An automatic mode matching control device and method for mems gyroscope based on negative stiffness effect

A negative stiffness effect and modal technology, applied in electric controllers, controllers with specific characteristics, measuring devices, etc., can solve complex control methods, difficult to meet large-scale production, and difficult to stabilize complete mode matching control and other issues to achieve the effect of simplifying the difficulty of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further explained below in conjunction with the accompanying drawings.

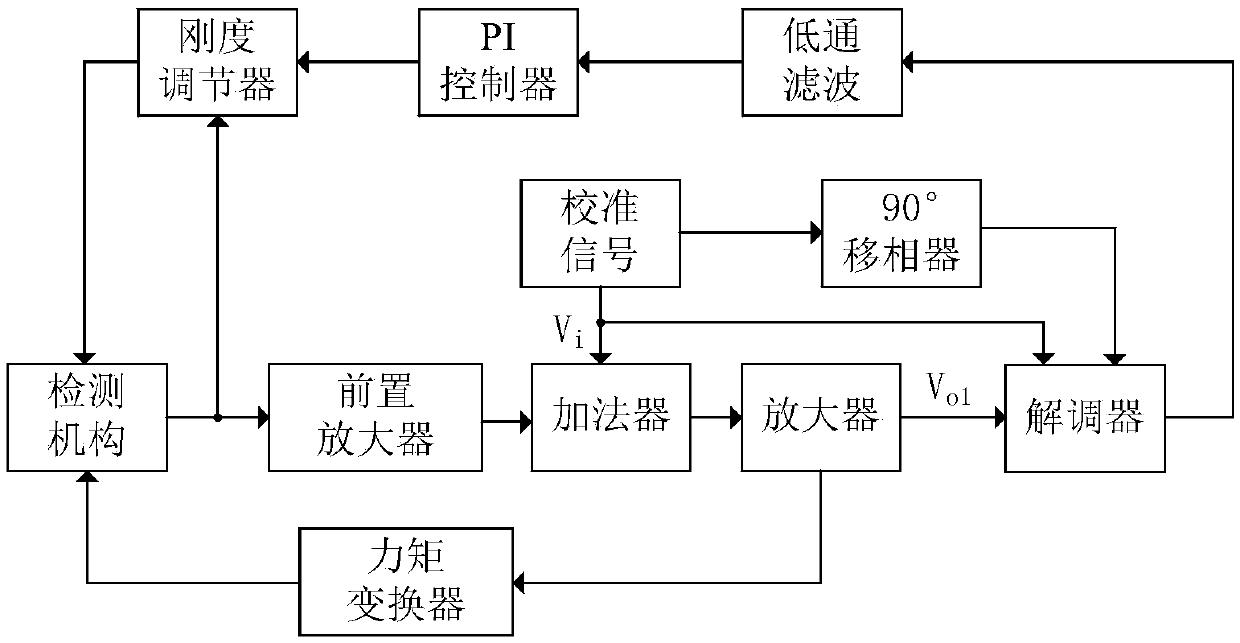

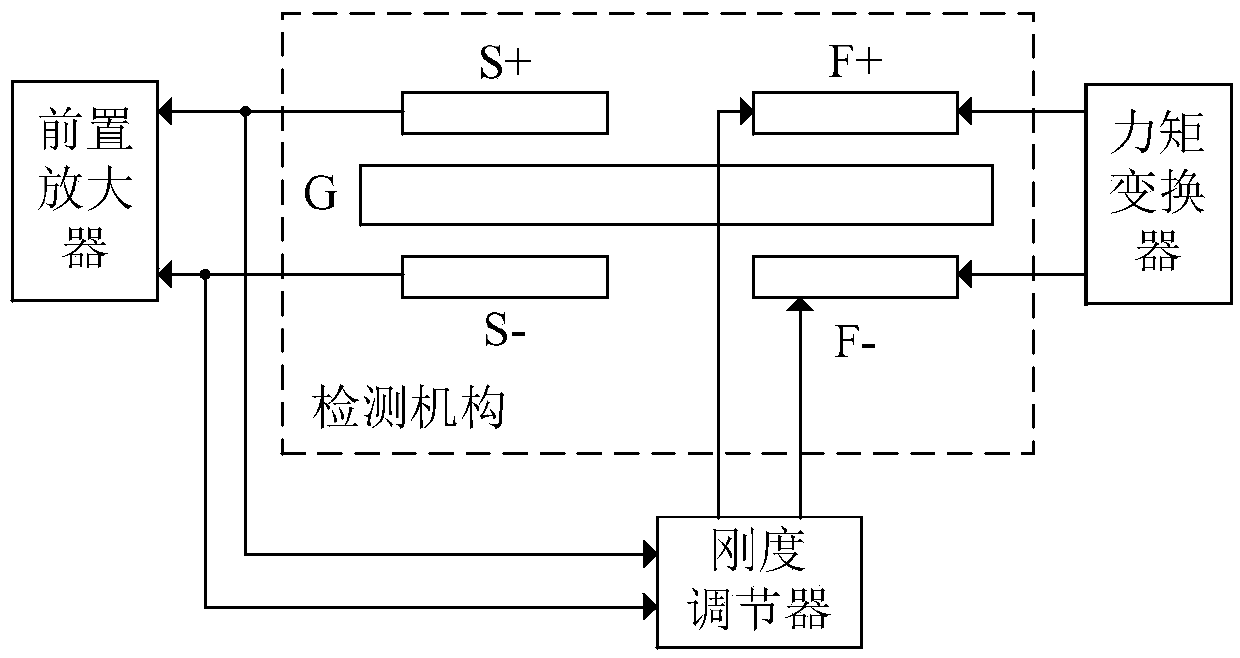

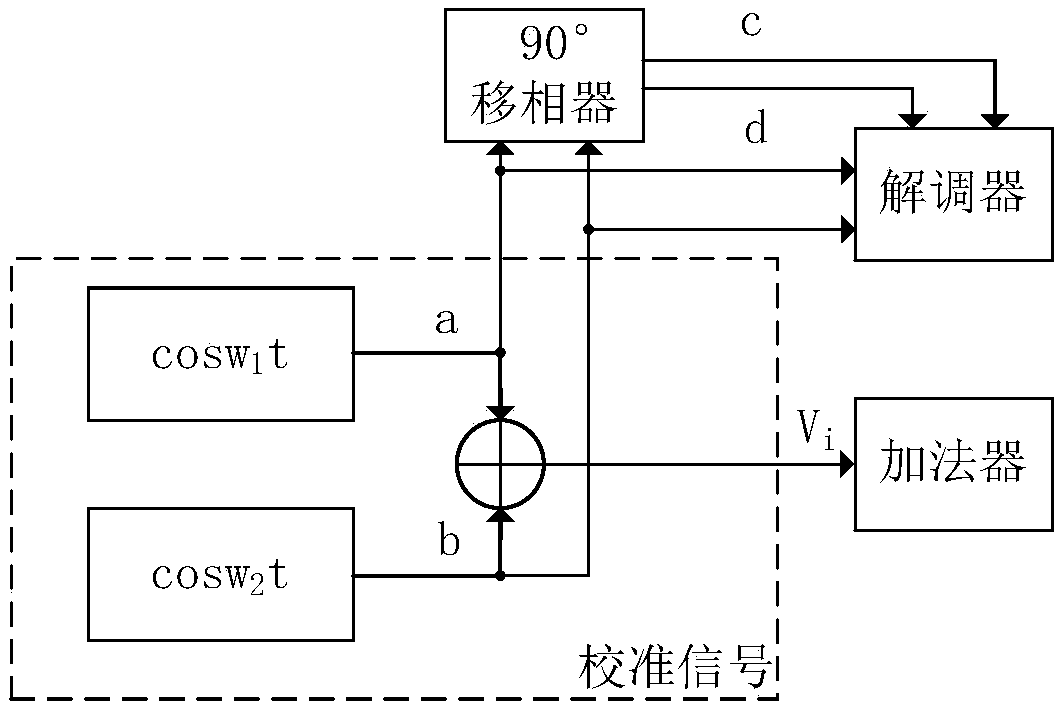

[0033] figure 1It is a structural diagram of the MEMS gyro automatic mode matching control device based on the negative stiffness effect of the present invention, including a detection mechanism, a preamplifier, an adder, an amplifier, a demodulator, a torque converter, a calibration signal generator, a phase shifter, Low pass filter, PI controller, stiffness regulator. The output of the detection mechanism is connected with the stiffness regulator, and the output of the stiffness regulator is used as the input of the detection mechanism, so as to achieve the purpose of adjusting the stiffness of the detection mechanism. At the same time, the output end of the detection mechanism is connected with the preamplifier, so as to realize the extraction of the output signal of the detection mechanism. The output of the preamplifier and the calibration signal are used as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com