Patents

Literature

260 results about "Tensile shear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tensile strength and shear strength related to following formula: Tensile strength = 1.73 * Shear stress. Which means that shear stress for mild steel will be 200–300 MPa.

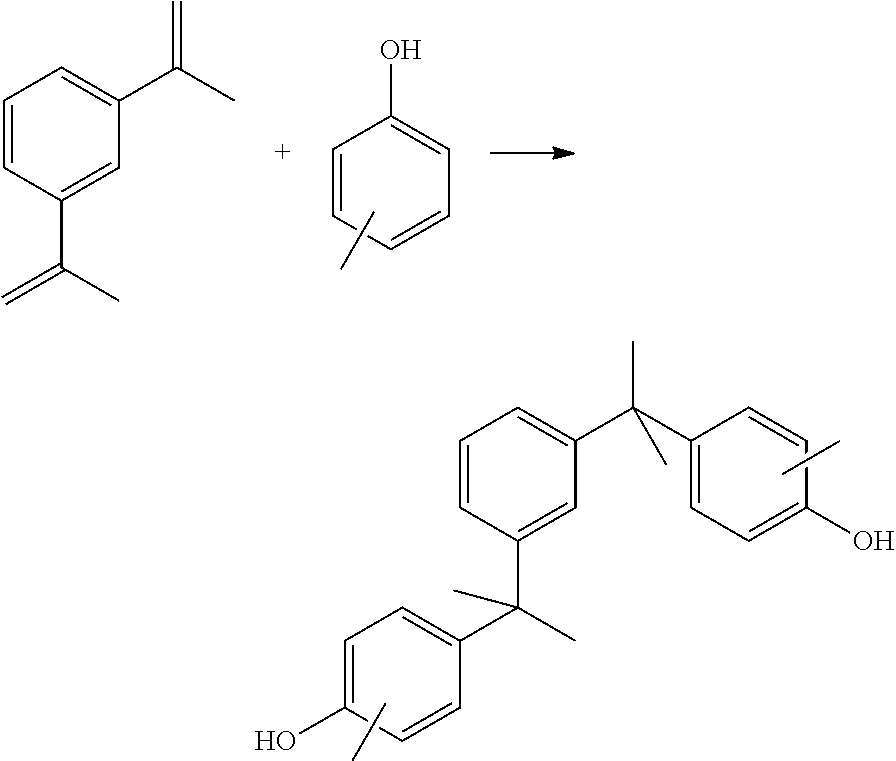

High-temperature-resistant modified polyfunctional epoxy matrix resin for advanced composite material and preparation thereof

The invention relates to high-temperature-resistant modified polyfunctional epoxy matrix resin for an advanced composite material. The resin comprises tetramaleimide resin, carboxy terminated nitrile rubber, polyfunctional epoxy resin, a curing agent and an organic solvent. A preparation method comprises the following steps of: adding the tetramaleimide resin, the carboxy terminated nitrile rubber and the polyfunctional epoxy resin into a reaction kettle and reacting at the temperature of 110 DEG C for one hour; adding the organic solvent and dissolving under stirring to obtain a component A;mixing the curing agent and the organic solvent and dissolving under stirring to obtain a component B; and mixing the component A and the component B and uniformly stirring during use. The high-temperature-resistant modified polyfunctional epoxy matrix resin provided by the invention has the advantages of high room temperature tensile shear strength, high heat resistance, wide application prospect in the fields such as electronics, micro-electronics, printed circuit boards (PCB), motors, aerospace and the like, simple preparation process, low cost and contribution to realizing industrial production.

Owner:DONGHUA UNIV +1

Preparation method of high temperature resistant single-component solventless epoxy adhesive

InactiveCN101649174AConvenient sourceSimple preparation processEpoxy resin adhesivesSolventThermoplastic polyimide

The invention relates to a preparation method of high temperature resistant single-component solventless epoxy adhesive. The method comprises the following steps: adding aromatic binary primary amine and strongly polar non-proton organic solvent in a reaction tank, stirring at room temperature to dissolve, adding aromatic binary acid anhydride to perform refluxing and water-segregating reaction at 120-150 DEG C for 6-12h, cooling, adding the reaction solution in a stamp tank with precipitant to precipitate solid powder, namely white thermoplastic polyimide powder, adding white thermoplastic polyimide powder and tertiary amine compound or imidazole compound in epoxy resin to react for 1-2h, adding active diluent and latent curing agent to stir evenly and obtaining the product. The production process is easy and the cost is low so as to realize industrialized production; the tensile shear intensions of the epoxy adhesive at room temperature and 120 DEG C are respectively up to 28Mpa and26Mpa and the epoxy adhesive has broad application prospect in fields such as electronics and microelectronics, electrical motors, aviation and aerospace and the like.

Owner:DONGHUA UNIV

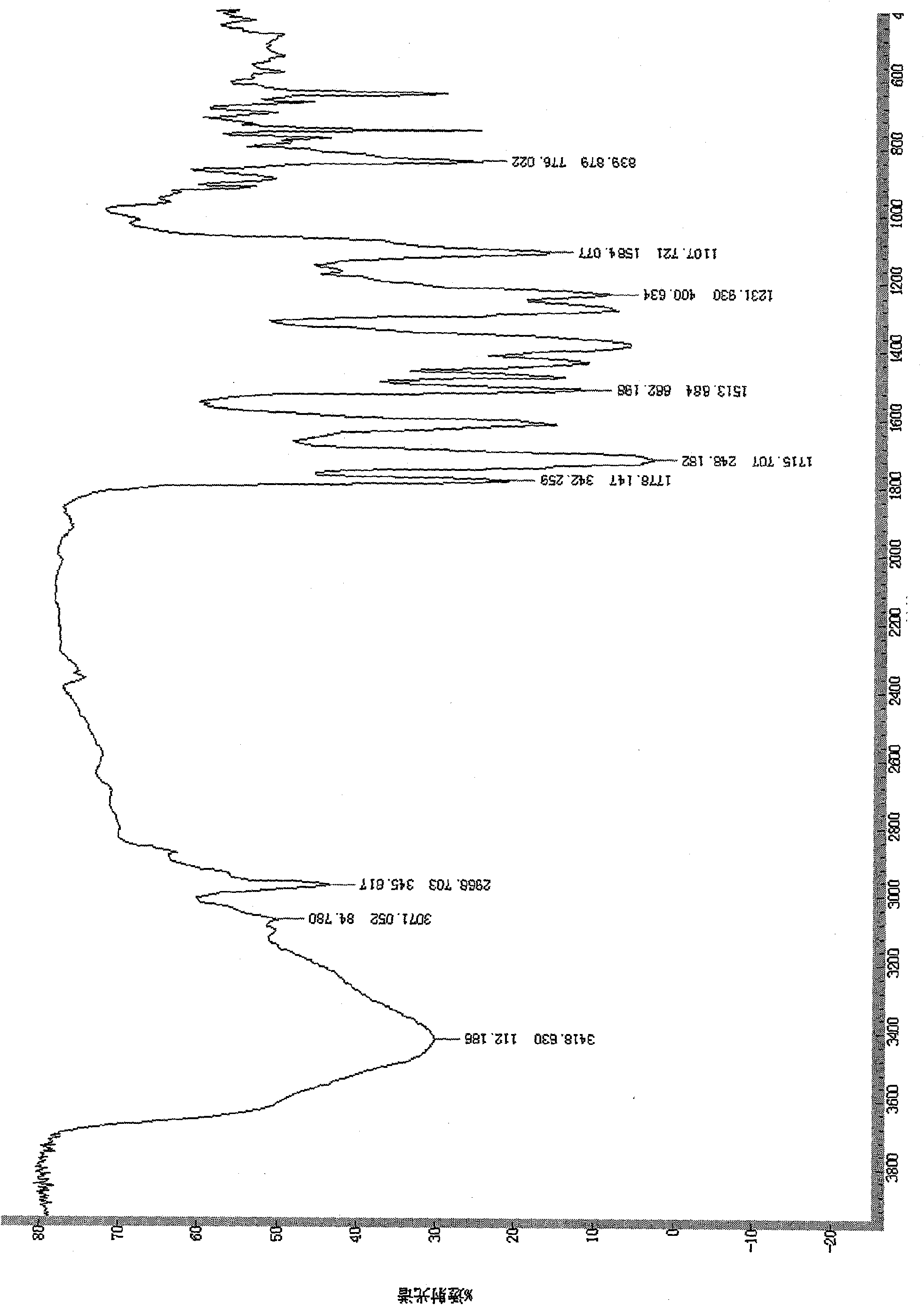

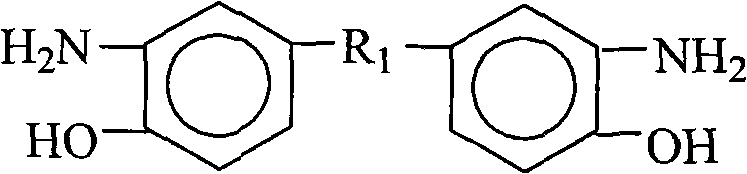

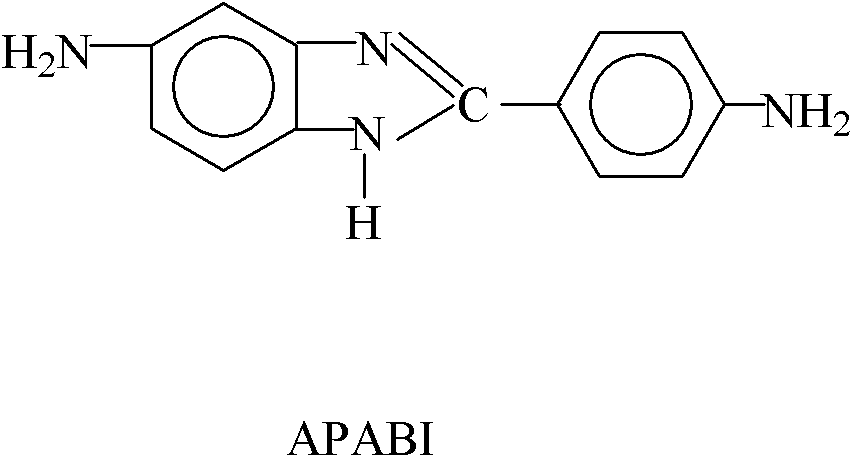

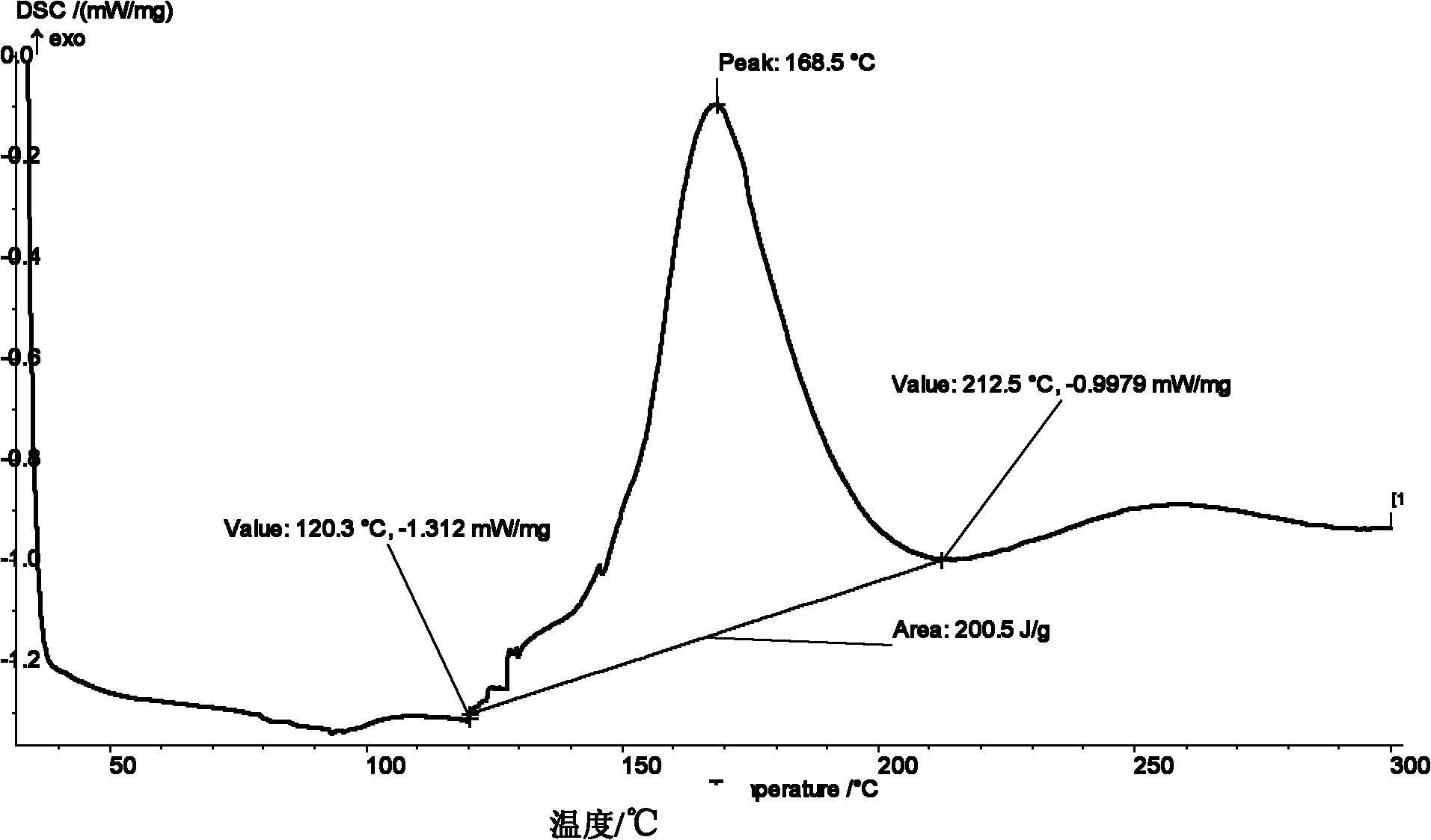

Benzimidazole diamine curing type epoxy adhesive and preparation method thereof

InactiveCN102031082AHigh tensile and shear strength at room temperatureConvenient sourceNon-macromolecular adhesive additivesCarboxyl rubber adhesivesViscous liquidElectronics

The invention relates to a benzimidazole diamine curing type epoxy adhesive and a preparation method thereof. The adhesive is prepared from the following raw materials: a component A, namely a benzimidazole diamine curing agent and a component B, wherein the component B is prepared from terminal carboxyl group butadiene-nitrile rubber, epoxy resin and a reactive diluent. The preparation method comprises the following steps of: (1) adding the terminal carboxyl group butadiene-nitrile rubber and the epoxy resin into a reaction kettle, reacting at the temperature of 90 DEG C with stirring, cooling to the temperature of 50 DEG C, adding the reactive diluent, and stirring at the temperature of 80 DEG C to obtain homogeneous and transparent viscous liquid, namely the component B; and (2) mixingthe components A and B, and stirring uniformly to obtain the adhesive. The tensile shear strength of the adhesive is 33.5MPa at the room temperature, and the adhesive has wide application prospect infields of electronics and microelectronics, rigid copper-clad laminates, motors, aerospace and the like; and the preparation process is simple, is low in cost and is convenient to operate, the resources of reaction raw materials are wide, and the adhesive can be conveniently industrially produced.

