Patents

Literature

14240results about How to "Guaranteed Strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

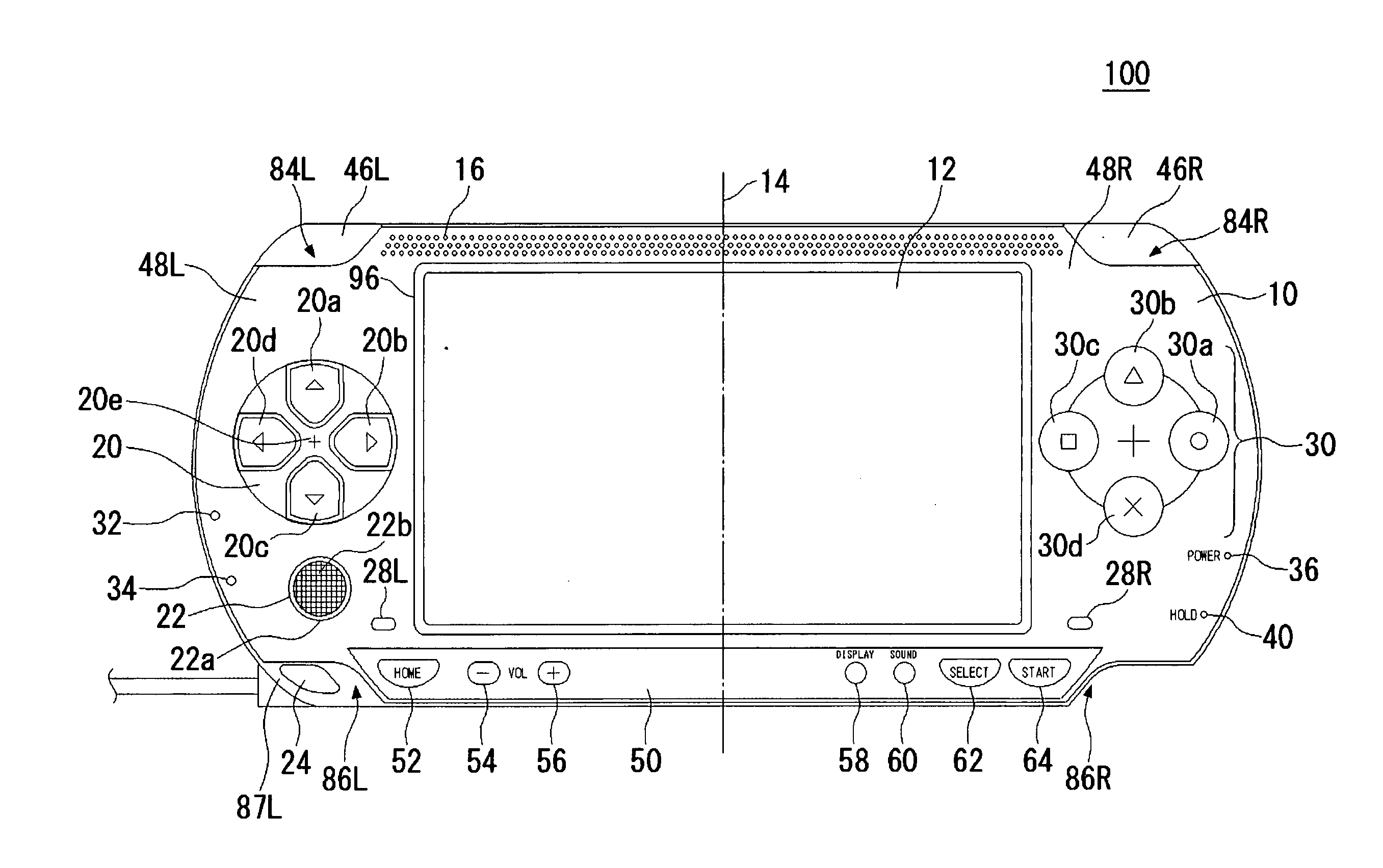

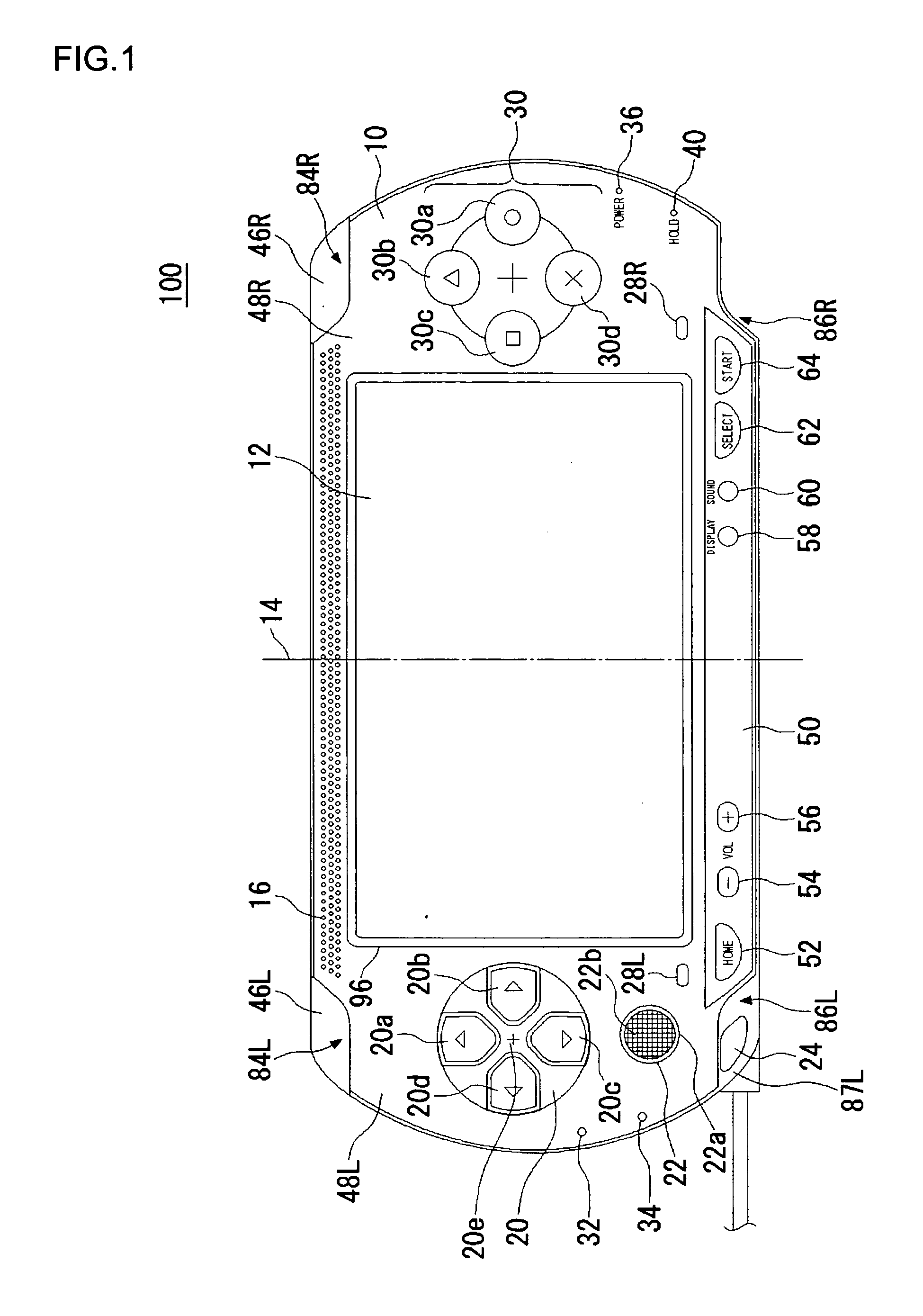

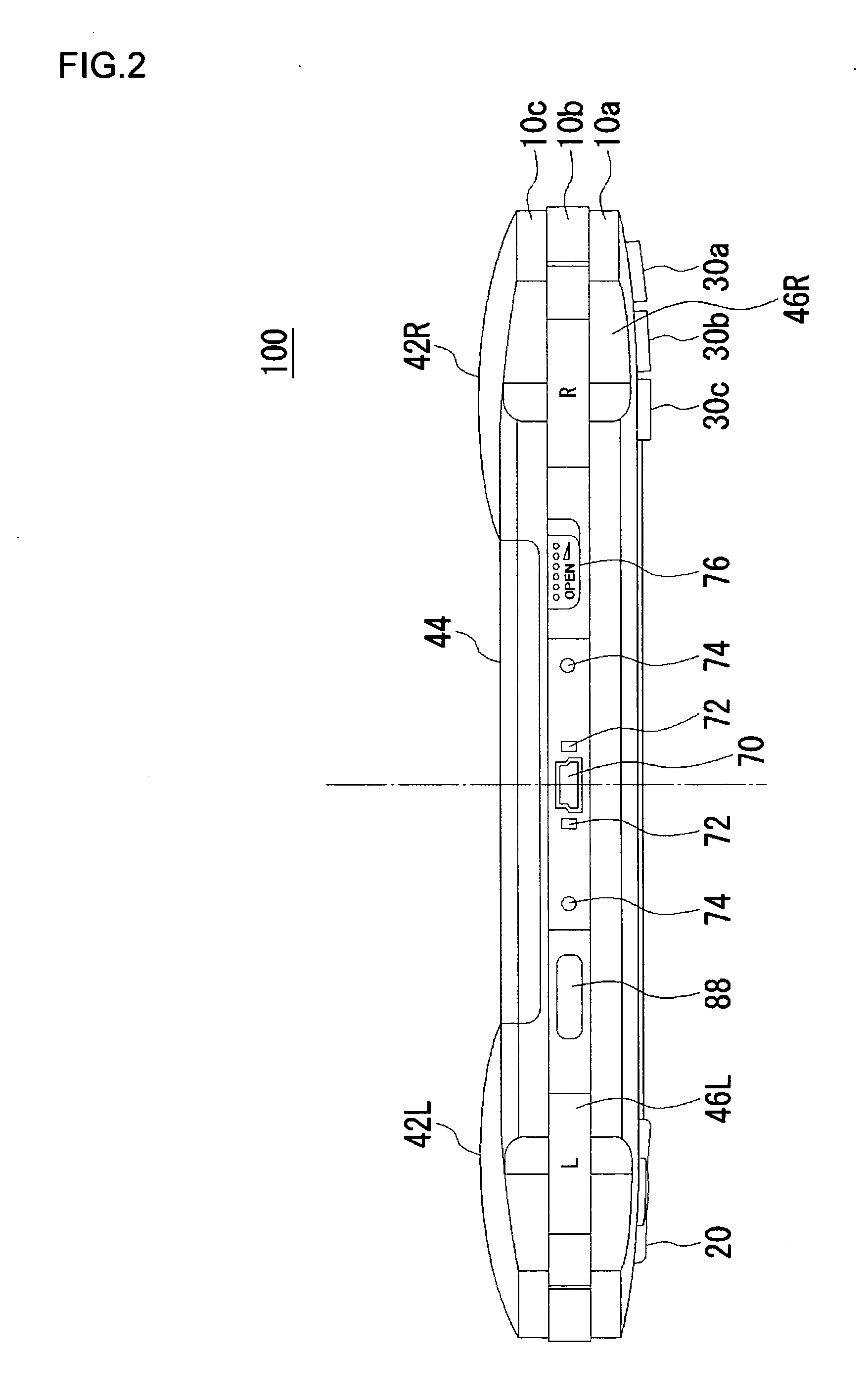

Portable Electronic Device

ActiveUS20070202956A1Easy to operateDifficult to gripDetails for portable computersVideo gamesOperabilityEngineering

A portable electronic device (100) has a long sideways housing (10) whose both ends are held by the hands of a user and an LCD fitted in the surface of the housing (10). Bulges (42L, 42R) projecting outward are formed on both end portions of the rear face of the housing (10), which both end portions being held by fingers of the user holding the housing. When the fingers and palms of user's hands are placed along the bulges (42L, 42R) with the fingers and palms bent naturally, the device fits the hands and operability is less likely to be impaired even the user violently moves in game play with the device.

Owner:SONY COMPUTER ENTERTAINMENT INC

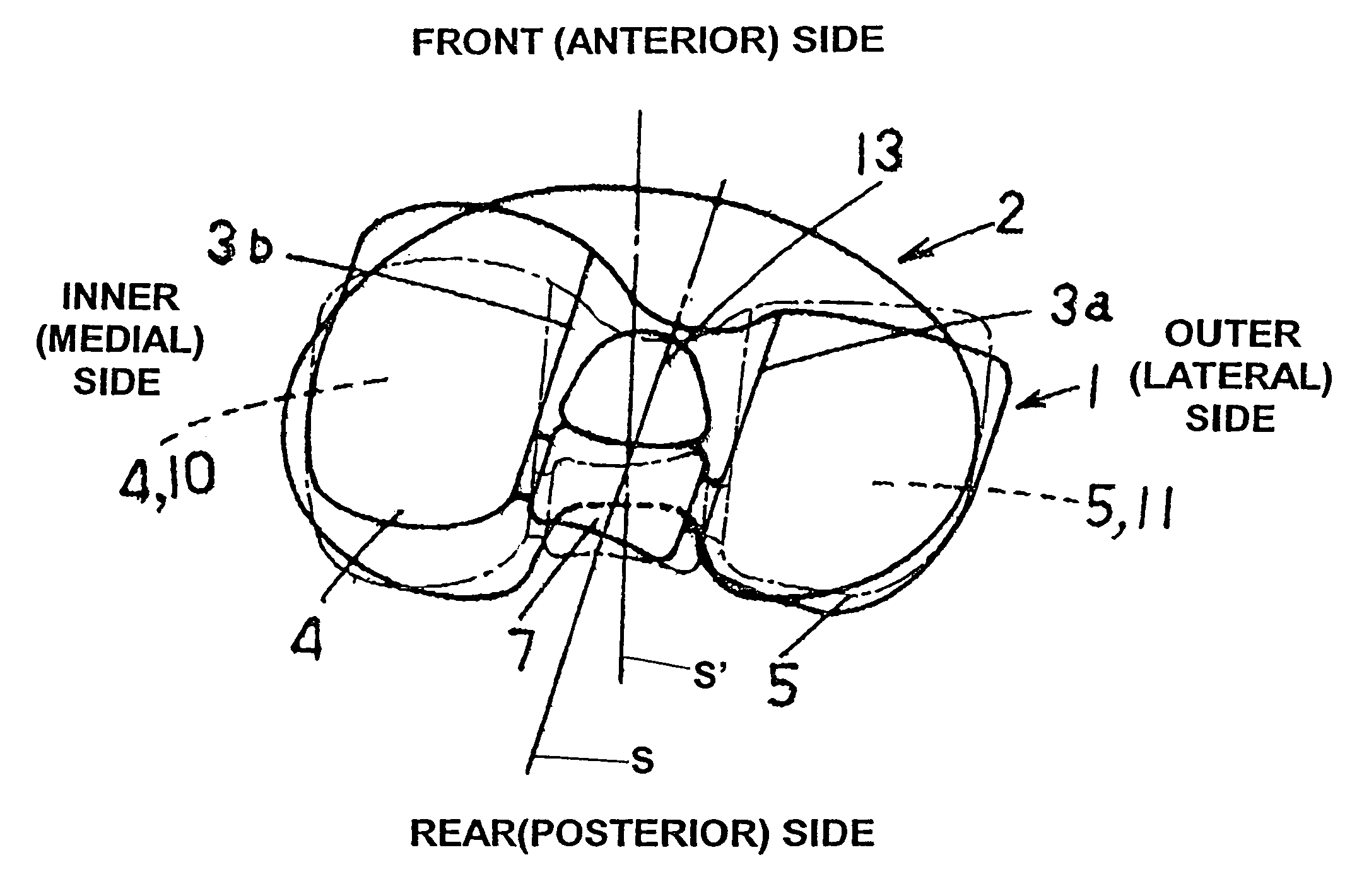

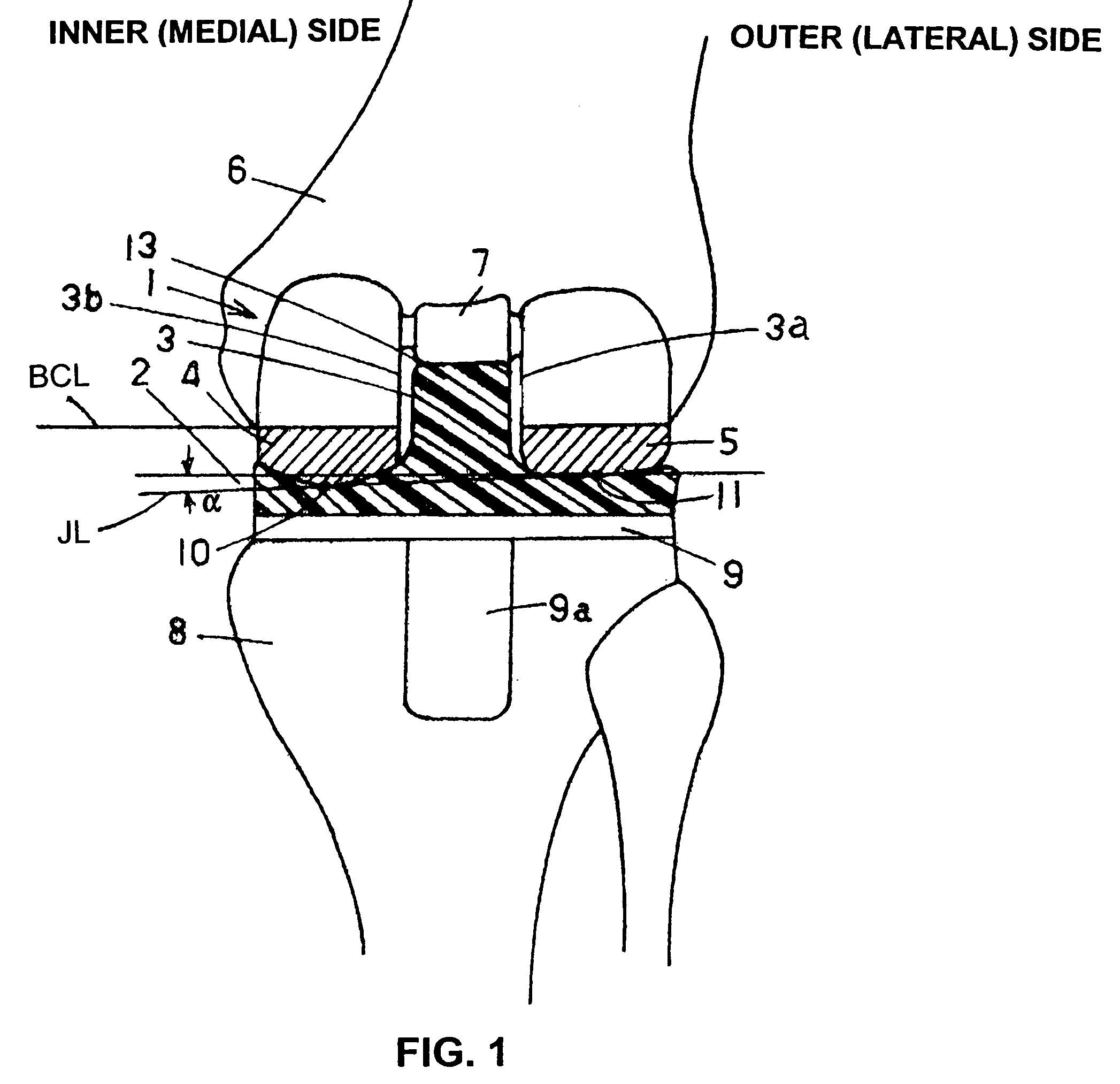

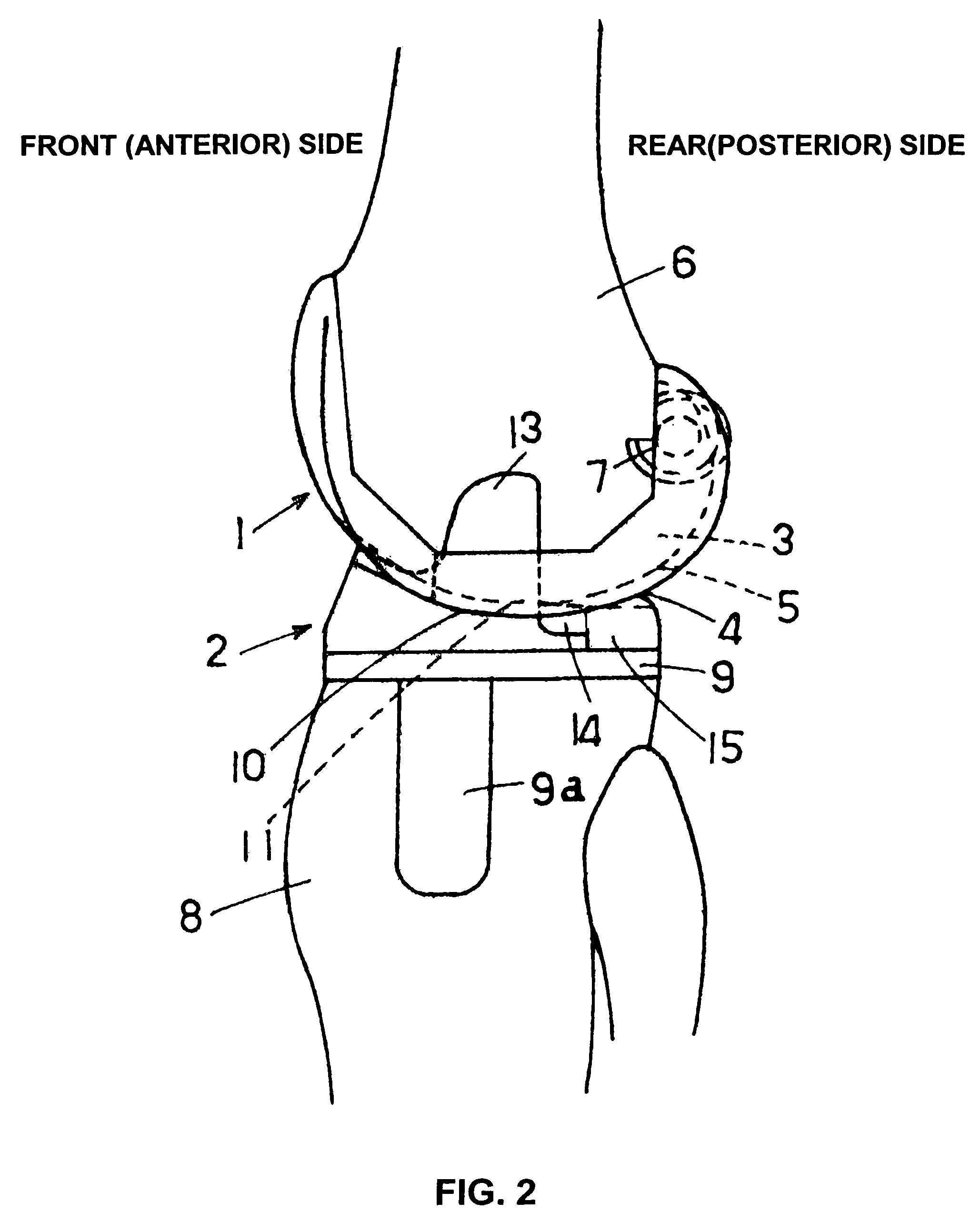

Artificial knee joint

An artificial knee joint including a femoral component and a tibial component which are in relation of making relative rotation, in which the tibial component has a post that has an outwardly curving posterior surface and is disposed approximately in the longitudinal center between the articular surfaces so that the post is inside an intercondylar groove that is between the medial and lateral condyles and extends from the posterior end to the anterior end of the femoral component; and the femoral component has a cam that is disposed at the posterior portion of the intercondylar groove and comes into contact with the posterior surface of the post when the above-described rotation proceeds; and the post and the cam are shaped so that the femoral component is turned outwardly when the cam comes into contact with the post as a result of the rotation and as the rotation proceeds.

