Martensite series wear-resistant steel and preparation method thereof

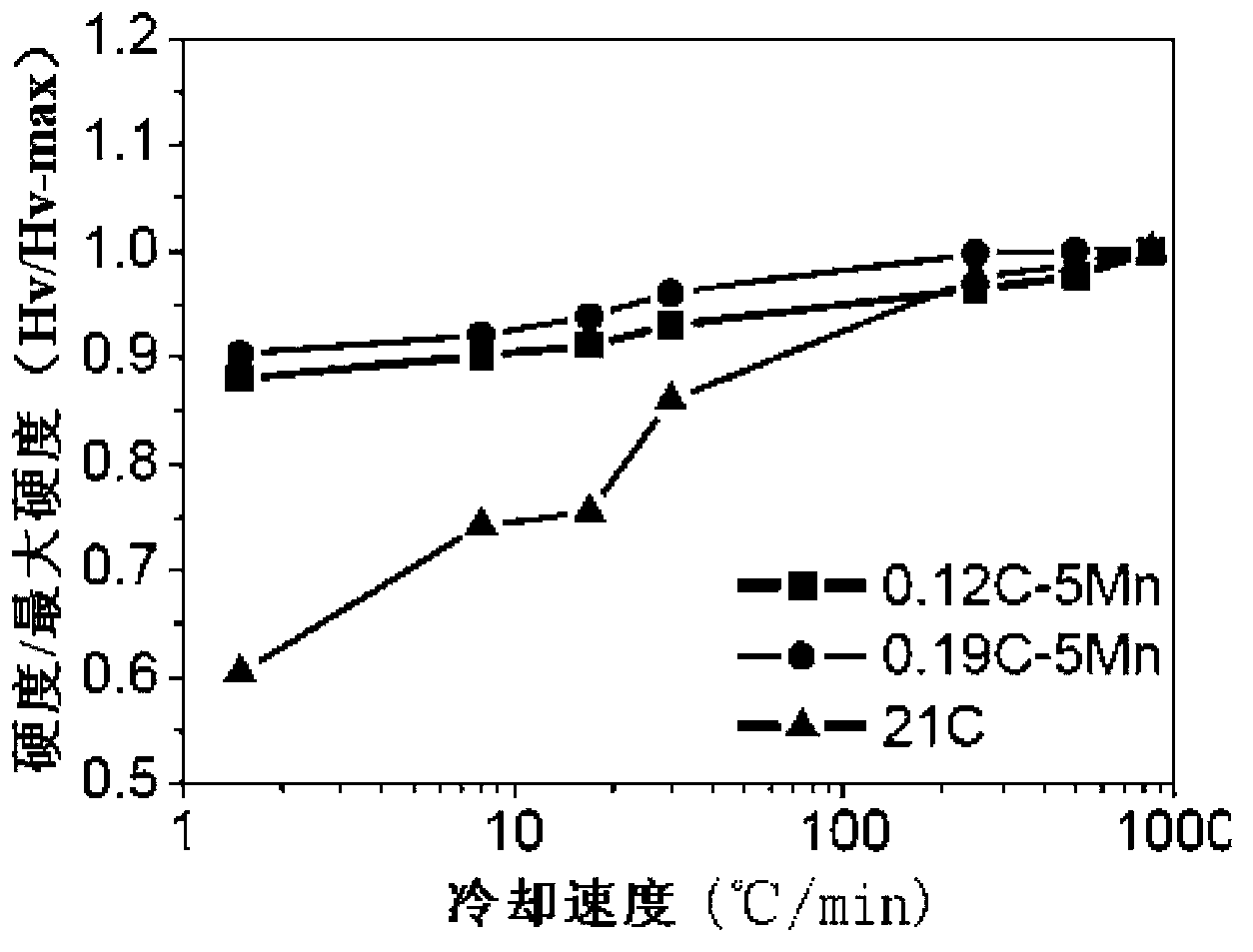

A martensitic and wear-resistant steel technology, applied in the field of wear-resistant steel, can solve the problems of uneven quenching structure, low hardenability and hardenability, etc., achieve uniformity of excellent structure and performance, and improve hardenability. and hardenability, the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

