Patents

Literature

1993results about "Forging press details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

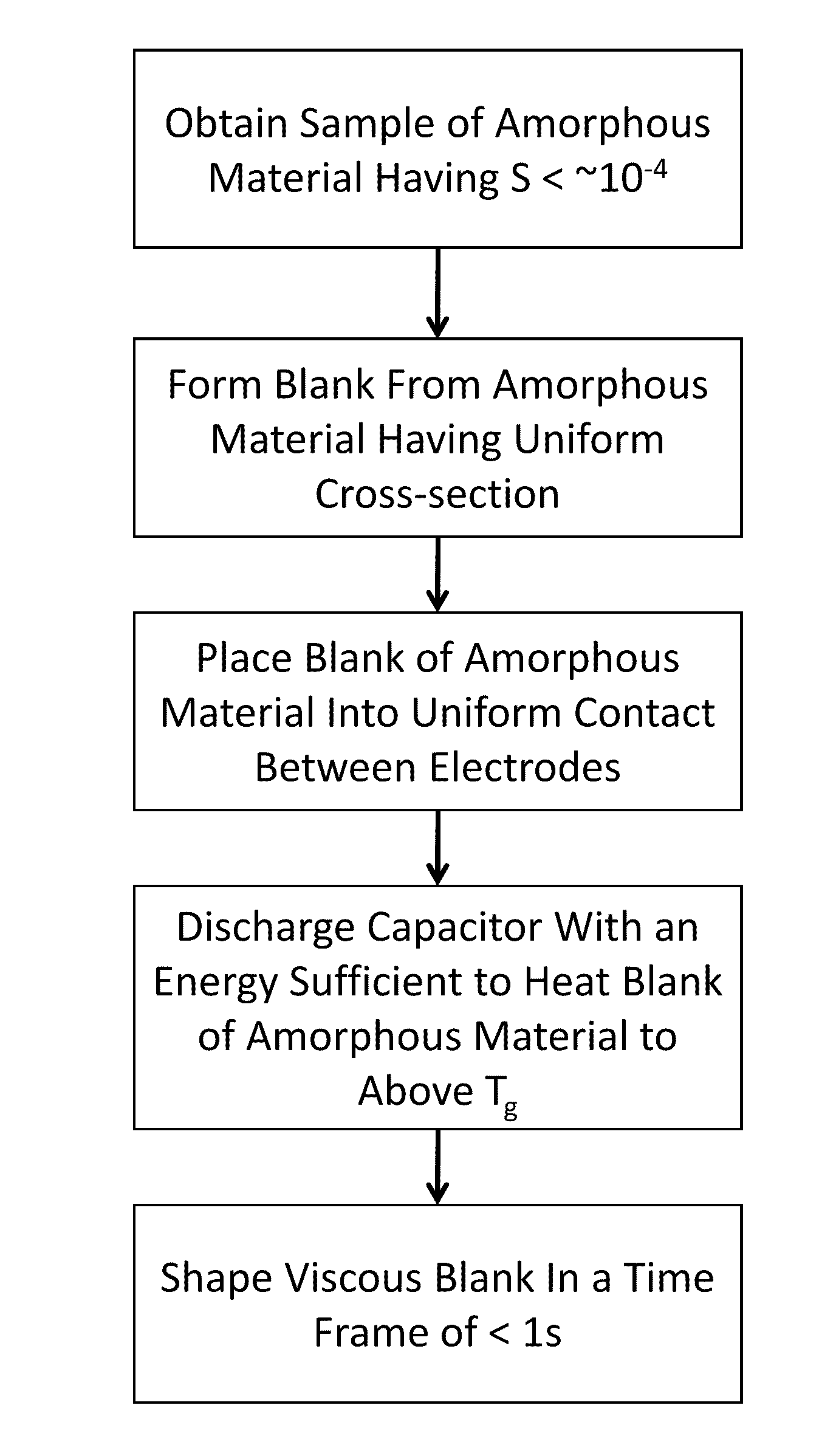

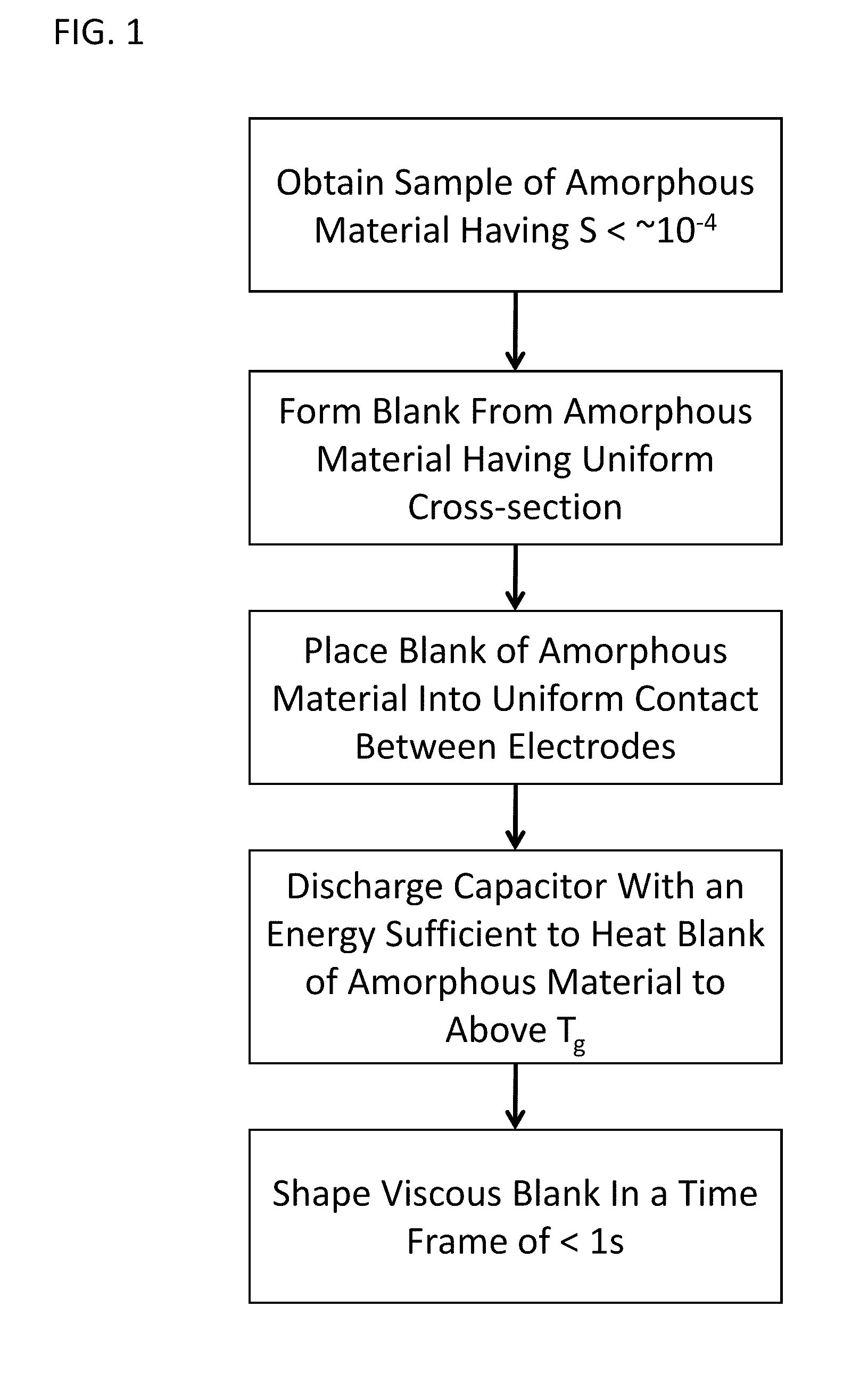

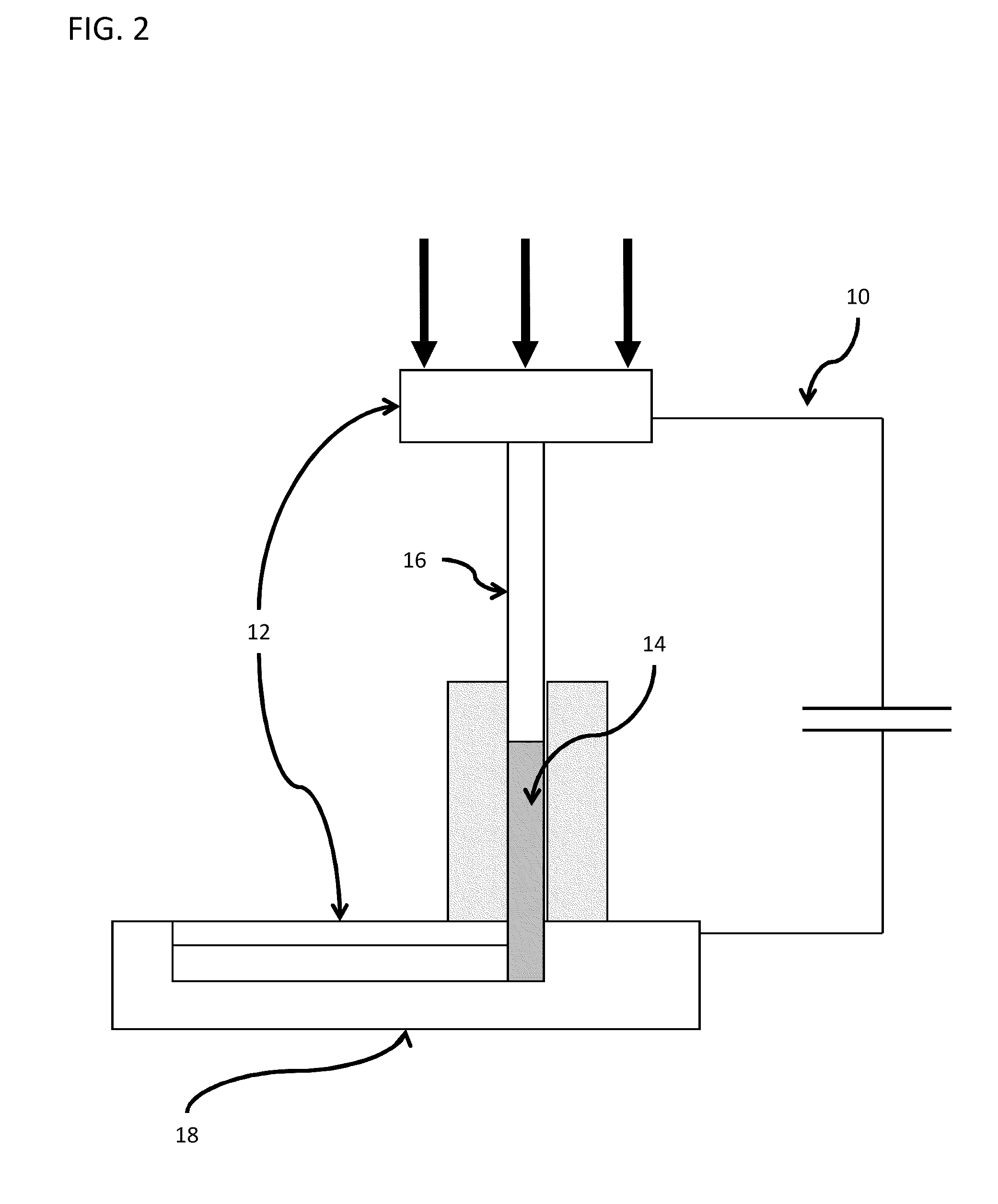

Forming of metallic glass by rapid capacitor discharge

ActiveUS20090236017A1Avoid failureAvoid thermal transport and development of thermalDielectric heatingShaping toolsAlloyGlass transition

An apparatus and method of uniformly heating, rheologically softening, and thermoplastically forming metallic glasses rapidly into a net shape using a rapid capacitor discharge forming (RCDF) tool are provided. The RCDF method utilizes the discharge of electrical energy stored in a capacitor to uniformly and rapidly heat a sample or charge of metallic glass alloy to a predetermined “process temperature” between the glass transition temperature of the amorphous material and the equilibrium melting point of the alloy in a time scale of several milliseconds or less. Once the sample is uniformly heated such that the entire sample block has a sufficiently low process viscosity it may be shaped into high quality amorphous bulk articles via any number of techniques including, for example, injection molding, dynamic forging, stamp forging, and blow molding in a time frame of less than 1 second.

Owner:CALIFORNIA INST OF TECH

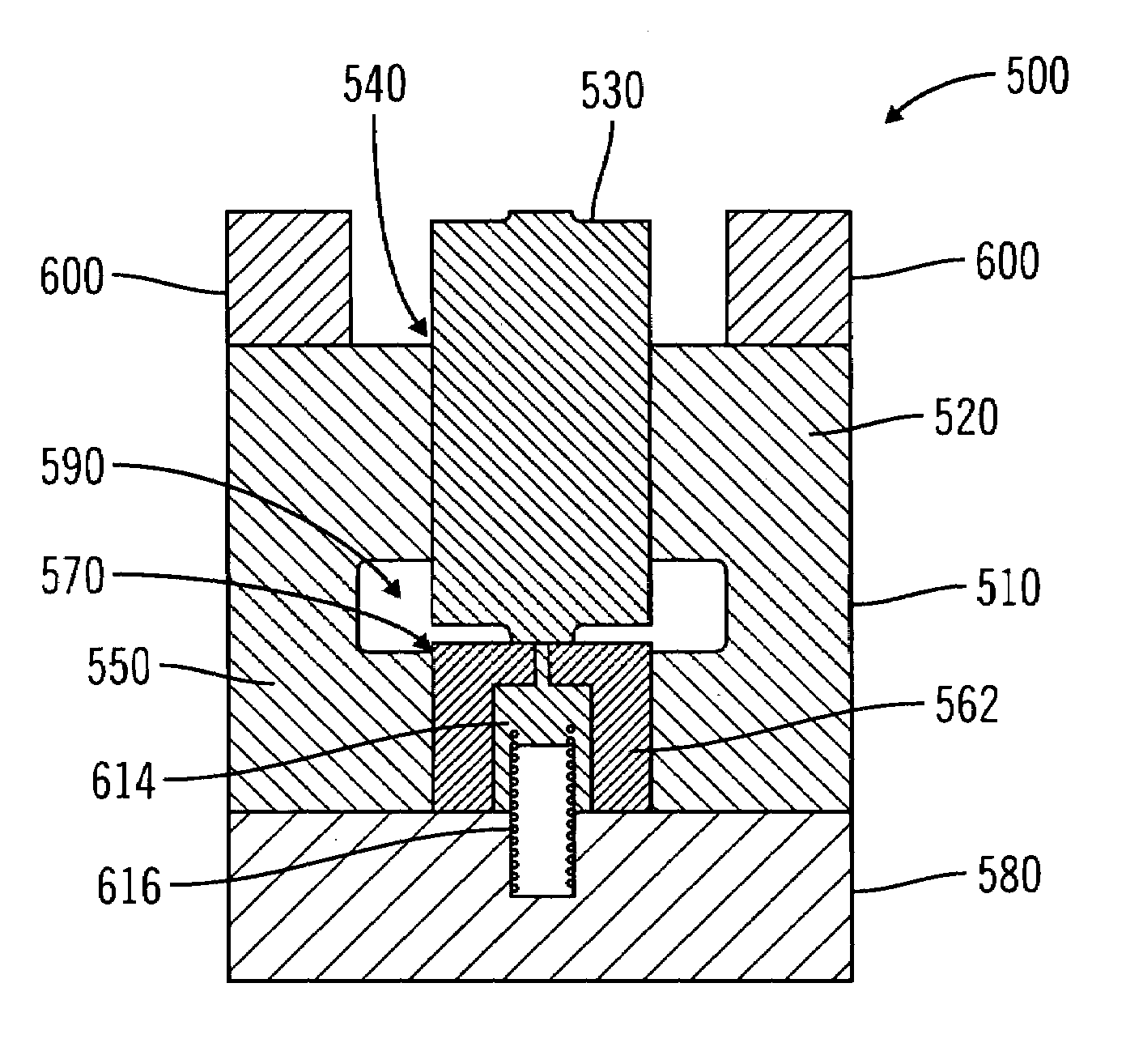

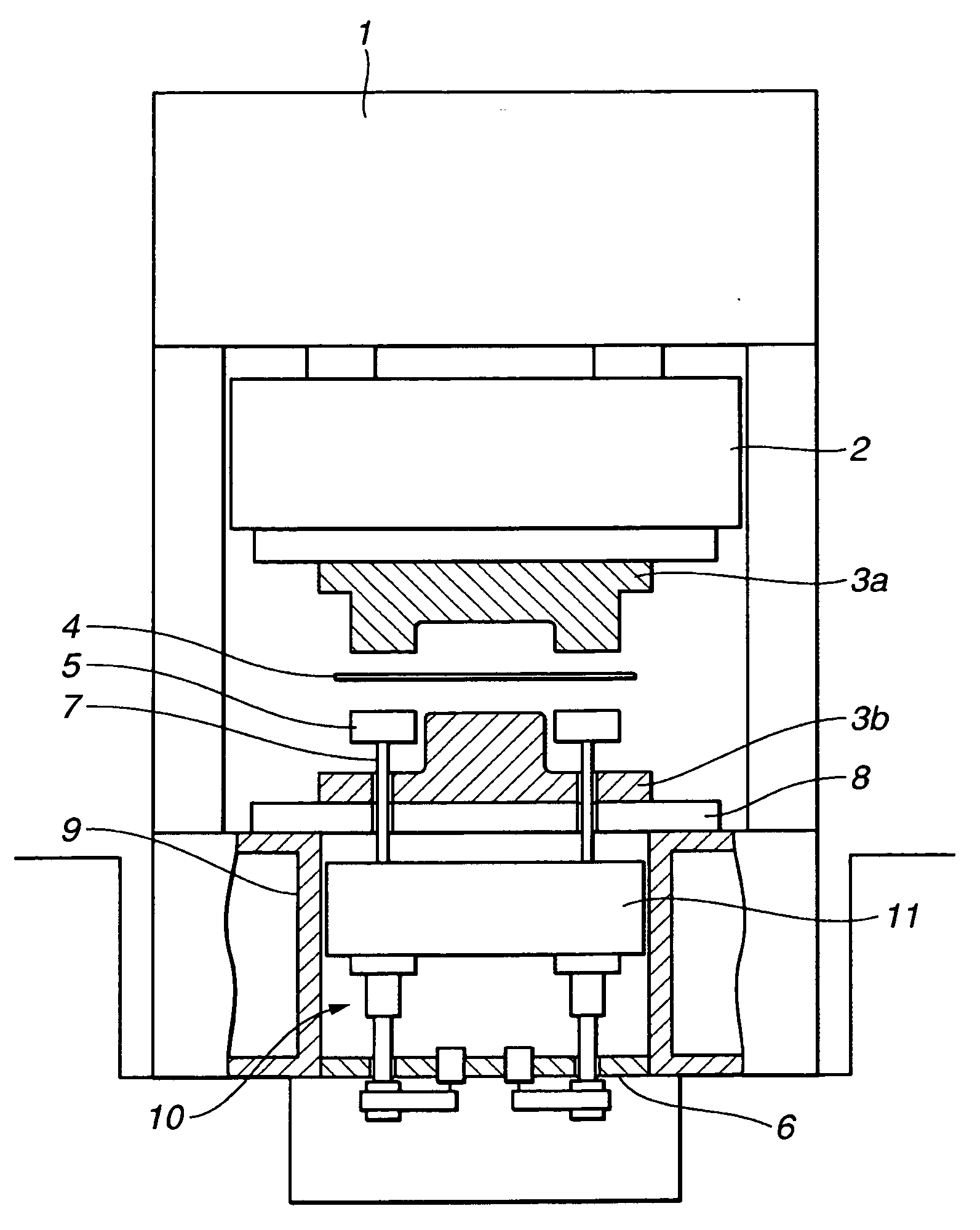

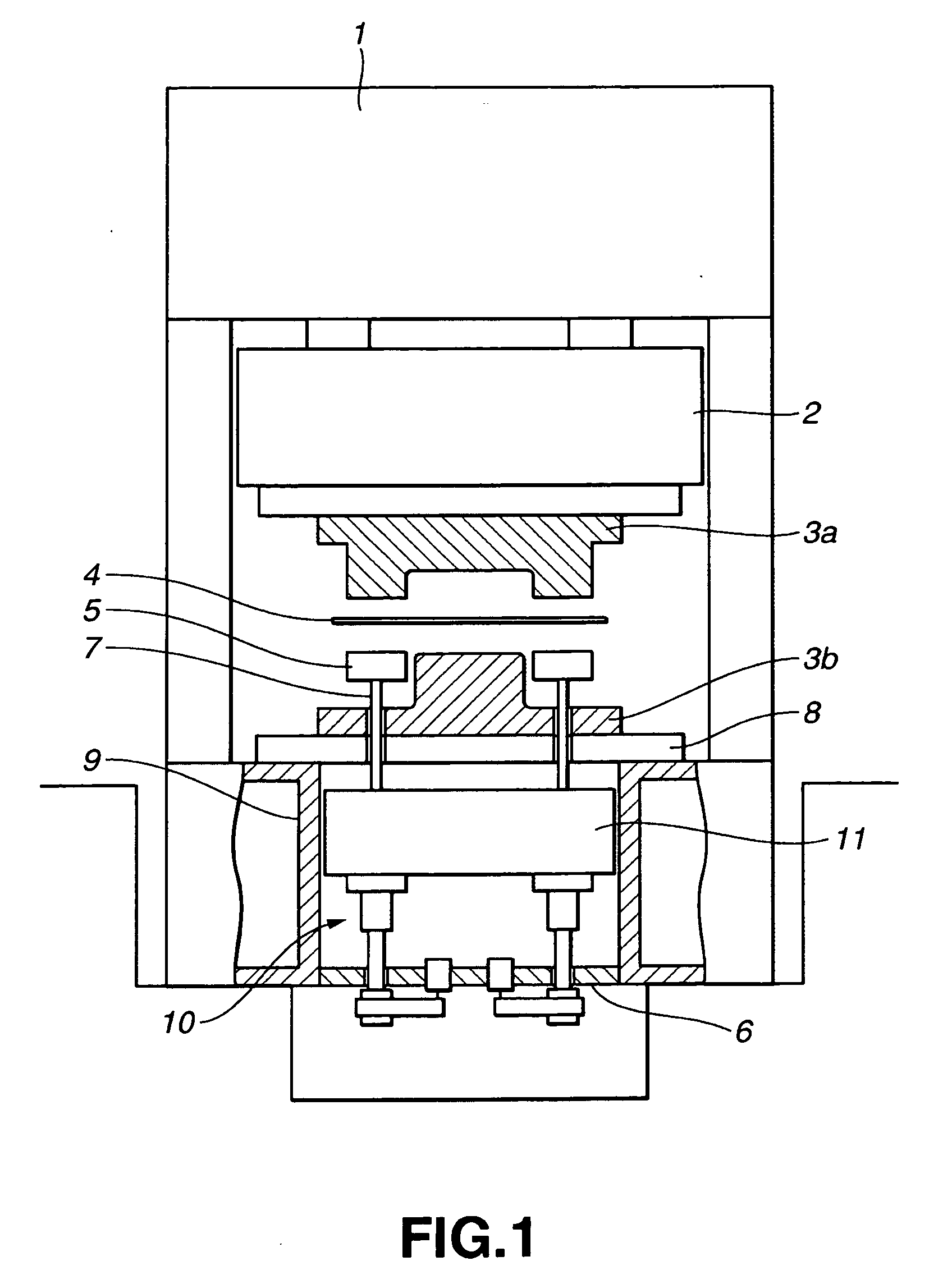

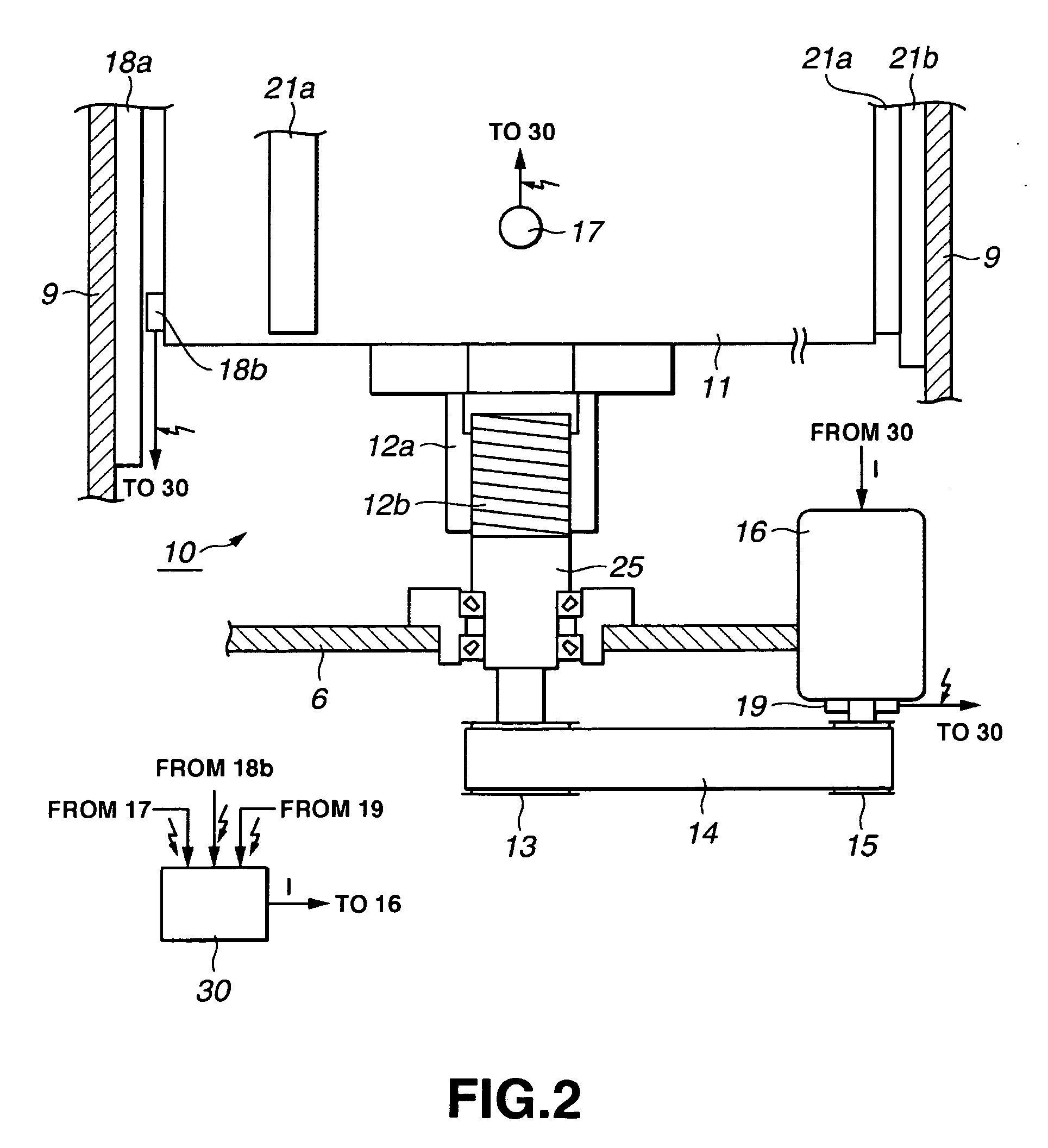

Stamping system for manufacturing high tolerance parts

ActiveUS7343770B2Minimize the numberTight toleranceShaping toolsPerforating toolsMachine pressStamping press

A system and process for stamping parts having tolerances below 1000 nanometers. The inventive system and process is particularly suited for producing optoelectronic parts. The system includes a stamping press and one or a progression of stamping stations for supporting a punch and die. The stamping stations are designed to maintain substantial alignment of the punch and die with minimal moving components. The stamping station includes a shaft for rigidly guiding the punch to the die. The stamping press is capable of providing the punch with the necessary force to perform the stamping operations. The system includes an interface system for interfacing the force of the press with the punch, while simultaneously structurally decoupling the press from the punch. The system also includes a locating sub-plate, for locating the stamping station in alignment relative to each other, and means for in-line machine stock material before entry into the stamping stations.

Owner:SENKO ADVANCED COMPONENTS

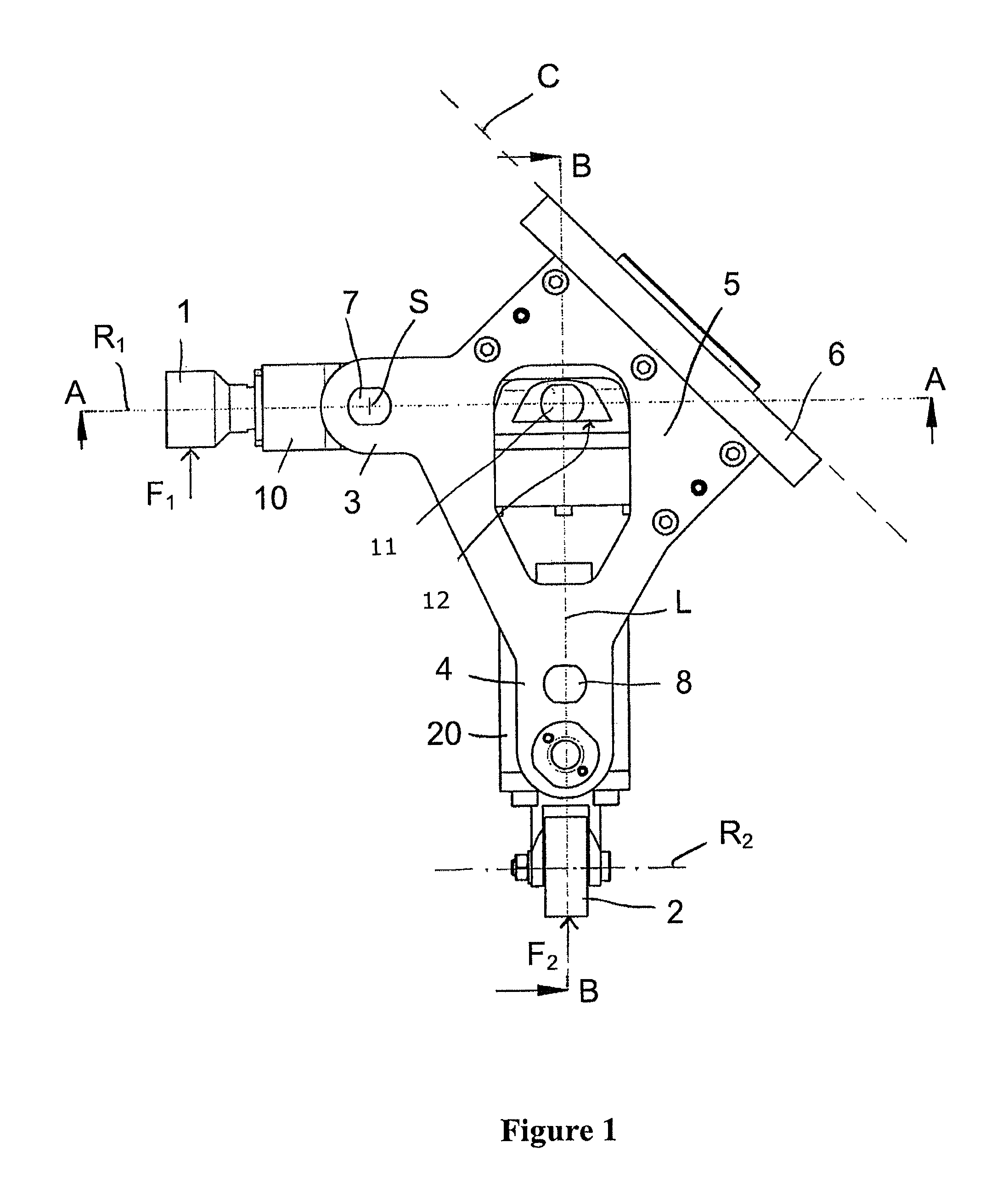

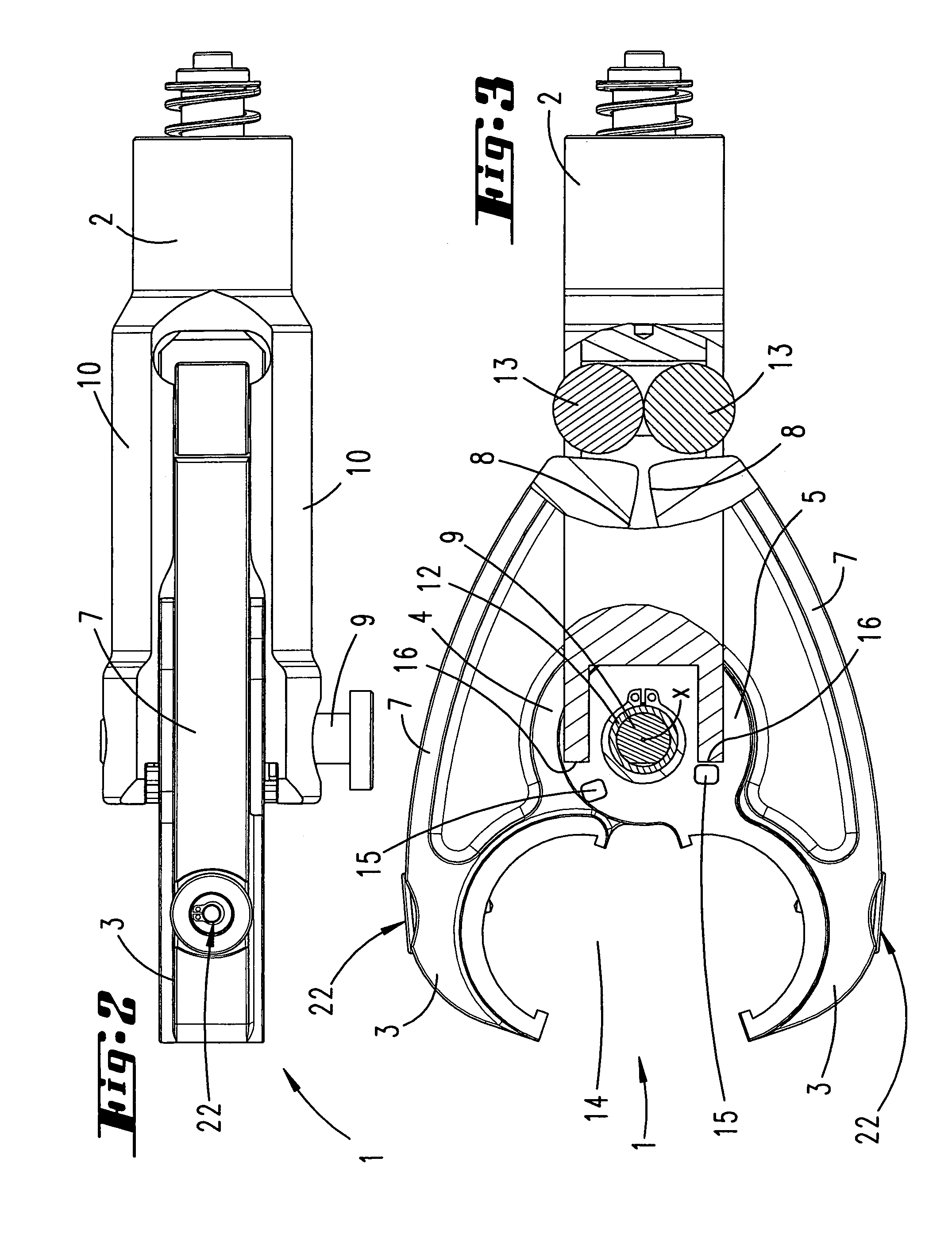

Edge curling tool

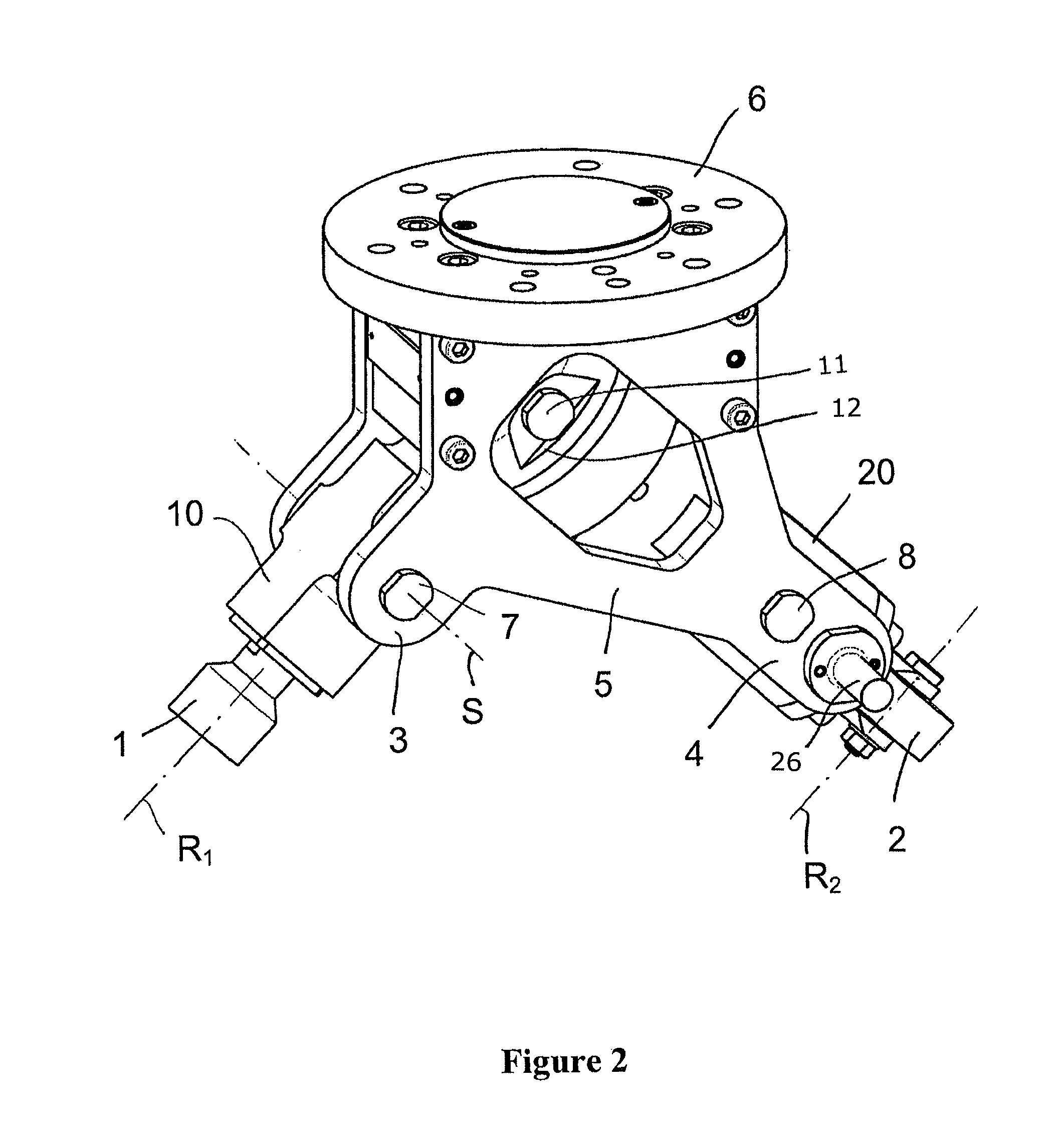

A roll-flanging tool, including a bearing structure having a connector, by which the tool can be connected via a connection plane to an actuator which can be moved spatially. A first arm and a second arm are spread apart from each other and connected to each other in a connection portion which includes the connector. A first flanging roller is mounted on an end of the first arm which faces away from the connection plane, such that it can be rotated about a first rotational axis which extends along the first arm and pierces the connection plane. A second flanging roller is mounted on an end of the second arm which faces away from the connection plane, such that it can be rotated about a second rotational axis. The first rotational axis intersects or crosses a perpendicular dropped onto the second rotational axis, in or on the roll-flanging tool.