Owner:NAKASHIMA PROPELLER +1

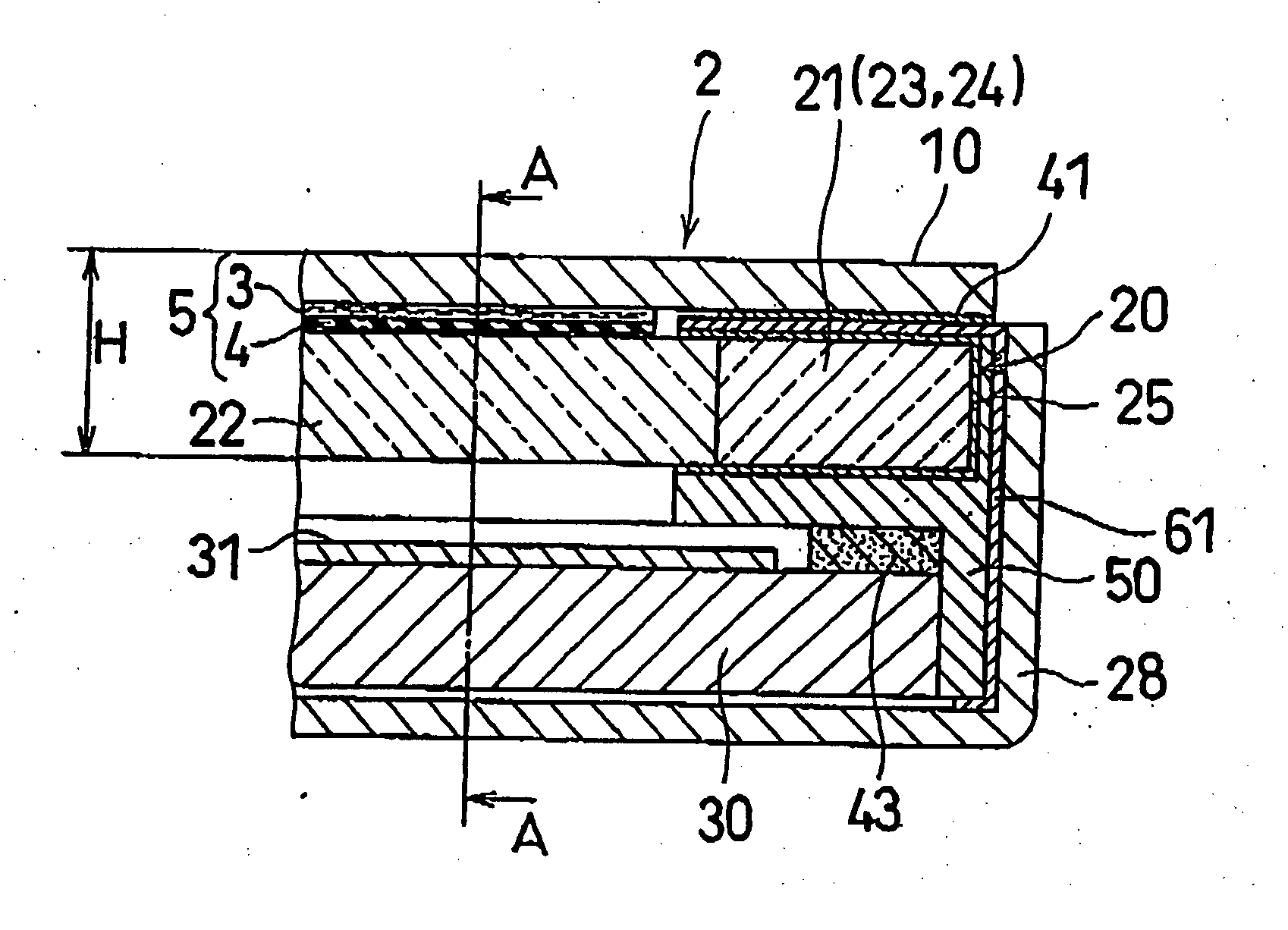

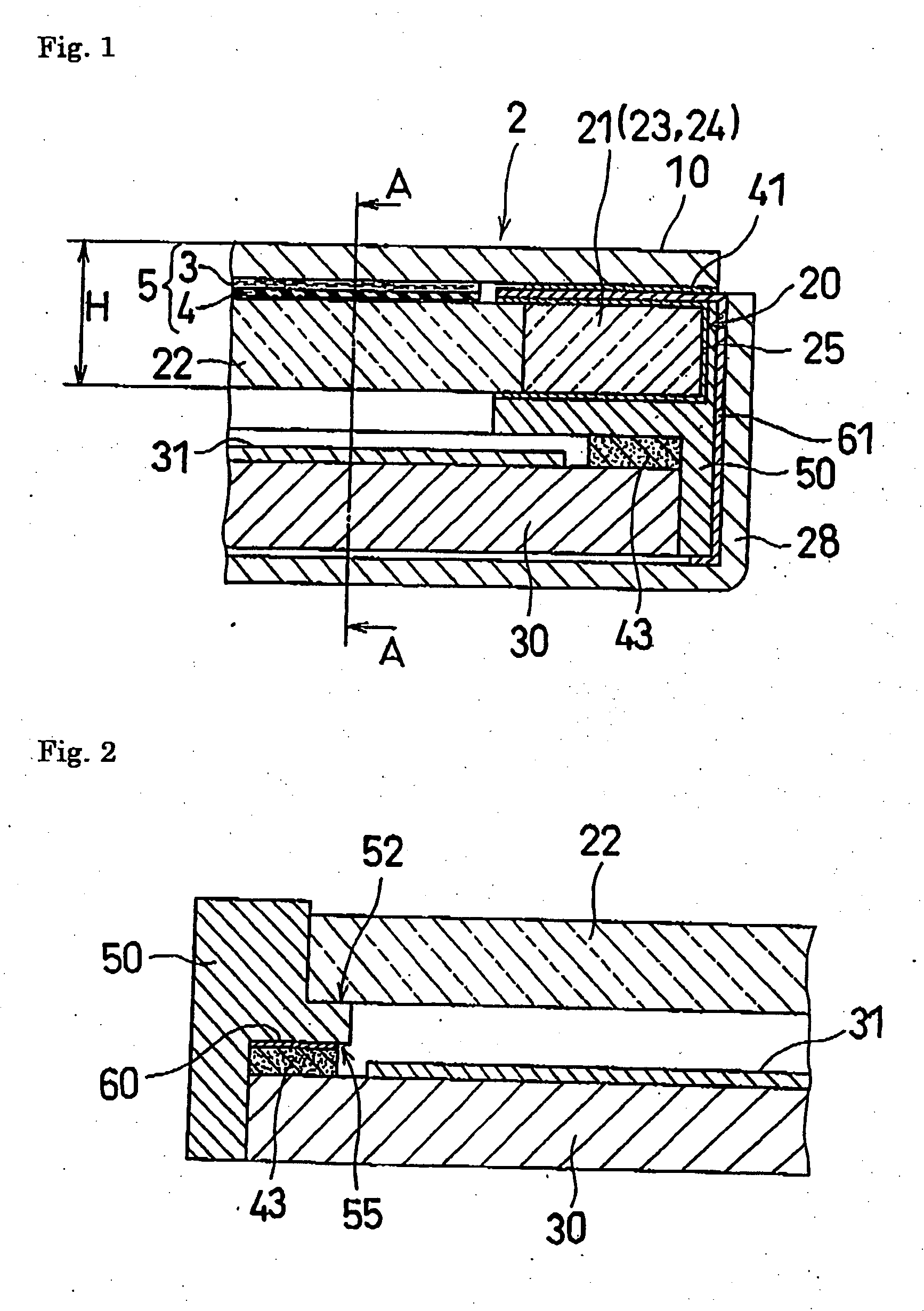

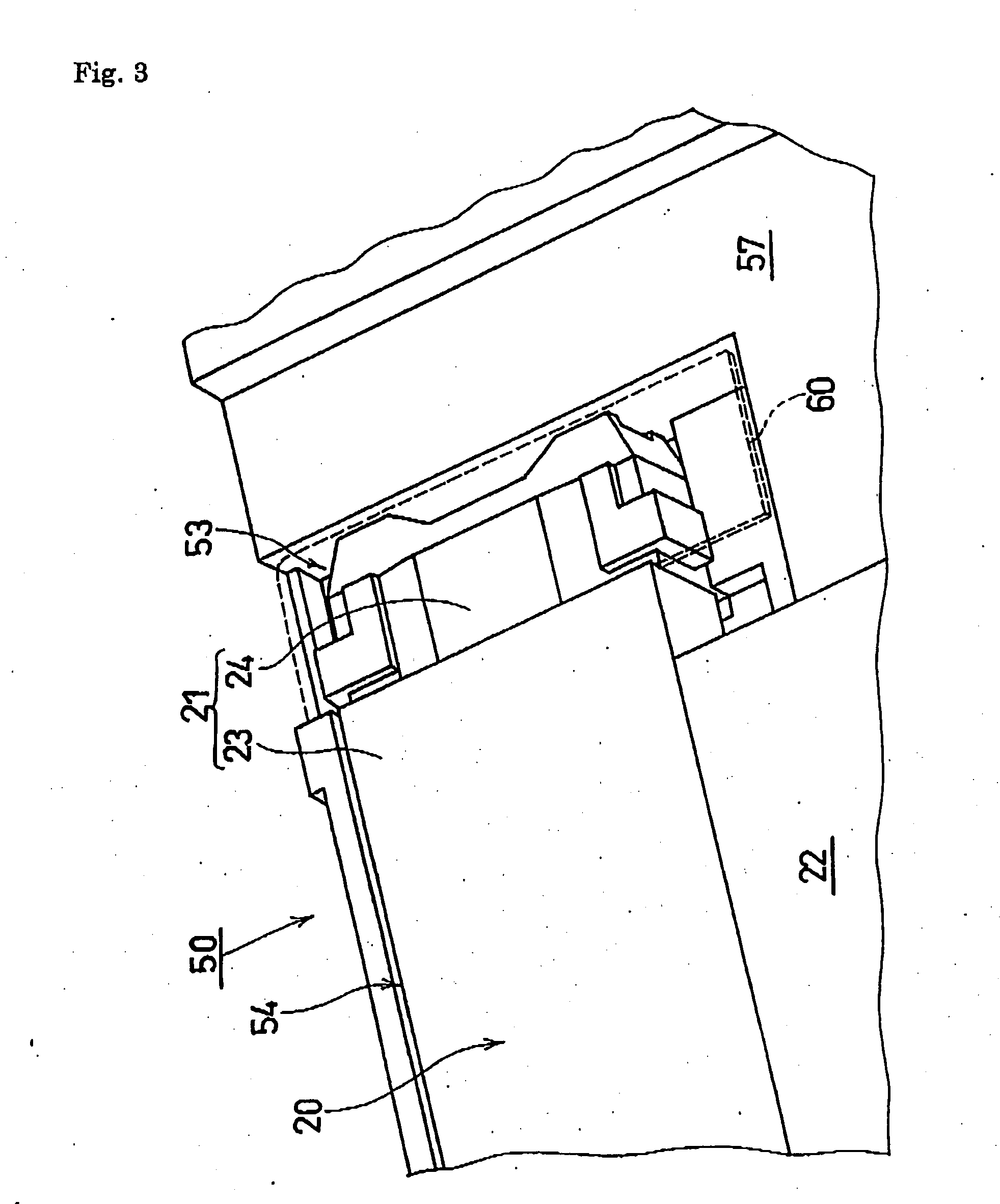

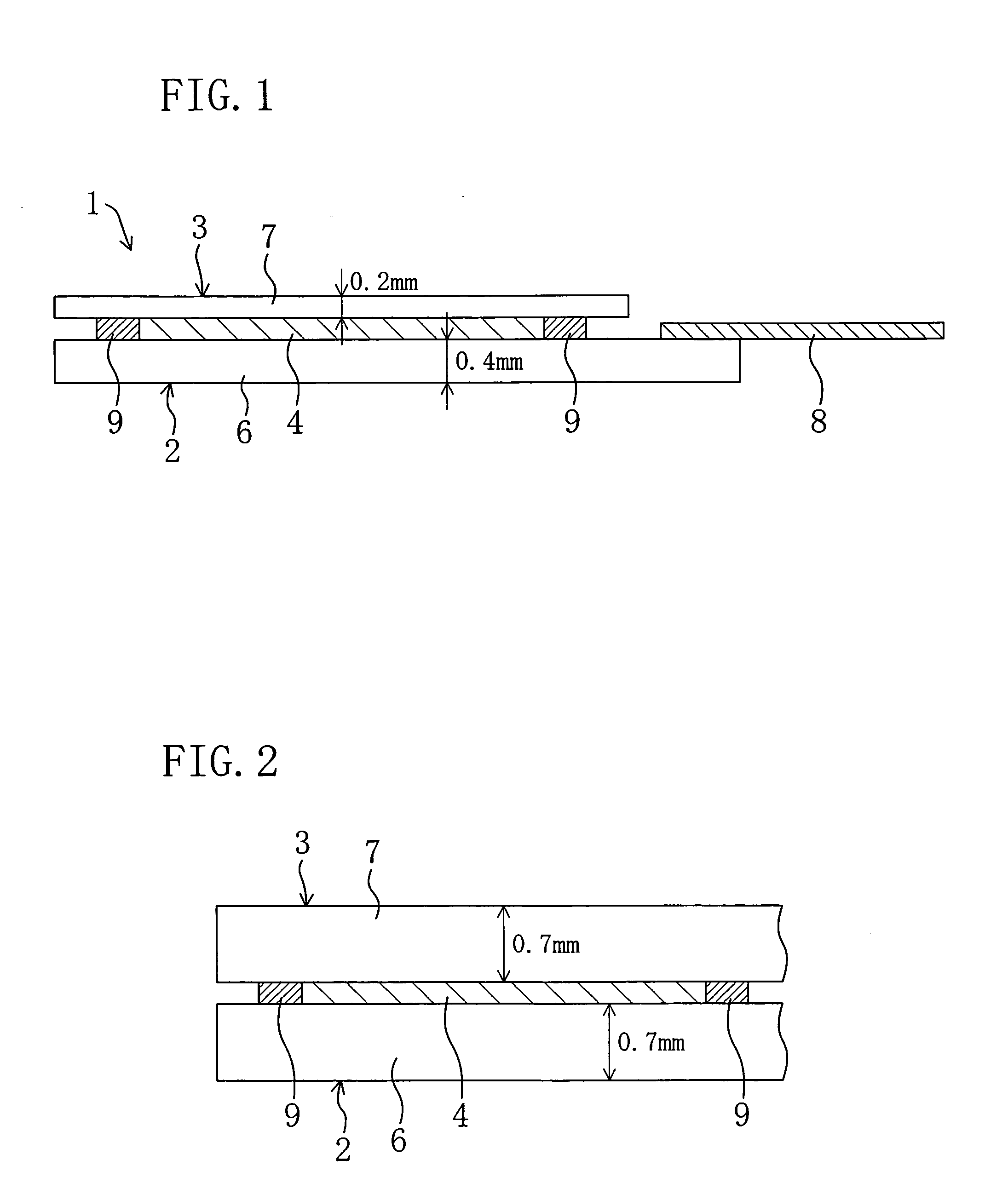

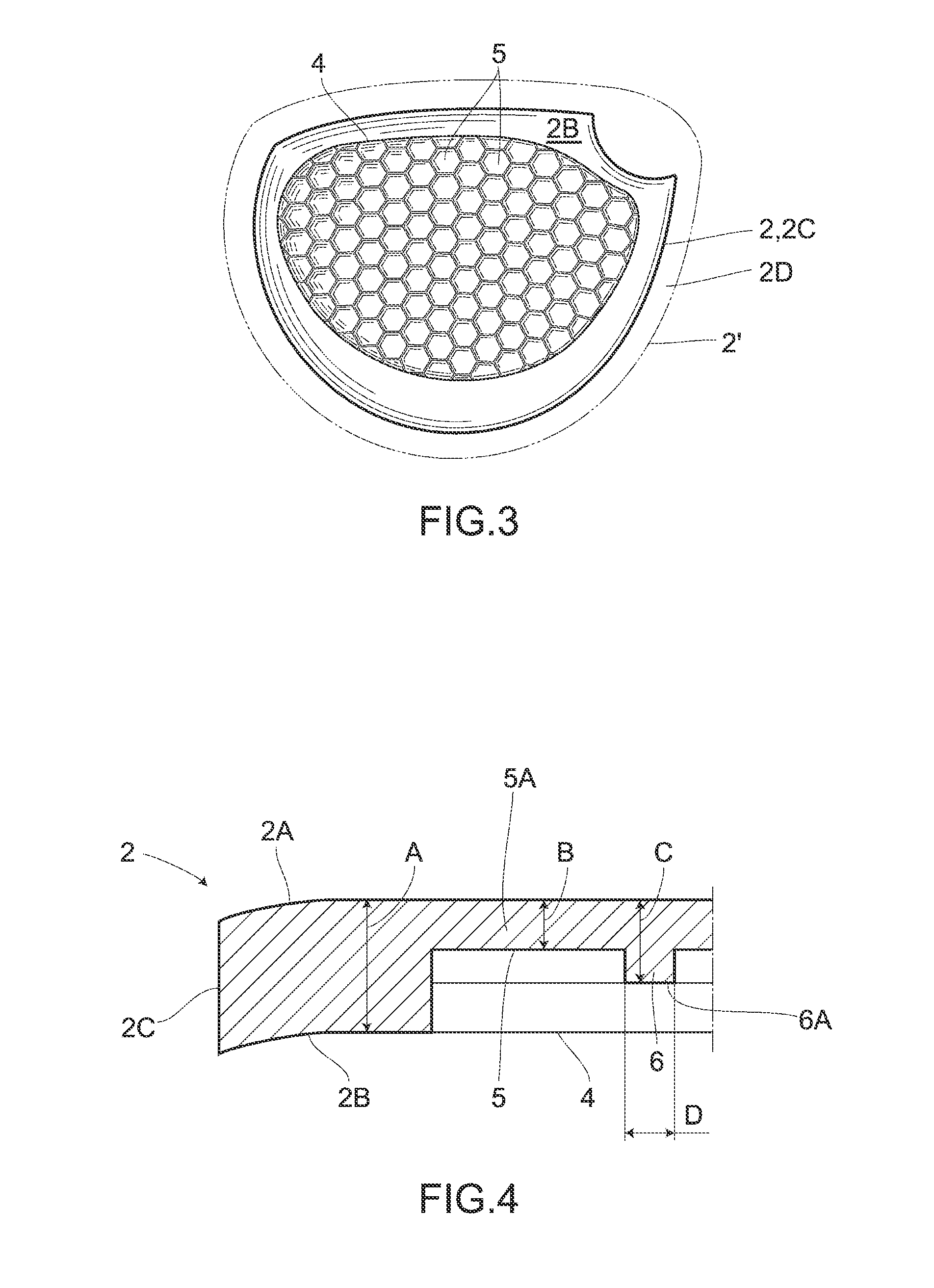

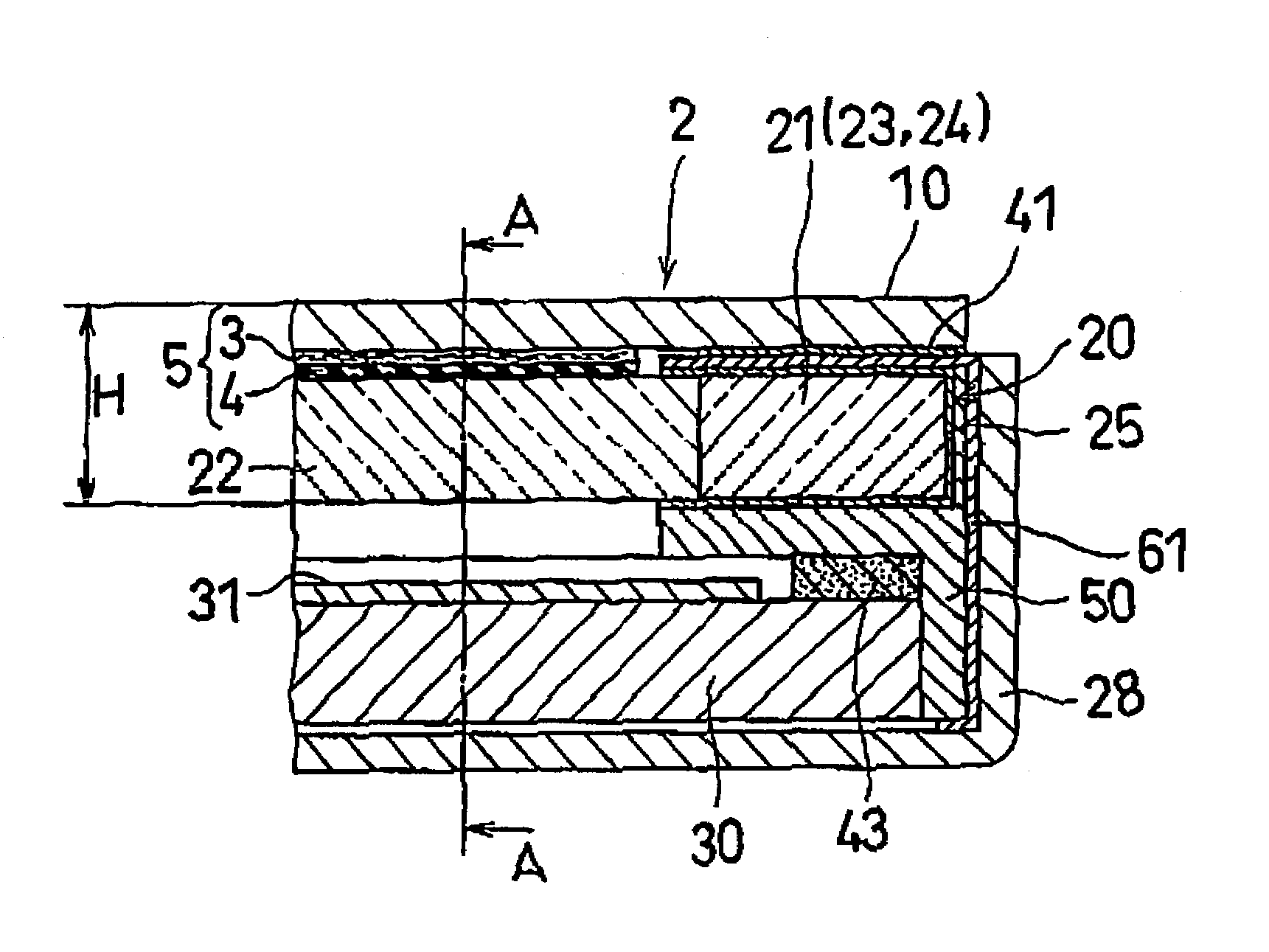

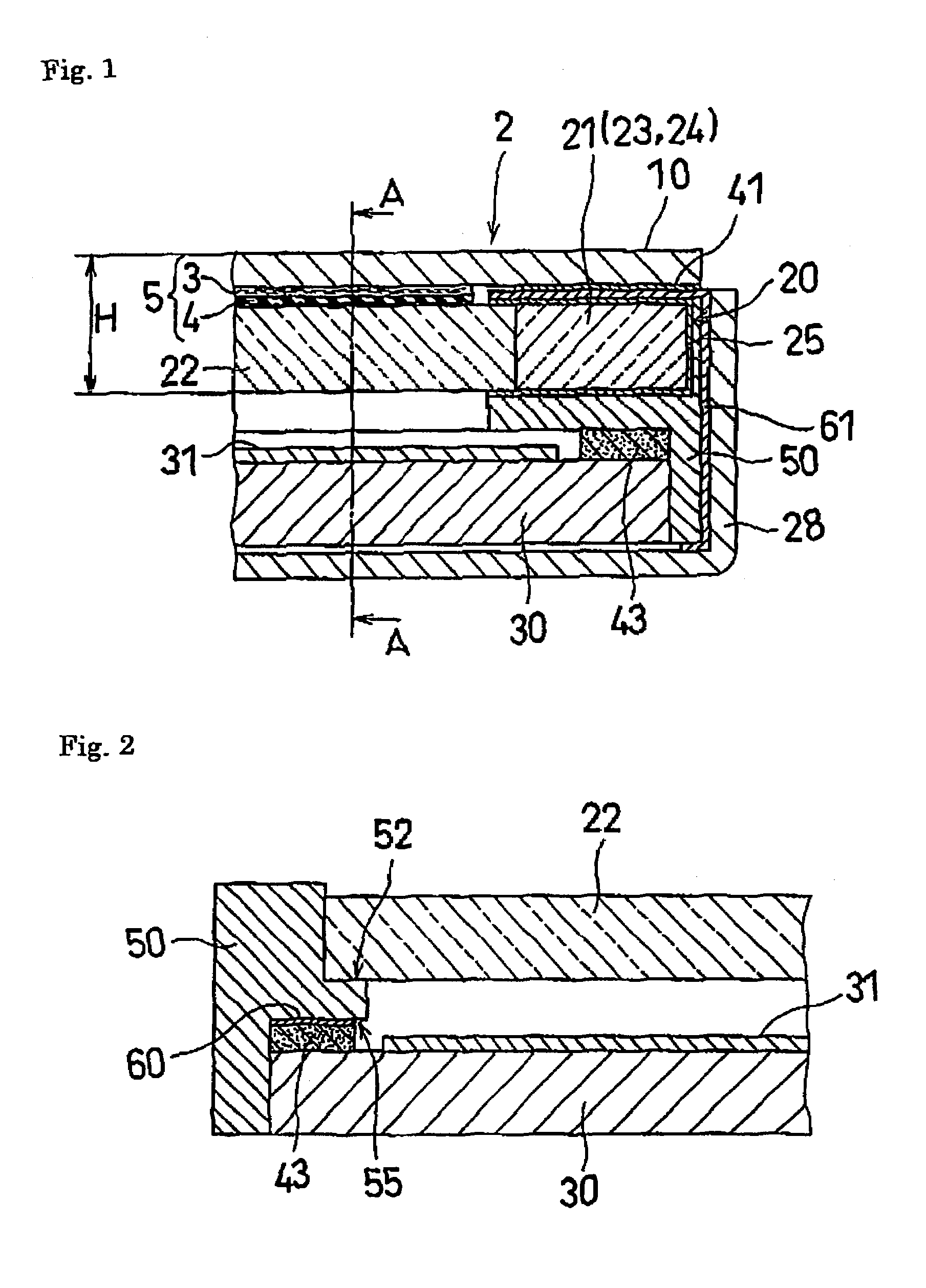

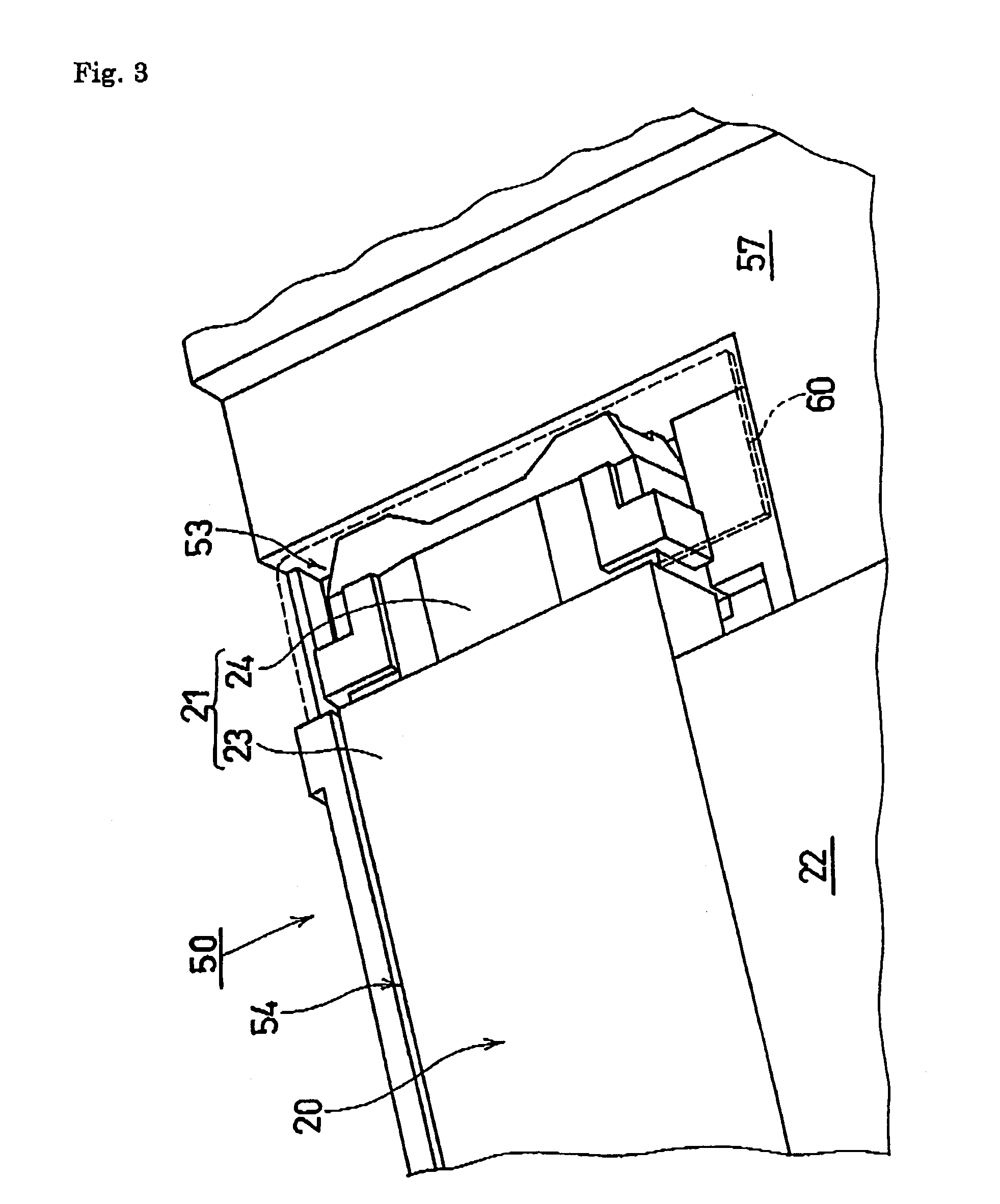

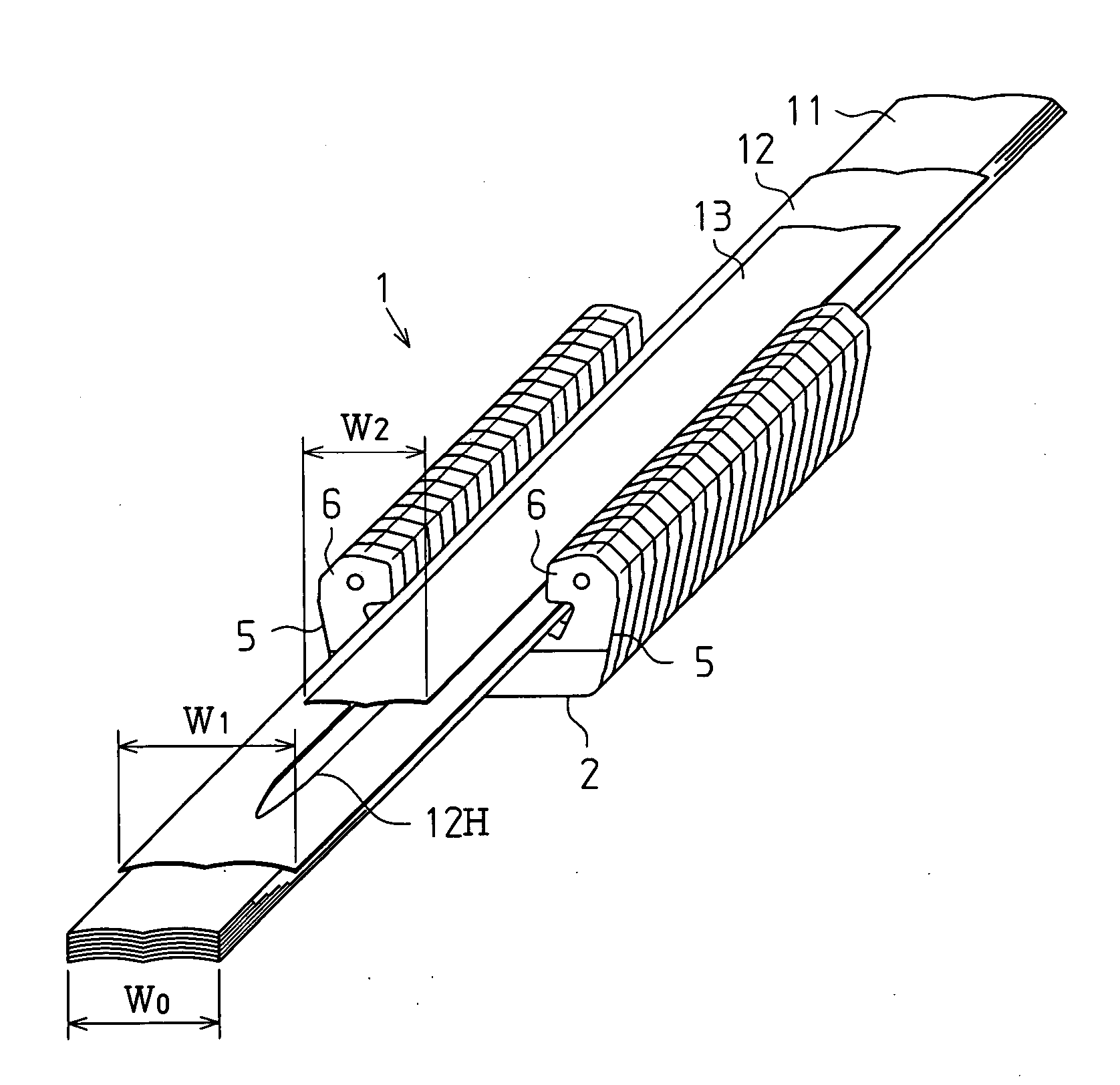

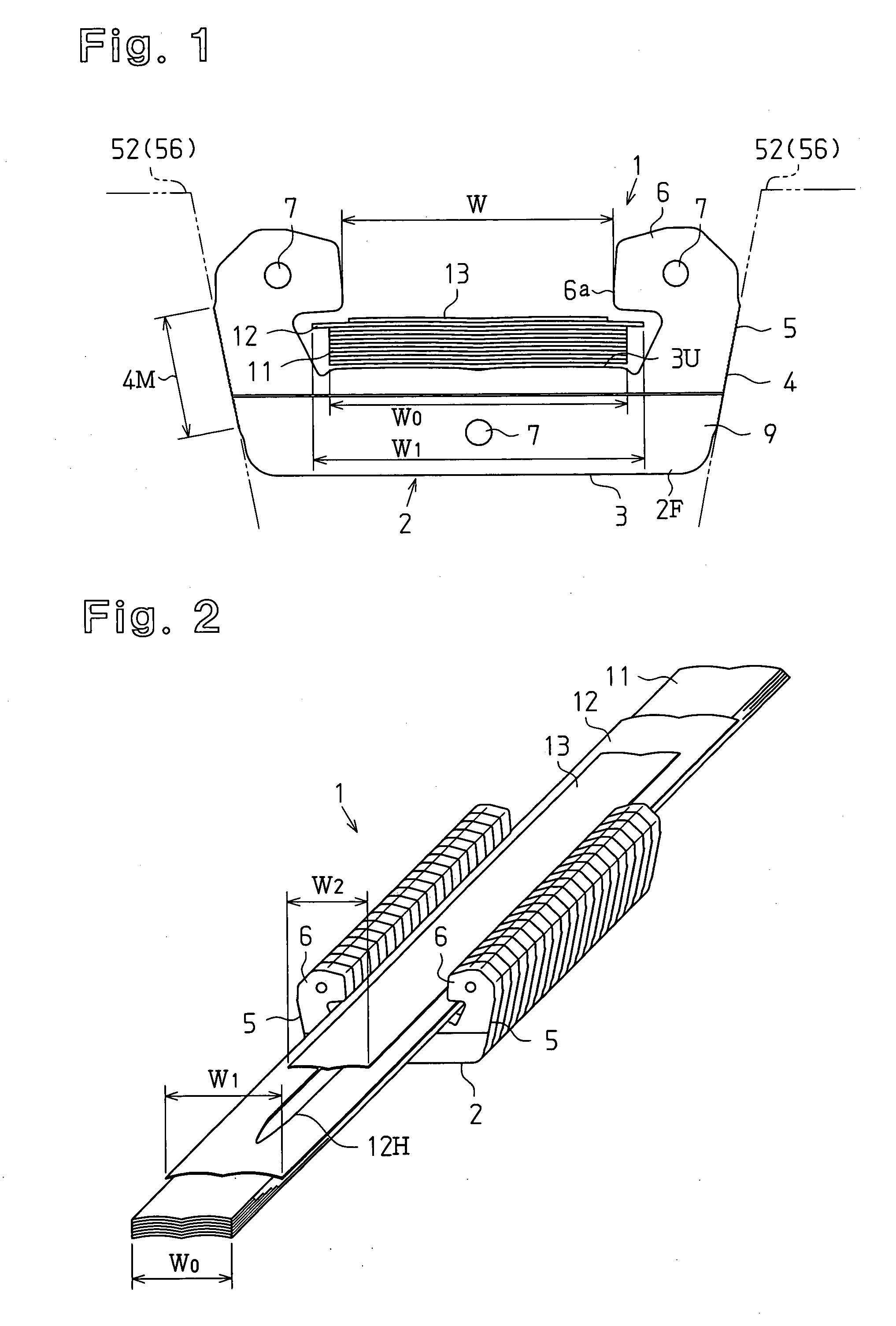

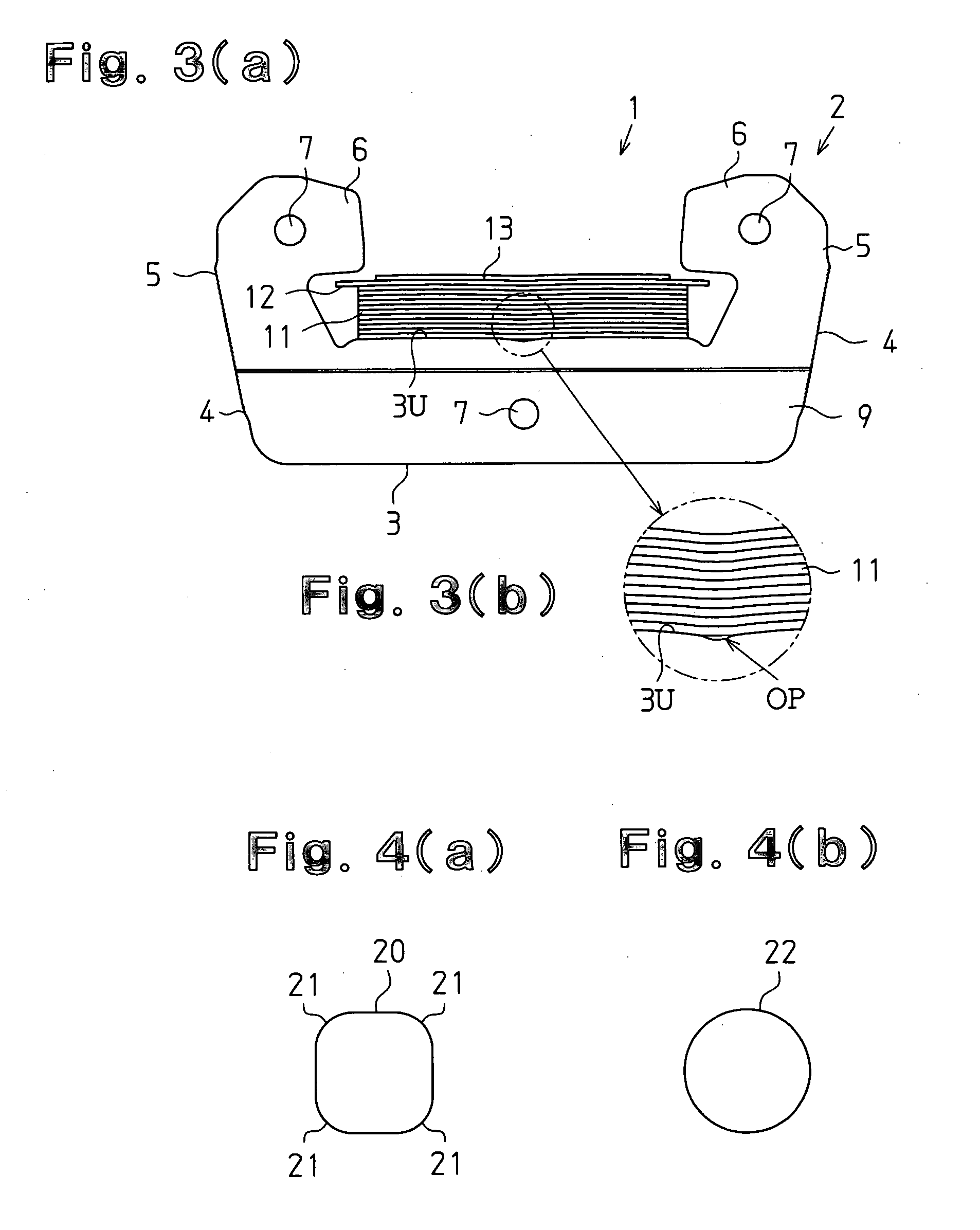

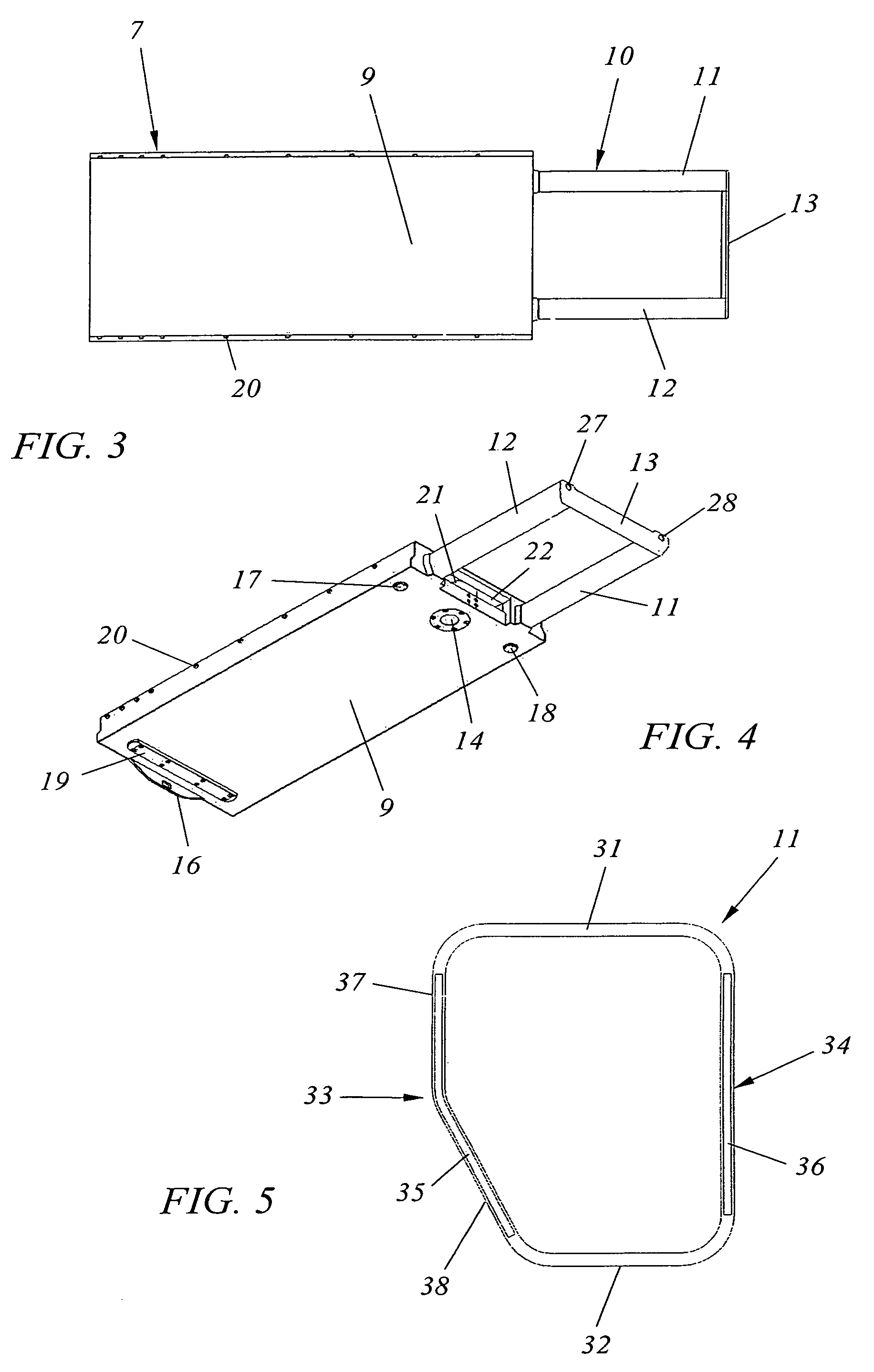

Touch panel assembly

InactiveUS20050030728A1Eliminate stickinessEasy to handleStatic indicating devicesNon-linear opticsLight guideEngineering

In a touch panel assembly, the thickness of a touch panel is successfully reduced by using a touch panel 10 provided with no reinforcement member. A housing frame 50 that supports the components of a front light unit 20 in an integral manner is provided with a touch panel positioning mechanism, and the touch panel 10 is fixed to the positioning mechanism, whereby the absence of a reinforcement member is duly compensated for, thus ensuring the strength of the touch panel 10. Deformation of the touch panel 10 that occurs when the touch panel 10 is pressed for operation can be attenuated by a transparent buffer member 5 disposed between the touch panel 10 and a light conductor plate 22. Therefore, the touch panel 10 deformed is prohibited from contacting and damaging the light conductor plate 22, thus preventing the light conductor plate 22 from deteriorating in its functional performance. Consequently, reduction in dimension and reduction of the number of components can be achieved without deteriorating the functional performance of the touch panel assembly.

