Production tooling for adhesive tensile shear strength test samples

A tensile shear strength, adhesive technology, applied in the direction of strength characteristics, using stable tension/pressure test material strength, measuring device, etc., to achieve the effect of ensuring coaxiality, ensuring parallelism, and accurately controlling the lap length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings and embodiments. Long thin-walled cylinder 5

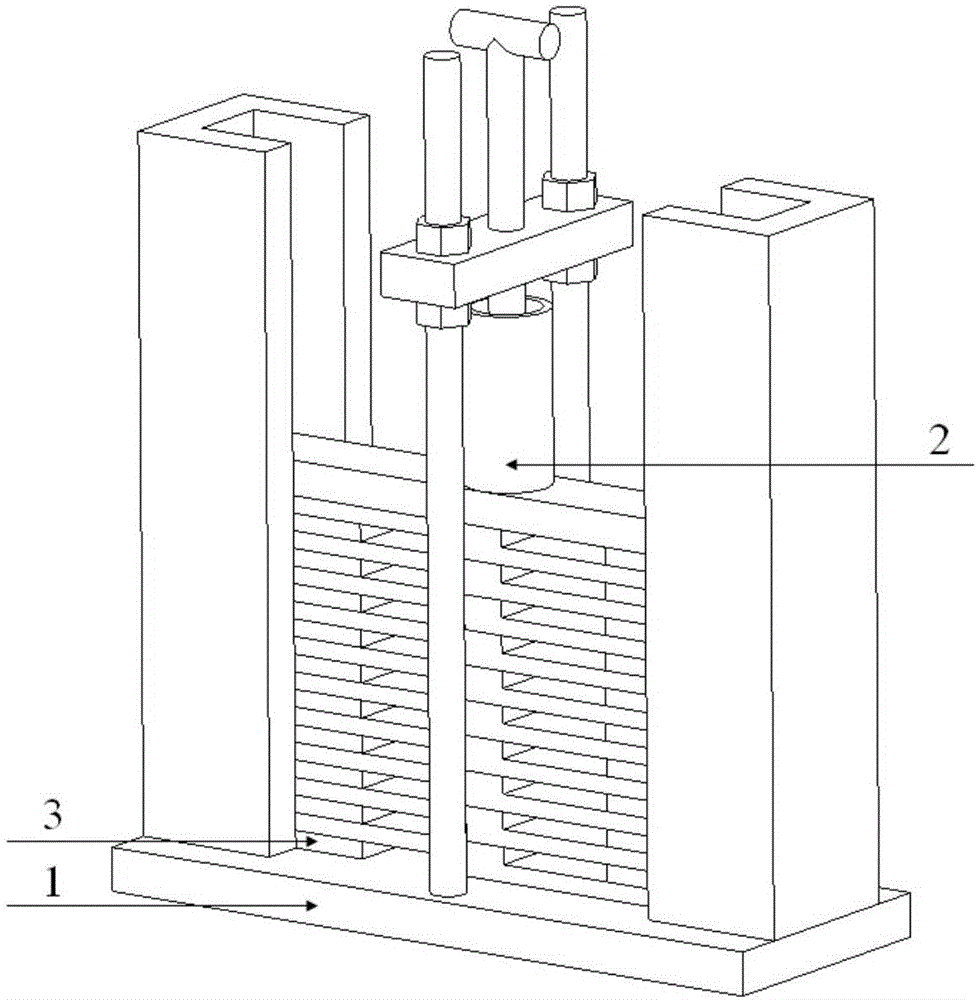

[0022] Such as figure 1 As shown, a tooling for making an adhesive tensile and shear strength sample includes a base 1, a pressure system 2, and a cushion block 3.