Owner:FFT PRODIONSSYST

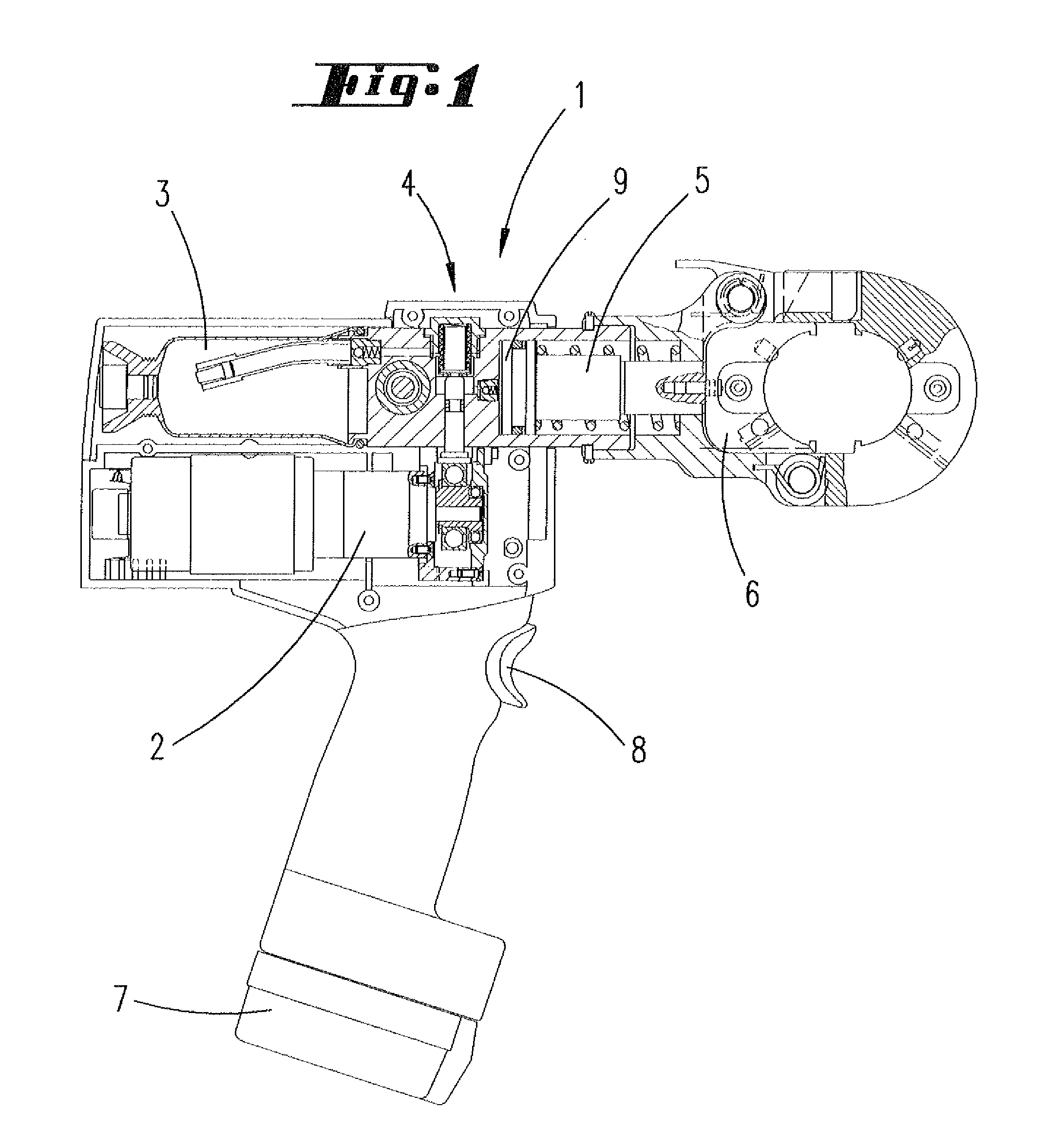

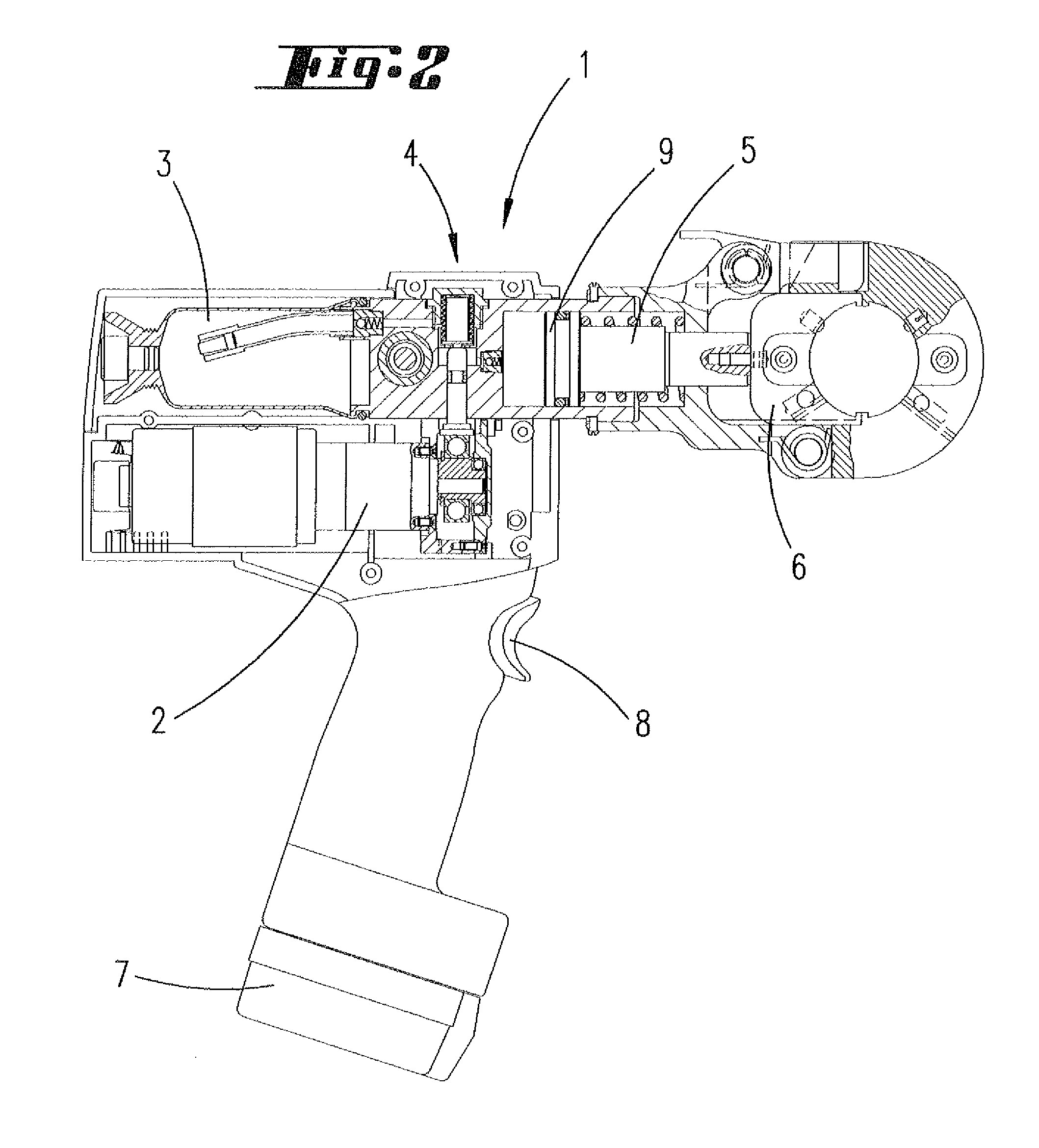

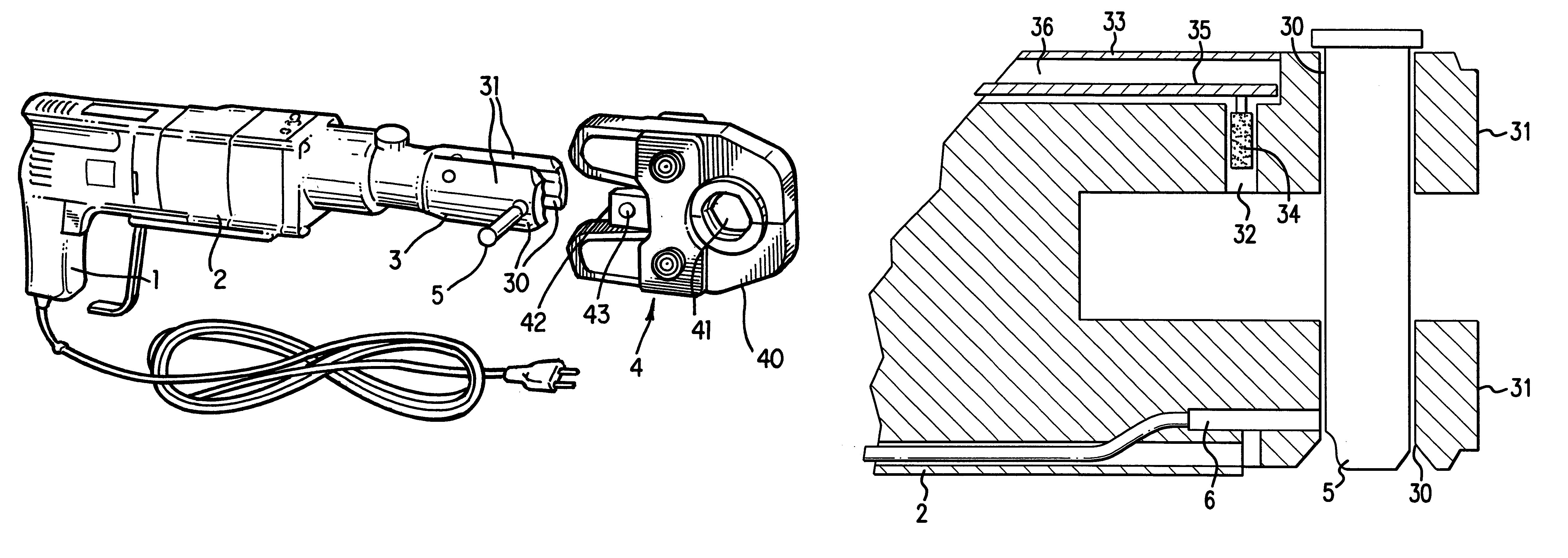

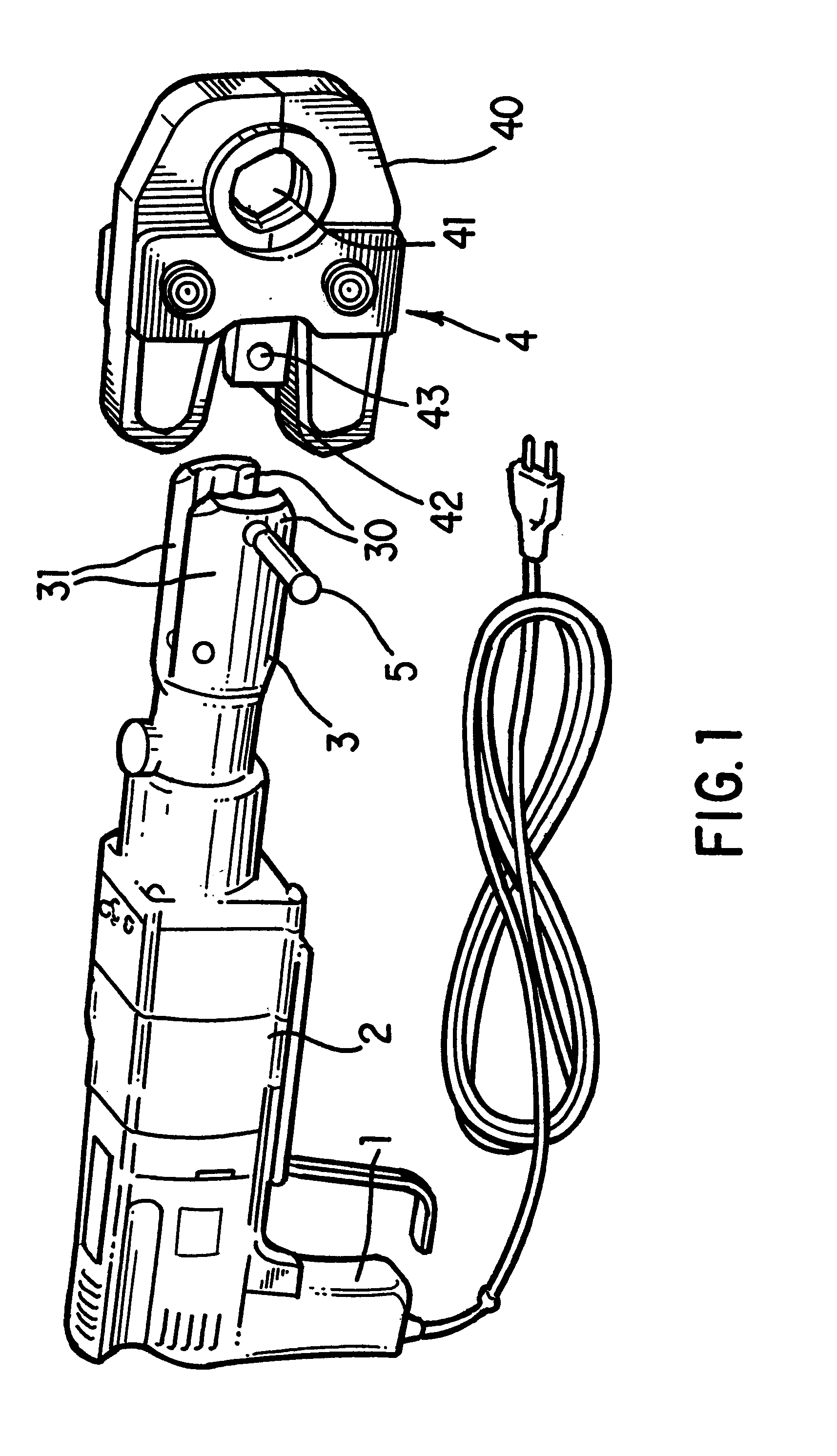

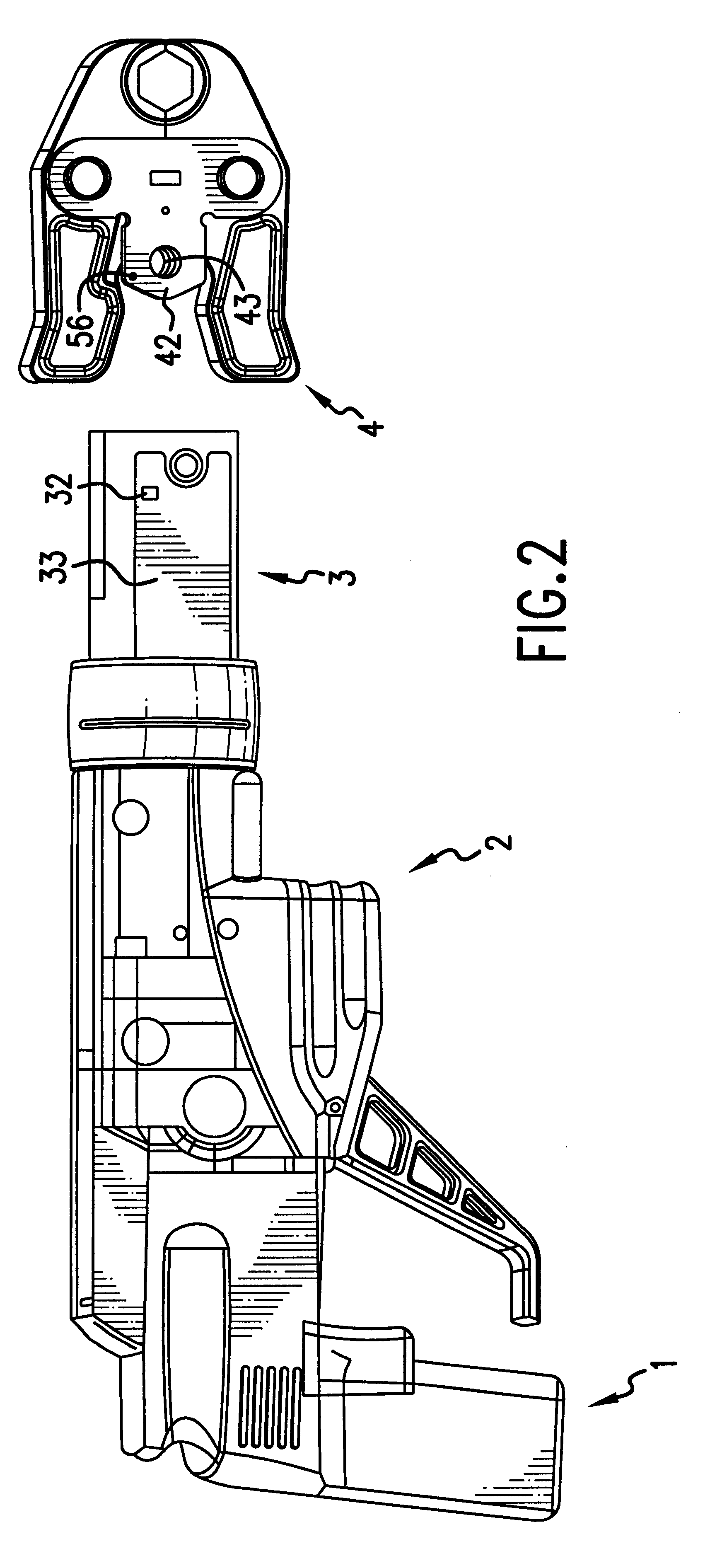

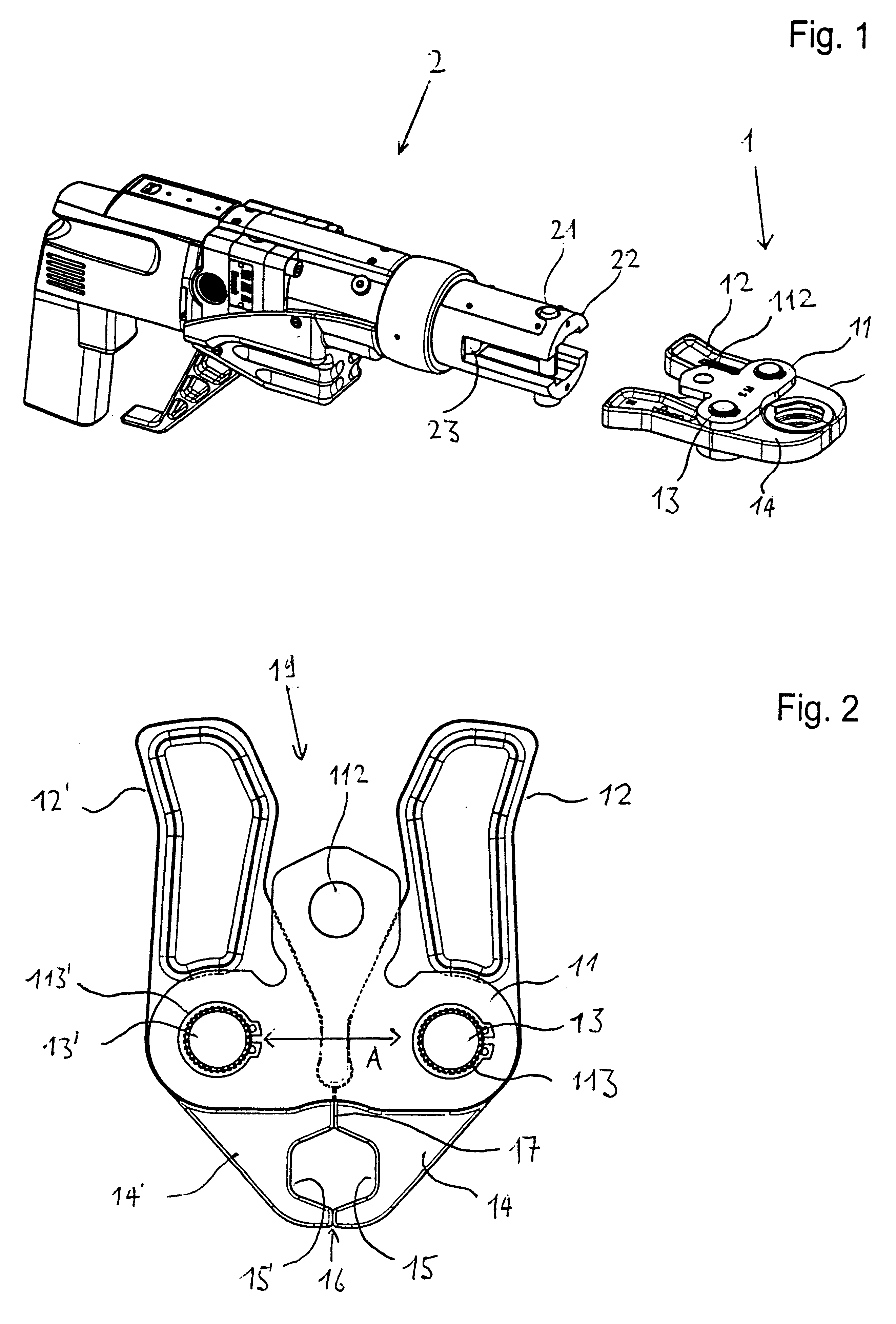

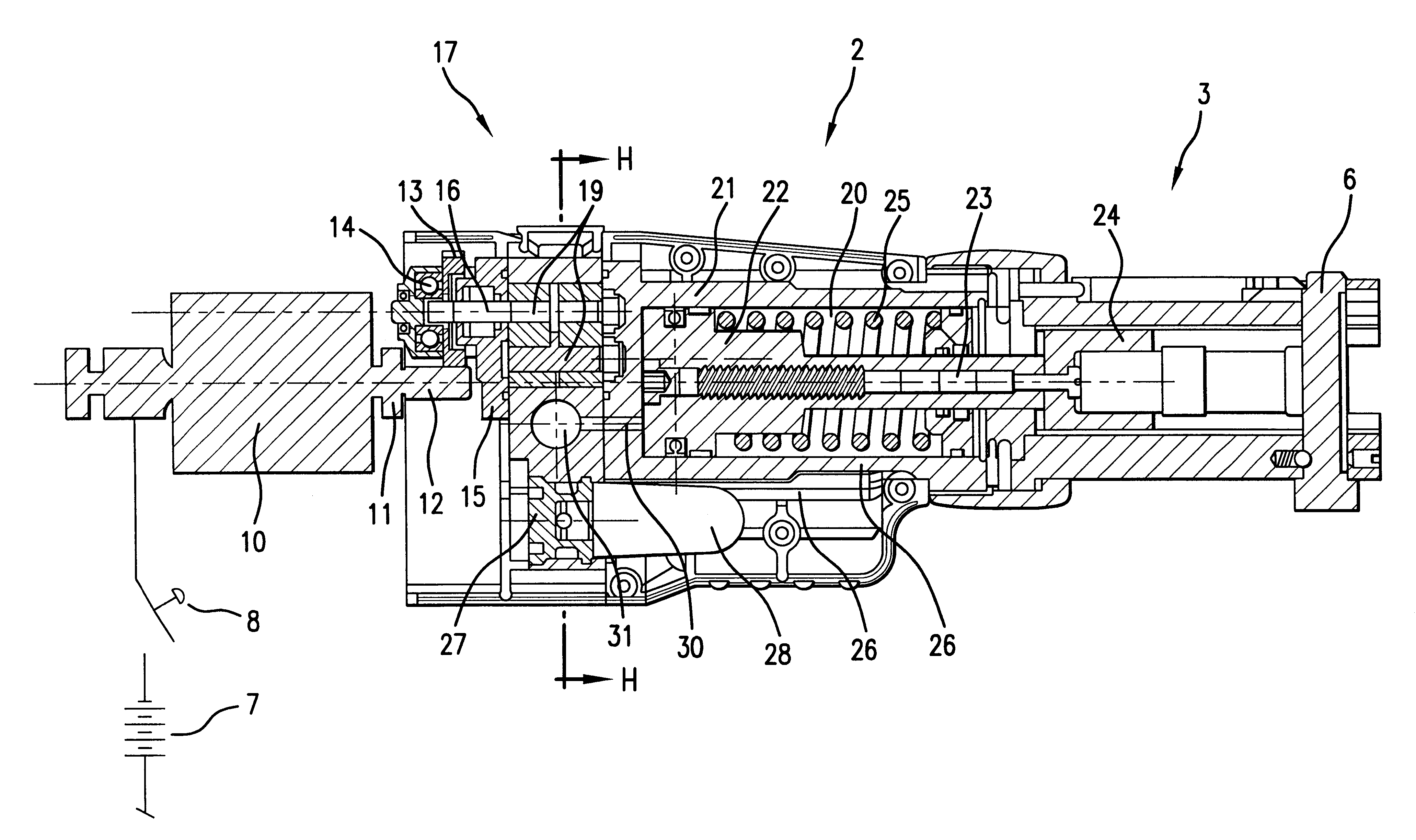

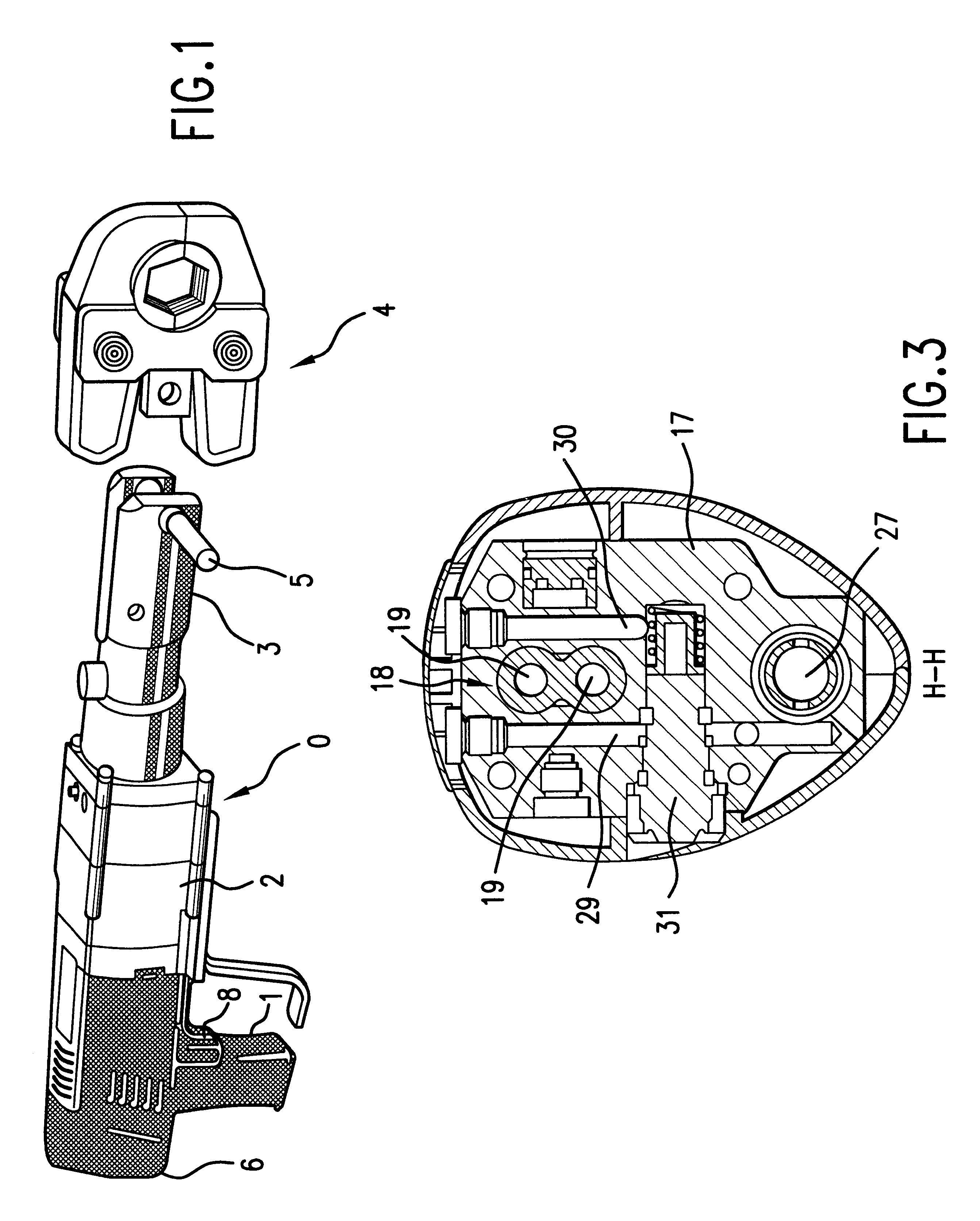

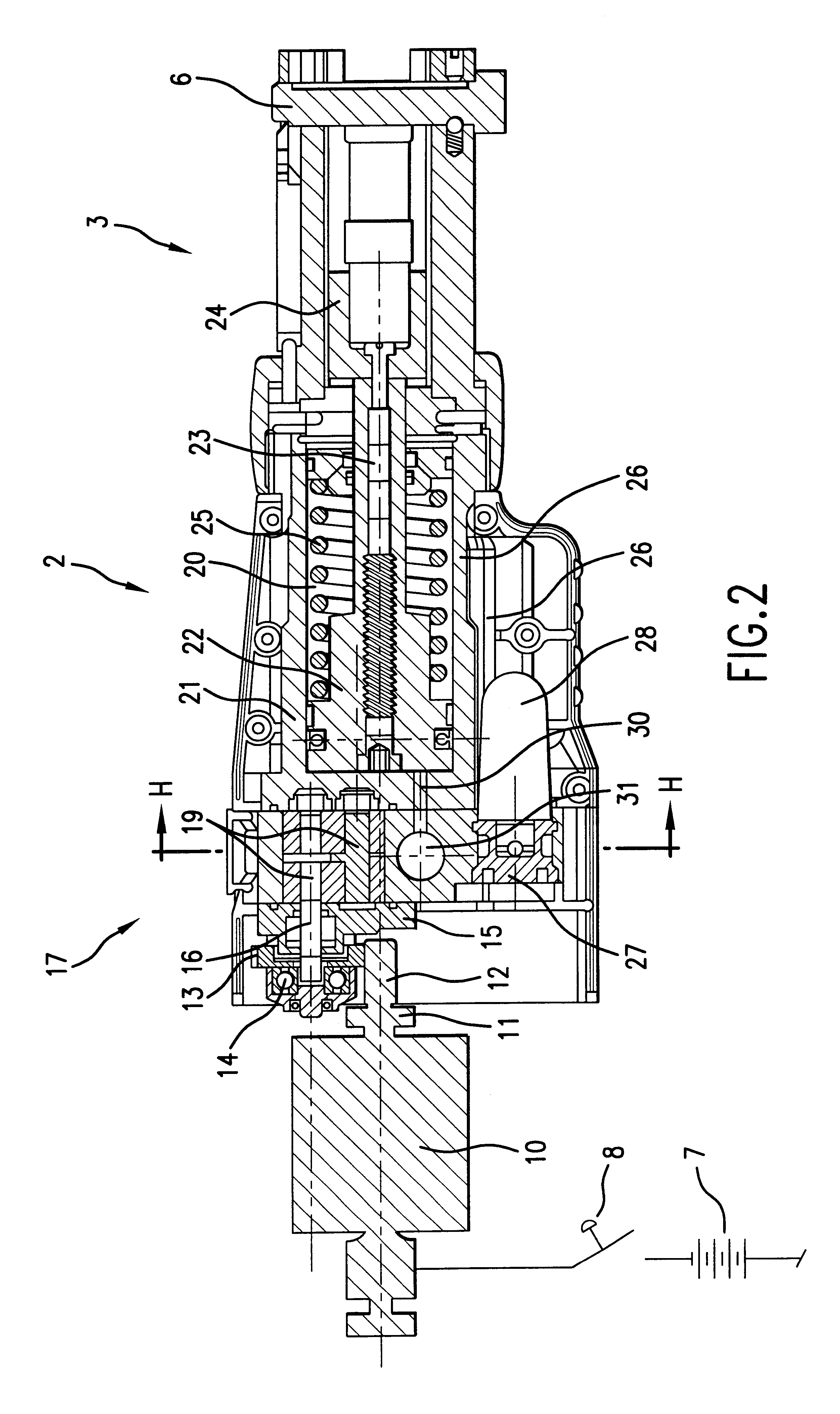

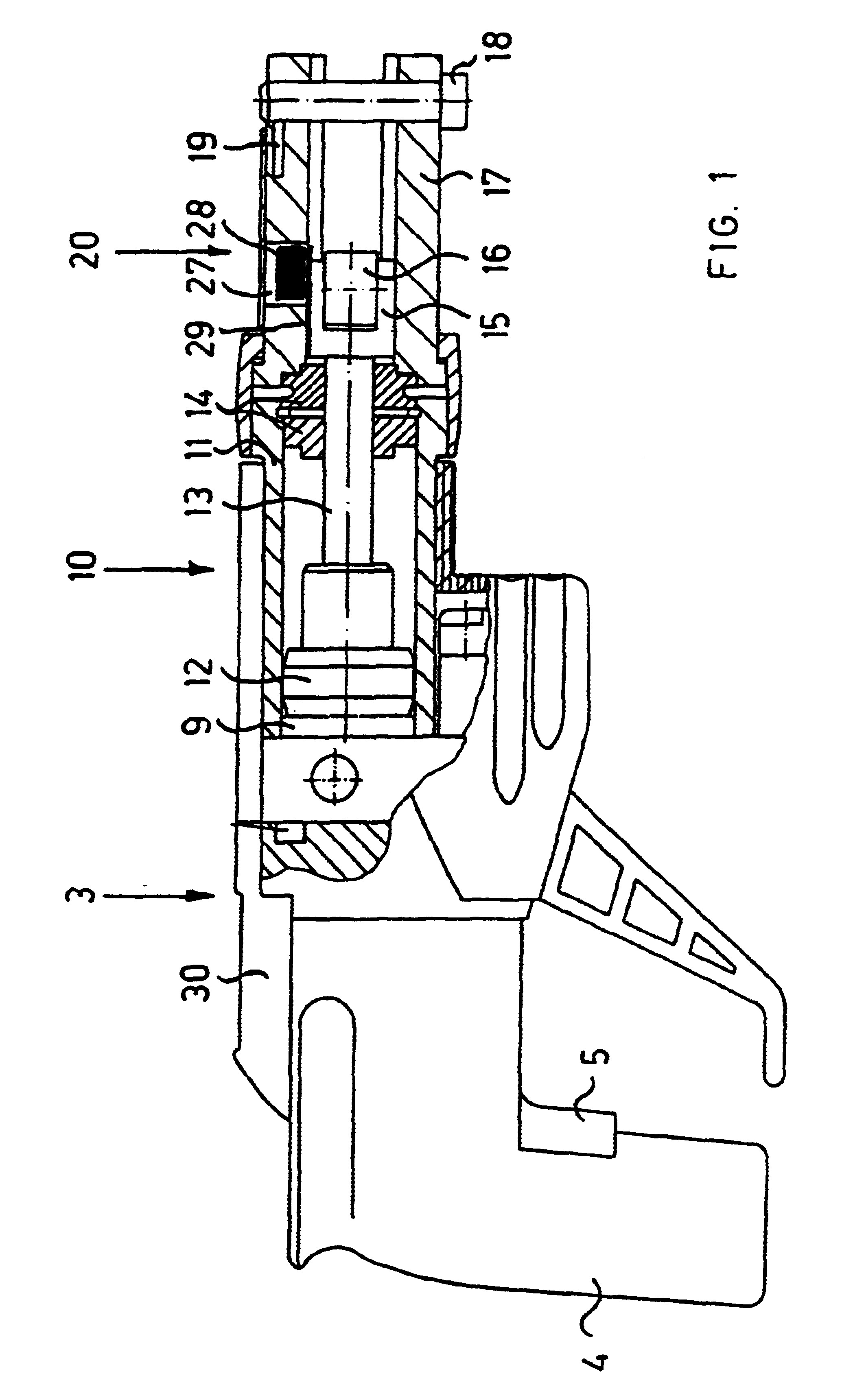

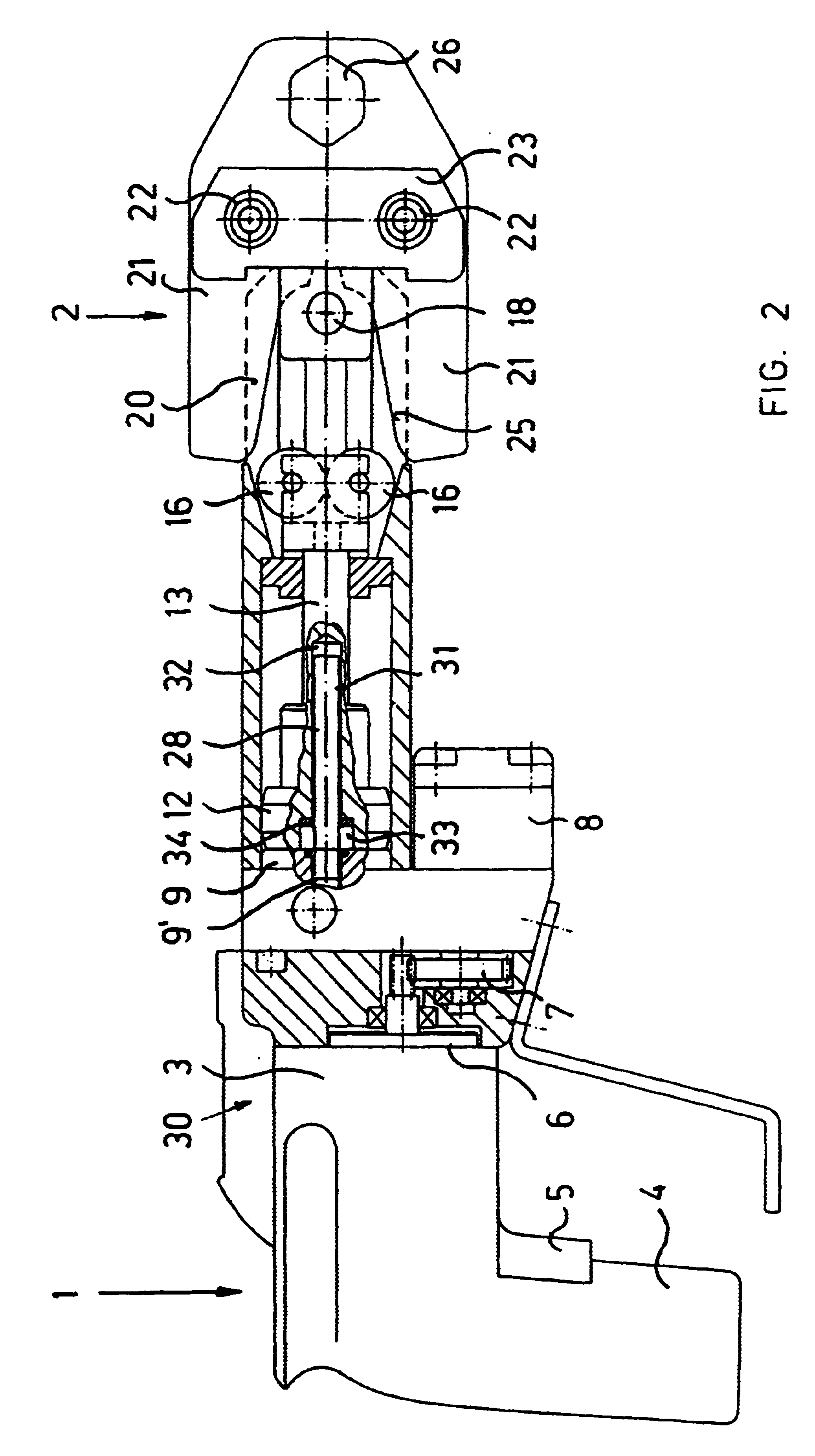

Method for the operation of a motor-driven hand-held pressing apparatus, and hand-held pressing apparatus

ActiveUS8056473B2Achieving Reliability RequirementsReliable maintenanceLine/current collector detailsForging press detailsReflux valveMotor drive

A hydraulic pressing unit includes a hydraulic pump, supply and hydraulic chambers, moving and stationary parts, a restoring spring, and a return valve provided within or attached to a housing. The moving part is displaced from a starting position into a pressing position as a result of filling the hydraulic chamber with a hydraulic medium from the supply chamber by using the hydraulic pump. The return valve is automatically displaced into an open position as a result of a hydraulic pressure corresponding to the pressing position, and the restoring spring moves the moving part. A piston acts on the flow of the hydraulic medium and lowers the pressure such that the return valve is displaced into the closed position.