Owner:MINEBEA CO LTD +2

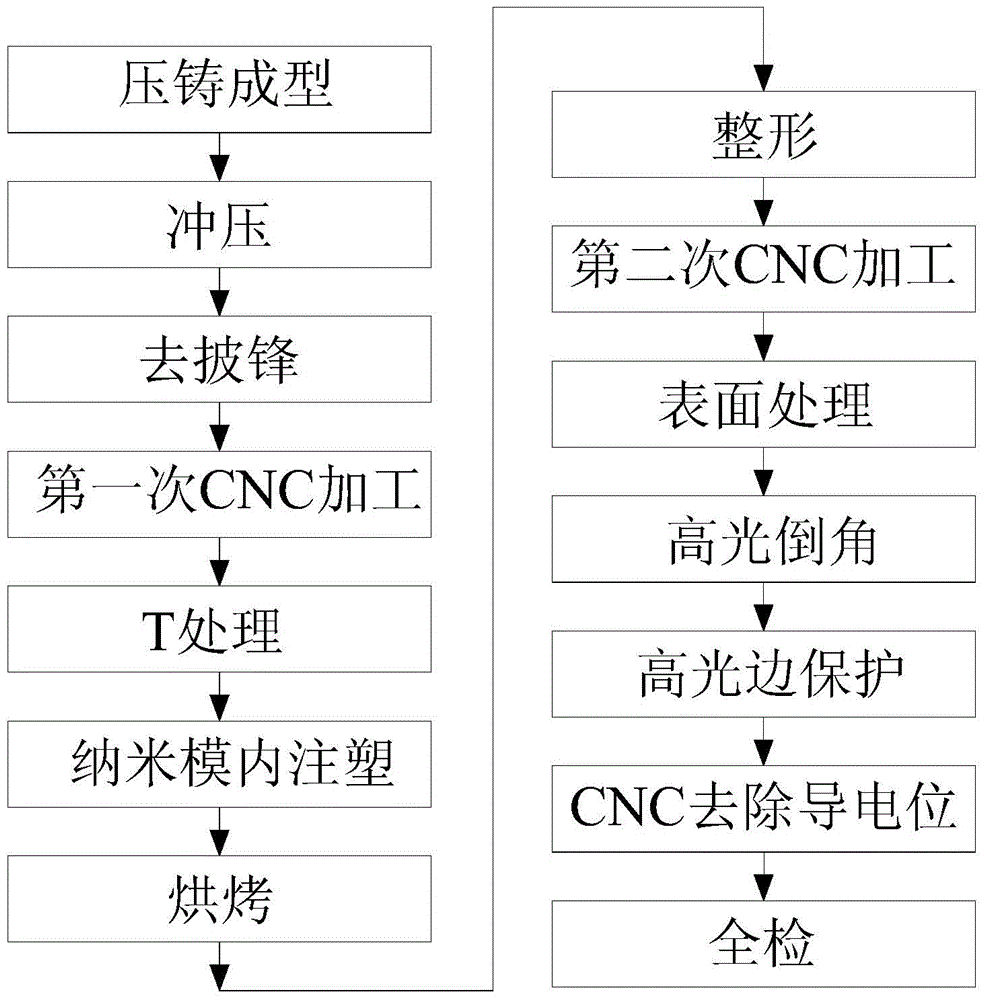

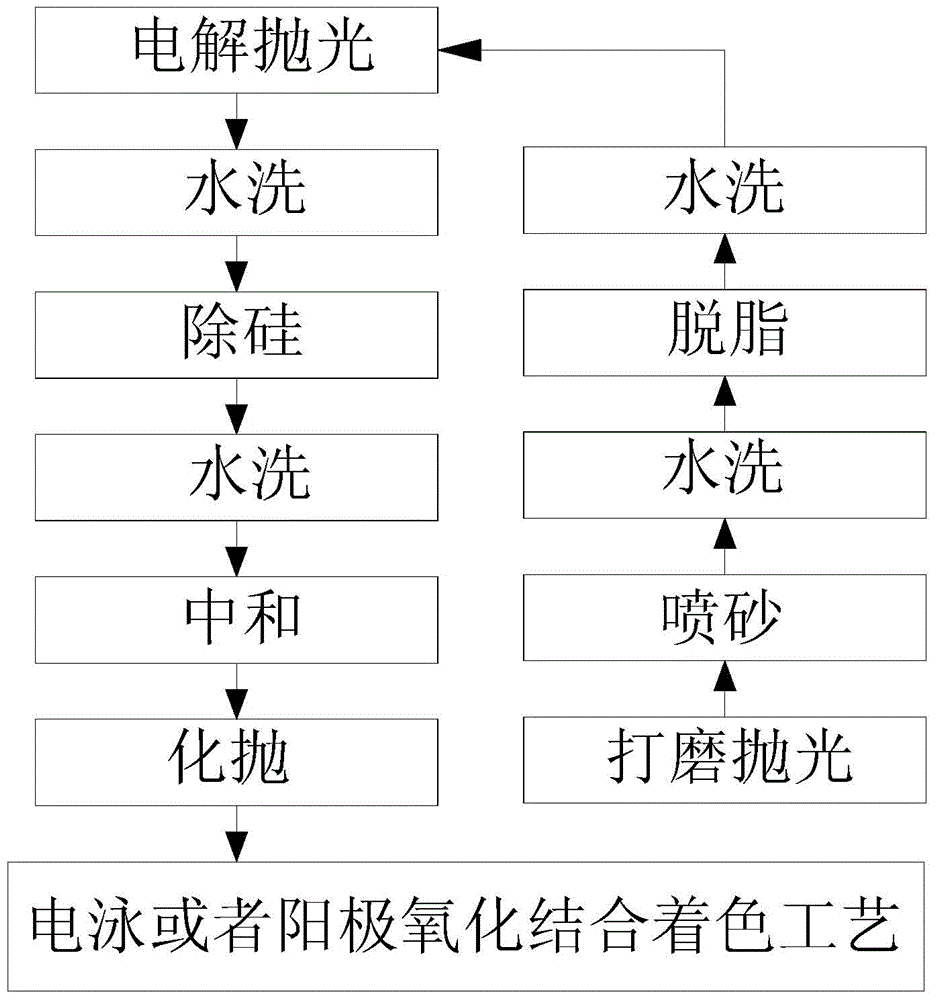

Processing technique of cellphone shell with metal luster

ActiveCN104607884AGuaranteed StrengthReduce processing costsCoatingsNumerical controlAbrasive blasting

The invention provides a processing technique of a cellphone shell with metal luster. The processing technique includes the steps of S1, performing compression molding; S2, performing stamping; S3, performing primary CNC (computer numerical control) machining; S4, performing T treatment; S5, performing injection molding in a nano mold; S6, performing secondary CNC machining; S7, performing surface treatment, to be specific, performing a, polishing, b, shot-blasting, c, degreasing, d, washing, e, electrolytic polishing, f, washing, g, silicon removal aiming to decrease silicon content of the polished surface of the cellphone shell, h, neutralizing, i, chemical polishing, and j, electrophoresis or combination of anodic oxidation and coloring, aiming to impart metal luster to the polished surface of the cellphone shell. The compete cellphone shell is made through the steps S1 to S6, the silicon content of the polished surface of the cellphone shell is processed, the cellphone shell never produces compounds of intervals such as Al-Mg-Si-Fe during following anodic oxidation, defects such as oxide film darkening, bluing or milky-whiting are avoided, and the metal-lustered cellphone shell is manufactured through the complete process.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

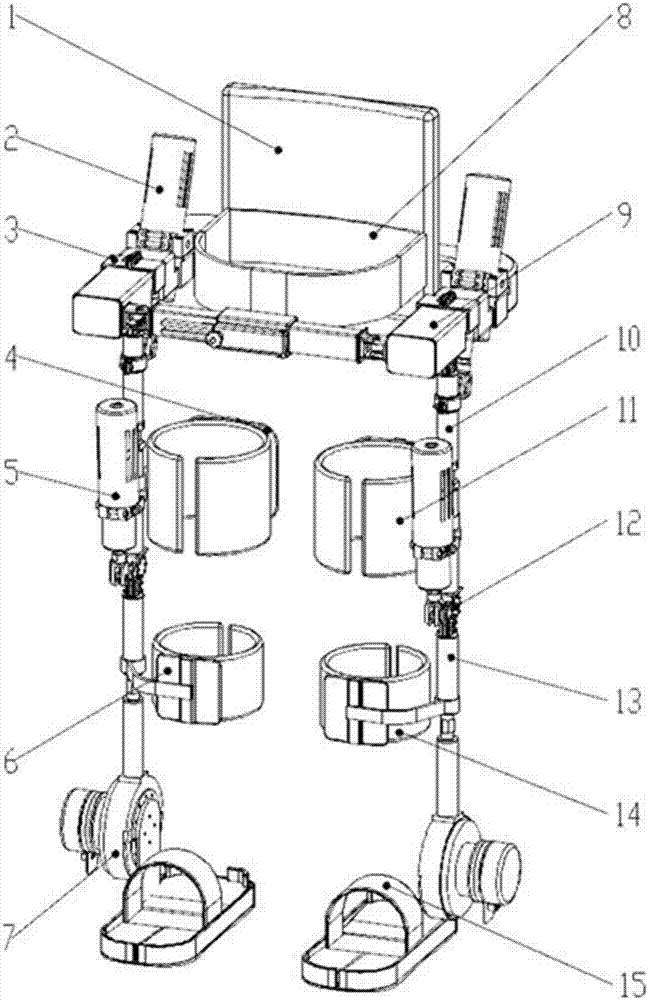

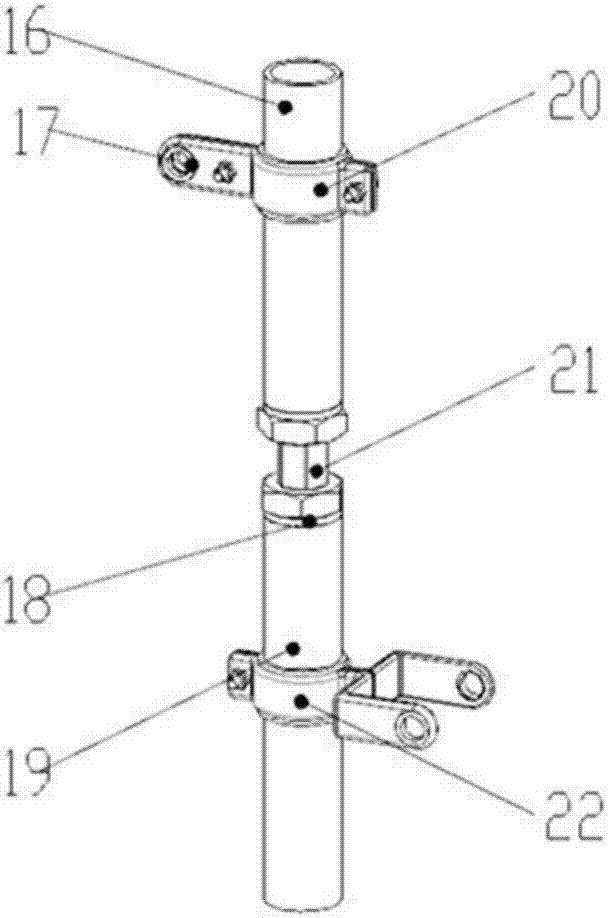

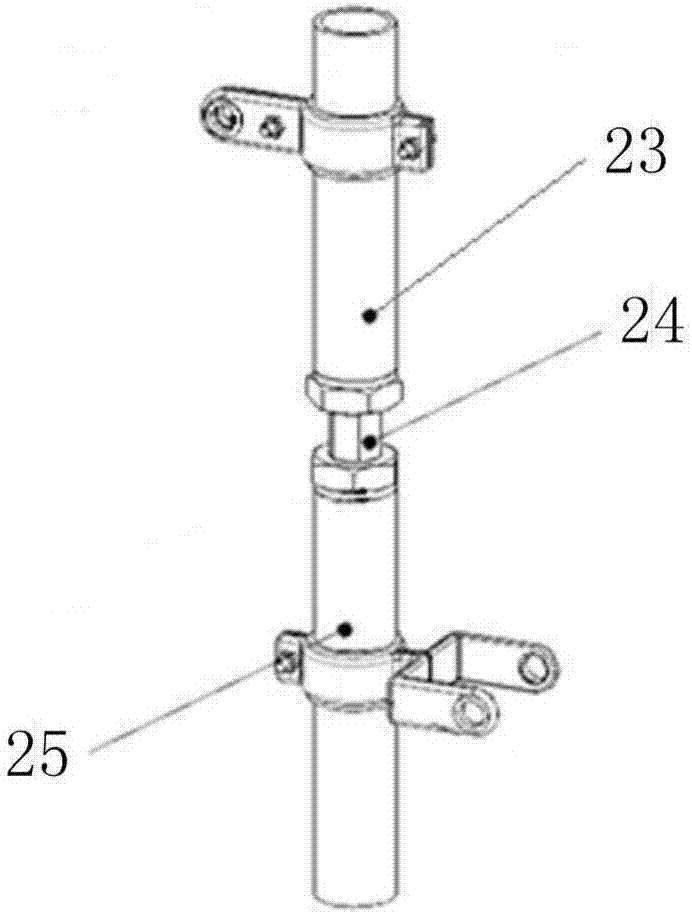

Exoskeleton rehabilitation robot for rehabilitation of lower limb walking function and control system and method thereof

ActiveCN107126344AIncrease active freedomSpeed up recoveryProgramme-controlled manipulatorChiropractic devicesKnee JointEngineering

The invention discloses an exoskeleton rehabilitation robot for rehabilitation of a lower limb walking function and a control system and method thereof. The robot comprises a backrest, a hip joint power source, a hip joint component, a waist component, a thigh bar component, a knee joint power source, a knee joint component, a shank bar component, an ankle joint component and a foot pedal. According to the lower limb exoskeleton rehabilitation robot, a driving scheme is designed by utilizing a bionics principle, so that the initiative degree of freedom of the ankle joint is increased; through initiatively pulling the heel tendon muscles of the patients, the rehabilitation speed of the ankle joint function is improved; the waist component, a connection rod mechanism and the foot pedal adopt a carbon fiber composite material, so that the structure weights and volumes are lightened while the strength is kept; and a non-polar adjustable function is set for the waist width, thigh length and shank length, and flexible bandages are equipped, so that the wearing comfort level requirement of the users is satisfied to the greatest extent. The robot disclosed by the invention not only can be used as a tool for riding instead of walk for the patients with walking disability, but also can help the stroke patients to obtain walking ability again through initiative training.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

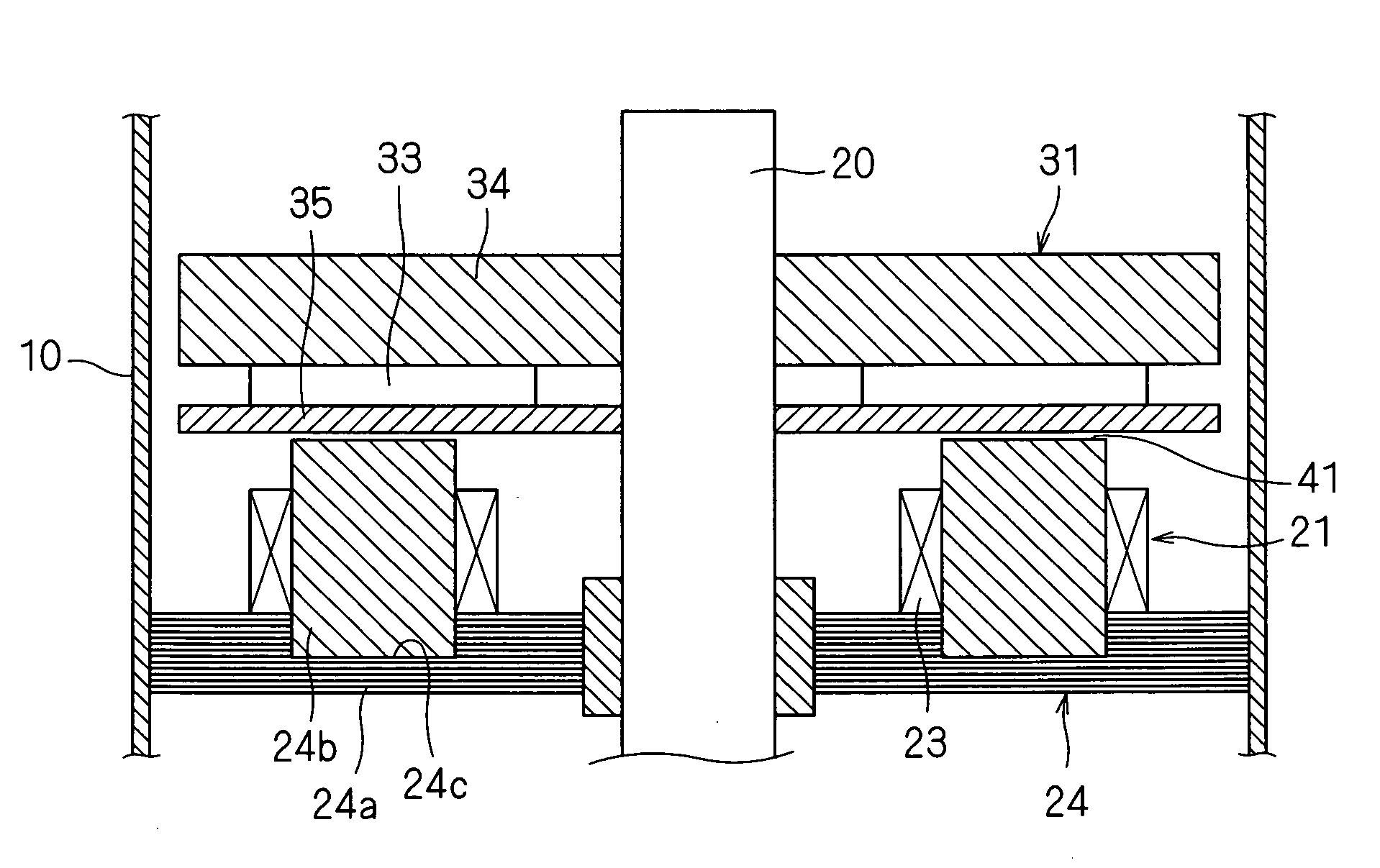

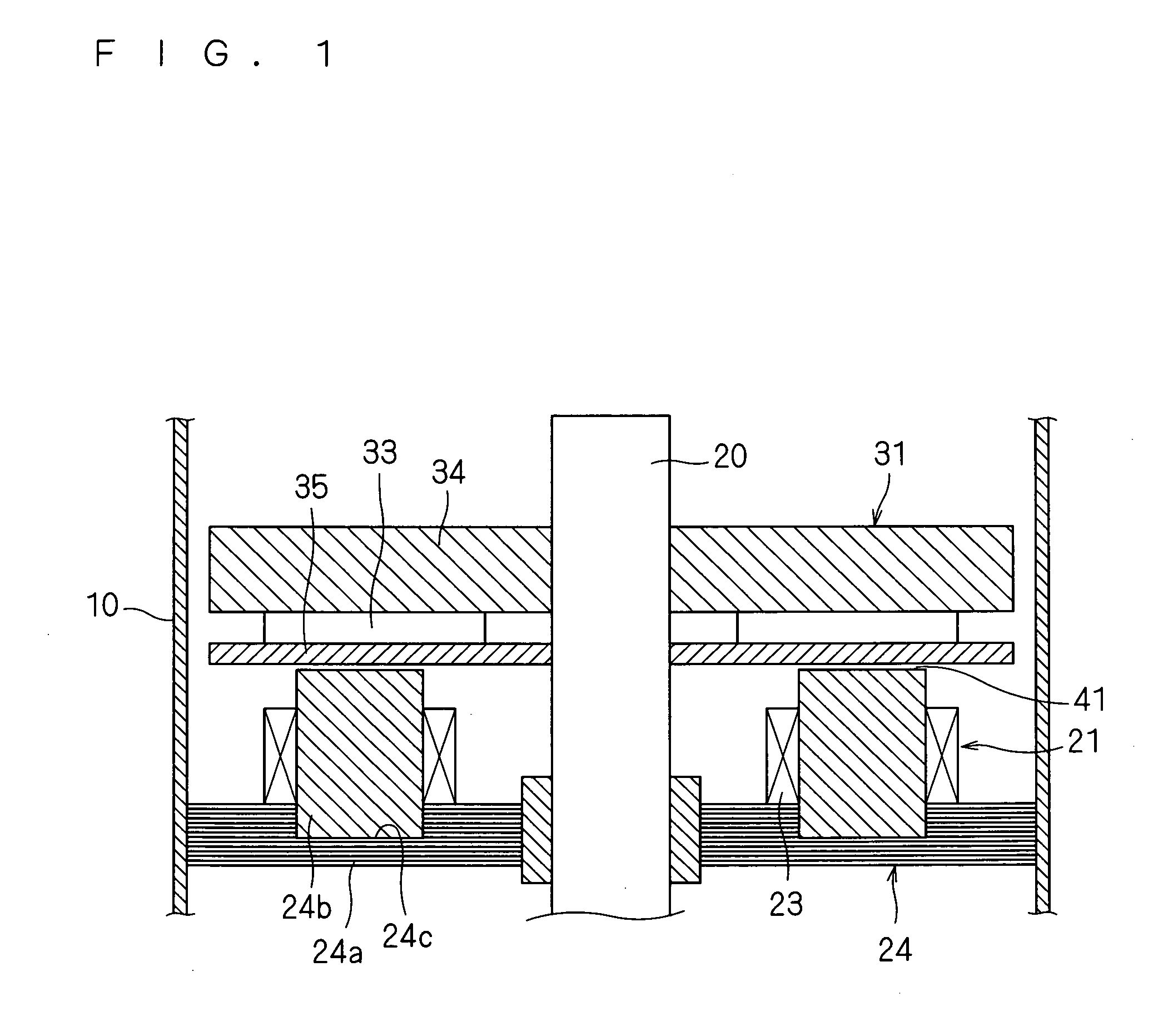

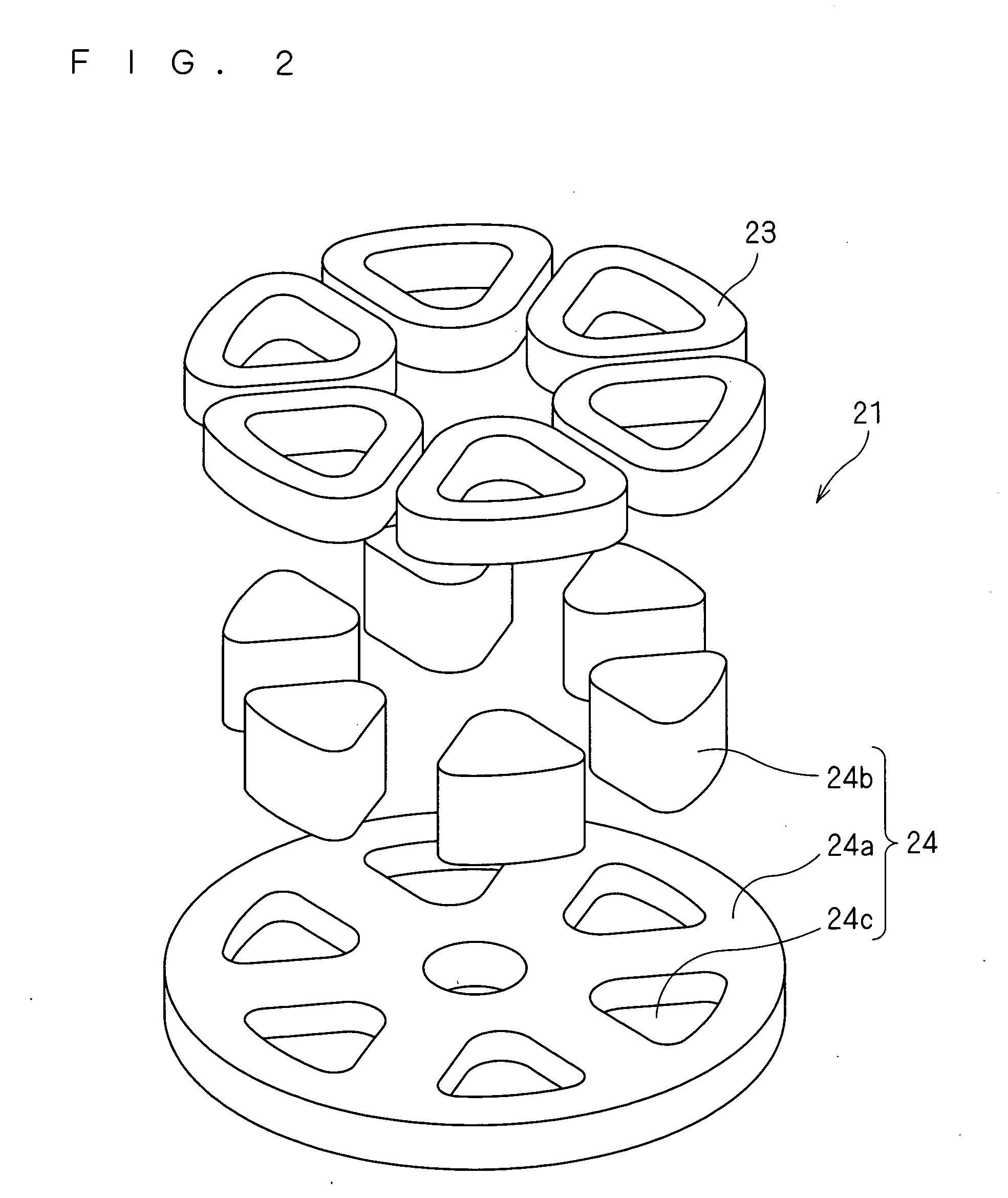

Display device and method for manufacturing the same

InactiveUS20060238695A1Reduce thicknessThin display deviceNon-linear opticsLiquid-crystal displayMedia layer

A liquid crystal display device includes: an active matrix substrate including a glass substrate; a counter substrate which is arranged to face the active matrix substrate and includes a glass substrate which is thinner than the glass substrate of the active matrix substrate; and a display medium layer which is provided between the active matrix substrate and the counter substrate. The rate at which the glass substrate of the active matrix substrate is etched by an etching solution is lower than the rate at which the glass substrate of the counter substrate is etched by the etching solution.

