Tangential driving double-difference butterfly-wing silicon microgyroscope and application method thereof

A silicon micro-gyroscope and butterfly-wing technology, which is applied in the direction of speed measurement by gyro effect, gyroscope/steering sensing equipment, measuring device, etc., can solve the problems of low stability and poor adaptability, and increase mechanical sensitivity and sensitivity Improve and reduce the effect of supporting energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

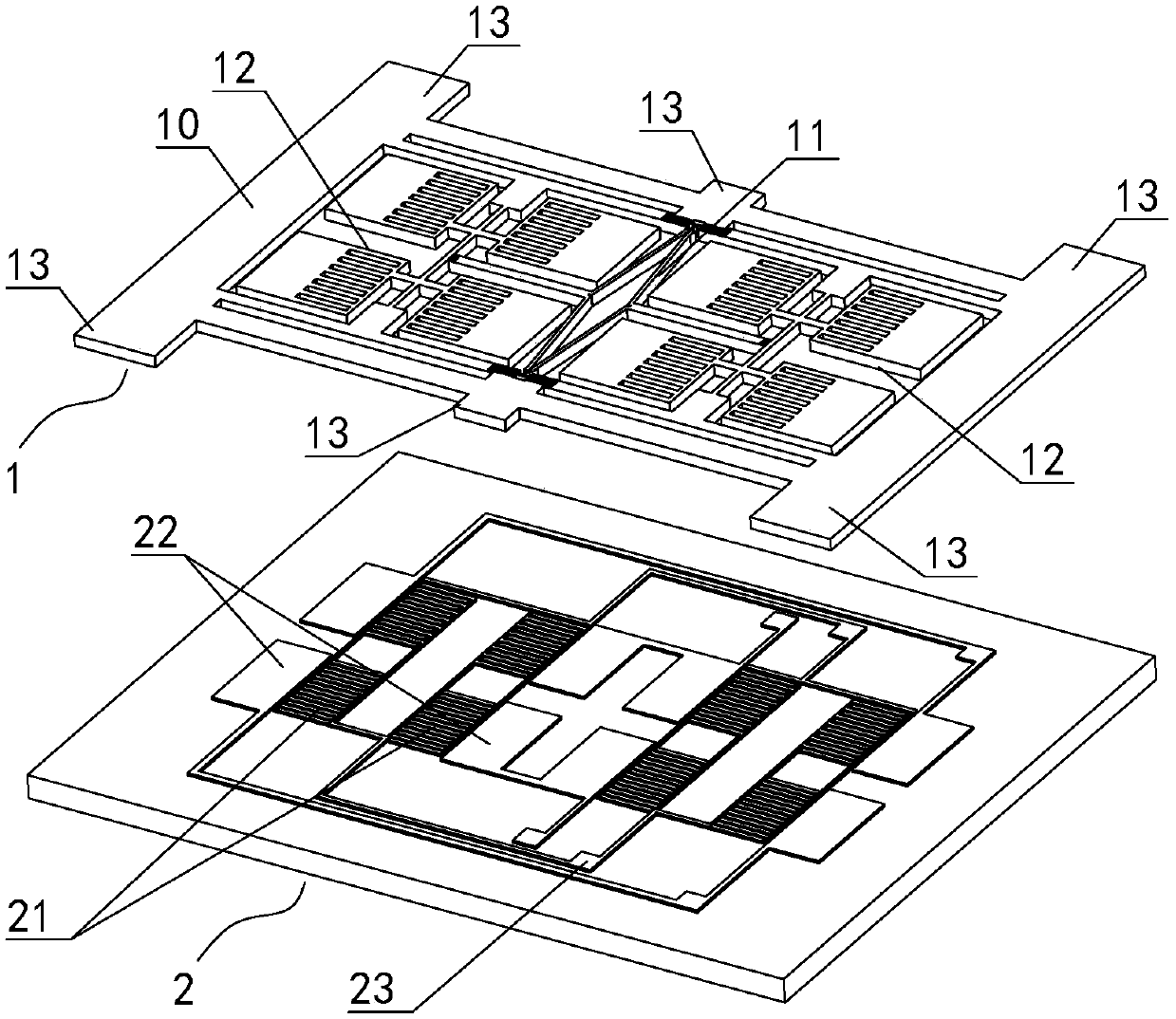

