Patents

Literature

75 results about "Normal displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Normal displacement is the ship's displacement "with all outfit, and two-thirds supply of stores, ammunition, etc., on board.".

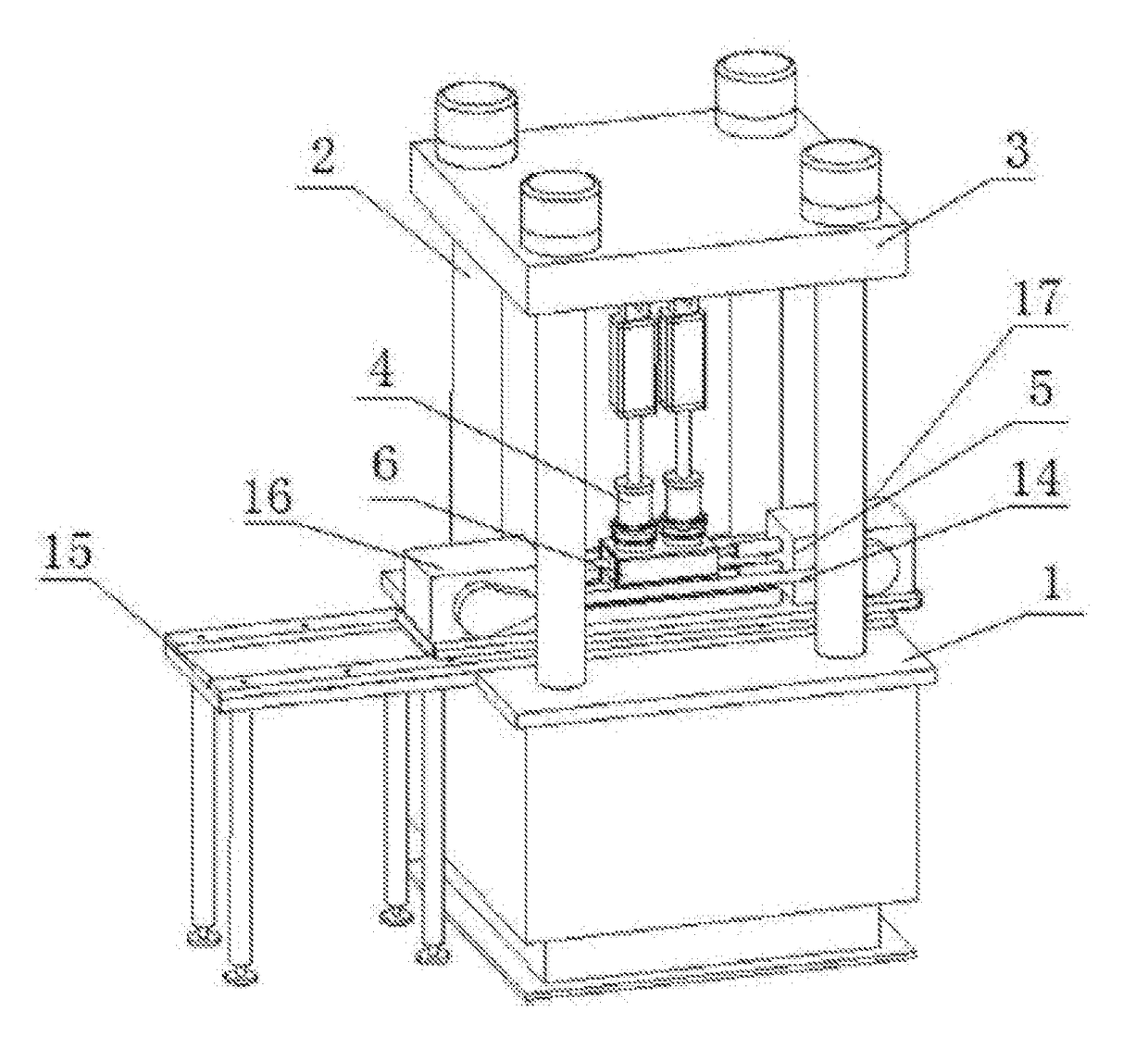

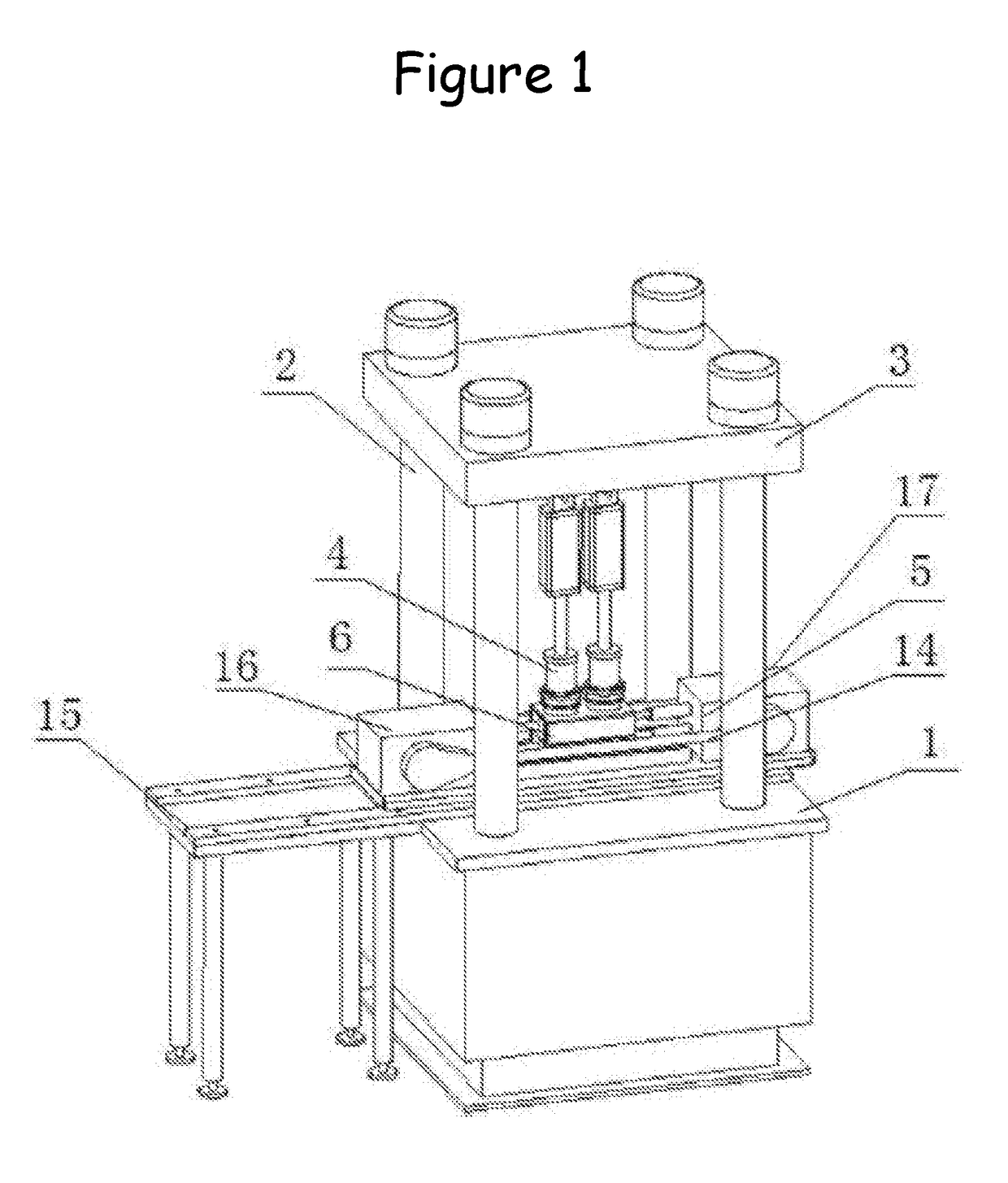

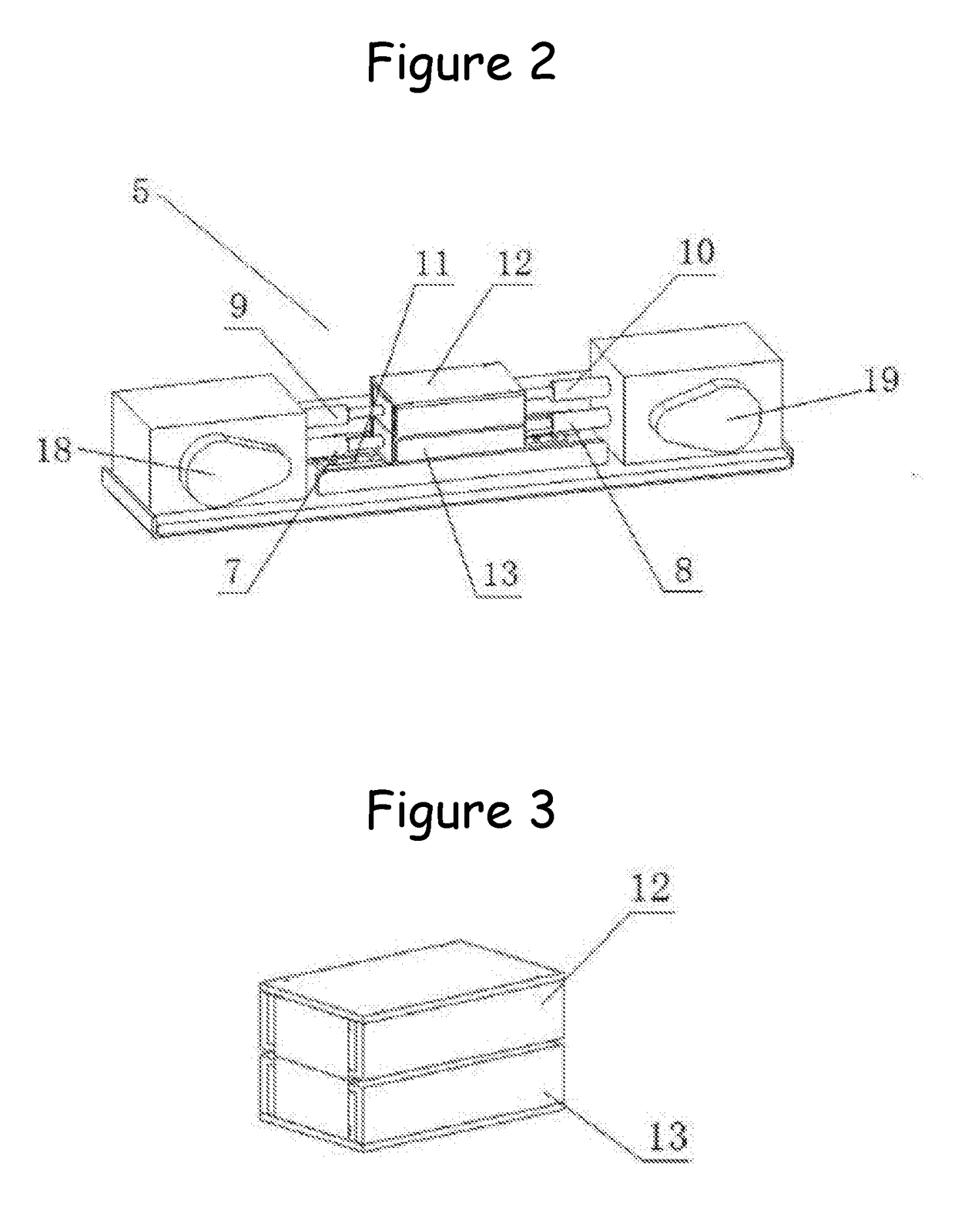

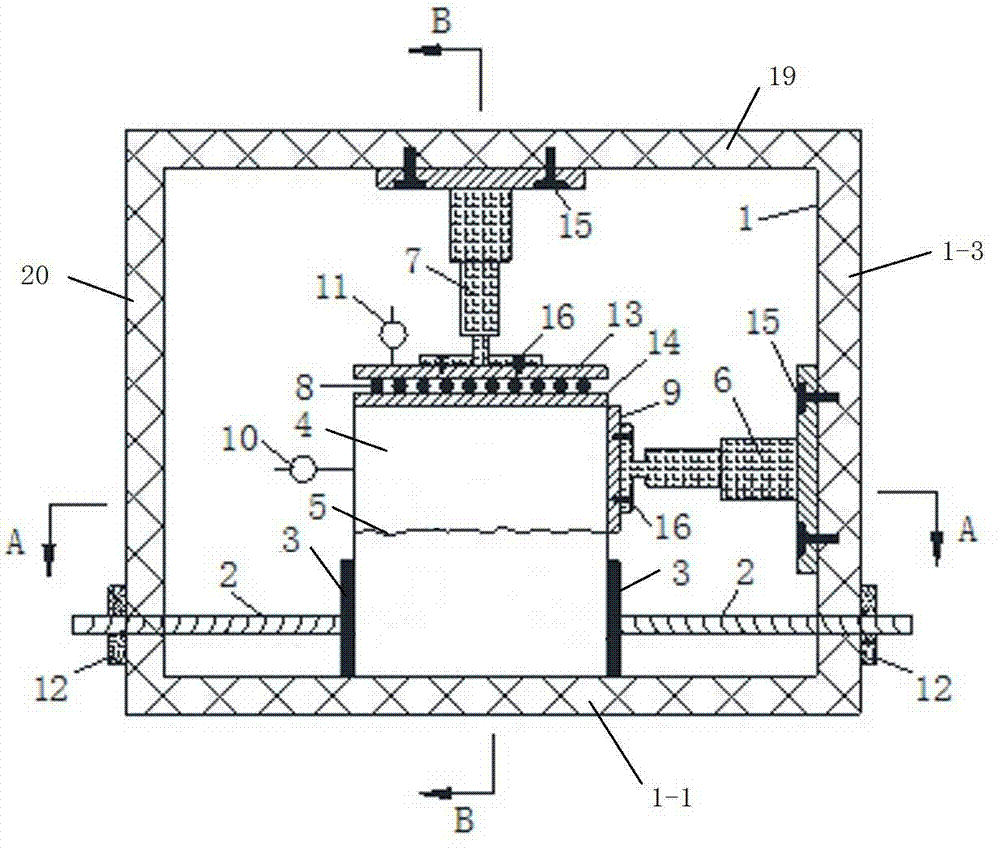

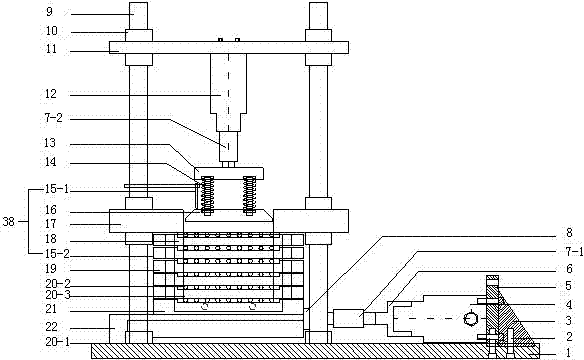

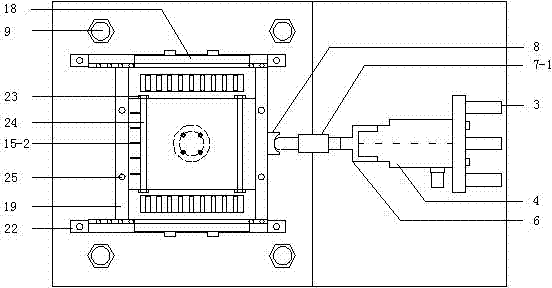

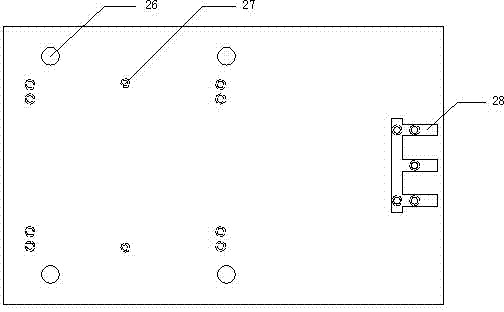

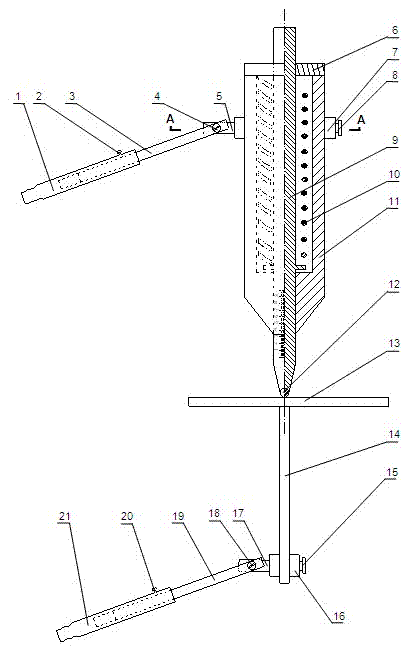

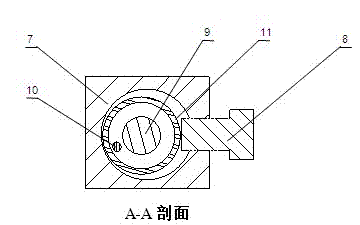

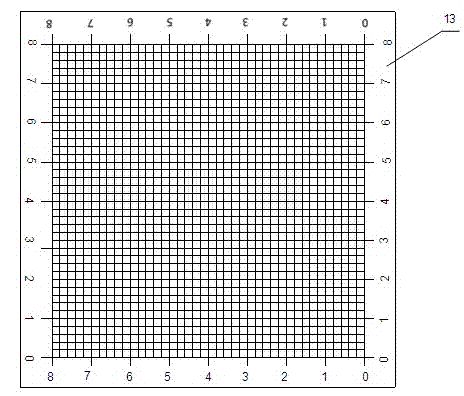

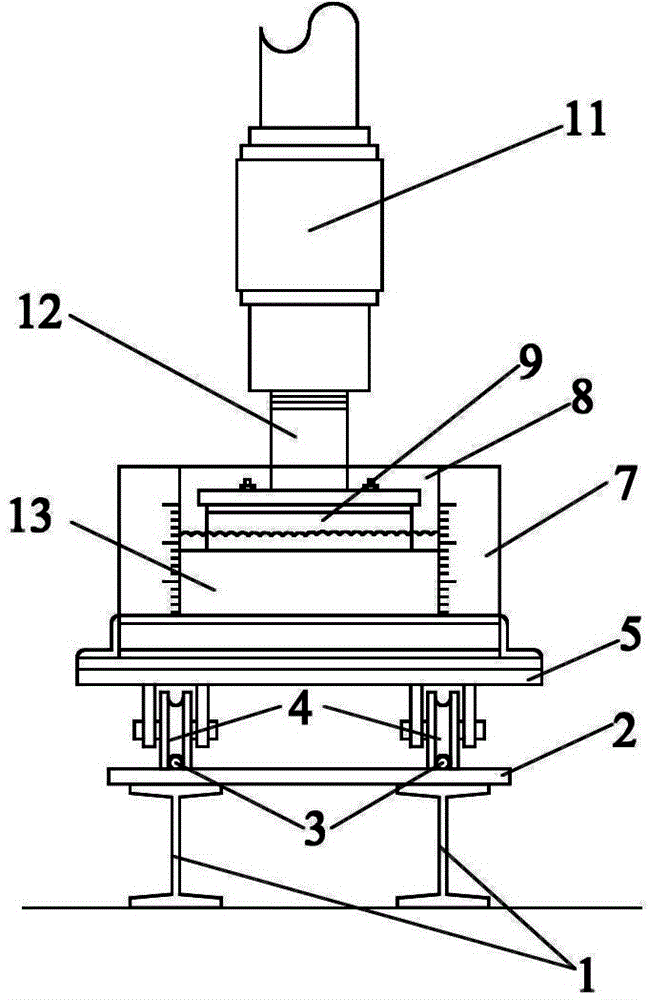

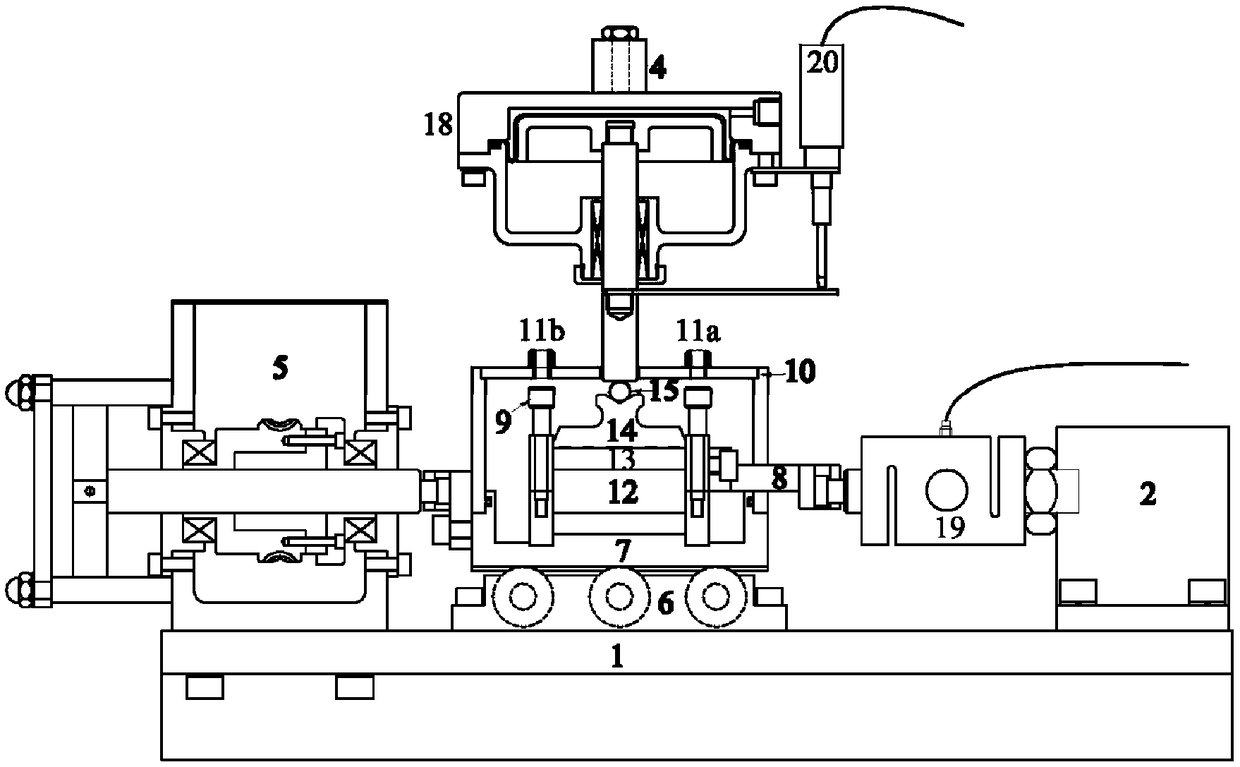

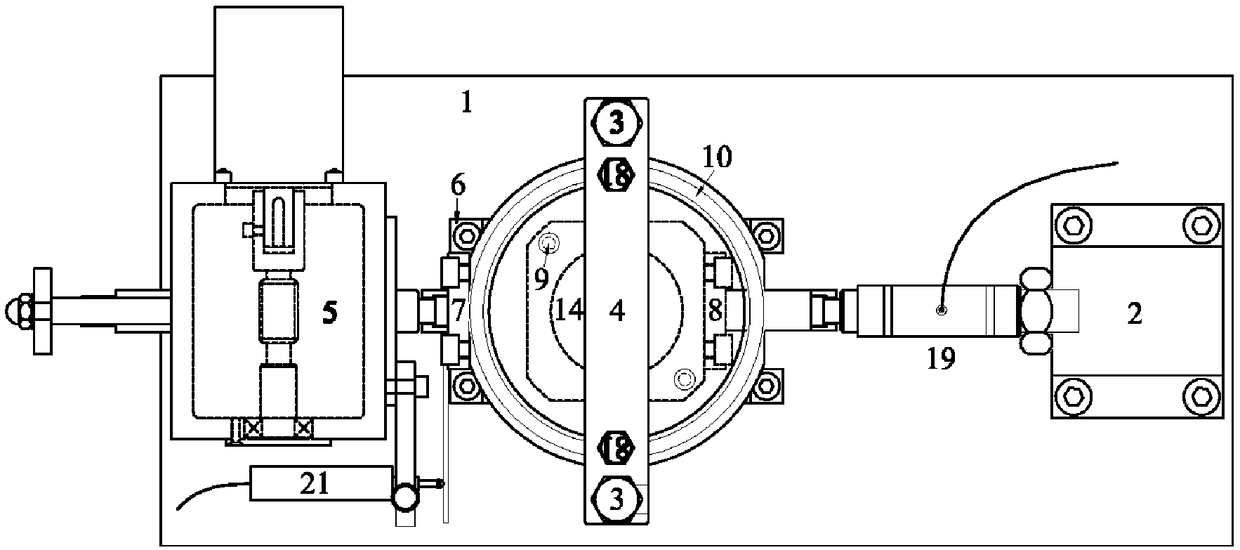

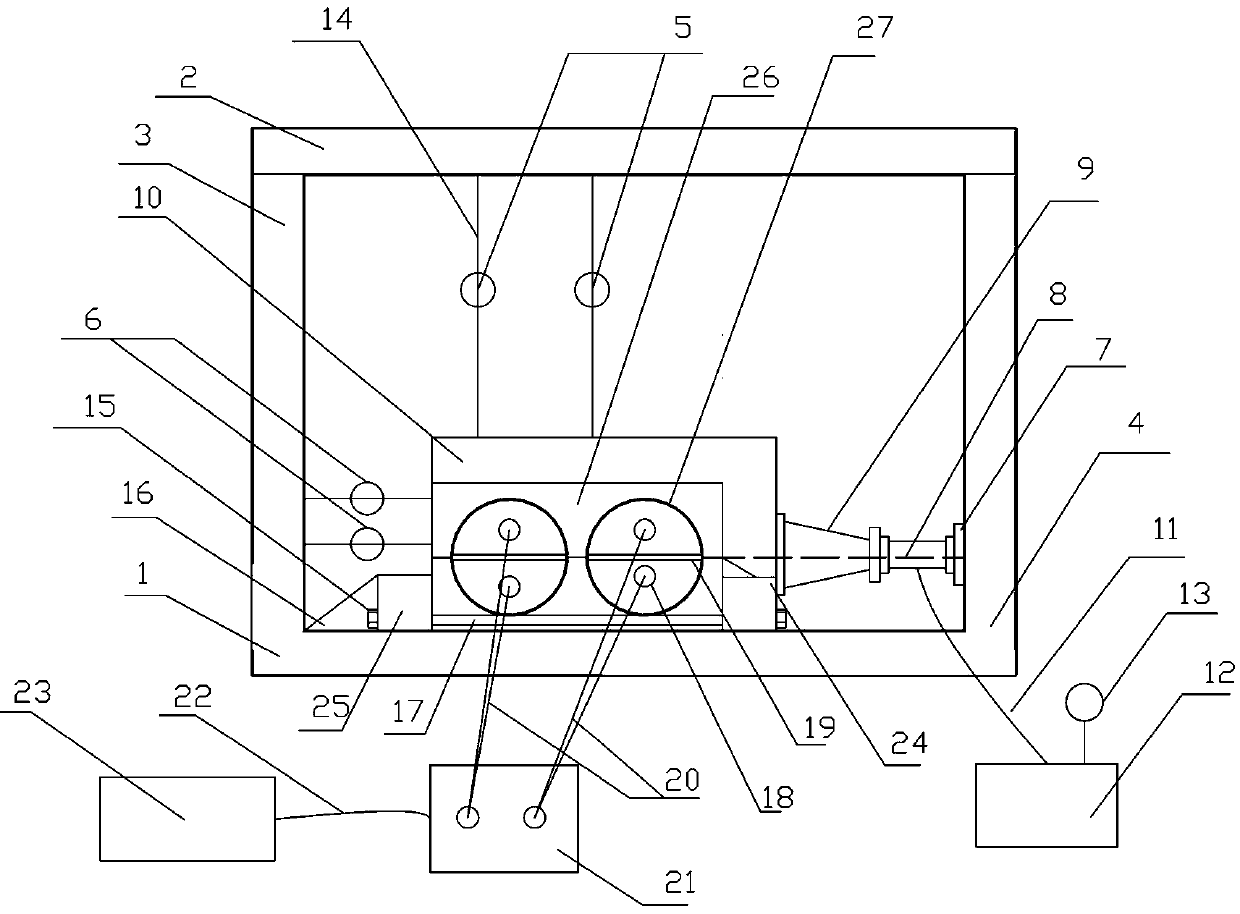

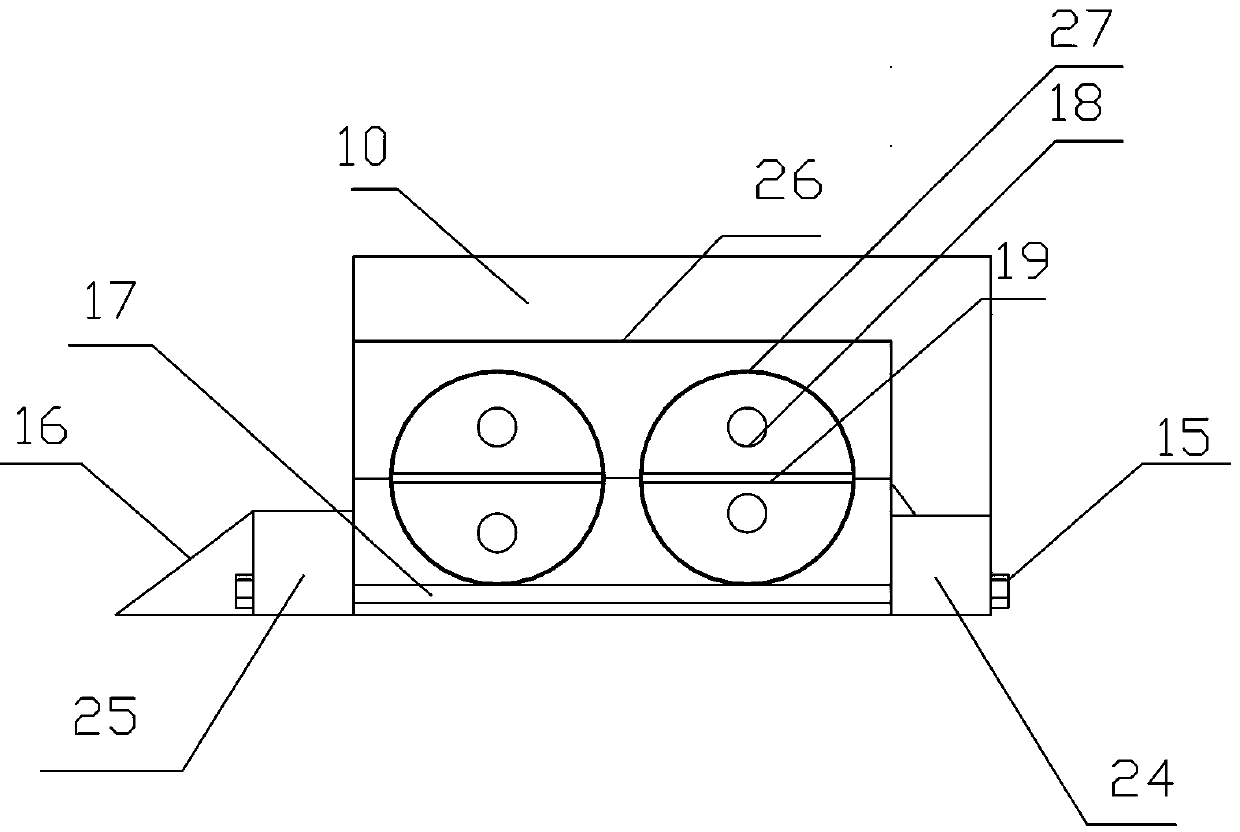

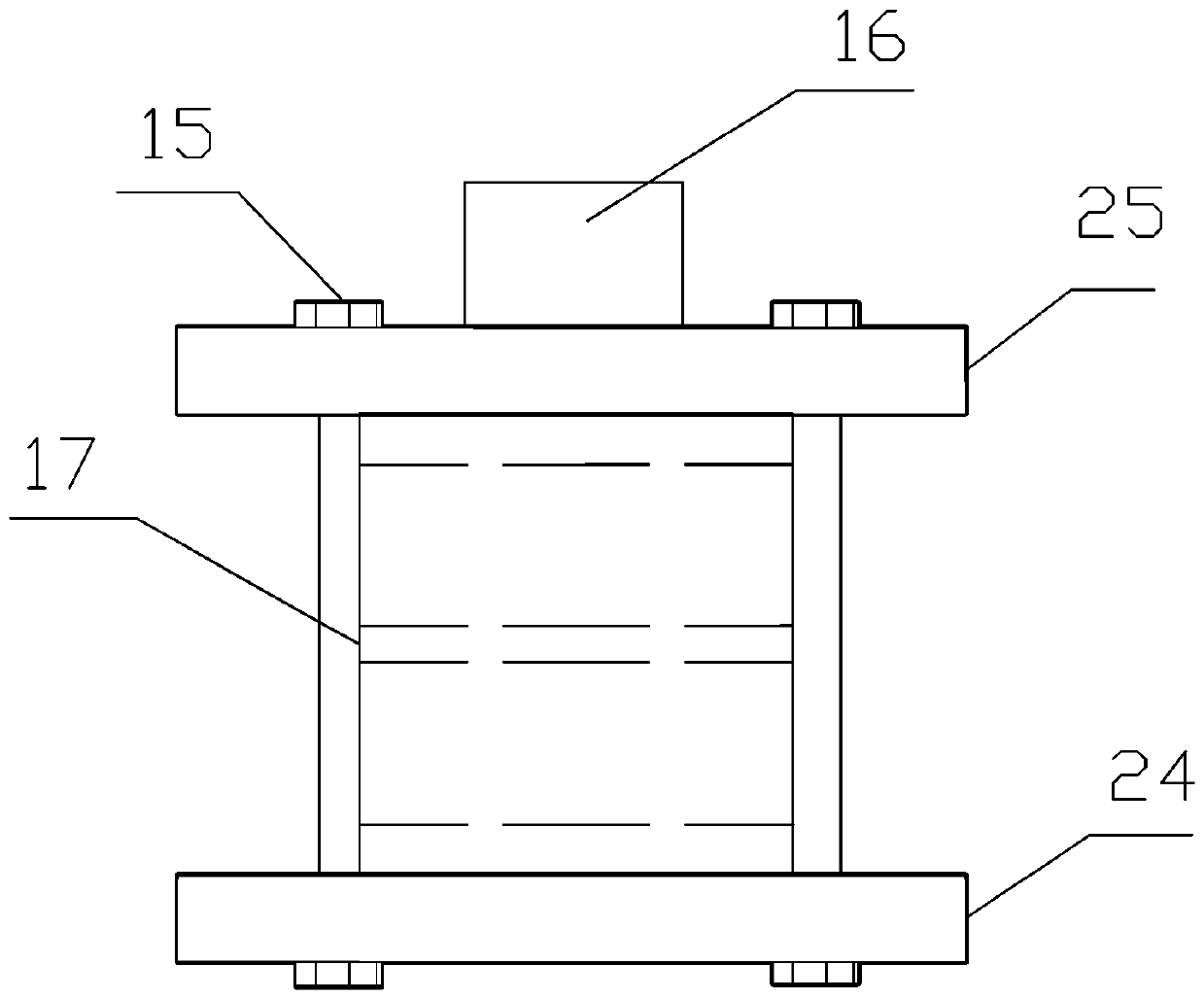

Shear test device and test method of rock mass discontinuities under constant normal stiffness condition