Owner:SHARP KK

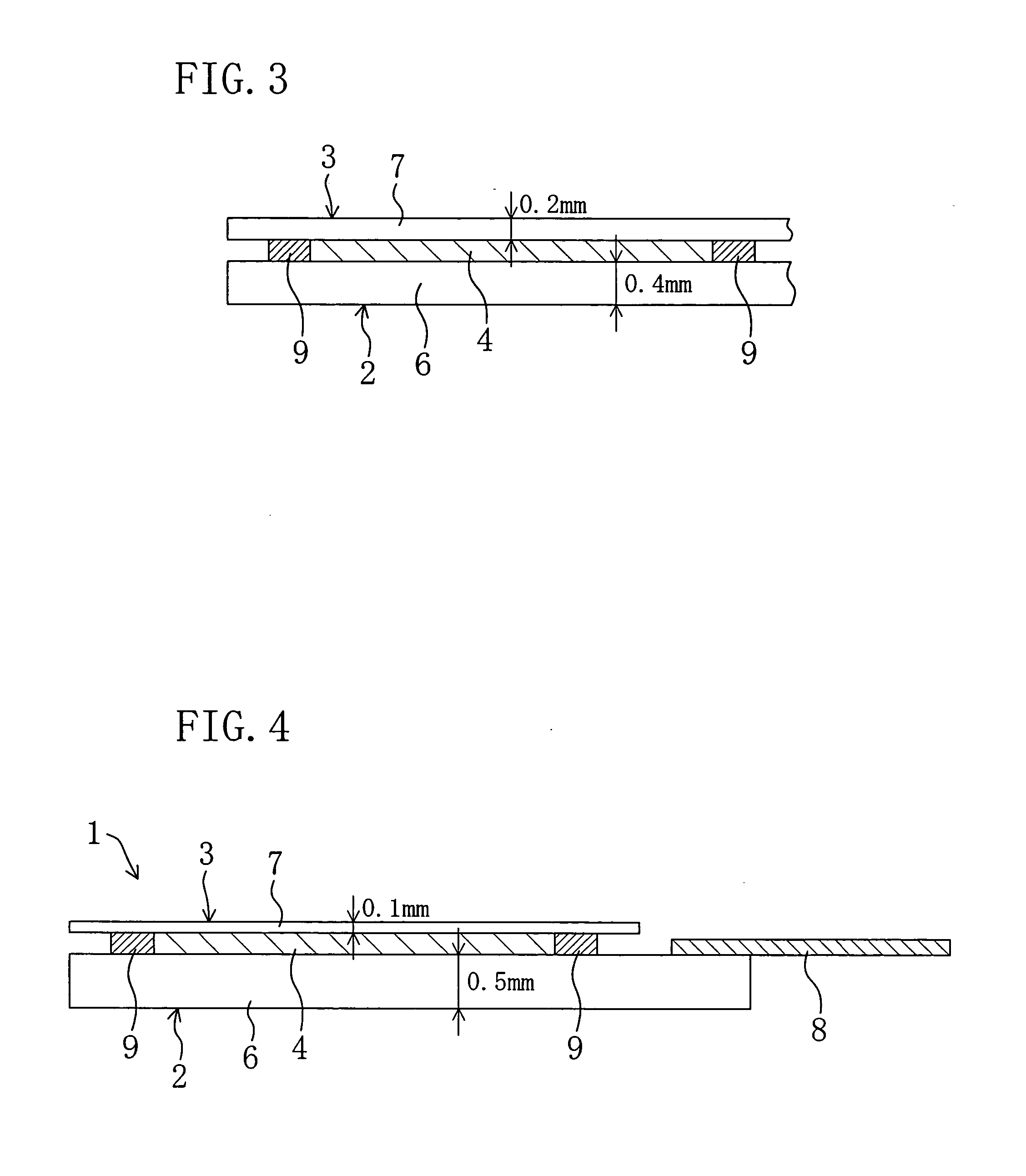

Sludge curing agent and application thereof

ActiveCN101081718AGood boardIncreased durabilitySludge treatment by de-watering/drying/thickeningSolid waste managementSludgeSlag

The present invention is sludge curing agent and its application, and belongs to the field of soil treating chemicals technology. The sludge curing agent includes powdered components and liquid components, the powdered components include cement clinker 30-60 weight portions, slag 30-60 weight portions, lime 3-8 weight portions, gypsum 1-7 weight portions and other sulfates 1-7 weight portions; and the liquid components include polyacrylamide 5-30 weight portions, polyaluminum chloride 0-20 weight portions, mannitol 0-30 weight portions, lignosulfonate 20-80 weight portions, lignosulfonate-iron or chromium ion complex 0-30 weight portions, alkylphenol ethoxylate 0.2-2 weight portions, tannin 0-10 weight portions, humate 0-10 weight portions, and alpa-olefin sulfonate 0.2-2.5 weight portions. The sludge curing agent has low cost, small consumption, high cumulate strength and high cumulate water tolerance, and may be applied widely.

Owner:BEIJING ZHONGYONGJI FIRMING AGENT TECH DEV

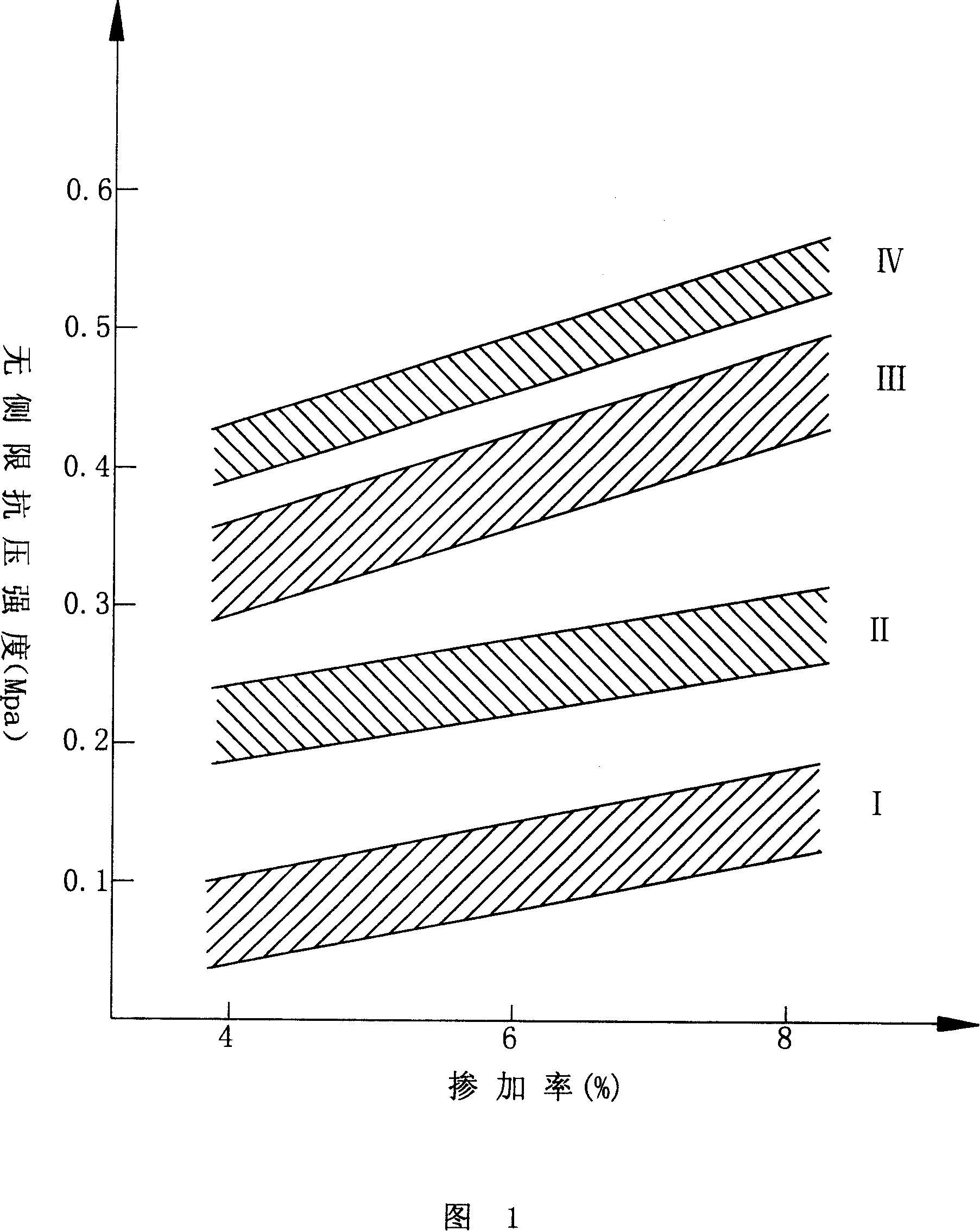

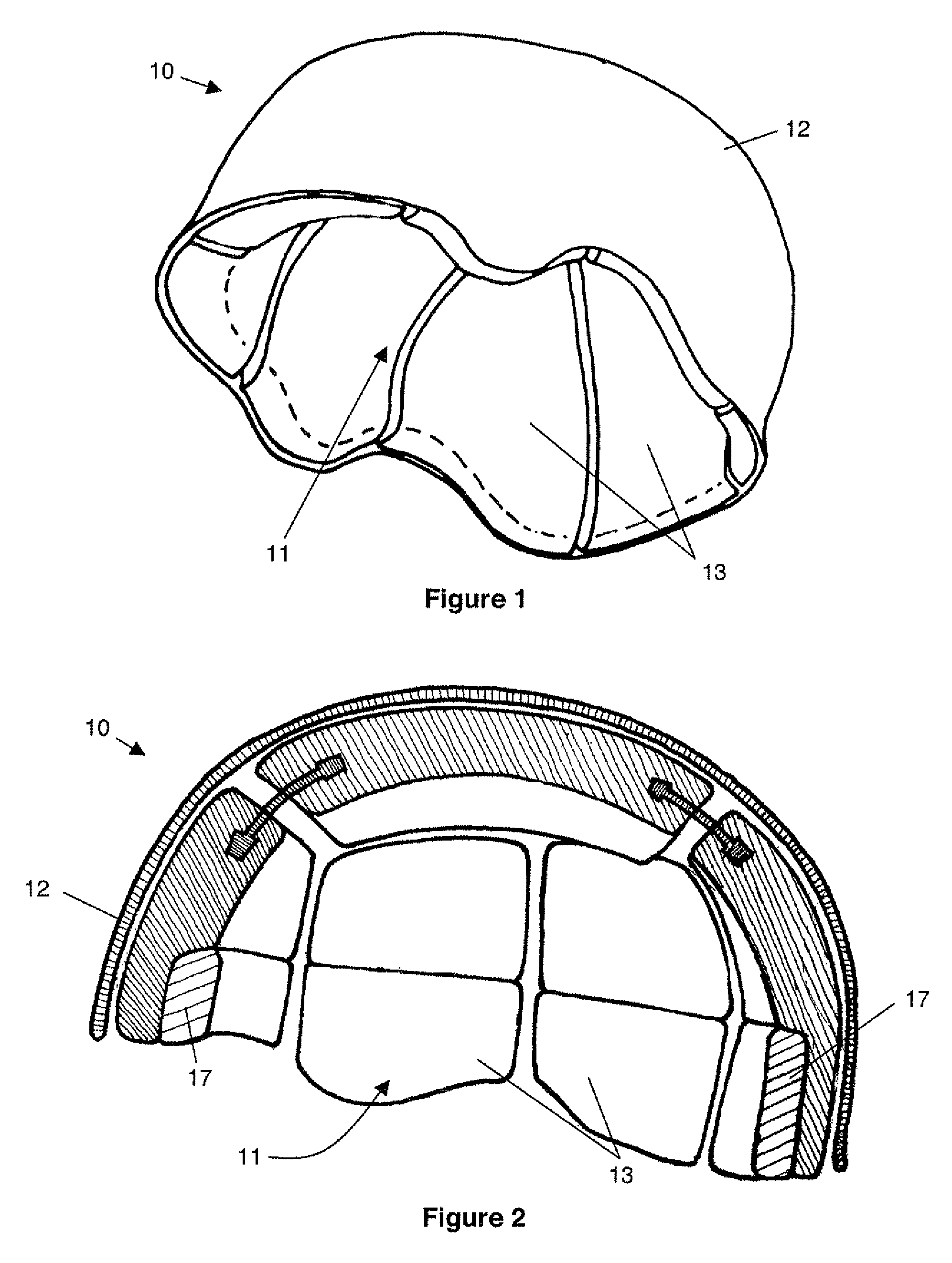

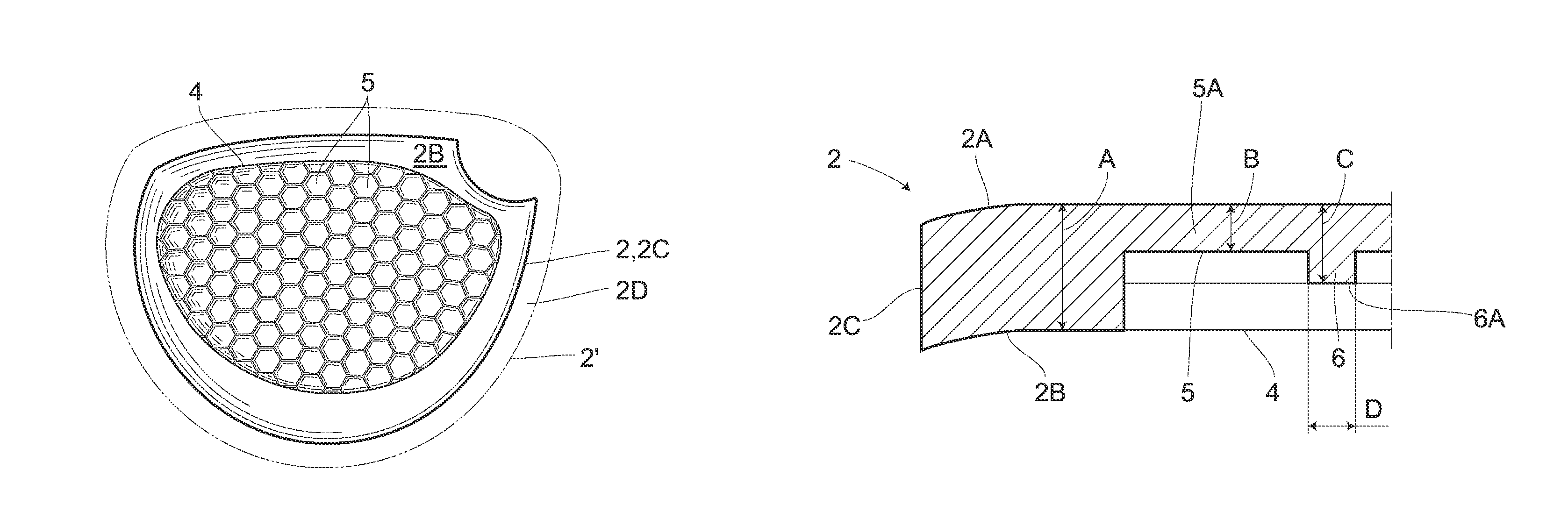

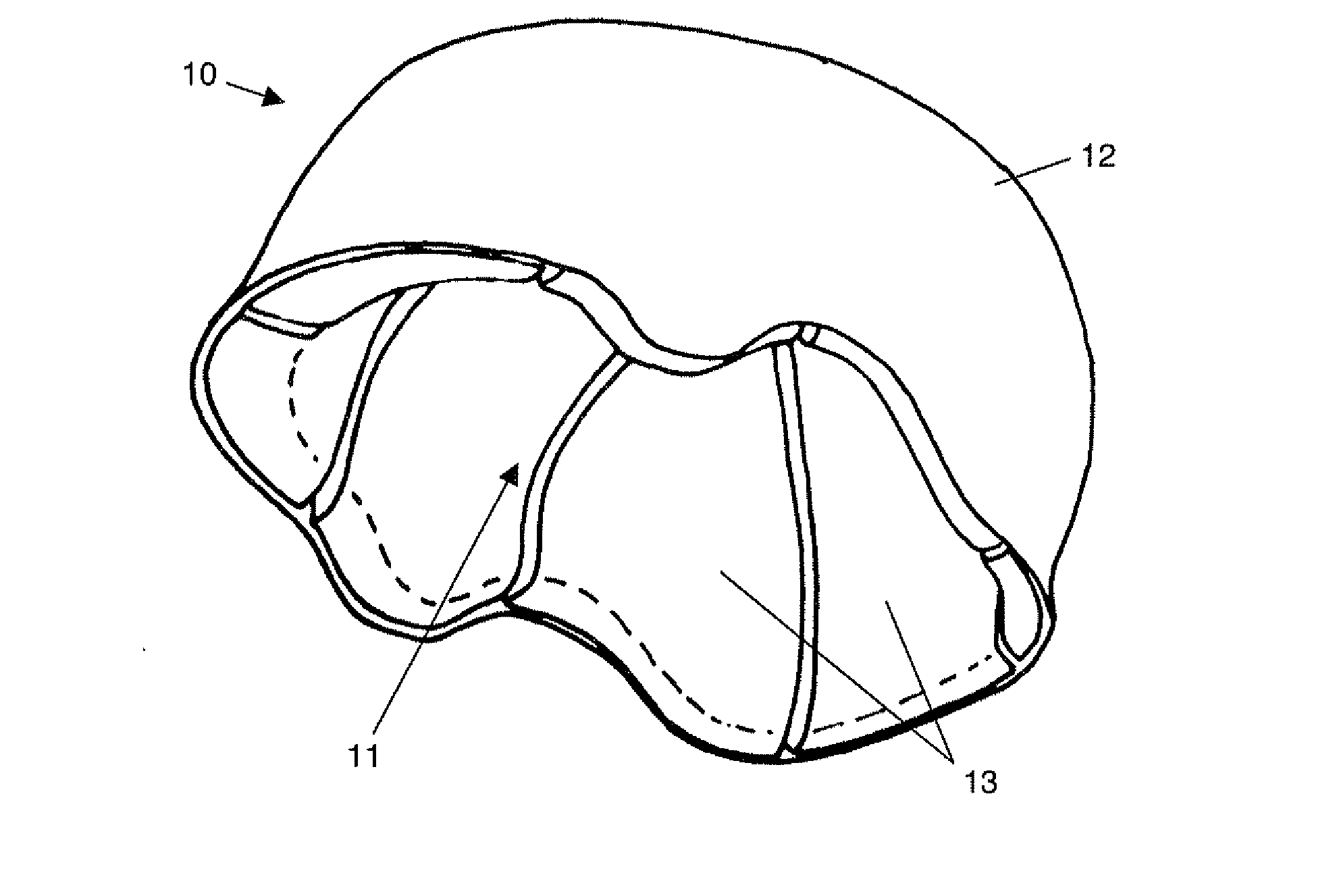

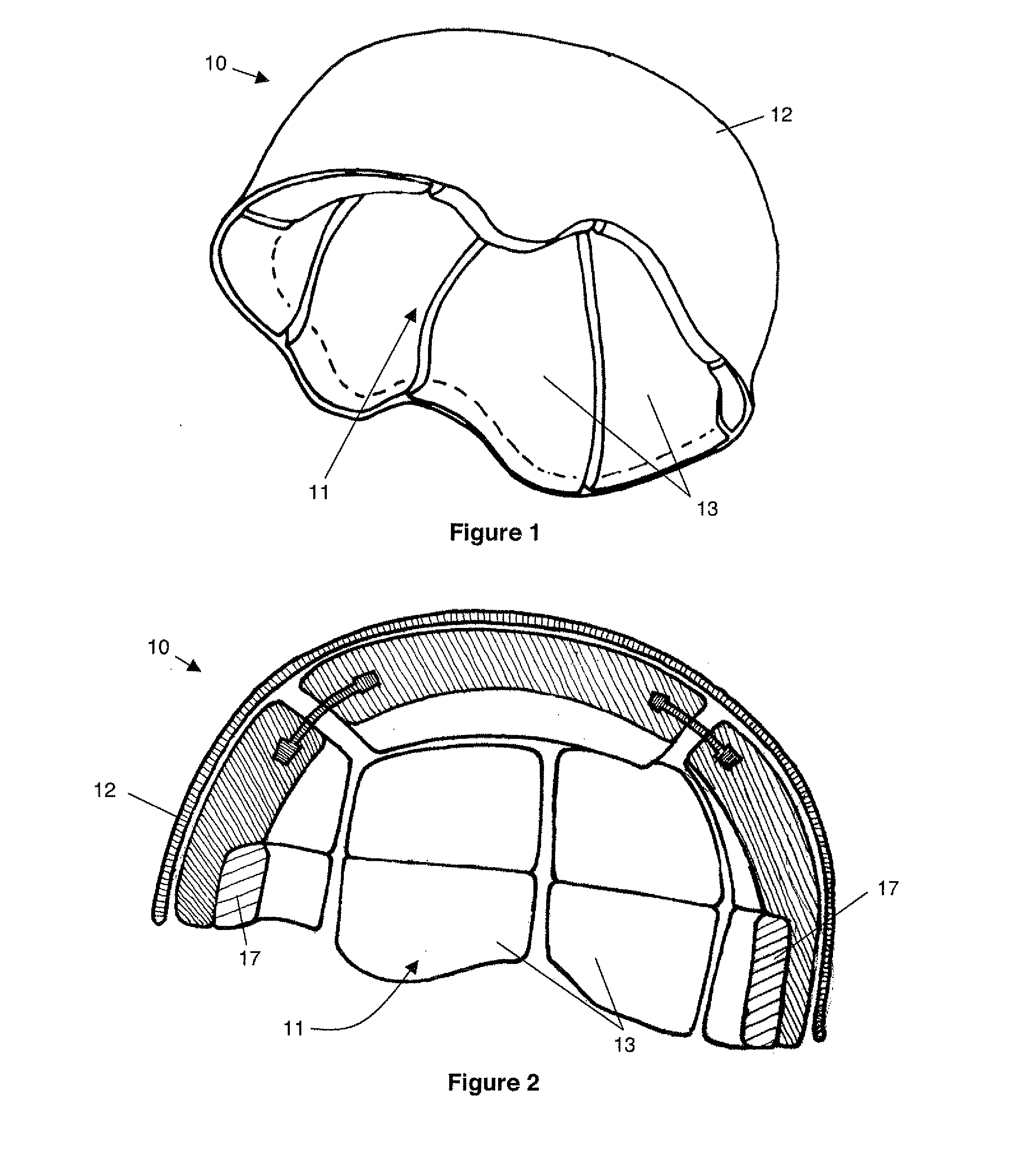

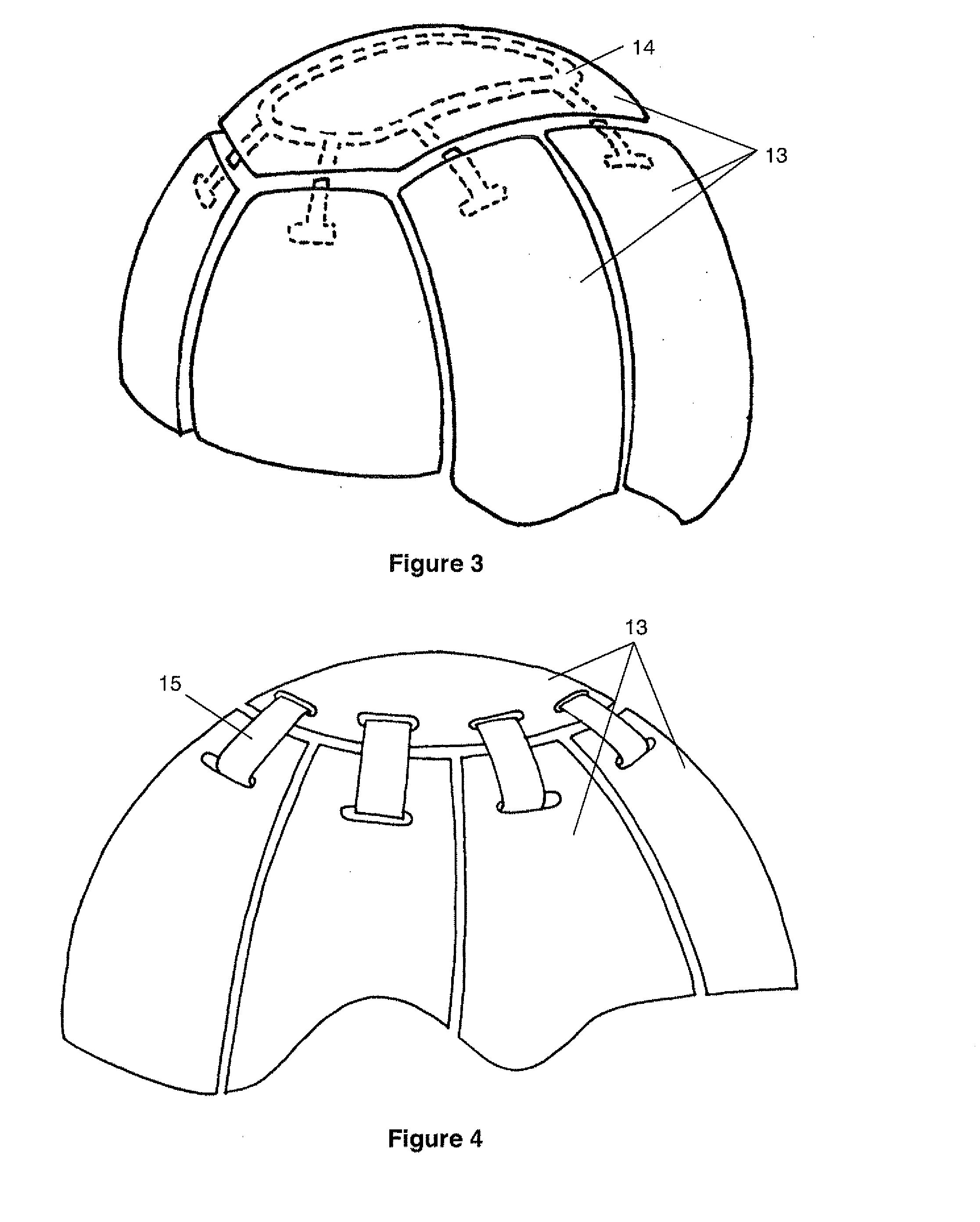

Deformable safety helmet

InactiveUS8850622B2Guaranteed StrengthAutomatically adjusts to morphology of user 's headHatsHeadwear capsEngineeringExpanded polystyrene

A safety helmet includes damping elements for example made from expanded polystyrene added onto a shell made from an elastically deformable material. The whole of the surface, facing the shell, of the damping elements arranged along the periphery of the opening is positioned against the shell to form an inner supporting belt completely in contact with the shell. The helmet is arranged in such a way that a position of the head in the cavity of the helmet causes a deformation of the supporting belt by elastic deformation of the shell according to the morphology of the head, generating permanent tightening of the supporting belt against the head in substantially uniform manner along the supporting belt.

Owner:KUJI SPORTS

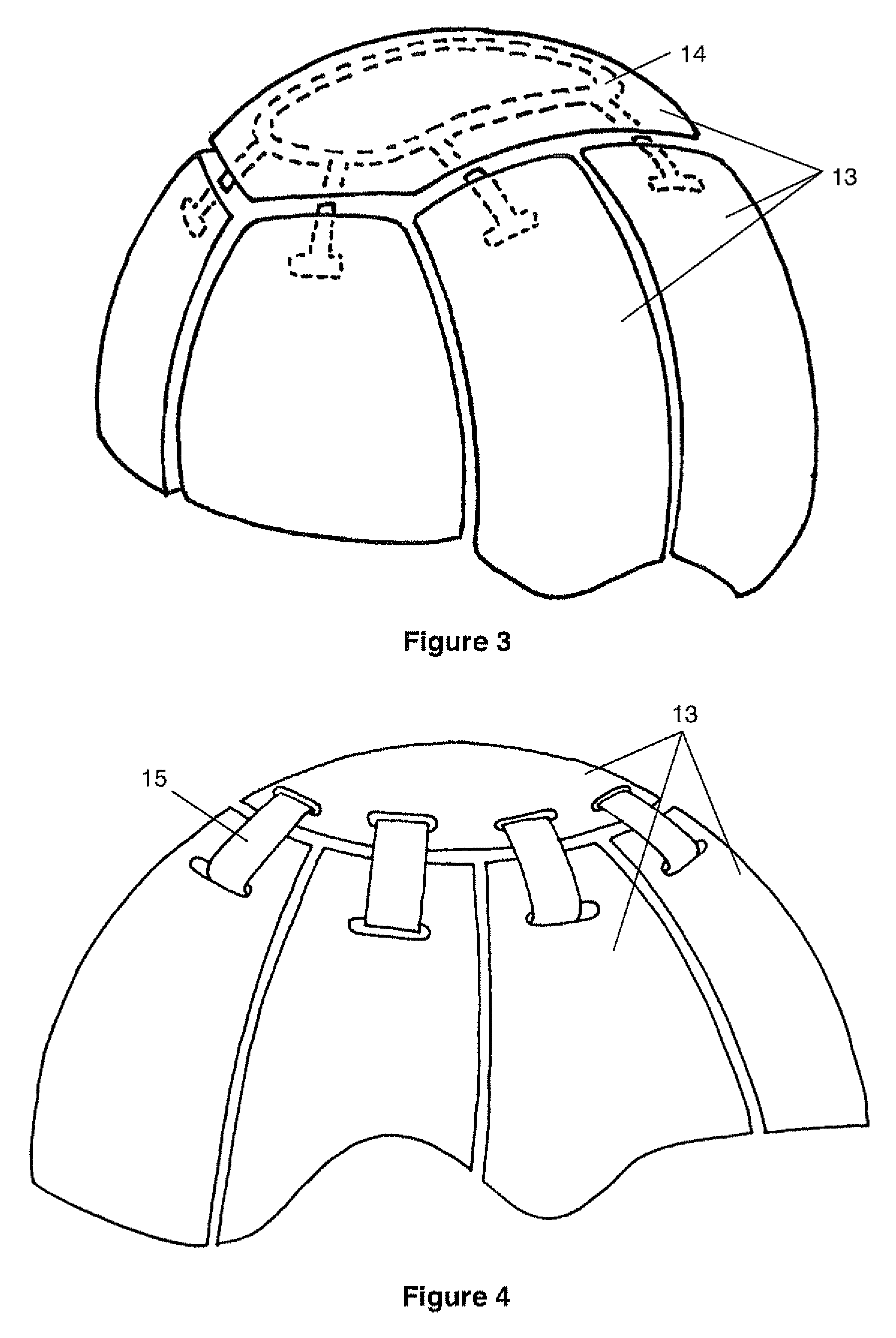

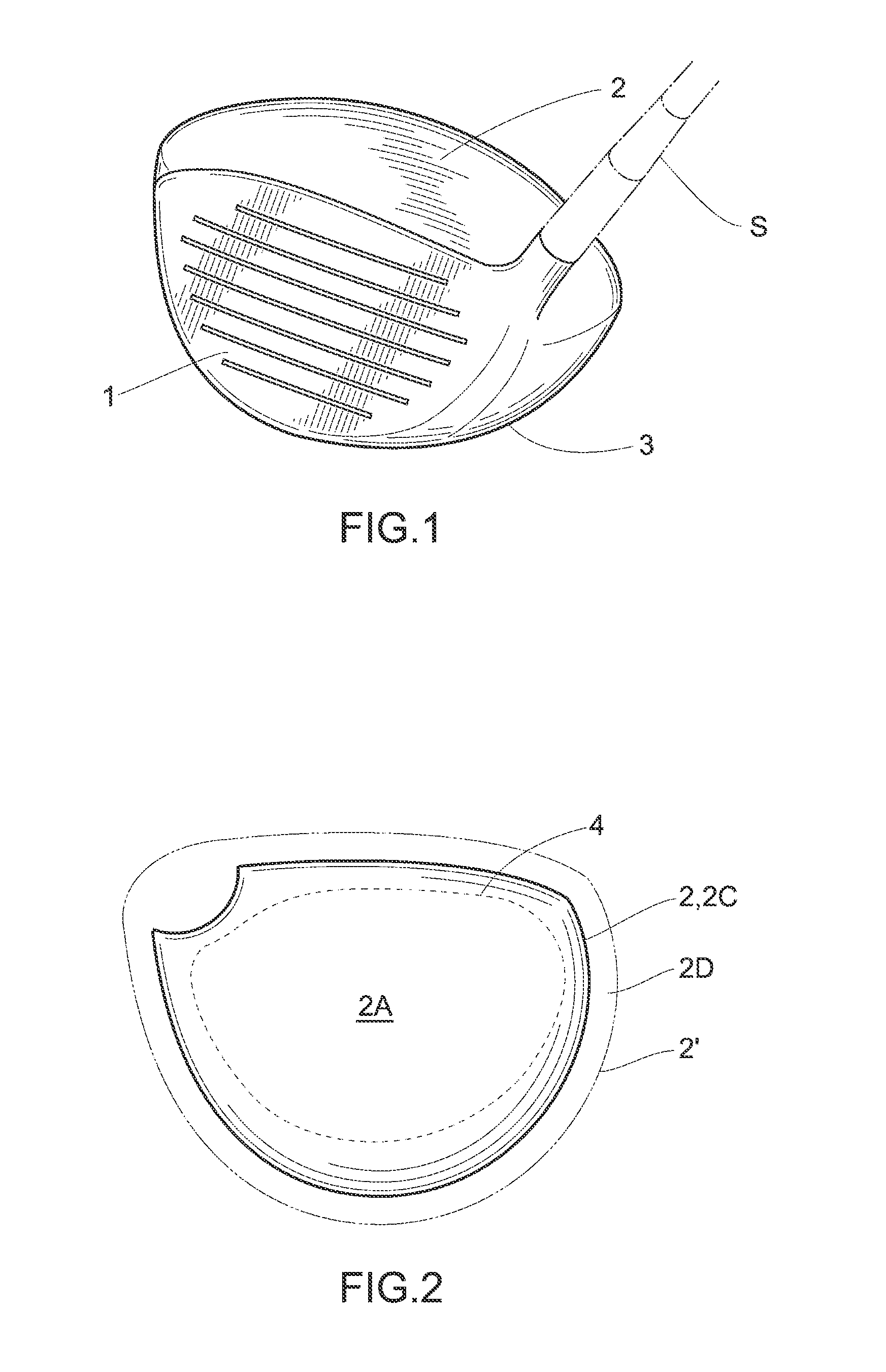

Hollow golf club head

InactiveUS8540590B2Improve performanceIncrease freedomGolf clubsStringed racketsRepulsion forceAlloy

There is provided a Ti alloy hollow club head which is more lightweight yet capable of realizing a better repulsion force by adjusting weight and thickness of a club head plate, with its strength ensured. Ribs are formed by chemically polishing the inner surface of a material of a crown plate to a 0.3 to 0.9 mm thickness, and a 0.3 to 4 mm width, and then first concave portions are formed to a 0.2 to 0.5 mm thickness. Thus, strength of the crown plate can be ensured by the ribs, while making the thickness thereof as thin as possible.