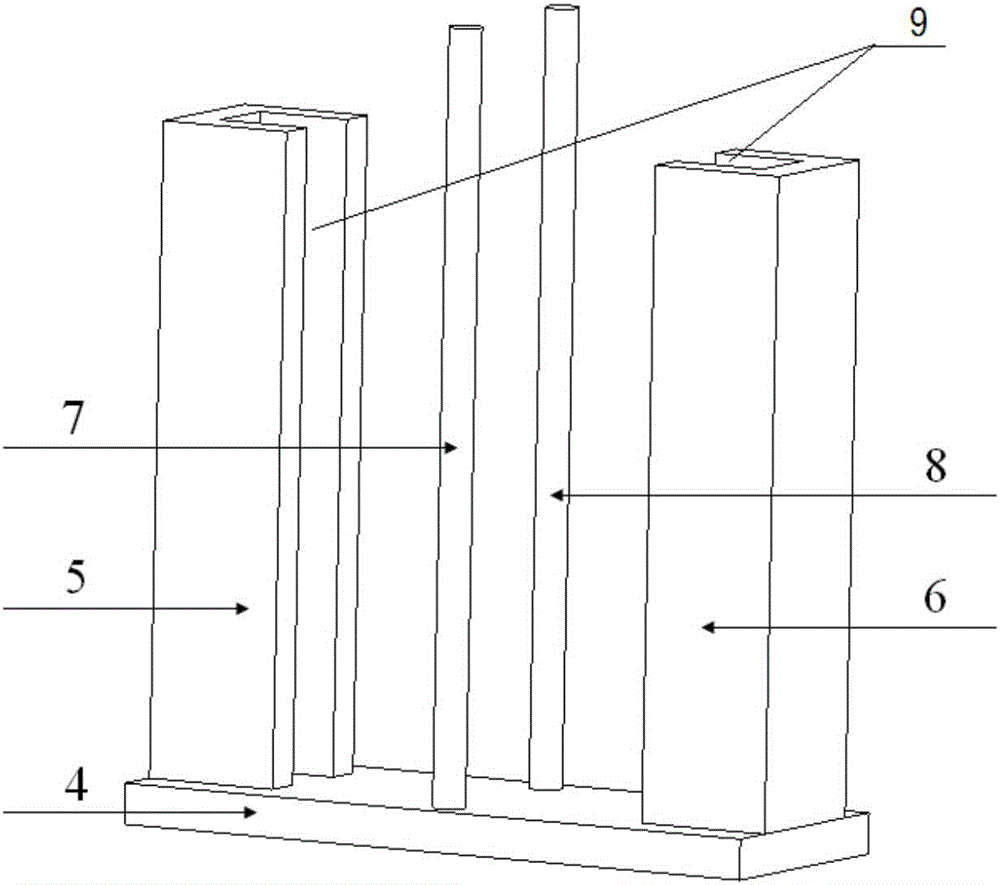

[0023] Such as figure 2 As shown, the base 1 includes a bottom plate 4, a left groove 5, a right groove 6, a front pillar 7 and a rear pillar 8. The left groove 5 and the right groove 6 are symmetrically and vertically arranged on both sides of the surface of the bottom plate 4 to form a sample groove 9. The front post 7 and the rear post 8 are threaded for fixing the pressurizing system 2.

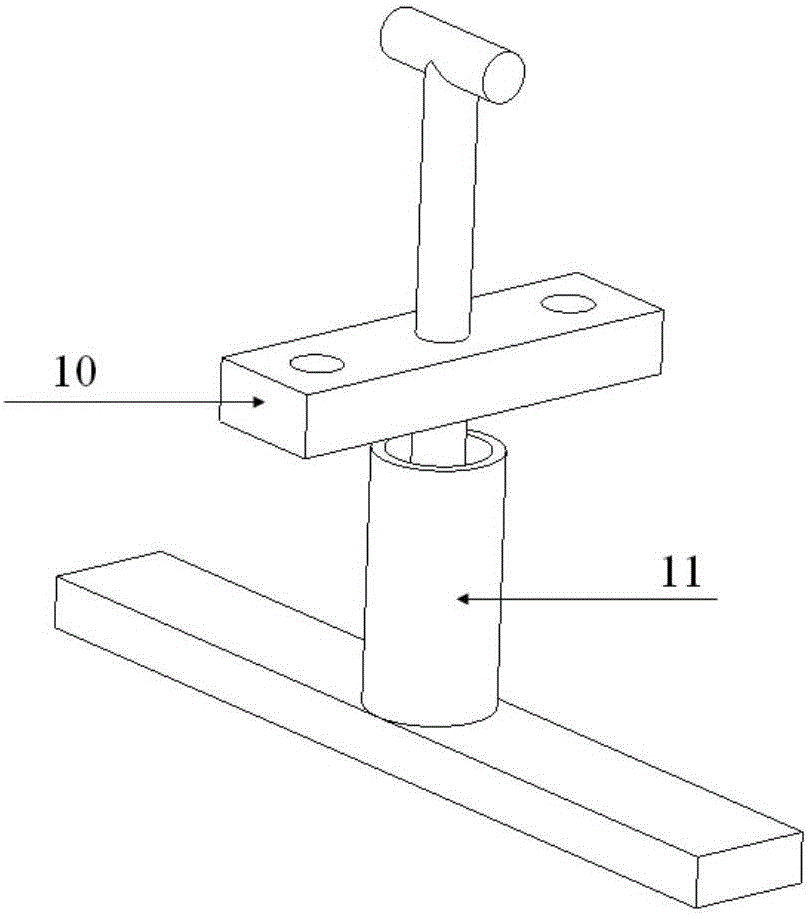

[0024] Such as image 3 As shown, the pressing system 2 is composed of a beam 10 and a pressing device 11.

[0025] Such as figure 1 As shown, the beam 10 is connected with the front column 7 and the rear column 8 by upper and lower nuts. The height of the beam can be adjusted by adjusting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com