ActiveUS20180031457A1Overcomes shortcomingMaterial strength using tensile/compressive forcesEarth material testingComputer control systemMonitoring system

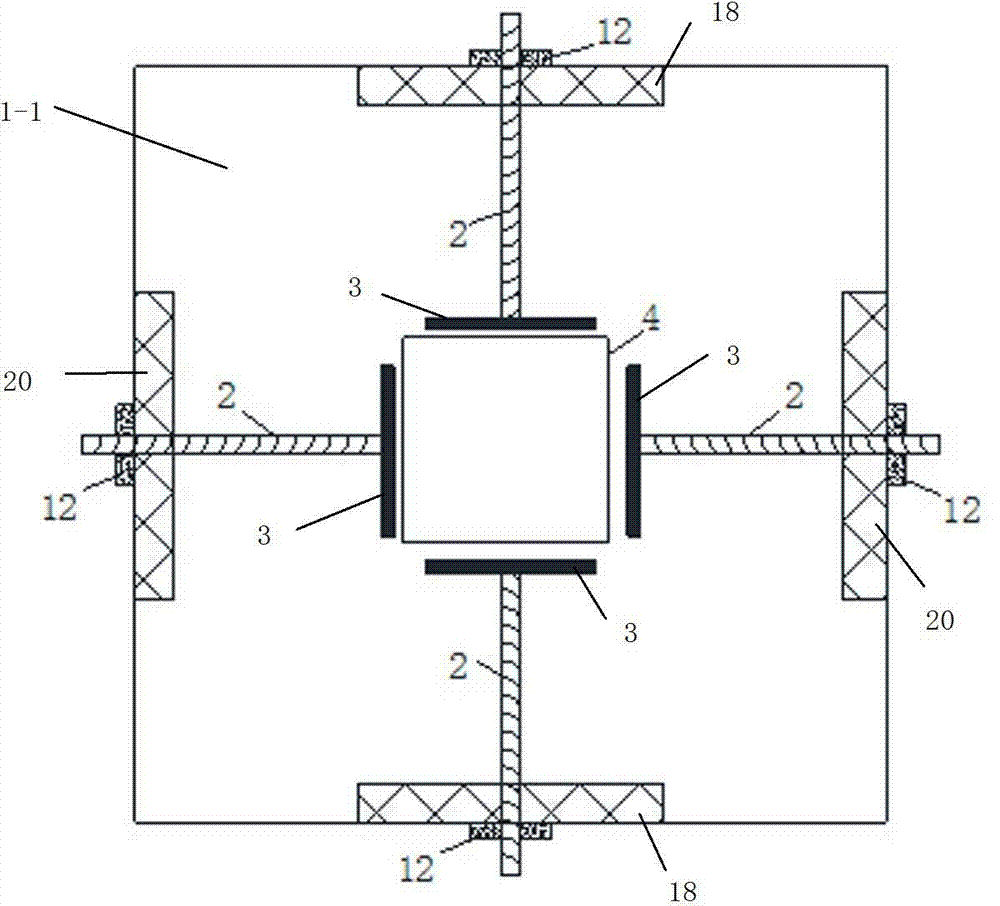

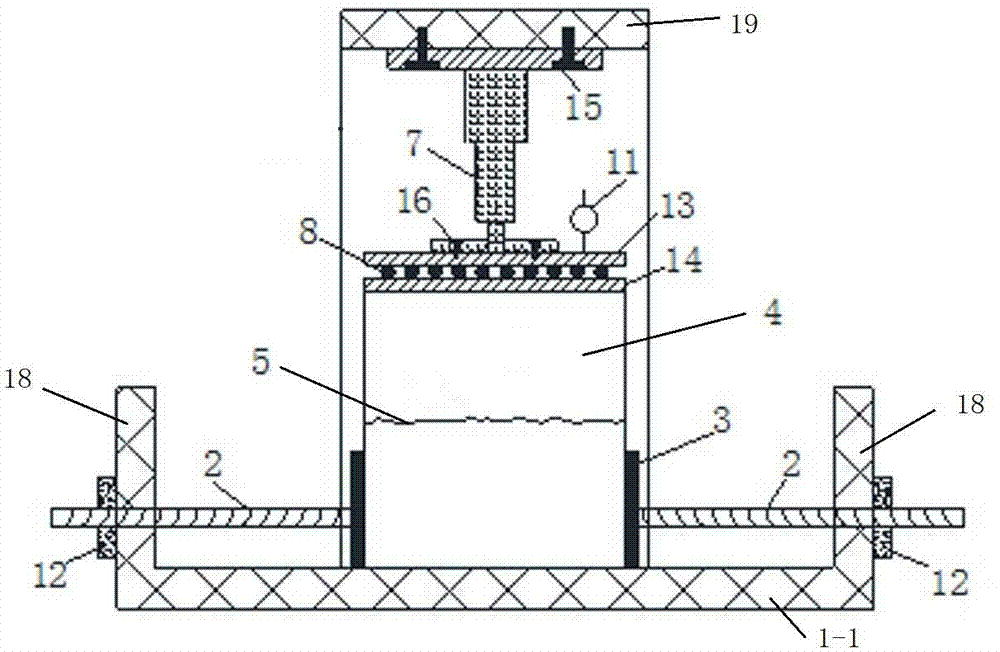

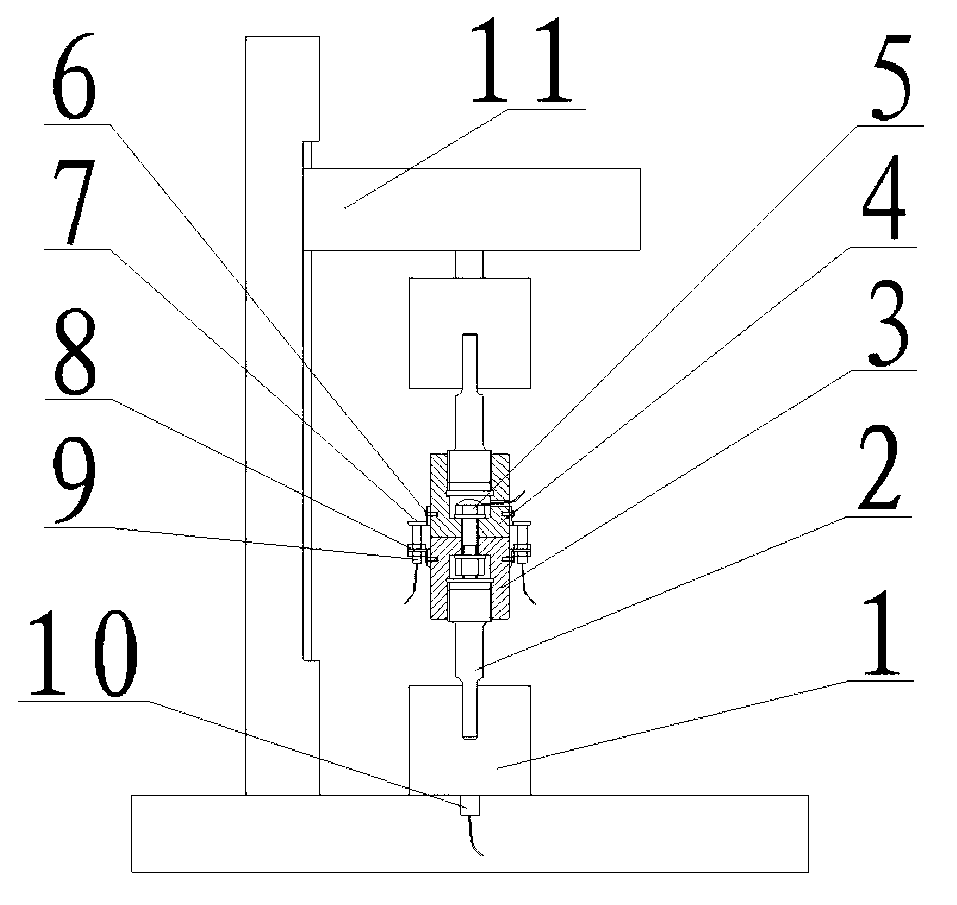

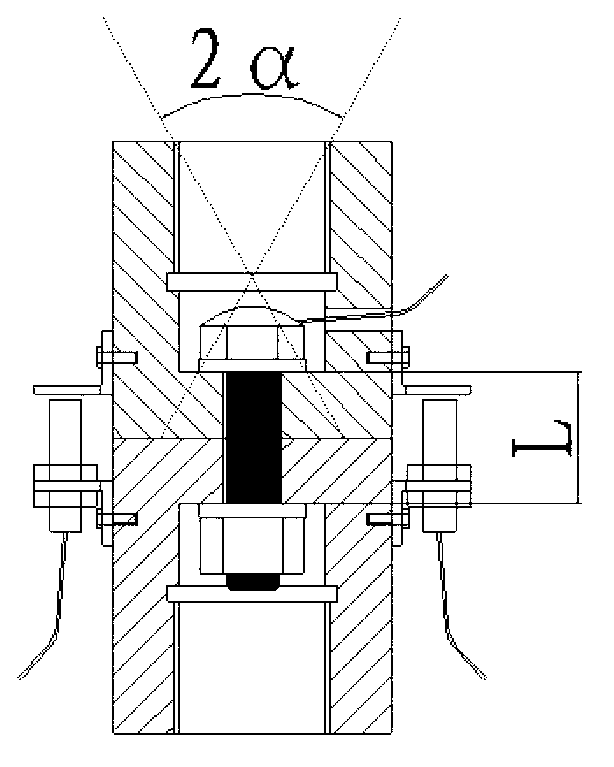

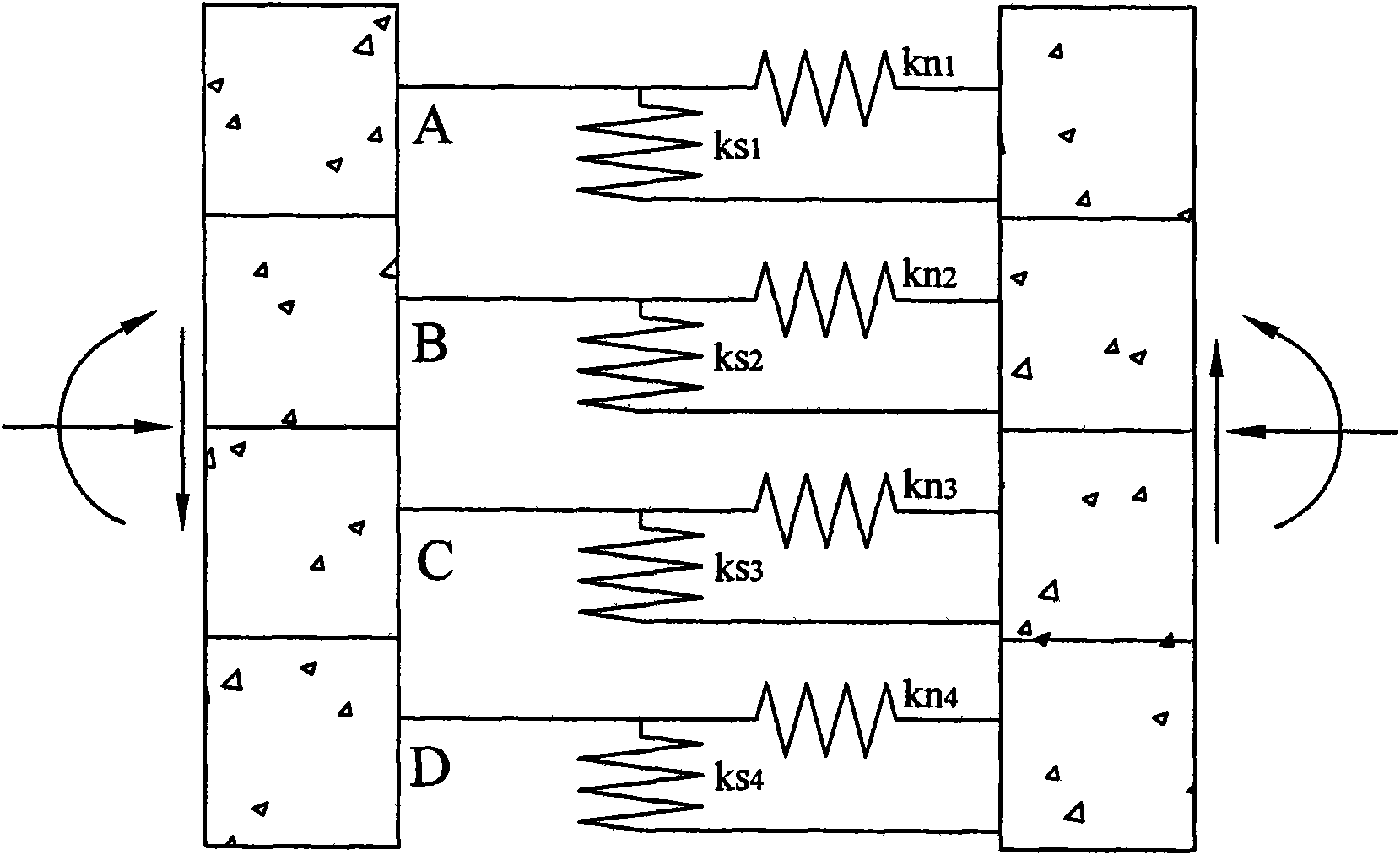

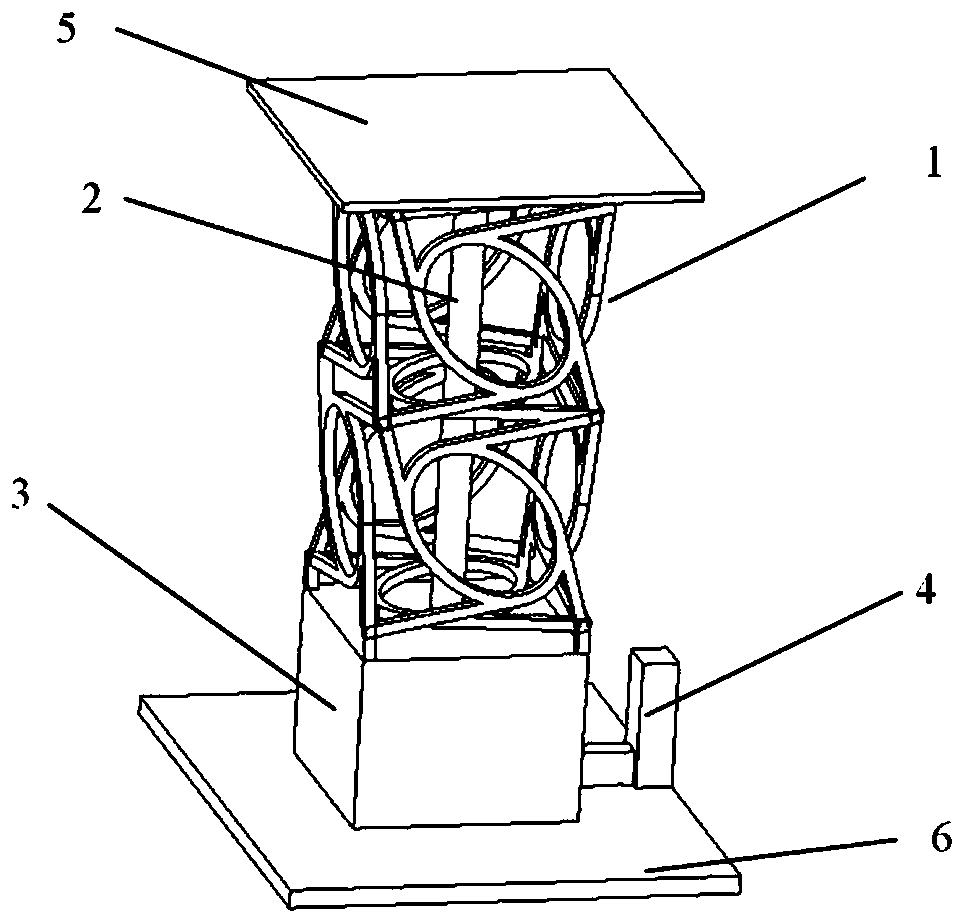

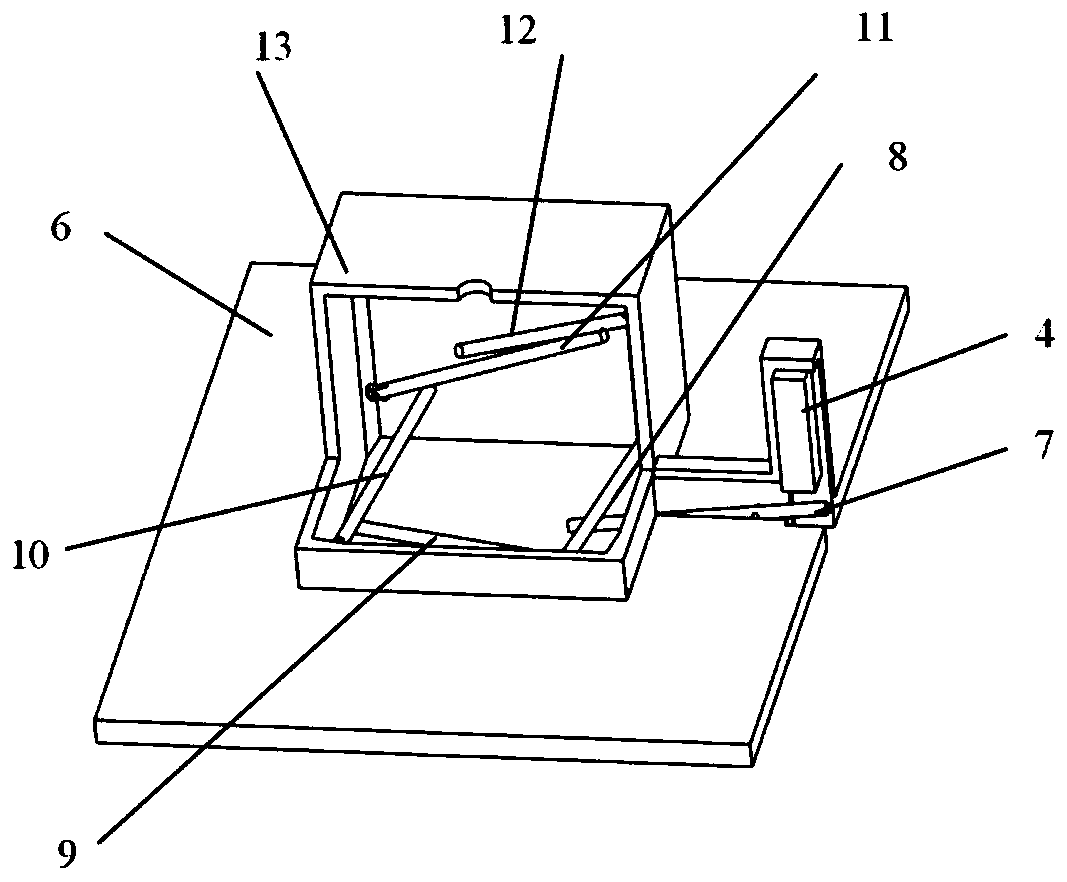

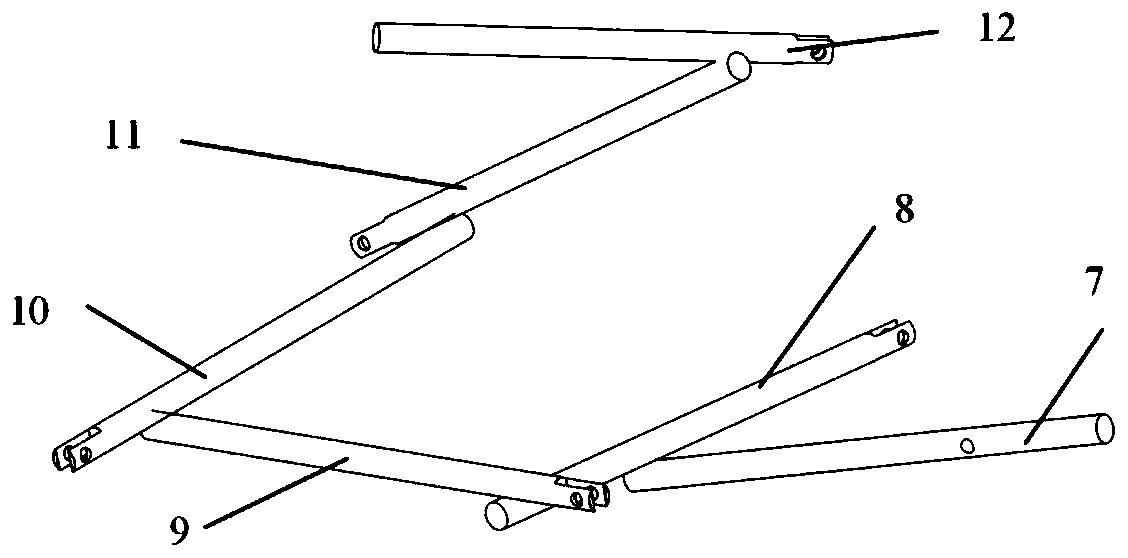

The present invention relates to a shear test device and test method of rock mass discontinuities under constant normal stiffness condition. The device includes: a base used for placing a test piece; a loading framework fixedly connected with the base; a shear loading system used for applying a shear force to the test piece; a normal loading system used for applying a normal pressure to the test piece; a normal displacement monitoring system used for measuring the magnitude of normal displacement of the test piece in real time; and a computer control system used for receiving the data of the normal displacement of the test piece in real time, and constantly adjusting the normal pressure applied by the normal loading system to the test piece according to the principle that the normal stiffness of the test piece is unchanged.

Owner:SHANDONG UNIV OF SCI & TECH

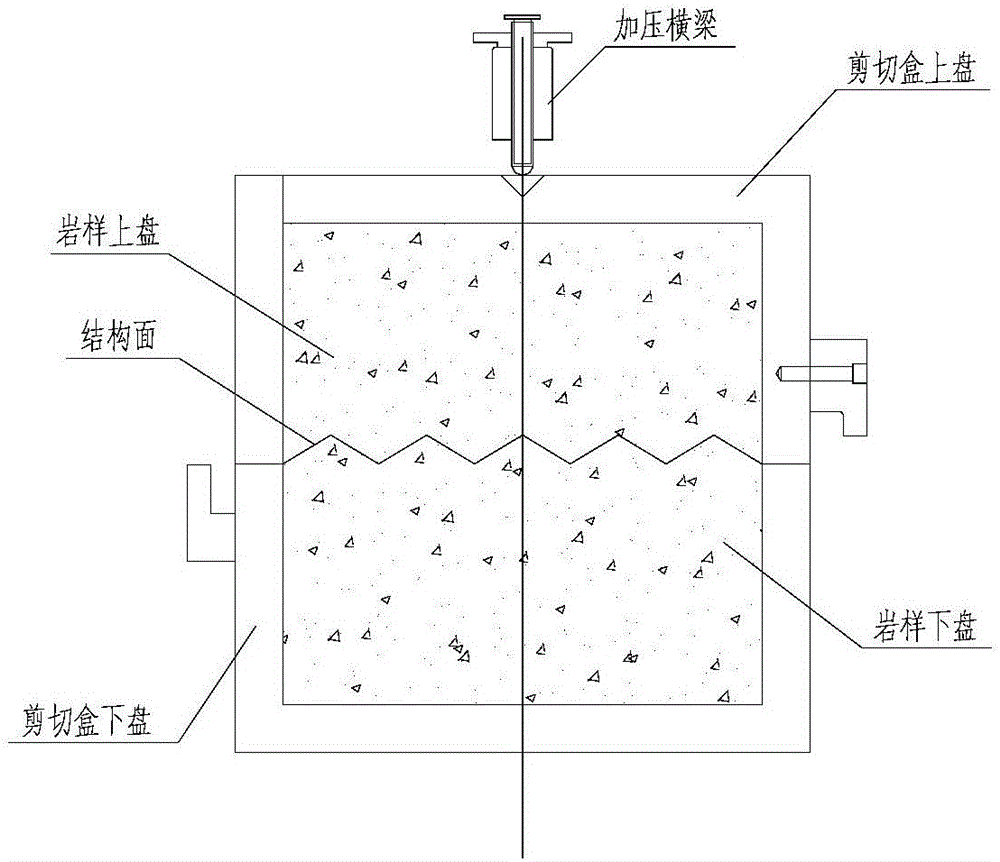

Rock mass structural surface shear test method and device

InactiveCN104749049AGuaranteed shear strengthGuaranteed StrengthMaterial strength using steady shearing forcesHorizontal axisSurface shear

The invention discloses a rock mass structural surface shear test method, which comprises the following steps of firstly, cutting a rock mass test piece into a cuboid and marking a vertical axis line and a horizontal axis line; then adjusting an adjusting rod, fixing the rock mass test piece by a movable steel baffle, enabling the vertical axis line of the rock mass test piece to coincide with the vertical axis line of a normal loading mechanism, enabling the horizontal axis line of the rock mass test piece to coincide with the horizontal axis line of a shear loading mechanism, and enabling the structural surface of the rock mass test piece to be located above the movable steel baffle; carrying out grading force application on the rock mass test piece by the normal loading mechanism from the vertical direction, and carrying out grading force application on the rock mass test piece by the shear loading mechanism from the horizontal direction; receiving the force application data of the normal loading mechanism and the shear loading mechanism and the displacement values of a normal displacement sensor and a horizontal displacement sensor by a computer, and analyzing and calculating the data. The invention also provides a rock mass structural surface shear test device. According to the invention, the stress bearing condition of a rock mass in the reality can be simulated, and test data are accurate and reliable.