Owner:ENDO MFG COMPANY

Deformable safety helmet

InactiveUS20120047635A1Improve protectionAutomatically adjusts to morphology of user 's headHelmetsHelmet coversExpanded polystyreneSupport belt

A safety helmet includes damping elements for example made from expanded polystyrene added onto a shell made from an elastically deformable material. The whole of the surface, facing the shell, of the damping elements arranged along the periphery of the opening is positioned against the shell to form an inner supporting belt completely in contact with the shell. The helmet is arranged in such a way that a position of the head in the cavity of the helmet causes a deformation of the supporting belt by elastic deformation of the shell according to the morphology of the head, generating permanent tightening of the supporting belt against the head in substantially uniform manner along the supporting belt.

Owner:KUJI SPORTS

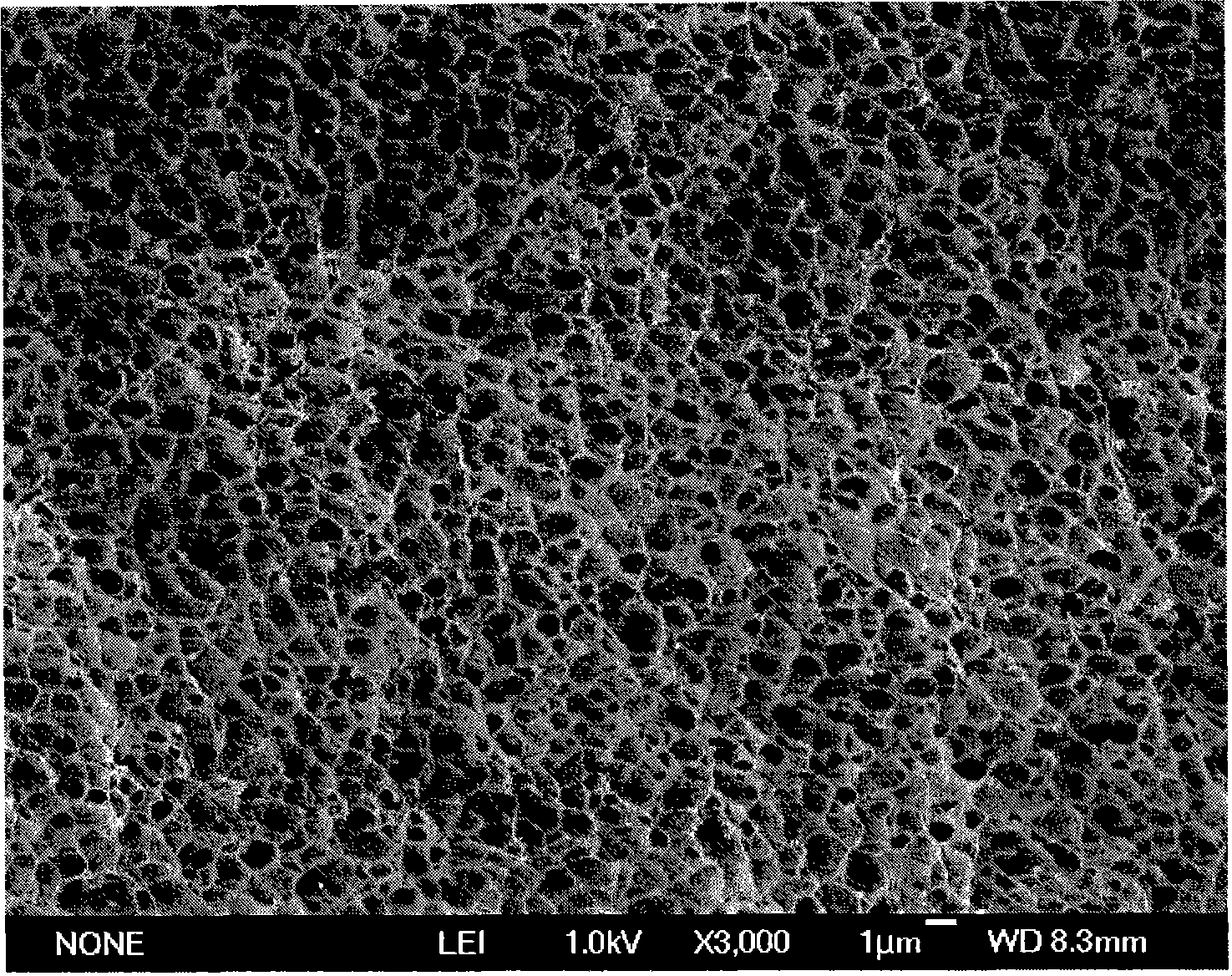

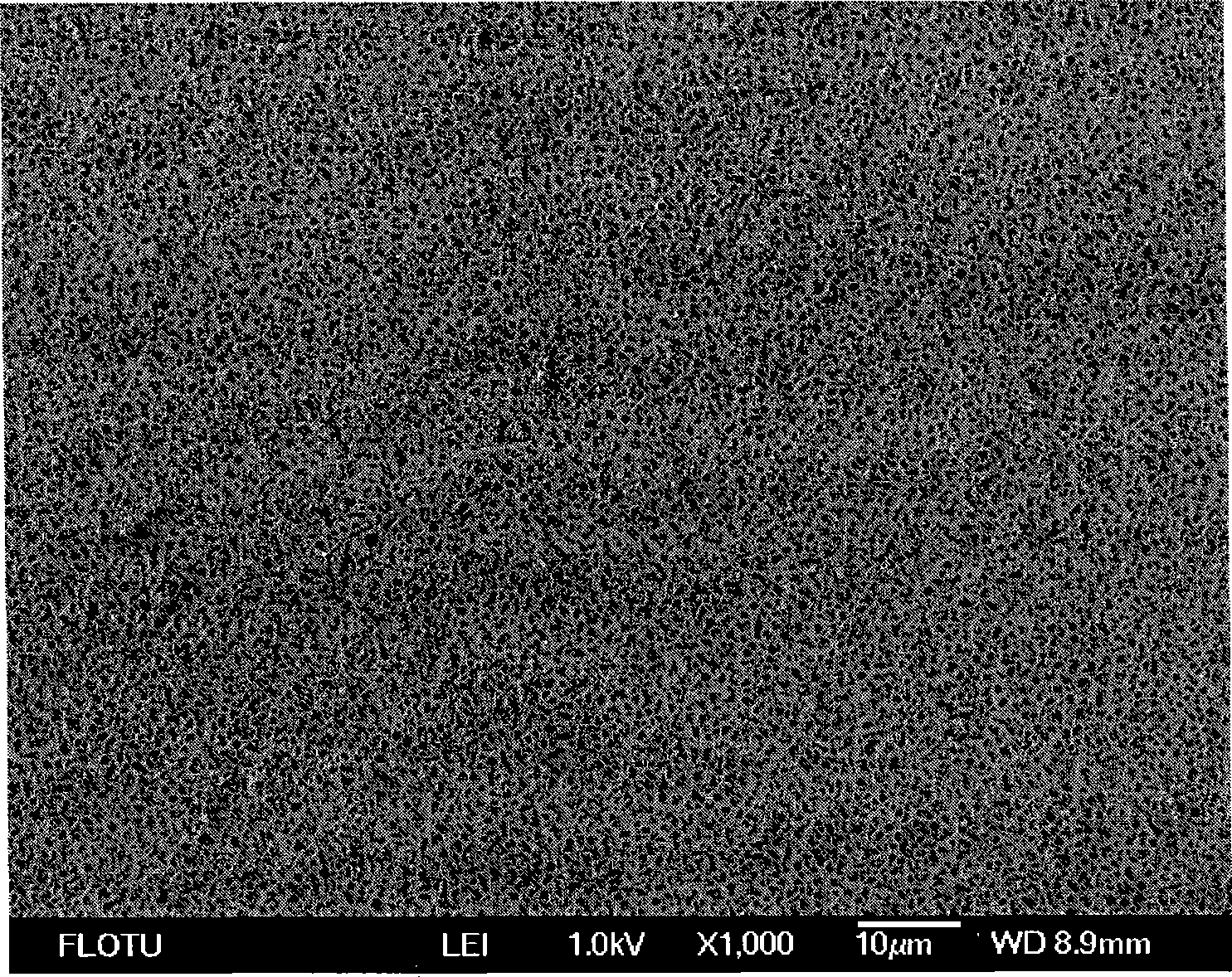

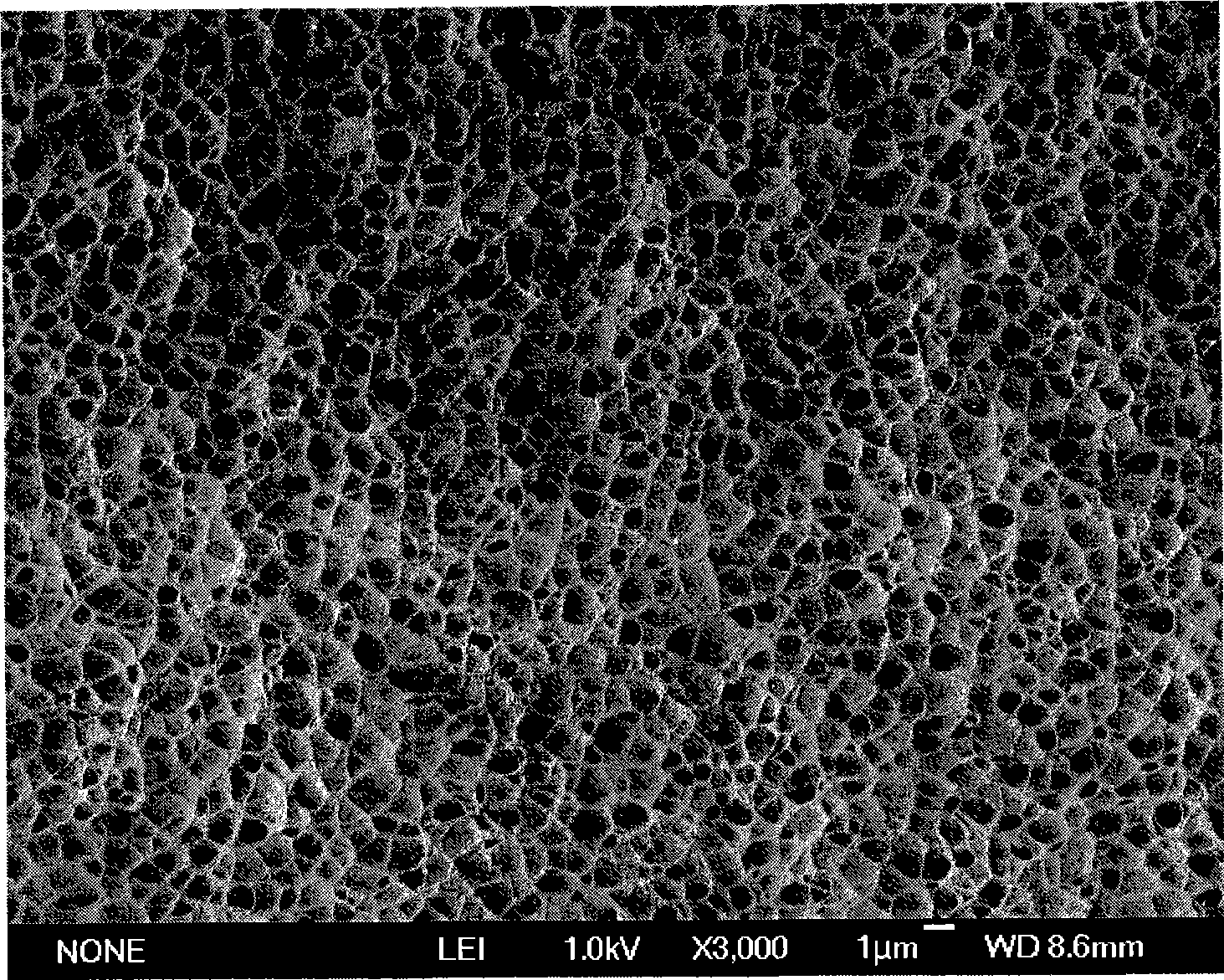

Method for preparing polyvinylidene fluoride porous membrane

ActiveCN101362057AGuaranteed StrengthGuaranteed high water fluxSemi-permeable membranesMembranesHollow fibreFiber

Owner:TSINGHUA UNIV

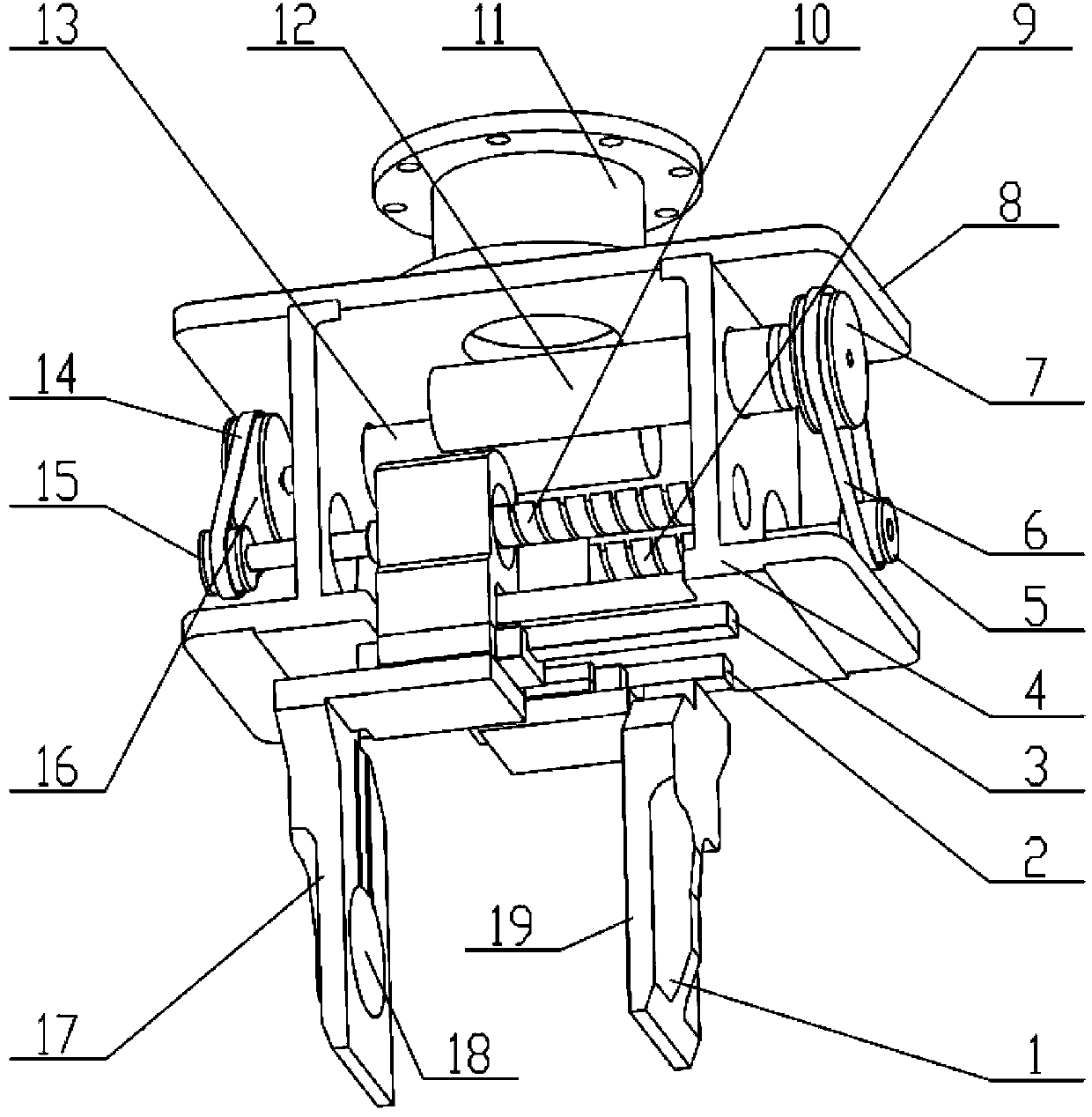

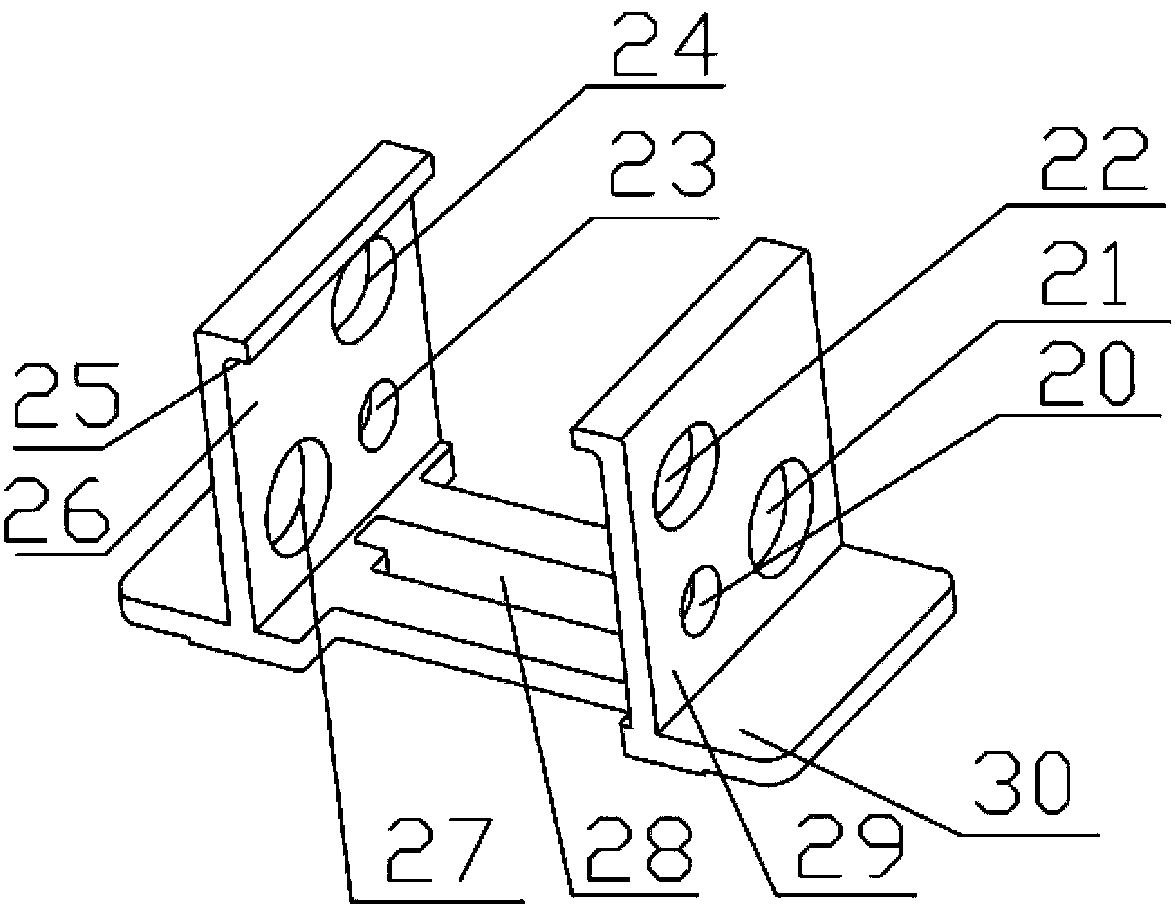

Double-finger double-driving translation clamping type flexible grip and control method

The invention discloses a double-finger double-driving translation clamping type flexible grip and a control method. The double-finger double-driving translation clamping type flexible grip comprises double servo motor systems, double motor end synchronous pulleys, double positioning sliding guide rail systems, double ball screw systems, double screw synchronous pulleys, double finger paws, a U-shaped main rack of the grip and a main rack cover plate, wherein the coordinating fetching action of two paws is realized by the control on two servo motors. A fetching method is characterized in that the double motors are used as power, double fingers are respectively fixedly arranged on two screw guide rail synchronous switching modules, through the rotation of two synchronous toothed belts between the double motor end synchronous pulleys and the ends of the double screw end synchronous pulleys, the rotation of the motor is converted into linear motion by a screw, so that the double fingers are translated respectively along two positioning sliding guide rails, and the translation switching on and off of the double paws along double guide rail surfaces can be realized. Due to the fact that the device is used for independently driving the corresponding paws to move by the double motors, so that the double fingers can more flexibly move, and different fetching speeds can be set for the double fingers, and the position precision is high.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

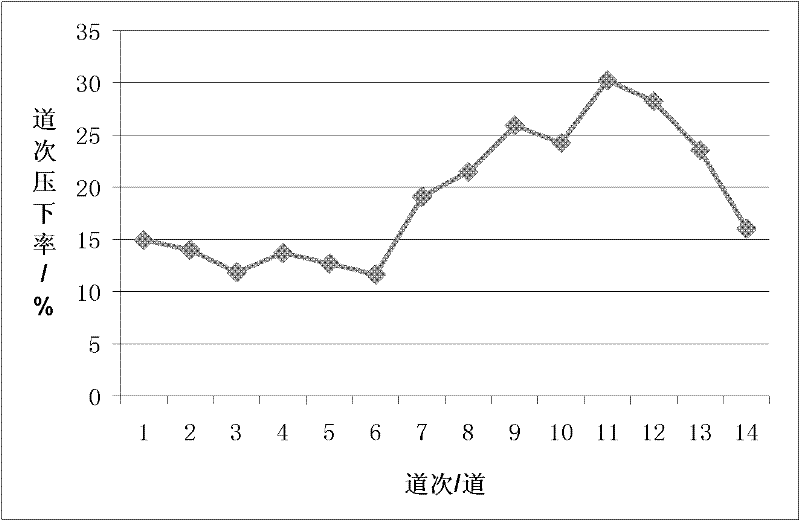

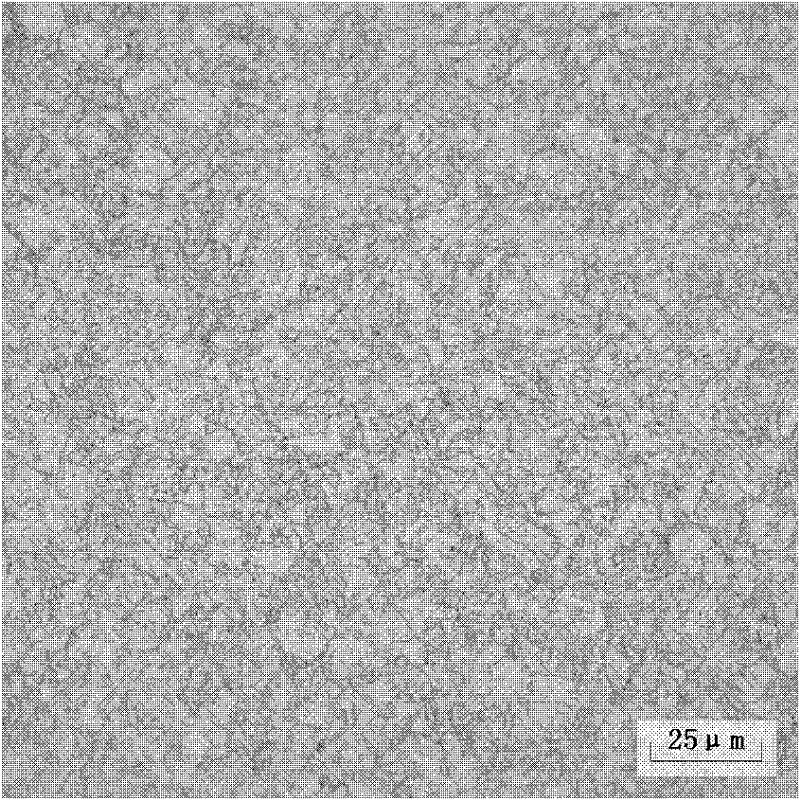

Ultrahigh-strength structural steel board for ocean engineering and production method thereof

The invention relates to an ultrahigh-strength structural steel board for ocean engineering and a production method thereof, belonging to the technical field of ultrahigh-strength steel. A board blank comprises the following components: 0.05-0.13% of C, 0.1-0.4% of Si, 0.7-1.7% of Mn, 0.01-0.04% of Alt, 0.02-0.05% of Nb, 0-0.05% of V, 0.008-0.02% of Ti, 0-0.6% of Cr, 0.2-0.4% of Mo, 0.15-0.8% of Ni, 0-0.5% of Cu, 0-0.0011% of B, less than 0.01% of P, less than 0.005% of S, less than 0.0010% of O, less than 0.005% of N, less than 0.00015% of H, and the balance of Fe and inevitable impurities, wherein Nb+V+Ti is not more than 0.12%. Aiming at different thickness standards, different chemical component as well as rolling and heat treatment process parameters are adopted. The production process comprises the steps of molten iron desulfurization, converter top and bottom blowing, vacuum treatment, continuous casting, controlled rolling and controlled cooling, quenching and tempering. The steel board has the advantages that: the production cost is lower, and the comprehensive mechanical properties can meet the requirements of the steel for the ocean engineering for various mechanical properties.

Owner:SHOUGANG CORPORATION +1

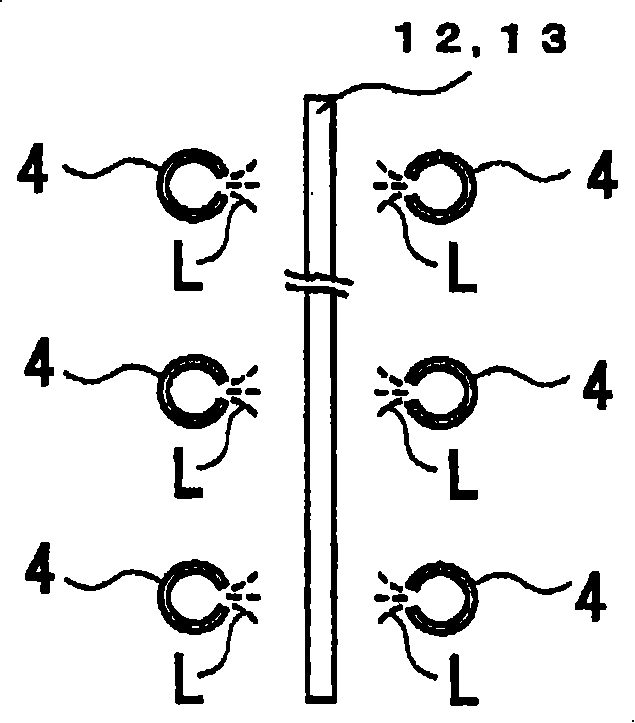

Armature Core, Motor Using It, and Its Manufacturing Method

InactiveUS20100225195A1High magnetic flux densityPrevents impairment of motor characteristicMagnetic circuit rotating partsPositive displacement pump componentsMagnetic fieldElectric motor

An object is to enable simple manufacture of a motor, especially, a stator core or a field without impairment of motor characteristics. The motor includes a shaft, a rotor fixed to the shaft, and a stator including a stator core that faces the rotor with a certain space therebetween and coils that are attached to the stator core. The stator includes a back yoke, and the stator core having a plurality of teeth that are circumferentially placed in an axial end face of the back yoke so as to stand upright axially of the back yoke, and that are formed of a dust core made of pressed magnetic powder. The above-mentioned teeth are buried axially to a certain depth in the back yoke.

Owner:DAIKIN IND LTD

High-strength high ductility gas protecting welding stick

InactiveCN101234457ASimple welding processStable welding wire qualityWelding/cutting media/materialsSoldering mediaChemical compositionUltra fine

The invention relates to a gas shielded welding wire with high strength and high toughness, which solves the defects that the existing strength grade in the technical field is unsuitable for market demand and is of high cost. The technical scheme of the invention is that the components of the welding wire (according to the weight percentage) are as follows: 0.04 to 0.10 of C, 0.30 to 0.80 of Si, 1.30 to 2.0 of Mn, 0.40 to 0.89 of Ni, 0.20 to 0.50 of Cr, 0.20 to 0.60 of Mo, 0.56 to 0.80 of Cu, 0.05 to 0.20 of Ti, 0.002 to 0.010 of B, less than 0.020 of P, less than 0.015 of S, less than 0.03 of Als and the rest of Fe and inevitable impurities. The welding wire of the invention has stable quality. The mechanical property of a deposited metal is that Rel is equal to 810MPa; Rm is equal to 840MPa; A is equal to 16 percent and Z is equal to 66 percent. The average impact power AKV in minus 20 DEG C is 141J; and the average impact power AKV in minus 40 DEG C is 128J; and the average impact power AKV in minus 60 DEG C is 70J. The welding wire is suitable for gas shielded welding of 800MPa grade of ultra-fine steel; as the content of Ni is reduced, the cost of the welding wire is reduced dramatically and the implementation is easy.