Owner:DONGHUA UNIV +1

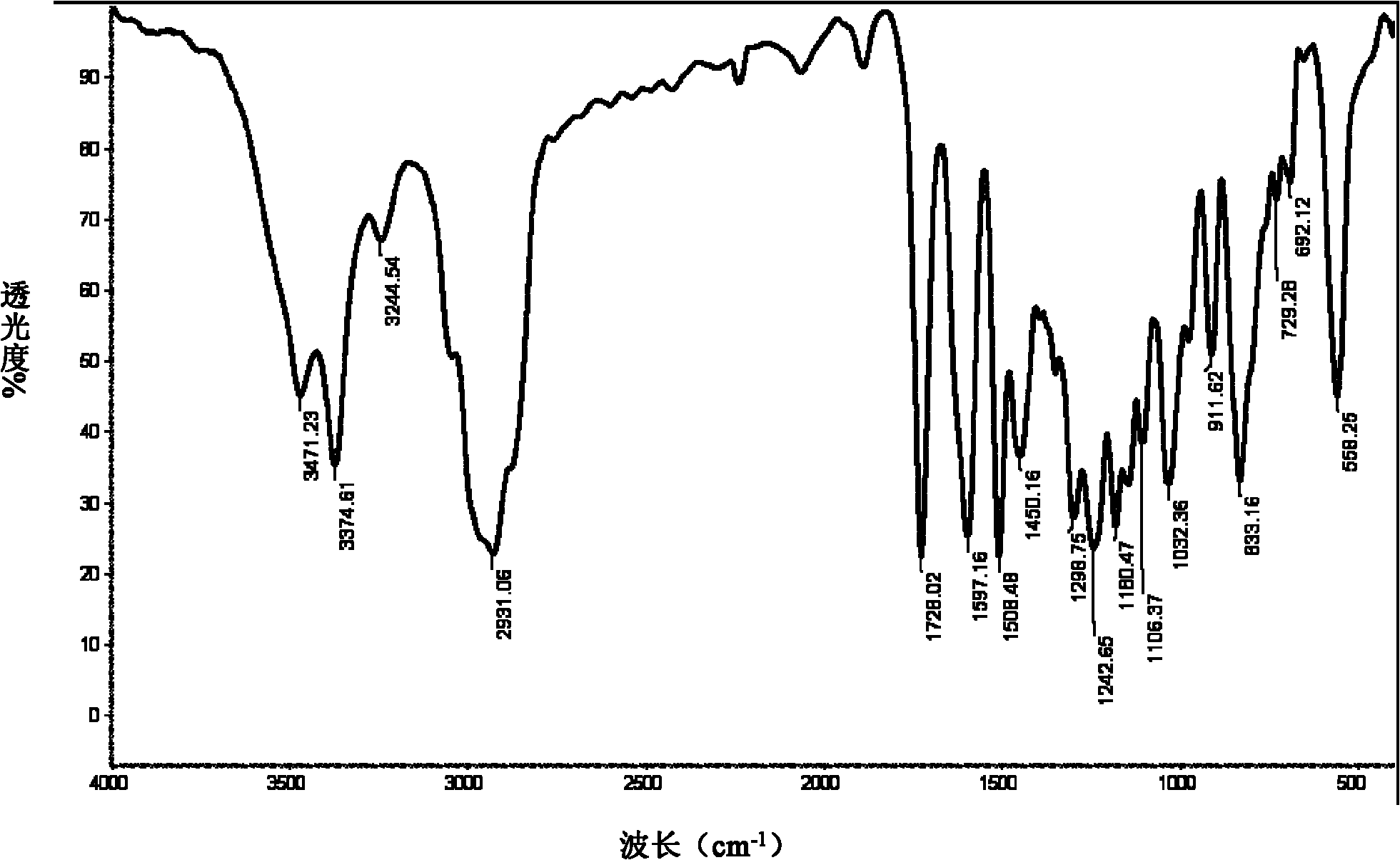

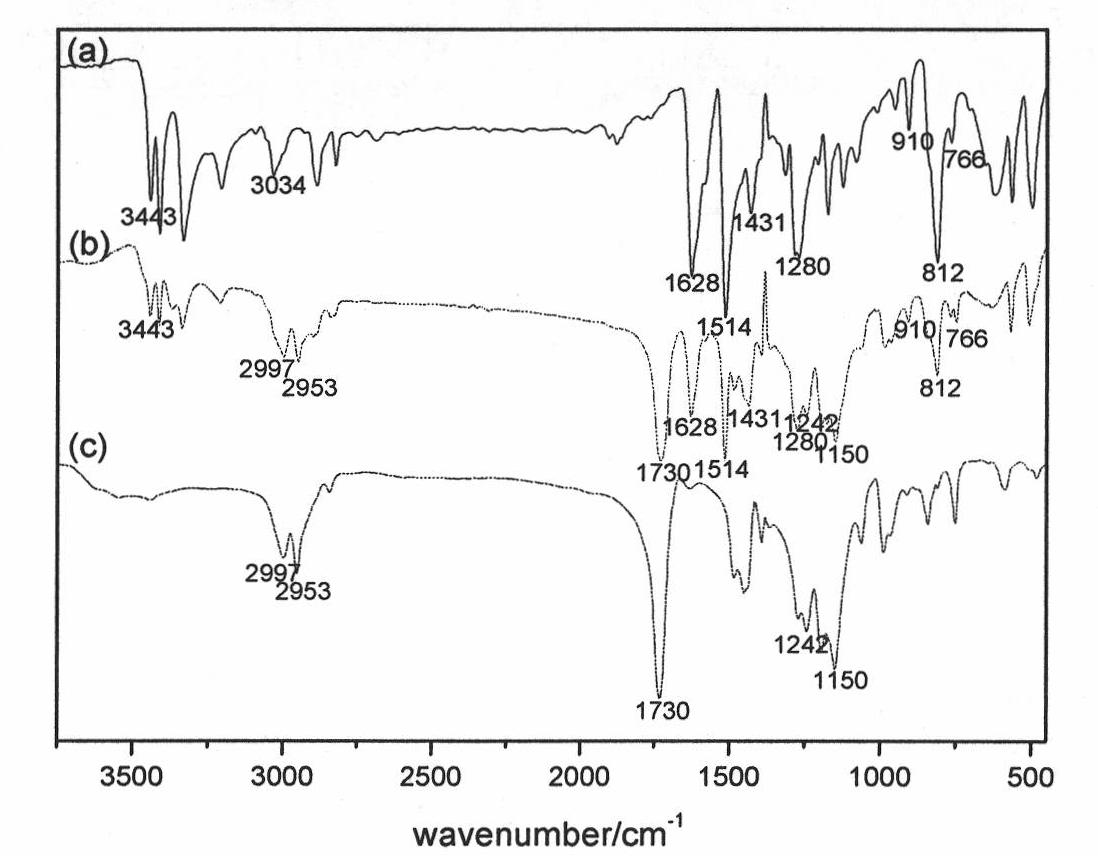

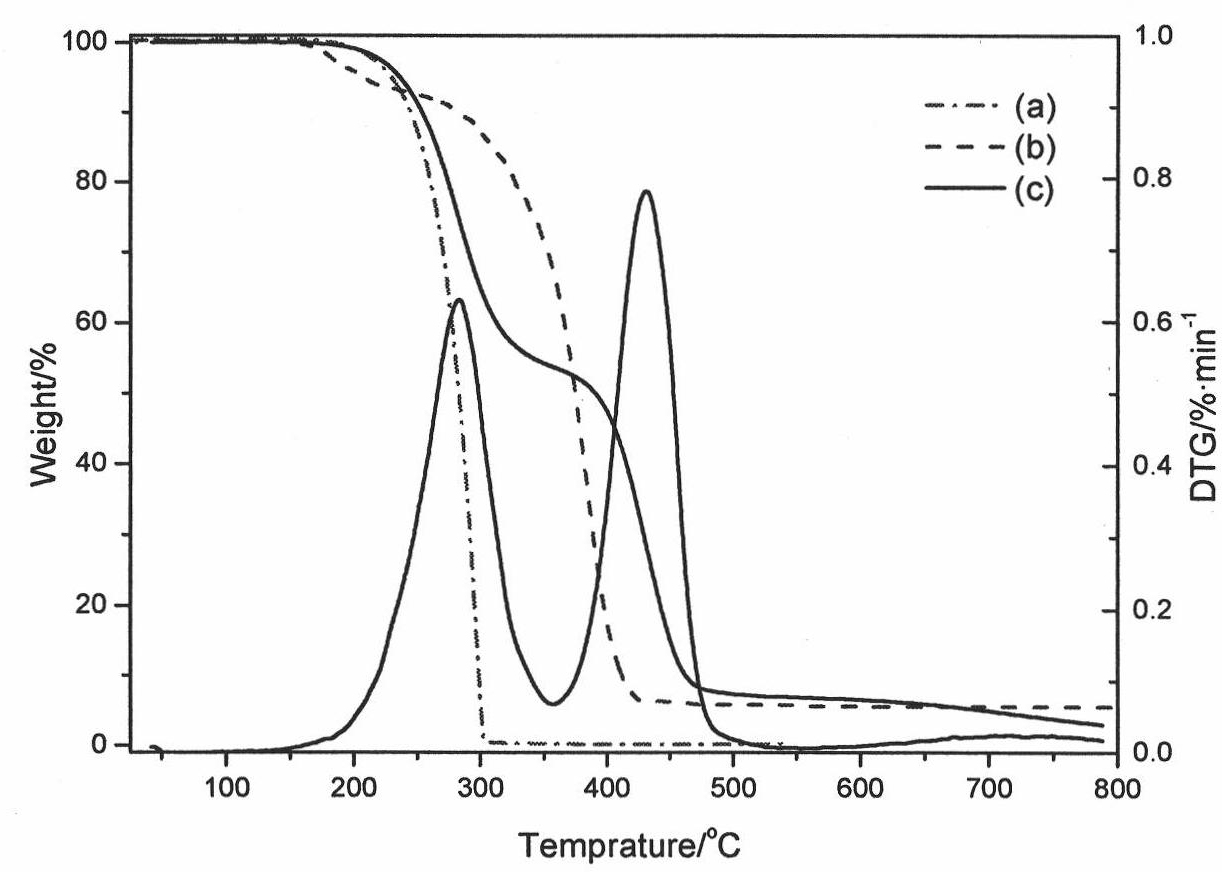

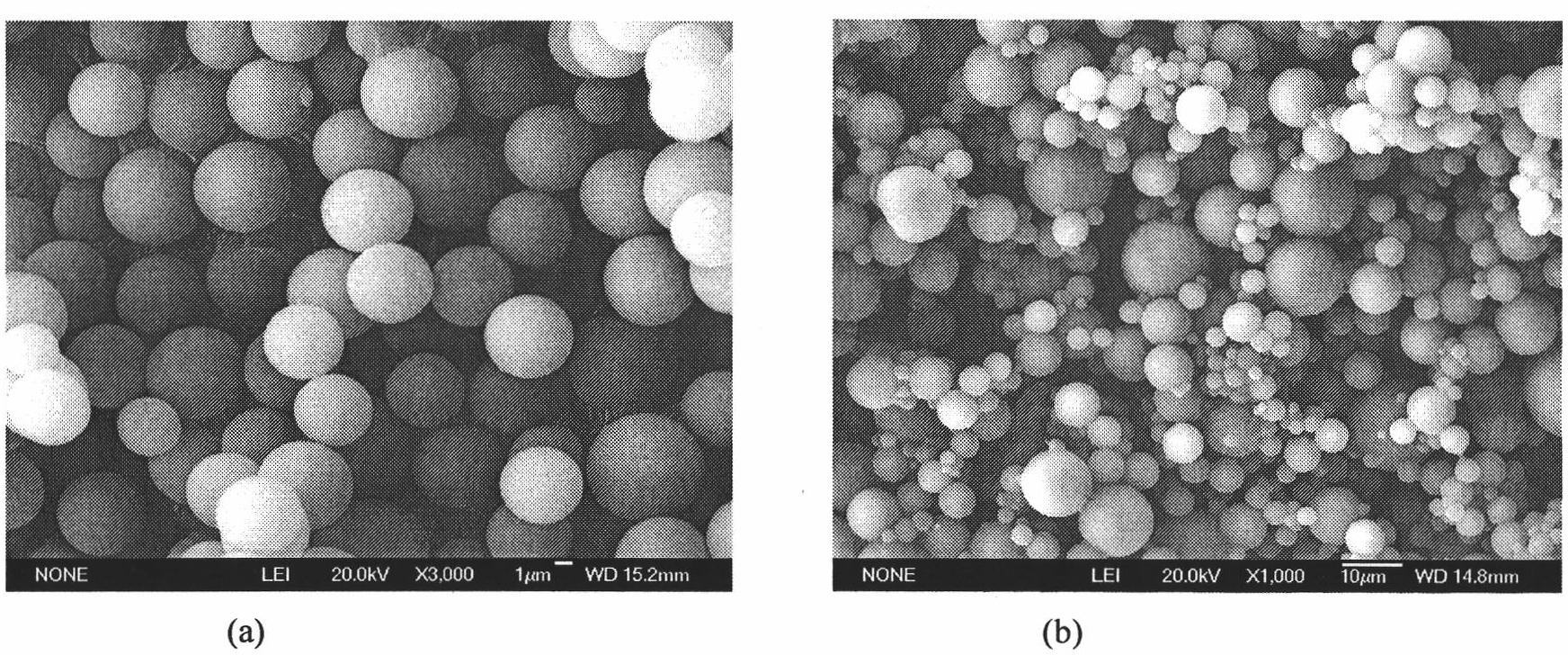

Latent microcapsule curing agent initiating thermosetting epoxy resin curing at medium temperature and preparation method of adhesive thereof

InactiveCN102423673AHigh core contentFlat surfaceMicroballoon preparationMicrocapsule preparationEpoxyMicrosphere

The invention relates to a latent microcapsule curing agent initiating thermosetting epoxy resin curing at medium temperature and a preparation method of an adhesive thereof. The latent microcapsule curing agent is technically characterized in that the high-activity medium temperature curing agent is taken as a core material, thermoplastic high polymer microspheres are taken as a wall material, the solvent evaporation technology is adopted for preparing the latent microcapsule curing agent with better curing performance and latent performance, and the latent microcapsule curing agent can be applied to an epoxy resin system for preparing the single-component medium temperature curing epoxy resin adhesive. Microcapsules prepared by the method are high in capsule core content, smooth in surfaces, narrow in particle size distribution and good in compatibility with matrix epoxy resin and can be better dispersed in the epoxy resin; and the prepared single component adhesive can realize curing at the medium temperature, the storage period at room temperature is longer and the tensile shear strength performance can be further improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

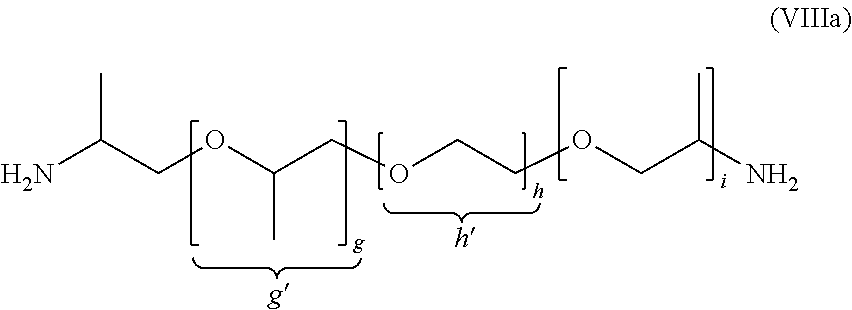

Amino group terminated impact strength modifier and use thereof in epoxy resin compositions

ActiveUS20130037213A1Efficiency and flexibilityHigh tensile shear strengthPolyureas/polyurethane adhesivesLaminationEpoxyUltimate tensile strength

The present disclosure relates to impact strength modifiers, the derivative products thereof, and the use thereof in producing two-component epoxy resin compositions. The disclosure in particular relates to amino group terminated impact strength modifiers prepared by reacting a polyurethane prepolymer having isocyanate groups, a primary diamine, and optionally at least one Michael acceptor. The two-component epoxy resin compositions thus formulated are characterized by a great increase in impact strength while retaining an acceptable tensile shear strength. The impact strength modifiers according to the disclosure and the epoxy resin compositions comprising same are in particular suitable for vehicle manufacturing.

