Rock mass structural surface shear test method and device

A technology of shear test and structural surface, which is applied in the field of rock engineering, can solve the problems that the specimen cannot be fixed well, the strength parameters of the structural surface deviate from the actual value, time-consuming and labor-consuming, etc., and achieve convenient shear strength test , easy to monitor the experimental process, the effect of easy equipment installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

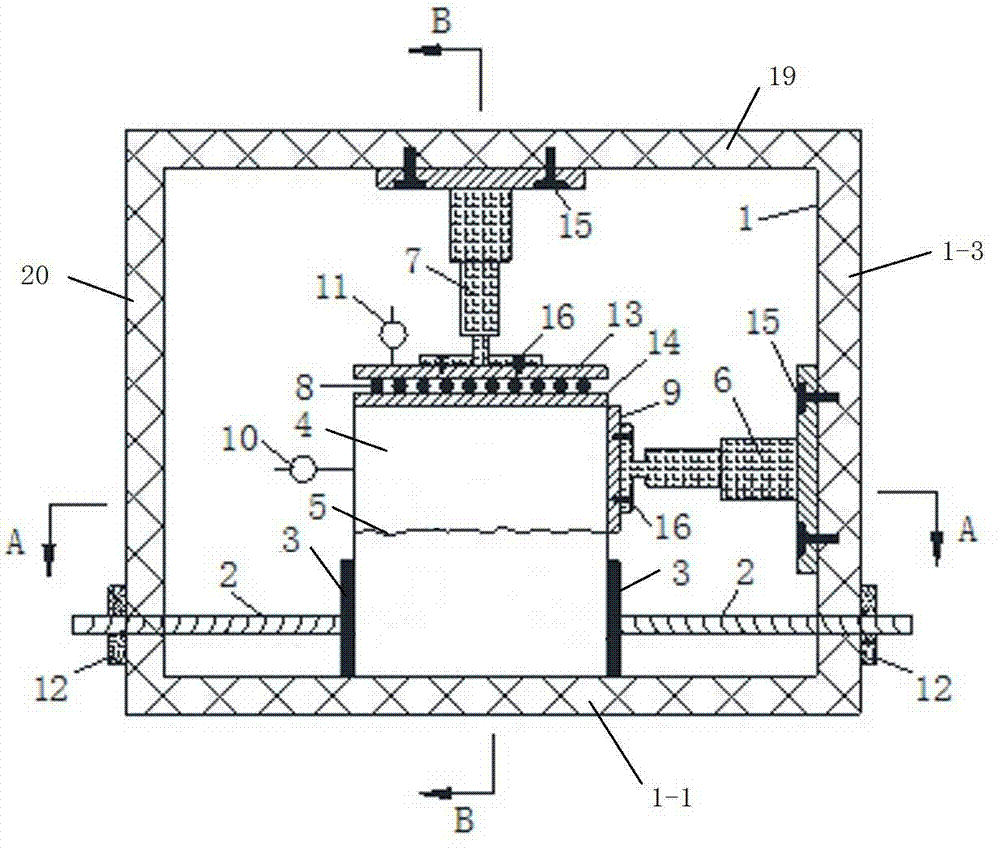

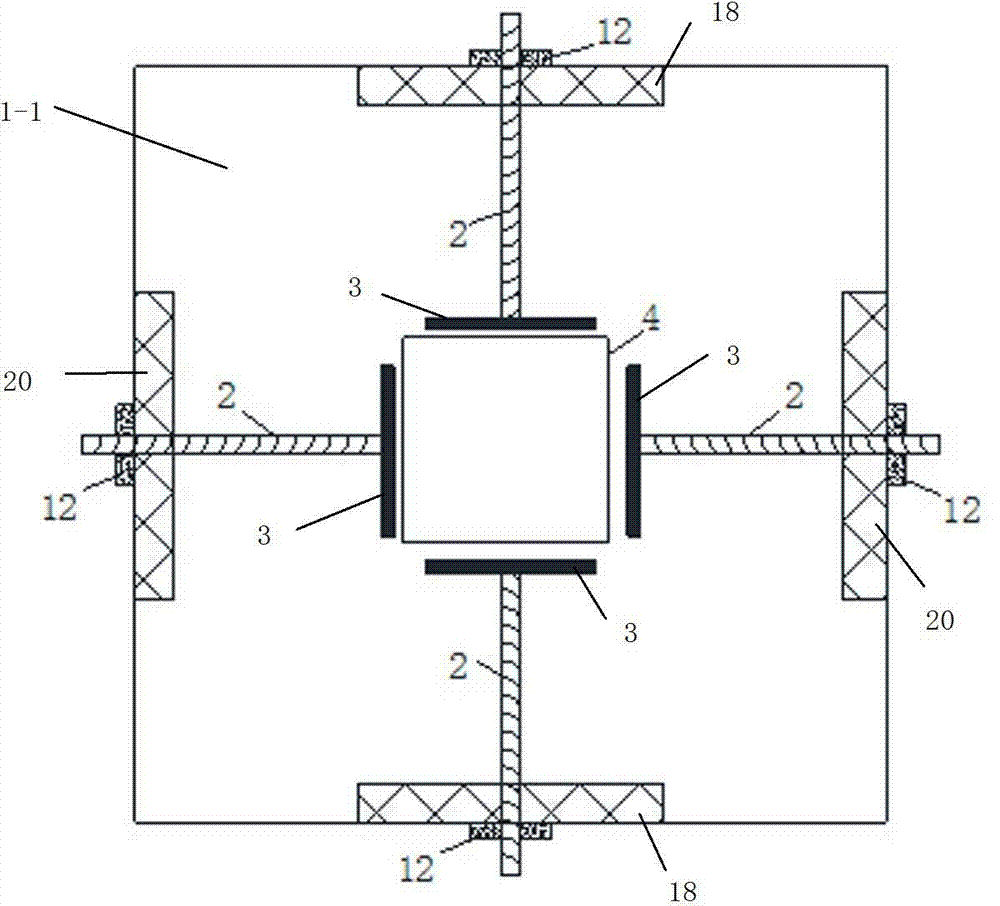

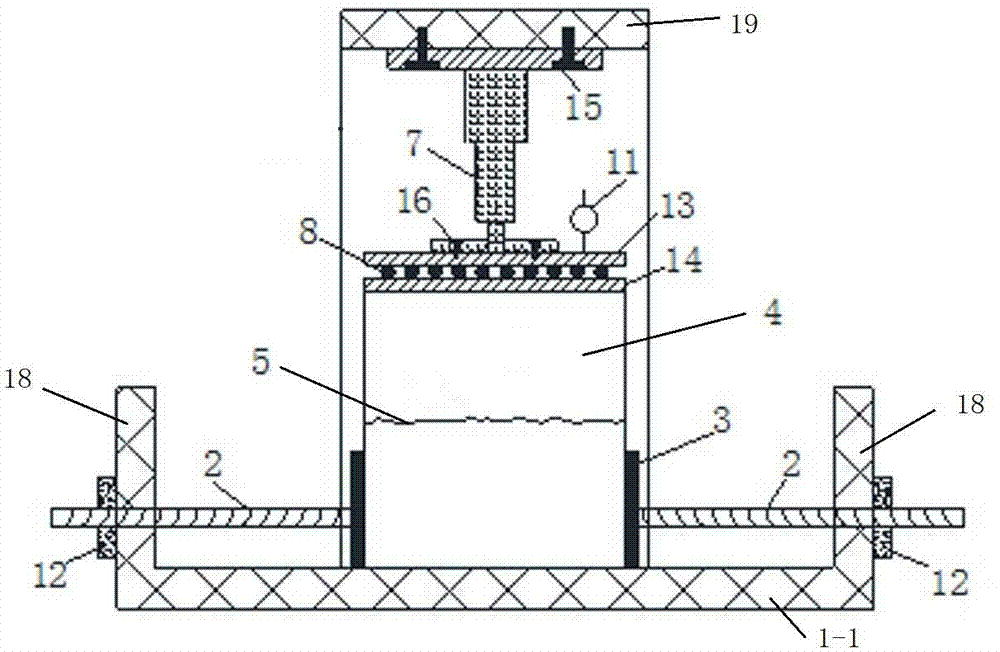

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

[0037] see Figure 1-Figure 3 , a rock mass structural surface shear test device, which includes a reaction force frame 1, a normal displacement sensor 11, a horizontal displacement sensor 10, a normal pressure sensor, a horizontal pressure sensor, a computer, the bottom of the reaction force frame 1 around A rock mass test piece fixing mechanism is provided, the side plate 20 of the reaction force frame 1 is fixed to the shear loading mechanism, and the top plate 19 of the reaction force frame 1 is fixed to the normal loading mechanism; the normal loading mechanism is connected to the rock mass test piece. Part 4 is in contact, and the vertical axis of the normal loading mechanism coincides with the vertical axis of the rock mass specimen 4; the shear loading mechanism is in contact with the rock mass specimen 4, and the horizontal axis of the shear loading mechanism ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com