Owner:GUSTAV KLAUKE GMBH

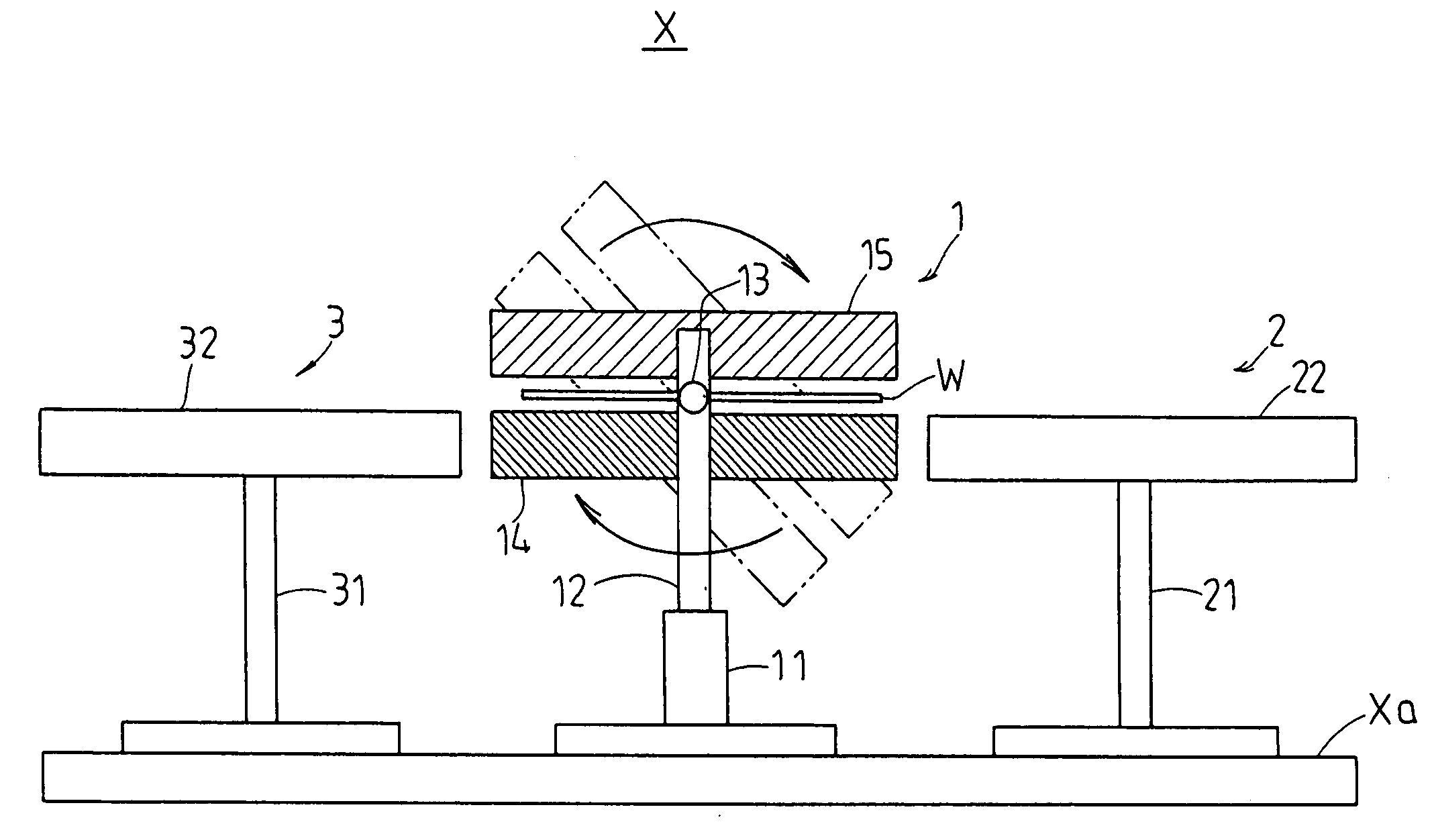

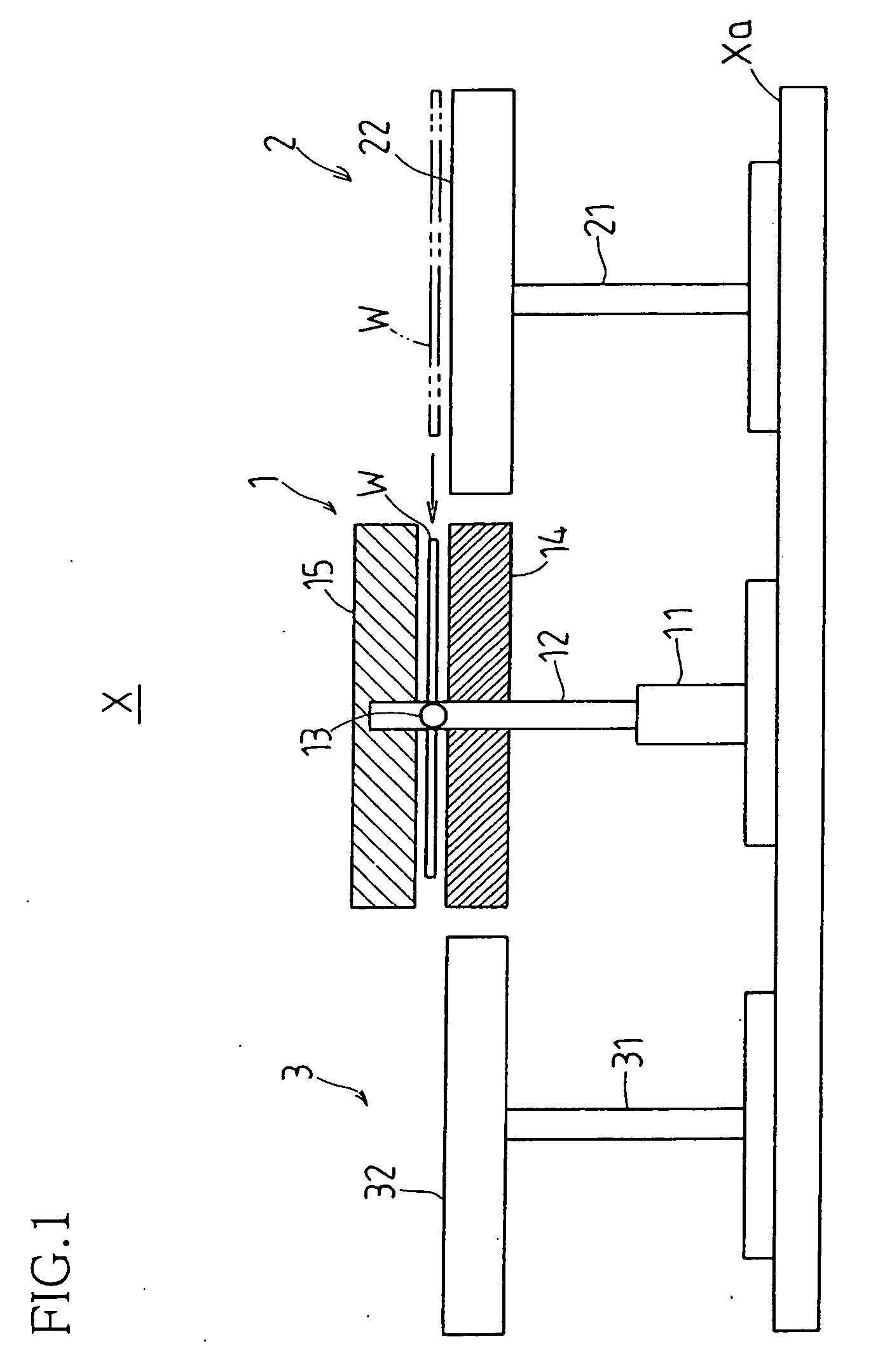

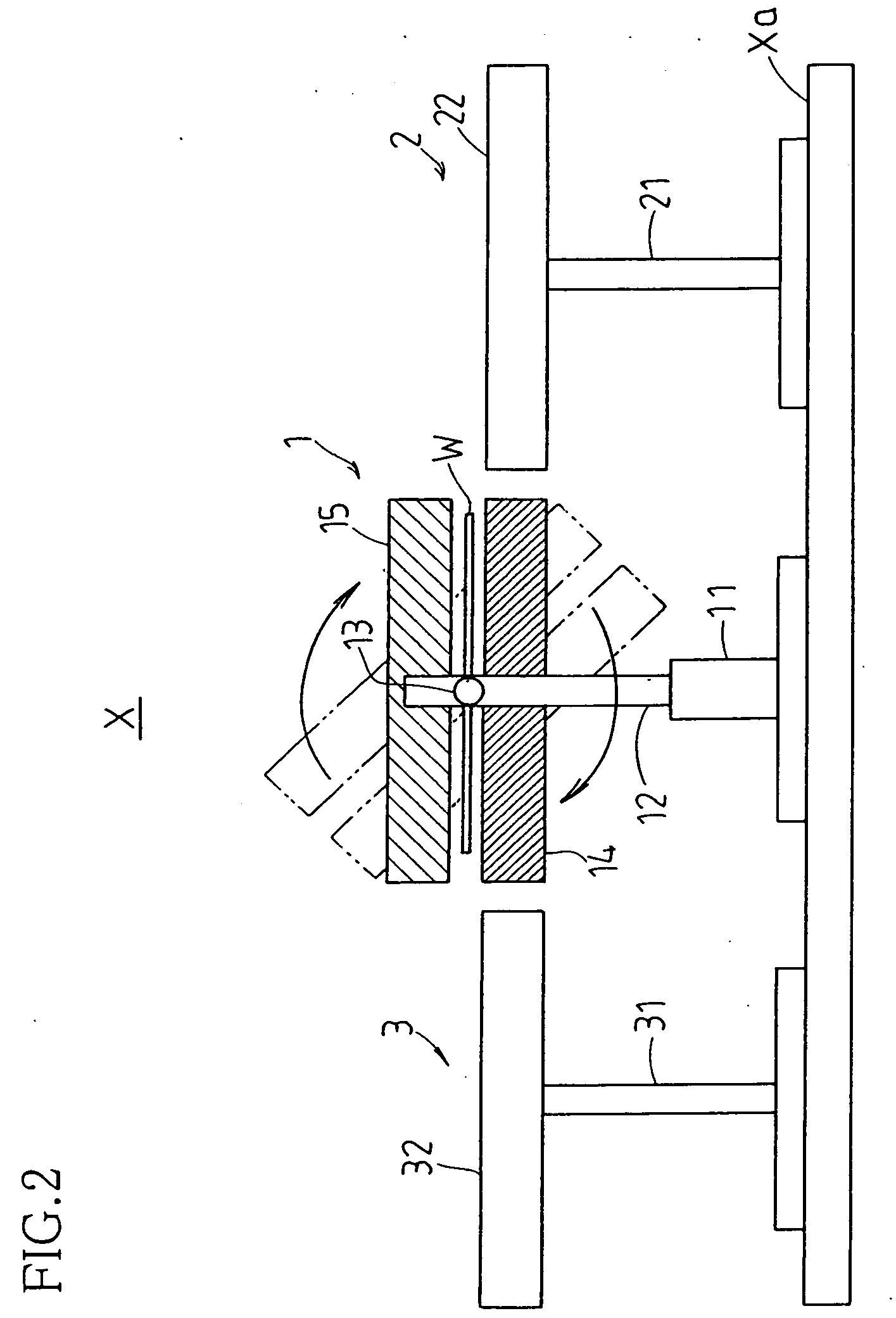

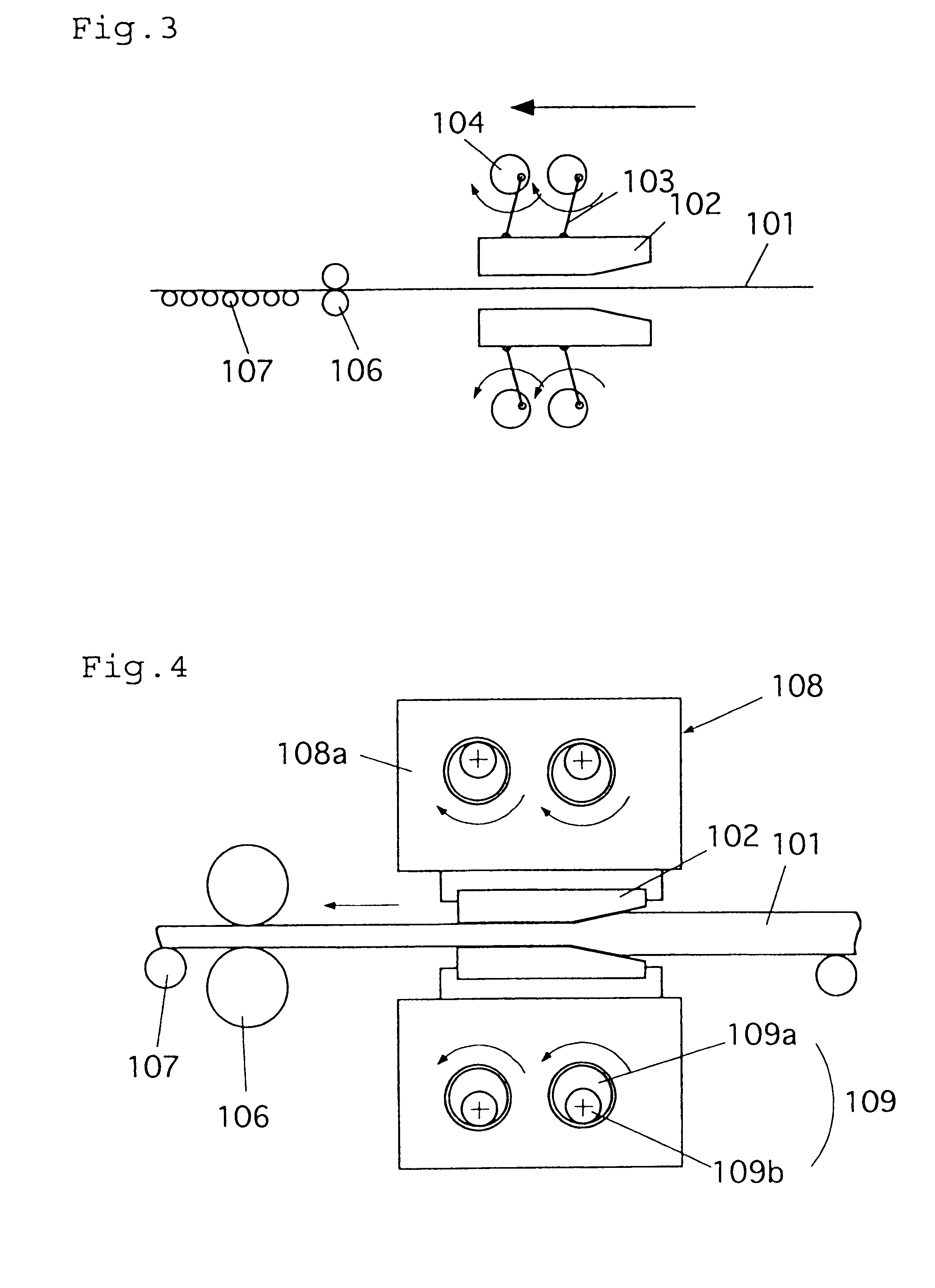

Workpiece transport apparatus

InactiveUS20040197184A1Reduce Particle GenerationEliminate mechanical partForging hammersSemiconductor/solid-state device manufacturingTransport engineering

While periphery or peripheries of workpiece(s) W lifted in floating fashion by simultaneous suction and expulsion of gas(es) between pair(s) of first and second, or upper and lower, transport stages 14, 15 is / are retained by plurality of elevator pins 16, respective transport stage(s) is / are inverted vertically and workpiece(s) is / are transferred from upper first transport stage(s) to lower second transport stage(s) such that workpiece(s) W is / are lifted in floating fashion thereabove by simultaneous suction and expulsion of gas(es) in accompaniment to lowering of respective elevator pin(s) at said first transport stage(s).

Owner:SHARP KK

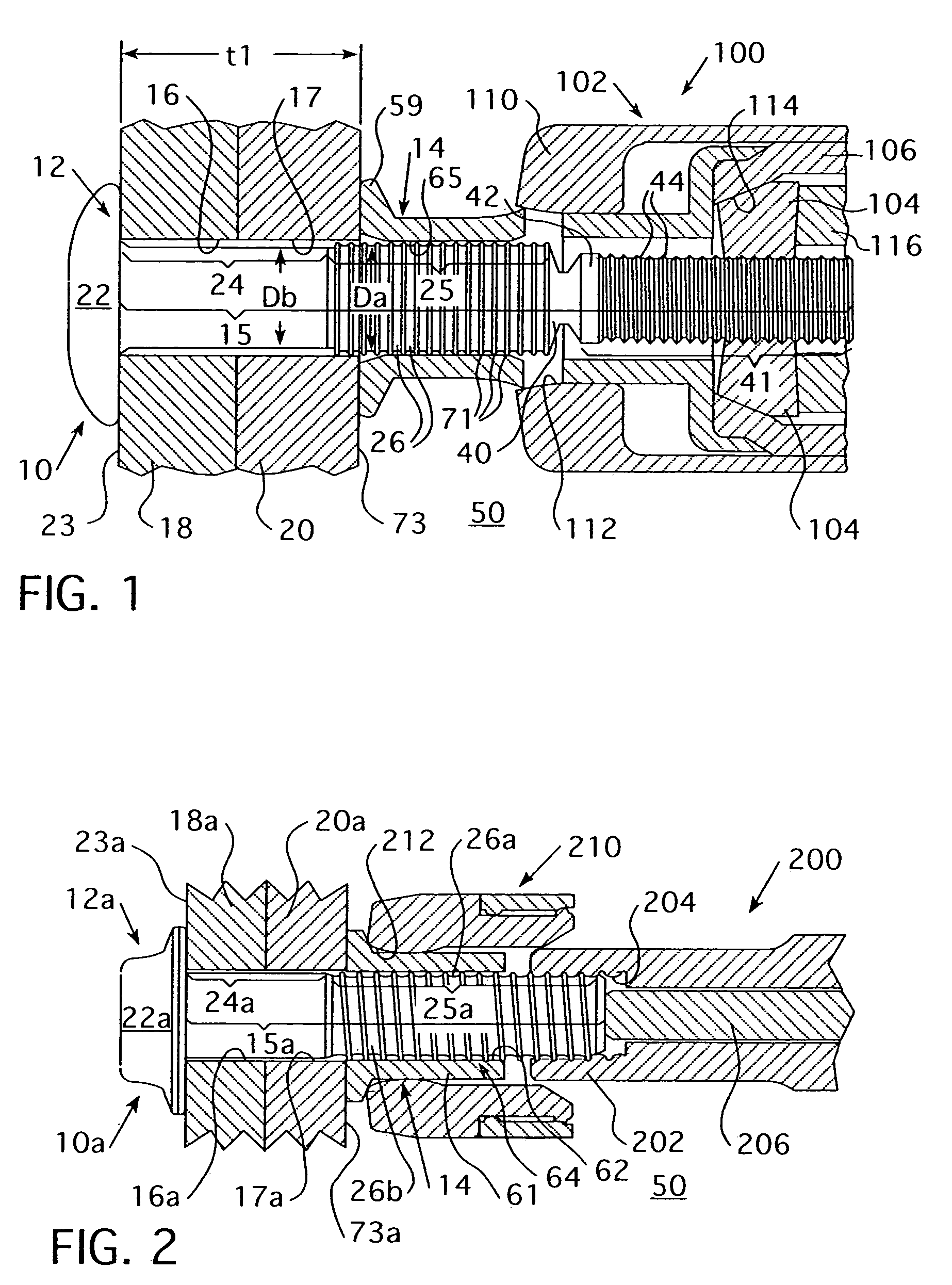

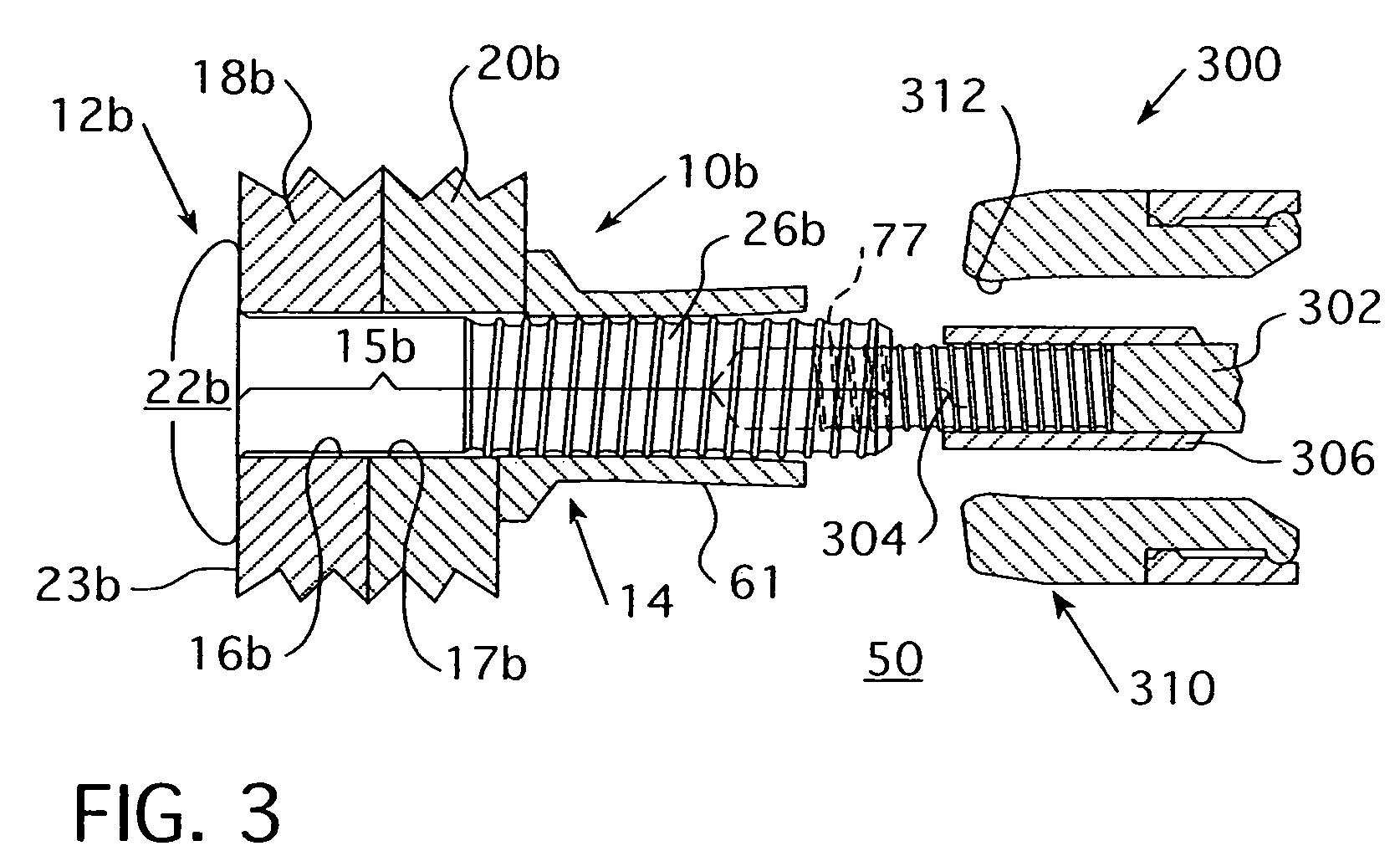

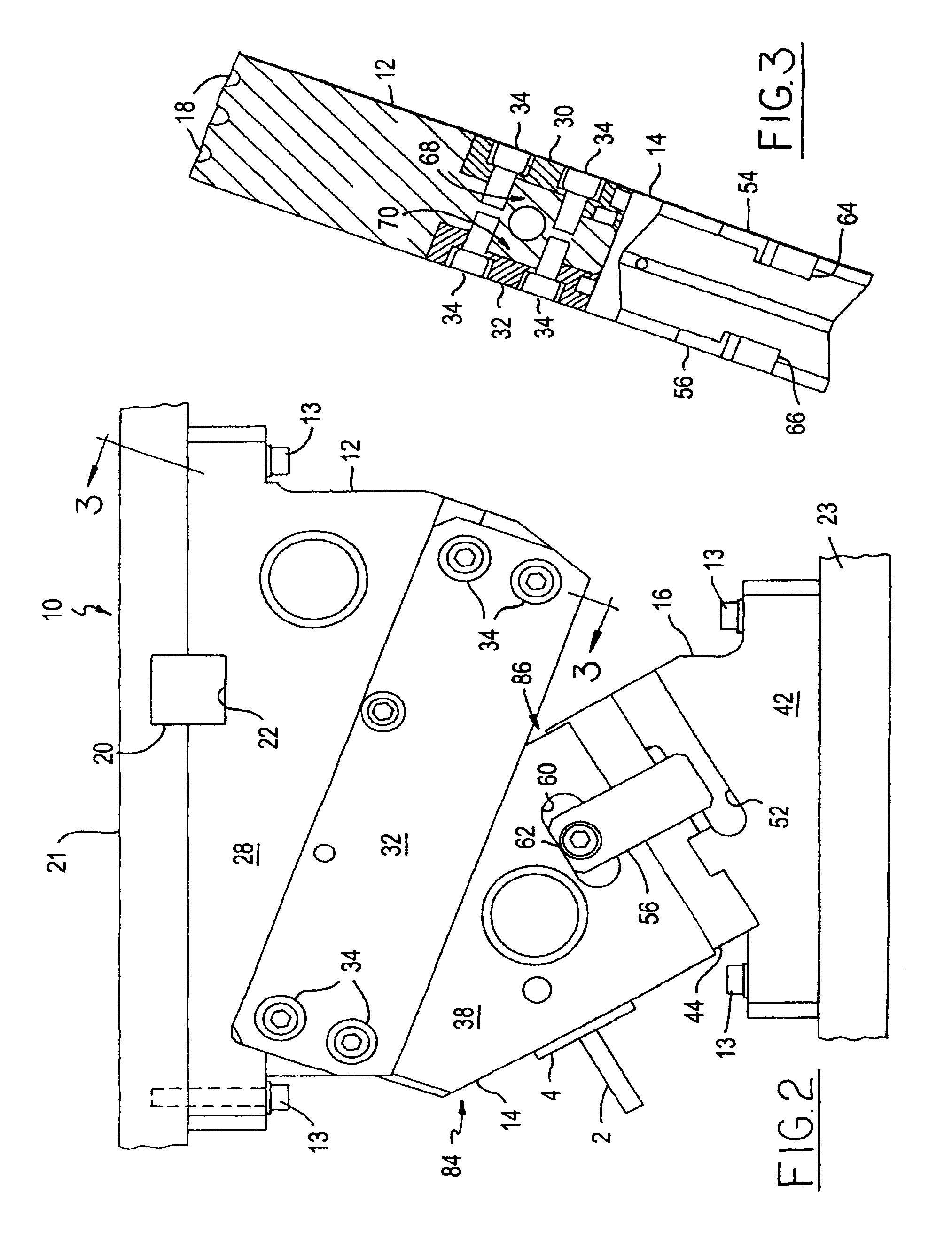

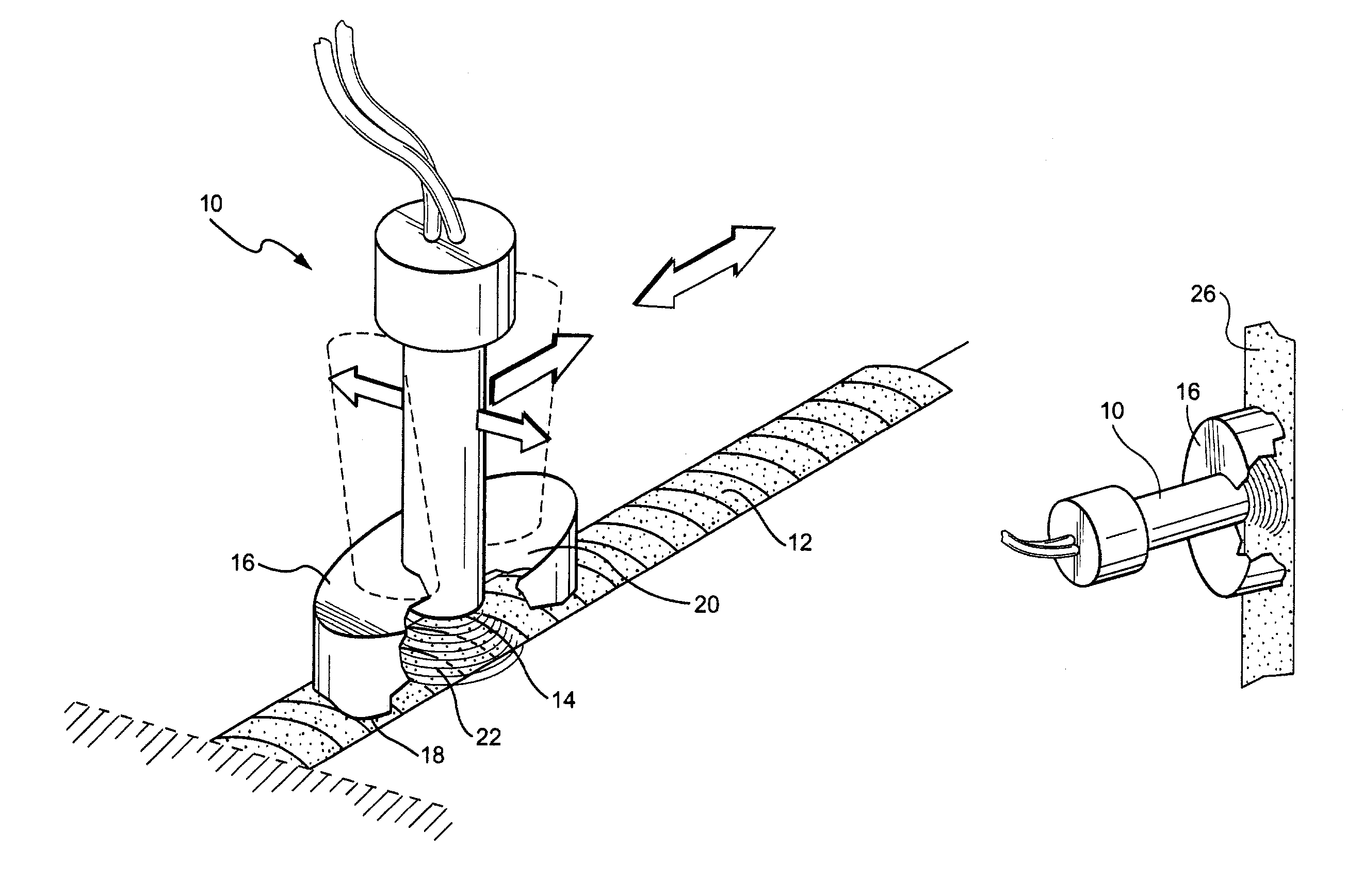

Low swage load fastening system and method

A low swage load fastening system is provided for installing swage-type fasteners to secure a plurality of workpieces together. The fastener includes a pin member having an elongated pin shank to be located in aligned openings in the workpieces. An enlarged head at one end of the pin engages one side of the workpieces. A grooved pin portion extends past an opposite side of the workpieces. A collar includes a shank portion adapted to be swaged into the pin lock grooves in response to a relative axial swage load applied by an installation tool. As one aspect of the system, the collar is as-headed and does not require thermal processing yet provides an optimum balance of reduced collar shank wall thickness and increased hardness, whereby the swage load is minimized. A low swage load thread form for the lock grooves of the pin is also provided, a reduced diameter, relatively short pull portion pin extension, installation tool improvements, and an associated method of use are also disclosed.

Owner:HUCK INT INC

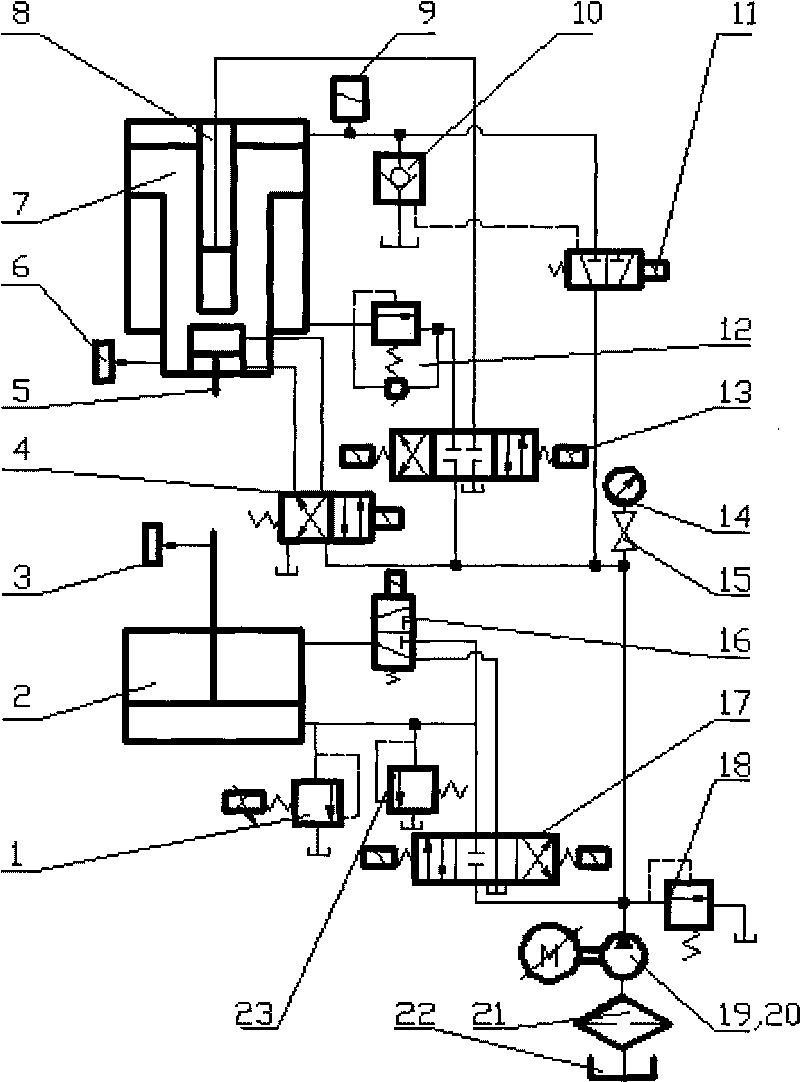

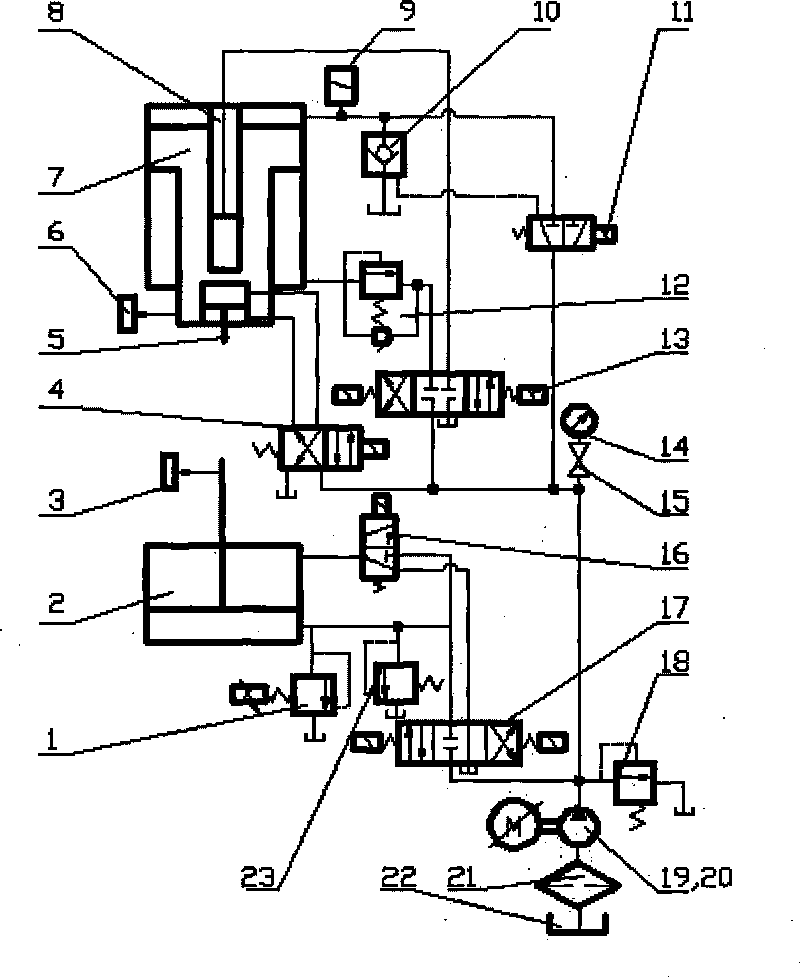

High performance and energy-saving double-acting hydrostatic press driven by servo motor

InactiveCN101712207AImprove performanceOvercome a series of disadvantagesExtrusion control devicesForging press detailsClosed loopHydrostatic pressure

The invention relates to a high performance and energy-saving double-acting hydrostatic press driven by a servo motor. The invention retains the rapid liquid-filling and direction control circuits in the common hydrostatic press, but uses a controllable hydraulic source composed of an AC servo motor and a quantitative oil pump to replace an uncontrollable hydraulic source driven by a common induction motor and combine with various sensors, and realizes the energy-saving pressure, position and speed control of the system under the control and regulation of the electrical motor; displacement sensors are added in a main cylinder and an auxiliary cylinder, a pressure sensor is added in the oil inlet line of the main cylinder, thus realizing the closed-loop control of position, speed and pressure; and a proportional relief valve is added at the oil outlet of the auxiliary cylinder, thus realizing variable blank holder force floating blank-holding of the auxiliary cylinder, wherein the electrical motor is the high-power AC servo motor, the electrical motor is connected with a controller, and the flow control and the volume velocity-governing and pressure-regulating of the main oil line can be realized by controlling the speed of the electrical motor. The invention completely uses the advantages of the high-power AC servo motor such as high efficiency, controllable performance, adjustable performance and good reliability to realize the optimization of process parameters, improve the hydrostatic press performance and reduce the energy consumption.