Owner:SIKA TECH AG

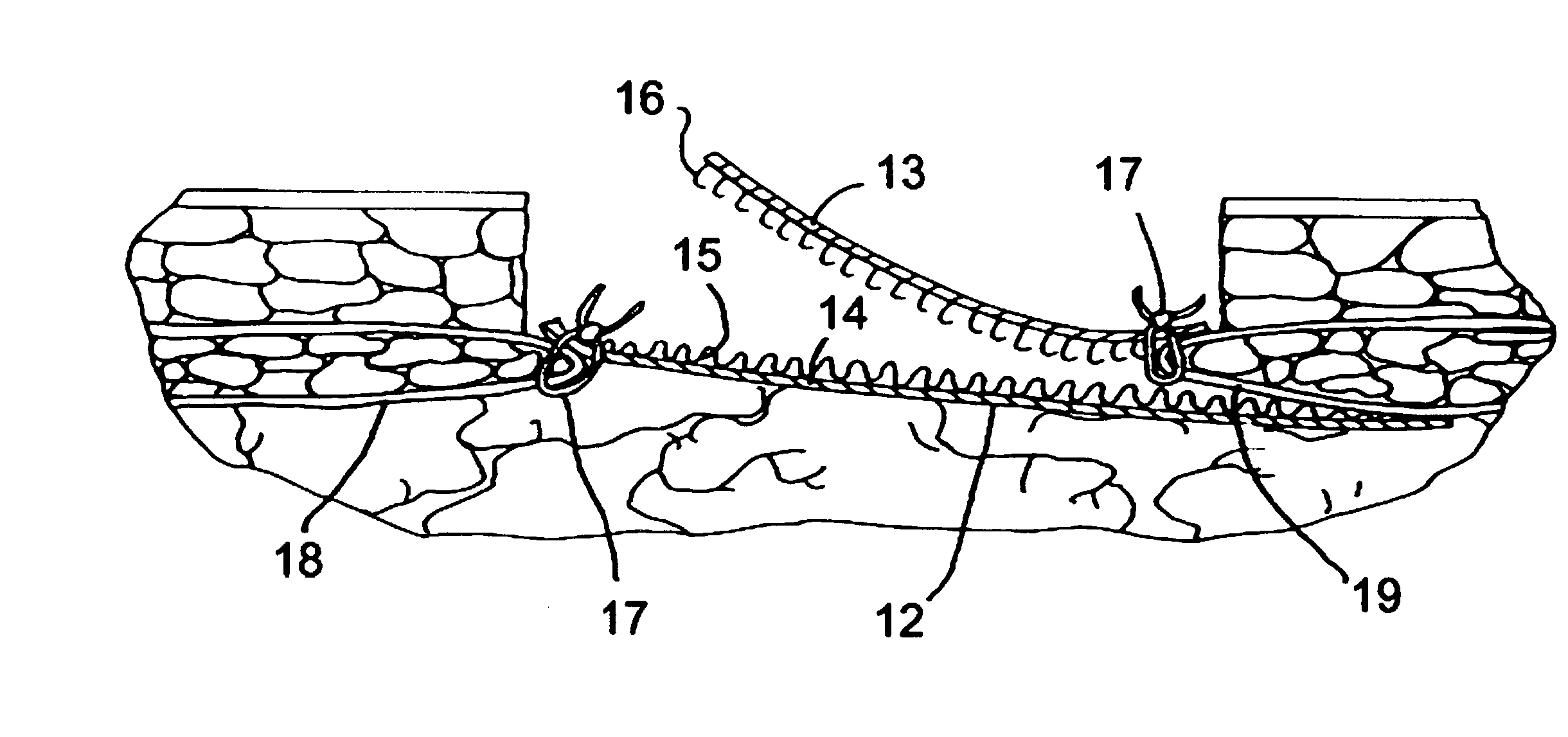

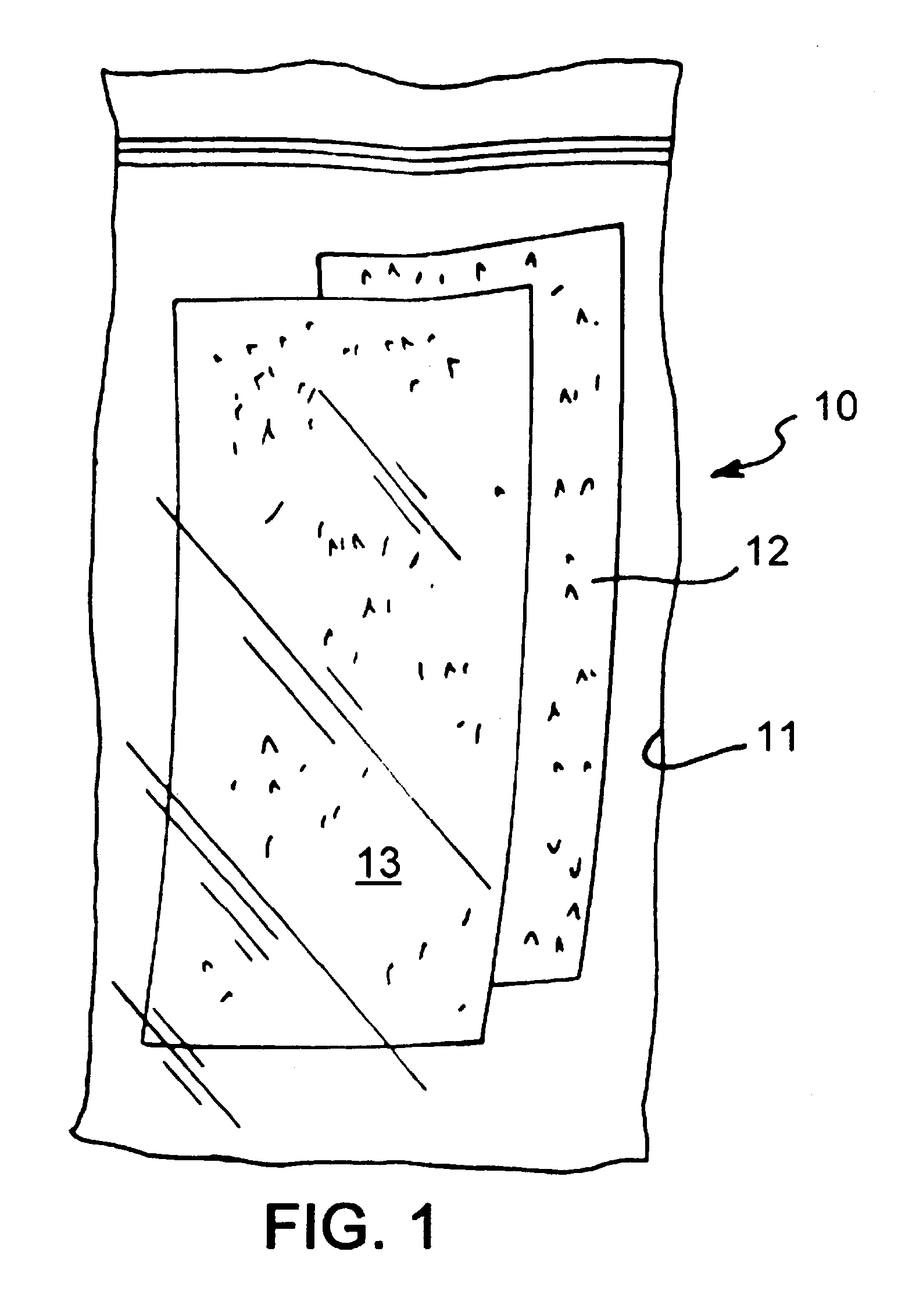

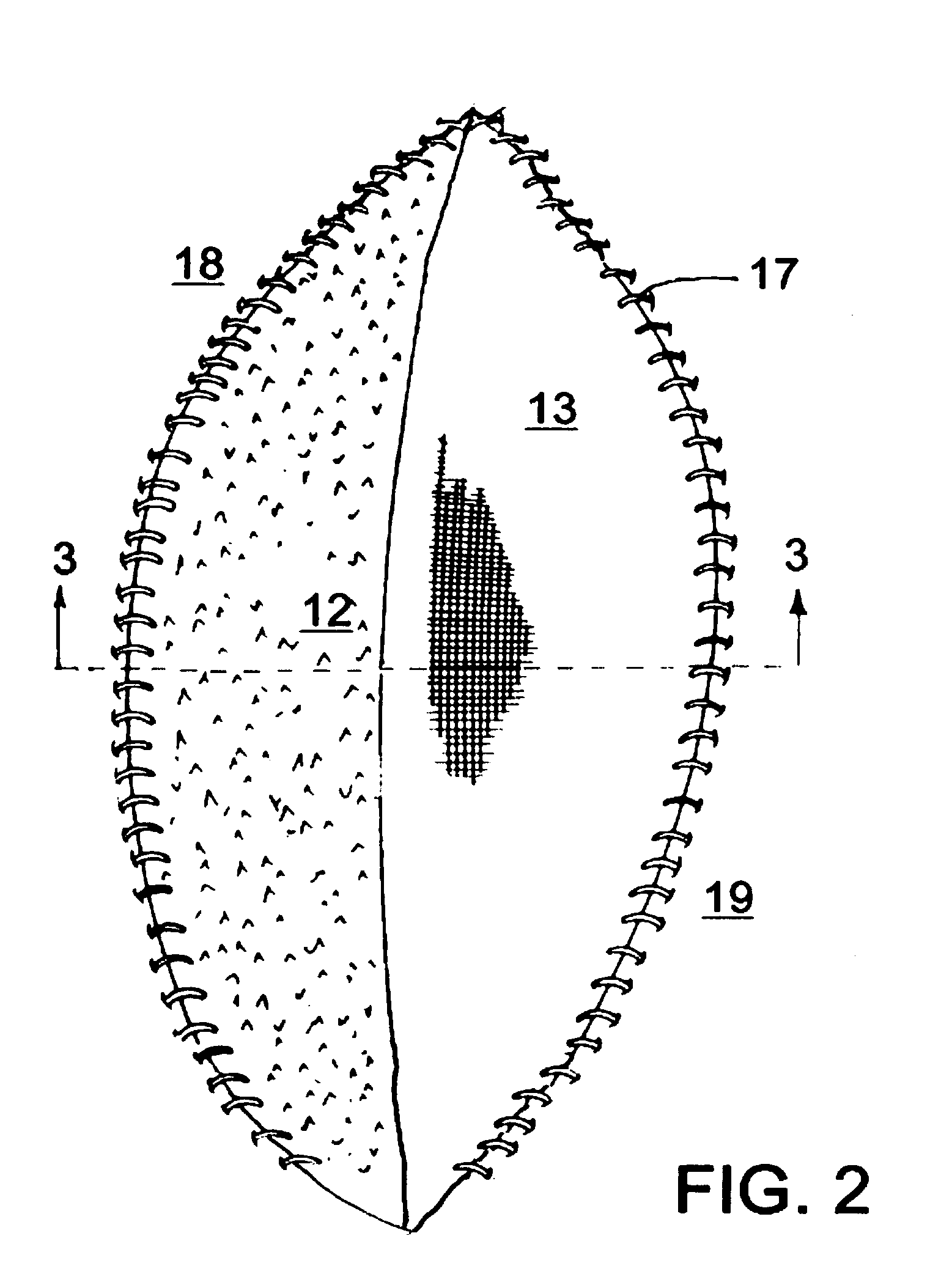

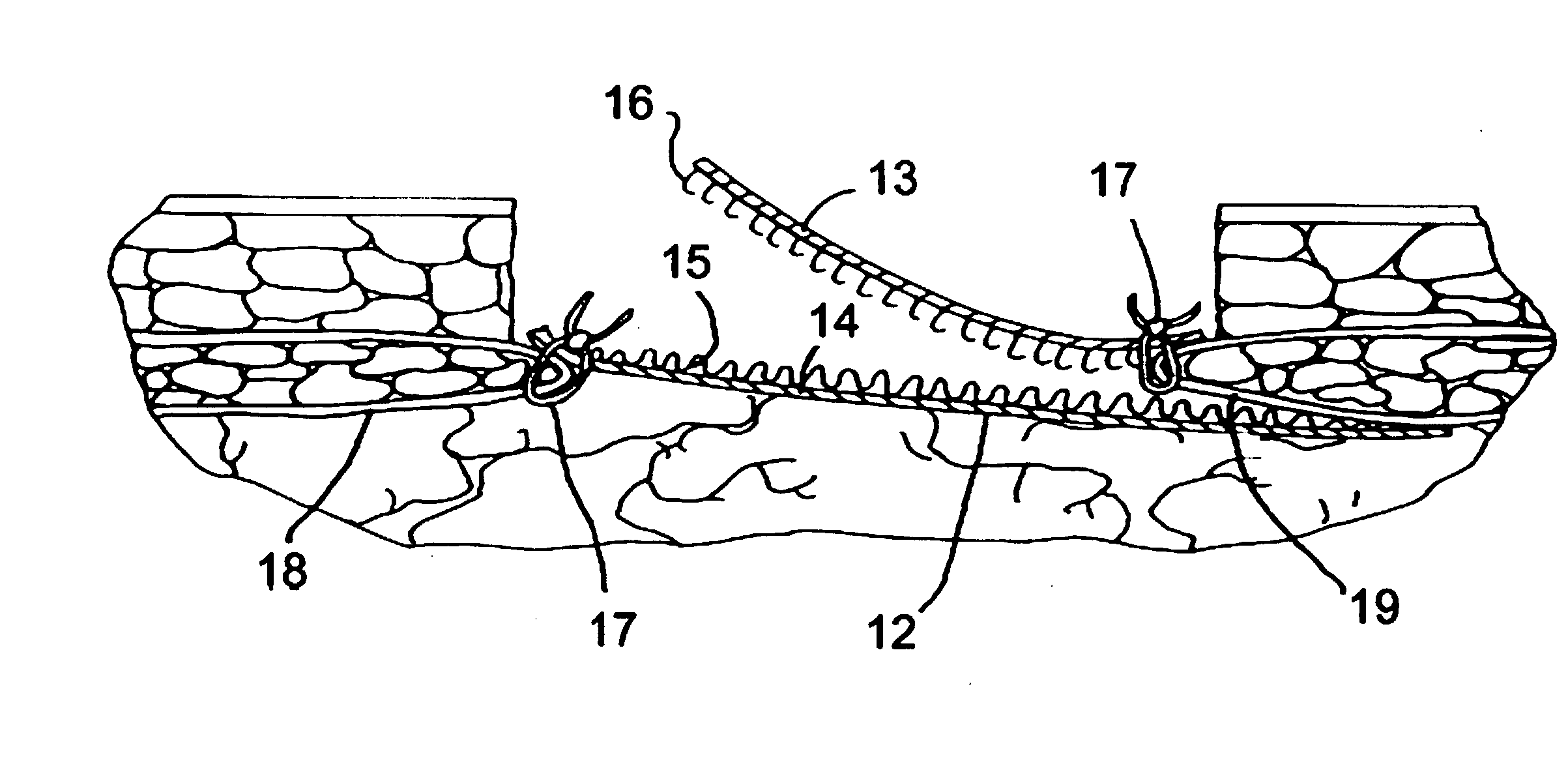

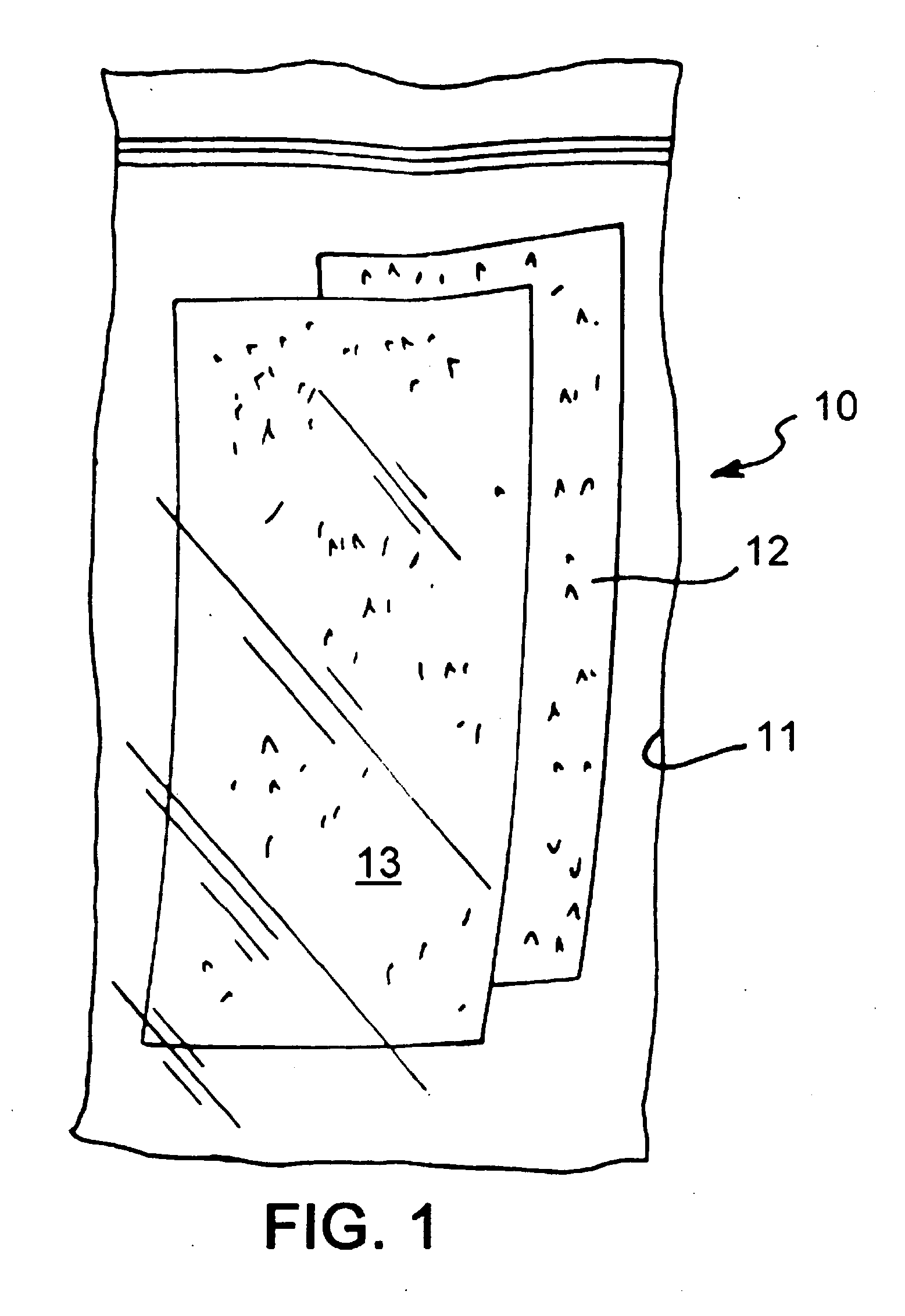

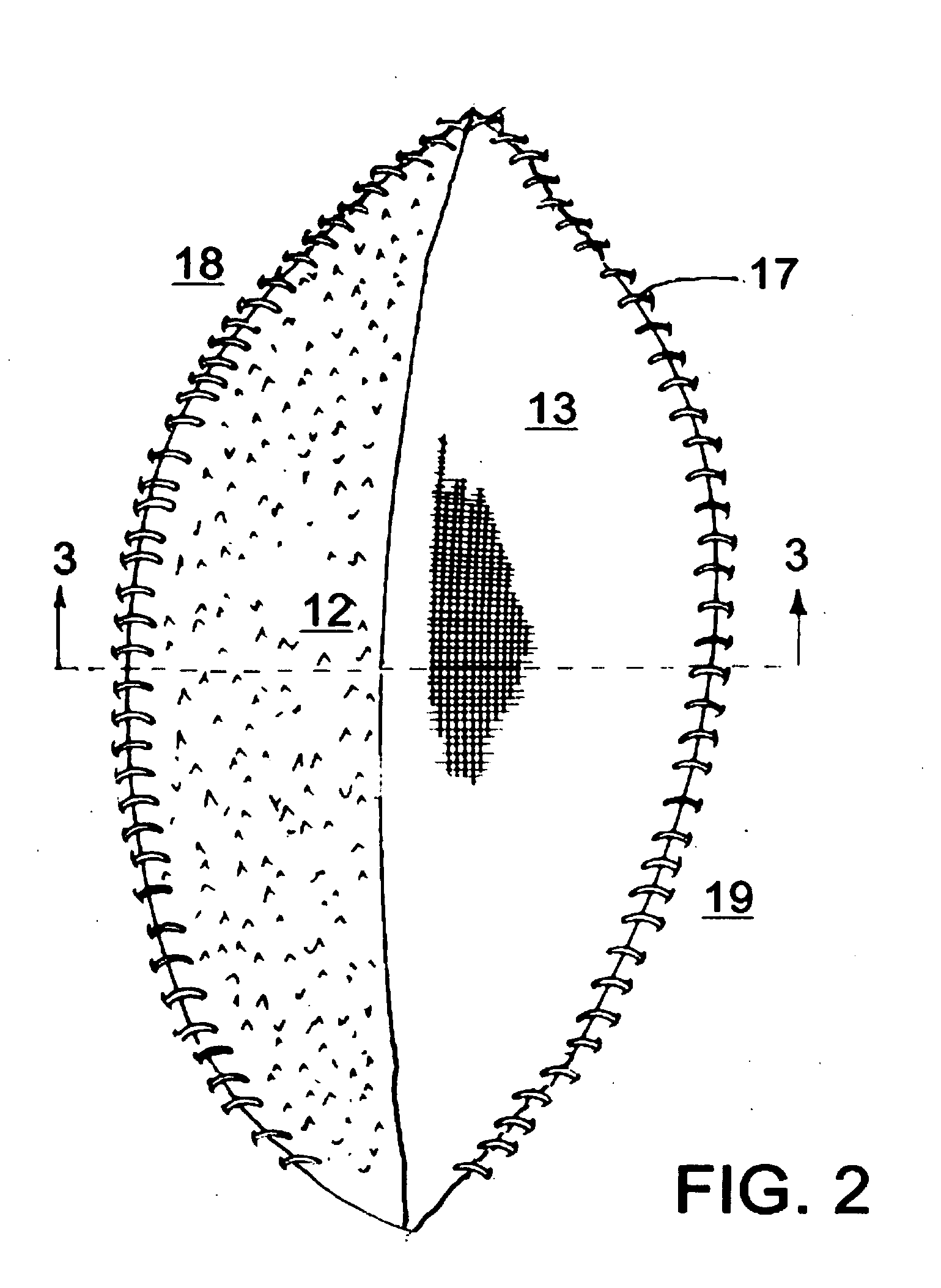

Prosthesis and method for lowering abdominal pressure

InactiveUS7662169B2Simple and effective and improvedIncrease pressureSuture equipmentsSnap fastenersBiocompatibility TestingOrgan system

A two-sheet fascial expander prosthesis for temporary use and method of using it to treat abdominal hypertension and associated organ system function impairment, in which each flat sheet is attached to the fascia only at opposite sides of an incision. One side of each sheet is armed with mating fastening elements that bond when united to bring about high tensile shear strength and low tensile peeling-off resistance permitting easy separation for diagnostic and therapeutic abdominal entry. The invention is useful because it expands the fascia and adds compliance to the envelope of the abdominal cavity by bridging the gap between free borders of the incised fascia containing intra-abdominal organs without strangulating their blood supply and retaining some tension on the fascia to prevent retraction and bringing the edges closer together as healing progresses, and permitting final removal of the patch and fascia-to-fascia closure. The method of producing and testing biocompatibility of the two-sheet fascia prosthesis also is disclosed.

Owner:WITTMANN DIETMAR H

Inorganic/organic nano particle compound modification epoxy resin adhesive and preparation method thereof

InactiveCN103131374AImprove high temperature performanceEasy to prepareNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyResin adhesive

The invention relates to an inorganic / organic nano particle compound modification epoxy resin adhesive and a preparation method thereof, aiming at solving the problem that the existing toughened epoxy resin adhesive has low bonding strength at high temperature and poor high temperature aging performance. The preparation method comprises the following steps of: firstly preparing an epoxy resin component, and then preparing a curing agent component, thereby obtaining the inorganic / organic nano particle compound modification epoxy resin adhesive. When the adhesive is used, the epoxy resin component and the curing agent component are mixed uniformly at normal temperature, tensile shear strength of the adhesive at 150 DEG C can reach 10MPa-15MPa, the tensile shear strength of the adhesive at 250 DEG C still can reach 4MPa-5MPa, the bonding strength at high temperature is high, after ageing for 1000 hours at 150 DEG C, the retention rate of the tensile shear strength of the adhesive still can be above 80%, the high temperature ageing property of the adhesive is good, the preparation method of the adhesive is simple and is applicable to the fields of aviation, aerospace, mechanical automation, automobile and the like.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

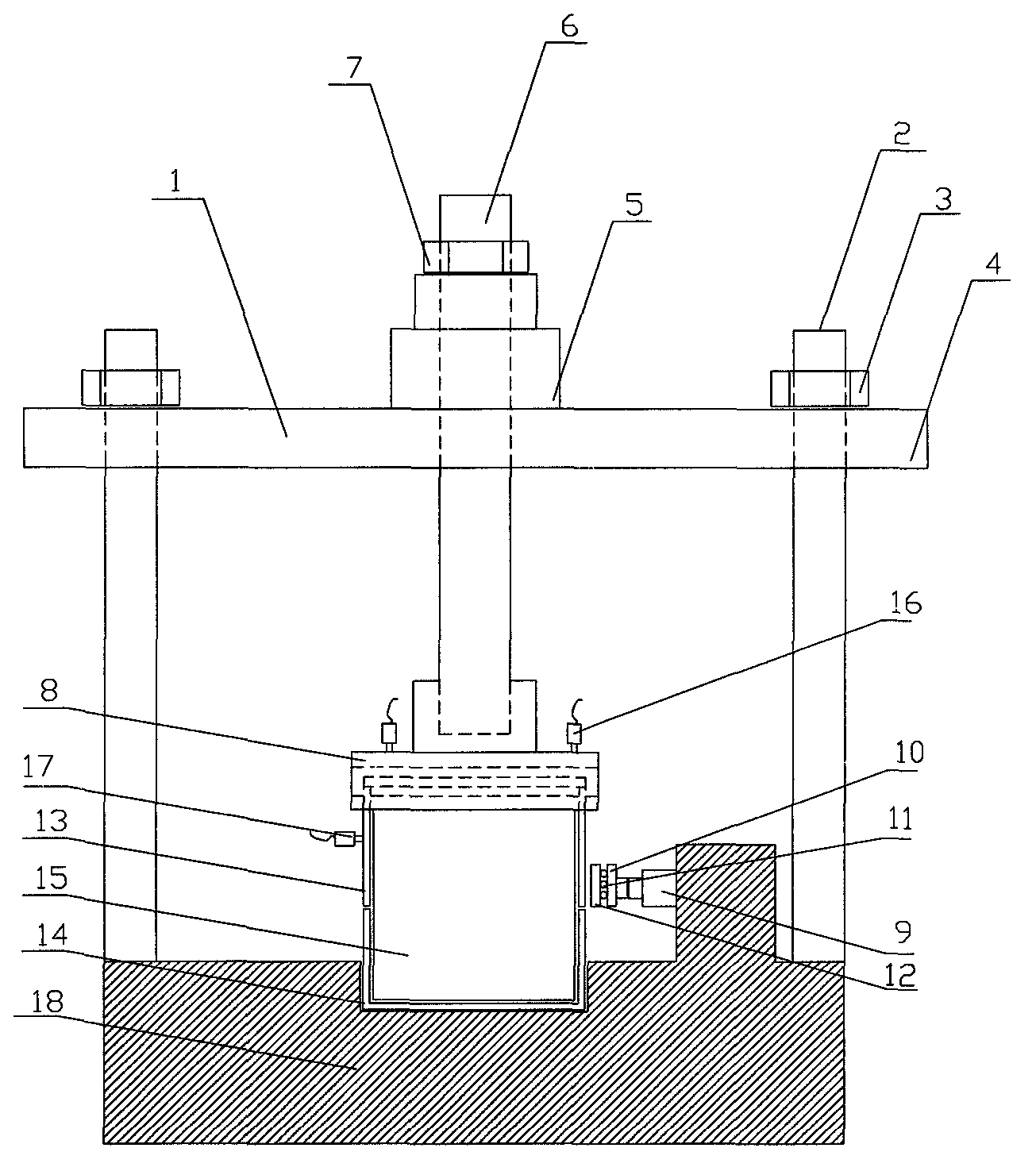

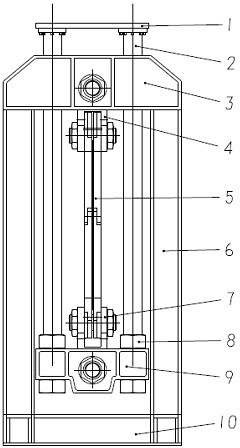

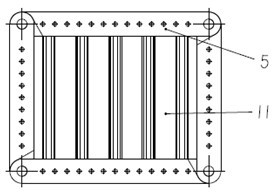

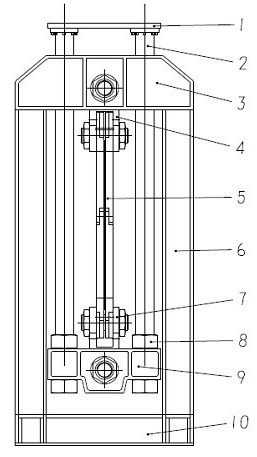

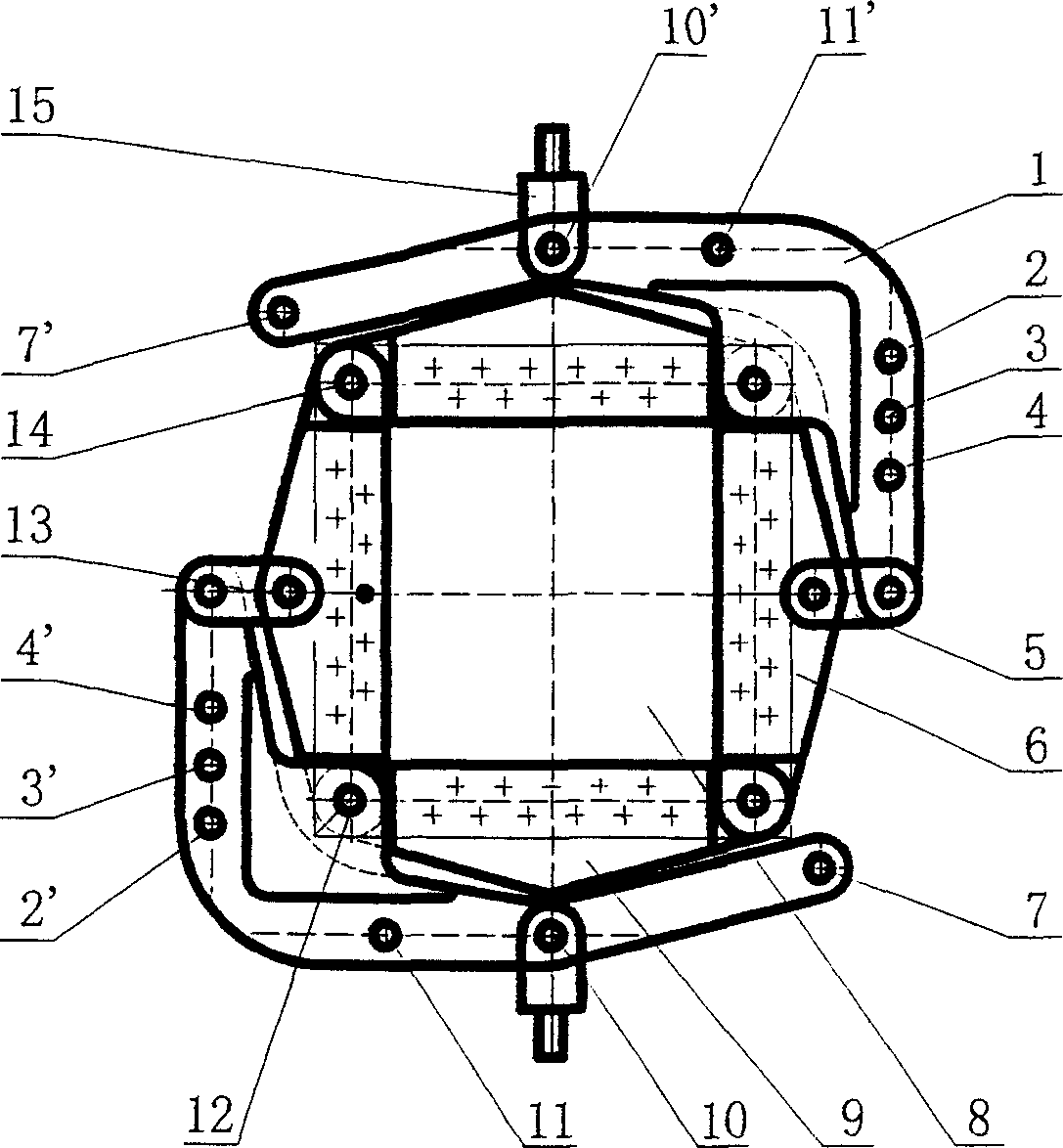

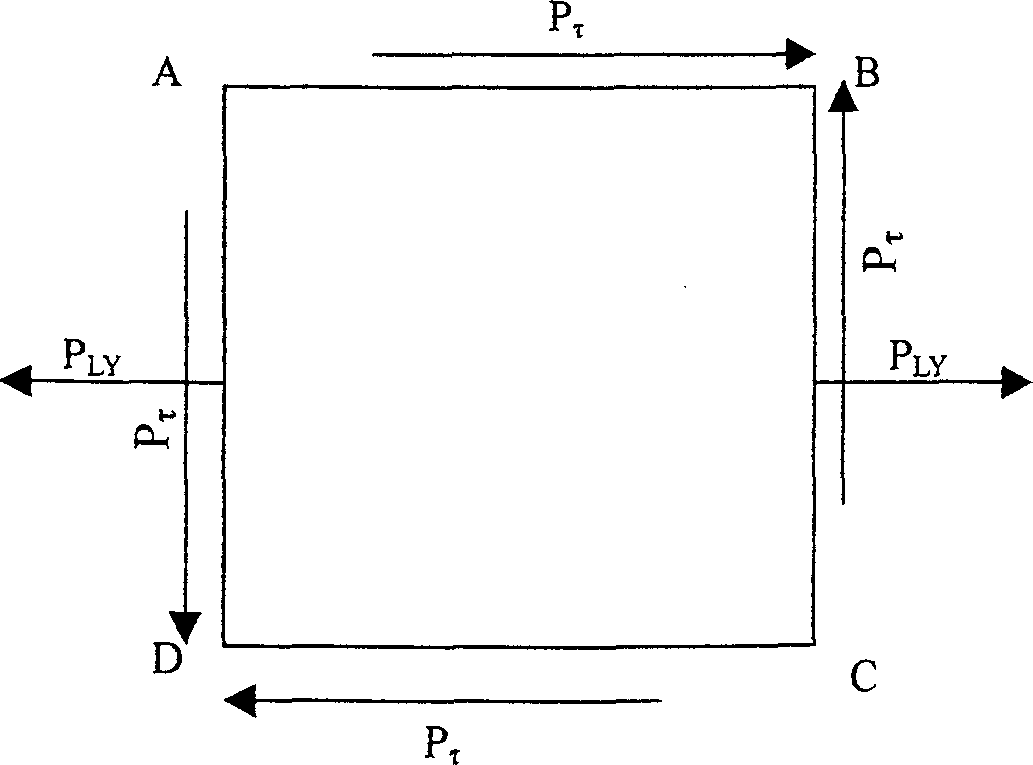

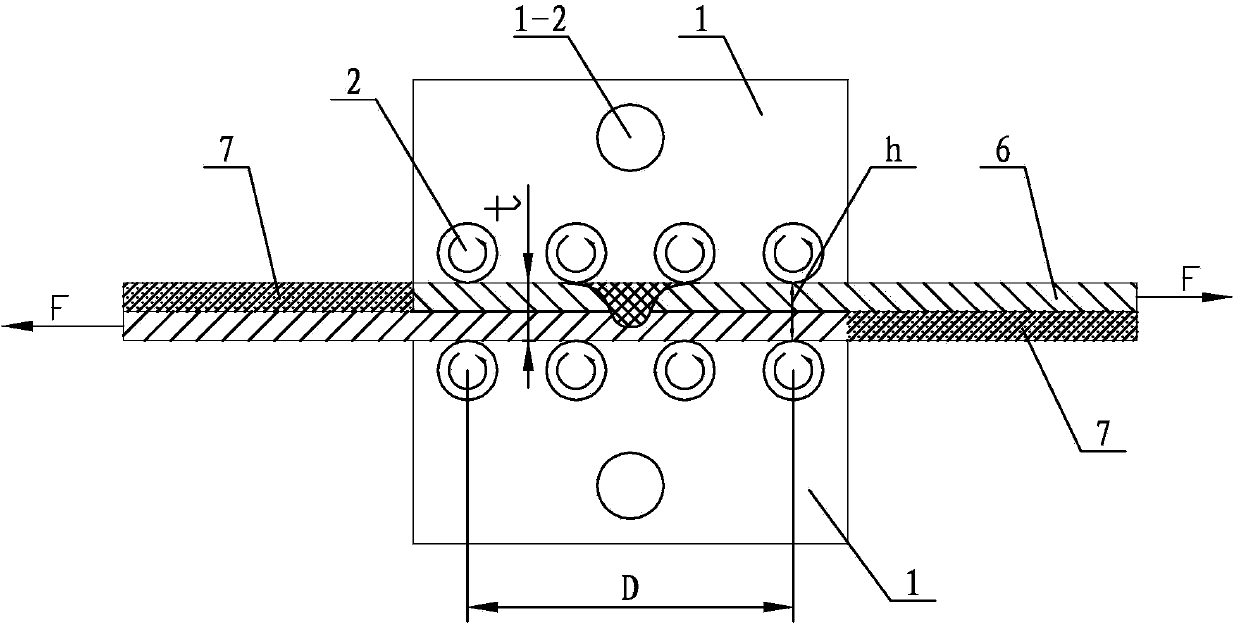

Rock tensile-shearing test system

ActiveCN103175738AGuaranteed free deformationImproving and Perfecting the Constitutive RelationsMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesNormal tensionRock sample

The invention relates to a tensile-shearing test system for rock experiments in mechanics and belongs to the technical field of geotechnical engineering. The test system comprises a counter-force device, a vertical load system, a horizontal load system, upper and lower shearing boxes, a measurement system and a base, wherein the vertical load system and the upper shearing box are connected through a tensile plate of which the lower end is provided with two guide slots. The direct shear test for the rock under different tensions can be performed; due to the assembled design of the upper and lower shearing boxes, the rock sample can be conveniently adhered and detached; due to the design mode of the tensile plate and the upper shearing box, free deformation of the rock in the horizontal direction under the horizontal thrust can be guaranteed, and the stability of the horizontal load system under the tensile action can be guaranteed according to the roller row which is arranged in the horizontal load direction. The current situation that the strength criterion of the rock can only be researched by employing the compression shear experimental mode at present is changed, the intensity parameters of the rock under the action of different normal tensions can be provided, and the constitutive relation of the rock under the shear-resistant stress is improved and perfected.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

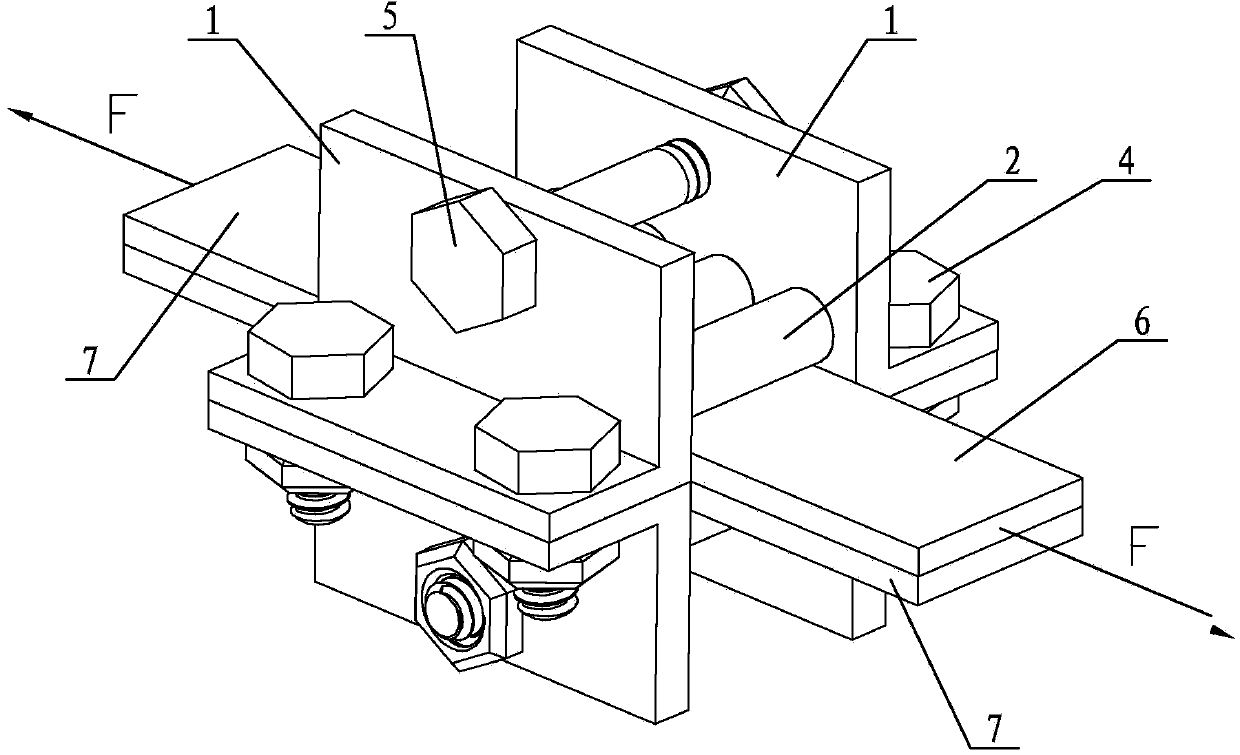

Tensile-shear test loading device with flight structure

InactiveCN102607940AAchieve shearMaterial strength using tensile/compressive forcesAviationEngineering

The invention relates to a test loading device, in particular to a tensile-shear test loading device with a flight structure. Compression bars are arranged between stand columns, the upper ends of the compression bars are extended to form an upper beam, a compression plate is arranged on the top ends of the stand columns, a lower beam is arranged on the bottom ends of the stand columns, an upper cross type joint is arranged between the compression bars on the bottom end of the upper beam, a lower cross type joint is arranged on the upper end of the lower beam between the compression bars; and a fixture is arranged between the upper cross type joint and the lower cross type joint. The test loading device provided by the invention can be used for converting pressure of a compression tester into tensile of a test piece or realizing shear force of the test piece through the action of the fixture, and can be used for a tensile or shear test of stiffened wall plates and similar structures without being provided with a special large loading tensile testing machine independently.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

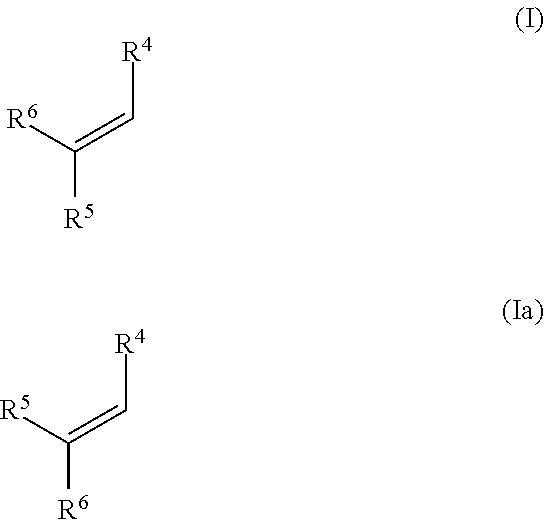

Cross-linkable materials based on organyl oxysilane-terminated polymers

ActiveUS20140155545A1Improve responseEasy to produceFilm/foil adhesivesPolyureas/polyurethane adhesivesAdhesiveAlkoxy group

Moisture curable adhesives of high tensile shear strength contain an alkoxysilyl-terminated polymer and an alkoxy-functional silicone resin.