Owner:WUHAN UNIV OF TECH

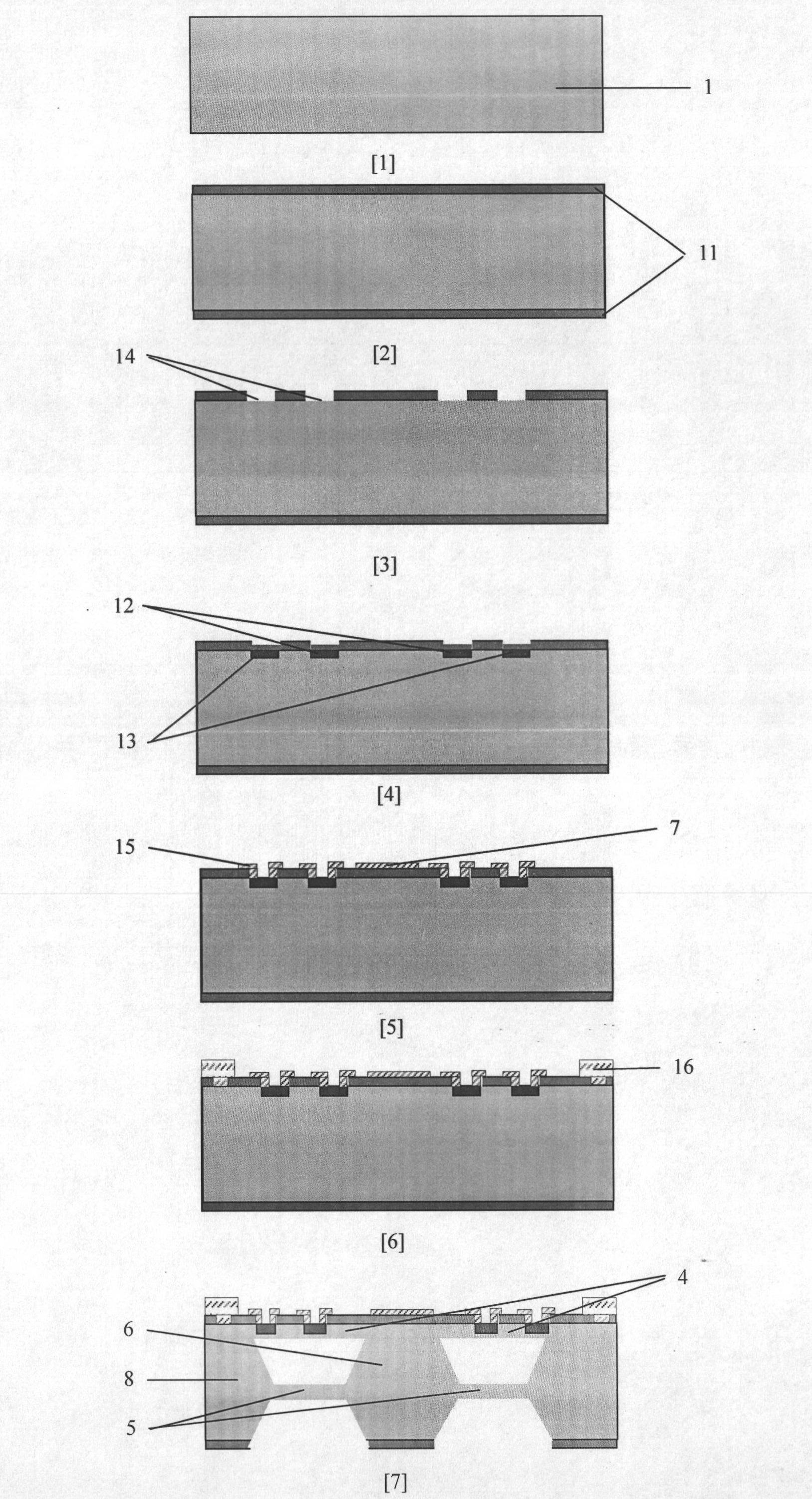

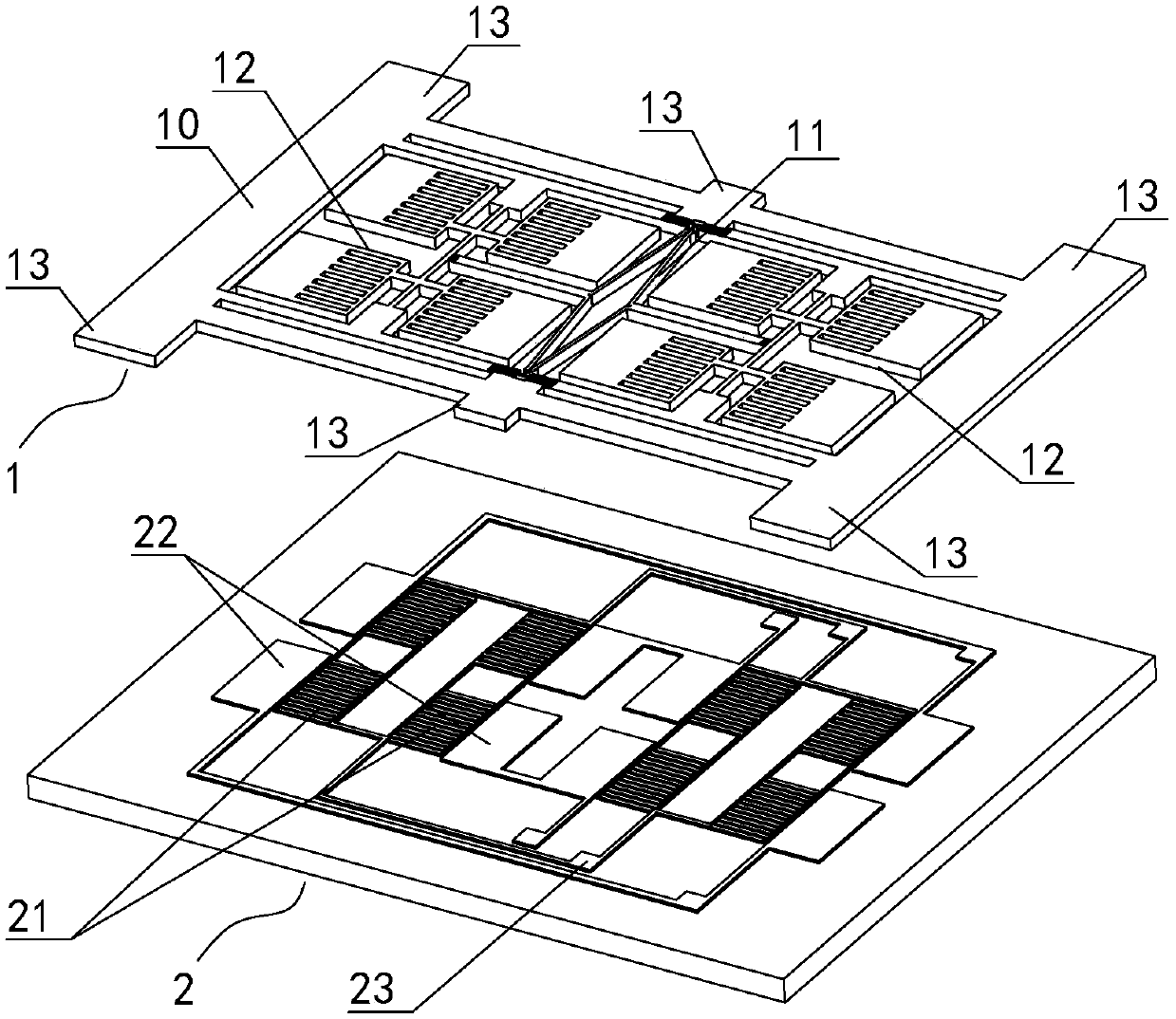

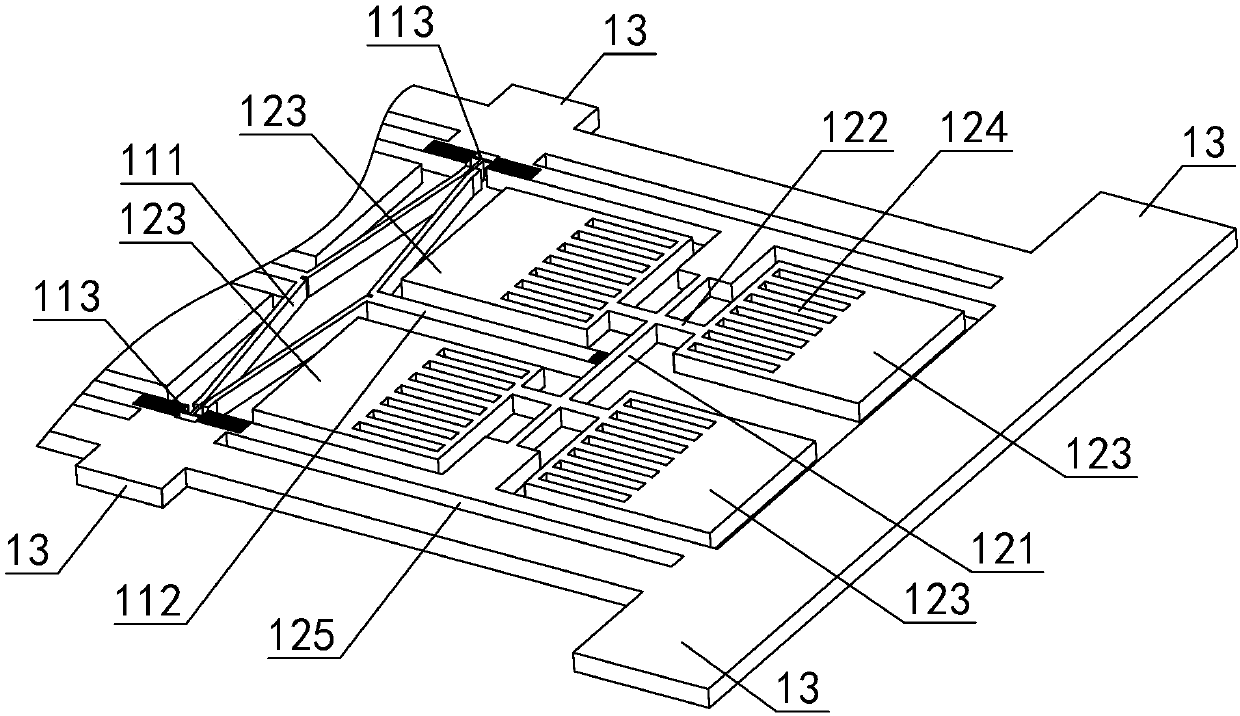

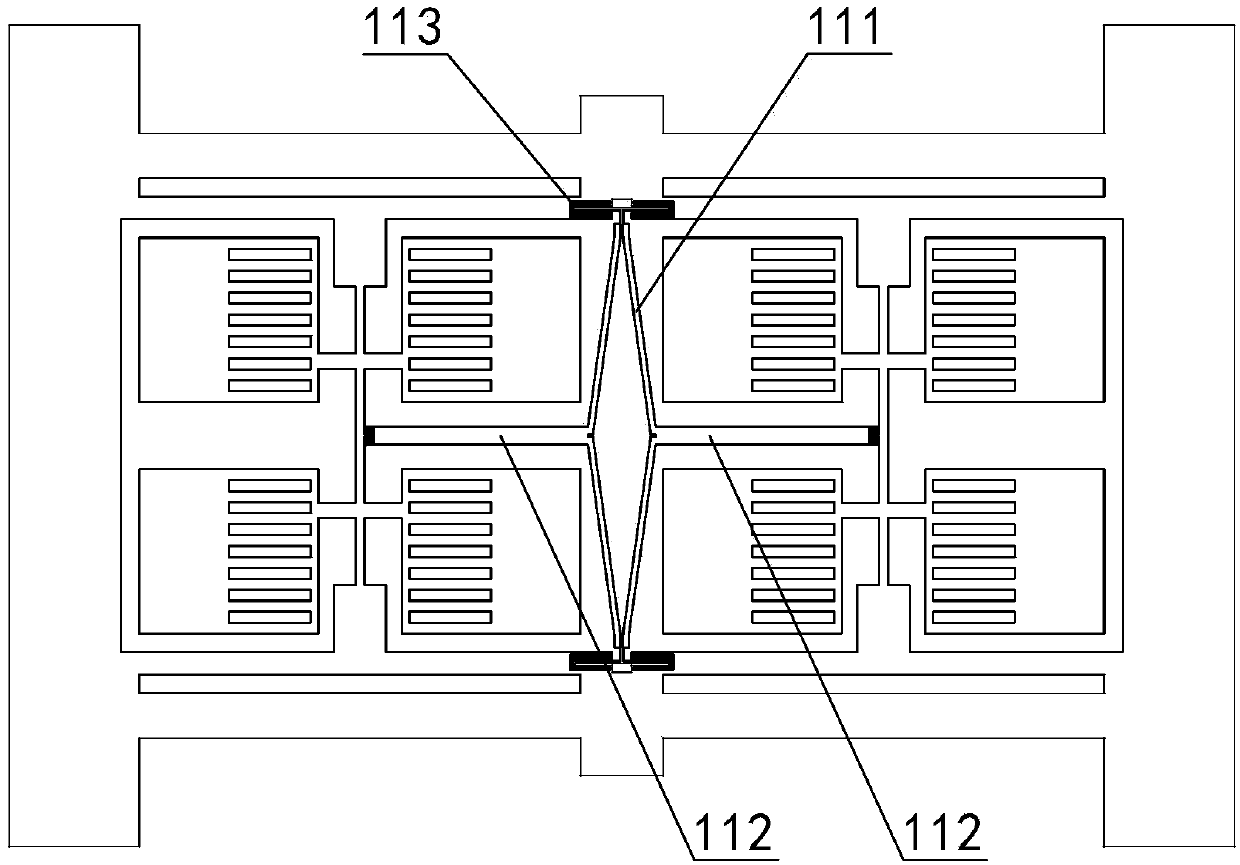

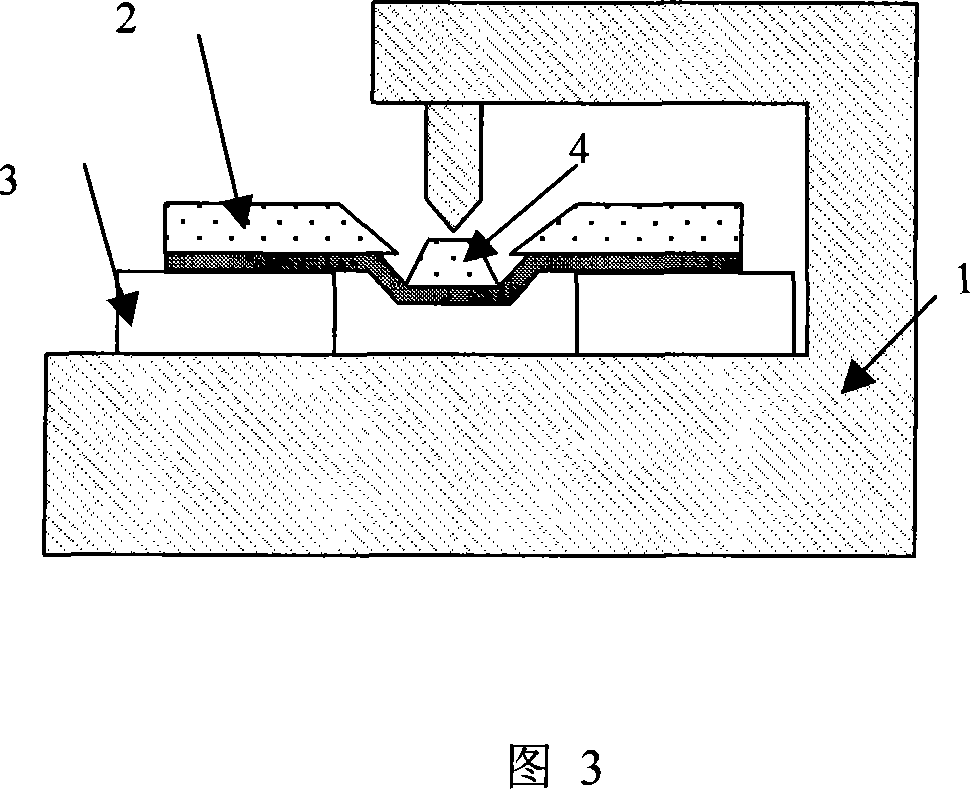

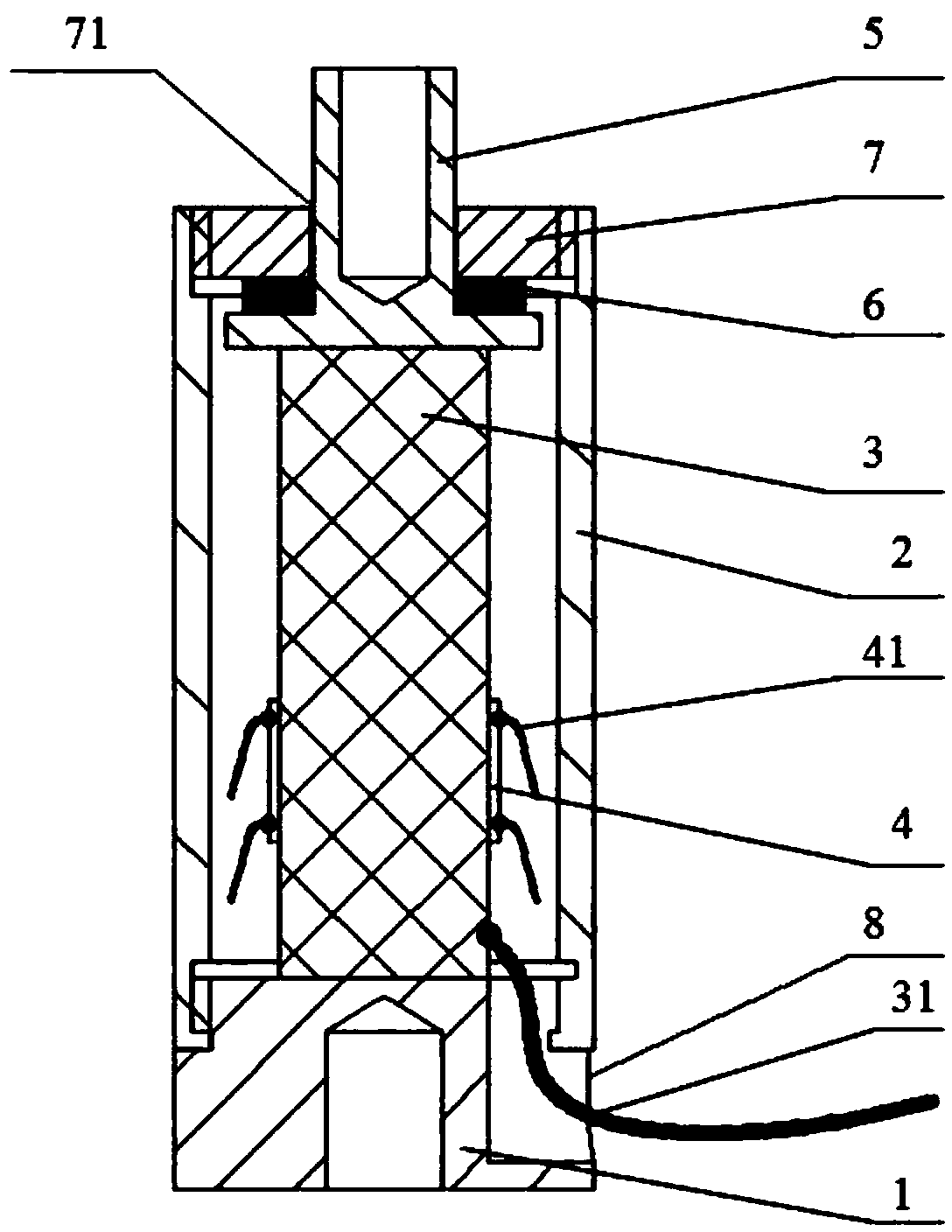

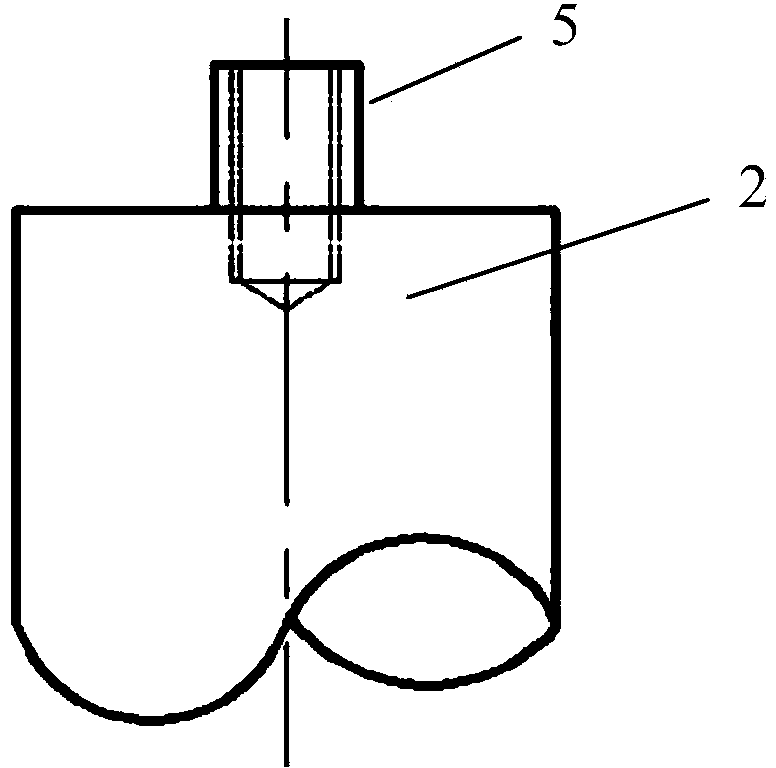

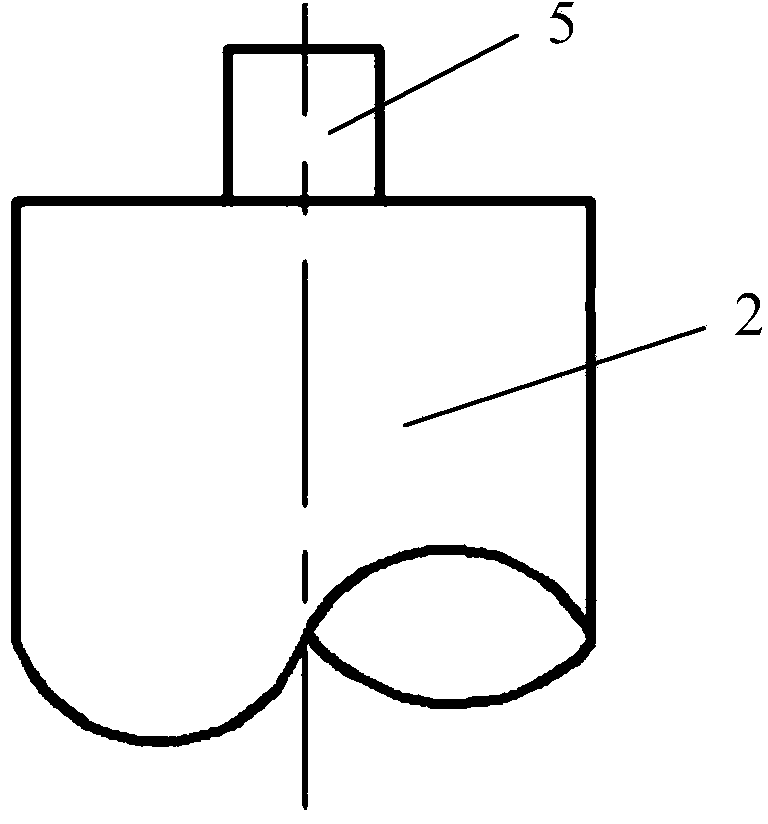

Resonance-equilibrium tunnel current type three-axis acceleration transducer and manufacturing method thereof

InactiveCN102608355AMeet high performance requirementsReduce cross-interferenceAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsResonanceClosed loop

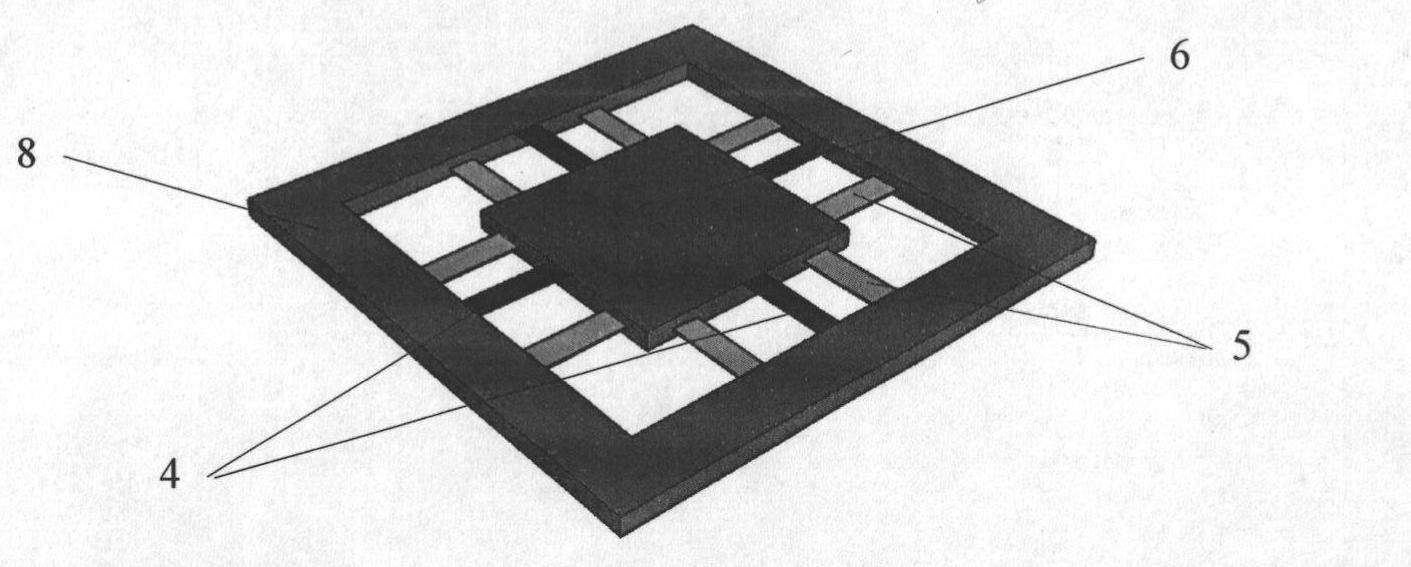

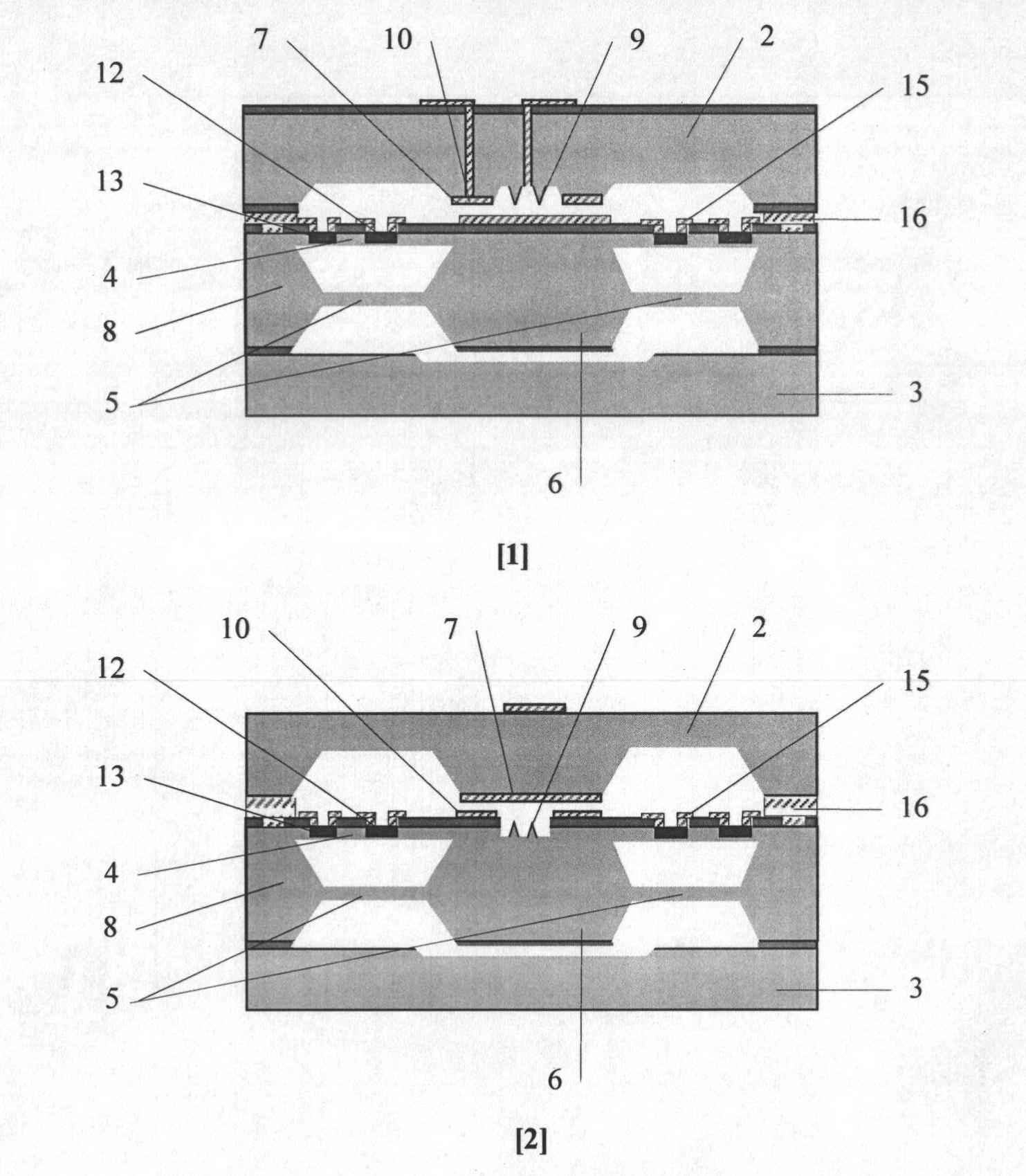

The invention discloses a resonance-equilibrium tunnel current type three-axis acceleration transducer and a manufacturing method thereof, which belong to the field of microelectronic mechanical systems. The resonance-equilibrium tunnel current type three-axis acceleration transducer is structurally characterized in that the three-axis transducer comprises an intermediate silicon wafer (1), a top cover plate (2) and a bottom plate (3), and double-end fixing beam resonators (4), a mass block (6) and supporting beams (5) are manufactured on the intermediate silicon wafer (1). Besides, in the aspect of the detection principle, acceleration signals of the X-axis and the Y-axis in the plane of the chip are detected by the double-end fixing beam resonators (4), variation of resonant frequency of the double-end fixing beam resonators (4) reflects acceleration and direction thereof, a tunnel tip (9), a control electrode (10) and a biased electrode (7) form a portion for detecting acceleration signal of the Z-axis, detection is realized according to the tunnel current type sensitive principle, and the transducer works in a closed-loop equilibrium mode. Besides, the normal displacement of the mass block (6) on the chip is small, and the cross interference introduced by the acceleration signals of the Z-axis to detection of X-axis acceleration and Y-axis acceleration is low.

Owner:CHINA JILIANG UNIV

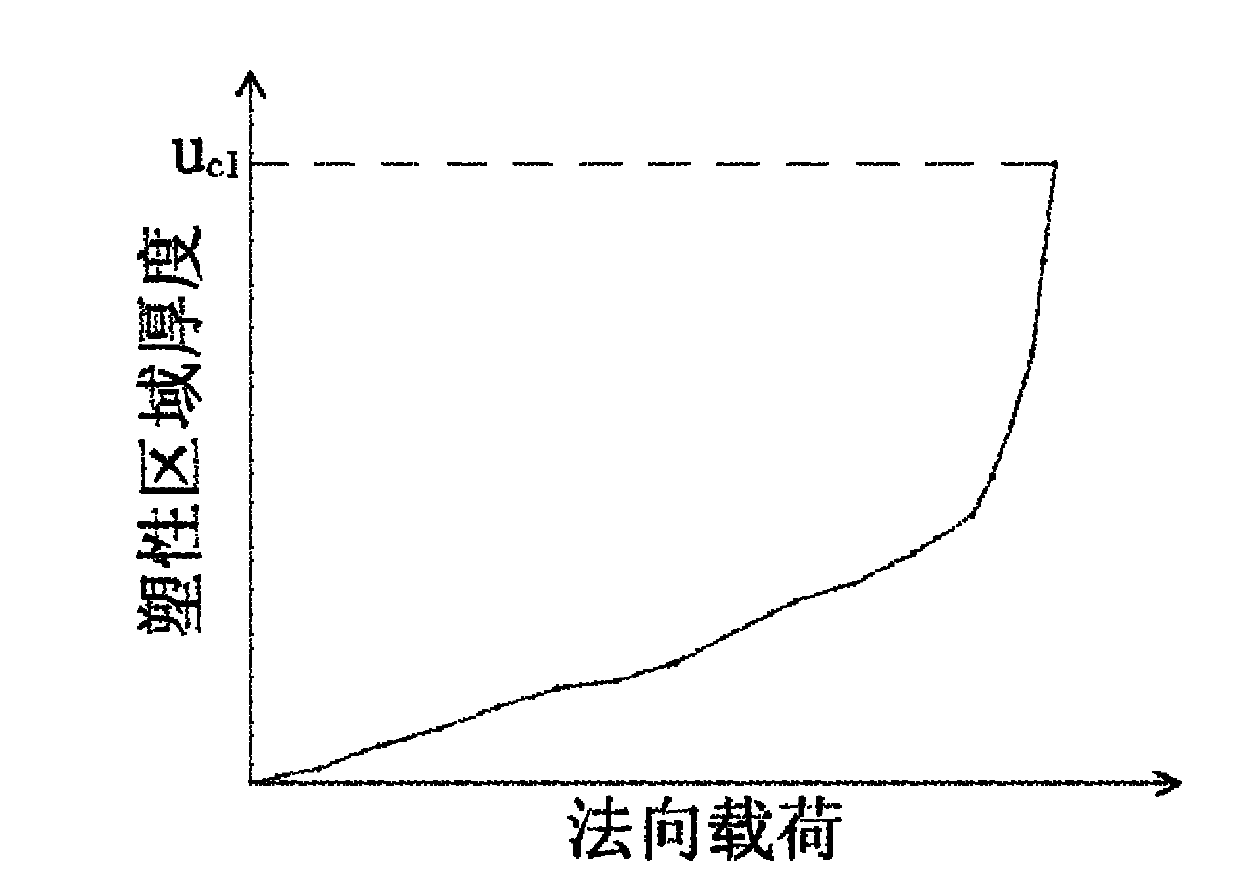

Movable plate stacking ring shearing apparatus capable of adapting to free shearing deformation

ActiveCN104849151ALess restraintReduce stress concentrationMaterial strength using steady shearing forcesShearing deformationTest equipment

The invention discloses a movable plate stacking ring shearing apparatus capable of adapting to free shearing deformation and belongs to the mechanical characteristic test equipment. The movable plate stacking ring shearing apparatus comprises a bracket, a lower shearing box, a stacking ring set shearing box, a vertical loading unit, a horizontal loading unit and a measuring unit, wherein the bracket consists of a bottom plate and a stand column; the lower shearing box and the stacking ring set shearing box are stacked between the bottom plate and the vertical loading unit in sequence; the vertical loading unit is fixed on the stand column; the horizontal loading unit is fixed on the bottom plate. According to the movable plate stacking ring shearing apparatus capable of adapting to free shearing deformation, a movable plate shearing frame capable of adapting to free shearing deformation can be used for performing a simple shear test and a direct shear test and also can be used for performing a pull-out test on geogrid, geotechnical cloth and the like. When the simple shear test is performed, the vertical loading unit can provide three normal boundary conditions of normal displacement, normal rigidity and normal stress, and the horizontal loading unit can be used for providing horizontal shearing force. The movable plate stacking ring shearing apparatus is delicate in design, convenient to operate, easy to assemble and disassemble, and capable of precisely performing research on shearing deformation characteristic between contact surfaces of geotechnical materials and structures.

