Dual-front axle wheel axle parallel position adjustment method

A positioning adjustment and axle technology, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of lack of knowledge on the positioning of heavy-duty vehicle wheels and axles, the inability to meet the precise positioning of wheels and axles, and expensive equipment, etc., to achieve reduction Effects of abnormal wear and fuel consumption, reduction of waste, and improvement of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

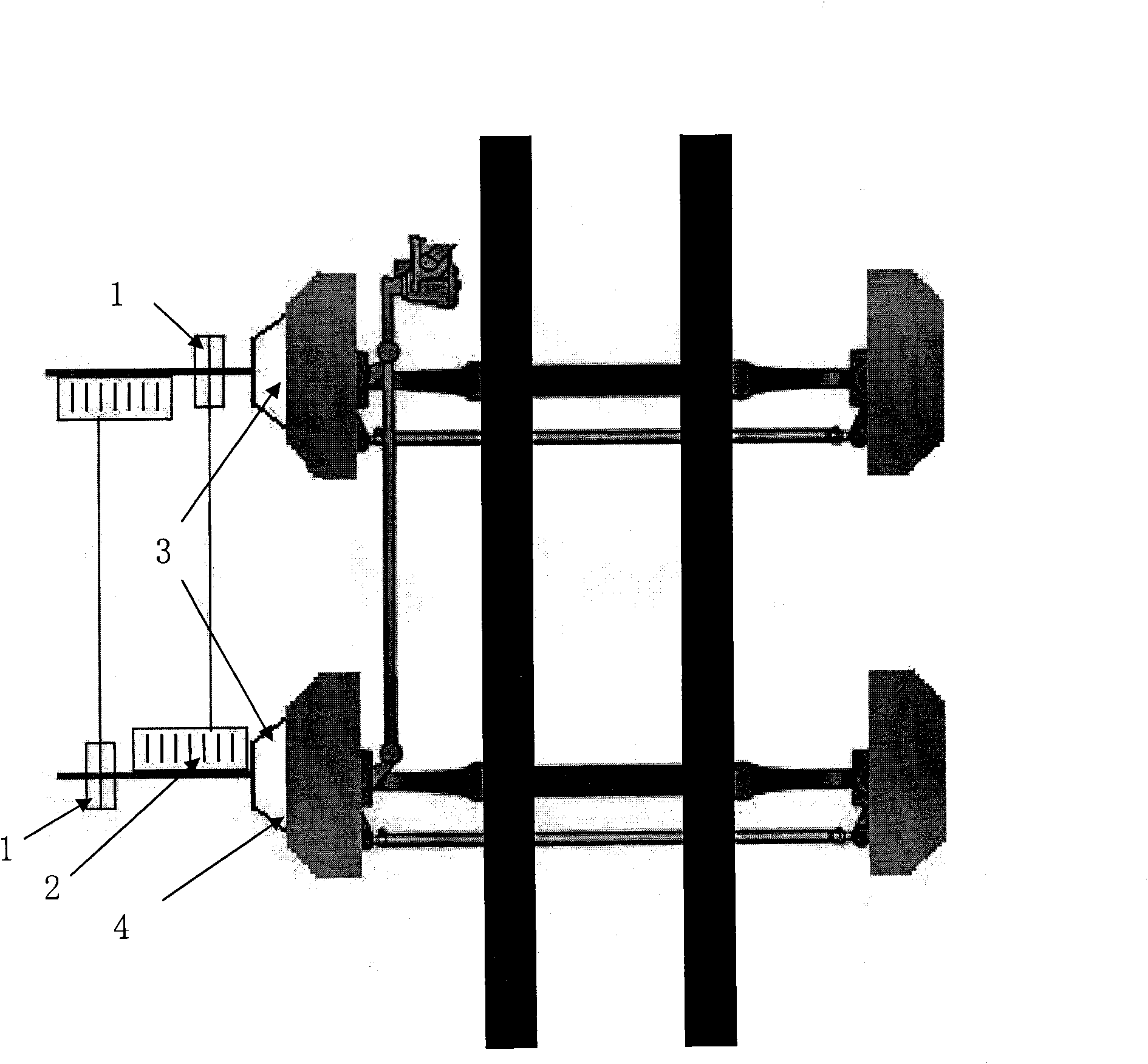

[0020] The invention relates to a method for adjusting the parallel positioning of the wheels and axles of double front axles. The method uses the distance between the two axles of the wheels of the double front axles, and sets up a parallel locator detection device to perform parallel positioning of the axles. All vehicles used after offline are common.