Owner:WACKER CHEM GMBH

Preparation of solidification type dead burning structure glue in low-temperature and humidity surroundings

InactiveCN101314706ALow viscosityEasy curingNon-macromolecular adhesive additivesEpoxy resin adhesivesCompressive strengthUltimate tensile strength

A method for preparing steel-bonding structural adhesive curable in low-temperature and humid environment comprises the following steps: preparing a component A; preparing a component B; and mixing the component A with the component B at a weight ratio of 1:(0.3 to 0.5) to obtain the steel-bonding structural adhesive curable in low-temperature and wet environment. The steel-bonding structural adhesive can fully meet the requirement for steel-bonding construction in the environment with a temperature of subzero 10 to 0 DEG C and a relative humidity larger than 65 percent. A test shows that, 168 hours after the curing, the compressive strength of the adhesive is equal to or larger than 65 MPa, steel-steel tensile shear strength is equal to or larger than 15 MPa, steel-steel adhesion tensile strength is equal to or larger than 33 MPa, and the normal tensile bonding strength with concrete is equal to or larger than 2.5 MPa.

Owner:镇江市天益工程科技有限公司

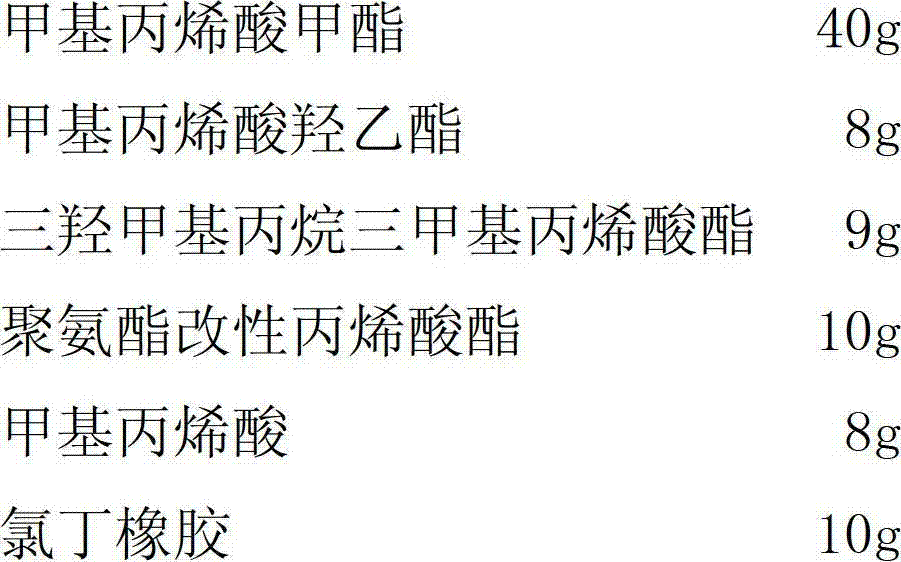

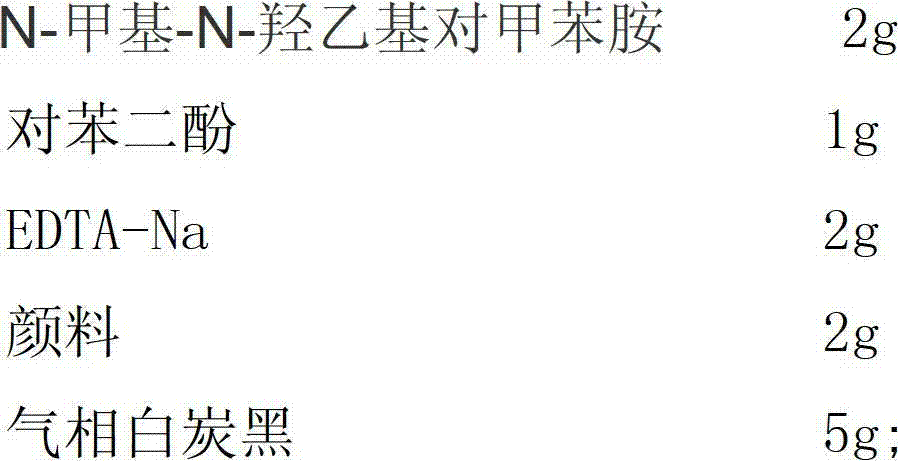

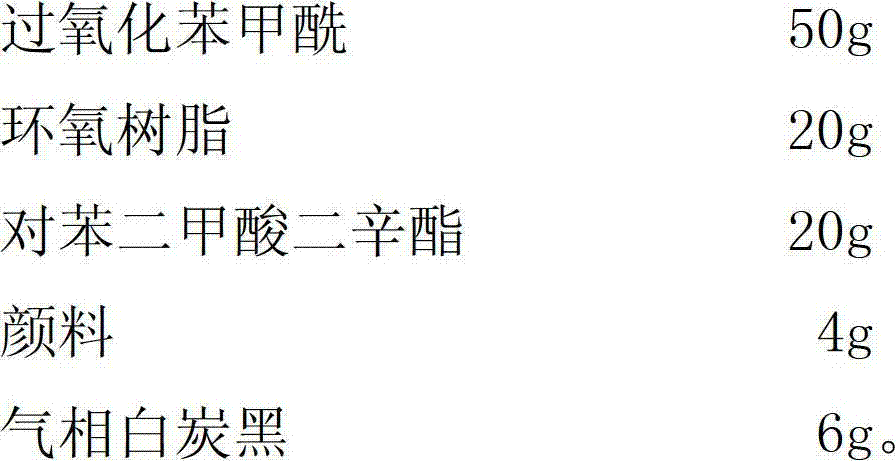

Acrylate structure adhesive and preparation method thereof

The invention discloses a novel acrylate structure adhesive and a preparation method thereof. The two-component acrylate structure adhesive comprises components A and B, wherein the volume ratio of the component A to the component B is (10-2):1; the component A comprises 55 to 75 parts of acrylate monomer, 0 to 25 parts of toughening agent, 10 to 35 parts of oligomer, 0.1 to 5 parts of reducing agent, 0.1 to 2 parts of stabilizer, and 0.1 to 10 parts of aids; and the component B comprises 15 to 50 parts of oxidant, 15 to 25 parts of toughening agent, 15 to 50 parts of plasticizer, and 0.1 to 10 parts of aids. Compared with the conventional acrylate adhesive (SGA), the novel acrylate structure adhesive prepared by the method has the advantages that under the condition of guaranteeing the same tensile shear strength, the elongation at break is over 30%, which is much higher than the 5% of elongation at break of common acrylate adhesives available in the market.

Owner:康达新材料(集团)股份有限公司

Bi-component acrylic ester adhesive

InactiveCN101392153AHigh viscosityImprove thixotropyOrganic non-macromolecular adhesiveElastomerAdhesive

The invention relates to the technical filed of acrylate adhesives. A bi-component acrylate adhesive comprises two components of A and B with equal proportion, wherein, the component A comprises the following components calculated by mass percentage: (a) 40 percent to 80 percent of acrylate monomer comprising at least one vinyl; (b) 0 percent to 20 percent of methacrylic acid; (c) 0 percent to 50 percent of prepolymer; (d) 0 percent to 40 percent of elastomer; (e) 0 percent to 40 percent of toughened resin; (f) 0.01 percent to 3 percent of stabilizer; (g) 0 percent to 5 percent of thixotropic agent; and (h) 1 percent to 5 percent of peroxide; and the component B comprises the following components calculated by mass percentage: (a) 50 percent to 90 percent of acrylate monomer comprising at least one vinyl; (b) 0 percent to 10 percent of methacrylic acid; (c) 0 percent to 40 percent of elastomer; (d) 0 percent to 50 percent of prepolymer; (e) 0 percent to 40 percent of toughened resin; (f) 0 percent to 5 percent of thixotropic agent; and (g) 1 percent to 10 percent of accelerant. The adhesive has higher viscosity, larger thixotropic index, and good tensile-shear strength and shearing-impact strength, thereby being convenient for application when in use and not easy to flow after application, and meeting the adhesive requirements and effects of elevation or places with larger gaps.

Owner:GUANGDONG HENGDA NEW MATERIALS TECH

Prosthesis and method for lowering abdominal pressure

InactiveUS20040221431A1Minimum tensionSnap fastenersSuture equipmentsAbdominal cavityBiocompatibility Testing

A two-sheet fascial expander prosthesis for temporary use and method of using it to treat abdominal hypertension and associated organ system function impairment, in which each flat sheet is attached to the fascia only at opposite sides of an incision. One side of each sheet is armed with mating fastening elements that bond when united to bring about high tensile shear strength and low tensile peeling-off resistance permitting easy separation for diagnostic and therapeutic abdominal entry. The invention is useful because it expands the fascia and adds compliance to the envelope of the abdominal cavity by bridging the gap between free borders of the incised fascia containing intra-abdominal organs without strangulating their blood supply and retaining some tension on the fascia to prevent retraction and bringing the edges closer together as healing progresses, and permitting final removal of the patch and fascia-to-fascia closure. The method of producing and testing biocompatibility of the two-sheet fascia prosthesis also is disclosed.

Owner:WITTMANN DIETMAR H

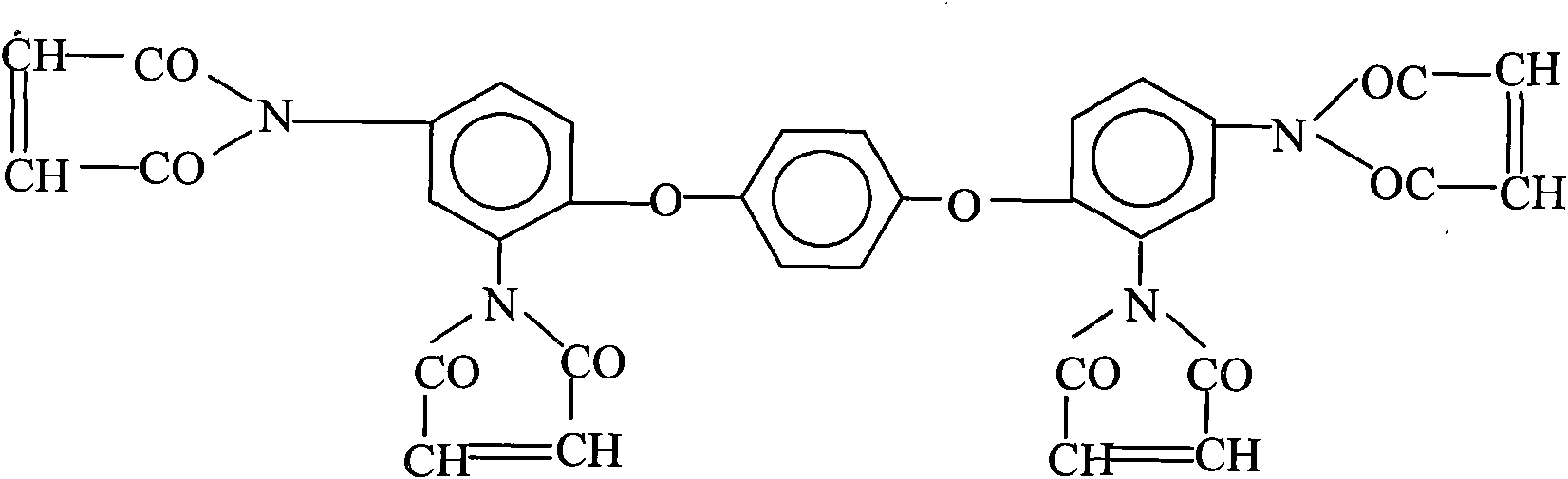

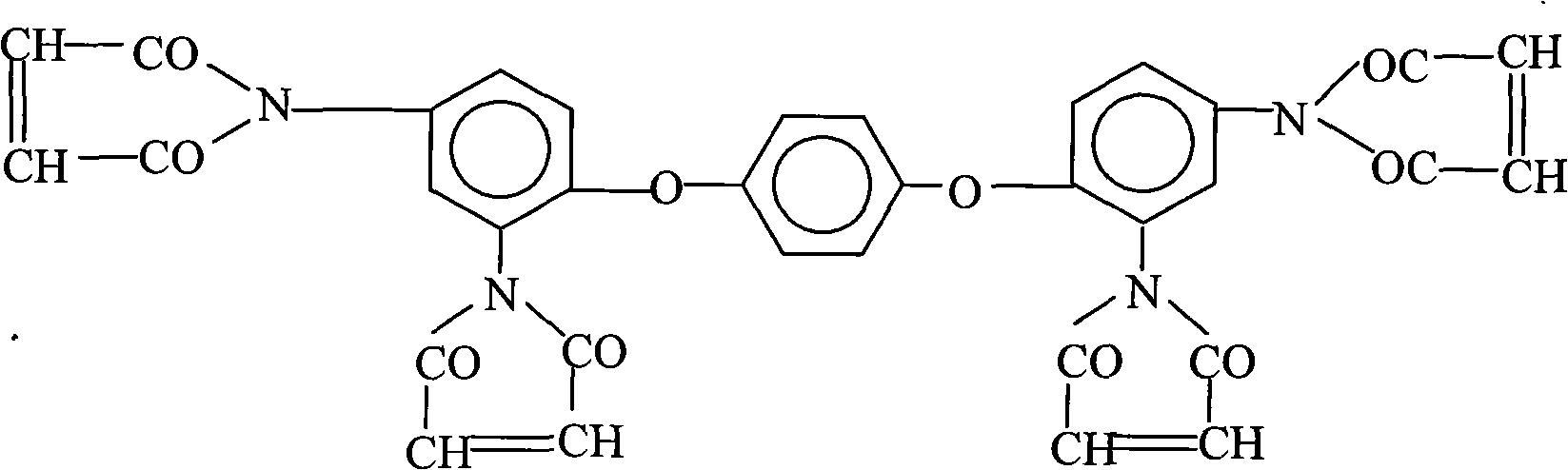

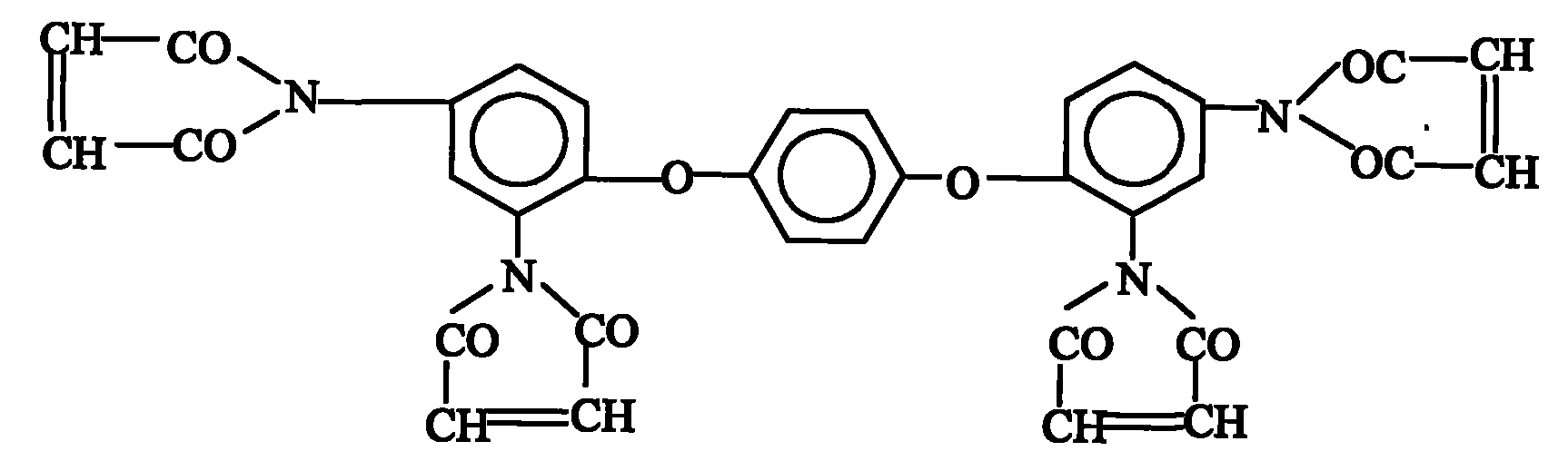

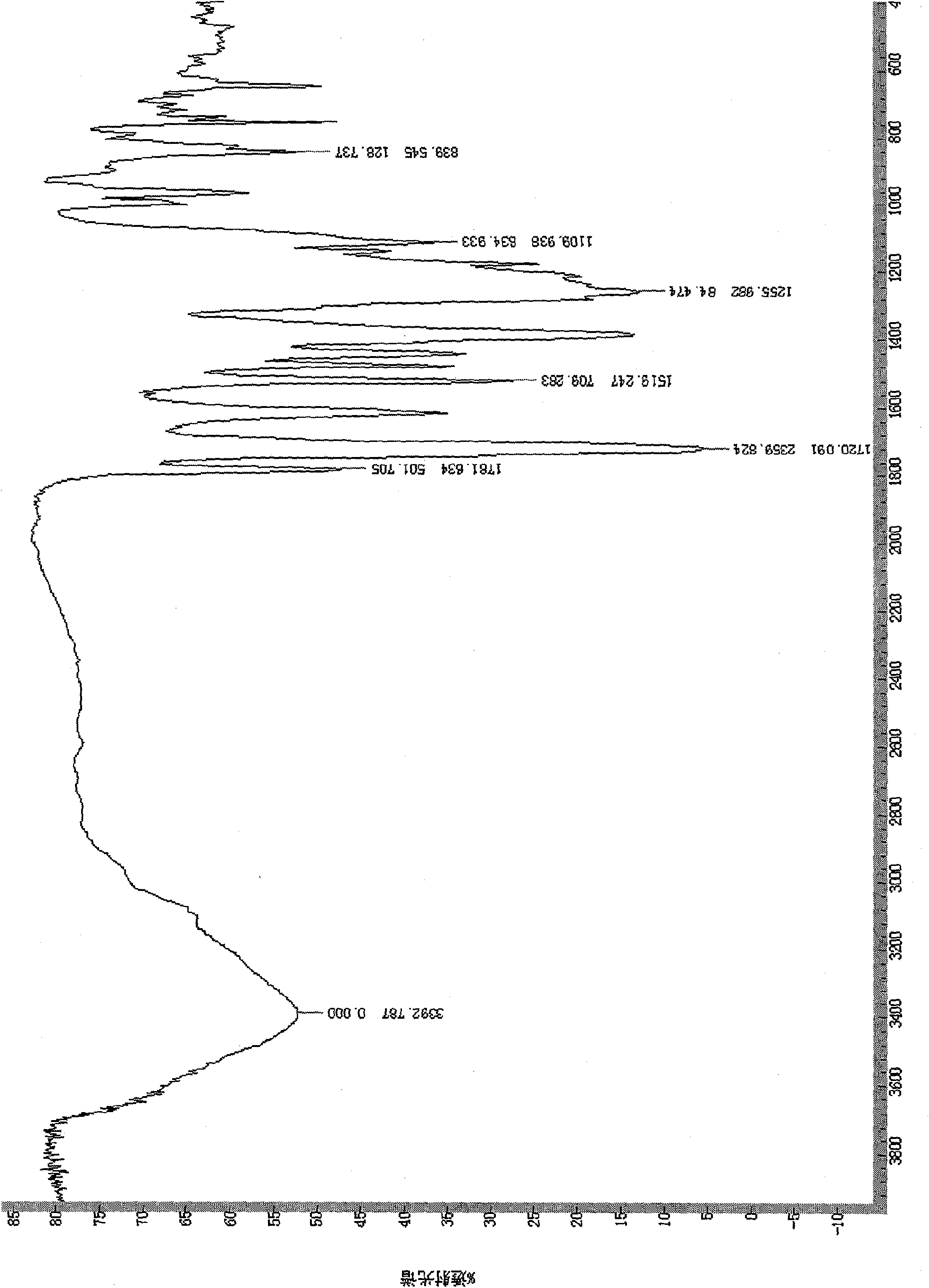

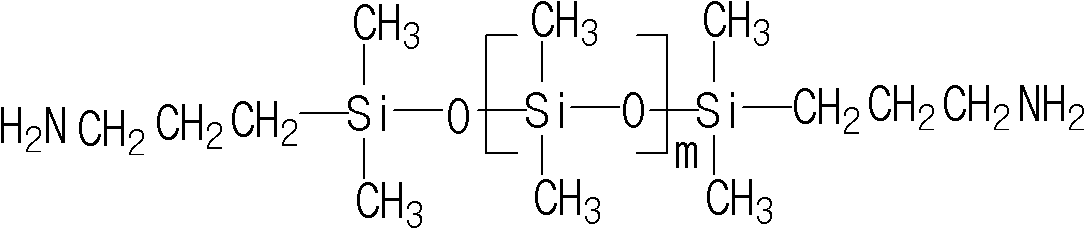

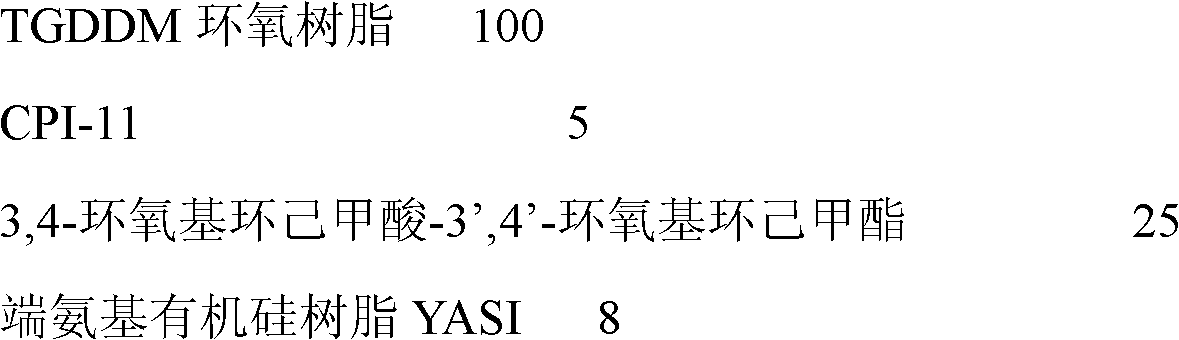

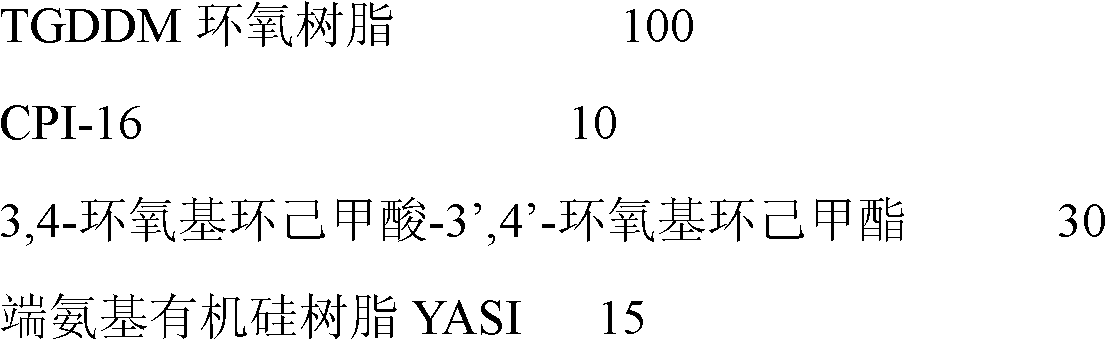

Organosilicone-epoxy-polyimide adhesive and preparation method thereof

InactiveCN102618200AImprove heat resistanceHigh tensile shear strengthEpoxy resin adhesivesEpoxyAdhesive

The invention relates to an organosilicon-epoxy-polyimide adhesive and a preparation method thereof. The organosilicon-epoxy-polyimide adhesive includes A component and B component, the A component is prepared by N, N', N'-quadri-glycidyl-4, 4'-diaminodiphenyl methane epoxy resin, carboxyl polyimide resin, alicylic epoxy resin and amino-terminated organosilicone, the B component is prepared by 2, 2-bi(4-(2,4-diaminobenzene epoxide) phenyl) propane. The preparation method of the organosilicon-epoxy-polyimide adhesive includes: only mixing the A component and the B component uniformly when in use. The organosilicone-epoxy-polyimide adhesive is fine in heatproof performance, simple in preparation process and free of solvent and has environment protection effect, and tensile shearing strength is up to 31.2MPa.

