Design device and design method of adjustable composite-material mold

A technology of adjusting device and mold design, applied in the field of satellite antennas, can solve the problems of guarantee and improvement, difficulty in mold surface accuracy, and difficulty in direct application, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing, the present invention is described in detail, specifically as follows:

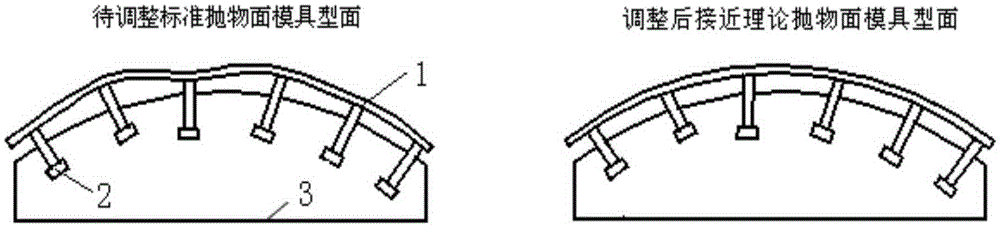

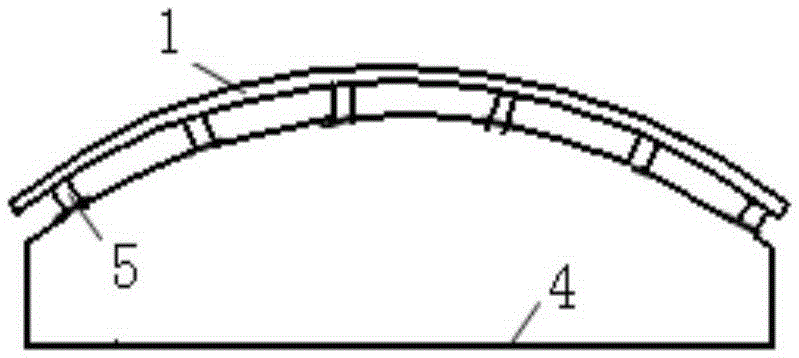

[0041] Such as figure 1 Shown is the schematic diagram of the adjusting device in the present invention, as figure 2 Shown is the mold bonding schematic diagram in the present invention, from figure 1 and figure 2 It can be seen that an adjustable composite material mold design device in the present invention is characterized in that it mainly includes a mold surface 1, an adjustment device 2, an adjustment tool 3, a mold support back frame 4 and a corner piece 5;

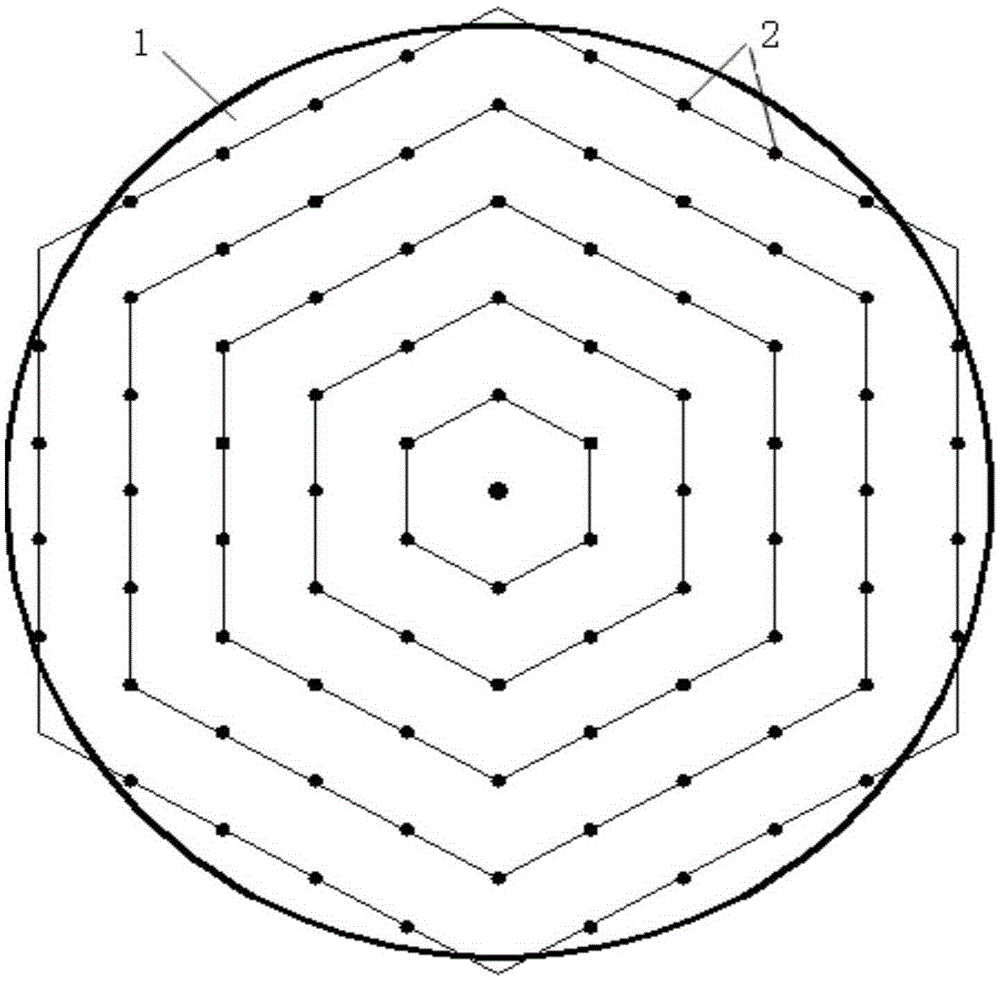

[0042] The adjustment device 2 is arranged on one side of the mold surface 1, and has a linear displacement feed function; the position of the adjustment device 2 can be arranged arbitrarily according to needs, preferably evenly arranged on the same side or the back of the working surface of the mold surface 1 side, such as image 3 Shown is a schematic diagram of the position distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com