Owner:WUHAN UNIV

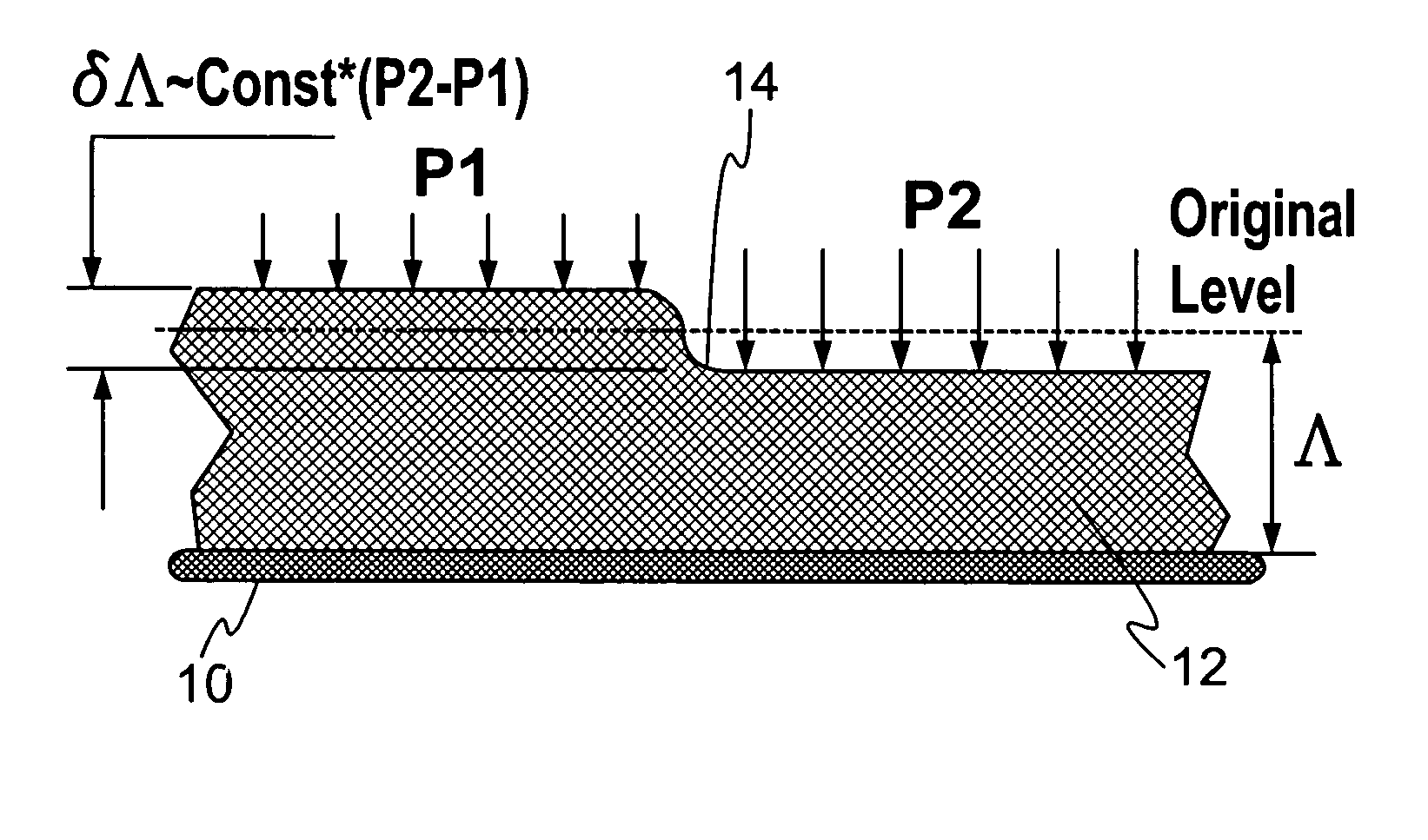

Method for determining a surface contact force

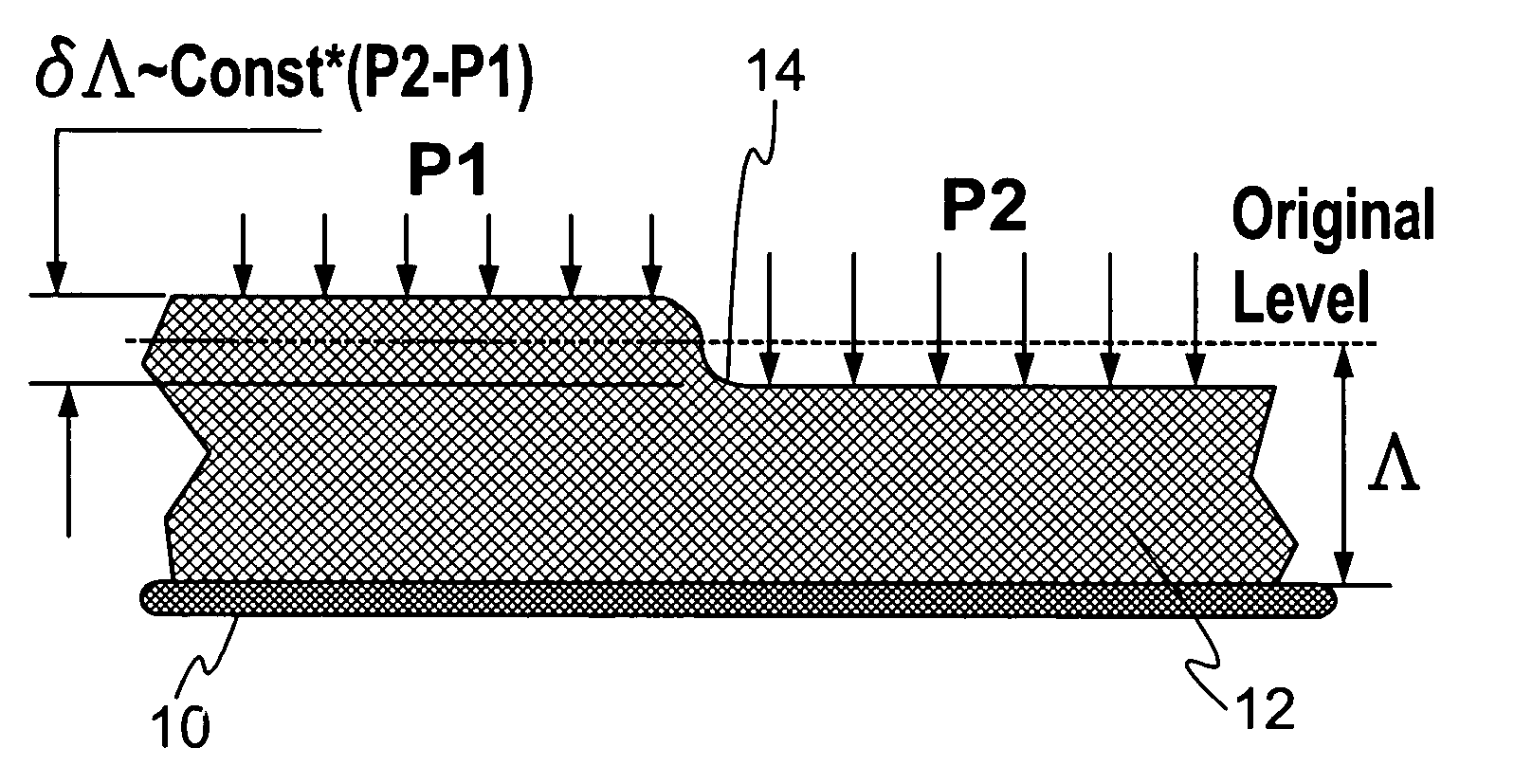

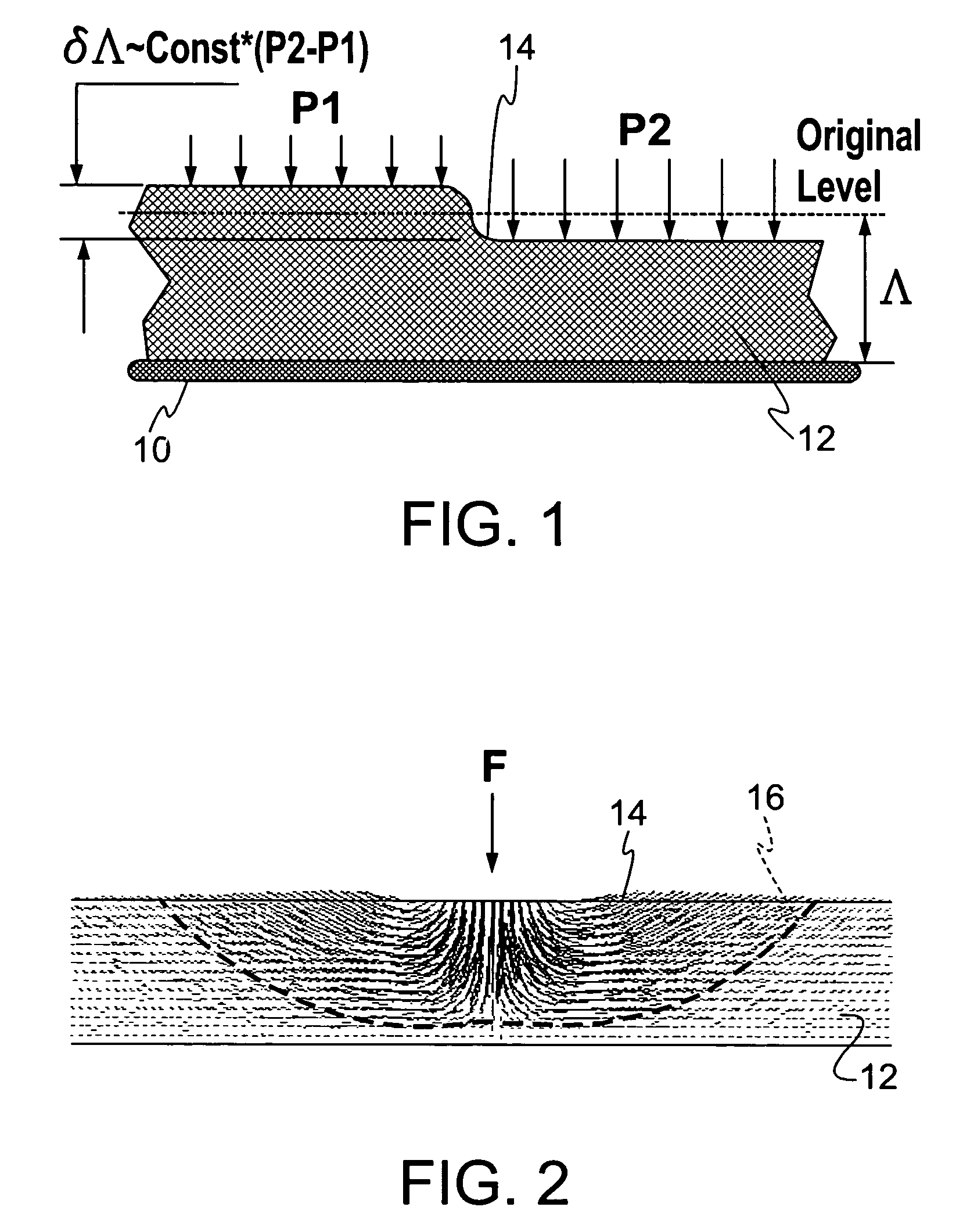

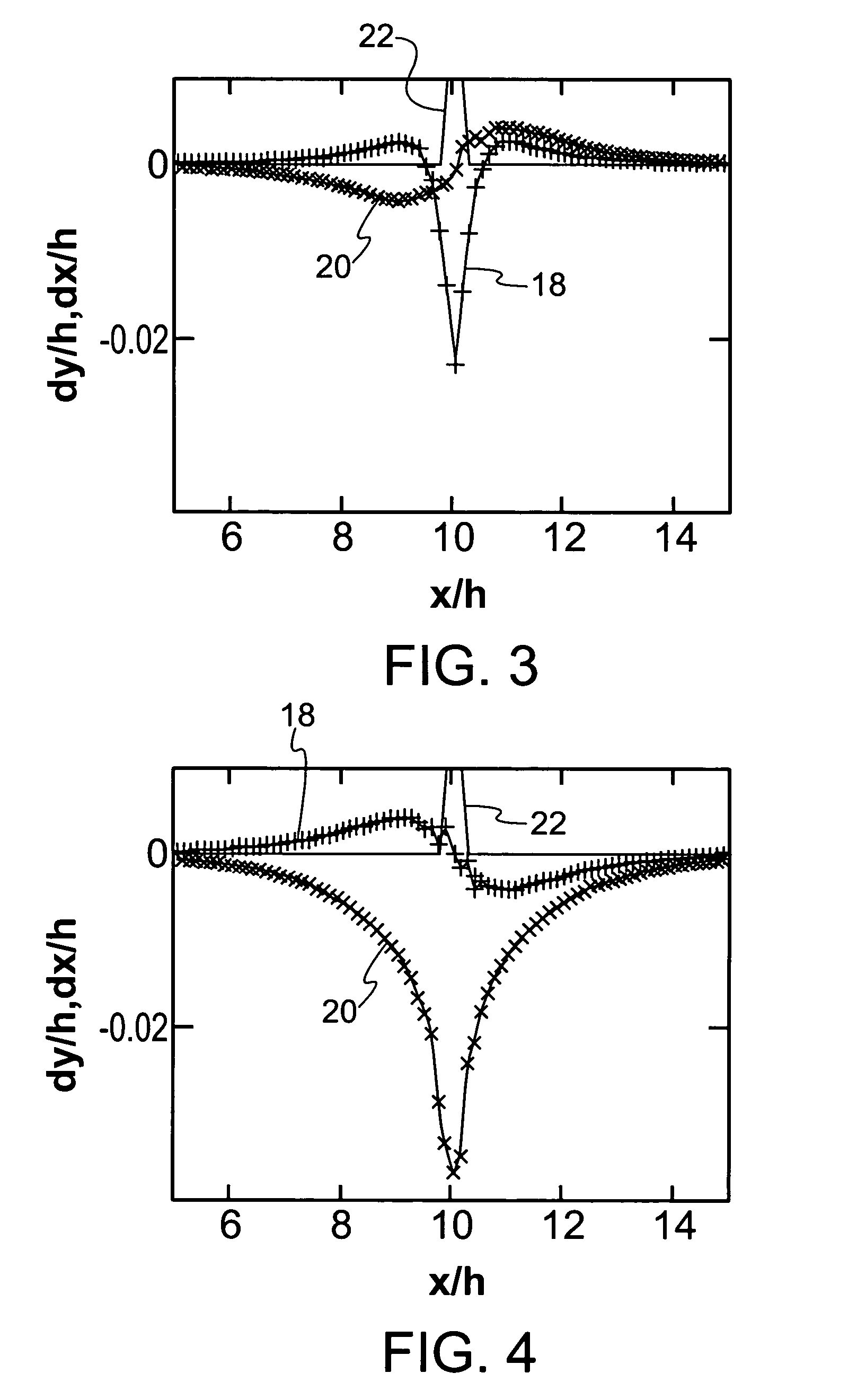

ActiveUS7127950B2Aerodynamic testingForce measurement by measuring optical property variationLuminophoreTangential displacement

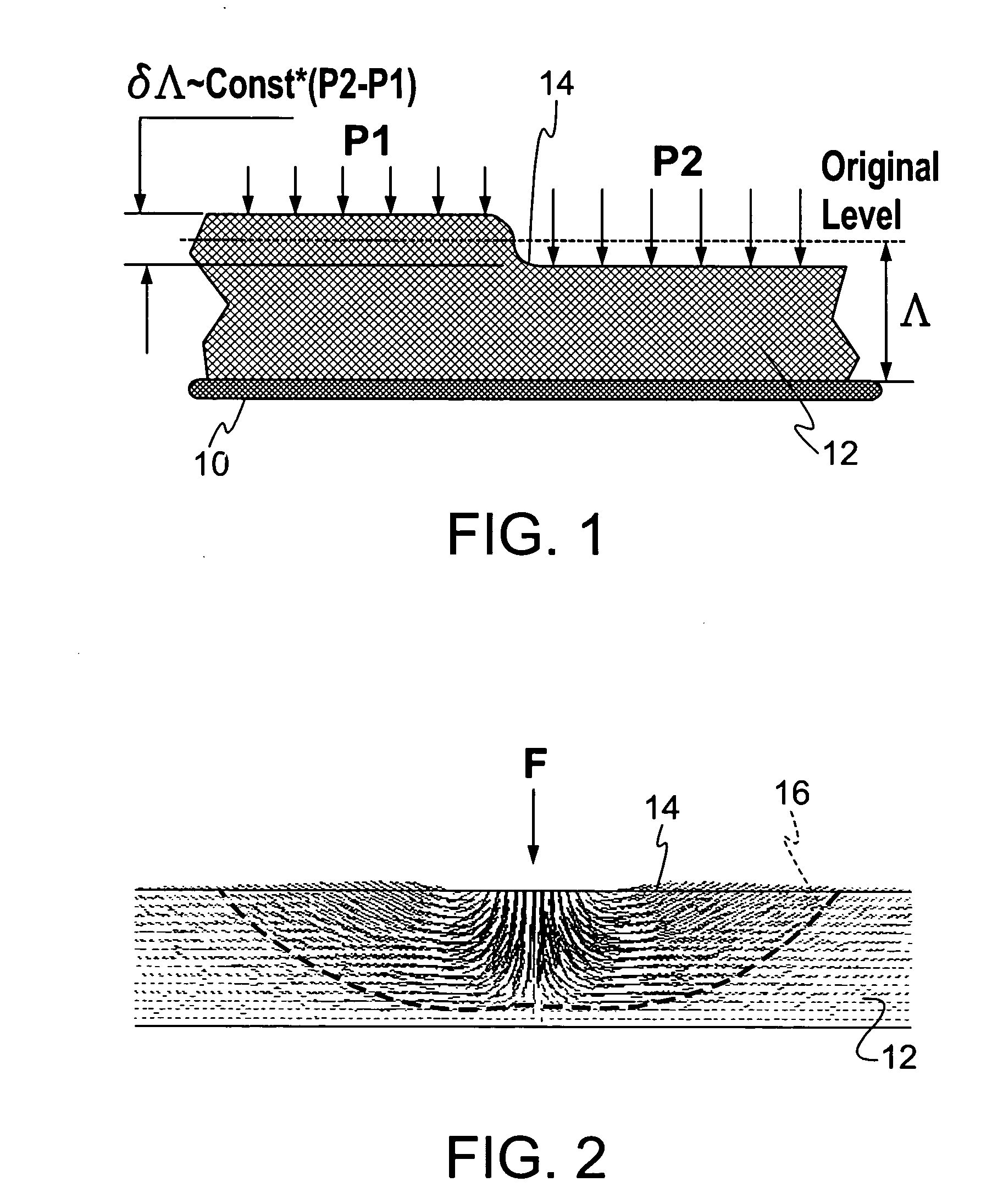

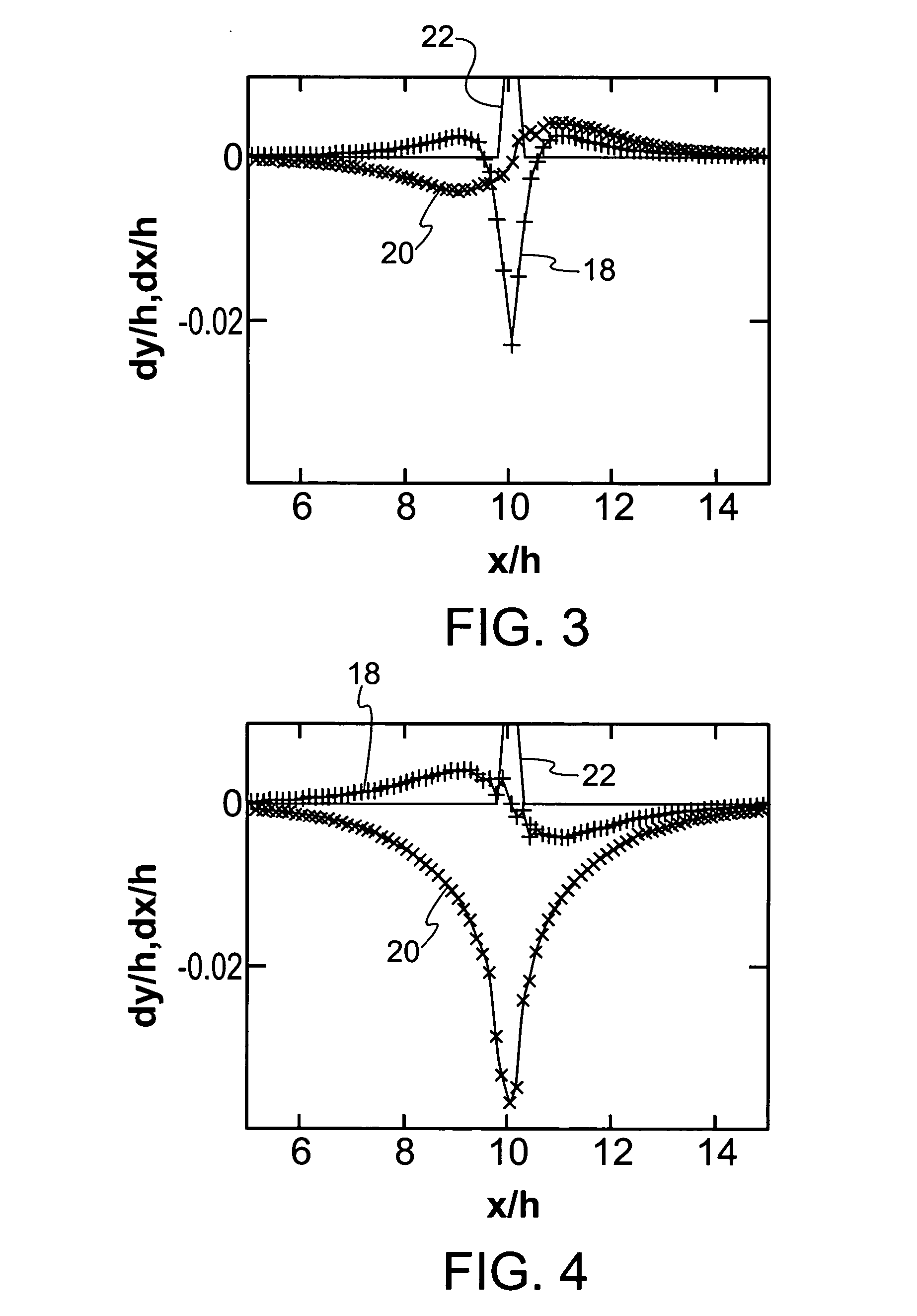

A method of measuring a load on a surface produced by a contact force. An elastic film or coating is located on a supporting surface to provide an indication of normal and tangential or shear forces applied to the surface. A thickness measurement, corresponding to a normal displacement, and a tangential displacement of the film, corresponding to a shear displacement, is obtained and input to a response function to reconstruct the normal and shear load components of the contact force on the surface. A differential thickness measurement of the film is detected by an optical method in which a luminescent output from a luminophore in the film is measured. A luminescent output from a reference luminophore located below the film is also measured to provide a measurement system independent of the illumination source used to produce the luminescent output.

Owner:INNOVATIVE SCI SOLUTIONS

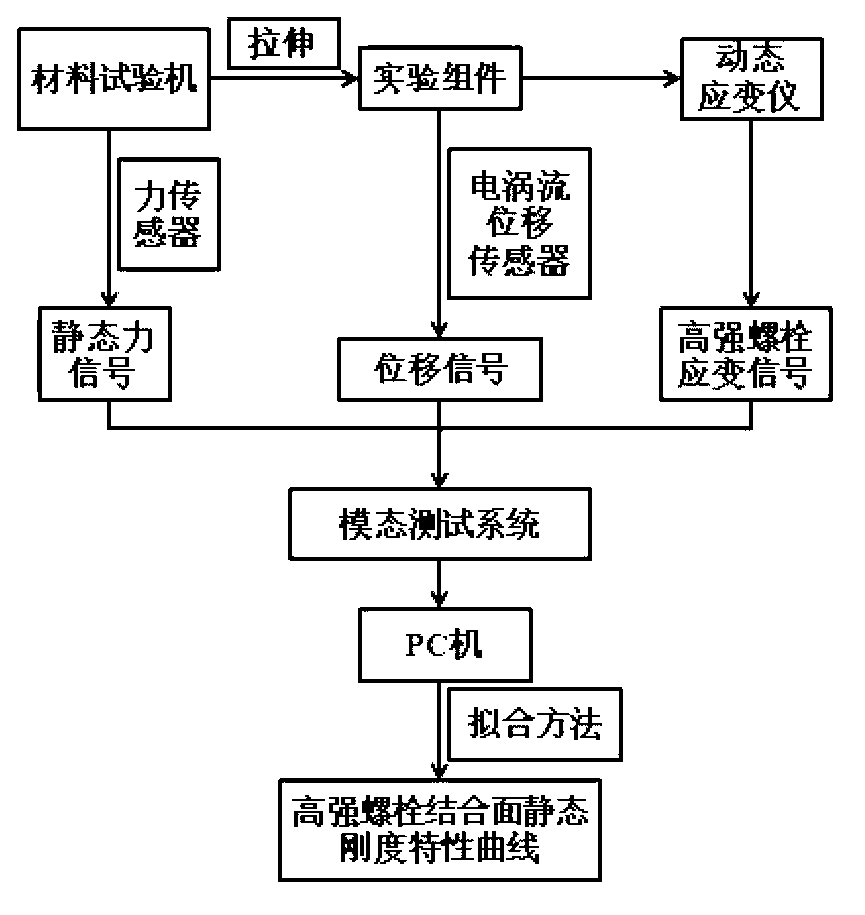

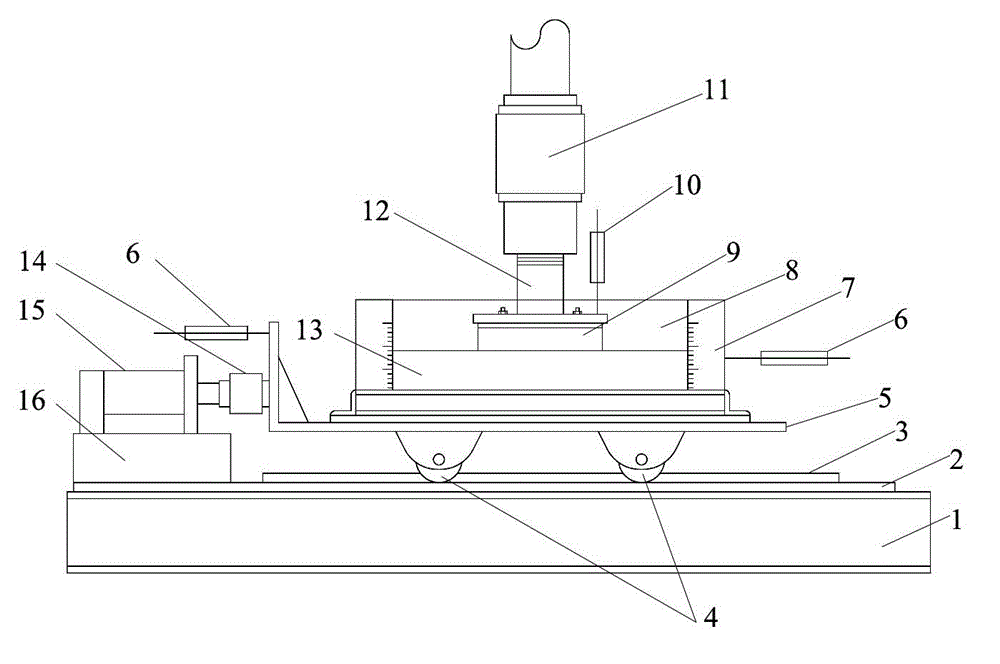

Device and method for testing normal static characteristics of junction surface of high-strength bolt

The invention discloses a device and a method for testing normal static characteristics of a junction surface of a high-strength bolt. The device for testing the normal static characteristics of the junction surface of the high-strength bolt comprises a material testing machine, two screws, a lower test piece, an upper test piece, the high-strength bolt, a slotless locating support, a slotted locating support, an eddy current displacement sensor, a force sensor, a dynamic strain indicator, a modal testing system and a personal computer (PC) machine. The high-strength bolt penetrates through the upper test piece and the lower test piece in a vertical mode so that the upper test piece and the lower test piece are mutually attached to form the junction surface, and a strain gage is embedded in the high-strength bolt. The eddy current displacement sensor is used for measuring the normal displacement variable quantity of the junction surface. The upper test piece and the lower piece are respectively connected with the material testing machine through the two screws. The material testing machine carries the force sensor and exerts static tensile force on the upper test piece and the lower test piece along the longitudinal direction. The dynamic strain indicator for measuring the pretightening force and a strain signal of the high-strength bolt, the eddy current displacement sensor for measuring the normal displacement variable quantity of the junction surface, and the force sensor for measuring a static force signal output self-signals to the modal testing system, and then the signals are transmitted to the PC machine.

Owner:BEIJING UNIV OF TECH

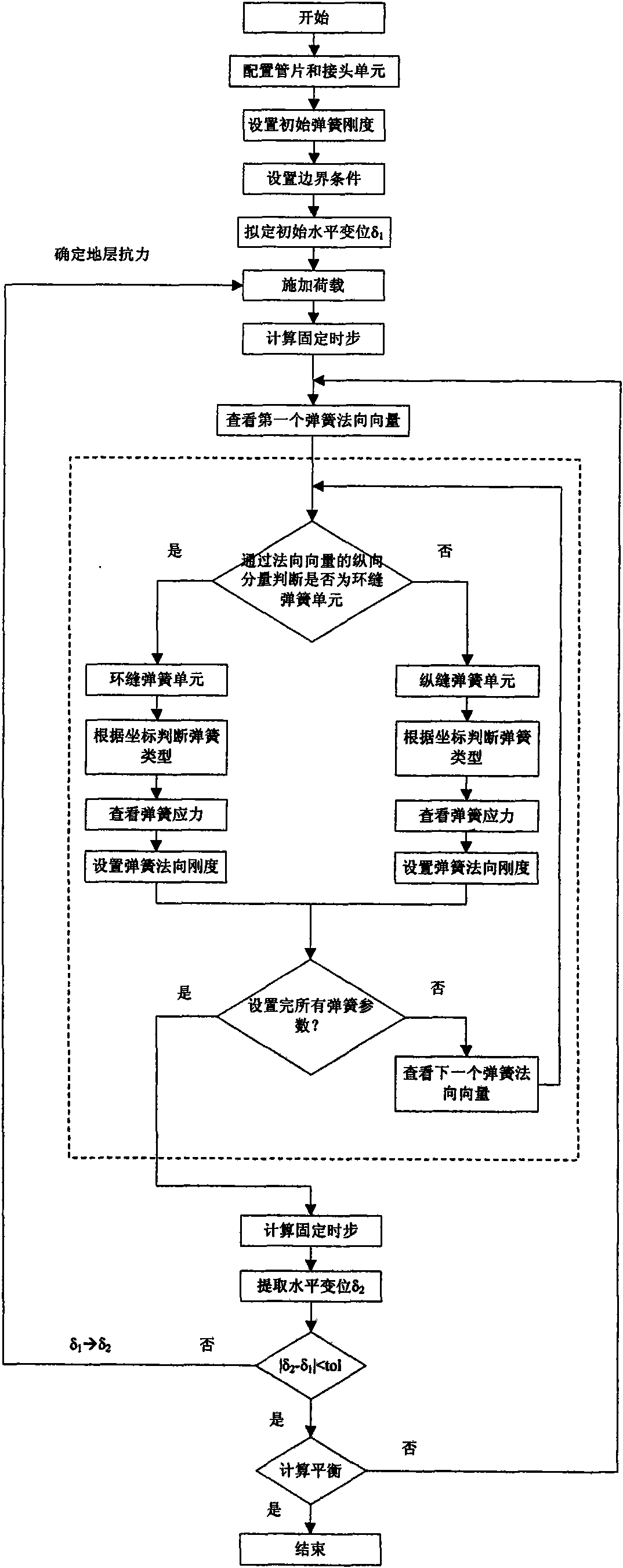

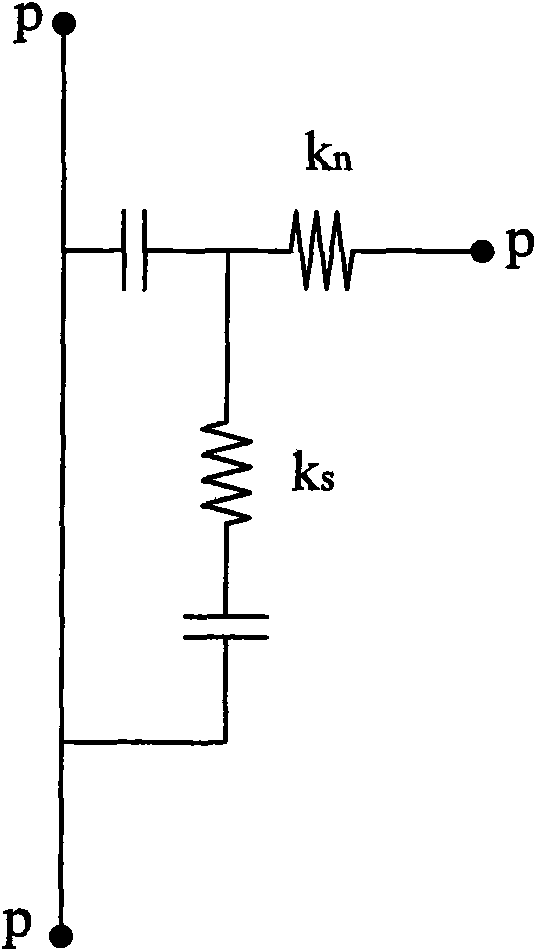

Simulation method of shield tunnel joint structure

InactiveCN101667220AStiffness parameters are easy to determineStiffness adjustmentSpecial data processing applicationsMechanical modelsUpper joint

The invention discloses a simulation method of a shield tunnel joint structure, which is characterized by comprising the steps of: (1) setting joint units: dispersing joint contact surfaces into a plurality of nodes, wherein the nodes are mutually connected by the joint units of simulation springs, circumferential upper joint units have a plurality of layers to respectively simulate force transmission liners, bolts and gaskets in real joints, and the types of the joint units at the same layer are the same; (2) setting the rigidity, the boundary condition and the joint initial displacement Delta1 of initial springs; (3) applying load; (4) examining a first joint unit; (5) setting the normal rigidity of the spring according to the type of the joint unit; (6) judging whether all the joint units are set, if so, starting the next step (7), and if not, examining the next joint unit and retuning to the step (5); (7) counting the real displacement delta 2 of the joints; and (8) comparing the delta1 with the delta2, if the difference between the two is in the allowed range tol, completing the account, and counting the deformation of the joints in the tunnel, and if the difference between the two is over the allowed range, counting the imposed load of the tunnel according to the delta2, and returning back to the step (3) to reapply the load. Based on the structure characteristics of theliner structure joints, the method builds the mechanical model of the liner structure joints, dynamically adjusts spring parameters in the process of counting according to the obtained node spring stress or the normal displacement, and uses joint models to count the whole ring liner structure. The method can consider the performance of the circumferential joints and the longitudinal joints of theliners, count the inner force and the deformation of the duct pieces and the joints of the liners, and more exactly show the status of deformation and force of the duct pieces.

