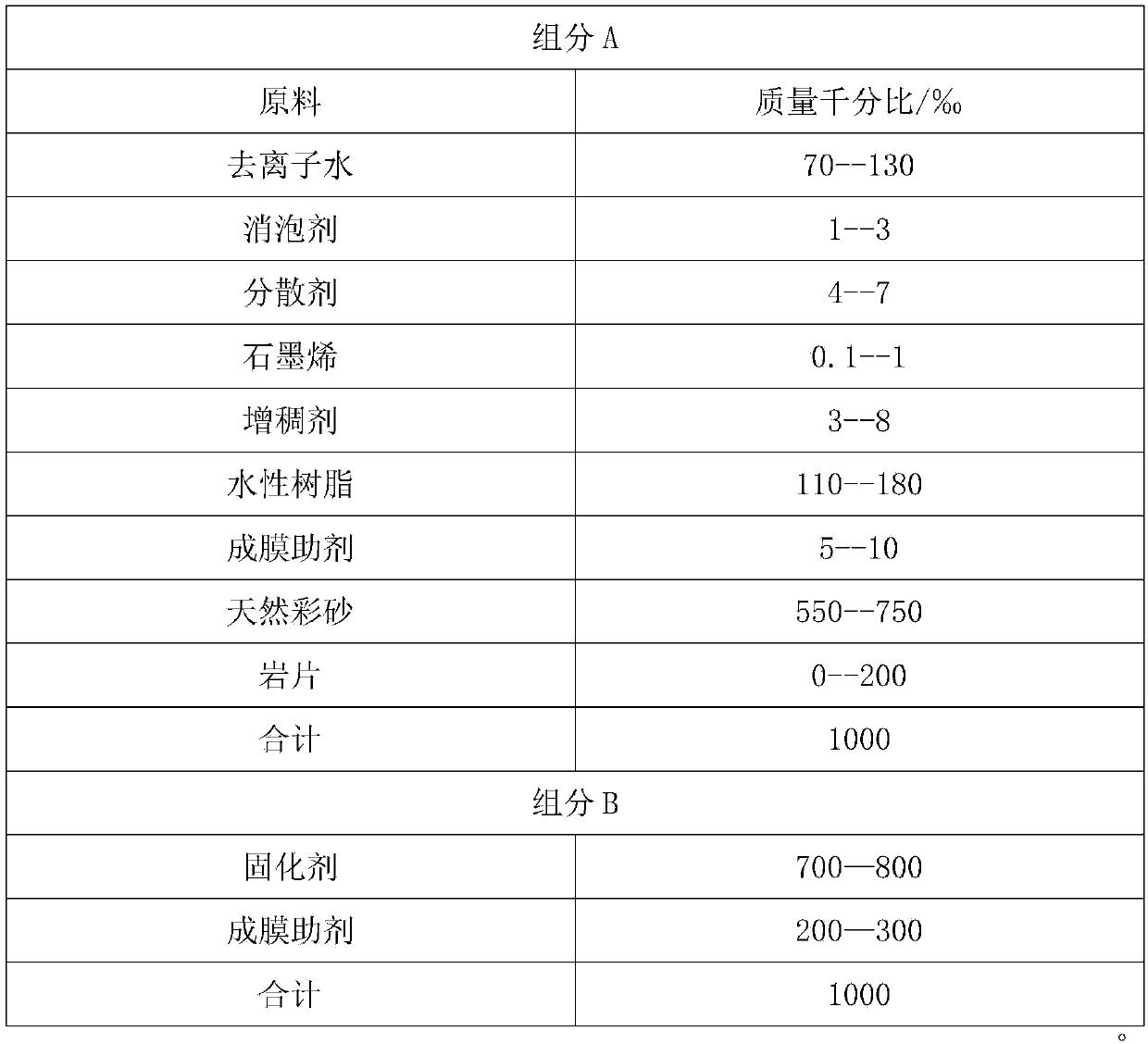

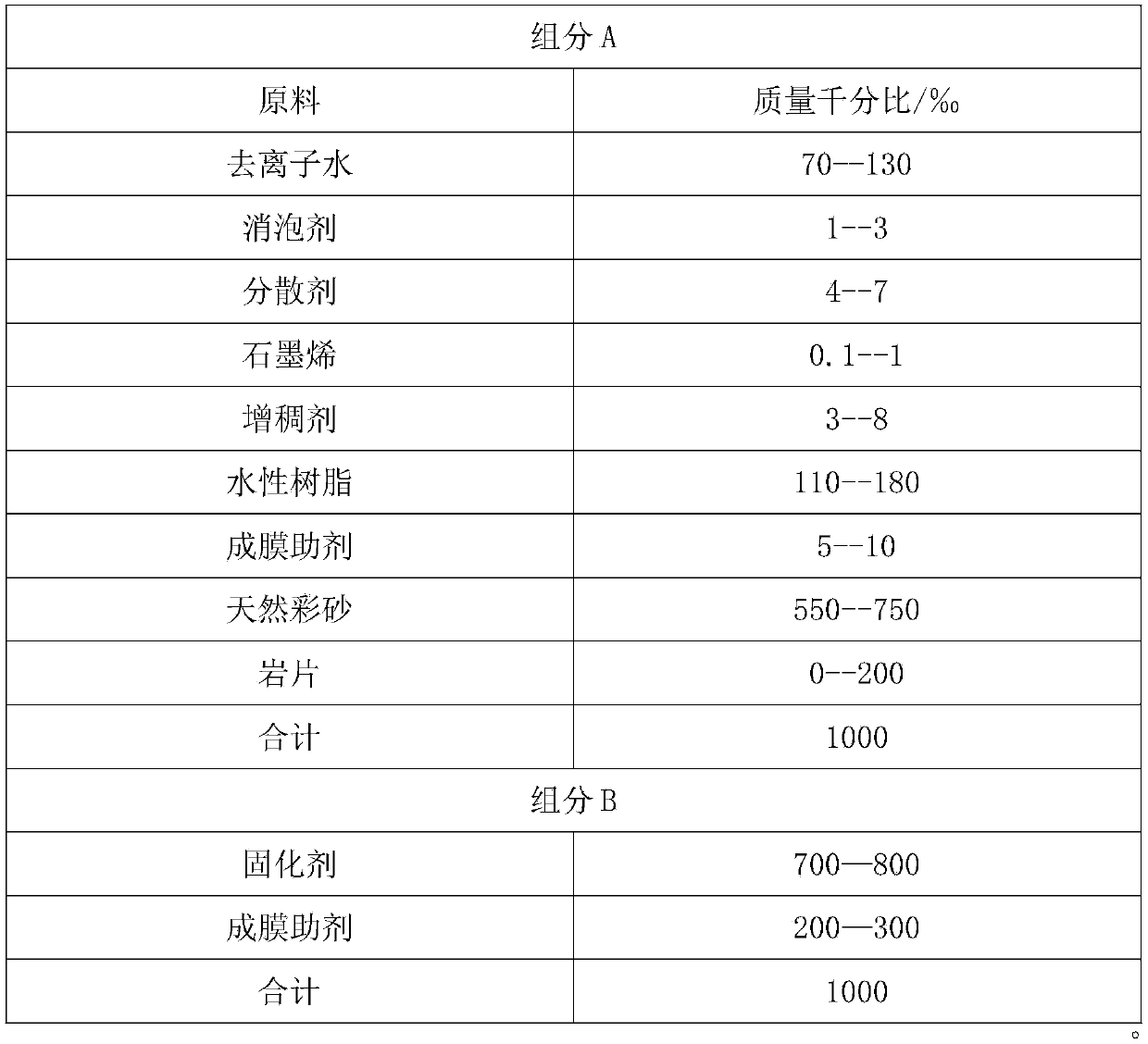

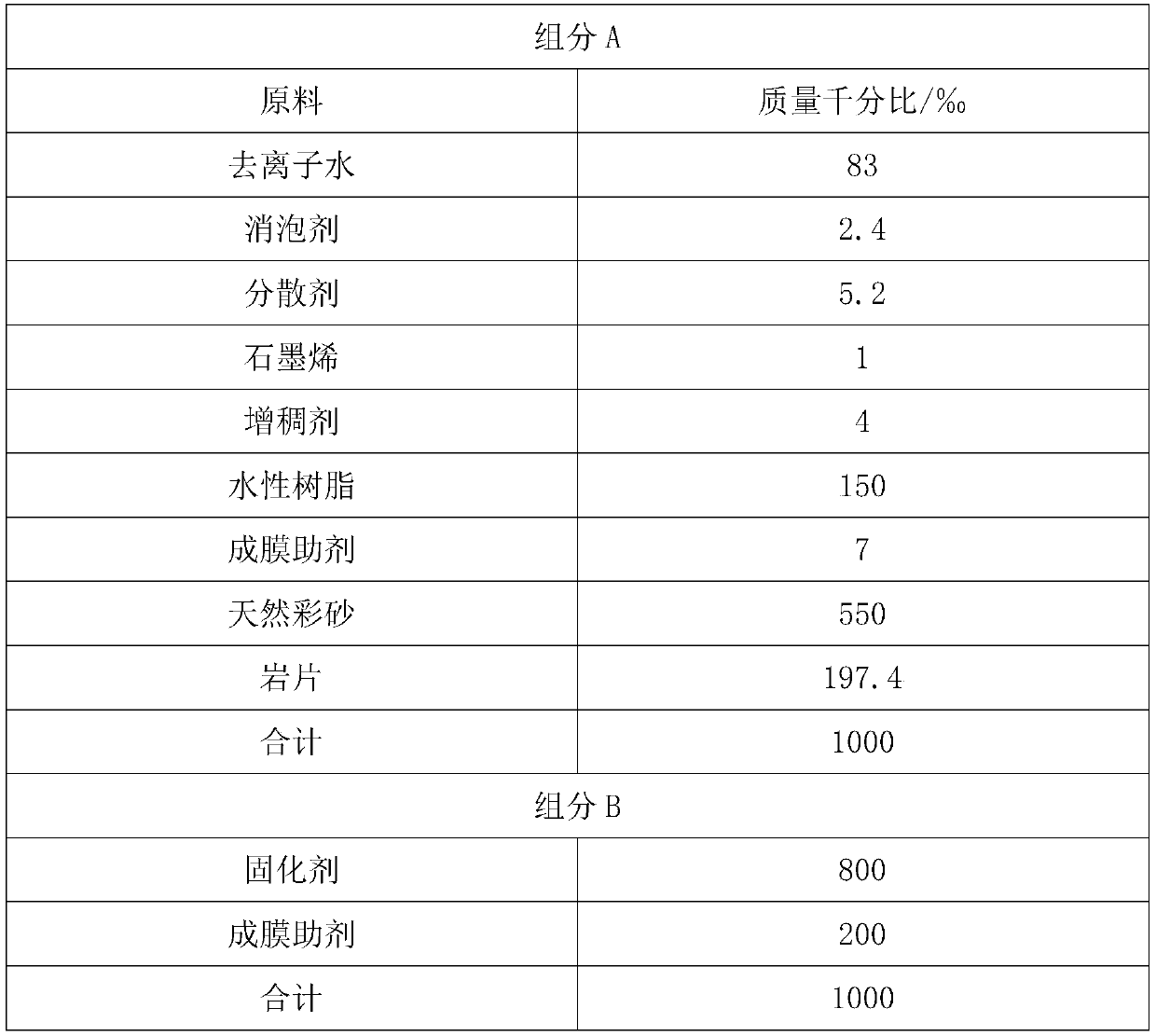

Graphene high-performance stone-like paint and preparation method thereof

The invention discloses graphene high-performance stone-like paint and a preparation method thereof. The graphene high-performance stone-like paint comprises a component A and a component B, wherein the component A comprises the following raw materials according to a mass permillage: 70-130%o of deionized water, 1-3%o of a defoamer, 4-7%o of a dispersant, 0.1-1%o of graphene, 3-8%o of a thickener,110-180%o of water-based resin, 5-10%o of a coalescing agent, 550-750%o of natural color sand and 0-200%o of a rock sheet; and the component B comprises the following raw materials according to the mass permillage: 700-800%o of a curing agent and 200-300%o of the coalescing agent. The preparation method comprises the following steps: (1) adding the deionized water to a dispersion tank, successively adding the defoamer, the dispersant, the graphene, the water-based resin, the coalescing agent and the thickener, after uniformly stirring, adding the color sand and / or the rock sheet; and (2) adding the curing agent and the coalescing agent to the dispersion tank, uniformly stirring to obtain the graphene high-performance stone-like paint. The graphene high-performance stone-like paint has theadvantages of excellent stain resistance, adhesive force, cracking resistance, water resistance, alkali resistance and temperature variation resistance and the like.