Owner:WUHAN IRON & STEEL (GROUP) CORP

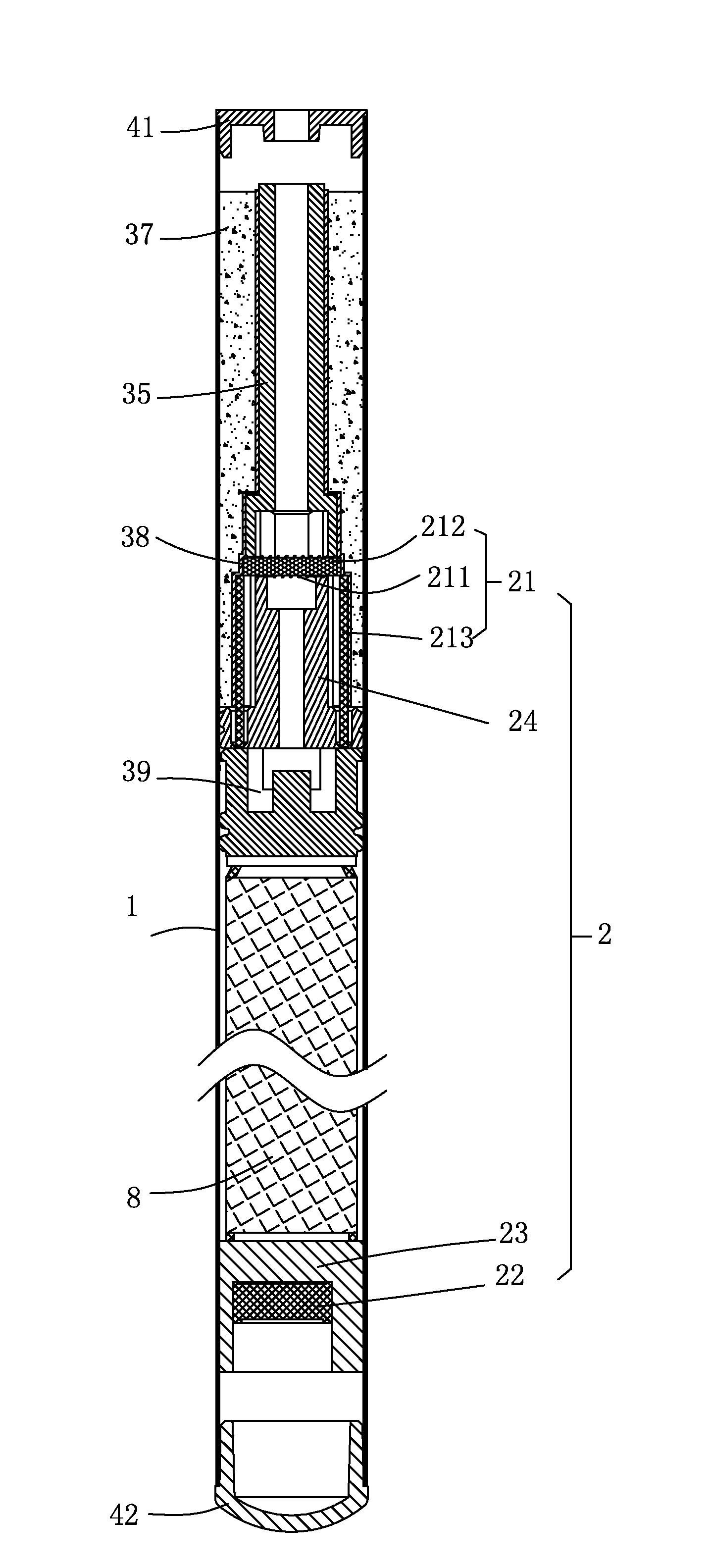

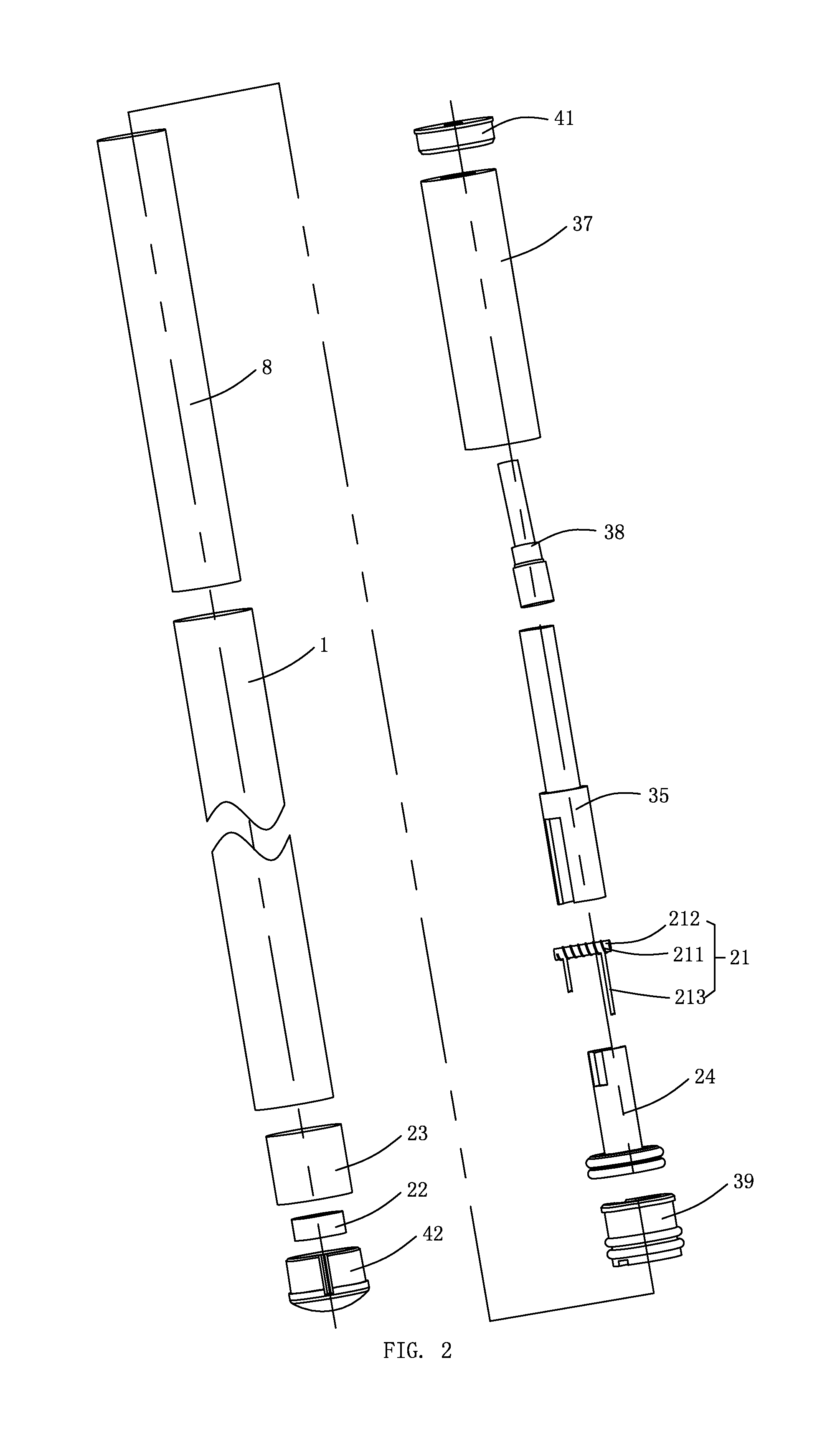

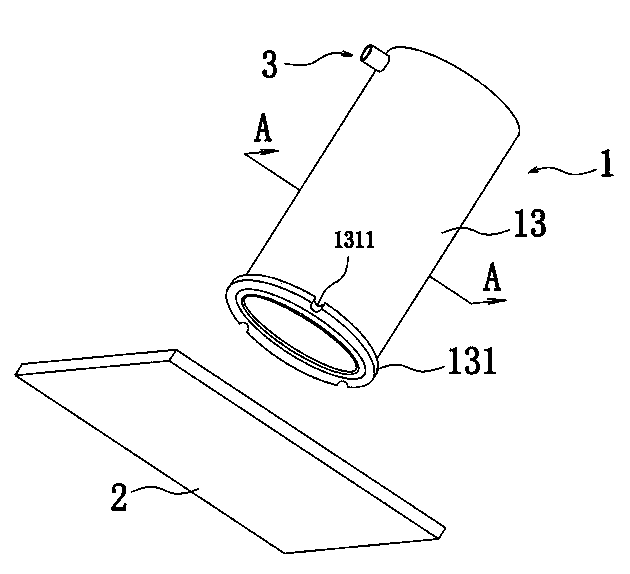

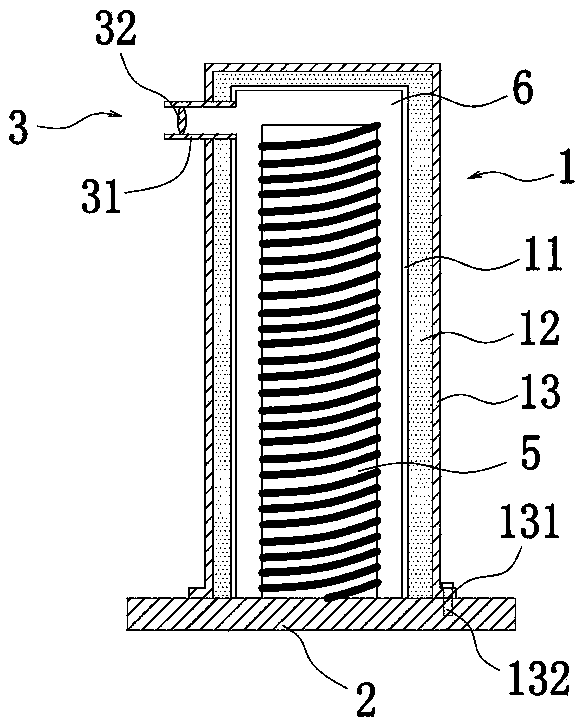

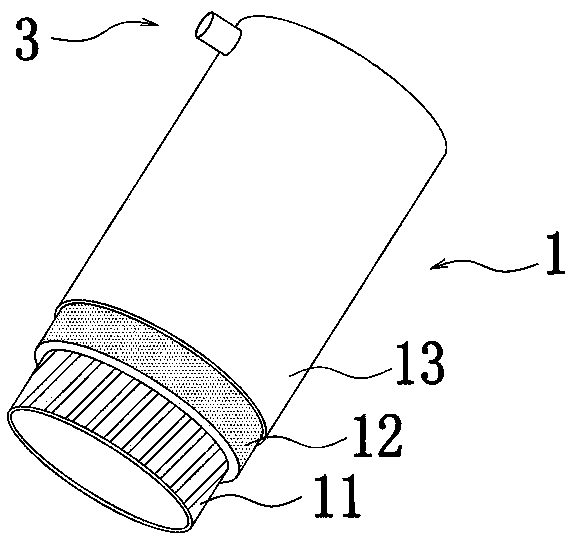

Organic cotton electronic cigarette

InactiveUS20140338684A1Stable internal structureLow costTobacco pipesTobacco devicesGlass fiberElectricity

An organic cotton electronic cigarette includes a liquid storage component and an atomization device. The atomization device includes a hollow spiral tubular electric heater coil and a liquid guiding member passing through the electric heater coil. The liquid guiding member is made from organic cotton free of glass fiber material. The atomization device further includes a smoke guiding tube passing through the liquid storage component for supporting the same and working as a smoke path. The smoke guiding tube includes an external casing and an internal casing one of which is inserted into another one so as to hold the liquid guiding member between the two. The two ends of liquid guiding member extend out of the smoke guiding tube and are tightly pressed against an inner wall of the liquid storage component. This kind of electronic cigarette is safe to human body and has stable internal construction.

Owner:HUIZHOU KIMREE TECH

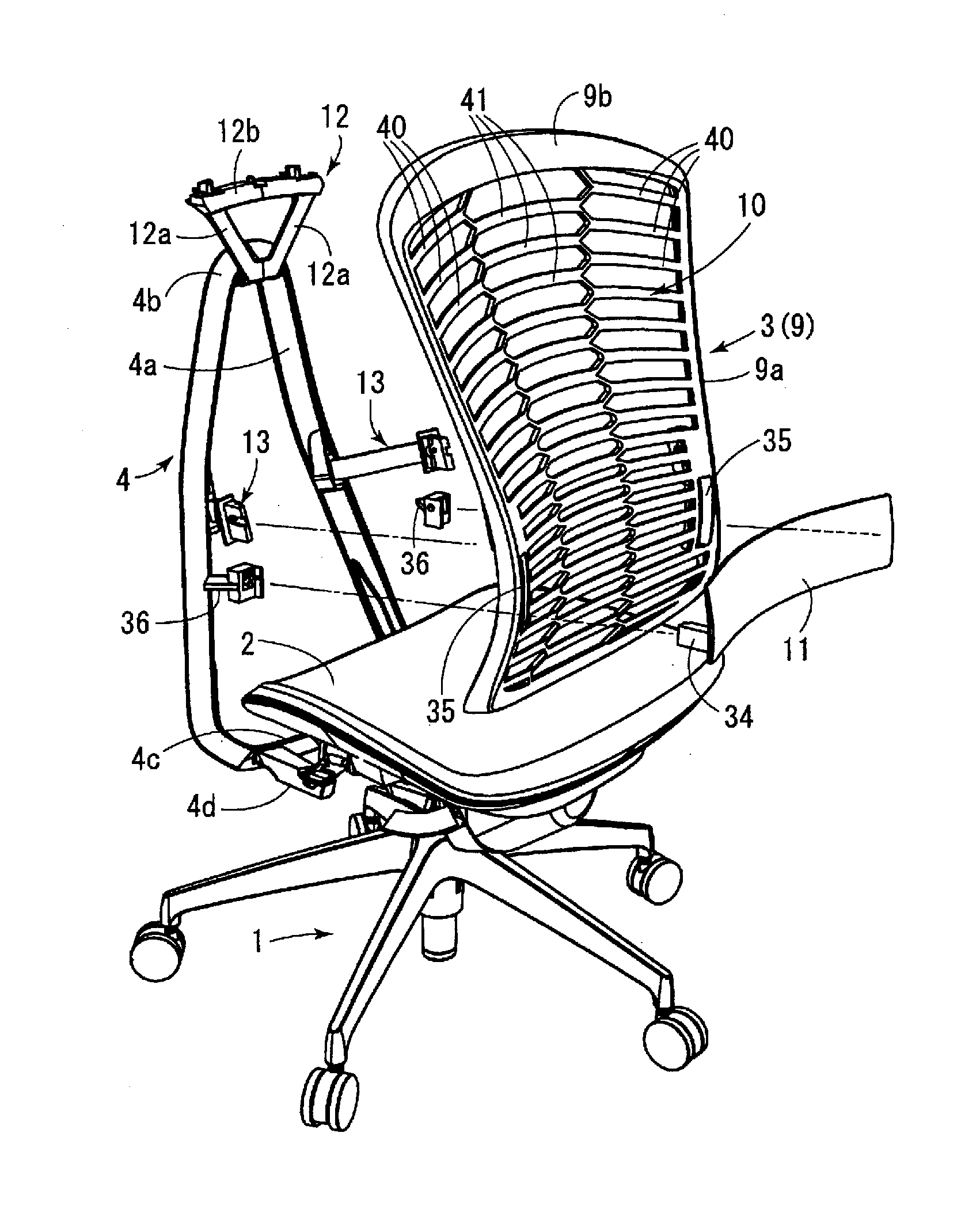

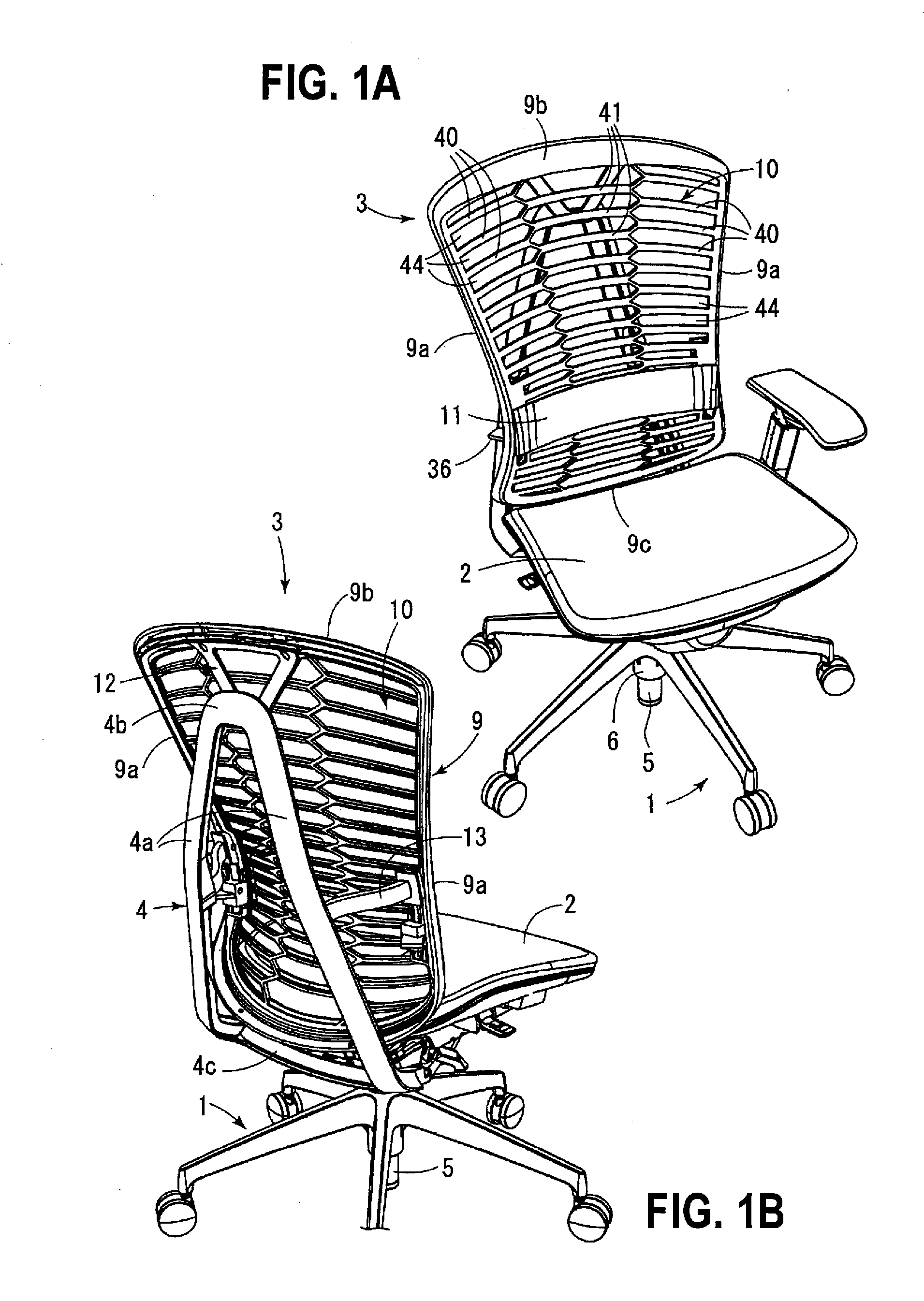

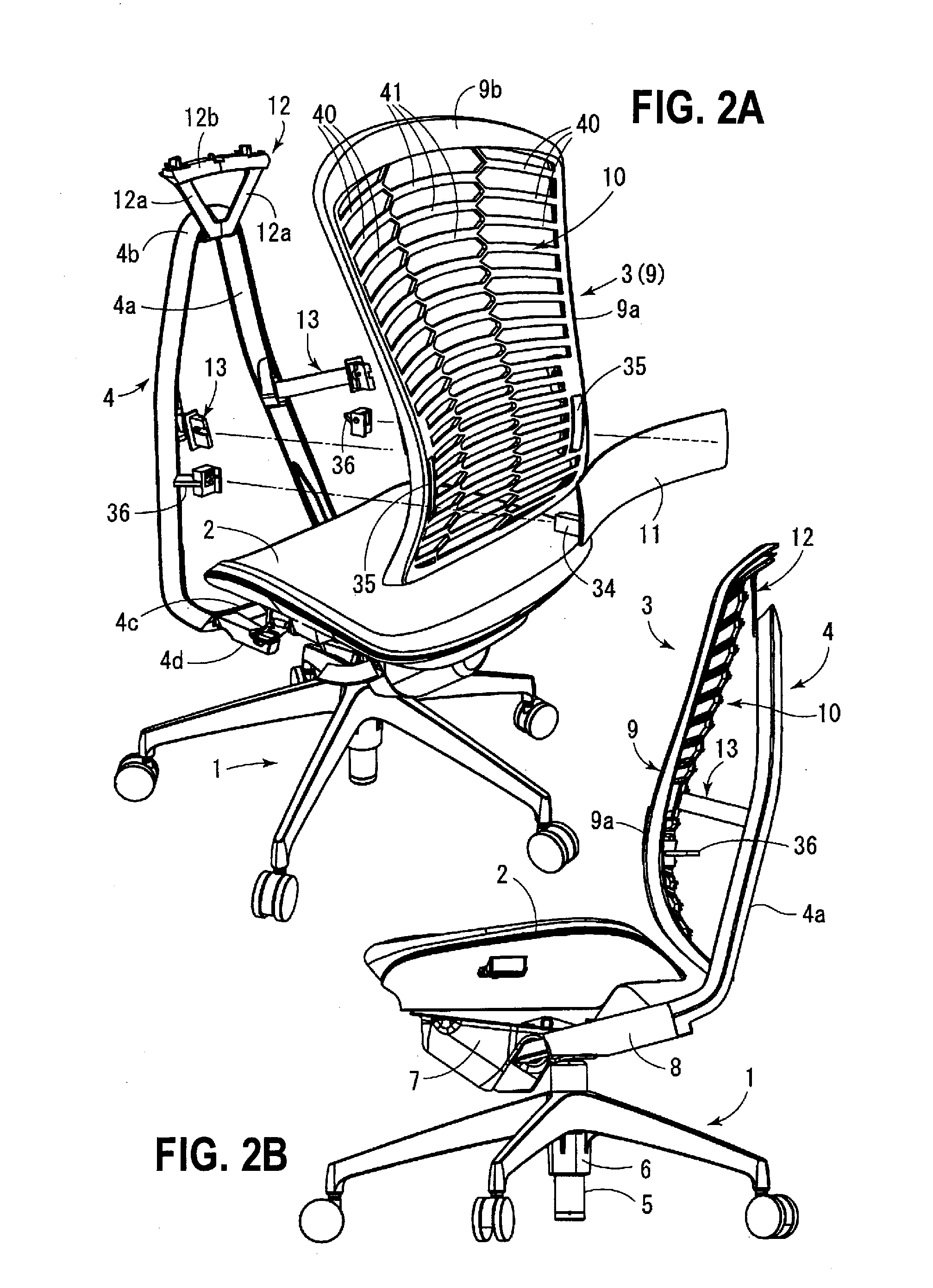

Chair

InactiveUS20160135603A1Improve stateEnsure strengthStoolsAdjustable chairsEngineeringRigid structure

A chair includes a seat, a backrest and a back frame having a rigid structure and arranged behind the backrest with an interval in between. The backrest is attached to the back frame by a first support device arranged at a height position close to an upper end of the backrest and by a second support device arranged at a position lower than the first support device and higher than a seat surface. The first support device is attached to a part close to a right-left middle part of the upper end part in the backrest. The second support device is attached to a left end part and a right end part of the backrest.

Owner:ITOKI CORP

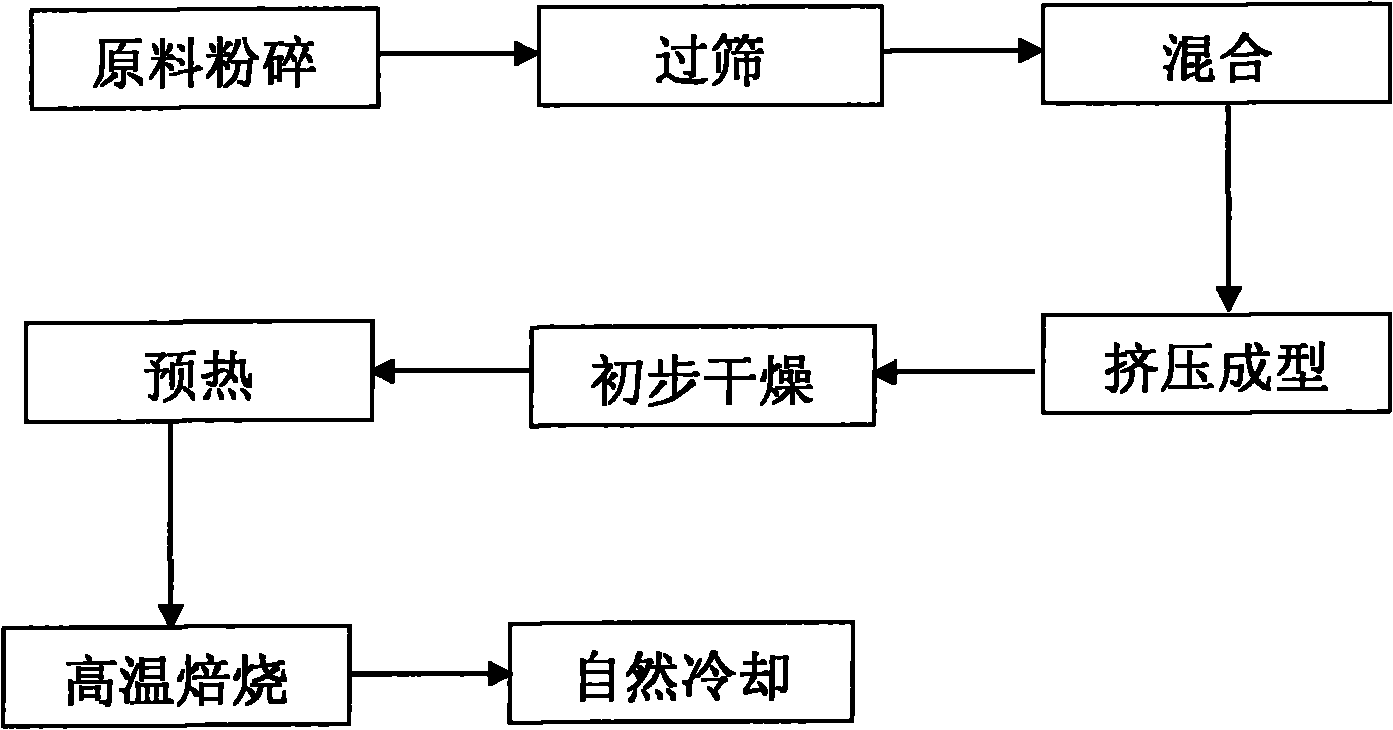

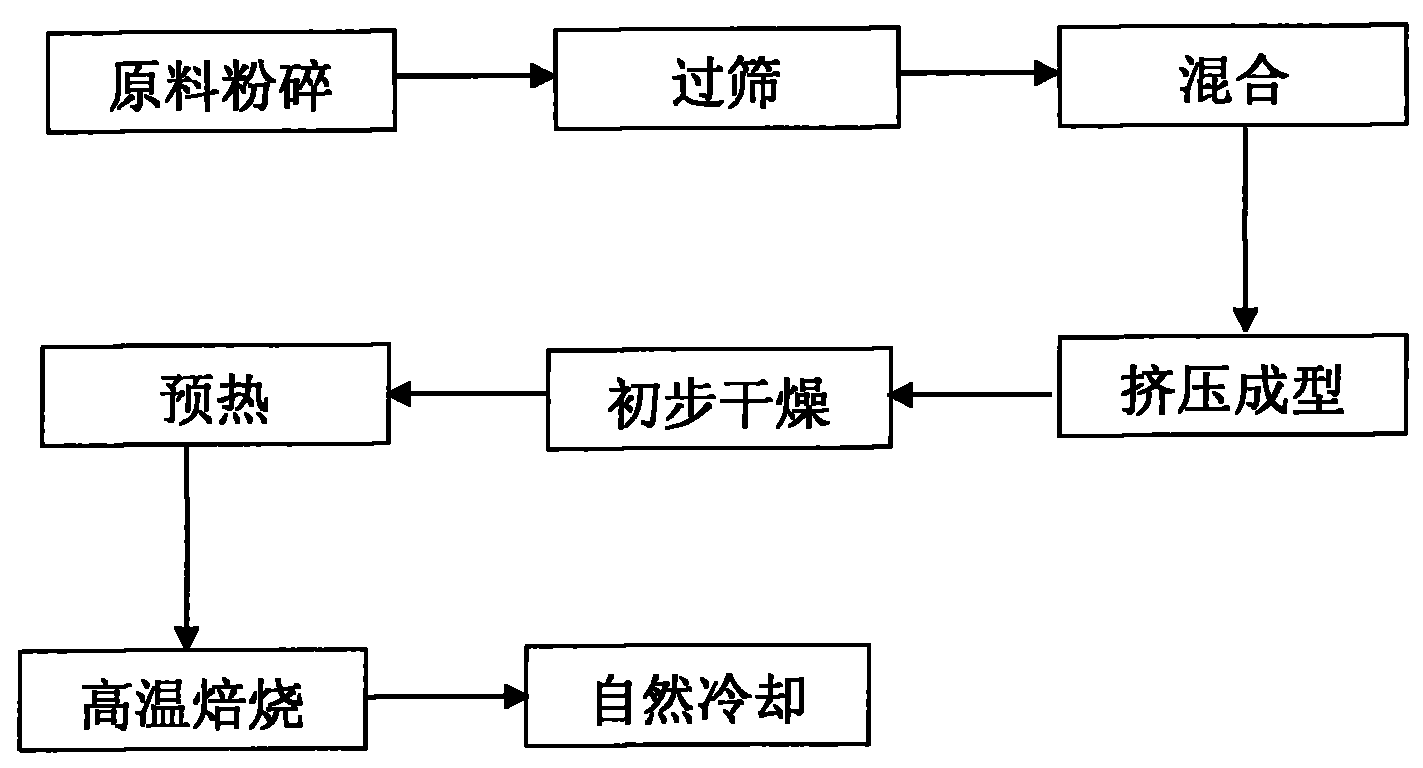

Purpose of heavy metal sludge, acid pellet and preparation method and purpose thereof

ActiveCN101805827AEnsure the quality of the furnaceImproving the Blast Furnace Charge StructureBlast furnace detailsHeavy metalsSludge

The invention discloses a purpose of heavy metal sludge, an acid pellet and a preparation method and a purpose thereof. The invention takes stainless steel cold-rolling heavy metal sludge as a raw material for preparing the acid pellet of the sludge. The acid pellet of the sludge is mainly prepared by the following raw materials by weight percent: 5-50 percent of stainless steel cold-rolling heavy metal sludge, 30-70 percent of iron ore concentrate, 2-8 percent of composite binding agent, 4-15 percent of carbon powder and 10-30 percent of water. The preparation method of the acid pellet of the sludge comprises the main steps of pretreatment of raw materials, mixing of raw materials, pelletizing and roasting. The acid pellet of the sludge is used as a raw material of a blast furnace. The invention solves the problems that the prior art can not effectively treat and comprehensively utilize the stainless steel cold-rolling heavy metal sludge.

Owner:BAOSHAN IRON & STEEL CO LTD

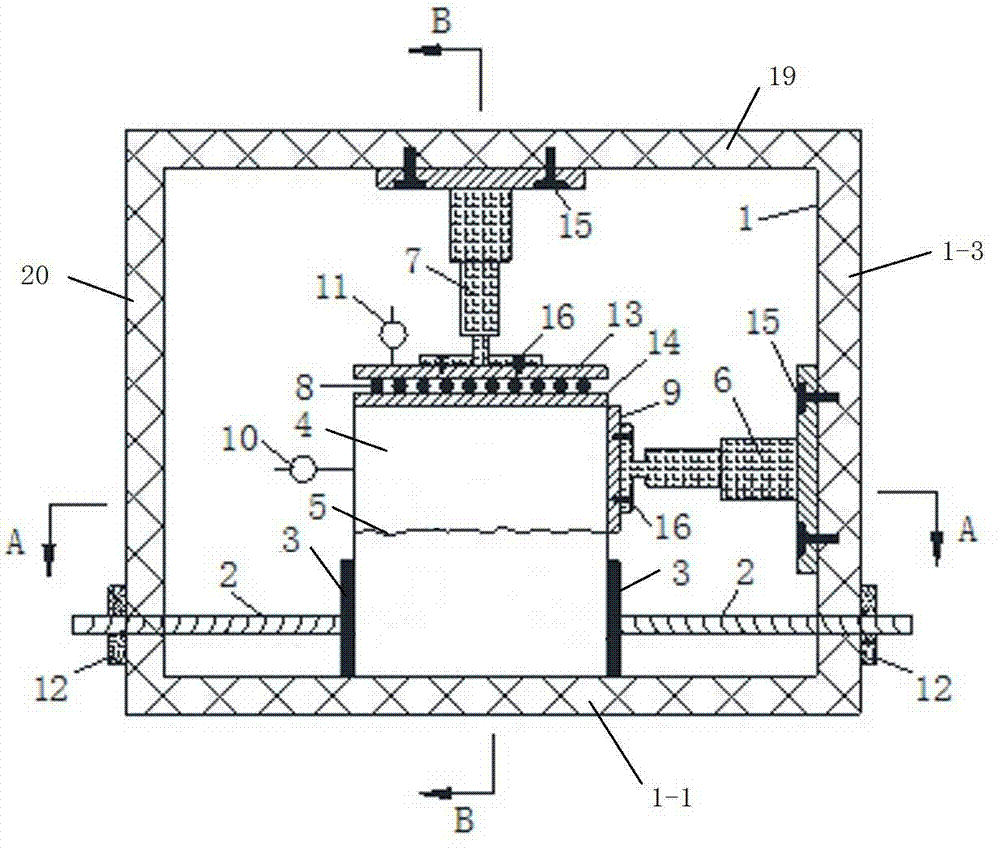

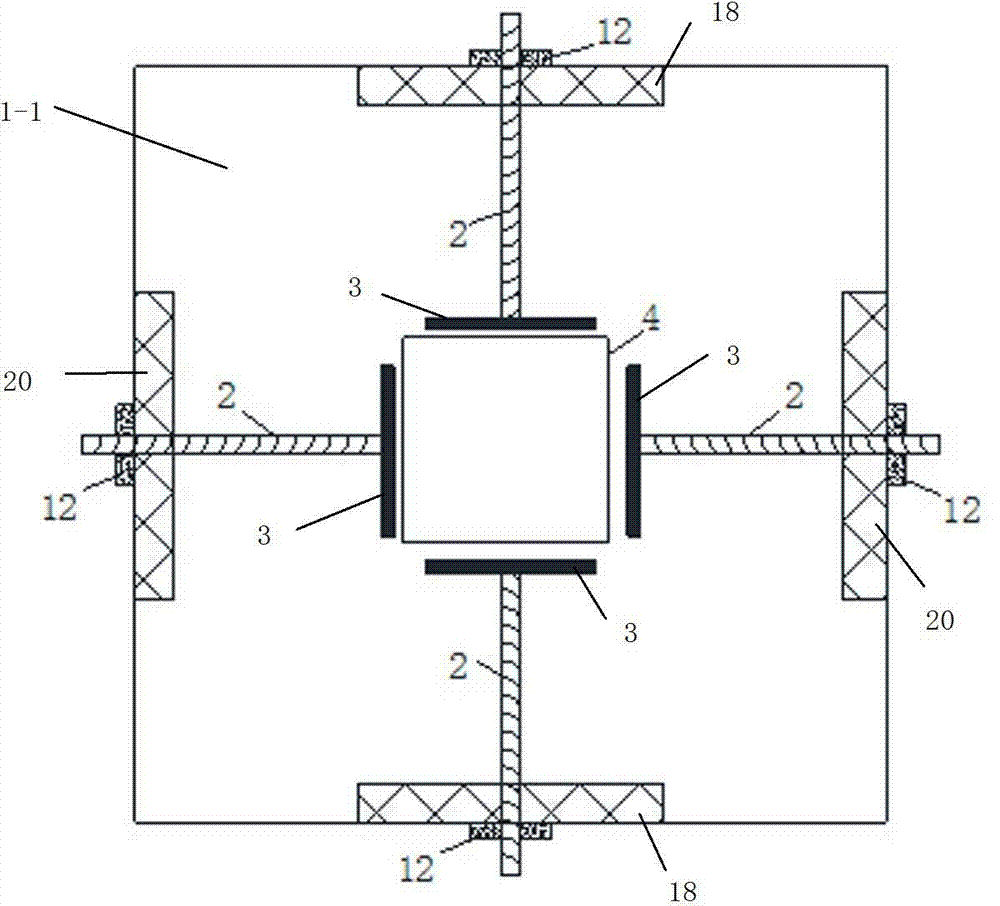

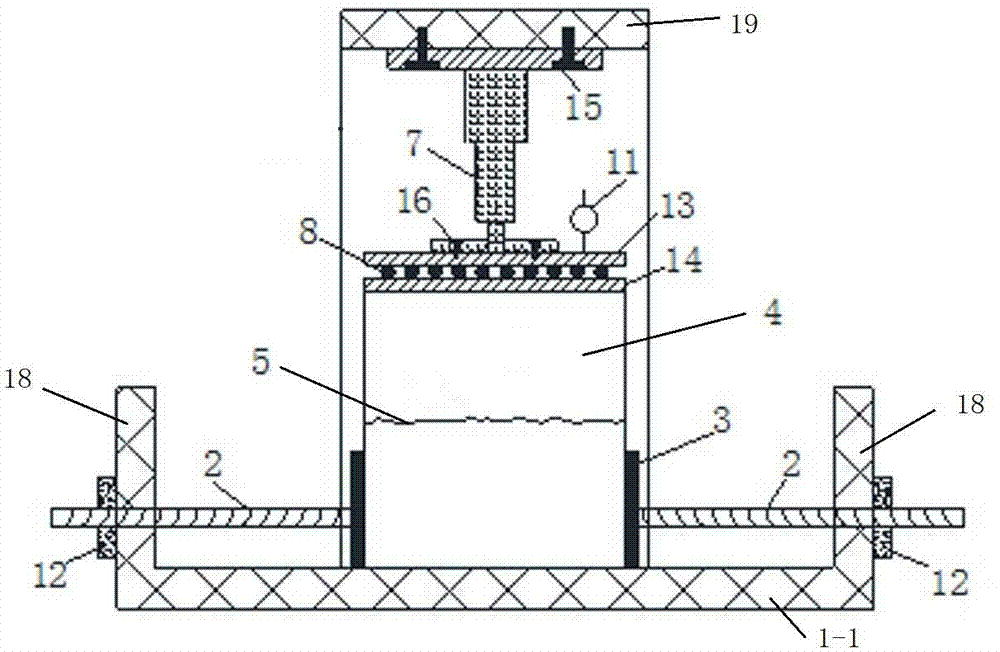

Rock mass structural surface shear test method and device

InactiveCN104749049AGuaranteed shear strengthGuaranteed StrengthMaterial strength using steady shearing forcesHorizontal axisSurface shear

The invention discloses a rock mass structural surface shear test method, which comprises the following steps of firstly, cutting a rock mass test piece into a cuboid and marking a vertical axis line and a horizontal axis line; then adjusting an adjusting rod, fixing the rock mass test piece by a movable steel baffle, enabling the vertical axis line of the rock mass test piece to coincide with the vertical axis line of a normal loading mechanism, enabling the horizontal axis line of the rock mass test piece to coincide with the horizontal axis line of a shear loading mechanism, and enabling the structural surface of the rock mass test piece to be located above the movable steel baffle; carrying out grading force application on the rock mass test piece by the normal loading mechanism from the vertical direction, and carrying out grading force application on the rock mass test piece by the shear loading mechanism from the horizontal direction; receiving the force application data of the normal loading mechanism and the shear loading mechanism and the displacement values of a normal displacement sensor and a horizontal displacement sensor by a computer, and analyzing and calculating the data. The invention also provides a rock mass structural surface shear test device. According to the invention, the stress bearing condition of a rock mass in the reality can be simulated, and test data are accurate and reliable.