Owner:TONGJI UNIV

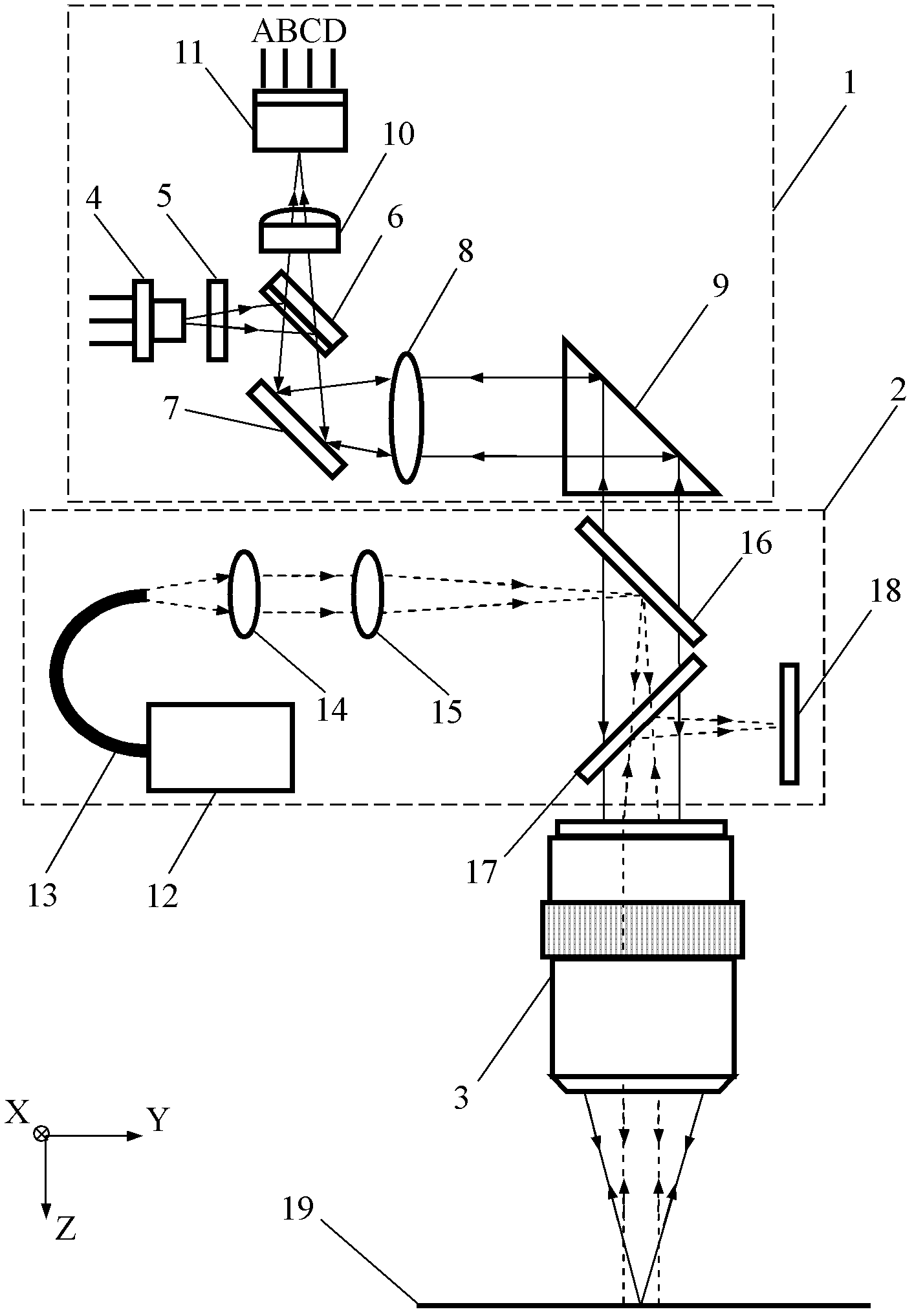

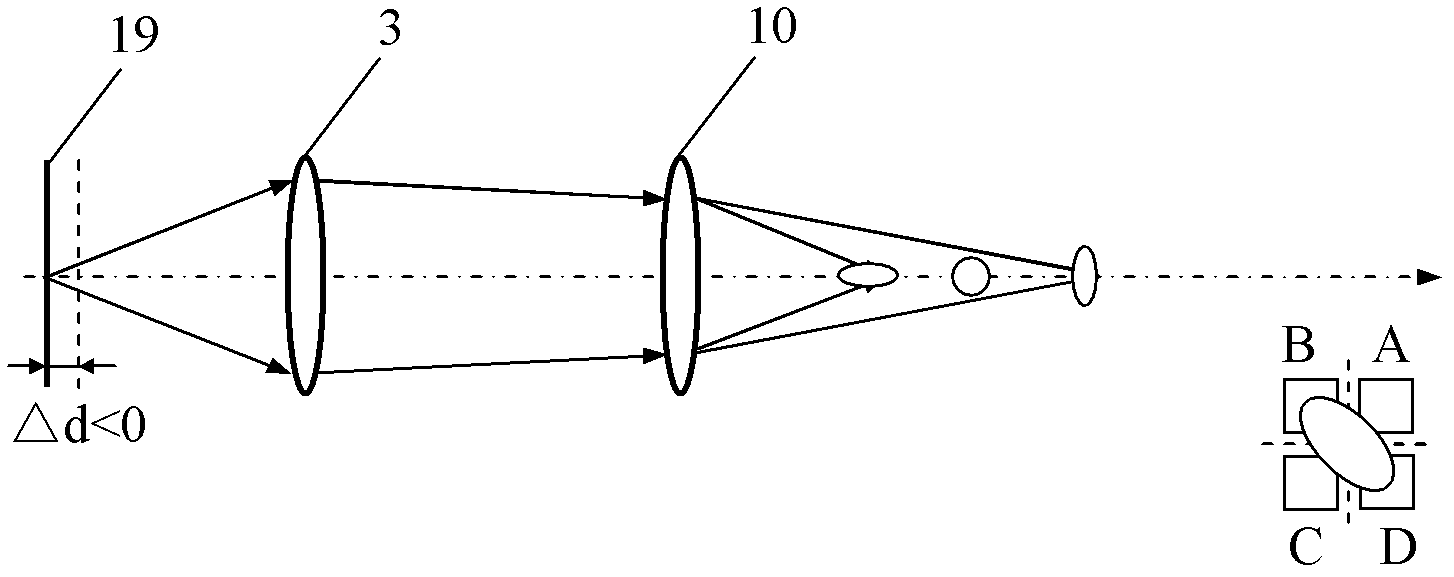

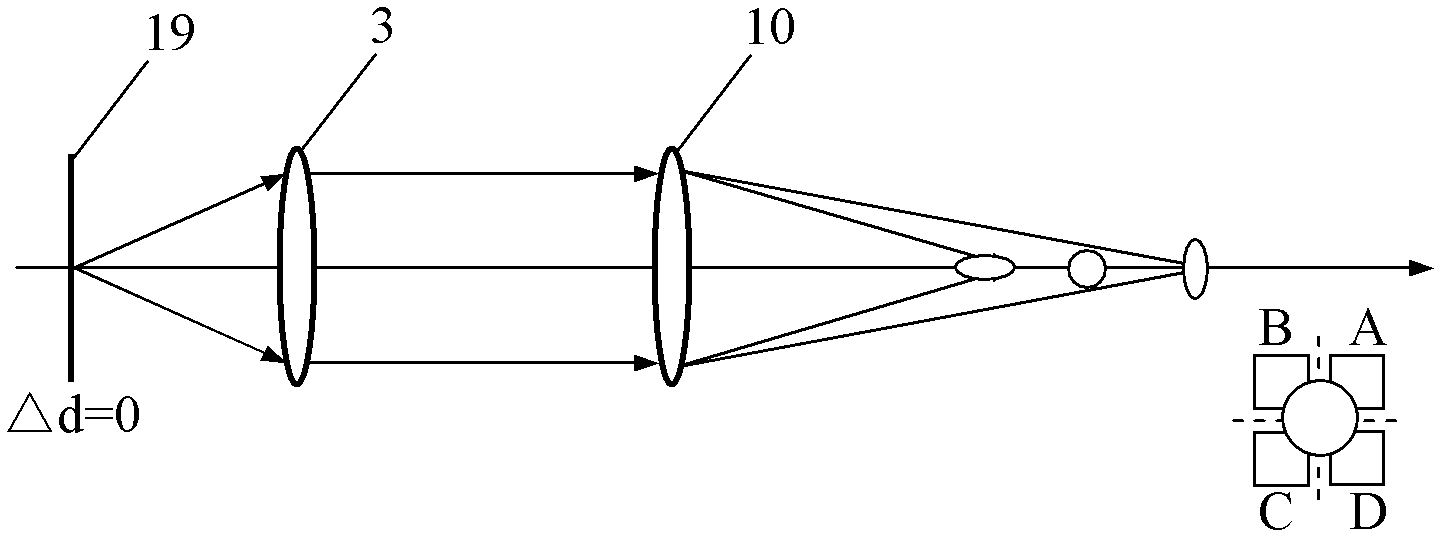

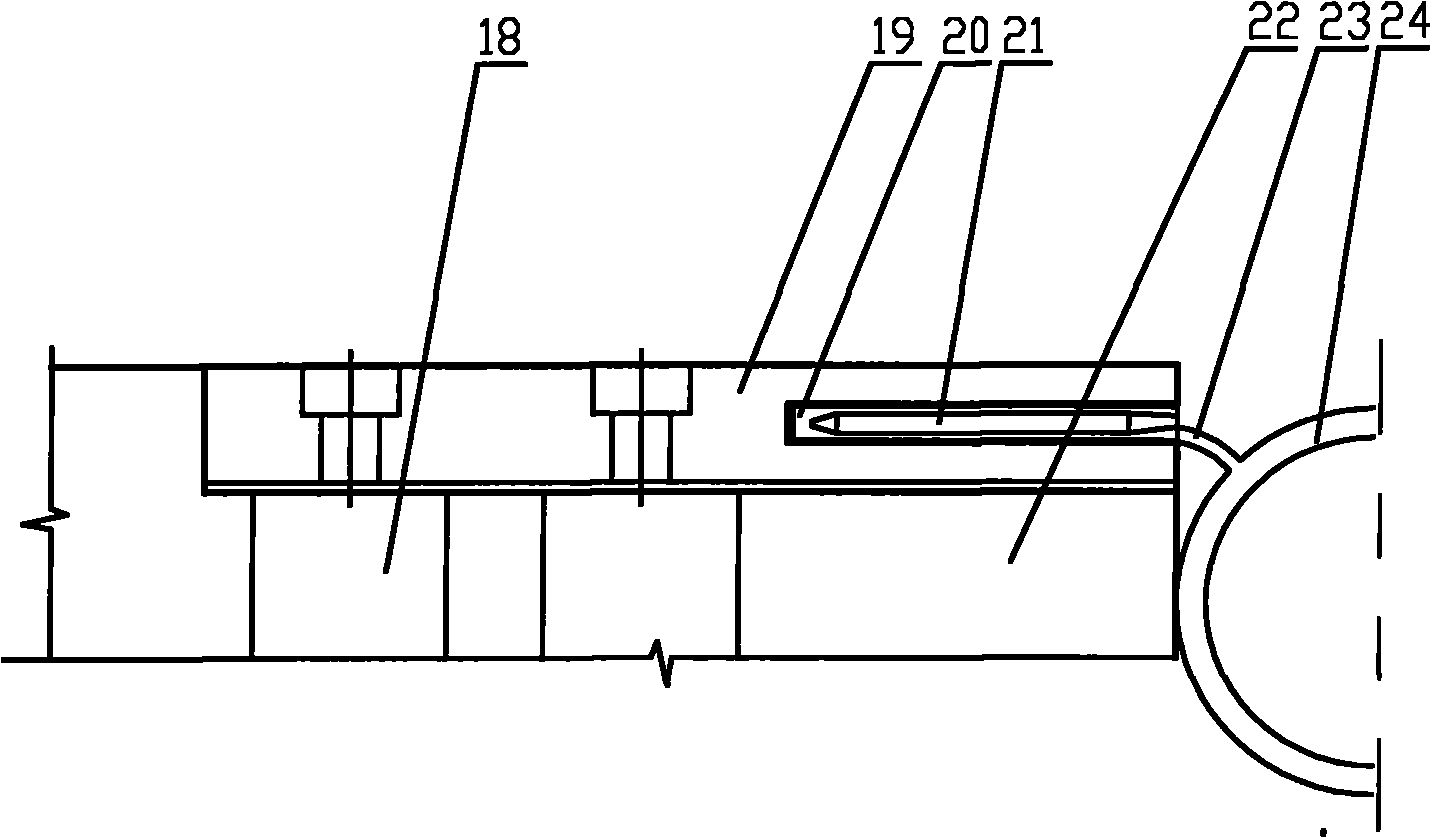

Normal displacement and angle sensing optical measuring head and measuring method thereof

The invention discloses a normal displacement and angle sensing optical measuring head and a measuring method thereof, optical measuring head laser light which is sent out by a semiconductor laser sequentially passes through a spectro-grating, a spectroscope and a reflecting mirror to be collimated into the collimated light beam, and the collimated light beam is reflected via a right-angle prism to enter a microobjective; the light beam which is reflected by an object to be measured returns back according to the same way to the spectroscope, and then is focused on a four-quadrant detector through an astigmatic lens; and laser light which is sent out by an infrared laser light source sequentially passes through a light guide optical fiber, a collimating lens and a focus lens to be focused on an infrared reflecting mirror to form a focus point which is superposed with the front focus of the microobjective, the infrared laser light is vertically reflected into the microobjective through the infrared reflecting mirror, the parallel infrared laser beam which is exited from the microobjective is reflected to the microobjective through the object to be measured, and an infrared beamsplitter reflects the returned infrared laser beam onto a two-dimensional phase-sensitive detector (PSD). The measuring head and the measuring method thereof can be effectively used for geometrical error measurement and calibration of the three freedom degrees of a linear guide rail, surface topographic reconstruction of a free-form surface and the like.

Owner:HEFEI UNIV OF TECH

Space relative deformation measuring device for upper disc and lower disc of in-situ rock joint plane

InactiveCN103499268AImproving deficiencies in relative deformation measurementsRealize measurementMechanical solid deformation measurementsMeasurement deviceEngineering

The invention relates to a measuring device for monitoring space relative deformation caused by space relative movement of an upper disc and a lower disc of an in-situ rock joint plane in the wild. The measuring device consists of an upper fixing rod, an upper fixing screw bolt, an upper telescopic rod, an upper fixed regulating screw bolt, an upper regulating rod, an upper connecting seat, an upper locking screw bolt, a lower fixing rod, a lower fixing screw bolt, a lower telescopic rod, a lower fixed regulating screw bolt, a lower regulating rod, a lower connecting seat, a lower locking screw bolt, a normal displacement measuring rod, a telescopic spring, an outer sleeve, rolling balls, a sealing cap, a dial and a support rod through assembling connection. The device is respectively fixed with the upper disc rock and the lower disc rock of the joint plane through the upper fixing rod and the lower fixing rod, in addition, the normal displacement measurement is realized through the telescopic effect of the normal displacement measuring rod, and the plane deformation measurement is realized through the movement of the lower end part of a normal deformation measuring rod on the dial, so the measurement on the space relative deformation between the upper disc and the lower disc of the joint plane can be realized, and the measuring device has the advantage that the space relative deformation value of the upper disc and the lower disc of the rock joint plane is directly obtained.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Shear test device for observing mechanical property of interface between underwater soil and structure

InactiveCN102914475AEasy to manufactureEasy to installMaterial strength using steady shearing forcesTest sampleElectro hydraulic

The invention relates to a mechanical property test device, in particular to a test device for observing the mechanical property of an interface between underwater soil and a structure, which is especially suitable for researching the mechanical property of the interface between the underwater soil and the structure in a hydraulic building (structure). The test device comprises a fixing mechanism, a horizontal movement mechanism, a soil box and a loading system, and an electro-hydraulic servo movable and static universal testing machine is used as a main machine frame. A designed soil material is loaded in the soil box fixed on the horizontal movement mechanism. A structure test block is arranged on an upper chuck of the electro-hydraulic servo movable and static universal testing machine, a normal stress is applied through the vertical loading system, and the shear mechanical behavior of the interface between the underwater soil and the structure under normal stress and complex stress paths can be represented through the horizontal loading system. The normal force and the shear force in the interfere shear test are measured through a load sensor, a vertical displacement meter arranged on the top surface of the structure test sample is used for measuring the normal displacement of the interface in the test, and horizontal displacement meters arranged on two sides of the soil box are used for measuring the shear displacement in the test.

Owner:CHINA UNIV OF MINING & TECH

Method for measuring normal rigidity of large contact interface by completely considering plastic influence

InactiveCN102169065AThe measurement results are close to the actualMeasuring Normal StiffnessStrength propertiesEngineeringContact system

The present invention discloses a method for measuring normal rigidity of a large contact interface by completely considering plastic influence. The method comprises the steps of adopting a contact system of two rough bodies as a measuring object and the complete equivalence of the system as a principle, using laser to mark three straight lines which fulfill the measuring requirement on the two rough bodies, and obtaining the normal rigidity of the contact interface by observing normal displacements of the three straight lines during a loading procedure. The method considers the influence of the contact interface shape degree on the normal contact rigidity on the basis of a prior method, and uses a simple and easy laser mark method to measure the normal rigidity of the large contact interface without being influenced by contact areas. Moreover, the method, which breaks using limits of the prior method, can be used not only in laboratories, but also in practical engineering conveniently.

Owner:XI AN JIAOTONG UNIV

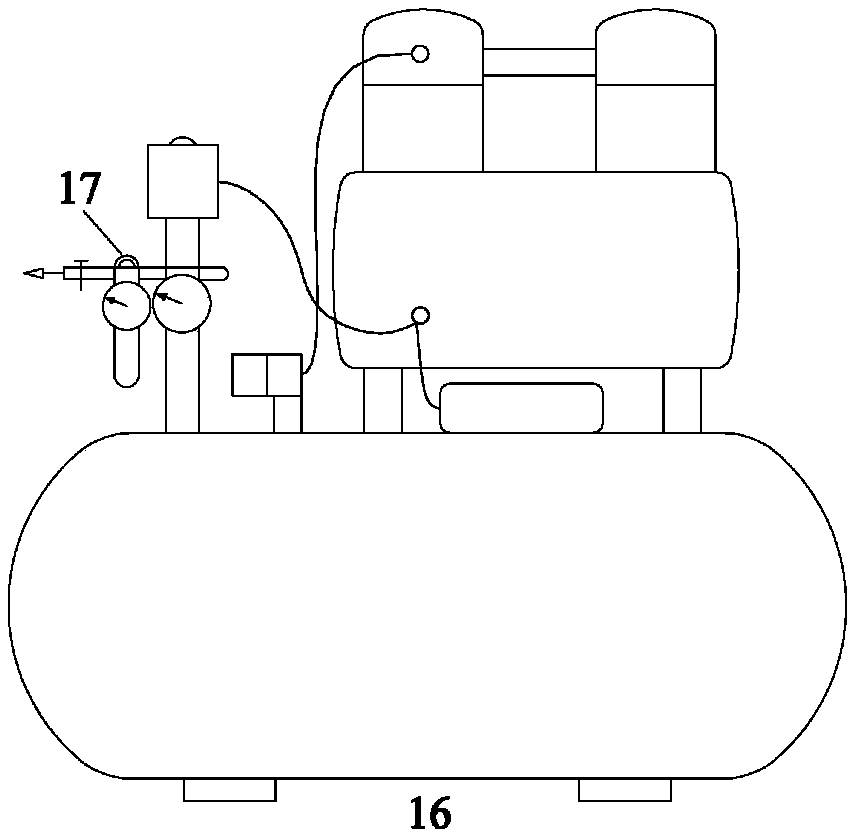

Full-automatic direct shear apparatus for densely-compacted bentonite unsaturated shear property study

ActiveCN109211687ARealize real-time measurementRealize acquisitionMaterial strength using steady shearing forcesAutomatic controlSodium Bentonite

The invention belongs to the technical field of the civil engineering (rock-soil) and geological engineering, and discloses a full-automatic direct shear apparatus for densely compacted bentonite unsaturated shear property study. The apparatus mainly comprises a shear system, a normal pressure loading system, a measurement system, an automatic control and data collection system, a gas-phase methodsuction control system; the shear system realizes a shear rate or continuous loading and unloading of shear force by adopting a servo motor; the normal pressure loading system adopts realize the continuous loading and unloading of normal stress by adopting an air compressor and a rolling diaphragm cylinder; the measurement system measures normal displacement, shear displacement and the shear force by adopting a high-precision sensor; the automatic control and data collection system automatically controls test process, data collection and display through computer software; and the gas phase method suction control system controls environment humidity in a shear box seal housing through a saturated salt solution and a combined seal housing. The automatic test on the densely compacted bentonite unsaturated shear property is realized.

Owner:TONGJI UNIV

Tangential driving double-difference butterfly-wing silicon microgyroscope and application method thereof

ActiveCN108020220AIncreased mechanical sensitivityReduce Capacitive GapSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesDouble differenceCapacitance

The invention discloses a tangential driving double-difference butterfly-wing silicon microgyroscope and an application method thereof. The silicon microgyroscope is of a silicon-glass double-layer structure which is constituted by a silicon sensitive structure and a glass electrode plate, the silicon sensitive structure comprises an external framework, an internal coupling spring structure and two silicon sensitive subsidiary structures, each silicon sensitive subsidiary structure comprises four inertial mass blocks which are connected to a supporting beam through a cantilever beam, driving comb teeth are arranged on the inertial mass blocks, a driving electrode, a detecting electrode and an electrode welding disc are arranged on the glass electrode plate, and detecting capacitors of thetwo silicon sensitive subsidiary structures constitute a double-difference slab detecting capacitor. The application method comprises the step of additionally applying static electrostatic stiffness to a unilateral silicon sensitive structure to change a modal control method of the system modal frequency. By means of the tangential driving double-difference butterfly-wing silicon microgyroscope and the application method thereof, the limit of normal displacement on driving amplitude and capacitive gaps can be effectively removed, the driving Q value can be effectively increased, the working state of the gyroscope is improved, thus the sensitivity of the gyroscope is improved, the bandwidth of the gyroscope is increased, and the stability of the gyroscope is improved.

Owner:NAT UNIV OF DEFENSE TECH

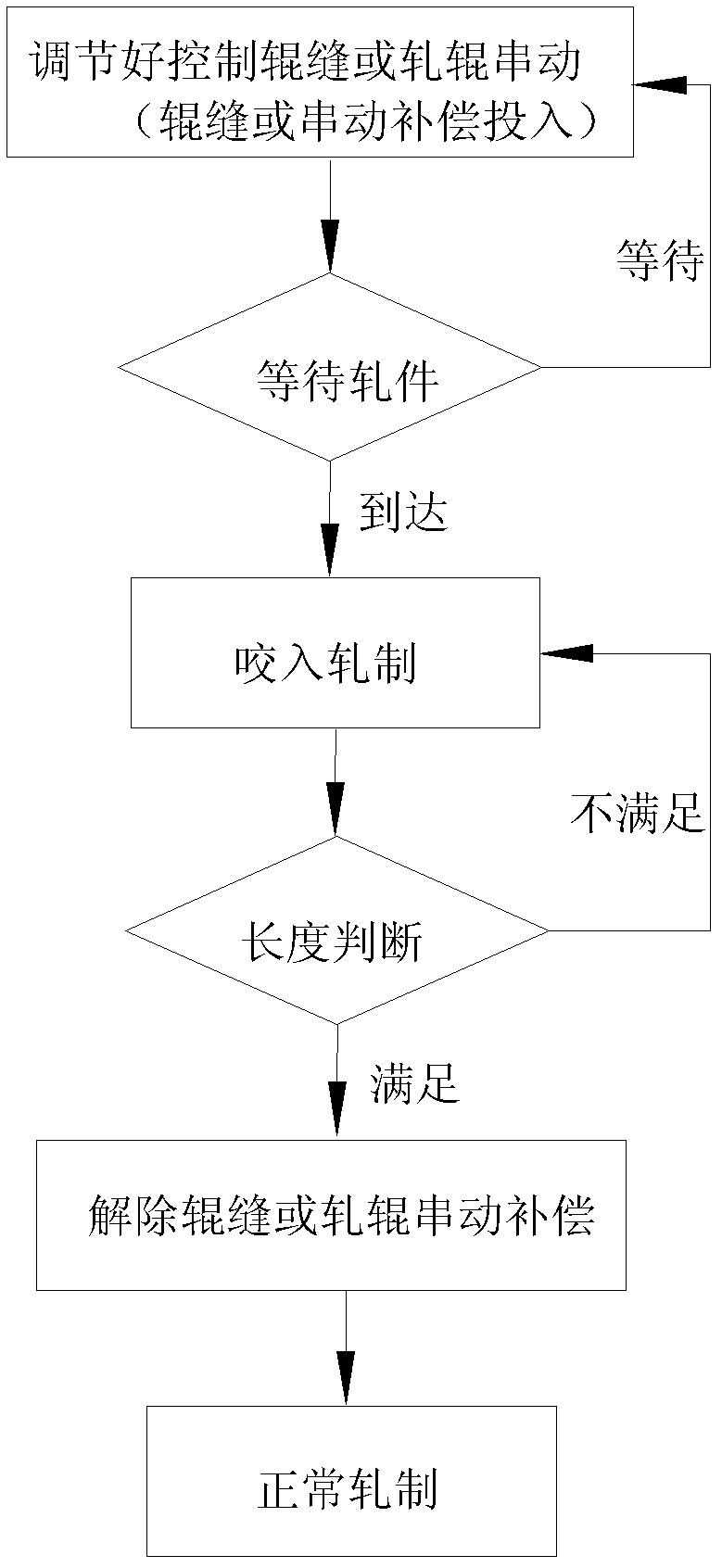

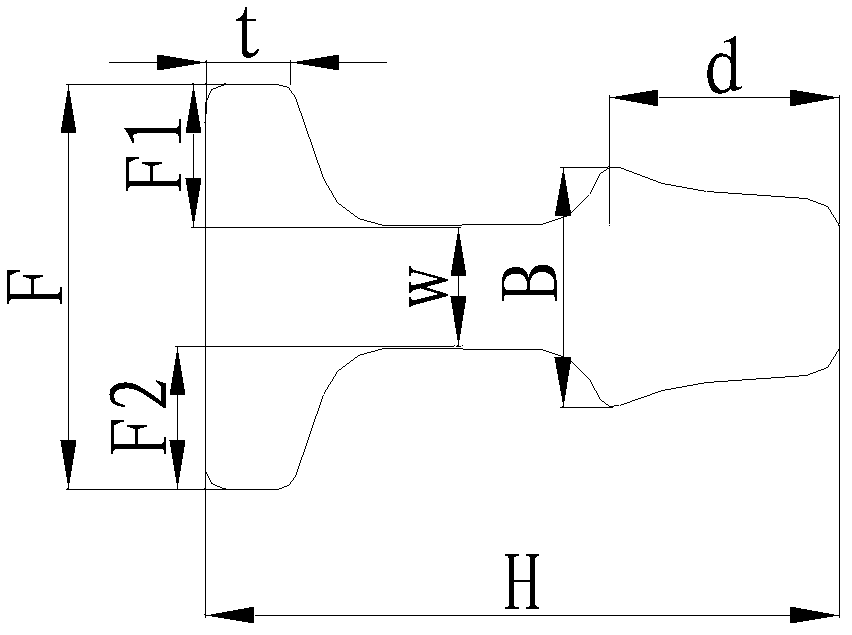

Steel rail cross section specification full-length fluctuation control method

ActiveCN102601125AReduced general length deviationImprove the correction effectRoll mill control devicesMetal rolling arrangementsEngineeringNormal displacement

The invention discloses a steel rail cross section specification full-length fluctuation control method. The method comprises obtaining the distribution length l of the full-length fluctuation abnormal part of each dimension of the cross section on a steel rail and the mean deviation of all dimension fluctuations of the cross section according to the steel rail cross section dimension detection curve under the normal steel rail rolling condition, determining the compensation part on the steel rail cross section, and determining the compensation value of a rolling part corresponding to the compensation part; selecting a compensation rolling mill and a compensation pass according to the rolling part and the compensation value, and determining the compensation amount of the compensation pass; determining to-be-compensated length L and compensating for the to-be-compensated length L of the steel rail during rolling; and when the to-be-compensated length L is reached, allowing the roll gap S at the rolling part on the compensation rolling mill to restore to the normal roll gap s, and allowing the displacement value Y to restore to the normal displacement value y. The method provided by the invention effectively controls steel rail cross section specification full-length fluctuation, reduces rolling deviation, requires no additional equipment and is mainly used for steel rail rolling control.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