Owner:NINGBO MORSH TECH

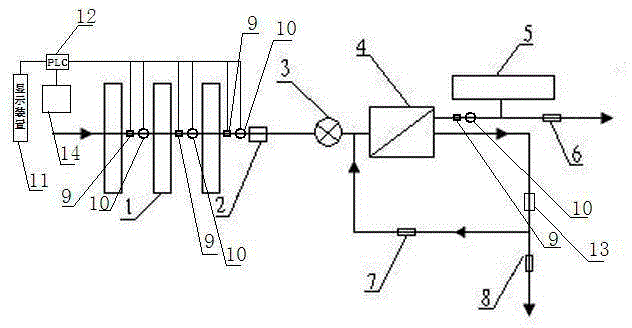

Object continuous sterilization osmosis water purifier with monitoring

The present invention relates to an object continuous sterilization osmosis water purifier with monitoring. According to the present invention, the water outlet ends of every grade of filtration cores of a filtration unit are respectively provided with a water flow rate monitoring device, the water outlet end of a RO reverse osmosis membrane treatment unit is provided with a TDS detection device, a wastewater pipe is further provided with a wastewater proportioner, a water flow rate sensor and the TDS detection device are connected to a PLC, the PLC is connected to a display device and a network transmission device, the PLC transmits a processed signal to the display device so as to be displayed, the network transmission device transmits the processed signal to a terminal device, and a water storage barrel, water pipes and the like are made from a sterilization material; and the beneficial effects of timely filtration assembly monitoring, RO reverse osmosis membrane service life improving, energy consumption reducing and wastewater output reducing are achieved.