Owner:GUANGDONG UNIV OF TECH

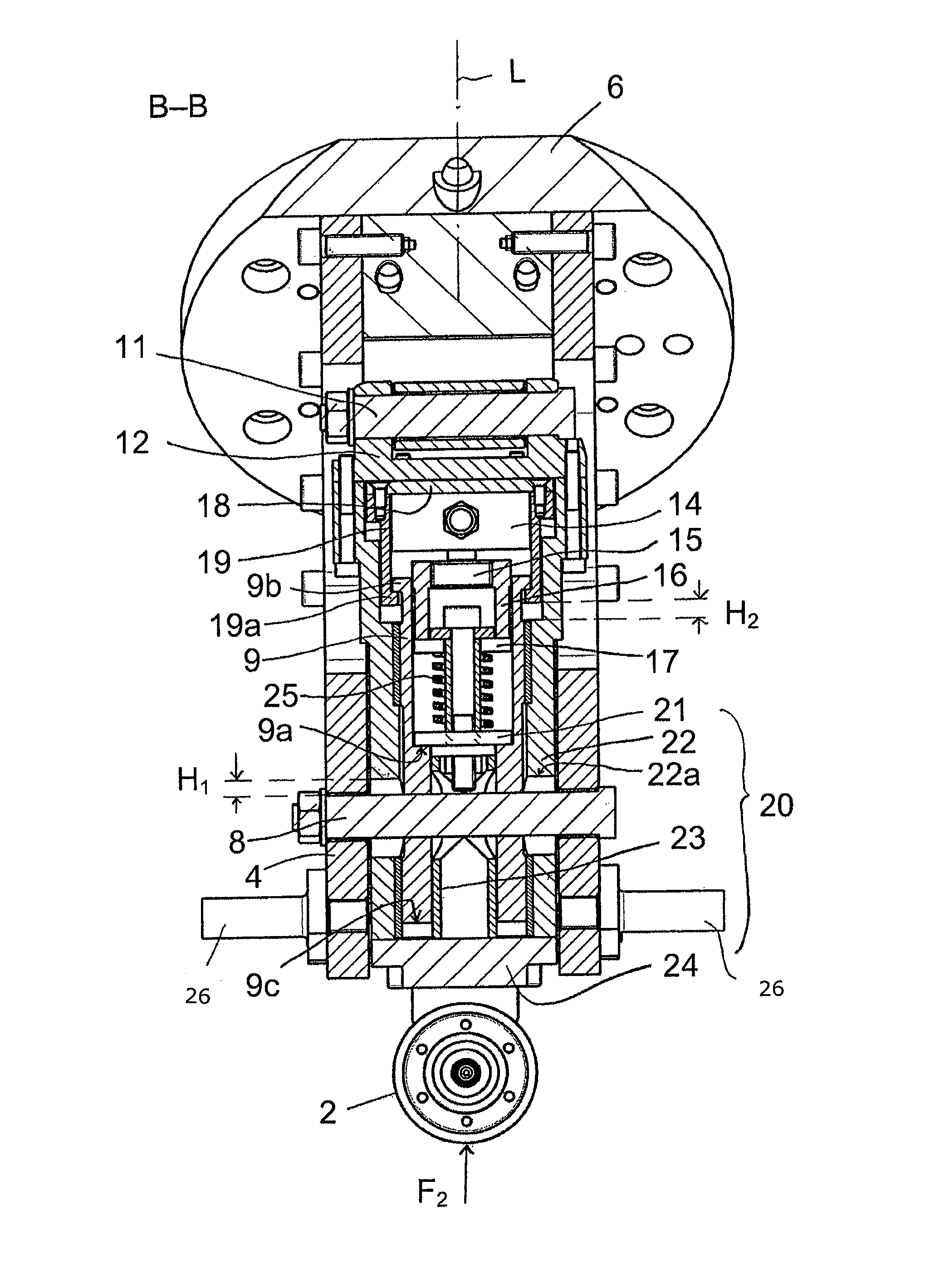

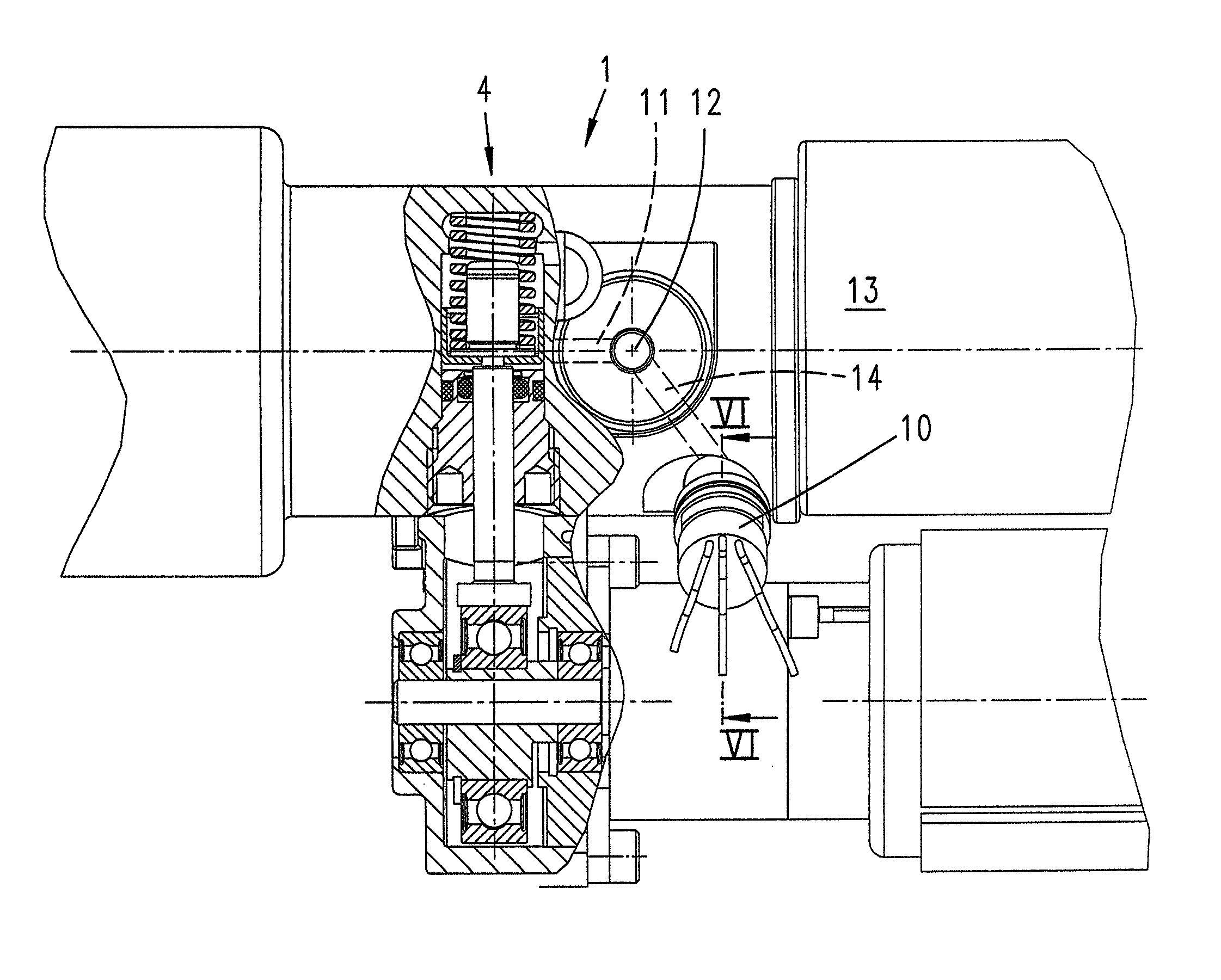

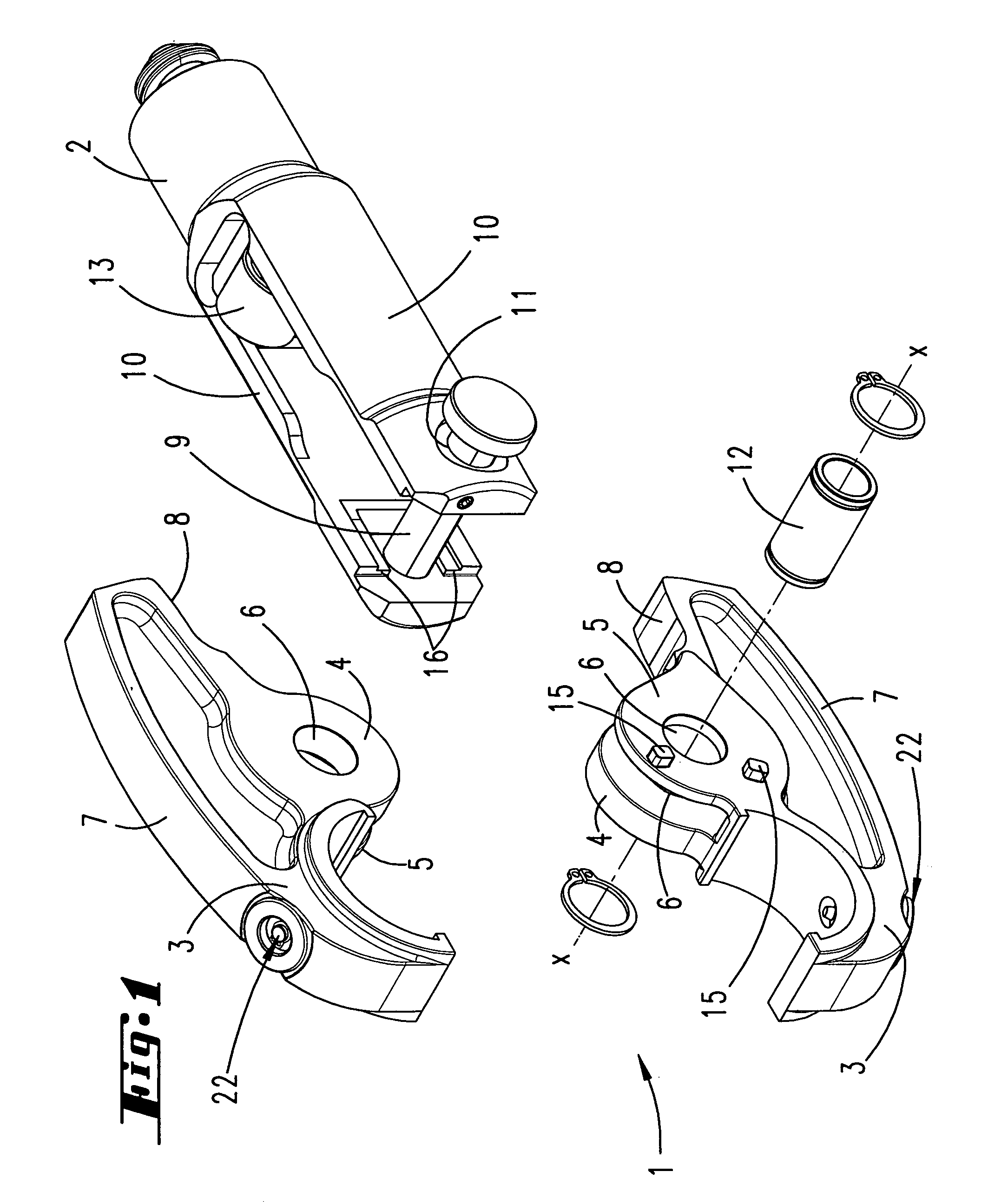

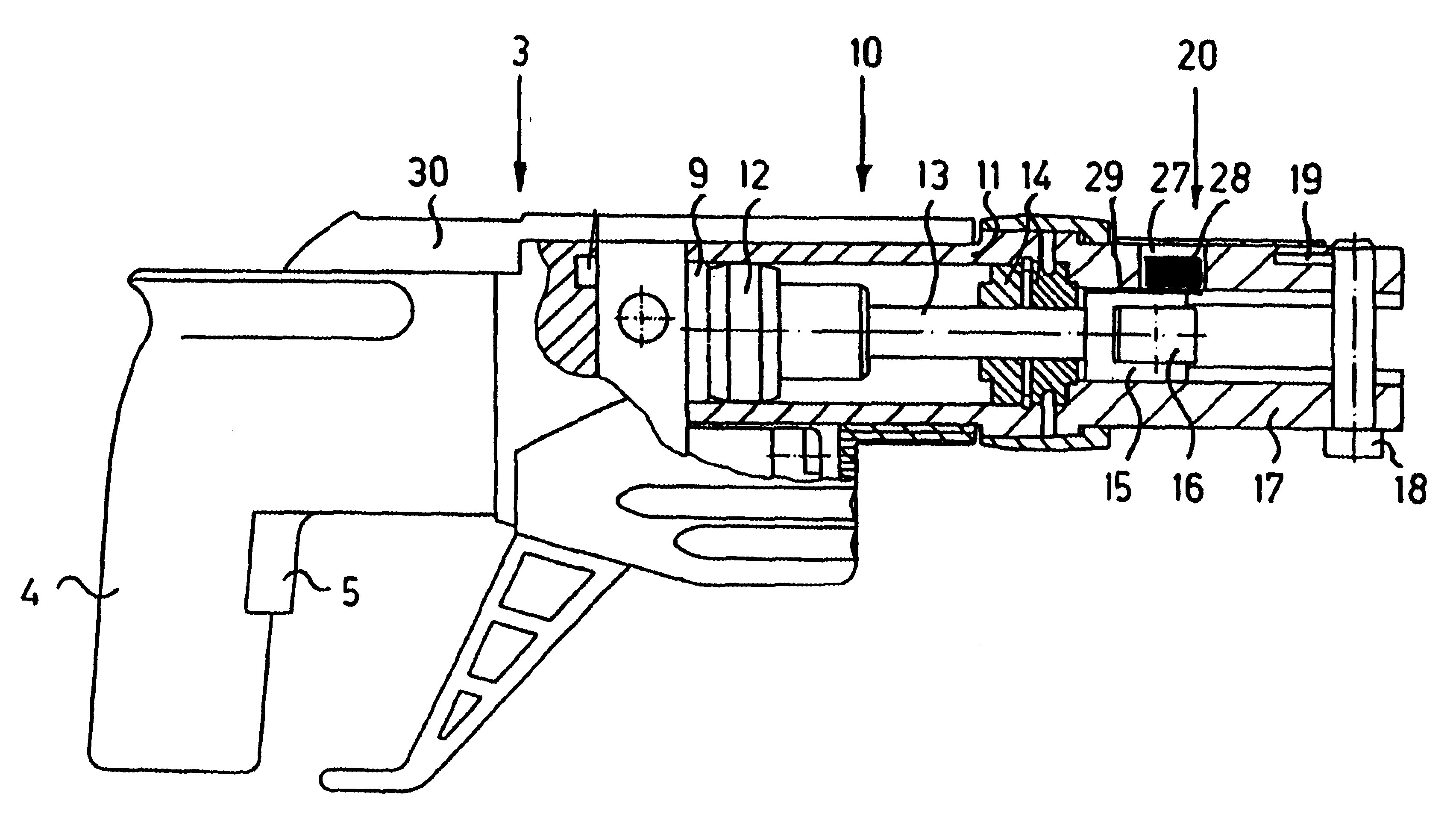

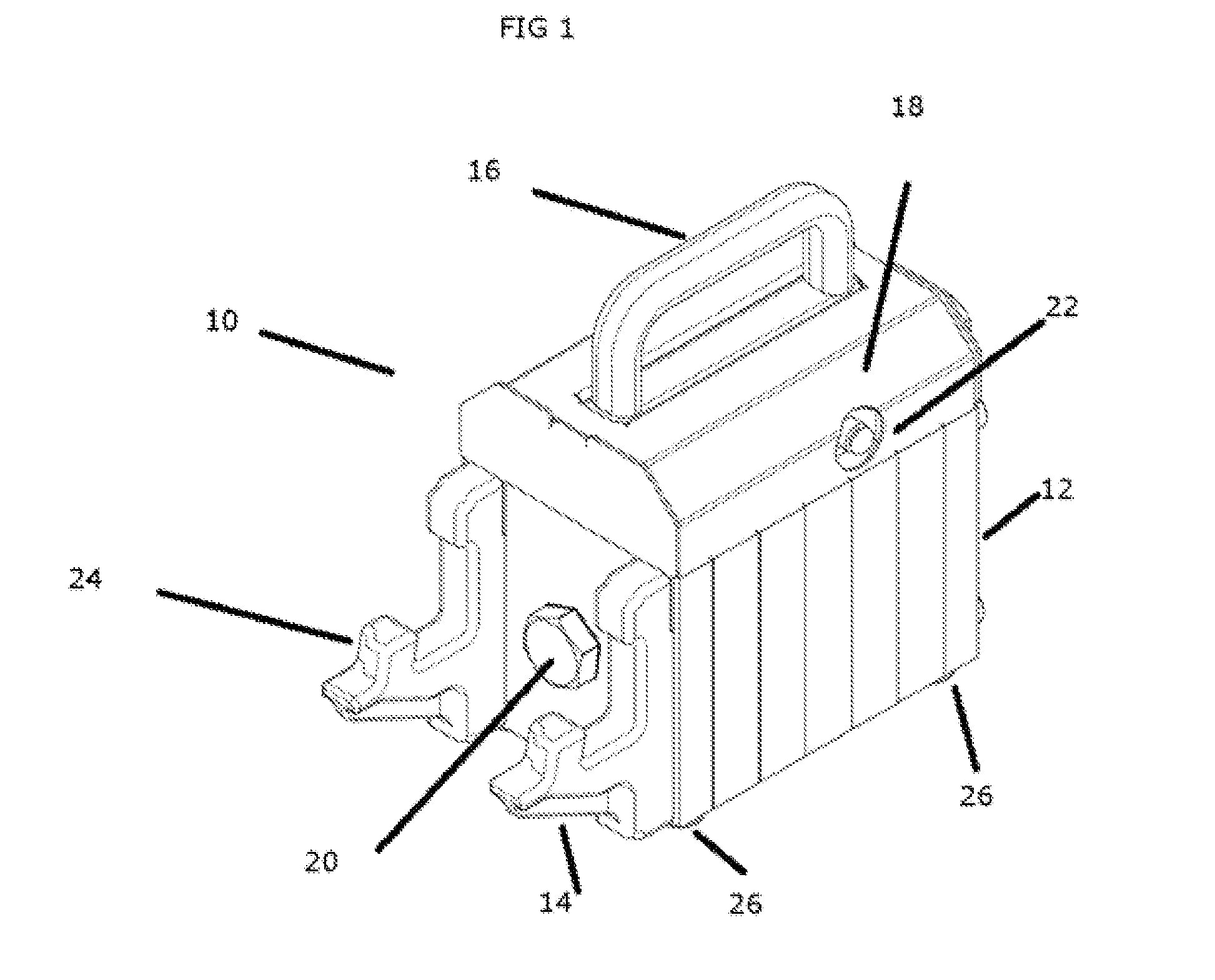

Pressing tool

A pressing tool for connecting pipe-shaped work pieces wherein the pressing tool has a fork-shaped receiver and a clamping tool interchangeably held in the receiver by a connecting bolt. The pressing tool has two clamping jaws which can be moved toward each other. A drive motor operates the clamping tool. The connecting bolt can be pushed through bores in the fork-shaped receiver and in the clamping tool, for maintaining the clamping tool in an exchangeable position within the fork-shaped receiver. A contactless electronic tracing device is arranged in the fork-shaped receiver, which determines a relative position of the clamping jaws in relation to the fork-shaped receiver. The contactless electronic tracing device also passes a signal to either an optical warning device or an acoustical warning device.

Owner:VON ARX AG

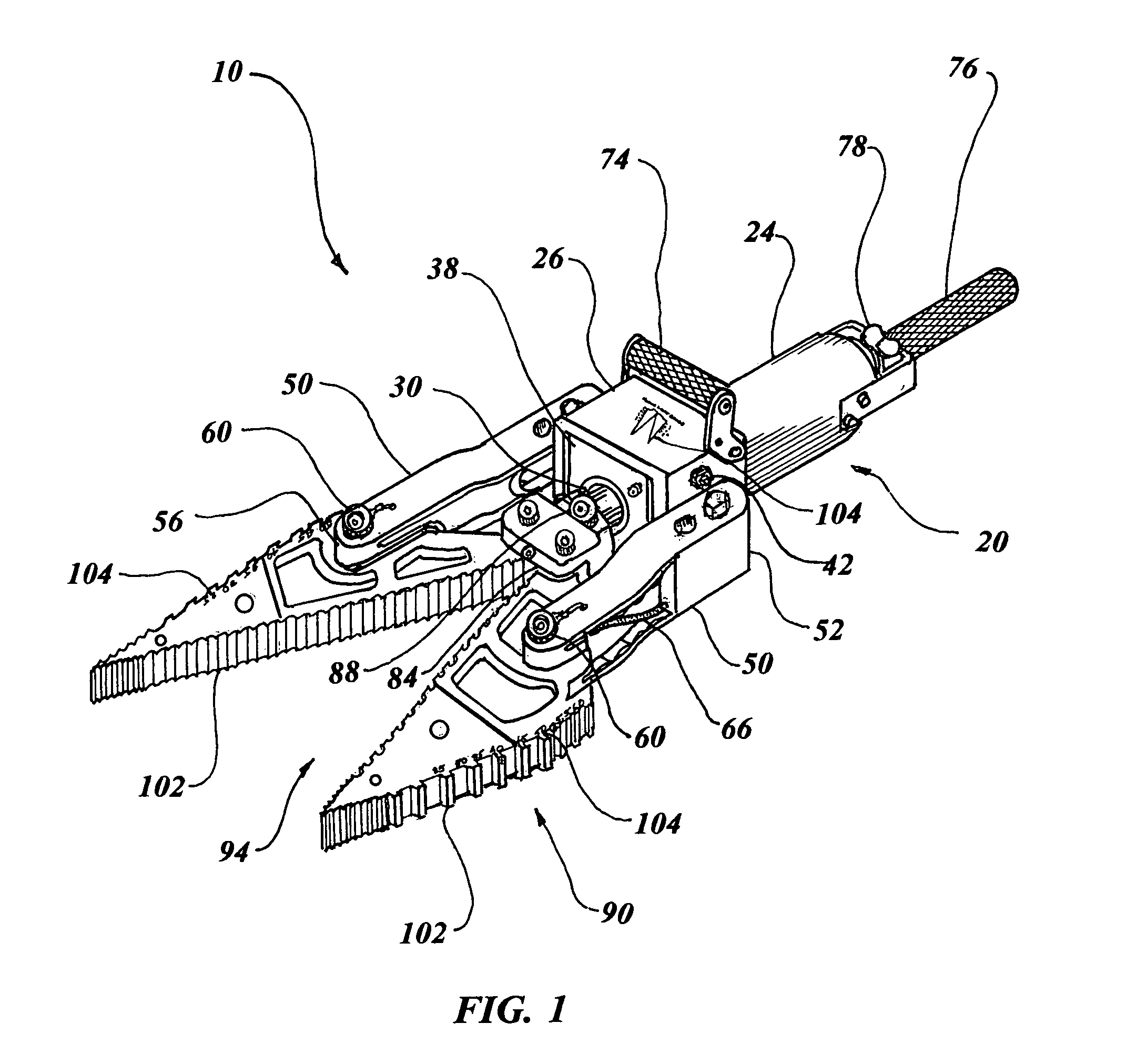

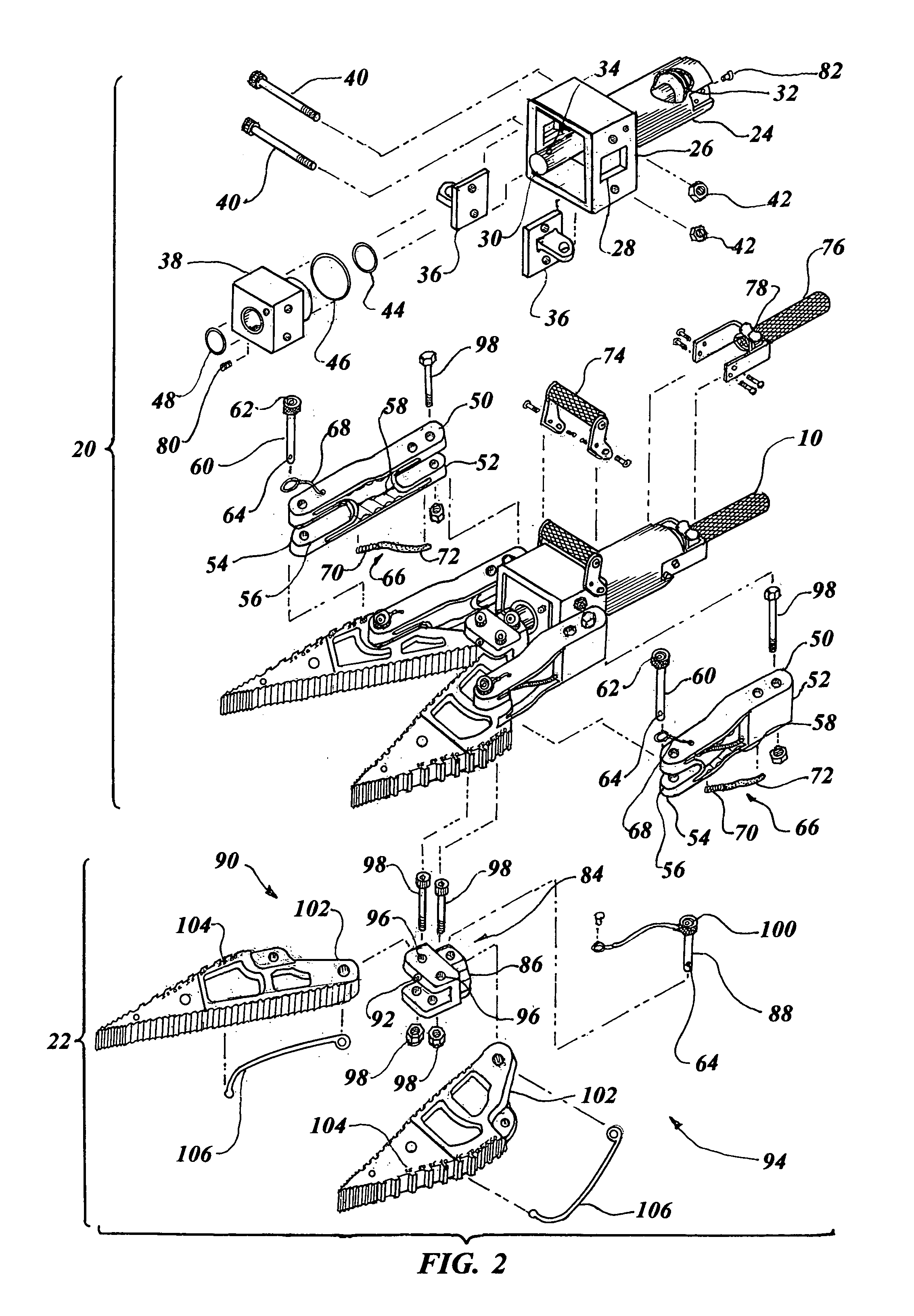

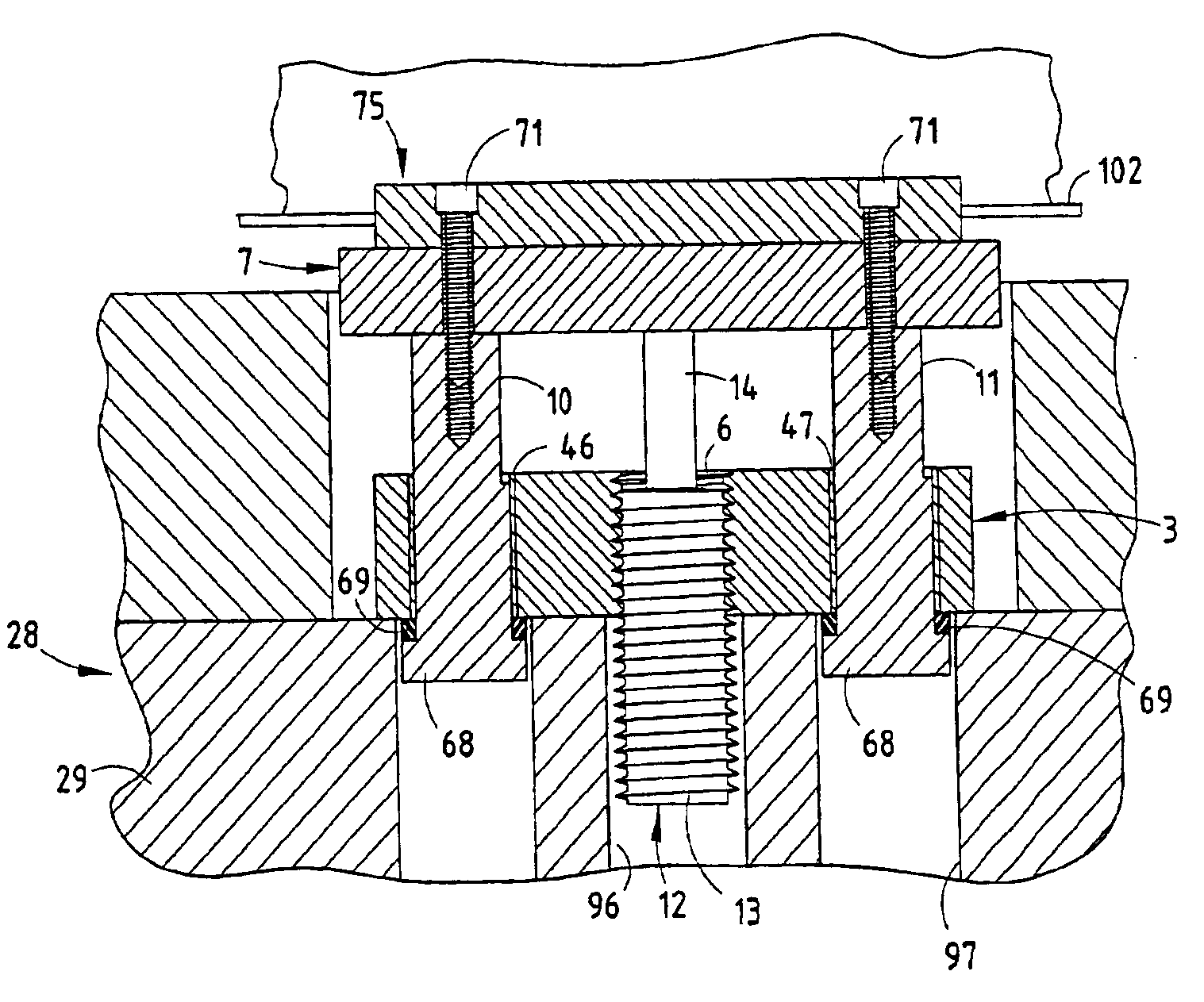

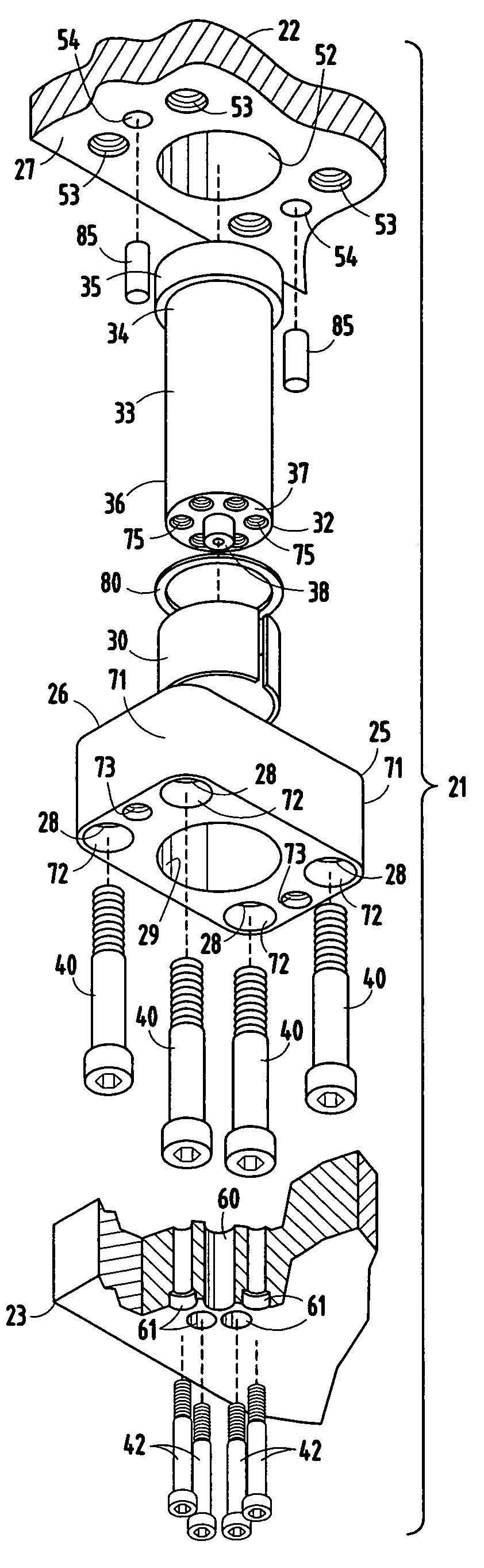

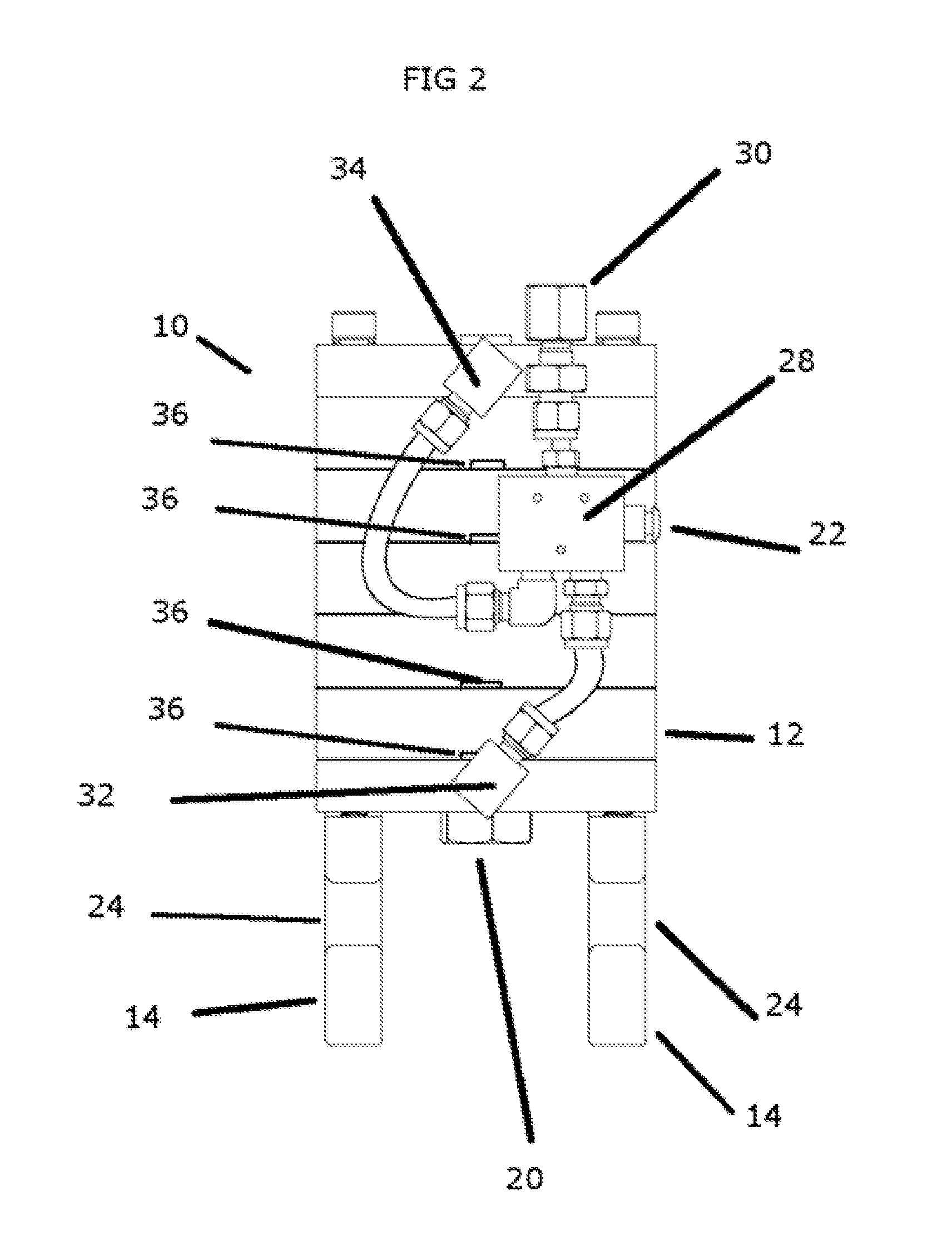

Hydraulic rescue tool

InactiveUS7568372B1Preventing pressurizationLimit hydraulic pressureDrawing diesBuilding rescueHydraulic cylinderThreaded fastener

A hydraulic rescue tool (10) is comprised of a hydraulic thrust apparatus (20) consisting of a hydraulic cylinder body (24) having slots (28) within a hollow end and interlocking ears (36) protruding from the slots. A gland (38) is interfaced between the ears, with the gland and ears connected to the cylinder hollow end with threaded fasteners (98). A connecting link (50) is attached to each interlocking ear and a quick disconnect implement unit (22) is attached to each link and to a piston rod (30) within the cylinder body (24). Six dissimilar embodiments of implement units, each having quick disconnect capabilities and different vehicle structure separating utility are attached to the hydraulic thrust apparatus (20).

Owner:FIVE STAR IP HLDG

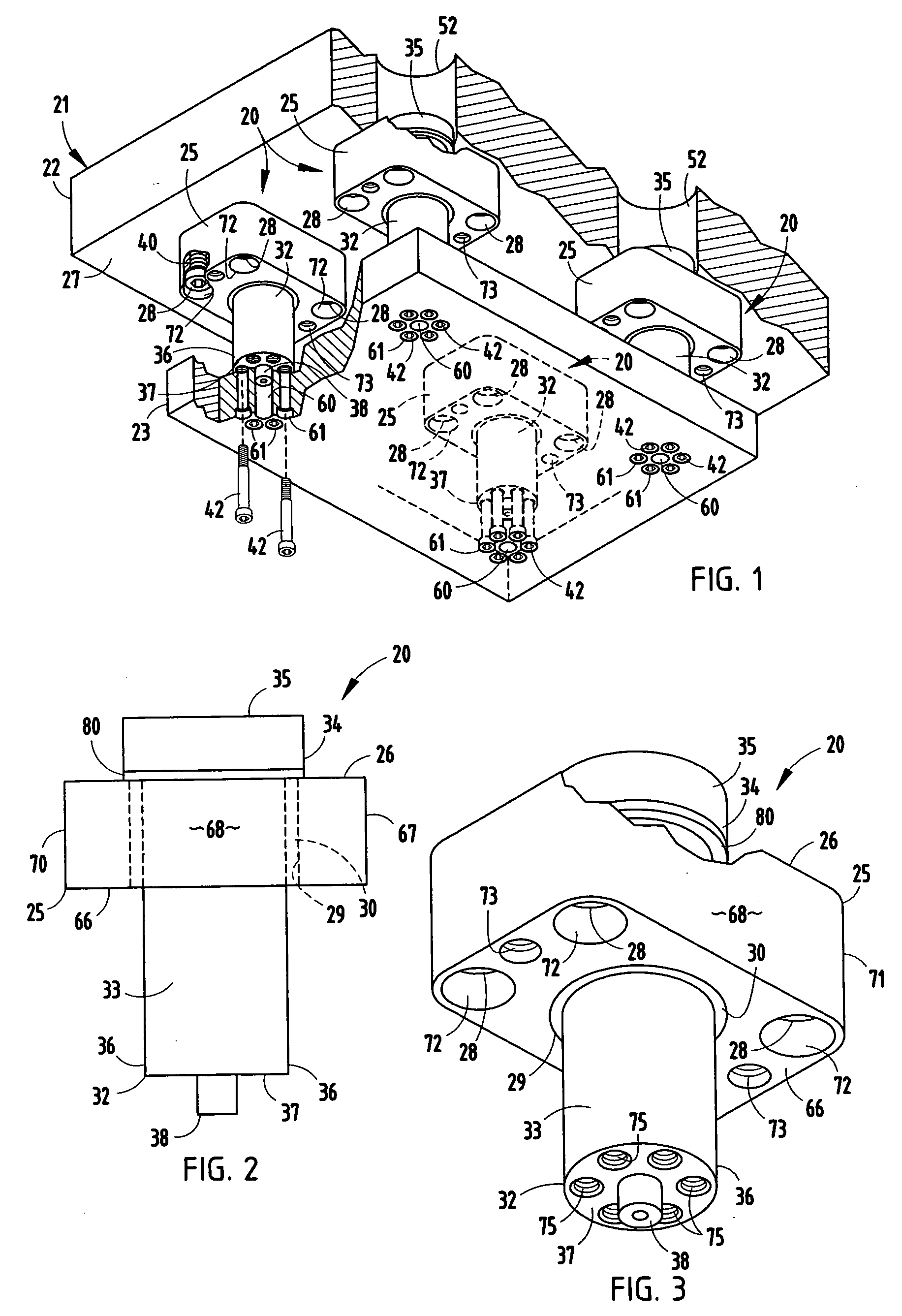

Stock lifter for metal forming dies and method for making the same

InactiveUS6848290B2Reduce design costReduce manufacturing costShaping toolsMetal-working feeding devicesMetal formingReciprocating motion

A self-contained stock lifter is particularly adapted for use in multiple station, progressive metal forming dies and the like, and includes a base plate with two vertical through holes adjacent opposite sides, and a vertical spring unit aperture located between the through holes. The stock lifter also includes a lifter bar having two vertical through holes in vertical registry with the base plate through holes. Two rigid guide shafts are mounted in the base plate through holes to permit the lifter bar to reciprocate in a manner which selectively lifts stock in the die to permit longitudinal shifting of the stock along the multiple die stations. A spring unit has a base retained in the spring unit aperture, and a reciprocating rod biased outwardly, with a free end abutting a central portion of the lifter bar to shift the lifter bar to an extended position, thereby defining a fully self-contained unit that can be readily mounted in and removed from the die to reduce manufacturing and repair costs.