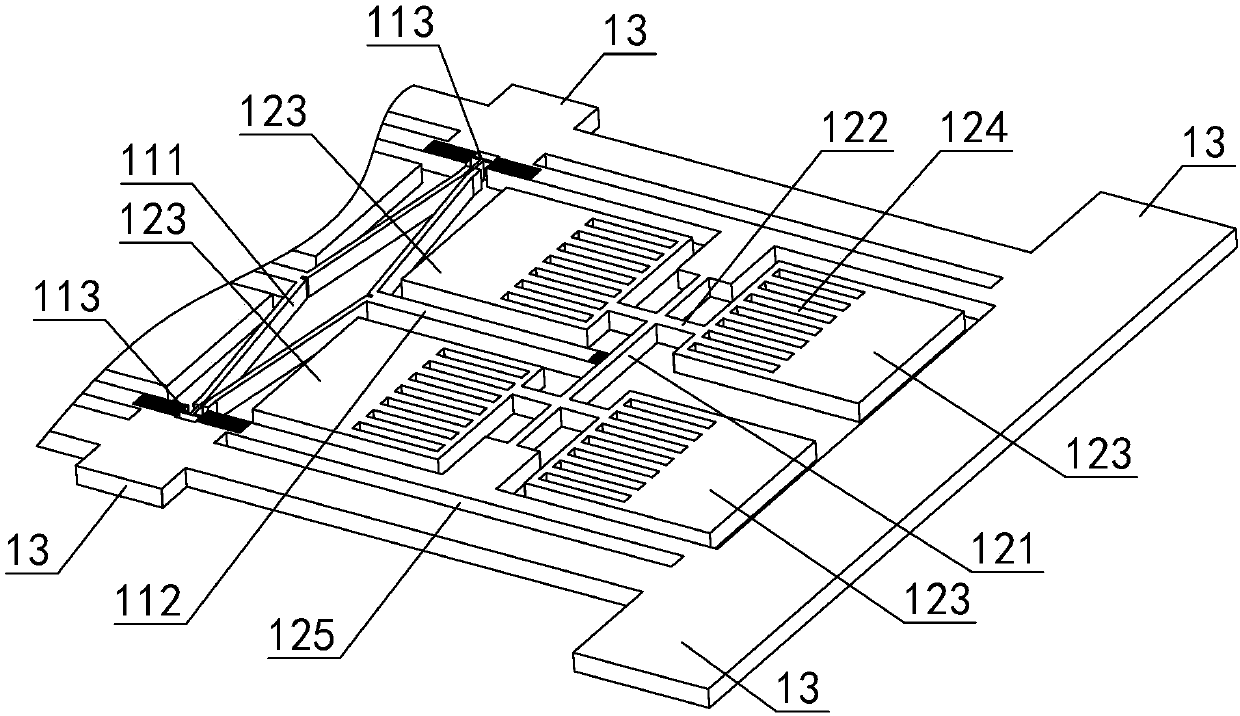

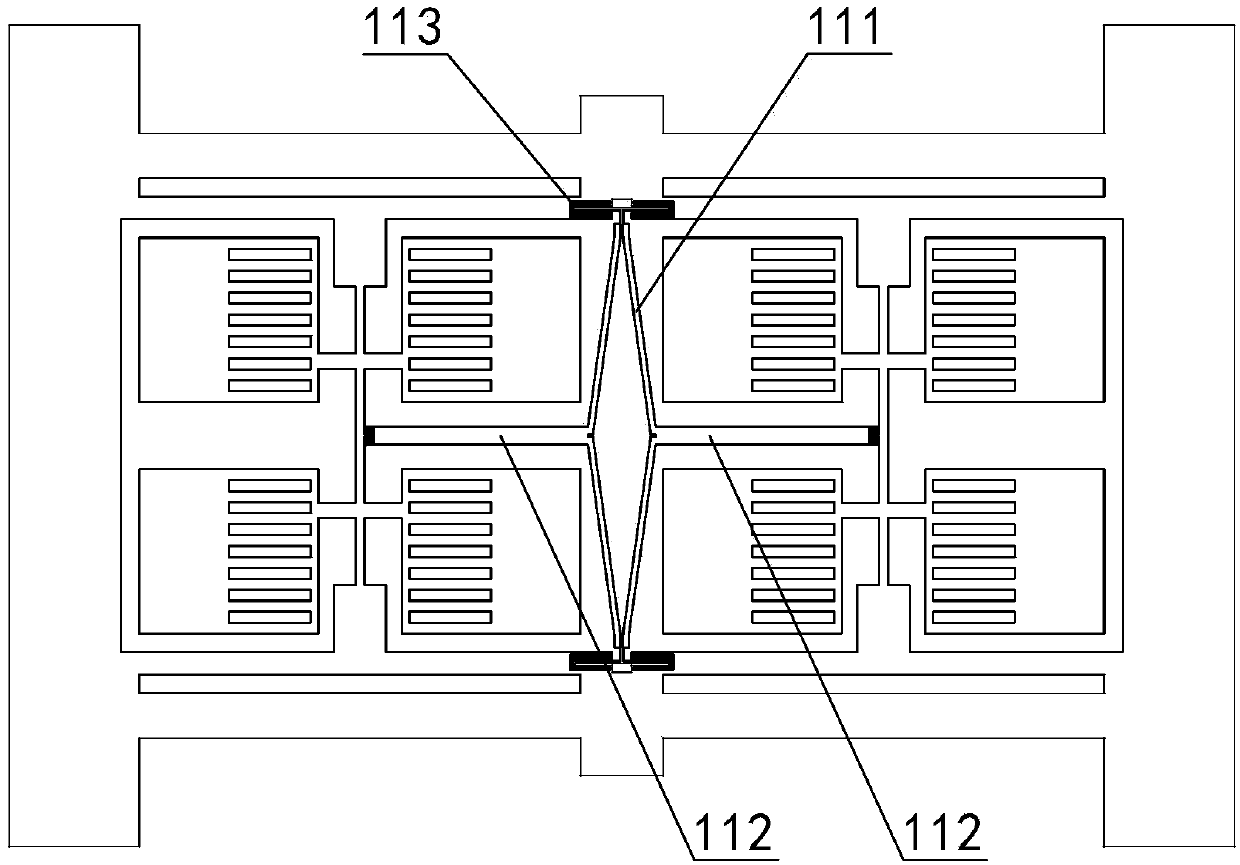

[0045] Such as figure 1 with figure 2 As shown, the tangentially driven double-differential butterfly-wing silicon microgyroscope of this embodiment includes a silicon-glass double-layer structure composed of a silicon sensitive structure 1 and a glass electrode plate 2. The silicon sensitive structure 1 includes an external frame 10, and the external frame 10 There is a coupling spring structure 11 and two silicon-sensitive substructures 12 connected through the coupling spring structure 11. The two silicon-sensitive substructures 12 are symmetrically arranged relative to the coupling spring structure 11. The silicon-sensitive substructure 12 includes a support beam 121 and a The cantilever beam 122 is connected to the four inertial mass blocks 123 on the support beam 121, the inertial mass block 123 is provided with evenly distributed drive combs 124, and the glass electrode plate 2 is provided with drive electrodes 20, detection electrodes 21 and electrode pads 22. The dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com