Owner:TAOEE QINGDAO WATER PURIFICATION EQUIP MFG

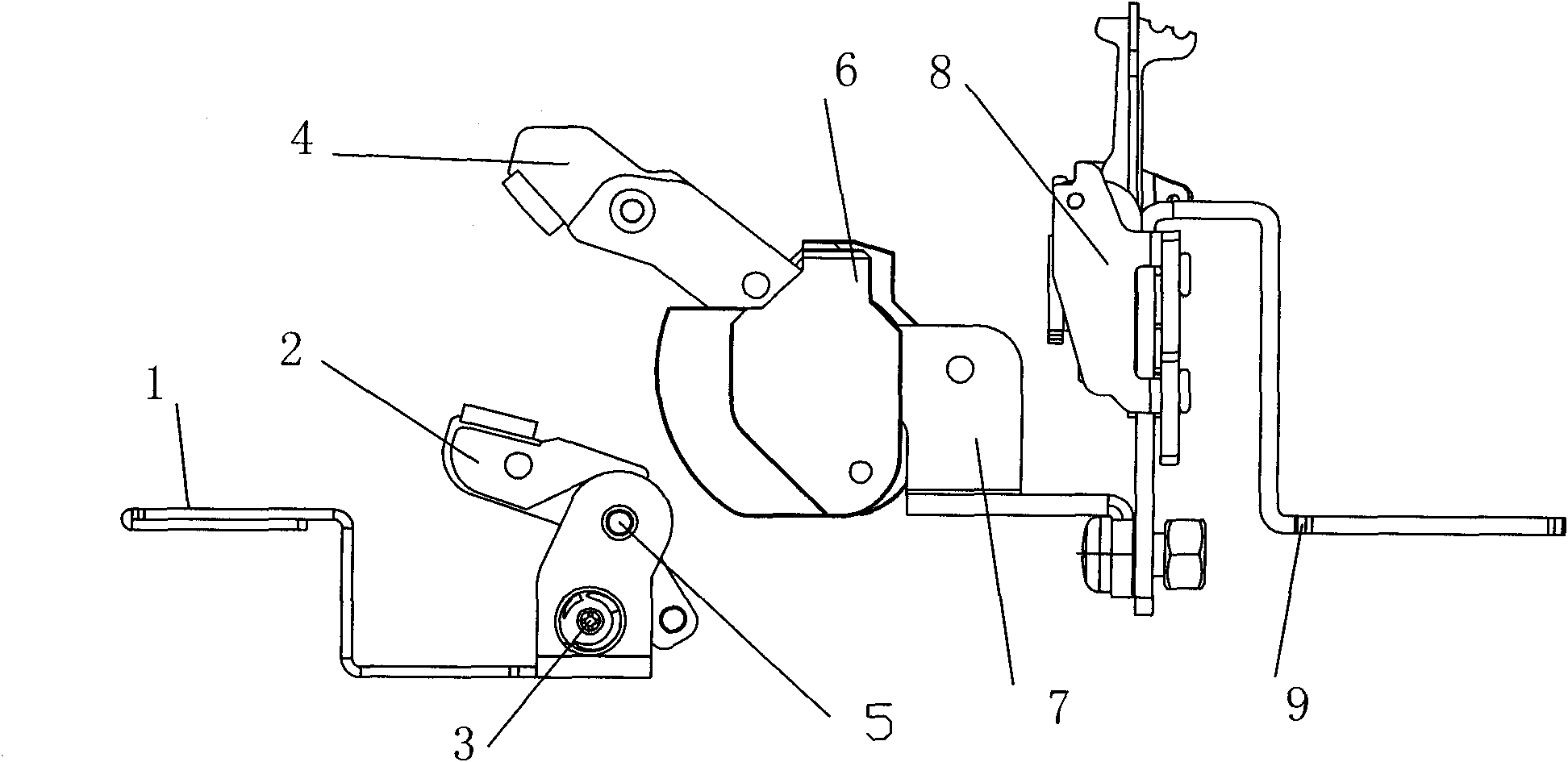

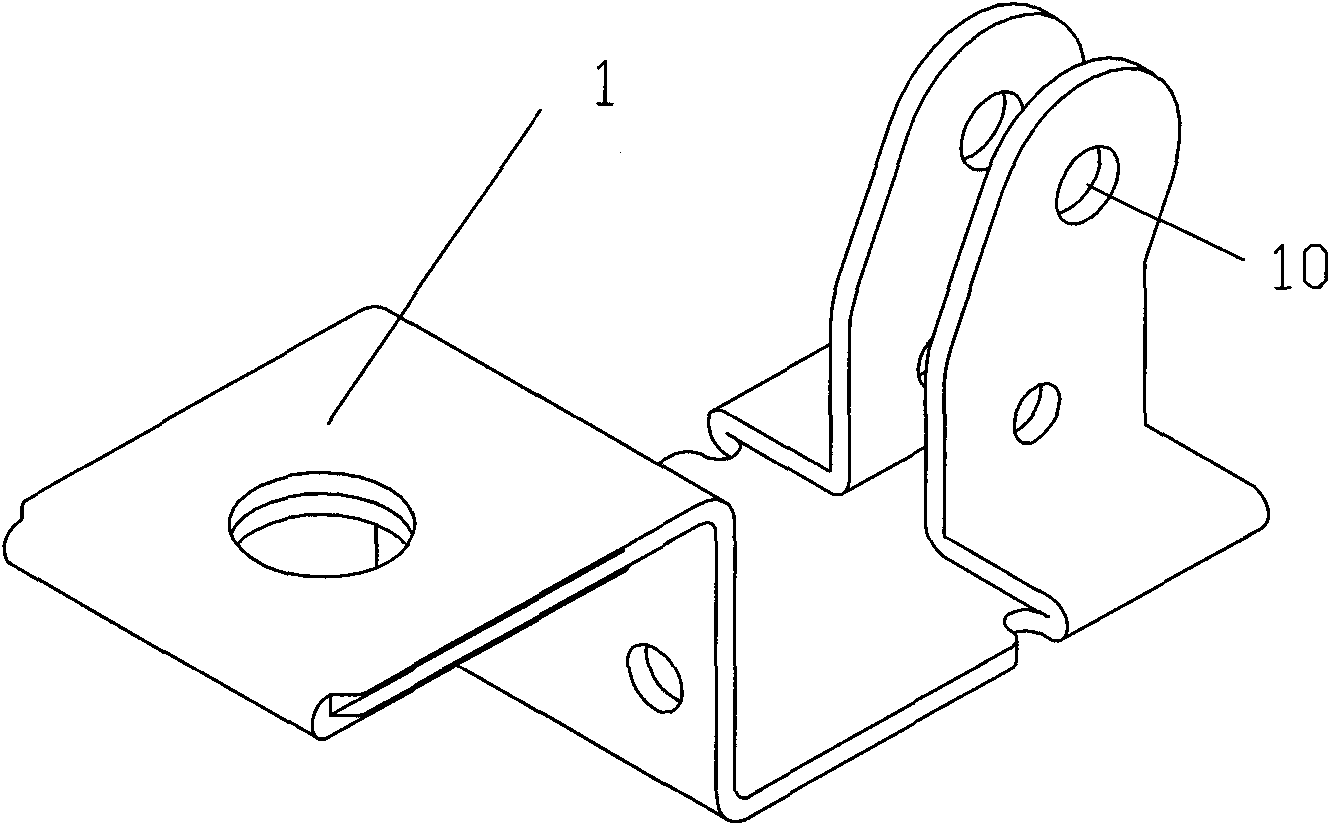

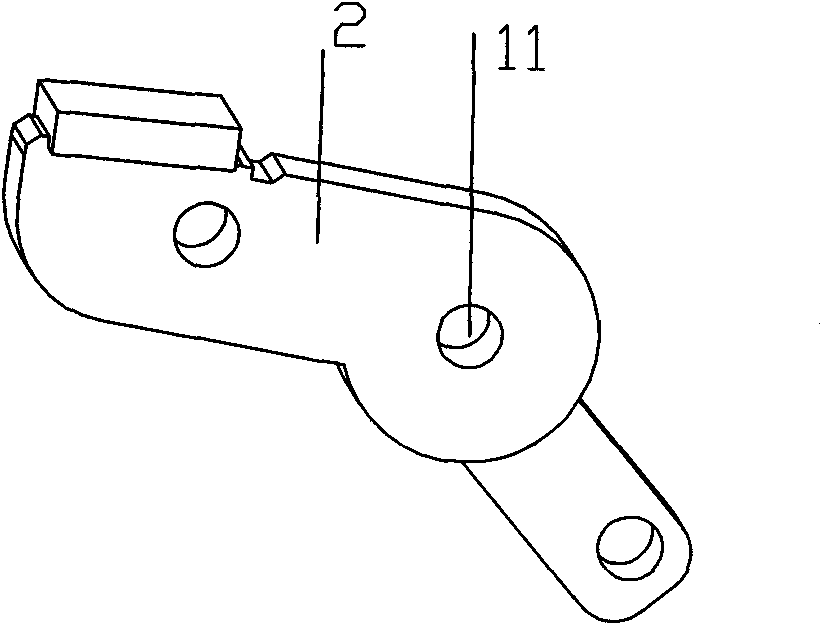

Conducting loop structure of low-voltage circuit breaker

ActiveCN101819908AReduce switching costsReduce temperature riseProtective switch terminals/connectionsProtective switch operating/release mechanismsLow voltage circuitsBusbar

The invention discloses a conducting loop structure of a low-voltage circuit breaker. A static contact is connected with a static contact clamping device which comprises three connecting parts: the left part is of a square structure which has a hole and is connected with a busbar; the right part is of a dual-plate clamping structure which is supported to the middle part, and the static contact is arranged between the dual-plate clamping structure in a revolving mode; the middle part of the static contact clamping device is lower than the left part and the right part; a dynamic contact is connected with a dynamic contact clamping device which comprises a left part and a right part, wherein the left part is of a round head dual-plate clamping structure, and the dynamic contact is arranged between the round head dual-plate clamping structure in a revolving mode; and a square structure of the right part is connected with a heating element which forms an integral structure with an outlet terminal of a tripping system. The whole conducting loop does not have soft connection and welding spots, the cost for switching on or off is lowered effectively, the temperature rise is lowered, the dynamic and thermal stability is enhanced, and the electric life and the mechanical life are prolonged.

Owner:EATON HUINENG LOW-VOLTAGE ELECTRICAL (JIANGSU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com