Owner:PYPER TOOL & ENG

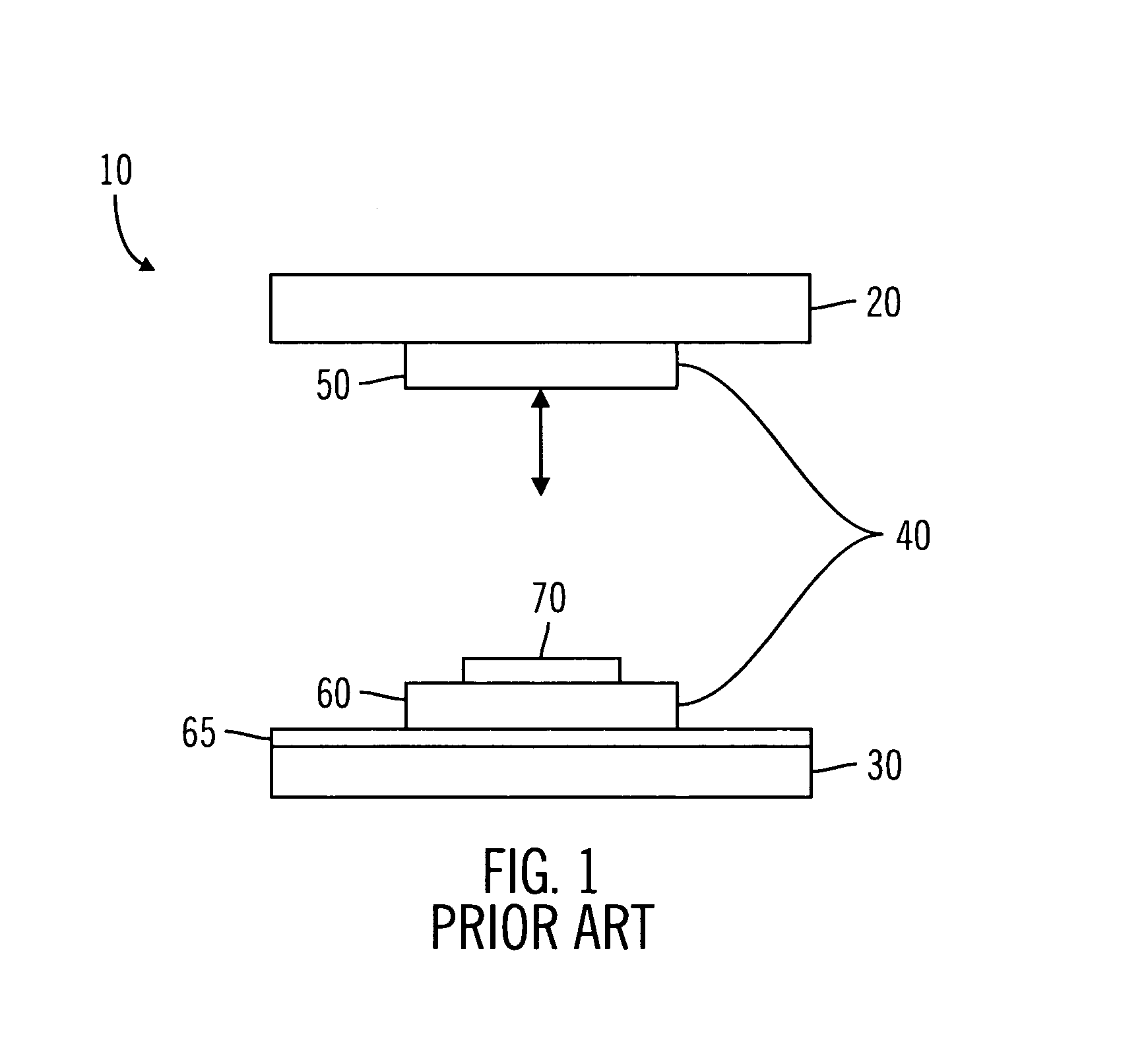

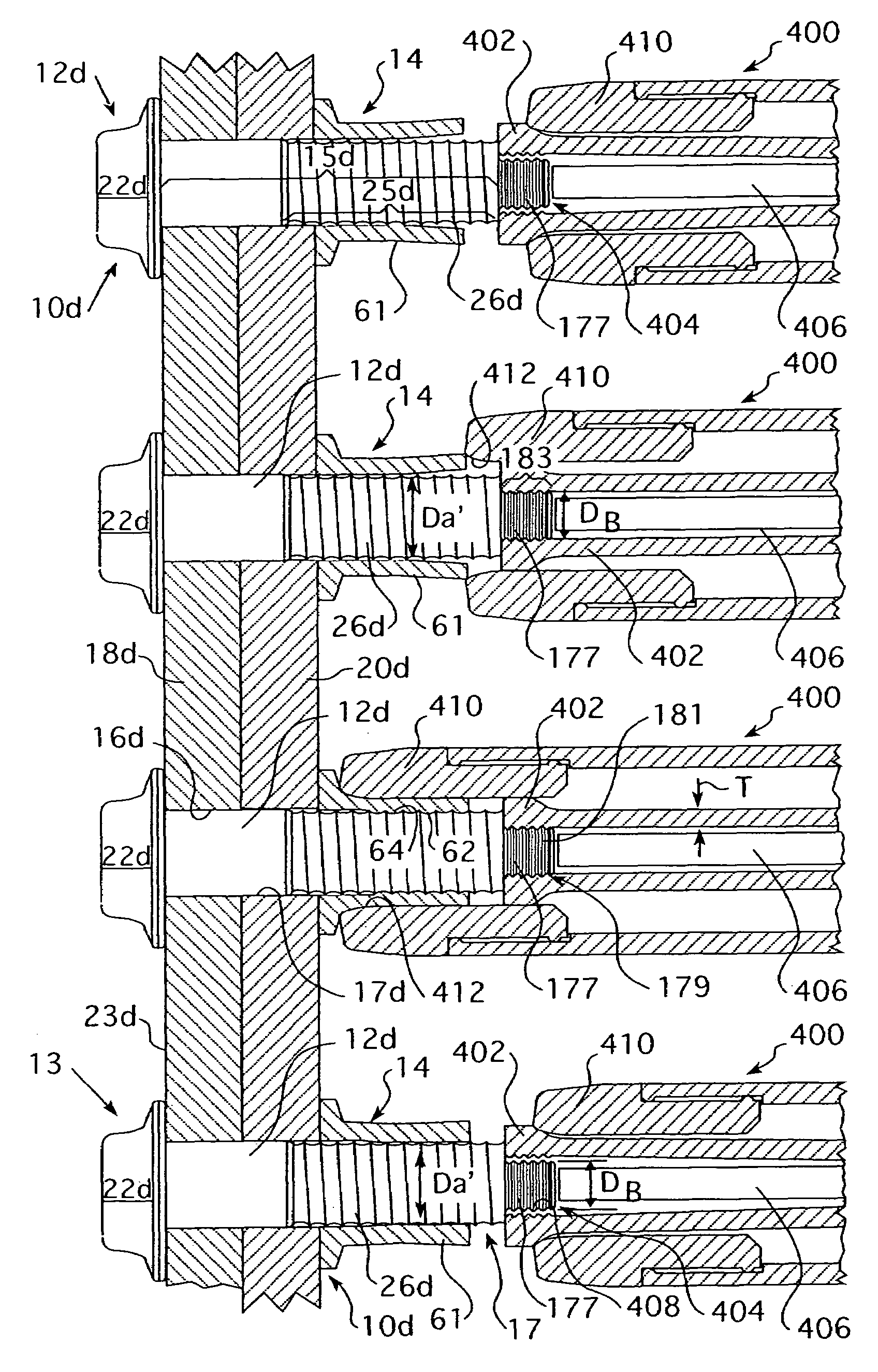

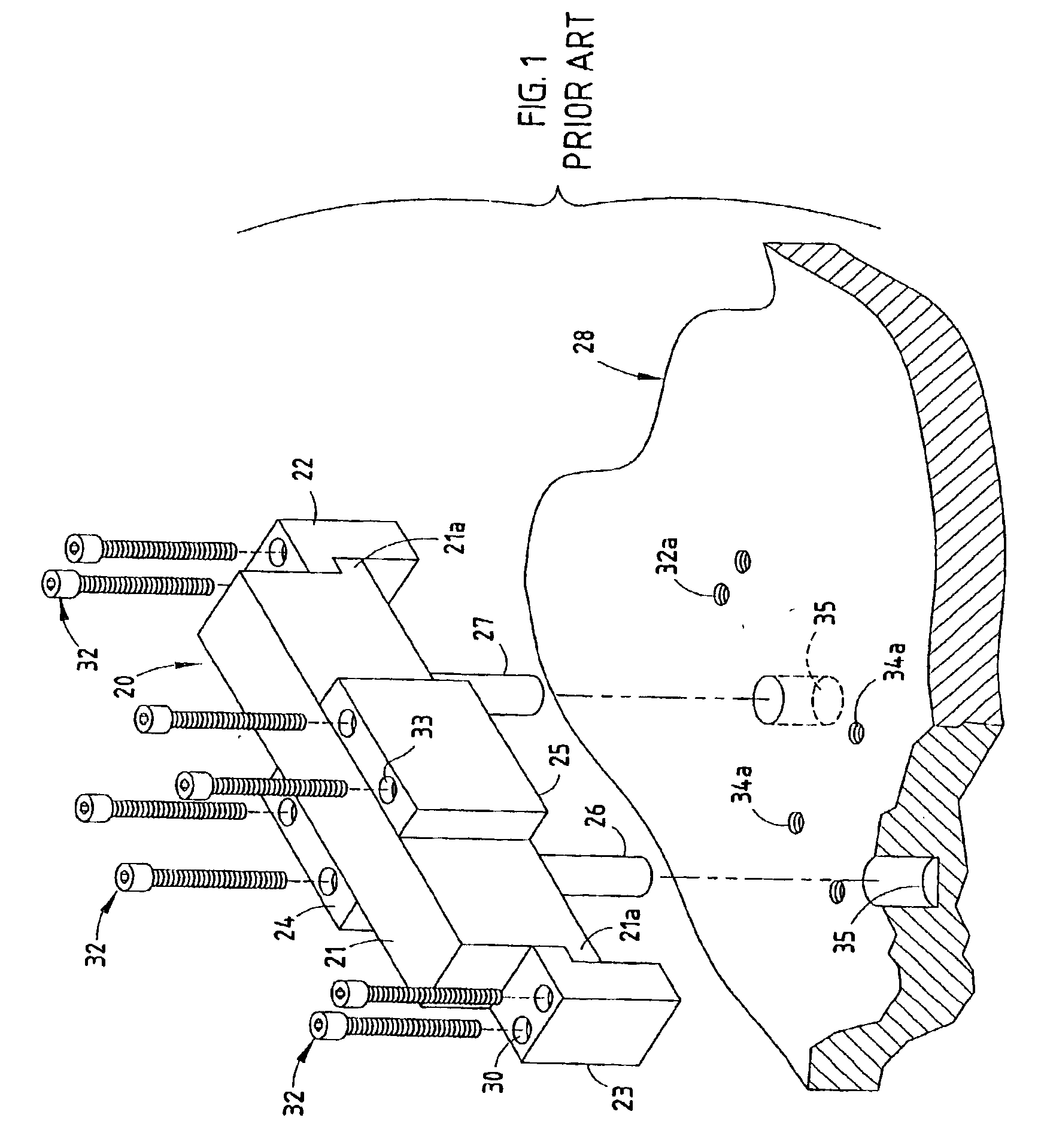

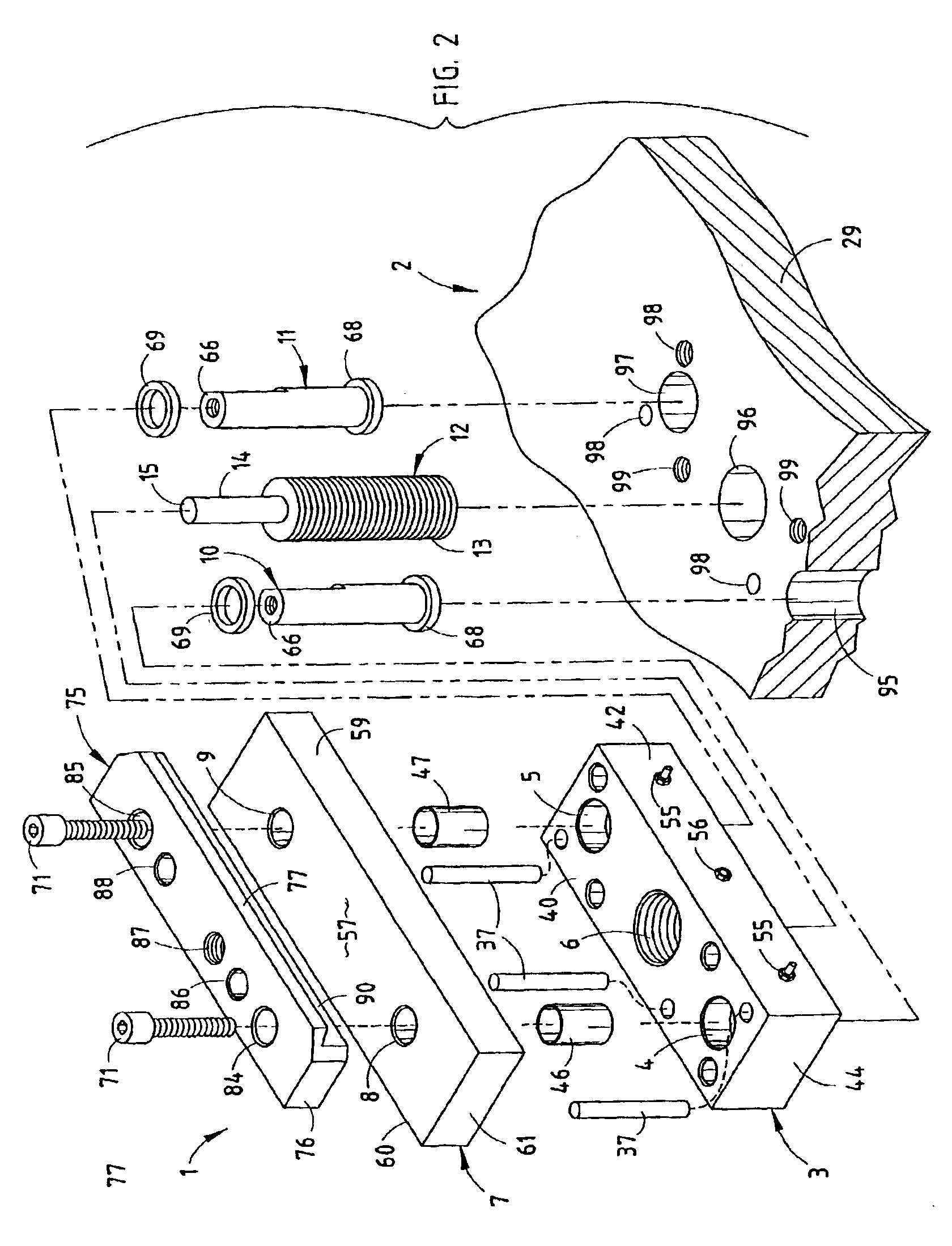

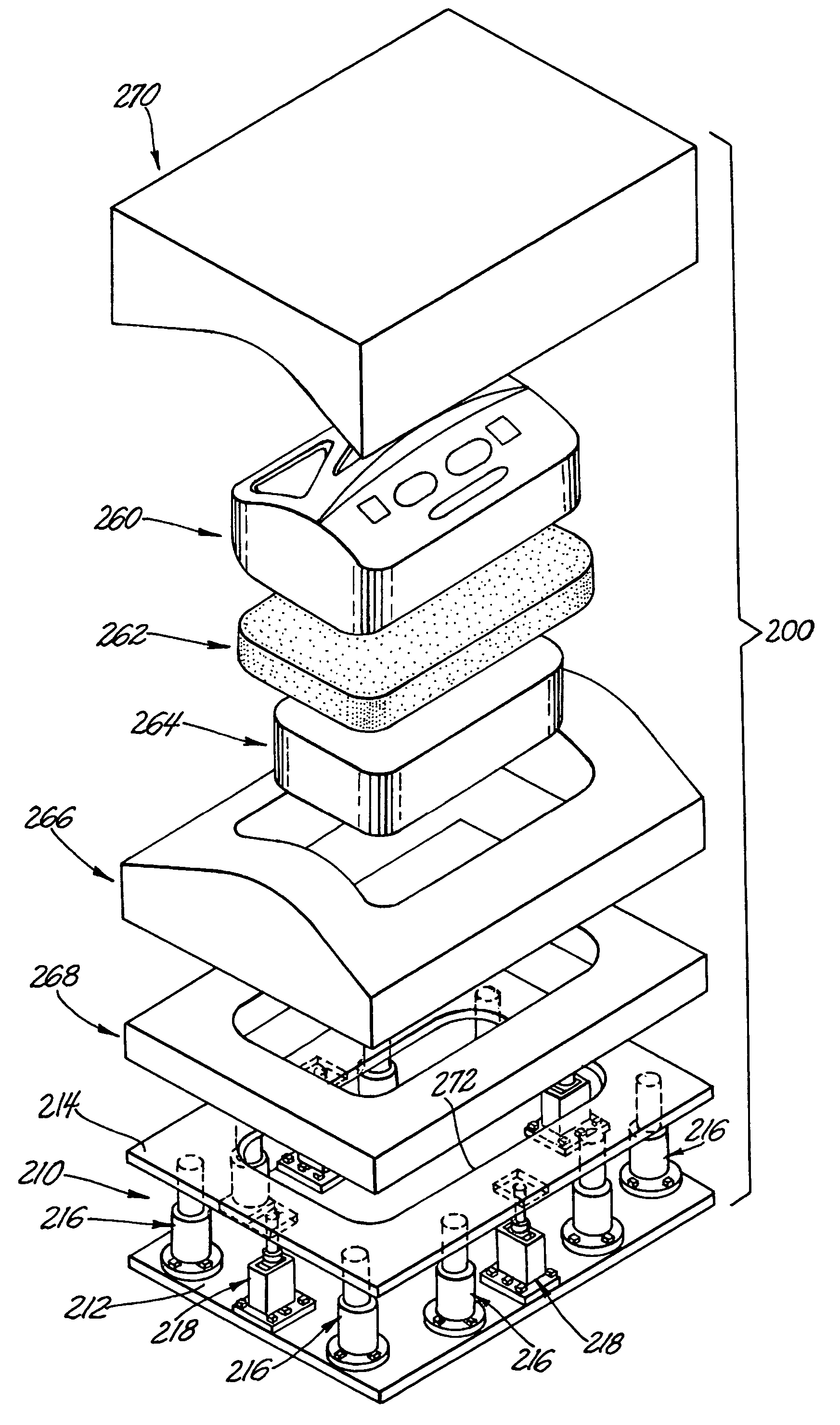

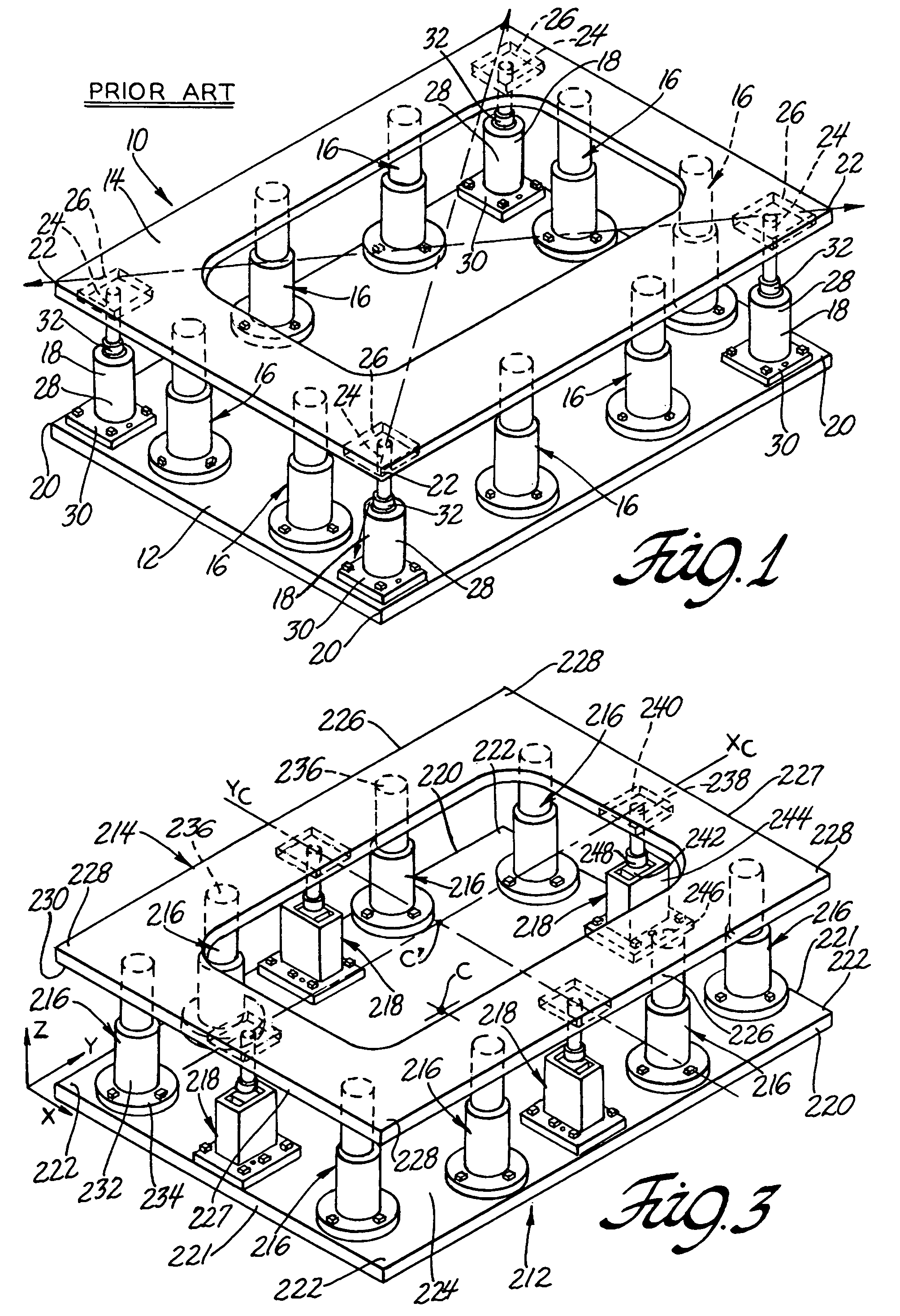

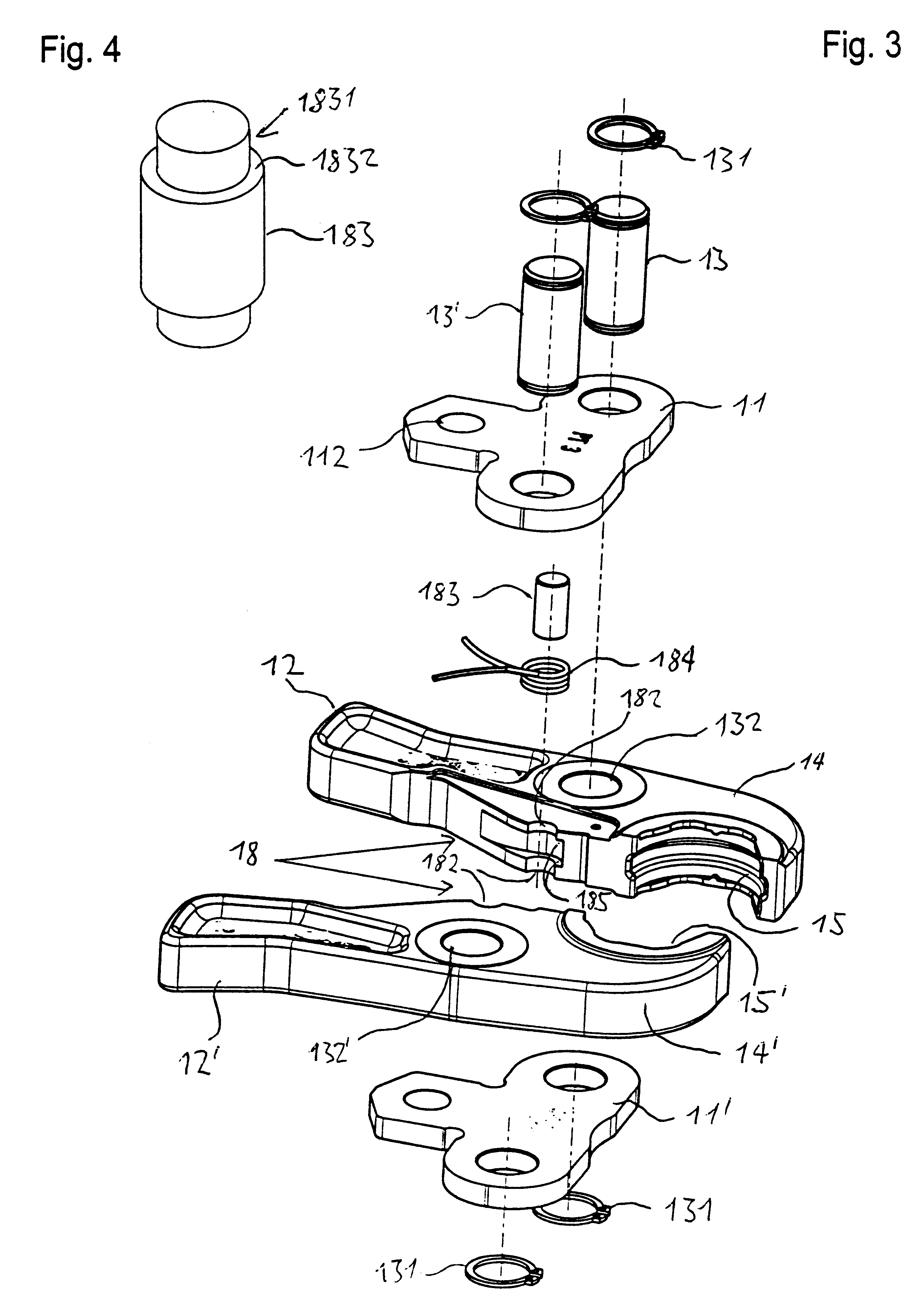

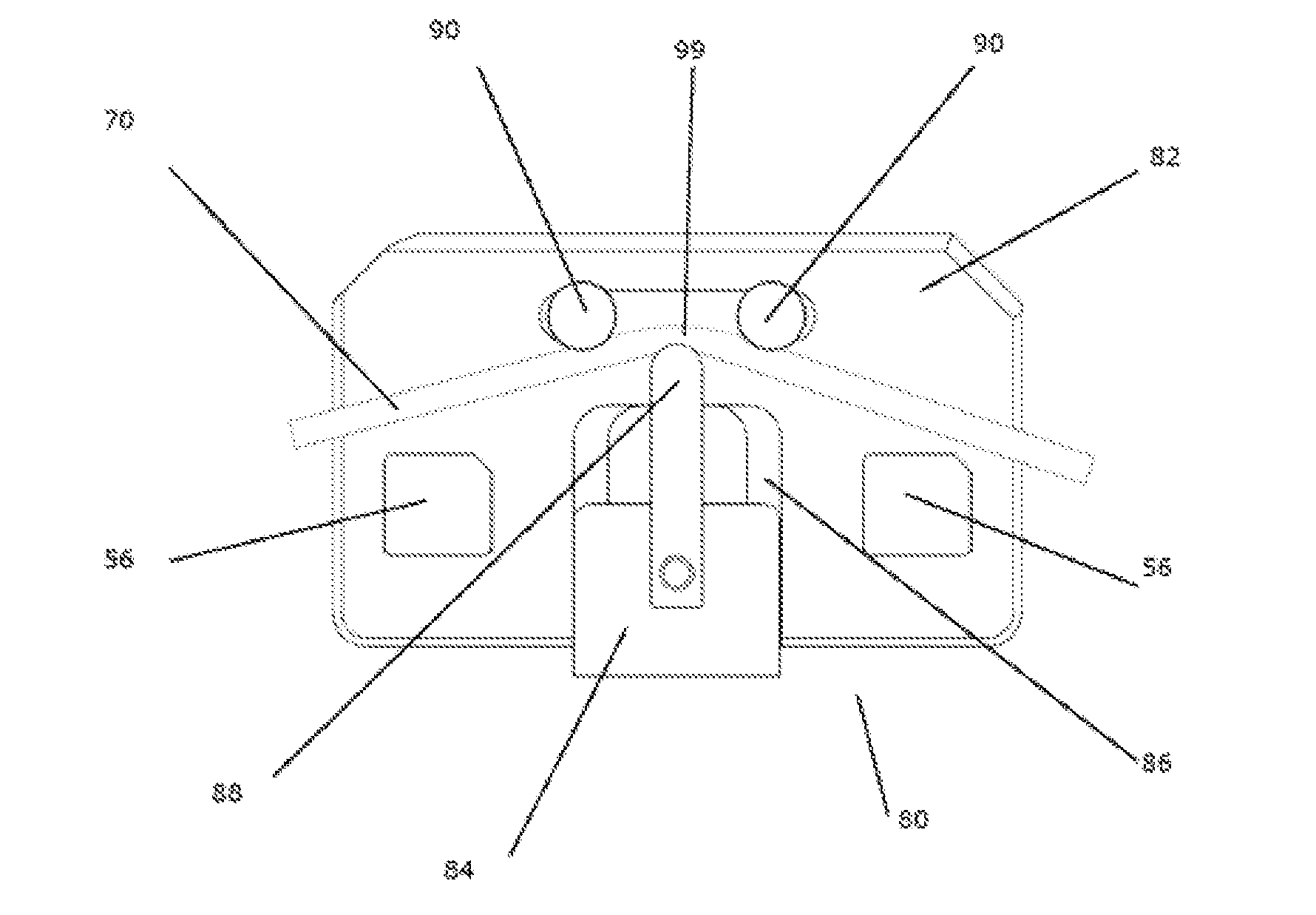

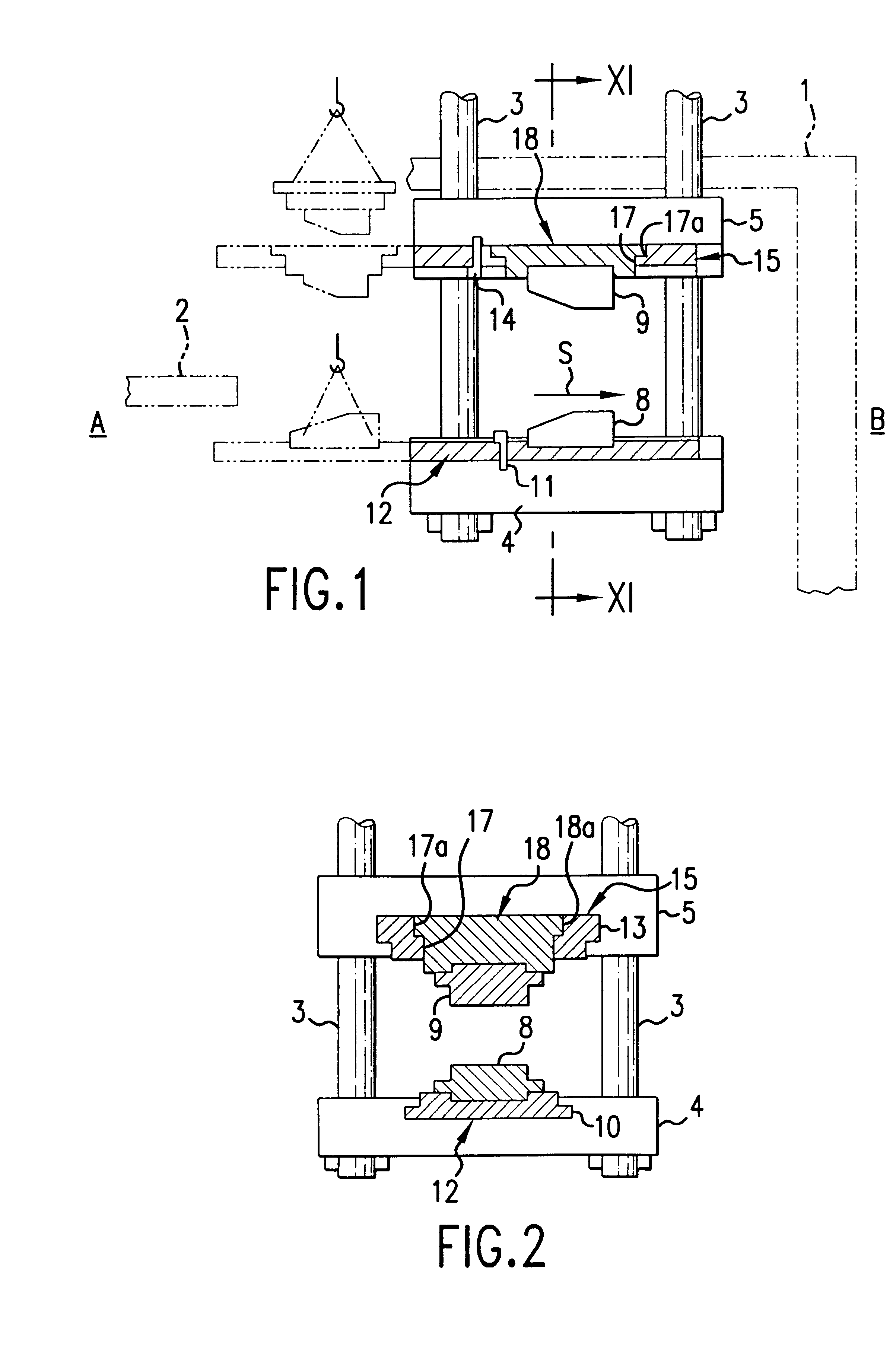

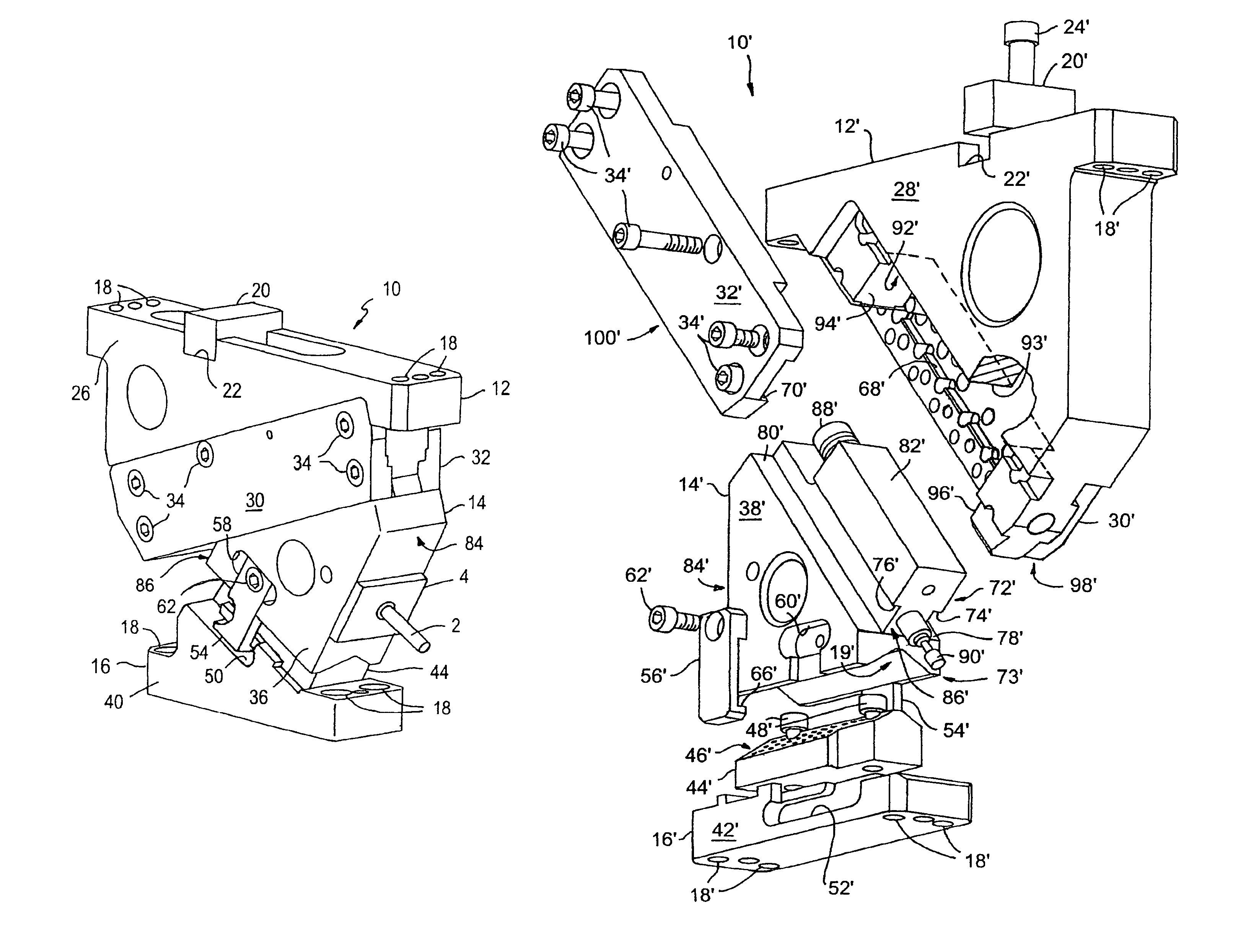

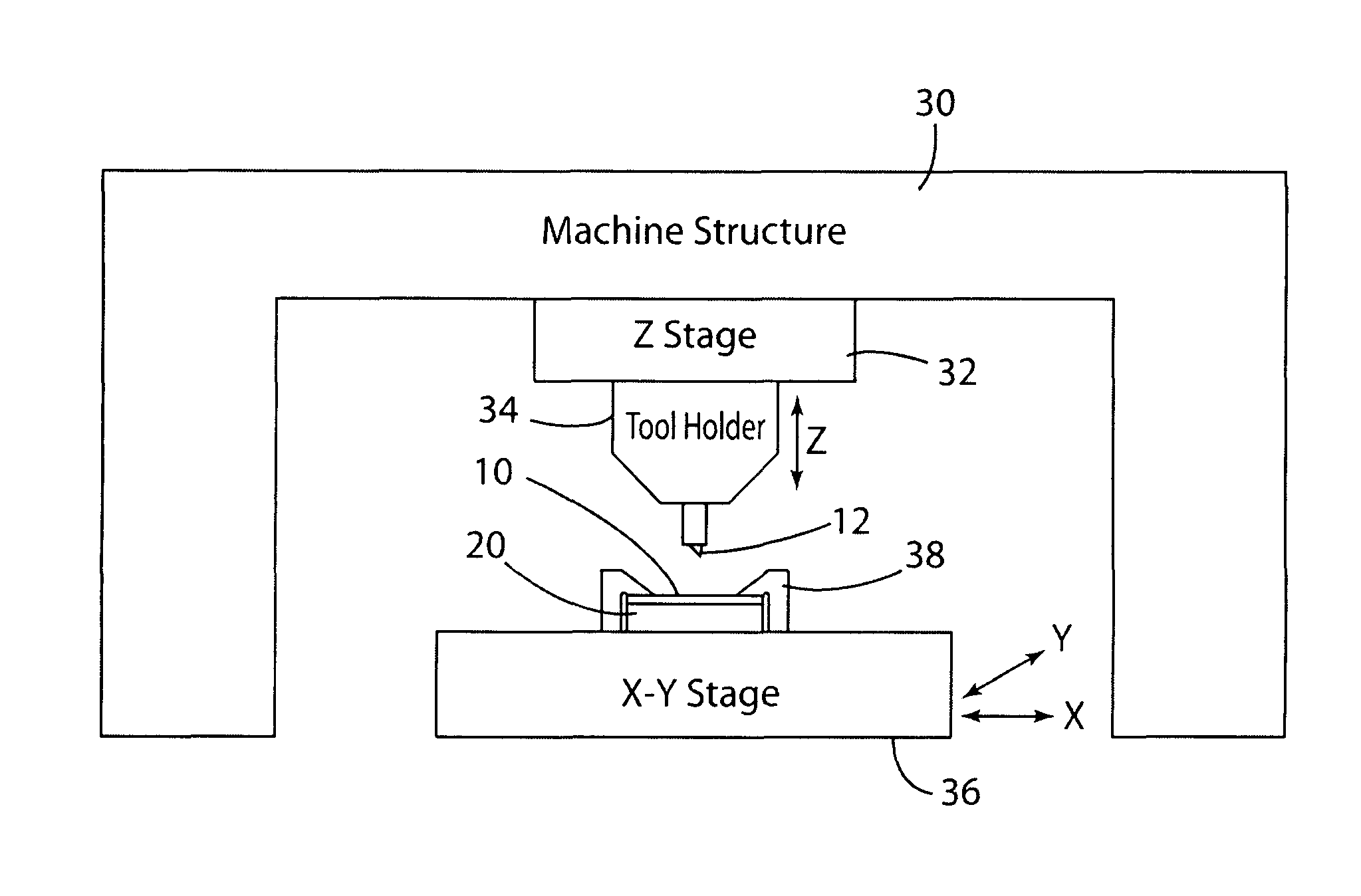

Guided keeper assembly and method for metal forming dies

ActiveUS20090193865A1Facilitate transport and mountingEasy to installShaping toolsStripping-off devicesMetal formingReciprocating motion

A guided keeper assembly and method for metal forming dies includes a base having a mounting face, a connector portion and a central aperture. A guide pin has a cylindrical center portion closely received in the central aperture of the base for reciprocation, an enlarged first end with an alignment member, and an outwardly opening circumferential groove. A retainer ring is removably mounted in and protrudes radially outwardly of the groove to securely, yet detachably, retain the base on the guide pin between the enlarged head and the retainer ring in an assembled condition to facilitate transport and mounting of the guided keeper assembly.

Owner:STANDARD LIFTERS INC

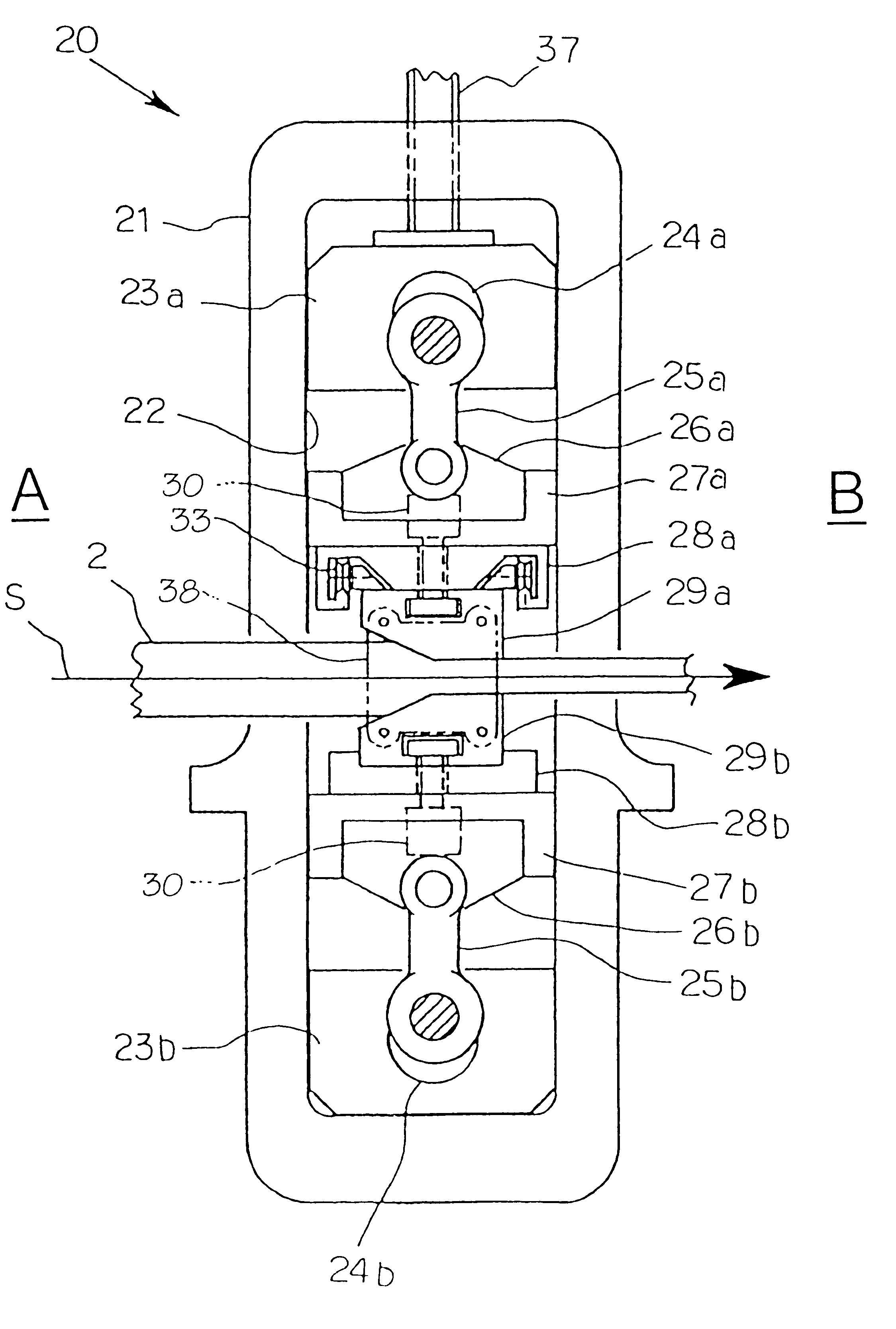

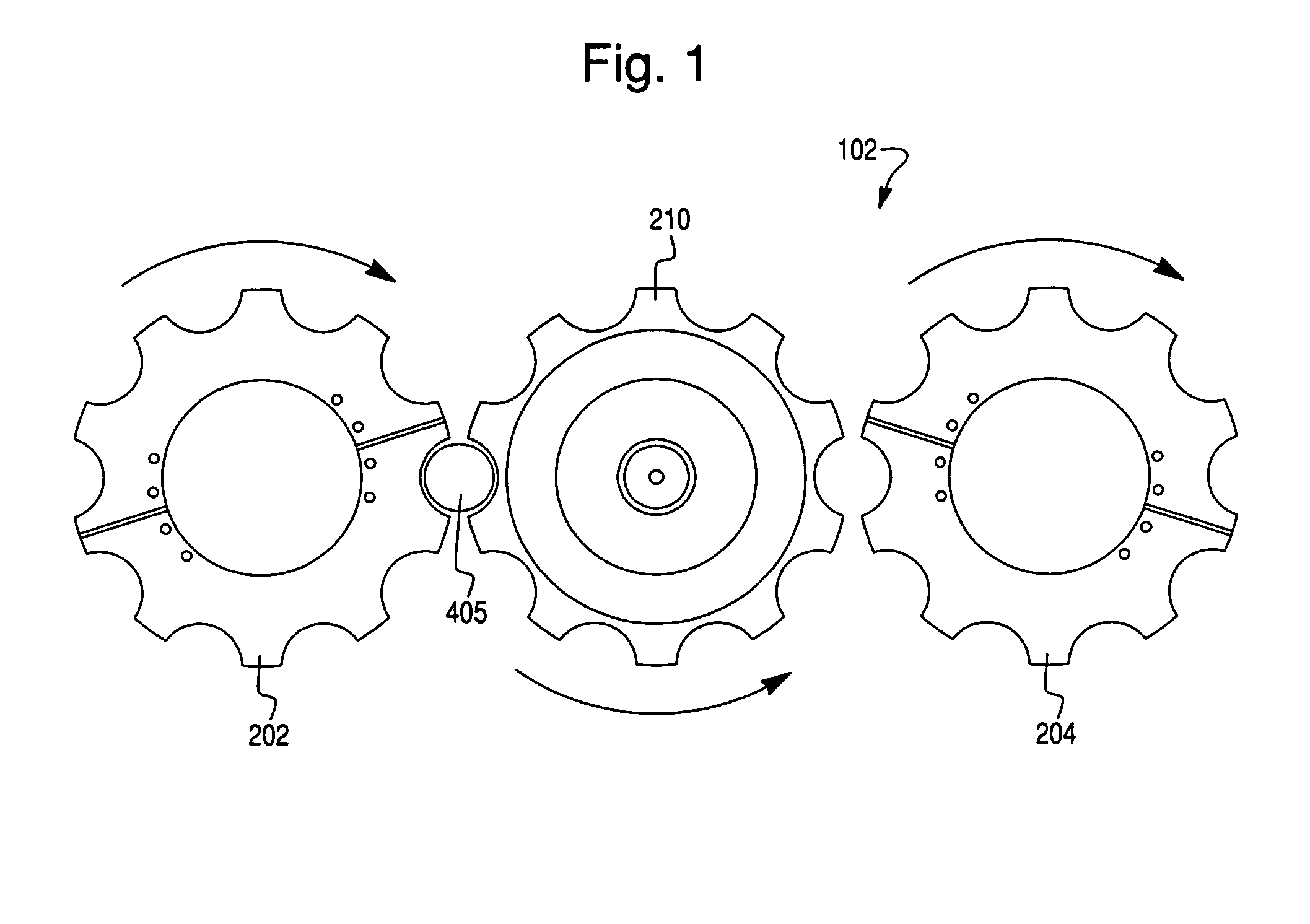

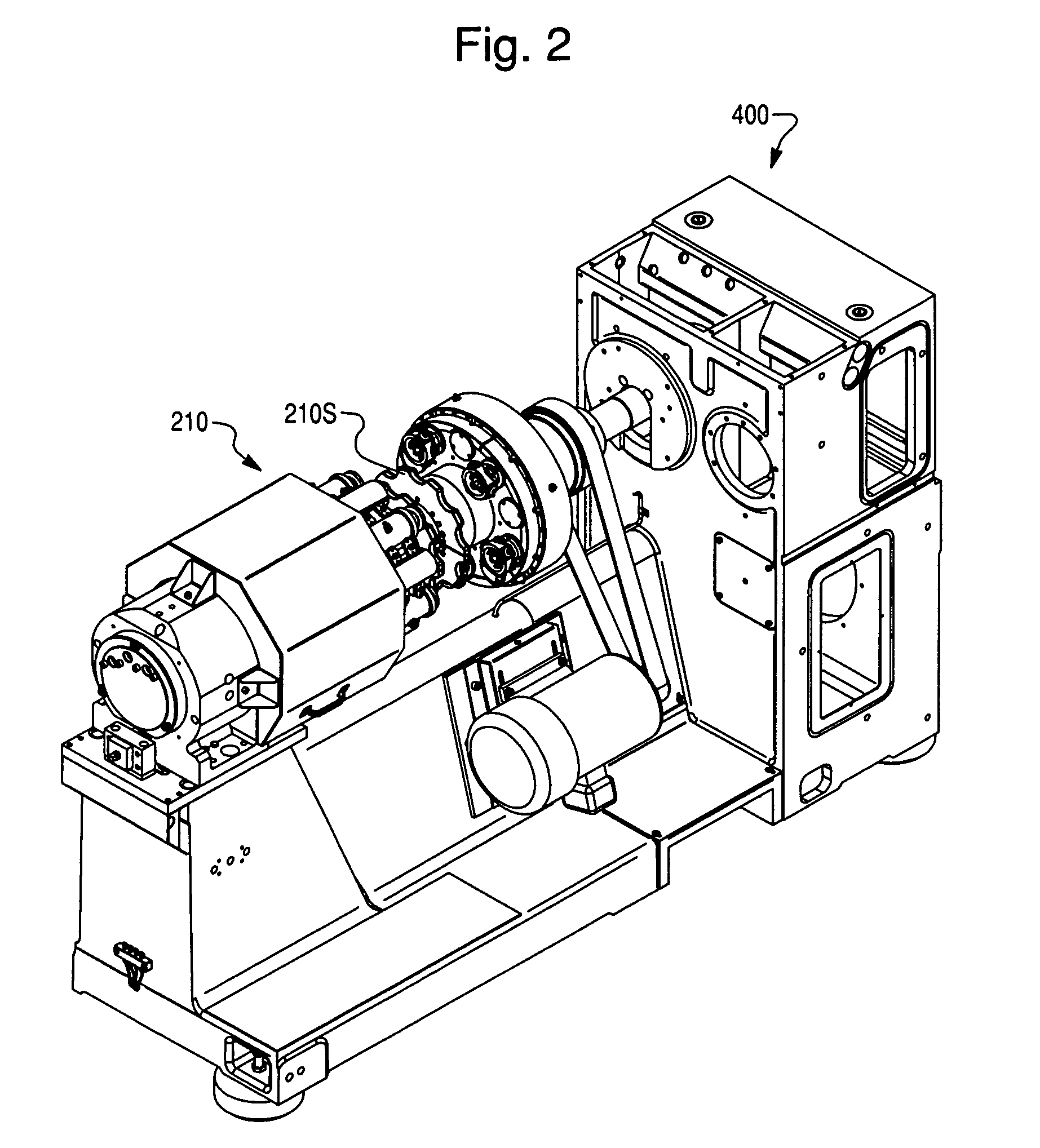

Swaging technology

InactiveUS6931899B2Practical and reliable and accurate and efficientForging hammersShaping safety devicesEngineeringCatheter

A swager for swaging marker bands to a medical catheter, comprises an article input mechanism, the article input mechanism having a first input roller assembly for receiving and conveying an article, a first sensor for detecting a predetermined aspect of the article, a second input roller assembly for receiving and conveying the article, a positioning roller assembly for precisely aligning the article with respect to the swaging head, and a second sensor all constructed and arranged in a streamwise orientation. The swager also has a radial compression swaging head with a central swaging aperture, the swaging head being aligned and communicatively coupled with the input mechanism to receive an input article from the article input mechanism and to swage the article, the swaging head being rotatable and including (i.) a unitary die plate including a plurality of die segments movably coupled to each other to provide a radial compressive force to the article disposed in the central swaging aperture; and (ii.) a closing plate pivotally coupled with respect to each other. The swager also has an output mechanism aligned and communicatively coupled with the swaging head to receive the swaged article. A swaging head and die are also disclosed.