Owner:WUHAN UNIV OF TECH

Construction material produced by utilizing industrial residue

The invention discloses a construction material produced from industrial residue, aims to provide a construction material having the advantages of light weight, sound insulation, heat insulation, low cost, fire resistance, dense products, high rigidity and the like, and solves the problems with land occupation and pollute environment of phosphate slag and phosphogypsum at the same time. the invention is realized through the following technical scheme: phosphate slag and phosphogypsum are used as raw materials for producing the construction material, which comprises the following components by the weight part: 35 to 65 parts of phosphate slag, 10 to 40 parts of phosphogypsum, 5 to 15 parts of lime, 15 to 28 parts of cement, 0.1 to 0.4 part of light aggregate, 0.02 to 0.05 part of soluble glass, 0.02 to 0.05 part of water-reducing agent, 0 to 0.004 part of retarding agent, 0 to 0.005 part of early-strength admixture, and 0 to 0.008 part of foam killer; the components are weighed by the formula weight part and added to a blender; water is added to the blender with the water-to-material proportion being 4 to 10 and mixed evenly with the materials; and the solution is cast into a die and natural air dried after molding. Dies with different structures can be used according to purposes to conduct cast molding. The construction materials such as wall plates, guardrail decoration pillars, door and window sleeves, vase sleeves and the like can be produced.

Owner:张勇飞

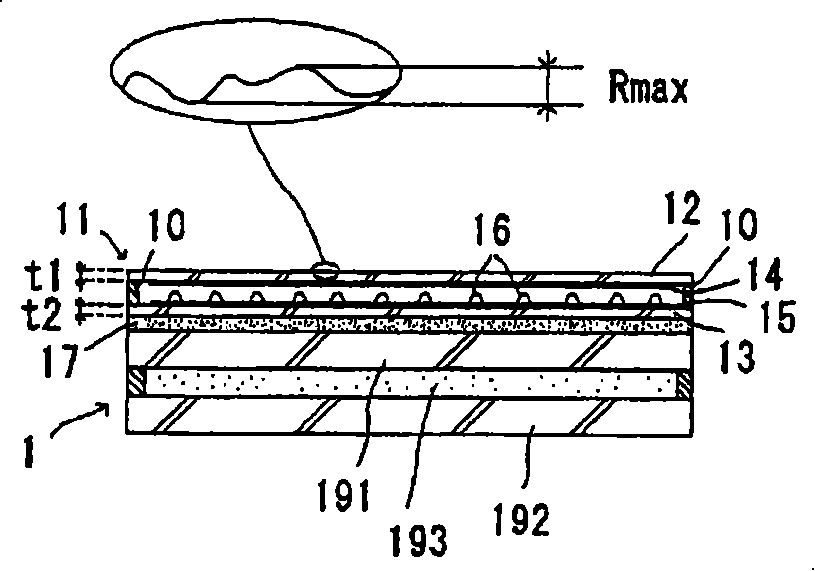

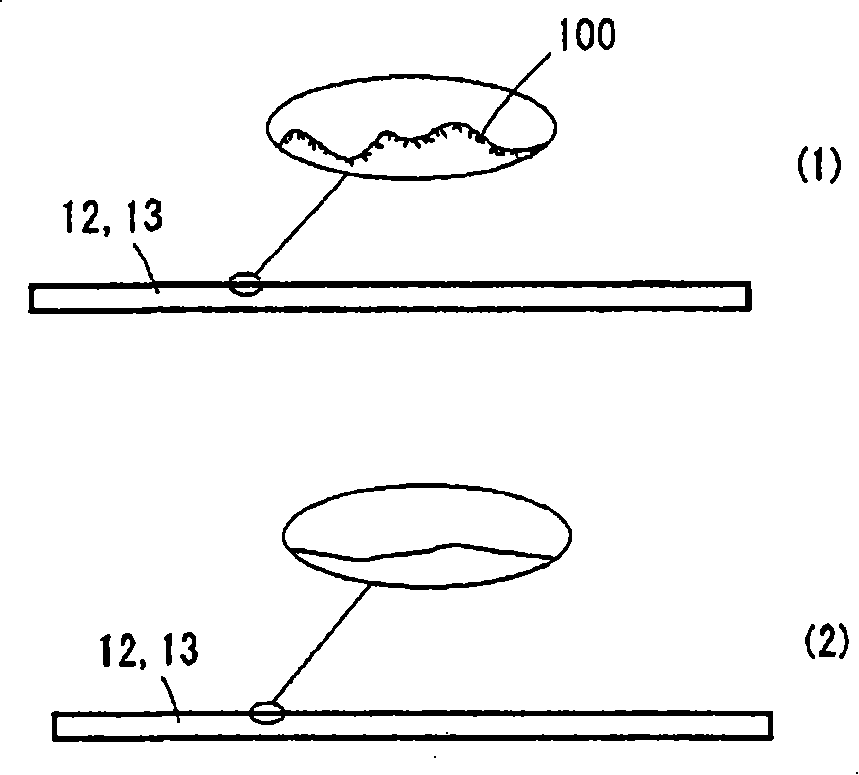

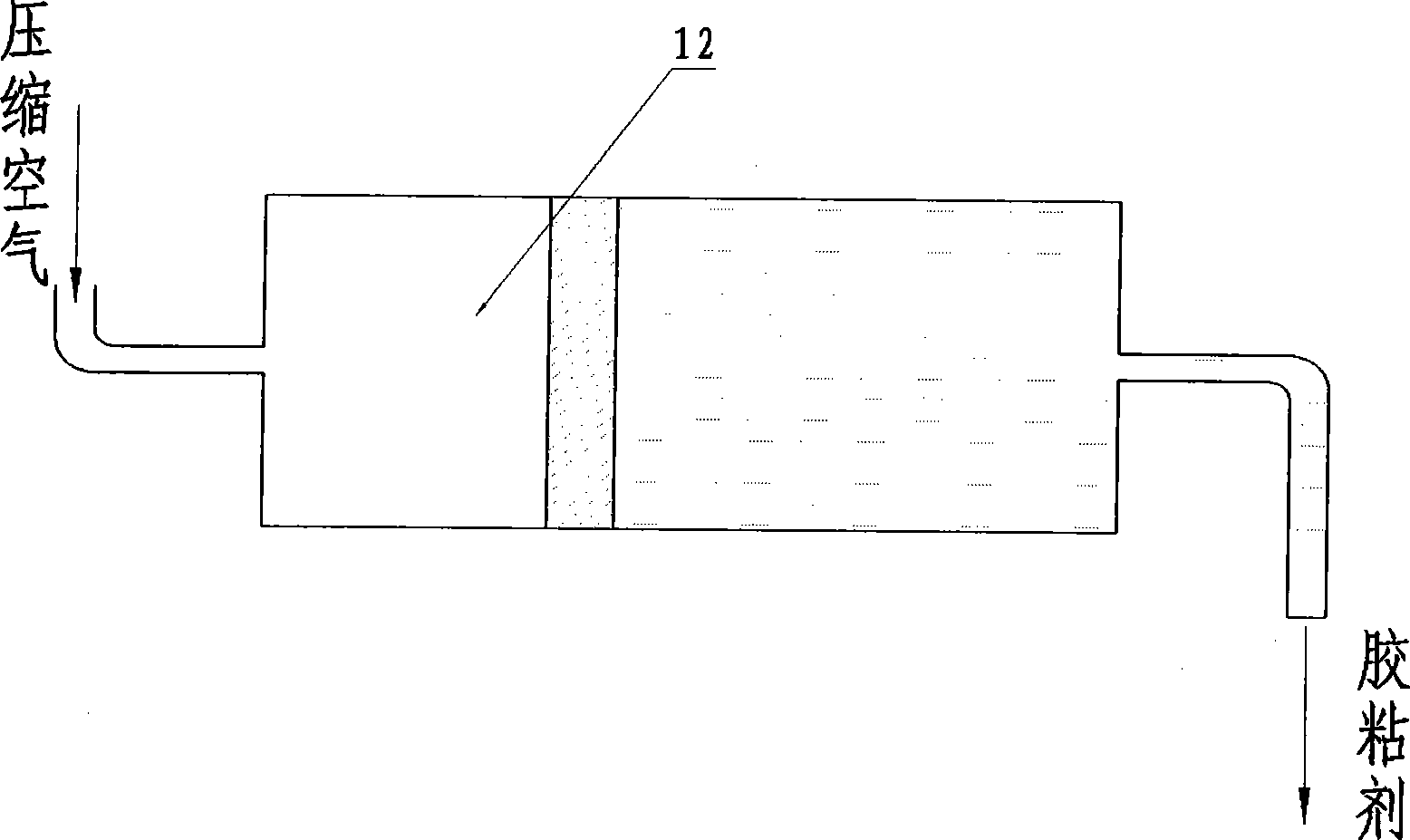

Touch panel display device, method for manufacturing touch panel unit and glass grinding machine for manufacturing touch panel unit

InactiveCN101206314AGuaranteed StrengthReduce thicknessGraph readingNon-linear opticsTouch panelSelf weight

The invention relates to a touch-plate display device, comprising a touch-plate unit (11) arranged at the front side of the display unit (1) and inputted with information through touch, wherein, the touch-plate unit (11) is adhered at the front of the display unit through a transparent adhesive agent (17); and the touch-plate unit (11) is provided with a glass panel (12 and 13) for covering the display unit (1). The glass panel (12 and 13) is flat, the surface of which is grinded mechanically when being impacted by dissolved liquid with an acceleration which is larger than the acceleration produced by the self weight after spraying out the dissolved liquid, with a thickness smaller than 0.5mm and a maximum surface roughness smaller than 0.5mum. The invention provides a thin touch-plate display device.

Owner:蔡孟廷 +1

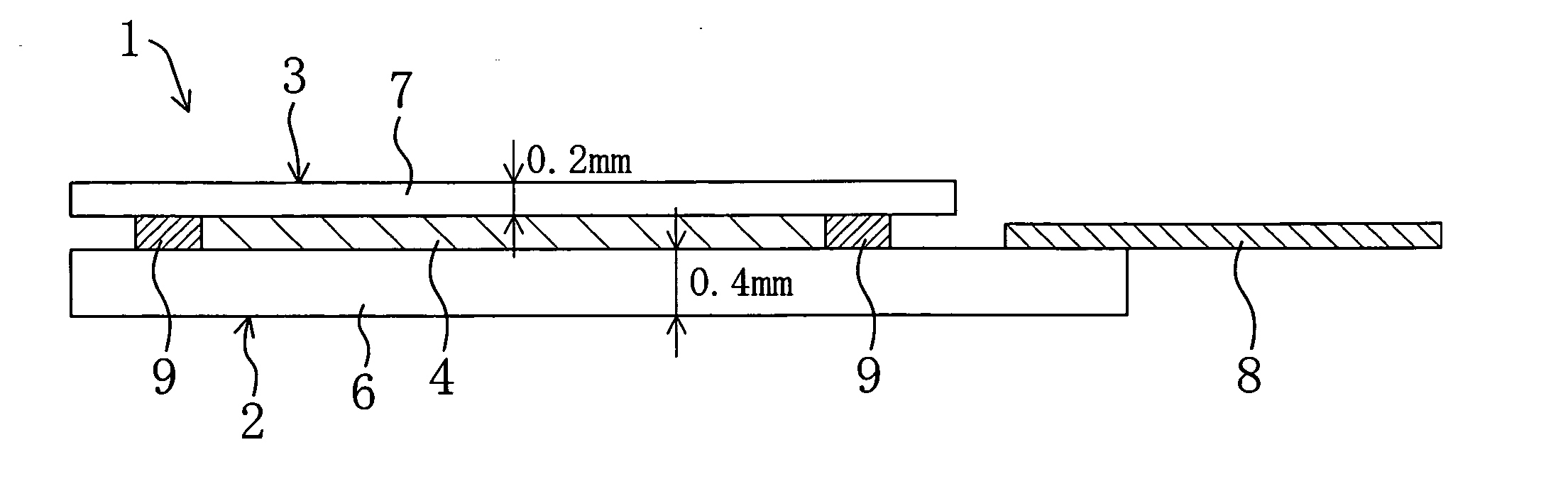

Touch panel assembly

InactiveUS7237937B2Guaranteed StrengthReduce thicknessCathode-ray tube indicatorsNon-linear opticsLight guideTouchpad

In a touch panel assembly, the thickness of a touch panel is successfully reduced by using a touch panel 10 provided with no reinforcement member. A housing frame 50 that supports the components of a front light unit 20 in an integral manner is provided with a touch panel positioning mechanism, and the touch panel 10 is fixed to the positioning mechanism, whereby the absence of a reinforcement member is duly compensated for, thus ensuring the strength of the touch panel 10. Deformation of the touch panel 10 that occurs when the touch panel 10 is pressed for operation can be attenuated by a transparent buffer member 5 disposed between the touch panel 10 and a light conductor plate 22. Therefore, the touch panel 10 deformed is prohibited from contacting and damaging the light conductor plate 22, thus preventing the light conductor plate 22 from deteriorating in its functional performance. Consequently, reduction in dimension and reduction of the number of components can be achieved without deteriorating the functional performance of the touch panel assembly.

Owner:MINEBEA CO LTD +2

Reformer of methanol-water hydrogen manufacturing equipment, and manufacturing technology of reformer

ActiveCN104229733AImprove insulation performanceReduce weightHydrogenChemical industryMethanol waterHydrogen

The invention discloses a reformer of methanol-water hydrogen manufacturing equipment, and a manufacturing technology of reformer, relating to the technical field of methanol-water hydrogen manufacturing equipment. The reformer of the methanol-water hydrogen manufacturing equipment comprises a reformer shell, wherein the reformer shell sequentially comprises a stainless steel inner shell, an insulating cotton layer and a mica outer shell from inside to outside, the diameter-thickness ratio of the reformer shell to the stainless steel inner shell is (150:0.8)-(150:2.5), the diameter-thickness ratio of the reformer shell to the insulating cotton layer is (150:10)-(150:20), and the diameter-thickness ratio of the reformer shell to the mica shell is (150:1.5)-(150:3.5). The reformer not only is high-temperature-resistant and high in strength, but also is good in insulating property, corrosion-resistant, oxidization-resistant, waterproof, non-conductive, and light in weight.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

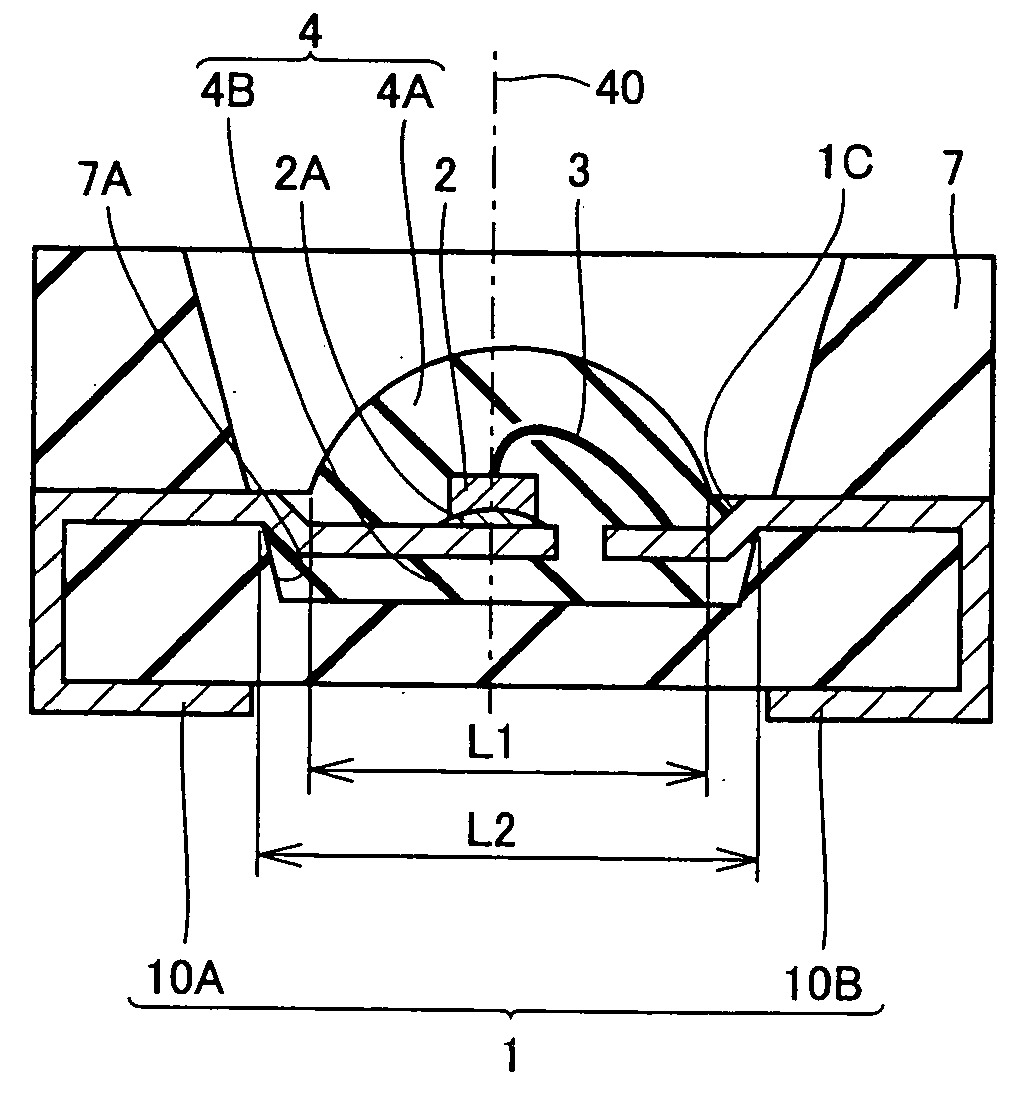

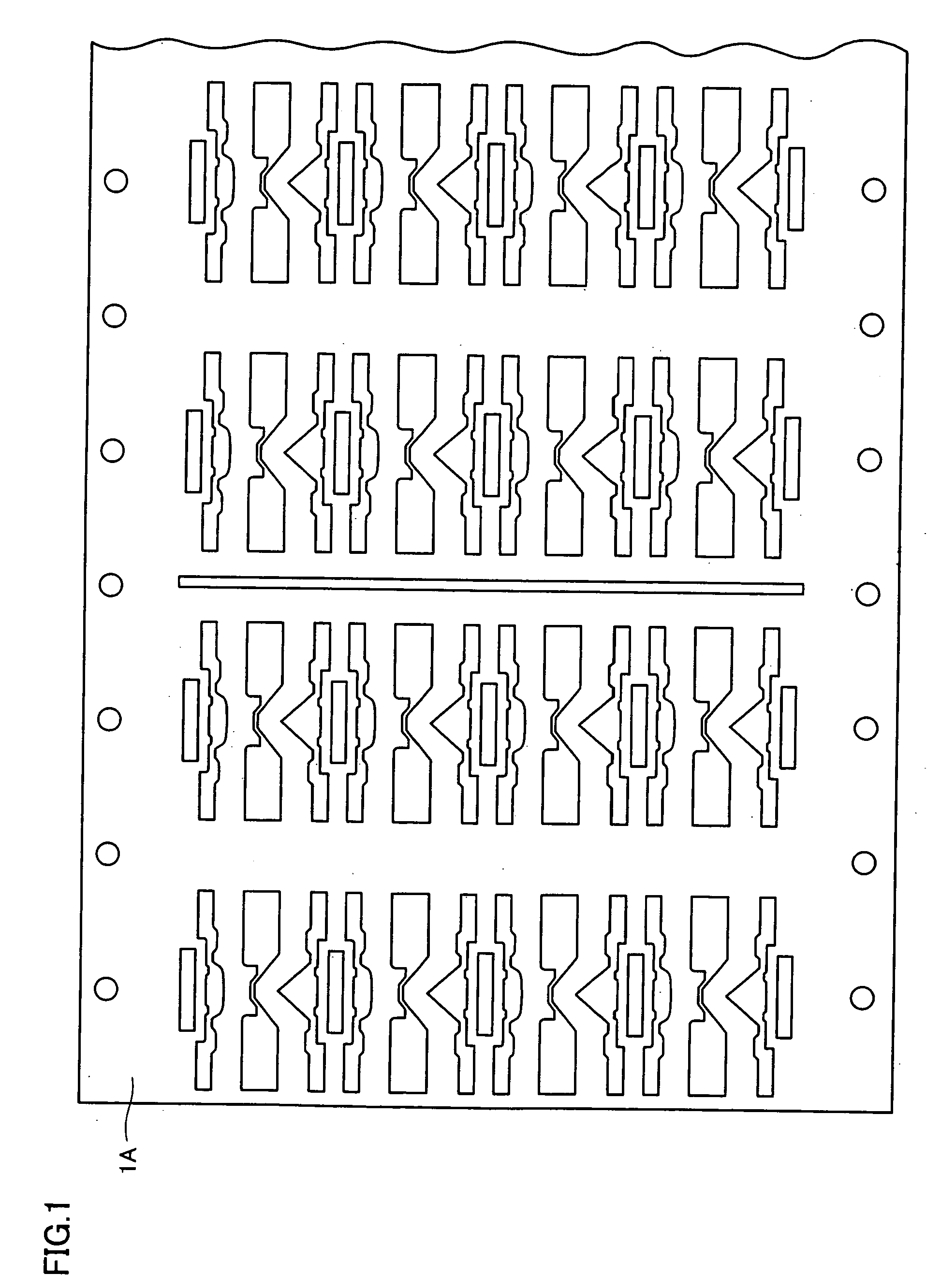

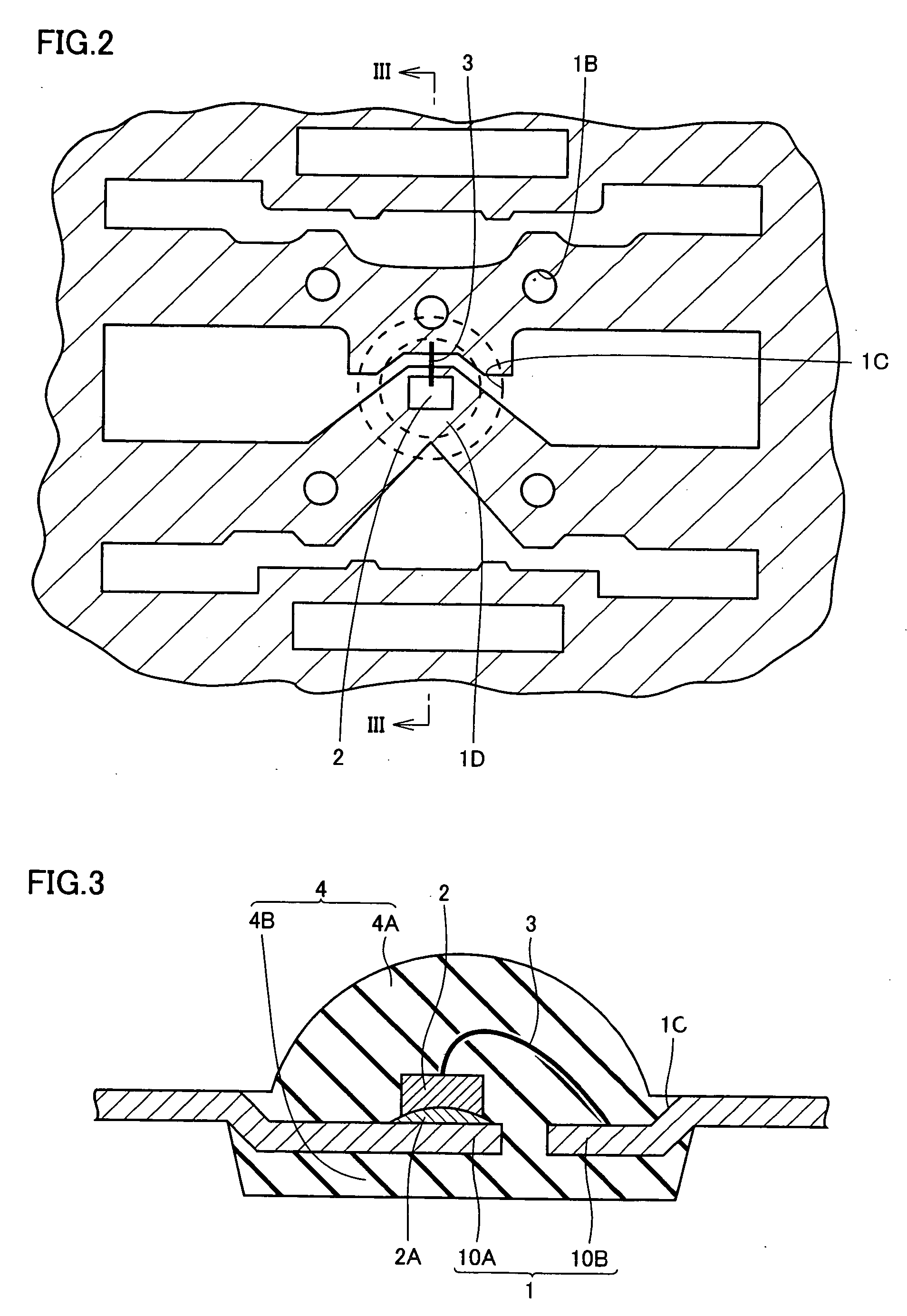

Semiconductor light emitting device and fabrication method thereof

ActiveUS20050236639A1Small sizeGuaranteed StrengthSolid-state devicesSemiconductor devicesEngineeringLead frame

A semiconductor light emitting device includes an LED element, a lead frame on which the LED is mounted, a lead frame electrically connected to the LED element via a wire, transparent resin formed on the LED element and on the lead frames, and light shielding resin having a reflectance higher than the reflectance of the transparent resin, surrounding the perimeter of the LED. The transparent resin includes a lens portion constituting a lens on the LED, and a holding portion holding the lead frame.