Owner:DONGHUA UNIV +1

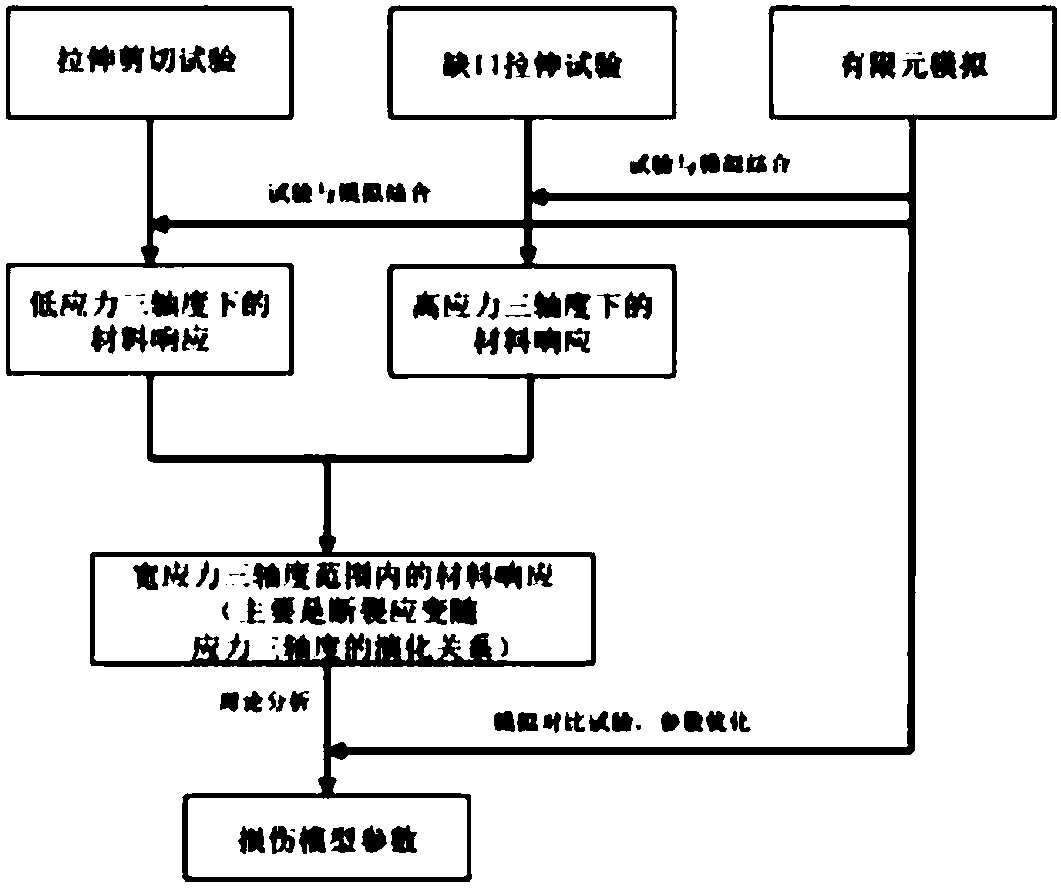

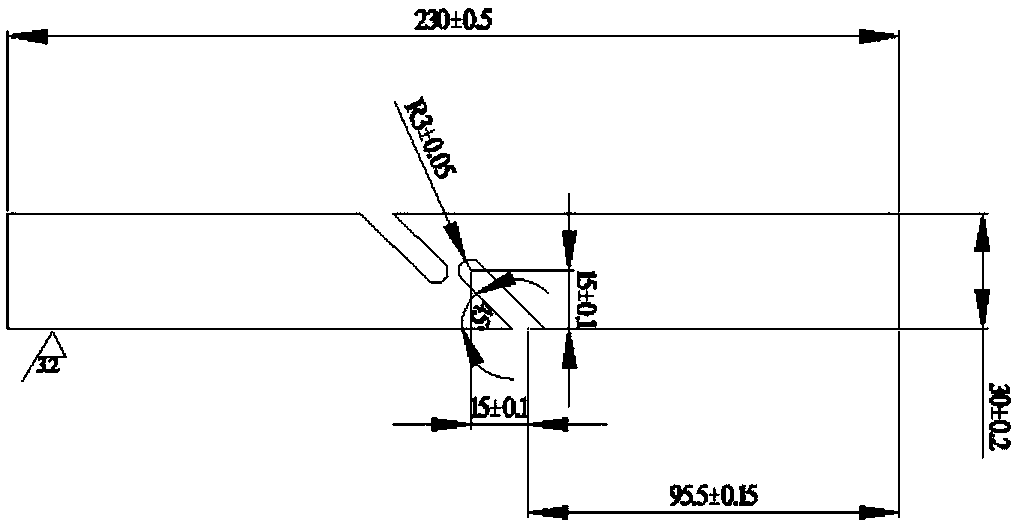

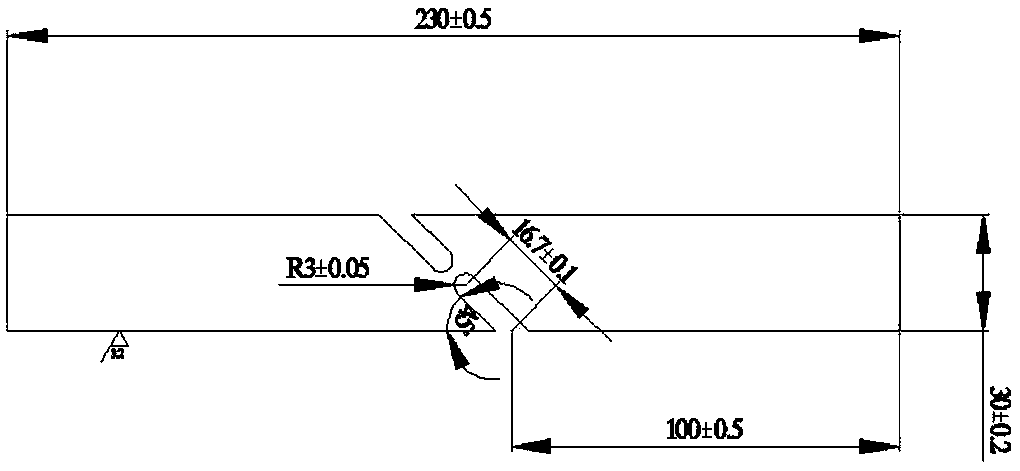

Damage model parameter calibration method based on tensile shear and notch tension tests

InactiveCN107655768AImprove calibration accuracyPrevent buildupDesign optimisation/simulationMaterial strength using steady shearing forcesShear stressStress–strain curve

The invention relates to the field of damage model parameter calibration and discloses a damage model parameter calibration method based on tensile shear and notch tension tests. The method includes:using a special-shaped tensile shear sample to convert uniaxial tensile load into pure shear load, and acquiring the shear stress-strain curve of a material under low stress triaxiality; using the notch tension test to convert uniaxial tension into triaxial tension, and acquiring the triaxial tension stress-strain curve of the material under high stress triaxiality; using full-size finite elementsimulation to acquire the precise stress-strain curve of the material in a wide stress triaxiality range and the evolutionary relationship of the fracture strain along with the stress triaxiality to provide a test foundation for damage model parameter calibration. By the method, workload can be reduced, and parameter calibration precision can be increased greatly.

Owner:CRRC QINGDAO SIFANG CO LTD

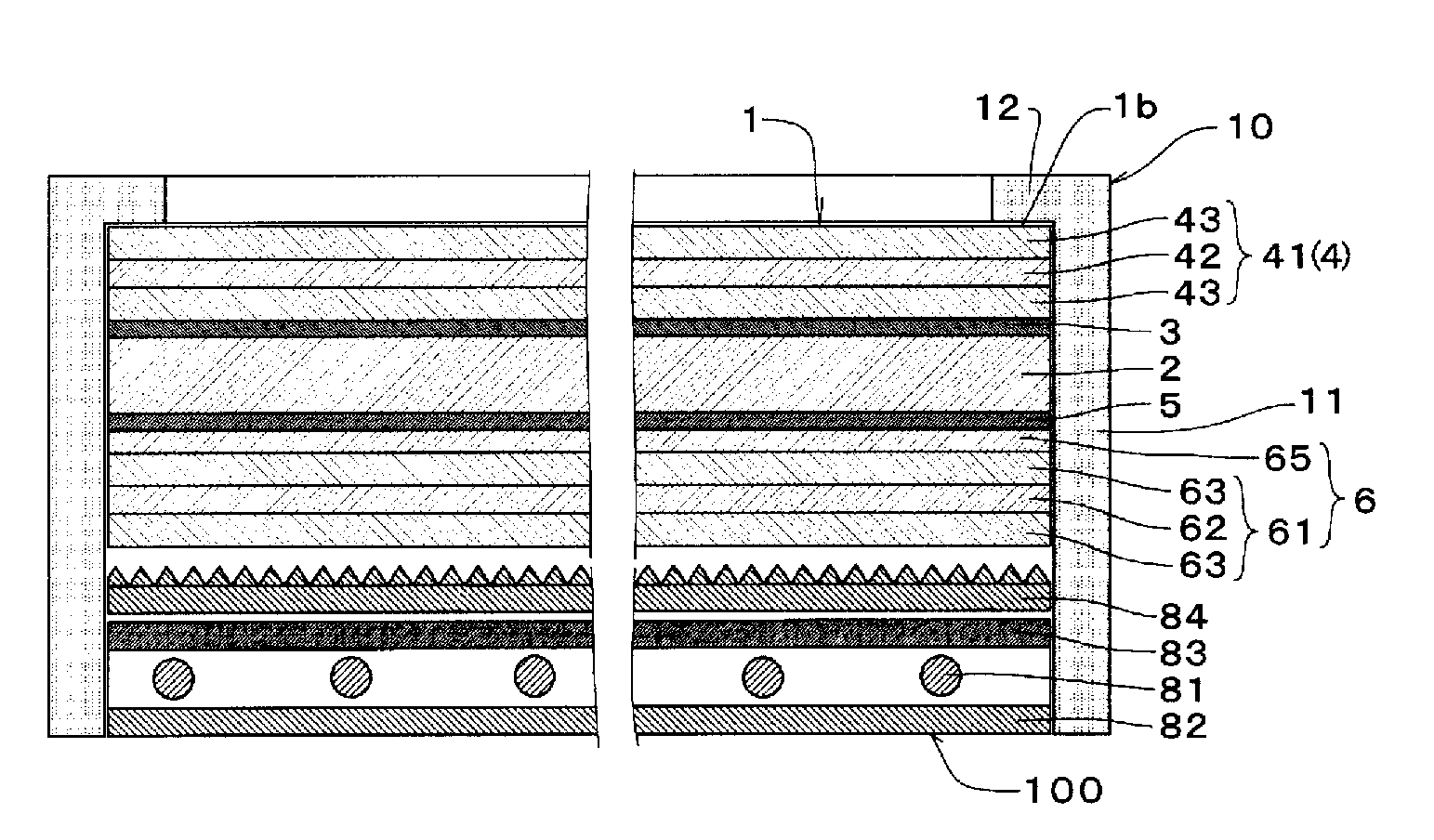

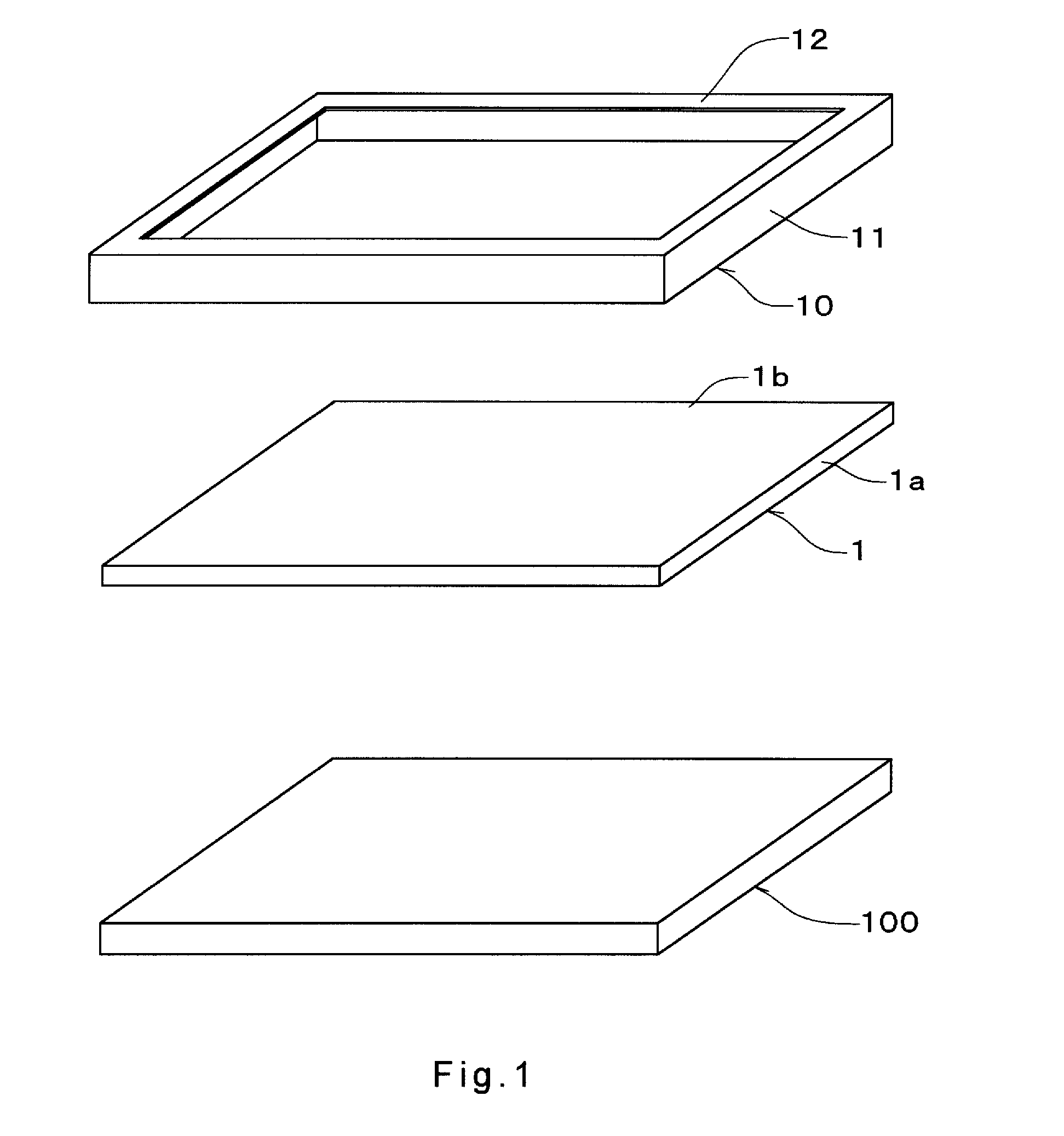

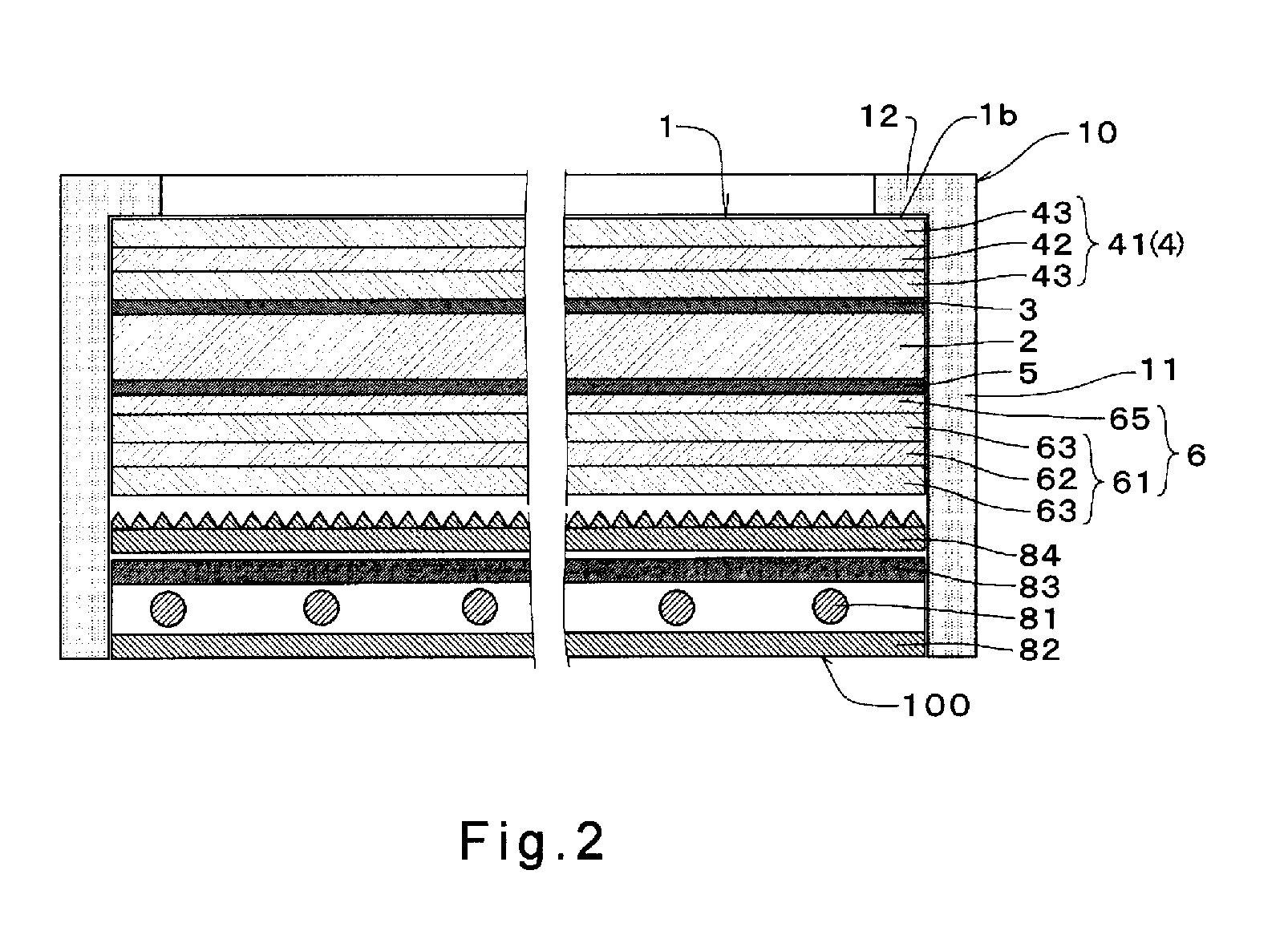

Liquid crystal panel and liquid crystal display apparatus

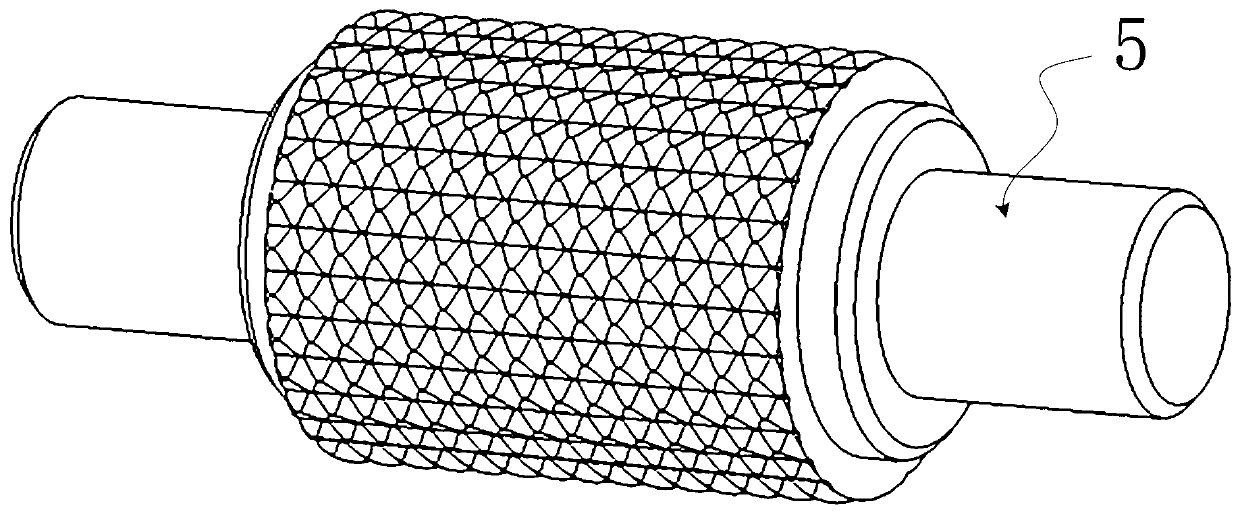

ActiveUS20090322994A1Easily peeled off and separatedImprove leakagePolarising elementsAcid polymer adhesivesLiquid crystal cellPressure sensitive

A liquid crystal panel has a first optical film (4) adhered to a viewing side of a liquid crystal cell (2) through a first pressure-sensitive adhesive layer (3), and a second optical film (6) adhered to the reverse side of the liquid crystal cell (2) through a second pressure-sensitive adhesive layer (5). A creep value (L1) of the first pressure-sensitive adhesive layer (3) is from 50 to 3000 μm. A creep value (L2) of the second pressure-sensitive adhesive layer (5) is from 10 to 400 μm. The creep value (L1) of the first pressure-sensitive adhesive layer (3) is larger than the creep value (L2) of the second pressure-sensitive adhesive layer (5). The creep value means the shift amount after one hour of the pressure-sensitive adhesive layer having a thickness of 20 μm in a case where a tensile shearing force of 4.9 N is applied to an adhesive area of 10 mm2 at 23° C.