Owner:MACHINE SOLUTIONS

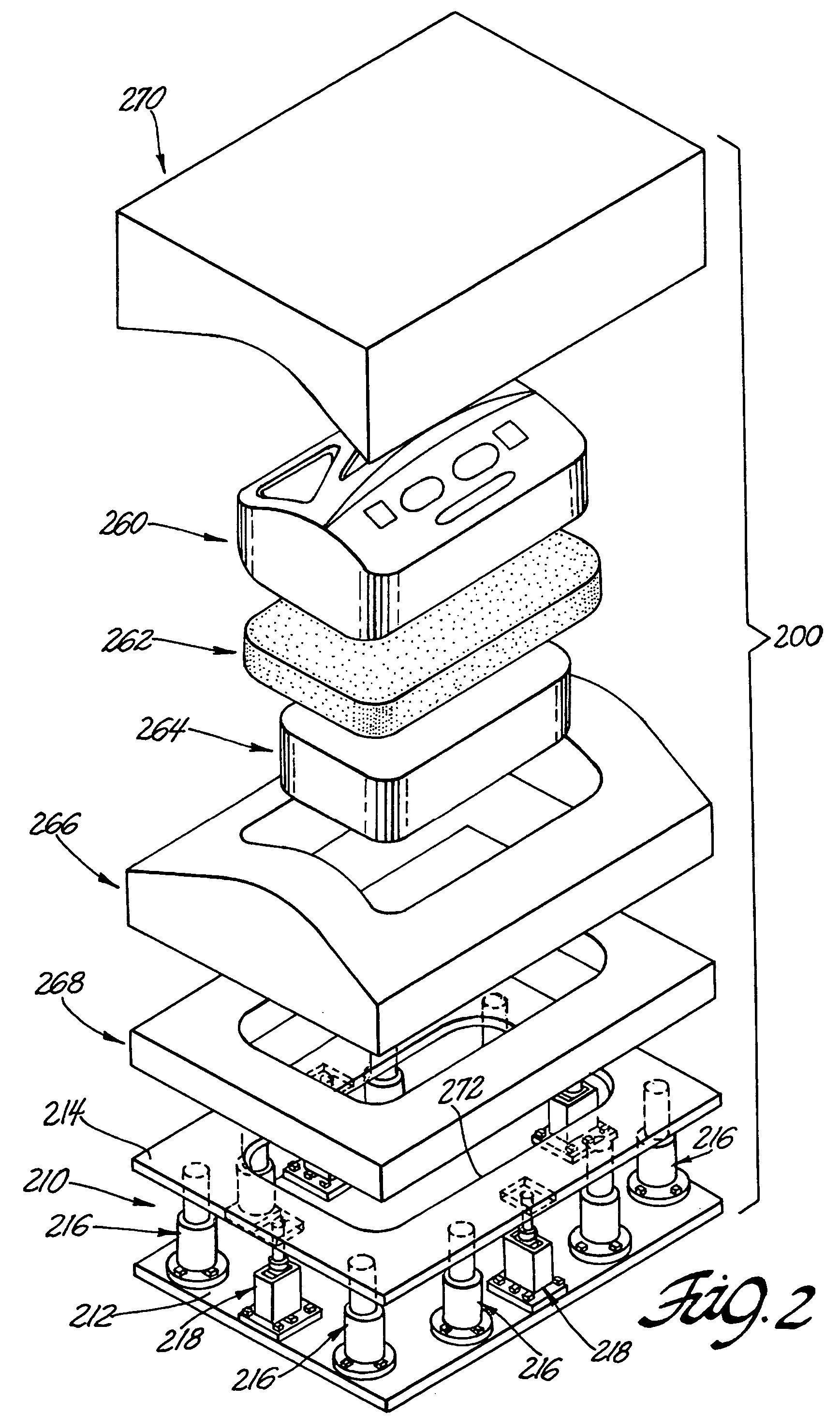

Die cushion apparatus for hot stretch-forming

ActiveUS7004007B2Accurate locationInhibit bindingShaping toolsPlywood pressesRelative displacementThermal expansion

A self-contained die cushion assembly for use in a stretch-forming process involving heated tooling. A lower plate is mounted below an upper plate that undergoes different thermal expansion than the lower plate. Guidance devices are mounted between the upper and lower plates and include a guide post, a bearing sleeve circumscribing the guide post, and a cylinder circumscribing the bearing sleeve. The guide post is mounted in fixed relation to the upper plate, and the cylinder is mounted in laterally translatable relation to the lower plate to accommodate lateral relative displacement between the upper and lower plates due to different thermal expansion thereof, thereby preventing binding of the guidance devices.

Owner:GM GLOBAL TECH OPERATIONS LLC

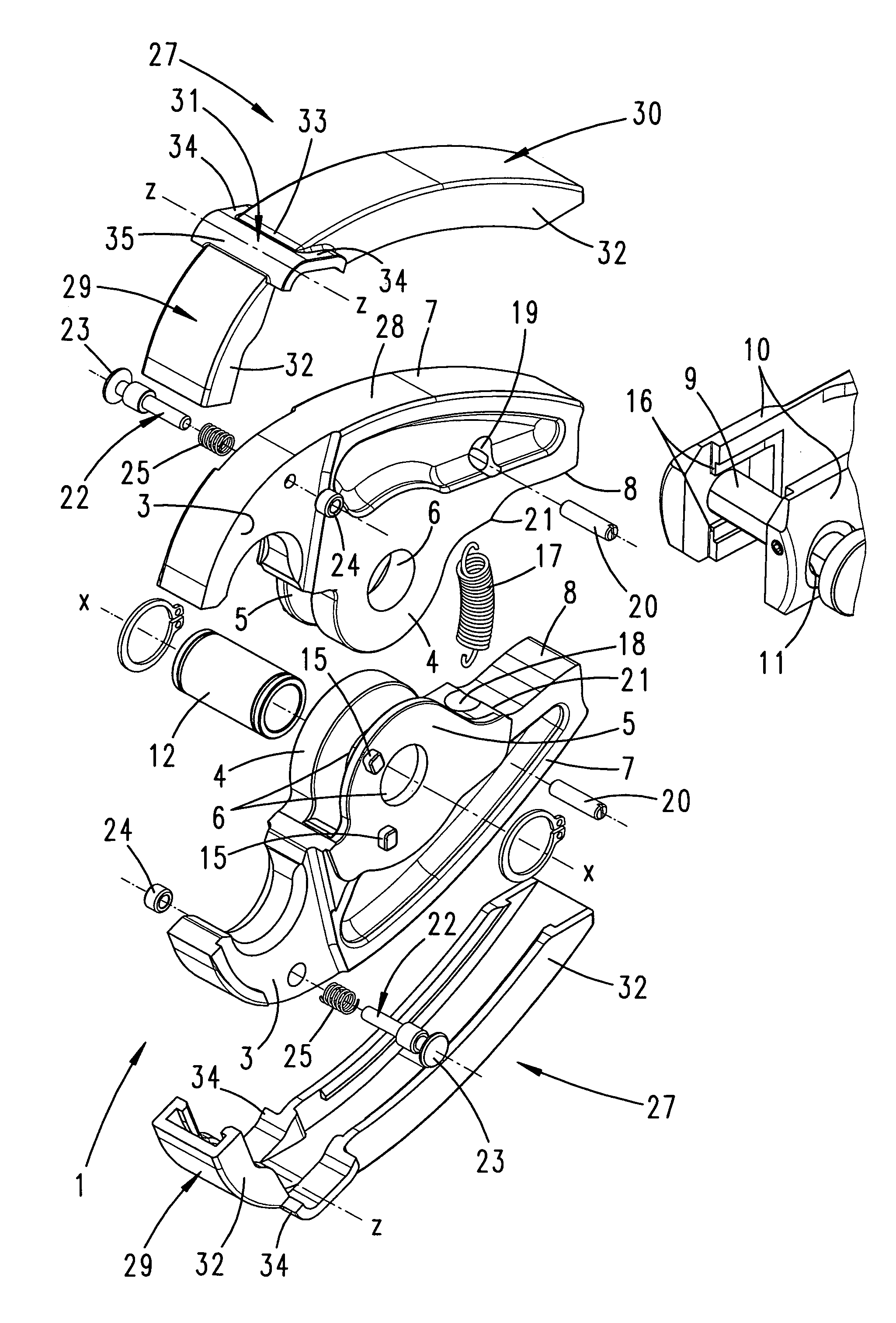

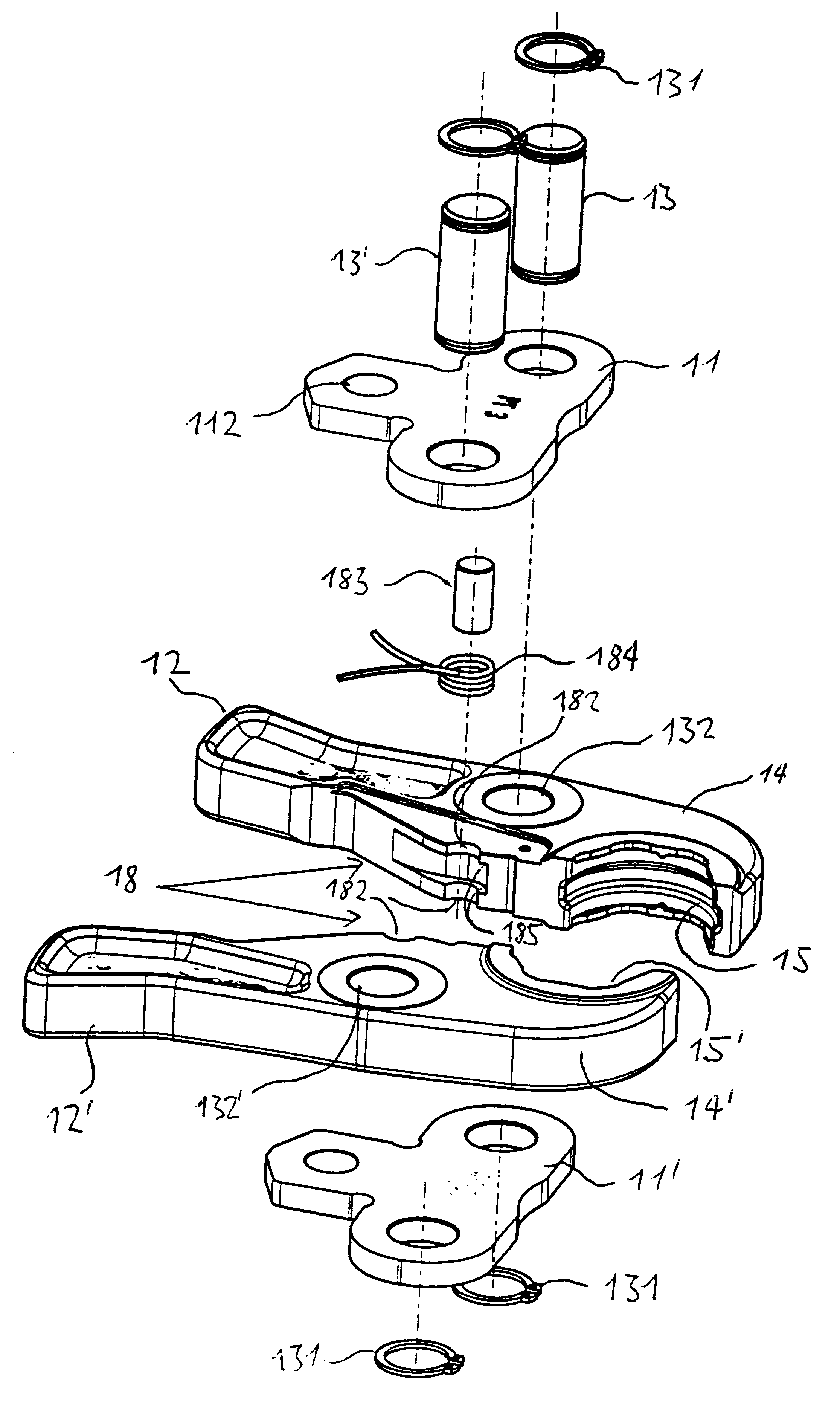

Pair of pressing jaws for hydraulic or electric pressing tools, and insulating covering for a pressing jaw

The invention relates to a pair of pressing jaws for hydraulic or electric pressing tools for pressing fittings onto pipes or for the press connection of electric cables, the two pressing jaws being disposed for rotation about a common axis and each pressing jaw forming a bearing eye for this purpose. In order to configure a pair of pressing jaws of the type in question in a more functionally advantageous manner, it is proposed that each pressing jaw forms two bearing eyes with coaxial bearing openings, and the bearing eyes are disposed in an interengaging manner in the assembled state.

Owner:GUSTAV KLAUKE GMBH

Die cushion controlling apparatus and die cushion controlling method

ActiveUS20050274243A1Cushion pressure of cushion can be controlledImprove accuracyShaping safety devicesForging press detailsEngineeringCushion

A die cushion controlling apparatus for controlling an operation of a cushion pad, which comprises a pad drive mechanism for driving to raise or lower the cushion pad while applying an upward energizing force, a load measuring unit for measuring a load generated in the cushion pad, a time detecting unit for detecting a generating time and a vanishing time of the load, and a control unit for controlling the pad drive mechanism so that a load measured value measured by the load measuring unit follows a preset load pattern during a period from when the time detecting unit detects the generating time of the load until when the time detecting unit detects the vanishing time of the load.

Owner:KOMATSU LTD +1

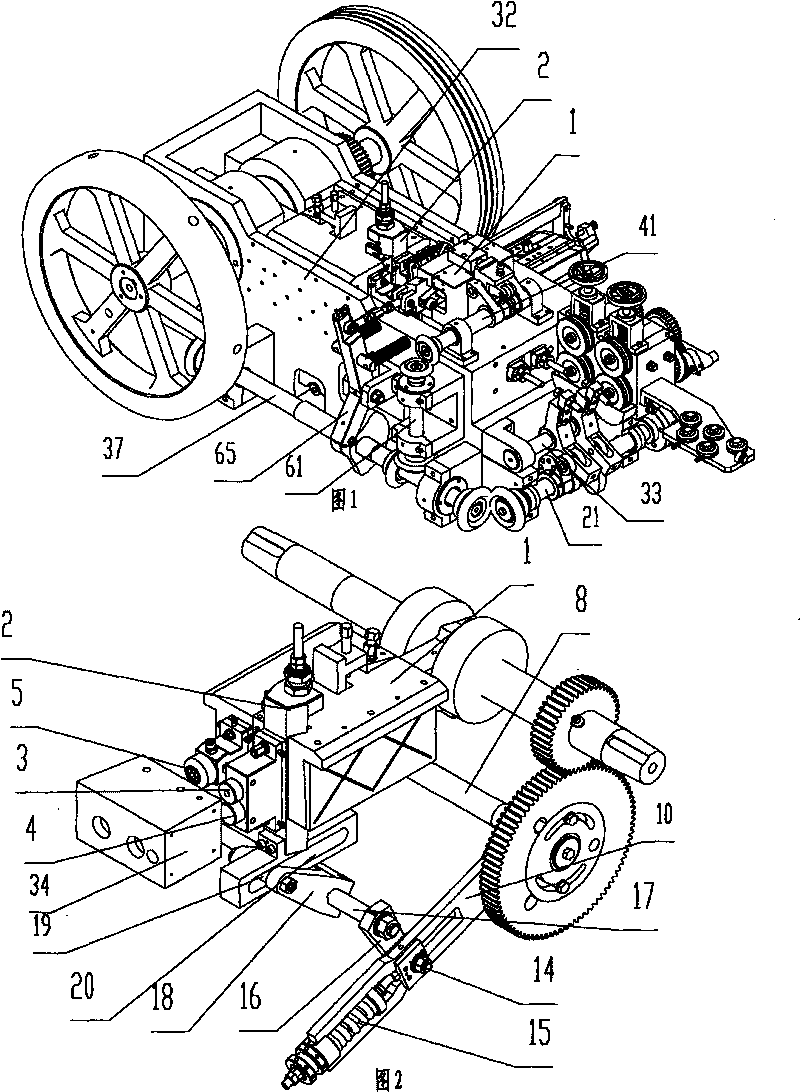

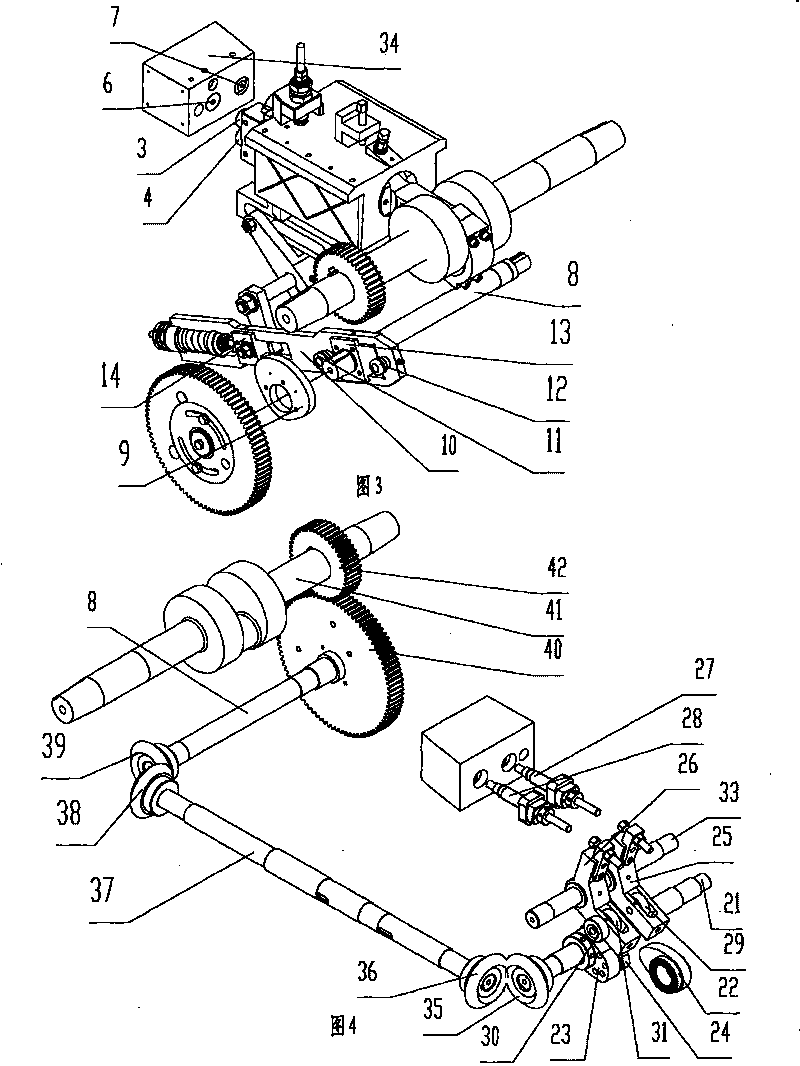

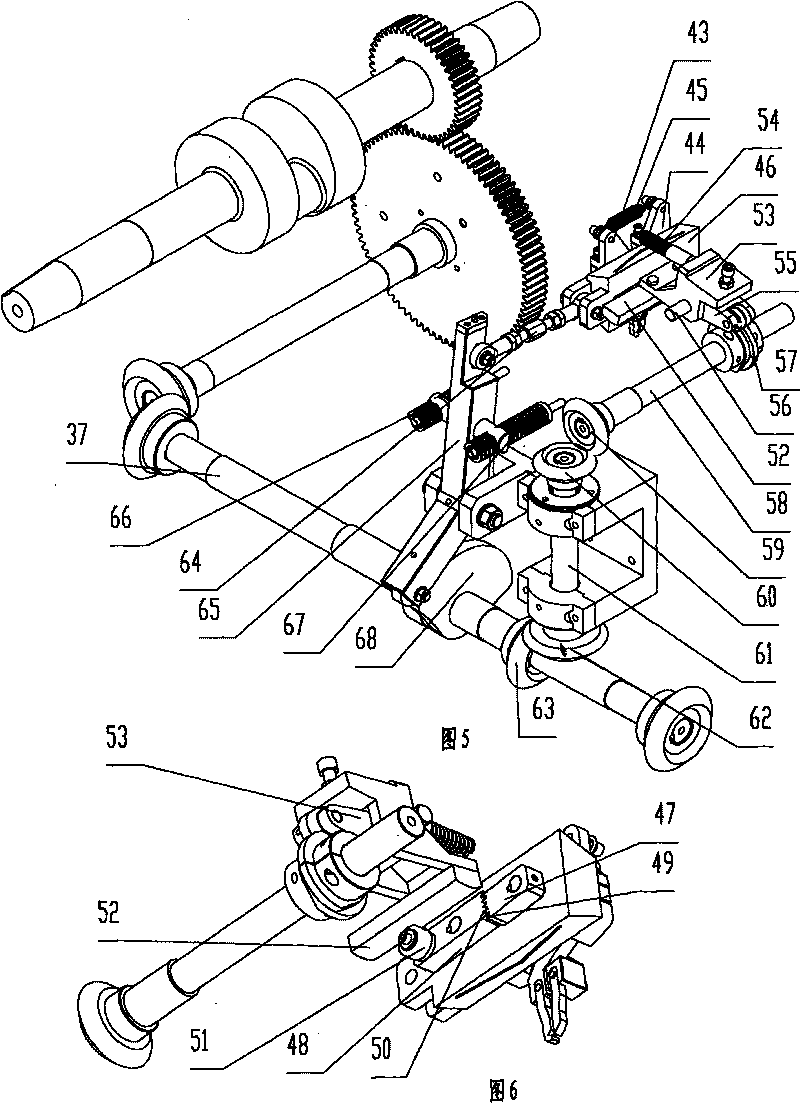

Two-die three-punch upsetter and working method

The invention relates to a two-die three-punch upsetter. A third punch die is a trimming die or a forging and pressing die and is arranged on a large slide block, and a first punch die and a second punch die are arranged on a lifting plate; a first concave die corresponds to the first punch die and the second punch die, and a second concave die corresponds to the third punch die; and axis of the second concave die and the third punch die are oppositely kept on the same straight line all the time. A working method comprises the following steps of: forming a workpiece by rotating a crank shaft twice; when the large slide block is upset for the first time, upsetting a blank into a primary upsetting semi-finished workpiece by the first punch die and preserving the semi-finished workpiece in the first concave die; upsetting a secondary upsetting semi-finished workpiece into a finished workpiece by the third die and ejecting the finished workpiece out; when the large slide block upsets for the second time, upsetting the primary upsetting semi-finished workpiece into the secondary upsetting semi-finished workpiece by the second punch die and ejecting the secondary upsetting semi-finished workpiece out; and air beating by the third punch die. The invention can achieve the functions of various upsetters, such as a one-die two-punch upsetter, an outer hexangular trimming machine, a three-die three-punch upsetter, and the like.

Owner:杨东佐

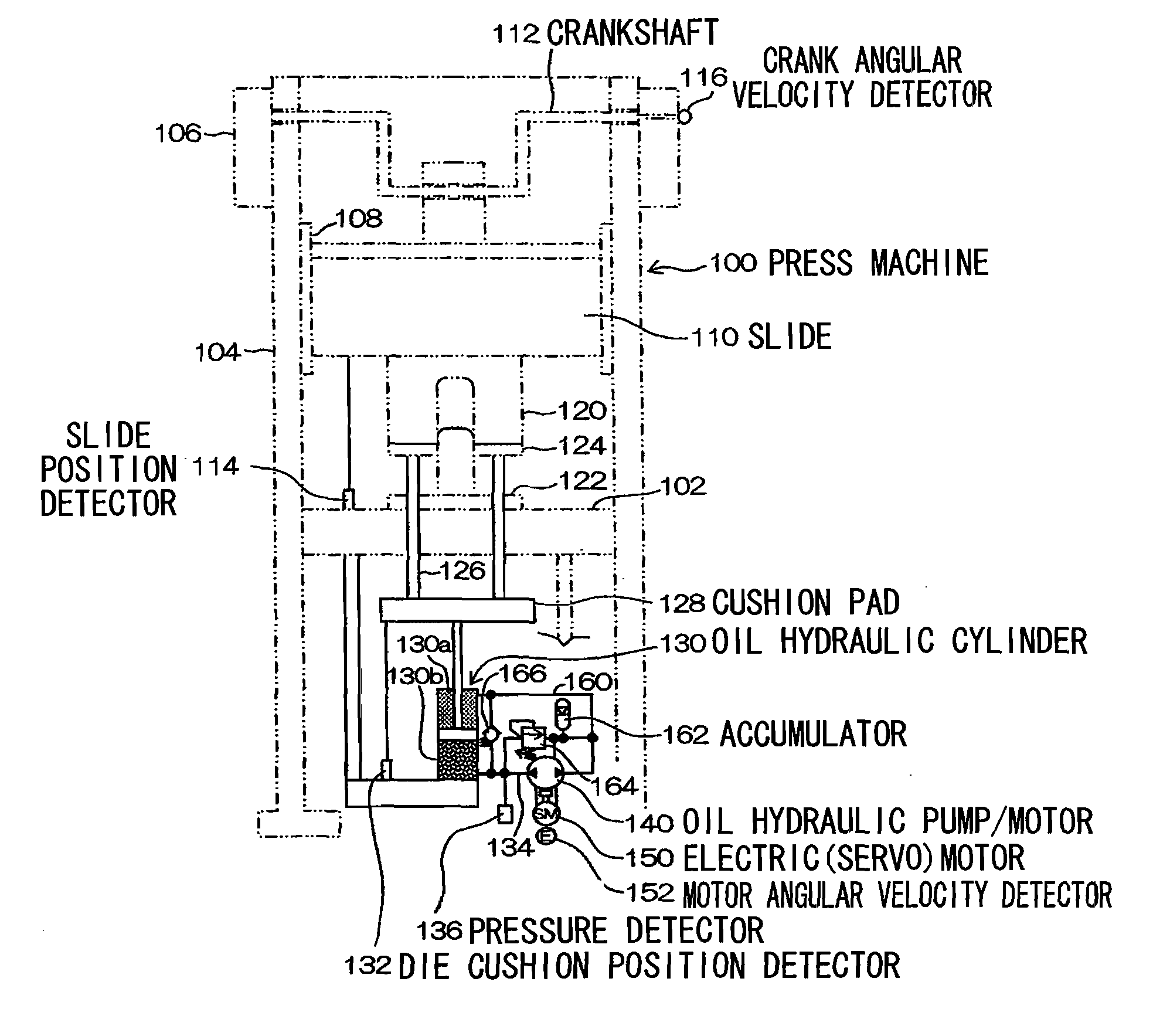

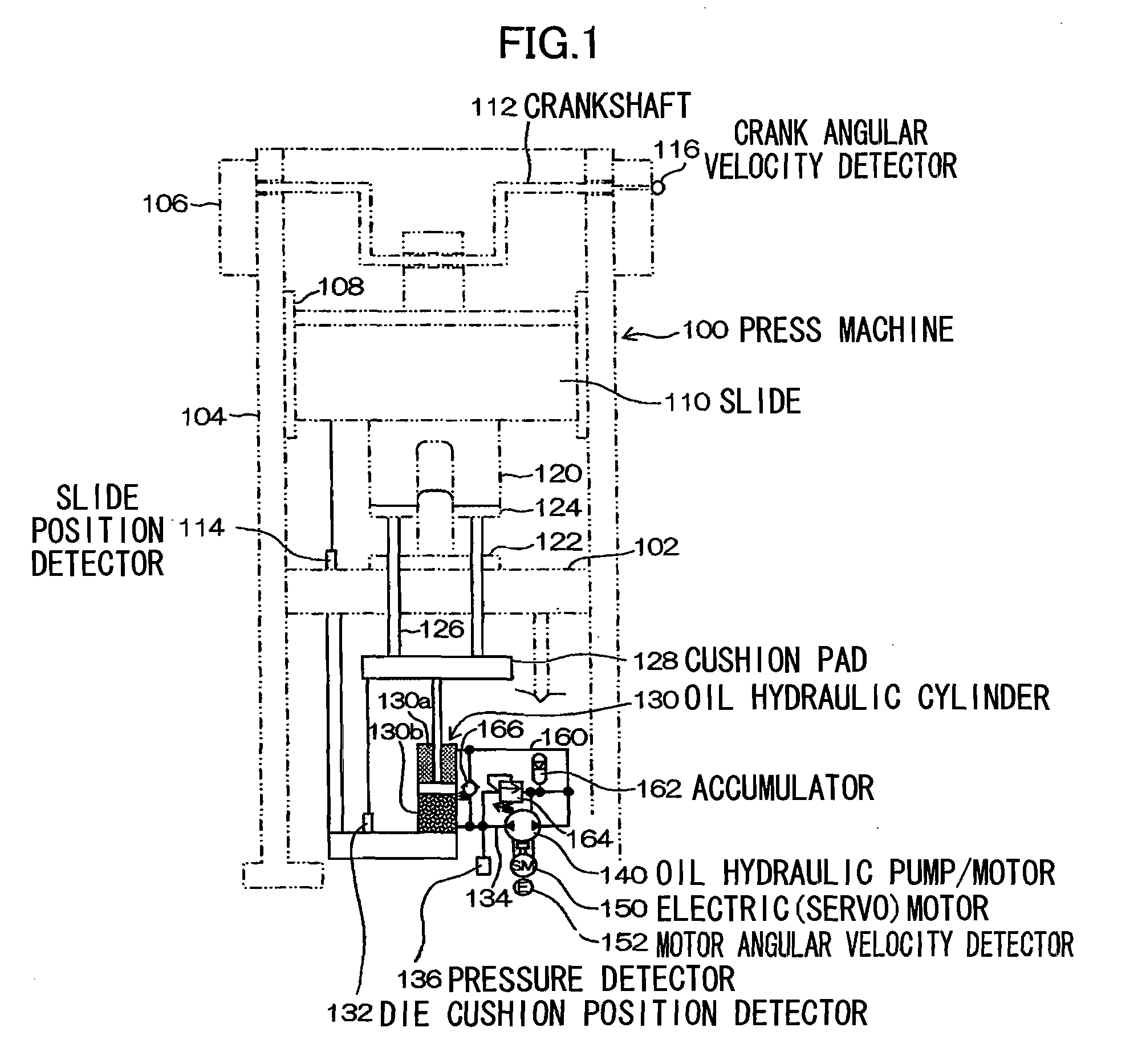

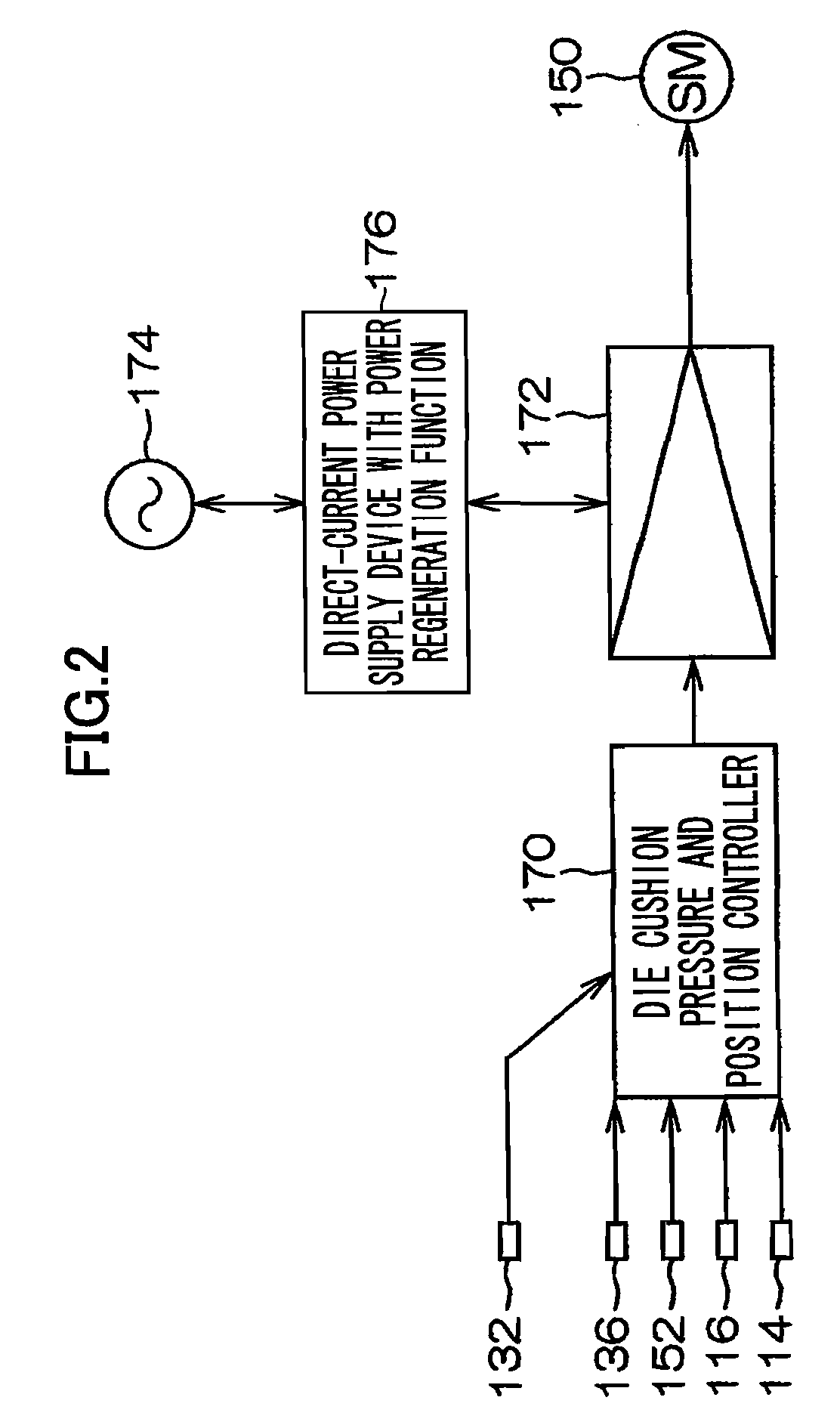

Die cushion device for press machine

ActiveUS20090071218A1Improve responseAvoid it happening againServometer circuitsForging press detailsHydraulic cylinderCushioning

A die cushion apparatus of a press machine in which a discharge opening of a fluid hydraulic pump / motor is directly connected to a pressure chamber on a cushion pressure production side of a fluid hydraulic cylinder and the torque of a rotating shaft of the fluid hydraulic pump / motor is controlled by an electric motor to control a pressure (die cushion pressure) of the pressure chamber on the cushion pressure production side. It is therefore possible to control the die cushion pressure with excellent responsiveness with respect to a die cushion pressure command and prevent occurrence of a surge pressure. The die cushion apparatus also has excellent energy efficiency since energy required for a die cushioning action that a cushion pad receives when effecting die cushioning of a press machine is regenerated as electrical energy through the fluid hydraulic cylinder, fluid hydraulic pump / motor, and electric motor.

Owner:AIDA ENG LTD

Pressing pincer

Owner:VON ARX AG

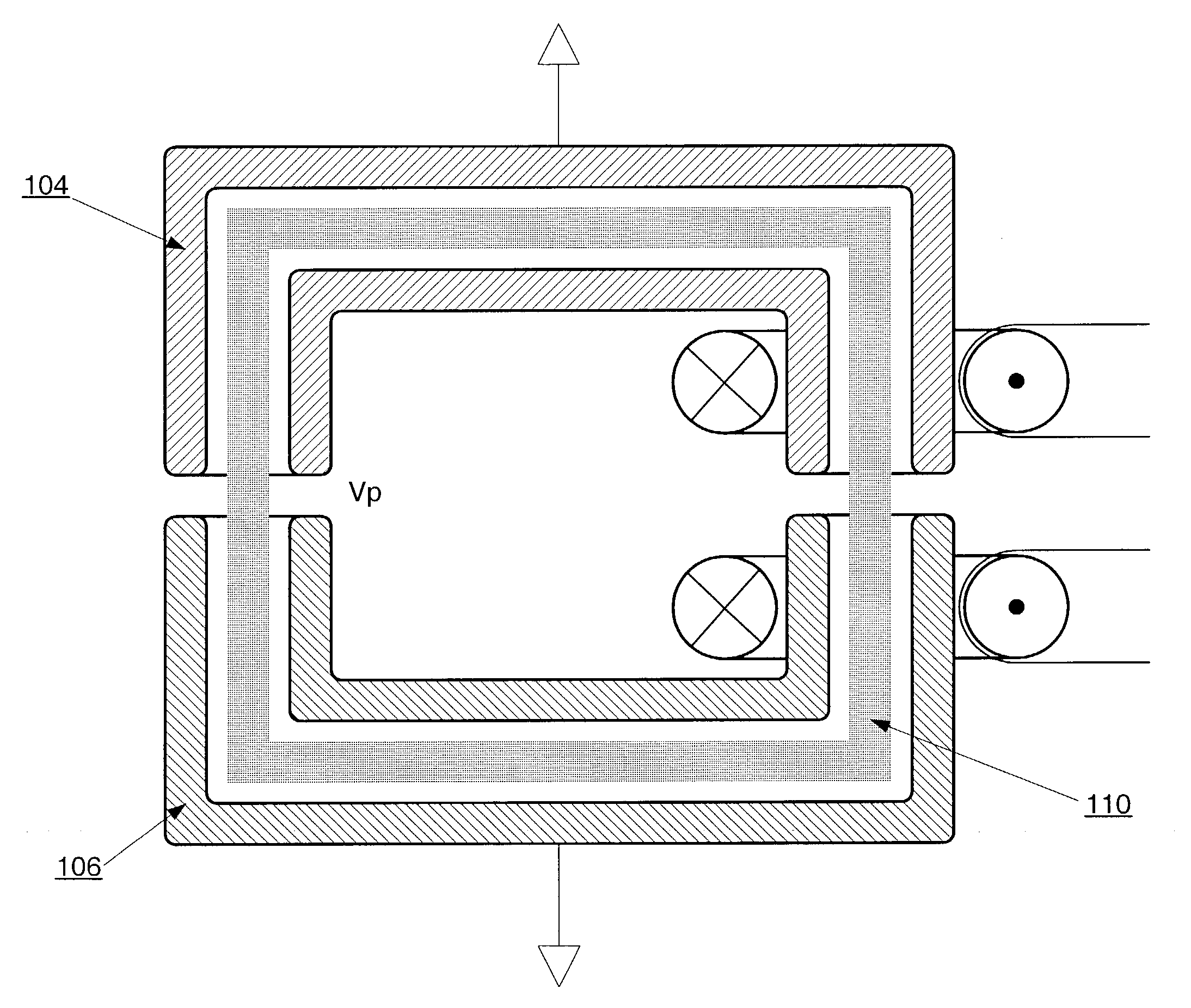

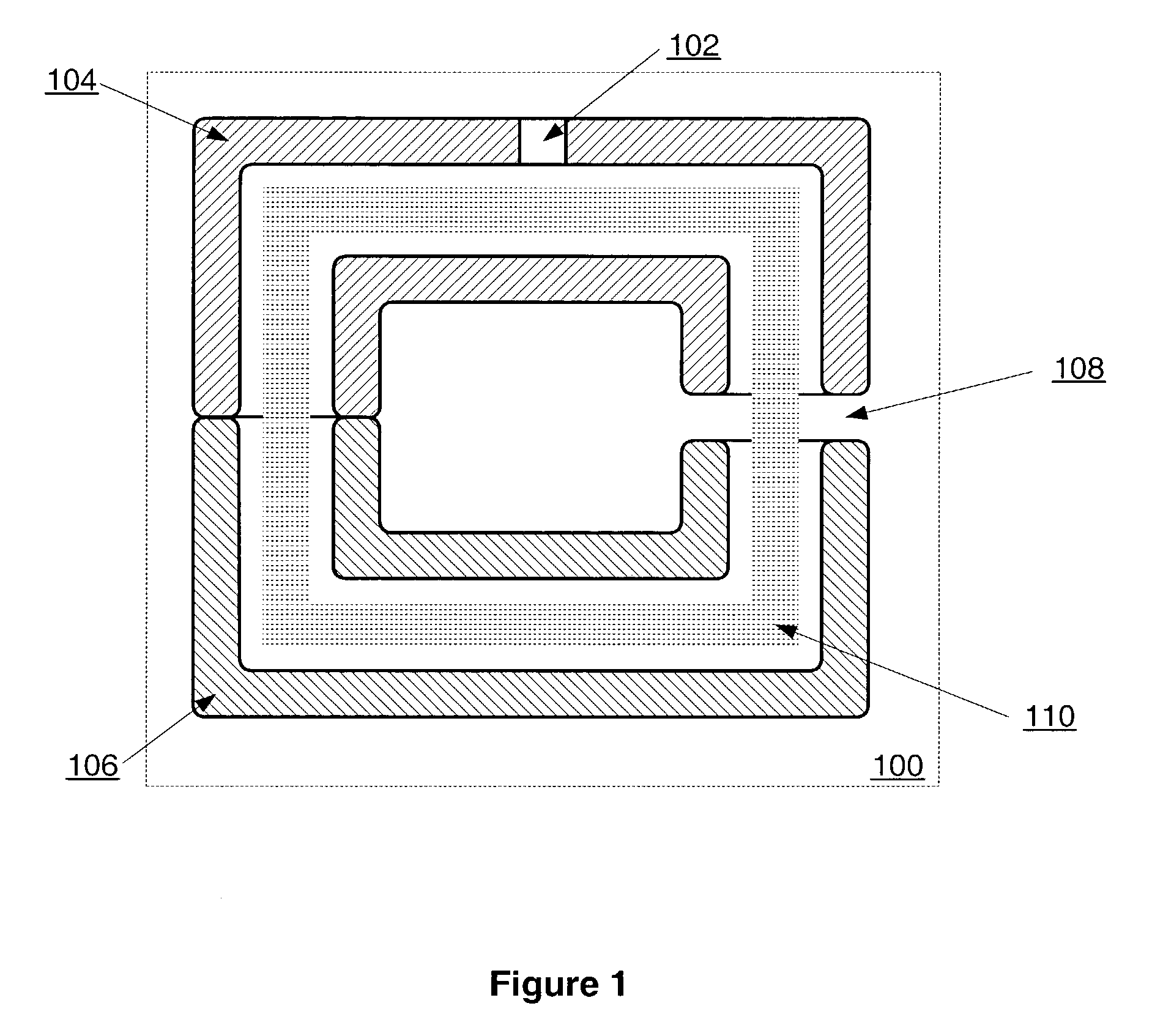

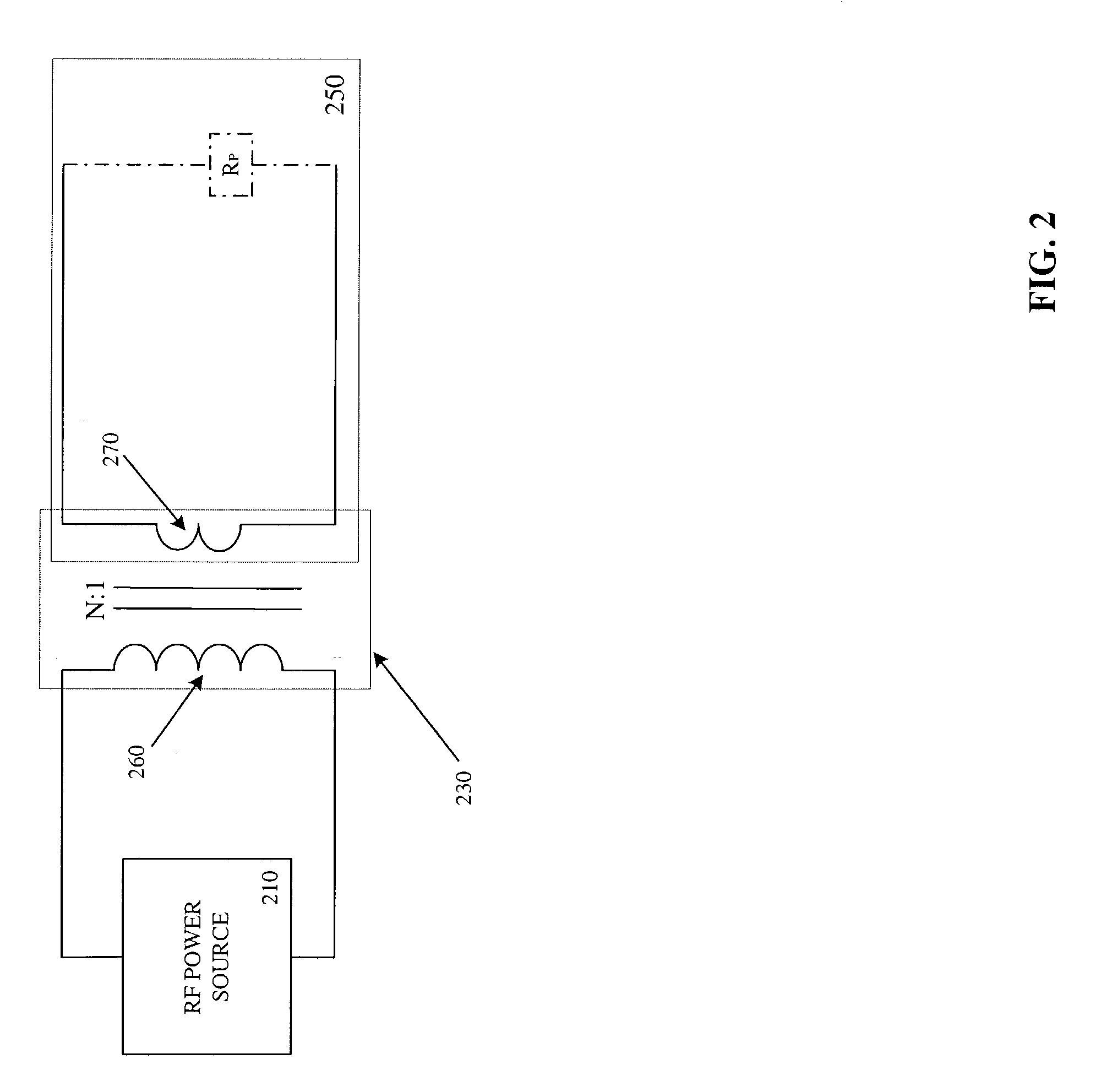

Deterioration resistant chambers for inductively coupled plasma production

InactiveUS6946063B1Improved wall resistanceVacuum evaporation coatingSputtering coatingElectricityIon bombardment

In one aspect of the invention is a method to construct plasma chambers with improved wall resistance to deterioration. In one embodiment of the invention, a chamber is made of an aluminum alloy having low concentrations of elements that form non-soluble, intermetallic particles to address coating / substrate issues, has swaged-in cooling tubes to reduce thermal stress by improving thermal resistance, and has a plurality of dielectric gaps to decrease ion bombardment.