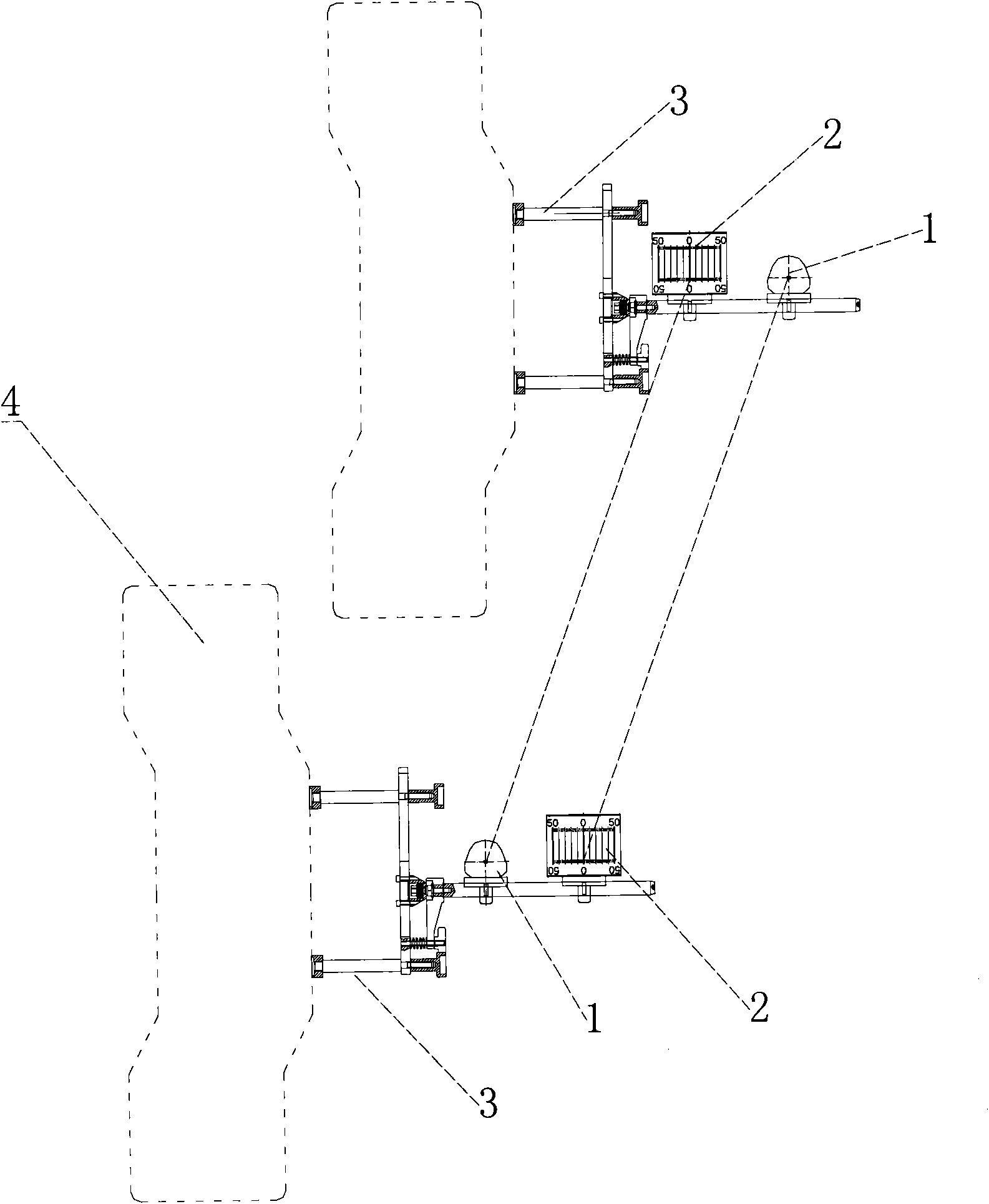

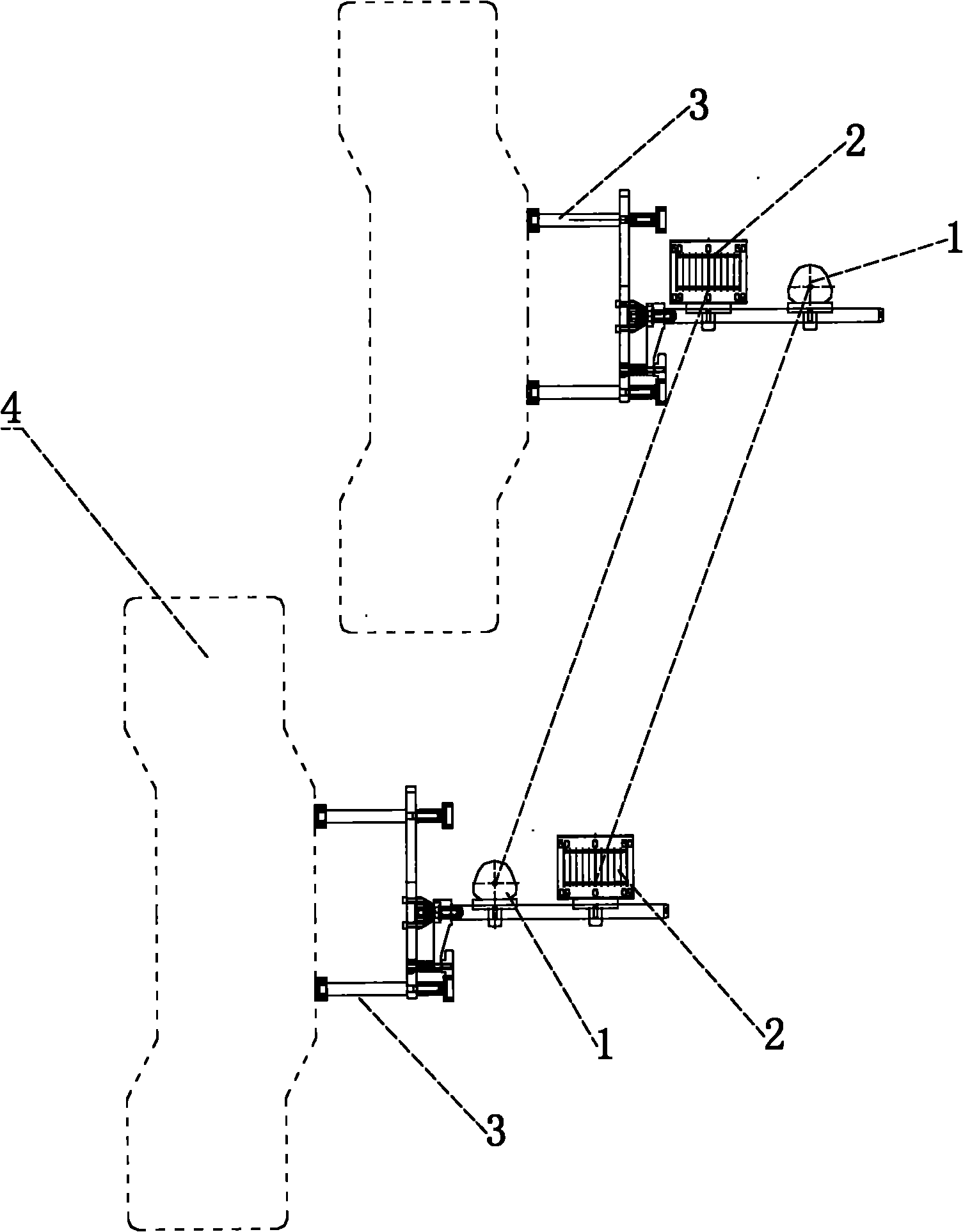

[0021] When detecting the parallelism of the double front axle, such as figure 1 Shown is the double front axle wheel parallel aligner used on the production line, figure 2 For the situation of using the equipment after the vehicle is offline, the method includes the steps of:

[0022] a), clamp installation, set magnetic clamps 3 respectively on the wheel hub 4 on the steering rod side of the first steering axle and the second steering axle of the vehicle to be positioned;

[0023] b), installing a laser emitter 1 and a target 2 on the axis of each fixture respectively;

[0024] c), turn the steering wheel of the vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com