Owner:NITTO DENKO CORP

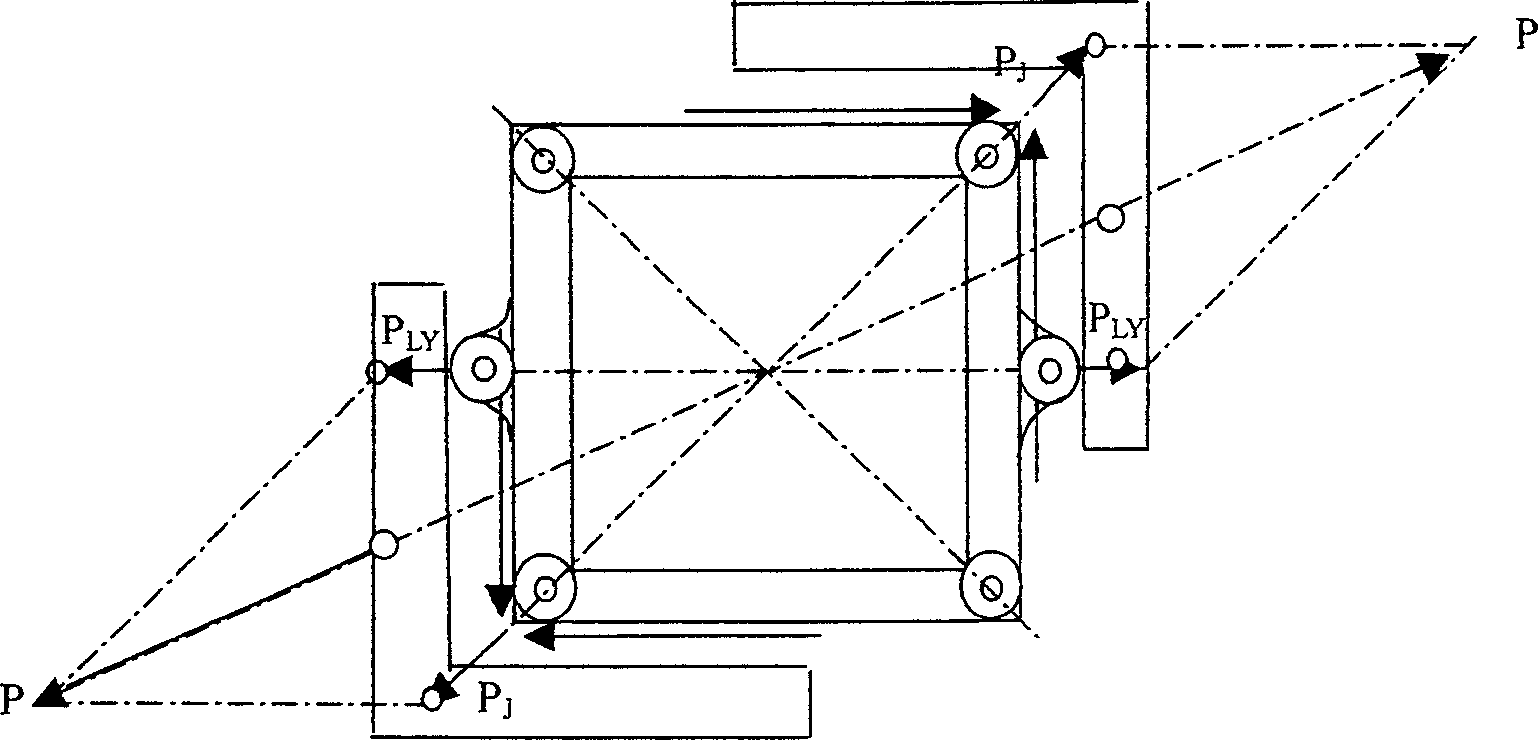

Tensile-shear compressive-shear complex loading tester

InactiveCN1670503ACompact structureEasy to useStructural/machines measurementStrength propertiesDiagonalEngineering

This invention relates to one pulling and pressing shearing test device and structure force test device, which comprises the following parts: four pieces of shearing and pulling and pressing loading boards; one rectangle loading frame; two L-shape lever symmetrically hinged with each other and fixed on the rectangle loading frame one catercorner, wherein the L-shape lever is separately loaded with pulling and pressing holes. The test device can realize the compound test on the same one test device of general test machine.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Phenolic epoxy resin system conductive adhesive and preparation thereof

InactiveCN101503608BEnvironmentally friendlyHigh utility valueEpoxynovolac adhesivesElectrically-conducting adhesivesAdhesiveDiluent

Owner:DONGHUA UNIV +1

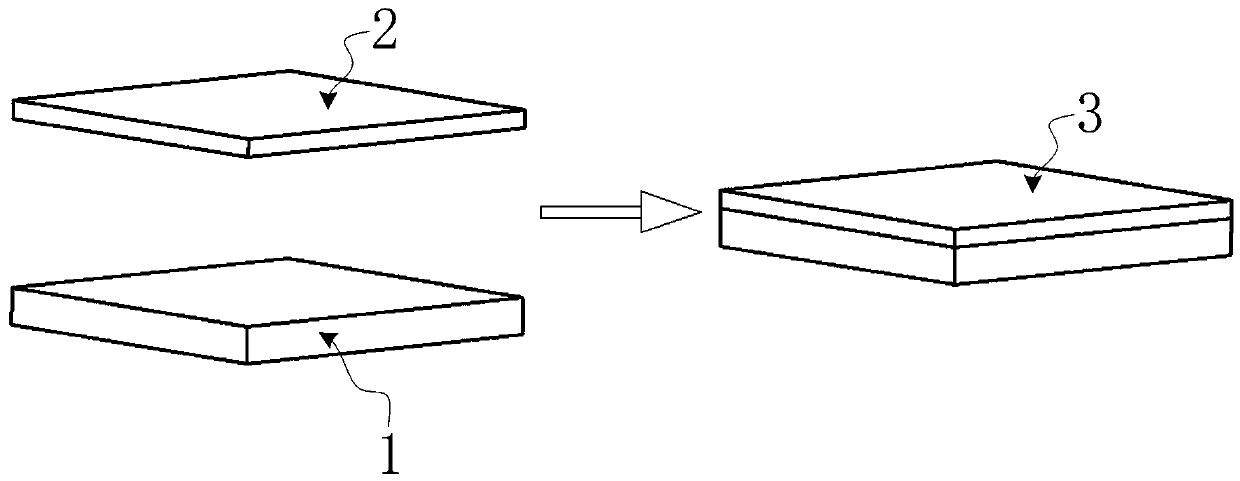

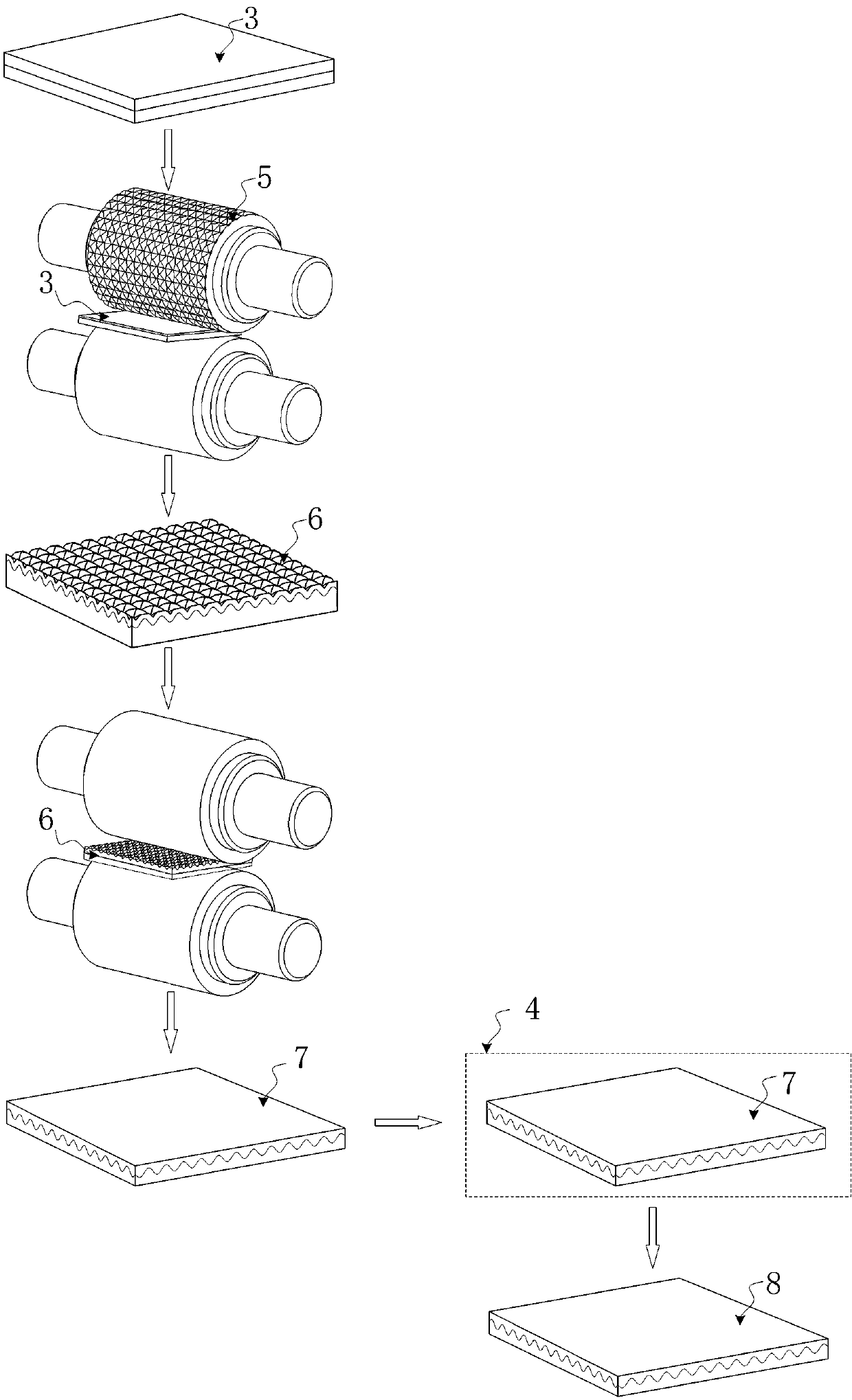

Method for strongly deforming and rolling bimetallic composite plate

ActiveCN110614275AHigh bonding strengthSpeed up the outflowRollsMetal rolling arrangementsComposite plateUltimate tensile strength

The invention relates to the technical field of preparation of a bimetallic composite plate, in particular to a method for strongly deforming and rolling a bimetallic composite plate, and aims to solve the technical problems of low bonding strength, large residual stress and serious warpage in an existing bimetallic plate rolling method. According to the technical scheme, a manufactured bimetalliccomposite plate blank is subjected to two passes of rolling, a wave plate rolling mill is adopted for the first pass, the upper roller is a crossed corrugated roller, and the lower roller is a flat roller; and a flat roller mill is adopted for the second pass, and the upper roller and the lower roller are all flat rollers. According to the rolling method, the composite plate with good comprehensive performance of the tensile shear strength and tensile strength in the rolling direction and the transverse direction is obtained, and the residual stress distribution inside the bimetallic composite board can be obviously improved; and by adopting the novel process for rolling the bimetallic composite plate, the bonding strength of the two plates can be improved, the residual stress distribution state is improved, and the plate warpage is reduced.