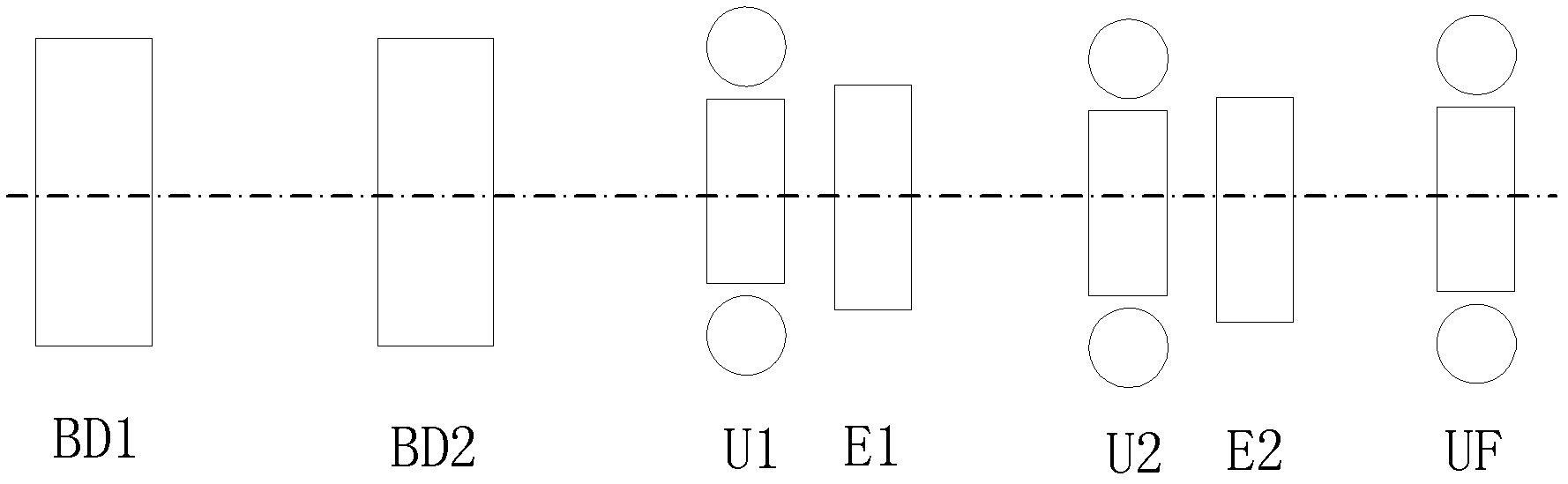

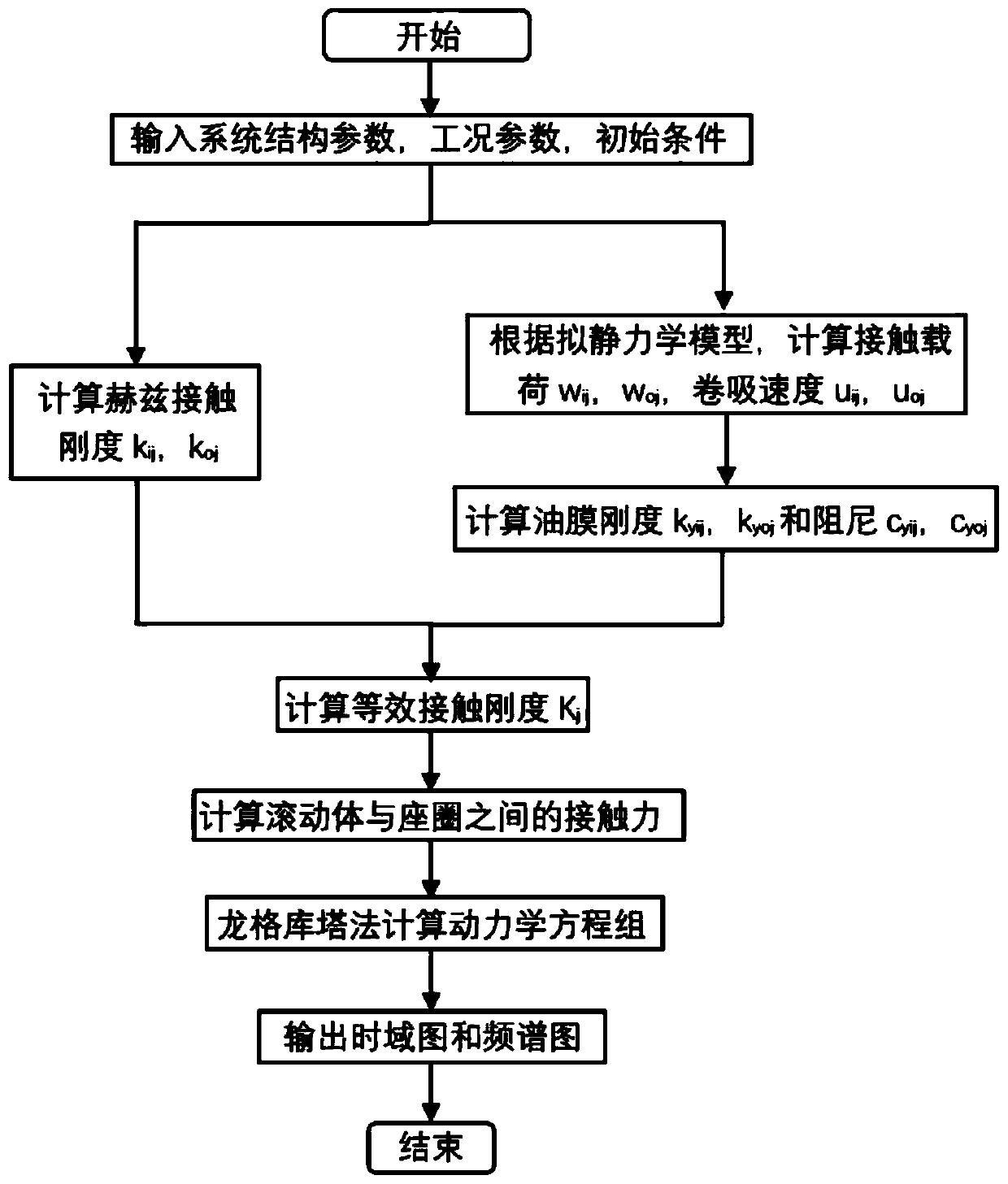

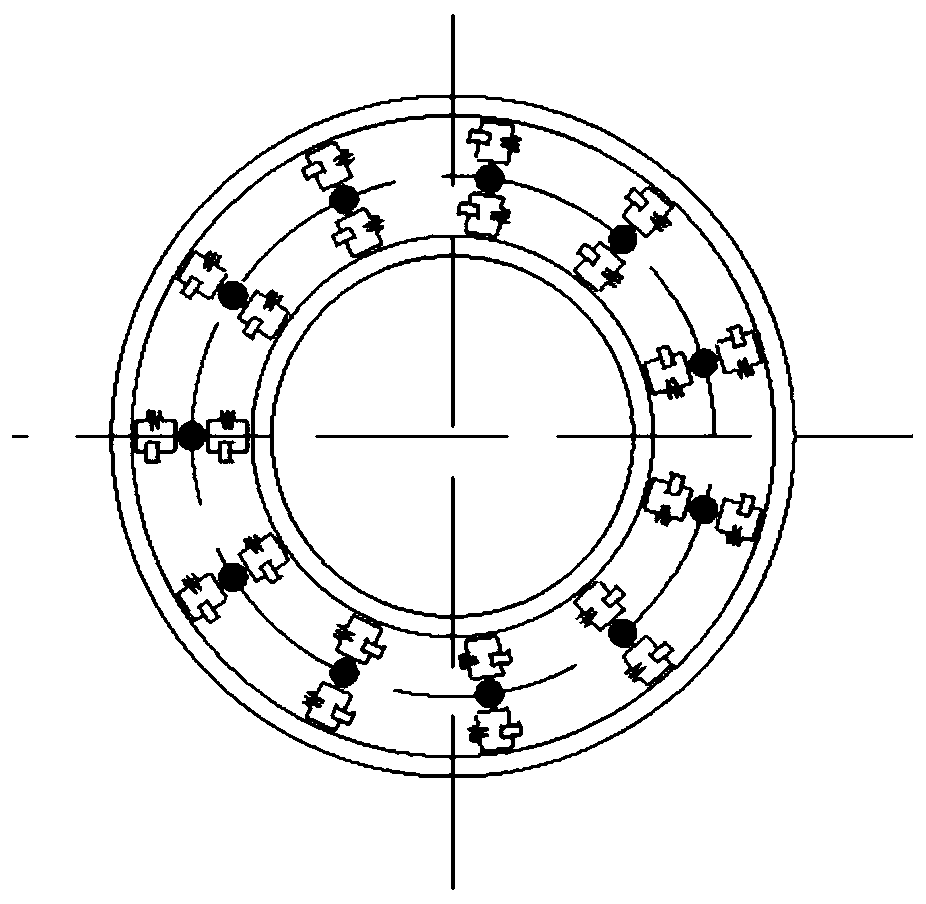

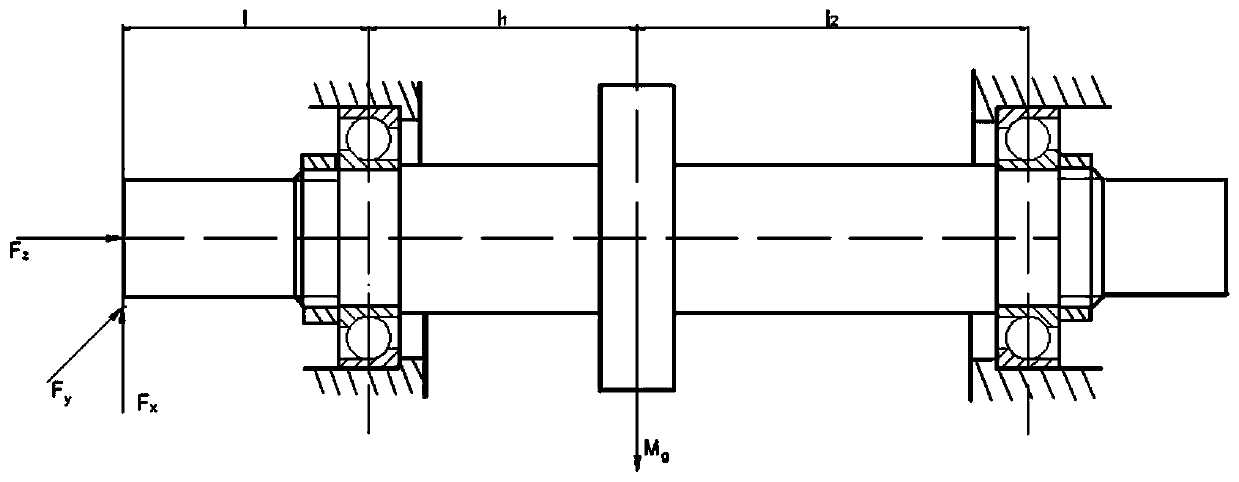

Dynamic characteristic analysis method of bearing-rotor system of high-speed motor of new energy automobile

The invention relates to a dynamic characteristic analysis method of a bearing-rotor system of a high-speed motor of a new energy automobile. The dynamic characteristic analysis method comprises the following steps of 1) acquiring a structural parameter, a working condition parameter and an initial value condition of the bearing rotor system, and building a model; 2) calculating an internal contact angle, an external contact angle and contact deformation by a high-rotational speed bearing quasi-static model; 3) respectively axial forces and radial forces of a left-side bearing and a right-sidebearing according to principles of torque balance and force balance, and solving an initial condition; 4) calculating a bearing entrainment speed and a contact load according to the internal contactangle, the external contact angle and the contact deformation; 5) calculating normal displacement quantity caused by consideration of vibration displacement between a left-side or right-side rolling body and a bearing sleeve ring and time-variable contact angle; 6) building six-degrees of freedom dynamic model of the bearing-rotor system; and 7) solving the bearing-rotor system by a variable-stepRunge-Kutta method, and simultaneously acquiring vibration response of the system. By the dynamic characteristic analysis method, the real-time operation condition of the bearing-rotor system can be accurately simulated, and meanwhile, the vibration response of the system is obtained.

Owner:WUHAN UNIV OF TECH

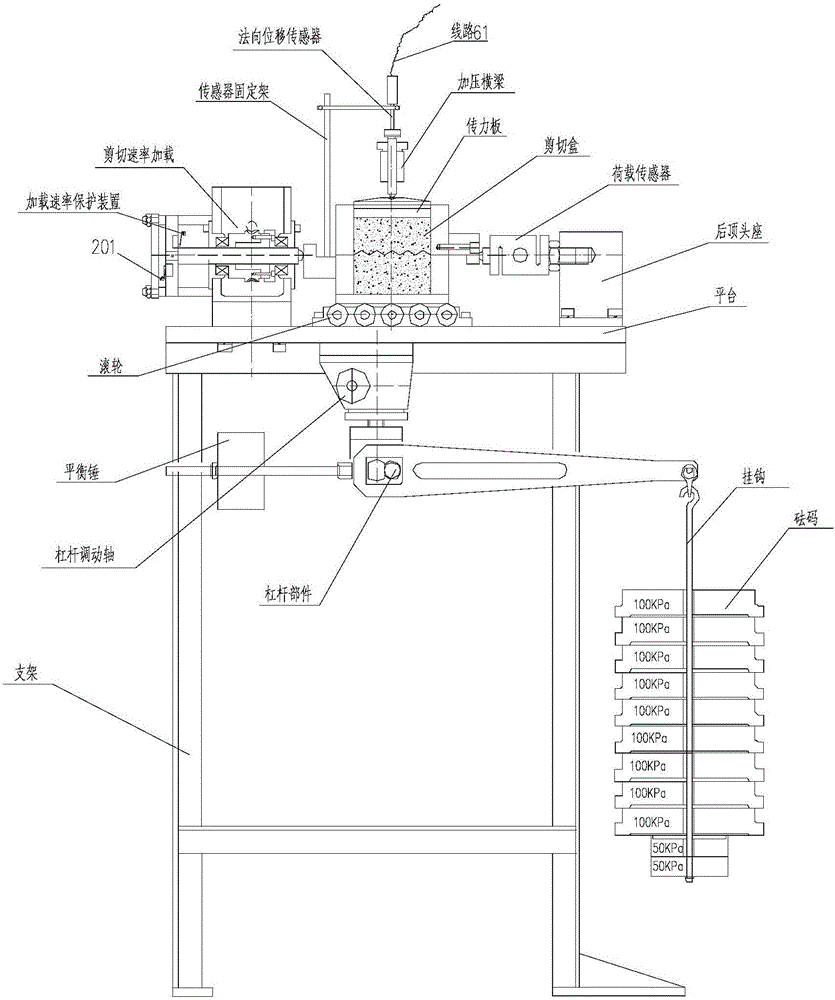

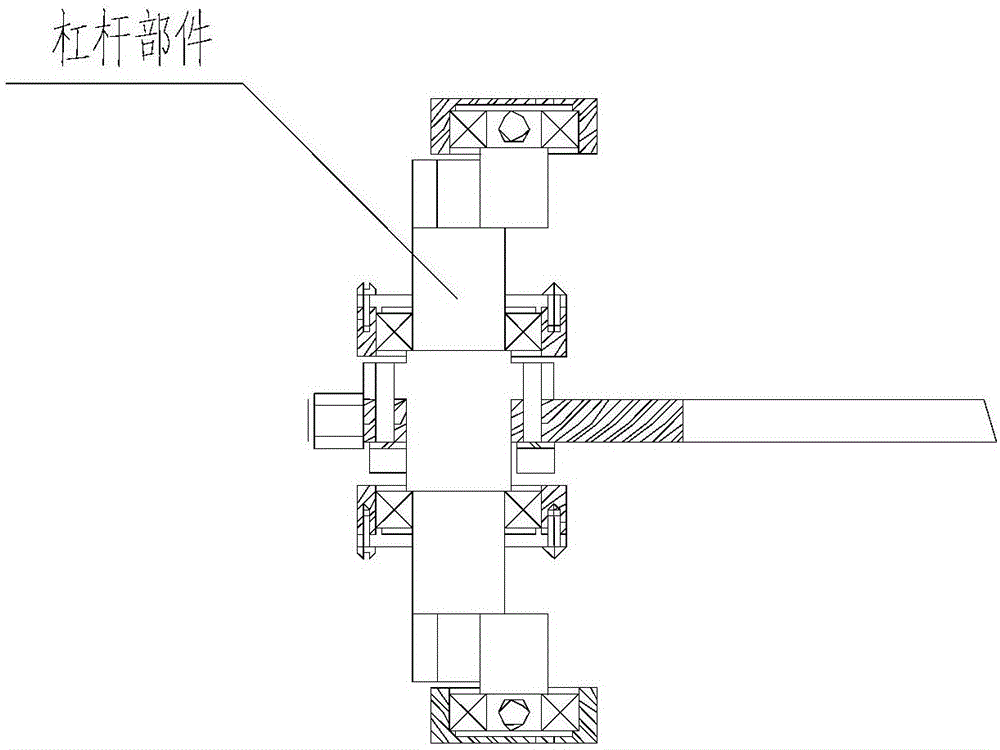

Portable rock structure surface direct shearing tester

InactiveCN106370528ALarge normal stressShort test cycleMaterial strength using steady shearing forcesTested timeEngineering

A portable rock structure surface direct shearing tester effectively solves the problems of bulkiness, long test time, large cost, long working period and difficulty in operation of apparatuses, adopts the lever principle to avoid adoption of a hydraulic device, and adopts rocks as a main test target. The tester has the advantages of realization of direct shearing test of a rock structure surface, simplicity, easiness in implementation, convenience in operation, short test cycle and low cost. The tester comprises a platform, a loading rate protection device, a shearing rate loader, a sensor fixing rack, a normal displacement sensor, a line, a normal displacement sensor line, a shearing strain sensor, a load sensor line, a pressurization crossbeam, a force transmission plate, a shearing box, a shearing box upper disc, a shearing box lower disc, a rock sample, a rock sample upper disc, a rock sample lower disc, a structure surface, rollers, a load sensor, a rear butting seat, a lever adjusting shaft, a balance weight, a lever part, a counterweight, a hook, a support, a shearing displacement sensor, a force transmission rack, a collecting system, a collecting device and a pinhole.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for determining a surface contact force

ActiveUS20050115331A1Aerodynamic testingForce measurement by measuring optical property variationLuminophoreTangential displacement

A method of measuring a load on a surface produced by a contact force. An elastic film or coating is located on a supporting surface to provide an indication of normal and tangential or shear forces applied to the surface. A thickness measurement, corresponding to a normal displacement, and a tangential displacement of the film, corresponding to a shear displacement, is obtained and input to a response function to reconstruct the normal and shear load components of the contact force on the surface. A differential thickness measurement of the film is detected by an optical method in which a luminescent output from a luminophore in the film is measured. A luminescent output from a reference luminophore located below the film is also measured to provide a measurement system independent of the illumination source used to produce the luminescent output.

Owner:INNOVATIVE SCI SOLUTIONS

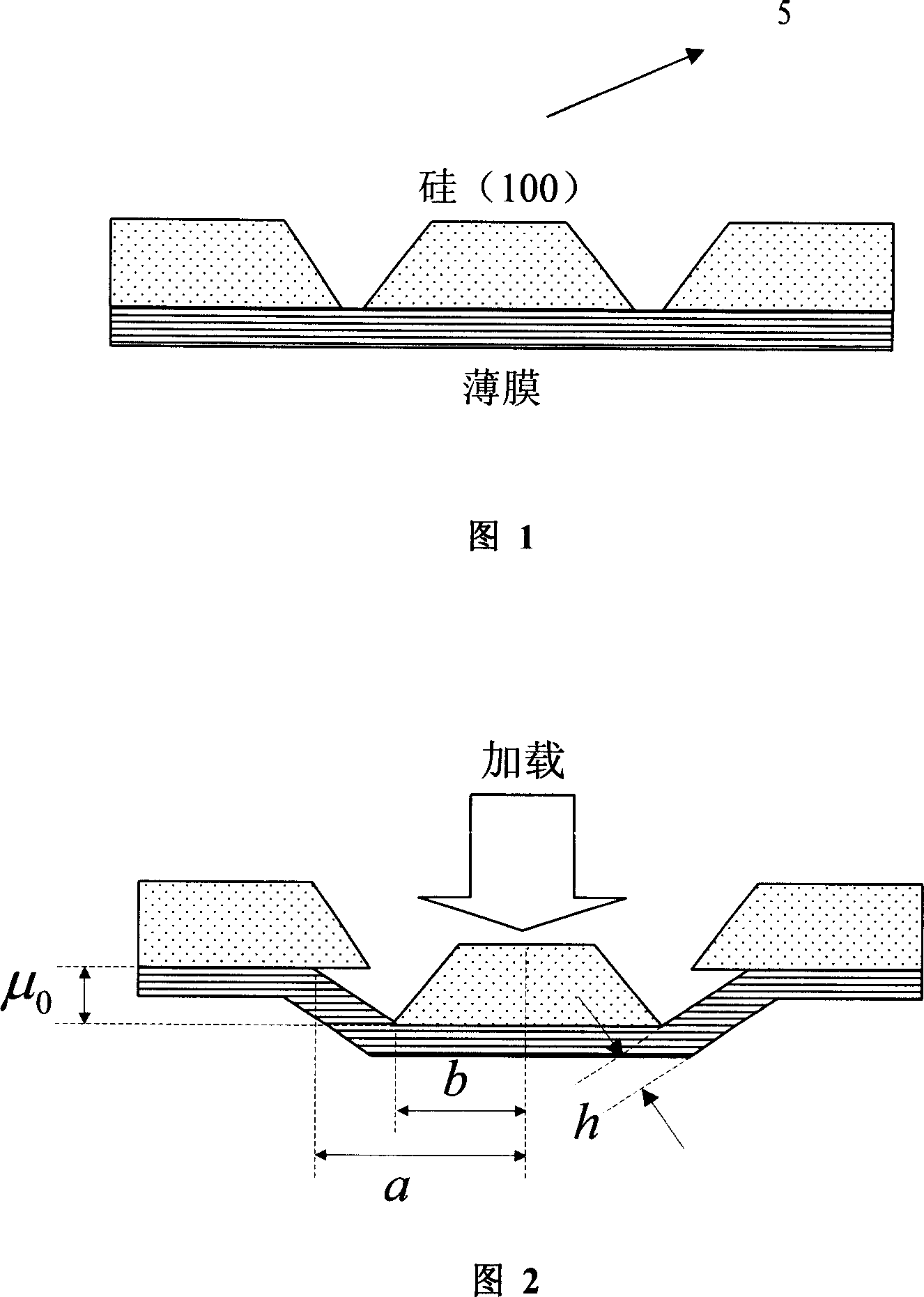

Method for measuring silicon base body and membrane base combination intensity

InactiveCN101144770AReduce cumbersomeAvoid the effects of compressionSemiconductor/solid-state device testing/measurementUsing mechanical meansSilicon matrixFree energies

The invention relates to a method to measure the bond strength of the silicon matrix and the membrane matrix in the measuring technical field. The method is realized by that a pattern with a window is made at the back of a silicon foundation base by an etching method, a part of foundation base is reserved as a loading platform in the window, a facial membrane of the foundation base is exposed in the back window, when the reserved matrix is pressed to break through the matrix and drive the membrane to break away with the matrix, a happened maximum normal displacement is recorded, a free energy releasing rate is gained by an prior formula, to characterize the bond strength of the membrane matrix system. The invention overcomes the shortage that the requirement of the observational measurement or the sample size of the prior detecting equipment is high, depends on the prior equipment and a mature sample making process, and uses a touching type back breaking through method to comparatively quickly detect the bond strength of the membrane matrix in the fixed quantity under a complex shape.

Owner:SHANGHAI JIAO TONG UNIV

Closed-loop-controlled encapsulating piezoelectric ceramic actuator and resistance strain gauge fixing method

ActiveCN103595292AEliminate hysteresisEliminate creepPiezoelectric/electrostriction/magnetostriction machinesClosed loopActuator

The invention discloses a closed-loop-controlled encapsulating piezoelectric ceramic actuator and a resistance strain gauge fixing method. Resistance strain gauges are arranged on the planes of the two opposite sides of piezoelectric ceramic so that nonlinear characteristics such as lag and creepage of the piezoelectric ceramic in the process of displacement output can be effectively eliminated. Consequently, the normal displacement output of the piezoelectric ceramic is guaranteed, and output accuracy is improved. Meanwhile, the displacement output amount can be fed back through the resistance strain gauges, so that closed loop control is achieved, and the actuator is simple and compact in overall structure and small in size. Due to the fact that the piezoelectric ceramic is arranged inside a stainless steel sleeve, the stainless steel sleeve is capable of effectively protecting the piezoelectric ceramic against external vibration, impact, inertia force and the like so as to improve reliability, stability and installability of the piezoelectric ceramic and ensure the service life of the piezoelectric ceramic.

Owner:苏州迈客荣自动化技术有限公司

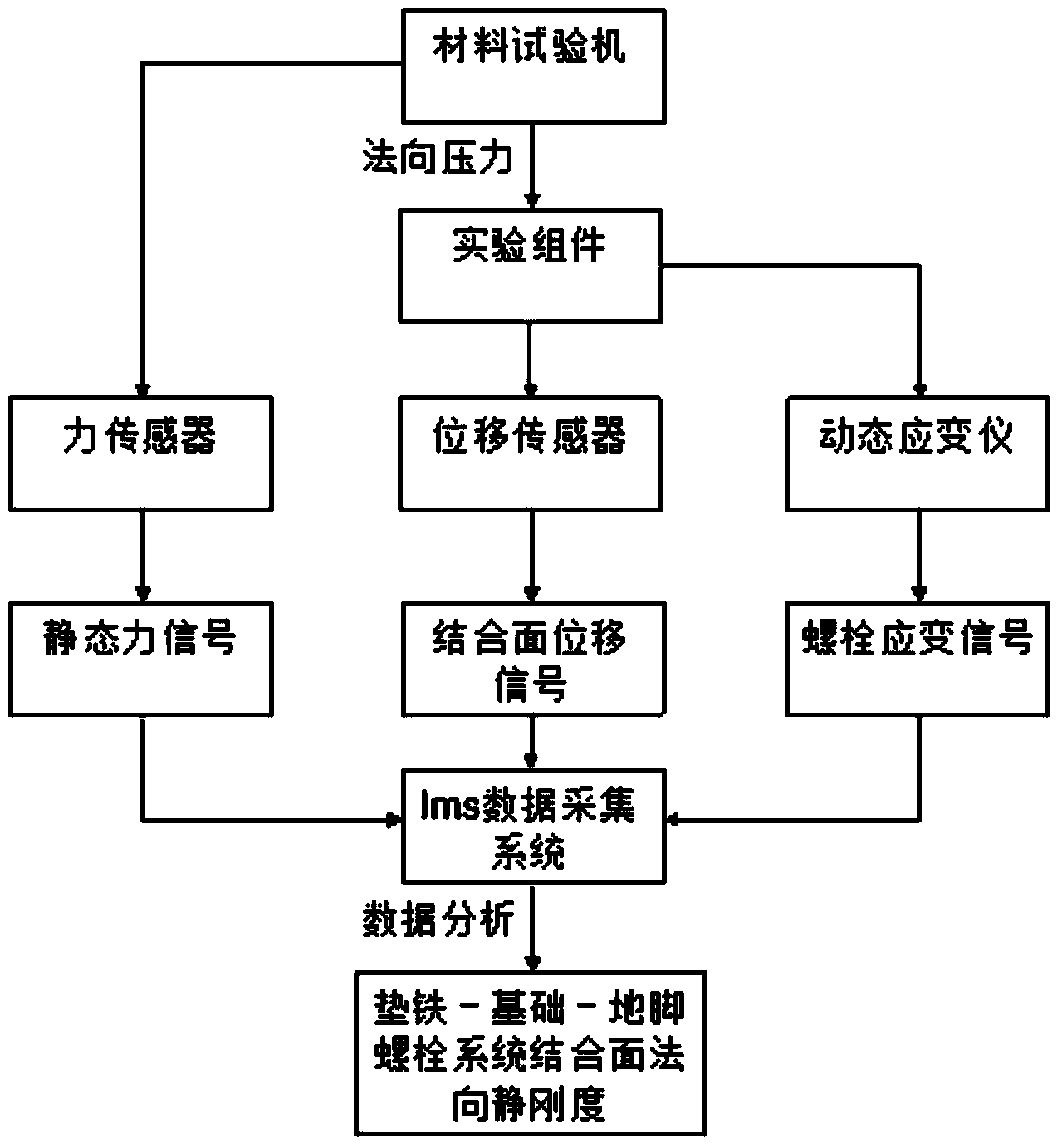

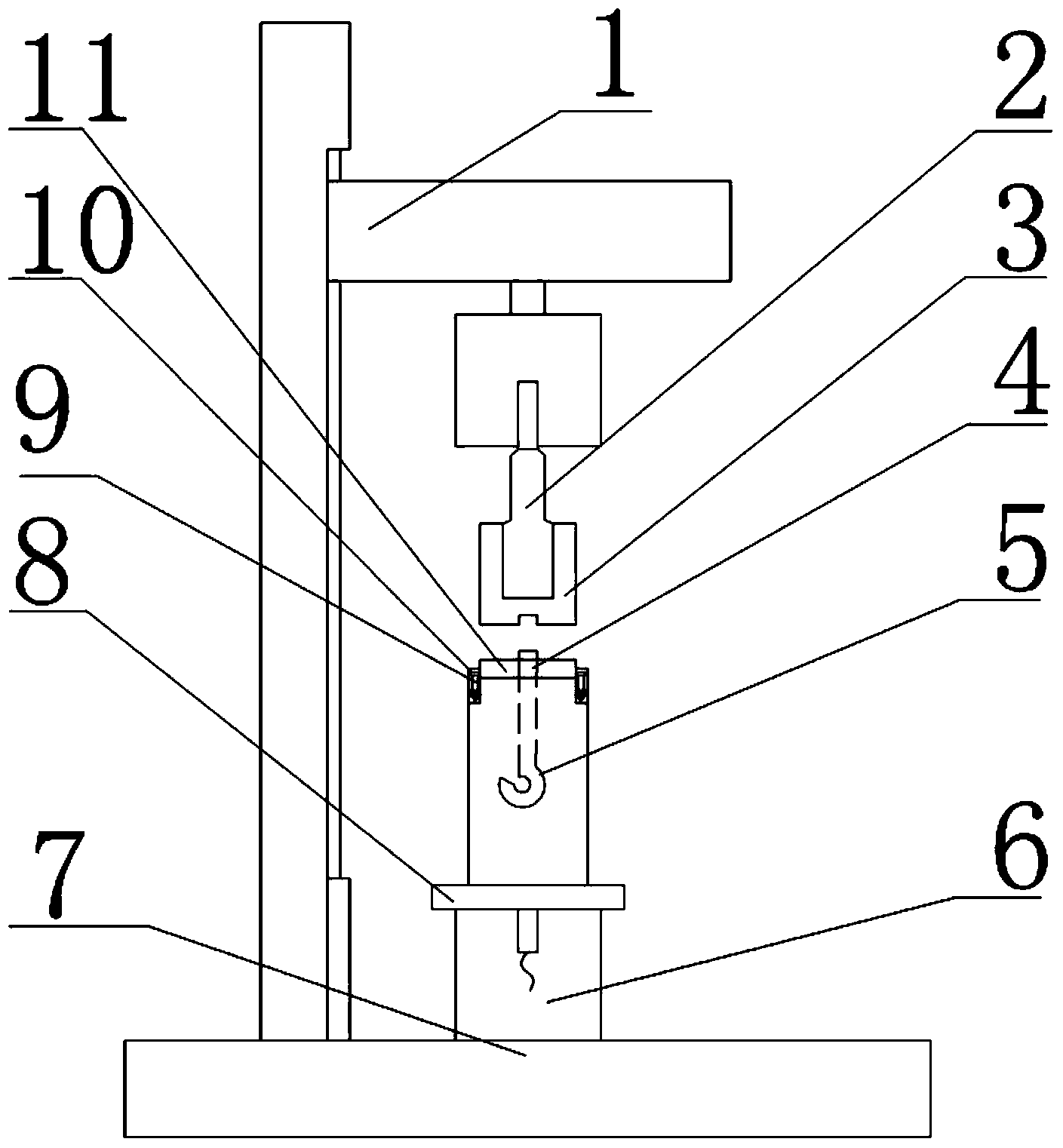

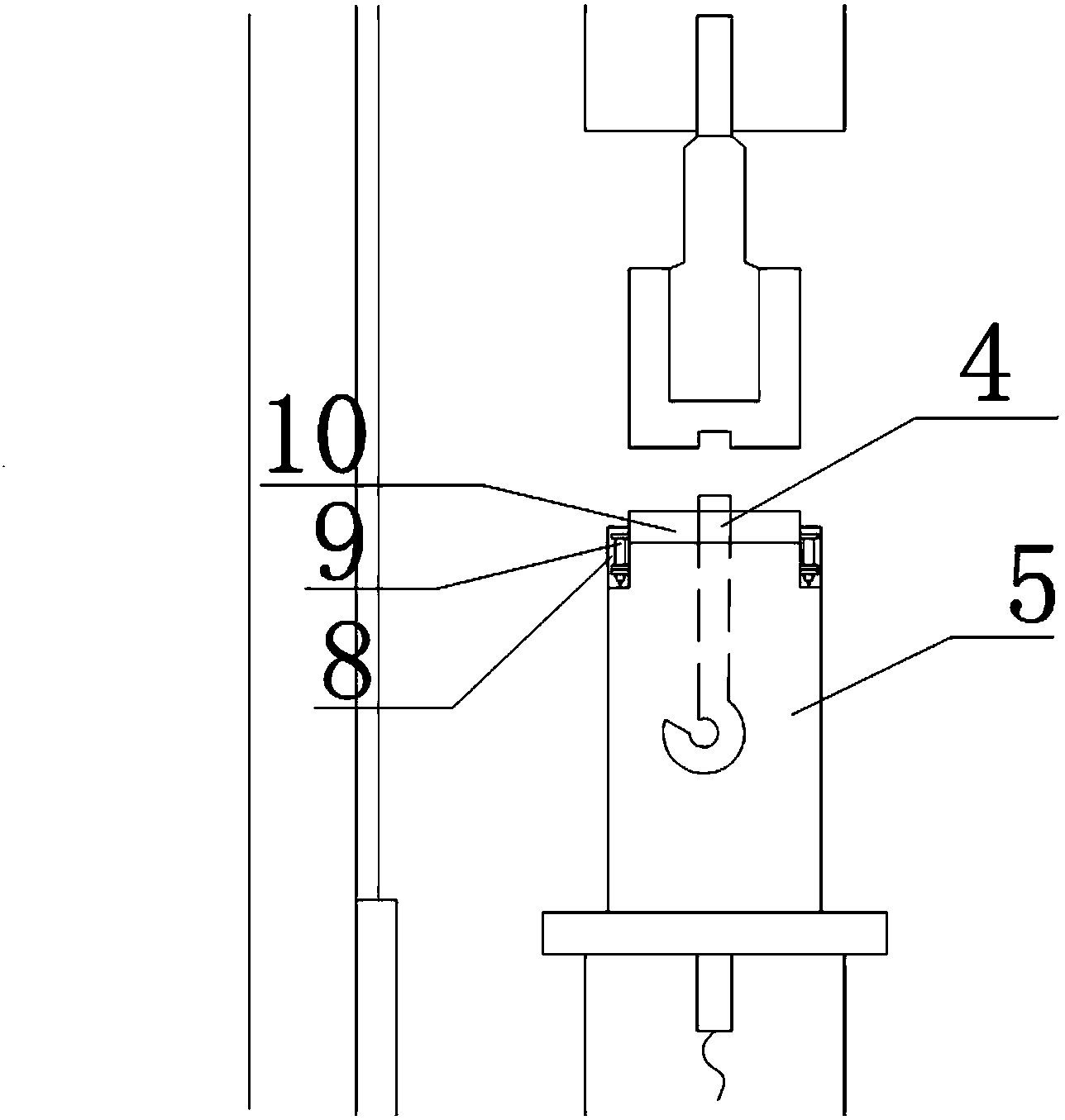

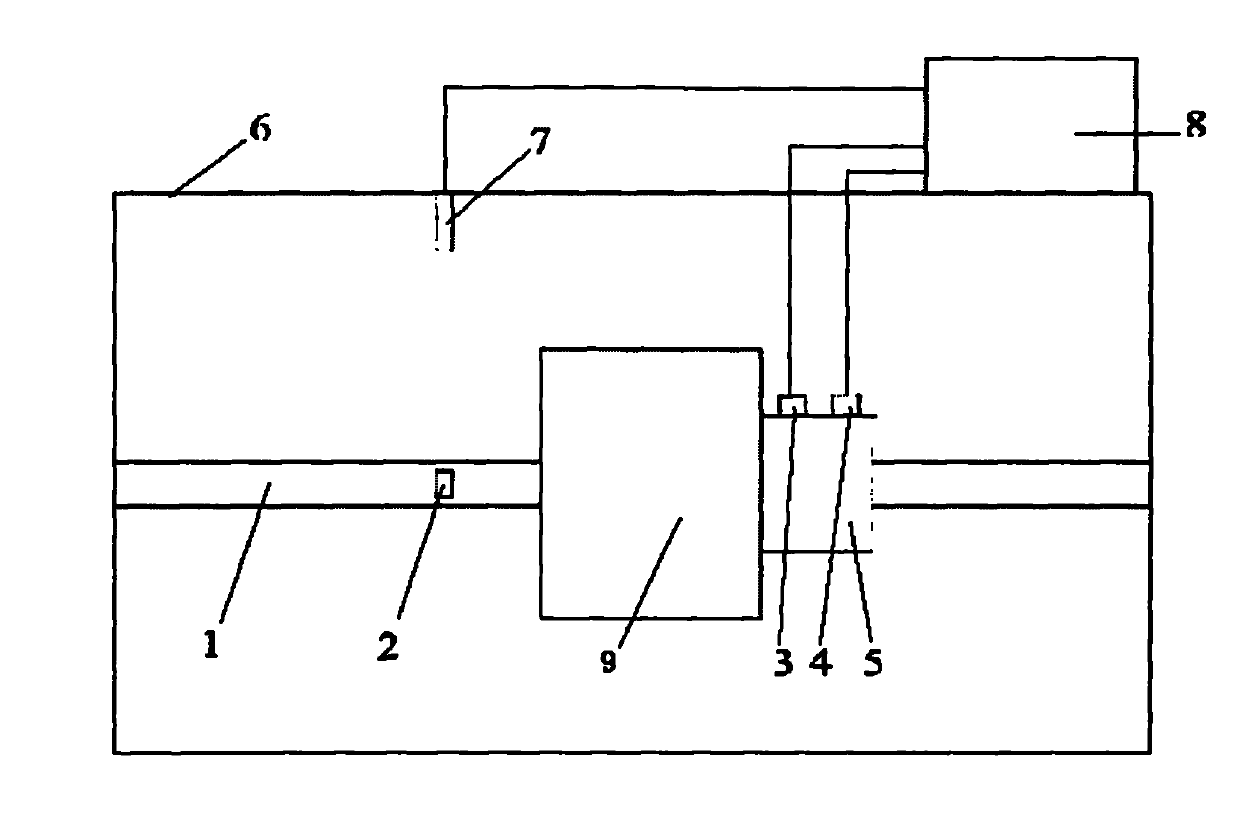

Device and method for testing normal static stiffness characteristics of joint surfaces of shim plate, foundation and foundation bolt of heavy-duty machine tool

InactiveCN104296980AReduce the number of physical quantitiesEasy to handleMachine part testingStrength propertiesMaterials testingData acquisition

The invention provides a device and method for testing normal static stiffness characteristics of joint surfaces of a shim plate, a foundation and a foundation bolt of a heavy-duty machine tool and belongs to the field of heavy-duty machine tool foundation experimentation. The device comprises a material testing machine, a screw rod, a slotted iron block, the foundation bolt, the concrete foundation, a material testing machine base, a force sensor, wood blocks, displacement sensors, a shim plate test piece, a dynamic strain indicator, a data acquisition system and a computer. After a secondary grouting process, the shim plate test piece is connected with the concrete foundation through the foundation bolt, and definite pre-tightening force is applied; a blind hole is formed in the foundation bolt and used for pre-burying of a strain gauge; the displacement sensors are used for measuring normal displacement quantities of the joint surfaces; the concrete foundation is placed on the force sensor of the material testing machine base, the slotted iron block is connected with the material testing machine through the screw rod, and the slotted iron block is attached to the shim plate test piece accordingly; the material testing machine applies static pressure to a stress application part in the longitudinal direction. A direct measurement method is adopted for the device and method, the number of tested physical quantities is reduced, and the deformation situation of a system is reflected really.

