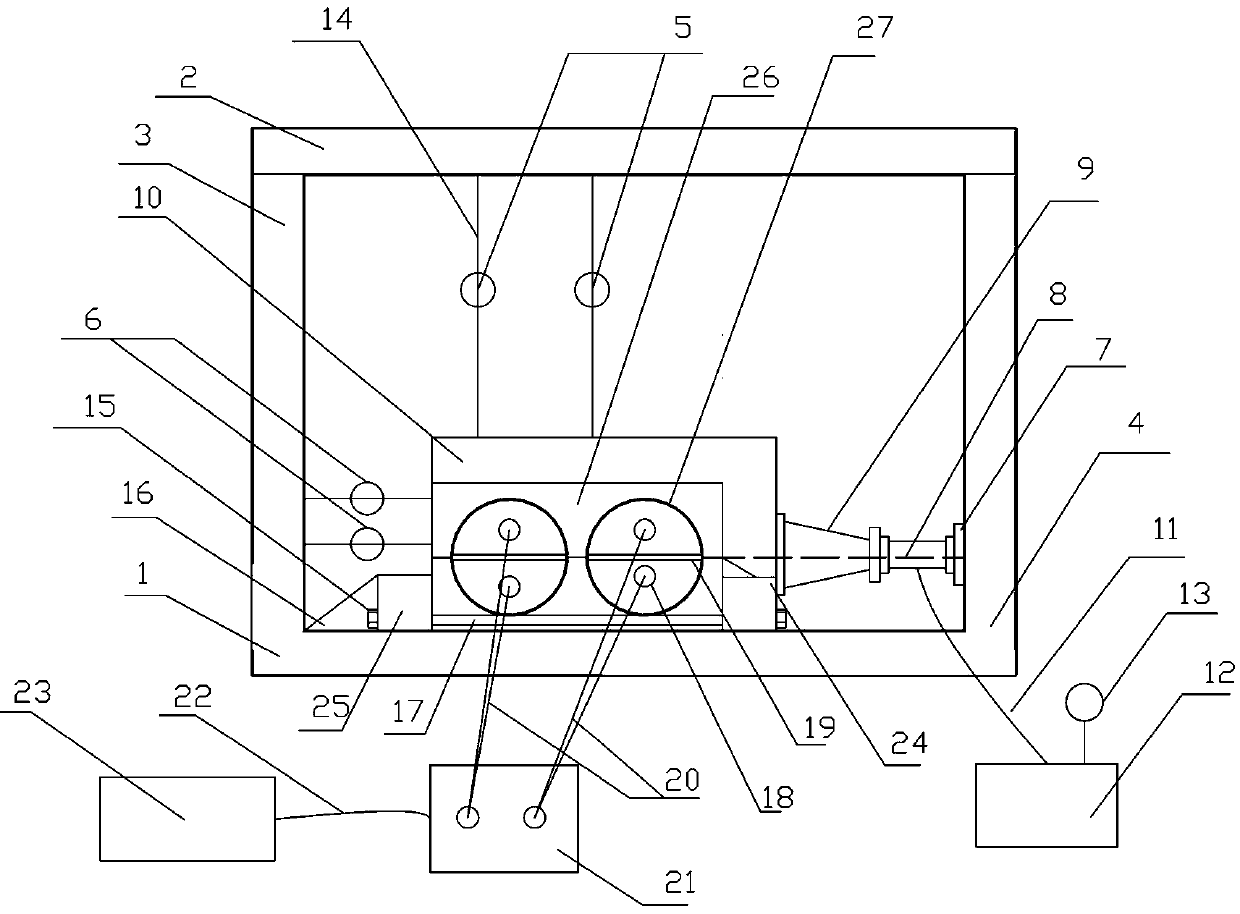

Rock stretching and tension-shear test device and method

A test device and rock technology, applied in the direction of testing material strength by applying stable shear force, testing material strength by applying stable tension/pressure, etc., can solve the problems of cumbersome test process, difficult operation, and low precision, and achieve The structure of the device is simple, the performance is reliable, and the accuracy is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