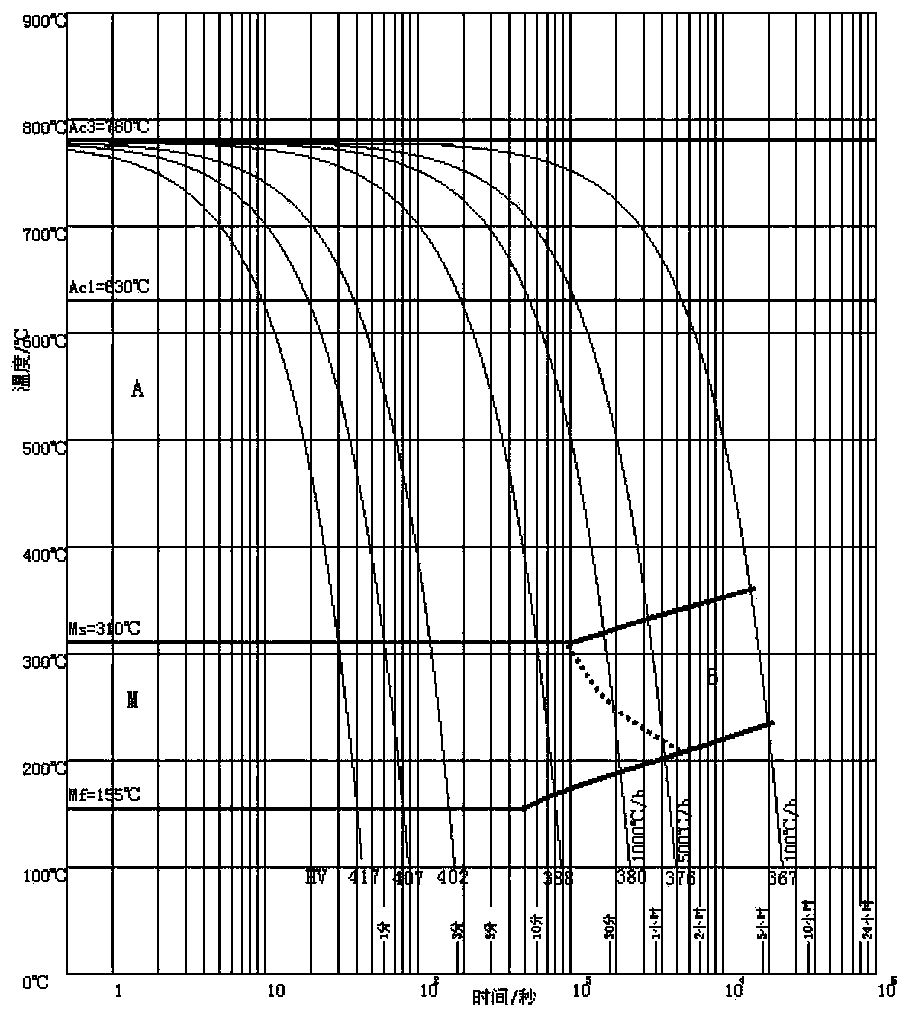

[0050] 1. Hot continuous rolling plate: the steel of the present invention is obtained by vacuum induction smelting in a laboratory to obtain 150 kg of ingot air-cooled, and a total of 20 furnaces of steel with different components. After high-temperature forging, the final 60mmx100mmx300mm square billet is heated again to 1200°C, rolled by the rough rolling mill for 7 passes, hot-rolled to a thickness of 25mm, and the initial rolling temperature is 1150 O C (there is a cooling from heating to rough rolling). Afterwards, 7 passes of finish rolling are carried out by the heat-connecting unit to a thickness of 12mm, and the final rolling temperature is 850 O C, air cooling after final rolling. Carry out the mensuration of mechanical property, toughness and wear resistance (sliding wear and impact wear) of steel of the present invention afterward.

[0051] Table 1 shows the chemical composition of part of the martensitic test steel that simulates hot continuous rolling; Table 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com