Owner:ADVANCED ENERGY IND INC

Pressing tool for pressing coupling elements

Owner:VON ARX AG

Pressing tool apparatus and control method

A pressing tool apparatus with a clamping pincer and a sensory mechanism that permits a measurement of a displacement which the piston covers with the closure procedure of the clamping pincer. With the first closure of the clamping pincer, without a pressing, there results a nominal displacement value which is realized by a displacement sensor and a ring magnet. Electronics in the housing store a measured nominal value and compares it to subsequent closure procedures with a pressing, accounting for programmable tolerance values. Pressings within a permitted range or outside the range are suitably displayed.

Owner:AG VON ARX

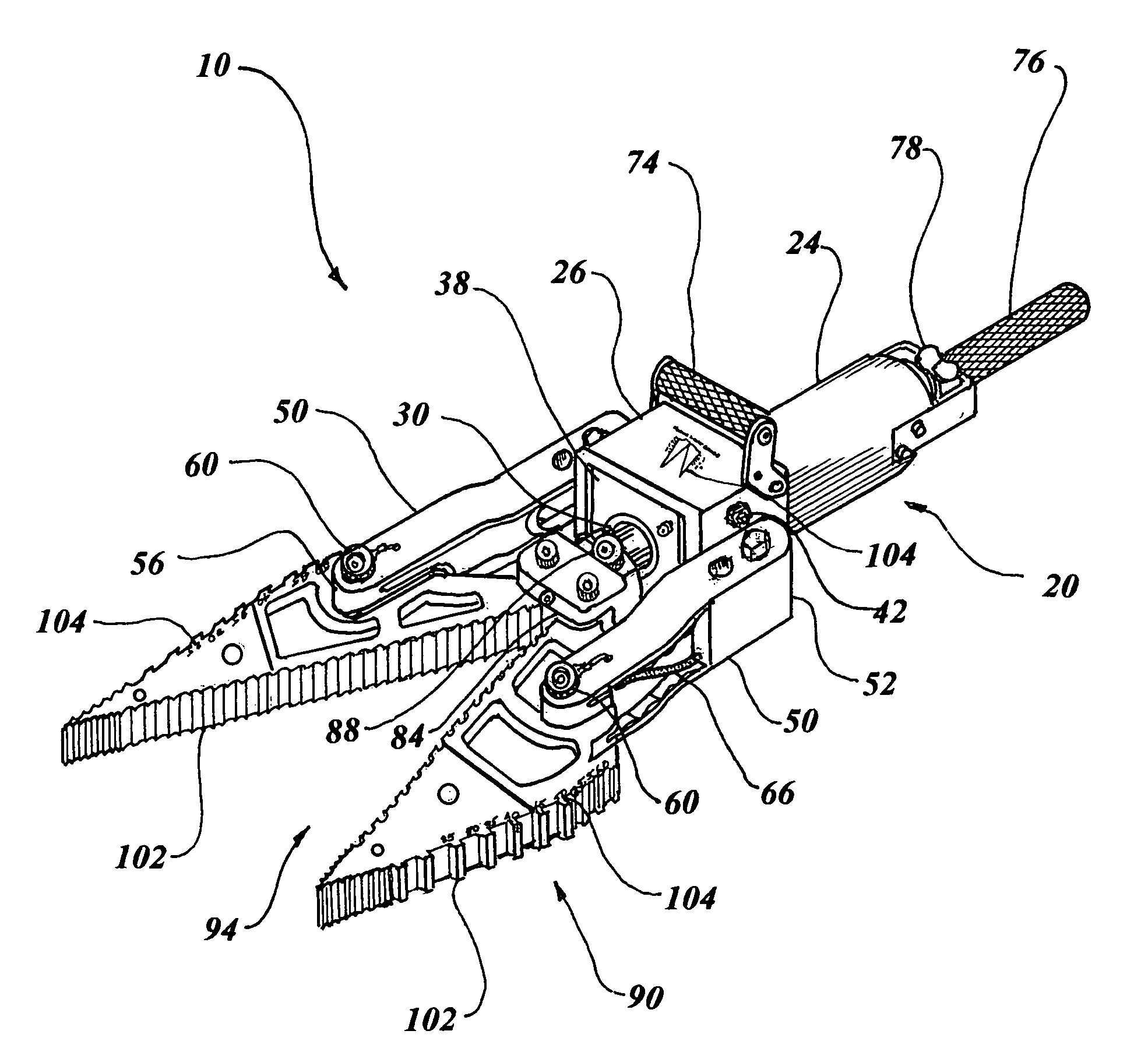

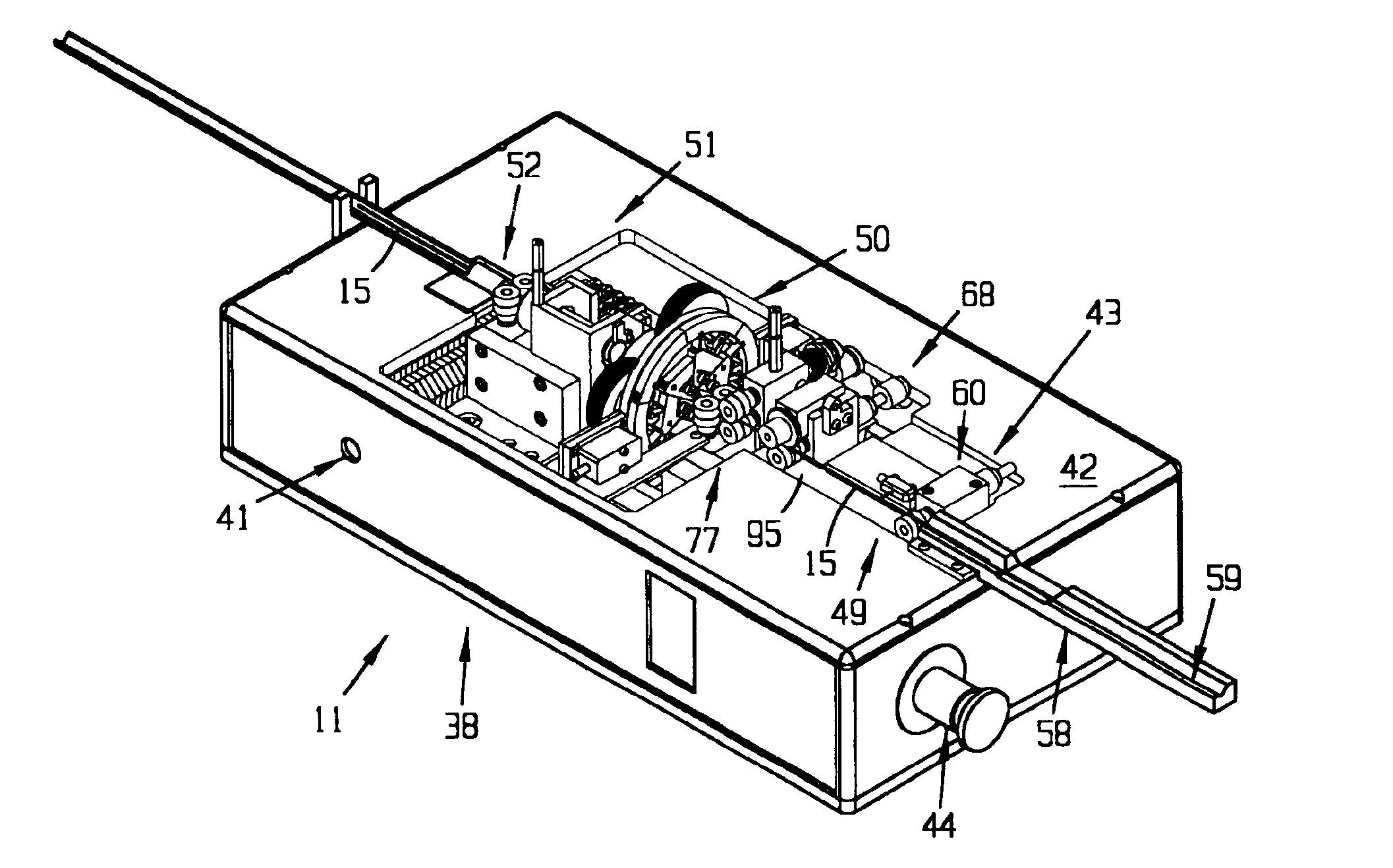

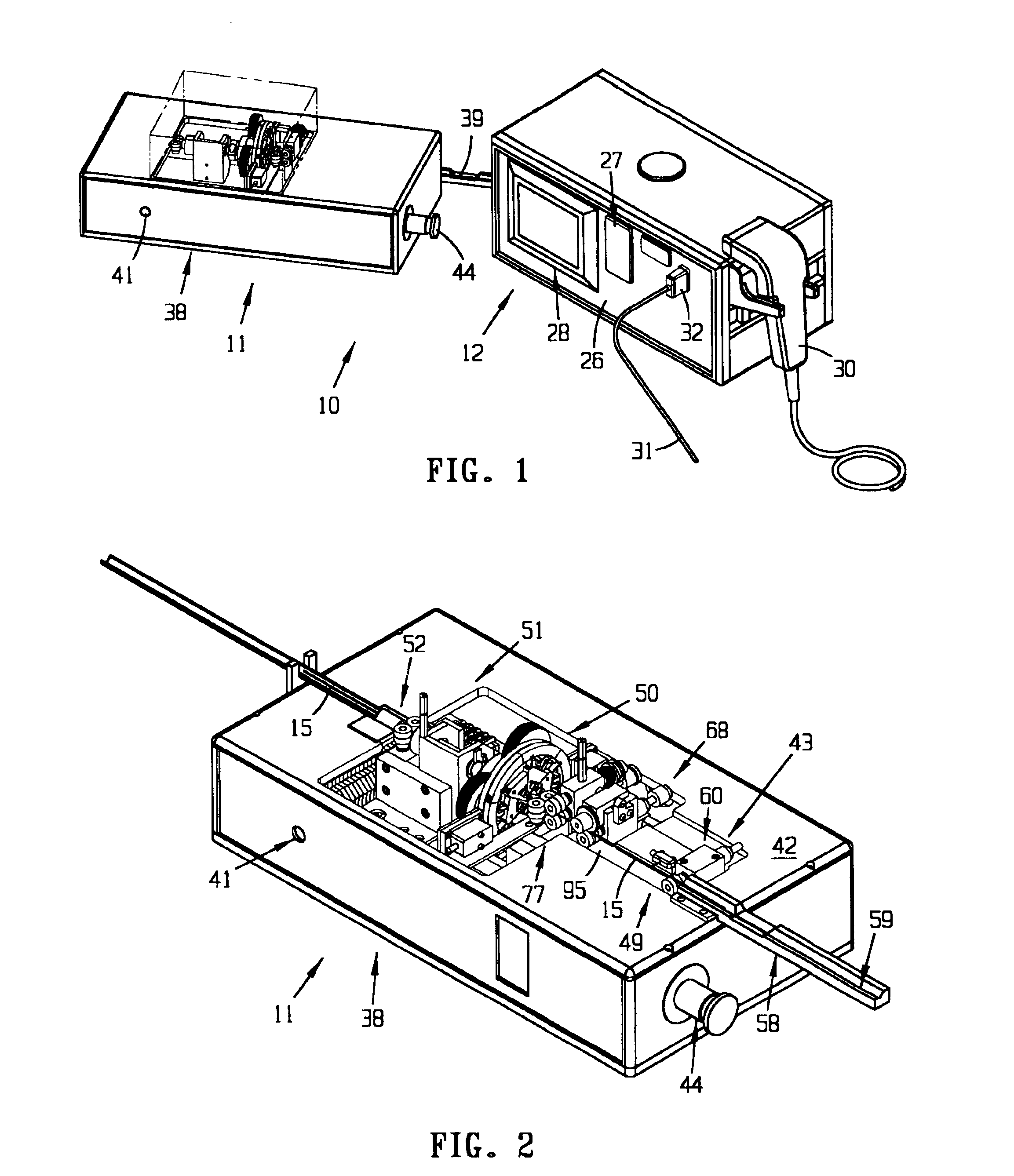

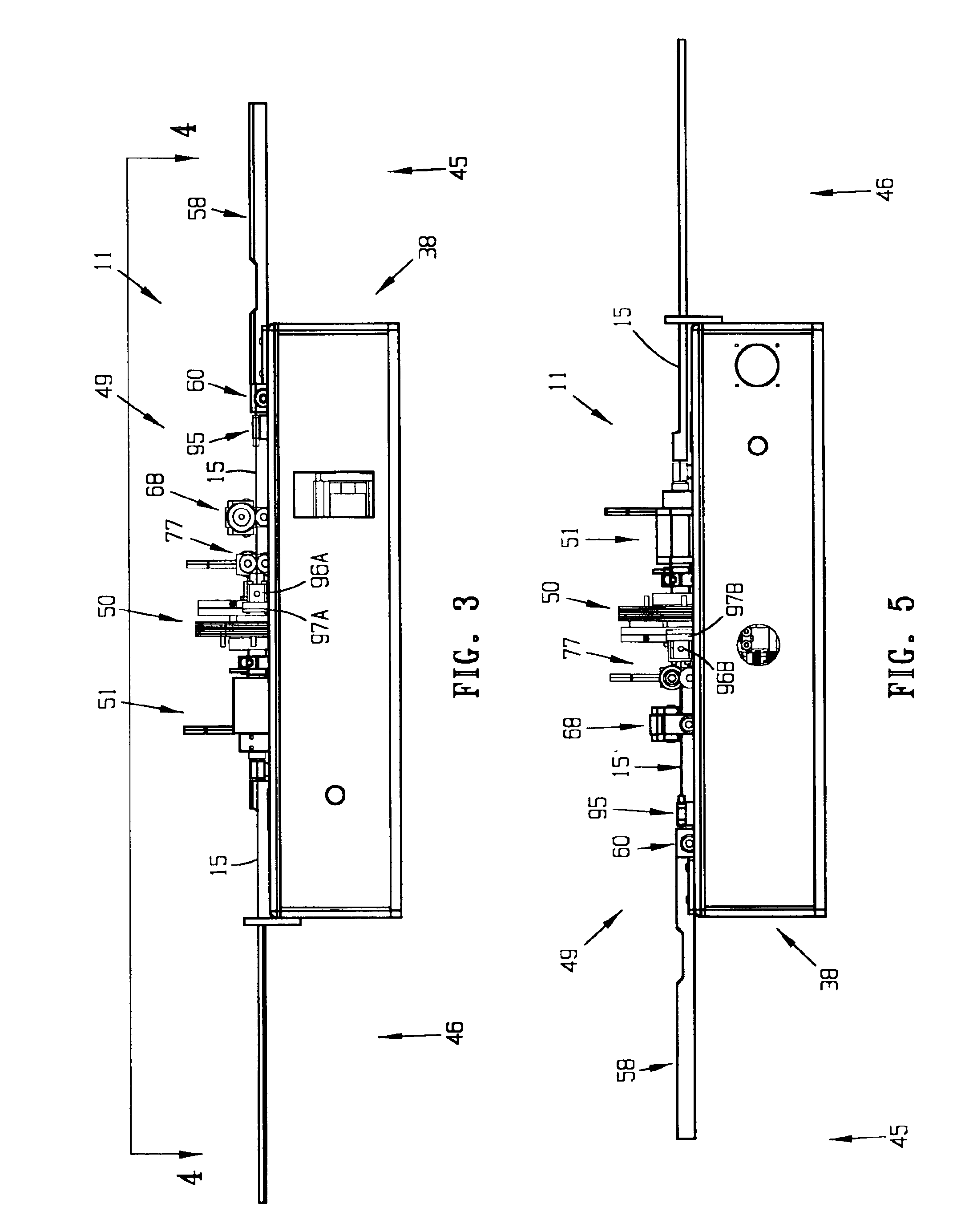

Automated surgical rod cutter and bender including a power-base, assembly for rod cutting, and assembly for rod bending

InactiveUS20120186411A1Linear changeStock shearing machinesForging press detailsMuscular forceEngineering

A rod manipulator including power-base and various assemblies, interchangeably attaching to the base. The power-base is composed of a pneumatic cylinder and piston which affects the function of various assemblies. The piston moves the central component of an assembly toward the fixed portion of that assembly. A bending assembly containing mobile pivots around which a surgical metal rod can be bent. A cutting assembly containing blades in central and fixed portions between which a surgical metal rod can be cut. The distal end of the cut rod is retained by replaceable, sterilizable, eject-grips during and immediately after the cutting operation. The general object of the invention is to provide an improved surgical rod cutter and surgical rod bender, capable of performing both tasks with one power source, requires one-person operation, eliminates the need for significant muscular forces and eliminates the opportunity for an unsafe projectile in the operating room.

Owner:LODAHI SEBSTIAN +2

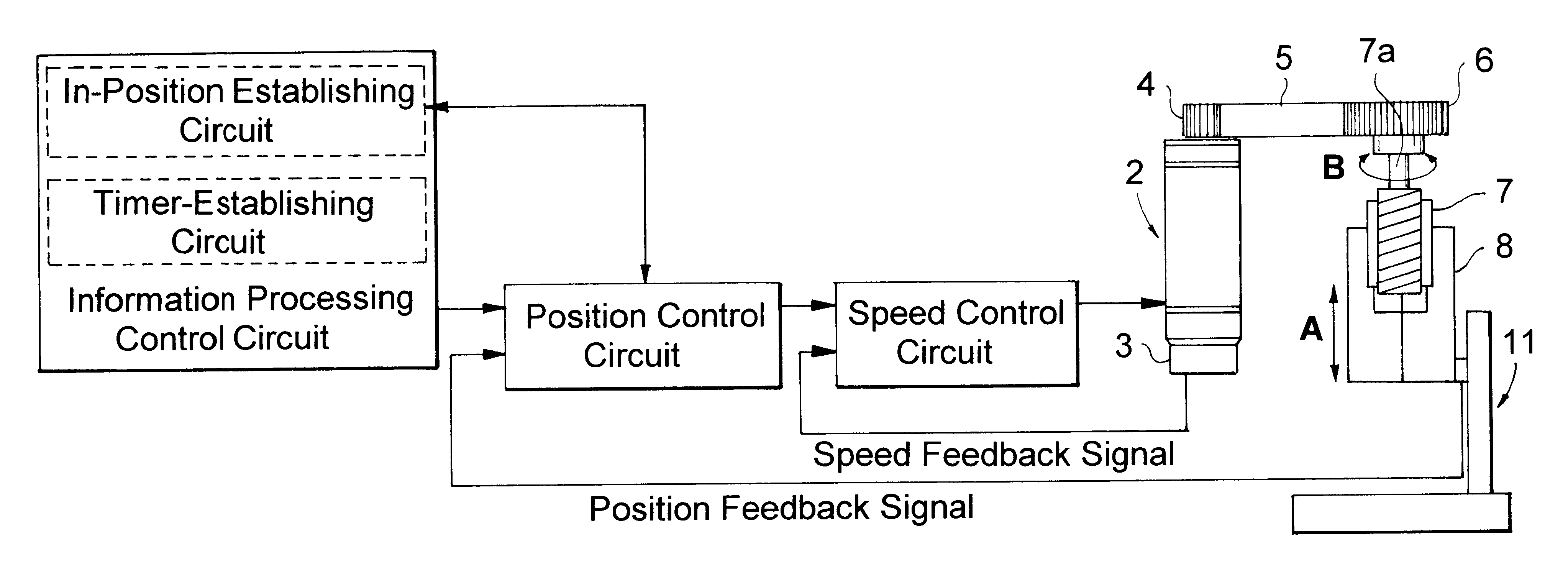

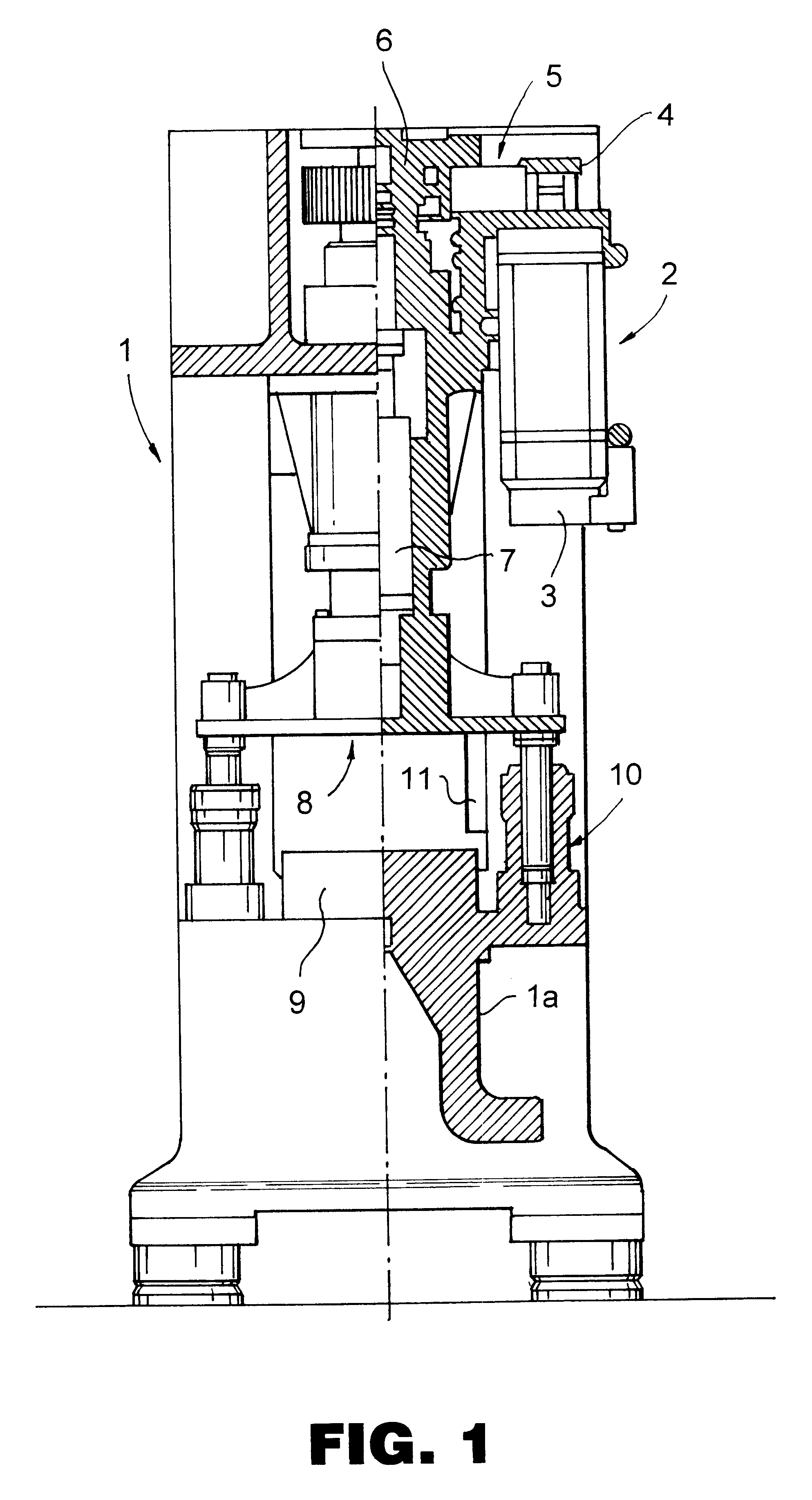

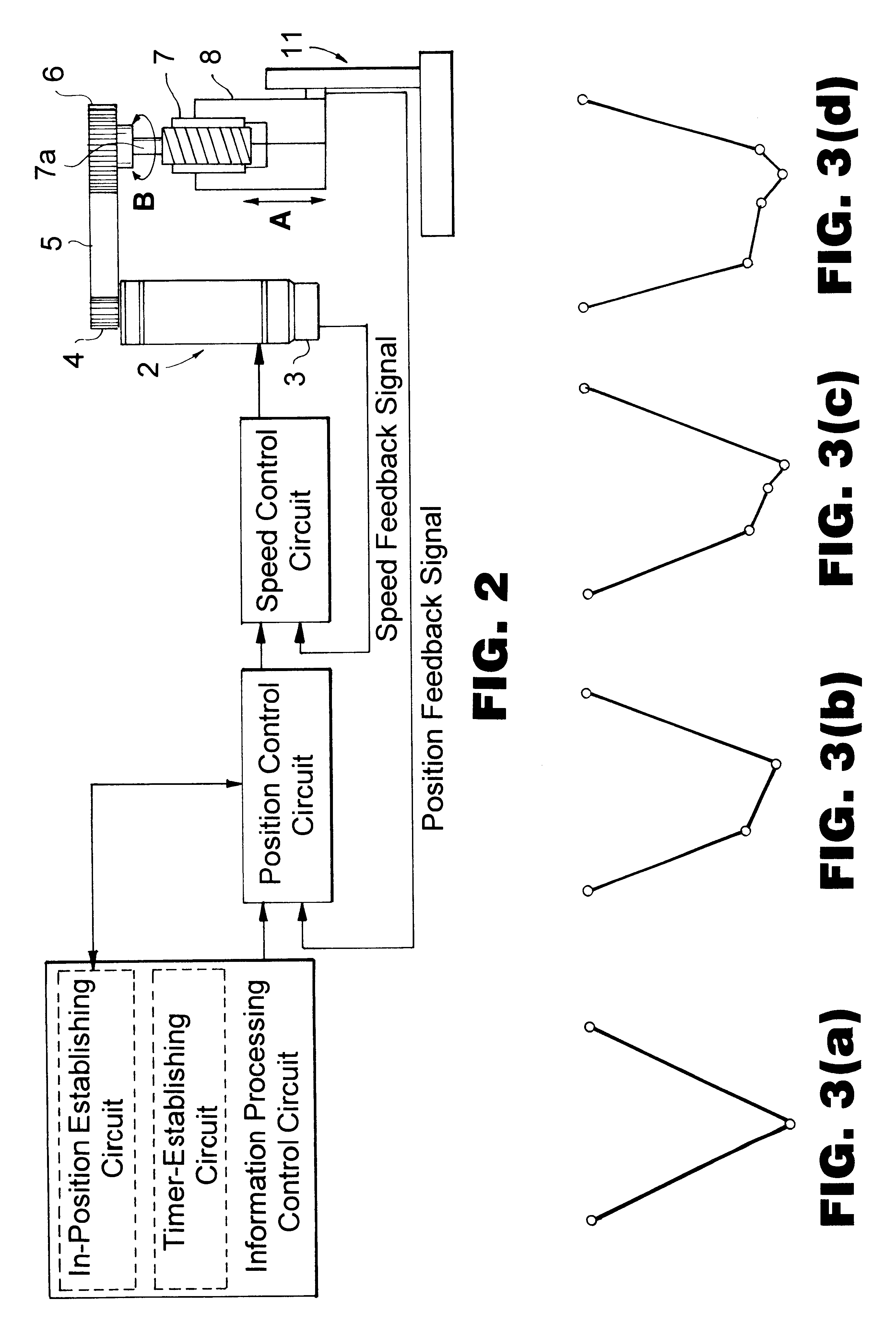

Screw press

InactiveUS6520077B1Precise positioningShaping safety devicesForging press detailsReduction driveControl theory

A screw press which can ensure the positional precision of the ram when the rotation amount of the press motor does not directly translate into the position of the ram because there is other machinery, such as a decelerator and the like, present between the motor (servo motor) and the screw mechanism, has a construction in which a position detection sensor, which detects the position of the ram, is provided, and the position of the ram is controlled by the output from this sensor.

Owner:AIDA ENG LTD

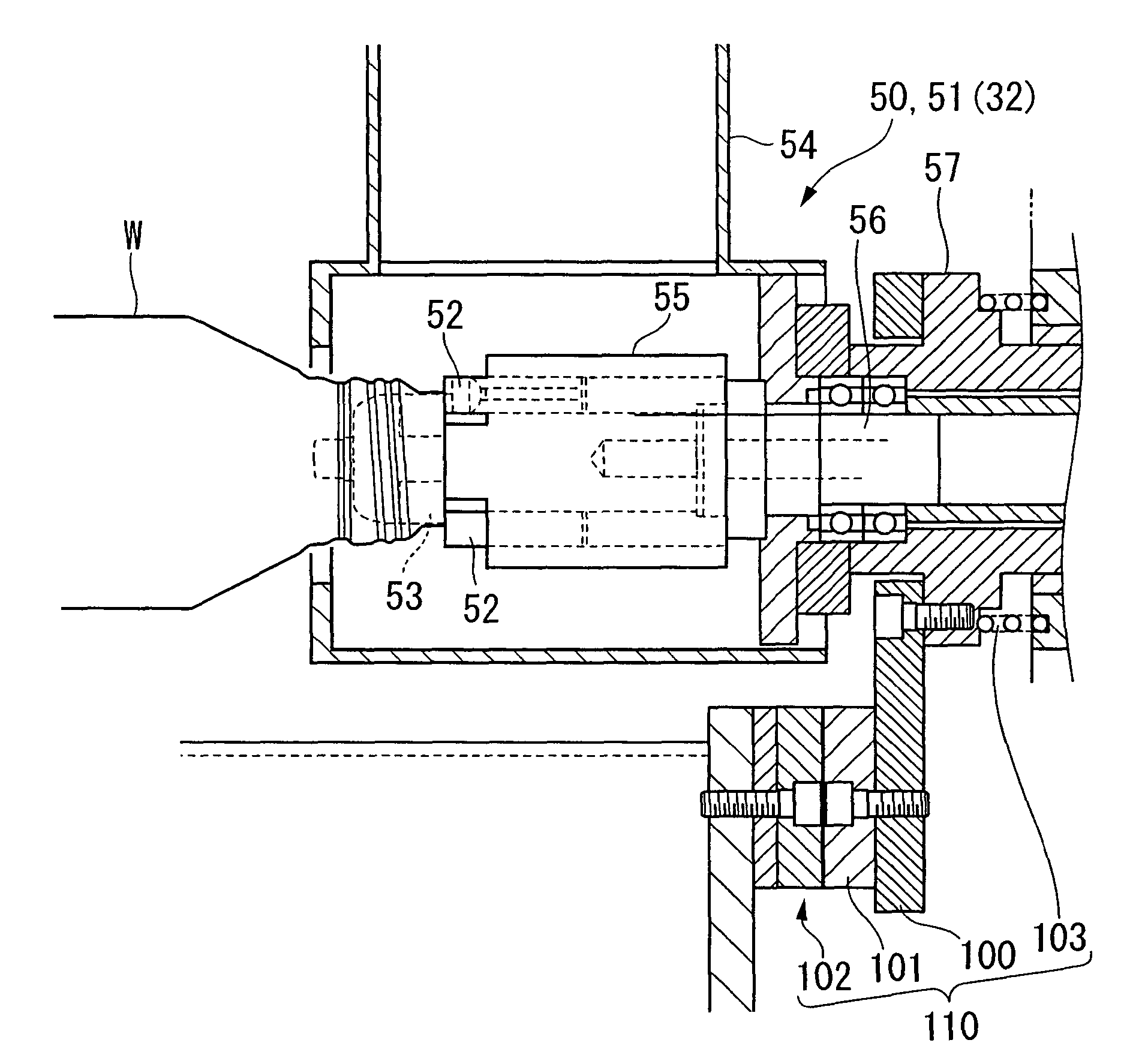

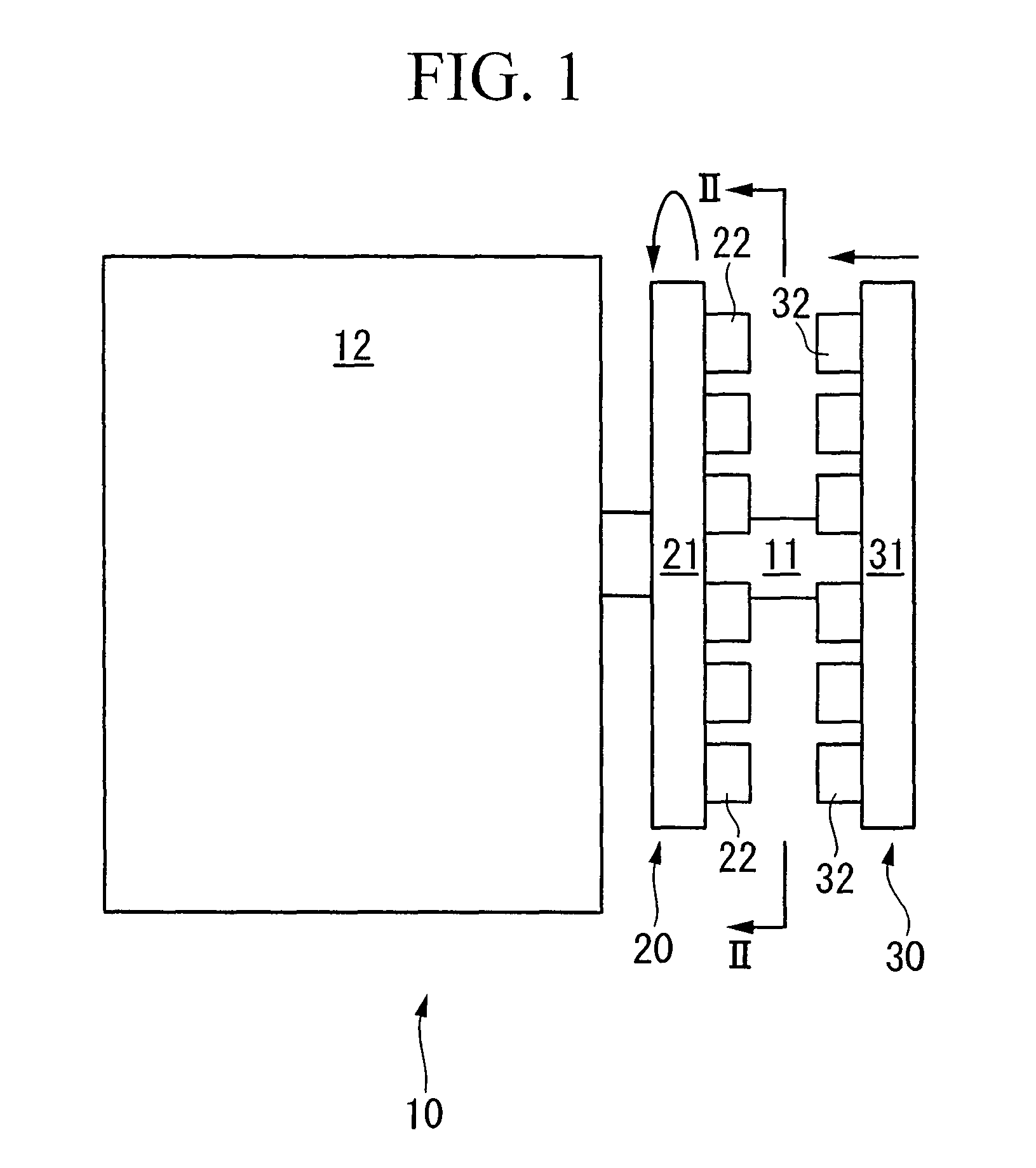

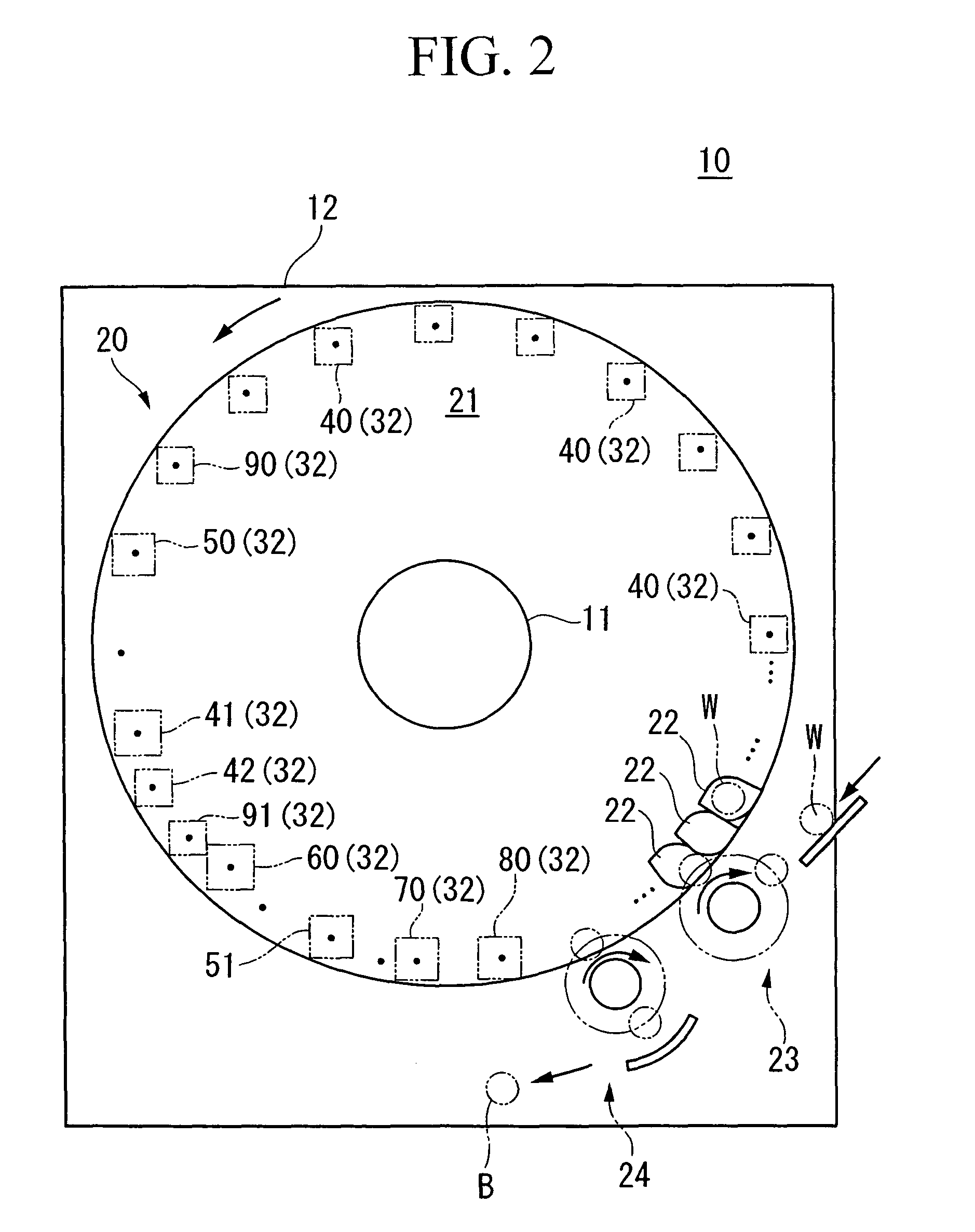

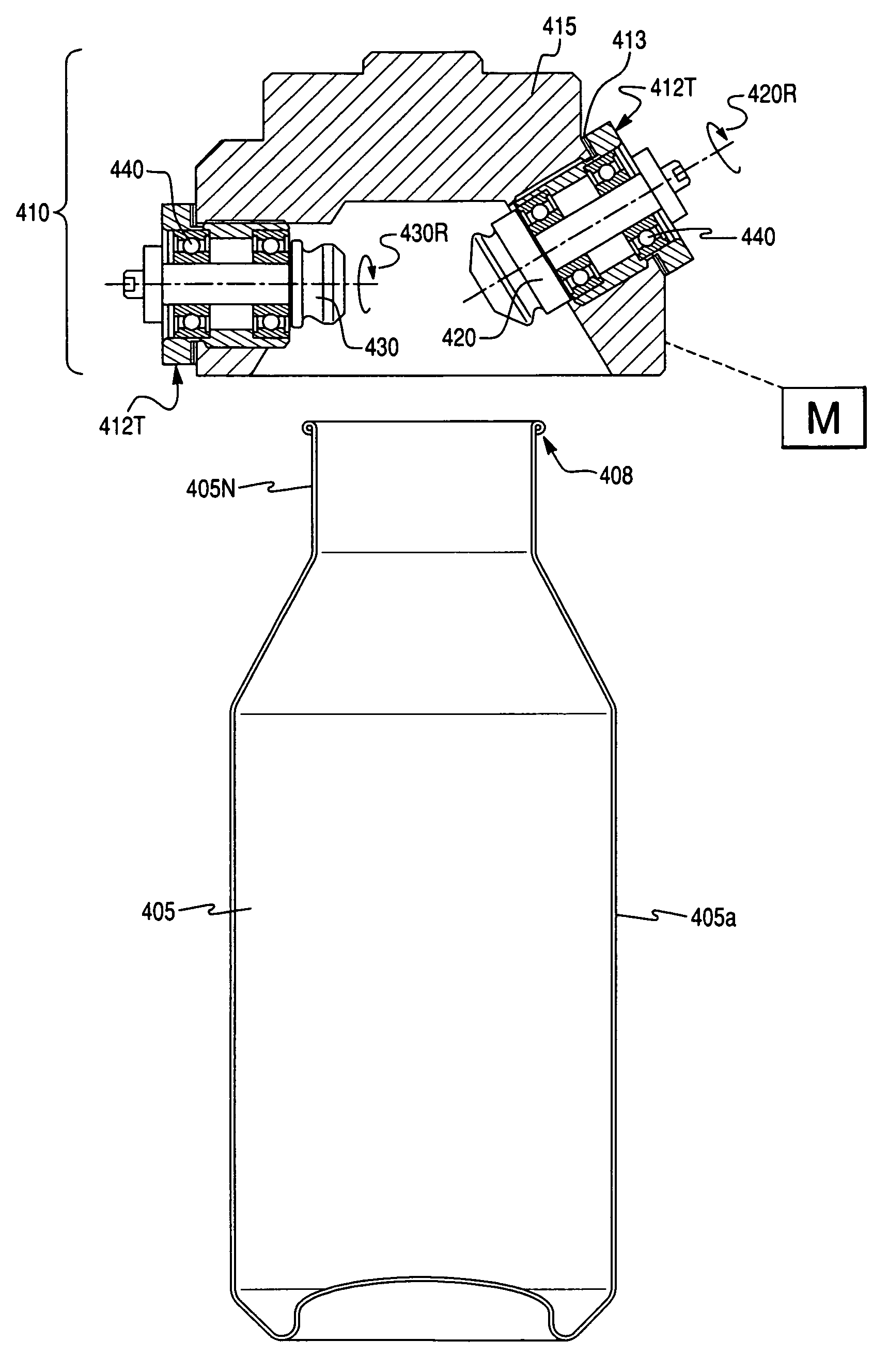

Apparatus for producing bottle can

This apparatus for producing a bottle can includes a die-ring 22 for holding bottom of a closed-end cylindrical body W, and a tool holding part disposed opposite an opening part of the closed-end cylindrical body W, having plural processing tools 32 for shaping the closed-end cylindrical body W into various forms, the die-ring 22 and the tool holding part being held so that each of them can rotate relatively and move in the direction of a center line of the closed-end cylindrical body W relatively to each other,each of the processing tools shaping the closed-end cylindrical body into various forms to produce a bottle can, further including:a regulating means 110 for regulating forward movement of each of the processing tools 32 or the die-ring 22 to prevent the space between each of the processing tools 32 and the die-ring 22 at the forward end of the tool holding part or the die-ring, from lessening to be not more than a predetermined value.