Owner:LEDCOMM LLC

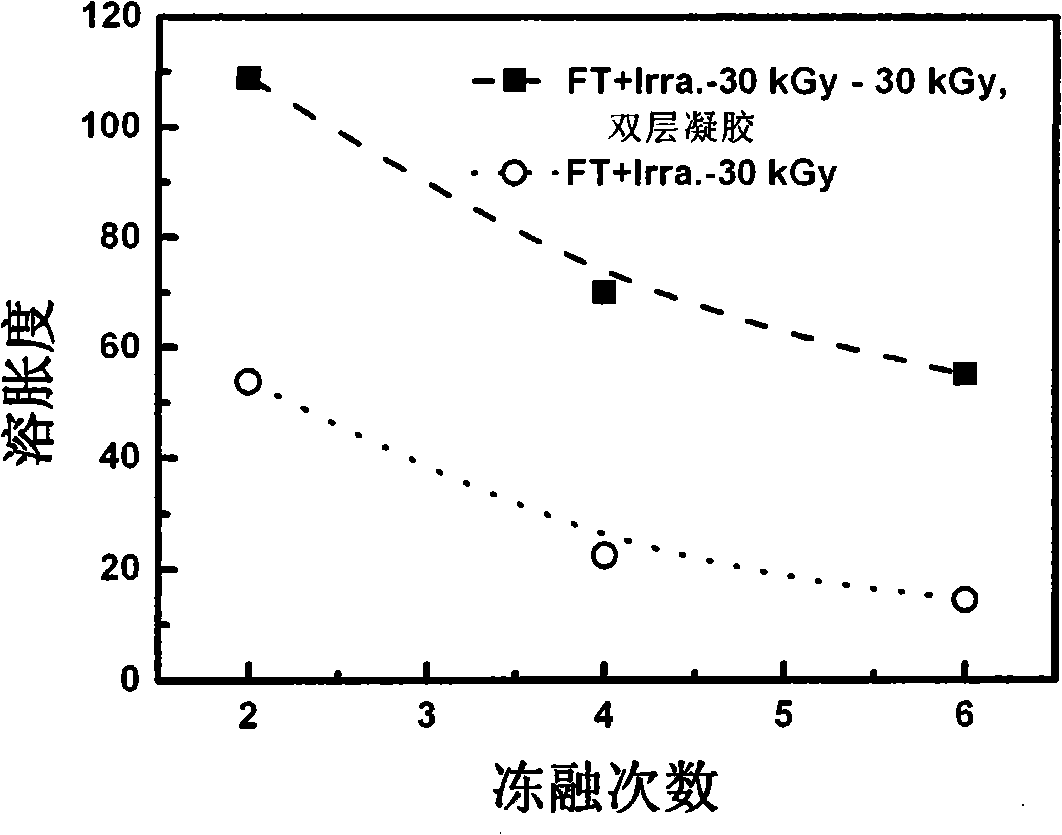

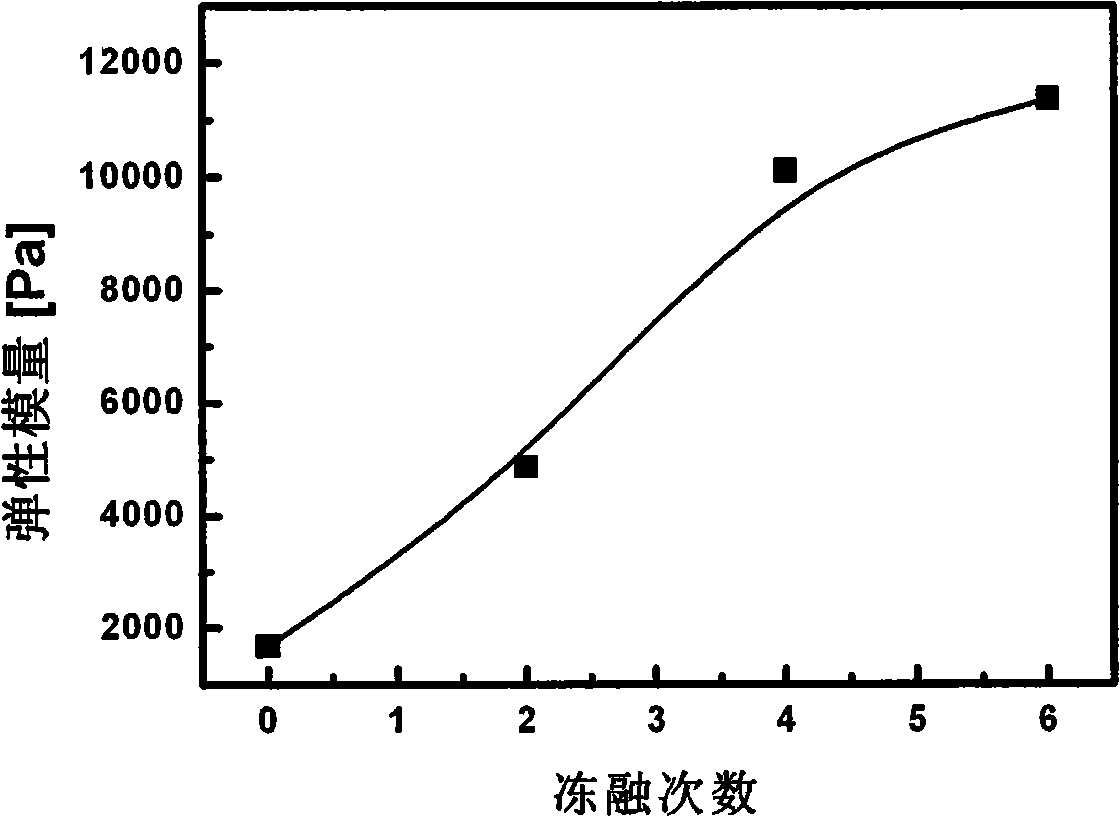

Hydrogel dressing and preparation method thereof

InactiveCN101337086AHigh strengthGuaranteed StrengthAbsorbent padsBandagesFreeze thawingPolymer science

The invention discloses hydrogel dressing which is composed of an upper layer and a lower layer. The lower-layer hydrogel is prepared by utilizing freeze thawing radiation method, and the upper-layer hydrogel is prepared by utilizing the radiation method; both the layers of hydrogel contain water-soluble polymer, and solvent for the residual; wherein, the lower-layer hydrogel contains polyvinyl alcohol. The invention also discloses a hydrogel-dressing preparation method which comprises the following steps: after the deaeration treatment of the water-soluble polymer solution containing polyvinyl alcohol, the hydrogel is prepared by utilizing circulating frozen thawing method; the water-soluble polymer solution after the deaeration treatment is positioned on the hydrogel, and then irradiation is performed under the high-energy rays. The hydrogel dressing has not only excellent strength and toughness, but also high transparence and wound fluid absorption ability. Meanwhile, the hydrogel dressing requires no additional chemical cross-linking agent or initiating agent, medical adhesive, and no reinforcing layer, such as fiber fabrics and woven fabrics, the two layers can be bonded firmly, and the preparation and the disinfection can be finished synchronously.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

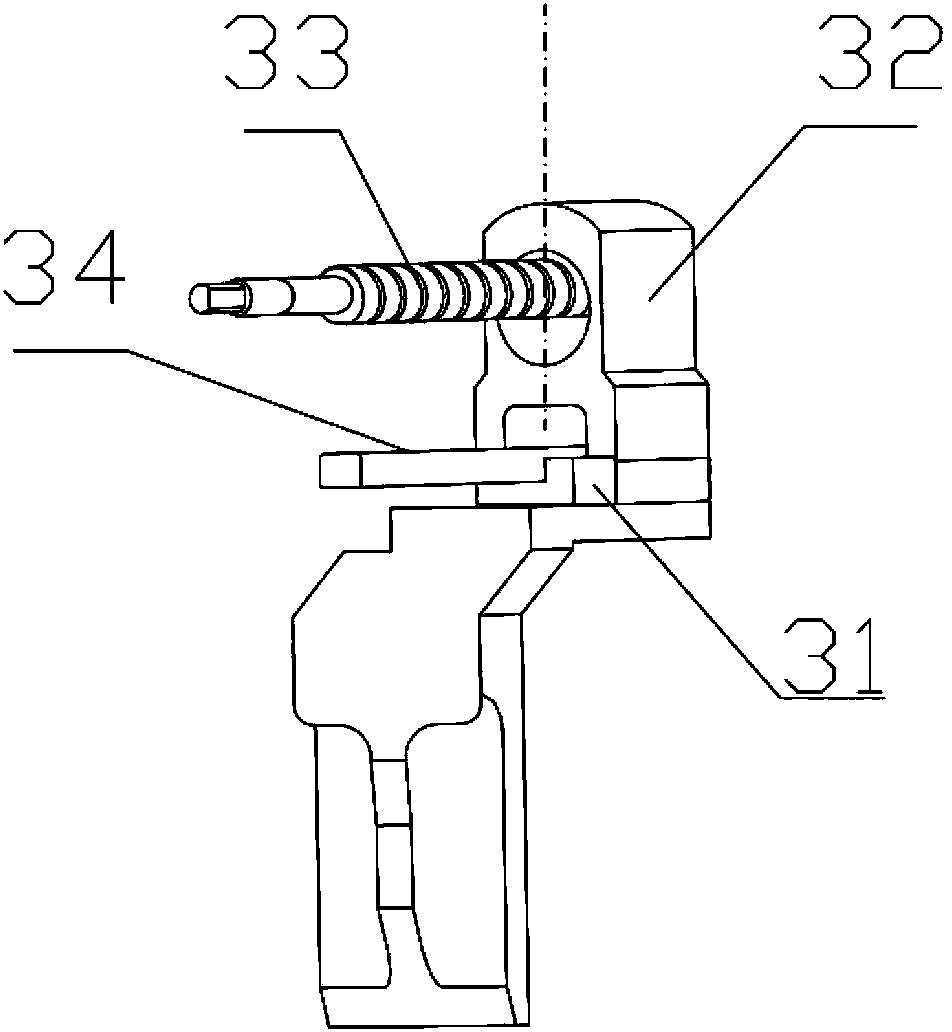

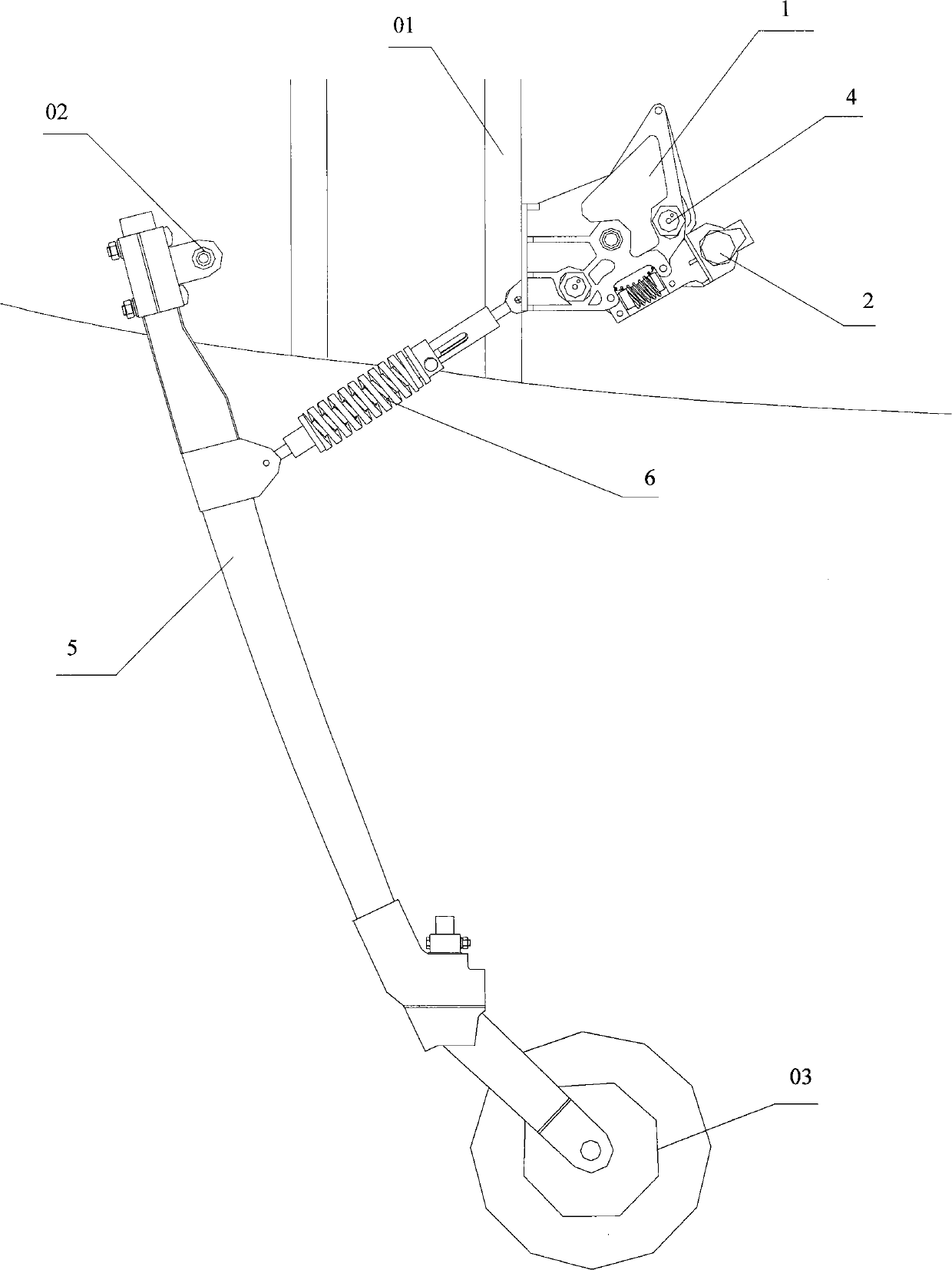

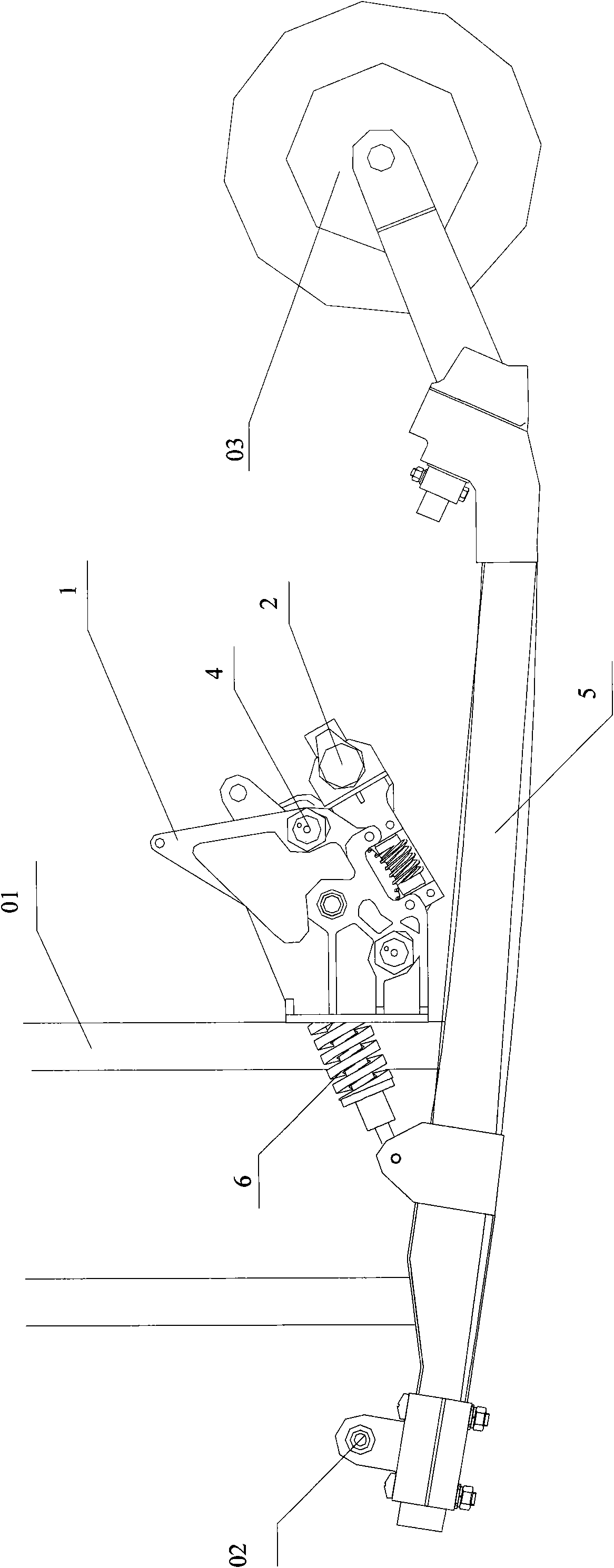

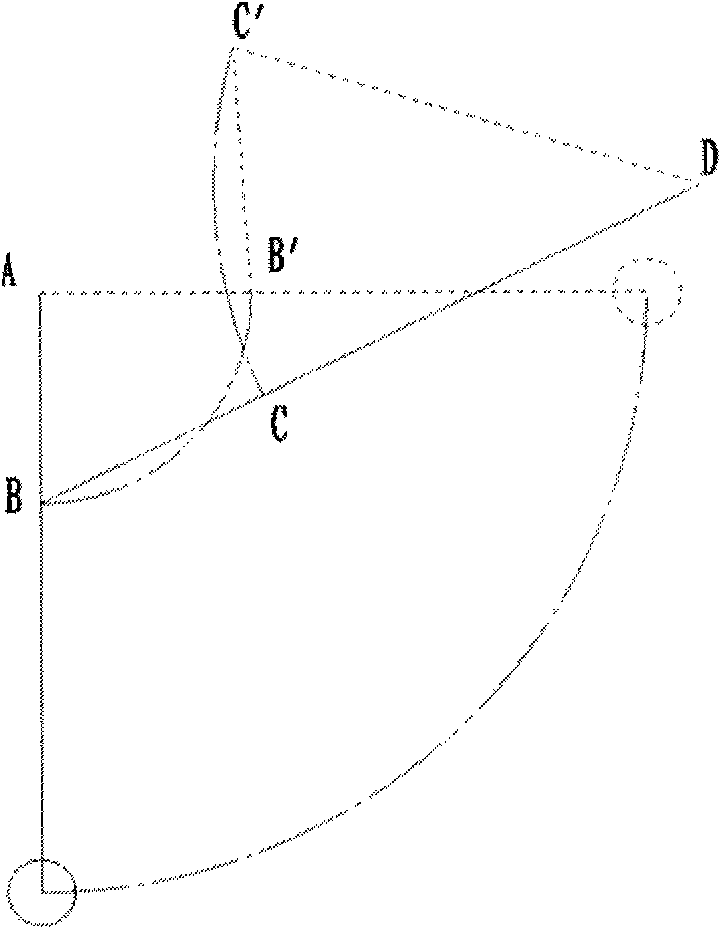

Unmanned plane undercarriage control system

ActiveCN101767649ASimple mechanical structureSimple electric drive equipmentUndercarriagesElectric driveLoad carrying

The invention discloses an unmanned plane undercarriage control system which comprises a control mechanism, a drive part, a control part, a sensor part, an undercarriage arm and a damper rod, wherein, the control mechanism has a worm wheel and worm structure, one end of the rocker of the control mechanism is fixedly connected with the worm wheel and the other end is connected with one end of the damper rod, the other end of the damper rod is connected with the upper part of the undercarriage arm through a pin roll, one end of the worm is connected with the drive part, the sensor part is arranged in the upper limit hole and the lower limit hole of the control mechanism, the control mechanism is fixedly arranged on the load-carrying structure of the plane body, the upper end of the undercarriage arm is connected with the plane body through a load-carrying rotating shaft on the plane body and the lower end of the undercarriage arm is connected with the front wheel of the plane, the control part is arranged on the avionics frame of the plane and respectively abutted with the drive part and the drive part through cables. The invention uses the simple mechanical structure, the simple electric drive apparatus and the spring-type damper rod and needs no supplementary structures or power-assisted devices for support, having a small volume and occupying little space. The invention can realize locking of the undercarriage up and down stations under the coordination of the worm wheel and worm structure, the crank link mechanism and the brushless motor static brake resistance.

Owner:CAIHONG DRONE TECH CO LTD

Metallic belt and push block used therefor

A single-band type metallic belt wound between annular V-grooves of a drive pulley and a driven pulley is provided. The metallic belt includes a metal endless band having at least one layer, and a plurality of metal push blocks engaged and superimposed on the band in a manner enabling sliding in a longitudinal direction of the band. The push block includes a body formed by bending a single wire material and subsequently performing pressing so as to have two outer side surfaces defining side contact surfaces that are inclined to respectively make frictional contact with two inner surfaces of the annular V-grooves. A pair of pillars respectively extend along extensions of the two contact surfaces of the body and have an outer surface that is continuous with the side contact surfaces of the body. A pair of opposed hooks extend. The outer side surface of the push block that makes frictional contact with the V-grooves include an oil film breaking portion. An opening is defined by the pair of hooks, and a band holding surface is formed on the body in the opening. The band is inserted in the opening of each push block and held on the band holding surface. A metal retainer is arranged on an outer surface of the band in a manner engageable with the pair of hooks to ensure engagement between the band and the push blocks. A ring is attached to the outer surface of the retainer to prevent deformation of the retainer.

Owner:FUKUJU INDS

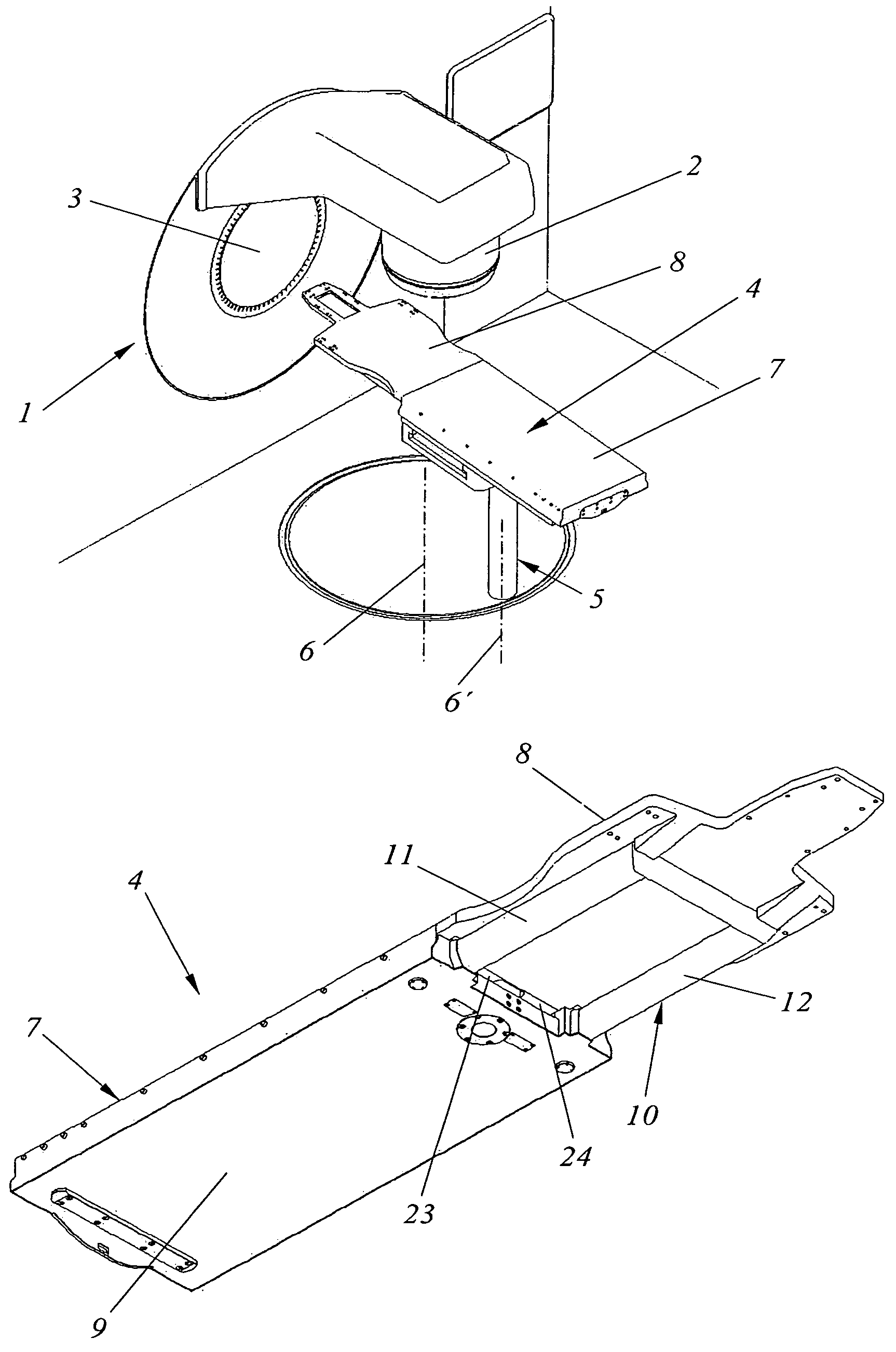

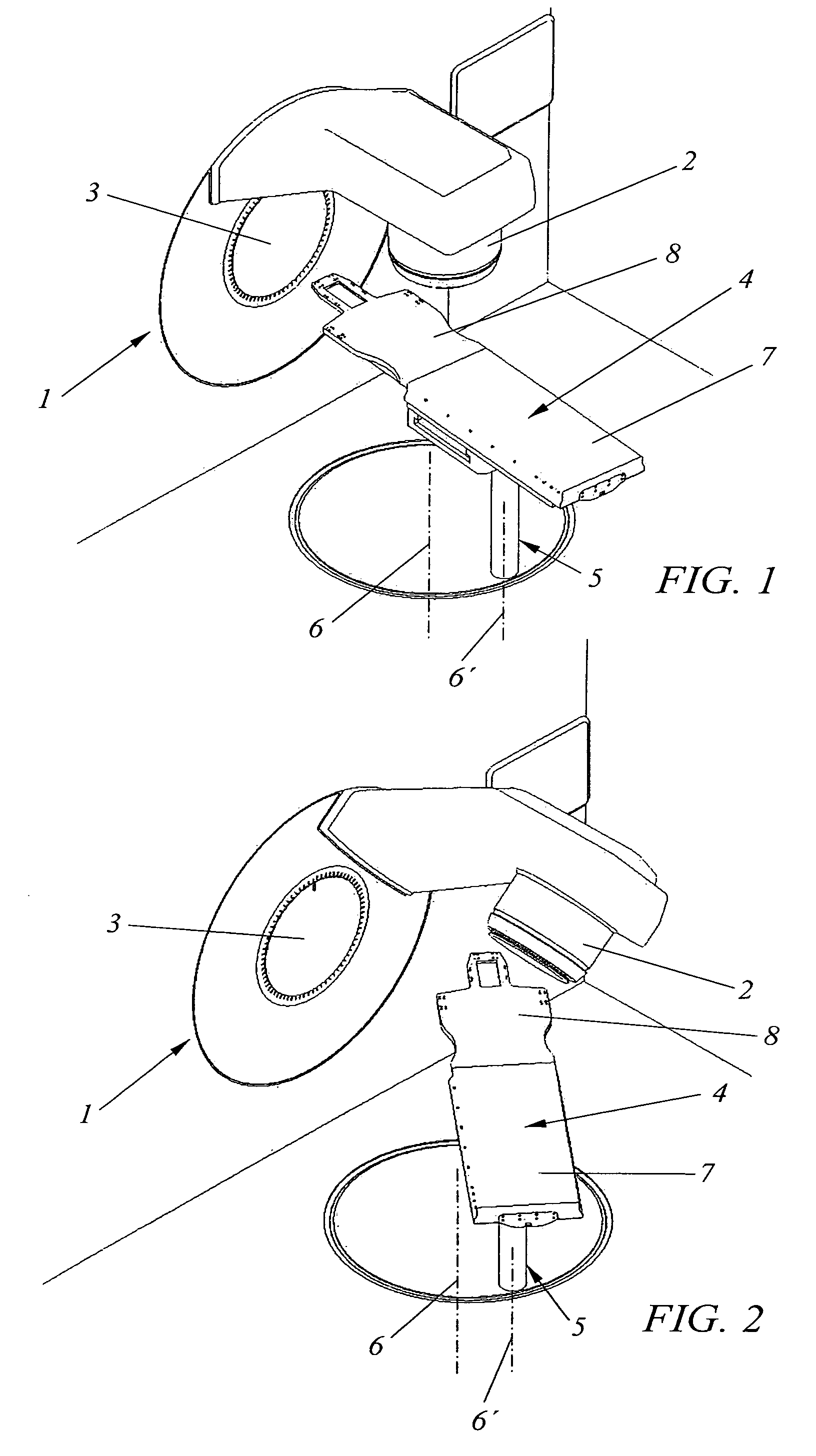

Modular patient support system for use in radiotherapy treatments

ActiveUS7076821B2Limited rangeEffective irradiationOperating tablesPatient positioning for diagnosticsSupporting systemEngineering

The invention relates to a modular patient support system for use with radiotherapy treatments comprising a basic portion to be fixedly mounted and an exchangeable radiotransparent modular portion, said portion to be fixedly mounted being provided with a radiotransparent supporting part intended for supporting an exchangeable modular portion and means being provided for exactly positioning said modular portion in relation to said basic portion and coupling it to said basic portion.

Owner:SINMED

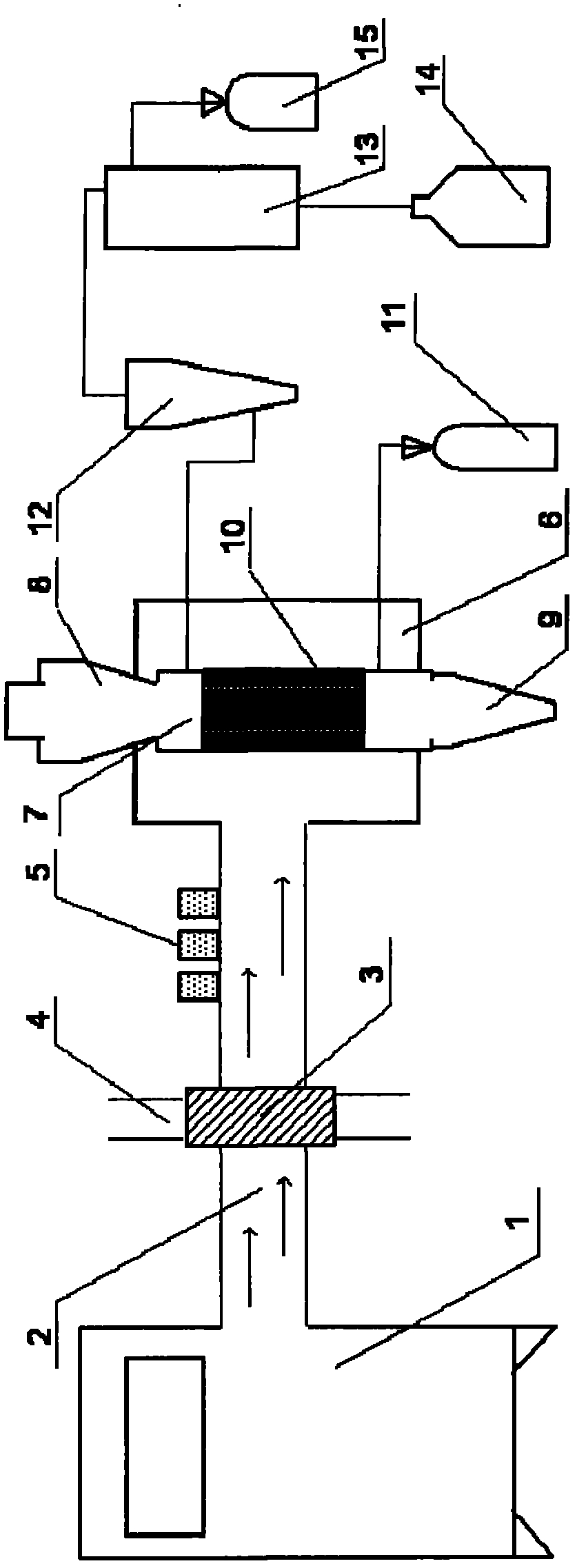

Continuous reaction device and method for microwave biomass pyrolysis

InactiveCN102580650APyrolysis continuous reaction realizedIncrease reaction rateBiofuelsLiquid hydrocarbon mixture productionMicrowaveFuel gas

The invention relates to a continuous reaction device and a method for microwave biomass pyrolysis. The continuous reaction device for the microwave biomass pyrolysis mainly comprises a microwave generator, a reactor and a resultant separating device. The continuous reaction device is a continuous operating system and can process 10-50kg of the biomass every hour. According to the continuous reaction device for the microwave biomass pyrolysis, characteristics of microwave volume heating, transient heating and selective heating are fully utilized, undried biomass is directly pyrolyzed so as toobtain three products of liquid bio-oil, bio-gas and solid coke, the pylolysis efficiency of the biomass is greatly improved, the yield and the quality of the liquid bio-oil are improved, the structure is simple, the design is reasonable, and the achievement of industrial application of the microwave biomass pyrolysis is facilitated.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

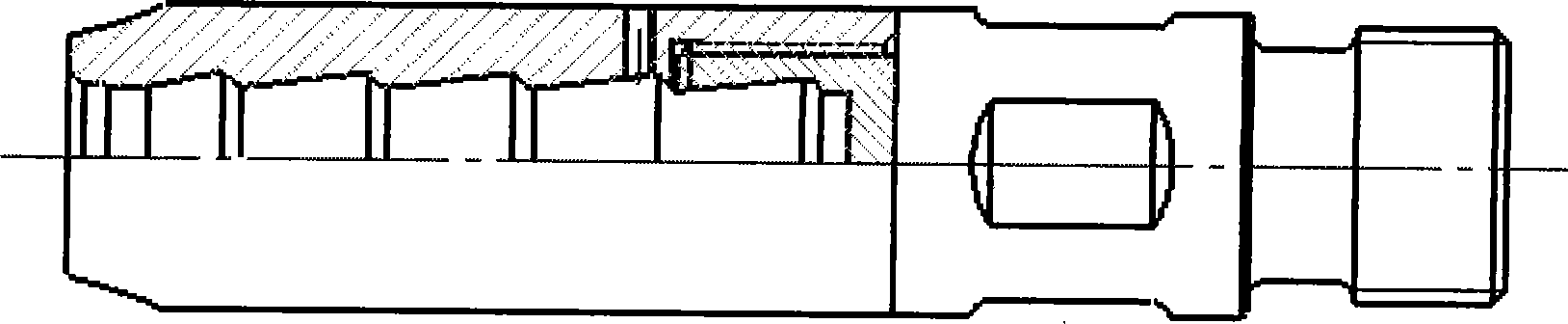

Preparation method and device of eccentric wear prevention pumping rod

InactiveCN101396874AExcellent performance of anti-eccentric wearPrevent slippageDrilling rodsDomestic articlesPre stressResin matrix

The invention relates to a method for preparing a composite material sucker rod which can prevent camber wear and a device thereof. Combining pultrusion and winding, fibre is immersed by resin matrix, and the composite material sucker rod is prepared by pultrusion, curing and shaping; the surface of the rod body is continuously wound with wearing fibre immersed by resin matrix glue after shaping; the rod body of the sucker rod, the surface of which is provided with a camber wear preventing layer of a spiral bar shape is obtained by curing; the rod body of the sucker rod is cut to be in fixed length, is connected with a metal joint by glue, and is treated in a joint curing furnace; the whole sucker rod is stretched by inherent stress. The surface of the rod body of the sucker rod is provided with the camber wear preventing layer of a spiral bar shape, thus having excellent camber wear preventing performance while ensuring a high intensity of the sucker body; the inverse cone structure of the metal joint and the pressure injection glue connection process ensure the joint part has the properties of high intensity and fatigue proof, the service life of which is consistent with the composite material rod body, and the reliability of the products is greatly improved.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com