Owner:TAIYUAN UNIV OF TECH

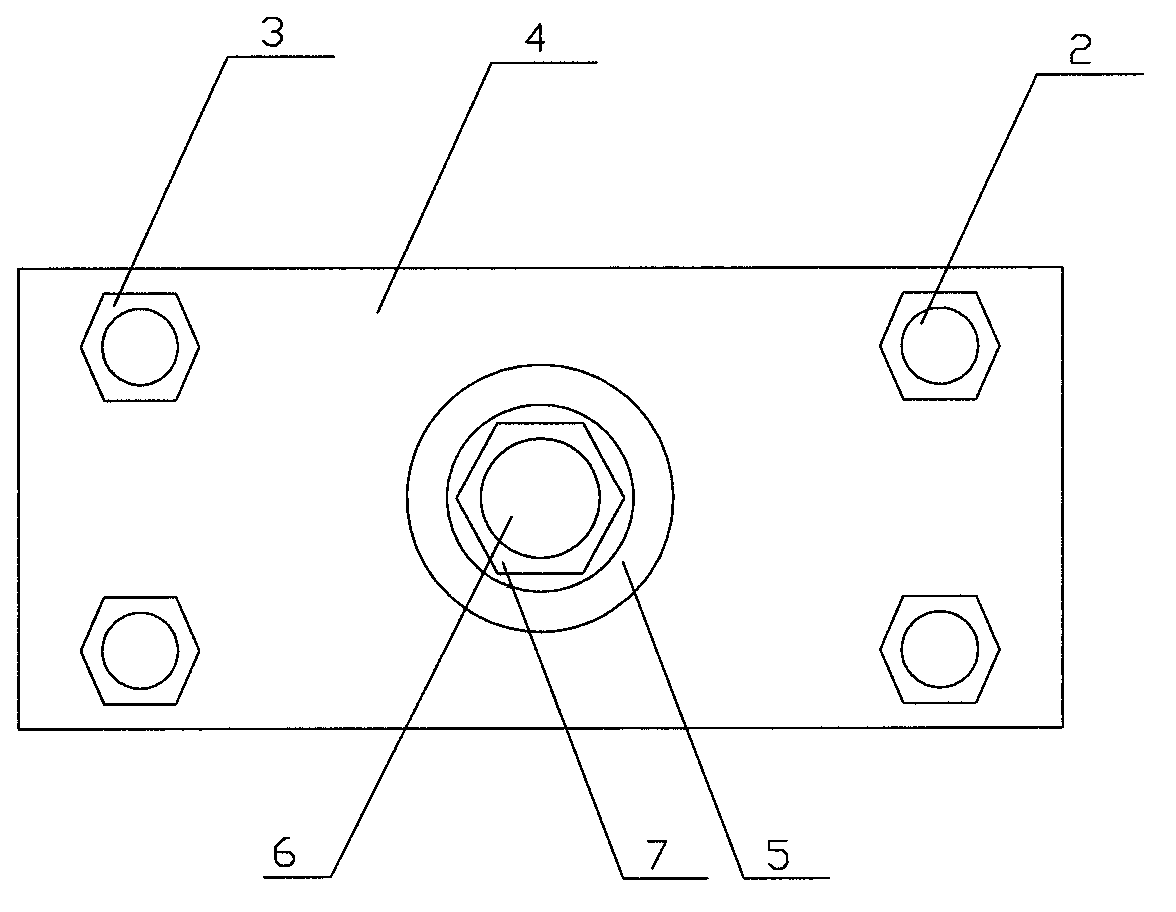

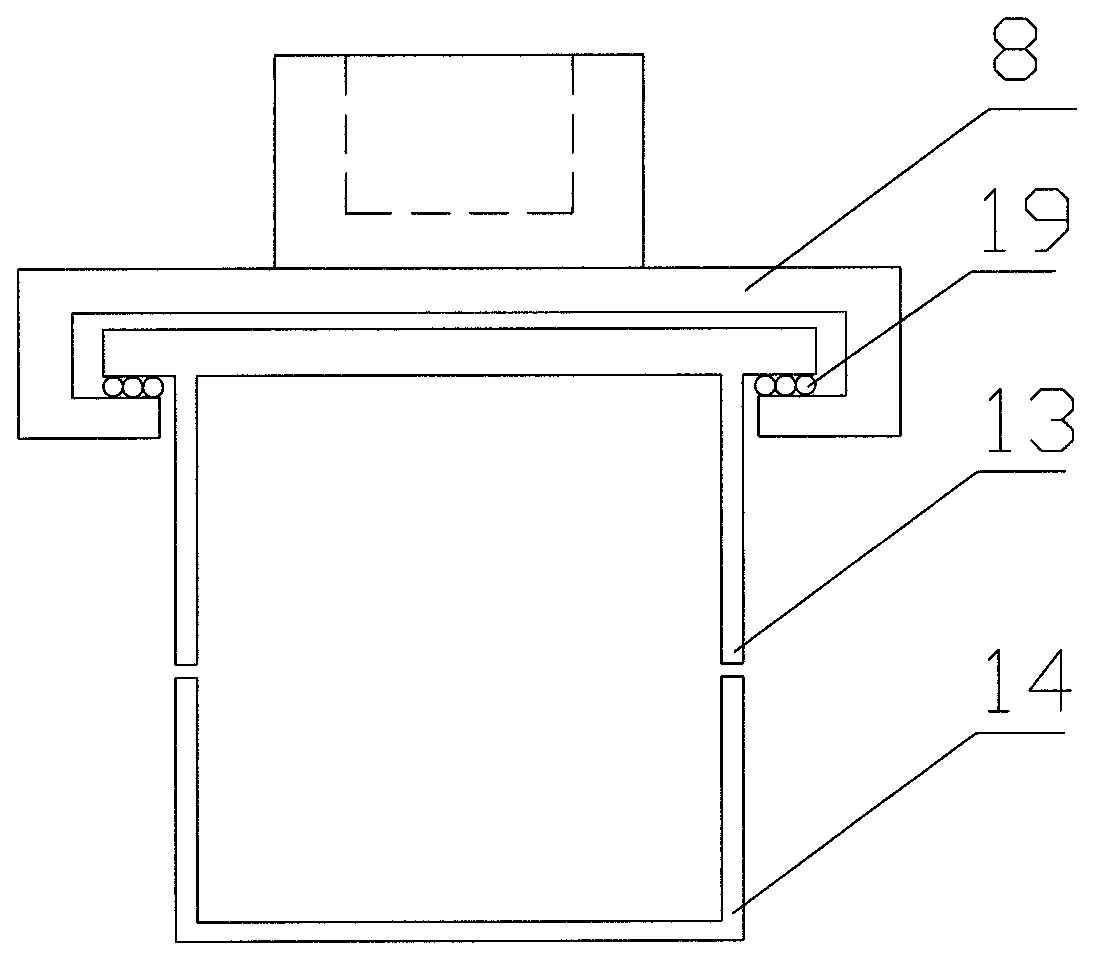

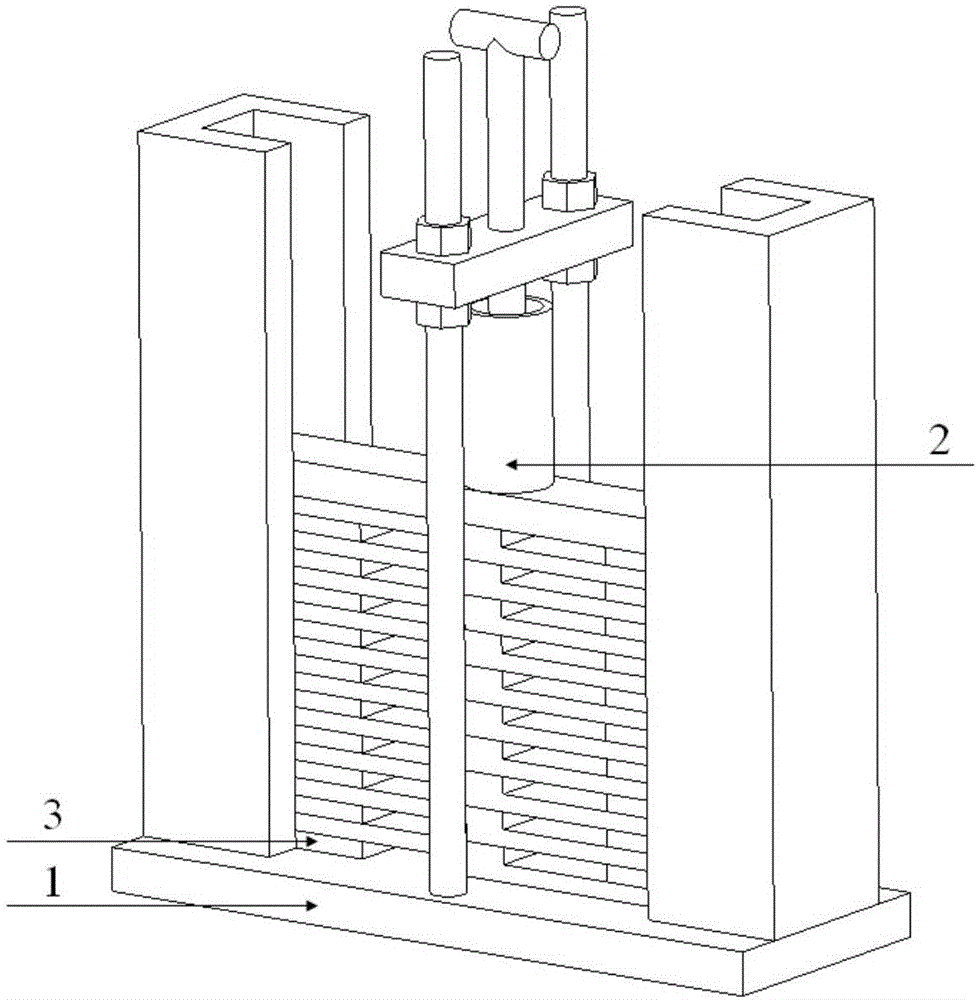

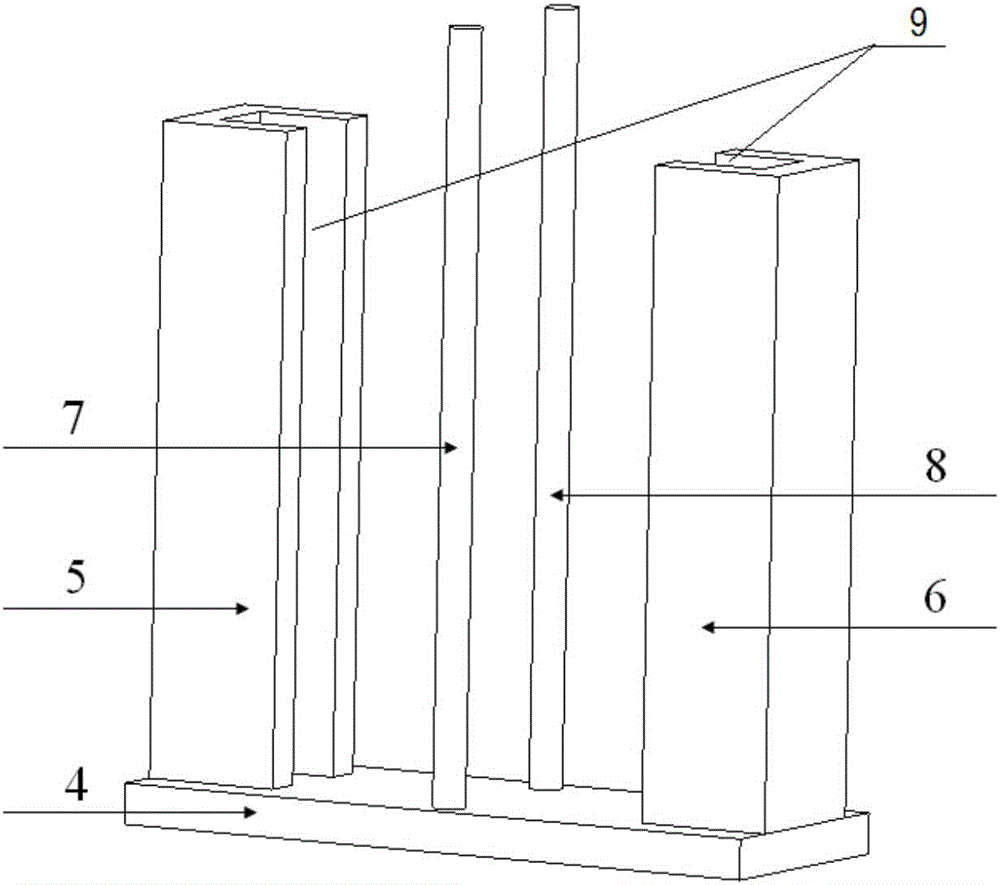

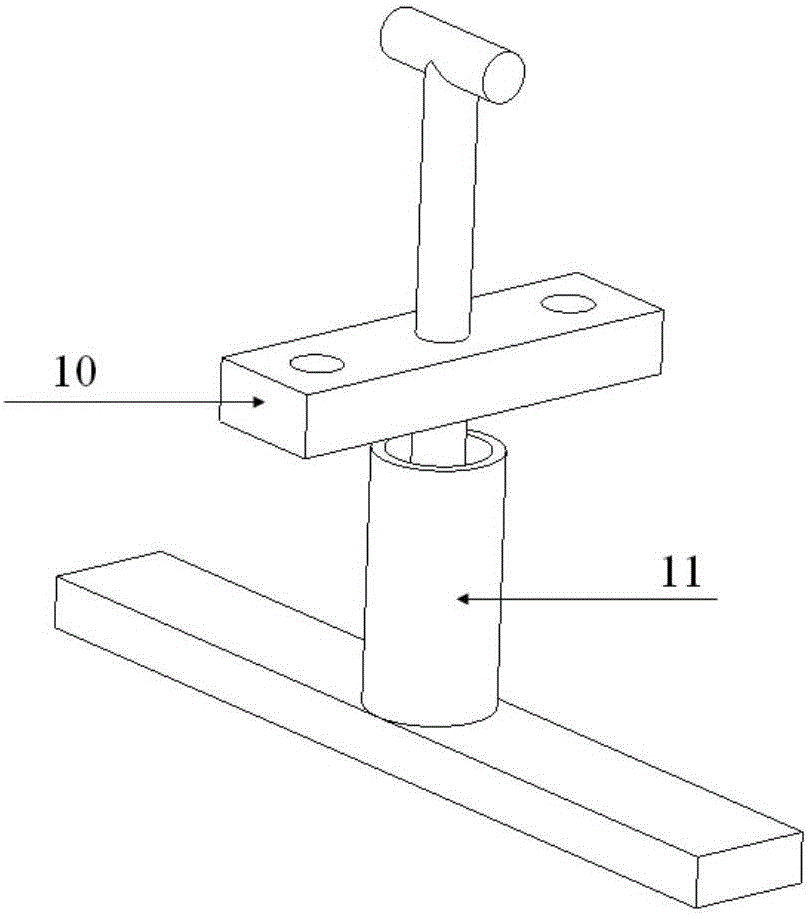

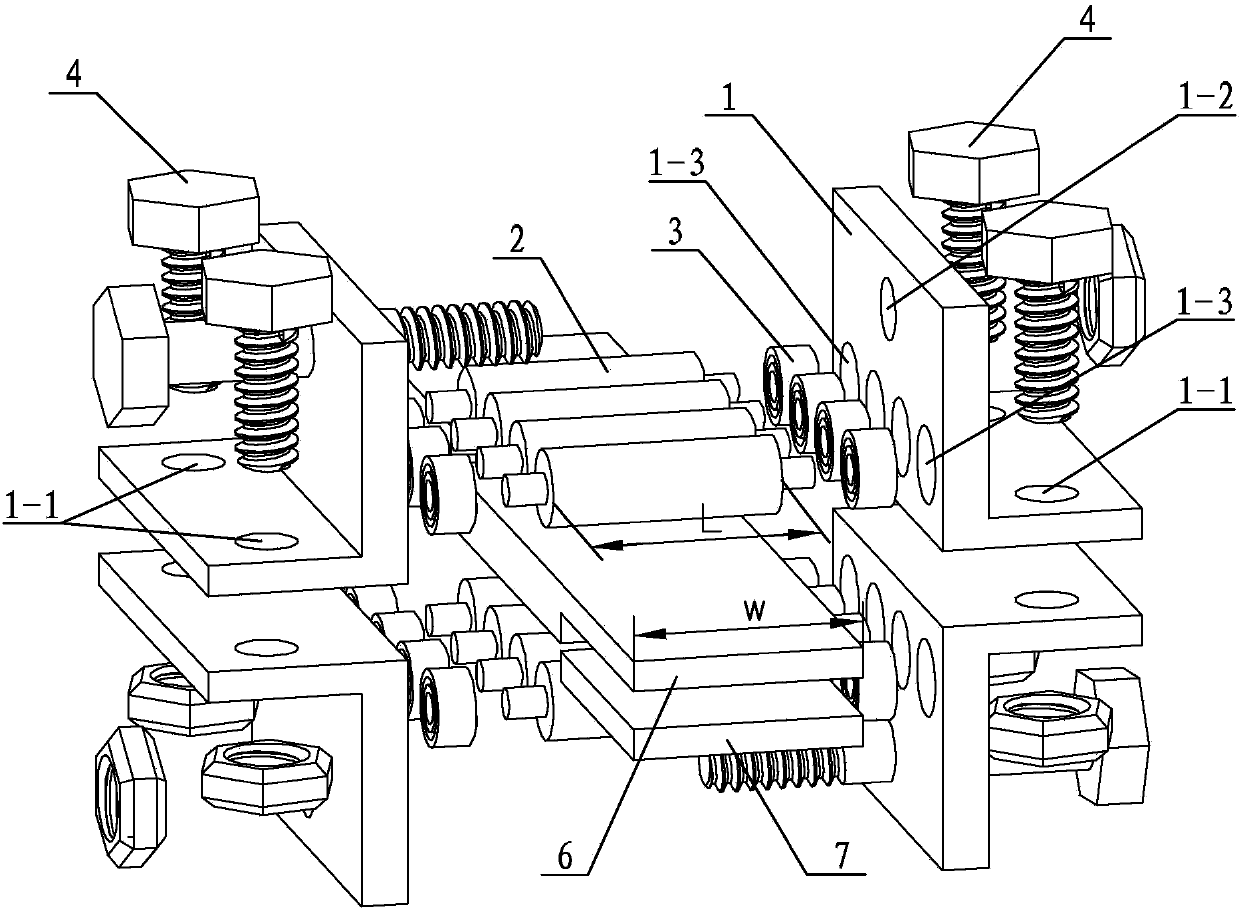

Production tooling for adhesive tensile shear strength test samples

InactiveCN106840872AGuaranteed parallelismGuaranteed coaxialityMaterial strength using tensile/compressive forcesTest sampleLayer thickness

The invention relates to a production tooling for adhesive tensile shear strength test samples. The production tooling comprises a base, a pressurization system and a cushion block, wherein the base consists of a bottom plate, a left groove, a right groove, a left upright post and a rear upright post; the pressurization system consists of a beam and a pressurization device; the pressurization device consists of a pressurization plate, a reset spring and a pressurization threaded rod; the thicknesses of the cushion blocks are the sums of the substrate thicknesses and the adhesive layer thicknesses of the test samples. According to the production tooling, the overlapping length of the test samples can be accurately controlled; in addition, the parallelism and the coaxiality of the test samples can be ensured; moreover, multiple test samples can be prepared at one time according to a requirement.

Owner:INNER MONGOLIA AEROSPACE HONGGANG MACHINERY

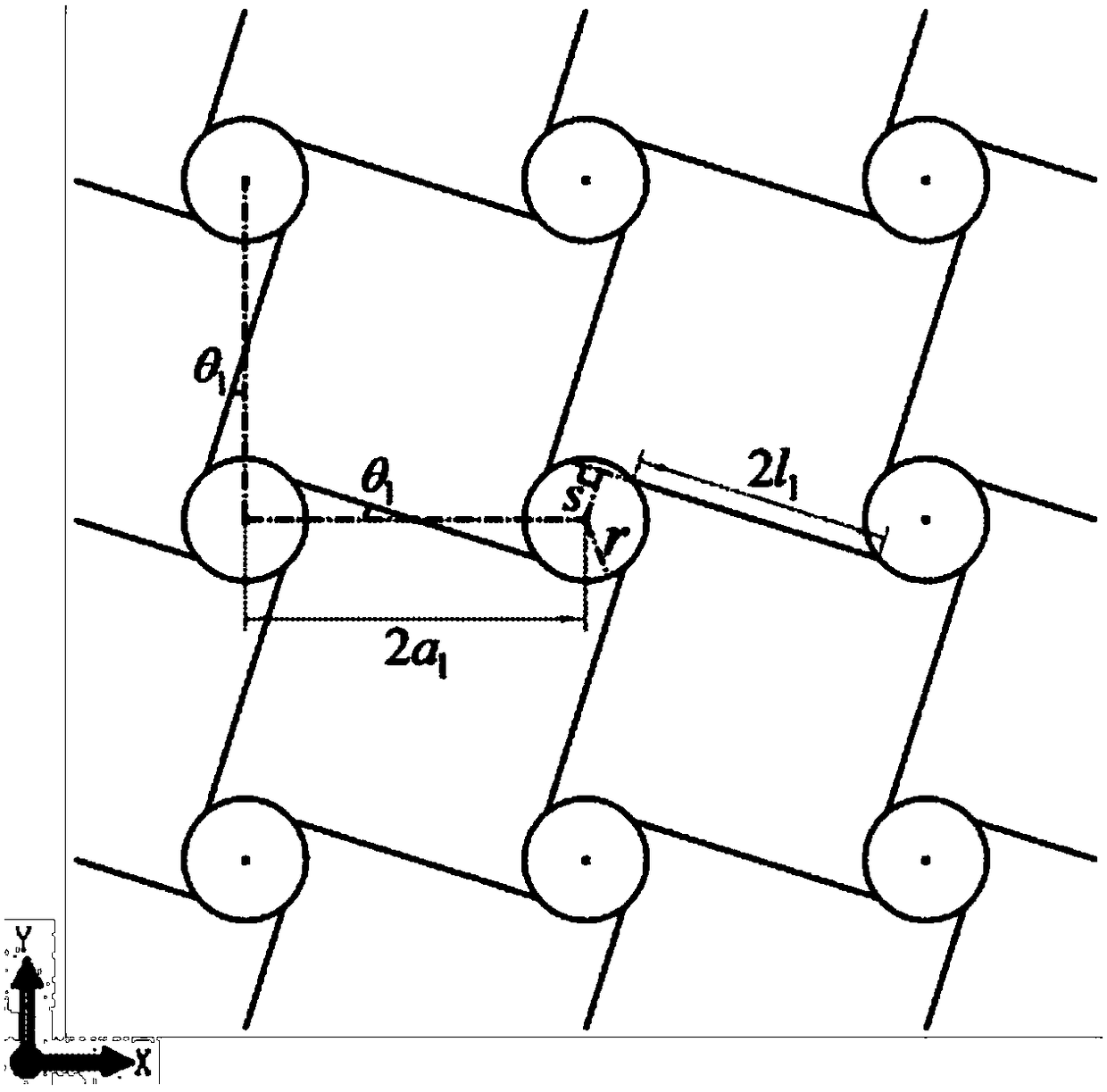

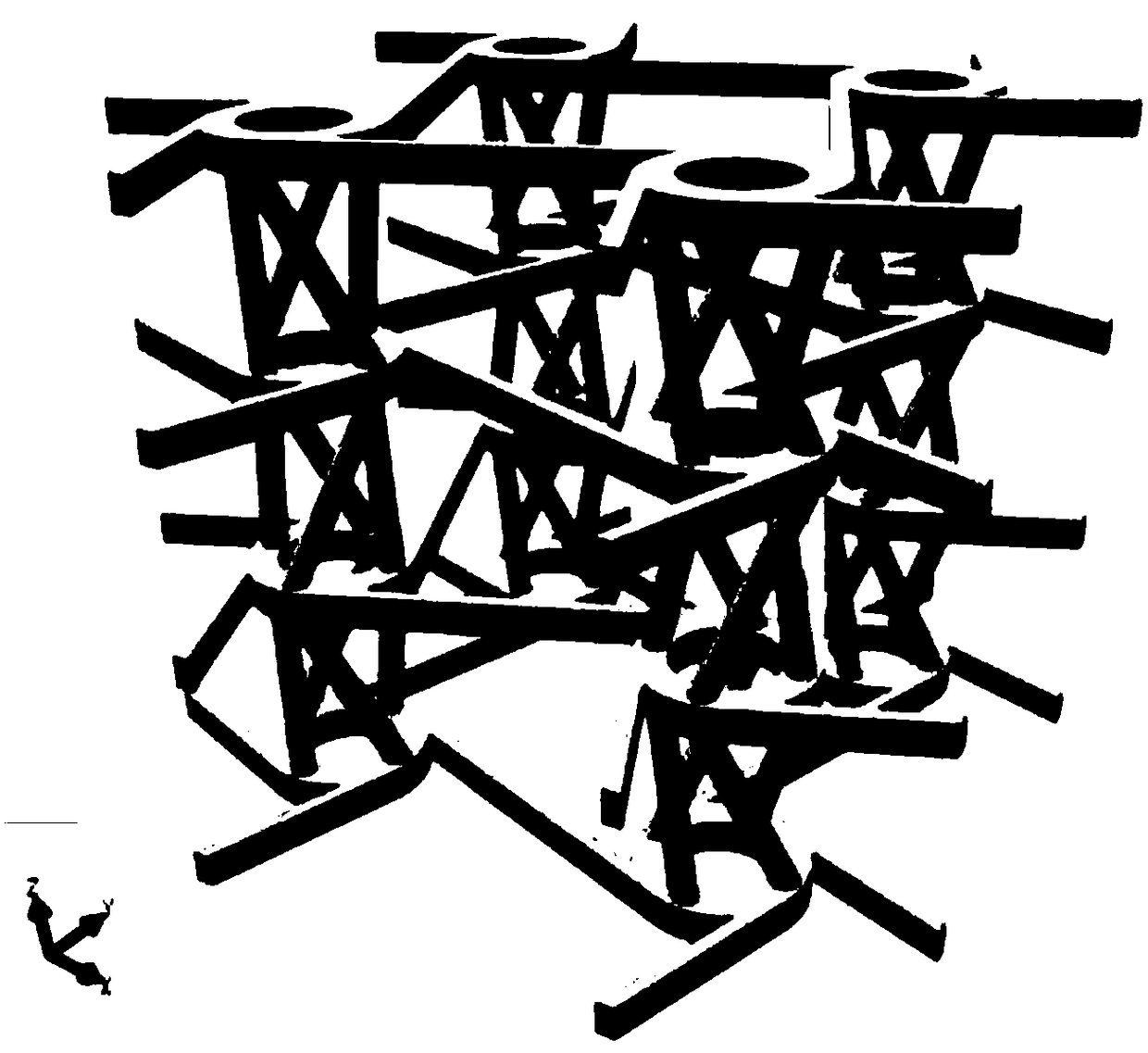

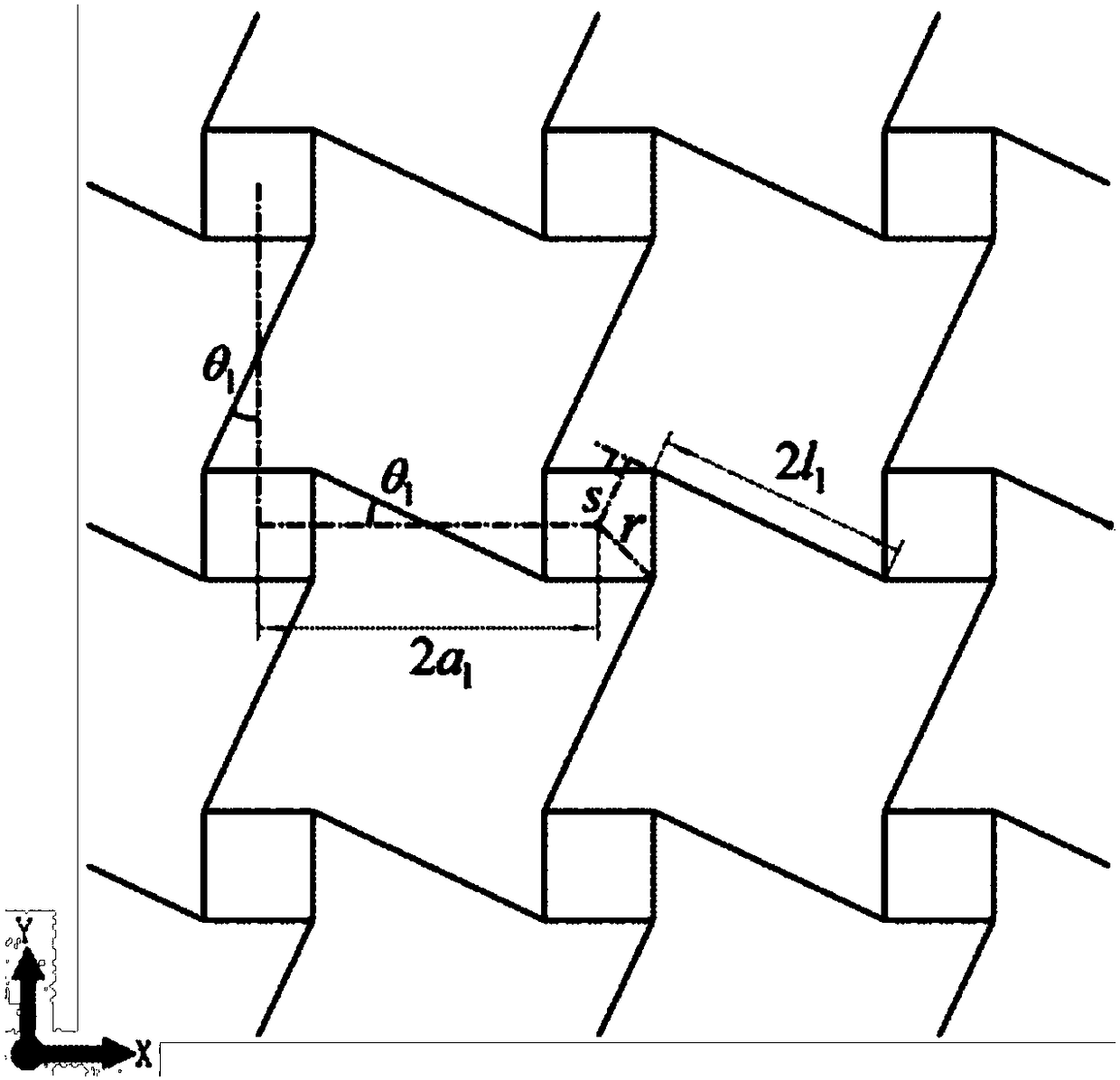

Porous material structure having three-dimensional negative Poisson's ratio

InactiveCN108394135AEliminate tension-shear coupling effectsWide range of changesLayered productsEngineeringSubstructure

The invention provides a porous material structure having a three-dimensional negative Poisson's ratio. The porous material structure comprises a plurality of net structures which are sequentially stacked in parallel along a Z-axis direction, and the upper net structure and the lower net structure which are adjacent are connected by a support ligament, wherein net structure extends along an XOY plane. The porous material structure having the three-dimensional negative Poisson's ratio eliminates the tensile-shear coupling effect of the two-dimensional substructure of the XOY plane during deformation, so the three-dimensional structure constitutive relationship usually is orthotropic, and can be easily designed and analyzed. Geometrical dimensions are adjusted to make the structure isotropicand greatly change the negative Poisson's ratio values in all three directions, so the choice of practical applications is increased.

Owner:SUN YAT SEN UNIV

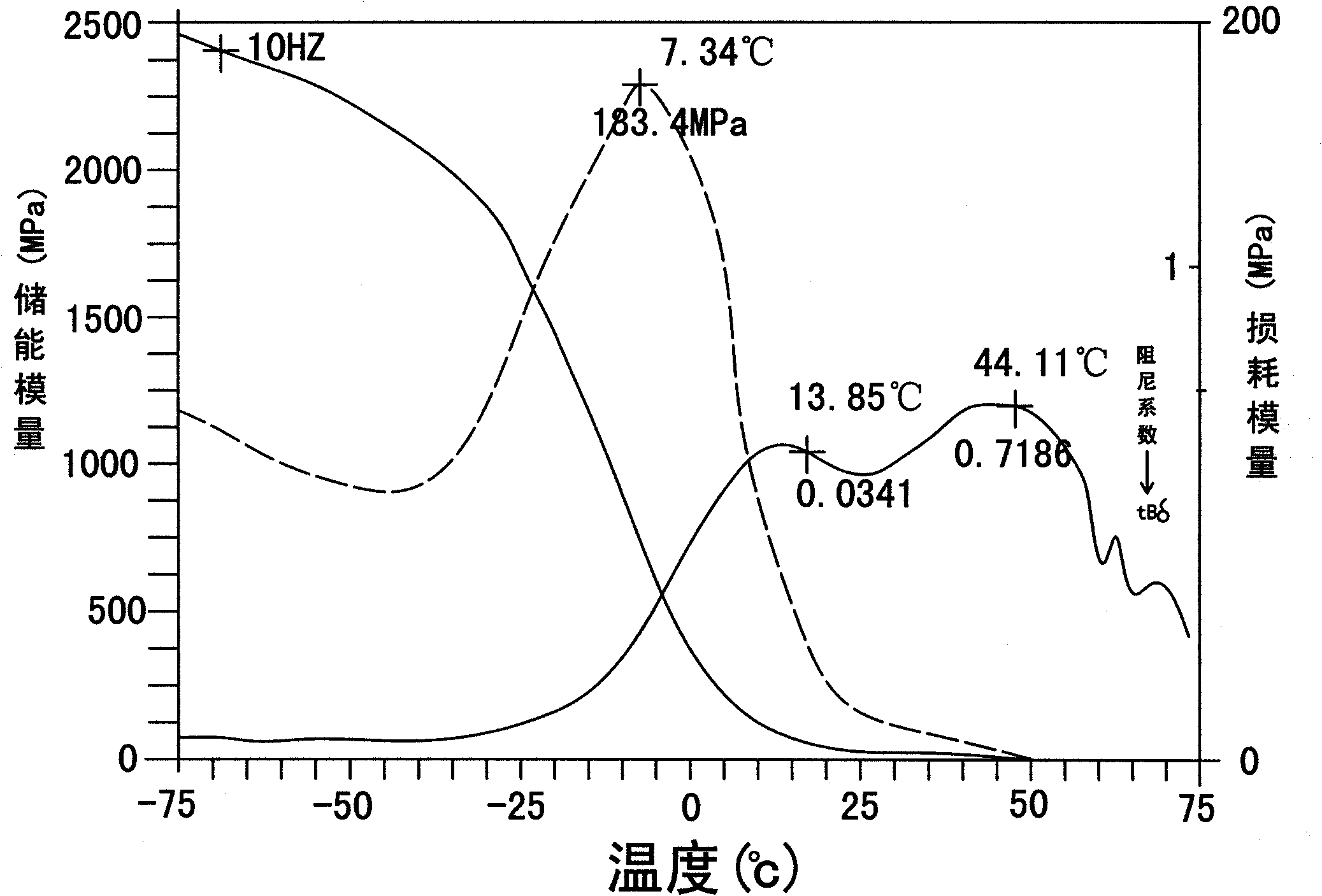

Epoxy resin base damping packaging material

InactiveCN101186803AImprove liquidityCuring reaction is gentleOther chemical processesWorking temperaturePolyamide

The invention relates to a damping package material of epoxy resin group, which consists of component A and component B, wherein the component A is composed of 0-90 parts of bisphenol A epoxy resin, 0-60 parts of polyurethane epoxy resin, 20-90 parts of flexible epoxy resin according to part by weight, the component B is composed of 25-55 parts of aliphatic amine, 10-45 parts of aliphatic cyclic amine, 0-80 parts of versamid and 0-8 parts of silane coupling agent according to part by weight, the parts are mixed uniformly according to part by weight of A:B=100:15-100. The invention has the advantages that the mixture has good mobility, the solidification reaction is mild, the condensate has good mechanical property and good tensile shear strength with metals, the invention can resist high and low temperature impact, thermal aging and humidity heat aging, the condensate does not erode rigid aluminium alloy, steel, aldary and PVC plastics in sealed humidity heat condition, the solidification shrinkage ratio is low, with the damping coefficient (tan delta max>=0.5). Particularly, the invention has instantaneous high impact property and the operational temperature is from -54 DEG C to 70 DEG C.