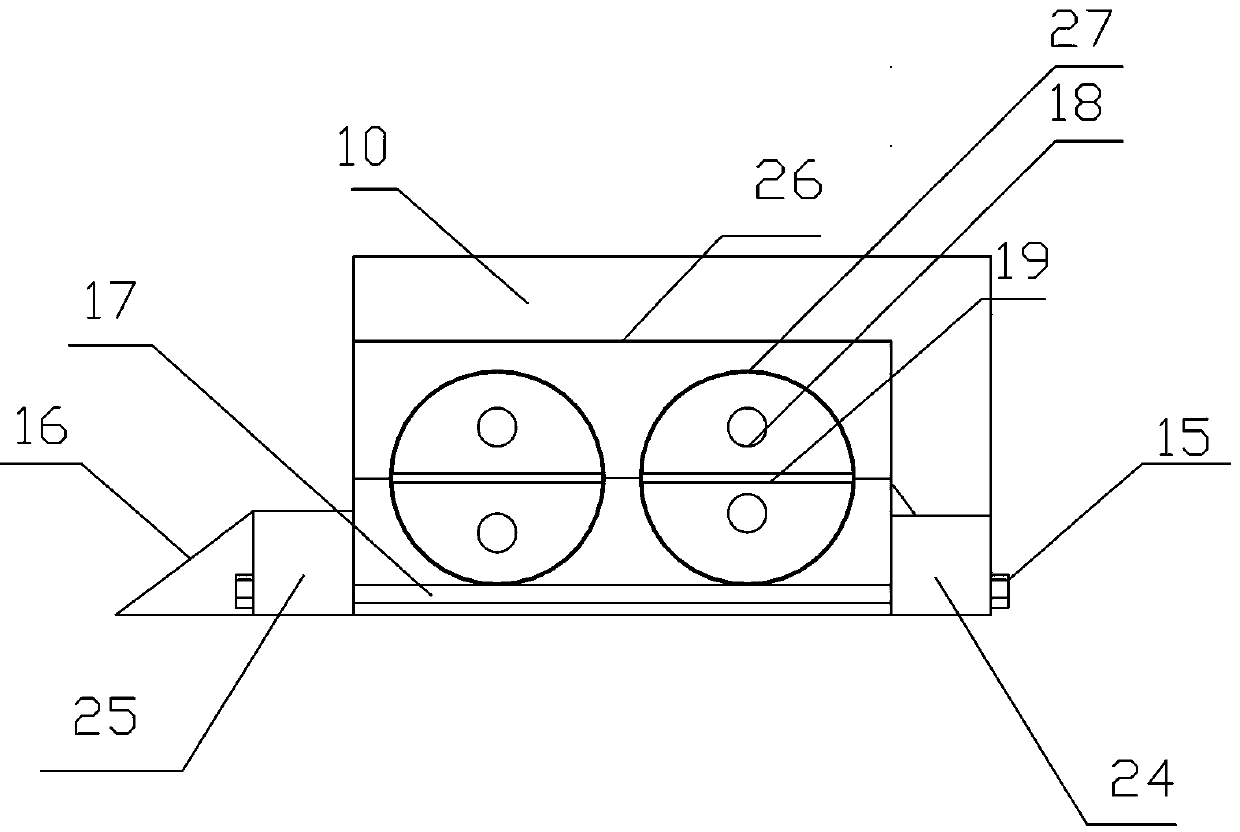

[0071] Step 1: Rock sample installation:

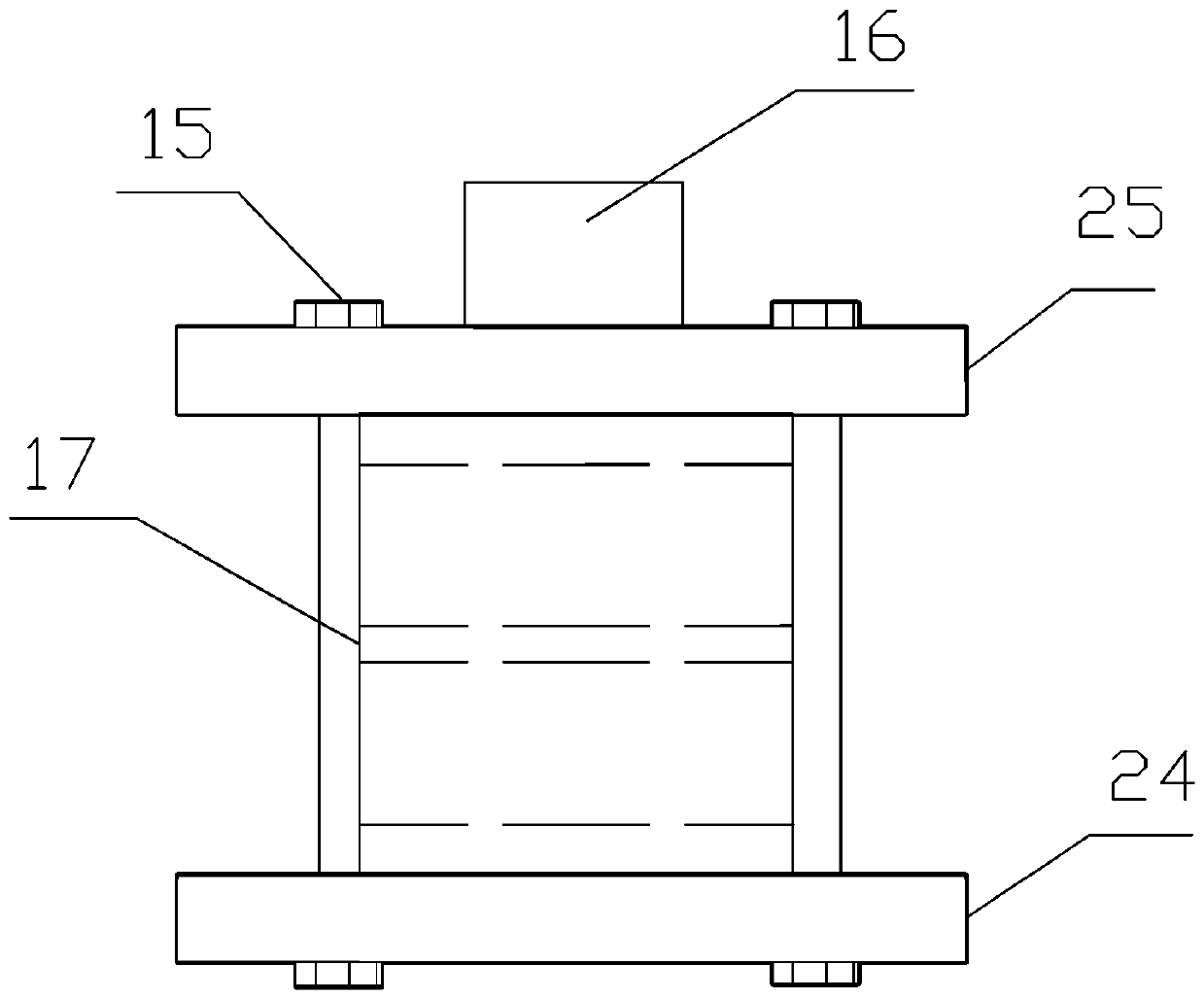

[0072] Such as figure 1 As shown, the rock sample 26 is a rock sample with a length × width of 115mm × 60mm. Two tunnels are arranged symmetrically to it. The diameter of the tunnel is 50mm long. The distance between the two tunnels is 5mm. There is a slit 28 parallel to the hole axis, the slit 28 is 5mm long, a pressure air bag 27 is placed in the tunnel, and a mica gasket 19 is placed in the middle of the tunnel. This rock sample 26 is the object of the present invention's test and analysis.

[0073] The sample fixing device is used to fix the rock sample 26;

[0074] The tensile stress applying device is for applying tensile stress to the rock sample 26;

[0075] The shear stress applying device is for applying shear stress to the rock sample 26;

[0076] Step 2: Application of tensile stress:

[0077] According to the tensile stress value set by the test, the above formula (3) is used Calculate the air pressure value that ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com