Owner:UNIVERSAL CAN CORP

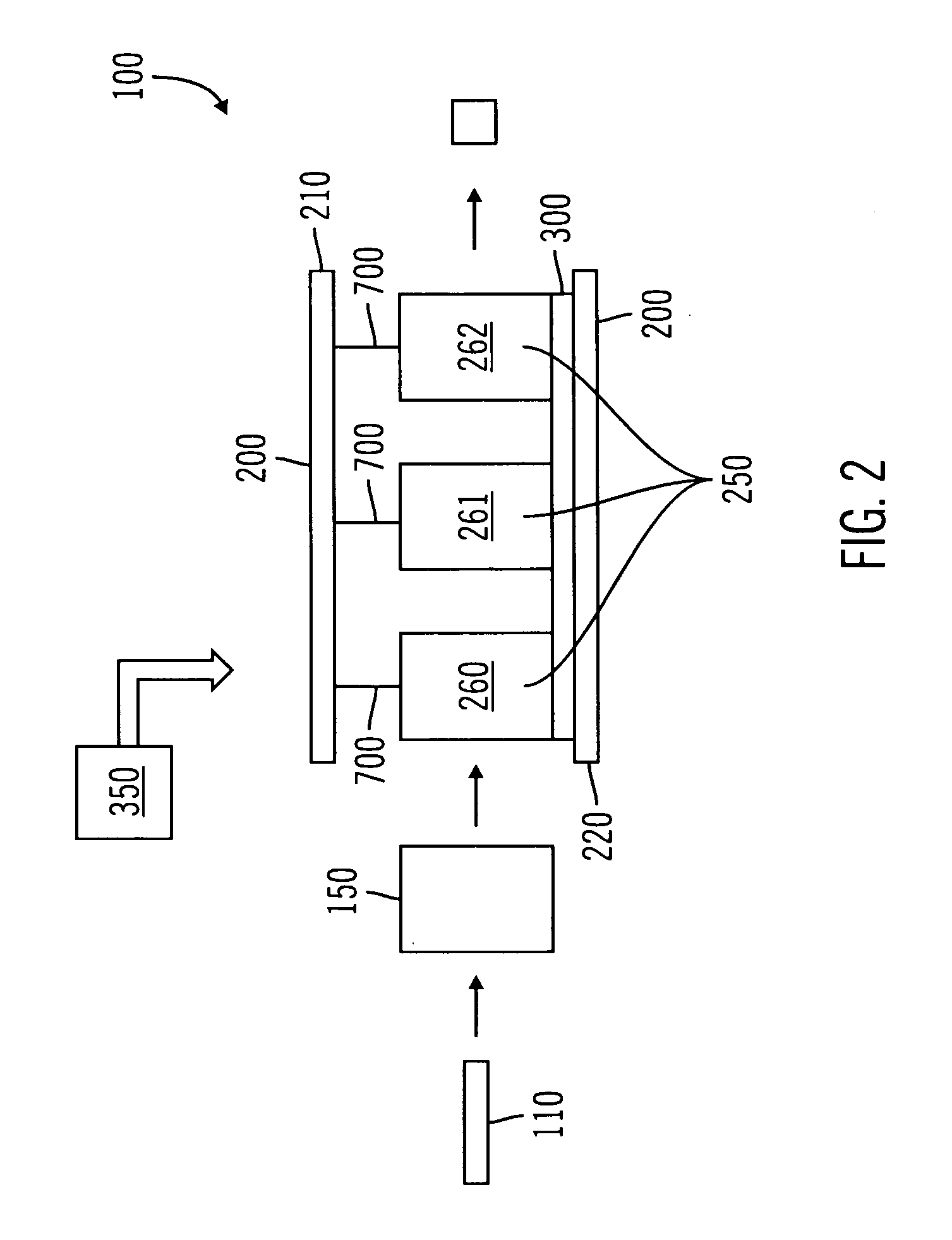

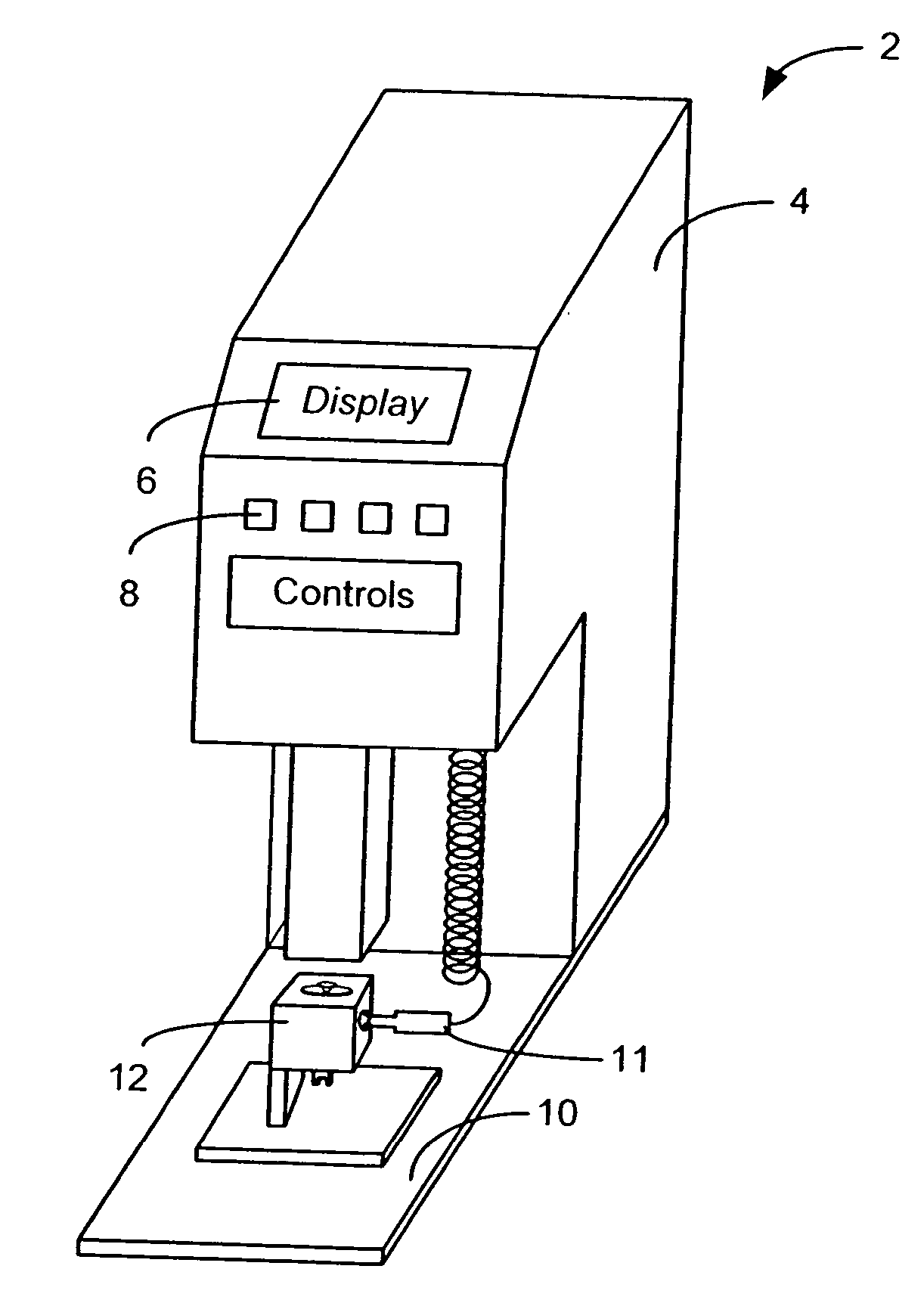

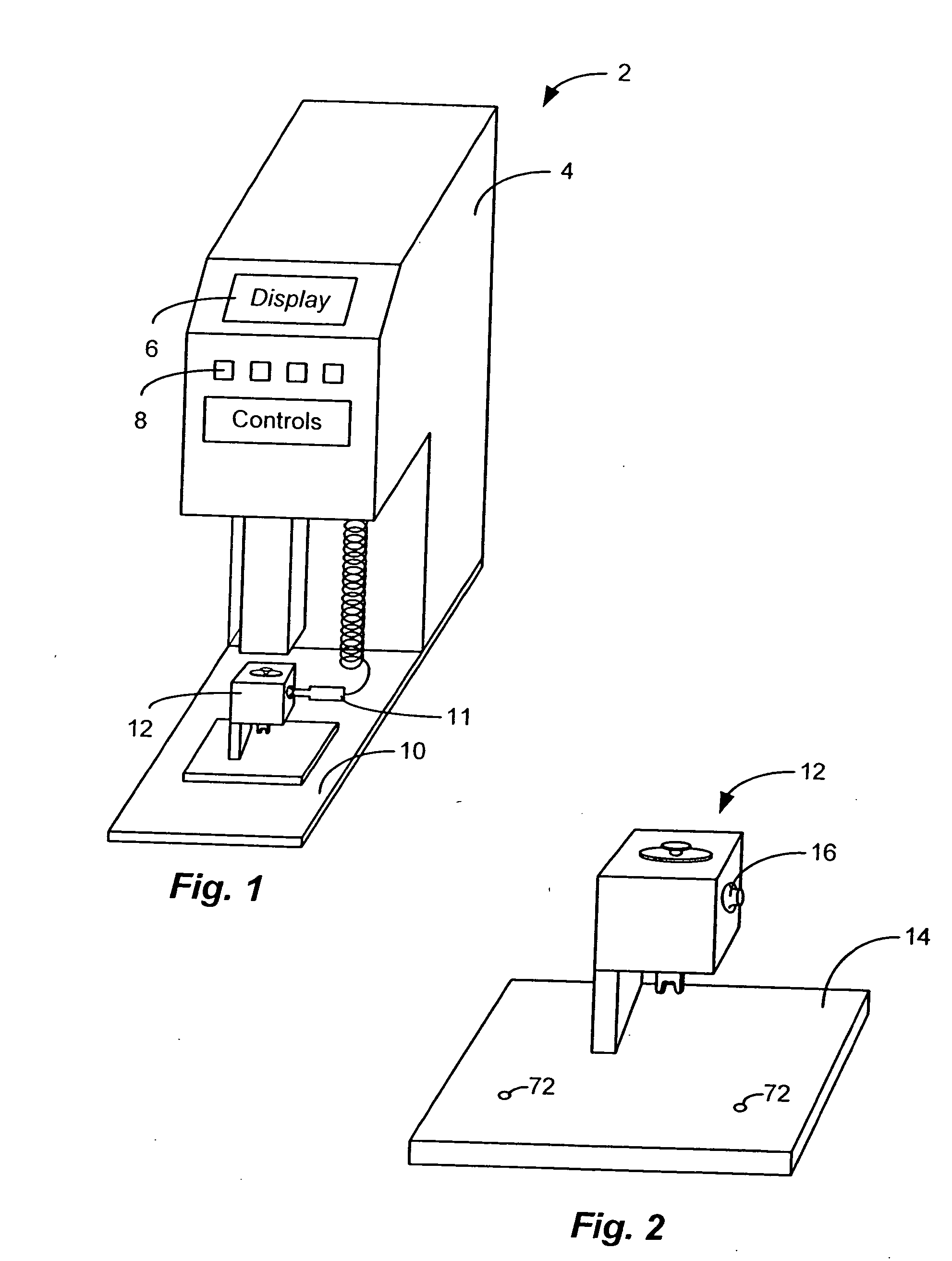

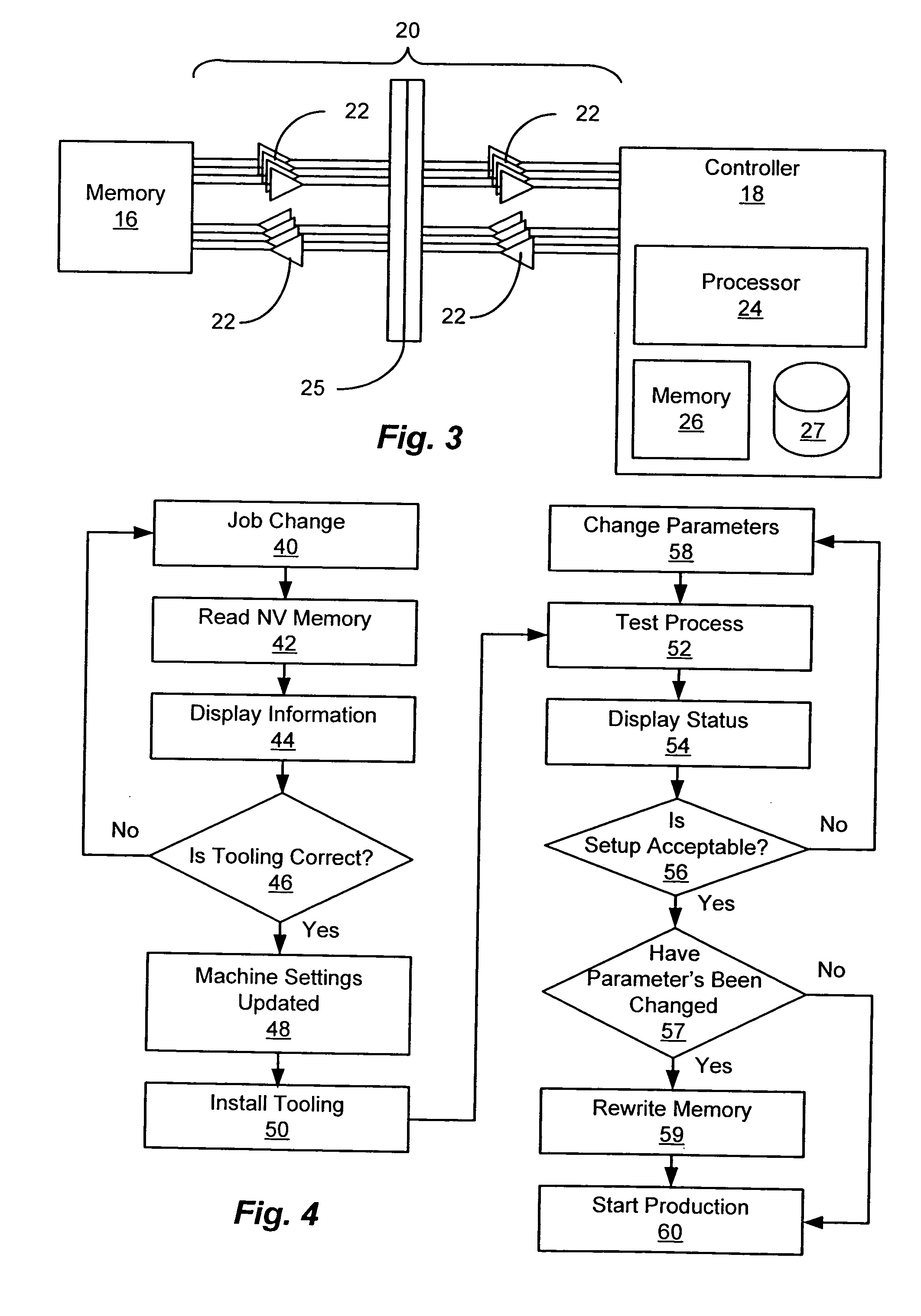

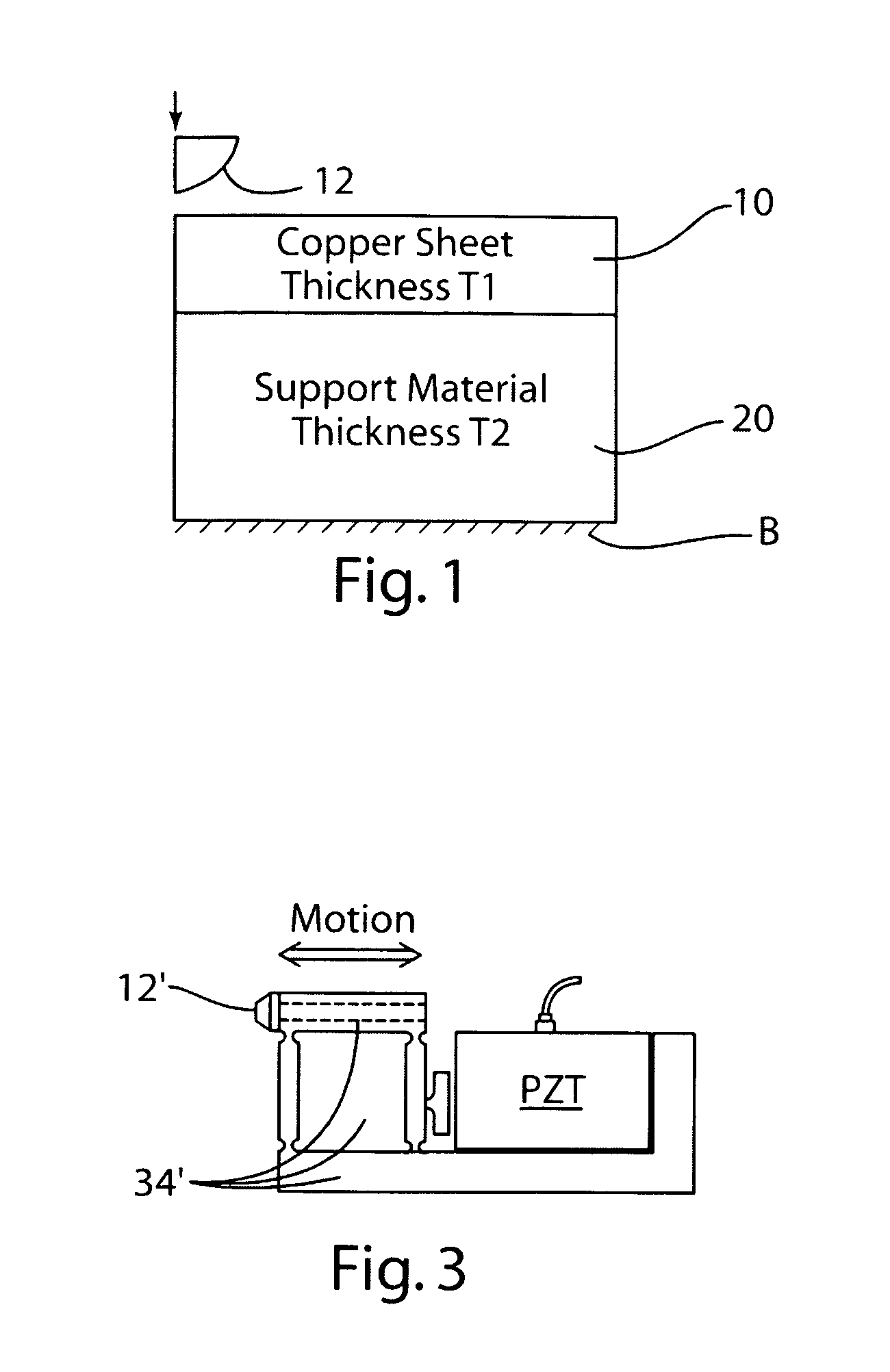

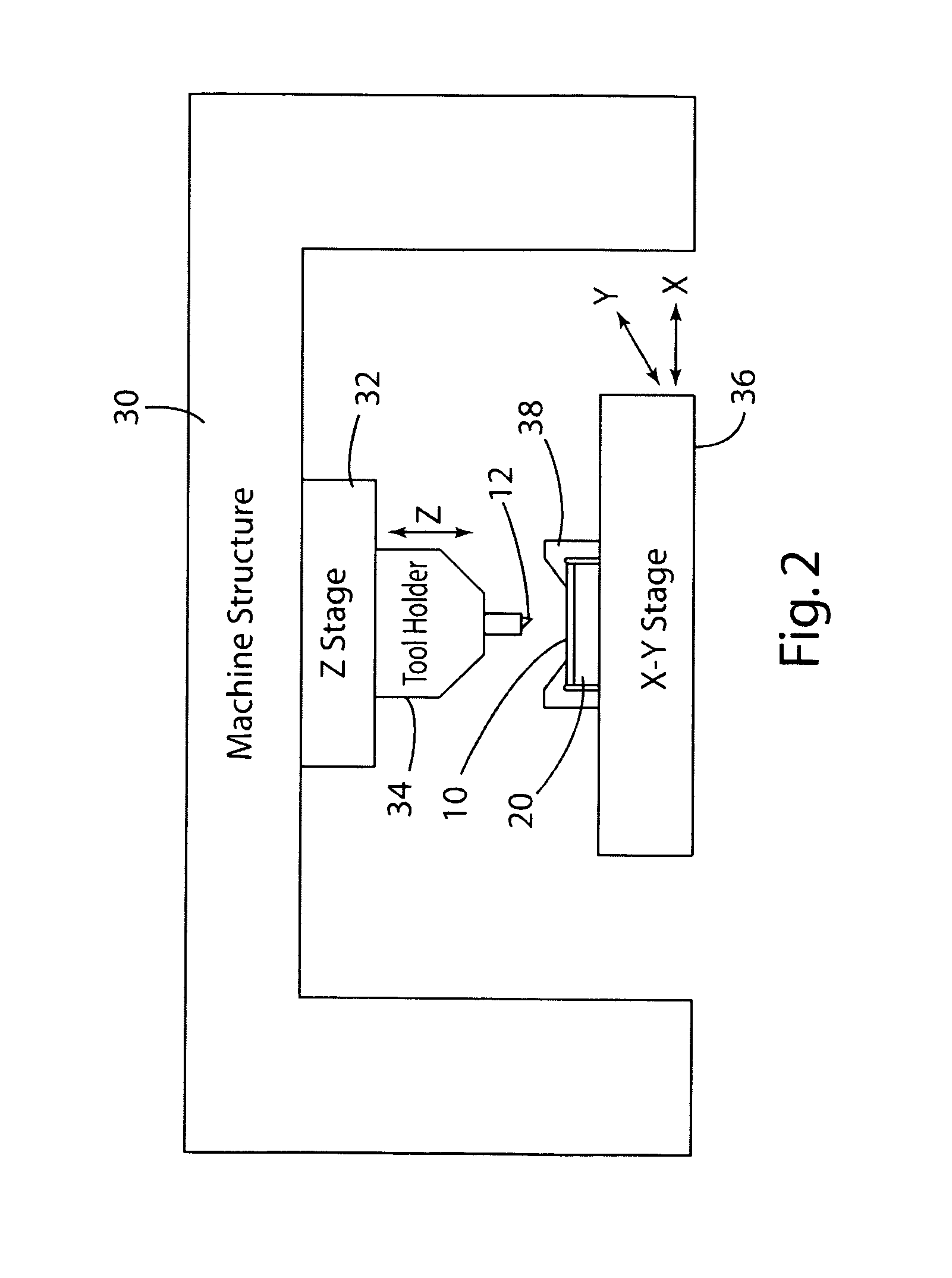

Automated machine setup with modular tooling

Apparatus and a method for establishing setup parameters for use in a machine. In one embodiment a tooling component is removably mountable to a host machine. The tooling component includes a memory that contains information defining setup parameters for the host machine for use with the tooling component. A controller associated with the host machine reads the information from the memory and configures the host machine based on the information read from the memory. In another embodiment, an information carrying tag, is associated with the tooling component. The information carrying tag is read and the identifying information obtained from the tag is used by a controller to select a set of setup parameters from one or more sets of setup parameters stored in a storage device accessible by the controller. A mechanism is provided to precisely position the adapter on the base plate for the host machine to minimize variations in production using the setup parameters derived from the stored information.

Owner:ZUSI CHRISTOPHER J

Apparatus and method for changing dies

The die changing apparatus for a plate reduction press machine, comprises an upper die support holder 28a and a lower die support holder 28b that are arranged vertically on opposite sides of a transfer line, and support holder guide rails 31 installed on the upper die support holder and extending substantially horizontally in the lateral direction of the transfer line, and an upper die 29a and a lower die 29b are mounted on the upper and lower die support holders, respectively using the rollers onto the dies, fixing devices 30 that fix the upper and lower dies on the upper and lower die support holders, respectively, die fastening members 38 which are placed on each side of the upper and lower dies, opposite each other in such a manner that they can be fastened to both dies, and a die changing mechanism that can move one of the die fastening members in a direction perpendicular to the transfer line.

Owner:JFE STEEL CORP +2

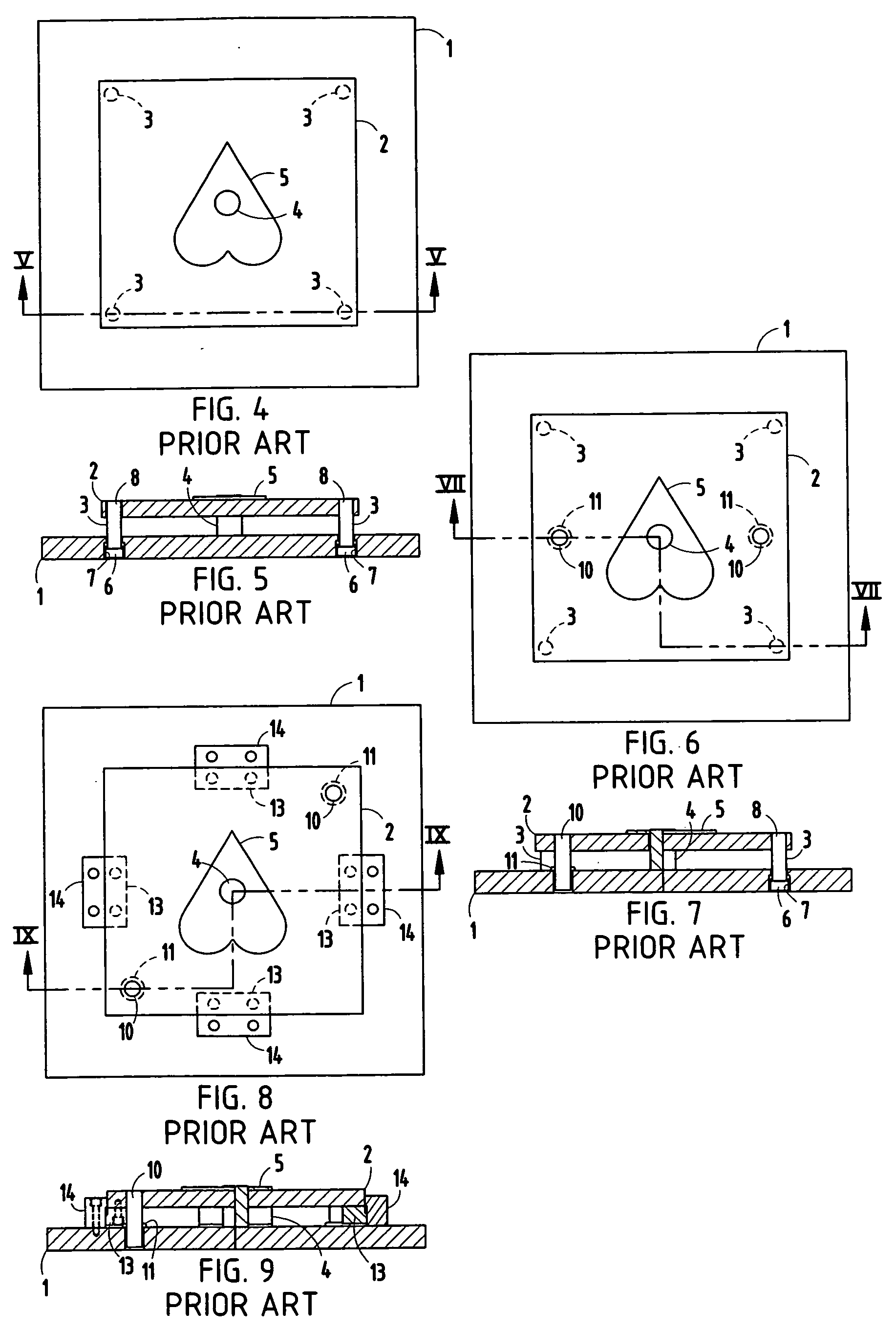

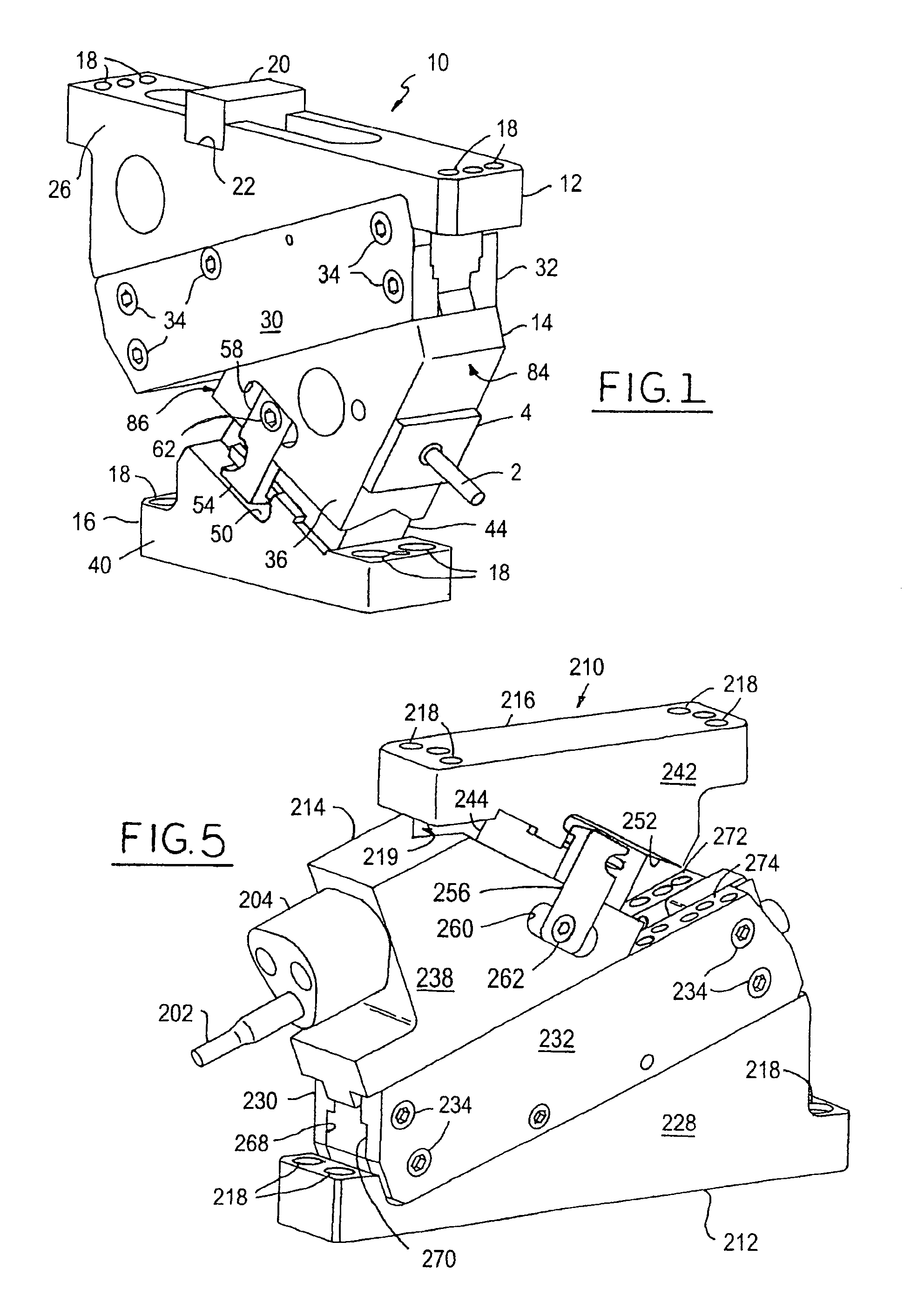

Narrow aerial and die-mount cams

InactiveUS6990844B1Efficient assemblyEffective installationShaping toolsForging press detailsCamBearing surface

Narrow aerial and die-mount cams, each having a cam adapter, a driver and a slide sandwiched between the cam adapter and driver. The narrow aerial cam slide has an elongate primary portion that has a T-shaped cross-section and has a primary bearing surface, and the cam adapter has a rectangular recess. An elongate keeper plate having a longitudinal slot is secured to each side of the cam adapter adjacent the rectangular recess to slidably retain the primary portion of the slide within the longitudinal slots and the rectangular recess. The primary bearing surface and a pair of intermediate bearing surfaces formed in the slide below the primary portion slidably support the keeper plates and thus the cam adapter. The driver slidably supports the slide. The narrow die-mount cam is basically an inverted version of the aerial cam.

Owner:ANCHOR LAMINA AMERICA INC

Apparatus for curling an article

An apparatus for providing a curl on a top edge of a can comprises a forming head; and a forming turret with a push ram to load the can into the forming head. The forming head includes a plurality of independent rollers mounted on a common head. The plurality of rollers includes a first set of rollers configured to form an inner portion of a curl and a second set of rollers configured to form an outer portion of the curl.

Owner:BELVAC PRODN MACHINERY

Methods for altering residual stresses using mechanically induced liquid cavitation

InactiveUS6993948B2Altering residual tensile stressEffectively water-hammeringBurnishing machinesForging press detailsCavitationTransducer

A mechanical transducer induces liquid cavitation, causing pressure waves in a liquid which are applied against a metal surface to afford localized elastic and plastic tensile microstrain. The pressure waves alter the surface tensile stresses in the treated metal by reducing the tensile stresses or forming surface compressive stresses. A boot is provided about the operating face of the transducer for confining a liquid through which compression waves are generated and applied to the metal surface, the boot sealing about the transducer and the surface undergoing treatment.

Owner:GENERAL ELECTRIC CO

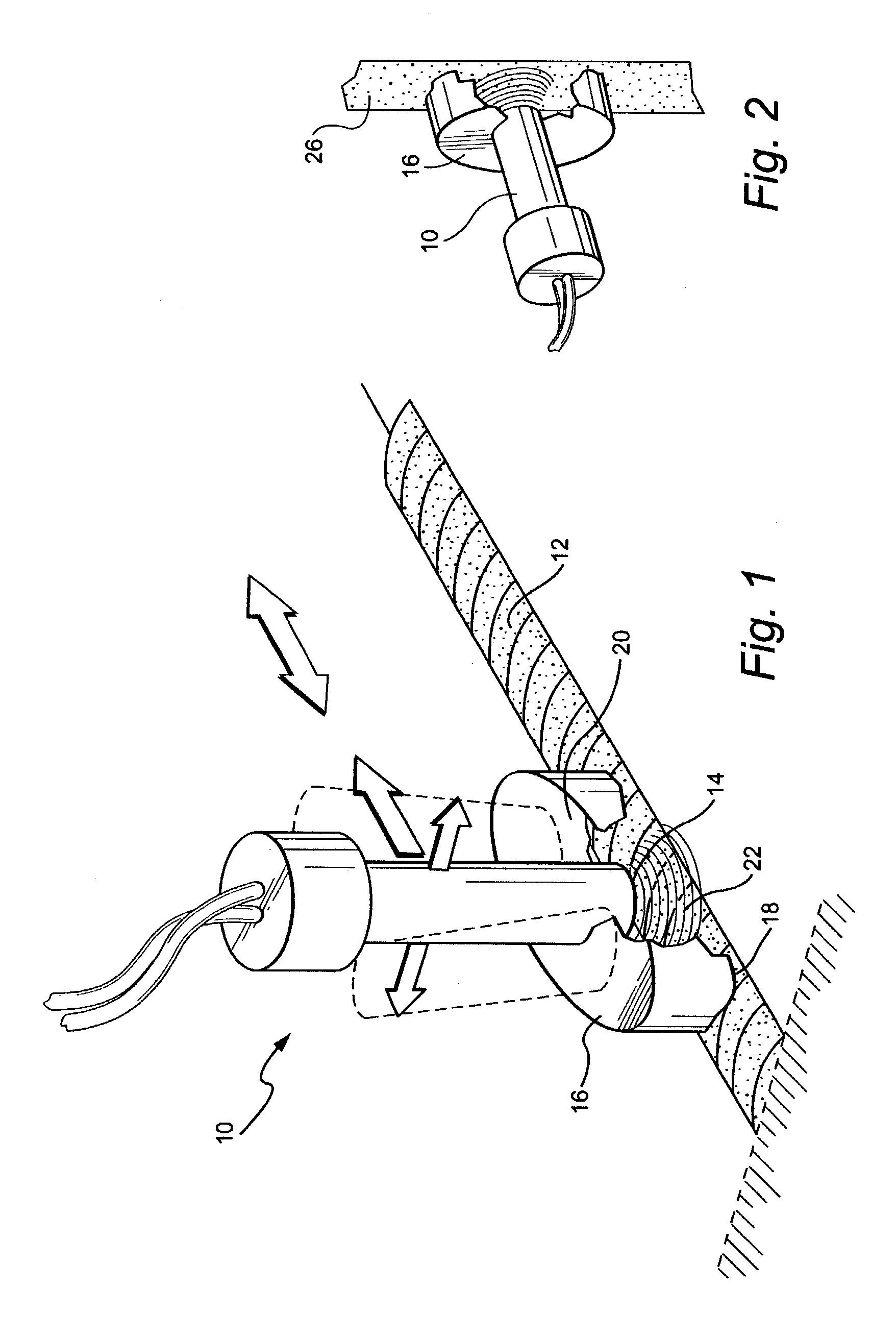

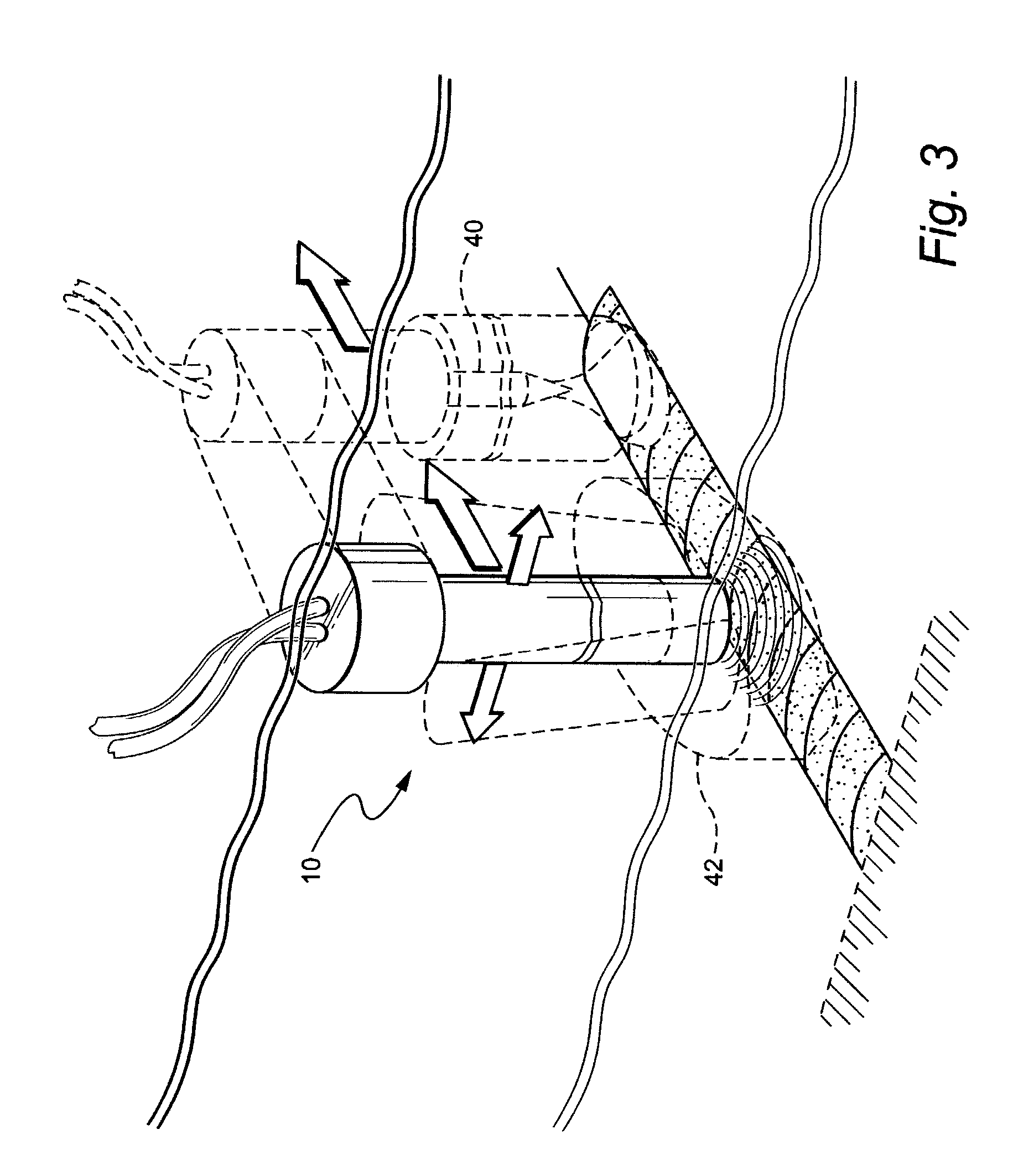

Microforming method and apparatus

ActiveUS8408039B2Reduce accumulationFaster and less-expensiveShaping toolsLayered productsYoung's modulusDimple

Method of forming depressions (e.g. dimples) in a sheet material to form a textured surface thereon involves pressing one or more tool tips into a metallic or non-metallic sheet material while the sheet material is supported by a support layer that is relatively softer (e.g. having a lower Young's modulus) than the sheet material so as to allow plastic deformation and reduce pile-up of raised displaced material of the sheet material at the edges of the depressions.

Owner:NORTHWESTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com