Owner:张向宇

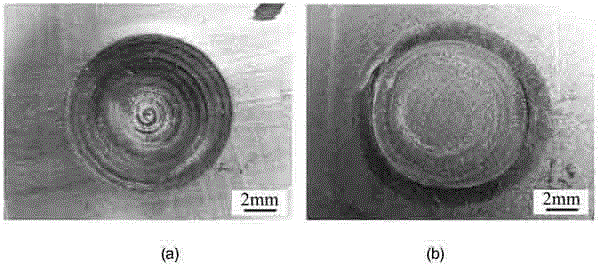

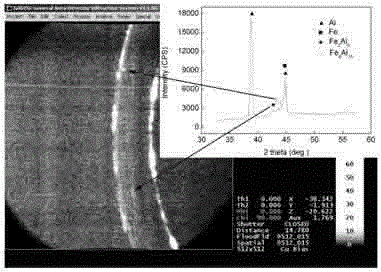

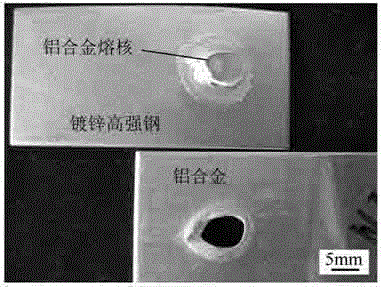

Intermediate frequency spot welding method for aluminum alloy and zinc-plated high-strength steel dissimilar material

InactiveCN105269137AEasy to trimEasy to implementResistance welding apparatusElectrical resistance and conductanceIntermediate frequency

The invention discloses an intermediate frequency spot welding method for an aluminum alloy and zinc-plated high-strength steel dissimilar material and belongs to the technical field of metal material welding. According to the intermediate frequency spot welding method, spot-welding electrodes are adopted for welding aluminum alloy and zinc-plated high-strength steel. The side of the aluminum alloy is provided with the radius tip electrode with the diameter of 30-100 mm, and the side of the zinc-plated high-strength steel is the flat electrode with the diameter of 8-15 mm. According to the intermediate frequency spot welding method, generation of splashing can be reduced in the spot welding process, and adhesion of a workpiece and the electrodes and an alloying reaction are prevented. Meanwhile, the size of a spot-welding nugget on the side of the aluminum alloy is increased, the growth behavior of an intermetallic compound on the interface of the aluminum alloy / zinc-plated high-strength steel is controlled, and generation of fragile FexAly intermetallic compound is reduced. The performance of an aluminum alloy and zinc-plated high-strength steel dissimilar material intermediate frequency spot-welded connector obtained through optimization of the technological parameters of resistance spot welding is significantly improved, and the tensile shearing force of the spot-welded connector can be as high as 5400 N. The thickness of the intermetallic compound on the interface of the aluminum alloy / zinc-plated high-strength steel is controlled to be below 5.0 [mu]m.

Owner:JILIN UNIV

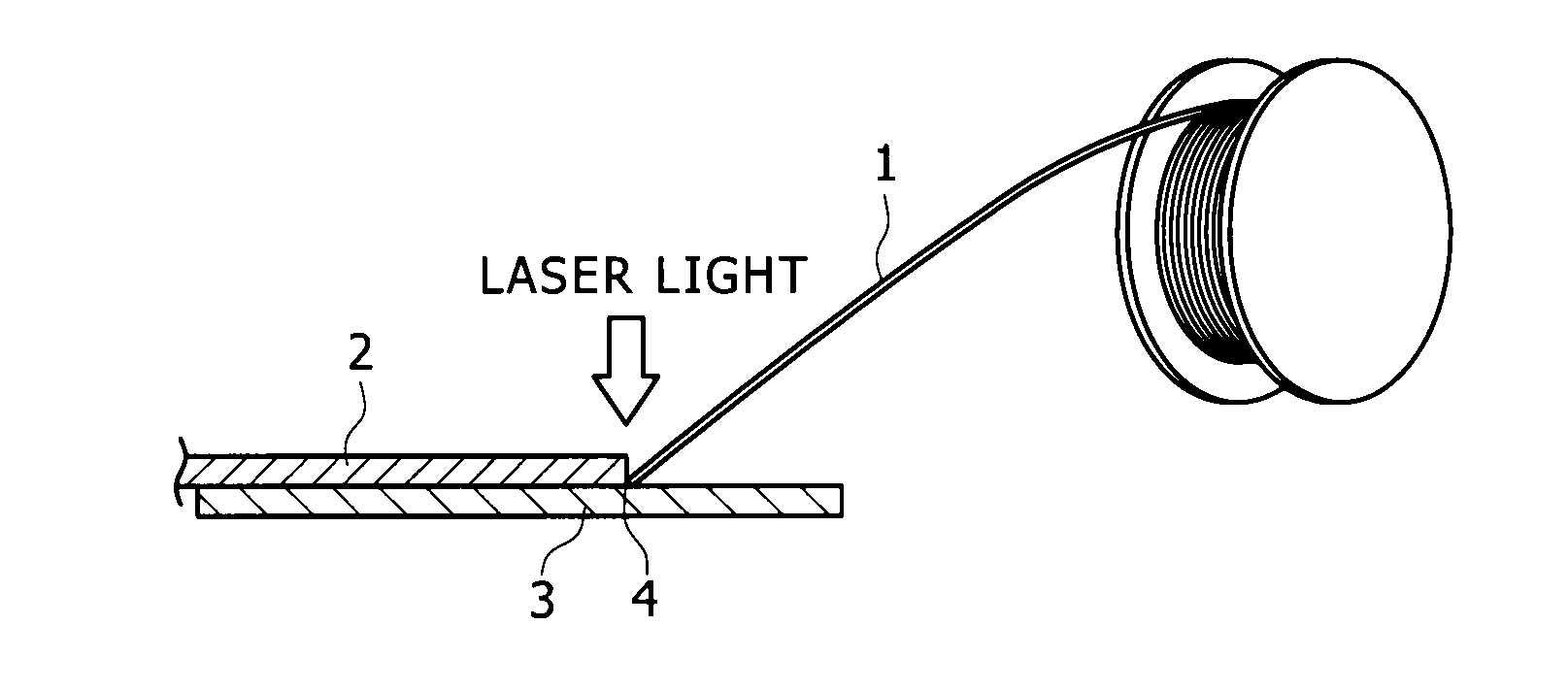

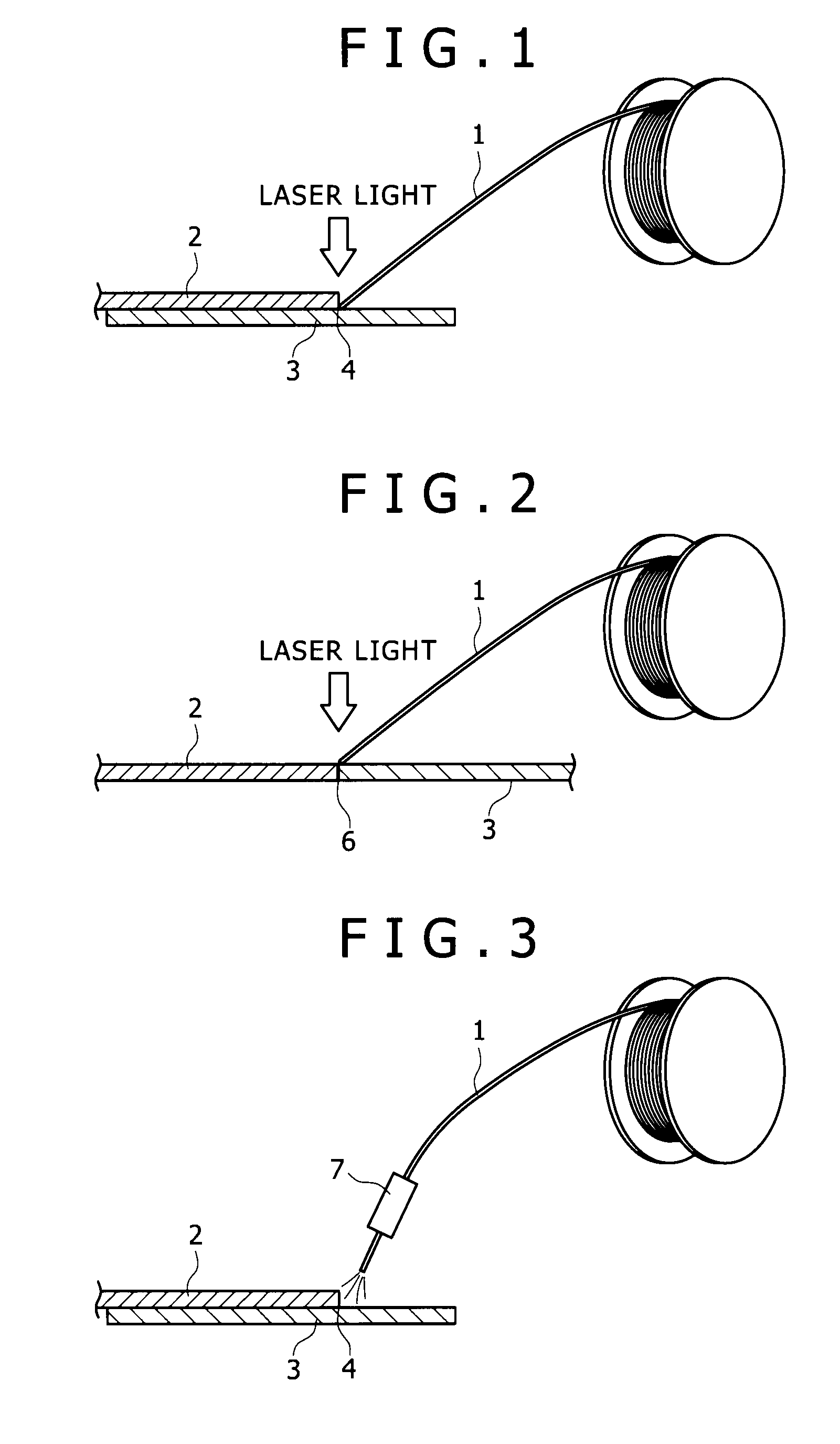

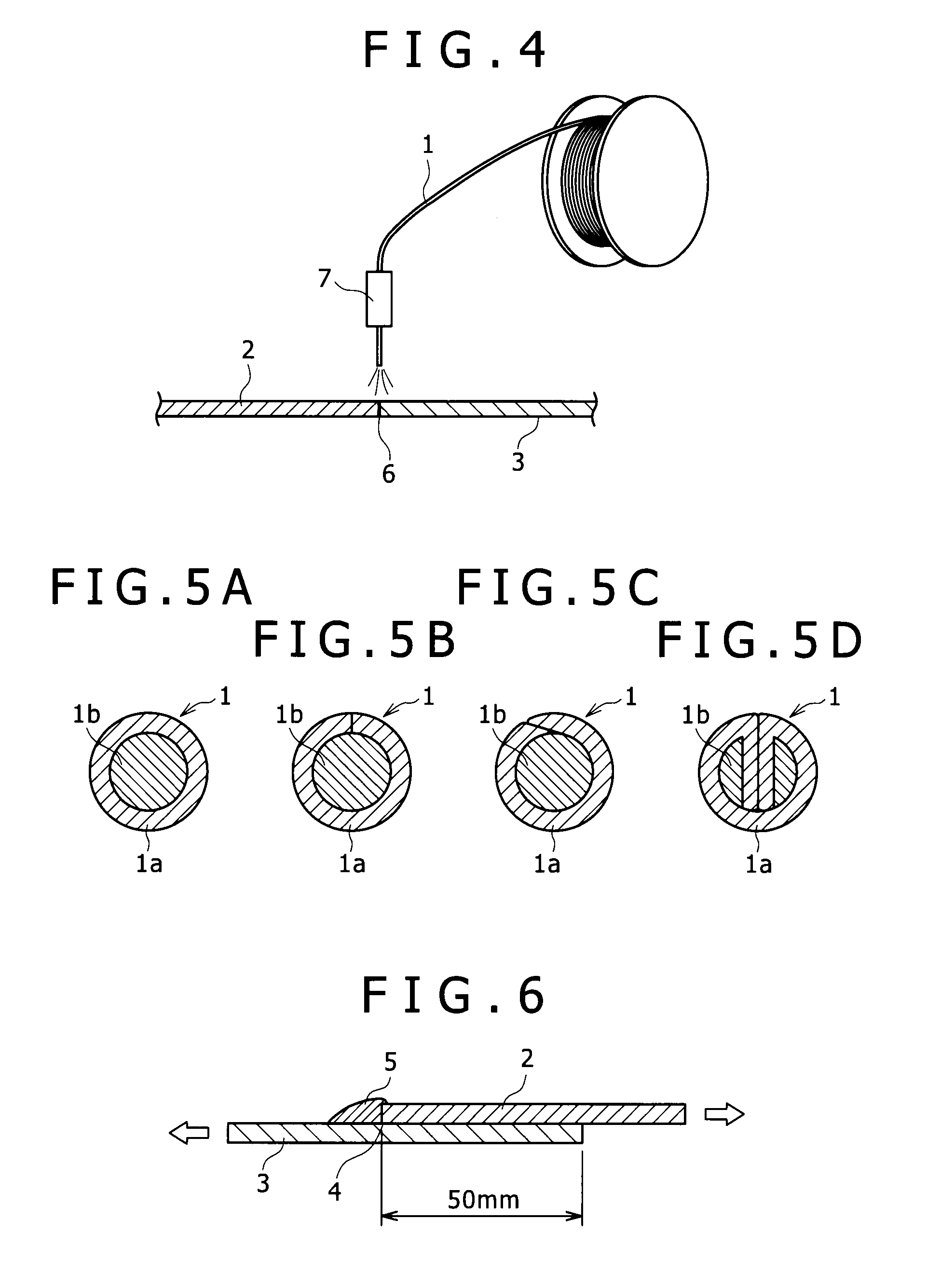

Flux-cored wire for welding different materials, method for laser welding of different materials and method for mig welding of different materials

ActiveUS20120074111A1Appropriate amountImprove joint strengthArc welding apparatusVehicle componentsFluorideUltimate tensile strength

There are provided a flux-cored wire for welding different materials, a method for laser welding of different materials and a method for MIG welding of different materials which can improve tensile shear strength of a welded joint portion and peeling strength of a welded portion interface in welding aluminum or an aluminum alloy material and a steel material. The flux-cored wire has a cylindrical sheath comprising an aluminum alloy which contains Si in an amount of 1.5 to 2.5% by mass and Zr in an amount of 0.05 to 0.25% by mass, with the remainder being aluminum and inevitable impurities, and a flux filling inside this sheath and containing cesium fluoride in an amount of 20 to 60% by mass, and the packing fraction of the flux being 5 to 20% by mass of the total mass of the wire.

Owner:KOBE STEEL LTD

Heat-resistant coating tensile shear strength test model and production method thereof

ActiveCN102954910AGuaranteed thicknessGuaranteed compactnessPreparing sample for investigationStrength propertiesFiberPaper adhesive tape

The invention discloses a heat-resistant coating tensile shear strength test model which comprises an upper sheet metal, a lower sheet metal, an intermediate adhesive layer, fiber cloth in the adhesive layer and paper adhesive tapes pasting around tensile shear adhesive surfaces of the sheet metals. A production method provided by the invention comprises adding the fiber cloth into the adhesive layer, thereby effectively controlling thickness and uniformity of the adhesive layer; and is added with a process of pasting paper adhesive tapes around the tensile shear adhesive surfaces, thereby reducing influences of irregular glue-spilling on test results, and improving stability of the test results.

Owner:CASIC DEFENSE TECH RES & TEST CENT

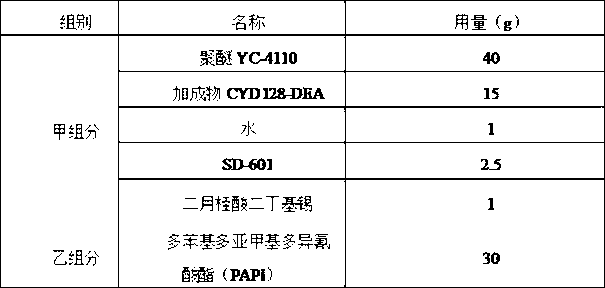

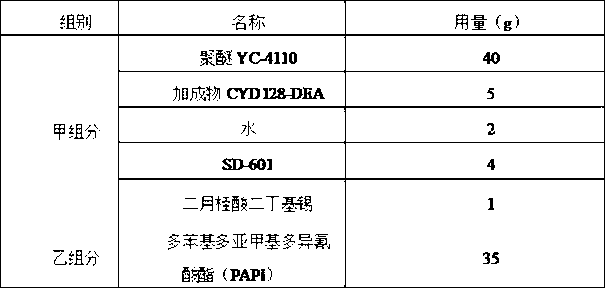

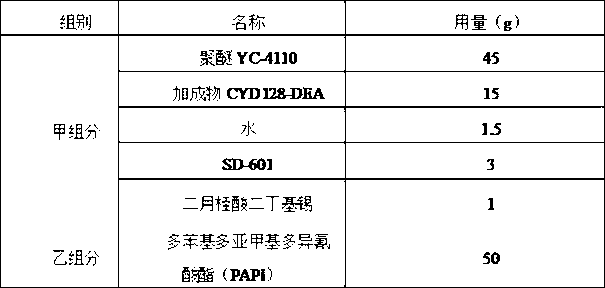

Epoxy modified polyurethane double-component grouting material for road engineering maintenance and preparation method thereof

InactiveCN102702473ASynthetic reaction conditions are mild and efficientIt has the function of self-catalysisEpoxyPolyol

The invention relates to an epoxy modified polyurethane double-component grouting material for road engineering maintenance and a preparation method thereof, wherein the grouting material comprises a component A and a component B; the component A comprises following components in part by weight: 700-800 parts of polyether glycol, 100-300 parts of epoxy resin addition product, 20-40 parts of foaming agent, 40-80 parts of foam stabilizer and 10-40 parts of catalyst; and the component B is polyphenyl polymethylene polyisocyanate. The preparation method comprises the step of mixing and stirring the component A and the component B according to the mass ratio of (0.8-1.5): 1 uniformly. The grouting material has the advantages that: when the material participates in foaming reaction and is cured, the compression strength and bonding force of the formed liquid cement are improved, and the maximum tensile shear strength can reach 4.3Mpa, so that the grouting material is better than the grounding material mixed by polyurethane and epoxy resin; and the grouting material reduces builder body damage and has a certain economic benefit.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

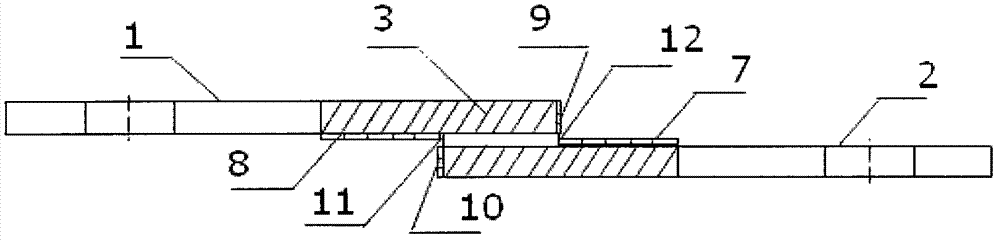

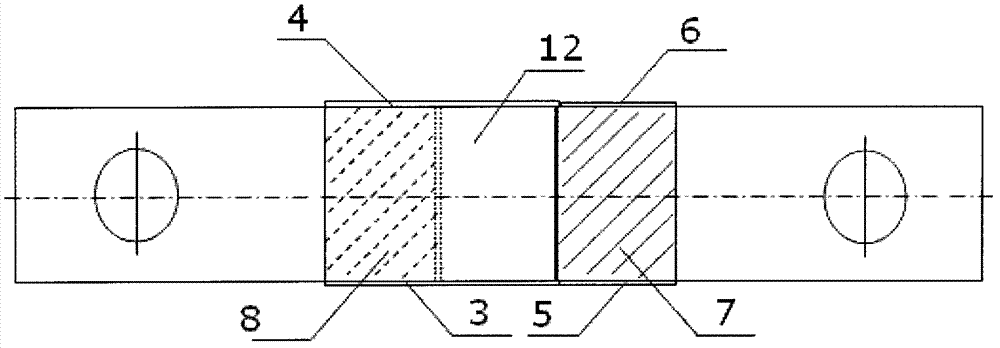

Fixture and method for measuring maximum tensile and shearing force of lap joint of friction stir welding

ActiveCN103592181AGuaranteed pure tensile shear failureEliminate additional bending momentsMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesFriction weldingLap joint

The invention provides a fixture and a method for measuring the maximum tensile and shearing force of a lap joint of friction stir welding to overcome the problem that additional bending moment influences measurement results of the maximum tensile and shearing force of a lap joint of friction stir welding in a traditional tensile and shearing test. According to the fixture, four bearing installing holes are arranged along a same horizontal line; eight rollers are arranged in two layers, each layer consisting of four parallely arranged rollers; the end parts of each roller is mounted in a corresponding bearing installing hole through a positioning bearing. The method comprises the following steps: 1, allowing the distance between axle centers of two rollers located at two outermost sides of each layer of rollers to be 10 to 20 times thickness of the lap part of a test piece for tensile and shearing testing; 2, placing the test piece for tensile and shearing testing between the upper layer of rollers and the lower layer of rollers; and 3, clamping the assembled test piece for tensile and shearing testing, the fixture and cushion blocks on a tensile and shearing testing machine, carrying out tensile and shearing testing on the test piece for tensile and shearing testing at a loading speed of 0.5 to 1.5 mm / min and recording a maximum tensile and shearing test load F. The fixture and the method provided by the invention are used for measuring the maximum tensile and shearing force of the lap joint of friction stir welding.

Owner:HARBIN INST OF TECH

Compound toughening bisphenol-A epoxy resin inserted-bar glue high in adhesive capability in high-temperature environment and preparation method of bispheonl-A epoxy resin inserted-bar glue

ActiveCN104726048AAcid and alkali resistance is easy to getImprove corrosion resistanceEpoxy resin adhesivesRebarToughening

The invention discloses compound toughening bisphenol-A epoxy resin inserted-bar glue high in adhesive capability in the high-temperature environment and a preparation method of the bispheonl-A epoxy resin inserted-bar glue. The compound toughening bisphenol-A epoxy resin inserted-bar glue is characterized by being made of raw materials comprising a component A and a component B, wherein the component A includes, by weight, 40-60 parts of bisphenol-A epoxy resin, 30-40 parts of end carboxyl nitrile modified bisphenol-A epoxy resin, 20-30 parts of polyurethane modified bisphenol-A epoxy resin and 3-5 parts of silane coupling agents, and the component B includes, by weight, 20-30 parts of polyether amine and 10-20 parts of phenolic aldehyde modified amine, and the component A and the component B are subjected to mixture construction after being evenly mixed according to the weight ratio of 3 to 1. The outstanding characteristic of the glue is that steel-steel tensile shear strength can be up to 38Mpa, so that embedding length-to-diameter ratio can be reduced during bar inserting. A-grade adhesive bonding effect can be achieved when reinforcing steel bars are embedded shallowly, use in the high temperature environment of 120 DEG C can be achieved, and the glue is applicable to the occasion that the reinforcing steel bars limited in embedding depth are still kept high in bonding strength.

Owner:DALIAN UNIV OF TECH

Damping glue for vibration reducing plate and preparation method thereof

ActiveCN102115647AHigh dampingGood damping propertiesConjugated diene hydrocarbon adhesivesEpoxyMixed materials

The invention discloses damping glue for a vibration reducing plate and a preparation method thereof. The component formula of the damping glue is as follows: 3 to 10 parts of nitrile-butadiene rubber 26 (NBR 26), 5 to 7 parts of nitrile-butadiene rubber 40 (NBR 40), 2 to 4 parts of additive, 2 to 12 parts of epoxy resin (EP), 1 to 5 parts of phenol formaldehyde resin (PF), 1 to 2 parts of curingagent, 0.3 to 0.5 part of peroxide, 0.5 to 1 part of zinc oxide, and 65 to 75 parts of solvent. The preparation process of the damping glue is as follows: the NBR 26 is firstly plasticated on a double-roll machine for 5 to 10 minutes, and then the zinc oxide is added and mixed with the NBR26 until the Williams plasticity is between 0.2 and 0.3; then the NBR40 is plasticated on the double-roll machine until the Williams plasticity is between 0.3 and 0.4; the mixed material is added to the solvent being stirred and stirred until being completely dissolved; and afterwards, the PF, the additive, the EP or a compound thereof, the curing agent and the peroxide are stirred until being completely dissolved into an evenly thick liquid, and then the normal-temperature damping glue for the vibrationreducing plate can be acquired. The main performances of the manufactured damping glue are as follows: the solid content is 25 to 35 percent; the glue solution viscosity (measured by a rotational viscometer) is 3.5 to 7 Pa.S (25 DEG C); the T-peel strength is larger than 20N / cm; the tensile shear strength is larger than 7MPa; tangent Delta is larger than or equal to 0.20; and the temperature range is minus 10 DEG C to 75 DEG C.

Owner:SHANGHAI PLASTICS RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com