Owner:BEIJING UNIV OF TECH

Method for testing dynamic stiffness of machine tool spindle based on MEMS (micro electro mechanical systems)

InactiveCN102175436AImprove test accuracyMachine part testingFourier transform on finite groupsEngineering

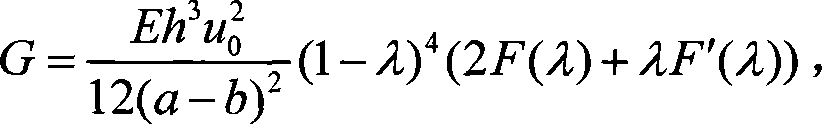

The invention provides a method for testing dynamic stiffness of a machine tool spindle based on MEMS (micro electro mechanical systems). The method comprises the following steps: firstly, arranging a force sensor and an acceleration transducer on a shaft shoulder of the machine tool spindle along the vertical direction; sticking a reflection belt on the machine tool spindle close to a grinding wheel; arranging a photoelectric sensor on the inner wall of a machine tool cabinet close to the position of the reflection belt; connecting the sensors with an industrial personal computer; and acquiring a normal displacement signal S(t) by utilizing the matrix laboratory (MATLAB) software to perform integration calculation on a signal a(t) for the acquired normal acceleration; acquiring a normal force F(Omega) and displacement S(Omega), by transforming the acquired normal force F(t) and the displacement S(t) into amplitude spectrums by performing the Fourier transform; calculating and acquiring a dynamic stiffness G(Omega) according to the normal force F(Omega) and the displacement S(Omega) by utilizing the following formula: G(Omega) is equal to F(Omega) / S(Omega); and lastly, judging if the working condition of the machine tool is safe, by comparing the detected dynamic stiffness at different conditions. By using the method, the precision for testing dynamic stiffness is increased. The method provided by the invention has the advantages that the precision for testing dynamic stiffness is high and the testing cost is low.

Owner:XIAN RUITE RAPID MFG ENG

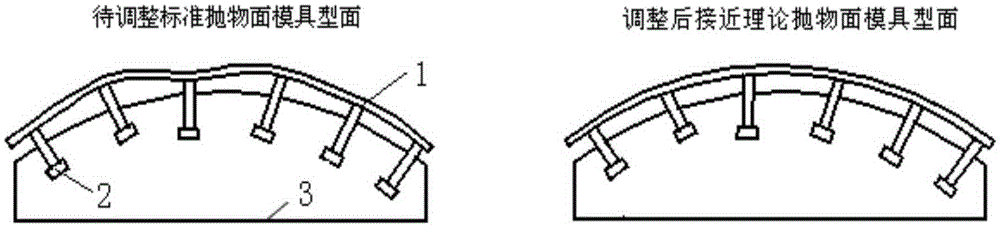

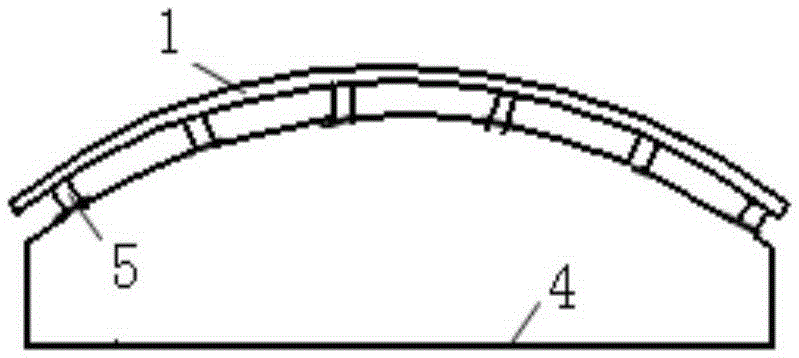

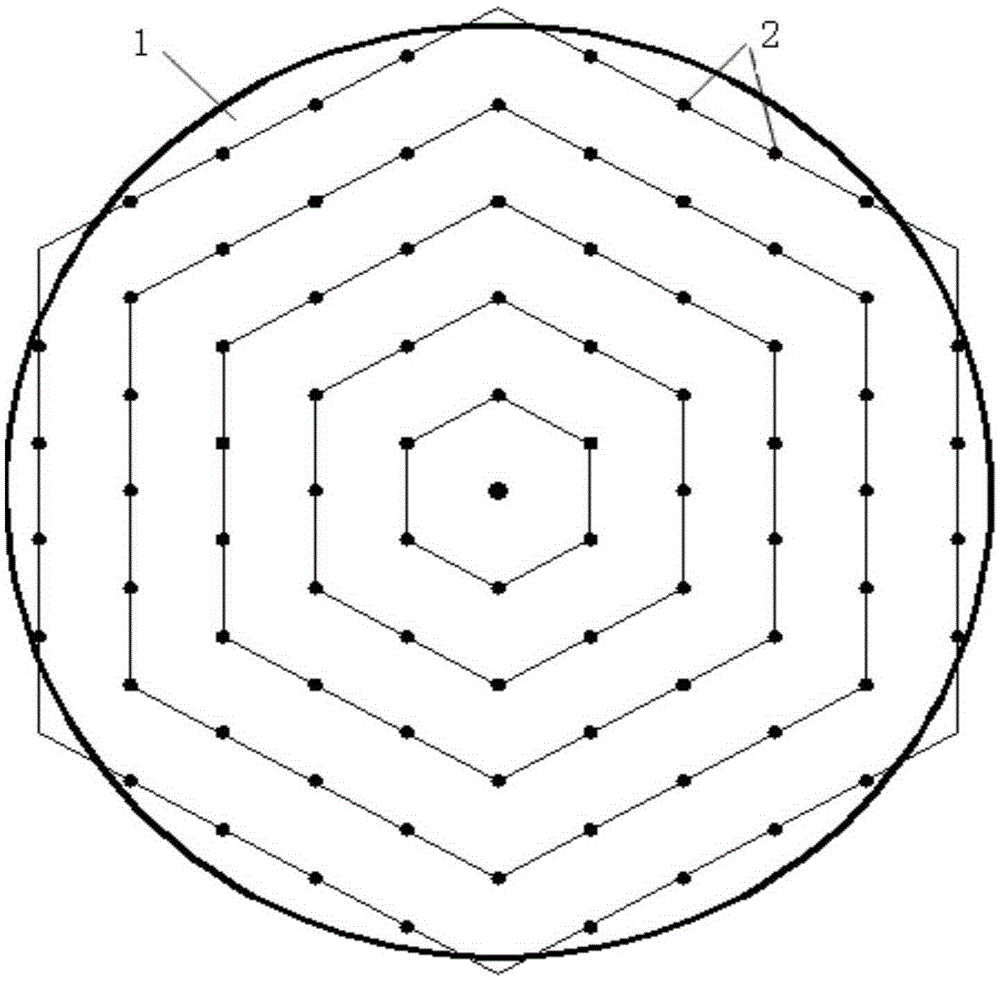

Design device and design method of adjustable composite-material mold

The invention discloses a design device and a design method of an adjustable composite-material mold. The device mainly comprises a mold profile, an adjusting device, an adjusting tool, a mold supporting back frame and an angle sheet, wherein the adjusting device is arranged on one side of the mold profile and equipped with a linear displacement feeding function; and the mold profile is connected to the adjusting tool by the adjusting device, a datum point on the adjusting tool is used to measure accuracy of the mold profile in order to obtain a normal displacement deviation of the adjusting device, the adjusting device adjusts the mold profile according to the normal displacement deviation, and the mold supporting back support is connected to the mold profile by the angle sheet after adjustment of the mold profile. The design device and the design method of the adjustable composite-material mold provided by the invention realize the high accuracy of the mold profile through the profile adjustment. The method can be used in research and manufacture of a high-accuracy reflector in a remote sensing satellite and a communication satellite, can also applied in research and manufacture of a ground high-accuracy reflector, and satisfies demands of a high-accuracy reflector antenna mold with a low thermal expansion coefficient.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

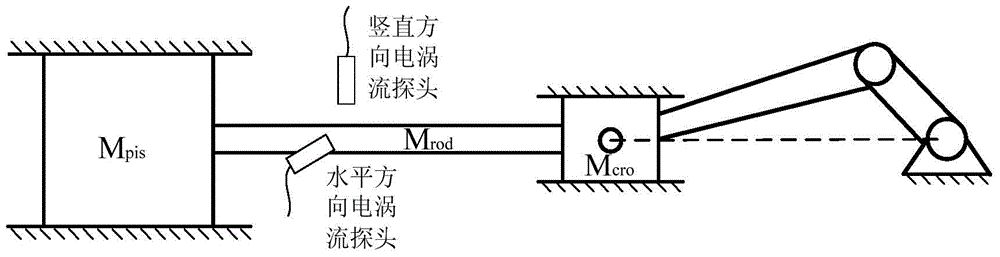

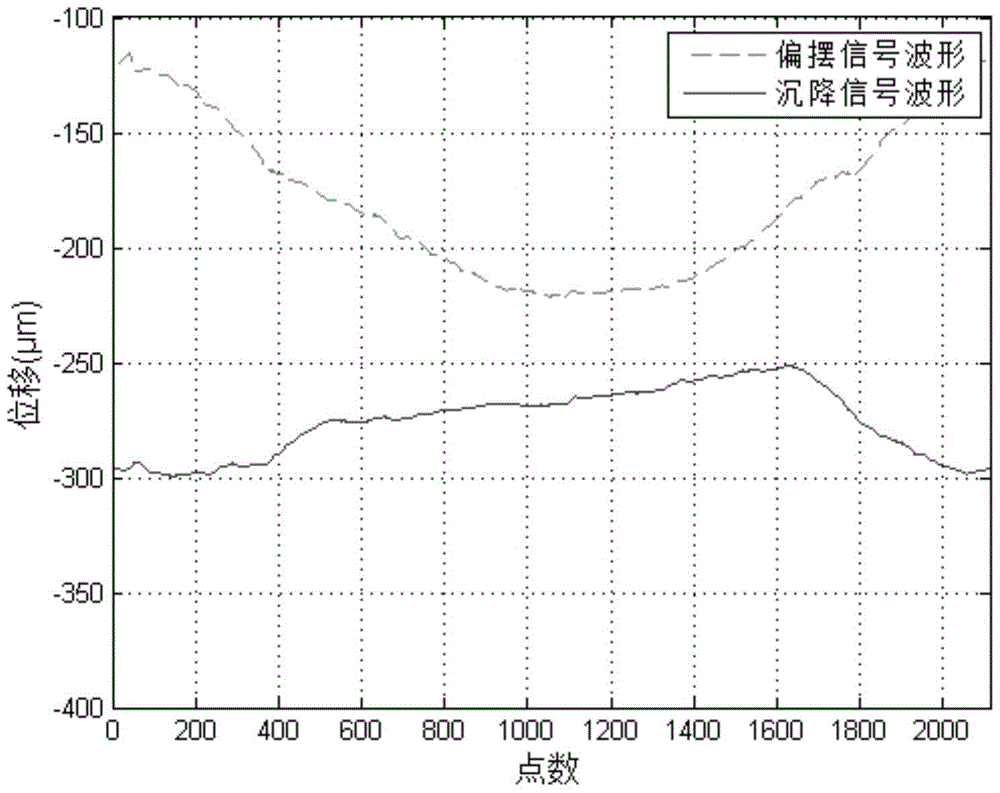

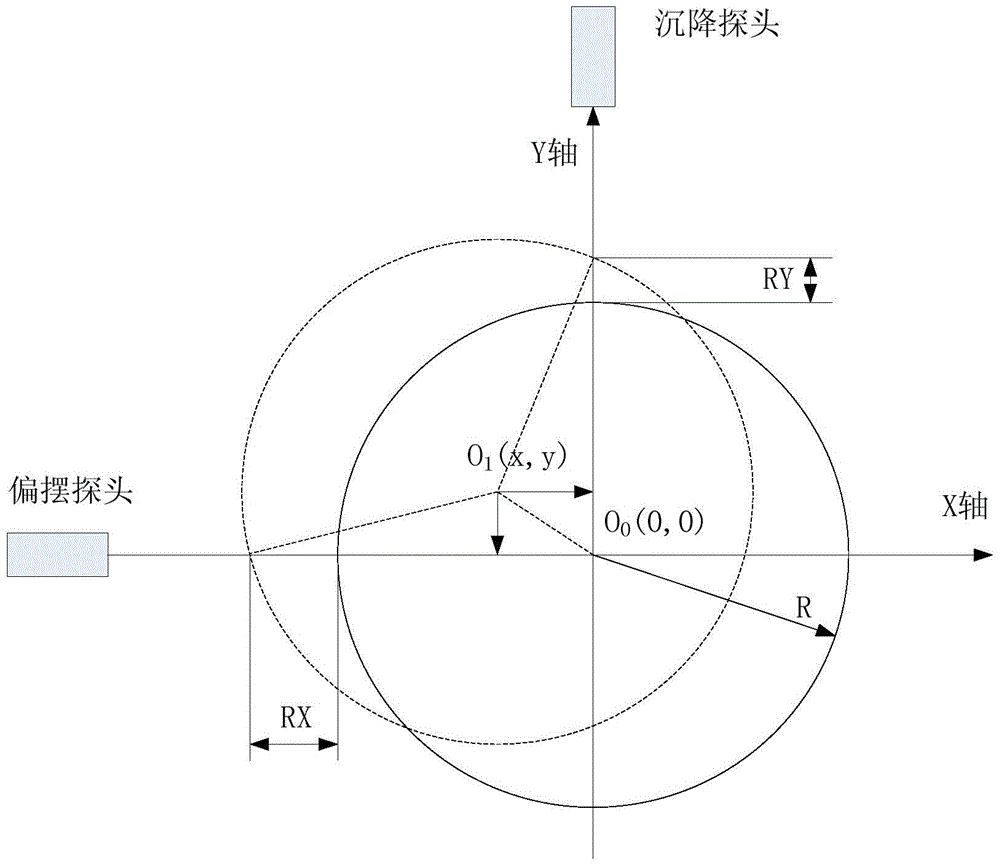

Malfunction alarm method based on piston rod vibration dynamic energy index

The invention relates to a malfunction alarm method based on piston rod vibration dynamic energy index. The method includes the following steps: establishing a piston rod axle center displacement locus square, using a normal piston rod displacement to monitoring signals, calculating to acquire a piston rod axle center displacement locus, and extracting a piston rod axle center vibration energy index and a locus area. According to the invention, the method is directed at typical malfunctions, such as supporting ring wear, piston rod fastening bolt loosening and piston rod fracture, based on piston rod axle center vibration energy index, can effectively overcome detects of response delay and poor sensitivity of malfunction alarm in normal displacement monitoring, and has better practical application.

Owner:BEIJING BOHUA XINZHI SCI & TECH

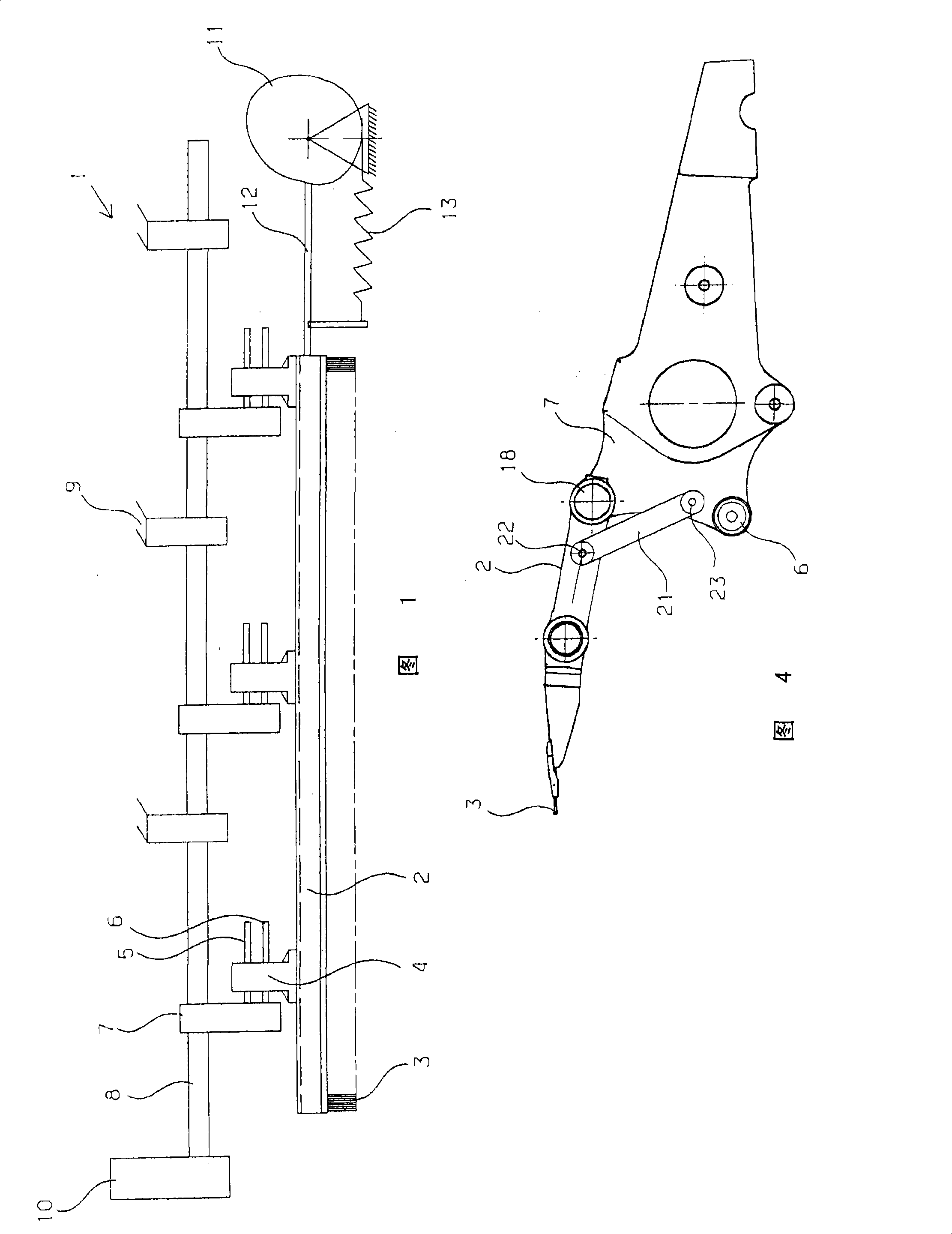

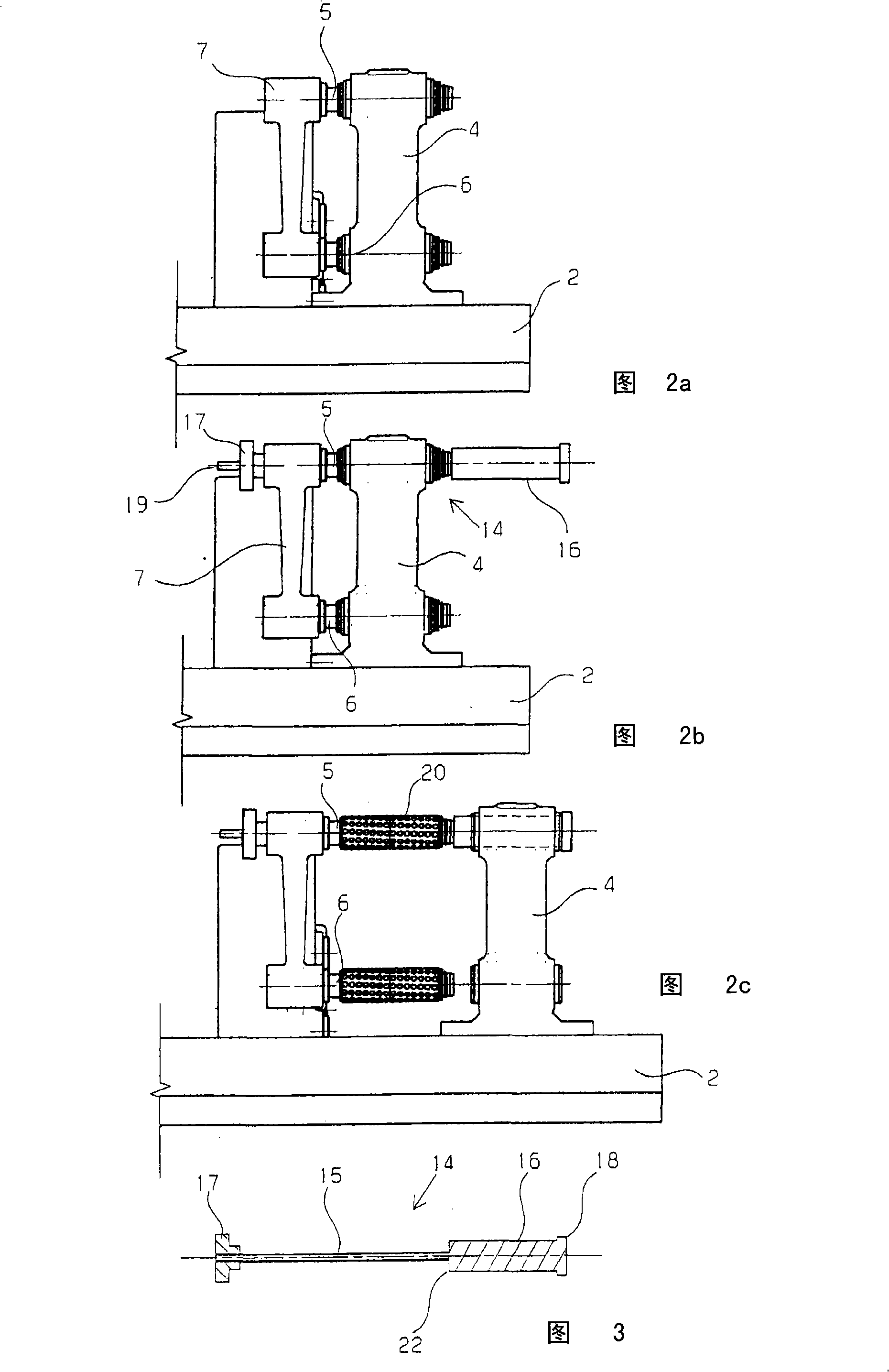

Warp knitting machine

InactiveCN101338486ALight in massStable supportWarp knittingMechanical engineeringNormal displacement

The present invention provides a knitting machine (1), which has a guide bar (2) comprising guide needles and suspended at guide levers (7), where each guide lever (7) is connected with the guide bar by at least a guide pin (5, 6) and has an anti-swivel mechanism for the guide bar (2). In operation of the knitting machine, breaks are desired to be kept short. Thus the guide pin (5) has a detachable projection (14) with which the guide bar (2) is adjusted beyond a normal displacement channel in a connected condition.

Owner:KARL MAYER TEXTILMASCHFAB GMBH

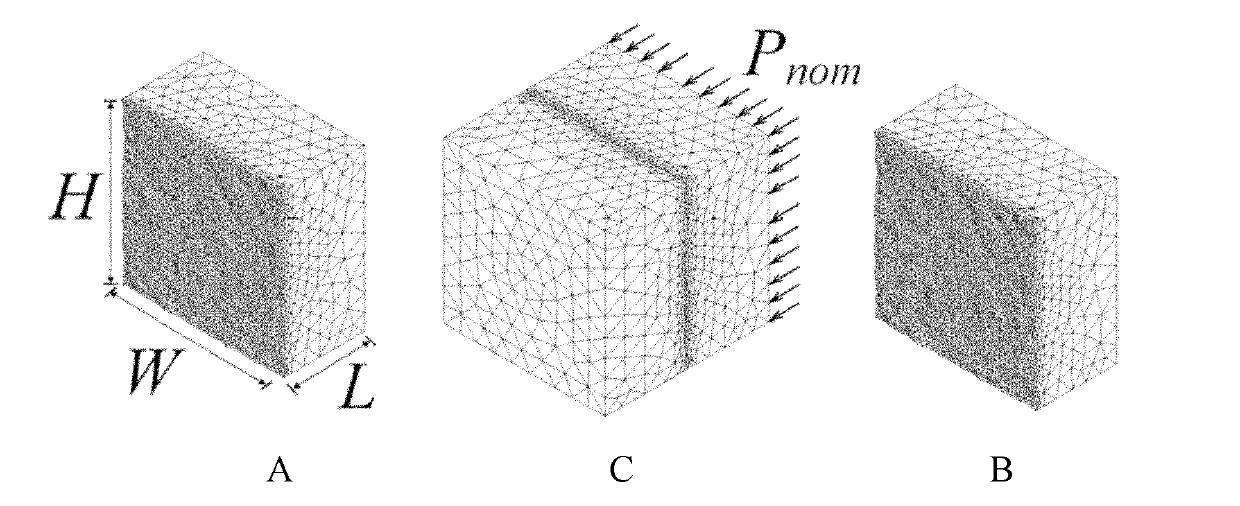

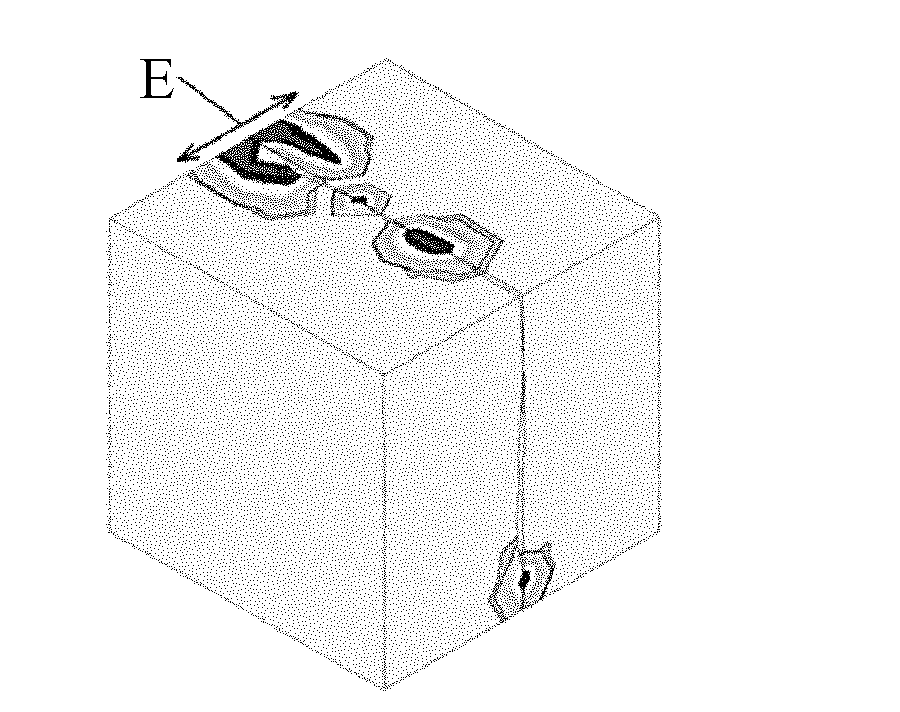

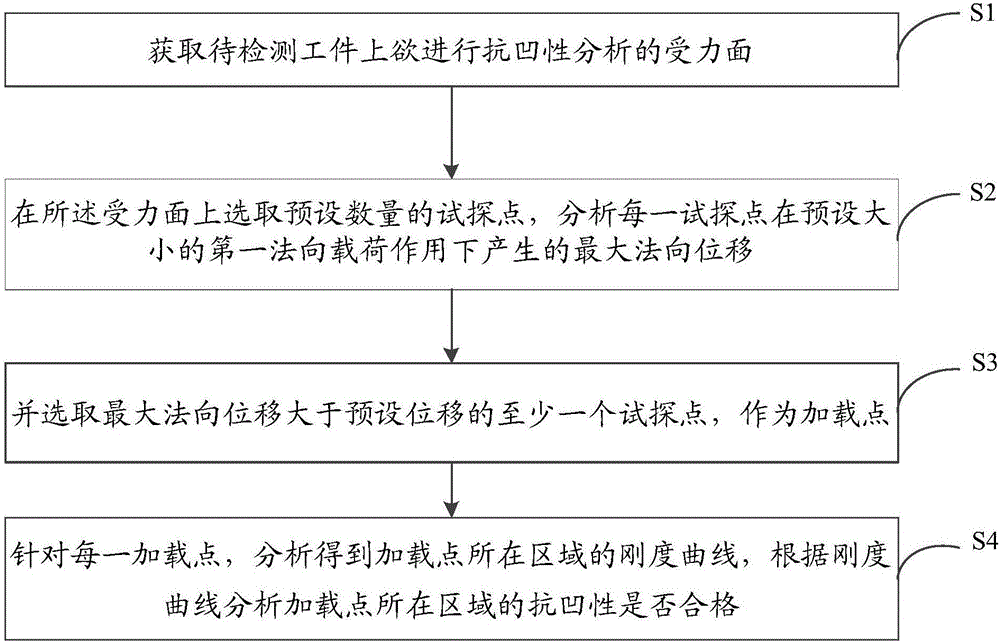

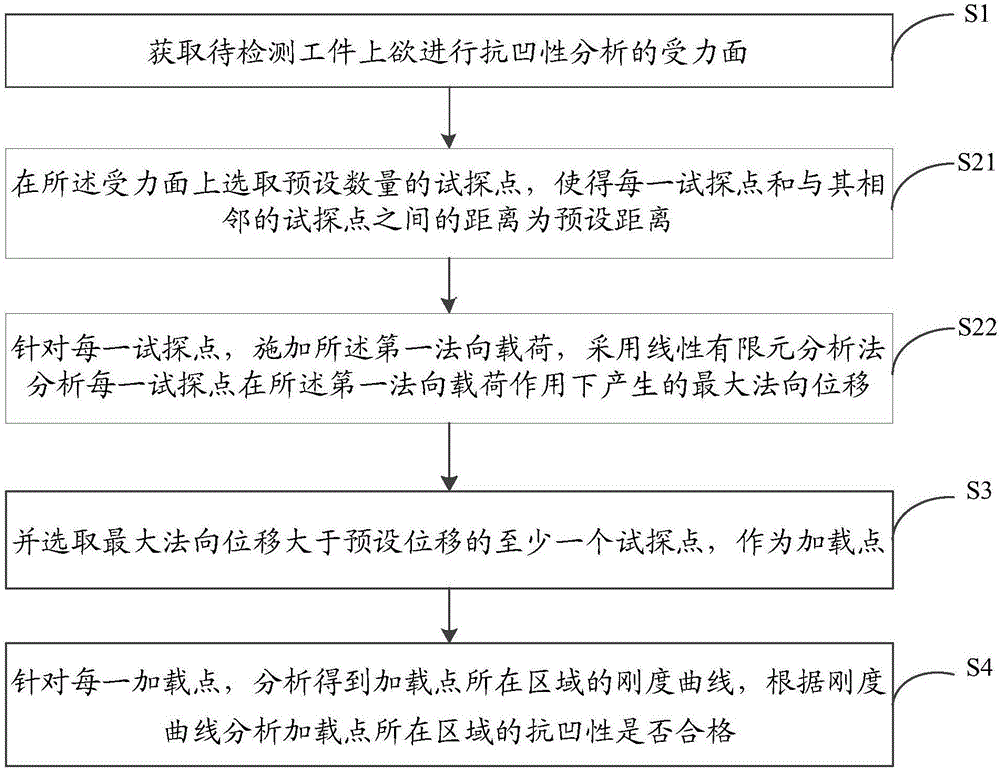

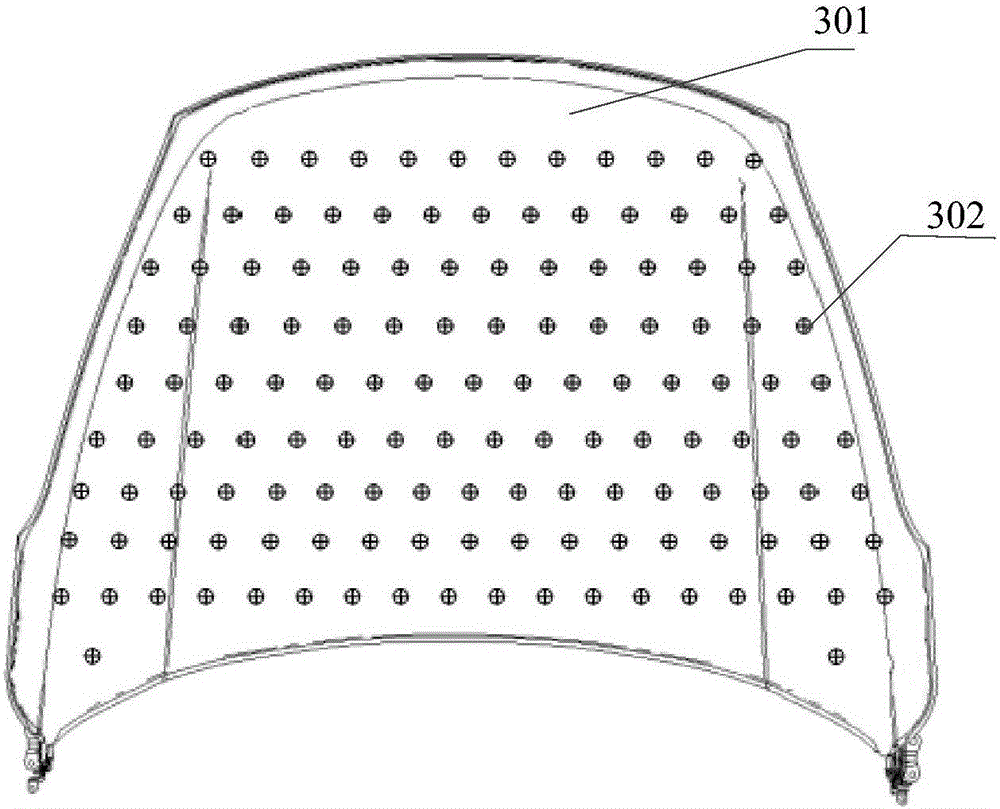

Anti-concavity property analysis method and device based on finite element method

InactiveCN106446451AConducive to lightweight designPrecise positioningGeometric CADDesign optimisation/simulationNormal loadExtended finite element method

The invention discloses an anti-concavity property analysis method and device based on a finite element method. The method includes the following steps: S1, obtaining a stress surface on the workpiece on which the anti-concavity property analysis will be conducted; S2, selecting a preset number of test points on the stress surface, and analyzing the maximum normal displacement produced by each test point under the action of a first normal load of a preset size; S3, selecting at least one test point with the largest normal displacement greater than the preset displacement as a loading point; S4, for each loading point, obtaining a stiffness curve of the area where the loading point is located by analyzing, and according to the stiffness curve, analyzing whether the anti-concavity property of area where the loading point is located is qualified or not. The anti-concavity property analysis method based on the finite element method can be used for the anti-concavity property analysis of the outer cover of a vehicle, a weak point on the outer cover can thus be accurately identified, and in the lightweight design, the structure is strengthened by simply sticking a glue film on the loading point, accordingly, the method is conducive to the lightweight design of the vehicle.

Owner:FAFA AUTOMOBILE (CHINA) CO LTD

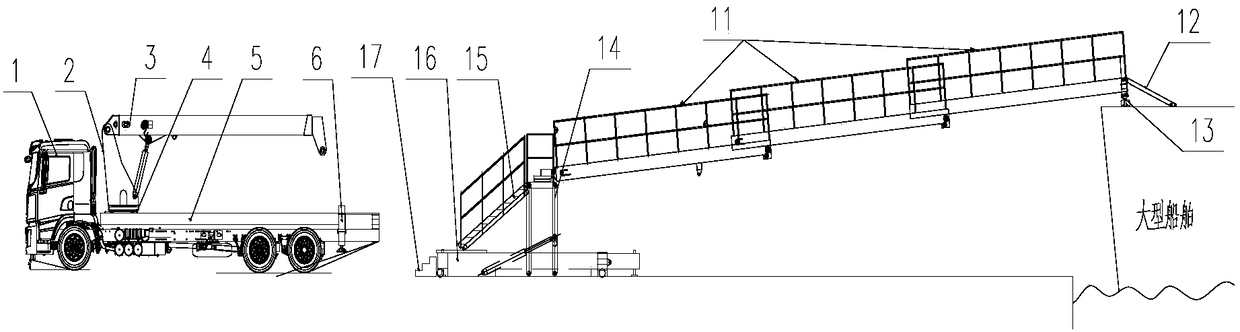

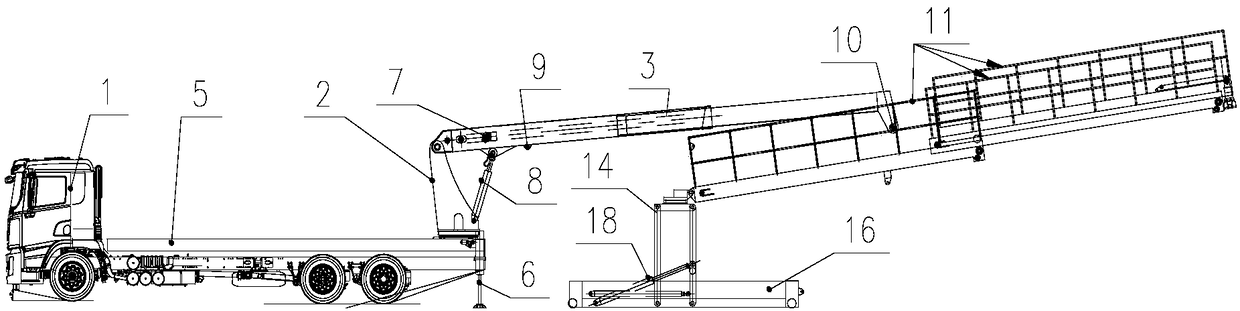

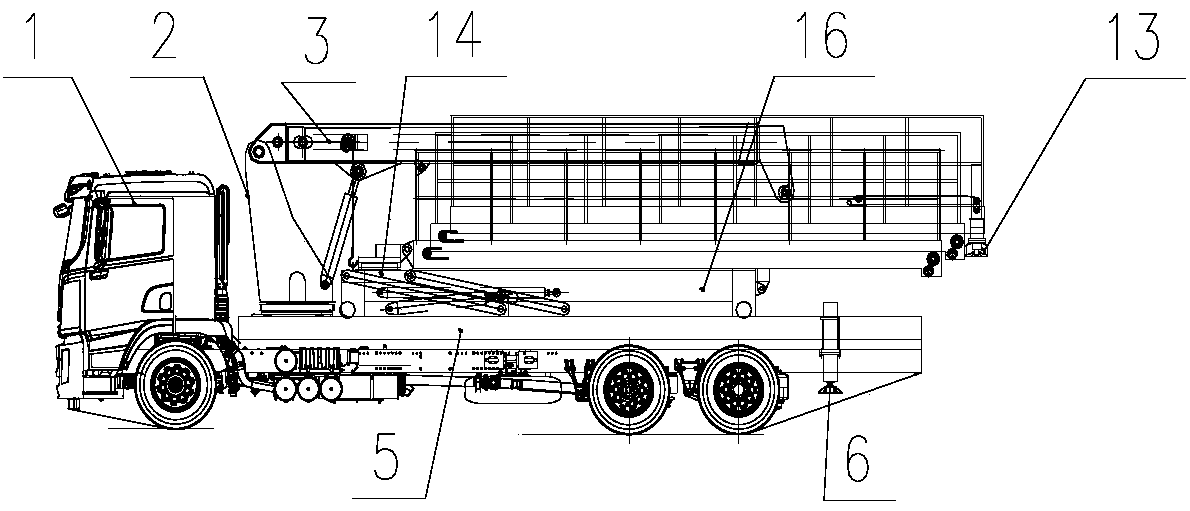

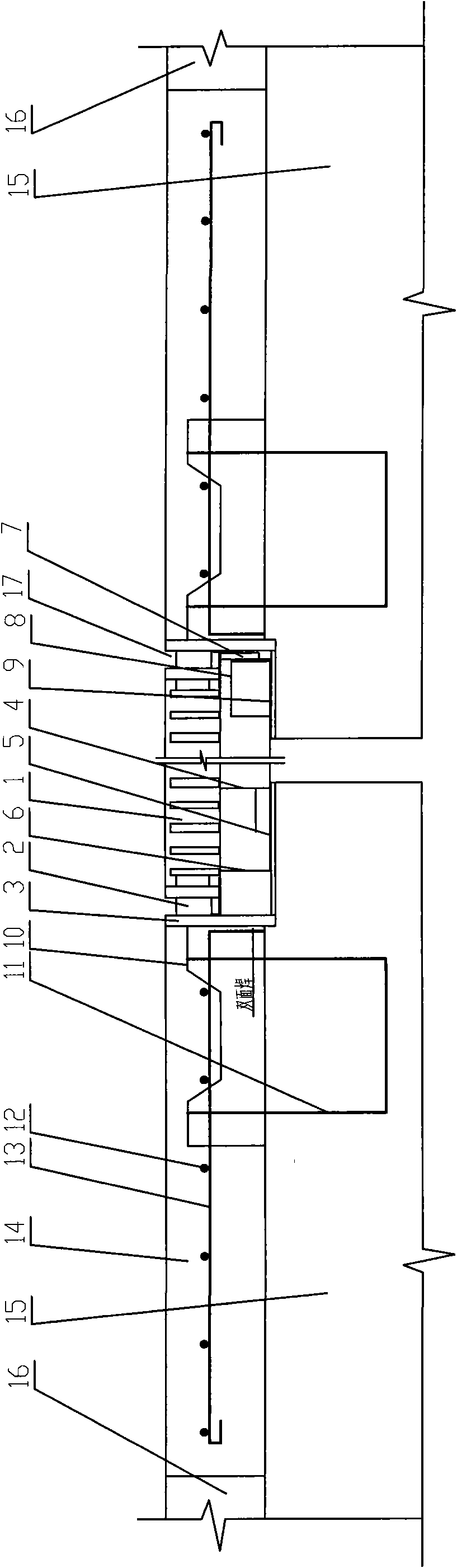

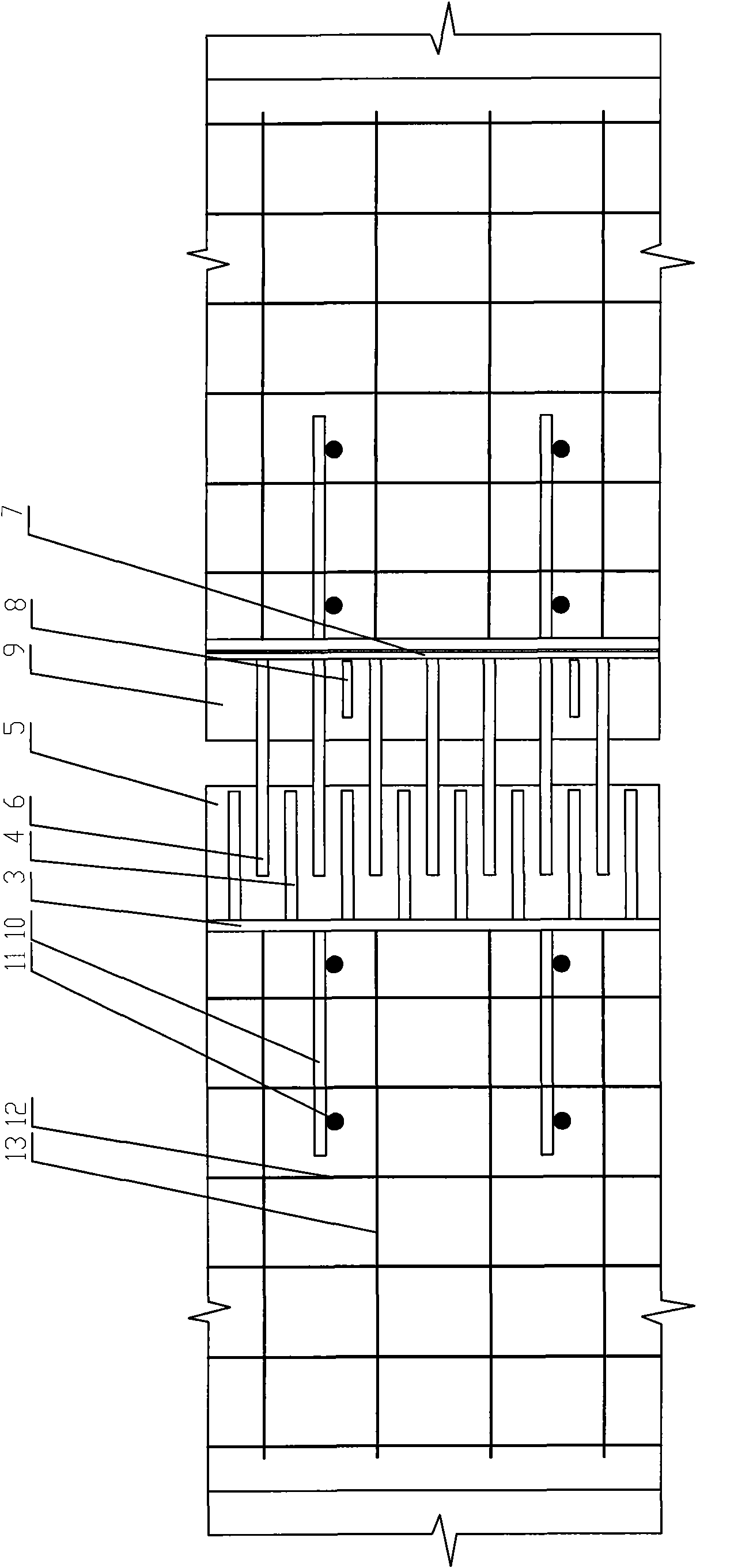

Motorized embarking equipment

InactiveCN108189974ALarge telescoping rangeLong working hoursCargo handling apparatusPassenger handling apparatusWinchNormal displacement

The invention relates to an auxiliary tool used for port wharves and ships, in particular to a mechanized accommodation ladder for a ship. Motorized embarking equipment comprises an erection vehicle and an embarking device; before erection, the embarking device is folded and retracted on the erection vehicle; during erection, a lorry-mounted crane moves to the tail position of the vehicle so as toconnect a hoisting pin, which is on an erection arm and a steel wire rope, which is in a hydraulic winch, with the embarking device; the erection arm is started to transfer the embarking device to aposition near the ship; after the transferring is finished, a lifting platform is lifted and a telescopic passage is unfolded so that a rotating shaft and a bulb of the telescopic passage are movablyconnected with a docking platform fixed on a deck of the ship. According to the motorized embarking equipment, the erection vehicle can run away without occupying the site after the embarking device is erected; the embarking device can adapt to normal displacements of the ship in three dimensions from top to bottom, from left to right and from front to back without an additional power source; thecontinuous working time is long; and no noise pollution is realized.

Owner:CHINA HARZONE IND CORP

Bridge deck steel-plastic body expansion device

InactiveCN101838965ASo as not to damageReasonable designBridge structural detailsElastomerBridge deck

The invention discloses a bridge deck steel-plastic body expansion device belonging to the technical field of bridge construction. The bridge deck steel-plastic body expansion device comprises a roadway expansion device and a sidewalk or a guardrail expansion device, a cross gap supporting structure forms a long groove shape steel structure on an expansion gap, a steel-plastic elastomer is arranged in the long groove shape steel structure and is welded with the long groove shape steel structure into a whole. Two sides of the steel-plastic elastomer are respectively provided with a sideboard, and a reinforcing steel bar is connected between the sideboard and a stop board; force bearing boards are evenly arranged between the stop boards on two sides; an elastic strip is connected between the head and the tail of two adjacent force bearing boards; and spaces formed by sideboards on two sides, the stop board, the force bearing boards and the elastic strip are filled with thermoforming artificial rubber. The bridge deck steel-plastic body expansion device has reasonable design, simple structure, convenient assembly and replacement, long service life, and water, dust and shock prevention, can satisfy normal displacement deformation requirement of a girder, is comfortable to travel and does not jump.

Owner:鲁应慧

Rock stretching and tension-shear test device and method

PendingCN110018052AEasy to installEasy to disassembleMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesShear stressEngineering

The invention relates to a rock stretching and tension-shear test device and method. Two pore canals are symmetrically arranged in a rock sample, kerfs parallel to the axis of the pore canals are reserved at the outer ends of the two pore canals, and a pressure air bag sleeves the internal portion of each pore canal. the test device also comprises a sample fixing device, a tension stress applyingdevice and a shear stress applying device, wherein the upper end of the rock sample is connected with a vertical displacement dial plate for measuring the normal displacement of the rock sample; and the side surface of the rock sample is connected with a horizontal displacement dial plate for measuring the transverse displacement of the rock sample. The rock stretching and tension-shear test device and method have the advantages of the simple and feasible structure, the reliable performance and the accurate test result.

Owner:CHINA THREE GORGES UNIV

Piezoelectric-driven three-dimensional micro-positioning platform

The invention provides a piezoelectric-driven three-dimensional micro-positioning platform comprising a rotating frame structure, an extension rod, a displacement amplifying device, a piezoelectric stack, a surface force-bearing plate, and a bottom plate. One end of the rotating frame structure is connected to the surface force-bearing plate and the other end is connected to the displacement amplifying device. The displacement amplifying device is installed on the bottom plate; and the piezoelectric stack is connected to the displacement amplifying device. The extension rod is arranged in therotating frame structure; and one end of the extension rod is connected to the displacement amplifying device and the other end is connected to the surface force-bearing plate. Under the piezoelectricstack driving, a force is applied to the rotating frame structure and thus the rotating frame structure is distorted by the force, thereby realizing the rotational movement of the positioning platform. According to the invention, with control of the output displacement of the piezoelectric stack, the precise control of the normal displacement of the positioning platform and the rotation angle ofthe horizontal plane is realized.

Owner:JIANGSU UNIV

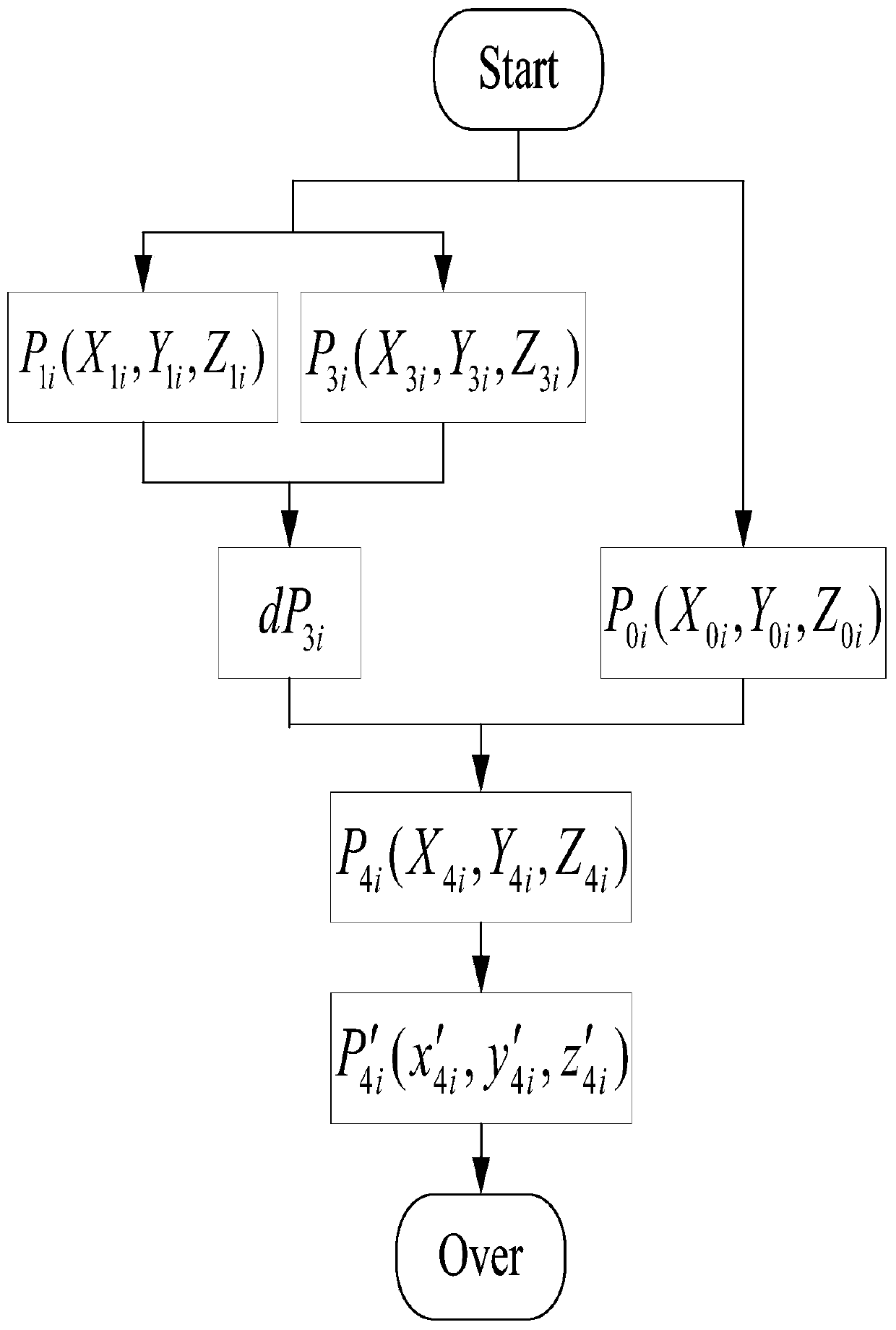

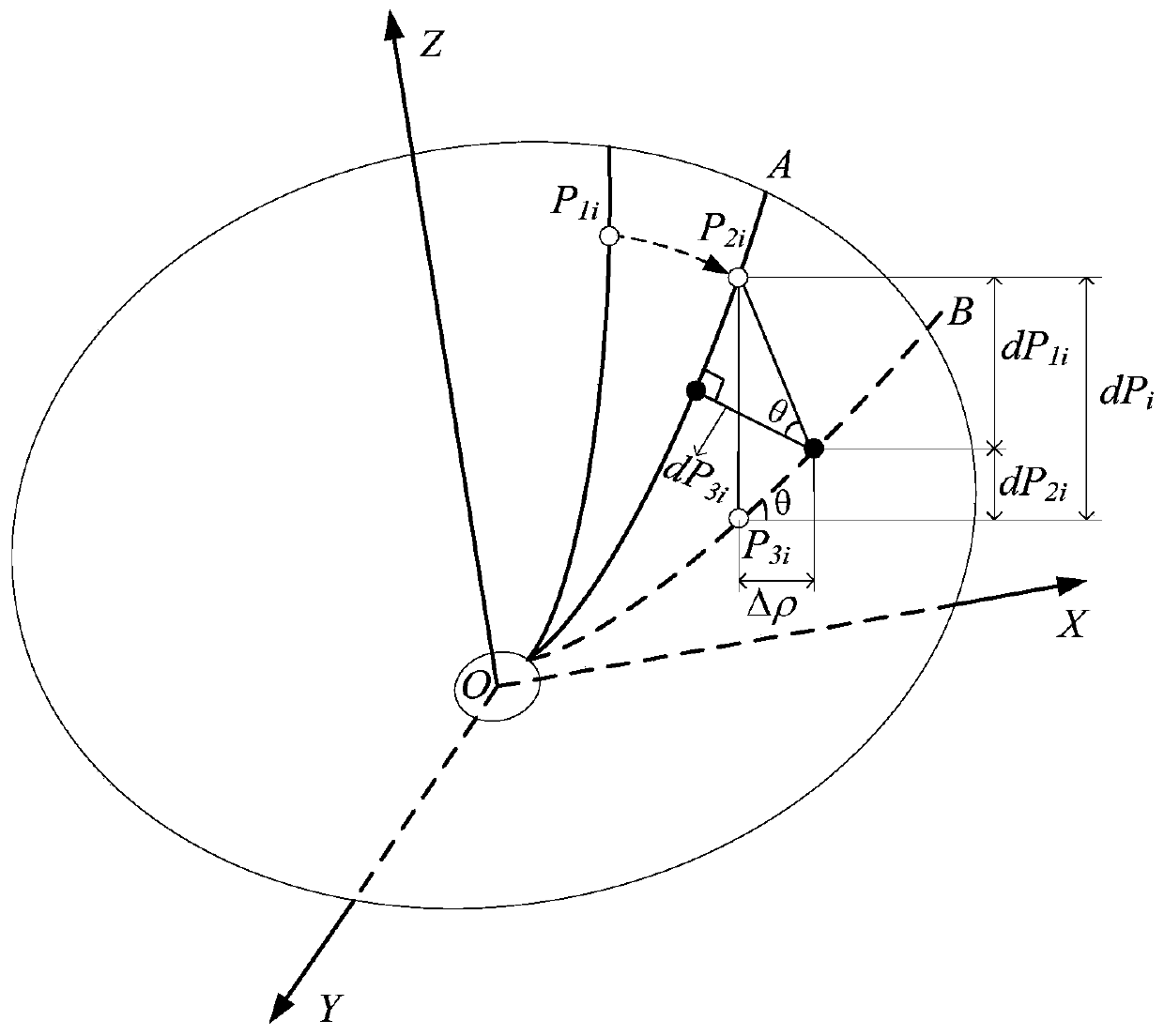

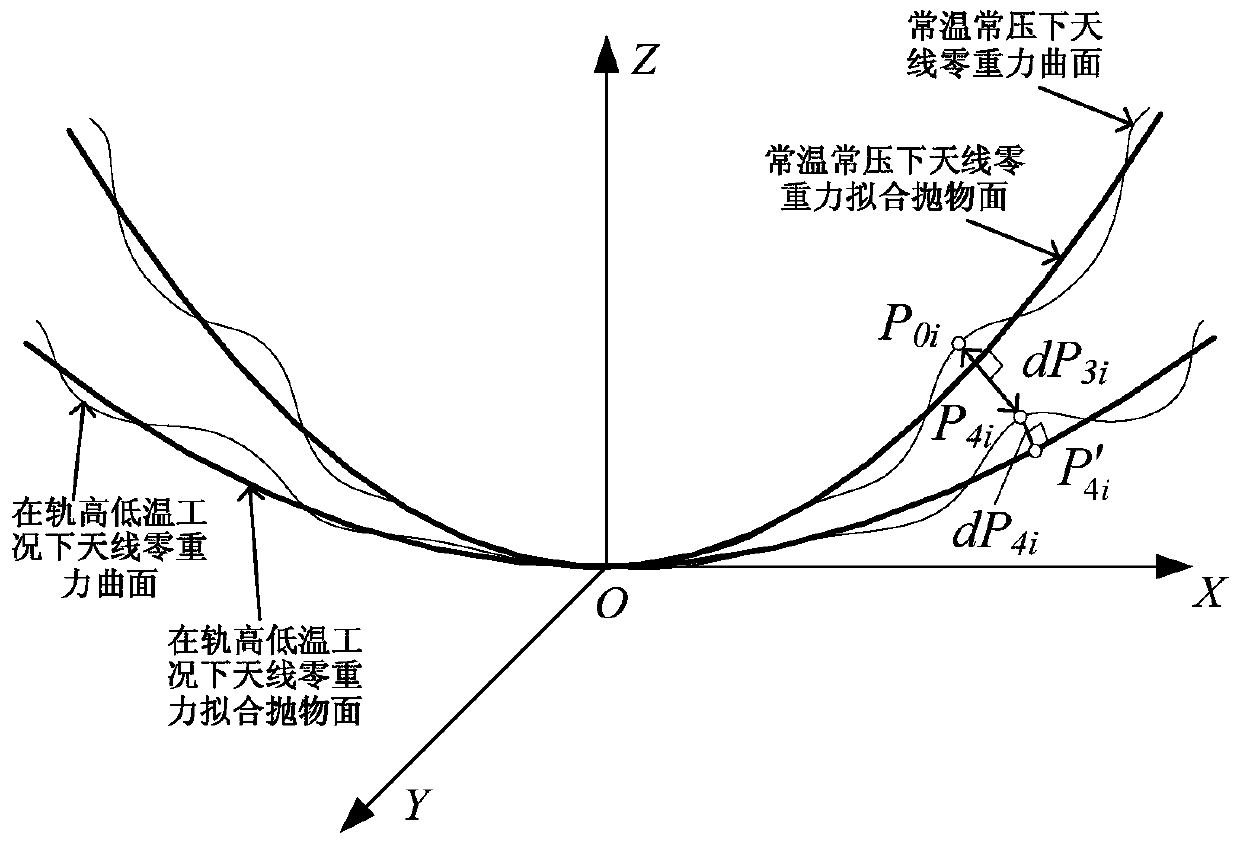

Method for determining shape of large-scale flexible antenna in in-orbit zero-gravity state

ActiveCN109883387AEliminate differences in consistency between heaven and earthInnovativeElectrical testingAntenna radiation diagramsMeasurement testMeasurement point

The invention discloses a method for determining the shape of a large-scale flexible antenna in an in-orbit zero-gravity state. The method for determining the shape of the large-scale flexible antennain the in-orbit zero-gravity state comprises the following steps that firstly, a thermal deformation normal displacement value of a cluster of antenna shape target points in a non-unloading state under various temperature field working conditions in a vacuum low-temperature environment relative to a cluster of antenna target points in a vacuum normal-temperature non-unloading state is obtained through a thermal deformation measurement test simulating a space environment; and then a cluster of antenna shape measurement points is superposed to obtain the cluster of the antenna shape target points in the unloading state under various temperature field working conditions; and then, the least square fitting method is adopted to obtain a zero-gravity fitting shape through cluster of coordinatepoints of the antenna shape in the zero-gravity unloading state of the antenna under various temperature field working conditions. According to the method for determining the shape of the large-scaleflexible antenna in the in-orbit zero-gravity state, the simulation result of the antenna zero gravity fitting shape antenna under high and low temperature working conditions can truly reflect the in-orbit actual running electrical performance index of the satellite-borne large flexible antenna.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com